Page 1

Building Technologies

Fire Safety & Security Products

FDOOT241-9, FDOOT241-8,

FDOOT221, FDO241, FDO221,

FDT241, FDT221

Automatic fire detectors

Technical manual

Page 2

Technical specifications and availability subject to change without notice.

© 2006-2009 Copyright Siemens Building Technologies, Inc.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Page 3

3

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

1

About this document ....................................................................................7

2 Safety............................................................................................................11

2.1 Safety notices................................................................................................11

2.2 Safety regulations for the method of operation .............................................13

2.3 Standards and directives complied with........................................................15

3 Structure and function................................................................................16

3.1 Overview .......................................................................................................16

3.1.1 Detectors with ASAtechnology (S-LINE) ....................................... 16

3.1.2 Detector with detection algorithms (C-LINE) .................................17

3.1.3 Details for ordering ........................................................................17

3.2 S-LINE and C-LINE.......................................................................................18

3.2.1 C-LINE ........................................................................................... 19

3.2.2 S-LINE ...........................................................................................20

3.3 Detectors .......................................................................................................22

3.3.1 Neural fire detector ........................................................................22

3.3.1.1 Variants of the FDOOT241-9 ....................................23

3.3.2 Wide-spectrum smoke detector .....................................................24

3.3.3 Heat detector .................................................................................25

3.4 Function.........................................................................................................26

3.4.1 Parameter sets...............................................................................26

3.4.2 Danger levels.................................................................................26

3.4.3 Diagnosis levels .............................................................................27

3.4.4 Line separator................................................................................29

3.4.5 Automatic recognition of the detector line protocol........................29

3.4.6 Internal alarm indicator ..................................................................29

3.4.7 Connection of external alarm indicators ........................................29

3.4.8 Renovation mode...........................................................................30

3.4.9 Test mode ......................................................................................30

3.4.10 Behavior in degraded mode...........................................................30

3.4.11 Interface to service devices ...........................................................31

3.4.12 Line tester ......................................................................................31

3.5 Mechanical setup ..........................................................................................32

3.6 Options ..........................................................................................................33

3.6.1 Detector base FDB221/FDB221-AA..............................................33

3.6.2 Detector base FDB201/FDB201-AA..............................................33

3.6.3 Detector base FDB222 ..................................................................34

3.6.4 Detector base FDB202 ..................................................................34

3.6.5 Sounder base FDSB291................................................................34

3.6.6 Sounder base FDSB292................................................................35

3.6.7 Base attachment FDB291..............................................................35

3.6.8 Base attachment humid FDB293...................................................35

3.6.9 Base adapter FDB281 ...................................................................36

3.6.10 Detector heating unit FDBH291.....................................................36

3.6.11 Designation plate FDBZ291...........................................................36

3.6.12 Designation plate DBZ1193A ........................................................37

3.6.13 Detector locking device FDBZ293 .................................................37

3.6.14 Dummy detector FDX291 ..............................................................37

3.6.15 Detector dust cap FDZ291............................................................. 37

3.6.16 Protective cage DBZ1194..............................................................38

Table of contents

Page 4

4

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.17 EMC-protective cage FDBZ294 .....................................................38

3.6.18 Micro terminal DBZ1190-AA ..........................................................38

3.6.19 Connection terminal DBZ1190-AB.................................................39

3.6.20 M20 x 1.5 metal cable gland ..........................................................39

4 Project engineering.....................................................................................40

4.1 Compatibility..................................................................................................40

4.2 Ambient features ...........................................................................................40

4.3 Parameter sets: Neural fire detector .............................................................42

4.3.1 Neural fire detector FDOOT241-x (sensor mode 0) ......................42

4.3.1.1 Description.................................................................42

4.3.1.2 Application .................................................................44

4.3.1.3 Specification ..............................................................45

4.3.2 Neural fire detector FDOOT241-x (sensor mode 1, 'Heat detector')46

4.3.3 Neural fire detector FDOOT241-x (sensor mode 2, 'Smoke

detector') ........................................................................................47

4.3.4 Neural fire detector FDOOT221.....................................................48

4.3.4.1 Description.................................................................48

4.3.4.2 Application .................................................................48

4.3.4.3 Specification ..............................................................48

4.4 Parameter sets: Wide-spectrum smoke detector..........................................49

4.4.1 Wide-spectrum smoke detector FDO241 ......................................49

4.4.1.1 Description.................................................................49

4.4.1.2 Application .................................................................49

4.4.1.3 Specifications ............................................................50

4.4.2 Wide-spectrum smoke detector FDO221 ......................................51

4.4.2.1 Description.................................................................51

4.4.2.2 Application .................................................................51

4.4.2.3 Specification ..............................................................51

4.5 Parameter sets: Heat detector ......................................................................52

4.5.1 Heat detector FDT241 ...................................................................52

4.5.1.1 Description.................................................................52

4.5.1.2 Specifications ............................................................53

4.5.2 Heat detector FDT221 ...................................................................54

4.5.2.1 Description.................................................................54

4.5.2.2 Specifications ............................................................54

4.6 Default settings..............................................................................................55

4.7 Application examples ....................................................................................56

5 Mounting / Installation ................................................................................57

5.1 Required space .............................................................................................57

5.2 Detector base FDB201/221...........................................................................58

5.3 Detector base FDB202/222...........................................................................59

5.4 Base attachment FDB291 .............................................................................60

5.5 Base attachment humid FDB293 ..................................................................61

5.6 Base adapter FDB281...................................................................................62

5.7 Detector locking device FDBZ293.................................................................63

5.8 Designation plate FDBZ291 ..........................................................................64

5.9 Designation plate DBZ1193A ........................................................................64

Page 5

5

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

5.10 Detector heating FDBH291 ...........................................................................65

5.10.1 Installation of the detector heating unit..........................................65

5.10.2 Connection of the detector heating unit.........................................66

5.11 Protective cages............................................................................................67

5.11.1 Installation of the protective cages ................................................67

5.11.2 Grounding of the EMC-protective cage FDBZ294.........................67

5.12 Cable entry....................................................................................................68

5.12.1 Auxiliary terminals DBZ1190-AA/-AB ............................................69

5.13 Detector lines ................................................................................................69

5.13.1 Connection diagram (addressed) ..................................................70

5.13.1.1 Use of unshielded cables .......................................... 70

5.13.1.2 Use of shielded cables ..............................................71

5.13.2 Connection diagram (collective) ....................................................73

5.13.2.1 Use of unshielded cables .......................................... 74

5.13.2.2 Use of shielded cables ..............................................75

5.13.3 Connection diagram (MS8)............................................................76

5.13.3.1 Use of unshielded cables .......................................... 76

5.13.3.2 Use of shielded cables ..............................................77

5.14 Detector dust cap FDZ291 ............................................................................78

6 Commissioning ...........................................................................................79

7 Maintenance / repair ...................................................................................80

7.1 Status polling with the detector exchanger and tester ..................................80

7.2 Performance check .......................................................................................80

7.3 Testing detectors...........................................................................................81

7.3.1 Testing detectors with detector exchanger and tester...................82

7.3.2 Testing detectors without detector exchanger and tester..............82

8 Specifications ..............................................................................................83

8.1 Technical data FDOOT241-x, FDOOT221 ...................................................83

8.1.1 General (irrespective of the detector line) .....................................83

8.1.2 Detector lines .................................................................................85

8.2 Technical data FDO221, FDO241.................................................................89

8.3 Technical data FDT221, FDT241.................................................................. 91

8.4 Dimensions....................................................................................................93

8.5 Environmental compatibility ..........................................................................93

9 Index .............................................................................................................94

Page 6

6

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Page 7

About this document

7

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

1 About this document

Goal and purpose

This document contains information on automatic fire detectors. Consistent

compliance with the instructions guarantees correct and safe use.

Target groups

The information in this document is intended for the following target groups:

