Siemens 1FK7 02, 1FK7 03 Series, 1FK7 06 Series, 1FK7 08 Series, 1FK7 10 Series Series Manual

...Page 1

Over 100 years cumulative experience

24 hour rush turnaround / technical support service

Established in 1993

The leading independent repairer of servo motors and drives in North America.

Visit us on the web:

www.servo-repair.com

www.servorepair.ca

www.ferrocontrol.com

www.sandvikrepair.com

www.accuelectric.com

Scroll down to view your document!

For 24/7 repair services :

USA: 1 (888) 932 - 9183

Canada: 1 (905) 829 -2505

Emergency After hours: 1 (416) 624 0386

Servicing USA and Canada

Page 2

Three-phase servomotors

1FK7 02. - 1FK7 10.

Instructions Edition 11 / 2001

Drehstrom-Servomotoren

Servomoteurs triphasés

Servomotores trifásicos

Servomotori trifasi

Trefas servomotorer

610.40 700.21

Page 3

ENGLISH

CONTENTS

ENGLISH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

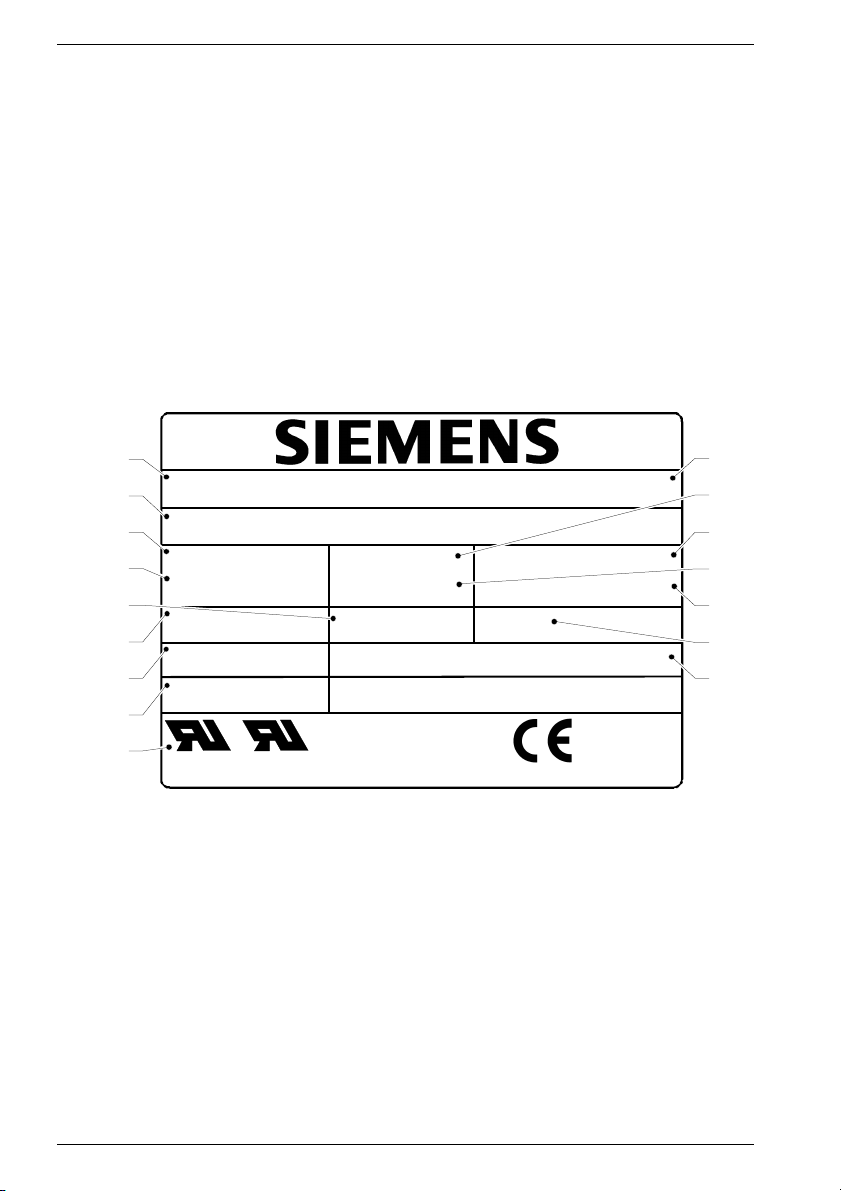

3.1 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Installation, Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Transport, Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Important instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

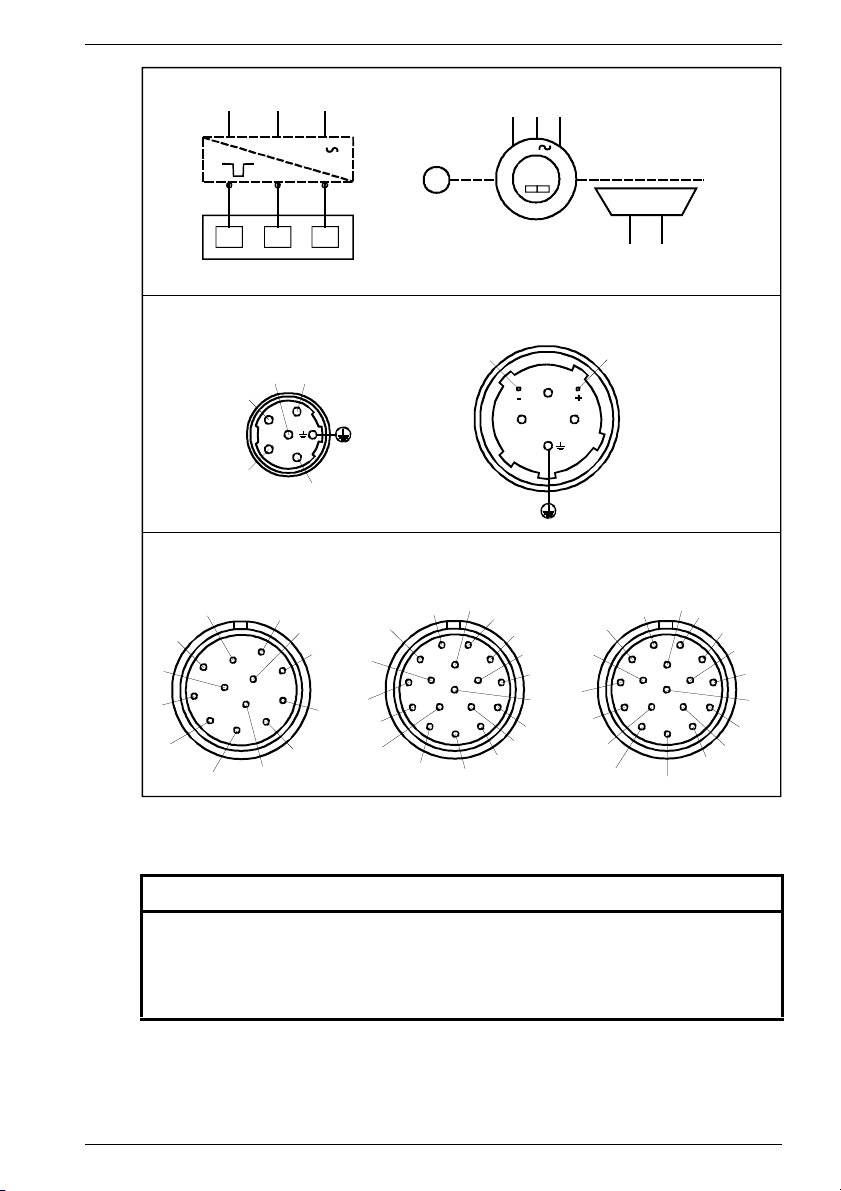

5.2 Plug design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Checks before starting up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Instructions in case of faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 Inspection, maintenance, disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 610.40 700.21 Siemens AG

Page 4

DEUTSCH

INHALT

DEUTSCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Allgemeine Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 Angaben zum Produkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Produktbeschreibung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Typenschild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Merkmale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Aufstellung, Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Transport, Lagerung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Aufstellung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Elektrischer Anschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Wichtige Hinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Steckerausführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Prüfungen vor Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Hinweise bei Störungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Inspektion, Wartung, Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Siemens AG 610.40 700.21

3

Page 5

FRANÇAIS

SOMMAIRE

FRANÇAIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1 Consignes générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2 Indications relatives au produit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1 Description du produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.2 Equipements fournis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Caractéristiques techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1 Plaque signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 Installation, montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1 Transport, positionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5 Raccordement électrique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 Consignes importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2 Modèle de prise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1 Vérifications avant la mise en service. . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7 Remarques en cas de dérangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Inspection, entretien, élimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4 610.40 700.21 Siemens AG

Page 6

ESPAÑOL

ÍNDICE

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1 Indicaciones generales de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2 Datos respecto al producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.1 Descripción del producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.2 Volumen de suministro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3 Datos técnicos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.1 Placa de características. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.2 Características. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 Instalación y montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.1 Transporte, almacenamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.2 Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5 Conexión eléctrica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1 Indicaciones importantes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Conexiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6 Puesta en servicio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.1 Comprobaciones antes de la puesta en servicio. . . . . . . . . . . . . . . . . . 57

6.2 Puesta en servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7 Indicaciones en caso de avería . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8 Inspección, mantenimiento, eliminación de residuos. . . . . . . . . . . . . . . . . 59

Siemens AG 610.40 700.21

5

Page 7

ITALIANO

INDICE

ITALIANO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1 Avvertenze generiche di sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2 Dati sul prodotto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.1 Descrizione del prodotto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.2 Fornitura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3 Caratteristiche tecniche. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1 Targhetta. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.2 Caratteristiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4 Installazione, montaggio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.1 Trasporto, stoccaggio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.2 Installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Collegamento elettrico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1 Note importanti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2 Tipo di connettore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6 Messa in funzione. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1 Verifica prima della messa in funzione . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2 Messa in funzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7 Istruzioni in caso di guasto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8 Ispezione, manutenzione, smaltimento . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6 610.40 700.21 Siemens AG

Page 8

SVENSKA

INNEHÅLL

SVENSKA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1 Allmän säkerhetsinformation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2 Uppgifter om produkten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.1 Produktbeskrivning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.2 Leveransens omfattning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3 Tekniska data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.1 Typskylt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2 Kännetecken . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4 Uppställning, montering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.1 Transport, lagring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.2 Uppställning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5 Elektrisk anslutning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.1 Viktig information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.2 Kontaktutförande . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6 Driftsättning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.1 Kontroller innan driftsättning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2 Driftsättning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7 Information vid störningar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8 Inspektion, underhåll, avfallshantering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Siemens AG 610.40 700.21

7

Page 9

ENGLISH

This manual contains notes which you should observe to ensure your own personal

safety, as well to protect the product and connected equipment. These notices are

highlighted in the manual by a warning triangle and are marked as follows to the level of

danger. They are shown as follows according to the degree of danger involved.

DANGER!

indicates an imminently hazardous situation which, if

Pictogram

not avoided by the appropriate precautionary

measures, will result in death, serious injury or

substantial material damage.

WARNING

indicates an imminently hazardous situation which, if

Pictogram

not avoided by the appropriate precautionary

measures, could result in death, serious injury or

substantial material damage.

CAUTION

Pictogram

used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

CAUTION

used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in damage to

property.

NOTICE

indicates a potential situation which, if not avoided, may result in an

undesirable result or state.

8 610.40 700.21 Siemens AG

Page 10

ENGLISH

Qualified Personnel

The device/system may only be set up and operated in conjunction with this manual. Only

qualified personnel should be allowed to install and work on the this equipment. Qualified

persons are defined as persons who are authorized to commission, to ground, and to bag

circuits, equipment, and systems in accordance with established safety practices and

standards.

Intended Usage

Please note the following:

This device and its components may only be used for the applications described in the

catalog or technical description, and only in connection with devices or components from

other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and

installed correctly, and operated and maintained as recommended.

Disclaimer of Liability

We have checked the contents of this manual. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in the manual are

reviewed regularly and any necessary corrections included in subsequent editions.

Suggestions for improvement are welcomed.

© Copyright Siemens AG 2001. All rights reserved

The reproduction, transmission or use of this document or its contents is not permitted

without express written authority. Offenders will be liable for damages.

