Page 1

3EK7 Medium Voltage

Silicone Insulated Surge Arresters

Answers for energy.

Page 2

Setting new Standards

The 3EK7‘s mechanical features:

Glass-collared MOV,

Silicone rubber housing,

FRP rods and

Aluminium end fi ttings.

Three types of 3EK7 surge arresters are available:

3EK7…-. C .. surge arresters according to IEC 60099-4

with metric thread,

3EK7...-. A .. surge arresters according to IEEE Std C 62.11

with imperial thread.

For special applications:

3EK7...-. B .. surge arresters according to IEEE Std C 62.11

with metric thread.

The new 3EK7 surge arrester from Siemens offers superior

protection against power surges for the equipment in

electrical distribution systems with operating voltages

of up to 72.5 kV. Besides being highly resistant to

environmental pollution of all kinds, its performance in

dealing with earth faults and its excellent short-circuit

ratings are setting entirely new standards. The silicone

on the new 3EK7 surge arrester refuses to allow any

deposits of pollution or fi lms of moisture to form on it.

Thus, surface currents caused by pollution will virtually

not occur. The 3EK7 arrester is also very lightweight,

robust and durable, due to its special cage design.

2

Page 3

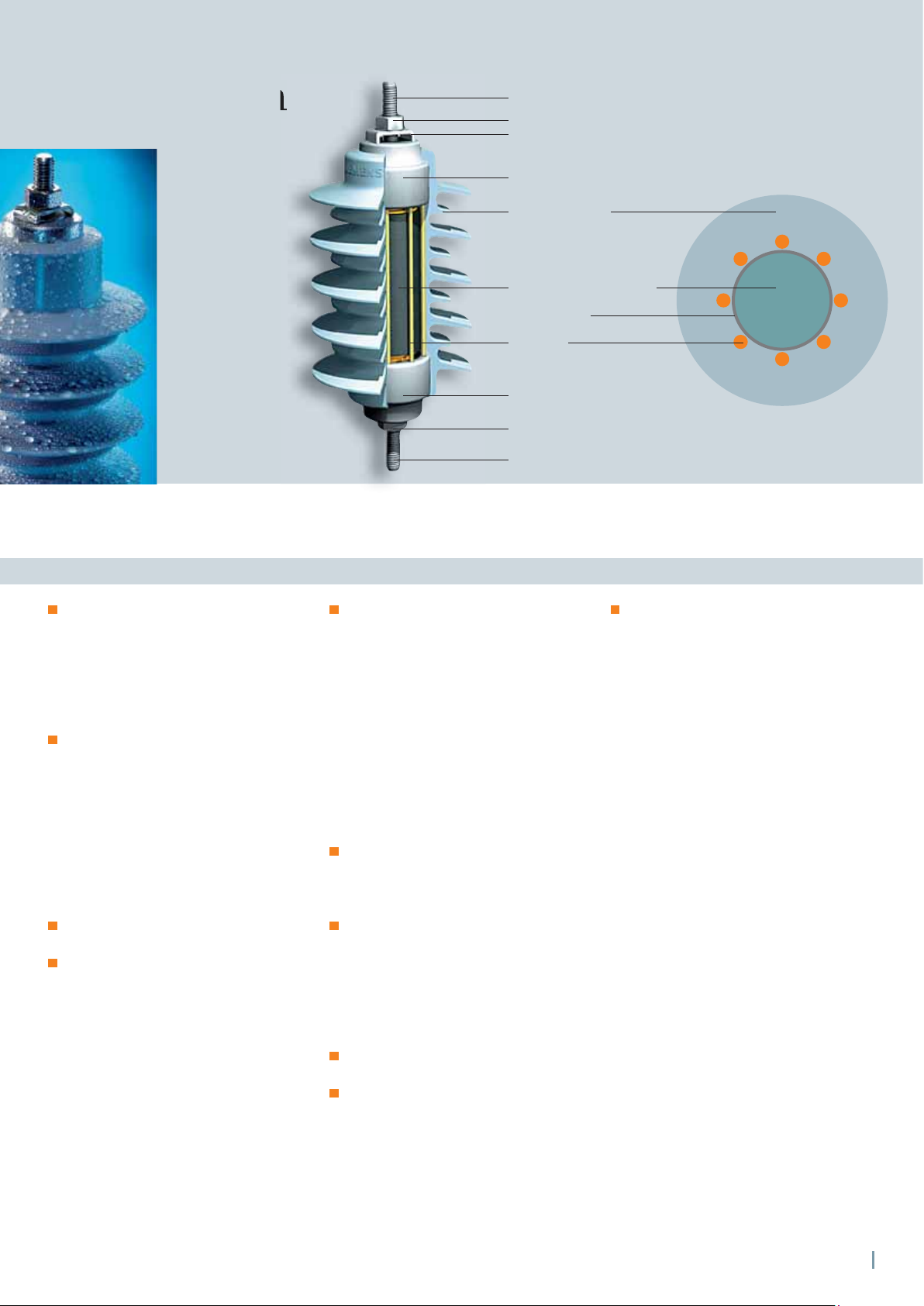

3EK7 Design

3

M12 or

Nut, washer

Clamp

End fi tting

Silicone housing,

directly molded

Metal oxide varistor MOV

Glass coating

FRP rods

End fi tting

Nut, washer

M12 or

8

/

inch stainless steel stud

3

8

/

inch stainless steel stud

3EK7 a top quality product

The silicone rubber (SR) housing is

molded directly onto the MOV blocks

and the protection cage. It provides an

excellent sealing system against

moisture ingress and partial discharges.

