Page 1

s

TELEPERM M

Introduction

System architecture

AS 235, AS 235 H and

AS 235 K

Automation Systems

Catalog PLT 111 · 1999

This catalog is no longer available in printed

form. However, it can still be used to obtain

information and for ordering spare parts.

Certain products from this catalog are no

longer available. Your Siemens partner will

offer appropriate substitutes wherever

possible.

Automation systems

I/O modules

Input and output devices

Bus communication

Coupling with other systems

Appendix

The products and systems

described in this catalog are

marketed under application of

the quality management system

certified by DQS in accordance

with DIN EN ISO 9001 (certificate

register No.: 2613-04). The

DQS certificate is recognized in all

EQ Net countries (Reg. No.: 2613).

REG. NO. 2613-04

Page 2

TELEPERM M

Introduction

This catalog is out of date, see note on page 1

Brief description

TELEPERM M process control system

The TELEPERM M process control system provides all functions

required for process automation. It is highly suitable for the complete automation of continuous and discontinuous (batch) processes.

The TELEPERM M systems are divided into function units optimized for different tasks associated with process automation:

•AS automation systems

•OS operator systems

•CS and PROFIBUS bus systems

AS automation systems

The various TELEPERM M automation systems have different

designs, ranges of functions and performances. The AS 235,

AS 235 H and AS 235 K automation systems described in this

catalog are proven and reliable. They can be configured within

wide limits and coupled to a wide range of subordinate systems.

The AS 235 H additionally has a redundant central unit and thus

satisfies particularly high availability demands. The AS 235 systems can communicate with one another and with higher-level

systems via the TELEPERM M CS 275 plant bus.

A wide range of TELEPERM M input/output modules is available

for connection of the process peripherals (sensors and final control element

systems. Some modules have their own processing features or

can be configured application-specific.

The AS 388/TM and AS 488/TM automation systems (see Catalog PLT 112) use the SIMATIC M7-300 and M7-400 automation

computers as the hardware platform and are compatible with the

AS 235 system. They are appropriate for the extension of existing TELEPERM M systems or for the design of new systems.

The AS 388/TM and AS 488/TM systems can be operated on the

PROFIBUS-TM plant bus. PROFIBUS-TM is based on the standardized PROFIBUS. The A

operated on the CS 275 plant bus.

ET 200M distributed I/O systems with a comprehensive range of

I/O modules can be connected to the AS 388/TM and AS 488/TM

systems via one or two PROFIBUS-DP interfaces.

OS operator systems

The bus-compatible OS 525 (Catalog PLT 122) and WinCC/TMOS (Catalog PLT 123) operator systems are used for process

communication. They communicate with the subordinate

TELEPERM M automation systems and with SIMATIC S5-155U

via the CS 275 plant bus or PROFIBUS-TM.

The operator systems can have a configuration variable from a

single-user system up to a multi-user system - where the OS

basic unit communicates with several terminals via a terminal

bus - and can thus cover the complete range from low-end to

high-end applications.

The OS 525

ating console with the complete range of OS 525 functions.

s) to the AS 235, AS 235 H and AS 235 K automation

S 488/TM system can additionally be

Local

system permits the design of a local AS oper-

TELEPERMM

Engineering

The PROGRAF AS+ configuring software is used for the AS 235,

AS 235 H, AS 235 K, AS 388/TM and AS 488/TM automation systems and offers a wide range of support for documentation and

configuring by means of a graphic functional diagram editor and

an integrated database, amongst others.

Any single-user system WinCC/TM-OS-Single with RC license

(Runtime+Configuration) is suitable as the configuring system

for WinCC/TM-OS, and an OS 525 single-user system/terminal

with OS 525-BIPRO configuring software for OS 525.

Plant bus

The plant bus is the central communication component of every

distributed process control system. Two different bus systems

are available for the TELEPERM M process control system, and

can also be combined together within a system:

•CS 275

• PROFIBUS-TM

The CS 275 plant bus which has been proven in many automa-

tion plants is predestined for communication between the

AS 235, AS 235 H, AS 235 K and AS 488/TM automation systems and the OS 525 and WinCC/TM-OS operator systems. The

CS 275 plant bus functions according to the token passing principle and can also have a redundant configuration. Several

buses

can be combined together using bus couplers such that

bus networks are produced corresponding to the plant structure. The bus system is provided with distributed control. The

bus interface of each subsystem may take over the master function according to specific criteria.

The AS 388/TM and AS 488/TM automation systems and the

OS 525 and WinCC/TM-OS operator systems can be connected

to the PROFIBUS-TM plant bus. The PROFIBUS-TM is characterized in that it complies with the modern PROFIBUS communication standards to EN 50170 but also uses the TELEPERM M

communication mechanisms of the CS 275 (AKS, BKS, MK

PL/PS telegrams) at the user level (link between bus interface

and application).

The PROFIBUS-TM plant bus also operates according to the

token passing principle. It can be designed as an electrical or

optical network. The two network instructions can also be mixed

together. PROFIBUS-TM is preferably used for new systems or

partial systems.

The CS 275 and PROFIBUS-TM buses can be connected

together by a CS-L2 bridge, thus permitting linking of existing

systems and new systems.

Note:

Information systems, computers from other manufacturers, personal computers and gateways can be connected to the C

plant bus. Personal computers with the Win TM software package can also be connected to PROFIBUS-TM.

