Page 1

Arnold

ARCADIS Varic

Replacements of Parts

System

SP

Replacement of Parts

08080017

Print No.:

Replaces: SPR2-310.841.01.06.02

SPR2-310.841.01.07.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 08.07

2005

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 2 of 98

Medical Solutions

Page 3

Table of Contents 3

0Table of Contents

1 _______ Prerequisites ___________________________________________________ 6

Required documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required tools, measurement devices, and accessories . . . . . . . . . . . . . . . . . . . . . . 6

Text emphasis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service, shutdown, hibernation, handover to the customer . . . . . . . . . . . . . . . . . . . . . . . 9

Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General safety information (in existing documents) . . . . . . . . . . . . . . . . . . . . . . . . . 10

General electrical safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Radiation safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety information, mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety information - risk of infection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser light localizer option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Information on the protective conductor resistance test . . . . . . . . . . . . . . . . . . . . . . 13

System leakage current measurement information . . . . . . . . . . . . . . . . . . . . . . . . . 15

Information on navigation systems installed as options . . . . . . . . . . . . . . . . . . . . . . 19

Cover panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Main system, rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Main system, SIREPHOS cover panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Monitor trolley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Concluding steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 _______ Main System - Replacing Components _____________________________ 23

D1 control board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacement and additional work steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D2 power board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D3 interface board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

D40 board for downward movement of the lifting column. . . . . . . . . . . . . . . . . . . . . . . . 27

M14 power supply, +5 V/+15 V/-15 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

M13 power supply 230V/13V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I.I. mini-voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Roederstein I.I. mini voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Spellman I.I. mini voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Exchanging the SIREPHOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Replacing the camera and the I.I. optics (camera version ≥ 2.0) . . . . . . . . . . . . . . . . . . 36

Removing/replacing the camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing/replacing the I.I. optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjusting the camera and I.I. optics (camera version ≥ 2.0). . . . . . . . . . . . . . . . . . . . . . 38

Centering the camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Reproduction scale adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Camera focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replacing the camera and the I.I. optics (camera version < 2.0) . . . . . . . . . . . . . . . . . . 41

Removing/replacing the camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 3 of 98

Page 4

4 Table of Contents

Removing/replacing the I.I. optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjusting the camera and I. I. optics (camera version < 2.0) . . . . . . . . . . . . . . . . . . . . . 44

Centering the camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Reproduction scale adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Camera focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replacing the I. I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Checking the temperature indicator of the new I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing the I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing the new I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Checks and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dose area product measuring device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Laser targeting device (SIREPHOS-side). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Integrated Laser light localizer (I.I. -side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing the C-arm rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Securing the basic unit against tilting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Set the C-arm and lifting column to the working position . . . . . . . . . . . . . . . . . . . . . 55

Removing the SIREPHOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removing the C-arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Replacing the rollers and reinstalling the C-arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Attaching the covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3 _______ Monitor Trolley - Replacing Components ___________________________ 58

Replacing the power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Replacing the UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing the UPS battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

UPS MGE Type 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

MGE UPS Type 850 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Replacing the keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing PC covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Opening the casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Removing the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replacing the lithium battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Restoring BIOS settings (necessary after battery replacement) . . . . . . . . . . . . . . . . 78

Replacing a PCI board PC M420 and M430 (e. g. CIPP board). . . . . . . . . . . . . . . . . . . 80

Replacing a PCI board PC M450 (e. g. CIPP board) . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Replacing or installing a double USB slot PC M420 and M430 (optional for CAN con-

verter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4 _______ Voltages ______________________________________________________ 89

Monitor trolley voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Main system voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

I.I. voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 4 of 98

Medical Solutions

Page 5

Table of Contents 5

Roederstein I.I. mini voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Spellman I.I. mini voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5 _______ Brake Force/Lubrication _________________________________________ 94

Brake force calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Adjustment of the angulation brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Lubricating the vertical column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Supplement, measuring the tube current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6 _______ Changes to the previous version __________________________________ 97

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 5 of 98

Page 6

6 Prerequisites

Required documents 0

1- 1Prerequisites

• ARCADIS Varic wiring diagram

• For the laser targeting device as applica-

ble:

Required tools, measurement devices, and accessories 0

NOTE

• Standard tool kit*

• Digital multimeter, e.g. Fluke 8060 APart no. 97 02 101 Y4290

• Oscilloscope > 50 MHz, e.g. Fluke

CombiScope PM 3390 A

All tools, measurement devices, and accessories with the exception of those marked with a "*" are listed along with their specifications in the STC (Service Tools Catalog).

Part no. 99 00 861 Y3155

Adjustment instructions/laser targeting

device RXR2-130.032.01..

• Dose measurement device

e. g. DALI PTW*

or NOMEX PTW*

or DIADOS PTW

no longer in ARTD

no longer in ARTD

Part no. 97 17 612 Y0388

• Ground wire test meter

e.g. Unimed 1000 tester Part no. 51 38 727 Y0766

• 1 set of resolution tests e.g. part no. 28 71 820 RE999

• 1 set of radiation filters e.g. part no. 97 98 596 G5321

• Centering cross e.g. part no. 96 60 051 RE999

• WPS heat conducting paste e.g. part no. 20 48 650 SRN 6400

• 200 N spring scale e.g. part no. 44 15 113 RH090

• Torque wrench 20 Nm to 100 Nm e.g. part no. 80 86 159 RE999

• Optimol Viscogen KL 300, 50 ml Part no. 72 79 107

• Sealing compound* Part no. 20 49 716 SRN 6002

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 6 of 98

Medical Solutions

Page 7

Prerequisites 7

Text emphasis 1.1

DANGER

WARNING

CAUTION

NOTICE

DANGER indicates an immediate danger of death or serious physical injury.

¹ n.a.

WARNING indicates a danger that may lead to death or serious

physical injury.

¹ n.a.

CAUTION used with the safety alert symbol indicates a risk of

minor or moderate physical injury and/or damage to property.

¹ n.a.

NOTICE used without the safety alert symbol indicates a risk that

if disregarded will lead or may lead to a situation which may result

in an undesirable result or state other than death, physical injury

or damage to property.

NOTE

¹ n.a.

NOTE contains information provided with special emphasis to

facilitate proper use of the equipment or proper execution of a

procedure, i.e. hints, tips.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 7 of 98

Page 8

8 Prerequisites

Symbols 1.2

X Checks and adjustments that must be performed with radiation ON are identified by the

radiation warning symbol.

V This symbol means "Dangerous voltage".

C This symbol means "Attention, refer to the documentation".

E This symbol indicates components sensitive to electrostatic discharge (ESD).

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 8 of 98

Medical Solutions

Page 9

Prerequisites 9

Service, shutdown, hibernation, handover to the customer 1.3

WARNING

NOTE

Switch off via hibernation (version VB13C and later) after service

or before handover to the customer is not sufficient.

Various error messages can appear after the next system boot

and configuration changes are not adopted.

¹ For correct saving of the changed configurations, a shut-

down must be performed. Shut down the system via the

upper monitor menu bar <Options>-<End Session>-<Shut Down System> and then press the off key on

the monitor trolley.

