Page 1

Preface

1

Safety information and

general information

2

Description

3

Usage planning

4

Installation

5

Connecting

6

Operating

7

Operating and parametrizing

8

Maintenance and Service

9

Technical specifications

10

Appendix

11

SIMATIC PC

Panel PC 670 V2/870 V2

Control unit

Operating Instructions

Edition 03/2004

Page 2

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety as well as to avoid

property damage. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol.

Danger

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Caution

used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Caution

used without safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

Notice

used without the safety alert symbol indicates a potential situation which, if not avoided, may result in

an undesirable result or state.

Wehn several danger levels apply, the notices of the highest level (lower number) are always displayed. If a

notice refers to personal damages with the safety alert symbol, then another notice may be added warning of

property damage.

Qualified Personnel

The device/system may only be set up and operated in conjunction with this documentation. Only qualified

personnel should be allowed to install and work on the equipment. Qualified persons are defined as persons who

are authorized to commission, to earth, and to tag circuits, equipment and systems in accordance with

established safety practices and standards.

Intended Use

Please note the following:

Warning

This device and its components may only be used for the applications described in the catalog or

technical description, and only in connection with devices or components from other manufacturers

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up and installed

correctly, and operated and maintained as recommended.

Trademarks

All designations marked with ® are registered trademarks of Siemens AG. Other designations in this

documentation might be trademarks which, if used by third parties for their purposes, might infringe upon the

rights of the proprietors.

Copyright Siemens AG ,2004.All rights reserved

Reproduction, transmission or use of this document or its contents is not permitted without

express written authority. Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are reserved.

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in the manual are reviewed regularly, and any

necessary corrections will be included in subsequent editions. Suggestions for

improvement are welcomed.

Siemens AG

Automation and Drives Group

P.O. Box 4848, D-90327 Nuremberg (Germany)

Siemens AG 2004

Technical data subject to change

Siemens Aktiengesellschaft Order No. CD Documentation and Drivers

Page 3

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

iii

Table of contents

1 Preface ................................................................................................................................................... 1-1

1.1 This manual................................................................................................................................ 1-1

1.2 Further Support.......................................................................................................................... 1-4

2 Safety information and general information ............................................................................................ 2-1

2.1 Safety Information...................................................................................................................... 2-1

2.2 General Information ................................................................................................................... 2-2

2.3 Operating panel guidelines ........................................................................................................ 2-3

3 Description.............................................................................................................................................. 3-1

3.1 Panel PC 670 V2: Computer unit and control unit..................................................................... 3-1

3.2 Panel PC 870 V2: Computer unit and control unit..................................................................... 3-2

3.3 Distributed Structure .................................................................................................................. 3-4

3.3.1 Overview .................................................................................................................................... 3-4

3.3.2 Configuration.............................................................................................................................. 3-5

3.4 Available combinations .............................................................................................................. 3-5

3.5 Options....................................................................................................................................... 3-5

4 Usage planning....................................................................................................................................... 4-1

4.1 Overview .................................................................................................................................... 4-1

4.2 Unpacking and checking the delivery unit ................................................................................. 4-1

4.3 Make note of identification data ................................................................................................. 4-2

4.4 Guidelines for Handling Electrostatic Sensitive Devices (EMC)................................................ 4-4

4.5 Mounting postion and attachment.............................................................................................. 4-4

4.5.1 Installation guidelines................................................................................................................. 4-4

4.5.2 Approved installation positions .................................................................................................. 4-6

4.5.3 Method of attachment ................................................................................................................ 4-7

4.5.4 Degree of protection .................................................................................................................. 4-7

4.6 Recessed mounting cut-out ....................................................................................................... 4-7

4.6.1 Selecting and completing recessed mounting cut-out ............................................................... 4-7

4.6.2 Dimensions ................................................................................................................................ 4-9

5 Installation .............................................................................................................................................. 5-1

5.1 Securing with clamps ................................................................................................................. 5-1

5.2 Securing with screws ................................................................................................................. 5-2

6 Connecting ............................................................................................................................................. 6-1

6.1 Interfaces ................................................................................................................................... 6-1

6.1.1 Front-sided interfaces ................................................................................................................ 6-1

6.1.2 Other interfaces ......................................................................................................................... 6-2

Page 4

Table of contents

Panel PC 670 V2/870 V2, Control unit

iv Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6.2 Connecting a decentralized design............................................................................................ 6-3

6.2.1 Overview .................................................................................................................................... 6-3

6.2.2 Decentralized design.................................................................................................................. 6-3

6.2.3 Equipotential bonding................................................................................................................. 6-4

6.2.4 Connecting equipotential bonding.............................................................................................. 6-5

6.2.5 Connecting the computer unit-control unit connecting cable ..................................................... 6-6

6.2.6 Connecting the power supply..................................................................................................... 6-6

6.2.7 Block diagram ............................................................................................................................ 6-7

7 Operating................................................................................................................................................ 7-1

7.1 Status displays ........................................................................................................................... 7-1

7.2 Operator controls on key panels ................................................................................................7-1

7.2.1 Overview .................................................................................................................................... 7-1

7.2.2 Keyboard.................................................................................................................................... 7-2

7.2.3 Labelling function keys and softkeys ......................................................................................... 7-5

7.2.4 Integrated mouse ....................................................................................................................... 7-6

7.3 Operator controls of the touch screen panels............................................................................ 7-7

7.3.1 Overview .................................................................................................................................... 7-7

7.3.2 Touch screen ............................................................................................................................. 7-8

8 Operating and parametrizing .................................................................................................................. 8-1

8.1 Start up....................................................................................................................................... 8-1

8.1.1 Overview .................................................................................................................................... 8-1

8.1.2 Turn on device ........................................................................................................................... 8-2

8.1.3 Setting up Microsoft Windows operating system ....................................................................... 8-3

8.1.4 Installing applications and drivers .............................................................................................. 8-3

8.2 Normal operation........................................................................................................................ 8-7

8.2.1 Turning on device....................................................................................................................... 8-7

8.2.2 Turning off the device................................................................................................................. 8-8

8.3 Additional drivers and applications ............................................................................................8-9

8.3.1 Overview .................................................................................................................................... 8-9

8.3.2 Setting up touchware ................................................................................................................. 8-9

8.3.3 Repeating calibration ............................................................................................................... 8-11

8.3.4 KeyTools .................................................................................................................................. 8-13

8.3.5 KeyHook................................................................................................................................... 8-14

8.3.6 Keypad ..................................................................................................................................... 8-15

8.3.7 SIMATIC SOM Safecard on Motherboard.............................................................................. 8-17

8.3.8 TouchInputPC .......................................................................................................................... 8-17

8.3.9 Set brightness .......................................................................................................................... 8-18

8.3.10 CheckLanguageID ................................................................................................................... 8-18

8.3.11 Installing user interface language ............................................................................................ 8-19

8.3.12 Changing user language.......................................................................................................... 8-20

8.3.13 Changing the standard language............................................................................................. 8-22

8.3.14 DVD ROM / CD RW ................................................................................................................. 8-23

8.3.15 USB keyboard controller driver and USB stack ....................................................................... 8-24

9 Maintenance and Service ....................................................................................................................... 9-1

9.1 Service ....................................................................................................................................... 9-1

9.2 Maintenance and replacement parts.......................................................................................... 9-2

9.3 Separating the control unit and the computer unit in the central design.................................... 9-2

9.3.1 Separating Panel PC 670 V2 .....................................................................................................9-2

9.3.2 Separating Panel PC 870 V2 .....................................................................................................9-4

10 Technical specifications........................................................................................................................ 10-1

Page 5

Table of contents

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

v

10.1 Technical data.......................................................................................................................... 10-1

10.1.1 EMC requirements ................................................................................................................... 10-1

10.1.2 Central design technical data................................................................................................... 10-2

10.1.3 Ambient and environmental conditions.................................................................................... 10-3

10.1.4 Decentralized design technical data ........................................................................................ 10-4

10.2 Dimensional drawings.............................................................................................................. 10-5

10.2.1 Overview .................................................................................................................................. 10-5

10.2.2 Panel PC 670 V2 dimensions for central design ..................................................................... 10-5

10.2.3 Panel PC 870 V2 dimensions for central design ..................................................................... 10-6

10.3 Interfaces ................................................................................................................................. 10-7

10.3.1 USB port................................................................................................................................... 10-7

10.4 Keyboard table ......................................................................................................................... 10-7

11 Appendix............................................................................................................................................... 11-1

11.1 Certificates and guidelines....................................................................................................... 11-1

11.1.1 Approvals ................................................................................................................................. 11-1

11.1.2 ESD guideline .......................................................................................................................... 11-1

11.2 Abbreviations ........................................................................................................................... 11-4

11.3 Glossary ................................................................................................................................... 11-5

Page 6

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Page 7

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

1-1

Preface

1

1.1 This manual

Purpose of the Manual

This manual provides you with information derived from the requirements for manuals in

conformity with mechanical engineering documentation according to DIN 8418. This

information refers to the device, its place of use, transport, storage, installation, usage and

maintenance.

