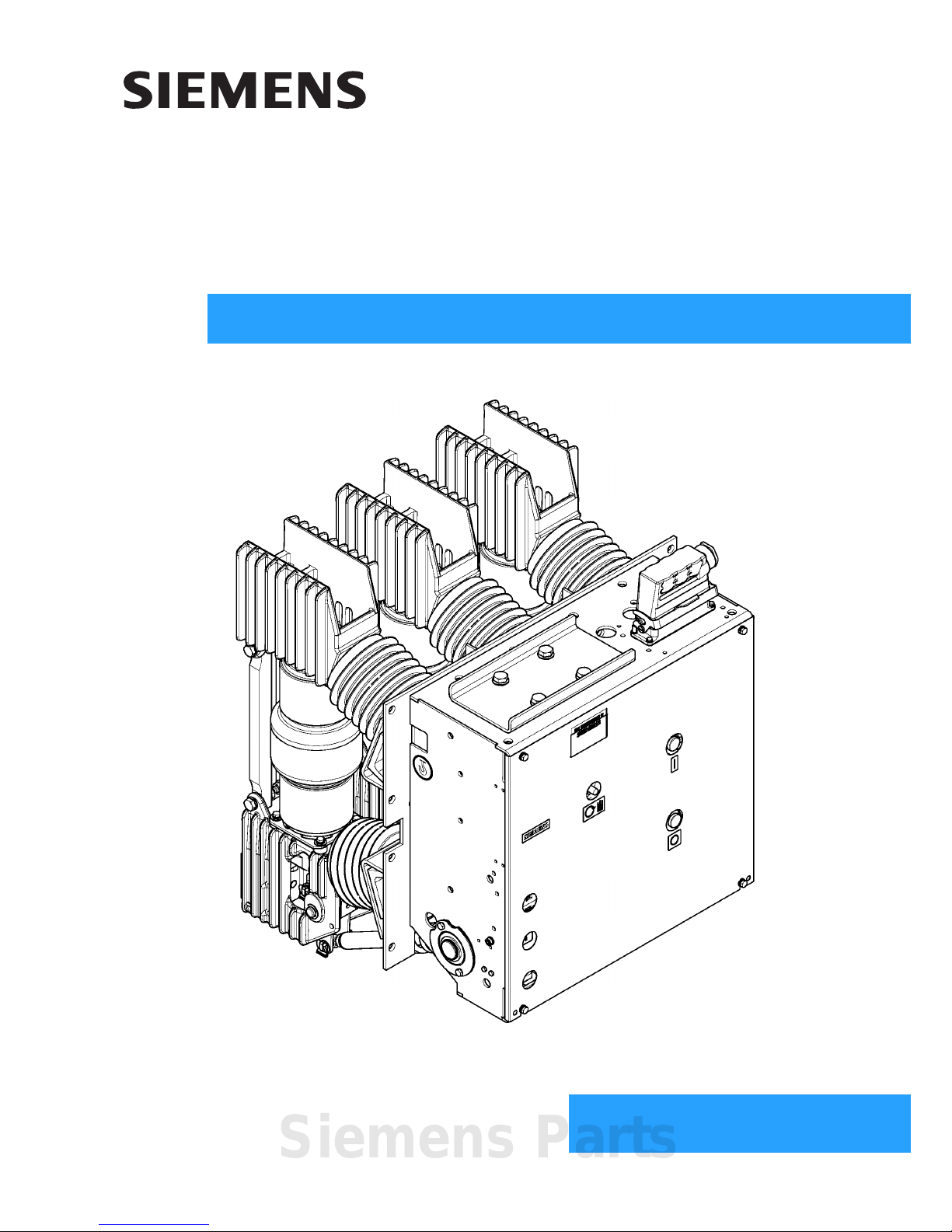

Siemens 3AH3, 3AH33, 3AH30 Operating Instructions Manual

© Siemens AG 1996. All rights reserved.

3AH3

Vacuum circuit-breaker

3AH30 ... 3AH33

OPERATING INSTRUCTIONS

Order no.: 9229 9860 176 0E

Ordering location: IC LMV LP PO P C41

AG 08.2013 en

Siemens Parts

2 9229 9860 176 0E

2013-08-22

For your safety

Signal terms and defini-

tions

Hazards are classified in accordance with ISO 3864-2 using the following keywords:

• DANGER, WARNING or CAUTION, where there is a risk of personal injury

• NOTE, where there is a risk of material damage.

Hazards are classified and indicated in the operating instructions and on the vacuum

circuit-breaker as follows:

Qualified personnel are, for the purposes of this manual or the warning notices on the vacuum circuit-

breaker, persons who are familiar with the transport, storage, placement, assembly,

commissioning, operation and maintenance of the product and have the qualifications corresponding to their activity, such as:

• training and authorization to energise, de-energise, clear, earth and tag circuits

and equipment in accordance with established safety practices.

• training in the proper care and use of protective equipment in accordance with

established safety practices;

• training in providing first aid.

Product liability

DANGER

signal word used to indicate an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING

signal word used to indicate a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION

signal word used to indicate a potentially hazardous situation which,

if not avoided, could result in minor or moderate injury.

Note

indicates a potentially damaging situation.

If the damaging situation is not avoided, the product or something in its vicinity

may sustain damage.

Note

Product liability claims are upheld only if the replacement of the purchased spare

parts is performed by personnel that have been trained and certified by Siemens.

9229 9860 176 0E 3

2013-08-22

Table of contents

For your safety .................................. ................................................................ ................................................. 2

Transport, storage and packing .............................. ............. ............. ............. ............. ............ ............. ....... 5

Transport ................................ ................ ................ ................ ................. ................ ..............................................5

Unpacking (I) .........................................................................................................................................................6

Unpacking (II) ..................................................................................................................................................... 10

Unpacking (III) .................................................................................................................................................... 12

Reusing the transport unit .................................................................................................................................. 15

Storage ...............................................................................................................................................................15

General information ....................................................................................................................................... 17

Range of application ...........................................................................................................................................17

Standards ..................................... ................. ................ ................ ................ ..................................................... 18

Design approval as per X-Ray Ordinance ..........................................................................................................18

Scope of delivery ................................................................................................................................................18

Description ........................................................................................................................................................ 19

Design ....................................... ................................................. .........................................................................19

Locking devices ................................................................................................................................................. 32

Rating plate ...................................... .......................................... ... ... .................................................................. 35

Technical data .....................................................................................................................................................35

Ambient conditions ............................................................................................................................................. 36

Installation altitudes ............................................................................................................................................36

Switching times .................................................................................................................................................. 37

Circuit diagrams ................................................................................................................................................. 38

Mounting ....................................... .......................... ............................. ............................. .................................. 43

Attachment in the switching cubicle .............................................................. ... ... .... ... .........................................43

Earthing ..................................... .................... ................... ................... .................... ........................................... 45

Electrical connection of the prime conductor ................................................................... .... ... ........................... 47

Operation .......................................... ................................ ............................. ..................................................... 49

Commissioning ...................................................................................................................................................49

First closing operation .........................................................................................................................................50

Closing ................................................................................ ................................................................................51

Opening ..............................................................................................................................................................51

Maintenance .................................... ................................................................... ............................................... 53

Maintenance and servicing .................................................................................................................................53

Interrupter service life ..... .... ... ... ... .... .......................................... ... ... .................................................................. 56

Accessories and spare parts ...............................................................................................................................56

Manufacturer's product liability ........................................................................................................................... 57

Disposal ..............................................................................................................................................................57

Service ................................... ............................................................................. ................................................57

Index of keywords .......................................................................................................................................... 59

Legend for all pages ...................................................................................................................................... 61

Note

Sections with Addendum (I), (II) or (III)

Sections with Addendum (I) refer to vacuum circuit-breakers with a rated operating current of < 3150 A. Sections

with Addendum (II) refer to vacuum circuit-breakers packed with brackets with vertical connecting bars and a rated

operating current of ≤ 4000 A. Sections with Addendum (III) refer to vacuum circuit-breakers with a rated operating

current of 3150 A.

