Page 1

DTU3005-B

Intelligent Data Transfer Device for Connection to PLCs and

Modbus Networks

Operator’s Manual

Page 2

Th

DANGER

Hazardous voltages and high-speed moving parts in electrical devices

communicating w ithWinPM.

Can cause death, serious injury or property damage.

See safety instruction contained herein. Restrictuse to qualified personnel.

e use of unauthorized parts in the repair of the equipment

or tampering by unqualified personnel will result in

dangerous conditions that can cause death, serious injury or

property damage.

IMPORTANT

The information contained here in is gen er al in natu re and not

intended for specific application purposes. It does not relieve

the user of responsibility to use sound practices in application, installation, operation, and maintenence of the

equipment purchased. Siemens reserves the right to make

changes at any time without notice or obligations. Should a

conflict arise between the general information contained in

this publication and the contents of drawings or supplementary material or both, the latter shall take precedence.

QUALIFIED PERSONNEL

For the purposes of this manua l and product labels, "qualif ied

personnel" is one who is familiar with the installation,

construction, or operation of the equipment and the hazards

involved. In addition, s/he has the following qualifications:

(a) is trained and authorized to energize, de-energize, clear,

ground, and tag circuits and equipment in accordance

with established safety practices.

(b) is trained in the proper care and use of protective gear

equipment suc h as rubber gl oves, h ard hat, sa fety glasses

or face shields, flash clothing, etc., in accordance with

established safety procedures

(c) is trained in rendering first aid.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation, or maintenence. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s

purposes, the matter should be referred to the local Siemens Energy & Automation, Inc. sales office.

THE CONTENTS OF THIS INSTRUCTION MANUAL SHALL NOT BECOME PART OF OR MODIFY ANY PRIOR OR

EXISTING AGREEMENT, COMMITMENT OR RELATIONSHIP. THE SALES CONTRACT CONTAINS ALL OBLIGATIONS OF SIEMENS ENERGY & AUTOMATION, INC. THE WARRANTY CONTAINED IN THE CONTRACT

BETWEEN THE PARTIES IS THE SOLE WARRANTY OF SIEMENS ENERGY & AUTOMATION, INC.

ACCESS, ISGS, Isolated Multi-Drop, S7-I/O, SBwin, SAMMS-LV, SAAMS-MV,SEAbus,SIEServe, Static Trip III,

Wisdom, and WinPM are trademark, Sensitrip and Sentron are registered trademarks of Siemens Energy &

Automation, Inc. SIEMENS is a registered trademark and Windows is a trademark of Microsoft Corporation. All

other product names mentioned herein are used for identification purposes only and may be the trademarks or

registered trademarks of their respective companies.

SUMMARY

Page 3

Table of Contents

1 Introduction.......................................1

1.1 Product Overview................................. 1

1.2 Software Overview............................... 1

1.3 Features................................................. 1

1.4 Applications.......................................... 1

1.4.1 PLC to SEAbus......................... 2

1.4.2 Modbus Master to SEAbus..... 3

1.4.3 SEAbus Port Expander............ 5

2 Installing the Software .....................6

3 Starting the Soft ware .......................8

3.1 Menu Navigation .................................. 8

3.2 Main Menu........................... ....... ...... .... 9

3.3 Using the Project Menu ....................... 9

3.4 Starting a New Project ......................... 9

4 Creating Project Files—PLC to

Devices12

4.1 Application Description ..................... 12

4.2 Configuring the Project File ............... 12

4.3 PLC Setup—Port 1 .............................. 13

4.4 Device Setup—Port 2.......................... 15

4.5 Passthrough Setup—Port 3................ 16

4.6 Device List Setup................................ 17

4.7 Configuring Custom Device Registers..

19

4.7.1 Configuring Custom Registers

for a Single Device19

4.7.2 Configuring Default Custom

Device Registers by Device21

4.8 Device Text Setup (7SJ600 Only)...... 23

4.9 Global Command Registers............... 25

4.10 Device Diagnostic Registers.............. 25

4.11 Device Command Registers .............. 26

4.12 Saving the Project File........................ 27

5 Creating Project Files—Modbus

Master to Devices28

5.1 Application Description ..................... 28

5.2 Configuring the Project File ............... 29

5.3 Modbus Setup—Port 1....................... 30

5.4 Device Setup—Port 2.......................... 32

5.5 Modbus/Passthrough Setup—Port 3. 33

5.6 Device List Setup................................ 35

5.7 Configuring Custom Device Registers..

37

5.7.1 Configuring Custom Registers

for a Single Device37

5.7.2 Configuring Default Custom

Device Registers39

5.8 Device Text Setup (7SJ600 Only)...... 41

5.9 Global Command Registers............... 43

5.10 Device Diagnostic Registers.............. 43

5.11 Device Command Registers .............. 44

5.12 Saving the Project File........................44

6 Creating Project Files—SEAbus Port

Expander45

6.1 Passthrough Setup—Port 1................46

6.2 SEAbus Device Setup—Port 2 ...........48

6.3 Passthrough Setup—Port 3................48

7 Transferring Project Files.................49

7.1 Downloading Projects ........................50

7.2 Uploading Projects ............................. 51

7.3 Verifying Projects................................51

7.4 Checking the DTU3005 Applicatio n ..51

8 Setting Options................................52

8.1 Setting the Project Directory.............. 52

8.2 Selecting the COM Port......................54

8.3 Setting the Printer Options ................54

8.4 Loading and Saving Options.............55

A Supported PLCs ...............................58

A.1 Allen-Bradley PLC 5, SLC500 and

MicroLogix PLCs58

A.2 GE Fanuc 90/20, 90/30 and 90/70 PLCs .

58

A.3 Idec Micro-3 PLCs................................58

A.4 Idec FA Ser ies PLCs and Square D Mod el

5058

A.5 Koyo/PLC Direct 205 Series PLCs.......58

A.6 Koyo/PLC Direct/TI 405 Series PLCs...59

A.7 Koyo/PLC Direct/TI 305 Series PLCs...59

A.8 Mitsubishi FX Series PLCs ................... 59

A.9 Modbus PLCs and Devices..................60

A.10 Omron PLCs ..... ....... ...... ....... ...... ....... ... 60

A.11 Siemens S7-200 PLCs .........................60

A.12 Square D Model 100-700 PLCs ...........60

A.13 Square D TSX07 PLCs .........................60

A.14 TI505 Series PLCs................................60

A.15 Toshiba EX and M Series PLCs............61

A.16 Toshiba T Series PLCs .........................61

A.17 Westinghouse PLCs .............................61

B Supported Devices ..........................62

B.1 Application Notes—Communication Port

Settings for 7-Series Protective Relays62

C Installing the Hardware...................63

C.1 Dimensions...........................................63

C.2 Power Requirements............................63

C.3 Connector Pinouts................................64

D Cable Connection Diagrams...........65

E Device Data Format .........................77

E.1 Device Type: SAMMS LV and MV ........ 77

Siemens Energy & Automation, Inc. i

Page 4

Table of Contents

E.2 Device Type: 4300 Power Meter ..........79

E.3 Device Type: 4700 Power Meter...........80

E.4 Device Type: 4720 Power Meter...........82

E.5 Device Type: Static Trip III ....................84

E.6 Device Type: SensiTrip III......................86

E.7 Device Type: SB-TL..............................87

E.8 Device Type: Pulse Reading Meter (PRM)

88

E.9 Device Type: ISGS................................89

E.10 Device Type: Sentron SB Energy Comm

Trip Unit91

E.11 Device Type: S7-I/O..............................93

E.12 Device Type: 7SA511............................94

E.13 Device Type: 7SA513............................99

E.14 Device Type: 7SD511..........................105

E.15 Device Type: 7SD512..........................108

E.16 Device Type: 7SJ511 ..........................111

E.17 Device Type: 7SJ512 ..........................114

E.18 Device Type: 7SJ531 ..........................118

E.19 Device Type: 7SJ600 ..........................124

E.20 Device Type: 7UT512..........................127

E.21 Device Type: 7UT513..........................130

F Diagnostic Data Format ................134

G Warranty.........................................135

Siemens maintains control of all specifications for the SEAbus and SEAbus Plus protocols. A modification to a protocol for any type of device

must be approved by Siemens Energy & Automation, Inc. to guarantee compatibility. Any changes made must be backward compatible so

that existing products can coexist on the communications bus without having to support the newer features of the protocol

Siemens con tinuous ly str ives to e nsure ba ckward com patib ility, reliability, and easy implem entati on of bot h protoco ls to me et curre nt mark et

communications requirements. Siemens therefore reserves the right to make improvements including changes to specifications at any time

without notice or obligation.

© Copyright 1999 Siemens Energy & Automation, Inc.

SIEMENS is a registered trademark of Siemens AG. ACCESS, WinPM, Static Trip III, SAMMS, SEAbus, ISGS, and Isolated

Multi-Drop are trademarks of Siemens Energy & Automation, Inc. DIGSI is a registered trademark of Siemens Energy & Automation, Inc. Windows is a trademark and Microsoft a registered trademark of Microsoft Corporation. All other product names

mentioned herein are used for identification purpos es only and may be the tra demarks or r egistere d trademarks of their r espective companies.

ii Siemens Energy & Automation, Inc.

Page 5

1 Introduction

1Introduction

1.1 Product Overview

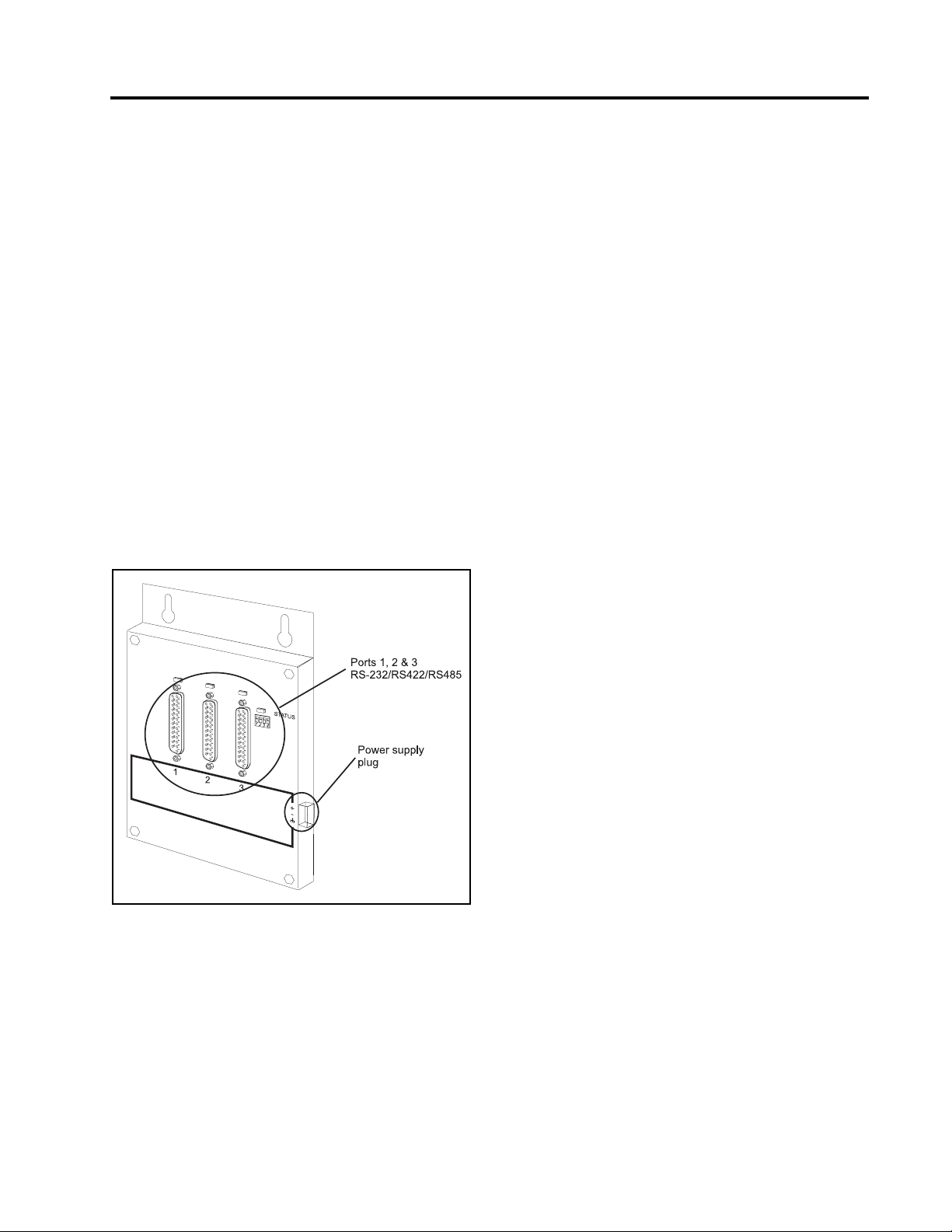

The Panel-Tec DTU3005 is an intelligent, multiplefunction data transfer unit that enables communications between Siemens communicating power

meters, trip units, and protective relays, and PLCs or

Modbus networks. The device is designed for the

harsh industrial environment and is suited for use in

switchgear. The device is shown below in Figure 1.1.

The device is powered from an external power supply.