This manual is aimed at the following target groups:

• Users

• Commissioners

• Service technicians

• Maintenance technicians

Please pay particular attention to the chapter "Safety Information and General Information."

Required Basic Knowledge

Thorough knowledge of personal computers and Microsoft operating systems is required.

General knowledge in the field of automation is recommended.

Where is this Manual valid?

This manual is valid for devices with the order numbers 6AV772…, 6AV773…, 6AV774…

and 6AV775….

Changes compared to the previous version 11/02

Start up instructions and device manual are combined in the control unit operating

instructions. The structure of the document was standardized: Heading and numbering of the

main chapter describe the main steps in their processing sequence.

Page 8

Preface

1.1 This manual

Panel PC 670 V2/870 V2, Control unit

1-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Incorporation into the communications environment

The documentation for the Panel PC comprises the following parts:

• SIMATIC Panel PC 670 V2 start up instructions,

SIMATIC Panel PC 870 V2, QuickStart with the following information:

– Starting up

– Legal notes

• SIMATIC Panel PC 670 V2 control unit device manual,

SIMATIC Panel PC 870 V2, control unit operating instructions with the following

information:

– Operation

– Error diagnostics

– Hardware

Referred to briefly as "control unit operating instructions" hereafter.

• SIMATIC Panel PC 670 V2 computer unit device manual,

SIMATIC Panel PC 870 V2, computer unit operating instructions with the following

information:

– Expansion possibilities

– Configuration

– Error diagnostics

– Hardware

Referred to briefly as "computer unit operating instructions" hereafter.

The documentation is delivered with the PC panel electronically on the "Documentation &

Drivers" CD in PDF format. QuickStart for the Panel PC 870 V2 is enclosed in printed form in

addition. The documentation is available in German, English, French, Italian and Spanish.

For further information concerning the Windows operating system, please visit the Microsoft

homepage at "www.Microsoft.com."

Online availability

The following links will guide you directly to the range of technical documentation for

SIMATIC products and systems in German, English, French, Italian and Spanish.

• SIMATIC Guide for Technical Documentation in German:

http://www.ad.siemens.de/simatic/portal/html_00/techdoku.htm

• SIMATIC Guide for Technical Documentation in English:

http://www.ad.siemens.de/simatic/portal/html_76/techdoku.htm

Page 9

Preface

1.1 This manual

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

1-3

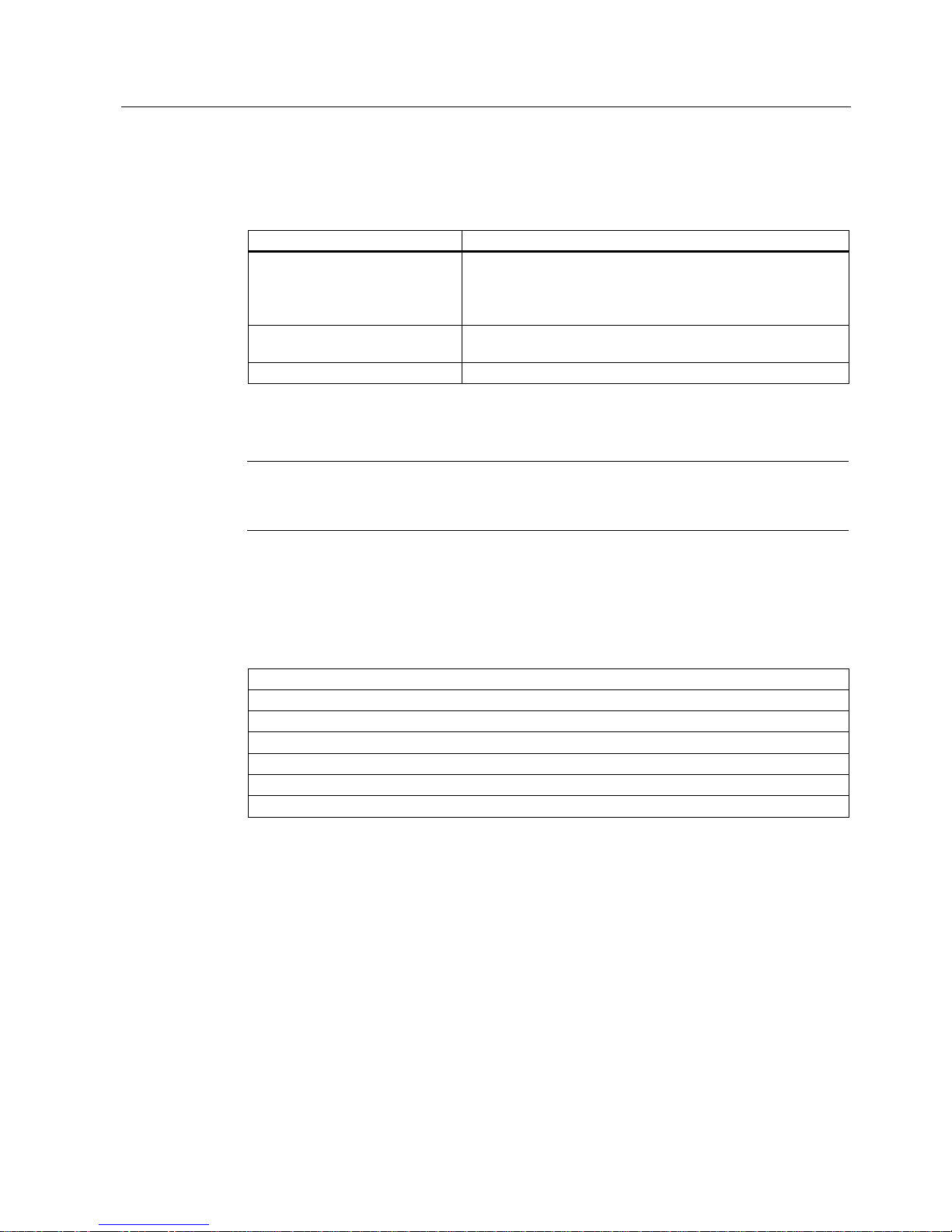

Conventions

The following text distinctions make it easier for you to read the manual:

Type of display Area of validity

"File"

• Terms which appear on the user interface, for example,

dialog names, tab controls, buttons, menu commands.

• Required entries, e.g. limit values, tag values.

• Path information

"File > Process" Operating sequences, e.g. menu commands, context menu

commands.

<F1>, <Shift>+<F1> Keys and key combinations

In these operating instructions, the standard term "device" replaces the terms "Panel PC

670/870 V2," "control unit," and "computer unit." The concrete term is used only where

necessary.

Note

A

reference is important information concerning the product, the handling of the product, or it

points out a certain part of the documentation to which particular attention should be paid.

Trademarks

All designations bearing the ® trademark symbol are registered trademarks of Siemens AG.

All other designations in this documentation are trademarks, whose use by third parties for

their own purposes might infringe on the rights of the owner.

HMI ®

SIMATIC ®

SIMATIC HMI ®

SIMATIC ProTool®

SIMATIC WinCC ®

Panel PC 670®

Panel PC 870®

Page 10

Preface

1.2 Further Support

Panel PC 670 V2/870 V2, Control unit

1-4 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

1.2 Further Support

Representatives and offices

Please consult your Siemens representative at the office nearest you for any other questions

regarding the use of the products described in the manual.

Locate your representative at:

http://www.siemens.com/automation/partner

Training Centers

Siemens offers a number of training courses to familiarize you with the automation system.

Please contact your regional training center or our central training center in 90327

Nuremberg, Germany for details:

Telephone: +49 (911) 895-3200.

Internet: http://www.sitrain.com/

Service & Support on the Internet

Extensive additional information concerning the SIMATIC products is available to you

through online services at "http://www.siemens.com/automation/service&support."

• The newsletter with continuously updated information about your products.

• Numerous documents available through search in Service & Support.

• A bulletin board, where users and experts from all over the world exchange their

experiences.

• Current product information, FAQs and downloads.

• Your local representative for Automation & Drives.

• Infomation about local service, repairs, replacement parts and much more under the

heading "Services."

Page 11

Preface

1.2 Further Support

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

1-5

A&D Technical Support

Available 24 hours a day worldwide:

Worldwide (Nuremberg)

Technical Support

(Free Contact)

Local time: Mo - Fr 7:00 am to 5:00 pm

Telephone: +49 (0) 180 5050-222

Fax: +49 (0) 180 5050-223

E-mail: adsupport@siemens.com

GMT: +1:00

Worldwide(Nuremberg)

Technical Support

(subject to fees, with SIMATIC Card

only)

Local time: 24 hours a day / 365 days a

year:

Telephone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

GMT: +1:00

Europe / Africa (Nuremberg)

Authorization

Local time: Mo - Fr 7:00 am to 5:00 pm

Telephone: +49 (911) 895-7200

Fax: +49 (911) 895-7201

E-Mail:

adauthorisierung@siemens.com

GMT: +1:00

United States(Johnson City)

Technical Support and Authorization

Local time: Mo - Fr 8:00 am to 7:00 pm

Telephone: +1 423 461-2522

Fax: +1 423 461-2289

E-mail:

simatic.hotline@sea.siemens.com

GMT: -5:00

Asia/Pacific(Beijing)

Technical Support and Authorization

Local time: Mo - Fr 8:30 am to 5:00 pm

Telephone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-mail:

adsupport.asia@siemens.com

GMT: +8:00

Information available in German and English.

