Page 1

Manual

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

ET 200SP

02/2014Edition

Answers for industry.

SIMATIC

Page 2

Analog input module AI 4xRTD/TC 2-/3-/4-

wire HF (6ES7134-6JD00-0CA1)

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

ET 200SP

Analog input module

AI 4xRTD/TC 2-/3-/4-wire HF

(6ES7134-6JD00-0CA1)

Manual

02/2014

A5E03573289

-AD

Preface

Guide to documentation

1

Product overview

2

Wiring

3

Parameters/address space

4

Interrupts/diagnostics alarms

5

Technical specifications

6

Parameter data record

A

Representation of analog

values

B

Page 3

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03573289-AD

Ⓟ

02/2014 Subject to change

Copyright © Siemens AG 2014.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Page 4

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

3

Preface

Purpose of the documentation

This device manual complements the system manual ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293). Functions that generally

relate to the system are described in this manual.

The information provided in this manual and in the system/function manuals supports you in

commissioning the system.

Conventions

Please also observe notes marked as follows:

Note

A note contains important information on the product describe

d in the documentation, on the

handling of the product and on the section of the documentation to which particular attention

should be paid.

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. You can find more information about industrial security on the Internet

(http://www.siemens.com/industrialsecurity).

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. You can find more information on the Internet

(http://support.automation.siemens.com).

Page 5

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

4 Manual, 02/2014, A5E03573289-AD

Table of contents

Preface ................................................................................................................................................... 3

1 Guide to documentation .......................................................................................................................... 5

2 Product overview .................................................................................................................................... 7

2.1 Properties ...................................................................................................................................... 7

3 Wiring ................................................................................................................................................... 10

3.1 Pin assignment ............................................................................................................................ 10

3.2 Schematic circuit diagram ........................................................................................................... 12

4 Parameters/address space ................................................................................................................... 13

4.1 Measurement types and measuring ranges................................................................................ 13

4.2 Parameters .................................................................................................................................. 18

4.3 Explanation of parameters .......................................................................................................... 23

4.4 Scalable measuring range .......................................................................................................... 28

4.4.1 Configuration ............................................................................................................................... 30

4.4.2 Evaluating data record 235 ......................................................................................................... 31

4.5 Address space ............................................................................................................................ 34

5 Interrupts/diagnostics alarms................................................................................................................. 35

5.1 Status and error display .............................................................................................................. 35

5.2 Interrupts ..................................................................................................................................... 37

5.3 Diagnostics alarms ...................................................................................................................... 38

6 Technical specifications ........................................................................................................................ 40

6.1 Technical specifications .............................................................................................................. 40

A Parameter data record .......................................................................................................................... 47

A.1 Dependencies when configuring with GSD file ........................................................................... 47

A.2 Parameter assignment and structure of parameter data record ................................................. 52

A.3 Switchable wire break check ....................................................................................................... 61

B Representation of analog values ........................................................................................................... 62

B.1 Representation of input ranges ................................................................................................... 63

B.2 Representation of analog values in voltage measuring ranges .................................................. 64

B.3 Representation of analog values for resistance-type sensors .................................................... 65

B.4 Representation of analog values for thermal resistors ............................................................... 66

B.5 Representation of analog values for thermocouples .................................................................. 69

Page 6

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

5

1

Introduction

This modular documentation of the SIMATIC products covers diverse topics concerning your

automation system.

The complete documentation for the ET 200SP distributed I/O system consists of a system

manual, function manuals and product manuals.

The STEP 7 information system (online help) also supports you during the configuration and

programming of your automation system.

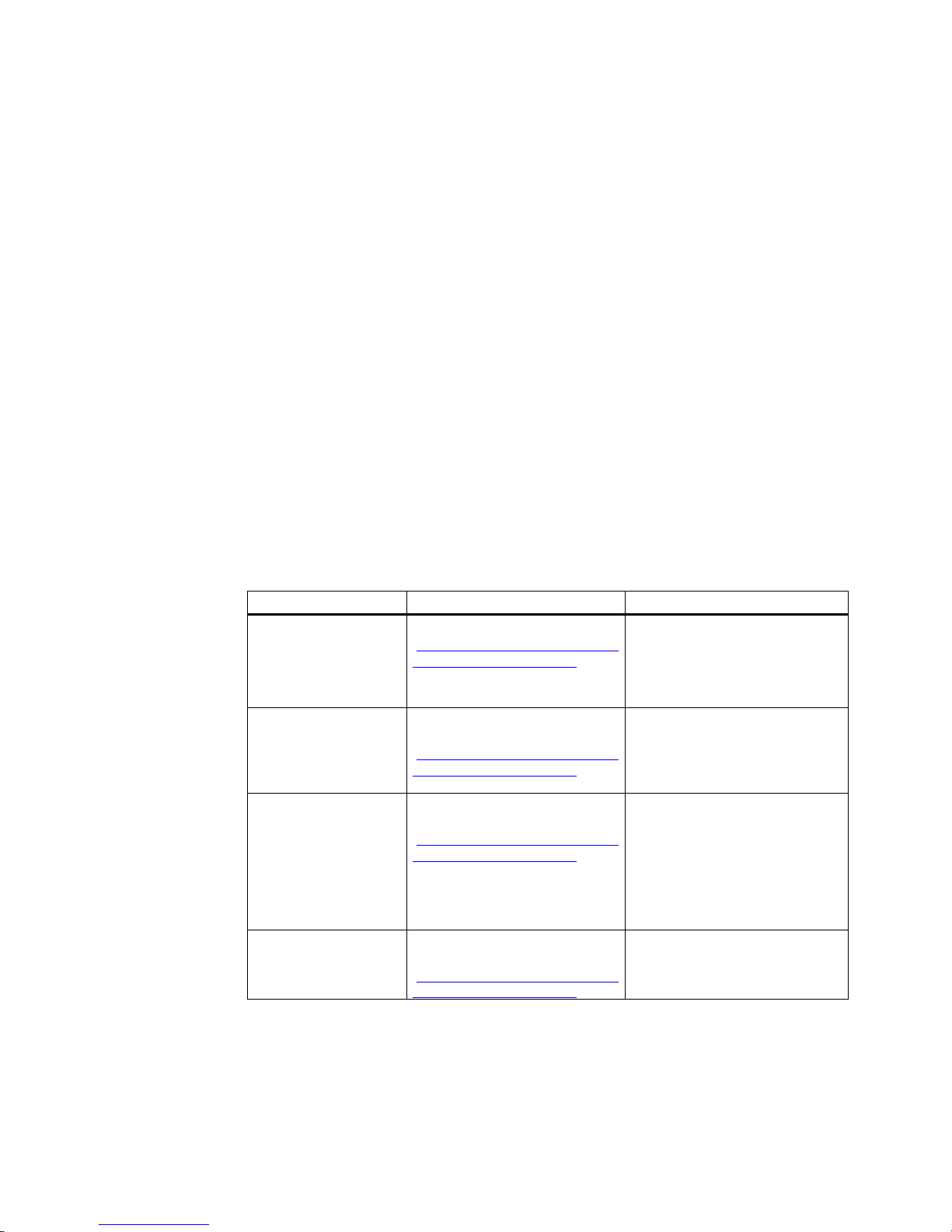

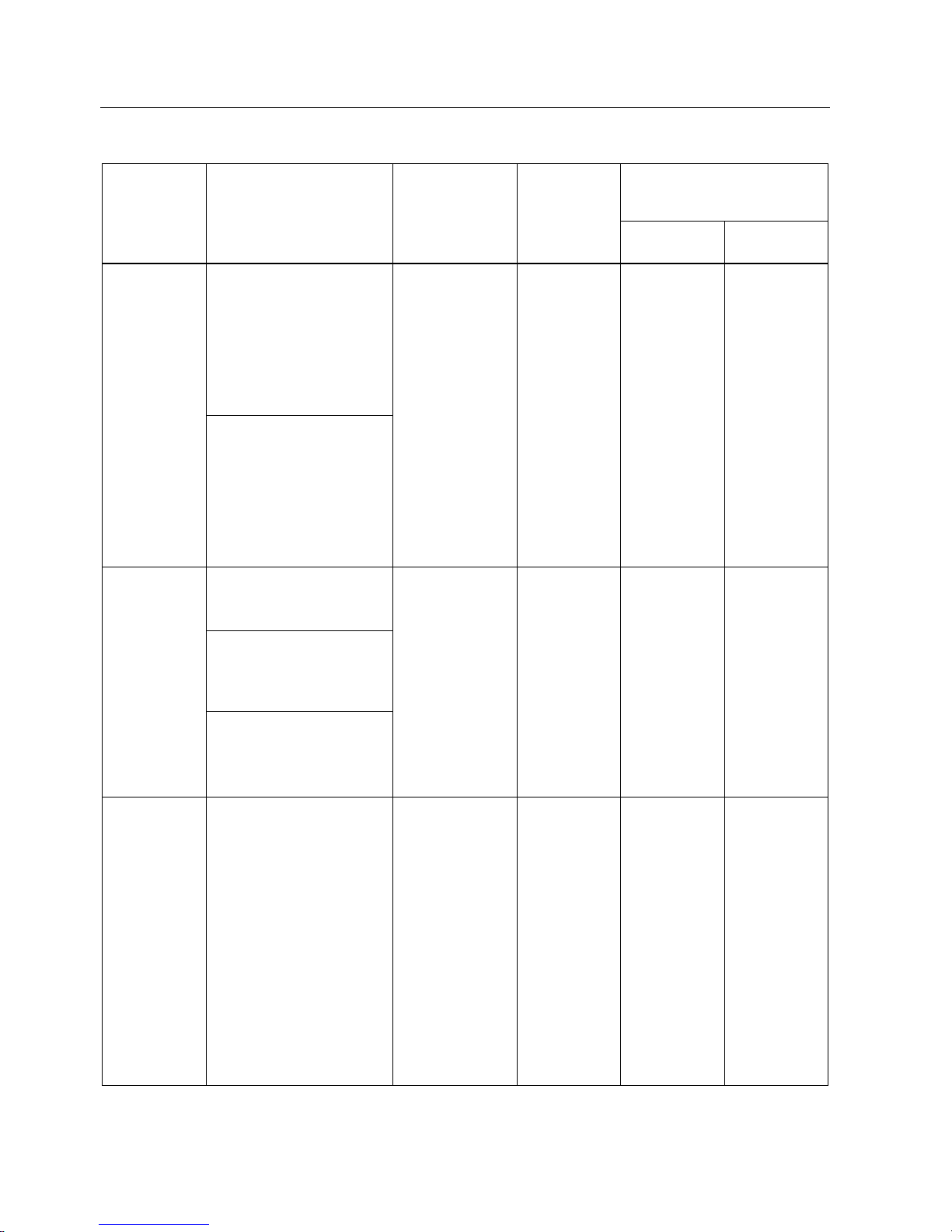

Overview of documentation for analog input module AI 4×RTD/TC 2-/3-/4-wire HF

The following table shows additional documentation that you need when using the

AI 4×RTD/TC 2-/3-/4-wire HF analog input module.

