Page 1

Version: 05/2012

Getting Started

SINAMICS V60

Controlled Power Module (CPM60.1)

Page 2

Table of contents

General information

1.1 System overview ..........................................................

1.2 Safety notes..................................................................

1.3 Identification..................................................................

1.4 Technical data..............................................................

Installation

2.1 Mechanical installation..................................................

Commissioning

3.1.1 Main menu...................................................................

3.1.2 Function menu.............................................................

3.1.3 Setpoints from NC.......................................................

3.1.4 First commissioning.....................................................

3.1.5 System commissioning................................................

3.1 Commissioning............................................................

3.2 Parameter list................................................................

Troubleshooting

EN-3

EN-4

EN-6

EN-8

2.1.1 Mounting the drive.......................................................

2.1.2 Mounting the motor......................................................

2.2 Electrical installation.....................................................

2.3 Interface definition.........................................................

4.1 LED status indicators.....................................................

4.2 Alarms...........................................................................

4.3 Errors during drive self-test...........................................

4.4 Other faults....................................................................

1-NEdetratS gnitteG )1.06MPC( eludoM rewoP dellortnoC 06V SCIMANIS

EN-10

EN-19

EN-25

EN-19

EN-20

EN-22

EN-23

EN-24

EN-10

EN-12

EN-12

EN-16

2.4 Signal sequence example.............................................

EN-18

EN-29

EN-29

EN-32

EN-32

中文版请见第 CHS-1 至 CHS-34 页。

For the Chinese version, see pages CHS-1 to CHS-34.

CPM 的固件(软件)已更新为 V1.7。当前驱动器在缺省状态下较旧版具有更强的动

态性。如需回到旧版工作状态,可将当前缺省值重设为第二缺省值(见 3.1.2 节)。

The firmware (software) in the CPM is already updated to V1.7. Now the performance of the drive in the default status is more dynamic than that of the old version.

If you want the drive to work in the old status, you can change the current default

value to the second default value (see section 3.1.2).

Page 3

EN-2 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 4

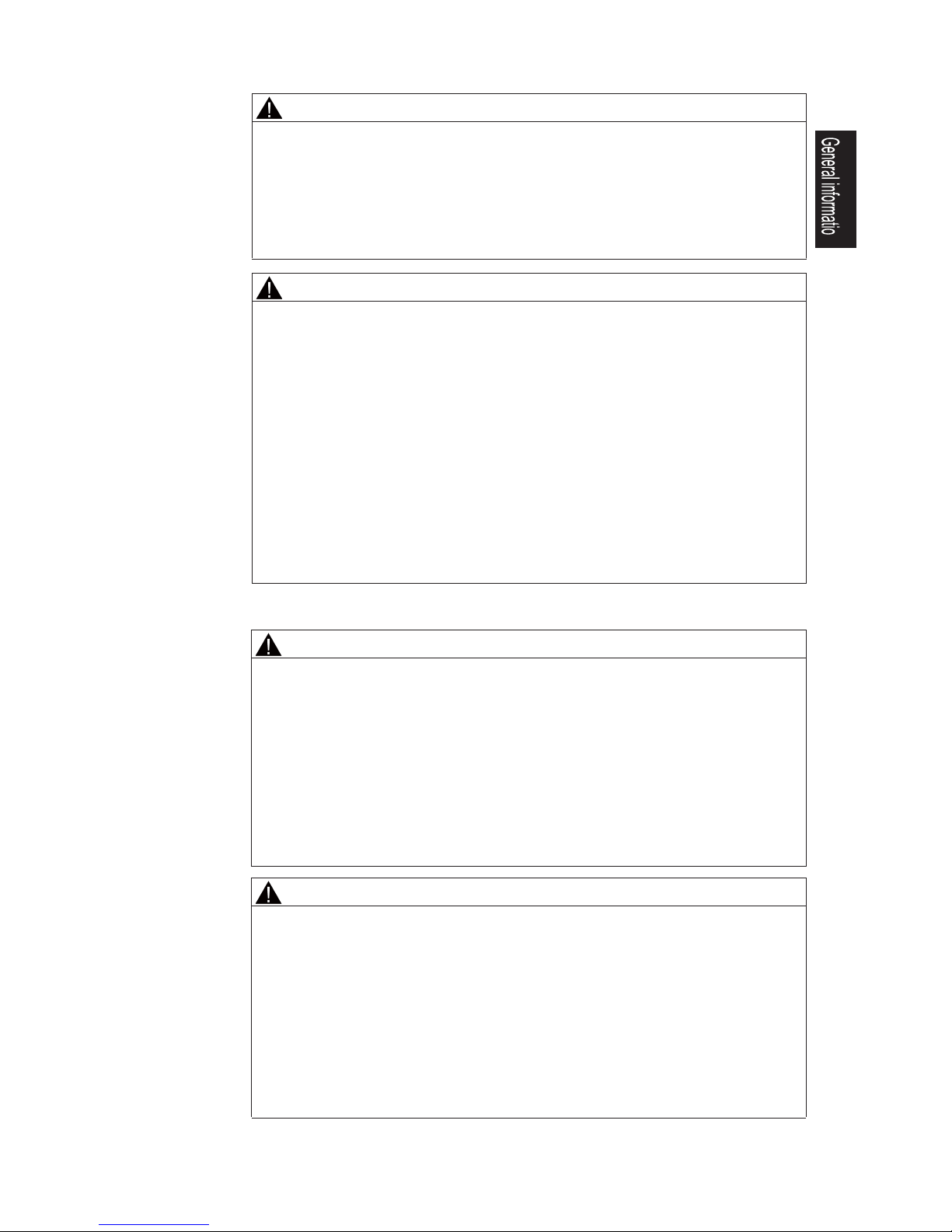

The SINAMICS V60 servo drive system is a new drive system developed by Siemens. It's designed for

use with a Siemens SINUMERIK 801 or SINUMERIK 802S base line numerical controller to control the

operation of a CNC turning or milling machine, and it can also be connected with a Siemens SIMATIC

PLC. Siemens delivers to each customer the whole drive system instead of only one drive device, which

includes: a drive module (CPM60.1, available in 4 A, 6 A, 7 A or 10 A version), an AC servo motor (type

1FL5, with or without a built-in brake and with or without a key ) and all necessary cables (for power,

encoder and brake, with a length of 5m or 10m).

The following picture illustrates possible system configuration

General Information

1.1 System Overview

3-NEdetratS gnitteG )1.06MPC( eludoM rewoP dellortnoC 06V SCIMANIS

or

or

or

Motor with brake Motor without brake

Brake cable

Motor cable

Encoder cable

Setpoint cable

SINUMERIK 801

SINUMERIK 802S base line

4 A/6 A/7 A

10 A

Page 5

1.2 Safety Notes

EN-4 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Only qualified personnel should be allowed to work on this drive system, and only after

becoming acquainted with all the safety notices regarding installing, connecting,

commissioning, operation and maintenance as set out in this manual. Failure to observe

these notices contained in this manual can result in death, severe personal injury or

considerable damage to property. Without prior authorization, you are not allowed to

perform any modification on the drive.

Deliverables received must be complete and intact. Exercise caution to ensure that you do

not put a damaged device into service. Make sure that the drive, the motor and the cables

received correspond with the specific drive package you ordered from Siemens.

Transport and storage must meet specified environmental conditions.

Do not handle the motor by gripping the connecting cable (motor cable, brake cable or

encoder cable) or the motor shaft.

Risk of fire or electric shock. Use caution to ensure that you do not install the drive and the

motor in an area which is subject to inflammables or combustibles, water or corrosion

hazards.

Do install the drive in a distribution cabinet with an adequate protection level.

Do not install the drive and the motor in a location where it is likely to be exposed to constant

vibrations or physical shocks.

Risk of fire. Make sure that no any foreign body (such as chips of wood or metal, dust, paper

scraps, etc.) falls into the drive or lies on its heatsink.

Keep sufficient clearance between drives, one drive and another device/inner wall of the

cabinet.

Siemens recommends that you tighten the screw on the terminal door of the drive, after you

have completed the installation work.

General

Identification

Transport & Storage

Mechanical installation

WARNING

WARNING

WARNING

CAUTION

CAUTION

NOTICE

Page 6

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-5

The drive must have been disconnected from the power supply for at least five minutes

before you perform any wiring to it.

Make sure that all connections are correct and reliable, and the drive and motor are always

properly grounded.

Do suppress radio interference according to EN61800, category C3 (for industrial

environment only).

SINAMICS V60 is an open-loop drive system, so it has no protection against wire breaks.

The drive must connect to the motor directly with no capacitor, inductor or filter, etc.

installed between them.

The mains supply voltage must fall in the range of voltage limits.

It is strictly prohibited to wire the mains input cable to motor terminals U, V, W or to wire a

motor cable to the line input terminals L1, L2, L3.

It is strictly prohibited to wire motor terminals U, V.W on the drive in an incorrect phase

sequence.

If the whole system has to be qualified with CE mark, please use shielded cables for motor

cable, mains input cable and brake cable.

Always install a 380 V three-phase AC isolating transformer at a mains supply network for

protective separation.

Route signal cables separately from power cables and lay them in different cable conduits.

Keep the signal cables a minimum of 10 cm away from the power cables.

Keep cables already connected away from rotating mechanical parts.

Before switching the power on, make sure that the drive system has been reliably installed

and connected, and the mains voltage falls in the permitted voltage limits.

Do not touch the motor shaft when the motor is running. Failure to comply may cause

personal injury.

Ensure that all connections to the SINAMICS V60 drive module have been disconnected

before you perform any voltage test (according to EN60201-1 (VDE0112-1), Article 20.4) for

an electrical device on the machine tool. The drive had passed the insulation test before its

delivery to the customer and doesn't require a second test (for avoiding additional voltage

stress).

