Page 1

This catalog is out of date, see note on page 2

Page 2

TELEPERM M

CS 275 Bus System

Catalog PLT 130 · 1994

This catalog is no longer available in printed

form. However, it can still be used to obtain

information and for ordering spare parts.

Certain products from this catalog are no

longer available. Your Siemens partner will

offer appropriate substitutes wherever

possible.

Summary

Mode of operation

Design

Modules and

ordering data

Appendix

SY--TRANS 300 CS Gateway

Documentation for

CS 275 bus system

Subject index

Conditions of sale and delivery

Page 3

Summary

This catalog is out of date, see note on page 2

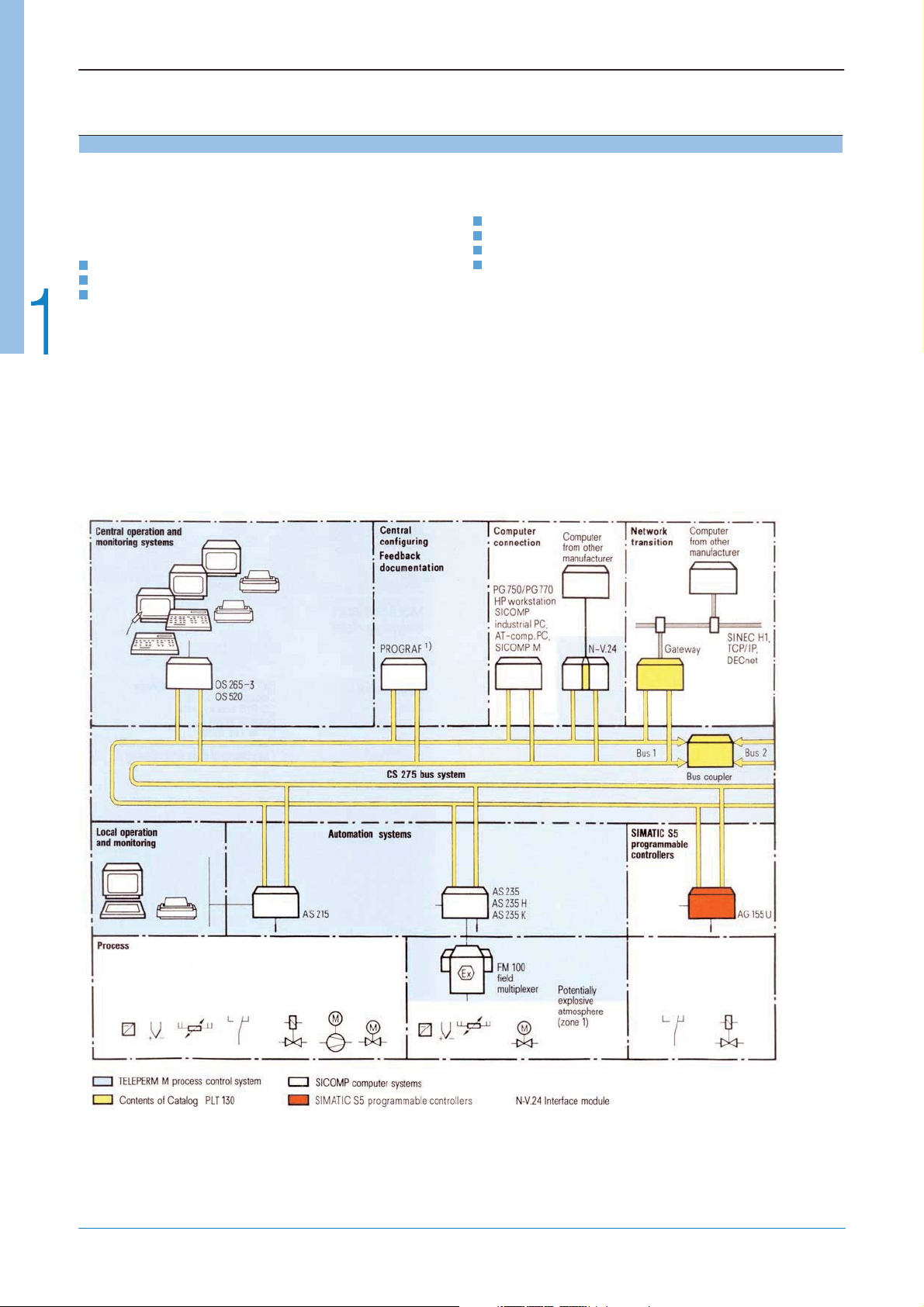

The TELEPERM M process control system consists of functionally different components which are optimized for the various

problems encountered in process automation. Because of their

modular design, these components are also referred to as systems.

The TELEPERM M process control system is divided into

AS automation systems,

OS operation and monitoring systems and

CS 275 bus system.

The CS 275 bus system is responsible for communication between all TELEPERM M components and to components of other

systems by means of serial data transmission on stranded conductors (local bus) or coaxial cables (remote bus), if applicable

also via optical fibers. Data exchange is mainly between the AS

automation systems themselves as well as between automation

systems, OS operation and monitoring systems and central

configuring console and the AS and OS systems.

In order to satisfy the high demands made on data communication in process control technology, the CS 275 bus system has

been par ticularly optimized for the following demands:

Efficient data transmission

High data reliability and availability

Uniform system time

Automatic establishment of communication.

The CS 275 bus system has exceptional real--time properties.

Every bus participant is provided with the current process data

at all times. The capacity of the bus system is large enough

such that sufficient reserve is available for transmitting messages (e. g. process alarms) even with a high cyclic loading.

Automatic test routines guarantee data reliability. The user can

configure which messages must be acknowledged by the receiver. The failure of a bus component has no influence on the

communication between the other participants.

Fig. 1/1 TELEPERM M, process control system, summary, including system-integrated links to SICOMP computer systems, SIMATIC S5 programmable

controllers and the SINEC communication network

1)

Not for AS 215 and OS 520 systems.

1/2

Siemens PLT 130.1994

Page 4

This catalog is out of date, see note on page 2

The bus system can be designed in redundant form if extremely

high demands are placed on the availability. This does not result

in additional configuring requirements.

Events are always recorded with the exact time since the individual bus participants can synchronize their clocks via the bus

system.

The simple configuring is one of the most important characteristics of the CS 275 bus system. Convenient system functions are

used to establish the connection, intervention by the operator is

not required. The parameters to be transmitted (analog/binary

values, messages etc.) are already declared when configuring

the automation systems and the operation and monitoring systems. The establishment of the connection for the operation and

monitoring systems is carried out automatically when starting

up, it is merely necessary to enter a coupling command for connections between automation systems.

Optimum utilization of the high performance of the CS 275 bus

system is only guaranteed with a large number of participants if

certain rules are observed when configuring the bus and if it is

ensured that the cyclic bus loading does not exceed 70 % of the

bus capacity. Thus 30 % are available for acyclic data transfer

(e. g. messages).

In the case of a specific configuration, the cyclic bus loading is

independent of

x

the configuration of the transmitter blocks in the automation

systems,

x

the transmission mode selected and

x

the processing cycle of the transmitter blocks.

Information on the establishment of data transfer with the coupling blocks for data exchange via the CS 275 bus system is

included in the publication ”Configuring guidelines” in the

Manual ”CS 275 bus system”. This publication describes the

determination of the cyclic bus loading using the bus loading

characteristics and lists the cyclic bus loading for a selected

configuration.

Summary

Siemens PLT 130.1994

1/3

Page 5

This catalog is out of date, see note on page 2

1/4

Siemens PLT 130.1994

Page 6

This catalog is out of date, see note on page 2

Mode of operation

Contents Page

Transfer control 2/2

Data protection 2/2

Data transfer 2/2

Addressing 2/3

Transmission modes 2/3

Redundant operation mode 2/4

Transmission reliability 2/4

Time synchronization 2/4

Configuring of communication 2/5

Siemens PLT 130.1994

2/1

Page 7

This catalog is out of date, see note on page 2

Mode of operation

Transfer control, data protection and transfer

Transfer control

Sequential data transmission systems require a transfer control

unit for organization of the data traffic on the line. This unit organizes and coordinates the data traffic so that only one subscriber transmits data on the bus at a time. This transfer control

function is decentralized in the CS 275 bus system. The availability of the data transmission system is therefore mainly determined by the line length.

Data transfer control in the CS 275 bus system operates according to the token principle, i. e. each participant (local bus interface module) accepts the transfer control function (master function) from time to time.

In a system with n participants, there is only one participant in

the master condition at any one time, all other (n--1) participants

are in the slave condition. The change of the master function

from one par ticipant to another is called master transfer. Since

every participant can assume the master function, this function

has n--times redundancy in a token system.

The ”bus protocol” also specifies how a participant becomes

master and how this status is transferred within the system. The

protocol complementar y methods for the assignment of the

master function to a participant are:

Time-out-controlled master transfer

Request-controlled master transfer

Instruction-controlled master transfer

Data protection

Data protection is achieved in the CS 275 bus system by generating line and column parities and is referred to as block parity.

The following errors are detected by the data protection:

1-bit, 2-bit and 3-bit errors,

Hamming distance d =4

Odd bit errors, 1-, 3-, 5-, 7- and 9-fold errors,

independent of location

Error bursts < 11 bit long

Error pattern (with exception of rectangular format).

--5

The bit error rate of p =10

SC-65-WG6 for process buses. According to this, an undetected transmission error in a message may occur on average

once in every 1000 years (at 250 kbit/s).

satisfies the requirements of IEC-

This presents the following advantages:

Easy configuring of communication (only the transmitter and

receiver blocks must be configured, not

for 20-m local bus)

Messages to several subscribers are simply transmitted on

the bus (several receiver blocks can access one transmitter

block)

Symbolic addressing (block name and number)

Complete documentation of all connections by self-documentation of systems

The communication procedure can be configured in a still

simpler manner in full-graphic mode on the screen by means

of the configuring tool PROGRAF and can also be documented in the same representation (see page 2/5).

