Page 1

DIGISCAN M

System Manual

Installation Instructions

System unpacking, installation and cabling

SP

© Siemens AG 2002

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 3 English

Print No.: SPB7-420.812.01.03.02 Doc . Gen. Date: 11.02

Replaces: SPB7-420.201.812.01.02.02 66 31 142

Page 2

0 - 2 Revision

Chapter Page Revision

All All 03

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempti ng installation or service procedures.

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 4 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 3

Contents 0 - 3

Page

1 _______Introduction ___________________________________________________1 - 1

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Documents required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Important notes on installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Basic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Unpacking, transport and installation . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Transport routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Overview of DIGISCAN M (standard system). . . . . . . . . . . . . . . . . . . . . . 1 - 3

Additional parts to the DIGISCAN M system . . . . . . . . . . . . . . . . . . . . 1 - 3

Installation sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

2 _______Unpacking and setup ___________________________________________2 - 1

Important information for the Siemens employee . . . . . . . . . . . . . . . . . . . . 2 - 1

Checking for completeness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Unpacking and setup of the acq uisition workstation . . . . . . . . . . . . . . . . . . 2 - 2

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Unpacking and setup of the image reader . . . . . . . . . . . . . . . . . . . . . . .2 - 3

General remarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Transporting the parts to the installation site . . . . . . . . . . . . . . . . . . . . 2 - 4

Unpacking and setup of the viewing station (option) . . . . . . . . . . . . . . . . . .2 - 6

Unpacking / Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Unpacking and setup of the options. . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

MOD drive (option to acquisition workstation) . . . . . . . . . . . . . . . . . . . .2 - 7

Communication switch (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

3 _______System cabling ________________________________________________3 - 1

Laying and connecting the cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Cable duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Cable connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Ferrite cores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 6

4 _______Final procedures _______________________________________________4 - 1

Remaining work steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Completing the installation protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

5 _______Installation protocol ____________________________________________5 - 1

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 3 of 4 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 4

0 - 4 Contents

6 ______ Changes to previous version _________________ __ ___ _______________6 - 1

DIGISCAN M Register 3 SPB7-420.812.01 Page 4 of 4 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 5

Introduction 1

Safety information 1

When carrying out the work steps and test, the product-specific safety information contained in this document, as well as the general safety information must be observed.

All texts mark ed with call attention to potential risks for health or life.

Documents required 1

• DIGISCAN M Wiring Diagrams in cluding Function Description SPB7-420.844.01...

• Product-accompanying documentation

Tools, meters and appliances required

Standard installation tool kit.

Prerequisites 1

The Installation and Start-Up of the MAMMOMAT 3000 Nova must be completed according to the appropriate SPB7-230.033... instructions.

1 - 1

Important notes on installation 1

Basic information 1

In some countries the image reader is installed, maintained and serviced by the local Fuji

organization. For further information, contact your local Siemens marketing representative.

NOTICE

Unpacking, transport and installation 1

NOTICE

CAUTION

The system responsibility is always within Siemens.

If the image reader is installed by Fuji the installation certificate

has to be filled out, see Page 5 - 1.

All components and accessories in a DIGISCAN M system, including the options, are comprised of high-quality electronic parts.

The components should be transported with extreme care using

suitable transport devices.

Risk of injury!

The picture tube in the SIMOMED monitor (option) is v acuum

parts and can implode if struck, scratched or dropped.

CAUTION

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Risk of damage to property.

The hard disk drive of the image reader is structurally attached

under the top cover.

Do not give any shock to the top co ver of the image reader.

Page 6

1 - 2 Introduction

Unpacking 1

NOTICE

The directional markings on the crates absolutely must be observed during transport,

storage and unpacking.

Because of the risk of accidents a nd endan germent of the cont ents , use only pr oper to ols

(nail puller) when unpacking the crates.

Pull out only those nails from the crate boards that have a cardboard or metal disk under

the nail heads.

CAUTION

The person doing the unpacking ma y not mix up the contents of

the individual cartons.