All rights, including rights created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Motion Control Systeme (MC)

D-97615 Bad Neustadt an der Saale

Siemens AG 610.40 700.21

9

Page 11

ENGLISH

1 General safety instructions

The servomotors correspond to the harmonized standards of the EN 60034 (VDE 0530)

series EN 60034-1, EN 60034-6, EN 60034-9 and EN 60204-1.

The three-phase servomotors 1FK6 conform to 73/23/EEC Low Voltage Directive.

Standard motors conform to UL regulations. The rating plates of these motors are marked

with UR.

Ensure that your end product conforms to all currently valid legal requirements.

Follow the compulsory national, local and installation-specific regulations.

Three-phase servomotors are exclusively intended for fitting in another machine or

machines.

These motors must not be brought into use until it has been established that the end

product conforms to the currently valid directives.

The operating manual applies in conjunction with the SIEMENS project planning guide

"Three-Phase Servomotors“, order no. 6SN1197-0AC20-0AP.

All safety instructions must be observed during the transport, storage, assembly,

disassembly and operation of the servomotors!

Failure to observe the instructions can lead to serious personal injuries or property damage.

The motors’ rotors contain permanent magnets with high magnetic flux densities which exert

strong attractive forces on ferromagnetic bodies.

People fitted with a heart pacemaker are at risk in the vicinity of a disassembled rotor. Data

stored on electronic data media may be destroyed.

It is forbidden to use the motors in areas at risk of explosion, unless expressly stated.

Thermal hazards

The surface temperatures of the motors can reach up to 140 °C (284 °F).

Do not touch hot surfaces!

Temperature-sensitive components (electric lines, electronic components) must not touch

hot surfaces.

Overheating in the motors may destroy the windings and bearings, and demagnetize the

permanent magnets.

Only operate the motors with effective temperature control.

Intended use

Usage for the intended purpose includes observing all the specifications in the operating

manual and the project planning guide "Three-Phase Servomotors“.

2 Product information

2.1 Product description

Motors of 1FK7 series are permanent magnet excited, three-phase synchronous motors

(three-phase servomotors) for operating with motor-controlled indirect a.c. converters

according to the sinusoidal current principle.

The motors are intended for driving and positioning machine tools, production machines,

robots and handling devices.

10 610.40 700.21 Siemens AG

Page 12

ENGLISH

2.2 Scope of delivery

The drive systems are arranged individually. Immediately upon receipt of delivery, check

whether the scope of delivery corresponds with the consignment notes. SIEMENS cannot

accept any liability for any shortages or deficiencies reported at a later date.

Complaint instructions:

- Report detectable transport damage immediately to the carrier.

- Report detectable defects / incomplete delivery immediately to the responsible

SIEMENS representative.

The operating manual is part of the scope of delivery and shall therefore be kept in an

accessible place.

As the delivery includes a separate type plate, the motor data must also be kept on or near

the machine or system.

3 Technical data

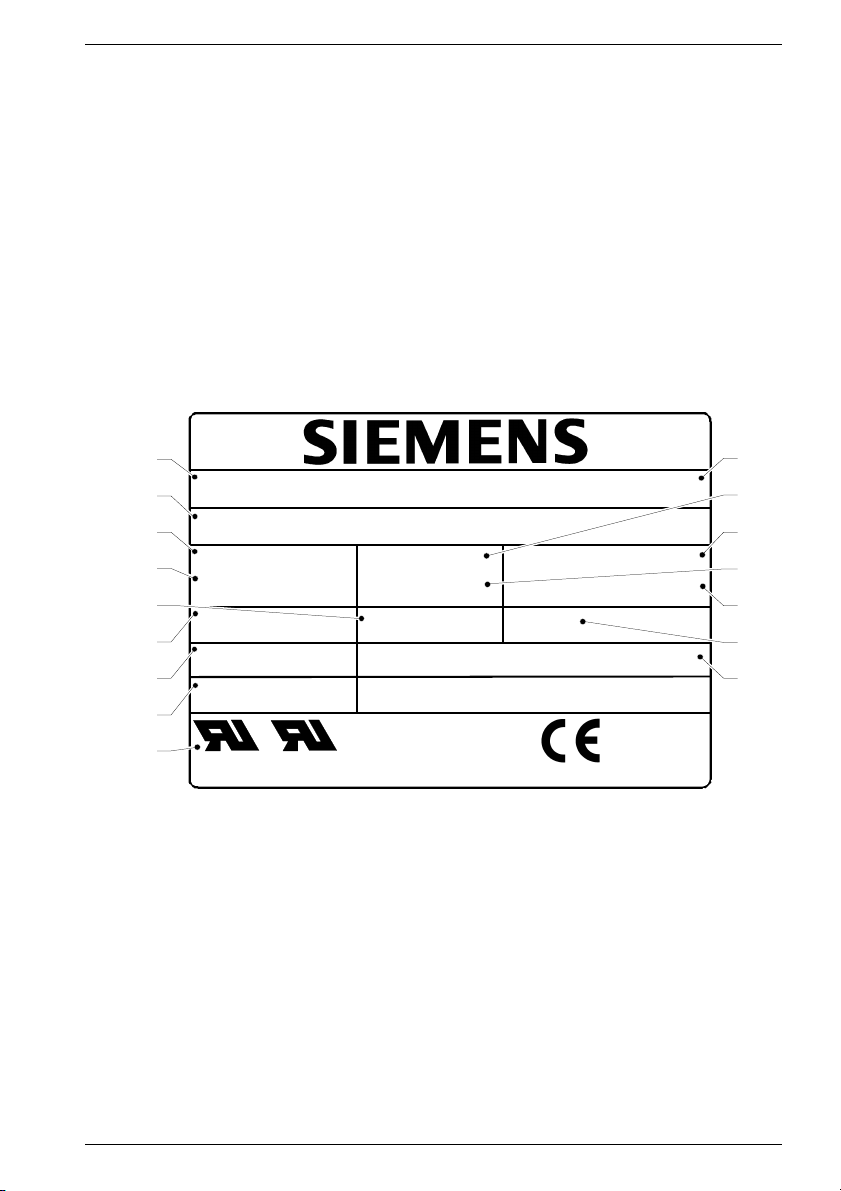

3.1 Rating plate

1

3~ Servomotor

2

No.YF: PN 184583 01 001

3

11 Nm IO 8,0 A n

M

4

5

O

7,3 Nm IN 5,6 A nN 3000 /min

M

N

Th.Cl. F U

6

1FK7063-5AF71-1AB3

6600 /min

max

263 V IP 64

IN

Encoder B01 Brake EBD 0.8BK / 24 V- / 19 W

7

Rev. No.: 000

8

9

EN 60034

Made in Germany

Fig. 1 Rating plate

1 Motor type: three-phase servomotor 10 SIEMENS motor type/ designation

2 IID No., production number 11 Zero-speed current I

3 Zero speed continuous torque M

4 Rated torque M

5 Induced voltage U

6 Temperature class 15 Degree of protection

7 Encoder type code 16 Holding brake data:

8 Version Type, voltage, power consumption

9 Standards and regulations

[Nm] 13 Rated current IN [A]

N

[V] 14 Rated speed nN [rpm]

IN

[Nm] 12 Maximum speed n

0

max

[A]

0

[rpm]

10

11

12

13

14

15

16

Siemens AG 610.40 700.21

11

Page 13

ENGLISH

3.2 Features

Types of construction IM B5 (IM V1, IM V3)

(EN 60034-7)

Degree of protection IP64

(EN 60034-5)

Cooling Self-cooling

(EN 60034-6)

A-grade sound intensity level

(EN 60034-9)

for speed range up to 3,000 rpm

1FK7 02., 1FK7 03., 1FK7 04. approx. 55 dB(A)

1FK7 06. approx. 65 dB(A)

1FK7 08., 1FK7 10. approx. 70 dB(A)

Thermal motor protection Temperature sensor KTY84

(EN 60034-11) in the stator winding

Shaft end cylindrical; without keyway,

(DIN 748-3; IEC 60072-1) Tolerance range k6

true running, coaxiality, axial run-out deviation Tolerance N

(DIN 42955; IEC 60072-1)

Vibration severity Grade N

(EN 60034-14)

Bearing Rolling contact bearing with permanent

Service life of bearing 20000 h (guideline)

Winding insulation Temperature class F

(EN 60034-1)

Ambient temperatures -15 °C to +40 °C (5 °F to 104 °F)

Installation altitude up to 1000 m a.s.l,

(EN 60034-1) 2000 m conversion factor 0,94

Magnetic material Rare-earth material

Electrical connections Revolving plug for output and

Encoder system fitted encoder

Additional technical parameters, dimensional sheets according to project planning guide

"Three-Phase Servomotors“, order no. 6SN1197-0AC20-0AP.

Options/expansions

Low inertia series HD (High Dynamic)

Type of protection IP 65; additional drive end flange IP67

(EN 60034-5)

grease lubrication (lifetime lubrication)

fixed bearing on non-drive end

otherwise the rated data are reduced

to 50 °C conversion factor 0,92

to 60 °C conversion factor 0,82

2500 m conversion factor 0,9

encoder signals

- speed recording

- recording the rotor position

- indirect positional recording

12 610.40 700.21 Siemens AG

Page 14

ENGLISH

Fitted/mounted elements - closed current holding brake

(DIN VDE 0580)

Supply voltage 24 V DC ±10%

- planetary gearing

Encoder system - incremental encoder sin/cos 1 V

- absolute value encoder EnDat

- simple, absolute value encoder

- resolver

Shaft end cylindrical with keyway and

(DIN 748-3; IEC 60072-1) feather key; Tolerance range k6

(balancing with half feather key)

You will find more technical details, e.g. motor dimensions, in the catalogs NC 60 and

DA 65.3.

