Page 1

DIGISCAN M

System Manual

Start-up

Acquisition workstation, image reader,

viewing station

SP

© Siemens AG 2002

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 4 English

Print No.: SPB7-420.815.01.04.02 Doc . Gen. Date: 11.02

Replaces: SPB7-420.815.01.03.02 66 31 159

Page 2

0 - 2 Revision

Chapter Page Revision

All All 04

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempti ng installation or service procedures.

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 4 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 3

Contents 0 - 3

Page

1 _______Introduction ___________________________________________________1 - 1

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

General remarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Documents required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Tools, meters and appliances required . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

General remarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

MAMMOMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

DIGISCAN M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Hardcopy camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Important notes on start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

General remarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Start-up sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

2 _______Start-up of the acquisition workstation_____________________________2 - 1

General remark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Install service images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Configuration of the barcode scanner. . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

3 _______Installation and start-up of the image reader ________________________3 - 1

Installation and start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Starting the M-Utility (three scenarios) . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Starting the M-Utility from the routi ne process mode (routine mode) . . . . . . . .3 - 1

Starting the M-Utility from the initialization process mode. . . . . . . . . . . . . . 3 - 2

Starting the M-Utility from the abnormality process mode. . . . . . . . . . . . . . 3 - 3

Exiting M-Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

DICOM installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Setting the configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Check HOSTS file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

4 _______Start-up of the viewing station (option)_____________________________4 - 1

MagicView 1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Start-up procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Software configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

MammoReportPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Start-up procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 6 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 4

0 - 4 Contents

Page

5 ______ Start-up of the hardcopy camera ___________________ _______________5 - 1

Hardcopy camera requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Recommended hardcopy cameras . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

6 ______ Function check ________________________________________________6 - 1

Switch on the system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Function check of the acquisition workstation . . . . . . . . . . . . . . . . . . . . . 6 - 1

Image transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Filming (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Function check of the viewing station (option) . . . . . . . . . . . . . . . . . . . . . 6 - 4

MagicView 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

MammoReportPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

7 ______ AEC settings _____________________ __ __ _________________ ________7 - 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Delay times between two exposures . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 4

Backup of existing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Object table group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

General conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Calibration conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Reference IP cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Mains voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Sensitivity conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Overview of work routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 9

DLF switch off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 10

Cassette loaded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 10

Increase grid speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 10

AEC Correction tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 11

Installation of AEC correction tables . . . . . . . . . . . . . . . . . . . . . . . .7 - 11

Calibrate correction tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 13

Recalibration of an object table. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 20

Sensitivity correction (fine setting) . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 25

Testing the AEC-function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 26

AEC performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 26

Reinstall/Install program parameters for OPDOSE. . . . . . . . . . . . . . . . . . .7 - 27

Factory settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 28

Testing OPDOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 29

Final procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 31

DIGISCAN M Register 4 SPB7-420.815.01 Page 4 of 6 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 5

Contents 0 - 5

Page

8 _______Image quality __________________________________________________8 - 1

Image quality test procedu re . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

9 _______Final work steps _______________________________________________9 - 1

Safety measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Components which can be detached from the mains cable. . . . . . . . . . . . . 9 - 1

Components which can not be detached from the mains cable. . . . . . . . . . . 9 - 1

Remaining work steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Completing the protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

10 ______Turning the system over to the customer__________________________10 - 1

11 ______Start-up protocol ______________________________________________11 - 1

Backup of existing system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

AEC performance test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 2

Wing 1 M3000, Wing 2 M1000 . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 2

Wing 2 M3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 3

OPDOSE settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 4

Final checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 5

12 ______Changes to previous version____________________________________12 - 1

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 5 of 6 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 6

0 - 6 Contents

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 6 of 6 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 7

Introduction 1

Safety information 1

General remarks 1

• The product-specific safety informat ion contained in this document, as wel l as the

general safety information must be observed.

• The general ESD guidelines must be observed.

Laser safety 1

• When working on an open laser, the leather gloves and laser saf ety glasses must be

worn.

• No reflective tools must be used.

• See also “Safety and Radiation Protection Guidelines” ARTD 2.

Documents required 1

• DIGISCAN M Software acquisition workstation, SPB7-420.816 .01...

• DIGISCAN M Software MagicView1000 configuration for mammography,

SPB7-420.816.02...

1 - 1

• DIGISCAN M Quality Control Manual, SPB7-420.210.01...

• DIGISCAN M Instructions for use, SPB7-420.201.01...

• MagicView 1000 Installation and Start-up, P02-021.814. ..

• MammoReport

• DIGISCAN M Hardcopy Camera Information, SPB7...

• Fuji Service Manual FCR 5000MA plus, 009-058...

• Product-accompanying documentation

Plus

Installation and Start-up Inst ructions, SPB7-420.814.01...

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 8 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 8

1 - 2 Introduction

Tools, meters and appliances required 1

General remarks 1

The recommended equipment meets the specifications and are suit able for the measurements and checks listed. If other equipment is used, make sure tha t they also meet the

specifications and are suitable for the listed measurements and checks.

If in doubt, contact CS Headquarters Support Center +49-9191-18 8080

The required adjustment and calibration intervals must be maintained.

Before any measurement or test equipment is used, it must first be subjected to a visual

check. Damaged measurement or test equipment which can influence the accuracy of the

test results may not be used.

NOTE

All tools, meters and appliances with the exception of those

marked “*”, are listed along with their specificati ons in the STC

(Service Tools Catalogue).

• Standard tool kit

• Protective ground wire tester

• Digital multimeter

• ESD equipment

• Gloves of cotton

• Cleaning agent*

• AEC calibration plexi

- Three plates, “2” cm (material No. 65 61 232)

- One plate, “1” cm (material No. 65 61 224)

NOTE

Tools, meters and appliances required for the image quality tests

are listed with the tests in the

DIGISCAN M Quality Control Manual, SPB7-420.210.01... .

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 8 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 9

Introduction 1 - 3

Prerequisites 1

MAMMOMAT 1

1. For all MAMMOMAT 3000 Nova, upgrade with isolation kit No. 63 96 704.

2. For MAMMOMAT 3000 Nova with serial No . low er than 6850, upgrade with

extended radiation field kit No. 64 83 551.

3. For MAMMOMAT 3000 Nova with serial No . low er than 7000, upgrade with AEC

kit No. 65 52 819. If the AEC kit is install ed directly before the prom kit No.

66 24 410, use proms from the prom kit if those are of higher version than the AEC

proms.

Prerequisites (installat ion kit no. 65 52 819):

Depending on the serial number and/or versio n of the software of your

MAMMOMAT, complementary measures may have to be taken. These measures

are described below.

- For MAMMOMAT 3000 with serial number lower than 2056:

If not done previously; chan ge the polarity of the stereo lever s witch.

- For MAMMOMAT 3000 with serial number lower than 3242:

Make sure that the articl e no. of the PC board D702 is 64 21 288.

- For MAMMOMAT 3000 software version lower than v1.5:

Replace HSE detectors. The part no. of th e HSE detectors must be 38 47 626.

- For MAMMOMAT 3000 software version lower than v2.2:

Calibrate the swivel-arm rotati on.

NOTICE

4. For all MAMMOMAT 3000 Nova with serial No. lower than 9300, upgrade with

prom kit No. 66 24 410.

The tables for Fuji CR HR-BD imaging plate in IP CASS-BD M will

be installed on D and will overwrite ex isting tables.

Make sure that the correction tables for the film/screen combination are installed on H.

If more than one film/screen combination has been installed, one

of them has to be removed.

DIGISCAN M 1

The DIGISCAN M system must hav e been install ed according to DIGISCAN M Instal lation

Instructions, SPB7-420.812.01... .

Hardcopy camera 1

If a hardcopy camera is conf igured, an appointment must have been scheduled with the

responsible emplo y ee from the camera manufac turer. The employee should be present at

startup - approximately 2 days after beginning of the installation through the sub contrac tor.

This employ ee will have the following tasks:

• Connecting the hardcopy camera to the network.

• Setting the hardcopy camera input to a linear LUT and opti cal density to max.

• Checking image transfer together with the Siemens employe e.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 8 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 10

1 - 4 Introduction

• Measuring the optical density values of th e ten gray steps of the SMPTE test pattern

together with the Siemens employee.

• Performing any adaptations on the hardcopy camera so tha t the reference values

(optical density) of the SMPTE test patter n can be achieved.

Important notes on start-up 1

General remarks 1

The system documentation is no longer available on paper. The documents are now published via CD-ROM or CB-DOC (intranet). The exceptions are Installation Instructions,

Start-up, Software , Wiring Diagrams and Di sposal Instructions that are deliv ered on paper

also.

The CD-ROM will be distributed only to the persons who ha ve attended the required training course and is therefore not available at the site!

The spare parts list found on the CD-ROM in the Fuji manual is the original Fuji list with

Fuji material numbers only. All available Siemens material numbers are listed on the

LINKONE CD-ROM spare parts catalog.

Network configuration 1

NOTE

If the system is integrated into an existing network, the records regarding “update” must

be adapted to the local conditions (hospital name, type of hardcopy camera).

It is also recommended that when the system is initially integrated into the network, the

standard system first be put into operation in accordance with the instructions in this document and its function checked.

Afterwards, the system can be integrated into the existing network by adapting the network configuration.

NOTE

If there is no network and if the DIGISCAN M system is operated

as a “stand-alone” network, configuration of the network can be

skipped.

This document describes a DIGISCAN M standard system and

presumes that the Siemens employee has completed the training

according to the Field Service Strategy.

Shipment 1

The parts of the DIGISCAN M system are adjusted, tested, documented and shipped separately.

Software 1

• The acquisition workstation is not shipped with t he software pre installed.

• For viewing station (option), see product- accompanying documentation.

DIGISCAN M Register 4 SPB7-420.815.01 Page 4 of 8 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 11

