Siemens KMS, Flender KMP Series, Flender KMPS Series, Flender KMPP Series Assembly And Operating Instructions Manual

Page 1

Vertical mill gear unit

KMS

Sizes 225 to 850

Assembly and operating instructions

BA 9137 en 12/2015

FLENDER gear units

Page 2

T

echnical data

T

T

1

Vertical mill gear unit

General notes

KMS

Sizes 225 to 850

Assembly and operating instructions

Translation of the original assembly and operating instructions

Safety instructions

ransport and

storage

echnical

description

Fitting

Startup

Operation

2

3

4

5

6

7

8

Faults, causes

and remedy

Maintenance

and repair

Spare parts,

customer service

Declarations

9

10

11

12

BA 9137 en 12/2015

2 / 89

Page 3

Legal notes

Warning note concept

This manual comprises notes which must be observed for your personal safety and for preventing material

damage. Notes for your personal safety are marked with a warning triangle, those only for preventing

material damage appear without a warning triangle. Depending on the level of hazard, the warning notes

are shown in reverse order of seriousness, as follows.

DANGER

means, that death or serious injury will result, if the appropriate preventive action is not taken.

WARNING

means that death or serious injury may result, if the appropriate preventive action is not taken.

CAUTION

means that a slight injury may result, if the appropriate preventive action is not taken.

NOTICE

means that material damage may result, if the appropriate preventive action is not taken.

Where there is more than one hazard level, the warning note for whichever hazard is the most serious is

always used. If in a warning note a warning triangle is used to warn of possible personal injury, a warning

of material damage may be added to the same warning note.

Qualified personnel

The product or system to which this documentation relates may be handled only by persons qualified for

the work concerned and in accordance with the documentation relating to the work concerned, particularly

the safety and warning notes contained in those documents.

Qualified personnel must be specially trained and have the experience necessary to recognise risks

associated with these products and to avoid possible hazards.

Proper use of Siemens products

Observe also the following:

WARNING

Siemens products must be used only for the applications provided for in the catalogue and the relevant

technical documentation. If products and components of other makes are used, they must be

recommended or approved by Siemens. The faultfree, safe operation of the products calls for proper

transport, proper storage, erection, assembly, installation, startup, operation and maintenance. The

permissible ambient conditions must be adhered to. Notes in the relevant documentations must be

observed.

Trademarks

All designations to which the registered industrial property mark ® is appended are registered trademarks

of Siemens AG. Other designations used in this document may be trademarks the use of which by third

parties for their own purposes may infringe holders’ rights.

Exclusion of liability

We have checked the content of the document for compliance with the hard and software described.

Nevertheless, variances may occur, and so we can offer no warranty for complete agreement. The

information given in this document is regularly checked, and any necessary corrections are included in

subsequent editions.

BA 9137 en 12/2015

3 / 89

Page 4

Foreword

The term "Assembly and operating instructions" will in the following also be shortened to "instructions"

or "manual".

The term

directive 94/9/EC, if the product is put on the market by 19.04.2016, and to the version designed in

conformity to directive 2014/34/EU, if the product is put on the market on or after 20.04.2016.

"2014/34/EU" used in these instructions applies to the version designed in conformity to

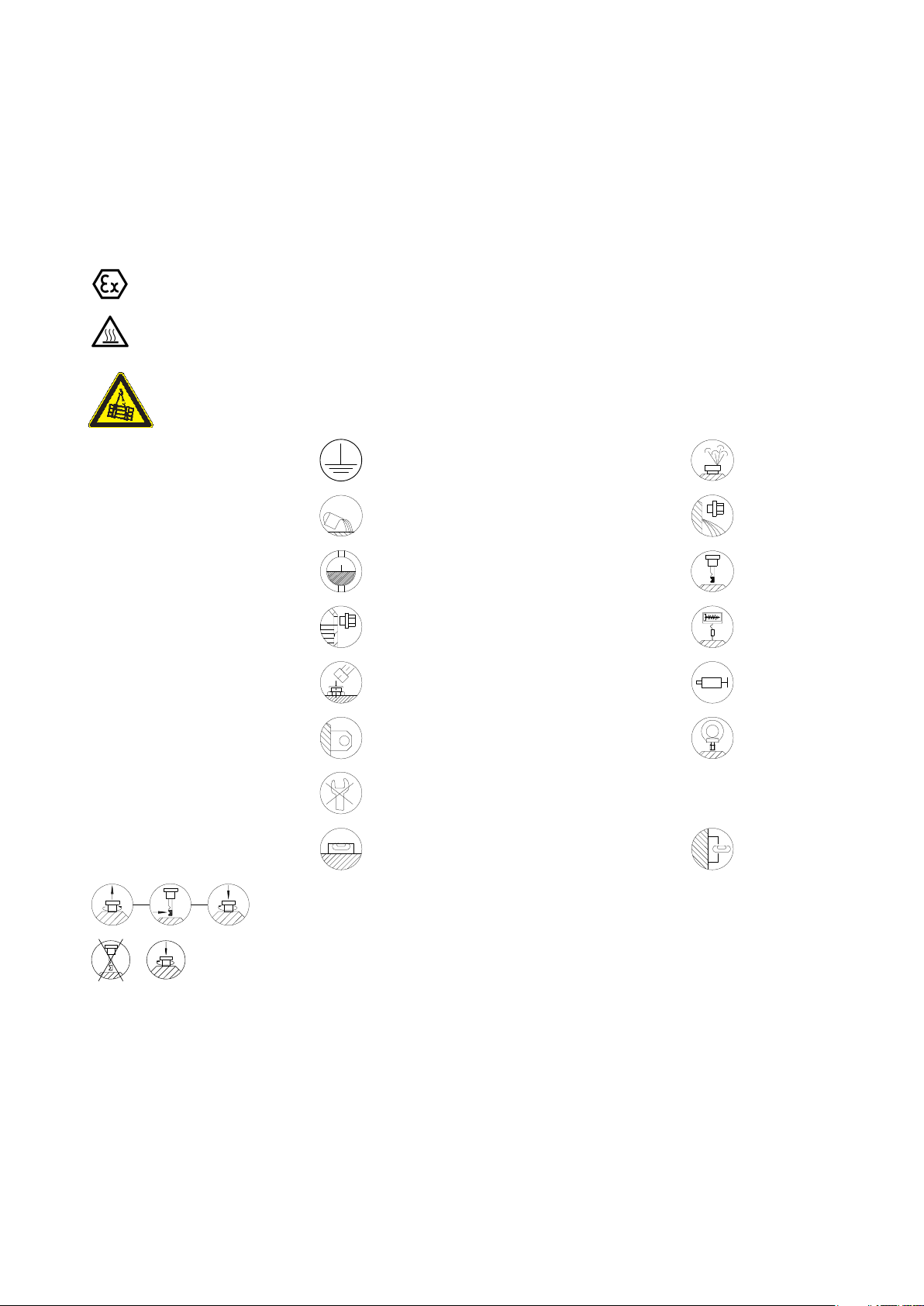

Symbols in these assembly and operating instructions

This symbol additionally indicates an imminent risk of explosion in the meaning of Directive 2014/34/EU.

This symbol additionally indicates an imminent risk of burns due to hot surfaces in the meaning of

standard "DIN EN ISO 137321".

This symbol warns against risks from lifted and/or suspended loads.

Earthconnection point Airrelief point yellow

Oilfilling point

Oil level

yellow Oildraining point white

red Oil level red

Oil level

Lubricating point red Apply grease

Lifting eye Eye bolt

Do not unscrew

Alignment surface, horizontal Alignment surface, vertical

These symbols indicate the oillevel checking procedure using the oil dipstick.

These symbols indicate that the oil dipstick must always be firmly screwed in.

red

Connection for

vibrationmonitoring device

BA 9137 en 12/2015

4 / 89

Page 5

Contents

1. Technical data 8.....................................................

1.1 General technical data 8...............................................................

1.2 Marking of the gear unit designed in accordance with Directive 2014/34/EU 9.................

1.2.1 Ambient temperature 9................................................................

1.3 Measuring-surface sound pressure level 9...............................................

1.4 List of equipment 9....................................................................

2. General notes 10.....................................................

2.1 Introduction 10........................................................................

2.2 Copyright 10..........................................................................

3. Safety instructions 11.................................................

3.1 Obligations of the user 11...............................................................

3.2 Special dangers and personal protective equipment 13......................................

3.3 The five safety rules 14.................................................................

3.4 Environmental protection 14.............................................................

4. Transport and storage 15.............................................

4.1 Content and check of the scope of delivery 15.............................................

4.2 Transport 15..........................................................................

4.3 Storing the gear unit 18.................................................................

4.4 Standard coating and corrosion prevention 18.............................................

4.4.1 Exterior preservation of metallic bright exterior surfaces 20..................................

4.4.1.1 Maximum durability period of the exterior preservation 20....................................

4.4.1.2 Prolongation of the preservation of metallic bright exterior surfaces of the gear unit 20...........

4.4.2 Preservation of the interior of the gear unit 20..............................................

4.4.2.1 Maximum durability period of the interior preservation of the gear unit 20.......................

4.4.2.2 Combined storage/packaging 22.........................................................

4.4.3 Renewal of the interior preservation of the gear unit for longer periods of storage of the gear unit

4.4.3.1 Renewal of the gear unit interior preservation with "Castrol Corrosion Inhibitor N 213" 26.........

4.4.3.2 Renewal of the gear unit interior preservation through complete filling with preservative or

4.4.3.3 Renewal of the interior preservation of the gear unit using the oil- supply system 30.............

that has not been taken into operation yet 26...............................................

operating oil. 28.......................................................................

5. Technical description 32..............................................

5.1 General description 32.................................................................

5.2 Delivery condition of the gear unit 32.....................................................

5.3 Lubrication 33.........................................................................

5.3.1 Hydrodynamic lubrication of the axial tilting pad thrust bearings 33............................

5.3.2 Hydrodynamic lubrication of the axial tilting pad thrust bearings in gear units

5.3.3 Hydrodynamic lubrication of the axial tilting pad thrust bearings with radial piston pump 34.......

5.3.4 Labyrinth seals 34.....................................................................

5.4 Drive coupling 35......................................................................

5.5 Heating 35............................................................................

5.6 Heating element on ex-version 36........................................................

5.6.1 Oil level monitoring of the heating elements 36.............................................

5.7 Indication of oil level 36.................................................................

5.8 Oil temperature monitoring 37...........................................................

5.9 Oil level monitoring system 37...........................................................

with hydrostatic start-up assistance 33....................................................

BA 9137 en 12/2015

5 / 89

Page 6

6. Fitting 38.............................................................

6.1 General assembly information 38........................................................

6.2 Set-up conditions 39...................................................................

6.2.1 Dimensions and weights 39.............................................................

6.2.2 Lifting device 39.......................................................................

6.3 Preparatory measures for gear unit installation 40..........................................

6.3.1 Maintaining preservation if the gear unit has been opened in the meantime 41..................

6.3.2 Foundation 42.........................................................................

6.4 Assembly of the gear unit 42............................................................

6.5 Installing the pipework 43...............................................................

6.6 Pickling of adapted pipes 43.............................................................

6.7 Installing the couplings 44...............................................................

6.8 Installing the motor 45..................................................................

6.9 Assembly of loose add-on parts included in the delivery 46..................................

6.10 Welding work on the mill 46.............................................................

6.11 Final work 47..........................................................................

6.12 Screw connection classes, tightening torques and initial stressing forces 47....................

6.12.1 Screw connection classes 47............................................................

6.12.2 Tightening torques and initial stressing forces 48...........................................

7. Start-up 50...........................................................

7.1 Procedure before start-up 50............................................................

7.1.1 Removal of preservative agent from exterior 50............................................

7.1.2 Removal of preservative agent from interior 51.............................................

7.1.3 Draining preservative oils 53............................................................

7.1.4 Flushing before initial start-up 54.........................................................

7.1.4.1 Oil quantity for flushing 54...............................................................

7.1.5 Fill in operating oil 54...................................................................

7.1.5.1 Oil level 55............................................................................

7.1.5.2 Procedure for filling 55..................................................................

7.1.6 Oil-supply system 57...................................................................

7.1.7 Checks before start-up 57...............................................................

7.2 Start-up 59...........................................................................

7.2.1 Pre-lubrication phase 59................................................................

7.2.2 Initial start-up 59.......................................................................

7.2.3 Checking procedure 60.................................................................

7.3 Removal from service 60...............................................................

7.3.1 Renewal of the gear unit interior preservation on gear units having already been in operation 61...

7.3.1.1 Renewal of the interior preservation of the gear unit using the oil- supply system 61.............

7.3.1.2 Renewal of the gear unit interior preservation with "Castrol Corrosion Inhibitor N 213" 63.........

7.3.1.3 Renewal of the gear unit interior preservation through complete filling with preservative

7.3.2 Exterior corrosion prevention 66.........................................................

or operating oil 65......................................................................