In addition, the MOV blocks are

glass-collared to prevent aging.

Highest quality materials. SR is highly

hydrophobic and maintains this ability

to repel water and any deposits of

pollution throughout its entire service

life. This results in high tracking and

erosion resistance. Furthermore, the

SR housing is self-extinguishing and

fl ame-retardant. These advantages

provide maintenance free and reliable

service life for 3EK7 arresters.

Manufacturing plants are certifi ed

under ISO 9001 and ISO 14001.

3EK7 arresters have been type tested

by an independent test laboratory.

Secure and reliable design

The 3EK7 series is based on a cage

of pre-stressed fi ber-reinforced plastic

rods for high mechanical strength,

reducing the risk of internal components

being ejected. In the extremely rare

event of the resistors being overloaded,

arcing cannot result in a build-up of

critical internal pressure, since the

resistors are not enclosed in a sealed

mechanical shell. Thus, the arc can

escape through the silicone sheath,

leaving the mechanical support

structure of the enclosure unharmed.

The cage is lightweight design and yet

it offers excellent torsional, tensile and

cantilever strength: Maximum working

cantilever strength of 350 Nm.

SR is resistant to UV and ozone exposure

as well as to all common organic and

non-organic solvents and cleaning

agents. Therefore, the 3EK7 is suitable

for any environmental conditions of

industrial areas as well as in desert or

coastal regions.

3EK7 arresters are suitable for a

temperature range from –55° C to +50° C.

Application altitude up to

3600 m a.s.l.

Fast delivery

Flexibility in production and in our

global network of service and sales

facilities provide fast and prompt

supply e. g. shipment ex stocks within

six days after your order has been

received for the surge arresters marked

with asterisk (*) (Refer to table on

page 4 and 6).