Introduction 1 - 5

r

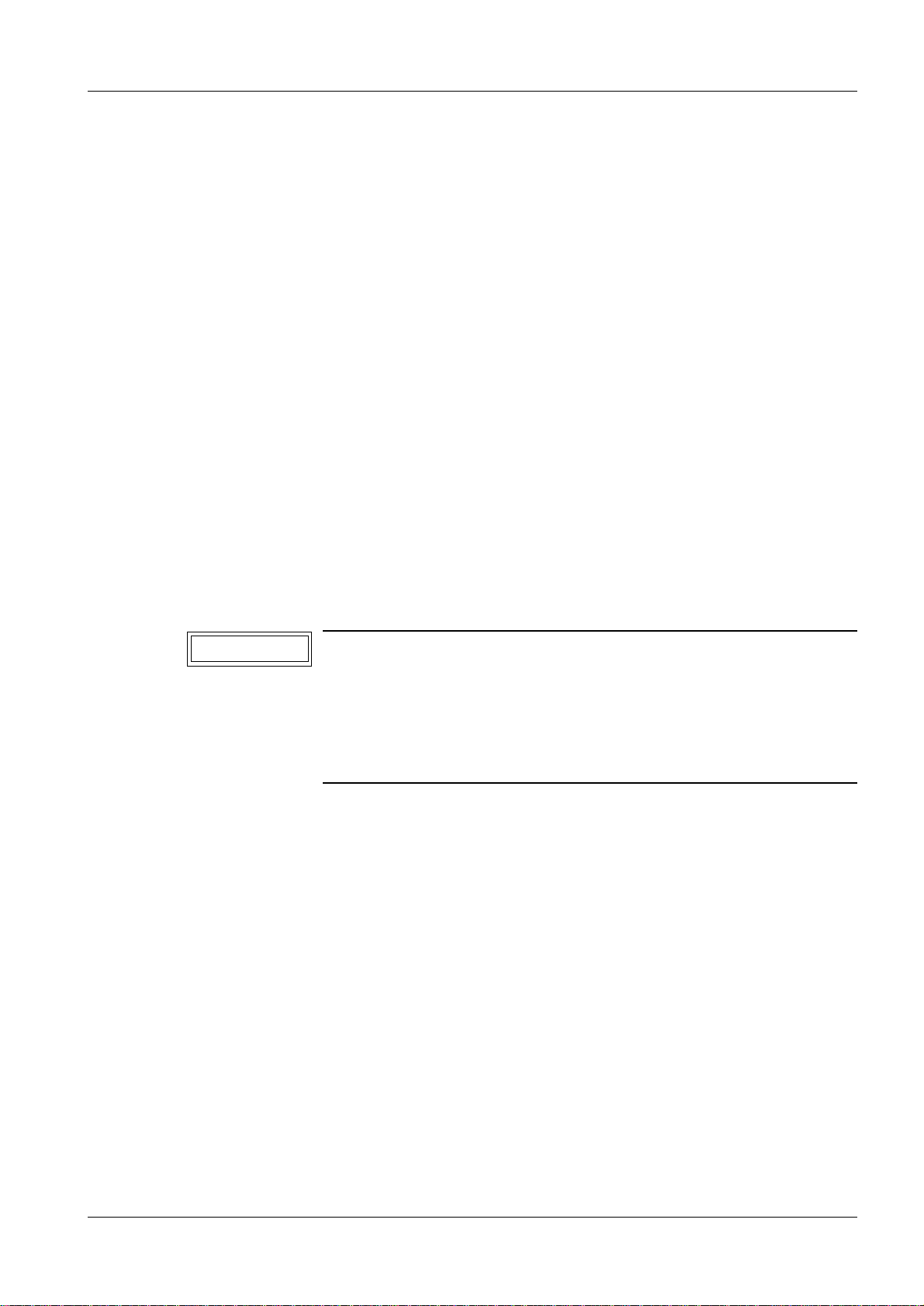

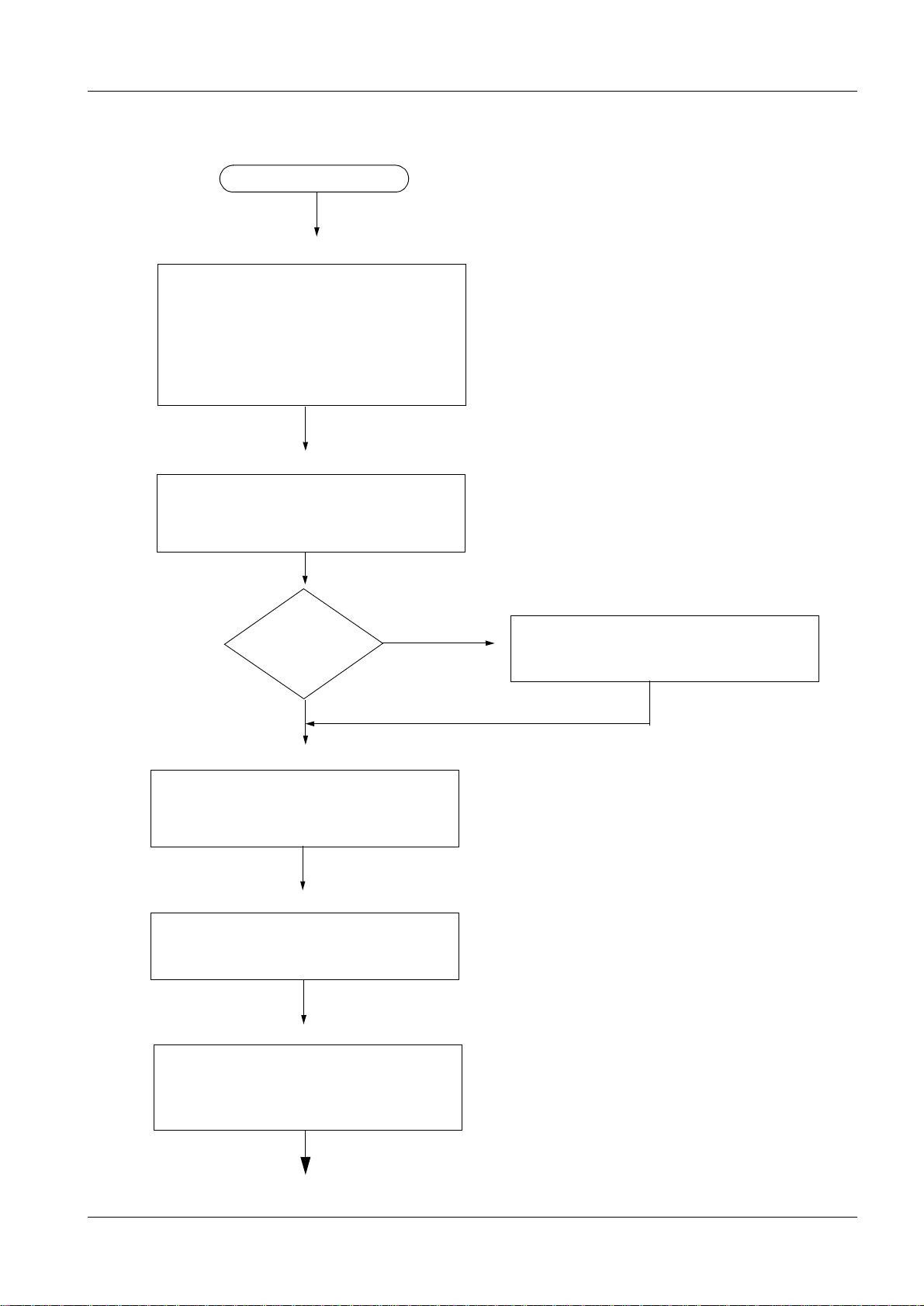

Start -up sequenc e 1

Start o f start-up

Chapter 1 Introduction

- Safety information

- Documents required

- Tools, meters and appliances

- Prerequisites

- Important notes

- Abbreviations

Chapter 2 Start-up of the acquisition workstation

- Software installation

- Software configuration

- Install service images

- Configure barcode scanner

Chapter 3 Installation and start-up of the image reade

Image reader in-

stalled by Fuji?

Yes

Chapter 4 Start-up of the viewing station (option)

- Start-up

- Software configuration

Chapter 5 Start-up of the hardcopy camera

- Hardcopy camera (recommendation)

Chapter 6 Function check

No

- Installation and start-up

- Configuration

- Screen saver timer setting

- Acquisition workstation

- Viewing station

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 5 of 8 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 12

1 - 6 Introduction

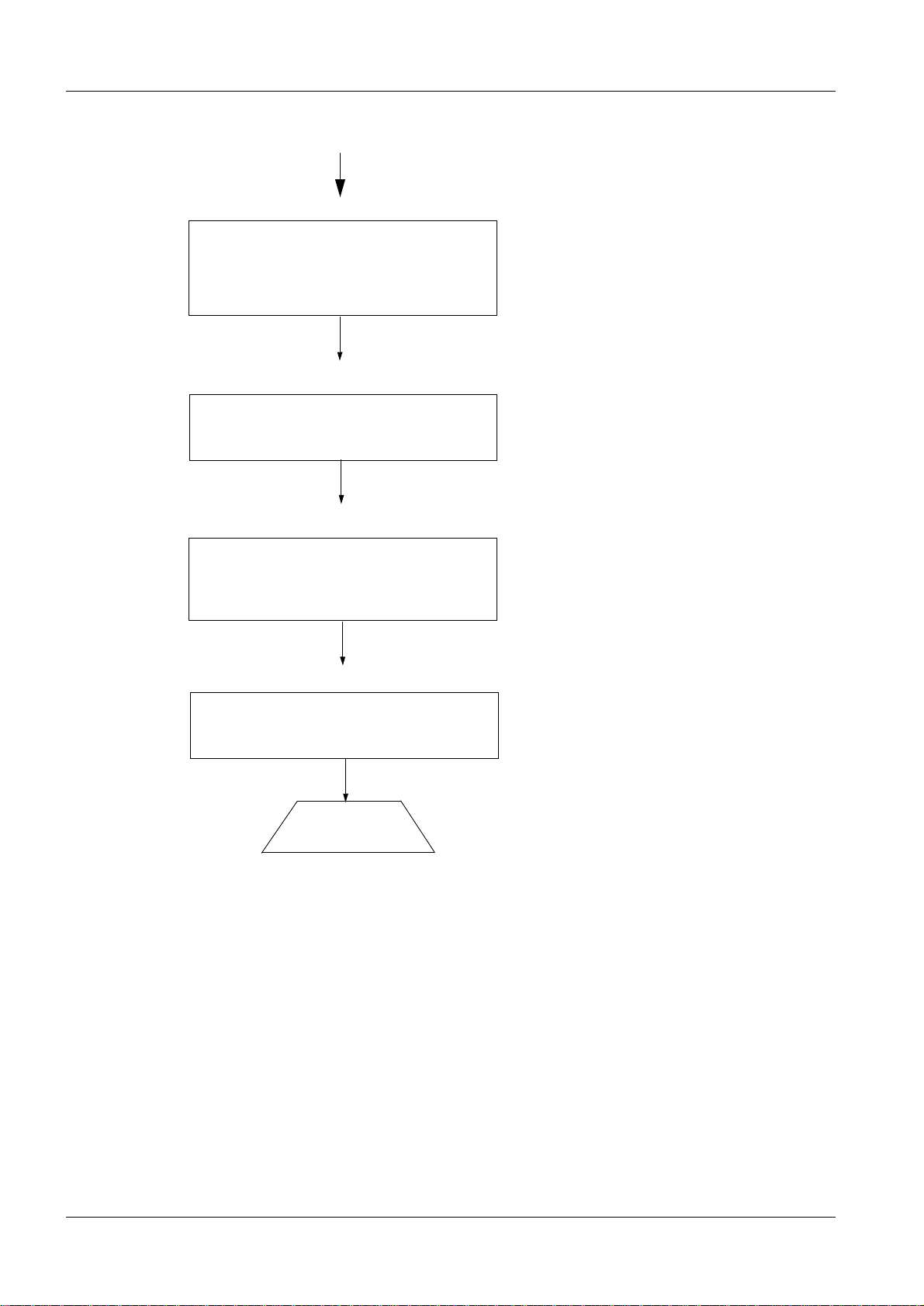

Chapter 7 AEC settings

- Backup of existing system

- Configuration of the AEC

- Testing

- Final procedures

Chapter 8 Image quality

- Acceptance test

Chapter 9 Final work steps

- Safety measurements

- Remaining work steps

- Complete protocol

Chapter 10 Turning the system over to the customer

- Customer adaptations

End of start-up

DIGISCAN M Register 4 SPB7-420.815.01 Page 6 of 8 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 13

Introduction 1 - 7

Abbreviations 1

AWS Acquisition Workstation

ASCRx Acquisition workstation software based on syngor

(x is product versi on)

FCR F

IVK I

IP I

IQ I

LUT L

MOD M

FCR 5000MA plus Fuji designation for the image reader

SCSI S

uji Computer Radiography

nstalled Volume Component

maging Plate

mage Quality

ookup Table

agneto Optical Disc

mall Computer System Interface

syngo is a registered trademark of Siemens AG.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 7 of 8 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 14

1 - 8 Introduction

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 8 of 8 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 15

Start-up of the acquisition workstation 2

General remar k 2

The DIGISCAN M system components must have been ins tal led according to

DIGISCAN M Installation Instructions, SPB7-420.812.01... .

Start-up procedure 2

Install and configure the software according to DIGISCAN M Software acquisition work-

station, SPB7-420.816.01... .

Install service images 2

Install the service images shall be used during image quality tests.

• System ON.

• Log in as meduser.

• Press the keyboard button to switch to Windo ws.

• Select Start > Programs > Accessories > Windows Explorer.

• Insert the ASCRx software CD-ROM in the CD-RW drive.

2 - 1

• Open the folder Service_Images on the CD-ROM.

• Copy all six images to C:\temp.

• Close the Windows Explorer.

• Activate the Viewing task card.

• Call up Transfer > Import from Off-line. ...

• Select C:\temp.

• Select all six “Service_Images .RF”.

• Press OK.

• Call up Patient > Browser and check that service_i mages are imported.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 6 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 16