The motor brake is only used for brake control over motor start/stop. Unless absolutely

necessary, do not apply it as an emergency stop mechanism.

Only after you have successfully carried out commissioning of the drive system while the

motor operates under dry-run conditions, can you perform commissioning of the drive

system while the motor operates under loaded conditions.

Do not touch the heatsink of the drive, the motor or other high-temperature parts during

equipment running or within a certain period since power disconnection. Failure to comply

may cause personal injury.

Ensure that you do not switch on/off the power frequently. This may cause damage to the

drive system.

The motor rotation direction is determined according to your view from the motor shaft end.

Viewing from the motor shaft end, counterclosewise (CCW) rotation is defined as forward

rotation while clockwise (CW) rotation is defined as reverse rotation.

Electrical installation

Commissioning/Operation

WARNING

WARNING

CAUTION

CAUTION

Page 7

1.3 Identification

EN-6 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

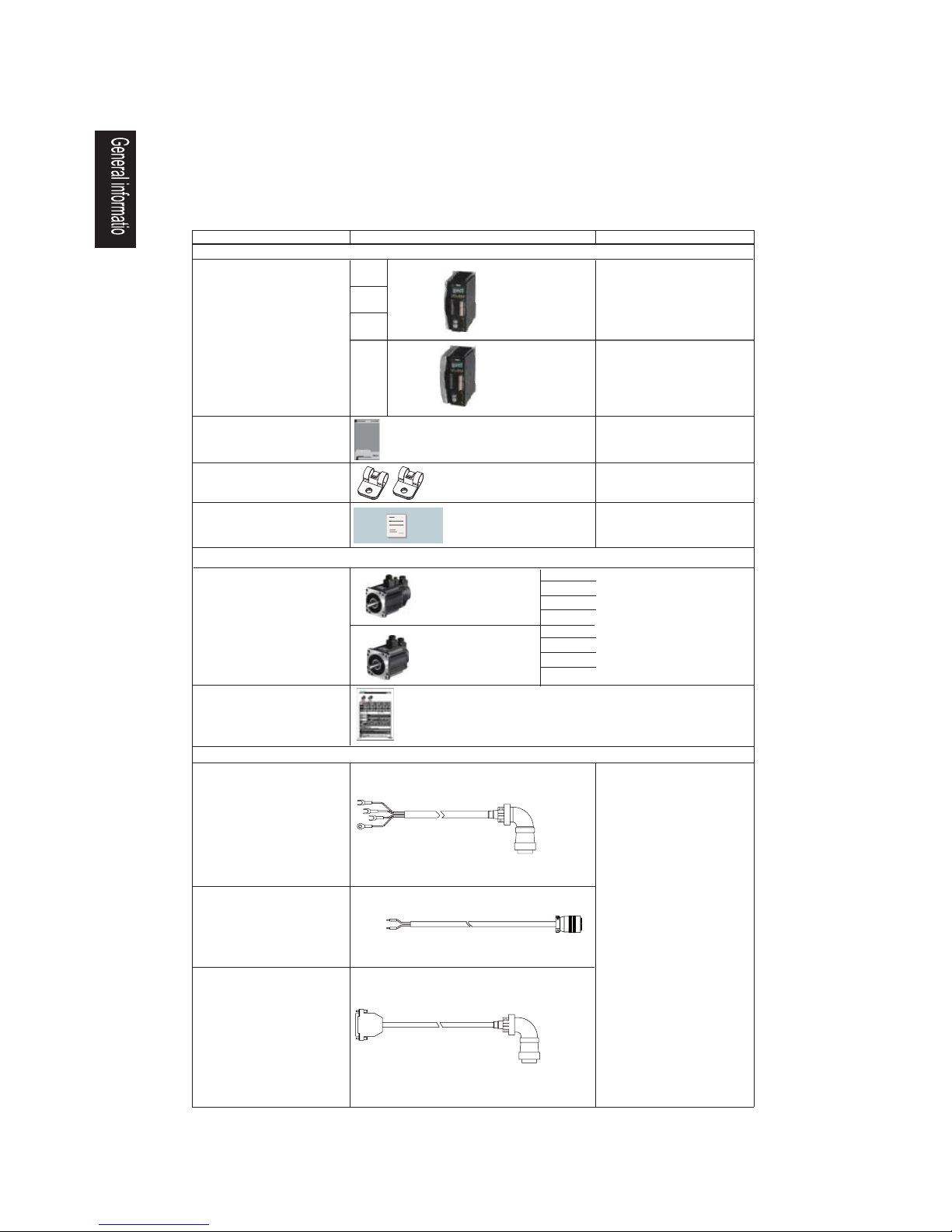

The drive will be always delivered with a complete axis package, including one drive unit

CPM60.1, one motor unit 1FL5. and some necessary cables.

Scope of delivery

Encoder cable (shielded)

Motor cable (unshielded)

Brake cable (unshielded)

Drive side

(to encoder interface X7)

Motor side

(to encoder socket)

4 Nm

4 A

6 A

7 A

10 A

10 Nm

6 Nm

7.7 Nm

4 Nm

10 Nm

6 Nm

7.7 Nm

Refer to the rating plate on

the motor housing for

motor-specific electrical data

Getting started

Warranty card

Cable clamps (2 pieces)

Controlled Power

Module CPM60.1

1FL5 motor

With the brake

Without the brake

Datasheet for 1FL5

motor

For each cable, two lengths

are available for your

selection:

- 5 m

- 10 m

Cables individually packaged

Drive side

(to motor interface U, V, W)

Motor side

(to motor socket)

Drive side

(to motor brake interface X3)

Motor side

(to motor brake socket)

Component Illustration

Remark

--

--

--

Components included in the drive unit package

Components included in the motor unit package

Dimension (W x H x D; in mm):

106 x 226 x 200

Dimension (W x H x D; in mm):

123 x 226 x 200

1FL5 motors have two main

types - with key and without

key. Each type involves motors

with brakes and without brakes.

Applicable to both shielded

and non-shielded cables

Page 8

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-7

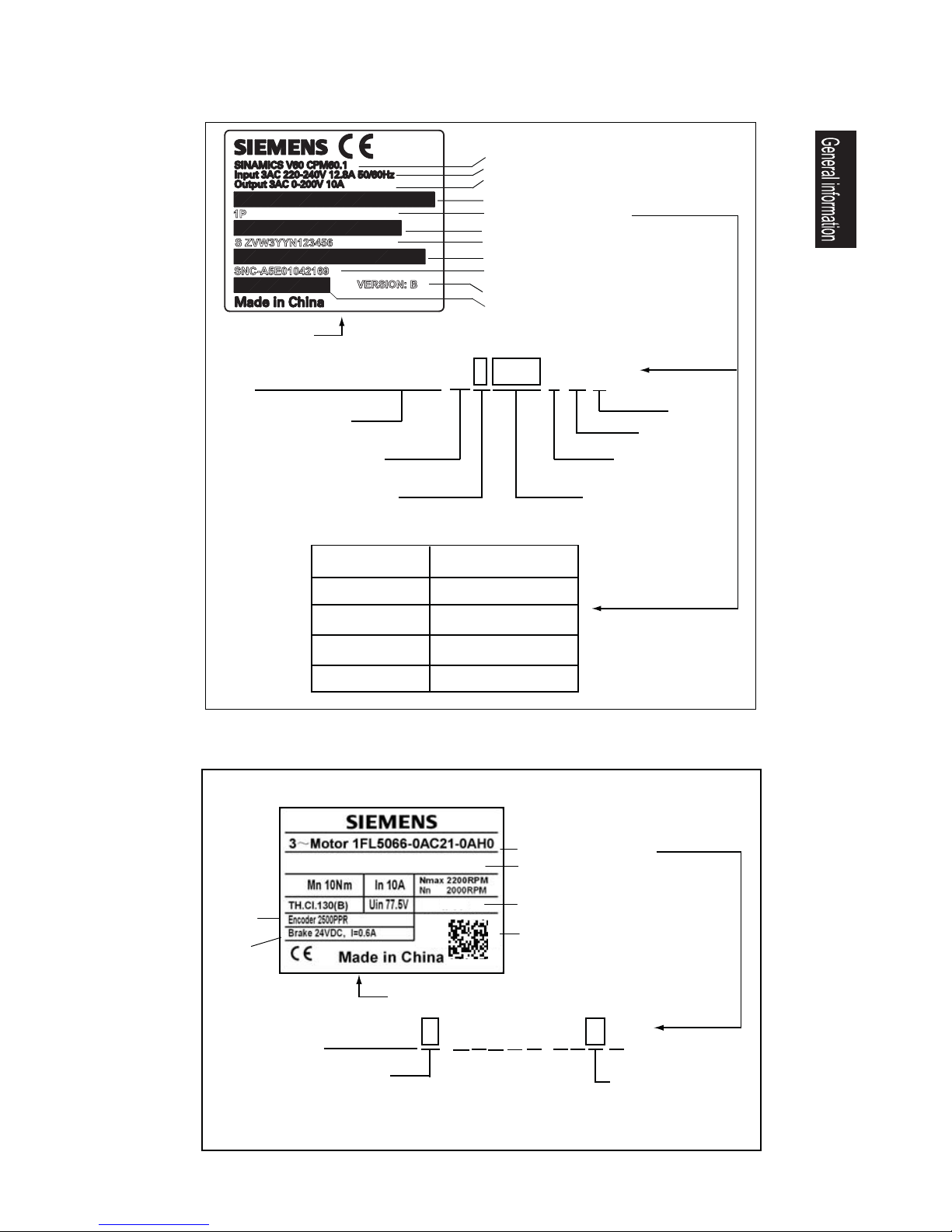

Product name

MLFB (order number)

