Page 1

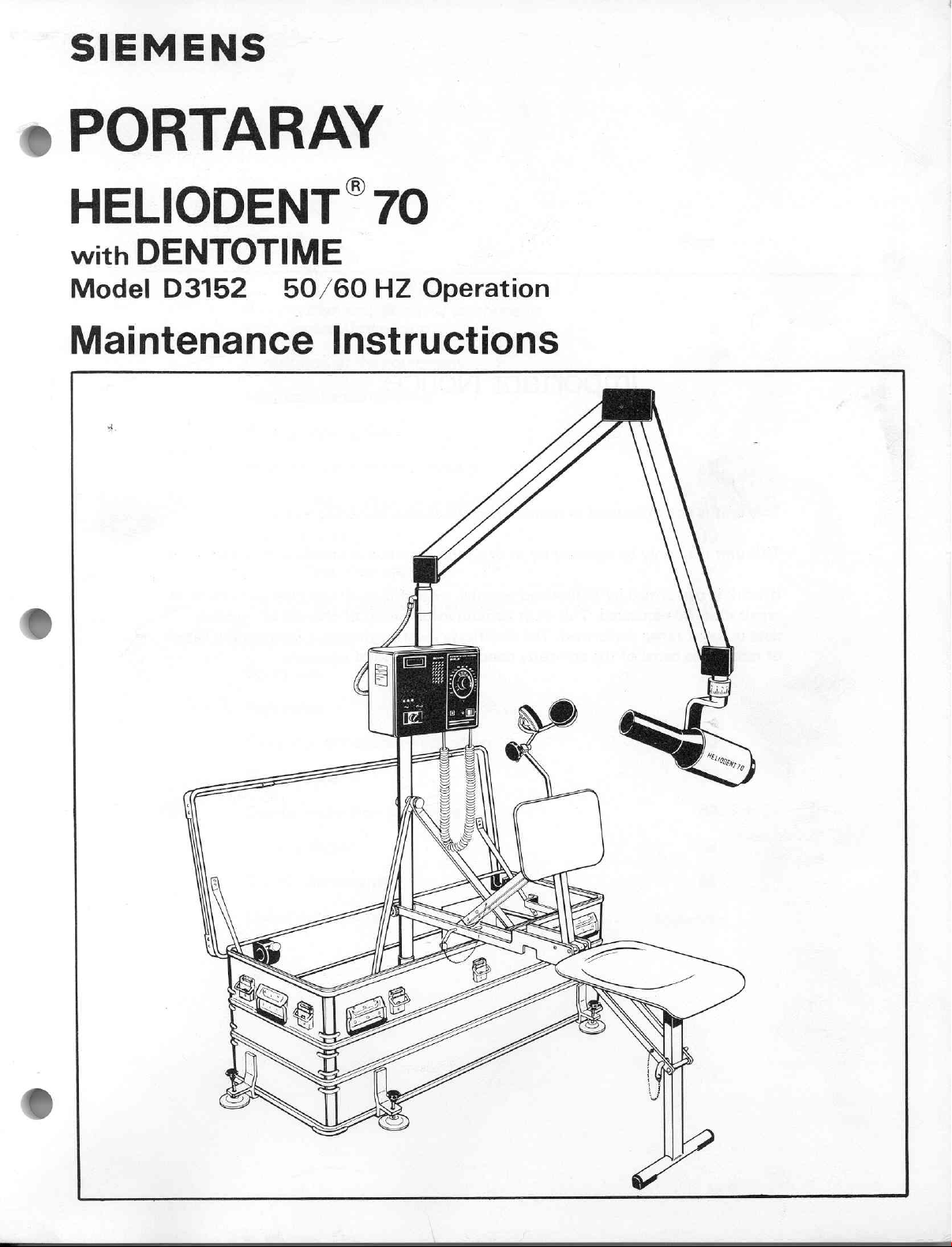

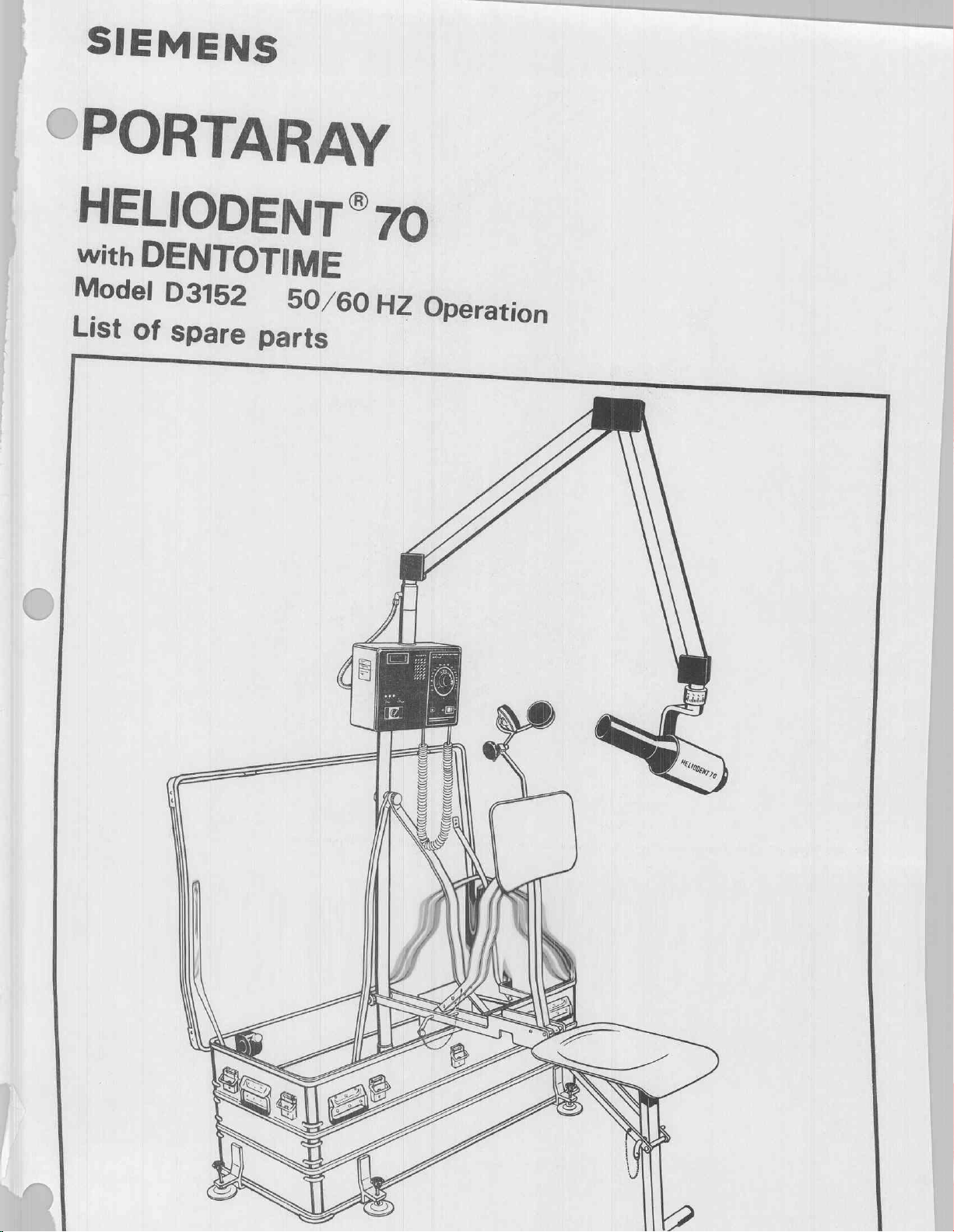

SIEMENS

PORTARAY

e

HELIODENT

with

Model

Maintenance

DENTOTIME

D3152

50/60

70

HZ

Instructions

Operation

Page 2

This

This

If

work

repair

data

of

repair,

unit

unit

must

or

is

not

may

is

performed

be

work

the

Important

to

be

used

only

be

repaired

by

authorized

reguested.

range

name

This

performed.

of

the

in

rooms

by

must

The

company

Notice

where

us

persons,

contain

certificate

concerned

an

or

a

representative

a

information

explosion

certificate

must

furthermore

and

a

valid

hazard

expressly

exists.

on the

of

changes

signature.

authorized

type

and

of

nominal

indicate

by

extent

the

date

us.

