Page 1

Two-State Constant Volume

Fume Hood Controller

Owner’s Manual

125-5033 Rev. AA, September 2007

Page 2

Page 3

Rev. AA, September 2007

NOTICE

The information contained within this document is subject to change without notice and should not be

construed as a commitment by Siemens Building Technologies, Inc. Siemens Building Technologies, Inc.

assumes no responsibility for any errors that may appear in this document.

All software described in this document is furnished under a license and may be used or copied only in

accordance with the terms of such license.

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with the instructions manual, may cause interference to radio communications. It has been

tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against such interference when operated in a

commercial environment. Operation of this equipment in a residential area is likely to cause interference in

which case users at their own expense will be required to take whatever measures may be required to

correct the interference.

SERVICE STATEMENT

Control devices are combined to make a system. Each control device is mechanical in nature and all

mechanical components must be regularly serviced to optimize their operation. All Siemens Building

Technologies branch offices and authorized distributors offer Technical Support Programs that will ensure

your continuous, trouble-free system performance.

For further information, contact your nearest Siemens Building Technologies, Inc. representative.

Copyright 2007 by Siemens Building Technologies, Inc.

TO THE READER

Your feedback is important to us. If you have comments about this manual, please submit them to

SBT_technical.editor.us.sbt@siemens.com

CREDITS

APOGEE is a registered trademark of Siemens Building Technologies, Inc.

Insight for Minicomputers is a registered trademark of Siemens Building Technologies, Inc.

Insight for Personal Computers is a registered trademark of Siemens Building Technologies, Inc.

™

UniTrak

is a trademark of Siemens Building Technologies, Inc.

Teflon is a registered trademark of DuPont.

Country of Origin: US

Page 4

Page 5

Table of Contents

How To Use This Manual ............................................................................................. VII

Manual Organization ................................................................................................. VII

Manual Conventions .................................................................................................. VII

Manual Symbols ........................................................................................................ VIII

Datamate Software .................................................................................................... VIII

Getting Help .............................................................................................................. VIII

Where To Send Comments ....................................................................................... VIII

Product Overview ......................................................................................................... 1

Introduction ................................................................................................................... 1

Related Equipment .................................................................................................... 1

Electronic Actuation ................................................................................................ 1

Pneumatic Actuation ............................................................................................... 1

Ordering Notes ....................................................................................................... 2

Hardware Inputs ........................................................................................................ 3

Analog ..................................................................................................................... 3

Digital ...................................................................................................................... 3

Hardware Outputs ..................................................................................................... 3

Analog ..................................................................................................................... 3

Digital ...................................................................................................................... 3

Power Wiring ............................................................................................................. 3

Communication Wiring .............................................................................................. 3

Controller LED Indicators .......................................................................................... 4

Operator Display Panel (ODP) .................................................................................. 4

Laboratory Exhaust Air Terminal ............................................................................... 5

Venturi Air Valves ...................................................................................................... 6

Electronic Actuator Assembly

................................................................................................................................... Err

or! Bookmark not defined.

Pneumatic Actuator ................................................................................................... 8

Analog Output-Pneumatic (AO-P) Module ................................................................ 9

Differential Pressure Transmitter .............................................................................. 10

Airflow Sensor ........................................................................................................... 10

Cables ....................................................................................................................... 10

Siemens Building Techologies, Inc. V

Page 6

Applications .................................................................................................................. 11

Fume Hood Controller: 2-Position Constant Volume ............................................... 11

Basic Operation ............................................................................................................ 12

High and Low Exhaust Flow Control ......................................................................... 12

Control Loops ......................................................................................................... 12

Calibration ................................................................................................................. 12

DO3 Output Functionality .......................................................................................... 13

Warning and Alarm Features .................................................................................... 13

Warning Operation .................................................................................................. 13

Alarm Operation ...................................................................................................... 13

Alarm Strategies ..................................................................................................... 14

Emergency Purge Feature ........................................................................................ 14

Emergency Purge Operation .................................................................................. 14

Emergency Purge Strategies .................................................................................. 15

Fail-safe Operation .................................................................................................... 16

Fume Hood Controller ............................................................................................ 16

ODP ........................................................................................................................ 16

Differential Pressure Transmitter ............................................................................ 16

Electronic Actuator Assembly ................................................................................. 16

Pneumatic Actuator ................................................................................................ 16

AO-P Module .......................................................................................................... 16

Point Database .............................................................................................................. 17

Troubleshooting ........................................................................................................... 20

Basic Service Information ......................................................................................... 20

Preventive Maintenance ............................................................................................ 20

Safety Features ......................................................................................................... 21

Controller LEDs ......................................................................................................... 21

Glossary ........................................................................................................................ 22

Index .............................................................................................................................. 26

VI Siemens Building Technologies, Inc.

Page 7

How To Use This Manual

This section covers manual organization, conventions, and symbols used in the

manual, and other information that will help you understand and use a Laboratory

Room Controller — Electronic Output.

Manual Organization

This manual contains the following sections:

• Chapter 1 Product Overview describes the hardware components and the

accessories that are used with the controller.

• Chapter 2 Applications describes the control applications available in the

controller.

• Chapter 3 Point Database defines the point database descriptors and

includes address and applications.

• The Glossary describes terms and acronyms.

• The Index helps you find information.

Manual Conventions

The following table lists conventions used in this manual.

Convention Example

Actions that you should

perform are specified in

boldface font.

Error and system

messages are displayed

in Courier New font.

New terms appearing for

the first time are

italicized.

Type F for Field panels.

Click OK to save changes and close the dialog box.

The message Report Definition successfully renamed

appears in the status bar.

The Open Processor continuously executes a user-defined set of

instructions called the control program.

Siemens Building Techologies, Inc. VII

Page 8

Manual Symbols

The following table lists symbols that are used to draw your attention to important

information.

