Page 1

SIMOTION

Preface

Description

Commissioning (hardware)

1

2

D410

Commissioning Manual

Configuring SIMOTION

D410

Commissioning (software)

Maintenance and service

Diagnostics data

Standards and approvals

ESD guidelines

Appendix

3

4

5

6

A

B

C

Valid for SIMOTION D410 DP and D410 PN

08/2008 Edition

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90327 NÜRNBERG

GERMANY

Copyright © Siemens AG 2008.

Technical data subject to change

Page 3

Preface

Contents of the commissioning manual

This manual is part of the SIMOTION D4xx documentation package, Edition 08/2008.

This manual describes commissioning of the SIMOTION devices D410 DP and D410 PN.

Information blocks in this manual

The following information blocks describe the purpose and use of the commissioning

manual.

● Description

This section provides information pertaining to the SIMOTION system and its integration

into the information landscape.

● Commissioning (hardware)

This section describes how to start up the device and what you must take into account.

● Configuring SIMOTION D410

This section describes how to integrate SIMOTION D410 in a project and how to

configure the interfaces.

● Commissioning (software)

This section describes how to configure a plant and how to test the drives and axes you

configured.

● Maintenance and service

This section describes how to replace a module, how to run updates, and how to modify

settings.

● Diagnostics data

This section provides information about diagnostic possibilities and LED states.

● Appendices with factual information for reference (for example, Standards and Approvals,

and ESD)

● Index for locating information.

SIMOTION Documentation

An overview of the SIMOTION documentation can be found in a separate list of references.

This documentation is included as electronic documentation with the supplied SIMOTION

SCOUT.

D410

Commissioning Manual, 08/2008 Edition

3

Page 4

Preface

The SIMOTION documentation consists of 9 documentation packages containing

approximately 80 SIMOTION documents and documents on related systems (e.g.

SINAMICS).

The following documentation packages are available for SIMOTION V4.1 SP2:

● SIMOTION Engineering System

● SIMOTION System and Function Descriptions

● SIMOTION Diagnostics

● SIMOTION Programming

● SIMOTION Programming - References

● SIMOTION C

● SIMOTION P350

● SIMOTION D4xx

● SIMOTION Supplementary Documentation

Hotline and Internet addresses

Technical support

If you have any technical questions, please contact our hotline:

Europe / Africa

Phone +49 180 5050 222 (subject to charge)

Fax +49 180 5050 223

Internet http://www.siemens.com/automation/support-request

Americas

Phone +1 423 262 2522

Fax +1 423 262 2200

E-mail mailto:techsupport.sea@siemens.com

Asia / Pacific

Phone +86 1064 719 990

Fax +86 1064 747 474

E-mail mailto:adsupport.asia@siemens.com

D410

4 Commissioning Manual, 08/2008 Edition

Page 5

Preface

Note

Country-specific telephone numbers for technical support are provided under the following

Internet address:

http://www.siemens.com/automation/service&support

Calls are subject to charge, e.g. 0.14 €/min. on the German landline network. Tariffs of other

phone companies may differ.

Questions about this documentation

If you have any questions (suggestions, corrections) regarding this documentation, please

fax or e-mail us at:

Fax +49 9131- 98 63315

E-mail mailto:docu.motioncontrol@siemens.com

Siemens Internet address

The latest information about SIMOTION products, product support, and FAQs can be found

on the Internet at:

● General information:

Additional support

– http://www.siemens.de/simotion (German)

– http://www.siemens.com/simotion (international)

● Product support:

– http://support.automation.siemens.com/WW/view/en/10805436

We also offer introductory courses to help you familiarize yourself with SIMOTION.

Please contact your regional training center or our main training center at D-90027

Nuremberg, phone +49 (911) 895 3202.

Information about training courses on offer can be found at:

www.sitrain.com

D410

Commissioning Manual, 08/2008 Edition

5

Page 6

Preface

Disposal and recycling

SIMOTION D410 is an environmentally friendly product! It includes the following features:

● In spite of its excellent resistance to fire, the flame-resistant agent in the plastic used for

the housing does not contain halogens.

● Identification of plastic materials in accordance with DIN 54840

● Less material used because the unit is smaller and with fewer components thanks to

integration in ASICs

SIMOTION D410 can be recycled because it is made with low-polluting materials.

For state-of-the art environmentally friendly recycling and disposal of your old modules,

contact your Siemens representative. To locate your representative, visit us online at:

http://www.ad.siemens.com/partner

Further information / FAQs

You can find further information on this manual under the following FAQs:

http://support.automation.siemens.com/WW/view/de/27585482

The following resources are also available:

● SIMOTION - Utilities & Applications CD: This CD is supplied together with the SIMOTION

SCOUT and, along with FAQs, also contains free utilities (e.g. calculation tools,

optimization tools, etc.) and application examples (ready-to-apply solutions such as

winder, cross cutter or handling).

● The latest FAQs for SIMOTION can be found at:

http://support.automation.siemens.com/WW/view/de/10805436

● SIMOTION SCOUT online help

● Additional documentation: see SIMOTION references

D410

6 Commissioning Manual, 08/2008 Edition

Page 7

Table of contents

Preface ...................................................................................................................................................... 3

1 Description...............................................................................................................................................

1.1 System overview ..........................................................................................................................

1.2 System components ....................................................................................................................

1.3 SIMOTION D410 DP display .......................................................................................................

1.4 SIMOTION D410 PN display .......................................................................................................

1.5 The CompactFlash card...............................................................................................................

1.6 Licensing ......................................................................................................................................

1.7 Safety information ........................................................................................................................

2 Commissioning (hardware)......................................................................................................................

2.1 Prerequisites for commissioning ..................................................................................................

2.2 Inserting the Compact Flash card ................................................................................................

2.3 Switching on the power supply ....................................................................................................

2.4 RESET button ..............................................................................................................................

2.5 User memory concept..................................................................................................................

2.5.1 SIMOTION D410 memory model.................................................................................................

2.5.2 Properties of the user memories..................................................................................................

2.5.3 Operator actions and their impact on user memory.....................................................................

3 Configuring SIMOTION D410 ..................................................................................................................

11

11

14

19

23

27

28

29

31

31

32

33

34

35

35

36

38

43

3.1 Software requirements.................................................................................................................

3.2 Inserting SIMOTION D410 into a project .....................................................................................

3.3 Configuring the PROFIBUS DP interface (only D410 DP) ..........................................................

3.3.1 General information about PROFIBUS DP communication ........................................................

3.3.2 Assignment of the PROFIBUS addresses in HW Config.............................................................

3.3.3 Operating SIMOTION D410 on PROFIBUS DP. .........................................................................

3.3.4 Creating a new PROFIBUS DP subnet .......................................................................................

3.3.5 Setting the DP cycle and system cycle clocks.............................................................................

3.3.6 Rules for SIMOTION D410 DP ....................................................................................................

3.4 Configuring PROFINET (only for D410 PN) ................................................................................

3.4.1 General information about PROFINET communication...............................................................

3.4.2 Operating SIMOTION D410 PN on PROFINET ..........................................................................

3.4.3 Setting the send cycles and system clocks .................................................................................

3.4.4 Rules for SIMOTION D410 PN ....................................................................................................

4 Commissioning (software) .......................................................................................................................

4.1 Overview of commissioning .........................................................................................................

4.2 Configuring the system in offline mode........................................................................................

D410

Commissioning Manual, 08/2008 Edition

43

43

46

46

47

48

48

49

50

52

52

53

56

58

61

61

62

7

Page 8

Table of contents

4.2.1 Overview ..................................................................................................................................... 62

4.2.2 Accessing the drive wizard..........................................................................................................

4.2.3 Configuring the components .......................................................................................................

4.2.4 Aligning HW Config.....................................................................................................................

4.2.5 Downloading the project to SIMOTION D410.............................................................................

63

64

70

71

4.3 Configuring the system in online mode.......................................................................................

4.3.1 Overview .....................................................................................................................................

4.3.2 Establishing the online connection..............................................................................................

4.3.3 Starting automatic configuration .................................................................................................

4.3.4 Editing SINAMICS components ..................................................................................................

4.3.5 Aligning HW Config.....................................................................................................................

4.3.6 Download the project to SIMOTION D410..................................................................................

4.4 Creating an axis ..........................................................................................................................

4.5 Integrating additional encoders (optional)...................................................................................

4.5.1 General information.....................................................................................................................

4.5.2 Configure the encoder interface on the drive side ......................................................................

4.5.3 Configuring a second encoder for a TO axis in SIMOTION........................................................

4.5.4 Configuring external encoders in SIMOTION .............................................................................

4.6 Using drive-related I/Os by SIMOTION.......................................................................................

4.6.1 Onboard I/Os and terminal modules configuration overview......................................................

4.6.2 Use of message frame 39x .........................................................................................................

4.6.3 Free message frame configuring with P915/P916 (only TM15/TM17 High Feature) .................

4.6.4 Configuring free message frames by means of BICO ................................................................

4.6.5 Expanding a message frame ......................................................................................................

4.6.6 Using high-speed outputs for output cams on D410.................................................................

4.6.7 Using probe inputs on D410......................................................................................................

4.6.8 Outputs of cam outputs and probe inputs on TM15/TM17 High Feature .................................

4.7 Creating and programming TM41 .............................................................................................

4.7.1 Overview ...................................................................................................................................

4.7.2 Configuring TM41 at SINAMICS Integrated..............................................................................

73

73

74

75

77

78

78

79

81

81

82

83

84

85

85

87

91

92

97

100

101

105

106

106

106

4.8 Creating a DMC20 ....................................................................................................................

4.8.1 DMC20 hub properties..............................................................................................................

4.8.2 Creating a DRIVE-CLiQ hub .....................................................................................................

4.9 Testing the configured drive using the drive control panel .......................................................

4.10 Testing the configured axis using the axis control panel ..........................................................

4.11 Downloading and saving user data...........................................................................................

4.12 Deleting data .............................................................................................................................

4.12.1 Overview of data deletion..........................................................................................................

4.12.2 Resetting the memory of SIMOTION D410 ..............................................................................

4.12.3 Deleting user data from the CompactFlash Card .....................................................................

4.12.4 Restoring the default settings of SINAMICS Integrated............................................................

4.12.5 Restoring the default settings of SIMOTION D410...................................................................

4.13 System shutdown......................................................................................................................

5 Maintenance and service.......................................................................................................................

5.1 Replacing modules....................................................................................................................

5.1.1 Removing and replacing the SIMOTION D410.........................................................................

5.1.2 Replacing DRIVE-CLiQ components ........................................................................................

5.2 Replacing the fan ......................................................................................................................

D410

107

107

108

109

111

113

114

114

115

117

118

118

119

121

121

121

124

125

8 Commissioning Manual, 08/2008 Edition

Page 9

Table of contents

5.3 Performing a software and firmware update..............................................................................126

5.4 SIMOTION CompactFlash Card ................................................................................................

5.4.1 Replacing the CompactFlash Card............................................................................................

5.4.2 Writing and deleting data on CompactFlash Cards ...................................................................

5.4.3 Formatting the CompactFlash Card...........................................................................................

5.4.4 Bootloader on the CompactFlash card ......................................................................................

6 Diagnostics data ....................................................................................................................................

6.1 Diagnostics by means of LED displays......................................................................................

6.2 Extended diagnostic capabilities................................................................................................

A Standards and approvals.......................................................................................................................

A.1 General rules..............................................................................................................................

A.2 Safety of electronic controllers...................................................................................................

A.3 Electromagnetic Compatibility....................................................................................................

B ESD guidelines ......................................................................................................................................

B.1 ESD definition ............................................................................................................................

B.2 Electrostatic charging of individuals...........................................................................................

B.3 Basic measures for protection against discharge of static electricity ........................................

C Appendix................................................................................................................................................

C.1 List of abbreviations...................................................................................................................

Index......................................................................................................................................................

131

131

131

132

133

135

135

138

139

139

140

142

143

143

143

144

145

145

147

D410

Commissioning Manual, 08/2008 Edition

9

Page 10

Page 11

Description

1.1 System overview

Overview

In SIMOTION D, the SIMOTION functionality is integrated directly in the closed-loop control

module of the SINAMICS S120 drive system.

SIMOTION D410 is a module drive system for single axes, which solves demanding drive

tasks for a very wide range of industrial applications. SIMOTION D410 supplements D425,

D435 and D445, the three power levels for multi-axis connections.

SIMOTION D is an integral part of the Totally Integrated Automation (TIA) concept. TIA

features standardized data management, configuration and communication over all products

and systems. Thus, an extensive toolbox of automation modules is also available for

SIMOTION D410.

Application

Combining a power module with SIMOTION D410 forms a compact single drive for machine

and plant engineering.

1

Applications include:

● Machine concepts with central drive (e.g., pressing, printing and packaging machines, . .

.)

● Modular machine concepts where the machine modules broken down to single axes

● Single drives with high accuracy, stability and concentricity requirements (compared with

standard drives) in machine and industrial plant engineering

● Single drives for transport tasks (conveying, raising, lowering)

● Single drives with integrated PLC functionality and expanded motion control functionality

such as output cam or cams

● Drives without power recovery (wire drawing, extruding)

● Drive connections with high availability requirements (incoming supply failure may not

cause all axes to fail)

Product variants

SIMOTION D410 comes in two variants:

● SIMOTION D410 DP with PROFIBUS DP interface.

● SIMOTION D410 PN with PROFINET interface.

D410

Commissioning Manual, 08/2008 Edition

11

Page 12

Description

1.1 System overview

System integration

SIMOTION provides an optimized system platform for automation and drive solutions where

the main focus is on motion control applications and technology tasks.

The SIMOTION system is made up of three components:

● SIMOTION SCOUT Engineering System

● Runtime Software

● Hardware platforms

The innovative SIMOTION concept involves integrating pure automation and motion

functions, which have been traditionally isolated in the past.

3/&IXQFWLRQDOLW\

,(&

7KHV\VWHPDSSURDFKRI

0RWLRQ&RQWURO

HJSRVLWLRQLQJ

V\QFKURQRXVRSHUDWLRQHWF

7HFKQRORJ\

IXQFWLRQV

HJK\GUDXOLFVWHPSHUDWXUH

FRQWUROHWF

Figure 1-1 System solution

6,027,21

7KHFRPELQLQJRIPRWLRQ

FRQWURO3/&DQG

WHFKQRORJ\IXQFWLRQV

SIMOTION can be used with all machines with motion control tasks. The focus is on a

simple and flexible solution to a wide variety of motion control tasks. In order to achieve this

in the best way possible, a new system approach has been introduced:

the fusion of motion control with two other control functions, which are found in most

machines: PLC and technology functions.

This approach enables motion control of axes and machines with only one system. The

same applies to technology functions, such as pressure control of a hydraulic axis. A

seamless switch can be made from position-controlled positioning mode to pressure control.

D410

12 Commissioning Manual, 08/2008 Edition

Page 13

Description

1.1 System overview

Combining the three control functions of motion control, PLC and technology functions has

the following benefits:

● Lower engineering expenditure and higher machine performance.

● Interfaces between individual components requiring rapid response are no longer

needed.

● Simple, standardized and transparent programming and diagnostics for the complete

machine.

D410

Commissioning Manual, 08/2008 Edition

13

Page 14

Description

1.2 System components

1.2 System components

Overview

SIMOTION D410 communicates with the components of the automation landscape via the

following interfaces:

● PROFIBUS DP (SIMOTION D410 DP only)

● PROFINET (SIMOTION D410 PN only)

● DRIVE-CLiQ (DRIVE Component Link with IQ)

● Power Module Interface (PM-IF)

● SIMOTION D features a SINAMICS Integrated drive element. Communication with the

SINAMICS Integrated (node 3) is via PROFIBUS mechanisms (DP integrated).

The most important system components and their functions are listed in the following table.

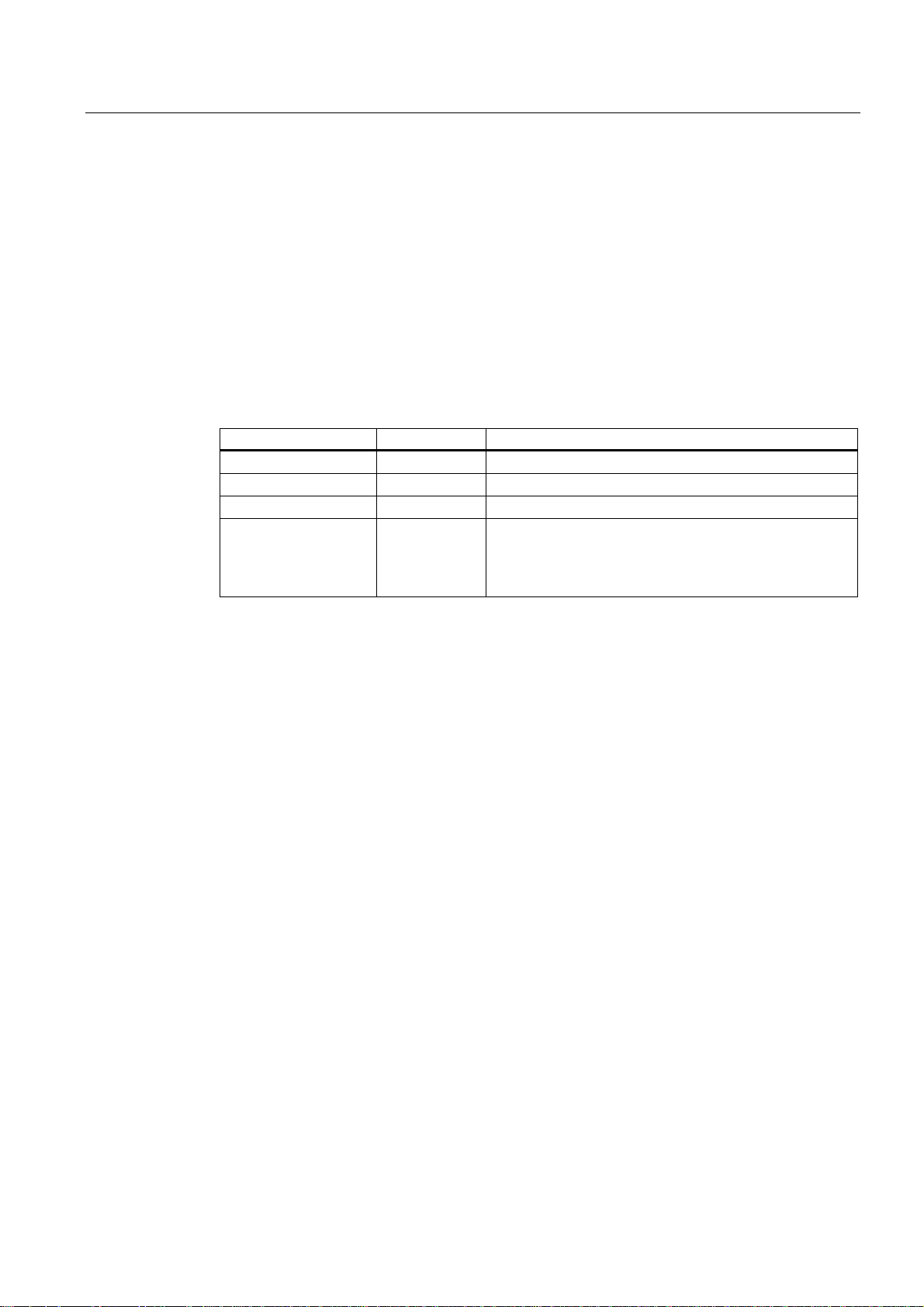

Table 1-1 System components

Components Function

SIMOTION D410 ... is the central motion control module.