4 Installation, Assembly

4.1 Transport, Storage

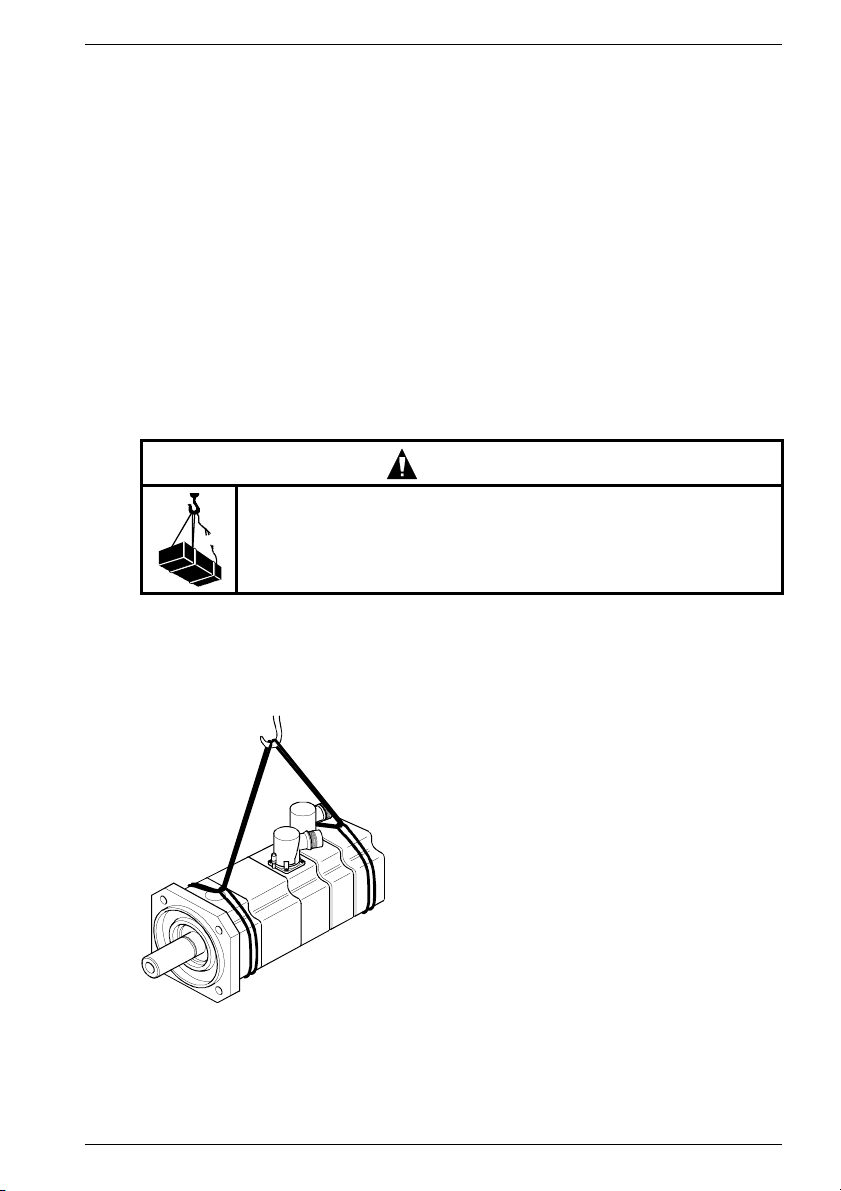

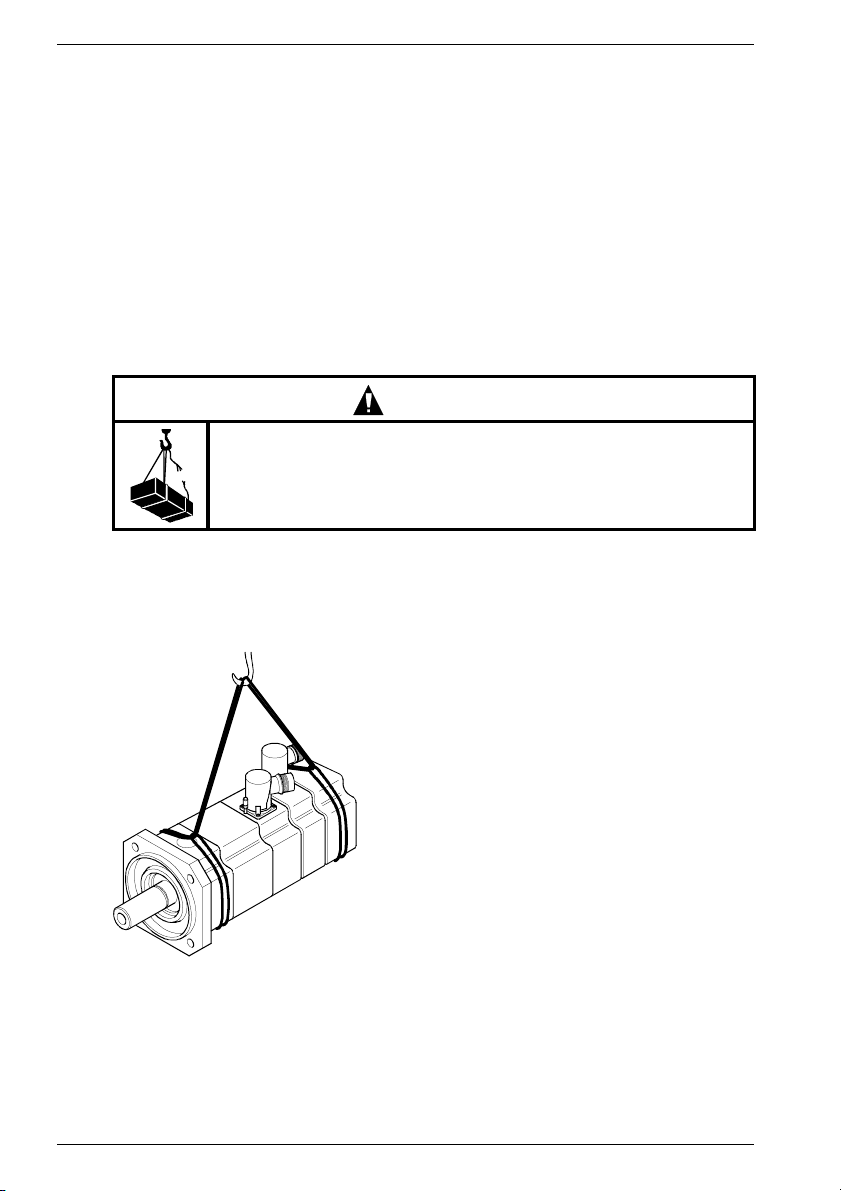

WARNING

Danger during lifting and transporting procedures!

Improper handling, unsuitable or defective devices, tools etc. can

cause injuries and/or property damage.

Lifting devices, ground conveyors and lifting tackle must correspond

to the valid regulations.

PP

Use suitable load suspension devices for transport and assembly.

Use lifting eyes for transporting the motors where these are provided by the manufacturer.

Lifting tackle as per 98/37/EU Directive for Machines, Appendix I.

The motors weigh up to 50 kg. For exact details, please refer to the catalog or dimensional

sheet.

Fig. 2 Lift and transport with suspension bands

Observe the transport regulations applying in the country/countries concerned.

Store in a dry, low-dust and low-vibration place (v

Siemens AG 610.40 700.21

< 0,2 mms-1)

eff

13

Page 15

4.2 Installation

ENGLISH

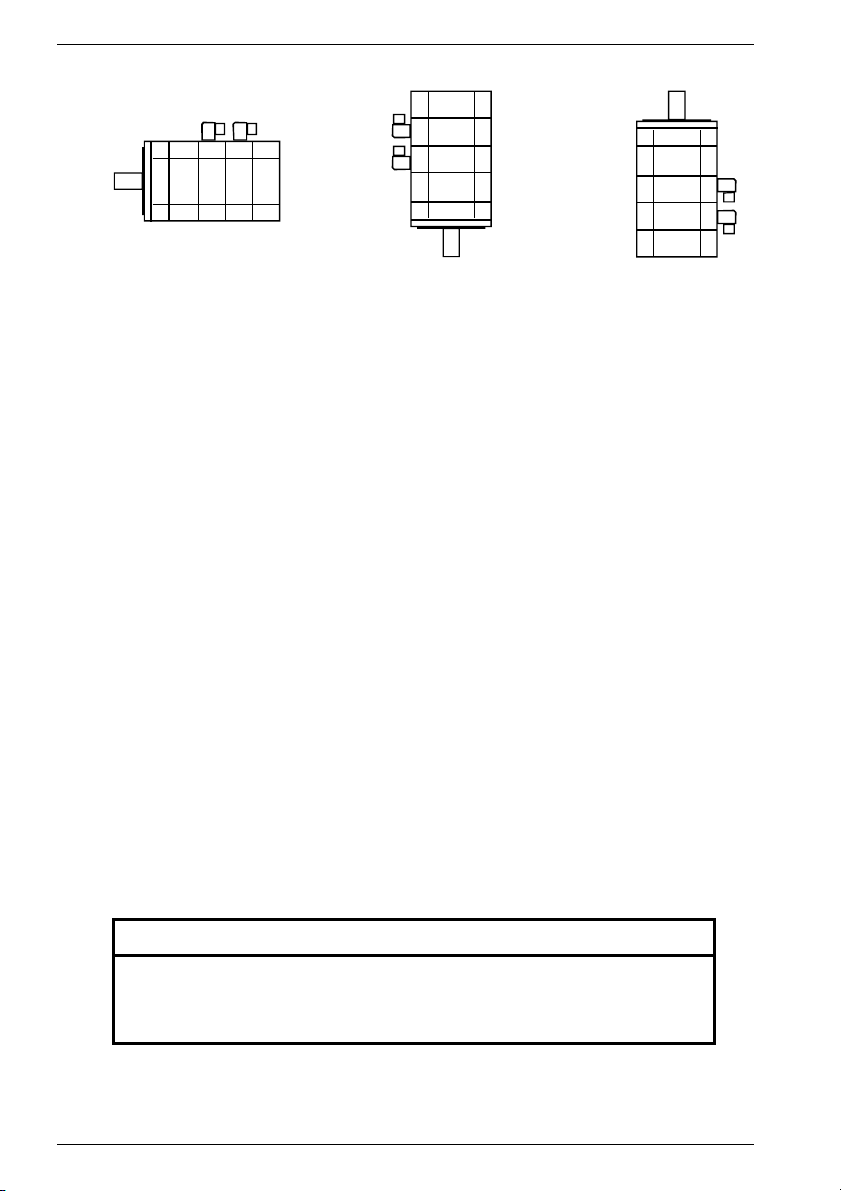

IM B 5 IM V 1

Fig. 3 Types of construction

- Take note of and observe the information on the rating plate and warning and informative

notices on the motor.

- Observe the permitted transverse and axial forces (see project planning instructions).

Axial forces are not permitted on motors with an integrated brake.

- Check for compliance with the conditions (e.g. temperature, site altitude) at the assembly

site (see Section 3.2).

- It is forbidden to use them in areas at risk of explosion.

- Remove all anti-corrosion agents from the shaft end (use commercially available

solvent).

- Ensure that waste heat is adequately dissipated.

It is recommended to maintain a clearance of 100 mm from adjacent parts on at least

three sides.

- Tighten the flanges equally, avoid distortions when tightening the fixing screws. Use

hexagon socket head cap screws, strength class at least 8.8.

- In the case of a vertical installation with the shaft end at the top, ensure that no fluid

penetrates into the upper bearing.

- Lifting eye-bolts which have been screwed in may be removed after the motor has been

installed.

- Turn the output elements by hand. If grinding noises occur, eliminate the cause or

contact the manufacturer.

IM V 3

Vibrations, balancing

Motors with a keyway are balanced by the manufacturer with a half feather key.

The site vibration response of the system is determined by the output elements, the

mounting conditions, the alignment, the installation and the effects of external vibrations.

This may cause a modification of the motor vibration values.

The vibrations immited in the fitted state must not exceed acceleration of 5 g.

Output elements

NOTICE

Do not strike the shaft or bearings of the motors.

Do not exceed the permissible axial and radial forces on the shaft end stated

in the configuration specification.

Axial forces are not permitted on motors with an integrated brake.