The contents of the individual cartons must be brought into the

room and kept separated.

To avoid risk of injury, completely remove nails and dispose of

them properly.

Wear safety shoes!

If the crate was also secured with metal straps, take extra care

when cutting them; they can lash back unexpectedly.

In such situations, there is particular risk of accident for eyes!

Transport routes 1

The transport routes should be selected so that the image reader components are subjected to as little stress as possible caused by vibration and dust.

The route should also be selected so that a minimum door opening width of 1100 mm is

maintained.

NOTE

If the door opening is narrower than 1100 mm, the image reader

has to be unpacked outside the roo m.

Cleaning 1

The units may only be wiped down with a cloth moistened with a cleaning agent.

Sprayed water is not permitted.

For further information, see product-accompanying documentation.

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 7

Introduction 1 - 3

5.2 GB

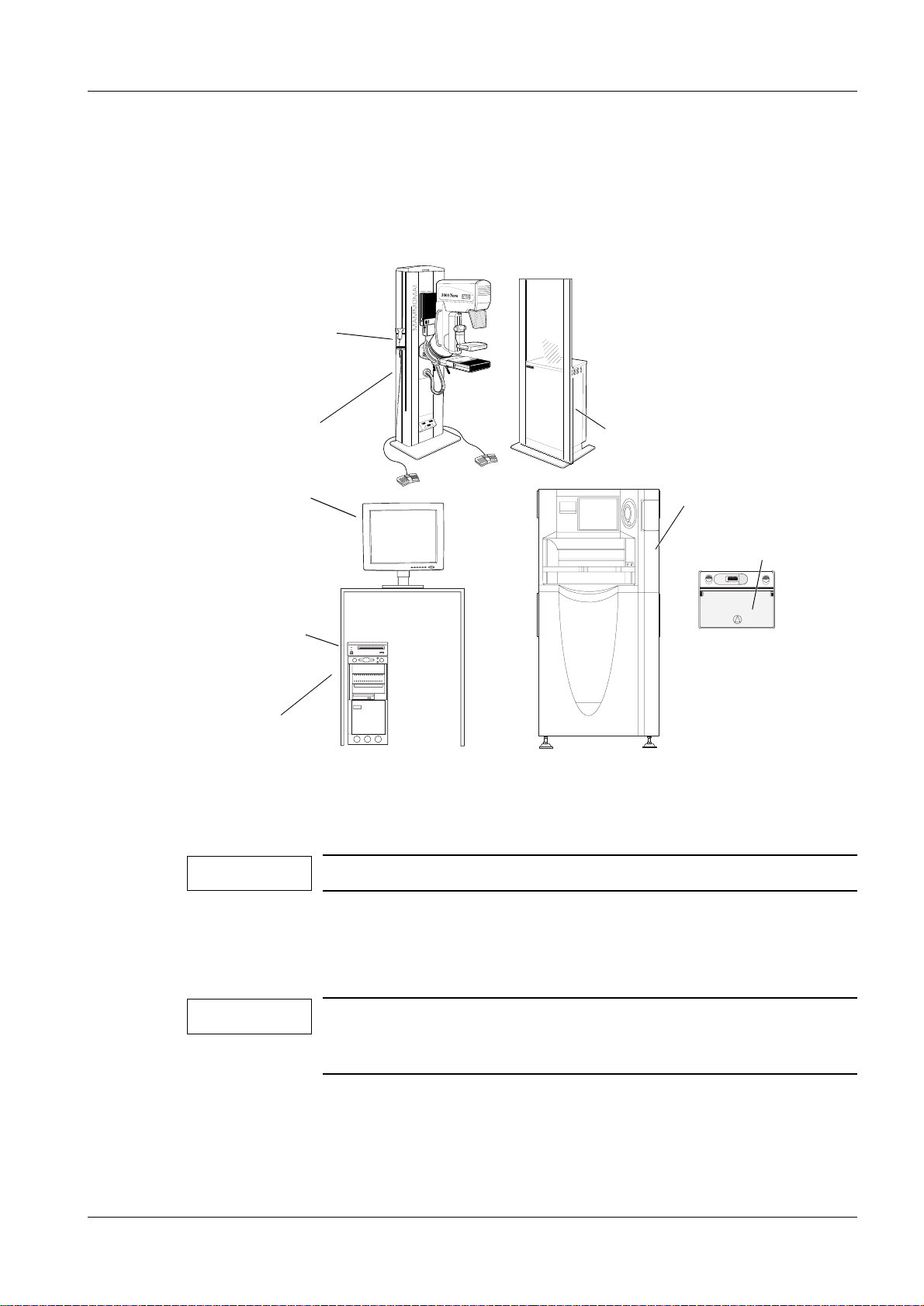

Overview of DIGISCAN M (standard system) 1

An overview of the DIGISCAN M system is provided below. The options of the standard

system are appropriately identified.

For detailed information ho w to arrange the components, see DIGISCAN M Planning

Guide, SPB7-420.891.01... and produc t-accompanying documentation.

Barcode scanner

Stand

with X-ray unit

LCD monitor

SIMOMED

Generator

Image reader

monitor (option)

IP cassette

A30008711C HR-BD

MOD drive (option)

Acquisition workstation

SONY

BUSY

POWER

5.2 GB

CELSIUS

MO

DISK

UNIT

RMO-S551

EJECT

400

FFDM00002

Fig. 1

Additional parts to the DIGISCAN M system 1

NOTE

For actual system options, see price book.

• Viewing station

• Archive system

• Hardcopy camera

NOTE

Use only released hardcopy cameras or a hardcopy camera that

can receive DICOM print, has a resolution of 50x50 µm,

density W 3.5 and can print 18x24 and 24x30 film format.

• HIS/RIS

• Communication switch

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 3 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 8