The module contains the programmable SIMOTION Runtime in

SIMOTION D410 and the SINAMICS S120 drive software.

You can use the integrated rapid digital I/Os as:

• Homing inputs

• Inputs for measuring inputs

• User-addressable process inputs/outputs

• Outputs for fast output cams

The measuring sockets can output any analog signals.

The DRIVE-CLiQ interface permits a fast connection to the SINAMICS drive

components.

System software The system software is delivered separately on a CompactFlash card (not

included in the scope of delivery).

Note: An additional license is not required for the real axis technology.

Power supply (PS) ... provides the electronic power supply for SIMOTION D410 (e.g., SITOP

power supply).

Note: If the SIMOTION D410 is snapped-on to a PM340 power module, the

power module may be used as the sole supply for the SIMOTION D410 in

certain cases (e.g., when digital outputs are not used, etc. . .). See the section

entitled in the SIMOTION D410 Manual.

D410

14 Commissioning Manual, 08/2008 Edition

Page 15

Description

1.2 System components

PROFIBUS DP

SIMOTION D410 DP can communicate via PROFIBUS DP interface to the following

components:

Table 1-2 Components on PROFIBUS DP

Components Function

PG/PC programming device ... configures, sets parameters, programs and tests using the

SIMOTION SCOUT Engineering System (ES).

SIMATIC HMI device ... is used for operator control and monitoring functions. It is not

absolutely required to run SIMOTION D410.

Drive units with

PROFIBUS DP interface

(e.g., SINAMICS,

SIMODRIVE 611 universal)

SIMATIC ET 200M Modular I/O system for control cabinet installation and high channel

SIMATIC ET 200S Finely scalable I/O system for control cabinet installation and

SIMATIC ET 200pro Modular I/O system with IP65/IP67 rating for machine-related

SIMATIC ET 200eco I/O system with IP65/IP67 rating for machine-related applications

Gateways

Teleservice adapter Remote diagnosis

Other controls (e.g.,

SIMOTION or SIMATIC)

... convert speed setpoints into signals for controlling the motor and

supply the power required to operate the motors.

Can also be operated as an isochronous, equidistant Slave on the

PROFIBUS DP.

densities.

particularly time-critical applications; including motor starters, safety

technology and individual grouping of load groups.

applications with no control cabinet; with new features such as more

compact designs, integrated PROFIsafe safety technology,

PROFINET connection and live module replacement.

with no control cabinet, with a flexible and fast connection system in

ECOFAST or M12.

• DP/AS Interface Link 20E and DP/AS Interface Link Advanced for

the PROFIBUS DP gateway to AS Interface

• DP/DP coupler to connect two PROFIBUS DP networks

Note

Note that only one real axis can be used on a SIMOTION D410.

D410

Commissioning Manual, 08/2008 Edition

15

Page 16

Description

1.2 System components

Note

Please note that not all modules for the I/O systems listed above are enabled for SIMOTION.

Moreover, system-related functional differences can come into play when these I/O or I/O

systems are used on SIMOTION vs. on SIMATIC. For example, special process-control

functions (e.g., HART modules, etc.) are not supported by SIMOTION for the ET 200M

distributed I/O system.

A list of all I/O modules that can currently be used with SIMOTION is available under the

following link:

http://support.automation.siemens.com/WW/view/de/11886029

In addition to the I/O modules enabled for SIMOTION, all certified standard slaves can, in

principle, be connected to SIMOTION if they support the following:

● Cyclic data traffic (DP-V0) and, possibly

● Acyclic data traffic (DP-V1) or

● Isochronous data traffic (DP-V2)

These modules are integrated via the GSD file from the device manufacturer.

Note

Please note that in individual cases further boundary conditions must be fulfilled in order to

integrate a standard slave into SIMOTION. For example, "driver modules" in the form of

function blocks are required for some modules, which enable integration or make it

especially easy.

For modules enabled for SIMOTION (e.g., S7-300 module FM 350-1, etc.), these driver

modules are part of the SIMOTION SCOUT Engineering System command library.

D410

16 Commissioning Manual, 08/2008 Edition

Page 17

Description

1.2 System components

PROFINET

SIMOTION D410 PN can communicate via PROFINET interface to the following

components:

Table 1-3 Components on PROFINET

Components Function

The master computer (at

company and production

management level)

PG/PC programming device ... communicates with the SIMOTION SCOUT Engineering

SIMATIC HMI device ... is used for operator control and monitoring functions. It is not

Drive units with PROFINET

interface (e.g., SINAMICS S120

with CBE20)

SIMATIC ET 200M Modular I/O system for control cabinet installation and high

SIMATIC ET 200S Finely scalable I/O system for control cabinet installation and

SIMATIC ET 200pro Modular I/O system with IP65/IP67 rating for machine-related

Gateways

Other controls (e.g., SIMOTION

or SIMATIC)

... communicates with other devices via Ethernet.

Systems (ES), STEP 7 and HMI (Human Machine Interface).

absolutely essential for running SIMOTION D410.

... convert speed setpoints into signals for controlling the motor

and supply the power required to operate the motors.

channel densities.

particularly time-critical applications; including motor starters,

safety technology and individual grouping of load groups.

applications with no control cabinet; with new features such as

more compact designs, integrated PROFIsafe safety technology,

PROFINET connection and live module replacement.

• IE/AS Interface Link PN IO for the PROFINET IO gateway to

AS Interface

• PN/PN coupler to connect two PROFINET IO networks

Note

Note that only one real axis can be used on a SIMOTION D410.

Note

A list of all I/O modules that can currently be used with SIMOTION is available at the

following link:

http://support.automation.siemens.com/WW/view/de/11886029

D410

Commissioning Manual, 08/2008 Edition

17

Page 18

Description

1.2 System components

DRIVE-CLiQ

SIMOTION D410 can communicate via DRIVE-CLiQ interface to the following components:

Table 1-4 Components on DRIVE-CLiQ

Components Function

SINAMICS S120 AC DRIVE drive

units

(with CUA31/CUA32)

TM15 and TM17 High Feature

terminal modules

TM31 terminal module ... enables terminal expansion via DRIVE-CLiQ (additional

TM41 terminal module ... enables terminal expansion (analog and digital inputs/outputs)

TM54F terminal module ... enables terminal expansion (secure digital inputs/digital

SMx sensor modules ... enable the acquisition of encoder data from the connected

Motors with DRIVE-CLiQ interface ... allow simplified commissioning and diagnostics, as the motor

DMC20 ... expands the number of DRIVE-CLiQ nodes

... convert speed setpoints into signals for controlling the motor

and supply the power required to operate the motors. The

AC DRIVE component PM340 is connected via CUA31/CUA32.

No more than one PM340 can be connected. Chassis power

module is connected via DRIVE-CLiQ.

Note: Booksize components are not supported!

The terminal modules TM15 and TM17 High Feature are used to

implement probe inputs and cam outputs. In addition, terminal

modules provide drive-related digital inputs and outputs with

short signal delay times.

analog and digital inputs/outputs).

and encoder simulation via DRIVE-CLiQ. The TM41 can be

connected to a real axis. It is important to note that exactly one

real axis can be configured on the D410.

outputs) for controlling the secure motion monitoring functions of

the integrated drive.

motors via DRIVE-CLiQ.

and encoder type are identified automatically.

Note

Note that SIMOTION D410 does not support the CX32 expansion!

D410

18 Commissioning Manual, 08/2008 Edition

Page 19

Description

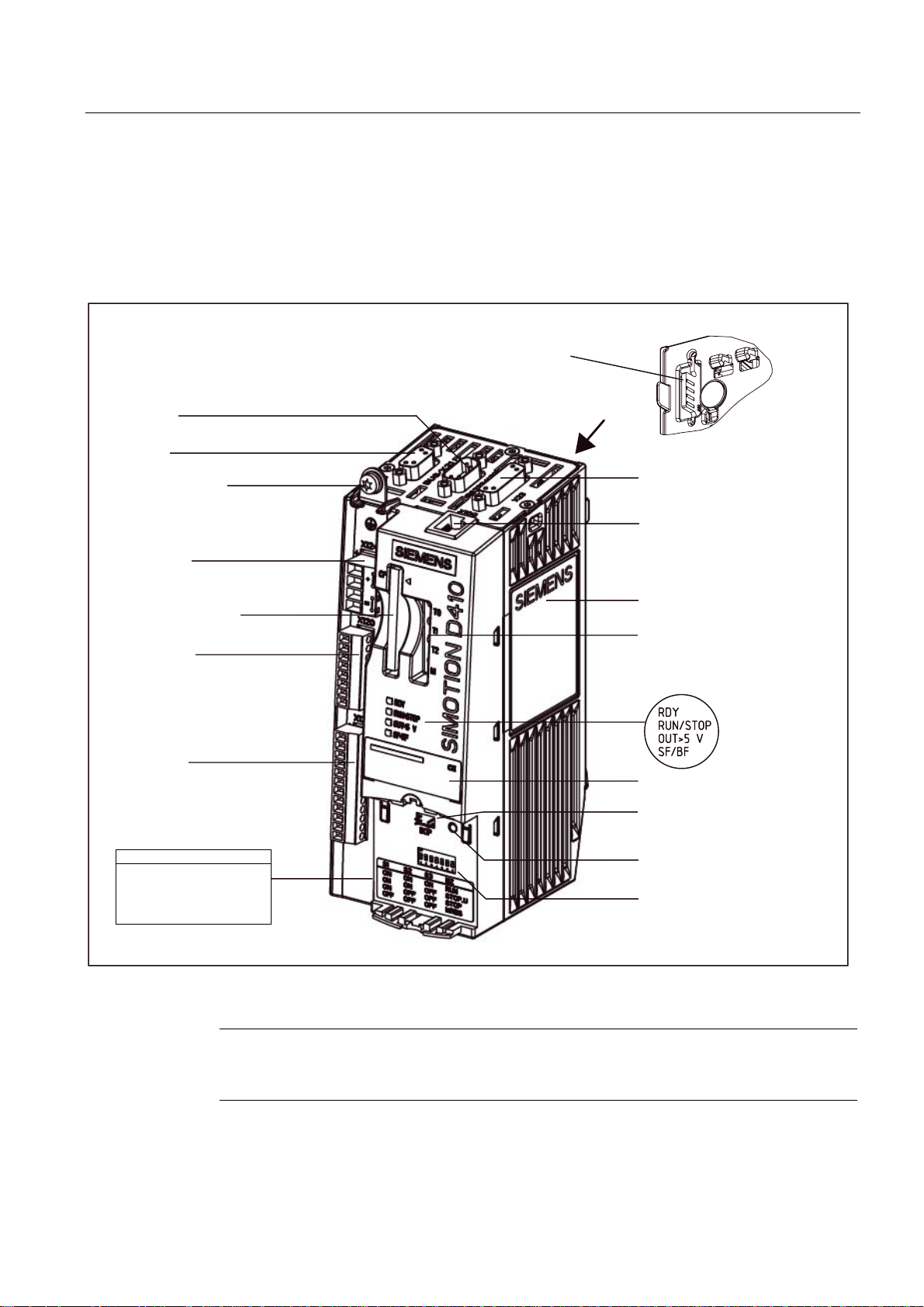

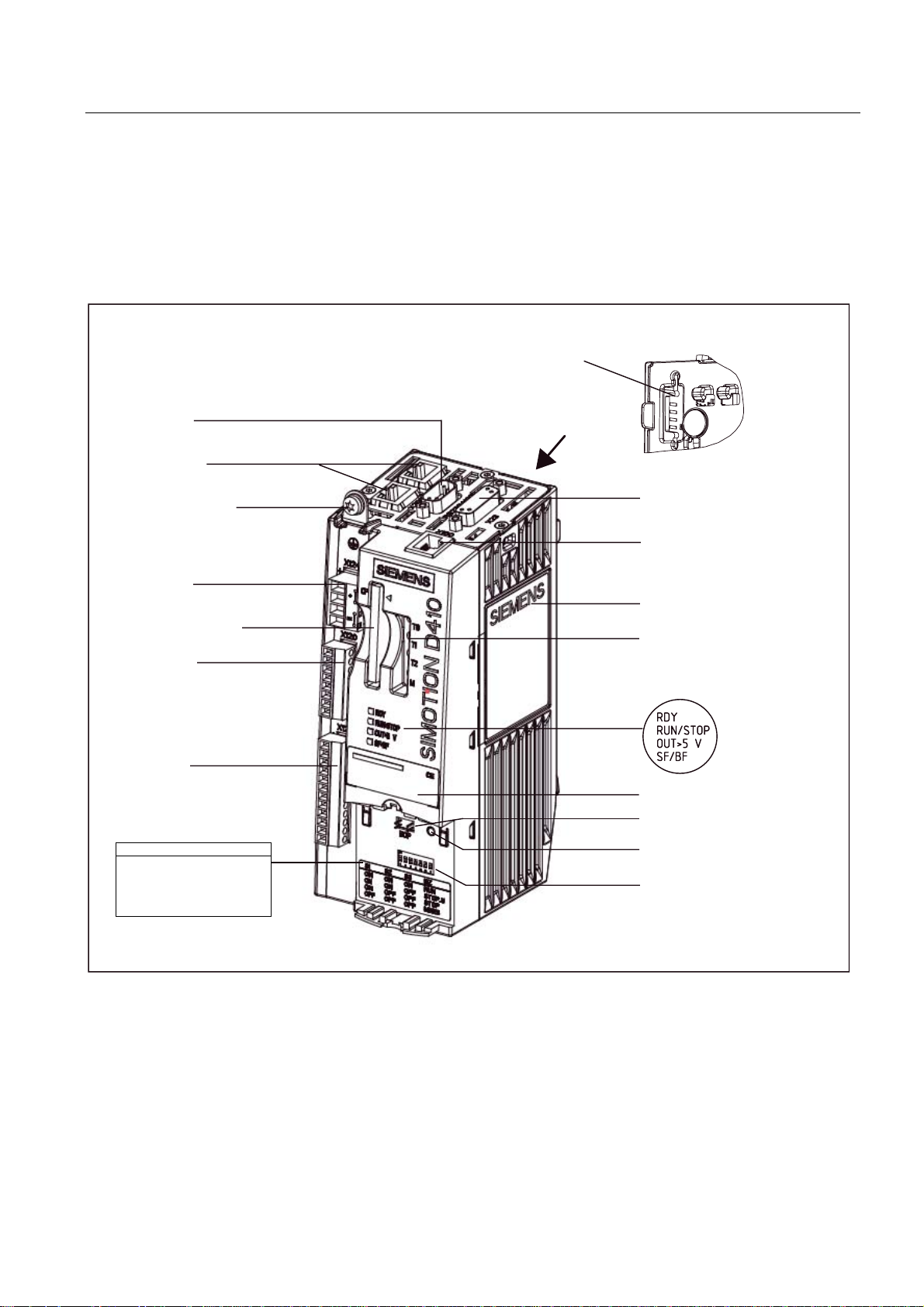

1.3 SIMOTION D410 DP display

1.3 SIMOTION D410 DP display

View

The following figure shows SIMOTION D410 DP with the interfaces and front elements.

3RZHU0RGXOH,QWHUIDFH30,)

;

6HULDOLQWHUIDFHQRIXQFWLRQ

;

352),%86

0VFUHZRQVKLHOG

FRQQHFWLRQ

;

(QFRGHULQWHUIDFH+7/77/66,

;

'5,9(&/L4LQWHUIDFH

;

(OHFWURQLFVSRZHUVXSSO\

&RPSDFW)ODVKbFDUG

;

(3WHUPLQDOVWHPSHUDWXUH

VHQVRUFRQQHFWLRQ

;

'LJLWDOLQSXWVRXWSXWV

6ZLWFKVHWWLQJVRQWKHPRGH

VHOHFWRUVZLWFK

26

6

6

6

21

21

21

2))

21

21

2))

2))

21

2))

2))

2))

581

6723B8

6723

05(6

Figure 1-2 Location of interfaces and front elements in SIMOTION D410 DP

6LGHQDPHSODWH

7770

0HDVXULQJVRFNHWV

/('GLVSOD\V

7\SHSODWH

%23LQWHUIDFH

QRIXQFWLRQ

5(6(7EXWWRQ

0RGHVHOHFWRUVZLWFK

',3VZLWFK

Note

The label underneath the mode selector lists the switch settings for the operating states of

the SIMOTION D410.

