Siemens 125-2134,547-005,547-006,547-002 Owner's Manual

Differential Pressure

Monitor Owner’s Manual

125-2134 Rev. DA, October 2006

Rev. DA, October 2006

NOTICE

The information contained within this document is subject to change without notice and should not be construed as a

commitment by Siemens Building Technologies, Inc. Siemens Building Technologies, Inc. assumes no responsibility

for any errors that may appear in this document.

All software described in this document is furnished under a license and may be used or copied only in accordance

with the terms of such license.

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in accordance

with the instructions manual, may cause interference to radio communications. It has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference in which case users at their own expense will be

required to take whatever measures may be required to correct the interference.

SERVICE STATEMENT

Control devices are combined to make a system. Each control device is mechanical in nature and all mechanical

components must be regularly serviced to optimize their operation. All Siemens Building Technologies, Inc.branch

offices and authorized distributors offer Technical Support Programs that will ensure your continuous, trouble-free

system performance.

For further information, contact your nearest Siemens Building Technologies, Inc. representative.

Copyright 2006 by Siemens Building Technologies, Inc.

TO THE READER

Your feedback is important to us. If you have comments about this manual, please submit them to

SBT_technical.editor@siemens.com

APOGEE is a registered trademark of Siemens Building Technologies, Inc.

Product or company names mentioned herein may be the trademarks of their respective owners.

Country of Origin: US

Differential Pressure Monitor Owner’s Manual

Table of Contents

How To Use This Manual..............................................................................................IV

Manual Organization..................................................................................................IV

Manual Conventions..................................................................................................V

Manual Symbols ........................................................................................................V

Datamate Software....................................................................................................V

Getting Help...............................................................................................................VI

Where To Send Comments.......................................................................................VI

Product Overview .........................................................................................................1

Introduction...................................................................................................................1

Differential Pressure Monitor.....................................................................................1

Ordering Notes........................................................................................................2

Hardware Inputs ........................................................................................................2

Hardware Outputs......................................................................................................2

Components............................................................................................................3

Remote Pressure Transmitter....................................................................................4

Components............................................................................................................4

Applications...................................................................................................................7

Basic Operation.............................................................................................................7

Pressurization Modes................................................................................................7

Setting Pressurization Mode...................................................................................8

Pressurization Switchover.......................................................................................8

Pressure Alarms ........................................................................................................8

Protective Isolation/Positive Pressurization Mode – Application 701 and 702.......9

Infectious Isolation/Negative Pressurization Mode – Application 703 and 704......9

Door Alarm.................................................................................................................10

Sensor Failure Alarm.................................................................................................10

Alarm Sequence ........................................................................................................10

DPM Inputs and Outputs ...........................................................................................10

Calibration..................................................................................................................11

Application 790: Slave Mode....................................................................................11

Using Relay Outputs..................................................................................................11

Door Input..................................................................................................................12

Alarm LED..................................................................................................................12

Siemens Building Technologies, Inc. I

Table of Contents

Normal LED ...............................................................................................................12

Horn...........................................................................................................................12

Loop Signal (4-20 mA)...............................................................................................12

Point Database..............................................................................................................13

Overview....................................................................................................................13

Troubleshooting............................................................................................................19

Basic Service Information..........................................................................................19

Preventive Maintenance............................................................................................19

Safety Features..........................................................................................................20

FLN Trunk Connections Check ...................................................................................20

External Alarm Output Check......................................................................................21

Equipment Required..................................................................................................21

Procedure if RELAY MODE is set to NOPEN.........................................................22

Procedure if RELAY MODE is set to NCLOSE.......................................................22

Door Switch Input Check .............................................................................................23

Equipment Required..................................................................................................23

Procedure if DOOR SW MODE is set to NOPEN...................................................24

Procedure if DOOR SW MODE is set to NCLOSE.................................................24

CV Controller Pressure Mode Output Check.............................................................25

Equipment required ...................................................................................................25

DPM without a Pressure Mode Key Switch...............................................................25

Procedure if DO MODE is set to NOPEN...............................................................25

Procedure if DO MODE is set to NCLOSE.............................................................26

DPM with a Pressure Mode Key Switch....................................................................26

Procedure if DO MODE is set to NOPEN...............................................................26

Procedure if DO MODE is set to NCLOSE.............................................................27

RPC Pressure Mode Output Check.............................................................................28

Equipment required ...................................................................................................28

DPM with a Pressure Mode Key Switch....................................................................28

4-20 mA Signal Output Check......................................................................................30

Equipment Required..................................................................................................30

Procedure ..................................................................................................................30

Troubleshooting.........................................................................................................31

II Siemens Building Technologies, Inc.