Before the system is handed over to the customer, the system

must be shut down via the menu bar <Options>-<End Session>-<Shut Down System>.

Switch off via hibernation (on/off button on the monitor trolley) is

not sufficient.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 9 of 98

Page 10

10 Prerequisites

Safety information and protective measures 1.4

General safety information (in existing documents) 0

WARNING

Danger of injuries, death or material damage.

Non-compliance can lead to death, injury or material damage.

Please note:

¹ The product-specific safety notes in these instructions,

¹ The general safety information in TD00-000.860.01... and

¹ The safety information in accordance with ARTD Part 2.

General electrical safety information 0

WARNING

Electrical safety!

Non-compliance can lead to severe injury or even death, as well

as material damage.

¹ Parts under electrical voltage are accessible when the

covers are open. To avoid danger, disconnect the system

from the power supply before opening the covers. Disconnect the power plug.

CAUTION

¹ If an uninterruptible power supply (UPS) is installed in

the system, the voltage output of the UPS must also be

deenergized or the voltage output plug must be disconnected.

¹ If work steps must be performed using electrical power,

the general safety information according to

TD00-000.860.01 must be observed.

Electrical voltage!

Non-compliance can result in material damage.

¹ When working on the system, ESD regulations must be

observed.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 10 of 98

Medical Solutions

Page 11

Prerequisites 11

Radiation safety information 0

WARNING

X ¹ Checks requiring the release of radiation are identified by

X-ray radiation!

Non-compliance can lead to illness, irreversible damage to body

cells and the genotype, severe injury and even death.

During work on the system in which radiation must be released,

the radiation protection directives and the rules for radiation protection according to ARTD-002.731.02.. must be complied with.

Please note:

¹ Use available radiation protection devices.

¹ Wear radiation protection clothing (lead apron).

¹ Stay as far away as possible from the radiation source.

¹ Release radiation only if necessary.

¹ Set the radiation activity as low as possible. (Low kV and

mA values, short radiation time)

¹ Release radiation for as short a time as possible.

the radiation warning symbol shown on the left.

Safety information, mechanical 0

CAUTION

Danger of burns from hot parts or components!

Non-observance can lead to mild to moderately severe burns, particularly on the hands.

¹ When the covers are opened, parts and components (e.g.

power supply components, heat sinks, electromagnetic

brakes) are accessible which during operation can reach

temperatures of > 50 degrees Celsius. To avoid burns,

switch off the system and let it cool down for at least 5

minutes before touching any parts or components.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 11 of 98

Page 12

12 Prerequisites

CAUTION

Danger of injuries from mechanical parts!

Non-observance can lead to mild to moderately severe injuries,

particularly to the hands.

¹ When the cover panels are opened, parts such as plugs,

threaded bolts, cut-off cable ties, and sharp component

edges are exposed. Inattention can lead to skin injuries

(crushing, scrapes, cuts), particularly to the hands.

¹ Work steps carried out on such parts and components

must be performed with particular attention and caution.

¹ Wear work gloves if necessary.

Safety information - risk of infection 0

WARNING

Risk of infection due to pathogens!

Non-compliance can lead to severe injury and even death.

¹ This product can be contaminated with infected blood or

other bodily fluids.

¹ Avoid all contact with blood or other bodily fluids!

¹ Strictly observe the safety information in

ARTD-002.731.37.. regarding prevention of infectious diseases during customer service calls.

Laser light localizer option 0

CAUTION

NOTE

Laser emissions!

This product contains class 2 lasers. (USA: Laser class 2)

Non-observance can lead to injury, particularly to the retina of the

eye, and can thus lead to irreversible visual impairment.

¹ Observe the safety information in ARTD-002.731.03...

When using the laser light localizer, do not look directly

into the laser beam.

Laser emissions!

There is no immediate danger to the eye (blinking reflex). Nevertheless, do not look directly into the laser beam.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 12 of 98

Medical Solutions

Page 13

Prerequisites 13

Information on the protective conductor resistance test 0

Observe the instructions in the "Safety Rules for Installation and Repair"

(ARTD-002.731.17 ...).

The protective conductor resistance must be measured after every intervention in the system.

However, documentation of the measured values is required only during periodic safety

checks.

If parts/components that can significantly influence the protective conductor resistance

(e.g., replacement of the power cable, replacement of the power-up module, replacement

of multi-pole connection cables which also create the protective conductor connection

between system parts (e.g., monitor cable or C-arm cable)) are replaced or if protective

conductor connections have been repaired, the protective conductor resistance must be

measured. The values must be documented and evaluated in the protective conductor

resistance protocol.

NOTE

For evaluation purposes, the first measured value and the values

documented during maintenance or safety checks must be compared to the measured values. A sudden or unexpected increase

in the measured values may indicate a defect in the protective

conductor connections - even if the limit value of 0.2 ohms is not

exceeded. (Protective conductor or contacts).

The measurement must be performed according to DIN VDE 0751, Part 1 (see ARTD Part

2). The protective conductor resistance for all touchable conductive parts must be measured during the normal operating state of the system.

Make sure that control cables or data cables between the components of the system are

not mistaken for protective conductor connections.

During the measurement, the power cable and additional connection cables which also

create the protective conductor connection between system parts (e.g. monitor cable

between the basic unit and monitor trolley) must be moved section by section to detect

cable breaks.

The protective conductor resistance must not exceed 0.2 Ohms.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 13 of 98