of

Page 3

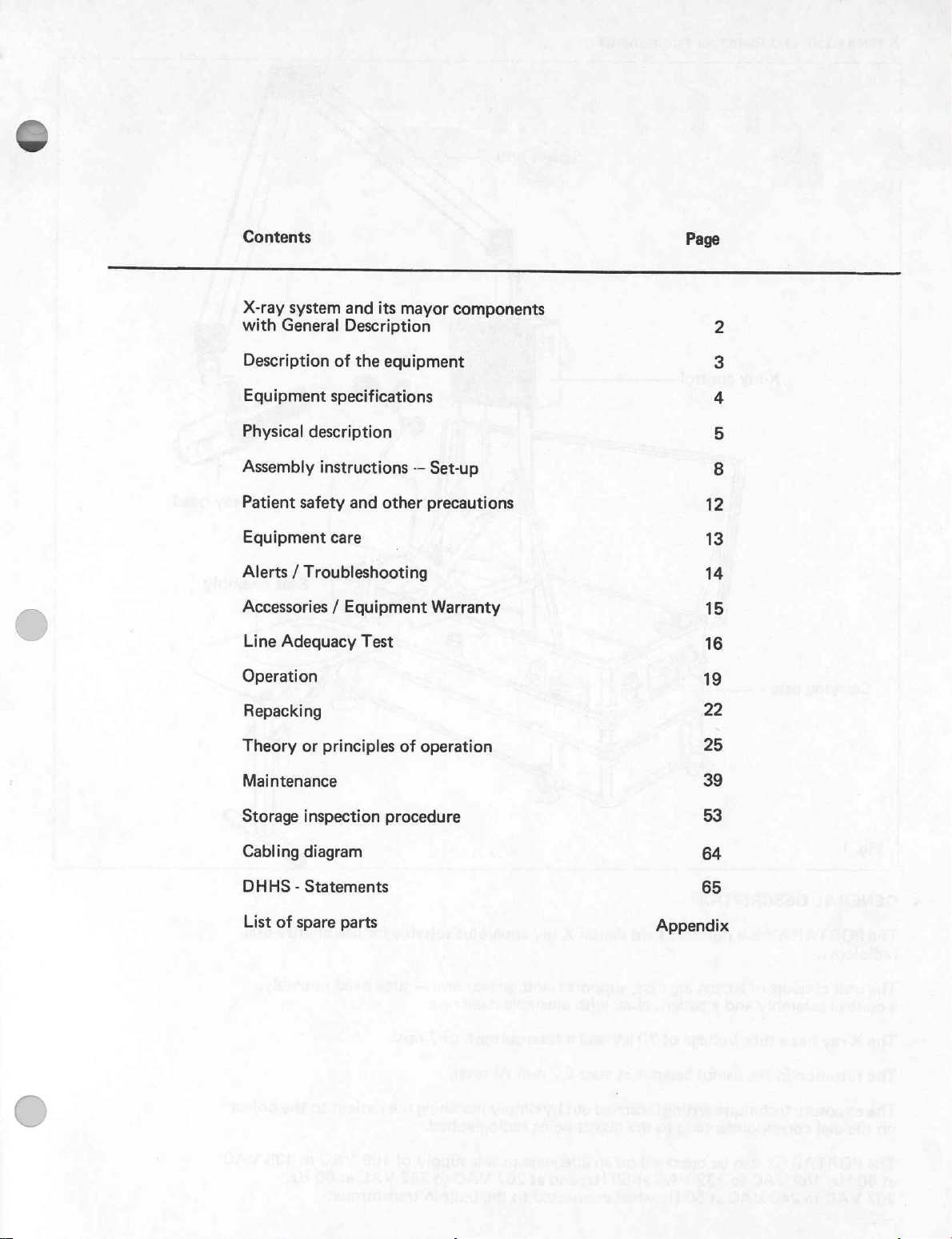

Contents

X-ray

with

system

General

and

its

mayor

Description

components

Page

2

Description

Equipment

Physical

Assembly

Patient

Eguipment

of

the

equipment

specifications

description

instructions — Set-up

safety

and

care

other

Alerts / Troubleshooting

Accessories / Eguipment

Line

Adeguacy

Operation

Test

Repacking

Theory

Maintenance

Storage

or

principles

inspection

procedure

of

precautions

Warranty

operation

3

4

5

8

12

13

14

15

16

19

22

25

39

53

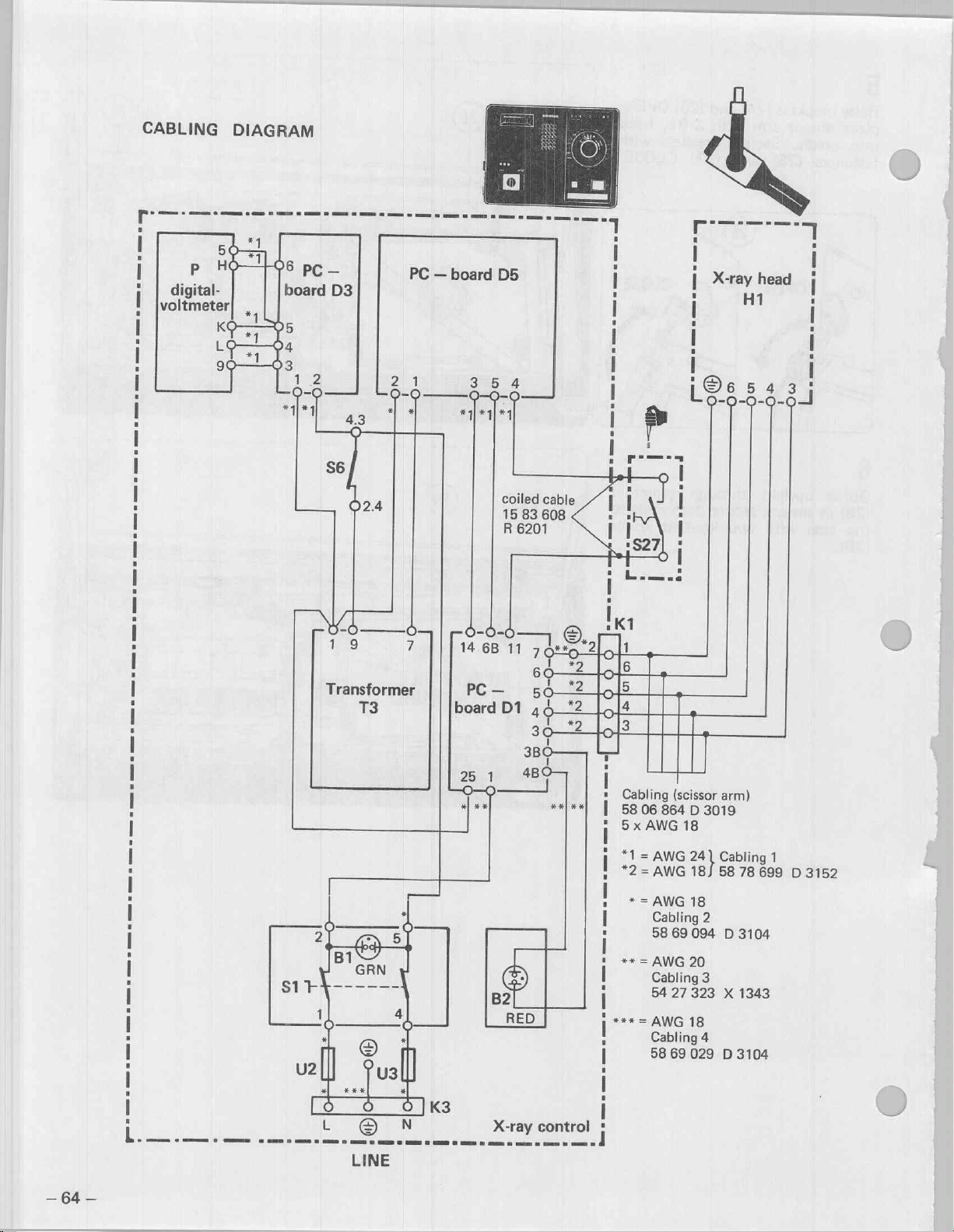

Cabling

diagram

DHHS - Statements

List

of

spare

parts

64

65

Appendix

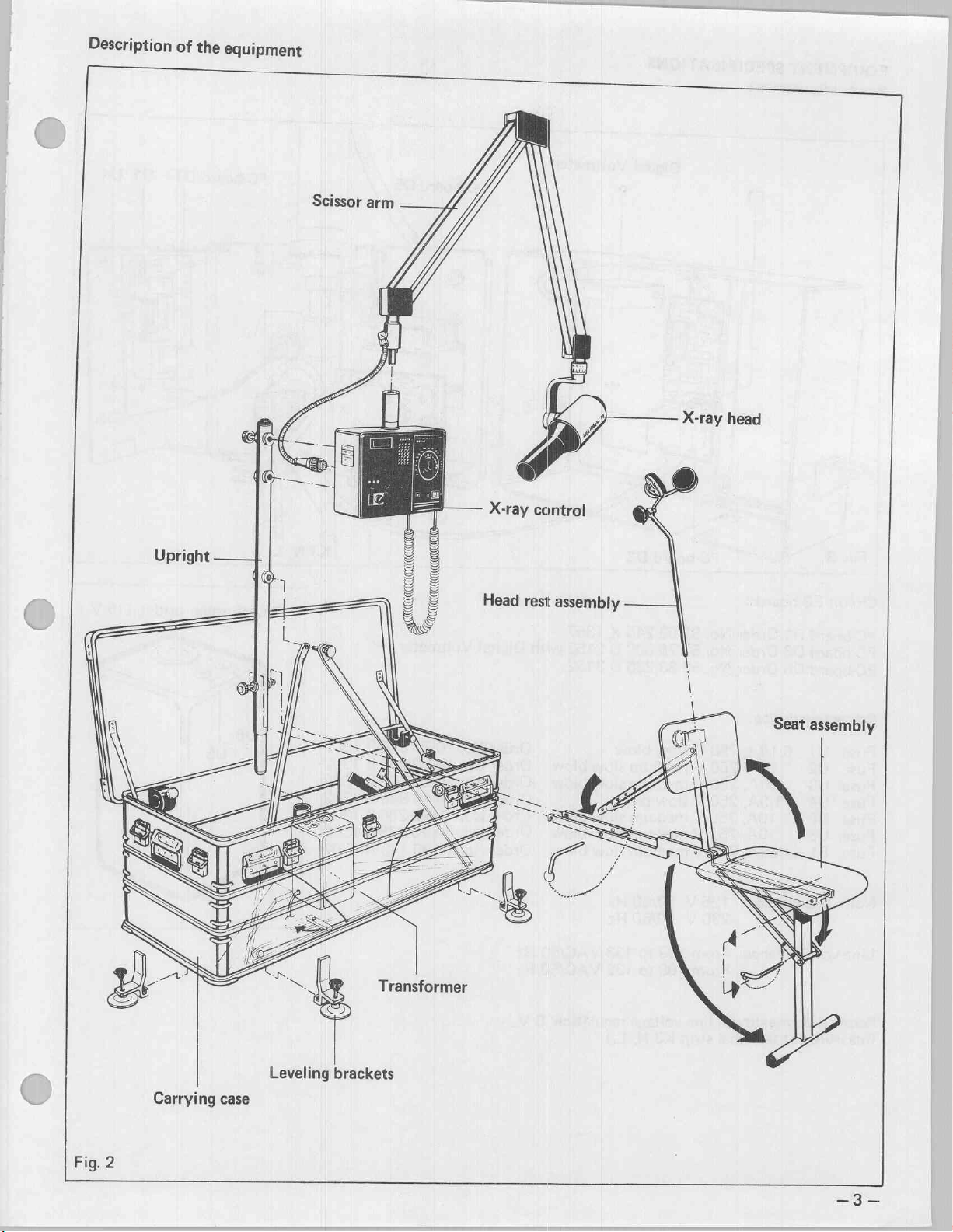

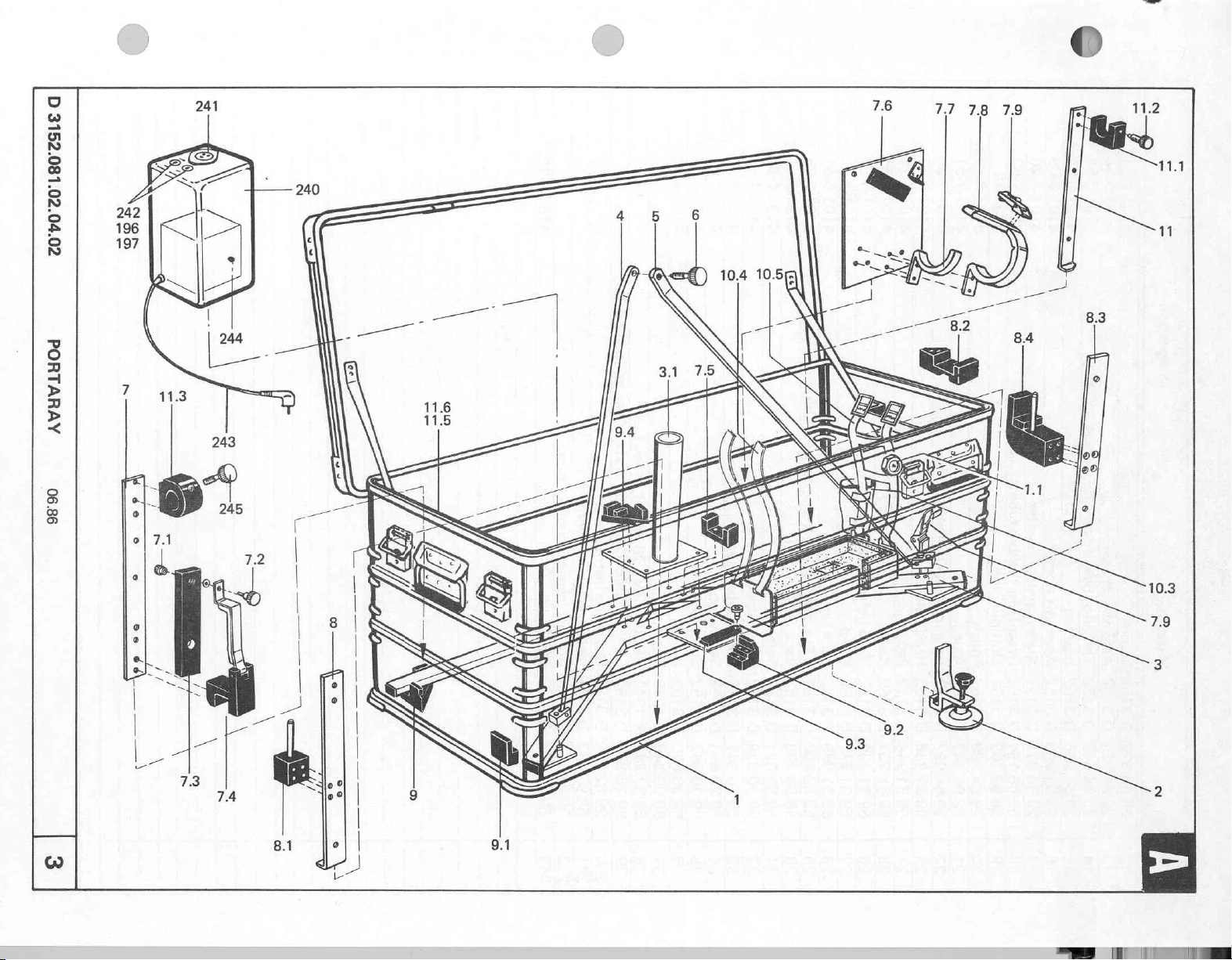

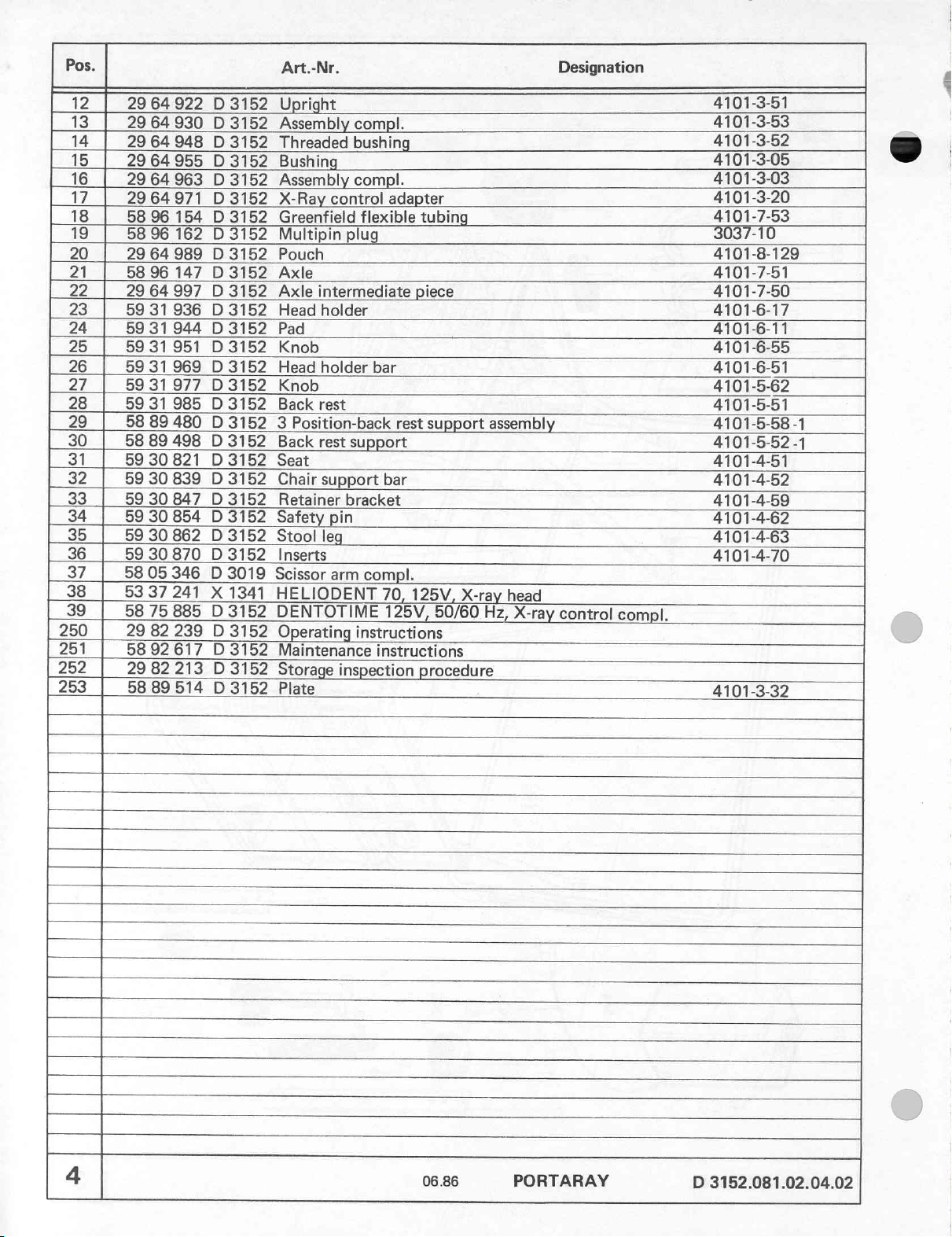

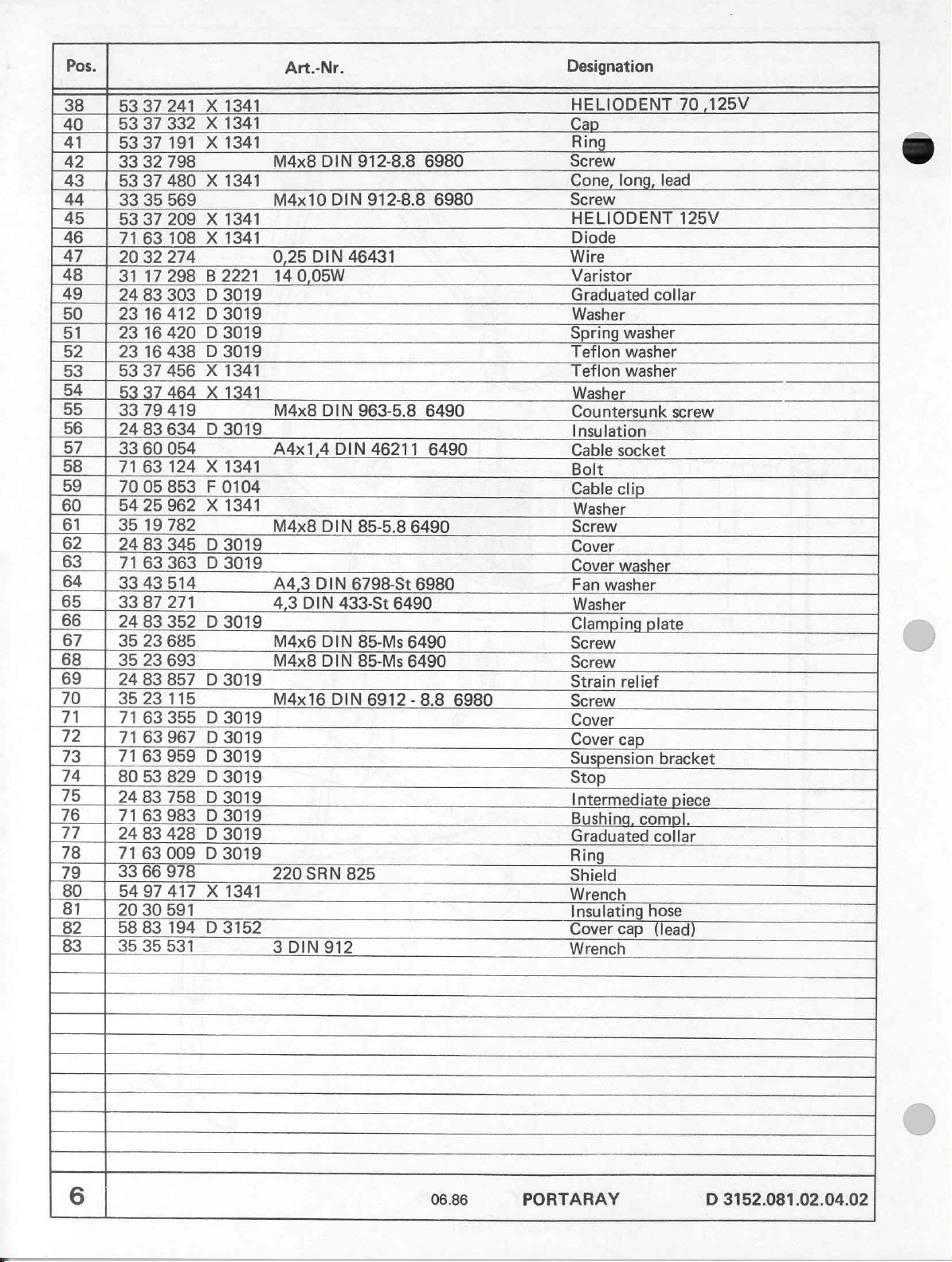

Page 4

Description

=

of

the

equipment

X-ray

head

Seat

assembly

Carrying

Fig.

2

case

Leveling

Transformer

brackets

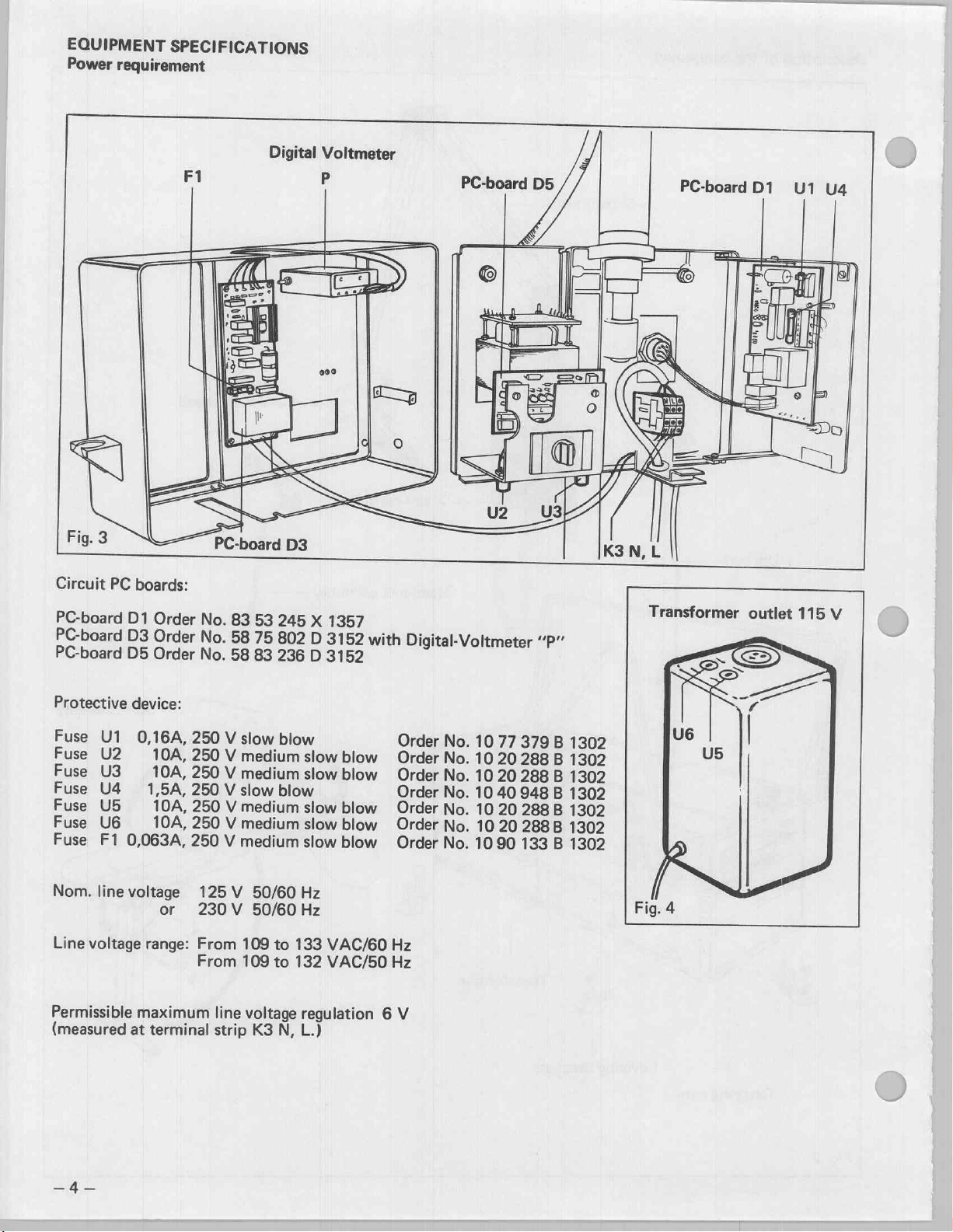

Page 5

EQUIPMENT

Power

requirement

SPECIFICATIONS

Fig.

3

Circuit

PC

boards:

F1

Sig

X

PC-board

9

Digital

|

D3

Voltmeter

P

000

Ey

o

PC-board

D5

PC-board

D1

PC-board

PC-board

PC-board

Protective

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Nom.

Line

Permissible

(measured

D1

D3

D5

device:

U1

U2

U3

U4

|

U5

U6

F1

0,063A,

line

voltage

voltage

at

Order

Order

Order

0,16A,

10A,

10A,

1,5A,

10A,

10A,

or

range:

maximum

terminal

No.

83

53

No.

58

75

No.

58

83

250

V

slow

250

V

medium

250

V

medium

250

V

slow

250

V

medium

250

V

medium

250

V

medium

125 V 50/60

230V

From

From

109

109

line

strip

50/60

to

to

voltage

K3

245

X

1357

802

D

3152

236

D

3152

blow

slow

blow

slow

blow

blow

slow

blow

slow

blow

slow

blow

Hz

Hz

133

VAC/60

132

VAC/50

regulation 6 V

N,

L.)

with

Digital-Voltmeter

Order

No.

Order

No.

Order

No.

Order

©

Order

Order

Order

Hz

Hz

No.

No.

No.

No.

10

77

10

20

10

20

10

40

10

20

10

20

1090

“P”

379

288

288

948

288

288B

133

B

B

В

B

B

1302

B

1302

1302

1302

1302

1302

1302

Page 6

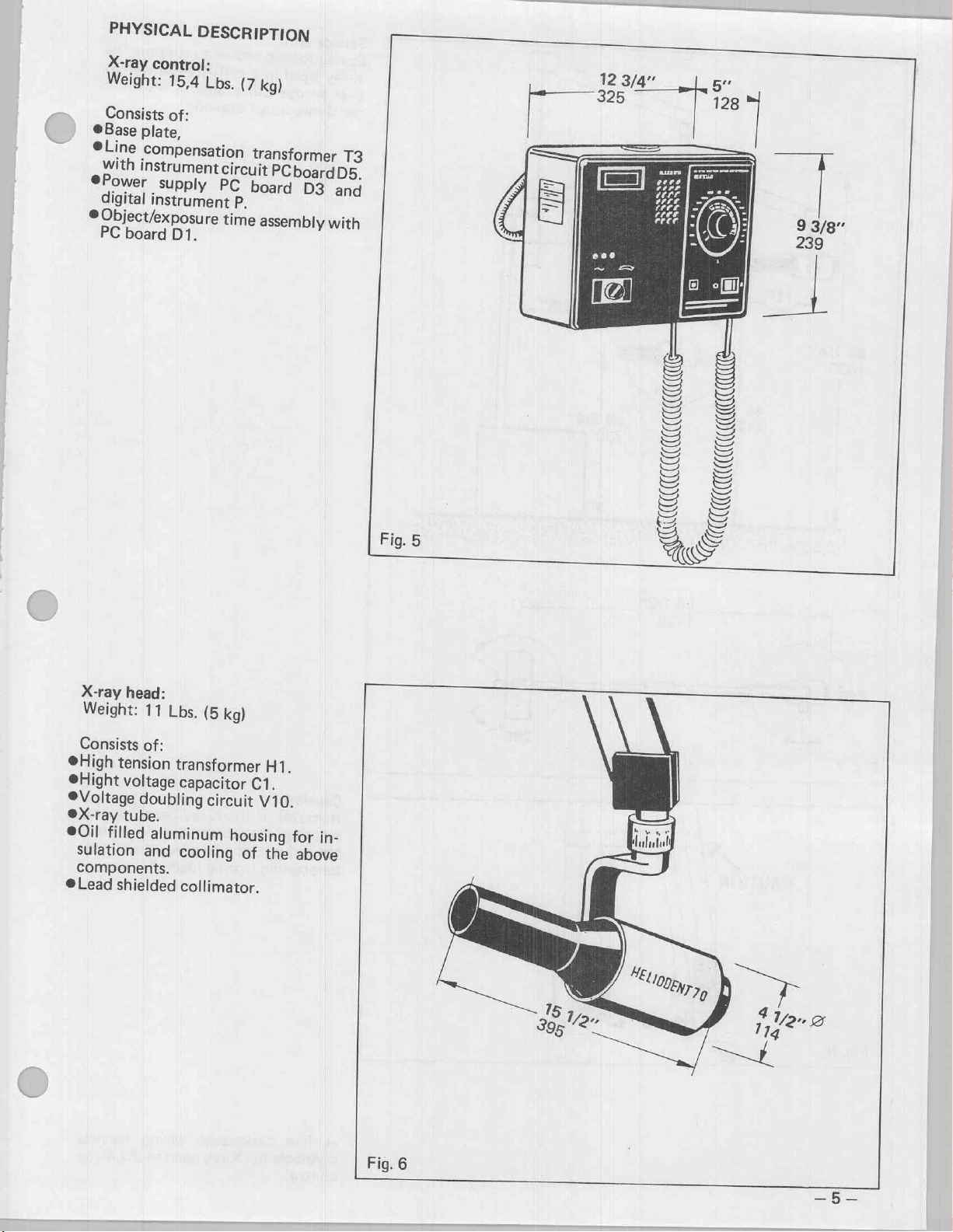

PHYSICAL

DESCRIPTION

Weight:

Consists

OBase

@Line

with

@Power

digital

©

Object/exposure

PC

15,4

of:

plate,

Compensation

instrument

supply

instrument

board

D1.

Lbs.

(7

circuit

PC

P.

time

kg)

transformer

PCboardD5.

board

D3

assembly

T3

and

with

Fig.

5

325

e

:

S

ミラ

E

SS

>

NSA

а

SE

S

Е

E

LÉ

128

>

に

ラ

RS

8

€

=

=

는

=

€

LS

=>

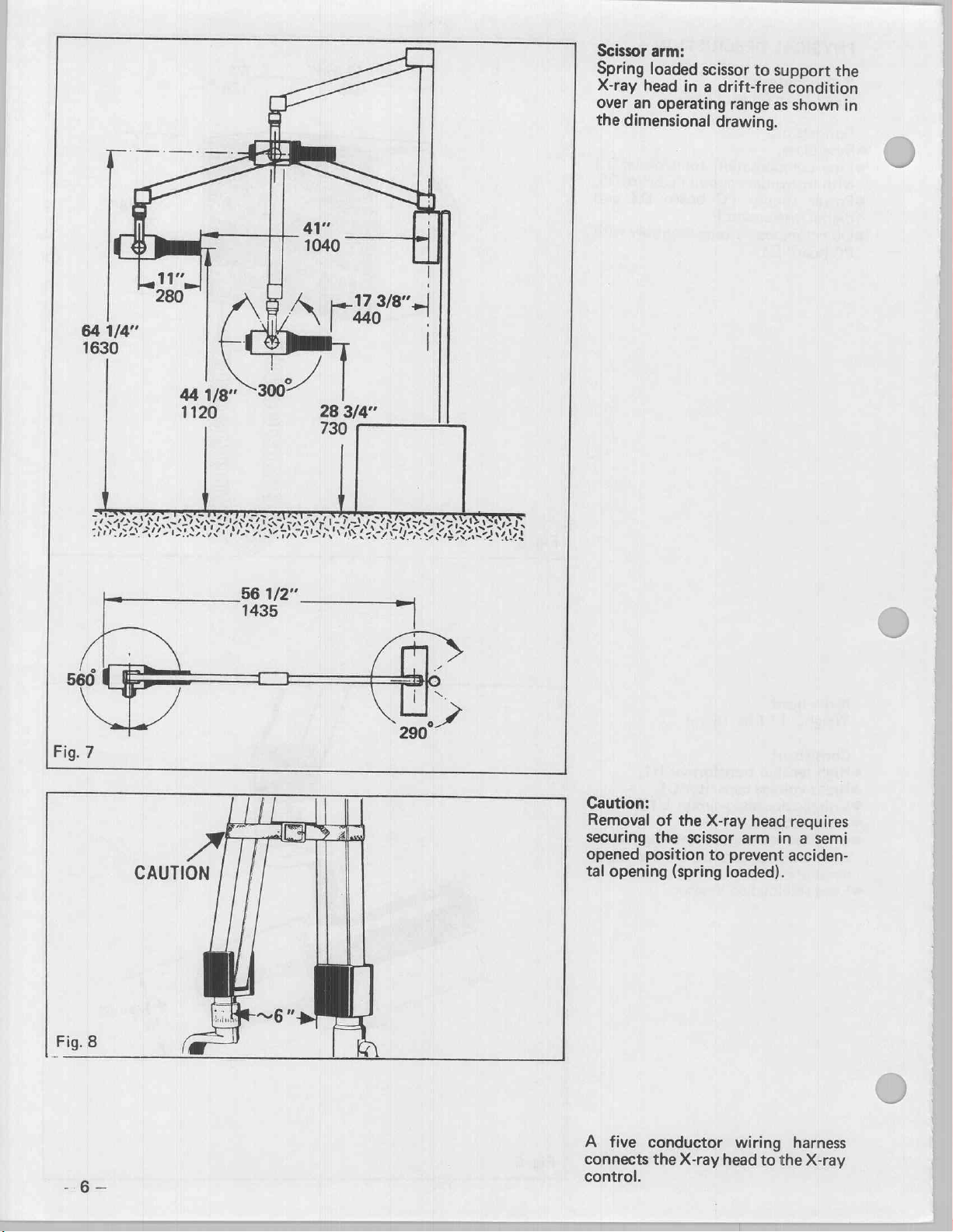

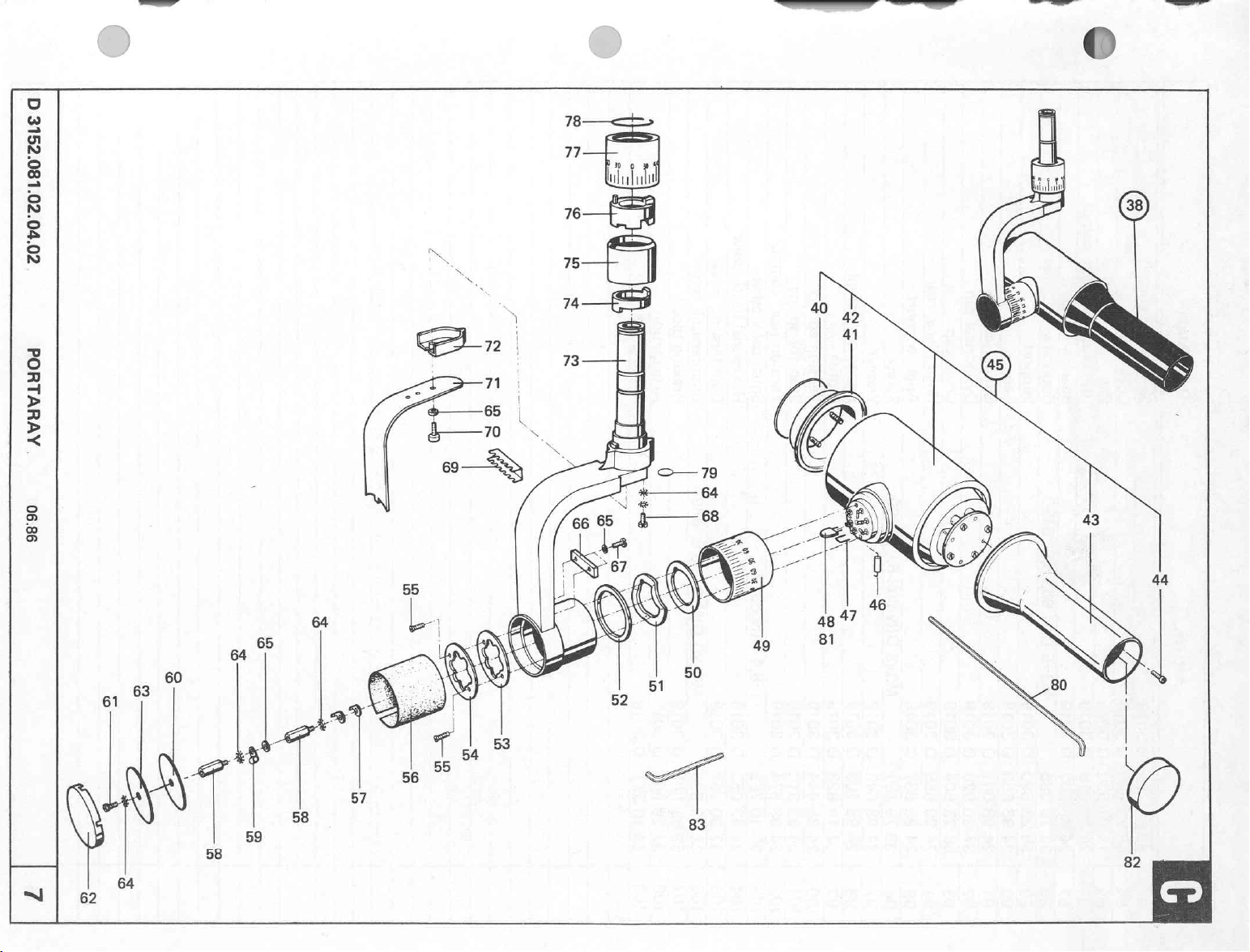

X-ray

head:

Weight:

Consists

@High

@Hight

Voltage

eX-ray

©0il

sulation

components.