Differential Pressure Monitor Owner’s Manual

ERROR STATUS Messages .........................................................................................34

Clearing an Error Condition.........................................................................................34

Glossary.........................................................................................................................35

Index...............................................................................................................................41

Siemens Building Technologies, Inc. III

How To Use This Manual

This manual is written for the owner and user of the Siemens Building Technologies, Inc.

Differential Pressure Monitor (DPM). This manual is designed to help you become familiar

with the monitor and its applications.

This chapter covers manual organization, manual conventions and symbols used in the

manual, and how to access help.

Manual Organization

This manual contains the following chapters:

•

Chapter 1 Product Overview, describes the components of the Differential Pressure

Monitor (DPM) and Remote Pressure Transmitter (RPT).

•

Chapter 2 Applications, describes the control applications available in the DPM.

•

Chapter 3 Point Database, defines the point database descriptors and includes

addresses and applications.

•

Chapter 4, Troubleshooting, describes corrective measures you can take should you

encounter a problem when using the DPM. For issues not covered in this chapter,

contact your local Siemens Building Technologies representative.

•

The Glossary describes the terms and acronyms used in this manual.

•

An Index assists you in finding information.

Siemens Building Technologies, Inc. IV

Manual Conventions

The following table lists conventions to help you use this manual in a quick and efficient

manner.

Convention Example

How To Use This Manual

Numbered Lists (1,2,3…)

indicate a procedure with

sequential steps.

Actions that you should perform

are specified in boldface font.

Error and system messages are

displayed in Courier New font.

New terms appearing for the first

time are italicized.

Manual Symbols

The following table lists the symbols used in this Owner’s Manual to draw your attention to

important information.

Notation Symbol Meaning

WARNING:

CAUTION:

1. Turn OFF power to the field panel.

2. Turn ON power to the field panel.

3. Contact your local Siemens Building Technologies representative.

Type F for Field panels.

Click OK to save changes and close the dialog box.

The message Report Definition successfully renamed

appears in the status bar.

The Open Processor continuously executes a user-defined set of

instructions called the control program.

Indicates that personal injury or loss of life may

occur to the user if a procedure is not performed

as specified.

Indicates that equipment damage, or loss of data

may occur if the user does not follow a procedure

as specified.

Datamate Software

Datamate is a customer software tool for all controller communications. There are two

versions: Datamate Base, and Datamate Advanced. Datamate Base works on an IBMcompatible Personal Computer (PC), or a Handheld PC or Pocket PC™ running Windows

CE. Datamate Advanced works only on an IBM-compatible Personal Computer. With

Datamate, you can backup, restore, and edit any APOGEE database (but only Datamate

Advanced allows you to edit points offline). Backing up and restoring a database can be

accomplished while connected to any APOGEE field panel, or to the Building Level Network

(BLN) or Floor Level Network (FLN) device in question. A modem and telephone lines can

also be used. Databases can be saved to a hard or floppy disk and kept for permanent

storage or used as backup.

For more information on Datamate software, refer to the appropriate user guide based on

which version of Datamate you are using (Base or Advanced), or contact your local Siemens

Building Technologies, Inc. representative.

Siemens Building Technologies, Inc. V

Differential Pressure Monitor Owner’s Manual

Getting Help

For more information about the Differential Pressure Monitor, contact your local Siemens

Building Technologies representative.

Where To Send Comments

Your feedback is important to us. If you have comments about this manual, please submit

them to

These manuals, along with information about other Siemens products, services, and

technical training classes, can be obtained from your local Siemens Building Technologies

representative.

SBT_technical.editor.us.sbt@siemens.com

VI Siemens Building Technologies, Inc.