8. Operation 67.........................................................

8.1 General 67............................................................................

8.2 Oil level 68............................................................................

8.3 Irregularities 68........................................................................

9. Faults, causes and remedy 70.........................................

9.1 General information on faults and malfunctions 70..........................................

9.2 Faults, causes and remedy 71...........................................................

BA 9137 en 12/2015

6 / 89

Page 7

10. Maintenance and repair 74............................................

10.1 General notes on maintenance 74........................................................

10.2 Clean the gear unit 75..................................................................

10.3 Clean the air filter 75...................................................................

10.3.1 Replacing the air filter cartridge 76.......................................................

10.4 Flushing 76...........................................................................

10.5 Oil filling 76...........................................................................

10.6 Inspection 77.........................................................................

10.7 Maintenance 78.......................................................................

10.7.1 Examine water content of oil, conduct oil analyses 79.......................................

10.7.2 Change oil 80.........................................................................

10.7.3 Check tightness of screw connections 82.................................................

10.8 Welding work on the mill 82.............................................................

10.9 Vibration measurements 83.............................................................

10.10 Repair 84.............................................................................

10.11 General inspection of the gear unit 85.....................................................

10.12 Lubricants 85.........................................................................

11. Spare parts, customer service 86......................................

11.1 Stocking spare parts 86.................................................................

11.2 Addresses for ordering spare parts and customer service 86.................................

12. Declarations 87.......................................................

12.1 Declaration of incorporation 87..........................................................

12.2 EU declaration of conformity 88..........................................................

BA 9137 en 12/2015

7 / 89

Page 8

1. Technical data

1.1 General technical data

The most important technical data are shown on the rating plate. These data and the contractual

agreements between Siemens and the customer for the gear unit determine the limits of its correct use.

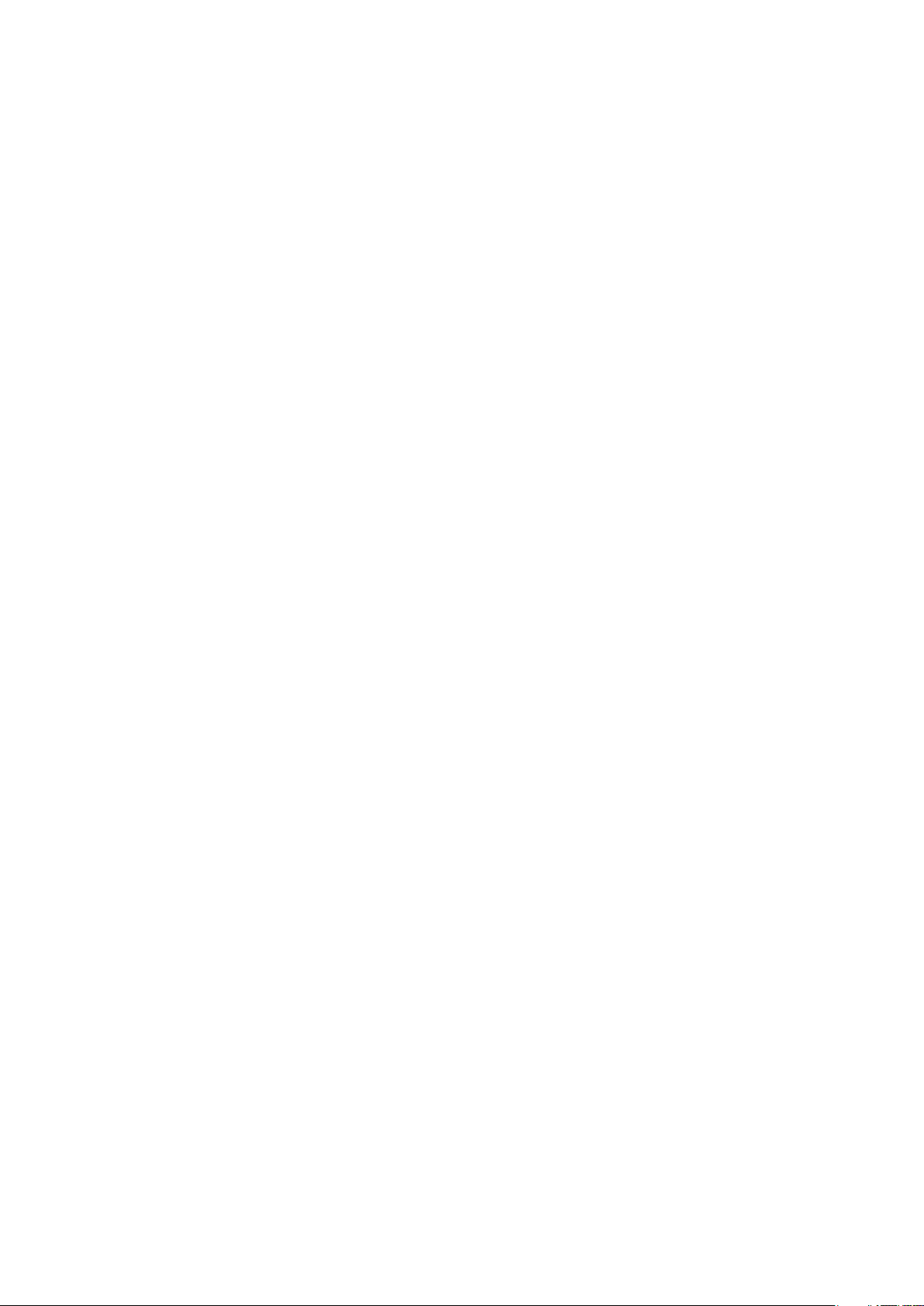

①

②

③

⑤

⑦

⑨

⑩

(see item 1.2)

⑪

⑫

Fig. 1: ATEX Rating plate on gear unit

① Company logo

② Serial number

#)

③ Total weight (without oil filling) in kg

④ Special information

⑤ Type, size

⑥ Power rating P

#)

Production site code / Order no. item seq. no. / Year built

*)Example

*)

in kW or torque T2 in Nm

2

④

⑥

⑧

⑦ Rotation speed n

⑧ Rotation speed n

1

2

in min

in min

-1

-1

⑨ Oil data (oil type, oil viscosity, oil quantity)

⑩ Instruction manual numbers

⑪ Manufacturer and place of manufacture

⑫ Country of origin

KMS

For details regarding weight and further technical data, refer to the drawings in the gear unit documentation

and the order-specific data sheet.

225

Size 225 … 850......................

Model S = Spur wheel section.....................

Area of use M = Vertical mill................

Gear unit type K = Bevel gear unit..............

