Page 1

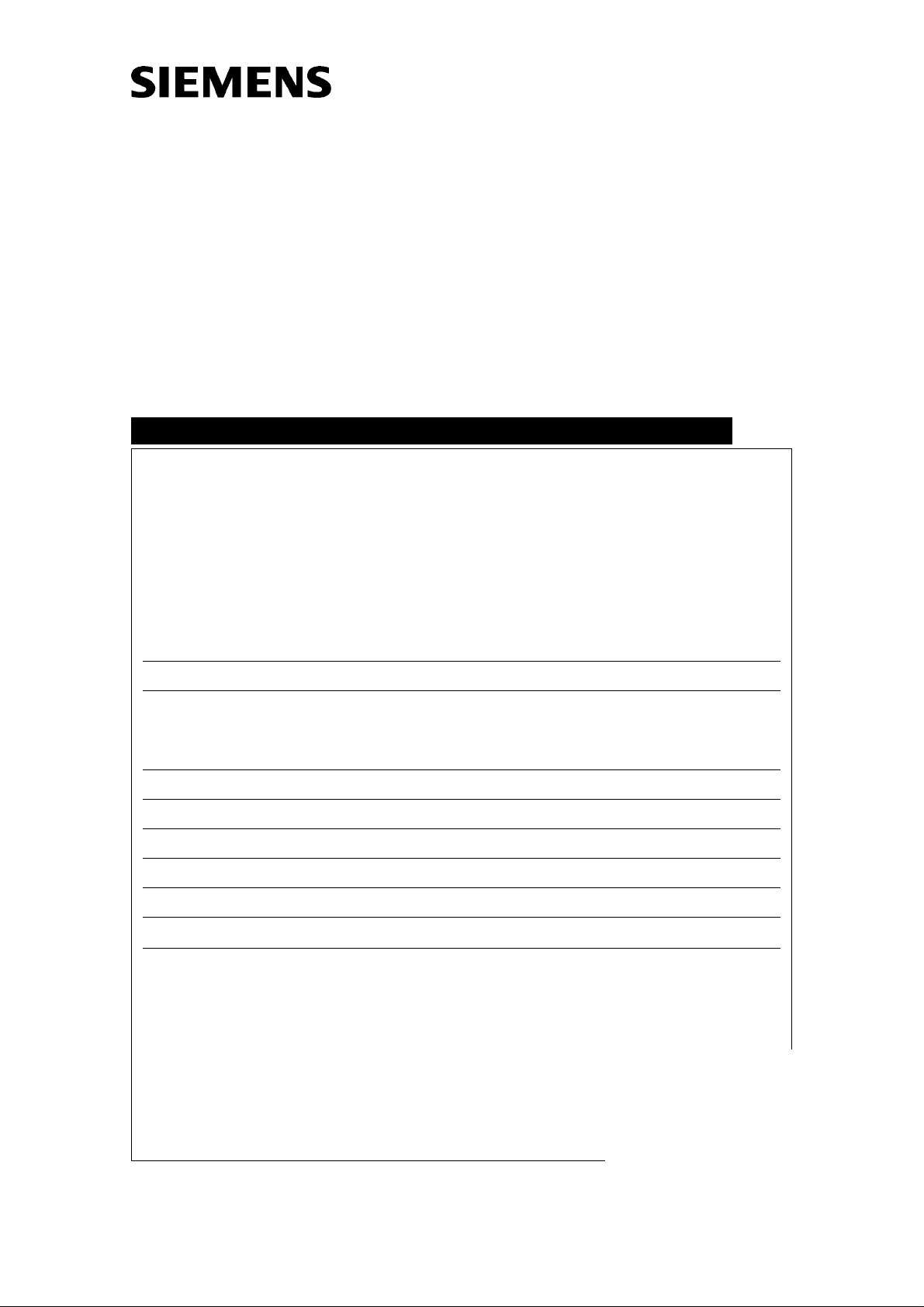

DIGISCAN M

Maintenance Protocol

Customer:

Address:

Department:

Room:

SP

Contact person:

Telephone:

Cust. specific no.:

Customer no.:

© Siemens AG 2002

The reproduction, transmission or

The Maintenance Instructions

SPB7-420.831.01.02.02

are required for this protocol

Register 8 English

Print Number: SPB7-420.832.01.02.02 Doc. Gen.Date: 12.02

Replaces: SPB7-420.832.01.01.02

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

66 31 993

Page 2

Maintenance Protocol

Information regarding the maintenance protocol

SIEMENS office:

Address:

Region:

Country:

Contact person:

Telephone:

CSE in charge:

Telephone:

Information regarding the maintenance protocol

The maintenance protocol serves as a quality record of the maintenance performed

Cust.-No.:

Maintenance must be performed in the prescribed intervals.