Page 14

14 Prerequisites

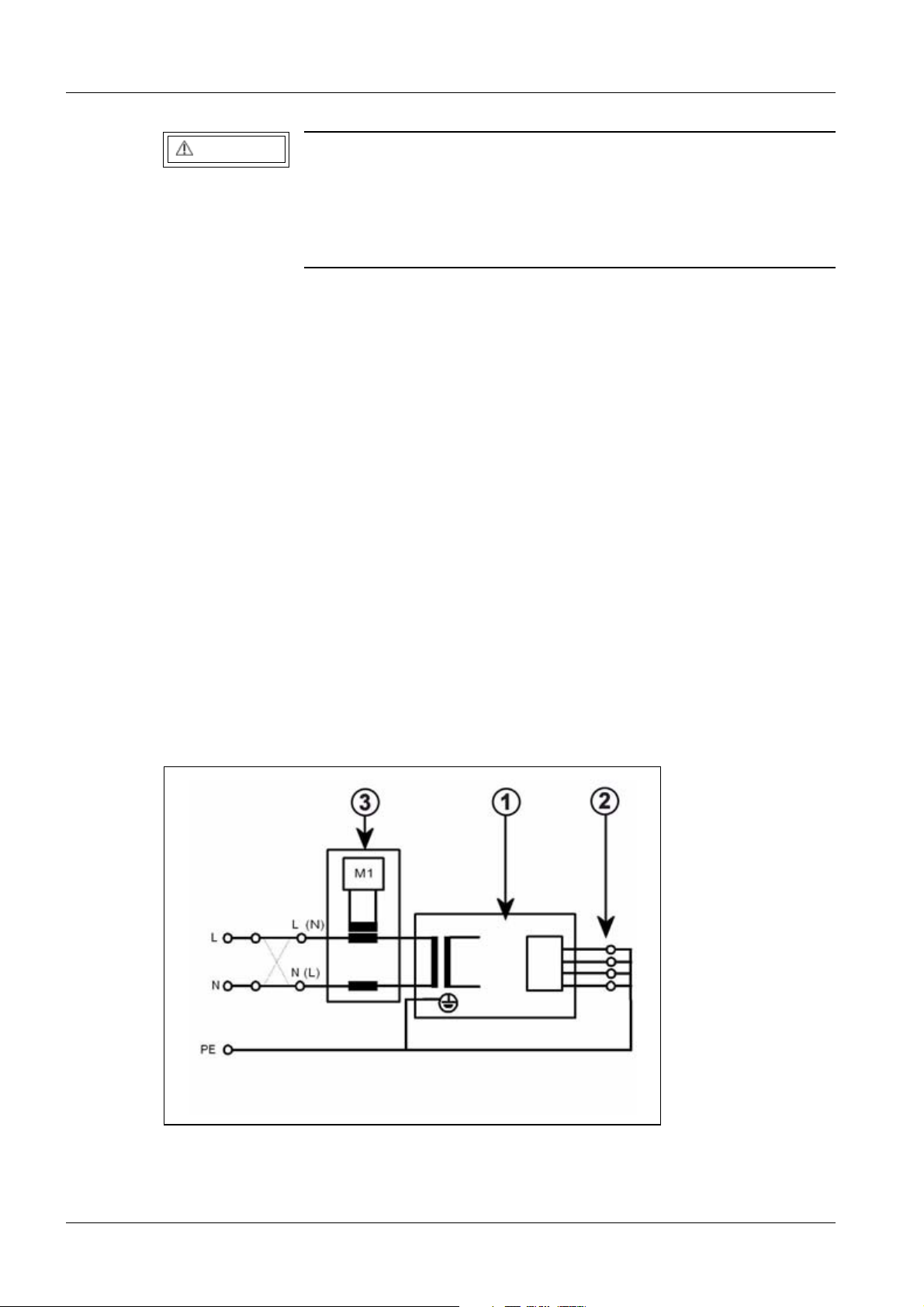

Fig. 1: Measuring circuit for measuring the protective conductor resistance for units that are

disconnected from power, in compliance with DIN VDE 0751-1/2001-10, Fig. C2.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 14 of 98

Medical Solutions

Page 15

Prerequisites 15

System leakage current measurement information 0

NOTE

If parts in the primary circuit (e.g. power cable, line filter, power

transformers, or complete ON/OFF assemblies) are replaced during service work, the system leakage current measurement must

be subsequently performed and recorded as a repeat measurement.

However, the first measured value must be newly determined and

a new protocol be must created under the following conditions:

- Lack of system leakage current measurement documentation.

- When local line voltage or line frequency deviates from the line

voltage and line frequency values documented in the protocol

(e.g., in the event of a site/operator change)

- When a different procedure for measuring the system leakage

current than the one documented in the protocol is used.

For the purpose of traceability, reference to the new protocol must

be written in the old protocol. The reason for newly determining

the first measured value must be documented and confirmed with

a name and signature.

Observe the instructions in the "Safety Rules for Installation and Repair"

(ARTD-002.731.17 ...).

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 15 of 98

Page 16

16 Prerequisites

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ The leakage current measurement may be performed on

systems of protection class I only after the protective

conductor test has been passed.

First measured value

The first measured value was already determined and documented in the system leakage

current protocol. The measuring procedure was also recorded.

The measurement was performed with the recorded line voltage, line frequency and with

the recorded measuring equipment.

Measurement

Perform the measurement according to DIN VDE 0751, Part 1 (see ARTD-002.731.17....),

and record the determined value.

The measuring procedure indicated in the protocol must be used.

If the first measured value has to be newly determined (see previous information), a measuring procedure can be selected (direct measurement or differential measurement).

Measurement of the system leakage current according to the differential current method

(measurement setup according to (Fig.2/p.16)) must be given preference, since this

method is not dangerous to the person performing the measurement and other persons.

However, please note the minimum resolution of the leakage current measuring instrument and any additional manufacturer's data restricting the use of the measuring device.

Fig. 2: Measuring circuit for measuring the system leakage current according to the differential

