Page 1

SIEMENS

Page 2

SIEMENS

Floppy Disk Drive FDD 100-8

INTRODUCTION

OPERATION

THEORY OF OPERATION

INSTALLATION

Technical Manual

Volume 1 Model 100-8D

Page 3

TABLE OF CONTENTS

1 IN T R O D U C TIO N .................................................................................................... 1-1

General .................................................................................................................. 1-1

Scope ..................................................................................................................... 1-1

De sc ription ....................................................................................................... 1-1

Disk C a r t r i d g e ................................................................................................ 1-3

Recording F o r m a t ......................................................

...

...............................

1-5

Encoding S c h e m e ......................

...

............................................................ 1-5

Trac k F o r m a t ............................................................................................. 1-5

Sector Fo r m at

.........................

...

............................................................ 1-6

Sector Content .................................................................................. 1-6

32-Sector F o r m a t ........................................................................... 1-6

IBM 37 40 Form at ........................................................................... 1-7

Disk Drive A s s e m b l y .................................................................................. 1-8

Printed Circuit Board .............................................................

...

1-8

Main Deck A s s e m b l y ........................................................................... 1-9

C a rrier A s s e m b ly .................................................................................. 1-9

Options-F ea tu r e s

.........................

...

.................

...

.................

...

..................... 1-9

Write P r o t e c t ............................................................................................. 1-1

Binary Select

. . . . . . .

................................

. ............................. 1-10

Radial Select ............................................................................................. 1-10

Hard S e c t o r ................................................................................................ 1-11

16/8 Sector ................................................................................................ 1-11

Auto E ra s e .................................................................................................... 1-11

Data Se parator (FM O n l y )

..................

...

...............................

...

1-11

Auto Head Load .......................................

...

1-12

Activity Indicator .................................................................................. 1-12

PC B A ssem bly Option C o n fig u r atio n s .................................... 1-12

Sp e cifi c a tio n s......................................................................................

...

1-12

2 O P E R A TIO N

................................

.............................................................................. 2-1

Gene r a l ......................................................................................

...

........................

2-1

Daily O p er a tio n ................................................................................................ 2-1

Floppy Disk Handling and S to ra g e ............................................... 2-1

Floppy Disk Loading and U nlo ad in g

...............

...

2-2

W rit e - P r o t e c t

.............................

...

............................................................ 2-3

ILL

Section Page

Page 4

TABLE OF CONTENTS (Continued)

3 THEORY OF OPERATION

........................................................................ 3-1

G e n e r a l.............................................................................................................. 3-1

Control S y s te m

.....................

...

. .

....................................................... 3-2

Command Execution

..................

...

................................................... 3-2

Status S e n sin g .......................................................................................... 3-3

Positioning System ................................................................................... 3-3

Stepper Motor C o n t r o l .......................................................

...

3-3

Stepper M o t o r .......................................................................................... 3-4

Carriage A s s e m b l y ............................................................................ 3-4

Read/W rite S y s t e m ................................................................................... 3-4

Read/Write Operation ..................................................................... 3-4

Functional D es c r ip t i o n ............................................................................ 3-5

Spindle Drive S y s t e m

........................................................................ 3-6

Spindle System ...............................

«............................................ 3-7

Read/W rite Head Positioning System ................................... 3-7

Head Load S y s t e m

............................................................................... 3-8

Control and Data T i m in g .................................................................. 3-8

Logic Con v ention s

..............

...

.................................................................... 3-10

Detailed Logic D e s c r i p tio n ................................................................. 3-10

Control L o g i c ................................................................................................ 3-10

Select ............................. ........................................................................... 3-13

Binary Select (Option)........................................................................ 3-14

Index/Sector D e t e c t i o n ..................................................................... 3-15

Hard Secto r (Option)............................................................................ 3-16

Ready ...............................

...

..........................................................

...

3 - 16

Activity Indicator ..................

...

.......................................................... 3-18

Door Lock (Option)

..............

...

............................................................. 3-19

Disk C h a n ge .............................................

...

3-19

Read /W rite Head Positioning Logic

............................................. 3-20

Head L o a d ................................................................................................ 3-20

Track 00 Switch ..............................................................

...

.................

3-20

Stepper Motor Drive ......................................................................... 3-22

Interface Gating. ...........................................................

...

3-22

State Counter ................................................................................... 3-22

Stepper Motor D river s .............................................................. 3-23

Stepper Motor ............................................................................... 3-24

Read/W rite L o g i c ...................................................................................... 3-25

Write-Protect . .................................................

...

3-26

Write Mode ............................................................................................. 3-26

Write and E rase Gating .......................................................... 3-26

Erase L o g i c .......................................................

...

...........................