1 - 4 Introduction

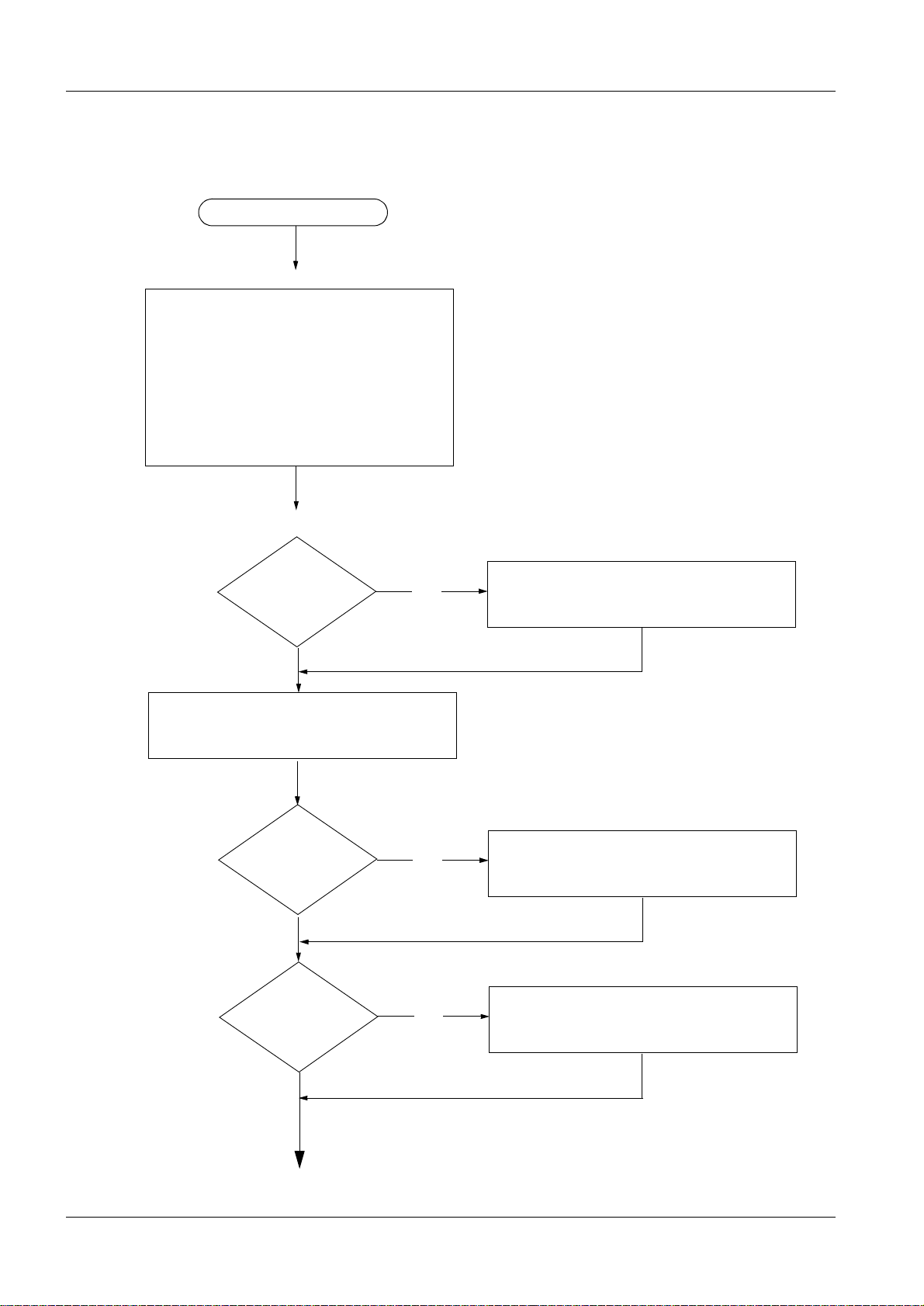

Installation sequence 1

Start of installation

Chapter 1 Introduction

- Safety information

- Documents required

- Tools, meters and appliances

- Prerequisites

- Important notes

- Overview of DIGISCAN M

- Abbreviations

Chapter 2

Unpacking and setup

Hardcopy camera

configured?

No

Check for completeness

Image reader in-

stalled by Siemens?

No

Yes

Yes

Make an appointment with the hardcopy

camera manufacturer at least 2 days prior to starting the installation

Unpack and setup the image reader

Image reader in-

stalled by Fuji?

Yes

In the installation protocol, fill out the

boxes related to the image reader and

sign it (Fuji and Siemens employee)

No

DIGISCAN M Register 3 SPB7-420.812.01 Page 4 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 9