2 - 2 Start-up of the acquisition workstation

F

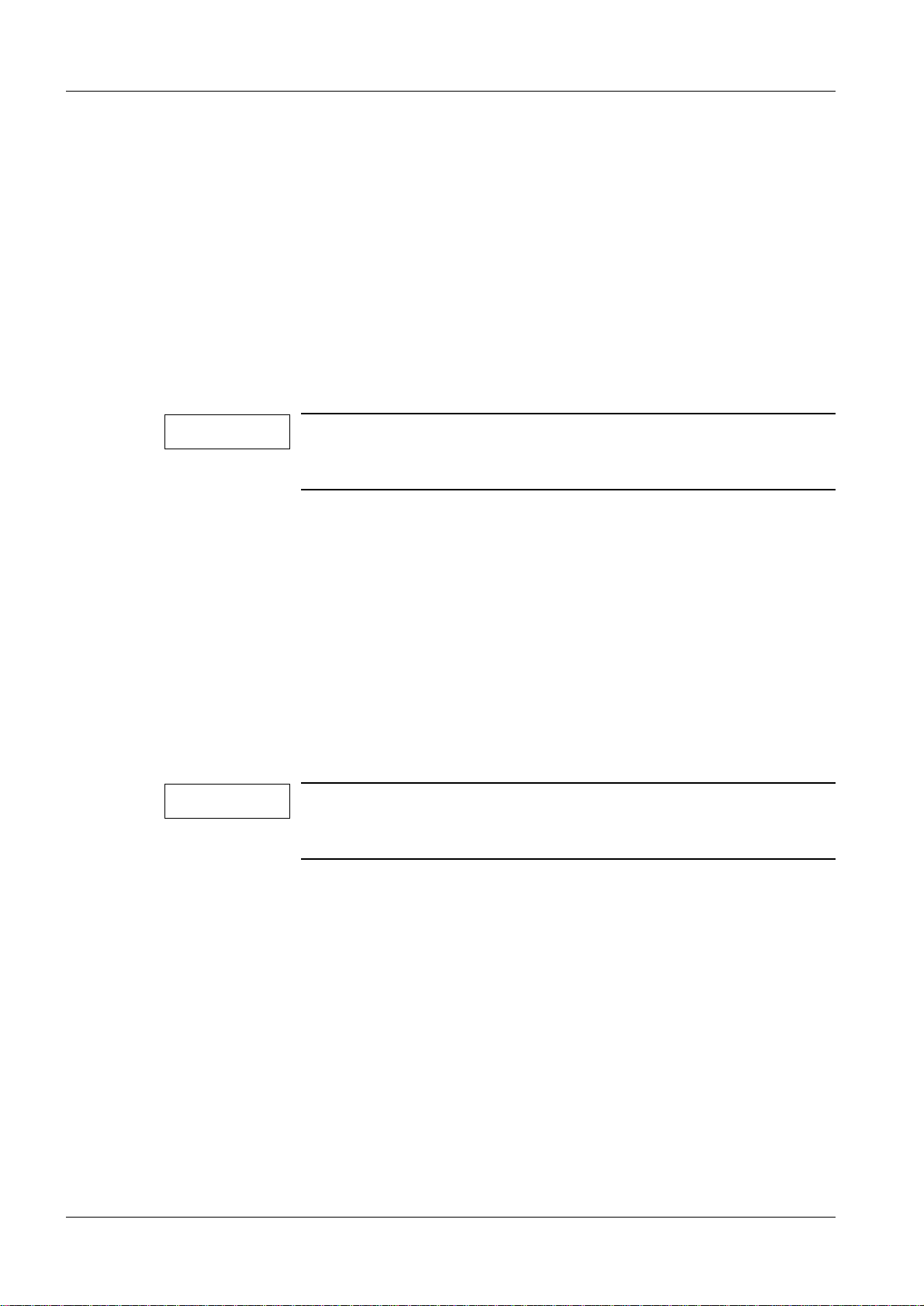

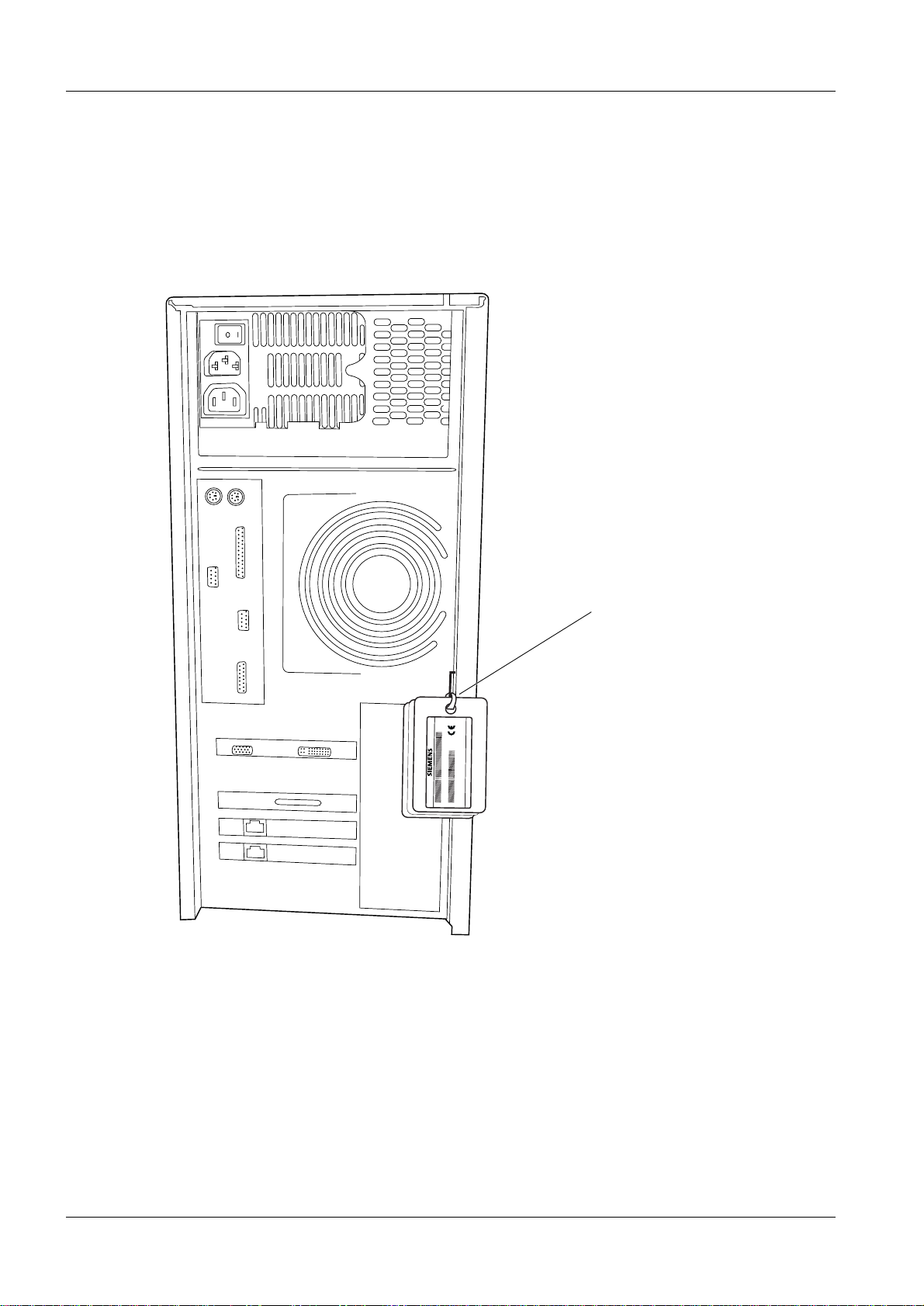

Labeling 2

Attach software version label (ASCRx), which is packed with the ASCRx software in the

installation packa ge , and syst em la bel (DI GISCAN M), which i s packed together with gray

plastic cards in the installation package, to two di fferent gray plastic cards. Fasten the

cards on the acquisition workstation with cab le t ies accor din g to Fig. 1. Attach the ac quis ition workstation label (ACQUISITION WORKSTATION), which is incl. in the acquisition

workstation package, in the same way.

Fig. 1

Fasten cable ties here

0413

Made in Sweden

Siemens-Elema AB, S171 95 Solna, Sweden

MODEL NO.:

SERIAL/LOT No.:

FDM00251

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 6 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 17

Start-up of the acquisition workstation 2 - 3

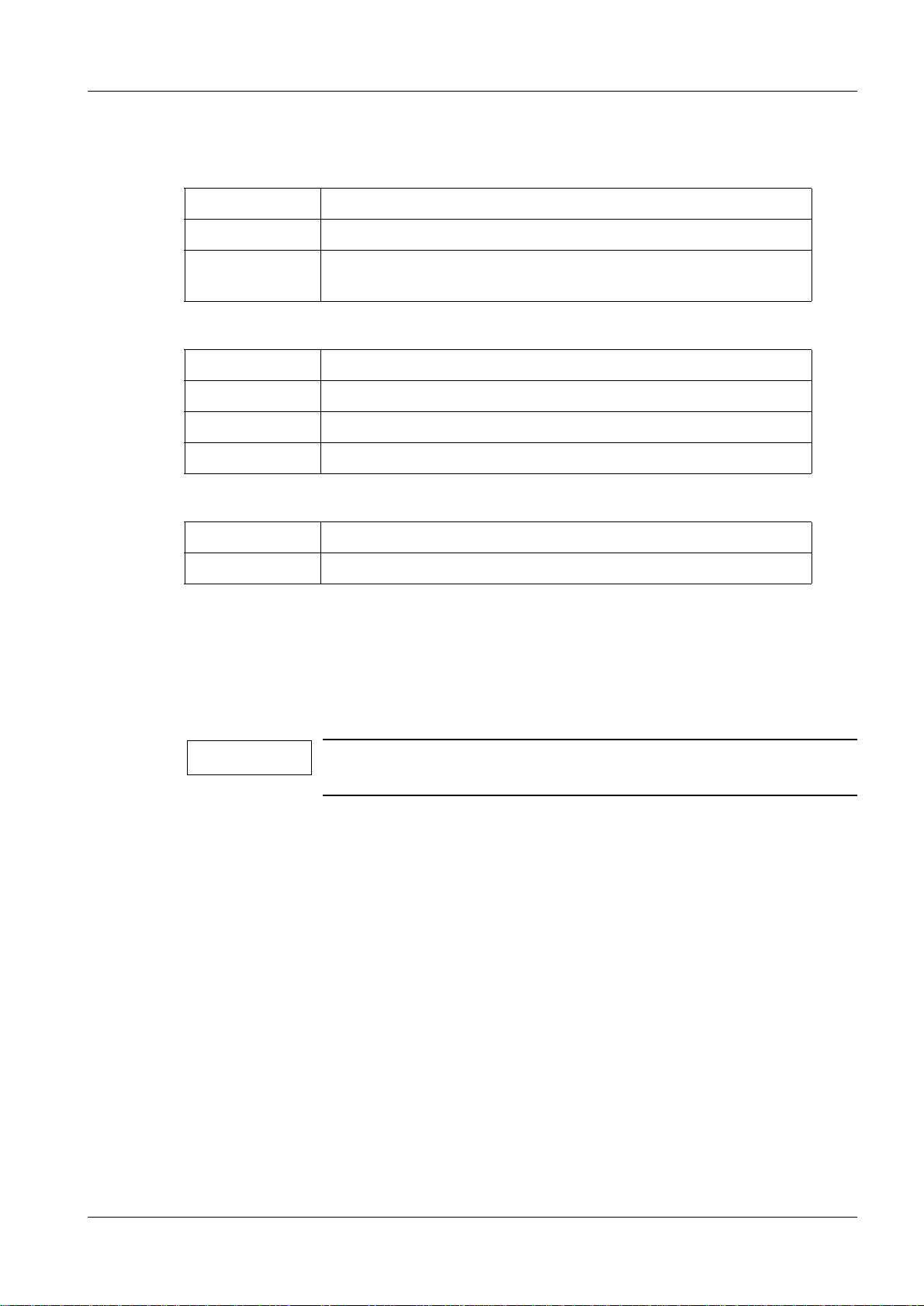

Configuration of the barcode scanner 2

Sound at acquisition workstation start-up

Beeper Meaning

L L L L Parameter s loaded correctly

H H H H

long tones

Sound during barcode scanner configuration

Beeper Meaning

H H H H Correct entry or exit from configuration mode

L Good read of a command

L L L Command read error

Sound during a normal read

Beeper Meaning

L Correct read of a code in normal mode

H= high tone

L= low tone

Parameter loading error, reading or writing error in the non v olatile memory

• Switch the acquisition workstation ON.

• Read the barcodes below to configure the barcode scanner. Conf irm by listening to the

sound.

NOTE

If problem occur during barcode scanner configuration, restart

with “Exit and save” and then “Restore default”.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 6 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 18

