Page 1

Field Panel Web Server

User Guide

125-3584T

Building Technologies

Page 2

Page 3

Table of Contents

How to Use This Manual ................................................................................................... 8

Related Documents ............................................................................................................. 8

Symbols Used in this Manual .............................................................................................. 8

Manual Conventions ............................................................................................................ 8

Contact Us ........................................................................................................................... 9

Chapter 1 - Introduction to Field Panel Web Server .................................................... 10

Applications ....................................................................................................................... 10

Chapter 2 - Field Panel Web Server System Administration ....................................... 13

Chapter Overview .............................................................................................................. 13

Prerequisites and Browser Requirements for Field Panel Web Server ............................ 13

Verifying that Adobe Flash has been Installed ................................................... 14

Prerequisites for FINlite Graphics Tool .............................................................................. 14

Enabling or Disabling Web Server ..................................................................................... 14

Loading the User Interface ................................................................................................ 16

Performance and Limitations ............................................................................................. 17

Tips to Improve Performance of Field Panel Web Server .................................. 18

System Security ................................................................................................................. 19

Language Support ............................................................................................................. 20

Chapter 3 - User Interface Navigation Overview .......................................................... 21

Welcome Page/Logon ....................................................................................................... 21

Configuring the Welcome Page Graphic ............................................................ 22

User Interface after Logon ................................................................................................. 22

Status Bar User Interface ................................................................................... 23

Navigation Pane User Interface ......................................................................... 23

Application Area User Interface ......................................................................... 27

Device/Points Navigation Tree ........................................................................... 28

Chapter 4 - Status Bar ..................................................................................................... 30

Status Bar Counts and Reports ......................................................................................... 30

Running an Alarm Report ................................................................................... 30

Acknowledging an Alarm .................................................................................... 30

Setup 31

Logoff 32

Chapter 5 - Point Commander ........................................................................................ 34

Chapter Overview .............................................................................................................. 34

Point Commander Application Overview ........................................................................... 34

User Interface Description for the Point Commander Application...................... 35

Tips for Using the Point Commander Application .............................................. 39

Using the Point Commander Application ........................................................................... 39

Siemens Industry, Inc.

125-3584T

3

Page 4

Commanding Point Values ................................................................................. 39

Disabling and Re-enabling a Point (Out-of-Service) .......................................... 40

Priority Arrays ..................................................................................................... 41

Chapter 6 - Graphics View .............................................................................................. 43

Chapter Overview .............................................................................................................. 43

Tips for Using the Graphics View ...................................................................................... 43

Using the Graphics View ................................................................................................... 43

Opening a Graphics View Tab ........................................................................... 43

Graphics Features .............................................................................................. 43

Graphics File Types ............................................................................................ 44

Graphics File Navigation .................................................................................... 44

Chapter 7 - Point Log Report .......................................................................................... 46

Chapter Overview .............................................................................................................. 46

Point Log Report Application Overview ............................................................................. 46

User Interface Description for the Point Log Report Application ........................ 46

Using the Point Log Report Application ............................................................................. 47

Running a Point Log Report ............................................................................... 47

Chapter 8 - Trend View .................................................................................................... 49

Chapter Overview .............................................................................................................. 49

Trend View Overview ......................................................................................................... 49

Tips for Using the Trend View Application ......................................................... 49

Using the Trend View ......................................................................................................... 49

Viewing Trend Data of a Single Trended Point .................................................. 49

Viewing Trend Data of Multiple Trended Points ................................................. 51

Printing a Trend Graph ....................................................................................... 52

Customizing a Trend Graph ............................................................................... 53

Chapter 9 - Schedule View .............................................................................................. 55

Chapter Overview .............................................................................................................. 55

Scheduler Application Overview ........................................................................................ 55

User Interface Description for the Scheduler Application ................................... 55

Tips for Using the Scheduler Application ........................................................... 56

Using the Scheduler Application ........................................................................................ 56

Chapter 10 - Create/Edit .................................................................................................. 58

Common Editor Fields and Buttons ................................................................................... 58

Trend 60

Section Overview ................................................................................................ 60

Trend Application Overview ............................................................................... 60

Using the Trend Editor Application ..................................................................... 64

Point 67

Section Overview ................................................................................................ 67

Point Editor Application Overview ...................................................................... 68

Using the Point Editor Application ...................................................................... 69

4

Siemens Industry, Inc. 125-3584T

Page 5

Schedule/Command/Calendar .......................................................................................... 74

Section Overview ............................................................................................... 74

Schedule/Command/Calendar Object Editors Overview ................................... 74

Using the Schedule/Command/Calendar Object Editors ................................... 77

Event Enrollment ............................................................................................................... 93

Section Overview ............................................................................................... 93

Event Enrollment Overview ................................................................................ 93

Using the Event Enrollment Editor ..................................................................... 95

Notification Class ............................................................................................................... 99

Section Overview ............................................................................................... 99

Notification Class Editor Overview ................................................................... 100

Using the Notification Class Editor ................................................................... 102

Remote Notification ......................................................................................................... 105

SMTP Configuration ......................................................................................... 106

Remote Recipient List ...................................................................................... 108

FLN 112

Section Overview ............................................................................................. 112

FLN Device Editor Overview ............................................................................ 112

Using the FLN Device Editor ............................................................................ 114

TEC Init 117

Section Overview ............................................................................................. 118

TEC Initial Value Editor Overview .................................................................... 118

Using the TEC Initial Value Editor .................................................................... 119

PPCL 121

Section Overview ............................................................................................. 121

PPCL Editor Overview ...................................................................................... 121

Using the PPCL Editor ..................................................................................... 124

Users 127

User Interface Description for the User Account Editor ................................... 127

Using the User Account Editor ......................................................................... 131

Change User Password ................................................................................................... 134

Change Panel Time ......................................................................................................... 135

Chapter 11 - FINlite Graphics Tool ............................................................................... 137

Chapter Overview ............................................................................................................ 137

FINlite Graphics Tool Overview ....................................................................................... 137

User Interface Description for the FINlite Graphics Tool ................................. 138

Tips for Using the FINlite Graphics Tool .......................................................... 145

Using the FINlite Graphics Tool ....................................................................................... 146

Launching the FINlite Graphics Tool ................................................................ 146

Logging in to the Controller .............................................................................. 147

Creating Graphics ............................................................................................ 147

Editing the Graphics Animation ........................................................................ 151

Saving and Publishing the Graphics File ......................................................... 152

Siemens Industry, Inc.

125-3584T

5

Page 6

Creating Device Templates .............................................................................. 153

Backing Up Graphics ........................................................................................ 155

Deleting Graphics Files .................................................................................... 156

Updating the FINlite User Guide ...................................................................... 158

Chapter 12 - Field Panel Features for Field Panel Web Server ................................. 160

Field Panel File System Operations ................................................................................ 160

Basic File System Operation Commands ......................................................... 160

Rename a File .................................................................................................. 162

Delete a File ..................................................................................................... 163

Move a File ....................................................................................................... 164

Copy a File ....................................................................................................... 164

Remove a Directory .......................................................................................... 166

Backing up and Restoring Databases ............................................................................. 168

Enabling Auto Save .......................................................................................... 169

Available Memory Diagnostic Point ................................................................................. 170

Chapter 13 - Troubleshooting ....................................................................................... 171

Log On Error Messages ................................................................................................... 172

Install, Upgrade, and Connection Errors.......................................................................... 173

Graphics Issues ............................................................................................................... 175

Other Issues ..................................................................................................................... 176

6

Siemens Industry, Inc. 125-3584T

Page 7

Copyright Notice

Copyright Notice

Notice

Document information is subject to change without notice by Siemens Industry, Inc.

Companies, names, and various data used in examples are fictitious unless otherwise

noted. No part of this document may be reproduced or transmitted in any form or by

any means, electronic or mechanical, for any purpose, without the express written

permission of Siemens Industry, Inc.

All software described in this document is furnished under a license agreement and

may be used or copied only in accordance with license terms.

For further information, contact your nearest Siemens Industry, Inc. representative.

Copyright 2012 by Siemens Industry, Inc.

To the Reader

Your feedback is important to us. If you have comments about this manual, please

submit them to: SBT_technical.editor.us.sbt@siemens.com

Credits

Staefa and TALON are registered trademarks of Siemens Industry, Inc.

Other product or company names mentioned herein may be the trademarks of their

respective owners.

Printed in USA

Siemens Industry, Inc.

125-3584T

7

Page 8

How to Use This Manual

Related Documents

How to Use This Manual

This manual is for users of TALON® Automation Systems who use Field Panel Web

Server to command and monitor their TALON field panels. It is designed to describe

the functions and applications of Field Panel Web Server.

To effectively use this manual, you must be familiar with the basic operation of the

TALON Building Automation Systems and a Web browser.

Related Documents

In addition to this User Guide, please review the following Siemens Industry, Inc.

documentation:

TALON Controllers User's Manual (588-580)

This manual, along with information about other Siemens Industry, Inc. products,

technical training classes, and services, can be obtained from the local Siemens

Industry, Inc. representative.