BA 9137 en 12/2015

8 / 89

Page 9

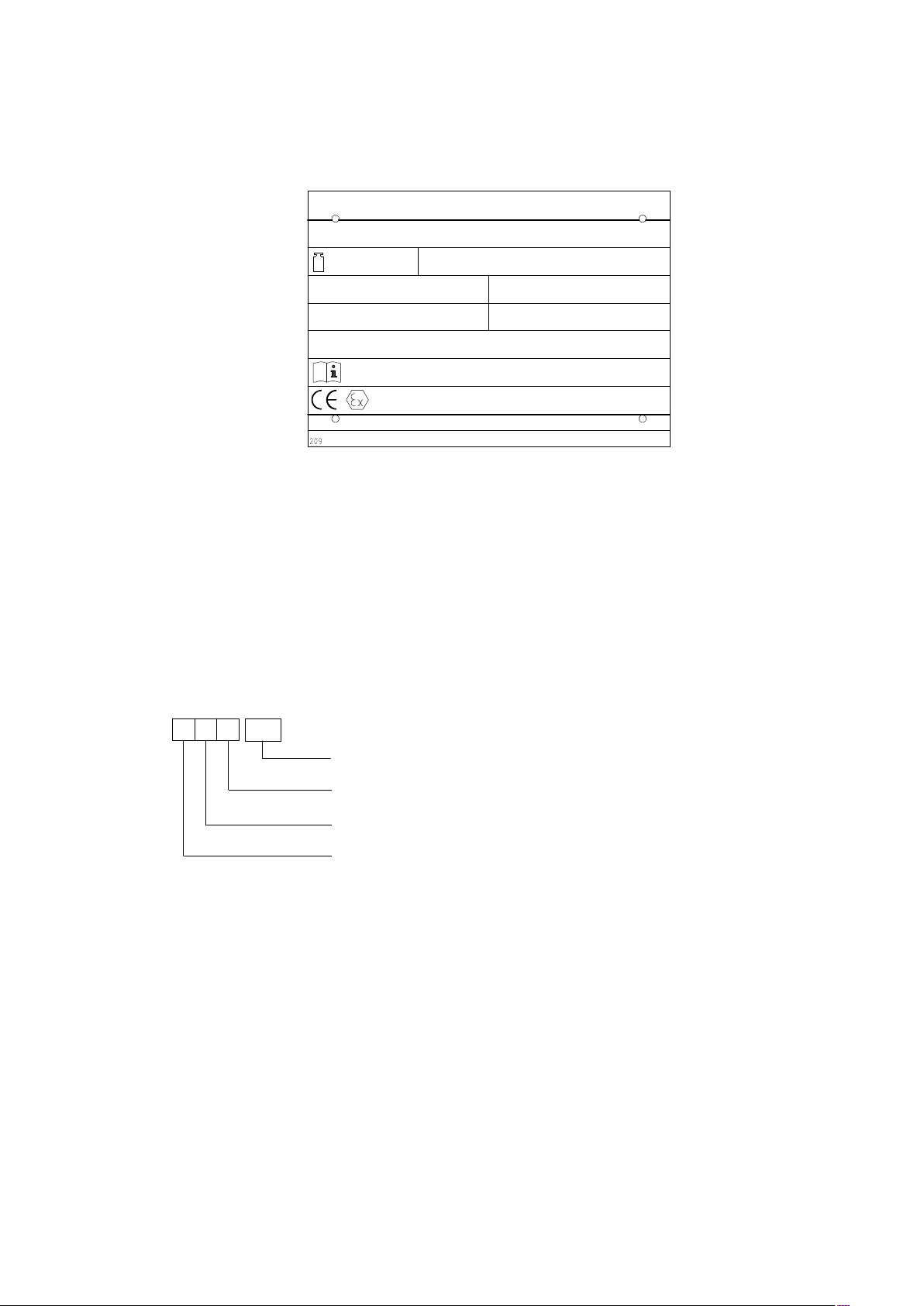

1.2 Marking of the gear unit designed in accordance with Directive 2014/34/EU

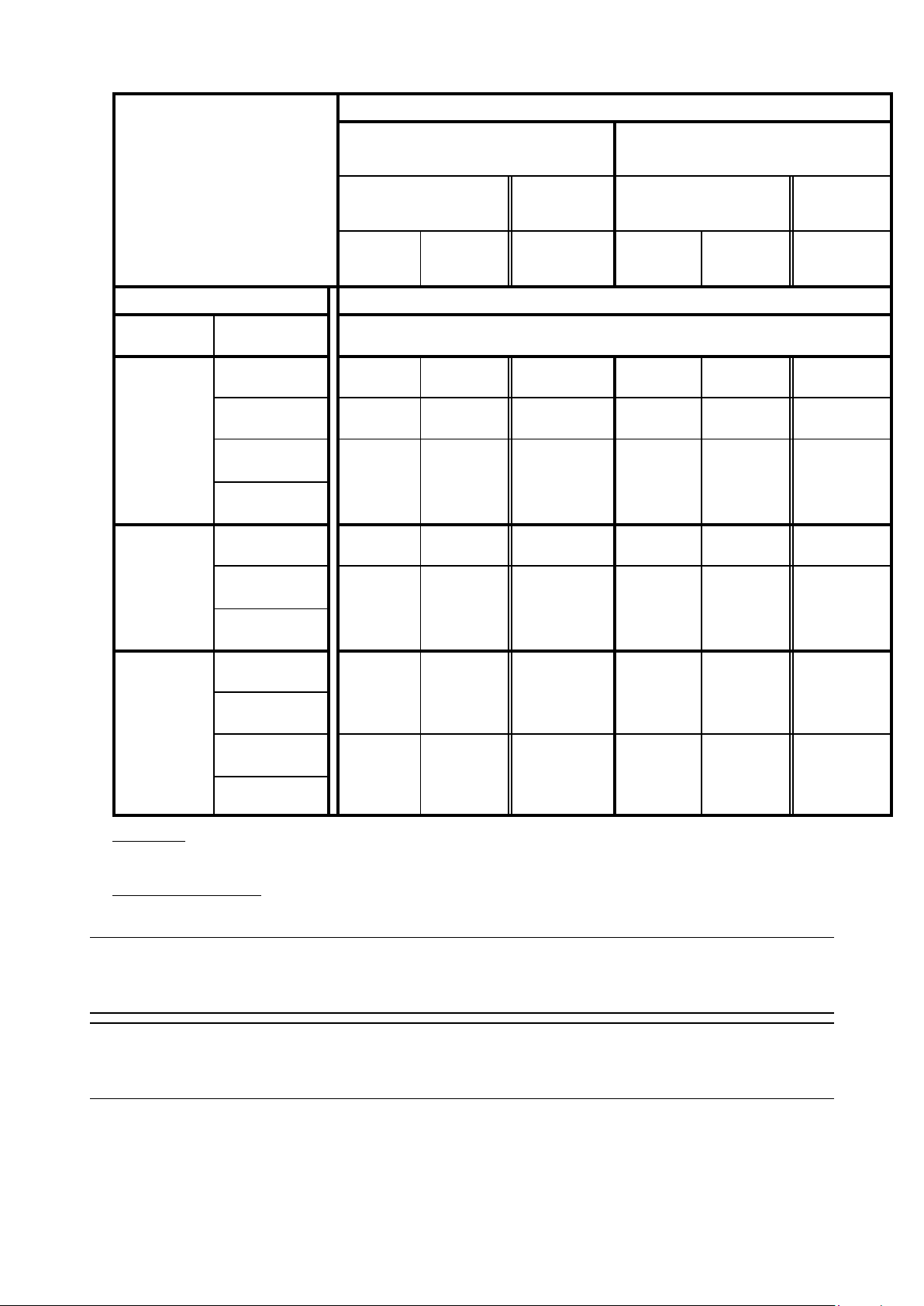

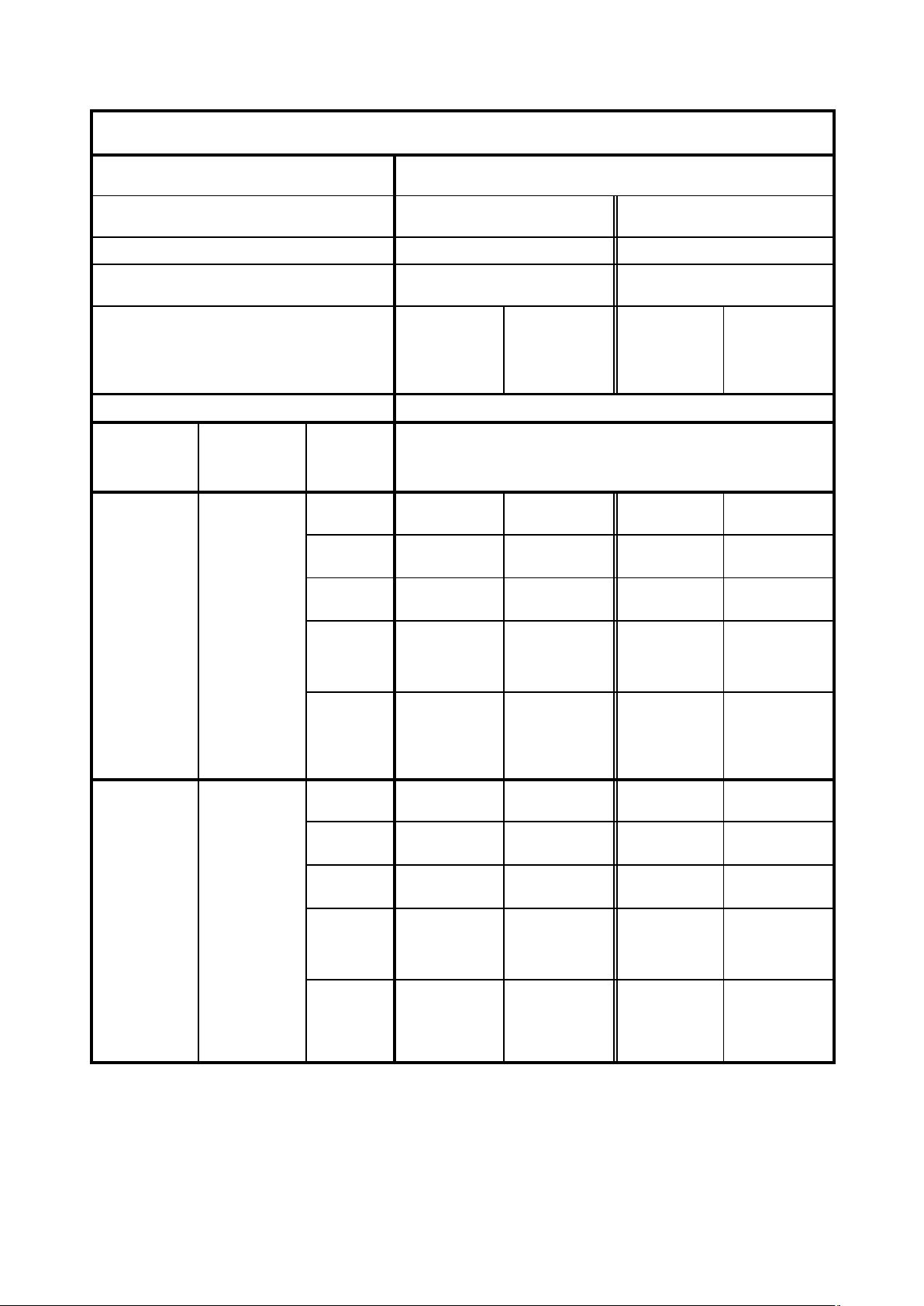

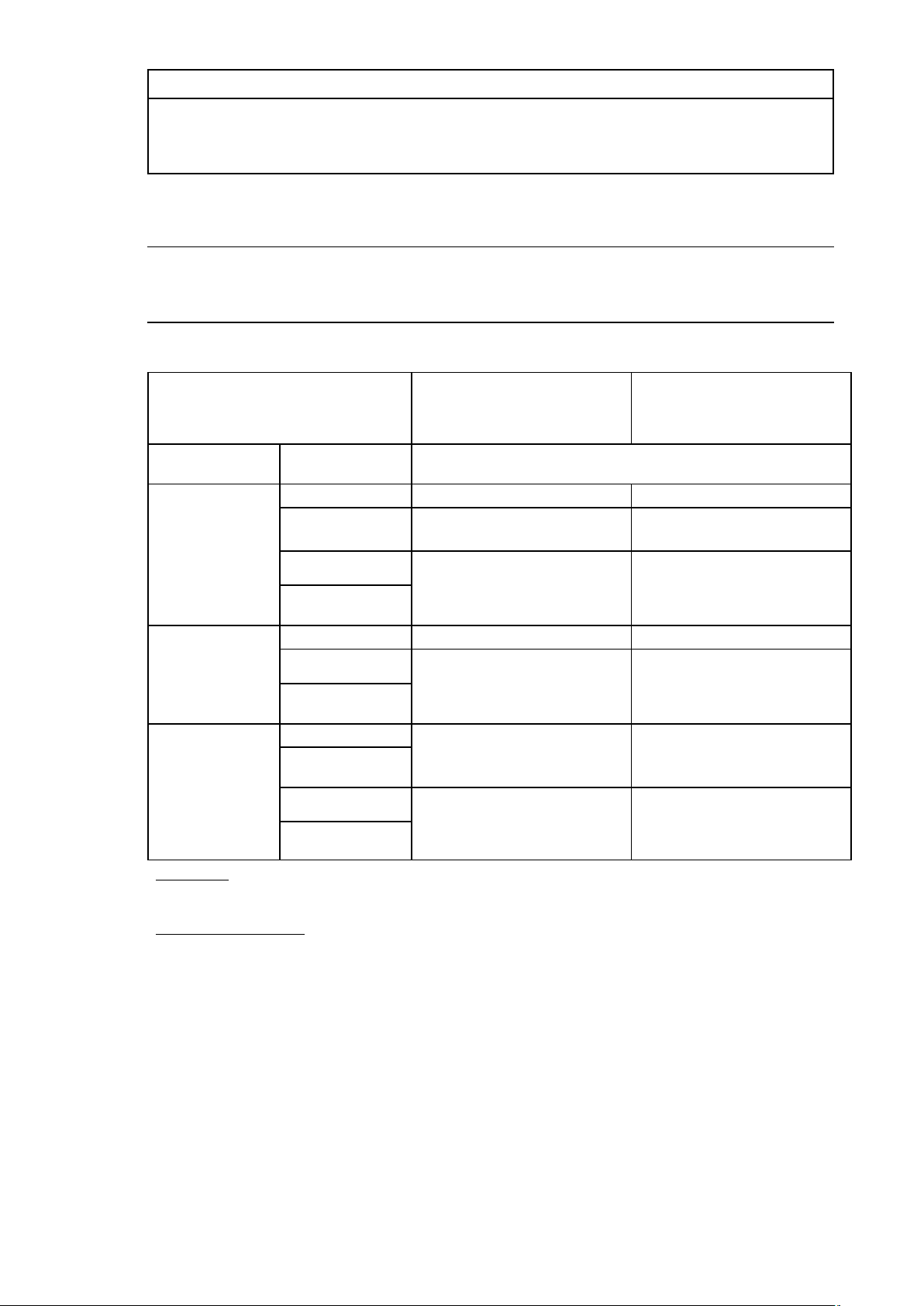

Table 1: ATEX identification for above-ground applications

Equipment

group

II 3 Dust (D) - -

1)

T

a min.

T

a min.

T

a max.

T

a

Equipment

category

≤ Ta ≤ T

Explosive

Atmosphere

= permissible ambient temperature range in °C:

a max.

= minimum permissible ambient temperature

= maximum permissible ambient temperature

= symbol for ambient temperature

Note

The ignition protection type "b" is not available for gear units without electrical explosion hazard

monitoring device (e. g. temperature, oil level).

The rating plate on the gear unit indicates the marking for the applicable case of application.

1.2.1 Ambient temperature

The specifications of Directive2014/34/EU apply to the ambient temperature range of from

- 20 °C to + 40 °C. By adopting various suitable measures, the gear unit may be used in ambient

temperatures from - 40 °C to + 60 °C. However, the temperature range and the expanded temperature

range must generally be approved by Siemens and be specified in the order text.

In individual cases the permissible ambient temperature range specified on the rating plate always applies.

1.3 Measuring-surface sound pressure level

Explosion

group

Temperature

class

Mark

II 3 D 120 °C bck Ta..

1)

A measuring-surface sound pressure level during operation cannot be specified, as the gear unit is

operated without load during the test run on the Siemens test bench.

1.4 List of equipment

Note

All important accessory components are specified in the order specific equipment list including your

technical data.

BA 9137 en 12/2015

9 / 89

Page 10

2. General notes

2.1 Introduction

These instructions are a part of the gear unit delivery and must always be kept on hand near the gear unit.

NOTICE

Property damage

Damage to the gear unit or occurrence of operating failures is possible.

All persons carrying out work on the gear unit must have read and understood the instructions and must

adhere to them.

Siemens accepts no responsibility for damage or disruption caused by disregard of these instructions.

The "FLENDER Bevel-helical gear unit" of the type "KMS" described in these instructions has been

designed for driving a vertical mill.

The gear unit is designed only for the application specified in the order-specific gear unit documentation.

Deviating operating conditions require new contractual agreements.

The gear unit is manufactured in accordance with the state of the art and is delivered in a condition ready

for safe and reliable use. The gear unit complies with the requirements in Directive 2014/34/EU.

The gear unit may only be used and operated in accordance with the conditions laid down in the service

and supply contract concluded between Siemens and the customer.

The gear unit described in these instructions conforms to the state of technical development at the time

when these instructions went to print.

In the interest of technical further development we reserve the right to make changes to the individual

assembly groups and accessory parts as we deem appropriate in order to increase their capacity and

safety while maintaining their essential characteristics.

2.2 Copyright

The copyright to these instructions is held by Siemens AG.

These instructions may be used neither in full nor in part for competitive purposes nor be made available

to third parties without our approval.