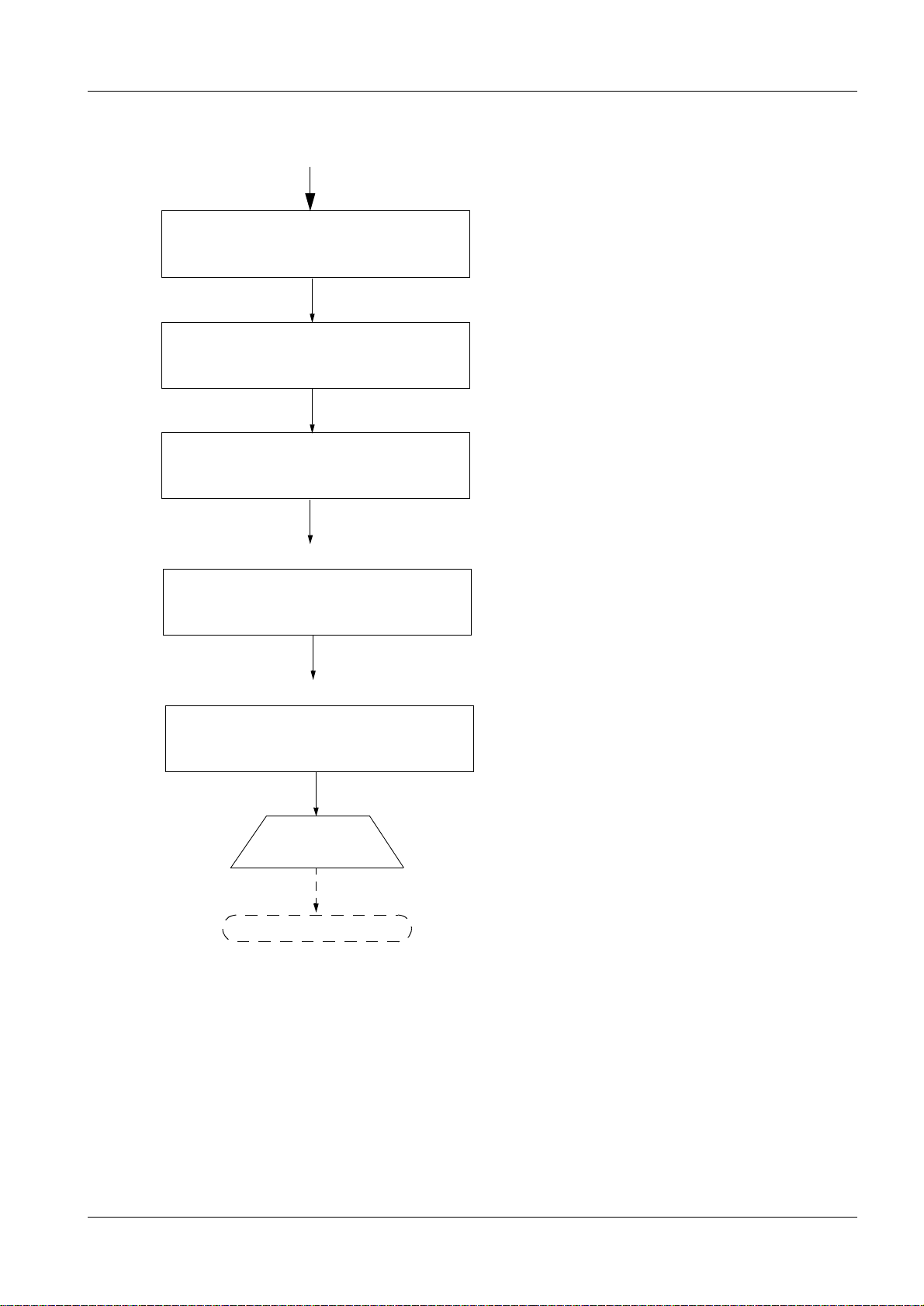

Introduction 1 - 5

Unpack and setup the acquisition workstation

Unpack and setup the viewing station (option)

Unpack and setup the options (if configured)

Chapter 3 System cabling

- Lay cables

- Connect cables

Chapter 4 Final procedures

- Remove packing material

- Complete installation protocol

End of installation

Start-up of the system

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 5 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 10

1 - 6 Introduction

Abbreviations 1

AW S = Acquisition Workstation

IP = I

LUT = L

MOD = M

SMPTE = S

maging Plate

ookup Table

agneto Optical Disc

ociety of Motion Picture and Television Engineers

DIGISCAN M Register 3 SPB7-420.812.01 Page 6 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 11

Unpacking and setup 2

Important information for the Siemens employee 2

If a hardcopy camera is configured, an employee of the hardcopy camera manufacturer

must be present during startup of the DIGISCAN M system; this should be approximately

2 days after start of installation.

This employ ee will have the following tasks:

- Connecting the hardcopy camera to the network.

- Setting the h ardcopy camera input to a linear LUT and the opti cal density to max.

- Checking image tr ansfer together with the Siemens employee.

- Measuring the opt ical density values of the ten gray st eps of the SMPTE test pattern

together with the Siemens employee.

- Performing any ada ptations on the hardcopy camera so that t he reference values

(optical density) of the SMPTE test patter n can be achieved.

2 - 1

NOTE

To avoid delays, it is recommended that the hardcopy camera

manufacturing company is contacted at this time to make an

appointment.

Checking for completeness 2

Check the DIGISCAN M system for completeness accordin g to the packing lists.