Page 12

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Page 13

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

2-1

Safety information and general information

2

2.1 Safety Information

Electrical Connection

Warning

Unplug the device before every intervention and after disconnecting it from the power

supply.

Avoid contact with network lines and data transmission lines during thunderstorms, and do

not connect any lines during this time.

High frequency radiation

Caution

Unintentional operating situation

High frequency radiation, e.g. from cell phones, can cause unintentional operating situations

under some circumstances. For more details, consult the technical data in the "EMC

Requirements" chapter.

Handling and disposal of lithium batteries

Warning

Danger of explosion and the release of harmful substances!

Do not throw lithium batteries into fire, do not solder onto the cell body, do not open, do not

short circuit, do not reverse pole, do not heat above 100 °C, dispose of according to

regulations, and protect from direct sunlight, moisture and condensation.

Replace lithium batteries with the same brand or a brand recommended by the

manufacturer.

Dispose of used lithium batteries individually as hazardous waste in accordance with the

local regulations.

Page 14

Safety information and general information

2.2 General Information

Panel PC 670 V2/870 V2, Control unit

2-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

2.2 General Information

Overview

Caution

The device is approved for operation in closed rooms only.

Notice

The guarantee is void if these stipulations are ignored.

Avoid extreme environmental operating conditions. Protect your device against dust,

moisture and heat. For additional information, refer to the specifications.

Do not place the device in direct sunlight.

Transport

Unpack the device at the its installation location. Transport the device only in the original

packaging. Do not transport the device when it is mounted.

Notice

Adhere to these stipulations each time the device is transported, otherwise the guarantee is

void.

Caution

Condensation

When transporting the device in low temperatures, ensure that no moisture gets on or in the

device. This also applies when the device is subjected to extreme changes in temperature.

Commissioning

Allow the device to slowly adjust to room temperature before commissioning the device. Do

no place the device near heat radiation. If moisture condensation occurs, wait at least about

12 hours before you switch on the device.

Vibration

CD/DVD drives are sensitive to vibration. Vibrations during operation may result in loss of

data or damage to the drive or data medium.

Before transporting the device, wait at least 20 seconds to allow the drive to stop completely.

Updates

Regularly check if hotfixes for your device are available at the Siemens Internet site.

Page 15

Safety information and general information

2.3 Operating panel guidelines

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

2-3

2.3 Operating panel guidelines

Reistance to chemicals

Caution

The panel of the control unit is only partially resistant to chemicals. More information is

available in the internet at "www.ad.siemens.de" under the heading "Products & Solutions."

Click on "Service & Support" under "Services" and look for the article-ID "16532108" on the

"Product Support" page. The desired article about chemical resistance will be displayed.

Sources of light

Notice

Position the screen so that it is not subject to direct sunlight or other strong sources of light.

Faulty pixels in the display

At present, the manufacturing process of modern displays does not guarantee that all pixels

of the display will be perfect. A small number of faulty pixels in the display, is therefore

unavoidable. This does not present a functional problem as long as the faulty pixels are not

bunched in one location.

For additional information, refer to the technical data.

TFT-LC display

A permanent picture with bright images can lead to a burn-in effect on the LCD.

If a screen saver is activated, please observe the following:

• The liquid crystals in screen savers which actuate active black when the backlighting is

on, e.g. flying stars "starfield simulation," renew themselves. Pay attention to the length of

time the backlighting is activated.

• The following applies to screen savers which turn off the the backlighting tubes: Each

time the backlighting is turned on, its life is reduced by 50 minutes.

Consider the following carefully:

• Use of a screen saver

• Turn off the backlighting regularly

• Permanent display of the customer application

Page 16

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Page 17

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

3-1

Description

3

3.1 Panel PC 670 V2: Computer unit and control unit

Design

The device is available in two different designs:

• Central design: Computer unit and control unit form an entity.

• Decentralized design: Computer unit and control unit are in separate locations.

Principle

In the central design, the computer is screwed to the back of the control unit with two

mounting rails. The computer unit is connected to the control unit by screws.

Computing unit

Operating unit

Figure 3-1 Panel PC 670 V2 as a complete device with central design

Page 18

Description

3.2 Panel PC 870 V2: Computer unit and control unit

Panel PC 670 V2/870 V2, Control unit

3-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Product brief

The device is available with different control units, which distinguish themselves by the size

of the display and by the membrane keyboard or touch screen.

Keyboard variants

• Color display with backlighting:

– 10.4'' TFT technology with the 640 x 480 pixels resolution

or

– 12.1'' TFT technology with 800 x 600 pixels resolution

or

– 15.1'' TFT technology with 1024 x 768 pixels resolution

• Membrane keyboard with alphanumeric keys, numeric keys, cursor keys and control keys

• Function keys and softkeys

• Integrated mouse

• LEDs for power supply, temperature, softkeys, <Shift> and <ACK> keys.

• Front-mounted USB 1.1 port for connecting external I/O modules

Touch screen variants

• Color display with backlighting

– 12.1'' TFT technology with 800 x 600 pixels resolution or

– 15.1'' TFT technology with 1024 x 768 pixels resolution

• LEDs for power supply and temperature

• Front-mounted USB 1.1 port for connecting external I/O modules, not included in order

option "control unit without front-mounted USB port"

For additional information, refer to the technical data.

3.2 Panel PC 870 V2: Computer unit and control unit

Design

The device is available in two different designs:

• Central design: Computer unit and control unit form an entity.

• Decentralized design: Computer unit and control unit are in separate locations.

Principle

In the central design, the computer is screwed to the back of the control unit with two

mounting rails.

Page 19

Description

3.2 Panel PC 870 V2: Computer unit and control unit

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

3-3

Operating unit Computing unit

Figure 3-2 Panel PC 870 V2 as a complete device in the central design

Product brief

The device is available with different control units, which distinguish themselves by the size

of the display and by the membrane keyboard or touch screen.

Keyboard variants

• Color display with backlighting:

– 12.1'' TFT technology with 800 x 600 pixels resolution

or

– 15.1'' TFT technology with 1024 x 768 pixels resolution

• Membrane keyboard with alphanumeric keys, numeric keys, cursor keys and control keys

• Function keys and softkeys

• Integrated mouse

• LEDs for power supply, temperature, softkeys, <Shift> and <ACK> keys

• Front-mounted USB 1.1 port for connecting external I/O modules

Page 20

Description

3.3 Distributed Structure

Panel PC 670 V2/870 V2, Control unit

3-4 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Touch screen variants

• Color display with backlighting

– 12.1'' TFT technology; 800 x 600 pixels resolution, available only in decentralized

design

or

– 15.1" TFT technology; 1024 x 768 pixels resolution

• LEDs for power supply and temperature

• Front-mounted USB 1.1 port for connecting external I/O modules, not icluded in the order

option "control unit without front-mounted USB port"

For additional information, refer to the technical data.

3.3 Distributed Structure

3.3.1 Overview

In the decentralized design, the control unit and computer unit are supplied as two separate

devices. The control unit and the computer unit are installed in separate locations.

USB cable

Interconnecting

cable

Receiver

Computing unit

Direct key module

(optional)

Transmitter

(fitted)

Power supply

cable

Operating Unit

Figure 3-3 Decentralized design overview

Page 21

Description

3.4 Available combinations

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

3-5

3.3.2 Configuration

The illustration in the overview depicts the components of the decentralized design:

• The remote module unit, also called receiver, and an optional direct key module are

attached to a mounting plate, which is screwed to the back of the control unit.

• The host module, also called sender, is installed below the computer unit between the

mounting rails.

• Connect the remote module and host module with a cable from the options.

Note

Refer to the relevant order variant in the catalog for the components of the decentralized

design. Before delivery from the factory, the order will beconfigured.

