Page 1

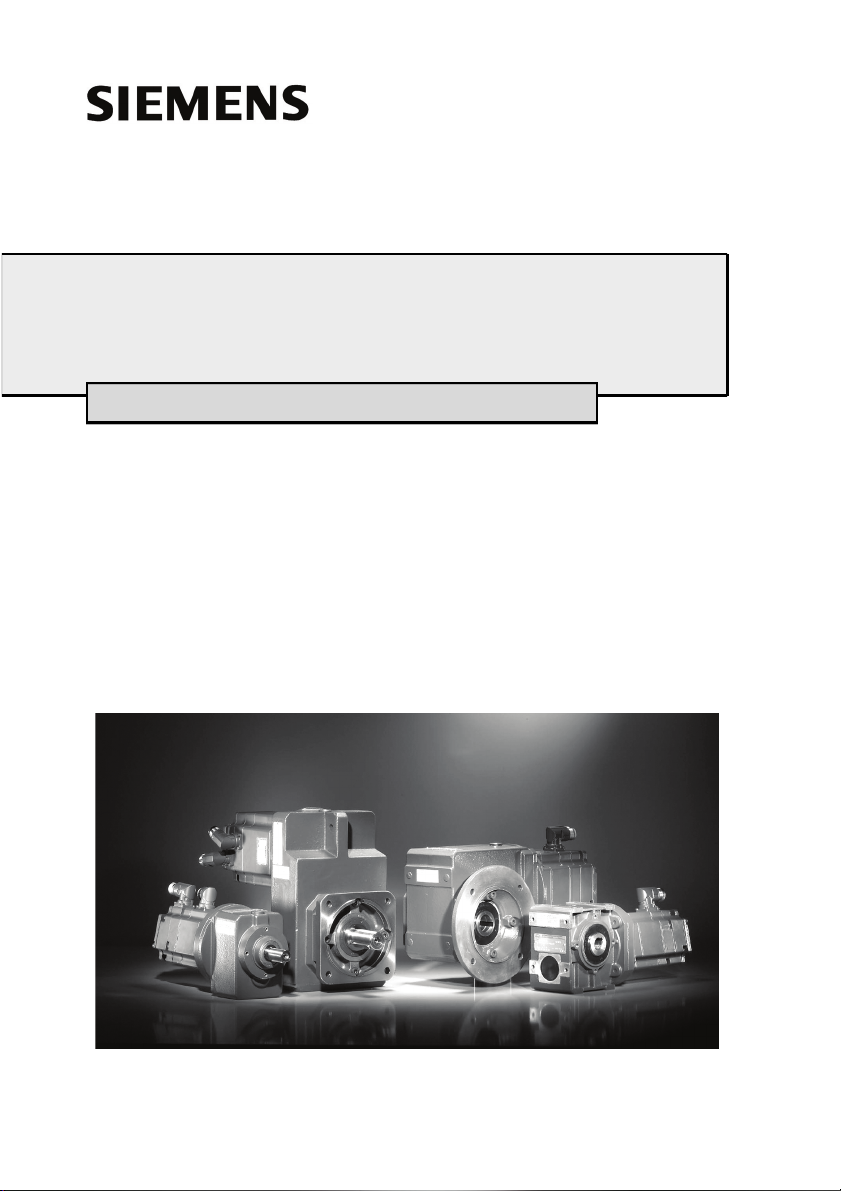

Geared motors Helical / Helical bevel gear units

Instructions Edition 03 / 2005

Getriebemotoren - Stirn-/Winkelgetriebe

Motoréducteurs - Réducteurs à engrenage cylindrique / réducteurs coniques

Motorreductores - Engranaje recto / acodado

Motoriduttori - Ingranaggio a ruote cilindriche/coniche

Kuggväxelmotorer - Kugg-/vinkeldrev

610.40 064.01

Page 2

ENGLISH

CONTENTS

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.2 Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.3 Motor adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.4 Hollow shaft with shrink disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.1.5 Hollow shaft and key link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.6 Torque bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.3 Motor adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Transport, assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 Transport, storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Installation, assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.2 Specific features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Checks before starting up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Instructions in case of faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 General instructions for rectifying faults . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 Inspection, maintenance, disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 Maintenance / repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Other applicable documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 610.40 064.01 Siemens AG

Page 3

DEUTSCH

INHALT

1 Allgemeine Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2 Angaben zum Produkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1 Produktbeschreibung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1.1 Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1.2 Getriebe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1.3 Motoradapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.1.4 Hohlwelle mit Schrumpfscheibe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.1.5 Hohlwelle mit Passfederverbindung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.1.6 Drehmomentstütze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.2 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1 Typenschild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.2 Merkmale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.1 Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.2 Getriebe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.3 Motoradapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Transport, Montage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1 Transport, Lagerung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 Aufstellung / Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2.1 Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2.2 Besonderheiten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.1 Prüfungen vor Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Hinweise bei Störungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Allgemeines zur Störungsbeseitigung . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Ersatzteile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7 Inspektion, Wartung, Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1 Wartung / Instandhaltung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1.1 Allgemeine Hinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1.2 Schmierung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Mitgeltende Unterlagen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Siemens AG 610.40 064.01

3

Page 4

FRANÇAIS

SOMMAIRE

1 Consignes générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2 Indications relatives au produit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.1 Description du produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.1.1 Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.1.2 Réducteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.1.3 Adaptateur à moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

2.1.4 Arbre creux pour connexion par disques frettés . . . . . . . . . . . . . . . . . . . . . . .63

2.1.5 Arbre creux avec connexion à clavette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.1.6 Dispositif de compensation de couple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2 Equipements fournis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3 Caractéristiques techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.1 Plaque signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2 Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.1 Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.2 Réducteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.3 Adaptateur à moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4 Transport, montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.1 Transport, positionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.2 Installation, montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.2.1 Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.2.2 Particularités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.1 Vérifications avant la mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.2 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6 Remarques en cas de dérangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.1 Généralités en matière de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2 Pièces détachées . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7 Inspection, entretien, élimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.1 Entretien / Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.1.1 Instructions générales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.1.2 Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2 Environnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8 Documents valables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4 610.40 064.01 Siemens AG

Page 5

ESPAÑOL

ÍNDICE

1 Indicaciones generales de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2 Datos del producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1 Descripción del producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1.1 Generalidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1.2 Engranaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1.3 Adaptador del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2.1.4 Árbol hueco con disco de contracción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2.1.5 Árbol hueco con conexión de lengüeta de ajuste. . . . . . . . . . . . . . . . . . . . . . 90

2.1.6 Soporte de momento de giro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

2.2 Volumen de suministro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3 Datos técnicos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.1 Placa de características. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.2 Características. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.2.1 Generalidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.2.2 Engranaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.2.3 Adaptador del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4 Transporte, montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.1 Transporte, almacenamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.2 Instalación / Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.2.1 Generalidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.2.2 Aspectos especiales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5 Puesta en servicio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.1 Comprobaciones antes de la puesta en servicio . . . . . . . . . . . . . . . . . 101

5.2 Puesta en servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6 Indicaciones en caso de avería . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.1 Indicaciones generales para la reparación de una avería . . . . . . . . . . 102

6.2 Piezas de recambio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7 Inspección, mantenimiento, eliminación de residuos. . . . . . . . . . . . . . . . 103

7.1 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.1.1 Indicaciones generales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.1.2 Lubrificación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.2 Evacuación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8 Documentación válida . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Siemens AG 610.40 064.01

5

Page 6

ITALIANO

INDICE

1 Avvertenze generiche di sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2 Dati sul prodotto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.1 Descrizione del prodotto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.1.1 Informazioni generali. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.1.2 Riduttore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.1.3 Adattatore per motore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.1.4 Albero cavo con calettatore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.1.5 Albero cavo e collegamento con chiavetta . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.1.6 Supporto di coppia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.2 Fornitura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3 Caratteristiche tecniche. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3.1 Targhetta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3.2 Caratteristiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.2.1 Informazioni generali. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.2.2 Riduttore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.2.3 Adattatore per motore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4 Trasporto, montaggio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.1 Trasporto, stoccaggio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.2 Installazione / Montaggio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.2.1 Informazioni generali. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.2.2 Particolarità. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

5 Messa in funzione. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

5.1 Verifiche prima della messa in funzione . . . . . . . . . . . . . . . . . . . . . . . 126

5.2 Messa in funzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6 Istruzioni in caso di guasto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6.1 Informazioni generali sull’eliminazione di guasti . . . . . . . . . . . . . . . . . 127

6.2 Pezzi di ricambio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

7 Ispezione, manutenzione, smaltimento . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

7.1 Manutenzione/Messa a punto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

7.1.1 Indicazioni generali . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

7.1.2 Lubrificazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

7.2 Smaltimento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8 Ulteriori documentazioni valide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

6 610.40 064.01 Siemens AG

Page 7

SVENSKA

INNEHÅLL

1 Allmän säkerhetsinformation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

2 Uppgifter om produkten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.1 Produktbeskrivning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.1.1 Allmänt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.1.2 Växel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.1.3 Motoradapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

2.1.4 Hålaxel med krympbricka . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

2.1.5 Hålaxel med fjäderkilsanslutning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

2.1.6 Vridmomentstöd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

2.2 Leveransens omfattning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3 Tekniska data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.1 Typskylt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.2 Kännetecken . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.2.1 Allmänt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.2.2 Växel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.2.3 Motoradapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

4 Transport, montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.1 Transport, lagring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.2 Uppställning / montering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

4.2.1 Allmänt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

4.2.2 Särskilda egenskaper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5 Driftsättning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5.1 Kontroller innan driftsättning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5.2 Driftsättning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6 Information vid störningar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6.1 Allmänt om åtgärdande av störningar . . . . . . . . . . . . . . . . . . . . . . . . . 151

6.2 Reservdelar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7 Inspektion, underhåll, avfallshantering . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.1 Underhåll / reparationer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.1.1 Allmänna anvisningar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.1.2 Smörjning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

7.2 Kassering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8 Ytterligare giltiga dokument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Siemens AG 610.40 064.01

7

Page 8

SVENSKA

8 610.40 064.01 Siemens AG

Page 9

ENGLISH

This manual contains notes which you should observe to ensure your own personal

safety, as well to protect the product and connected equipment. Notices relating to your

personal safety are highlighted by a warning triangle. Notices solely relating to material

damage do not have an accompanying triangle. They are shown as follows according to

the degree of danger involved.

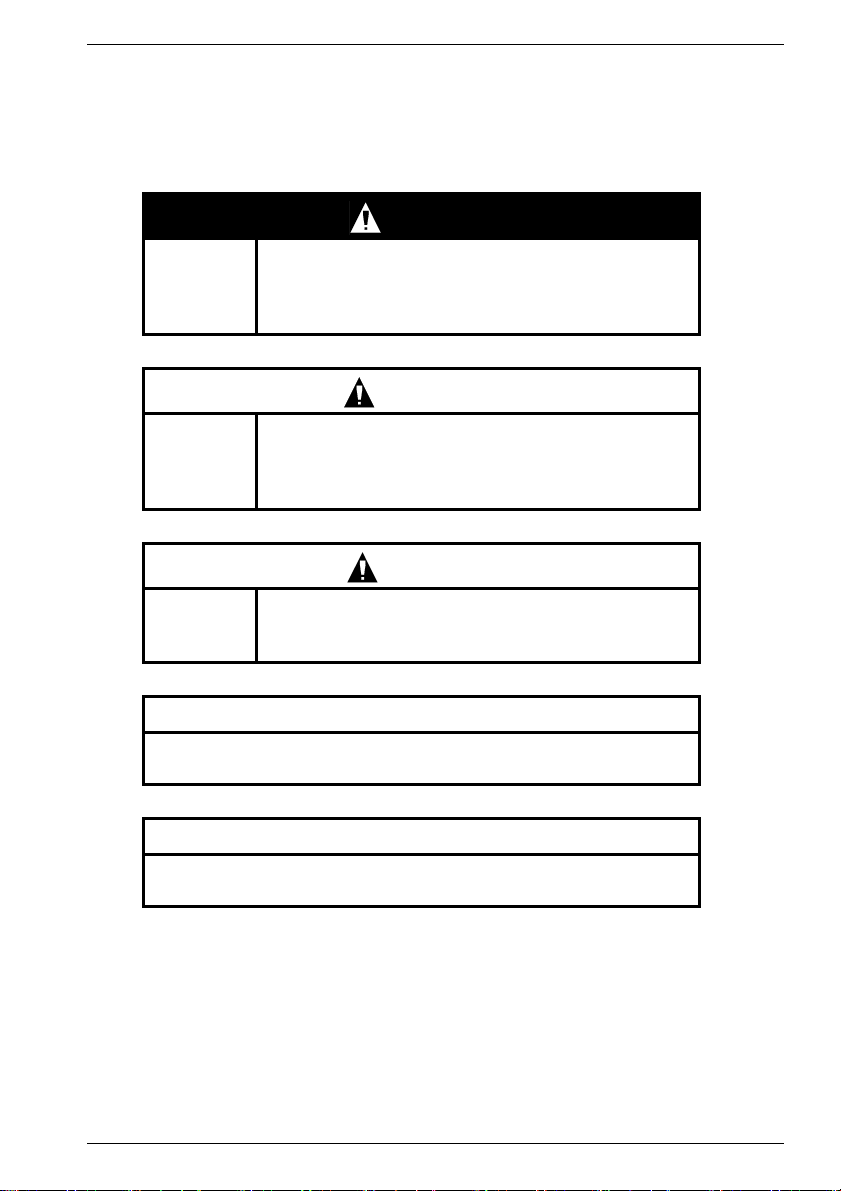

DANGER

indicates an imminently hazardous situation which, if

Pictogram

not avoided by the appropriate precautionary

measures, will result in death, serious injury or

substantial material damage.

