Siemens SIMATIC ET 200SP, CPU 1515SP PC F, CPU 1515SP PC, HMI 128PT, HMI 2048PT User Manual

...Page 1

Page 2

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

ET 200SP Open Controller

CPU 1515SP PC (F)

Manual

05/2017

A5E32701806

-AC

Preface

Documentation guide

1

Safety notes

2

Product overview

3

Installing

4

Connection

5

Diagnostics, error and

system alarm

6

Commissioning

7

Functions

8

Maintenance

9

Technical data

10

Accessories/spare parts

A

Abbreviations

B

Troubleshooting

C

Page 3

Siemens AG

Division Digital Fac

tory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E32701806-AC

Ⓟ

04/2017 Subject to change

Copyright © Siemens AG 2014 - 2017.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Page 4

CPU 1515SP PC (F)

4 Manual, 05/2017, A5E32701806-AC

Preface

Purpose of the documentation

This manual supplements the system manual for the ET 200SP distributed I/O system.

Functions that generally relate to the system are described in this manual.

The information contained in this product manual and the system / function manuals enable

you put the CPU 1515SP PC (F) into operation.

Basic knowledge required

The system must be operated and used by qualified staff only.

The following knowledge is required:

● Installation guideline for SIMATIC ET 200SP

● Programming with STEP 7

● PC based automation with an S7-1500 software controller and with

WinCC Runtime Advanced

● Basic knowledge of PC technology

● Windows Embedded Standard 7 operating system

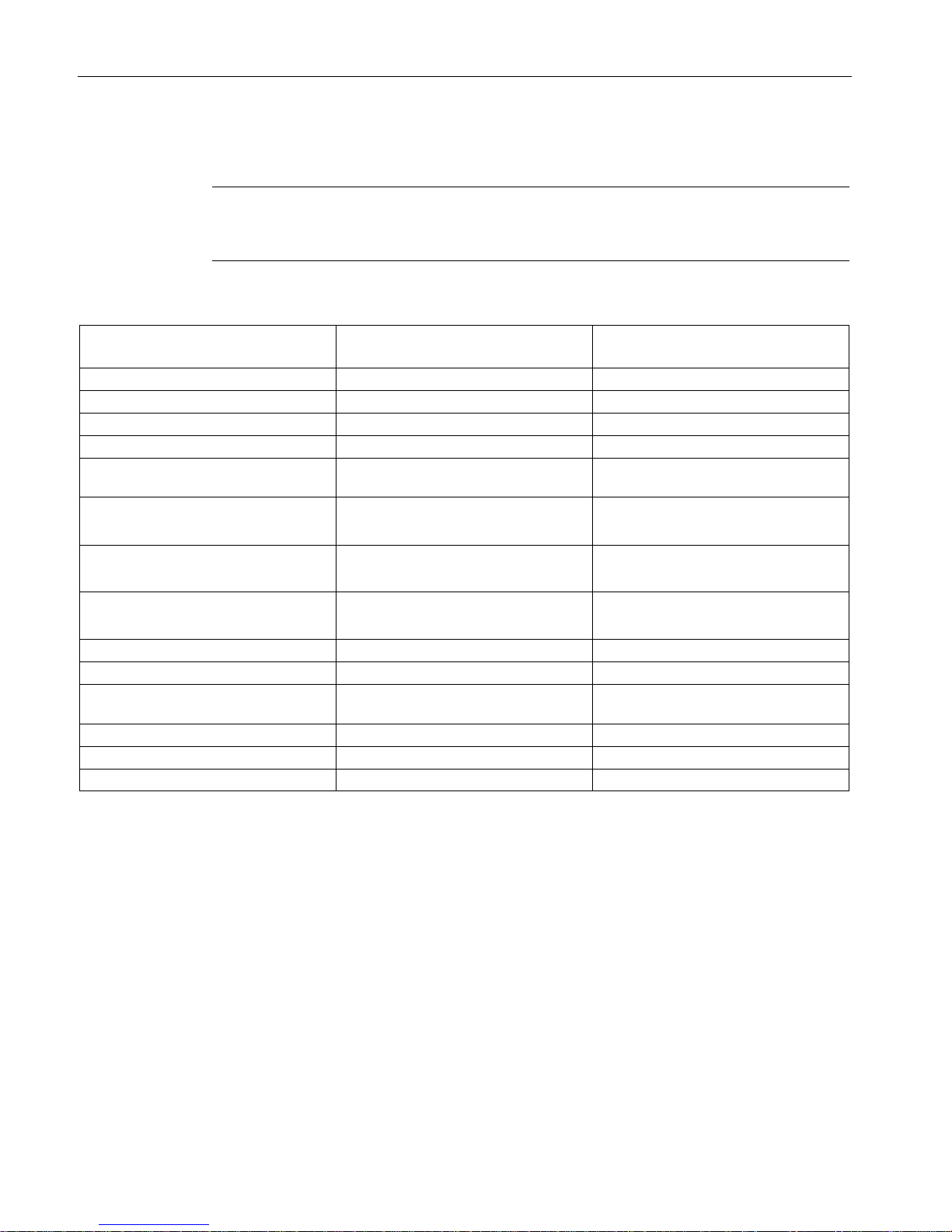

Scope of validity of the documentation

This documentation is valid for the following devices:

ET 200SP Open Controller

Article number

System version

WES7 E 32Bit 4GB RAM

System version

WES7 P 64Bit 4GB RAM

CPU 1515SP PC

6ES7677-2AA31-0EB0

6ES7677-2AA41-0FB0

CPU 1515SP PC + HMI 128PT

--

6ES7677-2AA41-0FK0

CPU 1515SP PC + HMI 512PT

--

6ES7677-2AA41-0FL0

CPU 1515SP PC + HMI 2048PT

--

6ES7677-2AA41-0FM0

CPU 1515SP PC F

6ES7677-2FA31-0EB0

6ES7677-2FA41-0FB0

CPU 1515SP PC F + HMI 128PT

--

6ES7677-2FA41-0FK0

CPU 1515SP PC F + HMI 512PT

--

6ES7677-2FA41-0FL0

CPU 1515SP PC F + HMI 2048PT

--

6ES7677-2FA41-0FM0

CPU 1515SP PC,

spare part, without CFast card, without soft-

ware

6ES7677-2AA40-0AA0

Page 5

Preface

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

5

Conventions

Conventions STEP 7: In this documentation, "STEP 7" is used as a synonym for all versions

of the configuration and programming software "STEP 7 (TIA Portal)".

Please also observe notes marked as follows:

Note

A n

ote contains important information on the product described in the documentation, on the

handling of the product or on the section of the documentation to which particular attention

should be paid.

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Page 6

Preface

CPU 1515SP PC (F)

6 Manual, 05/2017, A5E32701806-AC

Siemens Industry Online Support

You can find current information on the following topics quickly and easily here:

●

Product support

All the information and extensive know-how on your product, technical specifications,

FAQs, certificates, downloads, and manuals.

●

Application examples

Tools and examples to solve your automation tasks – as well as function blocks,

performance information and videos.

●

Services

Information about Industry Services, Field Services, Technical Support, spare parts and

training offers.

●

Forums

For answers and solutions concerning automation technology.

●

mySupport

Your personal working area in Industry Online Support for messages, support queries,

and configurable documents.

This information is provided by the Siemens Industry Online Support in the Internet

(http://www.siemens.com/automation/service&support).

Industry Mall

The Industry Mall is the catalog and order system of Siemens AG for automation and drive

solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power

(TIP).

Catalogs for all the products in automation and drives are available on the Internet

(https://mall.industry.siemens.com).

Information about third-party software updates

This product contains third-party software. Siemens accepts liability with respect to

updates/patches for the third-party software only when these are distributed by Siemens in

the context of a Software Update Service contract or officially approved by Siemens.

Otherwise, updates/patches are installed at the user's own risk. You can find more

information about our software update service offer under

(http://w3.siemens.com/mcms/topics/en/simatic/licenses/software-update-

service/Pages/Default.aspx).

Notes on protecting administrator accounts

A user with administrator rights has extensive access and manipulation possibilities.

Therefore, make sure that the administrator account is adequately protected to prevent

unauthorized changes. To do this, set secure passwords and use a standard user account

for regular operation. Other measures, such as the use of security policies, should be

applied as required.

Page 7

Preface

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

7

Page 8

CPU 1515SP PC (F)

8 Manual, 05/2017, A5E32701806-AC

Table of contents

Preface ................................................................................................................................................... 4

1 Documentation guide ............................................................................................................................ 11

1.1 Documentation on CPU 1515SP PC (F) ................................................................................ 14

2 Safety notes .......................................................................................................................................... 15

2.1 Notes on use .......................................................................................................................... 17

3 Product overview .................................................................................................................................. 18

3.1 Fail-safe option....................................................................................................................... 18

3.2 Properties ............................................................................................................................... 19

3.3 Sample configuration ............................................................................................................. 21

3.4 Components ........................................................................................................................... 23

3.5 Configuration of the devices .................................................................................................. 24

3.6 Operator controls and display elements ................................................................................ 25

3.7 Scope of delivery.................................................................................................................... 28

3.7.1 Unpacking the device ............................................................................................................. 28

3.7.2 Scope of delivery - System version WES7 E 32Bit 4GB RAM .............................................. 30

3.7.3 Scope of delivery - System version WES7 P 64Bit 4GB RAM .............................................. 32

4 Installing ............................................................................................................................................... 34

4.1 Basics ..................................................................................................................................... 34

4.2 Hardware configuration .......................................................................................................... 37

4.3 Installing CPU 1515SP PC (F) ............................................................................................... 38

5 Connection ........................................................................................................................................... 40

5.1 Notes on connection .............................................................................................................. 40

5.2 Terminal and block diagram ................................................................................................... 41

5.3 Electrical configuration ........................................................................................................... 42

5.4 Connecting devices to networks ............................................................................................ 44

5.5 Securing cables...................................................................................................................... 44

6 Diagnostics, error and system alarm ..................................................................................................... 46

6.1 Status and error display ......................................................................................................... 46

Page 9

Table of contents

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

9

7 Commissioning ..................................................................................................................................... 49

7.1 Notes on commissioning ......................................................................................................... 49

7.2 Initial commissioning ............................................................................................................... 50

7.3 Initial configuration of an Open Controller .............................................................................. 53

7.4 Installing license keys ............................................................................................................. 55

7.5 Windows Security Center ....................................................................................................... 57

7.6 Switching CPU 1515SP PC (F) on/off .................................................................................... 58

8 Functions .............................................................................................................................................. 59

8.1 Monitoring functions ................................................................................................................ 59

8.2 Retentive memory NVRAM ..................................................................................................... 60

8.3 BIOS description ..................................................................................................................... 61

8.3.1 Introduction ............................................................................................................................. 61

8.3.2 Starting BIOS setup ................................................................................................................ 62

8.3.3 BIOS setup menus .................................................................................................................. 63

8.3.3.1 Information menu .................................................................................................................... 65

8.3.3.2 Main menu .............................................................................................................................. 66

8.3.3.3 Advanced menu ...................................................................................................................... 67