current method in compliance with DIN VDE 0751-1/2001-10, Fig. C6 for protection

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 16 of 98

Medical Solutions

Page 17

Prerequisites 17

class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

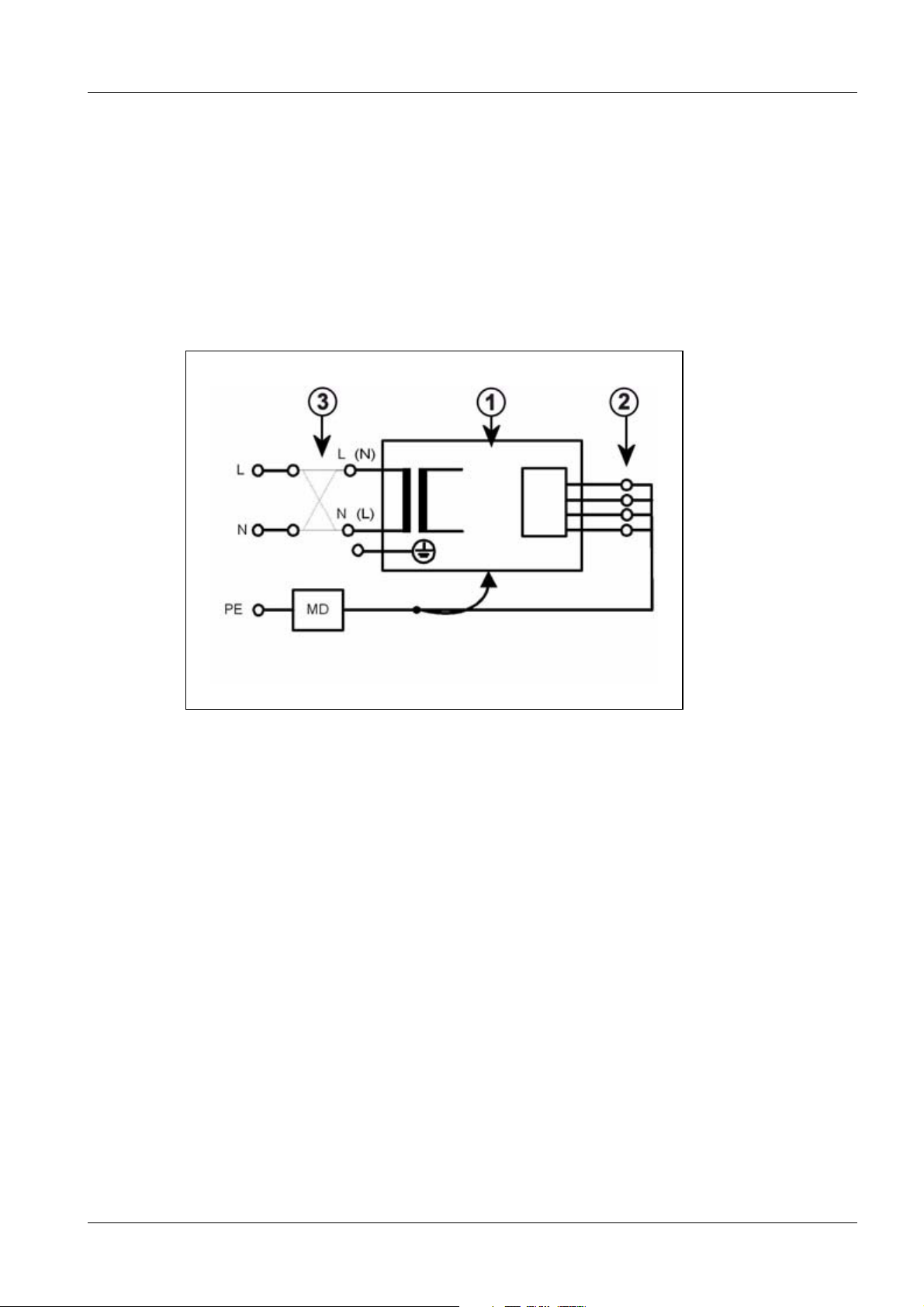

If the direct measurement of the system leakage current is used (measurement setup

according to (Fig.3/p.17)), the system must be insulated during the measurement and

must not be touched.

Fig. 3: Measuring circuit for direct measurement of the system leakage current in compliance

with DIN VDE 0751-1/2001-10, Fig. C5 for protection class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 17 of 98

Page 18

18 Prerequisites

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ No housing parts of the system may be touched during

direct measurement of the leakage current (measurement setup according to (Fig.3/p.17)).

¹ Third-person access to the system must be prevented.

The system must be switched on during measurement. Measuring devices with automated measuring sequences must therefore be set to manual measurement.

Enter the highest value in the system leakage current protocol.

This value must not exceed the permissible system leakage current values according to

DIN VDE 0751-1/2001-10, Table F.1, line "system leakage current for units according to

remarks 1 and 3" of 2.5 mA.

Do not exceed 2.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, correct the measured value to the value corresponding to a measurement at the nominal value of the line voltage. This must also be documented.

Document the measuring procedure (differential measurement or direct measurement)

and the measuring device used (designation and serial number).

In the case of repeat measurements, the measured value must also be evaluated.

NOTE

For evaluation purposes, the first measured value and the values

documented during maintenance or safety checks must be compared to the measured values. A sudden or unexpected increase

in the measured values may indicate that a fault has occurred in

the primary power supply circuit (insulation damage, damage

from moisture, defective interference suppressor, etc.) - even if

the limit value of 2.5 mA is not exceeded.

.

The evaluation is not necessary in the case of a new determination.

File the protocol sheet in the system binder or log book.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 18 of 98

Medical Solutions

Page 19

Prerequisites 19

Information on navigation systems installed as options 0

This ARCADIS system can be used in combination with navigation systems supplied by

various navigation system manufacturers.

The use of the navigation system lies within the responsibility of the customer.

Some service tasks can affect the accuracy of the navigation system.

WARNING

Service work steps that can affect the accuracy of the installed navigation system:

Some service work steps performed on the ARCADIS system will

lead to inaccuracy in a navigation system installed optionally.

Failure to take the necessary steps to address this situation can

lead to severe injuries in the patient.

¹ If service work steps are performed on the ARCADIS sys-

tem that can affect the accuracy of optionally installed

navigation systems (see list below), the customer must

be notified verbally and/or in writing that the accuracy of

the installed navigation system is no longer guaranteed

after such service work steps have been performed, and

that the accuracy of the navigation system must be

checked and certified before it is used again.

• All work steps that affect the geometry of the C-arm and its components, such as:

¹ Removing or installing the I.I.

¹ Removing or installing the I.I. housing

¹ Removing or installing the I.I. mounting ring on the I.I.

¹ Removing or installing the I.I. grid

¹ Removing or installing the I.I. optics

¹ Removing or installing the CCD camera

¹ Removing or installing any mechanical components of the C-arm

• Any adjustments that alter the geometry of the imaging components, such as:

¹ Adjustment of camera optics (optical sharpness, image size)

¹ Adjustment of camera rotation (positioning with respect to I.I. optics)

¹ Adjustment of I.I. geometry and sharpness (I.I. mini voltage supply)

• Any subsequent installation of released options that affect the geometry of the C-arm

and its components, such as:

¹ Integrated laser light localizer option (geometric alteration)

¹ I.I.laser light localizer option (weight alteration)

¹ 2D Navigation Option (Attachment of altered mounting ring to I.I.)

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 19 of 98

Page 20

20 Prerequisites

Cover panels 1.5

NOTE

Observe the safety information in this chapter!

Main system, rear cover 0

Removing the rear cover

1. Engage the foot brake.

2. Remove the screws from the rear cover.

3. Pull the cover back approximately 25 cm.

4. Unscrew the ground wire from the cover panel.

5. Pull the cover completely off and tilt it down.

6. Lift up the cover and raise both lateral metal brackets from the guide rails.

Installing the back cover

1. Fit the lateral metal brackets back into the guide rail.

2. Reattach the protective conductor to the rear cover.

3. Lift the cover and push it forward. Be careful with the EMC spring contact.

4. Reattach the cover and tighten the screws.

Main system, SIREPHOS cover panel 0

NOTE

1. Loosen the cover screws of the SIREPHOS cover.

2. Use a sharp knife to cut open the sealing compound all around the cover.

3. Lift off the SIREPHOS cover.

4. Remove the sealing compound residue from the cover and from the SIREPHOS.

5. On completing service, place the SIREPHOS cover on the SIREPHOS and completely

seal it with sealing compound.

6. Use a paper towel to wipe off excess sealing compound.

7. Once again, use sealing compound 2049716 to seal the SIREPHOS cover completely.

8. Refasten the SIREPHOS cover with the cover screws. If necessary, apply side pressure to the SIREPHOS cover until the sealing compound hardens.

The SIREPHOS cover panel is sealed all around against dirt contamination using a sealing compound (part no. 20 49 716).

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 20 of 98

Medical Solutions

Page 21

Prerequisites 21

Monitor trolley 0

Removing the cover panels

1. Remove the 4 screws from the middle back cover to access the imaging system (rear).

2. Remove the upper back cover plate of the log book compartment.

3. Remove the lower back cover to access the power supply.

4. Remove the front cover to access the imaging system (front).

Installing the cover panels

1. Install the covers in reverse order.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 21 of 98

Page 22

22 Prerequisites

Concluding steps 1.6

NOTE

Observe the guidelines on the protective conductor test and the

leakage current measurement in this chapter.

• If necessary, perform the leakage current measurement.

• After completing all work steps and closing all the cover panels, perform the protective

conductor test in accordance with ARTD-002.731.17...

¹ The protective conductor resistance must not exceed 0.2 Ohms.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 22 of 98

Medical Solutions

Page 23

Main System - Replacing Components 23

D1 control board 0

2- 2Main System - Replacin g Components

WARNING

Replacement and additional work steps 0

1. Make sure that a current backup of the main system is available.

2. Read out the load counter of the Sirephos (Path: <Service>-<Main System>-<Adjustment>-<Load Counter>).

3. Document this value because it is necessary for a Sirephos replacement. If the D1 is

defective, the load count is available in the offline report (path:<Service>-<Reports>-<Main System>-<Configuration Offline").

