Page 1

MICROMASTER 440

Parameter List Issue 01/06

User Documentation

6SE6400-5BB00-0BP0

Page 2

Available Documentation for the MICROMASTER 440

Getting Started Guide

Is for quick commissioning with SDP and BOP.

Operating Instructions

Gives information about features of the MICROMASTER

440, Installation, Commissioning, Control modes, System

Parameter structure, Troubleshooting, Specifications and

available options of the MICROMASTER 440.

Parameter List

The Parameter List contains the description of all

Parameters structured in functional order and a detailed

description. The Parameter list also includes a series of

function plans.

Catalogues

In the catalogue you will find all needs to select a certain

inverter, as well as filters chokes, operator panels or

communications options.

Page 3

MICROMASTER 440

Parameter List

User Documentation

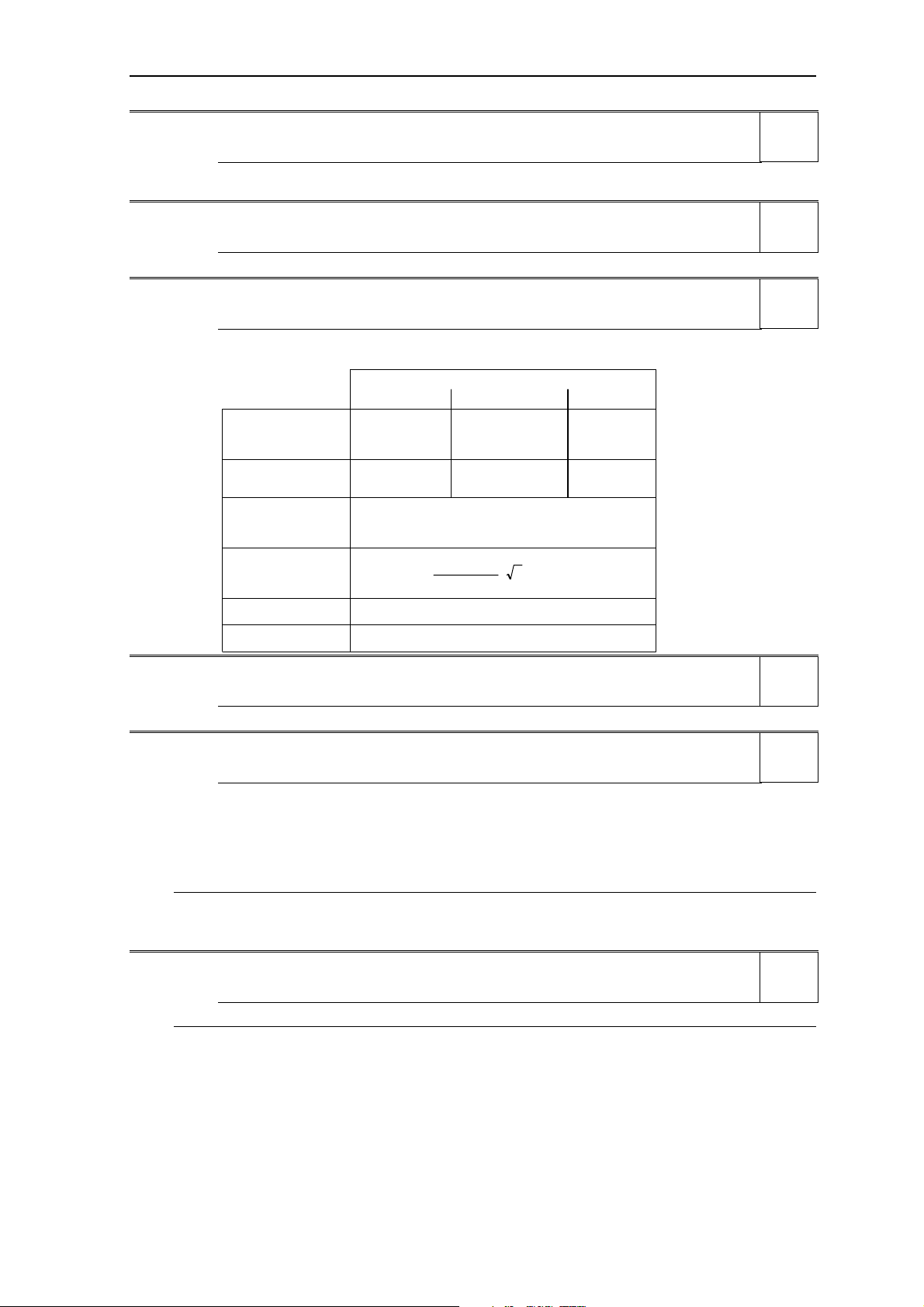

Valid for Issue 01/06

Converter Type Software Version

MICROMASTER 440 V2.1

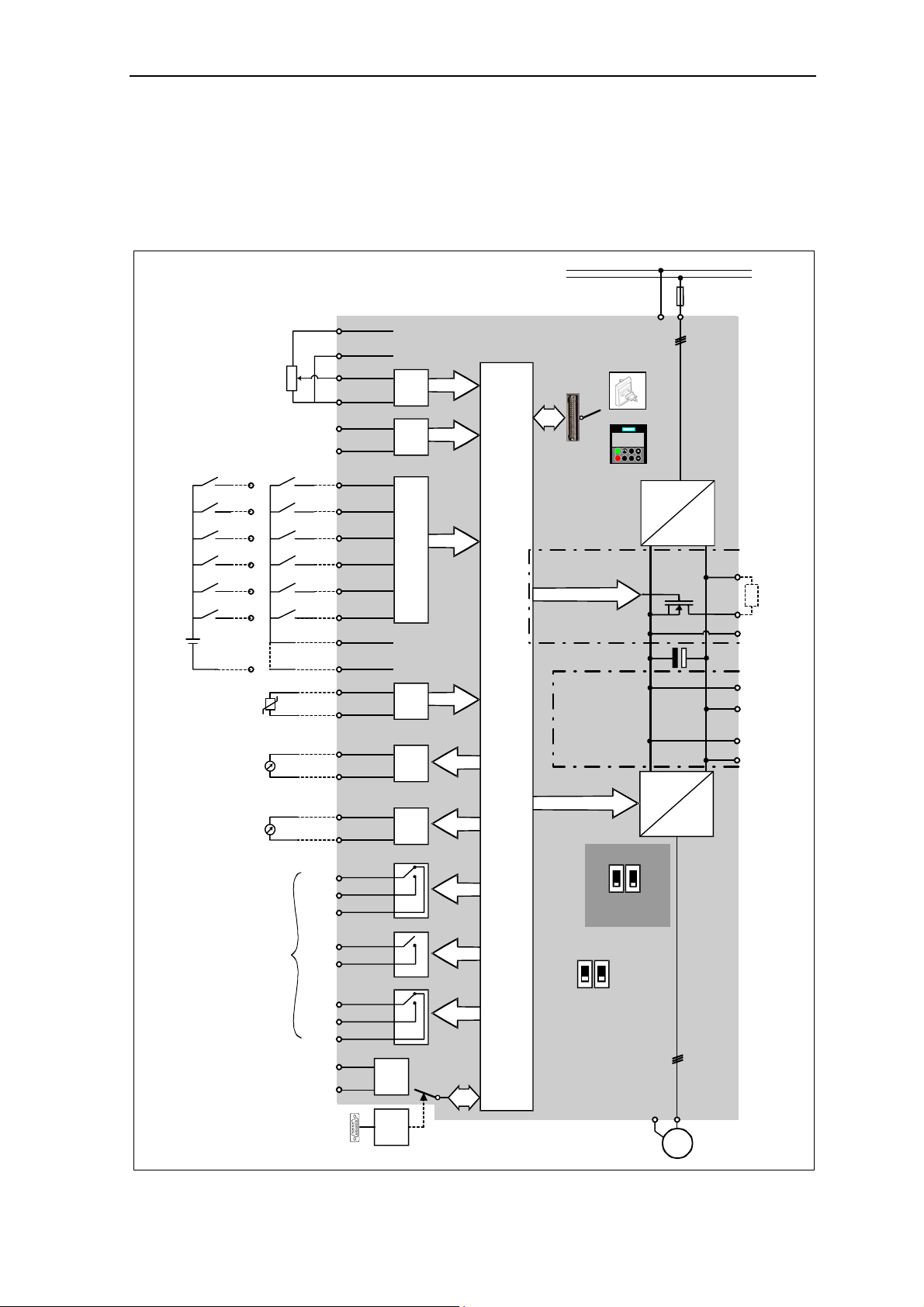

Block Diagram

and Terminals

Parameter List

Function Diagrams

Faults and Alarms

Abbreviations

Issue 01/06

Page 4

Notes Issue 01/06

Warning

!

Please refer to all Definitions and Warnings contained in the Operating Instructions.

You will find the Operating Instructions on the Docu CD delivered with your inverter. If

the CD is lost, it can be ordered via your local Siemens department under the Order

No. 6SE6400-5AD00-1AP0.

Information about MICROMASTER 440 is also available from:

Regional Contacts

Please get in touch with your contact for Technical Support in your Region for questions

about services, prices and conditions of Technical Support.

Central Technical Support

The competent consulting service for technical issues with a broad range of requirementsbased services around our products and systems.

Europe / Africa

Tel: +49 (0) 180 5050 222

Fax: +49 (0) 180 5050 223

Email: adsupport@siemens.com

America

Tel: +1 423 262 2522

Fax: +1 423 262 2589

Email: simatic.hotline@sea.siemens.com

Asia / Pacific

Tel: +86 1064 757 575

Fax: +86 1064 747 474

Email: adsupport.asia@siemens.com

Online Service & Support

The comprehensive, generally available information system over the Internet, from product

support to service & support to the support tools in the shop.

http://www.siemens.com/automation/service&support

Internet Address

Customers can access technical and general information under the following address:

http://www.siemens.com/micromaster

Printed in the Federal Republic of Germany

Approved Siemens Quality for Software and Training

is to DIN ISO 9001, Reg. No. 2160-01

The reproduction, transmission or use of this document, or its

contents is not permitted unless authorized in writing.

Offenders will be liable for damages. All rights including rights

created by patent grant or registration of a utility model or

design are reserved.

© Siemens AG 2001 - 2006 All Rights Reserved.

MICROMASTER® is a registered trademark of Siemens

Printed in the Federal Republic of Germany

MICROMASTER 440 Parameter List

4 6SE6400-5BB00-0BP0

Siemens-Aktiengesellschaft.

Other functions not described in this document may be

available. However, this fact shall not constitute an obligation

to supply such functions with a new control, or when

servicing.

We have checked that the contents of this document

correspond to the hardware and software described. There

may be discrepancies nevertheless, and no guarantee can be

given that they are completely identical. The information

contained in this document is reviewed regularly and any

necessary changes will be included in the next edition. We

welcome suggestions for improvement.

Siemens handbooks are printed on chlorine-free paper that

has been produced from managed sustainable forests. No

solvents have been used in the printing or binding process.

Document subject to change without prior notice.

Siemens-Aktiengesellschaft.

Page 5

Issue 01/06 Table of Contents

Parameters MICROMASTER 440

This Parameter List must only be used together with the Operating Instructions of the

MICROMASTER 440. Please pay special attention to the Warnings, Cautions, Notices

and Notes contained in these manuals.