14 610.40 700.21 Siemens AG

Page 16

ENGLISH

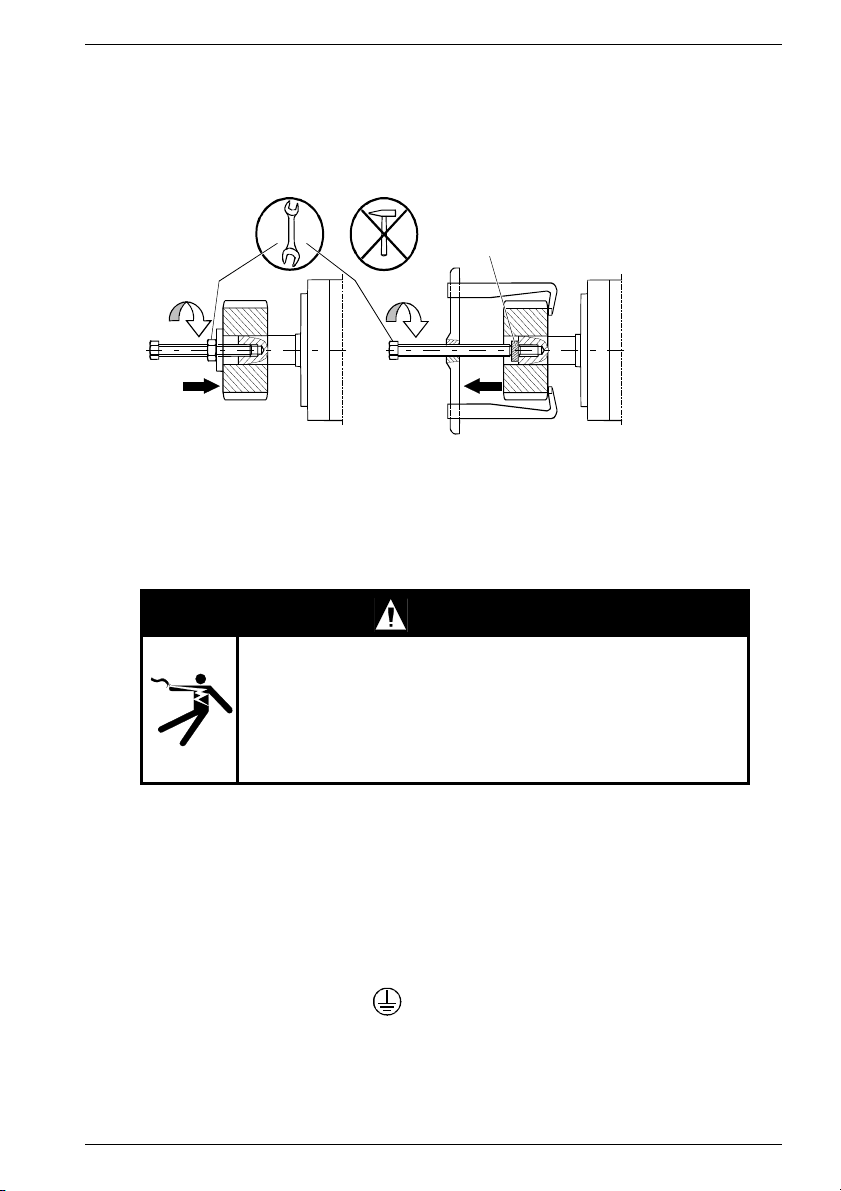

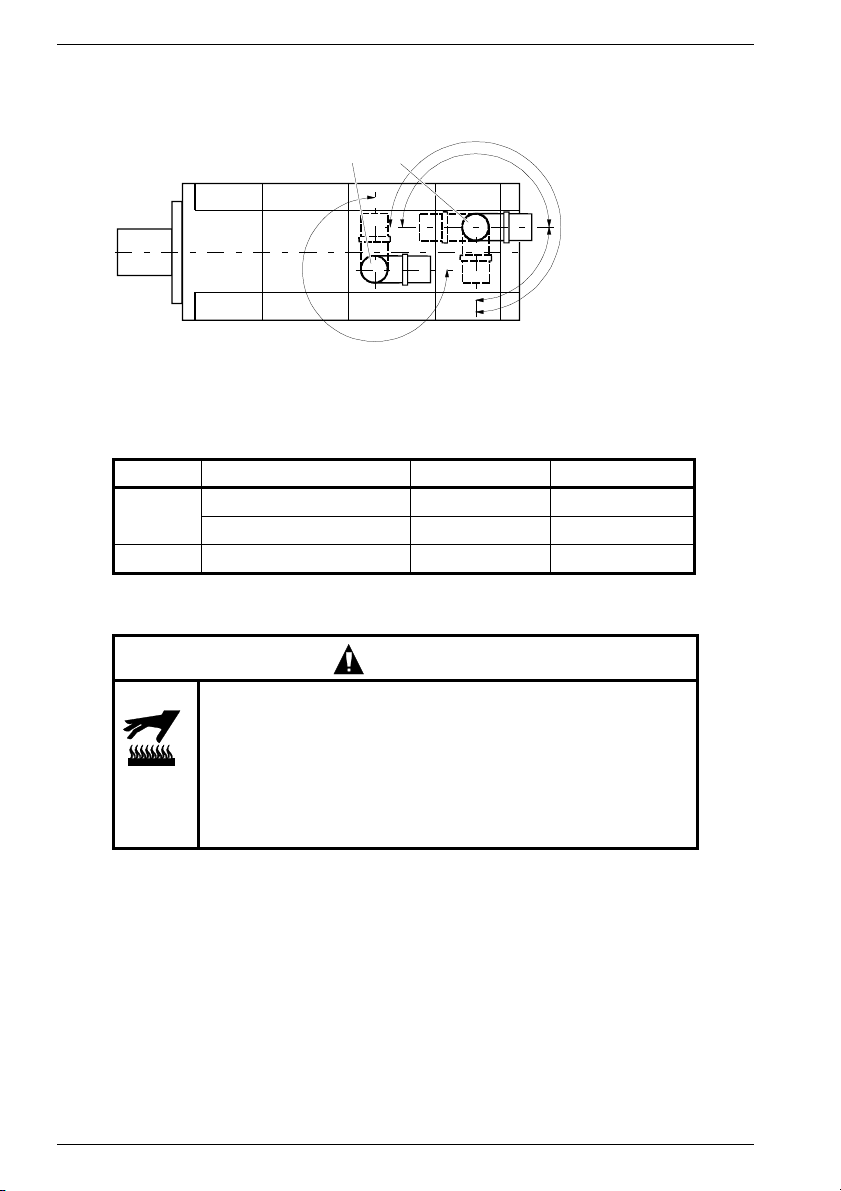

Suitable devices should always be used to push on or pull off the output elements (e.g. the

coupler, gear wheel, belt pulley, Fig. 4).

- Use the tapped hole in the shaft end.

- Heat up the output elements if necessary.

- Use a shim to protect the centering in the shaft end when pulling output elements off.

- If necessary, fully balance the motor with the output elements according to ISO1940

A

Fig. 4 Pulling off and putting on output elements.

A Shim (protects the centering in the shaft end)

5 Electrical connections

5.1 Important instructions

DANGER!

Electric shock hazard!

When the rotor is rotating, the motor terminals carry a voltage of

up to approx. 300 V.

Stop the motor before commencing any electrical work.

Only use trained, qualified personnel for assembly work on the

converters and plugs.

Observe the regulations for working in electrotechnical plants.

Safety rules for working in electrical installations as per

EN 50110-1 (DIN VDE 0105-100):

- Work always with the equipment electrically dead.

- Isolate from electrical supply.

- Secure against switching on again.

- Check electrical deadness.

- Earth and short-circuit.

- Cover or cordon off adjacent parts which are electrically live.

- Release for work.

- Connect the PE conductor to

Siemens AG 610.40 700.21

15

Page 17

ENGLISH

Assembly requirements

CAUTION

Warning of motor damage!

Connecting the motor directly to a three-phase system will destroy it.

Motors may only be driven with configured converters!

Ensure that the phase sequence is correct.

Encoder systems and temperature sensor contain electrostatically

endangered components (EEC).

Do not touch the connections with your hands or tools which could be

electrostatically charged!

Pre-assembled cables from SIEMENS are recommended (not included in scope of delivery).

These cables reduce the assembly time and increase operational safety.

- Proper installation is the responsibility of the manufacturer of the system / machine.

- Observe the data on the type plate (Section 3.1)and the information in the wiring

diagrams (Fig. 5).

- Connecting leads must be suitable for the type of application and for the anticipated

currents and voltages.

- If the motor is supplied by means of converters, high-frequency current and voltage

harmonics in the motor supply leads can cause electromagnetic interference to be

emitted.

Use shielded power and signal lines.

Observe the EMC instructions of the converter manufacturer.

- The inside of the plug must be kept clean and free from cable residues and moisture.

- Avoid protruding wire ends.

- Check the seals and sealing surfaces of plug to ensure that the degree of protection is

maintained.

- The connecting leads are to be equipped with the strain relief device and the devices

which protect against rotation and transverse forces, and must be prevented from

kinking. The plugs must not be subjected to continuous forces.

- The coding slot on the plug connector must be aligned when inserted into the female

connector in each case, and the union nut tightened up to the stop by hand.

The protective function with a fitted temperature sensor is inadequate for high thermal loads,

e.g. overload with the motor at a standstill. Additional protective measures are to be provided

for such cases, e.g. a thermal overcurrent relay.

16 610.40 700.21 Siemens AG

Page 18

Supply

L1 L2 L3

ENGLISH

UVW

3

U2

UV

Motor

Power connections

1FK7 02. - 1FK7 100

U

BR2

Connector size 1 Connector size 1,5

Signal connections

Resolver

- Temp

S2

8

1

10

2

3

not

connected

9

12

11

5

4

S1

R1

S4

not

connected

Fig. 5 Circuits

V2

W

1

6

5

+ Temp

7

6

3

W2

W

V

2

4

BR

S3

R3

not

conn.

not

connected

Encoder

GNYE

Incremental Encoder

sin/cos 1 V

P-Encoder

(5V)

5V

Sense

- Temp

+ Temp

0V

Sense

B +

10

9

16

8

7

M-Encoder

(0V)

1FK7 101 / 1FK7 103

BR2

WU

GNYE

PP

B -

A +

1

11

2

12

13

3

14

E

4

15

6

5

C +

C -

3

Motor

A -

R -

not

conn.

D -

D +

M

BR

(+)

BR

V

Absolute Encoder

Simple Absolute Encoder

P-Encoder

5V Sense

R +

- Temp

+ Temp

0V Sense

10

9

8

M-Encoder

BR2

(-)

B +

11

12

16

17

15

6

7

not

connected

B -

1

13

14

5

Brake

A +

A -

2

3

4

- Clock

+ Clock

- Data

+ Data

not

conn.

not

conn.

5.2 Plug design

NOTICE

Improper change of the plug output direction leads to damage to the connecting

cables.

Do not exceed the permissible twisting moments as per Fig. 6.

A maximum of ten changes to the plug output direction are permissible up to the

stop with the attached, matching, mating plug.

Power plug

1. Use plug size 1 or 1.5.

2. Assign the plugs according to figure Fig. 5 Connect the PE conductor.

3. Connect the brake via Fig. 5 the power plug.

Siemens AG 610.40 700.21

17

Page 19

ENGLISH

Signal plug for the encoder system and temperature sensor.

1. Use an appropriate plug.

2. Assign the plugs according to Fig. 5.

P Power plug S Signal plug

Fig. 6 Degree of rotation of plugs

Maximum permissible twisting moments M

Plug Motor Plug size M

P

SM

1FK7 02. - 1FK7 100 1 M

1FK7 101 / 1FK7 103 1.5 M

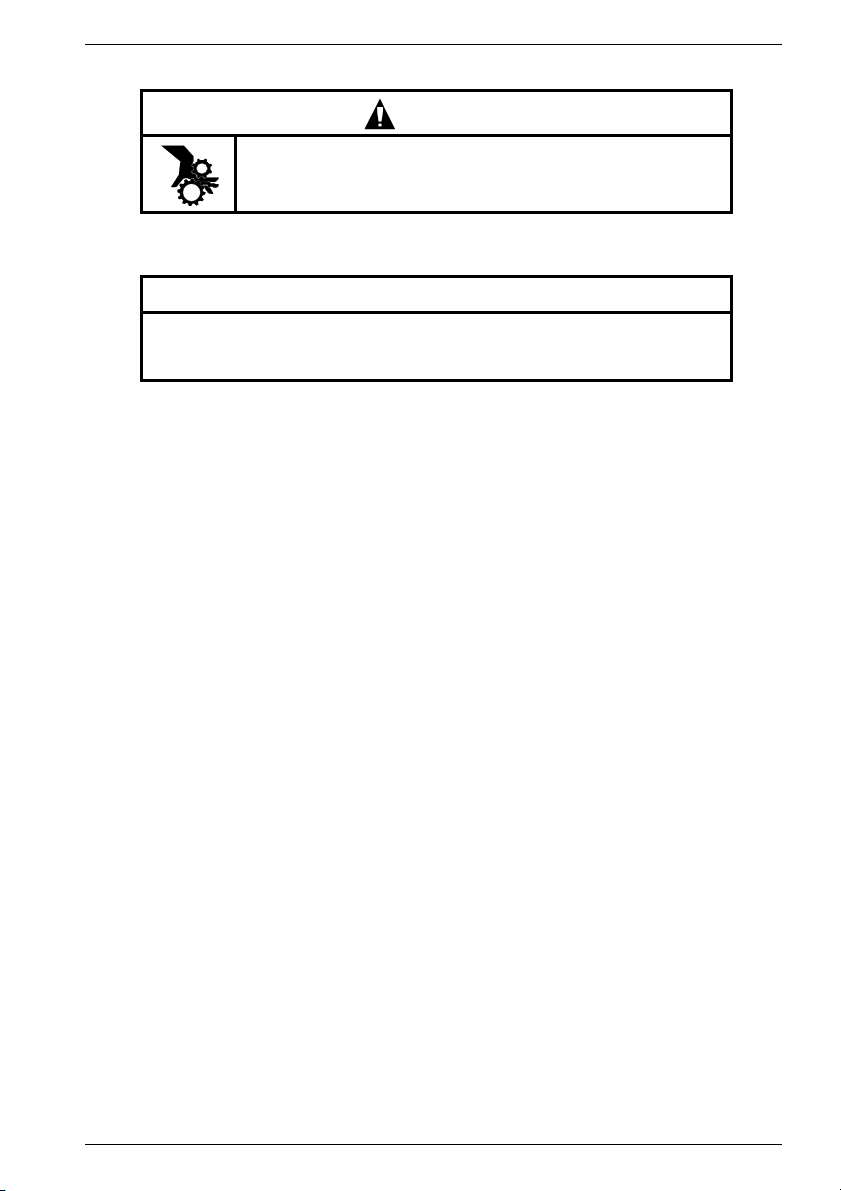

6Start-up

Thermal hazard from hot surfaces!