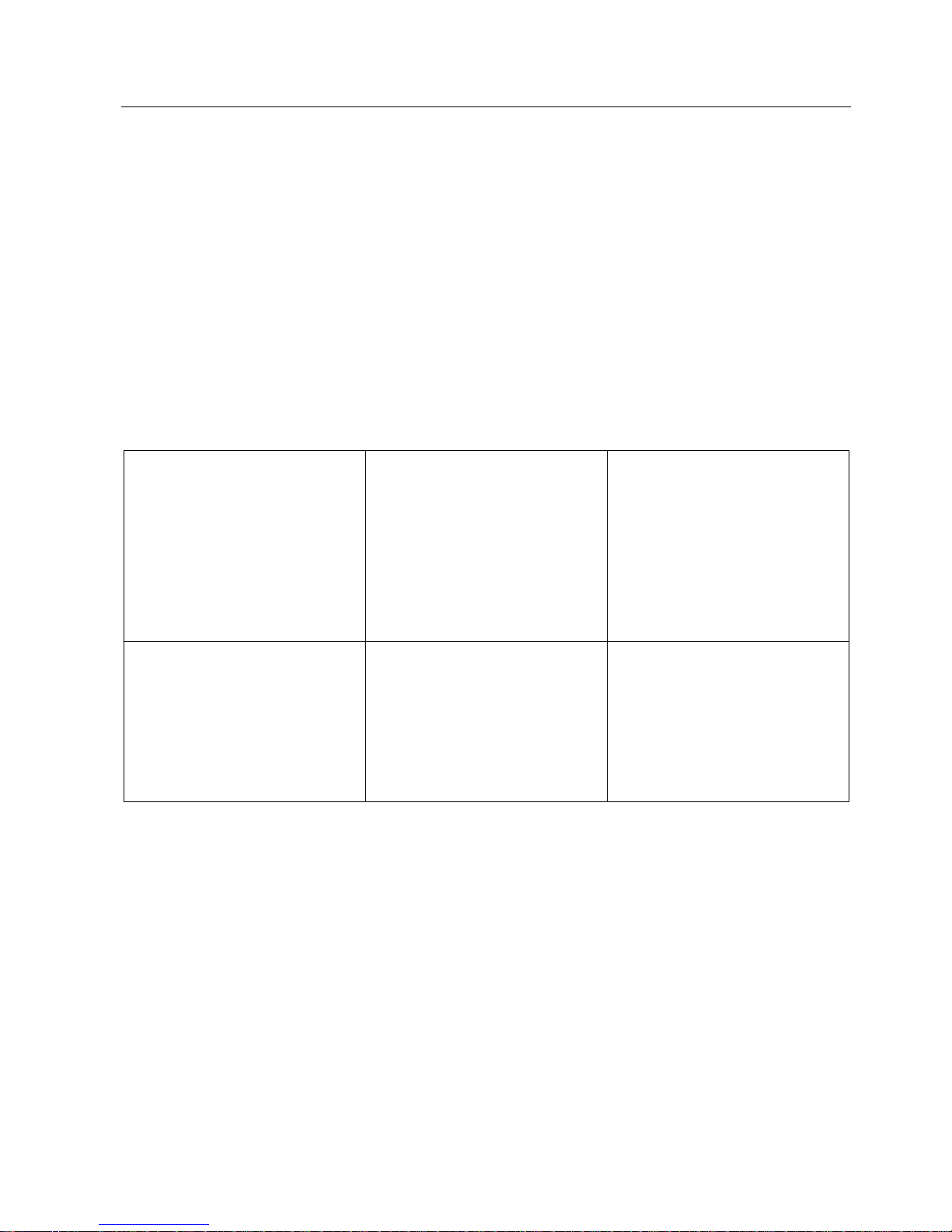

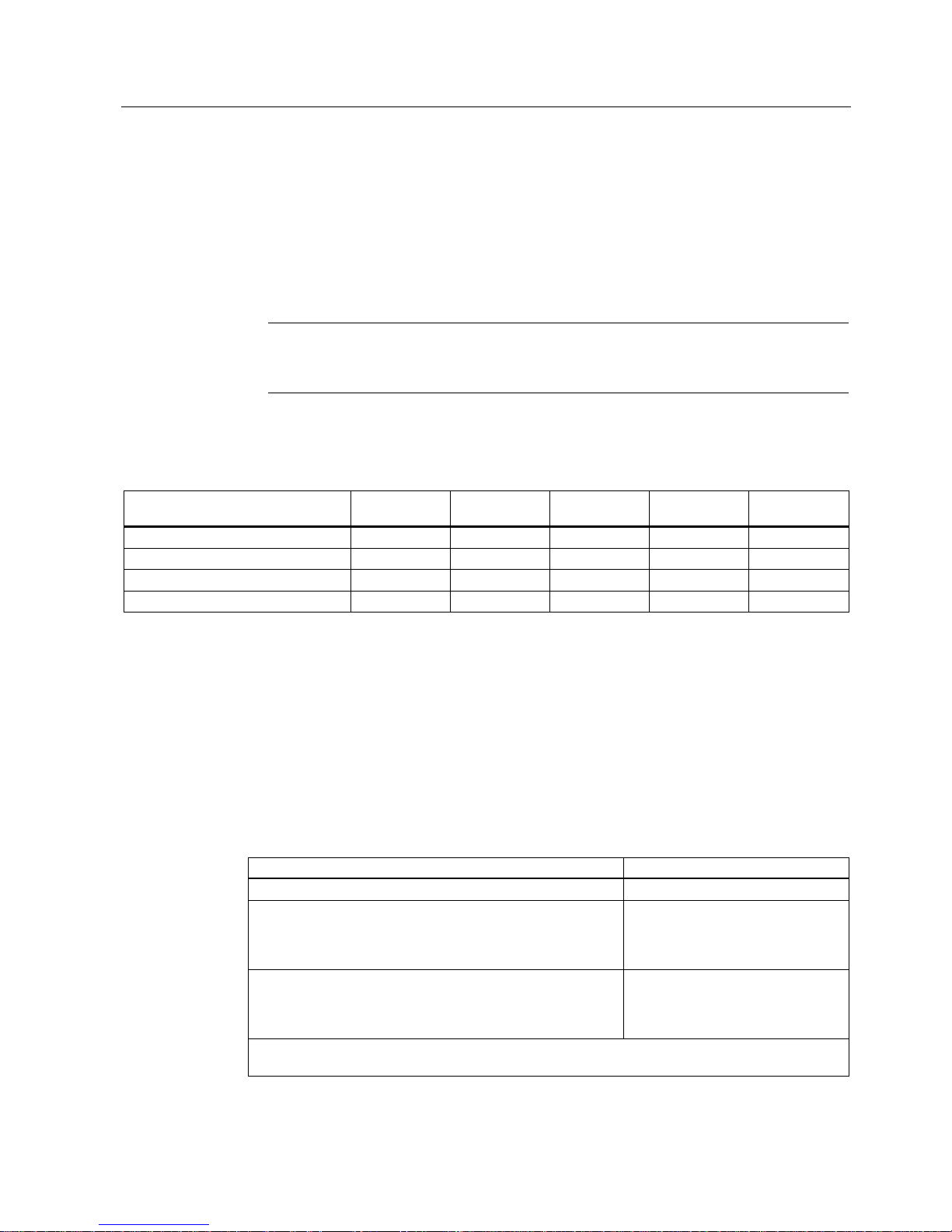

3.4 Available combinations

The available cominations of control unit and computer unit are listed in the table.

Control unit

computer unit

10.4" TFT 12.1" TFT 15.1" TFT 12.1" TFT

touch screen

15.1" TFT

touch screen

PC 670 V2 central design X X X X X

PC 670 V2 decentralized design — X X X X

PC 870 V2 central design — X X — X

PC 870 V2 decentralized design — X X X X

X = available

Direct key module

For more information, refer to the start up instructions included with the direct key module

3.5 Options

Components

The options comprise the following components:

Options Order No.

Direct key module 6AV7671-7DA00-0AA0

Film for protecting the touch screen panel against dirt and

scratches

for 12" touch screen varaiant

for 15" touch screen variant

6AV7671-2BA00-0AA0

6AV7671-4BA00-0AA0

Labeling strips

for 10" keyboard variant

for 12" keyboard variant

for 15" keyboard variant

6AV7671-0CA00-0AA0

6AV7671-3CA00-0AA0

6AV7671-5CA00-0AA0

The printing templates for the labelling strips can be obtained from the internet address in the

preface.