S and

S 275

1/2

Siemens PLT 111 · 1999

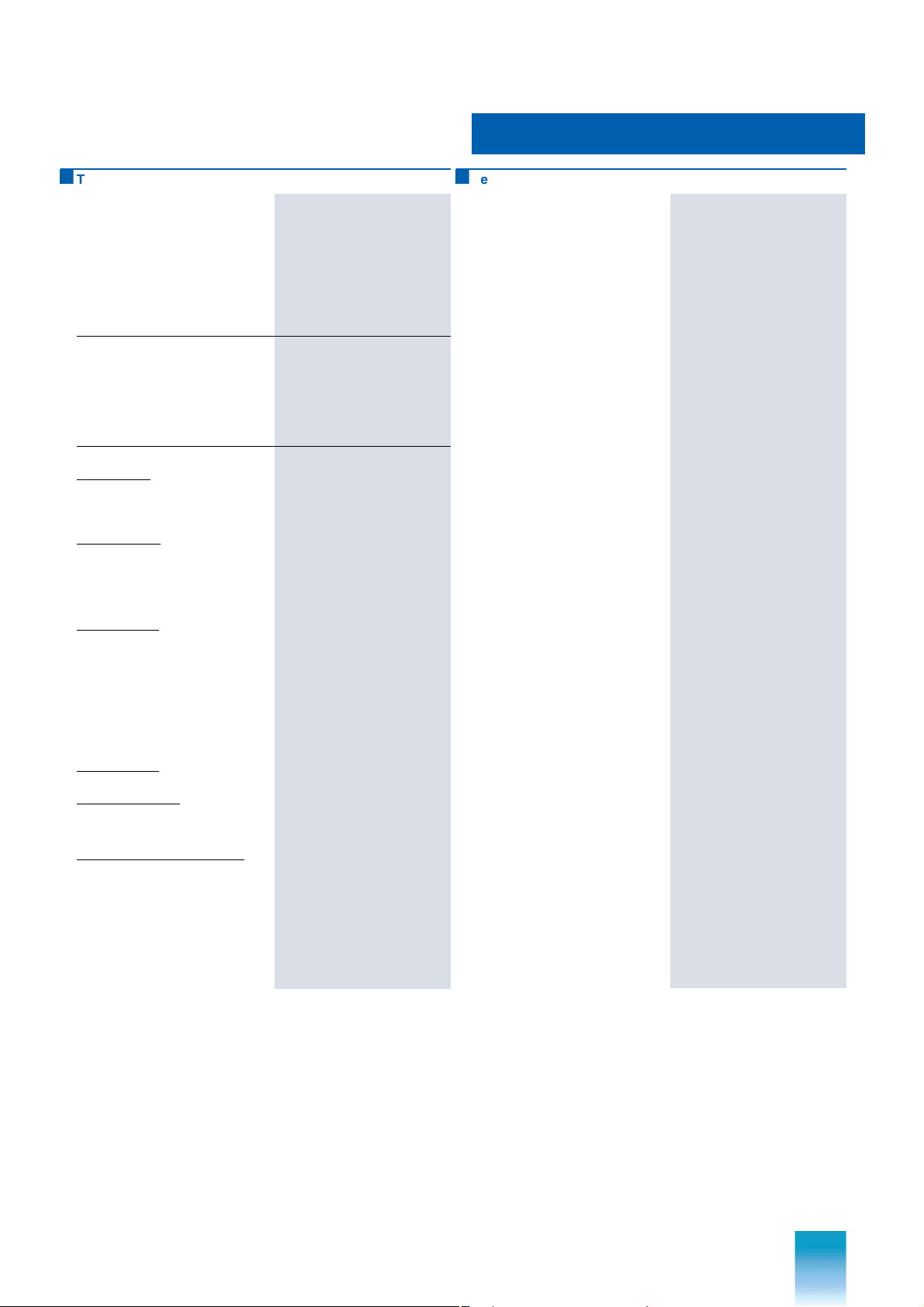

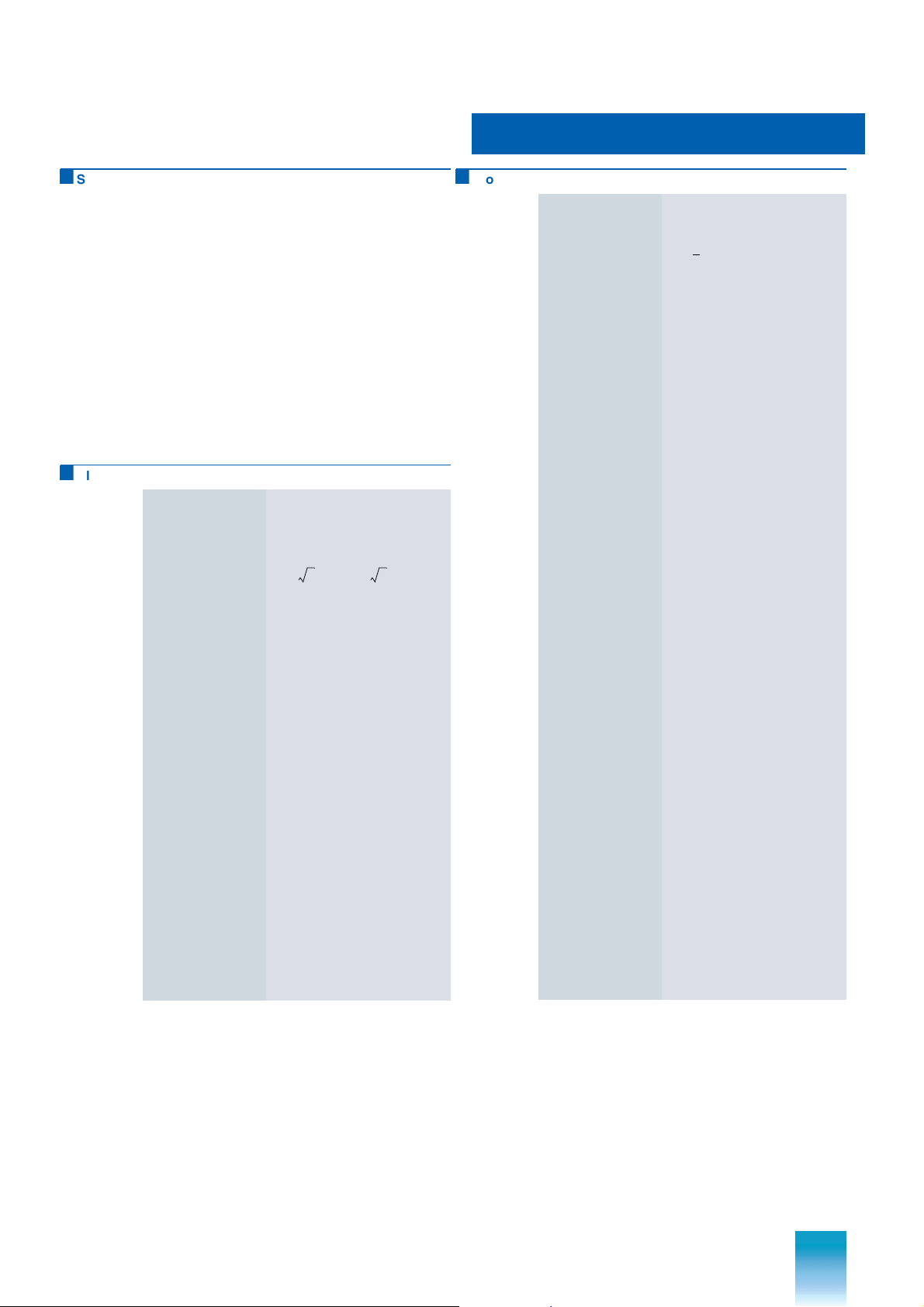

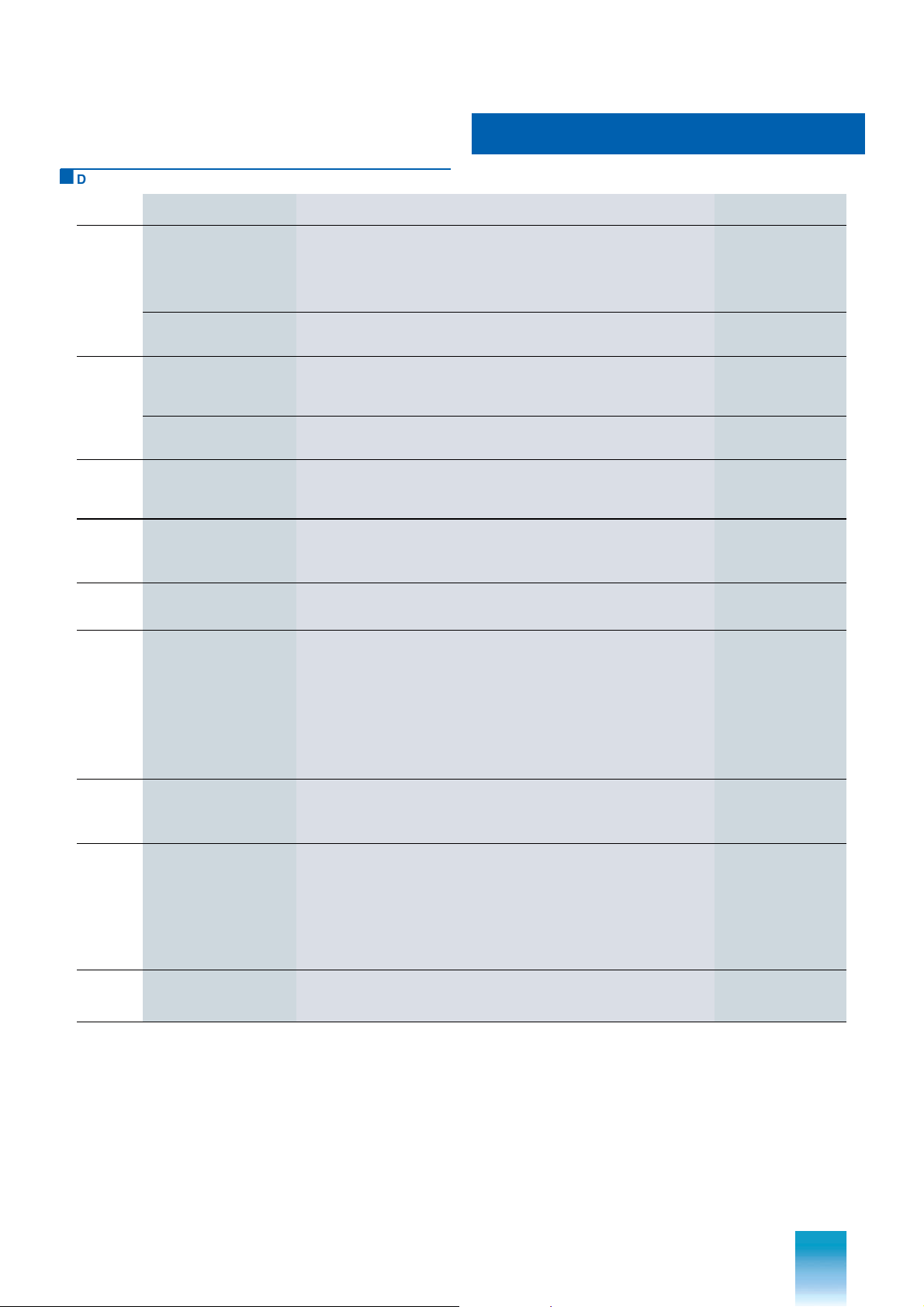

Page 3

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

Brief description

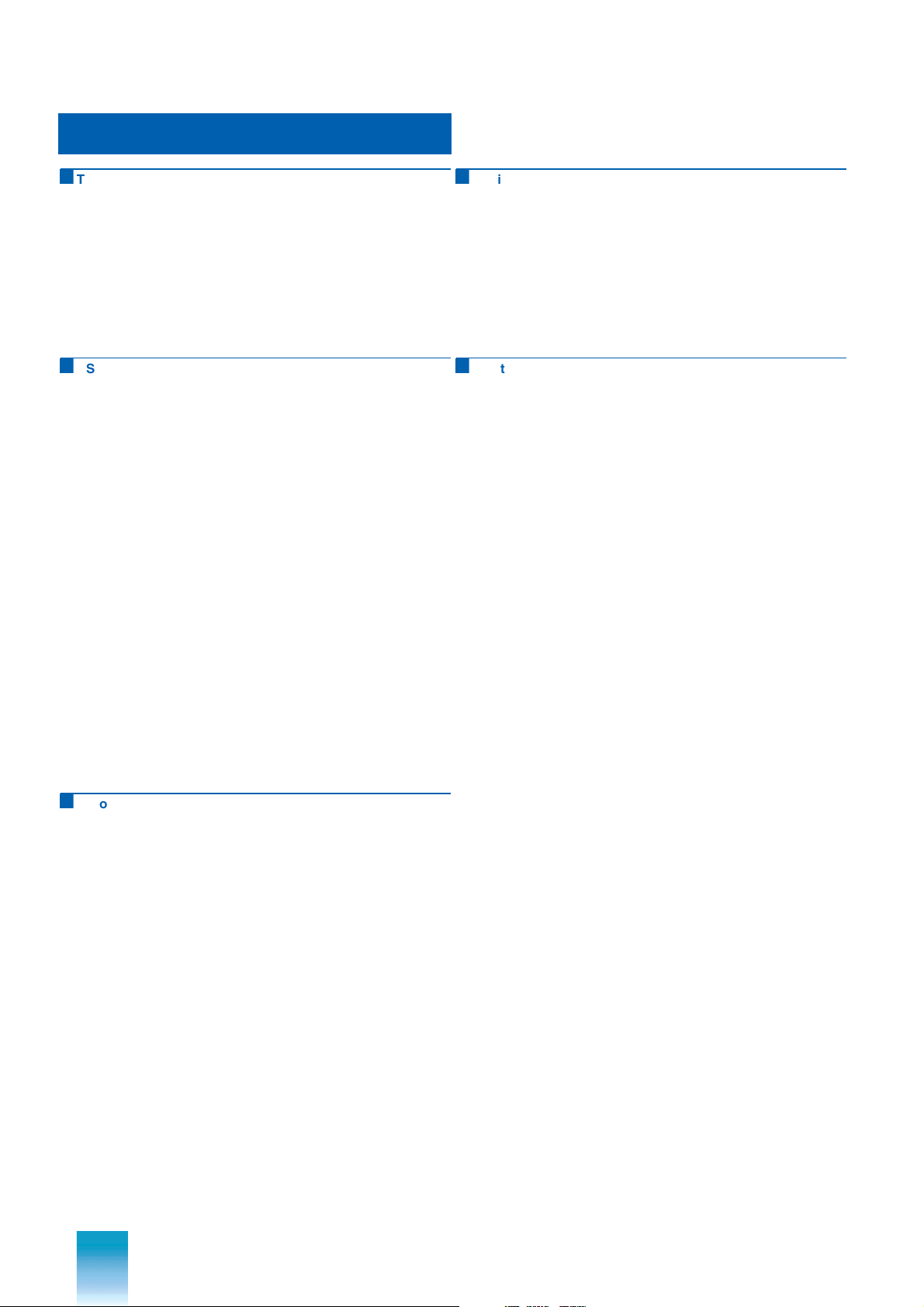

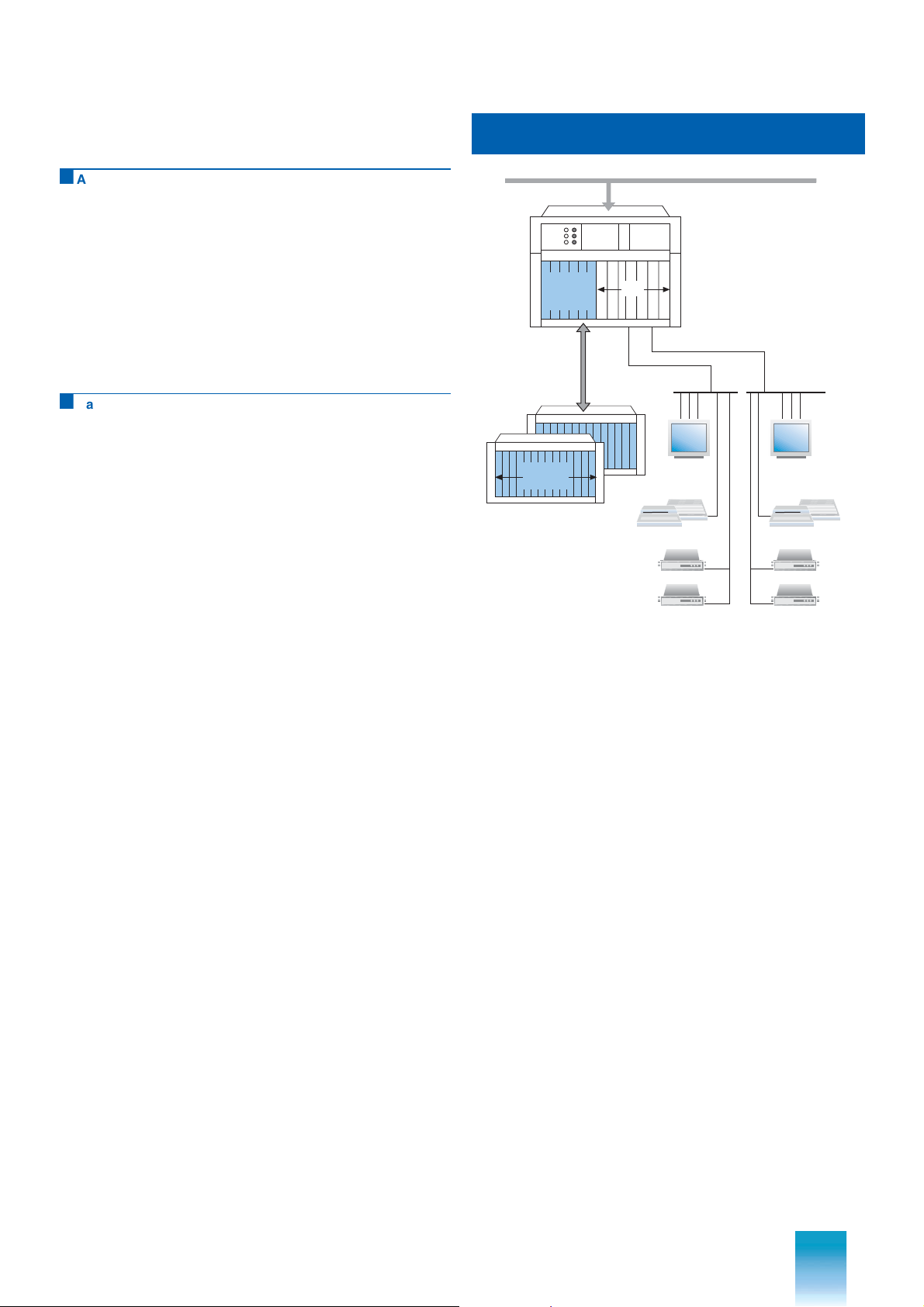

CS 275

WinCC/TM-OS

operator

terminals

WinCC/TMOS server

incl. WinCC/TM-CS 275

AS 235

TELEPERM M

I/O modules

Terminal bus

PROGRAF AS+

configuring

software

AS

488/TM

ET 200M

PROFIBUS-DP

Bridge

WinCC/TM-OS

operator

terminals

AS

488/TM

PROFIBUS-DP

WinCC/TMOS server

incl. WinCC/TMPROFIBUS

AS

388/TM

PROFIBUS-DP

SIMATIC PCS 7

operator

terminals

OS server

SIMATIC

PCS 7

PROFIBUS-TM

AS 414/

AS 416 / AS 417

PROFIBUS-DP

TELEPERM M

I/O modules

TELEPERM M SIMATIC PCS 7

Fig. 1/1 System configuration for the TELEPERM M process control system, with migration to the SIMATIC PCS 7 process control system

Functions of the AS 235 system

The AS 235, AS 235 H and AS 235 K automation systems provide all I & C functions such as measurement, supervision, calculation, closed-loop control and open-loop control, also

particularly taking into account batch processes. The automation systems also handle the tasks for local operation and monitoring, e.g. display, signalling, alarm output, process operation

and logging.

The AS 235 and AS 235 K only differ in their design. The AS 235

system is fitted in a cabinet, the AS 235 K system in a wall housing. The AS 235 H system with a redundant central unit is provided for applications with particularly high availability demands.

A large range of dedicated function blocks is available for

ing I & C tasks in the AS 235, AS 235 H and AS 235 K automation

systems. “Programming” of the automation systems is thus

made extremely simple since the function blocks present in the

system memory need only be activated by entering configuring

instructions and parameters.

In addition, the AS 235, AS 235 H and AS 235 K permit the use

of additional languages for special tasks - such as optimization,

startup and shutdown of open-loop controls - which are difficult

to solve using the existing function blocks or the batch functions.

The TML process language (TELEPERM M Language) is available for analog and binary processing operations, as well as

STEP M control language already known from the SIMATIC

industrial automation system. TML/STEP M can be used to

define new function blocks optimally tailored to the respective

task. Despite an extremely high degree of freedom, the clear

and transparent “Block technology” is not relinquished. Frequently occurring block combinations can be combined into socalled Typicals and can then be used just like a single block.

A wide range of input and output modules is available for the

AS 235, AS 235 H and AS 235 K systems as the interface to the

process.

Intelligent I/O modules, e.g. modules which can carry out

closed-loop control functions on their own, make it possible to

configure a subordinate individual single-loop control level. This

increases the availability of the automation system even further.

solv-

the

Further to this, the proce

lar for power applications or distributed small systems by sys-

tem-compatible coupling of SIMATIC components.

The AS 235, AS 235 H and AS 235 K systems have either one or

two autonomous operation channels for local operation and

monitoring. This means that the process operation keyboard,

process monitor and printer can be connected to each of the two

operation channels and carry out operation and monitoring functions independent of one another.

In addition to the standardized displays which are achieved by

addressing the automation function blocks without carrying out

any further configuring, the user can also configure free dis-

plays. A standardized display is e.g. the loop display for operation of a control loop, a free display is the schematic representation of plant components (flowcharts) in their respective process

status.

