Page 1

Chapter 3: Quick References

Preventive Maintenance...........................................................................3-1

Cleaning with a Bleach Solution ......................................................3-1

Lubricating Components ................................................................. 3-1

PM Procedures Reference List.........................................................3-1

Cuvette Manufacturing (Formation) Area............................. 3-1

IMT Area........................................................................... 3-2

Pumps................................................................................3-2

Reagent and Sample Areas .................................................. 3-2

Power and Control System Areas.........................................3-2

Thermal Chamber Area....................................................... 3-3

Waste Area......................................................................... 3-3

Table 3-1. Sensors and Switches Used on the Dimension

Table 3-1a. Sensors and Switches Used on the Dimension

with HM.....................................................................................3-6

Table 3-2. Voltage Destinations for 5 and 15 Volts............................3-7

Table 3-2a. Voltage Destinations for 5 and 15 Volts (RxL with HM).3-10

Table 3-3. Voltage Destinations for 24 Volts....................................3-11

Table 3-3a. Voltage Destinations for 24 Volts (RxL with HM)..........3-14

Table 3-4. Linear and Non-Linear Calibrations ................................3-15

Table 3-5. Verification Summary Sheet...........................................3-16

Table 3-6. LEDs on Motor Control Boards ......................................3-17

Table 3-7. Printer DIP Switch Settings for International Characters...3-18

Table 3-8. Component Differences Between XL and AR..................3-19

Table 3-9. Hot Keys (Keystroke Combinations)...............................3-21

Table 3-10. Cross Reference for Service Spares and OEM Parts........3-22

Table 3-11. Indirect IMT System Parameters...................................3-23

Table 3-12. Indirect IMT Ranges, References, and Coefficients ........3-23

Table 3-13. Indirect IMT Standard Solutions ...................................3-24

Table 3-14. Indirect IMT Rotary Valve Positions.............................3-24

Table 3-15. HM Consumables.........................................................3-24

®

XL...........3-4

®

RxL

Indirect IMT System Quick References..................................................3-23

Backplane Board Configuration......................................................3-25

Indirect IMT System Diagram.........................................................3-26

LEDs and Fuses on Control Boards ................................................3-27

Guidelines for Using IMT System Shutdown Procedure ...................3-28

Dimension® XL/RxL Service Manual December 1998

Page 2

Chapter 3: Quick References

3-2 December 1998 Dimension® XL/RxL Service Manual

Page 3

Chapter 3: Quick References

Preventive Maintenance

There are many procedures that need to be followed or reviewed when performing

Preventive Maintenance checks and replacements. Included are some general

guidelines for cleaning areas of the instrument with a bleach solution, lubricating

tips, and a reference list of PM procedures that are categorized by the instrument

system.

Cleaning with a Bleach Solution

Follow the guidelines below to create the proper concentration of bleach solution for

cleaning.

• Obtain a convenient quantity of bleach solution (available in one-gallon or about

3.3-liter volume).

• Note the concentration of the active ingredient, sodium hypochlorite (NaOCl) as

provided on the label. Normally the concentration of commercially available

bleach solution is 5.25%.

• Dilute the bleach solution to obtain a final active ingredient concentration of about

1.0%. To dilute the solution, make a five-fold dilution using 1.0 part original

bleach solution and 4.0 parts distilled or deionized water.

Note: Sometimes the 1.0% has been referred to as 20%. This is based on the

premise that the original bleach solution is 100% and a five-fold dilution of it

results in a 20% concentration.

Lubricating Components

Note: Lubricate with Tufoil¨ Compu-Lube or equivalent unless otherwise specified

in the PM Checklist.