8.3.3.4 Security menu ......................................................................................................................... 69

8.3.3.5 Power menu ............................................................................................................................ 70

8.3.3.6 Boot menu ............................................................................................................................... 71

8.3.3.7 Exit menu ................................................................................................................................ 73

8.3.4 BIOS setup default settings .................................................................................................... 74

8.3.5 BIOS update ........................................................................................................................... 75

8.4 Power options ......................................................................................................................... 76

8.5 Protective functions for data carriers ...................................................................................... 77

8.5.1 Enhanced Write Filter (EWF) .................................................................................................. 78

8.5.2 File-Based Write Filter (FBWF) ............................................................................................... 82

9 Maintenance ......................................................................................................................................... 84

9.1 Backing up and restoring data ................................................................................................ 84

9.2 Change partitioning ................................................................................................................. 85

9.2.1 Partitions in the delivery state ................................................................................................. 85

9.2.2 Change partitioning ................................................................................................................. 86

9.3 Restoring the delivery state .................................................................................................... 92

9.4 Restoring delivery state using USB stick ................................................................................ 95

9.5 Updating software ................................................................................................................... 97

9.6 Windows Embedded Standard 7 ............................................................................................ 98

9.7 Sending the device to customer service ................................................................................. 99

9.8 Removing and inserting the CFast card ............................................................................... 100

Page 10

Table of contents

CPU 1515SP PC (F)

10 Manual, 05/2017, A5E32701806-AC

10 Technical data ..................................................................................................................................... 101

10.1 Standards and approvals ..................................................................................................... 101

10.2 Electromagnetic compatibility .............................................................................................. 105

10.3 Shipping and storage conditions .......................................................................................... 108

10.4 Mechanical and climatic ambient conditions ........................................................................ 108

10.5 Information on insulation, protection class, degree of protection and rated voltage ........... 110

10.6 Use of the ET 200SP in zone 2 potentially explosive atmospheres .................................... 111

10.7 Module data ......................................................................................................................... 112

10.7.1 CPU 1515SP PC, system version WES7 E 32Bit 4GB RAM .............................................. 112

10.7.2 CPU 1515SP PC F, system version WES7 E 32Bit 4GB RAM ........................................... 115

10.7.3 CPU 1515SP PC, system version WES7 E 32Bit 4GB RAM - spare part ........................... 118

10.7.4 CPU 1515SP PC, system version WES7 P 64Bit 4GB RAM .............................................. 121

10.7.5 CPU 1515SP PC F, system version WES7 P 64Bit 4GB RAM ........................................... 124

10.7.6 CPU 1515SP PC, system version WES7 E 64Bit 4GB RAM - spare part ........................... 127

10.7.7 CPU 1515SP PC (F) + HMI ................................................................................................. 130

10.7.8 S7-1500 Software Controller CPU 1505SP (F) ................................................................... 130

10.8 Dimension drawings ............................................................................................................. 131

10.8.1 CPU 1515SP PC (F) ............................................................................................................ 131

A Accessories/spare parts ....................................................................................................................... 133

B Abbreviations ....................................................................................................................................... 135

C Troubleshooting ................................................................................................................................... 137

Glossary .............................................................................................................................................. 138

Page 11

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

11

1

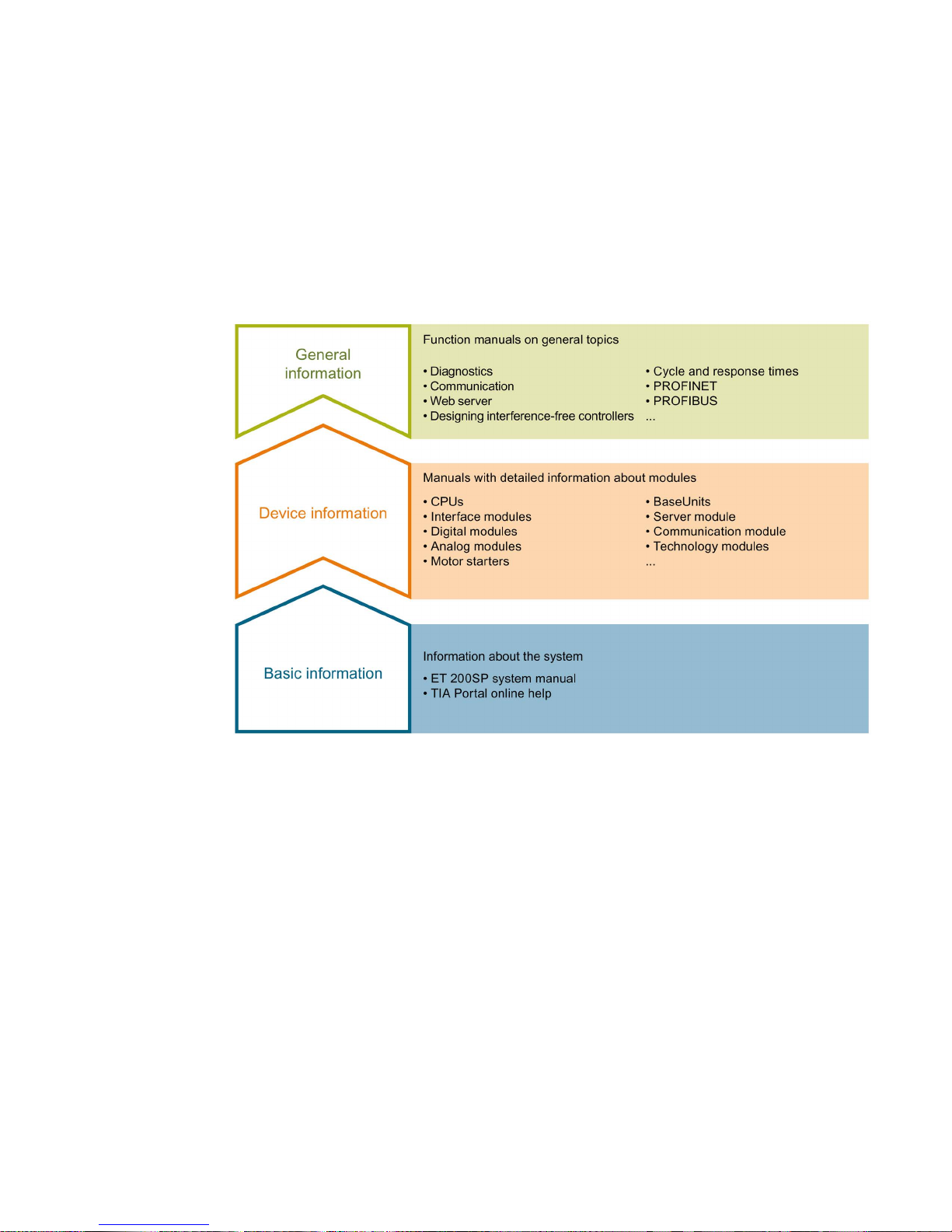

The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three

areas.

This arrangement enables you to access the specific content you require.

Basic information

The system manual describes in detail the configuration, installation, wiring and

commissioning of the SIMATIC ET 200SP. distributed I/O system. The STEP 7 online help

supports you in the configuration and programming.

Device information

Product manuals contain a compact description of the module-specific information, such as

properties, wiring diagrams, characteristics and technical specifications.

Page 12

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

12 Manual, 05/2017, A5E32701806-AC

General information

The function manuals contain detailed descriptions on general topics regarding the SIMATIC

ET 200SP distributed I/O system, e.g. diagnostics, communication, Web server, motion

control and OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/tech-doc-et200/Pages/Default.aspx).

Changes and supplements to the manuals are documented in a Product Information.

You can download the product information free of charge from the Internet

(https://support.industry.siemens.com/cs/us/en/view/73021864).

Manual Collection ET 200SP

The Manual Collection contains the complete documentation on the SIMATIC ET 200SP

distributed I/O system gathered together in one file.

You can find the Manual Collection on the Internet

(http://support.automation.siemens.com/WW/view/en/84133942).

"mySupport"

With "mySupport", your personal workspace, you make the most of your Industry Online

Support.

In "mySupport" you can store filters, favorites and tags, request CAx data and put together

your personal library in the Documentation area. Furthermore, your data is automatically

filled into support requests and you always have an overview of your current requests.

You need to register once to use the full functionality of "mySupport".

You can find "mySupport" in the Internet (https://support.industry.siemens.com/My/ww/en).

"mySupport" - Documentation

In the Documentation area of "mySupport", you have the possibility to combine complete

manuals or parts of them to make your own manual.

You can export the manual in PDF format or in an editable format.

You can find "mySupport" - Documentation in the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

"mySupport" - CAx Data

In the CAx Data area of "mySupport", you can have access the latest product data for your

CAx or CAe system.

You configure your own download package with a few clicks.

Page 13

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

13

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx Data in the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

Application examples

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus in individual products.

You can find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

TIA Selection Tool

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

Page 14

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

14 Manual, 05/2017, A5E32701806-AC

SIMATIC Automation Tool

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on various SIMATIC S7 stations as a bulk operation independently of the TIA

Portal.

The SIMATIC Automation Tool provides a multitude of functions:

● Scanning of a PROFINET/Ethernet network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the data and the programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● Localization of the CPU by means of LED flashing

● Reading out CPU error information

● Reading the CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

PRONETA

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a system.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

1.1

Documentation on CPU 1515SP PC (F)

The following additional documentation is required for using the CPU 1515SP PC (F):

● Operating manual S7-1500 software controller

(http://support.automation.siemens.com/WW/view/en/109249299)

● System manual WinCC Advanced V14

(http://support.automation.siemens.com/WW/view/en/109742297)

● System manual ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293)

● Manual Server module (http://support.automation.siemens.com/WW/view/en/63257531)

Page 15

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

15

Safety notes

2

WARNING

Life-endangering voltage when control cabinet is open

If the device is installed in a control cabinet, areas or components can be under lifeendangering voltage when the control cabinet is open.

Contact with these areas or components may lead to death through electric shock.

Switch off the power before opening the control cabinet.

If the device is operated in a machine in accordance with the machinery directive, the

provisions of the guideline 2006/42/EC apply.

Safe operation of a plant

WARNING

Risk of fire

The device is classified for use in the area of Industrial Control Equipment as "Open Type"

according to UL508. If overheating occurs, burning material may leak and cause a fire.

For this reason, observe the following information:

• For approval and operation in accordance with UL508, the device must be installed in a

housing complying with UL508.

• Install the device in an enclosure that meets the requirements of sections 4.6 and 4.7.3

of the standards EN 60950-1:2006 and IEC/UL/EN/DIN-EN 60950-1.

If you have questions about the validity of installation in the planned environment, please

contact our service representatives.

N

OTICE

Protective measures

To ensure safe operation of a plant, you have to take suitable IT security measures, for

example, network segmentation.

Seal the cover with lead to protect the CFast card with the operating system of the

CPU 1515SP PC (F) against unauthorized access.

For more information on Industrial Security, refer to the Internet

(http://www.siemens.com/industrialsecurity).

Page 16

Safety notes

CPU 1515SP PC (F)

16 Manual, 05/2017, A5E32701806-AC

Repairs

WARNING

Damage caused by opening the device

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or endanger the user.