The local operation devices may be omitted when using central

operation and monitoring in a network configuration.

Configuring

Configuring includes the incorporation of the automation structure into the automation system by using configuring instructions, by specifying parameters, by programming with TML and

STEP M if applicable, and the feedback documentation.

This is possible either without an additional programming

device/personal computer directly on the automation system

(direct configuring, input/output using lists) or by using a

PROGRAF AS+ engineering tool on a programming device/PC.

Both configuring methods can be used

• locally for one automation system or

• centrally from one AS 235 system or one PC with

PROGRAF AS+ for bus-coupled systems.

ss interface is supplemented in particu-

Siemens PLT 111 · 1999

1/3

Page 4

TELEPERM M

Introduction

System data

This catalog is out of date, see note on page 1

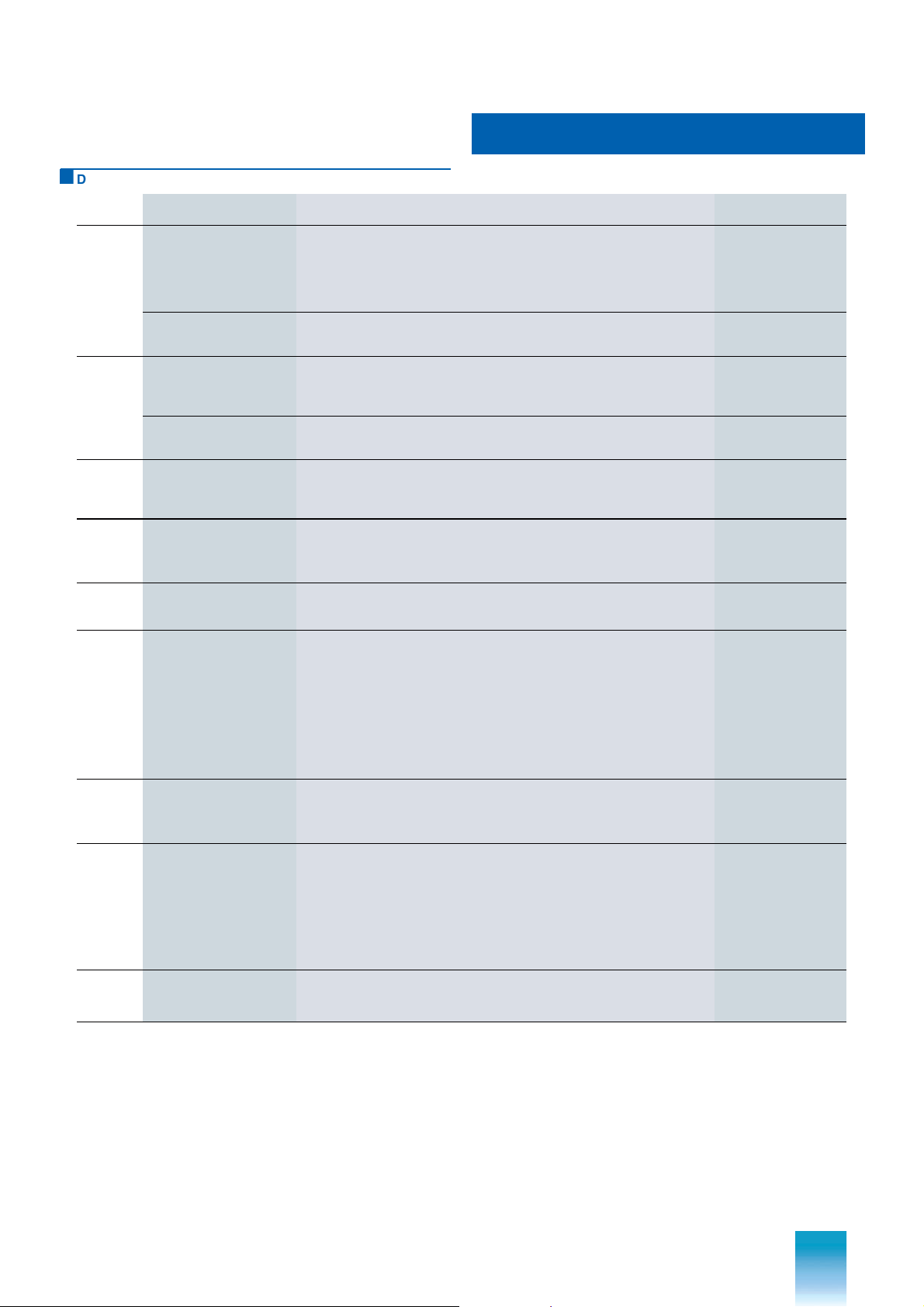

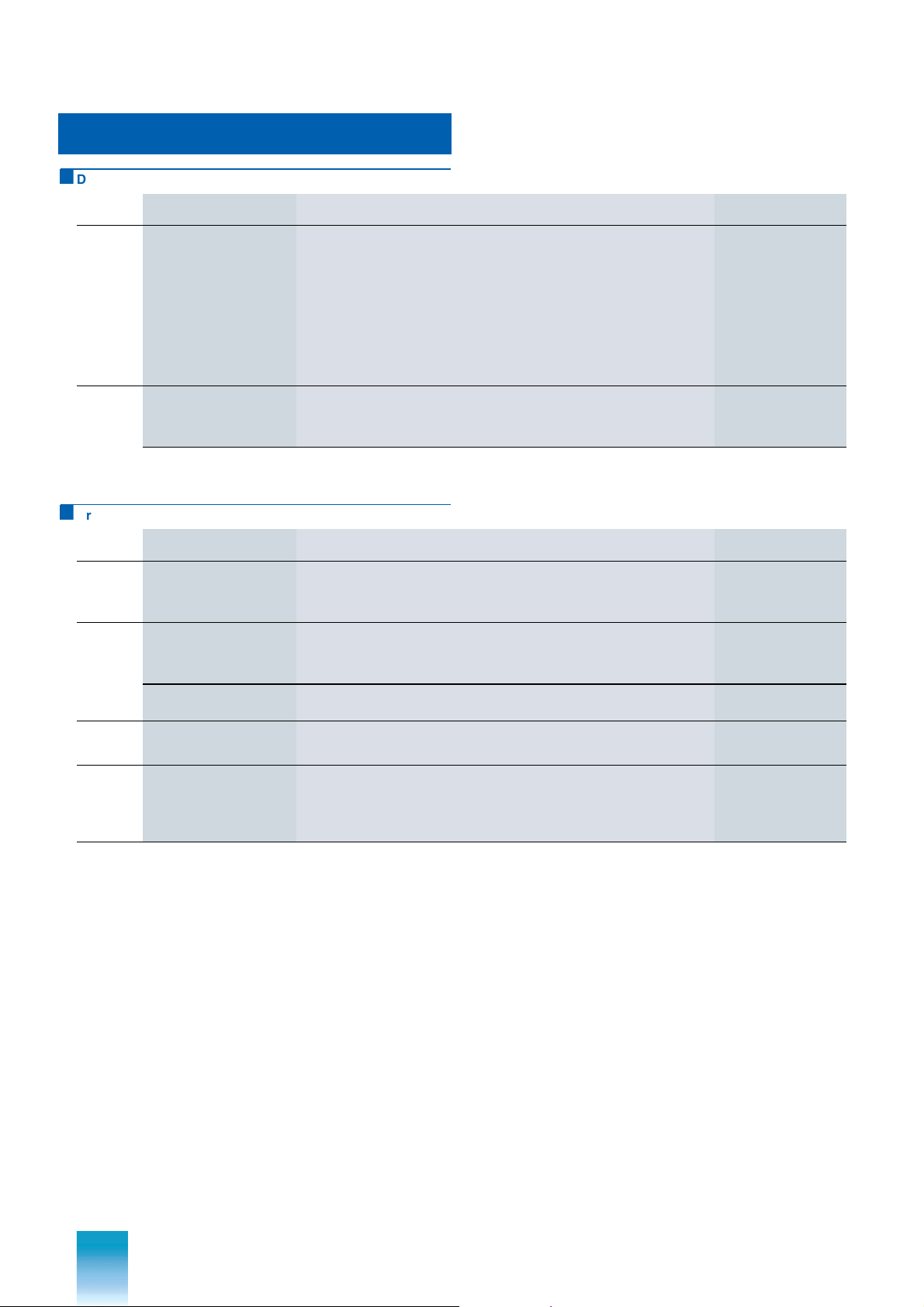

General system data

Permissible ambient temperature

• Modules

– Operation

– Δt/h

– Δt/min

– Transport and storage

• Cabinet (operation)

Cabinet ambient temperature at

1 m above cabinet base

Reduction in specified temperature

above 1000 m above sea level

Permissible humidity Operation Storage

– Annual average

– On 30 days/year

– On 60 days/year

Condensation not permissible

Mechanical ambient conditions

Operation stress

(modules in subrack)

– 10 to 60 Hz

– 60 to 500 Hz

System cabinet

– 10 to 58 Hz

– 58 to 500 Hz

Tran sport stress

(modules in subrack)

– 5 to 8 Hz

– 8 to 500 Hz

1)

0 to 70 °C

Max. 10 K

Max. 0,5 K

-40 to +70 °C

0 to 40 °C

10 K/1000 m

Max. 75 % Max. 65 %

Max. 95 % –

– Max. 85 %

0.15 mm deflection

2 g acceleration

0.035 mm deflection

0.5 g acceleration

7.5 mm deflection

2 g acceleration

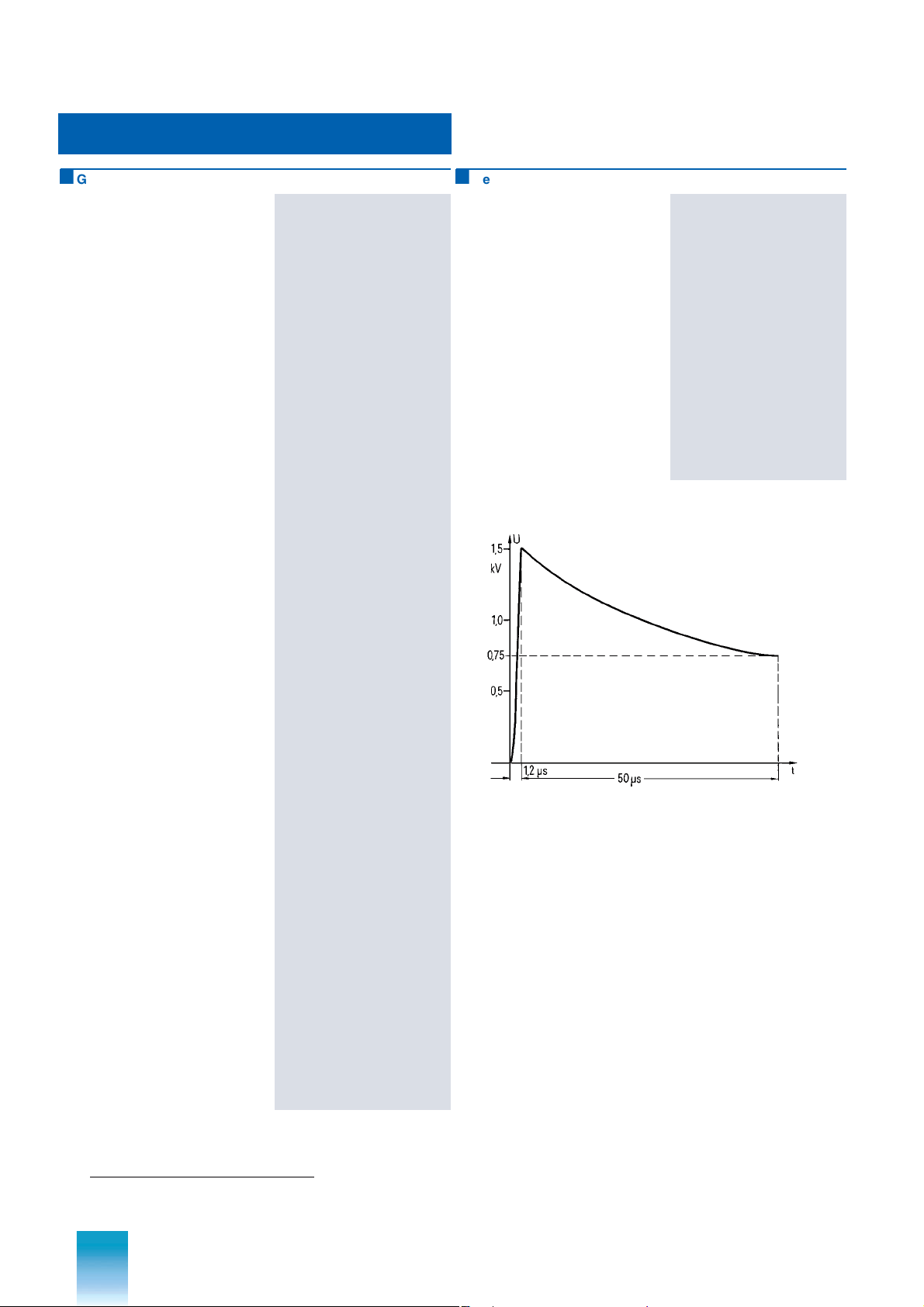

General system data

• Analog signals

DC voltage

– Rated range of use

– Overflow range

– Input resistance

– Output loading capacity

Direct current

– Rated range of use

– Overflow range

– Input resistance

– Rated output load

Analog signal outputs

Overvoltage resistance of binary and

analog inputs and outputs according

to IEC information 255-4 (Fig. 1/2)

Referred to MZ

-10 to +10 V

-10 to 0 V

0 to +10 V

-10.5 to +10.5 V

100 kΩ

1 mA

Referred to M

0 to 20 mA or 4 to 20 mA

0 to 21 mA or 3.7 to 21 mA

12.5, 50 or 350 Ω

500 or 600 Ω

Short-circuit-proof and overload-proof

Class II

Design, earthing conditions

Potential difference between all

ground star points of distributed

systems

Insulation

Protection class

Insulation of modules, clearances and

creepage distances from pin to pin or

from conductor to conductor

Signal data

(interface to field level)