If no addendum is given, the information is applicable for all 3AH3 vacuum circuit-breakers.

Siemens Parts

4 9229 9860 176 0E

2013-08-22

Blank page

Transport, storage and packing

9229 9860 176 0E 5

2013-08-22

Transport, storage and packing

Transport

Transport weight Refer to the delivery slip for the weight of the transport unit.

Place the transport unit on a level, non-slip and pressure-resistant surface for intermediate storage.

Transport vacuum circuit-breaker in the original transport unit up to the installation

site or storage location.

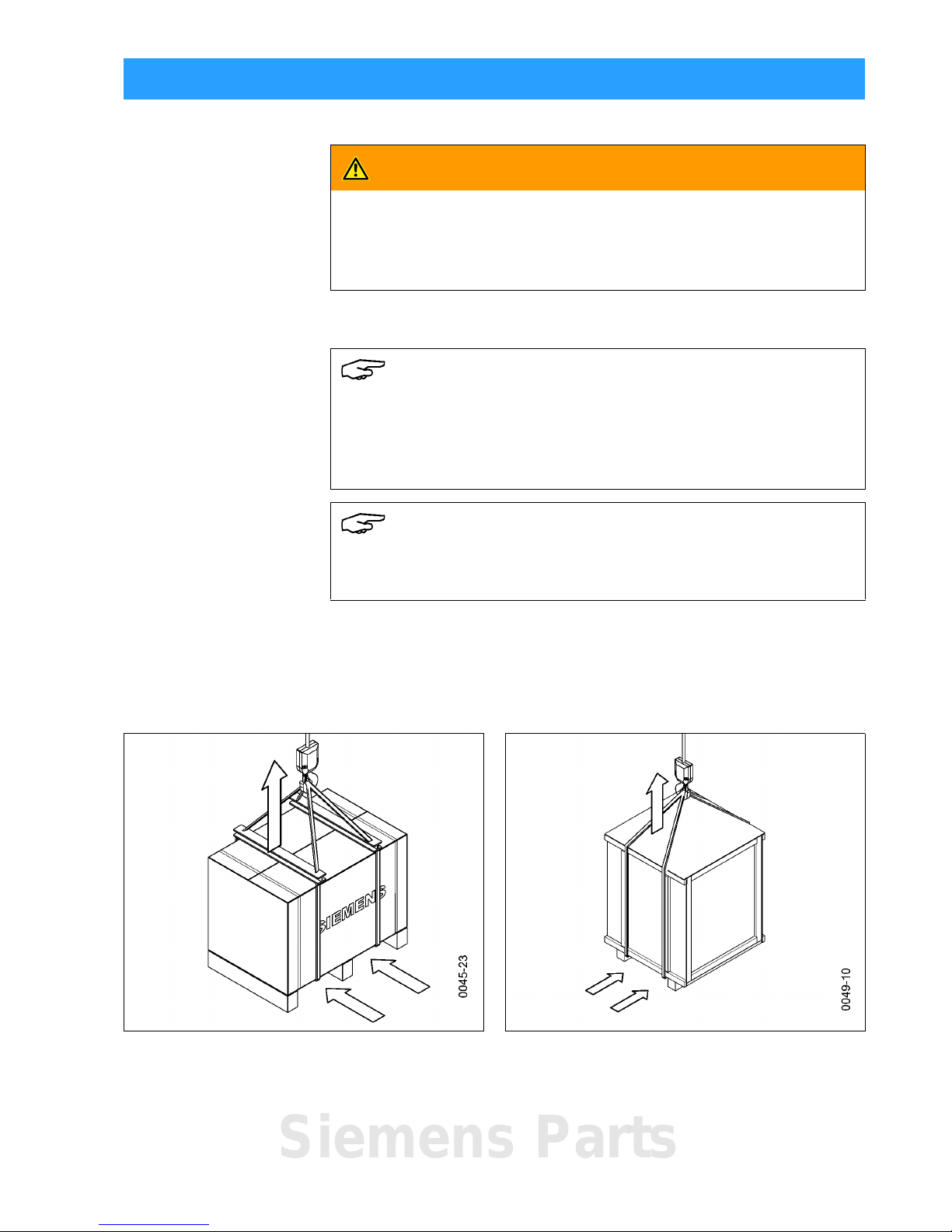

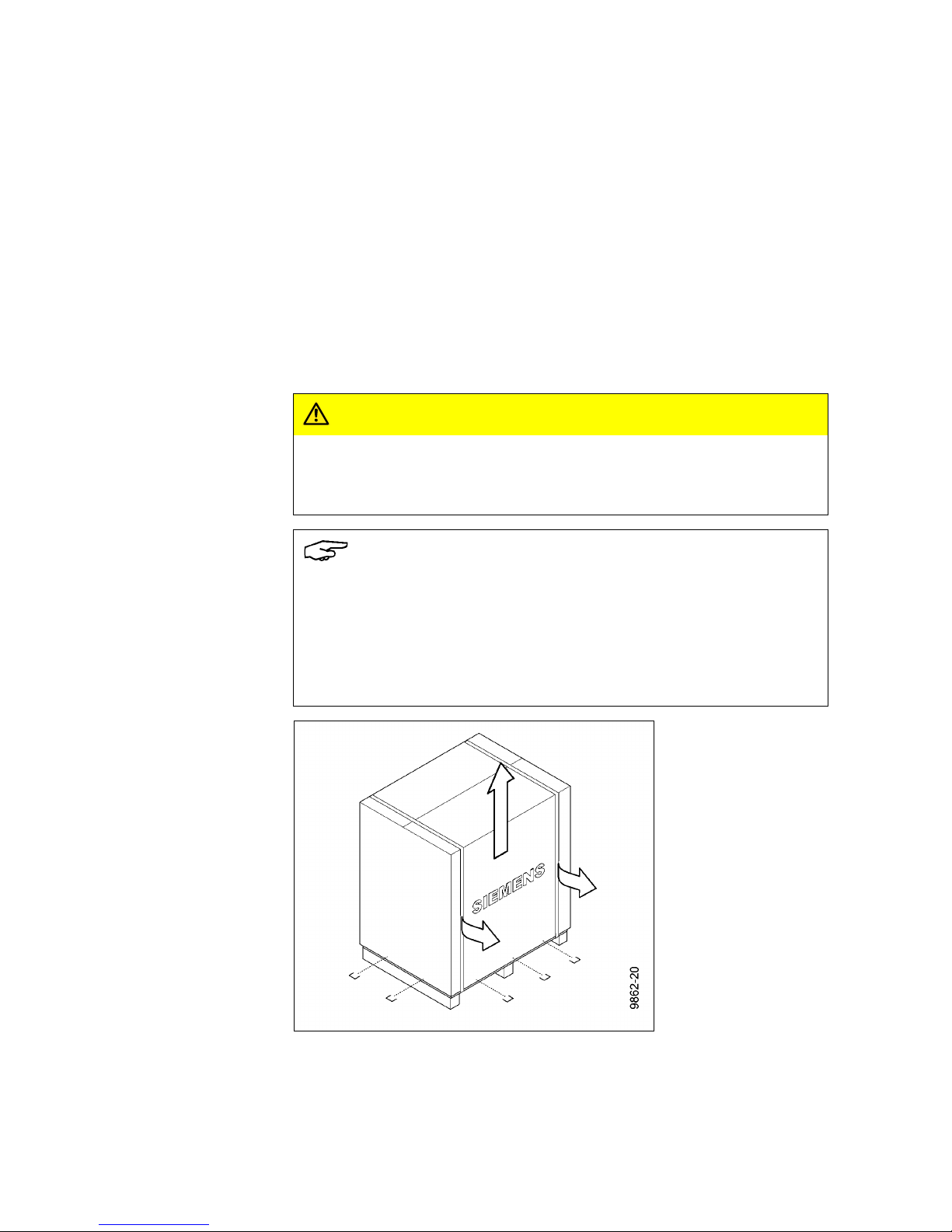

Transporting with crane or fork lift

WARNING

Heavy transport weight

Transport unit may fall and fail and sling gear may break.