3-27

DC U n s a f e .......................................................................................... 3-28

Write Current Control .............................................................. 3-29

Low Write Current C o n t r o l

...............................

...

................. 3-30

Section Page

iv

Page 5

TABLE OF CONTENTS (Continued)

3 THEORY O F OPERATION (Continued)

Read M o d e ......................

...

.......................................................................... 3-31

Read/W rite S e l e c t ........................................................................... 3-32

Read LSI Circuit, Read Amplifier, and Filt e r . . . 3-32

Differentiating Network

..................

...

. e . s s « ................ 3-34

Crosso v e r Detector ....................................................................... 3-35

Time Domain Filter .................................................................... 3-35

FM Data Separator (Option)............................................................. 3-36

Term inating R e sistor Network . ............................................... 3-37

4 INS T A L LA TION....................................................................................................................... 4-1

G e n e r a l

................................................................

...

.............................................. 4-1

Inspection

............................................................................................

...

4-1

Unpacking

.........................

...

.............................................................................. 4-1

Mechanical Checks .............................................................'

.......................

4-2

Connecting C a b l e s ...............

...

.....................................................

...

4-2

AC Po w er C a b l e ...................................................................................... 4-4

DC Power C a b l e ...................................................................................... 4-5

Interface Signal Cable ...............

...

.................

...

................................ 4-5

Interface Signal Descriptions ...............

...

...................................

...

. 4-6

Logic Levels and T e r m in a t io n ...................................................... 4-6

Input S i g n a ls................................................................................................ 4-8

Output S i g n a ls............................................................................................. 4-8

Interface T i m i n g

.......................................

...

.................................................

4-8

Sy stem C o n fig ura t io n s

.......................................

...

................................... 4-12

Single-Drive C o n fig u ra t i o n ............................................................. 4-12

Radial Sele ct......................................................................................... 4-12

Daisy-Chained Radial S e l e c t .................................................. 4-13

Binary S e l e c t

..............

...

...............................

...

...............................

4-14

Interfac e/Intern al Options Installation ........................................... 4-16

Radial Select

................................

...

........................................................ 4-16

Binary Select" ...........................................

...

.............................................. 4-18

Radial S t e p ...............

...

................................................................................. 4-18

Radial Ready

.......................................

...

4-19

Ready Option ............................................................................................. 4-20

Radial I n d e x /S e c to r

...............

...

............................................................ 4-20

Radial Head Load O p tio n .................................................................... 4-20

Auto Head Load O p ti o n .............................

...

.....................

...

4-21

Hard S e c t o r

..............................................

...

.............................................

4-22

16 or 8 Sector ..................

...

................................................................... 4-22

Activity Indicator S e l e c t...........................................

...

.................

...

4-22

FM Data S e p arato r . . ..................

...

.................................................

4-23

Section Page

v

Page 6

TABLE OF CONTENTS (Continued)

4 INSTALLATION (Continued)

Tunnel-Erase Option ......................................

...

........................

...

4-23

Write P r otect O p ti o n

..............................................................

...

4-23

Disk Change Option ............................................................................ 4-24

Pha se O p t i o n .......................................................

...

..............................

4-24

Installation .................................................................................................... 4-25

Mounting D im e n sio n s

........................................................................ 4-25

Section Page

vi

Page 7

LIST OF ILLUSTRATIONS

Figure Page

1-1 Floppy Disk Drive Model F D D 1 0 0 - 8 D

1-2 Floppy Disk and Protective Envelope

..............................................

..............................................

1-1

1-3

1-3 Single and Double Density Encoding .................................................. 1-5

1-4 32-Sector F o r m a t ..............................

... .

........................................

...

1-6

1-5 IBM 3740 F orm at ........................................................................................... 1-7

1-6 Physical Dim ensions and Mounting p r o v i s i o n s

2-1 Floppy Disk and Storage Envelope

..............

..........................

. . . .

.......................

1-16

2-2

2-2 Floppy Disk Loading .................................................................................... 2-3

3-1 Floppy Disk D r i v e, Simplified Block Diagram

3-2 Detailed Functional Block D i a g ra m

3-3 Spindle Drive S y s t e m

...................

..................................................... 3-5

...

............................................................. 3-6

..........................

3-1

3-4 Spindle S y s t e m .................................................................................................. 3-7

3-5 Read/W rite Head Positioning S ystem ............................................... 3-8

3-6 Control and Data T im in g .............................................................................. 3-9

3-7 Interface Logic L e v e l s .....................................................

...

.......................

3-10

3-8 Logic S y m b o lo g y .............................................................................................. 3-11

3-9 Select L o g i c ......................................................................................................... 3-13

3-10 Index D etection Logic ................................................................................ 3-15

3-11 Index Timing ..................................................................................................... 3-lo

3-12 Hard Sector and 16/8 Sector Option L o g i c

....................................