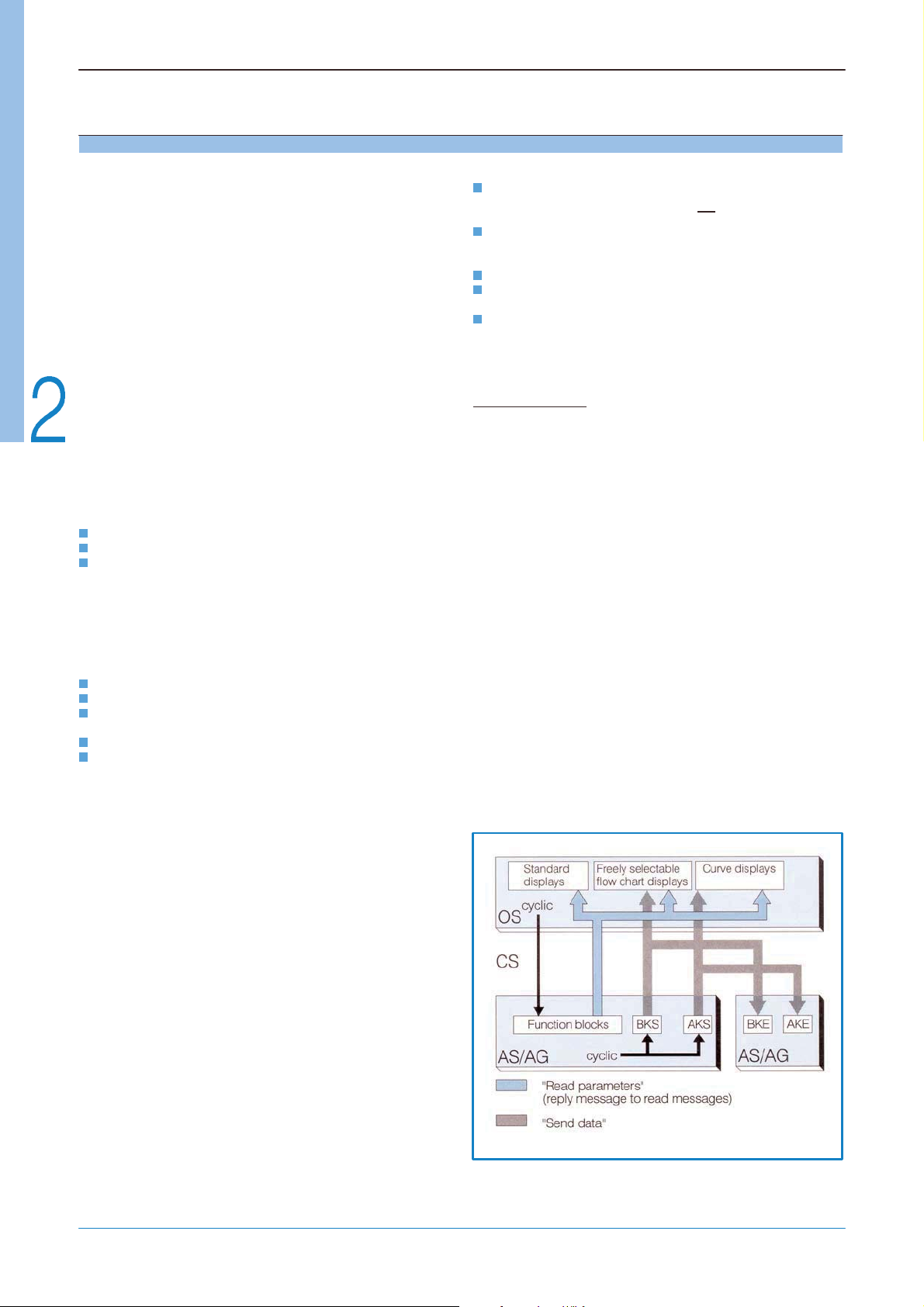

Cyclic data

Analog values are transmitted cyclically with the coupling

blocks AKS/AKE, binary values with the BKS/BKE blocks and

characters with the ZKS/ZKE blocks.

There are also further functions in addition to the cyclic data

transfer.

These functions include image updating in an OS operation and

monitoring system. The updating time is < 2 s in the TELEPERM

M process control system. In order to guarantee this value, the

bus system provides a function ”Read parameters”. This enables up to 30 different parameters per message to be read

from one AS system. The functional sequence is as follows:

The OS system sends the request to the bus system to read the

corresponding parameters from several AS systems for image

updating. The addresses of these parameters have already

been converted to on-line-accessible parameters from the symbolic addresses of the configuration during the system start-up.

Thus, the bus inter face modules can read the desired information out of the automation system memory by DMA, generate

corresponding reply messages and return these to the corresponding OS systems.

transfer

the interface modules

Data transfer

Blocks in the TELEPERM M system components are available for a

cyclic and a sporadic (acyclic) data transfer via the bus system:

Dedicated transmitter and receiver blocks handle all functions

associated with data transfer. Thus, the data transfer can be

established easily by configuring, just as the automation functions.

The user need only carry out the following to produce communication:

-- The inputs of the transmitter block must be provided with the

addresses of the data to be transmitted

-- The transmitter block must be inserted into the processing

sequence

-- The outputs of the corresponding receiver block must be

linked accordingly in another automation system

-- The receiver block must be inserted into the processing

sequence

-- The connection to the transmitter must be established using a

coupling instruction.

2/2

Fig. 2/1 Cyclic data transfer, example OS/AS and AS/AS

Siemens PLT 130.1994

Page 8

Addressing, transmission modes

This catalog is out of date, see note on page 2

Mode of operation

This method has the following important advantages:

There is far less loading on the bus system since only the

information is read from the automation system which is currently displayed on the monitor channels

Data need only be stored at one position as a result of the

distributed data base principle. Modifications are therefore

only necessary at one position

No special planning for the OS systems is required in the

automation systems (exception: curve display)

Acces to information in the automation systems by another

computer is possible without additional planning (by using the

function ”Read parameters”).

The cyclic data exchange is also used for a life test

pants connected to the CS 275 bus by an OS operation and

monitoring system. Each failure and also the return of a participant is supervised and signalled.

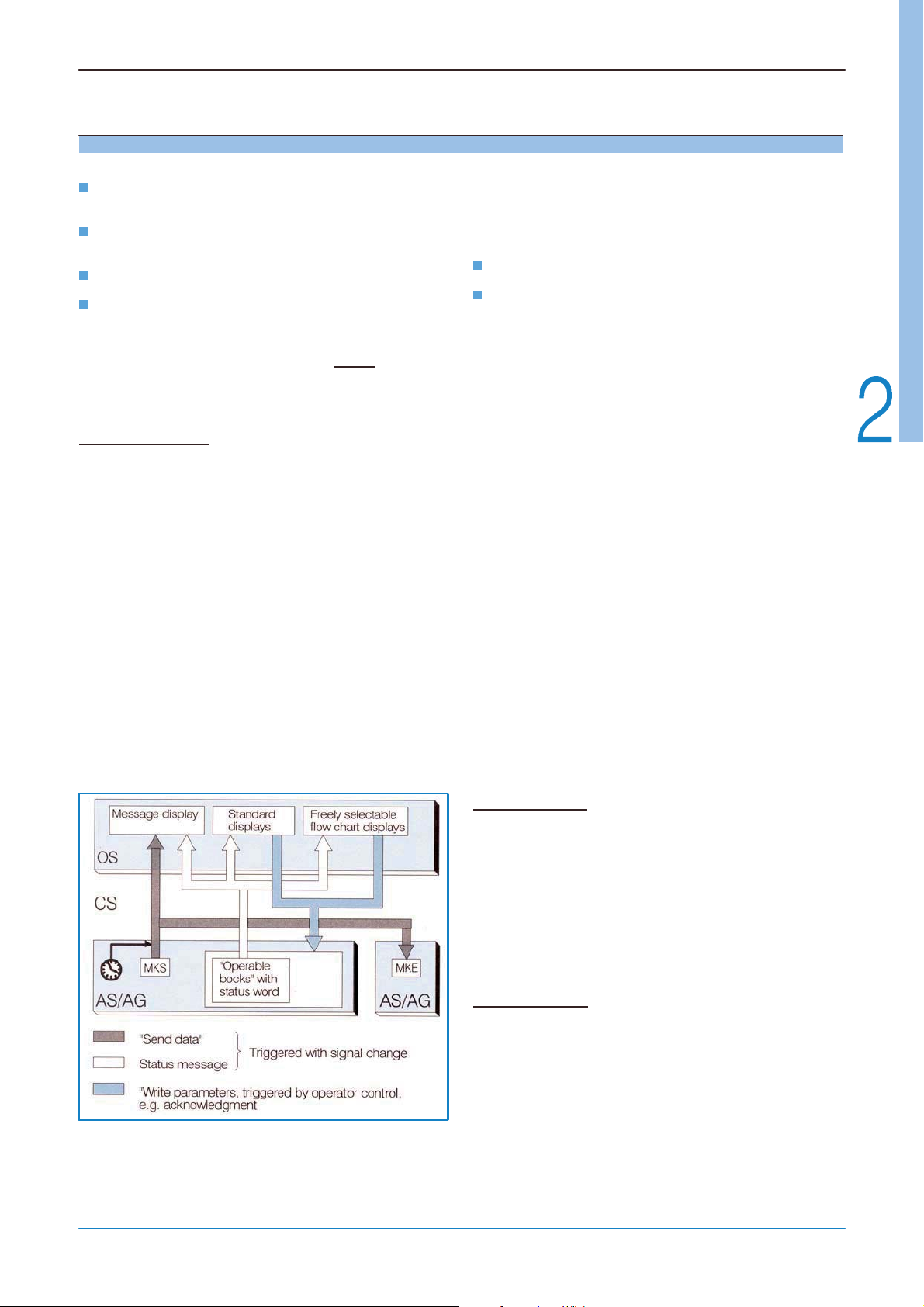

Sporadic data

Sporadic data transfer is necessary to rapidly pass on modifications in the process control system to other participants. Typical

examples are faults or changes in status (e. g. motor on/off)

which detects the automation system. Messages exchanged

between several automation systems are transmitted by means

of the coupling blocks MKS/MKE.

A status word is assigned to each function block for processing

with standardized operation and monitoring as well as to driver

blocks for I/O modules with standardized display. The changes

in signal are detected event -controlled by the status word or by

the MKS block, provided with the actual time (MKS only) and

transferred to the bus system. This then transfers MKS messages to a maximum of 6 participants (typically OS systems

and higher-level computers) which have ”registered” themselves for this information when the complete system was

started up. This presents the advantage that the automation

system need only transmit one message with one or several

destination addresses. In addition, only those stations receive

the information which actually require it.

Data transfer with OS systems and computers takes place using

the functions ”Read parameters” and ”Write parameters”.

transfer

of all partici-

Addressing

The addressing of the participants of the bus system is oriented

towards the transmission of messages between several autonomous buses and within a bus.

Each participant is identified by two addresses:

Bus address (0 to 7), i. e. 8 autonomous buses are possible.

7 bus couplers are needed in this case.

Participant address (0 to 99).

These two addresses are set on the local bus interface module

using jumpers or DIP switches.

The bus coupler behaves like a par ticipant with respect to each

bus. It has an address on each bus.

