Page 1

SIMOTION

CamTool

Configuration Manual

Preface

Description

Installing the Software

Configuring

Functions

1

2

3

4

12.2004

6AU1900-1AB32-0BA0

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Attention

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Copyright Siemens AG 2004. All rights reserved.

The distribution and duplication of this document or the utiliz ation and transmission of its

contents are not permitted without express written permission. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of a utility

model or design, are reserved.

Siemens AG

Automation and Drives

Postfach 4848, 90327 Nuremberg, Germany

Siemens Aktiengesellschaft 6AU1900-1AB32-0BA0

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the

hardware and software described. Since variance cannot be precluded entirely, we cannot

guarantee full consistency. However, the information in this publication is reviewed

regularly and any necessary corrections are included in subsequent editions.

Siemens AG 2004

Technical data subject to change

Page 3

Preface

Contents of manual

The accompanying manual describes the SIMOTION CamTool option package.

The document is part of the SIMOTION Engineering System documentation package with

order number: 6AU1900-1AB32-0BA0, Edition 12.2004

Scope

The accompanying manual applies to SIMOTION SCOUT in conjunction with the

SIMOTION CamTool option package.

Standards

The SIMOTION system was developed in accordance with the ISO 9001 quality guidelines.

Information blocks:

The following is a description of the purpose and use of the product manual.

• Description chapter

• Installation chapter

• Configuration chapter

• Functions chapter

This chapter provides a short overview of the basic functions of the SIMOTION CamTool

and the inclusion in SIMOTION SCOUT.

This chapter describes how the SIMOTION CamTool is installed and which prerequisites

must be satisfied to allow the use of SIMOTION CamTool.

This chapter describes the basic functions of SIMOTION CamTool. It shows you how to

process cams with CamTool.

In this chapter you learn how to create a cam with CamTool.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

iii

Page 4

Preface

SIMOTION documentation

An overview of the SIMOTION documentation is provided in a separate list of references.

The list of references is supplied on the "SIMOTION SCOUT" CD and is included in each

print copy order of the documentation package.

The list of references can be obtained separately under the following MLFB number:

Order no.: 6AU1900-1AA32-0BA0

Edition 12.2004

SIMOTION documentation consists of 10 documentation packages containing approximately

50 SIMOTION documents and documents on other products (e.g., SINAMICS).

The following documentation packages are available for SIMOTION V3.2:

• SIMOTION Engineering System

• SIMOTION System and Function Descriptions

• SIMOTION Diagnostics

• SIMOTION Programming

• SIMOTION Programming - Reference Lists

Hotline

• SIMOTION C230

• SIMOTION P350

• SIMOTION D4xx (incl. SINAMICS S120)

• SIMOTION Supplementary Documentation

• SIMOTION Function Library

If you have any questions, please contact our hotline (worldwide):

• A & D Technical Support: Phone: +49 (180) 50 50 222

• Fax: +49 (180) 50 50 223

• E-mail: ad.support@siemens.com

If you have any questions, suggestions, or corrections regarding the documentation, please

fax or e-mail them to the following:

• Fax: +49 (9131) 98 2176

• E-mail: motioncontrol.docu@erlf.siemens.de

• Fax form: refer to the reply form at the end of the document

CamTool

iv Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 5

Preface

Additional support

We also offer introductory courses to help you familiarize yourself with SIMOTION.

Please contact your regional training center or our main training center at D-90027

Nuremberg/Germany, phone +49 (911) 895 3202.

Siemens Internet address

The latest information on SIMOTION products can be found on the Internet at:

General information http://www.siemens.com/simotion

Technical information http://www4.ad.siemens.de/view/cs/de/10805438

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

v

Page 6

Page 7

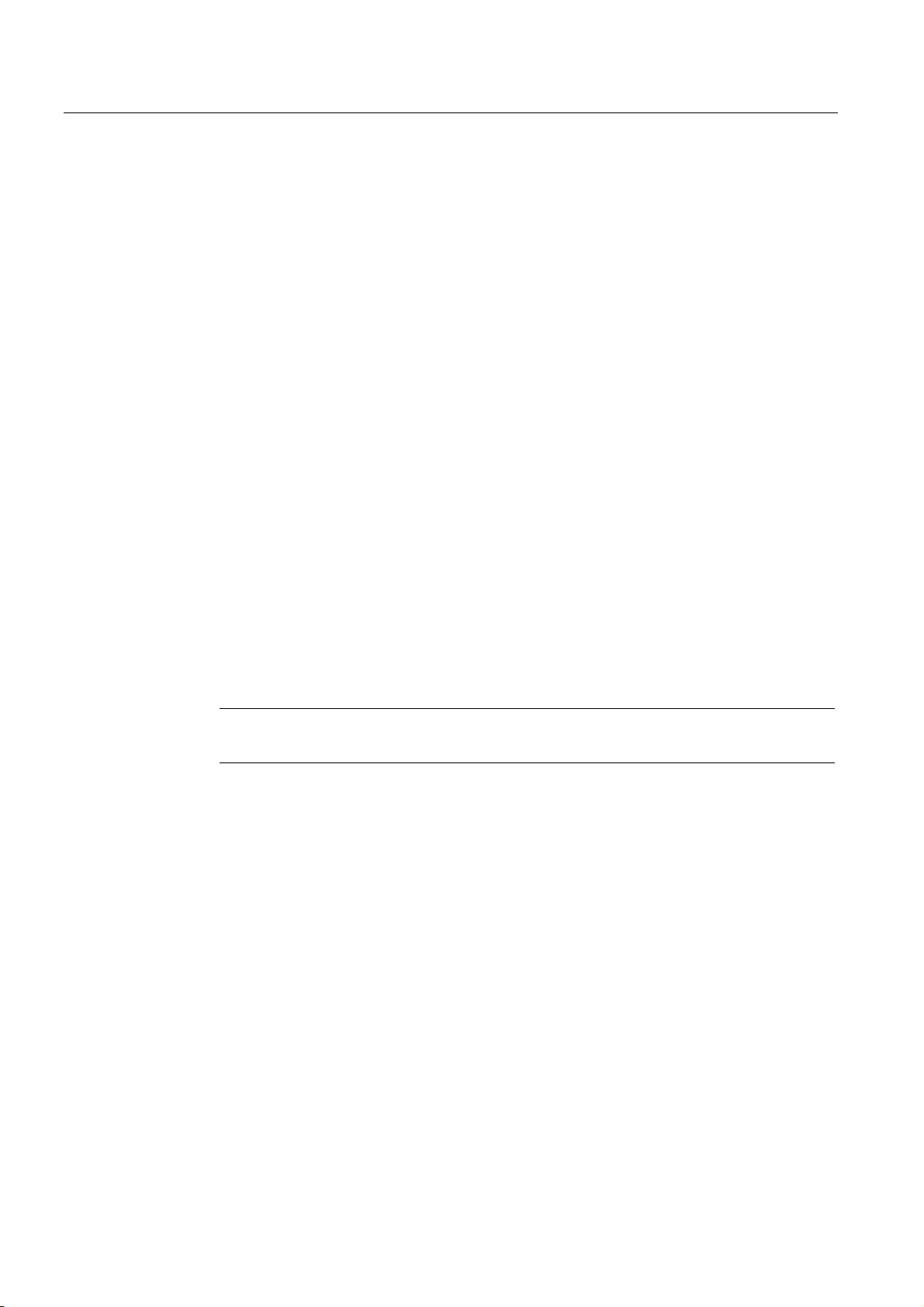

Table of contents

Preface ...................................................................................................................................................... iii

1 Description.............................................................................................................................................. 1-1

2 Installing the Software ............................................................................................................................ 2-1

2.1 Installing SIMOTION CamTool .................................................................................................. 2-1

2.2 Deinstalling SIMOTION CamTool ..............................................................................................2-2

3 Configuring ............................................................................................................................................. 3-1

3.1 Content....................................................................................................................................... 3-1

3.2 Customizing the Working Area Display ..................................................................................... 3-2

3.2.1 Changing the representation using the toolbar.......................................................................... 3-2

3.2.2 Maximizing working area ........................................................................................................... 3-4

3.3 Editing a Cam with CamTool ..................................................................................................... 3-5

3.3.1 Content....................................................................................................................................... 3-5

3.3.2 Adding a cam to a SCOUT project using CamTool ................................................................... 3-5

3.3.3 Edit cam created with CamEdit with CamTool........................................................................... 3-7

3.3.4 Import cam from text file .......................................................................................................... 3-10

3.3.5 Upload cam from SIMOTION device ....................................................................................... 3-12

3.4 Save cam ................................................................................................................................. 3-15

3.5 Customize the display of the cam ............................................................................................ 3-16

3.5.1 Display the cam ....................................................................................................................... 3-16

3.5.2 Show/hide diagram .................................................................................................................. 3-16

3.5.3 Change axis representation parameters.................................................................................. 3-17

3.5.4 Change diagram representation parameters ........................................................................... 3-20

3.5.5 Change lines and fonts representation parameters................................................................. 3-22

3.5.6 Displaying auxiliary lines in the diagram.................................................................................. 3-24

3.6 Download cam to SIMOTION device ....................................................................................... 3-26

4 Functions................................................................................................................................................ 4-1

4.1 Content....................................................................................................................................... 4-1

4.2 Structure of a cam...................................................................................................................... 4-2

4.3 Fixed point.................................................................................................................................. 4-3

4.3.1 Fixed Point Definition ................................................................................................................. 4-3

4.3.2 Insert fixed point......................................................................................................................... 4-3

4.3.3 Change fixed point position........................................................................................................ 4-5

4.3.4 Changing the velocity at the position of a fixed point: ............................................................... 4-5

4.3.5 Changing the acceleration at a fixed point position: .................................................................. 4-6

4.3.6 Delete fixed point ....................................................................................................................... 4-7

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

vii

Page 8

Table of contents

4.4 Straight line ................................................................................................................................ 4-7

4.4.1 Definition straight line................................................................................................................. 4-7

4.4.2 Insert straight line....................................................................................................................... 4-8

4.4.3 Change straight line position...................................................................................................... 4-9

4.4.4 Changing the velocity along a straight line .............................................................................. 4-10

4.4.5 Delete straight line ................................................................................................................... 4-11

4.5 Sine curve ................................................................................................................................ 4-11

4.5.1 Insert sine curve....................................................................................................................... 4-11

4.5.2 Change sine curve position...................................................................................................... 4-13

4.5.3 Change sine curve definition range ......................................................................................... 4-14

4.5.4 Delete sine curve ..................................................................................................................... 4-15

4.6 Arc Sine Curve ......................................................................................................................... 4-15

4.6.1 Insert arc sine curve................................................................................................................. 4-15

4.6.2 Change arc sine curve position................................................................................................ 4-17

4.6.3 Change arc sine curve definition range ................................................................................... 4-18

4.6.4 Delete arc sine curve ............................................................................................................... 4-19

4.7 Interpolation point..................................................................................................................... 4-20

4.7.1 Interpolation Point Definition .................................................................................................... 4-20

4.7.2 Insert interpolation point........................................................................................................... 4-20

4.7.3 Changing the interpolation point position................................................................................. 4-21

4.7.4 Delete interpolation point ......................................................................................................... 4-22

4.8 Optimizing a Cam..................................................................................................................... 4-23

4.8.1 Optimizing a Cam..................................................................................................................... 4-23

4.8.2 Optimize transition ................................................................................................................... 4-24

4.8.3 Interpolation Curve properties.................................................................................................. 4-26

4.9 Specify parameters for target device ....................................................................................... 4-30

4.9.1 Specify parameters for target device ....................................................................................... 4-30

4.9.2 Target device parameters ........................................................................................................ 4-31

4.10 Specify simulation settings....................................................................................................... 4-35