Technical enquiries should be directed to our factory or to one of our customer service centres:

Siemens AG

Am Industriepark 2

46562 Voerde

Tel.: +49 (0)2871 / 92‐0

Fax: +49 (0)2871 / 92‐1544

BA 9137 en 12/2015

10 / 89

Page 11

3. Safety instructions

WARNING

Risk of falling

Serious injury from falling is possible.

The gear unit and its add-on parts must not be accessed during operation.

The gear unit may only be accessed for maintenance and repair works during standstill of the gear unit.

WARNING

Risk of injury from changes made on own initiative

Changes made on own initiative are prohibited.

This also pertains to the protection equipment that is installed as contact protection.

3.1 Obligations of the user

• The operator must ensure that everyone carrying out work on the gear unit has read and understood

these instructions and is adhering to them in every point in order to:

─ avoid injury or damage to the user and third parties,

─ ensure the safety and reliability of the gear unit,

─ avoid loss of use and environmental damage caused by incorrect use.

• During transport, assembly, installation, demounting, operation and maintenance of the unit, the

relevant safety and environmental regulations must be observed at all times.

• The gear unit may only be operated, maintained and/or repaired by persons qualified for the work

concerned (see "Qualified personnel" on page 3 of this manual).

• The outside of the gear unit must not be cleaned with high-pressure cleaning equipment.

• All work must be carried out with great care and due regard for safety.

DANGER

Danger to life from switched on system

For carrying out work on the gear unit, the gear unit and an added on or separate oil-supply system must

generally be set in standstill.

The drive unit must be secured against accidental start-up (e.g. by locking the key switch or removing

the fuses from the power supply).

Attach a notice on the start switch stating clearly that work is in progress on the gear unit.

At the same time, the complete system must be free from load so that no danger is caused during the

disassembly work.

• No welding work may be done at all on the drive.

The drive systems must not be used as an earthing point for electric-welding operations. Toothed parts

and bearings can be irreparably damaged by welding.

BA 9137 en 12/2015

11 / 89

Page 12

NOTICE

Property damage

Damage to the gear unit is possible.

For gear units, which are operated together with electrical machines that generate power or that are

supplied with power (e. g. motors, generators, etc.), it must be ensured that no current can flow through

the gear unit. The flow of current can lead to irreparable damages on rolling bearings and gear teeth.

Flow of current can arise, e. g. through short circuits, flash arcs, conductive dust layers, etc.

Suitable measures may be:

– Use of isolators

– Earth the gear unit professionally

DANGER

Electrostatic discharge

Danger to life from ignition of present explosive atmosphere by electrostatic discharge.

A potential equalisation in accordance with the applying regulations and directives must be carried out.

Threaded holes for an earth connection are provided on the gear units or on the output flange. This work

must always be done by trained electricians.

NOTICE

Property damage

Damage to the gear unit is possible.

Immediately stop the gear unit by turning off the drive unit when inexplicable changes are noticed

during the operation, such as a significantly increased operating temperature or changed sounds of

the gear unit.

DANGER

Danger to life from rotating and/or moving parts

Risk of being gripped or drawn in by rotating and/or moving parts.

Rotating and/or movable drive parts must be provided with suitable safeguards to prevent contact.

Note

When the gear unit is incorporated in plant or machinery, the manufacturer of such plant or machinery

must ensure that the requirements, notes and descriptions contained in these instructions are

incorporated in its own instructions.

DANGER

Explosion hazard

Danger to life from ignition of present explosive atmosphere by use of unsuitable add-on parts.

All add-on parts must satisfy the requirements in Directive 2014/34/EU.

Simple electrical means (such as monitoring devices, switches, Pt100 measuring resistance) without

identification in accordance with Directive 2014/34/EU must be connected intrinsically safe by means

of suitable isolation amplifiers.

BA 9137 en 12/2015

12 / 89

Page 13

DANGER

Electrostatic discharge

Danger to life from ignition of present explosive atmosphere by electrostatic discharge.

The coating must not carry an electrostatic charge.

The operator must ensure that highly effective mechanisms which can set up a charge in the coating

are safely avoided.

• Removed safeguards must be refitted prior to starting up.

• Notices attached to the gear unit, such as rating plate and direction arrow, must always be observed.

They must be kept free from dirt and paint at all times. Missing plates must be replaced.

• Screws which have been damaged during assembly or disassembly work must be replaced with new

screws of the same strength class and type.

• Spare parts must be obtained from Siemens (see section 11. "Spare parts, customer service").

3.2 Special dangers and personal protective equipment

Depending on operating conditions, the surface of the gear unit may develop extreme temperatures.

WARNING

Risk of burns

Serious injury caused by burns on hot surfaces (> 55 °C) is possible.

Wear suitable protection gloves and protection clothing.

WARNING

Risk of low temperatures

Serious injury from cold damage (pain, numbness, frostbites) on cold surfaces (< 0 °C) is possible.

Wear suitable protection gloves and protection clothing.

WARNING

Risk of scalding

Serious injury from discharging hot operating media is possible when these are changed.

Wear suitable protection gloves, protection glasses and protection clothing.

WARNING

Risk of eye injury

Small foreign matter such as sand or dust can get into the cover plates of the rotating parts and might

be thrown back by these.

Wear suitable protective glasses.

BA 9137 en 12/2015

13 / 89

Page 14

Note

In addition to any generally prescribed personal protection equipment (protection shoes, protection

clothing, helmet, etc.) handling the gear unit requires wearing suitable safety gloves and suitable

safety glasses.

Note

The gear unit complies with the requirements in Directive 2014/34/EU.

DANGER

Explosion hazard

Danger to life from ignition of a present explosive atmosphere is possible when carrying out assembly

or disassembly works on the gear unit.

The gear unit must not be assembled or disassembled in an explosive environment.

3.3 The five safety rules

For your personal safety as well as avoidance of property damages, please always observe the safety

notices and the following five safety rules pursuant to the standard "DIN EN 50110-1" (Operations in

powered-down condition) when working on the electrical components of the system. Apply the five safety

rules from the start of the work on the machine, in the order cited above.

1) Disconnect

Also disconnect the auxiliary currents, e. g. standstill heating.

2) Secure against re-connection.

3) Verify that disconnected parts are have zero voltage.

4) Earth and short-circuit.

5) Cover or shield adjacent live parts.

Upon completion of the work, undo the taken measures in the reverse order.

3.4 Environmental protection

• Existing packaging material must be disposed of in accordance with the regulations or be given to

recycling.

• When changing oil, the used oil must be collected in suitable containers. Remove any pools of oil

immediately using an oil binding agent.

• Preservative agents should be stored separately from used oil.

• Used oil, preservative agents, oil binding agents and oil-soaked cleaning cloths must be disposed of

in accordance with environmental regulations.

• Disposal of the gear unit after its service life:

─ Drain all operating oil, preservative agent and/or cooling agent from the gear unit and dispose of it

in accordance with the regulations.

─ Depending on the national regulations, gear unit components and/or add-on parts may have to be

disposed of separately or be given to recycling.

BA 9137 en 12/2015

14 / 89

Page 15

4. Transport and storage

Observe the instructions in section 3. "Safety instructions"!

4.1 Content and check of the scope of delivery

The content of the delivery is listed on the packing slip. The completeness of the scope of delivery must

be checked against the packing slip directly on receipt. The packaging must not be opened for the check.

Damages on packaging and/or items missing from the package must be reported to Siemens in writing

within 2 weeks.

NOTICE

Property damage

Damage to the gear unit from corrosion is possible.

The packaging must not be opened in any case. Otherwise, the durability period of the gear unit

preservation will reduce.

Note

If the packaging is opened nonetheless, section 4.4 must be observed.

WARNING

Serious personal injury can be caused by a defective product

If there is any visible damage, the gear unit must not be taken into operation.

4.2 Transport

Note

The product weight is indicated on the rating plate.

DANGER

Danger to life

Danger to life from load falling down due to deficient attachment.

Do not stay underneath suspended loads.

When attaching, lifting, lowering and shifting the load, pay attention to the following:

– Observe the load limits

– Proper fastening of the attachment equipment

– Centre of gravity possibly being off centre

– Even load distribution on load-bearing equipment with multiple load hook-ups

– Low process speed

– Oscillating the load and/or attaching the load to objects

or building parts is prohibited.

– Load hooks may not be loaded at their tip

– Set down products only on even, non-slipping and stable underground

BA 9137 en 12/2015

15 / 89

Page 16

WARNING

Risk of crushing

Risk of being crushed by a transported component when the used lifting gear and load-bearing

equipment is not suitable and the component comes loose.

Attach the product for transport only on the marked attachment points. Lifting gear and load equipment

must be used that has adequate load-bearing capacity.

Observe the notes regarding load distribution on the packaging.

When being lifted the product must be transported slowly and carefully in order to avoid personal injury

and damage to the gear unit.

For example, impact on free shaft ends might lead to damage on the gear unit.

Gear units provided with pipework must be transported with particular care.

The gear unit is delivered in a fully assembled condition. If applicable, additional items are delivered

packaged separately.

Depending on the size of the unit and transport route, the gear unit will have different types of packaging.

Unless agreed otherwise by contract, the packaging complies with the Packaging Guidelines of the HPE

(Federal Association of Wood Packaging, Pallets, Export Packaging).

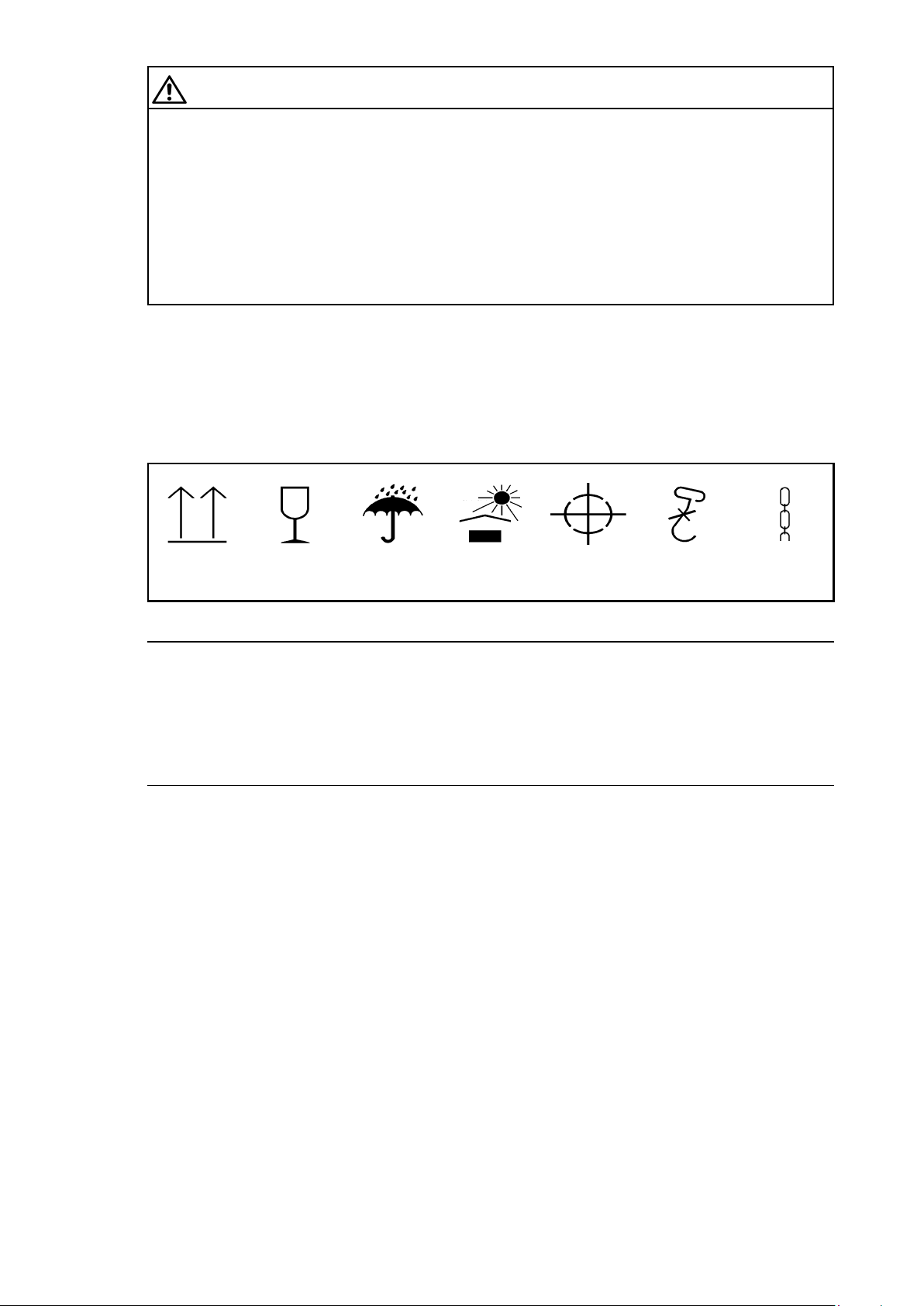

The symbols marked on the packaging must be observed at all times. These have the following meanings:

Top Fragile Keep dry Keep cool Centre of

gravity

Use no hand

hook

Attach

here

Fig. 2: Transport symbols

Note

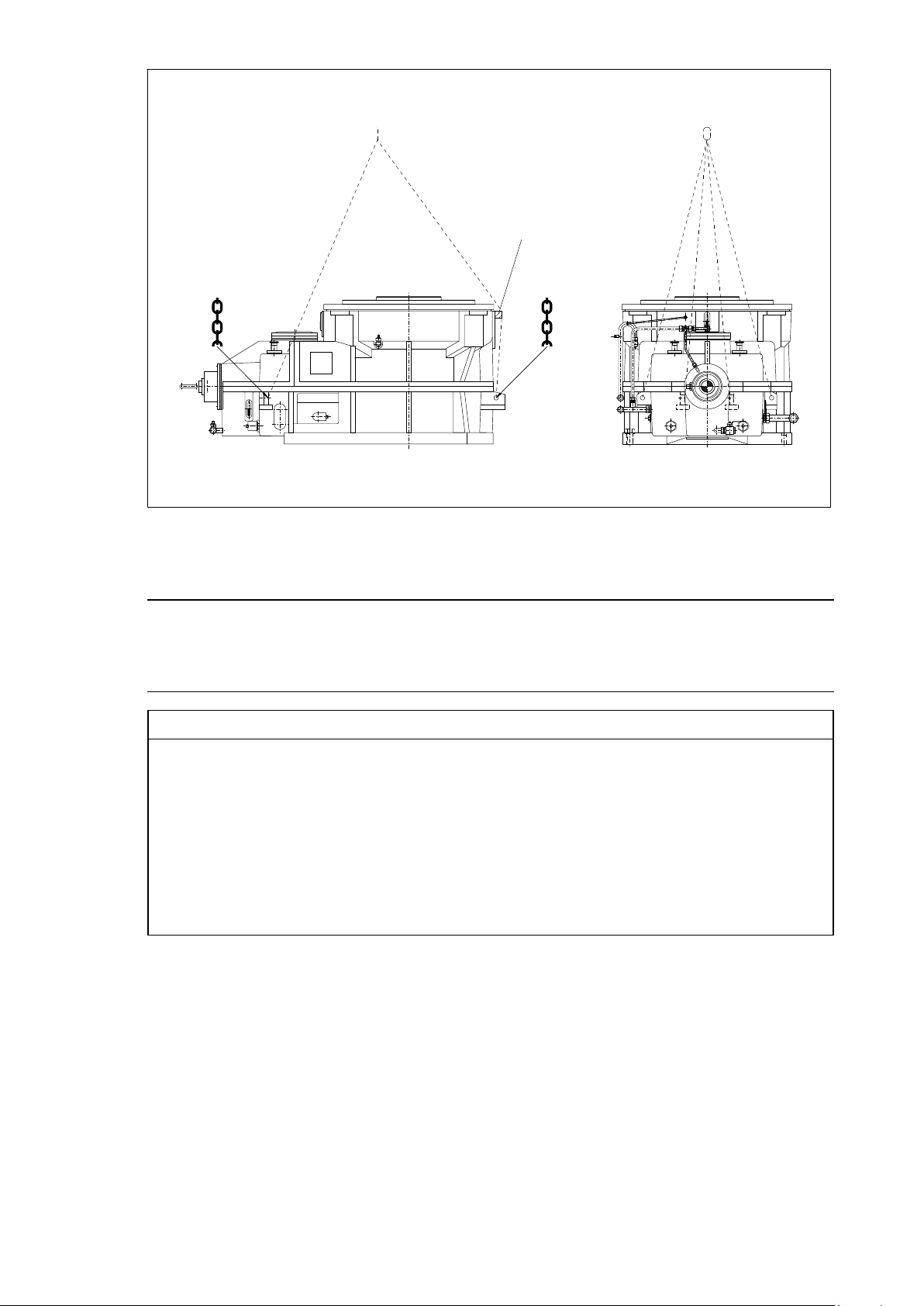

The gear unit may only be transported by means of transport equipment suitable for this purpose.

The gear unit should be transported without oil filling and be kept in/on the transport packaging.

If the gear unit is in seaworthy packaging (wooden box), the attachment points marked on the

packaging have to be used.

If the gear unit is delivered without seaworthy packaging, the attachment points as shown in Figure 3

have to be used.

BA 9137 en 12/2015

16 / 89

Page 17

1

Fig. 3: Alternative attachment points

1 Wooden block

Note

The detailed illustration of the gear unit, the position of the attachment points, and the positioning of

the wooden blocks for the protection of the gear unit during transport can be found on the dimensioned

and transport drawings in the order-specific gear unit documentation.

NOTICE

Property damage

Damage to the gear unit is possible when using the wrong attachment points. Use only the lifting eyes

provided to attach lifting gear to the unit. Attach slings with shackles to the eyebolts.

Transporting of the gear unit by attaching it to the pipework is not permitted.

The pipework must not be damaged.

Do not use the front threads at the shaft ends to attach slinging and lifting gear for transport.

Slinging and lifting gear must be adequate for the weight of the gear unit.

To prevent the housing, output flange and pipework from being damaged by the deflection of the

transport rope, wooden blocks must be placed under the rope.

The output flange of the gear unit must never be lifted.

BA 9137 en 12/2015

17 / 89

Page 18

4.3 Storing the gear unit

The gear unit must be stored with a cover, placed on a vibration-free dry base in a sheltered place, in the

position of the original packaging or in the position of use. Any storage methods deviating from this affect

the durability period of the gear unit preservation (see item 4.4).

NOTICE

Property damage

Any damage to the coating may cause the failure of the exterior protective coating and consequently

lead to corrosion.

When temporarily storing the gear unit and any components supplied with it, the applied corrosion

protection has to be preserved.

Ensure that the coat is not damaged.

DANGER

Danger to life from the gear unit toppling or dropping

Risk of being crushed or struck by a gear unit toppling or dropping.

Do not stack gear units on top of one another.

NOTICE

Property damage

Damage to the gear unit by deposit of foreign matter or moisture. If the gear unit is stored outdoors, it

must be covered particularly carefully and it must be ensured that neither moisture nor foreign material

can collect on the unit.

Waterlogging must be avoided.

NOTICE

Property damage

Damage to the gear unit from external effects.

Unless agreed otherwise by contract, the gear unit must not be exposed to harmful effects, such as

chemically aggressive products.

Special environmental conditions during transport (e.g. transport by ship) and storage (climate,

termites) must be agreed on by contract.

4.4 Standard coating and corrosion prevention

The gear unit is to be provided with interior preservation on delivery (see "Technical data" in the gear unit

documentation prepared specifically for the order), and the free shaft ends are to be provided with

protective preservation (see Table 2 in item 4.4.1.1).

The properties of the exterior preservation when using a Siemens standard priming are resistant to:

─ weak acids and alkalis

─ solvents

─ weathering, also tropical

─ temperatures up to 120 °C / 248 °F (for short periods up to 140 °C / 284 °F)

If a different exterior coating is intended by the customer (contrary to the Siemens standard), the protection

of the external coating will be within the customer's responsibility.

BA 9137 en 12/2015

18 / 89

Page 19

NOTICE

Property damage

Damage to the gear unit from corrosion is possible.

The gear unit is normally delivered completely ready with a priming and a finishing coat.

Where gear units are delivered with a priming coat only, it is necessary to apply a finishing coat

according to the standard procedures relevant for the specific application.

The priming coat alone is not suitable to provide sufficient long-term corrosion protection.

Note

The coating complies with the requirements for the conductivity of the coating and the limitation of the

layer thickness of the applied coating according to the standard "DIN EN 13463-1". Electrostatic

charging is not expected if coatings have a thickness of <200µm. Where gear units are delivered with

a priming coat only, it is necessary to apply a finishing coat according to the standard procedures

relevant for the specific application.

The priming coat alone is not suitable to provide sufficient long-term corrosion protection.

DANGER

Electrostatic discharge

Danger to life from ignition of present explosive atmosphere by electrostatic discharge.

The coating must not carry an electrostatic charge.

The operator must ensure that highly effective mechanisms which can set up a charge in the coating

are safely avoided.

Note

Examples of highly effective charge-generating mechanisms are:

– the rapid passage of heavily dust-laden air near by

– the sudden escape of particle-laden compressed gases

– other heavy friction action (not manual cleaning or rubbing with cleaning cloths)

NOTICE

Property damage

Any damage to the coating may cause the failure of the exterior protective coating and consequently

lead to corrosion.

Ensure that the coat is not damaged.

Note

Corrosion prevention durations of the interior preservation depend on the kind of transport, type of

packaging and the place of installation and/or storage (see Table 3 in item 4.4.2.1).

The durability period of the exterior preservation and the related requirements can be found in Table 2

under item 4.4.1.1.

The warranty starts upon notification of readiness for delivery (see "Technical data" in the gear unit

documentation). The provided interior gear unit preservation is also shown in "Technical data".

When storing differently from the durability periods of preservation as specified in Tables 2 and 3

applicable for the gear unit, the interior preservation must be prolonged (see item 4.4.3) and if necessary,

the exterior preservation must be renewed (see item 4.4.1).

Each prolongation of the interior preservation and any renewal of the exterior preservation must be logged.

Note

The record must be kept with these instructions.

BA 9137 en 12/2015

19 / 89

Page 20

4.4.1 Exterior preservation of metallic bright exterior surfaces

4.4.1.1 Maximum durability period of the exterior preservation

Table 2: Durability period for exterior corrosion prevention of shaft ends and other bright machined

surfaces

Durability

of protection

for indoor storage up

to 36 months

for outdoor storage

up to 12 months

1)

The gear unit must be stored with a cover on a vibration-free, dry base in a place sheltered from

1)

2)

Preservative agent

Tectyl 846 K19 approx. 50 µm

Layer thickness Remarks

Long-term wax-based

preservative agent:

– resistant to sea water

– and tropical conditions

– soluble with CH

weathering, in the position of use.

2)

If the gear unit is stored outdoors, it must be covered particularly carefully and it must be ensured that

neither moisture nor foreign material can collect on the unit. Waterlogging must be avoided.

4.4.1.2 Prolongation of the preservation of metallic bright exterior surfaces of the gear unit

In case storage periods exceed the periods specified in Table 2 under item 4.4.1.1, the exterior of the gear

unit must be re-preserved using the preservative agent shown in Table 2.

• Clean the surfaces.

• Apply preservative agent (see table 2).