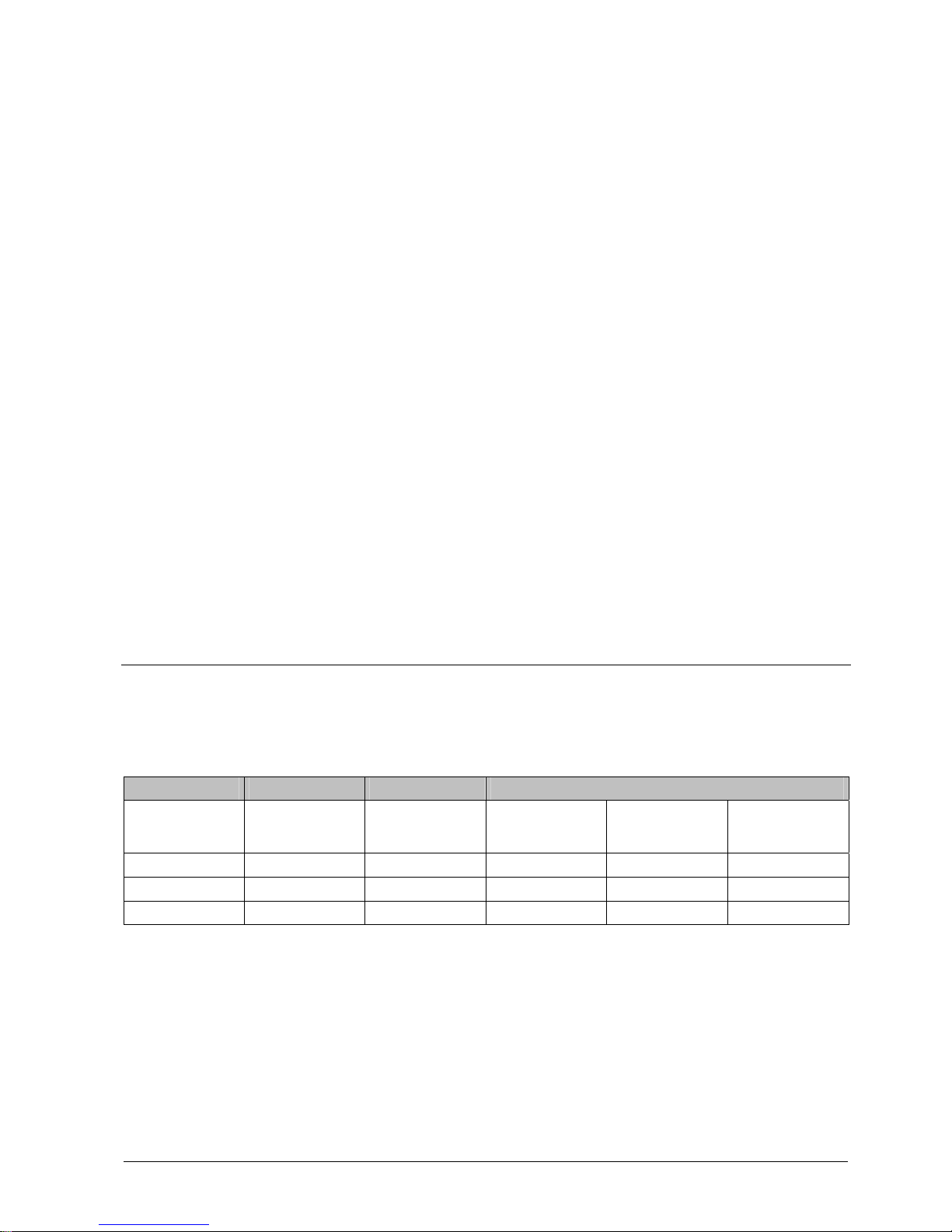

Target group Activity Qualification

Product Manager z Is responsible for information

passing between the manufacturer

and regional company.

z Coordinates the flow of information

between the individual groups of

people involved in a project.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for

Product Managers.

Project Manager z Coordinates the deployment of all

persons and resources involved in

the project according to the

schedule.

z Provides the information required to

run the project.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for Project

Managers.

Project Engineer z Parameterizes the product

according to country-specific and

customer-specific requirements.

z Checks operability and releases the

product for commissioning at the

place of installation.

z Searches for and corrects

malfunctions.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for Project

Engineers.

Installation personnel z Assembles and installs the product

components at the place of

installation.

z Carries out a performance check

following installation.

z Has received specialist training in the area of

building installation technology or electrical

installations.

Maintenance personnel z Carries out all maintenance work.

z Checks that the products are in

perfect working order.

z Searches for and corrects

malfunctions.

z Has obtained suitable specialist training for

the function and for the products.

Page 8

About this document

8

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Document identification

Position Information

Title page z Product type

z Product designation

z Document type

Last page, bottom left z Document ID

ID_ModificationIndex_Language_COUNTRY

z Edition date

Last page, bottom right z Manual

z Register

Conventions for text marking

Markups

Special markups are shown in this document as follows:

⊳ Requirement for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

'Text' Quotation, reproduced identically

<Key> Identification of keys

Supplementary information

The

i

symbol identifies supplementary information such as a tip for an easier

way of working.

Supplementary information is labeled using the 'i' symbol.

Page 9

About this document

9

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Technical terms

Term Explanation

AI Alarm indicator

ASA Advanced Signal Analysis

DA Detection algorithms

C-LINE Fire detector for standard applications

S-LINE Fire detector for sophisticated applications

ES Product version

FDnet Addressed detector line (field device net)

FET Field Effect Transistor

GMT Limit value detection technology (collective)

LED Light-emitting diode

MC link Maintenance and Commissioning Link; interface to the detector

exchanger and tester

MS8 Pulse detection technology (addressed); also known as PMT

PMT Pulse detection technology (addressed); also known as MS8

SIGMASYS Fire detection system

Reference documents

Document ID Title

008331 List of compatibility

007227 FDUD292 detector exchanger and tester

009718 FDUD293 intelligent detector tester

008250 FDUL221 line tester

010030 Fire detector application guideline

Page 10

About this document

10

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

History of changes

Document ID Edition date Brief description

007004_k_en_-- 04.2009 Sensitivities for FDOOT241-x with High

Suppression now 2.3 and 8 %/m.

Accessories with order no.

Detector base FDB2x1-AA with 1 micro terminal.

FDSB291 compatible with heat detector FDT2xx

(as of ES ≥43).

Connection diagram for shielded cables.

007004_j_de_-- 07.2008 Safety instructions revised

Technical data restructured

007004_i_de_-- 02.2008 Chap. 4.3.1.3: Only parameter set 8 doesn't satisfy

the EN 54-7 and CEA 4021 standards.

Parameters set 0 added to chaps. 4.3.2 and 4.3.3.

Index added.

007004_h_de_-- 02.2008 FM approvals supplemented.

IP protection category for FDB291/FDB293

corrected.

Structure in chap. 'Detector lines' uniform.

Various corrections to parameter sets of

FDOOT241-x, FDO241 and FDT241.

KMK in chap. 8.1.4: Par. sets specified more

precisely.

New chapters 'Default settings' and 'Protective

cages'.

New options:

- Detector base FDB202/FDB222

- Dummy detector FDX291

007004_g_de_-- 10.2007 Cross-reference list of detector names added in

chap. 'Overview'.

Display texts for detector exchanger and tester

added in 'Diagnosis levels' chapter.

Various corrections to FDOOT241-x parameter

sets.

EMC-protective cage FDBZ294 included in options.

'Mode' replaced by 'sensor mode'.

Supplements in the 'Technical data':

- Line separator

- IP protection categories

- LPCB approvals

- Standard EN 54-17

Images with language texts replaced by language-

neutral images

007004_f_de_-- 09.2006 Complete revision (devices with ES ≥ 30 included)

007004_e_de_-- 04.2005 Chapters 5.1, 5.3, 5.5.3, 5.7.2, 5.8.1, 5.8.2, 6.11.1,

6.11.2, 9.3.2, 9.3.3, 9.4, 9.5

007004_d_de_-- 01.2005 Chapters 4.4.1, 5, 9.3.1, 9.3.4, 9.3.6 and 9.4

adapted

007004_c_de_-- 12.2004 Text in chapter 0, titles 5.5.1, 5.5.2, 5.5.3 adapted

007004_b_de_-- 11.2004 Document layout adapted, parameter sets adapted,

various minor changes

007004_a_de_-- 06.2004 First edition

Page 11

Safety

11

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

2 Safety

2.1 Safety notices

The safety notices must be observed in order to protect people and property.

The safety notices in this document contain the following elements:

z Symbol for danger

z Signal word

z Nature and origin of the danger

z Consequences if the danger occurs

z Measures or prohibitions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of risks of injury.

Follow all measures identified by this symbol to avoid injury or death.

Additional danger symbols

These symbols indicate general dangers, the type of danger or possible

consequences, measures and prohibitions, examples of which are shown in the

following table:

General danger

Explosive atmosphere

Voltage/electric shock

Laser light

Battery

Heat

Page 12

Safety

12

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Signal word

The signal word classifies the danger as defined in the following table:

Signal word Danger level

DANGER DANGER identifies a dangerous situation, which will result

directly in death or serious injury if you do not avoid this

situation.

WARNING WARNING identifies a dangerous situation, which may result

in death or serious injury if you do not avoid this situation.

CAUTION CAUTION identifies a dangerous situation, which could result

in slight to moderately serious injury if you do not avoid this

situation.

NOTICE

NOTICE

identifies possible damage to property that may

result from non-observance.

How risk of injury of presented

Information about the risk of injury is shown as follows:

WARNING

Nature and origin of the danger

Consequences if the danger occurs

z Measures / prohibitions for danger avoidance

How possible damage to property is presented

Information about possible damage to property is shown as follows:

NOTICE

Nature and origin of the danger

Consequences if the danger occurs

z Measures / prohibitions for danger avoidance

Page 13

Safety

13

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

2.2 Safety regulations for the method of operation

National standards, regulations and legislation

Siemens products are developed and produced in compliance with the relevant

European and international safety standards. Should additional national or local

safety standards or legislation concerning the planning, assembly, installation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Electrical installations

WARNING

Electrical voltage

Electric shock

z Work on electrical installations may only be carried out by qualified

electricians or by instructed persons working under the guidance and

supervision of a qualified electrician, in accordance with the electrotechnical

regulations.

z Wherever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

z Lock volt-free areas to prevent them being switched back on again by mistake.

z Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

z Route mains connections to products separately and fuse them with their own,

clearly marked fuse.

z Fit an easily accessible disconnecting device in accordance with IEC 60950-1

outside of installation.

z Produce earthing as stated in local safety regulations.

Assembly, installation, commissioning and maintenance

z If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

z When starting the fire control panel ensure that unstable conditions cannot

arise.

z Ensure that all points listed in the 'Testing the product operability' section below

are observed.

z You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

Page 14

Safety

14

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Testing the product operability

z Prevent the remote transmission from triggering erroneously.

z If testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

z The activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions must be observed:

‒ Use the correct potential for activation; this is generally the potential of the

building installation.

‒ Only check controls up to the interface (relay with blocking option).

