Page 1

MICROMASTER 411 &

COMBIMASTER 411

Operating Instructions Issue 03/01

User Documentation

6SE6400-5CA00-0BP0

Page 2

MICROMASTER 411 / COMBIMASTER 411 Documentation

Getting Started Guide

Provides for Quick Commissioning of the Inverter.

Operating Instructions

Gives information about features of the MICROMASTER

411 / COMBIMASTER 411, Installation, Commissioning,

Control modes, System Parameter structure,

Troubleshooting, Specifications and available options of the

MICROMASTER 411 / COMBIMASTER 411.

Parameter List

The Parameter List contains the description of all

Parameters structured in functional order and a detailed

description. The Parameter list also includes a series of

function plans.

Catalogues

In the catalogue you will find all the necessary information

to select an appropriate inverter, as well as Operator

Panels and Communication Options.

Page 3

1

Overview

MICROMASTER 411 &

COMBIMASTER 411

Operating Instructions

User Documentation

Installation

Commissioning

Using the

COMBIMASTER 411

System Parameters

Troubleshooting

2

3

4

5

6

Valid for Release Issue 03/01

Inverter Type Control Version

MICROMASTER 411 & 1.2

COMBIMASTER 411

Specifications

Options

Electro-Magnetic

Compatibility

Engineering

Information

Appendices

7

8

9

10

A

B

C

Issue 03/01

Index

Page 4

Further information is available on the Internet under:

http://www.siemens.de/micromaster

Approved Siemens Quality for Software and Training

is to DIN ISO 14001, Reg. No. 2160-01

The reproduction, transmission or use of this document,

or its contents is not permitted unless authorized in

writing. Offenders will be liable for damages. All rights

including rights created by patent grant or registration of a

utility model or design are reserved.

© Siemens AG 2002. All Rights Reserved.

MICROMASTER® is a registered trademark of Siemens.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

4

Other functions not described in this document may be

available. However, this fact shall not constitute an

obligation to supply such functions with a new control, or

when servicing.

We have checked that the contents of this document

correspond to the hardware and software described.

There may be discrepancies nevertheless, and no

guarantee can be given that they are completely identical.

The information contained in this document is reviewed

regularly and any necessary changes will be included in

the next edition. We welcome suggestions for

improvement.

Siemens handbooks are printed on chlorine-free paper

that has been produced from managed sustainable

forests. No solvents have been used in the printing or

binding process.

Document subject to change without prior notice.

Siemens-Aktiengesellschaft

6SE6400-5CA00-0BP0

Page 5

Issue 03/01 Definitions and Warnings

Foreword

User Documentation

WARNING

Before installing and commissioning, you must read the safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make

sure that the warning labels are kept in a legible condition and replace missing or

damaged labels.

Information is also available from:

Technical Support Nürnberg

Tel: +49 (0) 180 5050 222

Fax: +49 (0) 180 5050 223

Email: techsupport@ad.siemens.de

Monday to Friday: 7:00 am to 5:00 pm (Central European Time)

Internet Home Address

Customers can access technical and general information at:

http://www.siemens.de/micromaster

Contact address

Should any questions or problems arise while reading this manual, please contact

the Siemens office concerned using the form provided at the back this manual.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

5

Page 6

Definitions and Warnings Issue 03/01

f

Definitions and Warnings

DANGER

indicates an immiently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

used with the safety alert symbol indicates a potentially hazardous situationwhich, i

not avoided, may result in minor or moderate injury.

PE

= Ground

CAUTION

used without safety alert symbol indicates a potentially hzardous situation which, if

not avoided, may result in a property demage.

NOTICE

indicates a potential situation which, if not avoided, may result in an undesireable

result or state.

NOTE

For the purpose of this documentation, "Note" indicates important information

relating to the product or highlights part of the documentation for special attention.

Qualified personnel

For the purpose of this Instruction Manual and product labels, a "Qualified

person" is someone who is familiar with the installation, mounting, start-up and

operation of the equipment and the hazards involved.

He or she must have the following qualifications:

1. Trained and authorized to energize, de-energize, clear, ground and tag

circuits and equipment in accordance with established safety procedures.

2. Trained in the proper care and use of protective equipment in accordance

with established safety procedures.

3. Trained in rendering first aid.

♦ PE – Protective Earth uses circuit protective conductors sized for short circuits

where the voltage will not rise in excess of 50 Volts. This connection is

normally used to ground the inverter.

♦

- Is the ground connection where the reference voltage can be the same

as the Earth voltage. This connection is normally used to ground the motor.

Use for intended purpose only

The equipment may be used only for the application stated in the manual and only

in conjunction with devices and components recommended and authorized by

Siemens.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6

6SE6400-5CA00-0BP0

Page 7

Issue 03/01 Safety Instructions

Safety Instructions

The following Warnings, Cautions and Notes are provided for your safety and as a

means of preventing damage to the product or components in the machines

connected. This section lists Warnings, Cautions and Notes, which apply generally

when handling COMBIMASTER 411 & MICROMASTER 411 Inverters, classified

as General, Transport & Storage, Commissioning, Operation, Repair and

Dismantling & Disposal.

Specific Warnings, Cautions and Notes that apply to particular activities are

listed at the beginning of the relevant chapters and are repeated or supplemented

at critical points throughout these chapters.

Please read the information carefully, since it is provided for your personal

safety and will also help prolong the service life of your COMBIMASTER 411

& MICROMASTER 411 Inverter and the equipment you connect to it.

General

WARNING

This equipment contains dangerous voltages and controls potentially

dangerous rotating mechanical parts. Non-compliance with Warnings or

failure to follow the instructions contained in this manual can result in loss of

life, severe personal injury or serious damage to property.

Only suitable qualified personnel should work on this equipment, and only after

becoming familiar with all safety notices, installation, operation and

maintenance procedures contained in this manual. The successful and safe

operation of this equipment is dependent upon its proper handling, installation,

operation and maintenance.

Risk of electric shock. The DC link capacitors remain charged for five minutes

after power has been removed. It is not permissible to open the equipment

until 5 minutes after the power has been removed.

HP ratings are based on the Siemens 1LA motors and are given for guidance

only; they do not necessarily comply with UL or NEMA HP ratings.

Do not operate the equipment in direct sunlight.

CAUTION

Children and the general public must be prevented from accessing or

approaching the equipment!

This equipment may only be used for the purpose specified by the

manufacturer. Unauthorized modifications and the use of spare parts and

accessories that are not sold or recommended by the manufacturer of the

equipment can cause fires, electric shocks and injuries.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

7

Page 8

Safety Instructions Issue 03/01

NOTICE

Keep these operating instructions within easy reach of the equipment and

make them available to all users

Whenever measuring or testing has to be performed on live equipment, the

regulations of Safety Code VBG 4.0 must be observed, in particular § 8

“Permissible Deviations when Working on Live Parts”. Suitable electronic tools

should be used.

Before installing and commissioning, please read these safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make

sure that the warning labels are kept in a legible condition and replace missing

or damaged labels.

Transport & Storage

WARNING

Correct transport, storage, erection and mounting, as well as careful operation

and maintenance are essential for proper and safe operation of the equipment.

Use the lifting eyes provided if a motor has to be lifted.

Do not lift machine sets by suspending the individual machines! Always check

the capacity of the hoist before lifting any equipment.

Do not paint over the black case finish of the inverter, as this will affect the

unit’s thermal performance.

CAUTION

Protect the inverter against physical shocks and vibration during transport and

storage. Also be sure to protect it against water (rainfall) and excessive

temperatures (see Table on page 94).

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

8

6SE6400-5CA00-0BP0

Page 9

Issue 03/01 Safety Instructions

Commissioning

WARNING

Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

Only permanently wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

If a Residual Current-operated protective Device (RCD) is to be used, it must

be an RCD type B.

Machines with a three-phase power supply, fitted with EMC filters, must not be

connected to a supply via an ELCB (Earth Leakage Circuit-Breaker - see DIN

VDE 0160, section 5.5.2 and EN50178 section 5.2.11.1).

The following terminals can carry dangerous voltages even if the inverter is

inoperative:

♦ power supply terminals L1, L2, L3

♦ motor terminals U, V, W

♦ additionally the terminals DC+, DC-

This equipment must not be used as an ‘Emergency Stop mechanism’ (see

EN 60204, 9.2.5.4).

The inverter electronics contain static sensitive devices therefore precautions

must be taken against electrostatic discharge (ESD) when handling the

separated inverter assembly. These include not touching the internal surfaces

of the inverter and ensuring that personnel are earthed while handling the unit.

The terminal housing, including Filter and I/O modules, contain no sensitive

components and therefore no special handling precautions are required when

separated.

CAUTION

The connection of power, motor and control cables to the inverter must be carried

out as shown in Figure 2-10 respectively, to prevent inductive and capacitive

interference from affecting the correct functioning of the inverter.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

9

Page 10

Safety Instructions Issue 03/01

Operation

WARNING

MICROMASTER 411/COMBIMASTER 411 operate at high voltages.

When operating electrical devices, it is impossible to avoid applying

hazardous voltages to certain parts of the equipment.

Emergency Stop facilities according to EN 60204 IEC 204 (VDE 0113) must

remain operative in all operating modes of the control equipment. Any

disengagement of the Emergency Stop facility must not lead to uncontrolled or

undefined restart.

Wherever faults occurring in the control equipment can lead to substantial

material damage or even grievous bodily injury (i.e. potentially dangerous

faults), additional external precautions must be taken or facilities provided to

ensure or enforce safe operation, even when a fault occurs (e.g. independent

limit switches, mechanical interlocks, etc.).

Certain parameter settings may cause the inverter to restart automatically

after an input power failure.

This equipment is capable of providing internal motor overload protection.

Refer to P0610 (level 3) and P0335, I

protection can also be provided using an external PTC via a digital input.

This equipment is suitable for use in a circuit capable of delivering not more

than 10,000 symmetrical amperes (rms), for a maximum voltage of 460 V

when protected by an H or K Class fuse (see Section 7.5).

This equipment must not be used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

2

t is ON by default. Motor overload

Repair

WARNING

Repairs on equipment may only be carried out by Siemens Service, by repair

centers authorized by Siemens or by qualified personnel who are thoroughly

acquainted with all the warnings and operating procedures contained in this

manual.

Any defective parts or components must be replaced using parts contained in

the relevant spare parts list.

Disconnect the power supply before opening the equipment for access.

Dismantling & Disposal

NOTE

Inverter packaging is re-usable. Retain the packaging for future use or return it

to the manufacturer.