4.10.1 Specify simulation settings....................................................................................................... 4-35

4.10.2 Simulation settings ................................................................................................................... 4-36

4.11 Edit cam created with CamTool with CamEdit......................................................................... 4-38

4.12 Export cam as text file .............................................................................................................. 4-38

4.13 Print cam .................................................................................................................................. 4-39

Index

Tables

Table 2-1

Table 3-1 SIMOTION CamTool toolbar icons ............................................................................................ 3-2

Table 3-2 Parameters in the Master Properties or S Diagram (Slave) Properties................................... 3-18

Table 3-3 Parameters for the V, A or J Diagram Properties windows ..................................................... 3-21

SIMOTION CamTool system requirements ............................................................................... 2-1

Table 3-4 Representation parameters in the diagrams............................................................................ 3-23

Table 3-5 Parameters in the Line tab ....................................................................................................... 3-23

Table 3-6 Parameters in the Font tab....................................................................................................... 3-24

CamTool

viii Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 9

Table of contents

Table 4-1 Parameters in the Type tab (Interpolation Curve Properties window) ..................................... 4-26

Table 4-2 Parameters in the Parameters tab (Interpolation Curve Properties window) .......................... 4-27

Table 4-3 Parameters in the Type tab (Interpolation Curve Properties window) ..................................... 4-28

Table 4-4 Parameters in the Coordinates tab (Target Device Parameters window) ............................... 4-31

Table 4-5 Parameters in the Interpolation tab (Target Device Parameters window) ............................... 4-32

Table 4-6 Parameters in the Scaling tab (Target Device Parameters window)....................................... 4-33

Table 4-7 Parameters in the Master tab (Simulation Settings window) ................................................... 4-36

Table 4-8 Parameters in the Slave tab (Simulation Settings window) ..................................................... 4-37

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

ix

Page 10

Page 11

Description

Introduction

The graphical user interface in SIMOTION CamTool allows you to create, edit and optimize

cams.

SIMOTION CamTool is fully integrated in SIMOTION SCOUT. This allows you to also use in

SIMOTION CamTool information configured in SIMOTION SCOUT (e.g. axis settings).

Basic functions

SIMOTION CamTool provides the following basic functions:

• Insert and edit cams.

• Modifying the representation of the cam in CamTool

• Converting cams from SIMOTION CamTool to SIMOTION CamEdit.

1

Cams can be added to a SCOUT project using SIMOTION CamTool. In addition, you can

edit with CamTool a cam created with CamEdit: Cams can also be imported from a text

file or uploaded from a SIMOTION device.

In SIMOTION CamTool, you can show and hide diagrams, change the representation

parameters of the axes and diagrams, and adapt the lines and fonts. You can also

represent auxiliary lines in the diagram.

To edit with SIMOTION CamEdit a cam edited in SIMOTION CamTool, the cam must be

converted.

• Exporting cams into a text file.

• Downloading cams to a SIMOTION device

• Printing a cam.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

1-1

Page 12

Page 13

Installing the Software

2.1 Installing SIMOTION CamTool

Introduction

SIMOTION CamTool is an option package for SIMOTION SCOUT.

SIMOTION SCOUT must have been installed on the system on which you want to install

SIMOTION CamTool. For further information, refer to the system prerequisites.

Notice

You require administrator rights for the installation.

After the installation, every user (also those without administrator rights) can work with

SIMOTION CamTool.

2

System requirements

The following table provides a detailed overview of the system requirements for

SIMOTION CamTool.

Table 2-1 SIMOTION CamTool system requirements

Minimum requirement

Programming device or

PC

Operating system

Software required

• Processor: Intel Pentium II or compatible. 400 MHz (WIN NT 4.0, WIN

2000)

• Processor: Intel Pentium III or compatible. 500 MHz

(WIN XP Professional)

• 256 MB RAM; 512 MB recommended

• Screen resolution: 1024 x 768 pixels

• Microsoft Windows NT 4.0 ≥ Service Pack 6 or

• Microsoft Windows 2000 ≥ Service Pack 3

• Microsoft Windows XP Professional ≥ Service 1

• Microsoft Internet Explorer Version 5.0.1

• SIMATIC STEP 7 Version 5.1 ≥ Service Pack 6 or STEP 7 Version 5.2

(required for SIMOTION D435)

• SIMOTION SCOUT ≥ Version 2.1

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

2-1

Page 14

Installing the Software

2.2 Deinstalling SIMOTION CamTool

Installing SIMOTION CamTool

To install SIMOTION CamTool:

1. Insert the CD with installation software into the CD-ROM drive.

2. Start Windows Explorer and select the CD-ROM drive.

3. Open the CamTool\Disk1 directory.

4. Double-click on setup.exe. The installation program is started.

5. Run through the installation program. SIMOTION CamTool will be installed.

2.2 Deinstalling SIMOTION CamTool

Deinstalling SIMOTION CamTool

To deinstall SIMOTION CamTool:

1. Click Start > Settings > System Control in the Windows taskbar. The System Control

window appears.

2. Double-click Add/Remove Programs. The Software Properties window is displayed.

3. Mark the SIMOTION SCOUT CamTool entry in the Install/Deinstall tab.

4. Click Add/Remove. The deinstallation program is started.

5. Run through the deinstallation program. SIMOTION CamTool will be deinstalled.

Notice

You require administrator rights for the deinstallation.

CamTool

2-2 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 15

Configuring

3.1 Content

Overview

This chapter describes how you work with SIMOTION CamTool. You learn how

• to customize the display of the working area

• to edit a cam with CamTool

• to save a cam

• to customize the display of the cam

• to download a cam to a SIMOTION device

Note

The following operating instructions primarily describe the operation of

SIMOTION CamTool using the functions in the menu bar.

You can also execute the functions from the context menus. In this case, right-click the

element that you want to edit.

3

You can also execute the most import functions using the icons in the

SIMOTION CamTool toolbar. Pay attention to the tooltip which is displayed when you

place the mouse pointer on an icon in the toolbar.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-1

Page 16

Configuring

3.2 Customizing the Working Area Display

3.2 Customizing the Working Area Display

3.2.1 Changing the representation using the toolbar

Introduction

You can show or hide the scaled curve, the V diagram (velocity diagram), the A diagram

(acceleration diagram) and the J diagram (jerk diagram) via icons in the toolbar. You can use

the zoom tool to increase or reduce the size of the display or use the hand tool to move the

display.

Changing the representation using the toolbar

To change the representation of the diagrams via the toolbar

Toolbar icons

1. When the mouse pointer is placed on an icon in the toolbar, a tooltip is displayed.

2. Click the icon of the function that you want to use.

The screen display can be changed using the following functions:

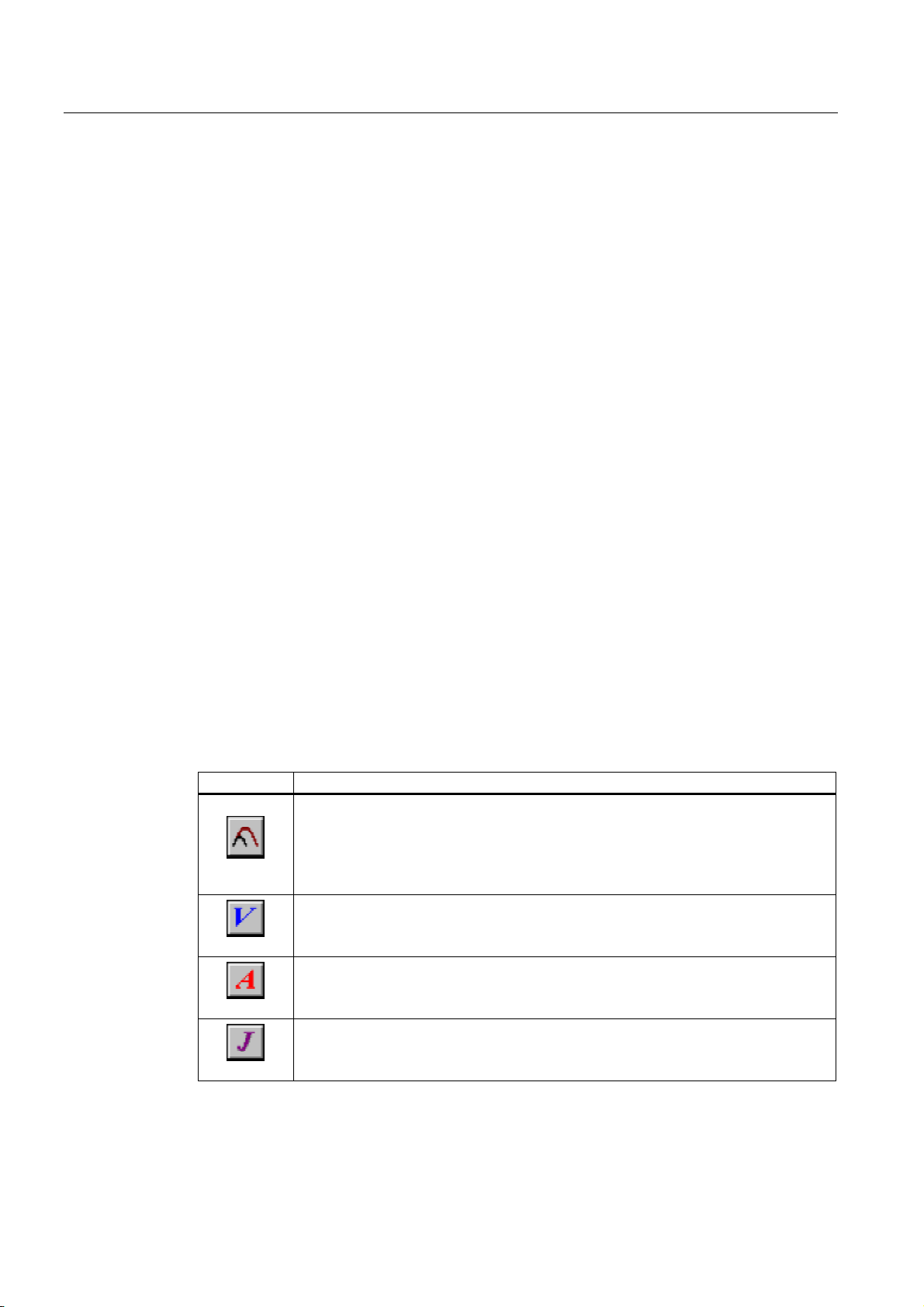

Table 3-1 SIMOTION CamTool toolbar icons

Symbol Explanation / instructions

With this icon, you can activate or deactivate the display of the scaled curve. If you

have not specified a scaling, the icon is shown grayed-out.

Note:

If the scaled curve is displayed, you cannot edit the original curves in the diagram

displays.

With this icon, you can show or hide the V diagram (velocity diagram).

With this icon, you can show or hide the A diagram (acceleration diagram).

With this icon, you can show or hide the J diagram (jerk diagram).