‒ Make sure that only the controls to be tested are activated.

z Inform people before testing the alarming control devices and allow for possible

panic responses.

z Inform people about any noise or mist which may be produced.

z Before testing the remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system layout and products

Modifications to the system and to individual products may lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies for modifications or additions.

Modules and spare parts

z Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

z Only use fuses with the specified fuse characteristics.

z Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent battery type recommended by

Siemens.

z Batteries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they are delivered, Siemens products are tested to ensure they function

correctly when used properly. Siemens disclaims all liability for damage or injuries

caused by the incorrect application of the instructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

z Personal injuries or damage to property caused by improper use and incorrect

application

z Personal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

z Personal injury or damage to property caused by poor maintenance or lack of

maintenance

Page 15

Safety

15

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Disclaimer

We have checked that the content of this document matches the hardware and

software described. Despite this, we cannot rule out deviations and cannot

therefore assume liability for them matching completely. The details in this

document are checked regularly and any corrections needed included in

subsequent editions.

We are grateful for any suggestions for improvement.

2.3 Standards and directives complied with

A list of the standards and directives complied with is available from your Siemens

contact.

Page 16

Structure and function

16

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3 Structure and function

3.1 Overview

In this document the following detectors are summarized under the term

"Automatic fire detectors":

z Neural fire detector FDOOT2x1-x

z Wide-spectrum smoke detector FDO2x1

z Heat detector FDT2x1

The same detectors may have different names, depending on the document type.

Detector type Designation 1 (e.g. in technical documentation

etc.)

Designation 2 (e.g. in catalog sheets etc.)

FDOOT221 Neural fire detector Multi-sensor smoke detector, neural DA

FDOOT241-x Neural fire detector Multi-sensor smoke detector, neural ASA

FDO221 Wide-spectrum smoke detector Smoke detector, FDnet wide spectrum DA

FDO241 Wide-spectrum smoke detector Smoke detector, FDnet wide spectrum ASA

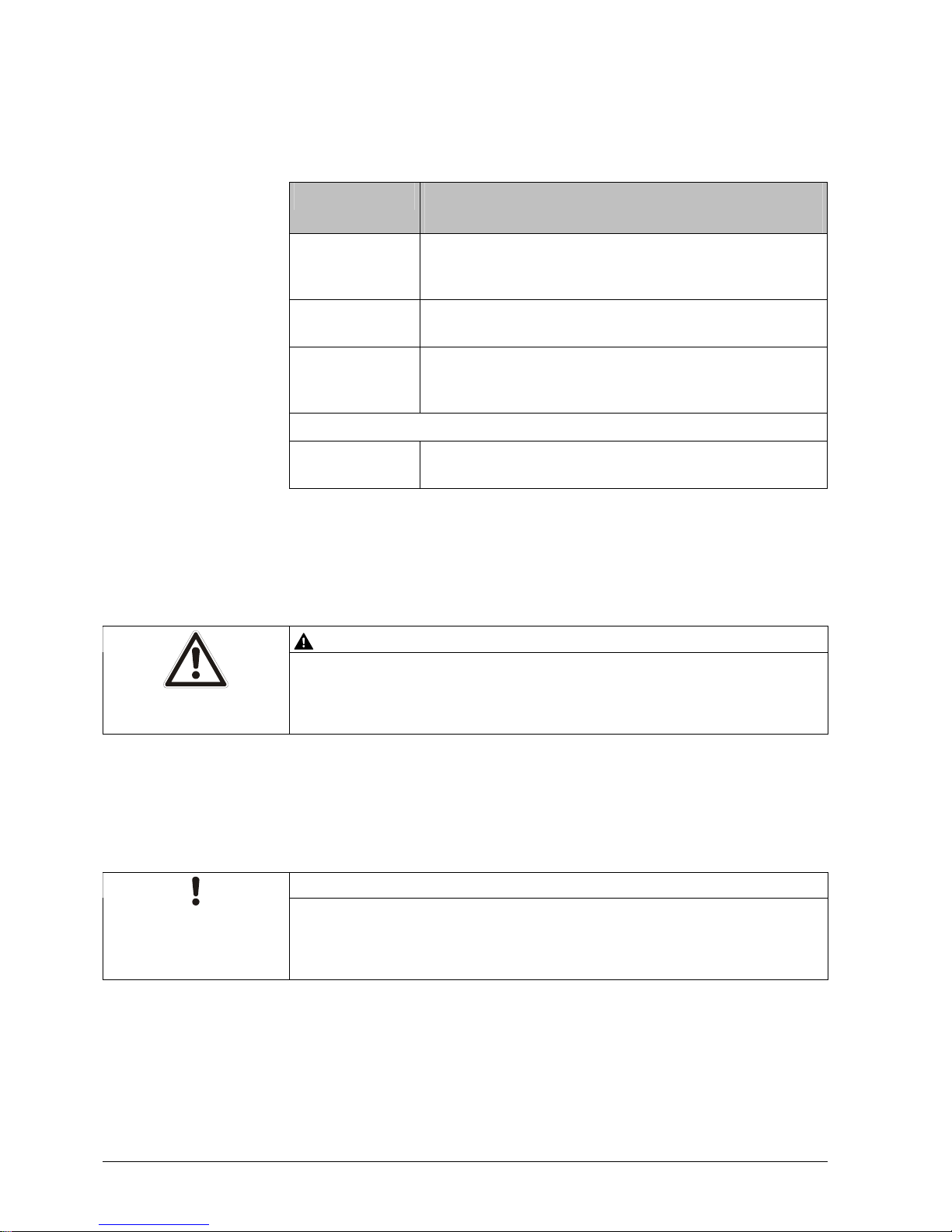

3.1.1 Detectors with ASAtechnology (S-LINE)

Neural fire detector

FDOOT241-9

Neural fire detector

FDOOT241-8

Wide-spectrum smoke

detector

FDO241

Heat detector

FDT241

Can be used either

addressed in FDnetor

collectively

Can be used either

addressed in MS8/PMT or in

FDnet

Can be used addressed on

the FDnet

Can be used addressed on

the FDnet

Can be set as neural fire detector, wide-spectrum smoke

detector or heat detector on the part of the software

Selectable detection behavior thanks to application-specific ASA parameter sets

Page 17

Structure and function

17

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.1.2 Detector with detection algorithms (C-LINE)

Neural fire detector

FDOOT221

Wide-spectrum smoke

detector FDO221

Heat detector FDT221

Can be used addressed on the FDnet

Selectable detection behavior thanks to different DA parameter sets

3.1.3 Details for ordering

Type Order no. Designation

FDOOT241-9 A5Q00004813 Neural fire detector

FDOOT241-8 A5Q00004663 Neural fire detector

FDO241 A5Q00004811 Wide-spectrum smoke detector

FDT241 A5Q00004812 Heat detector

FDOOT221 A5Q00001566 Neural fire detector

FDO221 A5Q00001565 Wide-spectrum smoke detector

FDT221 A5Q00001567 Heat detector

Page 18

Structure and function

18

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.2 S-LINE and C-LINE

Regarding the detectors, there are two product lines: S-LINE and C-LINE. They

differ regarding the different detector variants and functionalities in both the

detectors and control panels. The application range of the S-LINE detectors is

wider than that of the C-LINE detectors.

Application range

fast /

sensitive

Response behavior slow / insensitive

S-LINE

C-LINE

Few Deceptive phenomena Many

z

S-LINE detectors are suited to applications where many deceptive phenomena

have to be expected, or fast fire detection is required.

z C-LINE detectors are suited to applications where few deceptive phenomena

have to be expected.

FDnet devices of the S-LINE and C-LINE can be combined on the same detector

line.