Easy-to-release screw and snap connectors allow you to break the unit down

into its component parts. You can then re-cycle these component parts,

dispose of them in accordance with local requirements or return them to

the manufacturer.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

10

6SE6400-5CA00-0BP0

Page 11

Issue 03/01 Table of Contents

Table of Contents

1

1.1

1.2

2

2.1

2.2

2.3

2.4

2.5

3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

4.4

4.5

Overview ................................................................................................................15

MICROMASTER 411 / COMBIMASTER 411 ......................................................... 16

Design Features ...................................................................................................... 17

Installation .............................................................................................................19

Installation after a Period of Storage....................................................................... 21

Ambient operating conditions..................................................................................22

Mechanical Installation MICROMASTER 411......................................................... 23

Mechanical Installation COMBIMASTER 411......................................................... 30

Electrical Installation................................................................................................ 33

Commissioning .....................................................................................................41

Block Diagram ......................................................................................................... 43

General Information................................................................................................. 44

Commissioning Procedure Overview ...................................................................... 45

General operation.................................................................................................... 56

Using the MICROMASTER 411 / COMBIMASTER 411 ....................................... 61

Frequency Setpoint ................................................................................................. 62

Command Sources (P0700).................................................................................... 63

OFF and Braking Functions .................................................................................... 63

Control Modes (P1300) ........................................................................................... 65

Faults and warnings ................................................................................................ 65

5

5.1

5.2

5.3

6

6.1

6.2

6.3

7

7.1

7.2

7.3

7.4

7.5

System Parameters...............................................................................................67

Introduction to System Parameters.........................................................................68

Parameter Structure................................................................................................ 69

Parameter List (short form) ..................................................................................... 70

Troubleshooting .................................................................................................... 79

Troubleshooting with the Inverter LED.................................................................... 80

Troubleshooting with the Basic Operator Panel...................................................... 80

Faults and Alarms ...................................................................................................81

Specifications ........................................................................................................ 93

Technische Daten ...................................................................................................94

Case Size Rating Information .................................................................................95

Tightening Torque, Cable cross sections for Power Supply and Motor Terminals. 96

Tightening Torque for Fixing Screws ......................................................................96

Fuses and Circuit Breakers.....................................................................................97

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

11

Page 12

Table of Contents Issue 03/01

8

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

9

9.1

10

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.10

10.11

10.12

10.13

10.14

10.15

Options...................................................................................................................99

MICROMASTER 411/COMBIMASTER 411 User Options ..................................... 99

MICROMASTER 411/COMBIMASTER 411 Programming Options ..................... 100

Basic Operator Panel (BOP) / Advanced Operator Panel (AOP) ......................... 101

PROFIBUS Module ............................................................................................... 102

EM Brake Module.................................................................................................. 103

MICROMASTER 411 Operator Panel Mounting Kit.............................................. 104

PC to Inverter Connection Kit................................................................................ 105

PC to AOP Connection Kit ....................................................................................106

Door Mounting Kit for Single Inverter control ........................................................ 107

Wall Mounting Kit for MICROMASTER 411..........................................................108

Electro-Magnetic Compatibility (EMC).............................................................. 109

Electro-Magnetic Compatibility (EMC) .................................................................. 110

Engineering Information..................................................................................... 115

Current Limit and Overload Operation .................................................................. 116

Control and Operating Modes............................................................................... 120

Braking ..................................................................................................................132

Derating Factors.................................................................................................... 135

Thermal Protection and Automatic De-rating........................................................137

Operation from Unearthed Supplies...................................................................... 137

Lifetime of Inverters............................................................................................... 137

Working with Binary Connectors (BiCo)................................................................ 138

Harmonic Currents ................................................................................................ 145

Use of MM4 Input Chokes..................................................................................... 146

Power Losses........................................................................................................146

Shock and Vibration .............................................................................................. 147

PROFIBUS ............................................................................................................ 148

PROFIBUS Module ............................................................................................... 149

Variant Independent Options ................................................................................152

Appendices...............................................................................................................................155

A

B

C

D

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

12

Applicable Standards .........................................................................................155

List of Abbreviations........................................................................................... 156

MICROMASTER 411 / COMBIMASTER 411 Parts Identification.....................157

Index ..................................................................................................................... 158

6SE6400-5CA00-0BP0

Page 13

Issue 03/01 Table of Contents

List of Tables

Table 2-1 MICROMASTER 411 Dimension Detail................................................................................26

Table 2-2 Gland Plate Detail.................................................................................................................28

Table 3-1 Ramp Time Adjustment Jumpers..........................................................................................46

Table 3-2 Ramp Time Jumper Behaviour .............................................................................................47

Table 3-3 Control Circuit Jumper Settings ............................................................................................48

Table 3-4 Control Circuit Jumper Behaviour .........................................................................................48

Table 3-5 Default Settings for BOP Operation ......................................................................................50

Table 6-1 Inverter LED Indication .........................................................................................................80

Table 7-1 MICROMASTER 411 / COMBIMASTER 411, Leistungsdaten .............................................94

Table 7-2 Case Size B ..........................................................................................................................95

Table 7-3 Case Size C..........................................................................................................................95

Table 7-4 Power Supply & Motor Terminal Wire Sizes/Tightening Torques .........................................96

Table 7-5 Fixing Screw Recommended Tightening Torque ..................................................................96

Table 7-6 MICROMASTER 411/COMBIMASTER 411 Fuses and Circuit Breakers .............................97

Table 8-1 Key to Programming Options..............................................................................................100

Table 9-1 Environment - General Industrial ........................................................................................111

Table 9-2 Environment - Filtered Industrial .........................................................................................111

Table 9-3 Environment - Filtered for Residential, Commercial and Light Industry ..............................112

Table 9-4 EMC Compliance Table......................................................................................................113

Table 9-5 MICROMASTER 411 Measured Results ............................................................................113

Table 10-1 Measured Current Monitoring Accuracy..............................................................................117

Table 10-2 Trip Levels ..........................................................................................................................119

Table 10-3 Derating with Switching Frequencies..................................................................................136

Table 10-4 BiCo Connections (r0019 to r0054) ....................................................................................141

Table 10-5 BiCo Connections (r0055 to r1119) ....................................................................................142

Table 10-6 BiCo Connections (r1170 to r2050) ....................................................................................143

Table 10-7 BiCo connections (r2053 to r2294) .....................................................................................144

Table 10-8 Three Phase 400 V Connection..........................................................................................145

Table 10-9 Maximum Cable Lengths for Data Transfer Rates..............................................................150

Table 10-10 Technical data – 411 PROFIBUS Module...........................................................................151

Table 10-11 PROFIBUS Ordering information........................................................................................151

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

13

Page 14

Table of Contents Issue 03/01

List of Illustrations

Figure 1-1 MICROMASTER 411 and COMBIMASTER 411 Variable Frequency Inverters....................18

Figure 2-1 Forming.................................................................................................................................21

Figure 2-2 MICROMASTER 411, Internal Layout ..................................................................................25

Figure 2-3 MICROMASTER 411 Case Size B Dimensions....................................................................26

Figure 2-4 MICROMASTER 411 Case Size C Dimensions ...................................................................26

Figure 2-5 Cable Glands........................................................................................................................27

Figure 2-6 Installation of Cable Gland....................................................................................................27

Figure 2-7 MICROMASTER 411 Gland Dimensions..............................................................................28

Figure 2-8 COMBIMASTER 411 Case Size B Dimensional Detail.........................................................31

Figure 2-9 COMBIMASTER 411 Case Size B Dimensional Detail.........................................................32

Figure 2-10 Motor and Power Supply Connections..................................................................................36

Figure 2-11 Control Terminals .................................................................................................................37

Figure 2-12 PTC Connections..................................................................................................................38

Figure 3-1 COMBIMASTER 411 & MICROMASTER 411 Block Diagram..............................................43

Figure 3-2 MICROMASTER 411 / COMBIMASTER 411 Commissioning Guide ...................................45

Figure 3-3 Ramp Time Jumpers.............................................................................................................46

Figure 3-4 Control Circuit Jumpers ........................................................................................................48

Figure 3-5 Basic Operator Panel Controls .............................................................................................51

Figure 3-6 Changing parameters via the BOP .......................................................................................52

Figure 3-7 Typical Motor Rating Plate Example.....................................................................................55

Figure 3-8 Default Setup Terminal Connections ....................................................................................56

Figure 3-9 Connect BOP/AOP with the MICROMASTER 411 ...............................................................58

Figure 5-1 Parameter Structure with Filter (P0004)................................................................................69

Figure 10-1 Current Limit Interaction......................................................................................................117

Figure 10-2 PTC Resistor Connections..................................................................................................118

Figure 10-3 Boost-Level.........................................................................................................................120

Figure 10-4 Quick response with overshoot: P2280 = 0.30; P2285 = 0.03 s .........................................124

Figure 10-5 Quick response with overshoot, but instability:P2280 = 0.55; P2285 = 0.03 s.................... 124

Figure 10-6 Damped response: P2280 = 0.20; P2285 = 0.15 s .............................................................125

Figure 10-7 Response to 5 Hz step: L = 100 ms.................................................................................... 126

Figure 10-8 Response to 5 Hz step: T = 700 ms....................................................................................127

Figure 10-9 Step Response in PI control with P2280 = 9.84 and P2285 = 0.30 ....................................127

Figure 10-10 PI Basic Block Diagram ......................................................................................................128

Figure 10-11 Energy Saving Mode 1........................................................................................................130

Figure 10-12 Energy Saving Mode 2........................................................................................................131

Figure 10-13 Frequency Ramp Down ......................................................................................................132

Figure 10-14 DC Braking .........................................................................................................................133

Figure 10-15 Compound Braking .............................................................................................................134

Figure 10-16 Reduktionsfaktoren durch die Umgebungstemperatur........................................................135

Figure 10-17 Derating with Altitude..........................................................................................................135

Figure 10-18 Power Losses MICROMASTER 411 / COMBIMASTER 411 ..............................................146

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

14

6SE6400-5CA00-0BP0

Page 15

Issue 03/01 1 Overview

1 Overview

This Chapter contains:

A summary of the major features of the COMBIMASTER 411 & MICROMASTER

411 range.

1.1

1.2 Design Features...................................................................................................... 17

MICROMASTER 411 / COMBIMASTER 411 ......................................................... 16

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

15

Page 16

1 Overview Issue 03/01

1.1 MICROMASTER 411 / COMBIMASTER 411

The Siemens COMBIMASTER 411 & MICROMASTER 411 variable frequency (V/f)

range of inverters are used to control the speed of three phase AC induction

motors.

COMBIMASTER 411 provides for a ready to use Inverter/Motor combination unit

MICROMASTER 411 offers an Inverter for adaptation to a compatible motor with

terminal boxes of size GK030.

Inverters are available in ranges 370 W to 3.0 kW 380/480 V AC for three phase

units.

The inverters are microprocessor-controlled and use state-of-the-art Insulated Gate

BipoIar Transistor (IGBT) technology. This makes them reliable and versatile. A

special pulse-width modulation method with selectable Pulse frequency permits

quiet motor operation. Comprehensive protective functions provide excellent

inverter and motor protection.

With the factory default settings, the MICROMASTER 411 / COMBIMASTER 411 is

suitable for many variable speed applications. Using the functionally grouped

parameters, the MICROMASTER 411 / COMBIMASTER 411 can adapted to more

demanding applications.