Use lifting gear, transporting and sling gear suited to the requirements and load-

carrying capacity. Observe transport symbols.

Note

Observe stacking height

For transport, no more than three constructionally identical transport units must

be piled on top of each other.

Observe the loads specified on the transport unit.

Note

Secure load

For transport, secure the load in such a way that the transport unit is not at risk.

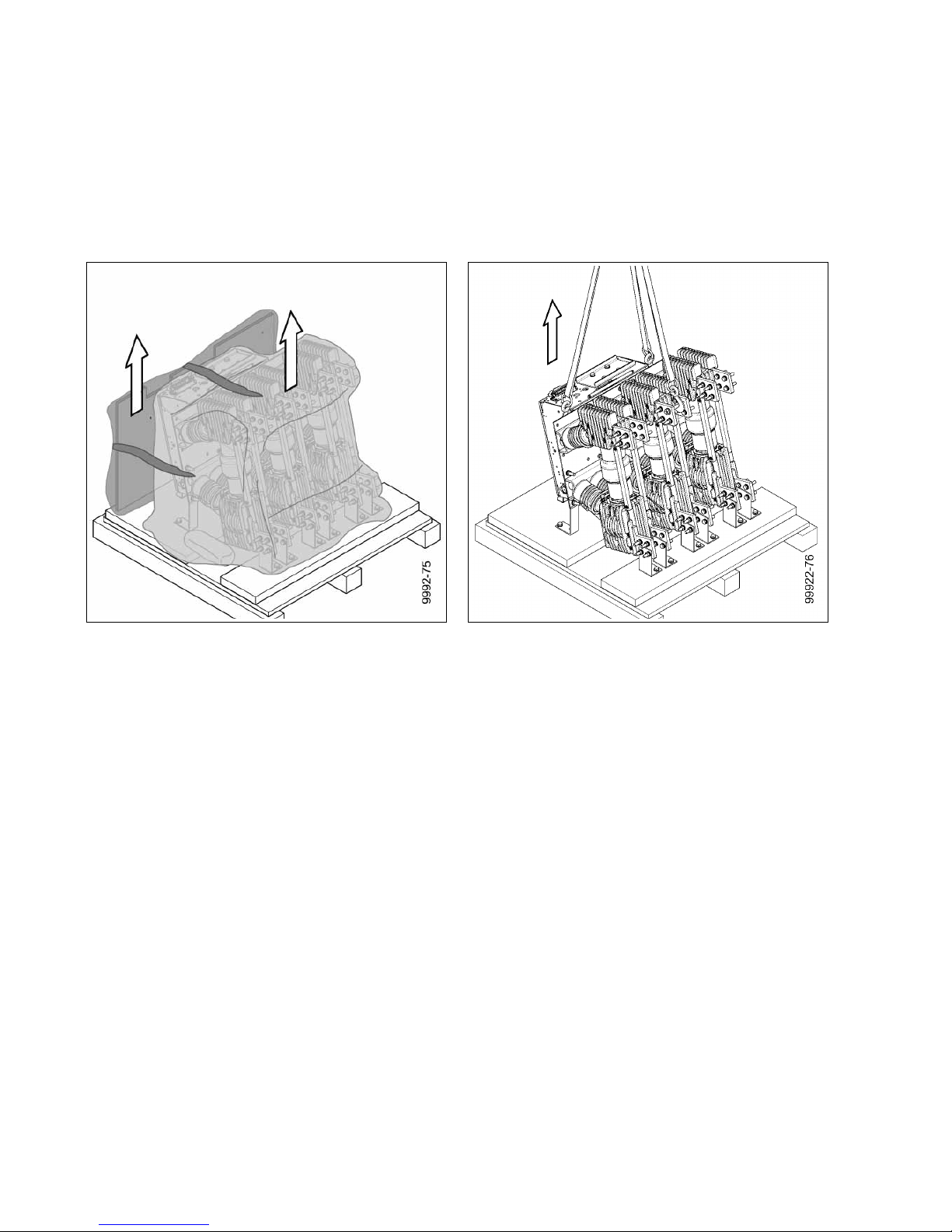

Fig. 1 Transporting the pallet with carton (I) Fig. 2 Transporting the wooden case (III)

Siemens Parts

Transport, storage and packing

6 9229 9860 176 0E

2013-08-22

Transporting with packing Transport the transport unit to the installation site or storage location

• with a fork lift or

• with sling gear suspended from a crane

- at an angle of twist of approx. 60° or

- with a spreader bar.

After receipt of delivery:

Checking the transport

unit

• Check transport unit for damage.

• Major damage must be documented photographically.

• Ensure that any damage to the transport unit is confirmed by the transport company.

Unpacking (I)

Working equipment Required tools:

- Knife/scissors

- Lifting equipment with lifting gear

- Pliers or lever.

Opening the transport unit • Place the transport unit on a level, non-slip and pressure-resistant surface.

• Remove lifting gear or transport means.

• Remove plastic wrap.

• Lever out fasteners from the carton and lift off carton.

CAUTION

Risk of injury from sharp edges!

Fasteners may break, leaving sharp edges.

Always use a suitable tool to lever out fasteners.

Note

Do not cut open or damage the carton, since it is designed t o be reused and

because of the belt straps located underneath.

Belt straps could be severed on the pallet floor when cutting open the carton.

The vacuum circuit-breaker is attached to the pallet with belt straps. It is not pos-

sible to transport the vacuum circuit-breaker on the pallet without using belt strap s

(see Fig. 5).