CamTool

3-2 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 17

Configuring

3.2 Customizing the Working Area Display

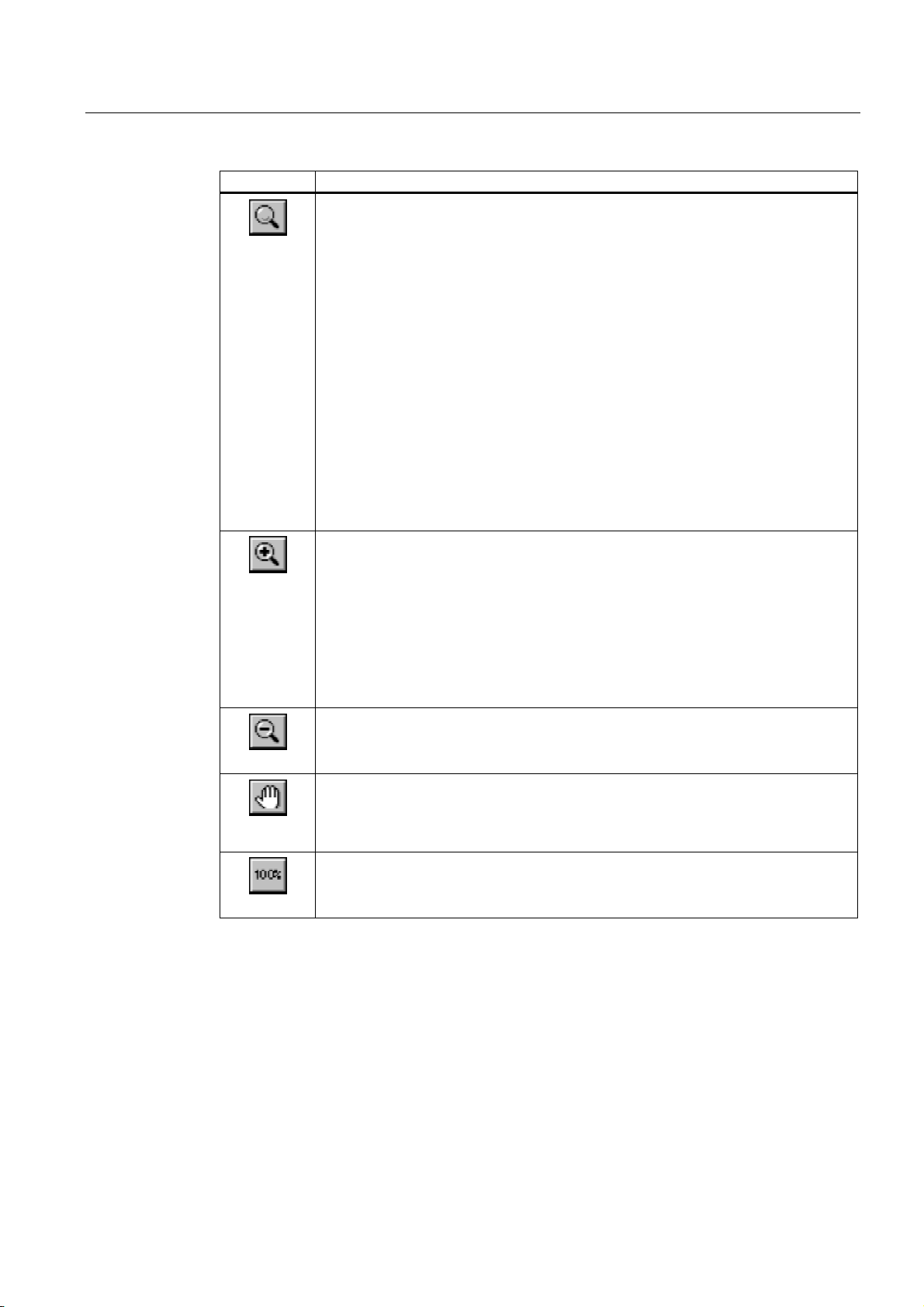

Symbol Explanation / instructions

With this icon, you can activate or deactivate the zoom tool. You can also deactivate

the zoom tool using the ESC key.

You can perform various functions with the activated zoom tool. The function is

dependent on whether the mouse pointer is on the diagram area or on a coordinate

axis and whether the SHIFT key is also pressed:

Zoom tool on the diagram area (zoom in all directions at the same time)

Left-click to increase the size of the display by the factor 2.

Right-click to decrease the size of the display by the factor 2.

Zoom tool on the coordinate axis (zoom in all directions at the same time)

Left-click to increase the size of the display by the factor 2 in the direction of the

coordinate axis on which you are pointing.

Right-click to decrease the size of the display by the factor 2 in the direction of the

coordinate axis on which you are pointing.

Zoom tool with pressed SHIFT key

The mouse pointer is activated as a hand tool while you keep the SHIFT key pressed.

With activated hand tool, you can move the diagram area with drag&drop. All

displayed diagrams are adjusted to the move.

With this icon, you can activate or deactivate the zoom function. You can also

deactivate the zoom function using the ESC key.

Zoom function on the diagram area

With activated zoom function, you can lasso a section of the diagram area that you

want to enlarge with the mouse button pressed.

Zoom function on the coordinate axis

With activated zoom function, you can lasso a section of a coordinate axis that you

want to enlarge with the mouse button pressed. The enlargement is in the direction in

which you lasso the section of the coordinate axis.

With this icon, you can restore the previous zoom setting.

With this icon, you can activate or deactivate the hand tool. You can also deactivate

the hand tool using the ESC key.

With activated hand tool, you can move the diagram area with drag&drop. All

displayed diagrams are adjusted to the move.

With this icon, you can restore the whole display to the normal view.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-3

Page 18

Configuring

3.2 Customizing the Working Area Display

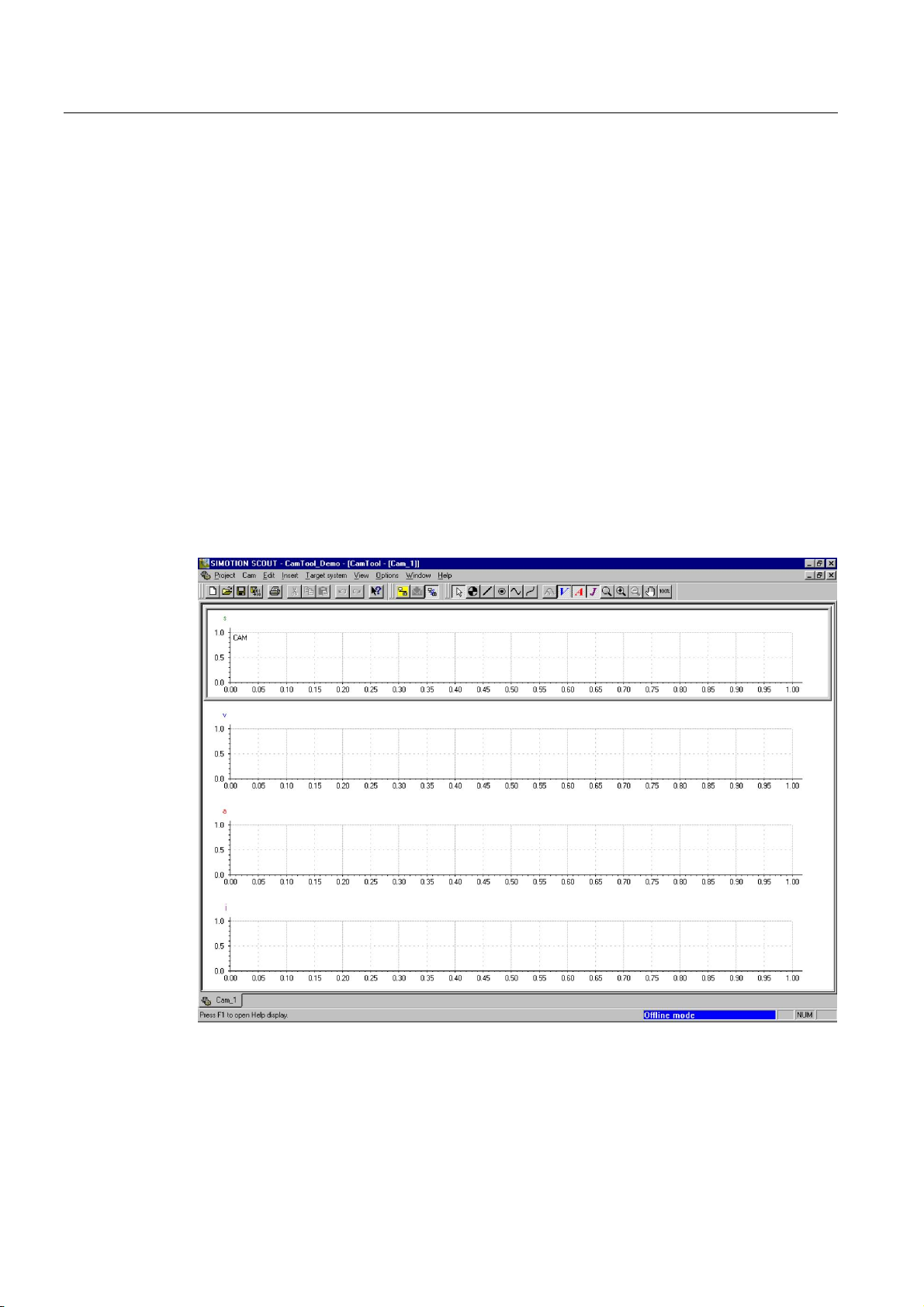

3.2.2 Maximizing working area

Maximizing the working area

To set the largest possible working area for SIMOTION CamTool:

1. In the View menu, click Maximized working area. Detail view and project navigator are

closed.

2. Maximize the window with the diagrams of the cam.

or

1. Close the project navigator via the menu View > Project navigator.

2. Close the detail view via the menu View > Detail view.

3. Maximize the window with the diagrams of the cam.

Figure 3-1 Maximized cam diagrams in the SIMOTION SCOUT working area

CamTool

3-4 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 19

Configuring

3.3 Editing a Cam with CamTool

3.3 Editing a Cam with CamTool

3.3.1 Content

Overview

With SIMOTION CamTool, you can edit a cam that is inserted in a SCOUT project.

You can use the following methods to insert and edit a cam. You can

• add a cam to a SCOUT project using SIMOTION CamTool.

• edit with CamTool a cam created with CamEdit.

• import and edit a cam from a text file.

• upload and edit a cam from a SIMOTION device.

3.3.2 Adding a cam to a SCOUT project using CamTool

Requirements

SIMOTION CamTool is installed as an option package for SIMOTION SCOUT.

The project, into which you want to insert the cam, is opened in SIMOTION SCOUT. At least

one SIMOTION device is configured in this project.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-5