1

Product Overview

Introduction

Differential Pressure Monitor

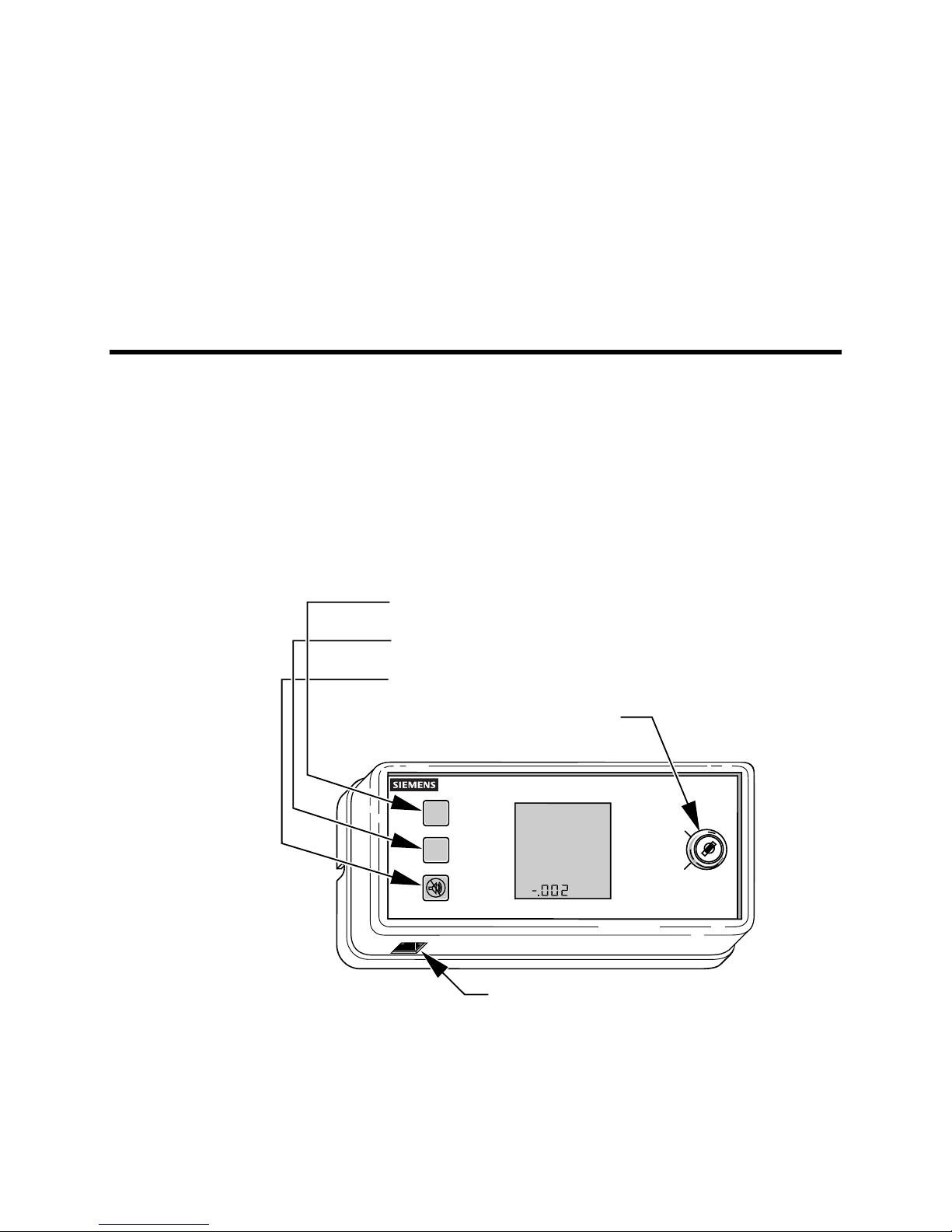

The Differential Pressure Monitor (DPM) is a Siemens Building Technologies FLN product.

The DPM monitors the differential pressure between a room and an adjacent space, and

No Isolation/

Neutral

Negative Pressure

Figure 1).

provides visual and audible alarms to alert a user of alarm conditions (

NORMAL LED (GREEN)

ALARM LED (RED)

HORN SILENCE BUTTON

PRESSURE MODE KEY SWITCH

(OPTIONAL)

SWITCH OVERRIDE DOOR OPEN

HIGH PRESSURE LOW PRESSURE

GENERAL FAILURE ANTEROOM

NEGATIVE ISOLATION

PROTECTIVE ISOLATION

INFECTIOUS ISOLATION

NEGATIVE PRESSURE

POSITIVE PRESSURE

INCHES OF H20

PORTABLE OPERATOR’S

TERMINAL PORT

Infectious Isolation/

SEN0175R3

Normal

Alarm

Horn

Silence

Siemens Building Technologies, Inc. 1

Figure 1. Differential Pressure Monitor.