Three ports allow for connection to the Siemens

ACCESS devices and selected protective relays, a PLC

or a Modbus RTU or ASCII master system, and a

passthrough, which allows direct communications

with port 1 or port 2 from port 3. Status lights indicate

proper operation, and DIP switches allow access to

programming and diagnostic modes.

The DTU3005 device supports a wide variety of PLCs

and Siemens ACCESS devices. Appendix A lists the

PLCs and protocols supported by the DTU3005.

Appendix B lists the supported Siemens ACCESS

devices and protective relays.

1.2 Software Overview

The DTU3005 Editor software is a MS-DOS based program for configuring the DTU3005 device. It provides

for uploadin g and d ownlo ad ing co nfig urat ion s via the

computer’s serial port. You can edit and save configurations in project files on your computer’s hard drive.

Chapters 2 through 8 discuss installing and using the

editor software to configure your DTU3005 device.

1.3 Features

Device Features:

• Com pact size (8" x 6" x 1")

• Port 1 and Port 3 Features

• Transfer data directly to one of 25 PLCs su pported

• Baud rates up to 187,500

• Addressable Modbus RTU slave capability

• (Port 3) Passthrough Port for connection to

WinPM

• Port 2 Features

Figure 1.1 Panel-Tec DTU300 5 View Showing 3 Ports

and Power Supply

• Twelve Siemens ACCESS devices supported

• Ten Siemens protective relays supported

Editor Software Features:

• MS-DOS based (also runs under Microsoft Windows)

• Menu driven

• Mouse supported (but not required)

1.4 Applications

The following are possible hardware configurations

using the DTU3005 to connect to Siemens ACCESS

devices.

Siemens Energy & Automation, Inc. 1

Page 6

1 Introduction

1.4.1 PLC to SEAbus

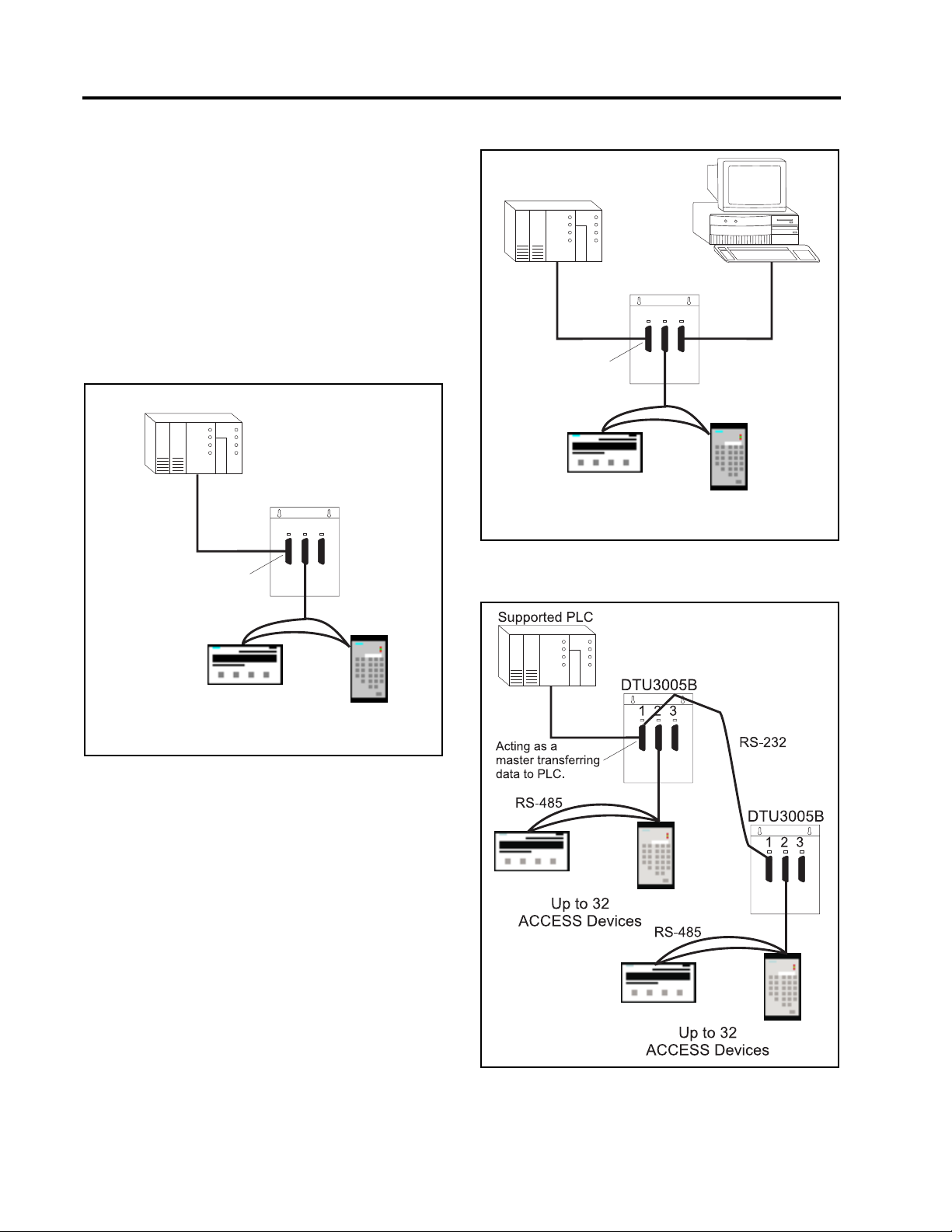

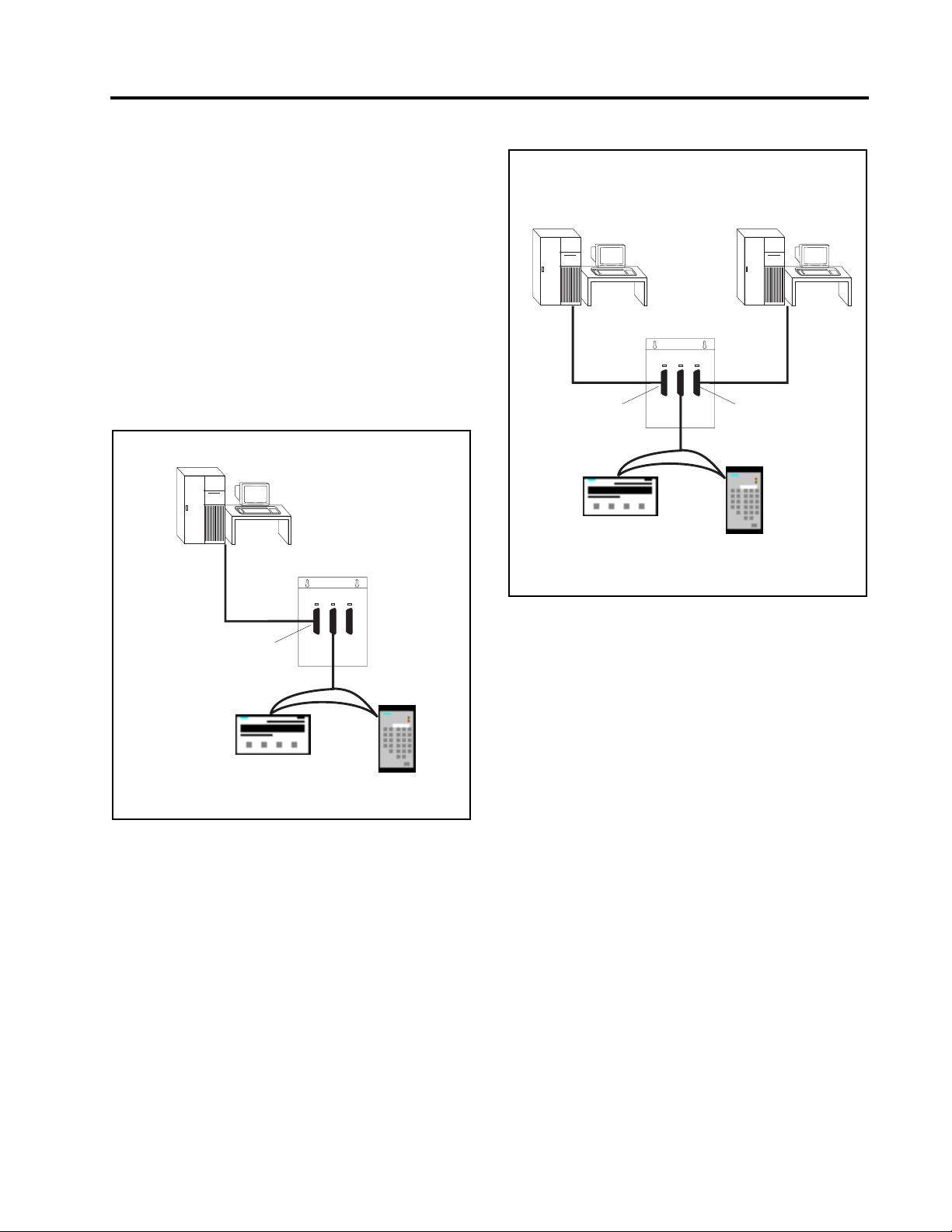

The basic configuration is a PLC att ached to port 1 of

the DTU3005, and the Siemens ACCESS devices

attached to port 2. This is shown bel ow in Figure 1.2.

Port 3 can be configured as a pa s sthr o ug h t o the SEA bus devices. This allows a personal computer running

Siemens WinPM™ or other supervisory software to

connect directly to the SEAbus devices at the same

time as the PLC. This is shown in Figure 1.3. An addi-

tional DTU3005 device can be attached to port 3. Up to

32 DTU3005 devices can be daisy chained together,

each connected to up to 32 Siemens devices. This is

shown in Figure 1.4.

Supported PLC

Supported PLC

Acting as a

master transferring

data to PLC.

WinPM

DTU3005B

123

RS-232

RS-485

DTU3005B

1 2 3

Acting as a

master transferring

data to PLC.

RS-485

Up to 32

ACCESS Devices

Figure 1.2 PLC to SEAbus Application

Up to 32

ACCESS Devices

Figure 1.3 PLC to SEAbus with Passthrough

Figure 1.4 Daisy Chained DTU3005 Units

2 Siemens Energy & Automation, Inc.

Page 7

1.4.2 Modbus Master to SEAbus

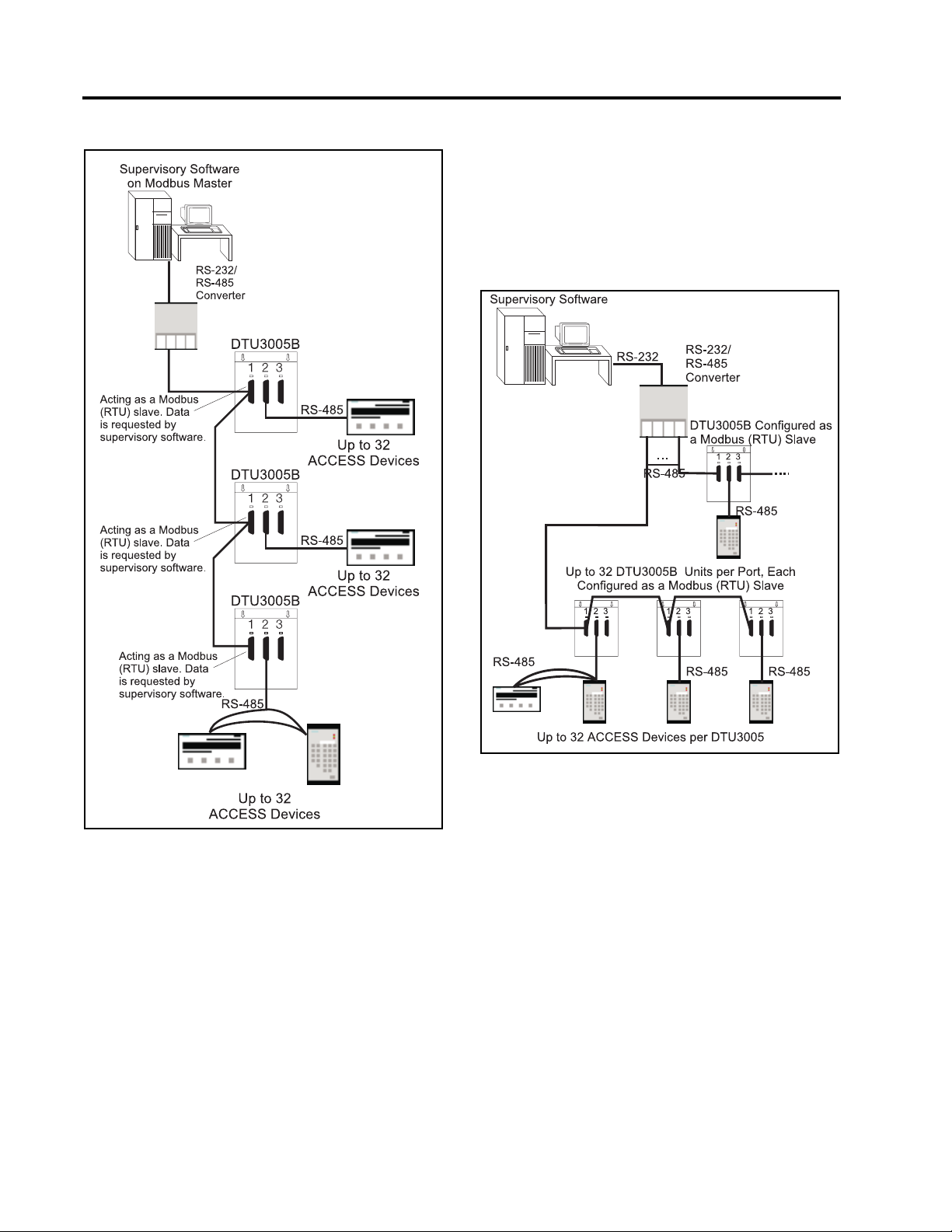

The DTU3005 unit can be configured as a Modbus

(RTU) slave. In this configuration, a Modbus master

device (usually a SCADA system) is connected to port

1. The Modbus master uses the DTU3005 to monitor

and/or control Siemens ACCESS devices. A typical

Modbus application is shown below in Figure 1.5. The

passthroug h port (port 3) can be used to co nnect to a

supervisory computer running WinPM software. It can

also be used to connect to a second, independent

Modbus Master device. This is shown in Figure 1.6.