Image reader

Acquisition workstation

Viewing station (opti on)

Installation material

Options

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 8 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 12

2 - 2 Unpacking and setup

F

Unpacking and setup of the acquisition workstation 2

Unpacking 2

• Overseas only: unpack the acquisi tion workstation and accessories fr om the crate.

• Unpack accessories from the crat e.

• Do not remove the protectiv e film.

Transport 2

• Move the acquisition workstation and acces sories over the planned transport route using

suitable transport devices to the installation site.

• Remove the protective film f rom the acquisition workstation. Setup 2

• Connect the computer, monitor, keyboard, mouse and barcode scanner according t o

DIGISCAN M Wiring Diagrams including Function Description, SPB7-420.844.01... .

• Mount the holder for the barcode scanner on the MAMMOMAT 3000 Nova stand at a

height of 125+5 cm. Secure the cable in the holder to pr event the barcode scanner from

hitting the floor if dropped.

+

125 5 cm

FDM00255

Fig. 1

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 8 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 13

Unpacking and setup 2 - 3

Unpacking and setup of the image reader 2

General remarks 2

The parts of the image reader are packed as followi ng:

• 1 pallet containing the machine main body.

• 1 pallet containing accessory parts (the light-coll ecting guide assemblies,

documentation, boards, diskettes etc .).

• 1 separately shipped carton containing cassettes and IPs.

Preparation 2

CAUTION

Sensitive parts.

Special care measures must be observed when the parts of the

image reader are unpacked.

The parts may only be unpacked shortly before installing the

components because for this.

Some preparations may howev er be done:

• Remove the top protective cover and the crate pieces. Do not re move the moistur e-proof

sheet.

Fig. 2

• Dispose of the crate pieces. Do not dispose of the top protective cov er, this is required for

transport of the image reader.

• Remove the carton with the separatel y packed accessory parts, do not unpack t hem.

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 3 of 8 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 14

2 - 4 Unpacking and setup

Transporting the parts to the installation site 2

NOTICE

CAUTION

Transport on the casters is permitted only for short distances.

Transporting the image reader across streets and over routes on

the castors installed on the component is not allowed.

Sharp nails.

Risk of injury.

Pull all nails from the carrier pa llet.

• Move the image reader on the carrier pallet to the i nstallation site using a lift truc k.

• Remove the moisture-proof sheet (Fig. 2).

• Remove the four cla mps and raise the adjustable fees of the machine all the way up.

Fig. 3

• Nail the top protective cover onto the carrier pallet ( on the rear side of the machine).

Fig. 4

DIGISCAN M Register 3 SPB7-420.812.01 Page 4 of 8 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 15

Unpacking and setup 2 - 5

• Lower the machine from the carrier pallet.

Fig. 5

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 5 of 8 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 16

2 - 6 Unpacking and setup

5.2 GB

Unpacking and setup of the viewing station (option) 2

NOTE

With the standard system, the vie wing station is equipped with

two monitors.

Unpacking / Transport 2

• If present, remove the protective film from the indivi dually packaged items only at the

installation site.

• Unpack the viewing station tabl e (option) from the crate and transpor t it to the installation

site.

• Unpack the monitors.

• Carry the monitors to the installation site and place them on the viewing station table.

• Carry the computer, keyboard, MOD drive (option), mouse, as well as the cables for the

viewing station to the instal lation site.

• Place the computer and MOD drive (option) on the shelf according to Fig. 6.

• Remove the remaining protective film.

Fig. 6

NOTE

NOTE

CAUTION

MO

DISK

UNIT

RMO-S551

SONY

BUSY

POWER

EJECT

5.2 GB

SIENET

MagicView 1000

U 60

FFDM00212

For details on your type of viewing station,

see product-accompanying documentation.

The documentation for the table (option) is marked Opdimar.

Vertically adjustable tabletop.

Risk of squeezing of the computer and the MOD drive (option).

Make sure not to squeeze the computer or the MOD drive (option)

when the tabletop is vertically adjusted.