Transmission modes

A differentation is made between two transmission modes when

configuring and defining the AKS and BKS transmitter blocks:

-- Direct coupling (DI)

-- Common data (CD).

Fig. 2/2 Sporadic/acyclic data exchange, example OS/AS and AS/AS

Siemens PLT 130.1994

Direct coupling

The registered participants are directly addressed by the trans mitter blocks, i. e. each participant only receives the data which

is assigned for it. Up to 6 receivers can be registered with a

transmitter block and receive the data (analog or binary values)

pertaining to it with each transmission cycle of this block.

Any participant on the bus can be a receiver. Transmission can

also take place via bus couplers. A receiver is entered as such

in the transmitter block in the respective automation system.

The MKS block only operates in direct coupling mode.

Common-Data

The transmitter block sends the data simultaneously to all connected participants of a particular bus. Thus certain identical

data can be planned in a transmitter block for many participants

on a bus and many destination addresses can then be reached.

The CD procedure can only be used for subscribers with the

same bus address. Addressing via bus couplers is not possible.

The par ticipants on a bus connected via a bus coupler can be

addressed via their own CD procedure.

(DI)

(CD)

2/3

Page 9

This catalog is out of date, see note on page 2

Mode of operation

Redundant operation mode, transmission reliability, synchronization

Redundant operation mode

The CS 275 bus system can be redundant in order to increase

the availability. The interface modules for the local bus are already designed for a redundant local bus line. A bus converter

UI and a connector board AF are required for connection of a

redundant remote bus per remote bus cable. Different remote

bus cable lengths are permissible between bus A and the redundant bus B.

The bus system is started up on bus A. Besides this, no preference is given to either bus. The bus system carries out a cyclic

test to see whether a changeover criterion is satisfied. An automatic changeover is carried out if this is the case.

Changeover

criteria

An image of the local bus is generated through each bus line

approx. every 750 ms. If the image of the passive bus contains more entries than that of the active bus, the system

switches to the passive bus.

If the images on the two bus lines are the same, but the master detects a transfer request on the passive bus, a changeover also takes place to the passive bus. A slave sends transfer requests on the passive bus if transfers are no longer

possible for it on the active bus.

If the current master fails because of a fault, the slave with the

smallest participant address assumes the master function on

the previously passive bus (if one exists).

The bus changeover is signalled to all bus participants.

Time synchronization

The real-time clocks of the particular TELEPERM M subsystems

are synchronized by signals from an OS operation and monitoring system. This can be synchronized by a radio clock (DCF 77

radio transmitter) or a standard clock.

The subscribers on the CS 275 bus system must be synchronized with high accuracy. Because of it, the transit time of the

synchronization message is corrected within the milliseconds

range by the internal buffers of the local bus interface modules

of the automation systems and programmable controllers or by

bus couplers.

Date and time

transmission

program

Remote bus 1

Time receive

memory

Intermediate time

counter ' t(ms)

Transmission

buffer

Remote bus 2

Transmission reliability

In addition to data security of the transmission method, the following measures ensure high transmission reliability in the

physical transmission path:

Noise immunity to IEC 255-4

T riple screened cable, redundant

Coarse overvoltage protection in the building entry (option)

Fine overvoltage protection in the connector board AF (option)

Deflection of noise using braided screens and metal front

plugs

Passive line without amplifier

Non--reactive inductive coupling

Appropriate signal coding on the remote bus (bipolar current

signals)

Automatic signal equalization independent of location

Balanced (to earth) transmission

High signal voltages

Electrical isolation of par ticipants on remote bus

Distributed transfer control.

Fig. 2/3 Time generation, time synchronization

2/4

Siemens PLT 130.1994

Page 10

This catalog is out of date, see note on page 2

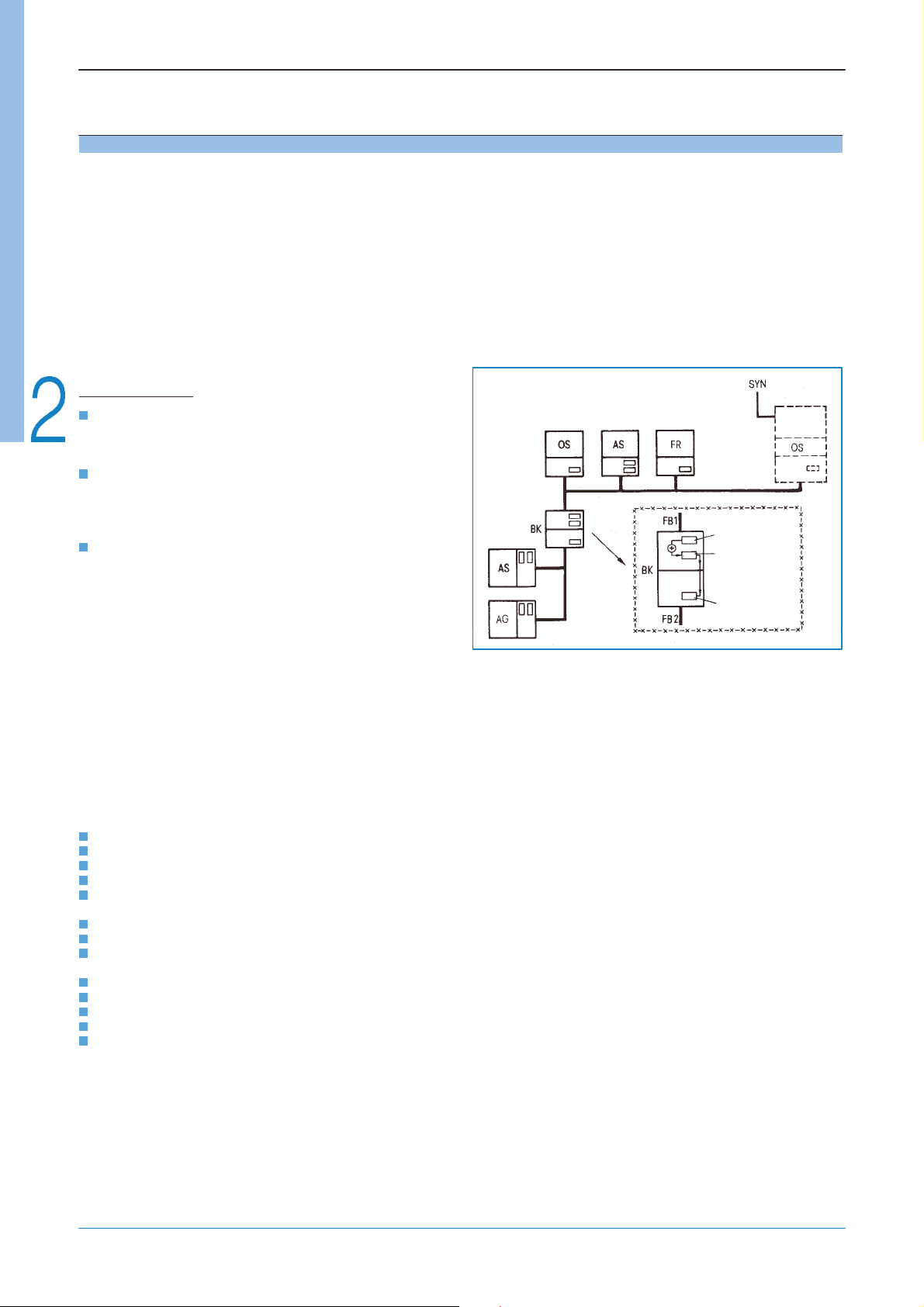

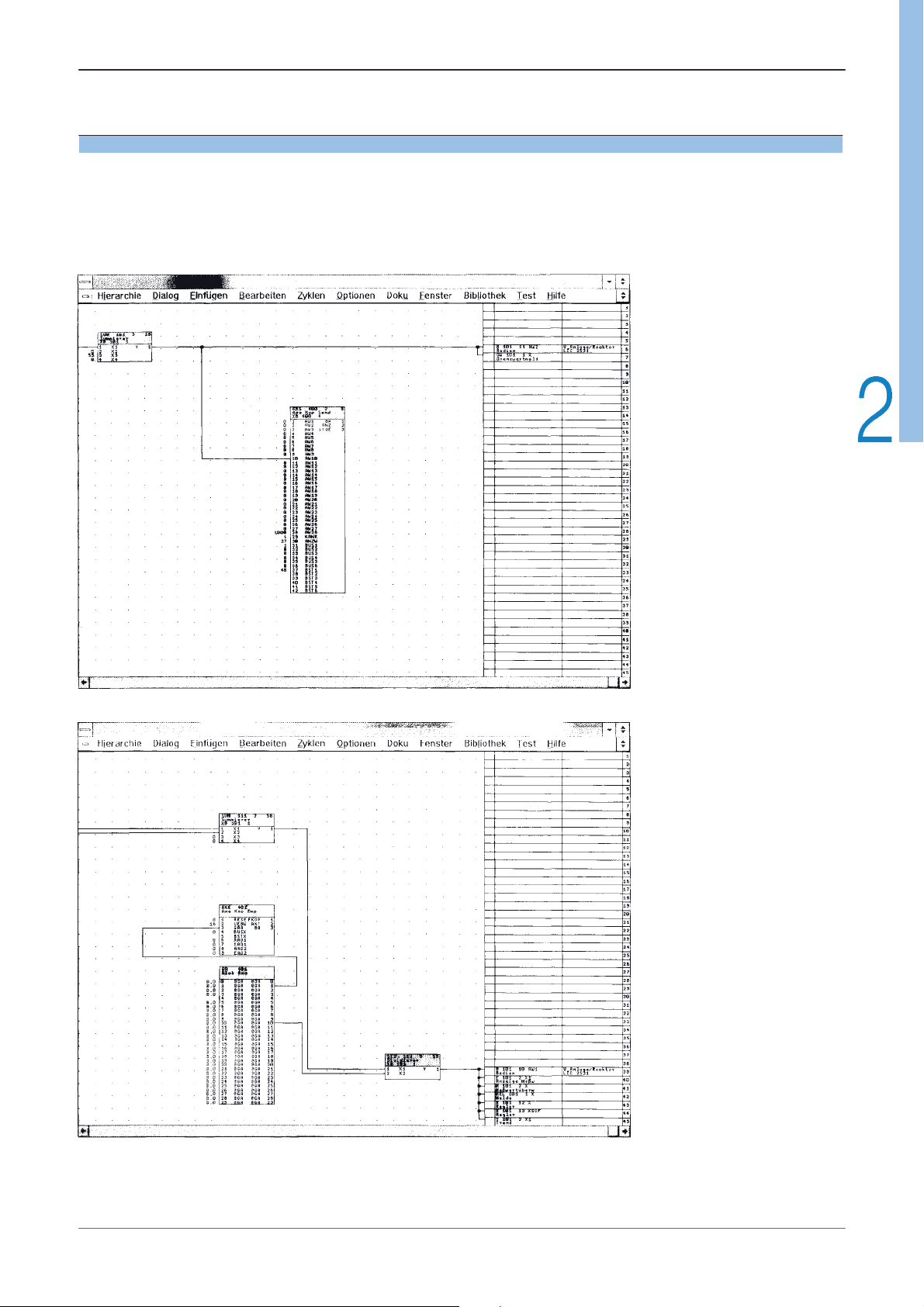

Configuring of communication

Configuring of communication

Since the communication via the CS 275 bus system is handled

like the automation functions via function blocks, they can also

be configured in full-graphic mode on the screen by means of

the configuring tools PROGRAF. Examples for AS/AS communication are shown in Figs. 2/4 and 2/5.