The surface temperatures of the motors can reach up to 140 °C

(284 °F).

Do not touch hot surfaces!

Protection must be provided against accidental contact if

necessary.

Temperature-sensitive components (electric lines, electronic

components) must not touch hot surfaces.

2

7

0

°

SP

max

180°

CAUTION

270°

9

°

0

max

= 12 Nm

max

= 20 Nm

max

= 12 Nm

max

6.1 Checks before starting up

Before starting up, ensure that

- all connections have been properly made, and the plug connectors are secured against

working loose.

- all motor protection devices are active,

- the drive is not blocked,

- no other possible sources of danger are present,

- the drive is undamaged (no damage from transport/storage),

- the feather keys in the shaft end (if present) are secured against being thrown out.

18 610.40 700.21 Siemens AG

Page 20

ENGLISH

6.2 Start-up

WARNING

Hazard from rotating rotor!

Protect the output elements against accidental contact!

Secure feather key (if present) against being thrown out.

Observe the start up and commissioning instructions for the converter (e.g. SIMODRIVE,

MASTERDRIVES MC).

NOTICE

The brake is designed for emergency stops (power cut, emergency stop).

It is not permitted to be used as a working brake.

After the motor has been switched off, it functions as a holding brake.

1. Release brake, in as far as this is necessary.

2. Check the brake function (open and close).

Apply 24 V DC ±10% to the pins BR, BR2 (Fig. 5), and ensure that the rotor is running

freely (no rubbing noises).

3. Check the mounting, seating and alignment of the motor.

4. Check the suitability and setting of the output elements for the intended conditions of

use, for example belt tension.

5. Check the power and signal plug connections.

6. Check the functional condition of the auxiliary devices present.

7. Check the protection against accidental contact with moving and live parts.

8. Bring the drive system into operation in accordance with the operating manual for the

converter or inverse rectifier.

9. Check that the maximum permissible speed n

details). The maximum permissible speed is the highest permissible, short-term

operating speed.

10. The fitted temperature sensor cannot cater for all possible faults (note the instructions

in the project planning guide).

is observed (see type plate for

max

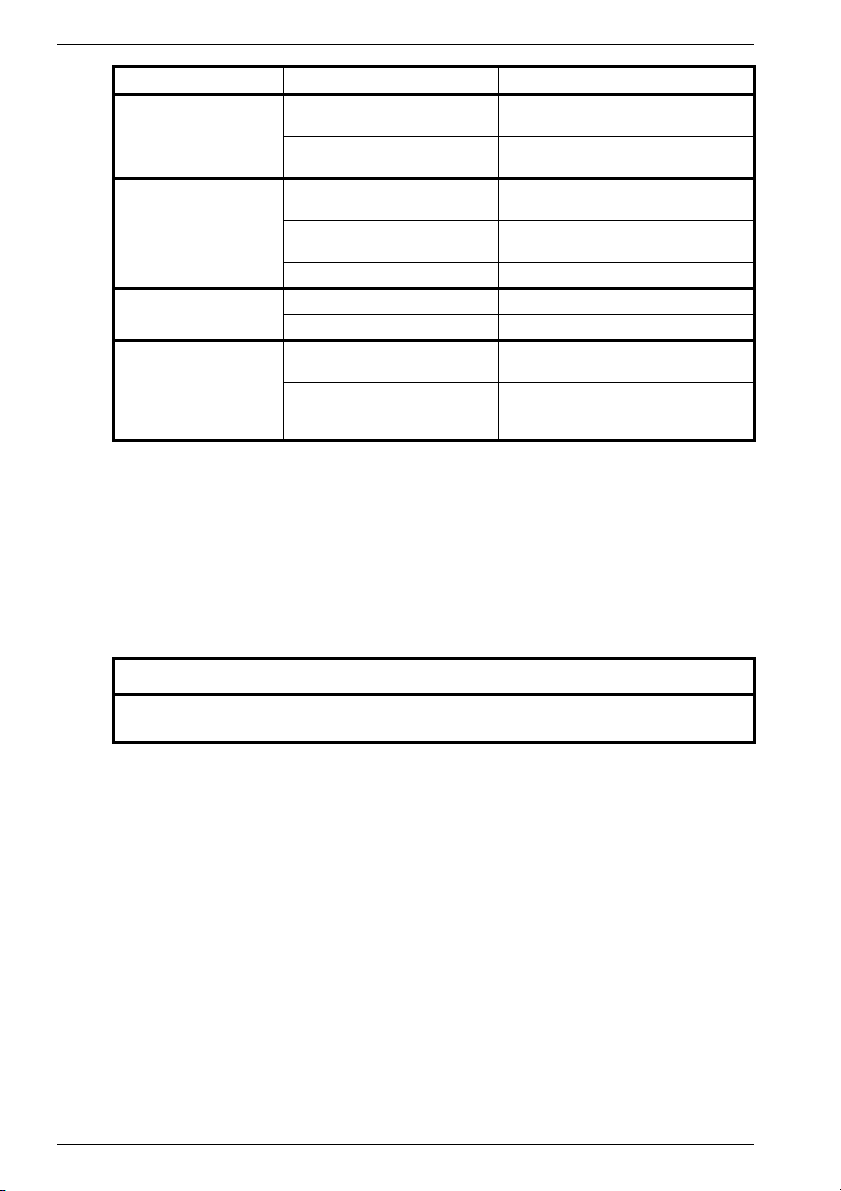

7 Instructions in case of faults

In case of deviation from normal operation or faults, proceed first according to the following

list:

In this connection, please also refer to the relevant section of the operating manual for the

components of the entire drive system.

Do not disable the protective devices, even in trial operation.

Consult the manufacturer or the SIEMENS service center when necessary.

For start up, system motor converter: A&D Hotline +49 180 50 50 222

For motor / motor components: Contact in the works +49 174-3110669

Siemens AG 610.40 700.21 19

Page 21

ENGLISH

Fault Cause Remedy

Irregular running Inadequate screening of the

Vibrations Coupling elements or driven

Running noises Foreign bodies inside the motor Repair by the manufacturer

Motor overheats

(surface temperature

> 140 °C (284 °F))

Temperature monitoring

responds

motor or encoder cable.

Amplification of the drive controller too high

machine are badly balanced

Inadequate alignment of the drive

train

Fixing screws are loose Check and tighten screw connections

Bearing damage Repair by the manufacturer

Drive overloaded Check load (see type plate)

Heat dissipation impaired by

deposits

Check screening and grounding (see

Section 5.1)

Adjust controller (see converter operating manual)

Rebalance

Realign the machine set

Clean surface of drives.

Ensure that the cooling air can flow

freely in and out

8 Inspection, maintenance, disposal

Clean according to the degree of local contamination in order to ensure that the waste heat

is adequately dissipated.

As the operating conditions vary greatly, one can only cite general intervals for fault-free

operation.

Guidelines:

- Bearing service life 20,000 hours

- Radial shaft seals approx. 5,000 hours with oil lubrication.

NOTICE

The encoder system must be readjusted each time after the motor has been

disassembled.

Dispose of the motor in accordance with the national and local regulations in the standard

recycling process or return it to the manufacturer.

Dispose of the encoder electronics properly as electronic scrap.

20 610.40 700.21 Siemens AG

Page 22

DEUTSCH

Diese Betriebsanleitung enthält Hinweise, die Sie zu Ihrer persönlichen Sicherheit sowie

zur Vermeidung von Sachschäden beachten müssen. Die Hinweise zu Ihrer persönlichen

Sicherheit sind durch ein Warndreieck hervorgehoben, Hinweise zu alleinigen

Sachschäden stehen ohne Warndreieck. Je nach Gefährdungsgrad werden sie

folgendermaßen dargestellt:

GEFAHR

bedeutet, dass Tod, schwere Körperverletzung oder

Piktogramm

erheblicher Sachschaden eintreten werden, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

WARNUNG

bedeutet, dass Tod, schwere Körperverletzung oder

Piktogramm

erheblicher Sachschaden eintreten können, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

VORSICHT

Piktogramm

mit Warndreieck bedeutet, dass eine leichte

Körperverletzung eintreten kann, wenn die

entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

VORSICHT

ohne Warndreieck bedeutet, dass ein Sachschaden eintreten kann,

wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

ACHTUNG

bedeutet, dass ein unerwünschtes Ereignis oder Zustand eintreten

kann, wenn der entsprechende Hinweis nicht beachtet wird.

Siemens AG 610.40 700.21 21

Page 23

DEUTSCH

Qualifiziertes Personal

Inbetriebsetzung und Betrieb des Gerätes dürfen nur von qualifiziertem Personal

vorgenommen werden. Qualifiziertes Personal im Sinne der sicherheitstechnischen

Hinweise dieser Betriebsanleitung sind Personen, die die Berechtigung haben, Geräte,

Systeme und Stromkreise gemäß den Standards der Sicherheitstechnik in Betrieb zu

nehmen, zu erden und zu kennzeichnen.

Bestimmungsgemäßer Gebrauch

Beachten Sie folgendes:

Das Gerät darf nur für die im Katalog und in der Projektierungsanleitung vorgesehenen

Einsatzfälle und nur in Verbindung mit von Siemens empfohlenen bzw. zugelassenen

Fremdgeräten und -komponenten verwendet werden.

Der einwandfreie und sichere Betrieb des Produktes setzt sachgemäßen Transport,

sachgemäße Lagerung, Aufstellung und Montage sowie sorgfältige Bedienung und

Instandsetzung voraus.

Haftungsausschluss

Wir haben den Inhalt der Druckschrift geprüft. Dennoch können Abweichungen nicht

ausgeschlossen werden, so dass wir für die vollständige Übereinstimmung keine Gewähr

übernehmen. Die Angaben in dieser Druckschrift werden regelmäßig überprüft, und

notwendige Korrekturen sind in den nachfolgenden Auflagen enthalten. Für

Verbesserungsvorschläge sind wir dankbar.

© Copyright Siemens AG 2001. All rights reserved

Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und Mitteilung ihres

Inhalts ist nicht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen

verpflichten zum Schadenersatz.

Alle Rechte vorbehalten, insbesondere für den Fall der Patenterteilung oder

GM-Eintragung.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Motion Control Systeme (MC)

D-97615 Bad Neustadt an der Saale

22 610.40 700.21 Siemens AG

Page 24

DEUTSCH

1 Allgemeine Sicherheitshinweise

Die Servomotoren entsprechen den harmonisierten Normen der Reihe

EN 60034-1, EN 60034-6, EN 60034-9 sowie EN 60204-1.

Für die Drehstrom-Servomotoren 1FK6 besteht Konformität mit

73/23/EWG Niederspannungsrichtlinie.

Standardmotoren entsprechen den UL-Vorschriften. Diese Motoren sind auf dem

Leistungsschild mit UR gekennzeichnet.

Sichern Sie für Ihr Endprodukt die Einhaltung aller bestehenden Rechtsvorschriften!

Beachten Sie die verbindlichen nationalen, örtlichen und anlagenspezifischen

Vorschriften!

Drehstrom-Servomotoren sind ausschließlich zum Einbau in (eine) andere Maschine(n)

bestimmt.

Die Inbetriebnahme der Motoren ist so lange untersagt, bis die Konformität des

Endprodukts mit den geltenden Richtlinien festgestellt ist.

Die Betriebsanleitung gilt in Verbindung mit der SIEMENS-Projektierungsanleitung

„Drehstrom-Servomotoren“, Best.-Nr. 6SN1197-0AC20-0AP0.

Für Transport, Lagerung, Montage, Demontage und Betrieb der Servomotoren müssen alle

Hinweise zur Sicherheit beachtet werden!