Table 1- 1 Documentation for analog input module AI 4×RTD/TC 2-/3-/4-wire HF

Topic

Documentation

Key contents

System description ET 200SP distributed I/O system

(http://support.automation.siemens.

com/WW/view/en/58649293)

system manual

• Application planning

• Installation

• Wiring

• Commissioning

Designing interferencefree controllers

Designing interference-free

controllers

(http://support.automation.siemens.

com/WW/view/en/59193566)

function manual

• Basics

• Electromagnetic compatibility

• Lightning protection

Analog value processing Function manual

Analog value processing

(http://support.automation.siemens.

com/WW/view/en/67989094)

• Basics of analog technology

(wiring, processing, installation

technology)

• Description/explanation of

meaning, e.g., conversion and

cycle times, basic error limits,

operational limits

System diagnostics Function manual

System diagnostics

(http://support.automation.siemens.

com/WW/view/en/59192926)

• Overview

• Diagnostics evaluation of

hardware/software

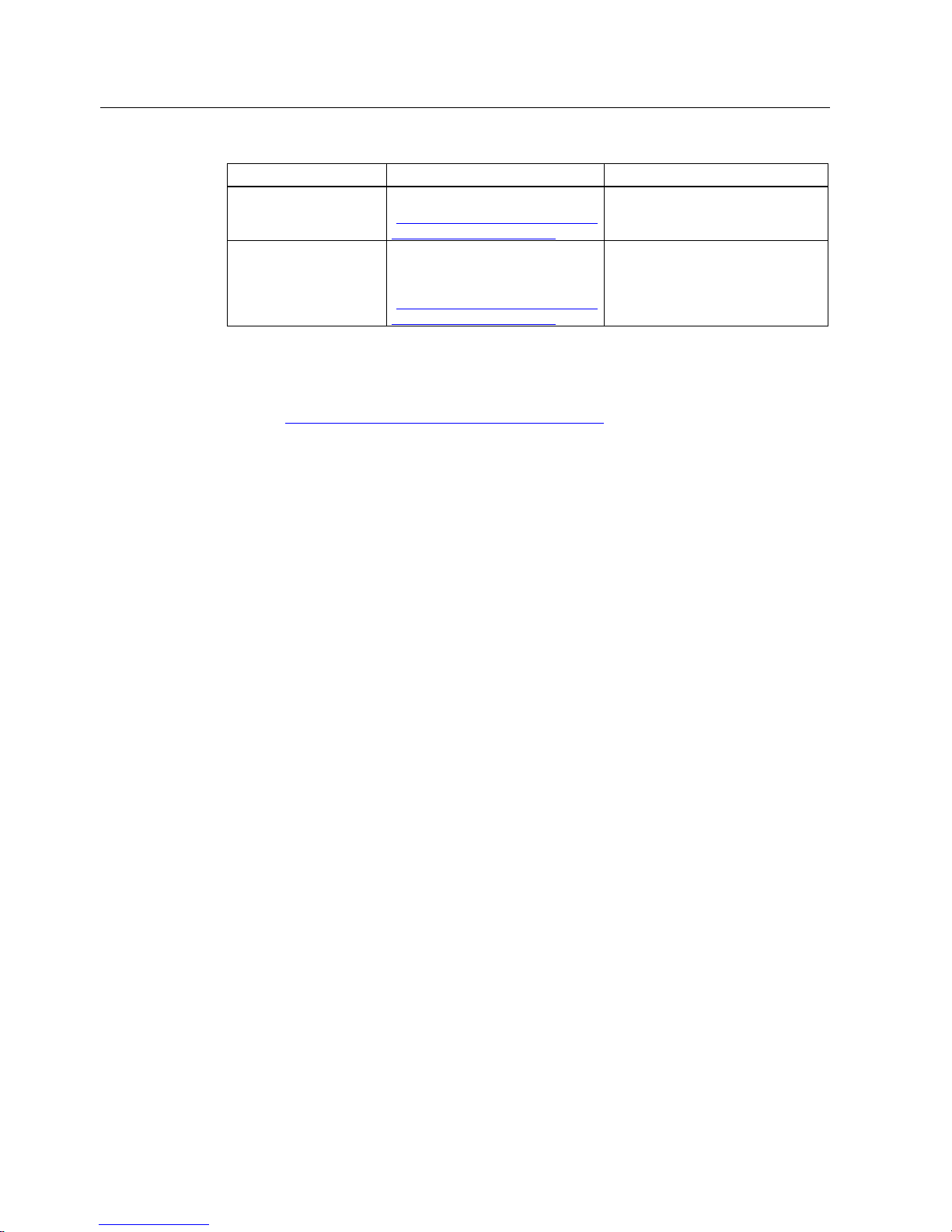

Page 7

Guide to documentation

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

6 Manual, 02/2014, A5E03573289-AD

Topic

Documentation

Key contents

BaseUnits Manual ET 200SP BaseUnits

(http://support.automation.siemens.

com/WW/view/en/59753521)

Technical specifications

Amendments and special

features of the ET 200SP

distributed I/O system

Product information on

documentation of the ET 200SP

distributed I/O system

(http://support.automation.siemens.

com/WW/view/en/73021864)

Current information not yet

documented in the system manuals,

function manuals, or product

manuals.

SIMATIC manuals

All current manuals for SIMATIC products are available to download free of charge on the

Internet (http://www.siemens.com/simatic-tech-doku-portal).

Page 8

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

7

2

2.1

Properties

Article number

6ES7134-6JD00-0CA1

View of the module

Figure 2-1 View of the module AI 4×RTD/TC 2-/3-/4-wire HF

Page 9

Product overview

2.1 Properties

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

8 Manual, 02/2014, A5E03573289-AD

Properties

The module has the following technical properties:

● Analog input module with 4 inputs

● Resolution: Up to 16 bits including sign

● Voltage measurement type can be set per channel

● Resistor measurement type can be set per channel

● Thermal resistor (RTD) measurement type can be set per channel

● Thermocouple (TC) measurement type can be set per channel

● Configurable diagnostics for each channel

● Hardware interrupt on limit violation can be set per channel (two high and two low limits

per channel)

● Automatic compensation of the line resistance with 3-wire connection

The module supports the following functions:

● Firmware update

● I&M identification data

● Reconfiguration in RUN

Table 2- 1 Version dependencies of other module functions

Function

Product version of

the module as of

Firmware version of

the module as of

Calibration in runtime

1

as of V2.00.00

Value status (PROFINET IO only)

1

as of V1.01.00

Scalable measuring range

1

as of V2.00.00

Selectable conductor resistance for 2-wire connection

1

as of V2.00.00

Switchable wire break check

1

as of V2.00.00

You can configure the module with STEP 7 (TIA Portal) and with a GSD file.

Accessories

The following accessories must be ordered separately:

● Labeling strips

● Color identification labels

● Reference identification label

● Shield connection

Page 10

Product overview

2.1 Properties

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

9

See also

You can find more information on accessories in the ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293) system manual.

Page 11

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

10 Manual, 02/2014, A5E03573289-AD

3

3.1

Pin assignment

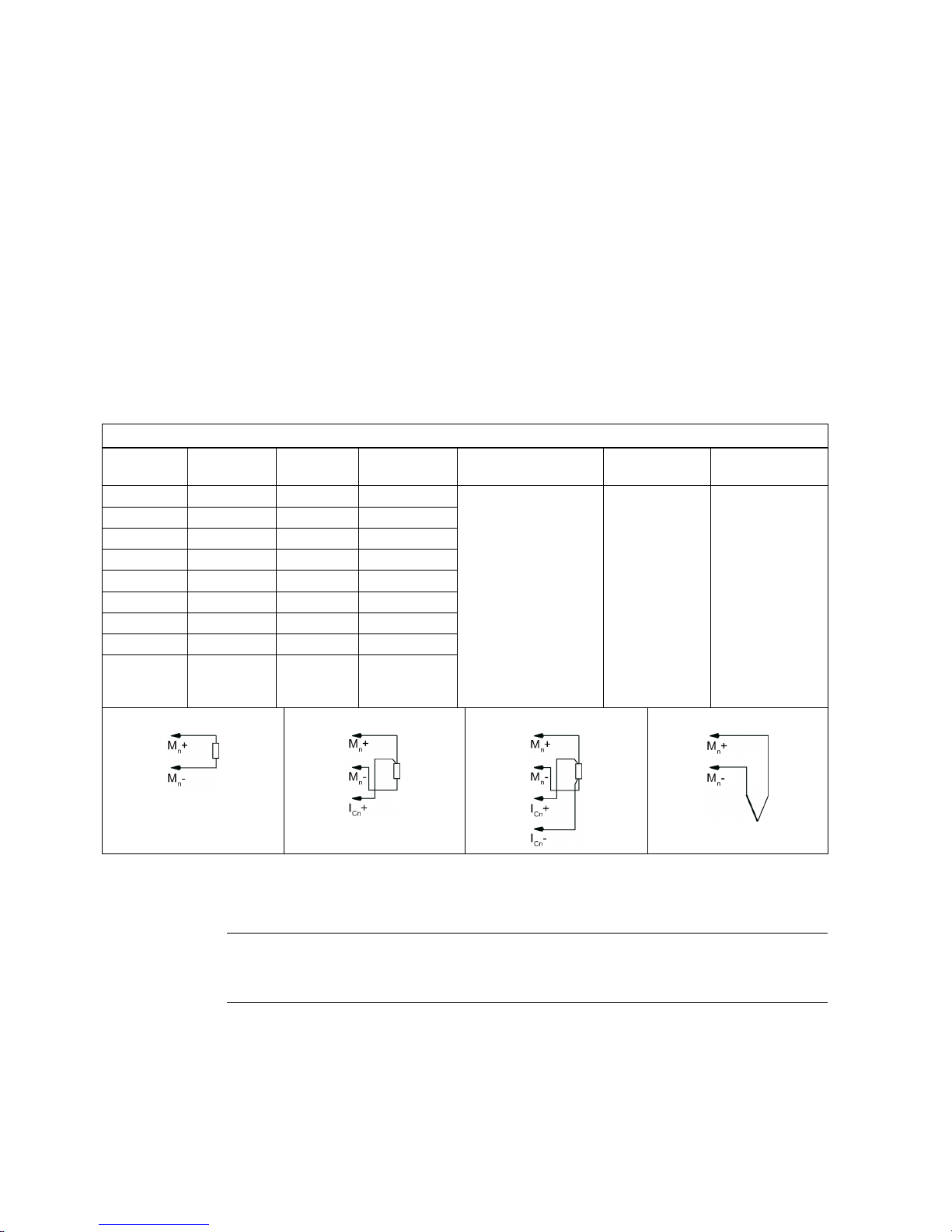

General pin assignment

Table 3- 1 Pin assignment for AI 4xRTD/TC 2-/3-/4-wire HF

Pin assignment for AI 4×RTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Terminal

Assignment

Terminal

Assignment

Notes

BaseUnits

1

Color

identification label

1

M0+ 2 M1+

• Mn+: Measuring

line positive,

channel n

• M

n

-: Measuring line

negative, channel n

• ICn+: Constant

current line

positive, channel n

• I

Cn

-: Constant

current line

negative, channel n

A0

A1

---

3

M2+ 4 M3+

5

M0- 6 M1-

7

M2- 8 M3- 9 IC0+

10

IC1+

11

IC2+

12

IC3+

13

IC0-

14

IC1-

15

IC2-

16

IC3-

L+

24 VDC

M

M

RTD 2-wire connection

RTD 3-wire connection

RTD 4-wire connection

TC

1

Usable BaseUnit types, can be identified by the last two digits of the article number. See also "ET 200SP distributed I/O

system" system manual.