Mode of operation

Fig. 2/4 Connection of an analog value out of an adder block to the transmitter block AKS (e. g. as subscriber 3 on bus 1 in an automation system)

Fig. 2/5 Take-off of the transmitted analog value from the receiver module

AKE/GA (e. g. as subscriber 7 on bus 1 in an automation system) and connection to a divider block

Siemens PLT 130.1994

2/5

Page 11

This catalog is out of date, see note on page 2

2/6

Siemens PLT 130.1994

Page 12

This catalog is out of date, see note on page 2

Design

Contents Page

General notes 3/2

Local range 3/2

Remote range 3/3

Bus components 3/3

Technical data 3/5

Bus configurations 3/6

Siemens PLT 130.1994

3/1

Page 13

Design

General notes, local range

This catalog is out of date, see note on page 2

The CS 275 bus system is physically divided into

-- a local range

-- a remote range

up to 20 m (local bus) and

up to 4 km, or up to 12 km with bus couplers.

Each par ticipant requires a local bus interface module to enable

bus communication, redundant systems such as the AS 235 H

automation system require two modules. These interface modules convert the various internal system bus interfaces of the

participants into the uniform local bus interface. The transfer

control function for the complete bus is transferred from participant to participant. This function is also handled by the local

bus interface module of the respective participant which currently possesses the master function.

The design of the local bus inter face modules depends on the

participant system to be connected. Thus the modules e. g. for

connection of the automation systems are of double ”EUROPE”

format, and those for connection of SICOMP industral PCs are of

A T format. In the local range, the local bus interface modules

are connected together into a ”local bus island” using cables.

Systems not belonging to TELEPERM M require additional coupling software to match their inter nal communication interface to

that of the CS 275 bus system. This software is available,

amongst others, for the connection of personal computers with

MS-Windows or UNIX operating systems, for workstations and

for SIMATIC S5 programmable controllers.

In the remote range, individual participants or complete local

bus islands are connected to the remote bus via inductive bus

couplers UI. Different designs of coaxial cable are available for

the connection depending on the associated mechanical stress.

The local bus is always redundant, the remote bus can be either

single or redundant.

Local range

The transmission is on multi-conductor cables with a max. total

length of 20 m.

Three line signals are used. The data themselves are transmitted sequentially on one data line. A second line transmits the

clock, the third is used for synchronization.

It is necessary to differentiate between electrical participants

and (bus) participants when determining the maximum possible

number of participants. Electrical participants are the local bus

interface modules, the bus converter modules UI and connection multiplexers AV (for connection of a local bus interface

module).

(Bus) participants are e.g . an AS 215 automation system

(1 electrical participant) or an AS 235 H automation system

(2 electrical participants). Up to 9 electrical participants are

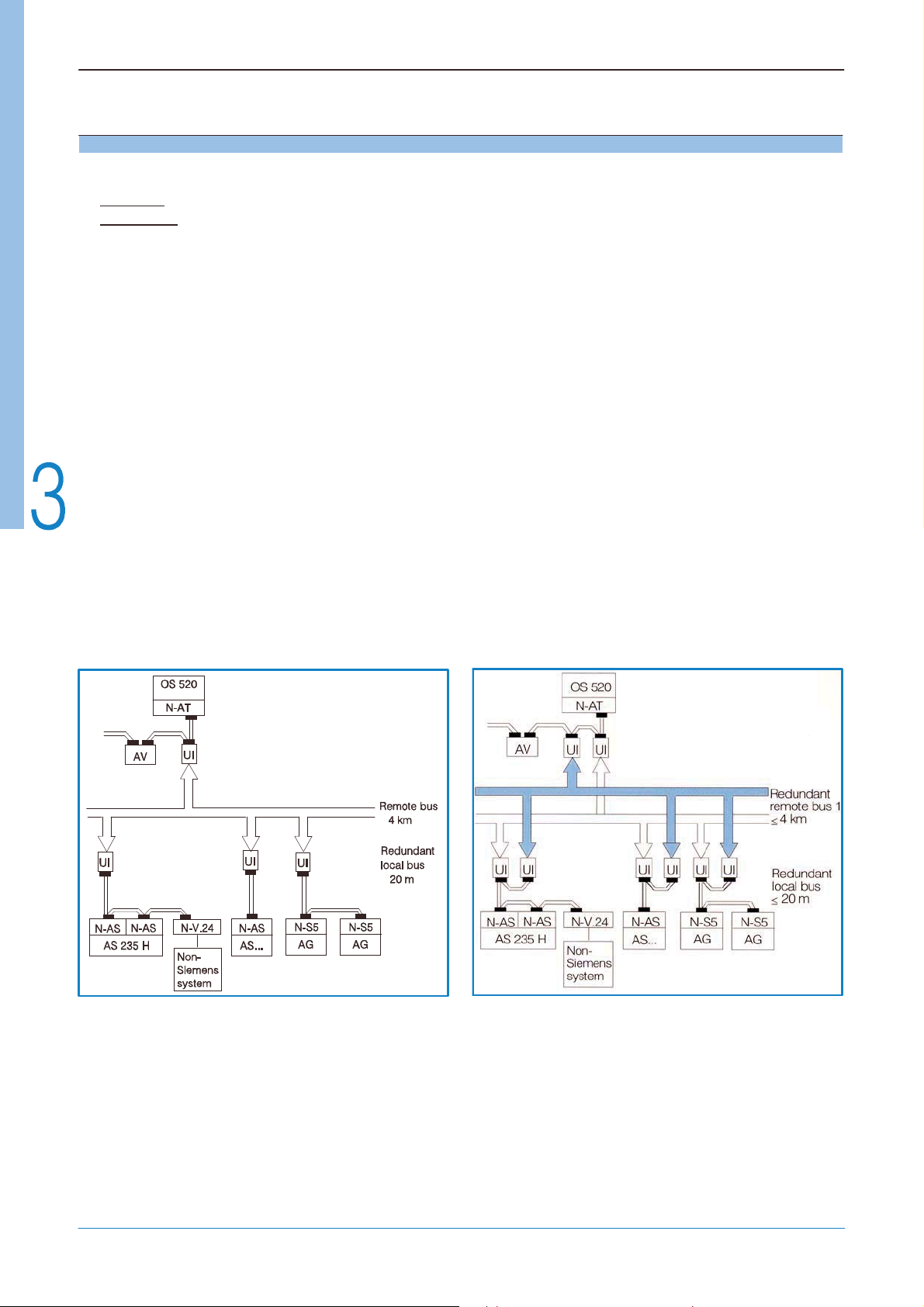

permissible on a local bus. For example, this means $ 7bus

participants for a local bus island connected to a redundant

remote bus via two bus converters UI (cf. Figs. 3/1 and 3/2.)

Depending on their type, the local bus interface modules can be

either floating or non-floating. Certain design guidelines must be

observed when connecting into a local bus island in order to

prevent interferences (also refer to Manual ”TELEPERM M,

Information and Guidelines for Planning, Installation and Operation”, Order No. C79000-G8076-C417).

≤

≤

AS Automation system

AG SIMATIC S5 programmable controller

AV Connection distributor for local bus

N-AT, N- AS,

N-V.24, Interface modules for 20-m local bus

N-S5

OS Operation and monitoring system

UI Bus converter unit

Fig. 3/1 CS 275 bus system, example for interconnection of local bus and

remote bus (non-redundant remote bus); local bus island (left) with 2 communication subscribers and 4 electric participants.

}

3/2

AS Automation system

AG SIMATIC S5 programmable controller

AV Connection distributor for local bus

N-AT, N- AS,

N-V.24, Interface modules for 20-m local bus

N-S5

OS Operation and monitoring system

UI Bus converter unit

Fig. 3/2 CS 275 bus system, example for interconnection of local bus and

remote bus (redundant remote bus); local bus island (left) with 2 communication subscribers and 5 electric participants.

}

Siemens PLT 130.1994

Page 14

Remote range, bus components

This catalog is out of date, see note on page 2

Design

The following therefore applies:

In the case of electrically isolated local bus interface modules,

the ground potential of the bus interface is decoupled from the

ground potential of the subrack system. In addition, the 0-V

level of the interface logic is matched to the potential of the coupling partner via the local bus cable. This prevents equalizing

currents from flowing via the local bus cable in the event of voltage differences > 0.2 V between the grounds of the coupling

partners. These currents would interfere with the bus traffic.

In this manner, it is possible e. g. to extend a local bus island

(0-V island) consisting of basic and extension cabinets by

means of exter nal, electrically isolated local bus participants

(N-AS/N-A T). Any local bus interface modules can be linked

together within this local bus island since they are powered from

the same power distribution subrack. The following conditions

apply: max. length 20 m, max. 9 participants, where each bus

converter UI also counts as one participant.

It is not permissible to mix non-floating participants with different earthing concepts, e. g. SIMATIC S5 or SICOMP M with

OS 265-3 systems or interface module N-V.24 in the same local

bus island.

The interface modules for the local bus have a redundant local

bus interface. They are each connected to one another by only

one cable which contains the redundant local bus.

The cables are fitted at one end with a front plug for connection

to the local bus inter face modules, the other cable end is prepared for the connection and is soldered to the front plug of the

cable of the next inter face module. A single front plug is required for the n-th local bus par ticipant. This is not necessary

for standard connections, e. g. to the bus conver ter UI for the

remote bus, since prefabricated cables are available with

looped-through wiring to up to 5 plugs.

The total length of the cables must not exceed 20 m.