4. Disconnect and replace the D1 board.

Electrical voltage!

See chapter 1, Safety Information.

¹ Make sure that LED V400 on the D2 board is off prior to

performing any work on boards D1 and D2. This should

occur approximately 3 minutes after switching OFF the

ARCADIS system.

5. Install the new D1 board and reconnect all cable connections. Be sure that the shielding and ground wire connections are connected correctly.

6. Set the jumpers and switches according to the wiring diagram.

7. Perform the download procedure for the D1 control board (path: <Service>-<Main System> -<Download>-<C-Arm>).

NOTE

If the EE-PROM of the replacement D1 is not completely deleted, it

will be automatically cleared after the host software has been

downloaded. The delete procedure is indicated as "d" on the

7-segment display and requires approximately 5 minutes. During

the delete procedure, do not switch off the system or perform additional programming. After successful deletion, the 7-segment display returns to the normal status display.

8. After download, wait for the system to reboot.

NOTE

With software version VB11A, the system serial number (1xxxx)

must be entered and saved manually under <Main System>-<Configuration>-<Main System> before a restore of the main system is

carried out.

9. Restore the main system parameters (path: <Service>-<Backup & Restore> "Packages" - "Main System").

10. Perform a generator adjustment (path: <Service>-<Main System>-<Adjustment>-<Generator Adjust.>).

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 23 of 98

Page 24

24 Main System - Replacing Components

11. Check the dose rate control and adjust it as necessary (path: <Service>-<Main System>-<Adjustment>-<Dose rate>).

12. Ensure that camera rotation is functioning properly. Adjust, if necessary.

13. Ensure that the collimator is functioning properly. Adjust, if necessary.

14. Check the display functions and the setting of the blades on the monitor. Adjust, if necessary.

15. Ensure that the area dose measurement device (if present) is functioning correctly.

16. Test the FL/PFL/DR and direct exposure functions of the system.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 24 of 98

Medical Solutions

Page 25

Main System - Replacing Components 25

D2 power board 2.1

WARNING

1. Disconnect D1 and D2 boards completely.

2. Disconnect the cables between boards D1 and D2.

3. Remove boards D1 and D2.

4. Apply heat conducting paste to the heat sink for the power semiconductor on the new

D2 board.

5. Reinstall boards D2 and D1 and reattach all connections.

6. Ensure that the shielding and ground connections are positioned correctly.

7. Perform the kV offset adjustment and the generator adjustment (filament learning).

8. Test the FL/PFL/DR and direct exposure functions, if there is a cassette holder.

Electrical voltage!

See chapter 1, Safety Information.

¹ Make sure that LED V400 is off prior to performing any

work on boards D1 and D2. This should occur approximately 3 minutes after switching OFF the ARCADIS system.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 25 of 98

Page 26

26 Main System - Replacing Components

D3 interface board 2.2

WARNING

1. Replace the D3 interface board.

2. Check the +26.75 V voltage for the I.I. mini-voltage supply. Adjust it, if necessary. Refer

to chapter 3 of these instructions, Checking the Operating Voltages.

3. Check the radiation release/format switchover/vertical column movement functions.

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch system power supply off and disconnect the

power plug.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 26 of 98

Medical Solutions

Page 27

Main System - Replacing Components 27

D40 board for downward movement of the lifting column 2.3

WARNING

1. Replace the D40 board.

2. Using the operating instructions for the basic system, check both the movements of the

C-arm and the signal messages.

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch system power supply off and disconnect the

power plug.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 27 of 98

Page 28

28 Main System - Replacing Components

M14 power supply, +5 V/+15 V/-15 V 2.4

WARNING

1. Replace the power supply.

2. Check the power supply voltage and adjust it if necessary. Refer to chapter

(Voltages / p. 89).

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch the system power supply off and disconnect the

power plug.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 28 of 98

Medical Solutions

Page 29

Main System - Replacing Components 29

M13 power supply 230V/13V 2.5

WARNING

1. Replace the power supply.

2. Check the power supply voltage according to chapter (Voltages / p. 89).

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch the system power supply off and disconnect the

power plug.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 29 of 98

Page 30

30 Main System - Replacing Components

I.I. mini-voltage supply 2.6

WARNING

WARNING

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch the system power supply off and disconnect the

power plug.

Electrical voltage!

See chapter 1, Safety Information.

¹ Prior to removing the mini-voltage supply, the system

must be switched off for at least 3 minutes, until the high

voltage in the system and in the I.I. mini-voltage supply

dissipates.

Roederstein I.I. mini voltage supply 0

Fig. 4: I. I. mini-voltage supply

1. Remove the cylindric cover on the I.I..

2. Replace the I.I. mini-voltage supply (Fig.4/p.30).

3. Refer to the I.I. test certificate 1 for the E1/E2/E3 and A voltages. Check and adjust

them as necessary according to the "Voltages" chapter.

4. Check the functions and adjustments of the collimator. Readjust them, if necessary.

5. Check the display functions and the setting of the blades on the monitor. Adjust them, if

necessary.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 30 of 98

Medical Solutions

Page 31

Main System - Replacing Components 31

6. Check the overall resolution according to the IQ test.

7. Perform the IQ test.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Spellman I.I. mini voltage supply 0

Fig. 5: 9 inch / 23 cm I.I. with Spellman I.I. mini power supply

Pos. 1 Mounting screws

Pos. 2 Plugs E1 to E3, Penning and anode

Pos. 3 Ribbon cables

Pos. 4 DIP switches

Pos. 5 Test points

1. Remove the cover on the I.I.

2. Replace the I.I. mini-voltage supply.

3. Refer to the I.I. test certificate 1for the E1/E2/E3 and A voltages. Check and adjust them

as necessary according to the "Voltages" chapter.

4. Check the functions and adjustments of the collimator. Readjust them, if necessary.

5. Check the display functions and the setting of the blades on the monitor. Adjust them, if

necessary.

6. Check the overall resolution according to the IQ test.

7. Perform the IQ test.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 31 of 98

Page 32

32 Main System - Replacing Components

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 32 of 98

Medical Solutions

Page 33

Main System - Replacing Components 33

Collimator 2.7

1. Replace the collimator.

2. Ensure that the collimator is functioning properly and is set correctly. If necessary,

adjust it.

3. Ensure that the collimator blades of the iris diaphragm are visible during fluoroscopy in

survey format and zoom format on at least 2 sides of the monitor image.

4. Check collimation for direct exposure if a cassette holder is being used.

5. Check the display of the blades on the monitor and adjust it if necessary.

6. Remove the old set of collimator labels near the SIREPHOS and attach the included

new labels in the same position.

7. Check that the original collimator labels are the same as the new ones.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 33 of 98

Page 34

34 Main System - Replacing Components

Exchanging the SIREPHOS 2.8

1. Read out and note the number of resets and the current load counts from the SIREPHOS tank. Path: <Service>-<Main System>-<Adjustment>-<Load Counter>.