• Binary signals

DC voltage Referred to M potential

Signal definition

– L (low)

– H (high)

Input currents

– Electronic transmitters

– Contacts

Output currents with DC 24 V

Power signals

Binary signal outputs

Max. 7 V

According to VDE 0160

Class l

According to VDE 0110

Inputs Outputs

-30 to +4.5 V 0 to 2.5 V

+13 to +33 V L+ to

0.5 mA Typical values for

4 mA configuring

8.5 mA/100 mA/120 mA

Max. 400 mA

Short-circuit-proof and

overload-proof

(L+ - 2.5 V)

Fig. 1/2 Overvoltage resistance / dynamic destruction limit

1) Deviations possible in individual cases. Refer to technical data of individ-

ual components

1/4

Siemens PLT 111 · 1999

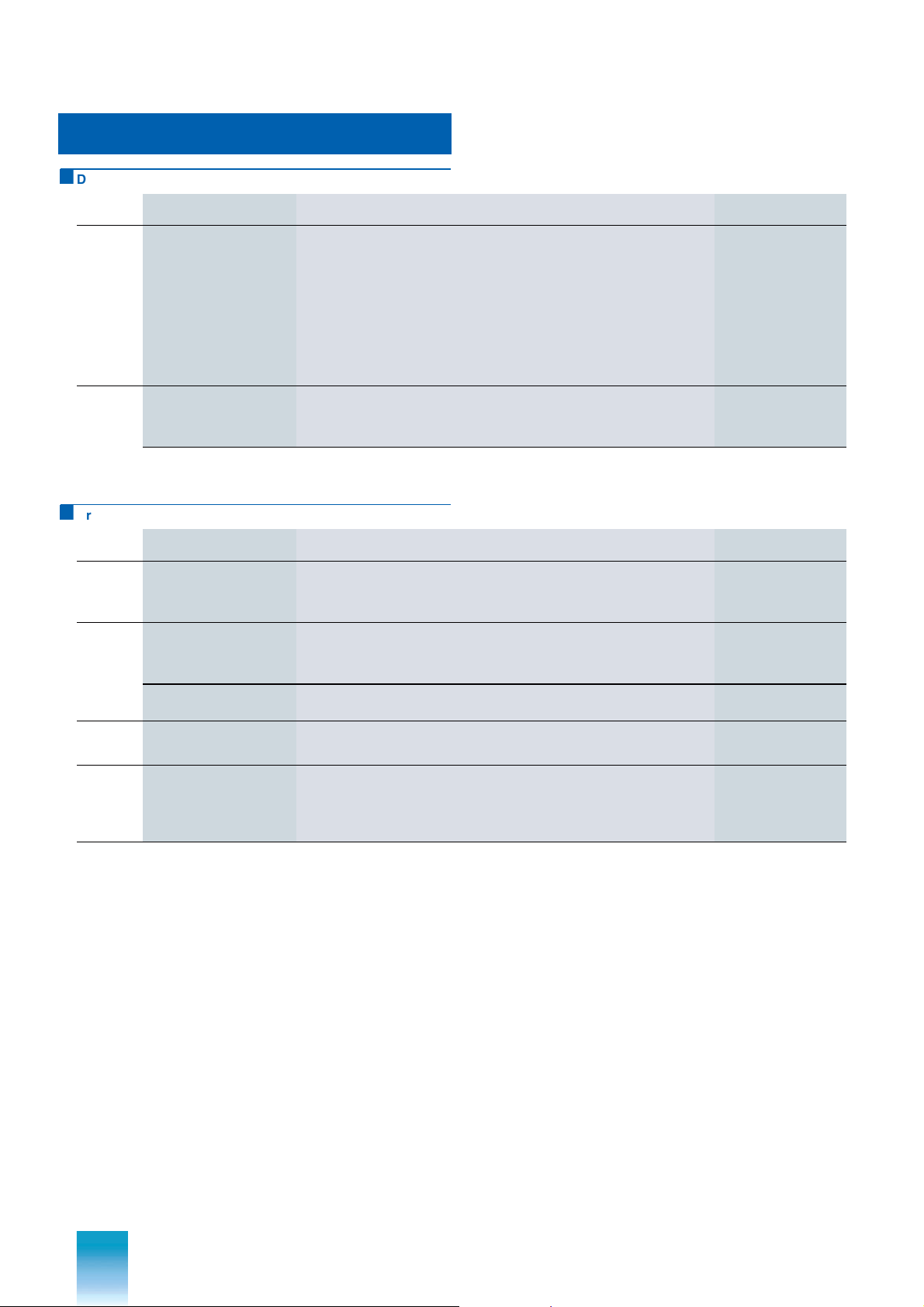

Page 5

This catalog is out of date, see note on page 1

Technical data of automation systems

Central unit

Central processor Microprogrammed

Arithmetic unit processing width

Process execution levels

• Acyclic

•Cyclic

Memory (EDC)

Interface to central processor

Main memory (RAM)

Memory for system software (RAM)

Memory backup time (RAM)

Input and output devices

Operation unit 1 process monitor

• Number of operation units which

can be used simultaneously

Process monitor

• Vertical frequency

• Horizontal frequency

• Video signals

Graphic display

• Semi-graphics

• Format

• Colors

•Resolution

•Message line

• Working field

• Input line

Configuring unit

Mini floppy disk unit

•Diskette format

• Max. storage volume per diskette

Logging printer/message printer

• Number of logging/message printers which can be operated simultaneously

• Format

• Printing speed with normal font

T

min

32 bit

5

2 (alarm and background levels)

2 (125 ms, 1 s) and communica-

tion level

1-bit correction when reading

16 bit wide

4000 kbyte

1 Mbyte

480 h

1 process operation keyboard

2

50 Hz non-interlaced

15.625 kHz

RGB with SYNC in green chan-

nel

32 lines with 64 characters each

8

High-resolution

1

29 lines

1, for configuring

1 configuring keyboard,

1 mini floppy disk unit

5.25 inch

1 Mbyte

Needle and ink-jet printers

2 / 2

DIN A4 (80 characters/line) or

DIN A3 (136 characters/line)

300 characters/s

TELEPERM M

Technical data of automation systems (continued)

Power supply for AS

Supply voltage DC 24 V

• Redundant supply

• Permissible range including ripple

Permissible ripple

(DC 24 V systems)

Limiting range of use

(DC 24 V systems)

Voltage dip with U

(DC 24 V systems)

External fusing required

Current consumption of basic unit/

basic system (typical value without

I/O modules)

Power consumption

(basic unit/system)

Permissible thermal load in cabinet

(for AS 235 and AS 235 H)

• Without heat exchanger

– Without fan subassembly

– With fan subassemblies

• With heat exchanger and fan subassemblies

Heat to be dissipated from housing

(only AS 235 K)

Degree of protection EN 60 529

• Standard cabinet without heat

exchanger

• Standard cabinet with heat

exchanger

• Sheet-steel housing

• Subrack

Impairment of function by gases

=24 V

N

1)

(AS 235 K also

AC 50/60 Hz, 230 V)

With AS 235 H and

AS 235 K, DC 24 V;

as option with AS 235

DC 20.8 to 33 V (AS 235 and

AS 235 K, DC 24 V)

DC 21.6 to 31 V (AS 235 H)

15 % of mean DC value within

the permissible range

35 V ≤ 500 ms

45 V ≤ 10 ms

0 V ≤ 5 ms, recovery time 10 s

– Max. 80 A with I/O modules

(AS 235 and AS 235 H)

– 25 A (AS 235 K, DC 24 V)

– 10 A (AS 235 K, AC 230 V)

5.5 A (AS 235)

8.5 A (AS 235 H)

6.5 A (AS 235 K, DC 24 V)

1.0 A (AS 235 K, AC 230 V)

– Max. 160 W (AS 235,

without I/O modules)

– Max. 200 W (AS 235 H,

without I/O modules)

– Max. 220 W (AS 235 K,

DC 24 V, with I/O modules)

– Max. 330 VA (AS 235 K,

AC 230 V, with I/O modules)

Max. 350 W

Max. 700 W

Max. 1000 W

Max. 200 W

AS 235/235 H AS 235 K

IP 20 –

IP 54 –

–IP 21

IP 00 IP 00

Industrial atmospheres for occupied rooms are permissible

Introduction

System data

1) With cabinet inlet temperature 40 °C

Siemens PLT 111 · 1999

1/5

Page 6

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

System data

Technical data of automation systems (continued)

I/O modules

Function modules/calculation modules

Signal modules

Counter modules

Coupling modules

Max. number of I/O modules

Typical quantity breakdown

Control loops 30 to 80

Additional analog-value monitoring

Sequential controls

Logic controls

Any number of flowcharts (up to 8

colors) and individually formatted

logs

Dimensions / weight

Dimensions (

• Standard cabinets

– With degree of protection IP 20

– With degree of protection IP 20

and IP 54

• Housing with degree of protection

IP 21

Weight

•AS 235 / AS 235 H

•AS 235 K (DC)

AS 235 K (AC)

H x W x D

) in mm

Autonomous closed-loop and

individual control drive modules

or user-configured with own

microprocessor

Binary and analog

Metered pulse module, pro-

portioning counter module

For SIMATIC S5/S7 peripheral

I/O modules and devices, and

for subordinate devices and sys-

tems

90 / 1141)(AS 235)

1)

91 / 103

1)

6 / 108

50 to 120

5 to 15

100 to 250

2200 x 900 x 400

2200 x 900 x 600

820 x 600 x 360

200 to 250 kg

3)

77 kg

3)

85 kg

(AS 235 H)

(AS 235 K)

2)

1) When used with ES 100 K extension system

2) Typical value, depends on configuration with I/O modules

3) Without I/O modules

1/6

Siemens PLT 111 · 1999

Page 7

This catalog is out of date, see note on page 1

System

architecture

2/2 Performance characteristics

2/4 Redundancy with AS 235 H

Configuring

2/5 Standard function blocks

2/10 User function blocks

Siemens PLT 111 · 1999

2/1

Page 8

This catalog is out of date, see note on page 1

System architecture

Performance characteristics

Performance characteristics

The AS 235, AS 235 H and AS 235 K systems are programmable

automation systems of the TELEPERM M process control system

based on function blocks. They have a different design and

availability, but the same range of functions. The AS 235 K sys-

tem is fitted in a wall housing, the AS 235 and AS 235 H systems

are fitted in cabinets. The AS 235 H automation system has a

redundant central unit to satisfy particularly high demands

placed on the availability.

The systems can either be used on their own with local operation

and monitoring, or coupled in system networks with central operation and monitoring.

System configuration

The automation sys

•A basic unit (AS 235, AS 235 H) or a basic system (AS 235 K)

•ES 100 K extension systems (wall housing) or extension units

(for fitting in cabinets) as extension for configuring with input/

output modules.

Standard input/output devices enable local communication with

the automation system during the configuring and commission-

ing phases as well as during later operation. The following can

be connected:

• 54-cm (21-inch) process monitors

• Process operation keyboard and configuring keyboard,

max. 2 of each for 2 independent operating consoles

• Max. 4 logging printers

• 1 mini floppy disk unit for booting the system memory and for

loading/saving the user memory.

Basic system/basic unit

The basic unit (AS

(AS 235 K) mainly contains

• the power supply modules,

• the central processor module,

• a memory module with user memory with 4,000 Kbyte capacity

and battery backup and

• the interface modules for the input and output devices and the

CS 275 bus system,

each of which is redundant in the AS 235 H system.

The central processor is microprogrammed and has a maximum

processing width of 32 bits. Three basic cycles are present for

processing (125 ms, 1 s and background level). An acyclic

mode can also be defined.

The basic unit of the AS 235 and the basic system of the

AS 235 K each has 6 slots for I/O modules. No I/O modules can

be plugged into the ba

The following can be fitted into the systems as standard:

•AS 235 Max. 90 I/O modules

•AS 235 H Max. 91 I/O modules

•AS 235 K Max. 108 I/O modules

The number of usable I/O slots with the AS 235 and AS 235 H

can be increased by additional use of ES 100 K extension sys-

tems:

•AS 235 Max. 114 I/O modules

•AS 235 H Max. 103 I/O modules

tems consist of:

235, AS 235 H) or the basic system

sic unit of the AS 235 H systems.

(basic unit + 6 extension units)

(7 extension units)

(basic system + eight ES 100 K extension systems)

Systemarchitectur e

I/O modules

There are the following group

• S ignal modules

• Function modules

• Calculation modules

• Coupling modules.

Signal modules are required for input and output of the process

signals, usually without further processing (exception: adapta-

tion of characteristic with temperature measurements).

Function modules (closed-loop control modules) and calculation

modules have additional performance features which are independent of the central unit of the automation system and which

can be used to increase the total processing performance or the

availability by transferring backup functions should the central

unit of the automation system fail.

The calculation modules enable the configuring of individual

user functions.

Coupling modules enable the connection of I/O modules over

larger distances. They additionally enable use of non-intelligent

I/O modules of the SIMATIC S5 programmable controller

the ET 100U distributed I/Os for the automation systems.

Memory, configuring

The memory with battery backup of the automation systems is

divided into:

•a system memory and

•a user memory.

The write-protected system memory contains the software which

always belongs to the automation system, in the form of basic

programs and function blocks. Far more than 100 standardized

blocks are available for data acquisition, closed-loop control,

open-loop control, calculation, supervision, logging, display and

operation/monitoring.