Note

The first BaseUnit of a station must be a light

-colored BaseUnit. Keep this in mind also

during the configuration.

Page 12

Wiring

3.1 Pin assignment

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

11

See also

ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293)

Page 13

Wiring

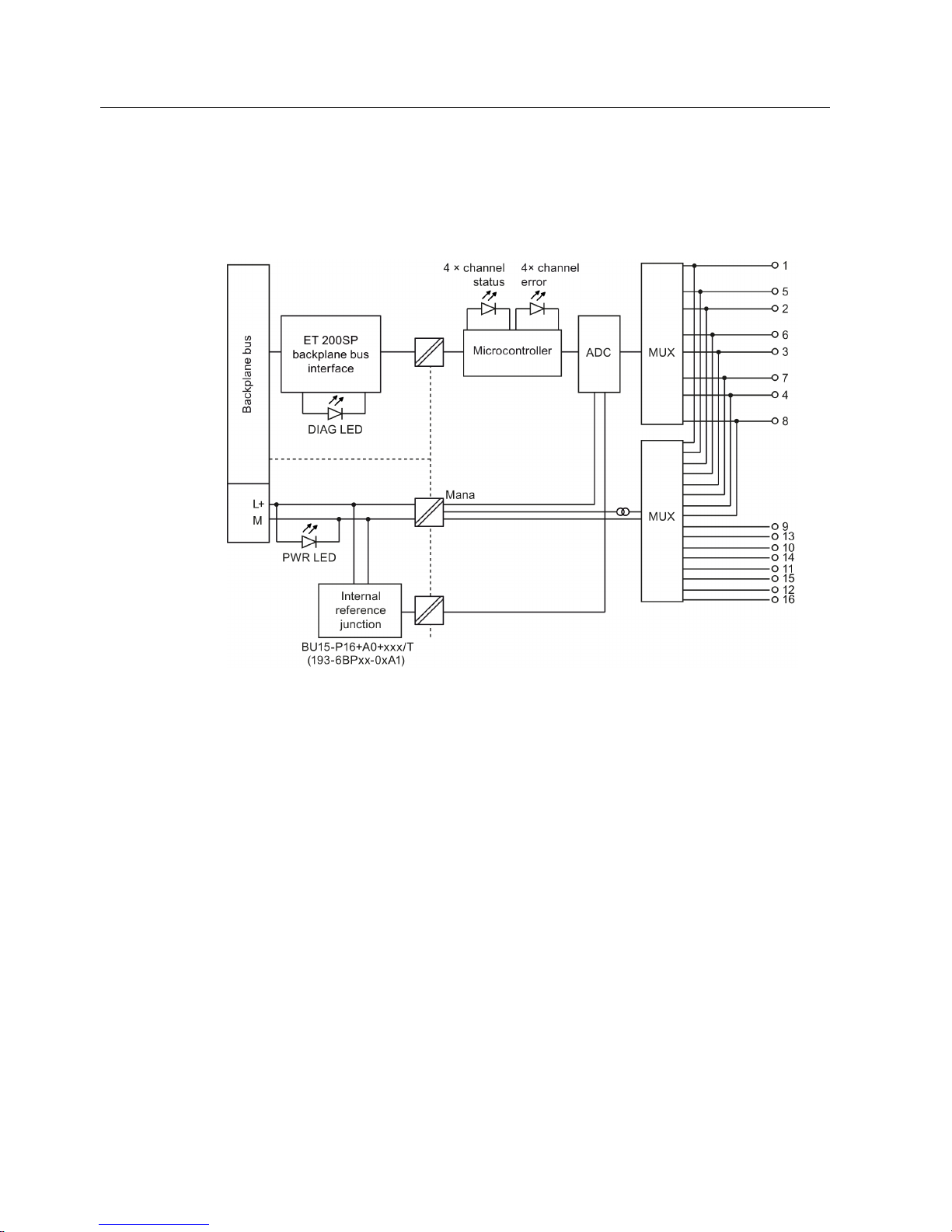

3.2 Schematic circuit diagram

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

12 Manual, 02/2014, A5E03573289-AD

3.2

Schematic circuit diagram

Schematic circuit diagram

Figure 3-1 Schematic circuit diagram AI 4×RTD/TC 2-/3-/4-wire HF

Page 14

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

13

4

4.1

Measurement types and measuring ranges

The following table describes the measuring range and the temperature coefficients you can

configure for each measurement type:

Table 4- 1 Measurement types and measuring ranges

Measurement type

Measuring range

Temperature coefficient

Deactivated

–

–

Resistor (2-, 3-, 4-wire connection) 150 Ω / 300 Ω / 600 Ω /

3 kΩ / 6 kΩ

–

Resistor (2-wire connection)

PTC

–

Thermal resistor RTD

(3-wire connection)

Climatic / Standard

Cu 10

Cu 0.004271

Thermal resistor RTD

(2, 3, 4-wire connection)

Climatic / Standard

Pt 100

Pt 200

Pt 500

Pt 1000

Pt 0.00385 /

Pt 0.003916 /

Pt 0.003902 /

Pt 0.00392 /

Pt 0.00385055

Climatic / Standard

Ni 100

Ni 120

Ni 200

Ni 500

Ni 1000

Ni 0.00618 /

Ni 0.00672

Climatic2 / Standard2

Ni 1000

Ni 0.005

Thermocouple (TC) Type E, N, J, K, L, S, R,

B, T, C, U, TXK (acc. to GOST)

Voltage ±50 mV / ±80 mV /

±250 mV / ±1 V

1

The preset temperature coefficients are valid for Europe.

2

For sensors LG-Ni 1000 from Siemens Building Ltd (Landis & Stäfa).

Page 15

Parameters/address space

4.1 Measurement types and measuring ranges

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

14 Manual, 02/2014, A5E03573289-AD

Special features when using Cu10 sensors

● Choose "Thermal resistor (3-wire connection)" and "Cu10" in the parameter assignment.

● Wire the Cu10 sensor into the 3-wire connection technology.

● During operation, automatic, internal compensation of the line resistance of the missing

measuring line takes place.

Note

To ensure optimum line compensation with Cu10, please observe the following:

• An accurate measured value is only attained if the cable resistance of the positive

const

ant current line to the Cu10 sensor and the cable resistance of the negative

measuring line are identical in value.

• Recommendation: Keep the measuring line as short as possible.

• Different resistance values may also occur due to the connection method used.

Page 16

Parameters/address space

4.1 Measurement types and measuring ranges

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

15

Special features when using PTC resistors

PTCs are suitable for monitoring temperature and/or as thermal protection devices of

complex drives or transformer windings.

● Choose "Thermal resistor (2-wire)" and "PTC" in the parameter assignment.

● Connect the PTC to the 2-wire connection technology.

● Use the PTC resistors, type A (PTC thermistor) in accordance with DIN/VDE 0660,

part 302.

● If "Underflow" diagnostic is enabled, a "Low limit violated" diagnostic is generated for

resistance values < 18 Ω, indicating a short-circuit.

● Sensor data for the PTC resistor:

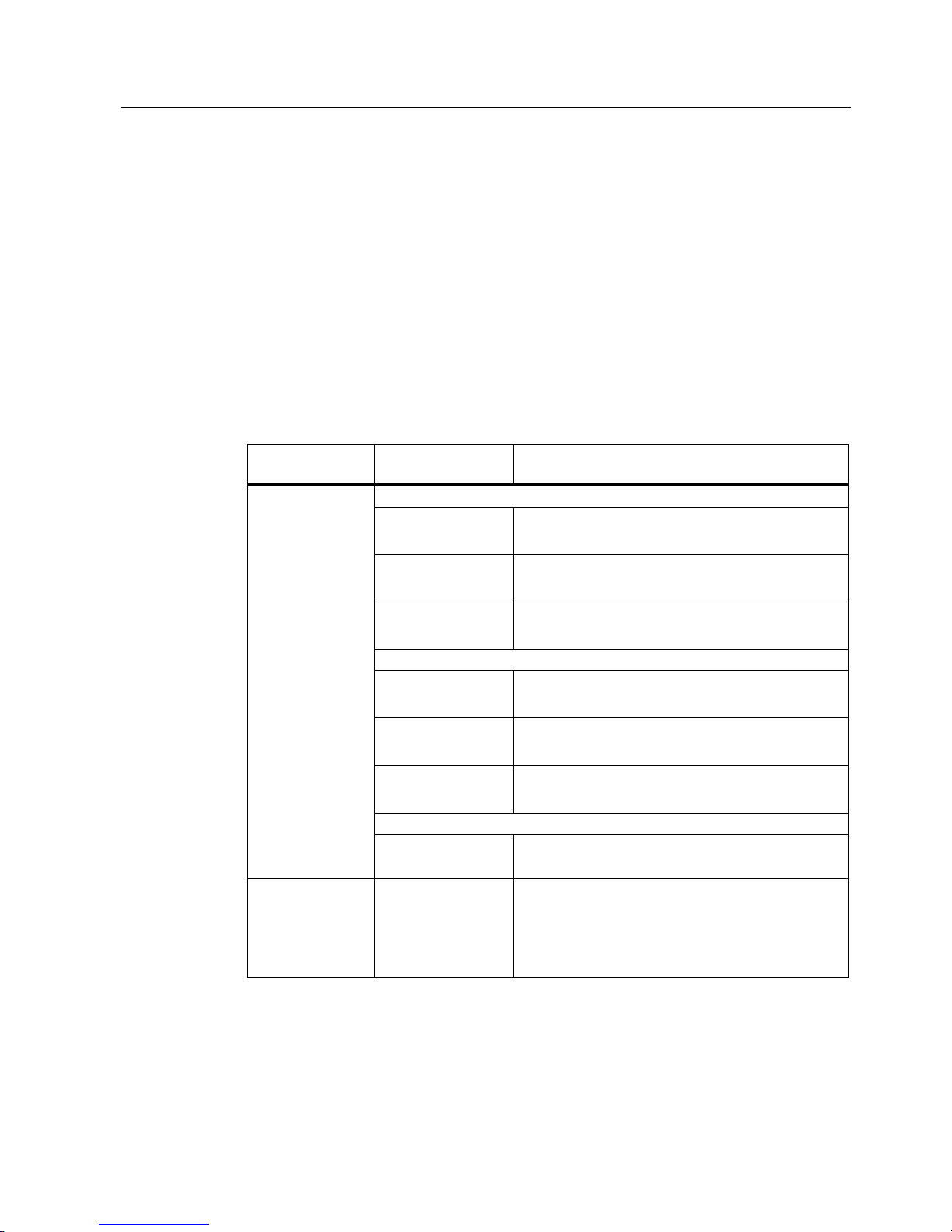

Table 4- 2 Using PTC resistors

Property Technical

specifications

Comment

Switching points Behavior with rising temperature

< 550 Ω Normal range:

• SIMATIC S7: Bit 0 = "0", Bit 2 = "0" (in the PII)

550 Ω to 1650 Ω Prewarning range:

• SIMATIC S7: Bit 0 = "0", Bit 2 = "1" (in the PII)