Page 20

Configuring

3.3 Editing a Cam with CamTool

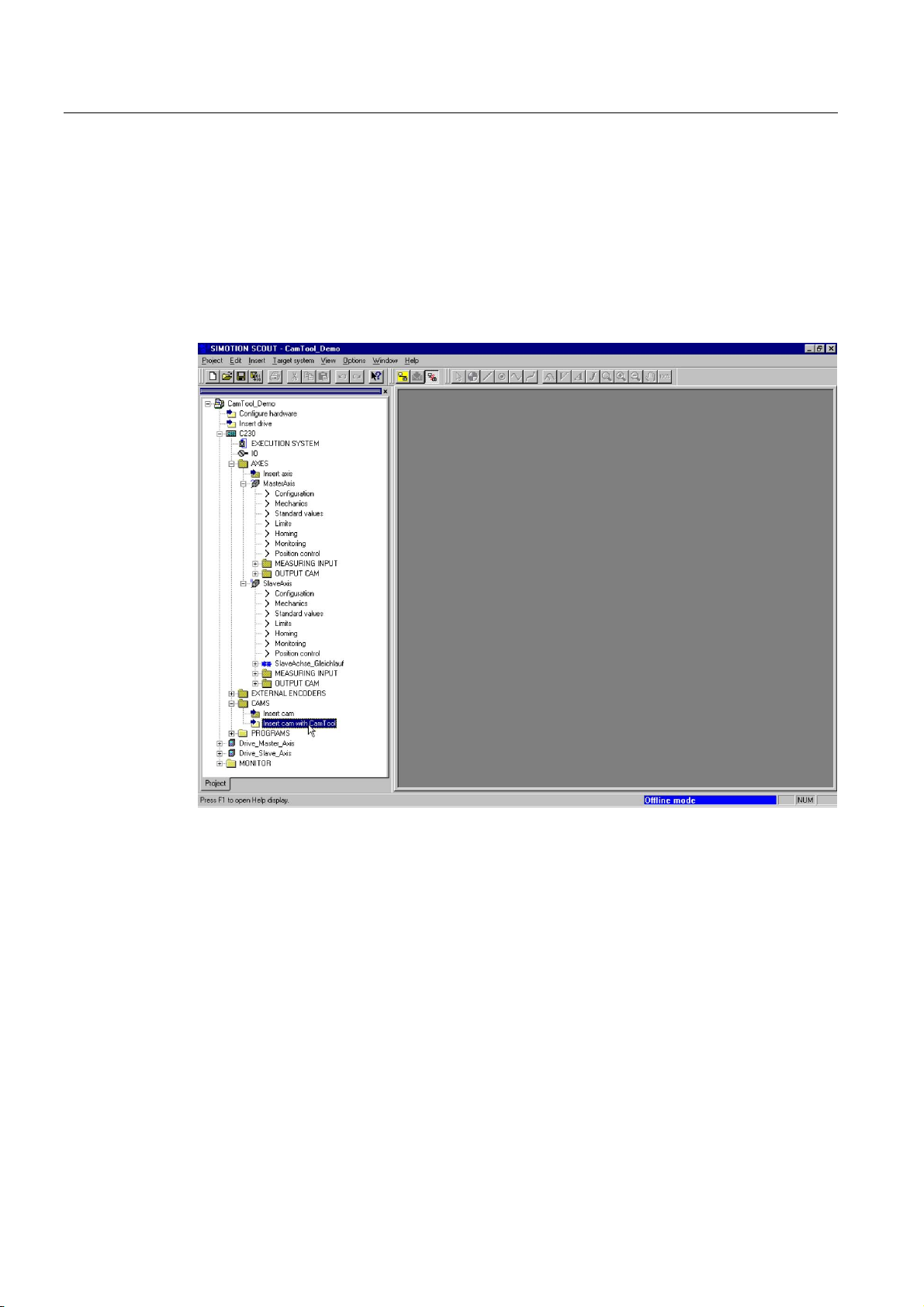

Inserting a cam in a SCOUT project

To insert a cam in a SCOUT project:

1. In the project navigator, find the SIMOTION device under which you want to insert a new

cam.

2. Open the Cams folder and double-click Insert cam with CamTool.

Figure 3-2 Inserting a cam with CamTool

CamTool

3-6 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 21

Configuring

3.3 Editing a Cam with CamTool

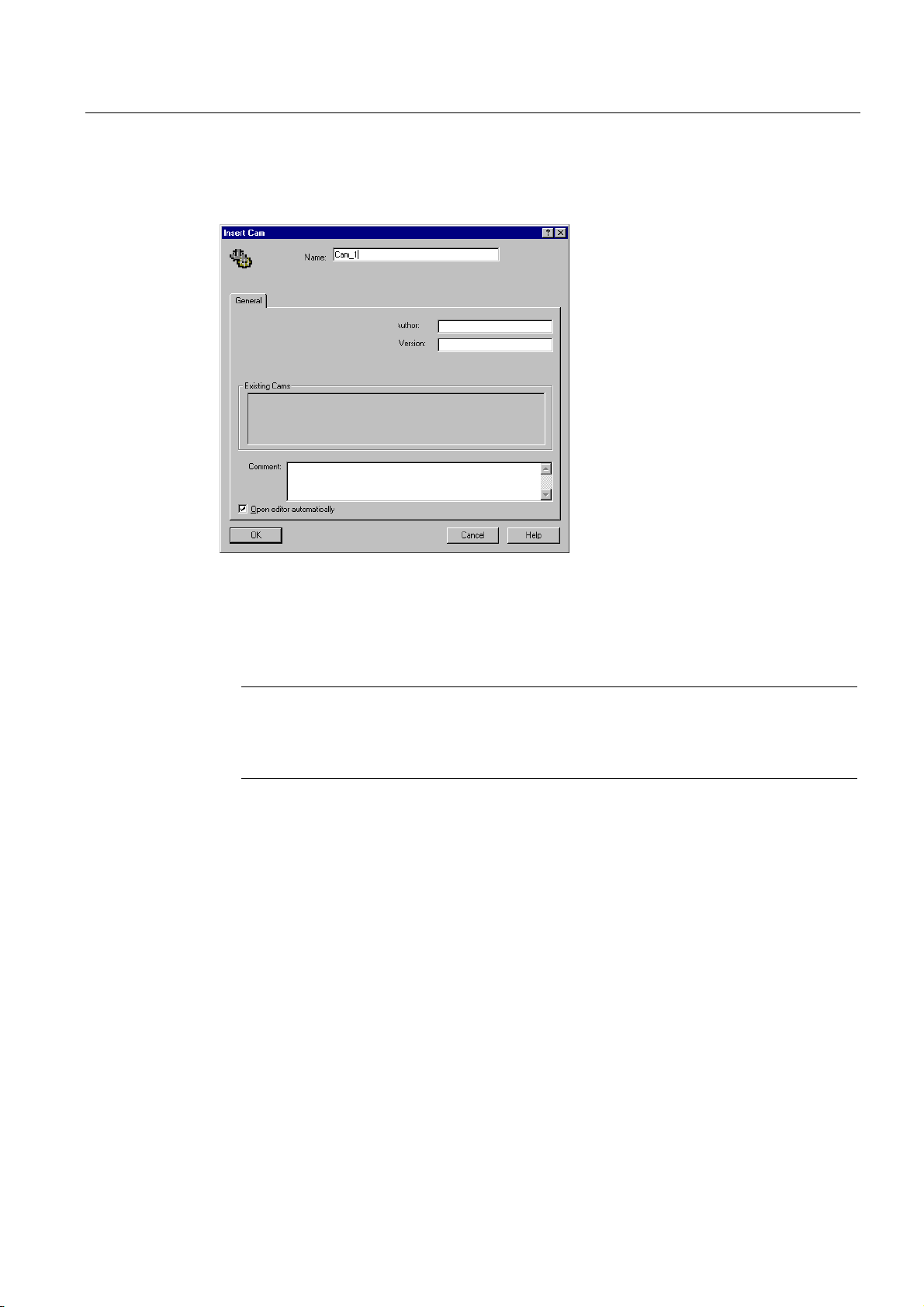

3. The Insert Cam window appears. Under Name, enter a unique name for the cam (all the

cams existing in the project are displayed under Existing cams).

Figure 3-3 Window for inserting a cam

4. Click OK. A window appears in the working area of SIMOTION SCOUT. The diagrams of

the cam depending on the settings in the menu Cam > Diagrams are displayed in this

window.

Notice

The following are represented in the cam diagrams:

• the master axis in the horizontal direction (X-axis) and

• the slave axis in the vertical direction (Y-axis).

3.3.3 Edit cam created with CamEdit with CamTool

Editing a Cam with CamTool

To edit a cam created with CamEdit with CamTool:

1. Close the cam in SIMOTION CamEdit.

2. Find the cam that you want to edit with SIMOTION CamTool in the project navigator.

3. Right-click the cam and select Convert to CamTool in the displayed context menu. The

cam is then opened the next time with SIMOTION CamTool.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-7