@Lead

of:

tension

voltage

doubling

tube.

filled

and

shielded

11

Lbs.

transformer

capacitor

aluminum

cooling

collimator.

(5

kg)

C1.

circuit

housing

of

H1.

V10.

the

|

for

in-

above

Fig.

6

Page 7

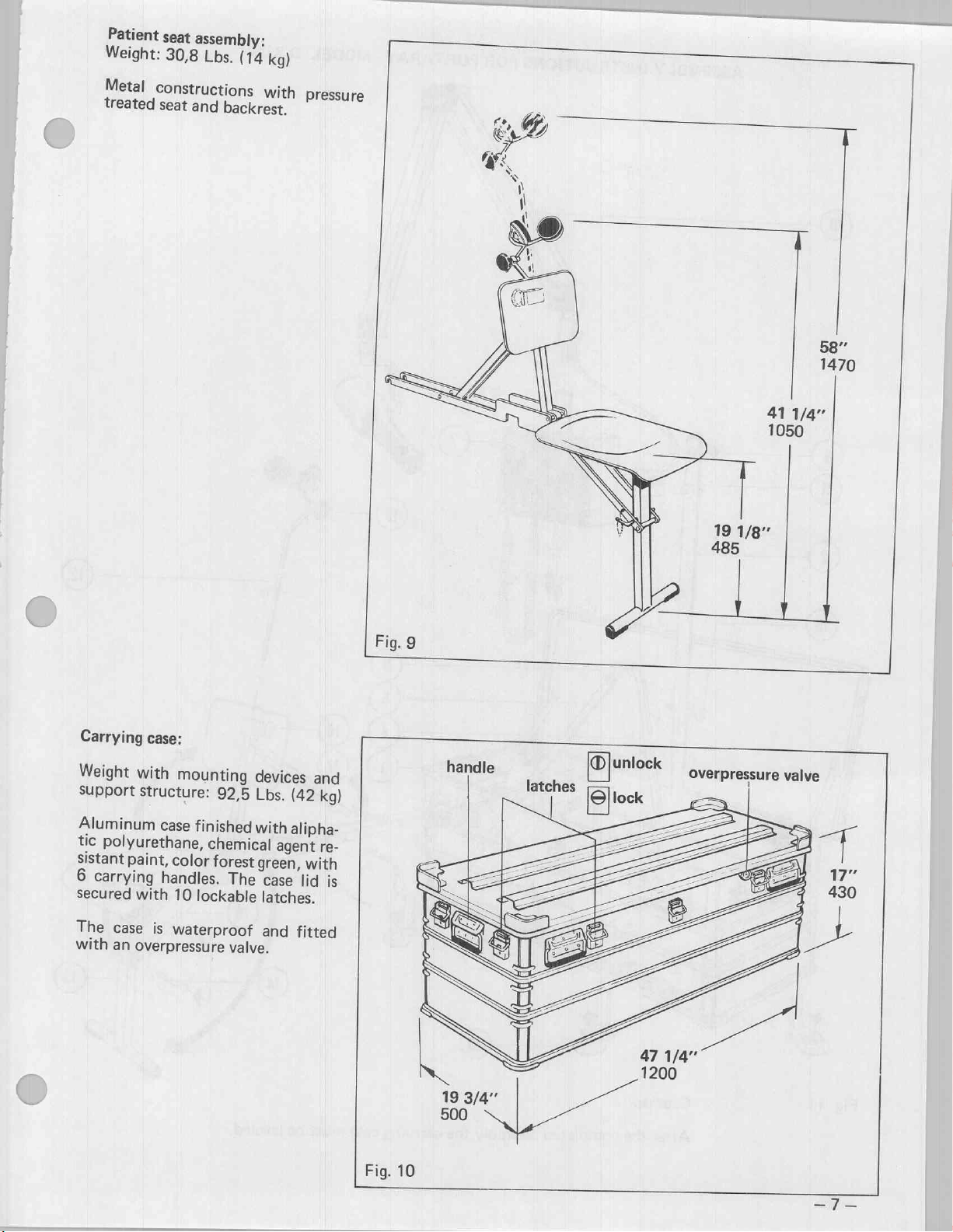

Scissor

Spring

X-ray

over

the

head

an

dimensional

arm:

loaded

scissor

in

a

operating

to

support

drift-free

range

as

drawing.

the

condition

shown

in

56

1/2”

1435

STW

AIREY

-

の ン

IS

ささ

ペスト の いん

UN

ベン

2

Caution:

Removal

securing

opened

tal

opening

of

the

the

scissor

position

(spring

X-ray

arm

to

prevent

loaded).

head

in a semi

requires

acciden-

A

five

connects

control.

conductor

the

X-ray

wiring

head

to

harness

the

X-ray

Page 8

Patient

Weight:

Metal

treated

constructions

seat

seat

assembly;

30,8

and

Lbs.

(14

backrest.

kg)

with

pressure

41

1/4”

1050

Carrying

Weight

Support

Aluminum

tic

sistant

6

secured

The

with

with

structure:

polyurethane,

paint,

carrying

with

case

an

overpressure

case:

mounting

case

finished

color

handles.

10

is

waterproof

92,5

chemical

forest

The

lockable

valve.

devices

Lbs.

(42

with

alipha-

agent

green,

with

case

lid

latches.

and

fitted

and

kg)

re-

is

19

3/4”

500

47

1/4”

1200

Fig.

10

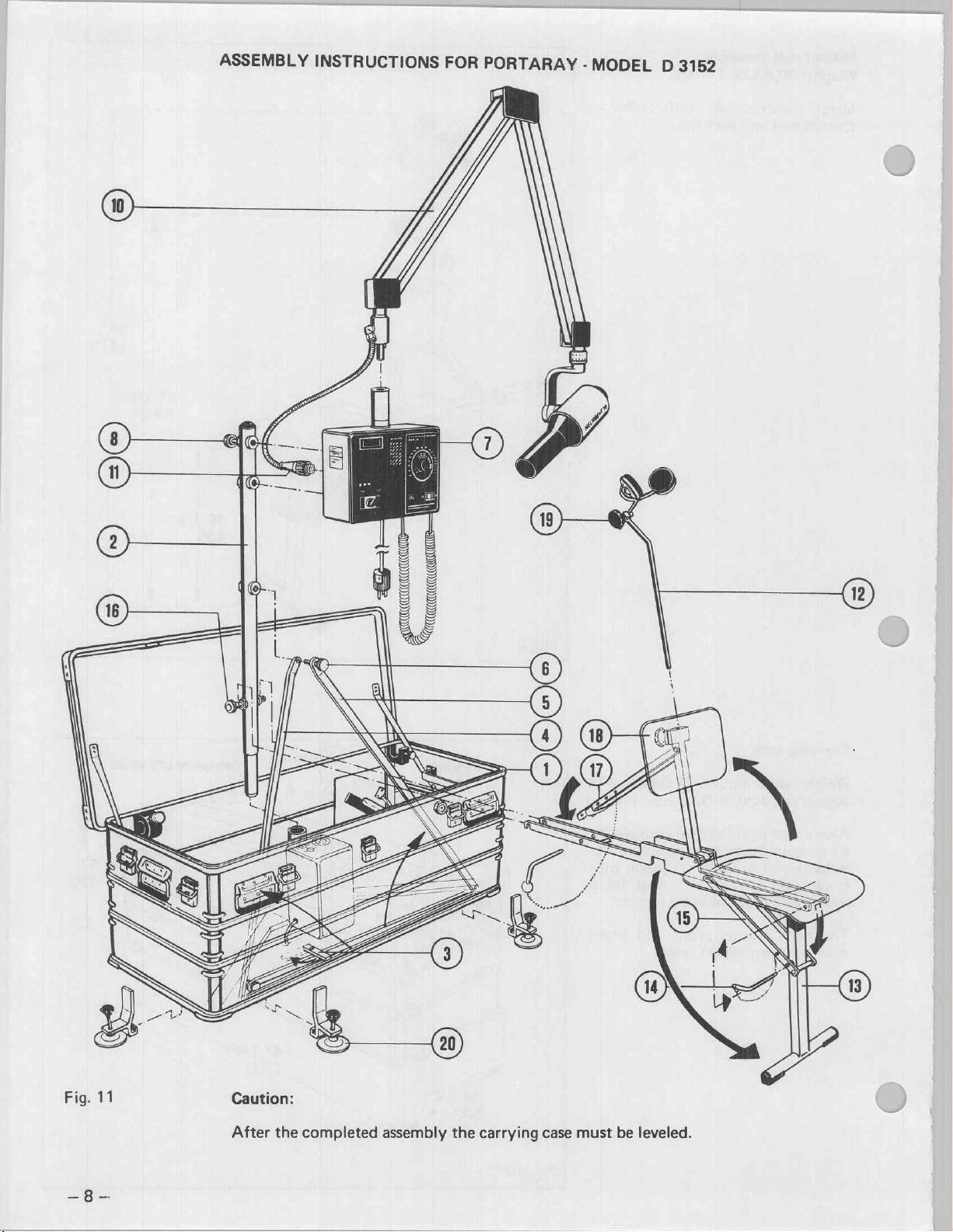

Page 9

Fig.

11

Caution:

After

the

completed

assembly

the

carrying

case

must

be

leveled.

Page 10

_)

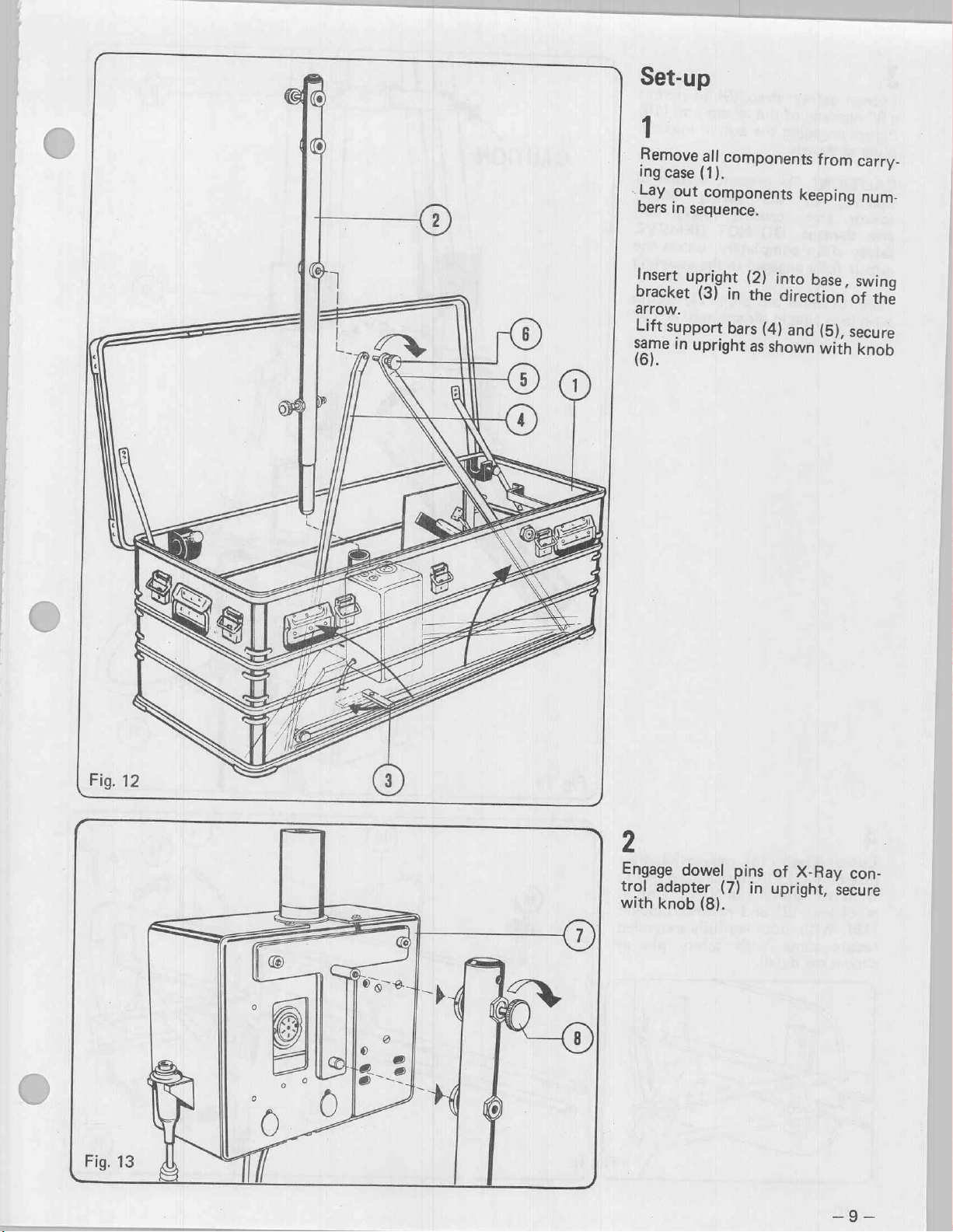

Set-up

1

Remove

ing

Lay

bers

all

(1).

case

out

components

in

sequence.

components

from

keeping

carry-

num-

Insert

bracket

arrow.

Lift

a

6).

upright

support

in

(3)

in

bars

upright

(2)

into

the

direction

(4)

and

as

shown

base,

(5),

with

swing

of

the

secure

knob

2

Engage

trol

with

dowel

adapter

knob

(8).

pins

(7)

of

in

upright,

X-Ray

con-

secure

Page 11

3

Loosen

a

6”

opening

before

pling

CAUTION!

opening

scissor

arm

safety

arm

Connect

with

engaging

as

damage.

strap

is

fully

lock

safety

of

shown.

To

of

arm,

completely,

engaged

multi

ring

strap

the

scissor

the

arm

prevent

the

spring

causing

DO

NOT

pin

plug

in

direction

(9)

to

in

accidental

injury

REMOVE

unless

in

the

(11)

permit

arm

(10)

the

cou-

loaded

and

the

coupling.

secure

of

arrow.

CAUTION

ine

^ ン 5

1

”

4

Loosen

assembly

Remove

stool

leg

(15).

With

secure

shown

see

knob

(12)

safety

(13)

stool

same

detail.

(18),

from

pin

and

leg

with

remove

storage

retainer

fully

headrest

position.

(14).

extended

safety

Unfold

bracket

pin

as

Page 12

eb

Engage

cure

rest

Position

brace

with

Insert

cure

height

stool

with

in

direction

(17)

safety

headrest

with

adjustment).

Support

knob

backrest

(3

Positions)

pin

(14a).

assembly

knob

(16).

of

arrow.

(18)

in

Raise

with

upright,

and

se-

back-

backrest

secure

(12),

(headrest

se-

TRANSFORMER

OUTLET

115

Adjust

with

headrest

knob

(19).

cradle

position

v

When

the

Connect

into

When

Connect

former's

the

the

230

In

case

diesel

rator

technical

Power

Volts:

Max.permissible

VAC

253

Max.

line

voltage

%

1.5

power

the

the

115

V

the

power

the

power

115

transformer's

V

wall

of

driven

must

rating:

230

permissible

at

meet

characteristics:

5

V

nominal,

during

VAC.

230

supply

power

wall

V

outlet.

a

portable

generator

kVA,

cord

outlet.

supply

cord

outlet

power

the

deviation:

fluctuation

standby:

is

115

directly

is

230

at

the

and

connect

cord

gasoline-

this

following

single

207

V:

V:

trans-

into

gene-

phase

to

of

6

Level

with

the

(20).

The

leveling

lower

carrying

carrying

aid

brackets

case

of

3-leveling

case

frame.

and

hook

upright

brackets

to

the

==

Page 13

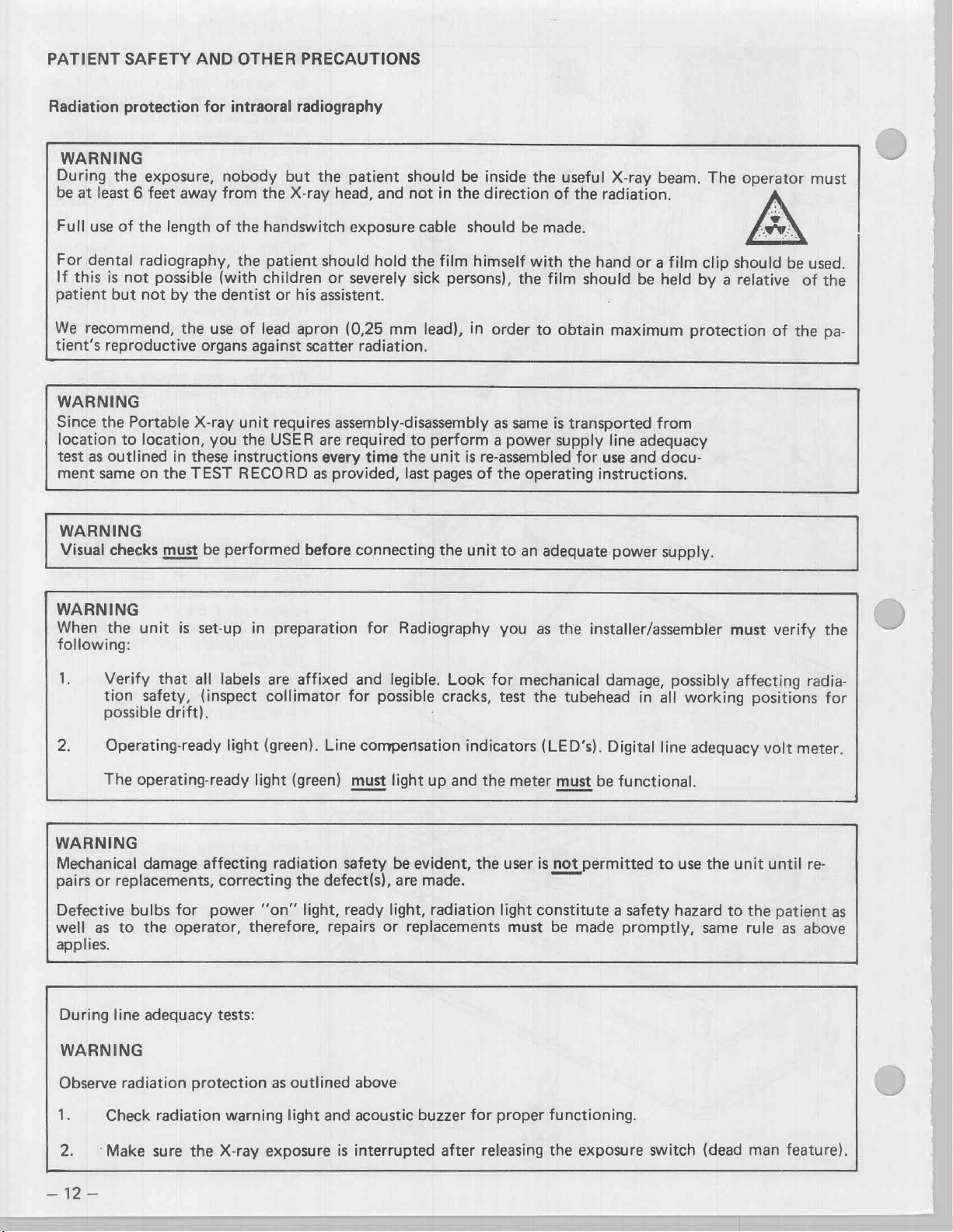

PATIENT

SAFETY

AND

OTHER

PRECAUTIONS

Radiation

WARNING

During

be

at

least 6 feet

Full

use

For

dental

If

this

patient

We

recommend,

tient's

WARNING

Since

the

location

test

as

ment

same

WARNING

Visual

WARNING

When

following:

protection

the

exposure,

away

of

the

length

radiography,

is

not

possible

but

not

reproductive

Portable

to

location,

outlined

on

checks

the

unit

by

the

in

the

must

is

the

these

TEST

for

intraoral

nobody

from

of

the

the

(with

dentist

use

of

organs

X-ray

unit

you

the

instructions

RECORD

be

performed

set-up

radiography

but

the

X-ray

handswitch

patient

children

his

or

lead

apron

against

in

scatter

requires

USER

before

preparation

the

patient

head,

exposure

should

or

severely

assistent.