Table of Contents

1 Block Diagram and Terminals ....................................................................7

1.1 Block Diagram ............................................................................................7

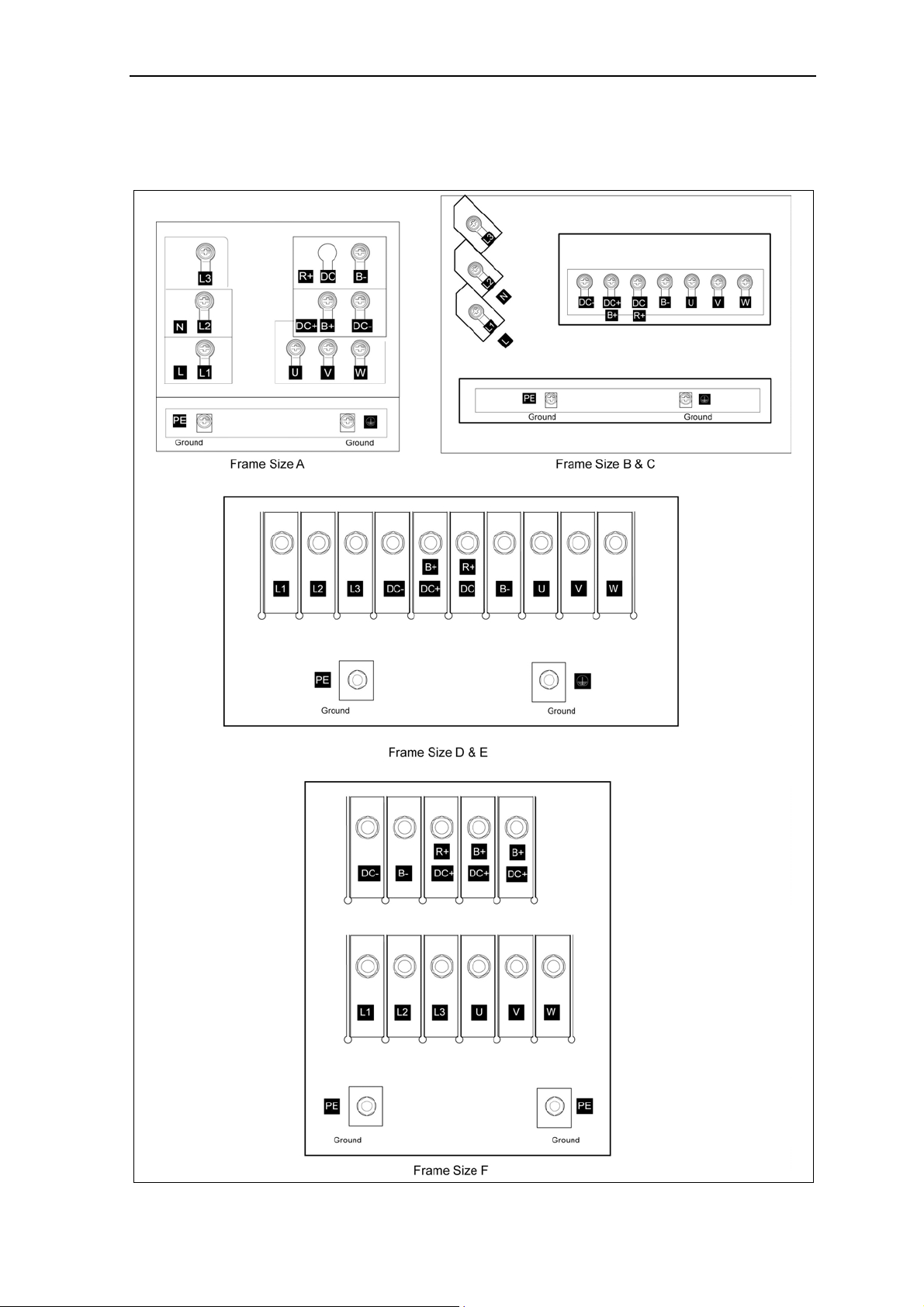

1.2 Power Terminals ........................................................................................8

1.3 Control Terminals .....................................................................................11

2 Parameters...............................................................................................12

2.1 Introduction to MICROMASTER System Parameters..............................12

2.2 Quick commissioning (P0010 = 1) ...........................................................15

2.3 Command and Drive Datasets - Overview...............................................17

2.4 Binector Input Parameters........................................................................21

2.5 Connector Input Parameters ....................................................................22

2.6 Binector Output Parameters.....................................................................22

2.7 Connector Output Parameters .................................................................23

2.8 Connector/Binector Output Parameters...................................................24

3 Parameter Description..............................................................................25

3.1 Common parameters................................................................................25

3.2 Diagnosis parameters ..............................................................................29

3.3 Inverter parameters (HW).........................................................................42

3.4 Motor parameters.....................................................................................50

3.5 Speed encoder .........................................................................................67

3.6 Application macros ...................................................................................69

3.7 Motor temperature....................................................................................69

3.8 Command source.....................................................................................75

3.9 Digital inputs.............................................................................................77

3.10 Digital outputs...........................................................................................84

3.11 Analog inputs............................................................................................86

3.12 Analog outputs .........................................................................................93

3.13 Parameter / command / drive data set.....................................................97

3.14 BICO command parameters.................................................................. 102

3.15 Communication parameters .................................................................. 105

3.16 Setpoint source ..................................................................................... 110

3.17 Fixed frequencies .................................................................................. 113

3.18 Motorized potentiometer (MOP)............................................................ 120

3.19 JOG ....................................................................................................... 122

3.20 Setpoint channel.................................................................................... 125

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

5

Page 6

Table of Contents Issue 01/06

3.21 Ramp-function generator....................................................................... 131

3.22 Flying restart.......................................................................................... 136

3.23 Automatic restart ................................................................................... 139

3.24 Motor holding brake............................................................................... 141

3.25 DC braking ............................................................................................ 143

3.26 Compound braking................................................................................ 146

3.27 Dynamic braking.................................................................................... 147

3.28 Vdc controller ........................................................................................ 148

3.29 Control mode......................................................................................... 153

3.29.1 V/f control technique.............................................................................. 156

3.29.1.1 Slip compensation ................................................................................. 162

3.29.1.2 Resonance damping ............................................................................. 163

3.29.1.3 Imax controller....................................................................................... 164

3.29.1.4 Soft starting ........................................................................................... 166

3.29.2 Field-orientated vector control............................................................... 167

3.29.2.1 Speed controller with/without encoder .................................................. 168

3.29.2.2 Droop..................................................................................................... 170

3.29.2.3 Speed controller pre-control.................................................................. 172

3.29.2.4 Torque control ....................................................................................... 173

3.29.2.5 Supplementary torque setpoint ............................................................. 176

3.29.2.6 Torque / power limiting.......................................................................... 177

3.29.2.7 Flux control............................................................................................ 179

3.29.2.8 Current controller................................................................................... 182

3.29.2.9 Motor model .......................................................................................... 183

3.30 Inverter parameters (Modulator) ........................................................... 188

3.31 Motor data identification ........................................................................ 189

3.32 Speed optimization................................................................................ 192

3.33 Reference parameters........................................................................... 192

3.34 Communication parameters (USS, CB) ................................................ 195

3.35 Faults, Alarms, Monitoring..................................................................... 207

3.36 Load torque monitoring ......................................................................... 218

3.37 Technology controller (PID controller)................................................... 222

3.38 Positioning down ramp.......................................................................... 239

3.39 Free function blocks (FFB).................................................................... 241

3.40 Inverter parameters............................................................................... 257

4 Function Diagrams ................................................................................ 259

5 Faults and Alarms ................................................................................. 307

5.1 Fault messages ..................................................................................... 307

5.2 Alarm Messages.................................................................................... 315

6 Abbreviations......................................................................................... 321

MICROMASTER 440 Parameter List

6 6SE6400-5BB00-0BP0

Page 7

Issue 01/06 Block Diagram and Terminals

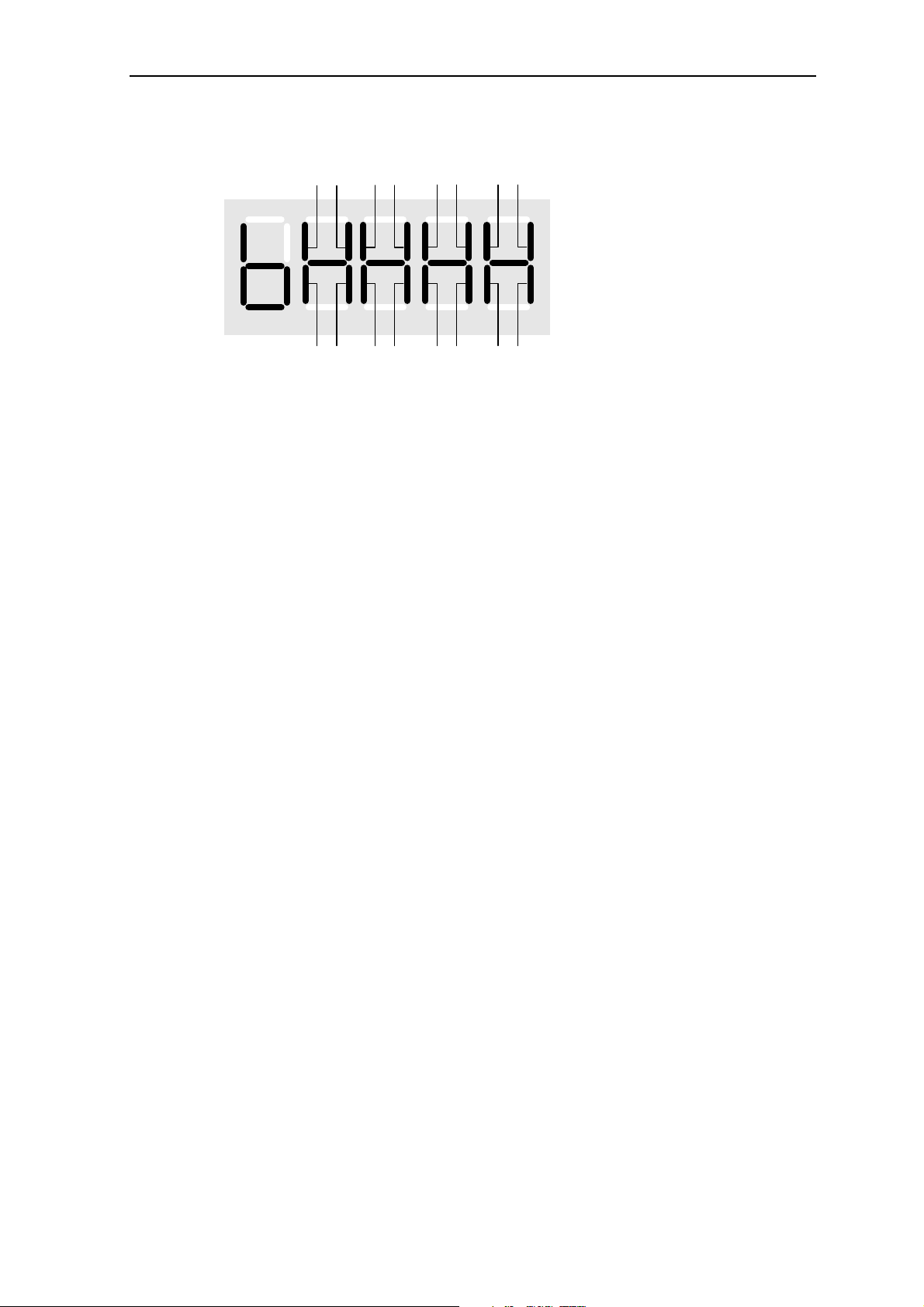

1 Block Diagram and Terminals

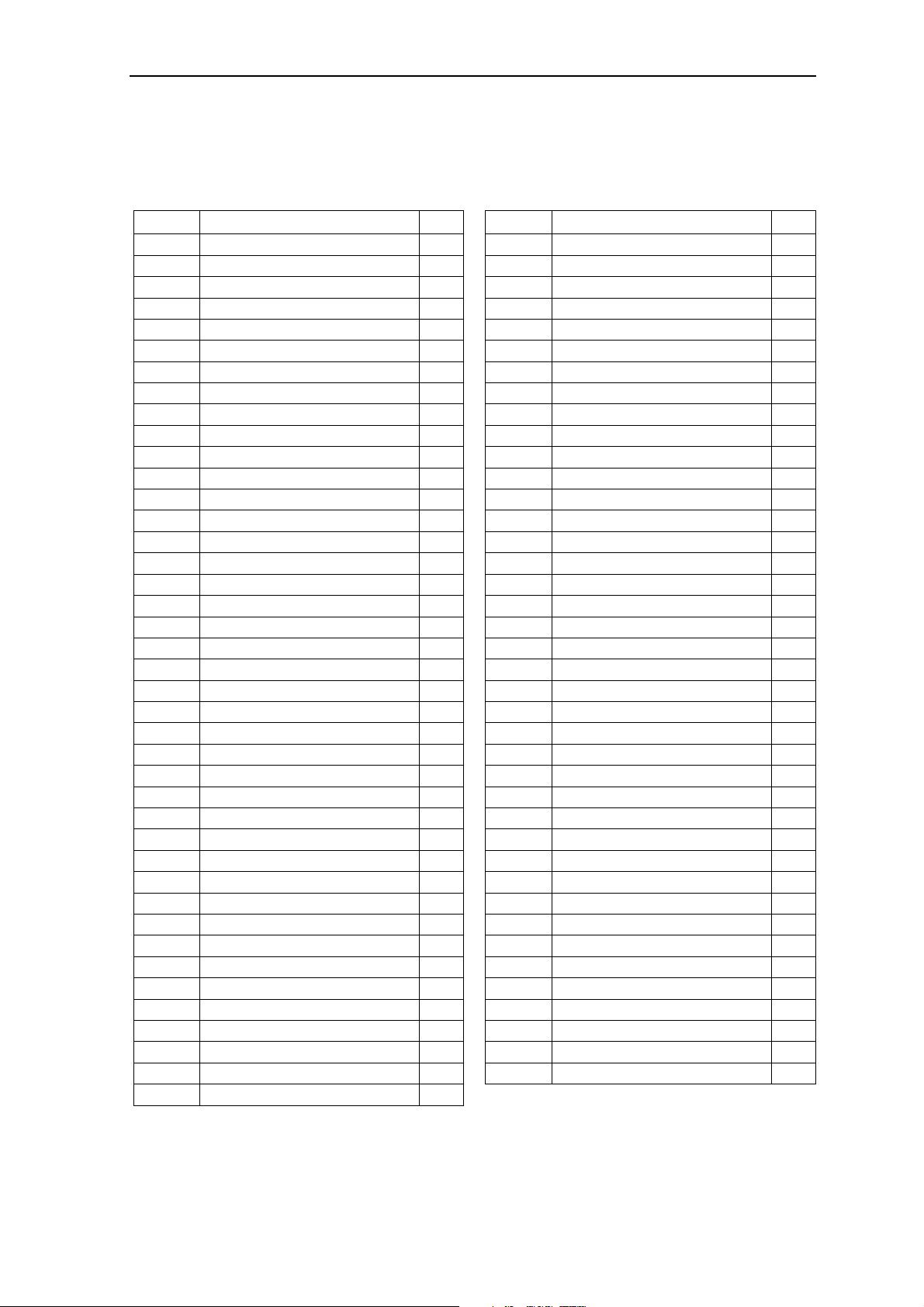

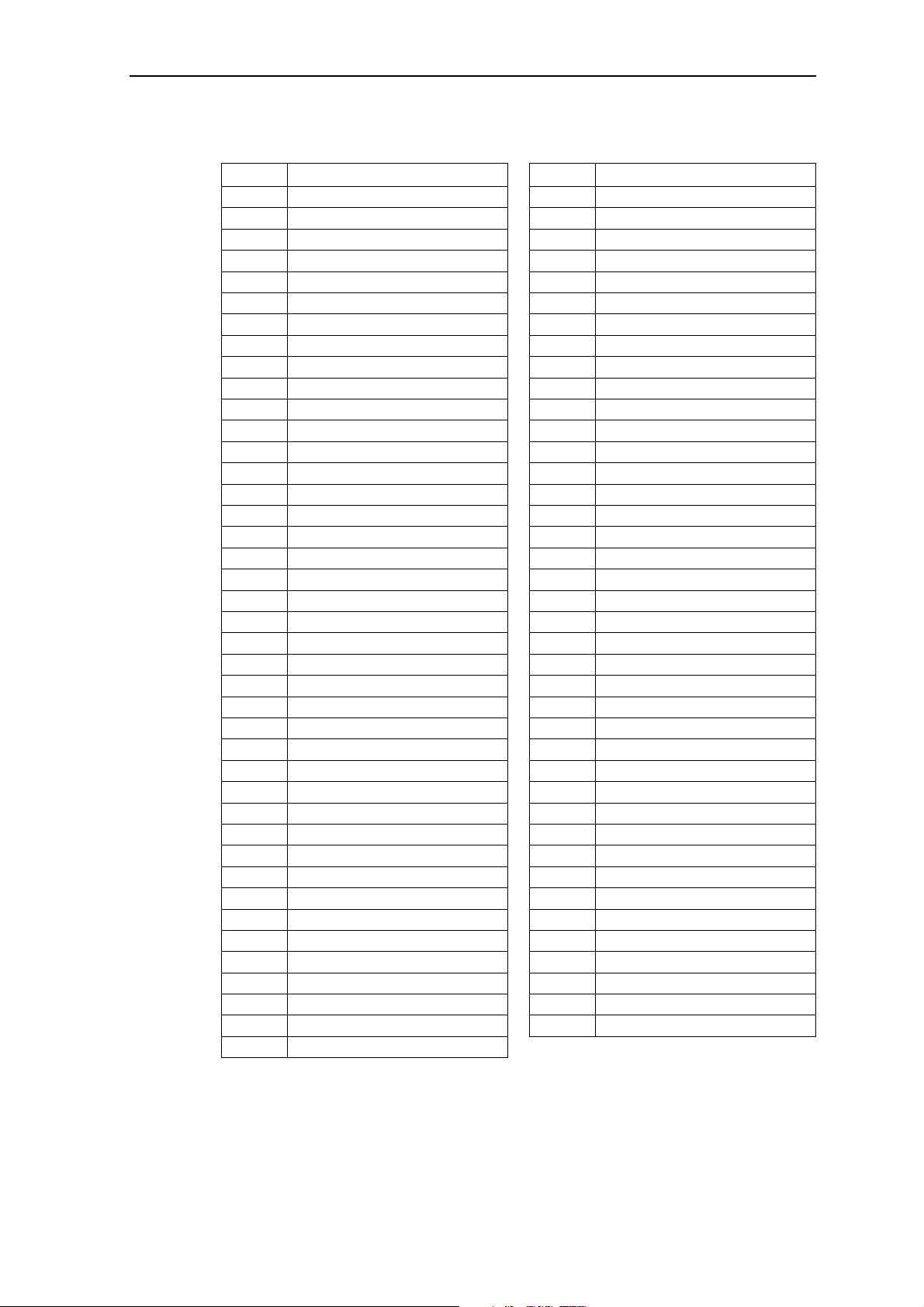

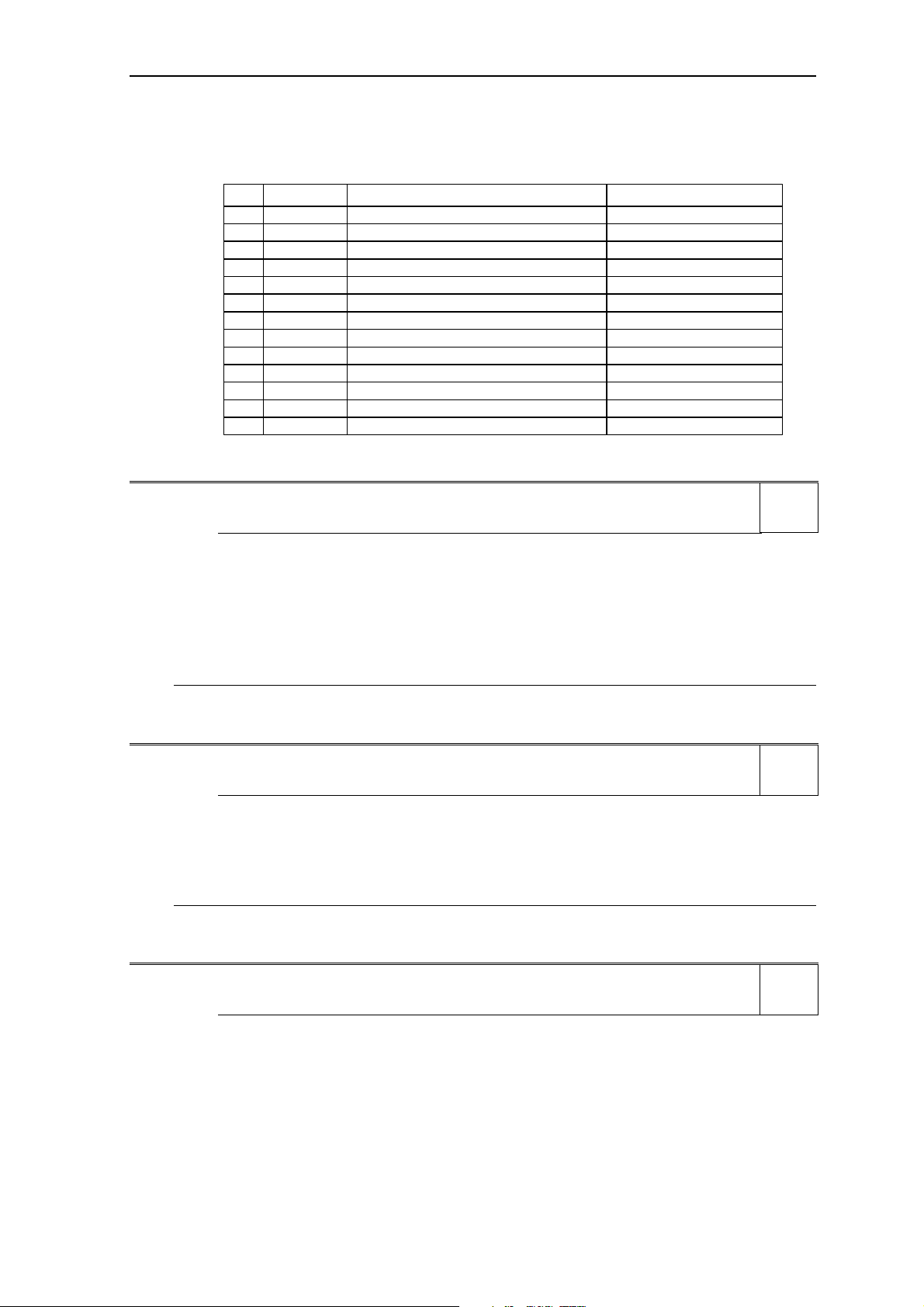

1.1 Block Diagram

PE

≥ 4.7 kΩ

External 24 V

DIN1

5

DIN2

6

DIN3

7

DIN4

8

DIN5

16

DIN6

Motor

PTC

KTY84

0 - 20 mA

max. 500 Ω

0 - 20 mA

max. 500 Ω

17

PNP

or

NPN

28

+

24 V

_

30 V DC / 5 A (resistive)

250 V AC / 2 A (inductive)

Relay1

Relay2

Relay3

1

2

3

4

10

11

5

6

7

8

16

17

9

28

14

15

12

13

26

27

20

19

18

22

21

25

24

23

29

30

ADC1+

ADC1-

ADC2+

ADC2-

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

PTCA

PTCB

DAC1+

DAC1-

DAC2+

DAC2-

COM

NO

NC

COM

NO

COM

NO

NC

P+

N-

+10 V

0 V

Output +24 V

max. 100 mA

(isolated)

Output 0 V

max. 100 mA

(isolated)

RS485

CB

Option

A/D

A/D

Opto Isolation

A/D

D/A

D/A

COM link

automatic

CPU

1/3 AC 200 - 240 V

3 AC 380 - 480 V

3 AC 500 - 600 V

BOP link

Frame sizes

A to F

Frame sizes

FX and GX

ADC1ADC

0 - 20 mA

current

0 - 10 V

voltage

12

RS232

150.00

Hz

Fn

I

Jog

P

0

BOP/AOP

Not

used

12

DIP switch

(on Control Board)

2

DIP switch

(on I/O Board)

=

60 Hz

50 Hz

PE

PE

~

SI

L/L1, N/L2

or

L/L1, N/L2,L3

or

L1, L2, L3

=

3 ~

U,V,W

M

DC-

DCNA

DCPA

DCNS

DCPS

B+/DC+

B-

R

External braking

Connection for

module connection

dv/dt filter

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

7

Page 8

Block Diagram and Terminals Issue 01/06

1.2 Power Terminals

You can gain access to the mains and motor terminals by removing the front covers.