> 1650 Ω Response range:

• SIMATIC S7: Bit 0 = "1", Bit 2 = "0" (in the PII)

Behavior with falling temperature

> 750 Ω Response range:

• SIMATIC S7: Bit 0 = "1", Bit 2 = "0" (in the PII)

750 Ω to 540 Ω Prewarning range:

• SIMATIC S7: Bit 0 = "0", Bit 2 = "1" (in the PII)

< 540 Ω Normal range:

• SIMATIC S7: Bit 0 = "0", Bit 2 = "0" (in the PII)

Reaction to short-circuit

< 18 Ω

• SIMATIC S7: Bit 7 (IB x+1) = "1", Bit 0 = "0" and

Bit 2 = "0"

(RRT-5) °C

(RRT+5) °C

(RRT+15) °C

Measuring voltage/

voltage at the PTC

Max. 550 Ω

min. 1330 Ω

min. 4000 Ω

Max. 7.5 V

1

TNF = Rated response temperature of the sensor

(according to DIN/VDE 0660)

1

Below 23 kΩ

Page 17

Parameters/address space

4.1 Measurement types and measuring ranges

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

16 Manual, 02/2014, A5E03573289-AD

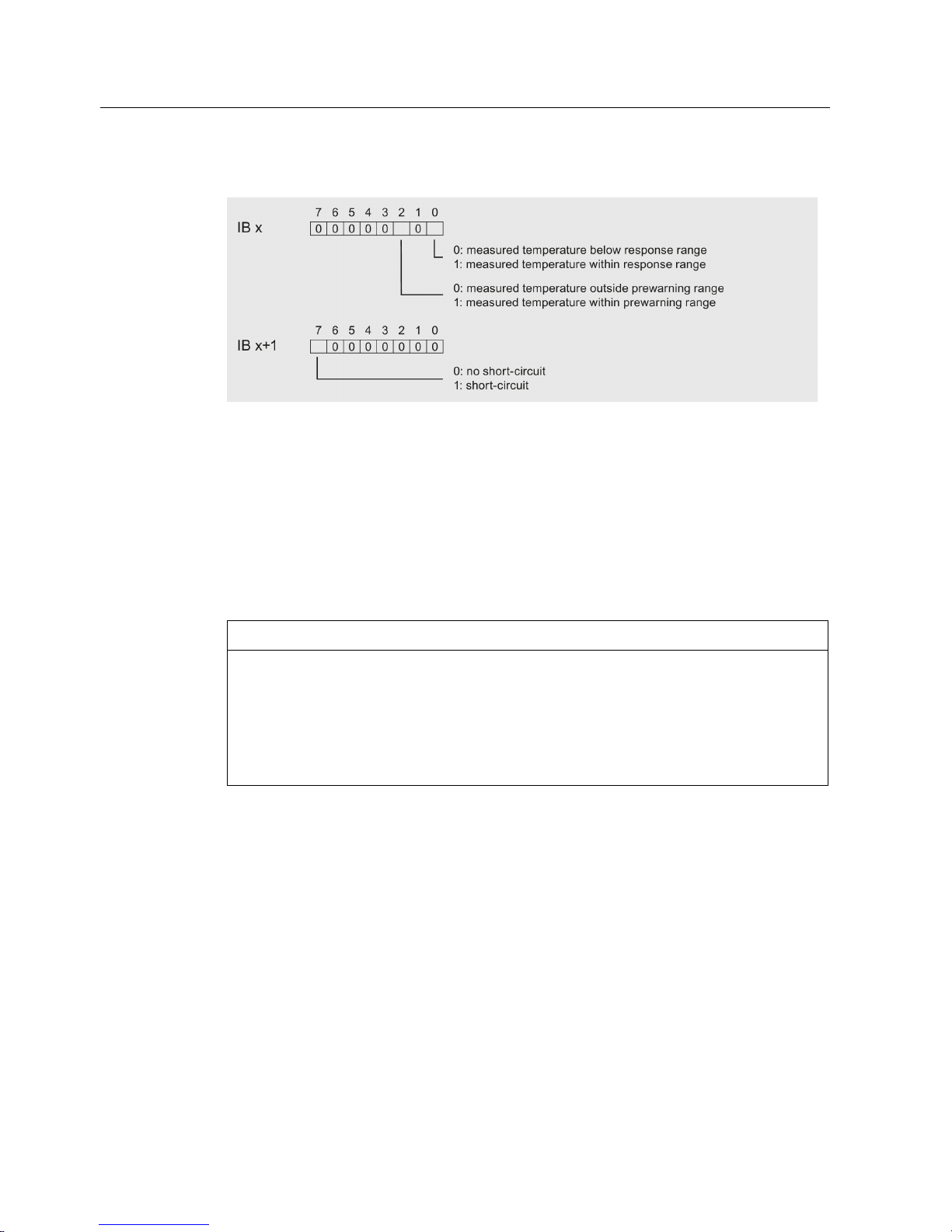

Assignment in the process image input (PII) with SIMATIC S7

Figure 4-1 Assignment in the process image input (PII)

Notes on programming

● Bits 0+2 are relevant for evaluation in the process image input. You can monitor, for

exampl

e, the temperature of a motor using bits 0+2.

● Bits 0+2 in the process image input cannot be saved. During parameter assignment, take

into consideration that a motor, for example, starts up in a controlled manner (via an

acknowledgment).

● Bits 0+2 can never be set at the same time; they are set one after the other.

NOTICE

No measurement is possible in the following cases:

• When I/O modules are pulled out

• When s

upply voltage to the I/O module fails

• When there is a wire break or short-circuit in the measuring lines

Therefore, always evaluate the diagnostics entries of the AI 4×RTD/TC 2-/3-/4-wire HF for

safety reasons.

Page 18

Parameters/address space

4.1 Measurement types and measuring ranges

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

17

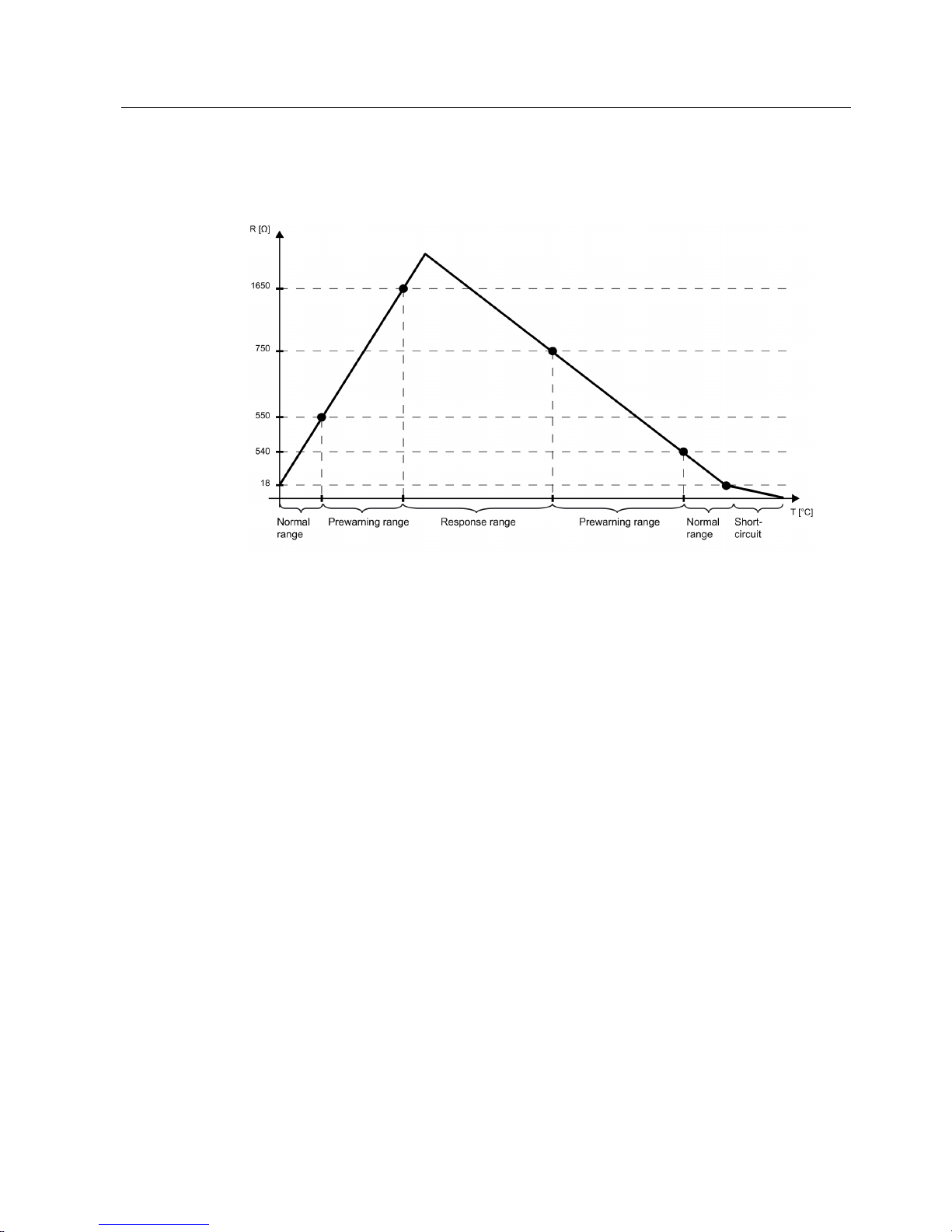

Example

The diagram shows the temperature curve and the associated switching points.

Figure 4-2 Temperature curve with prewarning range

See also

Technical specifications (Page 40)

Page 19

Parameters/address space

4.2 Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

18 Manual, 02/2014, A5E03573289-AD

4.2 Parameters

Parameters of the AI 4xRTD/TC 2-/3-/4-wire HF

The following table lists the configurable parameters. The effective range of the configurable

parameters depends on the type of configuration. The following configurations are possible:

● Distributed operation on PROFINET IO in an ET 200SP system

● Distributed operation on PROFIBUS DP in an ET 200SP system

When assigning parameters in the user program, use the WRREC instruction to transfer the

parameters to the module by means of data records, see section Parameter assignment and

structure of parameter data record (Page 52). The following parameter settings are possible:

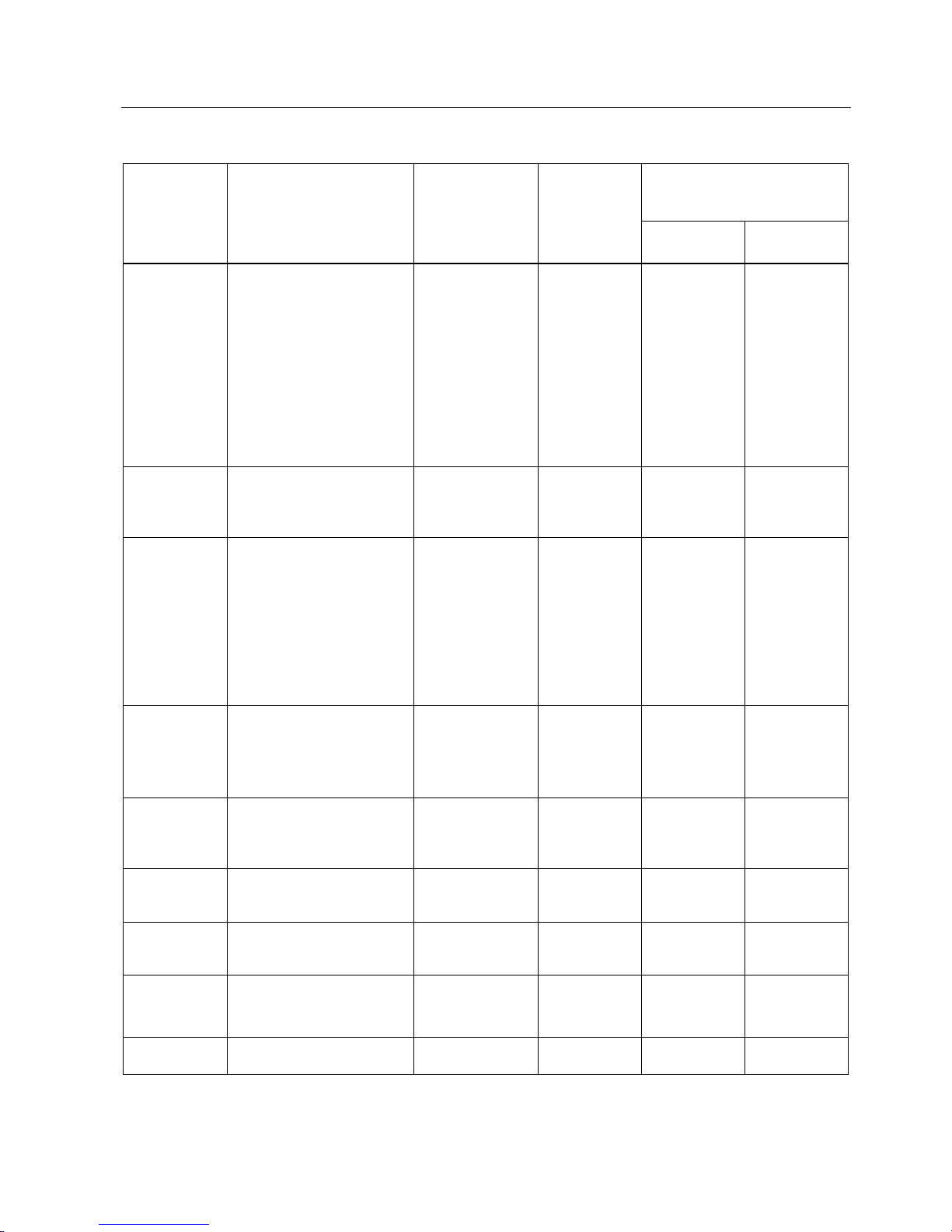

Table 4- 3 Configurable parameters and their defaults (GSD file)

Parameter Value range Default Reconfiguration

in RUN

Scope with configuration

software, e.g.,

STEP 7 (TIA Portal)

GSD file

PROFINET IO

GSD file

PROFIBUS DP

Diagnostics:

Missing supply

voltage L+

• Disable

• Enable

D

isable Yes Channel Channel

1

Diagnostics:

Reference

junction

• Disable

• Enable

D

isable Yes Channel Module

Diagnostics:

Overflow

• Disable

• Enable

Disable Yes Channel Module

Diagnostics:

Underflow

• Disable

• Enable

Disable Yes Channel

Diagnostics:

Wire break

• Disable

• Enable

Disable Yes Channel Channel

Page 20

Parameters/address space

4.2 Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

19

Parameter Value range Default Reconfiguration

in RUN

Scope with configuration

software, e.g.,

STEP 7 (TIA Portal)

GSD file

PROFINET IO

GSD file

PROFIBUS DP

Type/range of

measurement

• Deactivated

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

• Voltage ±50 mV

• Voltage ±80 mV

• Voltage ±250 mV

• Voltage ±1 V

Resistor

(2-, 3-, 4-wire connection)

• 150 Ω

• 300 Ω

• 600 Ω

• 3 kΩ

• 6 kΩ

Type/range of

measurement

Resistor (2-wire connection)

PTC

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

Type/range of

measurement

Thermal resistor

(2, 3, 4-wire connection)

• Pt 100 climatic range

• Pt 200 climatic range

• Pt 500 climatic range

• Pt 1000 climatic range

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

Thermal resistor

(2, 3, 4-wire connection)

• Pt 100 standard range

• Pt 200 standard range

• Pt 500 standard range

• Pt 1000 standard range

Page 21

Parameters/address space

4.2 Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

20 Manual, 02/2014, A5E03573289-AD

Parameter Value range Default Reconfiguration

in RUN

Scope with configuration

software, e.g.,

STEP 7 (TIA Portal)

GSD file

PROFINET IO

GSD file

PROFIBUS DP

Type/range of

measurement

Thermal resistor

(2, 3, 4-wire connection)

• Ni 100 climatic range

• Ni 120 climatic range

• Ni 200 climatic range

• Ni 500 climatic range

• Ni 1000 climatic range

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

Thermal resistor

(2, 3, 4-wire connection)

• Ni 100 standard range

• Ni 120 standard range

• Ni 200 standard range

• Ni 500 standard range

• Ni 1000 standard range

Type/range of

measurement

Thermal resistor

(2, 3, 4-wire connection)

• LG Ni 1000 climatic range

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

Thermal resistor

(2, 3, 4-wire connection)

• LG Ni 1000 standard

range

Thermal resistor (3-wire

connection)

• Cu 10 climatic range

• Cu 10 standard range

Type/range of

measurement

Thermocouple

• Type B (PtRh-PtRh)

• Type N (NiCrSi-NiSi)

• Type E (NiCr-CuNi)

• Type R (PtRh-Pt)

• Type S (PtRh-Pt)

• Type J (Fe-CuNi)

• Type L (Fe-CuNi)

• Type T (Cu-CuNi)

• Type K (NiCr-NiAl)

• Type U (Cu-CuNi)

• Type C (WRe-WRe)

• Type TXK

Thermal resistor

(4-wire connection)

Pt 100 standard

range

Yes Channel Channel

Page 22

Parameters/address space

4.2 Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

21

Parameter Value range Default Reconfiguration

in RUN

Scope with configuration

software, e.g.,

STEP 7 (TIA Portal)

GSD file

PROFINET IO

GSD file

PROFIBUS DP

Temperature

coefficient

• Pt 0.00385055

• Pt 0.003916

• Pt 0.003902

• Pt 0.00392

• Pt 0.00385

• Ni 0.00618

• Ni 0.00672

• LG-Ni 0.005

• Cu 0.00427

Pt 0.00385055 Yes Channel Channel

Temperature

unit

• Degrees Celsius

• Degrees Fahrenheit

• Kelvin

Degrees Celsius Yes Channel Module

Reference

junction

4

• No reference channel mode

• Reference channel of the

module

• Internal reference junction

• Reference channel of

group 0 to 3

• Fixed reference

temperature

No reference

channel mode

Yes Channel Channel

Smoothing

• None

• Weak

• Medium

• Strong

None Yes Channel Channel

Interference

frequency

suppression 3

• 60 Hz

• 50 Hz

2

• 16.6 Hz

50 Hz Yes Channel Channel

Scalable

measuring

range

• Disable

• Enable

D

isable Yes Channel -

Measuring

range

resolution

• 2 decimal places

• 3 deci

mal places

2 decimal places Yes Channel -

Measuring

range center

• Value within the nominal

range of the measuring

range

0 Yes Channel -

Conductor

resistance

5

0 to 50000 mΩ 0 Yes C

hannel -

Page 23

Parameters/address space

4.2 Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

22 Manual, 02/2014, A5E03573289-AD

Parameter Value range Default Reconfiguration

in RUN

Scope with configuration

software, e.g.,

STEP 7 (TIA Portal)

GSD file

PROFINET IO

GSD file

PROFIBUS DP

Hardware

interrupt high

limit 1 3

• Disable

• Enable

D

isable Yes Channel -

High limit 1 3

• Value

8500 Yes Channel -

Hardware

interrupt low

limit 1 3

• Disable

• Enable

D

isable Yes Channel -

Low limit 1 3

• Value

-2000 Yes Channel -

Hardware

interrupt high

limit 2 3

• Disable

• Enable

D

isable Yes Channel -

High limit 2 3

• Value

8500 Yes Channel -

Hardware

interrupt low

limit 2 3

• Disable

• Enable

D

isable Yes Channel -

Low limit 2 3

• Value

-2000 Yes Channel -

Potential group

• Use potential group of the

left module

• Enable new potential

group

Use potential

group of the left

module

No Module Module

1

Diagnostics: Missing supply voltage L+: Detection per module or alarm per channel

2

Interference frequency suppression: Interfering signals at 400 Hz are automatically included in the filtering at 50 Hz.

3

Due to the limited number of parameters at a maximum of 244 bytes per ET 200SP station with a PROFIBUS GSD

configuration, the configuration options are restricted. If required, you can still assign these parameters using data

record 128 as described in the "GSD file PROFINET IO" column (see table above). The parameter length of the

I/O module is 24 bytes.

4

Only for configuration with PROFIBUS GSD file: The set reference junction is used with the additional parameter "Kx

Reference junction activated" in the case of "Enable". In the case of "Disable", "No reference channel mode" is used for

RTD and "Fixed reference temperature" is used for TC.

5

For 2-wire connection only

Note

Unused channels

"Deactivate" unused channels in the parameter assignment to improve the cycle time of the

module.

A deactivated channel always returns the value 7FFF

H

.

Page 24

Parameters/address space

4.3 Explanation of Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

23

4.3 Explanation of parameters

Diagnostics: Missing supply voltage L+

Enabling of the diagnostics for missing or insufficient supply voltage L+.

Diagnostics: Reference junction

Enabling of the reference junction diagnostics if the reference temperature of the reference

junction needs to be determined for the TC channel being operated.

Reference junction using the PROFINET GSD file

A BaseUnit with an internal temperature sensor (BU..T), the reference channel of

group 0, 1, 2, 3, or channel 0 of the I/O module can be used as reference junction for the

TC measurement, if this has the parameter setting "Thermal resistor Pt100 climatic range

Degrees Celsius".

A possible parameter assignment is represented below:

Table 4- 4 RTD channel

Setting Description

No reference channel mode The temperature value at channel 0 can be used as a reference

value for the entire module.

Reference channel of group 0,

1, 2, 3

The channel acts as a transmitter for the reference junction

temperature of a group. The distribution is performed via the

interface module.

Table 4- 5 TC channel

Setting Description

Reference channel of the

module

The corresponding TC channel uses channel 0 of the same module

as the reference junction temperature. This must be configured as

"Thermal resistor Pt 100 climatic range Degrees Celsius" and

"No reference channel mode"; otherwise, Diagnostics: Reference

junction is triggered.

Internal reference junction The reference junction temperature is read by an internal

temperature sensor on the BaseUnit. Diagnostics: Reference

junction is triggered if there is an incorrect BaseUnit type.

Reference channel of group 0,

1, 2, 3

The channel acts as a receiver for the reference junction

temperature of a group.

Fixed reference temperature The reference temperature of the thermocouple is set to 0 °C. As a

result, no temperature compensation is performed.