PM Procedures Reference List

Cuvette Manufacturing (Formation) Area

Procedure Title Location

• Adjusting the Cuvette Manufacturing Solenoids XL Service, Chapter 5

• Aligning the Film Guides and Checking Tracking XL Service, Chapter 5

• Adjusting the Cuvette Air Pressure Regulator XL Service, Chapter 5

Dimension® XL/RxL Service Manual December 1998 3-1

Page 4

Chapter 3: Quick References

IMT Area

Procedure Title Location

• Replacing TCO2 Probe O-Ring and Gasket AR Reference, 6-1.1

• Replacing IMT Miscellaneous Tubing XL Service, Chapter 6

• Aligning the IMT Probe XL Service, Chapter 6

• Cleaning IMT Port XL Service, Chapter 6

Pumps

Procedure Title Location

• Replacing the Monopump Rotary Valve Seal XL Operator’s Guide

• Replacing Monopump Piston Lip Seal XL Service, Chapter 6

• Adjusting Dual Pump Home Switch AR Service 3-19

• Replacing Tubing (also see Water Tubing Diagram) AR Routine

• Replacing Syringe Tips XL Operator’s Guide

Module 3

Maintenance Guide

Sections 3 and 4

Module 3

Reagent and Sample Areas

Procedure Title Location

• Aligning Reagent Tray XL Service, Chapter 9

• Aligning the Sample Probe XL Service, Chapter 10

• Cleaning the Sample Drain XL Service, Chapter 10

• Replacing the Sample Tubing XL Operator’s Guide

Module 3

Power and Control System Areas

Procedure Title Location

• Checking the UPS Functionality XL Service, Chapter 8

• Cleaning the Thermal Print Head and Platen XL Service, Chapter 4

• Performing Printer Diagnostics XL Service, Chapter 4

• Performing Photometer Calibrations and Alignments XL Service, Chapter 7

• Restoring Backup to Disk XL Service, Chapter 4

3-2 December 1998 Dimension® XL/RxL Service Manual

Page 5

Chapter 3: Quick References

Thermal Chamber Area

Procedure Title Location

• Thermometer Calibration XL Service, Chapter 11

• Calibrating Temperature Monitor Screen XL Service, Chapter 11

Waste Area

Procedure Title Location

• Schematic Diagram XL Service, Chapter 14

Dimension® XL Service Manual December 1998 3-3

Page 6

Chapter 3: Quick References

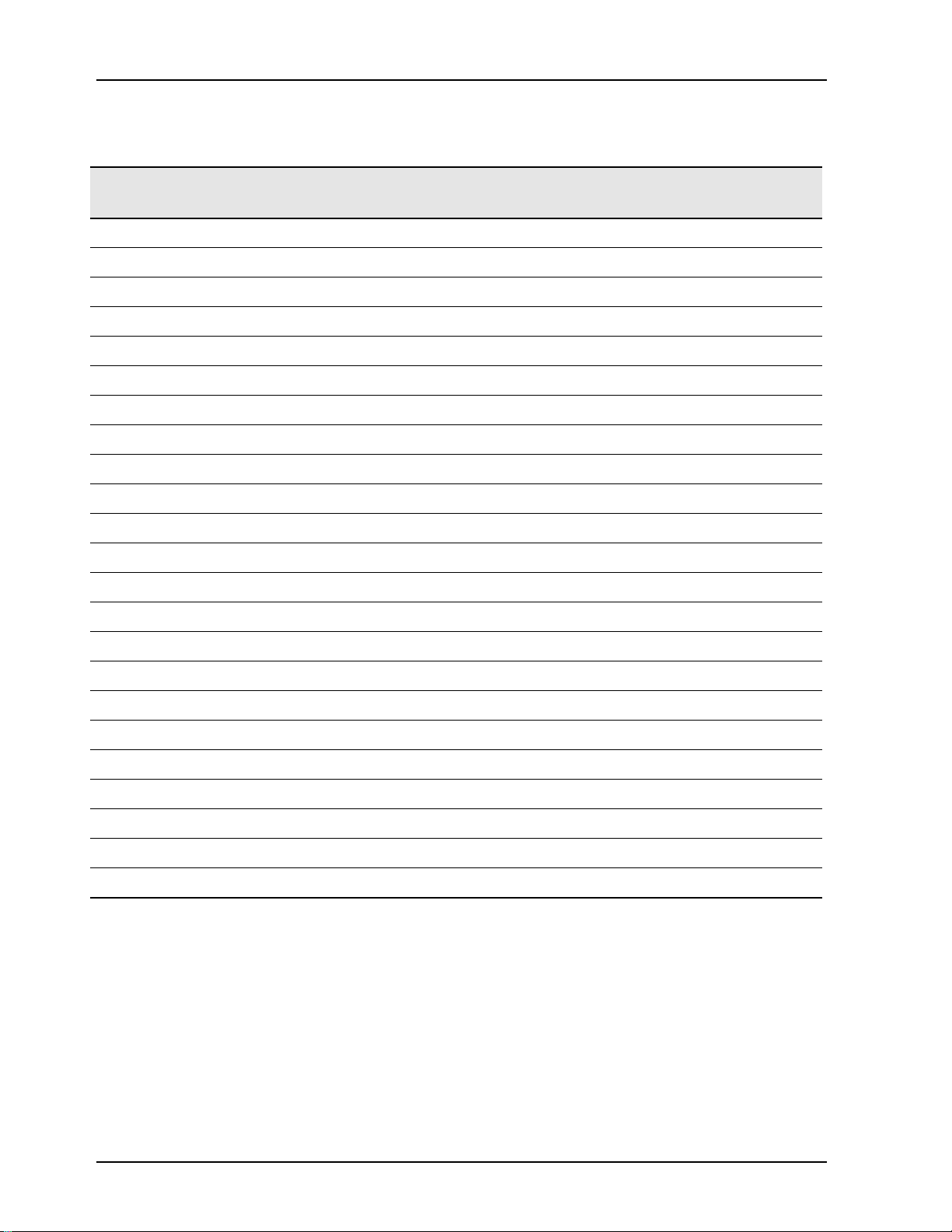

Table 3-1. Sensors and Switches Used on the Dimension¨ XL

SPL

Part Number Part Description Plug No. Controlled By

729597.901 Aliquot Lid Closed Sensor PJ31L MCB 1

729597.901 IMT Sampler Vertical Home Sensor PJ50E MCB 3

729597.901 IMT Sampler Rotational Home Sensor PJ50D MCB 3

729597.901 Photometric Sampler Vertical Home Sensor PJ50E MCB 3

729597.901 Photometric Sampler Rotational Home Sensor PJ50D MCB 3

285001.003 Autoflex Loader Home Sensor PJ22B MCB 2

285001.003 IMT Probe Hidden Sensor PJ58A MCB 3

285001.003 Photometer Arm Home Sensor PJ13D Photometer Board

285001.003 Sample Carousel Home Sensor PJ32C MCB 1

285001.003 R2 Arm Vertical Home Sensor PJ80B MCB 2

285001.003 R2 Arm Radial Home Sensor PJ80D MCB 2

285001.003 R2 Arm Angular Home Sensor PJ32D MCB 2

285001.003 R1 Arm Vertical Home Sensor PJ20D MCB 2

285001.003 R1 Arm Radial Home Sensor PJ20C MCB 2

716761.902 R1 Pump Flush Syringe Home Switch PJ16C MCB 1

716761.902 R2 Pump Flush Syringe Home Switch PJ16C MCB 1

716761.902 R1 Pump Meter Syringe Home Switch PJ16D MCB 1

716761.902 R2 Pump Meter Syringe Home Switch PJ16D MCB 1

716761.902 Sample Pump Flush Syringe Home Switch PJ15B MCB 1

716761.902 Sample Pump Meter Syringe Home Switch PJ15C MCB 1

716486.503 U-Seal Position Switch PJ13S Cuvette Board

716736.903 Cuvette Pressure Switch PJ30B Cuvette Board

716737.503 Cuvette Ring Position Sensor PJ32B Cuvette Board

MCB = Motor Control Board (continued)

3-4 December 1998 Dimension® XL/RxL Service Manual

Page 7

Chapter 3: Quick References

Table 3-1. Sensors and Switches Used on the Dimension¨ XL (continued)