MICROMASTER 411/COMBIMASTER 411 can be used in 'stand-alone' applications as well as being integrated into complete automation systems.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

16

6SE6400-5CA00-0BP0

Page 17

Issue 03/01 1 Overview

1.2 Design Features

Main Characteristics

Easy installation

Easy commissioning

High starting torque with programmable starting boost

Options for remote control:

♦ Basic Operator Panel

♦ Advanced Operator Panel

♦ Serial interface (RS232)

Factory default parameter settings pre-programmed for European and North

American requirements

Output frequency (and hence motor speed) can be controlled by one of four

methods:

♦ Internal Speed Control Potentiometer

♦ Analogue setpoint (voltage or current input)

♦ Fixed frequencies via binary inputs

♦ Serial interface

Programmable signal relay output incorporated

Rugged EMC design

Fast repeatable response time to control signals

Comprehensive range of parameters enabling configuration for a wide range of

applications

Simple connection

High switching frequencies for low-noise motor operation

Detailed status information and integrated messaging functions

External options for PC communications, Basic Operator Panel (BOP),

Advanced Operator Panel (AOP), PROFIBUS communications module

Option for integrated class B-filter (interference emission class A)

Optional housing for installing PROFIBUS module and EM control module

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

17

Page 18

1 Overview Issue 03/01

Performance Characteristics

Flux Current Control (FCC) for improved dynamic response and motor control

Fast Current Limitation (FCL) for trip-free operation

Built-in DC injection brake

Compound braking to improve braking performance

Ramp function generator with programmable smoothing

Control with Proportional-Integral control function (PI)

Multi-point V/f characteristic

Protection characteristics

MICROMASTER 411: Type of protection up to IP66 (comparable to NEMA 4X)

COMBIMASTER 411: Type of protection up to IP55 (comparable to NEMA 4)

Overvoltage/undervoltage protection

Overtemperature protection for the inverter

Short-circuit protection

2

i

t thermal motor protection

PTC for motor protection, via digital input 3

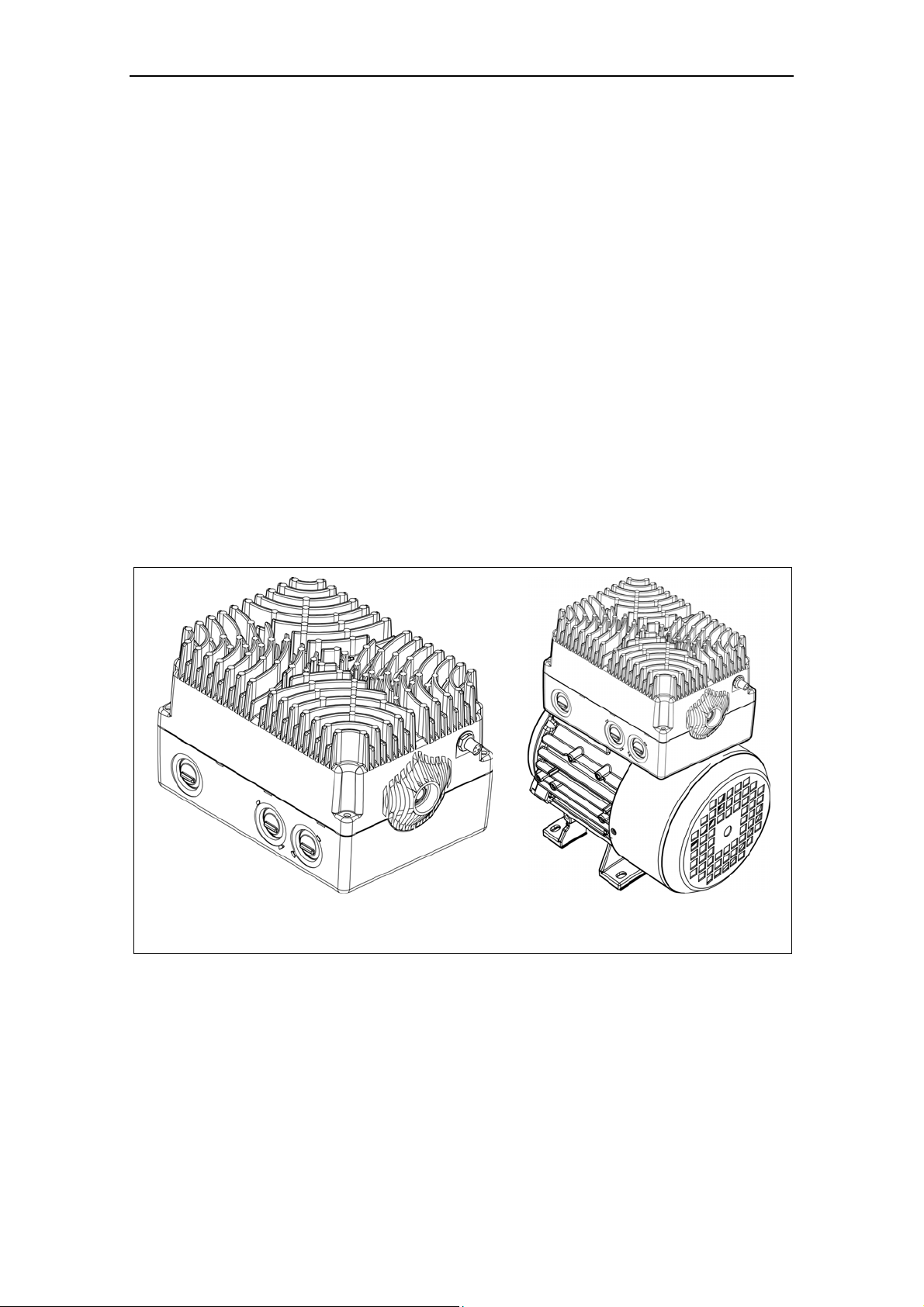

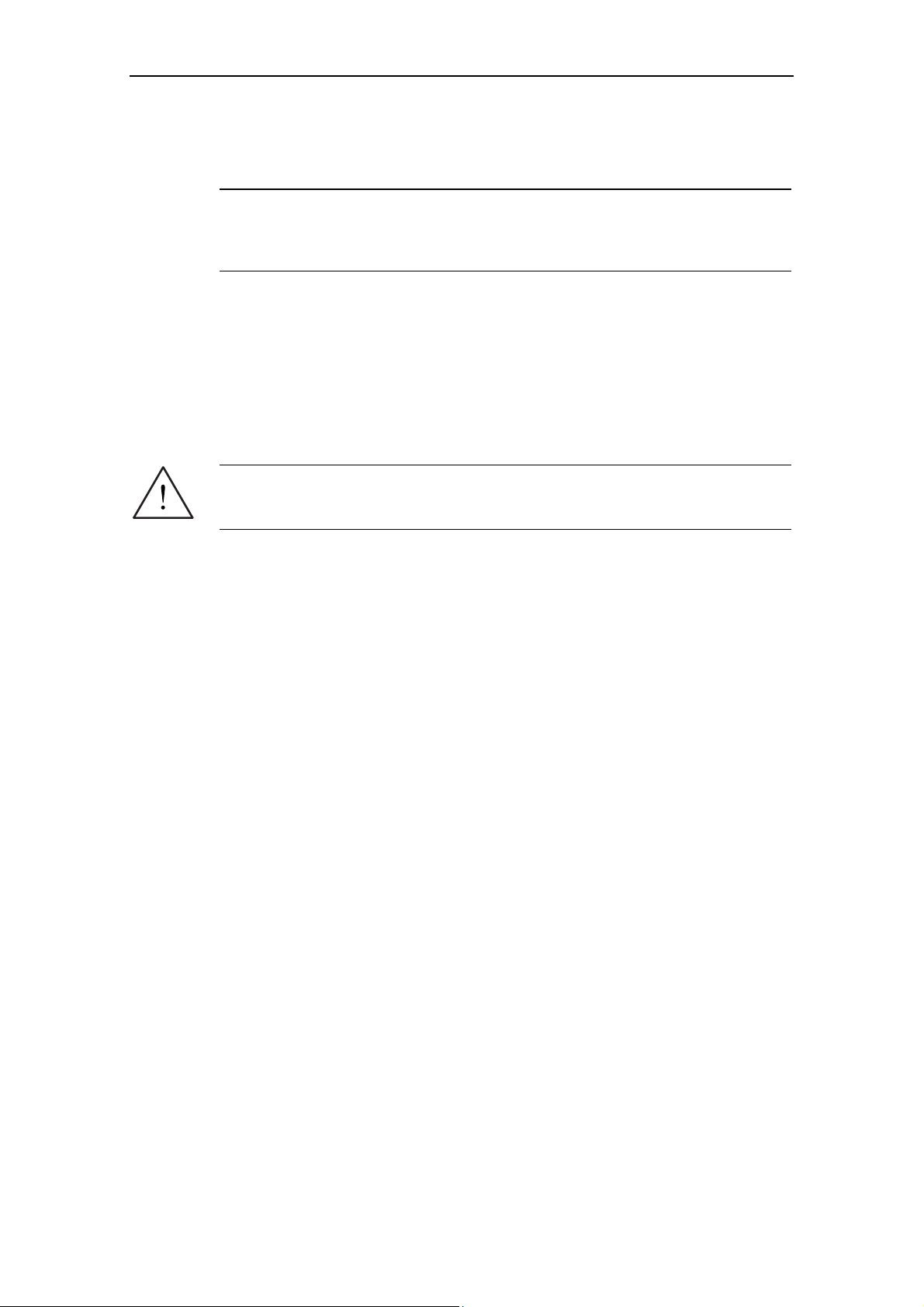

MICROMASTER 411 Variable Frequency Inverter COMBIMASTER 411 Variable

Frequency Inverter – Motor Combination

Figure 1-1 MICROMASTER 411 and COMBIMASTER 411 Variable Frequency Inverters

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

18

6SE6400-5CA00-0BP0

Page 19

Issue 03/01 2 Installation

2 Installation

This Chapter contains:

General data relating to installation

Inverter Dimensions

Wiring guidelines to minimize the effects of EMI

Details concerning electrical installation

2.1

2.2 Ambient operating conditions..................................................................................22

2.3

2.4

2.5

Installation after a Period of Storage....................................................................... 21

Mechanical Installation MICROMASTER 411......................................................... 23

Mechanical Installation COMBIMASTER 411......................................................... 30

Electrical Installation................................................................................................ 33

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

19

Page 20

2 Installation Issue 03/01

WARNING

Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

Only permanently wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

If a Residual Current-operated protective Device (RCD) is to be used, it must

be an RCD type B.

Machines with a three-phase power supply, fitted with EMC filters, must not be

connected to a supply via an ELCB (Earth Leakage Circuit-Breaker EN50178

Section 5.2.11.1).

The following terminals can carry dangerous voltages even if the inverter is

inoperative:

- power supply terminals L1, L2, L3

- motor terminals U, V, W

- additionally the terminals DC+, DC-

Always wait 5 minutes to allow the unit to discharge after switching off before

carrying out any installation work.

This equipment must not be used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

The minimum size of the earth-bonding conductor must be equal to or greater

than the cross-section of the power supply cables.

CAUTION

The connection of power and motor cables to the inverter must be carried out as

shown in Figure 2-10 to prevent inductive and capacitive interference from

affecting the correct functioning of the inverter.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