Page 22

Description

3.5 Options

Panel PC 670 V2/870 V2, Control unit

3-6 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

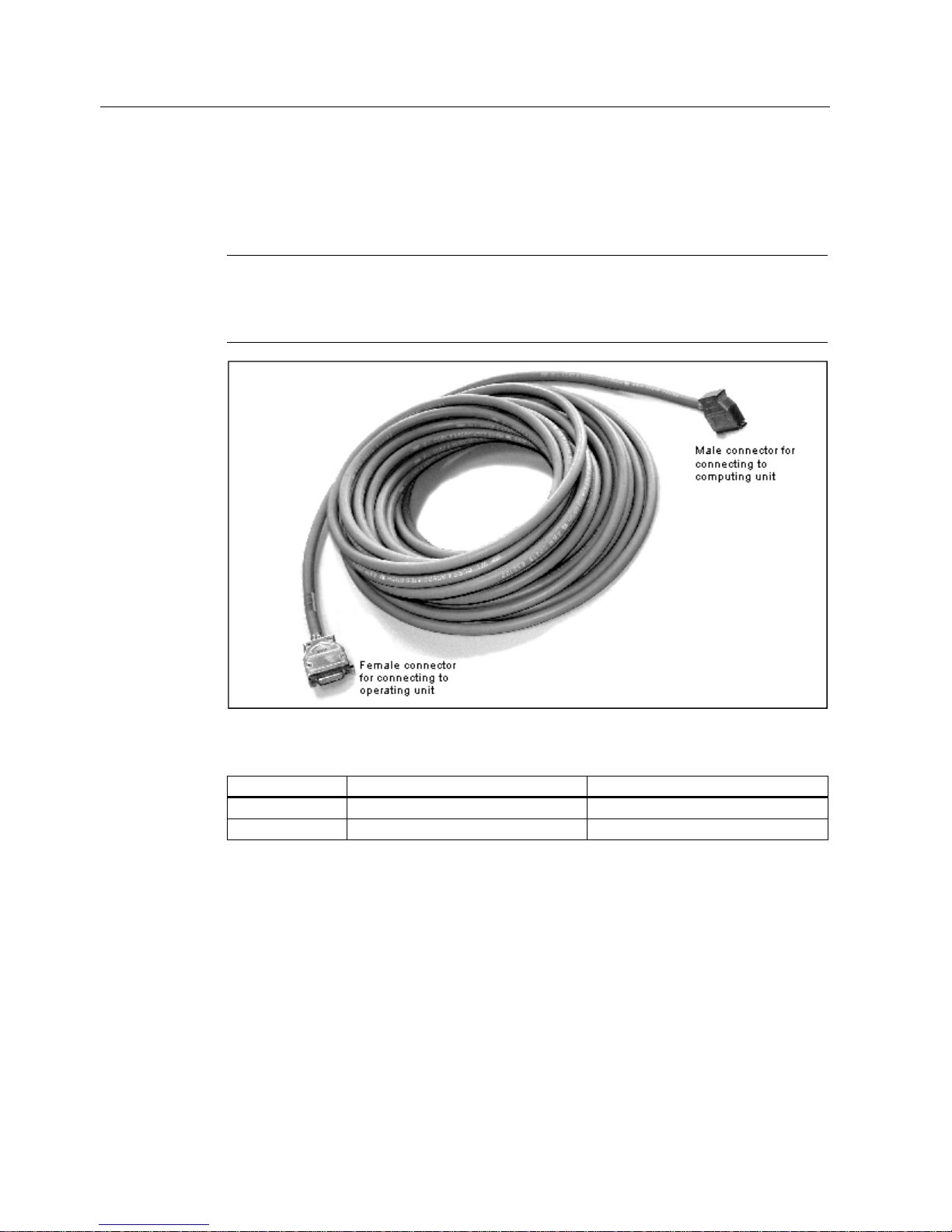

Computer unit-control unit connecting cable

For data exchange in the decentralized design, connect the remote module and the host

module with the up to 20 meters long green connecting cable.

Caution

Do not open the plug of the connecting cable and do not undo the connecting cable.

Otherwise the HF properties of the connecting cable will become irreversibly altered. Perfect

functioning is then no longer guaranteed.

Figure 3-4 Cable for connecting control unit and computer unit

Features Cable connector at the computer unit Cable connector at the control unit

Connector type 15pol. Sub-D male connector 15pol. Sub-D jack plug

Connector design 45° angle straight

Page 23

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-1

Usage planning

4

4.1 Overview

Introduction

This section describes the first steps after unpackaging, the permitted mounting positions

and the fixation. This section describes the necessary considerations for EMC.

Notice

Take note of the corresponding information in the operating instructions for the computer unit

and the operator unit.

Field of application

The SIMATIC Panel PC is an industry-standard PC platform for demanding tasks in the field

of PC-based automation. The Panel PC is designed for on-site use on the machine, installed

for example in:

• Control cabinets and consoles

• 19" racks

• Swivel arms (booms)

Note

In the following, the term "control cabinet" also refers to rack, mounting rack,

switchboard, operator panel and console. The term "device" represents the Panel PC and

its variants.

4.2 Unpacking and checking the delivery unit

Procedure

1. Upon delivery, check the packaging for damage incurred during transport.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device.

Page 24

Usage planning

4.3 Make note of identification data

Panel PC 670 V2/870 V2, Control unit

4-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4. Keep the packaging material in case you have to transport the unit again.

Notice

The packaging protects the device during transport and storage. Therefore, never

dispose of the original packaging material!

5. Please keep the enclosed documentation in a safe place. You will need the

documentation when you start up the device for the first time.

6. Check the package contents for completeness and any visible transport damage. Check

for completeness using the enclosed "Contents of Delivery" list.

7. Notify the delivery service in charge immediately if the packages contents are incomplete

or damaged.

Warning

Make sure that a damaged unit is not installed nor put into operation.

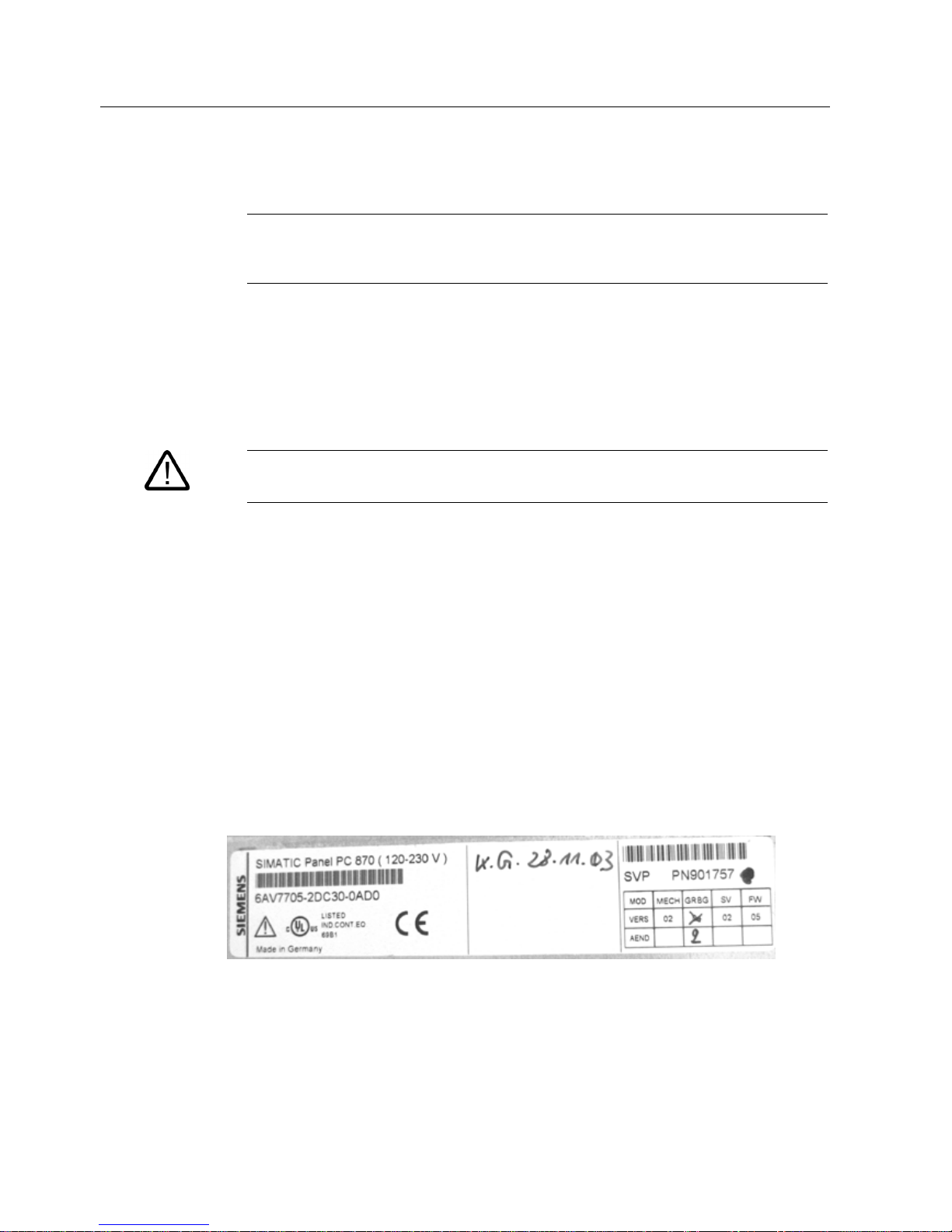

4.3 Make note of identification data

Procedure

1. Write down the Microsoft Windows Product Key of the Certificate of Authenticity COA in

the table at the end of this section. The product key is located on the power supply cover

of the computer unit. You will need the product key during the reinstallation of the

operating system.

2. Write down the manufacturer's number SVP and the order number of the computer unit,

e.g. "6AV..." in the table. If repairs are necessaryr, the device can be identified by the

service center on the basis of the SVP number and order number.

Both numbers are located on the rating label of the computer unit at the top of the

ventilator side.

Figure 4-1 Rating label of the computer unit, example

3. Write down the model designation, the serial number e.g. "ST-...," the order number of

the control unit, e.g. "A5E," and the version of the device. in the table. This data is located

on the rating label on the edge of the side of the control unit.

Page 25

Usage planning

4.3 Make note of identification data

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-3

Figure 4-2 Rating label of the control unit, example

4. Write down the ethernet address of the device: The ethernet address is located in the

"main" menu of the BIOS setup, "Hardware Options > Ethernet Address."