Page 25

Parameters/address space

4.3 Explanation of Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

24 Manual, 02/2014, A5E03573289-AD

Note

Shared Device and "Reference channel of group 0, 1, 2, 3"

If the transmitter and receiver for the reference junction temperature of a group are assigned

to different IO controllers, then both IO controllers must be performing data exchange with

the IO device to ensure error-free operation of the temperature compensation.

Reference junction using the PROFIBUS GSD file

A BaseUnit with an internal temperature sensor (BU..T), the reference channel of

group 0, 1, 2, 3, or channel 0 of the I/O module can be used as reference junction for the

TC measurement, if this has the parameter setting "Thermal resistor Pt100 climatic range

Degrees Celsius".

The set temperature unit (e.g. Degrees Celsius) is valid for the entire module with

temperature compensation "Reference channel of the module" and "Reference channel of

group 0, 1, 2, 3".

Table 4- 6 RTD channel

Setting Description

No reference channel mode The temperature value at channel 0 can be used as a reference

value for the entire module.

Reference channel of group 0,

1, 2, 3

The channel acts as a transmitter for the reference junction

temperature of a group. The distribution is performed via the

interface module.

Setting Description

Channel x Reference junction

activated

• Disable: Channel x is configured with the setting

"No reference channel mode".

• Enable: Channel x is configured with the setting selected above.

Table 4- 7 TC channel

Setting Description

Reference channel of the

module

The corresponding TC channel uses channel 0 of the same module

as the reference junction temperature. This must be configured as

"Thermal resistor Pt 100 climatic range Degrees Celsius" and

"No reference channel mode"; otherwise, Diagnostics: Reference

junction is triggered.

Internal reference junction The reference junction temperature is read by an internal

temperature sensor on the BaseUnit. Diagnostics: Reference

junction is triggered if there is an incorrect BaseUnit type.

Page 26

Parameters/address space

4.3 Explanation of Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

25

Setting Description

Reference channel of group 0,

1, 2, 3

The channel acts as a receiver for the reference junction

temperature of a group.

Fixed reference temperature The reference temperature of the thermocouple is set to 0 °C. As a

result, no temperature compensation is performed.

Setting Description

Channel x Reference junction

activated

• Disable: Channel x is configured with the setting

"Fixed reference temperature".

• Enable: Channel x is configured with the setting selected above.

Diagnostics: Overflow

Enabling of the diagnostics when the measured value exceeds the overrange.

Diagnostics: Underflow

Enabling of the diagnostics if the measured value falls below the underrange.

Diagnostics: Wire break

Enabling of the diagnostics if the module has no current flow or the current is insufficient for

measurement at the correspondingly assigned input.

Type/range of measurement

See the section Measurement types and measuring ranges (Page 13).

Temperature coefficient

The temperature coefficient depends on the chemical composition of the material. In Europe,

only one value is used per sensor type (default value).

The temperature coefficient (α value) indicates by how much the resistance of a specific

material changes relatively if the temperature increases by 1 °C.

The other values facilitate a sensor-specific setting of the temperature coefficient and

enhance accuracy.

Temperature unit

Selection between Degrees Celsius, Fahrenheit and Kelvin as the temperature unit for the

selected measuring range.

Page 27

Parameters/address space

4.3 Explanation of Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

26 Manual, 02/2014, A5E03573289-AD

Smoothing

The individual measured values are smoothed using filtering. The smoothing can be set in

4 levels.

Smoothing time = number of module cycles (k) x cycle time of the module.

The following figure shows how many module cycles it takes for the smoothed analog value

to approach 100%, depending on the configured smoothing. This specification is valid for all

signal changes at the analog input.

① No smoothing (k = 1)

② Weak (k = 4)

③ Medium (k = 8)

④ Strong (k = 16)

Figure 4-3 Smoot

hing for AI 4×RTD/TC 2-/3-/4-wire HF

Interference frequency suppression

Suppresses the interferences affecting analog input modules that are caused by the

frequency of the AC voltage network used.

The frequency of the AC voltage network is likely to have a negative effect on measured

values particularly with measurement in the low voltage range and on thermocouples. With

this parameter, the user specifies the line frequency that is predominant in the plant.

Measuring range resolution

Parameters for the measurement type thermal resistor standard and thermocouple.

Allows you to increase the resolution to 2 or 3 decimal places for a configurable section of

the measuring range. See the Scalable measuring range (Page 28) section.

Page 28

Parameters/address space

4.3 Explanation of Parameters

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

27

Measuring range center

Determines the temperature over which the scalable measuring range is symmetrically

spanned. The value must be within the nominal range of the underlying measuring range. It

is specified in integers.

Maximum / Minimum

Corres

ponds to overflow / underflow for the scalable measuring range.

Conductor resistance

Parameters for the measurement types resistor and thermal resistor (2-wire connection).

Used to compensate for the conductor resistance without having to interfere with the sensor

wiring.

If the "Conductor resistor" parameter is configured higher than a value 0 mΩ, the module

then automatically uses the factory calibration data.

Hardware interrupt enable

Enabling of a hardware interrupt if the high limit 1/2 or the low limit 1/2 is violated.

Low limit 1/2

Specify a threshold which triggers a hardware interrupt when violated.

High limit 1/2

Specify a threshold which triggers a hardware interrupt when violated.

Potential group

Specifies that a BaseUnit with incoming voltage supply is located on this slot

(see system manual ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293)).

Page 29

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

28 Manual, 02/2014, A5E03573289-AD

4.4 Scalable measuring range

Introduction

The scalable measuring range is available for the temperature measuring ranges of thermal

resistors (RTD) standard and thermocouples. The measuring ranges for voltage, resistor and

thermal resistor climatic are not supported.

The scalable measuring range is valid for the following ranges:

● Nominal range

● Underrange

● Overrange

Function

The scalable measuring range is a limited section of a measuring range supported by the

module.

It allows you to increase the resolution for a configurable section.

● The "Measuring range resolution" parameter determines the resolution to 2 or 3 decimal

places.

● The "Measuring range center" parameter determines the temperature over which the

scalable measuring range is symmetrically spanned.

Value ranges

Table 4- 8 Value ranges

Scalable measuring range Measuring range resolution Values hex.

2 decimal places 3 decimal places

Overflow >325.11 >32.511 7FFFH

High limit 325.11 32.511 7EFFH

Measuring range center 0 0 0H

Low limit -325.12 -32.512 8100H

Underflow <-325.12 <-32.512 8000H

To obtain an absolute temperature, the measuring range center in the application program

(as offset) must be calculated with the value of the user data of the scalable measuring

range.

The measuring range center is always output in the user data as the value "0". The user data

are correspondingly mapped to the bipolar input ranges in S7 format. Underflow / overflow is

also formed in accordance with the limits of S7.

Page 30

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

29

Rules

● The measuring range center must be within the nominal range of the underlying

measuring range. It is specified in integers.

● The scalable measuring range is spanned symmetrically over the measuring range

center. Depending on the resolution, various value ranges result (

①, ②).

● The scalable measuring range is limited by underflow and overflow of the underlying

measuring range:

– It is clipped at the underflow when it falls below the limit.

– It is clipped at the overflow when it exceeds the limit (

③).

Example

The following example illustrates the effect of scalable measuring ranges:

①

Scalable measuring range with 2 decimal places in hexadecimal S7 format

②

Scalable measuring range with 3 decimal places in hexadecimal S7 format

③

Scalable measuring range which is cut off at the overflow of the underlying measuring range (clipping)

Figure 4-4 Examples of scalable measuring ranges

Page 31

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

30 Manual, 02/2014, A5E03573289-AD

4.4.1 Configuration

Requirement

You must select a valid temperature measuring range for configuration.

Configuration

The function is activated using the "Scalable measuring range" parameter.

The following figure shows an example of a configuration in STEP 7:

Figure 4-5 Configuration for the scalable measuring range

Reference

You will find more information on the configuration in the STEP 7 online help.

Page 32

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

31

4.4.2

Evaluating data record 235

Evaluation in the user program

In the user program, you can evaluate the status and the limits of the scalable measuring

range with data record 235, which may result by reaching underflow/overflow.

Structure of data record 235

Figure 4-6 Structure of data record 235

Header information

The figure below shows the structure of the header information.

Figure 4-7 Header information of data record 235

Page 33

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

32 Manual, 02/2014, A5E03573289-AD

Parameters

The figure below shows the structure of the parameter.

If the corresponding bit is set to "1", the parameter is activated.

* x = 2 + (channel number x 8)

Figure 4-8 Structure of data record 235 - channel parameter byte x to x+7

Description of the parameters

Table 4- 9 Description of the parameters from data record 235

Parameter Description

Scalable measuring range enabled 1 = Function is active for this channel.

Clipping 1 = Scalable measuring range cut off at the overflow /

underflow of the underlying measuring range (see Figure

(Page 29)).

Resolution 2 or 3 decimal places

Measuring range center Temperature in whole °C / °F / K ("working point" for the

scaling)

Overflow/underflow Limits of the scalable measuring range

Page 34

Parameters/address space

4.4 Scalable measuring range

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

33

Example

The following example shows the values for a thermal resistor Pt 100 Standard, °C:

Table 4- 10 Example of a thermal resistor Pt 100 Standard

Hex. value

Dec. value

Evaluation of data record 235

00H 0 V0.0

08H 8 8 bytes

03H 3 Scalable measuring range active and clipped (clipping)

02H 2 Resolution: 2 decimal places

02EEH

750

Measuring range center: 750 °C

61A8H 25000 Overflow (Maximum):

250

.00

+ 750 = 1000.00 °C

Scalable measuring range is clipped at the overflow.

8100H -32512 Underflow (Minimum):

-325.12 + 750 = 424.88 °C

Page 35

Parameters/address space

4.5 Address space

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

34 Manual, 02/2014, A5E03573289-AD

4.5

Address space

Address space of the analog input module AI 4×RTD/TC 2-/3-/4-wire HF

The following figure shows the assignment of the address space with value status (Quality

Information (QI)). The addresses for the value status are only available if the value status is

enabled.

Figure 4-9 Address space AI 4×RTD/TC 2-/3-/4-wire HF with value status

Configuration options of the AI 4xRTD/TC 2-/3-/4-wire HF

The following configurations are possible:

● Configuration 1: Without value status

● Configuration 2: With value status

Evaluating the value status (as of firmware version V1.01)

An additional byte is occupied in the input address space if you enable the value status for

the analog module. Bit 0 to 3 in this byte is assigned to one channel and provides

information on the validity of the analog value (0 = value is incorrect).

Page 36

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

35

5

5.1

Status and error display

LED display

The figure below shows the LED displays of the AI 4xRTD/TC 2-/3-/4-wire HF:

①

DIAG (green/red)

②

Channel status (green)

③

Channel error (red)

④

PWR (green)

Figure 5-1 LED display

Page 37

Interrupts/diagnostics alarms

5.1 Status and error display

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

36 Manual, 02/2014, A5E03573289-AD

Meaning of the LED displays

The following tables contain the meaning of the status and error displays. Remedies for

diagnostics alarms can be found in section Diagnostics alarms (Page 38).

