Siemens COMBIMASTER CM55, COMBIMASTER CM25, COMBIMASTER CM75, COMBIMASTER CM12/2, COMBIMASTER CM37 Operating Instructions Manual

...Page 1

COMBIMASTER &

MICROMASTER Integrated

Operating Instructions

SIEMENS

Page 2

CONTENTS

Safety and CE Compliance................................................... 2

Installation ............................................................................. 4

General Wiring Guidelines.................................................................................. 4

Mechanical Installation | COMBIMASTER.......................................................... 4

Mechanical Installation | MICROMASTER Integrated......................................... 5

Electrical Installation | MICROMASTER Integrated ............................................ 5

Electrical Installation | COMBIMASTER and MICROMASTER Integrated.......... 6

Mains Cable Connections................................................................................... 6

Control Cable Connections................................................................................. 9

Drive Operation ................................................................... 10

General............................................................................................................. 10

Basic Operation................................................................................................ 11

Operation - External Analogue Control ............................................................. 11

Operation - Digital Control ................................................................................ 12

Stopping the Motor ........................................................................................... 12

If the Motor Does Not Start Up ......................................................................... 12

Options / Accessories ........................................................ 13

Electrical Data | COMBIMASTER ....................................... 13

Electrical Data | MICROMASTER Integrated ..................... 16

Parameter Summary List.................................................... 17

Technical Data, selection and ordering data (order numbers), accessories & availability are subject

to change.

© Siemens plc 1999 | G85139-H1731-U400-D2 1

Page 3

SAFETY AND CE COMPLIANCE

Before installing and operating this equipment read these safety instructions and warnings

carefully. Also read and obey all the warning signs attached to the equipment. Make sure that

the warning labels are kept in a legible condition and replace any missing or damaged labels.

WARNING

This equipment must be installed, operated and maintained by suitably qualified

personnel only.

Use only permanently-wired input power connections. The equipment must be

grounded (IEC 536 Class 1, NEC and other applicable standards).

Wait at least five minutes after the power has been turned off, before opening the

equipment. The dc-link capacitor remains charged to dangerous voltages even when

the power is removed. When working on open equipment, note that live parts are

exposed and do not touch these parts.

Some parameter settings can start the motor automatically when power is restored

after a mains failure.

Do not connect machines with a three-phase power supply, fitted with EMC filters, to a

supply via an ELCB (Earth Leakage Circuit Breaker - see EN50178, section 6.5).

Obey all general and regional installation and safety regulations relating to work on

high voltage installations, as well as regulations covering correct use of tools and

personal protective equipment.

Note that the following terminals can carry dangerous voltages even when the inverter

is inoperative:

Power supply terminals L1, L2 and L3

Motor terminals U, V and W

When using the analogue input, the jumpers must be correctly set and the analogue

input type selected (P023) before enabling the analogue input with P006. If this is not

done the motor may start inadvertently.

This equipment is capable of providing internal motor overload protection in

accordance with UL508C section 42.

This equipment is suitable for use in a circuit capable of delivering not more than

10,000 symmetrical amperes (rms), for a maximum voltage of 230V/480V/500V when

protected by a time delay fuse (see Electrical Data for details).

Do not operate the equipment in direct sunlight.

This equipment must not be used as an ‘emergency stop’ mechanism (see EN 60204,

9.2.5.4).

CAUTION

Do not allow children or the general public to access or approach this equipment.

High voltage insulation test equipment must not be used on cables connected to the

equipment.

Keep operating instructions within easy reach and give them to all users.

Use this equipment only for the purpose specified by the manufacturer. Do not carry

out any modifications, or fit any spare parts which are not sold or recommended by the

manufacturer; this could cause fires, electric shock or other injuries.

2 © Siemens plc1999 | G85139-H1731-U400-D2

Page 4

EUROPEAN LOW

VOLTAGE & EMC

DIRECTIVES

The COMBIMASTER

product complies with the

requirements of the Low

Voltage Directive 73/23/EEC

and the EMC Directive

89/336/EEC.

The MICROMASTER Integrated /

COMBIMASTER must not be put into service

until the machinery into which it is

incorporated has been certified to be in

compliance with the provisions of the

European Directive 89/392/EEC.

Note: Only valid for machinery to be

operated in the European Community.

The units are certified for compliance with

the following standards:

EN 60204-1 Safety of machinery Electrical equipment of machines

EN 60146-1-1 Semiconductor converters General requirements and line commutated

converters

BS EN50081-2: 1995 General Emission

Standard - Industrial Environment

BS EN50082-2: 1995 General Immunity

Standard - Industrial Environment

The MICROMASTER Integrated product

complies with the requirements of the Low

Voltage Directive 73/23/EEC.

The units are certified for compliance with

the following standards:

EN 60204-1 Safety of machinery Electrical equipment of machines

EN 60146-1-1 Semiconductor converters General requirements and line commutated

converters

EUROPEAN MACHINERY DIRECTIVE

The MICROMASTER Integrated /

COMBIMASTER products are suitable for

incorporation into machinery.

COMBIMASTER – UL CERTIFICATION

UL cUL listed power conversion equipment

type 5B33 in accordance with UL508C.

For use in pollution degree 2 environment.

(Applies to inverters only)

MICROMASTER Integrated – UR

CERTIFICATION

UR cUR recognised power conversion

equipment in accordance with UL508C.

For use in pollution degree 2 environment.

This equipment must be externally cooled by a

fan, the rating of which depends on the unit

Case Size. For Case Sizes A and B, the fan

must provide 0.42m3/min and 1.25m3/min

respectively.

BSI

R

D

E

E

G

R

I

S

E

T

© Siemens plc 1999 | G85139-H1731-U400-D2 3

ISO 9001

Siemens plc operates a quality management system which complies with

the requirements of ISO 9001.