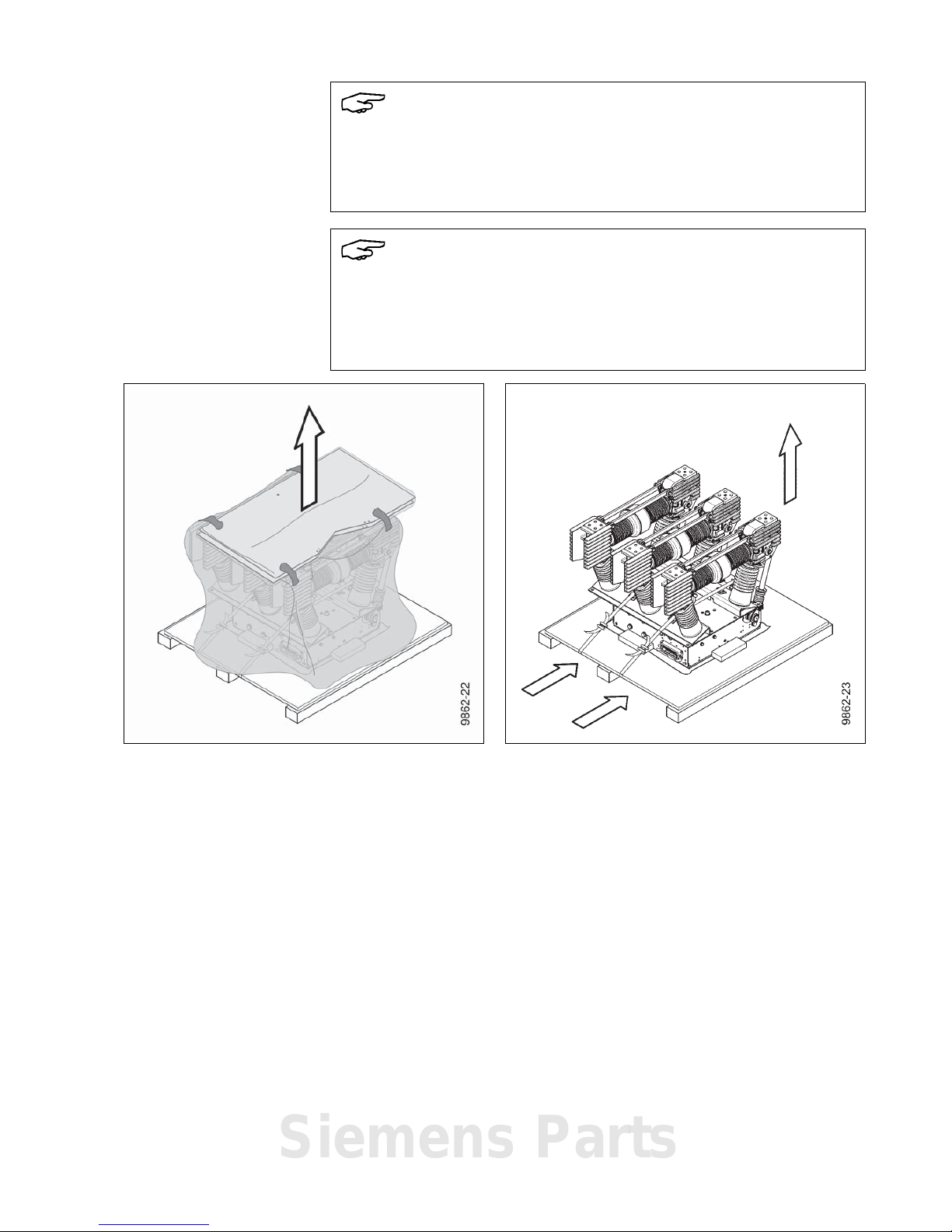

Fig. 3 Removing the carton

Transport, storage and packing

9229 9860 176 0E 7

2013-08-22

• Remove partitions and accessory pack and store safely in the packaging for

later attachment.

• Remove film from the vacuum circuit-breaker.

• In the case of overseas packaging, push the lower film onto the pallet floor.

• Check the delivery is complete.

• Check vacuum circuit-breaker for damage.

• If the vacuum circuit-breaker is damaged, ship it back in the original transport

unit (see “Reusing the transport unit”, page 15).

Transporting with pallet,

without carton

The vacuum circuit-breaker can be transported with the pallet, without the carton.

• Thread carrying straps under the pallet or

• transport with fork lift.

Note

Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks,

flaking, bent metal parts, damaged plug-in contacts, tears or bare cables.

Send it back in its original transport unit (see “Reusing the transport unit”,

page 15).

Note

Carrying straps may scrape along the vacuum circuit-breaker and damage it.

If necessary, cover carrying straps with edge protection.

Select length and position of the carrying straps so that the pole heads are not

compressed.

Fig. 4 Removing partitions and film Fig. 5 Transporting with pallet possible

Siemens Parts

Transport, storage and packing

8 9229 9860 176 0E

2013-08-22

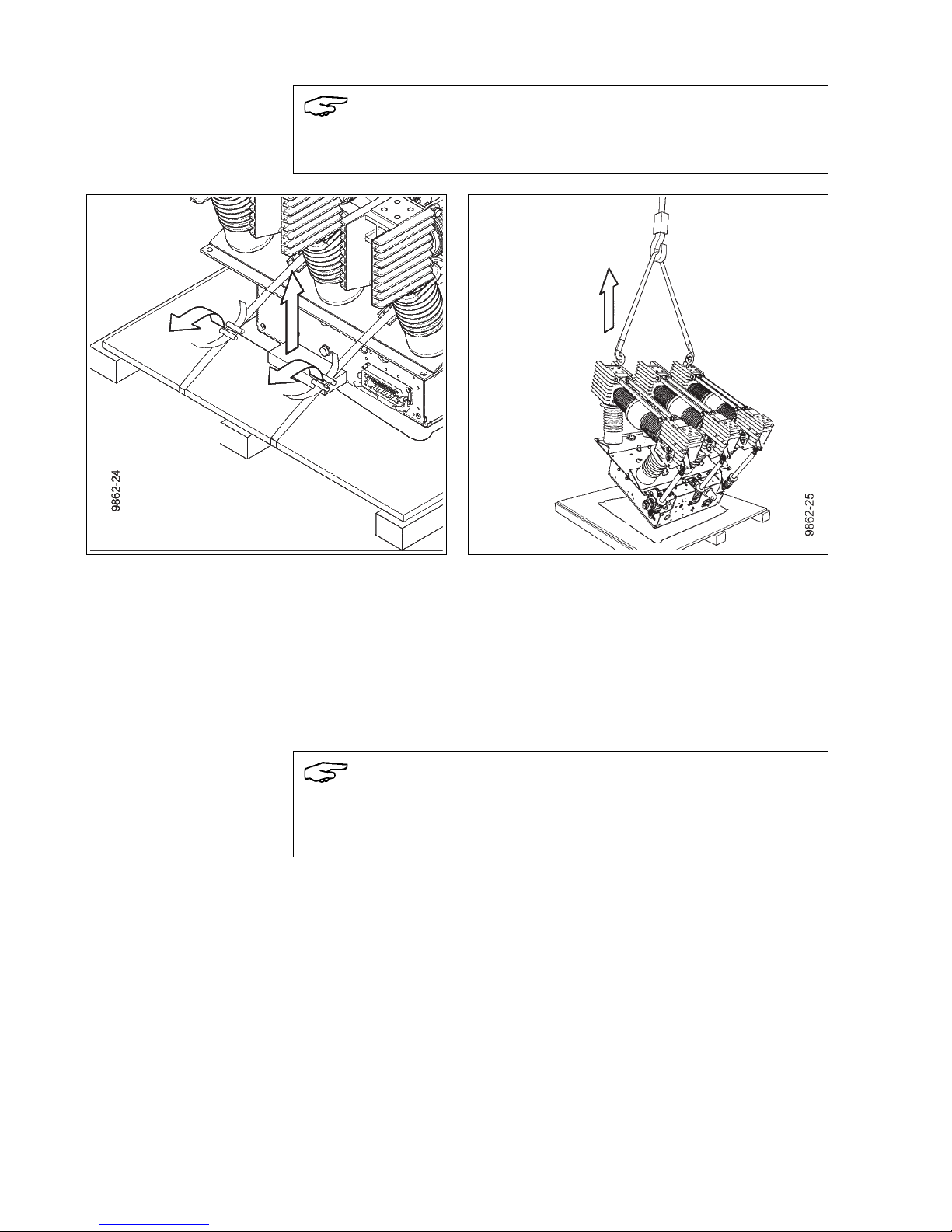

Transporting without pallet • Remove all tensioning belts and bits of fastening wood.

• Remove accessory pack, if applicable.

• Screw suitable eyebolts into the outer pole heads parallel to each other.

• Hang sling gear into the eyebolts.

• Carefully lift vacuum circuit-breaker off the pallet just enough that pieces of

square timber can be placed underneath.

Note

When fastening the eyebolts to the pole heads, ensure that the contact surfaces

are not damaged.

Fig. 6 Removing the tensioning belts Fig. 7 Screwing in eyebolts and lifting the vacuum

circuit-breaker

Note

Place pieces of square timber onto the pallet in such a way that the insulating

operating rods, contact pressure springs, angle levers and dashp ots are not damaged when setting down.