SPL

Part Number Part Description Plug No. Controlled By

716761.902 Dual Pump Switch PJ15B, PJ15C

PJ16B, PJ16D

716841.902 Filter Wheel Dual Sensor PJ34B Photometer Board

256254.001 Vacuum Switch PJ30C Auxiliary Board

734932.501 Flex Tray Sensor Assembly PJ50H MCB 2

734933.901 Reagent Lid Interlock Sensor (Not an SPL part) PJ30D Auxiliary Board

740049.901 Monopump Valve Position Sensor PJ84 Printer Sequencer Bd

285001.004 Monopump Piston Home Sensor PJ83 Printer Sequencer Bd

750164.501 Aliquot Wheel Home Sensor (Reflective) PJ31F MCB 1

750930.902 Flex Presence Sensor PJ22C Auxiliary Board

270779.001 Sample Lid Interlock Sensor (Not an SPL part) PJ10 Fuse B Board

MCB = Motor Control Board

MCB 1

Dimension® XL Service Manual December 1998 3-5

Page 8

Chapter 3: Quick References

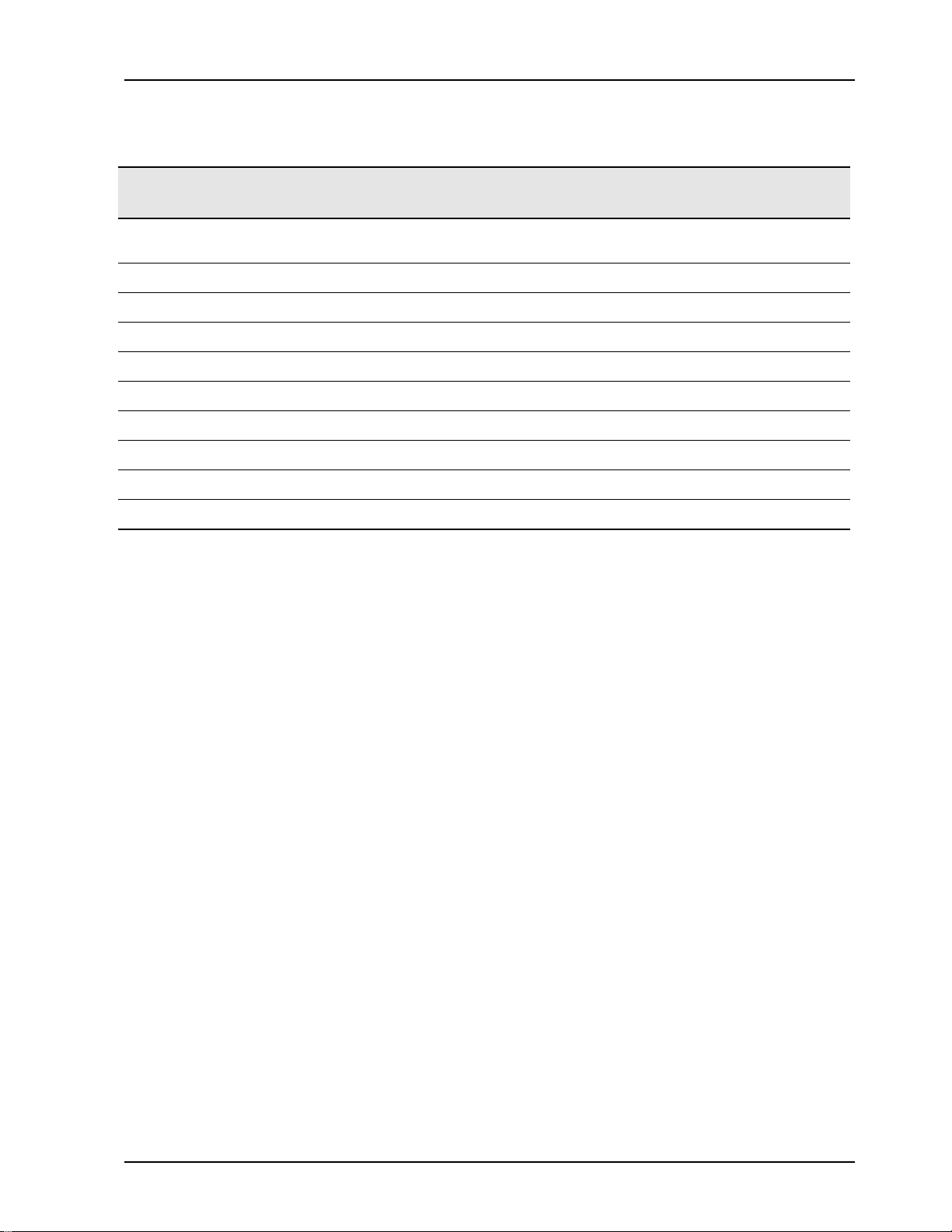

Table 3-1a. Sensors and Switches Used on the Dimension¨ RxL with HM

SPL

Part Number Part Description Plug No. Controlled By

285001.003 Wash Wheel Sensor PJ42B Motor Control PCB Slot 10

285001.003 Incubate Wheel Sensor PJ41B Motor Control PCB Slot 10

730145.901 Mix Position Sensor PCB PJ44B Cuvette PCB Slot 9

285001.003 Wash Probe Home Sensor PJ45B Motor Control PCB Slot 10

730515.901 Sample Drain Cleaner Bottle Sensor PJ46G Motor Control PCB Slot 10

730527.901 Probe Cleaner Bottle Sensor PJ46E Motor Control PCB Slot 10

730520.501 Wash Buffer Bottle Sensor PJ46D Motor Control PCB Slot 10

750930.902 Vessel Track Empty Sensor J46C Cuvette PCB Slot 9

716761.902 Wash Pump Home Switch PJ83 Motor Control PCB Slot 10

285001.003 Vessel Shuttle Sensor PJ48H, F, G Motor Control PCB Slot 10

285001.003 Vessel Transfer Home Sensor PJ48E Motor Control PCB Slot 10

730572.901 Vessel Gate Switch PJ48C Motor Control PCB Slot 10

NA Spare Sensor PJ46A Cuvette PCB Slot 9

730320.501 Wash Probe Vac. Sensor 1, 2 NC,

1, 2 Com

Cuvette PCB Slot 9

3-6 December 1998 Dimension® XL/RxL Service Manual

Page 9

Chapter 3: Quick References

Table 3-2. Voltage Destinations for 5 and 15 Volts

Voltage Pin No. From To

+5 B24 Auxiliary Board AC Power Waste Pump Assy

+5 B5 Auxiliary Board Sample Barcode Scanner (inside) 6P2

+5 B12 Auxiliary Board Sample Barcode Scanner (outside) 6P2

+5 B17 Auxiliary Board Autoflex Loader Flex Presence Sensor 6P2

+5 B8 Auxiliary Board Flex Barcode Assy 6P1

LED +5 B28 Auxiliary Board ÒOKÓ Add Flex Indicator 6P2

LED +5 A32 Auxiliary Board Vacuum LED

LED +5 B8 Auxiliary Board ÒOKÓ Add Sample Indicator 6P2

+5 A31 Auxiliary Board AC Distribution Board

+5 B24 Auxiliary Board Waste Pump

+5 B27 Cuvette Board Pressure LED

+5 C11 Cuvette Board Cuvette Ring Position Sensor

+5 B20 Cuvette Board Cuvette Ring Position Sensor

+5 B5 Motor Control Board 1 R1 Pump Flush Syringe Home Sensor 3P2

+5 B12 Motor Control Board 1 R1 Pump Meter Syringe Home Sensor 3P2

+5 B20 Motor Control Board 1 R2 Pump Flush Syringe Home Sensor 3P1

+5 B27 Motor Control Board 1 R2 Pump Meter Syringe Home Sensor 3P1

+5 B8 Motor Control Board 1 Sample Pump Flush Syringe Home Sensor 3P1

+5 B15 Motor Control Board 1 Sample Pump Meter Syringe Home Sensor 3P1

+5 B17 Motor Control Board 1 Sample Carousel Home Sensor 3P2

+5 C28 Motor Control Board 1 Sample Carousel Encoder Assy 3P2

LED +5 A15 Motor Control Board 1 Aliquot Wheel

+5 B24 Motor Control Board 1 Aliquot Reflective Home Sensor

+5 C29 Motor Control Board 1 Aliquot Wheel Encoder Assy 3P2

+5 C27 Motor Control Board 1 Aliquot Lid Closed Sensor 3P2

(continued)

Dimension® XL Service Manual December 1998 3-7

Page 10

Chapter 3: Quick References

Table 3-2. Voltage Destinations for 5 and 15 Volts (continued)

Voltage Pin No. From To

+5 B5 Motor Control Board 2 R2 Arm Vertical Home Sensor 4P2

+5 B12 Motor Control Board 2 R2 Arm Radial Home Sensor 4P2

+5 C28 Motor Control Board 2 R2 Arm Angular Encoder 4P2

+5 B17 Motor Control Board 2 R2 Arm Angular Home Sensor 4P2

+5 B27 Motor Control Board 2 R1 Arm Radial Home Sensor 4P1

+5 B20 Motor Control Board 2 R1 Arm Vertical Home Sensor 4P1

+5 B15 Motor Control Board 2 Autoflex Loader Home Sensor 4P1

+5 B8 Motor Control Board 2 Flex Tray Home Sensor 4P1

+5 C29 Motor Control Board 2 Flex Tray Encoder 4P2

+5 B8 Motor Control Board 3 Photometric Sample Handler Rotational Home

+5 B15 Motor Control Board 3 Photometric Sample Handler Vertical Home Sensor

+5 C28 Motor Control Board 3 Photometric Sample Handler Rotational Encoder

+5 B5 Motor Control Board 3 IMT Rotational Home Sensor 5P2

+5 B12 Motor Control Board 3 IMT Penetration Home Sensor 5P2

+5 C29 Motor Control Board 3 IMT Rotational Encoder Assy 5P2

+5 C8 Motor Control Board 3 IMT Needle Hidden Sensor 5P2

LED +5 A9 Photometer Board Filter Wheel Dual Sensor 1P1

LED +5 V10 Photometer Board Filter Wheel Dual Sensor 1P1

+5 B11 Photometer Board Filter Wheel Dual Sensor (Wht)

+5 B17 Photometer Board Photometer Arm Motor Encoder 1P2

+5 B24 Photometer Board Photometer Arm Home Sensor 1P2

+5 1 Power Supply Backplane Board

+5 E4 Power Supply Backplane Board

Sensor 5P1

5P1

Assy 5P2

+5 E8 Power Supply Backplane Board

(continued)

3-8 December 1998 Dimension® XL/RxL Service Manual

Page 11

Table 3-2. Voltage Destinations for 5 and 15 Volts (continued)