Page 5

INSTALLATION

WARNING

Take note of the general and regional installation and safety regulations regarding

work on high voltage installations (e.g. VDE). Adhere to relevant regulations regarding

correct use of tools and protective gear.

Use the lifting eyes provided if a motor has to be lifted. Do not lift machine sets by

suspending the individual machines! Always check the capacity of the hoist before

lifting any equipment.

Do not paint over the black case finish of the inverter as this will affect the unit’s

thermal performance.

General Wiring Guidelines

The Case Size A (CS A) and Case Size B

(CS B) COMBIMASTER and

MICROMASTER Integrated are designed to

operate in an industrial environment where a

high level of Electro-Magnetic Interference

(EMI) can be expected. Usually, good

installation practices will ensure safe and

trouble-free operation. However, if problems

are encountered, the following guidelines

may prove useful. In particular, grounding of

the system 0V at the inverter, as described

below, may prove effective.

1 All equipment must be well earthed using

short, thick earthing cable connected to a

common star point or busbar. It is

particularly important that any control

equipment connected to the inverter

(such as a PLC) is connected to the

same earth or star point as the inverter

via a short, thick link. Flat conductors

(e.g. metal brackets) are preferred as

they have lower impedance at high

frequencies.

2 Use screened leads for connections to

the control circuitry. Terminate the ends

of the cable neatly, ensuring that long

strands of unscreened wire are not left

visible.

3 Separate the control cables from the

power connections as much as possible,

using separate trunking, etc. If control

and power cables cross, arrange the

cables so that they cross at 90

4 Ensure that contactors are suppressed,

either with R-C suppressors for AC

contactors or ‘flywheel' diodes for DC

contactors, fitted to the coils. Varistor

suppressors are also effective.

Safety regulations must not be

compromised when installing the

COMBIMASTER or MICROMASTER

Integrated!

Mechanical Installation | COMBIMASTER

WARNING

Take suitable precautions to prevent transmission elements from being touched. If the

COMBIMASTER is started up without a transmission element attached, the featherkey

must be secured in position to prevent it from flying off while the shaft is rotating.

Tighten down screw-in lifting eyes prior to

using the COMBIMASTER.

Stable foundations or mounting conditions

and a well balanced transmission element

are essential for quiet, vibration-free running.

It may be necessary to balance the whole

rotor and transmission element.

The rotors are dynamically balanced with a

full featherkey inserted as standard. Since

1991 the type of balance has been marked

on the drive end of the shaft (shaft end face).

F denotes balanced with full featherkey; H

denotes balanced with half featherkey. Bear

in mind the type of balance used when fitting

the transmission element.

o

.

4 © Siemens plc1999 | G85139-H1731-U400-D2

Page 6

Poor running characteristics can arise in

cases where the transmission elements have

a length ratio of hub length to shaft end

length < 0.8 and they run at speeds greater

than 1500 rpm. In such cases rebalancing

may be necessary, e.g. by reducing the

distance by which the featherkey protrudes

from the transmission element and the shaft

surface.

Please check the following prior to

commissioning:

• The rotor turns freely without rubbing.

• The motor is assembled and aligned

properly.

• The transmission elements are adjusted

correctly (e.g. belt tension) and the

transmission element is suitable for the

given operating conditions.

• All electrical connections, mounting

screws and connecting elements are

tightened and fitted correctly.

• All protective conductors are installed

properly.

• Any auxiliary equipment that might be

fitted (e.g. mechanical brake) is in

working order.

• Protection guards are installed around all

moving and live parts.

• The maximum speed (see motor rating

plate) is not exceeded. The maximum

speed is the highest operating speed

permitted. Remember that motor noise

and vibration are worse at this speed

and bearing life is reduced.

The above list is not meant to be exhaustive

- additional checks may also be required.

Mechanical Installation | MICROMASTER Integrated

The motor / MICROMASTER Integrated

combination should be installed according to

guidelines similar to those given above for

the COMBIMASTER.

First fit the Motor Interface Plate (MIP) to the

motor. In most cases the MIP makes use of

the existing motor gasket. Refer to Siemens

Document ‘MMI Motor Adaptation

Guidelines’ (English) – (Available 2

1999.– G85139-H1731-U500-A1.

Electrical Installation | MICROMASTER Integrated

The motor wires should be connected in

either star or delta configuration on the MIP

Star Connection

Wire Terminal

U2/V2/W2 N

U1 U

V1 V

W1 W

Star connection Delta connection

V

W

TB1

U

N

(check motor rating plate).

Delta Connection

Wire Terminal

U1/W2 U

U2/V1 V

V2/W1 W

U1

U2

V1

V2

W1

W2

PTC

wires

V

W

TB1

nd

Qtr

U

N

Earth connection

Earth connection

Figure 1 Motor Wire Connection

© Siemens plc 1999 | G85139-H1731-U400-D2 5

Page 7

WARNING

It is essential that the MIP is correctly earthed to the motor. This is usually achieved

using a short earth cable connected between the MIP and a suitable connection point

on the motor. Death or severe injury can result if the motor is not correctly earthed.

Incorrect earthing can also prevent any MICROMASTER Integrated built-in EMC filter

from operating correctly.

Electrical Installation | COMBIMASTER and

MICROMASTER Integrated

Remove the four M5 cross-head screws on

the inverter's cover to access the electrical

terminals (see Figs 2 and 3).

Notes: Refer to the Electrical Data tables for

cable sizes.

CAUTION

The printed circuit boards contain CMOS components that are particularly sensitive to

static electricity. For this reason, avoid touching the boards or components with hands

or metal objects.