Bus components

Local bus interface

Interface

module for

20-m local bus

Typ e

N-AS

(-8AC)

N-AS

(-8AA)

N-BK Bus coupler x

N-AT OS 520 operation and monitoring system,

N16-M OS 265-3 operation and monitoring systems

N-V.24 SICOMP industrial PCs and non-Siemens com-

N-S5 SIMATIC S5-155U programmable controllers x

modules

Required to connect the following systems and

devices to the CS 275 bus system

AS 215, AS 235 and AS 235 K

automation system

AS 235 H automation system x

AT -compatible personal computers,

SICOMP industrial PCs and

PG 770 programmer

SICOMP M minicomputers

puters via V.24 or 20-mA current loop interface

floating

x

x

Cable connectors for local bus

To connect the interface modules for 20-m local bus to one

another and to the bus converter UI. A front plug is required for

the last participant on the local bus.

Front plug for local

bus

Metal front plug with 2 cable inlets and contact points. The

contact points must be used to connect the plug with a low

inductance to the subrack.

non-floating

x

x

Remote range

T ransmission takes place via a coaxial cable up to distances of

4 km. The signals are self-timing bipolar square-wave pulses.

The coupling to the remote bus is reaction-free.

Up to 100 bus participants can communicate with one another

via the remote bus. The remote bus and local bus are connected

together via inductive bus conver ters UI. The complete bus

system therefore has the same information.

T wo autonomous bus systems are connected together via a

coupler

so that only the information intended for the other bus is

bus

transferred. The bus coupler is counted in each of the two autonomous bus systems as one bus participant.

Connection

distributor

The connection distributor has a vacant plug connection to the

redundant 20-m local bus for the connection of configuring aids

(SICOMP industrial PC with PROGRAF program package) and

bus diagnostic aids. It must be connected to the local bus via a

separate cable connector for this purpose.

Inductive bus converter (bus converter unit

UI)

A bus converter is required to connect individual participants or

a local bus with several participants to a remote bus. It per forms continuous signal conversion between the local bus and

the remote bus or vice versa without intermediate storage. The

coupling is inductive and non-reactive.

Standard locations:

Basic cabinet of the AS 235 and AS 235 H automation system

Basic system of the AS 235 K automation system

OS 265-3 system cabinet

Remote bus connection unit

Bus coupler subrack

Remote bus connection subrack FAZ-S5.

Siemens PLT 130.1994

3/3

Page 15

Design

Bus components

This catalog is out of date, see note on page 2

Connector board

AF

The remote bus cable is connected to the bus conver ter via the

connector board AF.

The board is provided with a terminating resistor which can be

activated using a jumper. The resistor is activated in the connector board of the first and last bus participants (Fig. 3/3).

Standard locations:

Basic cabinet of the AS 235 and AS 235 H automation systems

Basic system of the AS 235 K automation system

OS 265-3 system cabinet

Remote bus connection unit.

e.g. TELEPERM M

cabinet with

AS 235 H

e.g. Remote bus

connection unit

(OS 265-3)

e.g. TELEPERM M

cabinet

Bus

coupler

Autonomous buses are connected together via a bus coupler.

Data transfer is then possible between several systems or system areas over larger distances (> 4 km) with decoupling of the

data traffic on the buses.

The intermediate connection of up to 2 bus couplers is per missible for data transfer between any two participants in the complete bus system.

T wo different structures are possible when designing a bus system with bus couplers:

Line structure

Hierarchical structure.

≤

≤

BK Bus coupler

Fig. 3/4 Bus system with linear structure

≤

4-km bus

a Terminating resistor F (activated by jumper)

AF Connector board

UI Bus converter

Fig. 3/3 Redundant remote bus with terminating resistors

Remote bus BRemote bus A

Remote bus connection unit

The remote bus connection unit is used to connect those bus

participants to the remote bus which are not installed in

TELEPERM M standard cabinets, as e. g. the OS 520 operation

and monitoring system.

The power supply module, inductive bus conver ters, connector

board for connection of one participant or of a participant group

(local bus island) are fitted ready for connection in a separate

housing which is to be placed underneath a table.

Remote bus connection

subrack

The remote bus connection subrack is used to connect those

bus participants to the remote bus which are fitted in cabinets

according to the customer requirements, e. g. SIMATIC S5-155U

programmable controllers.

The power supply module and inductive bus converters for connection of one or several participants installed in the cabinet are

accomodated in a subrack which has been prepared for installation in a cabinet.

≤

BK Bus coupler

Fig. 3/5 Bus system with hierarchical structure

In both applications, all buses or individual buses can be redundant as desired (Fig. 3/6).

BK Bus coupler

Bus 0 and bus 2 are redundant for availability reasons. To reduce cable

costs, bus 1 is not redundant and is e. g. the connection between two buildings.

Fig. 3/6 Redundant bus, example

3/4

Siemens PLT 130.1994

Page 16

Bus components, technical data

This catalog is out of date, see note on page 2

Design

Overvoltage pr

otection

The par ticipants connected to the remote bus can be extensively protected against destruction by overvoltages by means

of the coarse and fine overvoltage protection units.

The coarse protection limits high-voltage signals of high power

to the arc voltage. The coarse protection is able to handle brief

peaks in the kA range. It is installed where the remote bus cable

enters the building. The fine protection reduces the residual

voltage which passes the coarse protection down to a value

between the internal conductor and the screen of the remote

bus cable which is harmless for the amplifier of the inductive

coupler in the bus converter. The fine protection is fitted on the

connector board AF.

Remote bus

Standard coaxial cable

cable

is used as the remote bus cable. This

may be routed in potentially explosive atmospheres to

DIN 57 165/VDE 0165, Section 5.6.1. It is also suitable for burial

in the ground. The max. permissible length is 4000 m.

An in-house cable

with smaller outer diameter and smaller permissible bending radius can be used indoors. The max. permissible length is 2000 m.

An increased tensile strength up to 25 000 N is possible using a

cable with additional ar mouring

. If protection against damage

by rodents and mechanical damage is required, the cable with

additional steel-tape armouring should be used.

Connection of remote bus

cables

It may be necessar y when using remote bus cables to connect

sections together. The maximum available length of the in-house

cable is 200 m, with all other types of cable 1000 m.

The type of connection depends on the type of cable. Standard

and in-house cables are connected by splicing or by using RF

plugs. The 2 other types of cable can be connected by splicing.

To provide protection against mechanical damage, the connection should be enclosed in a metal sleeve. The cable armouring

can be electrically connected using a copper cable (e. g. as

additional overvoltage protection) and secured to prevent tension. The sleeve is filled with sealing compound following assembly. All parts required can be obtained as a parts kit for

splicing coaxial cables.

T echnical data

Number of participants

Distance without bus coupler Max. 4000 m

Data formats Va ri ab le

Bus control Distributed (token passing principle)

Data protection Block parity

Hamming distance d =4

Noise immunity IEC Recommendation 255-4

Local bus

Number of participants Max. 9

Tranmission rate 250 kbit/s

Data transfer rate Up to 2800 analog values/s or

Overall cable length between

participant interface modules

Standard cable 12x2x0.22m

Signal transmission Unbalanced

Signal level 5V

Signal form Unipolar

Coupling Open collector

Redundant local bus Standard

Remote bus

Number of converters (UI) Max. 32

Number of bus couplers Max. 7,

Transmission rate 250 kbit/s

Standard cable 2YC (mS) CY 1.6/10-75

Signal form Bipolar current signals

Coupling Inductive, non-reactive

Redundant remote bus Option

$ 100, dependent on bus loading

(bus conver ter UI counts as

participant)

The transmission rate is increased to

340 kbit/s with autonomous local buses, i. e. without remote bus coupling

up to 38400 binary values/s or

a corresponding combination

Max. 20 m

2

max. 2 between 2 communication

subscribers

(Z2/5) vs sw

Siemens PLT 130.1994

3/5

Page 17

Design

Bus configurations

This catalog is out of date, see note on page 2

Bus configuration,

20-m local bus Small plants

20-m local bus/4-km remote

bus

20-m local bus/4-km remote

bus, redundant

examples

Application Other conditions Cable connectors

Max. 9 par ticipants possible

Max. 20 m bus cable

Standard design redundant

Large plants

Max. 100 par ticipants possible

Max. 4 km remote bus cable

Large plants

Max. 100 par ticipants possible

Max. 4 km remote bus cable

Can only be used in instrumentation

rooms.

The guidelines for earthing and screening must be observed for the participants on the local bus.

Ensure in particular that the par ticipants have the same ground potential

(equipotential bonding, 0-V island).

Exceptions are valid for isolated local

bus interface modules N-AS and N-AT.

Max. 32 bus converters UI can be

used, power distribution subrack can

be used for 2 bus converters UI.

The guidelines for earthing and screening must be observed for the participants on the local bus.

Ensure in particular that the par ticipants have the same ground potential

(equipotential bonding, 0-V island).

Exceptions are valid for isolated local

bus interface modules N-AS and N-AT.

Max. 32 bus converters UI can be

used, power distribution subrack can

be used for 2 bus converters UI.

The guidelines for earthing and screening must be observed for the participants on the local bus.

Ensure in particular that the par ticipants have the same ground potential

(equipotential bonding, 0-V island).

Exceptions are valid for isolated local

bus interface modules N-AS and N-AT.

N1 to N2,

N2 to N3 etc.: 6DS8 201-8 . .

Front plug on N1: 6DS9 200-8AA

N1 to UI: 6DS8 205-8 . .

N1 to N2,

N2 to N3 etc.: 6DS8 201-8 . .

N1 to U/1 and UI2: 6DS8 204-8 . .

N1 to N2,

N2 to N3 etc.: 6DS8 201-8 . .

Individual participant on

4-km remote bus

Individual participant on

4-km remote bus, redundant

AF Connector board ”Remote bus” N Interface module for 20-m local bus

FB Remote bus UI Inductive bus conver ter

Medium-sized plants

Individual participant on remote bus

(large distances between individual

participants)

Max. peripheral configuration of

connected AS systems

Max. 32 par ticipants possible

Max. 4 km remote bus cable

Medium-size plants

Individual participant on remote bus

(large distances between individual

participants)

Max. peripheral configuration of

connected AS systems

Max. 32 par ticipants possible

Max. 4 km remote bus cable

Interface module(s) for 20-m local bus

and bus converter in same cabinet or

subrack.

Power distribution subrack can be

used for 2 bus conver ters UI per

cabinet.

Interface module(s) for 20-m local bus

and bus converter in same cabinet or

subrack.

Power distribution subrack can be

used for 2 bus conver ters UI per

cabinet.

N to UI: 6DS8 205-8 . .

N to UI1 and UI2: 6DS8 204-8 . .