Identification Number

1 Microsoft Windows Product Key

2 SVP number

3 Order number of the computer unit

4 Power supply version —

5 Approbation —

6 Model designation

7 Serial number

8 Control unit order number

9 Device version

10 Ethernet address

Page 26

Usage planning

4.4 Guidelines for Handling Electrostatic Sensitive Devices (EMC)

Panel PC 670 V2/870 V2, Control unit

4-4 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4.4 Guidelines for Handling Electrostatic Sensitive Devices (EMC)

Electromagnetic Compatibility

The device fulfills the requirements of the EMC law of the Federal Republic of Germany as

well as the EMC Guidelines of the Single European Market.

The device is designed as a built-in model with front-sided Protection Class IP 65. Ensure

compliance with the EN 61000-4-2 standard by installing the device in grounded metal

cabinets, e.g. MC cabinets, Siemens catalog NV21.

Note

Please refer to the appendix for for more information concerning the EMC requirements.

Installing the device according to EMC guidelines

Principles of interference-free operation:

• Installing the controls according to EMC guidelines

• Using interference immune cable

Note

The instructions "Guidelines for the assembly of interference immune programmable logic

controllers" with the article ID 1064706 and the manual "PROFIBUS networks" with the

article ID 1971286, which also applies to the installation of the device, is located on the

"Documentation and Drivers" CD.

4.5 Mounting postion and attachment

4.5.1 Installation guidelines

Before installing the device, please observe the following information which applies both to

the centralized and decentralized designs.

Warning

Dangerous voltage

When opening the switch cabinet, beware of exposed live parts which are dangerous upon

contact.

Isolate the power supply to the switch cabinet before opening it. Make sure that the power to

the switch cabinet cannot be turned on accidentally.

Caution

The device is approved for use in closed areas only.

Page 27

Usage planning

4.5 Mounting postion and attachment

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-5

• Make sure that the protective contact socket of the building installation is easily

accessible, and that a central power disconnector exists in switch cabinet installations.

• Position the screen in an ergonomic position favorable to the user. Choose a suitable

installation height.

• Position the screen so that it is not subject to direct sunlight or other strong sources of

light.

• Shocks CD/DVD drives are susceptible to shocks. Shocks during operation can lead to

the loss of data or damage to the drive or data carrier. Burners and CD/DVD are not

suitable for long-term writing.

• Applies to devices which are installed in swivel arm housings: Avoid rapid or jerky

movements of the swivel arm during operation. The ensuing forces could lead to possible

irreversible damage of the hard disk.

• The device with DC power supply is considered an open means of operation on the part

of the voltage supply. Therefore, make sure that the switch cabinet fulfills the the

requirements of a fire protection housing.

Note

The computer unit with AC power supply fulfills the requirements of a fire protection

housing according to EN60950. Therefore, no additional fire protection is necessary for

the installation.

• Provide adequate volume in the switch cabinet for air circulation and heat transport. Keep

a distance of at least 10 cm circumference between the device and switch cabinet.

• Do not allow the maximum air intake temperature to exceed 45 °C. Decisive is the

temperature measured at a distance of 10 cm from an air intake. The maxiumum air

intake temperature must be accounted for especially when sizing closed switch cabinets.

• The minimum distance between the device and the housing is 10 cm on the air output

side at the ventilator.

• Position the device so that the air vents of the housing are not covered up following

installation.

• Provide an extra 1 cm of space for air circulation for the decentralized design.

• Also provide enough free space to add on to the device.

• The connecting cable between the control unit and the computer unit is 20 meters

maximum.

• Equip the switch cabinet with struts for stabilizing the recessed mounting cut-out. Install

struts where necessary.

• Avoid extreme environmental conditions. Protect your device from dust, moisture and

heat.

• Install the device in such a way that it poses no danger, e.g. by falling over.

• During assembly, please comply with the approved installation positions.

Notice

If the device is installed in an unapproved position, the licenses expire in accordance with

UL 508 and EN 60950!

For additional information, refer to the dimension diagrams in the appendix.

Page 28

Usage planning

4.5 Mounting postion and attachment

Panel PC 670 V2/870 V2, Control unit

4-6 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

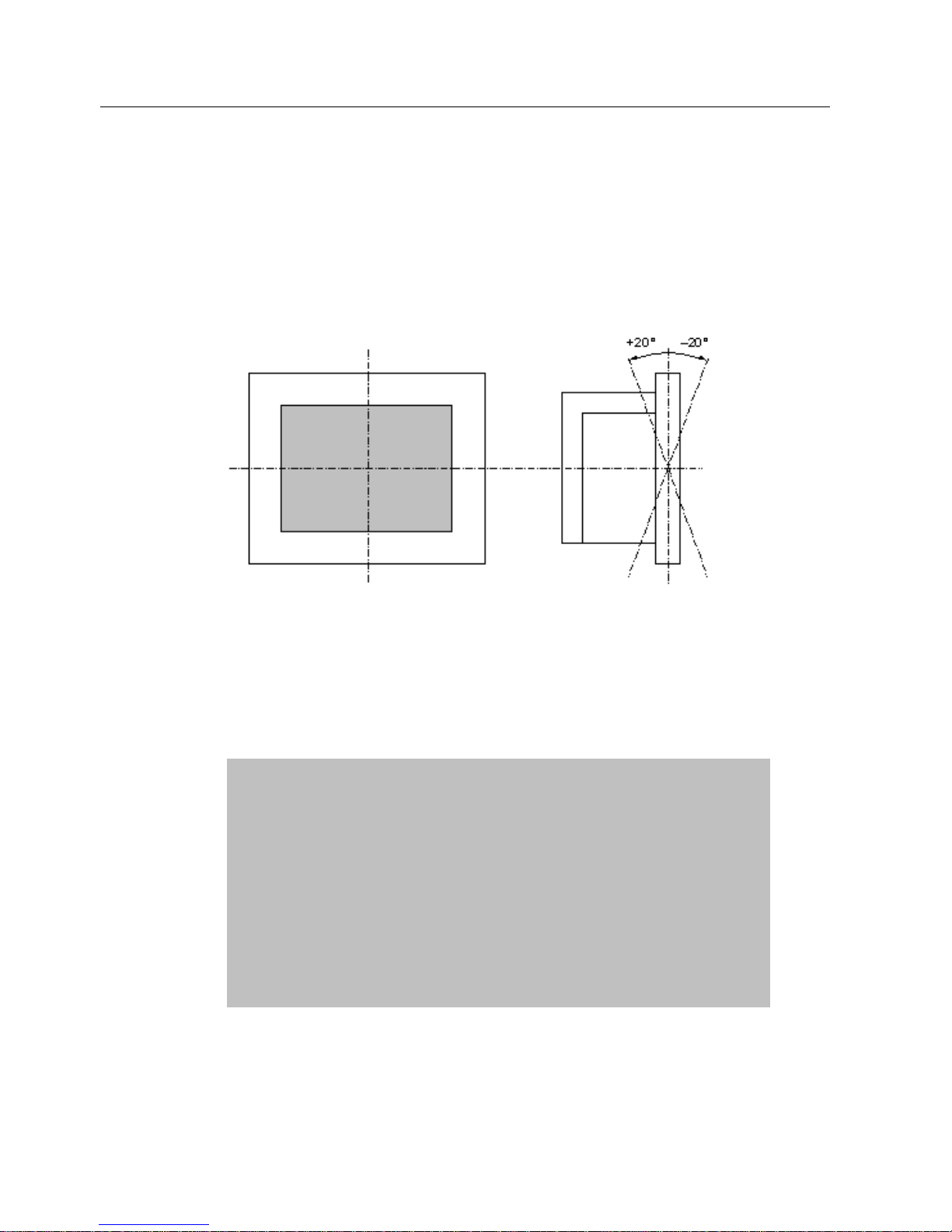

4.5.2 Approved installation positions

Approval

Depending on the design form described in the overview, certain installation positions are

approved for the device.

Central design:

Figure 4-3 Approved installation positions for central design

Vertical installation and deviations between +20° and -20° in the given directions is

permitted.

Decentralized design

Applies only to the control unit:

Figure 4-4 Approved installation positions for decentralized design

Vertical installation and deviations between +70° and -20° in the given directions is

permissible.

Page 29

Usage planning

4.6 Recessed mounting cut-out

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-7

4.5.3 Method of attachment

The control unit is secured in the recessed mounting cut-out either with clamps or screws.

Notice

Securing with screws is not possible with the 12.1" touch screen variant. For more

information, please refer to the chapter "Description."

Select the method of attachment suitable to your requirements for the degree of protection.

4.5.4 Degree of protection

Principle

Applies to the central and decentralized designs: The degree of protection depends on the

method of attachment.

Protection Class IP65

This degree of protection is provided when the control unit is attached with clamps and the

presence of an encircling seal.

IP54 degree of protection

This degree of protection is provided when the control unit is attached with screws.

4.6 Recessed mounting cut-out

4.6.1 Selecting and completing recessed mounting cut-out

Area of validity

No recessed mounting cut-out is necessary for the computer unit in the decentralized design.

The following applies to the complete device in the central design and the control unit in the

decentralized design.

Requirement

The degree of protection suitable to the field of application and thereby the method of

attachment have been selected.

Page 30

Usage planning

4.6 Recessed mounting cut-out

Panel PC 670 V2/870 V2, Control unit

4-8 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Procedure

1. Please comply with installation guidelines.

2. Select a location suitable for installation, taking into account the installation guidelines

and the chosen installation position.