Product serial number

Siemens part number

Rated input voltage, current and frequency

Rated output voltage & current

Hardware version

Bar code

Bar code

Bar code

Bar code

6 S L 3 2 1 0 - 5 C C 2 1 - 0 U A 0

SINAMICS AC Drive,

blocksize, with internal

air cooling

3 AC 220 ... 240 V rated

Multiplier for output current:

1: x 0.1

2: x 1

Rated output current:

4 - 0: 4 A

6 - 0: 6 A

7 - 0: 7 A

1 - 0: 10 A

Unfiltered

Standard

Version

Drive variant/

Rated output current

Order number

4 A

6 A

6SL3210-5CC14-0UA0

6SL3210-5CC16-0UA0

6SL3210-5CC21-0UA0

Drive rating plate

6SL3210-5CC21-0UA0

10 A

6SL3210-5CC17-0UA0

7 A

MLFB (order number)

2D-code

(for MLFB and

serial number)

Product serial number

Protection class

Rated

resolution

1 F L 5 0 6 0 - 0 A C 2 1 - 0 A H 0

Rated torque:

0: 4.0 Nm

2: 6.0 Nm

4: 7.7 Nm

6: 10.0 Nm

G: Without key, without brake

H: Without key, with brake

A: With key, without brake

B: With key, with brake

Motor (with brake)

rating plate

Brake

requirements

IPxx

Drive rating plate (example)

Motor rating plate (example)

VERSION: B

S ZVW3YYN123456

SNC-A5E01042169

1P

S 10025AA13LFBZ0001

Page 9

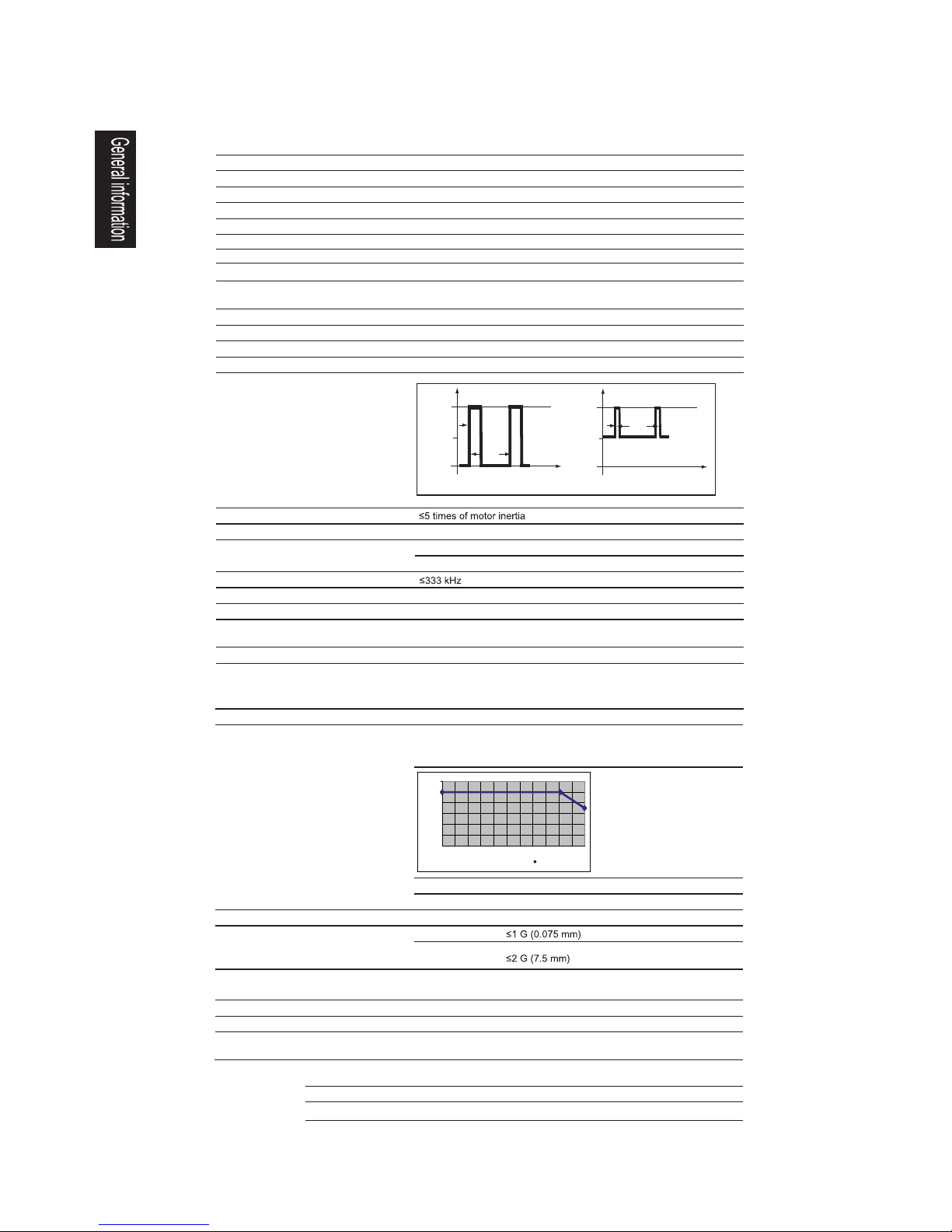

1.4 Technical data

For technical data of the motor, please refer to the Motor Specification delivered with the motor.

EN-8 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Vibration resistance

Relative humidity

Ambient temperature

< 95%

Operation

Transportation

Storage

-40°C to 70°C

-25°C to 55°C

Operation

Transport &

storage

< 1,000 m above sea level: without power derating;

1,000 to 2,000 m: with power derating (derated to 80%)

Installation altitude

Outline dimensions (W x H x D)

Protection class

Mechanical design

NOTICE

IP20

0 to 45 °C: without power derating (100% load);

45 to 55°C: with power derating (by 0% at 45°C

up to 30% at 55°C ).

Rated voltage: 3 AC 220 V to 240 V

Tolerance: - 15 % ~ + 10 %

50/60 Hz, unregulated DC-Link

Mains supply voltage

Protection functions

Input pulse frequency

Control mode

2. JOG mode

Drive output

Drive input

Encoder

Overcurrent, overvoltage, undervoltage, overload, IGBT overtemperature,

overspeed, encoder abnormal protections, I

2

t detection

TTL encoder 2,500p/r with U, V, W rotor position signal; one zero mark

1. Brake output 2. Servo alarm 3. Servo ready 4. Zero mark

Environmental conditions

Control performance

General performance

Order No.: 6SL3210- 5CC14-0UA0 5CC16-0UA0 5CC17-0UA0 5CC21-0UA0

Applicable load inertia

Overload capability

Setpoint interface

Keys on panel

Display

Axis

Configurable controller

Application field

Rated motor torque

Rated output power

Rated input power

Max. output current

Rated output current

6 Nm

1.2 kW

1.6 kW

2.0 kW

7.7 Nm 10 Nm

4 Nm

tt

I

I

8 A

4 A

6 A

7 A

10 A

12 A

14 A

20 A

0.8 kW

1.4 kW

1.9 kW

2.3 kW

0.9 kW

Turning machines, milling machines, engraving, packaging, printing etc.

SINUMERIK 801, SINUMERIK 802s base line, SIMATIC S7-200 and

SIMATIC S7-1200

Single-axis drive

6-digit, 7-segment LED display, two LED status indicators

4 tact switch keys

Pulse interface

1. Servo enable 2. Alarm cancel

1. Position control (Input mode: pulse + direction signals)

106 x 226 x 200

mm

106 x 226 x 200

mm

106 x 226 x 200

mm

123 x 226 x 200

mm

0

20

40

60

80

100

120

0 5 10 15 20 25 30 35 40 45 50 55

Output power

Temperature ( C)