D410

Commissioning Manual, 08/2008 Edition

19

Page 20

Description

1.3 SIMOTION D410 DP display

Interfaces

The SIMOTION D410 DP interfaces are described in the following tables.

Table 1-5 SIMOTION D410 interfaces

Interface Description

Digital inputs/outputs

X121

DRIVE-CLiQ interface

X100

PROFIBUS DP interface

X21

Power Module Interface

(PM-IF)

Encoder interface (HTL / TTL

/ SSI)

X23

EP terminals/temperature

sensor connection

X120

Power supply connection

X124

Measuring sockets

T0, T1, T2 and M

12-pin Mini Combicon:

• 4 digital inputs: for connecting switches or proximity sensors

• 4 digital inputs/outputs: for connecting actuators and sensors

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes

9-pin SUB-D socket to connect to PROFIBUS DP

8-pin direct connector to connect to a blocksize power module

15-pin SUB-D socket for connecting HTL, TTL and SSI encoders.

8-pin Mini Combicon for connecting Safety Integrated input terminals

or for connecting temperature sensing via KTY or PTC

4-pin screw terminal connection to connect the 24 V DC load power

supply

Sockets to output analog signals

D410

20 Commissioning Manual, 08/2008 Edition

Page 21

Description

1.3 SIMOTION D410 DP display

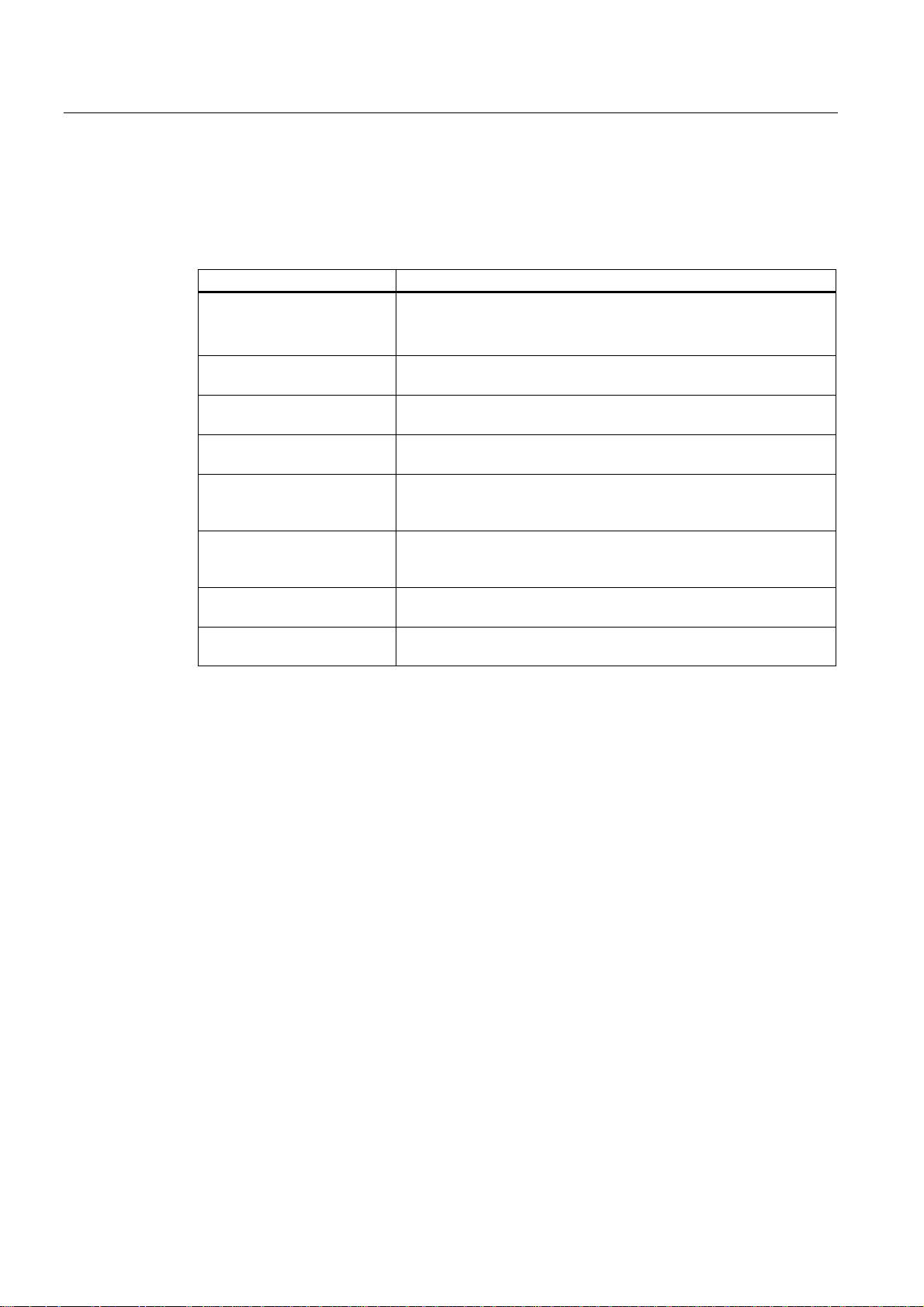

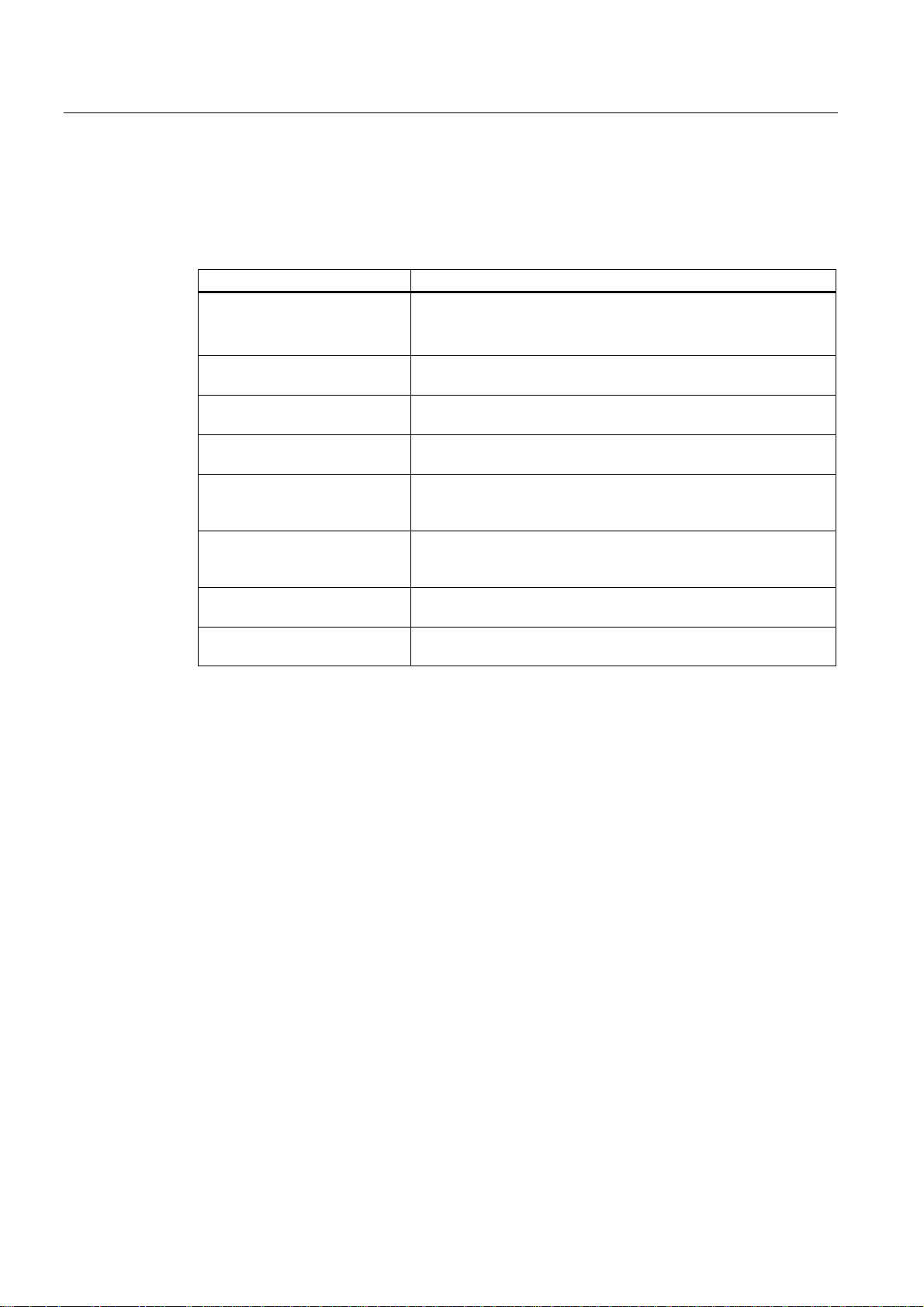

Nameplates

The following figure shows you all the information included on the nameplates located on the

side of the unit.

0RGXOHGHVLJQDWLRQ

2UGHUQXPEHU

6HULDOQXPEHU

+:YHUVLRQ

Figure 1-3 SIMOTION D410 nameplate

D410

Commissioning Manual, 08/2008 Edition

21

Page 22

Description

3$8$$$$

6DFK1U$(

9HUVLRQ

$

''3

1.3 SIMOTION D410 DP display

The following nameplate includes the SIMOTION D410 DP barcode numbers and is located

on the front side of the module.

%DUFRGH0/)%1R$8$$$$

3$8$$$$

%DUFRGH

6DFK1U$(

''3

7\SHGHVLJQDWLRQ

3URGXFWQXPEHU

2UGHUQXPEHU0/)%1R

6SDFHIRUDSSURYDOVLGHQWLILFDWLRQV

9HUVLRQ

5HYLVLRQOHYHO

Figure 1-4 SIMOTION D410 DP nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those

described in this Manual (e.g., updated product status, space for approvals and

identifications, etc.).

D410

22 Commissioning Manual, 08/2008 Edition

Page 23

Description

1.4 SIMOTION D410 PN display

1.4 SIMOTION D410 PN display

View

The following figure shows SIMOTION D410 PN with the interfaces and front elements.

3RZHU0RGXOH,QWHUIDFH30,)

;

6HULDOLQWHUIDFHQRIXQFWLRQ

;;

352),1(7VRFNHWV

0VFUHZRQVKLHOG

FRQQHFWLRQ

;

(QFRGHULQWHUIDFH+7/77/66,

;

'5,9(&/L4LQWHUIDFH

;

(OHFWURQLFVSRZHUVXSSO\

&RPSDFW)ODVKbFDUG

;

(3WHUPLQDOVWHPSHUDWXUH

VHQVRUFRQQHFWLRQ

;

'LJLWDOLQSXWVRXWSXWV

6ZLWFKVHWWLQJVRQWKHPRGH

VHOHFWRUVZLWFK

6

6

6

21

21

21

2))

21

21

2))

2))

21

2))

2))

2))

26

581

6723B8

6723

05(6

Figure 1-5 Location of interfaces and front elements in SIMOTION D410 PN

6LGHQDPHSODWH

7770

0HDVXULQJVRFNHWV

/('GLVSOD\V

7\SHSODWH

%23LQWHUIDFH

QRIXQFWLRQ

5(6(7EXWWRQ

0RGHVHOHFWRUVZLWFK

',3VZLWFK

D410

Commissioning Manual, 08/2008 Edition

23

Page 24

Description

1.4 SIMOTION D410 PN display

Interfaces

The SIMOTION D410 PN interfaces are described in the following tables.

Table 1-6 SIMOTION D410 interfaces

Interface Description

Digital inputs/outputs

X121

DRIVE-CLiQ interface

X100

PROFINET interface

(ports X200 and X201)

Power Module Interface

(PM-IF)

Encoder interface (HTL / TTL /

SSI)

X23

EP terminals / temperature

sensor connection

X120

Power supply connection

X124

Measuring sockets

T0, T1, T2 and M

12-pin Mini Combicon:

• 4 digital inputs: for connecting switches and proximity sensors

• 4 digital inputs/outputs: for connecting actuators and sensors

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes

8-pin RJ45plus socket to connect to PROFINET

8-pin direct connector to connect to a blocksize power module

15-pin SUB-D socket for connecting HTL, TTL and SSI encoders.

8-pin Mini Combicon for connecting Safety Integrated input

terminals or for connecting temperature sensing via KTY or PTC

4-pin screw terminal connection to connect the 24 V DC load

power supply

Sockets to output analog signals

D410

24 Commissioning Manual, 08/2008 Edition

Page 25

Description

1.4 SIMOTION D410 PN display

Nameplates

The following figure shows you all the information included on the nameplates located on the

side of the unit.

0RGXOHGHVLJQDWLRQ

2UGHUQXPEHU

6HULDOQXPEHU

+:YHUVLRQ

Figure 1-6 SIMOTION D410 nameplate

D410

Commissioning Manual, 08/2008 Edition

25

Page 26

Description

9HUVLRQ

$(

;;;;;;

$8$%$$

'31

$

1.4 SIMOTION D410 PN display

The following nameplate includes the MAC address of the PROFINET interface (ports X200

and X201) and is located on the front side of the module.

'31

$8$%$$

$(

;;;;;;

%DUFRGH0$&DGGUHVV

0$&DGGUHVV

3URGXFWQXPEHU

2UGHUQXPEHU0/)%1R

7\SHGHVLJQDWLRQ

9HUVLRQ

6SDFHIRUDSSURYDOVLGHQWLILFDWLRQV

5HYLVLRQOHYHO

Figure 1-7 SIMOTION PN nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those

described in this Manual (e.g., updated product status, space for approvals and

identifications, etc.).