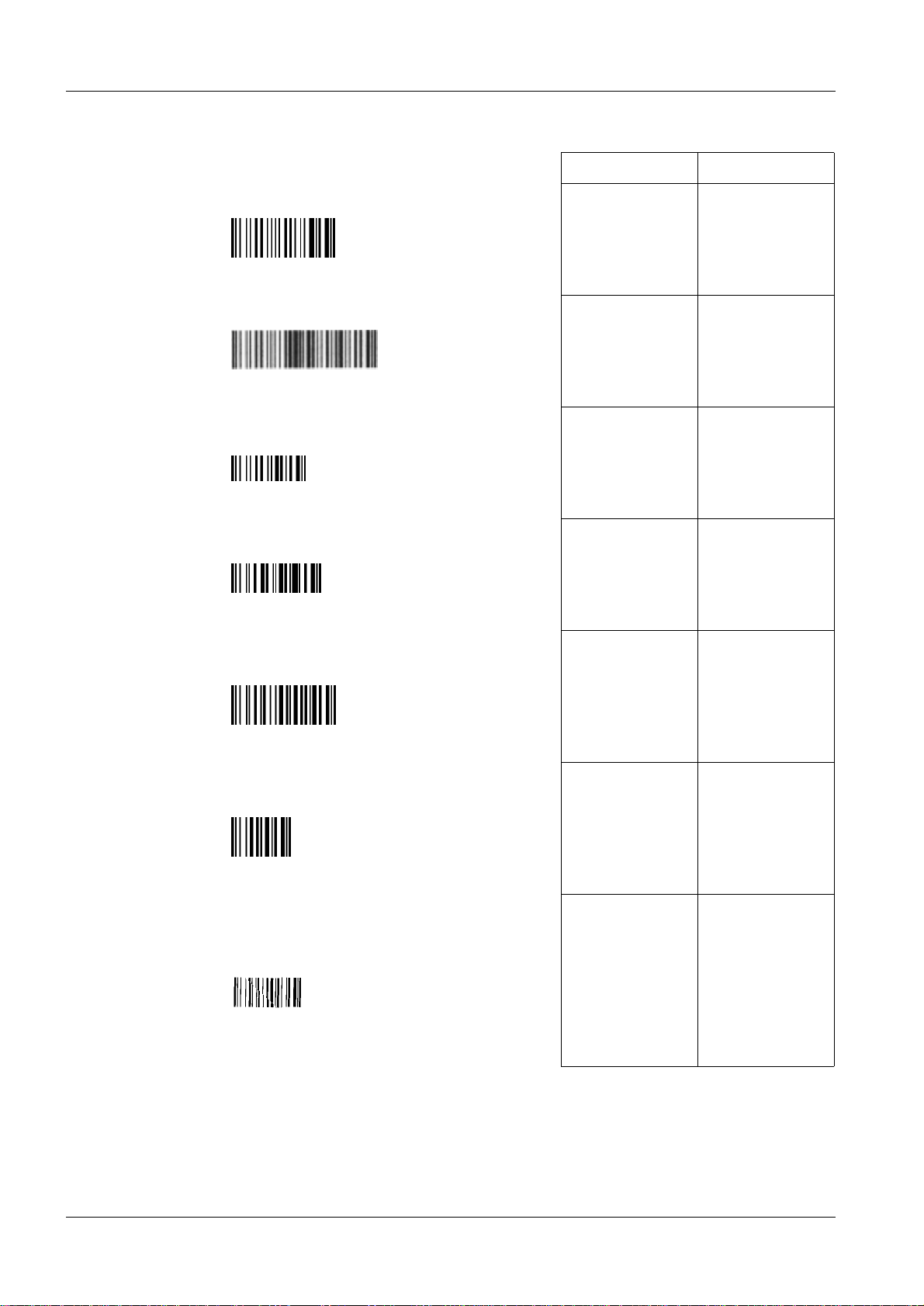

2 - 4 Start-up of the acquisition workstation

Scanner sound Decoder sound

1. Restore default HHHH HHHH

2. RS232 HHHH HHHH

3. Enter configuration (for scanner) HHHH

4. Disable all code families L

5. Codabar with no start stop character

equality check

6. No transmission of start and

stop characters

7. Increased decoding safety by forcing

the scanner to decode the barcode

three times before accepting the barcode

L

L

L

DIGISCAN M Register 4 SPB7-420.815.01 Page 4 of 6 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 19

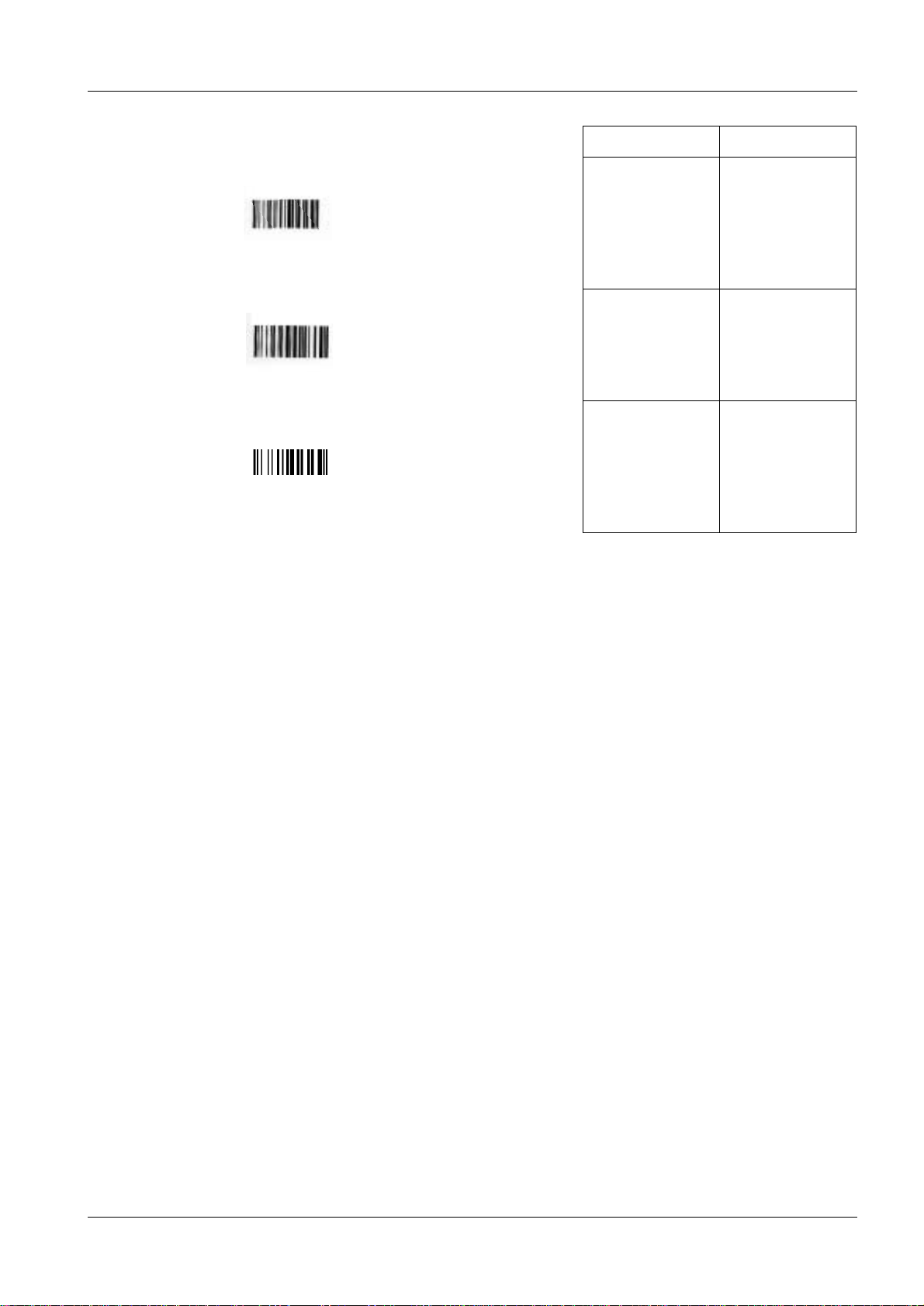

Start-up of the acquisition workstation 2 - 5

Scanner sound Decoder sound

8. Active level L

9. Hardware trigger L

10. Exit and save (scanner settings) L HHHH

• Configuration complete.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 5 of 6 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 20

2 - 6 Start-up of the acquisition workstation

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 6 of 6 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 21

Installation and start-up of the image reader 3

Installation and start-up 3

Install and start-up the image reader accordi ng to the table below:

3 - 1

Installation

procedure

Fuji Service Manual

FCR 5000MA plus, 009.058...

DIGISCAN M Start-up

(this document)

chapter Installation

1. Chapter 1 - 20

2. "DICOM installation" on Page 3 - 3.

3. "Setting the configuration" on Page 3 - 4

4. "Backup" on Page 3 - 8

5. Chapter 23 - 27

CAUTION

The light-collecting guide assemblies are easi ly damaged.

Handle the light-collecting guide assemblies with extreme care

and use the gloves of cotton.

Starting the M-Utility (three scenarios) 3

NOTE

Instructions how to start the M-Utility is given below. Follow this

procedure when the installati on and start-up instructions requires

that the M-Utility is started.

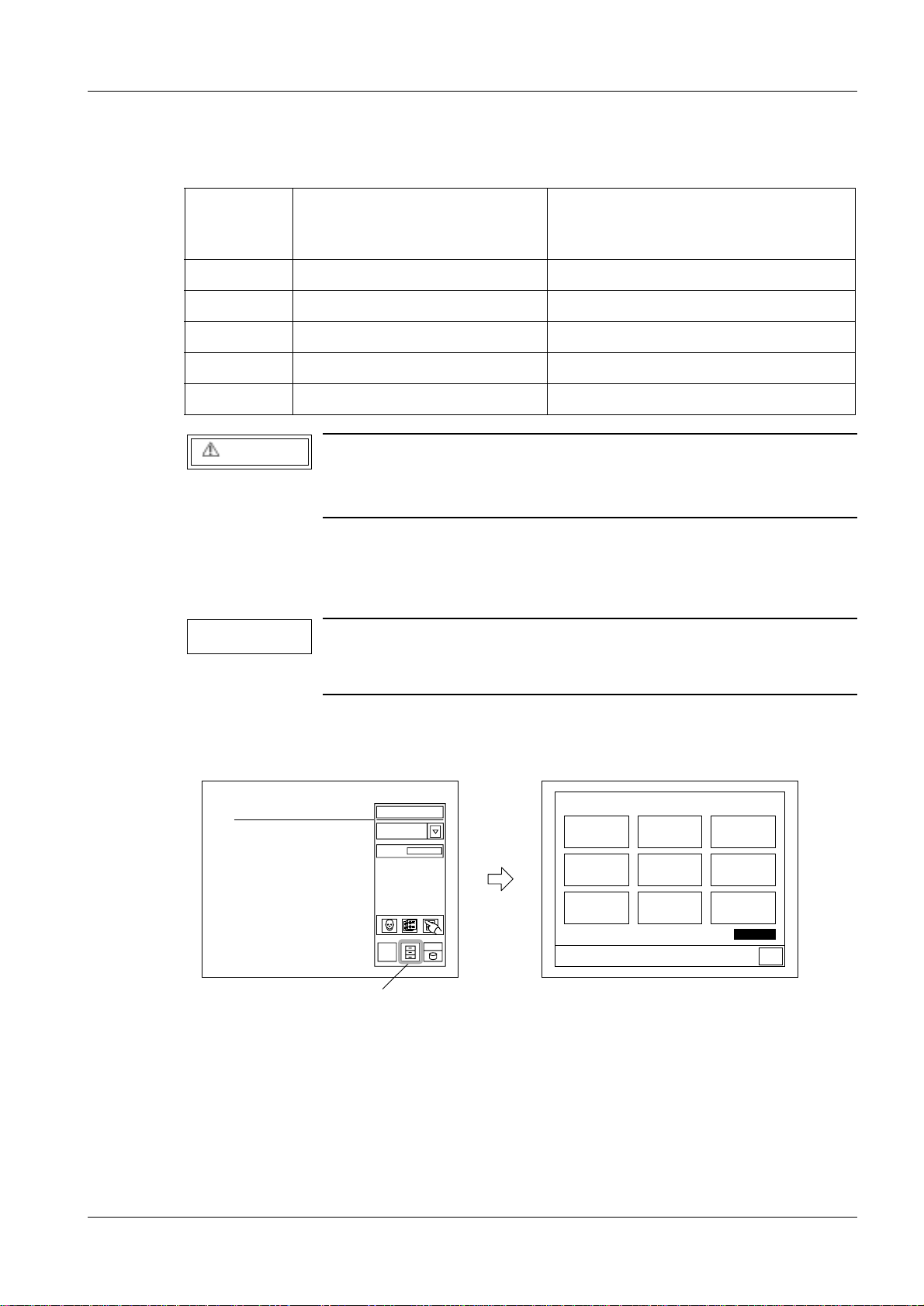

Starting the M-Utility from the routine process mode (routine mode) 3

• Press the U-Utility button.

U-Utility button

Read

Deleting images

waiting for

processing

Click sound

CRT test pattern

display

0

Processed image

reproduction

output

Touch panel

parallax correction

OUTPUT MULTI-

FRAME IMAGE

Utility

Date/time setup

Printer selection

FD operation

XXXXXX

Return

FFDM00210

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 10 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 22

3 - 2 Installation and start-up of the image reader

touch the corner.

• Touch the upper left-hand corner of the touch panel, a nd then, within two seconds, touch

the upper right-hand corner to st art the M-Utility.