Page 19

Structure and function

19

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

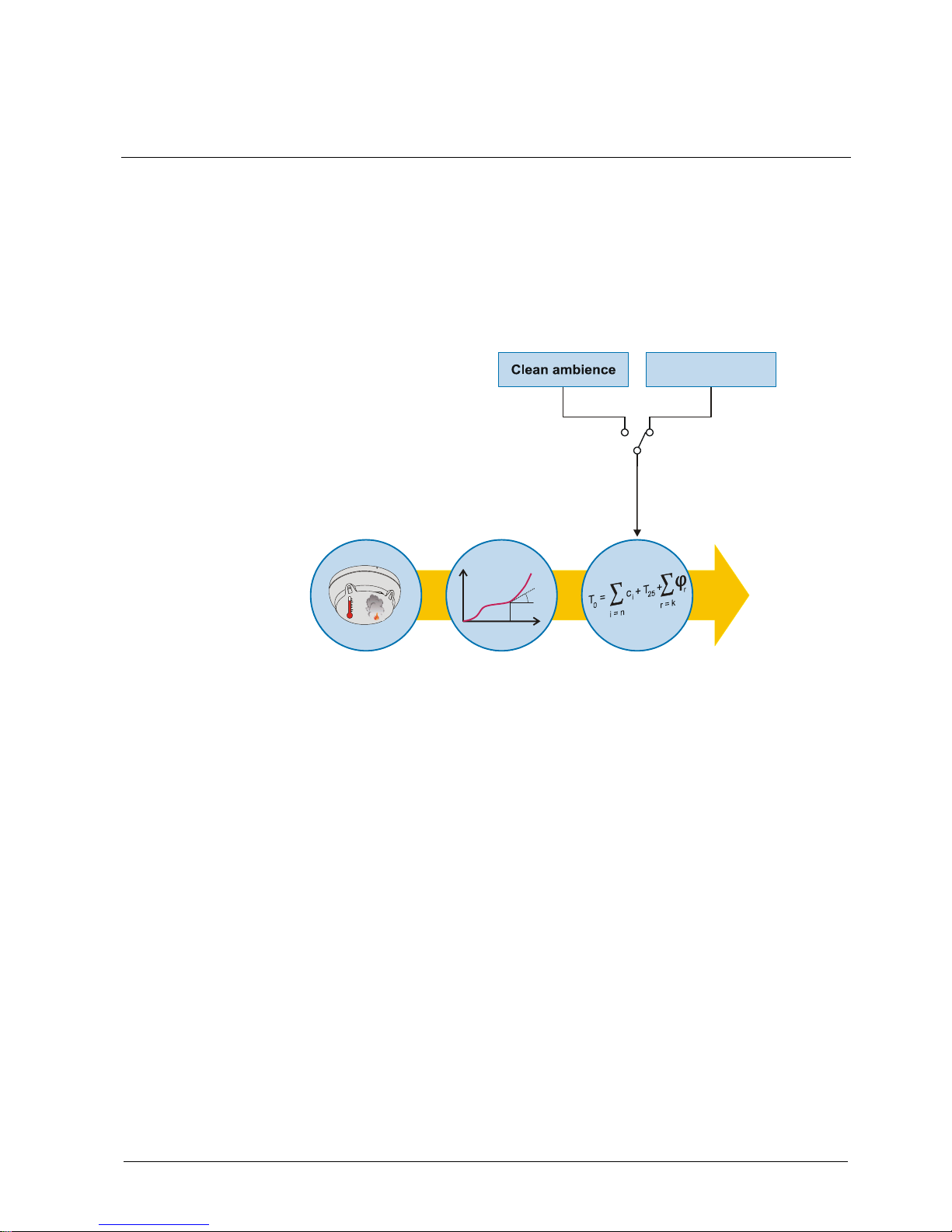

3.2.1 C-LINE

The C-LINE detectors are characterized by a very high detection reliability

combined with a high immunity to deceptive phenomena. The detectors have two

parameter sets, by means of which they can be adapted to the conditions

prevailing at the installation location.

Operating mode: Signal processing with detection algorithms

The following figure shows signal processing with C-LINE detectors in a diagram.

C

Sensory

Signal analysis

Algorithms

Result

Danger

level

Standard ambience

Selection of parameter

The signals captured by the sensor technology are transmitted to the algorithm.

The algorithm analyses and evaluates the course of the signals (signal intensity,

rate of rise and fluctuation). The algorithms are set by selecting the parameter set,

which sets the detectors to the expected types of fire and ambient influences.

Page 20

Structure and function

20

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

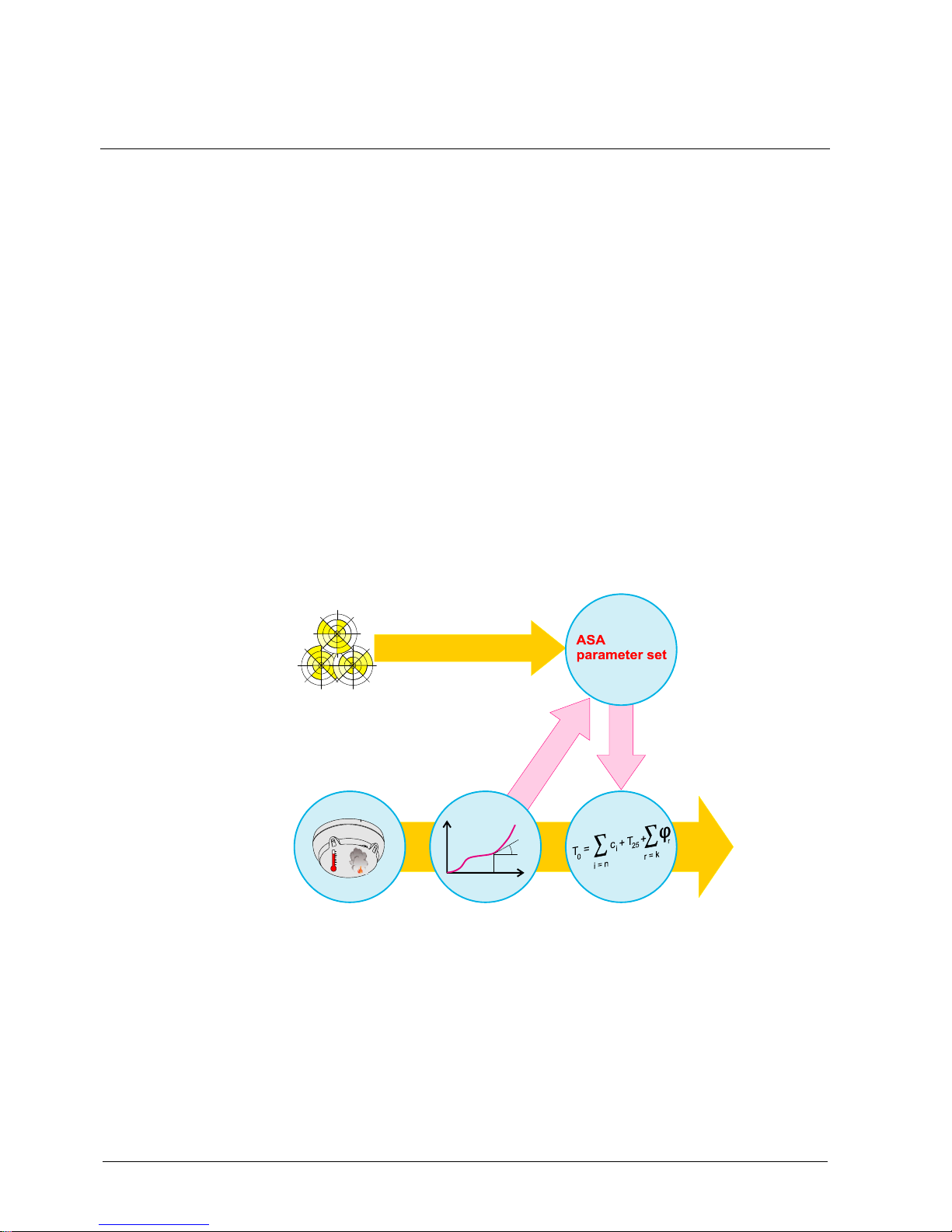

3.2.2 S-LINE

Properties

In contrast to the C-LINE detectors, S-LINE detectors have the following features:

z Dynamic influence on the parameter sets

z Pattern recognition

z Real time interpretation of the situation

z Process- and time-controlled switchover of the parameter sets

Signal processing of the S-LINE detectors is based on ASAtechnology (ASA =

Advanced Signal Analysis). ASAtechnology can also be characterized as second

generation algorithms. Signal processing with ASAtechnology permits optimum

adaptation of the detector behavior to the particular ambient conditions.

S-LINE detectors are characterized by their unique detection reliability and high

immunity to deceptive phenomena.

Operating mode: Signal processing with ASAtechnology

The following figure shows signal processing with S-LINE detectors in the form of a

diagram.

C

Dynamic influence

of parameter

Environment

Evaluation of the

situation

Danger

level

Result

Algorithms

Signal analysis

Sensory

Sensory

The signals captured by the sensory are transmitted to the algorithm. The

algorithms are set by selecting the parameter set.

Page 21

Structure and function

21

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Algorithms

In comparison to the detection algorithms (DA), the individual parameters of the

selected parameter set can be adapted with ASAtechnology. A real time

interpretation of the situation leads to a dynamic influence on the algorithm. This

results in a broadening of the application range of the parameter set and thus of

the detector. The detector reacts more sensitively in the event of fire, and more

robustly in the event of deceptive phenomena.

Switching over the parameter set

In addition to the selection of the parameter set, the S-LINE detectors enable timeor process-controlled switching over of the parameter sets (Manned/Unmanned

switchover). Thanks to this function, the detector can be used in places where the

situation changes regularly and frequently (e.g. kitchen, production hall).

Downloadable parameter sets

Detectors of the S-LINE have several permanently programmed parameter sets.

For special applications new, additional parameter sets can be downloaded in the

field (depending on the control panel).

Page 22

Structure and function

22

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.3 Detectors

3.3.1 Neural fire detector

The neural fire detector is a multiple criteria fire detector and is equipped with two

optical and two thermal sensors. The following neural fire detectors are available:

z FDOOT241-9

z FDOOT241-8

z FDOOT221

The following table shows the most important differences between the neural fire

detectors.

