Page 1

s

R

Y

.

.

.

.

.

.

.

C

Y

1

Q

H

Y

DESIGO ®™

LonWorks networks

Check list

T

1

1

D

2

D

.

.

.

CA110335en_01

30.03.2007

Building Technologies

Page 2

2 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies 30.03.2007

Page 3

Table of contents

1 About this document..................................................4

1.1 Revision history.............................................................4

1.2 Before you start............................................................. 4

1.2.1 Trademarks ................................................................... 4

1.2.2 Copyright ....................................................................... 5

1.2.3 Quality assurance.......................................................... 5

1.2.4 Use of documents / Request to the reader ................... 6

2 Introduction / Background .........................................7

2.1 Target ............................................................................ 7

2.2 Scope ............................................................................ 7

2.3 Target readers............................................................... 7

2.4 Glossary ........................................................................ 8

3 Principles.....................................................................9

3.1 Main characteristics....................................................... 9

3.2 Influencing factors ......................................................... 9

3.2.1 Topology guidelines ......................................................9

3.2.2 Bus termination guidelines .......................................... 10

3.2.3 Cable length guidelines............................................... 11

3.2.4 Guidelines on the number of bus subscribers............. 12

4 Empirical design values ........................................... 15

4.1 Free topology ..............................................................15

4.2 Line topology............................................................... 16

5 Topologies.................................................................17

5.1 Physical....................................................................... 17

5.1.1 Free topology ..............................................................17

5.1.2 Line topology............................................................... 17

5.2 Logical......................................................................... 18

6 Installation guidelines...............................................19

7 Checklist for handover of the installation .............. 20

8 Troubleshooting........................................................ 24

3 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Teble of contents 30.03.2007