3/6

Siemens PLT 130.1994

Page 18

This catalog is out of date, see note on page 2

Modules and

ordering data

Contents Page

Interface modules for 20-m local bus

N-AS 4/2

N-BK 4/3

N16-M 4/4

N-V.24 4/5

N-S5 4/7

N-AT 4/8

Bus converter UI 4/9

Connector board AF ”Remote bus” 4/10

Remote bus connection unit FAE 4/11

Remote bus connection subrack S5 4/12

Bus coupler 4/13

Front plug for 20-m local bus 4/15

Cable connectors for 20-m local bus 4/15

Overvoltage protection 4/16

Remote bus cables 4/18

Connection of remote bus cables 4/19

Siemens PLT 130.1994

4/1

Page 19

This catalog is out of date, see note on page 2

Interface modules for 20-m local bus (N-AS), 8 bit

Description and ordering data

-- The bits transmitted on the 20-m local bus are returned via the

receiver for checking. The fault signal occurs if the transmitted and received values differ (bit-by-bit comparison).

LED D (green)

The receiver control unit of the interface modules signals that

data transfer elements are on the bus. The brightness of the

display depends on the number of transfer elements received.

LED M (green)

Signals that the interface module has the master function.

LEDs A and B (green)

Indicate that the interface module is set on bus A or bus B.

Static light signals active bus.

LED T (green)

Signals that the bus processor is busy. The central processor

1 LED (yellow), signals ”maintenance protocol stored”

2 LED (red), signals faults (line protocol faulty, receiver memory overflow)

3 LEDs (green)

D signals ”Data transfer on bus”

M signals ”Interface module has master function”

T signals ”Bus processor busy”

B indicates setting of interface module on bus B

A indicates setting of interface module on bus A

4 DIP switch for function and address settings

5 DIP switch for function and address settings

6 Front plug for 20-m local bus

Fig. 4/1 Inter face module N-AS for 20-m local bus, 8 bit

generates read and write signals. The display goes out if the

central processor enters the STOP status.

Setting of addr

ess

In order to differentiate between the individual interface modules

in the autonomous bus system, each interface module must be

allocated a so-called participant address. In order to differentiate between several autonomous buses connected via bus couplers, each interface module must be allocated a bus address.

These two addresses are set via DIP switches on the front panel

of the interface module.

Application

To connect an AS 215, AS 235, AS 235 K (6DS1 223-8AC) or

AS 235 H (2 x 6DS1 223-8AA) automation system to the CS 275

bus system.

The module handles all duties specifically connected with data

transmission, including occasional control of data transfer.

Design

Compact subassembly, double height, with 2 base plugs and

one front plug.

Front panel width 30.48 mm = 2 standard slots.

The module can be selected as desired.

Mode of operation

Operational signals and fault

signals

LED W (yellow)

For maintenance staff only. It signals that diagnosis infor mations

which occured during operation are stored.

LED F (red), signals the following faults:

-- Line protocol faulty, e. g. faulty qualifier signal on the local

bus, parity error in data byte, incorrect message format

-- Receiver memory overflow, e. g. if the bus processor of the

interface module does not correctly read the receiver memory.

T echnical data

Power supply DC 5 V

Current consumption 1.4 A

Interfaces

-- B a s e p l u g

-- Front plug

Weight Approx. 0.4 kg

Central unit bus, 8 bit

Redundant 20-m local bus output,

open collector, asymmetric,

for connection of a cable connector

with metal front plug and contact points

Ordering data

Order No.

Interface module for 20-m local bus (N-AS),

8bit

¯ for AS 215, AS 235 and AS 235 K

automation systems

¯ for AS 235 H automation system 6DS1 223-8AA

Instructions

Interface module for 20-m local bus Order No.

N--AS and N--BK

German C79000-- B8000--C406

English C79000-- B8076--C406

French C79000-- B8077--C406

Spanish C79000-- B8078--C406

6DS1 223-8AC

4/2

Siemens PLT 130.1994

Page 20

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N-BK)

Description and ordering data

1 LED W (yellow), signals ”maintenance protocol stored”

2 LED F (red), signals faults (line protocol faulty, receiver memor y over flow)

3 LEDs (green)

D signals ”Data transfer on bus”

M signals ”Interface module has master function”

T signals ”Bus processor busy”

B indicates setting of interface module on bus B

A indicates setting of interface module on bus A

4 DIP switch for function and address settings

5 DIP switch for function and address settings

6 Front plug for 20-m local bus

Fig. 4/2 Inter face module for 20-m local bus (N-BK), 8 bit

LED F (red) signals the following faults:

-- Line protocol faulty, e. g. faulty qualifier signal on the local

bus, parity error in data byte, incorrect message format

-- Receiver memory overflow, e. g. if the bus processor of the

interface module does not correctly read the receiver memory

-- The bits transmitted on the 20-m local bus are returned via the

receiver for checking. The fault signal occurs if the transmitted and received values differ (bit-by-bit comparison).

LED M (green)

Signals that the interface module has the master function.

LEDs A and B (green)

Indicate that the interface module is set on bus A or B. Static

light signals active bus.

LED T (green)

Signals that the bus processor is busy. The central processor

generates read and write signals. The display goes out if the

central processor enters the STOP status.

Setting of addr

ess

In order to differentiate between the individual interface modules

in the autonomous bus system, each interface module must be

allocated a so-called participant address. In order to differentiate between several autonomous buses connected via bus couplers, each interface module must be allocated a bus address.

These two addresses are set via DIP switches on the front panel

of the interface module.

Application

The interface module N-BK is used in the remote bus/remote

bus coupler.

The module handles all duties specifically connected with data

transmission, including occasional control of data transfer.

Design

Compact subassembly, double height, with 2 base plugs and

one front plug.

Front panel width 30.48 mm = 2 standard slots.

The slot for the module in the subrack for the bus coupler is

preset.

Mode of operation

Operational signals and fault

signals

LED W (yellow)

For maintenance staff only. It signals that diagnosis infor mations

which occurred during operation are stored.

LED D (green)

The receiver control unit of the interface module signals that

data transfer elements are on the bus. The brightness of the

display depends on the number of transfer elements received.

T echnical data

Power supply DC 5 V

Current consumption 1.4 A

Interfaces

-- B a s e p l u g

-- Front plug

Weight Approx. 0.4 kg

Central unit bus, 8 bit

Redundant 20-m local bus output,

open collector, asymmetric,

for connection of a cable connector

with metal front plug

and contact points

Ordering data

Order No.

Interface module for 20-m local bus (N-BK) 6DS1 223-8AB

for bus coupler, 8 bit

Instructions

Interface module for 20-m local bus Order No.

German C79000-- B8000--C406

English C79000-- B8076--C406

French C79000-- B8077--C406

Spanish C79000-- B8078--C406

Siemens PLT 130.1994

4/3

Page 21

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N16-M), 16 bit

Description and ordering data

via the serial bus. A message can be sent to a single bus par ticipant, to several participants or to all participants.

Apart from certain cyclic messages, the receiver acknowledges

every message received.

The transmitter is immediately informed when a message has

been received without faults. In certain cases, the required data

are also transmitted immediately with this feedback, thus enabling short reaction times.

The interface module N16-M stores the messages in its transmitter and receiver buffers until they are processed and transmitted and thus dynamically decouples the OS 265-3 system or

the SICOMP M minicomputer from the data transfer on the bus

during times of peak loading. T o reduce the time required for

organizational tasks, the interface module collects several messages over a specific period and combines these into a package. This is not the case if short reaction times are required.

In addition to the data messages, the inter face module also

generates and processes organizational messages together

with the other interface modules on the CS 275 bus system.

These are required, for example, to transfer the master function,

1 LED F (red), signals faults (line protocol faulty, receiver memory overflow)

2 LEDs (green)

D signals ”Data transfer on bus”

M signals ”Interface module has master function”

T signals ”Bus processor busy”

B indicates setting of interface module on bus B

A indicates setting of interface module on bus A

3 DIP switch for setting the bus address and for selection of redundant/

non-redundant remote bus

4 DIP switch for setting the par ticipant address

5 Front plug for 20-m local bus

Fig. 4/3 Inter face module for 20-m local bus (N16-M), 16 bit

Application

To connect the OS 265-3 operation and monitoring system and

SICOMP M minicomputers to the CS 275 bus system. The

SICOMP M minicomputer must be equipped with the KSN-16M

coupling software to adapt bus communication. Local bus coupling (< 20 m) with other participants is only possible if these

have the same earth potential. Both coupling participants must

have the same earthing concept (e. g. OS 265-3 and AS 235/K/H

systems). The remote bus connection unit (cf. page 4/11 must be

used in all other cases and provides electrical isolation together

with the bus conver ters UI (page 4/9).

The module handles the following duties connected with data

transmission:

Collection of parameters and processing of input/output in-

structions on the I/O interface channel of the SICOMP M mini-

computer

Signalling of operating statuses and faults with defined dis-

plays.

Design

Plug-in module, triple height, with 1 base plug and 1 front plug.

Front panel width 15.24 mm = 1 standard slot.

Defined slot EA 01 in the SICOMP M minicomputer.

The interface processor of the modules is an SAB 80186 chip

with a 32-kbyte program memory (EPROM) and 8-kbyte data

memory (RAM).

Mode of operation

Handling of

messages

Depending on the type and parameterization of the communication instructions, the interface module N16-M transmits and receives protected messages of various lengths up to 128 byte

for routing information, redundancy tests, monitoring and signalling information.

Time synchr

onization

The interface module receives time messages and routes these

on to the OS 265-3 system or SICOMP M minicomputer. In the

opposite direction, it can also receive the time from the

OS 265-3 system or SICOMP M minicomputer and transmit it on

the bus in order to synchronize the participants.

Diagnostic

functions

The interface module detects and signals static and dynamic

faults and any states which could be critical for the bus loading.

It monitors the processes on the bus, on the interfaces to the

user system and in the interface module itself.

During operation, cyclically triggered test programs carry out an

extensive hardware test of the interface module. Faults are

therefore early detected and malfunctions and cumulative faults

are thus prevented. External bus diagnosis via the coupling

software is also possible. The interface module provides a diagnostic list with 23 positions which can be read for this purpose.

T echnical data

Power supply +5V

Current consumption

With + 5 V

With -- 12 V

Interfaces

-- B a s e p l u g

-- Front plug

Weight Approx. 0.55 kg

Ordering data

Interface module for 20-m local bus (N16-M), 6DS1 205-8AA

16 bit

Instructions

Interface module for 20-m local bus (N16-M), Order No.

German C79000-- B8000--C128

English C79000-- B8076--C128

French C79000-- B8077--C128

Spanish C79000-- B8078--C128

-- 1 2 V

2.8 A

0.05 A

SICOMP M I/O interface channel

Redundant 20-m local bus input/output,

open collector, asymmetric,

for connection of a cable connector

with metal front plug and contact points

Order No.