DIAG LED

Table 5- 1 Error display of the DIAG LED

DIAG LED Meaning

Off

Backplane bus supply of the ET 200SP not OK

Flashes

Module parameters not assigned

On

Module parameters assigned and no module diagnostics

Flashes

Module parameters assigned and module diagnostics

Channel status/channel error LED

Table 5- 2 Status and error display of the LED channel status / channel error

LEDs Meaning

Channel status Channel error

Off

Off

Channel deactivated

On

Off

Channel activated and no channel diagnostics

Off

On

Channel activated and channel diagnostics

On

On

Not permitted (error)

PWR LED

Table 5- 3 Status display of the PWR LED

PWR LED Meaning

Off

Supply voltage L+ missing

On

Supply voltage L+ present

Page 38

Interrupts/diagnostics alarms

5.2 Interrupts

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

37

5.2 Interrupts

Evaluating hardware interrupts with IO controller

The module generates a hardware interrupt at the following events:

● Violation of low limit 1

● Violation of high limit 1

● Violation of low limit 2

● Violation of high limit 2

You can obtain detailed information on the event in the hardware interrupt organization block with

the "RALARM" (read additional interrupt information) instruction and in the STEP 7 online help.

The module channel that triggered the hardware interrupt is entered in the start information

of the organization block. The following figure shows the assignment to the bits of double

word 8 in local data.

Figure 5-2 OB start information

Structure of the additional interrupt information

Table 5- 4 Structure of the additional interrupt information

Data block name Content Comment Bytes

USI

(User Structure Identifier)

W#16#0001 additional interrupt information for hardware

interrupts of the I/O module

2

Channel that triggered the hardware interrupt.

Channel B#16#00 to B#16#03 Channel 0 to 3 of the I/O module 1

Event that triggered the hardware interrupt.

Event B#16#03 Violation of low limit 1 1

B#16#04 Violation of high limit 1

B#16#05 Violation of low limit 2

B#16#06 Violation of high limit 2

Page 39

Interrupts/diagnostics alarms

5.3 Diagnostics alarms

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

38 Manual, 02/2014, A5E03573289-AD

Diagnostic error interrupt

The module generates a diagnostic error interrupt at the following events:

● Channel temporarily unavailable

● Hardware interrupt lost

● Reference channel error

● Error

● Violation of low limit

● Violation of high limit

● Wire break

● Supply voltage missing

● Parameter assignment error

5.3

Diagnostics alarms

A diagnostics alarm is output for each diagnostics event and the DIAG LED on the module

flashes. The diagnostics alarms can, for example, be read from the diagnostics buffer of the

CPU. You can evaluate the error codes with the user program.

Table 5- 5 Diagnostics alarms, their meaning and remedies

Diagnostics alarms

Error code

Meaning

Remedy

Channel temporarily

unavailable

1FH Firmware update is being performed.

Channel 0 applies to the entire module.

The module is currently not performing

any measurements.

–

The channel is currently being calibrated.

Wire break 6H Resistance of sensor circuit too high Use a different sensor type or modify

the wiring, for example, using cables

with larger cross-section

Wire break between the module and

sensor

Connect the cable

Channel not connected (open)

• Deactivate diagnostics

• Connect or deactivate the channel

Violation of high limit1 7H

Value lies above the overrange.

Correct module/sensor interplay

Wire break2

See Wire break

Violation of low limit1

8H

Value lies below the underrange.

Correct module/sensor interplay

Error 9H Internal module error has occurred

(diagnostics alarm on channel 0 applies to

the entire module).

Replace module

Page 40

Interrupts/diagnostics alarms

5.3 Diagnostics alarms

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

39

Diagnostics alarms

Error code

Meaning

Remedy

Parameter assignment

error

10H The module cannot evaluate parameters

for the channel: Module plugged in does

not match the configuration.

Incorrect parameter assignment.

• Correct the configuration

(comparison of preset and actual

setup).

• Correct the parameter assignment

(diagnostics wire break set only

with the permitted measuring

ranges).

Load voltage missing 11H Missing or insufficient supply voltage L+

• Check supply voltage L+ on the

BaseUnit

• Check BaseUnit type

Reference channel

error (reference

junction)

15H Reference temperature of the reference

junction for the TC channel being

operated with compensation is invalid.

• Check BaseUnit type

• Select correct reference junction

through parameter assignment

3

• Check whether the reference

junction (reference channel of the

group 0, 1, 2, 3) is only assigned

once as the sender in the entire

setup.

Hardware interrupt lost 16H At least one hardware interrupt could not

be reported because there were too many

pending hardware interrupts.

Correct the program or the process

1

The alarm refers to the diagnostics and depends on the configured measuring range.

2

For resistor and thermal resistor measuring ranges with deactivated diagnostics for "Wire break", this is reported by the

"Violation of high limit" diagnostic.

3

Shared Device and diagnostics "Reference temperature": If the sender and receiver of the reference junction

temperature of a group are assigned to different IO controllers, you may need to download both configurations again in

the case of diagnostics. First download the configuration containing the receiver.

Page 41

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

40 Manual, 02/2014, A5E03573289-AD

6

6.1

Technical specifications

Technical specifications of AI 4×RTD/TC 2-/3-/4-wire HF

6ES7134-6JD00-0CA1

Product type designation

AI 4xRTD/TC 2-/3-/4-wire HF

General information

Firmware version

V2.0

Usable BaseUnits

BU type A0, A1

Product function

I&M data

Yes; I&M0 to I&M3

Engineering with

STEP 7 TIA Portal can be configured/integrated as of version

V12 SP1 / V13

STEP 7 can be configured/integrated as of version

V5.5 SP3 / V5.5 SP4

PROFIBUS as of GSD version/GSD revision

GSD revision 5

PROFINET as of GSD version/GSD revision

GSDML V2.3

CiR Configuration in RUN

Reconfiguration in RUN possible

Yes

Calibration in RUN possible

Yes

Installation type/mounting

Rack mounting possible

Yes

Front installation possible

Yes

Rail mounting possible

Yes

Wall/direct mounting possible

No

Supply voltage

Rated value (DC)

24 V

Valid range low limit (DC)

19.2 V

Valid range high limit (DC)

28.8 V

Reverse polarity protection

Yes

Input current

Current consumption, max.

35 mA

Power loss

Power loss, typ.

0.75 W

Address area

Address space per module

Address space per module, max.

8 bytes; + 1 byte for QI information

Page 42

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

41

6ES7134-6JD00-0CA1

Analog inputs

Number of analog inputs

4

Maximum permissible input voltage for voltage input

(destruction limit)

30 V

Constant measurement current for resistance-type sensor, typ.

2 mA

Cycle time

(all channels), min. Sum of the basic conversion times

and additional processing times

(depending on the parameter

assignment of the activated

channels); an additional cycle is

necessary for cable compensation

for a 3-wire connection

Technical unit for temperature measurement can be set

Yes

Input ranges (rated values), voltages

-1 V to +1 V

Yes; 16 bits incl. sign

Input resistance (-1 V to +1 V)

1 MΩ

-250 mV to +250 mV

Yes; 16 bits incl. sign

Input resistance (-250 mV to +250 mV)

1 MΩ

-50 mV to +50 mV

Yes; 16 bits incl. sign

Input resistance (-50 mV to +50 mV)

1 MΩ

-80 mV to +80 mV

Yes; 16 bits incl. sign

Input resistance (-80 mV to +80 mV)

1 MΩ

Input ranges (rated values), thermocouples

Type B

Yes; 16 bits incl. sign

Input resistance (Type B)

1 MΩ

Type C

Yes; 16 bits incl. sign

Input resistance (Type C)

1 MΩ

Type E

Yes; 16 bits incl. sign

Input resistance (Type E)

1 MΩ

Type J

Yes; 16 bits incl. sign

Input resistance (Type J)

1 MΩ

Type K

Yes; 16 bits incl. sign

Input resistance (Type K)

1 MΩ

Type L

Yes; 16 bits incl. sign

Input resistance (Type L)

1 MΩ

Type N

Yes; 16 bits incl. sign

Input resistance (Type N)

1 MΩ

Type R

Yes; 16 bits incl. sign

Input resistance (Type R)

1 MΩ

Type S

Yes; 16 bits incl. sign

Input resistance (Type S)

1 MΩ

Type T

Yes; 16 bits incl. sign

Input resistance (Type T)

1 MΩ

Type U

Yes; 16 bits incl. sign

Input resistance (Type U)

1 MΩ

Page 43

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

42 Manual, 02/2014, A5E03573289-AD

6ES7134-6JD00-0CA1

Type TXK/TXK(L) according to GOST

Yes; 16 bits incl. sign

Input resistance (Type TXK/TXK(L) according to GOST)

1 MΩ

Input ranges (rated values), resistance thermometer

Cu 10

Yes; 16 bits incl. sign

Input resistance (Cu 10)

1 MΩ

Ni 100

Yes; 16 bits incl. sign

Input resistance (Ni 100)

1 MΩ

Ni 1000

Yes; 16 bits incl. sign

Input resistance (Ni 1000)

1 MΩ

LG-Ni 1000

Yes; 16 bits incl. sign

Input resistance (LG-Ni 1000)

1 MΩ

Ni 120

Yes; 16 bits incl. sign

Input resistance (Ni 120)

1 MΩ

Ni 200

Yes; 16 bits incl. sign

Input resistance (Ni 200)

1 MΩ

Ni 500

Yes; 16 bits incl. sign

Input resistance (Ni 500)

1 MΩ

Pt 100

Yes; 16 bits incl. sign

Input resistance (Pt 100)

1 MΩ

Pt 1000

Yes; 16 bits incl. sign

Input resistance (Pt 1000)

1 MΩ

Pt 200

Yes; 16 bits incl. sign

Input resistance (Pt 200)

1 MΩ

Pt 500

Yes; 16 bits incl. sign

Input resistance (Pt 500)

1 MΩ

Input ranges (rated values), resistors

0 to 150 ohms

Yes; 15 bits

Input resistance (0 to 150 ohms)

1 MΩ

0 to 300 ohms

Yes; 15 bits

Input resistance (0 to 300 ohms)

1 MΩ

0 to 600 ohms

Yes; 15 bits

Input resistance (0 to 600 ohms)

1 MΩ

0 to 3000 ohms

Yes; 15 bits

Input resistance (0 to 3000 ohms)

1 MΩ

0 to 6000 ohms

Yes; 15 bits

Input resistance (0 to 6000 ohms)

1 MΩ

PTC

Yes; 15 bits

Input resistance (PTC)

1 MΩ

Thermocouple (TC)

Technical unit for temperature measurement

°C/°F/K

Temperature compensation

•

Configurable

Yes

•

Reference channel of the module

Yes

Page 44

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

43

6ES7134-6JD00-0CA1

•

Internal reference junction

Yes; with BaseUnit type A1

•

Reference channel of the group

Yes

•

Number of reference channel groups

4; group 0 to 3

•

Fixed reference temperature

Yes

Resistance thermometer (RTD)

Maximum permissible input voltage for voltage input

(destruction limit)

30 V

Technical unit for temperature measurement

°C/°F/K

Cable length

Cable length shielded, max.

200 m; 50 m for thermocouples

Analog value generation

Measuring principle

Integrating (sigma-delta)

Integration and conversion time/resolution per channel

Resolution with overrange (bit including sign), max.