Imax

Imax = 2 x In

In

3s

10s

Imax

In

0.3s

10s

Technical data for CPM60.1 Drive Modules

Page 10

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-9

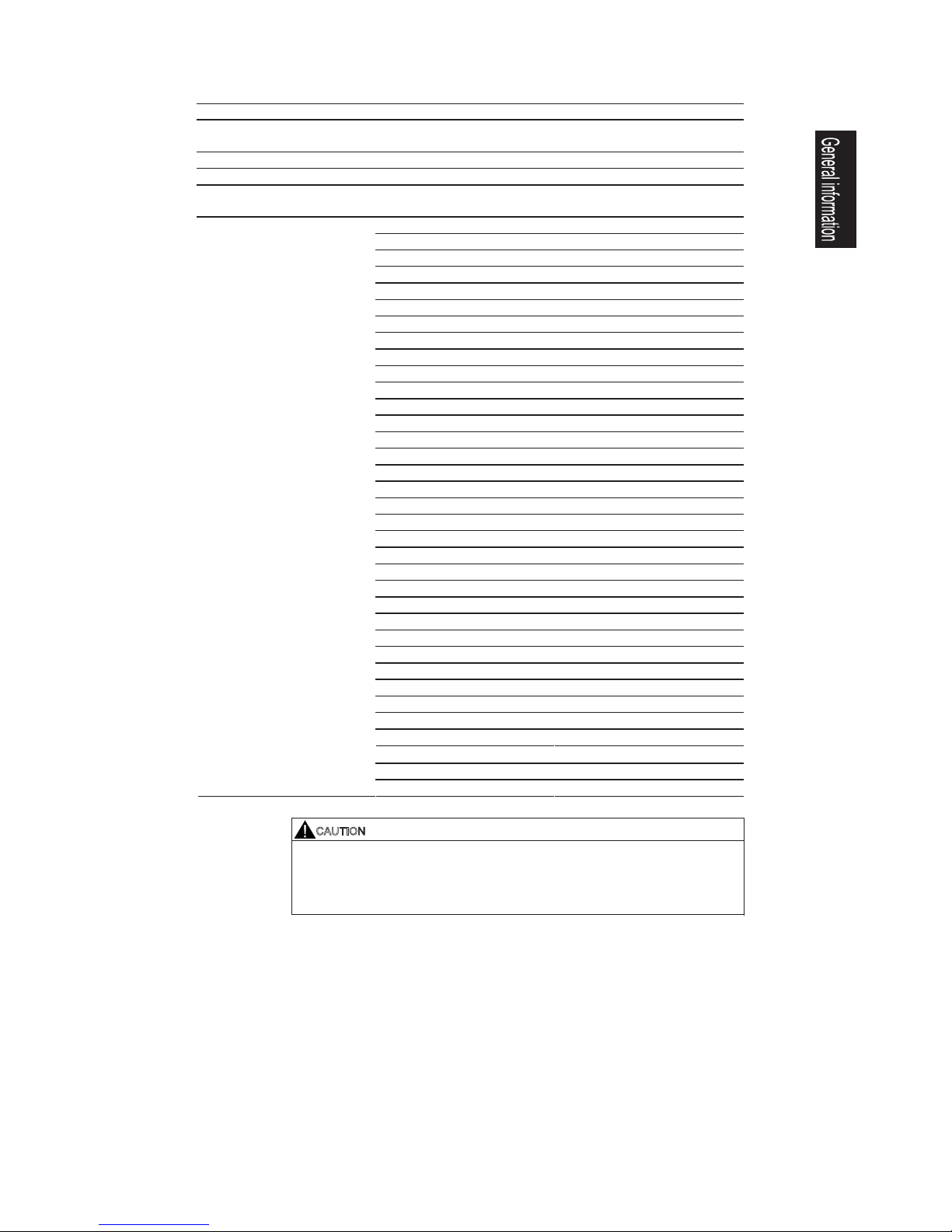

Technical data for transformer

Recommended transformer type 380 V/220 V SG series 3AC isolating transformer

V022/083CA3egatlovylppuS

50/60 Hz

Connection group Y/Y-12

Impedance voltage (Uk%) 4

No-load current (%) For a transformer =< 1.0 kVA, the no-load current < 18%;

For a transformer > 1.0 kVA, the no-load current < 14%.

Possible motor combination Transformer power (apparent power)

AVk0.1mN4

AVk5.1mN6

AVk0.2mN7.7

AVk5.2mN01

AVk5.1mN4+mN4

AVk5.1mN6+mN4

AVk5.1mN7.7+mN4

AVk0.2mN01+mN4

AVk0.2mN6+mN6

AVk0.2mN7.7+mN6

AVk5.2mN01+mN6

AVk0.2mN7.7+mN7.7

AVk5.2mN01+mN7.7

AVk0.3mN01+mN01

4 Nm + 4 Nm + 4 Nm 1.5 kVA

4 Nm + 4 Nm + 6 Nm 1.5 kVA

4 Nm + 4 Nm + 7.7 Nm 2.1 kVA

4 Nm + 4 Nm + 10 Nm 2.0 kVA

4 Nm + 6 Nm + 6 Nm 2.0 kVA

4 Nm + 6 Nm + 7.7 Nm 2.0 kVA

4 Nm + 6 Nm + 10 Nm 2.5 kVA

4 Nm + 7.7 Nm + 7.7 Nm 2.5 kVA

4 Nm + 7.7 Nm + 10 Nm 2.5 kVA

4 Nm + 10 Nm + 10 Nm 3.0 kVA

6 Nm + 6 Nm + 6 Nm 2.0 kVA

6 Nm + 6 Nm + 7.7 Nm 2.0 kVA

6 Nm + 6 Nm + 10 Nm 2.5 kVA

6 Nm + 7.7 Nm + 7.7 Nm 2.5 kVA

6 Nm + 7.7 Nm + 10 Nm 2.5 kVA

7.7 Nm + 7.7 Nm + 7.7 Nm 2.5 kVA

Power selection (for standard

turning/milling machines)

7.7 Nm + 7.7 Nm + 10 Nm 3.0 kVA

6 Nm + 10 Nm + 10 Nm 3.0 kVA

7.7 Nm + 10 Nm + 10 Nm 3.0 kVA

10 Nm + 10 Nm + 10 Nm 3.5 kVA

CAUTION

To reduce the risk of electric shock, interference from power supply and electromagnetic

field, an isolating transformer is necessary for the 3AC 380V mains system.

The customer may select the right transformer with reference to the table above

(Determine the right transformer power based on desired motor combinations)

Page 11

2

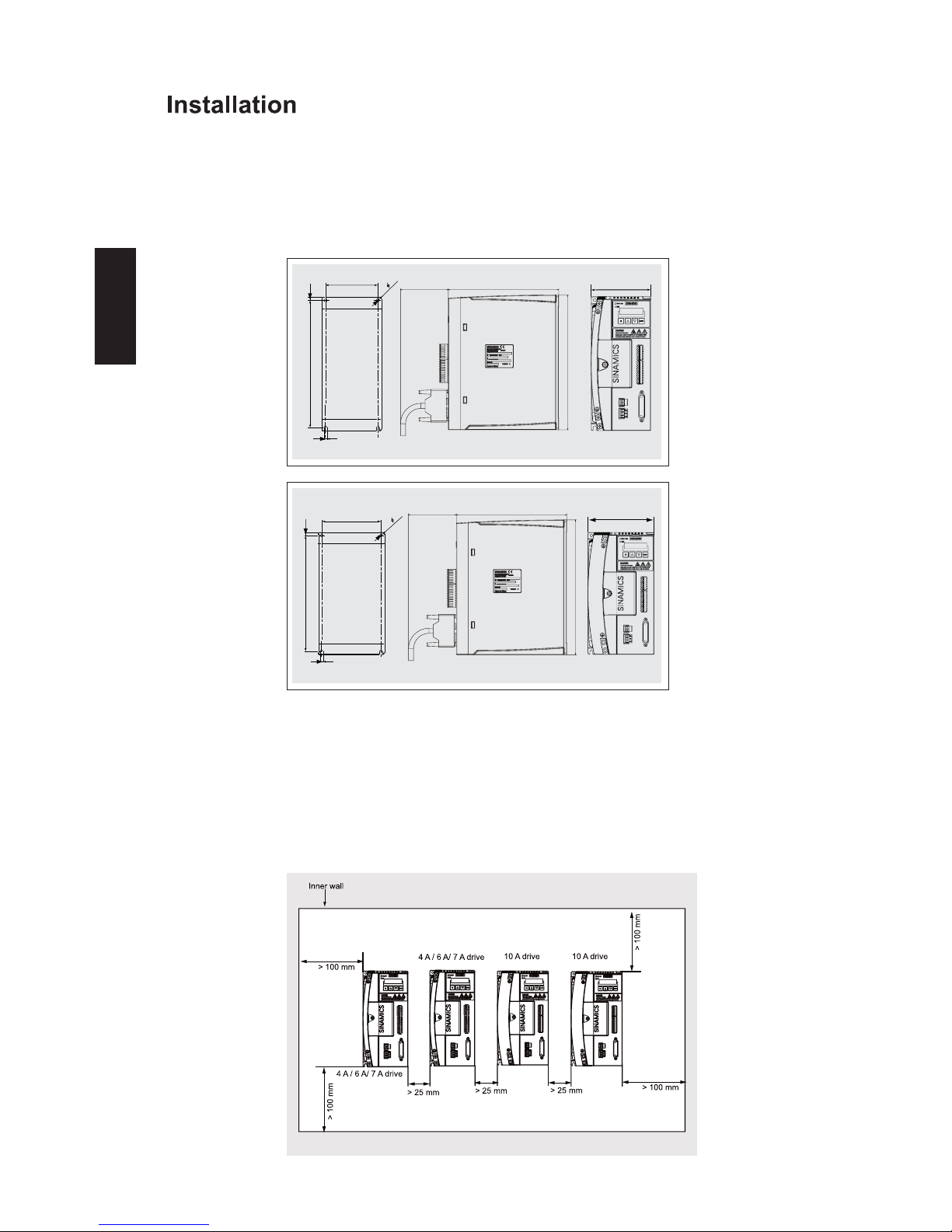

2.1 Mechanical Installation

2.1.1 Mounting the drive

Drill pattern and outline dimensions

Mounting method

Minimum mounting clearance

EN-10 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Installation

You mount the drive with four M5 screws to the inner wall of the cabinet. Note that the drive

must be mounted vertically to the cabinet wall, with the ventilation openings of the drive

pointing upwards. The screw tightening torque of the drive must be no more than 2.0 Nm.

To ensure sufficient heat dissipation, please observe the requirements for minimum

clearance between drives, one drive and another device/inner wall of the cabinet, as

illustrated in the picture below:

93

215

5.5

5.5

2- 5.5

106

RDY / JOG

ERR

80

185

226

215

5.5

110

2- 5.5

5.5

123

RDY/ JOG

ERR

80

185

226

4 A/ 6 A / 7A versions

10 A version

Page 12

11-NEdetratS gnitteG )1.06MPC( eludoM rewoP dellortnoC 06V SCIMANIS

The use of supplied cable clamps

If the CE marking requirements for cables are mandatory, the mains input cable and the motor cable

used must all be shielded type of cables. In that case, you can use the cable clamps as a ground

connection between the cable shielding layer and a common ground point.