Voltage Pin No. From To

Chapter 3: Quick References

+5 1 Printer/Monopump

+5 PJ54A

7

+5 2 Motor Control Board 3 Monopump Valve Position and Home Sensor 5P2

+5 3 Motor Control Board 3 Monopump Valve Position and Home Sensor 5P2

+5 1 Motor Control Board 3 Monopump Valve Position and Home Sensor 5P2

+15 A1 Auxiliary Board IMT Sensor Board

-15 A3 Auxiliary Board IMT Sensor Board

+15 2 Fuse Board B Sample Lid Switch Part 2

+15 3 Fuse Board B Key Switch Part 2

+15 4 Fuse Board B Key Switch Part 2

+15 C20 Photometer Board Photodiode Assy 1P1

-15 C22 Photometer Board Photodiode Assy 1P1

+15 E2 Power Supply Backplane Board

+15 E5 Power Supply Backplane Board

-15 E6 Power Supply Backplane Board

Interface Board

Printer/Monopump

Interface Board

System Printer Assy

Monopump Home Sensor 5P2

Dimension® XL Service Manual December 1998 3-9

Page 12

Chapter 3: Quick References

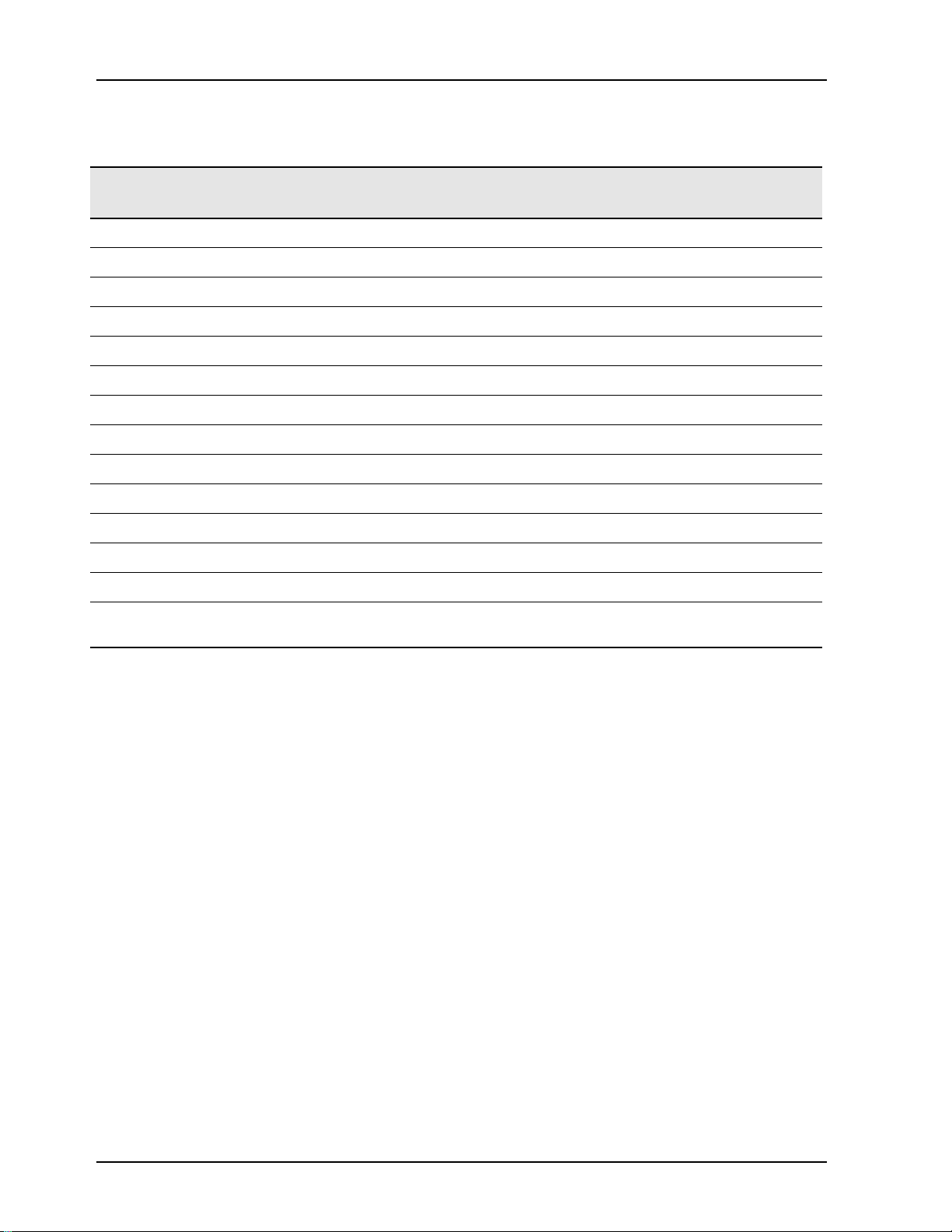

Table 3-2a. Voltage Destinations for 5 and 15 Volts (RxL with HM)

Voltage Pin No. From To

+5 C28 Motor Control PCB Slot 10 Incubate Wheel Encoder (10p2)

+5 C29 Motor Control PCB Slot 10 Wash Wheel Encoder (10p2)

+5 B5 Motor Control PCB Slot 10 Wash and Incubate Wheel Sensor (10p2)

+5 A31 Cuvette PCB Slot 9 Mixer Position Sensor PCB (9p1)

+5 C11 Motor Control PCB Slot 10 Spare Sensor (10p2)

+5 B12 Motor Control PCB Slot 10 Wash Probe Home Sensor (10p2)

+5 B20 Motor Control PCB Slot 10 Wash Pump Home Sensor (10p1)

+5 B20 Cuvette PCB Slot 9 Vessel Track Sensor (9p1)

+5 B27 Cuvette PCB Slot 9 Spare Sensor (9p1)

+5 A25 Cuvette PCB Slot 9 Spare Sensor (9p1)

+5 C15 Motor Control PCB Slot 10 Vessel Gate Switch (no connection) (10p2)

+5 C18 Motor Control PCB Slot 10 Vessel Shuttle PCB AssyÑVessel Shuttle

+5 B15 Cuvette PCB Slot 9 Vessel Transfer Home Sensor (10p1)

+5 B8 Cuvette PCB Slot 9 Vessel Transfer Encoder (9p1)

+5 B15 Motor Control PCB Slot 10 Photometric Sample Handler V. Encoder (5p2)

Sensor (10p1)

3-10 December 1998 Dimension® XL/RxL Service Manual

Page 13

Chapter 3: Quick References

Table 3-3. Voltage Destinations for 24 Volts

Voltage/Fuse Pin No. From To

+24 2, 5, 8 Photometer Board Printer Sequencer/Monopump Interface Board

+24 GND 3, 6, 9 Photometer Board Printer Sequencer/Monopump Interface Board

+24 Ò6BÓ A24 Auxiliary Board Autoflex Loader Solenoid 6P1

+24 A12 Auxiliary Board Sample Wash Valve 6P1

+24 B12 Auxiliary Board Sample Pump Valve 6P1

+24 C12 Auxiliary Board R2 Pump Valve 6P1

+24 C24 Auxiliary Board R1 Pump Valve 6P1

+24 A16 Auxiliary Board 24V Power Module

+24 A26 (6P1) Auxiliary Board Instrument Alarm 6P1

+24 B24 Auxiliary Board Water/Waste Overflow

+24 3, 4 Auxiliary Board Water Bottle Switch Assy (non-plumbed)

+24 A7 Auxiliary Board SSE Salt Solenoid

+24 B10 Auxiliary Board SSM Salt Solenoid

+24 C8 Auxiliary Board SSM Waste Solenoid

+24 A20 Auxiliary Board TCO2 Release Solenoid

+24 C14 Auxiliary Board Vacuum Solenoid

+24 C15 Auxiliary Board Solenoid Pump

+24 A17 Auxiliary Board Standard A Solenoid

+24 A11 Auxiliary Board Standard B Solenoid

+24 A21 Auxiliary Board Sample Pinch Solenoid

+24 C29 Auxiliary Board Air Solenoid

+24 J9 Backplane Board Photometer Source Lamp P72B

+24 Ò2CÓ A4 Cuvette Board Cuvette Heat Torch PCB

+24 Ò2CÓ A5 Cuvette Board Cuvette Heat Torch PCB

+24 Ò2BÓ A6 Cuvette Board Cuvette Formation Solenoid

+24 Ò2BÓ A7 Cuvette Board Cuvette Fan

+24 Ò2DÓ A15 Cuvette Board Cuvette Top Seal Heater

+24 Ò2DÓ A16 Cuvette Board Cuvette Top Seal Heater

+24 Ò2DÓ A27 Cuvette Board Cuvette Top Seal Solenoid

(continued)

