Page 1

AS/AH

AS Audible Strobe Appliances and AH Audibles

ENGINEER AND ARCHITECT SPECIFICATIONS

• ULlisted.ULC,CSFM,andFMpending.

• ADA/NFPA/UFC/ANSICompliant

• WallmountmodelsareavailablewithFieldSelectableCandela

Settingsof15/30/75/110cdor135/185cd(Multi-Candelamodels)

• Ceilingmountmodelsareavailablewitheldselectablecandela

settingsof15/30/75/95cdor115/177cd(Multi-

candelaceilingmodels)

• SelectableContinuousHornorTemporal(Code3).

• 3SelectabledBAsettings(99,95and90dBA)inbothtones

• Weatherproofmodelsareavailableforoutdooruse

• StrobescanbesynchronizedusingtheSiemensDSCsync

modules,FS-250panel,XLSpanel,orPAD-3powersupplywith

built-insyncprotocol.

AS-MC-CW AS-MC-R

• FastinstallationwithIN/OUTscrewterminalsusing#12to#18

AWGwires

Description

The Siemens 2-wire Series AS Audible Strobe Appliances and Series AH Audibles offer more features with

low current draw.

Strobe options for wall mount models include the Sie-

mens MC multi-candela wall strobes with eld selectable

candela settings of 15/30/75/110cd, or the high intensity

HMC strobe with eld selectable 135/185cd.

Ceiling mount models incorporate Siemens MC multi-

candela ceiling strobe with eld selectable settings of

15/30/75/95cd or the high intensity HMC strobe with eld

selectable settings of 115/177cd.

The audible provides a selectable choice of either a continuous horn or temporal pattern (Code 3) when constant

voltage from a Fire Alarm Panel (FACP) is applied. Each

tone has 3 dBA settings from which to choose.

When used with the Siemens DSC sync modules,

FS-250 panel, XLS panel, or PAD-3 power supply with

built-in sync protocol, synchronization of the continuous

horn tone provides the temporal (code 3) tone (mandated by NFPA 72) simultaneously for all audible appliances. This ensures a distinct temporal (code 3) pattern

when 2 or more audibles are within hearing distance. If

not synchronized the temporal sound could overlap and

not be distinctive. At the same time the strobes will be

synchronized. This provides the ability to comply with

ADA guidelines concerning photosensitive epilepsy and

the NFPA standards when installing

AH-W

2 or more visual appliances within the eld of view all of

this plus the ability to silence the audible is achieved by

using only 2 wires.

AH-R

Engineering Specications

The notication appliances shall be Siemens Series

AS Audible Strobe appliances and Series AH Audible

appliances or approved equals. The Series AS Audible

be listed for UL Standard 1971 (Emergency Devices for

the Hearing-Impaired) for Indoor Fire Protection Service.

The Series AH Audible shall be UL Listed under Standard 464 (Fire Protective Signaling). Both shall meet

the requirements of FCC Part 15 Class B. All inputs

shall be compatible with standard reverse polarity supervision of circuit wiring by a Fire Alarm Control Panel

(FACP).

The audible portion of the appliance shall have a mini-

mum of three (3) eld selectable settings for dBA levels

and shall have a choice of continuous or temporal (Code

3) audible outputs.

The strobe portion of the appliance shall produce a ash

rate of one (1) ash per second over the Regulated

Voltage Range and shall incorporate a Xenon ashtube

enclosed in a rugged Lexan® lens. The Series AS

shall be of low current design. Where Multi-Candela

CATALOG SHEET

2578

Page 2

appliances are specied, the strobe intensity shall have

eld selectable settings and shall be rated per UL Standard 1971 at 15/30/75/110 or 135/185 candela for wall

mount and 15/30/75/95 or 115/177 candela for ceiling

mount. The selector switch for selecting the candela

shall be tamper resistant.

When synchronization is required, the appliance shall

be synchronized using the Siemens DSC sync modules,

FS-250 panel, XLS panel, or PAD-3 power supply with

built-in sync protocol. The strobes shall not drift out of

synchronization at any time during operation. If the sync

module or Power Supply fails to operate, (i.e., contacts

remain closed), the strobe shall revert to a non-synchro-

that shall allow mounting to a single-gang, double-gang,

4-inch square, 100mm European type backboxes, or the

SHBBS Surface Backbox.

All notication appliances shall be listed for Special Applications.

• Strobes are designed to ash at 1 ash per second

minimum over their “Regulated Input Voltage Range”.

Note that NFPA-72 species a ash rate of 1 to 2

ashes per second and ADA Guidelines specify a ash

rate of 1 to 3 ashes per second.

• All candela ratings represent minimum effective Strobe

intensity based on UL Standard 1971.

nized ash-rate. The appliance shall also be designed

so that the audible signal may be silenced while maintaining strobe activation when used with Siemens synchronization.

The Series AS Audible Strobe and Series AH Audible

shall incorporate a Patented Universal Mounting Plate

Technical Information

For complete technical information, please consult the

relevant installation sheets as well as the Siemens

Compatibility Guide.

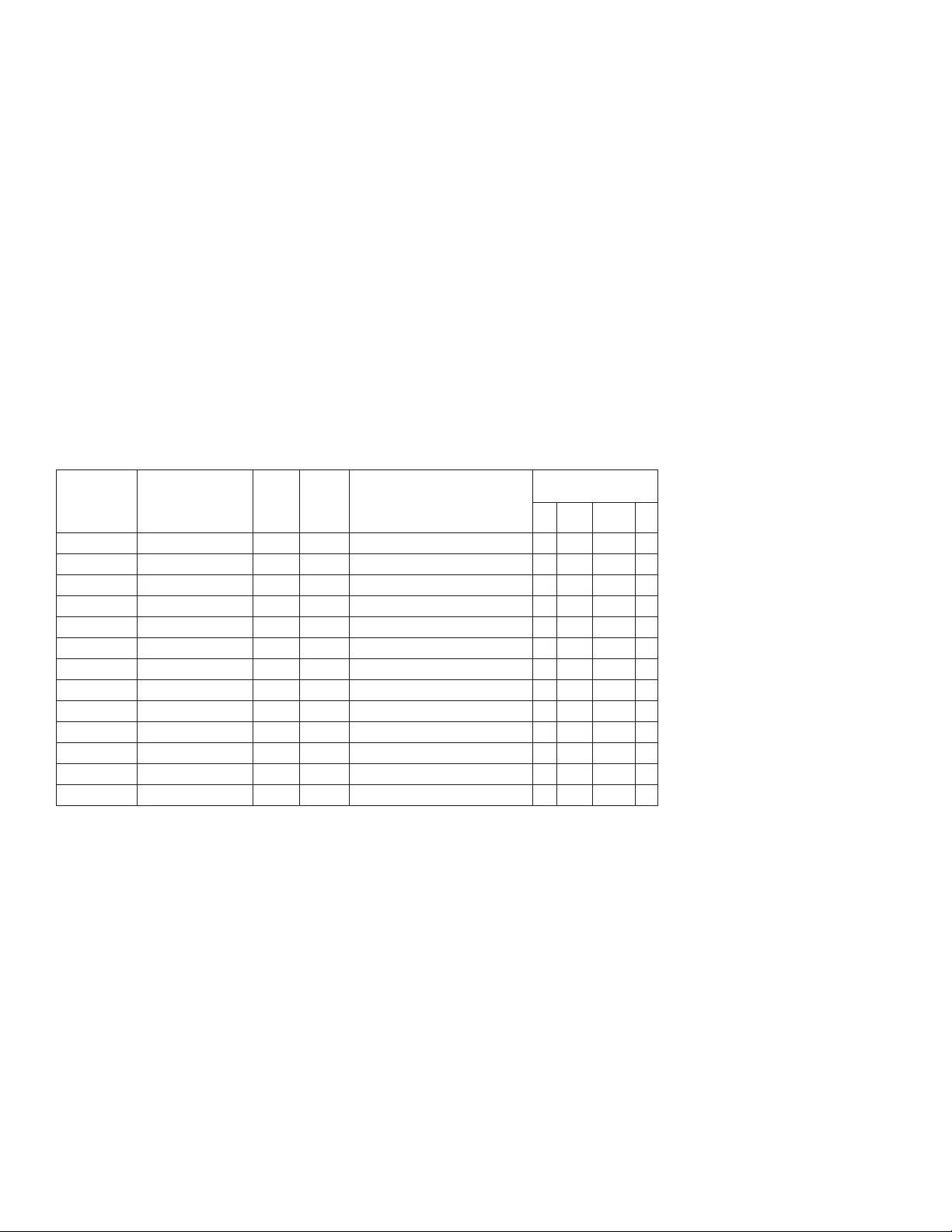

Ordering Information / Mounting Requirements / Approvals

Model

Number

AS-MC-R 500-636010 X - A,B,D,E,F,G,J,N,R,X X # # #

AS-MC-W 500-636011 X - A,B,D,E,F,G,J,N,R,X X # # #

AS-HMC-R 500-636012 X - A,B,D,E,F,G,J,N,R,X X # # #

AS-HMC-W 500-636013 X - A,B,D,E,F,G,J,N,R,X X # # #

AS-MC-CR 500-636006 - X A,B,D,E,F,G,J,N,R,X X # # #

AS-MC-CW 500-636007 - X A,B,D,E,F,G,J,N,R,X X # # #

AS-HMC-CR 500-636008 - X A,B,D,E,F,G,J,N,R,X X # # #

AS-HMC-CW 500-636009 - X A,B,D,E,F,G,J,N,R,X X # # #

AS-75-R-WP 500-636016 X - I X # # #

AS-75-CR-WP 500-636015 - X I X # # #

AH-R 500-636003 X X A,B,D,E,F,G,J,N,R,X X # # #

AH-W 500-636004 X X A,B,D,E,F,G,J,N,R,X X # # #

AH-R-WP 500-636005 X X K X # # #

Order Code

Wall

Mount

Ceiling

Mount

Mounting Options**

Agency Approvals

UL ULC CSFM FM

X = listed/approved # = pending * = Refer to Data Sheet #2585 for mounting options.

WARNING: PLEASE READ THESE SPECIFICATIONS AND INSTALLATION INSTRUCTIONS CAREFULLY BEFORE

USING, SPECIFYING OR APPLYING THIS PRODUCT. FAILURE TO COMPLY WITH ANY OF THESE INSTRUCTIONS,

CAUTIONS AND WARNINGS COULD RESULT IN IMPROPER APPLICATION, INSTALLATION AND/OR OPERATION

OF THESE PRODUCTS IN AN EMERGENCY SITUATION, WHICH COULD RESULT IN PROPERTY DAMAGE, AND

SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

Siemens Building Technologies

Fire Safety

Fire Safety

8 Fernwood Road

Florham Park, NJ 07932

Tel: (973) 593-2600

FAX: (973) 593-6670

Website: www.sbt.siemens.com/fis

7/07

5M

SFS-IG

Printed in U.S.A.

Fire Safety

2 Kenview Boulevard

Brampton, Ontario

Canada L6T 5E4

Tel: (905) 799-9937

FAX: (905) 799-9858

July 2007

New Issue

Page 3

MULTI-CANDELA AUDIBLE STROBE APPLIANCE

INSTALLATION INSTRUCTIONS

(WALL MOUNT VERSION)

IMPORTANT – All audible and visual signaling appliances must be

installed in accordance with all applicable national and local fire alarm

codes and any other required regulatory agencies.