Instead of programming the system with individual commands

and carrying out the required program tests, it is only necessary

in the TELEPERM M process control system to configure the

complete function blocks in order to obtain a “user program”. In

the simplest case, configuring means calling the function blocks

with the keyboard, several times if necessary, and then assign-

ing the respective linking instructions and parameters. The

resulting application-oriented configuring data are then stored in

the user memory.

Configuring is possible before the automation system is started

up as well as during operation. It is possible to temporarily

switch partial functions of the user system out of operation for

this purpose.

Convenient configuring using graphic inputs is possible using

the PROGRAF AS+ engineering tool which can be executed in a

personal computer connected locally to the AS 235/235 H/235 K

automation

system or centrally to the CS 275 bus system.

s of I/O modules:

s, plus

se

2/2

Siemens PLT 111 · 1999

Page 9

This catalog is out of date, see note on page 1

STEP M

In addition to the function blocks for binary processing, the

AS 235/235 H/235 K systems can use the STEP M control language, without leaving the block configuration, in order to formulate extensive and complex open-loop control tasks.

TML language

The TML process language can be used in addition to the firmware blocks for special tasks. It can be used to format special

function blocks and to implement particularly complex functions,

e.g. for the mixing of binary value arithmetic and measured value

arithmetic.

Operation and monitoring

The AS 235, AS 235 H and AS 235 K systems have either one or

two autonomous operation channels for local operation and

monitoring. This means that process operation keyboards, printers and process monitors can be connected in duplicate and

operated using operation/monitoring functions which are independent of one another. Some of the local operation devices can

be omitted in the cas

a network configuration.

Scope of performance

The user RAM of the automation systems has a memory capacity

of 4,000 Kbytes. This means that even one single system can

already implement larger automation tasks. Even the data quantities encountered with extensive batch processes can be handled. If it is taken into account that various tasks occur mixed

together, the performance is approximately as follows:

• 30 to 80 control loops

• 50 to 120 additional analog-value monitoring functions

• 5 to 15 sequential controls

• 100 to 250 logic controls

• Any number of flow charts (up to 8 colors) and individually

designed logs.

e of central operation and monitoring with

System architecture

Performance characteristics

Summary of system properties

• Automation system for autonomous operation with local

communication or for network operation with central

communication

• Fitted in wall housing or cabinet

• Configurable within wide limits

(up to 114 I/O modules depending on system)

•User memory up to 4,000 Kbytes on one module

• 32-bit processing of analog values

• Optimized data transfer rate resulting from separate

processing of analog and binary values

• Central unit redundant as option with synchronous processing of clocks (AS 235 H)

• Operation without fans possible

• Complete range of standard function blocks

•User function blocks with convenient TML program-

ming language, also STEP M programming language

for open-loop control tasks

• Configuring/programming either online without programmer (using lists) or with PC (using graphics)

• Local or central configuring (via bus)