D410

26 Commissioning Manual, 08/2008 Edition

Page 27

Description

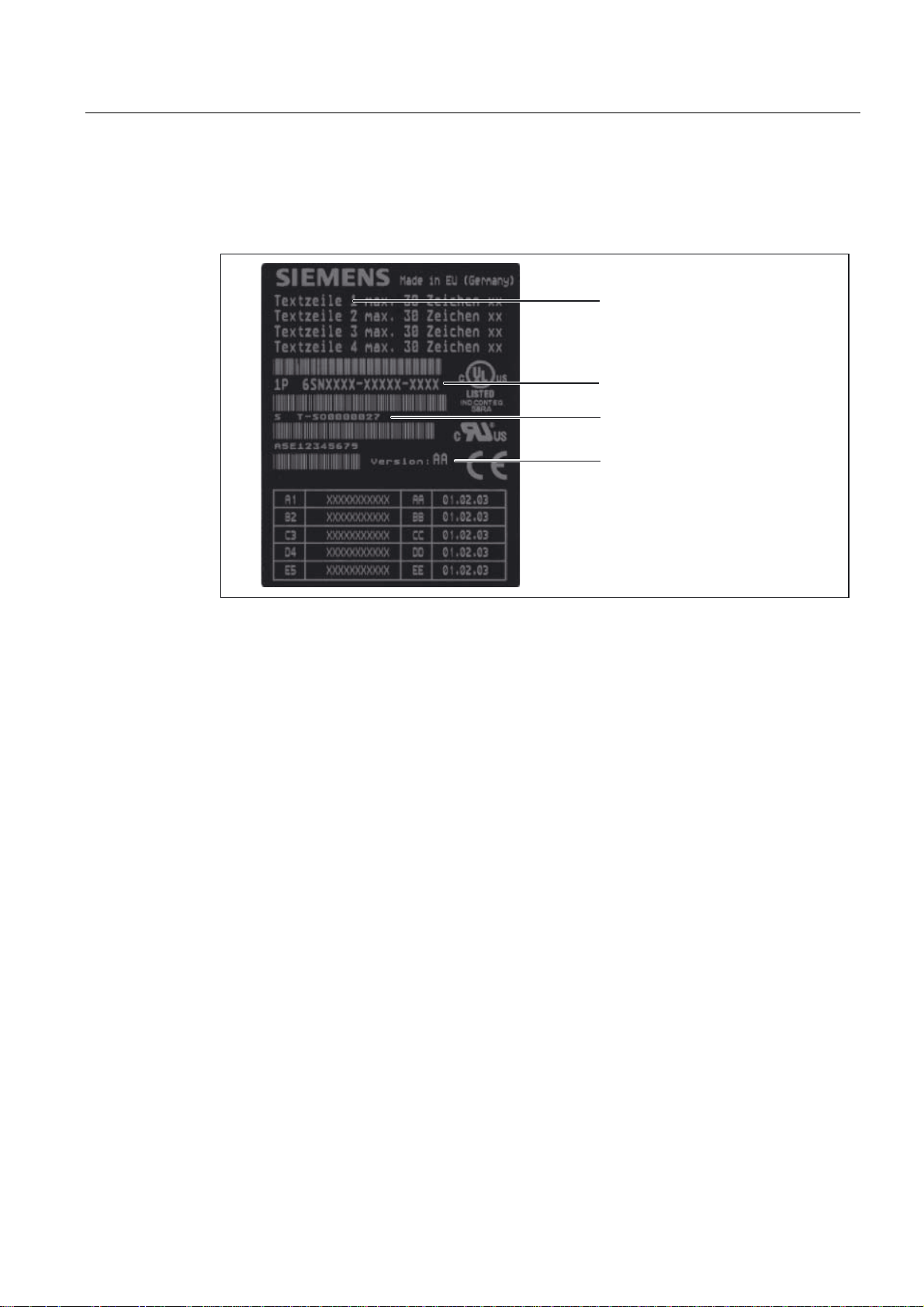

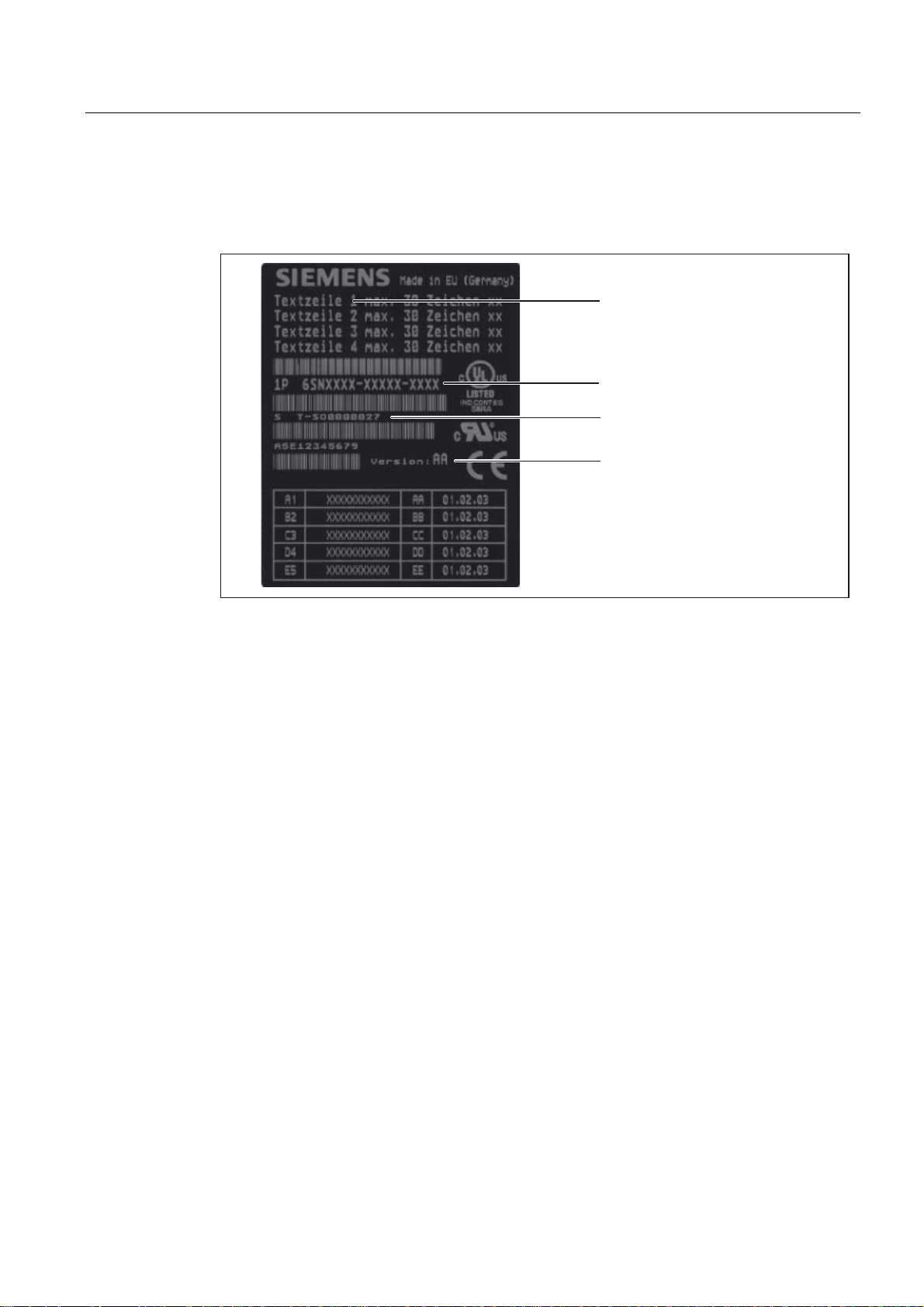

1.5 The CompactFlash card

1.5 The CompactFlash card

CompactFlash card

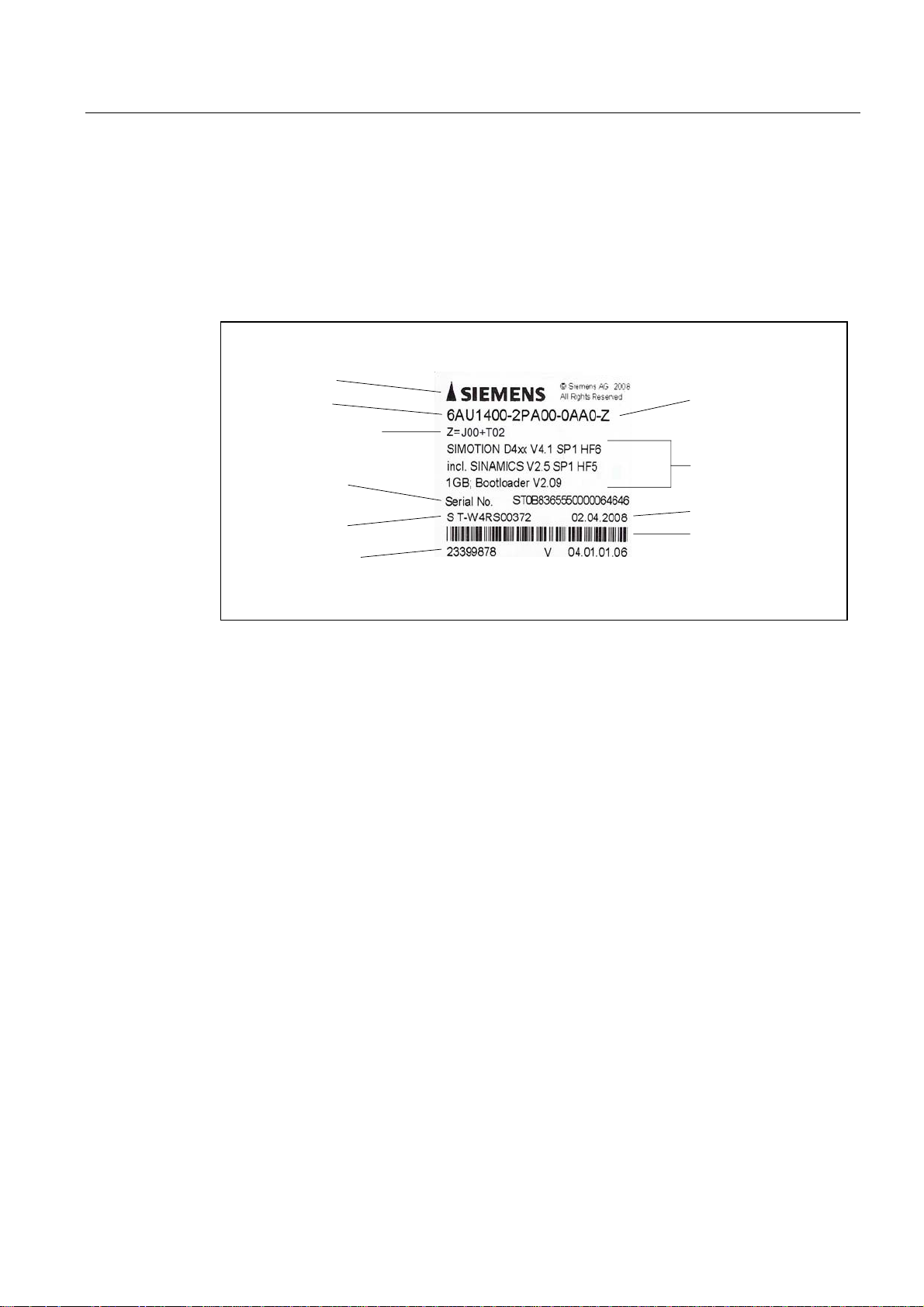

The following figure shows you all the information included on the nameplate of the

CompactFlash card (CF card).

3RLQWHUWRVKRZSOXJLQGLUHFWLRQ

RIWKH&)FDUG

2UGHUQXPEHU

/LVWRI=RSWLRQOLFHQVHV

RQWKH&)FDUGXSRQGHOLYHU\

+:VHULHVQXPEHU

RIWKH&)FDUG

8QLTXH,'QXPEHU

'HOLYHU\QRWHQXPEHU

'HVLJQDWLRQRI&)

FDUGZLWK=RSWLRQ

3URGXFWDQGYHUVLRQ

GHVLJQDWLRQ

&DUGFDSDFLW\

%RRWORDGHUYHUVLRQ

3URGXFWLRQGDWH

%DUFRGH

LQFOXGLQJRUGHUQXPEHU

Figure 1-8 CompactFlash card

Pre-installed runtime licenses

For versions V4.1 SP1 HF6 and higher, pre-installed licenses are printed on the type plate of

the CF card as a Z option underneath the order number.

Example with Z option for a combined SIMOTION IT license + 2 TControl licenses:

6AU1400-2PA00-0AA0-Z

Z=J00+T02

A maximum of 7 different Z options are printed on the type plate of the CF card. When there

are more than 7 different Z options, the text "Z = see delivery order" is printed on the CF card

in place of the Z option.

D410

Commissioning Manual, 08/2008 Edition

27

Page 28

Description

1.6 Licensing

Available Z options / licenses for SIMOTION D CF cards

The following Z options are available for SIMOTION D410:

TControl temperature control:

● Txx – TControl license and number (e.g. T03 = 3 TControl licenses)

SIMOTION IT:

● D00 – IT DIAG license

● X00 – OPC XML-DA license

● J00 – Combined license for SIMOTION IT, comprises SIMOTION IT Virtual Machine for

Java applications, SIMOTION IT DIAG and SIMOTION IT OPC XML-DA

Safety functions:

● Fxx - License for SINAMICS Safety Integrated Extended Functions (e.g., F01 = 1 license

for safety functions)

1.6 Licensing

SIMOTION D410 licensing

SIMOTION D410 is a modular drive system for single-axis applications. D410 contains the

Motion Control technology functions for exactly one real axis (speed-controlled, positioning,

synchronized axis or cam). This means that these technology functions do not require an

additional license. It is not possible to increase the number of axes using licenses. Along

with the one real axis, further virtual axes can be configured and loaded.

Licenses are required for runtime functions such as SIMOTION IT DIAG. These can be preinstalled on a CompactFlash card (CF card) or ordered separately.

Additional references

For more information about license management, see the

Manual

. General information about licensing can be found in the

SINAMICS S120 catalog and motors for production machines catalog, PM21 2008

SIMOTION SCOUT Configuring

Motion Control SIMOTION,

.

D410

28 Commissioning Manual, 08/2008 Edition

Page 29

Description

1.7 Safety information

1.7 Safety information

Observe the following safety information when working with SIMOTION D410 and its

components!

CAUTION

The CompactFlash card may only be unplugged and plugged in when SIMOTION D410 is

switched off (zero current)!

CAUTION

The 50 mm clearances above and below the components must be observed. The

ventilation openings may not be covered by connecting cables.

D410

Commissioning Manual, 08/2008 Edition

29

Page 30

Page 31

Commissioning (hardware)

2.1 Prerequisites for commissioning

Prerequisites

Prerequisites for commissioning the SIMOTION D410:

● You have completed installation and the wiring of your system with SIMOTION D410.

● A programming device / PC is available.

Connecting a programming device / PC to SIMOTION D410

You can interconnect the programming device / PC:

● With the PROFIBUS interface of SIMOTION D410 DP (X21 connector) using a

connecting cable.

Information pertaining to cable lengths for PROFIBUS DP is available in the

SIMOTION D410

● With the PROFINET interface of SIMOTION D410 PN (X200 or X201 connector) using a

twisted pair cable.

Manual.

2

Information pertaining to PROFINET communication is available in chapter "Configuring

PROFINET".

System requirements

System requirements for hardware commissioning:

● The programming device must be equipped with a PROFIBUS or Ethernet adapter.

● The programming device / PC must be interconnected with SIMOTION D410 DP

(connector X21) for online communication on PROFIBUS DP.

● The programming device / PC must be interconnected with SIMOTION D410 PN

(connector X200 and 201) for online communication on PROFINET.

● You need a CF adapter on the programming device / PC to write to the Compact Flash

Card (for example, a SIMOTION firmware update).

D410

Commissioning Manual, 08/2008 Edition

31

Page 32

Commissioning (hardware)

2.2 Inserting the Compact Flash card

2.2 Inserting the Compact Flash card

Properties of the CF card

The CF card is mandatory for operation of SIMOTION D410. The SIMOTION kernel and the

drive control software (SINAMICS firmware) are installed on the CF card.

The CompactFlash card must be inserted when you start up SIMOTION D410 in order to

load the SIMOTION kernel.

Procedure

Note

The Compact Flash Card may only be removed and inserted while SIMOTION D410 is in de-

energized state!

Insert the CompactFlash Card as follows:

1. The insertion direction of the CompactFlash Card is identified by an arrow on the card

and a matching arrow on the slot. Align the arrows when inserting the CompactFlash

Card.

2. Gently push the CompactFlash Card into the card slot of SIMOTION D410 until it

engages. The properly inserted card does not protrude from the SIMOTION D410

housing.

$UURZV

&RPSDFW)ODVK&DUG

6ORWIRU&RPSDFW)ODVK&DUG

Figure 2-1 Inserting the CompactFlash Card

D410

32 Commissioning Manual, 08/2008 Edition

Page 33

Commissioning (hardware)

2.3 Switching on the power supply

2.3 Switching on the power supply

Checking the system

Check the system installation and wiring once again before you switch it on. Observe the

safety-relevant items of the following checklist:

● Have you observed all ESD measures when handling the components?

● Are all connectors properly inserted and interlocked / screwed on?

● Are all components grounded and all shields terminated?

● Have you made allowances for sufficient load capacity of the central power supply?

Switching on the external power supply

Power is supplied to the SIMOTION D410 using an external power supply unit, for example,

using SITOP power supplies (in special circumstances, the SIMOTION D410 can also be

supplied using the PM340 Power Module, see SIMOTION D410 Manual).

CAUTION

It is imperative to prevent the external 24 VDC power supply to SIMOTION D410 from

being interrupted for a duration longer than 3 ms. Operation of SIMOTION D410 is stopped

on expiration of these 3 ms and can only be recovered by cycling power Off > On.

Additional information is available in chapter "User memory concept".

Startup of SIMOTION D410

The startup of SIMOTION D410 is initiated after the power supply is activated:

1. The RDY LED is lit and the red RUN/STOP LED briefly lights up at the beginning of the

startup sequence. These LEDs can be used to monitor the startup sequence. Any errors

are displayed.

2. Startup of the SIMOTION kernel.

3. All DRIVE-CLiQ connections (with SINAMICS S120 Power Module PM340, for example)

Switch on the power supply after having checked off all items of the checklist.

are identified automatically.

Note

Startup of SIMOTION D410 is completed as soon as its RDY LED is lit in green color and

the RUN/STOP LED is lit in yellow or green color.

The SIMOTION D410 is ready for configuring after successful completion of the startup.

D410

Commissioning Manual, 08/2008 Edition

33

Page 34

Commissioning (hardware)

2.4 RESET button

2.4 RESET button

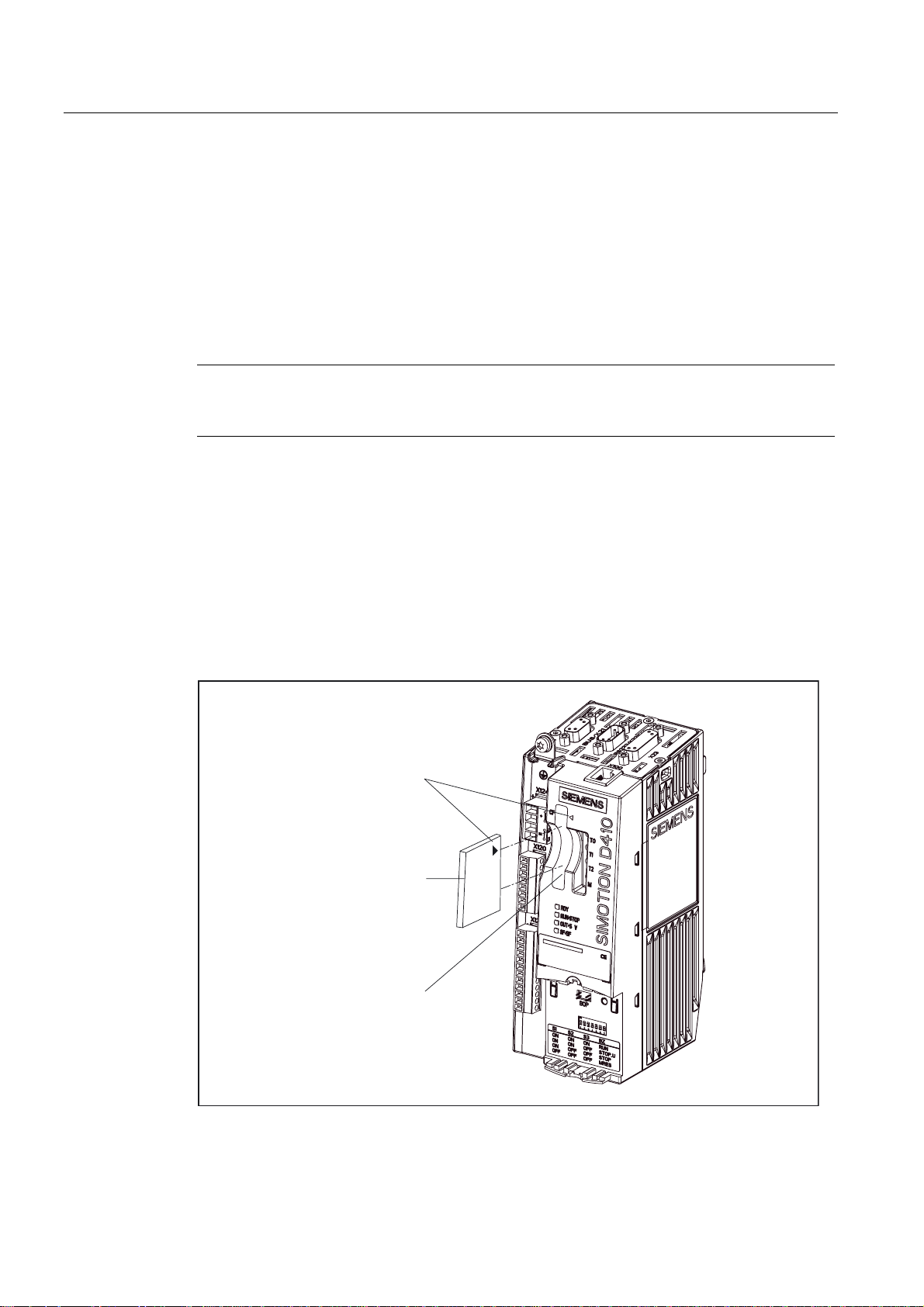

Arrangement

The RESET button is located behind the blanking plate on the SIMOTION D410.