Page 4

1 About this document

1.1 Revision history

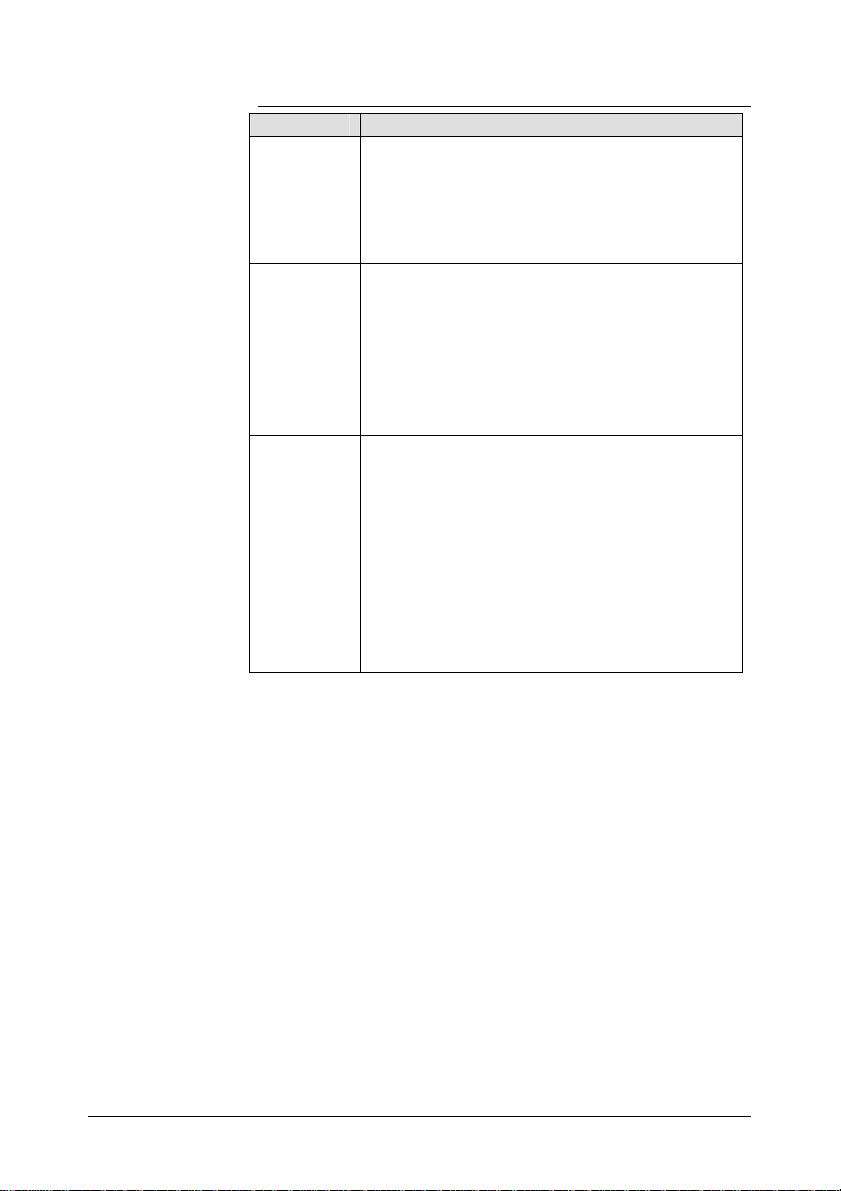

Version Date Changes Section Pages

_01

First edition 06.2003

03.2007 LON replaced with "L

New section

Cable length

Deleted: Recommended devices

Added: ConCab cable

Admissible cable types

ONWORKS"

1

3.2.3

3.2.4

4, 5

6

1.2 Before you start

1.2.1 Trademarks

The table below lists the trademarks used in this document and their

lawful owners. The use of these trademarks is subject to

international and national statutory provisions.

Trademark Statutory owner

BACnet™ American National Standard

(ANSI/ASHRAE 135-1995)

LonLink™, LON®,

LonManager®

,

LONMARK® , LonTalk®

LONWORKS®

Neuron® Echelon Corporation

All the product names listed in the table are trademarks (™) or

registered trademarks (®) of their respective owners, as specified in

the table. Further to the notes in this section, and to facilitate the

reading of the text, these trademarks will not be indicated (e.g. by

use of symbols such as ® or ™) elsewhere in the text.

Echelon Corporation

11

12

15, 16, 17

19

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies About this document 30.03.2007

Page 5

1.2.2 Copyright

This document may be duplicated and distributed only with the

express permission of Siemens and may be passed only to

authorized persons/companies with the required technical

knowledge.

1.2.3 Quality assurance

These documents have been prepared with great care.

The contents of all documents are checked at regular intervals.

All the necessary corrections are included in subsequent versions.

Documents are automatically amended as a consequence of

modifications and corrections to the products described.

Please ensure that you are aware of the latest revision date of the

documentation.

If you find any lack of clarity while using this document, or if you

have any criticisms or suggestions, please contact the product

manager in your nearest branch office, or write directly to the

support team at Headquarters in Zug (see below).

Support address:

Siemens Switzerland Ltd.

Building Technologies Group

International Headquarters

Field Support 5500

Gubelstrasse 22

6301 Zug, Switzerland

Tel +41 41 724 5500

Fax: +41 41 724 5501

E-mail:

fieldsupport-zug.ch.sbt@siemens.com

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies About this document 30.03.2007

Page 6

1.2.4 Use of documents /

Request to the reader

Before using our products, it is important that you read the

documents supplied with or ordered at the same time as the

products (equipment, applications, tools etc.) carefully and in full.

More information on the products and applications (e.g. system

descriptions etc.) is available via the Internet/intranet at

https://intranet.sbt.siemens.com/desigo-field/en/pro/pro_roo.asp.

We assume that the users of these products and documents have

the appropriate authorization and training, and that they are in

possession of the technical knowledge necessary to use the

products in accordance with their intended application.

Should there still be a lack of clarity or other problems associated

with the use of the documentation, please do not hesitate to contact

the Product Manager at your nearest branch office, or get in touch

directly with the support team.

E-mail:

fieldsupport-zug.ch.sbt@siemens.com

Please note that without prejudice to your statutory rights, Siemens

accepts no liability for any losses resulting from non-observance or

improper observance of the points referred to above.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies About this document 30.03.2007

Page 7

2 Introduction / Background

The following is a list of some common mistakes associated with the

physical installation of L

• Incorrect bus terminators (wrong position or value)

• Use of the wrong cables

• Loose connections (inadequate contact)

• Max. cable length exceeded

• Incorrect routing of cables (e.g. parallel to the power cables of

variable speed drives, causing EMC problems)

• Incorrect topology

• Incomplete or inadequate project documentation

With simple guidelines and check lists, these errors can be avoided.