4/4

Siemens PLT 130.1994

Page 22

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N-V.24)

Description

1 LED F (red), signals faults (line protocol faulty, receiver memor y over flow)

2 LEDs (green)

D signals ”Data transfer on bus”

M signals ”Interface module has master function”

T signals ”Bus processor busy”

B indicates setting of interface module on bus B

A indicates setting of interface module on bus A

3 Reset key RS

4 Front plug X3 for connection of a non-Siemens computer via V.24

or 20-mA current loop interface

5 Front plug X4 for connection to the 20-m local bus

6 Jumpers for function and address settings

Fig. 4/4 Interface module for 20--m local bus (N--V .24)

voltage +5 V is loaded with 2.4 A per N-V. 24 module thereby.

The number of useable interface modules N-V.24 is therefore

restricted.

Possible plug-in slots:

Slot for I/O module

In the AS 235 automation system (max. 2 modules N-V.24 per

system (basic unit or extension unit)

In the AS 235 K automation system (max. 2 modules N-V.24

per system (basic unit)

In the AS 235 H automation system (max. 1 module N-V.24

per extension unit with 5-V module.)

Use of the N-V.24 interface module in the ES 100 K extension

system or in the AS 215 automation system is not allowed.

Interfaces for non-Siemens

computer

(alternatively at front plug X3)

V.24 interface

T x D T ransmitted data

Information is sent to the peripheral device via this line

R x D Received data

Information is transferred to the system via this line

DSR Data set ready

Input for ”data set ready” message from data circuit

terminating equipment

CTS Clear to send

Input for ”clear to send” message from data circuit terminating equipment

DTR Data terminal ready

Output for operating status message of N-V .24 module

RTS Request to send

Output signal, switches the transmitter unit of the data

circuit terminating equipment

I1,I2 Internal constant-current sources

Application

For connection of non-Siemens computers to the CS 275 bus

system via a V.24 or 20-mA current loop interface.

The external computer must have a V.24 or 20-mA current loop

interface. Coupling software is required in the external computer

to handle communication with the interface module N-V.24.

The data transmission rate can be adapted to the requirements

between 110 bit/s and 9600 bit/s; for example, 120 measured

values/s can be transmitted at a data transfer rate of 9600 bit/s

via the serial interface.

The module handles duties specifically connected with data

transmission, including occasional control of data transfer.

Design

Compact subassembly, double height, with 1 base plug and

2 front plugs

Front panel width 30.48 mm = 2 standard slots.

The N-V.24 interface module is plugged into an I/O slot. It does

not receive its supply voltage via L+ (DC 24 V) but via the supply voltage +5 V of the I/O bus for the logic. The logic supply

20-mA current loop interface

R x D Received data

+ 20 mA: input, -- 20 mA: output

T x D T ransmitted data

+ 20 mA: input, -- 20 mA: output

Mode of operation

Communication between TELEPERM M systems and

non-Siemens computers

Data transfer between TELEPERM M systems and a

non-Siemens computer via the CS 275 bus system is carried out

using the same messages which are used for communication

between TELEPERM M systems. The defined types of order

(format, coding, acknowledgement mode) and the function of

the hardware interface (N-V.24) are described in the Instructions

for the inter face module N-V.24 and in the Manual ”N-V.24, Coupling of non-Siemens computers to the CS 275 Bus System”.

Coupling software must be installed in the external computer

which matches the computer to the communication conditions of

the N-V.24 inter face.

Setting of addr

ess

In order to differentiate between the individual interface modules

in the autonomous bus system, each interface module must be

allocated a so-called participant address. In order to differentiate between several autonomous buses connected via bus couplers, each interface module must be allocated a bus address.

These two addresses are set using plug-in jumpers on the front

panel of the interface module.

Siemens PLT 130.1994

4/5

Page 23

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N-V.24)

T echnical data and ordering data

Ordering data

Interface module for 20-m local bus (N-V.24)

with V.24 or 20-mA current loop interface

¯ with parts kit for front plug and installation

instructions in Ger man

¯ Without parts kit for front plug 6DS1 202-8AB

Parts kit for front plug

for interface module 6DS1 202-8AB

with installation instructions in Ger man

KSN-PC coupling software

for SICOMP industry-standard PC or

PG 750/PG 770 programmer

Order No.

6DS1 202-1AB

C79458-L437-D1

See Catalog PLT 150

This circuit cancels the

electrical isolation of the

N.-V.24 interface

Fig. 4/5 20-mA current loop interface with internal constant-current source

for transmitter (left) and receiver (right), connection example

Fig. 4/6 20-mA current loop interface with external current loop for transmitter (left) and receiver (right), connection example

T echnical data

Power supply DC 5 V

Current consumption 2.4 A

Interfaces

-- B a s e p l u g

-- Front plug X3

-- Front plug X4

Weight Approx. 0.75 kg

5-V power supply

Serial V.24 or

20-mA current loop inter face

for distances up to 15 or 1000m

respectively, 4-wire system

Redundant 20-m local bus output, open

collector, asymmetric,

for connection of a cable connector

with metal front plug and contact parts

Instructions

Interface module for 20-m local bus, Order No.

V.24- or 20-mA current loop interface

German C79000-- B8000--C3

English C79000-- B8076--C3

French C79000-- B8077--C3

Spanish C79000-- B8078--C3

Manuals

N-V .24: Coupling of non-Siemens

computers to the CS 275 bus system

German C79000-- G8000-- C87

English C79000-- G8076-- C87

20-m local bus V.24- or 20-mA

Transmission rate 340 kbit/s (autonomous)

Data protection Horizontal parity (d =4) Longitudinal parity

Operating mode Half-duplex Half-duplex,

Character frame Bus transfer element 8bit,code-transparent

Authorization for

data transmission

250 kbit/s (remote

bus connection

via inductive conver ter)

Token passing principle DIN 66 020

interface

110 bit/s to

9600 bit/s,

can be set on module

(d =2)

contention mode

(V.24)

4/6

Siemens PLT 130.1994

Page 24

Description and ordering data

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N-S5)

Mode of operation

Data received via the CS 275 bus system pass through the line

protocol controller of the bus interface logic in bit-serial mode

and are placed into intermediate storage. The microprocessor

reads the data byte-by -byte and stores them in the buffer

memory of the module. Up to 70 complete messages can be

stored in the buffer memory.

As soon as sufficient space is available in the dual-port RAM for

a complete message, this is entered into the receiver order list

of the dual-port RAM. Transmit messages are transferred from

the function blocks of the KSN-S5E coupling software to the

dual-port RAM system interface and entered into the transmitter

order list.

1 LED F (red), signals faults (line protocol faulty,

receiver memory overflow)

2 LEDs (green)

D signals ”Data transfer on bus”

M signals ”Interface module has master function”

T signals ”Bus processor busy”

B indicates setting of interface module on bus B

A indicates setting of interface module on bus A

3 DIP switch for function and address settings

4 DIP switch for function and address settings

5 Front plug for 20-m local bus

6 Base plug for connection to SIMATIC S5 bus

Fig. 4/7 Inter face module for 20-m local bus (N-S5)

Application

The module is used to connect a SIMATIC S5-155U programmable controller (CPU 946/947 or CPU 948) to the CS 275 bus

system.

The KSN-S55 coupling software must be installed in the programmable controller. It enables the controller to be matched to

the requirements of bus communication.

The module handles duties specifically connected with data

transmission, including occasional control of data transfer.

Setting of addr

ess

In order to differentiate between the individual interface modules

in the autonomous bus system, each interface module must be

allocated a so-called participant address. In order to differentiate between several autonomous buses connected via bus couplers, each interface module must be allocated a bus address.

These two addresses are set via DIP switches on the front panel

of the interface module.

T echnical data

Power supply DC 5 V

Current consumption 1.8 A

Interfaces

-- B a s e p l u g

-- Front plug

Weight Approx. 0.5 kg

Central unit of SIMATIC S5-155U

programmable controller

Redundant 20-m local bus output,

open collector, asymmetric,

for connection of a cable connector

with metal front plug and contact points

Ordering data

Order No.

Interface module for 20-m local bus (N-S5), 6DS1 206-8AA

8bit

KSN-S55 coupling software See Catalog PLT 150

Design

Compact subassembly, double height, with 2 base plugs and 1

front plug.

Front panel width 20.32 mm = 1

1/3

standard slots.

Possible plug-in slots:

Central unit 155U (CPU 946/947), slots 35, 43, 75, 83 and 107

to 131

Central unit 155U (CPU 948), slots19, 35, 51 and 67 to 131.

Siemens PLT 130.1994

Instructions

Interface module for 20-m local bus (N-S5) Order No.

German C79000-- B8000--C181

English C79000-- B8076--C181

French C79000-- B8077--C181

Spanish C79000-- B8078--C181

4/7

Page 25

This catalog is out of date, see note on page 2

Interface module for 20-m local bus (N-AT)

Description and ordering data

T echnical data

Power supply DC5V/DC12V

Current consumption Approx. 1.8 A (DC 5 V)

Interfaces

-- A T p l u g

-- Front plug

Weight Approx. 0.7 kg

viaATbus

AT bus of respective device

Redundant 20-m local bus output,

open collector, asymmetric,

for connection of a cable connector

with metal front plug

Fig. 4/8 Inter face module for 20-m local bus (N-AT)

Application

The module is used to connect the following systems/devices to

the CS 275 bus system:

OS 520 operation and monitoring system

SICOMP industry-standard PC

HP 9000/7xx workstation

A T-compatible personal computer.

For adaptation to the bus communication, a coupling software

must be installed in these devices (except of OS 520 sys tem).The interface module N-A T handles duties specifically connected with data transmission, including occasional control of

data transfer.

Design

Plug-in card in long AT format with one plug on the front panel.

Slot: extension slot in AT format in the above-mentioned

devices.

The interface module N-AT contains:

An SAB 80 188 microprocessor for controlling and monitoring

all functions

A dual-port RAM system interface to the AT bus with asso-

ciated control logic

An interface to the 20-m local bus with bus interface logic.

Mode of operation

Data received via the CS 275 bus system pass through the line

protocol controller of the bus interface logic in bit-serial mode

and are placed into intermediate storage. The microprocessor

reads the data byte-by -byte and stores them in the buffer

memory of the module.

As soon as sufficient space is available in the dual-port RAM for

a complete message, this is entered into the receiver order list

of the dual-port RAM. Transmit messages are transferred from

the coupling software to the dual-port RAM system interface

and entered into the transmitter order list.