Siemens PLT 111 · 1999

2/3

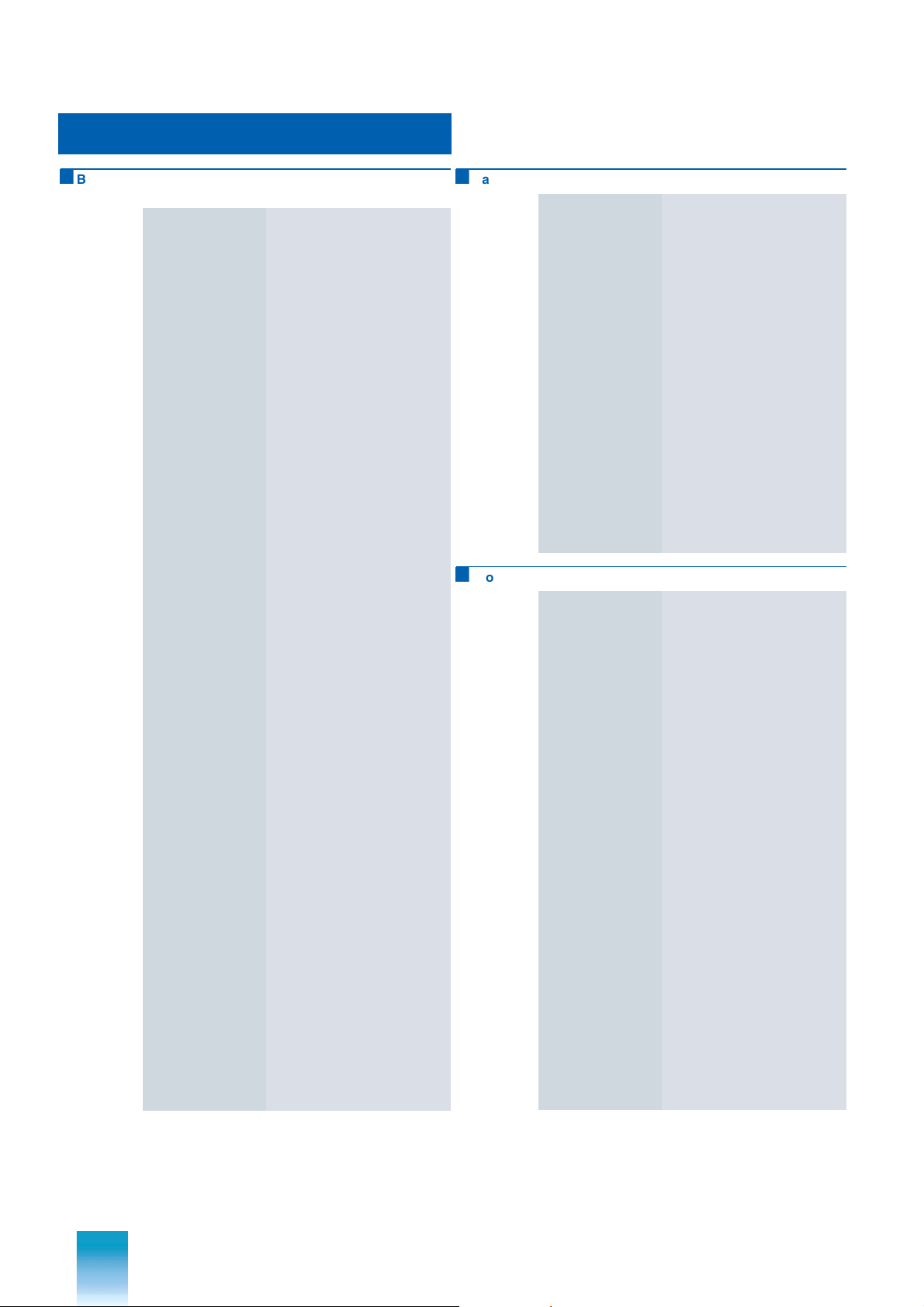

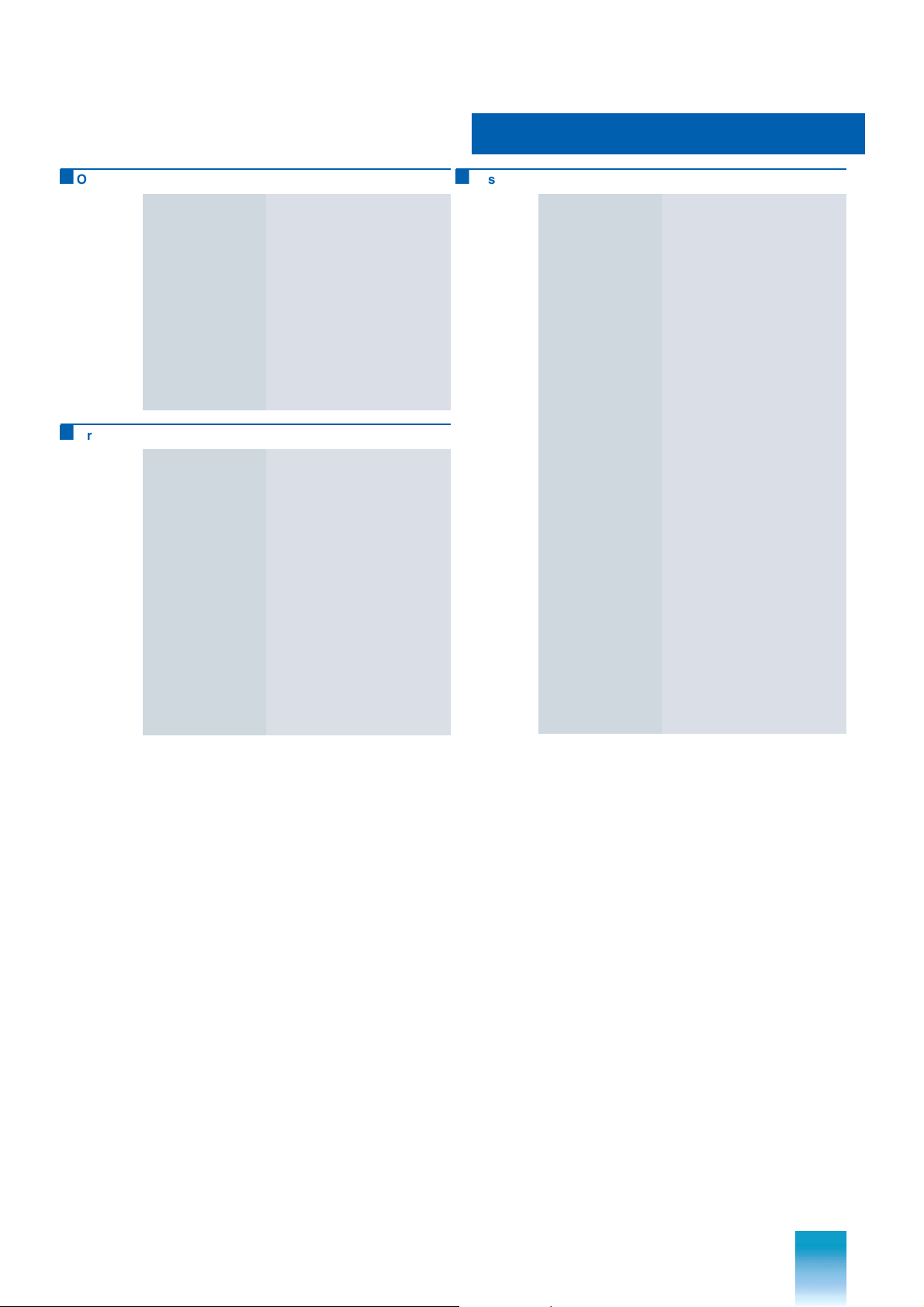

Page 10

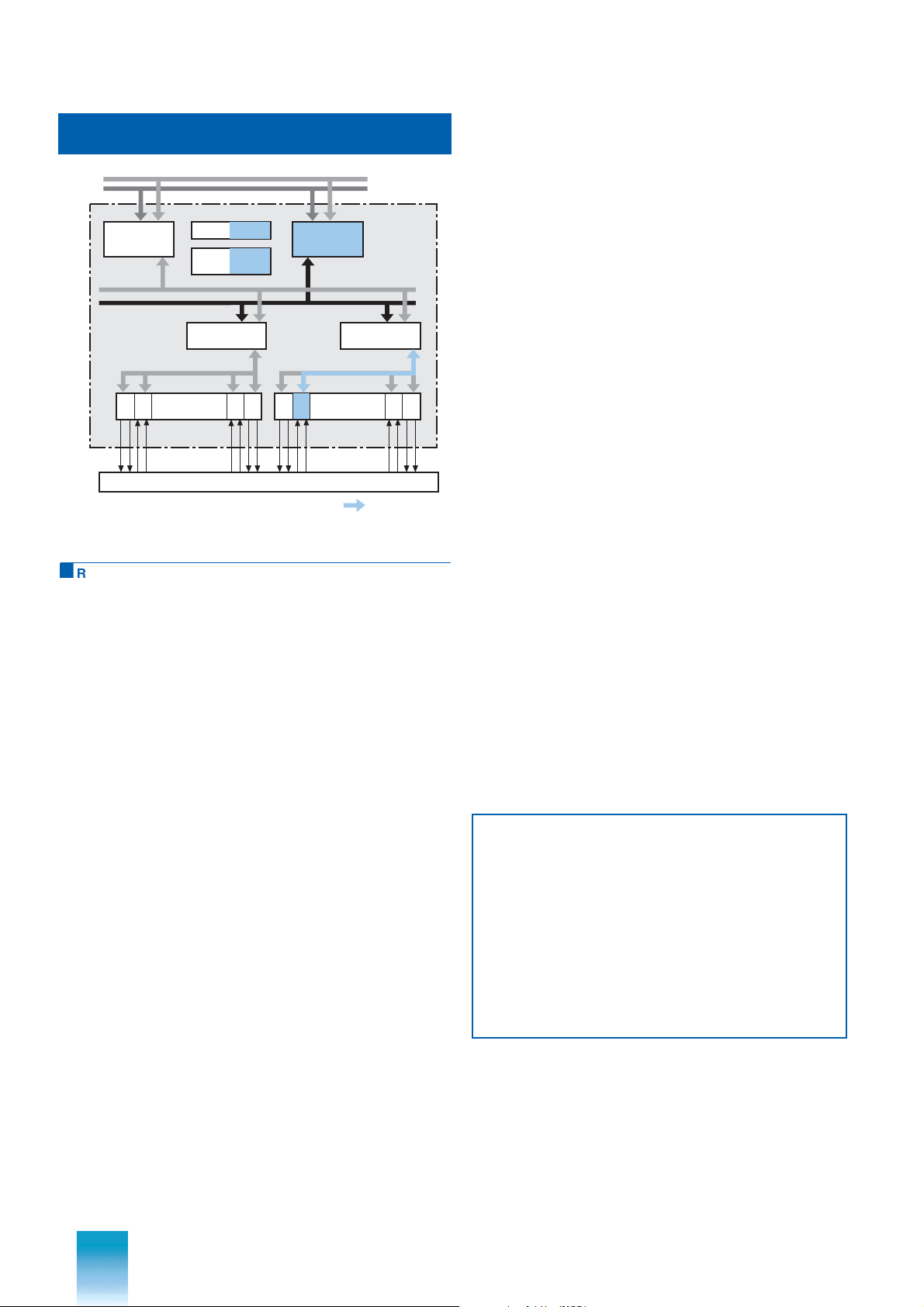

System architecture

Redundancy with AS 235 H

This catalog is out of date, see note on page 1

CS 275

plant bus

Central

processing

unit I

I/O bus I/O bus

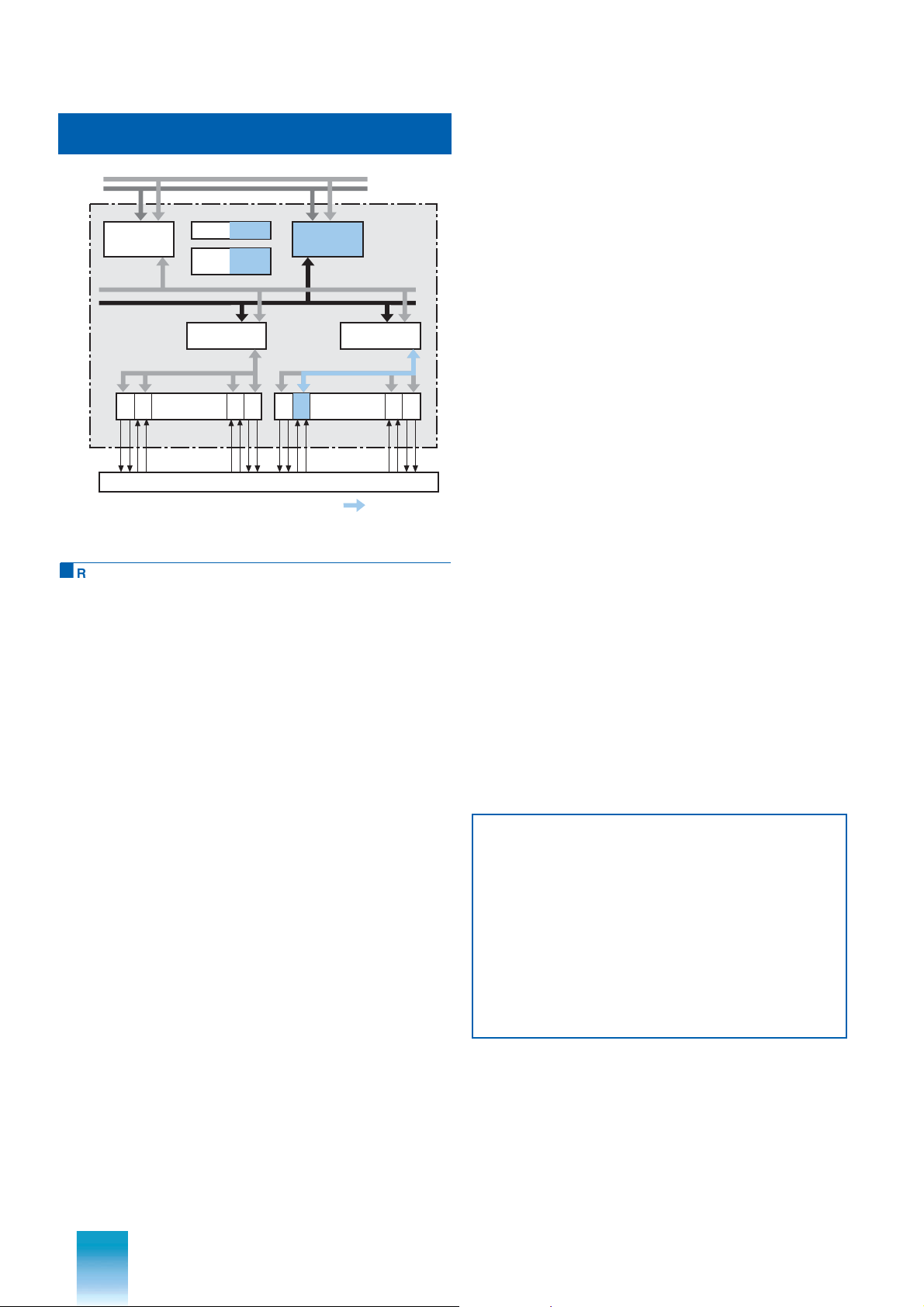

Fig. 2/1 1-out-of-2 redundancy structure with AS 235 H

Redundancy with the AS 235 H automation system

I/O

modules

Synchronization

Comparison,

cross-coupling

Comparison,

switchover

Process level

Central

processing

unit II

Redundant I/O bus

I/O

modules

Comparison,

switchover

Redundant path

Various system characteristics must be considered with regard

to the reliability and availability of a system. The requirements for

reliability are met by fault-tolerant (high-availability) systems

while those for safety are met by fail-safe systems.

According to VDI/VDE 3542 the following applies:

A system is fault-tolerant if occurring faults have no effect on its

function. Fail-safe is the ability of a technical system to remain in

a safe mode or to switch immediately to another safe mode in the

event of a fault.

The AS 235 H automation system is a high-availability system

with redundant central units operating with system clocks where

execution of the planned automation functions is not interrupted

by system faults.

The system operates according to the fault-tolerant 1-out-of-2

principle. The AS 235 H system is equipped with 2 identical central processing units for this purpose, the master unit and the

slave unit (Fig. 2/1). Each of the two CPUs contains a power supply module, central processor, memory module for system software and user program as well as 1 or 2 interface modules for

the I/O bus depending on the number of I/O modules connected. The user programs stored in the 2 memory modules are

identical.

Process signals are always applied to both CPUs. Only one of

these, the master unit, can output commands to the process via

the I/O modules. The other operates in hot s

tandby mode and is

always able to take over smooth control of the process should

the master unit fail.

The fully-synchronous mode of operation of the two partial

AS 235 H systems means that any assignment of the master is

possible: master/slave or slave/master. Both partial systems are

updated with the same information simultaneously because all

input data are applied to both, meaning that online backup data

transmission between the two partial systems is superfluous.

Central faults are detected very rapidly using a hardware comparator. This compares the redundant bus signals for each read

or write operation of the central processors operating with synchronous clocks. Software test programs are started in the event

of a fault in order to established its location.

The synchronous signals of the redundant I/O bus are checked

for equality for selective areas of up to 13 I/O modules each and

converted to the single-channel I/O bus of the standard I/O modules. Up to 3 selected I/O module areas can be supplied by the

redundant I/O bus (A), a further 4 selected I/O module areas can

be supplied by extending with a redundant I/O bus 2 (B). A strict

division into fault limiting regions thus ensures

that single faults

can only have an effect within one selective I/O module area.

The AS 235 H system enables maintenance and repair without

interfering with process operations. The corresponding partial

system, irrespective of whether it is the master or slave, is

removed from the synchronous operation. The partner system

then retains the master status, or is assigned it automatically,

and thus handles the active process operations. The disabled,

passive partial system now operates completely independently,

but without the I/O modules since these are required by the mas-

ter.

This simplex operation with 2 independent systems enable

s new

user programs to be configured, loaded or tested and to operate

on the process either on a trial basis or permanently. This flexibility prevents undesirable down times in the process when

changing the automation structure.

The backup of a passive partial system (transition from simplex

to duplex operation with a slave system ready for operation) is

initiated by the operator and is executed without influencing the

online processing of the master system. It is terminated by automatic synchronization. The second partial system is then the

slave and is ready to accept the master status at any time.

When connected to the CS 275 bus system, the redundant

AS 235 H system re

sponds like a single participant.

The user software of the AS 235 H automation system is compatible with that of the AS 235 and AS 235 K systems, i.e. user configurations which have been generated on these systems and

which function directly can also be used in the AS 235 H system

without limitations.

Important note:

The AS 235 automation system has been optimized for high

reliability and availability by means of fault tolerance and a

non-interacting design. However, it does not belong – just like

any other single or redundant programmable system – to the

class of special fail-safe systems approved by independent

testing authorities

(e.g. TÜV).

It is therefore important when automating processes or pro-

cess sections relevant to safety to ensure that suitable subordinate interlocking circuits or protective systems are provided for these areas in the AS 235 H system as in the

AS 235 / AS 235 K systems which make a dangerous operating state impossible should faults occur in the automation

system.

2/4

Siemens PLT 111 · 1999

Page 11

X

This catalog is out of date, see note on page 1

Standard function blocks

Dedicated function blocks are present in the automation sys-

tems to solve the control tasks. These are the so-called standard

function blocks. The AS 235, AS 235 H and AS 235 K systems

have the same standard function blocks for data acquisition,

closed-loop and open-loop control, calculation and monitoring.

The standard function blocks present in the system software are

activated by engineering tools using configuring instructions.

The blocks are combined into an automation structure which is

processed cyclically, and sometimes acyclically, by the central

processor of the automation system.

The configuration of the automation structure is us

ually generated graphically using the PROGRAF AS+ configuring tool (see

also page 2/9).

The following tables list the standard function blocks divided

according to their areas of application.

Blocks for analog and digital processing

Typ e Designation Function

SUM

MUL

DIV

RAD

LN

EXP

ABS Absolute value X = | X |

INT

DIF

PT

TOZ

MIN Minimum-value

MAX

TOB

PLG

GW

ASL

SPEI

Adder Y = X1 + X2 - X3 - X4

Multiplier Y = X1 · X2

Divider Y = X1/X2

Square-root extractor Y = or Y = K

Logarithm extractor Y = KF · Ioge | X |

Exponential value Y = e

Integrator Y = K · dt, K = 1/T

Differentiator Y(s)/X(s) = (T·s)/(1 + (T·s/v))

Delay Y(s)/X(s) = 1/(1 + T·s)

Dead time Y(s)/X(s) = e

selector

Maximum-value

selector

Dead band Y = X-TOBU for X < TOBU

Function generator Linear interpolation between 6

Limit monitor Limit check between two switch-

Analog-value switch Y = X1 for S = “0”

Analog-value memory

X X

x

-s·T

Y = minimum of X1, X2, X3

Y = maximum of X1, X2, X3

0for TOBU ≤

X-TOBO for X > TO BO

pairs of turning points

ing points

Y = X2 for S = “1”

Storage of up to 256 analog val-

ues

X

≤

TOBO

System architecture

Configuring

Standard function blocks

Blocks for binary processing

Type Designation Function

VU

VO

VN

VM Flag Flag of binary input signals (flip-

VZ

VS + STEP

MPX

BW

INKU

BCE

BCA

KA

KAK

KB

KBK

KS

KV

KE

KEK

HA

HUP

EAR

EBR

UBR

AND A = E1 ∧ E2 ∧ E3

OR A = E1 ∨ E2 ∨ E3

Negation A = E

flop)

Time delay Switch-on and switch-off delays

STEP M block Freely programmable in STEP M

Multiplexer To supply the STEP commands in

Binary selection Selection of status combination

Incremental converter

BCD input Conversion of a BCD signal into

BCD output Conversion of an analog value

Sequence start Marks the start of an ON/OFF

Sequence Conditions of a control step, for

Sequence step As KB, for process plants

Sequence branch Branch of a sequence into a max-

Sequence end Last block in a sequence

Auxiliary oil automatic unit

Horn block Triggers signalling equipment

Individual analogvalue allocation

Single-bit allocation Links individual binary outputs to

Universal binary

location

the following VS/KS block

from up to 3 binary signals

Converts analog value into an

open or close pulse

an analog value

into a BCD signal

branch of a subgroup control

As KA, but with additional func-

tions

power plants

As KB, but with additional func-

tions

imum of 6 branches, with process

plants

As KE, but with additional func-

tions

Controls electric auxiliary oil

pumps for oil supply to generator

sets

(optical and audible)

Allocates analog values from out-

puts in GA blocks

GB/GM data blocks

Links 16 binary outputs to GB/

GM data blocks

Siemens PLT 111 · 1999

2/5

Page 12

System architecture

Configuring

Standard function blocks

Blocks for processing with

standardized operation and monitoring

Typ e Designation Function

R

RN

M

V

B

S

G

GK

A

F

FN

T

SR

C

PKM

PKF

1) Displays in PROGRAF AS+

Closed-loop controller

Measured-value

monitoring

Ratio Generation of a ratio, e.g. with a

Operation block Display of analog values (internal

Control unit Operation and monitoring of a

Subgroup control

Group control

Output for binary

data

Window block Display of 5 measured values;

Window block Display and limit monitoring of 5

1)

Trend

Recorder

Selector To switch over binary signals,

Alarm acquisition Acquires planned alarms from

Alarm sequence dis-

play

1)

1)

PID control, e.g. for disturbance

variable feedforward, tracking of

setpoint and manipulated variable, limit formation

As R,

with additional functions

Monitors a measured value for 3

pairs of limits

Extension of a closed-loop control block for limit monitoring

Limitation of measured value at

the error limits

ratio control

Proportional adjuster, e.g. with

synchronization control or to influence the command variable in a

cascade

result of calculations, ...)

Access to analog and binary values (input of constants, ...)

sequence in process plants

Operation and monitoring of

sequences in power plants

As G,

with additional functions

Display of and access to a binary

value

each of the 5 values is monitored

for a pair of limits

measured values;

input of 5 pairs of limits each with

hysteresis as well as 5 ranges for

the measured value display

Display of the trend of 2 measured values as a bargraph; time

base between 1.625 s and 36 h

Summary of up to 4 series of

measurements, displayed on

screen as dashed-line curves;

4 pairs of limits for monitoring the

measured values

e.g. manual/automatic mode

binary input module/GB block

Output of PKM alarms; new

alarms of PKM blocks, display of

alarm history

This catalog is out of date, see note on page 1

Data blocks

Type Designation Function

GA

GB

GM

GT

FA

FSA

FB

FC

Blocks for signal exchange via CS 275

Type

AKS

AKE

BKS

BKE

ZKS

ZKE

MKS

MKE

SKS

PLPS

Data block for global

analog values

Data block for global

binary values

Data block for global

flags

Data block for global

times (timer)

Data field block for

analog values

Data field block for

analog values

Data field block for

binary data

Data field block for

characters

Designation Function

Analog coupling and

transmitter block

Analog coupling and

receiver block

Binary coupling and

transmitter block

Binary coupling and

receiver block

Character coupling

and transmitter block

Character coupling

and receiver block

Alarm coupling and

transmitter block

Alarm coupling and

receiver block

Status coupling and

transmitter block

Reading and writing

of parameters

Storage of 256 analog values

with error 10

storage of process image, histor-

ical values etc.