3

Page 4

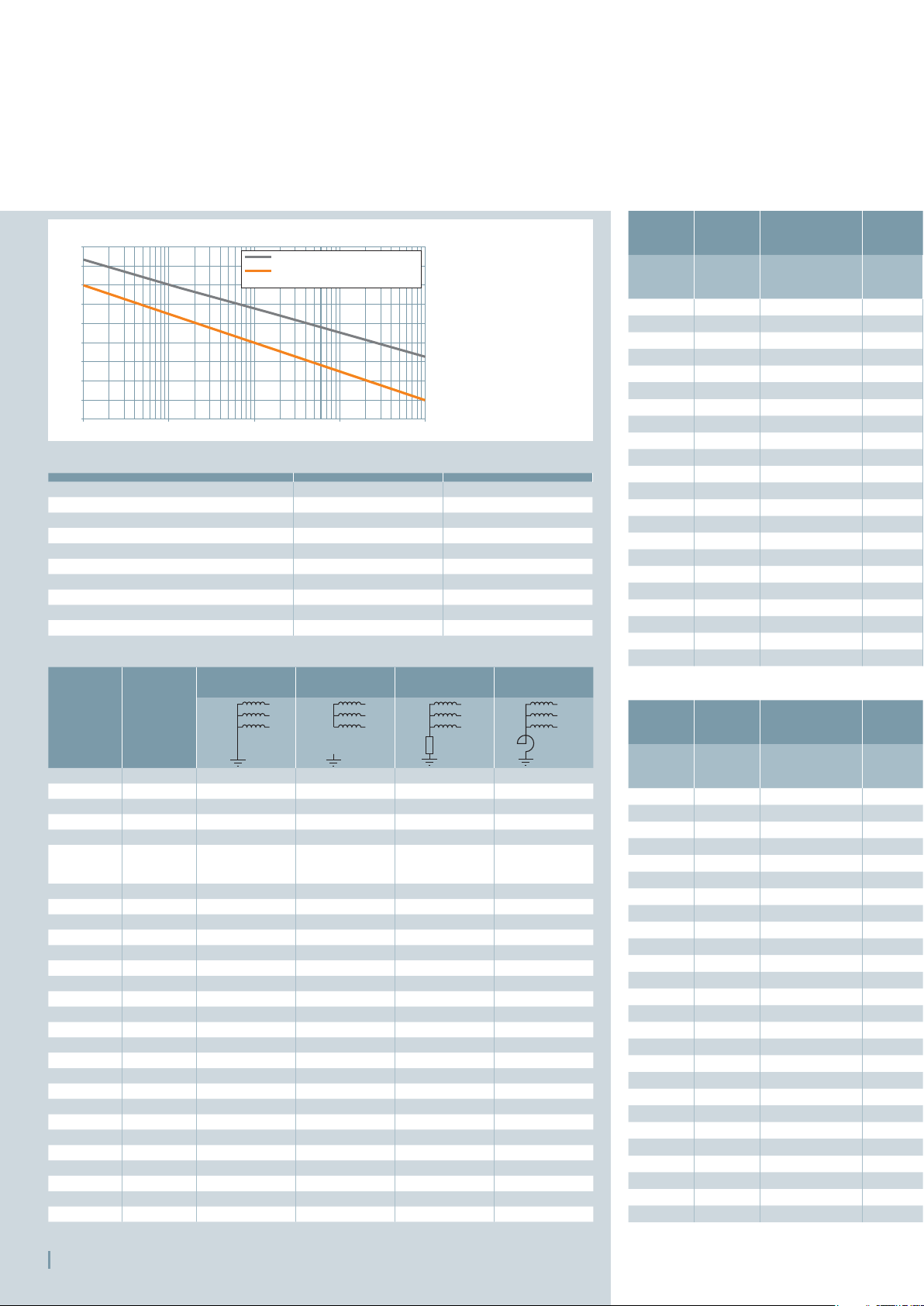

3EK7 Arresters According to IEC 60099-4

Selection and Main Data

Voltage per unit U

1.25

1.2

1.15

1.1

1.05

1

0.95

0.9

0.85

0.8

0.1 1 10 100 1000

r

Preheating to 40° C

Preheating to 60° C and stressing

with rated energy

Time in seconds

Table 1: IEC power-frequency voltage versus time characteristic

Nominal discharge current I

Maximum continous operating voltage U

Rated voltage U

Long duration current impulse 150 A 325 A

High current pressure relief 20 kA 20 kA

Low current pressure relief 600 A 600 A

High-current impulse 65 kA 100 kA

Maximum permisible static service load 280 Nm 350 Nm

Maximum permisible service load (MPSL) 400 Nm 500 Nm

Energy absorption capability 2.2 kJ/kV U

r

n

c

5 kA 10 kA

48 kV 48 kV

60 kV 60 kV

r

3.5 kJ/kV U

Table 2: 3EK7 arrester main data

Highest

voltage

for

equipment

U

m

[kV]

2.75 30; 45; 60 3EK7 030-.C.. 3EK7 050-.C.. 3EK7 030-.C.. 3EK7 050-.C..

3.6 20; 40 3EK7 030-.C.. 3EK7 050-.C.. 3EK7 030-.C.. 3EK7 050-.C..

5.5 45; 60; 75 3EK7 050-.C.. 3EK7 090-.C.. 3EK7 060-.C.. 3EK7 090-.C..

7.2 40; 60 3EK7 060-.C.. 3EK7 090-.C.. 3EK7 090-.C.. 3EK7 090-.C..

8.25 60; 75; 95 3EK7 090-.C.. 3EK7 105-.C.. 3EK7 090-.C.. 3EK7 105-.C..

12 60; 75; 95

15.5 75 3EK7 120-.C.. - 3EK7 150-.C.. -

15.5 85; 110 3EK7 120-.C.. 3EK7 210-.C.. 3EK7 150-.C.. 3EK7 210-.C..

17.5 75 3EK7 150-.C.. - 3EK7 180-.C.. -

17.5 95 3EK7 150-.C.. 3EK7 220-.C.. 3EK7 180-.C.. 3EK7 220-.C..

24 95 3EK7 210-.C.. - 3EK7 240-.C.. -

24 125; 145 3EK7 210-.C.. 3EK7 300-.C.. 3EK7 240-.C.. 3EK7 300-.C..

25 125; 145 3EK7 210-.C.. 3EK7 315-.C.. 3EK7 250-.C.. 3EK7 315-.C..

27 95 3EK7 210-.C.. - - -

27 125 3EK7 210-.C.. - 3EK7 270-.C.. -

27 150 3EK7 210-.C.. 3EK7 360-.C.. 3EK7 270-.C.. 3EK7 360-.C..

30 160 3EK7 240-.C.. 3EK7 390-.C.. 3EK7 300-.C.. 3EK7 390-.C..

36 145 3EK7 300-.C.. - 3EK7 360-.C.. -

36 170 3EK7 300-.C.. 3EK7 450-.C.. 3EK7 360-.C.. 3EK7 450-.C..

38 125 3EK7 300-.C.. - - -

38 150 3EK7 300-.C.. - 3EK7 390-.C.. -

38 200 3EK7 300-.C.. 3EK7 480-.C.. 3EK7 390-.C.. 3EK7 480-.C..

40.5 190 3EK7 315-.C.. 3EK7 510-.C.. 3EK7 420-.C.. 3EK7 510-.C..

48.3 150 3EK7 390-.C.. - - -

48.3 200 3EK7 390-.C.. - 3EK7 480-.C.. -

48.3 250 3EK7 390-.C.. 3EK7 600-.C.. 3EK7 480-.C.. 3EK7 600-.C..

52 250 3EK7 420-.C.. - 3EK7 540-.C.. -

72.5 325 3EK7 570-.C.. - - -

Rated

lightning

impulse

withstand

voltage

[kV]

Solidly earthed

neutral system

3EK7 090-.C..

or

3EK7 105-.C..

Isolated neutral

system

3EK7 150-.C.. 3EK7 120-.C.. 3EK7 150-.C..

Impedance earthed

neutral system

Resonant earthed

neutral system

Table 3: Typical 3EK7 arresters for system voltages according to IEC 60099-4

4

Rated

voltage U

[kV] [kV]

10.5* 8.4 3EK7 105 -2CB4 24.4

12* 9.6 3EK7 120 -2CC4 27.8

15* 12 3EK7 150 -2CC4 34.7

21* 16.8 3EK7 210 -2CD4 48.6

31.5 25.2 3EK7 315 -2CH4 72.9

r

Continuous

operating

r

voltage U

3 2.4 3EK7 030 -2CB4 7.0

6 4.8 3EK7 060 -2CB4 14.0

9* 7.2 3EK7 090 -2CB4 20.9

18 14.4 3EK7 180 -2CD4 41.7

24 19.2 3EK7 240 -2CE4 55.5

27 21.6 3EK7 270 -2CF4 62.6

30 24 3EK7 300 -2CF4 69.3

33 26.4 3EK7 330 -2CH4 76.4

36 28.8 3EK7 360 -2CH4 83.3

39 31.2 3EK7 390 -2CH4 90.5

42 33.6 3EK7 420 -2CH4 97.4

45 36 3EK7 450 -2CH4 104

48 38.5 3EK7 480 -2CK4 111

51 41 3EK7 510 -2CK4 118

54 43.2 3EK7 540 -2CK4 125

57 45.6 3EK7 570 -2CK4 132

60 48 3EK7 600 -2CK4 139

c

Arrester

part number

1 kA

8/20 µs

[kV cr]