(0,25

radiation.

assembly-disassembly

are

required

every

as

provided,

connecting

should

and

not

hold

the

sick

mm

to

time

the

last

for

Radiography

cable

lead),

be

inside

in

the

direction

should

film

himself

persons),

in

perform a power

unit

is

re-assembled

pages

of

the

unit

the

order

as

same

the

to

an

you

be

the

with

to

operating

as

useful

of

the

made.

the

hand

film

should

obtain

is

transported

supply

for

instructions.

adequate

the

installer/assembler

X-ray

beam.

radiation.

or

a film

be

held

maximum

from

line

adequacy

use

and

docu-

power

supply.

The

operator

clip

should

by

a

relative

protection

must

must

be

used.

of

of

the

verify

the

pa-

the

ir

Verify

tion

possible

2.

WARNING

Mechanical

pairs

Defective

well

applies.

Operating-ready

The

or

as

During

WARNING

Observe

k

Check

that

all

safety,

drift).

operating-ready

damage

replacements,

bulbs

for

to

the

operator,

line

adequacy

radiation

protection

radiation

labels

(inspect

affecting radiation

correcting

power

tests:

are

collimator

light

(green).

light

“on”

therefore,

as

warning

affixed and

Line

(green)

the

defect(s),

light,

repairs

outlined

light

and

legible.

for

possible

compensation

must

light

safety

ready

be

are

light,

or

replacements

above

acoustic

evident,

Look

cracks,

|

indicators

up

and

made.

radiation

buzzer

the

the

for

for

mechanical

test

the

tubehead

(LED’s).

meter

must

user

is

not

light

constitute a safety

must

be

made

proper

functioning.

damage,

in

Digital

be

functional.

permitted

promptly,

possibly

all

working

line

adequacy

to

use

hazard

the

to

same

affecting

positions

volt

unit

until

the

patient

rule

as

radia-

for

meter.

re-

as

above

2.

Make

=D

sure

the

X-ray

exposure

is

interrupted

after

releasing

the

exposure

switch

(dead

man

feature).

Page 14

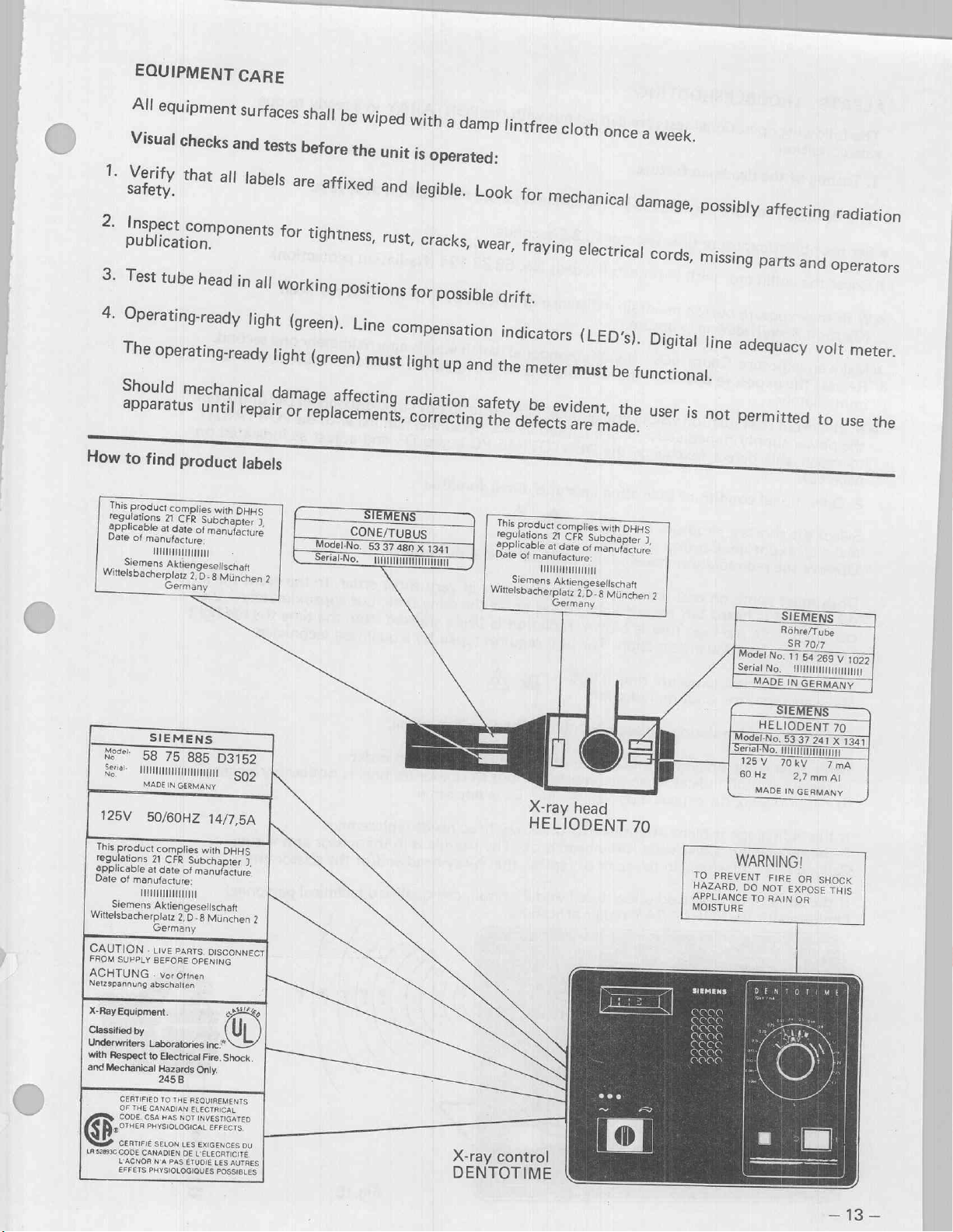

EQUIPMENT

All

equipment

Visual

2.

Inspect

E

li

3

Test

4.

Operating-ready

The

Operating-ready

Should

How

to

Wittelsbacherplatz

find

This

product

regulations

applicable

Date

of

manufacture

Siemens

НИИ

checks

Components

È

ion.

tube

head

mechanical

product

complies

CFR

date

with

Subchapter

of

manufacture

2.D-8

München

21

at

Aktiengesellschaft

Germany

CARE

surfaces

and

tests

in

all

Working

light

light

damage

labels

DHHS

J,

2

shall

before

or

tightness

(green).

(green)

Model-No.

Serial-No,

be

wiped

the

positions

Line

with

unit

is

Operated:

rust,

7

cracks,

r

or

Compensation

must

light

a

damp

7

possible

up

and

affecting radiation

5337

TI

480

X

1341

wea

lintfree

„

drift.

aying

Tr

Ying

cloth

indicators

the

meter

safety

be

evident,

This

product

regulations

applicable

Date

Witelsbacherplatz

complies

21

CFR

at

date

of

manufacture:

11111

Siemens

Aktiengesellschaft

Germany

once

el

ectrical

rica

(LED).

must

be

the

with

Subchapter

of

manufacture

2,D-8

München

a

week.

co

r

ds,

Digital

functional.

user

is

DHHS

)

2

missin

!

line

not

Ing

part:

arts

ar

adeguacy

permitted

d

ope

volt

to

r

ators

meter.

use

the

r

SIEMENS

Nec

58

Sere

MO

Wittelsbacherplatz

CAUTION

FROM

ACHTUNG

Netzspannung

X-Ray

Classified

Underwriters

with

and

G

LA

MADE

125V

50/60HZ

This

product

regulations

applicable

Date

pame

528936

21

at

of

manufacture:

Hi

Siemens

Germany

-

SUPPLY

.

abschalten

Equipment

by

Laboratories

Respect

to

Mechanical

CERTIFIED

OF

THE

CANADIAN

CODE.

CSA

PHYSIOLOGICAL

CERTIFIÉ

CODE

CANADIEN

L'ACNOR

N'A

EFFETS

PHYSIOLOGIOUES

LIVE

BEFORE

vor

75

885

D3152

IN

GERMANY

complies

CFR

date

of

Aktiengesellschaft

2,D-8

PARTS.

ottnen

Electrical

Hazards

245B

TO

THE

HAS

NOT

SELON

LES

DE

PAS

ÉTUDIE

S02

14/7,5A

with

DHHS

Subchapter

manufacture

OPENING

Only.

REQUIREMENTS:

ELECTRICAL

INVESTIGATED

EXIGENCES

L'ÉLECRTICITÉ

J,

Munchen

DISCONNECT|

LG

inc.”

Fire.

Shock.

EFFECTS,

OÙ

LES

AUTRES

POSSIBLES.

2

X-ray

DENTOTIME

X-ray

HELIODENT

control

head

T

7

70

TO

PREVENT

HAZARD,

APPLIANCE

Nd

Model

No.

Serial

No.

MADE

HELIODENT

Model-No.

erial-No.

TRN

125V 70kV

60

Hz

MADE

WARNING!

FIRE

DO

NOT

TO

RAIN

:

SR

70/7

11

54

HUTT

IN

GERMANY

53

37

2,7

mm

IN

GERMANY

OR

EXPOSE

GR

269

V

1022

70

241

X

1341

7

mA

AI

SHOCK

THIS

Page 15

ALERTS / TROUBLESHOOTING

The

following

rate

condition.

1.

Testing

The

deadman

e

Set the

e

Cover

®

With

(Caution

©

Make

Release

immediately,

e

In

the

to

page

2.

object/exposure

the

the

an

the

the

event

power

repair

43).

Operational

operational

of

the

deadman

feature

collimator

exposure

X-ray!)

exposure.

supply

this

during

exposure

the

radiation

immediately

defect

conditions

permits

time

with

button

exposure.

Count

button

(exchange

tests

are

carried

feature

the

premature

selector

cover

cap

(leaded)

maintain

5001

—

visible

indicating

a

(fivethousandone)

the

audible

and

audible

—

call

qualified

the

DENTOTIME

improper

out

to

3.2

seconds.

distance

and

with

the

immediate

No.

58

83

of

at

least

which

visible

indicators

service

timer

personnel

PC

function

PORTARAY

termination

194

(Radiation

6FT

from

equals

radiation

do

board

approximately

not

stop,

familiar

D1

in a ready

of

X-rays.

protection).

the

X-ray

indicators

disconnect

with

and

adjust

head

must

the

the

as

to

ope-

one

second.

terminate

unit

PORTARAY

indicated

from

on

Select

Make

the

an

Observe

Both

must

dible

signal

cond

later

comes

Select

Make

Observe

Both

In

(0.7

If

If

Call

If

familiar

on

the

an

must

the

event

to

the

radiograph

the

radiograph

a

qualified

the

conditions

shortest

exposure.

the

red

come

is

heard

the

—

insufficient

shortest

exposure.

the

red

come

both

1.0

second),

the

with

exposure

Caution

radiation

on

and

but

pre-heat

exposure

Caution

radiation

on

and

indicators

expose a periapical

is

blank

is

black

technician

described

PORTARAY

SIEMENS

time

radiation.

emission

terminate

no

fuse

emission.

time

radiation.

emission

terminate

come

(transparent)

the

to

under

0.066. > A

light

simultaneously

red

light

comes

is

blown,

X-ray

repair

repair

radiation

The

unit

0.066.

light(visualland

simultaneously

on

together

the

head

or

replace

test

1

and

procedure.

ΡΕΝΤΟΤΙΝΜΕ

!

(visual)

film.

is

and

on

requires

p

but

Develope

X-ray

ok.

The

the

2

prevail,

audible

in

at

the

is

being

repair

audible

in

very

the

head

trouble

X-ray

call

signal.

very

short

same

time,

emitted

by

a

signal.

short

exposure

same.

needs

replacement.

is

in

head

and/or

qualified

order.

but

approximately

from

the

qualified

order.

time

is

noticeably

the

scissor

the

technical

\

In

the

event

time

the

technician.

longer

arm

wiring.

scissor

arm.

personnel

the

1/2

red

au-

se-

light

Fig.18

-

=

=

Page 16

è

esi

Fig.19

ACCESSORIES

Lead

cap

provided

for

the

line

adequacy

test.

EQUIPMENT

Siemens

of

formed

following

period;

cation

Occurred

Subject

any

is

not

SIEMENS

WARRANTY

PLIED,

dental

one

year

b

y

conditions:

(2)

sesignated

in

to

these

defective

interrupted

MAKES

INCLUDING

WARRANTY

equipment

from

an

authorized

if

equipment

by

the

course

conditions,

parts.

IS

EXPRESSLY

the

date

(1)

Siemens

of

Siemens’

or

prolonged

NO

BUT

is

warranted

of

installation,

Siemens

Siemens

must

be

must

normal

Siemens’

warranty

by

WARRANTY

IN

NOT

LIMITED

Desiccant

bag

dental

must

returned

be

prepaid;

use

and

will

extends

any

repair

OTHER

LIEU

OF

against

dealer

receive

was

under

defects

provided

or

prompt

to

Siemens

(3)

Siemens’

not

its

only

or

replacement

THAN

ALL

TO

OTHER

THOSE

all

technician.

the

warranty

to

to

absorb

in

installation

notice

for

result

the

THE

OF

moisture

material

Siemens’

of

repair,

examination

of

misuse,

repair

original

provided

ONE

WARRANTIES

FITNESS

accumulated

and

workmanship

and

subsequent

warranty

any

defect

transportation

abuse,

or

replace

purchase

pursuant

SET

AND

within

must

show

accident

(at

of

the

FORTH

EXPRESSED

MERCHANTABILITY.

during

for

service

is

subject

the

charges

that

Siemens’

equipment

to

such

warranty.

ABOVE,

storage.

a

period

is

per-

to

warranty

to

the

the

defect

or

neglect.

option)

and

SUCH

OR

IM—

the

lo-

io

Page 17

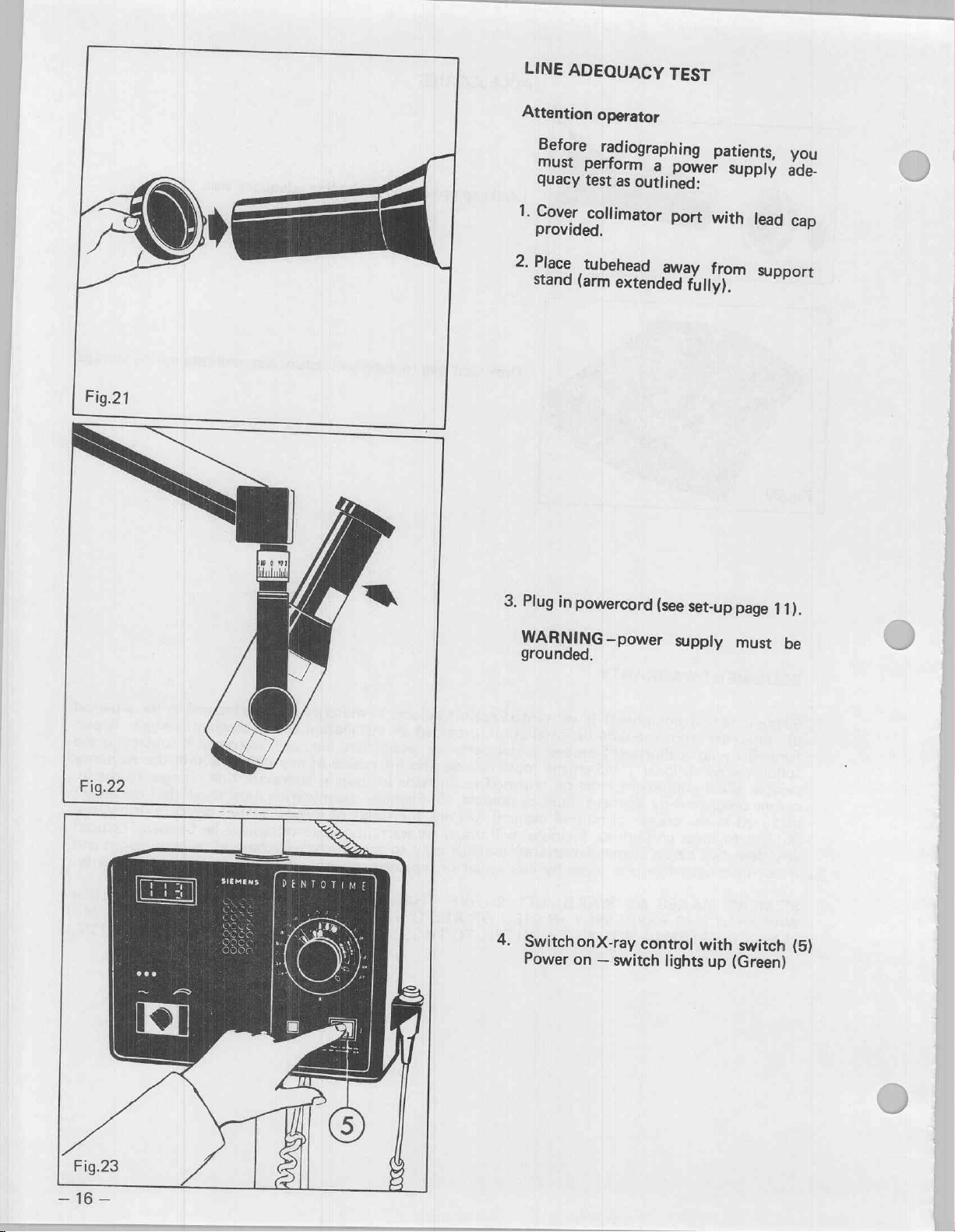

LINE

ADEQUACY

TEST

Fig.21

Attention

1.

2.

stand

Operator

Before

must

quacy

Cover

provided.

Place

perform

test

collimator

tubehead

(arm

radiographing

a

as

extended

power

outlined:

port

away

fully).

patients,

Supply

with

lead

from

support

you

ade-

cap

À

SÅ

Fig.22

3.

Plug

in

WARNING

grounded.

4.

SwitchonX-ray

Power

powercord

—power

on

—

switch

(see

set-up

supply

control

lights

with

up

page

must

switch

(Green)

11).

be

(5)

—

Page 18

109

-

133

V

(60

109

-

132

V

Fig.24

(50

Hz)

Hz)

5.

The

digital

read

between:

min

109,0

min

109,0

After

5

instrument,

rating

Instructions,

pow

v

V

minutes

on

er

supply

note

value

test

record

appendix).

test

133,0

132,0

displayed

(test

instrument

V

max.

at

V

max.

at

on

records

60

50

the

see

must

HZ

HZ

test

Ope-

6.

Verify

Yellow

(too

Corrections

Yellow

Red

CAUTION

call

Operate

(See

-

Select

turning

line)

Do

symbols.

that

low)

are

=

Turn

=

Turn

—

medical

Maintenance

with

not

If

maintenance

apparatus.

an

exposure

knob

3.2

on

depress

the

Green

(O.K)

made

switch

switch

green

(9)

to

scale.

knob

green

page

light

with

clockwise

counterclockwise

light

41).

time

align

when

(too

switch

will

Personnel

of

adult

aligning

diode

Red

High)

(7)

not

come

—

3.2

seconds

symbol

adult/child

(8)

is

on,

DO

NOT

(orange

lit:

by

17

—

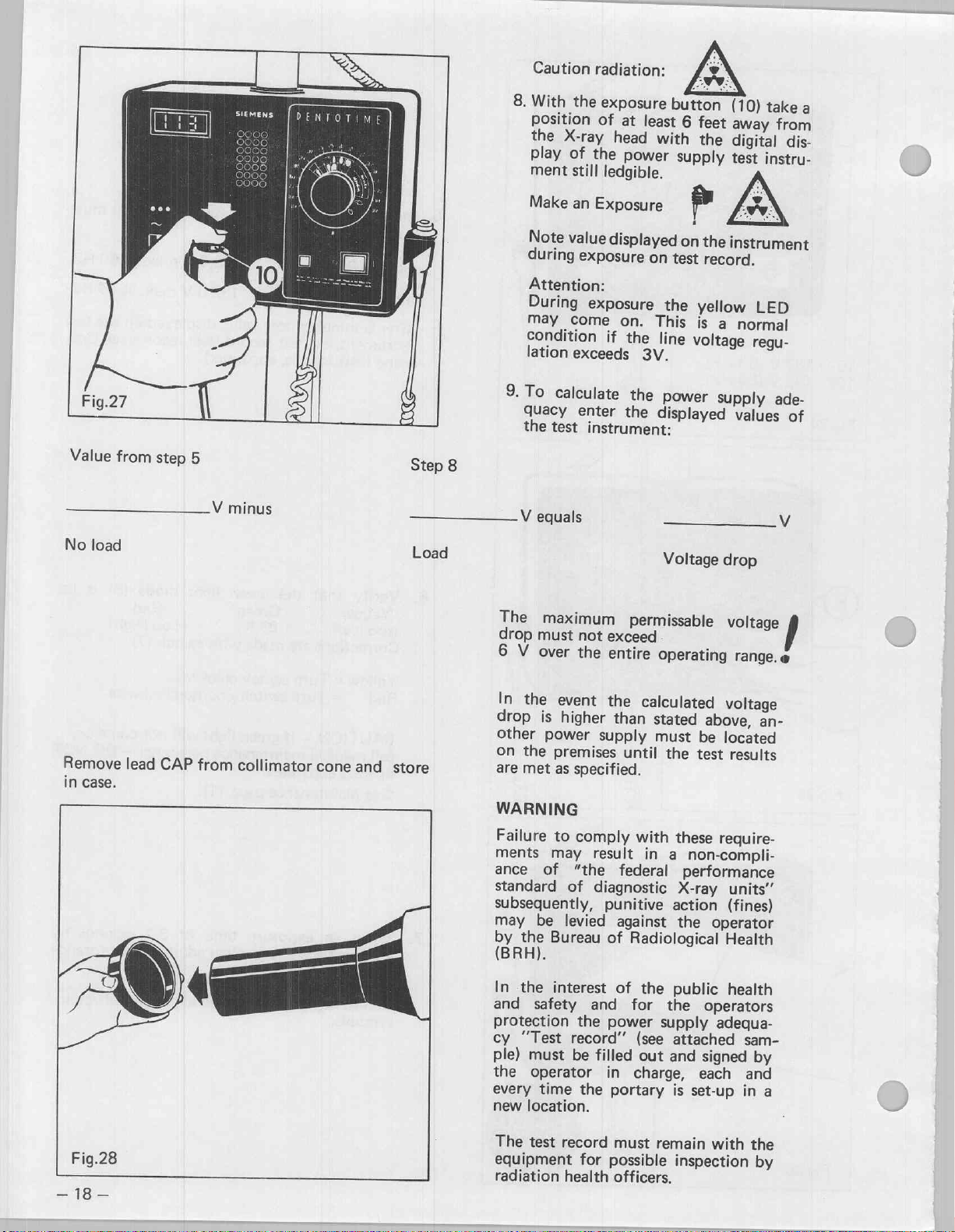

Page 19

Caution

radiation:

8.