Up to 32 DTU3005B units can be daisy ch ained using a

cable connected to port 1 of the three units. Each

DTU3005B device should have a different Modbus

device number. A daisy chained configuration is

shown in Figure 1.7.

Supervisory Software

on Modbus Master

Independent Modbus Networks

Supervisory Software

on Modbus Master

Acting as a Modbus

(RTU) slave. Data

is requested by

supervisory software.

RS-485

1 Introduction

Supervisory Software

on Modbus Master

DTU3005B

1 2 3

Acting as a Modbus

(RTU) slave. Data

is requested by

supervisory software.

DTU3005B

1 2 3

Acting as a Modbus

(RTU) slave. Data

is requested by

supervisory software.

RS-485

Up to 32

ACCESS Devices

Figure 1.5 Modbus Master to SEAbus

Up to 32

ACCESS Devices

Figure 1.6 Two Independent Modbus Master Devices

to SEAbus

Siemens Energy & Automation, Inc. 3

Page 8

1 Introduction

Multi-Drop Modbus Master to SEAbus

By using a Siemens Isolated Multi-Drop Converter,

you can conne ct your Modbus Mast er device to four

DTU3005 devices. Each DTU3005 can connect to up to

32 Siemens ACCESS devices, as well as be daisy

chained to up to 32 additional DTU3005 devices. An

example configuration is shown below in Figure 1.8.

Figure 1.8 Multi-Drop Conf iguration

Figure 1.7 Connection to Modbus Master using a

Multidrop Cable

4 Siemens Energy & Automation, Inc.

Page 9

1.4.3 SEAbus Port Expander

The DTU3005 can be used as a SEAbus port expander

for ACCESS devices, allowing two personal computers running WinPM (or other supervisory software) to

communicate with up to 32 ACCESS devices. This

configuration is shown below in Figure 1.9.

1 Introduction

Figure 1.9 SEAbus Port Expander

Siemens Energy & Automation, Inc. 5

Page 10

2 Installing the Software

2 Installing the Software

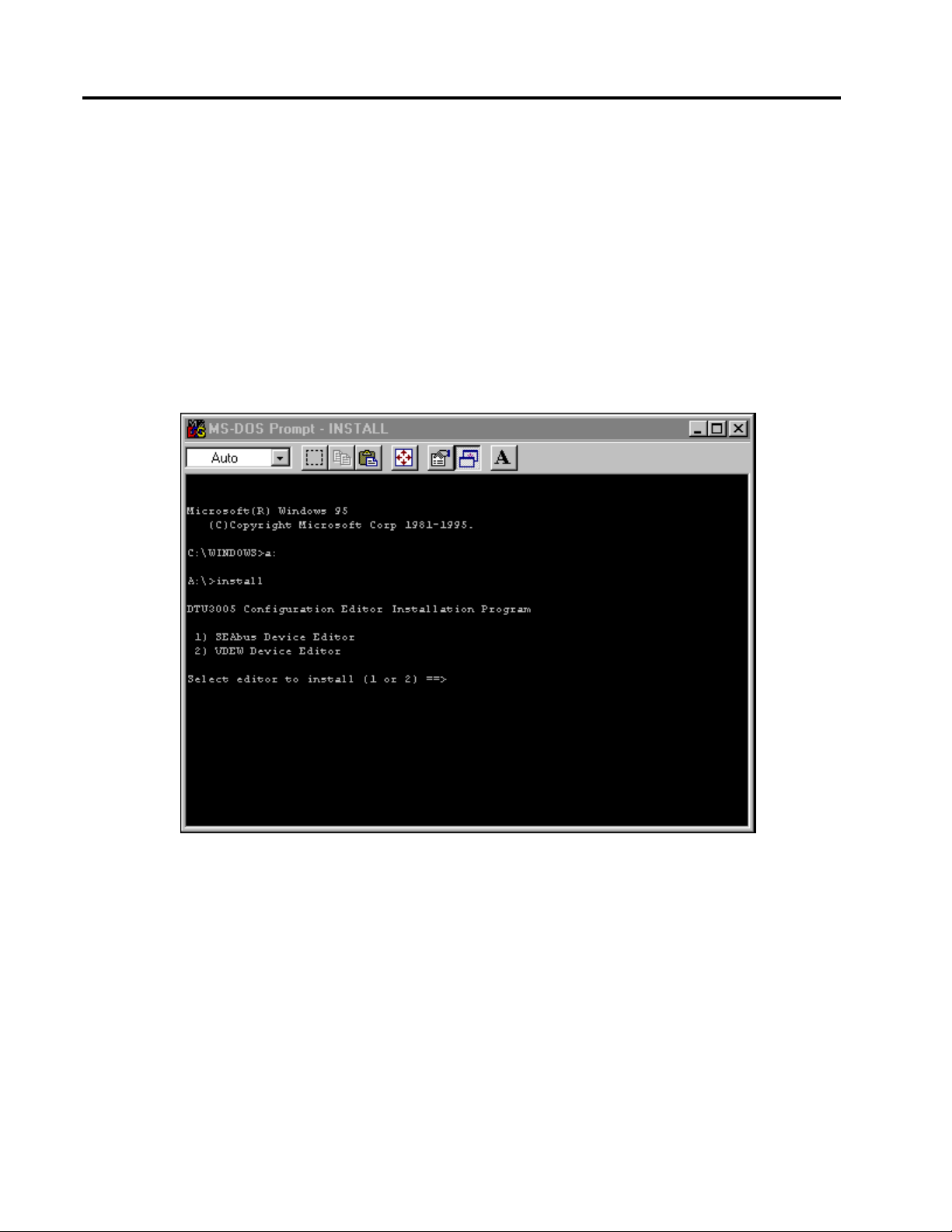

The DTU3005 Editor software can be installed from

the DOS prompt onto a P C running Microsoft® Windows version 3.1, 95, or 98. The PC processor must be

less than 300 MHz (or have a utility program installed

to slow down the processor speed) for the Editor software to work properly.

Note: The DTU3005 Editor software does not work in

a Windows NT environment.

If you are running Windows 3.1, double click the MSDOS Prompt icon in the Main window of Program

Manager. For Windows 95/98, select MS-DOS Prompt

from the Start menu. To install the Editor software,

insert the installation diskette into your computer and

follow the steps listed below. The computer screen,

showing the computer prompts and user responses,

is shown be low.

1. Change the cur ren t drive at the DOS pro mpt to the

diskette drive. Type A: (or B: if that is your 3½"

diskette drive), and then press Enter.

2. At the A:\> prompt, type install, and then

press Enter. The installation p ro mp ts y ou t o select

which Editor software to install, as shown in the

example screen below. Type 1 and press Enter to

install the SEAbus Device Editor, or type 2 and

press Enter to install the VDEW Device Editor.

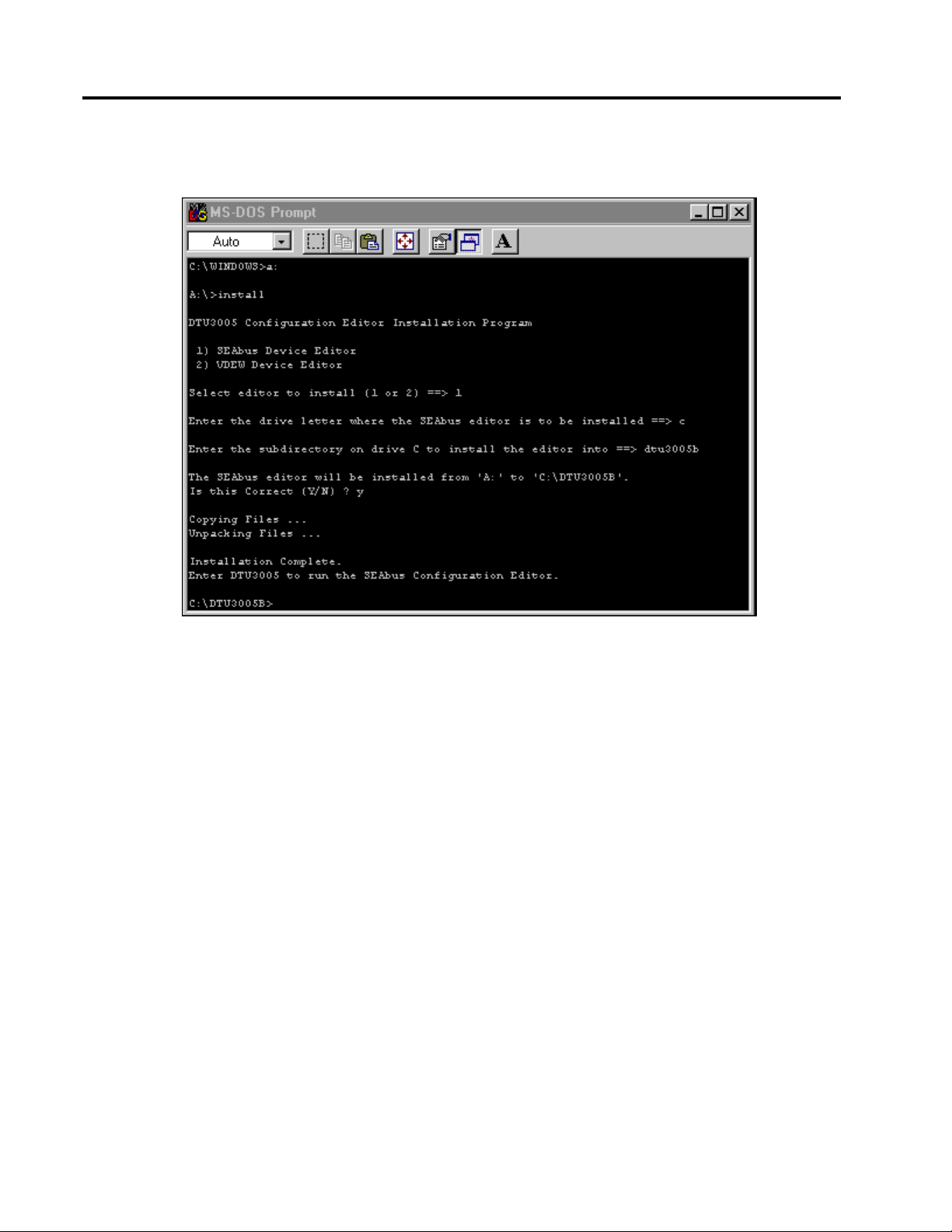

3. The program asks on which drive you want to

install the Editor software. For most computers,

this will be drive C. Type c and press Enter.

4. The installation program then asks to which subdirectory you want to install the DTU3005 Editor

software. This is where the program and configuration files will be placed. The suggested directory name is DTU3005B. Type the directory name

at the prompt and press Enter.

5. You will now verify your drive and directory

choices. The installation program repeats your

entries and asks if the information is cor rect . Enter

Y if it is correct, and N if it is incorrect or you have

changed your mind. Then press Enter.

6 Siemens Energy & Automation, Inc.

6. The installation program copies and unpacks the

editor program files onto your hard drive and

Page 11

2 Installing the Software

returns you to the DOS prompt as shown in the

example screen below.

7. If you are running Windows, type exit to close

the DOS window.

7 Siemens Energy & Automation, Inc.

Page 12

3 Starting the Software

3 Starting the Software

To start the DTU3005 Editor software, follow these

steps:

1. If you are running Windows 3.1, double click the

MS-DOS Prompt icon in the Main window of Program Manager. For Windows 95/98, select MS-

DOS Prompt from the Start menu.

2. At the DOS prompt, which is usually C:\> (or

C:\WINDOWS> if you are running a DOS prompt

from Windows) type CD \DTU3005B, where

DTU3005B is the directory where the Editor software is installed. Press Enter.

3. At t he new DOS prom pt (which is C:\DTU3005B>

if you installed the program to the suggested

directory), type DTU3005 and then press Enter.