Performing a reset operation

A reset causes the entire system to be reset and requires the system to be ramped-up again.

It is similar to a "Power On Reset" except that the 24 V power supply does not have to be

switched off.

D410

34 Commissioning Manual, 08/2008 Edition

Page 35

Commissioning (hardware)

2.5 User memory concept

2.5 User memory concept

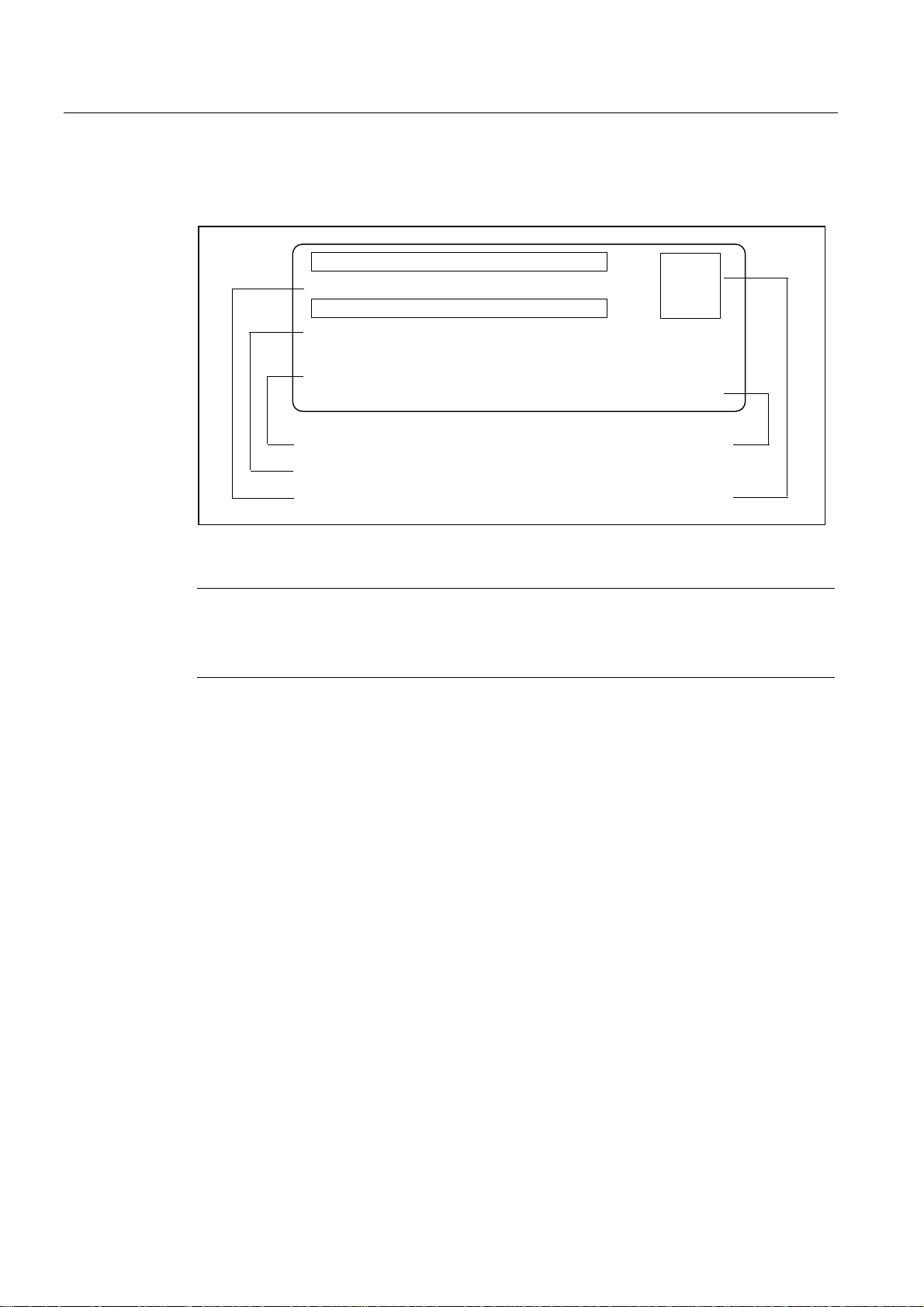

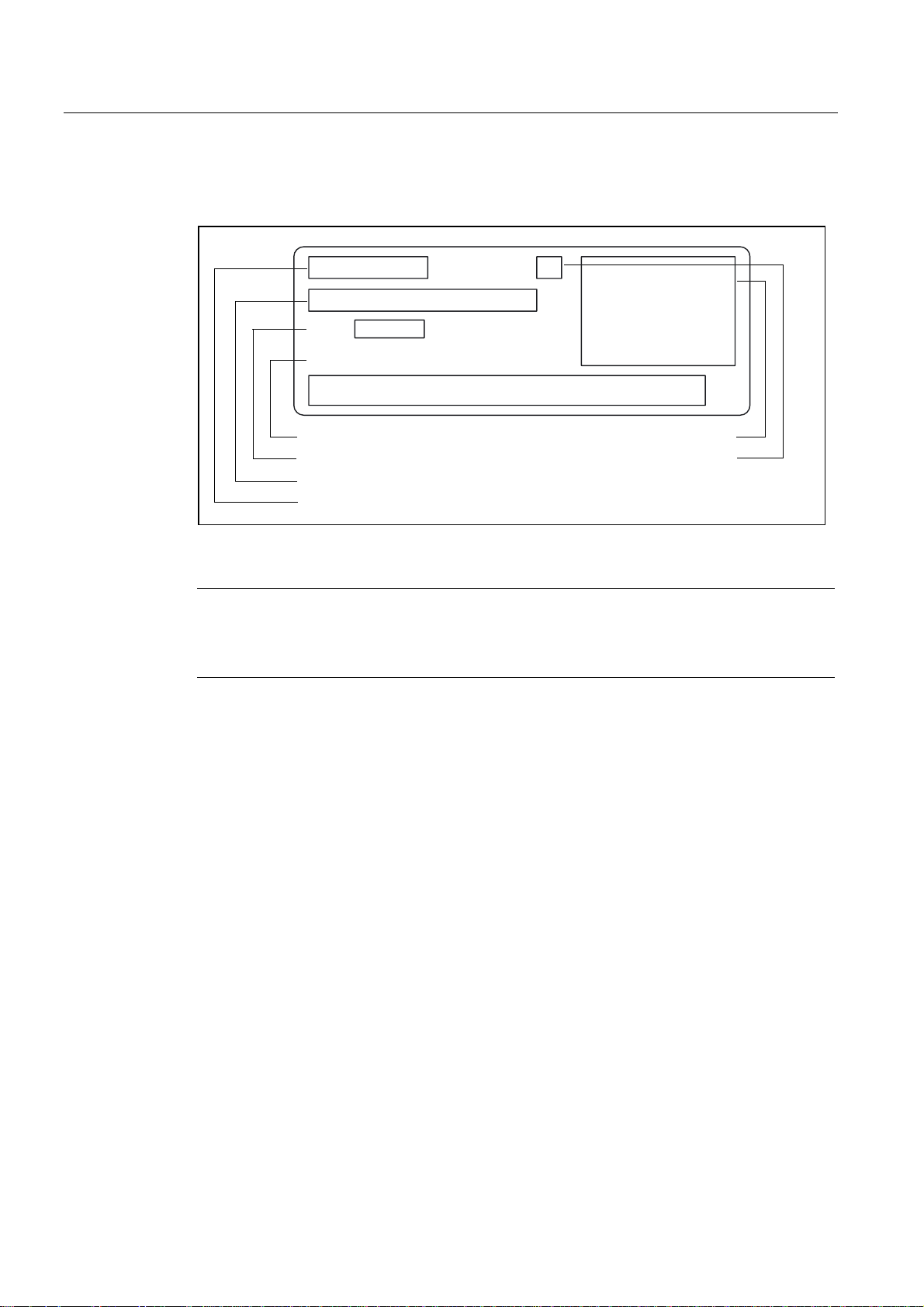

2.5.1 SIMOTION D410 memory model

The following figure provides an overview of the SIMOTION D410 memory model.

3URJUDPPLQJGHYLFH

(66,027,216&287

'RZQORDG

6,027,21b'

&RPSDFW)ODVK&DUG

73V

8VHUGDWD

,3SDUDPHWHUV

'3SDUDPHWHUV

6,027,21NHUQHO

5$0WR520

'VWDUWXS

'VWDUWXS

'VWDUWXS

9RODWLOHGDWD

73V

8VHUGDWD

6,027,21NHUQHO

1RQYRODWLOHGDWD

'LDJQRVWLFVEXIIHU

5HWHQWLYHXVHUDUHD

UHWDLQYDULDEOH

,3SDUDPHWHUV

'3SDUDPHWHUV

$EVROXWHHQFRGHU

RIIVHW

Figure 2-2 SIMOTION D410 memory model

The next chapters provide information pertaining to user memories and to the sequences of

specific user actions.

See also

Properties of the user memories (Page 36)

Operator actions and their impact on user memory (Page 38)

D410

Commissioning Manual, 08/2008 Edition

35

Page 36

Commissioning (hardware)

2.5 User memory concept

2.5.2 Properties of the user memories

Non-volatile data

Non-volatile data is used with the objective of retaining user- and system-relevant data when

SIMOTION D410 is in de-energized state. You will find information about the area that can

be used for non-volatile data in the

SIMOTION SCOUT

Non-volatile data available in SIMOTION devices:

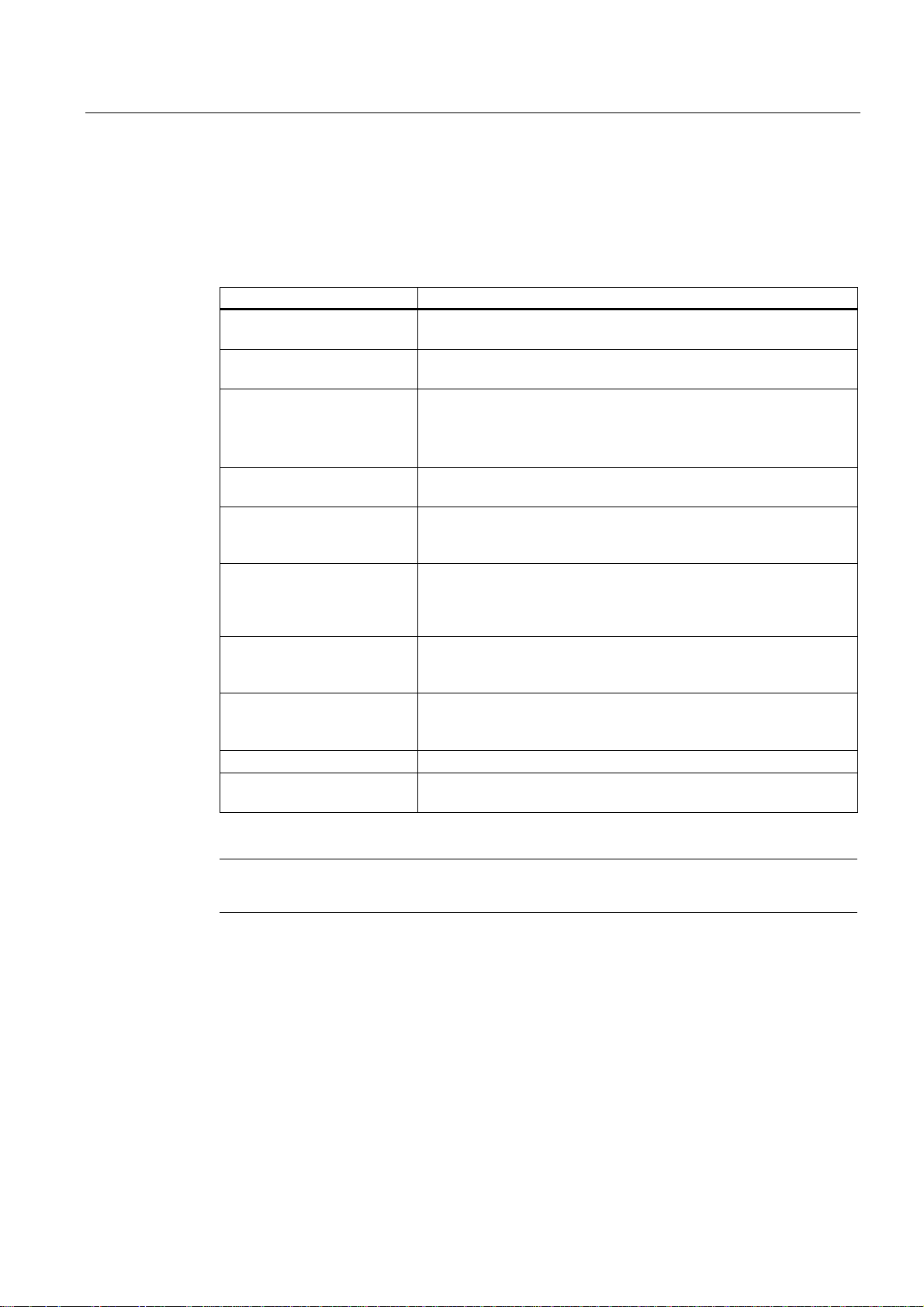

Table 2-1 Content of non-volatile data

Non-volatile data Content

Kernel data

Retain variables

Retain TO Absolute encoder offset

• Last operating state

• IP parameters (IP address, subnet mask, router address)

• DP parameters (PROFIBUS DP address, baud rate)

• Diagnostics buffer

• Variables in the interface or implementation section of a unit declared

with VAR_GLOBAL RETAIN

• Global device variables set with the "RETAIN" attribute

Configuration Manual.

Properties of non-volatile data of SIMOTION D410:

Table 2-2 Properties of non-volatile data

Properties Meaning

Location: Non-volatile data resides in the FRAM of SIMOTION D410.

Backup battery: A backup battery is not required.

Backup time: Unlimited

More information

IP and DP parameters in non-volatile data

The IP and DP parameters are loaded from configuration data on the CompactFlash Card

during startup for use by the SIMOTION device. The SIMOTION D410 can use the

addresses defined in these data to go online. The IP and DP parameters on the

CompactFlash Card are also written to non-volatile memory during startup. The IP and DP

parameters in non-volatile data is retained and used by the SIMOTION device if the system

is restarted with a CompactFlash Card which does not contain any configuration data. The

SIMOTION device can always be made available online if the configuration was downloaded

to the device at least once using SIMOTION SCOUT, or if the SIMOTION device was started

up with Compact Flash Card.

D410

36 Commissioning Manual, 08/2008 Edition

Page 37

Commissioning (hardware)

2.5 User memory concept

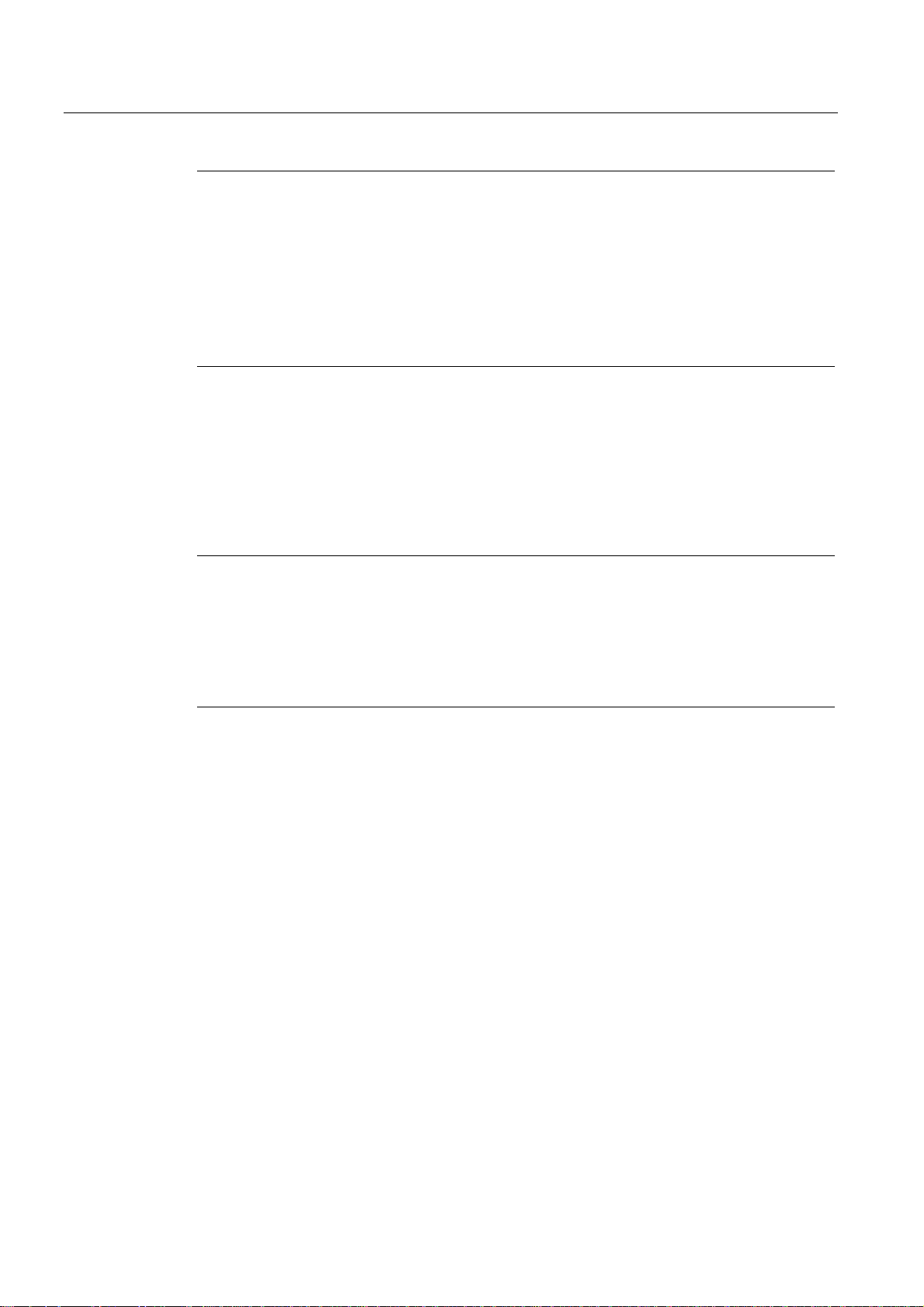

Volatile data

Definition of the properties of volatile data:

● Volatile data resides in the RAM area of SIMOTION D410.

