Page 1

© Siemens AG 2006. All rights reserved.

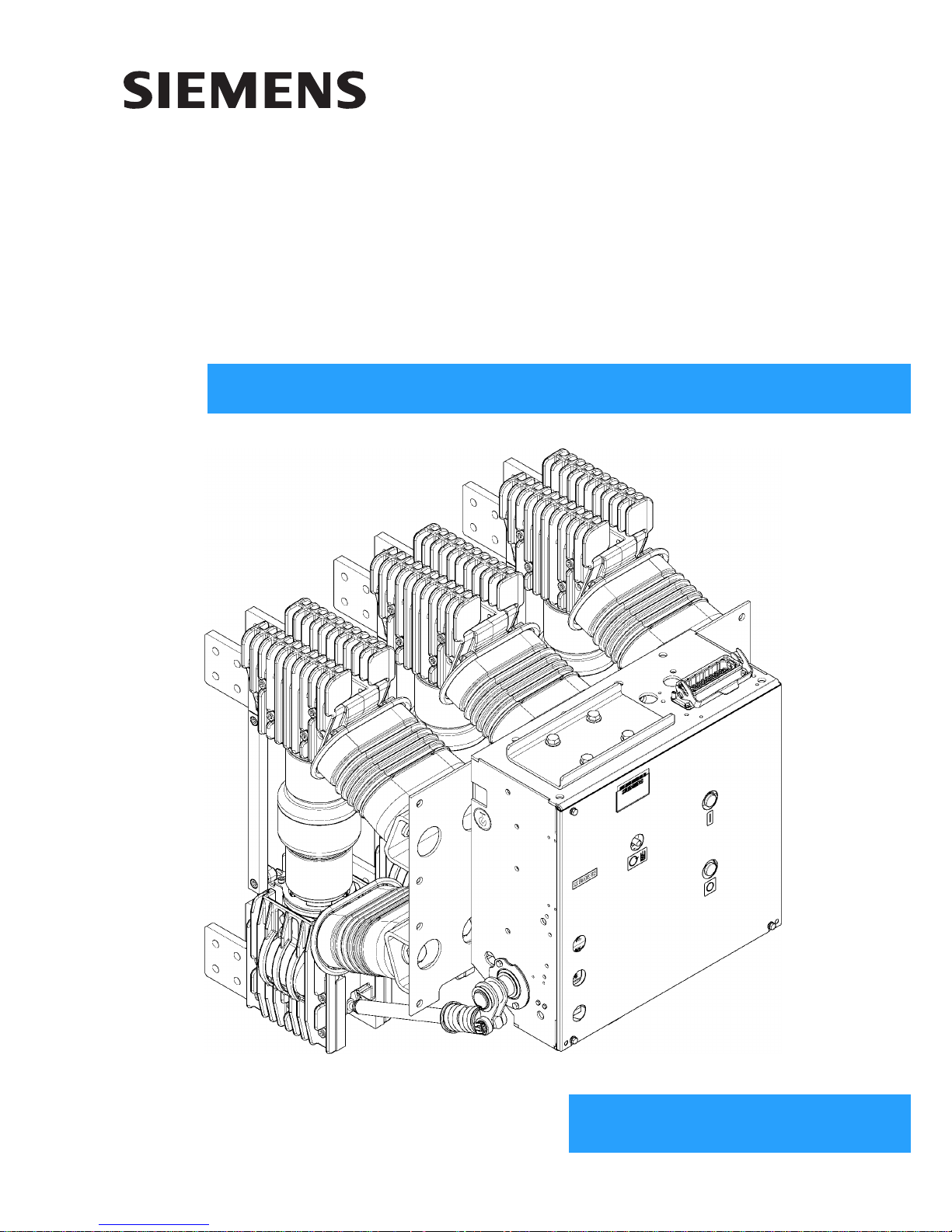

3AH37/38

Vacuum circuit-breaker

12 kV 90 kA as per IEC 62271-100

17.5 kV 50/63/72/80 kA as per IEEE C37.013

24 kV 50/63/72 kA as per IEEE C37.013

OPERATING INSTRUCTIONS

Order no.: 9229 9992 176 0D

Ordering location: IC LMV LP PO P C41

AG 07.2013 en

Page 2

2 9229 9992 176 0D

2013-07-08

For your safety

Signal terms and

definitions

Hazards are classified in accordance with ISO 3864-2 using the following keywords:

• DANGER, WARNING or CAUTION, where there is a risk of personal injury

• NOTE, where there is a risk of material damage.

Hazards are classified and indicated in the operating instructions and on the vacuum

circuit-breaker as follows:

Qualified personnel are, for the purposes of this manual or the warning notices on the vacuum circuit-

breaker, persons who are familiar with the transport, storage, placement, assembly,

commissioning, operation and maintenance of the product and have the

qualifications corresponding to their activity, i. e:

• training and authorization to energize, de-energize, clear, ground and tag

circuits and equipment in accordance with established safety practices.

• training in the proper care and use of protective equipment in accordance with

established safety practices;

• training in providing first aid.

Product liability

DANGER

signal word used to indicate an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING

signal word used to indicate a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION

signal word used to indicate a potentially hazardous situation which,

if not avoided, could result in minor or moderate injury.

Note

indicates a potentially damaging situation.

If the damaging situation is not avoided, the product or something in its vicinity

may sustain damage.

Note

Product liability claims are upheld only if the replacement of the purchased spare

parts is performed by personnel that has been trained and certified by Siemens.

Page 3

9229 9992 176 0D 3

2013-07-08

Table of contents

For your safety ................................................................................................................................................... 2

Transport, storage and packing .................................................................................................................. 5

Transport ............................................................................................................................................................. 5

Unpacking (I) ....................................................................................................................................................... 6

Unpacking (II) .................................................................................................................................................... 11

Unpacking (III) ................................................................................................................................................... 13

Reusing the transport unit ................................................................................................................................. 16

Storage ............................................................................................................................................................. 16

General information ....................................................................................................................................... 17

Range of application ......................................................................................................................................... 17

Standards .......................................................................................................................................................... 18

Design approval as per X-Ray Ordinance ........................................................................................................ 18

Scope of delivery .............................................................................................................................................. 18

Description ........................................................................................................................................................ 19

Design ............................................................................................................................................................... 19

Interlocking devices .......................................................................................................................................... 32

Rating plate ....................................................................................................................................................... 34

Technical data ................................................................................................................................................... 34

Ambient conditions ............................................................................................................................................ 36

Installation altitudes .......................................................................................................................................... 36

Switching times ................................................................................................................................................. 37

Circuit diagrams ................................................................................................................................................ 38

Installation ......................................................................................................................................................... 43

Attachment in the switching cubicle .................................................................................................................. 43

Earthing ............................................................................................................................................................. 46

Electrical connection of the prime conductor .................................................................................................... 47

Operation ............................................................................................................................................................ 51

Commissioning ................................................................................................................................................. 51

First closing operation ....................................................................................................................................... 52

Closing .............................................................................................................................................................. 53

Opening ............................................................................................................................................................ 53

Maintenance ...................................................................................................................................................... 55

Maintenance and servicing ............................................................................................................................... 55

Interrupter service life ....................................................................................................................................... 58

Accessories and spare parts ............................................................................................................................. 58

Manufacturer's product liability .......................................................................................................................... 59

Disposal ............................................................................................................................................................ 59

Service .............................................................................................................................................................. 59

Index of keywords .......................................................................................................................................... 61

Legend for all pages ...................................................................................................................................... 63

Note

Sections with Addendum (I), (II) or (III)

Sections with Addendum (I) refer to vacuum circuit-breakers with a rated operating current of < 5000 A. Sections

with Addendum (II) refer to vacuum circuit-breakers packed with brackets with vertical connecting bars and a rated

operating current of ≤ 4000 A. Sections with Addendum (III) refer to vacuum circuit-breakers with a rated operating

current of 5000 A.

If no addendum is given, the information is applicable for all 3AH37/38 vacuum circuit-breakers.

Page 4

4 9229 9992 176 0D

2013-07-08

Blank page

Page 5

Transport, storage and packing

9229 9992 176 0D 5

2013-07-08

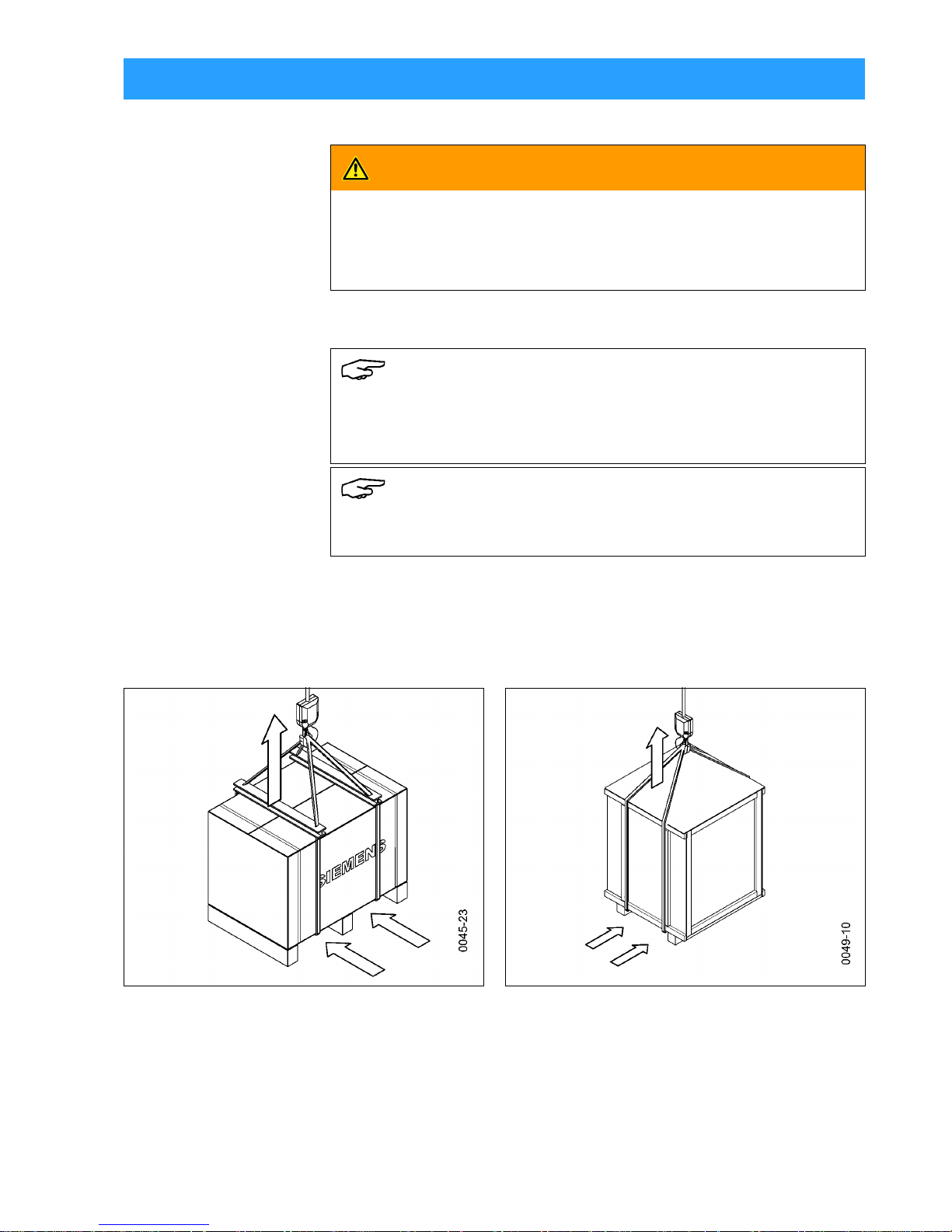

Transport, storage and packing

Transport

Transport weight Refer to the delivery slip for the weight of the transport unit.

Place the transport unit on a level, non-slip and pressure-resistant surface for

intermediate storage.

Transport vacuum circuit-breaker in the original transport unit up until the installation

site or storage location.

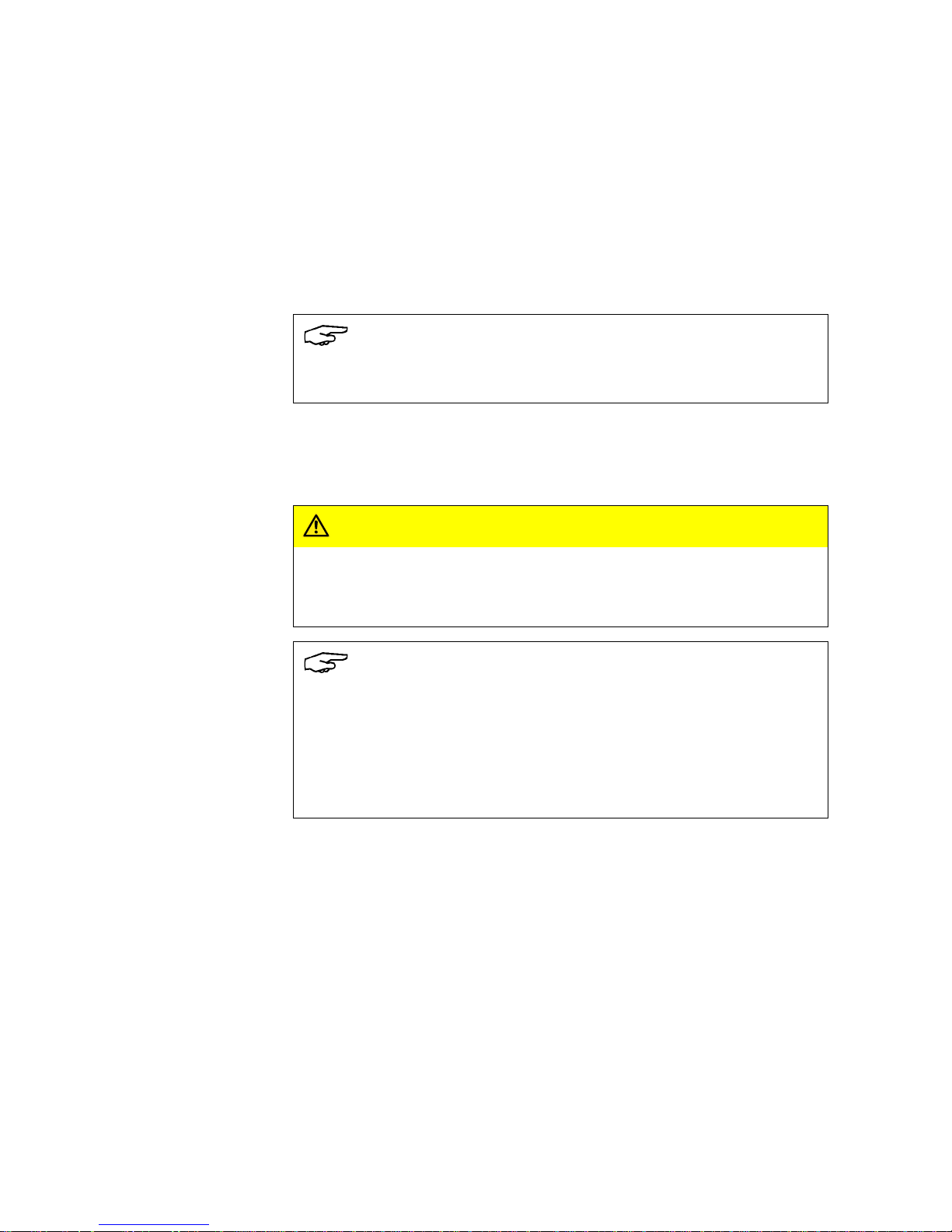

Transporting with crane or fork lift

WARNING

Heavy transport weight

Transport unit may fall and fail and sling gear may break.