Note

Before start-up, all preservation coats have to be removed from the gear unit according to section 7.1.1.

compounds

4.4.2 Preservation of the interior of the gear unit

4.4.2.1 Maximum durability period of the interior preservation of the gear unit

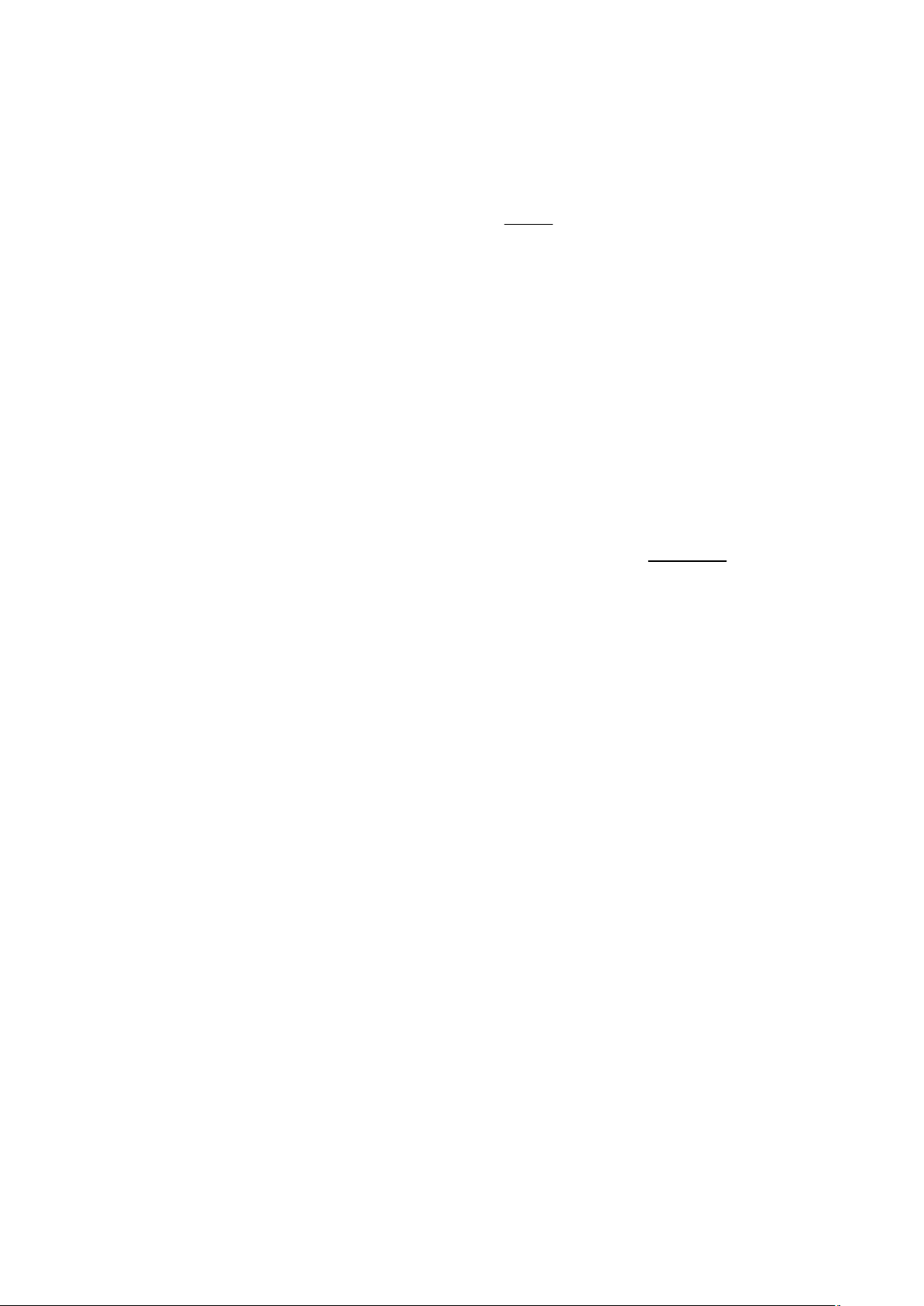

Table 3 shows the maximum durability of the interior gear unit preservation, depending on the kind of

transport, type of packaging and the setup or storage site.

Definition of climatic zones:

North Pole 90°N

Arctic Circle 66.5°N

A

Northern Tropic 23.5°N

B

A

South Pole 90°S

Equator 0°

Southern Tropic 23.5°S

Antarctic Circle 66.5°S

BA 9137 en 12/2015

20 / 89

Page 21

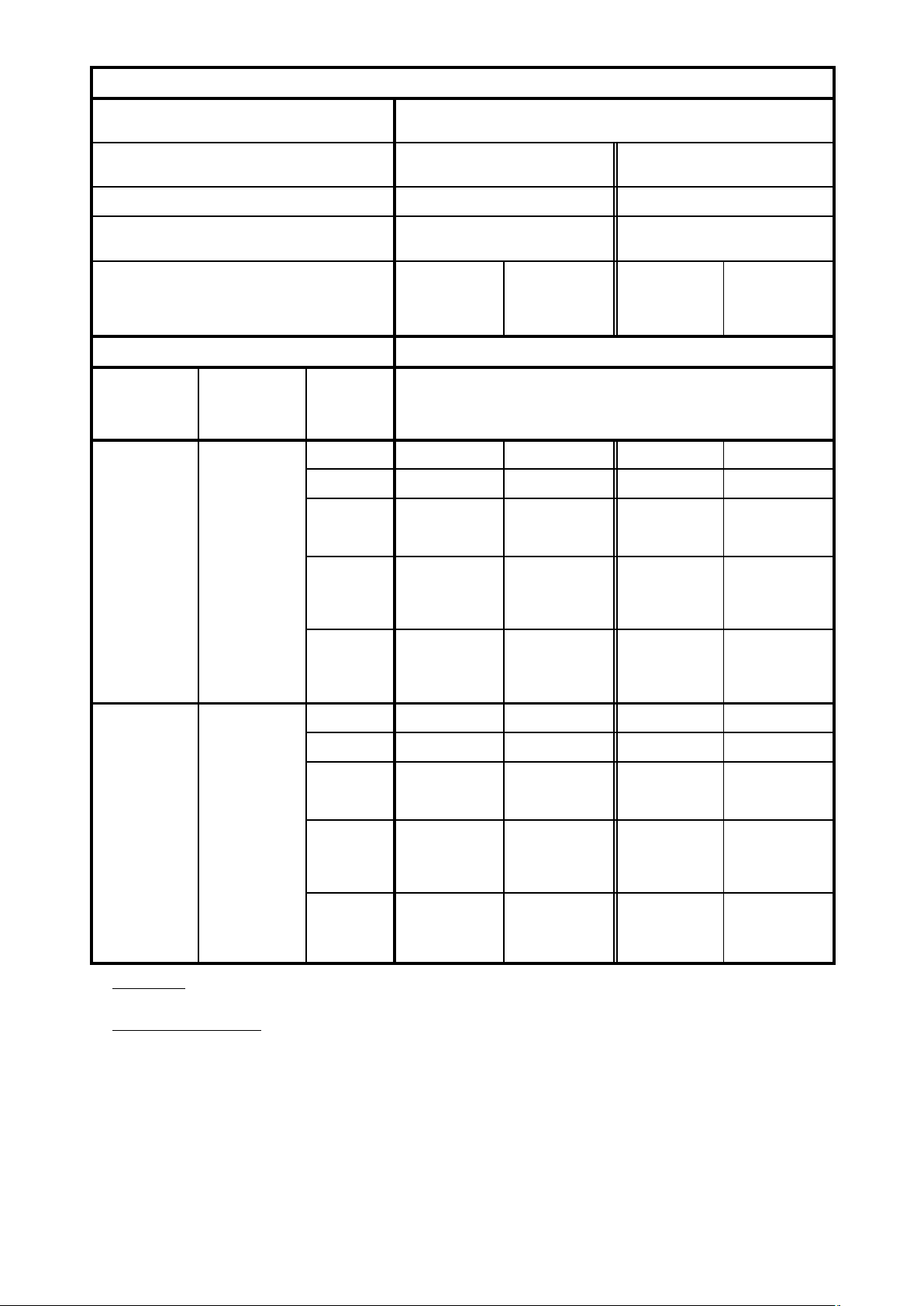

Table 3: Maximum durability period of the interior preservation of the gear unit

Setup and transport

Setup in climatic zone A and at least 50 km

distance from larger bodies of

None or simple

transport packaging

Without sea

transport

salt water

With sea

transport

Transport in

seaworthy

packaging

With or without

sea transport

2)

Storage

Packaging for

storage

Storage place of

packaged unit

maximum durability of the interior gear unit preservation HD (Durability Period)

months

Setup in climatic zone B and/or less than

50 km distance from larger bodies of

None or simple

transport packaging

Without sea

transport

salt water

With sea

transport

Transport in

seaworthy

packaging

With or

without sea

transport

/ HD

1

2)

in

2

No

packaging

covered at

least with

loose tarpaulin

seaworthy

packaging

2)

exposed

outdoors

covered with

loose tarpaulin

under roof

in closed, dry

exposed

outdoors

under roof

in closed, dry

exposed

outdoors

covered with

loose tarpaulin

under roof

in closed, dry

1)

room

1)

room

1)

room

5 3 5 3 3 3

7 3 8 4 3 5

15 3 20 11 3 14

7 3 8 4 3 5

19 3 24 13 3 17

15 3 20 15 3 20

19 3 24 19 3 24

1) under roof:

no direct exposure to sunlight and no direct contact with water

(rain or draining water)

2) Seaworthy packaging:

use of wooden box lined with bitumen paper. The content is sealed in foil and protected against moisture by

addition of drying agents for the prescribed storage period.

Note

On the goods receipt, the seaworthy packaging must be inspected for damages.

If damaged, the packing must be restored to its seaworthy condition.

Note

If different statements were made in agreement with the customer, as to the protective periods on precisely

defined conditions, a description can be found in the order confirmation from Siemens.

BA 9137 en 12/2015

21 / 89

Page 22

4.4.2.2 Combined storage / packaging

If the type of packaging and/or storage is changed within the durability period as HD

to the existing preservation and the present type of packaging and/or storage, a new

determined as the equivalent remaining durability period applicable as of the date of the change. For this

purpose, the following formula has to be used:

LD

HD

LD

HD

HD

HD

If several packaging and/or storage types are combined the following formula must be applied as from

the second change in packaging and/or storage types (

to determine the

= Storage period for the existing preservation

1

= Maximum durability period of the existing preservation

1

2

2äq

according to table 3 in item 4.4.2.1

= Maximum durability period after the change in the type of storage and/or packaging

according to table 3 in item 4.4.2.1

= Maximum remaining durability period after the change in the type of storage and/or

packaging

equivalent remaining durability period applying to the preservation:

HD

n*äq

+ (HD

2äq

+ (1 *

n*1äq

* LD

1

) HD

HD

1

equivalent remaining durability period > HD

n*1

2

) (

HD

, which is applicable

1

HD

2äq

HD

n

)

n*1

has to be

2 äq

)

HD

LD

HD

HD

HD

= Calculated durability period with the previous storage conditions

äq

n-1

= Actual duration of storage with the previous storage conditions

n-1

= Maximum durability period with the present storage conditions

n

n-1

n-

äq

specified in table 2 in item 4.4.2.1

= Maximum durability period with the previous storage conditions

specified in table 2 in item 4.4.2.1

= Remaining durability period after change in the packaging and/or storage types

BA 9137 en 12/2015

22 / 89

Page 23

Example:

─ A gear unit is stored exposed outdoors after sea transport, in climatic zone B, while it is kept in seaworthy

packaging

= 20 months

HD

1

(climatic zone:

for storage: seaworthy packaging, place of storage: exposed outdoors)

B, transport type: sea transport, transport packaging: seaworthy packaging, packaging

─ After 5 months (LD

besides the mill.

HD

= 4 months

2

(climatic zone:

for storage: no packaging, place of storage: covered with loose tarpaulin)

Now, the remaining durability period HD

The remaining durability period of the interior gear-unit preservation after changing the storage type is

3 months.

After one additional month (LD

remaining durability period HD

Given:

), the gear unit is unpacked, covered with a loose tarpaulin, and placed outdoors

1

B, transport type: sea transport, transport packaging: seaworthy packaging, packaging

has to be calculated as follows:

2äq

LD

HD

1

) HD

1

5

) 4

20

2

HD

HD

), the gear-unit is placed outdoors exposed without packaging. Now, the

2

3äq

+ (1 *

2äq

+ (1 *

2äq

HD

is to be calculated as follows:

+ 3months

2äq

HD

LD

HD

HD

HD

The remaining durability period of the interior gear-unit preservation is 1.5 months after combining the

storage types described in the example.