Mains Cable Connections

Ensure that the power source supplies the

correct voltage and is designed for the rated

current. Use the appropriate circuit-breakers

with the specified current rating between the

power supply and inverter.

Use Class 1 60/75

4-core screened cable. If crimp terminals are

used they must be insulated. If crimps are

not used, the strip length must not exceed

5mm.

o

C copper wire only. Use a

A ‘drip loop’ is recommended when

connecting the mains and control cables

(see Fig. 6).

Feed the power cable into the inverter via the

gland hole nearest to the motor shaft.

Connect the power leads to terminals L1, L2,

L3 (L1, L2 for single phase units) and the

separate earth.

Use a 4 - 5 mm cross-tip screwdriver to

tighten the terminal screws.

6 © Siemens plc1999 | G85139-H1731-U400-D2

Page 8

Earth

connection

Mains

connection

Control cable

connector

(PL800)

OPm2

connector

(SK200)

LED

(green)

LED

(yellow)

Control

Potentiometer

(R314)

JP 305 connects

PI- to 0V

V

I

Jumpers for

PI input type

Default = V

JP 303

JP 302

Note: Jumper in 'V' position = voltage input (default)

Jumper in 'I' position = current input

JP 304 connects

AIN- to 0V

V

I

Jumpers for

Analogue input type

Default = V

Figure 2 Electrical Connection (CS B)

Check that the supply voltage is correct for the

inverter used by referring to the rating label.

Cable Glands (Case Size B) PG21(Mains)

PG16(Signal)

JP 301

JP 300

IMPORTANT

Ensure that the following tightening torques are used:

Access cover retaining screws 4.0Nm

Gland hole covers: 1.0Nm

Mains connector screws 1.0Nm

Earth Connection 1.5Nm

© Siemens plc 1999 | G85139-H1731-U400-D2 7

Page 9

Earth

connection

Mains

connection

Note: Jumper in 'V' position = voltage input (default)

I

V

Analogue input type

JP 300

JP 301

Jumpers for

Default = V

Jumper in 'I' position = current input

JP 305

connects

PI- to 0V

I

V

Jumpers for

PI input type

Default = V

JP 302

JP 303

JP 304

connects

AIN- to 0V

OPm2 connector

(SK200)

LED

(green)

LED

(yellow)

Control cable connector

(PL700)

Control Potentiometer

(R314)

Figure 3 Electrical Connection (CS A)

IMPORTANT

Check that the supply voltage is correct for the

inverter used by referring to the rating label.

Cable Glands (Case Size A) PG16

8 © Siemens plc1999 | G85139-H1731-U400-D2

Ensure that the following tightening torques are used:

Access cover retaining screws 4.0Nm

Gland hole covers: 1.0Nm

Mains connector screws 1.0Nm

PL700 Screws 0.5Nm

Earth Connection 1.5Nm

Page 10

Control Cable Connections

CAUTION

The control and power supply cables must be laid separately. They must not be fed

through the same cable conduit / trunking.

Use screened cable for the control lead.

Feed the control cable into the inverter via

the appropriate gland hole . Connect the

control wires in accordance with the

information in Figures 4,5 and 6 having first

unplugged connector block PL800 from the

PCB (CS B only).

IMPORTANT: A wire link must be fitted

between control terminals 5 (DIN1) and 1

(P10+) if it is required to start the inverter

from the control potentiometer R314, or the

analogue input. The wire link must be

removed when operation via a run/stop

switch is required.

COMBIMASTER Control Terminals

Cabling Information

CS A (PL700): CS B (PL800)

Cable AWG 22 - 18 28 – 20

= approx. mm

Strip length (mm) 5 – 6 5 – 6

Strip length (inch) 0.22 0.22

2 0.35 – 0.82 0.08 – 0.50

Note that the optional potentiometer fitted as

an analogue set point shown in Figure 4

assumes that jumper JP304 is connecting 0V

(pin 2) to AIN- (pin 4).

Also, +15V can be used as an alternative to

P10+ for the digital inputs.

Plug the connector block back into the PCB

(CS B only), refit the cover and tighten the

four securing screws.

Relay (RL1)

(30V dc. 1.0 A max.)

PI+ PI- +15V

JP305 JP304

1

DIN3 DIN2 DIN1 AIN- AIN+ 0V P10+

12 11 10 9 8 7 6 554433221

PI +ve Input

RLC

(COM)

or 0 - 20mA)

RLB

(NO)

(0 - 10V

PI -ve Input

PI Power Supply

(+15V,

max. 50mA)

Digital Inputs

(7.5 - 33V, max. 5mA)

PL800 (CS B) / PL700 (CS A) SK200 Socket

Analogue Input

(0/2 - 10V,

or 0/4 - 20mA)

Power Supply

for Digital and

Analogue

Inputs

(+10V, max. 10mA)

1 - +5V (250mA max.)

2 - N (-)

3 - 0V

4 - P (+)

5 - no connection

Figure 4 Control Terminal Connections

© Siemens plc 1999 | G85139-H1731-U400-D2 9

Page 11

1.8mm max. screwdriver

Figure 5 Connecting Control Wires to PL800

Figure 6 Cable Connections with Drip Loop

DRIVE OPERATION

WARNING

The equipment must not be switched on until after its cover has been fitted and the

cover screws have been tightened to the correct torque (see Fig. 2 & 3).

After the power has been turned off, you must always wait five minutes so that the dc

link capacitors can discharge. Do not remove the cover until this time has elapsed.

All settings must be only entered by qualified personnel, paying particular attention to

the safety precautions and warnings.

General

For basic operation of COMBIMASTER, no

additional equipment is required. However,

for more complex operation, OPm2 – Clear

Text Display is required (OPm2 is available

as an option, but must be ordered

separately).