Table 4: 3EK7 nominal discharge current 5 kA

Rated

voltage U

[kV] [kV]

10.5* 8.4 3EK7 105 -4CB4 22.8

12* 9.6 3EK7 120 -4CC4 25.9

15* 12 3EK7 150 -4CC4 32.3

18* 14.4 3EK7 180 -4CD4 38.8

21* 16.8 3EK7 210 -4CD4 45.3

22* 17.6 3EK7 220 -4CE4 47.5

24* 19.2 3EK7 240 -4CE4 51.7

30* 24 3EK7 300 -4CF4 64.6

31.5 25.2 3EK7 315 -4CH4 67.9

36* 28.8 3EK7 360 -4CH4 77.6

50.5* 40.5 3EK7 505 -4CK4 107

Continuous

operating

r

voltage U

3 2.4 3EK7 030 -4CB4 6.6

5 4 3EK7 050 -4CB4 10.8

6 4.8 3EK7 060 -4CB4 13.0

9* 7.2 3EK7 090 -4CB4 19.4

25 20 3EK7 250 -4CE4 53.9

27 21.6 3EK7 270 -4CF4 58.2

33 26.4 3EK7 330 -4CH4 71.1

39 31.2 3EK7 390 -4CH4 84.2

42 33.6 3EK7 420 -4CH4 90.7

45 36 3EK7 450 -4CH4 97.2

48 38.5 3EK7 480 -4CK4 104

51 41 3EK7 510 -4CK4 110

54 43.2 3EK7 540 -4CK4 117

57 45.6 3EK7 570 -4CK4 123

60 48 3EK7 600 -4CK4 130

c

Arrester

part number

1 kA

8/20 µs

[kV cr]

Table 5: 3EK7 nominal discharge current 10 kA

Page 5

Lightning

impulse

withstand

voltage

Height

“H”

Net

1)

weight

Packed

weight

Pallet

weight

Qty. per

3 kA

8/20 µs

[kV cr]

Maximum discharge voltage

5 kA

8/20 µs

[kV cr]

10 kA

8/20 µs

[kV cr]

15 kA

8/20 µs

[kV cr]

20 kA

8/20 µs

[kV cr]

125 A

30/60 µs

[kV cr]

Creepage

distance

Flashover

distance

500 A

30/60 µs

[kV cr] [mm] [mm] [kV] [mm] [kg] [kg] [kg] [pcs]

7.7 8.1 8.8 9.6 10.4 6.2 6.6 372 180 104 170 1.5 2.1 488 221

15.3 16.1 17.5 19.0 20.6 12.2 13.2 372 180 104 170 1.5 2.1 488 221

22.8 24.0 26.2 28.3 30.7 18.2 19.7 372 180 104 170 1.6 2.2 510 221

26.7 28.1 30.6 33.2 36.0 21.4 23.0 372 180 104 170 1.6 2.2 510 221

30.4 32.0 34.9 37.8 41.0 24.3 26.2 485 210 122 200 1.8 2.4 494 195

37.9 39.9 43.5 47.1 51.1 30.3 32.7 485 210 122 200 1.9 2.5 514 195

45.5 47.9 52.2 56.5 61.3 36.4 39.3 605 248 144 240 2.2 2.8 506 169

53.1 55.9 60.9 66.0 71.6 42.5 45.8 605 248 144 240 2.3 2.9 523 169

60.6 63.8 69.5 75.3 81.7 48.5 52.3 775 286 166 270 2.6 3.3 535 156

68.3 71.9 78.4 84.8 92.0 54.6 59.0 900 318 184 300 2.9 3.6 491 130

75.7 79.7 86.9 94.0 102 60.6 65.4 900 318 184 300 2.9 3.6 491 130

79.6 83.8 91.3 98.9 107 63.7 68.7 1230 418 242 400 3.7 4.4 545 117

83.4 87.8 95.7 104 112 66.7 72.0 1230 418 242 400 3.7 4.4 545 117

91.0 95.8 104 113 123 72.8 78.6 1230 418 242 400 3.8 4.5 557 117

98.8 104 113 123 133 79.0 85.3 1230 418 242 400 3.8 4.5 557 117

106 112 122 132 143 85.1 91.8 1230 418 242 400 3.9 4.6 569 117

114 120 131 142 154 91.2 98.4 1230 418 242 400 3.9 4.6 569 117

122 128 140 151 164 97.3 105 1595 520 302 510 4.8 5.6 464 78

129 136 148 161 174 103 112 1595 520 302 510 4.8 5.6 464 78

137 144 157 170 184 109 118 1595 520 302 510 4.9 5.7 471 78

144 152 166 179 195 116 125 1595 520 302 510 4.9 5.7 471 78

152 160 174 189 205 122 131 1595 520 302 510 5.0 5.8 479 78

pallet

Lightning

impulse

withstand

voltage

Height

“H”