Series Multi-Candela Audible Strobe Appliance (AS-MC) is the

industry’s first 2-wire horn strobe alarm appliance that provides 4

selectable candela settings (15, 30, 75, 110). Siemens Audible Strobe

Appliances provide a selectable continuous or code 3 horn tone and

non-synchronized strobe when connected directly to a Fire Alarm

Control Panel (FACP). They can also provide a synchronized code 3

(or March time) horn tone and synchronized strobe when connected to

a notification appliance circuit running the Siemens sync protocol. The

AS- MC Appliance is UL Listed under Standard 1971 for Emergency

Appliances for the Hearing Impaired and UL Standard 464 for Audible

Signal Appliances. The AS-MC is also ULC Listed under Standard

CAN/ULC-S526- 02 for Visual Signaling Appliances and Standard

CAN/ULC-S525- 99 for Audible Signaling Appliances. This appliance

is listed for wall mounting and indoor use only and is equipped with

a universal mounting plate (UMP) that can be mounted to single-gang,

double-gang, 4” backbox, 100mm European backbox or SHBBS

surface backbox (See wiring and mounting information). The AS-MC

Appliance uses a xenon flashtube with solid state circuitry enclosed in

SPECIFICATIONS:

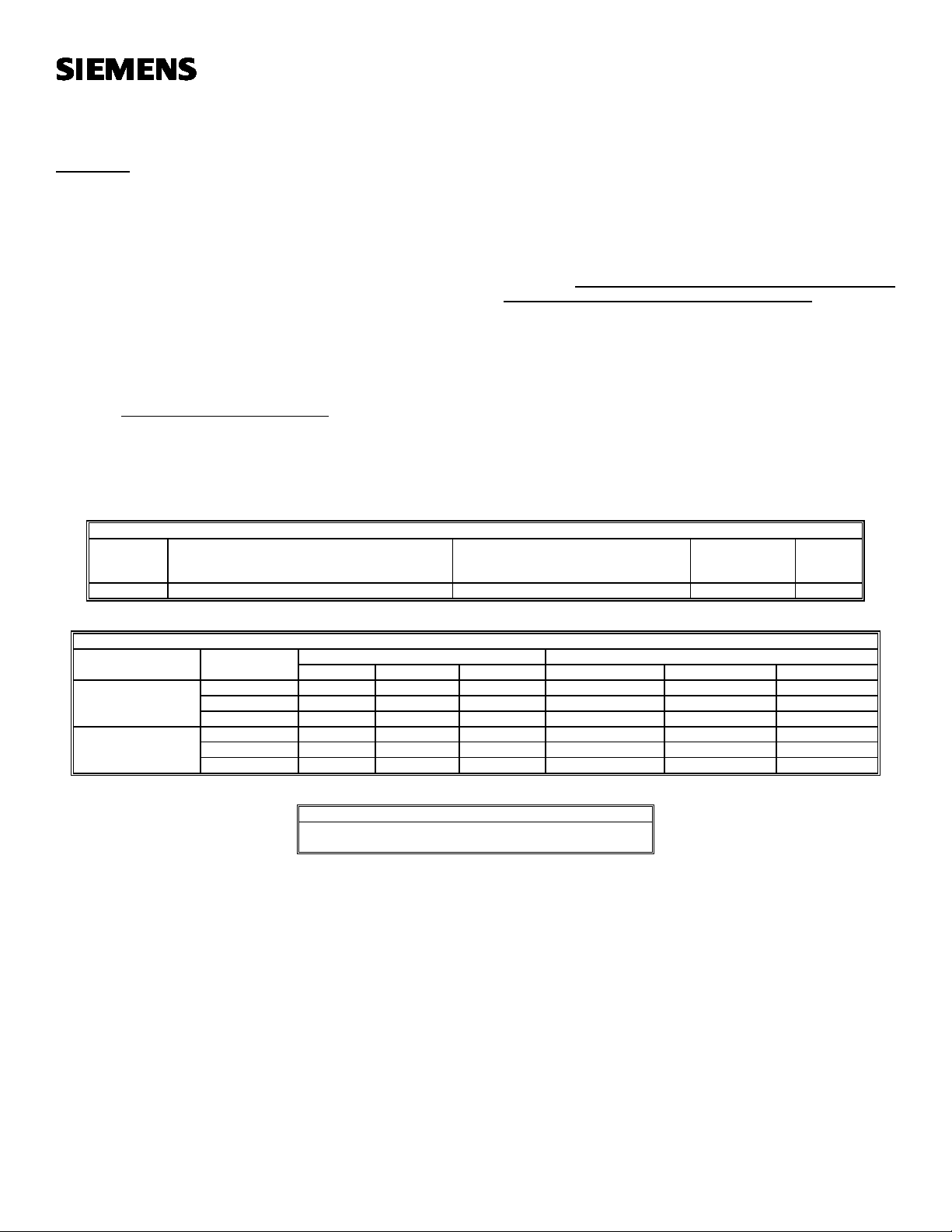

Table 1: UL/ULC Ratings

Operating Voltage (Special Application)

Model* Candela Options

Per UL 1971/464

(VDC/VRMS)

AS-MC 16.0-33.0 20.0-31.0 15/30/75/110 A,B,C,D

*Available in red and white.

a polycarbonate lens to provide maximum visibility and reliability for

effective visible signaling.

The AS-MC Appliance can be field set to provide either high (HI) dBA,

medium (MED) dBA or low (LO) dBA sound output.

NOTE: The Code 3 temporal pattern (1/2 second on, 1/2 second off,

1/2 second on, 1/2 second off, 1/2 second on, 1-1/2 off and repeat) is

specified by ANSI and NFPA 72 for standard emergency evacuation

signaling. The Code 3 Horn should be used only for fire

evacuation signaling and not for any other purpose.

This model is designed for use with either filtered DC (VDC) or

unfiltered full-wave-rectified (VRMS) input voltage. All inputs are

polarized for compatibility with standard reverse polarity supervision of

circuit wiring by an FACP.

NOTE: All Canadian installations should be in accordance with the

Canadian Standard for the Installation of Fire Alarm Systems -

CAN/ULC-S524- 01 and Canadian Electrical Code, Part 1. Final

acceptance is subject to authority having jurisdiction (AHJ).

NOTE: Refer to P/N 315-096363 for the maximum number of

appliances on a single notification appliance circuit.

Voltage Range Per

Strobe Mounting

CAN/ULC-S526- 02/S525-99

(VDC/VRMS) (cd)

Table 2: dBA Sound Output

Description Volume Reverberant Per UL 464 Anechoic dBA Per CAN/ULC-S525-99 at 10 Feet

16.0VDC 24.0VDC 33.0VDC 20.0VDC 24.0VDC 31.0VDC

Low 80 83 86 88 90 91

Continuous Horn Medium 85 88 91 93 95 97

High 88 91 93 97 99 100

Low 75 79 82 88 90 91

Code 3 Horn Medium 80 84 86 93 95 97

(or March Time)** High 84 87 90 97 99 100

**Available in sync mode only.

Table 2A: ULC Directional Characteristics

-3 dBA: 48 degrees left, 41 degrees right

-6 dBA: 50 degrees left, 58 degrees right

NOTES:

1. Strobe will produce 1 flash per second over the Input Voltage range.

2. This strobe/horn model meets the required light distribution patterns defined in UL 1971 and ULC-S526-02.

3. This model is UL/ULC Listed for indoor use with a temperature range of +32F to +120F (0C to +49C) and maximum humidity of 93%, 2% RH.

The effect of shipping and storage temperatures shall not adversely affect the performance of the appliance when it is stored in the original cartons

and not subjected to misuse or abuse.

When calculating the total current: Use Table 3 to determine the highest value of “RMS Current” for an individual AS Appliance then multiply the value

by the total number of AS Appliances. Be sure to add the currents for any other appliances powered by the same source and include any required

safety factors.

THESE APPLIANCES WERE TESTED TO THE VOLTAGE LIMITS OF 16.0-33.0 VOLTS FOR 24V MODELS USING FILTERED DC OR

UNFILTERED FULL-WAVE-RECTIFIED VOLTAGE. DO NOT APPLY VOLTAGE OUTSIDE OF THIS RANGE.

Note: Refer to the installation instructions for the appropriate NAC to find the maximum allowed voltage drop. Use this value along with the current

draw for the appliance to determine the allowable wire resistance. The maximum wire resistance between strobes shall not exceed 35 ohms.

This appliance is not designed to be used on coded systems in which the applied voltage is cycled on and off.

Siemens Building Technologies, Inc. Siemens Building Technologies, Ltd.

8 Fernwood Road 2185 Derry Road West

Florham Park, New Jersey 07932 Mississauga Ontario L5N 7A6

P83947- 007 C Canada

Page 4

CANDELA SETTING WILL DETERMINE THE CURRENT DRAW OF THE PRODUCT.

Table 3: Current Ratings (AMPS)

Maximum RMS Current with Hi dBA Setting

Input Voltage 15cd 30cd 75cd 110cd

DC 16.0-33.0VDC 0.094 0.133 0.212 0.283

FWR 16.0-33.0VRMS 0.134 0.191 0.307 0.405

Maximum RMS Current with Med dBA Setting

Input Voltage 15cd 30cd 75cd 110cd

DC 16.0-33.0VDC 0.079 0.117 0.202 0.269

FWR 16.0-33.0VRMS 0.119 0.183 0.292 0.397

Maximum RMS Current with Low dBA Setting

Input Voltage 15cd 30cd 75cd 110cd

DC 6.0-33.0VDC 0.073 0.112 0.193 0.260

FWR 16.0-33.0VRMS 0.112 0.176 0.287 0.393

Note: These notification appliances are UL Listed as “Special Application”. They are intended to be used only with Siemens notification appliance

circuits.