Only authorized personnel are permitted to repair the device.

For additional information on repairs, see section Sending the device to customer service

(Page 99).

ESD guidelines

Modules containing electrostatic sensitive devices (ESDs) can be identified by the following

label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive to

ESD:

● Before working with modules with ESD, you need to ensure that you are free of

electrostatic charge (e.g. by touching a grounded object).

● All devices and tools must be free of static charge.

● Always pull the mains connector and disconnect the battery before installing or removing

modules which are sensitive to ESD.

● Handle modules fitted with ESDs only by their edges.

● Do not touch any connector pins or conductors on modules containing ESDs.

See also

Electromagnetic compatibility (Page 105)

Page 17

Safety notes

2.1 Notes on use

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

17

2.1 Notes on use

WARNING

Hazards at an unprotected machine or plant

According to the results of a risk analysis, hazards can occur at an unprotected machine.

The hazards may lead to personal injury.

According to the risk analysis, the risk of injury to persons can be countered with the

following measures:

• Additional protective equipment at the machine or plant. In this case, the programming,

parameter assignment and wiring of the I/O used, in particular, must be performed in

accordance with the safety criteria (SIL, PL or Cat.) ascertained by means of an

appropriate risk analysis.

• Use of the device for its intended purpose, which can be established by performing a

functional test on the plant. This allows errors in programming, parameter assignment

and wiring to be detected.

• Documentation of the test results which can be entered, if required, into the relevant

safety certificates.

NOTICE

Ambient conditions

Ambient conditions for which the device is not suitable can lead to faults or damage the

device.

Note the following:

• Only operate the device in enclosed areas. If you do not comply with this instruction, the

warranty becomes void.

• Only operate the device in accordance with the ambient conditions given in the technical

specifications.

• Protect the device from dust, moisture and heat.

• Do not expose the device to direct sunlight or other strong sources of light.

• The device must not be used in places with more difficult operating conditions through

corrosive vapors or gases without taking additional protective measures, for example,

supply of clean air.

Page 18

CPU 1515SP PC (F)

18 Manual, 05/2017, A5E32701806-AC

3

3.1

Fail-safe option

Areas of application

F-CPUs are mainly designed for personal and machine protection. In addition to the safety

program, you can also program standard applications. You can operate the F-CPUs in safety

mode or in standard mode.

Reference

Information on the use of F-CPUs in safety mode is available in the programming and

operating manual SIMATIC Safety - Configuring and Programming

(http://support.automation.siemens.com/WW/view/en/54110126).

You can find information on using the CPU 1505SP (F) software controller in the

corresponding product manual

(https://support.industry.siemens.com/cs/ww/en/view/109740725) and in the F product

information (https://support.industry.siemens.com/cs/ww/en/view/109478599).

Page 19

Product overview

3.2 Properties

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

19

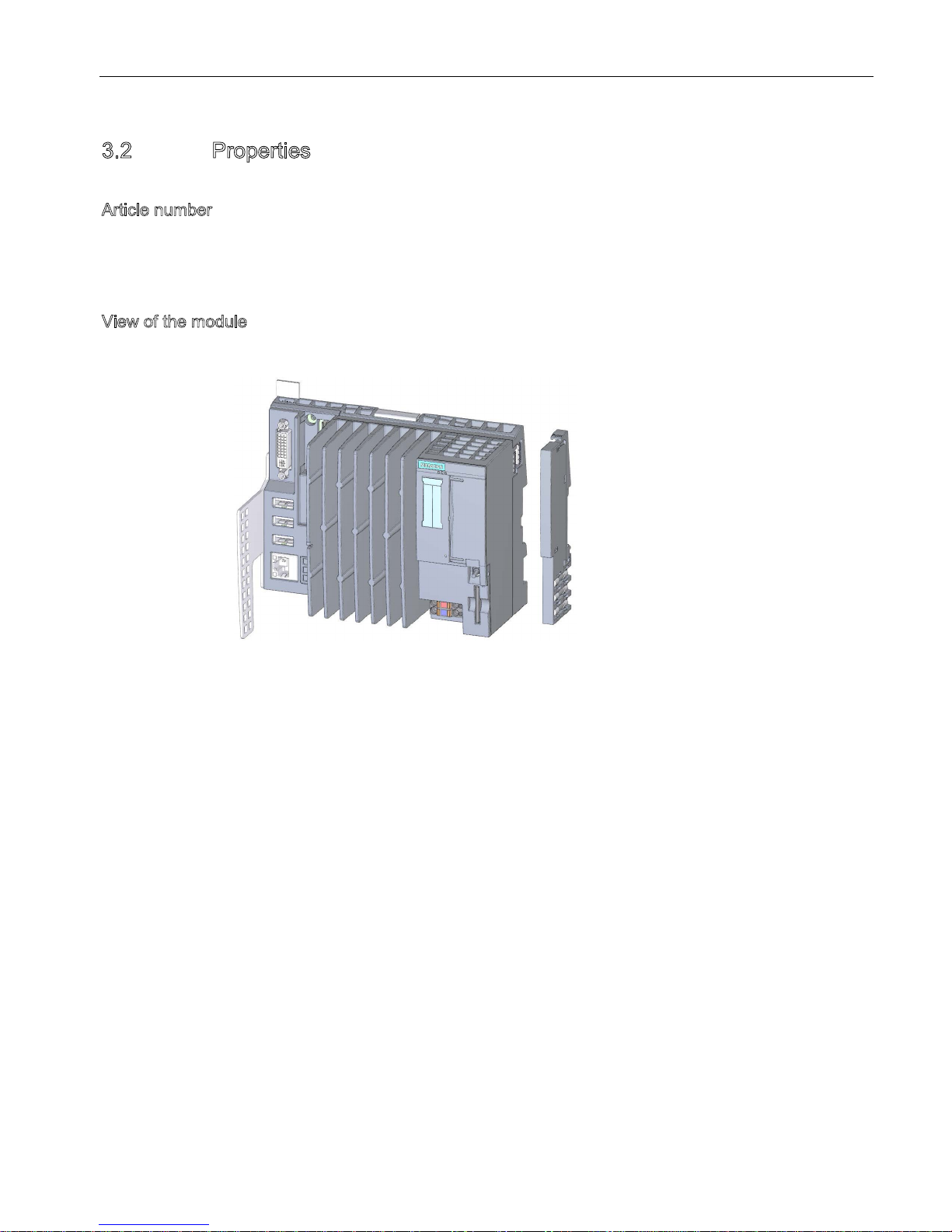

3.2 Properties

Article number

6ES7677-2xAxx-0xx0

The complete article number depends on the system version and the ordering option.

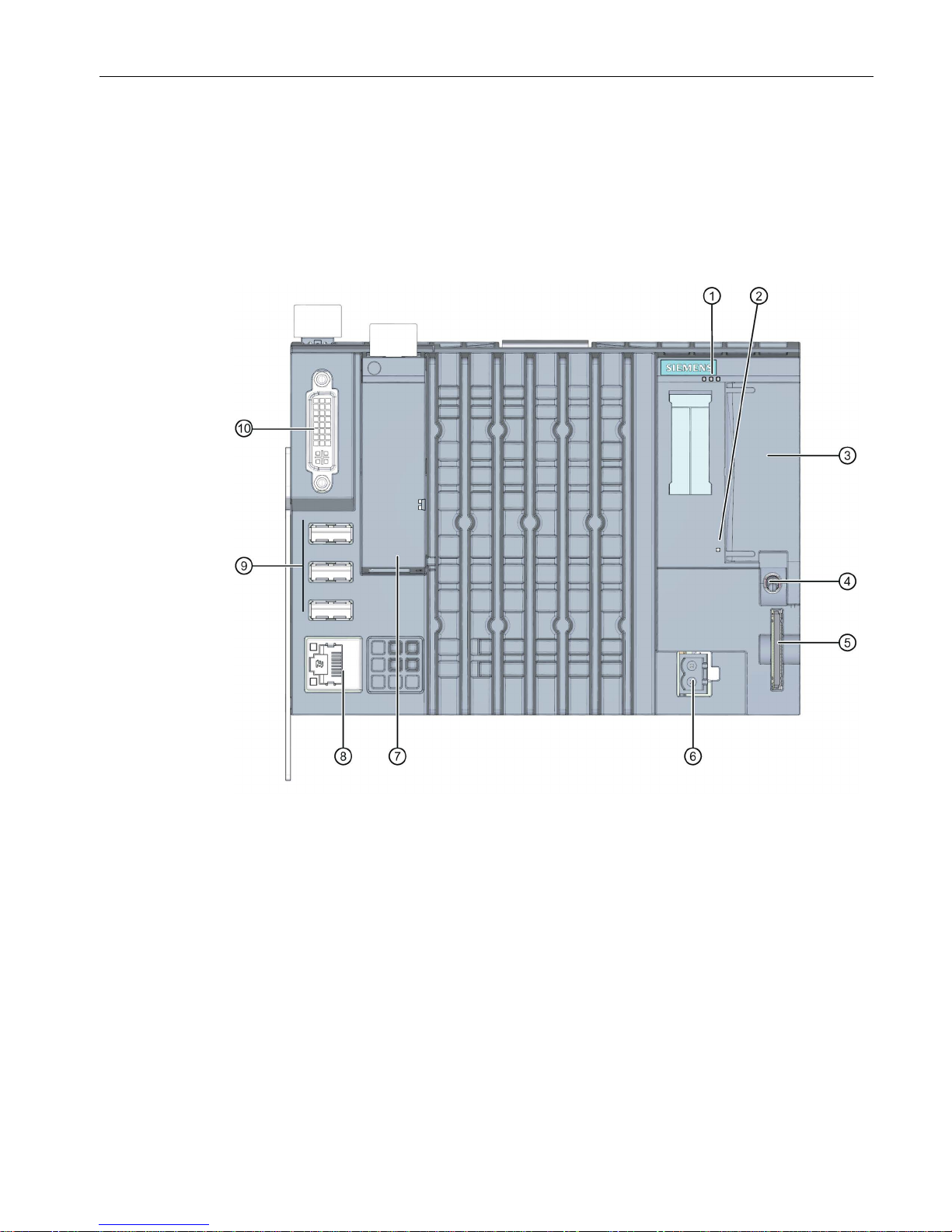

View of the module

The figure below shows the CPU 1515SP PC.

Figure 3-1 CPU 1515SP PC with supplied accessories

Page 20

Product overview

3.2 Properties

CPU 1515SP PC (F)

20 Manual, 05/2017, A5E32701806-AC

Properties

CPU 1515SP PC (F) is a PC based automation device in the design of the ET 200SP. It is

used for control and visualization purposes. The supplied IPC DiagBase software provides

basic diagnostics functions and supports you in handling the BIOS.