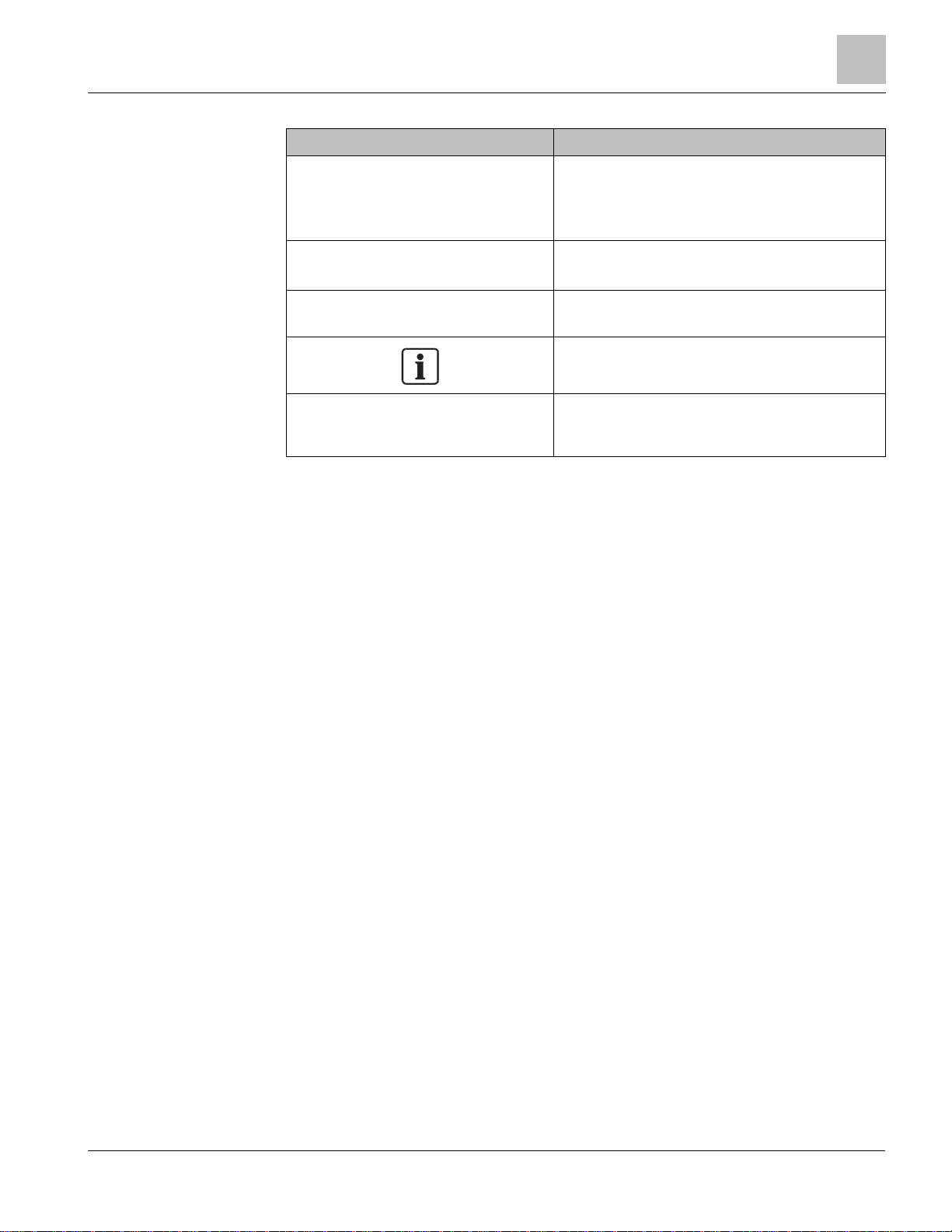

Symbols Used in this Manual

The following table lists the safety symbols used in this manual to draw attention to

important information.

Symbol Meaning Description

NOTICE CAUTION Equipment damage may occur if a procedure or instruction is not

CAUTION Minor or moderate injury may occur if a procedure or instruction is not

WARNING Personal injury or property damage may occur if a procedure or

DANGER Electric shock, death, or severe property damage may occur if a

followed as specified. (For online documentation, the NOTICE displays

in white with a blue background.)

followed as specified.

instruction is not followed as specified.

procedure or instruction is not followed as specified.

Manual Conventions

The following table lists conventions to help you use this manual in a quick and

efficient manner.

8

Siemens Industry, Inc. 125-3584T

Page 9

Convention Examples

How to Use This Manual

Contact Us

Numbered Lists (1, 2, 3…) indicate a

procedure with sequential steps.

Actions that should be performed are specified

in boldface font.

New terms appearing for the first time are

italicized.

Cross references to other information are

indicated with an arrow and the page number,

enclosed in brackets: [→92]

1. Turn OFF power to the field panel.

2. Turn ON power to the field panel.

3. Contact the local Siemens Solution Partner, Authorized

TALON Dealer.

Type F for Field panels.

Click OK to save changes and close the dialog box.

The field panel continuously executes a user-defined set

of instructions called the

This symbol signifies Notes. Notes provide additional

information or helpful hints.

For more information on creating flowcharts, see

Flowcharts [→92].

control program

.

Contact Us

Your feedback is important to us. If you have comments about this manual, please

submit them to SBT_technical.editor.us.sbt@siemens.com

Siemens Industry, Inc.

125-3584T

9

Page 10

Chapter 1 - Introduction to Field Panel Web Server

A

pplications

Chapter 1 - Introduction to Field Panel Web

Server

The Graphical User Interface software or files can only be loaded into a TC Modular or

TC Compact 36 controller. Due to space constraints, the Web Server user interface

cannot be loaded into a TC Compact 16 or 24 controller.

Once loaded into a panel on the network, the user interface can be accessed from any

compatible Web browser (see the

browser, you can access and interact with any BACnet IP-enabled controller in the

network that has the FPWeb license enabled, including Compact 16 and Compact 24

controllers.

Browser Requirements

Siemens FINlite Graphics Tool

The Siemens FINlite Graphics Tool is a graphic utility program which can be used to

create, modify, animate, and save graphics files to be used with the Web Server

Graphics View.

For more information, see the

FINlite Graphics Tool

section). Through the

section.

Field Panel Features for Field Panel Web Server

There are several new field panel features which can be used with Field Panel Web

Server using the HMI. New basic file system operation features include renaming,

moving, deleting, and copying a file. Other new features include Auto Save and

Graphics Backup.

Applications

Field Panel Web Server includes all the applications a facility operator needs to easily

configure, monitor, and control the TALON® Automation System through a simple

Web-based user interface.

In the Siemens FINlite graphics utility program and in the Web Server user interface,

limit the total number of tabs that are open simultaneously to six (6). This means that

any combination of tabs displaying editors or graphics files should not exceed six

tabs.

Status Bar Reports

Provides the ability to view reports of various conditions.

Point Editor

Allows you to create, modify, and delete points.

Point Commander

10

Siemens Industry, Inc. 125-3584T

Page 11

Chapter 1 - Introduction to Field Panel Web Server

A

pplications

Shows details for a selected point.

Allows commanding of point values and priorities, and disabling of points.

Provides navigation to the trending application.

Point Log Report

Displays a Point Log Report for the selected points.

Generates a printer-ready format of the Point Log Report.

Event Enrollment Editor

Allows you to create, modify, and delete Event Enrollment objects.

Notification Class Editor

Allows you to create, modify, and delete Notification Class objects.

Remote Recipient List Editor

Allows you to add, modify, and delete Remote Recipient addresses.

SMTP Configuration Editor

Allows you to configure the settings required by the SMTP E-Mail server in order to

use Remote Notification.

Graphics

Allows you to display/view the graphics that have been created and published to

the panel using the Siemens FINlite graphics utility program.

Trend Editor

Allows you to create, modify, and delete Trend Log objects

Trending

Displays Trend data in graphical or report format.

Allows the ability to view Trend Log Object data or dynamic trend data by polling

point objects.

Generates a printer-ready format of the Trend Graph.

Schedule/Command/Calendar Object Editors

Allows you to create, modify, and delete Schedule, Command and Calendar

objects.

Scheduling

11

Siemens Industry, Inc.

125-3584T

Page 12

Chapter 1 - Introduction to Field Panel Web Server

A

pplications

Displays schedules for a selected date, in several views: Today, Day, Work Week,

Week, and Month.

PPCL Editor

Allows you to create, modify and delete Powers Process Control Language (PPCL)

programs.

FLN Device Editor

Allows you to create, modify, and delete FLN Devices.

TEC Initial Value Editor

Allows you to set and modify TEC initial values.

User Account Editor

Allows you to create, modify, and delete user accounts.

Change User Password

Allows you to modify passwords.

Change Panel Time

Allows you to modify panel time.

12

Siemens Industry, Inc. 125-3584T

Page 13

Chapter 2 - Field Panel Web Server System Administration

Chapter Overview

Chapter 2 - Field Panel Web Server System

Administration

Chapter Overview

Chapter 2 discusses the following topics:

Prerequisites and Browser Requirements for Field Panel Web Server

Prerequisites for FINlite Graphics Tool

Enabling and Disabling Web Server

Loading the User Interface

Performance and Limitations

System Security

Language Support

Prerequisites and Browser Requirements for Field

Panel Web Server

Prerequisites

Before using the Field Panel Web Server, be sure to verify the following:

The panels being accessed by Field Panel Web Server use Firmware 3.2.2 or later

– Firmware Revision 3.2.2 must be loaded using FLT 3.11 or later

The FPWeb license must be installed and enabled in each controller that the Web

Server UI will be accessing

The panels have Web Server enabled via the HMI

The browser requirements below are met

For more information, see the

Server

section, and the TALON Controllers User's Manual (588-580).

Browser Requirements

Internet Explorer (IE) Version 6.0, 7.0, and 8.0, or Firefox 3.0 or later is required for

Field Panel Web Server.

NOTE: Field Panel Web Server has been tested with IE 6.0, 7.0, and 8.0, and

Firefox 3.0, but any browser that supports Flash Player 10.1 can be used.

Cookies must be enabled. This can be done by selecting Options from the Tools

menu in most browsers.

The Adobe Flash Player Plug-in Version 10.1 or later is required. The user

interface may prompt you to update if an older version of Adobe Flash Player is

installed. If Adobe Flash Player is not installed, the browser may display an empty

browser window.

Loading the User Interface and Connecting to Web

Siemens Industry, Inc.

125-3584T

13

Page 14

Chapter 2 - Field Panel Web Server System Administration

Prerequisites for FINlite Graphics Tool

Verifying that Adobe Flash has been Installed

Adobe Flash Player Plug-In Version 10.1 or later is required for the Field Panel Web

Server.

In Internet Explorer (IE), complete the following steps to determine whether or not the

correct version Adobe Flash is installed on your computer:

1. Launch IE.

2. From the Tools menu, click Internet Options.

3. In the Internet Options dialog box, click the Programs tab.

4. Click Manage Add-ons.

5. Scroll down through the list of add-ons and verify that “Shockwave Flash Object”

from Adobe Systems, Incorporated has been installed.