● The download data of SIMOTION SCOUT is written to this memory.

● These data is lost after the SIMOTION D410 is shut down.

● Contents of the "volatile data" area:

– SIMOTION kernel

– Technology packages (TP)

– User data (programs, configuration data, parameters)

7DUJHW

GHYLFH

'RZQORDG

8SORDG

5$0WR

520

0LFUR0HPRU\&DUG

&RPSDFW)ODVK&DUG

0HPRU\&DUG

Figure 2-3 Configuration data and system variables on volatile memory

520

FRS\

5$0

ORDGPHPRU\

&RQILJGDWDLQ

581

6\VWHP

YDULDEOHV

&RS\DFWXDOGDWD

WR5$0

QRV\VWHP

YDULDEOHV

&RPPLVVLRQLQJ

1H[W

72UHVWDUW

RULPPHGLDWHO\

&XUUHQW5$0

ZRUNLQJPHPRU\

You can find additional information about memory management in SIMOTION in the

SIMOTION Basic Functions

Function Manual.

D410

Commissioning Manual, 08/2008 Edition

37

Page 38

Commissioning (hardware)

2.5 User memory concept

CompactFlash Card

The CompactFlash Card contains the following data:

● SIMOTION kernel

● Technology packages (TP)

● User data (units, configuration data, parameters, task configuration)

● IP parameters (IP address, subnet mask, router address)

● DP parameters (PROFIBUS DP address, baud rate)

2.5.3 Operator actions and their impact on user memory

The next section describes the user actions identified in the "SIMOTION D410 memory

model" by arrows and their impact on user memory.

Download SIMOTION SCOUT

The "Download" command transfers the following data from the Engineering System to the

"volatile data" area:

● User data (units, configuration data, parameters, task configuration)

● Technology packages

The IP and DP parameters are furthermore saved to the "non-volatile data" area. The retain

variables are initialized with their start values. This however, depends on the settings in

SIMOTION SCOUT. Volatile data is lost if you shut down the SIMOTION D410 module after

the download.

Copy RAM to ROM

The "Copy RAM to ROM" command is used on the ES to save the following data to the

CompactFlash Card:

● Technology packages and user data (units, configuration data, parameters, task

● Actual values are copied to the "volatile data" area, depending on the settings in

configuration) of the "volatile data" area

SIMOTION SCOUT

Note

The "Copy RAM to ROM" command does not save the actual values of the retain

variables to the CompactFlash Card:

D410

38 Commissioning Manual, 08/2008 Edition

Page 39

Commissioning (hardware)

2.5 User memory concept

Startup of SIMOTION D410

The SIMOTION kernel is loaded from the CompactFlash Card to the "volatile data" area

during the startup of SIMOTION D410.

Volatile data is lost if you shut down the SIMOTION D410 module after the download. Data

loaded from the CompactFlash Card at the next restart:

● The technology packages and user data to the "volatile data" area

● IP and DP parameters to the "non-volatile data" area

Backup of non-volatile data

The "_savePersistentMemoryData" system function is used to save the contents of nonvolatile data to the CompactFlash Card. This backup prevents the retain variables and the

absolute encoder position from being lost if a component is replaced.

The backup copy is saved to the "PMEMORY.XML" backup file in the "USER/SIMOTION"

folder. On system side it is always ensured that a consistent overall image of the non-volatile

data is available at the next restart, even if there is a power failure during backup. An already

existing backup file is renamed to "PMEMORY.BAK" before a new backup file is generated.

If the backup to this new file fails (for example, due to insufficient storage capacity of the

CompactFlash Card), the existing backup file is used in the next attempt to restore the

content of non-volatile data. The backup file is deleted if the new file was successfully

created.

NOTICE

An absolute encoder overflow after "_savePersistentMemoryData" was executed indicates

that the restored non-volatile data contains an incorrect actual position value. The encoder

must be referenced again (absolute encoder adjustment)!

D410

Commissioning Manual, 08/2008 Edition

39

Page 40

Commissioning (hardware)

2.5 User memory concept

Startup and non-volatile data

The table below describes the startup situations which may develop in terms of the nonvolatile data and how to handle such situations.

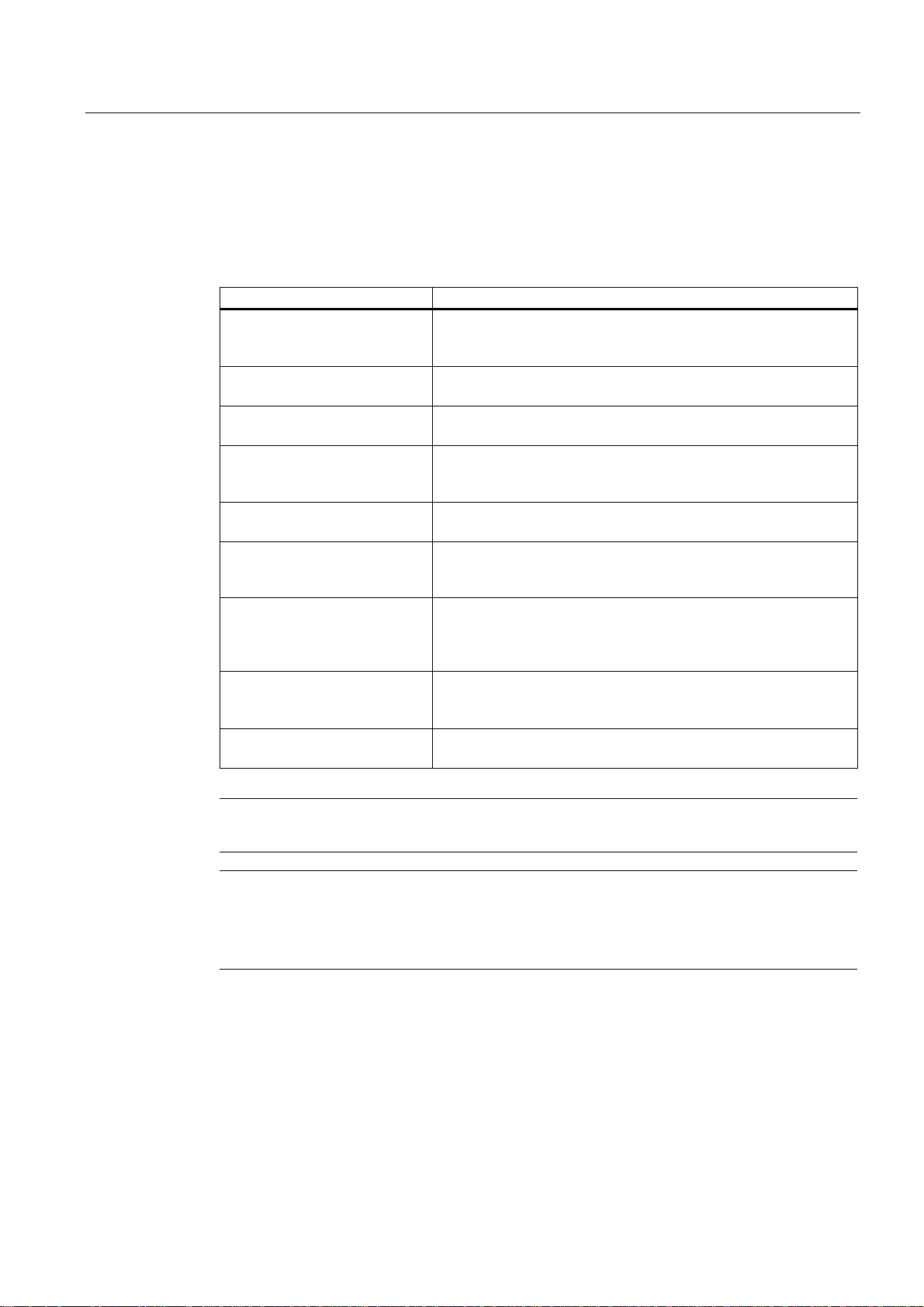

Table 2-3 Startup situations with non-volatile data

Situa

tion

1 Valid contents of non-volatile data. Startup of SIMOTION D410 with the non-volatile data.

2 Invalid contents in non-volatile data, and neither a backup

3 Invalid contents in non-volatile data. A backup file

4 Invalid contents in non-volatile data and in the backup file,

5 Invalid contents in non-volatile data and in the backup file,

Initial condition Result

The PROFIBUS address in non-volatile data is

therefore valid, for example.

SIMOTION D410 copies the factory defaults to its nonfile (PMEMORY.XML), nor a backup copy

(PMEMORY.BAK) exists.

(PMEMORY.XML) with valid contents is available.

and a backup copy (PMEMORY.BAK) is not available.

and a backup copy (PMEMORY.BAK) with valid contents

is available.

volatile data and restarts using this data. The default

PROFIBUS address is valid in this case, for example.

SIMOTION D410 copies the contents of the backup file

to its non-volatile data and starts using this data.

SIMOTION D410 copies the factory defaults to its non-

volatile data and restarts using this data. The default

PROFIBUS address is valid in this case, for example.

SIMOTION D410 copies the contents of the backup file

to its non-volatile data and starts using this data.

Diagnostics of non-volatile data

Users can determine the status of non-volatile data by reading the diagnostics buffer and the

system variable.

The following message events are entered once in the diagnostics buffer when they occur:

Table 2-4 Messages of the diagnostics buffer

Entry Meaning To correct or avoid errors

Non-volatile data loaded from file

(Persistent Data File Loading done)

Non-volatile data loaded from the backup file

(Persistent Data Backup File Loading done)

Error while loading non-volatile data from a

file

(Persistent Data File Loading Failure)

D410

Non-volatile data successfully restored

from the backup file to the

CompactFlash Card.

Non-volatile data successfully restored

from the backup copy to the

CompactFlash Card.

Backup file or backup copy could not be

loaded.

Possible causes:

• Backup file or backup copy not

available

• Invalid data in backup file

-

-

Use the

"_savePersistentMemoryData"

system function to generate a

backup file with valid contents.

40 Commissioning Manual, 08/2008 Edition

Page 41

Commissioning (hardware)

2.5 User memory concept

See also

Refer to the

SIMOTION SCOUT

Configuration Manual for information about how to read out

the contents of the diagnostic buffer.

System variable "persistentMemoryPowerMonitoring.persistentDataState" indicates the

status of non-volatile data after startup:

Table 2-5 Status of non-volatile data after startup

Status Meaning

FROM_RAM (1) Non-volatile data is activated in the SIMOTION device

FROM_FILE (2) Non-volatile data was restored from the backup file

FROM_BACKUP (3) Non-volatile data was restored from the backup copy

INVALID (4) Non-volatile data and data in the backup file / backup copy are invalid, or do

not exist, or were deleted.

The SIMOTION device copied the factory defaults to its non-volatile data

and started using this data.

SIMOTION D410 memory model (Page 35)

D410

Commissioning Manual, 08/2008 Edition

41

Page 42

Page 43

Configuring SIMOTION D410

3.1 Software requirements

SIMOTION SCOUT Engineering System

The SIMOTION SCOUT Engineering System must be installed on your programming device

/ PC in order to commission the SIMOTION D410. Observe the information on the current

"SIMOTION SCOUT" CD.

For information on how to install SIMOTION SCOUT on your programming device / PC, refer

SIMOTION SCOUT

to the

3.2 Inserting SIMOTION D410 into a project

Creating a project and configuring the programming device / PC interface

Proceed as follows in order to create a project in SIMOTION SCOUT and to insert a

SIMOTION D410:

Configuration Manual.

3

1. Select the "Project > New..." menu.

2. Enter a name for your project in the "New Project" dialog box and confirm your entry with

"OK".

A new folder is generated in the Project Navigator and assigned the name of the project.

3. Double-click "Create new device" in the Project Navigator. The "Create New Device"

dialog box opens. Select D410 from the "CPU type" field and the characteristic of your

module (D410 DP or D410 PN) from the "Variant" field. Confirm with "OK".

4. The "Properties" dialog box of the (PROFIBUS or PROFINET) interface opens where you

set up the connection to the programming device / PC according to the module

characteristics.

D410

Commissioning Manual, 08/2008 Edition

43

Page 44

Configuring SIMOTION D410

3.2 Inserting SIMOTION D410 into a project

Communication with the programming device / PC via PROFIBUS (only for D410 DP)

1. Select the PROFIBUS interface from the "Properties - PROFIBUS/MPI" dialog box and

confirm your selection with "OK".

2. The connection to the programming device / PC is activated automatically and HW Config

opens.

Note

The active state setting of the connection to the programming device / PC is only

visualized in NetPro!

Interconnection with the programming device / PC on PROFINET (only for D410 DN)

The "Properties - Ethernet Interface" dialog box is open.