Fig. 1-1 Frame Size A - F

MICROMASTER 440 Parameter List

8 6SE6400-5BB00-0BP0

Page 9

Issue 01/06 Block Diagram and Terminals

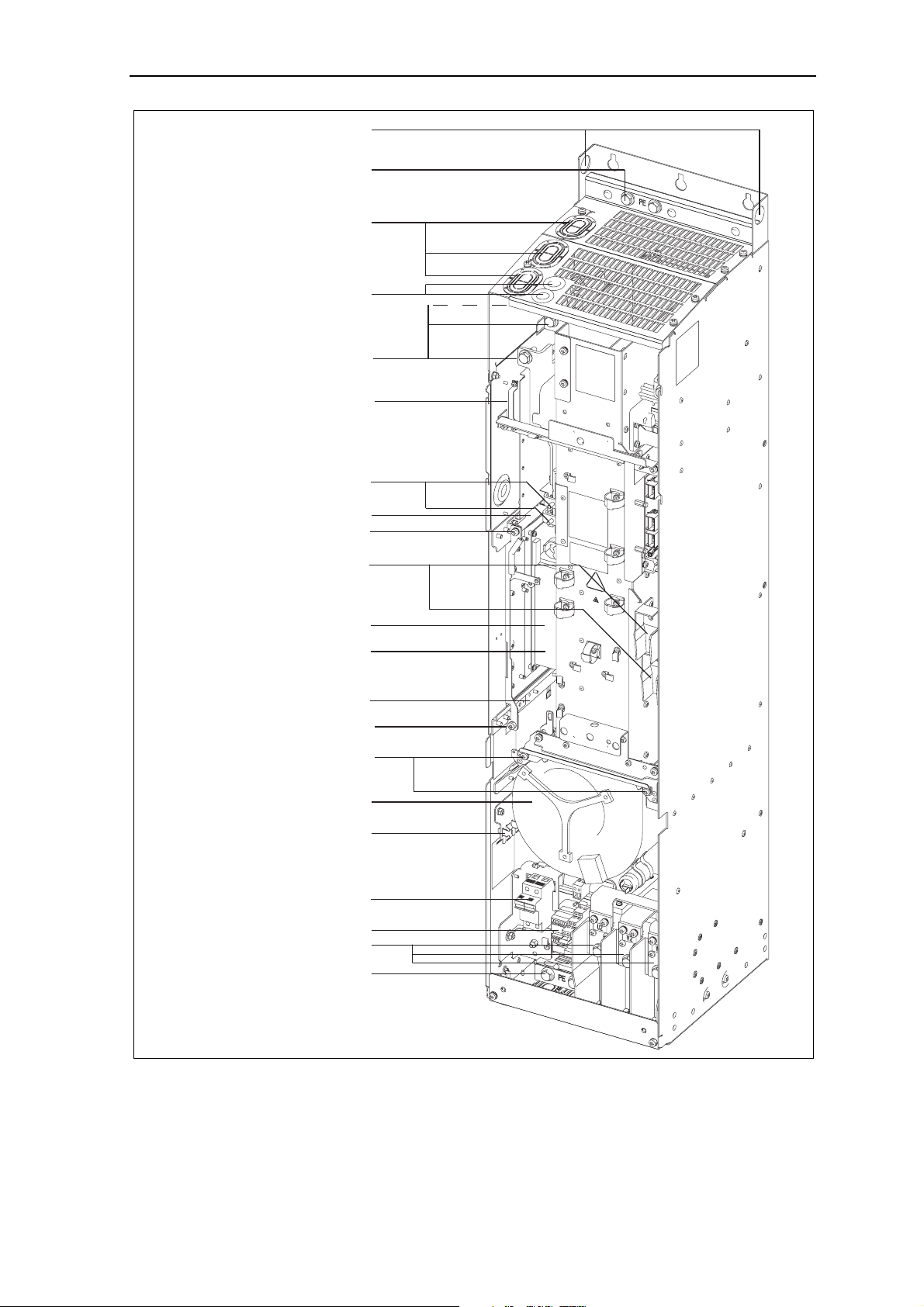

Hoisting eyes

Shield connection

Mains cable PE

Cable opening for

mains conection

U1/L1, V1/L2, W1/L3

Cable opening DCPA, DCNA

for connection of an

external braking unit

Mains cable

Phase U1/L1, V1/L2, W1/L3

Connection to

Y-Capacitor

Connection DCPA, DCNA

for external braking unit

Top adjustment rail

Top retaining screw

Connection for dv/dt filter

DCPS, DCNS

Status Display Panel

Elektronic box

Bottom adjustment rail

Bottom retaining screw

Shield connection

control leads

Transformer adaption

Motor cable

Phase U2, V2, W2

Motor cable

PE Shield connection

Fig. 1-2 Frame Size FX

Fan screws

Fan

Fan fuses

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

9

Page 10

Block Diagram and Terminals Issue 01/06

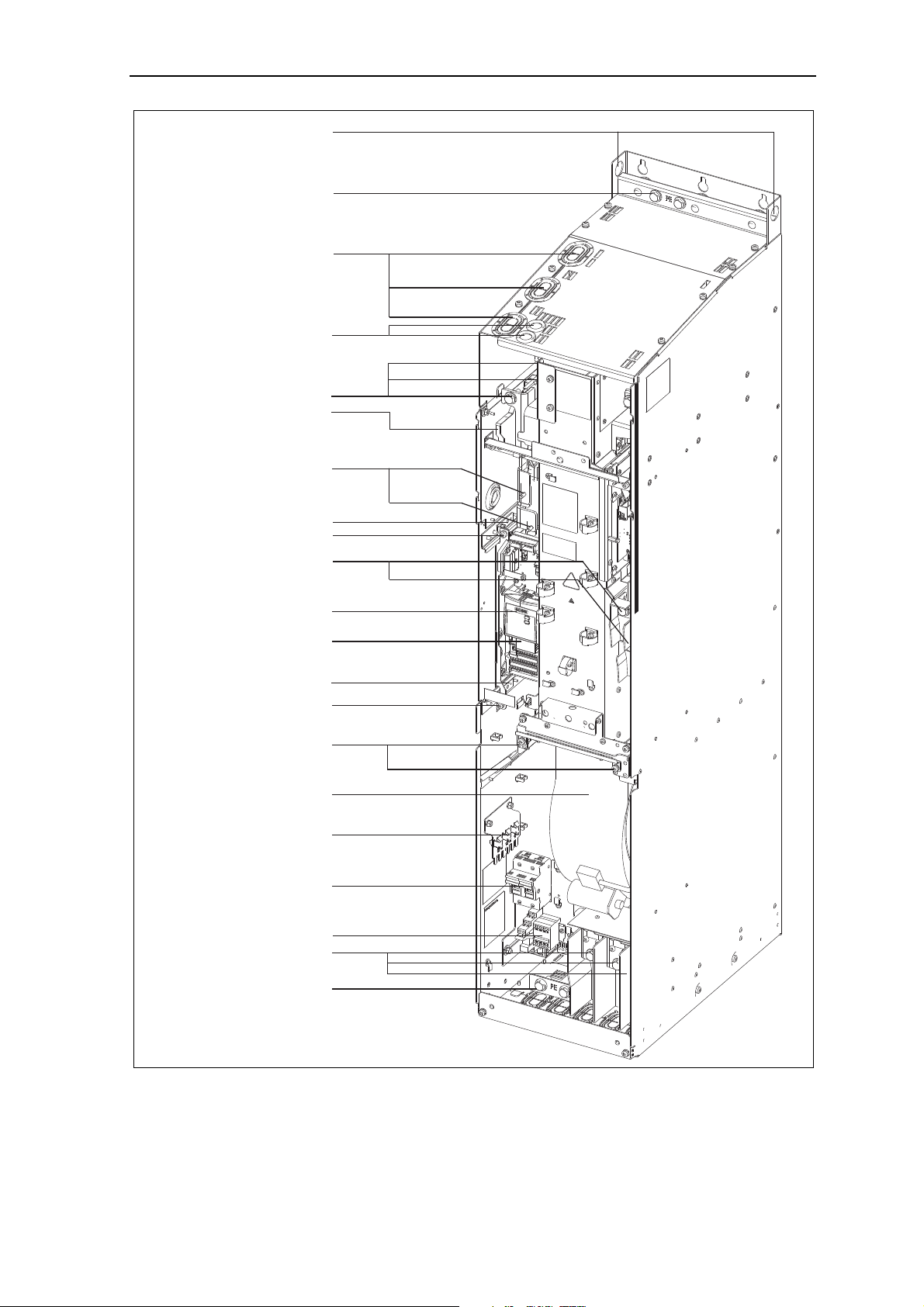

Hoisting eyes

Shield connection

Mains cable PE

Cable opening for

mains conection

U1/L1, V1/L2, W1/L3

able opening DCPA, DCNA

for connection of an

external braking unit

Phase U1/L1, V1/L2, W1/L3

Connection DCPA, DCNA

for external braking unit

Connection for dv/dt filter

Status Display Panel

Bottom adjustment rail

Bottom retaining screw

Mains cable

Connection to

Y-Capacitor

Top adjustment rail

Top retaining screw

DCPS, DCNS

Elektronic box

Fan screws

Fan

Shield connection

control leads

Fan fuses

Transformer adaption

Motor cable

Phase U2, V2, W2

PE Shield connection

Motor cable

Fig. 1-3 Frame Size GX

MICROMASTER 440 Parameter List

10 6SE6400-5BB00-0BP0

Page 11

Issue 01/06 Block Diagram and Terminals

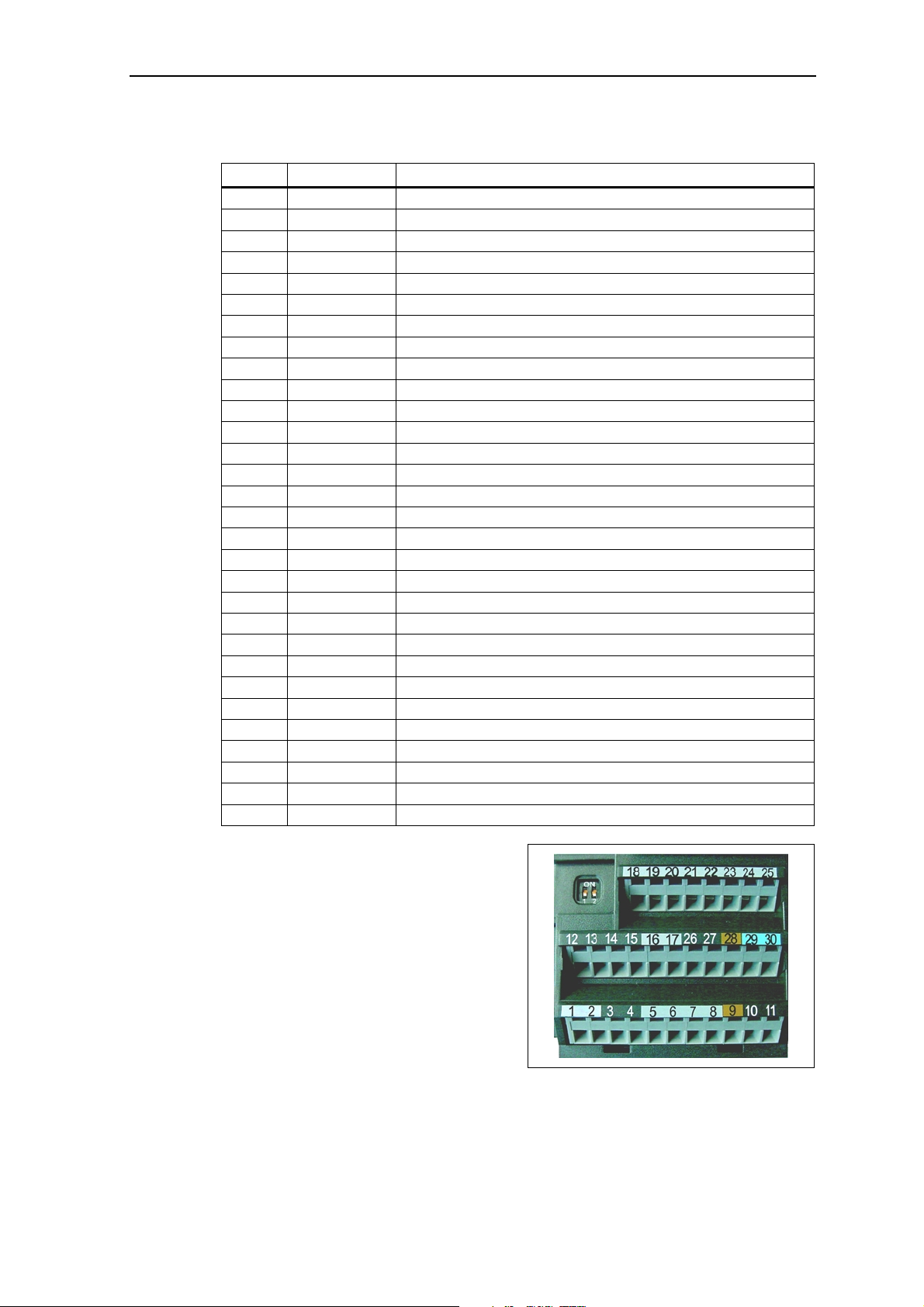

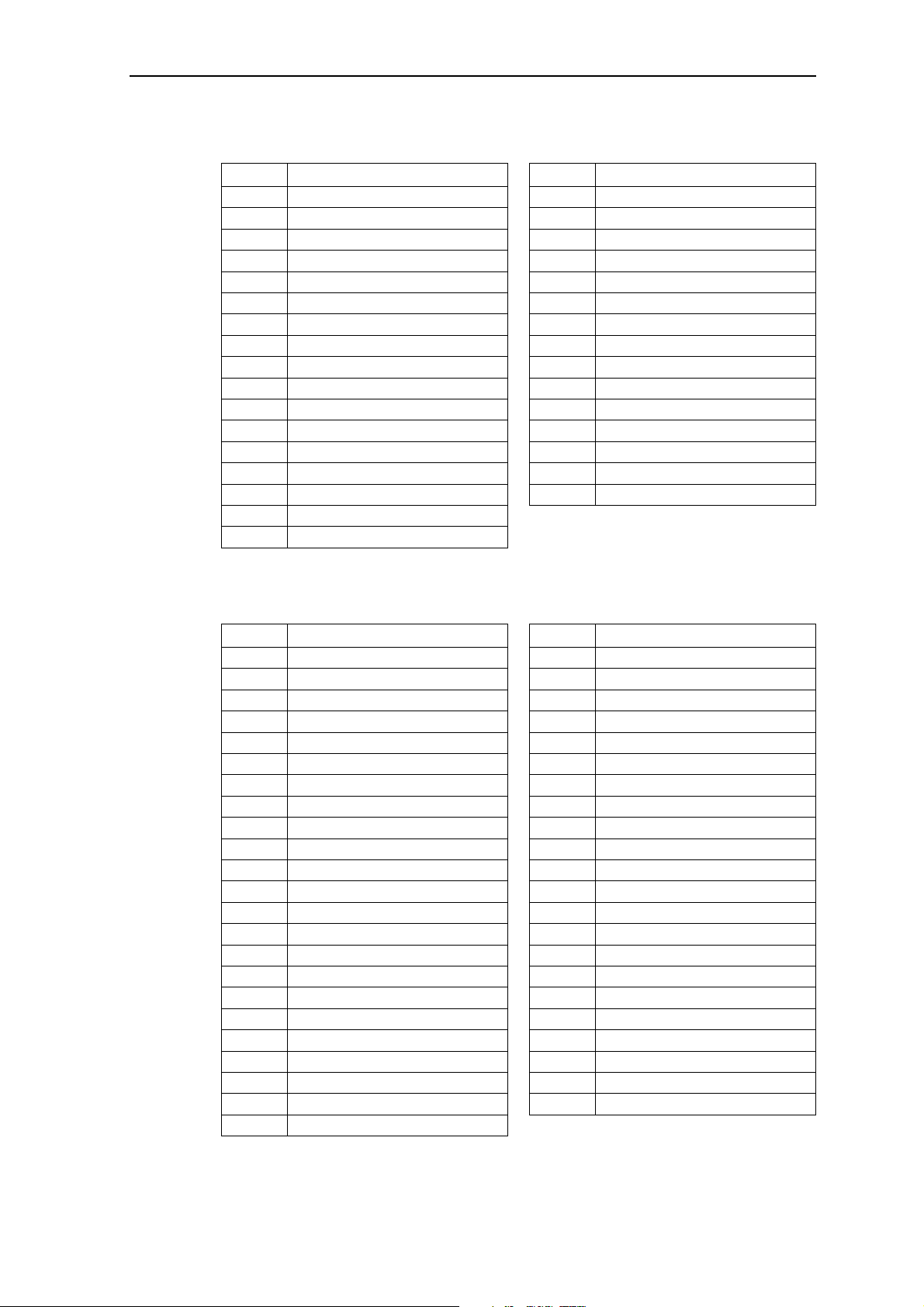

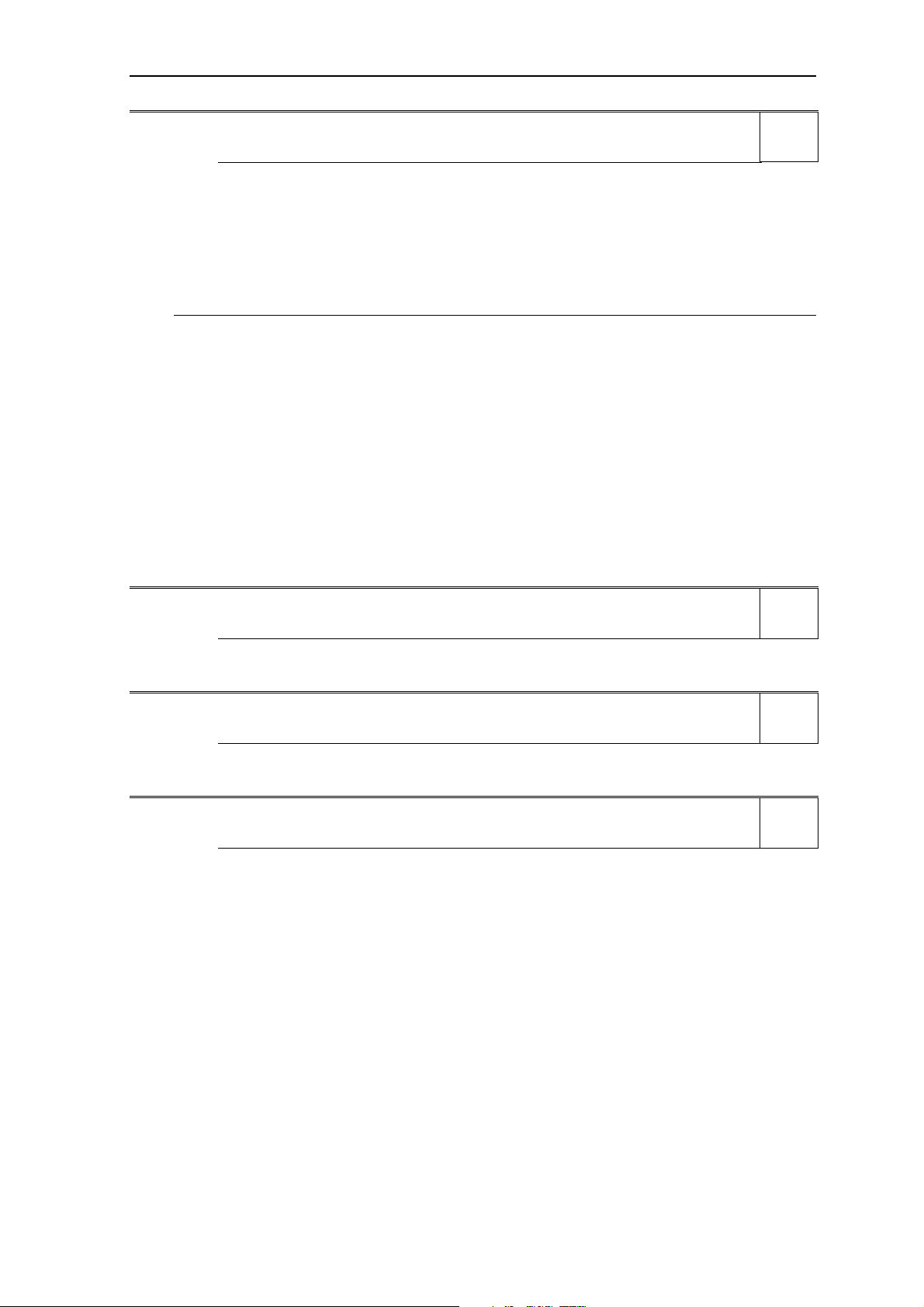

1.3 Control Terminals

Terminal Designation Function

1 - Output +10 V

2 - Output 0 V

3 ADC1+ Analog input 1 (+)

4 ADC1- Analog input 1 (-)

5 DIN1 Digital input 1

6 DIN2 Digital input 2

7 DIN3 Digital input 3

8 DIN4 Digital input 4

9 - Isolated output +24 V / max. 100 mA

10 ADC2+ Analog input 2 (+)

11 ADC2- Analog input 2 (-)

12 DAC1+ Analog output 1 (+)

13 DAC1- Analog output 1 (-)

14 PTCA Connection for PTC / KTY84

15 PTCB Connection for PTC / KTY84

16 DIN5 Digital input 5

17 DIN6 Digital input 6

18 DOUT1/NC Digital output 1 / NC contact

19 DOUT1/NO Digital output 1 / NO contact

20 DOUT1/COM Digital output 1 / Changeover contact

21 DOUT2/NO Digital output 2 / NO contact

22 DOUT2/COM Digital output 2 / Changeover contact

23 DOUT3/NC Digital output 3 / NC contact

24 DOUT3/NO Digital output 3 / NO contact

25 DOUT3/COM Digital output 3 / Changeover contact

26 DAC2+ Analog output 2 (+)

27 DAC2- Analog output 2 (-)

28 - Isolated output 0 V / max. 100 mA

29 P+ RS485 port

30 P- RS485 port

Fig. 1-4 Control terminals of

MICROMASTER 440

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

11

Page 12

Parameters Issue 01/06

2 Parameters

2.1 Introduction to MICROMASTER System Parameters

The layout of the parameter description is as follows.