Das Nichteinhalten kann schwere Körperverletzungen oder Sachschäden bewirken.

Die Läufer der Motoren enthalten Permanentmagnete mit hohen magnetischen

Flussdichten und starken Anziehungskräften zu ferromagnetischen Körpern.

In der Nähe eines demontierten Läufers sind Personen mit Herzschrittmacher gefährdet.

Auf elektronischen Datenträgern gespeicherte Daten können zerstört werden.

Der Einsatz in explosionsgefährdeten Bereichen ist verboten, sofern nicht ausdrücklich

bestätigt.

Thermische Gefährdung

Die Oberflächentemperatur der Motoren kann bis 140 °C betragen.

Berühren Sie nicht heiße Oberflächen!

Temperaturempfindliche Bauteile (elektrische Leitungen, elektronische Bauteile) dürfen

nicht an heißen Oberflächen anliegen.

Überhitzung der Motoren kann Zerstörung der Wicklungen und Lager und

Entmagnetisierung der Permanentmagnete bewirken.

Betreiben Sie die Motoren nur mit wirksamer Temperaturkontrolle!

Bestimmungsgemäßer Gebrauch

Das Einhalten aller Vorgaben der Betriebsanleitung und der Projektierungsanleitung

„Drehstrom-Servomotoren“ ist Bestandteil der bestimmungsgemäßen Verwendung.

2 Angaben zum Produkt

2.1 Produktbeschreibung

Motoren der Baureihe 1FK7 sind permanentmagneterregte Drehstrom-Synchron-Motoren

(Drehstrom-Servomotoren) zum Betrieb mit motorgesteuerten Pulswechselrichtern nach

dem Sinusstromprinzip.

Die Motoren sind vorgesehen für Antrieb und Positionierung von Werkzeug- und

Produktionsmaschinen sowie Robotern und Handhabungsgeräten.

Siemens AG 610.40 700.21 23

Page 25

DEUTSCH

2.2 Lieferumfang

Die Antriebssysteme sind individuell zusammengestellt. Überprüfen Sie nach Erhalt der

Lieferung sofort, ob der Lieferumfang mit den Warenbegleitpapieren übereinstimmt. Für

nachträglich reklamierte Mängel übernimmt SIEMENS keine Gewährleistung.

Reklamieren Sie

- erkennbare Transportschäden sofort beim Anlieferer,

- erkennbare Mängel/ unvollständige Lieferung sofort bei der zuständigen

SIEMENS-Vertretung.

Die Betriebsanleitung ist Bestandteil des Lieferumfanges und somit zugänglich

aufzubewahren.

Das der Lieferung lose beigefügte Typenschild ist dafür vorgesehen, die Motordaten

zusätzlich an oder bei der Maschine oder Anlage aufzubewahren.

3 Technische Daten

3.1 Typenschild

1

3~ Servomotor

2

No.YF: PN 184583 01 001

3

11 Nm IO 8,0 A n

M

4

5

O

7,3 Nm IN 5,6 A nN 3000 /min

M

N

Th.Cl. F U

6

1FK7063-5AF71-1AB3

6600 /min

max

263 V IP 64

IN

Encoder B01 Brake EBD 0.8BK / 24 V- / 19 W

7

Rev. No.: 000

8

9

EN 60034

Made in Germany

Fig. 1 Typenschild

1 Motorart: Drehstrom-Servomotor 10 SIEMENS Motortyp/ Bezeichnung

2 Ident. Nr., Produktionsnummer 11 Stillstandsstrom I

3 Stillstandsdauerdrehmoment M

4 Bemessungsdrehmoment M

5 Induzierte Spannung U

6 Wärmeklasse 15 Schutzart

7 Kennzeichnung Gebertyp 16 Daten zur Haltebremse:

8 Versionsstand Typ, Spannung, Leistungsaufnahme

9 Normen und Vorschriften

IN

[Nm] 12 Maximaldrehzahl n

0

[Nm] 13 Bemessungsstrom IN [A]

N

[V] 14 Bemessungsdrehzahl nN [1/min]

[A]

0

[1/min]

max

10

11

12

13

14

15

16

24 610.40 700.21 Siemens AG

Page 26

DEUTSCH

3.2 Merkmale

Bauform IM B5 (IM V1, IM V3)

(EN 60034-7)

Schutzart IP64

(EN 60034-5)

Kühlung Selbstkühlung

(EN 60034-6)

A-bewerteter Schallleistungspegel

(EN 60034-9)

für Drehzahlbereich bis 3000 min

1FK7 02., 1FK7 03., 1FK7 04. ca. 55 dB(A)

1FK7 06. ca. 65 dB(A)

1FK7 08., 1FK7 10. ca. 70 dB(A)

Thermischer Motorschutz Temperatursensor KTY84

(EN 60034-11) in der Ständerwicklung

Wellenende Zylindrisch; ohne Passfedernut,

(DIN 748-3; IEC 60072-1) Toleranzfeld k6

Rundlauf, Koaxialität, Planlauf Toleranz N

(DIN 42955; IEC 60072-1)

Schwingstärke Stufe N

(EN 60034-14)

Lager Wälzlager mit Fettdauerschmierung

Lagergebrauchsdauer 20000 h (Richtwert)

Wicklungsisolation Wärmeklasse F

(EN 60034-1)

Umgebungstemperaturen -15 °C bis +40 °C (5 °F bis 104 °F)

Aufstellhöhe ≤ 1000 m über NN,

(EN 60034-1) 2000 m Leistung Faktor 0,94

Magnetmaterial Selten-Erd-Material

Elektrischer Anschluss drehbare Stecker für Leistung und

Gebersystem eingebauter Geber

Weitere technische Kennwerte, Maßblätter nach Projektierungsanleitung

„Drehstrom-Servomotoren“, Best.-Nr. 6SN1197-0AC20-0AP0.

Optionen/Erweiterungen

Baureihe geringer Trägheit HD (High Dynamic)

Schutzart IP 65; zusätzlich AS-Flansch IP67

(EN 60034-5)

Ein-/Anbauten - Ruhestromhaltebremse (DIN VDE 0580)

Siemens AG 610.40 700.21 25

-1

(Lebensdauerschmierung)

Festlager auf B-Seite

sonst Reduzierung der Nenndaten

bis 50 °C Leistung Faktor 0,92

bis 60 °C Leistung Faktor 0,82

2500 m Leistung Faktor 0,9

Gebersignale

- Erfassung der Drehzahl

- Erfassung der Rotorlage

- indirekte Lageerfassung

Anschlussspannung 24 V DC ±10%

Page 27

DEUTSCH

- Planetengetriebe

Gebersystem - Inkrementalgeber sin/cos 1 V

- Absolutwertgeber EnDat

- Einfach-Absolutwertgeber

- Resolver

Wellenende zylindrisch mit Passfedernut und

(DIN 748-3; IEC 60072-1) Passfeder; Toleranzfeld k6

(Wuchtung mit halber Passfeder)

Weitere technische Angaben, z.B. Motorabmessungen, finden Sie im Katalog NC 60 oder

DA 65.3.

4 Aufstellung, Montage

4.1 Transport, Lagerung

WARNUNG

Gefährdung bei Hebe- und Transportvorgängen!

Unsachgemäße Ausführung, ungeeignete oder schadhafte Geräte und

Hilfsmittel können Verletzungen und/oder Sachschäden bewirken.

Hubgeräte, Flurförderzeuge und Lastaufnahmemittel müssen den

Vorschriften entsprechen.

Für Transport und Montage geeignete Lastaufnahmemittel benutzen.

Hebeösen für den Transport der Motoren verwenden, wenn vom Hersteller vorgesehen.

Lastaufnahmemittel nach 98/37/EG Richtlinie für Maschinen, Anhang I.

Die Motoren haben eine Masse bis zu 50 kg. Genaue Angaben siehe Katalog bzw. Maßblatt.

PP

Fig. 2 Heben und Transportieren mit Schlaufenhebegurten

Beim Transport landesspezifische Vorschriften einhalten.

Die Lagerung erfolgt im trockenen, staub- und schwingungsarmen (v

Innenraum.

26 610.40 700.21 Siemens AG

< 0,2 mms-1)

eff

Page 28

4.2 Aufstellung

DEUTSCH

IM B 5 IM V 1

Fig. 3 Bauformen

- Angaben des Leistungsschildes, Warn- und Hinweisschilder am Motor beachten.

- Zulässige Quer- und Axialkräfte beachten (siehe Projektierungsanleitung).

Bei Motoren mit integrierter Bremse sind Axialkräfte nicht zulässig.

- Übereinstimmung mit den Bedingungen (z.B. Temperaturen, Aufstellhöhe) am

Montageort prüfen (siehe 3.2).

- Der Einsatz in explosionsgefährdeten Bereichen ist verboten.

- Wellenende gründlich von Korrosionsschutzmittel befreien (handelsübliche

Lösungsmittel verwenden).

- Ausreichende Abführung der Verlustwärme sichern.

Es wird empfohlen, an mindestens drei Seiten Abstände von 100 mm zu benachbarten

Teilen einzuhalten.

- Gleichmäßige Auflage der Flanschbefestigung beachten, Verspannungen beim

Anziehen der Befestigungsschrauben vermeiden. Zylinderschrauben mit

Innensechskant, Festigkeitsklasse mindestens 8.8 verwenden.

- Bei vertikaler Aufstellung mit Wellenende nach oben sicherstellen, dass keine Flüssigkeit

in das obere Lager eindringen kann.

- Eingeschraubte Hebeösen können nach dem Aufstellen entfernt werden.

- Abtriebselemente von Hand drehen. Bei möglichen Schleifgeräuschen die Ursache

beseitigen oder den Hersteller konsultieren.

IM V 3

Immitierte Schwingungen, Wuchtung

Motoren mit Passfedernut werden durch den Hersteller mit halber Passfeder ausgewuchtet.

Das Schwingverhalten des Systems am Einsatzort wird beeinflusst durch Abtriebselemente,

Anbauverhältnisse, Ausrichtung, Aufstellung und Fremdschwingungen. Damit können sich

die Schwingwerte des Motors ändern.

Die immitierten Schwingungen im eingebauten Zustand dürfen Beschleunigungen von 5 g

nicht überschreiten.

Abtriebselemente

ACHTUNG

Welle und Lager der Motoren nicht mit Schlägen belasten.

Zulässige Axial- und Radialkräfte auf das Wellende nach

Projektierungsvorschrift nicht überschreiten.

Bei Motoren mit integrierter Bremse sind Axialkräfte nicht zulässig.

Siemens AG 610.40 700.21 27

Page 29

DEUTSCH

Auf- und Abziehen von Abtriebselementen (z. B. Kupplung, Zahnrad, Riemenscheibe) nur

mit geeigneten Vorrichtungen ausführen (Fig. 4).

- Gewindebohrung im Wellenende benutzen.

- Abtriebselemente bei Bedarf erwärmen.

- Beim Abziehen Zwischenscheibe zum Schutz der Zentrierung im Wellenende benutzen.

- Bei Bedarf Motor mit Abtriebselementen nach ISO1940 komplett auswuchten.

A

Fig. 4 Auf- und Abziehen von Abtriebselementen

Zwischenscheibe (Schutz der Zentrierung im Wellenende)

A

5 Elektrischer Anschluss

5.1 Wichtige Hinweise

GEFAHR

Stromschlaggefahr!

Bei rotierendem Läufer liegt an den Motorklemmen Spannung von

ca. 300 V an.

Alle Elektroarbeiten nur bei Motorstillstand ausführen!

Für Montagearbeiten an Umrichter und Stecker nur qualifizierte

Fachkräfte einsetzen!

Vorschriften für Arbeiten in elektrotechnischen Anlagen einhalten!

Sicherheitsregeln für das Arbeiten in elektrischen Anlagen nach

EN 50110-1 (DIN VDE 0105-100):

- Nur im spannungslosen Zustand arbeiten.

- Freischalten.

- Gegen Wiedereinschalten sichern.

- Spannungsfreiheit feststellen.

- Erden und Kurzschließen.

- Benachbarte, unter Spannung stehende Teile abdecken oder abschranken.