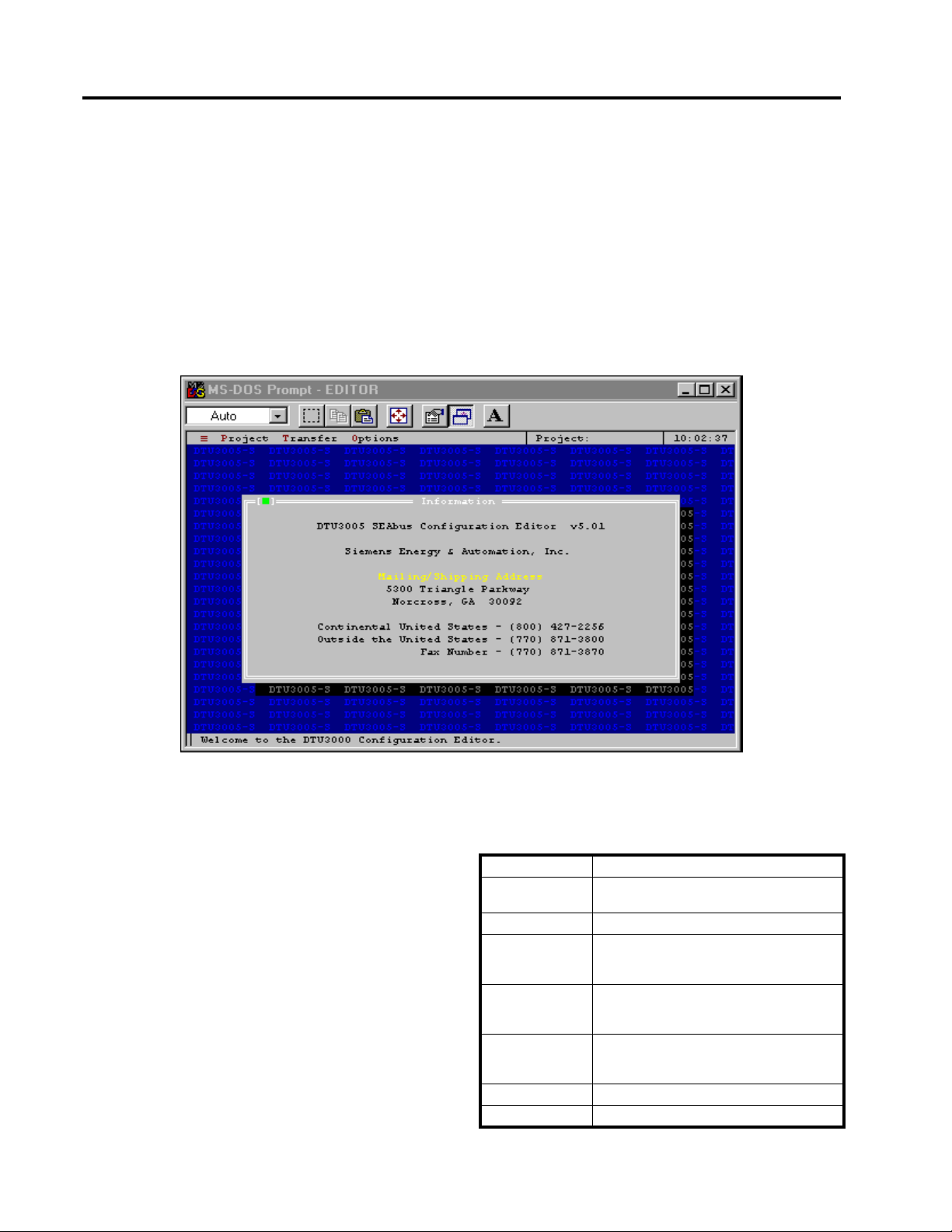

4. T he DTU3005 E ditor software starts . An information screen appears as shown below.

5. Press Enter or Esc to close this information

screen and start using the program.

3.1 Menu Navigation

Navigation of the program menus and dialog boxes

can be performed with either the keyboard or a

mouse. The Editor software uses the standard menu

and dialog box user interface used by many other

DOS and Windows programs. The mouse can be used

to make menu selections, highlight and select items in

a dialog box, and perform commands by clicking on

dialog box buttons. Keyboard equivalents to mouse

actions are described in Table 3.1 below. Informatio na l

messages are displayed on the bottom line of the

screen to give you help with keyboard navigation.

Note: To use a mouse in DOS, be sure the mouse

driver is loaded before starting the Editor

software. This is usually done automatically

from a command in the CONFIG.SYS or

AUTOEXEC.BAT startup files, or if you are

running the program from Windows, by

Windows itself. For information on how to

8 Siemens Energy & Automation, Inc.

load a mouse driver, refer to the instructions included with your mouse.

Table 3.1 Keyboard Shortcuts for Menu Navigation

Key Description

Arrow keys Moves the highlight in the direction of

Enter Performs the highlighted command.

Esc Cancels a function, closes the menu or

Tab and

Shift+Tab

Letter keys The colored letter in each menu item

Spacebar Selects or deselects a highlighted item.

Alt + Q Quits the program.

the arrow.

dialog box, and returns you to the previous menu or dialog box.

The Tab key moves forward one item at

a time within a dialog box. Shift+Tab

moves backward one item at a time.

indicates which key performs that command.

Page 13

3 Starting the Software

3.2 Main Menu

The main menu is located on the top line of the

screen. In addition to the menu selections, the name

of the current project and the time of day is displayed

on the top l ine. There a re five mai n menu select ions.

They are

• ≡, or the Program Information menu. Selecting it

displays the program information screen.

•The Project menu enables you to create, load,

save, view and print project files. It also allows

you to switch to a DOS prompt or quit the program. Its operation is described below in

Section 3.3 and Section 3.4.

•The Edit menu enables you to configure projects

and is available only when a project is open.

Chapters 4, 5, and 6 describe the process of configuring the different project types.

•The Transfer menu uploads and downloads

project files to the DTU3005 unit. These procedures are described in Chapter 7.

•The Options menu allows you to change settings

on where the program finds its project files, and

which COM and LPT ports to use. Its operation is

described in Chapter 8.

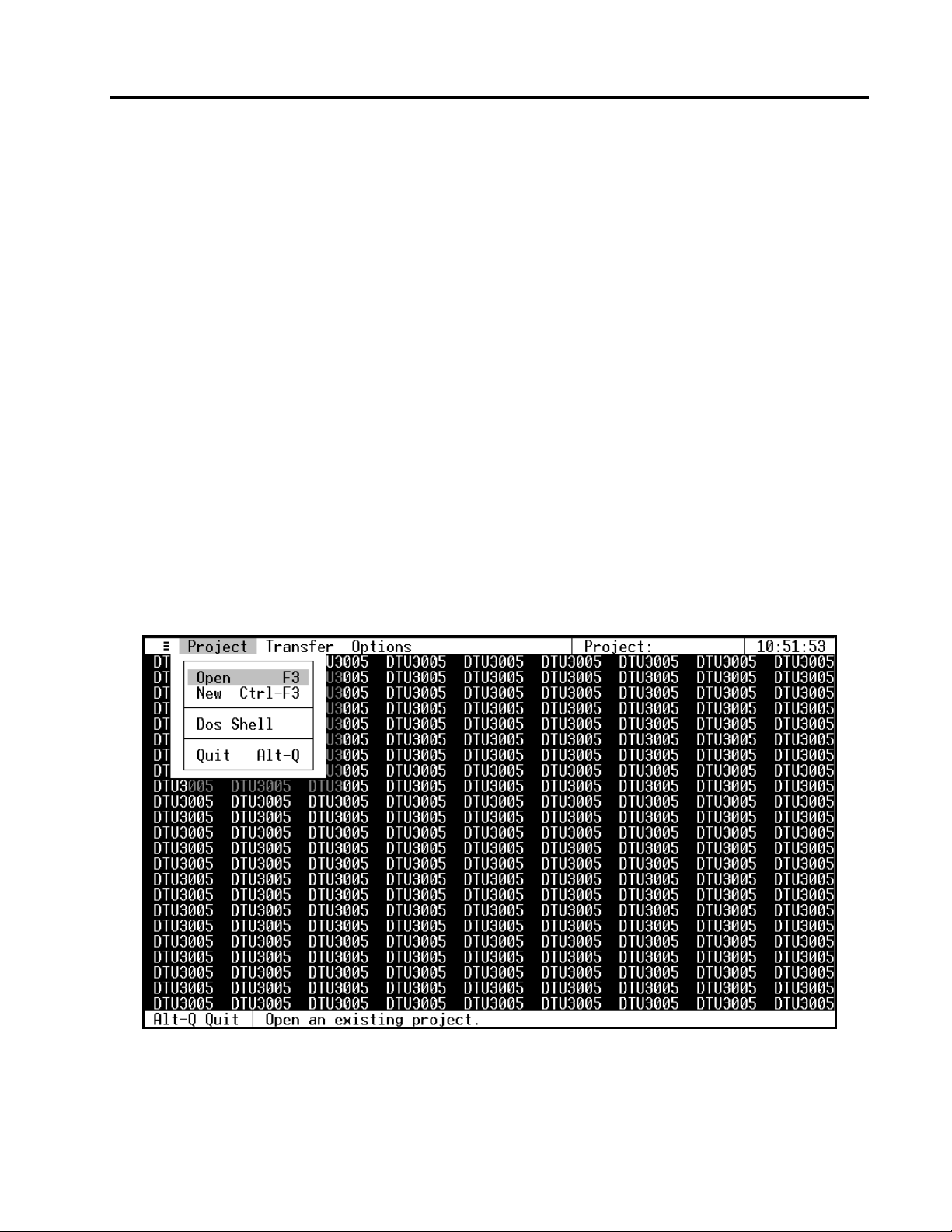

3.3 Using the Project Menu

When you first start the DTU3005 Editor software, and

no project file is lo aded, t he fo llowing menu selections

are available in the Project menu (see example screen

below):

• Open, allows you to open any saved project file.

• New, allows you to create a new project file.

• Dos Shell, allows you to switch to MS-DOS wi thout closing the DTU3005 Editor software. To

return to the program, type exit and then press

the Enter key at the DOS prompt.

• Quit, allows you to exit the DTU3005 Editor software.

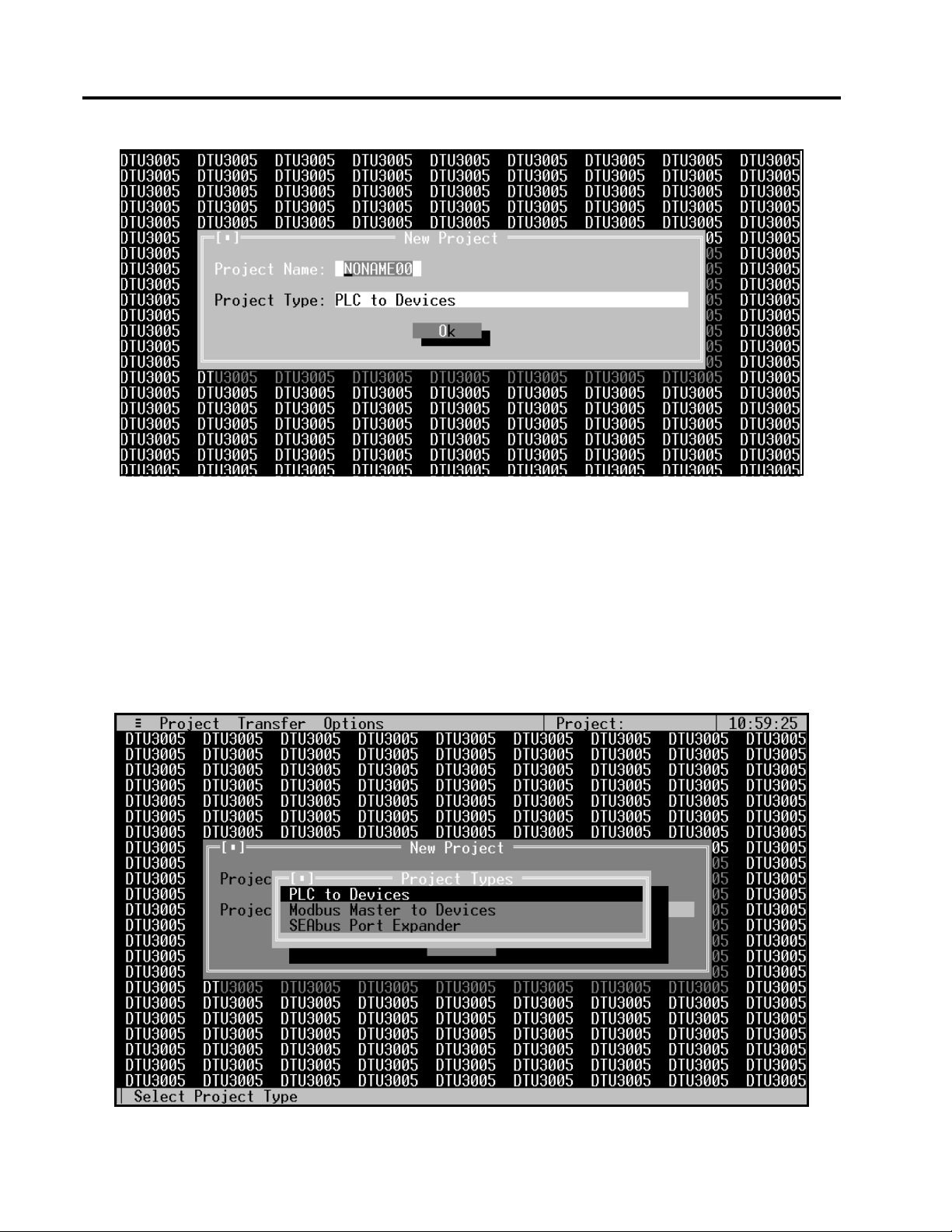

3.4 Starting a New Project

Projects contain the configuration information to be

downloaded to the DTU3005 device. To create a new

project:

1. S el e ct t he Project menu with the mouse, or use

the arrow keys to highlight Project and displ ay the

Project menu:

2. Select New with the mouse, use keyboard shortcut Ctrl + F3, or use the arrow keys to highlight

New and press Enter. The New Project dialog box

appears.