WARNING: MAKE SURE THAT THE TOTAL RMS CURRENT REQUIRED BY ALL APPLIANCES THAT ARE CONNECTED TO THE SYSTEM’S

PRIMARY AND SECONDARY POWER SOURCES DO NOT EXCEED THE POWER SOURCES’ RATED CAPACITY OR THE CURRENT RATINGS

OF ANY FUSES ON THE CIRCUITS TO WHICH THESE APPLIANCES ARE WIRED. OVERLOADING POWER SOURCES OR EXCEEDING FUSE

RATINGS COULD RESULT IN LOSS OF POWER AND FAILURE TO ALERT OCCUPANTS DURING AN EMERGENCY, WHICH COULD RESULT

IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

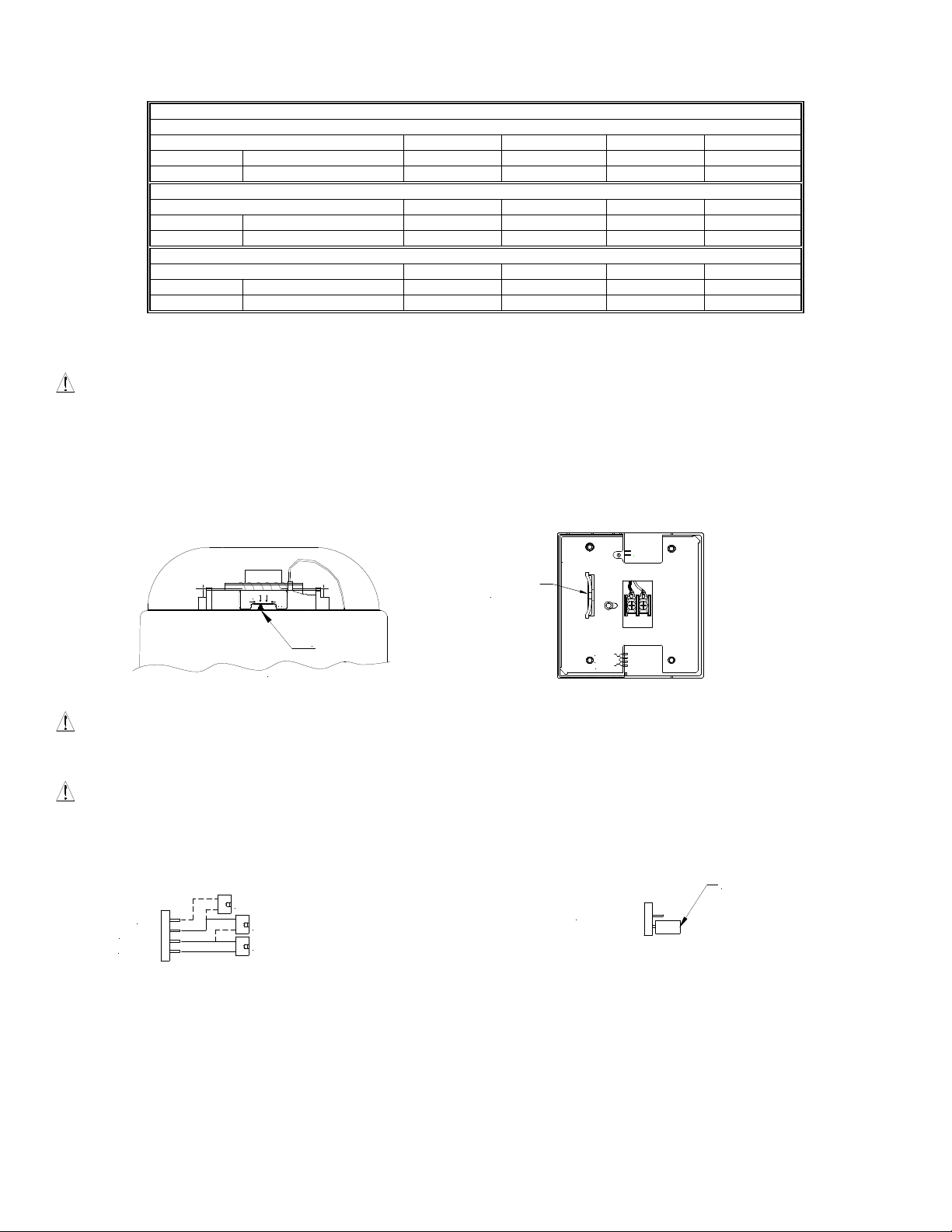

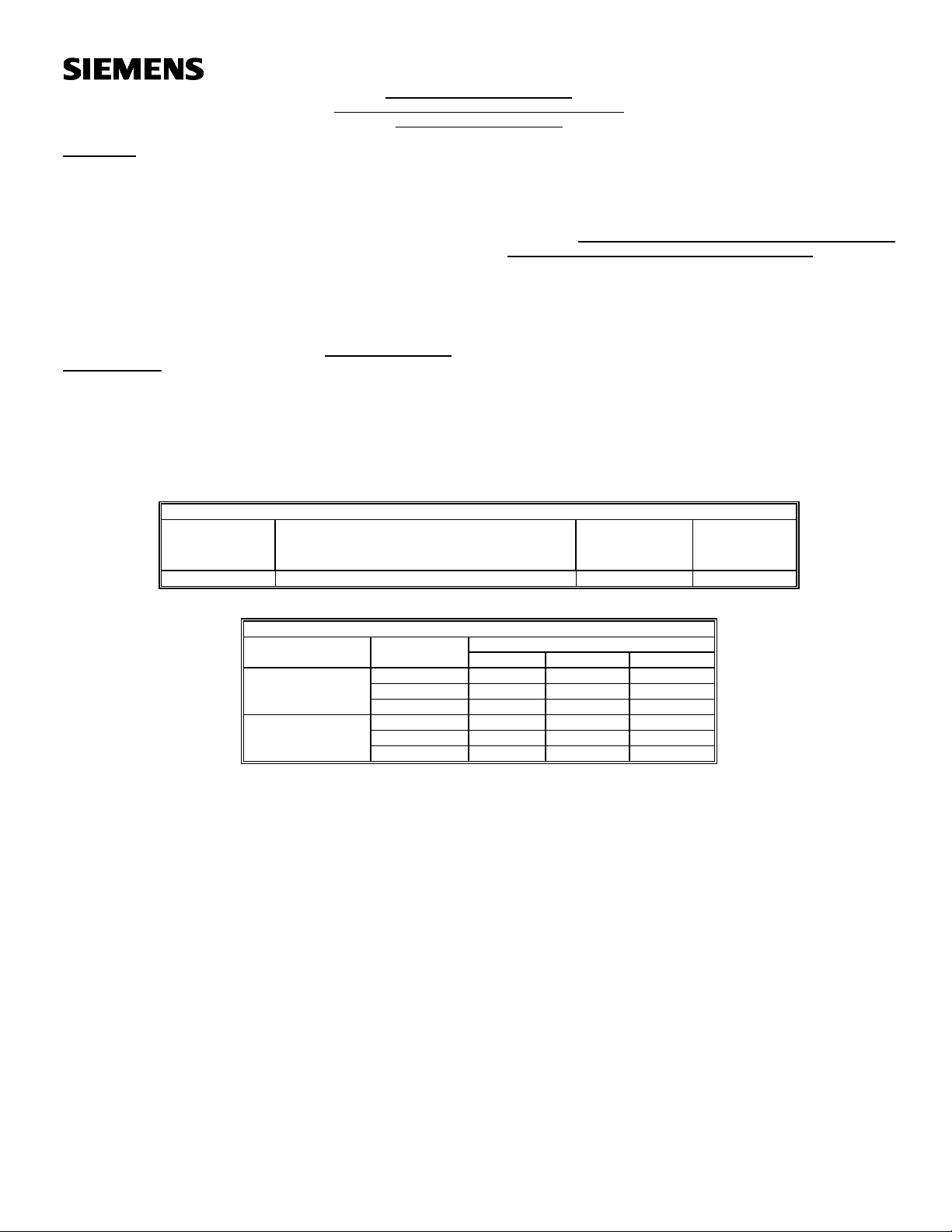

CANDELA AND SOUND OUTPUT SETTINGS:

To set the candela, slide the switch to the desired setting. The setting is indicated by the pointer and label visible on the bottom side of the lens.

Figure 1: Figure 2: Showing Location of Jumper Plug (Back View)

CODE 3

15

75 1301 0

CANDELA

SLIDE

SWITCH

CANDELA

POINTER

HI

MED

LO

BOTTOM VIEW

Factory setting is on Medium dB, Code 3 (or March Time) and 15 candela.

WARNING: THE CANDELA SELECT SWITCH MUST BE FIELD SET TO THE REQUIRED CANDELA INTENSITY BEFORE INSTALLATION.

WHEN CHANGING THE SETTING OF THE CANDELA SELECT SWITCH, MAKE CERTAIN THAT IT “CLICKS” IN PLACE. AFTER CHANGING

THE CANDELA SETTING, THE APPLIANCE MUST BE RETESTED TO VERIFY PROPER OPERATION.

WARNING: THE AUDIBLE STROBE APPLIANCES MUST BE FIELD SET TO THE DESIRED TONE AND dBA SOUND OUTPUT LEVEL

BEFORE THEY ARE INSTALLED. THIS IS DONE BY PROPERLY INSERTING JUMPER PLUGS IN ACCORDANCE WITH THESE

INSTRUCTIONS.

Figure 3: Jumper plug settings for High, Medium, Low and Code 3

(or March Time)

SHOWN SET ON HIGH dB

HI

MED

LOW

SHOWN SET ON MED dB

SHOWN SET ON LOWdB

(Use needle nose pliers to pull and properly set the jumper plugs)

Figure 4: Jumper plug setting for Continuous Horn

CODE 3

No jumper plug is needed for continuous horn setting.

However, it is recommended that the jumper plug be

retained in the unit for future use (if needed) as shown in

Figure 4.

NOTE: The AS-MC must be set for Code 3 (or March Time) when used with a synchronized notification appliance circuit (NAC).

P83947- 007 C

Sheet 2 of 4

Page 5

WIRING AND MOUNTING INFORMATION:

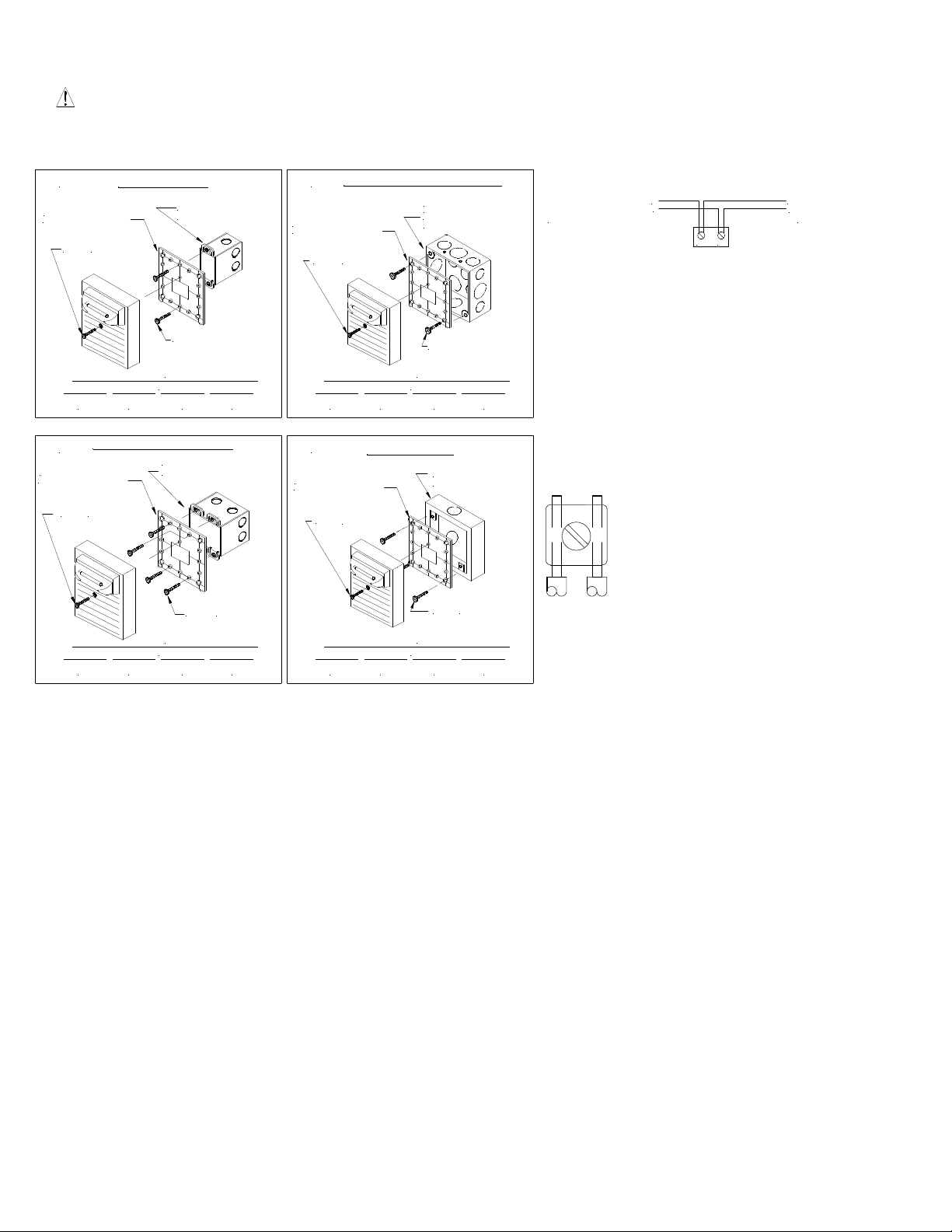

CAUTION: The following figures (A-D) show the maximum number of field wires (conductors) that can enter the backbox used with each mounting

option. If these limits are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the wires could

damage the product. Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially

if sheathed multiconductor cable or 3/4" conduit fittings are used.

A FLUSH MOUNTING

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

MAXIMUM NUMBER OFCONDUCTORS

AWG#18 AWG#16 AWG #14 AWG #12

4 444

FLUSH OR SURFACEMOUNT

C

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

MAXIMUM NUMBER OFCONDUCTORS

AWG#18 AWG#16 AWG #14 AWG #12

4 444

STD.SINGLE-GANG

BACKBOX 2.0"DEEP

#6-32SCREWS

DOUBLE-GANGX 2-1/4"

DEEPBACKBOX

#6-32 SCREWS

FLUSH OR SURFACEMOUNTING

B

4" SQ. X 1-1/2"