- Freigabe zur Arbeit.

- Schutzleiter an anschließen!

28 610.40 700.21 Siemens AG

Page 30

DEUTSCH

Montageanforderungen

VORSICHT

Warnung vor Motorschäden!

Der direkte Anschluss an das Drehstromnetz führt zur Zerstörung des Motors.

Motoren nur mit den projektierten Umrichtern betreiben!

Richtige Phasenfolge beachten!

Gebersysteme und Temperatursensor sind elektrostatisch gefährdete

Bauteile (EGB).

Berühren Sie nicht die Anschlüsse mit den Händen oder Werkzeugen, die

elektrostatisch aufgeladen sein können!

Konfektionierte Leitungen von SIEMENS werden empfohlen (nicht im Lieferumfang).

Diese Leitungen verringern den Montageaufwand und erhöhen die Betriebsicherheit.

- Sachgerechte Installation liegt in der Verantwortung des Herstellers der Anlage/

Maschine.

- Daten des Typenschildes (Kap. 3.1) und Angaben der Schaltbilder (Fig. 5) beachten.

- Anschlussleitungen der Verwendungsart, den auftretenden Spannungen und

Stromstärken anpassen.

- Bei Umrichterspeisung können hochfrequente Strom- und Spannungsschwingungen in

den Motorzuleitungen elektromagnetische Störungen bewirken.

Abgeschirmte Leistungs- und Signalleitungen verwenden.

EMV-Hinweise des Umrichterherstellers beachten.

- Das Innere des Steckers muss sauber und frei von Leitungsresten und Feuchtigkeit sein.

- Abstehende Drahtenden vermeiden.

- Dichtungen und Dichtflächen der Stecker prüfen, damit Schutzart eingehalten wird.

- Anschlussleitungen mit Verdreh-, Zug- und Schubentlastung sowie Knickschutz

versehen. Dauerkräfte auf die Stecker sind nicht zulässig.

- Codiernut der Steckverbindung muss jeweils fluchtend in den Buchsenstecker eingeführt

und Überwurfmutter von Hand bis zum Anschlag fest angezogen sein.

Bei hoher thermischer Belastung, z. B. Überlastung bei Motorstillstand, kann die

Schutzfunktion mit eingebautem Temperatursensor nicht ausreichend sein. Für diese Fälle

zusätzliche Schutzmaßnahmen vorsehen, z.B. thermisches Überstromrelais.

Siemens AG 610.40 700.21 29

Page 31

Supply

L1 L2 L3

DEUTSCH

UVW

3

U2

UV

Motor

Power connections

1FK7 02. - 1FK7 100

W

U

1

6

5

BR2

Connector size 1 Connector size 1,5

Signal connections

Resolver

- Temp

S2

R1

S4

not

connected

1

2

not

connected

+ Temp

8

9

12

10

11

3

5

4

S1

Fig. 5 Schaltungen

V2

V

2

4

BR

S3

7

6

not

connected

3

W

R3

not

conn.

W2

GNYE

Incremental Encoder

sin/cos 1 V

P-Encoder

(5V)

5V

Sense

- Temp

+ Temp

0V

Sense

M-Encoder

(0V)

Encoder

B +

11

10

12

9

16

8

15

7

3

M

Motor

1FK7 101 / 1FK7 103

BR2

WU

GNYE

PP

B -

A +

A -

1

13

E

6

C -

R -

2

R +

3

not

14

conn.

4

5

D -

D +

C +

BR

BR2

(+)

(-)

BR

V

Absolute Encoder

Simple Absolute Encoder

M-Encoder

B +

10

9

16

8

11

15

7

not

connected

P-Encoder

5V Sense

- Temp

+ Temp

0V Sense

Brake

B -

A +

A -

- Data

1

2

14

5

3

4

- Clock

+ Clock

+ Data

not

conn.

not

conn.

12

13

17

6

5.2 Steckerausführung

ACHTUNG

Unsachgemäße Änderung der Steckerabgangsrichtung führt zu Schäden an den

Anschlussleitungen.

Zulässige Verdrehmomente nach Fig. 6 nicht überschreiten.

Es sind nur maximal zehn Änderungen der Steckerabgangsrichtung mit dem

aufgesetzten passenden Gegenstecker bis zum Anschlag zulässig.

Leistungsstecker

1. Stecker Größe 1 oder Größe 1,5 verwenden.

2. Steckerbelegung nach Fig. 5 ausführen, Schutzleiter anschließen.

3. Bremse über Leistungsstecker nach Fig. 5 anschließen.

30 610.40 700.21 Siemens AG

Page 32

DEUTSCH

Signalstecker für Gebersystem und Temperatursensor

1. Passenden Stecker verwenden.

2. Steckerbelegung nach Fig. 5 ausführen.

P Leistungsstecker S Signalstecker

Fig. 6 Verdrehbarkeit der Stecker

Maximal zulässige Verdrehmomente M

Stecker Motor Steckergröße M

P

SM

1FK7 02. - 1FK7 100 1 M

1FK7 101 / 1FK7 103 1.5 M

6 Inbetriebnahme

Thermische Gefährdung durch heiße Oberflächen!

Die Oberflächentemperatur der Motoren kann bis 140 °C

betragen.

Heiße Oberflächen nicht berühren!

Bei Bedarf Berührungsschutz vorsehen!

Temperaturempfindliche Bauteile (elektrische Leitungen,

elektronische Bauteile) dürfen nicht an heißen Oberflächen

anliegen.

2

7

0

°

VORSICHT

SP

max

180°

270°

9

°

0

max

= 12 Nm

max

= 20 Nm

max

= 12 Nm

max

6.1 Prüfungen vor Inbetriebnahme

Vergewissern Sie sich vor der Inbetriebnahme, dass

- alle Anschlüsse ordnungsgemäß ausgeführt wurden und die Steckverbinder gegen

Lösen gesichert sind,

- alle Motorschutzeinrichtungen aktiv sind,

- der Antrieb nicht blockiert ist,

- keine anderen Gefahrenquellen vorhanden sind,

- der Antrieb unbeschädigt ist (keine Schäden durch Transport/Lagerung),

- die Passfedern im Wellenende (sofern vorhanden) gegen Herausschleudern gesichert

sind.

Siemens AG 610.40 700.21 31

Page 33

DEUTSCH

6.2 Inbetriebnahme

WARNUNG

Gefährdung durch rotierenden Läufer!

Abtriebselemente mit Berührungsschutz sichern!

Passfeder (sofern vorhanden) gegen Herausschleudern sichern!

Berücksichtigen Sie die Inbetriebnahmeanleitung des Umrichters (z. B. SIMODRIVE,

MASTERDRIVES MC).

ACHTUNG

Die Bremse ist für Notstopps (Stromausfall, Not-Aus) ausgelegt.

Der Einsatz als Arbeitsbremse ist nicht zulässig.

Nach Abschalten des Motors Wirkung als Haltebremse.

1. Bremse öffnen, sofern erforderlich.

2. Funktion (Öffnen und Schließen) der Bremse prüfen.

Dazu an Pins BR, BR2 (Fig. 5) 24 V DC ±10% anlegen und freien Lauf des Läufers

(keine Schleifgeräusche) feststellen.

3. Montage des Motors, Festsitz und Ausrichtung prüfen.

4. Eignung und Einstellung der Abtriebselemente für die vorgesehenen

Einsatzbedingungen prüfen, z.B. Riemenspannung.

5. Leistungs- und Signalsteckerverbindung prüfen.

6. Funktionsfähigkeit der Zusatzeinrichtungen (sofern vorhanden) prüfen.

7. Berührungsschutzmaßnahmen für bewegte und spannnungsführende Teile prüfen.

8. Antriebssystem entsprechend der Betriebsanleitung des Um- bzw. Wechselrichters in

Betrieb nehmen.

9. Einhalten der maximal zulässigen Drehzahl n

Die maximal zulässige Drehzahl ist die höchste kurzzeitig zulässige

Betriebsdrehzahl.

10. Der eingebaute Temperatursensor kann nicht alle denkbaren Störfälle abdecken

(Hinweise in der Projektierungsanleitung beachten).

prüfen (Angabe siehe Typenschild).

max

7 Hinweise bei Störungen

Bei Veränderungen gegenüber dem normalen Betrieb oder Störungen gehen Sie zuerst

anhand der nachfolgenden Auflistung vor.

Beachten Sie hierzu auch die entsprechenden Kapitel in den Betriebsanleitungen der

Komponenten des gesamten Antriebssystems.

Schutzeinrichtungen auch im Probebetrieb nicht außer Funktion setzen.

Bei Bedarf Hersteller oder SIEMENS-Servicezentrum konsultieren.

Für Inbetriebnahme, System Motor-Umrichter: A&D Hotline 0180 50 50 222

Für Motor/Motorkomponenten: Rückfrage im Werk 0174-3110669

32 610.40 700.21 Siemens AG

Page 34

DEUTSCH

Störung Ursache Beseitigung

Unruhiger Lauf Schirmung der Motor- oder

Vibrationen Kupplungselemente oder Arbeits-

Laufgeräusche Fremdkörper im Motorinneren Reparatur durch Hersteller

Motor wird zu warm

(Oberflächentemperatur

>140 °C)

Temperaturüberwachung

spricht an

Geberleitung unzureichend

Verstärkung des Antriebsreglers

zu groß

maschine schlecht ausgewuchtet

Mangelnde Ausrichtung des

Antriebsstranges

Befestigungsschrauben locker Schraubverbindungen kontrollieren und

Lagerschaden Reparatur durch Hersteller

Überlastung des Antriebes Belastung überprüfen (siehe Typen-

Wärmeabfuhr durch Ablagerungen behindert

Schirmung und Erdung überprüfen

(siehe Kap. 5.1 )

Regler anpassen (siehe Betriebsanleitung Umrichter)

Nachwuchten

Maschinensatz neu ausrichten

sichern

schild)

Oberfläche der Antriebe reinigen

Für ungehinderte Zu- und Abfuhr der

Kühlluft sorgen

8 Inspektion, Wartung, Entsorgung

Je nach örtlichem Verschmutzungsgrad Reinigung vornehmen, um eine ausreichende

Abführung der Verlustwärme sicherzustellen.

Da die Betriebsverhältnisse sehr unterschiedlich sind, können nur allgemeine Fristen bei

störungsfreiem Betrieb genannt werden.

Richtwerte:

- Lagergebrauchsdauer 20.000 Stunden

- Radialwellendichtringe ca. 5.000 Stunden bei Ölschmierung.

ACHTUNG

Nach jeder Demontage des Motors muss das Gebersystem neu justiert werden.

Entsorgung der Motoren unter Einhaltung der nationalen und örtlichen Vorschriften im

normalen Wertstoffprozess oder Rückgabe an den Hersteller.

Die Geberelektronik fachgerecht als Elektronikschrott entsorgen.

Siemens AG 610.40 700.21 33

Page 35

FRANÇAIS

Ce mode d’emploi contient des conseils que vous devez respecter pour assurer votre

sécurité personnelle et éviter tout dommage matériel. Les conseils pour votre sécurité

personnelle sont précédés d’un triangle de mise en garde; les conseils n’ayant trait

qu’aux dommages matériels ne sont pas précédés d’un tel triangle. Selon leur degré de

dangerosité, ils sont représentés comme suit :

DANGER

signifie que lorsque les mesures de sécurité

Pictogramme

correspondantes ne sont pas adoptées, il y a risque

de mort, de blessures corporelles ou de dégâts

matériels graves.

AVERTISSEMENT

signifie que lorsque les mesures de sécurité

Pictogramme

correspondantes ne sont pas adoptées, il peut exister

un risque de mort, de blessures corporelles ou de

dégâts matériels graves.

ATTENTION

Pictogramme

avec un triangle de mise en garde signifie qu’il y a

risque de blessure corporelle légère lorsque les

mesures de sécurité correspondantes ne sont pas

adoptées.

ATTENTION

sans triangle de mise en garde signifie qu’il y a risque de dégât

matériel lorsque les mesures de sécurité correspondantes ne sont

pas adoptées.

INDICATION

signifie qu’une situation ou un événement non désiré peuvent

survenir lorsque le conseil n’est pas observé.