= 3 months (previously calculated)

2äq

= 1 month (actual duration of storage with the previous storage conditions)

2

= 3 months (maximum durability period with the present storage conditions

3

2

n-äq

specified in table 2 in item 4.4.2.1

= 4 months (maximum durability period with the previous storage conditions

specified in table 2 in item 4.4.2.1

= HD

3äq

HD

3äq

HD

+ (HD

3äq

HD

3äq

* LD2) (

2äq

+ (3 * 1) (

+ 1.5months

3

4

)

HD

HD

3

)

2

BA 9137 en 12/2015

23 / 89

Page 24

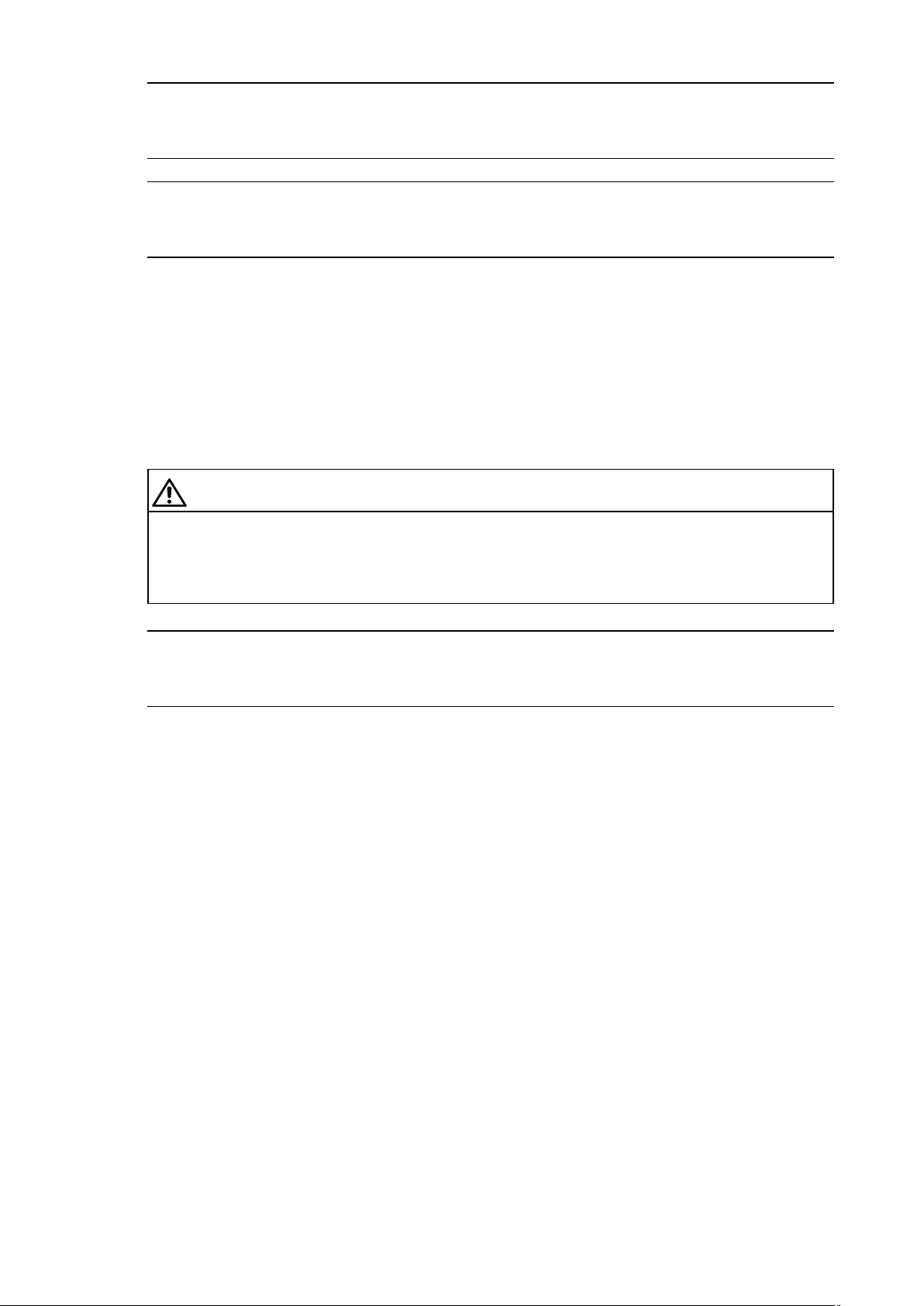

Table 4: Examples of combined storage (maximally one change in storage) and the resulting remaining

durability of the interior preservation of the gear unit

Original place of storage of the gear

In which climatic zone is the construction site

located?

How was the gear unit packaged for transport? None or simple

How was the gear unit transported? without sea transport with or without sea transport

In what packaging was the gear unit stored at the

construction site?

Where/how was the packed unit stored?

in closed room

or under roof

Setup in climatic zone A and at least 50 km

distance from larger bodies of salt water

Transport packaging

no packaging seaworthy packaging

covered with

1)

loose tarpaulin

in closed room

or under roof

Transport in

seaworthy packaging

1)

Change in place of storage

New

Packaging for

storage

Storage place of

the newly

packaged unit

Change of

original

storage

method after

1 month 4 1/2 4 5 4 1/2

3 months 4 3 4 1/2 4

6 months 3 1 4 3 1/2

Durability period of interior preservation of the gear unit for the new

storage method in consideration of the previous storage period in months

2)

2)

exposed

outdoors

covered with

loose tarpaulin

or

without

packaging

covered with

loose tarpaulin

exposed

outdoors

exposed

outdoors

12 months 1

not permissible,

18 months

1 month 6 1/2 6 7 1/2 7 1/2

3 months 5 1/2 4 7 7

6 months 4 1 6 5 1/2

12 months 1 1/2

18 months

max. durability

period

15 months

not permissible,

max. durability

period

15 months

not permissible,

max. durability

period 7 months

not permissible,

max. durability

period 7 months

not permissible,

max. durability

period 7 months

not permissible,

max. durability

period 7 months

2 1/2 2

1 1/2 1/2

4 3

2 1

BA 9137 en 12/2015

24 / 89

Page 25

Original place of storage of the gear

In which climatic zone is the construction site

located?

How was the gear unit packaged for transport? None or simple

How was the gear unit transported? without sea transport with or without sea transport

In what packaging was the gear unit stored at the

construction site?

Where/how was the packed unit stored?

in closed room

or under roof

Setup in climatic zone B and/or less than 50 km

distance from larger bodies of salt water

Transport packaging

no packaging seaworthy packaging

covered with

1)

loose tarpaulin

in closed room

or under roof

Transport in

seaworthy packaging

1)

Change in place of storage

New

Packaging for

storage

without

packaging

Storage place of

the newly

packaged unit

exposed

outdoors

Change of

original

storage

method after

1 month 2 1/2 2 3 3

3 months 2 1 2 1/2 2 1/2

6 months 1 1/2

12 months

Durability period of interior preservation of the gear unit for the new

storage method in consideration of the previous storage period in months

not permissible,

max. durability

period

11 months

not permissible,

max. durability

period 4 months

not permissible,

max. durability

period 4 months

2 2

1 1/2 1

2)

2)

exposed

outdoors

covered with

loose tarpaulin

or

covered with

loose tarpaulin

exposed

outdoors

not permissible,

18 months

1 month 3 1/2 3 5 5

3 months 3 1 4 1/2 4

6 months 2

12 months

18 months

max. durability

period

11 months

not permissible,

max. durability

period

11 months

not permissible,

max. durability

period

11 months

not permissible,

max. durability

period 4 months

not permissible,

max. durability

period 4 months

not permissible,

max. durability

period

4 months

not permissible,

max. durability

period

4 months

1 1/2

4 3 1/2

2 1/2 2

1 1/2 1/2

1) under roof:

no direct exposure to sunlight and no direct contact with water (rain or draining water)

2) Seaworthy packaging:

use of wooden box lined with bitumen paper. The content is sealed in foil and protected against moisture by

addition of drying agents for the prescribed storage period.

BA 9137 en 12/2015

25 / 89

Page 26

Note

On the goods receipt, the seaworthy packaging must be inspected for damages.

If damaged, the packing must be restored to its seaworthy condition.

Note

If different statements were made in agreement with the customer, as to the protective periods on

precisely defined conditions, a description can be found in the order confirmation from Siemens.

4.4.3 Renewal of the interior preservation of the gear unit for longer periods of storage of the gear unit that has

not been taken into operation yet

If the gear unit is taken into operation at a point in time, when the maximum durability of the interior

preservation of the gear unit exceeds the durability as specified in Table 3 under item 4.4.2.1 or if it has

reached remaining durability period specified in item 4.4.2.2, the interior preservation of the gear unit must

be renewed following the expiration of the durability period.

4.4.3.1 Renewal of the gear unit interior preservation with "Castrol Corrosion Inhibitor N 213"

For the renewal of the gear unit interior preservation, the VCI gas discharging fluid

"Castrol Corrosion Inhibitor N 213" is recommended.

CAUTION

Risk of injury

Risk of injury to eyes or hands from chemically aggressive operating substances.

Wear suitable protection glasses and protection gloves.

Remove any spilled oil immediately using an oil binding agent.

Note

In this renewal of the gear unit interior preservation, it must be ensured that the ambient and gear unit

temperature is above 5 °C during filling.

The following control measures must be taken:

• The pressure, suction and/or return lines are sealed with blind flanges.

• The oil drain cocks on the gear unit and on the tilting pad thrust bearing chamber are sealed with screw

plugs.

• The labyrinth seal on the output flange is sealed with the round cord hollow profile (13) and masked

airtight (see Figure 4 in item 4.4.3.2).

The following procedure is recommended:

• Remove screw plugs that have been screwed in for transport instead of the air filter.

• Fill gear unit with "Castrol Corrosion Inhibitor N 213" through the openings of the air filters.

Filling quantity: 1 litre per cubic metre of the entire free interior volume of the gear unit (to be enquired

from Siemens). The interior volume of the gear unit can be ascertained in approximation also by means

of the length x width x height of the gear unit.

• The vent holes of the air filter for the gear unit have to be closed and sealed again with screw plugs

(these must be replaced again at the start-up).

BA 9137 en 12/2015

26 / 89

Page 27

NOTICE

Property damage

Corrosion is possible when the gear unit is opened for too long.

Close the gear unit airtight again, at the latest one hour after opening.

Table 5 shows the maximum durability period for the preservation renewal with

"Castrol Corrosion Inhibitor N 213" depending on the packaging and setup or storage site. The definition

of climatic zones can be found in item 4.4.2.1.

Note

If the gear unit is transported after the preservation was renewed, the durability period according to

Table 3 in item 4.4.2.1 has to be observed.

Table 5: Maximum durability period of the preservation renewal with

"Castrol Corrosion Inhibitor N 213"

Packaging for

Storage

No

packaging

covered at least

with

loose tarpaulin

seaworthy

packaging

2)

Setup in climatic zone A and at

least 50 km distance from larger

Storage place of

packaged unit

exposed outdoors 5 3

covered with loose

tarpaulin

under roof

in closed,

dry room

exposed outdoors 8 5

under roof

in closed,

dry room

exposed outdoors

covered with loose

tarpaulin

under roof

in closed,

dry room

1)

1)

1)

bodies of

salt water

Maximum durability period of the preservation renewal with

"Castrol Corrosion Inhibitor N 213" (in months)

8 5

20 14

24 17

20 20

24 24

Setup in climatic zone B and/or

less than 50 km distance from

larger bodies of

salt water

1) under roof:

no direct exposure to sunlight and no direct contact with water

(rain or draining water)

2) Seaworthy packaging:

use of wooden box lined with bitumen paper. The content is sealed in foil and protected against moisture

by addition of drying agents for the prescribed storage period.

BA 9137 en 12/2015

27 / 89

Page 28

NOTICE

Property damage

With larger filled-in quantities of the "Corrosion Inhibitor N 213" (above 5 % of the operating oil

quantity), the mixture of operating oil and "Corrosion Inhibitor N 213" must not be used as operating

oil. Before start-up, the remaining "Corrosion Inhibitor N 213" has to be drained and the gear unit must

be flushed thoroughly with operating oil (in this regard, see item 10.4.)

NOTICE

Property damage

Damage to the gear unit is possible.

The gear unit may not be turned.

Note

Before start-up of the gear unit, the measures according to section 7.1 and 7.2 have to be carried out.

4.4.3.2 Renewal of the gear unit interior preservation through complete filling with preservative or operating oil.

A further possibility for renewal of the gear unit interior preservation is to fill the gear unit with preservative

or operating oil until the oil level indicator on the tilting pad thrust bearing chamber shows it is filled

completely with oil.

The durability of this kind of preservation depends on the used oil and has to be enquired with the oil

manufacturer.

For the complete filling, a sealing cap (can be obtained from Siemens) must be mounted on the gear unit

for sealing the input shaft.

The preservation will remain intact for as long as the gear unit remains sealed and the storage durability

of the oil is not exceeded.

Note

Refer to the BA 7300 operating instructions supplied separately for the approved preservative oils. The

viscosity of the operating oil is stated on the rating plate.

For better filling it is recommended to choose an oil with low viscosity, which however is not suitable

for later operation of the gear unit and will thus have to be fully drained. When filling, the filled-in oil

should have a maximum viscosity of 7500 cSt (at VG 320 > 0°C).

For complete filling, also the later operating oil can be used, which has to be drained to the operating

oil level before start-up.

NOTICE

Property damage

Insufficient lubrication due to the incompatibility of the oils.

If the gear unit is preserved with "TRIBOL 1390" (see "Technical data"), it must be flushed before the

complete filling (see BA 7300).