DEEPBACKBOX OR

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

MAXIMUM NUMBER OFCONDUCTORS

AWG#18 AWG#16 AWG #14 AWG #12

4 444

100mmSQ.X 37.5mm

EUROPEAN BACKBOX

#8-32SCREWS

D SURFACE MOUNT

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

MAXIMUM NUMBER OFCONDUCTORS

AWG#18 AWG#16 AWG #14 AWG #12

4 444

SHBBS

SURFACE BACKBOX

#8-32SCREWS

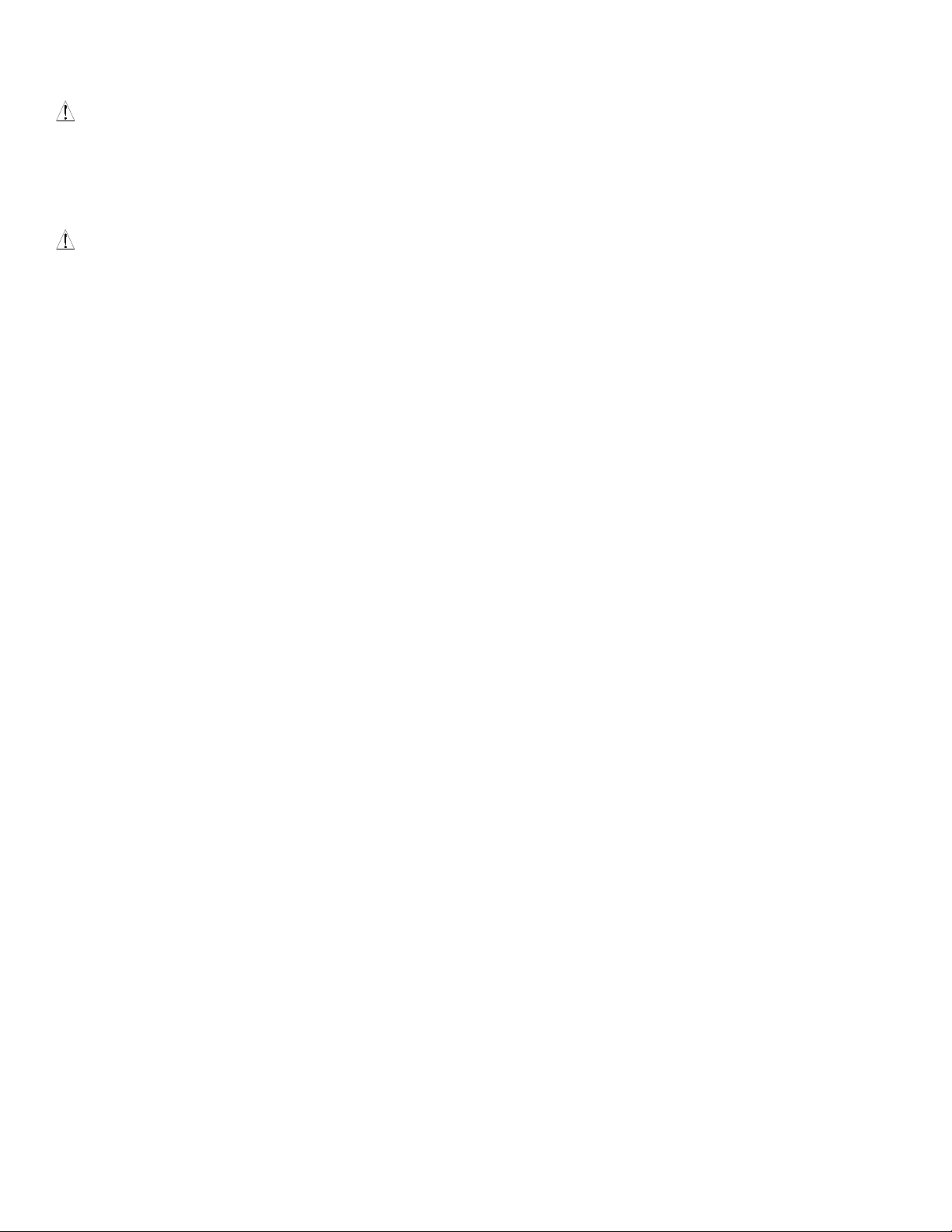

FROMPRECEDING

APPLIANCEOR FIRE

ALARM CONTROL

PANEL (FACP)

Figure 6:

AS-MC Appliance has in -out wiring terminals

Break all in-out wire runs on supervised

Figure 5:

+

-

(+) (-)

+

TONEXTAPPLIANCE OR

-

ENDOF LINE

RESISTOR (EOLR)

that accepts two #12 to #18 American W ire Gauge

(AWG) wires at each screw terminal. Strip leads

3/8” inches for connection to screw terminals.

circuit supervision as shown in Figure 6. The

polarity shown in the wiring diagrams is for the

operation of the appliances. The polarity is

reversed by the FACP during supervision.

MOUNTING PROCEDURES:

1. This model can be flush mounted to a standard single -gang backbox (Figure A), 4” backbox (Figure B) or double-gang backbox (Figure C). They

can also be surface mounted to a 4” or 100mm backbox (Figure B), a double -gang backbox (Figure C) or a SHBBS surface backbox (Figure D).

Mounting hardware for each mounting option is supplied. For proper mounting, be sure to use the mounting screws supplied with the unit.

2. The Universal Mounting Plate (UMP) must be oriented correctly when it is mounted to the backbox. Turn the UMP so that the arrow above the

words “Horizontal Strobe” points to the top side of the UMP.

3. Conduit entrances to the backbox should be selected to provide sufficient wiring clearance for the installed product. Do not pass additional wires

(used for other than the signaling appliance) through the backbox. Such additional wires could result in insufficient wiring space for the si gnaling

appliance.

4. When terminating field wires, do not use more lead length than required. Excess lead length could result in insufficient wiring space for the

signaling appliance. Position the field wires in the backbox so that they use minimum space and produce minimum stress on the product. This is

especially important for stiff, heavy gauge wires and wires with thick insulation or sheathing.

5. Thread the 4 field wires through the opening of the UMP. Mount the UMP to backbox.

6. Connect 4 field wires to the AS-MC terminal block (polarity must be observed). Bend the 4 field wires up 90oat the connection to the terminal block.

7. Carefully push the 4 field wires into the backbox through the opening of the UMP by hand.

8. Hook the 2 slots on the inside wall of the AS-MC onto the 2 tabs of the UMP and screw the AS-MC to the UMP using the #6-20 screw supplied.

P83947- 007 C

Sheet 3 of 4

Page 6

The 110cd strobe setting is Listed for use in sleeping or non-sleeping areas when installed in accordance with appropriate NFPA Standards and AHJ.

WARNING: INSTALLATION OF THE 110 CANDELA STROBE PRODUCTS IN SLEEPING AREAS SHOULD BE WALL MOUNTED AT LEAST

24" BELOW THE CEILING AS FOLLOWS: (1) THE ON-AXIS (DIRECTLY IN FRONT OF LENS) LIGHT OUTPUT SHOULD BE DIRECTED AT THE

EYE-LIDS OF THE SLEEPING PERSON, E.G. PILLOW END OF BED, BED HEAD; (2) NO PART OF THE BED SHALL BE MORE THAN SIXTEEN

(16) FEET FROM THE STROBE NOTIFICATION APPLIANCE. INSTALLERS MUST ADVISE OWNERS AND OPERATORS OF BUILDINGS WITH

SLEEPING OCCUPANTS, E.G. HOTELS AND MOTELS, TO WARN GUESTS, RESIDENTS AND EMPLOYEES TO NOT MOVE THE BED

LOCATION TO A POSITION VIOLATING POINTS (1) AND (2) ABOVE OR SERIOUS INJURY AND/OR LOSS OF LIFE MAY OCCUR DURING A

FIRE MEERGENCY.

WARNING: A SMALL POSSIBILITY EXISTS THAT THE USE OF MULTIPLE STROBES WITHIN A PERSON'S FIELD OF VIEW, UNDER

CERTAIN CIRCUMSTANCES, MIGHT INDUCE A PHOTO-SENSITIVE RESPONSE IN PERSONS WITH EPILEPSY. STROBE REFLECTIONS IN A

GLASS OR MIRRORED SURFACE MIGHT ALSO INDUCE SUCH A RESPONSE. TO MINIMIZE THIS POSSIBLE HAZARD, IT IS STRONGLY

RECOMMENDED THAT THE STROBES INSTALLED SHOULD NOT PRESENT A COMPOSITE FLASH RATE IN THE FIELD OF VIEW WHICH

EXCEEDS FIVE (5) Hz AT THE OPERATING VOLTAGE OF THE STROBES. IT IS STRONGLY RECOMMENDED THAT THE INTENSITY AND

COMPOSITE FLASH RATE OF INSTALLED STROBES COMPLY WITH LEVELS ESTABLISHED BY APPLICABLE LAWS, STANDARDS,

REGULATIONS, CODES AND GUIDELINES.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the separation between the

equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult the

dealer or an experienced radio/TV technician for help.

P83947- 007 C

Sheet 4 of 4

Page 7

MULTI-CANDELA AUDIBLE STROBE APPLIANCE

IMPORTANT

installed in accordance with all applicable national and local fire alarm

codes and any other required regulatory agencies.

Series Audible Strobe Multi-Candela (AS-MC-C) Appliance is the

industry’s first 2-wire horn strobe alarm appliance that provides 4

selectable candela settings (15, 30, 75, 95). Siemens Audible Strobe

Appliances provide a selectable continuous or code 3 horn tone and

non-synchronized strobe when connected directly to a Fire Alarm

Control Panel (FACP). They can also provide a synchronized code 3

(or March time) horn tone and synchronized strobe connected to a

notification appliance circuit running the Siemens sync protocol. The

AS-MC-C Appliance is UL Listed under Standard 1971 for Emergency

Appliances for the Hearing Impaired and UL Standard 464 for Audible

Signal Appliances. This appliance is listed for ceiling mounting and

indoor use only

(UMP) that can be mounted to single-gang, double-gang, 4” backbox,

or 100mm European backbox (See wiring and mounting information).

The AS-MC-C Appliance uses a xenon flashtube with solid state

circuitry enclosed in a polycarbonate lens to provide maximum

visibility and reliability for effective visible signaling.

SPECIFICATIONS:

NOTES:

1. Strobe will produce 1 flash per second over the Input Voltage range.

2. This strobe/horn model meets the required light distribution patterns defined in UL 1971.

3. This model is UL Listed for indoor use with a temperature range of +32ºF to +120ºF (0ºC to +49ºC) and maximum humidity of 93% + 2% RH. The

effect of shipping and storage temperatures shall not adversely affect the performance of the appliance when it is stored in the original cartons and

not subjected to misuse or abuse.

When calculating the total current: Use Table 3 to determine the highest value of “RMS Current” for an individual AS Appliance then multiply the value

by the total number of AS Appliances. Be sure to add the currents for any other appliances powered by the same source and include any required

safety factors.

CANDELA SETTING WILL DETERMINE THE CURRENT DRAW OF THE PRODUCT.

THESE APPLIANCES WERE TESTED TO THE VOLTAGE LIMITS OF 16.0-33.0 VOLTS FOR 24V MODELS USING FILTERED DC OR

UNFILTERED FULL-WAVE-RECTIFIED VOLTAGE. DO NOT APPLY VOLTAGE OUTSIDE OF THIS RANGE.

Note: Refer to the installation instructions for the appropriate NAC to find the maximum allowed voltage drop. Use this value along with the current

draw for the appliance to determine the allowable wire resistance. The maximum wire resistance between strobes shall not exceed 35 ohms.

This appliance is not designed to be used on coded systems in which the applied voltage is cycled on and off.

Siemens Building Technologies, Inc. P84395-003 B

8 Fernwood Road Sheet 1 of 3

Florham Park, New Jersey 07932

– All audible and visual signaling appliances must be

and is equipped with a universal mounting plate

Operating Voltage (Special Application)

Model*

AS-MC-C 16.0-33.0 15/30/75/95 A,B,C,D

Description Volume Reverberant Per UL 464

16.0VDC 24.0VDC 33.0VDC

Low 80 83 86

Continuous Horn Medium 85 88 91

High 88 91 93

Low 75 79 82

Code 3 Horn Medium 80 84 86

Or March Time** High 84 87 90

INSTALLATION INSTRUCTIONS

(CEILING MOUNT VERSION)

The AS-MC-C Appliance can be field set to provide either high (HI)

dBA, medium (MED) dBA or low (LO) dBA sound output.

NOTE: The Code 3 temporal pattern (1/2 second on, 1/2 second off,

1/2 second on, 1/2 second off, 1/2 second on, 1-1/2 off and repeat) is

specified by ANSI and NFPA 72 for standard emergency evacuation

signaling. The Code 3 Horn should be used only for fire

evacuation signaling and not for any other purpose.

This model is designed for use with either filtered DC (VDC) or

unfiltered Full-Wave-Rectified (FWR) input voltage. All inputs are

polarized for compatibility with standard reverse polarity supervision of

circuit wiring by a (FACP).

Table 1: UL Ratings

Per UL 1971/464

(VDC/VRMS)

* Available in red and white.

Table 2: dBA Sound Output

**Available in sync mode only

NFPA 72/ANSI 117.1 conform to ADAAG Equivalent Facilitation

Guidelines in using fewer, higher intensity strobes within the same

protected area.

NOTE: Refer to P/N 315-096363 for the maximum number of

appliances on a single notification appliance circuit.

Strobe

Candela

(cd)

Mounting

Options

Page 8

Table 3: Current Ratings (AMPS)

Maximum RMS Current with Hi dBA Setting

Voltage 15cd 30cd 75cd 95cd

DC 16.0-33.0VDC 0.101 0.147 0.235 0.303

FWR 16.0-33.0VRMS 0.144 0.202 0.324 0.424

Maximum RMS Current with Med dBA Setting

Voltage 15cd 30cd 75cd 95cd

DC 16.0-33.0VDC 0.085 0.130 0.213 0.285

FWR 16.0-33.0VRMS 0.132 0.185 0.312 0.414

Maximum RMS Current with Low dBA Setting

Voltage 15cd 30cd 75cd 95cd

DC 16.0-33.0VDC 0.079 0.120 0.210 0.279

FWR 16.0-33.0VRMS 0.122 0.180 0.308 0.409

Note: These notification appliances are UL Listed as “Special Application”. They are intended to be used only with Siemens notification appliance

circuits.