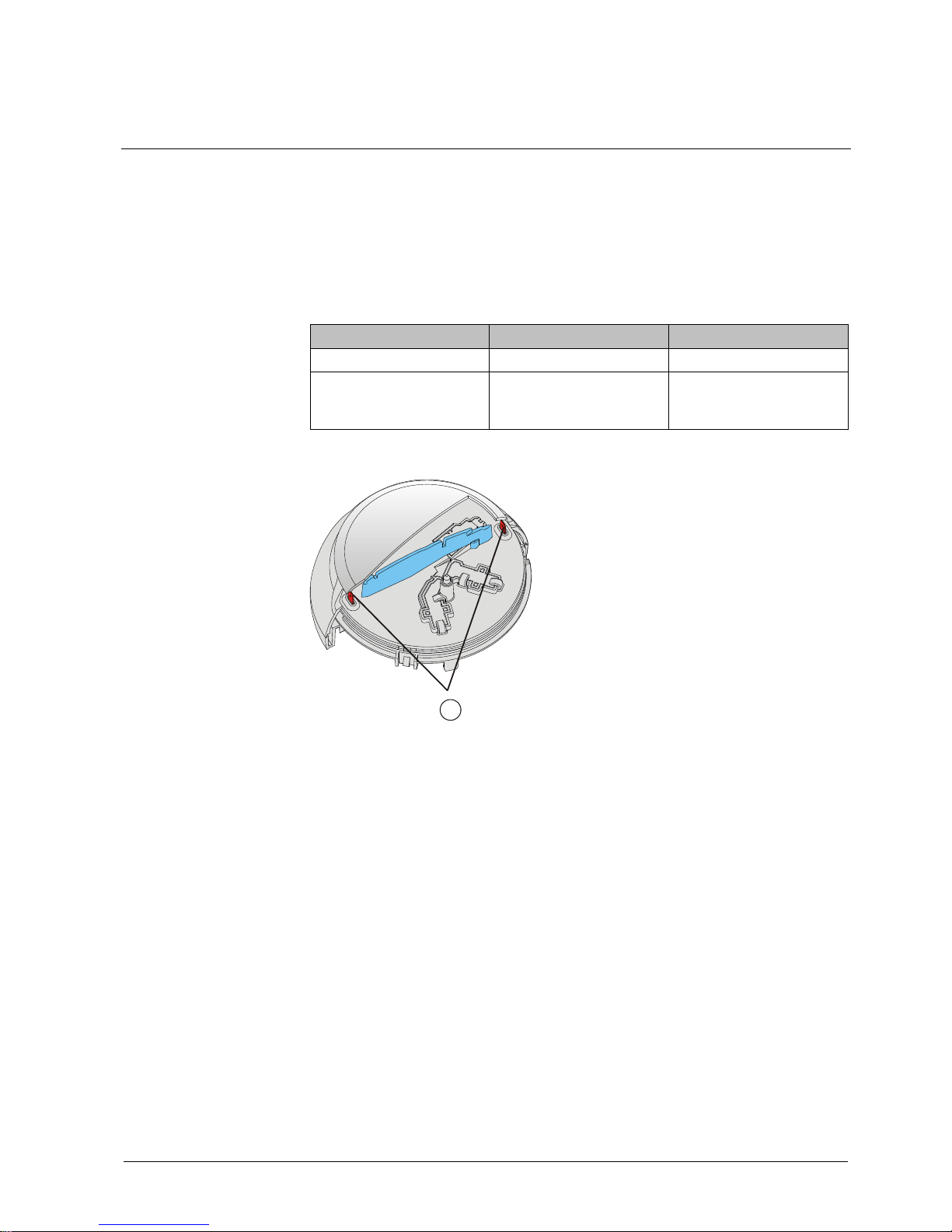

Parameter FDOOT241-9 FDOOT241-8 FDOOT221

Signal processing ASAtechnology ASAtechnology Detection algorithms

Communication protocol z FDnet

z Collective

z FDnet

z MS8

z FDnet

Structure and function

1 2

3

4

1 Heat sensors 3 Forward scatterer

2 Backward scatterer 4 Labyrinth

The detector has a sophisticated opto-electronic measuring chamber with two

optical emitters, an optical receiver and two thermal sensors.

The transmitters illuminate the smoke particles from different angles. One sensor

acts as forward scatterer, the other as backward scatterer. The scattered light then

hits the receiver (photodiode) and generates a measurable electric signal.

The combination of a forward and backward scatterer facilitates an optimum

detection and the differentiation of light and dark particles, which leads to a

homogenous response behavior and optimizes the differentiation of wanted signals

and deceptive phenomena.

Page 23

Structure and function

23

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

In addition, the heat sensors make it possible to detect fires without smoke

generation.

The combination of optical and thermal sensor signals optimizes detection

reliability. This has the following advantages:

z Early detection of all types of fire, whether they generate light or dark smoke, or

no smoke at all.

z The neural fire detector can be operated at a lower sensitivity level and thus

achieves a higher immunity against false alarms which may otherwise be

caused by cold aerosols (e.g. by smoking, electrical welding, etc.). In the case

of an open fire, the smoke sensitivity is heightened by the temperature

increase, which means that a detection reliability level that is comparable to

that of the wide-spectrum smoke detector can be achieved.

The neural fire detectors FDOOT241-8/9 may as well be applied either as optical

smoke detectors or as out-and-out heat detectors. This is possible by selecting one

of the following sensor modes (with the detector exchanger and tester or on the

control panel):

z Sensor mode 0: Application as neural fire detector

z Sensor mode 1: Application as heat detector

z Sensor mode 2: Application as smoke detector

In sensor mode 1 or 2 the parameter sets of the heat detector FDT241 or of the

wide-spectrum smoke detector FDO241, respectively, can be selected. Then,

these neural fire detectors behave like the heat detector FDT241 or smoke detector

FDO241.

3.3.1.1 Variants of the FDOOT241-9

The neural fire detector FDOOT241-9 is available in three different variants A, B

and C. The compatibility differs depending on the variant. The following table

provides an overview of the compatibility of the different variants. Refer to

document 008331 'List of compatibility' for compatibility details.

Variants Part number Product version Compatibility

FDnet Collective control

panels from

Germany

Collective control

panels from

Switzerland

A A5Q00004813 < 13 X X –

B A5Q00015955 13 ≤ ES < 30 X – only CZ10

C A5Q00004813 ≥ 30 X X X

Notes

z Variant B has been available only as kit (FDOOT241-9M) consisting of the

neural fire detector and the detector base FDB201.

z The specifications of variant B largely correspond to those of variant A. Any

possible deviations are marked accordingly in this document.

z Variant C is available both as single detector and as kit (FDOOT241-9M).

Page 24

Structure and function

24

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

The following figure shows how the different variants are marked (to the left:

Variant B; to the right: Variants A and C).

3.3.2 Wide-spectrum smoke detector

The wide-spectrum smoke detector is an optical smoke detector with an optical

sensor. It works according to the principle of forward scattering. This detector

reacts with extreme sensitivity to light fire aerosols. The following wide-spectrum

smoke detectors are available:

z FDO241 (with ASAtechnology)

z FDO221 (with detection algorithms)

Structure and function

1

2

1 Labyrinth 2 Forward scatterer

The wide-spectrum smoke detector has the same measuring chamber as the

neural fire detector, however, it has only a forward scatterer. The increased

sensitivity makes the early detection of smoldering and open fires possible.

Page 25

Structure and function

25

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.3.3 Heat detector

The heat detector is a pure heat detector with two thermal sensors. The following

heat detectors are available:

z FDT241

z FDT221

The following table indicates the most important differences between the two heat

detectors.

Parameters FDT241 FDT221

Signal processing ASAtechnology Detection algorithms

Alarm activation by: z Temperature increase

z Reaching the maximum

temperature

z Temperature increase

Setup and function

1

1 Heat sensors

Thanks to the two sensors, a total failure can be avoided if one of the two sensors

fails or breaks down.

Page 26

Structure and function

26

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.4 Function

3.4.1 Parameter sets

The parameter sets influence the detection behavior of the detectors and

specifically set them to the expected fire phenomena and ambient influences in the

environment to be monitored.

All parameter sets are programmed in the detectors. During commissioning, the

optimum parameter set must be selected for the conditions at the place of

installation. On a FDnet detector line, this is carried out at the control panel. On a

collective or MS8 detector line this is done with the detector exchanger and tester.

On a FDnet detector line, the parameter set must always be set explicitly. Unless a

parameter set is selected in collective or MS8 operation, the detector works with

the default parameter set '0'. In this case the number of the selected parameter set

is always '0'.

See also

Parameter sets: Neural fire detec

tor [J 42]

Parameter sets: Wide-spectrum s

moke detector [J 49]

Parameter sets: Heat detector [J 52]

3.4.2 Danger levels

The detector's signal processing efficiently distinguishes between fire events and

deceptive phenomena. The basis for reaching a danger level is not only given by

measured values exceeding a "response threshold"; moreover, the smoke density

progression is observed over a longer period of time and assessed by the

algorithms.

Fire detectors can transmit the following danger levels to the control panel:

Danger level Meaning Comment

0 No danger Normal condition

1 Check situation A different parameter set should

potentially be selected (inappropriate

application)

2 Warning Possible danger

3 Alarm Fire

Notes

z The evaluation of the danger level and the decisions to be taken (e.g. activation

of remote transmission) are configured in the control panel.

z On a collective line only the danger levels 0 and 3 can be transmitted to the

control panel.

Page 27

Structure and function

27

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.4.3 Diagnosis levels

For the most part, the detector monitors its function by itself. The signals of all

sensors are permanently monitored. In particular, the temperature sensors, light

emitters, and light receivers are monitored to ensure that they are functioning

correctly. Signal processing takes account of the monitoring results and adapts its

behavior accordingly.

The following diagnosis levels are derived from the different control measurements:

z Normal

z Observe information

z Replacement recommended

z Replacement necessary

z Fault

See the table below for details.

A fault message is signaled in the event of a fatal error that makes the proper

function of the detector impossible. To correct the cause of the fault, additional

information is available in the detector. This information may be displayed, for

example, by the detector exchanger and tester FDUD29x (for details see

documents 007227 and 009718).