Use lifting gear, transporting and sling gear suited to the requirements and loadcarrying capacity. Observe transport symbols.

Note

Observe stacking heightFor transport, not more than three constructionally

identical transport units must be piled on top of each other.

Observe loads specified on the transport unit.

Note

Secure loadFor transport, secure the load in such a way that the transport unit

is not at risk.

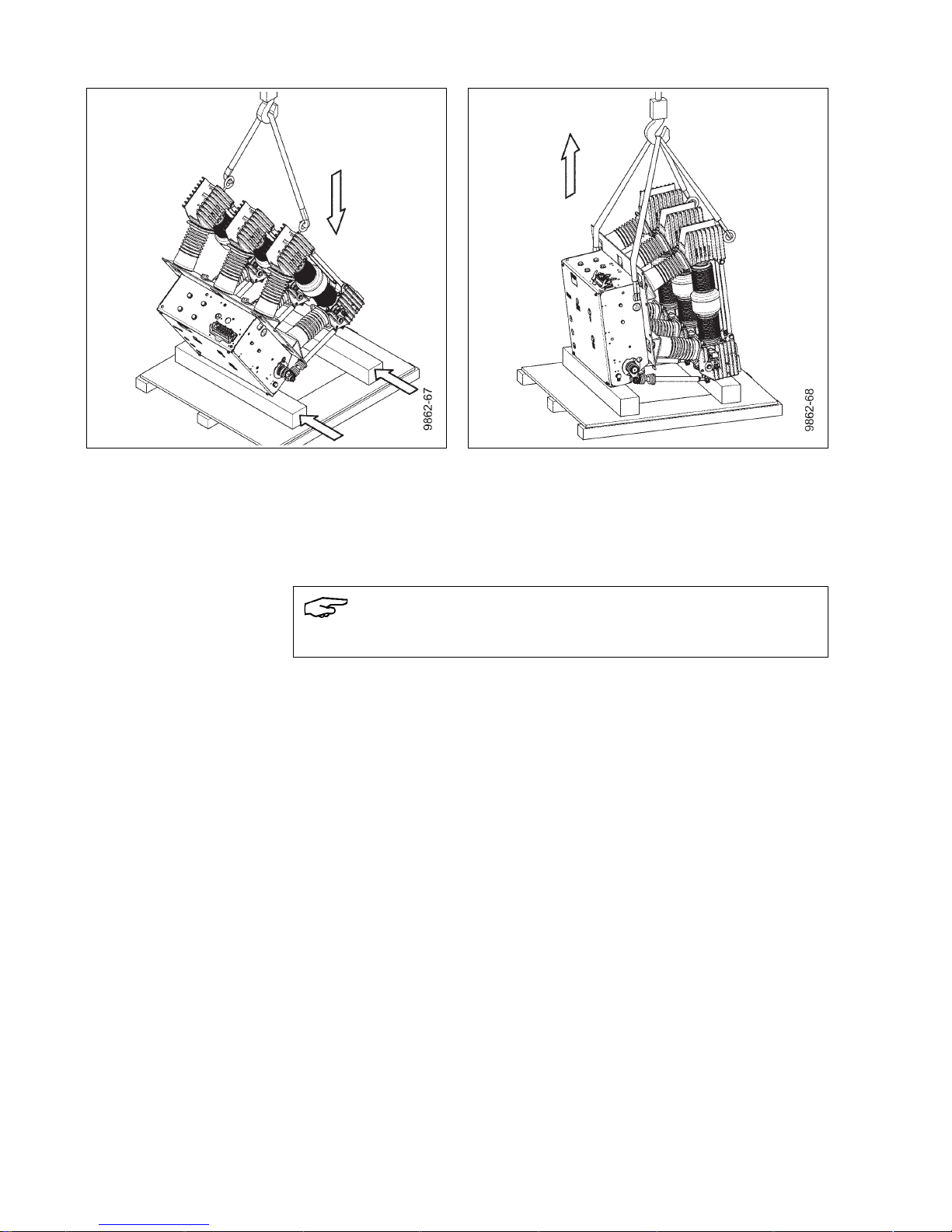

Fig. 1 Transporting the pallet with carton (I) Fig. 2 Transporting the wooden case (III)

Page 6

Transport, storage and packing

6 9229 9992 176 0D

2013-07-08

Transporting with packing Transport the transport unit to the installation site or storage location

• with a fork lift or

• with sling gear suspended from a crane

- at an angle of twist of approx. 60° or

- with a spreader bar.

After receipt of delivery:

Checking

the transport unit

• Check transport unit for damage;

• Major damage must be documented photographically.

• Ensure that any damage to the transport unit is confirmed by the transport

company.

Unpacking (I)

Working equipment Required tools:

- Knife/scissors

- Lifting equipment with lifting gear

- Pliers or lever

Note

Some of the images in this section show a different circuit-breaker type. These

images are exemplary and also apply to the vacuum circuit-breaker 3AH37/38.

CAUTION

Risk of injury from sharp edges!

Fasteners may break, leaving sharp edges.

Always use a suitable tool to lever out fasteners.

Note

Do not cut open or damage the carton, since it is designed to be reused and

because of the belt straps located underneath.

Belt straps could be severed on the pallet floor when cutting open the carton.

The vacuum circuit-breaker is attached to the pallet with belt straps. It is not

permissible to transport the vacuum circuit-breaker on the pallet without using

belt straps (see Fig. 5).

Page 7

Transport, storage and packing

9229 9992 176 0D 7

2013-07-08

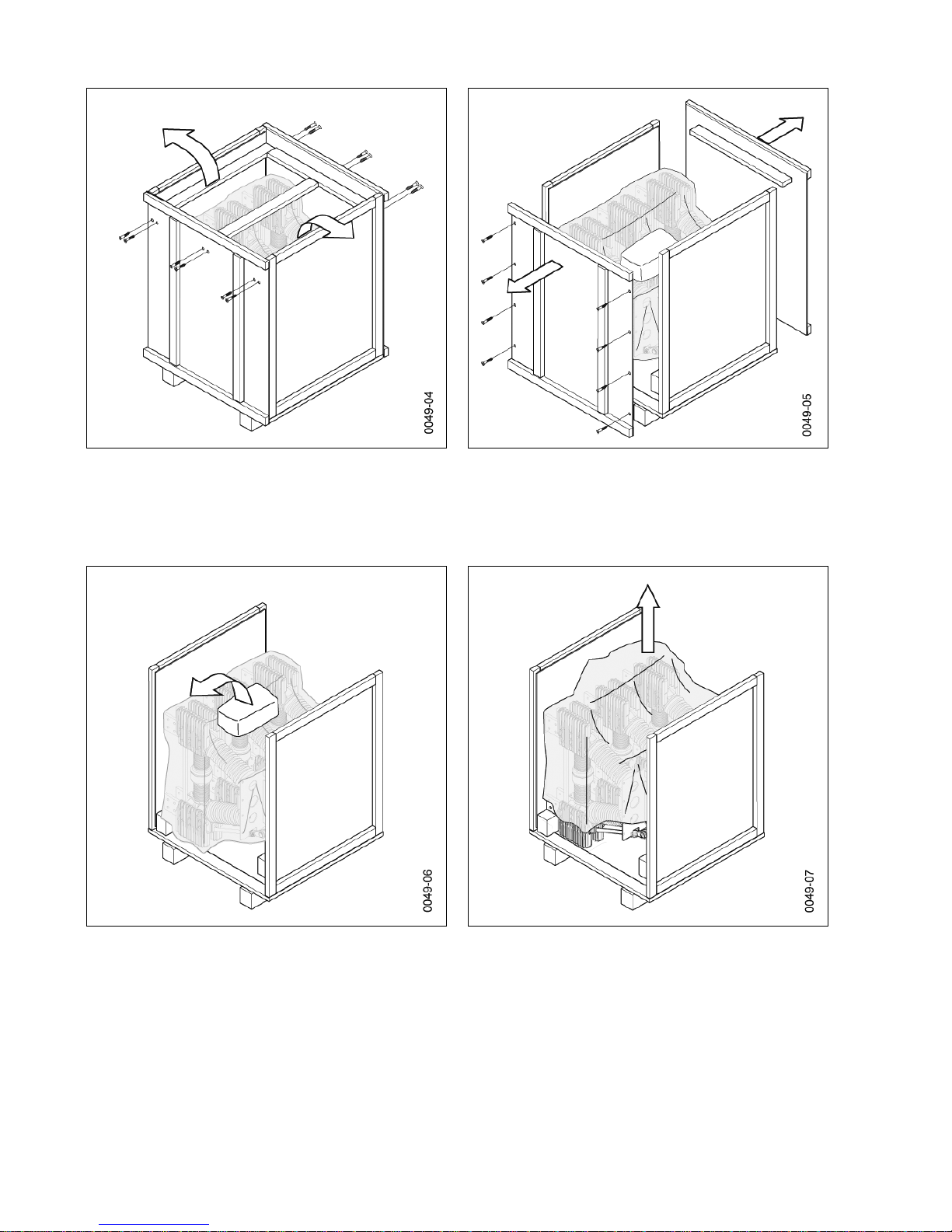

Opening the transport unit • Place the transport unit on a level, non-slip and pressure-resistant surface.

• Remove lifting gear or transport means.

• Remove plastic wrap.

• Lever out fasteners from the carton and lift off carton.

Fig. 3 Removing the carton

Note

Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks,

flakings, bent metal parts, damaged plug-in contacts, tears or bare cables.

Send it back in its original transport unit (see “Reusing the transport unit”,

page 16).

Note

Carrying straps may scrape along the vacuum circuit-breaker and damage it.

If necessary, cover carrying straps with edge protection.

Select length and position of the carrying straps so that the pole heads are not

compressed.

Page 8

Transport, storage and packing

8 9229 9992 176 0D

2013-07-08

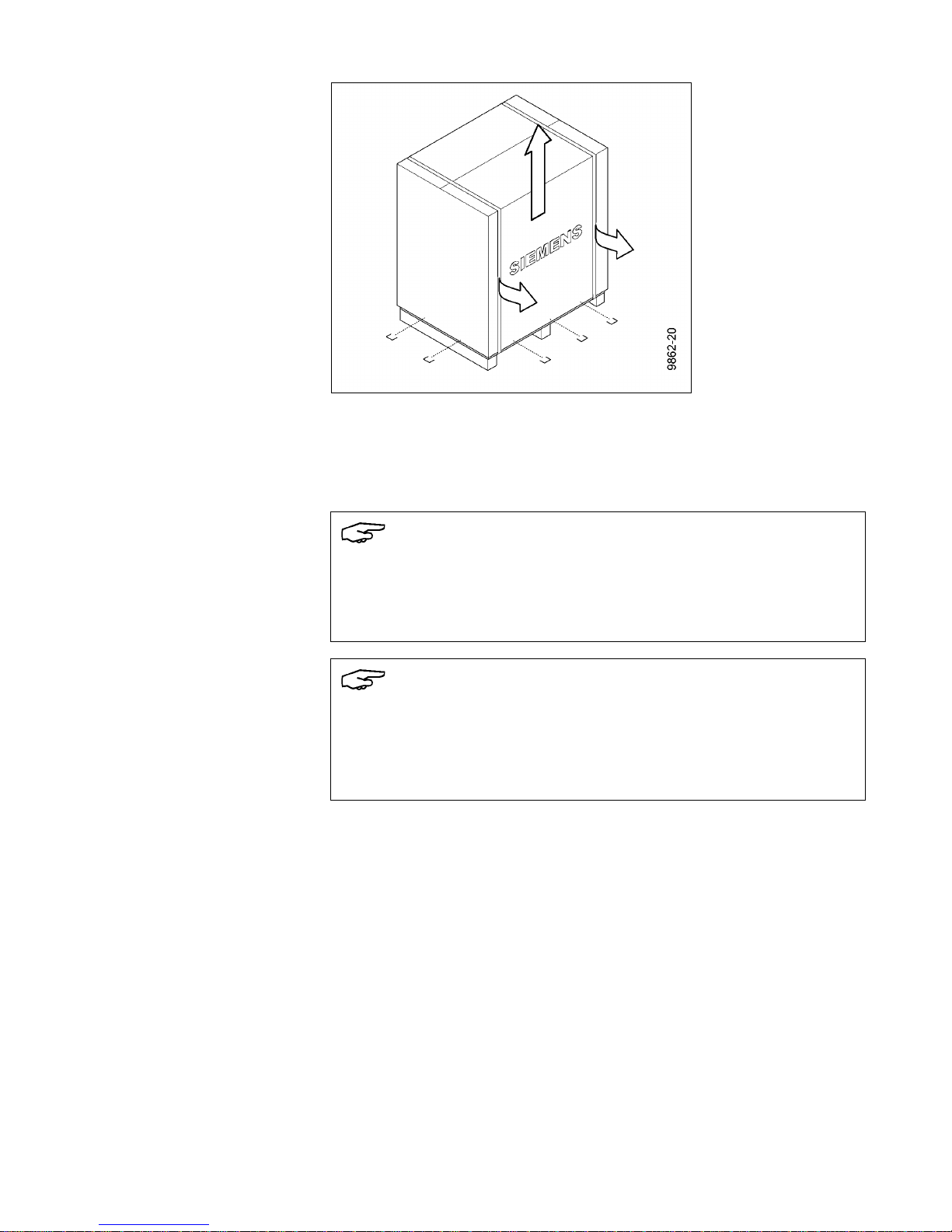

• Remove partitions and accessory pack and store safely in the packaging for

later attachment.