3-17

3-13 INDEX/SECTOR T i m i n g .............................................................................. 3-17

3-14 Ready L o g i c ........................................................................................

...

3-18

3-15 Head Load L o g ic ............................................................................................... 3-19

3-16 Track 00 L o g ic

...................

...

.......................................................................... 3-21

3-17 Track 00 Timing .............................................................................................. 3-21

3-18 Stepper Motor Interface Gating L o g ic ............................................... 3-22

3-19 Stepper Motor Timing ................................................................................. 3-23

3-20 Stepper Motor Drivers Logic ................................................................ 3-24

3-21 Write Initiate T i m in g

3-22 W rite -P r o tect Logic .........................................................

3-23 Write and E rase Gating L o g ic

........................

................

...

.................* .................................. 3-25

...

...

.................

.......................

... .

....................

3-26

3-27

3-24 E rase L o g i c ......................................................................................................... -*-28

3-25 Erased Data P a t t e r n

3-26 DC Unsafe L o g i c .................................................................................

3-27 Write Current Control L ogic . . . . . .

........................

...

....................

..............................

... .

....................

...

. 3-29

...

3-29

...

3-30

vii

Page 8

LIST OF ILLUSTRATIONS (Continued)

Figure Page

3-28 Write Current S w i tch in g

............................................................................ 3-31

3-29 Write Current Timing ................................................................................ 3-32

3-30 Read Initiate Timing .................................................................................... 3-33

3-31 Read Logic, Simplified Diagram ........................................................ 3-33

3-32 Read P ream p lifier and F i lter C ir c u i t .............................................. 3-34

3-33 Differentiating Netw o rk....................................

...

......................................... 3-34

3-34 Read Data Waveforms

..........................................

...

.................................. 3-35

3-35 Time Domain Filter Logic ...................................................................... 3-35

3-36 FM Data Separator (Option) Logic ..................................................... 3-35

3-37 FM Data Separator Output Timing ..................................................... 3-36

3-38 Terminating R e s istor N e tw o rk ............................................................... 3-37

4-1 Principal Parts Locatio n ............................................................................. 4-3

4-2 AC Connector J 2 .............................................................................................. 4-5

4-3 DC Connector J 2 .............................................................................................. 4-5

4-4 Interconnecting D ia g ra m ............................................................................. 4-7

4-5 S ingle-Driv e C o nfig u ratio n ............................................................

...

4-12

4-6 Radial Selec t C o n figu r a t ion ...................................................................... 4-13

4-7 Daisy-C h ained Radial Sele ct C o n figura tion .................................... 4-14

4-8 Binary Select C onfig u ration

...................................................................... 4-15

4-9 Interface/internal O ption s.......................................................................... 4-17

viii

Page 9

LIST OF TABLES

1-1 Floppy Disk C h a r a c t e r i s ti c s

..................

...

........................................ . 1-4

1-2 Principal S p ec ific a tio n s

.......................................

...

............................

...

. 1-13

2-1 Floppy Disk Loading and Unloading . , .........................

...

, , . . 2-3

3-1 Disk Drive Selection

........................................................................

...

3-14

4-1 AC Power R eq u i r em e n t s ............................................................................

...

4-4

4-2 DC Pow er Req uirements ............................................................................... 4-5

4-3 Reco m m ended J3 Mating C o n n e cto rs..................................

...

4-6

4-4 Interface Input S i g n a l s

.....................................

...

.......................................... 4-9

4-5 Interface Output Signals , , , , ................................................

...