Dimension® XL Service Manual December 1998 3-11

Page 14

Chapter 3: Quick References

Table 3-3. Voltage Destinations for 24 Volts (continued)

Voltage/Fuse Pin No. From To

+24 Ò2DÓ B15 Cuvette Board Cuvette U-Seal Solenoid

+24 Ò2CÓ B16 Cuvette Board Cuvette Area Interlock Switch P13S

+24 Ò2CÓ C16 Cuvette Board Cuvette Area Interlock Switch P13S

+24 Ò2CÓ C19 Cuvette Board Cuvette Ring Index Motor (B Phase)

+24 Ò2CÓ C26 Cuvette Board Cuvette Ring Index Motor (A Phase)

+24 Ò2CÓ A11 Cuvette Board Thermal Chamber Heater

+24 Ò2CÓ A12 Cuvette Board Thermal Chamber Heater

+24 Ò2CÓ A13 Cuvette Board Thermal Chamber Heater

+24 Ò2DÓ A23 Cuvette Board Thermal Chamber Heater

+24 Ò2DÓ A24 Cuvette Board Thermal Chamber Heater

+24 Ò2DÓ A25 Cuvette Board Thermal Chamber Heater

+24 Ò3CÓ A5 Motor Control Board 1 R1 Pump Flush Syringe Motor 3P2

+24 Ò3CÓ A6 Motor Control Board 1 R1 Pump Flush Syringe Motor 3P2

+24 Ò3CÓ A12 Motor Control Board 1 R1 Pump Meter Syringe Motor 3P2

+24 Ò3CÓ A13 Motor Control Board 1 R1 Pump Meter Syringe Motor 3P2

+24 Ò3BÓ A20 Motor Control Board 1 R2 Pump Flush Syringe Motor 3P1

+24 Ò3BÓ A21 Motor Control Board 1 R2 Pump Flush Syringe Motor 3P1

+24 Ò3BÓ A27 Motor Control Board 1 R2 Pump Meter Syringe Motor 3P1

+24 Ò3BÓ A28 Motor Control Board 1 R2 Pump Meter Syringe Motor 3P1

+24 Ò3AÓ A8 Motor Control Board 1 Sample Pump Flush Syringe Motor 3P1

+24 Ò3AÓ A9 Motor Control Board 1 Sample Pump Flush Syringe Motor 3P1

+24 Ò3AÓ A15 Motor Control Board 1 Sample Pump Meter Syringe Motor 3P1

+24 Ò3AÓ A16 Motor Control Board 1 Sample Pump Meter Syringe Motor 3P1

+24 Ò3DÓ A17 Motor Control Board 1 Sample Carousel Motor 3P2

+24 Ò3DÓ A18 Motor Control Board 1 Sample Carousel Motor 3P2

+24 Ò3DÓ A24 Motor Control Board 1 Aliquot Wheel Motor 3P2

+24 Ò3DÓ A25 Motor Control Board 1 Aliquot Wheel Motor 3P2

+24 Ò4CÓ A5 Motor Control Board 2 R2 Arm Vertical Motor 4P2

+24 Ò4CÓ A6 Motor Control Board 2 R2 Arm Vertical Motor 4P2

(continued)

3-12 December 1998 Dimension® XL/RxL Service Manual

Page 15

Chapter 3: Quick References

Table 3-3. Voltage Destinations for 24 Volts (continued)

Voltage/Fuse Pin No. From To

+24 Ò4CÓ A12 Motor Control Board 2 R2 Arm Radial Motor 4P2

+24 Ò4CÓ A13 Motor Control Board 2 R2 Arm Radial Motor 4P2

+24 Ò4DÓ A17 Motor Control Board 2 R2 Arm Angular Motor 4P2

+24 Ò4DÓ A18 Motor Control Board 2 R2 Arm Angular Motor 4P2

+24 Ò4BÓ A20 Motor Control Board 2 R1 Arm Vertical Motor 4P1

+24 Ò4BÓ A21 Motor Control Board 2 R1 Arm Vertical Motor 4P1

+24 Ò4BÓ A27 Motor Control Board 2 R1 Arm Radial Motor 4P1

+24 Ò4BÓ A28 Motor Control Board 2 R1 Arm Radial Motor 4P1

+24 Ò4AÓ A15 Motor Control Board 2 AutoFlex Loader Motor 4P1

+24 Ò4AÓ A16 Motor Control Board 2 AutoFlex Loader Motor 4P1

+24 Ò4AÓ A8 Motor Control Board 2 Flex Tray Wheel Motor 4P1

+24 Ò4AÓ A9 Motor Control Board 2 Flex Tray Wheel Motor 4P1

+24 Ò5AÓ A8 Motor Control Board 3 Photometric Sampler Rotational Motor

+24 Ò5AÓ A9 Motor Control Board 3 Photometric Sampler Rotational Motor

+24 Ò5AÓ A15 Motor Control Board 3 Photometric Sampler Vertical Motor 5P1

+24 Ò5AÓ A16 Motor Control Board 3 Photometric Sampler Vertical Motor 5P1

+24 Ò5DÓ A17 Motor Control Board 3 Monopump Valve Motor 5P2

+24 Ò5DÓ A18 Motor Control Board 3 Monopump Valve Motor 5P2

+24 Ò5DÓ A24 Motor Control Board 3 Monopump Piston Motor 5P2

+24 Ò5DÓ A25 Motor Control Board 3 Monopump Piston Motor 5P2

+24 Ò5CÓ A5 Motor Control Board 3 IMT Rotational Motor 5P2

+24 Ò5CÓ A6 Motor Control Board 3 IMT Rotational Motor 5P2

+24 Ò5CÓ A12 Motor Control Board 3 IMT Penetration Motor 5P2

+24 Ò5CÓ A13 Motor Control Board 3 IMT Penetration Motor 5P2

+24 Ò5DÓ A20 Motor Control Board 3 SSE 1 Peristaltic Pump Motor 5P1

+24 Ò5DÓ A21 Motor Control Board 3 SSE 1 Peristaltic Pump Motor 5P1

+24 Ò1AÓ A5 Photometer Board Photometric Arm Motor 1P2

+24 Ò1AÓ A6 Photometer Board Photometric Arm Motor 1P2

+24 E3 Power Supply Backplane Board

+24 E9 Power Supply Backplane Board

Dimension® XL Service Manual December 1998 3-13

Page 16

Chapter 3: Quick References

Table 3-3a. Voltage Destinations for 24 Volts (RxL with HM)

Voltage/Fuse Pin No. From To

24C A6 Motor Control PCB Slot 10 Wash Wheel Motor (Phase B)

24C A5 Motor Control PCB Slot 10 Wash Wheel Motor (Phase A)

24A A8 Motor Control PCB Slot 10 Incubate Wheel Motor (Phase A)

24A A9 Motor Control PCB Slot 10 Incubate Wheel Motor (Phase B)

24C A11 Cuvette PCB Slot 9 Incubate Heater

24D A25 Cuvette PCB Slot 9 Vessel Mix Motor 1

24D A16 Cuvette PCB Slot 9 Vessel Mix Motor 2

24D A21 Cuvette PCB Slot 9 Vessel Aspirate Pump 1 & 2

24C A12 Motor Control PCB Slot 10 Wash Probe Motor (Phase A)

24C A13 Motor Control PCB Slot 10 Wash Probe Motor (Phase B)