Notation Symbol Meaning

CAUTION:

WARNING:

Datamate Software

Datamate is a customer software tool for all controller communications. There are

two versions: Datamate Base, and Datamate Advanced. Datamate Base works on an

IBM-compatible Personal Computer (PC), or a Handheld PC or Pocket PC™ running

Windows CE. Datamate Advanced works only on an IBM-compatible Personal

Computer. With Datamate, you can backup, restore, and edit any APOGEE database

(but only Datamate Advanced allows you to edit points offline). Backing up and

restoring a database can be accomplished while connected to any APOGEE field

panel, or to the Building Level Network (BLN) or Floor Level Network (FLN) device in

question. A modem and telephone lines can also be used. Databases can be saved

to a hard or floppy disk and kept for permanent storage or used as backup.

For more information on Datamate software, refer to the appropriate user guide

based on which version of Datamate you are using (Base or Advanced), or contact

your local Siemens Building Technologies, Inc. representative.

Getting Help

Indicates that equipment damage or loss of data may occur

if the user does not follow a procedure as specified.

Indicates that personal injury or loss of life may occur to the

user if a procedure is not performed as specified.

If at any time you find that you need help with a Laboratory Room Controller issue

not covered in this manual, contact your local Siemens Building Technologies, Inc.

representative.

Where To Send Comments

Your feedback is important to us. If you have comments about this manual, please submit them

to SBT_technical.editor.us.sbt@siemens.com

VIII Siemens Building Technologies, Inc.

Page 9

1

Product Overview

Introduction

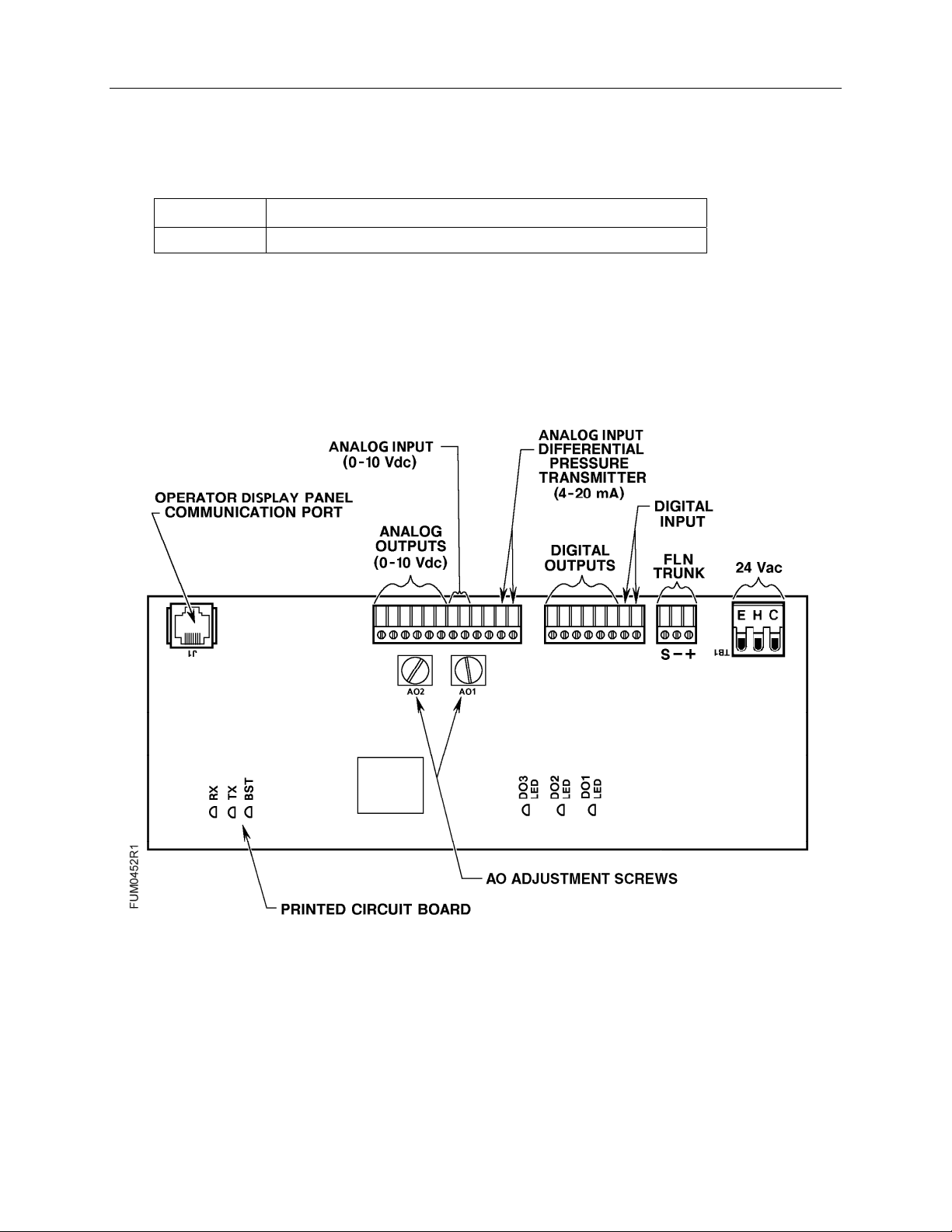

The Fume Hood Controller is an equipment controller designed to provide Direct Digital

Control (DDC) for 2 position fume hoods. The controller consists of a controller board and a

controller enclosure. The controller board (Figure 1) is the central computing/controlling

component of the system.

Related Equipment

• Operator Display Panel (ODP)

• Laboratory Exhaust Air Terminal

• Venturi Air Valve

• Differential Pressure Transmitter (See NOTE)

• Airflow Sensor (See NOTE)

• Cables

Electronic Actuation

• Electronic Actuator Assembly (See NOTE)

Pneumatic Actuation

• Analog Output-Pneumatic (AO-P) Module (See NOTE)

• Pneumatic Actuator (See NOTE)

NOTE: These components may be included in the Laboratory Exhaust Terminal or

Venturi Air Valve.

Siemens Building Technologies, Inc. 1

Page 10

Fume Hood Controller Owner's Manual

Table 1. Fume Hood Controller – Electronic Output Applications.

Application Description

940 2 Position Fume Hood Controller

Ordering Notes

Fume Hood Controller – Electronic Output (940) 546-00750

Figure 1. Fume Hood Controller Board .