WARNING

indicates an imminently hazardous situation which, if

Pictogram

not avoided by the appropriate precautionary

measures, could result in death, serious injury or

substantial material damage.

CAUTION

Pictogram

used with the warning triangle indicates a potentially

hazardous situation which, if not avoided, may result

in minor or moderate injury.

CAUTION

used without the warning triangle indicates a potentially hazardous

situation which, if not avoided, may result in damage to property.

NOTICE

indicates that an undesirable result or event may occur if the notice

is not observed.

Siemens AG 610.40 064.01

9

Page 10

ENGLISH

Qualified Personnel

The device/system may only be set up and operated in conjunction with this manual. Only

qualified personnel should be allowed to install and work on the this equipment. Qualified

persons within the meaning of the safety instructions in this manual are persons who are

authorized to commission, ground, and mark devices, systems and circuits in accordance

with established safety practices and standards.

Intended Usage

Please note the following:

This device and its components may only be used for the applications described in the

catalogue and configuration guide, and only in conjunction with devices or components

from other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and

installed correctly, and operated and maintained as recommended.

Disclaimer of Liability

We have checked the contents of this manual. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in the manual are

reviewed regularly and any necessary corrections included in subsequent editions.

Suggestions for improvement are welcomed.

© Copyright Siemens AG 2005. All rights reserved

The reproduction, transmission or use of this document or its contents is not permitted

without express written authority. Offenders will be liable for damages.

All rights, including rights created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Motion Control Systeme (MC)

D-97615 Bad Neustadt an der Saale, Germany

10 610.40 064.01 Siemens AG

Page 11

ENGLISH

1 General safety instructions

These operating instructions contain all the necessary information concerning the transport, installation, initial start up, maintenance etc. of geared motors.

This operating manual applies in conjunction with the SIEMENS project planning guide

and the operating manual "Three-Phase Servomotors".

The fulfilment of any rights under the warranty is conditional upon exact compliance with

the specifications and instructions in these operating instructions.

To prevent hazards of any kind arising during transport, storage, mounting, start

up, maintenance etc., the instructions relating to safety and hazards in these operating instructions and the operating instructions for three-phase servomotors

(1FK7.) must be complied with, without fail. Failure to observe the instructions can

lead to serious personal injuries or property damage.

Ensure that your end product conforms to all currently valid legal requirements.

Follow the compulsory national, local and installation-specific regulations.

These motors must not be brought into use until it has been established that the

end product conforms to the currently valid directives.

Mechanical hazards, arising for example from a freely revolving transmission shaft,

must be prevented by suitable protective devices. All the keys in the shafts must be secured.

Electrical hazards must be prevented by precisely following the instructions in the

"Initial start up" section.

The motors’ rotors contain permanent magnets with high magnetic flux densities which

exert strong attractive forces on ferromagnetic bodies.

People fitted with a heart pacemaker are at risk in the vicinity of a disassembled

rotor.

Data stored on electronic data media may be destroyed.

It is forbidden to use these servomotors in areas at risk of explosion, unless this is ex-

pressly authorized.

The drive must be specially equipped by the manufacturer for operation outside the per-

missible temperature range.

Hazards with high temperature. Do not touch the hot gearbox/motor casing with your

bare hands. A high operating temperature may cause burns or nervous reactions. The

surface temperature of the motors can reach 140°C, that of the gear 90°C.

Do not touch hot surfaces!

Temperature-sensitive components (electric lines, electronic components) must not

touch hot surfaces. Overheating in the motors may destroy the windings and bearings,

and demagnetize the permanent magnets.

Only operate the motors with effective temperature control.

Intended Usage

Usage for the intended purpose includes observing all the specifications in the operating

manual and the project planning guide "Three-phase servomotors".

The gears/geared motors have been designed for the permissible outputs and loads stated in the catalog.

The geared motors may only be used for the purpose for which they have been designed,

taking all operating factors into account. Any overload of the drives is deemed as not being use for the intended purpose. The manufacturer shall not be liable for any damage

ensuing from any unauthorized modifications to any part of the drive.

Siemens AG 610.40 064.01

11

Page 12

2 Product information

2.1 Product description

2.1.1 General information

The geared motors consist of a three-phase servomotor (1FK7.) with a

flange-mounted gearbox. The three-phase servomotors are supplied with mounted gearboxes. Some models are supplied with an additional clutch.

The three-phase servomotor may be combined with all the gears / motor adapters

(clutches) described. The configuration (selection of the combination of three-phase servomotor and gear/clutch) has to be user-related to achieve this.

Three-phase servomotors (1FK7.) are permanent magnet excited, three-phase synchronous

motors (three-phase servomotors) for operating with motor-controlled indirect a.c. converters according to the sinusoidal current principle. The motors are intended for driving

and positioning machine tools, production machines, robots and handling devices.

2.1.2 Gears

2.1.2.1 General information

There are various models and designs of gears.

The gearing down stages reduce the usually high input speed to the desired lower output

speed. The input torque is multiplied by the ratio to the output torque (reduced by a slight

efficiency loss in the gear).

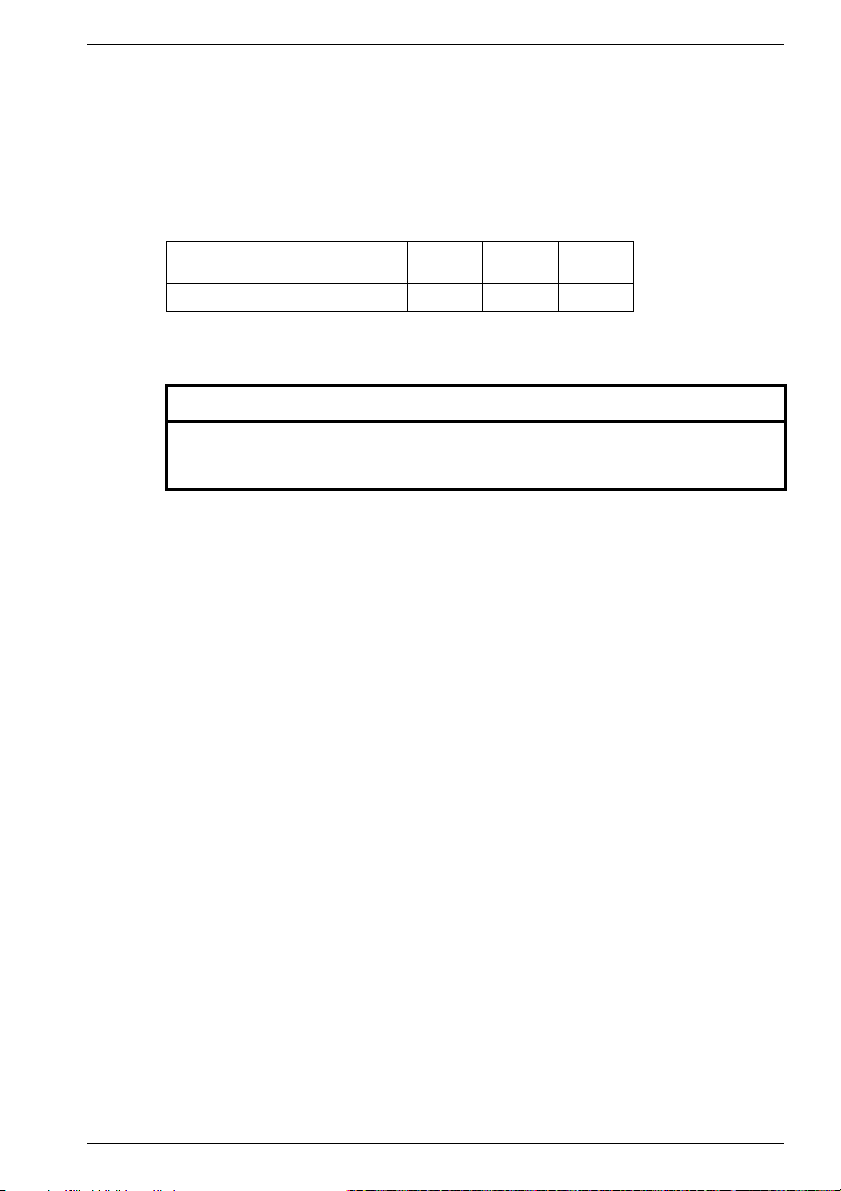

Design with Types of construction Gear shaft types

Worm gear and bevel

wheel gear

Flat gear - Flange design

Circular gear - Foot mounting construction

- Circle of tapped holes

- Flange design

- Foot mounting construction

- Foot mounting construction

- Circle of tapped holes

- Circle of tapped holes

- Flange design

- Foot mounting construction

- Foot mounting construction

ENGLISH

and circle of tapped holes

and flange design

and circle of tapped holes

and flange design

- Solid shaft with key

- Hollow shaft with a

keyway

- Hollow shaft with shrink

disk

- Solid shaft with/without

key

- Hollow shaft with a

keyway

- Hollow shaft with shrink

disk

- Solid shaft with/without

key

NOTE

See the type plate for the particular design and mounting position.

The quantity of lubricant to fill (quantity of oil) depends upon the position in

which the gearbox is mounted, and is stated on the type plate.