In Firefox, complete the following steps to determine whether or not the correct version

Adobe Flash is installed on your computer:

1. Launch Firefox.

2. From the Tools menu, click Options.

3. In the Options dialog box, select the General tab, and then click the Manage AddOns button.

4. In the Add-Ons dialog box, click Plugins.

5. Scroll down through the list of add-ons and verify that Shockwave Flash has been

installed.

If Adobe Flash has not been installed, or if an upgrade is necessary, it can be

downloaded and installed by the administrator of the computer by following the

instructions at http://get.adobe.com/flashplayer/.

Prerequisites for FINlite Graphics Tool

Adobe AIR has been installed (be sure to accept upgrades to Adobe AIR).

Siemens FINlite graphics application has been installed.

The Adobe Flash Player Plug-in Version 10.1 or later is required. The user

interface may prompt you to update if an older version of Adobe Flash Player is

installed. If Adobe Flash Player is not installed, the browser may display an empty

browser window.

For more information, see the

Interface

section, and the TALON Controllers User's Manual (588-580).

FINlite Graphics Tool

section, the

Loading the User

Enabling or Disabling Web Server

Use these procedures to enable or disable Web Server via the HMI.

14

Siemens Industry, Inc. 125-3584T

Page 15

Chapter 2 - Field Panel Web Server System Administration

Enabling or Disabling Web Server

Be sure that the FPWeb license is installed on the field panel.

HMI S, H, E, W, M (System, Hardware, Ethernet, Webserver, Modify

Example

10:13:04 07/30/2010 FRI Logged on successfully Field panel

<40091>

User: <high> <High default user account>

>Point, Application, Time, Message, Cancel, System, passWord,

Bye? s

>Diagnostics, Users, dSt, Bacnet, Error_msgs, Hardware, Text,

Quit? h

>Fieldpanels, Ethernet, nodeNametable, Disks, Reportprinter,

Licensemanager, Quit? e

>ipSettings, Bbmd, Telnet, Webserver, Quit? w

>Display, Modify, Uiupgrade, Graphicsbackup, Quit? m

>Webserver Enabled (Y/N) : y

>Ok to coldstart (Y/N) : y

Use these procedures to check the enabled/disabled status of Web Server.

HMI S, H, E, W, D (System, Hardware, Ethernet, Webserver, Display

Example

10:13:04 07/30/2010 FRI Logged on successfully Field panel

<40091>

User: <high> <High default user account>

>Point, Application, Time, Message, Cancel, System, passWord,

Bye? s

>Diagnostics, Users, dSt, Bacnet, Error_msgs, Hardware, Text,

Quit? h

>Fieldpanels, Ethernet, nodeNametable, Disks, Reportprinter,

Licensemanager, Quit? e

>ipSettings, Bbmd, Telnet, Webserver, Quit? w

>Display, Modify, Uiupgrade, Graphicsbackup, Quit? d

Webserver Enabled : Enabled

Siemens Industry, Inc.

125-3584T

15

Page 16

Chapter 2 - Field Panel Web Server System Administration

Loading the User Interface

Loading the User Interface

Be sure that the FPWeb license is enabled for each field panel.

Recommended Method: Loading or Upgrading the User Interface via

Human-Machine Interface (HMI)

To load or upgrade the User Interface file via HMI (recommended method):

Copy the UIUpgrade folder and its contents from Vantage Web site onto the root of

a USB memory device (such as a thumb drive). Do not change the folder or file

structure.

NOTE: The files within the UIUpgrade folder include wsroot/fpweb.swf as well as

language (.mo) files and other support files.

1. Insert the USB memory device into the USB port of the field panel.

NOTE: Due to USB memory device manufacturer, size, and contents, the time to

detect the device will vary from several seconds to one or more minutes. You may

verify that the device is attached by using the HMI commands S/H/F/F/L to list the

available drives on the Field Panel, and confirm that Drive B is listed.

2. Use the HMI Uiupgrade function

(System/Hardware/Ethernet/Webserver/Uiupgrade). When prompted, type Y for

Yes, and press ENTER.

The User Interface and support files will be copied from the USB memory

device in the field panel’s B:\ drive to the field panel’s internal flash drive (IFD)

and to the field panel’s A:\ drive.

Alternate Method: Loading or Upgrading the User Interface via File

Transfer Protocol (FTP)

There are many user-friendly FTP tools publicly available that can be used for

transferring files between your computer and the field panel.

Telnet must be enabled in order to use FTP. Remember to disable Telnet on the field

panel when you are done using the Telnet and FTP services. For information on

enabling Telnet, see

Telnet must be enabled in order to use FTP. Remember to disable Telnet on the field

panel when you are done using the Telnet and FTP services. For information on

enabling Telnet, see the TALON Controllers User's Manual (588-580).

To load or upgrade the User Interface file via FTP (alternate method; HMI method is

recommended):

Troubleshooting

.

Use FTP to copy the UIUpgrade folder and its contents from Vantage Web site or

your computer to the root of Drive A on the field panel.

After the transfer, the contents of Drive A should look similar to the following folder

structure:

Do one of the following:

16

Siemens Industry, Inc. 125-3584T

Page 17

Chapter 2 - Field Panel Web Server System Administration

Performance and Limitations

Use the HMI “Uiupgrade” function

(System/Hardware/Ethernet/Webserver/Uiupgrade)

Use FTP to transfer the uiupgrade.txt file from Vantage Web site or your computer

to the root of Drive A on the field panel.

After the upgrade is complete, the UIupgrade folder is automatically removed from

Drive A. No coldstart is necessary.

If a coldstart occurs, all files are preserved in the IFD.

Performance and Limitations

An interface is available via the Human-Machine Interface (HMI) to save files to

and restore files from the RAM drive, USB media, or the Field Panel’s internal flash

drive (IFD). For more information, see the TALON Controllers User's Manual (588-

580).

Graphics files can be published from the Siemens FINlite Graphics Tool to the field

panel’s RAM (Drive A) or USB (Drive B). For graphics to be preserved across a

coldstart, files must be saved on the internal flash drive (IFD) or stored on a USB

drive. Any graphics files stored only on the panel’s RAM drive will not be preserved

across a coldstart. Files can be saved to the IFD using the Graphics Backup

feature in the HMI.

There are 8MB of RAM available on the RAM (Drive A), but it is recommended that

4MB of RAM is kept available for field panel operations. Individual graphic sizes

typically range from 300KB to 500KB, depending on background resolution.

Cache refresh time is affected by the number of objects and FLN devices on the

panel. Panels with multiple FLN applications will experience longer refresh times.

USB devices must be formatted as FAT. Due to USB memory device

manufacturer, size, and contents, the time to detect the device will vary from

several seconds to one or more minutes.

The following devices are supported by the installed device drivers. Cruzer,

SanDisk, and Kingston brand devices were used during development and testing.

– ADISK USB 1.1 32MB flash disk

– Aigo USB 1.1 64M flash disk

– Crucial 1G flash disk

– FPT-D US5B2H01 18-in-1 USB card reader/writer

– HP 1G flash disk

– IBM Portable Diskette Drive (floppy drive)

– Integral USB 2.0 2GB flash disk

– Kingston DataTraveler 1GB flash disk

– Kingston DataTraveler 100 2GB flash disk

– Kingston DataTraveler 16GB flash disk

– LACIE USB 2.0 40GB mobile hard drive

– Lexar Media JumpDrive Secure USB 2.0 512MB flash disk

– Memorex 2GB flash disk

– NCP XDrivePlus MMC/SD reader

– Newman USB 1.1 64MB flash disk

– PNY Attache USB 1.1 64MB flash disk

Siemens Industry, Inc.

125-3584T

17

Page 18

Chapter 2 - Field Panel Web Server System Administration

Performance and Limitations

– PNY Attache (U3) 1GB

– PNY Attache 2GB

– PNY Attache 8GB

– PQI MMC/SD reader

– RedLeaf USB 2.0 256MB flash disk

– SanDisk Cruzer USB 2.0 256MB flash disk

– SanDisk Cruzer Micro 2GB flash disk

– SanDisk Cruzer Micro (U3) 2GB flash disk

– SanDisk Cruzer Micro (U3) 4GB flash disk

– SONY MICROVAULT USM256U2 USB 2.0 256MB flash disk

– Transcend JF V30 4GB flash disk

– Edge DiskGO™ 1GB USB Flash Drive Enhanced for ReadyBoost™

– Edge DiskGO™ 2GB USB Flash Drive Enhanced for ReadyBoost™

– Imation 1GB Swivel USB Flash Drive

– Imation 2GB Swivel USB Flash Drive

– Integral 1GB USB Memory Stick

– MARKEM 1GB USB Memory Stick

– Memorex 1GB TravelDrive™ USB Flash Drive

– Memorex 2GB TravelDrive™ USB Flash Drive

– PNY 1GB Attache USB Flash Drive

– SanDisk 2GB Cruzer® Crossfire USB Flash Drive

– SanDisk 512MB Cruzer® Micro USB Flash Drive

– SanDisk 2GB Cruzer® Micro USB Flash Drive

– SanDisk 4GB Cruzer® Micro USB Flash Drive (U3 function not initialized)

– Sony 512MB Micro Vault Tiny USB Flash Drive

– Sony 2GB Micro Vault Tiny USB Flash Drive

– Sony 1GB Micro Vault Classic USB Flash Drive

– Sony 4GB Micro Vault Classic USB Flash Drive

– X Digital Media 1GB Itty Bit USB Flash Drive

– X Digital Media 1GB Poker Chip USB Flash Drive

– X Digital Media 2GB Itty Bit USB Flash Drive

Field Panel Web Server was benchmarked with five (5) users. However, there is no

limit to the number of users that can access Field Panel Web Server

simultaneously. Certain actions will cause some performance degradation, when

performed by multiple users simultaneously (for example: refreshing the cache,

running point log reports, opening graphics, etc.).

Field Panel Web Server was benchmarked with ten (10) panels. However, there is

no hard limit to the number of panels accessible through Field Panel Web Server.

Access time and performance is affected by the number of panels. As the number

of panels on the system increases, so will the login and caching time.