• Remove foil from the vacuum circuit-breaker.

• In the case of overseas packaging, push the lower foil onto the pallet floor.

• Check delivery for completeness.

• Check vacuum circuit-breaker for damage.

• If the vacuum circuit-breaker is damaged, ship it back in the transport unit

(see “Reusing the transport unit” on page 16).

Transporting with pallet,

without carton

The vacuum circuit-breaker can be transported with the pallet, without the carton.

• Thread carrying straps under the pallet or

• Transporting with fork lift.

Fig. 4 Removing partitions and foil Fig. 5 Transporting with pallet possible

Page 9

Transport, storage and packing

9229 9992 176 0D 9

2013-07-08

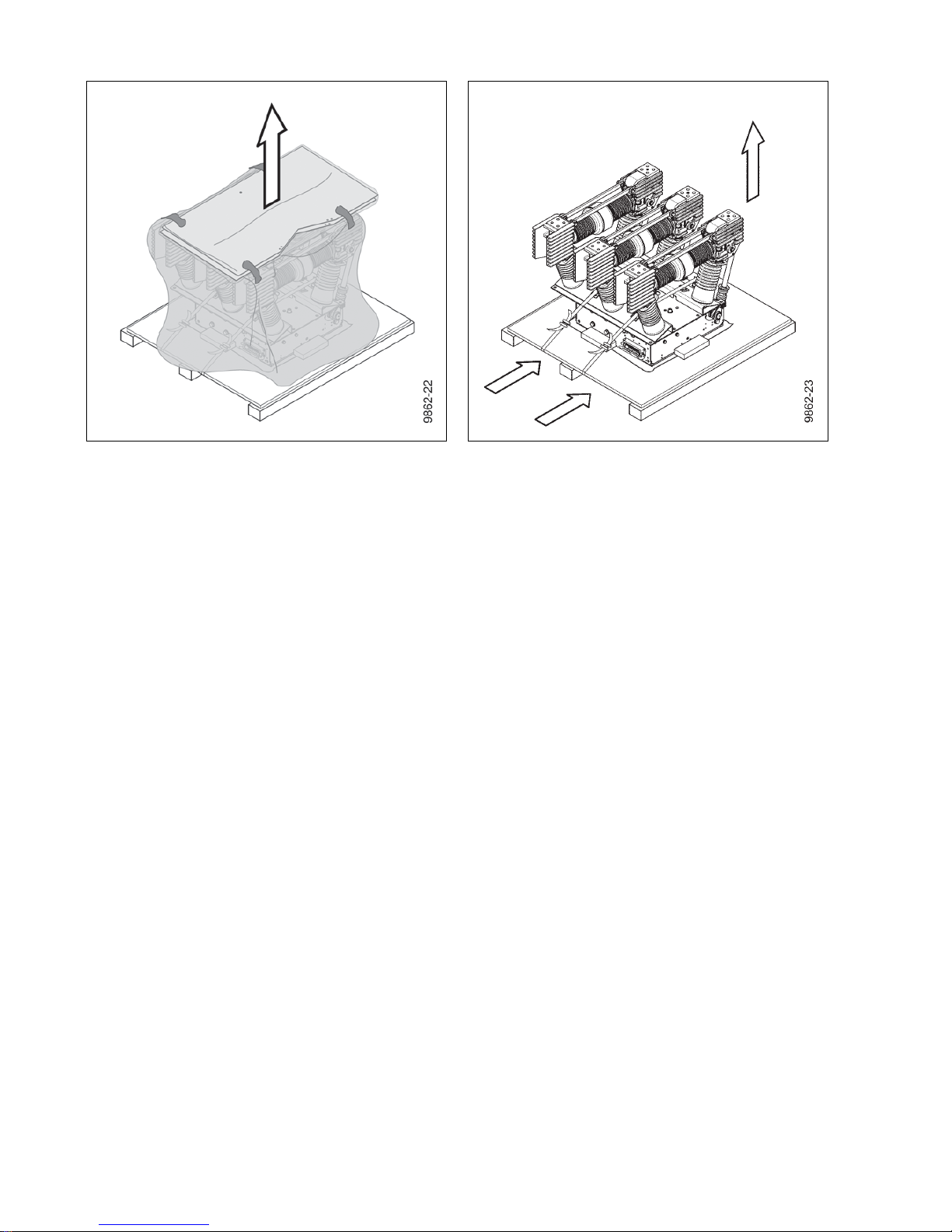

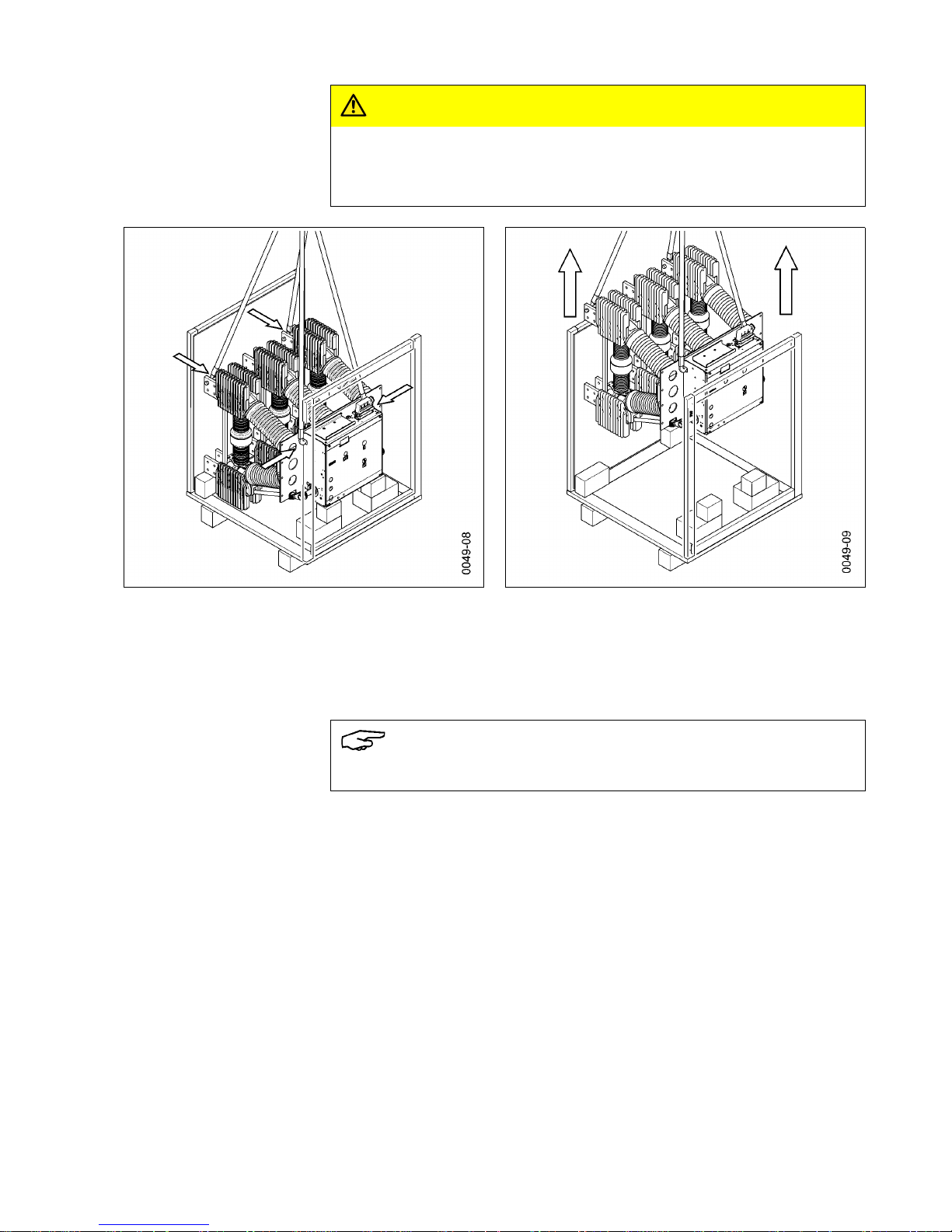

Transporting without pallet • Remove all tensioning belts and bits of fastening wood.

• Remove accessory pack, if applicable.

• Screw suitable eye bolts into the outer pole heads parallel to each other.

• Hang sling gear into the eye bolts.

• Carefully lift vacuum circuit-breaker off the pallet just enough that pieces of

square timber can be placed underneath.

Note

When fastening the eyebolts to the pole heads, ensure that the contact surfaces

are not damaged.

Fig. 6 Removing the tensioning belts Fig. 7 Screwing in eye bolts and lifting the vacuum

circuit-breaker

Note

Place pieces of square timber onto the pallet in such a way that the insulating

operating rods, contact pressure springs, angle levers and dashpots are not

damaged when setting down.

Page 10

Transport, storage and packing

10 9229 9992 176 0D

2013-07-08

• Set the vacuum circuit-breaker down onto the square timbers.

• Hang further sling gear into the transport boreholes.

• Transport to installation site or leave suspended from crane for further

work steps.

Fig. 8 Positioning the square timbers and setting

down the vacuum circuit-breaker

Fig. 9 Transporting without pallet

Note

Keep partitions and accessory pack ready for the installation.

Page 11

Transport, storage and packing

9229 9992 176 0D 11

2013-07-08

Unpacking (II)

Variant with bracketsRemove carton as described in Fig. 3.

Working equipment Required tools:

- Knife/scissors

- Screwdriver

- Open-end wrench

- Lifting equipment with lifting gear.

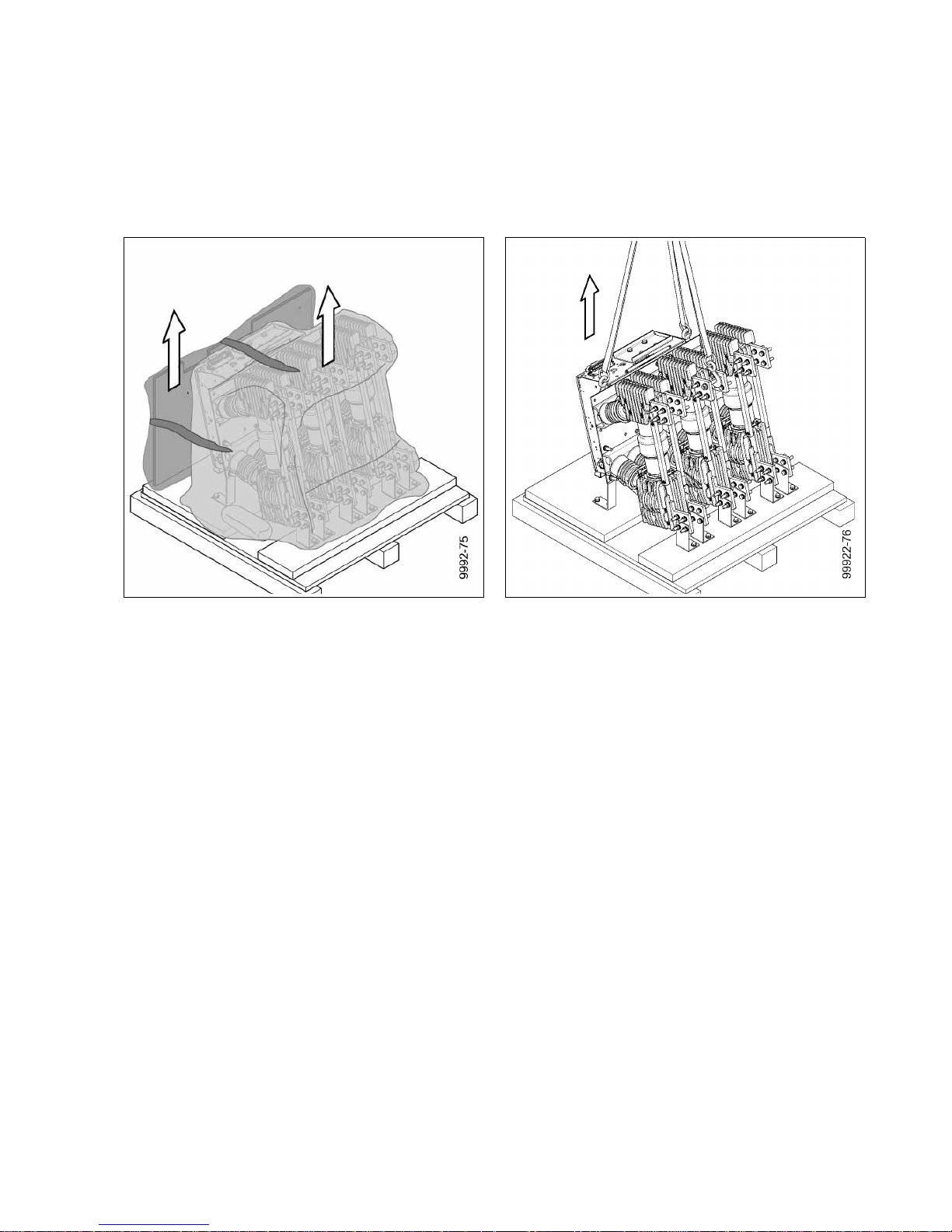

Transporting with brackets • Remove partitions and accessory pack and store safely in the packaging for

later attachment.

• Attach suitable bolt in the middle pole head.

• Attach sling gear to bolt and to transport boreholes.