CPU 1515SP PC (F) has the following technical properties:

● A removable CFast card with the following pre-installations is used as storage medium:

– Windows Embedded Standard 7 operating system

– S7-1500 Software Controller CPU 1505SP (F)

– Optionally with HMI: WinCC Runtime Advanced as of V14 SP1

● Interfaces

– An interface for the exchangeable ET 200SP BusAdapters for connection of

PROFINET IO (2 ports)

– An interface for connecting devices using Industrial Ethernet (Gigabit Ethernet)

– 3 interfaces for USB devices

– One DVI-I interface for a monitor

– A sealable slot for the CFast card

– A slot for an SD/MMC card as additional optional drive

● Supply voltage 1L+ 24 V DC (SELV/PELV). The connection plug is included in the scope

of delivery.

● CPU 1515SP PC (F) is designed for use in industrial environment:

– Compact design

– Fan-less operation

– High robustness

● The CPU 1515SP PC (F) is approved for the degree of protection IP20 and for the

installation in a control cabinet.

Page 21

Product overview

3.3 Sample configuration

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

21

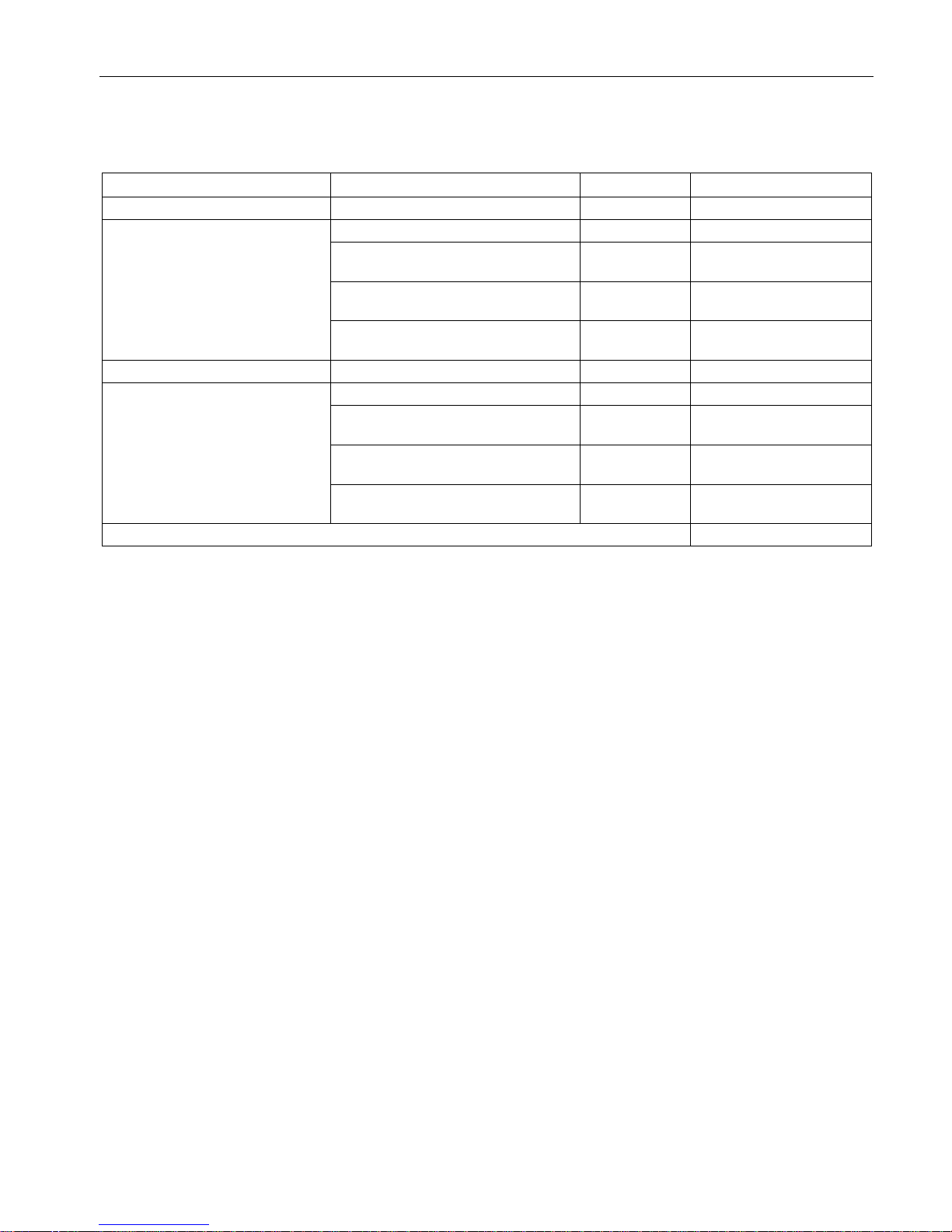

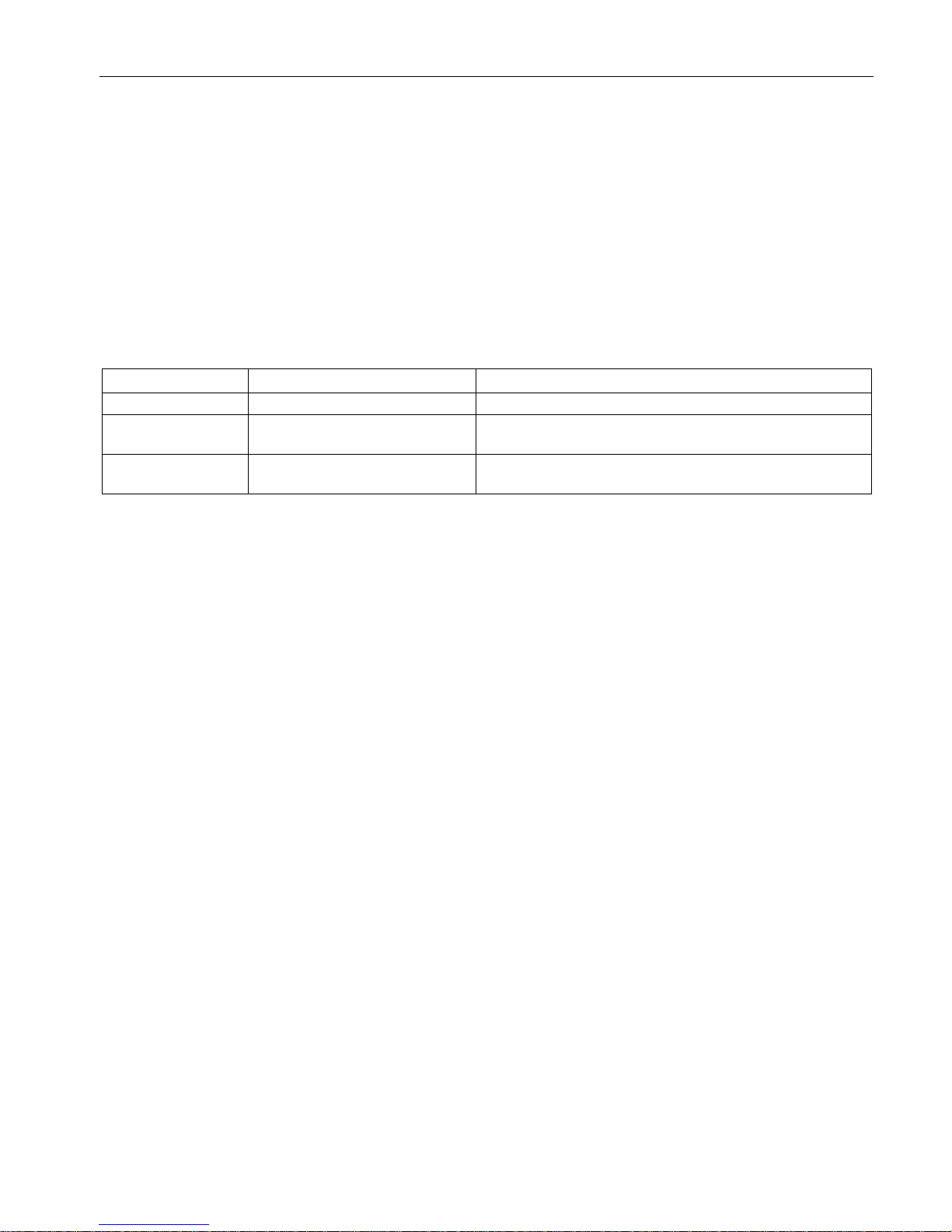

System versions and ordering options

System version

SIMATIC software

CFast card

Article number

WES7 E 32Bit

CPU 1505SP V2.1

30 GB

6ES7677-2AA31-0EB0

WES7 P 64Bit

(multitouch functionality)

CPU 1505SP V2.1 30 GB 6ES7677-2AA41-0FB0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 128PT

30 GB 6ES7677-2AA41-0FK0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 512PT

30 GB 6ES7677-2AA41-0FL0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 2048PT

30 GB 6ES7677-2AA41-0FM0

WES7 E 32Bit

CPU 1505SP F V2.1

30 GB

6ES7677-2FA31-0EB0

WES7 P 64Bit

(multitouch functionality)