Page 28

Structure and function

28

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Information displayed on the

detector exchanger and

tester

Meaning Measures

'No deviation' Normal, no fault is present

The detector is fully functional

None

'maybe excha.' 1 Observe information

The detector is fully functional

z FDOOT:

– Slightly soiled

Check cause during periodic maintenance

'advice excha.' 1 Replacement recommended

Detector is still functional, in spite of minor

problems

z FDOOT:

– Average soiling

– Untypical sensor values caused by

environmental influence

z FDO:

– Average soiling

z Remedy the cause during the next

maintenance

z Replace detector if necessary

'needed excha.' 1 Replacement necessary

Detection possibly restricted; alarming is

still possible

z FDOOT:

– Heavily soiled, failure of one optical

sensor

– Failure of one or both thermal sensors

z FDO:

– Heavily soiled

z Call maintenance service

z Replace detector

Fault present

Detection is no longer guaranteed, or

invalid parameter setting

z FDOOT:

– Failure of both optical sensors

z FDO:

– Failure of the optical sensor

z FDT:

– Failure of one or both thermal sensors

z Remedy cause

z Adjust parameter setting

z Replace detector

Supply fault z Check detector line voltage

z Replace detector

Software error (watchdog error) Replace detector

Memory error Replace detector

Any fault message 2

Communication error involving detector and

control panel

Remedy cause

1

The information displayed on the detector exchanger and tester is always in

English; no translation into the corresponding language.

2

This status can be displayed together with another status, e.g. 'needed excha.'

(replacement necessary).

Page 29

Structure and function

29

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.4.4 Line separator

All FDnet devices are equipped with a line separator.

The FDnet device is equipped with electronic switches which isolate the defective

part in case of a short-circuit on the detector line. The rest of the detector line

remains serviceable. On a loop line all FDnet devices remain fully functional after a

simple error.

3.4.5 Automatic recognition of the detector line protocol

The two multiple protocol detectors FDOOT241-9 and -8 may communicate via

different detector line protocols. These detectors recognize the protocol on the

detector line (e.g. FDnet or collective) and automatically switch to the protocol in

question. This functionality facilitates commissioning in case of modernization, as

no actions need to be taken on the detector itself. See document 008331 'List of

compatibility' for exceptions.

3.4.6 Internal alarm indicator

The detectors have an internal alarm indicator. The internal alarm indicator shows

the operating condition of the detector (see table).

Operating condition Flashing mode of the AI

Normal AI flashes weakly every 4 seconds

Test AI flashes weakly every 0.5 seconds

Alarm AI lights up every second

3.4.7 Connection of external alarm indicators

Two external alarm indicators can be connected to every detector. In the FDnet the

alarm indicator can be connected to any detector; activation of the alarm indicator

can be programmed in the control panel.

Instead of an optical alarm indicator that flashes in the event of an alarm, the

sounder base is provided with an acoustic alarm indicator.

See also

Connection diagram (addressed) [J 70]

Connection diagram (collective) [J 73]

Connection diagram (MS8) [J 76]

Page 30

Structure and function

30

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.4.8 Renovation mode

Renovation mode should be selected when work that generates a lot of dust or

aerosols is being performed in the room.

In renovation mode, the neural fire detector and the heat detector only trigger alarm

when the temperature exceeds 80 °C for 20 seconds.

The wide-spectrum smoke detector does not trigger alarms in renovation mode

but continues to work normally.

3.4.9 Test mode

For testing purposes the detectors can be set to test mode. In test mode the

detectors react faster and with a higher sensitivity level. All detectors can be tested

with the detector exchanger and tester FDUD29x. Optical detectors may also be

tested with the test gas REF 8 or REF 8-S. Heat detectors can be tested with a hot

air fan.

See also

Testing detectors [J 81]

3.4.10 Behavior in degraded mode

If the main processor of the fire control panel fails, the control panel enters

degraded mode operation. Depending on the control panel, the fire control panel

may continue to provide the main alarming functions and signaling functions in

degraded mode operation.

Characteristics of degraded mode operation on control panels supporting degraded

mode operation:

z Alarming is still ensured in degraded mode operation. However, in degraded

mode operation, only collective alarming is possible. This means that in the

event of an alarm, it is possible to identify the detector line but not the exact

location of the detector triggering the alarm.

z If a sounder base is connected to the output for the external alarm indicator, it

is activated in degraded mode operation if there is a fire alarm (only with

detectors and sounder bases with ES ≥ 30); configuration for a specific control

panel is possible.

z When the connection for the external alarm indicator is used for a control

function (e.g. hold-open system), the output assumes the configured fail-safe

position (only with detectors with ES ≥ 30); configuration for a specific control

panel is possible.

Degraded mode operation on the FDnet is not supported in the same way by all

control panels. During planning, observance of the information in document

008331 'List of compatibility' and the respective control panel documentation is

therefore mandatory.

Page 31

Structure and function

31

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.4.11 Interface to service devices

All point detectors have a non-contact interface to the detector exchanger and

tester FDUD29x (service device for commissioning and maintenance). The

detector exchanger and tester communicates with the detector via this interface

(MC link). Detailled information is listed in the operating instructions for the detector

exchanger and tester (see documents 007227 and 009718).

See also

Status polling with the detector e

xchanger and tester [J 80]

3.4.12 Line tester

The line tester FDUL221 is able to recognize and localize the following errors on

the FDnet:

z Wiring error

z Open line

z Short-circuit

z Ground fault

In addition, the line tester recognizes the devices connected to the FDnet detector

line. For details, see document 008250.

Page 32

Structure and function

32

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.5 Mechanical setup

To install a point detector, a detector base is always required. After mounting the

detector base the point detector is simply screwed into the base by hand with the

detector exchanger or with the detector exchanger and tester.

Properties

z Quick installation and reliable contact due to screwless terminals

z Insertion of the insulated wires without any tools

z The centered alarm indicator makes an alignment of the detector base

superfluous

z Space for up to 6 auxiliary terminals for detector heating units etc.

A wide range of accessories that can be combined for the corresponding

application is available for the different applications.

See also

Options [J 33]

Mounting / Installation [J 57]

Page 33

Structure and function

33

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6 Options

3.6.1 Detector base FDB221/FDB221-AA

z For the installation of point detectors and alarm

sounders

z For the recess-mounted cable entry

z For the surface-mounted cable entry, up to 6 mm

cable diameter

z Addressed

z Orange terminal block

z Detector base FDB221-AA additionally with a micro

terminal

z Compatible with:

– Point detector

– Alarm sounder FDS221

– Alarm sounder with beacon FDS229

z Order no. FDB221: A5Q00001664

z Order no. FDB221-AA: A5Q00012741

See also

Detector base FDB201/221 [J 58]

3.6.2 Detector base FDB201/FDB201-AA

z For the installation of point detectors

z For the recess-mounted cable entry

z For the surface-mounted cable entry, up to 6 mm

cable diameter

z Collective

z Gray terminal block

z Detector base FDB201-AA additionally with a micro

terminal

z Compatible with:

– Neural fire detector FDOOT2419-9

z Order no. FDB201: A5Q00003814

z Order no. FDB201-AA: A5Q00012742

See also

Detector base FDB201/221 [J 58]

Page 34

Structure and function

34

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.3 Detector base FDB222

z For the installation of point detectors and alarm

sounders

z For the recess-mounted cable entry

z Directly attached to the mounting surface

z Addressed

z Orange terminal block

z Compatible with:

– Point detector

– Alarm sounder FDS221

– Alarm sounder with beacon FDS229

z Order no.: A5Q00016447

See also

Detector base FDB202/222 [J 59]

3.6.4 Detector base FDB202

z For the installation of point detectors

z For the recess-mounted cable entry

z Directly attached to the mounting surface

z Collective

z Gray terminal block

z Compatible with:

– Neural fire detector FDOOT2419-9

z Order no.: A5Q00016446

See also

Detector base FDB202/222 [J 59]

3.6.5 Sounder base FDSB291

z For acoustic alarming in the case of an event

z For the FDnet detector line

z Orange terminal block

z With two micro terminals

z For the recess-mounted cable entry

z For the surface-mounted cable entry, up to 6 mm

cable diameter

z Compatible with:

– Neural fire detector FDOOT2xx

– Neural fire detector FDOOTC2xx

– Wide-spectrum smoke detector FDO2xx

– Heat detector FDT2xx (as of ES ≥43)

z For details, see document 007025

z Order no.: A5Q00001647

Page 35

Structure and function

35

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.6 Sounder base FDSB292

z For acoustic alarming in the case of an event

z For the collective detector line

z Gray terminal block

z With two micro terminals

z For the recess-mounted cable entry

z For the surface-mounted cable entry, up to 6 mm

cable diameter

z Compatible with:

– Neural fire detector FDOOT241-9

z For details, see document 009769

z Order no.: A5Q00013755

3.6.7 Base attachment FDB291

z For the installation of detector bases

z For the surface-mounted cable entry, as of 6 mm

cable diameter

z Compatible with:

– Detector base FDB2x1

– Detector base FDB2x2

z Order no.: A5Q00001603

See also

Base attachment FDB291 [J 60]

3.6.8 Base attachment humid FDB293

z For installation in wet rooms

z Compatible with:

– Detector base FDB2x1

– Detector base FDB2x1-AA

– Detector base FDB2x2

– Detector heating unit FDBH291

– Designation plate DBZ1193A

– M20 x 1.5 metal cable gland

z Order no.: A5Q00003945

See also

Base attachment humid FDB293 [J 61]

Page 36

Structure and function

36

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.9 Base adapter FDB281

z For adapting MS8 to Sinteso

TM

detector systems

z With fitted detector base FDB221

z Compatible with:

– MS8 detector base

– Neural fire detector FDOOT2419-8

z Order no.: A5Q00004929

See also

Base adapter FDB281 [J 62]