The maintenance results must be entered in the maintenance protocol.

The page numbers in the check list at the end of the protocol refer to the corresponding

pages in the associated maintenance instructions (refer to the cover sheet ).

The maintenance protocol must be completely filled out by the CSE in charge.

In other words,

• All fields must be completed. If a fi eld does not apply to the system or if ther e is no

information to be entered, enter ’n.a. ’ in the field.

• The customer number must be entered in the header of every page (CSE No.) so that

every page is assigned to a customer.

• In case of complaints, enter I VKs for the component as well as the type of complai nt in

the ’Open points’ table provided. Recor d the open items in the table with the date and

signature. Correction of these open poi nts should also be documented in this table a long

with the date and signature. If there are no open points, draw a line through the entir e

table and enter the date/initials.

• Enter the values measured during t he maintenance in the space / table provided.

• After completing the maintenance, fi ll out page 3 of the protocol and sign it.

Processing and archiving the maintenance protocol:

The maintenance protocol is considered a record and must be archived. It must be filed

after completion of maintenance in the co rresponding Register of the Maintenance binder.

If necessary, a copy should be distrib uted to the customer.

Siemens-Elema AB Register 8 SPB7-420.832.01 Page 2 of 10 DIGISCAN M

Solna, Sweden Rev. 02 12.02 SPS-UD System Manual

Page 3

Maintenance Protocol

System Status:

System:

Ser.No.:

Software Version:

Maintenance contract no.:

Type of contract:

The equipment has no problems

Results of the image quality test

showed no deviations from the

required reference values.

The equipment has minor problems that do not restrict its use.

However they should be corrected as a preventive measure.

Results of the image quality test

showed no deviations from the

required reference values.

Cust.-No.:

The equipment has major problems. For safety reasons, the

equipment may not be used until

the problem has been resolved.

Location

Date

Name of CSE

Signature

Siemens-Elema AB Register 8 SPB7-420.832.01 Page 3 of 10 DIGISCAN M

Solna, Sweden Rev. 02 12.02 SPS-UD System Manual

Page 4

Cust.-No.:

Maintenance Protocol

Performed tasks

Date:

Performed tasks:

OK not OK n.a.