Siemens Energy & Automation, Inc. 9

Note: All menus and dialog box selections are

accessible from the keyboard or by using

the mouse. From this point the manual will

only say “select this” or “highlight this.”

Refer to Section 3.1 for menu navigation

instructions and keyboard shortcuts.

Page 14

3 Starting the Software

3. Type in a name for th e project up to eight letters

and numbers in the Project Name: field an d pr ess

Enter. The Project Type: field will then be highlighted. Press the spacebar to display the project

types, which are:

• PLCs to Devices—allows a PLC to control

and/or monitor up to 32 supported Siemens

devices. See Chapter 4 for configuring this

project type.

• Modbus Master to Devices—allows a Modbus speaking host system, personal computer running SCADA software, or PLC to read

and write regist er s in up to 32 sup ported Siemens devices. See Chapter 5 for configuring

this project type.

• SEAbus Port Expan der—allows two Siemens

ACCESS supervisory computers to connect

up to 32 Siemens ACCESS devices. See

Chapter 6 for configuring this project type.

10 Siemens Energy & Automation, Inc.

Page 15

3 Starting the Software

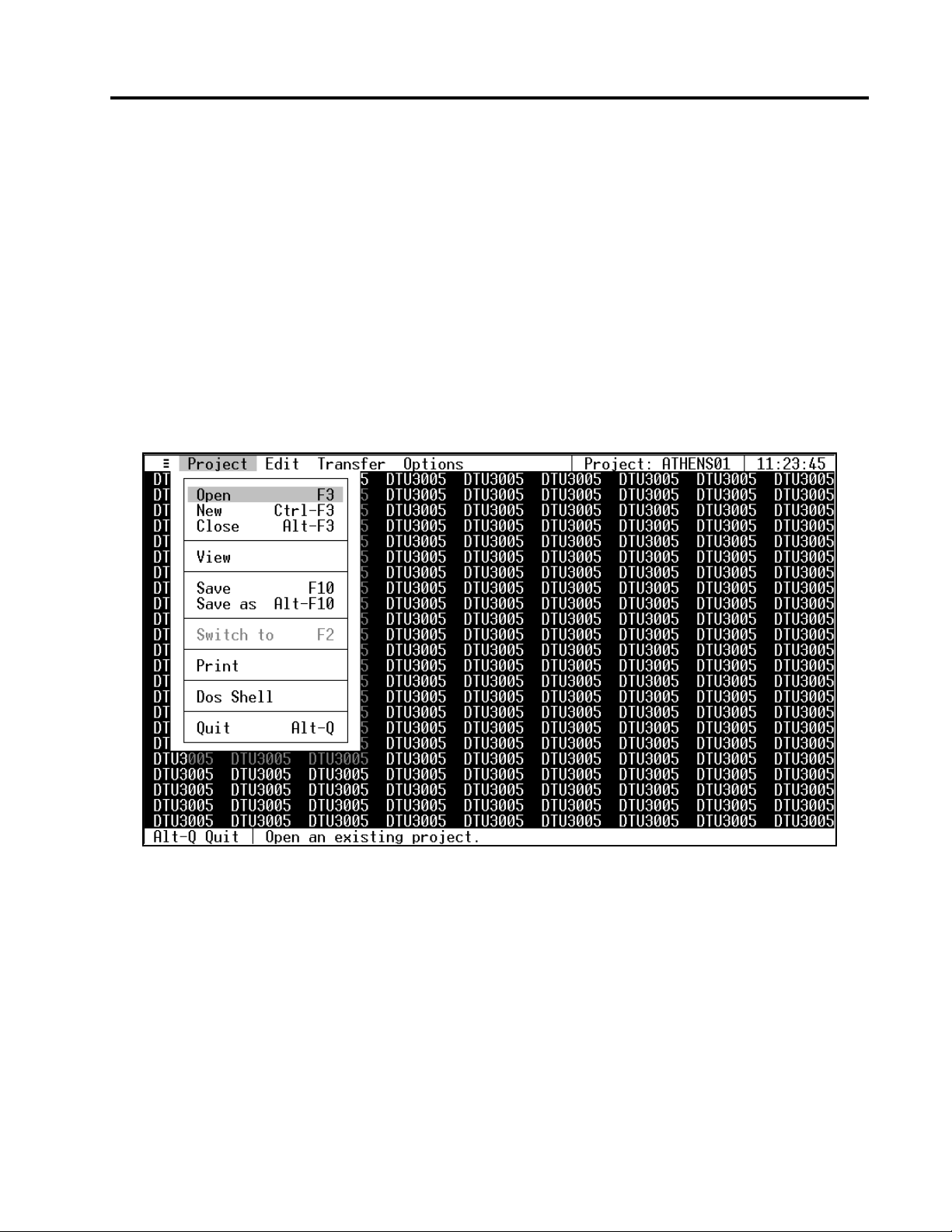

4. To select a project type, highlight the type and

either press Enter or click the left mouse button.

Then highlight the Ok button on the dialog box

and either press Enter or click the left mouse button.

5. When the screen refreshes, the Project menu is

displayed with additional menu options now available. These options apply to the open project file

that is active (i.e., the project name appears in the

top line of the screen).

• Close—allows you to close a project file.

(More than one project file can be open at any

time.)

• View—allows you to view a project informa-

tion screen which shows the project file

name, project file type, th e sel ectio ns f or each

of the DTU3005’s ports, and the number of

devices.

• Save—allows you to save the current project

file.

• Save As—allows you to save the project file

under a different file name.

• Switch To —allows you to s witch between the

opened project files. (Multiple project files

can be open at the same time.)

• Print—allows you to print the project file’s

configuration information.

6. Select Save, or use the keyboard shortcut F10 to

save your new project. You are now ready to configure your project.

Siemens Energy & Automation, Inc. 11

Page 16

4 Creating Project Files—PLC to Devices

4 Creating Project Files—PLC to

Devices

This chapter covers configuration of the DTU3005 for PLC

communications with Siemens devices. Once you have created a PLC to Devices project (see Chapter 3), follow the

directions in this chapter to configure the project file. Then

see Chapter 7 for directions on downloading the project to

the DTU3005. See also Appendix D for wiring diagr ams for

your particular PLC, as required.

4.1 Application Description

The PLC to Devices application allows a PLC to control and

monitor up to 32 SEAbus devices or Siemens protective

relays. In this application, the DTU3005B initiates all communications with both the PLC and the Siemens devices.

The DTU3005B uses an internal transfer table to transfer

data to the PLC. The transfer table contains a block of

selected real-time data parameters obtained from a device.

The DTU3005B unit acts as a master to the PLC, and continuously transfers the table data to the selected block of

registers on the PLC. A delay option is provided for each

device’s table entry to prevent unnecessarily slowing down

the scan time of the PLC as well as to give some device

data transfers higher priority than others.

No ladder logic is required on the PLC to use the basic feature of this application, which allows a limited amount of

information to be transferred between the PLC and the

devices. Ladder logic programming is required to use the

command block function. The command block is used to

send commands to the devices, such as operating or

releasing relays, or resetting energy counters. See

Section 4.11 for information on configuring this feature on

the DTU3005B. The format of the command registers for

each device are described in Appendix E.

The DTU3005B can automatically update diagnostic information in the PLC. It allows the PLC to determine when a

device is not communicating. See Section 4.10 for information on enabling and configuring this feature. The format and

content of the diagnostic registers are described in detail in

Appendix F.

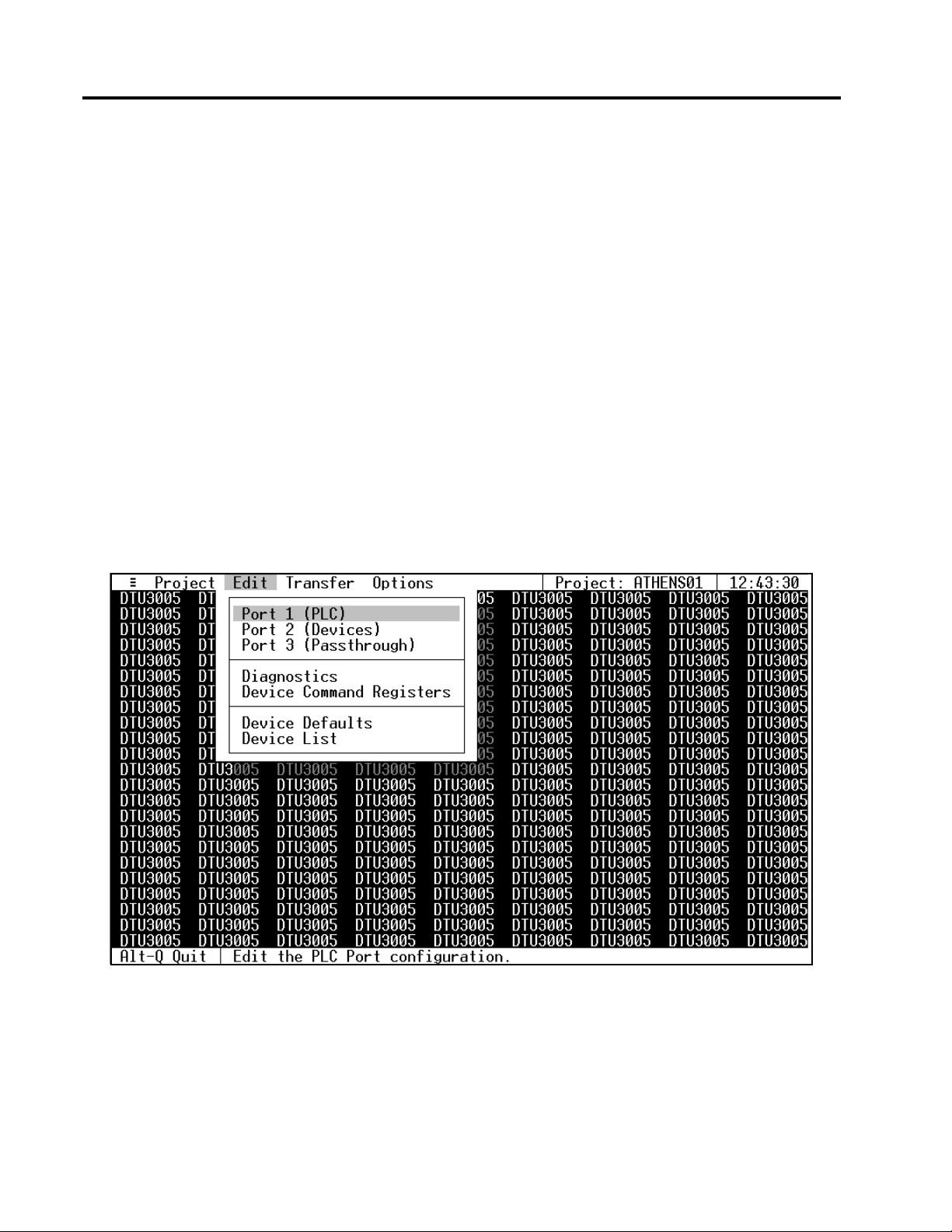

4.2 Configuring the Project File

Once you have created or opened the project file, select

Edit from the main menu to display the following menu

items:

• Port 1 (PLC)—allows you to select the model and configure the communications settings for the PLC connected to port 1.

• Port 2 (Devices)—allows you to co nfigure communications settings for SEAbus devices or Siemens Protective relays connected to port 2.

12 Siemens Energy & Automation, Inc.

• Port 3 (Passthrough)—allows you to select whether

port 3 is used as a passthrough to the devices or the

PLC.

• Diagnostics—allows you to indicate if you want the

DTU3005 to write communications diagnostic information to the PLC.

Page 17

4 Creating Project Files—PLC to Devices

• Device Command Registers—allows you to indicate

which PLC registers will be u sed for dev ice co mmands.

• Device Defaults—allows you to set the default data

registers for more than one device of a certain type,

e.g., set the defaults for all 4720 power meters or all

S7-I/O units. The data registers can still be customized

for each device, as required. See Section 4.7.2 for

more information.

• Device List—allows you to indicate which SEAbus

devices or Siemens protective relays are connected to

port 2 and which PLC registers they are communicating with.

If the Device Protocol for port 2 is set to VDEW (see

Section 4.4), then two additional menu items are available:

Global Command Registers and Device Text to Values

Table. See Section 4.8 and Section 4.9 for instructions on

using these menu items.