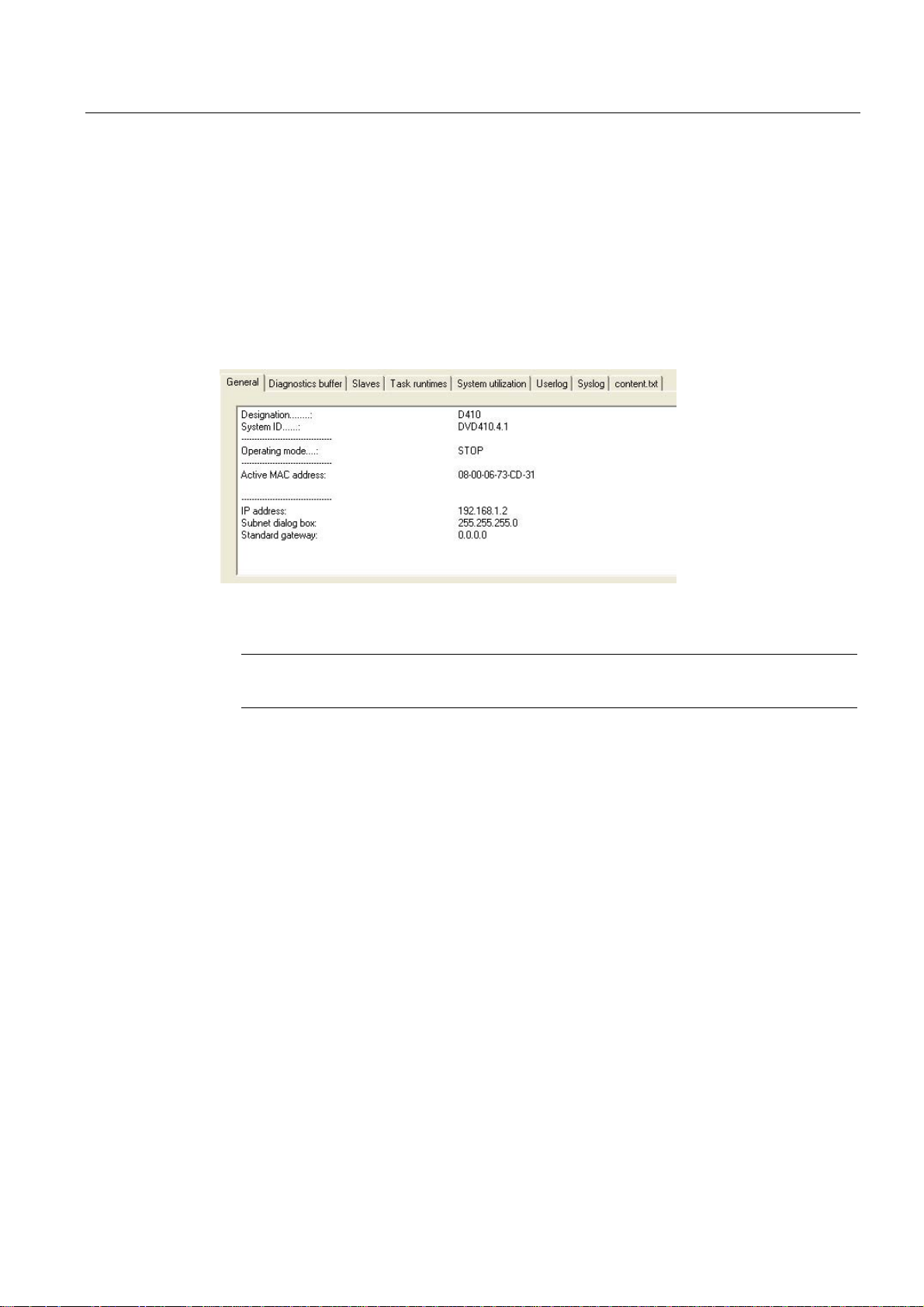

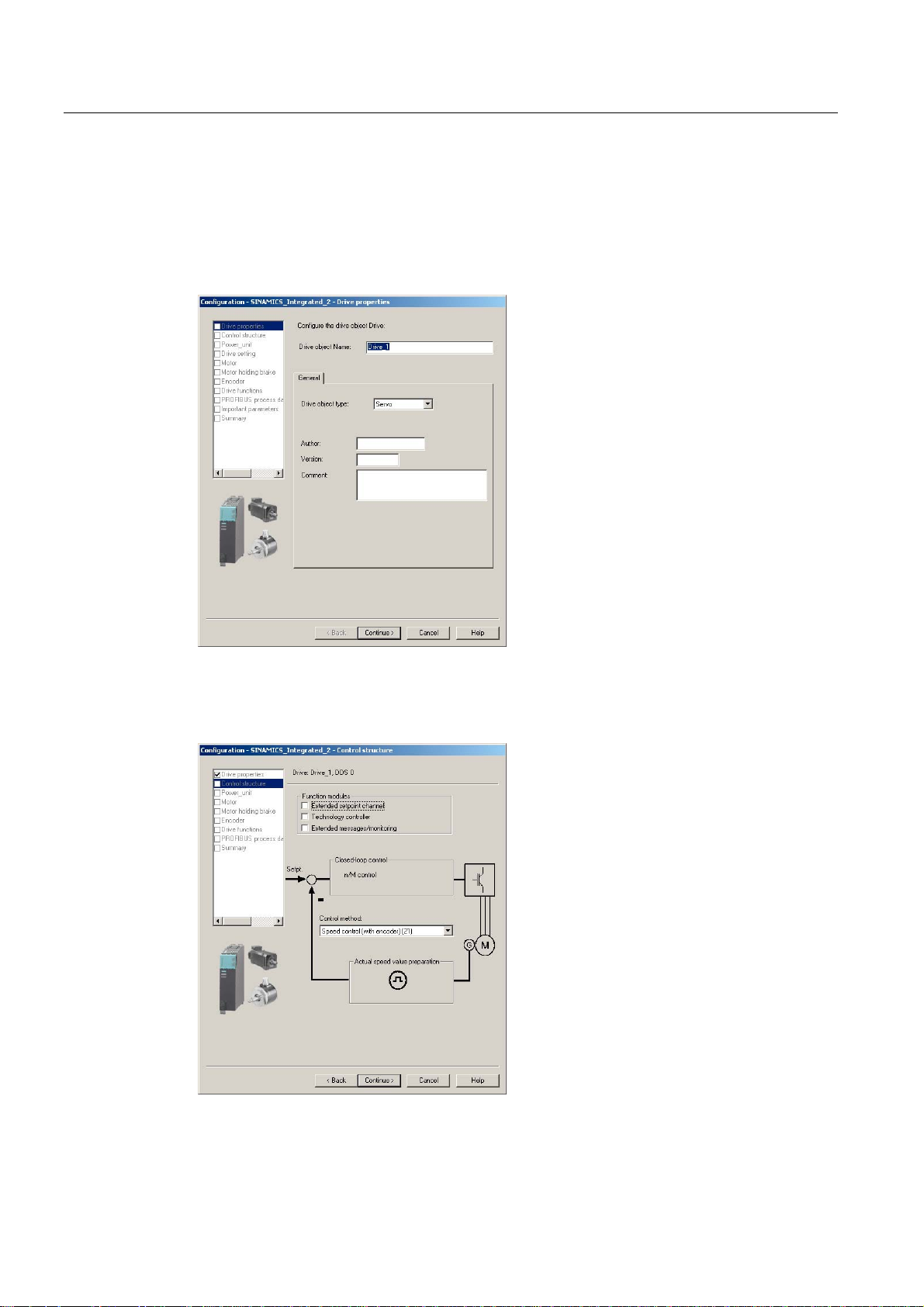

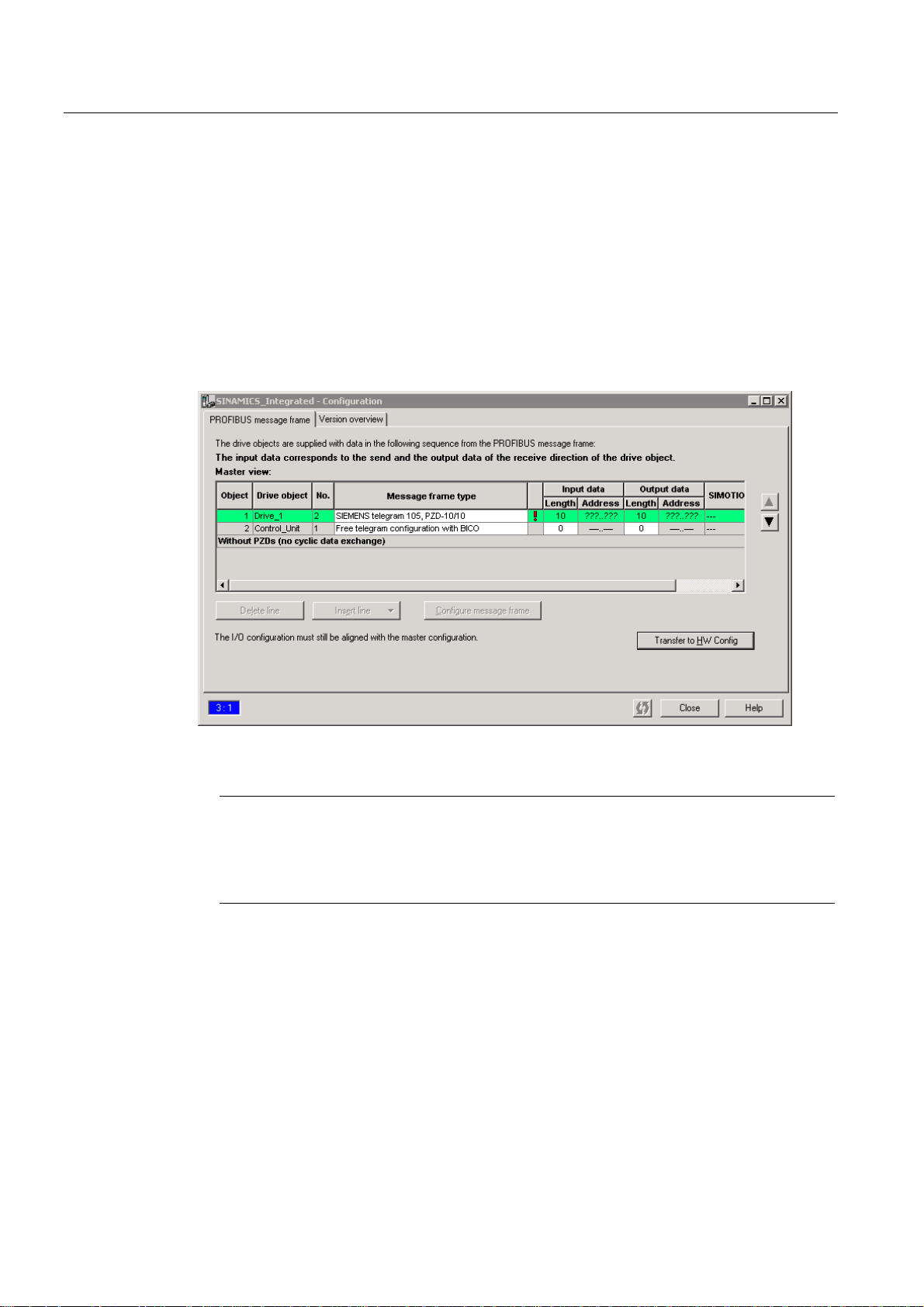

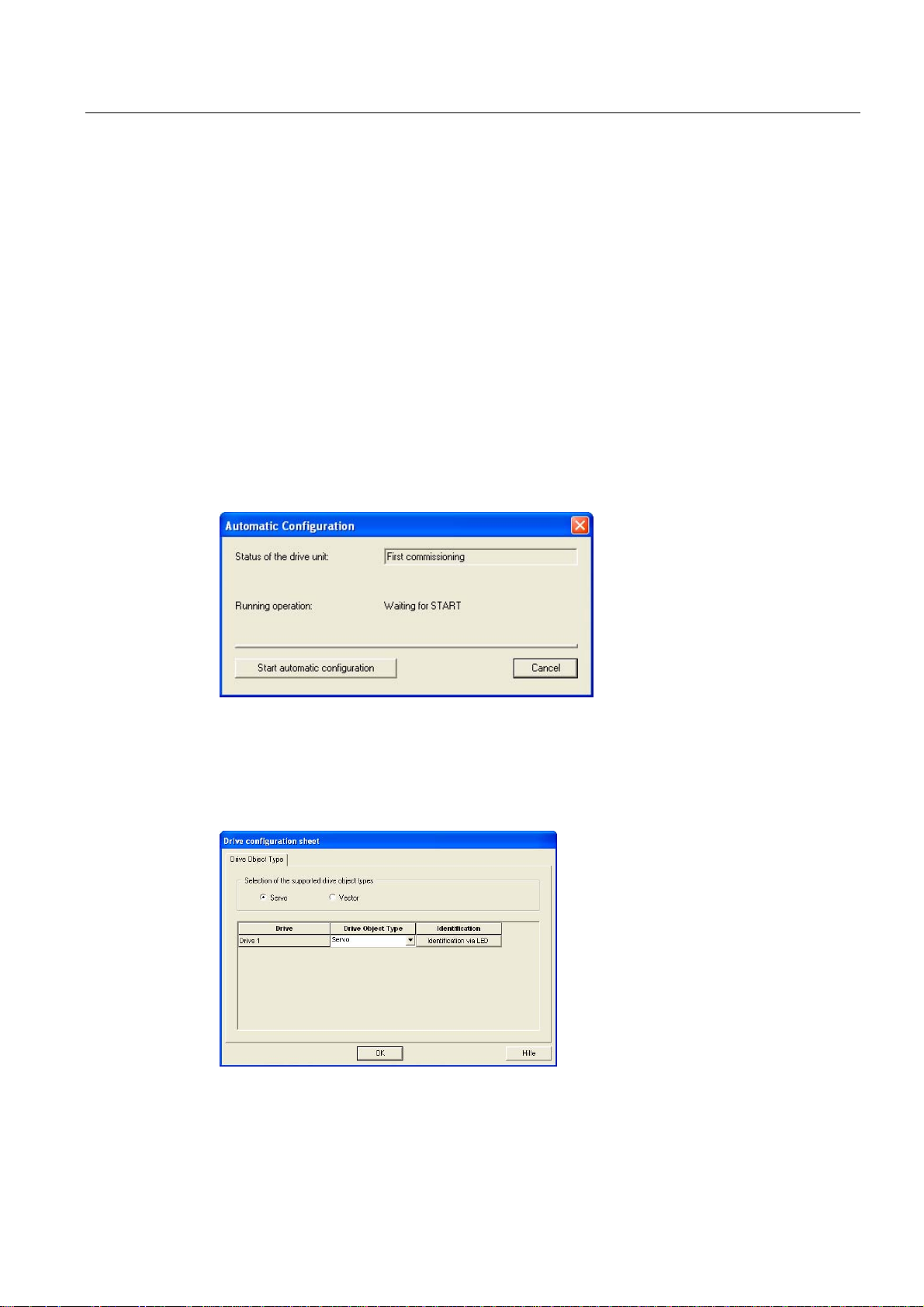

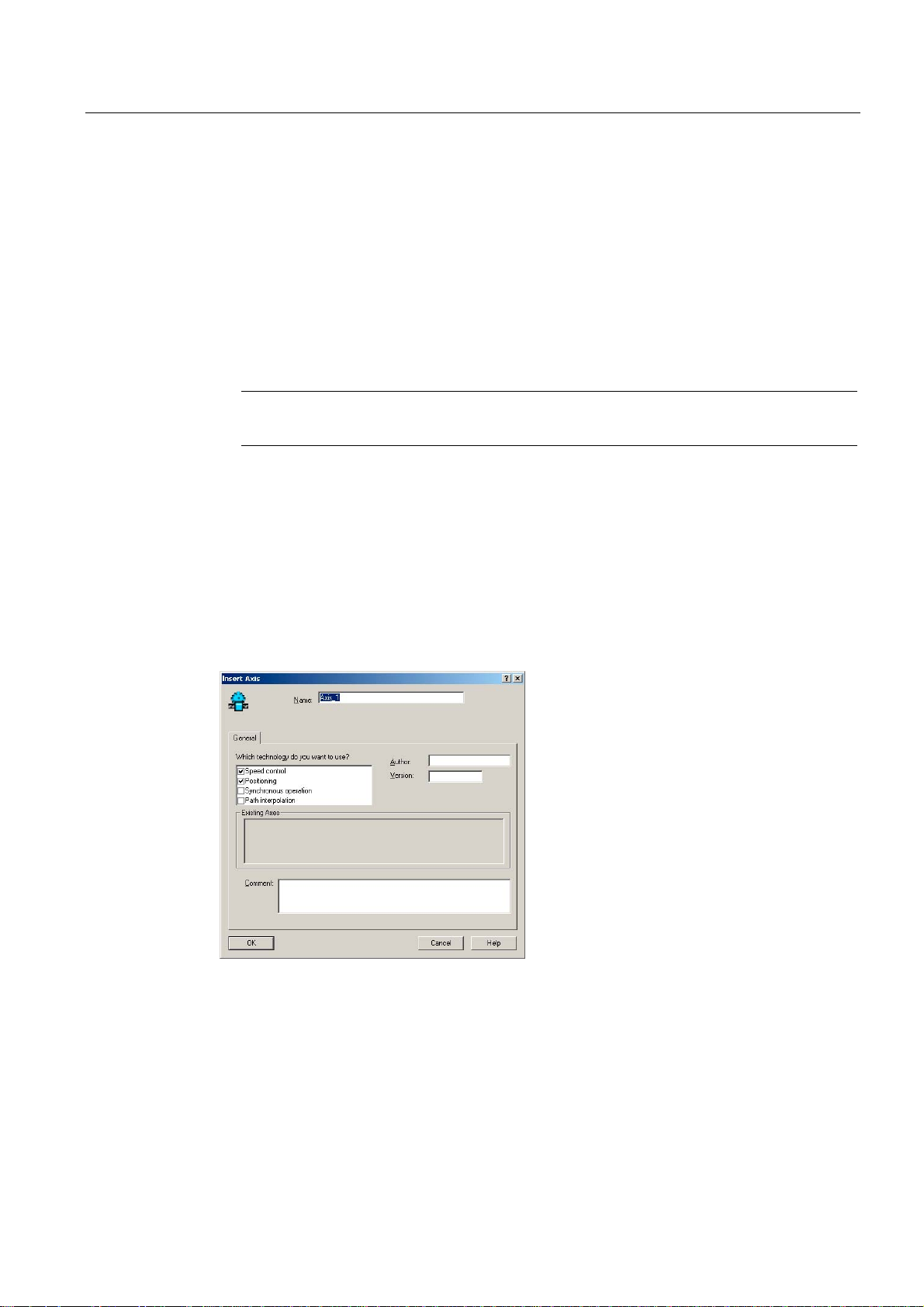

Figure 3-1 Properties of the Ethernet interface

Program the following parameters in the "Properties - Ethernet Interface" dialog box:

1. Click "New".

The "New Subnet Industrial Ethernet" dialog box opens. Rename the new subnet, or

accept the default name by clicking "OK".

2. Select the new Ethernet subnet which is now displayed in the "Properties - Ethernet

Interface" dialog box.

3. Define your addresses in the "IP address" and "Subnet mask" fields of the "Properties -

Ethernet Interface" dialog box. Change to the "Network node" field and define whether

you are going to use a router and, if yes, enter the router address. Confirm with "OK".

4. Select the PROFINET interface from the "Properties" dialog box and confirm your

selection with "OK".

5. The connection to the programming device / PC is activated automatically and HW Config

opens.

D410

44 Commissioning Manual, 08/2008 Edition

Page 45

Configuring SIMOTION D410

3.2 Inserting SIMOTION D410 into a project

Note

The active state setting of the connection to the programming device / PC is only

visualized in NetPro!

Representation in HW Config

SIMOTION D410 is represented in HW Config.

Figure 3-2 Image of a SIMOTION D410 PN in HW Config

D410

Commissioning Manual, 08/2008 Edition

45

Page 46

Configuring SIMOTION D410

3.3 Configuring the PROFIBUS DP interface (only D410 DP)

3.3 Configuring the PROFIBUS DP interface (only D410 DP)

3.3.1 General information about PROFIBUS DP communication

Definition of PROFIBUS DP

PROFIBUS DP is an international, open field bus standard specified in the European field

bus Standard EN 50170 Part 2. PROFIBUS DP is optimized for high-speed, time-sensitive

data transfer at field level.

Components communicating on PROFIBUS DP are classified as master and slave

components.

● Master (active bus node)

Components representing a bus master determine the data traffic on the bus and are

therefore also referred to as active bus nodes.

● Slaves (passive bus nodes)

These devices may only receive, acknowledge and return messages to the master if

requested by the master.