2. Open the SIREPHOS cover. See chapter 1, (Cover panels / p. 20).

3. Remove the laser targeting device, if present.

4. Remove the dose measurement chamber, if present.

5. Remove the collimator.

6. Disconnect the SIREPHOS plug.

7. Remove the ground screw for the protective conductor.

8. Remove the rubber stop of the C-arm on the SIREPHOS side. The screws that secure

the SIREPHOS are now visible.

9. Remove the SIREPHOS screws. When doing this, have a second person hold the

X-ray tube unit.

10. Place the new X-ray tube unit on the guide bolts and secure it with the two Allen screws.

11. Ensure that all cables are routed properly.

12. Reconnect the SIREPHOS plug and secure it.

13. Reconnect the protective conductor using the ground screw.

14. Do not install the rubber stop yet.

15. Reinstall the collimator and connect it.

16. Reinstall the dose measurement chamber/laser targeting device and connect them.

WARNING

17. Enter the new serial no. of the new single tank. Path: <Service>-<Main System>-<Configuration>-<Load <Counter>.

X 18. Adjust the generator. Path: <Service>-<Main System>-<Adjustment>-<Generator

Adjustment>.

19. Reset the load counter. Path: <Service>-<Main System>-<Adjustment>-<Load

<Counter>.

20. Ensure that the collimator is functioning properly and is set correctly.

21. Ensure that the collimator blades are centered in the blanking circle.

X-ray radiation!

See chapter 1, Safety Information.

¹ Protect against radiation exposure. Wear a lead apron.

22. If possible, loosen the Sirephos screws slightly and tilt the SIREPHOS to adjust it.

23. Retighten the SIREPHOS screws.

24. Ensure that the collimator blades of the iris diaphragm are visible during fluoroscopy in

the survey format and zoom format on at least 2 sides of the monitor image.

25. Check the display of the blades on the monitor screen and adjust it as necessary.

26. Check collimation for direct exposure if there is a cassette holder.

27. Reinstall the rubber stop.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 34 of 98

Medical Solutions

Page 35

Main System - Replacing Components 35

28. Ensure that the area/dose product measurement device is functioning properly (if

present).

29. Check the setting of the laser targeting device and adjust it as necessary according to

the Adjustment Instructions for the Laser Targeting Device, RXR2-130.815.01.

30. Reattach the SIREPHOS cover.

31. Seal the SIREPHOS cover using sealing compound. See chapter 1, (Cover

panels / p. 20).

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 35 of 98

Page 36

36 Main System - Replacing Components

Replacing the camera and the I.I. optics (camera version ≥ 2.0) 2.9

Relevant systems: ARCADIS Varic system serial no. 10218, 10219, 10222 and systems

with serial no. > 10223; camera version ≥ 2.0 (see ID label).

Fig. 6: II _ Connection

Fig. 7: Replacing the camera and I.I. optics

Removing/replacing the camera 0

1. Switch the system off.

2. Remove the upper I.I. cover (already removed in (Fig.6/p.36)).

3. Unplug the connectors (1/Fig.6/p.36), (2/Fig.6/p.36) and disconnect the fan wires

(3/Fig.6/p.36).

4. Loosen the clamping screw (1/Fig.7/p.36).

5. Rotate the clamping ring (2/Fig.7/p.36)a half rotation in the counterclockwise direc-

tion to loosen the camera. For this purpose, insert an Allen key (2.5 mm) into the hole

(2/Fig.7/p.36) and push the clamping ring in the counterclockwise direction.

6. Remove the 3 Allen screws (3/Fig.7/p.36).

7. Turn the entire camera (4/Fig.6/p.36) counterclockwise until it is no longer attached.

For subsequent reinstallation, count the number of turns when removing the camera.

The connector (2/Fig.6/p.36) should be in the position shown in (Fig.6/p.36).

8. Install the (new) camera in reverse order.

9. Adjust the camera and I.I. optics.

10. Perform the IQ test.

11. Complete the country-specific acceptance (§16 partial acceptance... /DHHS...).

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 36 of 98

Medical Solutions

Page 37

Main System - Replacing Components 37

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Removing/replacing the I.I. optics 0

Prerequisites: Camera must already be removed.

1. Remove the 3 M4 screws (4/Fig.7/p.36).

2. Remove the I.I. optics.

3. Install the (new) optics and camera in reverse order.

¹ When screwing in the 3 M4 screws (4/Fig.7/p.36), make sure that the optic is

pressed against the centering bolts.

4. Adjust the camera and I.I. optics.

5. Perform the IQ test.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 37 of 98

Page 38

38 Main System - Replacing Components

Adjusting the camera and I.I. optics (camera version ≥ 2.0) 2.10

Relevant systems: ARCADIS Varic system serial no. 10218, 10219, 10222 and systems

with serial no. >10223; camera version ≥ 2.0 (see ID label).

Fig. 8: Adjusting the camera

Centering the camera 0

NOTE

WARNING

The camera can be centered by moving the optics. Centering is

performed in the factory and should be acceptable. The camera

optics must be moved toward the centering bolts.

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Reproduction scale adjustment 0

Prerequisites: Camera centering should be OK.

1. Loosen the clamping screw (4/Fig.8/p.38).

2. Loosen the lock ring (5/Fig.8/p.38).

3. Unplug the connectors (1/Fig.6/p.36), (2/Fig.6/p.36) and disconnect the fan wires

(3/Fig.6/p.36).

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 38 of 98

Medical Solutions

Page 39

Main System - Replacing Components 39

4. Remove the 3 Allen screws from the camera flange (1/Fig.8/p.38).

5. You can increase/decrease the image size by turning the entire camera. The camera

plugs must not be in the same position.

¹ Turn clockwise = larger image

¹ Turn counterclockwise = smaller image

T 6. Rotate the camera until the plugs are at the same location as prior to the adjustment

and retighten the 3 M2 Allen screws (1/Fig.8/p.38).

¹ Tightening torque 14 ± 1Ncm

7. Tighten the lock ring (5/Fig.8/p.38).

8. Retighten the clamping screw (4/Fig.8/p.38).

9. Reattach the connectors (1/Fig.6/p.36), (2/Fig.6/p.36) and the fan wires

(3/Fig.6/p.36).

X 10. Release fluoro and check the image size. Repeat the adjustment if necessary.

11. Open the service application and adjust the 0 degree position of the image.

Path: <Service>-<Main System>-<Adjustment>-<Image Rotation>.

12. Perform the IQ test.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Camera focus 0

Prerequisites: Camera reproduction scale should be OK.

1. Loosen the focus ring clamping screw (2/Fig.8/p.38).

2. You can adjust the optimum sharpness by turning the focus ring (3/Fig.8/p.38).

X 3. Release fluoro and check the sharpness. Repeat the adjustment if necessary.

4. Retighten the focus clamping screw (2/Fig.8/p.38).

5. Perform the IQ test.

NOTE

Adjusting the camera focus also has a slight effect on the reproduction scale. The reproduction scale adjustment may have to be

repeated.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 39 of 98

Page 40

40 Main System - Replacing Components

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 40 of 98

Medical Solutions

Page 41

Main System - Replacing Components 41

Replacing the camera and the I.I. optics (camera version < 2.0) 2.11

Relevant systems: ARCADIS Varic serial no. < 10218 and 10220, 10221, 10223; or the

camera was already replaced with the new camera version ≥ 2.0 (see ID label).