1 Par number 2 Parameter name 9 Min:

[index] 3 CStat: 5 Datatype 7 Unit: 10 Def:

4 P-Group: 6 active: 8 Quick Comm: 11 Max:

13 Description:

1. Parameter number

Indicates the relevant parameter number. The numbers used are 4-digit numbers

in the range 0000 to 9999. Numbers prefixed with an “r” indicate that the

parameter is a “read-only” parameter, which displays a particular value but cannot

be changed directly by specifying a different value via this parameter number (in

such cases, dashes “-“ are entered at the points “Unit”, “Min”, “Def” and “Max” in

the header of the parameter description.

All other parameters are prefixed with a “P”. The values of these parameters can

be changed directly in the range indicated by the “Min” and “Max” settings in the

header.

[index] indicates that the parameter is an indexed parameter and specifies the

number of indices available.

2. Parameter name

Indicates the name of the relevant parameter.

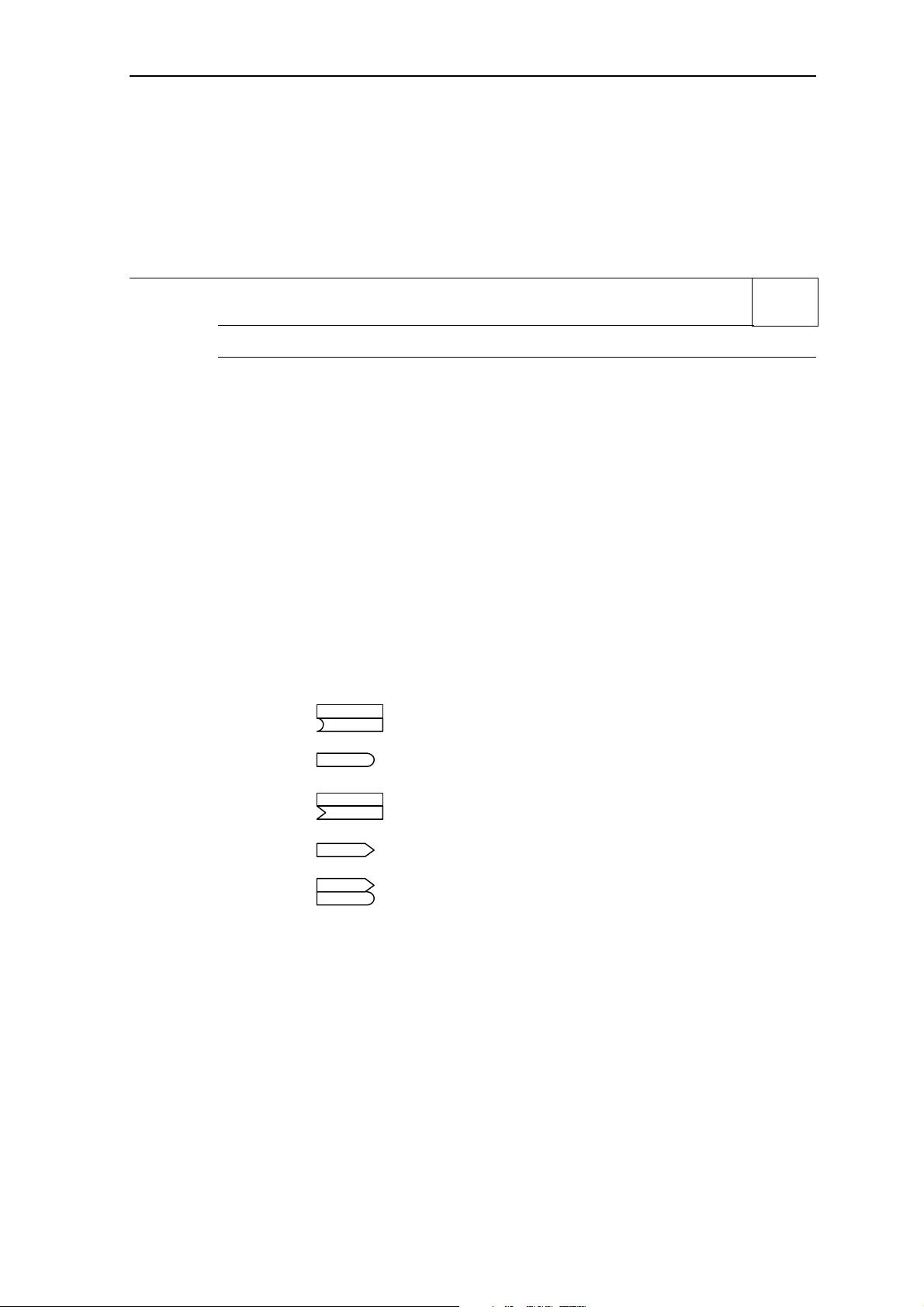

Certain parameter names include the following abbreviated prefixes: BI, BO, CI,

and CO followed by a colon.

These abbreviations have the following meanings:

BI =

P9999

Binector input, i.e. parameter selects the source of a binary

(0)

signal

12 Level:

2

BO =

CI =

CO =

r9999

r9999

(999:9)

r9999 [99]

Binector output, i.e. parameter connects as a binary signal

Connector input, i.e. parameter selects the source of an

analog signal

Connector output, i.e. parameter connects as an analog

signal

CO/BO =

r9999

r9999

Connector/Binector output, i.e. parameter connects as an

analog signal and/or as a binary signal

To make use of BiCo you will need access to the full parameter list. At this level

many new parameter settings are possible, including BiCo functionality. BiCo

functionality is a different, more flexible way of setting and combining input and

output functions. It can be used in most cases in conjunction with the simple,

level 2 settings.

The BiCo system allows complex functions to be programmed. Boolean and

mathematical relationships can be set up between inputs (digital, analog, serial

etc.) and outputs (inverter current, frequency, analog output, relays, etc.).

MICROMASTER 440 Parameter List

12 6SE6400-5BB00-0BP0

Page 13

Issue 01/06 Parameters

3. CStat

Commissioning status of the parameter. Three states are possible:

Commissioning C

Run U

Ready to run T

This indicates when the parameter can be changed. One, two or all three states

may be specified. If all three states are specified, this means that it is possible to

change this parameter setting in all three inverter states

4. P-Group

Indicates the functional group of the particular.

Note

Parameter P0004 (parameter filter) acts as a filter and focuses access to

parameters according to the functional group selected.

5. Datatype

The data types available are shown in the table below.

Notation Meaning

U16 16-bit unsigned

U32 32-bit unsigned

I16 16-bit integer

I32 32-bit integer

Float Floating point

6. Active

Indicates whether

♦ Immediately changes to the parameter values take effective immediately after

they have been entered, or

♦ Confirm the “P” button on the operator panel (BOP or AOP) must be

pressed before the changes take effect.

7. Unit

Indicates the unit of measure applicable to the parameter values

8. QuickComm

Indicates whether or not (Yes or No) a parameter can only be changed during

quick commissioning, i.e. when P0010 (parameter groups for commissioning) is

set to 1 (quick commissioning).

9. Min

Indicates the minimum value to which the parameter can be set.

10. Def

Indicates the default value, i.e. the value which applies if the user does not specify

a particular value for the parameter.

11. Max

Indicates the maximum value to which the parameter can be set.

12. Level

Indicates the level of user access. There are four access levels: Standard,

Extended, Expert and Service. The number of parameters that appear in each

functional group depends on the access level set in P0003 (user access level).

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

13

Page 14

Parameters Issue 01/06

13. Description

The parameter description consists of the sections and contents listed below.

Some of these sections and contents are optional and will be omitted on a caseto-case basis if not applicable.

Description: Brief explanation of the parameter function.

Diagram: Where applicable, diagram to illustrate the effects of parameters on a

Settings: List of applicable settings. These include

Example: Optional example of the effects of a particular parameter setting.

Dependency: Any conditions that must be satisfied in connection with this parameter. Also

Warning / Caution / Notice / Note:

More details: Any sources of more detailed information concerning the particular parameter.

characteristic curve, for example

Possible settings, Most common settings, Index and Bitfields

any particular effects, which this parameter has on other parameter(s) or which

other parameters have on this one.

Important information which must be heeded to prevent personal injury or

damage to equipment / specific information which should be heeded in order to

avoid problems / information which may be helpful to the user

Operators

The following operators are used in the parameter list to represent mathematical

interrelationships:

Arithmetic operators

+ Addition

- Subtraction

* Multiplication

/ Division

Comparison operators

> Greater than

>= Greater than / equal to

< Less than

<= Less than / equal to

Equivalence operators

== Equal to

!= Not equal to

Logical operators

&& AND logic operation

|| OR logic operation

MICROMASTER 440 Parameter List

14 6SE6400-5BB00-0BP0

Page 15

Issue 01/06 Parameters

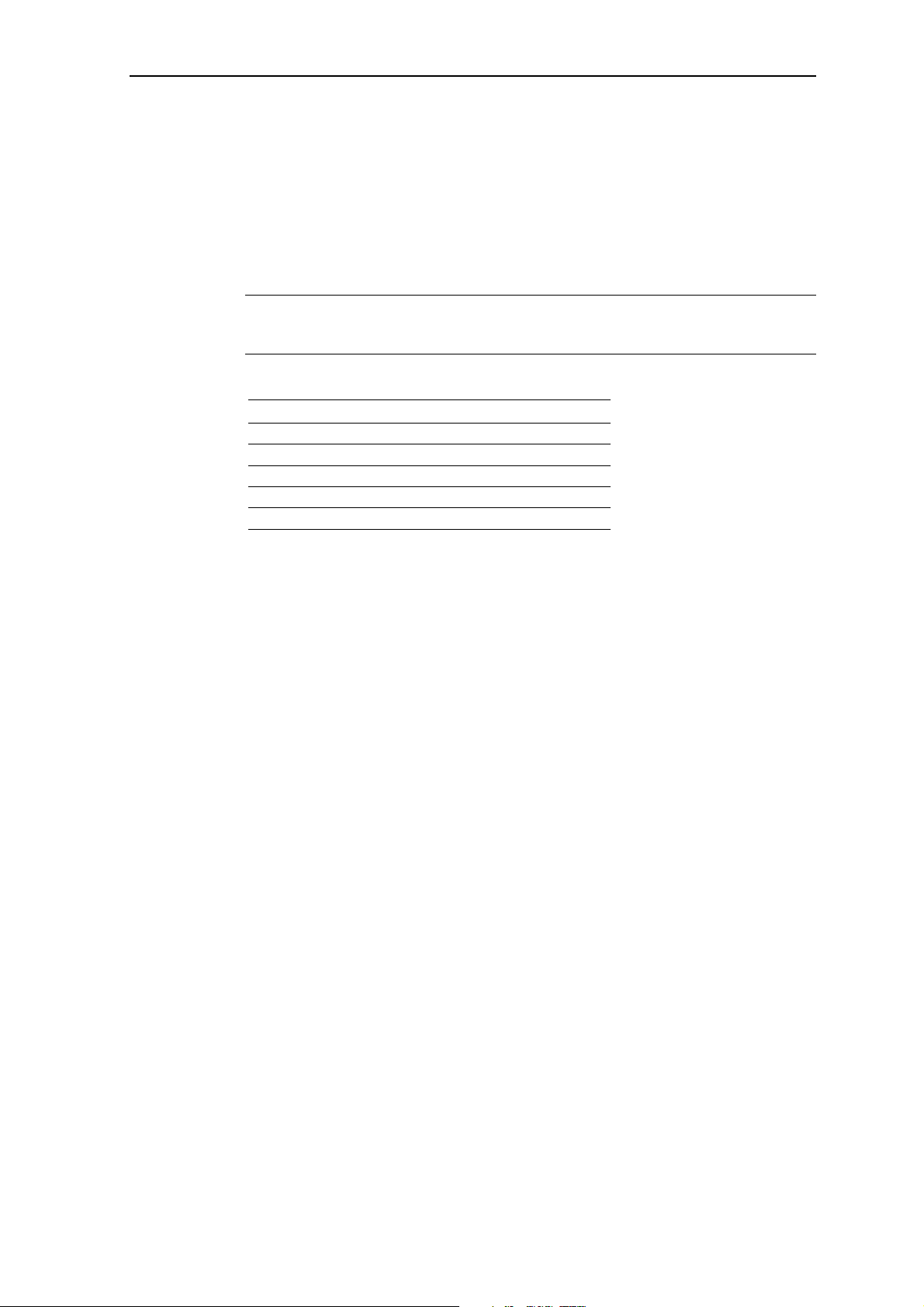

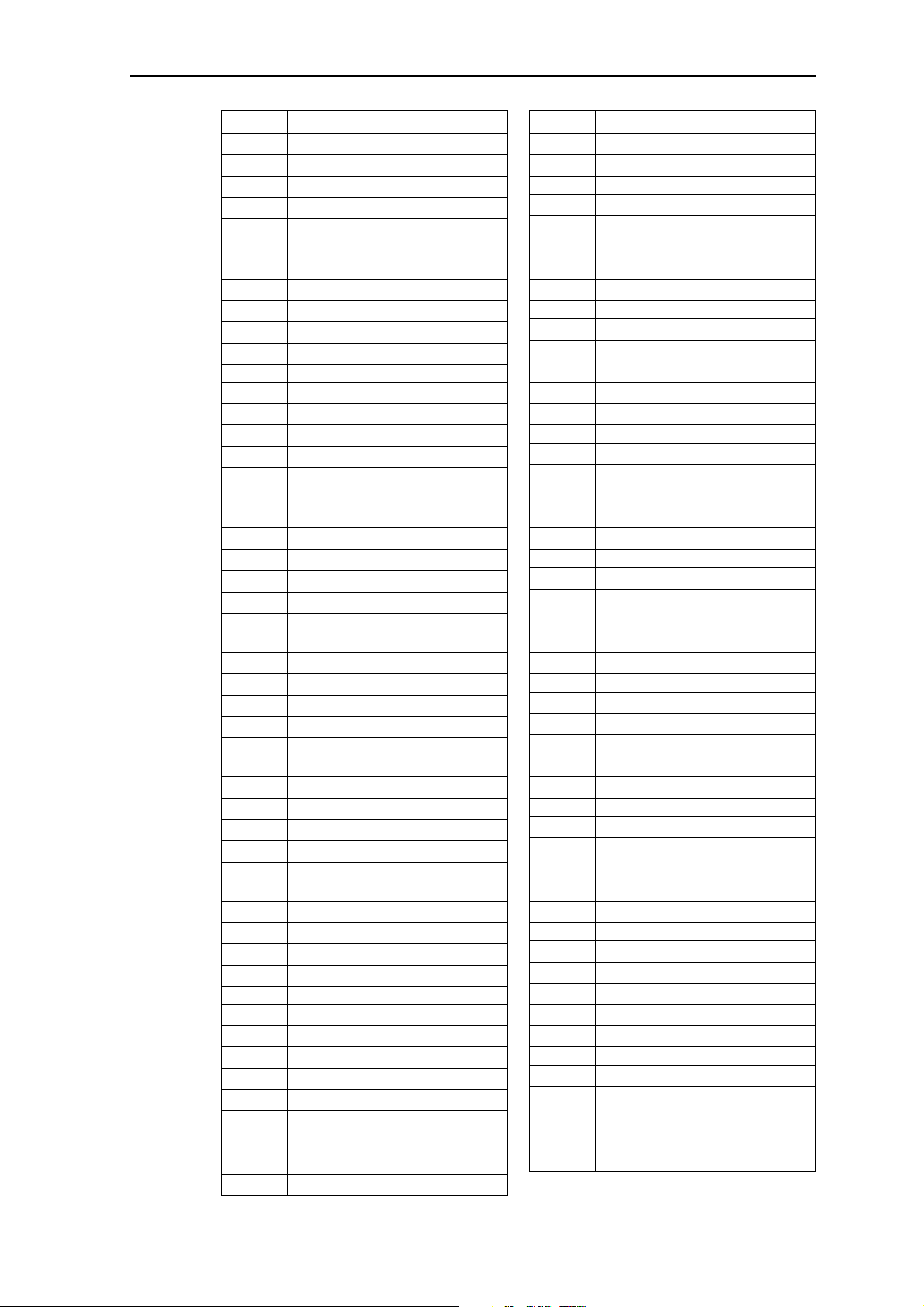

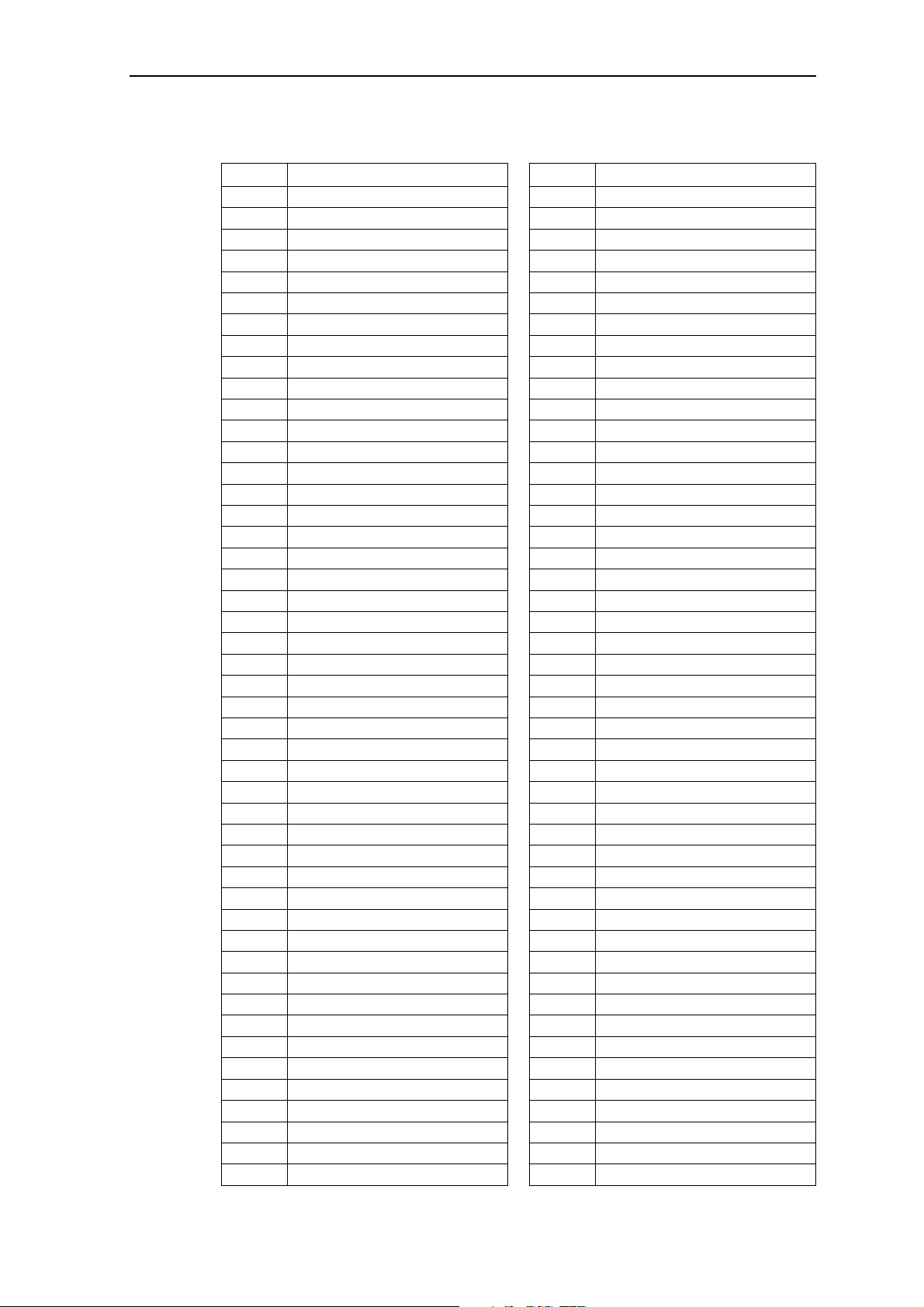

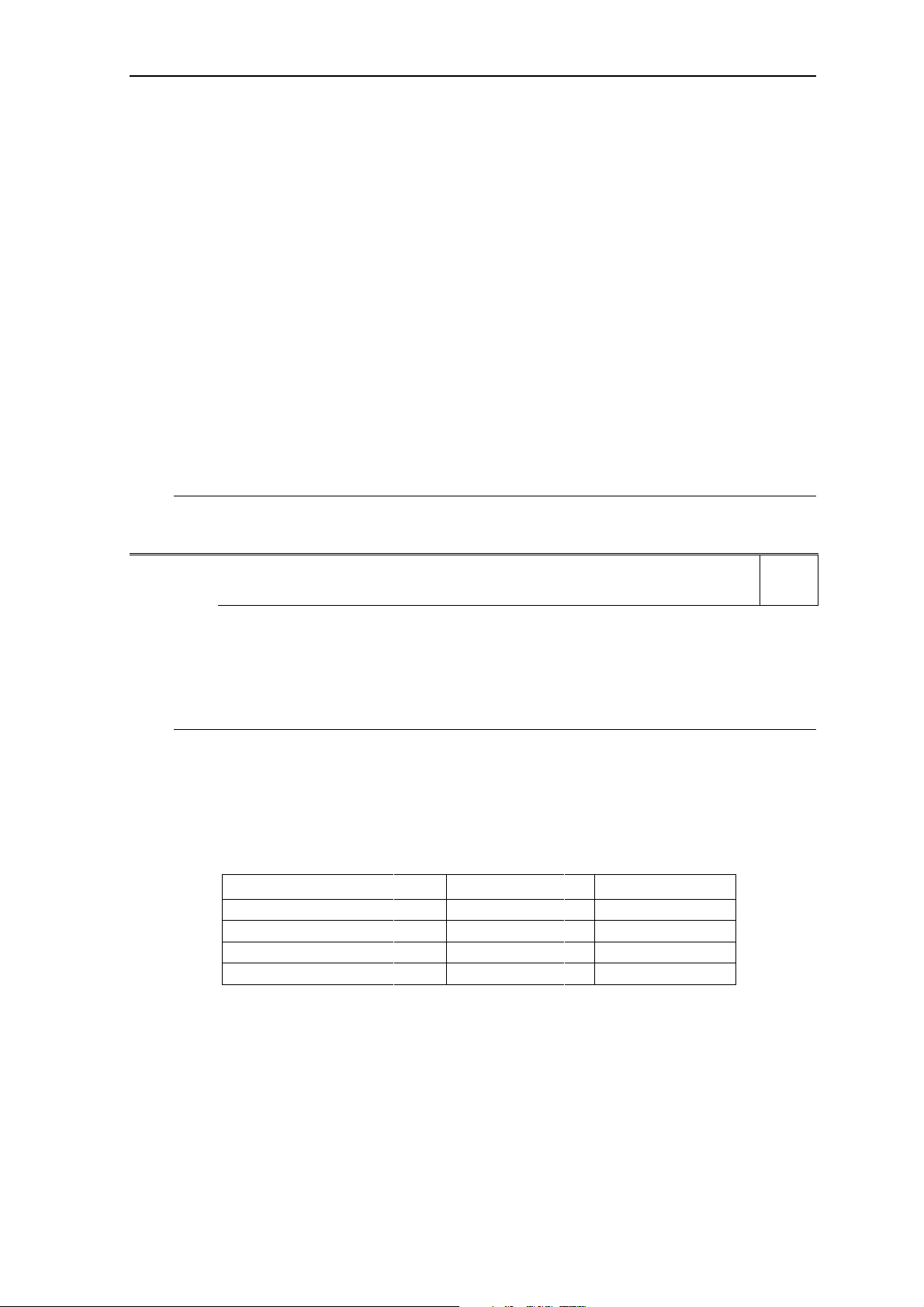

2.2 Quick commissioning (P0010 = 1)

The following parameters are necessary for quick commissioning (P0010 = 1).

Quick commissioning (P0010 = 1)

Par.-No. Name Access level Cstat

P0100 Europe / North America 1 C

P0205 Inverter application 3 C

P0300 Select motor type 2 C

P0304 Motor voltage rating 1 C

P0305 Motor current rating 1 C

P0307 Motor power rating 1 C

P0308 Motor cosPhi rating 1 C

P0309 Motor efficiency rating 1 C

P0310 Motor frequency rating 1 C

P0311 Motor speed rating 1 C

P0320 Motor magnetizing current 3 CT

P0335 Motor cooling 2 CT

P0640 Motor overload factor [%] 2 CUT

P0700 Selection of command source 1 CT

P1000 Selection of frequency setpoint 1 CT

P1080 Min. speed 1 CUT

P1082 Max. speed 1 CT

P1120 Ramp-up time 1 CUT

P1121 Ramp-down time 1 CUT

P1135 OFF3 ramp-down time 2 CUT

P1300 Control mode 2 CT

P1500 Selection of torque setpoint 2 CT

P1910 Select motor data identification 2 CT

P1960 Speed control optimisation 3 CT

P3900 End of quick commissioning 1 C

When P0010 = 1 is chosen, P0003 (user access level) can be used to select the

parameters to be accessed. This parameter also allows selection of a user-defined

parameter list for quick commissioning.

At the end of the quick commissioning sequence, set P3900 = 1 to carry out the

necessary motor calculations and clear all other parameters (not included in P0010

= 1) to their default settings.

Note

This applies only in Quick Commissioning mode.

Reset to Factory default

To reset all parameters to the factory default settings; the following parameters should

be set as follows:

Set P0010 = 30

Set P0970 = 1

Note

The reset process takes approximately 10 seconds to complete. Reset to Factory

default

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

15

Page 16

Parameters Issue 01/06

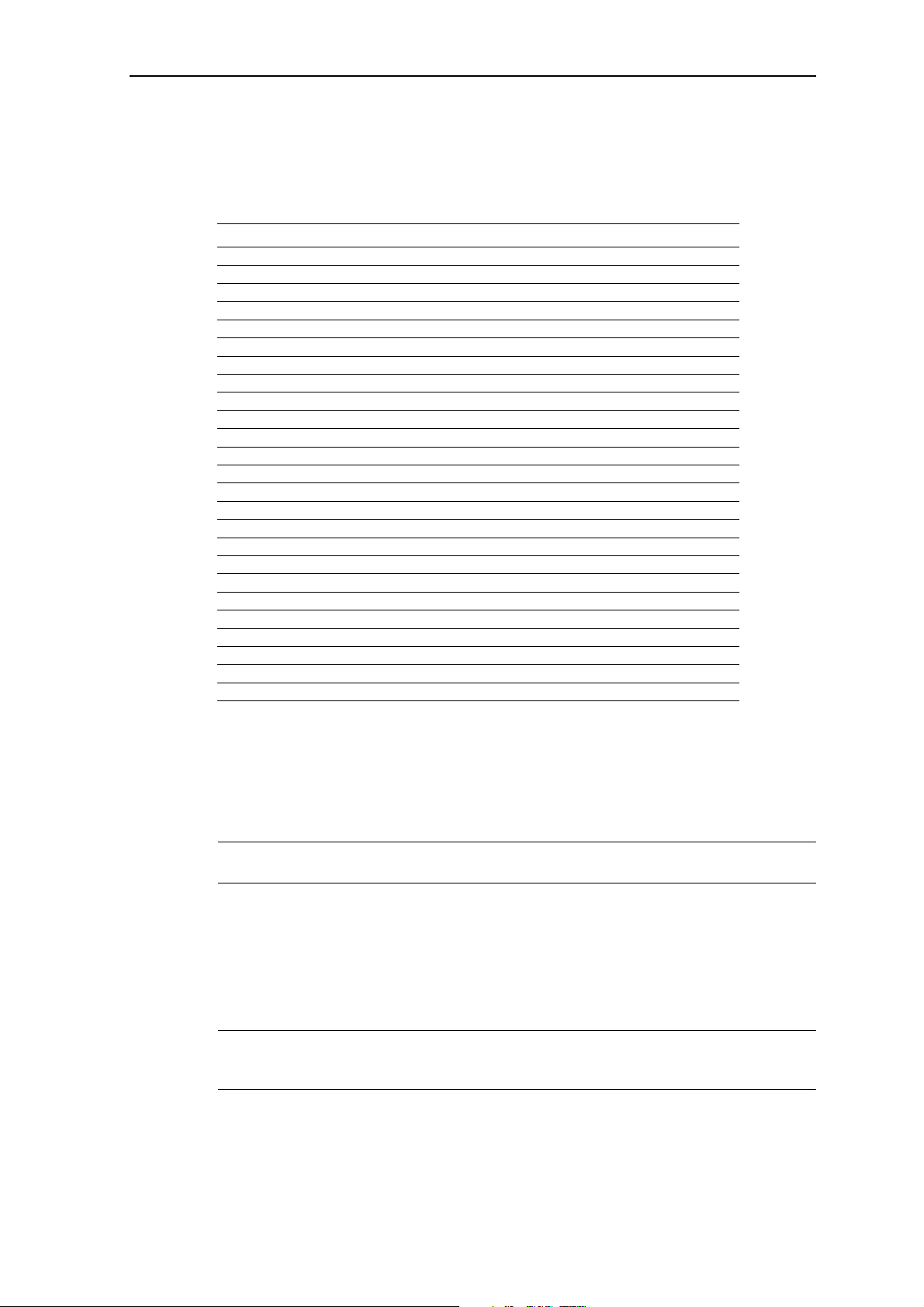

Seven-segment display

The seven-segment display is structured as follows:

9 811 1013 1215 14Segment Bit

Segment Bit

1 03 25 47 6

The significance of the relevant bits in the display is described in the status and

control word parameters.

MICROMASTER 440 Parameter List

16 6SE6400-5BB00-0BP0

Page 17

Issue 01/06 Parameters

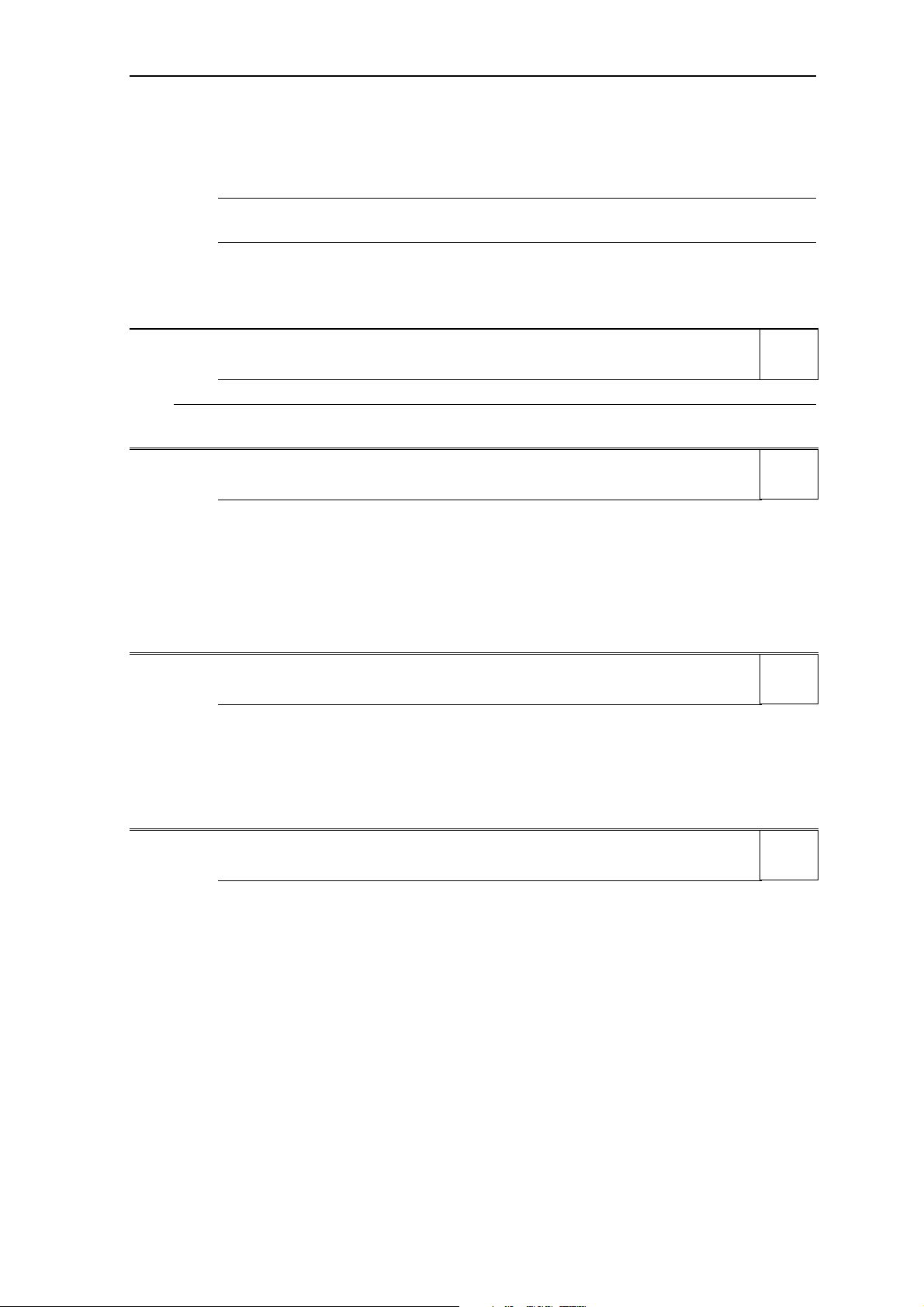

2.3 Command and Drive Datasets - Overview

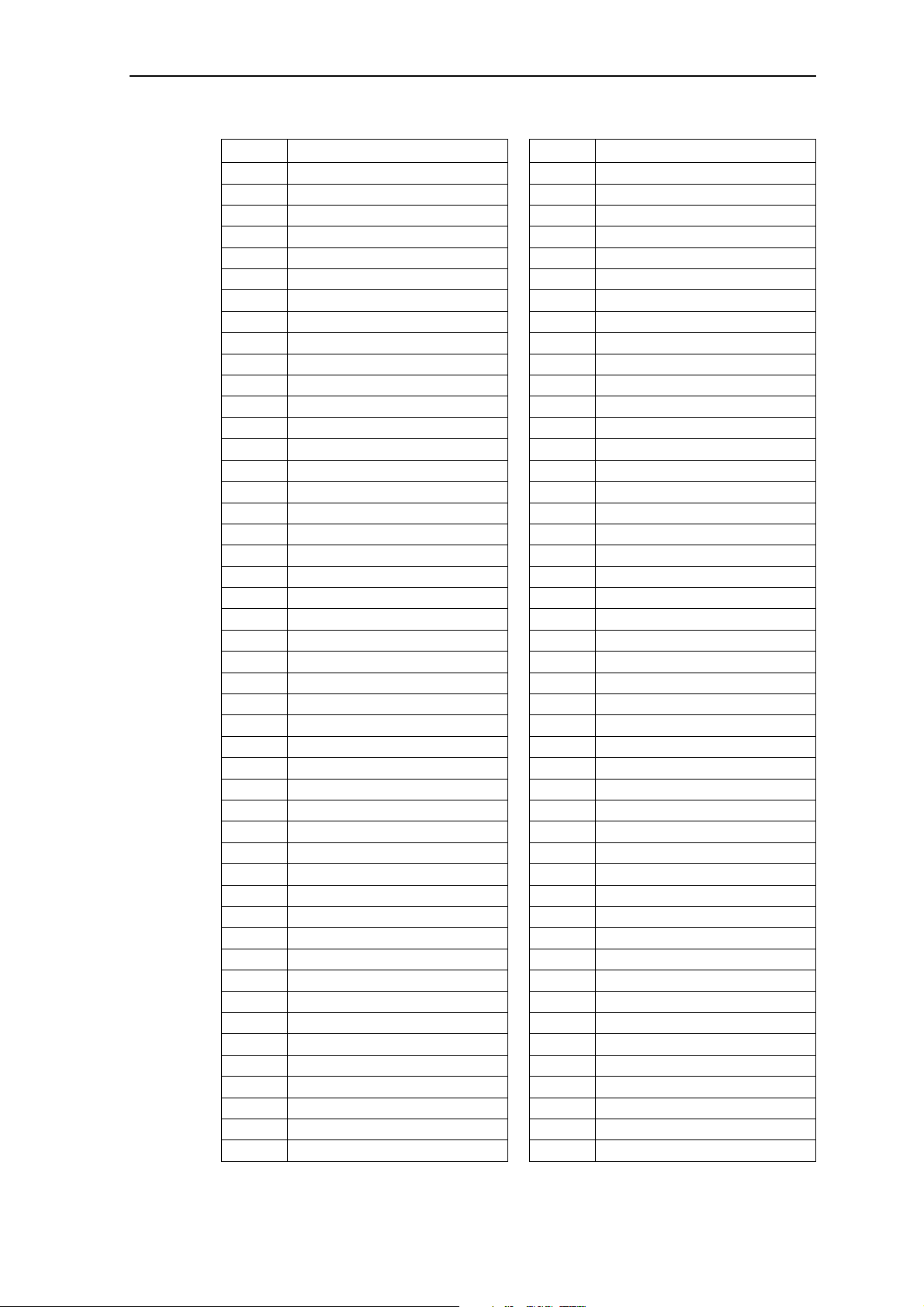

Command Datasets (CDS)

ParNo Parameter text 1)