DIGISCAN M Register 8 SPB7-420.832.01 Page 4 of 10 Siemens-Elema AB

System Manual Rev. 02 12.02 SPS-UD Solna, Sweden

Page 5

Maintenance Protocol

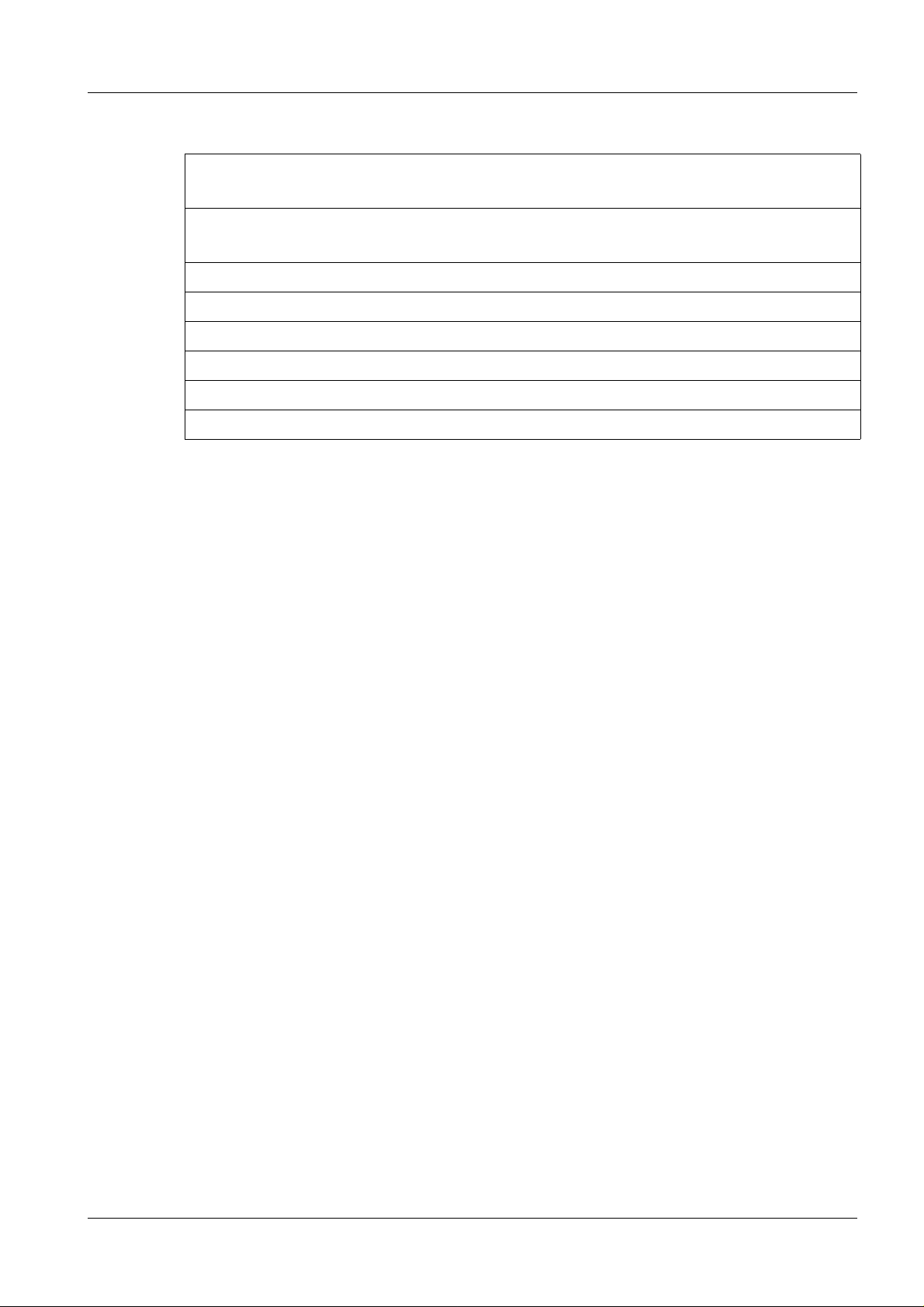

Open points

Yes No

IVK Component Open Points Solved

Cust.-No.:

(Date) Signature

Explanation of the acronyms:

Abbrev. Explanation

SI Safety Inspection

SIE Safety Inspection Electrical Safety

SIM Safety Inspection Mechanical Safety

PM Preventive Maintenance

PMP Preventive Maintenance Preventive Parts Exchange, External Inspection, etc.

PMA Preventive Maintenance Adjustment s

PMF Preventive Maintenance Function, Operating-Value Check

Q Quality Check

QIQ Quality Check Image

QSQ Quality Check System

SW Software Maintenance

Siemens-Elema AB Register 8 SPB7-420.832.01 Page 5 of 10 DIGISCAN M

Solna, Sweden Rev. 02 12.02 SPS-UD System Manual

Page 6

Cust.-No.:

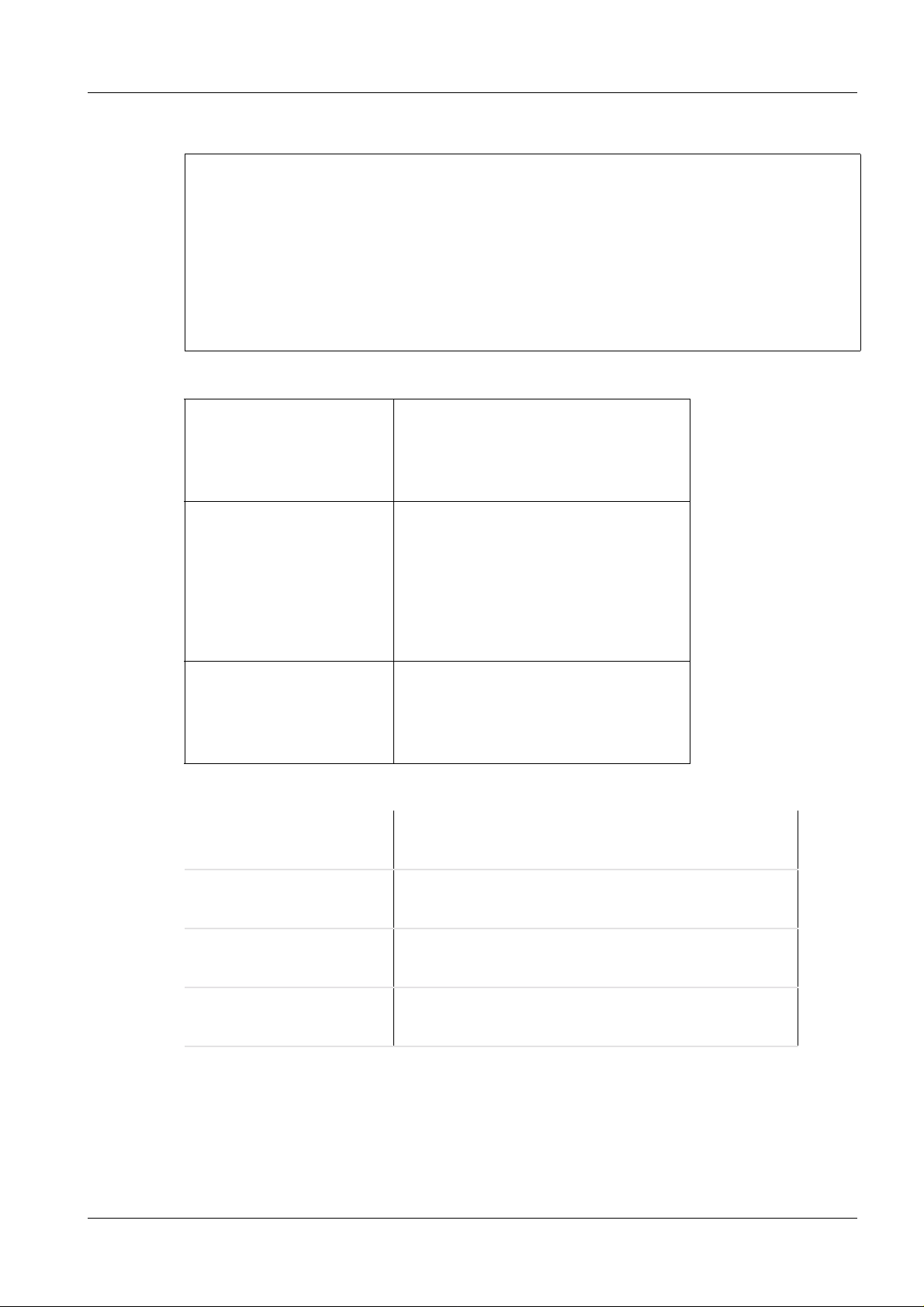

Maintenance Protocol

Measurement devices

Please enter all measuring devices used for maintenance in the table.

Measurement Devices Type Serial No. Date of use Calibrated

until

DIGISCAN M Register 8 SPB7-420.832.01 Page 6 of 10 Siemens-Elema AB

System Manual Rev. 02 12.02 SPS-UD Solna, Sweden

Page 7

Maintenance Protocol

Cust.-No.:

OK notOKn.a.

Page

1 General remarks 1 - 1

1.1. Safety information 1 - 1

1.1.1 General remarks 1 - 1

1.1.2 Laser safety 1 - 1

1.2. Documents required 1 - 1

1.3. Tools, meters and appliances 1 - 2

1.3.1 General remarks 1 - 2

1.3.2 Tools, meters and appliances required 1 - 2

1.4. Important notes on inspection and maintenance 1 - 3

1.5. Explanation of maintenance relevant abbreviations 1 - 5

1.6. Abbreviations 1 - 5

2 Check of the image reader 2 - 1

2.1. General remarks 2 - 1

2.1.1 Half year 2 - 1

PM Checking the error log 2 - 1

PM Cleaning FD drive 2 - 1

PM Deleting the error log 2 - 1

QIQ Checking the image 2 - 1

2.1.2 One year 2 - 2

PM Removing the covers 2 - 2

PM Turning OFF the high-voltage switch 2 - 2

PM Cleaning the air filters 2 - 2

PM Removing cassette set unit 2 - 2

PM IP removal u n it 2 - 2

PM IP removal u n it 2 - 2

PM IP removal u n it 2 - 2

PM IP removal u n it 2 - 2

PM IP removal u n it 2 - 2

PM Cassette set unit 2 - 2

PM Installing the cassette set unit 2 - 3

PM Remove the erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Erasure conveyor 2 - 3

PM Installing the erasure conveyor 2 - 3

PM Pulling out the scanner unit 2 - 3

PM Removing the side-positioning conveyor 2 - 3

PM Side-positioning conveyor 2 - 3

PM Side-positioning conveyor 2 - 4

PM Subscanning unit 2 - 4

Siemens-Elema AB Register 8 SPB7-420.832.01 Page 7 of 10 DIGISCAN M

Solna, Sweden Rev. 02 12.02 SPS-UD System Manual

Page 8

Cust.-No.:

Maintenance Protocol

OK notOKn.a.