Differential Pressure Monitor Owner’s Manual

Ordering Notes

Differential Pressure Monitor with Keyed

Switch for negative pressurization.

Differential Pressure Monitor with Keyed

Switch for positive pressurization.

Differential Pressure Monitor without

Keyed Switch.

Related Equipment

Remote Pressure Transmitter for use with

the Differential Pressure Monitor.

Calibration tool for Remote Pressure

Transmitter.

Hardware Inputs

Digital

•

Remote pressure transmitter (2 for App. 702 and 704, patient room and anteroom)

Door switch (optional)

•

547-005

547-006

547-002

547-003

547-004

Hardware Outputs

Analog

4-20 mA pressure signal

•

2-value resistive signal to identify pressurization mode to Room Pressurization

•

Controller

Digital

Alarm relay

•

2-state signal for pressurization mode to Constant Volume Controller

•

2 Siemens Building Technologies, Inc.

Components

The components of the DPM include:

LCD Messages

The LCD shows the differential pressure of the room in inches of H2O or Pascals. It also

shows the status of the DPM with the following messages:

•

Liquid Crystal Display (LCD)

Light Emitting Diodes (LEDs) (2)

•

Horn Silence Button

•

Portable Operator’s Terminal Port

•

Pressure Mode Key Switch (optional)

•

Chapter 1 – Hardware

LCD Message… Indicates that the…

LOW PRESSURE room differential pressure is below the user-

defined limit.

HIGH PRESSURE room differential pressure is above the user-

defined limit.

DOOR OPEN door to the occupied space is open if it is being

monitored.

GENERAL FAILURE RPT has lost power or the DPM is not receiving

the pressure signal from the RPT.

SWITCH OVERRIDE database points that determine pressurization

mode have been set from a field panel. This

overrides the pressure mode key switch position,

rendering it ineffective.

ANTEROOM LCD is displaying the anteroom pressure in

response to pressing the Horn Silence button, or

anteroom differential pressure is not being

maintained.

NO ISOLATION device is monitoring for neutral pressure.

PROTECTIVE ISOLATION /POSITIVE

PRESSURE

INFECTIOUS ISOLATION/NEGATIVE

PRESSURE

device is monitoring for positive pressure

(Applications 701 and 702).

device is monitoring for negative pressure

(Applications 703 and 704).

Siemens Building Technologies, Inc. 3

Differential Pressure Monitor Owner’s Manual

LED Status

The LEDs indicate the following status:

LED color… Indicates that the DPM is operating in…

Green a normal condition.

Red an alarm condition.

Button Functions

The Horn Silence button on the DPM has the following functions:

Button Functions

Horn Silence • Pressing this button turns the alarm horn OFF

• For Applications 702 and 704 only. The following

(applies to all applications).

function applies to Applications 702 and 704 when

displaying the differential pressure of the anteroom:

Pressing the Horn Silence button for 5 seconds

displays the “ANTEROOM” descriptor and the

anteroom differential pressure on the LCD.

Pressure Mode Key Switch (Optional)

The Pressure Mode Key Switch (optional) allows the operator to locally select the pressure

mode.