34 610.40 700.21 Siemens AG

Page 36

FRANÇAIS

Personnel qualifié

Seul un personnel qualifié est autorisé à mettre l’appareil en marche et à en assurer le

fonctionnement. Dans l’esprit des conseils au niveau des techniques de sécurité, le

personnel qualifié est composé des personnes autorisées à mettre en service, à mettre

à la terre et à marquer les appareils, les systèmes et les circuits électriques.

Utilisation conforme

Veuillez respecter les exigences suivantes :

L’appareil ne peut être utilisé que dans les cas d’utilisation prévus au catalogue et dans

les instructions de projection et ce, uniquement en relation avec les appareils et

composants étrangers conseillés ou agréés par Siemens.

L’exploitation sans problèmes et sûre du produit sous-entend un transport approprié, un

stockage, une installation et un montage appropriés préalables, ainsi qu’un maniement

et un maintient en état scrupuleux.

Exemption de responsabilité

Nous avons vérifié le contenu du texte imprimé. Cependant, comme des divergences ne

peuvent pas être exclues, nous ne pouvons garantir une concordance intégrale. Les

données reprises dans cette brochure sont revues régulièrement et les corrections

nécessaires sont apportées dans les éditions suivantes. Nous vous sommes

reconnaissants pour toute suggestion d’amélioration.

© Copyright Siemens AG 2001. Tous droits réservés

La diffusion ainsi que la reproduction de ce document, l’exploitation et la divulgation de

son contenu sont interdites dans la mesure où elles n’ont pas été autorisées

explicitement. Les infractions sont sujettes à indemnisation.

Tous droits réservés, particulièrement en cas de délivrance de brevet ou

d’enregistrement du produit.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Motion Control Systeme (MC)

D-97615 Bad Neustadt an der Saale

Siemens AG 610.40 700.21 35

Page 37

FRANÇAIS

1 Consignes générales de sécurité

Les servomoteurs sont conformes aux normes harmonisées de la série

EN 60034-1, EN 60034-6, EN 60034-9 et EN 60204-1.

Les servomoteurs triphasés 1FK6 sont en conformité avec

73/23/CEE la Directive de basse tension.

Les moteurs standard sont conformes aux normes UL. Ces moteurs sont indiqués par

l’abréviation UR sur la plaque signalétique.

Veillez à assurer pour votre produit final le respect de toutes les prescriptions

légales ! Les prescriptions et exigences nationales, locales ou spécifiques à

l’installation doivent être respectées.

Les servomoteurs triphasés sont exclusivement destinés à être montés sur une ou plusieurs

autre(s) machine(s).

Les moteurs ne doivent pas être mis en service tant que la conformité du produit final

avec les directives en vigueur n’a pas été établie.

Le mode d’emploi doit être utilisé en liaison avec les instructions de configuration SIEMENS

« Servomoteurs triphasés », Réf. 6SN1197-0AC20-0AP.

Il y a lieu de respecter tous les instructions de sécurité pour le transport, l’installation, le

montage, la dépose et l’exploitation des servomoteurs triphasés !

Le non-respect de ces instructions peut engendrer des blessures corporelles ou des

dommages matériels graves.

Les rotors des moteurs contiennent des aimants permanents à flux magnétique intense

exerçant une force d’attraction importante sur les corps ferromagnétiques.

Les rotors démontés présentent un risque pour les personnes qui portent un stimulateur

cardiaque. Les données enregistrées sur supports électroniques peuvent être détruites.

L’utilisation dans des zones menacées par les explosions est interdite, à moins que le

moteur n’ait été specialement conçu à cet effet.

Menace thermique

Les températures superficielles des moteurs peuvent atteindre de près de 140 °C.

Ne touchez pas les surfaces chaudes !

Les éléments sensibles à la température (câbles électriques, composants électroniques) ne

peuvent pas toucher les surfaces chaudes.

Une surchauffe des moteurs peut détruire les enroulements et les paliers et démagnétiser

les aimants permanents.

Ne pas utiliser les moteurs si le dispositif de contrôle de la température n’est pas en

état de marche !

Utilisation conforme

L’observation de toutes les directives du mode d’emploi et des instructions de configuration

« Servomoteurs triphasés » constitue une composante de l’utilisation conforme aux

stipulations.

2 Indications relatives au produit

2.1 Description du produit

Les moteurs de la série 1FK7 sont des moteurs synchrones à courant triphasé et aimants

permanents (servomoteurs triphasés) destinés à être utilisés avec des onduleurs à

commande par moteur selon le principe du courant sinusoïdal.

Les moteurs sont conçus pour actionner et positionner des machines-outils et des appareils

de production, ainsi que des robots et des manipulateurs.

36 610.40 700.21 Siemens AG

Page 38

FRANÇAIS

2.2 Equipements fournis

Les systèmes d’entraînement sont configurés individuellement. A la réception des moteurs,

vérifier immédiatement que les marchandises livrées sont bien conformes au bordereau

d’accompagnement. SIEMENS décline toute responsabilité en cas de réclamation

ultérieure.

Adresser la réclamation

- directement au livreur en cas de dommages survenus lors du transport,

- dans les meilleurs délais à la succursale SIEMENS responsable en cas de dommages

visibles/de livraison incomplète.

Le mode d’emploi fait partie des accessoires fournis et doit donc être conservé dans un

endroit accessible.

La plaque signalétique livrée avec le moteur est destinée à être placée sur la machine ou

l’installation ou à proximité afin de pouvoir consulter à tout moment les caractéristiques du

moteur.

3 Caractéristiques techniques

3.1 Plaque signalétique

1

3~ Servomotor

2

No.YF: PN 184583 01 001

3

M

11 Nm IO 8,0 A n

4

5

O

7,3 Nm IN 5,6 A nN 3000 /min

M

N

Th.Cl. F U

6

1FK7063-5AF71-1AB3

6600 /min

max

263 V IP 64

IN

10

11

12

13

14

15

Encoder B01 Brake EBD 0.8BK / 24 V- / 19 W

7

16

Rev. No.: 000

8

9

EN 60034

Made in Germany

Fig. 1 Plaque signalétique

1 Type de moteur : Servomoteurs triphasés 10 Type de moteur/ appellation SIEMENS

2 Identifiant, numéro de production 11 Courant d’arrêt I

3 Couple permanent d’arrêt M

4 Couple de rotation nominal M

5 Tension induite U

6 Classe d’isolation thermique 15 Protection

7 Marquage du type de transmetteur 16 Données relatives au frein d’arrêt :

8 Version type, tension, puissance absorbée

9 Normes et directives

[V] 14 Régime de calcul nN [tr-mn]

IN

[Nm] 12 Régime maximal n

0

[Nm] 13 Courant de calcul IN [A]

N

0

[A]

max

[tr-mn]

Siemens AG 610.40 700.21 37

Page 39

FRANÇAIS

3.2 Caractéristiques

Types de construction IM B5 (IM V1, IM V3)

(EN 60034-7)

Type de protection IP64

(EN 60034-5)

Refroidissement Refroidissement naturel

(EN 60034-6)

Niveau de puissance sonore pondéré par coefficient A

(EN 60034-9)

lorsque le régime est inférieur à 3000 tr-mn

1FK7 02., 1FK7 03., 1FK7 04. 55 dB(A) env.

1FK7 06. 65 dB(A) env.

1FK7 08., 1FK7 10. 70 dB(A) env.

Protection thermique du moteur Sonde thermométrique KTY84

(EN 60034-11) intégré dans l’enroulement du stator

Bout d’arbre cylindrique ; sans rainure,

(DIN 748-3; IEC 60072-1) zone de tolérance k6

Concentricité, coaxialité, axialité Tolérance N

(DIN 42955; IEC 60072-1)

Force de vibration de niveau N

(EN 60034-14)

Palier Palier à roulement à lubrification permanente

(lubrification à vie)

Palier fixe côté B

Durée d’utilisation des paliers 20000 h (valeur indicative)

Isolation de l’enroulement Classe d’isolation thermique F

(EN 60034-1)

Températures ambiantes de -15 °C á +40 °C (de 5 °F á 104 °F)

Hauteur de montage ≤ 1000 m au-dessus du niveau de la mer

(EN 60034-1) 2000 m, facteur de puissance 0,94

Composition des aimants Terres rares

Raccordement électrique Prises pivotables pour la puissance et

Système de transmission Transmetteur intégré

Autres valeurs caractéristiques, fiches techniques selon les instructions de configuration

« Servomoteurs triphasés », Réf. 6SN1197-0AC20-0AP.

Options/Extensions

Série à faible inertie HD (High Dynamic)

Type de protection IP 65; bride AS supplémentaire IP67

(EN 60034-5)

Eléments encastrés/rapportés - Frein d’arrêt à courant continu

sinon réduction des caractéristiques nominales

moins de 50 °C, facteur de puissance 0,92

moins de 60 °C, facteur de puissance 0,82

2500 m, facteur de puissance 0,9

les signaux de transmission

- Saisie du régime

- Saisie de la position du rotor

- Saisie indirecte de la position

(DIN VDE 0580)

Tension de raccordement 24 V DC ±10%

- Engrenage planétaire

38 610.40 700.21 Siemens AG

Page 40

FRANÇAIS

Système de transmission - Transmetteur incrémental 1 V

- Transmetteur de valeur absolue EnDat

- Transmetteur de valeur absolue simple

- Résolveur

Bout d’arbre cylindrique à rainure et

(DIN 748-3; IEC 60072-1) languette ; zone de tolérance k6

(équilibrage avec demie languette)

Vous trouverez d’autres données techniques, par ex. les dimensions du moteur, dans le

catalogue NC 60 ou DA 65.3.

4 Installation, montage

4.1 Transport, positionnement

AVERTISSEMENT

Danger en cas de levage et de transport !

Une réalisation incorrecte, des outils et des moyens inappropriés ou

défectueux peuvent occasionner des blessures et /ou des dégâts

matériels.

Les instruments de levage, de déplacement et les porte-charges

doivent satisfaire aux prescriptions en vigueur.

Utiliser des dispositifs de suspension de charge adéquats lors du transport et du montage.

Utiliser des boucles de levage pour transporter les moteurs si c’est prévu par le

constructeur.

Dispositifs de suspension de charge conformément à la directive 98/37/CEE sur les

machines, annexe I.

Les moteurs ont une masse maximale de 50 kg. Pour connaître les données précises, voir

le catalogue ou la fiche des cotes.

PP

Fig. 2 Levage et transport avec des sangles enroulables

Respecter les directives nationales en vigueur lors du transport.

Les moteurs doivent être entreposés dans une pièce sèche, à l’abri de la poussière et des

vibrations (v

Siemens AG 610.40 700.21 39

< 0,2 mms-1).

eff

Page 41

4.2 Installation

FRANÇAIS

IM B 5 IM V 1

Fig. 3 Types de construction

- Respecter les indications de la plaque signalétique, plaques d’avertissement et

panneaux indicateurs situés sur le moteur.

- Respect des forces transversales et axiales (voir les instructions de configuration).

Les forces axiales ne sont pas autorisées dans le cas de moteurs à frein intégré.

- Vérifier la conformité avec les conditions (par ex. températures, hauteur de montage) sur

le lieu d’installation (voir chapitre 3.2).

- L’utilisation dans des zones menacées par les explosions est interdite.

- Retirer toutes les traces de produits anti-corrosifs sur le bout de l’arbre d’entraînement

(utiliser des solvants vendus dans le commerce).

- Prendre les mesures nécessaires pour garantir l’évacuation de la chaleur libérée.

Il est recommandé de laisser un espace de 100 mm ou plus par rapport aux autres pièces

sur trois côtés au moins.

- Vérifier que la fixation par bride est uniforme, éviter toute déformation en serrant les vis

de fixation. Utiliser des vis à tête cylindrique à six pans creux de classe de résistance de

8.8 au moins.

- En cas de montage vertical avec le bout d’arbre vers le haut, faire attention à ce qu’aucun

liquide ne puisse pénétrer dans le palier supérieur.

- Après l’installation, les œillets de levage peuvent être démontes.

- Faire tourner les organes de transmission à la main. En cas de bruits de frottement,

remédier à la cause ou consulter le fabricant.

IM V 3

Vibrations, Équilibrage