10 © Siemens plc1999 | G85139-H1731-U400-D2

The inverter does not have a mains power

switch and is therefore live when the mains

supply is connected.

When delivered, the inverter has a frequency

setpoint range of between 0 Hz and 50 Hz.

Regardless of its initial position, internal

potentiometer R314 must be turned fully

counter-clockwise before it will start the

inverter.

Page 12

R314 can be accessed by removing the

right-hand gland hole cover (see Fig. 2 & 3).

Analogue input type is selected by jumpers

JP300 and JP301. JP300 closed selects

current input, JP301 closed (default) selects

voltage input. These jumpers can only be

accessed when the cover is removed (see

Fig. 2 & 3).

Basic Operation

If the motor is run unloaded (e.g. for test

purposes) and vibration or trip conditions

occur, change P077 from 0 to 3 (requires

OPm2).

There are two basic modes of operation for

the inverter.

1 Using the internal potentiometer only:

a For forward rotation, ensure that a link

is fitted between DIN1 (pin 5) and

P10+ (pin 1) on PL800/PL700 (see

Fig. 4). For reverse rotation, connect

the link to DIN2 (pin 6) instead of

DIN1.

b Apply mains power. The green and

yellow LEDs will illuminate to show

that power is applied. Turn

potentiometer R314 fully counterclockwise, otherwise the

COMBIMASTER cannot be started.

c Turn the potentiometer clockwise until

the yellow LED extinguishes. This

indicates that power is now applied to

the motor. Continue turning clockwise

to increase the speed of the motor.

d Turn the potentiometer counter-

clockwise to reduce the speed of the

motor. Turning the potentiometer fully

counter-clockwise causes the motor to

slow to a complete stop. Check that

both LEDs are illuminated (STANDBY

mode).

2 Using a combination of the internal

potentiometer and a run/stop switch:

a Connect a run/stop switch between

IMPORTANT: Remove the link, if fitted,

between pins 5 and 1 before the run/stop

switch is fitted.

b Apply mains power. The green and

c Set the external run/stop switch to

d Turn potentiometer R314 clockwise to

e Stop the motor by setting the external

Operation - External Analogue Control

DIN1 (pin 5) and P10+ (pin 1) on

PL800 (see Fig. 4) if forward rotation

is required. If reverse rotation is

required instead, connect the switch to

DIN2 (pin 6) instead of DIN1.

yellow LEDs will illuminate to show

that power is applied.

ON.

set the required motor speed.

on/off switch to OFF. When the switch

is set to ON again, it will run at the

speed previously set using the

potentiometer.

1 Connect a 4.7 kΩ potentiometer to the

control terminals as shown in Fig. 4 or

apply a 0 - 10 V signal between pin 2

(0V) and pin 3 (AIN+). In both cases,

position jumper JP304 to connect 0V to

AIN-.

2 Ensure that a link is fitted between pin 5

(DIN1) and pin 1 (P10+).

3 Check that voltage input is selected by

ensuring that the jumper is fitted to

JP301.

4 Refit the cover, tighten the cover screws

to the correct torque and then apply

mains power to the inverter.

© Siemens plc 1999 | G85139-H1731-U400-D2 11

5 Turn the external potentiometer (or

adjust the analogue control voltage) until

the desired frequency is achieved. The

unit will not switch on until a minimum of

2 V has been applied.

Note: The frequency set by the external

voltage is added to the frequency set by the

internal potentiometer.

As with Basic Operation (2), a run/stop

switch can be used to start and stop the

motor, or the direction of rotation can be

changed by connecting the link to DIN2

instead of DIN1.

Page 13

Operation - Digital Control

This method of operation requires either a

Clear Text Display (OPm2) or a serial link

connection. For a basic startup configuration

using digital control, proceed as follows:

1 Remove the link that connects control

terminal 5 to terminal 1 (if one has been

fitted).

2 Connect control terminal 5 to terminal 1

via a simple on/off switch. This sets up

the inverter for clockwise rotation

(default). If counter-clockwise operation

is required, connect a switch between

control terminals 6 and 1.

3 Connect the OPm2 or serial link to

SK200. Refit the cover, tighten the cover

screws to the correct torque and then

apply mains power to the inverter.

4 Set parameter P006 to 000 to specify

digital setpoint.

5 Set parameter P005 to the desired

frequency setpoint.

6 Set the external on/off switch to ON or

press the ON button on the OPm2 (set

P007 = 001 to use the OPm2). The

inverter will now run at the frequency set

by P005.

Stopping the Motor

Via the external on/off switch: Setting the

switch to OFF overrides the setting on the

potentiometer and causes the motor to come

to a controlled stop.

Via the potentiometer: Turning the

potentiometer counter-clockwise until the

input voltage drops below 2 V causes the

motor to slow to a stop. . If an external

potentiometer is applied, the input voltage

must also be below 2V to stop.

If the Motor Does Not Start Up

Check the LEDs on the side of the inverter:

LED State COMBIMASTER / MICROMASTER Integrated Status

Green Yellow

ON ON Mains power on, inverter not running (STANDBY)

ON OFF Inverter running, as per control commands (ON)

Flashing Flashing Current limit warning

Flashing ON Inverter overtemperature (PTC)

ON Flashing Motor overtemperature

OFF ON Other fault (e.g. tripped)

OFF Flashing Mains undervoltage

OFF OFF Mains supply fault (e.g. faulty external switch)

If a fault occurs:

Switch off, disconnect and then reconnect

the power, and then switch on again. Switch

off if the fault condition persists. Trips can be

reset by using DIN3.

If a warning occurs:

Switch off, disconnect and reconnect the

power and then switch on again.

If the fault/warning persists, further

investigation requires an OPm2 or a serial

link connection.