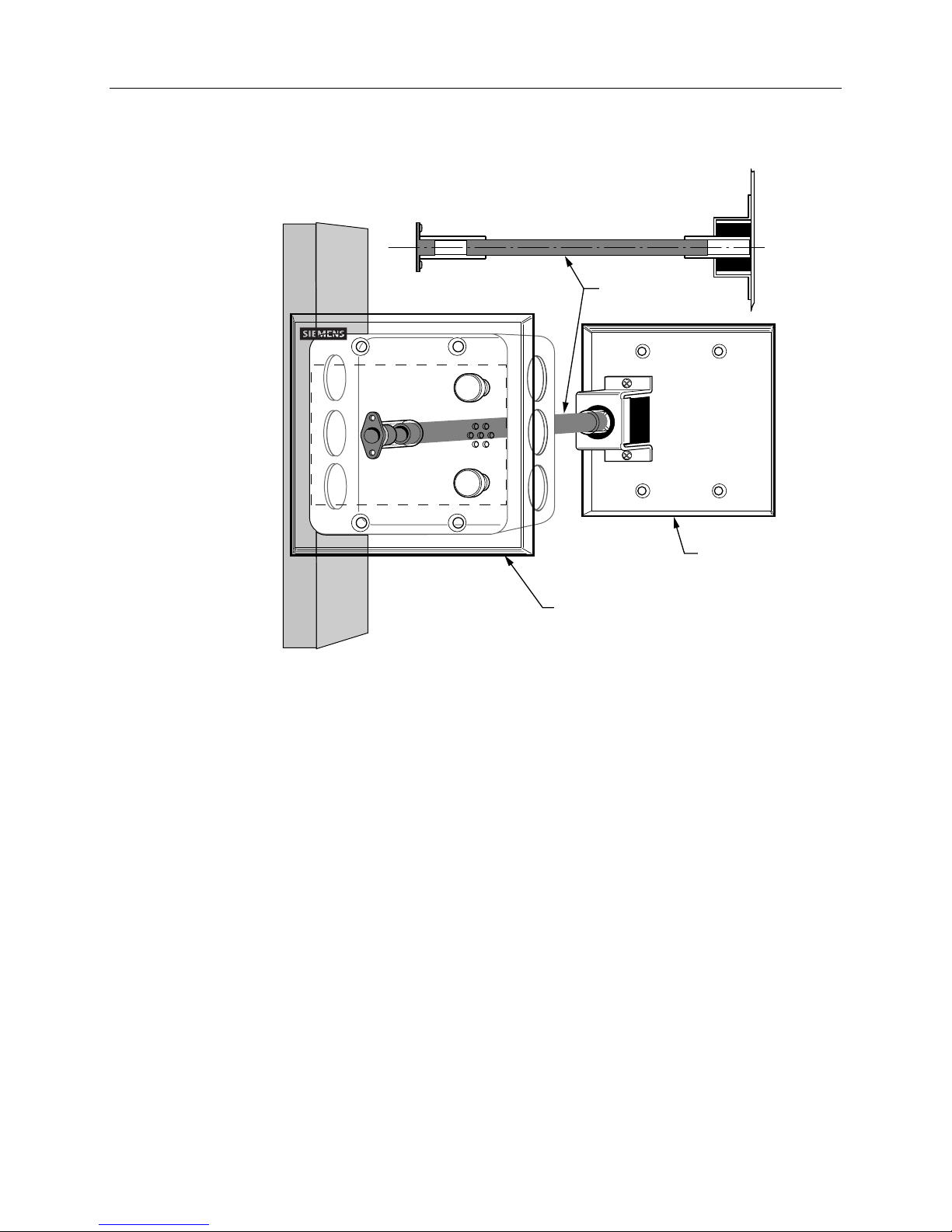

Remote Pressure Transmitter

The Remote Pressure Transmitter (RPT) is a Siemens Building Technologies, Inc.

Laboratory Control product. The RPT (

between a room and the adjacent space. The RPT sends that measurement to the

Differential Pressure Monitor.

Components

The components of the RPT include (Figure 2):