CPU 1505SP F V2.1

30 GB

6ES7677-2FA41-0FB0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 128PT

30 GB 6ES7677-2FA41-0FK0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 512PT

30 GB 6ES7677-2FA41-0FL0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 2048PT

30 GB 6ES7677-2FA41-0FM0

CPU 1515SP PC, spare part, without CFast card, without software

6ES7677-2AA40-0AA0

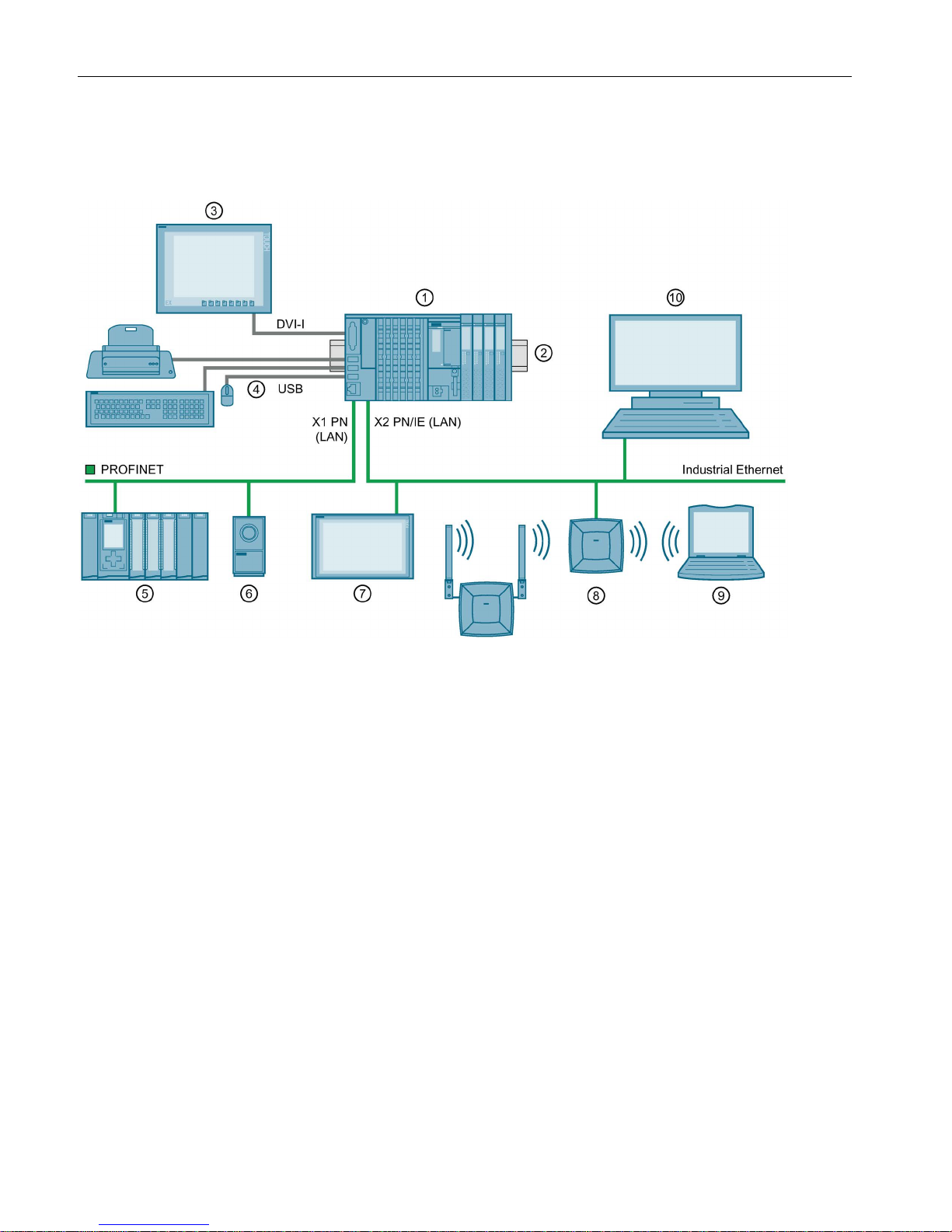

3.3

Sample configuration

Configuration

CPU 1515SP PC (F) is mounted on the mounting rail according to EN 60715. A modular

system is formed with ET 200SP modules in the central rack.

You can use the CPU 1515SP PC (F) as PROFINET IO controller. The PROFINET IO

devices are connected with the SIMATIC BusAdapter BA 2xRJ45 via the ports of the

interface X1 PN (LAN).

Devices can be connected via Industrial Ethernet using the integrated interface

X2 PN/IE (LAN).

The connection to PROFIBUS can be made using the DP master module.

Page 22

Product overview

3.3 Sample configuration

CPU 1515SP PC (F)

22 Manual, 05/2017, A5E32701806-AC

Sample configuration

The figure below shows an example configuration with CPU 1515SP PC (F).

Figure 3-2 Example configuration with the CPU 1515SP PC (F)

①

CPU

1515SP PC (F), I/O module, server module

②

Mounting rail

③

Flat Panel

- Wide Screen Display

④

USB devices: Keyboard, mouse, printer ...

⑤

PROFINET IO device

⑥

Camera

⑦

Industrial Thin Client ITC

⑧

SCALANCE W786

⑨

Field programming device

⑩

P

C/Programming device

Page 23

Product overview

3.4 Components

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

23

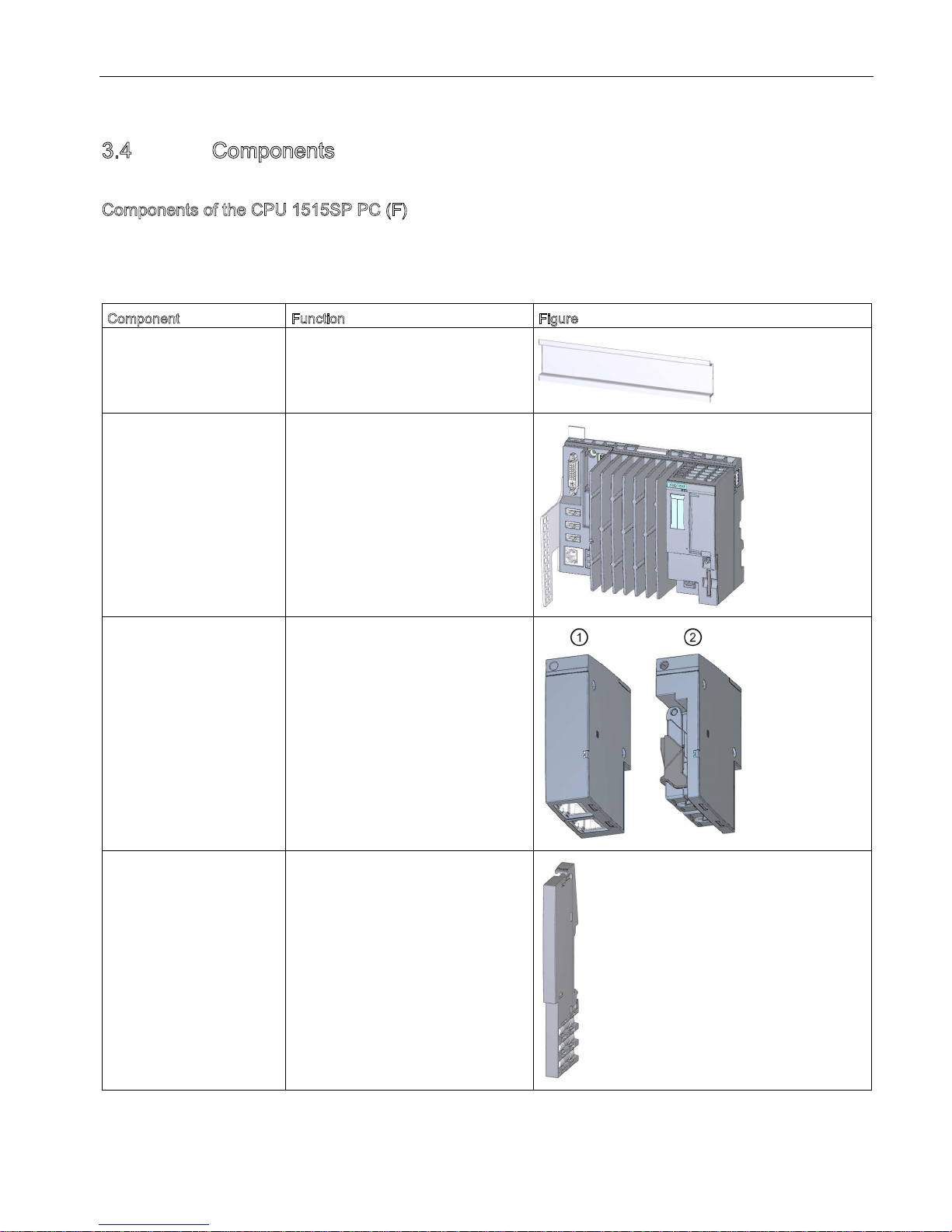

3.4 Components

Components of the CPU 1515SP PC (F)

The table below contains an overview of the components of the CPU 1515SP PC (F):

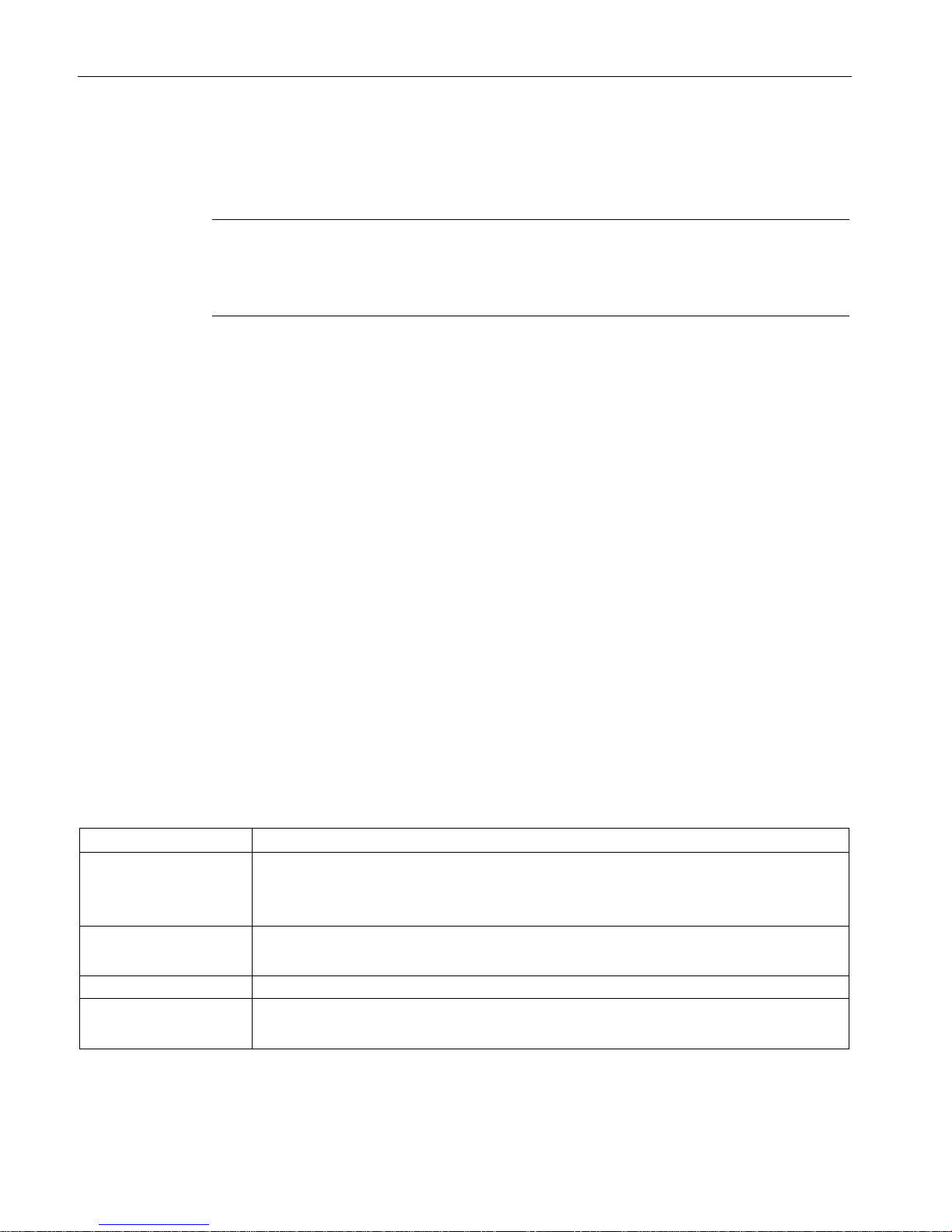

Table 3- 1 Components of the CPU 1515SP PC

Component

Function

Figure

Mounting rail in accordance

with EN 60715

The mounting rail is the module carrier for the CPU 1515SP PC (F).

CPU 1515SP PC (F) CPU with strain relief and white refer-

ence labels

BusAdapter The BusAdapter allows free selection

of the connection technology for

PROFINET IO. The following versions

are available for CPU 1515SP PC (F):

• For standard RJ45 plug

(BA 2×RJ45)

①

• For direct connection of the bus

cable (BA 2×FC) ②

Server module The server module completes the

configuration of the

CPU 1515SP PC (F) with I/O modules.