24B A20 Motor Control PCB Slot 10 Wash Pump Motor (Phase A)

24B A21 Motor Control PCB Slot 10 Wash Pump Motor (Phase B)

24D A23 Cuvette PCB Slot 9 Wash Pump Valve 1

24D A24 Cuvette PCB Slot 9 Wash Pump Valve 2

24D C21 Cuvette PCB Slot 9 Probe Cleaner Pump

24D B21 Cuvette PCB Slot 9 Sample Drain Cleaner Pump

24D B15 Cuvette PCB Slot 9 Vessel Feed Motor

24B C23 Cuvette PCB Slot 9 Spare Drive

24A A15 Motor Control PCB Slot 10 Vessel Transfer Motor (Phase B)

24A A16 Motor Control PCB Slot 10 Vessel Transfer Motor (Phase A)

24D A15 Cuvette PCB Slot 9 Vessel Shuttle Solenoid

24D A27 Cuvette PCB Slot 9 Vessel Gate Solenoid

24B A7 Cuvette PCB Slot 9 Vessel Friction Drive Motor

3-14 December 1998 Dimension® XL/RxL Service Manual

Page 17

Table 3-4. Linear and Non-Linear Calibrations

Procedure Perform these steps:

Preparation 1. Perform system check within last 24 hours.

Chapter 3: Quick References

Choose Methods/Lots 2. Choose methods and lot numbers to be calibrated. Calibrate methods

Prepare Calibrators 3. Follow insert sheet instructions for calibrator preparation and use.

Set Up Calibration(s) 4. Using the Calibration Set-Up screen, request calibration for those methods

Request QC 5. Request QC to be run along with the calibrators by pressing the

Assign Cups/Load

Samples

Process Calibrators/QC 7. Press the PROCESS ALL key. When calibration is completed, the

Evaluation 8. Evaluate the precision and accuracy of the replicate values. Determine

together that use same calibrator:

For Linear, CHEM 1 = BUN, CA, CREA, GLU, TP, URCA

For Non-Linear, DRUG CALIBRATOR = DIG, PHNO, PTN, THEO

and lot numbers identified in Step 2 by specifying the calibrator to be used

and filling in the bottle values.

QC yes/no function key.

6. Press the function key to assign cup positions for the calibrator and QC.

Press the LOAD/RUN function key and then load the calibrators and QC

samples in the appropriate cup positions.

instrument will provide a printout with calibrator results, statistics, and QC

results

.

whether the slope and intercept are acceptable

For Linear Calibration: Slope specification = 0.097Ð1.03 and

intercept guideline = 0 or clinically insignificant. Determine if QC is within

range.

For Non-Linear Calibration: Slope specification = 0.95Ð1.05 and

intercept guideline = 0 or clinically insignificant. Determine If QC is within

range

.

If slope/intercept/QC =

OK

If slope/intercept/QC =

not OK

9. Press the ACCEPT DATA function key.

Press the CALCULATE function key; evaluate the new data and QC

and, if OK, press the ACCEPT DATA function key.

Dimension® XL Service Manual December 1998 3-15

Page 18

Chapter 3: Quick References

Table 3-5. Verification Summary Sheet

Procedure Perform these steps:

Preparation 1. Perform system check within last 24 hours.

Choose Methods/Lots 2. Choose methods and lot numbers to be calibrated. (verified??) Try to

Prepare Verifiers 3. Follow insert sheet instructions for verifier preparation and use.

Set Up Verification(s) 4. Using the Calibration Set-Up screen, request verification for those

Request QC 5. Request QC to be run along with the verifiers by pressing the QC

Assign Cups/Load Samples 6. Press the function key to assign cup positions for the calibrator

Process Verifiers/QC 7. Press the PROCESS ALL key. When verification is completed, the

Evaluation 8. Evaluate the precision and accuracy of the replicate values.

If slope/intercept/QC = OK

If slope/intercept/QC = not OK

For Lipase and CK-MB Only:

If Lipase slope /intercept/QC =

not OK

verify methods together that use the same verifier: for example,

ENZYME VERIFIER = ALP,AMY,GGT,GOT,GPT,LDH

methods and lot numbers identified in Step 2 by specifying the verifier

to be used and filling in the bottle values.

yes/no function key.

(verifier??) and QC. Press the LOAD/RUN function key and then

load the calibrators and QC samples in the appropriate cup positions.

instrument will provide a printout with verifier results, statistics, and

QC results

Determine whether the slope and intercept are acceptable

Slope specification = 0.90Ð1.10 (lipase = 0.85Ð1.05) and intercept

guideline = 0 or clinically insignificant. Determine if QC is within range.

.

.

9. Press the ACCEPT DATA function key.

Perform normal chemistry troubleshooting (for example, check for

clerical errors, proper preparation of verifiers and QC, etc.).

Press the CALCULATE function key; evaluate the new data and QC

and, if OK, press the ACCEPT DATA function key.

If CK-MB slope/intercept/QC =

not OK

Press the CALCULATE function key IF the data at Level 1 verifier

IS NOT between -3 to +3; evaluate the new data and QC, if it is now

between -3 to +3, press the ACCEPT DATA function key.

3-16 December 1998 Dimension® XL/RxL Service Manual

Page 19

Chapter 3: Quick References

Table 3-6. LEDs on Motor Control Boards

LED Motor Control Board 1 Motor Control Board 2 Motor Control Board 3

CR2A Sample Flush Pump Home Flex Wheel Home Sampler Angular Home

CR2B N/C N/C N/C

CR2C Sample Meter Pump Home Flex Auto Load Home Sampler Vertical Home

CR2D N/C N/C N/C

CR3A R2 Flush Pump Home R1 Vertical Home N/C

CR3B N/C N/C N/C

CR3C R2 Meter Pump Home R1 Radial Home IMT Valve Home

CR3D N/C N/C IMT Valve Position

CR5A R1 Flush Pump Home R2 Vertical Home IMT Angular Home

CR5B N/C N/C IMT Needle Guard Home

CR5C R1 Meter Pump Home R2 Radial Home IMT Vertical Home

CR5D N/C N/C Level Sense

CR6A Sample Wheel Home R2 Angular Home Monopump Piston Home

CR6B N/C N/C N/C

CR6C Aliquot Wheel Home N/C Monopump Valve Home

CR6D Aliquot Lid Closed N/C Monopump Valve Position

Dimension® XL Service Manual December 1998 3-17

Page 20

Chapter 3: Quick References

Table 3-7. Printer DIP Switch Settings for International Characters

International

Characters DIP Switch Settings for SW1

4 3 2 1

U. S. ON ON ON ON

France ON ON ON OFF

Germany ON ON OFF ON

Spain 1 ON OFF OFF OFF

Italy ON OFF OFF ON

* XXXX

Japan

* X=Switch 1 (SW1) positions 1Ð4 can be ON or OFF.

Switch 2 (SW 2) position 6 must be OFF for Japan.

Note: Dip Switches are located on the top of the printer, underneath

the top cover.