Fig. 10 Removing partitions and foil Fig. 11 Lifting the vacuum circuit-breaker

Page 12

Transport, storage and packing

12 9229 9992 176 0D

2013-07-08

Transporting without

brackets

• Only lift the vacuum circuit-breaker so that all sling gear is tensioned.

• Remove angle plate and bracket screws from the pallet.

• Lift the vacuum circuit-breaker from the pallet.

• Remove all screw connections from the brackets on the pole plate and the

terminals.

• Remove angle plate below mechanism box.

• Transport to installation site or leave suspended from crane for further

work steps.

Fig. 12 Removing screws from the pallet Fig. 13 Removing the angle plate and brackets

Note

Keep partitions and accessory pack ready for the installation.

Page 13

Transport, storage and packing

9229 9992 176 0D 13

2013-07-08

Unpacking (III)

Working equipment Required tools:

- Screwdriver

- Knife/scissors

- Lifting equipment with lifting gear.

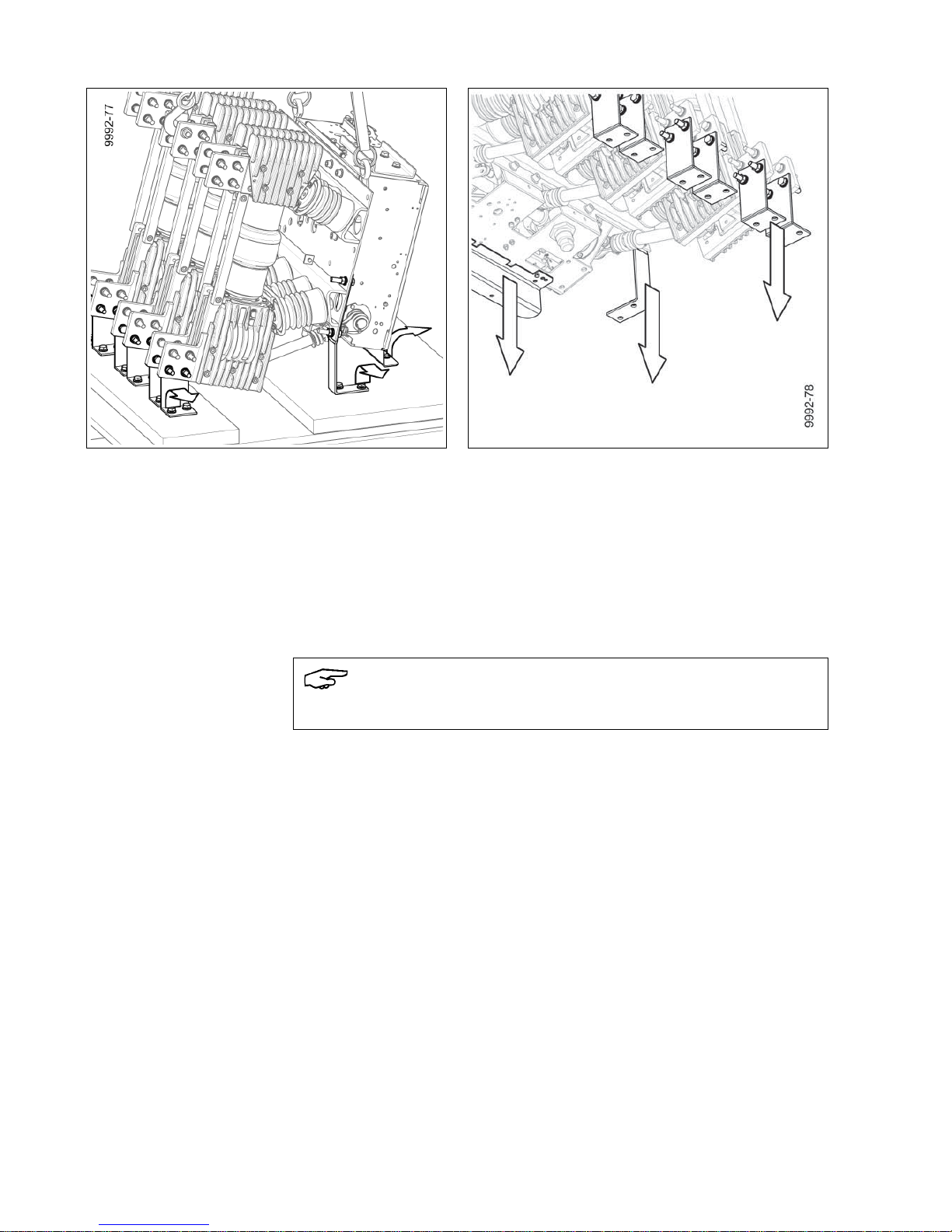

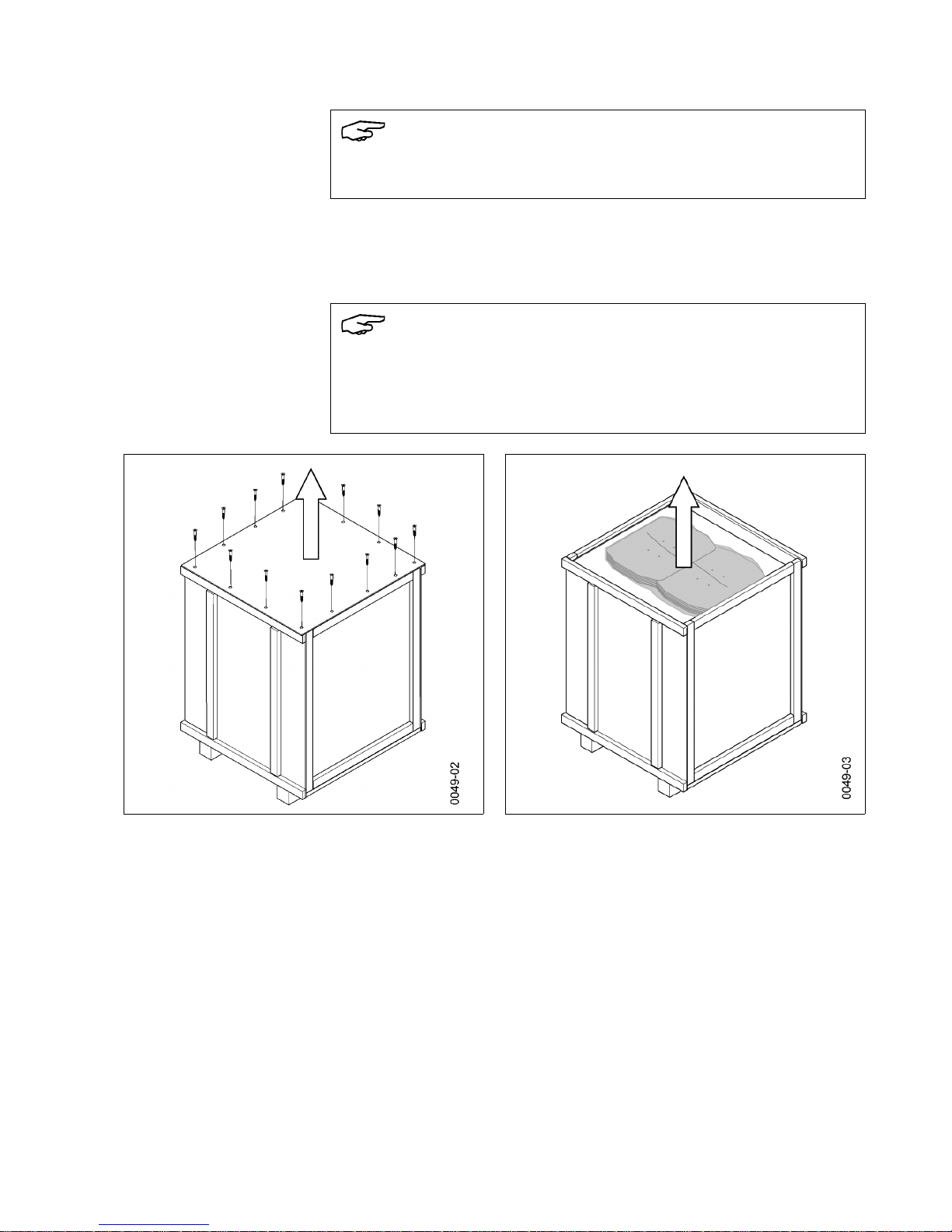

Opening the transport unit • Place the transport unit on a level, non-slip and pressure-resistant surface.

• Remove lifting gear or transport means.

• Unscrew all the screws from the cover and lift it off.

• Take out the partitions and check for damage.

Note

Some of the images in this section show a different circuit-breaker type. These

images are exemplary and also apply to the vacuum circuit-breaker 3AH37/38.

Note

Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks,

flakings, bent metal parts, damaged plug-in contacts, tears or bare cables.

Send it back in its original transport unit (see “Reusing the transport unit”,

page 16).

Fig. 14 Removing the cover Fig. 15 Taking out the partitions

Page 14

Transport, storage and packing

14 9229 9992 176 0D

2013-07-08

• Unscrew all the screws from the side walls.

• Take the supports out of the transport unit.

• Remove the side walls.

• Remove accessory pack and store safely in the packaging for later attachment.

• Remove foil.

• Check the vacuum circuit-breaker 3AH37/38 for damage.

• Undo tensioning belts, if applicable.

Fig. 16 Removing the supports Fig. 17 Removing the side walls

Fig. 18 Taking out the accessory pack Fig. 19 Removing the foil

Page 15

Transport, storage and packing

9229 9992 176 0D 15

2013-07-08

Transporting to the

installation site

• Hook crane hooks into the transport screws and into the openings on the

mechanism box.

• Observe crane hook symbols.

• Vertically lift out vacuum circuit-breaker.

CAUTION

Crushing hazard

Hands may get crushed when lifting out the vacuum circuit-breaker.

Do not reach between the transport box and the vacuum circuit-breaker.

Fig. 20 Preparing for lifting out Fig. 21 Lifting out

Note

Keep partitions and accessory pack ready for the installation.

Page 16

Transport, storage and packing

16 9229 9992 176 0D

2013-07-08

Reusing the transport unit

Reusing the transport unit To transport the vacuum circuit-breaker again, the pallet with carton or the wooden

case with the most components can be reused.

Do not reuse severed tensioning straps or plastic wrap.

Pack the vacuum circuit-breaker in reverse order:

• Attach the vacuum circuit-breaker safely to the pallet using the appropriate

tools.

• Cover with foil and seal with adhesive tape.

• Attach accessories pack.

• Attach carton securely to the pallet base.

• Screw the wooden case back together.

• Before returning to the factory, ask the responsible Siemens representative for a

returned goods number (see also “Service” on page 59).

• When returning a vacuum circuit-breaker, always indicate the type and serial

number (see “Rating plate” on page 34).

Storage

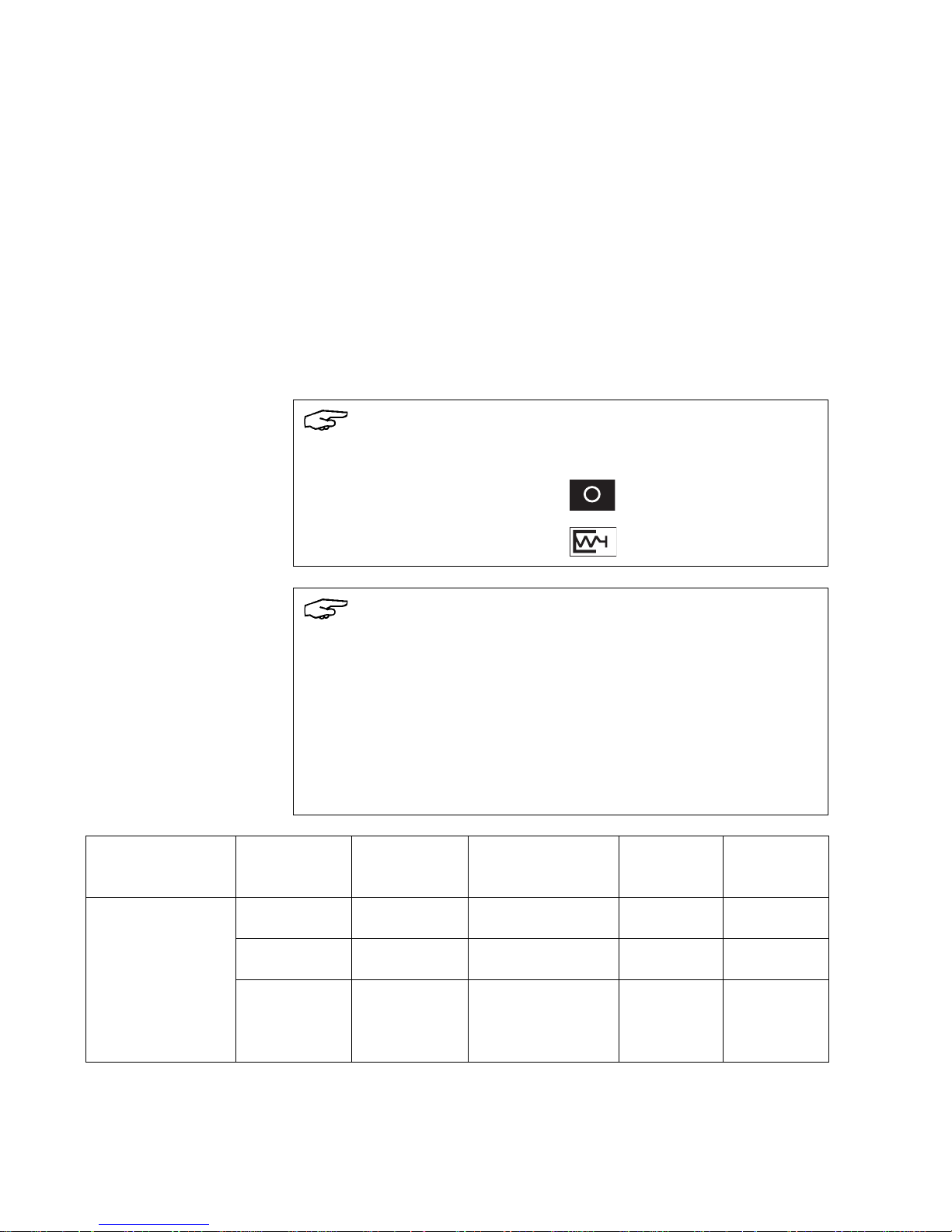

Note

Store the vacuum circuit-breaker in the following condition:

• OPEN switching position

• Closing spring discharged

Note

Risk of corrosion damage if stored improperly!