WARNING: MAKE SURE THAT THE TOTAL RMS CURRENT REQUIRED BY ALL APPLIANCES THAT ARE CONNECTED TO THE SYSTEM’S

PRIMARY AND SECONDARY POWER SOURCES DO NOT EXCEED THE POWER SOURCES’ RATED CAPACITY OR THE CURRENT RATINGS

OF ANY FUSES ON THE CIRCUITS TO WHICH THESE APPLIANCES ARE WIRED. OVERLOADING POWER SOURCES OR EXCEEDING FUSE

RATINGS COULD RESULT IN LOSS OF POWER AND FAILURE TO ALERT OCCUPANTS DURING AN EMERGENCY, WHICH COULD RESULT

IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

CANDELA AND SOUND OUTPUT SETTINGS:

To set the candela, slide the switch to the desired setting. The setting is indicated by the pointer and label visible on the bottom side of the lens.

Figure 1: Figure 2: Showing Location of Jumper Plug

CANDELA

15

30

75

95

SLIDE

SWITCH

CODE 3

CANDELA

POINTE R

BOTTOM VIEW

Back View

HI

MED

LO

Factory setting is on Medium dB, Code 3 (or March Time) and 15 candela.

THE CANDELA SELECT SWITCH MUST BE FIELD SET TO THE REQUIRED CANDELA INTENSITY BEFORE INSTALLATION. WHEN

CHANGING THE SETTING OF THE CANDELA SELECT SWITCH, MAKE CERTAIN THAT IT “CLICKS” IN PLACE. AFTER CHANGING THE

CANDELA SETTING, THE APPLIANCE MUST BE RETESTED TO VERIFY PROPER OPERATION

THE AUDIBLE STROBE APPLIANCES MUST BE FIELD SET TO THE DESIRED TONE AND dBA SOUND OUTPUT LEVEL BEFORE THEY ARE

INSTALLED. THIS IS DONE BY PROPERLY INSERTING JUMPER PLUGS IN ACCORDANCE WITH THESE INSTRUCTIONS.

Figure 3: Jumper plug settings for High, Medium, Low and Code 3 Figure 4: Jumper plug setting for Continuous Horn

TURN PLUG 90°

SHOWN SET ON HIGH dB

HI

MED

LOW

(Use needle nose pliers to pull and properly set the jumper plugs)

SHOWN SET ON M ED dB

SHOWN SET ON LOW dB

NOTE: The AS-MC-C must be set for Code 3 (or March Time) when used with a synchronized notification appliance circuit (NAC).

WIRING AND MOUNTING INFORMATION:

CAUTION: The following figures (A-D) show the maximum number of field wires (conductors) that can enter the backbox used with each mounting

option. If these limits are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the wires could

damage the product. Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit,

especially if sheathed multiconductor cable or 3/4" conduit fittings are used.

CODE 3

No jumper plug is needed for continuous horn setting.

However, it is recommended that the jumper plug be

retained in the unit for future use (if needed) as shown in

Figure 4.

Siemens Building Technologies, Inc. P84395-003 B

Sheet 2 of 3

Page 9

A

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

FLUSH MOUNTING

STD. SINGLE-GANG

BACKBOX 2.0" DEEP

#6-32 SCREWS

FLUSH OR SURFACE MOUNTING

B

UNIVERSAL

MOUNTING PLATE

SCREW

#6-20

4" SQ. X 1-1/2"

DEEP BACKBOX OR

100mm SQ. X 37.5mm

EUROPEAN BACKBOX

#8-32 SCREW S

FROM PRECEDING

APPLIANCE OR FIRE

ALARM CONTROL

PANEL (FACP)

Figure 5:

+

-

(-)

(+)

+

TO NEXT APPLIANCE OR

-

END OF LINE

RESISTOR (EOLR)

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

FLUSH OR SURFACE MOUNT

C

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

DOUBLE-GANG X 2-1/4"

DEEP BACKBOX

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

D

UNIVERSAL

MOUNTING PLATE

#6-20

SCREW

SURFACE MOUNT

SHBBS

SURFACE BACKBOX

Figure 6:

• AS-MC-C Appliance has in-out wiring

terminals that accepts two #12 to #18

American Wire Gauge (AWG) wires at

each screw terminal. Strip leads 3/8”

inches for connection to screw terminals.

#6-32

SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#8-32

SCREWS

• Break all in-out wire runs on supervised

circuit supervision as shown in Figure 6.

The polarity shown in the wiring diagrams

is for the operation of the appliances. The

polarity is reversed by the FACP during

supervision.

MOUNTING PROCEDURES:

1. This model can be flush mounted to a standard single-gang backbox (Figure A), 4” backbox (Figure B) or double-gang backbox (Figure C). They

can also be surface mounted to a 4” or 100mm backbox (Figure B), a double-gang backbox (Figure C) or a SHBBS surface backbox (Figure D).

Mounting hardware for each mounting option is supplied. For proper mounting, be sure to use the mounting screws supplied with the unit.

2. The Universal Mounting Plate (UMP) must be oriented correctly when it is mounted to the backbox. Turn the UMP so that the arrow above the

words “Horizontal Strobe” points to the top side of the UMP.

3. Conduit entrances to the backbox should be selected to provide sufficient wiring clearance for the installed product. Do not pass additional wires

(used for other than the signaling appliance) through the backbox. Such additional wires could result in insufficient wiring space for the signaling

appliance.

4. When terminating field wires, do not use more lead length than required. Excess lead length could result in insufficient wiring space for the

signaling appliance. Position the field wires in the backbox so that they use minimum space and produce minimum stress on the product. This is

especially important for stiff, heavy gauge wires and wires with thick insulation or sheathing.

5. Thread the 4 field wires through the opening of the UMP. Mount the UMP to backbox.

6. Connect 4 field wires to the AS-MC-C terminal block (polarity must be observed). Bend the 4 field wires up 90

o

at the connection to the terminal

block.

7. Carefully push the 4 field wires into the backbox through the opening of the UMP by hand.

8. Hook the 2 slots on the inside wall of the AS-MC-C onto the 2 tabs of the UMP and screw the AS-MC-C to the UMP using the #6-20 screw

supplied.

WARNING: A SMALL POSSIBILITY EXISTS THAT THE USE OF MULTIPLE STROBES WITHIN A PERSON'S FIELD OF VIEW, UNDER

CERTAIN CIRCUMSTANCES, MIGHT INDUCE A PHOTO-SENSITIVE RESPONSE IN PERSONS WITH EPILEPSY. STROBE REFLECTIONS IN A

GLASS OR MIRRORED SURFACE MIGHT ALSO INDUCE SUCH A RESPONSE. TO MINIMIZE THIS POSSIBLE HAZARD, IT IS STRONGLY

RECOMMENDED THAT THE STROBES INSTALLED SHOULD NOT PRESENT A COMPOSITE FLASH RATE IN THE FIELD OF VIEW WHICH

EXCEEDS FIVE (5) Hz AT THE OPERATING VOLTAGE OF THE STROBES. IT IS ALSO STRONGLY RECOMMENDED THAT THE INTENSITY

AND COMPOSITE FLASH RATE OF INSTALLED STROBES COMPLY WITH LEVELS ESTABLISHED BY APPLICABLE LAWS, STANDARDS,

REGULATIONS, CODES AND GUIDELINES.

The 15/30/75/95cd settings are Listed for use in sleeping or non-sleeping areas when installed in accordance with appropriate NFPA Standards and the

AHJ.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the separation between the

equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult the

dealer or an experienced radio/TV technician for help.

Siemens Building Technologies, Inc. P84395-003 B

Sheet 3 of 3

Page 10

MULTI-HIGH-CANDELA AUDIBLE STROBE APPLIANCE

IMPORTANT

installed in accordance with all applicable national and local fire alarm

codes and any other required regulatory agency.

Series Audible Strobe Multi-High-Candela (AS-HMC-C) Appliance is the

industry’s first 2-wire horn strobe alarm appliance that provides two

selectable candela settings (115, 177). Siemens Audible Strobe

Appliances provide a selectable continuous or code 3 horn tone and

non-synchronized strobe when connected directly to a Fire Alarm

Control Panel (FACP). They can also provide a synchronized code 3

(or March time) horn tone and synchronized strobe when connected to

a notification appliance circuit running the Siemens sync protocol. The

AS-HMC-C Appliance is UL Listed under Standard 1971 for Emergency

Appliances for the Hearing Impaired and UL Standard 464 for Audible

Signal Appliances. This appliance is listed for ceiling mounting and

indoor use only

(UMP) that can be mounted to single-gang, double-gang, 4” backbox,

100mm European backbox or SHBBS surface backbox (See wiring and

mounting information). The AS-HMC-C appliance uses a xenon

flashtube with solid state circuitry enclosed in a polycarbonate lens to

provide maximum visibility and reliability for effective visible signaling.

SPECIFICATIONS:

NOTES:

1. Strobe will produce 1 flash per second over the Input Voltage range.

2. This strobe/horn model meets the required light distribution patterns defined in UL 1971.

3. This model is UL Listed for indoor use with a temperature range of +32ºF to +120ºF (0ºC to +49ºC) and maximum humidity of 85% RH. The effect of

When calculating the total current: Use Table 3 to determine the highest value of “RMS Current” for an individual AS Appliance then multiply the value by

the total number of AS Appliances. Be sure to add the currents for any other appliances powered by the same source and include any required safety

factors.

THESE APPLIANCES WERE TESTED TO THE VOLTAGE LIMITS OF 16.0-33.0 VOLTS FOR 24V MODELS USING FILTERED DC OR UNFILTERED

FULL-WAVE-RECTIFIED VOLTAGE. DO NOT APPLY VOLTAGE OUTSIDE OF THIS RANGE.

Note: Refer to the installation instructions for the appropriate NAC to find the maximum allowed voltage drop. Use this value along with the current draw

for the appliance to determine the allowable wire resistance. The maximum wire resistance between strobes shall not exceed 35 ohms.

This appliance is not designed to be used on coded systems in which the applied voltage is cycled on and off.

CANDELA SETTING WILL DETERMINE THE CURRENT DRAW OF THE PRODUCT.

Siemens Building Technologies, Inc. P84448-003B

8 Fernwood Road Page 1 of 1

Florham Park, New Jersey 07932

– All audible and visual signaling appliances must be

and is equipped with a universal mounting plate

Model

AS-HMC-C* 16.0-33.0 115/177 A,B,C,D

Description Volume Reverberant Per UL 464

16.0VDC 24.0VDC 33.0VDC

Low 80 83 86

Continuous Horn Medium 85 88 91

High 88 91 93

Low 75 79 82

Code 3 Horn Medium 80 84 86

(or March Time)** High 84 87 90

shipping and storage temperatures shall not adversely affect the performance of the appliance when it is stored in the original cartons and not

subjected to misuse or abuse.

INSTALLATION INSTRUCTIONS

(CEILING MOUNT VERSION)

Table 1: UL Ratings

Operating Voltage (Special Application)

Per UL 1971

(VDC/VRMS)

* Available in red and white.

Table 2: dBA Sound Output

** Available in sync mode only.

The AS-HMC-C Appliance can be field set to provide either high (HI)

dBA, medium (MED) dBA or low (LO) dBA sound output.

This model is designed for use with either filtered DC (VDC) or

unfiltered full-wave-rectified (FWR) input voltage. All inputs are

polarized for compatibility with standard reverse polarity supervision of

circuit wiring by a FACP.

NOTE: The Code 3 temporal pattern (1/2 second on, 1/2 second off,

1/2 second on, 1/2 second off, 1/2 second on, 1-1/2 off and repeat) is

specified by ANSI and NFPA 72 for standard emergency evacuation

signaling. The Code 3 Horn should be used only for fire evacuation

signaling and not for any other purpose.

NFPA 72/ANSI 117.1 conform to ADAAG Equivalent Facilitation

Guidelines in using fewer, higher intensity strobes within the same

protected area.

NOTE: Refer to P/N 315-096363 for the maximum number of

appliances on a single notification appliance circuit. .

Strobe

Candela

(cd)

Mounting

Options

.

Page 11

Table 3: Current Ratings (AMPS)

Maximum RMS Current with Hi dBA Setting

Voltage 115cd 177cd

DC 16.0-33.0VDC 0.356 0.488

FWR 16.0-33.0VRMS 0.499 0.705

Maximum RMS Current with Med dBA Setting

Voltage 115cd 177cd

DC 16.0-33.0VDC 0.361 0.493

FWR 16.0-33.0VRMS 0.509 0.716

Maximum RMS Current with Low dBA Setting

Voltage 115cd 177cd

DC 16.0-33.0VDC 0.356 0.499

FWR 16.0-33.0VRMS 0.488 0.705

Note: These notification appliances are UL Listed as “Special Application.” They are intended to be used only with Siemens notification appliance circuits.