Page 22

Configuring

3.3 Editing a Cam with CamTool

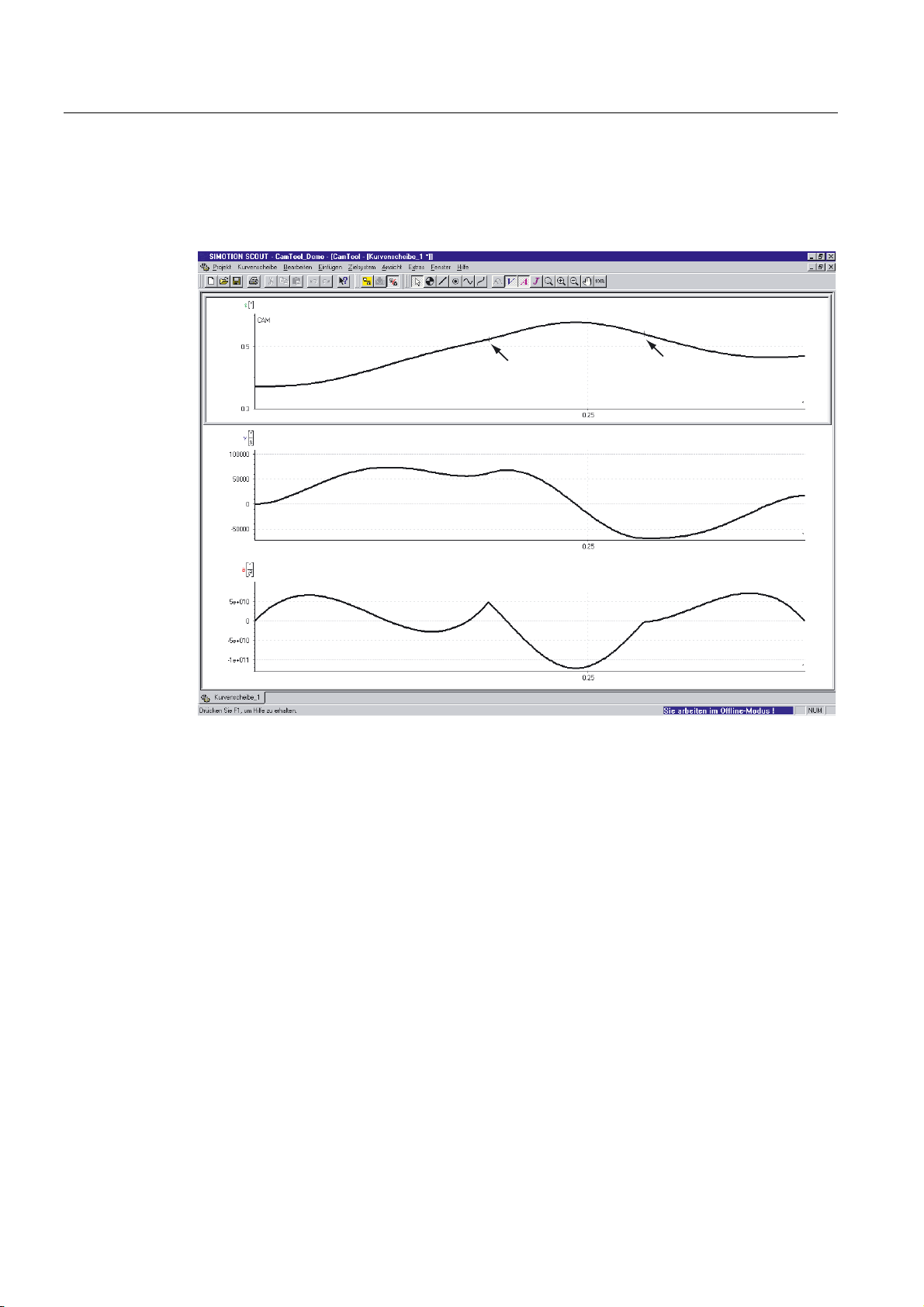

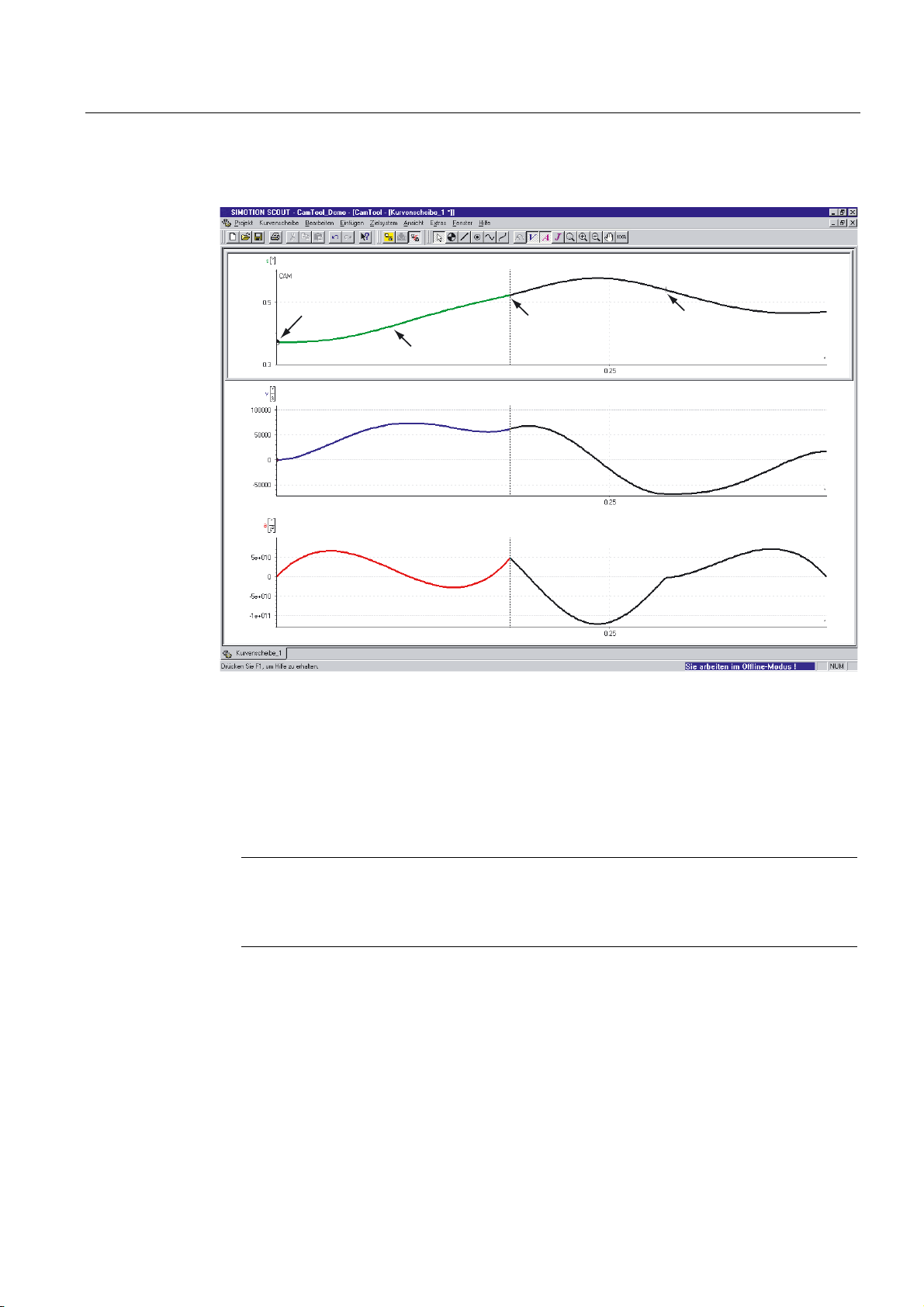

4. Double-click the cam. The cam is opened with SIMOTION CamTool and displayed.

Segment limits between individual cam segments are marked in the S diagram (distance

diagram).

6GLDJUDPGLVWDQFHGLDJUDP

6HJPHQWERXQGDU\

9GLDJUDPYHORFLW\GLDJUDP

6HJPHQWERXQGDU\

$GLDJUDPDFFHOHUDWLRQGLDJUDP

Figure 3-4 Open with CamTool a cam created with CamEdit

5. Select the cam segment that you want to edit. Note the displayed segment limits.

CamTool

3-8 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 23

Configuring

3.3 Editing a Cam with CamTool

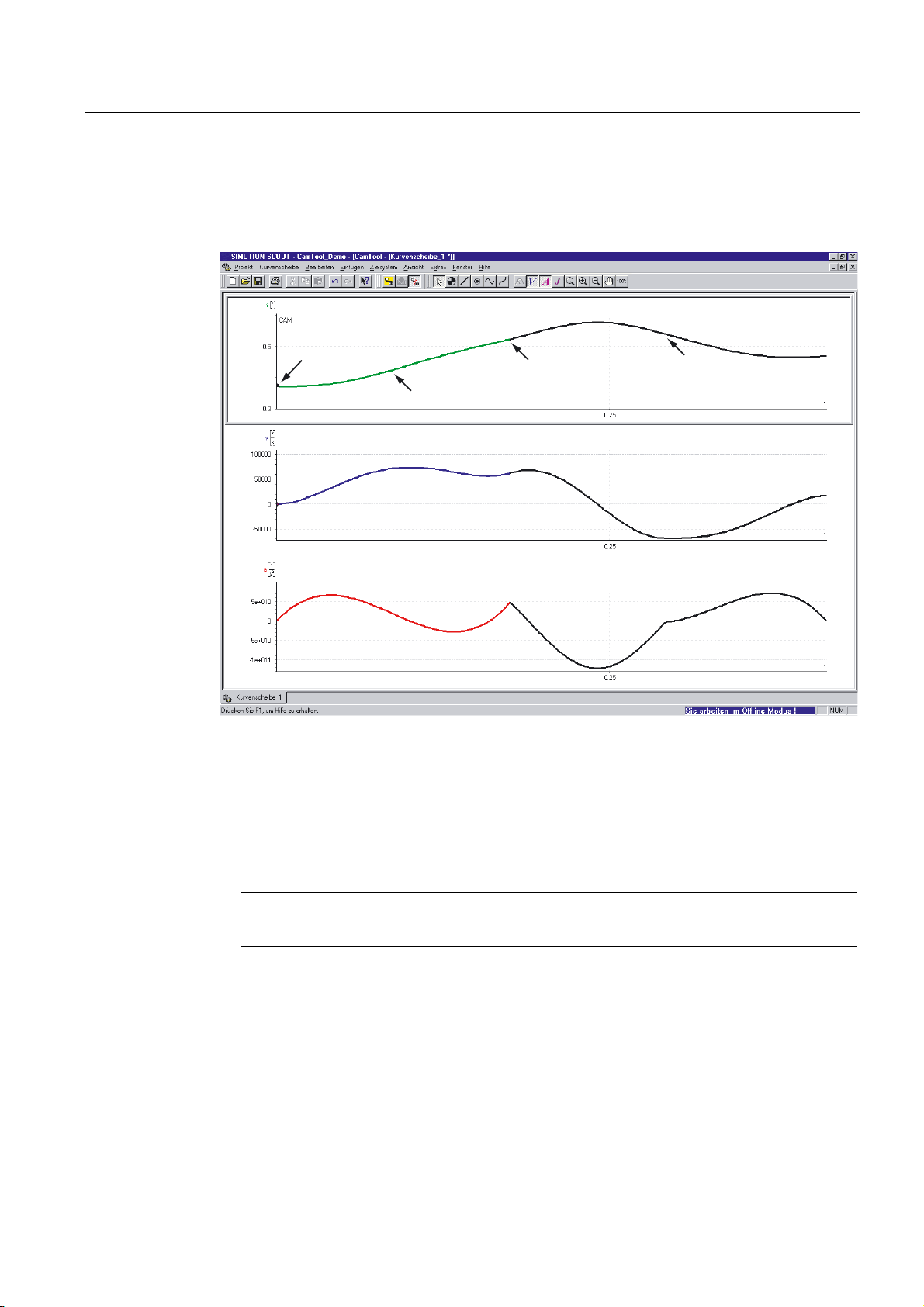

6. Delete the cam segment by pressing the DEL key. The cam segment is replaced by an

interpolation curve (transition) by SIMOTION CamTool. If required, fixed points are

inserted in the curve to maintain the corner points of the original curve.

6GLDJUDPGLVWDQFHGLDJUDP

)L[HGSRLQW

6HJPHQWERXQGDU\

,QWHUSRODWLRQFXUYHWUDQVLWLRQ

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

Figure 3-5 Cam segment replaced by SIMOTION CamTool with fixed point and transition

(interpolation polynomial)

6HJPHQWERXQGDU\

7. The cam segment (e.g. fixed point) inserted by SIMOTION CamTool can be edited (e.g.

change position).

8. The interpolation curve (transition) inserted by SIMOTION CamTool can be optimized

(e.g. velocity).

Notice

With SIMOTION CamTool, you can edit all cams created with SIMOTION CamEdit.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-9

Page 24

Configuring

3.3 Editing a Cam with CamTool

3.3.4 Import cam from text file

Introduction

You can re-import a cam exported as text file from SIMOTION CamTool back into CamTool

(e.g. to re-import a cam edited in an external program).

Importing a cam

Notice

The cam representation in the text file must correspond to the Microsoft Excel CSV format.

To import a cam from a text file:

1. Open with SIMOTION CamTool the cam in which you want to import the cam from the

text file.

or

Add a new cam in which you want to import the cam from the text file.

6GLDJUDPGLVWDQFHGLDJUDP

6HJPHQWERXQGDU\

6HJPHQWERXQGDU\

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

Figure 3-6 Cam imported from a text file

CamTool

3-10 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 25

Configuring

3.3 Editing a Cam with CamTool

2. Click a diagram to show the Cam menu.

6GLDJUDPGLVWDQFHGLDJUDP

)L[HGSRLQW

6HJPHQWERXQGDU\

,QWHUSRODWLRQFXUYHWUDQVLWLRQ

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

Figure 3-7 Cam segment replaced by SIMOTION CamTool with fixed point and transition

(interpolation polynomial)

6HJPHQWERXQGDU\

3. Click the menu Cam > Import. The file selection window is displayed.

Navigate under Find in to the text file that contains the cam and select the text file. The

name of the text file is entered under Name.

4. Click OK in the file selection window. The cam is imported.

Notice

When you import a cam from a text file and have previously changed the displayed cam,

a window appears. You can accept the changed cam into the project via the window. The

cam is then imported from the text file.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-11

Page 26

Configuring

3.3 Editing a Cam with CamTool

Edit imported cam

To edit a cam imported into SIMOTION CamTool:

1. The cam imported from a text file is displayed in SIMOTION CamTool. Segment limits

between individual cam segments are marked in the S diagram (distance diagram).

Select the cam segment that you want to edit. Note the displayed segment limits.

2. Delete the cam segment by pressing the DEL key. The cam segment is replaced by an

interpolation curve (transition) by SIMOTION CamTool. If required, fixed points are

inserted in the curve to maintain the corner points of the original curve.

3. The cam segment (e.g. fixed point) inserted by SIMOTION CamTool can be edited (e.g.

change position).

4. The interpolation curve (transition) inserted by SIMOTION CamTool can be optimized

(e.g. velocity).

3.3.5 Upload cam from SIMOTION device

Requirements

The cam is opened with SIMOTION CamTool.

Notice

If you create a cam and the cam has never been previously downloaded to the SIMOTION

device, you must first download the entire configuration with the new cam to the SIMOTION

device.

Only then can you upload the cam currently opened with SIMOTION CamTool from the

SIMOTION device. The upload is only possible in ONLINE status.

CamTool

3-12 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 27

Configuring

3.3 Editing a Cam with CamTool

Upload cam

To upload a cam from a SIMOTION device:

1. Click the menu Project > Connect to target system. The system changes to ONLINE

status.