This flushing oil must not be used for operation.

NOTICE

Property damage

Corrosion damages on the gear unit possible from the loss of the preservative effect

Filled gear units can become untight and the gear unit oil might leak. Tightness of the filled gear units

must be monitored. Leaks must be removed. Siemens does not accept any liability for damages that

are caused from leaking gear unit oil during storage.

BA 9137 en 12/2015

28 / 89

Page 29

The following control measures must be taken:

• The pressure, suction and/or return lines (6, 8, 9) are sealed with blind flanges.

• The oil drain cock of the tilting pad thrust bearing chamber (10) is sealed with a screw plug.

• The vent holes for the gear unit (4) are sealed with a screw plug.

• The labyrinth seal of the output flange is sealed with the round cord hollow profile (13) and masked

airtight.

The following procedure is recommended:

• Seal input shaft with a sealing cap (3).

• Seal bottom oil drain of the sealing cap (2) with a screw plug.

• The oil to be filled in must be filtered beforehand with a filter mesh of 25 μm (0.0010 inch).

1

3

2

12

7

10

5

Fig. 4: Gear unit features for preservation measures

13

4

9

8

4

6

1 Breather of sealing cap

2 Oil drain sealing cap

3 Sealing cap

4 Air filter (gear unit)

5 Oil level indicator (gear unit)

6 Suction line (gear unit)

7 Oil drain (gear unit)

8 Pressure line (gear unit)

9 Pressure line (tilting pad thrust bearing

chamber)

10 Oil drain tilting pad thrust bearing

chamber

12 Indication of oil level (tilting pad thrust

bearing chamber)

13 Round cord hollow profile

BA 9137 en 12/2015

29 / 89

Page 30

• Fill sealing cap on the input shaft through the ventilation of the sealing cap (1) The ventilation (1) is to

be closed, only once the oil filling of the gear unit is completed, unless oil is escaping from this opening

before then.

• For filling, remove the sealing cap that seals the oil drain cock of the gear unit (7). The gear unit must

be filled with oil through the bottom oil drain cock of the gear unit (7).

Note

The gear unit will be filled completely only when the oil level indicator on the tilting pad thrust bearing

chamber (12) is filled completely with oil.

• The lower oil drain cock on the gear unit (7) must be provided and sealed with a screw plug.

• If not already done beforehand, close ventilation of the sealing cap (1).

Note

Before the start-up of the gear unit, the measures according to section 7.1 and 7.2 have to be carried

out.

4.4.3.3 Renewal of the interior preservation of the gear unit using the oil- supply system

The prerequisite for this is that the gear unit is still below the mill and connected to the oil-supply system.

"Castrol Alpha SP 220 S" or "Tribol 1390" can be used as preservative agent. The oil level must never be

below the MIN mark on the oil level indicator of the main gear unit, the tilting pad thrust bearing chamber

and/or on the oil-supply system (if the model has a tank, also see the operating manual of the oil-supply

system). For this purpose, the oil-supply system has to be switched on and the gear unit must be turned

without load (at least 1 rotation on the output shaft). The oil must be drained, the gear unit and oil-supply

system be closed, masked and sealed airtight. Air filters have to be replaced for sealing caps and be

sealed. The gear unit has to be sealed airtight with a round cord hollow profile between the gear unit

housing and the output flange. The labyrinth seals on the input shaft and on the output flange must be

masked airtight within 1 hour.

Note

Clean the air filters thoroughly (see item 10.3) and keep it in a safe place (these will be required when

starting up again).

BA 9137 en 12/2015

30 / 89

Page 31

Table 6: Maximum durability period of the interior preservation of the gear unit through operating the

oil-supply system.

Packaging for

Storage

No

packaging

covered at least

with

loose tarpaulin

seaworthy

packaging

2)

Setup in climatic zone A and at

least 50 km distance from larger

Storage place of

packaged unit

exposed outdoors 5 3

covered with loose

tarpaulin

under roof

in closed,

dry room

exposed outdoors 8 5

under roof

in closed,

dry room

exposed outdoors

covered with loose

tarpaulin

under roof

in closed,

dry room

1)

1)

1)

bodies of salt

water

Maximum durability period of the preservation renewal through

operation of the oil-supply system (in months)

8 5

20 14

24 17

20 20

24 24

Setup in climatic zone B and/or

less than 50 km distance from

larger bodies of salt water

1) under roof:

no direct exposure to sunlight and no direct contact with water

(rain or draining water)

2) Seaworthy packaging:

use of wooden box lined with bitumen paper. The content is sealed in foil and protected against moisture

by addition of drying agents for the prescribed storage period.

Note

Before restarting the gear unit, the measures according to section 7.1 and 7.2 have to be carried out.

BA 9137 en 12/2015

31 / 89

Page 32

5. Technical description

Observe the instructions in section 3. "Safety instructions"!

5.1 General description

The gear unit described is a "FLENDER Bevel- helical gear unit" of the type "KMS" designed for driving

a vertical mill.

The axial and radial forces resulting from the grinding process are led into the foundation through the gear

unit housing.

A detailed illustration of the gear unit is contained the drawings in the gear unit documentation.

NOTICE

Property damage

Destruction of the gear unit or gear unit parts from wrong rotation direction is possible.

The gear unit is approved for one direction of rotation only.

Observe the direction-of-rotation arrows on the housing.

5.2 Delivery condition of the gear unit

The input shaft of the gear unit is equipped with a radial shaft sealing ring (1), which is installed hidden and

ensures the necessary airtight sealing of the gear unit interior for the specified preservation period

(see Figure 5). Removing the radial shaft sealing ring during the start-up is not required. Should the radial

shaft sealing ring no longer fulfil its sealing function after start-up, this does not impede the reliability of the

shaft sealing.

A round cord hollow profile (2) is used as sealing between the gear unit housing and the output flange. This

seal additionally serves for the airtight sealing of the gear unit interior for the specified preservation period.

If the gear unit is opened (e.g. by removing the adhesive tape on the labyrinth seal of the input shaft and/or

the output flange, by removing the round cord hollow profile (2) or by opening a lid or screw plug), the

start-up must take place within one week or the gear unit must be re-preserved according to item 4.4.3.

1

2

1 Radial shaft sealing ring 2 Round cord hollow profile

Fig. 5: Arrangement of the round cord hollow profile and radial shaft sealing ring (schematic

illustration)

NOTICE

Property damage

Corrosion is possible when the gear unit is opened too early.

Any opening of the gear unit (e.g. by removing the adhesive tape on the input shaft or on the output

flange, removing the round cord hollow profile, or by opening a lid or a screw plug) reduces the

guaranteed preservation period. If the gear unit is opened, it must be taken into operation within one

week. If the start-up is delayed, special measures are necessary to maintain preservation (see

item 4.4.3).

BA 9137 en 12/2015

32 / 89

Page 33

5.3 Lubrication

The lubrication and cooling is provided by continuous oil circulation through a separate oil-supply system.

To prevent vibration and to compensate for heat expansion, compensators are provided in the pipe

system.

Note

When operating and servicing the components of the oil supply system, observe the operating

instructions of the components.

For technical data, refer to the data sheet and/or the list of equipment.

For a detailed illustration of the gear unit and oil-supply system, refer to the drawings in the gear unit

documentation.

The kind of lubrication can be found on the order-specific equipment list, the lubrication diagram and the

"Technical Data Sheet" of the gear unit.

Depending on the gear unit version, one of the following three lubrication systems is installed in the gear

unit.

Toothed parts and rolling bearings are force-lubricated and cooled through the low-forced lubrication

circuit.

5.3.1 Hydrodynamic lubrication of the axial tilting pad thrust bearings

In low ambient temperatures, the oil must be pre-warmed. If agreed by contract, immersion heaters will be

installed in the gear unit housing or the oil tank, or a separate heating circuit will be provided (see equipment

list and lubrication diagram).

The oil is drawn in by the oil pump, cleaned in the double-changeover filter, which is fitted with an optical

and electrical contamination indicator, then cooled in the cooler and conducted to the lubricating points.

The oil flow is divided by valves and orifice plates or control valves for the lubrication of the gears and tilting

pad thrust bearing.

Volumetric flow, pressure and temperature are constantly monitored by monitoring equipment. To prevent

vibration and to compensate for heat expansion, compensators are provided in the pipe system.

5.3.2 Hydrodynamic lubrication of the axial tilting pad thrust bearings in gear units with hydrostatic start-up assistance

In addition to the hydrodynamic lubrication, part of the oil is fed immediately downstream of the cooler to

the high-pressure pump through a branch circuit.

The high-pressure pump is designed as a radial piston pump and supplies a constant oil quantity at each

connection. The oil is conducted to four axial thrust bearing segments distributed around the

circumference. Before the mill is started, the oil is pumped between the pads and the race. A bearing oil

film will form immediately. After 2 minutes in operation at operating speed, the high-pressure pump must

be turned off.

Pressure switches without pressure transmitter this operating phase and the non-return valves built into

the pads prevent the oil from backing up during normal operation.

BA 9137 en 12/2015

33 / 89

Page 34

5.3.3 Hydrodynamic lubrication of the axial tilting pad thrust bearings with radial piston pump

In addition to the hydrodynamic lubrication, part of the oil is fed immediately downstream of the cooler to

the high-pressure pumps through a branch circuit.

The high-pressure pumps are designed as radial piston pumps and supply a constant oil quantity at each

connection. The same oil quantity is supplied to each bearing pad independently of the counter pressure.

The oil connections are distributed so that no two adjacent pads are supplied by one high-pressure pump.

The drive can continue to be operated throughout the time required for replacing a broken-down

high-pressure pump.

In order to ensure that the high-pressure pumps are operating and no oil line is defective, the oil flows are

monitored for minimum and maximum pressure. The pressure is set through the pressure actually exerted

by the grinding rollers.

If the minimum setting of a pressure- or flow-monitored component is fallen short of, the main drive will be

switched off. If the maximum pressure is exceeded, a warning is given or the main drive is shut off. The

non-return valves built into the pads prevent the oil from backing up during normal operation.

5.3.4 Labyrinth seals

The input shaft and output flange are sealed with labyrinth seals. Air filters are provided on the housing to

regulate the pressure.

Labyrinth seals are non-contacting seals. Labyrinth seals prevent wear and tear on the shaft, are

maintenance-free and ensure favourable temperature characteristics.

1

2

Fig. 6: Labyrinth seal (schematic illustration)

1 Labyrinth seal on output flange 2 Labyrinth seal on input shaft

NOTICE

Property damage

Deficient lubrication is possible from oil leakage on the gear unit.

For reliable operation, labyrinth seals require stationary, horizontal positioning away from dirty water

and high dust concentrations.

Overfilling of the gear unit can cause leakage, as can oil with high foam content.

BA 9137 en 12/2015

34 / 89

Page 35

5.4 Drive coupling

A flexible coupling is to be provided for the gear unit drive. Observe the operating instructions of the

coupling for assembly, operation and maintenance of the coupling.

NOTICE

Property damage

Damage to the gear unit or individual components is possible from inadequate alignment.

When installing the drives, make absolutely certain that the individual components are accurately

aligned to one other. Unacceptable large errors in the alignment of the shaft ends to be connected due

to angular and/or axial misalignments result in premature wear and material damage.

Note

If couplings of other manufacturers are used, the Siemens standard operating instructions for

equivalent couplings provide the minimum requirements for the alignment of the coupling. It cannot be

assured by Siemens whether these minimum requirements are sufficient in any case. If stricter

requirements in the operating instructions of the supplier or similar document are defined, these will

apply.

5.5 Heating

At low temperatures, it may be necessary to heat the gear oil before switching on the drive unit or even

during operation. In such cases, e. g. heating elements can be used. These heating elements convert

electrical energy into heat which is conducted to the surrounding oil. The heating elements are located in

protective tubes inside the housing, thus making it possible to replace them without draining the oil

beforehand.

Heating elements must fully submerge into the oil bath.

The heating elements can be controlled by a resistance thermometer or a temperature monitor, which

emits a signal that is amplified when minimum and maximum temperatures are reached.

A detailed illustration of the gear unit and the position of the add-on parts can found in the drawings of the

gear unit documentation.

DANGER

Explosion and fire hazard

Fire hazard or ignition of an explosive atmosphere by exposed heating rods is possible.

Never switch on the heating elements, unless complete immersion of the heating element in the oil bath

is ensured.

If heating elements are installed afterwards, the maximum heating capacity (see table7) on the outer

surface of the heating element must not be exceeded.