3-18 December 1998 Dimension® XL/RxL Service Manual

Page 21

Chapter 3: Quick References

Table 3-8. Component Differences Between the XL and AR Instruments

System Component

Control System ¥ ComputerÑoff-the-shelf, OEM computer

¥ Control Boards:

Ð Backplane board

Ð Fuse boards A and B distribute DC power to instrument

Ð Photometer board

Ð Cuvette/Thermal board

Ð Motor Control boards (3)

Ð Auxiliary board

Ð Ultrasonics board

¥ Printer/Monopump sequencer board

¥ Cardcage fan/filter

¥ Software

¥ KeyboardÑcustomized OEM keyboard with enhanced functionality

¥ MonitorÑoff-the-shelf, OEM monitor

¥ PrinterÑSeiko Model DPU 5000

Power System ¥ Uninterruptable Power Supply (UPS)Ñoff-the-shelf, OEM part

¥ AC Power Selection Board

¥ Service Key Switch

¥ AC Distribution Board

¥ Circuit breaker

¥ 24-volt power supply

¥ Transformer

Cuvette Manufacturing System

¥ Cuvette Arm

¥ Solenoid Formation Arm

¥ U-Seal Solenoid bracket

(continued)

Dimension® XL Service Manual December 1998 3-19

Page 22

Chapter 3: Quick References

Table 3-8. Component Differences Between the XL and AR Instruments (continued)

System Component

IMT System

Measuring System

Reagent System

Sample System

Thermal System

Accessory Kit (See Accessory Kit List provided)

¥ Monopump

¥ SSE/SSM Board

¥ Standard C

¥ IMT Sample Handler

¥ Solenoid Valves

¥ IMT Drain

¥ IMT Port

¥ IMT Standard Bottle Lance

¥ IMT Probe

¥ IMT Tubing (Standard, Pump, Sample, and Miscellaneous)

¥ Manifold Assembly

¥ IMT Sample Handler Rotational Sensors

¥ Magnetic Separation System (DGNA)

¥ Photodiode Assembly

¥ Photometer

¥ 340 Filter

¥ Bar Code Reader

¥ R1 Arm

¥ R2 Arm

¥ R1 Tubing

¥ Reagent Ultrasonics

¥ Flexª Automatic Loader System

¥ Aliquot Wheel Assembly

¥ Photometric Sample Handler

¥ Segmented Sample Wheels

¥ Sample Carousel

¥ Bar Code Readers (Inner and Outer)

¥ Sample Ultrasonics

¥ Sample Lid Switch

¥ Sample Handler Rotational Sensors

¥ Sample Tubing

¥ Non-CFC Refrigeration System

¥ Thermal Chamber

¥ Thermal Chamber Heating Element

¥ Thermal Chamber Monitoring Thermocouple

¥ Cuvette Ring Thermistor

3-20 December 1998 Dimension® XL/RxL Service Manual

Page 23

Chapter 3: Quick References

Table 3-9. Hot Keys (Keystroke Combinations)

Key Combination Function

Alt/F Displays an explanation and troubleshooting information for the error

message that is on the screen.

Alt/I Takes you directly to Review Reagent Cartridge inventory.

Alt/L Displays Short Sample screen.

Alt/M Displays explanations for active error messages.

Alt/N Takes you directly to the System Needs screen.

Alt/O

(not the number zero)

Alt/P Prints out the entire screen appearing on the display. This printout cannot

Alt/R Whenever the reagent manager icon appears in the Operating Conditions

Alt/S Takes you directly to the Sample Status screen from which you can see

Control/Stop Stops all operations in progress in a manner that will not damage the

Control/Help Displays help information for each field and icons on the Main Operating

Shift/Exit Returns you directly to the Operating menu.

Advances the paper feed on the system printer.

be sent to an external printer.

Note: You will not be able to move to any other screen when using

Control/P to print; however, printing only takes about 30 seconds.

Status area of the screen, press Alt/R to see the information on why this

icon appeared.

the status of either the segment positions currently loaded on the

instrument (On Board Segments view) or all segments (All Segments

view).

instrument. All tests in progress will be aborted. However, all scheduled

tests will be retained in instrument memory. To resume operations, press

the Reset key.

Menu.

Shift/Delete Deletes all characters in a field.

Help Gives you help on the current screen.

Note: Alt/Help will display a list of Hot Keys.

Dimension® XL Service Manual December 1998 3-21

Page 24

Chapter 3: Quick References

Table 3-10 lists modules that are purchased completely assembled and tested from

original equipment manufacturers (OEMs). They are serviced only at the module

level. Therefore, no supporting technical documentation is provided. These

assemblies are replaced only in their entirety. The column headed “Service Spare

P/N” is the Dade service spare part number. The “OEM” section of the table lists

sources, models, and manufacturers’ part numbers only if the module is available

from them as a stocked item. If the module is custom built for the Dimension

is not available commercially and the OEM model or part number is not listed. These

modules may be purchased only from Dade.

Table 3-10. Cross Reference for Service Spares and OEM Parts

Part Name Service Spare P/N OEM Information

Manufacturer Model No. P/N

Monitor 750312.502 Mitsubishi Diamond Pro 14 Plus SD4561CA

Printer 732538.501 Seiko LTP 5442-832 DPU-5442-OHK

UPS 750909.502 Sola 056-303-02-1300VA 056-00303-0200-99

®

XL, it

Computer 750080.502 Intel Custom Model 486LP4S250

Keyboard 750525.503 * Ñ Ñ

Multioutput DC

Power Supply 750907.501 Power One SPF4A1C4D2 SPF4A1C4D2

Transformer 732660.901 ** Ñ Ñ

* ÒCustom OEMÓ Keyboard; not commercially available

** ÒCustom OEMÓ package; not commercially available

3-22 December 1998 Dimension® XL/RxL Service Manual

Page 25

Indirect IMT System Quick References

Table 3-11. Indirect IMT System Parameters

Throughput 70 samples or 280 tests per hour

Cycle Time 50.4 seconds per sample

Sample Size 45 mL for LYTES and Na/K tests (remains

45 mL when SSM available)

Fluids Run Serum, Plasma, and Urine samples

Aqueous Calibrators and Standards

Serum-based QC products

Pumping Rate 64 to 77 mL /revolution

Chapter 3: Quick References

Air/Liquid

Air

Liquid

Table 3-12. Indirect IMT Ranges, References, and Coefficients

Acceptable IMT Slope Ranges Na K Cl TCO

Reference Ranges Na K Cl TCO

Reference Ranges for:

Serum/Plasma 136Ð145 3.5Ð5.1 98Ð107 22Ð29 NA

Urine 40Ð220 25Ð125 110Ð250 NA NA

Assay Ranges for:

Serum/Plasma 50Ð200 1Ð10 50Ð200 5Ð45 NA

Urine 5Ð300 1Ð300 10Ð330 NA NA

(Air value must be 2 times greater than liquid)

>0.8

<0.6

53 to 62 53 to 62 -60 to -40 30 to 55

2

Urine

2

Coefficients Na K Cl TCO

C0 1.5 Ð0.2 Ð2.5 Ð6.0 Ð20

C1 1.01 1.05 1.06 1.15 1.06

2

Urine Cl

Dimension® XL Service Manual December 1998 3-23

Page 26

Chapter 3: Quick References

Table 3-13. Indirect IMT System Standard Solutions

Consumable Test Equivalents

Standard A 1500

Standard B 650

Flush 1800

Salt Bridge 2500

per Bottle or

Cartridge

TCO

2

Release Agent

Diluent 700

QuikLYTEª Multisensor

Cartridge

Sample Ñ

Table 3-14. Rotary Valve Positions

Component Position Number

Sample 1

Air 2

Std. A 3

Std. B 5

None 7

250

1000

Table 3-15. HM Consumables

Consumable

Reaction Vessels

Flexª Reagent Cartridges

Chemistry Wash

Reagent Probe Cleaner

Sample Probe Cleaner

IMT Probe Cleaner

3-24 December 1998 Dimension® XL/RxL Service Manual

Page 27

Chapter 3: Quick References

Backplane Board Configuration

Top

Board

Row

Bottom

Board

Pin 1

6J1C

6J1B

6J1A

Row

Auxiliary Board

Jack 6J1

Backplane Rear View

J3J2J1

7J1

U1

Pin 32

Row 1

Ground Bar

6J2B

6J2A

Row 2

6J2C

Pin 1

Auxiliary Board

Jack 6J2

U2

SPARE

SPARE

U3

J7

J8

SPARE

8J19J110J1

6J1

ULTRASONIC BD.