Transport, storage and packing

9229 9860 176 0E 9

2013-08-22

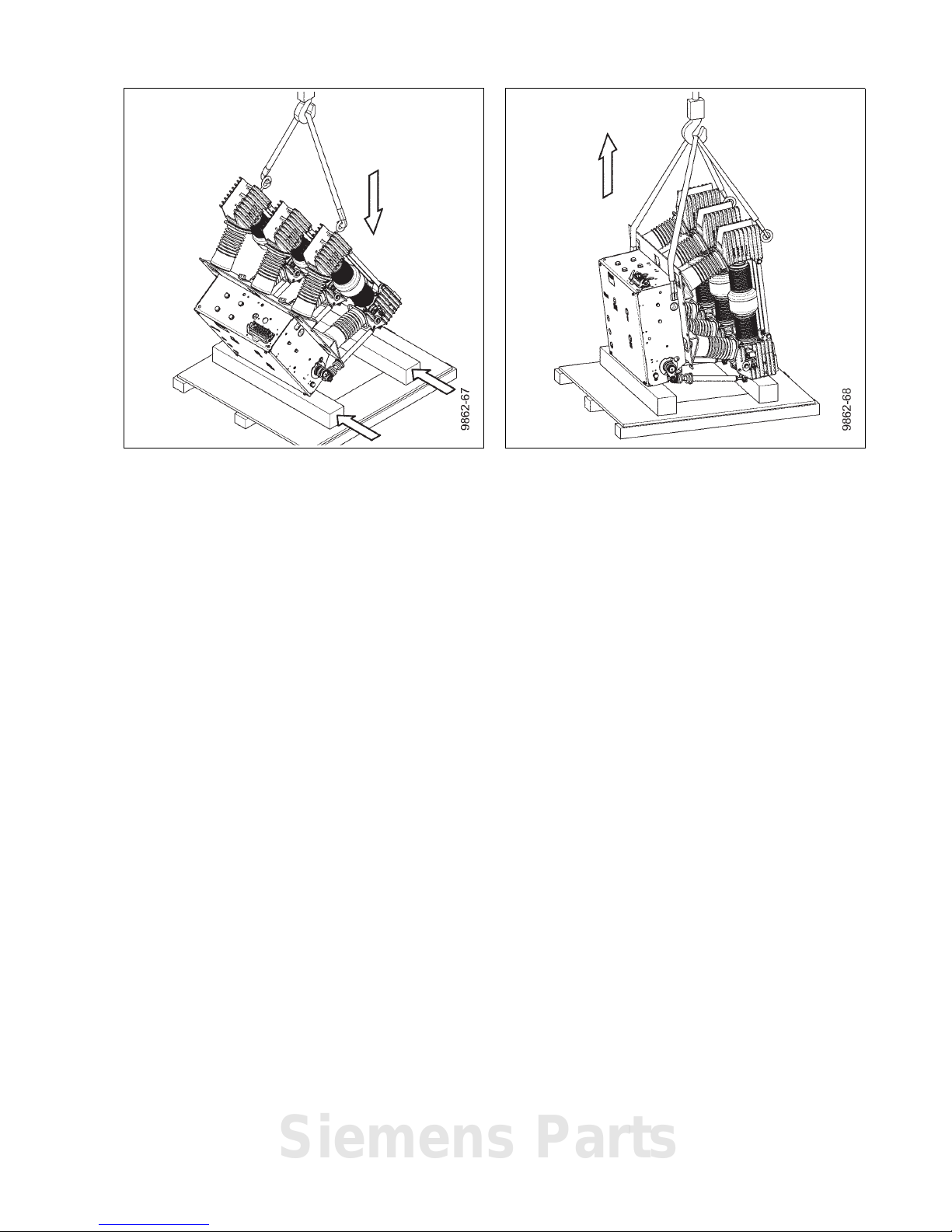

• Set the vacuum circuit-breaker down onto the square timbers.

• Hang further sling gear into the transport boreholes.

• Transport to installation site or leave suspended from crane for further work

steps.

Fig. 8 Positioning the square timbers and setting

down the vacuum circuit-breaker

Fig. 9 Transporting without pallet

Siemens Parts

Transport, storage and packing

10 9229 9860 176 0E

2013-08-22

Unpacking (II)

Variant with brackets

Remove carton as described in Fig. 1 and Fig. 3.

Working equipment Required tools:

- Knife/scissors

- Screwdriver

- Open-end wrench

- Lifting equipment with lifting gear.

Transporting with brackets • Remove partitions and accessory pack and store safely in the packaging for

later attachment.

• Attach suitable bolt in the middle pole head.

• Attach sling gear to bolt and to transport boreholes.

Fig. 10 Removing partitions and film Fig. 11 Lifting the vacuum circuit-breaker

Transport, storage and packing

9229 9860 176 0E 11

2013-08-22

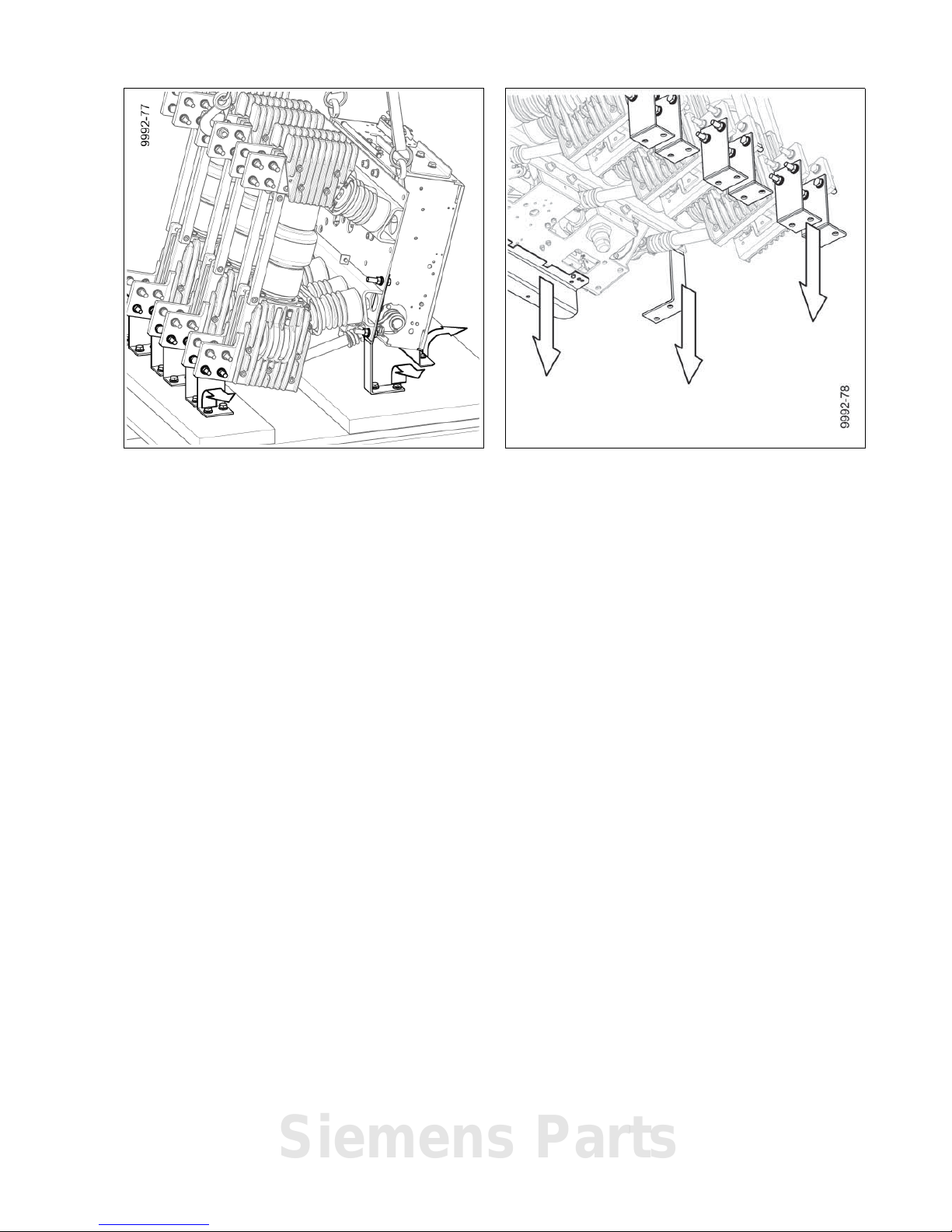

Transporting without

brackets

• Only lift the vacuum circuit-breaker far enough to put all sling gear under tension.