WARNING: MAKE SURE THAT THE TOTAL RMS CURRENT REQUIRED BY ALL APPLIANCES THAT ARE CONNECTED TO THE SYSTEM’S

PRIMARY AND SECONDARY POWER SOURCES DO NOT EXCEED THE POWER SOURCES’ RATED CAPACITY OR THE CURRENT RATINGS OF

ANY FUSES ON THE CIRCUITS TO WHICH THESE APPLIANCES ARE WIRED. OVERLOADING POWER SOURCES OR EXCEEDING FUSE

RATINGS COULD RESULT IN LOSS OF POWER AND FAILURE TO ALERT OCCUPANTS DURING AN EMERGENCY, WHICH COULD RESULT IN

PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

CANDELA AND SOUND OUTPUT SETTINGS:

To set the candela, slide the switch to the desired setting. The setting is indicated by the pointer and label visible on the bottom side of the lens.

Figure1: Figure 2: Showing Location of Jumper Plug

CODE 3

CANDELA

115

177

SLIDE

SWITCH

CANDELA

PO IN TER

BOTTOM VIEW

Back View

WARNING: THE CANDELA SELECT SWITCH MUST BE FIELD SET TO THE REQUIRED CANDELA INTENSITY BEFORE INSTALLATION.

WHEN CHANGING THE SETTING OF THE CANDELA SELECT SWITCH, MAKE CERTAIN THAT IT “CLICKS” IN PLACE. AFTER CHANGING THE

CANDELA SETTING, THE APPLIANCE MUST BE RETESTED TO VERIFY PROPER OPERATION.

WARNING: THE AUDIBLE STROBE APPLIANCES MUST BE FIELD SET TO THE DESIRED TONE AND dBA SOUND OUTPUT LEVEL BEFORE

THEY ARE INSTALLED. THIS IS DONE BY PROPERLY INSERTING JUMPER PLUGS IN ACCORDANCE WITH THESE INSTRUCTIONS.

Figure 3: Jumper plug settings for High, Medium, Low and Code 3

(or March Time)

HI

MED

LOW

(Use needle nose pliers to pull and properly set the jumper plugs)

NOTE: The AS-HMC-C must be set for Code 3 (or March Time) when used with a synchronized notification appliance circuit (NAC).

WIRING AND MOUNTING INFORMATION:

Siemens Building Technologies, Inc. P84448-003 B

Factory setting is on Medium dB, Code 3 (or March Time) and 177 candela.

SHOWN SET ON HIGH dB

SHOWN SET ON M ED dB

SHOWN SET ON LOW dB

Figure 4: Jumper plug setting for Continuous Horn

CODE 3

No jumper plug is needed for continuous horn setting.

However, it is recommended that the jumper plug be

retained in the unit for future use (if needed) as shown in

Figure 4.

HI

MED

LO

TURN PLUG 90°

Page 2 of 2

Page 12

The following figures (A-D) show the maximum number of field wires (conductors) that can enter the backbox used with each mounting option. If these

limits are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the wires could damage the

product. Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially if sheathed

multiconductor cable or 3/4" conduit fittings are used.

A

UNIVERSAL

MOUNTING PLATE

#6-20 SCREW

FLUSH MOUNTING

STD. SINGLE-GANG

BACKBOX 2.0" DEEP

FLUSH OR SURFACE MOUNTING

B

UNIVERSAL

MOUNTING PLATE

SCREW

#6-20

4" SQ. X 1-1/2"

DEEP BACKBOX OR

100mm SQ. X 37.5mm

EUROPEAN BACKBOX

FROM PRECEDING

APPLIANCE OR FIRE

ALARM CONTROL

PANEL (FACP

+

-

Figure 5:

(-)

(+)

+

TO NEXT APPLIANCE OR

-

END OF LINE

RESISTOR (EOLR)

#6-32 SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

FLUSH OR SURFACE MOUNT

C

UNIVERSAL

MOUNTING PLATE

#6-20 SCR EW

DOUBLE-GANG X 2-1/4"

DEEP BACKBOX

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

D

UNIVERSAL

MOUNTING PLATE

#6-20

SCREW

SURFACE MOUNT

#8-32 SC REWS

SHBBS

SURFACE BACKBOX

Figure 6:

• AS-HMC-C has in-out wiring terminals that

accepts two #12 to #18 American Wire Gauge

(AWG) wires at each screw terminal. Strip leads

3/8” inches for connection to screw terminals.

• Break all in-out wire runs on supervised circuit

supervision as shown in Figure 6. The polarity

shown in the wiring diagrams is for the operation

of the appliances. The polarity is reversed by the

FACP during supervision.

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#6-32

SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#8-32

SCREWS

MOUNTING PROCEDURES:

1. This model can be flush mounted to a standard single-gang backbox (Figure A), 4” backbox (Figure B) or double-gang backbox (Figure C). They can

also be surface mounted to a 4” or 100mm backbox (Figure B), a double-gang backbox (Figure C) or a SHBBS surface backbox (Figure D).

Mounting hardware for each mounting option is supplied. For proper mounting, be sure to use the mounting screws supplied with the unit.

2. The Universal Mounting Plate (UMP) must be oriented correctly when it is mounted to the backbox. Turn the UMP so that the arrow above the words

“Horizontal Strobe” points to the top side of the UMP.

3. Conduit entrances to the backbox should be selected to provide sufficient wiring clearance for the installed product. Do not pass additional wires

(used for other than the signaling appliance) through the backbox. Such additional wires could result in insufficient wiring space for the signaling

appliance.

4. When terminating field wires, do not use more lead length than required. Excess lead length could result in insufficient wiring space for the signaling

appliance. Position the field wires in the backbox so that they use minimum space and produce minimum stress on the product. This is especially

important for stiff, heavy gauge wires and wires with thick insulation or sheathing.

5. Thread the 4 field wires through the opening of the UMP. Mount the UMP to backbox.

6. Connect 4 field wires to the AS-HMC-C terminal block (polarity must be observed). Bend the 4 field wires up 90

o

at the connection to the terminal

block.

7. Carefully push the 4 field wires into the backbox through the opening of the UMP by hand.

8. Hook the 2 slots on the inside wall of the AS-HMC-C onto the 2 tabs of the UMP and screw the unit to the UMP using the #6-20 screw supplied.

The 177cd setting is Listed for use in sleeping or non-sleeping areas when installed in accordance with appropriate NFPA Standards and the AHJ.

WARNING: A SMALL POSSIBILITY EXISTS THAT THE USE OF MULTIPLE STROBES WITHIN A PERSON'S FIELD OF VIEW, UNDER CERTAIN

CIRCUMSTANCES, MIGHT INDUCE A PHOTO-SENSITIVE RESPONSE IN PERSONS WITH EPILEPSY. STROBE REFLECTIONS IN A GLASS OR

MIRRORED SURFACE MIGHT ALSO INDUCE SUCH A RESPONSE. TO MINIMIZE THIS POSSIBLE HAZARD, SIEMENS STRONGLY

RECOMMENDS THAT THE STROBES INSTALLED SHOULD NOT PRESENT A COMPOSITE FLASH RATE IN THE FIELD OF VIEW WHICH

EXCEEDS FIVE (5) Hz AT THE OPERATING VOLTAGE OF THE STROBES. SIEMENS ALSO STRONGLY RECOMMENDS THAT THE INTENSITY

AND COMPOSITE FLASH RATE OF INSTALLED STROBES COMPLY WITH LEVELS ESTABLISHED BY APPLICABLE LAWS, STANDARDS,

REGULATIONS, CODES AND GUIDELINES.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the separation between the equipment and receiver, 3) Connect

the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult the dealer or an experienced radio/TV

technician for help.

Siemens Building Technologies, Inc. P84448-003 B

Page 3 of 3

Page 13

INSTALLATION INSTRUCTIONS

AUDIBLE STROBE WEATHERPROOF APPLIANCE

(WALL/CEILING MOUNT VERSION)

IMPORTANT

– All audible and visual signaling appliances must be

installed in accordance with all applicable national and local fire alarm

codes and any other required regulatory agencies.

Series AS-WP appliance is the industry’s first 2-wire horn strobe alarm

appliance that provides a selectable continuous or Code 3 horn tone

and continuous strobe when connected directly to the Fire Alarm

Control Panel (FACP), or provides a synchronized Code 3 horn tone

(or March Time) and synchronized strobe when connected to a

notification appliance circuit running the Siemens sync protocol.

Additionally, Siemens Multi-High-Candela (AS-HMC-WP and AS-HMCC-WP) appliances provide two selectable settings (135/185 or 115/177,

respectively). The AS-WP appliance is UL Listed for indoor/outdoor

use under Standard 1638 for Emergency Devices for the Hearing

Impaired (Visual Signal Appliances), UL464 for Audible Signal

Appliances and UL Standard 1971 for Emergency Appliances for the

Hearing Impaired. For outdoor application the AS-WP must be

mounted to the Weatherproof Backbox (WPBBS). The AS-WP uses a

xenon flashtube with solid state circuitry enclosed in a polycarbonate

lens to provide maximum visibility and reliability for effective visible

The AS-WP appliance can be field set to provide high (HI) dBA,

medium (MED) dBA or low (LO) dBA sound output.

The strobe is designed for use with either filtered DC (VDC) or

unfiltered full-wave-rectified (FWR) input voltage. All inputs are

polarized for compatibility with standard reverse polarity supervision of

circuit wiring by a FACP.

NOTE: The Code 3 temporal pattern (1/2 second on, 1/2 second off,

1/2 second on, 1/2 second off, 1/2 second on, 1-1/2 off and repeat) is

specified by ANSI and NFPA 72 for standard emergency evacuation

signaling. The Code 3 Horn should be used only for fire

evacuation signaling and not for any other purpose.

NFPA 72/ANSI 117.1 conform to ADAAG Equivalent Facilitation

Guidelines in using fewer, higher intensity strobes within the same

protected area.

NOTE: Refer to P/N 315-096363 for the maximum number of

appliances on a single notification appliance circuit.

signaling.

CAUTION: NOT RECOMMENDED FOR USE AT REFRIGERATOR / FREEZER DOOR ENTRANCES OR OTHER AREAS WITH PERSISTENT

CONDENSATION.

SPECIFICATIONS:

Operating Voltage

Model**

AS-75-R-WP 16.0-33.0 115 30/180 * 0.178 0.249 0.164 0.239 0.159 0.233

AS-75-CR-WP 16.0-33.0 115 30/180 * 0.178 0.249 0.164 0.239 0.159 0.233

AS-HMC-C-WP* 16.0-33.0 50/75 115/177 0.376/0.509 0.546/0.742 0.360/0.493 0.509/0.716 0.355/0.498 0.488/0.705

AS-HMC-WP* 16.0-33.0 65/90 135/185 0.376/0.509 0.546/0.742 0.360/0.493 0.509/0.716 0.355/0.498 0.488/0.705

(Special Application)

Per UL1638, UL1971 and UL464

(VDC/VRMS)

UL Rated Strobe

Candela (cd)

At -40°C

(UL1638)

Table 1: Models and Ratings

At 25°C

(UL1971)

Maximum RMS Current

w/Hi dBA (Amps)

DC FWR DC FWR DC FWR

Maximum RMS Current

w/Med dBA (Amps)

Maximum RMS Current

w/Low dBA (Amps)

*180cd is on Axis only.

**Available in red and white.

Table 2: ASWP - dBA Sound Output

Description Volume Reverberant Per UL 464 Anechoic dBA at 10 Feet

16.0VDC 24.0VDC 33.0VDC 20.0VDC 24.0VDC 31.0VDC

Low 80 83 86 88 90 91

Continuous Horn Medium 85 88 91 93 95 97

High 88 91 93 97 99 100

Low 75 79 82 88 90 91

Code 3 Horn Medium 80 84 86 93 95 97

(or March Time)*** High 84 87 90 97 99 100

***Available in sync mode only.

NOTES:

1. Strobe will produce 1 flash per second over the Input Voltage range.

2. These models meet the required light distribution patterns defined in UL 1638, UL 464 and UL 1971.

3. All models are UL Listed for indoor and outdoor use with a temperature range of -40°F to 150°F (-40°C to +66°C) and maximum humidity of 98% ±

2% RH. The effect of shipping and storage temperatures shall not adversely affect the performance of the appliance when it is stored in the original

cartons and is not subjected to misuse or abuse.

When calculating the total current: Use Table 1 to determine the highest value of “RMS Current” for an individual AS-WP Appliance then multiply the

value by the total number of AS-WP Appliances. Be sure to add the currents for any other appliances powered by the same source and include any

required safety factors.

These appliances are not designed to be used on coded systems in which the applied voltage is cycled on and off.