P0700[3] Selection of command source X

P0701[3] Function of digital input 1 X

P0702[3] Function of digital input 2 X

P0703[3] Function of digital input 3 X

P0704[3] Function of digital input 4 X

P0705[3] Function of digital input 5 X

P0706[3] Function of digital input 6 X

P0707[3] Function of digital input 7 X

P0708[3] Function of digital input 8 X

P0719[3] Selection of cmd. & freq. setp. X

P0731[3] BI: Function of digital output 1 X

P0732[3] BI: Function of digital output 2 X

P0733[3] BI: Function of digital output 3 X

P0800[3] BI: Download parameter set 0 –

P0801[3] BI: Download parameter set 1 –

P0840[3] BI: ON/OFF1 X

P0842[3] BI: ON reverse/OFF1 X

P0844[3] BI: 1. OFF2 X

P0845[3] BI: 2. OFF2 X

P0848[3] BI: 1. OFF3 X

P0849[3] BI: 2. OFF3 X

P0852[3] BI: Pulse enable X

P1000[3] Selection of frequency setpoint X

P1020[3] BI: Fixed freq. selection Bit 0 X

P1021[3] BI: Fixed freq. selection Bit 1 X

P1022[3] BI: Fixed freq. selection Bit 2 X

P1023[3] BI: Fixed freq. selection Bit 3 X

P1026[3] BI: Fixed freq. selection Bit 4 X

P1028[3] BI: Fixed freq. selection Bit 5 X

P1035[3] BI: Enable MOP (UP-command) X

P1036[3] BI: Enable MOP (DOWN-command) X

P1055[3] BI: Enable JOG right X

P1056[3] BI: Enable JOG left X

P1070[3] CI: Main setpoint X

P1071[3] CI: Main setpoint scaling X

ParNo Parameter text 1)

P1074[3] BI: Disable additional setpoint X

P1075[3] CI: Additional setpoint X

P1076[3] CI: Additional setpoint scaling X

P1110[3] BI: Inhibit neg. freq. setpoint X

P1113[3] BI: Reverse X

P1124[3] BI: Enable JOG ramp times X

P1140[3] BI: RFG enable X

P1141[3] BI: RFG start X

P1142[3] BI: RFG enable setpoint X

P1230[3] BI: Enable DC braking X

P1330[3] CI: Voltage setpoint X

P1477[3] BI: Set integrator of n-ctrl. X

P1478[3] CI: Set integrator value n-ctrl. X

P1500[3] Selection of torque setpoint X

P1501[3] BI: Change to torque control X

P1503[3] CI: Torque setpoint X

P1511[3] CI: Additional torque setpoint X

P1522[3] CI: Upper torque limit –

P1523[3] CI: Lower torque limit –

P2103[3] BI: 1. Faults acknowledgement X

P2104[3] BI: 2. Faults acknowledgement X

P2106[3] BI: External fault X

P2200[3] BI: Enable PID controller –

P2220[3] BI: Fixed PID setp. select Bit 0 X

P2221[3] BI: Fixed PID setp. select Bit 1 X

P2222[3] BI: Fixed PID setp. select Bit 2 X

P2223[3] BI: Fixed PID setp. select Bit 3 X

P2226[3] BI: Fixed PID setp. select Bit 4 X

P2228[3] BI: Fixed PID setp. select Bit 5 X

P2235[3] BI: Enable PID-MOP (UP-cmd) X

P2236[3] BI: Enable PID-MOP (DOWN-cmd) X

P2253[3] CI: PID setpoint X

P2254[3] CI: PID trim source X

P2264[3] CI: PID feedback X

1) X = Parameters will be altered during data set

– = Parameters will be altered in the state "Ready" only

switchover (CDS) in the state "Run"

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

17

Page 18

Parameters Issue 01/06

Drive Datasets (DDS)

ParNo Parameter text

P0005[3] Display selection

r0035[3] CO: Act. motor temperature

P0291[3] Inverter protection

P0300[3] Select motor type

P0304[3] Rated motor voltage

P0305[3] Rated motor current

P0307[3] Rated motor power

P0308[3] Rated motor cosPhi

P0309[3] Rated motor efficiency

P0310[3] Rated motor frequency

P0311[3] Rated motor speed

r0313[3] Motor pole pairs

P0314[3] Motor pole pair number

P0320[3] Motor magnetizing current

r0330[3] Rated motor slip

r0331[3] Rated magnetization current

r0332[3] Rated power factor

r0333[3] Rated motor torque

P0335[3] Motor cooling

P0340[3] Calculation of motor parameters

P0341[3] Motor inertia [kg*m^2]

P0342[3] Total/motor inertia ratio

P0344[3] Motor weight

r0345[3] Motor start-up time

P0346[3] Magnetization time

P0347[3] Demagnetization time

P0350[3] Stator resistance (line-to-line)

P0352[3] Cable resistance

P0354[3] Rotor resistance

P0356[3] Stator leakage inductance

P0358[3] Rotor leakage inductance

P0360[3] Main inductance

P0362[3] Magnetizing curve flux 1

P0363[3] Magnetizing curve flux 2

P0364[3] Magnetizing curve flux 3

P0365[3] Magnetizing curve flux 4

P0366[3] Magnetizing curve imag 1

P0367[3] Magnetizing curve imag 2

P0368[3] Magnetizing curve imag 3

P0369[3] Magnetizing curve imag 4

ParNo Parameter text

r0370[3] Stator resistance [%]

r0372[3] Cable resistance [%]

r0373[3] Rated stator resistance [%]

r0374[3] Rotor resistance [%]

r0376[3] Rated rotor resistance [%]

r0377[3] Total leakage reactance [%]

r0382[3] Main reactance [%]

r0384[3] Rotor time constant

r0386[3] Total leakage time constant

P0400[3] Select encoder type

P0408[3] Encoder pulses per revolution

P0491[3] Reaction on freq. signal loss

P0492[3] Allowed frequency difference

P0494[3] Delay frequency loss reaction

P0500[3] Technological application

P0530[3] Unit for positioning signal

P0531[3] Unit conversion

P0601[3] Motor temperature sensor

P0604[3] Threshold motor temperature

P0625[3] Ambient motor temperature

P0626[3] Overtemperature stator iron

P0627[3] Overtemperature stator winding

P0628[3] Overtemperature rotor winding

r0630[3] CO: Ambient temperature

r0631[3] CO: Stator iron temperature

r0632[3] CO: Stator winding temperature

r0633[3] CO: Rotor winding temperature

P0640[3] Motor overload factor [%]

P1001[3] Fixed frequency 1

P1002[3] Fixed frequency 2

P1003[3] Fixed frequency 3

P1004[3] Fixed frequency 4

P1005[3] Fixed frequency 5

P1006[3] Fixed frequency 6

P1007[3] Fixed frequency 7

P1008[3] Fixed frequency 8

P1009[3] Fixed frequency 9

P1010[3] Fixed frequency 10

P1011[3] Fixed frequency 11

P1012[3] Fixed frequency 12

MICROMASTER 440 Parameter List

18 6SE6400-5BB00-0BP0

Page 19

Issue 01/06 Parameters

ParNo Parameter text

P1013[3] Fixed frequency 13

P1014[3] Fixed frequency 14

P1015[3] Fixed frequency 15

P1031[3] Setpoint memory of the MOP

P1040[3] Setpoint of the MOP

P1058[3] JOG frequency right

P1059[3] JOG frequency left

P1060[3] JOG ramp-up time

P1061[3] JOG ramp-down time

P1080[3] Min. frequency

P1082[3] Max. frequency

P1091[3] Skip frequency 1

P1092[3] Skip frequency 2

P1093[3] Skip frequency 3

P1094[3] Skip frequency 4

P1101[3] Skip frequency bandwidth

P1120[3] Ramp-up time

P1121[3] Ramp-down time

P1130[3] Ramp-up initial rounding time

P1131[3] Ramp-up final rounding time

P1132[3] Ramp-down initial rounding time

P1133[3] Ramp-down final rounding time

P1134[3] Rounding type

P1135[3] OFF3 ramp-down time

P1202[3] Motor-current: Flying start

P1203[3] Search rate: Flying start

P1232[3] DC braking current

P1233[3] Duration of DC braking

P1234[3] DC braking start frequency

P1236[3] Compound braking current

P1240[3] Configuration of Vdc controller

P1243[3] Dynamic factor of Vdc-max

P1245[3] Switch on level kin. buffering

r1246[3] CO:Switch-on level kin buffering

P1247[3] Dyn. factor of kinetic buffering

P1250[3] Gain of Vdc-controller

P1251[3] Integration time Vdc-controller

P1252[3] Differential time Vdc-controller

P1253[3] Vdc-controller output limitation

P1256[3] Reaction of kinetic buffering

ParNo Parameter text

P1257[3] Freq limit for kinetic buffering

P1300[3] Control mode

P1310[3] Continuous boost

P1311[3] Acceleration boost

P1312[3] Starting boost

P1316[3] Boost end frequency

P1320[3] Programmable V/f freq. coord. 1

P1321[3] Programmable V/f volt. coord. 1

P1322[3] Programmable V/f freq. coord. 2

P1323[3] Programmable V/f volt. coord. 2

P1324[3] Programmable V/f freq. coord. 3

P1325[3] Programmable V/f volt. coord. 3

P1333[3] Start frequency for FCC

P1335[3] Slip compensation

P1336[3] Slip limit

P1338[3] Resonance damping gain V/f

P1340[3] Imax freq. controller prop. gain

P1341[3] Imax freq. ctrl. integral time

P1345[3] Imax voltage ctrl. prop. gain

P1346[3] Imax voltage ctrl. integral time

P1350[3] Voltage soft start

P1400[3] Configuration of speed control

P1442[3] Filter time for act. speed

P1452[3] Filter time for act. freq (SLVC)

P1460[3] Gain speed controller

P1462[3] Integral time speed controller

P1470[3] Gain speed controller (SLVC)

P1472[3] Integral time n-ctrl. (SLVC)

P1488[3] Droop input source

P1489[3] Droop scaling

P1492[3] Enable droop

P1496[3] Scaling accel. precontrol

P1499[3] Scaling accel. torque control

P1520[3] CO: Upper torque limit

P1521[3] CO: Lower torque limit

P1525[3] Scaling lower torque limit

P1530[3] Motoring power limitation

P1531[3] Regenerative power limitation

P1570[3] CO: Fixed value flux setpoint

P1574[3] Dynamic voltage headroom

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

19

Page 20

Parameters Issue 01/06

ParNo Parameter text

P1580[3] Efficiency optimization

P1582[3] Smooth time for flux setpoint

P1596[3] Int. time field weak. controller

P1610[3] Continuous torque boost (SLVC)

P1611[3] Acc. torque boost (SLVC)

P1654[3] Smooth time for Isq setpoint

P1715[3] Gain current controller

P1717[3] Integral time current controller

P1745[3] Variance flux error

P1750[3] Control word of motor model

P1755[3] Start-freq. motor model (SLVC)

P1756[3] Hyst.-freq. motor model (SLVC)

P1758[3] Chng-ov. del. t SLVC op.-lp ctrl

P1759[3] Chng-ov. del. t SLVC cl.-lp ctrl

P1764[3] Kp of n-adaption (SLVC)

P1767[3] Tn of n-adaption (SLVC)

P1780[3] Control word of Rs/Rr-adaption

P1781[3] Tn of Rs-adaption

P1786[3] Tn of Xm-adaption

P1803[3] Max. modulation

P1820[3] Reverse output phase sequence

P1909[3] Ctrl. word of motor data ident.

P2000[3] Reference frequency

P2001[3] Reference voltage

P2002[3] Reference current

P2003[3] Reference torque

P2004[3] Reference power

P2150[3] Hysteresis frequency f_hys

P2153[3] Time-constant frequency filter

P2155[3] Threshold frequency f_1

P2156[3] Delay time of threshold freq f_1

P2157[3] Threshold frequency f_2

P2158[3] Delay time of threshold freq f_2

P2159[3] Threshold frequency f_3

P2160[3] Delay time of threshold freq f_3

P2161[3] Min. threshold for freq. setp.

P2162[3] Hysteresis freq. for overfreq.

P2163[3] Entry freq. for perm. deviation

P2164[3] Hysteresis frequency deviation

P2165[3] Delay time permitted deviation

P2166[3] Delay time ramp up completed

P2167[3] Switch-off frequency f_off

P2168[3] Delay time T_off

ParNo Parameter text

P2170[3] Threshold current I_thresh

P2171[3] Delay time current

P2172[3] Threshold DC-link voltage

P2173[3] Delay time DC-link voltage

P2174[3] Torque threshold M_thresh

P2176[3] Delay time for torque threshold

P2177[3] Delay time for motor is blocked

P2178[3] Delay time for motor pulled out

P2181[3] Belt failure detection mode

P2182[3] Belt threshold frequency 1

P2183[3] Belt threshold frequency 2

P2184[3] Belt threshold frequency 3

P2185[3] Upper torque threshold 1

P2186[3] Lower torque threshold 1

P2187[3] Upper torque threshold 2

P2188[3] Lower torque threshold 2

P2189[3] Upper torque threshold 3

P2190[3] Lower torque threshold 3

P2192[3] Time delay for belt failure

P2201[3] Fixed PID setpoint 1

P2202[3] Fixed PID setpoint 2

P2203[3] Fixed PID setpoint 3

P2204[3] Fixed PID setpoint 4

P2205[3] Fixed PID setpoint 5

P2206[3] Fixed PID setpoint 6

P2207[3] Fixed PID setpoint 7

P2208[3] Fixed PID setpoint 8

P2209[3] Fixed PID setpoint 9

P2210[3] Fixed PID setpoint 10

P2211[3] Fixed PID setpoint 11

P2212[3] Fixed PID setpoint 12

P2213[3] Fixed PID setpoint 13

P2214[3] Fixed PID setpoint 14

P2215[3] Fixed PID setpoint 15

P2231[3] Setpoint memory of PID-MOP

P2240[3] Setpoint of PID-MOP

P2480[3] Position mode

P2481[3] Gearbox ratio input

P2482[3] Gearbox ratio output

P2484[3] No. of shaft turns = 1 Unit

P2487[3] Positional error trim value

P2488[3] Distance / No. of revolutions

MICROMASTER 440 Parameter List

20 6SE6400-5BB00-0BP0

Page 21

Issue 01/06 Parameters

2.4 Binector Input Parameters

ParNo Parameter text

P0731[3] BI: Function of digital output 1

P0732[3] BI: Function of digital output 2

P0733[3] BI: Function of digital output 3

P0800[3] BI: Download parameter set 0

P0801[3] BI: Download parameter set 1

P0810 BI: CDS bit 0 (Local / Remote)

P0811 BI: CDS bit 1

P0820 BI: DDS bit 0

P0821 BI: DDS bit 1

P0840[3] BI: ON/OFF1

P0842[3] BI: ON reverse/OFF1

P0844[3] BI: 1. OFF2

P0845[3] BI: 2. OFF2

P0848[3] BI: 1. OFF3

P0849[3] BI: 2. OFF3

P0852[3] BI: Pulse enable

P1020[3] BI: Fixed freq. selection Bit 0

P1021[3] BI: Fixed freq. selection Bit 1

P1022[3] BI: Fixed freq. selection Bit 2

P1023[3] BI: Fixed freq. selection Bit 3

P1026[3] BI: Fixed freq. selection Bit 4

P1028[3] BI: Fixed freq. selection Bit 5

P1035[3] BI: Enable MOP (UP-command)

P1036[3] BI: Enable MOP (DOWN-command)

P1055[3] BI: Enable JOG right

P1056[3] BI: Enable JOG left

P1074[3] BI: Disable additional setpoint

P1110[3] BI: Inhibit neg. freq. setpoint

P1113[3] BI: Reverse

P1124[3] BI: Enable JOG ramp times

P1140[3] BI: RFG enable

P1141[3] BI: RFG start

P1142[3] BI: RFG enable setpoint

P1230[3] BI: Enable DC braking

P1477[3] BI: Set integrator of n-ctrl.

ParNo Parameter text

P1501[3] BI: Change to torque control

P2103[3] BI: 1. Faults acknowledgement

P2104[3] BI: 2. Faults acknowledgement

P2106[3] BI: External fault

P2200[3] BI: Enable PID controller

P2220[3] BI: Fixed PID setp. select Bit 0

P2221[3] BI: Fixed PID setp. select Bit 1

P2222[3] BI: Fixed PID setp. select Bit 2

P2223[3] BI: Fixed PID setp. select Bit 3

P2226[3] BI: Fixed PID setp. select Bit 4

P2228[3] BI: Fixed PID setp. select Bit 5

P2235[3] BI: Enable PID-MOP (UP-cmd)

P2236[3] BI: Enable PID-MOP (DOWN-cmd)

P2810[2] BI: AND 1

P2812[2] BI: AND 2

P2814[2] BI: AND 3

P2816[2] BI: OR 1

P2818[2] BI: OR 2

P2820[2] BI: OR 3

P2822[2] BI: XOR 1

P2824[2] BI: XOR 2

P2826[2] BI: XOR 3

P2828 BI: NOT 1

P2830 BI: NOT 2

P2832 BI: NOT 3

P2834[4] BI: D-FF 1

P2837[4] BI: D-FF 2

P2840[2] BI: RS-FF 1

P2843[2] BI: RS-FF 2

P2846[2] BI: RS-FF 3

P2849 BI: Timer 1

P2854 BI: Timer 2

P2859 BI: Timer 3

P2864 BI: Timer 4

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

21

Page 22

Parameters Issue 01/06

2.5 Connector Input Parameters

ParNo Parameter text

P0095[10] CI: Display PZD signals

P0771[2] CI: DAC

P1070[3] CI: Main setpoint

P1071[3] CI: Main setpoint scaling

P1075[3] CI: Additional setpoint

P1076[3] CI: Additional setpoint scaling

P1330[3] CI: Voltage setpoint

P1478[3] CI: Set integrator value n-ctrl.