• Remove angle plate and bracket screws from the pallet.

• Lift the vacuum circuit-breaker from the pallet.

• Remove all screw connections from the brackets on the pole plate and the terminals.

• Remove angle plate below mechanism box.

• Transport to installation site or leave suspended from crane for further work

steps.

Fig. 12 Removing screws from the pallet Fig. 13 Removing the angle plate and brackets

Siemens Parts

Transport, storage and packing

12 9229 9860 176 0E

2013-08-22

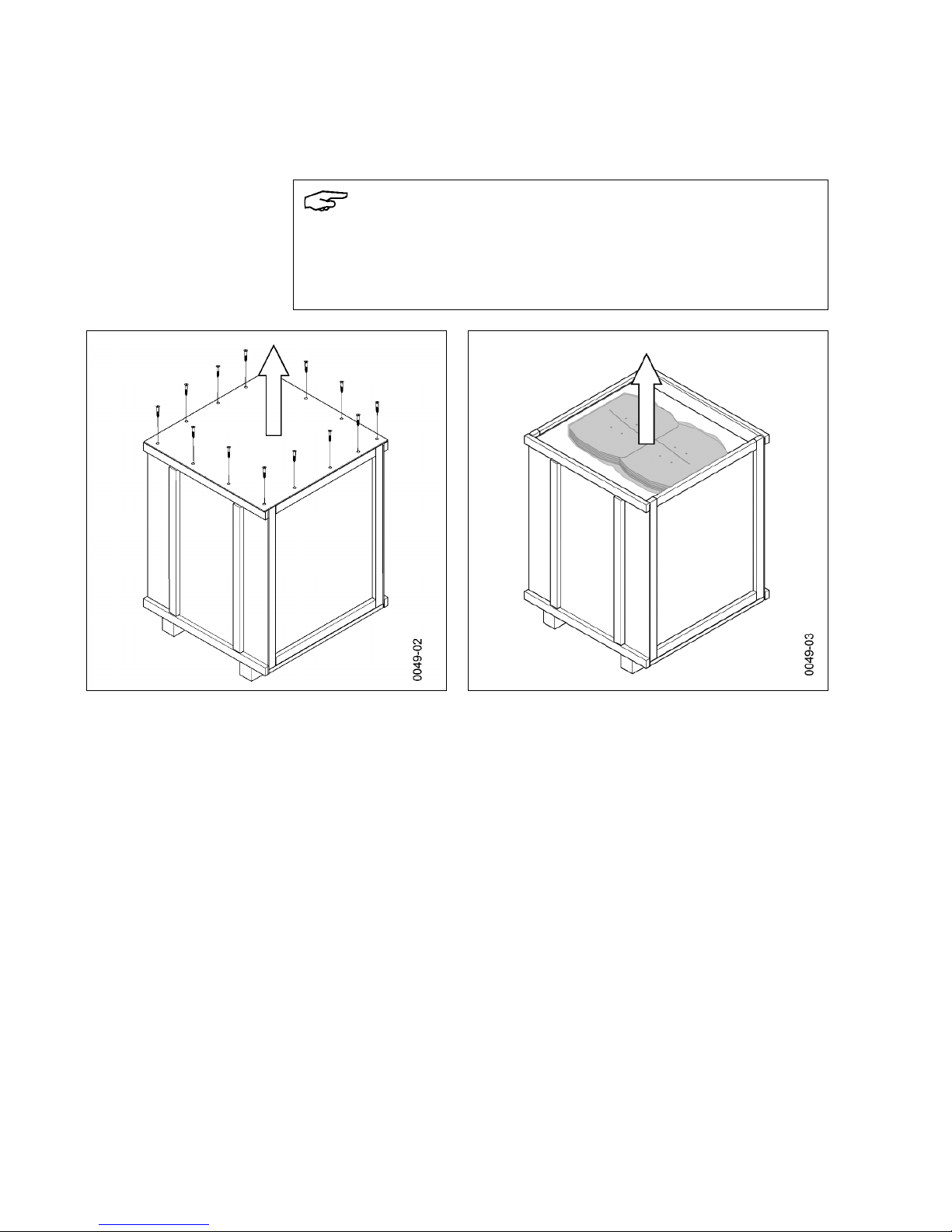

Unpacking (III)

Working equipment Required tools:

- Screwdriver

- Knife/scissors

- Lifting equipment with lifting gear.

Opening the transport unit • Place the transport unit on a level, non-slip and pressure-resistant surface.

• Remove lifting gear or transport means.

• Unscrew all the screws from the cover and lift it off.

• Remove partitions and store safely in the packaging for later attachment.

Note

Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks,

flaking, bent metal parts, damaged plug-in contacts, tears or bare cables.

Send it back in its original transport unit (see “Reusing the transport unit”,

page 15).

Fig. 14 Removing the cover Fig. 15 Taking out the partitions

Transport, storage and packing

9229 9860 176 0E 13

2013-08-22

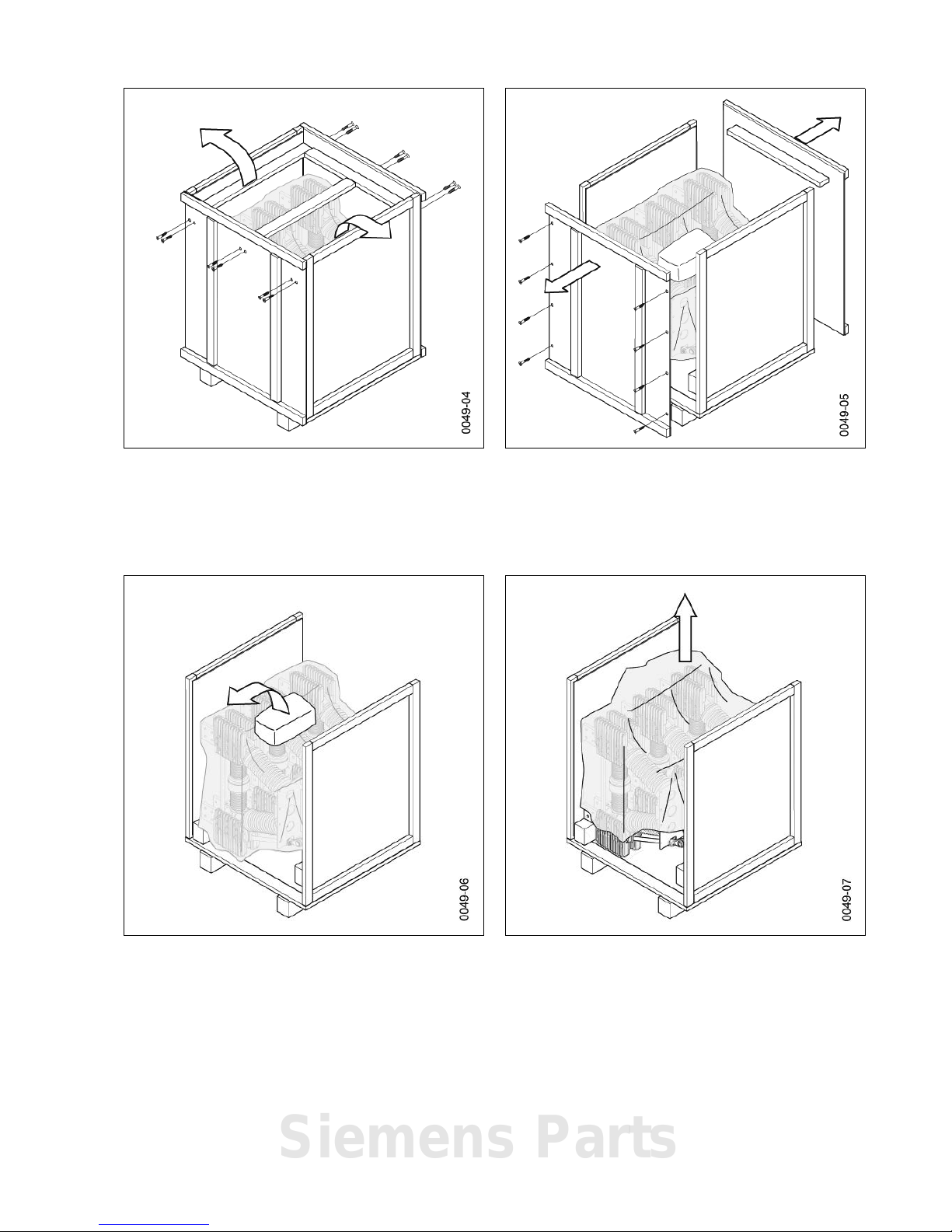

• Unscrew all the screws from the side walls.