Clamps can also be helpful in better fixing cables (the unshielded motor cable and the mains input

cable) in place.

The illustration below shows you how to use the clamps to fix both cables and to make a shielding

connection with the cable.

Cable Clamp

PE

(for connection to earth

tightening torque: 2.0 Nm)

Ground wire

Ground wire

Mains input cable (shielded)

Motor cable

Caution

Note

Make sure that the clamp for fixing the shielded motor cable is in close contact

with the shielding layer of the cable.

After the installation, it is recommended that the screws on the terminal covers

should be screwed down to ensure the safety.

Installation

Siemens does not provide the shielded motor cable. Please prepare the shielded

motor cable by yourselves for CE certification.

Page 13

Page 14

When using the drive together with the SIMATIC PLC, you are recommended to use a

standard 24 V DC power supply for the SIMATIC PLC and use a Siemens cable

(6ES7298-2DS23-0XA0) to connect the two ones.

Page 15

EN-14 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Installation

For PNP types (example)

For NPN types (example)

(orange)

(blue)

(brown)

(white)

(yellow)

(orange)

(blue)

(brown)

(white)

(yellow)

(gray)

(purple)

(black)

(red)

(purple+white)

(red+white)

(gray)

(purple)

(red)

(black)

(purple+white)

(red+white)

PULS1 (orange)

RST (white)

M24 (black)

PULS2 (orange + white)

DIR1 (blue)

ENA1 (brown)

ALM1 (purple)

RDY1 (gray)

RDY2 (red + white)

+24V (red)

Z-M (green)

Z-M24 (green + white)

ALM1 (purple + white)

ENA2 (brown + white)

DIR2 (blue + white)

PULS2 (orange + white)

RST (white)

M24 (black)

PULS1 (orange)

DIR1 (blue + white)

ENA1 (brown + white)

ALM1 (purple)

RDY1 (gray)

RDY2 (red + white)

+24V (red)

Z-M (green)

Z-M24 (green + white)

ALM1 (purple + white)

ENA2 (brown)

DIR2 (blue)

PEPEM L+

L+MI0.0 I0.1 I0.2

1M

1M

Q0.0 Q0.1 Q0.2 Q0.31L+

CPU 224XP CN

DC / DC / DC

DC 24 V

PULS DIR ENA RST

ALM RDY Z-M P24V/M M P24V

DC 24 V

PE

PE

M

L+

L+MI0.0 I0.1 I0.2

1M

1M

Q0.0 Q0.1 Q0.2 Q0.3

PULS DIR ENA RST

M/V42PM-ZYDRMLA M P24V

CPU 224XPsi CN

DC / DC / DC

If SIMATIC PLC is S7-200 series, please see following wiring diagrams:

NOTE

As 65 signal from SINAMICS V60 drive is recommended for emergency stop, it is not used in SIMATIC

PLC/SINAMICS V60 signal cable.

For a SIMATIC PLC (S7-200 series), signal PULS can only be connected to output terminal Q0.0 or Q0.1,

and terminal Q0.2 or Q0.3 is used for direction output.

For PNP and NPN types, connectors on X5 are differently arranged. So, be sure to connect to X5

correctly according to the actual situation.

Based on contact colors, connect the contacts on the PLC (left)and those on the V60 (right)

respectively, as shown on page EN-13. The contact colors on the PLC, however, do not match those

on the V60.

Page 16

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-15

Installation

SIMATIC PLC/SINAMICS V60 signal cable

It is recommended to use SIEMENS-designed SIMATIC PLC/SINAMICS V60 signal cable (length: 3m) to

connect SIMATIC PLC and SINAMICS V60. This signal cable can be ordered with MLFB of 6ES7298-2DS230XA0.

PE

PE

MM

3M3L+

L+L+ 1M I0.0

Q0.0 Q0.1 Q0.2 Q0.3 Q0.4 Q0.5 Q0.6

I0.1 I0.2

DC 24 V

PULS DIR ENA RST

CPU 1214C

DC / DC / DC

ALM RDYZ-MP24V/MMP24V

If SIMATIC PLC is S7-1200 series, please see the following wiring diagram (example):

(orange)

(blue)

(brown)

(white)

(yellow)

(gray)

(purple)

(red)

(black)

(purple+white)

(red+white)

PULS1 (orange)

RST (white)

M24 (black)

PULS2 (orange + white)

DIR1 (blue)

ENA1 (brown)

ALM1 (purple)

RDY1 (gray)

RDY2 (red + white)

+24V (red)

Z-M (green)

Z-M24 (green + white)

ALM1 (purple + white)

ENA2 (brown + white)

DIR2 (blue + white)

The CPM60.1 drive unit should be connected to an external 24 V DC power supply (rated input current 2 A),

which enables the drive to normally work under the voltage range of 24 V (- 15% to +20%). Since the excellent

quality of a DC power supply is critical to the stable operation of a drive system, Siemens recommends you to

select a SIEMENS DC 24 V stabilized power supply (order number: 6EP1333-3BA00). If there is no SIEMENS

DC 24 V power supply available, you can use a non-SIEMENS high-quality power supply instead.

External 24 V DC Power Supply

Filter

Circuit breaker

A line filter (rated current 16 A, protection level IP20) is required so that the system can pass the CE certification

(radiated emission test or conducted emission test). The filter recommended by SIEMENS has an order number

of 6SN1111-0AA01-1BA1.

You can install a mains linear breaker (rated current: 15 A for 7 A or 10 A version of the drive and 10 A for 4 A

or 6 A version of the drive; rated voltage: 250 VAC) to protect the system.

NOTE

As 65 signal from SINAMICS V60 drive is recommended for emergency stop, it is not used in SIMATIC

PLC/SINAMICS V60 signal cable.

For a SIMATIC PLC (S7-1200 series), signal PULS can only be connected to output terminal Q0.0 or

Q0.2, and terminal Q0.1 or Q0.3 is used for direction output.

Page 17

2.3 Interface Definition

Line supply connection L1, L2, L3

Motor output connection U, V, W

Motor brake connection X3

DC 24 V power supply connection X4

EN-16

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Installation

Setpoint interface X5

Pulse input setpoint ++PULS

-PULS

+DIR

+ENA

-ENA

-DIR

Direction of motor setpoint +

Pulse enable +

Pulse enable -

Direction of motor setpoint -

Pulse input setpoint -

1

2

3

4

5

6

I

I

I

I

I

I

Interface

Signal name

Description

Interface

Signal name

Schematic connection diagram

Description

Interface

Signal name

Schematic connection diagram

Description

Interface

Interface

Pin

Signal name

Signal

name

I/O

type

Remark

Remark

Description

Description

Voltage 24 V DC

(20.4 - 28.8 V)

Current consumption:

brake power supply

power supply

Maximum conductor cross-section: 1.5 mm

2

Maximum conductor cross-section: 1.5 mm

2

Maximum conductor cross-section: 2.5 mm

2

Maximum conductor cross-section: 2.5 mm

2

+ 24 V, motor brake

voltage positive

B+

B- 0 V, motor brake

voltage negative

B+

White

Black

Drive side

(Terminal strip)

Motor side

(Socket connector)

B-12

B-

B+

2

1

U

Drive side

(Terminal strip)

Motor side

(Socket connector)

V

W

1

Black

Yellow-Green

Black

Black

2

3

U

PE

V

W

2

1

3

4

U

V

W

Motor phase U

Motor phase V

Motor phase W

L1

L2

L3

Line phase L1

Line phase L2

Line phase L3

24 V

0 V

PE

- -

Protective earth

0 V

DC 24 V

5V differential signal

Too high input

voltage may cause

a damage to the

device.

Max. conductor cross section: 0.5 mm

If the drive is connected with a SIMATIC PLC, please make sure that the time delay between PULS and

DIR signals should be more than 16 s.

Please ensure that all the terminals of interface X5 should be firmly wired, otherwise, it is forbidden to start

the machine.

It’s recommended that the

differential drive mode is used here

so that the pulse data can be

transmitted correctly.

220

220

servo amplifier

PULS+

PULS-

SIGN+

SIGN-

2

drive side

1 2

3 4 5 6

Page 18

Digital I/O interface X6

Encoder interface X7

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-17

24 A+

12 A-

TTL encoder A phase signal

Servo enable

Interface

Interface

Pin

Pin

Signal

name

Description

Description

I/O

type

Remark

Alarm cancel

Servo enable and alarm

cancel reference ground, 0 V

Alarm relay contact 1 terminal

Alarm relay contact 2 terminal

Servo ready contact 1 terminal

Servo ready contact 2 terminal

Zero mark power supply

Zero mark reference ground 0 V

Maximum conductor cross section: 1.5 mm

2

1)

To cancel an active alarm, apply a high level (+24V) at this terminal.

tuptuo kram oreZZ-M

M24

9

10

RST

M24

ALM1

RD

Y1

ALM2

RDY2

+24V8

+24 V = high active

1)

+24 V = drive enable

0 V = drive disable

I

I

I

I

I

-

-

-

-

O

1

2

3

4

5

6

7

65

23 B+

11 B-

TTL encoder B phase signal

22 Z+

10 Z-

TTL encoder Z phase signal

21 U+

9 U-

TTL encoder U phase signal

20 V+

8 V-

TTL encoder V phase signal

19 W+

7 W-

TTL encoder W phase signal

13 NC

25 NC

Not connected

(reserved)

5/6/17/18 EP5

1/2/3/4 EM

1

13

14

25

A+

Drive side

(25-pin socket connector X7)

Motor side

(15-pin socket connector)

A-

24

12

B+

B-

23

11

Z+

Z-

22

10

U+

U-

21

9

V+

V-

20

8

W+

W-

19

7

N.C.