12 610.40 064.01 Siemens AG

Page 13

2.1.2.2 Worm gear

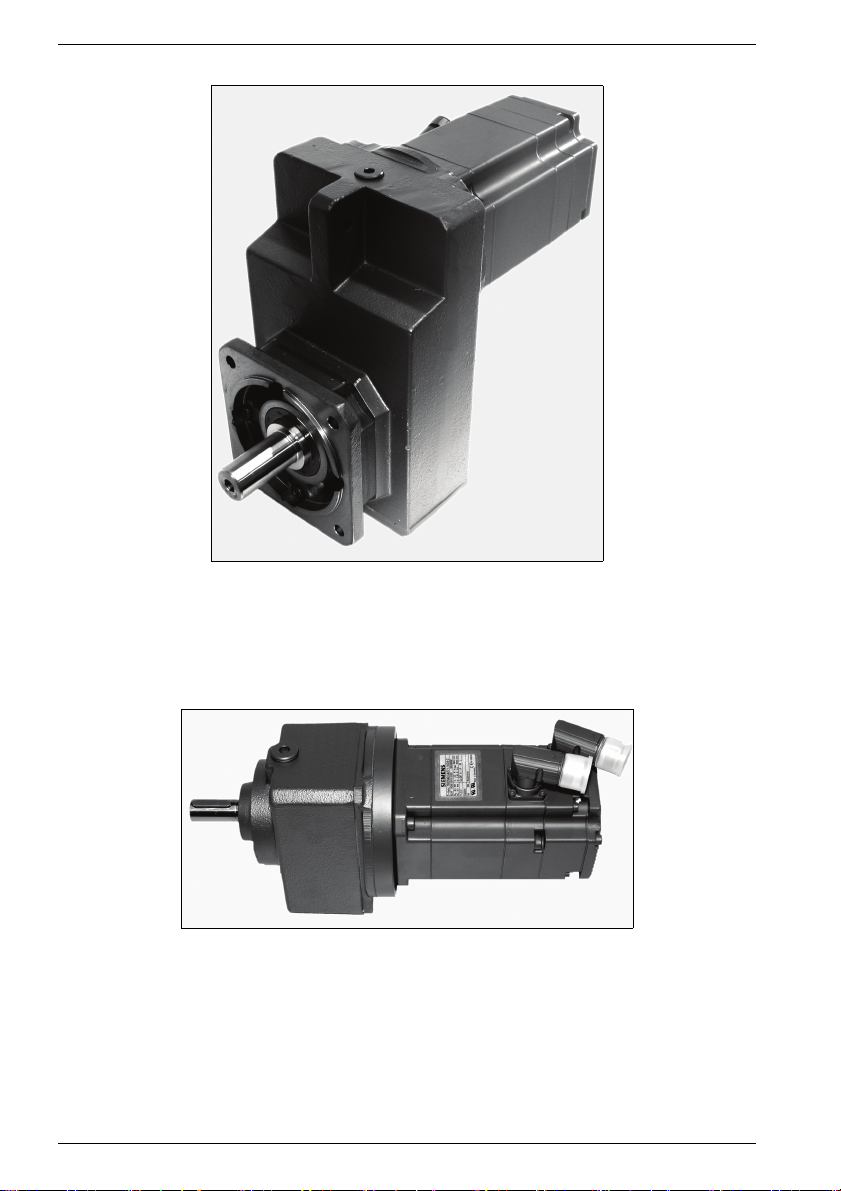

Fig. 1 Motor with worm gear (example)

Worm gear/motors are constructed in block design, and have one or two spur gear stages (2 or 3 stage gear) upstream of the worm unit. The output shaft outputs at an angle of

90° to the input shaft. The worm unit has a hardened, ground steel worm and bronze

worm wheel, it dampens impacts and shocks. The teeth have a narrow flank clearance.

2.1.2.3 Bevel wheel gear

ENGLISH

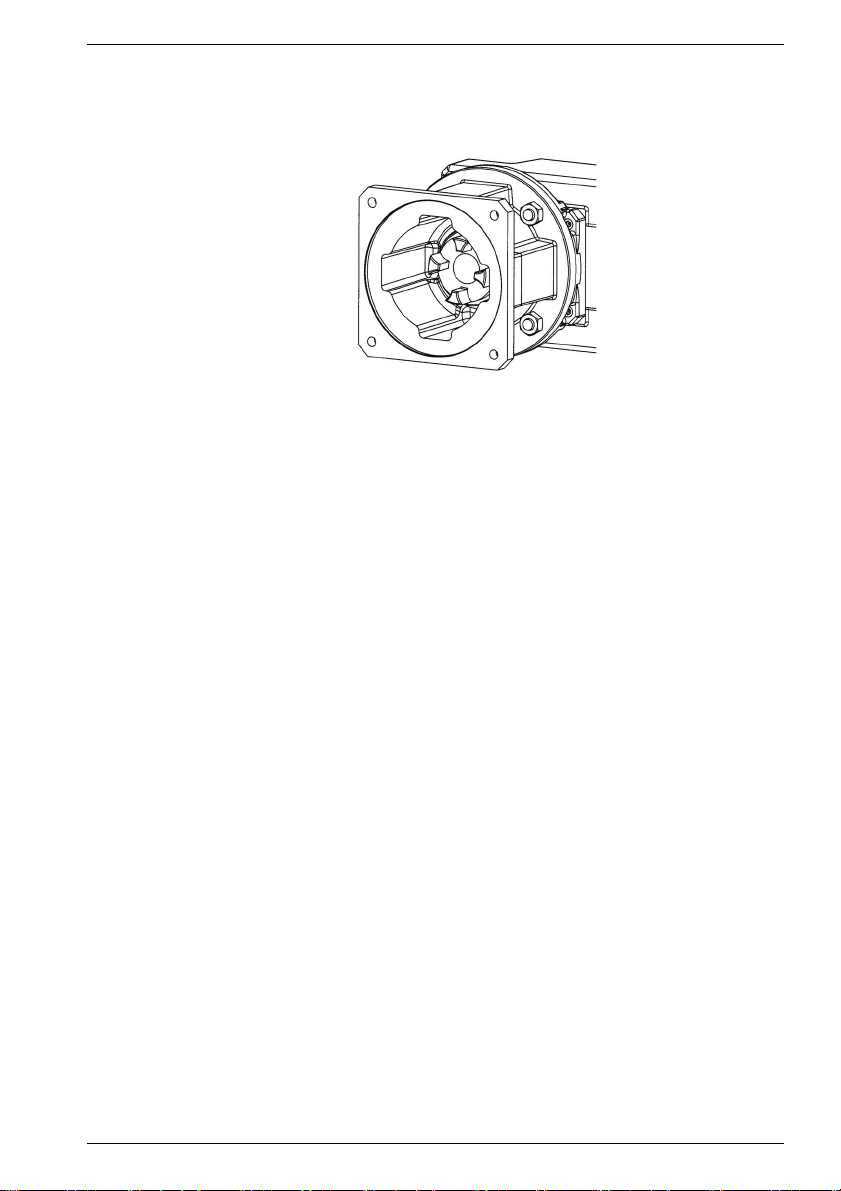

Fig. 2 Motor with bevel wheel gear (example)

Bevel wheel gear/ motors are constructed in block design.

The gear sizes K2 to K4 not only have the bevel wheel stage but also one or two upstream spur gear stages (2 or 3-stage gear). Sizes K5 to K10 not only have the bevel

wheel stage but are also equipped with one downstream and one or two upstream spur

gear stages (3 or 4-stage gear). The output shaft is arranged 90° offset from the drive

shaft. The curved tooth bevel wheel stage allows a narrow flank clearance.

Siemens AG 610.40 064.01

13

Page 14

2.1.2.4 Flat gear

Fig. 3 Motor with flat gear (example)

ENGLISH

Flat gear/motors are constructed in compact block design with a 2 or 3 stage spur gear,

an extremely flat casing and a long axle distance.

The output shaft is designed as a solid or hollow shaft.

2.1.2.5 Circular gear

Fig. 4 Motor with circular gear (example)

Spur gear/ motors are constructed in compact block design with a 2 or 3 stage spur gear

transmission. The drive and output shafts are coaxial.

14 610.40 064.01 Siemens AG

Page 15

ENGLISH

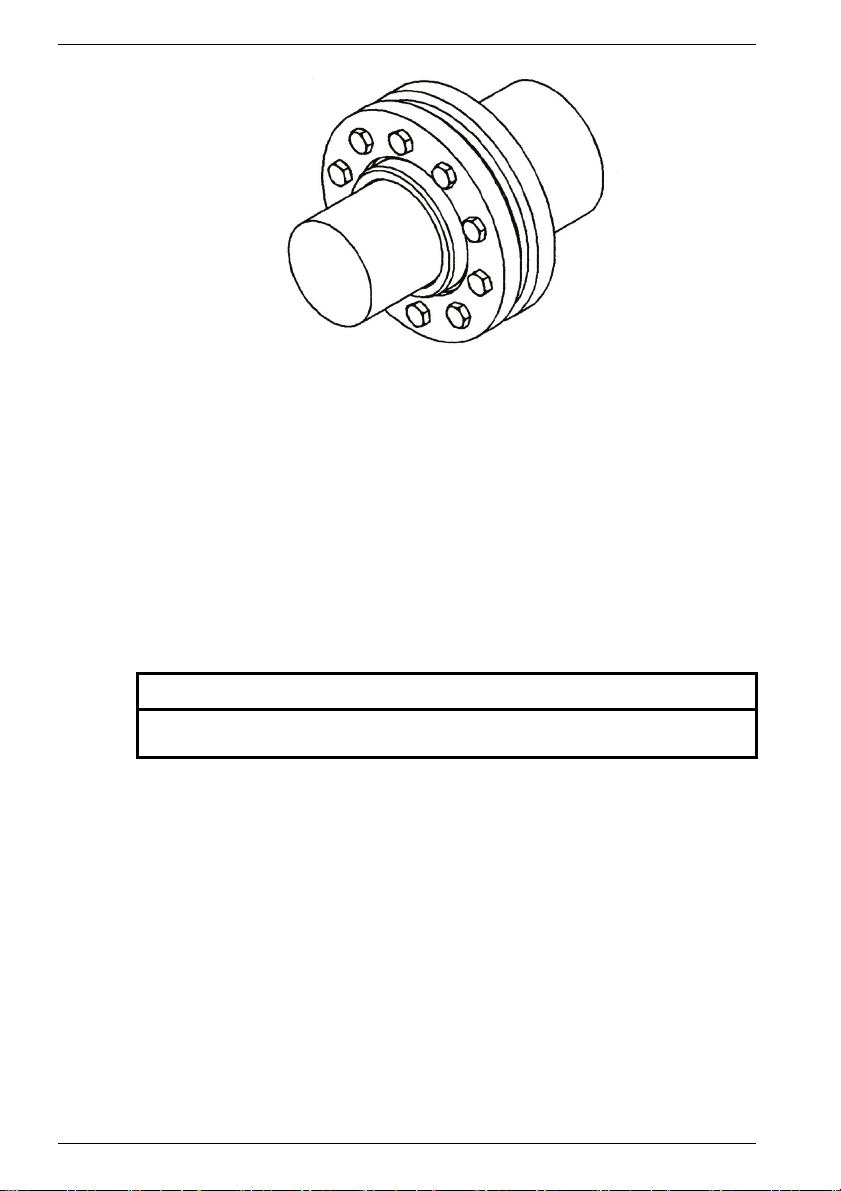

2.1.3 Motor adapter

If no direct motor gear mounting is provided, motor adapters (with a square flange) are

used for mounting servomotors (according to IEC or NEMA-C) on a gearbox.

Fig. 5 Motor adapter (example)

2.1.3.1 Motor adapter with curved tooth clutch

Servomotors are mounted on the gearbox by means of motor adapters (with a square

flange). Servomotors can be mounted if the shaft end and mounting flange have standard

true running, axial run-out deviation and coaxial qualities complying with DIN 42955-N.

The motor does not have to be oil-tight. The centering diameter must be designed with a

tolerance complying with ISO j6, the shaft end complying with tolerance ISO k6, and the

key complying with DIN 6885 sheet 1. The motor can be mounted and dismounted without coming into contact with lubricant. The motor shaft is linked to the gear input shaft by

the freely movable, torsionally rigid and maintenance-free curved tooth clutch. The clutch

runs dry and has a maximum continuous operating temperature of 80°C. The motor

adapter does not require any special maintenance.

2.1.3.2 Motor adapter with plug-in connector, zero-backlash

Motor adapters with zero backlash, axially braced, plug-in metal bellows-type clutch are

used for mounting servomotors on gearboxes. The motors preferably have smooth shafts

(without key). The clutch bush mounted on the gear side has a spring-loaded metal bellows. For this reason, standard true running, axial run-out deviation and coaxial qualities

complying with DIN 42955-N are adequate for the shaft ends and the mounting flange of

the mounted motor.

2.1.4 Hollow shaft with shrink disk

Shaft mounted gearboxes are inserted onto the drive shaft of the machine that is to be

driven. The reaction torque must be supported either by flange-mounting the gearbox on

the machine or by a torque bracket. In the case of flange mounting, the deviation from

perpendicularity between the flanged end surface on the machine and the shaft axis must

not exceed 0.03/100 mm because of the danger of distorting the bearing or causing an

impermissible bending load on the machine shaft.