Tips to Improve Performance of Field Panel Web Server

18

Siemens Industry, Inc. 125-3584T

Page 19

Chapter 2 - Field Panel Web Server System Administration

System Security

Allow Browser Caching of Adobe Flash Player

This setting will be particularly helpful once the panel database is stable. This allows

the Field Panel Web Server to keep information about the panel database without

needing to continuously read it from the panel.

1. Right click while in a browser and accessing the Field Panel Web Server.

2. Click Settings.

3. In the Adobe Flash Player Settings window, open the folder (icon) tab.

4. Choose a local storage setting appropriate to the system being used.

Distribute Points from a Particular Panel among Several Graphics

Loading a graphic with a large number of points from a single panel may degrade the

performance of the panel and will cause it to take longer to load and report changes of

values (COVs). Particularly, the loading of a graphic with points from a TC Compact 16

or 24, or their associated FLN devices, will occur more slowly, since these panels use

a slower processor with lower memory.

To improve performance when loading graphics, distribute the points from the panel

among several different graphics files.

Use Device Template Graphics for Viewing FLN Device Points on a

Graphic

For information about creating Device Template graphics (also called

Create Device Templates

the

section.

relativizing

), see

Limit Open Tabs to Six

In the Siemens FINlite graphics utility program and in the Web Server user interface,

limit the total number of tabs that are open simultaneously to six (6). This means that

any combination of tabs displaying editors or graphics files should not exceed six tabs.

System Security

Siemens Industry, Inc.

125-3584T

19

Page 20

Chapter 2 - Field Panel Web Server System Administration

Language Support

User access to the Field Panel Web Server is controlled through individual User

Accounts. Each User Account has access levels determined by a system

administrator, which grant or deny permissions to work with the specific applications

and features of the Field Panel Web Server.

User Accounts are password protected. The passwords are encrypted when they are

entered by the user at the Web Server User Interface.

When a User Account is created, a password expiration time can be determined by the

system administrator. If a user account is created with an expiration date on the

password, and if a user attempts to log in to that account three times using an incorrect

password, the User Account will be locked, requiring a system administrator to unlock

it. A locked User Account can be unlocked through a modification to the User Account

by a system administrator.

For more information about access levels and passwords, see the

the TALON Controllers User's Manual (588-580).

Language Support

Dynamic text

information that can be defined by the user.

Static text

FINlite Graphics Tool), such as menu titles, labels, error messages, and other

information that cannot be modified by the user.

Dynamic text support requires appropriate host computer regional settings or the

specified language.

Static text support at the Web Server user interface and FINlite Graphics Tool requires

downloading the appropriate language (.mo) files in the appropriate place. See the

Setup

section and the

static language.

Static and dynamic text support at the HMI requires downloading the appropriate

language files during firmware loading via Firmware Loading Tool (FLT), typically

English and a second language (French, Chinese, Korean, or Japanese).

See the TALON Controllers User's Manual (588-580) for more information about

language support.

refers to text that lists object names, descriptors, state text, and other

refers to text in the user interfaces (HMI, Web Server user interface, and

FINlite Graphics Tool

Users

section and

sections for information on selecting a

Importing a Language File

Additional language (.mo) files can be downloaded from Vantage Web site into the field

panel via FTP or a USB memory device. These language files will then become

accessible by the user interface for static text display.

20

Siemens Industry, Inc. 125-3584T

Page 21

Chapter 3 - User Interface Navigation Overview

Welcome Page/Logon

Chapter 3 - User Interface Navigation Overview

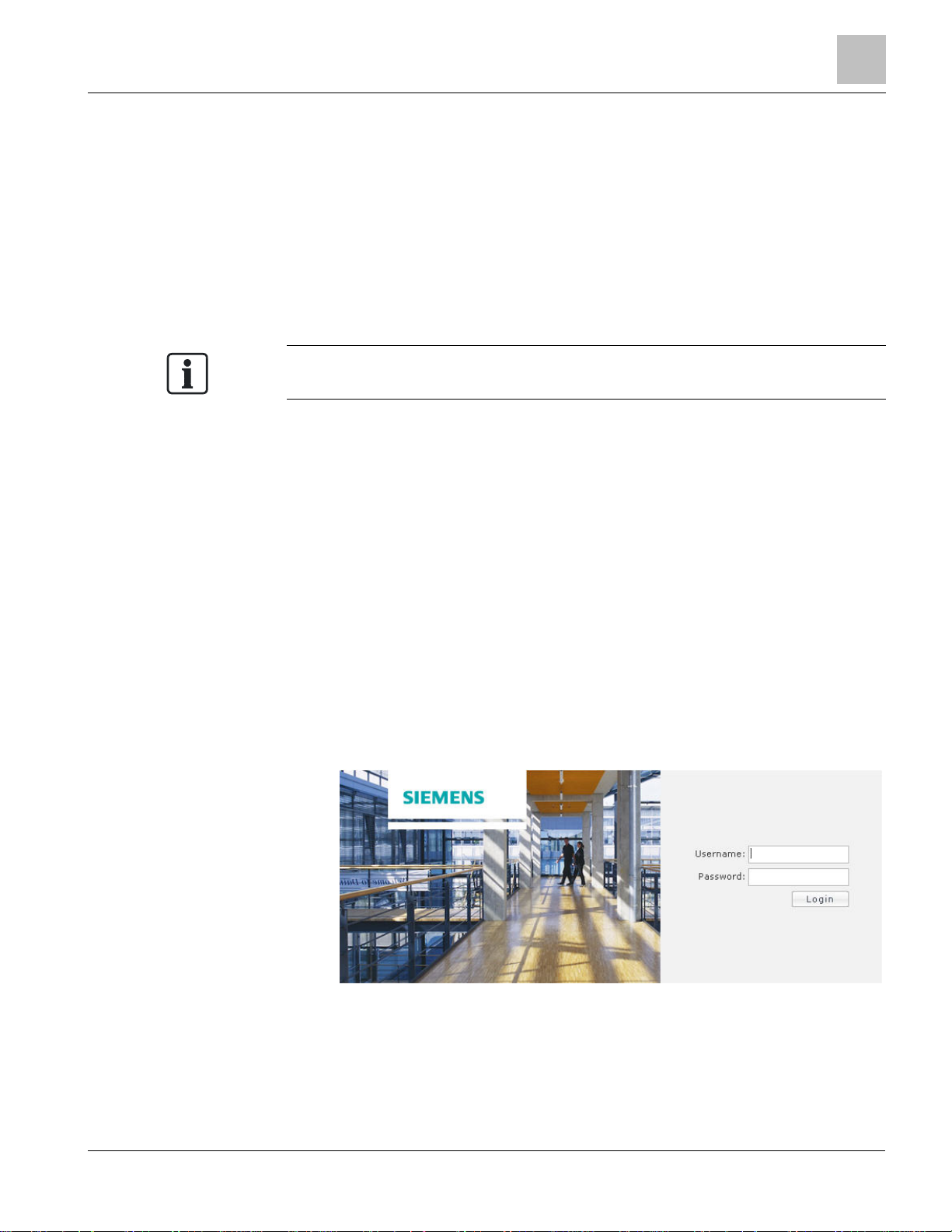

Welcome Page/Logon

Begin a Field Panel Web Server session with a Web browser URL request to the

panel, using either its IP address or panel name/Fully Qualified Domain Name. The

panel will respond with the Web Server

the system.

If you have problems connecting to the Field Panel Web Server or logging on, see the

Troubleshooting

section.

Welcome

Steps for Logging On

1. Launch a supported Web browser on the computer.

page, which allows you to log on to

2. Type one of the following into the address field:

- IP address of the field panel

- Field panel node name/Fully Qualified Domain Name

NOTE: The browser must be configured to ignore the proxy settings for the

panel names and/or IP addresses. See the

information.

The End User License Agreement page displays.

3. Click Accept.

The Field Panel Web Server Welcome page displays.

NOTE: The graphic that displays on the Welcome page can be customized.

See the

Settings

section.

Troubleshooting

section for more

4. Type the user name and password of any ALN user account into the appropriate

fields in the log-on window and click Login.

If the log-on is successful, a log-on message is sent to all configured alarm printers.

The Panel Navigation screen will display, showing a list of panels connected.

Siemens Industry, Inc.

125-3584T

21

Page 22

Chapter 3 - User Interface Navigation Overview

\

User Interface after Logon

Configuring the Welcome Page Graphic

Field Panel Web Server provides a Welcome page image, which can be changed by

the user.

To change the image on the Welcome page:

1. Create a custom image file that is 398 × 263 pixels.

2. Name the file login.png.

3. Save the file to a USB drive.

4. There are several ways to save this file in the panel:

5. Using the USB drive as drive B:\ of the panel, copy the login file to

A:/wsroot/login.png. Be sure to copy the file to the Internal Flash Drive

(IFD:\wsroot\login.png) as well, in order to preserver the file after a panel coldstart.

For the HMI command prompts to perform the file copy, see the

Features for Field Panel Web Server

OR

6. Using the USB drive as drive B:\ of the panel, save the file to the WSROOT

subdirectory in the UIUpgrade directory, along with the standard contents of the

UIUpgrade folder. Perform the UIUpgrade, using the HMI command prompts. The

login file will be transferred properly to the correct folder in both the A: and IFD

drives. For the HMI command prompts to perform the file copy, see the

Features for Field Panel Web Server

OR

Field Panel

section of this document.

Field Panel

section of this document.

7. Use File Transfer Protocol (FTP) to save the file to WSROOT.

The custom image will display on the Welcome page. If login.png does not exist in

the WSROOT directory, the default welcome page image displays.