N.C.

13

25

EP5

5/6/17/18

EM

1/2/3/4

4

7

5

8

6

9

10

13

11

14

12

15

2

A+

AB+

BZ+

ZU+

UV+

VW+

WEP5

EM

PE

3

1

Screw type: UNC 4-40 (plug-in terminal block)

Tightening torque : 0.5 - 0.6 Nm

Encoder power supply + 5 V

Signal name

Encoder power supply GND

ALM1

ALM2

RDY1

RDY2

Pulse width: 2 ~ 3 ms

H = +24 V, L = 0 V

Internal relay terminals

Relay picks up in case

of an alarm

NC can receive this

alarm from drive

Internal relay terminals

Relay picks up when

drive is ready for

operation

7

8

9

10 11 12 13 1415 16

Page 19

Power-on sequence

Power-off sequence

EN-18

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Installation

2.4 Signal Sequence Example

24 V

Main power

16 ms

16 ms

1.5 s

32 ms

16 ms

65 enable

RDY signal

ENA enable

DIR signal

PULS signal

......

......

......

......

......

......

......

0.5 s

......

......

Main power

24 V

Page 20

3

3.1.1 Main Menu

3.1 Commissioning

Displays and settings

The status menu items

Commissioning

Main Menu

Status

Parameter Set

Function

Data Display

M

M

M

M

ENTER

......

......

......

To cancel the alarm,

power off the drive, then

power on again

Normal

status

display

Status-1

Status-2

Status-3

Status-4

Status-RUN

Status-A01

Status-A09

......

Status-A14

Status-A21

Status-A23

Status-A41

Status-A45

...... ......

The default menu item

under current menu level

Actual menu display

Alarm

status

display

Display of the 1st detected alarm

(the alarm no. always contains

a letter “L” to indicate this is the

first alarm.)

Display of the 2nd detected alarm

Display of the 3rd detected alarm

2 sec

2 sec

2 sec

When more than one error occurs at the same

time, the rule for error display is as the following

example:

8.8.8.8.8.8.

S-RUN

Alarm status

Normal status

Menu Item

Definition

Preconditions for display of normal status

S-A01

...

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-19

Page 21

3.1.2 Function Menu

NOTICE

Descriptions of main keys:

Key Definition Function

M

ENTER

Mode selection

Enter

Switch between 4 main menu items (Status, Parameter Set , Data

Display and Function) or return current display to next higher-level.

Go to next lower-level menu item or back to higher-level item, confirm

value (save modified value into RAM) or cancel an alarm.

Accessibility to "JOG" mode or 'Save user parameter" mode (see the picture above) depends on the

current display status of the drive:

when the drive is in "S-3" (waiting for 65 enable) state and P05 = 1, access to JOG mode is possible.

Please save modified parameters via the Store function in the function menu, otherwise, the parameter

changes will be lost if the drive is powered off. It must be noted that signal of servo enable (terminal

X6-"65") or signal of pulse enable (terminal X5-"+ENA"/"-ENA") should be cut off if you try to save the

EN-20 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Function Menu

Save user

parameter

Restore

default

ENTER

JOG

No

ENTER

or

or

ENTER

ENTER

M

or

Status

Parameter Set

Function

Data Display

M

M

M

M

M

ENTER

or

M

M

ENTER

or

M

ENTER

or

The default menu item

under current menu level

or

If the current drive operating status supports JOG

funtion, “JOG RUN”will be displayed.

Otherwise, “Forbidden” will be displayed.

Keeping Up key pressed can make the motor run

counter-clockwise.

Keeping Down key pressed can make the motor run

clockwise

Releasing the key can stop the motor.

Key release

Yes

Forbidden

Forbidden

Finish

JOG RUN

JOG RUN

JOG RUN

If the current drive operating status

supports “Save user parameter”

function, “Finish” will be displayed.

Otherwise, “Forbidden” will be

displayed.

If the current drive operating status supports

“Restore default” function, “Finish” will appear.

Otherwise, “Forbidden” will appear.

Key release

Restore

default

the second

No

ENTER

or

or

ENTER

ENTER

M

or

M

or

M

ENTER

or

Yes

Forbidden

Finish

No

ENTER

or

or

ENTER

ENTER

M

or

M

or

M

ENTER

or

Yes

Forbidden

Finish

The 2nd default values are the default values of FW V1.6 and the lower.

Page 22

P47 value (default)

Parameter Set Menu

Status

Parameter Set

Function

Data Display

M

M

M

M

M

ENTER

ENTER

ENTER

M

or

: save value to RAM and return

M

ENTER

: return without saving

Menu display change after Mode button is pressed:

The point will turn dark under the following circumstances:

- At next power-on;

- After the value has been saved to the memory using

“Save user parameter” function under “Function” main

menu item.

Point is lit

Point is lit

Increase value Decrease value

Par. No. 47

Par. No. 99

Par. No. 01

Par. No. 05

Press or for several seconds,

the value can be increased or descreased faster.

“P01” will be displayed by default at first power-on only.

The last parameter you changed before power-off will be

displayed by default at next power-on.

To change parameter settings, change the default setting of P01

first.

Figure 6-3 "Parameter Set" menu

Note

All parameter settings made in Parameter Set mode will be saved to RAM only. At next drive

power-on, the settings made will be recovered to the setting prior to the last setting

automatically. To save the setting permanently, you should use "Save user parameter" menu

entry under "Function" main menu.

Detailed description of individual parameters can be found in Section 6.2 "Parameter list

(Page 44)".

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-21

Page 23

Data Display Menu

Status

Parameter Set

Function

Data Display

M

M

M

M

M

ENTER

ENTER

ENTER

M

or

D10 value

Data No. 11

Data No. 81

Data No. 82

Data No. 10

The default menu item

under current menu level

Actual menu display

Figure 6-4 "Data Display" menu

N

ote

Detailed description of individual display data can be found in Section 6.5 "Display data list

(Page 49)".

31400

31020

STEP_RESOL

ENC_RESOL PPR

IPR

X, Z (for 801)

X, Y, Z (for 802S base line)

X, Z (for 801)

X, Y, Z (for 802S base line)

10,000

10,000

Encoder revolution (2,500)

x Multiplier (4)

Steps per servo motor revolution

noitpircseDtniopteSnoitangiseDataD enihcaM Unit Axis

3.1.3 Setpoints from NC

EN-22 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 24

3.1.4 First commissioning

Start

Switch on the DC 24 V power supply

to the drive

Remove write protection (P01 = 1)

Is "S-2" displayed?

Yes

Connecting the unit

Check the connections

1)

2)

It’s necessary to connect the cables below:

(refer to Section 2.2)

- Encoder cable

- Motor cable

- Mains input cable

- DC 24 V cable

- Brake cable

Check points:

- Is the device or cable damaged?

- Do the connected cables sustain

excessive pressure, load or tension?

- Are the connected cables put on sharp

edges?

- Is the mains supply within the allowable

range?

- Are all the terminals firmly and correctly

connected?

- Are all the connected system components

well grounded?

No

Refer to Section 3.1.1 for possible causes

Refer to Section 3.1.1 for possible causes

Set JOG speed (P46)

Yes

Save settings to memory?

Pressing to return to the main

menu, and then to

No

M

Set internal JOG enable function (P05 = 1)

Enable drive terminal 65 via external DC 24 V power supply

Switch on the mains supply (3AC 220 V) to the drive

Go to "Func" main menu, select "JOG" -> "JOG RUN".

Keep Up or Down key pressed to enable motor trial run.

Adjust speed controller performance (P20 & P21) , if necessary.

No

Yes

Alternative 1:

Alternative 2:

Is “S-3 displayed”?

End

If there is need to adjust speed controller

performance (P20&P21), value of P47 should be

set to be 0 first.

3)

Prior to the adjustment of speed controller

performance, please refer to the explanation

to P47 in the parameter list and set P47=0

1

1

Follow the procedure below to complete the first commissioning of the drive and motor:

Go to "Func" main menu,select "Store" to store settings into the

memory (whether a changed drive parameter takes effect

immediately or after power-on, be sure to perform the “Store”

operation. For details, see Section 3.1.2).

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-23

Page 25

3.1.5 System Commissioning

Start

Connect the drive with NC (SINUMERIK 801 or

SINUMERIK 802S base line) Connect setpoint cable and BERO signal wires

from NC to drive (Refer to Section 2.2)

Set parameters on NC

(refer to Section 3.1.3 Setpoints from NC)

Switch off the drive

Check the connections

Switch on the DC 24 V power supply

to the drive and NC

Switch on the mains supply (3AC 220 V) to the drive

Yes

Is "S-2" displayed?

No

No

Yes

Yes

Is “S-3 displayed”?

Enable drive terminal 65 via external DC 24 V power supply

No

Is “S-4 displayed”?

Refer to Section 3.1.1 for possible causes

Refer to Section 3.1.1 for possible causes

Refer to Section 3.1.1 for possible causes

Start NC operation

Yes

Adjust speed controller performance (P20 & P21) as well as

position controller performance (P30 & P31), if necessary.

Yes

Are you satisfied with

the system performance?

No

End

Is "S-RUN" displayed?

Yes

No

Yes

Turn on NC to enable terminals ENA+ and ENA- at drive interface X5

Refer to Section 3.1.1 for possible causes

Follow the procedure to complete the system commissioning:

EN-24 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 26

3.2 Parameter List

1. This parameter specifies the proportional gain of position loop.

2. The bigger the value, the higher both the gain and rigidity, and at the same pulse command frequency the

smaller the position hysteresis. However, excessively high value setting may cause system oscillation or

overshooting.

3. The setting depends on specific drive and load.

Sets the maximum possible motor speed.