3.6.10 Detector heating unit FDBH291

z For applications where there is danger of moisture

condensation or icing

z Compatible with:

– Base attachment humid FDB293

z Order no.: A5Q00004439

See also

Detector heating FDBH291 [J 65]

3.6.11 Designation plate FDBZ291

z To identify the location

z Compatible with:

– Detector base FDB2x1

– Detector base FDB2x2

– Sounder base FDSB29x

– Base attachment FDB291

– Base adapter FDB281

z Order no.: A5Q00002621

See also

Designation plate FDBZ291 [J 64]

Page 37

Structure and function

37

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.12 Designation plate DBZ1193A

z To identify the location

z Compatible with:

– Base attachment humid FDB293

z Order no.: BPZ:4864330001

See also

Designation plate DBZ1193A [J 64]

3.6.13 Detector locking device FDBZ293

z For protection against theft

z Compatible with:

– Point detector

– Alarm sounder FDS221

– Alarm sounder with beacon FDS229

z Order no.: A5Q00005035

See also

Detector locking device FDBZ293 [J 63]

3.6.14 Dummy detector FDX291

F

D

X

2

9

1

S

5

4

3

1

9

-

F

2

-

A

1

z To protect the detector base from dirt

z External labelling for identification

z Does not open the contact in the detector base

z Compatible with:

– Detector base FDB2xx

– Sounder base FDSB29x

z Order no.: S54319-F2-A1

3.6.15 Detector dust cap FDZ291

z To protect the detector from dust

z Compatible with:

– Point detector

– Alarm sounder FDS221

– Alarm sounder with beacon FDS229

z Order no.: A5Q00004814

See also

Detector dust cap FDZ291 [J 78]

Page 38

Structure and function

38

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.16 Protective cage DBZ1194

z To protect the devices against mechanical damage

z Compatible with:

– Base attachment humid FDB293

z Order no.: BPZ:4677110001

See also

Protective cages [J 67]

3.6.17 EMC-protective cage FDBZ294

z To protect the devices against mechanical damage

and electromagnetic fields

z Must be connected with earth connection

z Compatible with:

– Base attachment humid FDB293

z Order no.: A5Q00023040

See also

Protective cages [J 67]

3.6.18 Micro terminal DBZ1190-AA

z For connecting cables

z For T-branches of additional cabling for detector

heating units, sounder base, external alarm

indicators, etc.

z For wire diameters of 0.28 … 0.5 mm

2

z 4-pin

z Order no.: BPZ:4677080001

See also

Auxiliary terminals DBZ1190-AA/-AB [J 69]

Page 39

Structure and function

39

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

3.6.19 Connection terminal DBZ1190-AB

z For connecting cables

z For T-branches of additional cabling for detector

heating units, sounder base, external alarm

indicators, etc.

z For wire diameters of 1 … 0.10 in

2

z 3-pin

z Order no.: BPZ:4942340001

See also

Auxiliary terminals DBZ1190-AA/-AB [J 69]

3.6.20 M20 x 1.5 metal cable gland

z For introducing a cable into a housing

z Compatible with:

– M20 x 1.5 metal counter nut

z Order no.: A5Q00004478

Page 40

Project engineering

40

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4 Project engineering

4.1 Compatibility

All detectors can be operated on the FDnet detector line. The neural fire detector

FDOOT241-9 may also be operated on a collective detector line and the

FDOOT241-8 may be operated on an MS8 detector line (for details, please refer to

document 008331).

4.2 Ambient features

In selecting the optimum parameter set, the following factors must be taken into

account:

z Risk of injury to persons

z Concentration of valuable items

z Room geometry

z Deceptive phenomena

z Risk of fire

z Critical fire size

Risk of injury to persons

People are extremely endangered in localities such as concert halls, nursing

homes or hospitals. The risk of damage to persons is thus very high in these

localities. In canteen kitchens the situation is different. Few people work in such

facilities and are able to save themselves in the event of timely alarms. The risk of

injury to persons is thus rather low in this case.

Concentration of valuable items

Irreplaceable cultural assets are often on display in museums. Computer centers

house servers with large data volumes. The concentration of valuable items is

rather high. In a normal hotel room the concentration of valuable items must be

classified as low.

Room geometry

High ceilings, complex room shapes or well ventilated rooms have a complex room

geometry. This aggravates early fire detection, as it is difficult for the fire

phenomenon to reach the fire detector. An office room with normal ceiling height

has a simple room geometry.

Page 41

Project engineering

41

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Deceptive phenomena

Deceptive phenomena can deceive a fire detector and bring about a false alarm.

Depending on the fire detector in question, the deceptive phenomena may be e.g.

vapor, cigarette smoke, dust, dry ice in discotheques, exhaust fumes, aerosols

occurring during welding or heat sources such as radiant heaters or hot engines.

In a small hotel room with a rather low ceiling where vapor from the bathroom may

penetrate the room, or in operating facilities where a lot of dust is generated, many

deceptive phenomena must be taken into consideration. In a clean room where

electronic modules are fabricated the risk of deceptive phenomena is rather low.

Risk of fire

In production facilities where highly combustible materials such as flammable

liquids, cotton, paper etc. are processed and where electrical machines are

operated, the fire risk is very high. Minor overheating or sparks may cause a fire. In

a storehouse where steel is stored and where no electrical installation is provided

with the exception of lighting, the fire risk is very low.

Critical fire size

When a waste paper basket in a metal-processing facility catches fire, the

consequential damage is usually rather low. Here we are talking about a critical,

medium fire size that can still be tolerated. The situation is completely different in

pharmaceutical production facilities where even the lowest smoke concentration

may impair the process and where combustible materials are processed. Even the

smallest fire must be detected immediately. In this case, we speak of a small

admissible critical fire size.

Page 42

Project engineering

42

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.3 Parameter sets: Neural fire detector

4.3.1 Neural fire detector FDOOT241-x (sensor mode 0)

4.3.1.1 Description

(Parameter set numbers in brackets)

High Suppression (8):

To cover applications with permanent, optical deceptive phenomena (dry ice in

discotheques, welding), this parameter set only reacts when a temperature rise of

approx. 8 K is detected in addition to the optical signal. Due to the combination of

optical and thermal signals, it is better suited than a pure heat detector. This

parameter set is also suited for applications that can otherwise only be covered

with special detectors.

Suppression (5):

Thanks to its very robust behavior, the 'Suppression' parameter set is particularly

suited for rooms where deceptive phenomena such as cigarette smoke or exhaust

fumes can be expected. It reacts in a very robust way to the deceptive

phenomenon vapor.

High Compensation (7):

This parameter set reacts in the same way as the 'Robust' parameter set; however,

the compensation range is twice as large. This parameter set is thus especially

suited for rooms in which a lot of dust and other deposits can be expected during

longer periods.

Robust (2):

The priority of the 'Robust' parameter set is to a robust response. The sensitivity is

the same as with the 'Suppression' parameter set; however, deceptive phenomena

are not explicitly analyzed and suppressed. It is thus particularly suited for us in

rooms where deceptive phenomena such as cigarette smoke or dust can be

expected. The 'Robust (2)' parameter set is suitable for higher rooms in

comparison to the 'Suppression (5)' parameter set.

Insensitive (0):

This parameter set is only available with the FDOOT2419-9 (ES <13) in collective

operation. Regarding visible aerosols the priority is on robust response. The

response behavior regarding open fires is sensitive and fast.

Balanced (4):

The 'Balanced' parameter set reveals a balanced response behavior regarding

reaction to fires and robustness to deceptive phenomena. It reacts faster with open

fires. It reacts slower with vapor, cigarette smoke or smoldering fires.

Page 43

Project engineering

43

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

Sensitive (0):

This parameter set is only available with the FDOOT241-8 in MS8 operation. It has

been specially developed for the migration of ionization detectors to MS8 control

panels.

Regarding sensitivity and response time, the FDOOT2418 with the 'Sensitive'

parameter set reacts in a similar way to an MS8 ionization detector. The difference

in the response behavior of an optical and an ionization detector must be taken into

account.

When the detector is migrated to an FDnet detector line the parameter setting

should be changed to 'Fast Response'.

Fast Response (6):

This parameter set reacts in a fast and highly sensitive manner. It is thus especially

suited for rooms without deceptive phenomena, where the priority is on detecting

the fire as early as possible.

High Sensitive Fast (9):

This parameter set is suited for applications requiring very high sensitivity levels. It

reveals a significantly higher optical and thermal sensitivity than 'Fast Response'.

This parameter set is also suited for applications that can otherwise only be

covered with special detectors.

Download 1 (14) / Download 2 (15):

Application-specific parameter sets that can be loaded on site (depending on the

control panel).