12 © Siemens plc1999 | G85139-H1731-U400-D2

Page 14

OPTIONS / ACCESSORIES

Description: Order Number: Shortcode:

Clear Text Display (OPm2) 6SE3290-0XX87-8BF0

Interface cable for OPm2 - 3m screened 6SE9996-0XA31

Reference Manual 6SE9996-0XA35

PROFIBUS Module (CB155)

Note : For CS B , Issue A units :

PROFIBUS T-Connector 6SE9996-0XA21

PROFIBUS Terminator 6SE9996-0XA22

PROFIBUS Cable - 1m 6SE9996-0XA23

PROFIBUS Cable - 5m 6SE9996-0XA24

PROFIBUS Cable - 10m 6SE9996-0XA25

PROFIBUS Cable Link 6SE9996-0XA26

CS A Inverter Fan Option

(MICROMASTER Integrated only)

CS B Inverter Fan Option

(MICROMASTER Integrated only)

CS A Electro-mechanical Brake Control

(Note :Expected Product release: August

Unit

1999)

CS B Electro-mechanical Brake Control

Unit

CS B Pulse Resistor Braking Unit 6SE9996-0XA11

SIMOVIS PC Software 6SE3290-0XX87-8SA2

Note:

CS A covers power range 120W to 1.5kW

CS B covers power range 1.5kW to 7.5kW

6SE9996-0XA18

use : 6SE9996-0XA20

6SE9996-0XA01 M41

6SE9996-0XA02 M41

6SE9996-0XA07

6SE9996-0XA10

(for ordering with unit)

© Siemens plc 1999 | G85139-H1731-U400-D2 13

Page 15

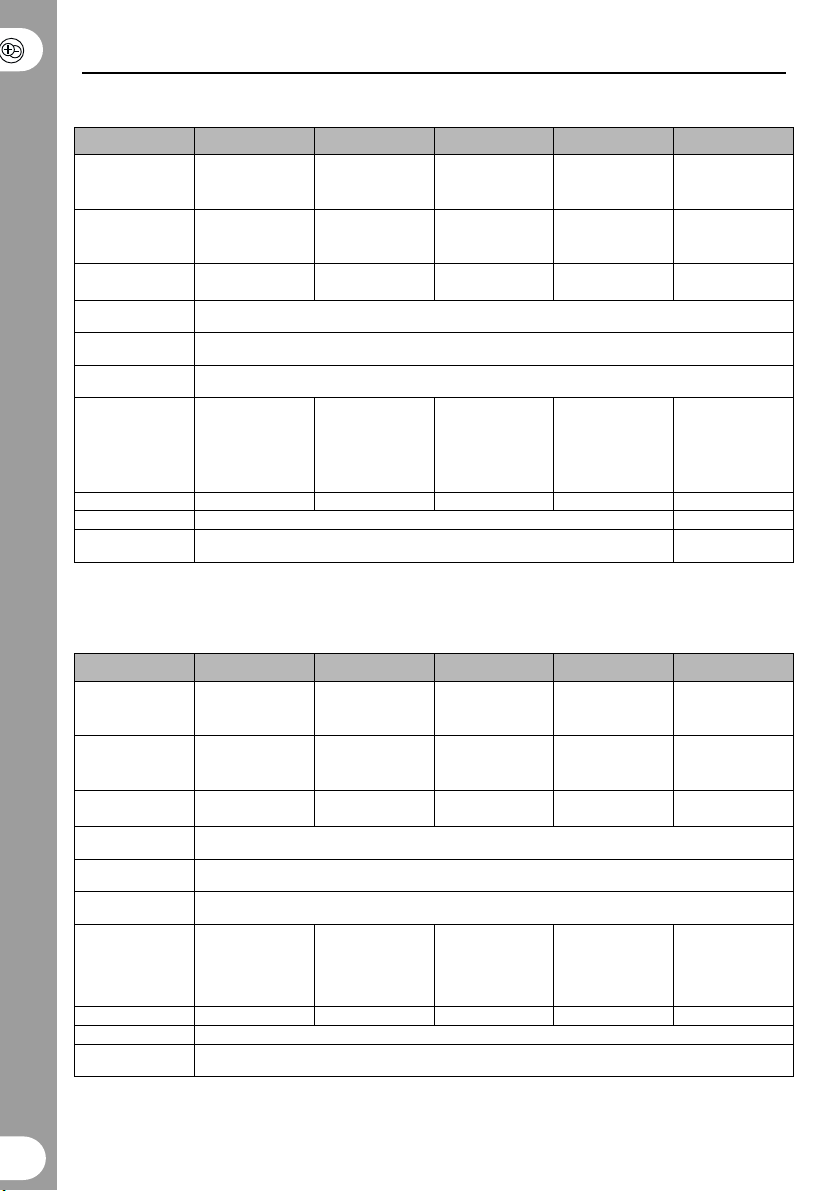

ELECTRICAL DATA | COMBIMASTER

CS A Low Voltage Single Phase Units

Model: CM12 CM25 CM37 CM55 CM75

Order Number:

2 pole

4 pole

Frame size:

2 pole

4 pole

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

2 pole

4 pole

Input Current: 1.8 A rms 3.2 A rms 4.6 A rms 6.2 A rms 8.2 A rms

Mains fuse: 10 A 16 A

Mains Lead crosssection

* [z] = filter option: U = Unfiltered, A = Class A filter, B = Class B filter.

Position 12 (shown as “.”) is for the construction type from the Siemens M11 catalogue.(ref.: E2002-K1711-

A201-A2-7600)

CS A Low Voltage Three Phase Units

Model: CM12/2 CM25/2 CM37/2 CM55/2 CM75/2

Order Number: *

2 pole

4 pole

Frame size: *

2 pole

4 pole

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

2 pole

4 pole

Input Current: 1.1 A rms 1.9 A rms 2.7 A rms 3.6 A rms 4.7 A rms

Mains fuse: 10 A

Mains Lead crosssection

* Note that these units are available Unfiltered only.