Siemens Building Technologies, Inc. P84820-001 B

8 Fernwood Road Sheet 1 of 3

Florham Park, New Jersey 07932

Page 14

THESE APPLIANCES WERE TESTED TO THE VOLTAGE LIMITS OF 16.0-33.0 VOLTS FOR 24V MODELS USING FILTERED DC OR UNFILTERED

FULL-WAVE-RECTIFIED VOLTAGE. DO NOT APPLY VOLTAGE OUTSIDE OF THIS RANGE.

Note: Refer to the installation instructions for the appropriate NAC to find the maximum allowed voltage drop. Use this value along with the current draw

for the appliance to determine the allowable wire resistance. The maximum wire resistance between strobes shall not exceed 35 ohms.

CANDELA SETTING WILL DETERMINE THE CURRENT DRAW OF THE PRODUCT.

Note: These notification appliances are UL Listed as “Special Application”. They are intended to be used only with Siemens notification appliance

circuits.

WARNING: MAKE SURE THAT THE TOTAL RMS CURRENT REQUIRED BY ALL APPLIANCES THAT ARE CONNECTED TO THE SYSTEM’S

PRIMARY AND SECONDARY POWER SOURCES DO NOT EXCEED THE POWER SOURCES’ RATED CAPACITY OR THE CURRENT RATINGS

OF ANY FUSES ON THE CIRCUITS TO WHICH THESE APPLIANCES ARE WIRED. OVERLOADING POWER SOURCES OR EXCEEDING FUSE

RATINGS COULD RESULT IN LOSS OF POWER AND FAILURE TO ALERT OCCUPANTS DURING AN EMERGENCY, WHICH COULD RESULT IN

PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

CANDELA AND SOUND OUTPUT (SPL) SETTINGS:

To set the candela, slide the switch to the desired setting. The setting in indicated by the pointer and label visible on the bottom of the lens.

Figure 2: Showing Location of

Figure 1: Jumper Plug

HI

MED

LO

CANDELA

POINTER

177

115

BOTTOM VIEW

CANDELA

185

135

CANDELA

POINTER

BOTTOM VIEW

SLIDE

SWITCH

CODE 3

Factory setting is on medium dB and Code 3 (or March Time). AS-HMC comes preset at 185cd. AS-HMC-C comes preset at 177cd.

WARNING: THE CANDELA SELECT SWITCH MUST BE FIELD SET TO THE REQUIRED CANDELA INTENSITY BEFORE INSTALLATION.

WHEN CHANGING THE SETTING OF THE CANDELA SELECT SWITCH, MAKE CERTAIN THAT IT “CLICKS” IN PLACE. AFTER CHANGING THE

CANDELA SETTING, THE APPLIANCE MUST BE RETESTED TO VERIFY PROPER OPERATION.

Figure 3: Jumper plug settings for High, Medium, Low and

Figure 4: Jumper plug setting for Continuous Horn

Code 3 (or March Time).

HI

MED

LOW

(Use needle nose pliers to pull and properly set the jumper plugs)

SHOWN SET ON HIGH dB

SHOWN SET ON MED dB

SHOWN SET ON LOW dB

CODE 3

No jumper plug is needed for continuous horn setting.

TURN PLUG 90°

However, it is recommended that the jumper plug be

retained in the unit for future use (if needed) as shown in

Figure 4.

NOTE: The AS-WP must be set for Code 3 (or March Time) when used on synchronized notification appliance circuit (NAC).

WIRING AND MOUNTING INFORMATION:

CAUTION: The following figure shows the maximum number of field wires (conductors) that can enter the backbox used with each mounting option.

If these limits are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the wires could damage

the product. Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially if

sheathed multiconductor cable is used.

Figure 5: Figure 6:

FROM PRECEDING

APPLIANCE OR FIRE

ALARM CONTROL

PANEL (FACP)

+

-

(-)

(+)

+

TO NEXT APPLIANCE OR

-

END OF LINE

RESISTOR (EOLR)

• The AS-WP Appliance has in-out wiring terminals

that accepts two #12 to #18 American Wire Gauge

(AWG) wires at each screw terminal. Strip leads

3/8” inches for connection to screw terminals.

• Break all in-out wire runs on supervised circuit

supervision as shown in Figure 6. The polarity

shown in the wiring diagrams is for the operation of

the appliances. The polarity is reversed by the

FACP during supervision.

IF THE AS-WP HOUSING DOES NOT PROPERLY CONTACT THE GASKET ON THE WPBBS BACKBOX, MOISTURE MAY SEEP INTO THE ASWP WHEN USED IN A OUTDOOR APPLICATION AND THIS COULD RESULT IN IMPROPER OPERATION OF THE PRODUCT.

Siemens Building Technologies, Inc. P84820-001 B

Sheet 2 of 3

Page 15

SURFACE (INDOOR/OUTDOOR)

#6-20

SCREW

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4

4

THIS UNIT MUST BE MOUNTED ON A FLAT SURFACE, SO THAT THE SURFACE COVERS THE ENTIRE BACK SURFACE OF THE BACKBOX.

WPBBS

BACKBOX

WOOD

SCREWS

44

WHEN USED IN AN OUTDOOR APPLICATION OR A NEMA 3R APPLICATION, USE WEATHER PROOF RATED CONDUIT FITTING ON ALL

KNOCKOUTS OF THE BACKBOX.

1. Conduit entrances to the backbox should be selected to prov ide sufficient wiring clearance for the installed product. The knock-out opening on the

backbox is sized for a ½” conduit and matching connector. Be sure that a proper watertight conduit fitting is used to connect the backbox for

outdoor/severe environment applications. Do not pass additional wires (used for other than the signaling appliance) through the backbox. Such

additional wires could result in insufficient wiring space for the signaling appliance.

2. When terminating field wires, do not use more lead length than required. Excess lead length could result in insufficient wiring space for the

signaling appliance.

3. Connect 4 field wires to the AS-WP terminal block (polarity must be observed).

4. Bend the 4 field wires up 90° at the connection to the terminal block and carefully push the 4 field wires into the backbox by hand.

5. Carefully press the AS-WP to the backbox, verifying that the AS-WP is in contact with the gasket all the way around. It should not be

resting on the lip of the backbox.

6. Screw the AS-WP to the WPBBS using the #6-20 screw.

WARNING: A SMALL POSSIBILITY EXISTS THAT THE USE OF MULTIPLE STROBES WITHIN A PERSON'S FIELD OF VIEW, UNDER

CERTAIN CIRCUMSTANCES, MIGHT INDUCE A PHOTO-SENSITIVE RESPONSE IN PERSONS WITH EPILEPSY. STROBE REFLECTIONS IN A

GLASS OR MIRRORED SURFACE MIGHT ALSO INDUCE SUCH A RESPONSE. TO MINIMIZE THIS POSSIBLE HAZARD, SIEMENS STRONGLY

RECOMMENDS THAT THE STROBES INSTALLED SHOULD NOT PRESENT A COMPOSITE FLASH RATE IN THE FIELD OF VIEW, WHICH

EXCEEDS FIVE (5) Hz AT THE OPERATING VOLTAGE OF THE STROBES. SIEMENS ALSO STRONGLY RECOMMENDS THAT THE INTENSITY

AND COMPOSITE FLASH RATE OF INSTALLED STROBES COMPLY WITH LEVELS ESTABLISHED BY APPLICABLE LAWS, STANDARDS,

REGULATIONS, CODES AND GUIDELINES.

WARNING: REMOVAL OF THE PRINTED CIRCUIT BOARD COVER AT THE BACK OF THE MOUNTING PLATE COULD RESULT IN SEVERE

ELECTRIC SHOCK.

The 135/185cd and 177cd settings are listed for use in sleeping or non-sleeping areas when installed in accordance with appropriate NFPA Standards

and the AHJ.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the separation between the

equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult the

dealer or an experienced radio/TV technician for help.

Siemens Building Technologies, Inc. P84820-001 B

Sheet 3 of 3

Page 16

IMPORTANT

installed in accordance with all applicable national and local fire alarm

codes and any other required regulatory agencies.

Series AH Appliances provide a selectable Continuous or Code 3

Horn tone when connected directly to the Fire Alarm Control Panel

(FACP). They can also provide a synchronized code 3 or March

Time horn tone when connected to a notification appliance circuit

running the Siemens sync protocol. The AH Appliances are UL Listed

under UL Standard 464 for Audible Signal Appliances and ULC Listed

under Standard CAN/ULC-S525-99 for Audible Signaling Appliances.

They are listed for indoor use only

Universal Mounting Plate (UMP) that can be mounted to single-gang,

double-gang, 4” square backbox, 100mm European or SHBBS

surface backbox (See Mounting Options).

SPECIFICATIONS:

NOTES:

WARNING: CHECK THE MINIMUM AND MAXIMUM OUTPUT OF THE POWER SUPPLY AND STANDBY BATTERY AND SUBTRACT THE

VOLTAGE DROP FROM THE CIRCUIT WIRING RESISTANCE TO DETERMINE THE APPLIED VOLTAGE TO THE SIGNALING APPLIANCE.

FOR UL APPLICATIONS THESE APPLIANCES WERE TESTED TO THE OPERATING VOLTAGE LIMITS OF 16-33 VOLTS FOR 24V MODELS

USING FILTERED (DC) OR UNFILTERED FULL-WAVE-RECTIFIED (FWR). DO NOT APPLY 80% AND 110% OF THESE VOLTAGE VALUES

FOR SYSTEM OPERATION.

FOR ULC APPLICATIONS THESE APPLIANCES WERE TESTED TO THE OPERATING VOLTAGE LIMITS OF 20-31 VOLTS FOR 24V MODELS

USING FILTERED (DC) OR UNFILTERED FULL-WAVE-RECTIFIED (FWR). APPLY 80% AND 110% OF THESE VOLTAGE VALUES FOR

SYSTEM OPERATION.

– All audible and visual signaling appliances must be

and are equipped with a

Operating Voltage

Model*

AH 16-33 20-31 0.021 0.043 0.080 0.041 0.051 0.090

Low 80 83 86 88 90 92

Continuous Horn Medium 85 88 91 90 95 97

High 88 91 93 92 97 99

Low 75 79 82 88 90 92

Code 3 Horn or Medium 80 84 86 90 95 97

March Time* High 84 87 90 92 97 99

1. All models are UL/ULC Listed for indoor use with a temperature range of +0°C to +49°C (+32°F to +120°F) and maximum humidity of 93%

± 2% RH.

(Special Application)

Per UL 464

(VDC/VRMS)

AH

INSTALLATION INSTRUCTIONS

AUDIBLE HORN APPLIANCES

AH Appliances can be field set to provide either High (HI) dBA,

Medium (MED) dBA or Low (LO) dBA sound output. All AH models

are designed for use with either filtered DC or unfiltered Full-WaveRectified (FWR) input voltage. All inputs are polarized for

compatibility with standard reverse polarity supervision of circuit

wiring by a FACP.

NOTE: The code 3 horn incorporates the temporal pattern (1/2

second on, 1/2 second off, 1/2 second on, 1/2 second off, 1/2 second

on, 1-1/2 off and repeat) specified by ANSI/NFPA for standard

emergency evacuation signaling. The code 3 horn shall be used

only for fire evacuation signaling and not for any other purpose.

Table 1: UL/ULC Listed Models and Ratings

ULC Voltage

Range

(VDC/VRMS)

* Available in red or white.

Table 1A: ULC Current Ratings

(VDC/VRMS)

20.0 .014 .020 .035

24.0 .017 .025 .050

31.0 .021 .030 .065

Table 2: dBA Sound Output for 24VDC Models

Reverberant dBA Per UL 464 Anechoic Per CAN/ULC-S525-99 Description Volume

16.0VDC 24VDC 33.0VDC 16.0VDC 24VDC 33.0VDC

* Available in sync mode only.

Table 2A: ULC Directional Characteristics

-3 dBA: 48 degrees left, 41 degrees right

-6 dBA: 50 degrees left, 58 degrees right

Lo Med Hi Lo Med Hi

Average Current (AMPS) Model ULC Voltage

Lo Med Hi

Maximum RMS Current (AMPS)

DC FWR

Siemens Building Technologies, Inc. P83519-005 B

8 Fernwood Road Sheet 1 of 3

Florham Park, New Jersey 07932

Page 17

WARNING: MAKE SURE THAT THE TOTAL RMS CURRENT, TOTAL AVERAGE CURRENT AND TOTAL PEAK CURRENT REQUIRED BY

ALL APPLIANCES THAT ARE CONNECTED TO THE SYSTEM’S PRIMARY AND SECONDARY POWER SOURCES DO NOT EXCEED THE

POWER SOURCES’ RATED CAPACITY OR THE CURRENT RATINGS OF ANY FUSES ON THE CIRCUITS TO WHICH THESE APPLIANCES

ARE WIRED. OVERLOADING POWER SOURCES OR EXCEEDING FUSE RATINGS COULD RESULT IN LOSS OF POWER AND FAILURE TO

ALERT OCCUPANTS DURING AN EMERGENCY, WHICH COULD RESULT IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO

YOU AND/OR OTHERS.