Siemens AG 610.40 064.01

15

Page 16

ENGLISH

Fig. 6 Hollow shaft (example)

Shrink disc connection:

The hollow shaft is connected to the smooth machine drive shaft by frictional engagement produced by elastically constricting the hollow shaft with a shrink disk. This shafthub link has absolute zero-backlash, and is therefore also non-wearing.

It can transmit high torques and axial forces with a high degree of true-running accuracy

(as a result of its self-centering characteristic).

The hollow shaft is made of high-tensile tempering steel.

Hollow shaft models (dependent upon size of gearbox):

- Hollow shafts with slots in the shrink seating area:

Machine shaft with tolerance complying with ISO h9.

- Hollow shafts without slots in the shrink seating area:

Machine shaft with tolerance complying with ISO h6.

CAUTION

The end of the hollow shaft with the shrink disk seating must not be loaded with

a radial operational force.

16 610.40 064.01 Siemens AG

Page 17

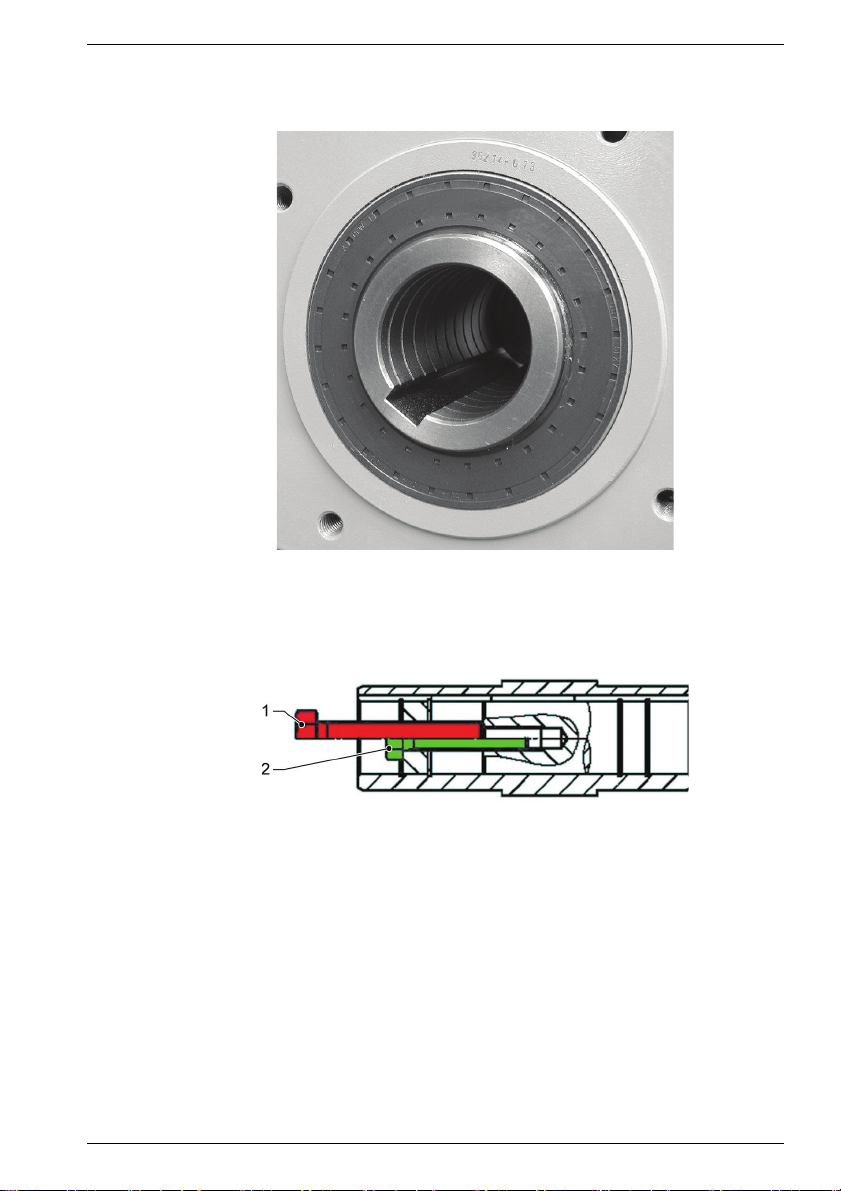

2.1.5 Hollow shaft and key link

The hollow gear shaft has a spiral groove which acts as a grease reservoir and prevents

fretting corrosion.

Fig. 7 Hollow shaft and key link

ENGLISH

The machine shaft can be dismounted with the aid of a forcing off disk (see also Chapter

4.2.2.1 “Geared motor with hollow shaft and key link”).

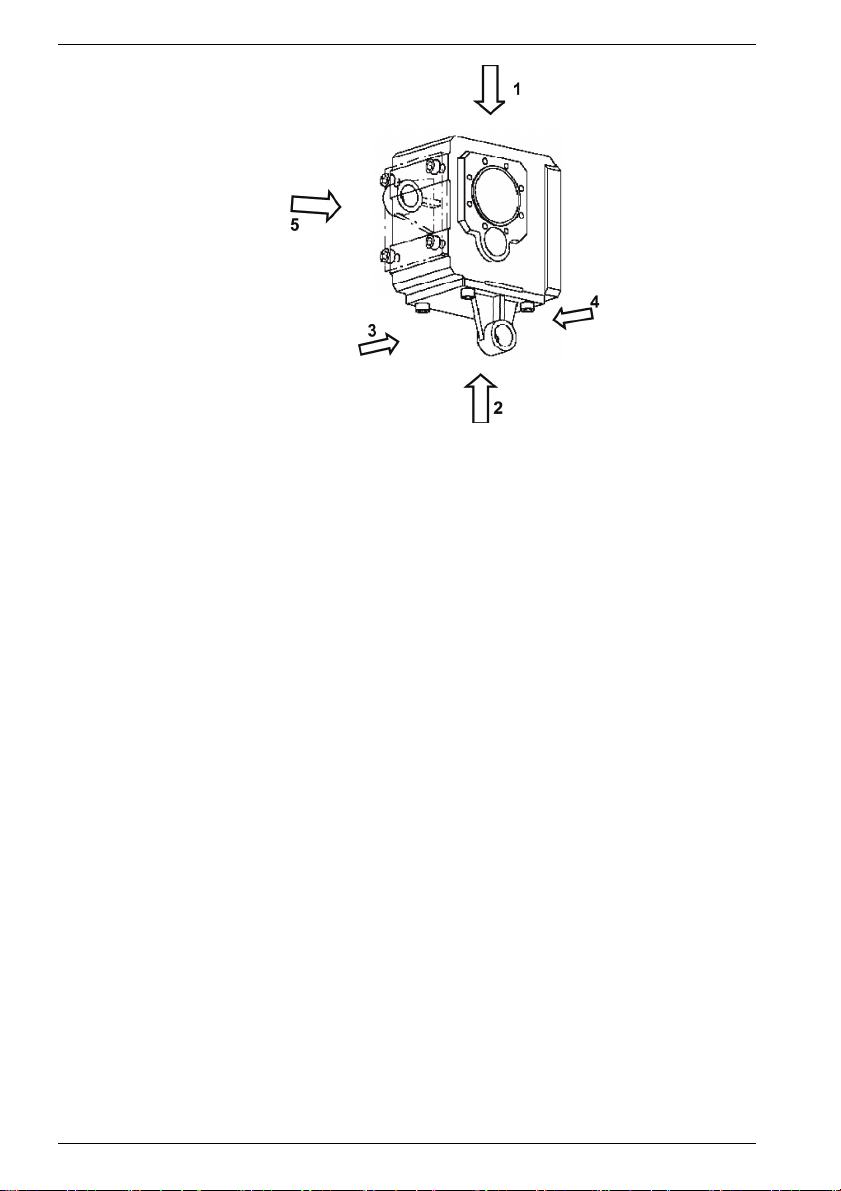

Fig. 8 Dismounting the machine shaft

1 Force off

2Shrink on

2.1.6 Torque bracket

A torque bracket can be mounted on three sides (GS1; GS2; GS5) of bevel gears (conical/worm gears) by screwing on a drive plate. The corresponding torque bracket can also

be mounted in two positions of rotation.

Siemens AG 610.40 064.01

17

Page 18

Fig. 9 Example of arrangement of the torque bracket on the side of the

gear (GS) 2; Eye of the torque bracket in the GS4 direction.

2.2 Scope of Delivery

The drive systems have been assembled individually, they have been tested and properly packed in the works.

Upon receipt of delivery, check that the delivery is complete, check for transport damage,

and whether the scope of delivery corresponds with the consignment notes.

SIEMENS cannot accept any liability for any shortages or deficiencies reported at a later

date. Any complaints must be reported to the transport company without delay.

Complaint instructions:

- Report detectable transport damage immediately to the carrier/transport company,

- Report detectable defects / incomplete delivery immediately to the responsible

SIEMENS representative.

The operating manual is part of the scope of delivery and shall therefore be kept in an

accessible place. As the delivery includes a separate type plate, the motor data must also

be kept on or near the machine or system.