Position 12 (shown as “.”) is for the construction type from the Siemens M11 catalogue.(Ref.: see above)

1UA7053-2B[z]0.

1UA7060-4B[z]0.

56

63

0.12kW

0.16hp

0 – 100Hz

0 –140Hz

1UA7053-2BU1.

1UA7060-4BU1.

56

63

0.12kW

0.16hp

0 – 100Hz

0 –140Hz

1UA7063-2B[z]0.

1UA7070-4B[z]0.

63

71

0.25kW

0.33hp

0 – 100Hz

0 – 140Hz

1UA7063-2BU1.

1UA7070-4BU1.

63

71

0.25kW

0.33hp

0 – 100Hz

0 – 140Hz

1UA7070-2B[z]0.

1UA7073-4B[z]0.

71

71

0.37kW

0.49hp

1∅ AC 208 – 240 Vrms ± 10%

47 – 63 Hz

0 – 50Hz

0 – 100Hz

0 – 140Hz

2

1mm

1UA7070-2BU1.

1UA7073-4BU1.

71

71

0.37kW

0.49hp

3∅ AC 208 – 240 Vrms ± 10%

47 – 63 Hz

0 – 50Hz

0 – 100Hz

0 – 140Hz

2

1mm

1UA7073-2B[z]0.

1UA7080-4B[z]0.

71

80

0.55kW

0.73hp

0 – 100Hz

0 – 140Hz

1UA7073-2BU1.

1UA7080-4BU1.

71

80

0.55kW

0.73hp

0 – 100Hz

0 – 140Hz

1UA7080-2B[z]0.

1UA7083-4B[z]0.

80

80

0.75kW

1.0hp

0 – 100Hz

0 – 140Hz

1.5mm

1UA7080-2BU1.

1UA7083-4BU1.

80

80

0.75kw

1.0hp

0 – 100Hz

0 – 140Hz

2

14 © Siemens plc1999 | G85139-H1731-U400-D2

Page 16

CS A High Voltage Three Phase Units

Model: CM37/3 CM55/3 CM75/3 CM110/3 CM150/3

Order Number: *

2 pole

4 pole

Frame size:

2 pole

4 pole

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

2 pole

4 pole

Input Current: 2.2 A rms 2.8 A rms 3.7 A rms 4.9 A rms 5.9 A rms

Mains fuse: 10 A

Mains Lead crosssection

1UA7070-2B[zz].

1UA7073-4B[zz].

71

71

0.37kW

0.49hp

3∅ AC 380 – 500 V

100 Hz

140Hz

1UA7073-2B[zz].

1UA7080-4B[zz].

73

80

0.55kW

0.73hp

rms ± 10% (all units) 3∅ AC 380 – 480 Vrms ± 10% (filtered units only)

Torque derating required below 380Vrms

100Hz

140Hz

1UA7080-2B[zz].

1UA7083-4B[zz].

80

80

0.75kW

1.0hp

47 – 63 Hz

0 – 50Hz

100Hz

140Hz

2

1mm

1UA7083-2B[zz].

1UA7090-4B[zz].

80

90S

1.1kW

1.5hp

100Hz

140Hz

1UA7090-2C[zz].

1UA7096-4C[zz].

90S

90L

1.5kW

2.0hp

100Hz

140Hz

* [zz] = filter option: U = Unfiltered, A = Class A filter, B = Class B filter and mains voltage code: 2 = 380 – 500V,

3 = 460 – 500V/60Hz . Allowed combinations: A2, B2, U2 and U3.

Position 12 (shown as “.”) is for the construction type from the Siemens M11 catalogue. (Ref.: see above)

CS B High Voltage Three Phase Units

Model: CM150/3 CM220/3 CM300/3 CM400/3 CM550/3 CM750/3

Order Number: *

2 pole

4 pole

Frame size:

2 pole

4 pole

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output

Frequency with

Opm2 or serial

link:

2 pole

4 pole

Input Current: 3.5 A rms 4.7 A rms 6.4 A rms 10.0 A rms 12.2 A rms 16.0 A rms

Mains fuse: 10 A 16 A 20 A

Mains Lead

cross-section

* [zz] = filter option: U = Unfiltered, A = Class A filter, B = Class B filter and mains voltage code: 2 = 380 – 500V,

3 = 460 – 500V/60Hz . Allowed combinations: A2, B2, U2 and U3.

Position 12 (shown as “.”) is for the construction type from the Siemens M11 catalogue. (Ref.: see above)

1UA7090-

2B[zz].

1UA7096-

4B[zz].

90S

90L

1.5kW

2.0hp

3∅ AC 380 – 500 Vrms ± 10% (all units) 3∅ AC 380 – 480 Vrms ± 10% (filtered units only)

100 Hz

140Hz

1mm

1UA7096-

2B[zz].

1UA7106-

4B[zz].

100L

2.2kW

2.9hp

100Hz

140Hz

2

1UA7106-

2B[zz].

1UA7107-

4B[zz].

90L

100L

100L

3.0kW

4.0hp

Torque derating required below 380Vrms

47 – 63 Hz

0 – 50Hz

100Hz

140Hz

1.5mm

1UA7113-

2B[zz].

1UA7113-

4B[zz].

112M

112M

4.0kW

5.3hp

100Hz

140Hz

2

1UA7130-

2B[zz].

1UA7130-

4B[zz].

132S

132S

5.5kW

7.3hp

90Hz

140Hz

2.5mm

1UA7131-

2B[zz].

1UA7133-

2B[zz].