6GLDJUDPGLVWDQFHGLDJUDP

6HJPHQWERXQGDU\

Figure 3-8 Cam uploaded from SIMOTION device

6HJPHQWERXQGDU\

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-13

Page 28

Configuring

3.3 Editing a Cam with CamTool

2. Click a diagram to show the Cam menu.

6GLDJUDPGLVWDQFHGLDJUDP

)L[HGSRLQW

6HJPHQWERXQGDU\

,QWHUSRODWLRQFXUYHWUDQVLWLRQ

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

Figure 3-9 Cam segment replaced by SIMOTION CamTool with fixed point and transition

(interpolation polynomial)

6HJPHQWERXQGDU\

3. Click the menu Cam > Upload cam. The cam is uploaded from the SIMOTION device.

4. After the upload, you can change back to OFFLINE status. Click the menu

Project > Disconnect from target system.

Notice

When you upload a cam from the SIMOTION device and have previously changed the

displayed cam, a window appears. You can accept the changed cam into the project via

the window. The cam is then uploaded from the SIMOTION device.

CamTool

3-14 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 29

Configuring

3.4 Save cam

Edit uploaded cam

To edit a cam uploaded from a SIMOTION device:

1. The uploaded cam is displayed in SIMOTION CamTool. Segment limits between

individual cam segments are marked in the S diagram (distance diagram).

Select the cam segment that you want to edit. Note the displayed segment limits.

2. Delete the cam segment by pressing the DEL key. The cam segment is replaced by an

interpolation curve (transition) by SIMOTION CamTool. If required, fixed points are

inserted in the curve to maintain the corner points of the original curve.

3. The cam segment (e.g. fixed point) inserted by SIMOTION CamTool can be edited (e.g.

change position).

4. The interpolation curve (transition) inserted by SIMOTION CamTool can be optimized

(e.g. velocity).

3.4 Save cam

Requirements

Save cam

The cam is opened with SIMOTION CamTool.

Notice

When you exit SIMOTION CamTool and have previously changed the cam, a window

appears. You can accept the changed cam into the project via the window.

SIMOTION CamTool is then closed.

When you upload a cam from a SIMOTION device and have previously changed the

displayed cam, a window appears. You can accept the changed cam into the project via the

window. The cam is then uploaded from the SIMOTION device.

When you import a cam from a text file and have previously changed the displayed cam, a

window appears. You can accept the changed cam into the project via the window. The cam

is then imported from the text file.

To save a cam:

1. Click the menu Project > Save. The cam is transferred to the SCOUT project.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-15

Page 30

Configuring

3.5 Customize the display of the cam

3.5 Customize the display of the cam

3.5.1 Display the cam

Diagram display

The S diagram (distance diagram) of the cam is always displayed in the SIMOTION SCOUT

working area. You can show or hide the V diagram (velocity diagram), the A diagram

(acceleration diagram) and the J diagram (jerk diagram) via icons in the toolbar.

Representation parameters

You can customize the display parameters (e.g. representation range) for the master axis,

the slave axis and the individual diagrams. This also includes the fonts and lines used for the

display.

3.5.2 Show/hide diagram

Requirements

The cam is opened with SIMOTION CamTool.

Show/hide diagram

To show/hide a diagram:

1. Click a diagram to show the Cam menu.

CamTool

3-16 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 31

Configuring

3.5 Customize the display of the cam

2. Click the diagram that you want to show or hide under menu Cam > Diagrams. The

diagram is shown or hidden.

Figure 3-10 Show/hide diagrams again

3.5.3 Change axis representation parameters

Requirements

The cam is opened with SIMOTION CamTool.

Change axis representation parameters

To change the representation parameters for the master or slave axis:

1. Click a diagram to show the Cam menu.

2. Click the axis whose representation parameters you want to change under

menu Cam > Representation parameters.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-17

Page 32

Configuring

3.5 Customize the display of the cam

3. Either the window Master Properties (for the master axis) or the window S Diagram

Properties (Slave) (for the slave axis) is displayed.

For the master axis, change the representation parameters in the window Master Properties.

Figure 3-11 Master Properties window

For the slave axis, change the representation parameters in the window S Diagram (Slave)

Properties.

Figure 3-12 Slave Properties window

Table 3-2 Parameters in the Master Properties or S Diagram (Slave) Properties

Field/button Explanation/instructions

Master Range

(Master Properties)

Start Enter the start point of the curve, or the start of the master

End Enter the end point of the curve, or the end of the master

CamTool

You specify the master range (definition range) of the curve

via start and end points. Cam segments must lie within this

master range (see also Master range under Target device

properties in the Coordinates tab).

range of the curve here.

range of the curve here.

3-18 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 33

Configuring

3.5 Customize the display of the cam

Field/button Explanation/instructions

Representation range

Start

(Number of periods deactivated)

End

(Number of periods deactivated)

Number of periods

(cyclical absolute,

cyclical relative)

Grid lines

Set automatically If you activate Set automatically, the grid lines will be

Main line spacing You can activate the display of the grid lines for the main

Auxiliary line spacing

(Main line spacing activated)

Specify here the Start point of the representation range.

If the Number of periods option has been activated, the

system will determine the start point.

Specify here the End point of the representation range.

If the Number of periods option has been activated, the

system will determine the end point.

If under Target device parameters in the Coordinates tab,

you have specified the cyclic absolute execution type or the

cyclic relative execution type, you can select the

option Number of periods. Enter the number of periods that

you want to display.

displayed automatically with an optimum spacing.

If you deactivate Set automatically, you can use Main line

spacing or Auxiliary line spacing to specify the grid line

spacing.

line spacing here.

If you deactivate the Set automatically option, you can

specify the grid line spacing for the main line spacing.

Note:

The spacing that you specify for the grid lines in the main

line spacing must be a multiple of the spacing that you

specify for the grid lines in the auxiliary line spacing.

If the main line spacing option has been activated, you can

also activate the display of the grid lines for the auxiliary line

spacing.

If you deactivate the Set automatically option, you can

specify the grid line spacing for the auxiliary line spacing.

Note:

The spacing that you specify for the grid lines in the main

line spacing must be a multiple of the spacing that you

specify for the grid lines in the auxiliary line spacing.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-19

Page 34

Configuring

3.5 Customize the display of the cam

3.5.4 Change diagram representation parameters

Requirements

The cam is opened with SIMOTION CamTool.

Change diagram representation parameters

To change the representation parameters for the V diagram (velocity diagram), the A

diagram (acceleration diagram) or the J diagram (jerk diagram):

1. Click a diagram to show the Cam menu.

2. Click the diagram whose representation parameters you want to change under

menu Cam > Representation parameters.

3. Either the window V Diagram Properties (for the velocity diagram), the window A Diagram

Properties (for the acceleration diagram) or the window J Diagram Properties (for the jerk

diagram) is displayed.

For the V diagram (velocity diagram), change the representation parameters in the

window V Diagram Properties.

Figure 3-13 V Diagram Properties window

For the A diagram (acceleration diagram), change the representation parameters in the

window A Diagram Properties.

Figure 3-14 A Diagram Properties window

CamTool

3-20 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 35

Configuring

3.5 Customize the display of the cam

For the J diagram (jerk diagram), change the representation parameters in the

window J Diagram Properties.

Figure 3-15 J Diagram Properties window

Table 3-3 Parameters for the V, A or J Diagram Properties windows

Field/button Explanation/instructions

Representation range

Automatically If you activate Automatically, the representation range in the

Y-direction will be automatically changed to the value range

of the displayed curve.

If you deactivate Automatically, you can use maximum

value and minimum value to specify the representation

range in the Y-direction.

Maximum value

(automatically deactivated)

Minimum value

(automatically deactivated)

Grid lines

Set automatically If you activate Set automatically, the grid lines will be

Main line spacing You can activate the display of the grid lines for the main

Specify here the maximum value of the representation

range.

If the Automatically option has been activated, the system

will determine the maximum value.

Specify here the minimum value of the representation

range.

If the Automatically option has been activated, the system

will determine the minimum value.

displayed automatically with an optimum spacing.

If you deactivate Set automatically, you can use Main line

spacing or Auxiliary line spacing to specify the grid line

spacing.

line spacing here.

If you deactivate the Set automatically option, you can

specify the grid line spacing for the main line spacing.

Note:

The spacing that you specify for the grid lines in the main

line spacing must be a multiple of the spacing that you

specify for the grid lines in the auxiliary line spacing.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-21

Page 36

Configuring

3.5 Customize the display of the cam

Field/button Explanation/instructions

Auxiliary line spacing

(Main line spacing activated)

If the main line spacing option has been activated, you can

also activate the display of the grid lines for the auxiliary line

spacing.

If you deactivate the Set automatically option, you can

specify the grid line spacing for the auxiliary line spacing.

Note:

The spacing that you specify for the grid lines in the main

line spacing must be a multiple of the spacing that you

specify for the grid lines in the auxiliary line spacing.

3.5.5 Change lines and fonts representation parameters

For the representation of the diagrams, default parameters are used for the lines and fonts.

You can change these default settings.

/LQHIRUFDPVHJPHQWV

/LQHIRUVLPXODWHGLQWHUSRODWLRQ

<FRRUGLQDWHD[LV

;FRRUGLQDWHD[LV

$X[LOLDU\OLQH

,QWHUSRODWLRQFXUYHLQWKHGLVWDQFHGLDJUDP

$X[LOLDU\JULGOLQHV

0DLQJULGOLQH

9HORFLW\FXUYH

$X[LOLDU\OLQH

$FFHOHUDWLRQFXUYH

-HUNFXUYH

/LQHDWSK\VLFDOOLPLW

Figure 3-16 Representation parameters in the diagrams (line for the scaling not shown)

CamTool

3-22 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 37

Configuring

3.5 Customize the display of the cam

Table 3-4 Representation parameters in the diagrams

Representation parameters Note

Main grid line Type and color of the line can be changed.

Auxiliary grid lines Type and color of the line can be changed.

Auxiliary line Type, color and width of the line can be changed.

Line at physical limit Type, color and width of the line can be changed.

X-coordinate axis Color and width of the line can be changed.

Y-coordinate axis Color and width of the line can be changed.

Line for simulated interpolation Color and width of the line can be changed.

The line for simulated interpolation is used to

display a transition interpolated by the target

device.

Interpolation curve in the distance diagram Color and width of the line can be changed.

Velocity curve Color and width of the line can be changed.

Acceleration curve Color and width of the line can be changed.

Jerk curve Color and width of the line can be changed.

Line for cam segments Color and width of the line can be changed.

Line for scaling Color and width of the line can be changed.

The line for scaling is used to display a scaled

and offset curve.

Requirements

The cam is opened with SIMOTION CamTool.

Change lines and fonts representation parameters

To change the representation parameters for lines and fonts:

1. Click a diagram to show the Cam menu.

2. Click Lines and fonts under menu Cam > Representation parameters.

3. The Lines and Fonts window appears.

You can change the representation parameters for the lines in the Line tab.

Table 3-5 Parameters in the Line tab

Field/button Explanation/instructions

Line type Select the line type that you want to specify here.

Settings Note:

Type Specify the type of the line.

Under Settings, the associated parameters are displayed

and the line type shown.

Grayed-out parameters cannot be changed.

The line type is displayed in the Preview.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-23

Page 38

Configuring

3.5 Customize the display of the cam

Field/button Explanation/instructions

Color Specify the color of the line.

The line is displayed in the Preview.

Width Specify the thickness of the line.

The line type is displayed in the Preview.

Preview Under Preview, the line type specified via type, color and

width is shown.

You can change the representation parameters for the fonts in the Font tab.

Table 3-6 Parameters in the Font tab

Field/button Explanation/instructions

Settings

Font Select the font here.

The font is displayed in the Preview.

Font style Select the font style here.

The font is displayed in the Preview.

Font size Select the font size here.

The font is displayed in the Preview.

Preview Under Preview, the font specified via font, font style and font

size is shown.