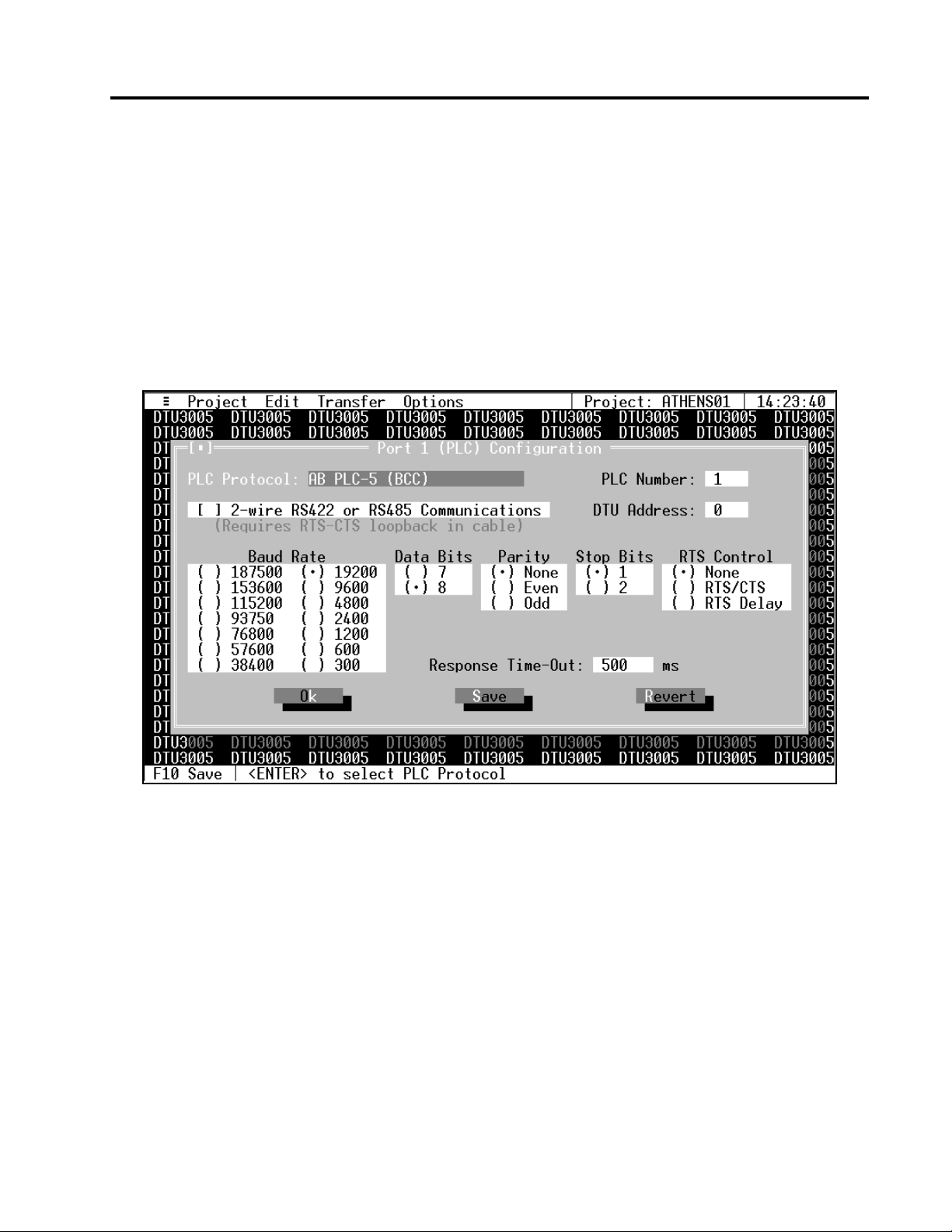

4.3 PLC Setup—P ort 1

You must have a PLC to Devices project file open to configure port 1 using the instructions in this section. Select Port

1 (PLC) from the Edit menu, and the Port 1 PLC Configura-

tion screen appears.

Siemens Energy & Automation, Inc. 13

Page 18

4 Creating Project Files—PLC to Devices

To select the PLC connected to port 1, highlight PLC Protocol and press Enter. The PLC Protocols selection menu

appears:

PLC Protocol

Use the Down Arrow and Up Arrow keys to scroll through

the list of available PLC Protocols, since not all choices are

visible at one time. To select a protocol, highlight the selection and press Enter.

PLC Number

After you have selected your PLC, the PLC Number selection box is highlighted. The PLC Number is used to identify

which PLC the DTU is to communicate with (if the selected

type of PLC is addressable). The PLC Number is often

called a PLC Slave Address or Slave ID.

Type in the PLC Number and press Enter.

2-Wire RS422 or RS485 Communications

After you have entered the PLC Number, the 2-Wire RS422

or RS485 Communications selection box is highlighted.

This box will only need to be ch eck ed if th e comm unication s

with your PLC is a 2-wire RS485 or RS422 interface. When

2-wire communications are being used, RTS must be

looped back to CTS on the DTU side of the cable. This can

be done on the RS232 side by looping pins 4 and 5 or on

the RS422/485 side by looping 16 to 18 and 17 to 19. See

Appendix D for wiring diagrams for your particular PLC,

and whether it uses a 2-wire connection.

To select the checkbox, click on it with the mouse or, with

the 2-Wire RS422 or RS485 Communications selection

highlighted, press the spacebar. An “X” will appear inside

the brackets when it is selected.

Press the Tab or Right Arrow key to move to the next field

without selecting this checkbox.

DTU Address

Some PLC protocols require each device on the PLC network to be assigned a unique address or ID. The DTU

Address is the address assigned to the DTU on the PLC

network. Highlight this field and type in the address number

for the DTU3005B, then press Enter.

Communications Settings

The communications settings are automatically set to the

default values for each type of PLC when the PLC is first

selected. Before changing any of these settings, consult

your PLC manual for the correct settings. To move between

the communications settings, press the Tab or Enter keys.

To select a setting, use the Up or Down Arrow key to move

to the desired setting and press the spacebar to change

your selection.

RTS Control (Request to Send Control)

RTS Control selection is an option provided for modems or

for PLCs that require RTS to be active only while the DTU is

transmitting to the PLC.

•If RTS/CTS is selected, the DTU will activate RTS and

wait until CTS is active before transmitting to the PLC.

•If RTS Delay is selected, the DTU will activate RTS and

wait for the specified delay time to pass before transmitting to the PLC. When RTS D ela y is selected, the

14 Siemens Energy & Automation, Inc.

Page 19

4 Creating Project Files—PLC to Devices

program displays an entry box for the RTS delay time.

Enter the time in milliseconds.

Response Time-Out

The Response Time-Out tells the DTU how long to wait

after transmitting a request to the PLC if no response has

been received from the PLC. After this amount of time

passes with no response being received, the DTU will

assume that no response is coming and will retry the

request. Enter the time in milliseconds.

Saving Port 1 Configuration Information

Once you have entered all the configuration information,

select Save to save the configuration to the project file.

Then select Ok or press the Esc key to close the configuration screen.

If you have changed the configuration and have not saved it

to the project file, you will be prompted to either save or discard the changes. Select Revert to return to the last previously saved configuration without saving any changes.

4.4 Device Setup—Port 2

One or more Siemens devices may be connected to port 2.

You must have a PLC to Devices project file open to configure port 2 using the instructions in this section.

Select Port 2 (Devices) from th e Edit menu, and the Port 2

configuration screen appears.

Device Protocol

The Device Protocol indicates which Siemens devices can

be connected to port 2. This protocol is based on which

version of the DTU3005 Editor software was installed as

described in Chapter 2.

•The SEAbus protocol (as shown in the example screen

above) indicates connection to Siemens ACCESS communicating trip units, relays, power meters and other

devices.

Siemens Energy & Automation, Inc. 15

•The VDEW protocol indicates connection to Siemens

protective relays using the VDEW protocol.

Note: Not all Siemens devices are supported. For a list

of supported devices, see Appendix B.

Other Configurat io n In for m ati o n

The remaining configuration selections are the same as

those for port 1. Refer to Section 4.3 for instructions on

these fields.

Page 20

4 Creating Project Files—PLC to Devices

Saving Port 2 Configuration Information

Once you have entered all the configuration information,

select Save to save the configuration to the project file.

Then select Ok or press the Esc key to close the configuration screen.

If you have changed the configuration and have not saved it

to the project file, you will be prompted to either save or discard the changes.

Select Revert to return to the last previously saved configuration without saving any changes.

4.5 Passthrough Setup—Port 3

Port 3 is for passthrough communications. It allows direct

communication with either the PLC on port 1 or the Sie-

mens SEAbus devices on port 2. (Passthrough communications to port 2 are not available for VDEW devices.)

In passthrough mode, any messages received on port 3 of

the DTU are simply “passed through” to the PLC (port 1) or

devices (port 2). For example, passthrough communications

enables a PC running WinPM, or other supervisory software

connected to port 3 of the DTU3005, to communicate

directly with the SEAbus devices connected to port 2.

You must have a PLC to Devices project file open to configure port 3 using the instructions in this section.

Select Port 3 (Passthrough) from the Edit menu, and the

Port 3 configuration screen appears.

The first option on the configuration screen allows you to

choose passthrough to port 1 or port 2. Select the appr opriate port with the mouse, or use the Up or Down Arrow

keys to highlight the selection and press Enter.

To change the intermessage time-out, select Intermes-

sage Time-Out and type in the value in milliseconds, then

press Enter.

Saving Port 3 Configuration Information

The remaining configuration selections except for Intermessage Time-out are the same as those for port 1. Refer to

Section 4.3 for instructions on these fields.

Intermessage Time-Out

The DTU3005 uses the intermessage time-out to determine

when a complete message has been received on the

passthrough port. Once the first character of a message has

been received, if the amount of time specified by the intermessage time-out passes with no additional characters

being received, the DTU3005 will consider the message to

be complete and process it.

16 Siemens Energy & Automation, Inc.

Once you have entered all the configuration information,

select Save to save the configuration to the project file.

Then select Ok or press the Esc key to close the configuration screen.

If you have changed the configuration and have not saved it

to the project file, you will be prompted to either save or discard the changes. Select Revert to return to the last previously saved configuration without saving any changes.

Page 21

4 Creating Project Files—PLC to Devices

4.6 Device List Setup

The Device List menu item enables you to indicate which

registers on the PLC will receive data from the devices. In

this screen, you will enter the device type and address for

each Siemens device connected to port 2. You will also indi-

cate to which registers on the PLC you want the DTU3005

to write device data.

Select Device List from the Edit menu to display the

device list screen:

This screen is divided into two parts:

• On the left side of the screen is a list of the devices connected to port 2 (the list is initially empty). Up to 32

devices can be attached; however, only 17 of the

devices are visible on the screen at one time. To see all

the devices, click on the scroll bar with the mouse, or

use the Up and Down Arrow and Page Up and Page

Down keys.

• The right side of the screen is used to configure the

data register information for the selected device, as

shown in the example screen on the next page. You

can add or delete devices, or change device configuration by highlighting the Device Type on the left side of

the screen, then using the fields and buttons on the

right side of the screen.

Adding a Device

To add a device to the device list:

1. Highlight the first line where the Device Type and

Address fields are blank—this should be the first available device number No field .

2. Press Enter or Tab to add a device. The cursor will

move to the Device Type field on the right side of the

screen. Press Enter, and the Device Types list dis-

plays:

Siemens Energy & Automation, Inc. 17

Page 22

4 Creating Project Files—PLC to Devices

3. Select the device from the list by pressing Ente r or the

spacebar. The highlight moves to the Address field,

and the PLC register fields now display as shown in the

example screen below .

4. W ith the Address field highlighted, enter the device’s

address. This number should be between 1 and 254,

and match the number programmed into the device

itself. Press the Tab key twice to go to the Real-Time

Data Registers field.

5. Highlight the File field and enter the file number. This

parameter is used only with Allen-Bradley PLCs to

specify the file number in the PLC that contains the register values that are transferred to or from the device.

18 Siemens Energy & Automation, Inc.

Page 23

4 Creating Project Files—PLC to Devices

6. Enter the beginning register number in the Real-Time

Data Registers field. Refer to Appendix A for valid

register numbers for your PLC application. The

DTU3005 Editor software supplies the last register

number after you enter the first. In the example above,

the 4700 Power Meter uses 41 registers for its data.

When you enter 1 for the first register, the last register

becomes 42. If you change the starting register to 10,

the last register will automatically change to 51.

Note: These registers indicate the exact location

in the PLC where the DTU3005 will store

the real-time data for this device.

7. Press Shift+Tab, or click the left mouse button to high-

light the File field and enter the file number. This

parameter is used only with Allen-Bradley PLCs to

specify the file number in the PLC that contains the register values that are transferred to or from the device.

8. The device command registers are displayed below the

real-time data registers. They are configured from the

Device Command Registers menu selection on the

Edit menu. See Section 4.11 for information on setting

these registers and programming the PLC to perform

commands. Be sure that the register numbers are not

also used by the device. This can cause unexpected

operation of the device.

9. If you want to use a customized subset of the available

data registers, see Section 4.7.2 for instructions on

creating a default set of custom registers for all devices

of the same type. Type an “X” in th e Use customized

real-time data ordering? field to begin the custom

data setup, or press Tab to go to the next field.

10. Enter th e Real-Time Data Delay Time in its field. This

is the delay from the time that the DTU3005 receives

data from the device to the time the DTU3005 transfers

the data to the PLCs registers.

11. Select Save to save the device information to the

project f i le , a n d t h en select Ok or press Esc to exit the

device list configuration screen. If at any time you want

to return to the last saved version of the device list,

select Revert without saving any changes.

Removing a Device

To remove a device from the device list, highlight the device

on the left side of the screen and press Tab or Enter. The n

change the device type to Not In Use.

Additional Options for Data Registers

The Device List screen has three additional options for

working with a device’s data registers:

• Select Set Reg to place the data registers into contiguous register numbers and minimize the size to the data

register block. This option also sets the initial register

number to 1.

•The Set All comma nd performs the same fun ction as

Set Reg, but allows you to set the initial register number. See Appendix A for information on acceptable

register number ranges for each PLC model.

• Select Pack to mini mize the siz e of the command register block, removing registers for deleted devices.