2 Siemens Building Technologies, Inc.

Page 11

Hardware Inputs

Analog

• Differential pressure transmitter

Digital

• Operator Display Panel (ODP)

• ATTN.UNATTN (through DI1)

• OCC.UNOCC (through DI1)

Hardware Outputs

Product Overview

Analog

• AO-E/AO-P module (Floating Control)

• Operator Display Panel (ODP)

• AO2 (Flow Signal, 1 to 10 Vdc)

Digital

• FLN communications trunk

• DO3 (24 Vac, Alarm/Hi.Low Output)

Power Wiring

The controller is powered by 24 Vac. Power wiring connects to the three screw terminals on

the controller labeled “C” (Common), “H” (Hot) and “E” (Ground) on the terminal block labeled

“TB1”. Earth ground connection is required (Figure 2).

Communication Wiring

The controller connects to the field panel by means of a Field Level Network (FLN) trunk.

Communication wiring connects to the three screw terminals on the controller labeled “+”

(positive), “-“ (negative), and “S” (Shield) (Figure 3).

Siemens Building Technologies, Inc. 3

Page 12

Fume Hood Controller Owner's Manual

24V COMMON

24V HOT

LAB00140R1

GROUND

Figure 2. Power Wiring. Figure 3. Communication Wiring.

Controller LED Indicators

FLN TRUNK

+-

S

(SHIELD) (SHIELD)

(-)

(-)

TEC0470R1

(+)

(+)

The controller has six Light Emitting Diode (LED) indicators. See Table 2.

Table 2. Controller LEDs.

LED Type Label

(if present)*

DO LED 1 - LED 3 Indicates the ON/OFF status of the DO associated with it. A

glowing LED indicates that the DO is energized.

Transmit TX Indicates, when flashing, that the controller is transmitting

information to the field panel.

Receive RX Indicates, when flashing, that the controller is receiving

information from the field panel.

BST

”Basic Sanity Test”

BST Indicates, when flashing ON and OFF once per second, that

the controller is functioning properly.

Operator Display Panel (ODP)

The Operator Display Panel (ODP) is the interface device between the Fume Hood Controller

and the operator. Its main functions are to display normal, warning, and alarm conditions to

the operator. The ODP consists of a housing, three Light Emitting Diodes (LEDs), a liquid

crystal display (LCD), four buttons, and a portable operator's terminal port. See Figure 4. The

ODP buttons function as follows:

Horn Silence button – Pressing the Horn Silence button turns the audible alarm off for the

current alarm event.

Indication

Emergency Purge button – Pressing the Emergency Purge button removes contaminated

air from the fume hood by switching to an emergency exhaust flow level. The internal audible

alarm will sound. Emergency Purge automatically overrides any other control mode in the

Fume Hood Controller.

4 Siemens Building Technologies, Inc.

Page 13

Product Overview

Pressing the Emergency Purge button a second time reverts the Fume Hood Controller to

normal operation for the current conditions.

HI/LO: HI/OFF Select button – Pressing this button changes the controller from a high flow

setpoint to a low flow setpoint and back again or changes the controller from a high flow

setpoint to and OFF state and back again.

Auxiliary Button – The Auxiliary buttons are not used currently.

For more information on the ODP, see the Fume Hood Controller Operator Display Panel

User's Card (125-1976).

Figure 4. Operator Display Panel.

Laboratory Exhaust Air Terminal

The Laboratory Exhaust Air Terminal is a pre-packaged, easy to install, airflow measurement

and control station. See Figure 5. It combines an orifice plate flow sensor, differential

pressure transmitter, an electronic actuator assembly, or No. 3 pneumatic actuator, and

Analog Output-Pneumatic (AO-P) Module, and butterfly damper in a 20 gauge 316 stainless

steel duct section.

This arrangement provides fast acting, stable, and precise VAV fume hood exhaust airflow

control.

Siemens Building Technologies, Inc. 5

Page 14

Fume Hood Controller Owner's Manual

The terminal is available in diameters ranging from 4 to 18 inches. The terminal is available in

a variety of end configurations to match the ductwork construction. It is also available in

TEFLON® coated 18-gauge steel for highly corrosive environments.

Venturi Air Valves

The Venturi Air Valve is a pre-packaged, easy to install airflow measurement and control

station. See Figure 6. This assembly combines the orifice plate flow sensor, differential

pressure transmitter, Electronic actuator and a Venturi Air Valve.

This arrangement provides fast acting, stable, and precise exhaust airflow control.

Figure 5. Laboratory Exhaust Air Terminal.

FUM0400R1

Figure 6. Single-Body Venturi Air Valve.

6 Siemens Building Technologies, Inc.

Page 15

High Speed Electronic Actuation

The High speed electronic actuator assembly consists of two parts, the electronic actuator

and the interface board. The actuator is connected to the exhaust flow control device in the

fume hood exhaust duct. The electronic actuator assembly is used because of its small size

and quick response time.

CAUTION:

Due to the design parameters and the response time required by the Fume Hood

Controller, the assembly must be replaced with the same part or a Siemens

Building Technologies, Inc. approved equivalent. Any modifications that are not

approved may affect the safety and performance of the Fume Hood Controller.

Product Overview

4.5

FUM0319R3

3.5

14.5

ACTUATOR

AO - E

MODULE

1 1 1

11.75

Figure 7. Electronic Actuator Assembly in an Exhaust Air Terminal Enclosure.

Siemens Building Technologies, Inc. 7

Page 16

Fume Hood Controller Owner's Manual

Low Speed Electronic Actuation

Alternately, when speed of response is not an issue, slower speed electronic actuation may

be used. This can be used when the change-of-state between High and Low can take place

in 15 seconds or more.

Pneumatic Actuation

The pneumatic actuator is connected to an exhaust flow control device in the fume hood

exhaust duct. The standard pneumatic actuator (Figure 8) used with the Fume Hood

Controller is the No. 3 unit. The No. 3 actuator is used because of its small size and quick

response time. The actuator has a deep drawn aluminum housing, a rubber diaphragm, and

a spring return rated at 8 to 13 psi. Pneumatic actuation requires two components, the

actuator and the transducer (AO-P module).