P1503[3] CI: Torque setpoint

P1511[3] CI: Additional torque setpoint

P1522[3] CI: Upper torque limit

P1523[3] CI: Lower torque limit

P2016[8] CI: PZD to BOP link (USS)

P2019[8] CI: PZD to COM link (USS)

P2051[8] CI: PZD to CB

2.6 Binector Output Parameters

ParNo Parameter text

P2253[3] CI: PID setpoint

P2254[3] CI: PID trim source

P2264[3] CI: PID feedback

P2869[2] CI: ADD 1

P2871[2] CI: ADD 2

P2873[2] CI: SUB 1

P2875[2] CI: SUB 2

P2877[2] CI: MUL 1

P2879[2] CI: MUL 2

P2881[2] CI: DIV 1

P2883[2] CI: DIV 2

P2885[2] CI: CMP 1

P2887[2] CI: CMP 2

ParNo Parameter text

r0751 BO: Status word of ADC

r2032 BO: CtrlWrd1 from BOP link (USS)

r2033 BO: CtrlWrd2 from BOP link (USS)

r2036 BO: CtrlWrd1 from COM link (USS)

r2037 BO: CtrlWrd2 from COM link (USS)

r2090 BO: Control word 1 from CB

r2091 BO: Control word 2 from CB

r2811 BO: AND 1

r2813 BO: AND 2

r2815 BO: AND 3

r2817 BO: OR 1

r2819 BO: OR 2

r2821 BO: OR 3

r2823 BO: XOR 1

r2825 BO: XOR 2

r2827 BO: XOR 3

r2829 BO: NOT 1

r2831 BO: NOT 2

r2833 BO: NOT 3

r2835 BO: Q D-FF 1

ParNo Parameter text

r2836 BO: NOT-Q D-FF 1

r2838 BO: Q D-FF 2

r2839 BO: NOT-Q D-FF 2

r2841 BO: Q RS-FF 1

r2842 BO: NOT-Q RS-FF 1

r2844 BO: Q RS-FF 2

r2845 BO: NOT-Q RS-FF 2

r2847 BO: Q RS-FF 3

r2848 BO: NOT-Q RS-FF 3

r2852 BO: Timer 1

r2853 BO: Nout timer 1

r2857 BO: Timer 2

r2858 BO: Nout timer 2

r2862 BO: Timer 3

r2863 BO: Nout timer 3

r2867 BO: Timer 4

r2868 BO: Nout timer 4

r2886 BO: CMP 1

r2888 BO: CMP 2

MICROMASTER 440 Parameter List

22 6SE6400-5BB00-0BP0

Page 23

Issue 01/06 Parameters

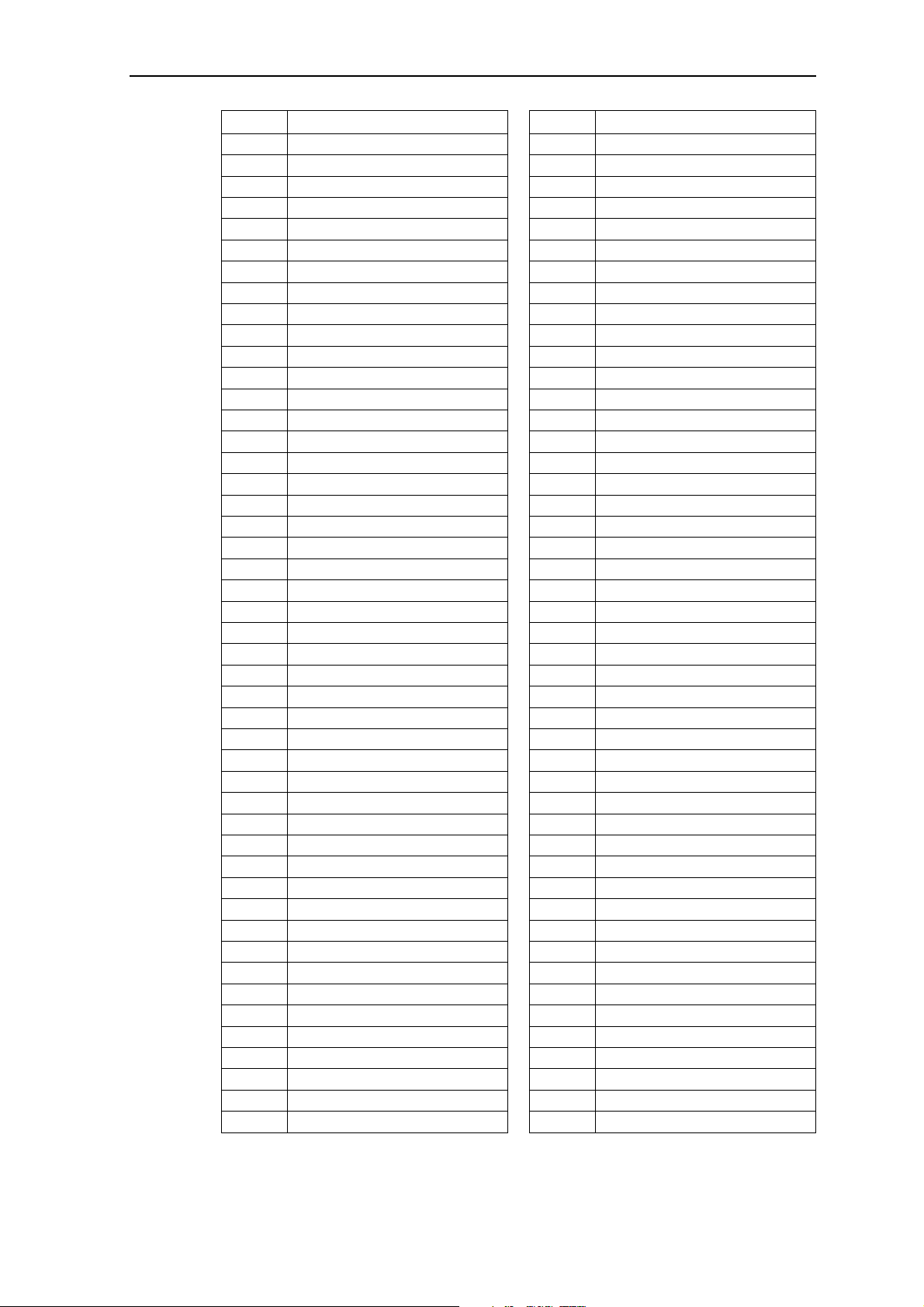

2.7 Connector Output Parameters

ParNo Parameter text

r0020 CO: Freq. setpoint before RFG

r0021 CO: Act. filtered frequency

r0024 CO: Act. filtered output freq.

r0025 CO: Act. filtered output voltage

r0026 CO: Act. filtered DC-link volt.

r0027 CO: Act. filtered output current

r0029 CO: Flux gen. current

r0030 CO: Torque gen. current

r0031 CO: Act. filtered torque

r0032 CO: Act. filtered power

r0035[3] CO: Act. motor temperature

r0036 CO:Inverter overload utilization

r0037[5] CO: Inverter temperature [°C]

r0038 CO: Act. power factor

r0039 CO: Energy consumpt. meter [kWh]

r0050 CO: Active command data set

r0051[2] CO: Active drive data set (DDS)

r0061 CO: Act. encoder frequency

r0062 CO: Freq. setpoint

r0063 CO: Act. frequency

r0064 CO: Dev. frequency controller

r0065 CO: Slip frequency

r0066 CO: Act. output frequency

r0067 CO: Act. output current limit

r0068 CO: Output current

r0069[6] CO: Act. phase currents

r0070 CO: Act. DC-link voltage

r0071 CO: Max. output voltage

r0072 CO: Act. output voltage

r0074 CO: Act. modulation

r0075 CO: Current setpoint Isd

r0076 CO: Act. current Isd

r0077 CO: Current setpoint Isq

r0078 CO: Act. current Isq

r0079 CO: Torque setpoint (total)

r0080 CO: Act. torque

r0084 CO: Act. air gap flux

r0086 CO: Act. active current

r0090 CO: Act. rotor angle

r0394 CO: Stator resistance IGBT [%]

ParNo Parameter text

r0395 CO: Total stator resistance [%]

r0396 CO: Act. rotor resistance

r0630[3] CO: Ambient temperature

r0631[3] CO: Stator iron temperature

r0632[3] CO: Stator winding temperature

r0633[3] CO: Rotor winding temperature

r0755[2] CO: Act. ADC after scal. [4000h]

r0947[8] CO: Letzte Fehlermeldung

r0948[12] CO: Fehlerzeit

r0949[8] CO: Fehlerwert

r1024 CO: Act. fixed frequency

r1050 CO: Act. Output freq. of the MOP

r1078 CO: Total frequency setpoint

r1079 CO: Selected frequency setpoint

r1114 CO: Freq. setp. after dir. ctrl.

r1119 CO: Freq. setpoint before RFG

r1170 CO: Frequency setpoint after RFG

r1242 CO: Switch-on level of Vdc-max

r1246[3] CO:Switch-on level kin buffering

r1315 CO: Total boost voltage

r1337 CO: V/f slip frequency

r1343 CO: Imax controller freq. output

r1344 CO: Imax controller volt. output

r1438 CO: Freq. setpoint to controller

r1445 CO: Act. filtered frequency

r1482 CO: Integral output of n-ctrl.

r1490 CO: Droop frequency

r1508 CO: Torque setpoint

r1515 CO: Additional torque setpoint

r1518 CO: Acceleration torque

P1520[3] CO: Upper torque limit

P1521[3] CO: Lower torque limit

r1526 CO: Upper torque limitation

r1527 CO: Lower torque limitation

r1536 CO: Max. trq. motoring current

r1537 CO: Max trq regenerative current

r1538 CO: Upper torque limit (total)

r1539 CO: Lower torque limit (total)

P1570[3] CO: Fixed value flux setpoint

r1583 CO: Flux setpoint (smoothed)

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

23

Page 24

Parameters Issue 01/06

ParNo Parameter text

r1597 CO: Outp. field weak. controller

r1598 CO: Flux setpoint (total)

r1718 CO: Output of Isq controller

r1719 CO: Integral output of Isq ctrl.

r1723 CO: Output of Isd controller

r1724 CO: Integral output of Isd ctrl.

r1725 CO: Integral limit of Isd ctrl.

r1728 CO: Decoupling voltage

r1770 CO: Prop. output of n-adaption

r1746 CO: Flussabweichung

r1771 CO: Int. output of n-adaption

r1778 CO: Flux angle difference

r1801 CO: Act. pulse frequency

r2015[8] CO: PZD from BOP link (USS)

r2018[8] CO: PZD from COM link (USS)

ParNo Parameter text

r2050[8] CO: PZD from CB

r2169 CO: Act. filtered frequency

r2224 CO: Act. fixed PID setpoint

r2250 CO: Output setpoint of PID-MOP

r2260 CO: PID setpoint after PID-RFG

r2262 CO: Filtered PID setp. after RFG

r2266 CO: PID filtered feedback

r2272 CO: PID scaled feedback

r2273 CO: PID error

r2294 CO: Act. PID output

r2870 CO: ADD 1

r2872 CO: ADD 2

r2874 CO: SUB 1

r2876 CO: SUB 2

r2878 CO: MUL 1

r2880 CO: MUL 2

r2882 CO: DIV 1

r2884 CO: DIV 2

P2889 CO: Fixed setpoint 1 in [%]

P2890 CO: Fixed setpoint 2 in [%]

2.8 Connector/Binector Output Parameters

ParNo Parameter text

r0019 CO/BO: BOP control word

r0052 CO/BO: Act. status word 1

r0053 CO/BO: Act. status word 2

r0054 CO/BO: Act. control word 1

r0055 CO/BO: Act. control word 2

ParNo Parameter text

r0056 CO/BO: Status of motor control

r0403 CO/BO: Encoder status word

r0722 CO/BO: Binary input values

r0747 CO/BO: State of digital outputs

r0785 CO/BO: Zustand Analogausgang

r1407 CO/BO: Status 2 of motor control

r2197 CO/BO: Monitoring word 1

r2198 CO/BO: Monitoring word 2

MICROMASTER 440 Parameter List

24 6SE6400-5BB00-0BP0

Page 25

Issue 01/06 Parameter Description

3 Parameter Description

Note

Level 4 Parameters are not visible with BOP or AOP.

3.1 Common parameters

r0000 Drive display Min: -

Datatype: U16 Unit: - Def: P-Group: ALWAYS Max: -

Displays the user selected output as defined in P0005.

Note:

Pressing the "Fn" button for 2 seconds allows the user to view the values of DC link voltage, output

frequency, output voltage, output current, and chosen r0000 setting (defined in P0005).

r0002 Drive state Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays actual drive state.

Possible Settings:

0 Commissioning mode (P0010 != 0)

1 Drive ready

2 Drive fault active

3 Drive starting (DC-link precharging)

4 Drive running

5 Stopping (ramping down)

Dependency:

State 3 visible only while precharging DC link, and when externally powered communications board is fitted.

P0003 User access level Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 1

P-Group: ALWAYS Active: first confirm QuickComm.: No Max: 4

Defines user access level to parameter sets. The default setting (standard) is sufficient for most simple

applications.

Possible Settings:

0 User defined parameter list - see P0013 for details on use

1 Standard: Allows access into most frequently used parameters.

2 Extended: Allows extended access e.g. to inverter I/O functions.

3 Expert: For expert use only.

4 Service: Only for use by authorized service personal - password protected.

P0004 Parameter filter Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 0

P-Group: ALWAYS Active: first confirm QuickComm.: No Max: 22

Filters available parameters according to functionality to enable a more focussed approach to

commissioning.

Possible Settings:

0 All parameters

2 Inverter

3 Motor

4 Speed sensor

5 Technol. application / units

7 Commands, binary I/O

8 ADC and DAC

10 Setpoint channel / RFG

12 Drive features

13 Motor control

20 Communication

21 Alarms / warnings / monitoring

22 Technology controller (e.g. PID)

Example:

P0004 = 22 specifies that only PID parameters will be visible.

Level

1

Level

2

Level

1

Level

1

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

25

Page 26

Parameter Description Issue 01/06

Dependency:

The parameters are sub-divided into groups (P-Group) according to their functionality. This increases the

transparency and allows a parameter to be quickly searched for. Furthermore, parameter P0004 can be

used to control the ability to be visualized for the operator panel.

0

INVERTER

2

3

ENCODER

4

TECH_APL

5

COMMANDS

7

TERMINAL

8

SETPOINT

10

12

CONTROL

13

20

21

22

"Running".

P-Group

ALWAYS

MOTOR

FUNC

COMM

ALARMS

TECH Technological controller (PID controller)

All parameters

Drive inverter parameters

Motor parameters

Speed encoder

Technical applications / units

Control commands, digital I/O

Analog inputs/outputs

Setpoint channel and ramp-function gen.

Drive inverter functions

Motor open-loop/closed-loop control

Communications

Faults, warnings, monitoring functions

Group

Parameter area

0200 .... 0299

0300 ... 0399 + 0600 .... 0699

0400 .... 0499

0500 .... 0599

0700 .... 0749 + 0800 ... 0899

0750 .... 0799

1000 .... 1199

1200 .... 1299

1300 .... 1799

2000 .... 2099

2100 .... 2199

2200 .... 2399

Level

2

Level

3

Level

3

Value

Parameters marked "Quick Comm: Yes" in the parameter header can only be set when P0010 = 1 (Quick

Commissioning).

P0005[3] Display selection Min: 2

CStat: CUT Datatype: U16 Unit: - Def: 21

P-Group: FUNC Active: first confirm QuickComm.: No Max: 4000

Selects display for parameter r0000 (drive display).

Index:

P0005[0] : 1st. Drive data set (DDS)

P0005[1] : 2nd. Drive data set (DDS)

P0005[2] : 3rd. Drive data set (DDS)

Common Settings:

21 Actual frequency

25 Output voltage

26 DC link voltage

27 Output current

Notice:

These settings refer to read only parameter numbers ("rxxxx").

Details:

See relevant "rxxxx" parameter descriptions.

P0006 Display mode Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 2

P-Group: FUNC Active: first confirm QuickComm.: No Max: 4

Defines mode of display for r0000 (drive display).

Possible Settings:

0 In Ready state alternate between setpoint and output frequency. In run display output frequency

1 In Ready state display setpoint. In run display output frequency.

2 In Ready state alternate between P0005 value and r0020 value. In run display P0005 value

3 In Ready state alternate between r0002 value and r0020 value. In run display r0002 value

4 In all states just display P0005

Note:

- When inverter is not running, the display alternates between the values for "Not Running" and

- Per default, the setpoint and actual frequency values are displayed alternately.

P0007 Backlight delay time Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 0

P-Group: FUNC Active: first confirm QuickComm.: No Max: 2000

Defines time period after which the backlight display turns off if no operator keys have been pressed.

Value:

P0007 = 0:

Backlight always on (default state).

P0007 = 1 - 2000:

Number of seconds after which the backlight will turn off.

MICROMASTER 440 Parameter List

26 6SE6400-5BB00-0BP0

Page 27

Issue 01/06 Parameter Description

P0010 Commissioning parameter Min: 0

CStat: CT Datatype: U16 Unit: - Def: 0

P-Group: ALWAYS Active: first confirm QuickComm.: No Max: 30

Filters parameters so that only those related to a particular functional group are selected.

Possible Settings:

0 Ready

1 Quick commissioning

2 Inverter

29 Download

30 Factory setting

Dependency:

- Reset to 0 for inverter to run.

- P0003 (user access level) also determines access to parameters.

Note:

P0010 = 1

The inverter can be commissioned very quickly and easily by setting P0010 = 1. After that only the important

parameters (e.g.: P0304, P0305, etc.) are visible. The value of these parameters must be entered one after

the other. The end of quick commissioning and the start of internal calculation will be done by setting P3900

= 1 - 3. Afterward parameter P0010 and P3900 will be reset to zero automatically.

P0010 = 2

For service purposes only.

P0010 = 29

To transfer a parameter file via PC tool (e.g.: DriveMonitor, STARTER) parameter P0010 will be set to 29 by

the PC tool. When download has been finished PC tool resets parameter P0010 to zero.

P0010 = 30

When resetting the parameters of inverter P0010 must be set to 30. Resetting of the parameters will be

started by setting parameter P0970 = 1. The inverter will automatically reset all its parameters to their

default settings. This can prove beneficial if you experience problems during parameter setup and wish to

start again. Duration of factory setting will take about 60 s.

P0011 Lock for user defined parameter Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 0

P-Group: FUNC Active: first confirm QuickComm.: No Max: 65535

Details:

See parameter P0013 (user defined parameter)

P0012 Key for user defined parameter Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 0

P-Group: FUNC Active: first confirm QuickComm.: No Max: 65535

Details:

See parameter P0013 (user defined parameter).

P0013[20] User defined parameter Min: 0

CStat: CUT Datatype: U16 Unit: - Def: 0

P-Group: FUNC Active: first confirm QuickComm.: No Max: 65535

Defines a limited set of parameters to which the end user will have access.

Instructions for use:

1. Set P0003 = 3 (expert user)

2. Go to P0013 indices 0 to 16 (user list)

3. Enter into P0013 index 0 to 16 the parameters required to be visible in the user-defined list. The

following values are fixed and cannot be changed:

- P0013 index 19 = 12 (key for user defined parameter)

- P0013 index 18 = 10 (commissioning parameter filter)

- P0013 index 17 = 3 (user access level)

4. Set P0003 = 0 to activate the user defined parameter.

Level

1

Level

3

Level

3

Level

3

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

27

Page 28

Parameter Description Issue 01/06

Index:

P0013[0] : 1st user parameter

P0013[1] : 2nd user parameter

P0013[2] : 3rd user parameter

P0013[3] : 4th user parameter

P0013[4] : 5th user parameter

P0013[5] : 6th user parameter

P0013[6] : 7th user parameter

P0013[7] : 8th user parameter

P0013[8] : 9th user parameter

P0013[9] : 10th user parameter

P0013[10] : 11th user parameter

P0013[11] : 12th user parameter

P0013[12] : 13th user parameter

P0013[13] : 14th user parameter

P0013[14] : 15th user parameter

P0013[15] : 16th user parameter

P0013[16] : 17th user parameter

P0013[17] : 18th user parameter

P0013[18] : 19th user parameter

P0013[19] : 20th user parameter

Dependency:

First, set P0011 ("lock") to a different value than P0012 ("key") to prevent changes to user-defined

parameter. Then, set P0003 to 0 to activate the user-defined list.

When locked and the user-defined parameter is activated, the only way to exit the user-defined parameter

(and view other parameters) is to set P0012 ("key") to the value in P0011 ("lock").

Note:

- Alternatively, set P0010 = 30 (commissioning parameter filter = factory setting) and P0970 = 1 (factory

reset) to perform a complete factory reset.

- The default values of P0011 ("lock") and P0012 ("key") are the same.