The server module is included in the

CPU's scope of delivery.

Page 24

Product overview

3.5 Configuration of the devices

CPU 1515SP PC (F)

24 Manual, 05/2017, A5E32701806-AC

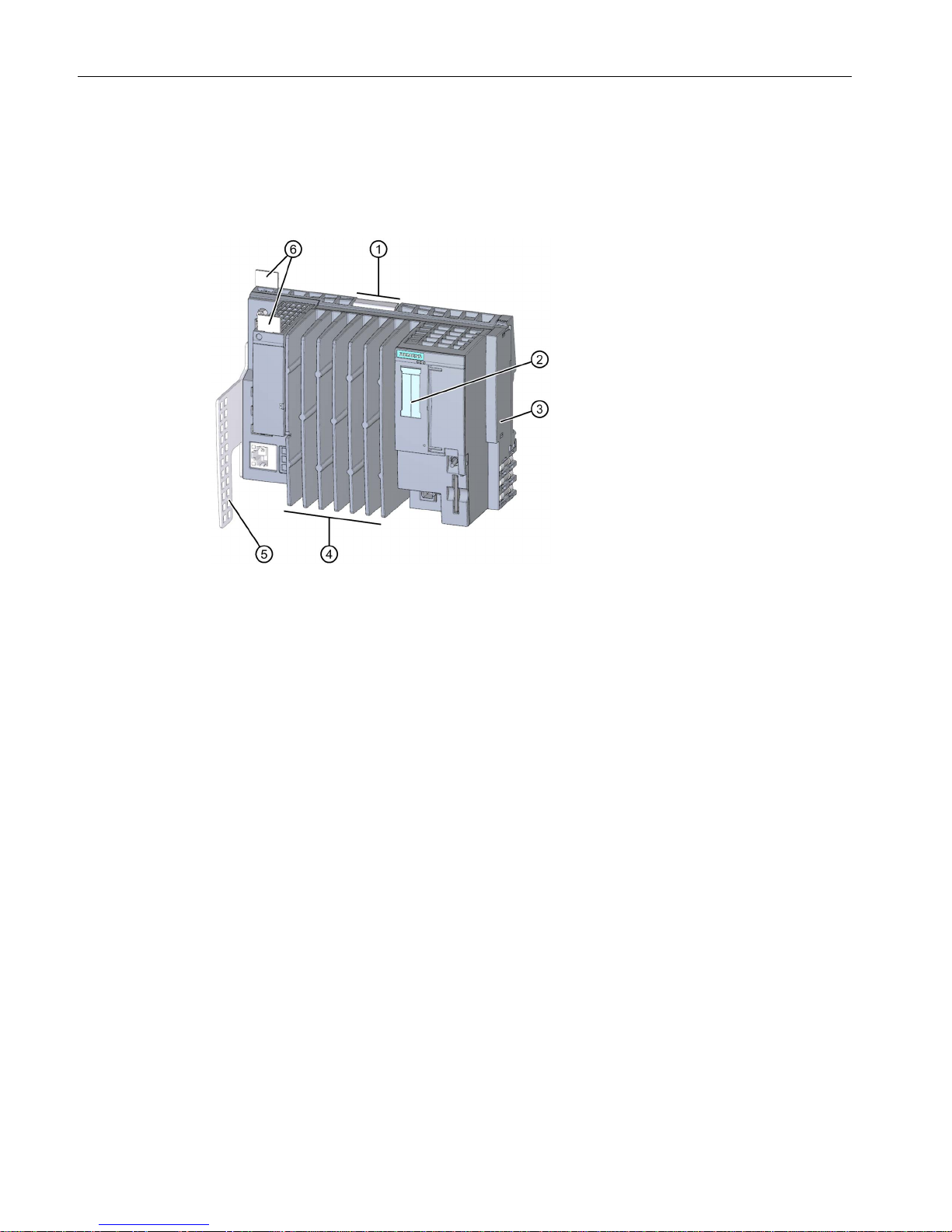

3.5

Configuration of the devices

Front view

Figure 3-3 Front view CPU 1515SP PC (F)

① Mounting rail release mechanism

② Labeling strips

③ Server module

④ Cooling fins

⑤ Strain relief

⑥ Reference labels

Page 25

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

25

3.6

Operator controls and display elements

Front view of the module

The figure below shows the operator control and connection elements of the

CPU 1515SP PC (F).

Figure 3-4 View of the CPU 1515SP PC (F)

①

LED displays for the current operating mode and diagnostic status of the CPU

②

Power LED

③

X50:

Slot for the CFast card (flash memory), sealable

④

Mode selector

⑤

X51:

Slot for an optional SD/MMC card

⑥

X80:

Connector for 24 V DC supply voltage

⑦

X1 PROFINET

(LAN):

Slot for BusAdapter for connection of PROFINET IO;

status display for PROFINET

⑧

X2 PN/IE (LAN):

GbE Ethernet connection with integrated display

⑨

X60, X61, X62:

3 USB connections

⑩

X70 DVI-I:

Connection for monitor

Page 26

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

26 Manual, 05/2017, A5E32701806-AC

Slot for CFast card

The operating system, Runtime software and project are installed on the supplied SIMATIC

CFast card. The CFast card is the only mass storage device of the CPU 1515SP PC (F).

Note

Unauthorized access

Seal the cover of the shaft with lead to protect the CFast card with the operating system of

the CPU

1515SP PC (F) against unauthorized access and manipulation.

Slot for SD/MMC card

You can use a SIMATIC SD or MMC card as additional storage drive. This drive can be used

to store data via Windows, for example a backup, but not the operating system, the Runtime

software or the project.

Permitted SD cards: SDHC up to 32 GB, SDXC up to 2 TB.

USB connections

Two USB high-current (500 mA) interfaces and one low-current (100 mA) interface can be

used at the same time.

MAC addresses

The MAC address consists of a 3-byte manufacturer ID and a 3-byte device ID (consecutive

number).

Each device is already assigned four MAC addresses in the factory. The front of the CPU

1515SP PC (F) is lasered with the MAC addresses 1 and 4. With the MAC addresses 2 and

3, the consecutive numbers are incremented. If, for example, the first MAC address is

08-00-06-6B-80-C0, the second MAC address is 08-00-06-6B-80-C1.

Table 3- 2 Assignment of the MAC addresses

Assignment

MAC address 1

X2 PN/IE (LAN)

• Visible in STEP 7 for accessible devices

• Lasered on the front of the CPU (start of the number range)

MAC address 2

X1 PROFINET (LAN)

• Visible in STEP 7 for accessible devices

MAC address 3

Port X1 P1 (required for LLDP, for example)

MAC address 4

Port X1 P2 R (required for LLDP, for example)

• Lasered on the front of the CPU (end of the number range)

Page 27

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

27

Connector for supply voltage

CPU 1515SP PC (F) has a 2-pole terminal for the power supply.

The connection plug for the supply voltage is plugged in when the CPU is shipped from the

factory.

Mode selector

Use the mode selector to set the CPU operating mode.

Table 3- 3 Mode selector positions

Position

Meaning

Description

RUN

Operating mode RUN1

The CPU is processing the user program.

STOP Operating mode STOP1 The CPU is not processing the user program.

The outputs are set to a "safe" state.

MRES Memory reset

For active S7-1500 software controller

2

only:

CPU memory reset

1

RUN and STOP indicate the

selected

operating state. The LED displays RUN and STOP display the

actual

operating

state of the CPU 1515SP PC (F).

2

See the S7-1500 software controller manual

Page 28

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

28 Manual, 05/2017, A5E32701806-AC

3.7

Scope of delivery

3.7.1

Unpacking the device

When unpacking

When unpacking, make sure to check the following:

● Check packaging and contents for visible damage from transport.

● Check the delivery for completeness.

Please inform your Siemens contact partner should you determine damages from

transport or any irregularities.

● Keep the supplied documentation and licenses. They belong to the device and are the

proof that you have purchased the software preinstalled on the CFast card.

Documentation and licenses are required for initial commissioning and for any questions

that arise.

● Keep the original packaging in case the device needs to be transported again.

NOTICE

Damage to the device during transport and storage

If a device is transported or stored without packaging, it is unprotected from shocks,

vibrations, pressure and moisture. Damaged packaging indicates that environmental

conditions have already had a significant impact on the device.

The device might be damaged.

Do not dispose of the original packaging. Pack the device for transport and storage.

NOTICE

Damage to the device caused by condensation

If the device was exposed to low temperatures or extreme variations in temperature during

transport, this may cause moisture to build up on or in the device (condensation).

Moisture can cause short-circuits in the electrical circuits and damage the device.

Proceed as follows to avoid damage:

• Store the device in dry conditions.

• Make sure it adapts to room temperature before commissioning.

• Do not expose the device to direct heat radiation from a heater.

• If condensation has developed, wait for approximately 12 hours or until the device is

completely dry before you switch it on.

Page 29

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

29

WARNING

Electric shock and fire hazard from damaged device

A damaged device can carry dangerous voltage and trigger a fire in the machine or plant. A

damaged device has unpredictable properties and states.

Death or severe injury could occur.

Make sure that the damaged device is not installed and commissioned accidentally. Label

the damaged device correspondingly and keep it locked up. Have the device repaired

without delay.

Identification data

The identification data can be used to clearly identify the device when a repair is necessary.

Make a note of the following data for your devices:

● The article number of the CPU 1515SP PC (F) is located on the order form.

● Depending on the scope of delivery, the "Certificate-of-License" is included in the license

verification for the S7-1500 software controller and for WinCC Runtime Advanced V14

SP1.

● The "Microsoft Windows Product Key" can be found on the "Certificate of Authenticity"

label.

● The first and the last MAC addresses are located on the device.

Page 30

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

30 Manual, 05/2017, A5E32701806-AC

3.7.2

Scope of delivery - System version WES7 E 32Bit 4GB RAM

Note

The designation CPU 1515SP PC

with the article number 6ES7677

-2AA40-0AA0

is always

on the device regardless of the order option.

The following components are included in the scope of delivery of the CPU 1515SP PC:

Order option

CPU 1515SP PC

CPU 1515SP PC

(spare part)

Article number

6ES7677-2AA31-0EB0

6ES7677-2AA40-0AA0

CPU

X

X

Strain relief with fixing screws

X

X

Server module

X

X

30 GB CFast card with the following

pre-installations:

• Windows Embedded Standard 7 E

operating system

X –

• S7-1500 Software Controller

CPU 1505SP

X –

• WinCC RT Advanced as of V14

SP1

– –

Restore DVD for image restore

X

–

"Documentation and Drivers" DVD

X

–

Windows-Certificate of Authenticity

(CoA)

X –

Certificate of License (COL)

X – USB stick with SIMATIC license keys

X

–

Product information

X

–

Page 31

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

31

The following components are contained in the scope of delivery of the CPU 1515SP PC F:

Order option

CPU 1515SP PC F

Article number

6ES7677-2FA31-0EB0

CPU X

Strain relief with fixing screws

X

Server module

X

30 GB CFast card with the following pre-installations:

• Windows Embedded Standard 7 E operating system

X

• S7-1500 Software Controller CPU 1505SP F

X

• WinCC RT Advanced as of V14 SP1

–

Restore DVD for image restore

X

"Documentation and Drivers" DVD

X

Windows-Certificate of Authenticity (CoA)

X

Certificate of License (COL)

X

USB stick with SIMATIC license keys

X

Product information

X

Page 32

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

32 Manual, 05/2017, A5E32701806-AC

3.7.3

Scope of delivery - System version WES7 P 64Bit 4GB RAM

Note

The designation CPU 1515SP PC

with the article number 6ES7677

-2AA40-0AA0

is always

on the device regardless of the order option.