If the storage conditions listed below are met, the vacuum circuit-breaker can be

stored for up to a year in its transport unit.

If the storage conditions are not met, the vacuum circuit-breaker cannot be stored

in the transport unit any longer than 6 months.

If storage of longer than one year is planned, unpack the vacuum circuit-breaker

from the transport unit. Further storage may necessitate fresh corrosion

protection, and it must be ensured that the vacuum circuit-breaker cannot be

damaged.

Storage room Transport unit Storage time Temperature range Comments Number of

units per

stack

Enclosed, dry, well

ventilated and as

free from dust as

possible, with a

relative humidity of

less than 60 %.

unopened max. 6 months -40 °C to +55 °C — max. 4

unopened max. 1 year -5 °C to +40 °C — max. 4

open over 1 year -5 °C to +40 °C

if necessary,

with new

corrosion

protection

—

Page 17

General information

9229 9992 176 0D 17

2013-07-08

General information

Smooth and safe operation of this device requires proper transport and storage, and

professional installation and assembly as well as careful operation and

maintenance.

The basic version and all listed configurations of the vacuum circuit-breakers

3AH37/38 are type-tested devices as per IEEE (12 kV 90 kA as per IEC).

Range of application

Vacuum circuit-breakers 3AH37/38 are indoor circuit-breakers for high switching

capacity and a rated voltage range of 17.5 kV and 24 kV (additionally 12 kV 90 kA).

Under normal operating conditions, the vacuum circuit-breakers 3AH37/38 are

maintenance-free up to 10 000 operating cycles.

Intended use 3AH37/38 vacuum circuit-breakers are suitable for switching any type of alternating

current circuits under normal operating conditions, such as:

• Three-phase motors for reversing, turning and direct operation

• Transformers

• Capacitors

• Generators

• Resistor consumers.

Suitable for high frequency of operation and unlimited on-time.

3AH37/38 vacuum circuit-breakers operate in continuous, periodic and short-time

operation.

WARNING

Dangerous voltage and mechanical movements

When operating electrical devices, certain parts will always be live, and

mechanical parts may move very quickly, even when remotely controlled.

If the warnings are not observed, serious injury or damage to material may be

the result.

Only personnel with the relevant qualifications may work on or in the vicinity of

this device. This personnel must be familiar with all the warnings and servicing

measures specified in these operating instructions.

Note

In the event of subsequent attachments or fittings, e. g. locking parts in

connection with switchgear, ensure that

• fast moving parts are not additionally loaded by masses or forces and

• additional parts are sufficiently far away especially from moving and live

parts.

If vacuum circuit-breakers are to be equipped with additional functions by the

customer, we recommend consulting the factory, since tried and tested solutions

are frequently available (see also “Additional equipment” on page 23).

Page 18

General information

18 9229 9992 176 0D

2013-07-08

Standards

The 3AH37/38 vacuum circuit-breakers comply with the regulation IEEE C37.013.

All 3AH37/38 vacuum circuit-breakers comply with the specifications for C2-,

E2- and M2-class circuit-breakers in accordance with IEC 62271-100.

Design approval as per X-Ray Ordinance

The vacuum interrupters installed in the vacuum circuit-breakers are of a design

approved under the X-Ray Ordinance (RöV) of the Federal Republic of Germany.

They meet the requirements of RöV of 8 January 1987 (BGbl. I, page 114) § 8 and

Annex II No. 5 up to the level of the rated voltage stipulated according to

DIN VDE/IEC.

Scope of delivery

Delivery includes:

• Vacuum circuit-breaker 3AH37/38

• Hand crank for circuit-breaker 3AX 1530-2B (optional)

• If applicable, partitions with mounting drawing

• Operating instructions and unpacking instructions

• Circuit-breaker-specific circuit diagrams

Page 19

Description

9229 9992 176 0D 19

2013-07-08

Description

Design

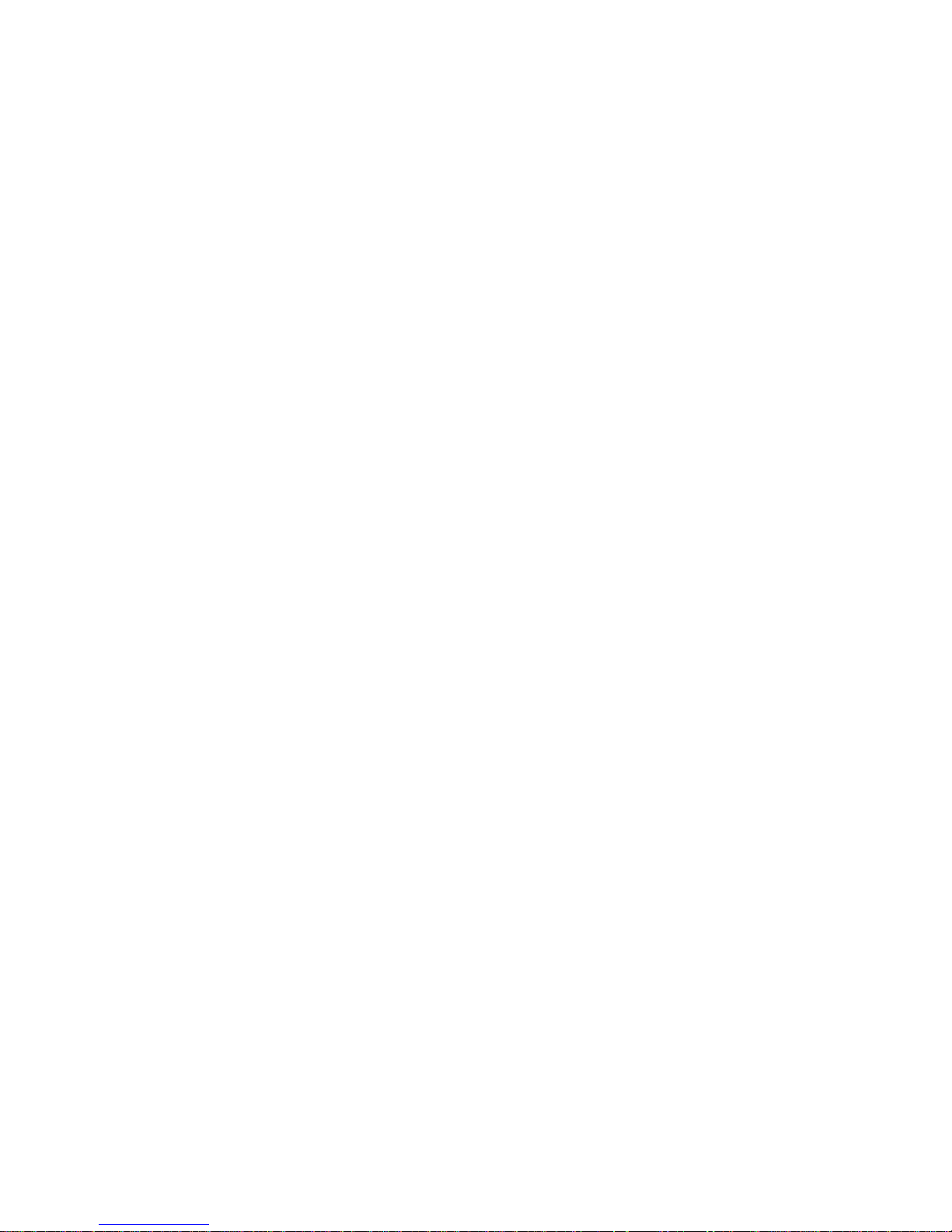

Vacuum circuit-breaker The 3AH37/38 vacuum circuit-breaker consists of

• the mechanism box (60.),

• the 3 pole assemblies (19.) with vacuum interrupters (30.),

• the cast resin post insulators (16.1 and 16.2) with reinforcing struts (28.) and

• the insulating operating rods (48.) with contact pressure springs (49.) required

for contact actuation.

Each of the 3 pole assemblies (19.) is carried by the cast resin post insulators

(16.1 and 16.2) that are screwed to the pole plate (15.).

Fig. 22 Side view

15. Pole plate

16.1 Upper post insulator

16.2 Lower post insulator

19. Pole assembly, complete

28. Strut

30. Vacuum interrupter

48. Insulating operating rods

49. Contact pressure spring

60. Mechanism box

Page 20

Description

20 9229 9992 176 0D

2013-07-08

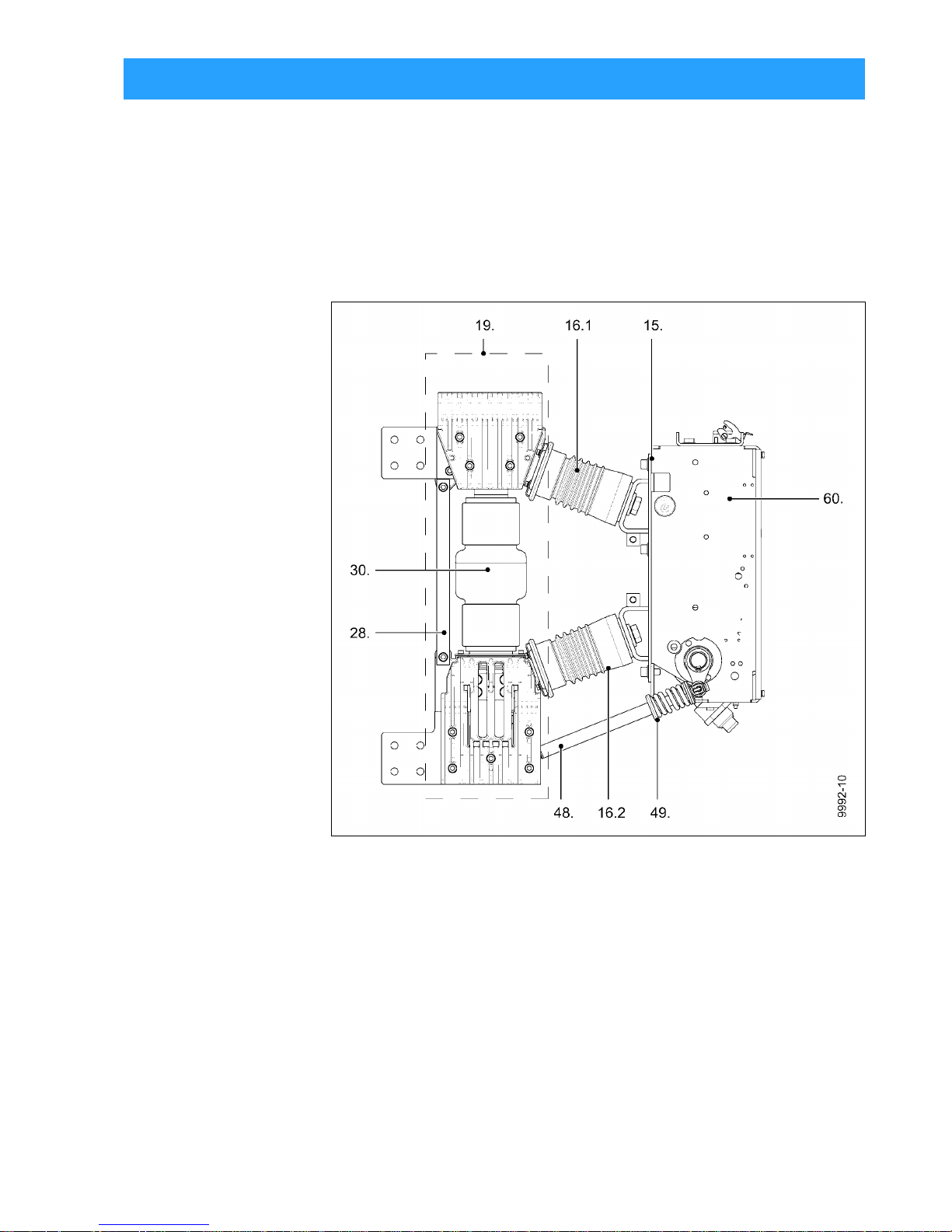

Pole assembly The pole assembly (19.) of the 3AH37/38 vacuum circuit-breaker consists of

• the upper interrupter support (20.)

• with the upper terminal (27.)

• of the vacuum interrupter (30.);

• the lower interrupter support (40.) with the lower terminal (29.) and the

clamp (29.2) with flexible connector (29.1);

• as well as the angle lever (48.6.).

The centering (28.1) and the struts (28.) relieve the interrupters of external forces.

Contact system in the vacuum interrupters

A slight change in the contact stroke that occurs over the entire useful life of the

vacuum circuit-breaker has no effect on its function. There is no need for a status

indicator for the contact system.

Fig. 23 Pole assembly (I) Fig. 24 Pole assembly (II or III)

19. Pole assembly 29.1 Flexible connector

20. Upper interrupter support 29.2 Clamp

27. Upper terminal 30. Vacuum interrupter

28. Strut 40. Lower interrupter support

28.1 Centering 48.6 Angle lever

29. Lower terminal

Page 21

Description

9229 9992 176 0D 21

2013-07-08

Mechanism box The mechanism box (60.) contains all the electrical and mechanical components

required to switch the vacuum circuit-breaker on or off. Insulating operating rods

(48.) transfer the switching movement to the pole assemblies.

The mechanism box is closed with a removable cover (60.1).

There are openings in the cover (60.1) for the operating and indicator elements.

Functions The CLOSE pushbutton (53.) is used to close the vacuum circuit-breaker. The motor

(50.4) immediately charges the closing spring (62.). If the supply voltage for the

motor fails, the closing spring can be charged with a hand crank (50.). There is an

opening (50.1) for this in the cover, behind which you will find the hand crank

coupling (50.5) of the gear unit (50.2).

Indicators The charged state of the springs is indicated via the spring state indicator (55.). The

position indicator (59.) shows the CLOSED or OPEN state. The operating cycle

counter (58.) indicates the number of operating cycles. An operating cycle consists

of one closing and one opening. The rating plate (51.) is attached to the mechanism

box and readable through an opening (51.1) in the cover.