The Login.png file will be deleted from the A:

file should be copied to the Internal Flash Drive (IFD) so that it will be preserved after

a panel coldstart occurs.

drive after a coldstart of the panel. The

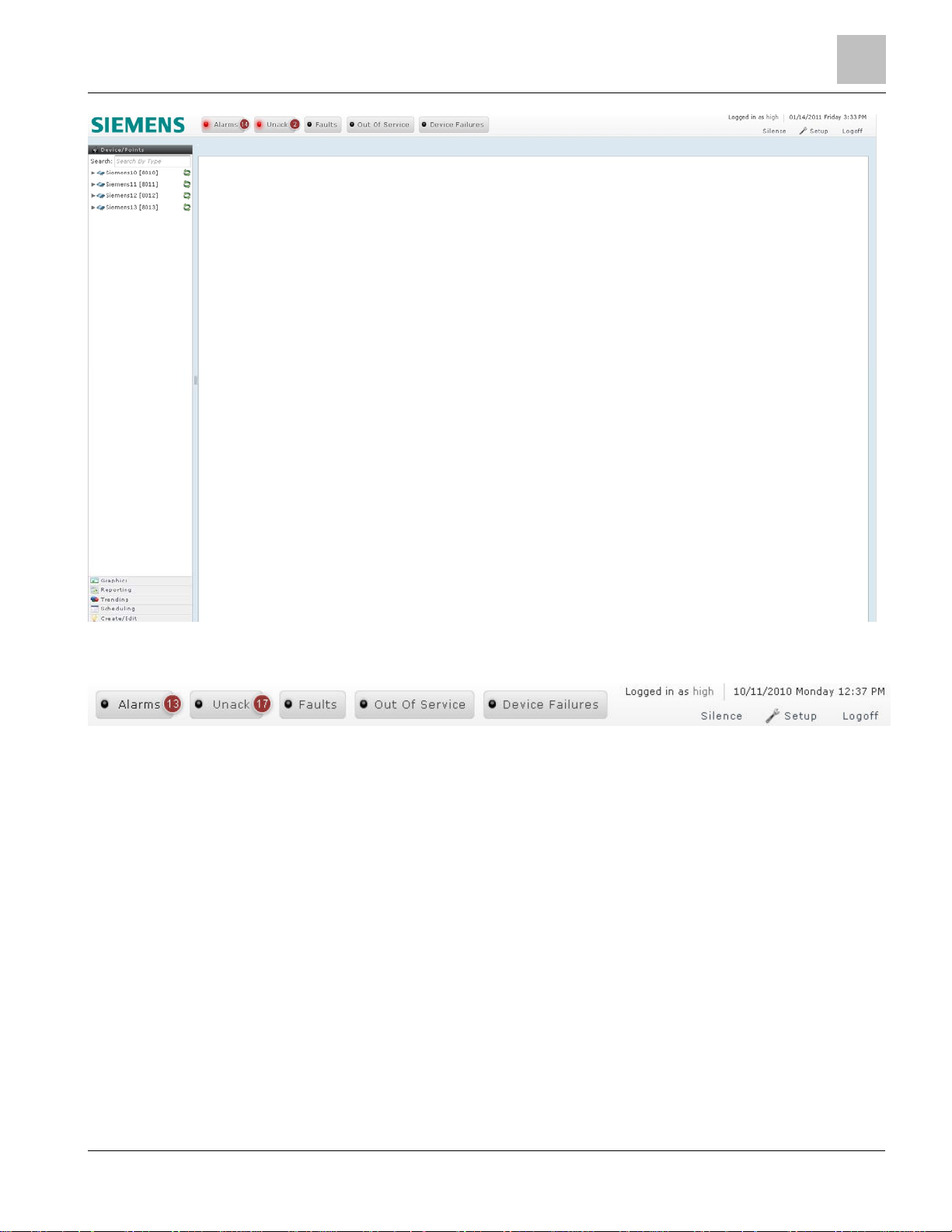

User Interface after Logon

Once you are logged in, the Field Panel Web Server user interface is divided into the

status bar

, the

navigation pane

, and the

application area

.

22

Siemens Industry, Inc. 125-3584T

Page 23

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

Status Bar User Interface

The Status Bar at the top includes the following features:

Alarms, Unack, Faults, Out Of Service, and Device Failures buttons indicate a

count for the number of items in that status. These buttons can be clicked to

generate a detailed report for each item in that status. See the

and Reports

The Silence button allows you to stop the Alarms, Unack, Faults, Out Of Service,

section.

Status Bar Counts

and Device Failures buttons from flashing until a new item is added to the list.

The Setup button opens a Setup window that allows you to choose colors, text

Setup

language, font size, and refresh rate of Status Bar buttons. See the

The Logoff button allows you to manually log off and return to the Welcome page.

Logoff

See the

User log in information and panel time are displayed.

section.

section.

Navigation Pane User Interface

Siemens Industry, Inc.

125-3584T

23

Page 24

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

The navigation pane on the left side includes six horizontal main application bars.

These main application bars allow you to access the available applications. For

descriptions of icons used in the Navigation Pane, see the

Messages

Accessible/Inaccessible Panels on the ALN

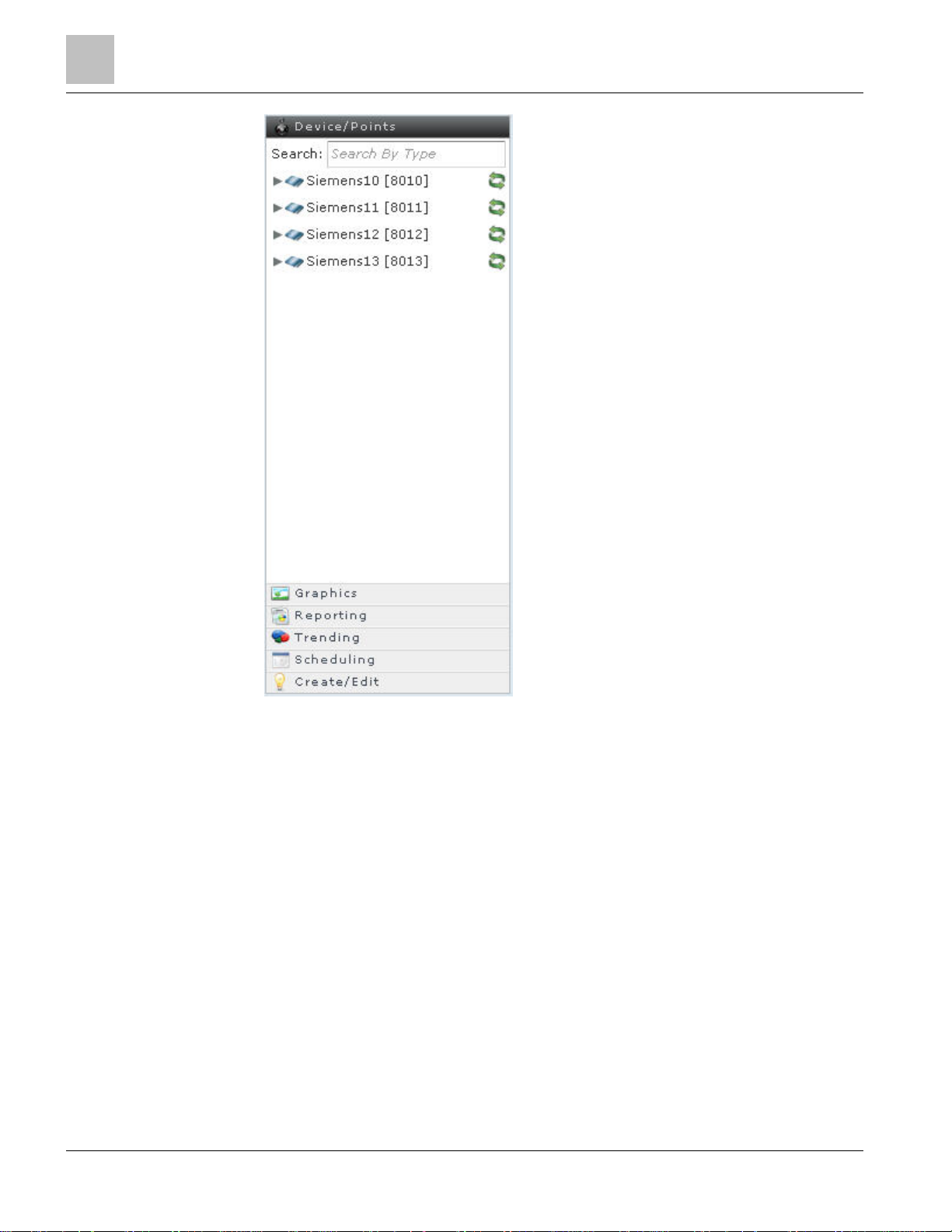

Device/Points: This application bar opens by default after successful logon. It

section. For information about panel accessibility, see the

section.

Device/Points Bar Icons and

provides a tree view of ALN and FLN panels and their associated objects and

FLNs. This tree view can be used to start several applications including Point

Commander, Trend View, Schedule View, and Graphics View by selecting the

appropriate object.

Graphics: This application bar provides a tree view of panels and their associated

graphics files. Clicking on a specific graphics file name in this tree view loads that

graphic in the Graphics View application.

Reporting: This application bar provides a button for Point Log Reports. Clicking on

the Point Log Reports button starts the Point Log Reports application.

Trending: This application bar provides a tree view of panels and their associated

Trend Log objects. Clicking on a specific Trend Log object in this tree view

launches the trend view application displaying the trend graph for the selected

object.

24

Siemens Industry, Inc. 125-3584T

Page 25

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

Scheduling: This application bar provides a tree view of panels and their

associated Schedule, Command, and Calendar objects. Clicking on a specific

Schedule object in this tree view launches the scheduler view application

displaying the schedule data for the selected object.

NOTE: The Command and Calendar objects in this tree view are inactive. They are

not used to start the Schedule View application.

Create/Edit: This application bar provides buttons to start the editing applications.

The editing applications include Trend Editor, Point Editor, Schedule Editor,

Command Editor, Calendar Editor, Event Enrollment Editor, Notification Class

Editor, Remote Recipient List Editor, SMTP Configuration Editor, FLN Editor, TEC

Initial Value Editor, PPCL Editor, User Account Editor, Password Reset, and

Change Panel Time.

See the specific application sections for more information.

Device/Points Bar Icons and Messages

The Device/Points application bar opens by default after successful logon, or can be

opened during any Web Server session by clicking the Device/Points bar in the

Navigation Pane. The Device/Points tree view provides status of and information about

the ALN panels and their associated objects and FLNs.