This parameter specifies the integral action time (Tn, integral component) of speed control loop.

The smaller the value, the higher the gain and rigidity. The setting depends on specific drive and load.

Note:

Default value varies with software version.

Factory defaults:

This parameter specifies the proportional gain (Kp, proportional component) of speed control loop.

The bigger the value, the higher the gain and rigidity. The setting depends on specific drive and load.

Generally, the bigger the load inertia, the bigger the value is to set. If however, there is no oscillation occurred

in the system, you can set the value as big as possible.

Note:

Default value varies with software version.

Factory defaults:

Specifies the maximum motor current (2 x rated motor current) of your choice.

0: Sets all parameters other than P01 as read-only parameters.

1: Sets all parameters to be both readable and writable.

P01 automatically resets to 0 after power-on!

P05 automatically resets to 0 after power-on!

Parameter write protection

Maximum motor current

evitceffEtnemercnItluafeDegnaRemaN.oN .raP

Unit

Internal enable

0: JOG mode can be enabled externally.

1: JOG mode can be enabled internally.

P30

Position loop proportional gain

Speed loop proportional gain

Maximum motor speed

Speed loop integral time

constant

P26

P21

P20

P16

P05

P01

0.1-3.2

0-2,200

0.1-300.0

0.01-5.00

0-100

0-1

0-1

0

0

1

1

-

-

100 1 %

Depends on

drive version

Depends on

drive version

2,200 20 rpm

0.1

0.1

0.01

ms

Nm*s/rad

1,000/min Immediately

Immediately

Immediately

Immediately

Immediately

Power On

Power On

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-25

4 Nm: 0.81(0.54); 6 Nm: 1.19(0.79); 7.7 Nm: 1.50(1.00); 10 Nm: 2.10(1.40)

4 Nm: 17.7(44.2); 6 Nm: 17.7(44.2); 7.7 Nm: 17.7(44.2); 10 Nm: 18.0(45.0)

3.0(2.0)

Page 27

1. This parameter specifies the feedforward gain of position loop.

2. Setting the value to 100 % means position hysteresis is always 0 at any pulse command frequency.

3. Increasing the feedforward gain of position loop improves the high-speed response characteristics of

the control system, but meanwhile causes the system's position loop unstable and liable to oscillation.

4. Unless very high response characteristics are necessary, set the feedforward gain of position loop to 0

This parameter specifies the maximum possible following error. When the actual following error is larger than

the setpoint, the drive sends an over-position alarm (A43)

When the drive is enabled, the drive brake will be opened after a delay which is set by P41.

Drive can be enabled under the following conditions:

A: When the following three conditions are all met:

1. Terminal 65 (external enable) has been enabled;

2. The drive has received an enable signal from NC;

3. No alarm is detected by the drive.

B: When the following two conditions are both met:

1. Terminal 65 (control enable) has been activated;

2. Motor operates in "JOG-RUN" mode (enabled from function menu )

C: When the following two conditions are both met:

1. P05 = 1 (The JOG mode can be enabled internally);

2. Motor operates in "JOG-RUN' mode (enabled from function menu )

When motor speed exceeds 30 rpm and the drive generates an alarm, if, within the specified brake close time

(P42),the actual motor speed becomes smaller than the P43 setpoint, brake is closed when the actual speed

reaches the speed P43 sets.

This parameter specifies the input pulse multiplier. For example, when P36 = 100, input frequency = 1 kHz,

output frequency = 1 kHz x 100 = 100 kHz.

When motor speed exceeds 30 rpm and the drive generates an alarm, if, within the specified brake close

time (P42), actual motor speed remains bigger than brake close speed setpoint (P43), brake is closed after

the specified brake close time (P42) expires.

When motor speed is lower than 30 rpm, the drive remains enabled within the time period set by P44

after brake close.

This parameter specifies the motor speed in JOG mode.

This parameter defines the time period when the motor ramps up from 0 rpm to 2,000 rpm or ramps down

from 2, 000 rpm to 0 rpm.

Reserved for Siemens internal use only

Note:

Pulse frequency setpoint = Actual pulse frequency x input pulse multiplier;

This parameter is applicable only when the software version is V01.06 or later;

When P36 = 100 or 1,000, speed stability will decrease with higher multiplication factor.

Input pulse multiplier

Maximum following error

Position loop feedforward gain

Par. No.

Name

Range

Default

Increment Unit

Effective

1, 2, 4, 5, 8,

10, 16, 20,

100, 1,000

1

-

-

Power On

P99

P47

Ramp-up/-down time constant

JOG speed

Drive enable time after

the brake close

Brake close speed while

motor operation

Brake close time while

motor operation

Brake open delay

P46

P44

P43

P42

P41

P36

P34

P31

0.0 - 10.0 4.0 0.1 s Power On

0 - 2,000 200 10 rpm Immediately

20 - 2,000 600 10 ms Power On

20 - 2,000 100 20 r/min Power On

20 - 2,000 100 10 ms Power On

20 - 2,000 100 10 ms Power On

20 - 999 500 1 100 pulses Immediately

0 - 100 85(0) 1 % Immediately

EN-26 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Note:

The default values in brackets are the second default values.

Page 28

Data no. Name Data format Unit Data group

mN tnioptes euqroT *01D

mN euqrot eht fo eulav lautcA *11D

D12* Actual value of the phase

current

Decimal

(See table below)

A

Current

MPR tnioptes deeps rotoM 02D

MPR deeps rotom lautcA 12D

Speed

D30 Position revolution se snoitulover rotoM tniopt

)r/00001( stnemercnI tnioptes elgna noitisoP 13D

D32 Actual position revolu snoitulover rotoM snoit

D33 Actual position ang )r/00001( stnemercnI el

D34 Position deviation angle

Integer

Increments (10000/r)

Position

xeh ni stiB langis tupni latigiD *05D

D51* Digital output signal

Bit (See table below)

Bits in hex

I/O

D80* Firmware version (See table below)

D81 Power Board rated current Integer

D82* Parameter version number (See table below)

HW, FW

* The data type of D10, D11, D12, D80, D82 is all decimal format. The display value for D50 and D51

respectively varies as the case may require.

3.3

Display data list

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-27

Page 29

Dark

Pulse not enabled

Pulse enabled

Drive status displays (D50)

Drive not enabled

Drive enabled

Alarm not cancelled

Alarm cancelled

No zero mark input

Zero mark input

IGBT under-temperature

IGBT over-temperature

Drive status displays (D51)

Dark

Alarm output off

Alarm output on

Drive not ready

Drive ready

Zero mark output on

Zero mark output off

Brake open

Brake closed

Power resistor off

Power resistor on

Display data format D10, D11 and D12

(Example)

The point is lit. This point stands for

the decimal number.

In this example, the value is “1804.1”

Display data format D80

(Example)

The point is lit. This point stands for

the decimal number.

In this example, the value means that

the firmware version number is “01.01”.

Display data format D82

(Example)

The point is lit. This point stands for

the decimal number.

In this example, the value means that

the parameter version number is “01.01”.

Figure 6-11 Special data displays (D10, D11, D12, D80, D82)

EN-28 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 30

4

4.1 LED status indicators

4.2 Alarms

Descriptions of LED status indicators

H1

H2

Description

RDY/JOG

Green LED

ERR red LED

7-segment LED

display description

Overview of alarms

”nur-J“ yalpsiDedom GOJkraDFlash light with 1 Hz

A45

A44

A43

A42

A41

A23

A22

A21

A14

A09

A08

A07

A06

A05

A04

A03

A02

A01

Emergency stop

I

2

t protection

Enable signal from Terminal 65 is lost during normal drive running

Signals from encoder phases U, V, W are detected all the same (all high or all

low)

Actual motor speeds is higher than 2,300 rpm

DC link voltage is lower than 200 V

DC link voltage is higher than 405 V

Encoder TTL signals error

Encoder UVW signals error

Software failure

TTL pulse error

IGBT current exceeds the upper limit for 300 ms

Grounding short circuit occurs during drive initialization

Internal chip is detected overcurrent

IGBT is detected overcurrent

Control voltage is lower than 3.5 V

Unable to write data to memory

Parameter validation error (CRC error, encoder type or parameter header

invalid)

Unable to identify the power board

Power board ID number error

DescriptionAlarm nameAlarm code

Parameter error

Memory-write failure

Control voltage error

IGBT overcurrent

Internal chip overcurrent

Grounding short circuit

IT protection

DC link voltage undervoltage

DC link voltage overvoltage

Internal error

Overspeed

IGBT becomes overheatingIGBT overtemperature

Motor load exceeds nominal motor torque

Following error exceeds the limit

Following error too big

DarkDark

Dark

Dark

Green

Green

Dark

Red

Red

Drive ready

Drive error

Initialization Display “8.8.8.8.8.8.”