Fig. 25 Operating and indicator elements

50.1 Opening for hand crank 58. Operating cycle counter

51. Ratinng plate 59. Position indicator CLOSED-OPEN

53. CLOSE pushbutton 60.1 Cover

54. OPEN pushbutton a) Tightening torque Md = 10 Nm

55. Spring state indicator

Page 22

Description

22 9229 9992 176 0D

2013-07-08

Fig. 26 Opened mechanism box

50.2 Gear unit 60. Mechanism box

50.4 Motor M1 61. Dashpot

50.4.1 Position switch 62. Closing spring

50.5 Hand crank coupling 63. Circuit-breaker shaft

51. Rating plate 64. Opening spring

53.1 Closing solenoid Y9 66. Closing damper

54.1 Shunt release Y1 68. Auxiliary switch S1

54.2 Shunt release Y2 68.1 Operating rod (for auxiliary switch S1)

54.3 Transformer-operated release Y4 68.7 Low-voltage interface X0

54.4 Undervoltage release Y7 69. Contactor relay K1

54.5 Transformer-operated release (0.1 Ws) Y6 70. Earth terminal

55. Spring state indicator 71. Heater (condensation water protection)

58. Operating cycle counter

59. Position indicator CLOSED-OPEN

Page 23

Description

9229 9992 176 0D 23

2013-07-08

Equipment

Basic equipment The basic equipment of the 3AH37/38 vacuum circuit-breaker contains:

Additional equipment Every 3AH37/38 vacuum circuit-breaker can also be fitted with the following

equipment:

In addition to the serial shunt release (Y1), the vacuum circuit-breaker can be

equipped with a maximum of 2 releases of the type 3AX11.

For the permitted possible combinations of the additional equipment as well as

special designs, refer to catalogue HG11, or contact the responsible Siemens

representative.

Motor (M1)

Contactor relay (electrical anti-pumping device) (K1)

Closing solenoid (Y9)

Shunt release (Y1)

Auxiliary switch (optional) (S1)

•6NO + 6NC

•12NO + 12NC

Position switch for signal "Closing spring charged" (S41, S42)

Circuit-breaker tripping signal, cut-out switch (S6, S7)

Low-voltage interface (optional) (X0)

• Plug-connector with sleeve housing 64-pin

• Plug-connector with sleeve housing 24-pin

• Terminal strip (X1)

Operating cycle counter

Mechanical anti-pumping device

Mechanical manual closing and opening

Shunt release 3AX1101

1)

1) Subsequent installation possible

(Y2, Y3)

Transformer-operated release 3AX1102

1)

(Y4, Y5)

Transformer-operated release 3AX1104 (0.1 AC)

1)

(Y6)

Undervoltage release 3AX1103

1)

(Y7)

Heater (condensation water protection)

1)

Electrical manual closing

2)

Mechanical interlock

1)

Priority opening

2)

2) No subsequent installation possible

Page 24

Description

24 9229 9992 176 0D

2013-07-08

Motor (M1)

*) The operator's supply voltage may deviate from the rated supply voltage of the

vacuum circuit-breaker by -15 % to +10 %.

**) Built-in automatic circuit-breaker with C characteristic

Fig. 28 Recommendation for motor protection device

Contactor relay K1

After the supply voltage is applied and if the closing

spring is discharged, the motor starts immediately and is

automatically deactivated internally after charging has

taken place.

Power consumption, maximum:

• in the event of direct voltage approx. 750 W

• in the event of alternating voltage 1400 W.

In the short charging time, the motor sometimes

operates in the overload range. See Fig. 28 for the rated

current for the required motor short-circuit protection.

Note: The motor protection devices are not included in

the delivery of the vacuum circuit-breaker and must be

ordered separately .

Fig. 27 Motor (50.4)

Rated supply voltage U*)

VDC24DC48DC60DC110

AC 50/60 Hz

110

DC

220

AC 50/60 Hz

230

Recommended rated current of the protective

device I**

)

A16106462 3

If simultaneous CLOSE and OPEN commands are

continuously applied to the vacuum circuit-breaker, it

returns to the open position after being closed.

Via the function of the contactor relay K1, the vacuum

circuit-breaker pauses there until the CLOSE command

is given again.

This prevents continuous closing and opening

(pumping).

Fig. 29 Contactor relay (69.)

Page 25

Description

9229 9992 176 0D 25

2013-07-08

Closing solenoid (Y9) 3AY1510

1 st shunt release (Y1) 3AY1510

The closing solenoid Y9 unlatches the charged closing

spring and switches the vacuum circuit-breaker on

electrically . It is available for DC or AC voltage .

The closing solenoid Y9 is not designed for continuous

operation and is automatically deactivated within the

circuit-breaker.

The operator's supply voltage may deviate from the

rated supply voltage of the vacuum circuit-breaker by

-15 % up to +10 %.

The closing solenoid Y9 can be operated using AC or

DC voltage and is protected against overvoltage.

Power consumption is approximately 140 W / VA

Fig. 30 Closing solenoid (53.1)

In the case of the 1st shunt release Y1, the electrically

fed tripping pulse is passed to the "OPEN" latch by

means of a directly acting magnet armature, thus

switching off the vacuum circuit-breaker.

The 1st shunt release Y1 is not designed for continuous

operation and is automatically deactivated within the

circuit-breaker.

The operator's supply voltage may deviate from the

rated supply voltage of the vacuum circuit-breaker by 30 % to +10 % in the event of DC voltage and by -15 %

to +10 % in the event of AC voltage.

The 1st shunt release Y1 can be operated using AC or

DC voltage and is protected against overvoltage.

Power consumption is approximately 140 W / VA

Fig. 31 1st shunt release (54.1)

Page 26

Description

26 9229 9992 176 0D

2013-07-08

Auxiliary switch S1

Breaking capacity

Fig. 33 Breaking capacity of the auxiliary switch 3SV92

Two versions of the auxiliary switch S1 are available for

delivery: with 6 or 12 NO / NC contacts each.

Rated insulation voltage: 250 V AC/DC

Insulation group: C as per VDE 0110

Continuous current: 10 A

Closing capacity: 50 A

Fig. 32 Auxiliary switch (68.)

AC 40 to 60 Hz DC

Operating voltage Operating current Operating voltage Operating current

U (V) I (A) U (V) I (A)

Ohmic

load

Inductive load

(T = 20 ms)

Up to 230 10

24 10 10

48 10 9

60 9 7

110 5 4

220 2,5 2

Page 27

Description

9229 9992 176 0D 27

2013-07-08

Position switch

Circuit-breaker tripping signal, cut-out switch (S6, S7)

S21, S22 Position switches (switch off the motor after

charging)

S3 Position switch (opens when closing spring

is charged)

S41, S42 Position switches (report charging state)

Fig. 34 Position switch (50.4.1)

The position switch S6 makes contact briefly when the

vacuum circuit-breaker is opened by means of an

electrical release.

This contacting can be used for a signal.

In the event of intentional mechanical opening, the

cut-out switch S7 interrupts the contacting.

Fig. 35 Circuit-breaker tripping signal

Page 28

Description

28 9229 9992 176 0D

2013-07-08

Low-voltage interface X0, 64-pin

For connection of the control line, the standard version of the vacuum circuitbreakers is equipped with a 64-pin low-voltage interface X0 (68.7).

The 64-pin plug (68.7.1) for the external terminal, is suitable for crimp termination of

control lines with a nominal cross-section of 1.5 mm

2

.

Terminal strip (optional) Instead of the 64-pin plug (68.7.1), a terminal strip (68.7.2) can be ordered as

interface to the terminal at the customer's site. Assignment of the terminals is done

according to the circuit diagram supplied.

Fig. 36 Low-voltage interface X0 Fig. 37 Terminal strip (optional)

Page 29

Description

9229 9992 176 0D 29

2013-07-08

A further shunt release, transformer-operated release, undervoltage release or

instantaneous release can be installed as a 2nd release.

2nd shunt release (Y2) 3AX1101

Transformer-operated releases (Y4, Y5) 3AX1102, (Y6) 3AX1104

The second shunt release Y2 is installed whenever more

than one shunt release is needed.

In this version, the electrical "off" command is passed by

means of a magnet armature to the "OPEN" latch by

release of an energy storage mechanism, thus switching

off the vacuum circuit-breaker. This tripping solenoid is

not designed for continuous operation. Any necessary

varistors and rectifiers are integrated in the release.

Power consumption is approximately 60 W / VA

Fig. 38 2. Shunt release (54.2)

The transformer-operated releases Y4, Y5 or Y6 consist

of an energy storage mechanism, an unlatching fixture

and an electromagnetic system. If the tripping current is

exceeded (90 % of the transformer-operated release's

rated current), the stored energy mechanism is

unlatched, thus initiating opening of the vacuum circuitbreaker.

For use of the transformer-operated release, matching

transformers are also needed for matching, in addition to

the main current transformers.

Power consumption for 0.5 A and 1 A ≤ 6 VA at ≤ 90 %

of the transformer-operated release's rated current and

with open armature.

Fig. 39 Transformer-operated releases (54.3)

Page 30

Description

30 9229 9992 176 0D

2013-07-08

Undervoltage release (Y7) 3AX1103

The undervoltage release Y7 has an electromagnet system that has voltage

permanently applied to it when the vacuum circuit-breaker is in the closed state. If

the voltage drops below a certain value, the undervoltage release Y7 is unlatched,

thus initiating opening of the vacuum circuit-breaker via the stored energy

mechanism.

Random tripping of the undervoltage release Y7 is generally performed by an

NC contact in the tripping circuit, but can also be done with the aid of an NO contact

by short-circuiting the solenoid coil. In the case of this latter method, the solenoid

coil's short-circuit current is limited by the built-in resistor.

The undervoltage release Y7 can also be connected to voltage transformers.

The undervoltage release Y7 automatically trips the vacuum circuit-breaker if the

rated supply voltage drops to an inadmissible value. Any necessary varistors and

rectifiers are integrated in the release.

Power consumption ≤ 6.5 W or ≤ 7.5 VA

Note

The undervoltage release Y7 must only be operated with the supplied series

resistor R1.

Note

For switching operations (mechanical or electrical), the undervoltage release

3AX1103… must be connected to control voltage, as otherwise closing is not

possible (see “Removing the transport securing device from the undervoltage

release”, page 47).

Fig. 40 Undervoltage release (54.4) Fig. 41 Typical circuit for connection of the

undervoltage release Y7

A

B

R1 resistor

S1 auxiliary switch

Y7 undervoltage release

Page 31

Description

9229 9992 176 0D 31

2013-07-08

Heater (condensation water protection)

Electrical manual closing/electr. locking device

In the basic version, the vacuum circuit-breaker with on-site connection is closed by

direct mechanical unlatching of the closing spring. Instead of this mechanical

manual closing , "electrical manual closing" is also available.

In this version, the closing circuit of the vacuum circuit-breaker module is electrically

actuated by a sensing device and must also be enabled via a command element

from the control room.

With on-site closing, this permits taking into account system-related interlocking and

allows you to prevent unintentional closing by the control room, for example. This

allows for interlocking the vacuum circuit-breaker module, for example, via the

auxiliary contact of a disconnector.

Vacuum circuit-breakers with electrical manual closing cannot be switched

mechanically.

The heater limits condensation and corrosion of the

vacuum circuit-breaker.

To this end, the heater has to be connected to the supply

voltage (see circuit diagram included with the delivery).

The heater's surface temperature is at the most 180 °C.

Power consumption 50 W, Rated voltage AC 230 V

Fig. 42 Heater (71.)

Page 32

Description

32 9229 9992 176 0D

2013-07-08

Interlocking devices

To lock vacuum circuit-breakers as a function of the switching position, the spring

drive mechanisms of the vacuum circuit-breaker can be equipped with an

interlocking device. This is also the case for vacuum circuit-breakers on switch gear

trucks, in withdrawable sections or with disconnectors.

Conditions The vacuum circuit-breaker must only be switched on in operating or disconnected

position. The operating or disconnected position is the position of the vacuum circuitbreaker on the switchgear truck or withdrawable section in the switchgear. At the

same time, the vacuum circuit-breaker may be moved on the switchgear truck or

withdrawable section only when it is open.

Positions of the vacuum circuit-breaker in the switchgear

Disconnected position The isolating distance between the vacuum circuit-breaker contacts and the

switchgear counter-contacts is attained fully.

Operating position The circuit-breaker is inserted fully into the switchgear and the vacuum circuit-

breaker contacts overlap completely with the switchgear counter-contacts.

Mechanical interlock (optional with spring drive mechanism)

An interrogation and actuation component (b) on the system side scans the

operating position (CLOSED/OPEN) of the vacuum circuit-breaker.

CLOSED position If the vacuum circuit-breaker is closed, actuation of the system's interrogation and

actuation component (b) is prevented. A mechanical system in the switchgear truck

or withdrawable section reliably blocks movements of the circuit-breaker on the

switchgear truck or withdrawable section.

OPEN position If the vacuum circuit-breaker is open, the interrogation and actuation component (b)

on the system side actuates, via the stroke (a), the vacuum circuit-breaker's

mechanical interlock and reliably blocks closing of the vacuum circuit-breaker.

Fig. 43 Mechanical interlock

The installation dimensions (c + d) for the interrogation and actuation component (b)

are in the dimension drawing.

X CLOSED position a Stroke (min. 10 mm, max. 30 mm)

Y OPEN position b Interrogation or actuation component (min. actuation force 70 N)

Z View from below c + d see dimension drawing

Page 33

Description

9229 9992 176 0D 33

2013-07-08

Priority opening

To lock the OPEN position, the drive mechanisms of the vacuum circuit-breaker can

be equipped with "priority opening" . This is also the case for vacuum circuitbreakers on switch gear trucks, in withdrawable sections or with disconnectors.

As long as the OPEN pushbutton is actuated, closing with the CLOSE pushbutton is

mechanically locked.