20

6SE6400-5CA00-0BP0

Page 21

Issue 03/01 2 Installation

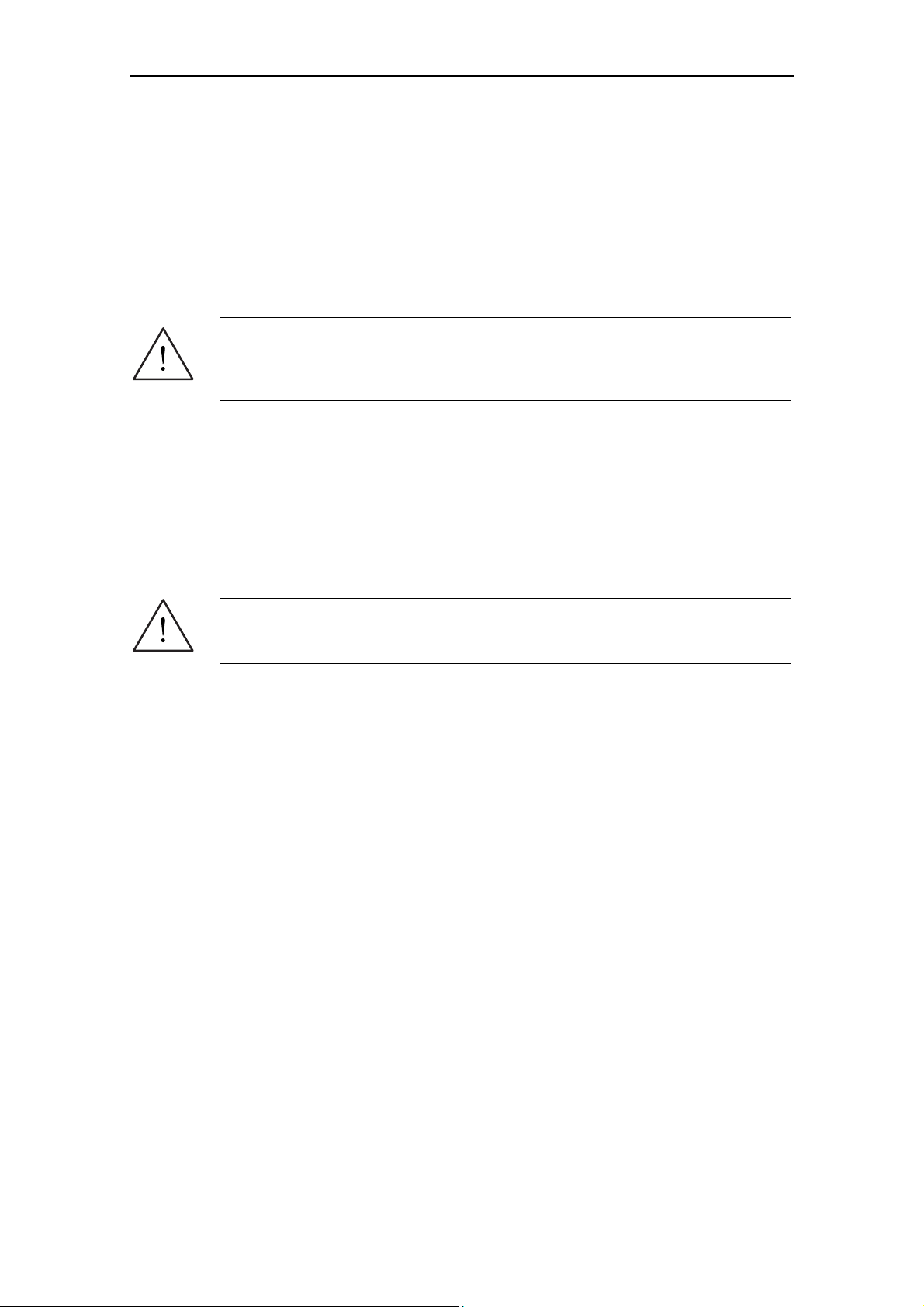

2.1 Installation after a Period of Storage

Following a prolonged period of storage, you must reform the capacitors in the

inverter. The requirements are listed below.

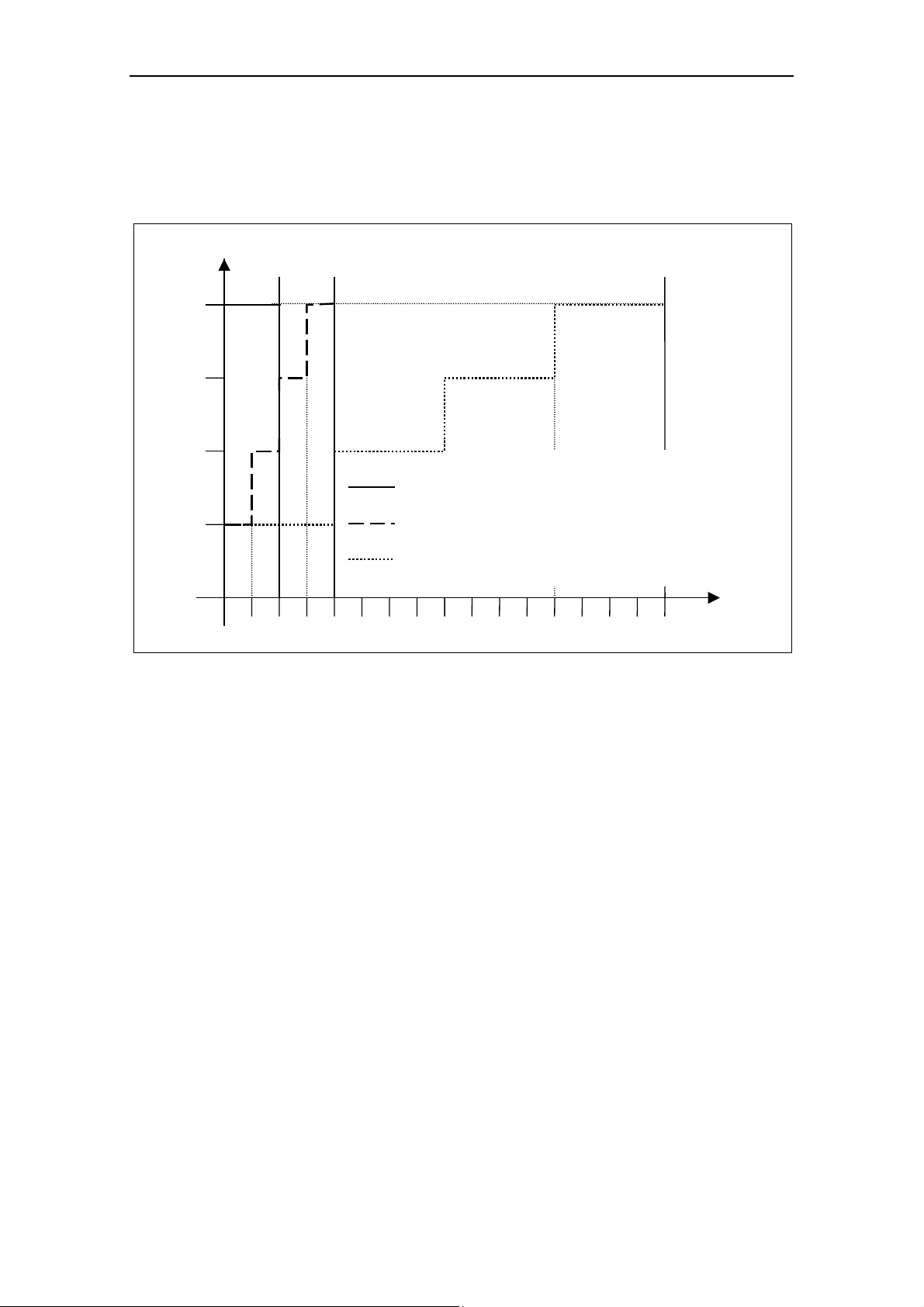

Voltage

[%]

100

75

50

0,5 1

Figure 2-1 Forming

Storage period less than 1 year:

Storage period 1 to 2 years:

Storage period 2 to 3 years:

Storage period 3 and more years:

2468

No action necessary

Prior to energizing, connect to

voltage for one hour

Prior to energizing, form

according to the curve

Prior to energizing, form

according to the curve

Time t [h]

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

21

Page 22

2 Installation Issue 03/01

2.2 Ambient operating conditions

Temperature

Operating temperature –10 °C to +40 °C

(power reduction at +50 °C see Section 10.4.1).

Humidity Range

≤ 99 %, Non-condensing

Altitude

If the inverter is to be installed at an altitude > 1000 m, derating will be required.

Refer to Section 10.4.2 for details.

Shock

Refer to the notes in Section 10.12.

Electromagnetic Radiation

Do not install the inverter near sources of electromagnetic radiation.

Overheating

MICROMASTER 411 / COMBIMASTER 411 are cooled by natural convection.

Mount the inverter with the heatsink fins above to ensure optimum cooling.

Mounting the inverter with the heatsink upside down is not allowed.

Ensure that airflow around the inverter housing is not obstructed. Allow 100 mm

clearance above and below the inverter.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

22

6SE6400-5CA00-0BP0

Page 23

Issue 03/01 2 Installation

2.3 Mechanical Installation MICROMASTER 411

WARNING

♦ This equipment must be grounded.

♦ To ensure safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

♦ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN

50178), as well as the relevant regulations regarding the correct use of tools

and personal protective gear.

♦ The Power supply, DC and motor terminals, can carry dangerous voltages

even if the inverter is inoperative; wait 5 minutes to allow the unit to

discharge after switching off before carrying out any installation work.

2.3.1 Preparation

Remove the MICROMASTER 411 installation kit from the packing. Check packing

box contents against the advice note supplied.

4

The installation kit should comprise the following items:

1. Inverter cover

2. Terminal Housing

3. Filter Module & screws (captive)

4. Input – Output Board & screws (captive)

5. Earth Lead

6. 10 Off Terminal Jumpers

7. Getting Started Guide and CD

8. 2 off Glands M25 IP68 withO-ring

9. 2 off M25 sealing plugs

10. 2 off M25 Gland Fixing Plates

11. 2 off U-clamp & screws (for earth/ground connection)

12. 4 off M4 Inverter to Motor fixing screws

(CSC only: additional 4 off M5 screws)

13. Motor Cable Sheath

14. 1 off Motor Gasket (CSC only: additional 1 off Motor Gasket)

15. 1 off M12 connector blanking plug

Any defective or missing items should be reported immediately to your local

Siemens Distributor or Sales Office.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

23

Page 24

2 Installation Issue 03/01

2.3.2 Installation Procedure

NOTE (MICROMASTER 411 ONLY):

Prior to installation it may be necessary to fit an Adaptation Plate to a non-Siemens

motor. The Adaptation Plate is prepared by the respective motor manufacturer.

Normally the Adaptation Plate makes use of the existing motor gasket.

Physical dimensions and characteristics for installation are given in Section:

2.3.3 for MICROMASTER 411

2.4.2 for COMBIMASTER 411

With the product items removed from their packaging carry out the following

installation procedure.

1. Separate the two halves (Inverter Cover and Terminal Housing).

2. Remove the Filter Module and I/O board.

CAUTION

Do not knock out cable gland blanking plates unless the inverter ‘electronics’ (Filter

& I/O boards) have been removed.

3. Remove the cable gland blanking plates (knockouts) as required (see Figure

2-6). The preferred gland arrangements are shown in the General Layout

Diagram Figure 2-5.

4. Fit cable glands to terminal housing, ensuring the O-rings are fitted to ensure

the seal is maintained.

5. Fit the earth lead to the earth terminal within the motor terminal box. If required

fit a Motor PTC cable (not supplied).

6. Run all cables between the motor and inverter within the cable sheath

provided.

7. Using the appropriate motor gasket, fix the terminal housing to the motor.

Screw fixing torque values are: 1.5 Nm – M4 and 2.5 Nm – M5.

8. Insert power and control cables through glands and make off ends as required.

9. Fit the Filter board (see Figure 2-2).

10. Secure Filter board with M3 taptite screws (torque values see Table 7-5 ).

11. Connect power cables as detailed in Section 2.5.2.

12. Connect up the motor terminals in either star or delta configuration as

explained in Section 2.5.2.