3. On the basis of the dimension diagrams, check whether the required screw and pressure

points on the backside and the hatched sealing area are easily accessible after the

completion of the recessed mounting cut-out. Otherwise the recessed mounting cut-out is

useless.

4. Complete the recessed mounting cut-out according to the dimension diagrams. Take into

account the mounting depth of the control unit in the decentralized design, which must be

deeper due to the direct key module and remote module.

Page 31

Usage planning

4.6 Recessed mounting cut-out

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-9

4.6.2 Dimensions

Central design

The following illustrations depict the installation dimensions of the complete device in the

central design.

Figure 4-5 Drill holes for the screws and pressure points for the clamp screws

L4, L5: Drill holes with 6mm diameter each

Page 32

Usage planning

4.6 Recessed mounting cut-out

Panel PC 670 V2/870 V2, Control unit

4-10 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Figure 4-6 Installation diemsnions of the control unit without CD-ROM drive

Page 33

Usage planning

4.6 Recessed mounting cut-out

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

4-11

Decentralized design

The following illustration shows the dimensions of the control unit in the decentralized design

The respective dimensions are dependent on the control unit.

Figure 4-7 Dimensions of the control unit with attached remote module and direct key module

Page 34

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Page 35

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

5-1

Installation

5

5.1 Securing with clamps

Area of validity

Applies to the central and decentralized designs: Skip this step if you have selected

"installing with screws."

Requirement

• The recessed mounting cut-out has been completed.

• Clamp from the options. Clamp and grub screws are included in the contents of delivery.

Figure 5-1 Clamp assembly

Procedure

1. Please follow the installation guidelines.

2. Insert the device or the control unit in the decentralized design into the recessed

mounting cut-out from the front.

3. Secure the control unit in the recessed mounting cut-out from behind with the clamp, as

shown in the installation cut-out in the dimension diagrams. Tighten the grub screw to a

torque of 0.4-0.5 Nm.

4. Applies only to the decentralized design: Mount the computer unit at at its planned

installation location. For additional information, please refer to computer unit operating

instructions.

Page 36

Installation

5.2 Securing with screws

Panel PC 670 V2/870 V2, Control unit

5-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

C

o

m

p

u

t

i

n

g

u

n

i

t

O

p

e

r

a

t

i

n

g

u

n

i

t

Knurled screw

Knurled screw

Hinge

Hinge

Figure 5-2 Device assembly

5.2 Securing with screws

Area of validity

Applies to the central and decentralized designs: Skip this step if you have selected

"installing with clamps."

Requirement

The recessed mounting cut-out has been completed.

Procedure

1. Please follow the installation guidelines.

2. Drill suitable holes at the prepared recessed mounting cut-out in accordance with the

specifications for L4 and L5, as shown in the installation cut-out in the dimension

diagrams.

3. Carefully drill out the drill hole caps on the front of the control unit. The drill hole caps are

illustrated at the end of this section.

4. Insert the device or the control unit in the decentralized design into the recessed

mounting cut-out from the front.

5. Secure the control unit by inserting suitable screws through the holes and attaching nuts.

Page 37

Installation

5.2 Securing with screws

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

5-3

6. Applies only to the decentralized design: Install the computer unit at its planned

installation location. For additional information, please refer to the computer unit

operating instructions.

Figure 5-3 Drill hole covers

Page 38

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6-1

Connecting

6

6.1 Interfaces

6.1.1 Front-sided interfaces

USB port

The USB port is located under the rubber cover on the front side with the control elements

and displays. Attach an external keyboard or an external mouse, for example, to the USB

port. The front-sided USB port supports the standard USB 1.1.

Caution

Wait at least 10 seconds between the unplugging and replugging of USB devices. This also

applie in particular to touch control in control units with touch screen panels. A short circuit of

the voltage supply at the USB front plug will cause the device to reset.

Notice

When the rubber cover over the USB port is removed in order to connect an USB

component, the degree of protection for the device is no longer guaranteed.

When using standard USB peripheral devices, please bear in mind that their EMC immunity

level is frequently designed for office applications only.

These devices are adequate for starting up and service purposes. For use in industry,

however, only devices suitable to industry are permitted.

The I/O modules are developments of the respective provider, who also markets them. The

respective product supplier offers support for the I/O modules. The liability conditions of the

manufacturer still apply.

The USB port is not available on the order option "control unit without front-sided USB port."

For additional information, refer to the technical data. Please refer to the chapter "Starting

up" in the computer unit operating instructions for more information concerning the

connection of a USB device.

Page 39

Connecting

6.1 Interfaces

Panel PC 670 V2/870 V2, Control unit

6-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6.1.2 Other interfaces

Other Connections

Caution

Please comply with the connections in the computer unit operating instructions

Back side

On the back side of the computer unit are two flatband cables for connecting to the computer

unit.

Figure 6-1 Other interfaces on the computer unit

• The I/O USB cable K1 at X1 comprises not only the signals of the display interface but

also the signals for the connection of control units.

• The display cable K2 connects the display of the control unit with the computer unit.

Page 40

Connecting

6.2 Connecting a decentralized design

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6-3

6.2 Connecting a decentralized design

6.2.1 Overview

Introduction

After installing the device, connect it.

Caution

Connection sequence

To avoid damage to the device, please follow the connection sequence of the device.

Other Connections

Please comply with the connections in the computer unit operating instructions.

Starting up

Before connecting the device, allow it to adjust to room temperature. Do not subject it

directly to heat radiation from a heating device, however.

Requirements

• The device has been installed in accordance with EMC guidelines.

• The device has been installed in accordance with the specifications of these operating

instructions.

Procedure

1. Connect equipotential bonding.

2. Connect computer unit-control unit connecting cable.

3. Connect power supply.

6.2.2 Decentralized design

Principle

In the decentralized design, the control unit and computer unit are in separate locations.

Components

The following illustration shows as an example of a 15" control unit on which a mounting

plate is attached to the back side. The remote module, also called receiver, and the optional

direct key module are attached to the mounting plate. The remote module has a AC

110/230V power supply. The remote module is also available with a DC 24 V power supply.

Page 41

Connecting

6.2 Connecting a decentralized design

Panel PC 670 V2/870 V2, Control unit

6-4 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Note

Make sure that the cable strain reliefs for the connection cable at the operating unit and

computer unit are mounted properly, especially if the devices are installed at a slant.

Power supply

120-240 V AC

Socket for

interconnecting cable

to transmitter

Receiver

Mounting plate

for receiver and direct key module

Operating unit

(rear)

Fastening screw

for mounting plate

USB cable Direct key module (optional)

Figure 6-2 Back side of the control unit with attached remote module and direct key module

6.2.3 Equipotential bonding

Differences in potential

Differences in potential arise between separated system parts, which in some cases leads to

high equalization currents. When cable shields are applied on both sides and are grounded

at different system parts, for example.

Causes of potential differences are different network feed-ins, for example.

Page 42

Connecting

6.2 Connecting a decentralized design

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6-5

Equipotential bonding requirements

Reduce the differences in potential by laying the equipotential bonding cables in such a way

that the affected electronic components function perfectly. Please comply with the following

guidelines when setting up equipotential bonding:

• The lower the impedance of the equipotential bonding cable, the greater the effectiveness

of the equipotential bonding.

• When two system parts are connected by means of a shielded signal cable, and their

shields are both connected to the ground or protected conductor, the following must be

observed: The impedance of the additonal equipotential bonding cable amounts to 10 %

of the shield impedance, at the most.

• Make sure that the diameter of the equipotential bonding cable is proportional to the

maximum equalization current. Equipotential bonding cables with a 16 mm diameter have

proven themselves in practice. 2.

• Use equipotential bonding cables made of copper or galvanized steel. Connect the

cables extensively with the ground or protective conductor. Protect the ground or

protective conductor from corrosion.

• Lay the equipotential bonding cable in such a way that the area between the equipotential

bonding cable and signal cables is as small as possible.

6.2.4 Connecting equipotential bonding.

Introduction

Caution

Equipotential bonding cable

Provide adequate cable diameter when setting up PROFIBUS DP networks and MPI

networks. Otherwise interface components will be damaged or destroyed.

Cable shileds are not suitable for the equipotential bonding. Use only the prescribed

equipotential bonding cable. Make sure that the diameter of the equipotential bonding cable

is at least 16 mm².

Procedure

Caution

Please follow the described guidelines concerning equipotential bonding. Otherwise

interface components will be damaged or destroyed.

1. Connect the device to the equipotential bonding as illustrated in the chapter "Connecting

a decentralized design."

Page 43

Connecting

6.2 Connecting a decentralized design

Panel PC 670 V2/870 V2, Control unit

6-6 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6.2.5 Connecting the computer unit-control unit connecting cable

Introduction

For data exchange, connect the control unit and the computer unit with the connecting cable

which is illustrated in the "Options" section.

Warning

Avoid contact with network lines and data transmission lines during thunderstorms and do

not disconnect any lines during this time.

For complete isolation from the power supply, always pull out the power plug.