PM Subscanning unit 2 - 4

PM Subscanning unit 2 - 4

PM Subscanning unit 2 - 4

PM Subscanning unit 2 - 4

PM Subscanning unit 2 - 4

PM Subscanning unit 2 - 4

PM Subcleaning unit 2 - 4

PM Subscanning unit 2 - 4

PM Installing the side-positi oning conveyor 2 - 4

PM Pushing in the scanner unit 2 - 5

PM Turning on the high-voltage switch 2 - 5

PM Installing and cleaning the covers 2 - 5

PM Checking the date and time 2 - 5

2.1.3 Two years 2 - 5

PMP Replacing the air filters 2 - 5

PMP Erasure conveyor 2 - 5

PMP Erasure conveyor 2 - 5

PM Subscanning unit 2 - 5

2.1.4 Three years 2 - 6

PMP IP removal unit 2 - 6

PMP IP removal unit 2 - 6

PMP IP removal unit 2 - 6

PMP Erasure conveyor 2 - 6

PMP Erasure conveyor 2 - 6

PMP Erasure conveyor 2 - 6

PMP Si de-positioning conveyor 2 - 6

PMP Subscanning unit 2 - 6

Page

3 Check of the acquisition workstation 3 - 1

3.1. Hardware maintenance 3 - 1

3.1.1 Computer 3 - 1

PM Secure mechanical adjustment 3 - 1

PM Fans - check proper operation and direction of the airflow 3 - 1

PM Fans - cleaning 3 - 1

PM Check internal cables and plugs 3 - 1

PM Cleaning 3 - 1

3.1.2 Cables 3 - 1

PM Check if cables are squeezed or broken 3 - 1

PM Check all external cable connections 3 - 1

PM Safe cable lay 3 - 1

3.1.3 Keyboard and mouse 3 - 1

PM Keyboard - cleaning 3 - 1

PM Mouse - operational Check 3 - 1

PM Mouse - cleaning 3 - 1

3.1.4 Monitor 3 - 2

PM Cleaning 3 - 2

3.1.5 Barcode scanner 3 - 2

PM Checking the barcode scanner 3 - 2

DIGISCAN M Register 8 SPB7-420.832.01 Page 8 of 10 Siemens-Elema AB

System Manual Rev. 02 12.02 SPS-UD Solna, Sweden

Page 9

Maintenance Protocol

Cust.-No.:

OK notOKn.a.

Page

4 Software maintenance 4 - 1

4.1. Acquisition workstation software update 4 - 1

SW Installation of recommended acquisition workstation software updates 4 - 1

4.2. Checks on syngo level 4 - 1

4.2.1 Check “messages” files 4 - 1

SW Check “messages” files for error messages 4 - 1

4.3. Backup of syngo configuration data 4 - 3

SW Backup of configuration data 4 - 3

5 Check of the image quality 5 - 1

QIQ Phantom image quality 5 - 1

QIQ Display and print conformity 5 - 1

QIQ Homogeneity 5 - 1

6 Final work steps 6 - 1

PM Checking the cover panels 6 - 1

PM Touch up paint scratches / chips 6 - 1

SI Protective ground / earth measurement 6 - 1

SI Protective ground / earth measurement 6 - 1

7 Changes to previous version 7 - 1

Siemens-Elema AB Register 8 SPB7-420.832.01 Page 9 of 10 DIGISCAN M

Solna, Sweden Rev. 02 12.02 SPS-UD System Manual

Page 10

Cust.-No.:

Maintenance Protocol

This page intentionally left blank.

OK notOKn.a.

Page

DIGISCAN M Register 8 SPB7-420.832.01 Page 10 of 10 Siemens-Elema AB

System Manual Rev. 02 12.02 SPS-UD Solna, Sweden

Loading...

Loading...