2.1 Target

The overall aim is to prevent problems from arising, through proper

planning and correct physical installation of the L

2.2 Scope

This document does not go into engineering, commissioning and

maintenance procedures. The information which follows applies to

ONWORKS networks communicating at 78 Kbps (kilobits per

L

second).

L

ONWORKS networks at 1.25 Mbps are not dealt with here.

2.3 Target readers

This document is primarily intended for commissioning and service

engineers and other engineering and sales personnel. To keep later

additional costs as low as possible, it is important, even in the sales

phase, to take account of the relevant constraints.

ONWORKS networks:

ONWORKS networks.

7 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Introduction / Background 30.03.2007

Page 8

2.4 Glossary

Term Description

Router Routers filter data packets. They only forward

packets for which there is a destination device at

the other end of the router. The filtering process is

based on information from the Network Layer.

Routers have to be configured.

Gateway Gateways operate at the Application Layer. They

perform the conversion from one application

protocol to another, e.g. from LONMARK to BACnet.

There are other gateways that keep the same

application protocol, e.g. LONMARK to LONMARK

(RXZ03.1 point coupler).

Gateways have to be engineered.

Bus

repeater

Repeaters regenerate the electrical or optical

signal. They are not responsible for packet

filtering.

ONWORKS distinguishes between:

L

– Physical repeaters

Straightforward conditioning of the electrical

signal only (without neuron chip)

– Logical repeaters

Electrical and logical signal conditioning (timing

and checksum)

8 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Introduction / Background 30.03.2007

Page 9

3 Principles

For the principles in detail, and guidance on the planning and

installation of L

installation guides.

DESIGO RXC: CA110334 Installation guide

DESIGO PX: CA110396, Mounting and installation guide

3.1 Main characteristics

• Topology (line or free)

• Transceiver type (FFT10 or LPT10) Æ relevant for bus supply

• Number of bus subscribers (nodes)

• Type of supply. Some third-party devices do not use the same

voltages as the Siemens devices, and will require an additional

transformer.

3.2 Influencing factors

The characteristics of the network are influenced by the factors

detailed below.

3.2.1 Topology guidelines

The bus topology is determined by the required cable lengths and

the structure of the building.

ONWORKS networks please refer to the relevant

01890en

.

.

.

Main bus cable

Stubs

Building structure Length of stubs from the main bus cables:

9 / 24

Siemens LonWorks networks CA110335en_01 Building Technologies Principles 30.03.2007

Page 10

Notes

Note

< 3 m Æ Line topology

> 3 m Æ Freie Topologie

In RXC systems, the bus stub is often connected to the room unit.

We recommend that this should only be done in cases where access

to the L

ONWORKS network is absolutely essential. The extra cable

length must be taken into account.

• Frequently this results in stubs of more than 3 m, necessitating a

free topology.

• These additional cables are also susceptible to EMI (they act as

antennae for interference).

3.2.2 Bus termination guidelines

• Line topology

Æ 2 bus terminators, 105 Ω each (RXZ02.1) at each end of the

network.

• Free topology

Æ 1 bus terminator, 520 Ω (RXZ01.1) at the key point in the

network.

System devices (repeaters and routers) often have a built-in bus

terminator with a resistance selector.

10 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Principles 30.03.2007

Page 11

3.2.3 Cable length guidelines

When deciding on the topology, relevant factors are the maximum

cable length and the maximum distance between two bus

subscribers.

Various tested cable types are suitable.

For details refer to the RXC installation guide, document CA110334.

Cable length Cable type Max. Max. cable

length (including

cables to room units)

Free topology Category 5 450 m 250 m

ConCab 450 m 250 m

JY(St)Y 2x2x0.8 500 m 320 m

Level IV 500 m 400 m

Belden 8471 500 m 500 m

Line topology

Category 5 900 m No info

ConCab 900 m No info

JY(St)Y 2x2x0.8 900 m 750 m

Level IV 1400 m 1150 m

Belden 8471 2700 m 2200 m

FTT only FTT & LPT

If shielded cable is used, the shield must be capacitively earthed

(connected to ground) at least once per segment. In the event of a

high level of interference, this may be required at each node.

For details refer to the RXC installation guide, document CA110334.

If LPT-10 nodes (QAX5..) and bus power supply are used, the DC

power consumption of the LPT nodes must be taken account of

when designing the cable length and cross section (line resistance).