3.5.6 Displaying auxiliary lines in the diagram

You can represent horizontal and vertical auxiliary lines in the individual diagrams. You can,

for example, determine the position of individual points of the curve via auxiliary lines.

Requirements

The cam is opened with SIMOTION CamTool.

Representing a horizontal auxiliary line in a diagram

To represent a horizontal auxiliary line (in the direction of the x-coordinate) in a diagram:

1. Click in the diagram, in which you want to represent a horizontal auxiliary line, on the xcoordinate and keep the mouse button pressed. The current position of the auxiliary line

is displayed in the position window.

CamTool

3-24 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 39

Configuring

3.5 Customize the display of the cam

2. Drag the auxiliary line to the position at which you want to represent the auxiliary line and

release the mouse button. The auxiliary line and the position window with the current

position are displayed in the diagram.

Figure 3-17 Displaying a horizontal auxiliary line

Representing vertical auxiliary lines in all displayed diagrams

To represent a vertical auxiliary line (in the direction of the y-coordinate) in all displayed

diagrams:

1. Click in a diagram on the y-coordinate axis and keep the mouse button pressed. The

current position of the auxiliary line is displayed in the position window.

2. Drag the auxiliary line to the position at which you want to represent the auxiliary line and

release the mouse button. The auxiliary line and the position window with the current

position are both displayed in all the displayed diagrams.

Figure 3-18 Displaying a vertical auxiliary line

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-25

Page 40

Configuring

3.6 Download cam to SIMOTION device

Moving the position window along an auxiliary line

To move a position window with the current position of the auxiliary line along the horizontal

or vertical auxiliary line:

1. Point at the position window. The mouse pointer shows the direction in which you can

move the window. Drag the window with the current position with drag&drop to the new

position.

Figure 3-19 Moving the position window horizontally

Deleting an auxiliary line in a diagram

To delete a horizontal or vertical auxiliary line in a diagram:

1. Select the auxiliary line that you want to delete.

2. Press the DEL key. The auxiliary line is deleted.

3.6 Download cam to SIMOTION device

Requirements

The cam is opened with SIMOTION CamTool.

Notice

If you create a cam and the cam has never been previously downloaded to the SIMOTION

device, you must first download the entire configuration with the new cam to the SIMOTION

device.

Only then can you download the cam independent of the other technology objects in the

SIMOTION device. The download is only possible in ONLINE status.

CamTool

3-26 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 41

Configuring

3.6 Download cam to SIMOTION device

Download cam to SIMOTION device

To download a cam to a SIMOTION device:

1. Click the menu Project > Connect to target system. The system changes to ONLINE

status.

2. Click a diagram to show the Cam menu.

3. Click the menu Cam > Download cam. The cam is downloaded to the SIMOTION device.

4. After the download, you can change back to OFFLINE status. Click the menu

Project > Disconnect from target system.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

3-27

Page 42

Page 43

Functions

4.1 Content

Overview

In this chapter you learn how you can use SIMOTION CamTool to create and optimize a

cam, and to make the simulation settings. In addition, you learn how you can use CamTool

to edit a cam created with CamEdit and how you can export a cam as a text file.

Note

The following operating instructions primarily describe the operation of SIMOTION CamTool

using the functions in the menu bar.

You can also execute the functions from the context menus. In this case, right-click the

element that you want to edit.

You can also execute the most import functions using the icons in the SIMOTION CamTool

toolbar. Pay attention to the Tooltip which is displayed when you place the mouse pointer on

an icon in the toolbar.

4

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-1

Page 44

Functions

4.2 Structure of a cam

4.2 Structure of a cam

Introduction

Create the cam in the S diagram (distance diagram). The curve represents the path-related

dependency between the master axis (X-axis in the diagram) and the slave axis (Y-axis in

the diagram).

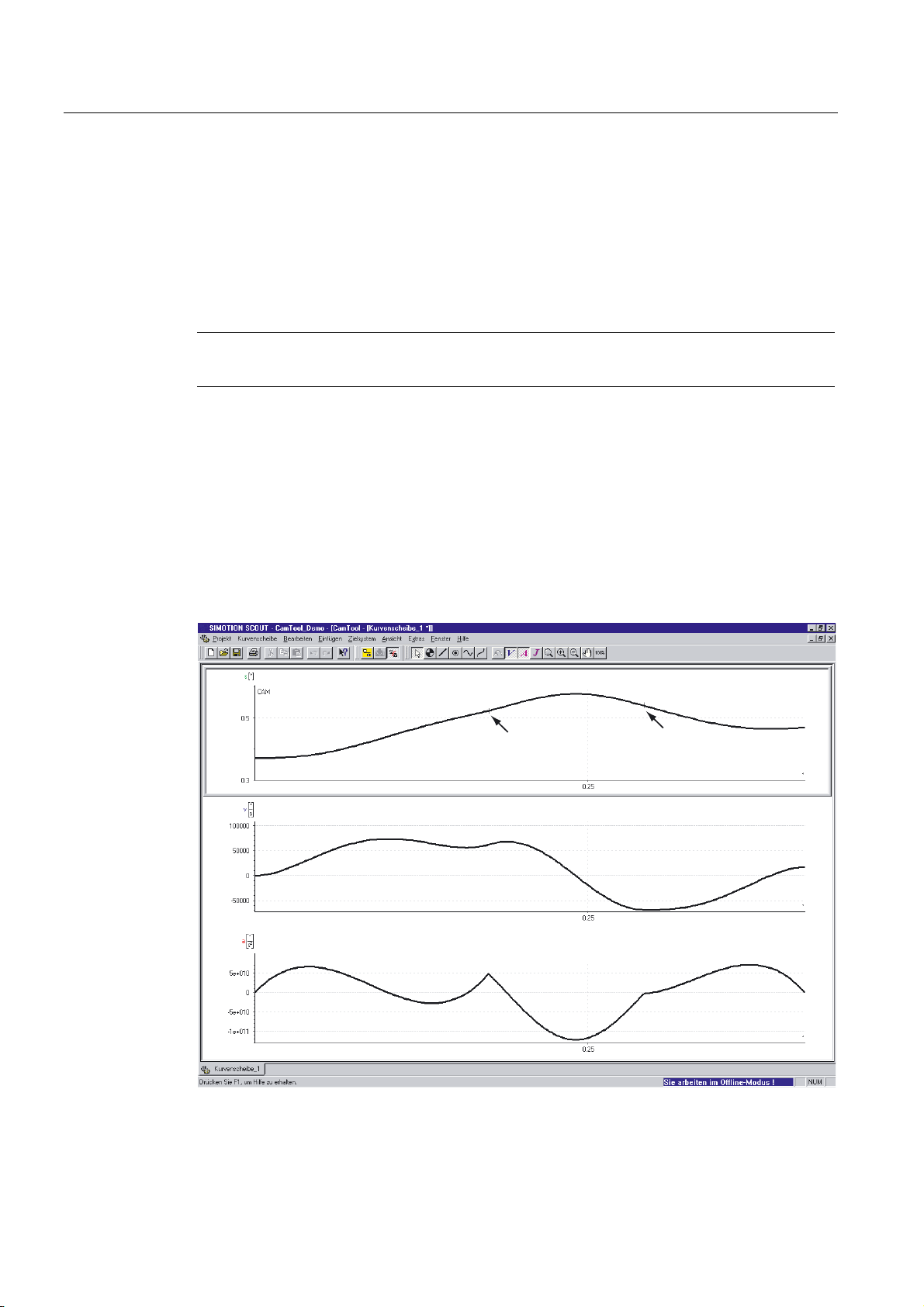

Structure of a cam

The cam consists of individual cam segments.

Under SIMOTION CamTool, you can use fixed points, straight lines, sine curves, arc sine

curves and interpolation points as cam segments.

SIMOTION CamTool calculates interpolation curves between the individual cam segments

and displays the V diagram (velocity diagram), the A diagram (acceleration diagram) and the

J diagram (jerk diagram).

6WUDLJKWOLQH

)L[HGSRLQW

,QWHUSRODWLRQFXUYH

,QWHUSRODWLRQFXUYH

6WUDLJKWOLQH

6GLDJUDPGLVWDQFHGLDJUDP

,QWHUSRODWLRQFXUYH

Interpolation curve

9GLDJUDPYHORFLW\GLDJUDP

$GLDJUDPDFFHOHUDWLRQGLDJUDP

-GLDJUDPMHUNGLDJUDP

Figure 4-1 Example of a cam with interpolation curves

CamTool

4-2 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 45

Functions

4.3 Fixed point

4.3 Fixed point

4.3.1 Fixed Point Definition

Definition

The cam consists of individual cam segments. Under SIMOTION CamTool, you can use

fixed points, straight lines, sine curves, arc sine curves and interpolation points as cam

segments.

A fixed point is a specified position of the slave axis for a certain position of the master axis.

You can specify the velocity and acceleration at the fixed point position.

Notice

With a fixed point, you define a single fixed position. The transitions between adjacent cam

segments are optimally calculated by CamTool.

If you want to specify an arbitrary characteristic, you must use interpolation points. The

individual interpolation points are connected by CamTool with cubic splines in order to

generate a curve specified by the interpolation points which is as exact as possible.

4.3.2 Insert fixed point

Requirements

The cam is opened with SIMOTION CamTool.

Insert fixed point

To insert a fixed point:

1. Click in the S diagram (distance diagram) to activate the diagram.

2. Click under menu Cam > Insert at fixed point. The mouse pointer changes.

3. With the changed mouse pointer, click the position in the S diagram (distance diagram) at

which you want to insert the fixed point.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-3

Page 46

Functions

4.3 Fixed point

The fixed point is displayed in the diagram. The position of the fixed point shown in the

tooltip.

Figure 4-2 Insert fixed point

Notice

Once the function Cam > Insert > Fixed point is activated, you can insert fixed points in

the S diagram (distance diagram) until

• you press the ESC key,

• you press the right mouse button (this activates the selection tool in the toolbar) or

• you activate another cam segment (straight line, sine curve, arc sine curve, interpolation point)

for insertion.

CamTool

4-4 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 47

Functions

4.3 Fixed point

4.3.3 Change fixed point position

Requirements

The cam is opened with SIMOTION CamTool.

Change fixed point position

To change the position of a fixed point:

1. Select the fixed point in the S diagram (distance diagram). The position of the fixed point

shown in the tooltip.

2. Move the fixed point with drag&drop to the new position.

or

1. Double-click the fixed point. The Fixed Point Properties window appears.

2. Enter the new x- or y-position of the fixed point in the Position tab and click OK. The

representation of the fixed point in the diagram will be updated and displayed at the new

position.

4.3.4 Changing the velocity at the position of a fixed point:

Requirements

The cam is opened with SIMOTION CamTool.

Change velocity at fixed point

To change the velocity at the fixed point position:

1. The velocity at a fixed point position is represented by a handle in the V diagram (velocity

diagram).

Select the handle. The mouse pointer shows the direction in which you can move the

handle.

2. Move the handle with drag&drop to the new position.

or

1. Double-click the fixed point. The Fixed Point Properties window appears.

2. Enter the new velocity as specified in the following table in the Dynamic response tab and

click OK. The handle in the V diagram (velocity diagram) is shown at the new position.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-5

Page 48

Functions

4.3 Fixed point

Field/button Explanation/instructions

v = Under v =, the current velocity at the position of the fixed point is

displayed.

(see note below)

a =

(manual input activated)

Manual input If you activate Manual input, you can enter an acceleration value

Under a =, the current acceleration at the position of the fixed

point is displayed.

If Manual input is deactivated, the acceleration value is

calculated by the system. The jerk diagram (J diagram) is

smooth at the position of the fixed point.

If Manual input is activated, you can enter an acceleration value.