DIGISCAN M Register 3 SPB7-420.812.01 Page 6 of 8 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 17

Unpacking and setup 2 - 7

F

Unpacking and setup of the options 2

MOD drive (option to acquisition workstation) 2

SCSI ID switchFunction switches AC IN

A0BCDEFGH

1

SCSI CONNECTOR

4

SCSI ID

Connector for incoming SCSI cab le

Connector for external SCSI terminator

AC IN

F GND

FDM00254

Fig. 7

• Set SCSI ID switch to 4.

• Set the function switches accordingly:

Switch Setting Function

A 0 SCSI parity check is enabled

B 1 Peripheral device type 00H (Direct Access Device)

C 0 Enable write cache

D 1 Fast SCSI compatible

E 1 All write operations are verified (with a verify pass)

F 0 The internal terminator is OFF

G 0 Inserting a disk causes the spindle motor to rotate

H 0 Disk cartridge can be ejected by pressing the EJECT butt on

• Connect the power supply cable, the external SCSI terminator and the SCSI cabl e.

Communication switch (option) 2

Unpack the communication switch and mount it on the MAMMOMAT 3000 Nova or on the

wall.

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 7 of 8 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 18

2 - 8 Unpacking and setup

This page intentionally left blank.

DIGISCAN M Register 3 SPB7-420.812.01 Page 8 of 8 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 19

System cabling 3

Cable X205-X2

Laying and connecting the cables 3

Lay and connect the cables according to DIGISCAN M Wiring Diagrams including Func-

tion Description, SPB7-420.844.01... .

3 - 1

NOTICE

Risk of stumbling and damage to property.

Use cable ties or cable ducts to arrange the cables in an

organized way along the floor or wall.

Cable duct 3

Lay cable X205-X2 (cable between MAMMOMAT 3000 Nova stand and MAMMOMAT

3000 Nova generator) in the cable duct.

• Disconnect the printer cable (if connected) from the MAMMOMAT 3000 Nova generator.

• Open the cable duct between the generator and the stand and lift up the cabl e (if

present).

• Place the new cable with connectors marked X205 and X2 in the cable duct between the

generator and the stand / biopsy contr oller. Use compartment according t o the figure

below.

Fig. 1 Cable duct compartments

FFDM00049

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 20

3 - 2 System cabling

Cable connections 3

• Mount connector DB9F and connector marked “SCANNER” to one of the cable holders

according to Fig. 2.

1 lock washer

nut

SCANNER

Cable holder

Acquisition workstation

Fig. 2

Barcode scanner

Cable to keyboard

FFDM00602

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 21

System cabling 3 - 3

s

• Fit the cable holder to the cable outlet cover with a new longer screw (16 mm) and two

washers.

2 washer

Screw

SCANNER

FFDM00093

Cable outlet cover

Fig. 3 Top-down view cable holder

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 3 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 22

3 - 4 System cabling

CAUTION

Risk of short circuit!

The cable connection X205-X205 shall be placed outside the cabl e

outlet cover.

• The connectors marked X205 can be fasten to the other side of the cable outlet c over or

not, see alternatives in Fig. 4.

Acquisition workstation

MAMMOMAT

3000 Nova

FFDM00578

AWS AWS

Fig. 4

Alternative 1

X205

X205

X2

2 washers

1 lock washer

nut

Alternative 2

X205

1 lock washer

nut

X205

X2

DIGISCAN M Register 3 SPB7-420.812.01 Page 4 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 23

System cabling 3 - 5

• If a communication switch is installed (option), connect the c ables according to Fig. 5.

Acquisition workstation

Biopsy controller

MAMMOMAT

3000 Nova

Fig. 5

Communication

switch

FFDM00577

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 5 of 6 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 24

3 - 6 System cabling

Ferrite cores 3

• Mount ferrite cores on the acquisition workstation-image reader cabl e and the

acquisition workstation-networ k cable. The ferrite cores shall be plac ed 100-150 mm

from the connectors according to Fi g. 6. Fasten with cable ties.