WARNING:

Due to the design, parameters and the response times required by the

Fume Hood Controller, the No. 3 actuator always must be replaced

with the same part or a Siemens Building Technologies, Inc. approved

equivalent. Any modifications that are not approved may affect the

safety and performance of the Fume Hood Controller.

Low Speed Actuator (GMA13x).

8 Siemens Building Technologies, Inc.

Page 17

Product Overview

Figure 8. Pneumatic Actuator.

Analog Output-Pneumatic (AO-P) Module

The Analog Output-Pneumatic (AO-P) Module is an electric-to-pneumatic interface between

the Fume Hood Controller and the pneumatic actuator. The AO-P Module translates electrical

signals from the Fume Hood Controller into pneumatic signals that command the actuator.

The AO-P Module consists of two industrial grade solenoids that supply or bleed air to the

actuator by using a pulse modulation technique. See Figure 9. Minimum air supply to the AOP Module is 18 psi and the maximum is 30 psi. The valves are rated for 24 Vac.

5.00" (127.0mm)

(SUPPLY)

18-30 PSI

S

(ACTUATOR)

FUM0240R1

R

SUPPLY

EXHAUST

COMMON

EXHAUST

SUPPLY

3.70"

(94.0mm)

Figure 9. AO-P Module.

Siemens Building Technologies, Inc. 9

Page 18

Fume Hood Controller Owner's Manual

NOTE: While the pneumatic actuator is being commanded, you may hear a hissing or

clicking sound coming from the AO-P module. This is due to the movement of the

air valves and the bleeding of air from the actuator. This is normal operation.

Differential Pressure Transmitter

The differential pressure transmitter is used to send a signal that represents the velocity of air

in the duct to the controller. The differential pressure transmitter receives the velocity

pressure signal from the airflow sensor (orifice plate). The transmitter is a dead-end device

which prevents the exhausted fume hood air from flowing through the transmitter or the

sensor.

NOTE: In accordance with laboratory ventilation safety standards and regulatory

agencies, the performance of the fume hood should be checked annually, as a

minimum, to ensure continued safe and proper operation. Consult Siemens

Building Technologies for more information about a comprehensive laboratory

ventilation system evaluation and associated test programs.

Airflow Sensor

Airflow sensors are used in conjunction with the differential pressure transmitter. The airflow

sensor senses an average air velocity across the duct section. Using the average air velocity

and the duct area, the controller calculates the airflow.

CAUTION:

Cables

The Fume Hood Controller connects to the portable operator's terminal with the controller

interface cable (P/N 540-143). This cable has an RJ-11 connector (similar to a phone jack)

on one end, and a larger, 9-pin connector on the other end. The RJ-11 connector plugs into

the bottom of the ODP. For more information, see the Fume Hood Controller Operator

Display Panel User's Card (125-1976). The 9-pin connector plugs in the communication port

of the portable operator's terminal. For more cable information, contact your local Siemens

Building Technologies, Inc. representative.

Ensure that the sensor and exhaust system materials match the fume hood usage.

Exhausting corrosive fumes may corrode the sensor and exhaust system.

10 Siemens Building Technologies, Inc.

Page 19

2

Applications

Fume Hood Controller: 2-Position Constant Volume

Application 940 is designed for use with a constant volume or two-position fume hood in a

manifold fume hood exhaust system. In this application, two position fume hoods have an

individual exhaust damper or venturi air valve connected to a central fan. The application

modulates the exhaust flow control device to maintain a high or low flow setpoint based on

inputs from the ODP (Operators Display Panel), Digital Input, an exhaust airflow sensor, and

the controller setpoints (Figure 10).

Figure 10. Application 940 Control Drawing shown using a damper.

Siemens Building Technologies, Inc. 11

Page 20

Fume Hood Controller Owner's Manual

Basic Operation

The Fume Hood Controller provides Direct Digital Control (DDC) technology for controlling

fume hood face velocities in a manifolded fume hood exhaust system.

High and Low Exhaust Flow Control

The Fume Hood Controller can operate at two different setpoints, described as HI flow and

LOW flow setpoints. The low setpoint can be set to zero to send the controller into an OFF

mode. The OFF mode shuts off the flow alarms and closes the exhaust flow control device

and allows the controller to go into a standby mode of operation.

The Operators Display Panel (ODP) can display HI/LOW setpoint or output exhaust flow in

CFM. Due to display limits, the actual number displayed is CFM divided by 10.

Control Loops

The PID loop controls the exhaust flow control device based on the values of the exhaust

flow and the flow setpoint. The loop output controls the supply and exhaust through a time

modulation scheme. The control loopout ranges from -100 to 100%.

• -100% is the maximum supply that closes the exhaust flow control device at full

speed.

• 0% holds the exhaust flow control device at its current position.

• 100% is the maximum exhaust that opens the exhaust flow control device at full

speed.

Electronic

The controller sends a separate signal to each of the two inputs that reside on the AO-E

module. For values of 100% to 0%, the controller sends a decreasing percentage of the full

signal length to the retract input. For values of 0% to -100%, the controller sends an

increasing percentage of the full signal to the extend input.

Pneumatic

The controller sends a separate signal to each of the two solenoids that reside on the AO–P

module. For values of 100% to 0%, the controller sends a decreasing percentage of the full

signal length to the exhaust solenoid. For values of 0% to -100%, the controller sends an

increasing percentage of the full signal length to the supply solenoid.

Calibration

Air Velocity Sensor - Calibration of the controller's air velocity sensor is periodically required

to maintain accurate air velocity readings.

12 Siemens Building Technologies, Inc.

Page 21

DO3 Output Functionality

DO3 is designed to operate in two different modes. DO3 can follow the alarm status of the

controller by turning ON during alarm conditions and OFF during normal operation; or DO3

can follow the HI.LOW setpoint status of the controller by turning ON while the controller is in

LOW flow operation and OFF when the controller is in HI flow operation.

Warning and Alarm Features

The Fume Hood Controller indicates fume hood performance problems at two levels,

WARNING and ALARM. The two levels are available so different procedures can be

instituted for each condition. Both levels are indicated locally at the ODP and, if connected to

a field panel, centrally through the APOGEE alarm features.