ENGLISH

18 610.40 064.01 Siemens AG

Page 19

3 Technical specifications

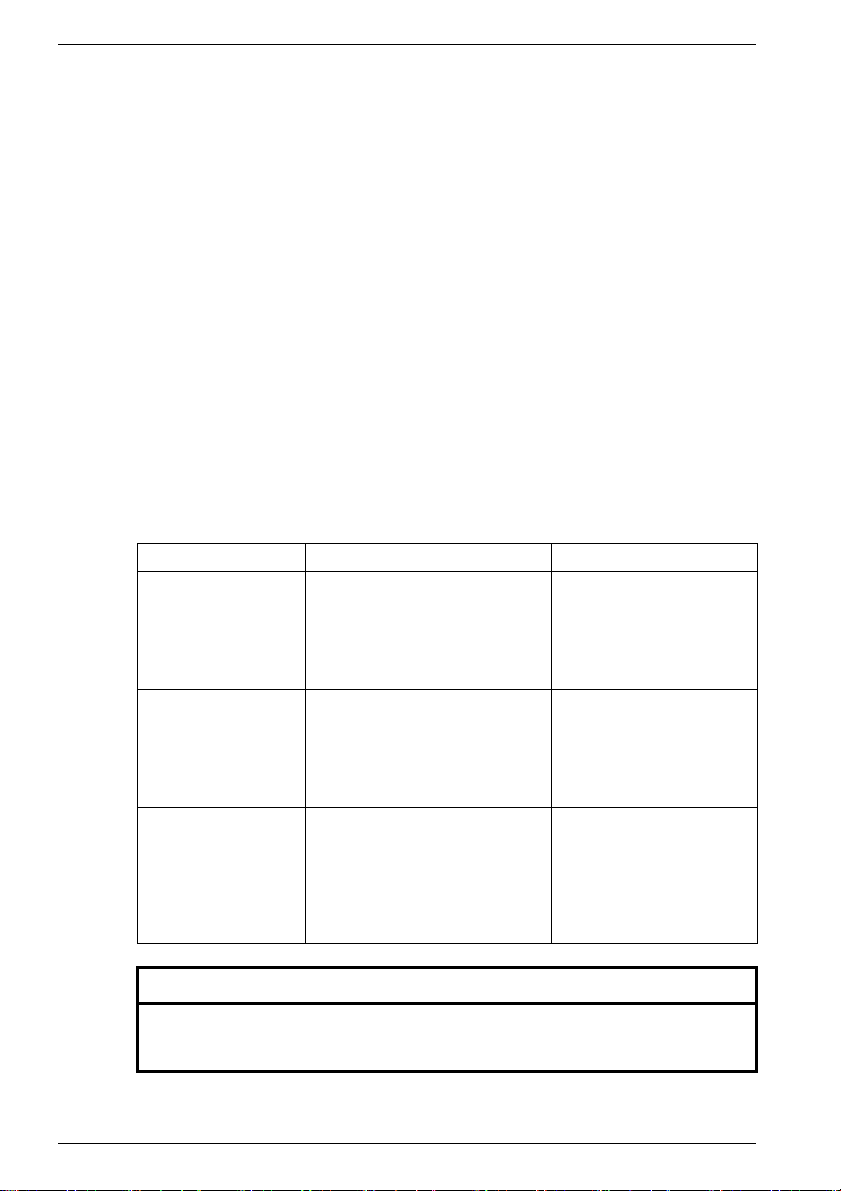

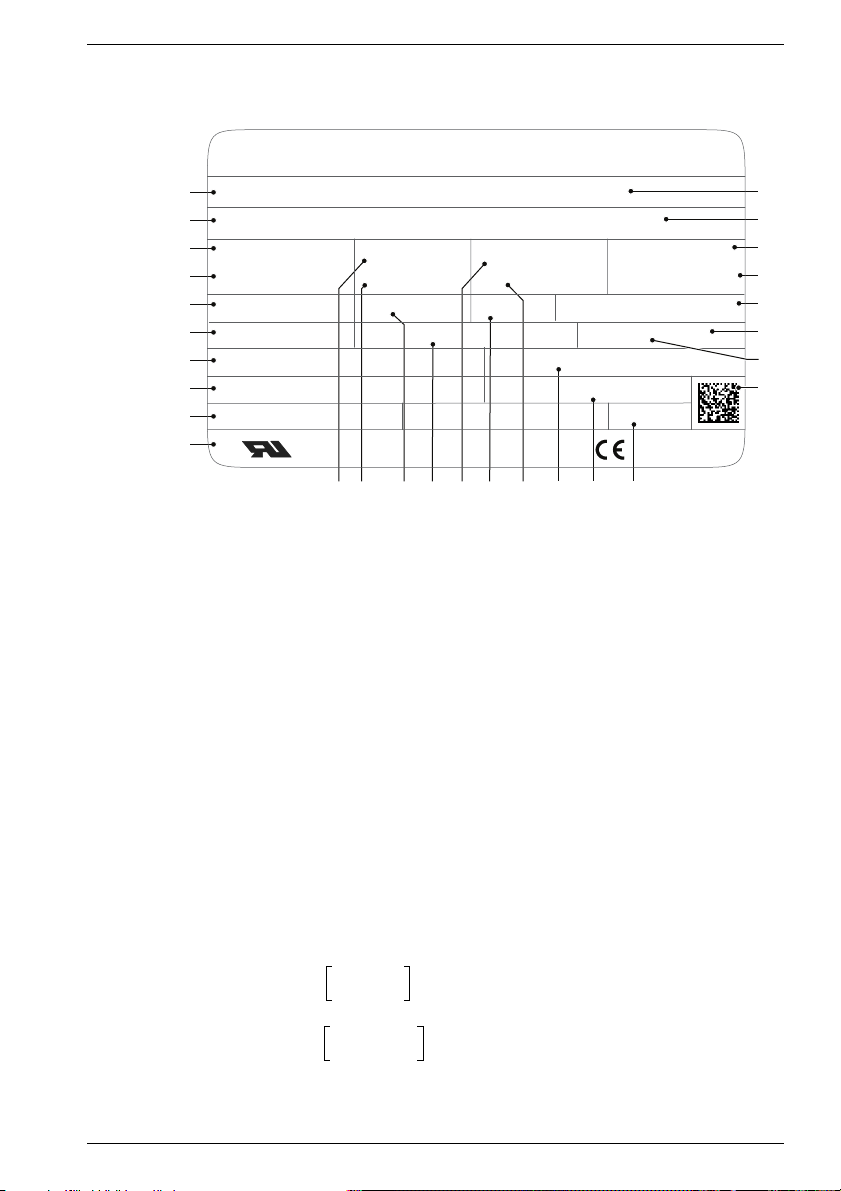

3.1 Rating plate

SIEMENS

1

3~ Motor

2

3

M

27,0

10

4

M

15,5

1N

5

Th.Cl. (F)

6

Resolver p=4

7

gear unit type: K402ANG0060

8

ratio: I=6,000

9

mounting position: any

10

Fig. 10Rating plate (example)

1 Motor type: Three-phase servomotor

2 ID No., Production number

3 Zero speed continuous torque M

4 Rated torque M

5 Temperature class

6 Encoder type code

7 Gear type code

8 Gear ratio code; [exact transmission

9 Mounting position code Geared motor

10 Standards and regulations

11 Zero-speed current I

12 Rated current I

13 Induced voltage U

14 Holding brake data

15 Maximum speed n

C US

[Nm]

ratio]

motor (gear drive)

1FK7101 - 5AF1 - 1SU5 - Z

T131 9430 01

I

Nm

Nm

11 12 13 1614 17 18 19 2015

[Nm]

N

0

[A]

N

[V]

IN

1max

19,0AA

0

I

11,8

N

U

270 V

iN

BRAKE 24VDC 17,6W 3043501

[6/1]

[A]

[rpm] of the

ENGLISH

001No. YF

Made in Germany

0

Z:

B42 + G63 + H11

n

n

IP

1max

1N

2700

3000

64

/min

/min

M

90,2 (S3-60%)Nm

2N

l

max

n

2

49,2

500

A

/min

RN 000 N01

oil type: Mobil SHC 629

quantity of oil: 2,50 l

m: kg61

EN 60034

16 Type of protection

17 Rated speed n

[rpm] of the motor

1N

(gear drive)

18 Gearbox oil name

19 Gearbox oil quantity

20 Geared motor weight m [kg]

21 Bar code

22 Geared motor version

23 Encoder version

24 PTO rated torque M

(operating mode) *)

25 PTO speed n

power take-off **)

2

26 Maximum current I

[1/min]

max

2N

[Nm];

[A]

27 Order options

28 SIEMENS motor type/ designation

28

27

26

25

24

23

22

21

M

*)

n1Nn

**)

n1Nn

Siemens AG 610.40 064.01

2N

f M1N()=

1max

1max

n

1N

=⇒≤

n

---------

2

i

n

1max

=⇒>

n

--------------

2

i

19

Page 20

3.2 Features

3.2.1 General information

The technical data of the drive is stated on the type plate.

Dimensions can be taken from the dimensional sketches in the relevant planning guide

or the DP tool "CAD-Creator".

Comply with permissible torques, make a current limitation on the servo

frequency converter if necessary.

Transport temperature -20 °C to +40 °C (-4 °F to 104 °F)

Storage temperature 0 °C to +40 °C (32 °F to 104 °F)

Ambient temperatures -15 °C to +40 °C (5 °F to 104 °F)

Installation altitude ≤up to 1000 m a.s.l,

Weight Refer to the type plate

Degree of protection as per EN 60-529 IP 65

Sound pressure level as per EN 60 034-9 approx. 75 dB(A)

Vibration severity grade as per EN 60 034-14 Grade N

True running, coaxiality, axial run-out devia-

tion as per IEC 60 072-1

ENGLISH

otherwise the rated data are reduced

to 50 °C conversion factor 0,92

to 60 °C conversion factor 0,82

2000 m conversion factor 0,94

2500 m conversion factor 0,9

Tolerance N

The dimensional sheets of the DP tool "CAD-Creator" and the "Three-phase

servomotors" operating instructions contain additional technical values.

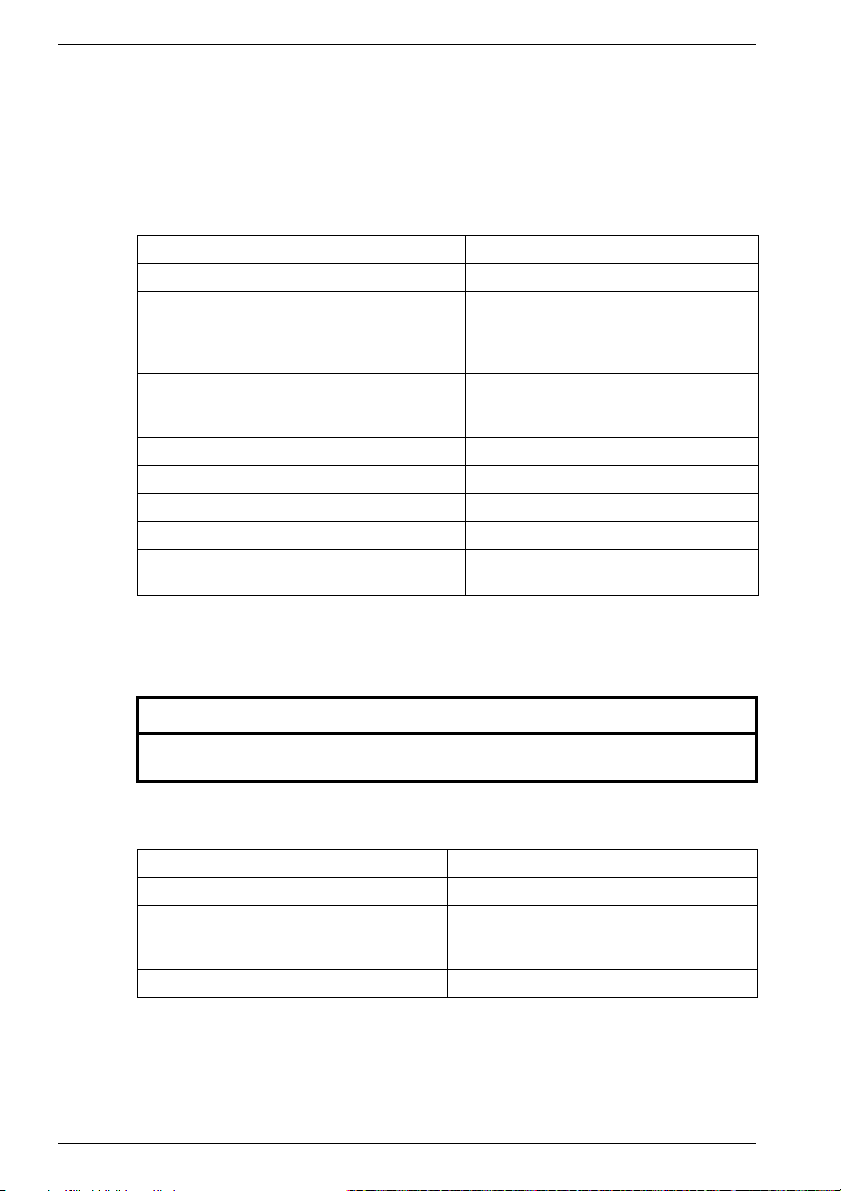

3.2.2 Gears

NOTE

The corresponding gear size can be seen in the second item of the gear type (see

type plate, fig. 7) or the second item of the first block of the order option.

3.2.2.1 Worm gear

Lubricant see rating plate

Oil filling quantity see rating plate

Bleeding:

- gear size 0 (mounting positions 2 and 5)

- gear sizes 1 to 4

Transport lifting tackle without

20 610.40 064.01 Siemens AG

- valve open

- valve lockable

Page 21

3.2.2.2 Bevel wheel gear

Lubricant see rating plate

Oil filling quantity see rating plate

Venting (lockable)

- gear sizes 1 to 4

- gear sizes 5 to 10

Transport lifting tackle Lifting eyes (for gear sizes 5 to 10 only)

3.2.2.3 Flat gear

Lubricant see rating plate

Oil filling quantity see rating plate

Venting (lockable)

- gear sizes 1 to 4

- gear sizes 5 to 6

Transport lifting tackle Borehole for lifting eyes on the gearbox

3.2.2.4 Circular gear

Lubricant see rating plate

Oil filling quantity see rating plate

Venting (lockable)

- gear sizes 0 to 5

- gear sizes 6 to 10

Transport lifting tackle Lifting eyes (for gear sizes 7 to 10 only)

ENGLISH

- without bleeding

- with bleeding

- without bleeding

- with bleeding

frame

- without bleeding

- with bleeding

3.2.3 Motor adapter

3.2.3.1 Motor adapter with curved tooth clutch

Operating temperature - 30 °C to 100 °C

Continuous operating temperature 80 °C (max. peak temperature 120 °C)

Motor shaft with key

3.2.3.2 Motor adapter with plug-in connector, zero-backlash

Operating temperature - 30 °C to 100 °C

Continuous operating temperature 80 °C (peak temperature max. 120 °C)

Motor shaft without key

Siemens AG 610.40 064.01

21

Page 22

4 Transport, assembly

The specifications for transport, installation and assembly in the operating

instructions for the three-phase servomotor 1FK7 (order/item number

610.40 700.21) must be complied with.