For details refer to the RXC installation guide, document CA110334.

The cable length can be doubled by use of a physical repeater.

STOP

Caution

No more than 1 physical repeater may be connected in series.

max. max.

cable length

Physical

Repeater

cable length

01891

Max. distance

between two

devices (nodes)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

_

_

_

11 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Principles 30.03.2007

Page 12

Note

DESIGO RXC

DESIGO PX

3.2.4 Guidelines on the number of bus

subscribers

The relevant factor here is the number of bus subscribers per

physical segment or channel. A physical segment is a continuous

section of the L

routers or gateways.

The number of bus subscribers per physical segment can be

calculated using the following formula:

(Number of bus subscribers with LPT10 transceivers) + (2 * number

of bus subscribers with FTT10 transceivers) ≤ 128

Rather than connecting the maximum load to the segments, we

recommend the inclusion of a spare capacity of 20% in the

calculation.

•

RXC... & RXZ03 FTT10 transceiver

•

QAX50 and QAX51 LPT10 transceiver

•

PXC… & PXM20 FTT10 transceiver

As most bus subscribers are fitted with FTT10 Transceivers, the

approximate numbers are as follows:

• = 64 bus subscribers per L

Æ No repeaters required

ONWORKS network, uninterrupted by repeaters,

ONWORKS network

01892

12 6364

• 64 ≤ 128 bus subscribers per L

Æ Use one physical repeater and divide the L

ONWORKS network

ONWORKS network

into two physical segments with 64 bus subscribers each.

Physical

Repeater

1

64 85 128

01893

If heavy local bus traffic is anticipated in both segments, then

instead of the physical repeater, a L

ONWORKS router or an L-

Switch (LonTalk switch supplied by Loytec) should be used.

12 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Principles 30.03.2007

Page 13

• 128 ≤ 256 bus subscribers per LONWORKS network

Æ Subdivide the network with L

ONWORKS router or L-switch.

Different variants are used, depending on the traffic on the bus:

a) Bus load distributed evenly over all segments:

Router /

L-Switch

Router /

L-Switch

Router /

L-Switch

01894

Note

Caution

STOP

Transceiver type

and bus supply

Caution

STOP

164

128 129 192 193 256

85

b) Backbone with heavy bus traffic Application with master

device or integration:

Master

Device

Router /

L-Switch

Router /

L-Switch

Router /

L-Switch

Router /

L-Switch

01895

164

65 128

129 192

193 256

The appropriate bus terminators are required for each physical

segment.

L

ONWORKS routers and logical repeaters cannot be used for

DESIGO PX, as the buffers are too small for BACnet messages.

Physical repeaters and L-switches can be used. Wherever possible,

the BACnet router, type code PXG80-N, should be used.

• FTT10 transceivers only

Æ No additional bus supply required

• With LPT10

Æ Bus power supply required

When the L

ONWORKS network is divided up by repeaters, routers or

L-switches, a bus power supply is required in every physical

segment having an LPT10 transceiver.

Bus power supplies have a built-in bus terminator, normally with

scope to switch between 520 Ω and 105 Ω.

13 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Principles 30.03.2007

Page 14

Number of

L

ONMARK devices

per PXR

• PXR11 Æ 60 devices (RXC and third-party L

• PXR12 Æ 120 devices (RXC and third-party L

ONMARK)

ONMARK)

The quantities shown are deliberately smaller than the multiple of the

maximum number of bus subscribers per physical segment. Routers,

PC-based tools and the PXR itself are also bus subscribers.