Saving the Device List Configuration

Once you have entered the device information for all the

devices attached to port 2, select Save to save the device

information to the project file. Then select Ok or press Esc

to close the device list configuration screen.

If you have changed the device information and have not

saved it to the project file, you will be prompted to either

save or discard the changes.

Select Revert to return to the last previously saved configuration without saving any changes.

4.7 Configuring Custom Device

Registers

You can configure which data items from the SEAbus or

VDEW devices are transferred from the DTU3005 device to

the PLC or Modbus master. In this way, the DTU3005 acts

as a data concentrator , in addition to converting the SEAbus

and VDEW protocol data. You can configure the custom

data items so that every device of the same type sends the

same data items (see Section 4 .7.2), or have each device

send particular data items of interest (see Section 4.7.1).

SEAbus devices can be configured to send 16 words of

device data. VDEW devices can be configured to send from

1 to 64 words.

4.7.1 Configuring Custom Registers for a

Single Device

To configure custom registers for a single device:

1. Select Device List from the Edit menu.

2. Highlight the device that you wish to configure and

press Enter.

3. Highlight the Use customized real-time data order-

ing? check box. Press the spacebar to place an “X” in

the check box. Then select Custom Data to display

the Customized Real-Time Data dialog box.

Siemens Energy & Automation, Inc. 19

Page 24

4 Creating Project Files—PLC to Devices

4. Select a data register on the list and press Enter to see

a list of available real time data. These data items are

identical to the standard data items listed in Appendix

E. Not all data items are visible on the screen at one

time. Use the mouse and the scroll bar , or the Page Up

and Page Down keys to view all of the data items.

20 Siemens Energy & Automation, Inc.

Page 25

4 Creating Project Files—PLC to Devices

5. Select the data word (16 bit data) from the list and

press Enter. Continue to set the other data words in

the same manner. Many data items consist of two

words (32 bit data). It is important that you configure

both words in order to transmit us eful information to the

DTU3005’s registers.

6. Use these options as follows:

a. Select Set Defaults to copy the default custom

device registers to the list. See Section 4.7.2 for

instructions on setting custom device registers by

device type.

b. Select Clear All to delete all register names from

the list.

c. Select Set as Def aults to save the current cus-

tom register list as the default custom register list.

This will not change the custom registers of other

devices of the same type. See Section 4 .7.1 for

instructions on setting custom device registers for

a single device.

4. Select Save to save your custom register list and then

Ok to exit this dialog box. Select Cancel to exit this

dialog box without making changes.

To conserve registers when using VDEW devices, you

should set all unused registers to “Not Used” and place

them at the end of the list. The DTU3005 will then only allocate registers for those containing device data. (This does

not apply to SEAbus devices, for which the DTU3005 allocates 16 registers regardless if they are used or not.)

4.7.2 Configuring Default Custom Device

Registers by Device

If you are configuring custom device registers for more than

one device of a certain type, you may configure the default

custom registers from the Edit Menu Device Defaults

command. After configuring the default device registers, you

may use them for any or all devices, or further customize

individual registers for any of your devices. SEAbus devices

can have 16 custom registers. VDEW devices may have

between 1 and 64 custom registers.

To configure default custom registers for a particular device

type:

1. Select Device Defaults from the Edit menu. A list of

devices appears. If you have configured por t 2 f or SEAbus devices, only SEAbus devices will appear on the

menu. Likewise, if you have configured port 2 for VDEW

devices, only VDEW devices will appear on the menu.

2. Select the device you wish to configure. The default

custom register configuration menu appears. The first

time you select this command, the first 16 registers (64

for VDEW devices) from the device’s standard data register list appear on the default real-time data list. Not all

of the entries are visible on the menu. Use the scroll bar

or the Page Up and Page Down keys to view all the

entries.

Siemens Energy & Automation, Inc. 21

Page 26

4 Creating Project Files—PLC to Devices

3. Select a data item and press Enter to see a list of

device real time data that can be assigned to that data

word. Select Not Used if you do not want that data

word to be used. Not all of the entries are visible on the

menu. Use the scroll bar or the Page Up and Page

Down keys to view all the entries. Select Clear All to

set all data words to “Not Used.” Select Set to Base to

restore the data words to the first 16 registers (64 for

VDEW devices) from the device’s standard data register list.

4. Select Save to save your configuration or Revert to

restore the last previously saved configuration for that

device. When you are finished configuring the default

22 Siemens Energy & Automation, Inc.

data registers for that device, select Ok to close this

screen.

Page 27

4 Creating Project Files—PLC to Devices

To conserve registers when using VDEW devices, you

should set all unused registers to “Not Used” and place

them at the end of the list. The DTU3005 will then only allocate registers for those containing device data. (This does

not apply to SEAbus devices, for which the DTU3005 allocates 16 registers regardless if they are used or not.)

4.8 Device Text Setup (7SJ600 Only)

The Device Text to Values Table menu item is only available

for configuring the 7SJ600 relay. It is used to convert status

codes returned from select parameters in the 7SJ600 relay

(only) to values in a format useful to the system connected

to port 2 of the DTU3005. This affects the status readouts

from the device's binary inputs, signal and trip rated contacts, and the LEDs.

To edit this table, select D evice Text to Values Table from

the Edit menu. This selection is only available when the

device protocol for port 2 is set for “VDEW.”

Once open, 64 conversions can be defined. To define a

conversion, enter the 7SJ600 relay status code i n the Text #

column and enter the corresponding output value desired in

the Value column.

Siemens Energy & Automation, Inc. 23

Page 28

4 Creating Project Files—PLC to Devices

The relevant status codes (Text #) are listed below.

Table 4.1 7SJ600 Relay Information

For Requesting Status of the 7SJ600 Relay’s Three Binary Inputs

Text Number/Status Code

(default value returned if

not converted)

1342 I1,2 Inactive : I3 Active 4 0 1 0 0

1343 I1,3 Inactive : I2 Active 2 0 0 1 0

1344 I1 Inactive : I2,3 Active 6 0 1 1 0

1345 I2,3 Inactive : I1 Active 1 0 0 0 1

1346 I2 Inactive : I1,3 Active 5 0 1 0 1

1347 I3 Inactive : I1,2 Active 3 0 0 1 1

1348 I1,2,3 Active 7 0 1 1 1

Description of Returned Binary

Input Status Codes: I1

indicates Input 1; I2,3 indicates

Inputs 2 and 3

For Requesting Status of the 7SJ600 Relay’s Two Trip Contacts and Two Signal Contacts

Text Number/Status Code

(default value returned if

not converted)

1349 S1,2 T1,2 Open 0 0 0000

1350 S1,2 T1 Open : T2 Closed 2 0 0010

1351 S1,2 T2 open : T1 Closed 1 0 0001

1352 S1,2 Open : T1,2 Closed 3 0 0011

1353 S1 T1,2 Open : S2 Closed 8 0 1000

1354 S1 T1 Open : S2 T2 Closed 10 0 1010

1355 S1 T2 Open : S2 T1 Closed 9 0 1001

1356 S1 Open : S2 T1,2 Closed 11 0 1011

1357 S2 T1,2 Open : S1 Closed 4 0 0100

1358 S2 T1 Open : S1 T2 Closed 6 0 0110

1359 S2 T2 Open : S1 T1 Closed 5 0 0101

1360 S2 Open : S1 T1,2 Closed 7 0 0111

1361 T1,2 Open : S1,2 Closed 12 0 1100

1362 T1 Open : S1,2 T2 Closed 14 0 1110

1363 T2 Open : S1,2 T1 Closed 13 0 1101

1364 S1,2 T1,2 Closed 15 0 1111

Description of Returned Trip

and Signal Relay Status

Codes: S1,2 indicates Signal

Relays 1 and 2; T1,2 indicates

Trip Relays 1 and 2

For Requesting Status of the 7SJ600 Relay’s Four Programmable LEDs

Text Number/Status Code

(default value returned if

not converted)

1365 L1,2,3,4 Off 0 0 0000

1366 L4 On : L1,2,3 Off 8 0 1000

1367 L3 On : L1,2,4 Off 4 0 0100

1368 L3,4 On : L1,2 Off 12 0 1100

1369 L2 On : L1,3,4 Off 2 0 0010

1370 L2,4 On : L1,3 Off 10 0 1010

1371 L2,3 On : L1,4 Off 6 0 0110

Description of Returned LED

Status Codes: L1,2 indicates

LEDs 1 and 2

Suggested Value (Using This Conversion Table)

Value

Value

Value

Inputs I3 I2 I1

00 000

Suggested Value (Using This Conversion Table)

Outputs S2S1T2T1

Bits 15 . . . 43210

Suggested Value (Using This Conversion Table)

Outputs L4L3L2L1

Bits 15 . . . 43210

24 Siemens Energy & Automation, Inc.

Page 29

4 Creating Project Files—PLC to Devices

Table 4.1 7SJ600 Relay Information (Continued)

1372 L2,3,4 On : L1 Off 14 0 1110

1373 L1 On : L2,3,4 Off 1 0 0001

1374 L1,4 On : L2,3 Off 9 0 1001

1375 L1,3 On : L2,4 Off 5 0 0101

1376 L1,3,4 On : L2 Off 13 0 1101

1377 L1,2 On : L3,4 Off 3 0 0011

1378 L1,2,4 On : L3 Off 11 0 1011

1379 L1,2,3 On : L4 Off 7 0 0111

1380 L1,2,3,4 On 15 0 1111

Once you are finished entering data, select Save to save

your configuration, then select Ok to exit the dialog box.

Select Revert to bring back the previous settings.

4.9 Global Command Registers

This option allows you to specify global commands for all

the devices specified in the Device List. It is available only for

VDEW devices.

The Global Command Registers consist of six registers.

These registers allow the PLC to transmit commands to all

the devices in the Device List. To send a command, all the

PLC needs to do is to place the command values into the

appropriate PLC registers, which the DTU3005 unit reads

and then processes.

4.10 Device Diagnostic Registers

This option programs the DTU3005 to send communications diagnostic information to a set of registers on the PLC.

The infor mati on can be used to trou bles hoot proble ms wi th

the devices and the communications network.

The format and content of the diagnostic registers are

described in detail in Appendix F.

1. To configure the device diagnostic registers, select

Diagnostics from the Edit menu. The following screen

displays:

2. To enable the sending of diagnostic information to the

PLC, select the Do you want device diagnostics

information sent to PLC? checkbox with the mouse

or the spacebar. Then enter the starting register number in the PLC Registers: field. The register block is 6

Siemens Energy & Automation, Inc. 25

bytes long. Be sure that the registers you specified are

not being used by other devices.

3. Press Shift+Tab, or click the left mouse button to high-

light the File field and enter the file number. This

Page 30

4 Creating Project Files—PLC to Devices

parameter is used only with Allen-Bradley PLCs. It

specifies the file number in the PLC that contains the

register values that are transferred to or from the

device.

4. Select Save to save the information to the project file,

and then select Ok or press Esc to exit the device

diagnostic registers screen. If at any time you want to

return to the last saved version of the device diagnostics registers, select Revert without saving any

changes.

4.11 Device Command Registers

The device command registers consist of two consecutive

registers for each device entered in the device list. These

registers allow the PLC to transmit commands to each of

the devices. To send a command, all the PLC needs to do is

to place the command values into the appropriate PLC registers, which the DTU3005B unit reads and then processes.

The first register contains the command, and the second

register contains the data associated with the command.

The format of the command registers for each device are

described in Appendix E. All the command registers are

placed in contiguous locations in the PLC’s registers and

are assigned by the DTU3005 to each device in the order

that they are listed in the device list.

To use the command registers for a particular device, the

PLC program must do the following, in order:

1. First, set the command word to 0 or -1 (FFFF hexadecimal).

2. Set the data word to the appropriate value.

3. Set the command word to the appropriate value.

4. After the command is set the PLC must wait for the

DTU3005B unit to change the command word to either

0 (to indicate successful processing of the command),

or -1 (to indicate an error).

To indicate the location of the command registers on the

PLC, follow these steps:

1. Select Device Command Registers from the Edit

menu. The Device Command Registers screen

appears:

2. Enter the starting register address in the PLC Regis-

ters field. The DTU3005 Editor software will determine

the proper number of registers for the number of

devices entered in the device list and indicate the final

register number. These registers must be different from

those used for device data and diagnostics. Refer to

Appendix A for a list of valid register numbers for your

PLC. Failure to use different register addresses will

cause communication errors, and may cause unexpected operation of the devices.

26 Siemens Energy & Automation, Inc.

3. Press Shift+Tab, or click the left mouse button to high-

light the File field and enter the file number. This

parameter is used only with Allen-Bradley PLCs to

specify the file number in the PLC that contains the register values that are transferred to or from the device.

Page 31

4 Creating Project Files—PLC to Devices

4. Enter the value for the Command Block Read Delay.

This is the delay between times that the DTU3005

reads the data from the PLC’s command registers. This

controls the frequency that the registers are read to

allow for critical PLC scan times.

5. Select Save to save the device information to the

project f i le , a n d t h en select Ok or press Esc to exit the

device command registers screen. If at any time you

want to return to the last saved version of the device

command registers, select Revert without saving any

changes.

4.12 Saving the Project File

Now you have completed configuring the DTU3005 for PLC

to device communications. Select Save from the Project

menu and press Enter, or press F10 to save the project file

to disk. The next step is to transfer the project to the

DTU3005 unit. This topic is covered in Chapter 7.