Page 44

Project engineering

44

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

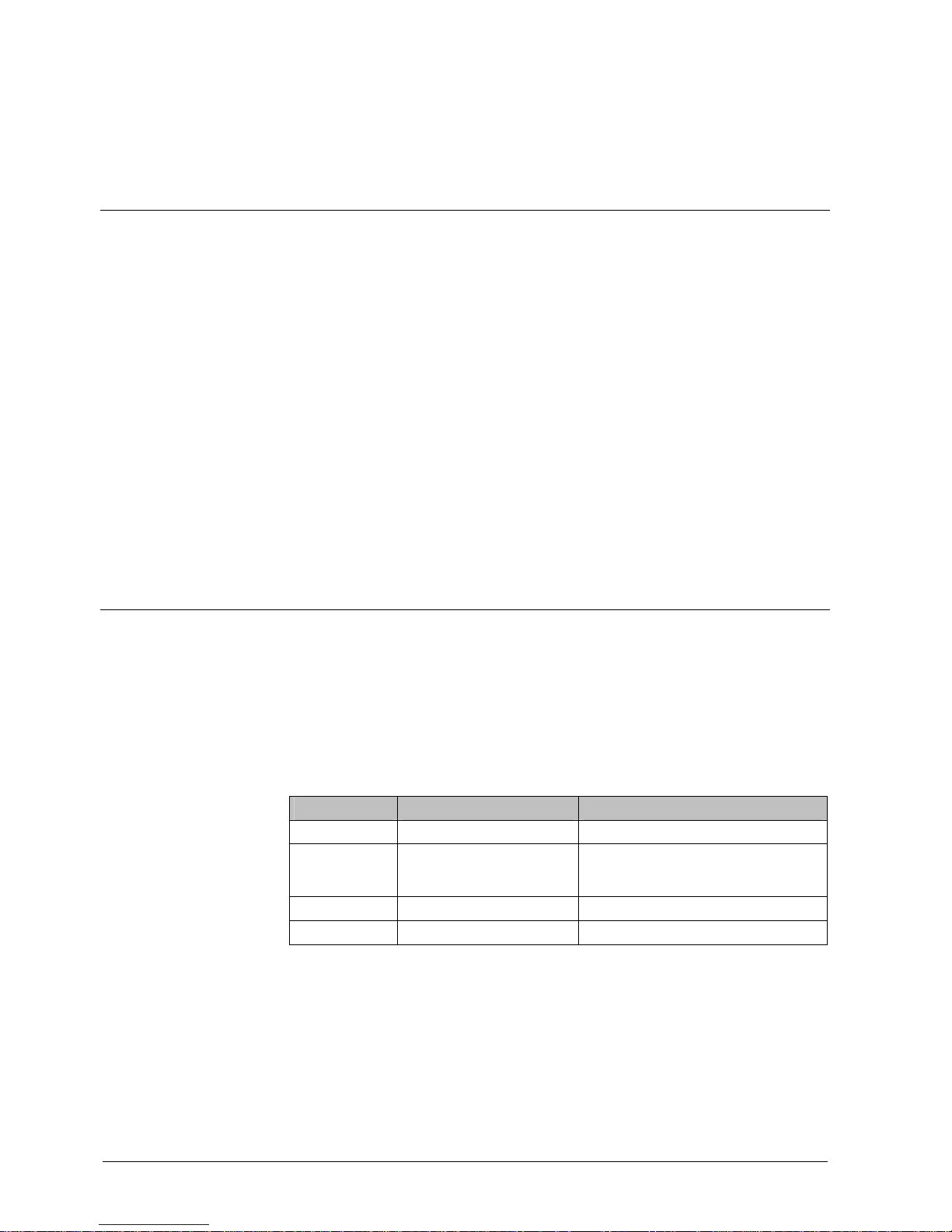

4.3.1.2 Application

Risk of injury to

persons

Concentration

of valuable

items

Room

geometry

Deceptive

phenomena

Risk of fire Critical fire size No. Name

small …

large

low…

high

simple…

complex

few…

many

small …

large

small …

medium

8 High

Suppression

5 Suppression

7 High

Compensation

2 Robust

0 Insensitive

4 Balanced

0 Sensitive

6 Fast Response

9 High Sensitive

Fast

Comment

The 'High Suppression' and 'High Sensitive Fast' parameter sets are only suited for

special applications.

Page 45

Project engineering

45

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.3.1.3 Specification

The following table shows the characteristics and application fields of the

parameter sets of the neural fire detectors FDOOT241-9 and FDOOT241-8.

Optical Thermal

Typ. response

time

from - typ. - to

Sensitivity,

open fire

Sensitivity,

smoldering fire

Static

activation

temperature

Differential

activation

temperature3

Differential

activation

possible from:

No. Name

[s] [%/m] [%/m] [°C] ∆T [K] [°C]

8 High Suppression

(as of ES ≥30)

2

60 - 80 - 360 2,3 8 80 25 30

5 Suppression 90 -160 - 760 3,2 11,4 80 29 30

7 High Compensation 80 3,2 11,4 80 29 30

0 1 High Compensation

(only FDnet

operation)

80 3,2 11,4 80 29 30

0 1 High Compensation

(only collective

operation from ES ≥

13)

80 3,2 11,4 80 29 30

2 Robust 80 3,2 11,4 80 29 30

0 1 Insensitive

(only collective

operation up to ES <

13)

30 3,2 11,4 80 29 30

4 Balanced 40 - 64 - 300 2,3 8 80 25 30

0 1 Sensitive

(only MS8 operation)

30 1,6 5,6 80 22 30

6 Fast Response 20 - 30 1,6 5,6 80 22 3

9 High Sensitive Fast

(from ES ≥ 30)

20 - 30 0,8 2,8 60 16 3

14

15

Application-specific parameter sets

1

= Delivery status; only selectable in collective operation and MS8 operation.

2

Note chapter '4.3.1.1 Description', 'High Suppression (8)' paragraph.

3

Applicable with fast temperature increases >10 K/min.

All parameter sets except for 8 comply with standards EN 54-7 and CEA 4021.

Page 46

Project engineering

46

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.3.2 Neural fire detector FDOOT241-x (sensor mode 1, 'Heat detector')

This sensor mode is especially suited for applications where the detector should

only react thermally.

No. Name at ES <30 Name at ES ≥ 30

0 1 A2R A1R

1 A2R A1R

2 BR BR

3 A2S A1S

4 BS BS

1

= Delivery status; only selectable in collective operation and MS8 operation.

All parameter sets meet the criteria of standard EN 54-5.

See also

Description [J 52]

Page 47

Project engineering

47

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.3.3 Neural fire detector FDOOT241-x (sensor mode 2, 'Smoke

detector')

This mode should be selected when fast temperature changes may occur which

are not caused by fire (e.g. radiant heaters, hot engines). In this sensor mode the

detector only reacts optically; this is comparable with a wide-spectrum smoke

detector. Thanks to a second optical sensor, however, it reveals a balanced

response behavior in relation to the different types of fire.

Robust (2):

This parameter set reacts to aerosols in a similar way as the neural fire detector

FDOOT241 in sensor mode 0 with the 'Robust' parameter set, without taking into

account the temperature.

Universal (1):

With 'Universal' the sensitivity and response time to aerosols are between 'Robust'

and 'Sensitive'.

Sensitive (3):

With regard to aerosols, this parameter set reacts in a way that is comparable to

'Fast Response' in sensor mode 0 without temperature influence.

No. Name Response time [s] Sensitivity

open fire / smoldering fire

[%/m]

0 1 Universal 50 2,3 / 8

2 Robust 80 2,3 / 8

1 Universal 50 2,3 / 8

3 Sensitive 30 1,6 / 5,6

1

= Delivery status; only selectable in collective operation and MS8 operation.

All parameter sets meet the criteria of standard EN 54-7.

Page 48

Project engineering

48

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.3.4 Neural fire detector FDOOT221

4.3.4.1 Description

Standard (2):

The priority of the 'Standard' parameter set is set to robust response. It is thus

particularly suited for us in rooms where deceptive phenomena such as cigarette

smoke or dust can be expected.

Standard Plus (4):

This parameter set is fast and highly sensitive. It is thus especially suited to rooms

without deceptive phenomena, where the priority is on early fire detection.

4.3.4.2 Application

Risk of injury to

persons

Concentration of

valuable items

Room geometry Deceptive

phenomena

Risk of fire Critical fire size No. Name

small …

large

low…

high

simple…

complex

few…

many

small …

large

small …

medium

2 Standard

4 Standard Plus

4.3.4.3 Specification

Optical Thermal

Response time Sensitivity, open

fire

Sensitivity,

smoldering fire

Static activation

temperature

Differential activation

temperature1

No. Name

[s] [%/m] [%/m] [°C] ∆T [K]

2 Standard 64 3,2 11,4 80 29

4 Standard Plus 50 2,3 8 80 25

1

Applicable with fast temperature increases >10 K/min.

All parameter sets meet the criteria of standard EN 54-7.

Page 49

Project engineering

49

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.4 Parameter sets: Wide-spectrum smoke detector

4.4.1 Wide-spectrum smoke detector FDO241

4.4.1.1 Description

Robust (2):

The priority of the 'Robust' parameter set is to a robust response. It is thus

particularly suited for the application in rooms where deceptive phenomena such

as cigarette smoke can be expected.

Universal (1):

With the 'Universal' parameter set the sensitivity and response time are between

'Robust' and 'Sensitive'.

Sensitive (3):

This parameter set is both fast and sensitive. It is thus especially suited for rooms

without deceptive phenomena, where the priority is on possibly early fire detection.

Download 1 (14) / Download 2 (15):

Application-specific parameter sets that can be loaded on site (depending on the

control panel).

4.4.1.2 Application

Risk of injury to

persons

Concentration

of valuable

items

Room

geometry

Deceptive

phenomena

Risk of fire Critical fire size No. Name

small …

large

low…

high

simple…

complex

few…

many

small …

large

small …

medium

2 Robust

1 Universal

3 Sensitive

Page 50

Project engineering

50

Building Technologies 007004_k_en_--

Fire Safety & Security Products 16.04.2009

4.4.1.3 Specifications

No. Name Response time [s] Sensitivity [%/m]

2 Robust 70 2.8

1 Universal 50 2.0

3 Sensitive 30 1.4

14

15

Application-specific parameter sets