13. Connect control wires as detailed in Section 2.5.3.

14. Fit the I/O board (see Figure 2-2).

15. Secure I/O board with M3 taptite screws. (torque values see Table 7-4 ).

16. Fit jumpers as required – see Section 3.3.

17. Place the inverter cover onto the assembled terminal housing.

18. Secure the inverter cover with the four M5 captive screws.

Use either a 4-5 mm flat bladed screwdriver or a 2pt Pozidrive Head

screwdriver.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

24

6SE6400-5CA00-0BP0

Page 25

Issue 03/01 2 Installation

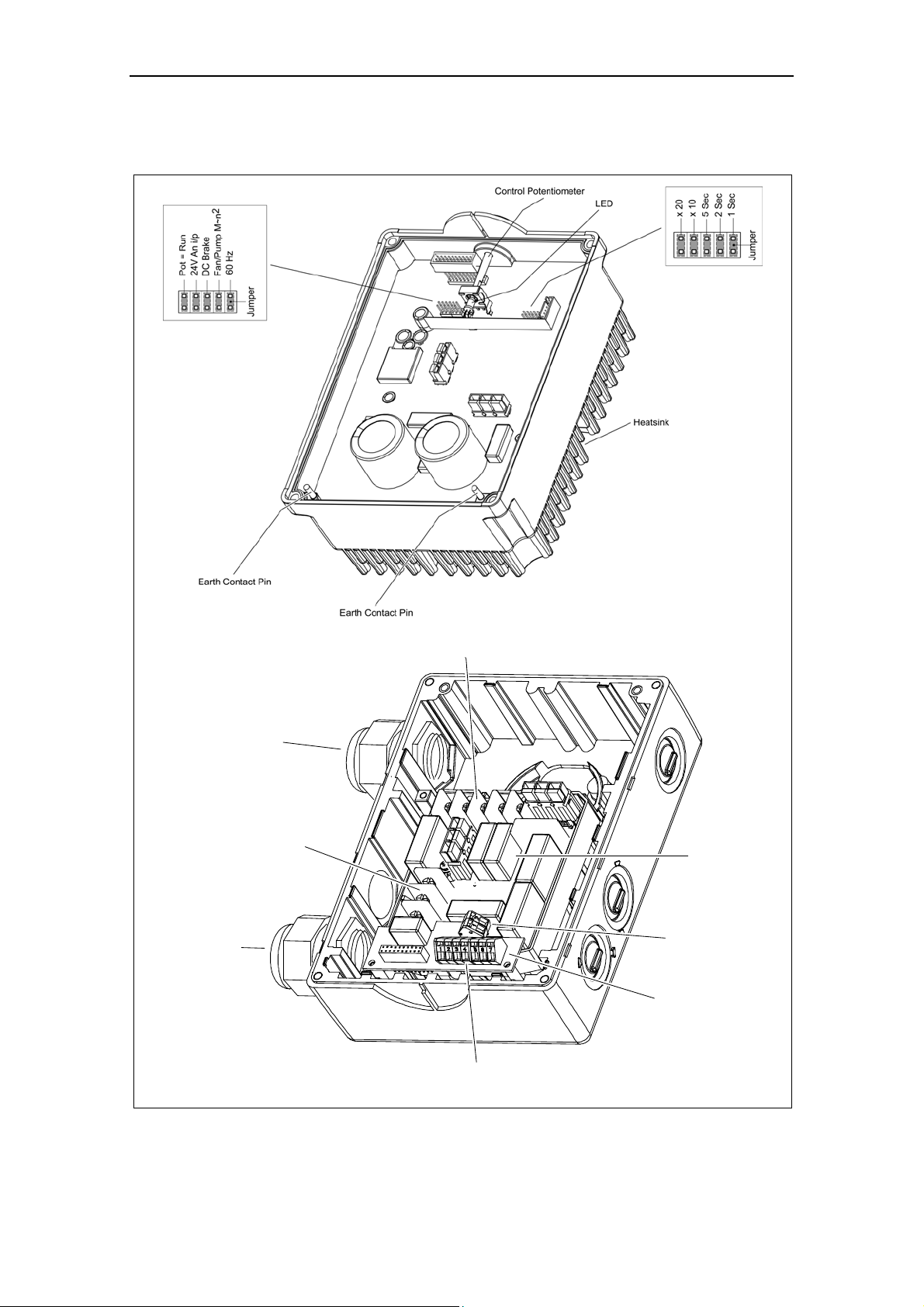

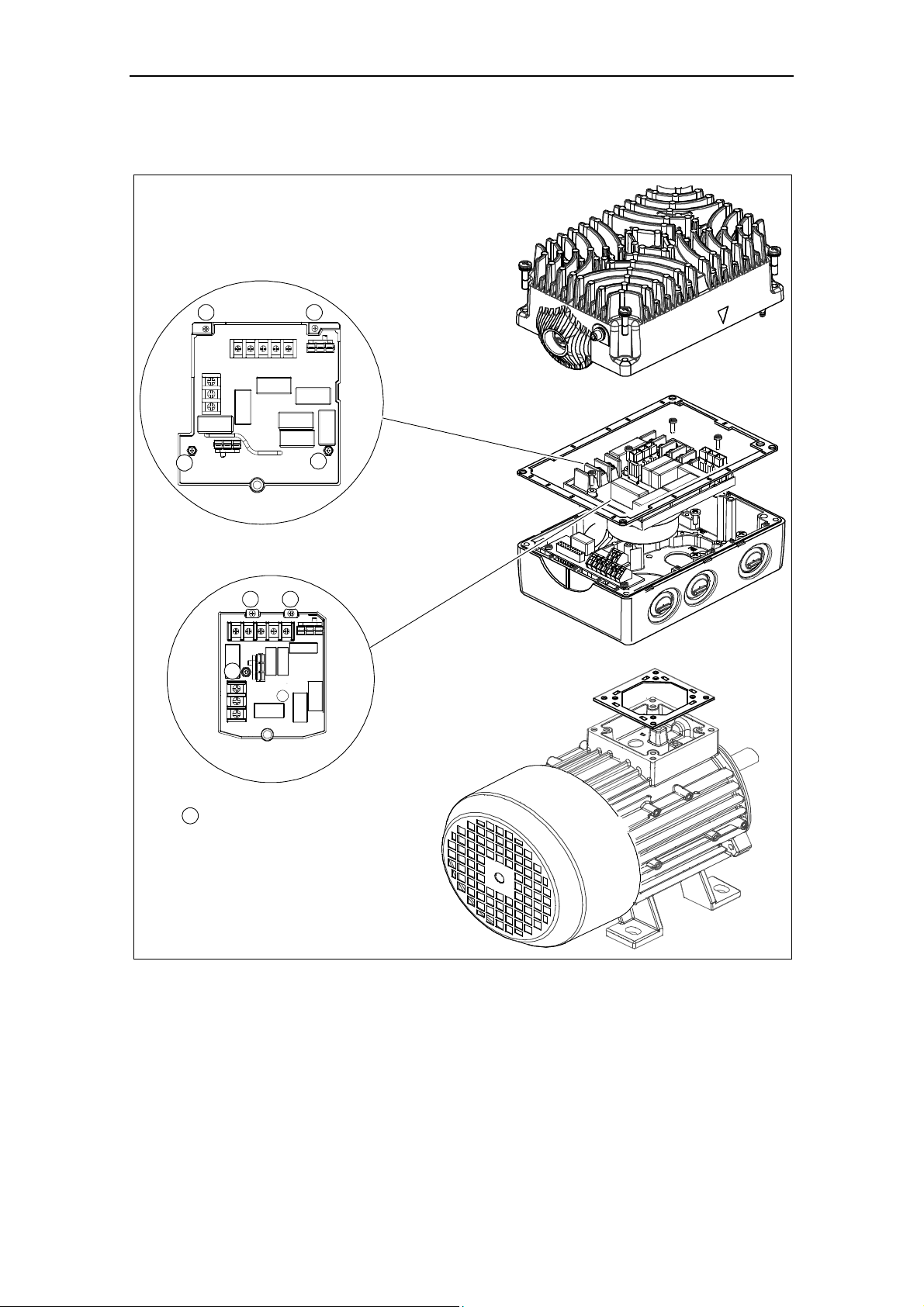

2.3.3 Layout of MICROMASTER 411

(Power Supply)

Cable Gland

(Control)

Cable Gland

Power Supply

Terminals

Inverter Cover (CSB)

Motor Terminals

Filter Module

Output Relay

Terminals

Input/Output

Board

Control Terminals

Terminal Housing (CSB) (Cable glands shown in preferred positions)

Figure 2-2 MICROMASTER 411, Internal Layout

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

25

Page 26

2 Installation Issue 03/01

MICROMASTER 411 Dimensional Detail

Figure 2-3 MICROMASTER 411 Case Size B Dimensions

Figure 2-4 MICROMASTER 411 Case Size C Dimensions

Table 2-1 MICROMASTER 411 Dimension Detail

Case

Size

B

C

Height (H) Width (W) Depth (D) Weight Power Range

mm

(Inches)

135.6

(5.31)

170.6

(6.61)

mm

(Inches)

154

(6.06)

177

(6.97)

mm

(Inches)

222

(8.74)

255

(10.04)

kg

(lbs)

4.9

(10.77)

7.4

(16.34)

kW

(hp)

0.37 – 1.5

(0.5 – 2.0)

2.2 – 3.0

(3.0 – 4.0)

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

26

6SE6400-5CA00-0BP0

Page 27

Issue 03/01 2 Installation

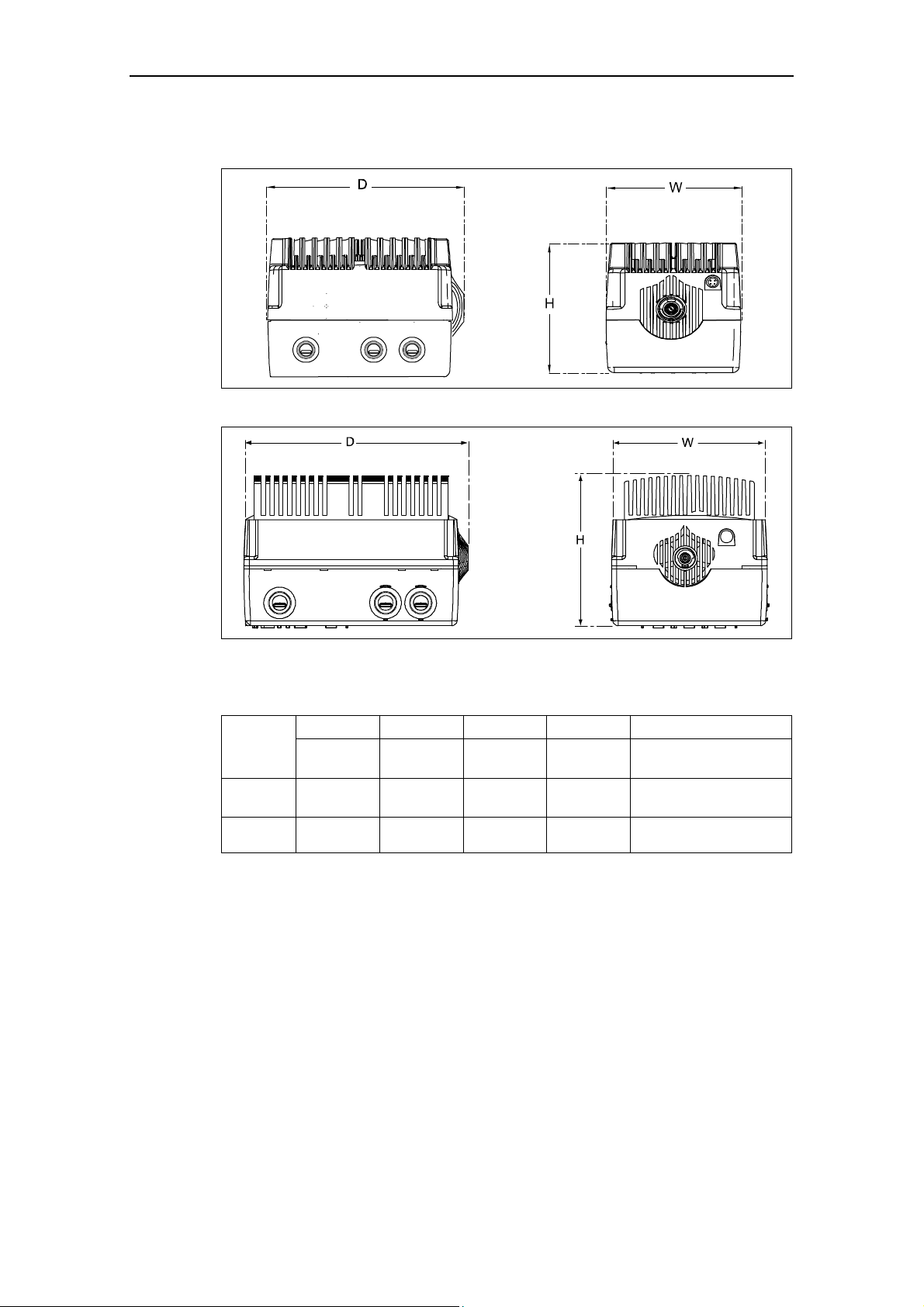

2.3.4 Installation of Cable Glands

Figure 2-5 Cable Glands

Before power and control cables can be

connected to their respective circuits it will

first be necessary to fit the cable glands

supplied.