Deleting images

waiting for

processing

Click sound

CRT test pattern

display

Processed image

reproduction

Touch panel

parallax correction

OUTPUT MULTI-

FRAME IMAGE

Utility

: Location to be touched

output

Date/time setup

Printer selection

FD operation

XXXXXX

Return

0. QUIT

1. ERROR LOG UTILITY

2. CONFIGURATION SETTING

3. TEST MODE

4. ELECTRICAL UTILITY

5. SCANNER UTILITY

6. MECHANICAL UTILITY

7. FILE UTILITY

8. BACKUP MEMORY

9. HV ON(OFF)

10. MENU SETTING

11. SYSTEM UTILITY

AB C

DE F

789

456

123

0.SP

DEL BS ENT

Caps

FFDM00211

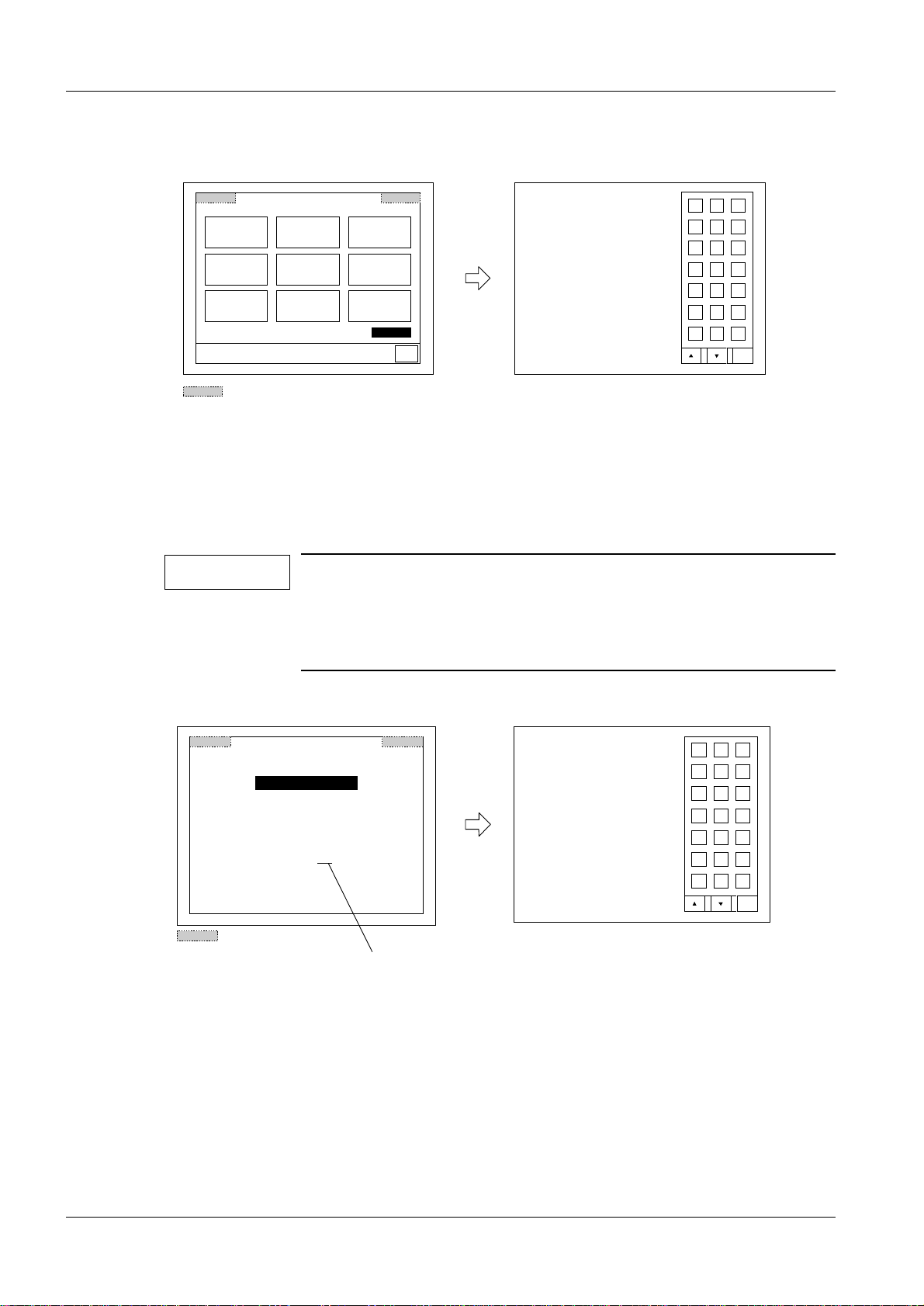

Starting the M-Utility from the initialization process mode 3

After the machine is powered ON, the initialization screen appears, and subsequently a

software version number is displayed for about five seconds. During that period of time,

touch the upper left-hand corner of the oper ati on panel, and then, wit hin t w o seconds, the

upper right-hand corner.

NOTE

After the display of the software version number ends, the operation panel does not respond at all even if y ou touch it. In such an

instance, perform a reset and wait until the software version n umber appears on the screen, or enter t he rout ine pr ocess mode and

then start the M-Utility.

Copyright (c) 2000 Fuji Photo Film Co.,Ltd

Software ID

Software Version

: Location to be touched

C R - I R 3 4 7

: 114Y5437003

: A00

Software version number

1. ERROR LOG UTILITY

2. CONFIGURATION SETTING

3. ELECTRICAL UTILITY

4. SCANNER UTILITY

5. MECHANICAL UTILITY

6. FILE UTILITY

7. BACKUP MEMORY

8. HV ON(OFF)

9. MENU SETTING

10. SYSTEM UTILITY

AB C

DE F

789

456

123

0.SP

DEL BS ENT

Caps

FFDM00233

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 10 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 23

Installation and start-up of the image reader 3 - 3

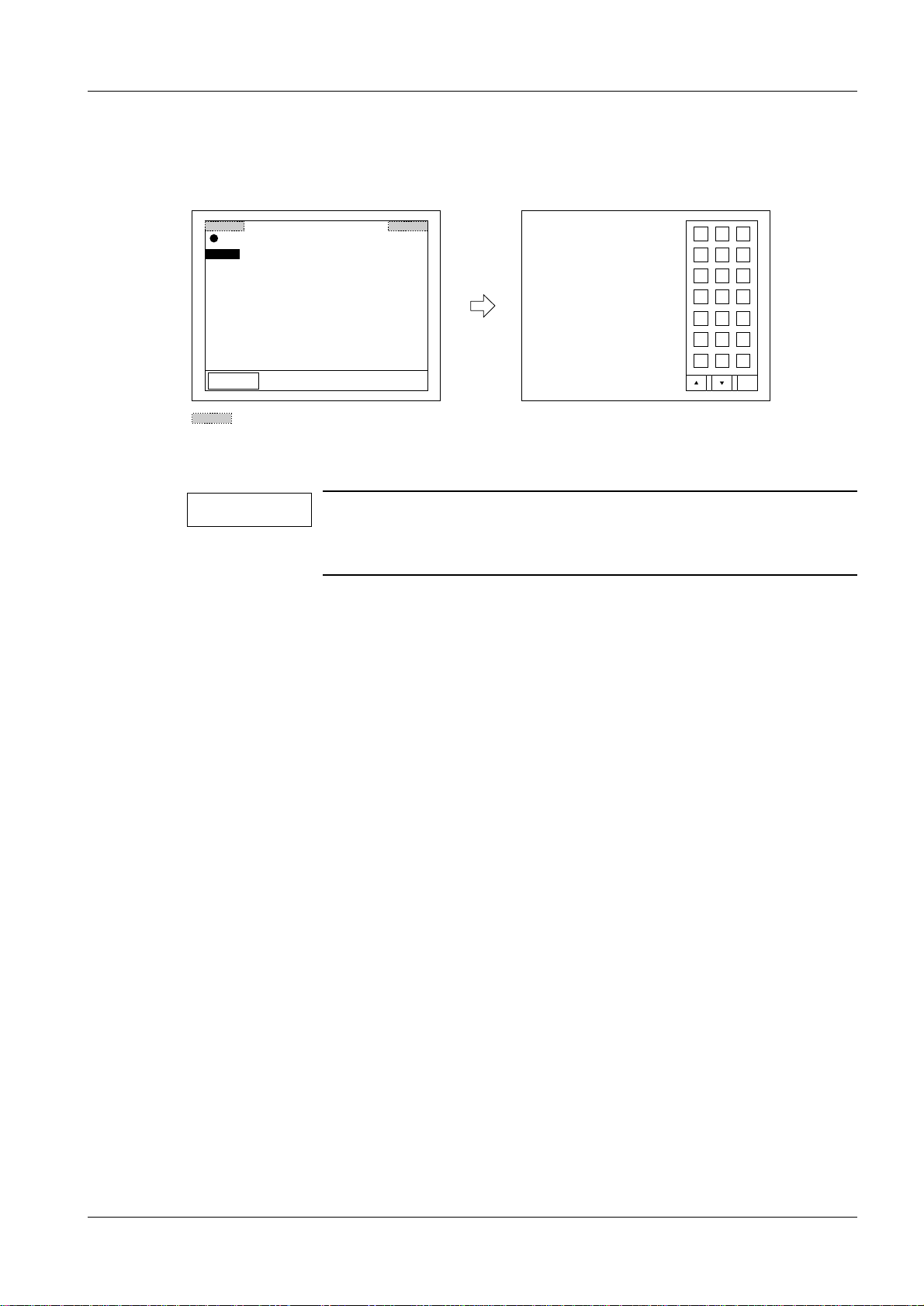

FFDM00234

1. ERROR LOG UTILITY

2. CONFIGURATION SETTING

3. ELECTRICAL UTILITY

4. SCANNER UTILITY

5. MECHANICAL UTILITY

6. FILE UTILITY

7. BACKUP MEMORY

8. HV ON(OFF)

9. MENU SETTING

10. SYSTEM UTILITY

0.SP

DE F

AB C

789

456

123

DEL BS ENT

Caps

03D2

Call maintenance personnel.

IP position information error.

System down

Stop alarm

: Area to be touched

Starting the M-Utility from the abnormality process mode 3

Touch the upper left-hand corner of the operation panel, and then, within two seconds,

touch the upper right-hand corner.

Exiting M-Utility 3

NOTE

If M-Utility is entered during the initi aliza ti on sequence, “0. QUIT”

does not appear. Thus,

after quitting M-Utility, the machine should be reset.

• While the M-Utility main menu is displayed, select 0. QUIT.

• Press the reset button.

DICOM installation 3

• Start the M-Utility.

• Select [7][ENT] for FILE UTILITY.

• Put the DICOM for OEM floppy disk into the floppy disk drive.

• Select [7][ENT] for EXECUTION.

• Select [2][ENT] for INSTALL.

• Select [1][

• When the installation is finished, touch [0][ ENT].

• Touch [0][ENT].

• Touch [QUIT].

ENT] to accept that selected file is executed.

€

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 10 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

• Remove the floppy disk from the floppy disk drive.

• Turn OFF the system power switch and back ON.

• Touch [OK] when the message appears:

“The following settings have been added/delet ed. Press OK key. “

Page 24

3 - 4 Installation and start-up of the image reader

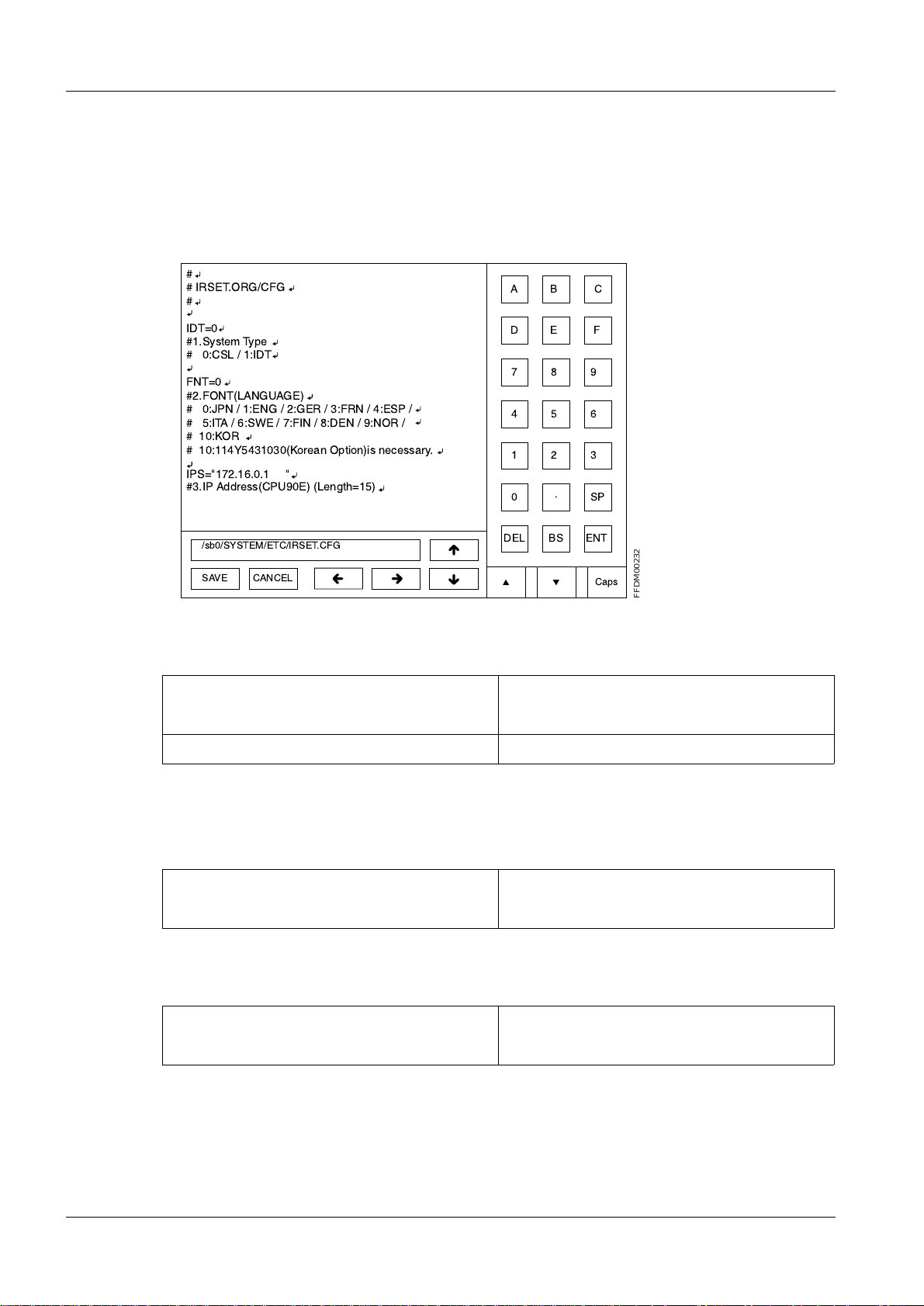

Setting the configuration 3

• Start the M-Utility.