4.1 Transport, storage

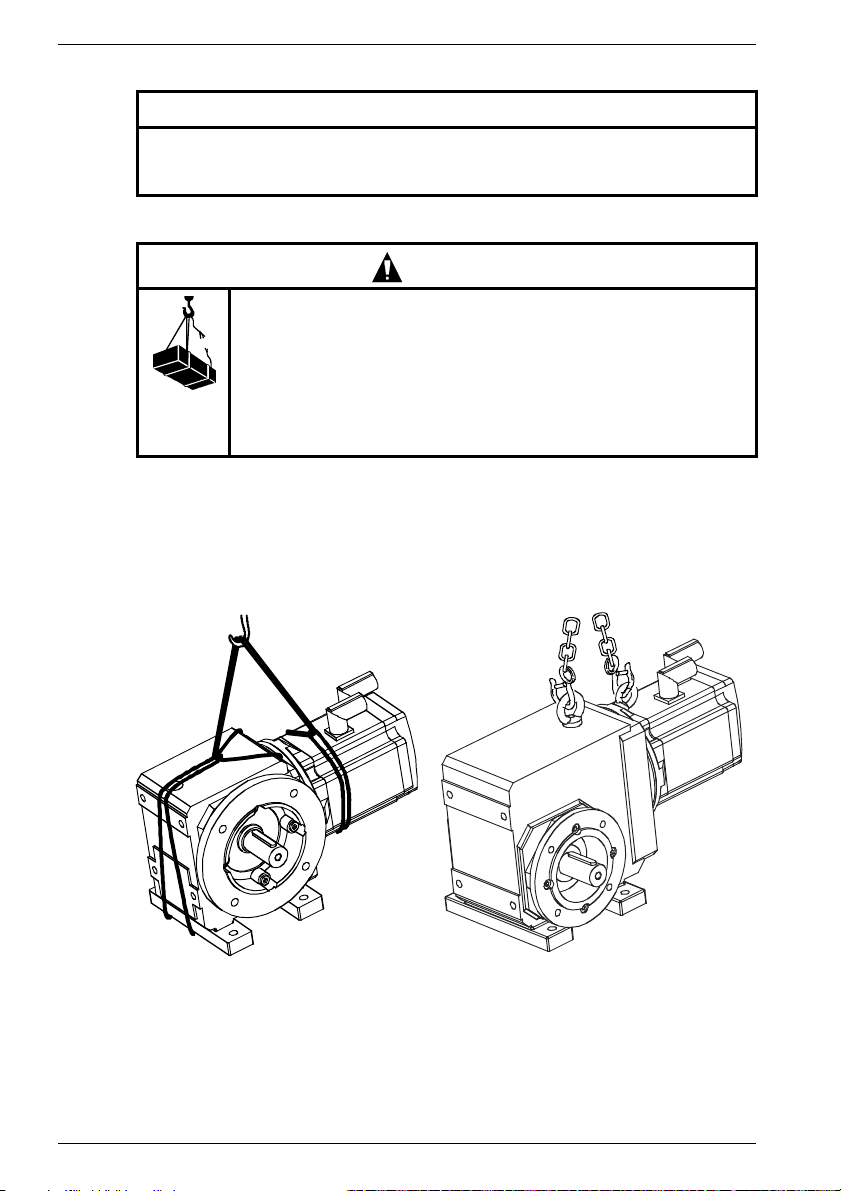

Danger during lifting and transporting procedures!

Improper handling, unsuitable or defective devices, tools etc. can

cause injuries and/or property damage.

Lifting devices, floor conveyors and lifting tackle must conform to

the currently valid regulations.

The relevant safety regulations (e.g. VBG 8) for standing under

suspended loads must be complied with during assembly work on

the holding brake or on the brake motor.

Use suitable lifting tackle for transport and assembly.

Use suspension bands and lifting eyes for transporting the geared motors.

Lifting tackle as per 98/37/EU Directive for Machines, Appendix I.

Refer to the type plate for exact specifications of the weight of the motors.

Observe the transport regulations applying in the country/countries concerned.

Shafts and their bearings must not be damaged by impacts.

ENGLISH

CAUTION

WARNING

A

Fig. 11Examples for lifting and transporting

A with suspension bands (carrying rope) B with lifting eyes/chains

For transporting the unpacked drive within the works:

- lift large geared motors with lifting eyes in the ring bolts,

- lift smaller geared motors with suitable suspension bands (carrying rope) on the

geared motor.

22 610.40 064.01 Siemens AG

B

Page 23

Store in a dry, low-dust and low-vibration place (v

temperatures, see Chapter 3 “Technical specifications”.

Condensed water in the oil chamber of the gearbox leads to rusting, which must be avoided at all costs. Its intensity is determined by the degree of relative air humidity and large

temperature fluctuations.

It is necessary to contact SIEMENS Service if the gearbox is to be temporarily stored. If

long-term storage is foreseen, the gearbox must be completely filled with lubricant by the

manufacturer. This then has to be reduced to the correct quantity shown on the type plate

before the drive is started. The bare parts of the gearing must be conserved.

4.2 Installation, assembly

4.2.1 General information

Impacts on the shaft and bearings must be avoided at all costs as they damage

the bearing race. Do not exceed the permissible axial and radial forces on the

shaft end stated in the configuration specification.

The protective lacquer on the ends of the shaft and centering shoulders must be completely removed before erection/assembly.

If solvents are used, they must not be allowed to come into contact with the lip

seals of the shaft seal rings.

Mounting position, mounting location

The drive may only be mounted in the ordered mounting position.

If the mounting position is changed, the internal construction of the gearbox and the

quantity of lubricant may also have to be changed. The lubrication fittings also have to

be exchanged. In such a case, it is absolutely essential to contact SIEMENS Service.

ENGLISH

NOTICE

CAUTION

< 0,2 mms-1); transport and storage

eff

CAUTION

It must be ensured that air can circulate freely in order to prevent heat

accumulating in the entire gearbox.

Bleeding

Depending upon the design /gear size, some geared motors are vented (see technical

data). The design of the venting valve for worm gears depends upon the mounting position.

CAUTION

In the case of a lockable venting valve, it must be opened without fail before

starting up the drive by turning the knurled knob to the left (corresponding to the

symbol on the knurled knob).

In the case of a loosely attached venting valve, it must be exchanged in the

intended mounting position for the screw plug located in the gearbox.

Siemens AG 610.40 064.01

23

Page 24

ENGLISH

Installation

The subframe for attaching the foot or flanged gearbox must be level and torsionally rigid

in order to prevent strain on the gearbox or output shaft bearing.

The tapped center hole of the output shaft (according to DIN332 sheet 2) is provided both

for shrinking on and for axially attaching transmission elements (gear wheel, chain wheel,

belt pulley, clutch hub) by a central screw.

Shaft ends up to a diameter of 55 have tolerance ISO k6, over 55 have ISO m6.

The key complies with DIN 6885 sheet 1.

4.2.2 Specific features

4.2.2.1 Geared motor with hollow shaft and key link

Shaft mounted gearboxes are inserted onto the drive shaft of the machine that is to be

driven. The reaction torque must be supported either by flange-mounting the gearbox or

by a torque bracket.

In the case of flange mounting, the deviation from perpendicularity between the flanged

end surface on the machine and the shaft axis must not exceed 0.03/100 mm because

of the danger of distorting the bearing or causing an impermissible bending load on the

machine shaft.

The hollow shaft borehole is designed to comply with tolerance ISO H7 and the keyway

with DIN 6885 sheet 1. The machine shaft must comply with ISO k6. The machine shaft

must have a tapped center hole complying with DIN 332 sheet 2.

The shrink on/forcing off disk fitted in the hollow shaft is provided for axially attaching the

gear by a central screw.

Assembly/shrinking of the gear onto the machine shaft:

- Paint the machine shaft with MoS2 paste.

- Paint the hollow shaft spiral groove and keyway with rust preventing grease.

- Shrink the gear on by means of the central screw. Do not hit with a hammer!

CAUTION

Never slip on a dry gear, as otherwise it will be impossible to pull it off to make a

repair because it will have rusted on.

Disassembly:

- Force the gear off by means of a forcing off disk and a suitable forcing-off screw.

Protect the centering of the machine shaft with a support.

- If the shaft is stuck, we recommend allowing rust dissolving oil to work into the

machined seat on the shaft ends for a lengthy period of time.

4.2.2.2 Geared motors with hollow shaft and shrink disk connection

The instructions listed above apply here (see Chapter 4.2.2.1 “Geared motor with hollow

shaft and key link”)! These hints must be observed without fail!

In the case of gears supplied with a shrink disk, this is already mounted on the end of the

hollow shaft and is therefore ready for assembly (conical surfaces and screws of the

shrink disk have been greased in the works).

CAUTION

Do not on any account tighten the locking screws of the shrink disk before the

machine shaft has been mounted as otherwise the inner ring and the hollow shaft

hub will be plastically deformed.

24 610.40 064.01 Siemens AG

Page 25

ENGLISH

Preparations for assembly:

1. Degrease the machine shaft in the pressing area of the shrink disk.

2. Remove the sealing cap and the covering cap from the hollow shaft and shrink disk

respectively.

3. Remove conservation lacquer from the shrink seating and seating face of the hollow

shaft borehole.

The hollow shaft borehole and the machine shaft must be grease-free in the area

of the shrink seating.

Assembly:

1. Slip the gear onto the machine shaft (do not hit with a hammer) and bring into

position.

2. In the case of a slotted hollow shaft, take note of the position of the shrink disk.

3. Tighten the hexagonal screws in the shrink disk evenly one after the other (not crisscross) in several cycles (tightening them by between a quarter and half turn each

time) until all the screws have the necessary pre-tensioning given by the specified

tightening torque.

It must be ensured that the two conical spring washers are lying plane-parallel to one

another.

4. Check the tightening torque with a torque wrench as shown in Table 1.

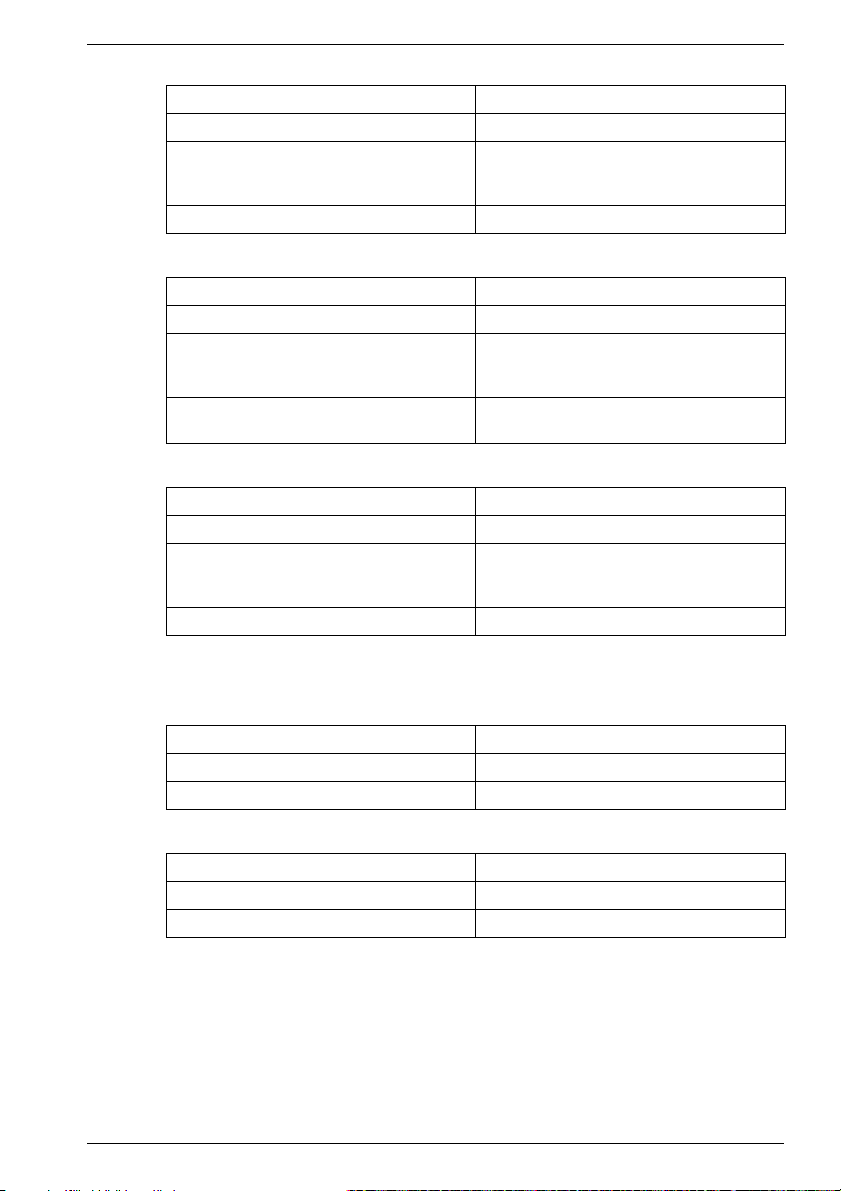

Screws

Hexagonal wrench

Tightening torque [Nm]

(at µ

= 0,1)

ges

M5

8.8M610.9/12.9M810.9/12.9

8 10131719

5 12/14 30/35 59/69 100/120

M10

10.9/12.9

M12

10.9/12.9

Table 1: Tightening torque

WARNING

Hazard from rotating rotor/freely revolving transmission shaft.