Each gland should be located ideally to

allow for convenient cable runs to the

terminals located on the Filter and I/O

boards.

1. Using a hammer and a flat-head

screwdriver as shown in Figure 2-6

strike the gland plate or ‘knockout’ to

obtain a clearance for the 25 mm

cable gland.

NOTE

Care must be taken to prevent

damage to the Terminal Housing, as

this may affect the IP rating of the

inverter.

2. Remove any sharp edges from the

gland area and any swarf from the

terminal housing.

3. After the knockout has been removed

it should be safely discarded and the

cable glands fitted as shown in Figure

2-6.

1

Terminal Housing

A

1

2

A

B

B

B

A

2

Figure 2-6 Installation of Cable Gland

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

27

Page 28

2 Installation Issue 03/01

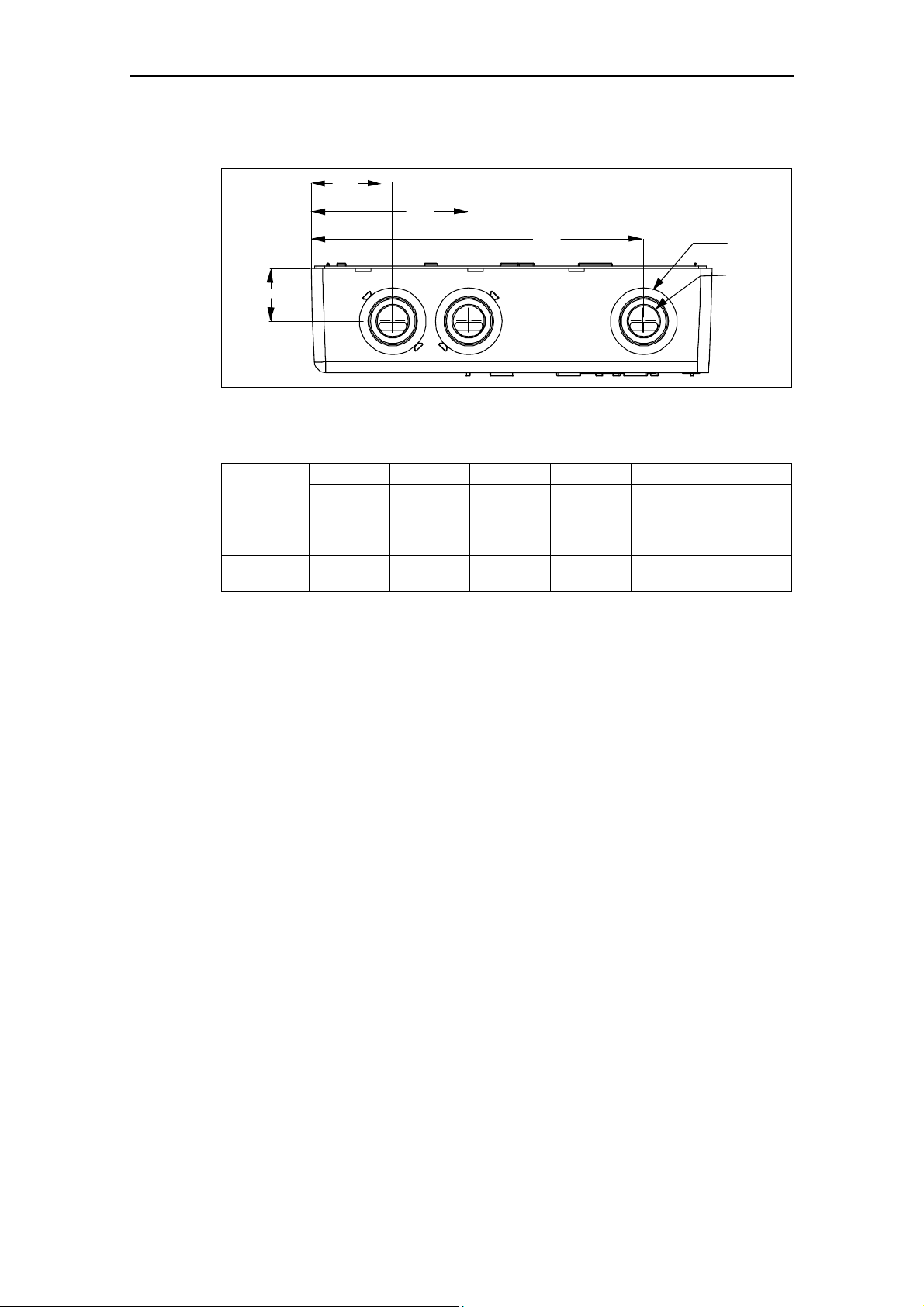

MICROMASTER 411 – Cable Gland Dimensions.

GW1

GW2

GW3

GH

Figure 2-7 MICROMASTER 411 Gland Dimensions

Table 2-2 Gland Plate Detail

GW1 GW2 GW3 GH GD1 GD2

Case Size

B

C

mm

(inch)

42,9

(1,68)

43,0

(1,69)

mm

(inch)

82,9

(3,26)

83,0

(3,27)

mm

(inch)

175,0

(6,89)

203,4

(8,01)

mm

(inch)

27,6

(1,09)

38,3

(1,51)

mm

(inch)

35

(1,38)

36

(1,42)

GD1

GD2

mm

(inch)

26

(1,02)

26

(1,02)

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

28

6SE6400-5CA00-0BP0

Page 29

Issue 03/01 2 Installation

2.3.5 Mounting the Inverter on a Siemens Motor

1 1

1

1

FSC

1 1

1

FSB

Filter Board Captive Retaining Screws

1

2.3.6 Wall Mounting the Inverter

Wall mounting of MICROMASTER 411 see Section 8.10.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