With

the

position

the

play

ment

Make

Note

during

Attention:

During

may

condition

lation

of

X-ray

of

the

still

an

Exposure

value

exposure

exposure

come

exceeds

exposure

at

head

power

ledgible.

displayed

on.

if

the

3V.

button

least

with

supply

on

test

the

This

line

6

feet

the

p

on

the

record.

yellow

is

a

voltage

(10)

take

away

from

digital

test

instrument

normal

dis-

instru-

LED

regu-

a

ré

È

Fig.27

Value

No

Remove

in

load

case.

©

from

lead

ia

step

CAP

4

5

V

from

minus

collimator

cone

and

Step

Load

store

8

9.To

The

drop

6

In

drop

other

on

are

WARNING

Failure

ments

ance

standard

subseguently,

may

by

(BRH).

In

and

protection

cy

ple)

the

every

new

calculate

quacy

the

test

V

equals

maximum

must

V

over

the

event

is

higher

power

the

premises

met

as

specified.

to

may

of

of

be

levied

Bureau

the

the

interest

safety

“Test

record”

must

be

operator

time

location.

enter

not

the

comply

“the

the

the

the

the

instrument:

exceed

entire

the

supply

result

diagnostic

punitive

of

and

power

filled

in

portary

displayed

permissable

operating

calculated

than

stated

must

until

with

in

federal

against

Radiological

of

the

for

(see

out

charge,

power

Voltage

above,

be

the

test

these

a

non-compli-

performance

X-ray

action

the

operator

public

the

operators

supply

attached

and

signed

each

is

set-up

supply

values

drop

voltage

range.

voltage

an-

located

results

reguire-

units“

(fines)

Health

health

adequa-

sam-

by

and

in

a

ade-

of

e

)

>

Fig.28

2

—

18

—

The

eguipment

radiation

test

record

for

health

must

remain

possible

officers.

inspection

with

the

by

Page 20

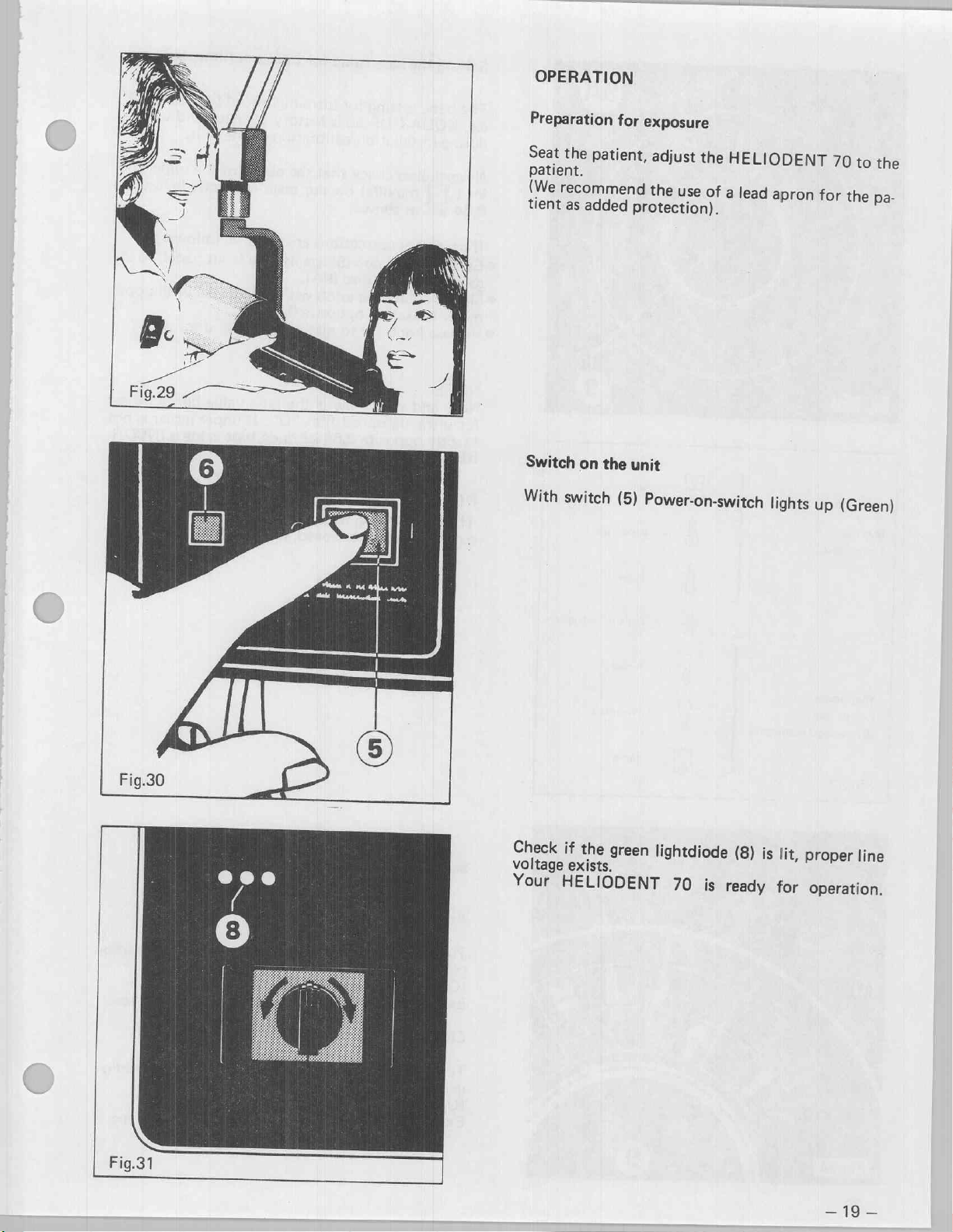

OPERATION

Preparation

Seat

the

patient,

patient.

(We

recommend

tient

as

added

Switch

With

on

switch

for

exposure

adjust

the

protection).

the

unit

(5)

Power-on-switch

use

the

HELIODENT

of

a

lead

apron

lights

70

for

up

to

the

the

pa-

(Green)

Fig.31

Check

voltage

Your

HELIODENT

if

the

exists.

green

lightdiode

70

is

(8)

ready

is

lit,

proper

for

operation.

—

line

19

—

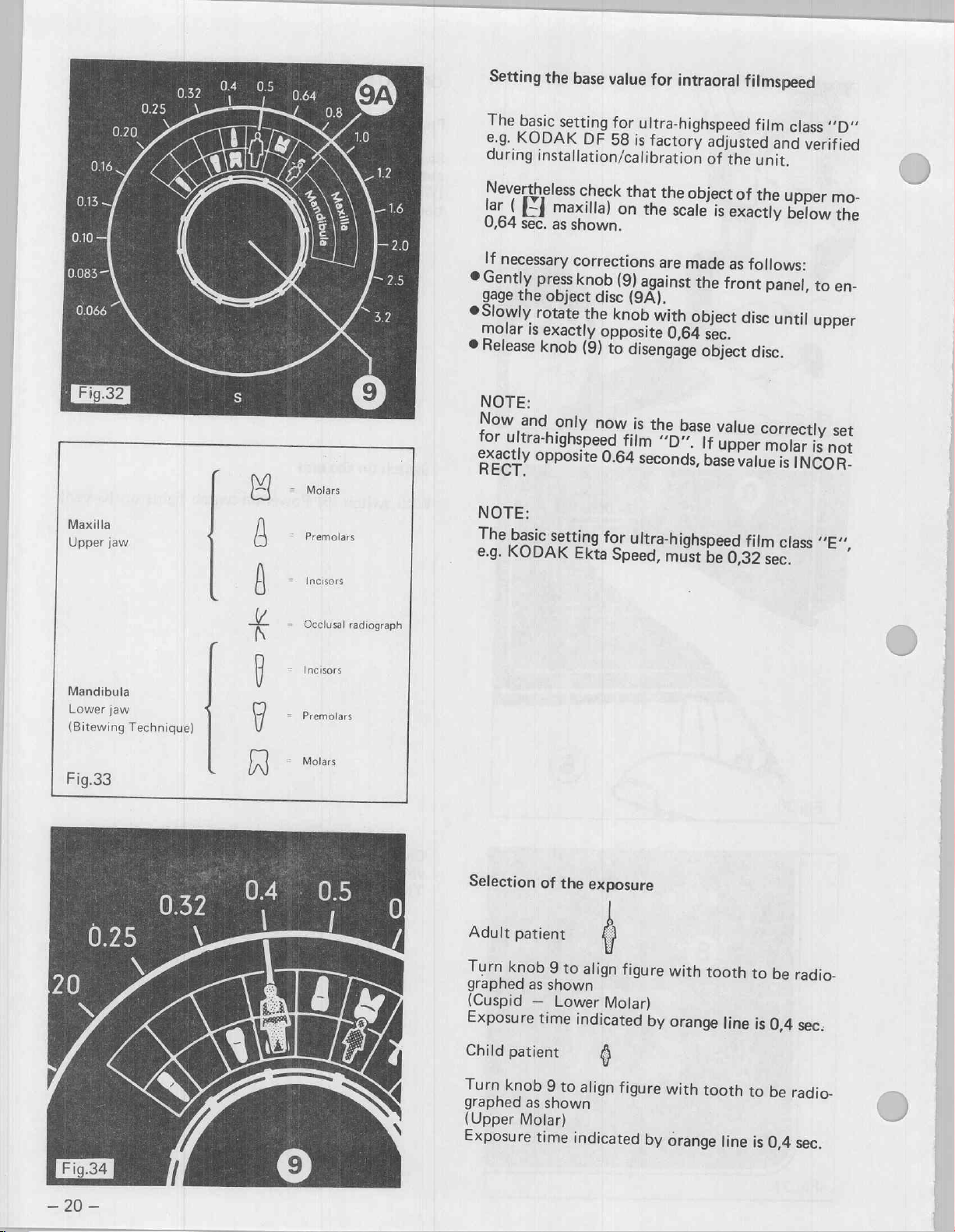

Page 21

Setting

The

basic

e.g.

KODAK

during

the

base

value

for

intraoral

setting

installation/calibration

DF

for

ultra-highspeed

58

is

factory

adjusted

of

filmspeed

film

and

the

unit.

class

verified

“D“

Maxilla

Upper

jaw

fe

f=

c=

ラド

=

Molars

-

Premolars

=

Incisers

Occlusal

radiograph

Nevertheless

lar

(

E

0,64

sec.

If

necessary

©

Gently

gage

©

Slowly

molar

©

Release

NOTE:

Now

for

exactly

RECT.

NOTE:

The

e.g.

press

the

rotate

is

knob

and

ultra-highspeed

opposite

basic

KODAK

check

maxilla)

as

shown.

corrections

knob

object

exactly

disc

the

(9)

only

setting

Ekta

that

the

on

the

scale

are

(9)

against

(9A).

knob

with

opposite

to

now

0.64

for

Speed,

0,64

disengage

is

the

film

“D”.

seconds,

ultra-highspeed

must

object

made

the

object

sec.

object

base

If

base

be

of

is

exactly

as

follows:

front

disc

value

upper

value

film

0,32

the

upper

below

panel,

until

disc.

correctly

molar

is

INCOR-

class

sec.

mo-

the

to

en-

upper

set

is

not

SEM,

Mandibula

Lower

jaw

(Bitewing

Fig.33

Technique)

4

ニコ

|

の

ご

2

=

Incisors

Premolars

Molars

Selection

Adult

Turn

graphed

(Cuspid

Exposure

Child

Turn

graphed

(Upper

Exposure

of

patient

knob

as

—

time

patient

knob

9

as

shown

Molar)

time

the

9

to

align

shown

Lower

indicated

to

align

indicated

exposure

0

figure

Molar)

@

figure

by

by

with

orange

with

tooth

orange

tooth

line

line

to

is

to

is

be

0,4

be

0,4

radio-

sec.

radio-

sec.

Page 22

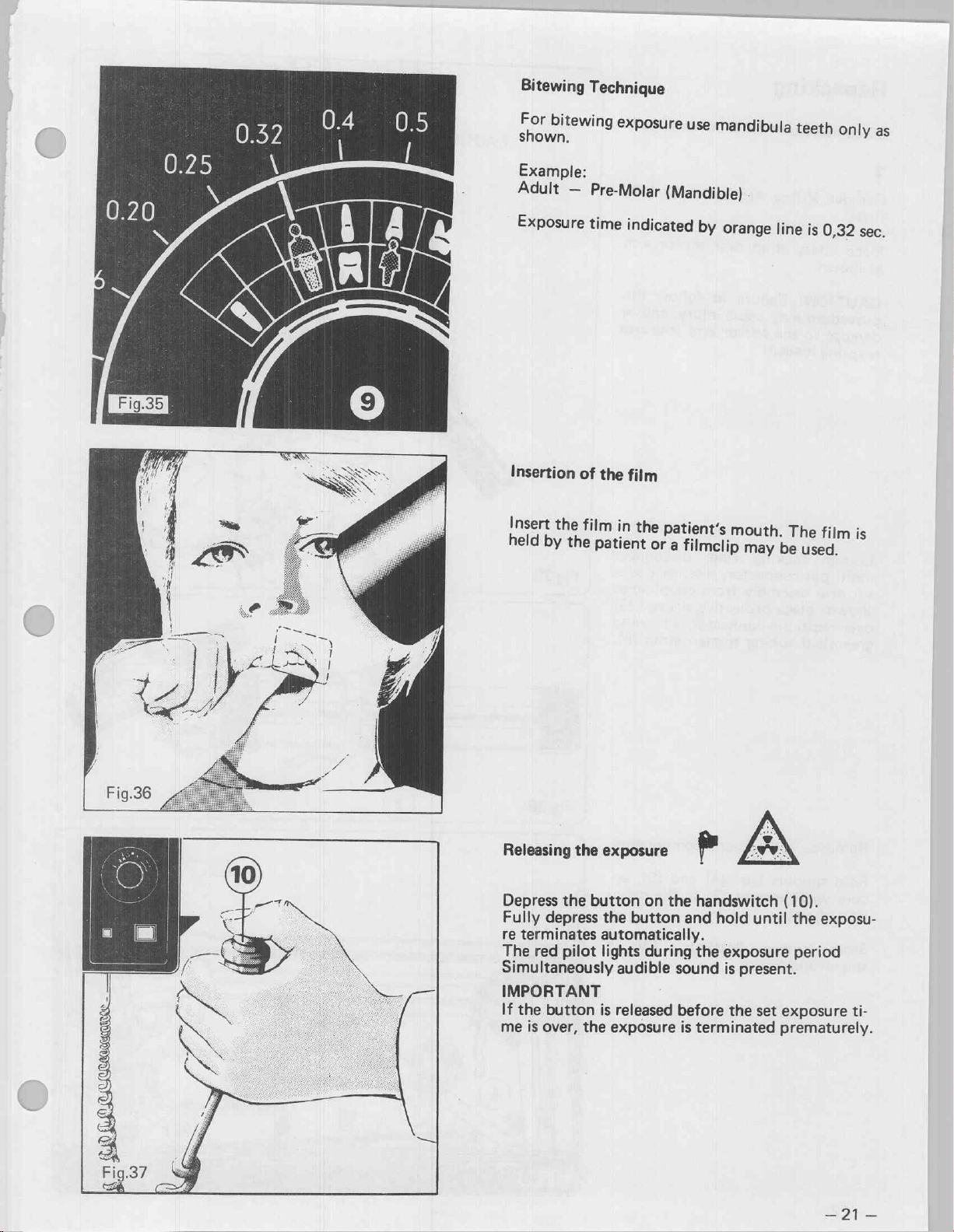

Bitewing

For

bitew

Example:

Adult

—

Technique

ng

exposure

Pre-Molar

use

mar

dibula

(Mandible)

teeth

onl

as

y

Exposure

Insertion

Insert

the

held

by

the

time

of

the

film

patient

indicated

film

in

i

the

patient's

or

a

by

orange

mouth.

filmclip

may

line

:

The

be

used.

is

film

0,32

mi

sec.

i

°

Sit

Depress

Fully

re

terminates

The

Simultaneously

IMPORTANT

If

the

me

is

cca

the

button

depress

red

pilot

button

over,

the

the

button

automatically.

lights

audible

is

released

exposure

on

the

and

during

sound

before

is

handswitch

hold

until

the

exposure

is

present.

the

set

terminated

(10).

the

exposu-

period

exposure

prematurely.

ti-

20

Page 23

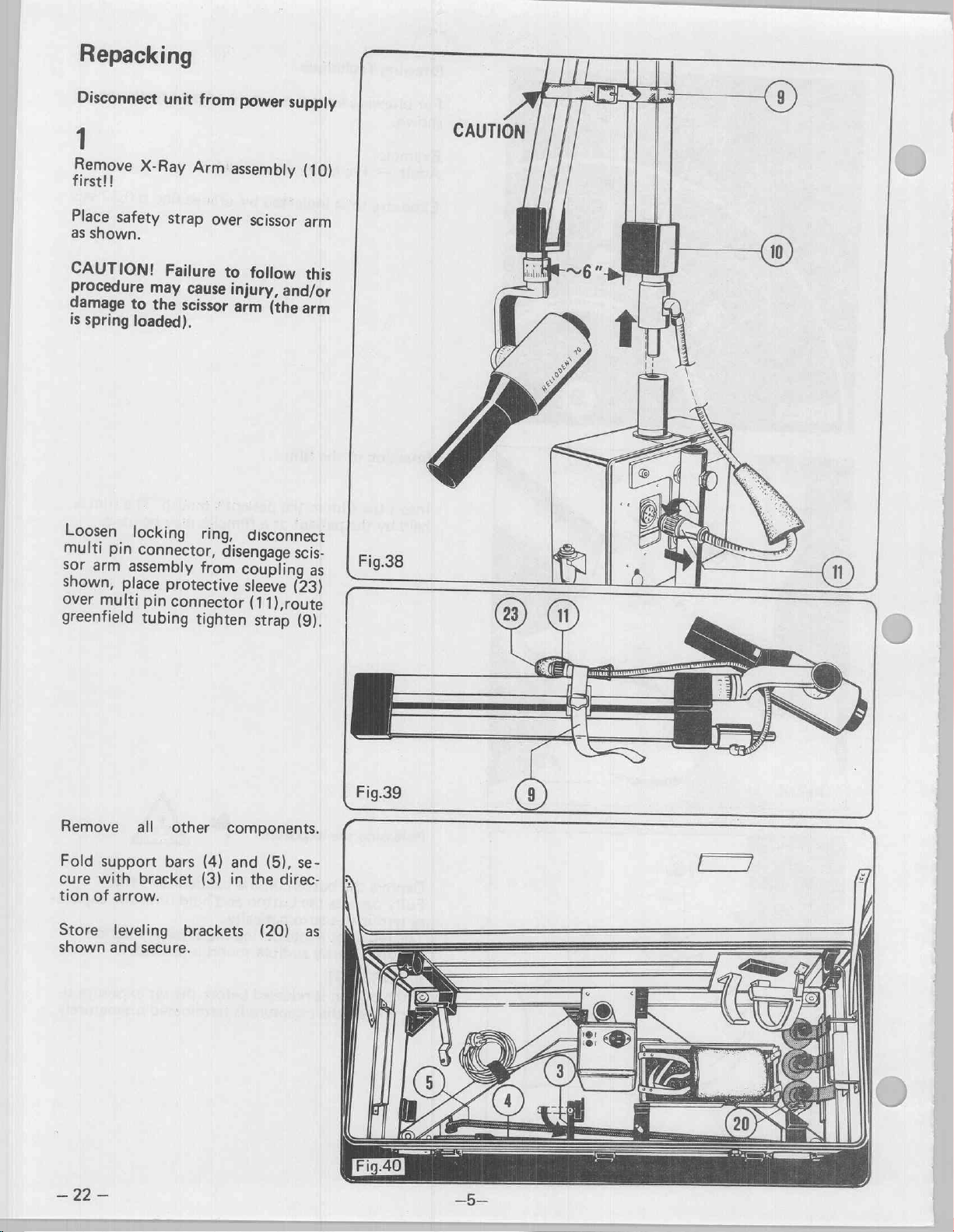

Repacking

Disconnect

1

Remove

first!!

X-Ray

unit

from

Arm

power

assembly

supply

CAUTION

(10)

Place

safety

as

shown.

CAUTION!

Procedure

damage

is

Loosen

multi

Sor

shown,

Over

greenfield

spring

pin

arm

place

multi

to

loaded).

locking

assembly

strap

over

Failure

may

cause

the

scissor

connector,

pin

tubing

ring,

from

protective

connector

tighten

scissor

to

follow

injury,

arm

disengage

and/or

(the

disconnect

coupling

sleeve

(11),route

strap

arm

this

arm

scis-

as

(23)

(9).