P0014[3] Store mode Min: 0

CStat: UT Datatype: U16 Unit: - Def: 0

P-Group: - Active: first confirm QuickComm.: No Max: 1

Sets the store mode for parameters ("volatile" (RAM) or "nonvolatile" (EEPROM)).

Possible Settings:

0 Volatile (RAM)

1 Nonvolatile (EEPROM)

Index:

P0014[0] : Serial interface COM link

P0014[1] : Serial interface BOP link

P0014[2] : PROFIBUS / CB

Note:

1. With the BOP the parameter will always be stored in the EEPROM.

2. P0014 itself will always be stored in the EEPROM.

3. P0014 will not be changed by performing a factory reset (P0010 = 30 and P0971 = 1).

4. P0014 can be transferred during a DOWNLOAD (P0010 = 29).

5. If "Store request via USS/CB = volatile (RAM)" and "P0014[x] = volatile (RAM)", you can make a

transfer of all parameter values into the nonvolatile memory via P0971.

6. If "Store request via USS/CB" and P0014[x] are not consistent, the setting of P14[x] = "store nonvolatile

(EEPROM)" has always higher priority.

Store request via USS/CB

EEPROM

EEPROM

RAM

RAM

Value of P0014[x] Result

RAM

EEPROM

EEPROM

EEPROM

RAMRAM

EEPROM

EEPROM

Level

3

MICROMASTER 440 Parameter List

28 6SE6400-5BB00-0BP0

Page 29

Issue 01/06 Parameter Description

3.2 Diagnosis parameters

r0018 Firmware version Min: -

Datatype: Float Unit: - Def: P-Group: INVERTER Max: -

Displays version number of installed firmware.

r0019 CO/BO: BOP control word Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays status of operator panel commands.

The settings below are used as the "source" codes for keypad control when connecting to BICO input

parameters.

Bitfields:

Bit00 ON/OFF1 0 NO 1 YES

Bit01 OFF2: Electrical stop 0 YES 1 NO

Bit08 JOG right 0 NO 1 YES

Bit11 Reverse (setpoint inversion) 0 NO 1 YES

Bit13 Motor potentiometer MOP up 0 NO 1 YES

Bit14 Motor potentiometer MOP down 0 NO 1 YES

Note:

When BICO technology is used to allocate functions to panel buttons, this parameter displays the actual

status of the relevant command.

The following functions can be "connected" to individual buttons:

- ON/OFF1,

- OFF2,

- JOG,

- REVERSE,

- INCREASE,

- DECREASE

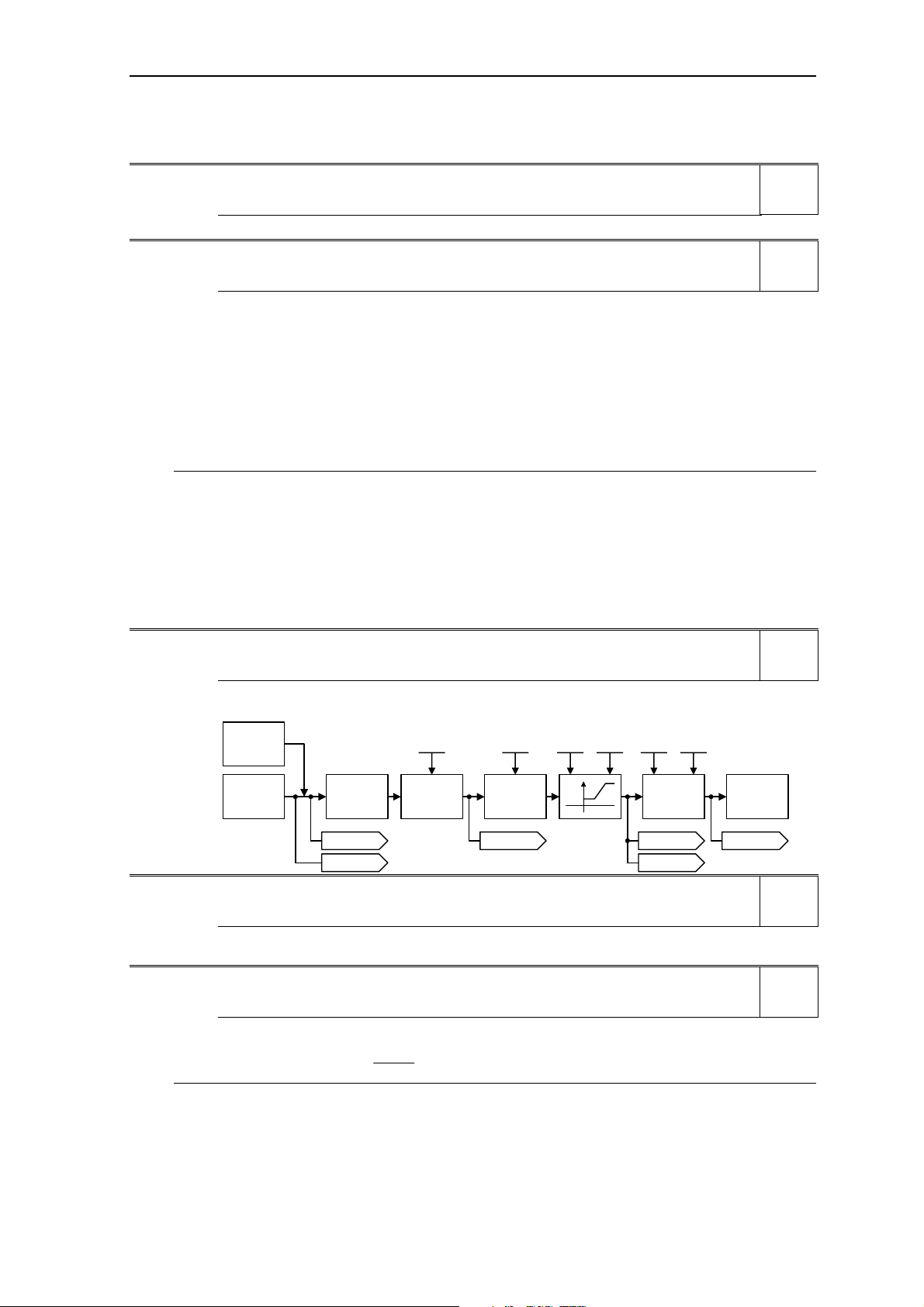

r0020 CO: Freq. setpoint before RFG Min: -

Datatype: Float Unit: Hz Def: -

P-Group: CONTROL Max: -

Displays actual frequency setpoint (input from ramp function generator).

Level

1

Level

3

Level

3

JOG

P1110 P1091 P1080 P1082 P 1120 P1135

. . .

Setpoint

source

Reverse

r1079 r0020 r1170

r1078

Inhibit

neg. freq.

setpoint

Skip

frequency

r1114

IfI

RFG

r1119

r0021 CO: Act. filtered frequency 1 Min: -

Datatype: Float Unit: Hz Def: -

P-Group: CONTROL Max: -

Displays actual inverter output frequency (r0021) excluding slip compensation, resonance damping and

frequency limitation.

r0022 Act. filtered rotor speed Min: -

Datatype: Float Unit: 1/min Def: -

P-Group: CONTROL Max: -

Displays calculated rotor speed based on inverter output frequency [Hz] x 120 / number of poles.

60

[Hz] r0021 [1/min] r0022 ⋅=

r0313

Note:

This calculation makes no allowance for load-dependent slip.

Motor

control

Level

2

Level

3

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

29

Page 30

Parameter Description Issue 01/06

r0024 CO: Act. filtered output freq. Min: -

Datatype: Float Unit: Hz Def: -

P-Group: CONTROL Max: -

Displays actual output frequency. Slip compensation, resonance damping and frequency limitation are

included.

r0025 CO: Act. filtered output voltage Min: -

Datatype: Float Unit: V Def: -

P-Group: CONTROL Max: -

Displays [rms] voltage applied to motor.

r0026 CO: Act. filtered DC-link volt. Min: -

Datatype: Float Unit: V Def: -

P-Group: INVERTER Max: -

Displays DC-link voltage.

Mains

200 - 240 V 380 - 480 V 500 - 600 V

U

DC_max_trip

U

DC_min_trip

U

DC_max_warn

U

DC_max_ctrl

U

DC_min_warn

U

DC_min_ctrl

U

DC_Comp

U

DC_Chopper

F0002

F0003 215 V

A0502

(P1240)

A0503

(P1240)

(P1236)

(P1237)

420 V (FS A - C)

410 V (FS D - F)

840 V (FS A - C)

820 V (FS D - F)

820 V (FS FX, GX)

430 V (FS A - F)

380 V (FS FX, GX)

r1242

[%] P1245

100

⋅⋅

r1242 0.98⋅

r1242 0.98⋅

1020 V

530 V

P02102

r0027 CO: Act. filtered output current Min: -

Datatype: Float Unit: A Def: -

P-Group: CONTROL Max: -

Displays [rms] value of motor current [A].

r0029 CO: Act. filtered current Isd Min: -

Datatype: Float Unit: A Def: -

P-Group: CONTROL Max: -

Displays flux-generating current component.

The flux-generating current component is based on the nominal flux, which is calculated from the motor

parameters (P0340 - Calculation of motor parameters).

Dependency:

Applies when vector control is selected in P1300 (control mode); otherwise, the display shows the value

zero.

Note:

The flux-generating current component is generally constant up to the base speed of the motor; above base

speed, this component is weakened (field weakening) thus enabling an increase in motor speed but at

reduced torque.

r0030 CO: Act. filtered current Isq Min: -

Datatype: Float Unit: A Def: -

P-Group: CONTROL Max: -

Displays torque-generating current component.

Note:

For asynchronous motors, a limit is calculated for the torque generating current component (in conjunction

with the maximum possible output voltage (r0071), motor leakage and current field weakening (r0377)) and

this prevents motor stalling.

Level

3

Level

2

Level

2

Level

2

Level

3

Level

3

MICROMASTER 440 Parameter List

30 6SE6400-5BB00-0BP0

Page 31

Issue 01/06 Parameter Description

r0031 CO: Act. filtered torque Min: -

Datatype: Float Unit: Nm Def: -

P-Group: CONTROL Max: -

Displays electrical torque.

3

L

m

m

M

2

L

R

Valid for V /f-caracteristic:

cos |i| u

s

≈

i

sq

R

e

⋅Ψ⋅⋅⋅=

iZ

sqrdp

2

|i|

⋅−ϕ⋅⋅

s

s

:

m

Motor torque

M

:

Z

Pole pair number

p

:

Ψ

Rotor flux

rd

:

L

Rotor inductance

R

:

L

Magnetizing inductance

m

:

Torque-generating current

i

sq

Motor counter EMF

:e

Output value will be zero at low speeds when the current injection is active (r1751.5 = 1).

Note:

The electrical torque is not the same as the mechanical torque, which can be measured on the shaft. Due to

windage and friction a part of the electrical torque is lost in the motor.

r0032 CO: Act. filtered power Min: -

Datatype: Float Unit: - Def: -

P-Group: CONTROL Max: -

Displays motor power (power output at the motor shaft).

M f 2 M P

⋅⋅π⋅=⋅ω=

1

1000

r0022

π 2

60

[Nm] r0031 [1/min]

Motor

ω, M

mech

⇒

[kW ] r0032 ⋅⋅⋅⋅=

Level

2

Level

2

[kW] r0032 0.75 [hp] r0032 ⋅=

Dependency:

Value is displayed in [kW] or [hp] depending on setting for P0100 (operation for Europe / North America).

r0035[3] CO: Act. motor temperature Min: -

Datatype: Float Unit: °C Def: -

P-Group: MOTOR Max: -

Displays measured motor temperature.

Index:

r0035[0] : 1st. Drive data set (DDS)

r0035[1] : 2nd. Drive data set (DDS)

r0035[2] : 3rd. Drive data set (DDS)

Level

2

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

31

Page 32

Parameter Description Issue 01/06

r0036 CO:Inverter overload utilization Min: -

Datatype: Float Unit: % Def: -

P-Group: INVERTER Max: -

Displays inverter overload utilization calculated via I2t model.

The actual I2t value relative to the max. possible I2t value supplies utilization in [%].

If the current exceeds the threshold for P0294 (inverter I2t overload warning), alarm A0505 (inverter I2t) is

generated and the output current of the inverter reduced via P0290 (inverter overload reaction).

If 100 % utilization is exceeded, alarm F0005 (inverter I2t) is tripped.

Example:

Normalized output current

r0027

r0207

100 %

Reaction via P0290

Default: "current reduction"

i2t [%]

r0036

P0294 (95 %)

A0505

1

0

Dependency:

r0036 > 0:

If the nominal current of the inverter is exceed, utilization will be displayed. Otherwise, 0 % utilization is

displayed.

r0037[5] CO: Inverter temperature [°C] Min: -

Datatype: Float Unit: °C Def: -

P-Group: INVERTER Max: -

Displays measured heatsink temperature and calculated junction temperature of IGBTs based on thermal

model.

Index:

r0037[0] : Measured heat sink temperature

r0037[1] : Chip temperature

r0037[2] : Rectifier temperature

r0037[3] : Inverter ambient temperature

r0037[4] : Control board temperature

r0038 CO: Act. power factor Min: -

Datatype: Float Unit: - Def: -

P-Group: CONTROL Max: -

Displays actual power factor.

Dependency:

Applies when V/f control is selected in P1300 (control mode); otherwise, the display shows the value 1.

r0039 CO: Energy consumpt. meter [kWh] Min: -

Datatype: Float Unit: kWh Def: -

P-Group: INVERTER Max: -

Displays electrical energy used by inverter since display was last reset (see P0040 - reset energy

consumption meter).

tt

r0039

Dependency:

Value is reset when P0040 = 1 (reset energy consumption meter).

act

=

P

∫

act

=⋅

∫

W

00

dtcosiu3dt

⋅ϕ⋅⋅⋅

Level

4

t

t

t

Level

3

Level

3

Level

2

MICROMASTER 440 Parameter List

32 6SE6400-5BB00-0BP0

Page 33

Issue 01/06 Parameter Description

P0040 Reset energy consumption meter Min: 0

CStat: CT Datatype: U16 Unit: - Def: 0

P-Group: INVERTER Active: first confirm QuickComm.: No Max: 1

Resets value of parameter r0039 (energy consumption meter) to zero.

Possible Settings:

0 No reset

1 Reset r0039 to 0

Dependency:

No reset until "P" is pressed.

r0050 CO: Active command data set Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays currently selected and active command data set (CDS).

Possible Settings:

0 1st. Command data set (CDS)

1 2nd. Command data set (CDS)

2 3rd. Command data set (CDS)

Details:

See parameter P0810.

r0051[2] CO: Active drive data set (DDS) Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays currently selected and active drive data set (DDS).

Possible Settings:

0 1st. Drive data set (DDS)

1 2nd. Drive data set (DDS)

2 3rd. Drive data set (DDS)

Index:

r0051[0] : Selected drive data set

r0051[1] : Active drive data set

Details:

See parameter P0820.

Level

2

Level

2

Level

2

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

33

Page 34

Parameter Description Issue 01/06

r0052 CO/BO: Act. status word 1 Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays first active status word of inverter (bit format) and can be used to diagnose inverter status.

Bitfields:

Bit00 Drive ready 0 NO 1 YES

Bit01 Drive ready to run 0 NO 1 YES

Bit02 Drive running 0 NO 1 YES

Bit03 Drive fault active 0 NO 1 YES

Bit04 OFF2 active 0 YES 1 NO

Bit05 OFF3 active 0 YES 1 NO

Bit06 ON inhibit active 0 NO 1 YES

Bit07 Drive warning active 0 NO 1 YES

Bit08 Deviation setpoint / act. value 0 YES 1 NO

Bit09 PZD control 0 NO 1 YES

Bit10 Maximum frequency reached 0 NO 1 YES

Bit11 Warning: Motor current limit 0 YES 1 NO

Bit12 Motor holding brake active 0 NO 1 YES

Bit13 Motor overload 0 YES 1 NO

Bit14 Motor runs right 0 NO 1 YES

Bit15 Inverter overload 0 YES 1 NO

Dependency:

r0052 Bit00 - Bit02:

State-sequence diagram after Power On or ON/OFF1 respectively: ==> see below

Power ON

Drive ready

r0052

Bit00

ON/OFF1

Pre-charging active

Drive ready to run

r0052

Bit01

Pulse enable

Drive running

r0052

Bit02

Ramping finished

r0053

Bit09

r0052 Bit03 "Drive fault active":

Output of Bit3 (Fault) will be inverted on digital output (Low = Fault, High = No Fault).

r0052 Bit08 "Deviation setpoint / act. value" ==> see parameter P2164

r0052 Bit10 "f_act >= P1082 (f_max)" ==> see parameter P1082

r0052 Bit12 "Motor holding brake active" ==> see parameter P1215

1

1

0

1

0

1

0

1

0

1

0

1

0

1

0

Level

2

t0

t

t

t

t

t

t

t

MICROMASTER 440 Parameter List

34 6SE6400-5BB00-0BP0

Page 35

Issue 01/06 Parameter Description

r0052 Bit14 "Motor runs right" ==> see below

ON/OFF1

ON

r0054

Bit00

Reverse

r0054

Bit11

f

act

0 t

Drive running

r0052

Bit02

Motor runs

right

r0052

Bit14

left

not defined

last state is displayed

Details:

The 7-segment display of the bit-parameters (binary parameters) is explained in the Introduction of the

Parameter List.

r0053 CO/BO: Act. status word 2 Min: -

Datatype: U16 Unit: - Def: -

P-Group: COMMANDS Max: -

Displays second status word of inverter (in bit format).

Bitfields:

Bit00 DC brake active 0 NO 1 YES

Bit01 f_act > P2167 (f_off) 0 NO 1 YES

Bit02 f_act <= P1080 (f_min) 0 NO 1 YES

Bit03 Act. current r0027 > P2170 0 NO 1 YES

Bit04 f_act > P2155 (f_1) 0 NO 1 YES

Bit05 f_act <= P2155 (f_1) 0 NO 1 YES

Bit06 f_act >= setpoint 0 NO 1 YES

Bit07 Act. Vdc r0026 < P2172 0 NO 1 YES

Bit08 Act. Vdc r0026 > P2172 0 NO 1 YES

Bit09 Ramping finished 0 NO 1 YES

Bit10 PID output r2294 == P2292 (PID_min) 0 NO 1 YES

Bit11 PID output r2294 == P2291 (PID_max) 0 NO 1 YES

Bit14 Download data set 0 from AOP 0 NO 1 YES

Bit15 Download data set 1 from AOP 0 NO 1 YES

Note:

- r0053 Bit00 ==> see parameter P1233

- r0053 Bit01 ==> see parameter P2167

- r0053 Bit02 ==> see parameter P1080

- r0053 Bit03 ==> see parameter P2170

- r0053 Bit04 ==> see parameter P2155

- r0053 Bit05 ==> see parameter P2155

- r0053 Bit06 ==> see parameter P2150

- r0053 Bit07 ==> see parameter P2172

- r0053 Bit08 ==> see parameter P2172

t

t

t

t

Level

2

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

35

Page 36

Parameter Description Issue 01/06

r0053 Bit09 "Ramping finished" ==> see below

ON

OFF

f

f

set

f