Ordering data

Coupling package (hardware) to couple ATcompatible personal computers to the CS 275

bus system,

comprising

-- Interface module for 20-m local bus

6DS1 222-8AB for AT-compatible personal

computers

-- Cable connector for 20-m local bus

6DS8 208-8KC with 1 ES 902 plug and 1 Cannon plug, 2.5 m long

-- Instructions for the interface module

¯ with German documentation

¯ with English documentation

Cable connectors

for bus participants with N-AT interface module

for 20-m local bus

¯ Cable connector for 20-m local bus

with 3 plugs ES 902 and 1 Cannon plug

to connect a remote bus connection unit

with 2 UI bus converters and a connection

distributor

¯ Cable connector for 20-m local bus

with 1 Cannon plug and

one free cable end

(for soldering on)

¯ Cable connector for 20-m local bus

with 3 Cannon plugs to connect a bus

participant with N-AT interface module to

another bus participant with N-AT interface

module

1.5 m EC 3m MC 4m QC

1.8 m GC 3.3 m NC 4.5 m RC

2.2 m JC 3.6 m PC 5mSC

Coupling software

¯ For PC with MS-DOS and MS-Windows:

TM

WIN

¯ For HP 9000/7xx workstation with RTAP/Plus

under UNIX: CS

275-Scantask

Order No.

6DS1 222-1AB10

6DS1 222-1AB20

6DS8 210-8

6DS8 211-8

6DS8 212-8

See Catalog PLT 150

4/8

Siemens PLT 130.1994

Page 26

Description and ordering data

This catalog is out of date, see note on page 2

Bus converter unit UI

1 LED ET (green), flashes in rhythm with the messages received

from the remote bus

2 LED F (red), signals faults (line protocol faulty, transfer element

format faulty)

3 LED B (green), indicates setting of module on bus B

4 LED A (green), indicates setting of module on bus A

5 Reset key RS

6 LED SV (green), signals the presence of all operating

voltages

7 Coding jumper

8 Power supply unit

9 Bus interface

10 Inductive coupler

Fig. 4/9 Bus converter 6DS4 400-8AB

Application

To convert signals from a 20-m local bus to a 4-km remote bus.

Signal coupling-in and coupling-out inductive and without feedback.

Design

The bus converter consists of 3 single-height modules.

Front panel width:

Power supply unit 30.48 mm = 2 standard slots

Bus interface 15.24 mm = 1 standard slot

Inductive coupler 45.72 mm = 3 standard slots

The bus interface module has a 20-m local bus interface and

constitutes the input of the bus converter. The inductive coupler

module has 2 lengths of coaxial cable fixed to the front panel.

These are screwed onto the connector board AF (page 4/10)

and form the connection to the remote bus cable.

Possible plug-in locations:

AS 235 K automation system, basic unit

AS 235 automation system, power distribution subrack in the

basic cabinet

AS 235 H automation system, power distribution subrack in

the basic cabinet

Remote bus connection unit (e. g. for OS 520 and OS 265-3

desk-top units)

Remote bus connection subrack (e. g. for SIMATIC S5-155 U,

SICOMP industry-standard PC or OS 265-3 rack-type version)

Bus coupler (BK-FF).

1)

Redundant 24 V supply only when a remote bus connection subrack

6DS4 426--8AA is used

Fig. 4/10 Bus converter, function diagram

T echnical data

Power supply DC 24 V (20 to 33 V)

Current consumption 450 mA

Module fuse 1.6 A medium-slow

Interfaces

-- Local bus

-- R e m o t e b u s

Signal coupling-in inductive, reaction-free

Weight Approx. 1.18 kg

TTL level, open collector, asymmetric,

redundant

Biphase signals

(levels approx. á 1V)

Ordering data

Order No.

Bus converter (UI), 6DS4 400-8AB

consisting of power supply unit, bus interface

and inductive coupler

Instructions

Bus converter , inductive Order No

German C79000-- B8000--C4

English C79000-- B8076--C4

French C79000-- B8077--C4

Spanish C79000-- B8078--C4

Siemens PLT 130.1994

4/9

Page 27

Connector board AF

Description and ordering data

This catalog is out of date, see note on page 2

Fig. 4/11 Connector board AF ”Remote bus” 6DS9 203-- 8DA, with

mounting plate

Application

To convert the remote bus coaxial cable to the two lengths of

coaxial cable fixed in the bus converter UI and to convert the

standard remote bus cable and the remote bus cable for special

applications to thin remote bus cable (Inhouse cable). To terminate the remote bus coaxial cable with the characteristic impedance. For uninterruptable switching on and off of remote bus

participants.

The connector board AF with mounting plate is provided for the

AS 235 and AS 235 H automation systems which are installed in

standard cabinets, the OS 265-3 operation and monitoring system (rack version), the bus coupler and the SIMATIC S5-155U

programmable controller.

The connector board AF without mounting plate is provided for

the AS 235 K automation system and for the remote bus connection unit (page 4/11).

For applications in critical environments (EMC), the connector

board AF can be retrofitted with an overvoltage fine protection

device.

Possible locations:

AS 235, AS 235 H, OS 265-3 systems and SIMATIC S5: On

the front right-hand cabinet member, up to 2 connector

boards can be mounted on 1 cabinet member

AS 235 K system: In the subrack on the left of the power supply assembly

Remote bus connection unit: In the subrack.

Fig. 4/12 Connector board AF ”Remote bus” 6DS9 203-- 8CA, without

mounting plate

4-km bus

Remote bus 1a Remote bus 1b

a Terminating resistor F (activated by jumper)

AF Connector board

UI Bus converter

Fig. 4/13 Redundant remote bus with terminating resistors

Ordering data

Order No.

Connector board AF ”Remote bus”

with terminating resistor F

¯ Without mounting plate

¯ With mounting plate, for rack-mounted

systems

Overvoltage fine protection,

can be retrofitted (see page 4/16)

6DS9 203-8CA

6DS9 203-8DA

6DS9 210-8AA

4/10

Siemens PLT 130.1994

Page 28

This catalog is out of date, see note on page 2

Remote bus connection unit FAE

1 Connection distributor for 20-m local bus, 6DS9 207-8AA;

for commissioning and servicing, can be retrofitted

2 Bus converter 6DS4 400-8AB

3 Connector board AF ”Remote bus” 6DS9 203-8CA

4 Power supply module

Fig. 4/14 Remote bus connection unit, redundant design;

front door removed

Application

The remote bus connection unit connects desk-top systems, as

e. g. the OS 265-3 operation and monitoring system or SICOMP

industry-standard PC to a redundant or non-redundant remote

bus. Electrical isolation between the local and the remote buses

is achieved at the same time. Non-redundant AC 230 V power

supply.

Design

The remote bus connection unit consists of a housing for floor or

wall mounting, 2 single-height subracks, a mounting rail, mains

filter and power supply module for AC 50 Hz 230 V.

It provides space for the 2 bus converters (cf. page 4/9) required to convert the 20-m local bus interface to the remote bus

interface. The connector boards AF for converting the cable

cross-section (cf. page 4/10) are also fitted into the remote bus

connection unit. One connector board is required for each bus

converter.

The remote bus connection unit can be fitted with a connection

distributor for 20-m local bus for commissioning and servicing.This is an open local bus interface for intermediate connection of e. g. a SICOMP industry-standard PC with PROGRAF

AS/OS program package for central configuring.

The remote bus connection unit is connected to the interface

module for 20-m local bus fitted in the system to be connected

via a cable connector.

AF Connector board ”Remote bus”for converting the cable cross-section

AV Connection dstributor for 20-m local bus

FS Front plug for 20-m local bus

SV Power supply unit of bus converter

UI Bus interface and inductive coupler of bus converter

Fig. 4/15 Remote bus connection unit, function diagram

T echnical data

Power supply AC 50/60 Hz 230 V + 6 %/-- 10 %

Power consumption Approx. 20 VA

Permissible ambient

temperature

-- Operation

-- Transport and storage

Degree of protection to

DIN 40 050

Dimensions (h x d) 500 mm x 236 mm x 313 mm

Weight Approx. 13.5 kg (without bus conver-

(with 2 bus converters UI)

0to+40qC

--40to+70qC

IP 20

ters and connector boards)

Ordering data

Order No.

Remote bus connection unit (basic unit) 6DS4 425-8AA

with slots for 2 bus conver ter units Ul

Options to be ordered in addition, twice in the

case of a redundant bus connection:

Bus converter Ul

Connector board AF ”Remote bus”

Overvoltage fine protection, can be retrofitted 6DS9 210-8AA

Connection distributor for 20-m local bus

for commissioning and servicing

Cable connector with 1 plug, 0.3 m long

for connection distributor for 20-m local bus

Instructions

Remote bus connection unit (FAE) Order No.

German C79000-- B8000--C127

English C79000-- B8076--C127

French C79000-- B8077--C127

Spanish C79000-- B8078--C127

Bus converter unit, inductive

German C79000-- B8000--C4

English C79000-- B8076--C4

French C79000-- B8077--C4

Spanish C79000-- B8078--C4

6DS4 400-8AB

6DS9 203-8CA

6DS9 207-8AA

6DS8 201-8MB

Siemens PLT 130.1994

4/11

Page 29

This catalog is out of date, see note on page 2

Remote bus connection subrack S5

Description and ordering data

1 Mains terminals AC 230 V

2 Power supply modules

3 Bus converters UI 6DS4 400-8AB

Fig. 4/16 Remote bus connection subrack S5 6DS4 426-8CA

Application

The remote bus connection subrack S5 connects rack-mounted

systems, especially SIMATIC S5-155U programmable controllers, to a redundant or non--redundant remote bus. Electrical

isolation between the local and remote buses is achieved at the

same time.

Non--redundant or redundant DC 24 V or AC 230 V power supplyispossible.

Note: The remote bus connection subrack is not used in the

basic cabinets of the AS 235 and AS 235 H automation systems

and in the OS 265-3 operation and monitoring system (rack version) for DC 24 V.

Design

Single-tier 19-inch subrack with 2 slots for bus converter units

UI, optionally with power supply module(s).

The power supply in the case of DV 24 V is from the cabinet

supply of the programmable controller, in the case of AC 230 V

via the power supply module C79451-A3276-A1 (redundant as

option).

T echnical data

Power supply

-- 6DS4 426-8AA

-- 6DS4 426-8BA and

-- 6DS4 426-8CA

Power consumption Approx. 20 VA

Permissible ambient

temperature

-- Operation

-- Transport and storage

Degree of protection

to DIN 40 050

Protection class

(6DS4 426-8BA and

6DS4 426-8CA)

Dimensions (hxwxd) 134 mm x 485 mm x 260 mm