• Select [2][ENT] for CONFIGURATION SETTING.

• Select [1][ENT] for SYSTEM.

To move the cursor, use the arrow keys or touc h the screen.

#

# IRSET.ORG/CFG

#

AB C

IDT=0

#1.System Type

# 0:CSL / 1:IDT

FNT=0

#2.FONT(LANGUAGE)

# 0:JPN / 1:ENG / 2:GER / 3:FRN / 4:ESP /

# 5:ITA / 6:SWE / 7:FIN / 8:DEN / 9:NOR /

# 10:KOR

# 10:114Y5431030(Korean Option)is necessary.

IPS="172.16.0.1 "

#3.IP Address(CPU90E) (Length=15)

/sb0/SYSTEM/ETC/IRSET.CFG

SAVE

CANCEL

DE F

789

456

123

.

0

DEL

SP

BS ENT

Caps

• Set system type to IDT:

Old New

IDT=0↵ IDT=1↵

#1.System Type↵ #1.System Type↵

#0:CSL / 1:IDT↵ #0:CSL / 1:IDT↵

FFDM00232

• Set font (language) to match the syngor installation:

For english use the fo llowing settings:

Old New

FNT=0↵ FNT=1↵

#2.FONT (LANGUAGE)↵ #2.FONT (LANGUAGE)↵

For german use the following settings:

Old New

FNT=0↵ FNT=2↵

#2.FONT (LANGUAGE)↵ #2.FONT (LANGUAGE)↵

DIGISCAN M Register 4 SPB7-420.815.01 Page 4 of 10 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 25

Installation and start-up of the image reader 3 - 5

For french use the following settings:

Old New

FNT=0↵ FNT=3↵

#2.FONT (LANGUAGE)↵ #2.FONT (LANGUAGE)↵

For spanish use the following settings:

Old New

FNT=0↵ FNT=4↵

#2.FONT (LANGUAGE)↵ #2.FONT (LANGUAGE)↵

• Replace the IP address of the CPU90F board (Item No. 4):

Old New

IPI=”172.16.0.2 “↵ IPI=”192.168.1.100 “↵

#4.IPAddress(CPU90F)(Length=15)↵ #4.IPAddress(CPU90F)(Length=15)↵

NOTE

Make sure that the length of the IP address is 15, i.e.

IPI=”192.168.1.100xx” where x is empty space.

• Change the screen saver setting time from 5 minutes to 1 minute (Ite m No. 14):

Old New

SSI=5↵ SSI=1↵

#14. Screen Saver Timer↵ #14. Screen Saver Timer↵

#0-60 [min]↵ #0-60 [min]↵

• Enable the distribution code:

Old New

ID_DST=0↵ ID_DST=1↵

#44. Distribution Code Setting↵ #44. Distribution Code Setting↵

#0:DISABLE / 1:ENABLE↵ #0:DISABLE / 1:ENABLE↵

• Touch [SAVE].

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 5 of 10 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 26

3 - 6 Installation and start-up of the image reader

• Select [4][ENT] for EQUIPMENT.

• Replace iip with AWS:

Old New

IDT iip↵ IDT AWS↵

and type # in front of DISPLAY to disable t hat function.

• Touch [SAVE].

• Select [6][ENT] for NETWORK HOST INTERFACE (DEVICE).

• Replace:

Old New

iip:DISPLAY,0200,,,↵ AWS:DISPLAY,0200,,,2↵

• Touch [SAVE].

• Select [7][ENT] for HOST ADRESSES (HOSTS).

• Replace:

Old New

172.16.0.2 fcr5000-n↵ 192.168.1.100 fcr5000-n↵

172.16.1.20 iip↵ 192.168.1.1 AWS↵

• Touch [SAVE].

• Select [8][ENT] for DISTRIBUTION (CODEDSTB).

• Add:

Old New

#Code Host Name [HostName]...↵ #Code Host Name [HostName]...↵

00000001 AWS↵

• Touch [SAVE].

• Select [10][ENT] for NETMASKS (NETMASKS).

• Add:

Old New

172.16.0.0 255.255.0.0↵ 172.16.0.0 255.255.0.0↵

192.168.1.0 255.255.255.0↵

• Touch [SAVE].

DIGISCAN M Register 4 SPB7-420.815.01 Page 6 of 10 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 27

Installation and start-up of the image reader 3 - 7

• Select [11][ENT] for DICOM (Base on DICOM).

• Replace:

Old

fcr5000-n,STORAGE_U:DICOM_IR,,1,1,100,600,2↵

iip,STORAGE_P:DICOM_IIP,21760,1,1,100,600,2↵

New

fcr5000-n,STORAGE_U:DICOM_DPR,,2,0,100,600,2↵

AWS,STORAGE_P:DICOM_HIC,21760,2,0,100,600,2↵

NOTE

Make sure that the settings are correct.

• Touch [SAVE].

• Touch [0][ENT].

• Touch [0][ENT].

• Touch [QUIT].

• Turn OFF the system power switch and back ON.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 7 of 10 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 28

3 - 8 Installation and start-up of the image reader

PLEASE SET A FD.

ARE YOU SURE TO COPY SCANNER DATA FILES TO THE FD ?

1.YES 2.NO (DEFAULT=2) :

<When the FD is full>

<When there is some file that cannot be written to the FD>

Backup 3

• Start the M-Utility.

• Select [7][ENT] for FILE UTILITY.

• Select [3][ENT] for BACKUP.

• Select 1. SCANNER DATA.

FFDM00213

• Put the floppy disk into the floppy disk dri ve, and select 1.

XXXXXXXXXX IS COPIED.

XXXXXXXXXX IS COPIED.

.

.

.

XXXXXXXXXX IS COPIED.

FFDM00214

XXXXXXXXXX: Fi le name

<When the FD is full>

THE FD IS FULL. EXCHANGE OTHER ONE.

1.CONTINUE 2.CANCEL (DEFAULT=2) :

Replace the floppy disk, and select 1.

<When there is some file that cannot be writ ten to the FD>

FILE I/O ERROR. (FILE=XXXXXXXXXX)

XXXXXXXXXX: File name

• Repeat this backup procedure for:

2. CONFIGURATION DATA

3. NETWORK DATA

4. IMAGE PROCESSING DATA

5. CSL MENU DATA

6. EDR PROCESSING DATA

• Touch [0][ENT].

FFDM00215

FFDM00216

• Touch [0][ENT].

• Touch [QUIT].

• Proceed with Checking and deleting the error log duri ng setup in Fuji Service Manual

FCR 5000MA plus, 009.058... chapter Install ation.

DIGISCAN M Register 4 SPB7-420.815.01 Page 8 of 10 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 29

Installation and start-up of the image reader 3 - 9

Check HOSTS file 3

• Press the keyboard button to call up the Windows Start menu.

• In the Start menu select Programs > Accessories > Windows Explorer.

• In Windows Explorer right click on the file C:\WINNT\system32\drivers\etc\HOSTS

and choose Open With... from the menu.

• The Open With di alogue window opens. Choose Notepad from the list and cli ck on the

OK button.

• Check that the file contains the following line:

192.168.1.100 fcr5000-n

• If not, add the line last in the file and choos e File > Save.

• Close the file.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 9 of 10 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 30

3 - 10 Installation and start-up of the image reader

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 10 of 10 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 31

Start-up of the viewing station (option) 4

MagicView 1000 4

Start-up procedure 4

Start-up the viewing station according to MagicView 1000 Installation and Start-up,

P02-021.814... .

4 - 1

NOTICE

The time zone must be set up according to the country of installation to avoid image transfer problems.

Make sure that the date and time zone settings are correct.

Software configuration 4

Install the mammography user account according to DIGISCAN M Software MagicView

1000 configuration for mammography, SPB7-420.816.02... .

NOTICE

MammoReport

This can be done only by a PACS trained CSE!

Plus

Start-up procedure 4

Start-up the viewing station according to MammoReport

Instructions, SPB7-420.814.01... .

Plus

Installation and Start-up

4

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 2 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 32

4 - 2 Start-up of the viewing station (option)

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 2 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 33

Start-up of the hardcopy camera 5

Hardcopy camera requirements 5

Recommended hardcopy cameras 5

Hardcopy cameras released for the DIGISCAN M system are listed in the document

DIGISCAN M Hardcopy Camera Information, SPB7....

5 - 1

NOTE

NOTE

The hardcopy camera must be operational.

NOTE

NOTE

Only these hardcop y cameras were tested and released. Other

hardcopy cameras may create unexpected trouble!

Requirements for optional hardcopy cameras:

That it can receive DICOM print, has a

resolution of 50x50 µm, density W3.5 and can print 18x24 and

24x30 film format.

The input for the hardcopy camera must be set to linear and maximum density by the camera manufacturer’s technician.

The function of the hardcopy c amer a is tested in "Function

check" on Page 6 - 1.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 2 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 34

5 - 2 Start-up of the hardcopy camera

This page intentionally left blank.

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 2 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 35

Function check 6

6 - 1

NOTE

The acquisition workstation must be properly entered in all corresponding modalities (viewing station etc.) prior to the network

function check.

The required steps are described in the instructions for the corresponding modalities. All required informat ion regarding this can

be taken from the chapter “Data sheet and notes for connected

stations” in DIGISCAN M Software acquisit ion workstation, SPB7-

420.816.01... .

Switch on the system 6

• Switch on the image reader.

➪ Booting takes approximately 5 minutes until the utility screen will be displayed.

• Switch on the MAMMOMAT 3000 Nova.

• Switch on the viewing station (option) and start t he application.

• Switch on the hardcopy camera (recommendation).

• Switch on the acquisition workstation and login as meduser.

➪ After approximatel y 30 seconds the Examination task card will be displayed.

Function check of the acquisition workstation 6

Image transfer 6

NOTE

• Activate the Examination task card at the acquisi tion workstation.

• Register a cassette according to DIGISCAN M Instructions for use , SPB7-420.201.01...

• Click on the Patient Registration button and re gister a patient with the follo wing entries:

Last name: enter the name “Function check”.

Date of Birth: enter the current date.

Sex: select Other.

• Click on the Exam button to finish the registrat ion.

• Slide the L-cc label on the object table into t he beam path.

• Expose an 18x24 mm IP cassette in the MAMMOMAT 3000 Nova using a

4 cm plexi.

• Read barcode for exposed IP cassette.

• Read the projection view barcode L-cc.

For detailed information how to perform an examination, see

DIGISCAN M Instructions for use, SPB7-420.201.01... .

• Read the IP cassette in the image reader.

• After approximately 100 seconds, the image sho uld have arrived at the acquisit ion

workstation.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 4 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 36

6 - 2 Function check

• Click on the End of examination button to exit the examinat ion.

• Depending on the work routine of the hospital, e nsure that the image is archived on the

MOD and/or CD-R and/or sent to an archive sy stem, and sent to a viewing station

(option).

WARNING

Images can not be archived on MOD or CD-R or sent to an ar chi ve

system from the MammoReport

Images will not be saved.

Send acquired images both to an archive system and to the Mam-

moReport

Plus

from the acquisition workstation.

Plus

(option).

• Following the above-listed procedure, expose and read out another image. Use the

same patient data but slide the R-cc label into the beam path and read the projection

view barcode R-cc.

• After the last image was displayed on the acquisition wor kstation, check in the Patient

Browser that the two images have been filed in one folder.

Filming (option) 6

• Activate the Viewing task card.

• Call up Options > Configuration... > Filming Layout .

• Select the Series tab.

• Deselect Reference image.

• Under Aspec t Ratio select Keep visible part.

• Press Apply and then OK.

• Select one of the images in the Patient Browser.

DIGISCAN M Register 4 SPB7-420.815.01 Page 2 of 4 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 37

Function check 6 - 3

• Call up Patient > Copy to Film Sheet in the main menu or by us ing the symbol keypad.

• Switch to the Filming task card.

• In Camera t ab, select Film Size Inch 11x14.

• In Images tab, select .

• Call up Film > Expose Film Sheet.

• Check that the image is exposed in normal size and without any de formation.

Make sure that the two projection v iews displayed in the image are shown from th e same

side.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 4 DIGISCAN M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 38

6 - 4 Function check

Function check of the viewing station (option) 6

MagicView 1000 6

Image transfer

• Open the “Function check” patient.