Page 34

Description

34 9229 9992 176 0D

2013-07-08

Rating plate

Technical data

Vacuum circuit-breakers with one phase per interrupter

Fig. 45 Technical data - connection of one phase per interrupter

Fig. 44 Example - vacuum circuit-breaker rating plate 3AH37/38

a Manufacturer

b Type designation

c Works serial number

d Rated voltage U

r

e Rated frequency f

r

f Rated short-circuit breaking

current I

sc

g Rated power frequency withstand

voltage U

d

h Rated lightning impulse withstand

voltage U

p

i Quality control seal

k Year of manufacture

m Rated operating current I

r

n Rated short-circuit duration t

k

o Mass m

p Rated operating sequence

r Classification to standard

Q

600806

Kontr

Made in Germany

Classification to IEEE C37.013, IEC 62271-100: E2, M2, C2

Rated operating sequence: CO - 30 min - CO

Type 3AH3818-8

No. S 3AH3/90004711

U

r 17.5 kV, 50/60 Hz

U

d/Up 50/110

I

sc 63 kA

kV

Year of manufact. 2006

I

r 4000 A

t

k 3s

m 320 kg

9992-16_en

r

p

o

n

m

k

i

b

a

c

d, e

f

g, h

Rated voltage* U

r

kV 17,5 24

Rated operating current I

r

A 3150, 4000, 5000, 6300

Rated lightning impulse withstand voltage (peak value) U

p

kV 110 125

Rated power frequency withstand voltage (effective value) U

d

kV 50

Rated short-circuit breaking current I

sc

kA 50, 63,72

Distance between pole centres mm 275, 300 300

Rated operating sequence A, B A, B

A O - 3 min - CO - 3 min - CO; operating sequence with and without load

B CO - 30 min - CO; operating sequence in the event of short-circuit current

* In the event of a rated frequency fr of 50/60 Hz

Page 35

Description

9229 9992 176 0D 35

2013-07-08

Per phase one vacuum circuit-breaker

Fig. 46 Technical data - connection of one vacuum circuit-breaker per phase

Dimensions and weights

The dimensions of the vacuum circuit-breaker can be taken from the relevant

dimension drawing. If required, these are available from your Siemens

representative.

The weight is given on the rating plate of the vacuum circuit-breaker (see Fig. 44) or

can be taken from the relevant dimension drawing.

Note

If one vacuum circuit-breaker is ordered per phase, the three vacuum circuitbreakers are synchronised at the factory. If one of the vacuum circuit-breakers is

exchanged, the three vacuum circuit-breakers must be re-synchronised.

Rated voltage* U

r

kV 12** 17,5 24

Rated operating current I

r

A4000

4000, 5000,

6300, 8000,

10000, 12000

4000, 5000,

6300, 8000,

10000, 12000

Rated lightning impulse withstand voltage (peak value) U

p

kV 75 110 125

Rated power frequency withstand voltage (effective value) U

d

kV 28 50 50

Rated short-circuit breaking current I

sc

kA 90 50, 63, 72, 80 50, 63, 72

Distance between pole centres mm ** 275 300

Rated operating sequence A, B A, B A, B

A O - 3 min - CO - 3 min - CO; operating sequence with and without load

B CO - 30 min - CO; operating sequence in the event of short-circuit current

* In the event of a rated frequency fr of 50/60 Hz

** Vacuum circuit-breaker with one pole assembly

**

Page 36

Description

36 9229 9992 176 0D

2013-07-08

Ambient conditions

Installation altitudes

Insulating capacity The insulating capacity of insulation in air decreases with rising altitude due to the

lower air density. In conformity with IEC 62271-102, the rated lightning impulse

withstand voltage values given in Fig. 45 are valid up to an installation altitude of

1,000 m above sea level.

As from an altitude of 1,000 m, the insulation level must be corrected as shown in

Fig. 48:

3AH37/38vacuum circuit-breakers are suitable for use in

the following climate classes in accordance with

IEC 60721, Part 3-3:

Class

• Climatic ambient conditions:

3K4

1)

,

3K6

2)

,

3Z2,

3Z5

• Biological ambient conditions: 3B1

• Mechanical ambient conditions: 3M2

• Chemically active substances:

3C2

3)

• Mechanically active substances:

3S2

4)

1) Peak value of the 24-hour means: +35 °C

2) Without ice formation and wind-driven precipitation

3) Without occurrence of salt fog and simultaneous condensation

4) Restriction: clean insulating parts

5) Average value, measured over 24 hours

6) Average value, measured over 1 month

Fig. 47 Ambient conditions

U U0 K

a

U Rated withstand voltage U under standard reference

atmosphere

U

0

Required rated withstand voltage for the installation

location

K

a

Altitude correction factor

K

a

= em

(H - 1000)/8150

Calculating the altitude correction factor Ka:

H = Installation altitude in metres

m = 1 for AC voltage, lightning impulse withstand

voltage (between phases, phase-to-earth, applied

longitudinally)

Example

For a required rated withstand voltage of 75 kV at an

altitude of 2,500 m, an insulation level of at least 90 kV

under standard reference atmosphere conditions is

required:

90 kV 75 kV e

1

(2500 - 1000)/8150

75 kV 1.2

Fig. 48 Altitude correction factor K

a

Page 37

Description

9229 9992 176 0D 37

2013-07-08

Switching times

Fig. 49 Switching times

Closing time = period between starting (command) of the closing movement and

the moment of contact touch in all poles.

Opening time = period between starting (command) of the opening movement and

opening of the last pole.

Arcing time = period from the start of the first arc to extinction of the arcs in all poles.

Break-time = period between starting (command) of the opening movement and

extinction of the arc in the pole extinct last (= opening time + arcing time).

Close/Open time = period in an OPEN/CLOSE cycle between the moment of

contact touch in the first pole during closing and the time when contact touch has

been cancelled in all poles during subsequent opening.

Dead-time = period from the end of the current flow in all poles up to the start of

current flow in the first pole.

Closing time < 75 ms

Opening time

1st shunt release (Y1) < 60 ms

2nd and 3rd release (Y2, Y4, Y6, Y7) < 55 ms

Arcing time < 15 ms

Break time

1st shunt release (Y1) < 75 ms

2nd and 3rd release (Y2, Y4, Y6, Y7) < 70 ms

Dead time 300 ms

Close/Open time

1st shunt release (Y1) < 90 ms

2nd and 3rd release (Y2, Y4, Y6, Y7) < 70 ms

Minimum command duration

Closing solenoid (Y9) 45 ms

1st shunt release (Y1) 40 ms

2nd and 3rd release (Y2, Y4, Y6, Y7) 20 ms

Shortest pulse time for breaker tripping signal

1st shunt release (Y1) > 15 ms

2nd and 3rd release (Y2, Y4, Y6, Y7) > 10 ms

Charging time if actuated electrically (M1) < 15 s

Synchronous operation error between the poles ≤ 2 ms

Page 38

Description

38 9229 9992 176 0D

2013-07-08

Circuit diagrams

The circuit diagrams show all the available components with their wiring options.

Fig. 50 to Fig. 56 show some non-binding examples of vacuum circuit-breakers.

The circuit diagrams for the vacuum circuit-breaker are compiled depending on

your order.

Mechanical manual closing and electrical closing

Fig. 50 Example - circuit diagram connection via low-voltage interface, 64-pin,

basic version

Electrical manual closing and electrical closing

Fig. 51 Example - circuit diagram with connection via low-voltage interface 64-

pin.

This legend is also valid for the following circuit diagrams.

-Y1 -Y2 -Y4

-Y4 -Y5

-Y6 -Y7

-Y7

"OPEN" release

-Y1 -Y2 -Y4

-Y4 -Y5

-Y6 -Y7

-Y7

"OPEN" release

extended auxiliary switch

HA Manual opening S3 Position switch (opens when closing spring is charged)

HE Manual closing S41, S42 Position switches (signal charging status)

K1 Contactor relay (anti-pumping device) S6, S7 Position switches (for breaker tripping signal)

M1 Motor X0 Low-voltage interface

P Energy storage mechanism Y1 1st shunt release

R1 Resistor Y2 2nd shunt release

S1 Auxiliary switch Y4, Y5, Y6 Transformer-operated release

S10, S11 Position switch (mechanical anti-pumping device) Y7 Undervoltage release

S12 Position switch (prevents electrical closing in the event

of mechanical interlocking)

Y9 Closing solenoid

S21, S22 Position switches (switch off the motor after charging) V6 Integrated rectifiers for motor

Page 39

Description

9229 9992 176 0D 39

2013-07-08

1) Integrated varistor

2) Integrated rectifier for AC/DC≥ 100 V

3) Line H07V-K1x2.5sw (as per EN 50525-2-31) when motors are used with DC 24 V / 48 V and 60 V

4) Only if a mechanical closing lock is ordered at the same time

a) Motor winding for DC

b) Motor winding with rectifier for AC

c) Closing

d) Closing with anti-pumping device

Fig. 52 Sample circuit diagram 64-pole (part 1) of the vacuum circuit-breaker

a) b) c) d)

Page 40

Description

40 9229 9992 176 0D

2013-07-08

1) Integrated varistor

2) Integrated rectifier for AC/DC≥ 100 V

a) 1st shunt release with 64-pole plug-connector

b) 1st shunt release with 24-pole plug-connector

c) 2nd shunt release with 64-pole plug-connector

d) 2nd shunt release with 24-pole plug-connector

Fig. 53 Sample circuit diagram (part 2) of the vacuum circuit-breaker

a) b) c) d)

Page 41

Description

9229 9992 176 0D 41

2013-07-08

1) Integrated varistor

2) Integrated rectifier for AC/DC≥ 100 V

3) Attention: connect L+ for direct current (DC)

a) Undervoltage release

b) Low-energy trip-coil

c) 1st transformer-operated release

d) Signal: spring state with 64-pole plug-connector

e) Signal: spring state with 24-pole plug-connector

f) Breaker tripping signal for 64-pole plug-connector

Fig. 54 Sample circuit diagram (part 3) of the vacuum circuit-breaker

a) b) c) d) e) f)

Page 42

Description

42 9229 9992 176 0D

2013-07-08

The unassigned auxiliary switch terminals are wired up (as shown) with the 64-pole

plug bottom.

Fig. 55 Example – auxiliary switch terminals

Fig. 56 Sample switching operation for connection of the undervoltage release Y7

Normal auxiliary switch Extended auxiliary switch

No wiring required if

a) 2nd shunt release Y2 available

b) Undervoltage release Y7 available

a) b)

System wiring Tripping via NO contactTripping via

NC contact

System wiring

Circuit-breaker wiring

Page 43

Installation

9229 9992 176 0D 43

2013-07-08

Installation

Attachment in the switching cubicle

The vacuum circuit-breaker is delivered in OPEN position. Before installing the

vacuum circuit-breaker, remove the transport aids (see “Unpacking (I)” on page 6,

“Unpacking (II)” on page 11 or “Unpacking (III)” on page 13).

Check data Before installing the vacuum circuit-breaker in a switching cubicle, check the details

on the rating plate (see “Rating plate” on page 34) in order to avoid confusion.

DANGER

High-voltage - danger to life

Touching live parts causes an electric shock.

• Do not touch live parts!

• When performing work on the switchgear, deenergise it and earth it.

• The work described in the following sections must only be performed when

the switchgear has been deenergised:

- Take safety measures to prevent reclosing.

- Observe industrial safety regulations.

- Ensure that the vacuum circuit-breaker is installed and commissioned only

by qualified personnel who are familiar with the operating instructions and

observe the warning notices.

WARNING

Risk of injury due to wrong transport means

Using wrong transport means may cause the vacuum circuit-breaker to fall and

injure persons.

• Observe weight

• Use means of transport suited to the requirements and load-carrying

capacity.

• The vacuum circuit-breaker must not fall over.

• Sharp edges may cause injury.

Note

For preliminary work, the vacuum circuit-breaker must be

• secured against falling over,

• placed onto a suitable support or

• suspended from a crane to prepare for installation.

Page 44

Installation

44 9229 9992 176 0D

2013-07-08

Mounting position The 3AH37/38 vacuum circuit-breaker can be installed indoors and vertically or

horizontally (optionally, mechanism box at the bottom) in relation to the interrupters.

Mounting the partitions Carefully take the partitions out of the packaging (see Fig. 4) and mount according

to the supplied mounting drawing.

Mounting the vacuum circuit-breaker

There are a total of 14 fixing holes on the pole plate (15) and on the mechanism

box (60.) for the various types of installation.

Use M12 screws – strength class 8.8 – for fastening. The binding dimension

drawings are relevant.

The framework must be made to suit the operating conditions and have sufficient

load bearing capacity and stability.

Fig. 57 Mounting position

Fig. 58 Example of mounted partitions

Page 45

Installation

9229 9992 176 0D 45

2013-07-08

* bores for M12 screws

Fig. 59 Fastening options Fig. 60 View Y and Z

Page 46

Installation

46 9229 9992 176 0D

2013-07-08

Earthing

Connecting to earth Connect the vacuum circuit-breaker on the earth terminal (70.) to the high-voltage

protective earth as specified (DIN EN 50341).

• Fully unscrew hexagon socket head screw M12 with washer on the earth

terminal (70.).

• Tighten ring terminal for the earth wire with the M12 hexagon screw and washer

on the earth terminal (70.) with 40 Nm.

Connect low-voltage Connect the low-voltage connecting cables in the customer's switch cabinet in such

a way that safe operation as per supplied circuit diagram is guaranteed.

Note

If the 3AH37/38 vacuum circuit-breaker is installed into an earthed metal frame

and is connected permanently and electrically conductive, no separate earthing

needs to be done.

Place serrated washers under the screw heads when fastening the vacuum

circuit-breaker in this case.

Fig. 61 Earth terminal Fig. 62 Connecting earth wire

Page 47

Installation

9229 9992 176 0D 47

2013-07-08

Removing the transport securing device from the undervoltage release

Undervoltage release (Y7)

present?

The vacuum circuit-breaker with an undervoltage release (Y7) 3AX1103 is supplied

with a transport securing device.

• Remove the two top screws (60.2) from the cover (60.1).

• Undo the two bottom screws (60.2) on the cover (60.1) until the cover (60.1) can

be taken off.

• Slightly tilt the cover (60.1) of the mechanism box and lift off.

• Shift the locking screw of the striker from position A to B (see reference note in

mechanism box [60.] of the vacuum circuit-breaker).