Alarm code

Dark No 24 V DC input or drive defect

Flash light with 1 Hz Drive not ready Current status

Depends on current menu operation

M

ENTER

Possible states

LED RDY / JOG (Ready / JOG mode)

Possible states

LED ERR (Error)

Dark

Flashing green

Lit green

Dark

Lit red

Flashing red

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-29

Page 31

Alarm list

Press Enter key on

the operator panel

or terminal RST of

X6 interface

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Free stop

Power on

Power on

Power on

Power on

Power on

Power on

Power on

Power on

Power on

Power on

Free stop

Press Enter key on

the operator panel

or terminal RST of

X6 interface

1. check the wiring or

whether the connection

to U, V or W is broken

2. make a correct

grounding

3. replace the motor

with a new one

4. replace the drive

with a new one

1. lower the start-stop

frequency

2. minish the limit value

of current

3. minish load inertia

4. use another drive and

motor with higher

power

The memory is damaged due to

unexpected power-off during

data saving

This alarm may

occur when the

DC link is

connected

This alarm may

occur when the

DC link is

connected

This alarm may

occur when the

24 V DC supply

is connected

There is failure at the internal

software

A short-circuit occurs to the

encoder

There is a failure at the circuit

board

This alarm may

occur when the

DC link is

connected

This alarm may

occur when the

DC link is

connected

This alarm may

occur when the

motor is running

This alarm may

occur when the

motor is running

This alarm may

occur when the

motor is running

This alarm may

occur when the

motor is running

The 24 V DC supply is abnormal

Replace the drive

with a new one

Replace the drive

with a new one

Replace the drive

with a new one

Replace the drive

with a new one

Replace the drive

with a new one

Check the wiring of

encoder

Check the power supply

Brake loop has no enough

space

The motor is mechanically

blocked

Check the mechanical

load

Overload

Reset by power-on

Restore default

parameters

The drive is defective

Check the 24 V DC

supply

Memory is damaged

Power board is broken

A01

A02

A03

A04

A06

A07

A08

A09

A14

A21

A22

A05

1. check the wiring

2. make a correct

grounding

3. replace the motor

with a new one

4. replace the drive

with a new one

1. There is a short-circuit

between terminals U, V, W

and PE on the drive

2. bad grounding

3. motor insulation is broken

4. the drive is broken

1. There is a short-circuit

between terminals U, V, W

and PE on the drive

2. bad grounding

3. motor insulation is broken

4. the drive is broken

1. IGBT module is broken

2. There is a short-circuit

between U, V or W and PE

1. replace the drive

with a new one

2. Check the wiring

1. replace the drive

with a new one

2. Check the interface

circuit of the encoder

1. check the wiring of

encoder cable

2. Check the interface

circuit of the encoder

1. UVW signals of the encoder

are bad

2. bad cable

3. bad cable shielding

4. bad wiring of the shielded

ground cable

5. there is a failure in the

interface circuit of the

encoder

1. connection failure of encoder

ABZ

2. bad cable

3. bad cable shielding

4. bad wiring of the shielded

grounded cable

5. there is a failure in the

interface circuit of the

encoder

1. the mains supply voltage is

too high

2. the waveform of mains

supply voltage is abnormal

1. disconnection of the internal

brake resistor

2. the internal brake resistor is

broken

1. lighten the load

2. use another drive

and motor with

bigger power

Alarm

code

Background

Possible Cause Remedy Result Acknowledgement

EN-30 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 32

Press Enter key on

the operator panel

or terminal RST of

X6 interface

Replace the drive with

a new one

Replace the drive with

a new one

Replace the motor with

a new one

Check the maximum

speed limitation (refer to

parameter P26)

Set a wider value range

for the detection of

following error (P34)

Use a drive and motor

with bigger power

Reduce the load

Give more gains

Check the limit value of

current (P16)

Replace the drive with

a new one

Check the ambient

temperature

Ambient temperature is too high

Check the drive load

Check the wiring

Check the wiring

Check the wiring

Replace the drive with

a new one

Check the power supply

Replace the drive with

a new one

Replace the drive with

a new one

The encoder cable is badly

connected

Replace the drive with

a new one

Circuit board fails

Circuit board fails

The drive is overloaded

Encoder fails

Replace the drive with

a new one

Check whether the

brake is open or not

Check the 65 enable

terminal

Circuit board fails

Low speed

No enough torque

The position loop gain is too

small

The maximumly-permitted

following error is too small

The rated torque is exceeded

Command pulse frequency is too

high

The brake is not open

The motor is not stable

The encoder is wrongly wired

The encoder fails

The encoder fails

Emergency

stop (the

motor will

stop with

the

maximum

energy or

torque)

Emergency

stop (the

motor will

stop with

the

maximum

energy or

torque)

Emergency

stop (the

motor will

stop with

the

maximum

energy or

torque)

Emergency

stop (the

motor will

stop with

the

maximum

energy or

torque)

Emergency

stop (the

motor will

stop with

the

maximum

energy or

torque)

Free stop

Press Enter key on

the operator panel

or terminal RST of

X6 interface

This alarm may

occur when the

24 V DC supply

is connected

This alarm may

occur when the

24 V DC supply

is connected

The motor does

not rotate or

reversely rotate

if the command

pulse is input

after DC-link and

mains line are

connected

This alarm may

occur when the

24 V DC supply

is connected

This alarm may

occur when the

DC-link is

connected

This alarm may

occur when the

motor is running

This alarm may

occur when the

motor is running

This alarm may

occur when the

motor starts

running

Press Enter key on

the operator panel

or terminal RST of

X6 interface

Press Enter key on

the operator panel

or terminal RST of

X6 interface

Press Enter key on

the operator panel

or terminal RST of

X6 interface

Press Enter key on

the operator panel

or terminal RST of

X6 interface

1. check the load

2. lower the start/Stop

frequency

3. use drive and motor

with more power

1. Lower the frequency

2. Check whether P36

has the right value

1. modify the gain value

2. lessen load inertia

by RST terminal.

The 65 enable signal is lost

when the motor is running

A23

A41

A42

A43

A44

A45

Alarm

code

Background

Possible Cause Remedy Result Acknowledgement

1. terminas U, V and W on the

motor are wrongly connected

2. encoder cable is wrongly

connected

1. terminas U, V and W on the

motor are wrongly connected

2. the encoder is wrongly wired

1. circuit board fails

2. fuse of the power is burnt out

3. rectifier is boken

1. low supply voltage

2. insufficient supply power

capacity

3. transient power failure

NOTICE

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-31

Page 33

4.3 Errors during drive self-test

4.4 Other faults

1. Brake not open

2. Axis position incorrect or axis does not move

3. Axis does not move

4. Axis keeps running in a single direction

Drive error list

Drive display Description Cause Remedy

Error 1 RAM damaged

Flash damaged

Program copy error

Replace the drive

Replace the drive

Replace the drive

Error 2

Error 3

EN-32 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 34

Appendix

A.1 Order numbers

Spare parts

rebmunredrOnoitpircseD

0AU0-41CC5-0123LS6A4-1.06MPC 06VSCIMANIS

SINAMICS V60 CPM60.1 - 0AU0-61CC5-0123LS6A6

SINAMICS V60 CPM60.1 - 0AU0-71CC5-0123 LS6A7

SINAMICS V60 CPM60.1 - 10A 6SL3210-5CC21-0UA0

Servomotor 1FL5 - 4Nm - without key, without brake

Servomotor 1FL5 - 4Nm - with key, without brake

Servomotor 1FL5 - 4Nm - with key, with brake

Servomotor 1FL5 - 4Nm - without key, with brake

1FL5060-0AC21-0AH0

Servomotor 1FL5 - 6Nm - without key, without brake

Servomotor 1FL5 - 6Nm - with key, without brake

1FL5062-0AC21-0AG0

1FL5062-0AC21-0AA0

Servomotor 1FL5 - 6Nm - without key, with brake

Servomotor 1FL5 - 6Nm - with key, with brake

1FL5062-0AC21-0AH0

1FL5062-0AC21-0AB0

Servomotor 1FL5 - 7.7Nm - without key, without brake

Servomotor 1FL5 - 7.7Nm - with key, without brake

1FL5064-0AC21-0AG0

1FL5064-0AC21-0AA0

Servomotor 1FL5 - 7.7Nm - without key, with brake

Servomotor 1FL5 - 7.7Nm - with key, with brake

1FL5064-0AC21-0AH0

1FL5064-0AC21-0AB0

Servomotor 1FL5 - 10Nm - without key, without brake

Servomotor 1FL5 - 10Nm - with key, without brake

1FL5066-0AC21-0AG0

1FL5066-0AC21-0AA0

Servomotor 1FL5 - 10Nm - without key, with brake

Servomotor 1FL5 - 10Nm - with key, with brake

1FL5066-0AC21-0AH0

1FL5066-0AC21-0AB0

Encoder cable for 1FL5 Servomotors - 5m

Encoder cable for 1FL5 Servomotors - 10m

Power cable for 1FL5 Servomotors - 5m

Power cable for 1FL5 Servomotors - 10m

Brake cable for 1FL5 Servomotors - 5m

Brake cable for 1FL5 Servomotors - 10m

6FX6002-2LE00-1BA0

1FL5060-0AC21-0AG0

1FL5060-0AC21-0AA0

1FL5060-0AC21-0AA0

6FX6002-2LE00-1AF0

6FX6002-5LE00-1AF0

6FX6002-5LE00-1BA0

6FX6002-2BR00-1AF0

6FX6002-2BR00-1BA0

SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started EN-33

Page 35

A.2 Technical support

If you have any question (any suggestion or amendment) about this product or this

document, please call SIEMENS technical support or visit SIEMENS internet:

For Chinese customers:

For customers outside China:

Fax

Telephone

0911 895 7222

New Support Request:

Internet:

FAQ:

0911 895 7223

http://www.siemens.com/automation/support-request

http://www.siemens.de/automation/service&support

http://www.siemens.de/automation/csi_en/product

Fax

Telephone

00 86 10 6471 9990 or 400 810 4288

400 810 4288@siemens.com

00 86 10 6471 9991

EN-34 SINAMICS V60 Controlled Power Module (CPM60.1) Getting Started

Page 36

A5E03975175

Address: IA&DT Division

SIEMENS Limited China (SLC)

NO. 7, Wangjingzhonghuannanlu Road

Chaoyang District, Beijing, China

Post: 100102

TEL: (+86) 010 - 64768888

FAX: (+86) 010 - 64764729

Subject to change without prior notice

© Siemens AG 2012

Order Number:

Loading...

Loading...