Fig. 9: Replacing the camera and the I. I. optics_1

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 41 of 98

Page 42

42 Main System - Replacing Components

Fig. 10: Replacing the camera and the I. I. optics_2

Removing/replacing the camera 0

1. Remove the I.I. cover (already removed in (Fig.9/p.41)).

2. Unplug the connectors (1/Fig.9/p.41), (2/Fig.9/p.41) and disconnect the fan wires

(3/Fig.9/p.41).

3. Loosen the clamping screw (4/Fig. 10 / p. 42).

4. Rotate the clamping ring (5/Fig. 10 / p. 42) a half rotation in the counterclockwise direc-

tion to loosen the camera. For this purpose, insert an Allen wrench (2.5 mm) into the

hole (5/Fig. 10 / p. 42) and push the clamping ring in the counterclockwise direction.

5. Turn the entire camera (4/Fig.9/p.41) counterclockwise until it is no longer attached.

For subsequent reinstallation, count the number of turns when removing the camera.

The connector (2/Fig.9/p.41) should be in the position shown in (Fig.9/p.41).

6. Install the (new) camera in reverse order.

7. Adjust the camera and I.I. optics.

8. Perform the IQ test.

9. Complete the country-specific acceptance (§16 partial acceptance... /DHHS...).

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 42 of 98

Medical Solutions

Page 43

Main System - Replacing Components 43

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Removing/replacing the I.I. optics 0

Prerequisites: Camera must already be removed.

1. Remove the 3 M4 screws (1/Fig. 10 / p. 42).

2. Remove the I.I. optics.

3. Install the (new) optics and camera in reverse order.

4. Adjust the camera and I.I. optics.

5. Perform the IQ test.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 43 of 98

Page 44

44 Main System - Replacing Components

Adjusting the camera and I. I. optics (camera version < 2.0) 2.12

Relevant systems: ARCADIS Varic serial no. < 10218 and 10220, 10221, 10223; or the

camera was already replaced with the new camera version ≥ 2.0 (see ID label).

Fig. 11: Replacing the camera and the I. I. optics_2

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 44 of 98

Medical Solutions

Page 45

Main System - Replacing Components 45

Fig. 12: Monitor orientation

Centering the camera 0

NOTE

WARNING

The camera can be centered by moving the optics. Centering is

performed in the factory and should be acceptable. The camera

optics must be moved toward the centering bolts.

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Reproduction scale adjustment 0

Prerequisites: Camera centering should be OK.

1. Loosen the clamping screw (4/Fig. 11 / p. 44).

2. Loosen the lock ring (5/Fig. 11 / p. 44).

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 45 of 98

Page 46

46 Main System - Replacing Components

3. Unplug the connectors (1/Fig.9/p.41), (2/Fig.9/p.41) and disconnect the fan wires

(3/Fig.9/p.41).

4. You can increase/decrease the image by turning the entire camera (Fig. 12 / p. 45).

Always turn it a full turn because the camera plugs should be in the same position.

¹ Turn clockwise = larger image

¹ Turn counterclockwise = smaller image

5. Reattach the connectors (1/Fig.9/p.41), (2/Fig.9/p.41) and the fan wires

(3/Fig.9/p.41).

6. Release fluoro and check the image size. Repeat the adjustment if necessary.

7. Retighten the clamping screw (4/Fig. 11 / p. 44).

8. Open the service application and adjust the 0-degree position of the image.

Path: <Service>-<Main System>-<Adjustment>-<Image Rotation>.

9. Perform the IQ test.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Camera focus 0

Prerequisites: Camera centering and camera reproduction scale should be OK.

1. Loosen the focus ring clamping screw (2/Fig. 11 / p. 44).

2. You can adjust the optimum sharpness by turning the focus ring (3/Fig. 11 / p. 44).

X 3. Release fluoro and check the sharpness. Repeat the adjustment if necessary.

4. Retighten the focus clamping screw (2/Fig. 11 / p. 44).

5. Perform the IQ test.

NOTE

Adjusting the camera focus also has a slight effect on the reproduction scale. The reproduction scale adjustment may have to be

repeated.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 46 of 98

Medical Solutions

Page 47

Main System - Replacing Components 47

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 47 of 98

Page 48

48 Main System - Replacing Components

Replacing the I. I. 2.13

Checking the temperature indicator of the new I.I. 0

1. Prior to removing the I.I., check the temperature indicator of the new I. I.

2. If the inner square field of the indicator is white, the I.I. did not exceed the temperature

range. Remove the temperature indicator.

3. If the indicator is discolored (inner field black), proceed according to IQ document

RXD-000.038.01.

Removing the I.I. 0

Fig. 13: Removing_the I. I.

CAUTION

1. Rotate the C-arm so that the I.I. is on top.

2. Remove the I. I. cover (see (1/Fig. 13 / p. 48)) and unsolder the cassette switch.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

Electrical voltage!

See chapter 1, Safety Information.

¹ Switch OFF the ARCADIS system and wait approximately

3 minutes for the voltage in the I.I. mini-voltage supply to

drop.

Page 48 of 98

08.07 CS PS SP

Medical Solutions

Page 49

Main System - Replacing Components 49

3. Disconnect all cables from the camera.

4. Remove the I.I. optics (incl. camera) refer to "Removing the I.I. Optics"

NOTE

Do not loosen the eccentric screws on the edge of the optics!

These are used to center the optics with respect to the I.I. output

screen. When removing the optics, make sure that no dust or dirt

contaminates the I.I. output window or the optics.

5. Disconnect the cables from the I.I. mini-power supply.

6. Rotate the C-arm so that the I. I. is underneath and the tube assembly is on top.

CAUTION

Risk of crushing!

See chapter 1, Safety Information.

¹ Apply all C-arm brakes.

7. Remove the attachment screws from the I.I. mounting. When doing this, hold onto the

I.I. Remove the I.I. from the mounting.

8. Remove and disconnect the mini-power supply from the I. I.

Installing the new I.I. 0

NOTE

When installing the optics make sure that no dust or dirt contaminates the I.I. output window or the optics.

1. Install and connect the mini-power supply.

2. Install (new) I. I., optic and camera in reverse order.

3. Connect the camera cables in reverse order.

Checks and adjustments 0

1. Check the I.I. electrode voltages according to the test protocol for the I.I.

2. Do not readjust in cases where there are only slight deviations from the values on the

test protocol (measurement device tolerances).

3. Check the centering, reproduction scale and camera focusing. Refer to the previous

description "Adjusting the Camera and I. I.Optics".

4. Check the setting of the X-iris and readjust it as necessary.

5. Check the display of the blades on the monitor and readjust it if necessary.

6. Check the dose rate and readjust it if necessary.

7. Perform the IQ test. Check the resolution first and readjust the optical resolution of the

I.I. optics if necessary. Refer to the previous description "Adjusting the Camera and I.I.

Optics".