Attach suitable protective devices (protection against accidental

contact/covers) before starting up the output elements.

Disassembly:

1. Secure the drive against being switched on unintentionally.

2. Remove the covers from the shrink disk.

Loosen the screws holding the shrink disk one after the other in several cycles,

starting with about one quarter turn (strain washer can jam).

WARNING

There is an injury hazard!

Do not unscrew the screws completely out of their tapped holes.

The strain washer may spring off.

3. After the screws and strain washers have been loosened, the frictional engagement

between the hollow shaft and machine shaft is released.

Insert a retaining ring into the available slot if necessary for pulling off the gear.

Siemens AG 610.40 064.01

25

Page 26

ENGLISH

4. To clean the shrink disk, relubricate screws and conical surface with MoS2 based

solid lubricant.

CAUTION

Before switching the motor on, ensure that:

- the drive does not traverse against a block

- all protective and safety devices are properly installed, even for trial

operations

- the direction of rotation of the drive is correct (important where there is a

back-run safety device)

4.2.2.3 Geared motor and motor adapter with curved tooth clutch

Preparations for assembly:

1. Unscrew the cardboard cover from the adapter casing, and take the clutch hub for the

motor out of the casing. Put the plastic clutch bush onto the counter hub.

2. Check whether the borehole diameter and the keyway fit the clutch hub for the motor

shaft. The borehole of the clutch hub has tolerance ISO H7; the keyway is

manufactured in accordance with DIN 6885 sheet 1.

According to the IEC regulation, the shaft shoulder and flange surface of the

motor must lie in the same plane. The motor shaft must not be longer than

stated in the standard.

Assembly:

1. Lightly grease the motor shaft.

2. Press the clutch hub onto the motor shaft as far as the shaft shoulder.

3. Securely tighten the set screw on the clutch hub.

4. Carefully put the motor onto the adapter casing so that the curved teeth of the clutch

hub easily mesh with the internal toothing of the plastic sleeve.

5. Screw the motor securely to the adapter casing.

The quality of the fixing screws (metric and UNC thread) and the tightening torques

must correspond to Table 2.

Screws

Tightening torque [Nm]

M5

8.8

25 49 85

M10

8.8

M12

8.8

Table 2: Tightening torque

4.2.2.4 Geared motor and motor adapter with plug-in connector, zero-backlash

NOTE

If the assembly instructions are followed, the plug-in connectors are

permanently fixed and maintenance-free.

Preparations for assembly:

The motor shaft shoulder and motor flange surface must lie in one plane (+

ensures the correct axial pre-tensioning of the clutch.

If the shaft shoulder is set back, the offset must be compensated by shims. No parts such

as screws etc. may project over the flange surface in the flange area of the motor.

26 610.40 064.01 Siemens AG

0.5 mm). This

Page 27

ENGLISH

The untensioned clutch hub has a fitting clearance to the motor shaft of 0.01 to 0.05 mm.

As a consequence of the frictional hub-clamp connection and the axial pre-tensioning of

the conical plug-in segments, the plug-in connector works with absolute zero-backlash.

Assembly:

1. Degrease the motor shaft and the clutch hub on the motor side.

2. Put the slotted clutch hub on the motor shaft and slide it against the shaft shoulder;

check the axial position of the hub.

3. Tighten the locking screw as shown in Table 3.

Screws

Tightening torque [Nm]

M5

8.8

61025

M6

8.8

M8

8.8

Table 3: Tightening torque

4. Screw the motor to the adapter casing, tighten the fixing screws as shown in Table 3.

CAUTION

When setting the motor on the adapter casing, the plastic cams of the motor-side

hub must be carefully inserted into the corresponding recesses in the gear side

clutch bush so that the metal bellows are not compressed or bent.

Siemens AG 610.40 064.01

27

Page 28

5 Start-up

The specifications for starting up / for connecting the motor in the operating

instructions for the three-phase servomotor 1FK7 (order/item number 610.40

700.21) must be complied with.

For the lubrication instructions see Chapter 7.1.2 “Lubrication”

The gear is not self-locking.

5.1 Checks before starting up

Thermal hazard from hot surfaces!

The surface temperatures of the motors may not exceed 140 °C.

Do not touch hot surfaces!

Protection must be provided against accidental contact if necessary.

Temperature-sensitive components (electric lines, electronic

components) must not touch hot surfaces.

Before starting up, ensure that

- all connections have been properly made, and the plug connectors are secured

against working loose.

- all motor protection devices are active,

- the drive is not blocked,

- no other possible sources of danger are present,

- the drive is undamaged (no damage from transport/storage),

- the keys in the shaft end (if present) are secured against being thrown out,

ENGLISH

CAUTION

CAUTION

- the direction of rotation of the drive is correct (important where there is a back-run

safety device).

WARNING

Hazard from rotating rotor/freely revolving transmission shaft.

Secure output elements with suitable protective devices (protection

against accidental contact).

Secure key (if present) against being thrown out.

5.2 Start-up

DANGER

Electrical connections must be made by specialist personnel in accordance with

the currently valid regulations (refer to DINVDE 0105 or IEC 364 for the

regulations concerning skilled workers).

The motor winding must be protected against thermal overload by thermal

contacts or PTC thermistor probes or similar.

The guarantee for the motor winding lapses if there is no motor protection.

28 610.40 064.01 Siemens AG

Page 29

ENGLISH

6 Instructions in case of faults

CAUTION

The instructions for faults contained in the operating instructions for the threephase servomotor 1FK7 (order/item number 610.40 700.21) must be complied

with.

6.1 General instructions for rectifying faults

Refer to Table 4 first if there are deviations from normal operation or faults. Contact the

works, please also refer to the relevant section of the operating manual for the components of the entire drive system.

Do not disable the protective devices, even in trial operation.

Consult the manufacturer or the SIEMENS service center when necessary.

- For start up, system motor converter: A&D Hotline +49 180 50 50 222

- For motor / motor components: Contact in the works +49 174-3110669

They will inform the customer of the nearest service partner if further action is required.

Fault Cause Remedy

Irregular running Inadequate screening of the

Vibrations Coupling elements or driven

Running noises Foreign bodies inside the

Motor overheats

(surface temperature

>140 °C)

Temperature monitoring responds

Table 4: Troubleshooting

motor or encoder cables.

Amplification of the drive controller too high

machine are badly balanced

Inadequate alignment of the

drive train

Fixing screws are loose Check and tighten screw connec-

motor

Bearing damage Repair by the manufacturer

Drive overloaded Check load

Heat dissipation impaired by

deposits

Check screening and grounding

Adjust controller (see converter

operating manual)

Rebalance

Realign the machine set

tions

Repair by the manufacturer

(see rating plate)

Clean surface of drives,

Ensure that the cooling air can flow

freely in and out

6.2 Spare parts

The following must be stated when ordering spare parts:

- Item no. of the part in the illustration of the spare parts list (request a copy if required)

- Type designation stated on the type plate on the geared motor

- Serial number stated on the type plate on the geared motor

NOTE

The spare parts lists are not assembly instructions! They are not binding for

assembly purposes. Only original parts may be used as spare parts.

We give no warranty and accept no liability for damage resulting from any parts

not supplied by us.

Siemens AG 610.40 064.01

29

Page 30

ENGLISH

7 Inspection, maintenance, disposal

7.1 Maintenance / repair

7.1.1 General instructions

Clean wherever and whenever the degree of contamination makes it necessary in order

to ensure that the waste heat is adequately dissipated. As the operating conditions vary

greatly, one can only cite general intervals for fault-free operation.

Guidelines:

- Bearing service life 20,000 hours

- Radial shaft seals approx. 5,000 hours with oil lubrication

WARNING

The motors’ rotors contain permanent magnets with high magnetic flux densities

which exert strong attractive forces on ferromagnetic bodies.

People fitted with a heart pacemaker are at risk in the vicinity of a disassembled

rotor. Data stored on electronic data media may be destroyed.

NOTICE

The encoder system must be readjusted each time after the motor has been

disassembled.

The maintenance of the geared motors is kept to a minimum by their design

concept (see Chapter 7.1.2 “Lubrication”).

All components subject to operational wear (for example friction linings of brakes)

must be included in the regular maintenance measures.

SIEMENS service partners are available for all maintenance work on gears (see Chapter

6 “Instructions in case of faults”).

DANGER!

Electric shock hazard!

When the rotor is rotating, the motor terminals carry a dangerous

voltage.

Stop the motor before commencing any electrical work.

Only use trained, qualified personnel for assembly work on the

converters and plugs.

Observe the regulations for working in electrotechnical plants.

Safety rules for working in electrical installations as per

EN 50110-1 (DIN VDE 0105-100):

- Work always with the equipment electrically dead.

- Isolate from electrical supply.

- Secure against switching on again.

- Check electrical deadness.

- Earth and short-circuit.

- Cover or cordon off adjacent parts which are electrically live.

- Release for work.

- Connect the PE conductor to

30 610.40 064.01 Siemens AG

Page 31

7.1.2 Lubrication

The points "mounting position" and "venting" in must be complied with Chapter 4.1

“Transport, storage”.

POLYGLYCOL based lubricant must not be mixed with mineral oil. The quantity

of lubricant to fill (quantity of oil) depends upon the position in which the gearbox

is mounted, and is stated on the type plate.

All used lubricants, cleansers, containers etc. must be disposed of according to

the legal regulations.

7.1.2.1 Motor with worm gear

Unless otherwise stated on the type plate, the gears are filled with high pressure gear oil.

The oil must be changed after about 5,000 operating hours, but after 2,000 operating

hours when used in damp rooms (this must be stipulated in the order!).

7.1.2.2 Motor with bevel wheel gear

Unless otherwise stated on the type plate, the gears are filled with high pressure gear oil.

Gears of sizes 1 to 4 have long-time lubrication, and do not require any maintenance if

used for the intended purpose.

Gears of sizes 5 to 10 need an oil change after 5, 000 operating hours, but after 2,000

operating hours when used in damp rooms (this must be stipulated in the order!).

7.1.2.3 Motor with flat gear

Unless otherwise stated on the type plate, the gears are filled with high pressure gear oil.

The gears have long-time lubrication, and do not require any maintenance if used for the

intended purpose.

7.1.2.4 Motor with circular gear

Unless otherwise stated on the type plate, the gears are filled with high pressure gear oil.

Gears of sizes 0 to 5 have long-time lubrication, and do not require any maintenance if

the drive is used for the intended purpose.

Gears of sizes 6 to 10 need an oil change after 5, 000 operating hours, but after 2,000

operating hours when used in damp rooms (this must be stipulated in the order!).