NOTE: Central alarms only work if the field panel is specifically set up to receive and

distribute the alarm information. Consult your local Siemens Building

Technologies, Inc. representative for more information on central alarming.

Applications

Warning Operation

The Fume Hood Controller announces warning conditions at the ODP. The ODP indicates a

warning condition by illuminating the yellow LED.

If the fume hood is operating and the exhaust volume exceeds the high or low warning limit

for a period greater than the delay timer a warning condition occurs.

For more information on ODP messages, see the Fume Hood Controller Operator Display

Panel User's Card (125-1976).

Alarm Operation

The Fume Hood Controller announces alarm conditions at the ODP. The ODP indicates an

alarm condition in the following three ways:

• The red LED illuminates.

• The horn sounds.

• A text message indicating the specific alarm condition displays.

If the fume hood exhaust flow exceeds the high or low alarm limit for a period greater than

the delay timer an alarm condition occurs. The text message FLO HI or FLO LO displays.

The fume hood operator may silence the horn for the current alarm event by pressing the

Horn Silence button.

Siemens Building Technologies, Inc. 13

Page 22

Fume Hood Controller Owner's Manual

Alarm Strategies

One approach is to use the ALARMs to indicate a condition that requires immediate attention

and the WARNINGs to indicate a condition that may require attention but is not urgent. In that

case, the alarm limits would be set to indicate that it is unsafe to work at the fume hood. The

warning limits would be set at a level that is safe, but indicates that the system may not be

operating correctly. These values should be selected by the person responsible for laboratory

safety.

The delay timer is adjustable and should be selected with safety in mind. Laboratory safety

procedures will not be effective if there are numerous nuisance alarms. The delay timer

should be set at a sufficiently large interval to prevent nuisance alarms. However, if the delay

timer interval is excessively large, there is a risk of having a laboratory worker standing in

front of an ineffective fume hood for a prolonged period. The delay timer interval should be

selected by the laboratory safety officer with the above considerations in mind.

Emergency Purge Feature

Under certain emergency conditions, such as a spill in the fume hood, it may be necessary to

purge the air from the fume hood. The Emergency Purge sequence enables the fume hood

user to override normal airflow setpoint and temporarily increase the airflow beyond the value

needed to maintain the airflow setpoint.

The Emergency Purge overrides any other control mode in the Fume Hood Controller and

has two modes of operation; maximum purge, and controlled purge.

The maximum purge moves the exhaust airflow control device to full open and holds it there

regardless of airflow. This mode has the advantage of providing immediate expulsion of the

contaminating agent, but may cause airflow problems in the fume hood and reduce the

airflow capacity at other fume hoods.

The controlled purge continues to modulate the exhaust airflow control device and controls

the airflow, but at a higher than normal level.

The Fume Hood Controller can be set up to purge in either mode or to start in maximum

purge and then switch to a controlled purge after an adjustable amount of time.

Emergency Purge Operation

The Emergency Purge sequence is initiated by pressing the Emergency Purge button on the

ODP. When the Emergency Purge button is pressed, the fume hood will go to the maximum

purge for the time selected in the emergency timer. After the emergency timer elapses, the

Fume Hood Controller will begin actively controlling the airflow, but at an increased setpoint.

The Emergency Purge sequence is canceled by pressing the Emergency Purge button a

second time. The ODP indicates an Emergency Purge sequence in three ways:

• The red LED illuminates.

• The horn sounds.

• EMERGENCY PURGE and EEE display.

14 Siemens Building Technologies, Inc.

Page 23

The fume hood operator may silence the horn by pressing the Horn Silence button on the

ODP without affecting the Emergency Purge sequence.

In addition to the ODP indicators, the emergency alarm point will toggle to ON and will remain

ON until the sequence is canceled. If the emergency alarm is alarmable in the field panel, the

condition can be indicated at selected terminals if the APOGEE Automation System is set up

for it.

Emergency Purge Strategies

The use of the Emergency Purge button is determined by the work practices established by

the laboratory safety officer. As a general rule, there are two groups that should be aware of

the use of the Emergency Purge button: the laboratory worker and the laboratory safety

officer.

Laboratory worker – In most cases, the laboratory worker uses the Emergency Purge

button to increase the fume hood airflow to minimize a dangerous situation.

Applications

The Emergency Purge button should not be used as a way to work around the established

face velocity and minimum flow setpoints in an effort to make the fume hood "even safer".

Laboratory safety officer – For the safety department personnel to use the Emergency

Purge feature effectively, they must select the purge mode that best suits their needs. The

selection may be based on knowledge of industrial hygiene, the chemicals used in the

laboratory, the organization's emergency procedures, and the capacity of the central exhaust

system.

If the maximum purge mode is selected, the emergency timer and the emergency setpoint to

their maximum values.

If the controlled purge mode is selected, the emergency timer is set to 0. Select the value for

the emergency setpoint to indicate how much you want the emergency airflow to increase

over the normal airflow. For example, if your emergency procedures call for closing the fume

hood and starting the emergency purge, decide how much airflow you want compared to the

minimum airflow. If you want twice as much airflow, set the emergency setpoint to 200%; if

you want a 50% increase, set the emergency setpoint to 150%. If you do not intend to have

the laboratory worker close the fume hood, then select the face velocity you want the fume

hood to control to in an emergency. Compare that value to the normal face velocity setpoint

and calculate the emergency setpoint in percent.

NOTE: During a controlled purge, the increased airflow called for in the controlled purge

may exceed the range of the flow sensor. If so, the system cannot accurately

regulate the airflow and the controller will open the exhaust flow control device

100%.

If a sequence initially employing maximum purge with a switch to controlled purge is desired,

set the emergency setpoint as described for the controlled purge. Select a value for the

emergency timer to tell the system how long to leave the exhaust flow control device open

before switching to controlled purge. Base this on the types of accidents anticipated, the

reason you require a maximum purge, and the reason you want to switch it down to a

controlled purge.

Siemens Building Technologies, Inc. 15

Page 24

Fume Hood Controller Owner's Manual

In addition to setting up the purge sequence to effectively handle the exhaust needs,

decisions must be made on how to use the information available at the central reporting

station. Consult your local Siemens Building Technologies, Inc. representative for more

information on central reporting and trending of emergency purge information.