16 bit

Integration time configurable

Yes

Basic conversion time including integration time, ms

•

Additional processing time for wire break check

2 ms; in the resistance thermometer,

resistor, and thermocouple areas

•

Additional wire break check of the power line

2 ms; for 3-/4-wire transducer

(resistance thermometer and

resistor)

Interference voltage suppression for interference frequency f1

in Hz

16.6 / 50 / 60 Hz

Conversion time (per channel)

180 / 60 / 50 ms

Smoothing of the measured values

Configurable

Yes

Setting: None

Yes

Setting: Weak

Yes

Setting: Medium

Yes

Setting: Strong

Yes

Sensors

Wiring the signal transmitters

For voltage measurement

Yes

for resistance measurement with 2-wire connection

Yes

for resistance measurement with 3-wire connection

Yes

for resistance measurement with 4-wire connection

Yes

Errors/accuracies

Linearity error (in relation to input range), (+/

-) ± 0.01%; +/- 0.1% for resistance

thermometer and resistor

Temperature error (in relation to input range)

± 0.0009%/K; +/- 0.005%/K for

thermocouple

Crosstalk between inputs, min.

-50 dB

Repeat accuracy in settled state at 25 °C (in relation to input

range), (+/-)

± 0.05%

Page 45

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

44 Manual, 02/2014, A5E03573289-AD

6ES7134-6JD00-0CA1

Operational limit in entire temperature range

Voltage in relation to input range, (+/-)

± 0.1%

Resistance in relation to input range, (+/-)

± 0.1%

Basic error limit (operational limit at 25 °C)

Voltage in relation to input range, (+/-)

± 0.05%

Resistance in relation to input range, (+/-)

± 0.05%

Interference voltage suppression for f = n x (f1 +/-1%),

f1 = interference frequency

Series

-mode interference (peak of the interference < rated

value of the input range), min.

70 dB

Common mode voltage, max.

10 V

Common mode interference, min.

90 dB

Interrupts/diagnostics/status information

Interrupts

Diagnostic error interrupt

Yes

Limit interrupt

Yes; two high limits and two low

limits each

Diagnostics alarms

Diagnostics

Yes

Monitoring of supply voltage

Yes

Wire break

Yes; channel-based

Overflow/underflow

Yes; channel-based

Diagnostics indicator LED

Monitoring of supply voltage

Yes; green PWR LED

Channel status display

Yes; green LED

For channel diagnostics

Yes; red LED

For module diagnostics

Yes; green/red DIAG LED

Electrical isolation

Electrical isolation channels

Between the channels

No

Between the channels and the backplane bus

Yes

Between the channels and the supply voltage of the electronics

Yes

Permitted potential difference

Between different circuits

75 VDC / 60 VAC (basic insulation)

Between the inputs (UCM)

10 VDC

Insulation

Insulation tested with

707 VDC (type test)

Dimensions

Width

15 mm

Weights

Weight, approx.

30 g

Page 46

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

45

Operational and basic error limits for resistance thermometers

Error limits for resistance thermometers

Operational limit (in the entire temperature range, in relation to input

range)

• Pt 100, Pt 200, Pt 500, Pt 1000 standard

±1.0 K

• Pt 100, Pt 200, Pt 500, Pt 1000 climatic

± 0.25 K

• Ni 100, Ni 120, Ni 200, Ni 500, Ni 1000 standard and climatic

± 0.4 K

• Cu 10

±1.5 K

Basic error limit (operational limit at 25 °C, in relation to input range)

• Pt 100, Pt 200, Pt 500, Pt 1000 standard

± 0.6 K

• Pt 100, Pt 200, Pt 500, Pt 1000 climatic

± 0.13 K

• Ni 100, Ni 120, Ni 200, Ni 500, Ni 1000 standard and climatic

± 0.2 K

• Cu 10

±1.0 K

Page 47

Technical specifications

6.1 Technical specifications

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

46 Manual, 02/2014, A5E03573289-AD

Operational and basic error limits for thermocouples

Error limits for thermocouples

Operational limit for thermocouples (in the entire temperature range, in

relation to the input range)

±1.5 K

Operational limit for type C thermocouples (in the entire temperature

range, in relation to the input range)1

± 7 K

Basic error limit for thermocouples (operational limit at 25 °C, in relation

to the input range)

±1 K

Basic error limit for type C thermocouples (operational limit at 25 °C, in

relation to the input range)

± 5 K

Overall error limits when using internal compensation

• Operational limit (in the entire temperature range at static thermal

state, ambient temperature change < 0.3 K/min)

2

± 2.5 K

• Basic error limit (operational limit at 25 °C at static thermal state,

ambient temperature change < 0.3 K/min)

3

±1.5 K

1

The indicated error limits apply as of the following temperatures:

Thermocouple type T: -200 °C

Thermocouple type K: -100 °C

Thermocouple type B: +700 °C

Thermocouple type N: -150 °C

Thermocouple type E: -150 °C

Thermocouple type R: +200 °C

Thermocouple type S: +100 °C

2

For thermocouple type C: ± 8 K

3

For thermocouple type C: ± 6 K

Dimension drawing

See manual ET 200SP BaseUnits

(http://support.automation.siemens.com/WW/view/en/58532597/133300)

Page 48

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

47

A

A.1

Dependencies when configuring with GSD file

When configuring the module with a GSD file, remember that the settings of some

parameters are dependent on each other.

Configuring with a PROFINET GSD file

The table lists the properties and their dependencies on the measurement type and

measuring range for PROFINET.

Table A- 1 Dependencies of the measurement type / measuring range

Measurement

type

Measuring range

Temperature

coefficient

Reference junction

Temperature unit

Conductor

resistance

Deactivated

* * * * *

Voltage

±50 mV, ±80 mV,

±250 mV, ±1 V

* * * *

Resistor

(2, 3, 4-wire

connection)

150 Ω, 300 Ω,

600 Ω, 3 kΩ, 6 kΩ

* * * x (with 2-wire

connection)

Resistor

(2-wire

connection)

PTC * * * *

Thermal resistor

(2, 3, 4-wire

connection)

Pt100 climatic Pt 0.00385055

Pt 0.003916

Pt 0.003902

Pt 0.00392

Pt 0.00385

Reference channel

of group 0, 1, 2, 3

Degrees Celsius x (with 2-wire

connection)

No reference

channel mode

Degrees Celsius

Degrees

Fahrenheit

Pt200

Pt500

Pt1000 climatic

No reference

channel mode

Degrees Celsius

Degrees

Fahrenheit

Ni100

Ni120

Ni200

Ni500

Ni1000 climatic

Ni 0.00618

Ni 0.00672

LG-Ni 1000

climatic

LG-Ni 0.005

Page 49

Parameter data record

A.1 Dependencies when configuring with GSD file

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

48 Manual, 02/2014, A5E03573289-AD

Measurement

type

Measuring range Temperature

coefficient

Reference junction Temperature unit Conductor

resistance

(3-wire

connection)

Cu 10 climatic Cu 0.00427 *

Thermal resistor

(2, 3, 4-wire

connection)

Pt100

Pt200

Pt500

Pt1000 standard

Pt 0.00385055

Pt 0.003916

Pt 0.003902

Pt 0.00392

Pt 0.00385

No reference

channel mode

Degrees Celsius

Degrees

Fahrenheit

Kelvin

x (with 2-wire

connection)

Ni100

Ni120

Ni200

Ni500

Ni1000 standard

Ni 0.00618

Ni 0.00672

LG-Ni 1000

standard

LG-Ni 0.005

Thermal resistor

(3-wire

connection)

Cu 10 standard Cu 0.00427 *

Thermocouple Type B, N, E, R, S,

J, L, T, K, U, C,

TXK

* R

eference channel

of the module1

Internal reference

junction

Reference channel

of group 0, 1, 2, 3

2

Degrees Celsius

Degrees

Fahrenheit

Kelvin

*

Fixed reference

temperature

x = property is allowed, – = property is not allowed, * = property is not relevant

1

Use of "Reference channel of the module":

- Channel 0 must be set as "Pt100 climatic" with temperature unit: "Degrees Celsius".

-For each TC channel of this module that i

s intended to use channel 0 as reference, "Reference junction" must be set to

"Reference channel of the module".

2

Use of "Reference channel of group 0, 1, 2, 3":

- An RTD channel must be set as "Pt100 climatic" with temperature unit: "Degrees Celsius".

- "Reference channel of group 0, 1, 2, 3" must be set as the "Reference junction" of this channel.

- There must only be one RTD channel with "Reference junction" = "Reference channel of group 0, 1, 2, 3" per group 0,

1, 2, 3 and IO device!

- For each TC channel in the IO device that is intended to use this reference, "Reference junction" must be set to

"Reference channel of group 0, 1, 2, 3".

- If the reference channel is on channel 0, it can also be used as "Reference channel of the module" at the same time.

Page 50

Parameter data record

A.1 Dependencies when configuring with GSD file

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

Manual, 02/2014, A5E03573289-AD

49

Configuring with a PROFINET GSD file

The table lists the properties and their dependencies on the measurement type for

PROFINET.

Table A- 2 Dependencies on the measurement type

Measurement type Scalable

measuring

range

Measuring range

resolution

Diagnostics

Underflow Overflow Wire break Missing

supply

voltage L+

Reference

junction

Deactivated * * * * * * *

Voltage – * x x – x –

Resistor

(2, 3, 4-wire

connection)

– * x x x x –

Resistor PTC

(2-wire connection)

– * x – – x –

Thermal resistor

(2, 3, 4-wire

connection)

x 2 and 3 decimal

places

x x x x –

Thermocouple x 2 and 3 decimal

places

x x x x x1)

x = property is allowed, – = property is not allowed, * = property is not relevant

1

Property is not relevant if "Fixed reference temperature" is used

Configuring with a PROFIBUS GSD file

The table lists the properties and their dependencies on the measurement type and

measuring range for PROFIBUS.

Measurement

type

Measuring

range

Temperature

coefficient

Slot

reference

junction

Temperature

unit

Diagnostics

Underflow

/ overflow

Wire

break

Missing

supply

voltage

L+

Reference

junction

Deactivated * * * * * * * *

Voltage ±50 mV,

±80 mV,

±250 mV,

±1 V

* * * x – x –

Resistor

(2, 3, 4-wire

connection)

150 Ω,

300 Ω,

600 Ω,

3 kΩ, 6 kΩ

* * * x x x –

Page 51

Parameter data record

A.1 Dependencies when configuring with GSD file

Analog input module AI 4xRTD/TC 2-/3-/4-wire HF (6ES7134-6JD00-0CA1)

50 Manual, 02/2014, A5E03573289-AD

Measurement

type

Measuring

range

Temperature

coefficient

Slot

reference

junction

Temperature

unit

Diagnostics

Underflow

/ overflow

Wire

break

Missing

supply

voltage

L+

Reference

junction

Resistor

(2-wire

connection)

PTC3 * * * x – x –

Thermal

resistor

(2,

3, 4-wire

connection)

Pt100

climatic

Pt 0.00385055

Pt 0.003916

Pt 0.003902

Pt 0.00392

Pt 0.00385

Reference

channel of

group 0, 1,

2, 3

Degrees

C

els

ius

x x x –

No

reference

channel

mode

Degrees

Celsius

Degrees

Fahrenheit

x x x –

Pt200

Pt500

Pt1000

climatic

Pt 0.00385055

Pt 0.003916

Pt 0.003902

Pt 0.00392

Pt 0.00385

No

reference