Storage and scanning of 256

binary values;

especially for binary process

inputs and outputs

Storage and scanning of 256

internal binary statuses

Storage and generation of times/

timers for execution of time-

dependent functions

Storage of internal/external ana-

log values with error 10

especially for internal results

Storage of internal/external ana-

log values with error 10

cially for internal results

Storage of internal/external

binary values; extension of GB/

GM blocks

Storage of characters (texts)

Tran smission of up to 28 analog

values and abbreviated time

(minutes and seconds) from an

AS 235 system to a max. of 6 or

32 receivers (AKE blocks)

Reception of up to 28 analog val-

ues via the CS 275 from the data

set of an MKS block of another

bus participant

Tran smission of up to 128 binary

signals and abbreviated time

from an AS 235 to a max. of 6 or

32 receivers (BKE blocks)

Reception of up to 128 binary val-

ues via the CS 275 from the data

set of a BKS block of another bus

participant

Tran smission of up to four S16

strings from an AS 235 to up to 6

or 32 receivers (ZKE blocks)

Reception of up to four S16

strings from another AS system

Tran sition of 32 binary signals as

alarms (with the time a signal

changes from 0

other bus participants

Reception of 32 binary signals of

an MKS block and the time of

transmission sent by another bus

participant via the CS 275

Tran sfer of status information to

higher-level systems (operator

system, computer)

Reading or writing of up to 20

parameters from a bus-coupled

AS 235 system

-9

;

→1 or 1→ 0) to

-9

;

-4

; espe-

2/6

Siemens PLT 111 · 1999

Page 13

This catalog is out of date, see note on page 1

System architecture

Configuring

Standard function blocks

Driver blocks for I/O modules

Typ e Designation Function For modules with

AE

Analog input

Acquisition of an analog signal via an analog input module channel (0 to 20 mA,

4 to 20 mA, 0 to ± 10 V; Pt 100 resistance thermometer, thermocouples) or an

analog input module of the SIMATIC S5 programmable controllers (instrument

range U)

AR

AA Analog output Output of an analog signal via a channel of an analog output module or an ana-

BEI Binary input Acquisition of binary signals via a binary input module;

BRA Binary allocation Acquisition of 8 binary signals via a binary input module;

BAU

RZ Input block for two-channel

RZA Output block for two-chan-

BU8

BU16 Binary transmitter monitor-

Analog input allocation

Acquisition of 8 analog process variables, conversion into physical variables;

storage in GA blocks or direct linking

log output module of the SIMATIC S5 programmable controllers (instrument

range U)

storage of binary signals in GB block

allocation of signals to specified linking addresses

Binary output Output of up to 32 binary signals to a binary output module

controller

nel controller

Binary transmitter monitor-

ing block

Acquisition of analog and binary signals from a channel of a two-channel controller module

Transfer of the manipulated variable increment ΔY or setpoint increment ΔW

from a closed-loop control block R or RN to a channel of a controller module

Acquisition and monitoring of 8 binary signals via a binary input module

Acquisition and monitoring of 16 binary signals via a binary input module

ing block

ZE Metered pulse input Acquisition of a channel of a metered pulse input module

DR Input/output for speed con-

trollers

E110 Binary input for SIMATIC

S5 input modules

A110 Binary output for SIMATIC

S5KE Coupling to S5

S5KS Coupling to S5

AEF Analog input (field multi-

S5 output modules

- receive

- transmit

plexer)

AAF Analog output (field multi-

plexer)

BEF Binary input (field multi-

plexer)

BAF Binary output (field multi-

plexer)

Acquisition of signals from the interface module, and transfer of signals to the

interface module

Reading in of 16 binary values from an interface module for input modules of

the SIMATIC S5-110 programmable controllers or for input modules of the

SIMATIC S5 programmable controllers (instrument range U) or for standard

binary input modules

Output of 16 binary values from an interface module for output modules of the

SIMATIC S5-110 programmable controllers or for output modules of the

SIMATIC S5 programmable controllers (instrument range U) or for standard

binary output modules

Acquisition of signals from the interface module via telegrams with point-topoint coupling

Transfer of signals to the interface modules via telegrams with point-to-point

coupling

Driver for acquisition of analog signals via the field multiplexer analog input

modules

Driver for acquisition of analog signals via the field multiplexer analog output

modules

2)

2)

Driver for acquisition of binary signals via the binary signal input modules of the

field multiplexer and for acquisition of fault signals from the binary I/O modules

of the field multiplexer

Driver for output of binary signals via the binary signal output modules of the

field multiplexer

2)

2)

PRA Testable relay module Driver for output of 16 binary signals to a testable relay output module

PBE Testable binary input Acquis ition of binary s ignals via a tes table binary input module, and transfer of

1) Coupling module

2) No longer available

the binary signals to binary-value fields

Order No.

6DS1 701-8AA, -8AB

6DS1 730-8AA

6DS1 731-8AA/-8BA/

-8EA/-8FA/-8RR +

6DS1 703-8AB, -8RR

6DS1 700-...

6DS1 321-8AA

6DS1 702-8AA, -8RR

6DS1 321-8AA

6DS1 601-...

6DS1 602-...

6DS1 615-8AA

6DS1 603-...

6DS1 604-8AA

6DS1 605-8BA

6DS1 402-...

6DS1 403-...

6DS1 620-8AA

6DS1 621-8AA

6DS1 600-8AA

6DS1 607-8AB

6DS1 303-8AA

6DS1 310-8AA/8AB

6DS1 321-8AA

6DS1 600-8AA

6DS1 601-8BA

6DS1 602-8..

6DS1 615-8AA

6DS1 310-8AA/8AB

6DS1 321-8AA

6DS1 603-8..

6DS1 604-8AA

6DS1 605-8BA

6DS1 333-8AB

6DS1 333-8AB

6DS1 706-8AA

6DS1 710-8AA

6DS1 711-8AA

6DS1 406-8AA/407-8AA

6DS1 610-8AA

6DS1 611-8AA

6DS1 612-8AA

6DS1 606-8BA

6DS1 618-8CA

1)

1)

2)

1)

1)

1)

1)

1)

1)

Siemens PLT 111 · 1999

2/7

Page 14

This catalog is out of date, see note on page 1

System architecture

Configuring

Standard function blocks

Driver blocks for configurable TELEPERM ME I/O modules

Typ e Designation Function For modules with

MSB

TVB Preselection and subloop

BRBK Organization and binary

ABR Analog input and output Acquisition and transfer of analog signals to the analog extension module via

REN Analog/binary inputs and

RSK

RSKB

Motor/valve and actuator

control

control

input/output block

output

Closed-loop control mod-

ule driver

Operation block for RSK

block

Acquisition and transfer of binary signals to the binary generation module

Acquisition and transfer of binary signals to the binary calculation module for

operation and monitoring of a preselection or subloop control

Acquisition of binary signals from the flag area of the binary calculation module,

coordination together with ABR, MSB or TVB

the binary calculation module

Acquisition and transfer of analog and binary signals of the analog calculation

module

Acquisition of signals from single-channel and two-channel configurable

closed-loop control modules

For operation and monitoring of configurable closed-loop control modules,

together with RSK block

Order No.

6DS1 717-8AA/-8RR

+ 6DS1 719-8AA/-8RR

6DS1 717-8AA/-8RR

6DS1 717-8AA/-8RR

6DS1 717-8AA/-8RR

+ 6DS1 720-8AA

6DS1 715-8BB

6DS1 408-8BB

6DS1 410-8BB

6DS1 411-8AA/-8RR

6DS1 412-8AA/-8RR

Driver blocks for I/O modules with standardized display

Typ e Designation Function For modules with

RE

RK

EM

EU

EV

EK

DZ Proportioning counter Acquisition of signals from proportioning counter modules (2/4 channels);

EG Individual control drives

FM Field multiplexer Acquisition of signals from a channel of the interface module for FM 100 field

1) No longer available

Closed-loop controller,

single-channel

Individual control drive,

motor

Individual control drive,

valve

(4 to 8 channels)

Acquisition of signals from single-channel closed-loop control modules;

transfer of commands and standardized increments to the closed-loop control

modules

As RE, with additional functions

Acquisition of signals from individual control drive modules and application of

signals to the binary outputs, e.g. for a subgroup control; transfer of commands

to the individual control drive modules

As EM, with additional functions

As EM, for the corresponding modules

As EV, with additional functions

connection of these signals to the block outputs;

transfer of commands and standardized analog values

Acquisition of signals from modules;

connection of these signals to the binary outputs;

transfer of commands

multiplexer

1)

; transfer of signals to the module

Order No.

6DS1 400-8BA

(S controller)

6DS1 401-8BA

(K controller)

6DS1 500-8BA

6DS1 502-8BA

6DS1 501-8BA/-8BB

6DS1 503-8BA

6DS1 613-8BB

6DS1 504-8AA

6DS1 505-8AA

6DS1 304-8AA

6DS1 304-8BB

2/8

Siemens PLT 111 · 1999

Page 15

Output blocks for printer and process monitor

Typ e Designation Function

GP

MEL

BILD

+LAYO

PROT

+LAYO

PKF

Organization blocks

Typ e

XB

XA

XZ

FUTA

RNAM

APRO+

PROB

Group display Design of display hierarchy:

Alarm output Output of planned plain text

Display output Output of plant-specific displays

Log output Output of plant-specific logs on

Process coupling/

alarm sequence dis-

play

Designation Function

Processing, cyclic To inhibit/release a group of func-

Processing, acyclic To inhibit/non-recurring release a

Time start For time-dependent switching-

Function keys For switching-on/off of XA/XB

Rename Modification of type name or

TML connection

(of PROBLEM

blocks)

area display and group display

alarms with time (resolution 1 s);

also standard blocks, such as M,

generate alarms

printers

Output of PKM alarms

tion blocks and to release each

n-th cycle

sequence of function blocks.

When installed in the alarm level

(ZYK 1) as an ALARM block:

1 x execution of subsequent

block sequence

on/off of XB blocks

blocks by operator input

block name

To insert a user-specific TML pro-

gram into the execution list

This catalog is out of date, see note on page 1

System architecture

Test blocks

Type Designation Function

TANZ

TUEB

SYST.

WART

Te st display Monitoring of binary and analog

Te st monitoring For sequence monitoring of TML

Te st and maintenance

Configuring

Standard function blocks

variables;

selective access to variables

possible (max. 16 analog and 16

binary within a standard display)

programs for:

• Cyclic sequence monitoring

• Non-recurring monitoring of a

program run

(up to 248 TML programs can be

monitored)

Menu-controlled calling of maintenance programs:

•XB switchover

•CS 275 coupling s tatus

• Activate error messages

•TML

• Reloading and selective

archiving

• System settings

Siemens PLT 111 · 1999

2/9

Page 16

This catalog is out of date, see note on page 1

System

architecture

2/2 Performance characteristics

2/4 Redundancy with AS 235 H

Configuring

2/5 Standard function blocks

2/10 User function blocks

Siemens PLT 111 · 1999

2/1

Page 17

This catalog is out of date, see note on page 1

System architecture

Performance characteristics

Performance characteristics

The AS 235, AS 235 H and AS 235 K systems are programmable

automation systems of the TELEPERM M process control system

based on function blocks. They have a different design and

availability, but the same range of functions. The AS 235 K sys-

tem is fitted in a wall housing, the AS 235 and AS 235 H systems

are fitted in cabinets. The AS 235 H automation system has a

redundant central unit to satisfy particularly high demands

placed on the availability.

The systems can either be used on their own with local operation

and monitoring, or coupled in system networks with central operation and monitoring.

System configuration

The automation sys

•A basic unit (AS 235, AS 235 H) or a basic system (AS 235 K)

•ES 100 K extension systems (wall housing) or extension units

(for fitting in cabinets) as extension for configuring with input/

output modules.

Standard input/output devices enable local communication with

the automation system during the configuring and commission-

ing phases as well as during later operation. The following can

be connected:

• 54-cm (21-inch) process monitors

• Process operation keyboard and configuring keyboard,

max. 2 of each for 2 independent operating consoles

• Max. 4 logging printers

• 1 mini floppy disk unit for booting the system memory and for

loading/saving the user memory.

Basic system/basic unit

The basic unit (AS

(AS 235 K) mainly contains

• the power supply modules,

• the central processor module,

• a memory module with user memory with 4,000 Kbyte capacity

and battery backup and

• the interface modules for the input and output devices and the

CS 275 bus system,

each of which is redundant in the AS 235 H system.

The central processor is microprogrammed and has a maximum

processing width of 32 bits. Three basic cycles are present for

processing (125 ms, 1 s and background level). An acyclic

mode can also be defined.

The basic unit of the AS 235 and the basic system of the

AS 235 K each has 6 slots for I/O modules. No I/O modules can

be plugged into the ba

The following can be fitted into the systems as standard:

•AS 235 Max. 90 I/O modules

•AS 235 H Max. 91 I/O modules

•AS 235 K Max. 108 I/O modules

The number of usable I/O slots with the AS 235 and AS 235 H

can be increased by additional use of ES 100 K extension sys-

tems:

•AS 235 Max. 114 I/O modules

•AS 235 H Max. 103 I/O modules

tems consist of:

235, AS 235 H) or the basic system

sic unit of the AS 235 H systems.