• Replace the cover (60.1) in the reverse order

• and fasten the screws (60.2) with a tightening torque of 10 Nm.

Electrical connection of the prime conductor

The busbars can be purchased from the Siemens Service Center.

Busbar connection

Adjust the busbars in such a way that, before fastening, they lie flat easily and fit the

holes on the contact areas of the vacuum circuit-breaker.

Fig. 63 Removing the cover Fig. 64 Removing the transport securing device

A

B

DANGER

High-voltage - danger to life

Test the vacuum circuit-breaker in the switchbay with high-voltage applied only

after faultless functioning has been ascertained (see “Commissioning” on

page 51).

Note

Grease the busbars with contact grease prior to mounting.

Page 48

Installation

48 9229 9992 176 0D

2013-07-08

Preparing contact areas Use a steel brush to carefully brush the contact areas (cross-wise) of the busbars

until they are metallically bright and wipe off any residue using a clean cloth.

After cleaning, very lightly grease the bright contact areas with acid-free Vaseline

(e. g. Shell-Vaseline 8420) and screw together immediately.

Fig. 65 Cleaning the contact areas Fig. 66 Cleaning the contact areas of the busbars

Note

Clean silver spray-plated and copper spray-plated contact areas with a cloth, do

not brush.

Different connection materials (AI/CU) must not be cleaned with the same

cleaning tools.

Silver-plated parts must not be bolted to aluminium bars/rails.

Page 49

Installation

9229 9992 176 0D 49

2013-07-08

Corresponding to the rated current strength, use M12 screws and nuts - strength

class 8.8 - for connection of the busbars and use the appropriate spring elements

and washers.

When tightening the screws, hold the nuts against tightening torque of 70 Nm with

a suitable screwdriver or socket wrench.

Screw-in depths in the upper and lower terminals

See dimension drawings.

Fig. 67 Installing busbars flat Fig. 68 Installing busbars flat

Note

For vacuum circuit-breakers with connecting bars, it is recommended to use the

stainless steel screws or non-magnetisable screws included in the accessory

pack.

Page 50

Installation

50 9229 9992 176 0D

2013-07-08

Blank page

Page 51

Operation

9229 9992 176 0D 51

2013-07-08

Operation

Commissioning

Before commissioning, check the following points to ensure that the 3AH37/38

vacuum circuit-breaker is functioning faultlessly:

DANGER

High-voltage - danger to life

Touching live parts causes an electric shock.

• Do not touch live parts!

• Ensure that the vacuum circuit-breaker is operated only by qualified

personnel who are familiar with the operating instructions and observe the

warning notices.

• Check through all of the items on the checklist and ensure correct functioning

before commissioning.

Checklist

Notes

Does the information on the rating plate (see page 34) match the ordering

data?

Ensure correct operating voltage.

If necessary, clean the vacuum circuit-breaker (details on this in section

“Cleaning” on page 55).

Check that screw connections are tightened securely.

Check terminal strip plug-connection for tightness.

Check functioning of the auxiliary switches.

If necessary, check and adjust customer's devices.

If there is an undervoltage release (Y7) 3AX1103 : has the locking screw

of the striker been shifted from position A to B (see “Removing the

transport securing device from the undervoltage release” on page 47)?

Test switching without supply voltage

Charge the closing spring (62.) with the hand crank (50.) (see Fig. 70),

then actuate the CLOSE pushbutton (53.) and, once closing has been

performed, actuate OPEN pushbutton (54.) .

Test switching with supply voltage

For test switching with motor, switch on the supply voltage. The motor

starts up immediately and charges the closing spring (62.). Check

indicator for charge state of the closing spring (mechanically and

electrically).

Electrically check through auxiliary switch S1 (68.) and position switch

(50.4.1) in both end positions – operate the 3AH37/38 vacuum

circuit-breaker to do so.

Check functioning of the closing solenoid Y9 (53.1) and all available shunt

releases by operating them electrically.

Page 52

Operation

52 9229 9992 176 0D

2013-07-08

First closing operation

If all functions have been checked and are ok, switch on high-voltage while

observing all of the safety regulations and operative requirements.

Charging the closing spring

If the supply voltage is applied, the closing spring (62.) is automatically charged by

the motor (50.4).

Hand crank If the supply voltage fails, the closing spring (62.) can be charged with a hand

crank (50.).

1. For this, fit the hand crank (50.) onto the hand crank coupling (50.5) through

the opening (50.1) with the adapter pushed forward (50.6).

69.Turn clockwise until the spring state indicator (55.) changes over:

WARNING

Do not commission the vacuum circuit-breaker if there are malfunctions.

If the malfunctions or the damage cannot be remedied, contact a Siemens

representative or Siemens Service and, if necessary, send back the vacuum

circuit-breaker .

WARNING

Risk of injury if hand cranks other than the original hand crank are used.

When the supply voltage is present, the motor immediately recharges the spring

after a closing operation. If the hand crank does not have a slip coupling, the hand

crank will also rotate.

To avoid injuries caused by the motor starting suddenly, the vacuum circuitbreaker must be charged only using the original hand crank.

Discharged Charged

Fig. 70 Charging the closing spring with the hand

crank

Fig. 71 Operating elements and spring state indicator

Page 53

Operation

9229 9992 176 0D 53

2013-07-08

The adapter (50.6) of the hand crank (50.) is designed in such a way that the hand

crank becomes uncoupled when the motor supply voltage returns.

Closing

Provided there is no lock-out due to a mechanical interlock, send the closing

command via the CLOSE pushbutton (53.) or the corresponding command element

until the vacuum circuit-breaker is closed and shows and signals the CLOSED

position.

Change of the position indicator (59.):

After switching on and possibly releasing the CLOSE pushbutton (53.), the closing

spring (62.) is immediately automatically charged by the motor and the symbol for

"Closing spring charged" becomes visible in the spring state indicator (55.).

Change of the spring state indicator (55.):

Opening

The opening spring (64.) is charged during the closing operation.

To open, send the opening command via the OPEN pushbutton (54.) or the

corresponding command element until the vacuum circuit-breaker is open and

shows and signals the OPEN switching position.

Change of the switching position indicator (59.) after electrical opening:

The spring state indicator (55.) does not change.

Discharging the closing spring

To discharge the closing spring,

• the supply voltage must be deactivated

• on the vacuum circuit-breaker, actuate the OPEN, CLOSE and OPEN

pushbuttons manually one after the other.

This ensures that the vacuum circuit-breaker is open and the closing spring is

discharged.

OPEN CLOSED

Charged Discharged Charged

Note

If an undervoltage release 3AX1103… is fitted, it must be connected to control

voltage for switching operations (mechanical or electrical), as otherwise closing

is not possible.

CLOSED OPEN

Page 54

Operation

54 9229 9992 176 0D

2013-07-08

Blank page

Page 55

Maintenance

9229 9992 176 0D 55

2013-07-08

Maintenance

Maintenance and servicing

The vacuum circuit-breaker 3AH37/38 is maintenance-free under normal operating

conditions. The maximum permitted mechanical operating cycle number is 10 000.

We recommend you carry out regular visual inspections all the same.

Cleaning

The insulating parts must be clean if their insulating capacity is to be guaranteed.

Wipe insulating parts and any outer circuit-breaker parts with a damp cloth. As a

cleaning agent, use only warm water with a mild, liquid household detergent added.

Special operating conditions

If the vacuum circuit-breaker 3AH37/38 is operated under unfavourable indoor

conditions that deviate from the normal operating conditions (frequent heavy

condensation, dusty air etc.), we recommend regular cleaning of the outer circuitbreaker parts and renewing the corrosion protection, if applicable.

For this, only the following agents may be used on the individual functional parts of

the circuit breaker:

Lubricant:

DANGER

High-voltage - danger to life

Touching live parts is fatal or causes serious physical injury.

Before beginning maintenance work, note the five safety rules for high-voltage

equipment specified in EN 50110-1, namely:

• Isolate from the power supply*)

• Secure against reclosing

• Verify safe isolation from the power supply

• Earth and short-circuit

• Cover or cordon off neighbouring live parts

*

)

On the vacuum circuit-breaker, actuate the OPEN, CLOSE and OPEN

pushbuttons manually one after the other. This ensures that the vacuum circuitbreaker is open and the closing spring is discharged.

Note

The vacuum circuit-breaker should be taken out of the switch cabinet or

switchgear for servicing.

Note

Joints and bearings that cannot be disassembled must not be washed out with a

detergent prior to work.

Bearings, sliding surfaces: Isoflex Topas L 32

Bearings and bearings of the auxiliary switch S1

that are inaccessible in terms of greasing:

Shell Tellus Oil 32

Page 56

Maintenance

56 9229 9992 176 0D

2013-07-08

Lubricants are available from the responsible Siemens representative:

Fig. 72 Bearings and sliding surfaces of the pole side

Order no.

180 g Klüber-Isoflex Topas L 32 3AX11 33-3H

1 kg Shell Tellus Oil 32 (special oil) 3AX11 33-2D

1 kg Klüber-Isoflex Topas L 32 3AX11 33-3E

Isoflex Topas L 32

t Bolts of the angle lever

u Bolts and eyebolt of the insulating operating rod

v Contact pressure spring, spring plate and spring bearing

w Spring guide and bolts of the angle lever

Page 57

Maintenance

9229 9992 176 0D 57

2013-07-08

Fig. 73 Bearings and sliding surfaces of the operating mechanism

Isoflex Topas L 32 Shell Tellus Oil 32

a Crankpin for sensing device actuation b Bearing for deflection lever

c Curve contour f Auxiliary switch

d Close-latch j Circuit-breaker shaft bearing

e Deflection of auxiliary switch p Opening spring bearing

g Opening spring guide r Spring eyelet on closing spring

h Deflection of auxiliary switch

kOPEN-latch

l Curve for OPEN-latch

m End stop

s Contact area of instantaneous release

Page 58

Maintenance

58 9229 9992 176 0D

2013-07-08

Interrupter service life

If switching operations occur frequently under overload or short circuit, the service

life of the vacuum interrupters may be reached prematurely.

Replace the interrupters after reaching the maximum permitted operating cycle

number of 10 000 mechanical or electrical load setting changes (up to the rated

current).

Short-circuit deactivations were proven as per IEEE C37.013 under various

conditions.

Accessories and spare parts

Replacing spare parts To ensure that the device operates reliably, spare parts must be replaced only by

trained and certified personnel.

Fig. 74 Accessories available for order

Always specify the vacuum circuit-breaker's type and serial no. (see “Rating plate”

on page 34) when ordering spare parts.

CAUTION

Risk of injury!

The vacuum circuit-breaker should be taken out of the switch cabinet or

switchgear for servicing.

Separate vacuum circuit-breakers from the control feed voltage or switch it off

and release low-voltage plug or clip connection.

Accessories/spare part Order no. Comments

Operating instructions 9229 9992 100

Hand crank 3AX1530-2B

Klüber lsoflex Topas L32 lubricant 3AX1133-3H 180 g

3AX1133-3E 1 kg

Shell Tellus lubricant 3AXl 133-2D 1 kg tin

Vaseline (contact grease)

e. g. Atlantic white, Atlantic Mineralölwerk GmbH

Pasty consistency, flame point

210 °C, low acid

Page 59

Maintenance

9229 9992 176 0D 59

2013-07-08

Manufacturer's product liability

The manufacturer's product liability shall be excluded if at least one of the following

criteria applies:

• Original Siemens spare parts are not used.

• Fitters carrying out replacements have not been trained and certified by

Siemens.

• Parts have been incorrectly fitted or adjusted.

• Adjustments are not made in accordance with Siemens specifications.

• After installation and adjustment, no final test is performed with a tester

approved by Siemens including documentation of the test results.

To keep documentation complete, it is important that measurement results are

submitted to the responsible Siemens representative.

Disposal

The materials of the vacuum circuit-breaker should be recycled. Disposal of the

vacuum circuit-breakers with minimum environmental impact is possible on the

basis of existing legal regulations.

Metal The circuit breaker's metal components can be recycled as mixed scrap, although

wide-ranging dismantling into sorted scrap and mixed scrap residues is more

environmentally sustainable.

Electronics Electronic scrap must be disposed of in accordance with applicable regulations.

Materials The vacuum circuit-breaker consists of the following materials:

• Steel (partly phosphatised, galvanised and yellow chromated)

• Copper (partly silver-plated)

• Plastics (epoxy resin, polyamide, polyester, polycarbonate, ABS-PC mixture;

partly glass fibre reinforced)

• Rubber materials

•Ceramics

•Lubricant

Packaging If the packaging is no longer needed, it can be fully recycled.

Hazardous substances When delivered by Siemens, the product does not contain any hazardous substances

within the scope of the hazardous substances regulations applicable to the territory of

the Federal Republic of Germany. For operation outside the Federal Republic of

Germany, the applicable local laws and regulations must be complied with.

Further information Contact your Siemens Service Center if you require further information.

Service

For details of contacts for service work, consult Siemens IC LMV SE Services at

• Telephone: +49 180/5247000

• Fax: +49 180/5242471 or

• on the Internet at the Web address: www.siemens.com/energy-support

• by e-mail: support.energy@siemens.com

• or any local Siemens office.

Page 60

Maintenance

60 9229 9992 176 0D

2013-07-08

Blank page

Page 61

Index of keywords

9229 9992 176 0D 61

2013-07-08

Index of keywords

A

Accessories available for order

............................. 58

Altitude correction factor

....................................... 36

Ambient conditions

................................................ 36

Angle lever

............................................................ 20

Auxiliary switch

..................................................... 22

B

Basic equipment

................................................... 23

Bearings and sliding surfaces

............................... 57

Busbars

................................................................. 49

C

Centering

.............................................................. 20

Circuit-breaker shaft

.............................................. 22

Circuit-breaker tripping signal

............................... 27

Climate classes

..................................................... 36

Closing damper

..................................................... 22

Closing solenoid

............................................ 22, 25

Closing spring

............................................... 22, 31

Contact pressure spring

........................................ 19

Contact stroke

....................................................... 20

Contact system

..................................................... 20

Contactor relay

...................................................... 22

Contactor relay K1

................................................ 24

Cover

.................................................................... 21

Cut-out switch

....................................................... 27

D

Dashpot

................................................................. 22

Disconnected position