ENGLISH

NOTICE

Siemens AG 610.40 064.01

31

Page 32

ENGLISH

7.2 Disposal

Motors must be disposed of in accordance with the national and local regulations by

putting them into the standard recycling process or by returning them to the manufacturer.

The following points must be observed when disposing of the motors:

- Dispose of oil in accordance wit the old oil ordinance (for example no mixing with

solvents, cold cleansers or lacquer residues)

- Separate components for recycling into:

- Electronic scrap (encoder electronics)

- scrap iron

- aluminium

- nonferrous metals (worm wheels, motor windings)

- permanent magnets

WARNING

Danger of crushing injuries. People with heart pacemakers must keep well away

as they at risk from the effects of the permanent magnets.

8 Other applicable documentation

These operating instructions are valid in conjunction with the following documentation:

- Project planning guide 1FK7.,

Ordering / Item number 6SN1197-0AD06-0AP0

- Operating manual, three-phase servomotor 1FK7., Three-phase servomotor 1FK7.,

Ordering / Item number 610.40 700.21

- Maintenance manuals, three-phase servomotor 1FK7., Three-phase servomotor

1FK7.,

Ordering / Item number 610.43 430.21

32 610.40 064.01 Siemens AG

Page 33

DEUTSCH

Diese Betriebsanleitung enthält Hinweise, die Sie zu Ihrer persönlichen Sicherheit sowie

zur Vermeidung von Sachschäden beachten müssen. Die Hinweise zu Ihrer persönlichen

Sicherheit sind durch ein Warndreieck hervorgehoben, Hinweise zu alleinigen

Sachschäden stehen ohne Warndreieck. Je nach Gefährdungsgrad werden sie

folgendermaßen dargestellt:

GEFAHR

bedeutet, dass Tod, schwere Körperverletzung oder

Piktogramm

erheblicher Sachschaden eintreten werden, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

WARNUNG

bedeutet, dass Tod, schwere Körperverletzung oder

Piktogramm

erheblicher Sachschaden eintreten können, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

VORSICHT

Piktogramm

mit Warndreieck bedeutet, dass eine leichte

Körperverletzung eintreten kann, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

VORSICHT

ohne Warndreieck bedeutet, dass ein Sachschaden eintreten kann,

wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

ACHTUNG

bedeutet, dass ein unerwünschtes Ereignis oder Zustand eintreten

kann, wenn der entsprechende Hinweis nicht beachtet wird.

Siemens AG 610.40 064.01

33

Page 34

DEUTSCH

Qualifiziertes Personal

Inbetriebsetzung und Betrieb des Gerätes dürfen nur von qualifiziertem Personal

vorgenommen werden. Qualifiziertes Personal im Sinne der sicherheitstechnischen

Hinweise dieser Betriebsanleitung sind Personen, die die Berechtigung haben, Geräte,

Systeme und Stromkreise gemäß den Standards der Sicherheitstechnik in Betrieb zu

nehmen, zu erden und zu kennzeichnen.

Bestimmungsgemäßer Gebrauch

Beachten Sie:

Das Gerät darf nur für die im Katalog und in der Projektierungsanleitung vorgesehenen

Einsatzfälle und nur in Verbindung mit von Siemens empfohlenen bzw. zugelassenen

Fremdgeräten und -komponenten verwendet werden.

Der einwandfreie und sichere Betrieb des Produktes setzt sachgemäßen Transport,

sachgemäße Lagerung, Aufstellung und Montage sowie sorgfältige Bedienung und

Instandsetzung voraus.

Haftungsausschluss

Wir haben den Inhalt der Druckschrift geprüft. Dennoch können Abweichungen nicht

ausgeschlossen werden, so dass wir für die vollständige Übereinstimmung keine Gewähr

übernehmen. Die Angaben in dieser Druckschrift werden regelmäßig überprüft, und

notwendige Korrekturen sind in den nachfolgenden Auflagen enthalten. Für

Verbesserungsvorschläge sind wir dankbar.

© Copyright Siemens AG 2005. All rights reserved

Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und Mitteilung ihres

Inhalts ist nicht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen

verpflichten zum Schadenersatz.

Alle Rechte vorbehalten, insbesondere für den Fall der Patenterteilung oder

GM-Eintragung.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Motion Control Systeme (MC)

D-97615 Bad Neustadt an der Saale

34 610.40 064.01 Siemens AG

Page 35

DEUTSCH

1 Allgemeine Sicherheitshinweise

Diese Betriebsanleitung enthält alle erforderlichen Informationen über Transport, Aufstellung, Inbetriebnahme, Wartung usw. der Getriebemotoren.

Diese Betriebsanleitung gilt in Verbindung mit der SIEMENS-Projektierungsanleitung sowie Betriebsanleitung „Drehstrom-Servomotoren“.

Die Erfüllung eventueller Garantieansprüche setzt die genaue Einhaltung der Angaben

und Hinweise dieser Betriebsanleitung voraus.

Zur Vermeidung von Gefährdungen jeglicher Art bei Transport, Lagerung, Anbau,

Inbetriebnahme, Wartung usw. müssen die Sicherheits- und Gefahrenhinweise

dieser Betriebsanleitung sowie der Betriebsanleitung für Drehstrom-Servomotoren (1FK7.) unbedingt eingehalten werden! Das Nichteinhalten kann schwere Körperverletzungen oder Sachschäden zur Folge haben.

Sichern Sie für Ihr Endprodukt die Einhaltung aller bestehenden Rechtsvorschriften! Beachten Sie die verbindlichen nationalen, örtlichen und anlagenspezifischen

Vorschriften!

Die Inbetriebnahme ist so lange untersagt, bis die Konformität des Endprodukts

mit den geltenden Richtlinien festgestellt ist.

Mechanische Gefährdungen, welche z.B. von einer freidrehenden Getriebewelle aus-

gehen, sind durch geeignete Schutzvorrichtungen auszuschließen! Alle Passfedern in

Wellen müssen gesichert sein!

Elektrische Gefährdungen sind durch genaue Beachtung der in Kapitel “Inbetriebnahme” gegebenen Anweisungen auszuschließen!

Die Läufer der Motoren enthalten Permanentmagnete mit hohen magnetischen Flussdichten und starken Anziehungskräften zu ferromagnetischen Körpern.

In der Nähe eines demontierten Läufers sind Personen mit Herzschrittmacher gefährdet.

Auf elektronischen Datenträgern gespeicherte Daten können zerstört werden.

Der Einsatz in explosionsgefährdeten Bereichen ist verboten, sofern nicht ausdrücklich

bestätigt.

Für den Betrieb außerhalb des zulässigen Temperaturbereiches muss der Antrieb

werkseitig dafür ausgerüstet sein.

Thermische Gefährdung durch Berühren des Getriebe-/Motorengehäuses mit bloßer

Hand! Es kann bei entsprechender Betriebstemperatur zu Verbrennungen oder zu

schreckhaften Reaktionen kommen! Die Oberflächentemperatur der Motoren kann bis

140 °C, die der Getriebe bis 90 °C betragen.

Berühren Sie nicht heiße Oberflächen!

Temperaturempfindliche Bauteile (elektrische Leitungen, elektronische Bauteile) dürfen

nicht an heißen Oberflächen anliegen. Überhitzung der Motoren kann Zerstörung der

Wicklungen und Lager und Entmagnetisierung der Permanentmagnete bewirken.

Betreiben Sie die Motoren nur mit wirksamer Temperaturkontrolle!

Bestimmungsgemäßer Gebrauch

Das Einhalten aller Vorgaben der Betriebsanleitung und der Projektierungsanleitung

„Drehstrom-Servomotoren“ ist Bestandteil der bestimmungsgemäßen Verwendung.

Die Getriebe/Getriebemotoren sind für die im Katalog angegebenen zulässigen Leistungen und Belastungen konzipiert. Die Getriebemotoren dürfen nur für den Einsatzfall verwendet werden, für den sie unter Berücksichtigung aller Betriebsfaktoren projektiert

wurden. Jegliche Überlastung der Antriebe gilt als nicht bestimmungsgemäße Verwendung. Eigenmächtige Veränderungen am gesamten Antrieb schließen eine Haftung des

Herstellers für daraus entstehende Schäden aus.

Siemens AG 610.40 064.01

35

Page 36

2 Angaben zum Produkt

2.1 Produktbeschreibung

2.1.1 Allgemeines

Die Getriebemotoren bestehen aus einem Drehstrom-Servomotor (1FK7.) mit

angeflanschtem Getriebe. Die Drehstrom-Servomotoren werden mit montierten Getriebe

ausgeliefert. Einige Ausführungen werden mit zusätzlicher Kupplung ausgeliefert.

Es ist möglich den Drehstrom-Servomotor mit allen beschriebenen Getrieben/

Motoradaptern (Kupplungen) zu kombinieren. Dazu muss die Projektierung (Auswahl

der Kombination Drehstrom-Servomotor und Getriebe/Kupplung) anwenderbezogen

realisiert werden.

Die Drehstrom-Servomotoren (1FK7.) sind permanentmagneterregte DrehstromSynchron-Motoren (Drehstrom-Servomotoren) zum Betrieb mit motorgesteuerten Pulswechselrichtern nach dem Sinusstromprinzip. Die Motoren sind vorgesehen für Antrieb

und Positionierung von Werkzeug- und Produktionsmaschinen sowie Robotern und

Handhabungsgeräten.

2.1.2 Getriebe

2.1.2.1 Allgemeines

Die Getriebe kommen in verschiedenen Ausführungen und Bauformen zum Einsatz.

Die ins Langsame übersetzenden Getriebestufen reduzieren die meist hohe Eintriebsdrehzahl auf die gewünschte niedrigere Abtriebsdrehzahl. Das Eintriebsdrehmoment

vervielfacht sich dabei um die Übersetzung auf das Abtriebsdrehmoment (vermindert um

den geringen Wirkungsgradverlust des Getriebes).

Ausführung mit Bauformen Getriebewellenformen

Schneckengetriebe und

Kegelradgetriebe

Flachgetriebe - Flanschausführung

Stirnradgetriebe - Fußausführung

- Gewindelochkreis

- Flanschausführung

- Fußausführung und

- Fußausführung und

- Gewindelochkreis

- Gewindelochkreis

- Flanschausführung

- Fußausführung und

- Fußausführung und

DEUTSCH

Gewindelochkreis

Flanschausführung

Gewindelochkreis

Flanschausführung

- Vollwelle mit Passfeder

- Hohlwelle mit

Passfedernut

- Hohlwelle mit

Schrumpfscheibe

- Vollwelle mit/ohne

Passfeder

- Hohlwelle mit

Passfedernut

- Hohlwelle mit

Schrumpfscheibe

- Vollwelle mit/ohne

Passfeder

HINWEIS

Die jeweilige Bauform bzw. Einbaulage ist dem Typenschild zu entnehmen.

Die Schmierstoff-Füllmenge (Ölmenge) ist von der Getriebe-Einbaulage

abhängig und auf dem Typschild angegeben.

36 610.40 064.01 Siemens AG

Page 37

2.1.2.2 Schneckengetriebe

Fig. 1 Motor mit Schneckengetriebe (Beispiel)

Schneckengetriebe/-motoren sind in Blockbauweise aufgebaut und haben zum Schneckensatz eine oder zwei vorgeschaltete Stirnradstufen (2- oder 3-stufiges Getriebe). Die

Abtriebswelle treibt im Winkel von 90° zur Eintriebswelle aus. Der Schneckensatz mit gehärteter und geschliffener Stahlschnecke und Bronze- Schneckenrad wirkt dämpfend bei

Stößen und Erschütterungen. Die Verzahnungen haben enges Flankenspiel.

2.1.2.3 Kegelradgetriebe

DEUTSCH

Fig. 2 Motor mit Kegelradgetriebe (Beispiel)

Kegelradgetriebe/-motoren sind in Blockbauweise aufgebaut.

Die Getriebegrößen K2 bis K4 haben zusätzlich zur Kegelradstufe eine oder zwei vorgeschaltete Stirnradstufen (2- oder 3-stufiges Getriebe). Die Größen K5 bis K10 sind zusätzlich zur Kegelradstufe mit einer nachgeschalteten und einer oder zwei