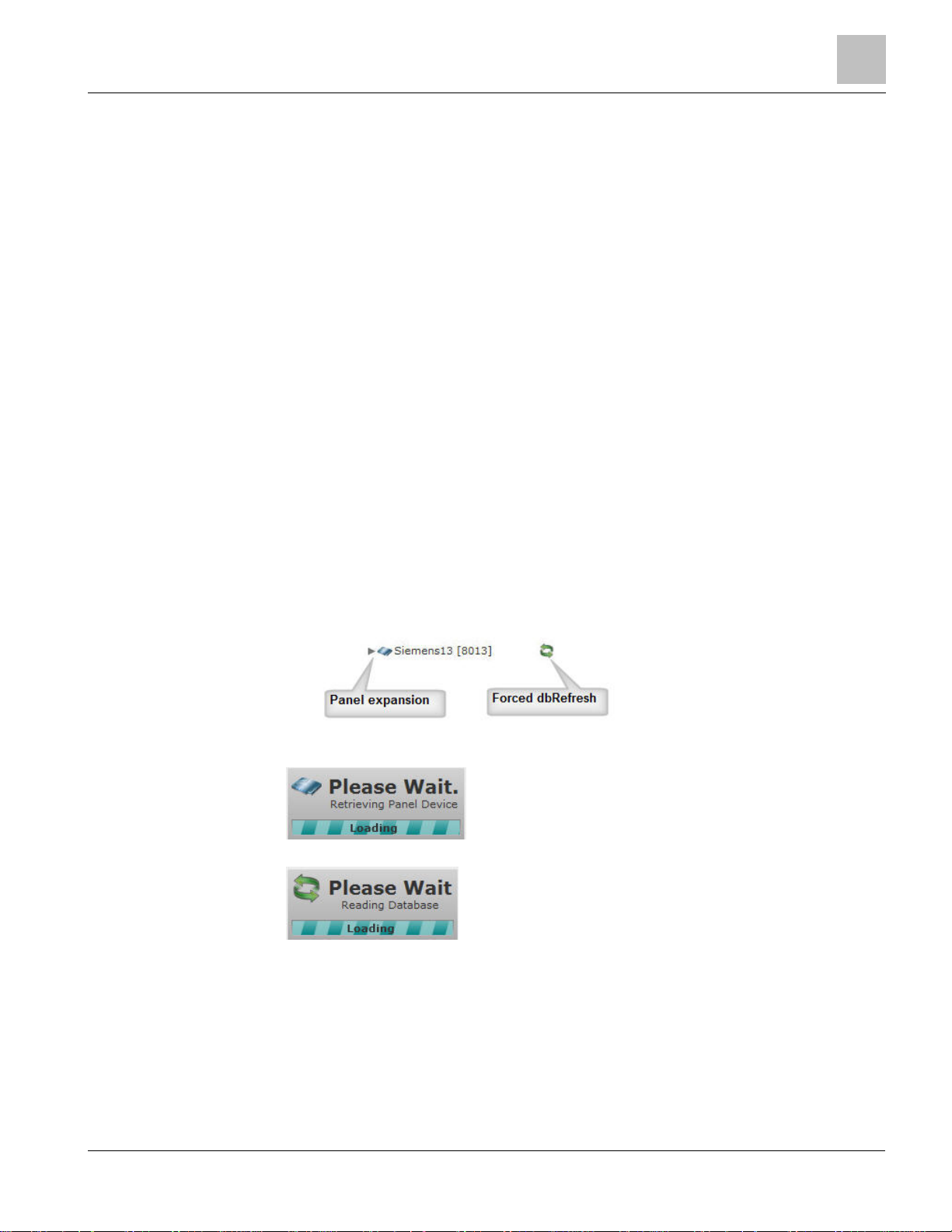

Discovering the Database

When a panel in the Device/Points bar is expanded using the gray arrow to the left of

the device name, a database discovery may be triggered.

A database discovery will also be triggered by clicking the green arrows to the right of

the device name.

During a database discovery, status messages will display:

Inaccessible Panels on the ALN

The Web Server application can only discover databases for panels on the Automation

Level Network (ALN) that are web-enabled, ready, and updated to the current firmware

revision.

Siemens Industry, Inc.

125-3584T

25

Page 26

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

Inaccessible Panels

Panels on the ALN that are not web-enabled will be identified in the Navigation Pane

as grayed out. These panels are not accessible in any Web Server editor applications

which require panel selection.

Panels on the ALN that are “not ready” will be identified in the Navigation Pane as

grayed out. These panels are not accessible in any Web Server editor applications

which require panel selection.

Panels on the ALN that are web-enabled and “ready” but not updated to the current

firmware revision will be identified in the Navigation Pane with a yellow triangle icon in

the Navigation pane next to the panel name. These panels are not accessible in any

Web Server editor applications which require panel selection.

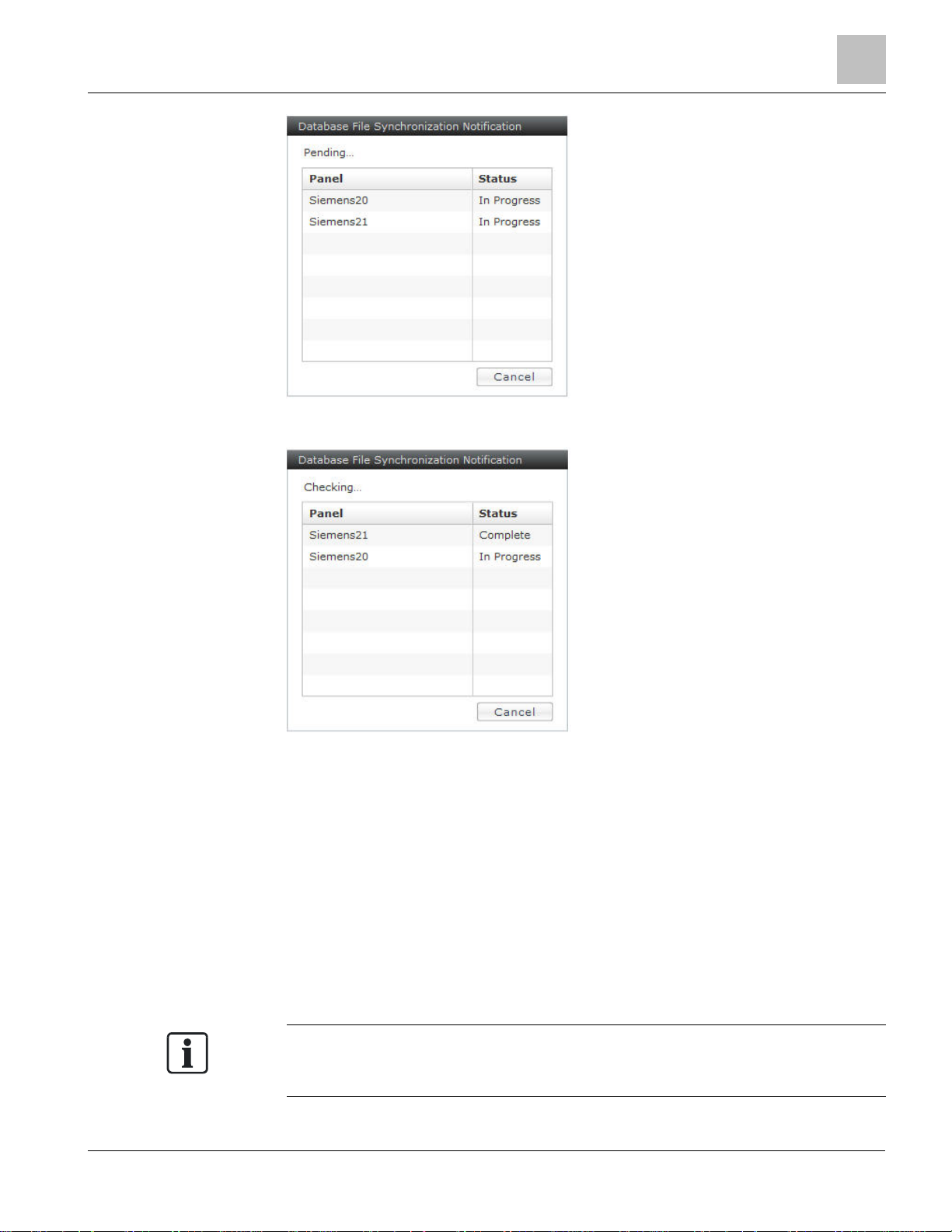

Pending Database File Synchronization

When a panel on the ALN is web-enabled, “ready”, and updated to the current

firmware revision, the Web Server application can discover its database, and provide

an indication when the database discovery is complete.

When a database discovery has been postponed or was never initiated, a yellow

triangle icon will display in the Navigation Pane next to the panel name to indicate a

conflict between the panel database file and the user interface database.

When a database discovery is needed, but the panel database file is being

synchronized, a message will display:

If this prompt appears while in the FLN Editor, it will only appear once, and the answer

will be preserved.

If this prompt appears following a panel expansion arrow selection, the answer will be

preserved until the database discovery is complete.

If you click No to this prompt, the yellow triangle icon will display in the Navigation

Pane next to the panel name, indicating your request to postpone database discovery.

If you click Yes to this prompt, the database will be discovered when the panel’s

database file is synchronized. A status table will display indicating the database file

synchronization status:

26

Siemens Industry, Inc. 125-3584T

Page 27

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

When a panel database file has been synchronized, the table will update the panel

status:

When all panel database files are synchronized, the status table will disappear, a

successful database discovery will occur, and the yellow triangle icon will be removed

from the Navigation Pane.

Application Area User Interface

The application area shows the output of the current active application. The information

displayed in the application area depends on the application being used. See the

specific application section for more information.

When an application is started from the Navigation Pane, either an application window

will open on the right side, or an application tab will be open on the right side.

Point Commander and Password Reset open in an application window. All other

applications open in tabs.

In the Web Server user interface, limit the total number of tabs that are open

Siemens Industry, Inc.

simultaneously to six (6). This means that any combination of tabs displaying editors

or graphics files should not exceed six tabs.