=

li

NEW

23

i

10

Remove

Fold

cure

tion

of

Store

shown

all

support

with

bracket

arrow.

leveling

and

secure.

other

bars

(4)

(3)

brackets

components.

and

(5),

se-

in

the

direc-

(20)

as

一

22

一

Page 24

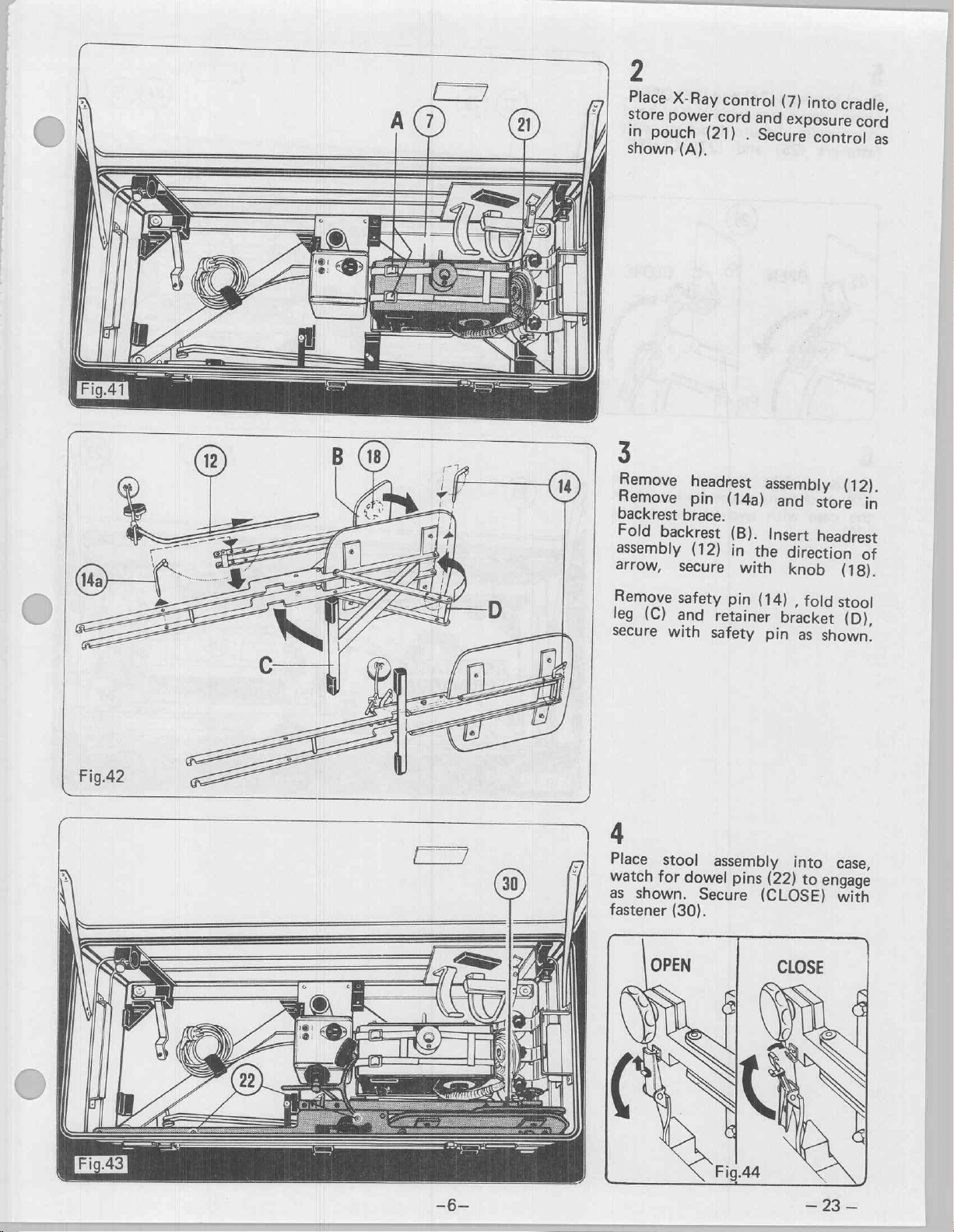

21

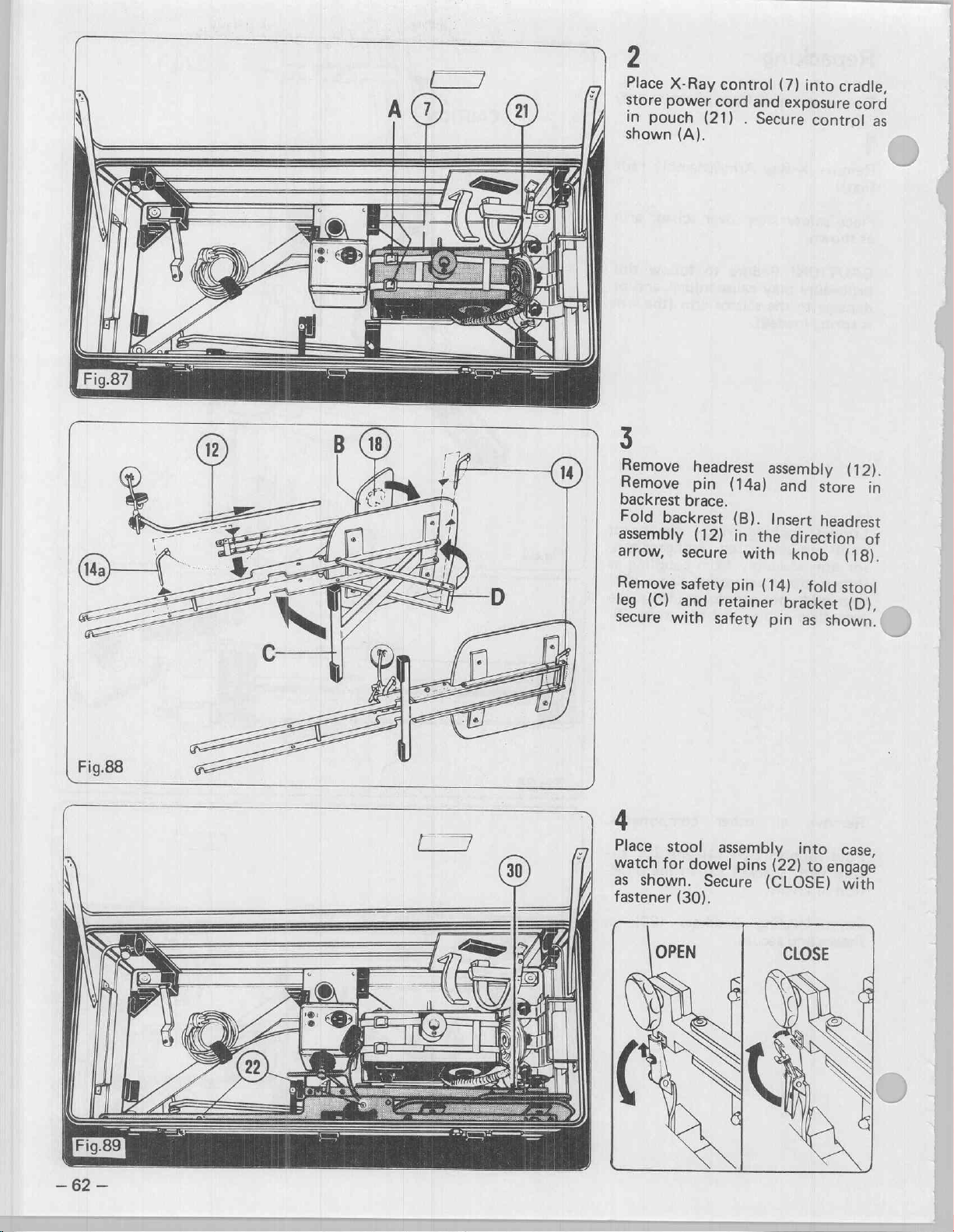

Place

store

in

pouch

shown

X-Ray

power

(A).

control

cord

(21)

and

.

Secure

(7)

into

exposure

control

cradle,

cord

as

3

Remove

Remove

backrest

Fold

assembly

arrow,

Remove

leg

secure

brace.

backrest

secure

safety

(C)

and

with

headrest

pin

(14a)

(B).

(12)

in

with

pin

retainer

safety

assembly

and

Insert

the

direction

knob

(14)

,

bracket

pin

as

4

Place

watch

as

fastener

stool

for

shown.

(30).

assembly

dowel

Secure

pins

into

(22)

(CLOSE)

(12).

store

headrest

(18).

fold

stool

(D),

shown.

case,

to

engage

with

in

of

Page 25

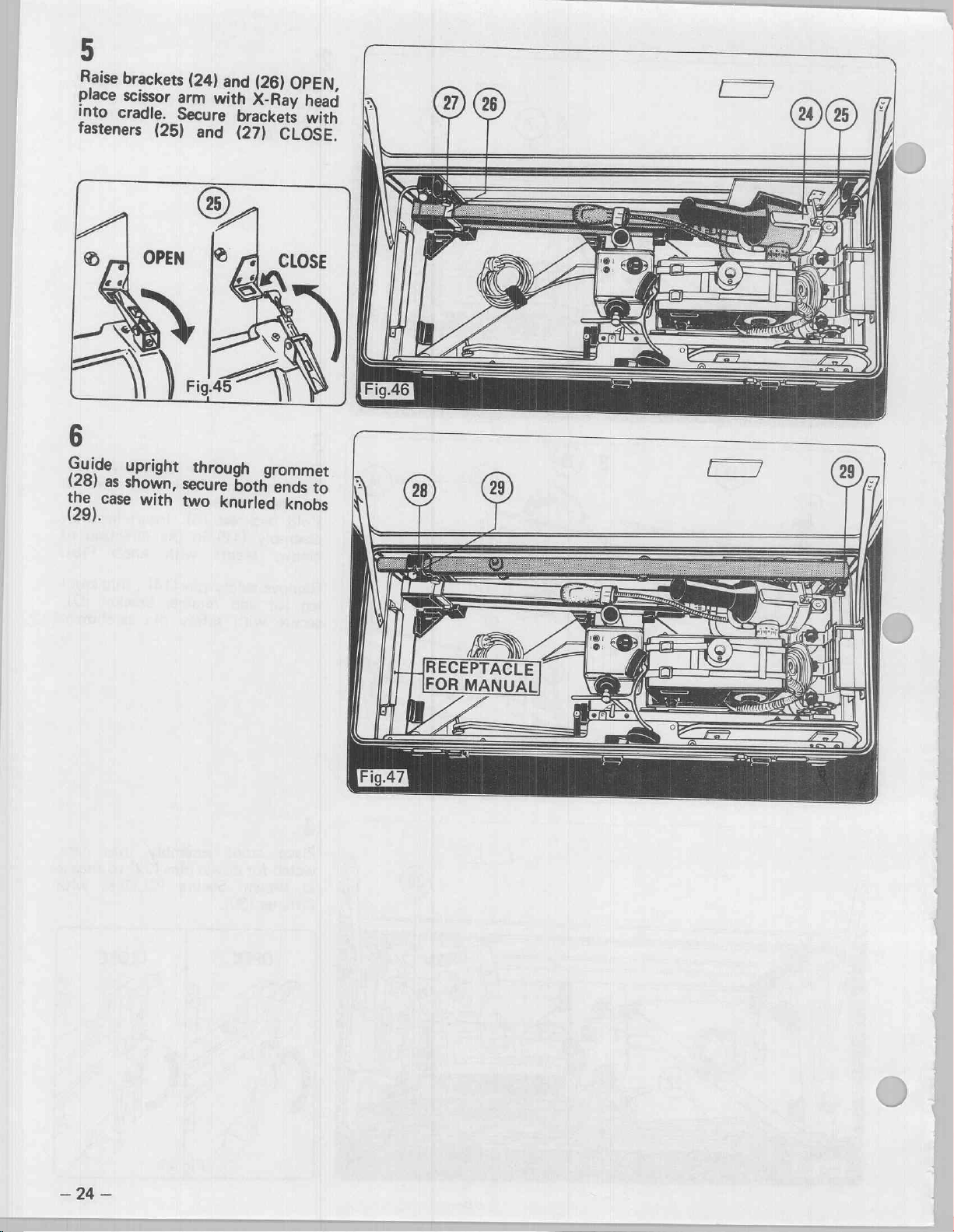

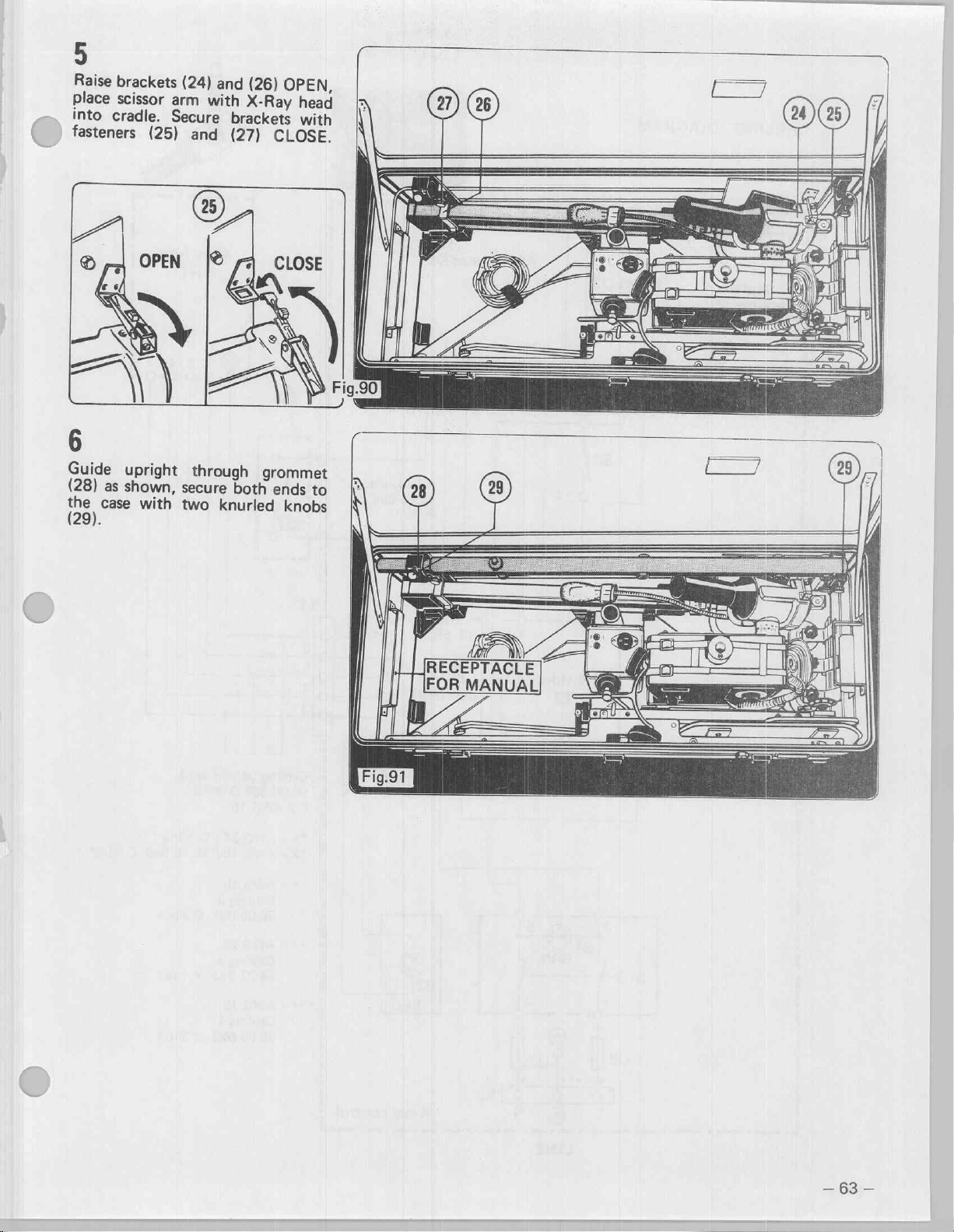

Raise

brackets

place

scissor

into

cradle.

fasteners

arm

Secure

(25)

(24)

with

and

and

(26)

X-Ray

brackets

(27)

OPEN,

head

with

CLOSE.

|

À

26

ES

VO

Guide

(28)

29).

upright

as

shown,

©

with

through

secure

two

knurled

grommet

both

ends

knobs

to

Fig.46

αλ

RECEPTACLE

FOR

MANUAL,

—

94

—

Page 26

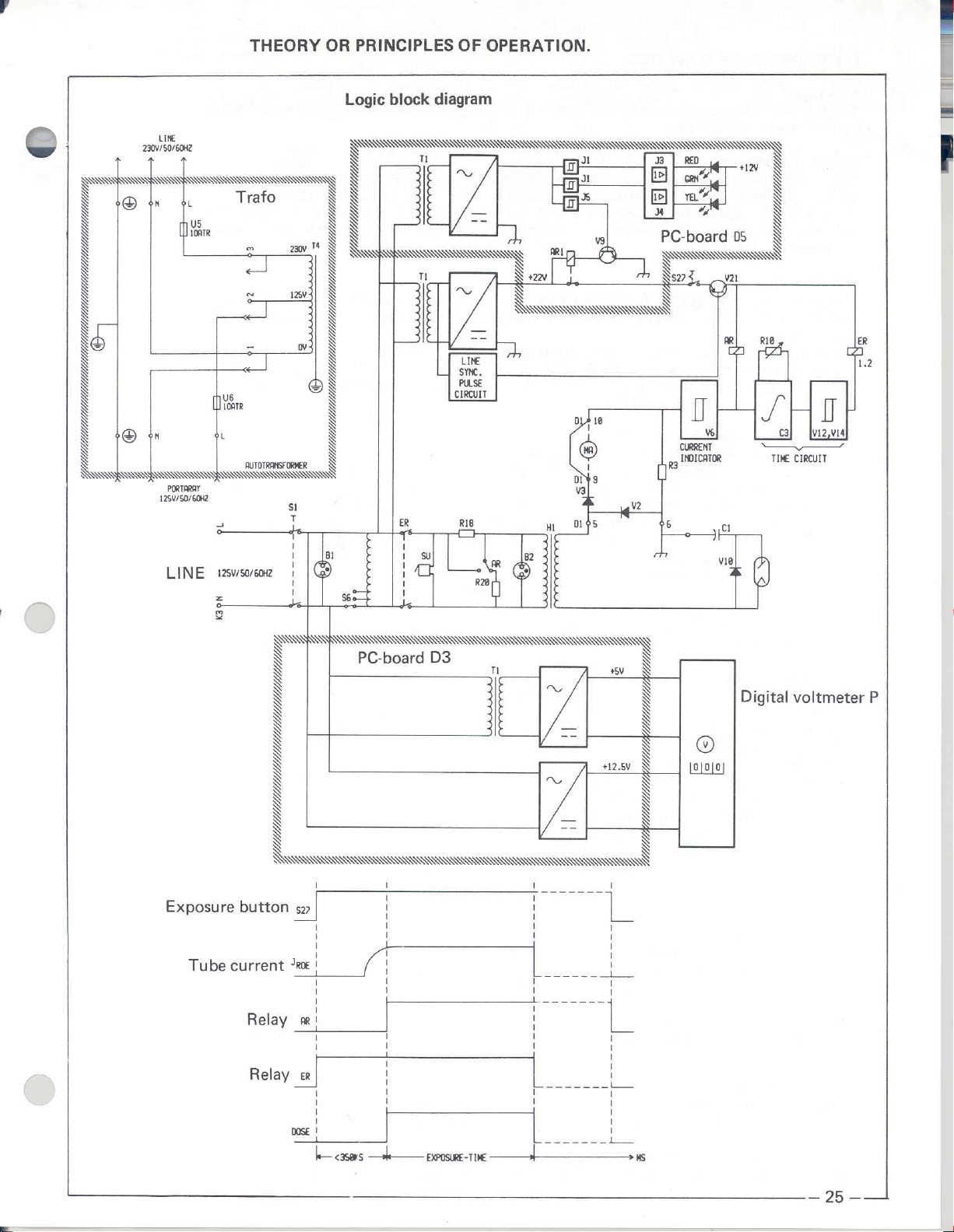

THEORY

OR

PRINCIPLES

OF

OPERATION.

VV

~

~

Y

sli

ae

1

|

©

di

©

è

PORTARAY

125V/50/60H2

LINE

SÌ

Trafo

—

vé

(Dicer

L

AUTOTRANSF

2

125v/50/6022

を

2

Logic

block

diagram

КА

А

T

5

N

NIN

NaN

T

SS

NS

XX

290.

À

KR

き

\

\

T

き

X

\

N

]

NW

S

き

À

N

き À

À き

き

き

N

À

à

N

き

き

S

À

T

N

SQ

S

き

à

き

き

à

À

N

N

\

ORMER

N

NS

S1

+

L

1

1

|

BI

|

1 1

1 1

Js

S6

PC-board

e

TE

Je

NN

1

1

1

1

n

ΤΙ

SU

ING

て

LINE

SYNC.

PULSE

CIRCUIT

me

=

—>

D3

ーー

À À

NE

/|

—

--

E

き

Ümmi

m

B2

R20

TI

Ty ' ee 7 °°

ma

Tm

了

ARI

a

NN

ο

區

~

АА

3

별

+12.5

+5V

<

А

3

|

mm

M

cil

πι

A

a

PC-board05

RSR

sor

Ÿ

S

\

À

X

N

并

JU

き

Li

~

V21

©

O)

ojojo

ii

S

\

À

V

き

き

Y

i

Mİ

RIS

ta

TH

o

τον

Digital

cs]

TIME

CIRCUIT

voltmeter

ER

Tİ

[avis

!

||

SS

1.2

P

—

ll

casas 一 和

|

一 一 fxp0suRE-Tike

жж

一

25 一 一

|

Page 27

DESCRIPTION

Line

input

The

line

if

input

the

switch

lights

OF

FUNCTION

is

protected

S

1

is

on.

with

the

fuses

U

2

and

U

3.

The

readiness

indicating

B

1

lamp

Control

The

control

voltage

Start

of

Depressing

cronized

energizes.

relay

The

relay

oltage

radiation

voltage

Since

base

the

The

drop

ing

exceeds

via

the

current

relays

emitter

in

it.

of

V

the

transformer

transformer

of

125

V

Exposure

exposure

to

the

power

contacts

through

the

indicator

dividers

capacitor

through

ER

1

and

current

It

is

12/V

thus

14,

value

the

of

in

the

line

button

supply.

ensures

place

the

voltage

B

2

are

R

31,

R

C

3

is

not

the

resistor

ER

2

energize.

of

V

14

possible

transistor

0.7

V

+

voltage

S

27

primary

divider

caused

32

controls

yet

flows

to

adjust

V

on

R

that

the

range

the.relays

The

schmitt

winding

R

18/R

to

operate

V

charged,

R

12/R

through

the

12

can

13.

Heliodent

of

109

ER

trigger

of

20.

At

and

20

and

the

transistor

14,

and

the

potentiometer

threshold

be

controlled

70

is

V

to

1

and

ER

(V

the

high-voltage

the

same

indicate

V

21

as

is

then

voltage

through

always

133

V

at

2

are

12,

V

14)

time

the

long

as

V

12

is

switched

R

of

the

only

operated

60

HZ,

controlled

switches

transformer

the

buzzer

duration

S

27

is

depressed.

blocked.

through.

13

and

once

causes

trigger

its

Schmitt

with

109

via

of

V

As

base

a

primary

V

to

V

21

and

the

H

1

SU

and

the

14

obtains

a

a

voltage

consist-

voltage

132

V

syn-

ER

under

the

X-ray

result,

Switching

As

У

through.

V

voltage

The

V

C

The

Converter

R

End

As

transistor

transistor

reduced;

V

Temperature

The

10°

Forced

In

switching

on.