Siemens Energy & Automation, Inc. 27

Page 32

5 Creating Project Files—Modbus Master to Devices

5 Creating Project Files—Modbus

Master to Devices

This chapter covers configuration of the DTU3005 for

Modbus master device communications with Siemens

devices. Once you have created a Modbus Master to

Devices project (see Chapter 3), follo w the directions

in this chapter to configure the project file. Then see

Chapter 7 for directions on downlo ad ing t he p r oj ect to

the DTU3005.

5.1 Application Descriptio n

The Modbus Master to Devices application allows a

Modbus master (usually a SCADA system) to control

and monitor up to 32 SEAbus devices or Siemens protective relays. In this application, the DTU3005B acts

as a slave, and al l communications wi th the Modbus

Master are initiated by the master device itself. The

DTU3005B converts Modbus requests received into

requests to access and control data on the Siemens

devices. Registers are assigned for each device in the

Holding Register range (40000 to 49999, where register 40001 is the first to be used). The Modbus Master

accesses real-time data from the Siemens devices by

reading these registers, and sends commands by writing to these registers. Refer to Figure 5.1 for a matrix

representation of these registers.

Figure 5.1 Modbus Master to Devices Project—Data Registers Matrix

28 Siemens Energy & Automation, Inc.

Page 33

5 Creating Project Files—Modbus Master to Devices

5.2 Configuring the Project File

Once you have created or opened the project file,

select Edit from the main menu. When the Device Pro-

tocol for p ort 2 is se t to SEAb us (see Section 5.4), the

following menu items appear:

• Port 1 (Modbus Master)—allows you to select the

protocol (RTU or ASCII) and configure the communications settings for the Modbus Master

device connected to port 1.

• Port 2 (Devices)—allows you to configure comm unications settings for SEAbus devices or Siemens

Protective relays connected to port 2.

• Port 3 (Modbus/Passthrough)—allows you to

select whether port 3 is used as a passthrough to

the devices on port 2, or used for connection to a

second Modbus Master device.

• Diagnostics—allows you to indicate if you want

the DTU3005 to write communications diagnostic

information to the Modbus Master.

• Device Command Registers—allows you to indicate which PLC registers will be used for device

commands.

• Device Defaults—allows you to set the default

data re gisters fo r more than one device of a certain type, e.g., set the defaults for all 4720 power

meters or all S7-I/O units. The data registers can

still be customized for each device, as required.

See Section 5.7.2 for more informat ion.

• Device List—allows you to indicate which SEAbus

devices or Siemens protective relays are connected to port 2 and which PLC registers they are

communicating with.

Note: If the Device Protocol for port 2 is set to

VDEW (see Section 5.4), then two additional menu items are available: Global

Command Registers and Device Text to

Values Ta ble. See Section 5.8 and Section

for instructions on using these menu items.

In addition, the port 3 menu item is

changed to Port 3 (Modbus Master)

because the passthrough feature is not supported with VDEW devices. Th e instru ctions

in Section 5.3 are applicable to por t 1 a nd to

port 3 for VDEW devices.

Siemens Energy & Automation, Inc. 29

Page 34

5 Creating Project Files—Modbus Master to Devices

5.3 Modbus Setup—Port 1

You must have a Modbus Master to Devices project

file open to configure port 1 using the instructions in

this section. Select Port 1 (Modbus Master) from the

Edit menu, and the Port 1 Modbus Master configuration screen appears.

To select the protocol for the Modbus Master device

connected to port 1, highlight Modbus Protocol and

press Enter. The Modbus Master Protocol selection

menu appears:

30 Siemens Energy & Automation, Inc.

Page 35

5 Creating Project Files—Modbus Master to Devices

Select either ASCII or RTU as your Modbus protocol,

then press the Tab key to highlight the Modbus ID

selection box. The Modbus ID is used to identify the

address of the DTU. Type in the Modbus ID number

and press Enter.

2-Wire RS422 or RS485 Communications

After you have entered the Modbus ID number, highlight the 2-Wire RS422 or RS485 Communications

selection box. This box will only need to be checked if

the communications with your Modbus Master device

uses a 2-wire RS485 or RS422 interface (see

Figure 5.2). When 2-wire communications are being

used, RTS must be looped back to CTS on the DTU

side of the cable. This can be done on the RS232 side

by looping pins 4 and 5 or on the RS422/485 s ide by

looping 16 to 18 an d 17 to 19. See Appendix D for wiring diagrams for your particular PLC, a nd whether it

uses a 2-wire connection.

To select the checkbox, click on it with the mouse or,

with the 2-Wire RS422 or RS485 Communications

selection highlighted, press the spacebar. An “X” will

appear inside the brackets when it is selected.

RTS Control (Request to Send Control)

RTS Control selection is an option provided for

modems or for Modbus Master devices that require

RTS to be active only while the DTU is transmitt ing to

the PLC.

•If RTS/CTS is selected, the DTU will activate RTS

and wait until CTS is active before transmitting to

the PLC.

•If RTS Delay is selected, the DTU will activate RTS

and wait for the specified delay time to pass

before transmitting to the PLC. When RTS Delay is

selected, the program displays an entry box for

the RTS delay time. Enter th e time in millis econds.

Press the Tab or Right Arrow key to move to the next

field without selecting this checkbox.

Figure 5.2 RS-485 Connector (two-wire)

Communications Sett ings

Before changing any of these settings, consult your

device manual for the correct settings. To move

between the communications settings, press the Tab

or Enter keys. To select a setting, use the Up or Down

Arrow key to move to the desired settin g and press th e

spacebar to change your selection.

Response Time-Out

The Response Time-Out tells the DTU how long to

wait after transmitting a request to the PLC if no

response has been received from the PLC. After this

amount of time passes with no response being

received, the DTU will assume that no response is

coming and will retry the request. Enter the time in

milliseconds.

Saving Port 1 Configuration Information

Once you have en tered all the co nfiguration information, select Save to save the configuration to the

project file. Then select Ok or press the Esc key to

close the configuration screen.

If you have changed the configuration and have not

saved it to the project file, you will be prompted to

either save or discard the changes.

Select Revert to return to the last previously saved

configuration without saving any changes.

Siemens Energy & Automation, Inc. 31

Page 36

5 Creating Project Files—Modbus Master to Devices

5.4 Device Setup—Port 2

One or more Siemens devices may be connected to

port 2. You must have a Modbus Master to Devices

project file open to configure port 2 using the instructions in this section.

Select Port 2 (Devices) from the Edit menu, and the

Port 2 configuration screen appears.

Device Protocol

The Device P rotoco l indicates which Siemens devices

can be connected to port 2. This protocol is based on

which version of the DTU3005 Editor software was

installed as described in Chapter 2.

•The SEAbus protocol (as shown in the example

screen above) indicates connection to Siemens

ACCESS communicating trip units, relays, power

meters and other devices.

•The VDEW protocol indicates connection to Sie-

mens protective relays using the VDE W protocol.

Note: Not all Siemens devices are supported. For

a list of supported devices, see Appendix B.

Other Configuration Information

The remaining configuration selections are the same

as those for po rt 1. Refer to Section 5.3 for instructions

on these fields.

Saving Port 2 Configuration Information

Once you have en tered all the co nfiguration information, select Save to save the configuration to the

project file. Then select Ok or press the Esc key to

close the configuration screen.

If you have changed the configuration and have not

saved it to the project file, you will be prompted to

either save or discard the changes.

Select Revert to return to the last previously saved

configuration without saving any changes.

32 Siemens Energy & Automation, Inc.

Page 37

5 Creating Project Files—Modbus Master to Devices

5.5 Modbus/Passthr ough Setup—Port

3

Port 3 can be used for passthrough communications

to your Siemens SEAbus devices or for connection to

a second Modbus Master device. Passthrough communications enables a PC running WinPM, or other

supervisory software connected to port 3 of the

DTU3005 to communicate directly with the SEAbus

devices connected to port 2. In passthrough mode,

any messages received on port 3 of the DTU are simply “passed through” to the devices.

Passthrough communications are not available for

VDEW devices; see Section 5.3 for Port 3 (Modbus

Master) configuration of VDEW devices.

You must have a Modbus Master to Devices project

file open to configure port 3 using the instructions in

this section. Select Port 3 (Modbus/Passthrough) from

the Edit menu, and the Port 3 configuration screen

appears.

The first option on th e config uration screen allo ws y ou

to choose connection to a second Modbus Master

device or passthrough to port 2. Select the appropriate

configuration with the mouse, or use the Up or Down

Arrow keys to highlight the selection and press the

spacebar.

Modbus Master

If you select Modbus Master, the screen appears as

shown above. Select the Modb us protocol by selecting the Modbus Protocol list box, highlighting either

ASCII or RTU, and pressing Enter. After you have

selected your protocol, press the Tab k ey to highlight

the Modbus ID selection box. The Modbus ID is used

to identify which Modbus Master device the DTU is to

communicate with. Type in the Modbus ID number

and press Enter.

The remaining configuration selections are for the

communications parameters and have the same

choices as those for port 1. Refer to Section 5.3 for

instructions on these fields.

Siemens Energy & Automation, Inc. 33

Page 38

5 Creating Project Files—Modbus Master to Devices

Passthrough to Port 2 (SEAbus)

If you select Passthrough to Port 2 (SEAbus), the

screen appears as shown below.

2-Wire RS422 or RS485 Communications

After you have selected Passthrough to Port 2 (SEAbus), press Tab or select 2-Wire RS422 or RS485 Communications. This box will only need to be checked if

the communications with your SEAbus devices use a

2-wire RS485 or RS422 interface. This is the usual

method of connecting SEAbus devices. When 2-wire

communications are being used, RTS must be looped

back to CTS on the DTU side of the cable. This can be

done on the RS 232 sid e by l oopi ng pins 4 and 5 o r on

the RS422/485 s ide by looping 16 to 18 and 17 to 19.

See Appendix D for wiring diagrams for your particu-

lar PLC, and whether it uses a 2-wire connection.

To select the checkbox, click on it with the mouse or,

with the 2-Wire RS422 or RS485 Communications

selection highlighted, press the spacebar. An “X” will

appear inside the brackets when it is selected.

Press the Tab or Right Arrow key to move to the next

field without selecting this checkbox.

Intermessage Time-Out

The DTU3005 uses the intermessage time-out to

determine when a complete message has been

received on the passthrough port. Once the first character of a message has been received, i f the amo unt of

time specified by the intermessage time-out passes

with no additional characters being received, the

DTU3005 will consider the message to be complete

and process it.

To change the intermessage time -ou t, sele ct Intermes-

sage Time-Out and enter the value in milliseconds,

then press Enter.

Saving Port 3 Configuration Information

Once you have en tered all the co nfiguration information, select Save to save the configuration to the

project file. Then select Ok or press the Esc key to

close the configuration screen.

If you have changed the configuration and have not

saved it to the project file, you will be prompted to

either save or discard the changes.

Select Revert to return to the last previously saved

configuration without saving any changes.

Other Configuration Information

The remaining configuration selections are the same

as those for po rt 1. Refer to Section 5.3 for instructions

on these fields.

34 Siemens Energy & Automation, Inc.

Page 39

5 Creating Project Files—Modbus Master to Devices

5.6 Device List Setup

The device list menu item enables you to indicate

which registers on the PLC will receive data from the

devices. In this menu, you will enter the device type

and address for each Siemens device connected to

port 2. You will also indicate to which registers on the

PLC you want the DTU3005 to write device data.

Select Device List from the Edit menu to display the

device list screen:

This screen is divided into two parts:

• On the left side of the screen is a list of the d evices

connected to port 2 (the list is initially empty). Up

to 32 devices can be attached; however, only 17 of

the devices are visible on the screen at one time.

To see all the devices, click on the scroll bar with

the mouse, or use the Up and Down Arrow and

Page Up and Page Down keys.

• The right side of the screen is used to configure

the data register information for the selected

device, as shown in the example screen on the

next page. You can add or delete devices, or

change device configuration by highlighting the

Device Type on the left side of the screen, then

using the fields and button s on the right s ide of

the screen.

Adding a Device

To add a device to the device list:

1. Highlight the firs t line where the Device Type and

Address fields are blank—this should be the first

available devic e num b e r No field.

2. Press Enter or Tab to add a device. The cursor will

move to the Device Type field on the right side of

the screen. Press Enter, and the Device Types list

displays:

Siemens Energy & Automation, Inc. 35

Page 40

5 Creating Project Files—Modbus Master to Devices

3. Select the device from the list by pressing Enter

or the spacebar. The highlight moves to the

Address field, and the PLC register fields now display as shown in the example screen below.

4. With the Address field highlighted, enter the

device’s address. This number sho uld be bet ween

1 and 254, and match the number programmed

into the device itself. Press the Tab key twice to go

to the Real-Time Data Registers field.

5. Enter the beginnin g regist er number in t he Real-

Time Data Registers field. Refer to Appendix A for

valid register numbers for your PLC application.

The DTU3005 Editor software supplies the last

36 Siemens Energy & Automation, Inc.

register number after you enter the first. In the

example above, the 4700 Power Meter uses 41

registers for its data. When you enter 1 for the firs t

register, the last register becomes 42. If you

Page 41

5 Creating Project Files—Modbus Master to Devices

change the starting register to 10, the last register

will automatically change to 51.

Note: The Modbus Master must read these regis-