125-3584T

27

Page 28

Chapter 3 - User Interface Navigation Overview

A

User Interface after Logon

fter a successful logon, the Application Area will either be blank or loaded with the

“Default.fnl” graphic file loaded in a Graphics View application tab. See the

Graphics Tool

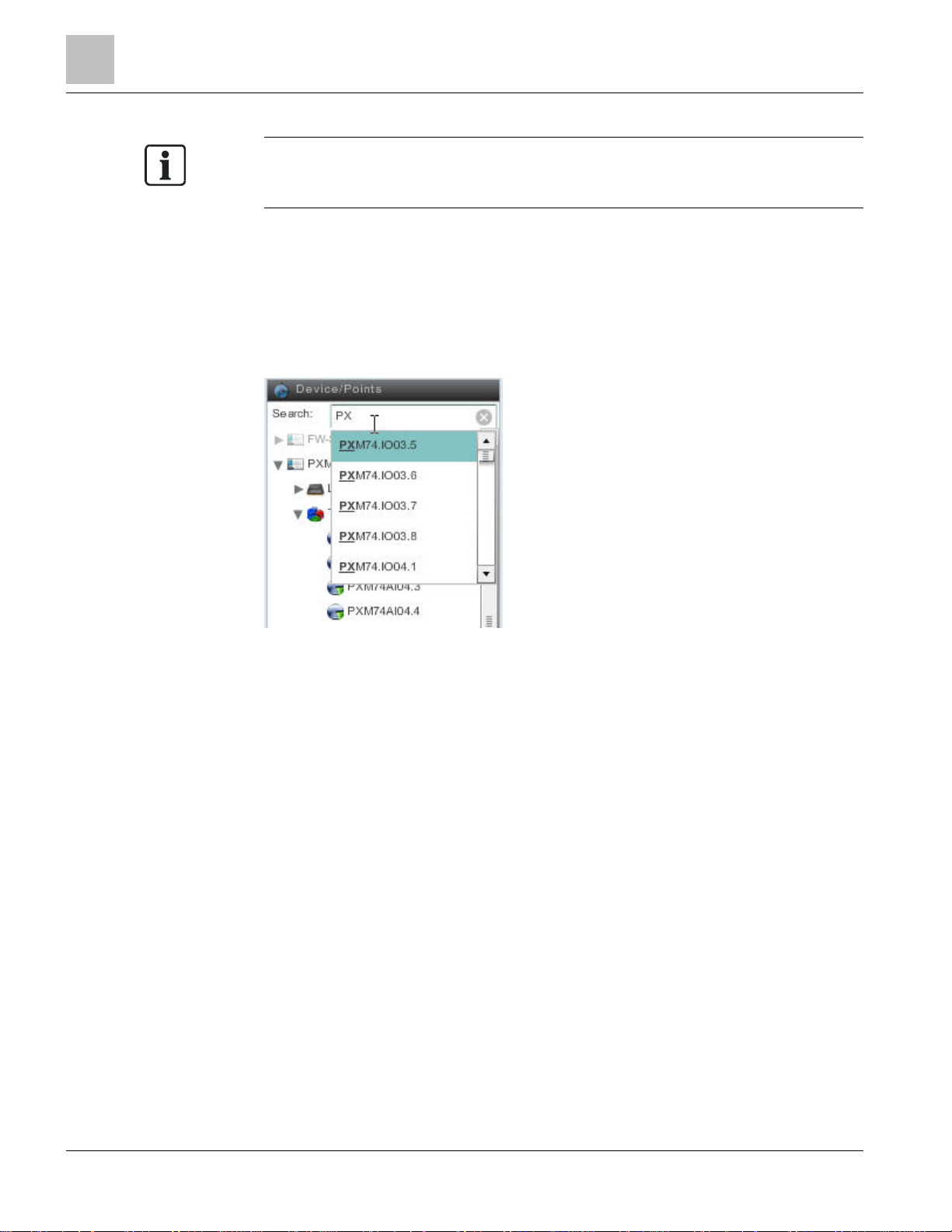

Device/Points Navigation Tree

When you click the Device/Points application bar, a navigation tree displays that

includes a

Search Box

section for more information about the default graphic.

search box

and a list of panels.

FINlite

The Device/Points search box allows searching for points by name. Type any part of

the desired point name into the search box and a list of matching point names will

display. Click the desired point name to access the point.

Panel List

Panels that are not grayed out are Web Server-enabled panels that are communicating

properly.

are

Panels that

enabled panels but are not communicating properly.

1. Hover over a panel name to view panel information. Click the arrow next to a Web

Server-enabled panel name to expand and display folders for local points and

available applications.

2. Click the arrow to expand the Local option and display the local points, categorized

by point type. Clicking a point name will start the Point Commander application.

3. Click the arrow to expand the Trends option to see the Trend Log objects on the

panel. Clicking a Trend Log object name will start the Trend View application.

4. Click the arrow to expand the Schedules option to see the Schedule, Command,

and Calendar objects on the panel. Clicking a Schedule object name will start the

Schedule View application.

NOTE: The Command and Calendar object names are inactive.

grayed out are either not Web Server-enabled, or are Web Server-

28

Siemens Industry, Inc. 125-3584T

Page 29

Chapter 3 - User Interface Navigation Overview

User Interface after Logon

5. Click the arrow to expand the Graphics options to display the graphic files on the

panel.

6. Click the name of a Field Level Network (FLN) option, if available, to display the

FLN devices on the panel, which can be further expanded to se the FLN device’s

points, categorized by point type. Click the desired point name to access the point

in the Point Commander application.

Siemens Industry, Inc.

125-3584T

29

Page 30

Chapter 4 - Status Bar

Status Bar Counts and Reports

Chapter 4 - Status Bar

Status Bar Counts and Reports

Running an Alarm Report

Alarm details can be viewed in the Alarm report, which is accessible via the Status Bar

(see the

Status Bar and its features). An Alarm report lists the details of both Event Enrollment

alarms and Intrinsic Alarms. Alarms can be acknowledged from the Alarm report.

Acknowledging the state of an object does not refresh the report. The report must be

re-run by clicking the count button to see updated data.

To run an Alarm report:

User Interface Navigation Overview

section for more information about the

1. Click the Alarms button in the Status Bar.

An Alarm report will display, listing alarm details.

2. Select the date and time in the Event Time column to see event time and

acknowledge time details.

Exporting, Saving, and Printing an Alarm Report

The Alarm report can be exported to the system printer with a preview, or exported as

a CSV file, and saved.

To export the Alarm report, click the Export to CSV button at the top right section of

the report pane. A dialog box will open. Browse to the desired location to save the

CSV (Comma Separated Variable) file.

To print the Alarm report, click the Print button at the top right section of the report

pane. A print dialog box will open. Choose the desired printer and click OK.

To close the Alarm report, click the X button to close the Report tab.

Acknowledging an Alarm

To acknowledge an Alarm:

30

Siemens Industry, Inc. 125-3584T

Page 31

Chapter 4 - Status Bar

Setup

1. Run an Alarm Report or an Unack report (see the

section).

2. Click the Unacknowledged button in the Acknowledge State column associated to

the desired alarm.

The button displays Acknowledged in the Acknowledge State column.

Running an Alarm Report

Setup

The Setup button allows you to choose colors, text language, font size, and refresh

rate of Status Bar buttons.

1. Click the Setup button on the Status Bar.

2. Change the font size by using the UP and DOWN arrows in the Font Size field.

3. Change the text language by using the drop-down Language menu.

4. Change the refresh rate of the Status Bar buttons by using the UP and DOWN

arrows in the Data Refresh Rate field.

5. Change the light colors of the Status Bar buttons by clicking the colored squares

and then choosing the desired colors.

6. Click Apply to save changes. Click Close.

7. Return to the default settings by clicking the Reset to Default button.

Selecting the Language

Field Panel Web Server provides static text in English as the default language. Other

language files are available for selection in the language field of the Web Server UI

Setup dialog box. Additional languages can be downloaded into the field panel, and

custom language files can be created if necessary. See the TALON Controllers User's

Manual (588-580) for more information about languages.

Siemens Industry, Inc.

125-3584T

31

Page 32

Chapter 4 - Status Bar

A

Logoff

The Setup option in the Status Bar allows you to change the static text language to a

language other than English, provided the Operating System supports the selected

language.

1. Click the Setup button on the Status Bar.

The UI Setup dialog box displays.

2. Use the Language drop-down to choose from the available static text languages.

3. Use the Font Size option to enlarge or reduce the font size.

4. Click Apply. Click Close.

5. Log out and log back in.

The static text changes to the selected language.

Most of the static text will change after you click

out and logging back in is required to change all of the static text language.

pply and Close. However, logging

Importing a Language File

Additional language files (.mo files) can be downloaded from Vantage Web site into the

field panel via FTP or a USB memory device. These language files will then become

accessible by the User Interface for static text display.

Logoff

You can end a Field Panel Web Server session by manually logging off using the logoff

button, or allowing the system to automatically log off. Manually logging off immediately

prevents unauthorized users from accessing to the system and reduces network traffic.

Whenever a Field Panel Web Server session ends, the system sends a logoff

message to all configured alarm printers and returns you to the Field Panel Web

Server Welcome page.

Manual logoff ends a Field Panel Web Server session.

– To log off manually, click the Logoff button on the right side of the Status Bar.

32

Siemens Industry, Inc. 125-3584T

Page 33

Chapter 4 - Status Bar

Logoff

Automatic logoff ends a Field Panel Web Server session after a period of inactivity

at the browser.

– Field Panel Web Server performs an automatic logoff after the auto-logoff delay

Users

time (defined in the User Account) expires. See the

If the Web browser is closed without logging off, the session will be closed after 20

section.

minutes. It is not recommended to close the browser without a manual logoff or

automatic logoff.

Siemens Industry, Inc.

125-3584T

33

Page 34

Chapter 5 - Point Commander

Chapter Overview

Chapter 5 - Point Commander

Chapter Overview

Chapter 5 discusses the following topics:

Point Commander Application Overview

– Tips for Using the Point Commander Application

– User Interface Description for the Point Commander Application

Point Commander Application Step-by-Step Instructions

– Commanding Point Values

– Disabling and Re-enabling a Point (Out of Service)

– Priority Arrays

Point Commander Application Overview

All points and point-like objects (AO, BO, MSO, AV, BV, MSV) with priority array can

be commanded from the Field Panel Web Server navigation tree, from a graphic

screen, and/or from a trend graph. Point value, status, and priority can be commanded.