Fail-safe Operation

If the Fume Hood Controller or one of its accessories fails, then a failure mode sequence will

be initiated.

Fume Hood Controller

If the Fume Hood Controller power fails, the exhaust flow control device will go to the full

open position. Since there would be no power to the controller, no LEDs or display will be

available on the ODP.

NOTE: If the power fails to both the exhaust fan and the controller, there will be no

indication except for the absence of the noise that the air makes during

normal operation.

ODP

If the ODP fails, the controller will continue to control the fume hood face velocity. However,

no display or audible alarming will be available.

Differential Pressure Transmitter

If the differential pressure transmitter fails, the controller will control the exhaust flow control

device to the fully open position. The ODP will display FFF and GENERAL FAILURE.

Electronic Actuator Assembly

If the electronic actuator or interface board fails then alarms are displayed on the ODP

indicating unsafe operating conditions.

Pneumatic Actuator

If the actuator fails due to a leak, then the exhaust flow control device will go to the full open

position. Alarms will be displayed on the ODP indicating unsafe operating conditions.

AO-P Module

If the AO-P module fails, alarms will be displayed on the ODP indicating unsafe operating

conditions.

16 Siemens Building Technologies, Inc.

Page 25

Point Database

3

Point Database

Chapter 3 presents a description of the Fume Hood Controller point database including point

descriptors, point addresses, and a listing of applications in which each point is found.

Address Descriptor Description

01 CTLR ADDRESS Identifies the controller on the FLN trunk. Valid values: 0 through 98.

02 APPLICATION The identification number of the Application running in the controller.

05 LOW ALM This point displays an ON or OFF status. When the exhaust flow goes below the

value specified at LOW ALM LMT for the time specified in ALARM TIME, the

point goes into an alarm state (ON); the red LED is illuminated, the alarm

sounds, and the message “FLOW LOW” displays at the ODP.

06 HIGH ALM This point displays an ON or OFF status. When the exhaust flow goes above the

value specified at HI ALM LMT for the item specified in ALARM TIME, the point

goes into an alarm state (ON); the red LED is illuminated, the alarm sounds, and

the message “FLOW HI“ displays at the ODP.

07 EMER ALM This point displays an ON or OFF status that indicates if the EMERGENCY

PURGE button on the ODP has been pressed. When the operator presses the

EMERGENCY PURGE button, the point is ON, the red LED is illuminated, the

alarm sounds, and EEE and EMERGENCY MODE display at the ODP. If pressed

again, then the point is OFF. This point can be commanded by a field panel.

08 GEN FAILURE Indicates a hardware failure (e.g., the pressure sensor) with an ON or OFF

status. The red LED is illuminated; the alarm sounds, and FFF and GENERAL

FAILURE display at the ODP.

10 HI ALM LMT The value above FLOW STPT, in percent, at which the red LED and audible

alarm are activated on the ODP. This point is the setpoint for HIGH ALM. Valid

values: 100 through 255%.

11 HI WARN LMT The value above FLOW STPT, in percent, at which the yellow LED is illuminated

on the ODP. Valid values: 100 through 255%.

12 LOW WARN LMT The value below FLOW STPT, in percent, at which the yellow LED is illuminated

on the ODP. Valid values: 0 through 100%.

13 LOW ALM LMT The value below FLOW STPT, in percent, at which the red LED and audible

alarm are activated on the ODP. This point is the setpoint for LOW ALM. Valid

values: 0 through 100%.

14 EMER TIMER When EMER ALM is set to ON, the time set for EMER TIMER is used as the

length of time the EXH FLOW is commanded to full flow (the exhaust flow control

device is full open). After the time in EMER TIMER times out, the EXH FLOW is

controlled to the value set in EMER STPT. Valid values: 0 through 32, 767

seconds.

Siemens Building Technologies, Inc. 17

Page 26

Fume Hood Controller Owner’s Manual

Address Descriptor Description

15 EMER STPT A value of the preset FLOW STPT, in percent, that the controller uses as the

setpoint when EMER ALM is ON.

16 LOW WARN This point displays an ON or OFF status. When the exhaust flow goes below the

value specified at LOW WARN LMT for the time specified in ALARM TIME, the

point goes into a warning state (ON); the yellow LED is illuminated at the ODP.

17 HIGH WARN This point displays an ON or OFF status. When the exhaust flow goes above the

value specified at HI WARN LMT for the time specified in ALARM TIME, the

point goes into a warning state (ON), the yellow LED is illuminated at the ODP.

19 ALM AKNLG This point displays an ON or OFF status that indicates the Horn Silence button

has been pressed at the ODP to acknowledge an alarm condition. The point will

reset when the alarm condition clears or another alarm is initiated.

27 AO2 DEADBAND When EXH FLOW and FLOW STPT are different by more than the AO2

DEADBAND, the AO2 FLOW SIG changes from setpoint to actual flow.

30 AO2 RANGE Scaling for the Analog Output (AO2) point. To get the correct output, the slope

and intercept of this point must match the point database of the room controller.

34 TRANS RANGE The maximum range, in inches of water (PA), of the differential pressure

transmitter. Standard values are 0.1 (25.3), 0.25 (62.275), 0.5 (124.55), and 1.0

(253).

35 EXH FLOW The calculated value, in CFM (LPS), of the exhaust airflow as measured with the

differential pressure transmitter sensor.

36 FLOW COEFF Gain factor for the flow sensor.

37 FLOW STPT Setpoint, in CFM (LPS), that the airflow is controlled to.

38 FLOW LO STPT The low flow setpoint used in FLOW STPT.

40 CAL DP TRANS YES or NO point used to calibrate the zero point of the differential pressure

transmitter.

41 DO1 SUP Digital output 1 is used to control the analog output-pneumatic (AO-P) supply

valve or the AO-E module supply input.

42 DO2 EXH Digital output 2 is used to control the analog output-pneumatic (AO-P) exhaust

valve or the AO-E module exhaust input.

43 DO3 Digital output 3 is a spare output.

44 AI1 DP TRANS Analog input 1, a 4 to 20 mA signal from the differential pressure transmitter.

The point displays the mA value of input from the sensor.