100-150 mm100-150 mm

Cable ties

Fig. 6

Acquisition workstation

Network

Image reader

CPU90F-LAN

Ferrite cores

FFDM00185

= Option

DIGISCAN M Register 3 SPB7-420.812.01 Page 6 of 6 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 25

Final procedures 4

Remaining wor k st eps 4

Remove and dis pose o f all packaging materials from the components except for the materials from the image reader , cassettes and IPs (this is des cribed in DIGISCAN M Start-up,

SPB7-420.815.01...).

Completing the installation protocol 4

If the image reader is installed b y Fuji, the install ation protoc ol on P age 5 - 1 must be com-

pleted and signed by the responsible person from Fuji.

If problems or i nconsist encies a rise during the i nstal lati on, this m ust be noted i n th e insta llation protocol.

4 - 1

NOTE

Use a ballpoint pen (not a pencil) to fill out the protocol.

To make corrections, cross out incorrect entries and write in the correct value write in the

date and your initials next to it.

There may not be any empty blocks in the completed certificate.

Boxes in which no entry needs to be made should be completed

with n.a. (not applicable).

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 2 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 26

4 - 2 Final procedures

This page intentionally left blank.

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 2 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Page 27

Installation pr oto co l 5

5 - 1

NOTE

System model: DIGISCAN M

Order No.:

Customer:

Installation site:

Installation team:

Start of installation:

End of installation:

Only to be used if the image reader is installed by Fuji or if

problems or inconsistencies arise during the installation.

completed without probl ems?

yes no System

Mechanical installation

component

not configured

Supported by subcontrac-

tor or Fuji personnel?

(signature next page)

yes

Acquisition workstation

Image reader

Monitor SIMOMED ❏❏ ❏

Acquisition workstation MOD ❏❏ ❏

Communication switch ❏❏ ❏

Viewing station ❏❏ ❏

Viewing station table ❏❏ ❏

Hardcopy camera/Printer ❏❏ ❏

Archive system ❏❏ ❏

HIS/RIS ❏❏ ❏

❏❏ ❏ ❏

❏❏ ❏ ❏

❏

❏

❏

❏

❏

❏

❏

❏

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 2 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 28

5 - 2 Installation protocol

The system was installed in accordance with the described installation instructions

regarding arrangement of the components, cabeling etc. All safety-relevant work steps

were performed in accordance with the applicab le and supplied Installation Instructions:

If “no” has been checked, give reason:

Location, Date Responsible subcontractor

or Fuji representative

Name in block letters Name in block letters

Regarding the pre installation work that w as performed, I was:

Very satisfied Satisfied Not satisfied Not applicable

Responsible Project

Manager

❏❏❏❏

What work steps were also performed?

NOTE

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 2 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

File a copy in Register 9 of the System Manual

“Certificates” at the corresponding site.

Page 29

Changes to previous version 6

Page Chapter Change

6 - 1

1-1 Unpacking, transport and installa-

tion

1-1 Basic Information Text added.

1-3 Additional parts to the

DIGISCAN M system

1-4 Installation sequence The word “recommendation” is removed in

2-6 Unpacking and setup of the view-

ing station (option)

2-7 Communication sw itch (option) New chapter.

3-2 Cable connections Picture changed in point 2 (bar code d ecoder

3-4 Cable connections Point 1 and 2 are completely removed.

3-5 Cable connections Fig. 5 is changed.

3-6 Cable connections Fig. 6 is new.

5-1 Installation protocol Viewing station MOD is removed.

First caution only applies to SIMOMED monitor (option).

Text changes.

first rhomb below “Chapter 2 Unpacking and

setup”.

First note is new.

removed and DB connector changed).

Communication switch is added.

Siemens-Elema AB Register 3 SPB7-420.812.01 Page 1 of 2 DIGISCAN M

Solna, Sweden Rev. 03 11.02 SPS-UD System Manual

Page 30

6 - 2 Changes to previous version

This page intentionally left blank.

DIGISCAN M Register 3 SPB7-420.812.01 Page 2 of 2 Siemens-Elema AB

System Manual Rev. 03 11.02 SPS-UD Solna, Sweden

Loading...

Loading...