29

Page 30

2 Installation Issue 03/01

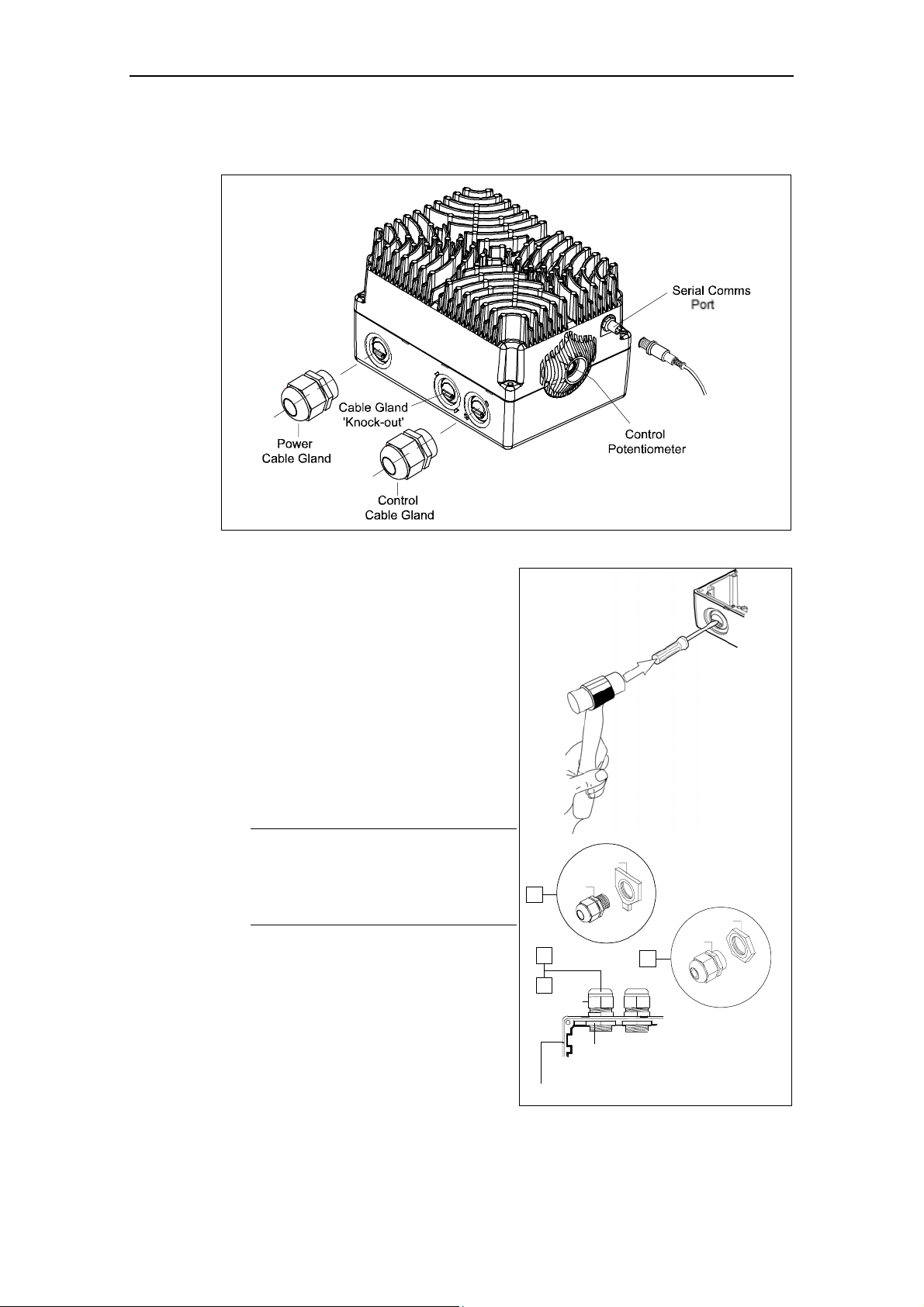

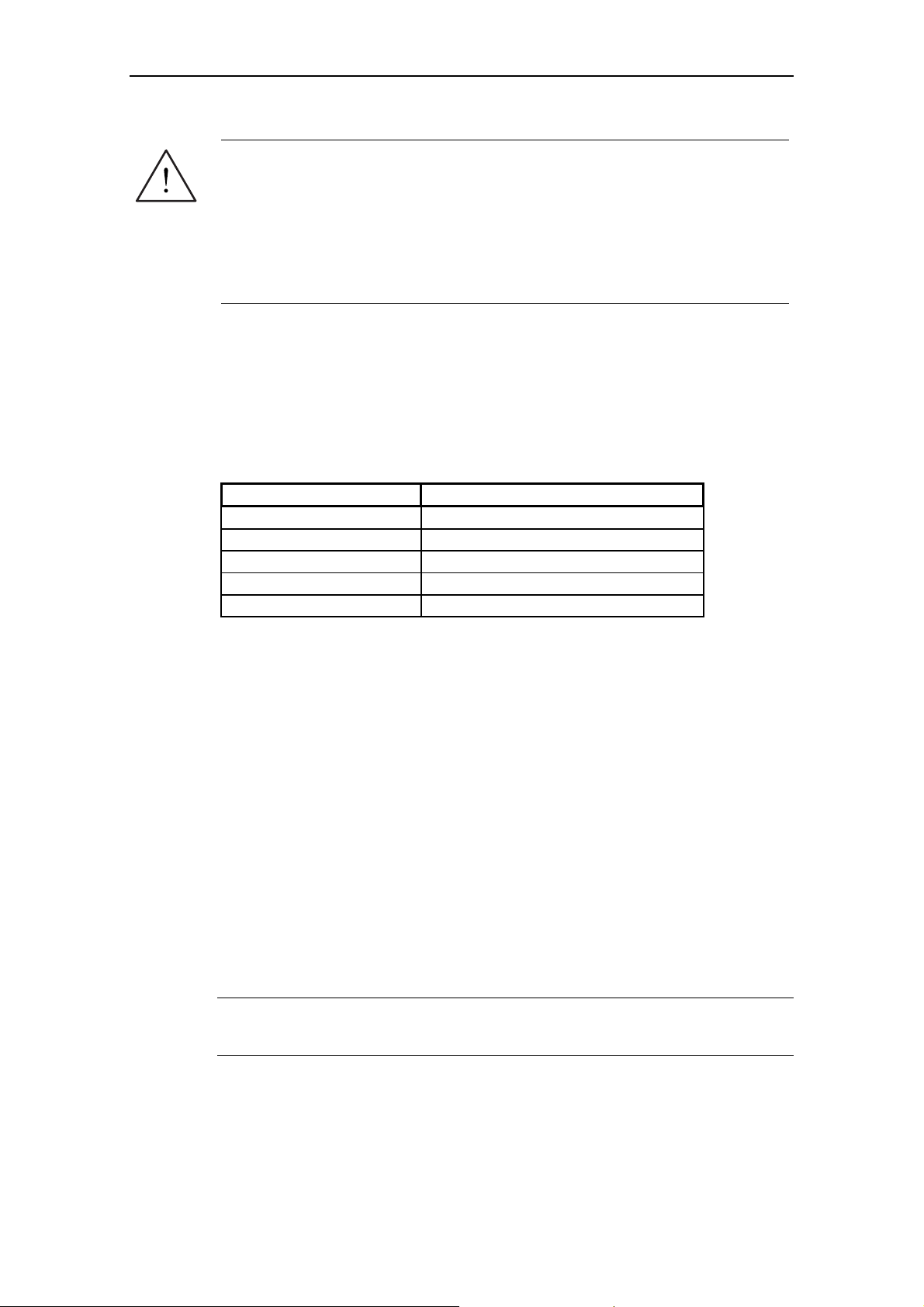

2.4 Mechanical Installation COMBIMASTER 411

2.4.1 COMBIMASTER 411 Installation Procedure

Ensure that any lifting eyes are tightened down prior to moving the

COMBIMASTER into position.

Use the lifting eyes provided if a motor has to be lifted. Always check the capacity

of the hoist before lifting any equipment.

WARNING

Do not attempt to lift the COMBIMASTER 411 using the inverter housing as this

could result in severe damage to the inverter or motor and possibly severe

personal injury.

Move the COMBIMASTER 411 into the required position and secure by inserting

suitable foundation bolts through the motor feet (see Figure 2-8 and Figure 2-9).

Allow adequate clearance of 100 mm minimum around the unit to provide for air

circulation.

COMBIMASTER 411 is supplied with a Power Supply Gland fitted to the preferred

cable entry port. Should it become necessary to select other cable entry ports for

either Power supply or Control then cable glands must be removed and the

redundant port blanked off. Always remember to remove Inverter electronics before

knocking out blanking plates. Blank off all redundant cable ports.

CAUTION

Do not knock out cable gland blanking plates unless inverter ‘electronics’ (Filter &

I/O boards) have been removed

Carry out the following checks prior to commissioning the COMBIMASTER 411:

1. The rotor is correctly aligned and free to rotate without obstruction.

2. Transmission elements are adjusted correctly (e.g. belt tensioned) and suitable

for the given operating conditions.

3. All electrical connections, mounting screws and connecting elements tightened

and fitted correctly.

4. Protective conductors installed properly

5. Any auxiliary equipment that might be fitted (e.g. mechanical brake) is in

working order.

6. Protection guards are installed around all moving and live parts and any

relevant safety notices displayed.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

30

6SE6400-5CA00-0BP0

Page 31

Issue 03/01 2 Installation

2.4.2 COMBIMASTER 411 Dimensional Detail

COMBIMASTER 411- Case Size B

27.6

Rear lip of Terminal Housing

taken as reference point for

Gland Measurements

222

36 128 168

Frame size 90S and 90L

have feet with 2 holes

each at the non-drive end.

154

135.6

Frame

Size

71M

80M

90S

Motor Poles

1LA7 070

1LA7 073

2 - 4

1LA7 080

2 - 4

1LA7 083

1LA7 090

1LA7 096

2 - 4

TL TW TH MF1 MF2 MF3 MS1 MS2 MB1

240

(9.4)

274

(10.8)

132

(5.2)

150

(5.9)

278.6

(11.0)

296.6

(11.7)

45

(1.8)

50

(2.0)

90

(3.5)

100

(3.9)

309

(12.2)

331

(13.0)

165

(6.5)

314.6

(12.4)

56

(2.2)

100

(3.9)

NOTES

1. All dimensions given in millimeters (and inches).

2. MF dimensions use Motor construction type IMB3.

Figure 2-8 COMBIMASTER 411 Case Size B Dimensional Detail

112

(4.4)

125

(4.9)

140

(5.5)

30

(1.2)

40

(1.6)

50

(2.0)

14

(0.6) 7 (0.3)

19

(0.7)

24

(0.9)

9.5

(0.4)

10

(0.4)

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

31

Page 32

2 Installation Issue 03/01

COMBIMASTER 411 - Case Size C

Rear lip of Terminal Housing

taken as reference point for

Gland measurements

38.3

Frame

Size

Motor Poles

90L 1LA7 096 4

100L 1LA7 100 2 - 4

255

40.8 161.1

201.1

170.6

TL TW TH MF1 MF2 MF3 MS1 MS2 MB1

332

(13.1)

373

(14.6)

165

(6.5)

196

(7.7)

349.5

(13.8)

370

(14.6)

56

(2.2)

63

(2.5)

100

(3.9)

140

(5.5)

140

(5.5)

160

(6.3)

50

(2.0)

60

(2.4)

177

24

(0.9)

28

(1.1)

10

(0.4)

12

(0.5)

NOTES

1. All dimensions given in millimeters (and inches).

2. MF dimensions use Motor construction type IMB3.

Figure 2-9 COMBIMASTER 411 Case Size B Dimensional Detail

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

32

6SE6400-5CA00-0BP0

Page 33

Issue 03/01 2 Installation

2.5 Electrical Installation

WARNING

This equipment must be grounded.

♦ To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

♦ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN

50178), as well as the relevant regulations regarding the correct use of tools

and personal protective gear.

♦ Never use high voltage insulation test equipment on cables connected to the

inverter.

♦ Power supply and motor terminals can carry dangerous voltages even if the

inverter is inoperative; wait 5 minutes to allow the unit to discharge after

switching off before carrying out any installation work.

CAUTION

The control and power supply cables must be laid separately. Do not feed them

through the same cable conduit/trunking.

2.5.1 General

WARNING

The inverter must always be grounded. If the inverter is not grounded correctly,

extremely dangerous conditions may arise within the inverter which could prove

potentially fatal.

Operation with Residual Current Device

If an RCD (also referred to as ELCB or RCCB) is fitted, the MICROMASTER 411

Inverters will operate without nuisance tripping, provided that:

A type B RCD is used.

The trip limit of the RCD is 300 mA.

The neutral of the supply is grounded.

Only one inverter is supplied from each RCD.

Operation with long cables

All inverters will operate at full specification with cable lengths of 5 m.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

33

Page 34

2 Installation Issue 03/01

2.5.2 Line and Motor Connections

WARNING

This equipment must be grounded.

♦ Isolate the electrical power supply before making or changing connections to

the unit.

♦ MICROMASTERS must not be connected to a higher voltage supply.

♦ Ensure that the motor is configured for the correct supply voltage 380 V to

480 V three-phase supply.

♦ When synchronous motors are connected or when coupling several motors in

parallel, the inverter must be operated with voltage/frequency control

characteristic (P1300 = 0, 2 or 3).

CAUTION

After connecting the power and motor cables to the proper terminals, make sure

that the cover has been replaced properly before supplying power to the unit!

NOTICE

♦ Ensure that the appropriate circuit-breakers/fuses with the specified current

rating are connected between the power supply and inverter (see Section

7.5).

♦ Use Class 1 75

o

C copper wire only. For tightening torque see Section 7.3.

♦ To tighten up the power terminal screws use either a 4-5 mm flat bladed

screwdriver or a 2pt Pozidrive Head screwdriver.

Access to the power and motor terminals

The procedure for accessing the power and motor terminals on the

COMBIMASTER 411 & MICROMASTER 411 Inverter is illustrated in Figure 2-10.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

34

6SE6400-5CA00-0BP0

Page 35

Issue 03/01 2 Installation

Power Connections

The information given in Figure 2-10 shows the connection of the motor wires to

the filter board terminals. Power cables should be connected to the inverter

terminals as detailed in the following procedure.

For cable size and rating refer to Section 7.3

1. If the Inverter cover (the top-half) has already been fitted, unscrew the four M5

cross-head captive screws on the inverter cover.

2. Remove inverter (cover) to access the connection terminals.

3. Feed the power cable into the terminal housing via the appropriate gland hole.

4. Connect power leads to terminals L1, L2, L3 and to the separate earth.

To avoid snagging on components when the inverter halves are brought

together, run cables along the base of the terminal housing.

5. Use Class 1 75

used they must be insulated. If crimps are not used, the strip length must not

exceed 5 mm. Use a 4 - 5 mm cross-tip screwdriver to tighten the terminal

screws.

6. Recommended tightening torque for power supply terminals is as given in

Section 7.3.

7. A ‘drip loop’ is recommended when connecting the mains and control cables.

8. Ensure that the power source provides the correct voltage and is designed for

the rated current. Use appropriate circuit-breakers with specified current rating

between the power supply and inverter.

9. Ensure the appropriate circuit breakers/fuses with the specified current rating

are connected between the power supply and the inverter. (See Section 7.5).

o

C copper wire only. Use a 4-core cable. If crimp terminals are

WARNING

It is essential that the Inverter be correctly earthed to the motor earth. Severe

injury may result if the motor is not correctly earthed.

If the Inverter is being installed after a period of storage please refer to the

information in Section 2.1

Motor Connections for Star/Delta

The information given in Figure 2-10 also shows the connection of motor wires to

the filter board inverter/motor terminals. Motor wires should be connected in either

star or delta configuration in accordance with the motor rating plate. For cable size

and rating refer to Section 7.3.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

35

Page 36

2 Installation Issue 03/01

Figure 2-10 Motor and Power Supply Connections

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

36

6SE6400-5CA00-0BP0

Page 37

Issue 03/01 2 Installation

2.5.3 Control Cable Connections

1. Feed the control cables into the inverter via one of the gland holes at the I/O

module end of the terminal housing.

2. Run the control cable underneath the I/O board toward the control terminals.

3. Connect the control wires in accordance with the terminal information given in

Figure 2-11.

4. Use screened cable for all control wiring.

8 9

NOTE

If a PTC resistor is fitted, this

1 2 3 4 5 6 7

should be connected between 4

(+24 V) and 3 (DIN 3).

Terminal Inputs Parameter Default operation

1 DIN 1 P0701 = ‘1’ ON/OFF1

2 DIN 2 P0702 = ‘12’ Reverse

3 DIN 3 P0703 = ‘9’ Fault Acknowledge

6/7 AIN (-/+) P0756 = 0 0 – 10 V Analogue Input

Option: DIN 4

8/9 Output Relay P0731 = ’52.3’ Fault identification

P0704

≠ 0

Figure 2-11 Control Terminals

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

37

Page 38

2 Installation Issue 03/01

2.5.4 Motor PTC Connections

In order for the inverter to monitor the motor PTC (if fitted) it will be necessary to

connect the Motor PTC to the Inverter Digital input 3 (DIN3) terminal.

Connect the Motor PTC extension cable (provided with the Inverter) between the

Inverter I/O terminals 3 & 4 and the Motor PTC terminals within the motor terminal

housing. The arrangement is as shown in.Figure 2-12).