45 AI2 0.10V Analog input 2 is a 0 to 10 Vdc spare input.

46 AO1 0.10V Spare analog output is a 0 to 10 Vdc output.

47 AO2 FLOW SIG Analog output 2 signal is used to indicate the exhaust flow setpoint. The output

is 1 to 10 Vdc, which corresponds to 0 to A02 RANGE (Point 30).

48 DI1 STPT SW Digital input for dry contact connection to control the HI/LOW flow setpoint of the

controller.

54 ODP DISPLAY Controls the function of the ODP display. It will display either CFM divided by

10 or HI FLOW / LO FLOW.

55 DO3 MODE Controls the function of the DO3. It will follow either the HI/LO setpoint or the

alarm status.

18 Siemens Building Technologies, Inc.

Page 27

Point Database

Address Descriptor Description

56 ODP STPT SW Indicates if the lower left button on the ODP has been pressed. This is a toggle

action digital input; when pressed, the controller changes between HI and LOW

flow setpoints.

57 RIGHT SW Indicates if the right auxiliary button on the ODP has been pressed. This is a

toggle action digital input; when pressed, the point is ON. If pressed again, the

point is OFF.

63 FLOW P GAIN The proportional gain value for the fume hood flow control loop.

64 FLOW I GAIN The integral gain value for the fume hood flow control loop.

66 FLOW D GAIN The derivative gain value for the fume hood flow control loop.

67 FLOW BIAS The bias, in percent, of the fume hood flow control loop.

68 CTRL LOOPOUT Control output of the flow loop. Range: -100% to 100%.

87 FLOW HI STPT The hi flow setpoint used in FLOW STPT.

89 HORN When this point is set to DISABLE, the audible alarm will not sound. All other

alarm functionality is still operational.

91 BLANK DSPLY When set to YES, the exhaust flow is not displayed at the ODP.

92 DO2 INVERTER Setting to NCLOSE allows the controller to operate industry standard floating

control actuators. Setting this point may stop the failsafe operation from

functioning.

93 ENG UNITS Toggles the display of the ODP from CFM to LPS. Toggling this point does not

change the displayed value at the portable operators terminal.

94 LAMP TEST Turns on all lights, prompts, and the audible alarm at the ODP.

96 ALARM TIME Time delay for the red and yellow alarm LEDs used to eliminate sudden changes

and false alarms. The exhaust flow must rise above any of the set limits (for

example, HI ALM LMT) for the amount of time specified at this point before the

ODP indicates an alarm condition.

97 DUCT AREA Area of the duct, in square feet (SQM), where the air velocity sensor is located.

98 LOOP TIME The time, in tenths of a second, between control loop calculations.

99 ERROR STATUS The status code that indicates any errors detected during controller power-up.

Siemens Building Technologies, Inc. 19

Page 28

4

Troubleshooting

This chapter describes corrective measures you can take should you encounter a problem

when using the Fume Hood Controller. For issues not covered in this section, contact your

local Siemens Building Technologies, Inc. representative.

You are not required to do any controller troubleshooting. Contact your local Siemens

Building Technologies, Inc. representative if a problem occurs or you have any questions

about the controller.

NOTE: When troubleshooting, record what the problem is and what actions were

performed immediately before the problem occurred. Being able to describe the

problem in detail is important should you need assistance from your local

Siemens Building Technologies, Inc. representative.

Basic Service Information

Always remove power to the controller when installing or replacing it. Since the controller

does not have a power switch, the recommended method of removing power to a locally

powered controller is to turn OFF the power to the 24 Vac transformer. The recommended

method of removing power to a controller on a power cable (even to service a single

controller) is to turn OFF the power at the transformer.

NOTE: When removing power to a controller to perform maintenance or service, make

sure that the person in charge of the facility is aware of this and that appropriate

steps are taken to keep the building in control.

Never remove the cover from the controller. There are no serviceable parts inside. If a

problem is found with a controller, contact your local Siemens Building Technologies

representative for replacement. An anti-static wrist strap is recommended when installing or

replacing controllers.

Preventive Maintenance

Most controller components are designed so that, under normal circumstances, they do not

require preventive maintenance. However, devices that are exposed to dusty or dirty

environments may require periodic cleaning to function properly. To ensure optimum system

performance, it is recommended that you discuss the operating requirements of your

application with your Siemens Building Technologies, Inc. representative to determine the

best service support program for your needs.

20 Siemens Building Technologies, Inc.

Page 29

Safety Features

The controller board stores the controller's address, applications, and point values. In the

event of a power failure or a reset, these values are retrieved from the controller’s permanent

memory and are used by the controller unless overridden by a field panel.

Controller LEDs

To determine if the controller is powered up and working, verify that the Basic Sanity Test

(BST) Light Emitting Diode (LED) is flashing ON/OFF once per second. The controller

contains six LEDs located on the circuit board. See the Controller LED lndicators section of

Chapter 1, Product Overview for more information about LEDs.

NOTE: The TX and RX LEDs indicate communication over the FLN.

Troubleshooting

Siemens Building Technologies, Inc. 21

Page 30

Glossary

The glossary contains terms and acronyms that are used in this manual. For definitions of

point database descriptors, see Chapter 3 - Point Database, in this manual. For definitions of

commonly used terms as well as acronyms and abbreviations associated with the APOGEE

Automation System, see the Technical Glossary of Building Controls Terminology and

Acronyms, (125-2185). This book is available from your local Siemens Building

Technologies, Inc. representative.

AI

Analog Input. An AI point is a physical point which accepts a continuous variable signal.

algorithm

Mathematical formula used to calculate an output value using varying inputs.

centralized control

The type of control offered by a controller that is connected, by means of a Floor Level

Network (FLN), with an APOGEE field panel.

control loop

A PID algorithm which is used to control an output based on a setpoint and an input reading

from a sensor.

CV

Constant Volume.

DDC

Direct Digital Control.

DI

Digital Input. A DI point is a physical output point which accepts a two-state signal (that is,

ON/OFF, OPEN/CLOSED, YES/NO, etc.).