_

_

_

14 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Principles 30.03.2007

Page 15

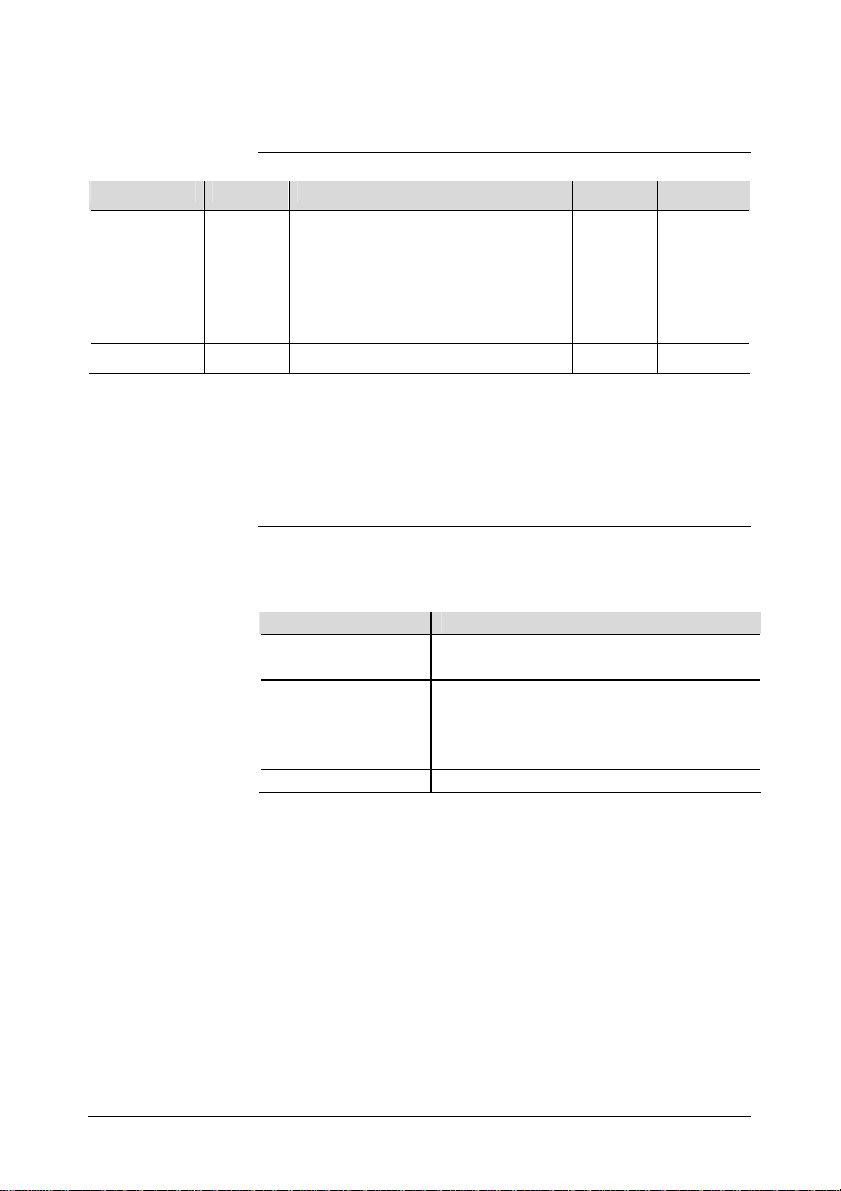

4 Empirical design values

4.1 Free topology

Activity Regulations Recommendation Practical experience

and comments

Max. cable length

for Category 5 cable

or ConCab

450 m 250 m The actual cable length is

difficult to estimate.

The maximum length of 450

m is subject to an ideal

installation in compliance

with all the regulations (see

Section 6).

.

.

.

Clearance between

two furthest nodes

Location of bus

terminators

1 x 52 Ω

1 x RXZ01.1

Number of bus

subscribers per

physical segment

Number of nodes

ONWORKS

per L

network

Location of the

master device

(PXR, NIDES.RX)

250 m 250 m This limitation is often

forgotten.

At key point

in the

network

64 (FTT10)

Formula as

in 3.2.4)

32,385 RXC: 240

No

regulations

Locate at the point

where data traffic is

at its highest

RXC: 50

(20% spare)

PX: 30

(performance)

(trunk limit)

PX: 30

(performance)

At key point in the

network

This varies from project to

project and there is not

always an ideal location (e.g.

bus power supply with built-

in termination)

This ensures that there is

enough space for the toolPC, repeaters and routers.

Larger networks must be

divided up by gateways

(PXR) or BACnet routers

(PXG80-N).

The master device is subject

to the heaviest data traffic

Locate centrally, if possible.

15 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Empirical design values 30.03.2007

Page 16

4.2 Line topology

Activity Regulations Recommendation Experience

Max. cable length

for Category 5 cable

or ConCab

Clearance between

two furthest nodes

Location of bus

terminators

2 x 105 Ω

2 x RXZ02.1

Number of devices

per physical

segment

Number of devices

per L

ONWORKS

network

Location of the

master device

(PXR, NIDES.RX)

Length of stubs 3 m 3 m RXC controllers are normally

900 m 900 m No problem, if cabling is in

accordance with regulations.