Net

1)

weight

Packed

weight

Pallet

weight

Qty. per

3 kA

8/20 µs

[kV cr]

Maximum discharge voltage

5 kA

8/20 µs

[kV cr]

10 kA

8/20 µs

[kV cr]

15 kA

8/20 µs

[kV cr]

20 kA

8/20 µs

[kV cr]

125 A

30/60 µs

[kV cr]

Creepage

distance

Flashover

distance

500 A

30/60 µs

[kV cr] [mm] [mm] [kV] [mm] [kg] [kg] [kg] [pcs]

7.1 7.5 8.1 8.7 9.3 5.8 6.2 372 180 104 170 1.5 2.1 488 221

11.7 12.4 13.3 14.4 15.3 9.4 10.1 372 180 104 170 1.6 2.2 510 221

14.2 15.0 16.1 17.4 18.5 11.4 12.2 372 180 104 170 1.6 2.2 510 221

21.1 22.3 24.0 25.9 27.6 17.0 18.2 372 180 104 170 1.7 2.3 532 221

24.7 26.1 28.1 30.3 34.6 20.0 22.7 372 180 104 170 1.7 2.3 532 221

28.2 29.8 32.0 34.6 36.8 22.7 24.3 485 210 122 200 2.0 2.6 533 195

35.1 37.1 39.9 43.1 45.9 28.3 30.3 485 210 122 200 2.1 2.7 553 195

42.2 44.5 47.9 51.7 55.1 34.0 36.4 605 248 144 240 2.4 3.0 540 169

49.2 52.0 55.9 60.4 64.3 39.7 42.5 605 248 144 240 2.5 3.1 557 169

51.6 54.5 58.6 63.3 67.4 41.6 44.5 775 286 166 270 2.8 3.5 566 156

56.1 59.3 63.8 68.9 73.4 45.3 48.5 775 286 166 270 2.8 3.5 566 156

58.5 61.8 66.5 71.8 76.5 47.2 50.5 775 286 166 270 2.9 3.6 581 156

63.3 66.9 71.9 77.7 82.7 51.0 54.6 775 318 184 300 3.2 3.9 530 130

70.1 74.1 79.7 86.1 91.7 56.6 60.6 775 318 184 300 3.2 3.9 530 130

73.7 77.9 83.8 90.5 96.4 59.5 63.7 1230 418 242 400 4.0 4.7 581 117

77.3 81.7 87.8 94.8 101 62.3 66.7 1230 418 242 400 4.1 4.8 592 117

84.3 89.1 95.8 104 110 68.0 72.8 1230 418 242 400 4.1 4.8 592 117

91.5 96.7 104 112 120 73.8 79.0 1230 418 242 400 4.2 4.9 604 117

98.6 104 112 121 129 79.5 85.1 1230 418 242 400 4.3 5.0 616 117

106 112 120 130 138 85.2 91.2 1230 418 242 400 4.4 5.1 627 117

113 119 128 138 147 90.9 97.3 1595 520 302 510 5.2 6.0 495 78

116 123 132 143 152 93.7 100 1595 520 302 510 5.3 6.1 503 78

120 127 136 147 156 96.6 103 1595 520 302 510 5.3 6.1 503 78

127 134 144 156 166 102 109 1595 520 302 510 5.4 6.2 510 78

134 141 152 164 175 108 116 1595 520 302 510 5.5 6.3 518 78

141 149 160 173 184 114 122 1595 520 302 510 5.6 6.4 526 78

1) Refer to fi gure 1 on page 8 (*) Available ex stock

pallet

5

Page 6

3EK7 Arresters According to IEEE Std C 62.11

Selection and Main Data

Voltage per unit MCOV

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1

0.01 0.1 1 10 100 1000 10000

3EK7 heavy duty

3EK7 riser pole

Time in seconds

Table 6: ANSI temporary overvoltage, preheating 60˚ C, no prior duty

Normal duty Heavy duty Riser pole

Maximum continous operating voltage MCOV 29 kV 29 kV 29 kV

Duty cycle voltage 36 kV 36 kV 36 kV

Low-current, long-duration 75 A 250 A 250 A

High current pressure relief 20 kA 20 kA 20 kA

Low current pressure relief 600 A 600 A 600 A

High-current, short-duration 65 kA 100 kA 100 kA

Coordinating current 5 kA 10 kA 10 kA

Maximum design cantilever load-static (MDCL) 280 Nm 280 Nm 280 Nm

Energy absorption capability 2.7 kJ/kV MCOV 4.6 kJ/kV MCOV 4.6 kJ/kV MCOV

Table 7: 3EK7 distribution arrester main data

System L-L Voltage

[kV]

2.4 3EK7 030-.A..

4.16 3EK7

4.26 3EK7

4.8 3EK7

6.9 3EK7

8.3 3EK7

12 3EK7

12.47

13.2 3EK7

13.8

20.78 3EK7 150-.A.. 3EK7 210-.A..

22.86 3EK7

23 3EK7

24.94 3EK7

27.6 3EK7

34.5 3EK7

Four-wire

multigrounded

neutral wye

030-.A.. 3EK7 060-.A.. 3EK7 060-.A..

060-.A.. 3EK7 090-.A..

090-.A.. 3EK7 120-.A..

3EK7

090-.A..

or

100-.A..

3EK7

100-.A.. 3EK7 150-.A..

100-.A..

3EK7

or

3EK7 120-.A..

150-.A.. 3EK7 210-.A..