NOTE

DIN 3 must be configured to read the PTC input [(P0703 = 29) (external trip)]

Figure 2-12 PTC Connections

PTC Resistor connects between

terminals 4 (+24 V) and 3 (DIN 3).

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

38

6SE6400-5CA00-0BP0

Page 39

Issue 03/01 2 Installation

2.5.5 Avoiding Electro-Magnetic Interference

The inverters are designed to operate in an industrial environment where a high

level of EMI can be expected. Usually, good installation practices will ensure safe

and trouble-free operation. If you encounter problems, follow the guidelines stated

below.

Action to Take

Make sure that any control equipment connected to the inverter (such as a

PLC) is connected to the same ground or star point as the inverter via a short,

thick link.

Flat conductors are preferred as they have lower impedance at higher

frequencies.

Separate the control cables from the power connections as much as

possible, using separate trunking, if necessary at 90

Ensure that contactors are suppressed, either with R-C suppressors for AC

contactors, or 'flywheel' diodes for DC contactors, fitted to the coils. Varistor

suppressors are also effective. This is important when the contactors are

controlled from the inverter relay.

Screened motor cables should be used when the motor is mounted separately

from the inverter.

Maximum motor cable length is 5 meters (16.40 feet).

WARNING

Safety regulations must not be compromised when installing inverters!

0

right angles.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

39

Page 40

2 Installation Issue 03/01

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

40

6SE6400-5CA00-0BP0

Page 41

Issue 03/01 3 Commissioning

3 Commissioning

This Chapter contains:

A schematic diagram of the MICROMASTER 411 / COMBIMASTER 411

An overview of the commissioning options and the display and operator panels

An overview of quick commissioing of the MICROMASTER 411 /

COMBIMASTER 411

3.1 Block Diagram ......................................................................................................... 43

3.2 General Information................................................................................................. 44

3.3 Commissioning Procedure Overview ...................................................................... 45

3.4 General operation.................................................................................................... 56

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

41

Page 42

3 Commissioning Issue 03/01

WARNING

COMBIMASTER411/MICROMASTER 411 operates at high voltages.

When operating electrical devices, it is impossible to avoid applying hazardous

voltages to certain parts of the equipment.

Emergency Stop facilities according to EN 60204 IEC 204 (VDE 0113) must

continue to function in all operating modes of the control equipment. Any

disengagement of the Emergency Stop facility must not lead to uncontrolled or

undefined restart.

Wherever faults occurring in the control equipment may lead to substantial

material damage, or even grievous bodily injury, (i.e. potentially dangerous

faults), additional external precautions must be taken or facilities provided to

ensure or enforce safe operation, even when a fault occurs (e.g. independent

limit switches, mechanical interlocks, etc.).

Certain parameter settings may cause the inverter to restart automatically after

an input power failure.

This equipment is capable of providing internal motor overload protection.

Refer to P0610 (level 3) and P0335, I

2

T is ON by default. Motor overload

protection can also be provided using an external PTC via a digital input.

This equipment is suitable for use in a circuit capable of delivering not more

than 10,000 symmetrical amperes (rms), for a maximum voltage of 460 V

when protected by an H or K Class fuse (see Table 7-6).

CAUTION

Only qualified personnel may enter settings in the control panels. Particular

attention must be paid to safety precautions and warnings at all times.

The COMBIMASTER 411 & MICROMASTER 411 is supplied with default

parameter settings that cover the following requirements:

The motor rating data, voltage, current and frequency are all compatible with

the inverter data.

Linear V/f motor speed, controlled by the control potentiometer.

-1

Maximum speed 3000 min

with 50 Hz (3600 min-1 with 60 Hz), controllable via

the control potentiometer or by using a potentiometer via the inverter’s

analogue input.

Ramp-up time / Ramp-down time = 10 s.

If more complex application settings are required, please refer to the parameter

listing.

To change parameters you will need one of the optional modules "Basic Operator

Panel" (BOP), the "Advanced Operator Panel" (AOP) or the set-up software (on the

Docu-CD supplied).

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

42

6SE6400-5CA00-0BP0

Page 43

Issue 03/01 3 Commissioning

3.1 Block Diagram

3 AC 380 V-480 V

Analogue Input sourc e

Input Voltage: 0 to +10 V / 24 V

(on 500 Ohm resistor)

+

24 V

–

External

Power supply

Output Relais (RL) Contacts

250 V AC, 2 A max.

30 V DC, 5 A max.

≥

4.7 k

Ω

+24 V(100 mA max)

0 V (isolated)

24 V

0 V

AIN +

AIN -

DIN1

DIN2

DIN3

RLB

RLC

Tx+

Rx

+6.5 V

EM Brake

Option

PE

4

5

7

6

A/D

Motor Potentiometer

FS1

PE

L1, L2,L3

~

1

2

3

4

5

8

9

COM 1

COM 2

0 V

COM 3

COM 4

RL

Serial

Interface

RS232

Brake

Interface

CPU

CPU

Control jumper

Ramp time

Jumpers

Pot = Run

24 V AIN

DC Brake

Fan/Pump M~n2

60 Hz

x 20

x 10

5 Sec

2 Sec

1 Sec

3

~

24 V max

Comm.

Options

(Shield)

The Analogue inpu t circuit can be configured ,

to provide an addition al digital input (DIN4) as shown

Switching voltage must b

7

DIN4

6

+

–

4

+24 V(100 mA max)

5

?????? V or 0 V (isolated )

SOL

(TTL)

PE

M

Figure 3-1 COMBIMASTER 411 & MICROMASTER 411 Block Diagram

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

43

Page 44

3 Commissioning Issue 03/01

3.2 General Information

For basic operation no additional equipment is required.

However, for more complex operation either the Basic Operator Panel (BOP),

Advanced Operator Panel (AOP) or the set-up software contained on the Docu-CD

is required.

The COMBIMASTER 411/MICROMASTER 411 can additionally be integrated into

automation systems via the PROFIBUS module (option) or USS interface.

When delivered the inverter has a frequency setpoint range of between 0 Hz and

50 Hz.

WARNING

The inverter does not have a power supply switch and is therefore live when the

power supply is connected.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

44

6SE6400-5CA00-0BP0

Page 45

Issue 03/01 3 Commissioning

3.3 Commissioning Procedure Overview

Figure 3-2 MICROMASTER 411 / COMBIMASTER 411 Commissioning Guide

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

45

Page 46

3 Commissioning Issue 03/01

3.3.1 Ramp Times Using Jumpers

Inverter ramp times are set using a series of 5 jumpers (fit jumper to enable

function). Each jumper must be set as shown in Table 3-1.

The jumpers overwrite the default settings or the ramp times specified using

BOP/AOP/IBN software.

The inverter recognizes when jumper values have been set when power is reapplied.

CAUTION

Jumpers have priority in setting ramp times. When the jumpers are removed the

ramp times are not changed. It is then possible to change ramp times via the

parameters (using the BOP).

Ramp times apply to Ramp Up and Ramp Down. Jumper locations are as shown in

Figure 3-3.

Figure 3-3 Ramp Time Jumpers

Using up to 5 jumpers allows ramp times to be set between 1 - 240 s. Also see

Table 3-1.

Table 3-1 Ramp Time Adjustment Jumpers

Time [s] X20 X10 5 s 2 s 1 s Time [s] X20 X10 5 s 2 s 1 s

10

20

30

50

60

1

×

2

×

3

× ×

5

×

6

× ×

7

× ×

8

× × ×

× ×

× ×

× × ×

× ×

× × ×

70

80

90

100 ×

120 ×

140 ×

150

160 ×

180

210

240

× × ×

× × × ×

× ×

× × ×

× × ×

× × × ×

× × × × ×

× ×

×

×

× ×

× × ×

×

×

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

46

6SE6400-5CA00-0BP0

Page 47

Issue 03/01 3 Commissioning

Behaviour of the Ramp Time Jumpers

In Table 3-2 the behaviour of the Ramp Time Jumpers are explained:

Table 3-2 Ramp Time Jumper Behaviour

Status before action(s) Action(s) Reaction(s) of the inverter

No jumper fitted

Ramp times have arbitrary setting

At least one Jumper fitted

Ramp times have arbitrary setting

Power down

Fit jumper(s)

Power up

Power down

Power up

Inverter uses the ramp times defined by the current

jumper setting

Inverter uses the ramp times defined by the current

jumper setting

At least one Jumper fitted

Ramp times have arbitrary setting

Power down

Remove jumper(s)

Power up

NOTE

The brake time is influenced by the setting for the ramp time (deceleration time).

The following relationship applies:

Braking time = P1121 (deceleration time) *

3.3.2 Control Circuit Jumpers

Control Jumpers (see Table 3-3) are provided for the following functions (fit jumper

to enable function). Jumpers can only be accessed when the cover is removed:

Pot = Run

Enables the control potentiometer as the Command Source (auto restart is

enabled).

24 V AIN

To change analogue input range from 0 –10 V to 0 – 24 V

DC Brake

To change Stop function from OFF1 to DC Brake.

Inverter uses the ramp times that were used before

removing the jumper(s)

P0305 (nominal motor current)

r0207 (nominal inverter current)

Fan/Pump: M~n2

To change V/f curve from Linear to Quadratic curve.

60 Hz operation

To change motor default settings from 50 Hz to 60 Hz.

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

47

Page 48

3 Commissioning Issue 03/01

Figure 3-4 Control Circuit Jumpers

Table 3-3 Control Circuit Jumper Settings

Jumper Jumper Fitted Jumper Removed

Pot = Run P0700 = 2

24 AIN No software effect No software effect

DC Brake Uses the jumper settings for the ramp settings by the

Fan/Pump: M~n2 P1300 = 2 (fan curve/quadratic vf) P1300 = 0 (linear vf)

50/60 Hz Rated Motor Frequency = 60 Hz Rated Motor Frequency = 50 Hz

P0705 = 1 (motor potentiometer)

P1210 = 6 automatic restart

duration of the direct current braking, to be calculated as

follows.

Duration of direct current braking =

P1121 (deceleration time)

If the drive is quicker to come to a standstill because of the

load conditions, the direct current braking still remains

active fo the calculated time time.

Otherwise the value is held in P1233 (duration of the diret

current braking)

P0305 (nominal motor current)

*

r0207 (nominal inverter current)

P0700 = 2

P0701 = 1

P1210 = 1

P1233 = 0

Control Jumpers

In Table 3-4 the behaviour of the Control Jumpers are explained.

Table 3-4 Control Circuit Jumper Behaviour

Status before action(s) Action(s) Reaction(s) of the inverter

Jumper not fitted Power down

Fit jumper(s)

Power up

Jumper fitted Cycle power Parameters influenced by jumper are not changed

Jumper fitted Power down

Remove jumper

Power up

Jumper not fitted Cycle power Parameters influenced by jumper are not changed

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

48

Parameters influenced by jumper will have jumper default

values

Parameters influenced by jumper will have “jumper

removed“ default values (normally factory default)

6SE6400-5CA00-0BP0

Page 49

Issue 03/01 3 Commissioning

3.3.3 Default setup

To change parameters it is necessary to use a Basic Operator Panel (BOP),

Advanced Operator Panel (AOP) or an external serial interface with DriveMonitor

or STARTER. The inverter is therefore delivered with the following default settings:

Setpoint control from the Analog input in addition to Control Potentiometer.

Supply frequency set for 0 to 50 Hz.

Digital inputs:

DIN 1 ON/OFF1.

DIN 2 Reverse.

DIN 3 Fault Acknowledge

Jumpers for Ramp and Control circuits set to open (default settings). Refer to

sections 3.3.1 and 3.3.2.

Relay – Fault conditions.

3.3.4 Commissioning Overview with BOP or AOP

Prerequisites

Mechanical and electrical Installation is completed.

NOTE

We recommend the commissioning according this scheme.

Setting the motor frequency