However, the actual cable

length is difficult to estimate.

900 m 900 m

Both ends Both ends

64 RXC: 50

(20% spare)

PX: 30

This ensures that there is

enough space for the toolPC, repeaters and routers.

(performance)

32,385 RX: 240

(trunk limit)

PX: 30

(performance)

in the middle

Larger networks must be

divided up by gateways

(PXR) or BACnet routers

(PXG80-N).

further away from stubs (in

fan-coil units, in VAV box,

etc.), and a free topology is

therefore required.

.

.

.

16 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Empirical design values 30.03.2007

Page 17

5 Topologies

5.1 Physical

5.1.1 Free topology

• Location of master device and bus terminator

• Cable length and distance apart for Category 5 or ConCab

cables.

max. 450m

RXZ01.1

.

.

.

01896

RXC

RXC

RXC

PXR

RXZ01.1

RXC

QAX

RXC RXC

RXC

max. 250m

5.1.2 Line topology

• Location of master device and bus terminator

• Cable length for Category 5 or ConCab cables.

max. 900m

RXZ02.1

RXZ02.1

RXC RXC

RXC

PXR

max. 3m

max. 3m

RXC

QAX

RXZ02.1

RXZ02.1

RXC RXC

max. 3m

01897

RXC

RXC

.

.

.

max. 900m

17 / 24

Siemens LonWorks networks CA110335en_01 Building Technologies Topologies 30.03.2007