Procedure

1. Plug the jack plug of the connection cable into the connector on the remote module of the

control unit, as illustrated in the section "Connecting a decentralized design."

2. Lock the jack plug.

3. Screw on the cable strain relief.

4. Plug the male connector of the connection cable into the connector on the host module of

the computer unit, as illustrated in the chapter "Description," "Connecting a decentralized

design."

5. Screw on the cable strain relief.

6.2.6 Connecting the power supply.

Principle

Warning

Select an adequately large cable diameter so that the device is not damaged by the cable

during a short circuit.

Power supply AC 110/230 V

The device can be operated in AC 110/230 V networks. The voltage is switched

automatically.

DC 24 V power supply

Caution

Connect the device with DC power supply only to 24V power supply networks which comply

with the requirements of a secure low voltage SELV.

Page 44

Connecting

6.2 Connecting a decentralized design

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

6-7

Procedure

1. Attach the supplied power supply cable into the AC/DC power supply connector of the

control unit. Applies only to the Panel PC 670 V2: When the computer unit is supplied

with electricity through the power supply connection, the device is in operation and begins

to boot.

2. Lock the power plug with the supplied cable clips. This prevents accidental removal of the

power plug from the control unit.

6.2.7 Block diagram

The following block diagram applies to the decentralized design. The connecting cable for

the computer unit-control unit is a maximum of 20 meters long.

Figure 6-3 Block diagram decentralized design

Page 45

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

7-1

Operating

7

7.1 Status displays

The two LEDs on the upper left hand side of the front panel display the operating mode:

• LED "POWER" Green: Active voltage.

• LED "TEMP" orange: Temperature threshold exceeded, will be adjusted in SIMATIC-

SOM.

For more information, please refer to the chapter "Additional drivers and applications" and to

the computer unit operating instructions.

7.2 Operator controls on key panels

7.2.1 Overview

The device has the following keypads:

• 2 x 8 vertical keypads with softkey functions

• 2 x 10 horizontal keypads with function keys F1 -F10

• Optional 32 direct key functions

The number of keys, their labelling and function is the same on all key panels. The various

panel types differ only in the arrangement of the keys, and in the size and type of the display.

The following illustration shows as an example the front view of the 12" variant with the

display, the operating mode display, the individual keypads, the integrated mouse and the

front-sided USB 1.1 port.

Page 46

Operating

7.2 Operator controls on key panels

Panel PC 670 V2/870 V2, Control unit

7-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Figure 7-1 Example of a 12" control unit with key panel

7.2.2 Keyboard

Principle

The layout of the membrane keyboard is "English/USA international."

Warning

Incorrect operation

If you activate several keys simultaneously, a malfunction on the device cannot be excluded.

Activate function keys and softkeys only in sequence! Use "KeyTools" as described in the

chapter "Additional Drivers and Applications."

Applies after the deactivation of the "security features" of "Key Tools" or after the

deinstallation of "KeyHook":

When the additional function keys F13 and S16 are used, or when using your own key code

table, serious malfunctions of the user software can occur, because the key codes behind

the function keys can also be activated by activating keys other than the configured ones.

Activating a key using a hard object, e.g. a screwdriver, reduces the life of the key.

Page 47

Operating

7.2 Operator controls on key panels

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

7-3

Overview

The keyboard is divided into different functional groups:

• Function keys and softkeys

• Control keys

• Alphanumeric keys

• Numeric keys

• Cursor keys

Function keys and softkeys

The softkeys are arranged on the left and on the right, and the function keys in a double row

below the display. Each key has an integrated LED.

Figure 7-2 Function keys and softkeys

Control keys

The control keys activate editing functions and control functions in different applications:

Figure 7-3 Control keys

Page 48

Operating

7.2 Operator controls on key panels

Panel PC 670 V2/870 V2, Control unit

7-4 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Alphanumeric keys

Enter letters, special characters, blank spaces and underline using the alphanumeric keys.

Figure 7-4 Alphanumeric keys

Toggling between lowercase and uppercase letters

Enter the lower case letters using the pre-defined assignment of the alphanumeric keys. To

enter an upper case letter, proceed as follows:

1. Hold down the <Shift> key.

2. Activate the desired alphanumeric key at the same time. The displayed upper case letter

will be entered.

3. To enter lower case letters, release the <Shift> key.

Numeric keys

Enter the numerals "0" to "9" and special characters, e.g. the decimal point, using the predefined assignment of the numeric keys.

Figure 7-5 Numeric keys

Page 49

Operating

7.2 Operator controls on key panels

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

7-5

Enter special characters, arithmetic signs and signs

Special characters, arithmetic signs and signs are also assigned to most of the alphanumeric

and numeric keys. These signs are indicated by white symbols on the top left of the keys. To

enter such a sign, proceed as follows:

1. Hold down the <FN> key.

2. Activate the desired alphanumeric or numeric key at the same time. The displayed

special character, arithmetic sign or signs will be entered.

3. To enter the signs of the pre-defined assignment again, release the <FN> key.

Cursor keys

Navigate, scroll or move the writing mark using the cursor keys. The cursor keys correspond

to the usual keys of the PC keyboard.

Figure 7-6 Cursor keys

External keyboards

The keyboard layout has been set to "English/USA international." If you use a keyboard with

a layout other than the "English/USA international" layout, the key codes of the internal and

external keyboards might no longer correspond.

7.2.3 Labelling function keys and softkeys

Area of validity

This section applies only to control units with key panels.

Introduction

The control unit has two horizontal and two vertical keypads Assign user specific functions to

the keys as needed. Label the keys with labelling strips from the options.

DIN A4 film is available for the production and insertion of the labelling strips, as described

under Service and Maintenance in the options.

Warning

Labeling

Label the function keys and softkeys to conform with the project. Labeling without reference

to a project leads to incorrect operations on the system to be observed.

Page 50

Operating

7.2 Operator controls on key panels

Panel PC 670 V2/870 V2, Control unit

7-6 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Procedure

1. Label the DIN A4 film with a laser printer with the printing templates from the options, for

example.

2. Cut the labeling strips along the pre-printed lines.

Note

Do not insert handwritten labeling strips until the ink has dried.

3. Insert the labeling strips into the slots provided on the rear side of the control unit.

Figure 7-7 Rear side of the control unit with connectors and slots for the labeling strips

7.2.4 Integrated mouse

The position on which you press the middle round button determines the direction in which

the cursor moves. The amount of pressure determines the speed of the cursor.

As an alternative, connect an external mouse at the USB 1.1 port.

Page 51

Operating

7.3 Operator controls of the touch screen panels

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

7-7

7.3 Operator controls of the touch screen panels

7.3.1 Overview

The 12" variant and the 15" variant differ in their dimensions and the size of the display. The

12" variant has no drill hole covers on the sides.

As an example, the following illustration shows the front view of the 15" variant with the

status displays, the front-sided USB 1.1 port, and the display.

Figure 7-8 Example of a 15" control unit with touch screen panel

Page 52

Operating

7.3 Operator controls of the touch screen panels

Panel PC 670 V2/870 V2, Control unit

7-8 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

7.3.2 Touch screen

The display is sensitive to touch, and application-specific surface elements, e.g. a button,

appear on the screen. By tapping the button with your finger, the function assigned to the

button is activated.

Caution

Do not touch the screen in the following situations:

— During the booting of the device until the beep tone

— When plugging or unplugging USB components

— When the warning "Do not touch the screen" appears.

Wait at least 1 second after the warning extinguishes.

The following exertions of pressure are permissible:

• Using a plastic pen with a 1 mm radius at the point: 25 g.

• Using a silicone finger with a diameter of 1.6 cm: 50 g.

Page 53

Panel PC 670 V2/870 V2, Control unit

Operating Instructions, Edition 03/2004, CD Documentation and Drivers

8-1

Operating and parametrizing

8

8.1 Start up

8.1.1 Overview

Checklist

Before starting up the device for the first time, go through the following checklist:

• Have you taken into account the proper ambient and environmental conditions for the

device and the connected I/O modules, as described in the technical information?

• Have you found out how to connect the equipotential bonding?

• Have you found out how to connect the power supply?

• Read over this information in the respective "Connecting" chapter of the control unit and

computer unit operating instructions. Please follow all guidelines.

Caution

Condensation

When transporting the device at low temperatures, prevent condensation from forming on

or in the device. The same applies when the device is subjected to extreme changes in

temperature. Wait 12 hours before switching the device on.

Before starting up the device, allow it to adjust slowly to room temperature. Do not

subject it directly to heat radiation from a heating device, however.

I/O modules

Connect the I/O modules using shielded cable and metal plugs. Otherwise the operating

license expires. Secure the plug of the interface cable on the housing of the device. This

improves the electrical shielding.

Start up

Do not switch off the device during the start up. Otherwise parts of the software will be

lost which are necessary for trouble-free operation.

Use the default values in the BIOS. Otherwise the operating system will not be installed

properly.

Page 54

Operating and parametrizing

8.1 Start up

Panel PC 670 V2/870 V2, Control unit

8-2 Operating Instructions, Edition 03/2004, CD Documentation and Drivers

Requirements

The following devices have been connected:

• Computer unit