The following components are included in the scope of delivery of the CPU 1515SP PC:

Order option

CPU 1515SP PC

CPU 1515SP PC + HMI

CPU 1515SP PC

(spare part)

Article number 6ES7677-2AA41-0FB0 6ES7677-2AA41-0FK0 HMI

128PT

6ES7677-2AA41-0FL0 HMI

512PT

6ES7677-2AA41-0FM0 HMI

2048PT

6ES7677-2AA40-0AA0

CPU

X X X

Strain relief with fixing

screws

X X X

Server module

X X X

30 GB CFast card with the

following pre-installations:

• Win-

dows Embedded Standar

d 7 P operating system

X X –

• S7-1500 Software Con-

troller CPU 1505SP

X X –

• WinCC RT Advanced as

of V14 SP1

– X –

Restore DVD for image re-

store

X X –

"Documentation and Drivers"

DVD

X X –

Windows Certificate of Au-

thenticity (CoA)

X X –

Certificate of License (CoL)

X X –

USB stick with SIMATIC

license keys

X X –

Product information

X X –

Page 33

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

33

The following components are contained in the scope of delivery of the CPU 1515SP PC F:

Order option

CPU 1515SP PC F

CPU 1515SP PC F + HMI

Article number 6ES7677-2FA41-0FB0 6ES7677-2FA41-

• 0FK0 HMI 128PT

• 0FL0 HMI 512PT

• 0FM0 HMI 2048PT

CPU X X

Strain relief with fixing screws

X

X

Server module X X

30 GB CFast card with the following

pre-installations:

• Windows Embedded Standard 7 P

operating system

X X

• S7-1500 Software Controller CPU

1505SP F

X X

• WinCC RT Advanced as of V14

SP1

– X

Restore DVD for image restore

X X "Documentation and Drivers" DVD

X

X

Windows Certificate of Authenticity

(CoA)

X X

Certificate of License (CoL)

X

X

USB stick with SIMATIC license keys

X X Product Information

X

X

Page 34

CPU 1515SP PC (F)

34 Manual, 05/2017, A5E32701806-AC

4

4.1

Basics

Introduction

The CPU 1515SP PC (F) is an open operation resource. This means that you may only

install it in enclosures, cabinets or electrical operating areas. These housings, cabinets or

electrical operating areas must only be accessible with a key or tool. Access may only be

possible for instructed or authorized personnel.

Installation location

CPU 1515SP PC (F) must be installed in a suitable enclosure or suitable control cabinet with

at least IP54 degree of protection according to EN 60529 and the ambient conditions for the

operation of the equipment must be taken into consideration.

Installation position

You can install the ET 200SP distributed I/O system in any position. The preferred mounting

position is horizontal mounting on a vertical wall.

The restrictions regarding ambient temperature and maximum configuration apply to the

CPU 1515SP PC (F) depending on the mounting position.

NOTICE

Damage to the modules

Modules can be damaged if exposed to ambient temperatures higher than permitted.

The following ambient temperatures must not be exceeded during operation:

• Horizontal mounting

– 60 °C for an installation with up to 32 I/O modules.

– 55 °C for an installation with up to 64 I/O modules.

• Vertical mounting

– 50 °C for an installation with up to 32 I/O modules.

For more detailed information, refer to section Mechanical and climatic ambient conditions

(Page 108)

Page 35

Installing

4.1 Basics

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

35

Mounting rail

CPU 1515SP PC (F) is mounted on a mounting rail according to EN 60715 (35 × 7.5 mm

and/or 35 × 15 mm).

You must ground the mounting rail separately in the control cabinet. Exception: If you install

the rail on grounded, zinc-plated mounting plates, there is no need to ground the rail

separately.

Note

If the ET 200SP distributed I/O system is exposed to vibration and shock loads, both ends of

the ET 200SP system assembly must be mechanically fixed to the mounting rail (e.g using

8WA1010

-1PH01 ground terminals). This measure prevents the ET 200SP from shifting to

the side.

Note

If the ET 200SP distributed I/O system is exposed to high vibration and shock load, we

recommend that you screw the mounting rail to the mounting surface at interval

s of approx.

200 mm.

Suitable surface finishes are:

● Steel strip in accordance with Appendix A of EN 60715 or

● Tinned steel strip. We recommend the use of the mounting rails in section

Accessories/spare parts (Page 133).

Note

Mounting rails of other manufacturers

If you use mounting rails from other manufacturers, ensure that they have the properties

required for your climatic and mechanical a

mbient conditions.

Check whether the mounting rails meet the requirements for a protective conductor.

Page 36

Installing

4.1 Basics

CPU 1515SP PC (F)

36 Manual, 05/2017, A5E32701806-AC

Minimum clearances

Maintain the following minimum clearances when installing or dismantling the

CPU 1515SP PC (F).

Figure 4-1 Minimum clearances

Installation rules

● After the CPU 1515SP PC (F) there is a BaseUnit BU..D with incoming supply voltage L+

(light terminal box).

● This is followed by BaseUnits BU..B (with dark-colored terminal box).

● The respective corresponding I/O modules can be connected to the BaseUnits.

Suitable combinations of BaseUnits and I/O modules can be found in the ET 200SP

System Manual (http://support.automation.siemens.com/WW/view/en/84133942).

● The server module completes the installation.

Note

Only install the CPU

1515SP PC (F) when the power supply is switched off.

Page 37

Installing

4.2 Hardware configuration

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

37

4.2

Hardware configuration

Maximum mechanical configuration

As soon as one of the following rules applies, the maximum configuration has been reached:

Table 4- 1 Maximum mechanical configuration

Properties

Rule

Number of modules

• Horizontal mounting

– 0 to 60 °C ambient temperature:

a maximum of 32 I/O modules

and

USB load

– 0 to 55 °C ambient temperature:

a maximum of 64 I/O modules

and

USB load

• Vertical mounting

– 0 to 50 °C ambient temperature:

a maximum of 32 I/O modules

and

USB load

Backplane bus length Maximum 1 m mounting width (without CPU 1515SP PC (F), including

server module)

Electrical maximum configuration

The number of operable I/O modules of a potential group is limited by the

● Power consumption of the I/O modules

● Power consumption of the components supplied via these I/O modules

The maximum current-carrying capability of the terminals on the BaseUnit L+/ground is 10 A.

USB load

In case of maximum configuration with the CPU 1515SP PC (F), the USB load must also be

taken into consideration:

● Horizontal mounting

– Ambient temperature of 0 to 60 °C with maximum 32 I/O modules

and

3 x 100 mA

USB load

– Ambient temperature of 0 to 55 °C with maximum 64 I/O modules

and

2 x 500 mA +

1 x 100 mA USB load

● Vertical mounting

– Ambient temperature of 0 to 50 °C with maximum 32 I/O modules

and

3 x 100 mA

USB load

Address space

The address space is predefined. However, you can adjust the address space in the user

program.

Page 38

Installing

4.3 Installing CPU 1515SP PC (F)

CPU 1515SP PC (F)

38 Manual, 05/2017, A5E32701806-AC

4.3

Installing CPU 1515SP PC (F)

Requirements

The mounting rail is fitted.

Required tools

3 to 3.5 mm screwdriver (only to fix the strain relief and dismantle the BusAdapter)

Fixing strain relief

Fasten the strain relief at the upper and lower left side of the CPU 1515SP PC (F) with the

supplied screws.

Installing CPU 1515SP PC (F)

1. Install the CPU on the mounting rail.

2. Swivel the CPU back until you hear the mounting rail release click into place

3. To check that the CPU has correctly clicked into place, pull on the underside of the

enclosure.

Figure 4-2 Installing CPU 1515SP PC (F)

Page 39

Installing

4.3 Installing CPU 1515SP PC (F)

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

39

Disassemble CPU 1515SP PC (F)

The BaseUnits with the I/O modules are located to the left of the CPU 1515SP PC (F):

1. Switch off the supply voltage on the CPU.

2. Press the mounting rail release button on the first BaseUnit and, at the same time, move

the CPU in parallel to the left until it comes off the remaining the module group.

Note: The mounting rail release button is located above the CPU.

3. While pressing the mounting rail release button on the CPU, swivel the CPU out of the

mounting rail.

Note

It is not necessary to remove the BusAdapter from the CPU

1515SP PC (F).

Page 40

CPU 1515SP PC (F)

40 Manual, 05/2017, A5E32701806-AC

5

5.1

Notes on connection

Note

Rules and regulations for operation

Observe the information contained in the

Wiring

section in the system manual ET 200SP

distributed I/O system (

http://support.automation.siemens.com/WW/view/en/58649293) and

in the function manual Designing interference

-free controllers

(

http://support.automation.siemens.com/WW/view/en/59193566).

NOTICE

Fault caused by I/O devices

The connection of I/O devices can lead to faults on the device.

Injury to persons and damage to the machine or plant could result.

Note the following when connecting I/O devices:

• Read the documentation related to the I/O devices. Follow all instructions given in the

documentation.

• Only connect I/O devices which are suitable for use in industrial environments according

to EN 61000-6-2/EC 61000-6-2.

• You may only connect hot-plug capable I/O devices when the power supply is switched

off.

Note

Feedback through USB devices

If USB devices are connected which

- contrary to the USB 2.0 specification - feed voltage

back to the host interface, the startup of the CPU

1515SP PC (F) is not ensured upon power

-

up.

Regenerative feedback

is generally not permitted.

Page 41

Connection

5.2 Terminal and block diagram

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

41

5.2

Terminal and block diagram

Block diagram

The figure below shows the block diagram of the CPU 1515SP PC (F).

①

Switch

X1 PN (LAN)

PROFINET interface X1

②

Electronics

P1

PROFINET interface X1 Port 1

③

Backplane bus interface

P2

PROFINET interface X1 Port 2

④

Internal supply voltage

L+

24 V DC supply voltage

⑤

Mode selector

M

Ground

X50

CFast card

LK1, LK2

LED Link TX/RX

X51

SD/MMC card

LK3

LED Link

X60

USB interface 2.0, 0.5 A

R/S

RUN/STOP LED (yellow/green)

X61, X62

USB interface 2.0, 0.5 A

ER

ERROR LED (red)

X70

DVI-I interface

MT

MAINT LED (yellow)

X80 24 V DC

Infeed of supply voltage

PWR

POWER LED (yellow/green)

X2 PN/IE (LAN)

Ethernet interface X2

Figure 5-1 Block diagram for CPU 1515SP PC (F)

Page 42

Connection

5.3 Electrical configuration

CPU 1515SP PC (F)

42 Manual, 05/2017, A5E32701806-AC

5.3

Electrical configuration

Non-isolated configuration

Note

Unlike the distribution I/O system ET

200SP, only a non-isolated configuratio

n is possible the

CPU

1515SP PC (F).