If

over

—

26

—

soon

as

(У

4)

=

Then,

7

allows

of

collector

6,

and

keeps

2

serve

for

transistor

10

and

of

exposure

soon

as

on

12

is

controlled

R

11

to

70°

exposure

case

of

system.

no

tube

R

16

relay

AR

the

tube

2,4

Учи

the

the

AR

125

without

current

V

6

interference

V

7

and

provides

C

3.

The

C

3

is

V

12

switches

V

12

short

the

other

through

compensation

hot

wire

C

range.

a

defect

The

current

after

approximately

current

(V5)

transistor

relay

to

damping.

of

V

7

in

the

overmodulated

suppression.

also

controls

a

supply

exposure

charged

through.

circuits

hand,

even

compensates

where

no

capacitor

pulse

triggers

allows

=

0.7

V

7

draw.

flows,

the

voltage

times

to

the

the

base

the

faster.

tube

C

the

0,7

a

voltage

V

+

U

also

at

the

relay

(V

controlled

same

is

This

state

transistor

stabilized

of

0.066

threshold

This

initiates

section

voltage

drop

Thus,

the

temperature

current

7

is

charged

Dentotime,

to

1

sec.

drop

6)

places

time

(flip-flop

V

17.

to

3.2

voltage,

a

of

on

the

1

signal

through

and

the

on

the

=

0.7

V,

through

the

Heliodent

through

This

by

V

18

sec.

are

which

flip-flop

V

14,

so

R

13

ER

relays

resistor

the

function).

transistor

set

decreases,

R

3

which

transistor

R

9.

The

70

transformer

V

8,

R

8,

The

serves

to

the

integrator,

in

18

steps

a

| | i

is

adjusted

process.

that

the

On

current

so

drop.

V

6

collector

R

capacitor

as

with

the

that

-

response

- : -

triggers

the

the

resistor

of

the

entire

Dentotime

R

there

16

-

the

transistor

timer

V

circuit

6

is

controlled

is

actuated.

is

greater

is

controlled

current

5

to

the

an

impedance

consisting

R

10.

with

R

one

hand,

through

the

transistor

ele

circuit

is

a

after

switching

than

of

under

base

of

C

7

and

of

13,

the

the

ER

is

in

the

forced

through

a

Page 28

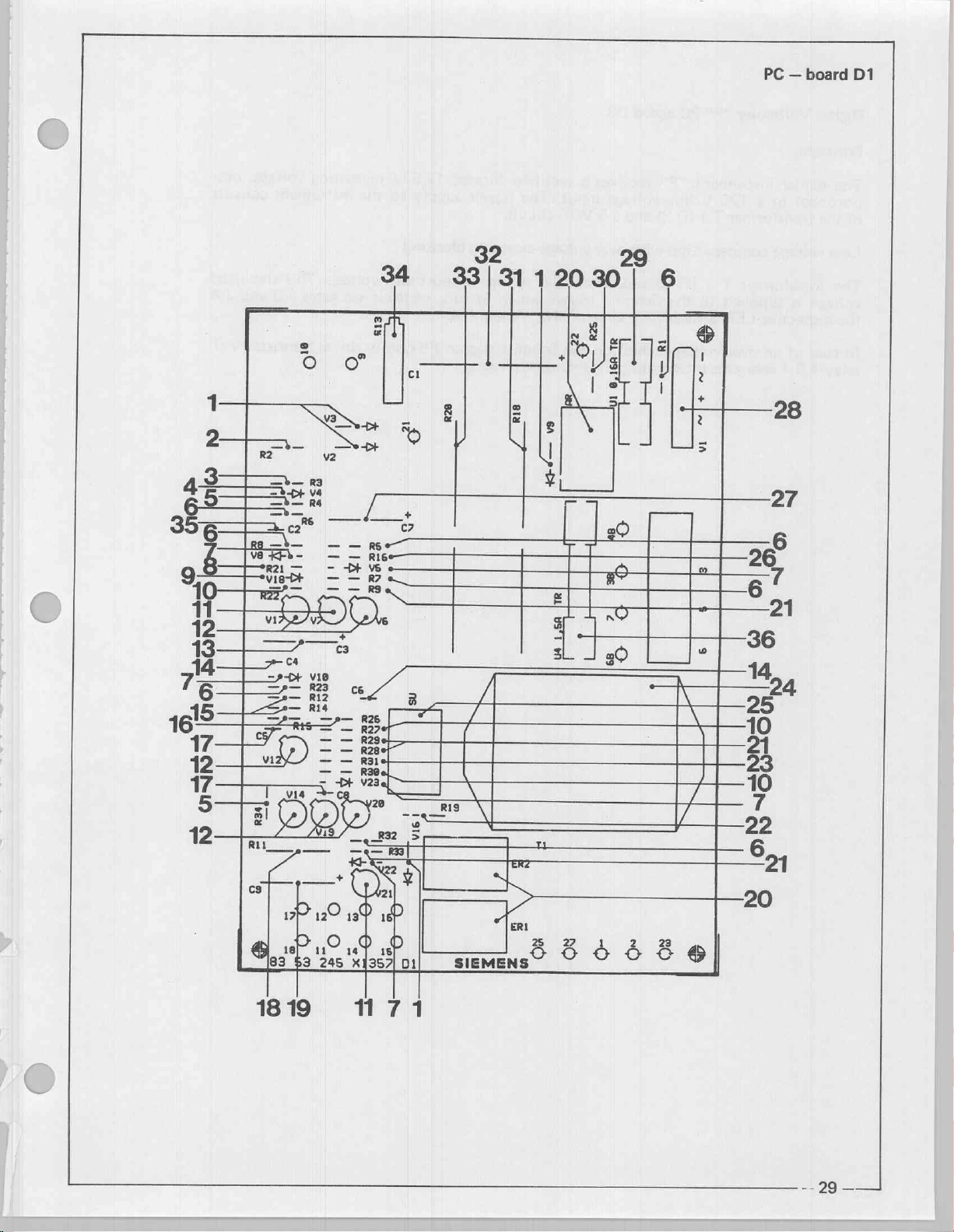

HZ

50/60

®

V

125

LINE

18A

MTR

®

je

1

1

|

|

1

1

i

i

181

1

1

|

1

1

1

ㅣ

|

i

|

ㅣ

I

da

B31

PN

È

と

109.44

|

oo

>

>

112.5V

LE

115.6V

È

>

118.8

121.9V

125.9

128.1V)€

jal

53.

e

31)

&

г

ga

2

N

<

一

Y

n

=

8

24

à

&

O

=

125v—

=

E

2160.16

V6,12,14,17,19,20..

V5,8,10,22,23.......

W,21

ТВ

VI

人

、B8eCise9

Фр

.BCYS8

e

siol]

©

k

KA

va

2.4V

R4

470

i

+

RI6

5.5

s

ai

anse

05.2.

(Page

_

05.1

_

DS.3

05.4

„BA

35)

(Раде

35}

(Page

35)

(Раде

35)

tube

e

current

jumper)

points

Measuring

for

(remove

|

Diva

3

오스

3

3

iow

01

i

cit

πιό

UG

|

QI

bri

16K

15916

527

a

р

И

ne

Di

ax

‘E

ul

©

I,

?

vz

|

Rol

las

ig

E

|

L

W

Re

*İC

IK

Ti

RI4

2.2K

RIS

2K

VIA

cs}

zer

Ra

Lie

Page 29

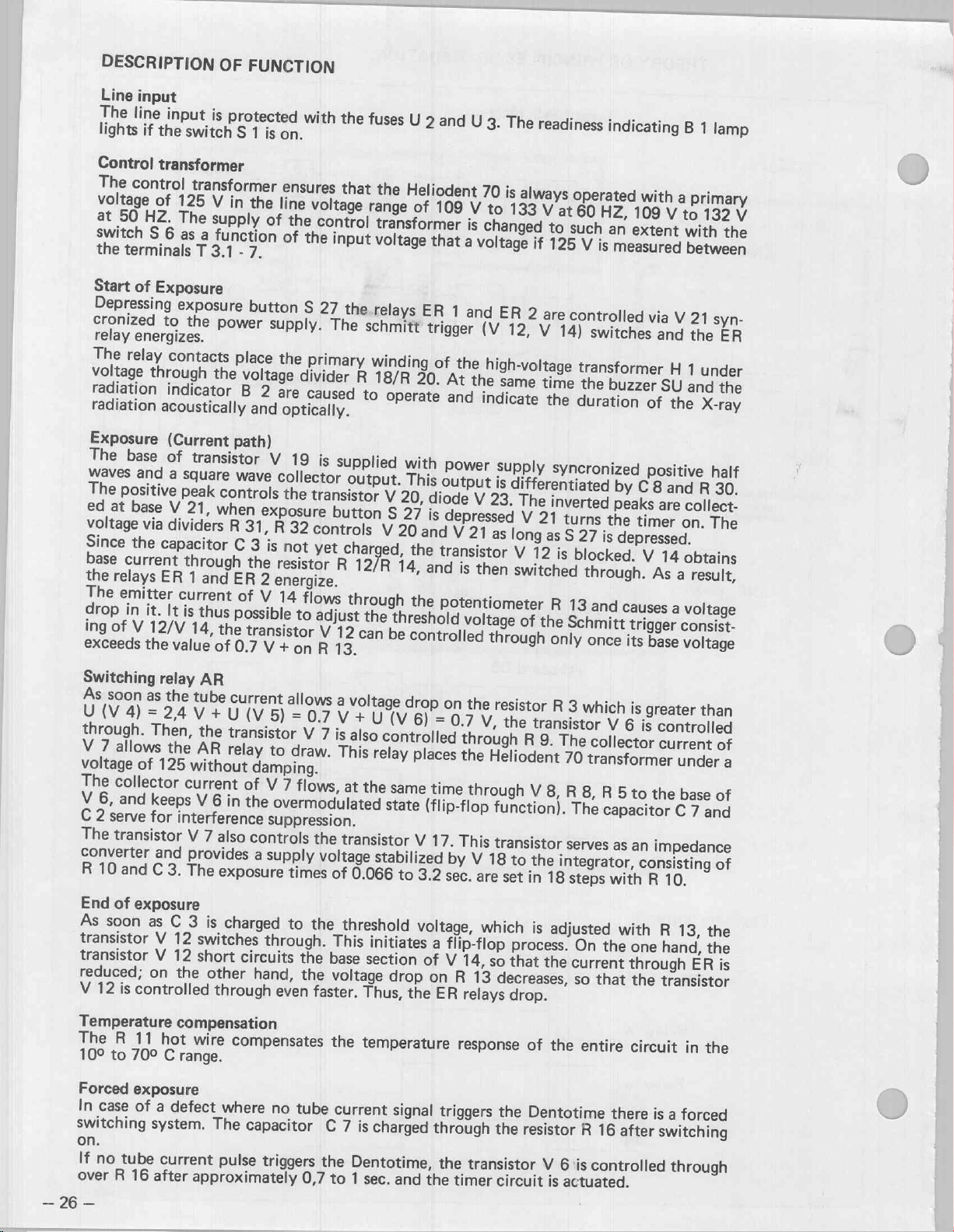

PC

—

board

>

SI-Diode

2

Zinkoxid

3

Metal

film

4

SI-Z-Diode

5

Metal

film

6

Carbon

7

SI-Planar-Diode

8

Metal

film

SI-Z-Diode

9

10

Metal

film

11

SI-PNP-Transistor

12

SI-NPN-Transistor

13

Capacitor

14

Ceramic

15

Metal

16

Metal

17

Ceramic

18

Measuring

19

Capacitor

20

Relay

21

Metal

22

Metal

23

Metal

24

Transformer

25

Relay

26

Resistor

27

Capacitor

28

SI-Rectifier

29

Fuse

30

Metal

31

Wire

32

Elko/Capacitor

33

Wire

34

Resistor

35

Ceramic

Fuse

36

Capacitor

film

film

Capacitor

N

film

film

film

N

film

wound

wound

spindel

Capacitor

D1

EGB

varistor

resistor

EGB

resistor

resistor

resistor

EGB

resistor

resistor

resistor

resistor

resistor

resistor

resistor

set

EGB

resistor

resistor

resistor

Adj.

EGB

EGB

EGB

V2, V3, V9,

R2

R3

Va

R4,

R34

R1,

R5,

V5,

V8,

R21

V18

R22,

R27,

V7,

V21

V6,V12,V14,V17,V19,V20

C3

C4,

C6

R12,

R14

R15,

R26

C5,

C8

R11

C9

AR,

ER1,

R9,

R28,

R19

R31

T1

SU

R16

C7

v1

U1

R25

R18

C1

R20

R13

C2

U4

R6,

V10

R30

ER2

R29,

V16

R7,

R33

R8

1000

V

1A

14

V

0,05W

510

Ohm

0,25W

BZX

97

C2V4

470

Ohm

0,25W

10k

0,25W

50

V

200

mA

390

Ohm

0,25W

ZPD12

100k

BCY78

BCY59

22MF

100NF

2,2k

22k

22NF

12

0,25W

IX

IX

TO-18

16

V-

100

0,25W

0,25W

100

V

1

2k5%0,1W

2,2MF

12

5,6k

5,6k

1k

125/17,

60

5,6M

4,7MF

B

0,16A

12k

6,8

1MF

82

100

330NF

1,5A

35

1U

V-

0,25W

0,5W

0,25W

5

1U

V-

0,25W

35

1A

V

80

250

0,5W

Ohm

V-

40

10W

Ohm

Ohm

100

V

250

V-

V23016

1

1%

V

V23016

V-

V

%

1

10W

+50

0,75W

V

slow

DO-41

1N

4007

069-X3011

1

%

Gr.

2,4

V

0,4W

1

%

Gr.

5

%

Gr.

0207

DO-35

V0,4W

1

%

TO-18

20%

V

10

1

%

%

Gr.

10

1

%

5

Gr.

32

45

0513

%

МБВ

Gr.

0207

0207

%

W5R

BAW

Gr.

%

DO-35

0207

V

200

V

200

7x5x4-2M

K11

20%

0408

0207

Gr.

1%

0309

Gr.

%

0207

Gr.

42

Typ

3VA

LO

0207

Gr.

%

1

Dry

0513

%

20

5x20

blow

slow

0309

Gr.

1045

Gr.

%

5

Gr.

%

-10

1045

Gr.

%

5

10

%

8x8x4-2M

WSR

%

10

1/4x1

blow

0207

5

%

DO-35

0207

76

0207

mA

mA

8x8x4-2M

mm

17x31

1/4”

κ

<

—

28

Page 30

17

一

2

asia

ЗбАЕ

[в

==

πα

E°

7

6

o

Bj

2

TO

12

>

=

_

一

一

ve

R2

VE

KFè-

а"

8

vz

——

一

—

/

一

Re

—

Ri6e—

и

ορ

Hf

ex

|

ーー

ca

ath

ua

?

120

0

poi

=

pe

13

=

1

1

=

2

1

©

一

a

È

y

a

Ng

4

al

Га

sasue

e

τι

ERZ

>

ERI

25

27

の

ららら

る

O

—

—e_R1

る

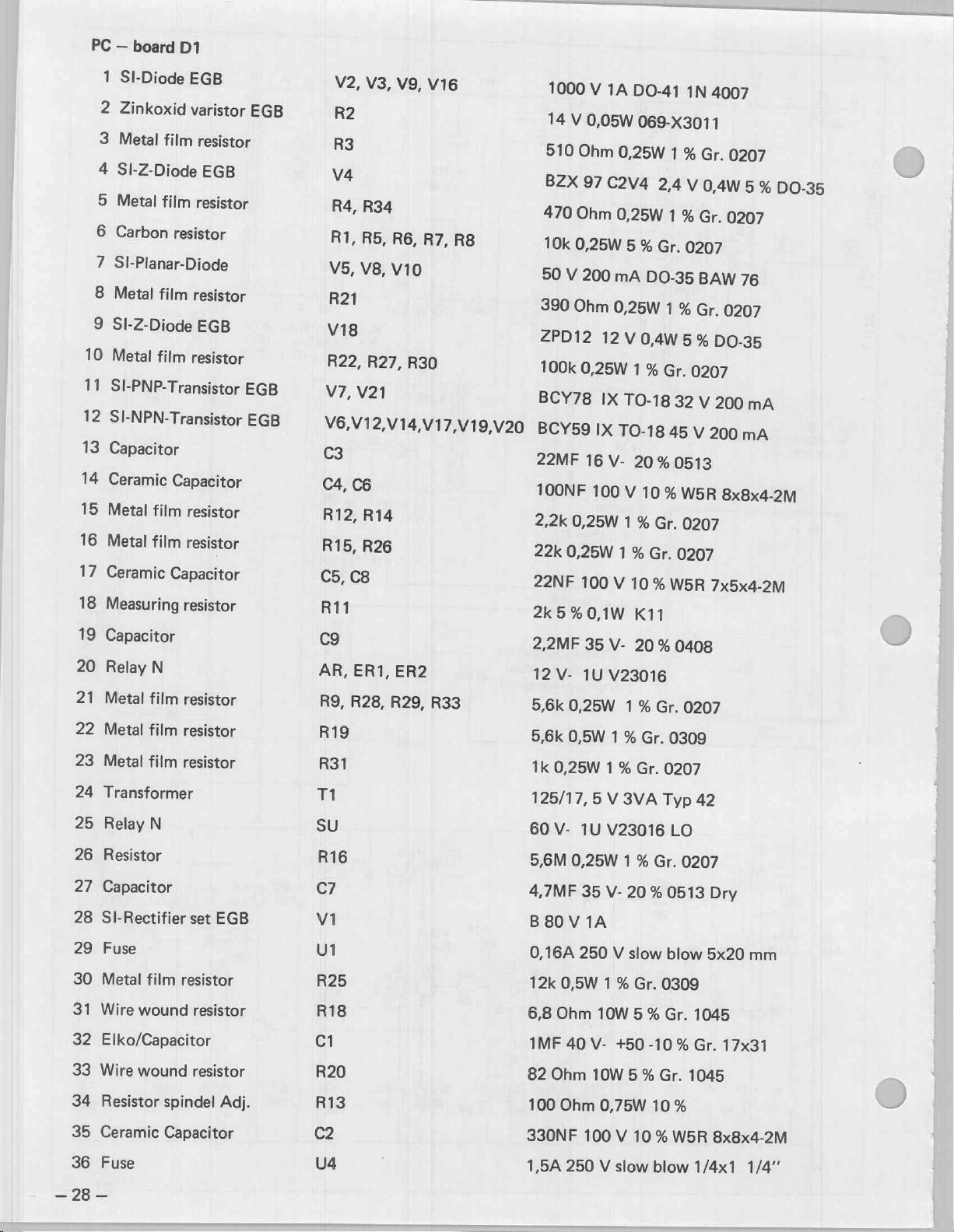

PC — board

Tel

vi

28

27

6

26

в’

a

dire

\

る

@|

264

ER

全

a

ri

21

|

'

00

D1

19

18

171

mogi

=]

Page 31

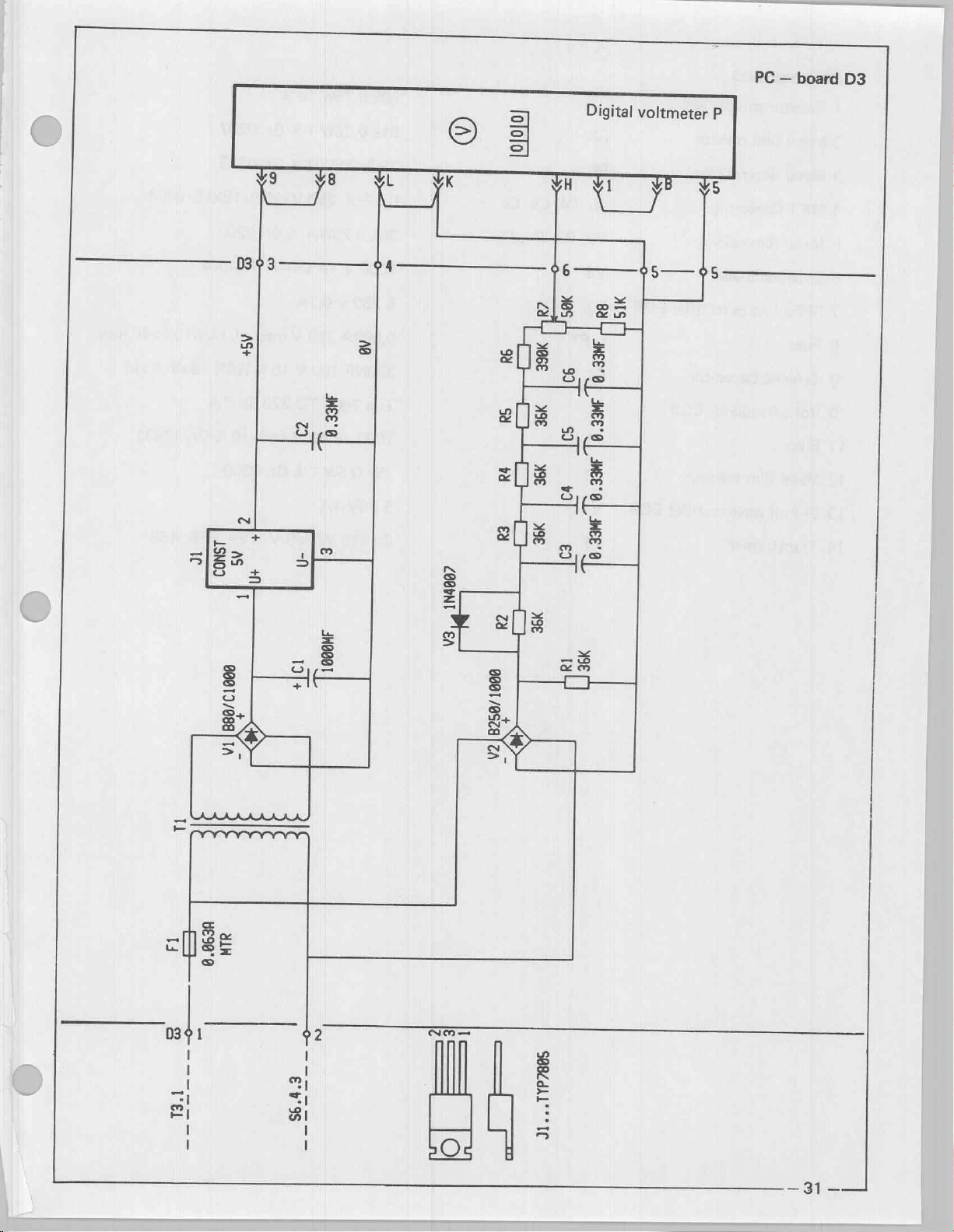

Digital

Principle

The

Voltmeter

digital

portional

of

the

transformer

Line

voltage

The

transformer

voltage

the

respective

In

case

relay

of

AR

instrument

to

a

compensation

is

supplied

LED'S

an

over

1

energizes

“P”

PC

125

V

T

1

(D

T

1

(D

to

the

Red

voltage

interrupting

board D3

"P"

receives

line

voltage

3)

and

with

5)

supplies

Schmitt

(RT),

condition

input.

a

5

over

trigger

Green

the

a

rectified

The

VDC

circuit.

voltage

a

line

exposure

voltage

which

(GN),

the

Schmitt

exposure

filtered

power

in

Yellow

trigger

circuit.