(basic unit + 6 extension units)

(7 extension units)

(basic system + eight ES 100 K extension systems)

Systemarchitectur e

I/O modules

There are the following group

• S ignal modules

• Function modules

• Calculation modules

• Coupling modules.

Signal modules are required for input and output of the process

signals, usually without further processing (exception: adapta-

tion of characteristic with temperature measurements).

Function modules (closed-loop control modules) and calculation

modules have additional performance features which are independent of the central unit of the automation system and which

can be used to increase the total processing performance or the

availability by transferring backup functions should the central

unit of the automation system fail.

The calculation modules enable the configuring of individual

user functions.

Coupling modules enable the connection of I/O modules over

larger distances. They additionally enable use of non-intelligent

I/O modules of the SIMATIC S5 programmable controller

the ET 100U distributed I/Os for the automation systems.

Memory, configuring

The memory with battery backup of the automation systems is

divided into:

•a system memory and

•a user memory.

The write-protected system memory contains the software which

always belongs to the automation system, in the form of basic

programs and function blocks. Far more than 100 standardized

blocks are available for data acquisition, closed-loop control,

open-loop control, calculation, supervision, logging, display and

operation/monitoring.

Instead of programming the system with individual commands

and carrying out the required program tests, it is only necessary

in the TELEPERM M process control system to configure the

complete function blocks in order to obtain a “user program”. In

the simplest case, configuring means calling the function blocks

with the keyboard, several times if necessary, and then assign-

ing the respective linking instructions and parameters. The

resulting application-oriented configuring data are then stored in

the user memory.

Configuring is possible before the automation system is started

up as well as during operation. It is possible to temporarily

switch partial functions of the user system out of operation for

this purpose.

Convenient configuring using graphic inputs is possible using

the PROGRAF AS+ engineering tool which can be executed in a

personal computer connected locally to the AS 235/235 H/235 K

automation

system or centrally to the CS 275 bus system.

s of I/O modules:

s, plus

se

2/2

Siemens PLT 111 · 1999

Page 18

This catalog is out of date, see note on page 1

STEP M

In addition to the function blocks for binary processing, the

AS 235/235 H/235 K systems can use the STEP M control language, without leaving the block configuration, in order to formulate extensive and complex open-loop control tasks.

TML language

The TML process language can be used in addition to the firmware blocks for special tasks. It can be used to format special

function blocks and to implement particularly complex functions,

e.g. for the mixing of binary value arithmetic and measured value

arithmetic.

Operation and monitoring

The AS 235, AS 235 H and AS 235 K systems have either one or

two autonomous operation channels for local operation and

monitoring. This means that process operation keyboards, printers and process monitors can be connected in duplicate and

operated using operation/monitoring functions which are independent of one another. Some of the local operation devices can

be omitted in the cas

a network configuration.

Scope of performance

The user RAM of the automation systems has a memory capacity

of 4,000 Kbytes. This means that even one single system can

already implement larger automation tasks. Even the data quantities encountered with extensive batch processes can be handled. If it is taken into account that various tasks occur mixed

together, the performance is approximately as follows:

• 30 to 80 control loops

• 50 to 120 additional analog-value monitoring functions

• 5 to 15 sequential controls

• 100 to 250 logic controls

• Any number of flow charts (up to 8 colors) and individually

designed logs.

e of central operation and monitoring with

System architecture

Performance characteristics

Summary of system properties

• Automation system for autonomous operation with local

communication or for network operation with central

communication

• Fitted in wall housing or cabinet

• Configurable within wide limits

(up to 114 I/O modules depending on system)

•User memory up to 4,000 Kbytes on one module

• 32-bit processing of analog values

• Optimized data transfer rate resulting from separate

processing of analog and binary values

• Central unit redundant as option with synchronous processing of clocks (AS 235 H)

• Operation without fans possible

• Complete range of standard function blocks

•User function blocks with convenient TML program-

ming language, also STEP M programming language

for open-loop control tasks

• Configuring/programming either online without programmer (using lists) or with PC (using graphics)

• Local or central configuring (via bus)

Siemens PLT 111 · 1999

2/3

Page 19

System architecture

Redundancy with AS 235 H

This catalog is out of date, see note on page 1

CS 275

plant bus

Central

processing

unit I

I/O bus I/O bus

Fig. 2/1 1-out-of-2 redundancy structure with AS 235 H

Redundancy with the AS 235 H automation system

I/O

modules

Synchronization

Comparison,

cross-coupling

Comparison,

switchover

Process level

Central

processing

unit II

Redundant I/O bus

I/O

modules

Comparison,

switchover

Redundant path

Various system characteristics must be considered with regard

to the reliability and availability of a system. The requirements for

reliability are met by fault-tolerant (high-availability) systems

while those for safety are met by fail-safe systems.

According to VDI/VDE 3542 the following applies:

A system is fault-tolerant if occurring faults have no effect on its

function. Fail-safe is the ability of a technical system to remain in

a safe mode or to switch immediately to another safe mode in the

event of a fault.

The AS 235 H automation system is a high-availability system

with redundant central units operating with system clocks where

execution of the planned automation functions is not interrupted

by system faults.

The system operates according to the fault-tolerant 1-out-of-2

principle. The AS 235 H system is equipped with 2 identical central processing units for this purpose, the master unit and the

slave unit (Fig. 2/1). Each of the two CPUs contains a power supply module, central processor, memory module for system software and user program as well as 1 or 2 interface modules for

the I/O bus depending on the number of I/O modules connected. The user programs stored in the 2 memory modules are

identical.

Process signals are always applied to both CPUs. Only one of

these, the master unit, can output commands to the process via

the I/O modules. The other operates in hot s

tandby mode and is

always able to take over smooth control of the process should

the master unit fail.

The fully-synchronous mode of operation of the two partial

AS 235 H systems means that any assignment of the master is

possible: master/slave or slave/master. Both partial systems are

updated with the same information simultaneously because all

input data are applied to both, meaning that online backup data

transmission between the two partial systems is superfluous.

Central faults are detected very rapidly using a hardware comparator. This compares the redundant bus signals for each read

or write operation of the central processors operating with synchronous clocks. Software test programs are started in the event

of a fault in order to established its location.

The synchronous signals of the redundant I/O bus are checked

for equality for selective areas of up to 13 I/O modules each and

converted to the single-channel I/O bus of the standard I/O modules. Up to 3 selected I/O module areas can be supplied by the

redundant I/O bus (A), a further 4 selected I/O module areas can

be supplied by extending with a redundant I/O bus 2 (B). A strict

division into fault limiting regions thus ensures

that single faults

can only have an effect within one selective I/O module area.

The AS 235 H system enables maintenance and repair without

interfering with process operations. The corresponding partial

system, irrespective of whether it is the master or slave, is

removed from the synchronous operation. The partner system

then retains the master status, or is assigned it automatically,

and thus handles the active process operations. The disabled,

passive partial system now operates completely independently,

but without the I/O modules since these are required by the mas-

ter.

This simplex operation with 2 independent systems enable

s new

user programs to be configured, loaded or tested and to operate

on the process either on a trial basis or permanently. This flexibility prevents undesirable down times in the process when

changing the automation structure.

The backup of a passive partial system (transition from simplex

to duplex operation with a slave system ready for operation) is

initiated by the operator and is executed without influencing the

online processing of the master system. It is terminated by automatic synchronization. The second partial system is then the

slave and is ready to accept the master status at any time.

When connected to the CS 275 bus system, the redundant

AS 235 H system re

sponds like a single participant.

The user software of the AS 235 H automation system is compatible with that of the AS 235 and AS 235 K systems, i.e. user configurations which have been generated on these systems and

which function directly can also be used in the AS 235 H system

without limitations.

Important note:

The AS 235 automation system has been optimized for high

reliability and availability by means of fault tolerance and a

non-interacting design. However, it does not belong – just like

any other single or redundant programmable system – to the

class of special fail-safe systems approved by independent

testing authorities

(e.g. TÜV).

It is therefore important when automating processes or pro-

cess sections relevant to safety to ensure that suitable subordinate interlocking circuits or protective systems are provided for these areas in the AS 235 H system as in the

AS 235 / AS 235 K systems which make a dangerous operating state impossible should faults occur in the automation

system.

2/4

Siemens PLT 111 · 1999

Page 20

X

This catalog is out of date, see note on page 1

Standard function blocks

Dedicated function blocks are present in the automation sys-

tems to solve the control tasks. These are the so-called standard

function blocks. The AS 235, AS 235 H and AS 235 K systems

have the same standard function blocks for data acquisition,

closed-loop and open-loop control, calculation and monitoring.

The standard function blocks present in the system software are

activated by engineering tools using configuring instructions.

The blocks are combined into an automation structure which is

processed cyclically, and sometimes acyclically, by the central

processor of the automation system.

The configuration of the automation structure is us

ually generated graphically using the PROGRAF AS+ configuring tool (see

also page 2/9).

The following tables list the standard function blocks divided

according to their areas of application.

Blocks for analog and digital processing

Typ e Designation Function

SUM

MUL

DIV

RAD

LN

EXP

ABS Absolute value X = | X |

INT

DIF

PT

TOZ

MIN Minimum-value

MAX

TOB

PLG

GW

ASL

SPEI

Adder Y = X1 + X2 - X3 - X4

Multiplier Y = X1 · X2

Divider Y = X1/X2

Square-root extractor Y = or Y = K

Logarithm extractor Y = KF · Ioge | X |

Exponential value Y = e

Integrator Y = K · dt, K = 1/T

Differentiator Y(s)/X(s) = (T·s)/(1 + (T·s/v))

Delay Y(s)/X(s) = 1/(1 + T·s)

Dead time Y(s)/X(s) = e

selector

Maximum-value

selector

Dead band Y = X-TOBU for X < TOBU

Function generator Linear interpolation between 6

Limit monitor Limit check between two switch-

Analog-value switch Y = X1 for S = “0”

Analog-value memory

X X

x

-s·T

Y = minimum of X1, X2, X3

Y = maximum of X1, X2, X3

0for TOBU ≤

X-TOBO for X > TO BO

pairs of turning points

ing points

Y = X2 for S = “1”

Storage of up to 256 analog val-

ues

X

≤

TOBO

System architecture

Configuring

Standard function blocks

Blocks for binary processing

Type Designation Function

VU

VO

VN

VM Flag Flag of binary input signals (flip-

VZ

VS + STEP

MPX

BW

INKU

BCE

BCA

KA

KAK

KB

KBK

KS

KV

KE

KEK

HA

HUP

EAR

EBR

UBR

AND A = E1 ∧ E2 ∧ E3

OR A = E1 ∨ E2 ∨ E3

Negation A = E

flop)

Time delay Switch-on and switch-off delays

STEP M block Freely programmable in STEP M

Multiplexer To supply the STEP commands in

Binary selection Selection of status combination

Incremental converter

BCD input Conversion of a BCD signal into

BCD output Conversion of an analog value

Sequence start Marks the start of an ON/OFF

Sequence Conditions of a control step, for

Sequence step As KB, for process plants

Sequence branch Branch of a sequence into a max-

Sequence end Last block in a sequence

Auxiliary oil automatic unit

Horn block Triggers signalling equipment

Individual analogvalue allocation

Single-bit allocation Links individual binary outputs to

Universal binary

location

the following VS/KS block

from up to 3 binary signals

Converts analog value into an

open or close pulse

an analog value

into a BCD signal

branch of a subgroup control

As KA, but with additional func-

tions

power plants

As KB, but with additional func-

tions

imum of 6 branches, with process

plants

As KE, but with additional func-

tions

Controls electric auxiliary oil

pumps for oil supply to generator

sets

(optical and audible)

Allocates analog values from out-

puts in GA blocks

GB/GM data blocks

Links 16 binary outputs to GB/

GM data blocks

Siemens PLT 111 · 1999

2/5

Page 21

System architecture

Configuring

Standard function blocks

Blocks for processing with

standardized operation and monitoring

Typ e Designation Function

R

RN

M

V

B

S

G

GK

A

F

FN

T

SR

C

PKM

PKF

1) Displays in PROGRAF AS+

Closed-loop controller

Measured-value

monitoring

Ratio Generation of a ratio, e.g. with a

Operation block Display of analog values (internal

Control unit Operation and monitoring of a

Subgroup control

Group control

Output for binary

data

Window block Display of 5 measured values;

Window block Display and limit monitoring of 5

1)

Trend

Recorder

Selector To switch over binary signals,

Alarm acquisition Acquires planned alarms from

Alarm sequence dis-

play

1)

1)

PID control, e.g. for disturbance

variable feedforward, tracking of

setpoint and manipulated variable, limit formation

As R,

with additional functions

Monitors a measured value for 3

pairs of limits

Extension of a closed-loop control block for limit monitoring

Limitation of measured value at

the error limits

ratio control

Proportional adjuster, e.g. with

synchronization control or to influence the command variable in a

cascade

result of calculations, ...)

Access to analog and binary values (input of constants, ...)

sequence in process plants

Operation and monitoring of

sequences in power plants

As G,

with additional functions

Display of and access to a binary

value

each of the 5 values is monitored

for a pair of limits

measured values;

input of 5 pairs of limits each with

hysteresis as well as 5 ranges for

the measured value display

Display of the trend of 2 measured values as a bargraph; time

base between 1.625 s and 36 h

Summary of up to 4 series of

measurements, displayed on

screen as dashed-line curves;

4 pairs of limits for monitoring the

measured values

e.g. manual/automatic mode

binary input module/GB block

Output of PKM alarms; new

alarms of PKM blocks, display of

alarm history

This catalog is out of date, see note on page 1

Data blocks

Type Designation Function

GA