Page 43

Connection

5.3 Electrical configuration

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

43

The figure below shows a CPU 1515SP PC (F) in the overall configuration with infeed from a

TN-S system. The power supply supplies the CPU 1515SP PC (F) and the load circuits for

the 24 V DC modules.

With the CPU 1515SP PC (F) there is a fixed connection between the ground infeed terminal

and the contact springs to the mounting rail. You must ground the mounting rail separately in

the control cabinet.

①

Master switch

②

Short-circuit and overload protection

③

Load current supply (galvanic isolation)

④

In the CPU 1515SP PC (F), this connection is automatically established.

The represented layout of the power connections does not correspond to the actual layout; it

was chosen for demonstration purposes only.

Figure 5-2 Connecting the load voltage reference potential

Page 44

Connection

5.4 Connecting devices to networks

CPU 1515SP PC (F)

44 Manual, 05/2017, A5E32701806-AC

5.4 Connecting devices to networks

The following options are available for integrating devices into existing or planned system

environments and networks.

Ethernet

You can use the integrated Ethernet interface X2 PN/IE (LAN) (10/100/1000 Mbps) for

communication and data exchange with automation devices, for example, SIMATIC S7.

Only ASCII characters are permitted in the name of the interface X2 PN/IE (LAN) in the

TIA Portal, e.g. PROFINET_2.

You need suitable software to do this: STEP 7, WinCC, SIMATIC NET.

N

ote

Use a Category 5e Ethernet cable (Cat

-5e cable) for operation with 1000 Mbps.

PROFINET

PROFINET operation is possible via the X1 PN (LAN) interface and the approved

BusAdapter.

PROFIBUS

The connection to PROFIBUS can be made using the DP master module.

5.5 Securing cables

The strain relief for connection lines prevents the USB and the PROFINET connector coming

loose from the CPU 1515SP PC (F). The strain relief is included in the scope of delivery.

WARNING

Flying sparks due to loose cables

Risk of explosion in hazardous areas.

USB cables and PROFINET connectors may detach from the device in the case of strong

oscillation and high vibrating loads.

Attach these cables to the strain relief of the device using cable ties.

Page 45

Connection

5.5 Securing cables

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

45

Requirements

● The strain relief is fixed to the CPU.

● The CPU is installed.

Procedure

Secure the USB and PROFINET cables to the strain relief using cable ties.

Figure 5-3 Secured cables

Page 46

CPU 1515SP PC (F)

46 Manual, 05/2017, A5E32701806-AC

6

6.1

Status and error display

LED display

The figure below shows the LED displays of the CPU 1515SP PC (F).

①

RUN/STOP LED (yellow/green LED)

②

ERROR LED (red LED)

③

MAINT LED (yellow LED)

④

POWER LED (yellow/green LED)

Figure 6-1 LED displays of the CPU 1515SP PC (F).

Page 47

Diagnostics, error and system alarm

6.1 Status and error display

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

47

Meaning of the LED displays with active software controller

CPU 1515SP PC (F) has a display of the current operating state and of the diagnostics

status (three LEDs).

The following table shows the meaning of the color combinations of the LED displays in

connection with the software controller.

Table 6- 1 Meaning of the LED displays

RUN/STOP LED

ERROR LED

MAINT LED

Meaning

LED off

LED off

LED off

POWER OFF

Starting of the CPU 1515SP PC (F) in

the "Windows only" mode

No power supply.

The software controller of the

CPU 1515SP PC (F) has not been downloaded or the

software controller of the

CPU 1515SP PC (F) is in the operating

state Power OFF.

LED off

LED flashes red

LED off

An error has occurred.

LED green

LED off

LED off

Software controller of the

CPU 1515SP PC (F) is in RUN mode.

LED green

LED flashes red

LED off

A diagnostics event is pending.

LED green

LED off

LED lights up

yellow

Maintenance demanded for the plant.

The affected hardware must be ex-

changed within a short period.

LED green

LED off

LED flashes yel-

low

Maintenance required for the plant.

You must exchange the affected hard-

ware within a foreseeable period.

Firmware update successfully completed

LED lights up

yellow

LED off

LED off

Software controller of the CPU is in the

operating state STOP.

LED lights up

yellow

LED flashes red LED flashes yel-

low

The user program is causing an error.

CPU defective

LED flashes yel-

low

LED off

LED off

CPU is performing internal activities

during STOP, e.g. ramp-up after STOP.

Loading the user program

LED flashes

yellow/green

LED off

LED off

Startup (transition from RUN → STOP)

Page 48

Diagnostics, error and system alarm

6.1 Status and error display

CPU 1515SP PC (F)

48 Manual, 05/2017, A5E32701806-AC

RUN/STOP LED

ERROR LED

MAINT LED

Meaning

LED flashes

yellow/green

LED flashes red LED flashes yel-

low

Startup (CPU booting)

Test of LEDs during startup, inserting a

module.

LED flashing test

POWER LED

Table 6- 2 POWER LED

POWER LED

Meaning

LED off

No supply voltage or supply voltage too low

LED lights up yellow

Supply voltage present;

running through BIOS phase;

operating system is shut down

LED green

Supply voltage present;

Booting or operation of the operating system

Page 49

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

49

Commissioning

7

7.1 Notes on commissioning

WARNING

Improper commissioning in hazardous areas

Device failure or risk of explosion in hazardous areas.

• Do not commission the device unless it is fully mounted and connected according to the

specifications in the section Enhanced Write Filter (EWF) (Page 78).

• Before commissioning, please consider the effects on other devices in the plant.

CAUTION

Hot surfaces

Risk of burns due to hot surfaces.

During operation, only touch the device with appropriate protective gloves.

N

OTICE

Condensation in the device

Damage to the device due to condensation if the temperature between transport or storage

and the installation site differs by more than 20 °C (36 °F).

Before commissioning the device, leave it to stand for several hours in the new

environment.

N

OTICE

Data loss

Data loss may occur if write filters are used incorrectly.

Therefore, note the information on write filters.

Two write filters are available for configuration under Windows Embedded:

• Enhanced Write Filter (Page 78)

• File Based Write Filter (Page 82)

Page 50

Commissioning

7.2 Initial commissioning

CPU 1515SP PC (F)

50 Manual, 05/2017, A5E32701806-AC

7.2

Initial commissioning

Requirements

The following conditions must be met before you commission the open controller for the first

time.

● CPU 1515SP PC (F) is mounted.

● The CFast card is inserted.

● No data carriers are connected via USB.

● The following hardware is available: A monitor, a USB keyboard, a USB mouse

Procedure

1. Connect a monitor via a DVI-I cable.

2. Connect a keyboard and a mouse to the CPU via USB.

3. Connect the power supply.

→ The PWR LED lights up yellow first, then green.

→ The device carries out the hardware initialization.

4. Wait until the Siemens logo disappears from the screen.

5. Follow the instructions on the screen to configure the device

NOTICE

Faulty installation

If you change the default values in the BIOS Setup or switch off the device during the

installation, the installation will be disrupted and the operating system will not be installed

correctly. The operational reliability of the device and the plant is endangered.

Do not switch of the device during the entire installation process. Do not change the default

values in the BIOS Setup.

Result

● The WES7 operating system is installed.

● WES7 P: The Multitouch functions are available.

● The operating system's start screen is displayed after each startup.

● A login window appears if a password was entered during the initial commissioning.

Page 51

Commissioning

7.2 Initial commissioning

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

51

Initial commissioning an open controller

The basic settings, user name, administrator password and IP address are prompted for

during initial power-up of your CPU 1515SP PC (F). The device is then automatically set up

for the operating system that is installed on the CFast card. Restart the device after the

operating system has been set up.

Note

The initial commissioning is not possib

le with a Multitouch panel, as the Multitouch driver is

only available after the installation of the operating system.

User name, computer name, password

When you enter a "User name", this is suffixed with "-PC" under "Computer name". The

computer name must not exceed 15 characters.

Note

This user has administrator rights!

For security reasons, enter a password for this user (administrator).

IP address

The IP address (192.168.1.1) and the subnet mask (255.255.255.0) for the X2 interface are

pre-set in the logon dialog.

You use the buttons to make your changes or to retain the pre-set values.

Note

The initial TIA Portal download must be performed using set IP address via the GB Ethernet

interface X2 in order that the PROFINET interface X1 and the

hardware configuration are

correctly assigned.

Page 52

Commissioning

7.2 Initial commissioning

CPU 1515SP PC (F)

52 Manual, 05/2017, A5E32701806-AC

User "Operator"

A user "Operator" with standard user rights is already created on the Windows system.

The user is in a user group "SIEMENS TIA Engineer". This grants the user the rights to use

the installed SIMATIC software products.

To be able to use the CPU 1515SP PC (F) directly, the Windows "Autologon" is activated for

the user "Operator". No password is preset.

Note

When you assign a password, change the entry for the Windows "Autologon" function

ac

cordingly in order that the function remains activated.

Administrator rights

You need administrator rights for the following actions:

● Back up the data in the root directory of the C partition.

● Installing the language pack

Screen resolution

In Windows Embedded Standard 7, the values that are determined for the monitor via the

DVI-I interface are set for the screen resolution.

Page 53

Commissioning

7.3 Initial configuration of an Open Controller

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

53

7.3

Initial configuration of an Open Controller

Creating the configuration

You have created a new project in the TIA Portal.

To create the configuration in the TIA Portal, follow these steps:

1. Double-click "Add new device" in the project tree.

2. In "PC-Systeme > SIMATIC S7 Open Controller > ET 200SP Open Controller >", select

the "CPU 1515SP PC (F) (+HMI)".

3. Select the appropriate version.

The configured Open Controller is displayed in the device view.

4. The following components can be seen in the Open Controller:

– Onboard interface X2 (GB Ethernet Windows interface) that is assigned directly to the

PC station (1 port)

– Replaceable BusAdapter X1, which is directly assigned to the software controller (2

ports)

– On the right side (behind the plugged modules in the rack): the configured software

controller CPU 1505SP (F) and WinCC Runtime Advanced.

5. Insert the server module.

The server module at the right end of the configuration forms the termination of the CPU

with the I/O modules.

Setting the IP addresses:

In the Inspector window under "Properties":

● Onboard interface X2: the configured, specified IP address is identical with the Windows

IP address that is set during the first commissioning on the open controller.

● BusAdapter X1: the configured, specified IP address is identical with the IP address that

is set during the first commissioning in the panel of the software controller (display

application).

Important properties of the Software Controller

Change the properties in the Inspector window under "Properties" if required:

● Selecting startup type

● System diagnostics

● Setting the storage location for retentive data

● Setting up copy protection

● Using the LEDs of the hardware

● Configuring the Web server

● Assigning interfaces for the communication

Page 54

Commissioning

7.3 Initial configuration of an Open Controller

CPU 1515SP PC (F)

54 Manual, 05/2017, A5E32701806-AC

Establish HMI connection