132S

132M

7.5kW

10.0hp

90Hz

140Hz

2

© Siemens plc 1999 | G85139-H1731-U400-D2 15

Page 17

ELECTRICAL DATA | MICROMASTER Integrated

CS A Low Voltage Single Phase Units

Model: MI12 MI25 MI37 MI55 MI75

Order Number: * 6SE9610-

7BF[y]0-Z=C87

6SE9611-

5BF[y]0-Z=C87

6SE9612-

0BF[y]0-Z=C87

6SE9612-

6BF[y]0-Z=C87

6SE9613-

4BF[y]0-Z=C87

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

Input Current: 1.8 A rms 3.2 A rms 4.6 A rms 6.2 A rms 8.2 A rms

Mains fuse: 10 A 16 A

Mains Lead crosssection

0.12kW

0.16hp

0.25kW

0.33hp

0.37kW

0.49hp

1∅ AC 208 – 240 Vrms ± 10%

47 – 63 Hz

0 – 50Hz

0 – 400Hz

2

1mm

0.55kW

0.73hp

0.75kW

1.0hp

1.5mm

* [y] = filter option: 1 = Unfiltered, 5 = Class A filter, 6 = Class B filter.

CS A Low Voltage Three Phase Units

Model: MI12/2 MI25/2 MI37/2 MI55/2 MI75/2

Order Number: * 6SE9610-7CF10-

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

Input Current: 1.1 A rms 1.9 A rms 2.7 A rms 3.6 A rms 4.7 A rms

Mains fuse: 10 A

Mains Lead crosssection

Z=C87

0.12kW

0.16hp

* Note that these units are available Unfiltered only.

6SE9611-5CF10-

Z=C87

0.25kW

0.33hp

6SE9612-0CF10-

Z=C87

0.37kW

0.49hp

3∅ AC 208 – 240 V

47 – 63 Hz

0 – 50Hz

0 – 400Hz

2

1mm

rms ± 10%

6SE9612-6CF10-

Z=C87

0.55kW

0.73hp

6SE9613-4CF10-

Z=C87

0.75kW

1.0hp

2

16 © Siemens plc1999 | G85139-H1731-U400-D2

Page 18

CS A High Voltage Three Phase Units

Model: MI37/3 MI55/3 MI75/3 MI110/3 MI150/3

Order Number: *

6SE9611-

1DF[y]0-Z=C87

6SE9611-

4DF[y]0-Z=C87

6SE9611-

8DF[y]0-Z=C87

6SE9612-

7DF[y]0-Z=C87

6SE9613-

7DF[y]0-Z=C87

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output Frequency

with Opm2 or

serial link:

Input Current: 2.2 A rms 2.8 A rms 3.7 A rms 4.9 A rms 5.9 A rms

Mains fuse: 10 A

Mains Lead crosssection

0.37kW

0.49hp

3∅ AC 380 – 500 Vrms ± 10% (all units) 3∅ AC 380 – 480 Vrms ± 10% (filtered units only)

0.55kW

0.73hp

0.75kW

1.0hp

47 – 63 Hz

0 – 50Hz

0-400Hz

2

1mm

1.1kW

1.5hp

1.5kW

2.0hp

* [y] = filter option: 1 = Unfiltered, 5 = Class A filter, 6 = Class B filter.

CS B High Voltage Three Phase Units

Model: MI150/3 MI220/3 MI300/3 MI400/3 MI550/3 MI750/3

Order Number: * 6SE9613-

Motor Output

Rating:

Operating Input

Voltage:

Operating Input

Frequency:

Output

Frequency:

Output

Frequency with

Opm2 or serial

link:

Input Current: 3.5 A rms 4.7 A rms 6.4 A rms 10.0 A rms 12.2 A rms 16.0 A rms

Mains fuse: 10 A 16 A 20 A

Mains Lead

cross-section

7DD[y]0-

Z=C87

1.5kW

2.0hp

3∅ AC 380 – 500 Vrms ± 10% (all units) 3∅ AC 380 – 480 Vrms ± 10% (filtered units only)

1mm

6SE9615-

8DD[y]0-

Z=C87

2.2kW

2.9hp

2

6SE9617-

3DD[y]0-

Z=C87

3.0kW

4.0hp

47 – 63 Hz

0 – 50Hz

0-400Hz

1.5mm

6SE9621-

1DD[y]0-

Z=C87

4.0kW

5.3hp

2

6SE9621-

3DD[y]0-

Z=C87

5.5kW

7.3hp

2.5mm

6SE9621-

7DD[y]0-

Z=C87

7.5kW

10.0hp

2

* [y] = filter option: 1 = Unfiltered, 5 = Class A filter, 6 = Class B filter.

PARAMETER SUMMARY LIST

This list is applicable for operation using Opm2 – Clear Text Display (optional).

● = Parameter can be changed during operation.

✩✩✩ = Value depends on the rating of the motor.