180-.A.. 3EK7 270-.A..

210-.A.. 3EK7 300-.A..

270-.A.. 3EK7 360-.A..

Three-wire

low impedance

grounded neutral circuit

3EK7

150-.A..

3EK7

150-.A.. 3EK7 180-.A..

Three-wire

high impedance

grounded neutral circuit

Table 8: Typical 3EK7 arresters for system voltages

according to the latest IEEE Std C 62.11

6

060-.A..

060-.A..

090-.A..

300-.A..

Duty

MCOV

cycle

[kV] [kV]

3 2.55 3EK7 030 -2AB4 10.0 8.2

6 5.1 3EK7 060 -2AB4 20.0 16.3

9* 7.65 3EK7 090 -2AB4 30.0 24.5

10* 8.4 3EK7 100 -2AB4 33.3 27.2

12 10.2 3EK7 120 -2AC4 38.8 31.7

15 12.7 3EK7 150 -2AC4 48.4 39.6

18* 15.3 3EK7 180 -2AD4 57.2 46.8

21 17 3EK7 210 -2AD4 66.8 54.6

24 19.5 3EK7 240 -2AE4 73.9 60.4

27* 22 3EK7 270 -2AF4 83.1 68.0

30 24.4 3EK7 300 -2AF4 92.3 75.6

33 27.5 3EK7 330 -2AH4 102 83.1

36 29 3EK7 360 -2AH4 111 90.7

Arrester part

number

FOW

[kV cr]

Table 9: 3EK7 normal duty

Duty

MCOV

cycle

[kV] [kV]

3* 2.55 3EK7 030 -3AB4 10.5 8.0

6* 5.1 3EK7 060 -3AB4 21.6 16.5

9* 7.65 3EK7 090 -3AB4 30.9 23.6

10* 8.4 3EK7100 -3AB4 32.3 24.7

12 10.2 3EK7120 -3AC4 41.0 31.3

15* 12.7 3EK7 150 -3AD4 51.3 39.1

18* 15.3 3EK7 180 -3AD4 61.5 47.0

21* 17 3EK7 210 -3AE4 67.3 51.4

24 19.5 3EK7 240 -3AF4 77.6 59.2

27* 22 3EK7 270 -3AF4 87.7 66.9

30* 24.4 3EK7 300 -3AH4 96.6 73.8

33 27.5 3EK7 330 -3AH4 108 82.7

36 29 3EK7 360 -3AH4 119 90.6

Arrester part

number

FOW

[kV cr]

Table 10: 3EK7 heavy duty

Duty

MCOV

cycle

[kV] [kV]

3 2.55

6 5.1

9* 7.65

10* 8.4

12 10.2

15 12.7

18* 15.3 3EK7 180 -4AE4 52.7 40.2

21 17

24 19.5

27* 22

30 24.4

33 27.5

36 29

Arrester part

number

3EK7 030 -4AB4

3EK7 060 -4AB4

3EK7 090 -4AB4

3EK7 100 -4AC4

3EK7 120 -4AD4

3EK7 150 -4AD4

3EK7 210 -4AF4

3EK7 240 -4AH4

3EK7 270 -4AH4

3EK7 300 -4AH4

3EK7 330 -4AK4

3EK7 360 -4AK4

FOW

[kV cr]

8.9 6.8

17.7 13.5

26.4 20.2

29.3 22.3

35.2 26.9

43.9 33.5

61.5 47.0

70.2 53.6

79.1 60.4

87.7 66.9

96.6 73.8

105 80.5

Table 11: 3EK7 riser pole

1.5 kA

8/20 µs

[kV cr]

1.5 kA

8/20 µs

[kV cr]

1.5 kA

8/20 µs

[kV cr]

Page 7

3 kA

8/20 µs

[kV cr]

Maximum discharge voltage

5 kA

8/20 µs

[kV cr]

10 kA

8/20 µs

[kV cr]

20 kA

8/20 µs

[kV cr]

40 kA

8/20 µs

[kV cr]

125 A

45/90 µs

[kV cr]

Creepage

distance

Flashover

distance

Lightning

impulse

withstand

voltage

500 A

45/90 µs

[kV cr] [mm] [mm] [kV] [mm] [kg] [kg] [kg] [pcs]

Height

“H”

Net

1)

weight

Packed

weight

Pallet

weight

Qty. per

8.6 9.1 9.9 11.6 14.0 6.9 7.4 372 180 104 170 1.4 1.6 393 240

17.3 18.2 19.8 23.3 28.0 13.8 14.9 372 180 104 170 1.4 1.6 406 240

25.9 27.2 29.7 34.9 42.0 20.7 22.3 372 180 104 170 1.5 1.7 419 240

28.8 30.3 33.0 38.8 46.6 23.0 24.8 372 180 104 170 1.6 1.7 426 240

33.5 35.2 38.4 45.1 54.3 26.8 28.9 485 210 122 200 1.8 2.0 375 180

41.8 44.0 48.0 56.4 67.8 33.5 36.1 485 210 122 200 1.8 2.1 385 180

49.4 52.0 56.7 66.6 80.1 39.5 42.7 605 248 144 240 2.2 2.4 444 180

57.7 60.7 66.2 77.7 93.5 46.1 49.8 605 248 144 240 2.2 2.4 454 180

63.8 67.2 73.2 86.0 103 51.0 55.1 775 286 166 270 2.5 2.7 510 180

71.8 75.6 82.4 96.7 116 57.4 62.0 900 318 184 300 2.8 3.1 383 120

79.7 83.9 91.5 107 129 63.8 68.8 900 318 184 300 2.9 3.1 390 120

87.7 92.3 101 118 142 70.2 75.7 1230 418 242 400 3.7 3.9 483 120

95.7 101 110 129 155 76.6 82.6 1230 418 242 400 3.7 3.9 489 120

pallet

Lightning

impulse

withstand

voltage

Height

“H”