•

Inside cover plate

Outside cover plate

•

Airflow tube

•

Figure 2) measures the difference in air pressure

4 Siemens Building Technologies, Inc.

Chapter 1 – Hardware

AIRFLOW TUBE

OUTSIDE

COVER PLATE

INSIDE

COVER PLATE

SEN0179R2

Figure 2. Remote Pressure Transmitter

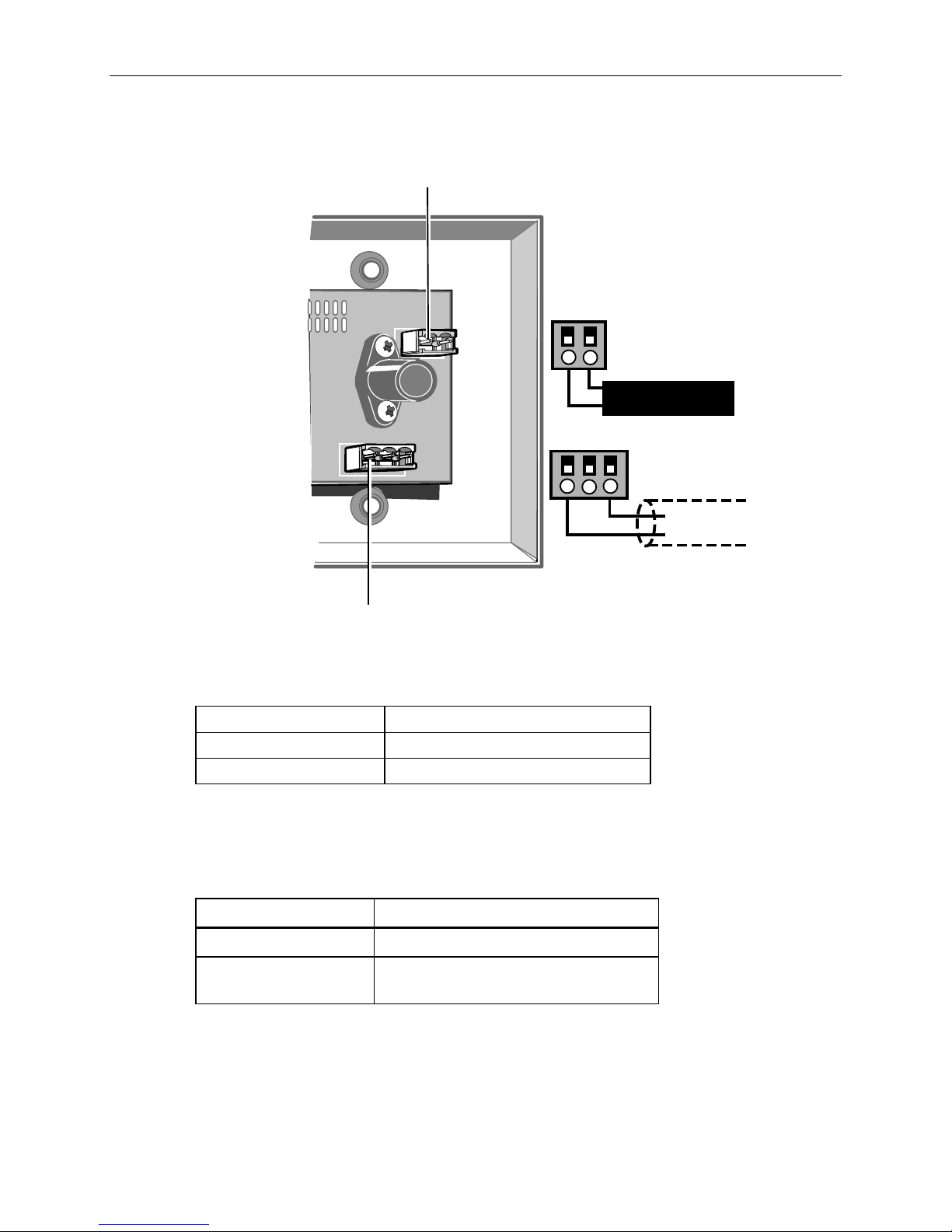

Circuit Board

The printed circuit board of the RPT (Figure 3) is the pressure signal generating area. The

circuit board is not visible once the RPT is installed. The following components are hidden

once the RPT is installed:

• • 24 Vac (wire receptacle)

Pressure signal (wire receptacle)

Siemens Building Technologies, Inc. 5

Differential Pressure Monitor Owner’s Manual

PIN #1

+

-

1 2 3

+ -

24V TRUNK

TO DPM

PRESSURE SIGNAL

SEN0177R1

PIN #1

Figure 3. RPT Circuit Board.

Operating and Power Specifications

Operating temperature

Operating range

Power consumption

65° to 85°F (18.3° to 29.5°C)

24 Vac, 50/60 Hz

1.4 VA, Class 2, at 24 Vac

Pressure Signal Output Definition and Specification

The pressure signal output is a digital pulse signal that represents the measured pressure

difference across the sensor.

Operating Range

Recommended Wire

Recommended max.

wire length

0-5 volt rectangular wave, 0-10 KHz

2 Conductor, 18 AWG Shielded Cable.

500 ft (152.4 m)

6 Siemens Building Technologies, Inc.

Loading...

Loading...