• Check that the two images are loaded and displayed correctly on the scre ens. Make sure

that the two projection views displ ayed in the images are shown from the same side.

• Check that the text information about the patient and the study is displayed correctl y in

the images.

• If the images were not archived on MOD and/or CD-R and/or sent to archive system from

the acquisition workstation, do i t from the viewing station.

• Check that the images were archived and/or sent correct ly.

• Remove the images from the viewing station.

• Import the images from MOD, CD-R or archive system.

• Check that the images are displayed correctly .

Filming (option)

• Click on the first image to select it.

• Select the Quick print function in the Networking menu.

• Check that the image is exposed in normal size and without any deformation. Make sure

that the two projection views displ ayed in the image are shown from the same side.

MammoReport

Image transfer

Plus

• Make sure that the images also are sent from the acquis ition workstation to an archi ve.

• Open the “Function check” patient.

• Select single tiling so that one image is shown on each screen.

• Check that the two images are loaded and displayed correctly on the scre ens. Make sure

that the two projection views ar e displayed in the images.

• Check that the text information that is displa yed in the images and in the patient li st is

correct.

Filming (option)

6

• Click on the DICOM print button.

• Click in the Print left Monitor check box.

• Press the Print button.

• Check that the images are printed out correctl y.

DIGISCAN M Register 4 SPB7-420.815.01 Page 4 of 4 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 39

AEC settings 7

General 7

These instructions describe installation of AEC floppy disk with material No. 66 01 897.

This floppy disk makes AEC tables for Fuji CR HR-BD imaging plate in IP CASS-BD M

available.

The AEC is based on correction tables. The tables are optimized for the IP/cassette

combinations in table 1.

Table 1 Correction table identifications

Scanner IP Cassette Sensitivity Mo/Mo Mo/Rh W/Rh

7 - 1

DIGISCAN M Fuji

CR HR-BD

Fuji

IP CASS-BD M

0 1401 1402 1403

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 1 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 40

7 - 2 AEC settings

m

A

p

Definitions 7

AD Value

D V alue

ax 1023

450

min 0

0.01 0.1 1 10

log Ex

Old backup floppy disk Backup floppy disk to store data from before the

installation. To be marked “Old backup” and with serial

No. of system, date, and version of the correction tables.

New backup floppy disk Backup floppy disk to store data during and after the

installation. To be marked “Ne w backup” and with serial

No. of system, date, and version of the correction tables.

Digiscan M Register 4 SPB7-420.815.01 Page 2 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 41

AEC settings 7 - 3

Protective measures 7

It is very important that any interv ention in the equipment wil l start by disconnect ing it from

the power supply with the main circuit-breaker.

WARNING

WARNING

If the system is only switched off at the control panel or with

S2/D711, line vol ta ge will still be prese nt a t the generat or l ine connection, line filter Z1, Z2, transformer T1, transformer T10 and

PC board D711 (see MAMMOMAT 3000 Nova Wiring Diagram).

Life-threatening electric shock hazard exists.

Disconnect mains cable and comply with the information on this

page.

After shut-down of the system, there may still be 380 V DC

present on the intermediate circuit.

Life-threatening electric shock hazard exists.

The voltage level will be indicated by LED V24 on PC board D710.

The voltage will dr op to less than 30 V withi n about 3 minutes, the

LED goes out at about 30 V.

Symbols 7

Checks and adjustments that m ust be perf ormed with radi ation ON are i dentif ie d

by the radiation w a rning symbol.

Delay times between two exposures 7

Delay times listed below must be followed in or der to prevent the tube from overheating.

Exposure mAs value Delay time between two e xposures (seconds)

max 100 min 15

max 200 min 30

max 300 min 45

max 400 min 60

max 500 min 75

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 3 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 42

7 - 4 AEC settings

Preparation 7

1. System ON.

2. Login as meduser.

3. Open Windows Explorer.

4. Create a new folder under drive D: and name it “AEC_i nst”.

5. Insert the service program floppy i n drive A:.

6. Copy the files service.exe and m3000.h60 fr om A: to AEC_inst.

7. Insert the floppy AEC correction tabl es in drive A:.

8. Copy the AEC correction tables from A: to AEC_inst.

9. Mark an empty backup floppy with new backup, s erial number of system, version

of the correction tables, and d ate. Insert the floppy in dri ve A.

10. Copy the content of AEC_inst to A:.

Use this floppy for the rest of the i nstallation.

11. If AEC correction tables have been install ed on the MAMMOMAT before, make a

backup of these tables, see "Backup of ex isting system" on Page 7 - 6.

12. Select Options > Service > Local Service in the window menu header.

13. Enter the service key (6 chara cters in 2nd mask).

14. Confirm the screen with OK. The Service Home menu appears.

Digiscan M Register 4 SPB7-420.815.01 Page 4 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 43

AEC settings 7 - 5

15. Select Quality Assurance.

16. In Source select AEC Calibration.

17. In AEC Calibration select Enable calibration mode.

18. Select Go in the action bar.

19. Minimize the Quality Assurance window.

20. Press Start and select Programs > Accessories > Command Prompt.

21. In the DOS prompt, type:

“A:” and press Enter,

“service” and press Enter.

22. - In the log in-menu, enter you r name and press Enter.

- Type the password for the service pr ogram and press Enter.

- In Program-mode set: normal.

23. Proceed with "Definiti ons" on Page 7 - 8.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 5 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 44

7 - 6 AEC settings

Backup of existing system 7

1. Press Start and select Programs > Accessories > Command Prompt.

2. In the DOS prompt, type:

“CD \” and press Enter,

“MKDIR mammomat” and press Enter,

“CD mammomat” and press Enter,

“A:” and press Enter.

3. Make sure that the service fl oppy is still in drive A:.

4. Start the service program by writi ng: Service , then press Enter.

5. - In the log in-menu, enter your name and pr ess Enter.

- Type the password for the service progra m and press Enter.

- In Program-mode set: normal.

6. Check that service program version 4. 3 or higher is used. The version is shown in

the top left corner of th e display.

7. In Mainmenu select Configuration > Power. Note the d isplayed power values in

the test protocol on Page 11 - 1.

8. Take the backup to hard disk: Backup > Copy insta llation area to disk > All.

9. Take out the floppy with the service pro gram and insert an empty floppy disk and

mark it with old backup, serial number of system, version of the cor rection tables,

and date. This floppy is defined as old backu p floppy.

10. In Mainmenu select Configuration > Save config file. Press F2 to save.

11. In Mainmenu select Service > Copy erro r buffer to file.

12. If the MAMMOMAT is equipped with OPDOSE, press the left program button on

the panel. Note the display ed exposure settings in the test prot ocol on Page 11 - 1.

Repeat for all four programs. Enter menu Conf iguration > Miscellaneous >

Auto limits. Note the three values i n test protocol on Page 11 - 1, in column

“Breast thickness”.

13. Quit the service program by pres sing F10.

14. Type “C:”.

15. Type “COPY *.TXT A:”.

Digiscan M Register 4 SPB7-420.815.01 Page 6 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 45

AEC settings 7 - 7

16. Check that the following backu p files are stored on the floppy disk (b y typing

“dir a:”, then pressing Enter):

- a_backup.txt for AEC parameters

- s_backup.txt for stand parameter s

- p_backup.txt for panel parameter s

- momo_h.txt for AEC correction tables

- morh_h.txt for AEC correction tabl es

- wrh_h.txt for AEC correction tabl es

- momo_d.txt for AEC correction tables

- morh_d.txt for AEC correction tabl es

- wrh_d.txt for AEC correction tabl es

- mammo.cfg for configuration parameters

- errorbuf.txt for err or log

17. Type “DEL *.TXT”.

18. Remove the floppy disk and make it write pr otected.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 7 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 46

7 - 8 AEC settings

Definitions 7

Object table group 7

An object table group contai ns all object tab les of the same type. There are four groups of

object tables - Grid, No grid, Magni fication and Stereo. For example the object tab le g roup

Grid, consists of Grid 18x24 and Grid 24x30.

NOTE

Stereo shall not be used together with DIGISCAN M.

General conditions 7

When performing the settings in this chapter, there are some general conditions valid for

all settings:

• The detector is to be in chest wall positi on.

MAM00616

• The AEC calibration plexi (material No. 65 61 224 and 65 61 232) must extend at leas t 10

mm beyond the chest wall edge of the table and be centere d. Place the AEC calibration

plexi in the same position for all exposures.

Calibration conditions 7

Compression plate must not be used during the calibration of corre ction tables. From the

point sensitivity correction (fine setting) a compression plate may be used.

Reference IP cassette 7

Every DIGISCAN M system should have a reference IP cassette. Use this reference IP

cassette where required and for the settings in this chapter. If there is no dedicated reference IP cassette, pick one IP cassette, mark it and use it for the settings in this chapter.

Mains voltage 7

Unless otherwise stated, the mains voltage and system must be ON and the service program running, before performing any setting in this chapter.

Sensitivity conditions 7

One step (1/8 E.P.) corresponds to approximately 4 AD Values.

Digiscan M Register 4 SPB7-420.815.01 Page 8 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 47

AEC settings 7 - 9

Overview of work routine 7

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

AEC

Miscellaneous

Filament

AEC

Reset installation parameters

Detector normalization

AEC Correction tables

Sensitivity correction

Copy H to D

Copy D to H

Sensitivity

MAM00611

1. "AEC Correction tables" on Page 7 - 11.

2. "Sensitivity correcti on (fine setting)" on Page 7 - 21.

3. "Sensitivity" on Page 7 - 25.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 9 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 48

7 - 10 AEC settings

DLF switch off 7

Deactivate the DLF switch. In Main menu select Configuration > Miscellaneous > DLF

switch, press space to set switch to OFF. Press F2 to save.

Cassette loaded 7

In Mainmenu select Configuration > Miscellaneous > Cassette loaded check. Set to

OFF during the whole installation.

Increase grid speed 7

Increase the grid speed. In Main menu select Configuration > Grid speed. Set the fol-

lowing values:

Grid

Grid fast speed time 1500

Grid fast speed 90

Grid slow speed 30

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

ms (2.5 s max)

% of max

% of max

MAM00761

Digiscan M Register 4 SPB7-420.815.01 Page 10 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 49

AEC settings 7 - 11

AEC correction tab

AEC Correction tables 7

This section will guide you through the following steps:

• Installation of correction tables ( F2).

• Calibration of correction tables (F3), including rough setting of sensitivity correction.

The AEC uses one correction table for each Anode/Filter/Speed combination. Each correction table has separ ate corrections for eac h object tabl e group (Magnifi cation, Grid and

No grid).

Installation of AEC correction tables 7

1. In Mainm enu select Configuration > AEC > AEC correction tables.

The dashes in the ID column show that no correct ion table is installed (

Fig. 1

).

AEC correction tab

Existing tables in the AEC:

Anode/Filter Speed ID Calibrated

Mo/Mo H ---- --- --- --- --Mo/Mo D ---- --- --- --- --Mo/Rh H ---- --- --- --- --Mo/Rh D ---- --- --- --- --W/Rh H ---- --- --- --- --W/Rh D ---- --- --- --- ---

<ESC> to exit, <F2> to install new table, <F3> to calibrate existing

1 Help 2 Inst Cal3 45678910Quit

Fig. 1 AEC correction tables

NOTE

Install the correction tables on D only!

les

Mag Grid No grid Stereo

MAM00599

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 11 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

2. Make sure that the new backup floppy is in serted.

3. Decide for which combination you need to inst all correction table. (F or av ailable

identifications for correc tion tables see Table 1, Page 7 - 1 or the new back up

floppy.)

Page 50

7 - 12 AEC settings

4. Place the cursor by one of the desired Anod e/Filter/Speed combinations. Press

F2.

Install new table

New ID: 0000

<F2> to continue, <ESC> to exit

MAM00600

5. Type the ID number of the new correction table ( see Table 1, Page 7 - 1) in the

dialog which appears. Press F2 to ins tall the table. A message box will appear

before the correction file has been f ound.

Searching for correction file...

MAM00736

Installing correction table

ID: 1401 for Mo/Mo D

29% done

MAM00880

6. When the transaction of tables is finished, a dialog like Fig. 2, Pag e 7 - 14 will

appear. To complete the calibr ation, proceed from step 5 of that se ction.

NOTICE

In order to resume calibrati ng aft e r having quit the program:

Follow the instructions from step 1 under "Calibrate correction

tables" on Page 7 - 13.

Digiscan M Register 4 SPB7-420.815.01 Page 12 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 51

AEC settings 7 - 13

AEC correction tab

Calibrate correction tables 7

NOTE

The new backup floppy must be inserted.

The Anode/Filter/Speed combinations should be cali brated one at a time.