Net

1)

weight

Packed

weight

Pallet

weight

Qty. per

3 kA

8/20 µs

[kV cr]

Maximum discharge voltage

5 kA

8/20 µs

[kV cr]

10 kA

8/20 µs

[kV cr]

20 kA

8/20 µs

[kV cr]

40 kA

8/20 µs

[kV cr]

125 A

45/90 µs

[kV cr]

Creepage

distance

Flashover

distance

500 A

45/90 µs

[kV cr] [mm] [mm] [kV] [mm] [kg] [kg] [kg] [pcs]

8.4 8.8 9.5 10.9 12.6 6.7 7.2 372 180 104 170 1.5 1.7 412 240

17.2 18.2 19.6 22.5 26.1 13.9 14.9 372 180 104 170 1.6 1.7 433 240

24.7 26.1 28.1 32.3 37.4 20.0 21.4 372 180 104 170 1.7 1.8 451 240

25.9 27.3 29.4 33.8 39.1 20.9 22.3 372 180 104 170 1.7 1.9 462 240

32.8 34.7 37.3 42.9 49.6 26.5 28.3 485 210 122 200 2.0 2.2 408 180

41.0 43.3 46.6 53.6 62.0 33.1 35.4 605 248 144 240 2.4 2.5 472 180

49.2 52.0 55.9 64.3 74.3 39.7 42.5 605 248 144 240 2.5 2.7 497 180

53.9 56.9 61.2 70.4 81.4 43.5 46.5 775 286 166 270 2.8 3.0 559 180

62.0 65.6 70.5 81.1 93.8 50.1 53.6 900 318 184 300 3.1 3.3 417 120

70.1 74.1 79.7 91.7 106 56.6 60.6 900 318 184 300 3.2 3.5 433 120

77.3 81.7 87.8 101 117 62.3 66.7 1230 418 242 400 4.0 4.2 523 120

86.6 91.5 98.4 113 131 69.9 74.8 1230 418 242 400 4.1 4.3 536 120

94.9 100 108 124 143 76.5 81.9 1230 418 242 400 4.2 4.5 556 120

Lightning

impulse

withstand

voltage

Height

“H”

Net

1)

weight

Packed

weight

Pallet

weight

Qty. per

3 kA

8/20 µs

[kV cr]

Maximum discharge voltage

5 kA

8/20 µs

[kV cr]

10 kA

8/20 µs

[kV cr]

8/20 µs

[kV cr]

20 kA

40 kA

8/20 µs

[kV cr]

125 A

45/90 µs

[kV cr]

Creepage

distance

Flashover

distance

500 A

45/90 µs

[kV cr] [mm] [mm] [kV] [mm] [kg] [kg] [kg] [pcs]

7.1 7.5 8.1 9.3 10.8 5.8 6.2 372 180 104 170 1.4 1.7 415 240

14.2 15.0 16.1 18.5 21.4 11.4 12.2 372 180 104 170 1.5 1.8 437 240

21.1 22.3 24.0 27.6 31.9 17.0 18.2 372 180 104 170 1.6 1.8 447 240

23.4 24.7 26.6 30.6 35.4 18.9 20.2 485 210 122 200 1.7 1.8 458 240

28.2 29.8 32.0 36.8 42.6 22.7 24.3 605 248 144 240 1.9 2.1 524 240

35.1 37.1 39.9 45.9 53.1 28.3 30.3 605 248 144 240 2.3 2.5 611 240

42.2 44.5 47.9 55.1 63.7 34.0 36.4 775 286 166 270 2.4 2.7 494 180

49.2 52.0 55.9 64.3 74.3 39.7 42.5 900 318 184 300 2.8 3.0 551 180

56.1 59.3 63.8 73.4 84.9 45.3 48.5 1230 418 242 400 3.0 3.3 413 120

63.3 66.9 71.9 82.7 95.6 51.0 54.6 1230 418 242 400 3.2 3.5 430 120

70.1 74.1 79.7 91.7 106 56.6 60.6 1230 418 242 400 4.0 4.2 522 120

77.3 81.7 87.8 101 117 62.3 66.7 1595 520 302 510 4.2 4.4 544 120

84.3 89.1 95.8 110 127 68.0 72.8 1595 520 302 510 4.3 4.5 555 120

1) Refer to fi gure 1 on page 8; (*) Available ex stock

pallet

pallet

7

Page 8

Drawings and Accessories

23.5

64

∅ 12.5

∅ 45

Figure 2: NEMA insulating bracket for Ur ≤ 21 kV

H*

Order code P12; 0.25 kg

26

52.5

39.5

50.5

171

125 20

∅ 14

38

41

3314

75

M12

or 3/8”