To change the acceleration, enter the new acceleration under a =

and click Accept or OK. The display of the fixed point in the

diagrams is refreshed.

under a =.

If you deactivate Manual input, the acceleration value is

calculated by the system. The jerk diagram (J diagram) is

smooth at the position of the fixed point.

Notice

To specify an absolute slave velocity, you must select an absolute master velocity for

calculations in the Simulation Settings window.

4.3.5 Changing the acceleration at a fixed point position:

Requirements

The cam is opened with SIMOTION CamTool.

Change acceleration at fixed point

To change the acceleration at the fixed point position:

1. Right-click the fixed point and select Direct entry for acceleration in the displayed context

menu.

2. The acceleration at a fixed point position is represented by a handle in the A diagram

(acceleration diagram).

Select the handle. The mouse pointer shows the direction in which you can move the

handle.

3. Move the handle with drag&drop to the new position.

or

CamTool

4-6 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 49

Functions

4.4 Straight line

1. Double-click the fixed point. The Fixed Point Properties window appears.

2. In the Dynamic response tab, activate the option Manual input and enter the new

acceleration.

3. Click OK. The handle in the A diagram (acceleration diagram) is shown at the new

position.

Notice

To specify an absolute slave acceleration, you must select an absolute master velocity

for calculations in the Simulation Settings window.

4.3.6 Delete fixed point

Requirements

The cam is opened with SIMOTION CamTool.

Delete fixed point

To delete a fixed point:

1. Select the fixed point that you want to delete.

2. Press the DEL key. The fixed point is deleted and the representation of the cam adjusted

in all diagrams.

4.4 Straight line

4.4.1 Definition straight line

Definition

The cam consists of individual cam segments. Under SIMOTION CamTool, you can use

fixed points, straight lines, sine curves, arc sine curves and interpolation points as cam

segments.

A straight line defines a synchronous distance in the cam. You can specify the velocity along

the straight line.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-7

Page 50

Functions

4.4 Straight line

4.4.2 Insert straight line

Requirements

The cam is opened with SIMOTION CamTool.

Insert straight line

To insert a straight line:

1. Click in the S diagram (distance diagram) to activate the diagram.

2. Click Straight line under menu Cam > Insert. The mouse pointer changes.

With the changed mouse pointer, click the position in the S diagram (distance diagram) at

which you want to insert the straight line. The straight line is inserted with a default size.

The current position of the straight line is shown in the tooltip.

Figure 4-3 Insert straight line

CamTool

4-8 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 51

Functions

4.4 Straight line

Notice

Once the function Cam > Insert > Straight line is activated, you can insert straight lines in

the S diagram (distance diagram) until

• you press the ESC key,

• you press the right mouse button (this activates the selection tool in the toolbar) or

• you activate another cam segment (fixed point, sine curve, arc sine curve, interpolation point)

for insertion.

4.4.3 Change straight line position

Requirements

The cam is opened with SIMOTION CamTool.

Change straight line position

To change the position of a straight line:

1. Select the straight line in the S diagram (distance diagram). The position of the straight

line is shown in the tooltip.

2. The straight line is shown with handles. Move the handles of the straight line with

drag&drop to the new positions.

or

1. Select the straight line in the S diagram (distance diagram). The position of the straight

line is shown in the tooltip.

2. Move the whole straight line with drag&drop to the new position.

Figure 4-4 Change the position of all straight lines

or

1. Double-click the straight line. The Straight Line Properties window appears.

2. Enter the new positions in the Position tab (left: x1 and y1, right: x2 and y2), and click OK.

The representation of the straight lines in the diagram will be updated and displayed at

the new positions.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-9

Page 52

Functions

4.4 Straight line

4.4.4 Changing the velocity along a straight line

Requirements

The cam is opened with SIMOTION CamTool.

Change velocity along a straight line

To change the velocity along a straight line:

1. The velocity along a straight line is represented by a line in the V diagram (velocity

diagram).

Select the line. The mouse pointer shows the direction in which you can move the line.

2. Move the line with drag&drop to the new position. The S diagram (distance diagram) is

automatically adjusted.

Figure 4-5 Changing the velocity along a straight line

or

1. Double-click the straight line. The Straight Line Properties window appears.

2. Enter the new velocity in the Dynamic response tab and click OK. The line in the V

diagram (velocity diagram) is shown at the new position. The S diagram (distance

diagram) is automatically adjusted.

Notice

To specify an absolute slave velocity, you must select an absolute master velocity for

calculations in the Simulation Settings window.

CamTool

4-10 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 53

Functions

4.5 Sine curve

4.4.5 Delete straight line

Requirements

The cam is opened with SIMOTION CamTool.

Deleting a straight line

To delete a straight line:

1. Select the straight line that you want to delete.

2. Press the DEL key. The straight line is deleted and the representation of the cam

adjusted in all diagrams.

4.5 Sine curve

4.5.1 Insert sine curve

Requirements

The cam is opened with SIMOTION CamTool.

Insert sine curve

To insert a sine curve:

1. Click in the S diagram (distance diagram) to activate the diagram.

2. Click Sine under menu Cam > Insert > Functions. The mouse pointer changes.

3. With the changed mouse pointer, click the position in the S diagram (distance diagram) at

which you want to insert the sine curve. The sine curve is inserted with a default size.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-11

Page 54

Functions

4.5 Sine curve

The current position of the sine curve is shown in the tooltip.

Figure 4-6 Insert sine curve

Notice

Once the function Cam > Insert > Sine is activated, you can insert sine curves in the S

diagram (distance diagram) until

• you press the ESC key,

• you press the right mouse button (this activates the selection tool in the toolbar) or

• you activate another cam segment (fixed point, straight line, arc sine curve, interpolation point)

for insertion.

CamTool

4-12 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 55

Functions

4.5 Sine curve

4.5.2 Change sine curve position

Requirements

The cam is opened with SIMOTION CamTool.

Change sine curve position

To change the position of a sine curve:

1. Select the sine curve in the S diagram (distance diagram).

The current position of the sine curve is shown in the tooltip.

2. The sine curve is shown with handles. Point to a handle. The mouse pointer shows the

direction in which you can move the handle.

3. Move the handles with drag&drop to the new positions.

Figure 4-7 Change sine curve position

or

1. Select the sine curve in the S diagram (distance diagram).

The current position of the sine curve is shown in the tooltip.

2. Move the whole sine curve with drag&drop to the new position.

Figure 4-8 Changing the position of the complete sine curve

or

1. Double-click the sine curve. The Fx Sine Properties window appears.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-13

Page 56

Functions

4.5 Sine curve

2. Enter the new position in the Position tab and click OK. The sine curve is shown at the

new position.

Figure 4-9 Position (Fx Sine Properties) tab

4.5.3 Change sine curve definition range

Requirements

The cam is opened with SIMOTION CamTool.

Change sine curve definition range

To change the definition range of a sine curve:

1. Select the sine curve in the S diagram (distance diagram).

The current position of the sine curve is shown in the tooltip.

2. The sine curve is shown with handles. The handles for the definition range are shown in

green. Point to a green handle. The mouse pointer shows the direction in which you can

move the handle.

3. Move the green handles with drag&drop to the new positions. While moving, the current

value of the respective limit of the definition range is displayed in the tooltip.

Figure 4-10 Change sine curve definition range

CamTool

4-14 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 57

Functions

4.6 Arc Sine Curve

4.5.4 Delete sine curve

Requirements

The cam is opened with SIMOTION CamTool.

Delete sine curve

To delete a sine curve:

1. Select the sine curve that you want to delete.

2. Press the DEL key. The sine curve is deleted and the representation of the cam adjusted

in all diagrams.

4.6 Arc Sine Curve

4.6.1 Insert arc sine curve

Requirements

The cam is opened with SIMOTION CamTool.

Notice

The arc sine curve is calculated as an interpolation point table. The number of interpolation

points can be specified in the Fx Arc Sine Properties window. Double-click the arc sine curve

to show the window.

Insert arc sine curve

To insert an arc sine curve:

1. Click in the S diagram (distance diagram) to activate the diagram.

2. Click Arc sine under menu Cam > Insert > Functions. The mouse pointer changes.

3. With the changed mouse pointer, click the position in the S diagram (distance diagram) at

which you want to insert the arc sine curve. The arc sine curve is inserted with a default

size.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-15

Page 58

Functions

4.6 Arc Sine Curve

The current position of the arc sine curve is shown in the tooltip.

Figure 4-11 Insert arc sine curve

Notice

Once the function Cam > Insert > Arc sine is activated, you can insert arc sine curves in

the S diagram (distance diagram) until

• you press the ESC key,

• you press the right mouse button (this activates the selection tool in the toolbar) or

• you activate another cam segment (fixed point, straight line, sine curve, interpolation point) for

insertion.

CamTool

4-16 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 59

Functions

4.6 Arc Sine Curve

4.6.2 Change arc sine curve position

Requirements

The cam is opened with SIMOTION CamTool.

Change arc sine curve position

To change the position of an arc sine curve:

1. Select the arc sine curve in the S diagram (distance diagram).

The current position of the arc sine curve is shown in the tooltip.

2. The arc sine curve is shown with handles. Point to a handle. The mouse pointer shows

the direction in which you can move the handle.

3. Move the handles with drag&drop to the new positions.

Figure 4-12 Change arc sine curve position

or

1. Select the arc sine curve in the S diagram (distance diagram).

The current position of the arc sine curve is shown in the tooltip.

2. Move the whole arc sine curve with drag&drop to the new position.

Figure 4-13 Changing the position of the complete arc sine curve

or

1. Double-click the sine curve.

The Fx Arc Sine Properties window appears.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-17

Page 60

Functions

4.6 Arc Sine Curve

2. Enter the new position and the number of interpolation points in the Position tab and

click OK. The arc sine curve is shown at the new positions. The arc sine curve is saved

by the system as an interpolation point table.

Figure 4-14 Position tab

4.6.3 Change arc sine curve definition range

Requirements

The cam is opened with SIMOTION CamTool.

Change arc sine curve definition range

To change the definition range of an arc sine curve:

1. Select the arc sine curve in the S diagram (distance diagram).

The current position of the arc sine curve is shown in the tooltip.

2. The arc sine curve is shown with handles. The handles for the definition range are shown

in green. Point to a green handle. The mouse pointer shows the direction in which you

can move the handle.

CamTool

4-18 Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

Page 61

Functions

4.6 Arc Sine Curve

3. Move the green handles with drag&drop to the new positions. While moving, the current

value of the respective limit of the definition range is displayed in the tooltip.

Figure 4-15 Change arc sine curve definition range

4.6.4 Delete arc sine curve

Requirements

The cam is opened with SIMOTION CamTool.

Delete arc sine curve

To delete an arc sine curve:

1. Select the arc sine curve that you want to delete.

2. Press the DEL key. The arc sine curve is deleted and the representation of the cam

adjusted in all diagrams.

CamTool

Configuration Manual, 12.2004, 6AU1900-1AB32-0BA0

4-19

Page 62

Functions

4.7 Interpolation point

4.7 Interpolation point

4.7.1 Interpolation Point Definition

Definition

The cam consists of individual cam segments. Under SIMOTION CamTool, you can use

fixed points, straight lines, sine curves, arc sine curves and interpolation points as cam

segments.

An interpolation point is a specified position in the S diagram (distance diagram).

4.7.2 Insert interpolation point

Requirements

The cam is opened with SIMOTION CamTool.

Notice

With a fixed point, you define a single fixed position. The transitions between adjacent cam

segments are optimally calculated by CamTool.

If you want to specify an arbitrary characteristic, you must use interpolation points. The

interpolation points are connected by CamTool with cubic splines in order to generate a

curve specified by the interpolation points which is as exact as possible.

Insert interpolation point