1. In Mainm enu select Configuration > AEC > AEC correction tables.

AEC correction tab

Existing tables in the AEC:

Anode/Filter Speed ID Calibrated

Mo/Mo H ---- --- --- --- --Mo/Mo D 1401 No No No No

Mo/Rh H ---- --- --- --- --Mo/Rh D 1402 No No No No

W/Rh H ---- --- --- --- --W/Rh D 1403 No No No No

<ESC> to exit, <F2> to install new table, <F3> to calibrate existing

1 Help 2 Inst Cal3 45678910Quit

les

Mag Grid No grid Stereo

MAM00881

NOTICE

All object table groups and Anode / Filter combinations available

at the site must be calibrated prior to release for clinical use.

2. Place the marker by one of the desired Anode/Fil ter/Speed combinations. Press

F3 to transfer the table.

3. This message box is displayed while the serv ice program receives the correction

table.

Receiving correction table

for Mo/Mo D

63% done

MAM00882

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 13 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 52

7 - 14 AEC settings

4. When the transfer is done, the dialog Calibr ation AEC correction table appears.

Calibration AEC correction table

Mo/Mo D, Table ID: 1401

Object table group

Magnification Not calibrated

Grid Not calibrated

No grid Not calibrated

Stereo Not calibrated

<ESC> to exit, <F2> to save, <F3> to calibrate, <F4> to clear calibration

1 Help 2 Save Cal3 45678910Quit

Fig. 2 Dialog Calibration AEC correction table shows which object tables, in the current Anode/Filter/Speed

combination, have been calibrated.

Clear

5. To calibrate the correction table for an object table group, place the cur sor in front

of the group. Press F3.

Please mount a

grid table

and press <ENTER> to continue

or <ESC> to cancel.

MAM00608

NOTE

<ENTER> - ok / <ESC> - cancel

Calibration of correction tabl es for Stereo is not included in

DIGISCAN M.

MAM00883

Digiscan M Register 4 SPB7-420.815.01 Page 14 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 53

AEC settings 7 - 15

6. Follow the instructions in t he message box above and press Enter.

Sensitivity correction

Used: 0

New: 0

<F2> save, <F3> exp support, <F4> continue, <ESC> exit

Fig. 3 Dialog Sensitivity correction

MAM00764

7. Before calibrating the i nstalled correction tab les, it is necess ary to make a rough

setting of the sensitivity co rrection for the chosen object tab le group .

8. Press the keyboard button to switch to the Examination task card. If the

Quality Assurance window is maximized, minimize i t.

9. Click on the Patient Registration butt on and register a patient with the fol lowing

entries:

Last name: enter the name “AEC patient”.

Date of Birth: enter the current date.

Sex: select Other.

10. Click on the Exam button to fini sh the registration.

11. Check that the AEC symbol is displayed on the Examination task card.

AEC symbol

12. Press the keyboard button and click on the Command Prompt button in the

lower taskbar to switch to the ser vice program.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 15 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 54

7 - 16 AEC settings

13. Insert the referenc e IP cassette in the object table.

NOTE

NOTE

Press F3.

14. Follow the instructions in the message box in the service program for pe rforming

an exposure.

15. Press Enter.

16. Press the keyboard button to switch to the Examination task card.

17. Read barcode for exposed IP cassette.

18. Read the projection view barcode L-cc.

Make sure the new backup floppy is inserted.

Do not use a compression plate.

Please put x cm of Plexi

on the object table.

Perform an exposure and

press <ENTER> when ready

or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

MAM00728

19. Read the IP cassette in the image rea der.

20. Register the mean value (AD Value) that i s displayed on the screen and press OK.

21. If the value differs from 450, switch to the service program, adj ust the values in

dialog AEC - Sensitivity correction (Fig. 3) and save the new Sensitivit y correction

value with F2. Repeat the procedures described f rom step 6 to step 20 until the

value 450 is reached.

If the value is satisfactory, proceed by pr essing F4. Switch to the Examination task

card and click on the End of examination butt on to exit the examination.

NOTE

One adjustment step of sensitivity correction (1/8 E.P.)

corresponds to approximately 4 AD Values, i.e.

450 x–

----------------- -

y=

4

x = obtained mean value

y = suggested adjustment for sensitivity correction

Digiscan M Register 4 SPB7-420.815.01 Page 16 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 55

AEC settings 7 - 17

NOTE

It is important to use 450 and the specified AEC calibration plexi

(material No. 65 61 224 and 65 61 232) during the procedures

under “Calibrate correction tables”, since measurements are

relative to factory results at 450.

The AD Value preferred by the customer can be adjusted later

either in Sensitivity correction or Sensitivity.

22. Press the keyboard button and click on the Command Prompt button in the

lower taskbar to switch to the ser vice program.

23. Take another IP cassette than the r eference IP cassette. Since it will not be

developed, the IP cassette can be used for all exposures during the following

calibration.

NOTE

Using secondary erasure, erase the used IP cassette after the

fourth exposure, otherwise the IP cassette cannot be utilized for

one day.

Calibration object table group

Mo/Mo D, Table ID: 1401, Object table group Grid

Exp. Plexi kV Dose rate Diff. from nominal

1 3 25 --------- ------2 3 28 --------- ------3 4 25 --------- ------4 4 32 --------- ------5 4 35 --------- ------6 6 25 --------- ------7 7 28 --------- ------8 7 32 --------- ------9 7 35 --------- -------

<ESC> to exit, <F2> to calibrate & save, <F3> to measure dose rate

1 Help 2 Save Exp support3 4 5 6 7 8 9 10 Quit

Fig. 4 Dialog Calibration object table group shows the dose rates for a number of exposures. The dashed

lines below Dose rate indicate that no exposures have been performed yet.

MAM00885

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 17 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 56

7 - 18 AEC settings

24. To proceed with the calibration, pl ace the cursor by one of the alternativ es. Press

F3.

Please put x cm of Plexi

on the object table.

Perform an exposure and

press <ENTER> when ready

or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

MAM00728

25. Follow the instructions in the message box shown.

NOTE

Do not use 2 8 1 cm plexi plates instead of a 2 cm plate.

26. When the exposure is done, the dialo g Calibration exposure appears with values

for Dose rate and Diff. from nominal.

Calibration exposure

Mo/Mo D, Table ID: 1401, Object table group Grid

Exp. 5

Tension 25 kV

PMMA 4 cm

Dose rate 267.23

Diff. from nominal -21.47%

<ESC> to exit, <F2> to save, <F3> to perform exposure

1 Help 2 Save Exp support3

5678910

4

Quit

MAM00884

NOTE

If the Diff. from nominal exceeds &50% ensure that the exposure

really has taken place, the thic kness of AEC calibration plexi

(material No. 65 61 224 and 65 61 232) is correct and properly

positioned and that the cassette (loaded with IP) is inserted and

repeat the last exposure. If the difference still exceeds +50%

accept the value and proceed.

27. Save the values with F2.

28. Repeat steps 24 to 27 until all expos ures are done.

29. Perform a primary erasure of the IP cas sette according to Fuji Operating Manual

FCR5000MA plus.

30. When all exposures for one object table gro up are done, save the values with F2

in the dialog Calibration object tab le group.

31. The dialog Calibration AEC correction table appea rs. Select the next object table

group and repeat steps 5 to 31.

Digiscan M Register 4 SPB7-420.815.01 Page 18 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 57

AEC settings 7 - 19

32. When all desired object t able groups are calibrated, pre ss F2 to install the

calibrated correction table in the AEC.

Installing correction table

ID: 1401 for Mo/Mo D

29% done

MAM00880

33. The dialog AEC correction tabl es appears. Repeat from step 2 until all avail able

Anode/ Filter combinations are cali brated.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 19 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 58

7 - 20 AEC settings

Recalibration of an object table 7

An already calibrated object table group can be recalibrated.

NOTE

1. Repeat the procedure described in steps 1 to 4, Page 7 - 13.

2. To recalibrate a correction table for an object table group, place the cur sor in front

of the group. Press F4. This will res et the existing calibration of the chosen object

table group and replace it with the origi nal correction table stored on the fl oppy.

3. Press F2 to save.

4. Recalibrate the desired object tabl e group according to the normal procedure,

from step 2, Page 7 - 13.

Make sure the new backup floppy is inserted.

Digiscan M Register 4 SPB7-420.815.01 Page 20 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 59

AEC settings 7 - 21

MAM00532

Sensitivity correction (fine setting) 7

NOTE

New backup floppy must be inserted. The specified AEC

calibration plexi (material No. 65 61 224 and 65 61 232) must be

used.

When all desired object table groups are calibrated, a fine setting of the sensi tivity correction should be performed for all av ailable object tables.

AEC - Sensitivity correction

HD

Mo/Mo Mo/Rh W/Rh Mo/Mo Mo/Rh W/Rh

Grid 18x24 0 00 000

Grid 24x30 0 0 0 0 0 0

No grid 18x24 0 0 0 0 0 0

No grid 24x30 0 0 0 0 0 0

Magnification 1.5 0 0 0 0 0 0

Magnification 1.8 0 0 0 0 0 0

Stereo 0 0 0 0 0 0

valid entries from -120 to 120 in 1/8 E.P. (+/-15 E.P.)

<ESC> to exit, <TAB> move to next entry field, <F2> to save, <F3> exp support

1 Help 2 Save 3 45678910Quit

Fig. 5 Set the sensitivity correction for all desired object tables.

Exp support

1. In Mainmenu select Configuration > AEC > Sensitivi ty correction.

2. Press the keyboard button to switch to the Examination task card.

3. Select Options > Service > Local Service in the window menu header.

4. Enter the service key (6 charac ters in 2nd mask).

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 21 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 60

7 - 22 AEC settings

5. Confirm the screen with OK. The Service Home menu appears.

6. Select Quality Assurance.

7. In Source select AEC Calibration.

8. In AEC Calibration select Enable calibration mode.

9. Select Go in the action bar.

10. Minimize the Quality Assurance windo w.

11. Click on the Patient Registration button and register a pat ient with the following

entries:

Digiscan M Register 4 SPB7-420.815.01 Page 22 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 61

AEC settings 7 - 23

Last name: enter the name “AEC patient”.

Date of Birth: enter the current date.

Sex: select Other.

12. Click on the Exam button to fini sh the registration.

AEC symbol

13. Install an object tabl e.

14. Insert the reference IP cassette in the object table.

15. Press the keyboard button and click on the Command Prompt button in the

lower taskbar to switch to the ser vice program.

16. Select F3 for support and perfor m an exposure.

NOTE

17. Press Enter.

18. Press the keyboard button to switch to the Examination task card.

19. Read barcode for exposed IP casset te.

20. Read the projection view barcode L-cc.

21. Read the IP cassette in the im age reader.

From this point forward a compression plate may be used.

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 23 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 62

7 - 24 AEC settings

22. Register the mean value (AD Value) that i s displayed on the screen and press OK.

23. The AD value should be as close to 400 (factory re commended value) or as close

to customer preferred value as possible. One adjustment step of sensitivi ty

correction (1/8 E.P.) corresponds to appro ximately 4 AD V alues . If the value is

more than 4 AD Values from the preferred value, swi tch to the service program

and adjust the values in dialog AEC - Sensit ivity correction (Fig. 5). Save wi th F2.

Switch to the Examination task card and clic k on the End of examination button

to exit the examination. Repeat t he procedure described in steps 2 to 22.

NOTE

One adjustment step of sensitivity correction (1/8 E.P.)

corresponds to approximately 4 AD Values, i.e.

400(or customer preferred) x–

-------------------------------------------------------------------------4

x = obtained mean value

y = suggested adjustment for sensitivity correction

24. Repeat this procedure for the other obj ect tables if applicable.

y=

Digiscan M Register 4 SPB7-420.815.01 Page 24 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 63

AEC settings 7 - 25

M

Sensitivity 7

Adjustment of AD Value for the whole AEC is performed under Mainmenu > Configuration > AEC > Sensitivity.

AEC - Sensitivity

HD

Sensitivity 0 0

valid entries from -64 to 64 in 1/8 E.P. (+/-8 E.P.)

<ESC> to exit, <TAB> move to next entry field

NOTE

Save

The AD Value preferred by the customer can be set with this

1 Help 2 3 5 678910Quit

function. The customer’s ow n phantom(s) can also be used.

AM00654

Siemens-Elema AB Register 4 SPB7-420.815.01 Page 25 of 32 Digiscan M

Solna, Sweden Rev. 04 11.02 SPS-UD System Manual

Page 64

7 - 26 AEC settings

Testing the AEC-function 7

AEC performance test 7

Testing of the AEC-function is to be performed according to the test protocol, and for the

object tables in question. (Should error codes Er013 or Er450 appear; change to AEC

calibration plexi (material No. 65 61 224 and 65 61 232) which is 1 cm thinner.)

NOTE

NOTE

Tolerance only valid for IP/cassette combinations listed in

Table 1 under "General" on Page 7 - 1.

Use the AEC calibration mode.

Digiscan M Register 4 SPB7-420.815.01 Page 26 of 32 Siemens-Elema AB

System Manual Rev. 04 11.02 SPS-UD Solna, Sweden

Page 65

AEC settings 7 - 27

Reinstall/Inst a ll program para meters for OPDOSE 7

NOTE

If OPDOSE shall be used for the IP cassettes, the following steps

must be done.