When calculating the total currents: Use Table 1 to determine the highest value of “RMS Current” for an individual AH Appliance (across the

expected operating voltage range of the AH Appliance) or use Table 1A to determine the highest value of “Rated Average Current” of an individual

AH Appliance (across the expected voltage range of the AH Appliance), then multiply these values by the total number of AH Appliances; be sure to

add the currents for any other appliances, powered by the same source and include any required safety factors.

Audible Horn appliances are not designed to be used on coded systems in which the applied voltage is cycled on and off.

WARNING: THE AUDIBLE HORN APPLIANCES MUST BE FIELD SET TO THE DESIRED TONE AND dBA SOUND OUTPUT LEVEL

BEFORE THEY ARE INSTALLED. THIS IS DONE BY PROPERLY INSERTING A JUMPER PLUG IN ACCORDANCE WITH THESE

INSTRUCTIONS.

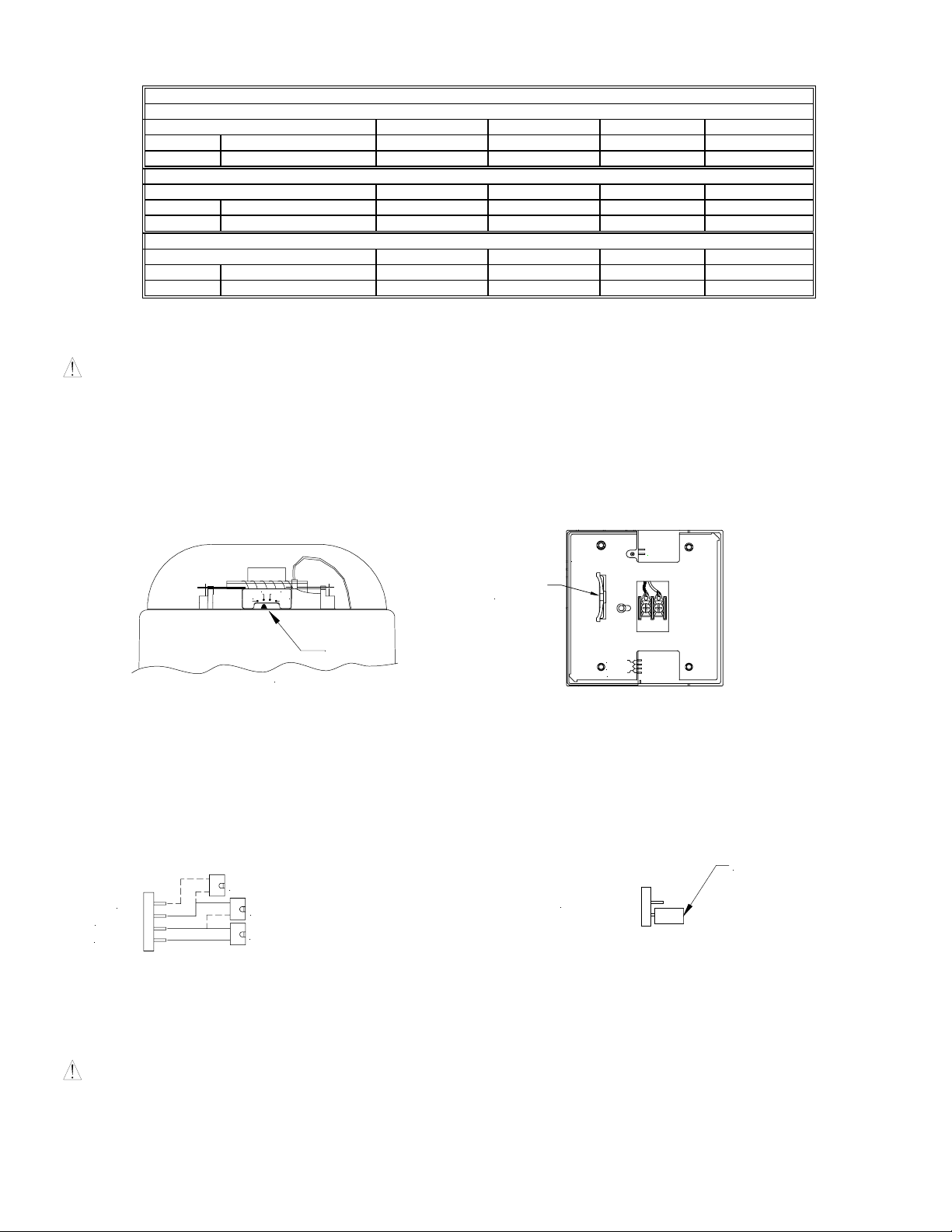

SOUND OUTPUT (SPL) SETTINGS:

Figure 1: Showing Location of Jumper Plug

CODE 3

Factory setting is on medium dB and code 3 (or March Time).

Figure 2: Jumper plug settings for high, medium, low and code 3

(or March Time).

SHOWN SET ON HIGH dB

SHOWN SET ON MED dB

SHOWN SET ON LOW dB

(Use needle nose pliers to pull and properly set the jumper plugs)

Note: The AH must be set for code 3 (or March Time) when used with the sync module.

* Continuous horn operation without sync module.

WIRING INFORMATION:

Figure 4:

FROM PRECEDING APPLIANCE,

FIRE ALARM CONTROL PANEL (FACP)

+

-

(+)

(-)

TO NEXT APPLIANCE OR

+

END OF LINE

-

RESISTOR (EOLR)

MOUNTING OPTIONS:

HI

MED

LO

Figure 3: Jumper plug setting for Continuous Horn.

CODE 3

CONTIUOUS HORN

*

No jumper plug is needed for continuous horn setting.

TURN PLUG 90°

However, it is recommended that the jumper plug be retained

in the unit for future use (if needed) as shown in Figure 3.

Figure 5:

1. AH Appliances have in-out wiring terminals

that accepts two #12 to 18 American Wire

Gauge (AWG) wires at each screw terminal.

Strip leads 3/8” inches for connection to

screw terminals.

2. Break all in-out wire runs on supervised

circuit to assure supervision as shown in

Figure 5. The polarity shown in the wiring

diagrams are for the operation of the

appliances. The polarity is reversed by the

FACP during supervision.

Siemens Building Technologies, Inc. P83519-005 B

Sheet 2 of 3

Page 18

A

UNIVERSAL

MOUNTING PLATE

#6-20 SCREWS

FLUSH MOUNTING

STD. SINGLE-GANG

BACKBOX 2.0" DEEP

FLUSH OR SURFACE MOUNT

B

UNIVERSAL

MOUNTING PLATE

#6-20 SCREWS

4" SQ. X 1-1/2"

DEEP BACKBOX OR

100mm SQ. X 37.5mm

EUROPEAN BACKBOX

C

UNIVERSAL

MOUNTING PLATE

#6-20 SCREWS

FLUSH MOUNTING

STD. DOUBLE-GANG

BACKBOX 2-1/4" DEEP

D

UNIVERSAL

MOUNTING PLATE

#6-20 SCREWS

SURFACE MOUNT

SHBBS

SURFACE BACKBOX

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#6-32 SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#8-32 SCREWS

#6-32 SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

#8-32 SCREWS

MAXIMUM NUMBER OF CONDUCTORS

AWG #18 AWG #16 AWG #14 AWG #12

4 444

MOUNTING PROCEDURES:

Use this mounting procedure to position the field wires in the backbox so that they use minimum space and produce minimum stress on the product.

This is especially important for stiff, heavy gauge wires and wires with thick insulation or sheathing.

NOTE: The Universal Mounting Plate (UMP) must be oriented correctly when it is mounted to the backbox Turn the UMP so that the arrow above the

words “Horizontal Strobe” points to the top side of the UMP.

1. Thread the 4 field wires through the opening of the UMP.

2. Mount the UMP to backbox.

3. Connect 4 field wires to the AH terminal block (polarity must be observed).

4. Bend the 4 field wires up 90

o

at the connection to the terminal block.

5. Carefully push the 4 field wires into the backbox through the opening of the UMP by hand.

6. Hook the 2 slots on the inside wall of the AH onto the 2 tabs of the UMP and screw the AH to the UMP using the #6-20 screw supplied.

MOUNTING NOTES:

Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially if sheathed

multiconductor cable or 3/4" conduit fittings are used.

1. All models can be flush mounted to a standard single-gang backbox (Figure A), 4” square backbox (Figure B) or double-gang backbox

(Figure C). They can also be surface mounted to a 4” square or 100mm backbox (Figure B), a double-gang backbox (Figure C) or a SHBBS

surface backbox (Figure D).

2. All models are equipped with a Universal Mounting Plate (UMP).

3. Mounting hardware for each mounting option is supplied. For proper mounting, be sure to use the mounting screws supplied with the unit.

4. Conduit entrances to the backbox should be selected to provide sufficient wiring clearance for the installed product.

5. When terminating field wires, do not use more lead length than required. Excess lead length could result in insufficient wiring space for the

signaling appliance.

6. Do not pass additional wires (used for other than the signaling appliance) through the backbox. Such additional wires could result in

insufficient wiring space for the signaling appliance.

7. The effect of shipping and storage temperatures do not adversely affect the performance of the appliances when stored in the original cartons

and are not subjected to misuse.

These appliances can produce a distinctive three pulse Temporal Pattern Fire Alarm Evacuation Signal (for total evacuation) in accordance with

NFPA 72.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the separation between the

equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult

the dealer or an experienced radio/TV technician for help.

Siemens Building Technologies, Inc. P83519-005 B

Sheet 3 of 3

Page 19

INDOOR/OUTDOOR AUDIBLE HORN APPLIANCES

INSTALLATION INSTRUCTIONS

IMPORTANT

– All audible and visual signaling appliances must be

installed in accordance with all applicable national and local fire

alarm codes and any other required regulatory agency.

Series AH-R-WP Appliances provide a selectable Continuous or

Code 3 Horn tone when connected directly to the Fire Alarm Control

Panel (FACP). They can also provide a synchronized code 3 or

march time horn tone when connected to a notification appliance

circuit running the Siemens sync protocol. The AH-R-WP

Appliances are UL Listed under UL Standard 464 for Audible Signal

Appliances. The AH-R-WP is ULC Listed under Standard

CAN/ULC-S525-99 for Audible Signaling Appliances. They are

listed for indoor and outdoor use and can be mounted to a 4”

backbox (See Mounting Options).

AH-R-WP Appliances can be field set to provide either High (HI)

dBA, Medium (MED) dBA or Low (LO) dBA sound output.

AH-R-WP models are designed for use with either filtered DC (VDC)

or unfiltered Full-Wave-Rectified (FWR) input voltage. All inputs are

polarized for compatibility with standard reverse polarity supervision

of circuit wiring by a FACP.

NOTE: The code 3 horn incorporates the temporal pattern (1/2

second on, 1/2 second off, 1/2 second on, 1/2 second off, 1/2

second on, 1-1/2 off and repeat) specified by ANSI/NFPA for

standard emergency evacuation signaling. The code 3 horn shall

be used only for fire evacuation signaling and not for any other

purpose.

SPECIFICATIONS:

Table 1: UL/ULC Listed Models and Ratings

Maximum RMS Current (AMPS)

DC FWR

Model

Operating Voltage

(Special Application)

Per UL464

(VDC/VRMS)

ULC Voltage

Range

(VDC/VRMS)

Lo Med Hi Lo Med Hi

AH-R-WP 16-33 20-31 0.023 0.049 0.090 0.046 0.057 0.096

Table 1A: ULC Current Ratings 24VDC Models

Average Current (AMPS) Model ULC Voltage

AH-R-WP

(VDC/VRMS)

20.0 .016 .022 .039

Lo Med Hi

24.0 .019 .029 .056

31.0 .023 .034 .073

Table 2: dBA Sound Output for 24VDC Models

Reverberant dBA Per UL 464 Anechoic Per CAN/ULC-S525-99 Description Volume

16.0VDC 24VDC 33.0VDC 16.0VDC 24VDC 33.0VDC

Low 80 83 86 88 90 92

Continuous Horn Medium 85 88 91 90 95 97

High 88 91 93 92 97 99

Low 75 79 82 88 90 92

Code 3 Horn or Medium 80 84 86 90 95 97