DO

Digital Output. A DO point is a physical output point which generates a two-state signal (that

is, ON/OFF, OPEN/CLOSED, YES/NO, etc.).

22 Siemens Building Technologies, Inc.

Page 31

Glossary

English units

The foot-pound-second system of units for weights and measurements.

equipment controller

A FLN device which provides additional point capacity to a field panel or provides DDC to

individual room or mechanical equipment control. The FHC is a specialized equipment

controller.

field panel

A device containing a microprocessor for centralized control of system components and

equipment controllers. A field panel samples and processes field data, initiates control

actions, communicates with its operators, and generates reports, displays and warnings.

FLN

Field Level Network (formerly known Floor Level Network).

Fume Hood Controller

Multi-application equipment controller designed to provide Direct Digital Control) for various

types of Variable Air Volume (VAV) fume hoods. The controller consists of a controller board

and a controller enclosure.

intercept

Factor which converts analog values (used by the controller) to a form which the user can

understand (engineering units). Slope and intercept constants are determined by the type of

field input/output represented by the physical or virtual point.

loopout

Output of the control loop expressed as a percentage.

LPS

Liters Per Second.

OCC mode

OCCupied mode.

OFF text

Text indicating the de-energized state of a digital point (for example, OFF, CLOSED, NO).

Siemens Building Technologies, Inc. 23

Page 32

Fume Hood Controller Owner's Manual

ON text

Text indicating the energized state of a digital point (for example, ON, OPEN, YES).

override switch

Button on room temperature sensor which can be pressed by an occupant to change the

status of a room from night mode to day mode for a predetermined time.

PID

Proportional, Integral, Derivative.

Portable Operator’s Terminal

DOS capable laptop computer used along with the Controller Interface Software to monitor

and communicate with Terminal Equipment Controllers.

RTS

Room Temperature Sensor.

sash sensor actuator

Device that rides along the sash sensor strip to vary the resistance reading to the Fume

Hood Controller.

SI units

Systeme International d’Unites. The international metric system.

slave mode

Default application that comes up when power is first applied to a Terminal Equipment

Controller.

slope

Factor which converts analog values (used by the controller) to a form which the user can

understand (engineering units). Slope and intercept constants are determined by the type of

field input/output represented by the physical or virtual point.

stand-alone control

The type of control offered by a controller that is providing independent DDC control to a

space.

24 Siemens Building Technologies, Inc.

Page 33

Glossary

Terminal Equipment Controller

Siemens Building Technologies, Inc. product family of equipment controllers (one is the Unit

Conditioner Controller – Electronic Output) that house the applications software used to

control terminal units, such as heat pumps, VAV terminal boxes, fan coil units, unit

ventilators, etc.

UNOCC mode

UNOCCupied mode.

Siemens Building Technologies, Inc. 25

Page 34

Index

A

AI see analog input

airflow sensor ..................................................... 9

analog input ........................................................ 2

analog output ..................................................... 2

AO ........................................... see analog output

AO-P module ...................................................... 8

application 907

control drawing ............................................. 15

applications ........................................................ 2

average face velocity control ........................... 10

B

Basic Sanity Test (BST) ................................... 23

basic service information ................................. 22

BST LED .......................................................... 23

differential pressure transmitter ......................... 9

digital input ......................................................... 2

digital output ....................................................... 2

Direct Digital Control .................................... 1, 10

DO ............................................. see digital output

E

electronic actuation ............................................ 1

electronic actuator

damper ........................................................... 7

emergency purge ............................................. 12

controlled purge ........................................... 12

lab workers ................................................... 13

maximum purge ........................................... 12

operation ...................................................... 12

safety officer ................................................. 13

strategies ...................................................... 13

emergency purge button .................................... 4

F

C

fail-safe operation ............................................ 14

cables ................................................................. 9

calibration ......................................................... 10

communication

port .......................................................... 2, 5, 9

communication wiring .................................... 3, 4

connector, RJ-11 ................................................ 9

controller

board .............................................................. 2

hardware ..................................................... 1–9

LEDs ......................................................... 4, 12

LEDs/LED indicators .................................... 23

ports ................................................................ 2

troubleshooting ............................................. 22

D

DDC ..............................see Direct Digital Control

DI ................................................ see digital input

26 Siemens Building Technologies, Inc.

ao-p module ................................................. 14

differential pressure transmitter ................... 14

electronic actuator ........................................ 14

fume hood controller .................................... 14

odp ............................................................... 14

pneumatic damper actuator ......................... 14

Field Level Network (FLN) ................................. 3

field panel ......................................................... 10

H

hardware ........................................................ 1–9

LEDs ............................................................... 4

power wiring ............................................... 3, 4

hardware inputs ................................................. 3

analog ............................................................. 3

digital .............................................................. 3

hardware outputs ............................................... 3

Page 35

Index

analog ............................................................. 3

digital .............................................................. 3

horn silence button ............................................. 4

L

laboratory exhaust air terminal ........................... 5

Light Emitting Diodes ......................................... 4

Light Emitting Diodes (LEDs) ........................... 23

BST ............................................................... 23

RX and TX .................................................... 23

O

Operator Display Panel ...................................... 4

buttons ............................................................ 4

Light Emitting Diodes (LEDs) ......................... 4

P

pneumatic actuation ........................................... 1

pneumatic actuator

damper ........................................................... 7

pneumatic damper actuator see damper actuator

point database .................................................. 18

power loss ........................................................ 14

power wiring ................................................... 3, 4

product overview

ordering .......................................................... 2

R

related equipment .............................................. 1

RJ-11 connector ................................................ 9

RX LED ............................................................ 23

S

service information, basic ................................ 22

static discharge ................................................ 22

T

troubleshooting

basic service information.............................. 22

controller ....................................................... 22

TX LED ............................................................ 23

V

VA rating ............................................................ 2

W

warning and alarms ......................................... 10

alarm operation ............................................ 11

alarm strategies ............................................ 11

warning operation ......................................... 11

warning limits ................................................... 10

wiring

communication wiring ................................. 3, 4

power wiring ............................................... 3, 4

Siemens Building Technologies, Inc. 27

Loading...

Loading...