© Siemens plc 1999 | G85139-H1731-U400-D2 17

Page 19

Parameter Function Default

Parameter Function Default

P000 Operating display -

P001 ● Display mode 0

P002 ● Ramp up time (seconds) 10.00

P003 ● Ramp down time (seconds) 25.00

P004 ● Smoothing (seconds) 0.0

P005 ● Digital frequency setpoint (Hz) 50.00

P006 Frequency setpoint source selection 1

P007 Keypad control 0

P009 ● Parameter protection setting 0

P011 Frequency setpoint memory 0

P012 ● Minimum motor frequency (Hz) 0.00

P013 ● Maximum motor frequency (Hz) 50.00

P014 ● Skip frequency 1 (Hz) 0.00

P015 ● Automatic restart after mains failure 0

P016 ● Start on the fly 0

P017 ● Smoothing type 1

P018 ● Automatic restart after fault 0

P019 ● Skip frequency bandwidth (Hz) 2.00

P020 Flying start ramp time (seconds) 25.00

P021 ● Minimum analogue frequency (Hz) 0.00

P022 ● Maximum analogue frequency (Hz) 50.00

P023 ● Analogue input type 2

P024 ● Analogue setpoint addition 0

P027 ● Skip frequency 2 (Hz) 0.00

P028 ● Skip frequency 3 (Hz) 0.00

P029 ● Skip frequency 4 (Hz) 0.00

P031 ● Jog frequency right (Hz) 5.00

P032 ● Jog frequency left (Hz) 5.00

P033 Jog Ramp Up time (V3.00) 10.00

P034 Jog Ramp Down time (V3.00) 10.00

P035 Reverse motor direction 0

P041 ● Fixed frequency 1 (Hz) 5.00

P042 ● Fixed frequency 2 (Hz) 10.00

P043 ● Fixed frequency 3 (Hz) 15.00

P044 ● Fixed frequency 4 (Hz) 20.00

P045 Inversion fixed setpoints for fixed

P046 ● Fixed frequency 5 (Hz) 25.00

P047 ● Fixed frequency 6 (Hz) 30.00

P048 ● Fixed frequency 7 (Hz) 35.00

P050 Inversion fixed setpoints for fixed

P051

P052 Selection control function (DIN2 –

P053 Selection control function (DIN3 –

P056 Digital input debounce time 0

P058 ● RUN command delay (seconds) 0.0

P061 Selection relay output RL1 6

P062 Electro-mechanical brake option

P063 External brake release delay

P064 External brake stopping time

P065 Current threshold for relay (A) 1.0

P071 ● Slip compensation (%) 0

P072 ● Slip limit (%) 500

P073 ● DC injection braking (%) 0

P074 ● I2t motor derating 0

PO76 Pulse Frequency 0 or 2

P077 Control mode 0

P078 ● Continuous boost (%) 50

P079 ● Starting boost (%) 0

P081 Nominal frequency for motor (Hz)

P082 Nominal speed for motor (RPM)

P083 Nominal current for motor (A)

P084 Nominal voltage for motor (V)

frequencies 1 – 4

frequencies 5 – 7

Selection control function (DIN1 –

terminal 5) fixed frequency 3 or binary

fixed frequency bit 0

terminal 6) fixed frequency 2 or binary

fixed frequency bit 1

terminal 7) fixed frequency 1 or binary

fixed frequency bit 2

control

(seconds)

(seconds)

0

0

1

2

10

0

1.0

1.0

✩✩✩

✩✩✩

✩✩✩

✩✩✩

18 © Siemens plc1999 | G85139-H1731-U400-D2

Page 20

Parameter Function Default

Parameter Function Default

P085 Nominal power for motor (kW/hp)

P086 ● Motor current limit (%) 150

P087 Motor PTC enable 0

P089 ●

P091 ● Serial link slave address 0

P092 ● Serial link baud rate 6

P093 ● Serial link timeout (seconds) 0

P094 ● Serial link nominal system setpoint

P095 ● USS compatibility 0

P099 ● Communication adapter type 0

P101 ● Operation for Europe or North America 0

P111 Inverter power rating (kW/hp)

P112 Inverter type 8

P113 COMBIMASTER model -

P121 Enable/disable RUN button 1

P122 Enable/disable FORWARD/REVERSE

P123 Enable/disable JOG button 1

P124

P125 Reverse direction inhibit 1

P131 Frequency setpoint (Hz) -

P132 Motor current (A) -

P133 Motor torque (% nominal torque) -

P134 DC link voltage (V) -

P135 Motor RPM -

P137 Output voltage (V) -

P140 Most recent fault code -

P141 Most recent fault code –1 -

P142 Most recent fault code –2 -

P143 Most recent fault code –3 -

P151 ● Green LED function 4

Stator resistance (Ω)

(Hz)

button

Enable/disable ∆ and ∇ buttons

✩✩✩

✩✩✩

50.00

✩✩✩

1

1

P152 ● Yellow LED function 5

P201 PI closed loop mode 0

P202 ● P gain (%) 1.0

P203 ● I gain (%) 0.00

P205 ● Sample interval (x 25 ms) 1

P206 ● Transducer filtering 0

P207 ● Integral capture range (%) 100

P208 Transducer type 0

P210 Transducer reading (%) -

P211 ● 0% setpoint 0.00

P212 ● 100% setpoint 100.00

P220 PI frequency cut-off 0

P331 Analogue mode 2

P332 Fine adjustment (%) 10

P723 State of digital inputs -

P845

P910 ● Local/Remote mode 0

P922 Software version -

P923 ● Equipment system number 0

P930 Most recent fault code -

P931 Most recent warning type -

P944 Reset to factory default settings 0

P971 ● EEPROM storage control 1

P986 Relay Output 0

Motor current limt for flying start

(V3.00)

50

WARNING

Please refer to the Reference Manual before changing any parameters.

© Siemens plc 1999 | G85139-H1731-U400-D2 19

Page 21

For Technical Support Information,

and to submit your suggestions

for improvements, see our Web Site:

http://www.con.siemens.co.uk

Herausgegeben vom

Bereich Automatisierungsund Antriebstechnik (A&D)

Geschäftsgebiet Standard Drives

Postfach 3269, D-91050 Erlangen

*6SE9996-0XA36*

6SE9996-0XA36

*H1731-U400-D2*

G85139-H1731-U400-D2

August 1999

English

Order Number: 6SE9996-0XA36

Siemens plc

Automation & Drives

Standard Drives Division

Siemens House

Varey Road

Congleton CW12 1PH

Änderungen vorbehalten

Specification subject to change without prior notice

Loading...

Loading...