• Take the supports out of the transport unit.

• Remove the side walls.

• Remove accessory pack and store safely in the packaging for late r attachment.

• Remove film from the vacuum circuit-breaker.

• Check the vacuum circuit-breaker for damage.

• Undo tensioning belts, if applicable.

Fig. 16 Removing the supports Fig. 17 Removing the side walls

Fig. 18 Taking out the accessory pack Fig. 19 Removing the film

Siemens Parts

Transport, storage and packing

14 9229 9860 176 0E

2013-08-22

Transporting to the instal-

lation site

• Hook crane hooks into the transport screws and into the openings on the mechanism box.

• Observe crane hook symbols.

• Vertically lift out vacuum circuit-breaker.

• Transport to installation site or leave suspended from crane for further work

steps.

CAUTION

Crushing hazard

Hands may get crushed when lifting out the vacuum circuit-breaker.

Do not reach between the transport box and the vacuum circuit-breaker.

Fig. 20 Preparing for lifting out Fig. 21 Lifting out

Note

Keep partitions and accessory pack ready for the installation.

Transport, storage and packing

9229 9860 176 0E 15

2013-08-22

Reusing the transport unit

Reusing the transport unit To transport the vacuum circuit-breaker again, the pallet with carton or the wooden

case with the most components can be reused.

Do not reuse severed tensioning belts or plastic wrap.

Pack the vacuum circuit-breaker in reverse order:

• Attach the vacuum circuit-breaker safely to the pallet using the appropriate

tools.

• Cover with film and seal with adhesive tape.

• Attach accessories pack.

• Attach carton securely to the pallet floor.

• Screw the wooden case back together.

• Before returning to the factory, ask the responsible sales representative for a

returned goods number (see also “Service”, on page 57).

• When returning a vacuum circuit-breaker, always indicate the type and serial

number (see “Rating plate”, on page 35).

Storage

Note

Store the vacuum circuit-breaker in the following condition:

• OPEN switching position

• Closing spring discharged

Note

Risk of corrosion damage if stored improperly!

If the storage conditions listed below are met, the vacuum circuit-breaker can be

stored for up to a year in its transport unit.

If the storage conditions are not met, the vacuum circuit-breaker ca nnot be stored

in the transport unit any longer than 6 months.

If storage of longer than one year is planned, unpack the vacuum circuit-breaker

from the transport unit. Further storage may necessitate fresh corrosion protection, and it must be ensured that the vacuum circuit-breaker cannot be damaged.

Storage room Transport unit Storage

time

Temperature

range

Comments Number of

units per

stack

Enclosed, dry, well

ventilated and as

free from dust as

possible, with a relative humidity of less

than 60 %.

unopened

max.

6months

-40°C to +55°C — max. 4

unopened

max.

1 year

-5 °C to +40 °C — max. 4

open over 1 year -5 °C to +40 °C

if necessary,

with new corrosion protection

—

Siemens Parts

Transport, storage and packing

16 9229 9860 176 0E

2013-08-22

Blank page

General information

9229 9860 176 0E 17

2013-08-22

General information

Smooth and safe operation of this device requires proper transport and storage, a nd

professional installation and assembly, as well as careful operation and maintenance.

The basic version and all listed configurations of the vacuum circuit-breakers are

type-tested devices as per IEC.

Range of application

3AH3 vacuum circuit-breakers are 3-pole interior circuit-breakers for a rated voltage

range of 7.2 kV - 36 kV.

Under normal operating conditions, the vacuum circuit-breaker (as per IEC 62271-1

and VDE 0671-1) is maintenance-free up to 10 000 operating cycles.

Intended use 3AH3 vacuum circuit-breakers are suitable for switching any type of alternating cur-

rent circuits under normal operating conditions, such as:

• Three-phase motors for reversing, turning and direct operation

• Transformers

• Capacitors

• Resistor consumers

Suitable for high frequency of operation and unlimited on-time.

3AH3 vacuum circuit-breakers operate in continuous, periodic and short-term oper-

ation.

WARNING

Dangerous voltage and mechanical movements

When operating electrical devices, certain parts will always be live, and

mechanical parts may move very quickly, even when remotely controlled.

If the warnings are not observed, serious injury or damage to material may be the

result.

Only personnel with the relevant qualifications may work on or in the vicinity of

this device. These personnel must be familiar with all the warnings and servicing

measures specified in these operating instructions.

Note

In the event of subsequent attachments or integrations, e. g. locking parts in connection with switchgears, ensure that

• fast-moving parts are not additionally loaded with mass or force, and

• additional parts have sufficient clearance, especially from moving and live

parts.

If vacuum circuit-breakers are to be equipped with additional functions by the customer, we recommend consulting the factory, since tried and tested solutions are

frequently available (see also “Additional equipment” on page 23).

Siemens Parts

General information

18 9229 9860 176 0E

2013-08-22

Standards

The 3AH3 vacuum circuit-breakers comply with the regulations:

• IEC 62271-1 and

• IEC 62271-100

All 3AH3 vacuum circuit-breakers comply with the specifications for C2-, E2- and

M2-class circuit-breakers in accordance with IEC 62271-100.

Design approval as per X-Ray Ordinance

The vacuum interrupters installed in th e vacuum circuit-breakers are of a design

approved under the X-Ray Ordinance (RöV) of the Federal Republic of Germany.

They meet the requirements of RöV of 8 January 1987 (BGbl. I, page 114) § 8 and

Annex II No. 5 up to the level of the rated voltage stipulated according to DIN

VDE/IEC.

Scope of delivery

Delivery includes:

• Vacuum circuit-breaker 3AH3

• Hand crank for circuit-breaker 3AX 1530-2B (optional)