7J28J29J210J2

6J2 5J2 4J2 3J2 2J2

6J1 A10

6J2

5J1

MOTOR #3

AUXILIARY BD.

GROUND BAR

GROUND BAR

Example:

A10

4J1

3J1

MOTOR #2

MOTOR #1

2J1

J5

J6

CUVETTE BD.

J9

Pin

Column

Pin

Row

RS422

(Open)

1J1

PHOTOMETER

1J2 CJ2 BJ2 AJ2

CJ1

J10

FUSE “C”

Keyswitch

BJ1 AJ1

FUSE “B”

231257A-59-S

15V

E1

E2

E3

E4

E5

E6

E7

E8

E9

FUSE “A”

E10E11

Plug 6P2

Pin 32

Backplane Board to Power Supply Connectors (see connectors on rear view above)

E1 0 V (DIG) J1 RSt0+ RSt0- (J1 slots 9 and 10)

E2 0 V (15) J2 RSt0+ RSt0- (J2 slots 8 and 9)

E3 0 V (24) J3 RSt0+ RSt0- (J3 slots 7 and 8)

E4 +5 V(Line) J5 RSt+ 1J1 RSt 1J1E5 +15 V (Line) J7 Computer com port 2

E6 -15 V (Line) J8 UPS

E7 0 V ((DIG) J9 Source lamp

E8 +5 V

E9 +24 V

E10 Ground

E11 Ground

Dimension® XL Service Manual December 1998 3-25

Page 28

Chapter 3: Quick References

Indirect IMT System Diagram

A1

TCO

Pinch Valve

TCO

2

Release

Agent

Pump

2

IMT

XA

X

To

Waste

TCO

Mixer

Fluid

Ground

TCO

Sensor

X3

Flush

D1

R1

Diluent

Salt

Bridge

Solution

2

D2

Diluent

Pump

IMT

Port

1

3

2

W2

To

Waste

F2

X2

2

Salt Bridge

Pinch Valve

QuikLYTEª

Integrated

Multisensor

X1

X0

IMT

Rotary Valve

F1

Standard B

Standard A

B

Flush

Pump

A

240833C-500

3-26 December 1998 Dimension® XL/RxL Service Manual

Page 29

Chapter 3: Quick References

5

+15

–15

24 1A

24 1B

24 2A

24 2B

24 3A

24 3B

24 1C

FUSE BOARD

A

12.5a

2.0a

2.0a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

FUSE BOARD

24 4A

24 4B

24 5A

24 5B

24 6A

24 6B

24 7A

24 7B

24 4C

24 4D

PHOTOMETER

CR1 TOKEN

B

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

6.3a

CR2A

CR2B

CR2C

CR2D

CR3A

CR3B

CR3C

CR3D

PHOTOMETER HOME

N/C

N/C

N/C

N/C

LAMP ON

FILTER POSITION

FILTER HOME

CUVETTE

CR1 TOKEN

CR2A

AIR COMPRESSOR

CR2B

REFRIG SOLENOID

CR2C

POSITION 1A

CR2D

HOME 1A

CR3A

HEAT TORCH SOL

CR3B

HEAT TORCH HTR

CR3C

THERM CHBR HTR

CR3D

INST CABINET FAN

CR4A

TOP SEAL HEATER

CR4B

U-SEAL SOLENOID

CR4C

U-SEAL HEATER

CR4D

CUVETTE FAN

CR5A

N/C

CR5B

N/C

CR5C

N/C

CR5D

TOP SEAL SOL

MOTOR

CONTROL

CR1 TOKEN

CR2A

HOME 1A

CR2B

POSITION 1A

CR2C

HOME 1B

CR2D

POSITION 1B

CR3A

HOME 1C

CR3B

POSITION 1C

CR3C

HOME 1D

CR3D

POSITION 1D

CR5 TOKEN

CR5A

HOME 2A

CR5B

POSITION 2A

CR5C

HOME 2B

CR5D

POSITION 2B

CR6A

HOME 2C

CR6B

POSITION 2C

CR6C

HOME 2D

CR6D

POSITION 2D

24 1D

24 2C

24 2D

24 3C

24 3D

BRANCH

SLOT

VOLTAGE

6.3a

6.3a

6.3a

6.3a

6.3a

24 5C

24 5D

24 6C

24 6D

6.3a

6.3a

6.3a

6.3a

AUXILIARY

CR1 TOKEN

CR2A

FLEX PRESENT

CR2B

WASTE FULL

CR2C

WASTE PUMP ON

CR2D

WATER FULL

CR3A

WATER EMPTY

CR3B

SSM CLEAN

CR3C

SAMPLE LID OPEN

CR3D

REAGENT LD OPEN

CR4A

SMP WHL ACTIVE

CR4B

FLEX LDR ACTIVE

CR4C

N/C

CR4D

24V ENABLE

CR5A

REF COMPRESSOR

CR5B

VACUUM DETECT

CR5C

VACUUM PUMP

CR5D

SMP LD OVRD OFF

ULTRASONICS

CR1A

R1 ENABLE

CR1B

R1 PROBE LOCK

CR1C

R1 POWER LEVEL

CR1D

CAP LEVEL SENSE IN/OUT

CR2A

R2 ENABLE

CR2B

R2 PROBE LOCK

CR2C

R2 POWER LEVEL

CR2D

ULTRASONIC LEVEL SENSE

CR3A

SAMPLE ENABLE

CR3B

SAMPLE PROBE LOCK

CR3C

S POWER LEVEL BIT 0

CR3D

S POWER LEVEL BIT 1

231257A-54-S

Dimension® XL Service Manual December 1998 3-27

Page 30

Chapter 3: Quick References

Guidelines for Using the IMT System

Shutdown Procedure

1. Operators will be trained to always keep IMT fluids on-board, even if not

running the system over a shift, day or weekend. Fluid usage should be

monitored and replaced as needed.

2. If IMT is not going to be run for an extended period (shift, day, weekend), the

operator should verify sufficient fluids are on-board to sustain the two-point

calibrations that will occur every two hours. The easiest approach in such a

circumstance may be to simply replace all fluids before the period of non-use. A

good rule of thumb is that the IMT system requires 48 consumable counts per

24-hour period of standby. Therefore, over a weekend you would want to have

approximately 100 counts of each fluid available when you leave on Friday. The

actual usage of each fluid during 24-hour standby is:

Std A 48 counts/24 hours

Std B 36 counts/24 hours

Std C 36 counts/24 hours

release 36 counts/24 hours

TCO

2

Salt Bridge 36 counts/24 hours

3. The shutdown procedure (replacement of IMT fluids with water, priming)

should only be used in exceptional circumstances, such as prolonged

shutdown/power down of the instrument (e.g., for instrument shipping) or if the

IMT is to be permanently deconfigured.

4. The following operational conditions may affect IMT fluid usage or system

performance:

a. Calibrations and cycling of IMT fluids will continue even if the sensor life

has exceeded 48 hours. Calibrations are only limited by the sufficiency of

fluids.

b. The manifolds valves are cycled (opened/closed) every five minutes, but no

fluids are consumed. This will always occur regardless of any consumables

except in diagnostics.

c. A two-point calibration will occur every two hours, whether the prior

calibration was successful or not. This ensures fluid and valve cycling

independent of sensor performance. The XL will stop calibrating if

unsuccessful.

d. In Diagnostics, no cycling or calibrating of IMT occurs. Prolonged periods in

Diagnostics may result in some difficulties recalibrating due to restart of

fluid flow and electrode drift. If in Diagnostics for prolonged periods of time

(>4 hours), working on the photometric side of the instrument, Diagnostics

should be exited periodically to recalibrate the IMT system.

3-28 December 1998 Dimension® XL/RxL Service Manual

Loading...

Loading...