Page 18

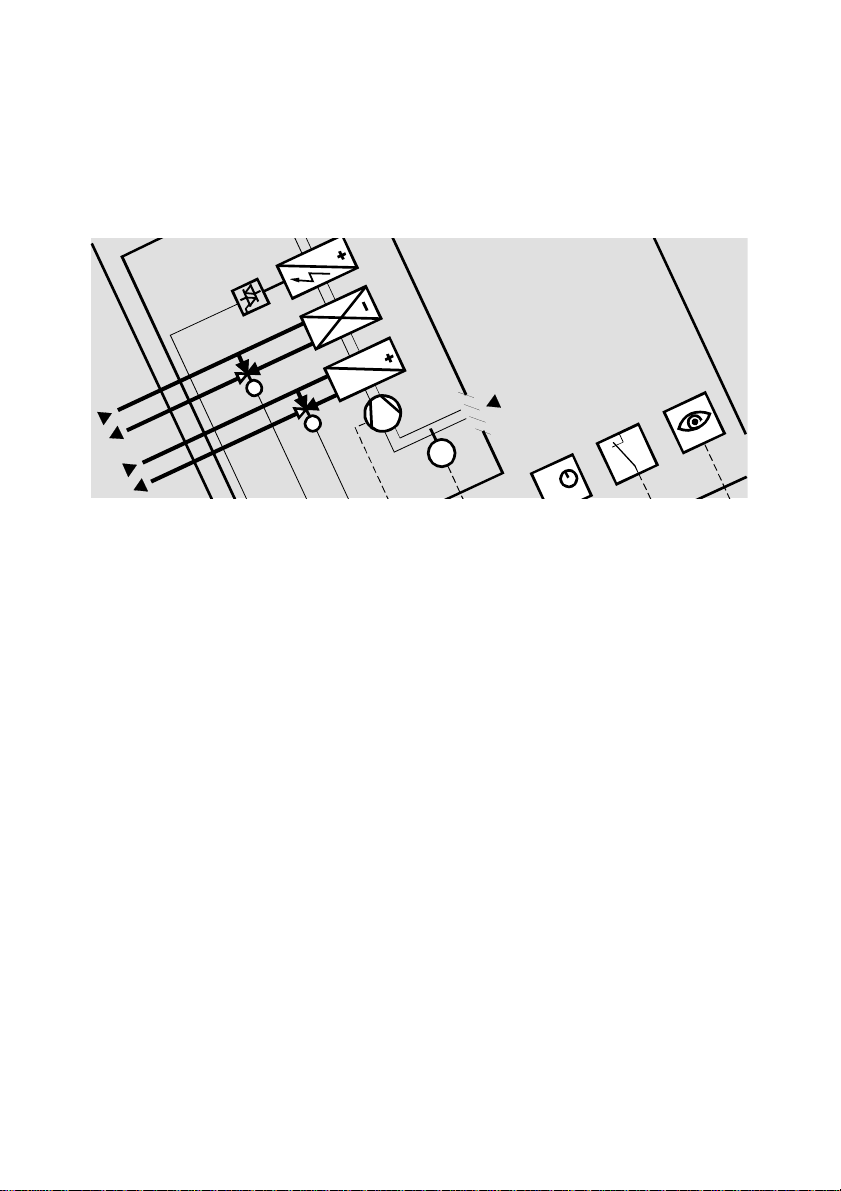

5.2 Logical

Hierarchical layout of a LONWORKS network

(DESIGO RXC application)

Trunk

Gateway

Trunk

01898

Explanation:

Trunk

Segment

Physical

Segment

Segment

Physical

Segment

LonWorks

Router

Physical

Segment

Segment

Physical

Segment

LonWorks

Router

Physical

Segment

Segment

Physical

Segment

In the DESIGO system, a field level network is divided into "trunks".

Trunks are connected by gateways (RXZ03.1). One trunk is

equivalent to one DESIGO RXC project.

Segments arise when a trunk is divided up by L

ONWORKS routers.

The L

ONWORKS devices are connected to a physical segment. A

segment can be divided with a physical repeater into several

physical segments.

Logical network topology

(DESIGO RXC application with integration via PXR)

Physical

segment segment

PXR

Segment

RXC

Trunk

RXC RXC

Physica l

Repeater

RXZ03.1

Segment

Physical

PXR

Trunk

LonWorks

Router

LonWorks

Router

RXC

RXC RXC

Segment

RXC RXC

Segment

RXC

01899en

18 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Topologies 30.03.2007

Page 19

Cable type

Cable routing

Connection /

Terminals

Documentation /

Labeling

Labeling on floor

plan

Storage of

documentation

6 Installation guidelines

Requirements when installing DESIGO systems:

• Only validated cables may be used. (e.g. ConCab or Category 5).

For a detailed list, refer to the RXC installation guide, document

CA11034.

• Bus cables must not be routed parallel with power cables (e.g. of

variable speed drives or stepper motors).

• Do not bundle bus and (AC 230V) power cables

by use of cable ties.

• Check that contacts are correct and secure (check by lightly

tugging the cable)

• Take care to observe polarity in the case of ring cable

configurations with bus power supplies.

• Draw in the cable routing on the floor plan for all floors of the

building.

• All bus subscribers (controllers, operator units, third-party devices,

repeaters, routers etc.) and bus terminators must be drawn on the

floor plan.

• Any deviations from the guidelines (e.g. several bus terminators)

are shown and explained.

• Changes must be documented.

• L

ONWORKS routers: Configuration mode, subnets on relevant

pages (report from DTS System Design and RXT)

• L-Switches: Configuration mode

• BACnet routers: Network number, BBMD status etc. (report from

DTS System Design)

• RXC controllers: Recommendation: refer to RXT report for labels

• Bus termination: value and type

• Bus power supply: type, and whether with or without bus

terminator

• The drawings must be accessible on site Recommendation: Pass

documents to the building operator, with an additional copy in

control panel.

.

.

.

.

.

19 / 24

Siemens LonWorks networks CA110335en_01 Building Technologies Installation guidelines 30.03.2007

Page 20

Documentary

evidence

Documentation

verification

7 Checklist for handover of

the installation

Objective: To ensure quality and to check that installation guidelines

have been observed. To establish clarity with subcontractors in the

event of liability.

The following points can be used as a basis for a handover report.

•

Is the documentation available?

•

Is the bus routing visible?

•

Are the bus subscribers shown?

•

Do theory and practice match?

•

Every bus terminator on the diagram must be checked in the

installation:

– Is the bus terminator in the correct location?

– Is it the correct value?

1st bus terminator Correct

location:

Yes/No

2nd bus terminator Correct

location:

Yes/No

nth bus terminatorn Correct

location:

Yes/No

Yes / No

Yes / Partially / No

Yes (all) / Some / No

Yes/Partially/No

Type:

RXZ01.1

RXZ02.1

Other..

Type:

RXZ01.1

RXZ02.1

Other..