Point types without priority array (AI, BI, AV, BV, MSV) can be commanded from the

commander navigation tree and/or from a graphic screen. Point value and status can

be commanded.

AO Analog Output Object

AI Analog Input Object

BO Binary Output Object

BI Binary Input Object

MSO Multi State Output Object

AV Analog Value Object

BV Binary Value Object

MSV Multi State Value Object

Multi State Input Object (MSI) Points are not supported on the FLN.

34

Siemens Industry, Inc. 125-3584T

Page 35

Chapter 5 - Point Commander

Point Commander Application Overview

CAUTION

Command points only when you know the possible effects of making a change.

Ideally, only command points when making temporary changes, such as setpoint

changes, or when commanding modes of operation, such as DAY and NIGHT. It is

inefficient to place a point in operator (OPER) command priority for long periods of time

or permanently.

The Field Panel Web Server Point Commander Application allows you to manually

control a point and override the pre-established automatic controls in a PPCL program

or the Scheduler application.

Under normal operating conditions, allow the TALON® Automation System to control

the building through programs such as PPCL, rather than relying on manual control.

However, there may be special circumstances when it is necessary to take temporary,

manual control of building operations.

Commanding a point may be necessary under the following conditions:

Troubleshooting a control strategy.

Responding to an alarm that indicates a malfunctioning device.

Managing run-time totalization.

Performing preventive maintenance tasks.

CAUTION: Always follow standard safety procedures when performing

maintenance tasks.

The Point Commander application window can be opened for a particular point object

from the Device/Points application bar in the Navigation Pane, or from a Graphics View

application tab.

User Interface Description for the Point Commander

Application

The Commanding window can be accessed via the Device/Points bar in the navigation

pane on the left side of the screen. Double click the point name (or single click the

Command button to the right of the point name) to open the basic (default)

Commanding window:

Siemens Industry, Inc.

125-3584T

35

Page 36

Chapter 5 - Point Commander

Point Commander Application Overview

Close the Commander window by clicking the X in the top right corner of the window.

The following fields and buttons are used in the basic Commanding window. If you do

not have access to a function, it will be grayed out.

The Command button at the bottom right of the window must be clicked to implement

any changes in the Commanding window.

Point Name and Description

The point name, point type, data type, and instance ID are displayed in the header

of the Commanding window.

The object name and description are displayed in the field on the left side of the

Commanding window. The Object Name field shows the point name. The

Description field (optional) displays additional point information.

Command Options and Status

The upper right section of the Commanding window displays command options.

The information in this section is only accessible to users with Command or higher

access level to the point.

Present Value displays the current point value, and allows you to change the value

of commandable points.

The “At” field (@) displays the current priority and allows you to change the point

priority.

Reliability displays any faults detected. If none, then No Fault Detected displays.

Event State indicates the status of the point (Normal, Failed).

The Out of Service checkbox allows you to disable or enable commandable points.

When a point is disabled:

– alarm reporting capabilities for the point are disabled

36

Siemens Industry, Inc. 125-3584T

Page 37

Chapter 5 - Point Commander

Point Commander Application Overview

– the Out of Service status indicator displays a check mark

Status Indicators

The lower right section of the Commanding window displays the following status

indicators, which indicate status with a check mark:

The In-Alarm check box indicates when the point is in an alarm status. See the

Status Bar

The Fault check box indicates when the point is in a fault status.

The Overridden check box indicates when the point has been manually overridden.

The Out Of Service check box indicates when the point has been disabled.

section for more information.

Dynamic Trending

Dynamic Trending for the point can be accessed by clicking the Trending button next

to the Advanced button at the bottom of the Commanding window. See the

Trend

section for more information.

Advanced Command Options (Points with Priority Array)

For points with priority array, the advanced command options can be accessed by

clicking the Advanced button at the bottom of the basic Commanding window. The left,

top, and bottom sections of the window remain the same. Click the Basic button to

toggle back to the basic Commanding window.

If the point has priority array, the priority values can be changed through a command to

a particular priority field. The priority fields that are not applicable will be grayed out.

Siemens Industry, Inc.

125-3584T

37

Page 38

Chapter 5 - Point Commander

Point Commander Application Overview

The Relinquish Default field displays the default value for relinquishing priority of

the point.

The Present Value field shows the present value of the point at the current highest

priority, and allows you to change that value.

The Priority dropdown shows the current priority, and allows you to change the

priority. Priorities 1 through 7 are not accessible; if they are chosen, the priority will

automatically default to the highest accessible priority value.

Command Feedback

A successful command will initiate an automatic refresh of the point values. The

Feedback field at the bottom left of the window displays a message indicating the

success or failure of each action. If the command was not successful an error message

displays, giving the reason for the failure. See the following table for a list of error

messages.

Error Code Situation

UNKNOWN_OBJECT

UNKNOWN_PROPERTY

PROPERTY_IS_NOT_AN_ARRAY

Specified object does not exist.

Specified property does not exist.

An array index is provided but the property is not

an array.

INVALID_ARRAY_INDEX

WRITE_ACCESS_DENIED

38

Siemens Industry, Inc. 125-3584T

An array index is provided that is outside the

range existing in the property.

The specified property is currently read-only.

Page 39

Using the Point Commander Application

Error Code Situation

Chapter 5 - Point Commander

INVALID_DATATYPE

VALUE_OUT_OF_RANGE

NO_SPACE_TO_WRITE_PROPERTY

DATATYPE_NOT_SUPPORTED

The data type of the value provided is incorrect

for the specified property.

The value provided is outside the range of values

that the property can take on.

There is not enough space to store the new

value.

The data being written has a data type not

supported by the property.

Tips for Using the Point Commander Application

Points can be commanded from the Navigation pane or from an animated graphic.

See the

FINlite Graphics Tool

a graphic.

You can only command points if you have been given Command or higher access

level to the point.

– Both analog and digital points can be commanded.

– Generally, only output points (AO, BO, and MSO) or virtual points (AV, BV,

MSV) can be commanded; however, AI and BI input points can be commanded

if taken out of service first.

If the same point is commanded from two different sessions, the command with the

higher priority will override. If the commands are made with the same priority, the

last command will override the earlier command.

Multi State Input Object (MSI) points are not supported on the FLN.

Use caution when moving the Commander window around the screen. If you move

it too far up the screen, you may not be able to access the title bar and move the

screen back down into view.

section for information on commanding a point from

Using the Point Commander Application

Commanding Point Values

Commanding a point means using the Point Commander Application to manually

override the system program instructions for either an output point or a virtual input

point. Point commanding changes the command priority from NONE.

This procedure is only available to users with Command or higher access to points.

Siemens Industry, Inc.

125-3584T

39

Page 40

Chapter 5 - Point Commander

Using the Point Commander Application

Steps for Commanding Point Values

1. Access the Commanding window through the Devices/Points bar in the navigation

2. Drill down to the desired point.

3. Double-click the point name (or single-click the command icon to the right of the

4. For points that have priority array, toggle between the Basic and Advanced

5. Make the necessary changes in the Commander window. For more information

6. Click Command to initiate the changes and begin controlling the point with the new

pane on the left side of the screen.

point name) to open the basic (default) Commanding window.

command options using the Advanced/Basic button at the bottom of the

Commander window.

about the fields available in the Commander window, see the

Descriptions for Point Commander

section.

User Interface

settings.

NOTE: It is not necessary to check or uncheck the Out of Service check box in a

separate step.

The status of the command displays in the Feedback field.

This procedure is now complete. Close the Commander window by using the X in the

top right corner of the window.

CAUTION

Release All Commanded Points

Remember to eventually release all commanded points to NULL priority so that the

system is automatically controlled.

In the Current Value field on the Basic or Advanced Commander window, type N. NULL

will be auto-filled into the field.

Failure to release commanded points may lead to unexpected results.

Disabling and Re-enabling a Point (Out-of-Service)

Disabling a point means using the Point Commander to manually change a point status

to Out-of-Service. Point priority does not change, and the value state cannot be

changed by an interface terminal or PPCL statement until the point is re-enabled.

When a point is disabled, the point status displays *O* on point logs and displays. This

procedure is normally used to validate control sequences and troubleshoot equipment.

This procedure is only available to users with Command or higher access to points.

Steps for Disabling/Re-enabling a Point

1. Access the Commanding window through the Devices/Points bar in the navigation

pane on the left side of the screen.

40

Siemens Industry, Inc. 125-3584T

Page 41

Chapter 5 - Point Commander

Using the Point Commander Application

2. Drill down to the desired point.

3. Double-click the point name (or single click the command icon to the right of the

point name) to open the basic (default) Commanding window.

4. In the Command Options section do one of the following:

- To disable the point, check the Disabled check box and click Command.

- To re-enable the point, clear the Disabled check box and click Command.

The status of the command displays in the Command Status section.

5. Click Command to initiate the changes and begin controlling the point with the new

settings.

NOTE: If the point value is being changed as well, it is not necessary to check or

uncheck the Out-of-Service check box in a separate step.

The status of the command displays in the Feedback field.

This procedure is now complete. Close the Commander window by using the X in the

top right corner of the window.

Priority Arrays

The Point Commander Application allows you to change the priority for commandable

points. For more information about point priority, see the TALON Controllers User's

Manual (588-580).

Point priority can be changed via the basic or advanced Commanding window. Toggle

between the Basic and Advanced command options using the Advanced/Basic button

at the bottom of the Commander window.

In the basic Commanding window, you can command the point to a new value and can

change only one priority, but in the advanced Commanding window, you can populate

the entire priority array with values.

This procedure is only available to users with Command or higher access to points.

Steps for Changing Point Priority (Basic Commanding Window)

In the basic Commanding window, the “At” field (@) displays the current priority and

allows you to change the point priority.

1. Use the drop-down arrow to change the priority.

2. Click Command to initiate the change. The status of the command displays in the

Feedback field.

The point value displays in the “At” field (@) as well as inthe current highest

priority field in the advanced Commanding window.

Steps for Changing Point Priority (Advanced Commanding Window)

Siemens Industry, Inc.

125-3584T

41

Page 42

Chapter 5 - Point Commander