Examples: SINAMICS drives, I/O modules

Note

If a SIMOTION D410 DP is operated as a passive PROFIBUS I-slave, the display,

measuring functions and controller optimization engineering functions will be very slow. If

possible, use the "active I-slave" setting for local commissioning (which does mean that an

equidistance is no longer possible) and for complete commissioning, switch to "passive Islave".

Additional references

You will find additional information about PROFIBUS DP in the

System Manual.

SIMOTION Communication

D410

46 Commissioning Manual, 08/2008 Edition

Page 47

Configuring SIMOTION D410

3.3 Configuring the PROFIBUS DP interface (only D410 DP)

3.3.2 Assignment of the PROFIBUS addresses in HW Config

Assigning PROFIBUS addresses

Assign a PROFIBUS address to all devices before you start networking these in order to

enable intercommunication.

Note

All PROFIBUS addresses you assign must be unique on the PROFIBUS subnet.

Information pertaining to the rules of communication on the PROFIBUS subnet is available in

SIMOTION D410

the

Manual.

Define the PROFIBUS address separately for each device on your programming device / PC

in HW Config. Certain PROFIBUS DP slaves are equipped with an address switch.

Note

The PROFIBUS addresses set at the devices using these switches must correspond with the

address settings in HW Config.

Recommendation for PROFIBUS addresses

Reserve PROFIBUS address "0" for a service programming device and "1" for a service HMI

device which are connected to the subnet as required.

Recommended PROFIBUS address setting for SIMOTION D410 in case of replacement or

service:

Reserve address "2" for a SIMOTION D410. This prevents redundancy of the addresses

after SIMOTION D410 is installed in the subnet with default settings (for example, when

replacing a SIMOTION D410). Assign addresses higher than "2" to any additional devices on

the subnet.

D410

Commissioning Manual, 08/2008 Edition

47

Page 48

Configuring SIMOTION D410

3.3 Configuring the PROFIBUS DP interface (only D410 DP)

3.3.3 Operating SIMOTION D410 on PROFIBUS DP.

PROFIBUS DP interface (X21)

SIMOTION D410 provides an interface for connecting to PROFIBUS DP. The interface

supports transmission rates up to 12 Mbit/s.

The PROFIBUS DP interface can be operated as:

● DP slave, isochronous

● DP master, isochronous

● DP slave, not isochronous

● DP master, not isochronous

Both PROFIBUS DP interfaces are set by default for operation as master at address 2 at a

transmission rate of 1.5 Mbit/s. The PROFIBUS DP network is automatically detected and

generated for this setting.

However, you can select other settings. Such user-specific settings must be configured in

HW Config and NetPro.

3.3.4 Creating a new PROFIBUS DP subnet

The SIMOTION D410 device is networked using SIMOTION SCOUT. Set up your userspecific bus parameters for the PROFIBUS interface when you configure the network.

Note

The actions outlined below only need to be taken if you have not selected an interface when

integrating SIMOTION D410 into the project (cf. chapter "Integrating SIMOTION D410 into a

project").

Next, interconnect the programming device / PC using NetPro with the device, see the

chapter "Configuring the programming device / PC interface".

1. Double-click the "D410" entry in the Project Navigator in order to open HW Config.

2. Double-click the DP/MPI interface in the SIMOTION D410 representation in HW Config.

The "Properties - DP/MPI" dialog box opens.

3. Click "Properties" in the "General" tab to open the "PROFIBUS interface DP/MPI" dialog

box.

4. Click "New" to open the "Properties - New PROFIBUS Subnet" dialog box.

5. Name the new subnet, and then enter its properties in the "Network settings" tab, for

example, the transmission rate.

6. Click "OK" to accept the settings.

The new subnet is now displayed in the "Properties - PROFIBUS interface DP/MPI"

dialog box and is ready for being interconnected with the PROFIBUS DP interface.

7. Save and compile the changes.

The PROFIBUS subnet you created is displayed as a graphic object in HW Config.

D410

48 Commissioning Manual, 08/2008 Edition

Page 49

Configuring SIMOTION D410

3.3 Configuring the PROFIBUS DP interface (only D410 DP)

3.3.5 Setting the DP cycle and system cycle clocks

All system clocks for SIMOTION D410 DP are based on the DP cycle of SINAMICS

Integrated, which must be set in HW Config.

Double-click the SINAMICS block at the integrated PROFIBUS. The "DP Slave Properties"

dialog box opens. You can synchronize the DP cycle of SINAMICS Integrated in the

"Isochronous mode" tab.

Table 3-1 Range of values for SIMOTION D410 DP

DP cycle: ≥ 1 ms

Resolution: 0.125 ms

The PROFIBUS DP interface of the SIMOTION D410 DP supports operation at a DP cycle

time ≥ 1 ms, at a resolution of 0.125 ms. SINAMICS Integrated always runs in isochronous

mode. The cyclic tasks of SIMOTION are therefore always in synchronism with

SINAMICS Integrated.

The set DP cycle of SINAMICS Integrated is displayed as "Bus cycle" in the "System Clocks

- D410..." dialog box in SIMOTION SCOUT. Select the SIMOTION D410 DP in the project

tree, and then select the "Set system clocks" option in the "Target system" > "Expert" menu.

The table below shows the ratios you can set for the system clocks of SIMOTION D410 DP

based on the DP cycle.

Table 3-2 Possible factors between the system cycle clocks

Bus cycle: Servo cycle clock Servo cycle clock: IPO

cycle

1 ... 4, 6, 8 1 … 6 2 … 64

IPO cycle: IPO2 cycle

The minimum configurable length of the servo cycle is 1 ms. In conjunction with technology

objects, a minimum servo cycle of 2 ms is recommended.

If you programmed the PROFIBUS DP interface for operation in isochronous master mode,

you must synchronize its DP cycle with the DP cycle of SINAMICS Integrated in HW Config.

The timebase for the system clocks is generated internally if the DP interface is operated in

isochronous or non-isochronous master mode. SIMOTION D410 does not have to

synchronize itself with an external cycle.

The PROFIBUS DP interface can also be operated in isochronous slave mode. In this

constellation system clocks are based on the clock signals received at the slave interface. A

substitute clock of a duration equivalent to the configured clock is generated internally if the

isochronous slave interface has not received a clock signal.

The clock settings are included in the project download to SIMOTION D410 DP and are

adjusted according to specification.

At a PROFIBUS DP interface operated in isochronous slave mode you can also step down

the clock ratio for synchronization with SINAMICS Integrated. This reduction of the clock

ratio at the isochronous slave interface for synchronization with SINAMICS Integrated allows

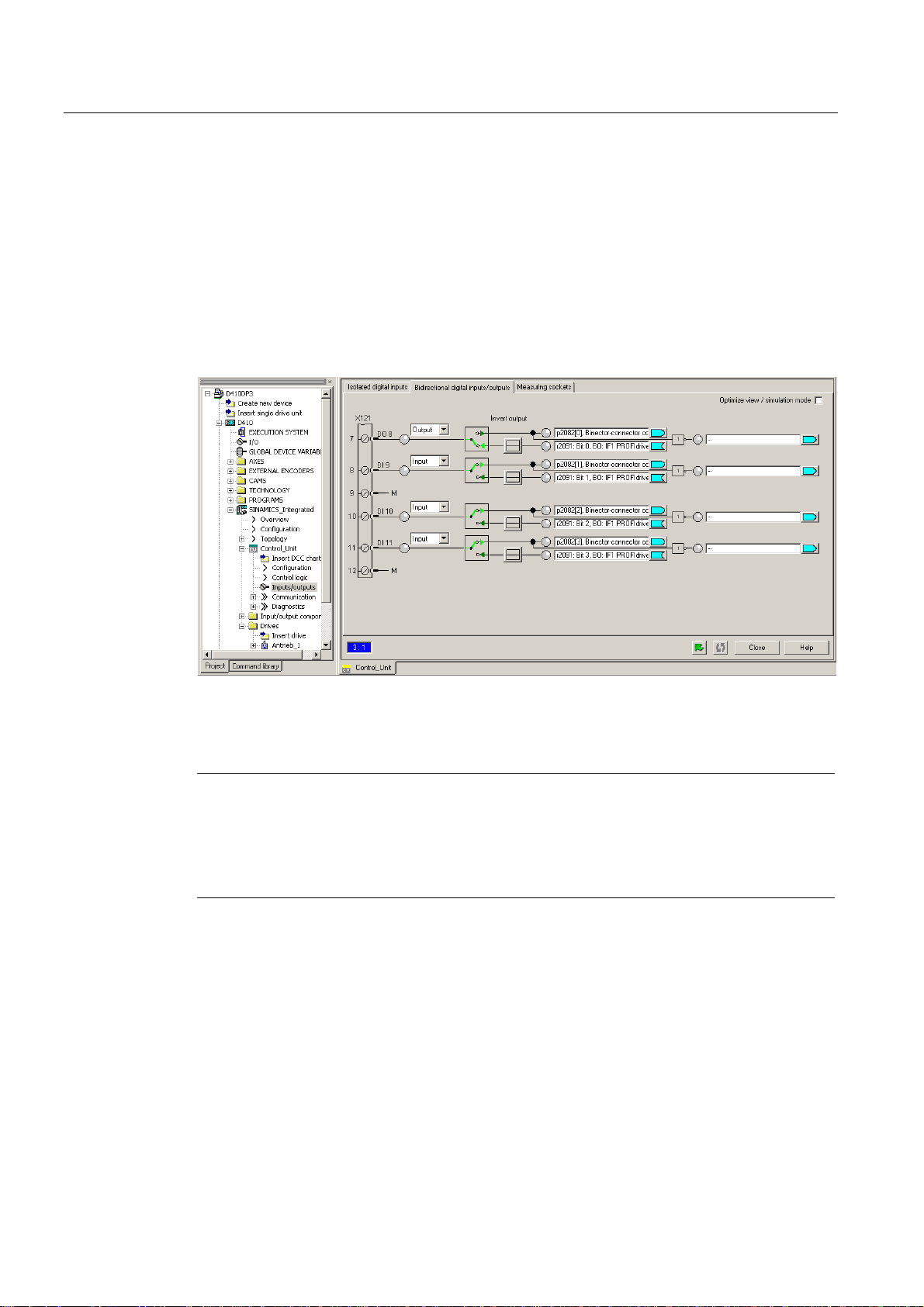

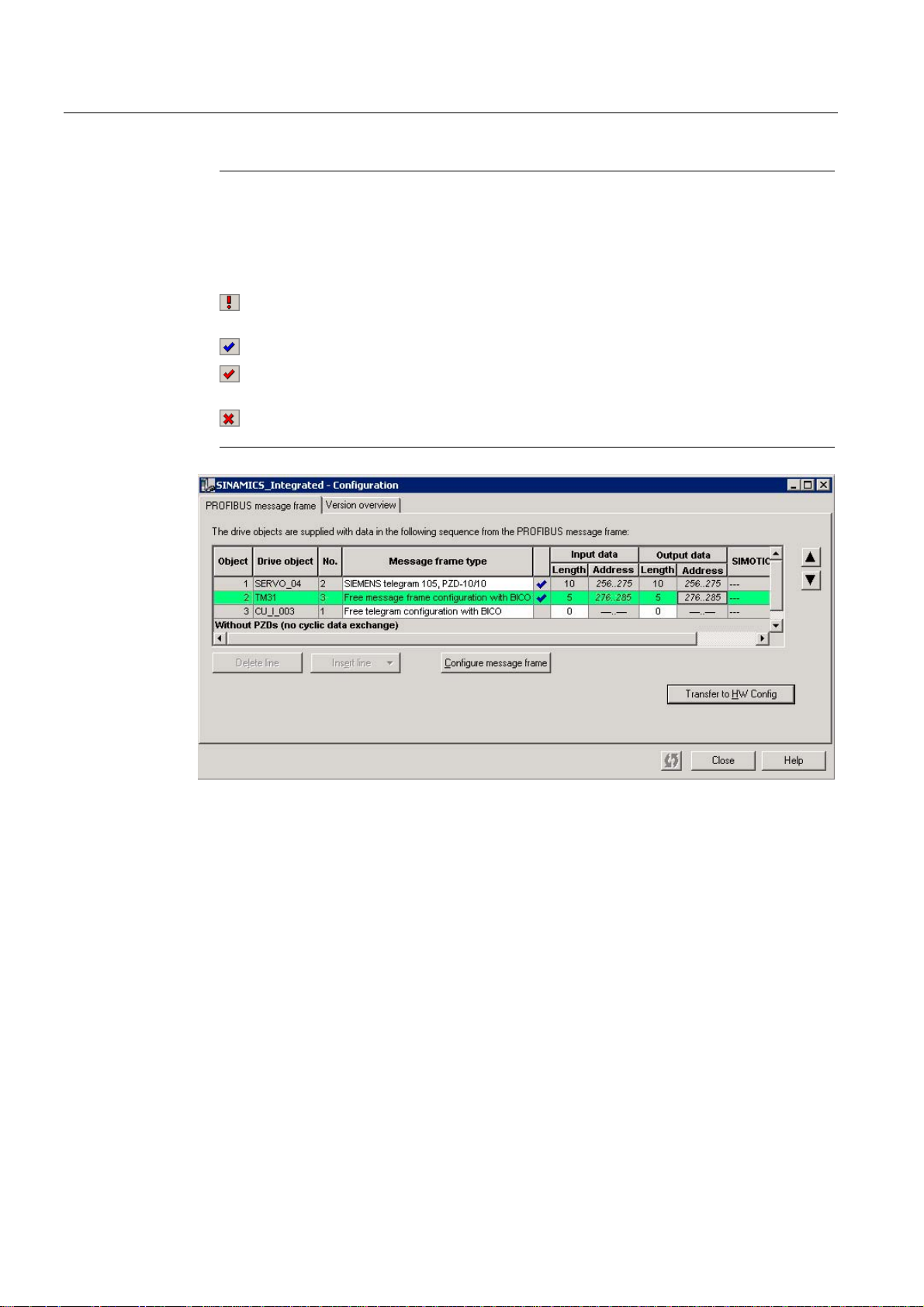

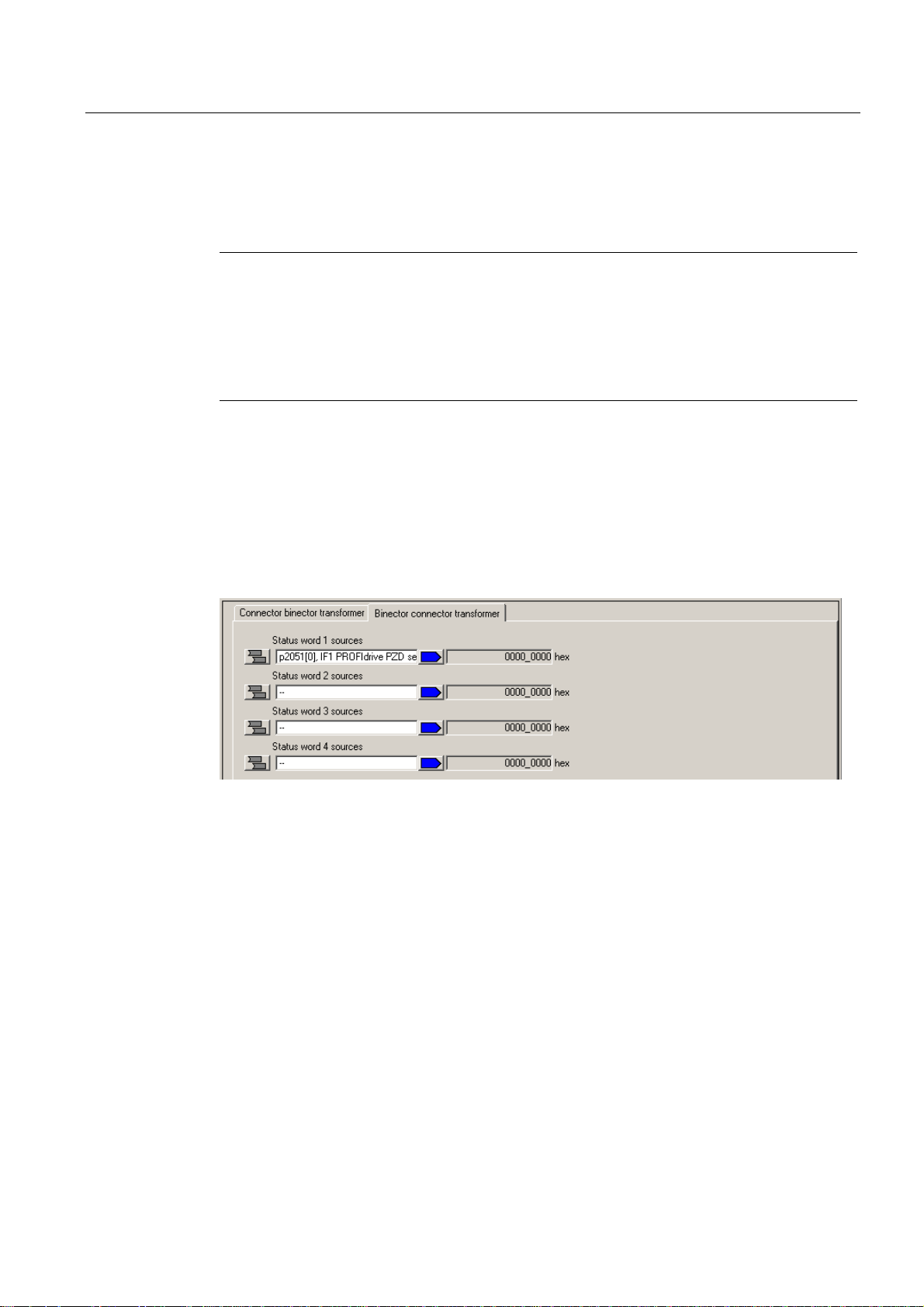

the operation of a DP cycle at the slave interface which is equivalent to an integer multiple