∅ 119

36

Figure 1: 3EK7 surge arrester main dimensions

* please see tables on page 5 or 7

214

173

12

23.5

64

∅ 12.5

52.5

26

256

210 20

Figure 3: NEMA insulating bracket for Ur > 21 kV

Order code P12; 0.4 kg

299

258

39.5

∅ 14

12

41

3314

75

24

Figure 4: DIN insulating bracket for U

Order code P22; 0.85 kg

8

14.5

15

≤ 21 kV

r

26

17

60

24

Figure 5: DIN insulating bracket for Ur > 21 kV

Order code P22; 1 kg

14.5

15

26

17

60

Page 9

14.5

12

∅ 13

16

75

20

Figure 6: L-bracket

Order code M12; 0.1 kg

∅ 13

40

450

33

∅ 13

13

∅ 13

8

263060

197

∅ 14

30

152

15

Figure 7: DIN metal bracket (stainless), Order code P23; 0.6 kg and

DIN metal bracket (hot dip galvanised), Order code P21; 0.6 kg

∅ 14 or 10.2 ∅ 14

50

25

152

202

Figure 8: Insulated ground lead/Insulated line lead

Order code P51/M51; 0.09 kg, 16 mm

221 (8.7”)

145

41 64

57

14.3

434320

2

14

20

18

25

40

Figure 10: Transformer bracket 8.7”

Order code Q11; 0.6 kg

78

Figure 9: NEMA metal bracket (hot dip galvanized)

Order code P11; 0.6 kg

280 (11”)

178

41 64

57

14.3

434320

14

20

Figure 11: Transformer bracket 11”

Order code Q12; 0.7 kg

18

78

25

40

9

Page 10

Drawings and Accessories

310 (12.25”)

178

14

41 63

57

14.3

434320

Figure 12: Transformer bracket 12.25”

Order code Q13; 0.8 kg

73

0…120

220

198

10.5…150

66

71

18

25

40

15.2

78

18

∅ 18

368 (14.5”)

327

46

86 64 86

69

14.3

55 40 40 55

19

54

Figure 13: Transformer bracket 14.5”

Order code Q14; 0.8 kg

∅ 254

∅ 200

3 x 120°

14

18

35

76

14

40

142

227

Figure 14: NEMA X-arm bracket

Order code Q51; 1.3 kg

Figure 16: Line clamp

Order code M11; 0.1 kg

10

cable ∅ 8…∅ 14

cable ∅ 14…∅ 18

253.5

Figure 15: Mounting plate, 37 mm height

Order code Q81; 1.6 kg

∅ 15

57

24.5

∅ 75

Figure 17: Bird protection cap

Order code M81; 50 g

Page 11

45

∅ 12.5

24

4

Figure 18: Stainless steel cap

Order code M71; 5 g

Figure 19: Disconnector

Order code P31; 0.1 kg

Outline drawings for common design options are shown

in fi gure 20, 21 and 22

M12 or 3/8”

Figure 20: 3EK7 surge arrester with

accessories P12 and P31

Figure 21: 3EK7 surge arrester with

accessories P12, P31 and Q51

Figure 22: 3EK7 surge arrester

with accessories P12, P31, P52 and Q11

11

Page 12

Example

Part number

Internal use

Rated voltage in kV x 10

–

Classification

Nominal discharge current In = 5 kA or distribution class, normal duty 2

Distribution class, heavy duty 3

Nominal discharge current In = 10 kA or riser pole 4

Standard

IEEE Std C 62.11 with imperial-thread terminals A

IEEE Std C 62.11 with metric-thread terminals B

IEC - 60099-4 with metric-thread terminals C

Housing size

170 mm B

200 mm C

240 mm D

270 mm E

300 mm F

400 mm H

510 mm K

Internal use 4

3 E K 7 300 – 4 C F 4

3EK7

300

–

Standard equipped at

high voltage terminal M12 or 3/8 inch stud

with clamp, washer and nut

earthing terminal M12 or 3/8 inch stud

with washer and nut

Example

Part number with mounting accessories

For additional parts only*

High-voltage terminal equipped with

Line clamp, washer, nut M11

L-bracket, washer, nut M12

Line lead, insulated, 450 mm/18 inch, 16 mm

Stainless steel cap M71

Bird-protection cap

Earth terminal equipped with

NEMA metal bracket (hot dip galvanized steel) P11

NEMA insulating bracket

DIN metal bracket (hot dip galvanized steel) P21

DIN insulating bracket P22

DIN metal bracket (stainless steel) P23

Disconnector

Ground lead, insulated, 450 mm/18 inch, 16 mm

Mounting auxiliaries

Transformer bracket 8.7 inch Q11

Transformer bracket 11 inch Q12

Transformer bracket 12.25 inch Q13

Transformer bracket 14.5 inch Q14

X-arm bracket Q51

Mounting plate for 200 mm and 10 inch bolt circle

*Other additional parts on request

Not all combinations are possible

2

2

3 E K 7 300 – 4 C F 4 –

Z M51 M81 P12 P31

Z

M51

M81

P12

P31

P51

Q81

Published by

and copyright © 2008:

Siemens AG

Please contact us at:

Phone: +49 (30) 3 86-33 222

E-mail: arrester@siemens.de

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Power Transmission Division

High Voltage Products

Nonnendammallee 104

13623 Berlin, Germany

www.siemens.com/arrester-download

www.siemens.com/energy

Power Transmission Division

Order No. E50001-G630-A110-X-4A00

Printed in Germany

Dispo 30000

TH 263-081130 470044 PA 11080.5

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its

affi liates, or their respective owners.

Subject to change without prior notice.

The information in this document

contains general descriptions of the

technical options available, which

may not apply in all cases. The required

technical options should therefore

be specifi ed in the contract.

Loading...

Loading...