• If applicable, partitions with mounting drawing

• Operating instructions and unpacking instructions

• Circuit-breaker-specific circuit diagrams

Description

9229 9860 176 0E 19

2013-08-22

Description

Design

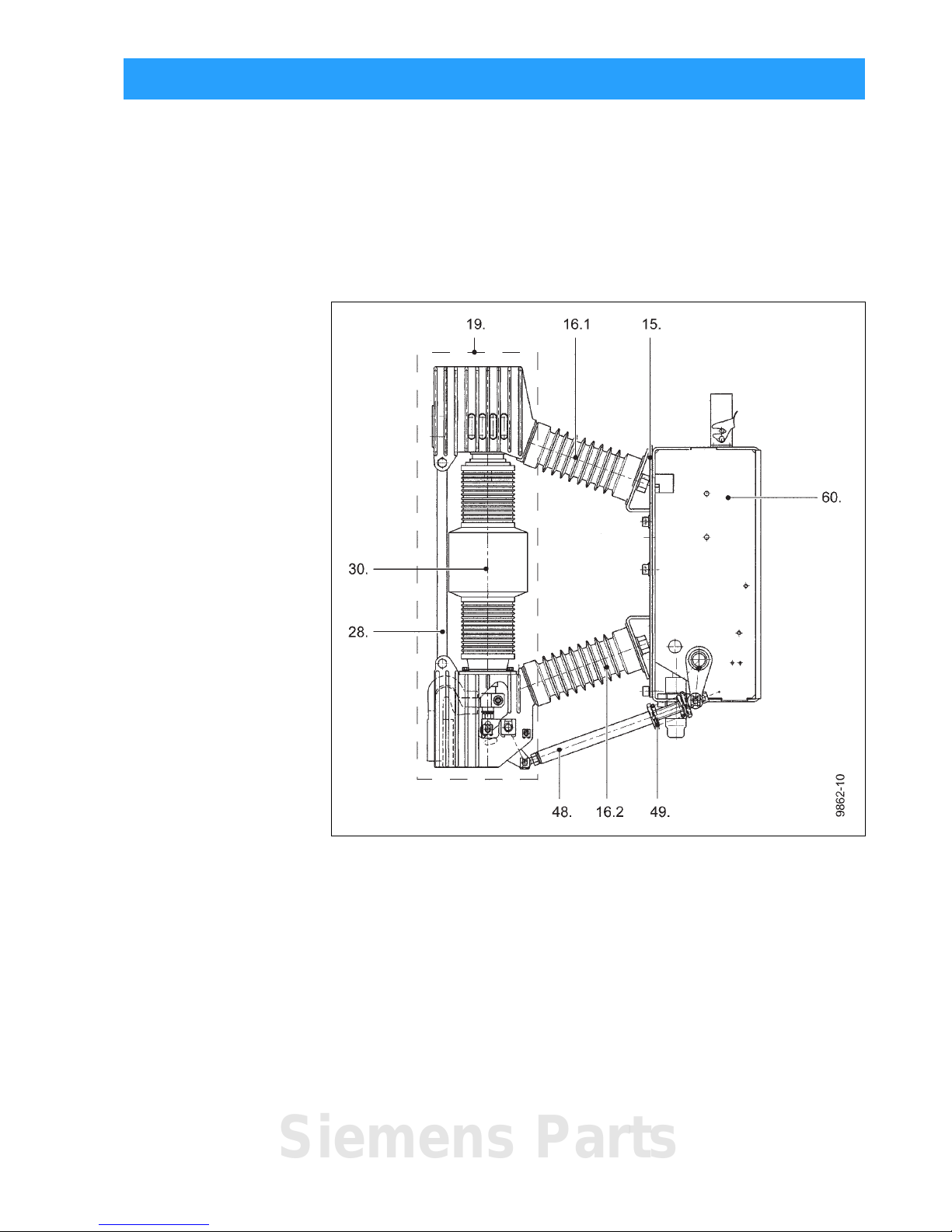

Vacuum circuit-breaker The 3AH3 vacuum circuit-breaker consists of

• the mechanism box (60.),

• the 3 pole assemblies (19.) with vacuum interrupters (30.),

• the cast resin post insulators (16.1 and 16.2) with reinforcing struts (28.) and

• the insulating operating rods (48.) with contact pressure springs (49.) required

for contact actuation.

Each of the 3 pole assemblies (19.) is carried by the cast resin post insulators (16.1

and 16.2) that are screwed to the pole plate (15.).

Fig. 22 Side view

15. Pole plate

16.1 Upper post insulator

16.2 Lower post insulator

19. Pole assembly, complete

28. Strut

30. Interrupter

48. Insulating operating rods

49. Contact pressure spring

60. Mechanism box

Siemens Parts

Description

20 9229 9860 176 0E

2013-08-22

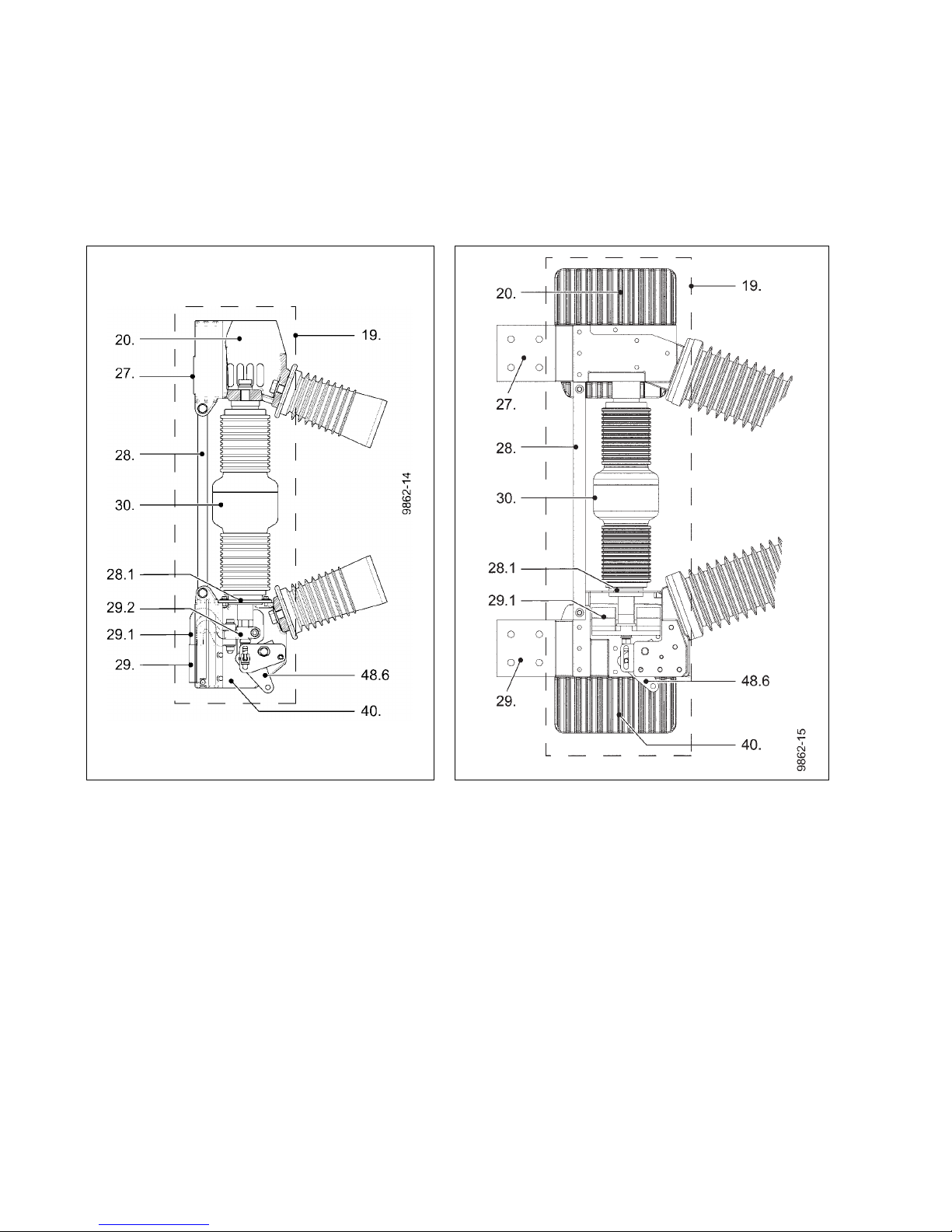

Pole assembly The pole assembly (19.) of the 3AH3 vacuum circuit-breaker consists of

• the upper interrupter support (20.)

• with the upper terminal (27.)

• the vacuum interrupter (30.),

• the lower interrupter support (40.) with the lower terminal (29.) and the clamp

(29.2) with flexible connector (29.1);

• as well as the angle lever (48.6.).

The centering (28.1) and the struts (28.) relieve the vacuum interrupters of external

forces.

Contact system in the interrupters

A slight change in the contact stroke that occurs over the entire useful life of the

interrupter has no effect on the function of the vacuum circuit-breaker. There is no

need for a status indicator for the contact system.

Fig. 23 Pole assembly (I) Fig. 24 Pole assembly (II and III)

19. Pole a ssembly 29.1 Flexible connector

20. Upper inter rupter support 29.2 Clamp

27. Upper terminal 30. Interrupter

28. Strut 40. Lower interrupter support

28.1 Centering 48.6 Angle lever

29. Lower terminal

Loading...

Loading...