12.5

V

supply

to

blocking

proportional

turn

controls

(GE).

J

5

output

measuring

the

instrument

voltage.

via

drives

This

gates

transistor

voltage,

consists

stabilized

J

3

and

pro-

J

VQ,

J

4

Page 32

19409

IC

o—

2

AS+

ζ

+

AS

+1

T

99917988|

ES

PC — board

Digital

]

MEE'6

I

=

€

-n

A

o

m

9

>

>

a

に

出

«9θύΝΙ

E

su

P

>

ace

|

№

|

ж

|

же

EI

99

30

#3

a

5;

066"

=

daa

voltmeter

P

D3

гар

440081

|

ТЕЛ

999!/9ZalZA

E

ЖЕ

十

%-

IA

I

4590°0

=>

πι

dlN

=

8

-

VEL

=

=

εν9ς

εεττ

E

O

=

=

SBBZdAL"

al"

"IC

—31——İ

Page 33

PC — board

1

Resistor

2

Metal

3

Metal

4

MKT-Capacitor

5

Metal

6

SI-Diode

7

SI-Full

8

Fuse

9

Ceramic

10

Volt.

11

Elko

12

Metal

13

SI-Full

14

Transformer

D3

spindel

film

resistor

film

resistor

film

resistor

EGB

wave

rectifier

Capacitor

Regulator

film

resistor

wave

rectifier

Adj.

EGB

EGB

EGB

R6

C3,

R2,

V3

v2

EF

C2

C1

R1

V1

T1

R7

R8

C4,

R3,

C5,

R4,

C6

R5

50k

51k

390k

0,33

36k

1000

B

250

0,063A

330NF

Typ

1000

36k

0,5W

80V

B

2x

115

0,75W

0,25W

0,5W

uF

250

0,25W

V

1A

V

0,7A

250

100

7805

uF

40

1A

V/2x

10%

1

%

1

%

V

-20

1%

DO-41

V

med.

V

10%

TO-220

V

+50

1

%

Gr.

6

V

Gr.

Gr.

Gr.

1N4007

5V/1A

-10%

0309

4VA

0207

0309

%

0207

sl.

W5R

18x15x9-6M

bl.

S10

5x10

8x8x4-2M

Gr.

17x31

TFB

468

mm

Page 34

Digital

na

©

voltmeter

P

58

6

25

©

K

ME

802

4

03152

3

03

cz

PC — board

>

D3

GB

GB

GB

B

M

334

Page 35

Linevoltage

The

15

switch

the

The

C

At

Via

(yellow)

As

controlled

The

the

As

J

The

diode

At

of

5.7

J

board

Schmitt

zener

4

smoothen

a

lower

the

the

control

light

light

the

control

1.1

controlled

output

V

a

control

J

5.1

from

inverter

diode

7

controlled

indication

V

stabilizer

D

1.

The

triggers

diodes

control voltage

lights

by

diode

of

(Green)

voltage,

to

L

V

the

signal

J

3

up.

voltage

R

11.

The

V

6

V

7

(Green)

voltage

via

R

J

3.12

is

deenergized

via

H.

J

and

and

over

voltage

J

2

receives

transformer

1

and

J

5.

3

and

V

4

increase

input

to

Schmitt,

the

Schmitt

the

AND

increases

output

is

deenergized

increases

10,

switches

changes

the

signal

lights

up

from

further

from

and

corresponding

R

12,

switches

exposure

its

input

T

1

trigger

gate

J

4,

output

of

the

J

3.12

(Nominal

H

L

to

light

diode

to

a

line

from

voltage

(D

5)

that

value

trigger

output

inverter

signal

inverter

in

turn

unit

(over

voltage

to

L.

H

and

V

voltage

H

to

interruption

from

the

supplies

J

of

via

the

R

1.2,

J

1.6

J

1.1

J

3.10

Schmitt

J

3.10

switches

-

changes

operating

condition)

J

3.15

changes

5

(Red)

lights

of

approx.

L,

thus

changing

PC

board

power

rectifier

C

circuit

and

J

and

J

signals

trigger

to

output

supply

V

R

5.2.

1.7

L,

the

J

from

D5

(signals)

1.7

from

condition).

the

output

from

H

up.

130

V,

the

the

output

of

1

the

8,

C

light

changes

L

to

to

output

the

voltage

3

and

are

diode

H.

H

to

signal

L.

The

signal

timing

for

R

5,

at

H.

V

6

to

L,

L

and

of

light

signal

of

Transistor

made.

be

can

V

9

conducts,

AR

1

energizes

thereby

interrupts

the

exposure.

No

exposure

Page 36

stě

#110

a

2

IE

MI

-—-

了

|

ay

91518

Lara

[Pet

4:

e

89°

GS

10

<

sa

deso

ze

DE

w

|

č

ЕЕ

E

O

|

|

=

ΖΙθέαλ!

*

"ес

|

|

|

=

|

|

91

—

yo

ASI+

|

|

|

E

E

€

刁

區

|

|

η

a

|

|

о

SET:

deren

=

er

8

A8

|

|

5°

5

8

a

ιο

4

8

618

29Z8

er’

218

이모

mb

AT

Ham]

301

|!

<

Sr

A

z

|»

ЗЕЕ"

€

n

NB

To

nez

NB

0!

=

ta

iF

2

*

15409

T

AZI

Mi

λθΙ

gly

「

「

1001

nez

z

L

LU

Ζ

ae

fai}

I

IC

」

A

ε

94

23008

3

a

y

E

ve

3

/

Ic

EC

3

“İş

—dsi}

El

<

a

3008

Г}

の

vi

ces

È

IA

MI

u

B

_

CEL

Vel

ΕΛ

So

YA

=.

2

sh

aa

e

+

sof

İmer

[eco

~

SA

==

Si

ea"

vat

44

MOI

na

Y

B

9

180bd4L"

m

"С

1

=

區

=

—

À

+

|

|

E

8

é

já

—

35

—

Page 37

PC — board

=

SI-Z-Diode

Carbon

Wu

W

Sl-npn-transistor

A

Double-OP-Amplifier

0

Capacitor

0D

Metal

3

SI-Diode

D5

resistor

film

EGB

SI-Z-Diode

O ©

Ga-As-P-Diode

=

o

Carbon

>

>

Ga-P-Diode

—

N

Capacitor

w

Ga-As-P-Diode

ER

B

Metal

Bk

一

q

Voltage

=

©

Resistor

=

M

Metal

>

©

Capacitor

=

©

Power

N

o

Capacitor

N

i

SI-Rectifier

resistor

film

resistor

regulator

spindel

film

resistor

inverter

EGB

resistor

EGB

EGB

EGB

EGB

Adj.

EGB

set

EGB

EGB

v8

R6,

R7,

vg

11,15

C3

R5,

R14,

v2

V3,

V4

V5

R8

V7

C2

V6

R1,

R2,

R3

12

R10, R11,

R4

C1

13

C4

VI

R13

R15,

R12

R18,

R19

ZPD5,6

820k

BCY

Typ

4,7

10k

50

V

ZPD8,2

5

mm

100

5

mm

22

uF

5

mm

470

7812

10k

100k

0,33

CMOS

2,2

uF

B80V

0,4W

59

1458

uF

35

0,5W

200

8,2

RM

Ohm

RM

25

yellow

Ohm

UC

0,75W

0,5W

uF

63

4049

40

1A

5,6

V

0,4W

5

%

VIII

TO-18

DIP

8pol.

V

20

1

%

Gr.

mA

DO-35

V

0,4W

2,5

red

0,2W

5

2,5

green

V

-20%

Typ

0,5W

1

TO-220

10%

1

%

Gr.

V

-20

B

DIP

V-

7x5x10

Gr.

%

7x5x10

0309

HLMP

%

0614

3400

%

Gr.

12

Lin

0309

%

Gr.

0309

5

Gr.

Typ

16

5

%

DO-35

45

V

200

(2x741c)

BAW

76

%

DO-35

0240

0204

3502

NASS

0309

V,

1A

liegend

06x19

mA

S

—

N

N

Flat

transformer

N

ω

AND-Gate

N

A

Relay

N

q

Ceramic-Capacitor

N

ο

Metal

film

N

N

Metal

film

36

—

4x2

EGB

resistor

resistor

TI

14

AR1

C5

R17

R16

127

C

MOS

12

V

0.33

120

4,7k

V/9,5

4081

-2U

uF

100

Ohm

0,5W

V

AU

V

0,5W

1%

1,8VA

B

DIP

LO

Monost.

10

1

%

Gr.

14

%

W5R

Gr.

0309

BV34

8x8x4-2M

0309

Page 38

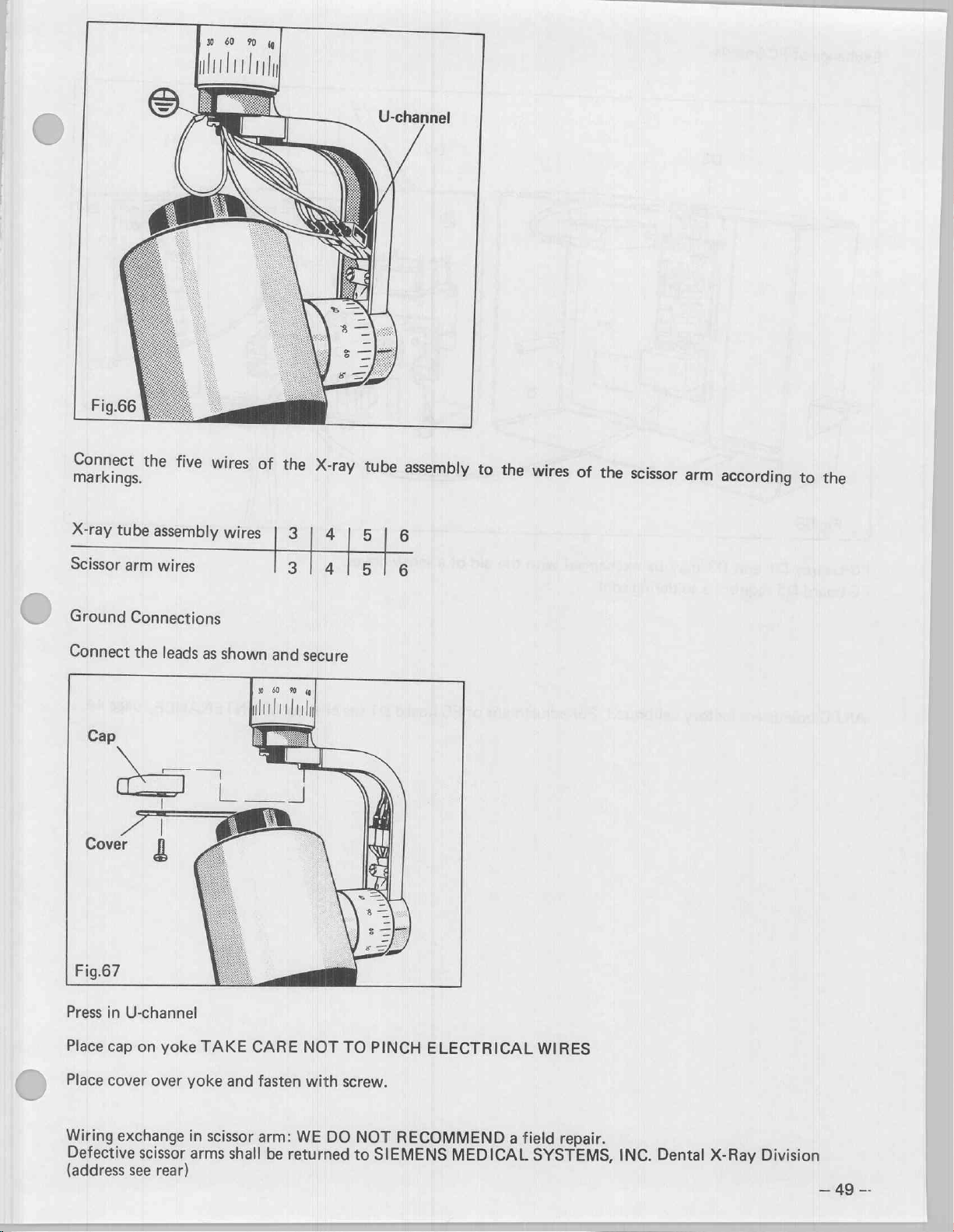

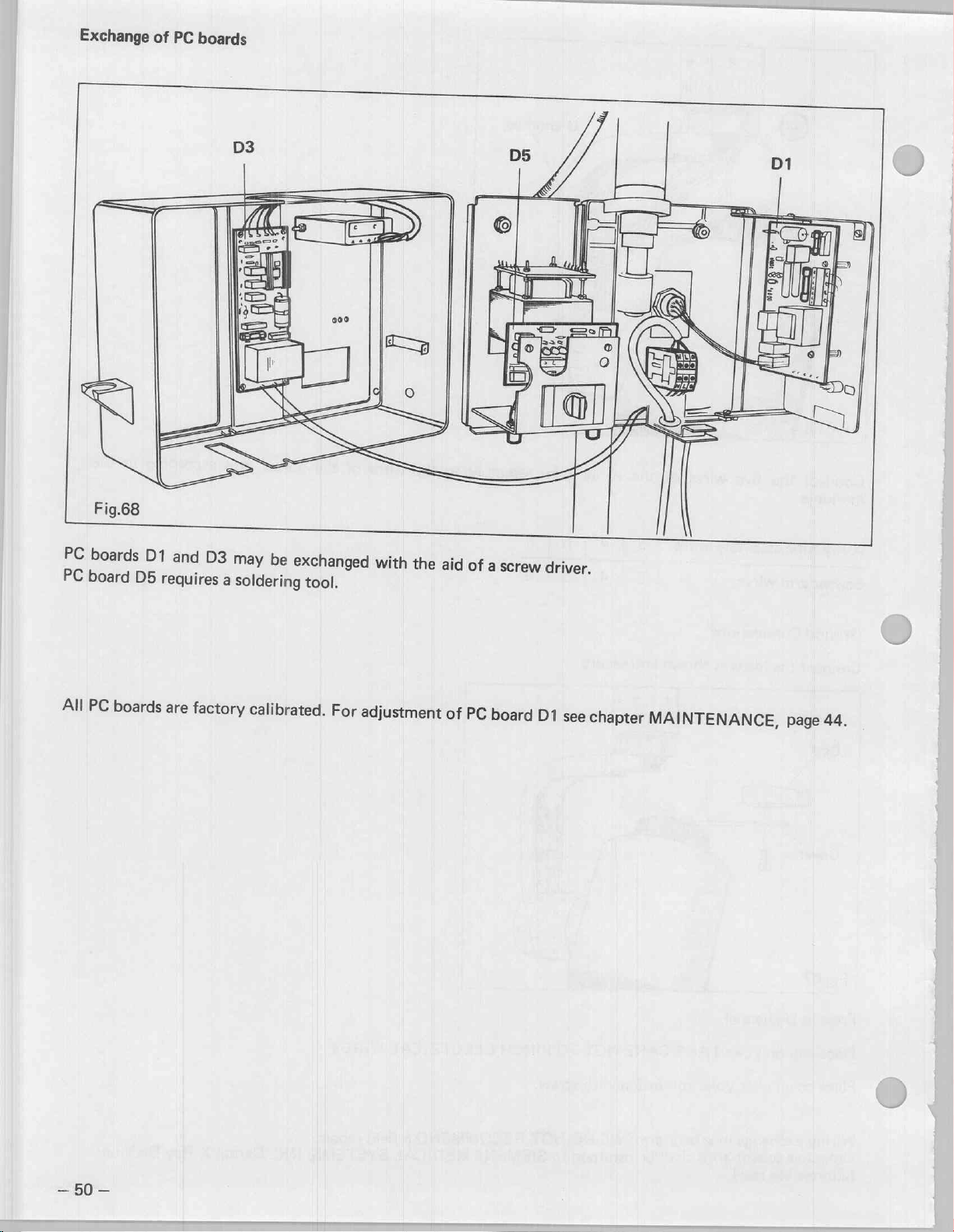

PC — board

D5

Lar

Page 39

PORTARAY

Heliodent

70

Dentotime

Description

The

X-ray

voltage

temperature

Current

energizes,

relay

Accordingly,

As

soon

trigger

The

AR

The

tube

alternating

capacitor

with

D

1.9/D

are

exceeds

shorts

the

relay

the

diodes

1.10.

tube

switched

and

as

timer

current

current

charging

of

function

of

of

the

a

the

the

resistor

the

Heliodent

the

capacitor

drops

V

the

Heliodent

on

at

filament

given

timer

circuit,

circuit

only

as

cannot

flows

current

2

and

Hi

the

same

is

value,

R

18

is

then

C

3

shuts

the

be

measured

there

has

V

3.

70

is

time.

reached

the

Schmitt

consisting

and

separates

operated

is

charged

the

ER

trigger

been

(tube

short

The

switch

current

tube

JU

Tİ

Ci

indirectly

Thus,

tube

(after

150

trigger

of

C

the

from

to

the

relays

is

released.

directly

plus

circuited

current

Avi

heated,

current

to

250

(V

3/R

10,

resistor

the

line

threshold

down,

between

capacitor-charging

in

may

msec).

6)

V

without

and

the

be

i.

e.,

flows

As

switches

12,

V

R

20

voltage

the

the

points

tube

current

measured

A

the

heater

only

once

soon

over,

14

is

triggered.

from

the

damping.

set

exposure

X

current).

measuring

between

and

the

as

the

peak

the

power

on

the

is

terminated.

and

Y

Thus,

the

the

high

emission

tube

AR

relay

The

AR

source.

Schmitt

since

an

the

circuit

points

Heliodent

The

iM

V

10,

H

Tube

diode

70

1).

Trans-

Former.

voltage

Capacitor

voltage

voltage

voltage

circuit

Gi

<0

of

kV

the

os

—

Å

201 一 一 一 一

Heliodent

ZN

一

70

consists

if

a

voltage-doubling

,

DS

circuit

(C

1,

The

half

transformer

Page

negative

wave

of

half

the

transformer

peak

voltage

wave

of

the

is

measured

transformer

voltage

is

on

voltage

added

the

tube.

to

charges

the

capacitor

the

capacitor

voltage,

C

so

1.The

that

twice

t

positive

the

Page 40

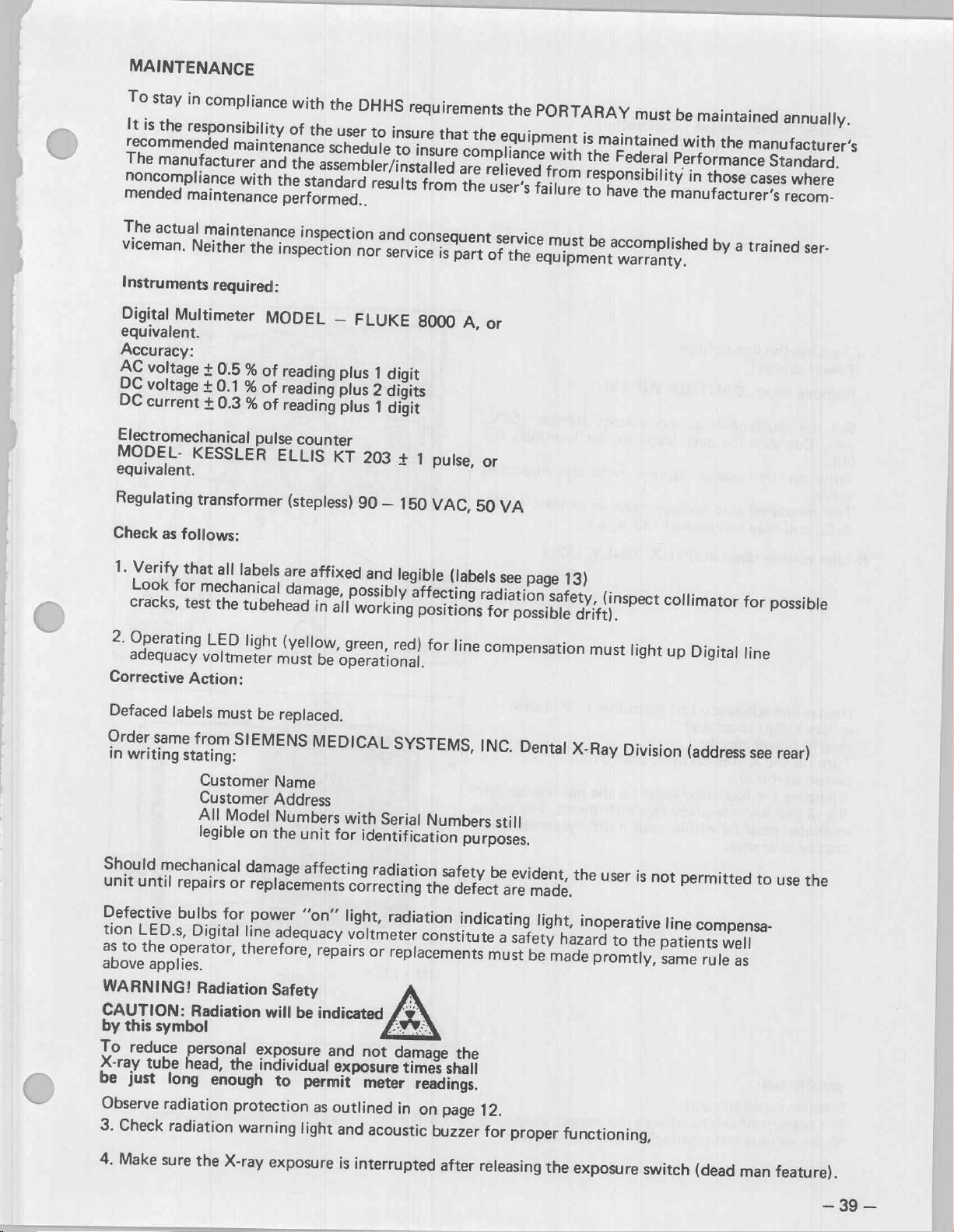

MAINTENANCE

To

stay

in

It

is

the

respo

recommended

The

actual

viceman.

Instruments

maintenance

Neither

compliance

nsibility

maintenance

the

required:

with

the

of

the

user

schedule

inspection

inspection

DHHS

to

and

nor

requirements

insure

to

insure

that

consequent

service

is

the

the