Type:

RXZ01.1

RXZ02.1

Other..

20 / 24

Siemens LonWorks networks CA110335en_01 Building Technologies Checklist for handover of the installation 30.03.2007

Page 21

Note

• Random sample to check equipment labeling

1st sample Device type

RXC

Correctly labeled:

Yes/No

PX..

Repeater

Router

2nd sample Device type

RXC

Correctly labeled:

Yes/No

PX..

Repeater

Router

Device type

RXC

Correctly labeled:

Yes/No

th

n

sample

PX..

Repeater

Router

• Check the quality of the bus wiring

– Check wiring with help of link power DC voltage

Connect bus power supply and measure voltage at nodes. For

nodes with LPT10 transceivers, the DC voltage should be

between 38.5V and 42.6V.

1st node with LPT10: DC voltage: ___VDC

2nd node with LPT10: DC voltage: ___VDC

nth node with LPT10: DC voltage: ___VDC

In the absence of a bus power supply, a DC source (battery or

DC power supply unit) may be used. The voltage must not

exceed the bus power supply range (<42.6V). L

ONWORKS

communications are not possible while the external power

supply is connected.

– Measure the signal level

The signal level (peak-to-peak value) in each physical segment

must be 1.2 Vpp ± 0.4 V.

In the case of the RXC controllers, bus traffic can be generated

with special application S0003.

In the case of the PX automation stations, the PXM20 can be

used for navigation in order to generate bus traffic as required.

21 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Checklist for handover of the installation 30.03.2007

Page 22

The signal voltage and shape can be measured and plotted

with a cathode-ray oscilloscope in AC mode. Do not connect

either a tool, or a L

ONWORKS analyzer while measurement is in

progress.

1st segment: Signal level: ___Vpp

2nd segment: Signal level: ___Vpp

nth segment: Signal level: ___Vpp

– Signal shape

Correct signal shape:

The signal level is constant throughout packet transmission,

and is within the tolerance band (0.8V to 1.6V). The noise level

is low. There is a large gap between the signal level and noise

level. These are optimum conditions for error-free

communications.

22 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Checklist for handover of the installation 30.03.2007

Page 23

Distorted signal:

STOP

Caution

The signal level is distorted during packet transmission and is

below the 0.8V limit value. Error-free communications cannot be

guaranteed. Variable speed drives, for example, are a possible

cause of this kind of interference.

Do not use if the signal level or signal shape are not correct.

23 / 24

Siemens LonWorks networks CA110335en_01

Building Technologies Checklist for handover of the installation 30.03.2007

Page 24

Signal level

too low

Signal level

(too) high

Link Power DC

voltage too low

Link Power DC

voltage = 0V

8 Troubleshooting

• Wrong bus terminator (e.g. RXZ01.1 instead of RXZ02.1)

• Too many bus terminators (e.g. the built-in bus terminator in a

repeater or in a bus power supply may have been forgotten)

• A high-level signal indicates signal reflections or that there is no

bus terminator or the wrong bus terminator.

• Bus terminator in wrong place

Æ Find the key point in the network by trial and error

• Faulty bus power supply

Æ Disconnect the L

and measure the no-load voltage of the bus power supply (38.5V

to 42.6V DC).

• Cables too long, or cross-section too small. Failure to observe the

installation guidelines or cable type specification

Æ Connect an additional repeater and another bus power supply

Important note: Only one

physical segment

• Load too high (max. 20 QAX5.. units per Siemens bus power

supply); remember to include any third-party devices with LPT10

transceivers

Æ Connect an additional repeater and another bus power supply.

Important note: Only one

per physical segment

• Bus power supply unit is non-existent, disabled or faulty.

• Reverse polarity (in ring cable configurations)

• The DC voltage is not transmitted across repeaters or routers. A

bus power supply must be used for each physical segment with an

LPT10 transceiver.

ONWORKS network from the bus power supply

bus power supply may be connected per

bus power supply may be connected

Siemens Schweiz AG

Building Technologies Group

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41-724 24 24

Fax +41 41-724 35 22

www.siemens.com/sbt

24 / 24

Siemens LonWorks networks CA110335en_01 Building Technologies Troubleshooting 30.03.2007

© 2003 - 2007 Siemens Switzerland Ltd.

Subject to change

Loading...

Loading...