8. Complete the country-specific acceptance (§16 partial acceptance... /DHHS...).

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 49 of 98

Page 50

50 Main System - Replacing Components

9. Solder the 2 wires to the cassette switch and remount the I. I. cover.

WARNING

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 50 of 98

Medical Solutions

Page 51

Main System - Replacing Components 51

Dose area product measuring device 2.14

1. Switch the system off.

2. Remove the single-tank cover.

3. Replace the dose area product measuring device.

4. Open the local service and select <Main System>-<Adjustment>-<DAP/Air Kerma>

and check the accuracy of the dose area product measuring device.

¹ Perform a DAP accuracy check if DAP display is configured on the monitor.

¹ Perform an Air Kerma accuracy check if Air Kerma display is configured on the

monitor.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 51 of 98

Page 52

52 Main System - Replacing Components

Laser targeting device (SIREPHOS-side) 2.15

CAUTION

1. Remove the SIREPHOS cover. See chapter (Cover panels / p. 20).

2. Replace the laser diodes after removing the bracket and unsolder the wires.

3. Adjust the laser diodes using the adjustment device supplied with the laser targeting

device.

4. Reattach the SIREPHOS cover.

5. Seal the SIREPHOS cover using sealing compound. See chapter 1.

Laser emissions!

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ Do not look directly into the laser beam!

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 52 of 98

Medical Solutions

Page 53

Main System - Replacing Components 53

Integrated Laser light localizer (I.I. -side) 2.16

CAUTION

1. Remove the I.I. ring at the I.I. input screen.

2. Remove the integrated I.I. laser light localizer and disconnect the small voltage plug,

after removing the I.I. ring.

3. Remove the grid from the defective integrated I.I. laser light localizer and insert it at the

new integrated I.I. laser light localizer .

4. Connect the voltage plug of the new integrated I.I. laser light localizer to the voltage

plug of the I.I.

5. Attach the laser light localizer including the grid and the I.I. ring to the I.I. and fasten it

with the screws.

6. Adjust the laser diode beams to the center point of the single tank. The I.I. should be on

top, the SIREPHOS should be at the bottom, the C-arm angulation should be in the 0

degree position.

WARNING

Laser emissions!

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ Do not look directly into the laser beam!

When these service tasks have been performed, the accuracy of

an optionally installed navigation system is no longer guaranteed.

See the chapter "Prerequisites," section "Safety information and

protective measures."

¹ If an optionally installed navigation system is present,

the customer must be notified that the accuracy of the

installed navigation system is no longer guaranteed, and

that the navigation system must be checked and certified

before it is used again.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 53 of 98

Page 54

54 Main System - Replacing Components

Replacing the C-arm rollers 2.17

CAUTION

Prerequisite:

- 2 persons for moving the C-arm in and out.

- Table with sufficient stability for holding the C-arm.

- Complete set of rollers (4 single rollers and 1 roller support).

Risk of crushing!

Risk of minor to medium physical injuries.

¹ As soon as the C-arm is relieved, the unit tilts easily to

the rear.

¹ Before the C-arm is relieved, secure the basic unit

against tilting to the rear.

Securing the basic unit against tilting 0

1. Push a wooden block or other stable object of sufficient height under the middle of the

basic unit (1/Fig. 14 / p. 54).

Fig. 14: Securing the basic unit

ARCADIS Varic SPR2-310.841.01.07.02 Siemens AG

08.07 CS PS SP

Page 54 of 98

Medical Solutions

Page 55

Main System - Replacing Components 55

Set the C-arm and lifting column to the working position 0

1. The ARCADIS is plugged into the mains and switched on for a short time.

2. Move the vertical lifting column into its highest position.

3. Switch the ARCADIS system off and separate it from the mains by pulling out the mains

plug.

4. Remove the SIREPHOS cover.

5. Remove the covers (3/Fig. 14 / p. 54) of the C-arm support.

6. Unscrew the cable holder on the C-arm support (2/Fig. 14 / p. 54).

7. Turn the C-arm to +90 degrees or -90 degrees; the C-arm is horizontal as shown in

(Fig. 14 / p. 54).

8. Plug the system into the mains and switch it on for a short time.

9. Position the C-arm over a table with sufficient stability.

10. Move the vertical lifting column so that the C-arm including the image intensifier and

SIREPHOS rest lightly on the table.

11. Switch system off and separate it from the mains. Pull out the mains plug.

Removing the SIREPHOS 0

1. Apply the angulation brake and the orbital brake of the C-arm.

2. Remove the end stop (rubber buffer) on the SIREPHOS side. The bolt with the mounting screws of the SIREPHOS is visible.

3. Remove all connection cables from the C-arm cable to the SIREPHOS.

4. Remove all connection cables to the collimator.

5. If a laser targeting device is present, unsolder the cables.

6. If a DIAMENTOR is present, disconnect the cable from the dose measuring chamber.

7. The image intensifier and C-arm must rest on the table.

8. One person holds the SIREPHOS, while the second person loosens the mounting

screws of the SIREPHOS.

9. Remove the SIREPHOS from the table and set it on a suitable base.

Removing the C-arm 0

1. The C-arm can now be turned completely out of the C-arm support.

2. Make sure that the image intensifier and C-arm always remain on the table.

3. All rollers are now accessible.

Siemens AG SPR2-310.841.01.07.02 ARCADIS Varic

Medical Solutions

08.07 CS PS SP

Page 55 of 98

Page 56

56 Main System - Replacing Components

Replacing the rollers and reinstalling the C-arm 0

1. Replace the 4 rollers for lateral guidance. To do this, remove the locking ring, replace

the rollers and refit the locking ring.

2. Replace the complete roller support .

3. Then thread the C-arm between the inner and outer rollers.

4. Mount the SIREPHOS back on the C-arm using Allen screws. Be careful not to crush

the cables.

5. Fasten the protective ground wire back to the SIREPHOS.

6. Reinstall all cable connections to the SIREPHOS, collimator and possibly available

laser targeting device and Diamentor ionization chamber options.

7. Plug the system into the mains and switch it on for a short time.

8. Move the vertical lifting column out completely and remove the table.

9. Switch the system off and separate it from the mains. Pull out the mains plug.

10. Remove the wooden block.

11. Fasten the cable holder of the C-arm cable back to the C-arm support.

Attaching the covers 0

1. Once again, use sealing compound 2049716 to seal the SIREPHOS cover completely.

2. Refit the SIREPHOS cover. If necessary, apply side pressure to the SIREPHOS cover

until the sealing compound hardens.

3. Refit the rubber buffer (orbital movement end stop) on the SIREPHOS side.

4. Refit the lateral covers of the C-arm support.

5. Refit the rear cover of the basic unit. Make sure the protective ground wire makes good

contact.

6. Refit any other removed covers and make sure that the protective ground wires are in

good contact.

Checks 0

1. Check the orbital movement in the vertical and horizontal angulation position of the

C-arm.

2. Check the orbital movement forces in an unbraked and braked condition according to

the service instructions.

3. Plug the ARCADIS system into the mains and switch it on.

4. Check the collimator settings (iris diaphragm and slot diaphragms) according to the service instructions.

5. If a cassette holder is present, check the cassette exposure collimation.

6. If a laser targeting device is present, check the function of the laser targeting device.