4-11

Table Page

ix

Page 10

Page 11

SECTION 1

INTRODUCTION

GENERAL

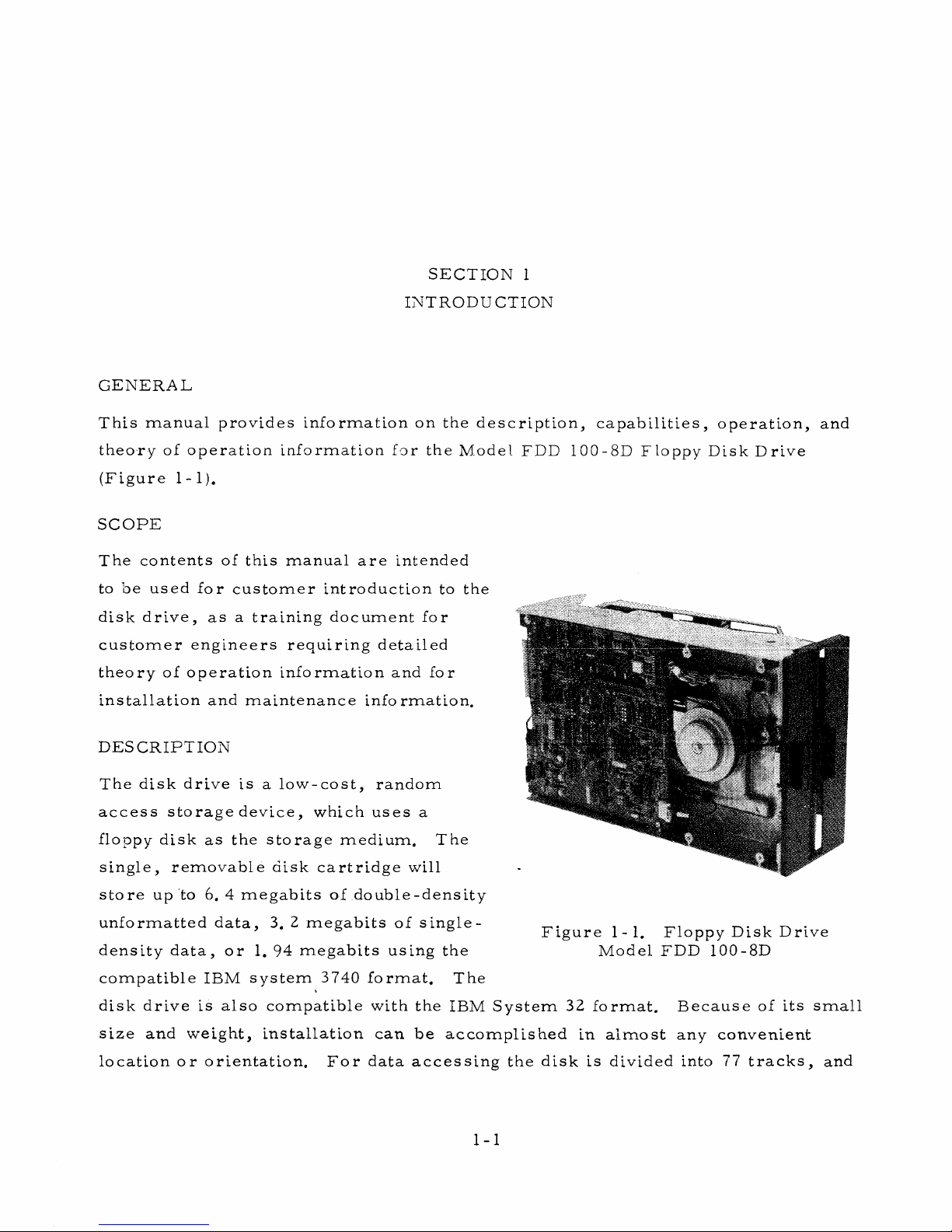

This manual provides information on the de

theory of operation information for the Mod

(Figure 1-1).

SCOPE

The contents of this manual are intended

to be used for custom er introduction to the

disk drive, as a training document for

cu stomer engineers requiring detailed

theory of operation information and for

installation and maintenance information.

DESCRIPTION

The disk drive is a low-cost, random

access storage device, which uses a

floppy disk as the storage medium. The

single, removable disk cartridge will

store up to 6. 4 megabits of double-density

unformatted data, 3. 2 m egabits of single-

density data, or 1. 94 m egabits using the

compatible IBM sy stem 3740 format. The

disk drive is also compatible with the IBM

size and w’eight, installation can be accoi

location o r orientation. F or data accessin

cription, capabilities, operation, and

1 FDD 100-8D Floppy Disk Drive

Figure 1-1. Floppy Disk Drive

Model FDD 100-8D

System 32 format. Because of its small

nplished in almost any convenient

I

the disk is divided into 77 tracks, and

1-1

Page 12

each track can be subdivided into as man y as 32 sec tors. A stepper motor positions

the read/write head at the track to be accessed . Index and sector holes punched into

the disk are sensed photoelectrically to produce sec tor and index pulses that permit

accessing the individual sectors of a track. When the optional write-protect slot in

the protective envelope is uncovered the w rite-pro tected condition is sensed photo

electrica lly, and write operations are inhibited.

Up to eight d rives can be interfaced to a single host controller. The controller

controls disk drive selection, head loading, track addressing, and read/write data

transfers.

When a disk cartridge is inserted and the acce s s door is closed, the drive spindle

rotates the disk at 360 revolutions per minute. When se lected, the drive accepts

a head load command, causing the read/write head to be loaded to the disk. With

the drive selected, sector/in d ex puls es, write-p r otect sta tus, track 00 position

status, and a read/write ready status is supplied to the controller. At the desired

track, a data tran sfer operation is performed; read-to the con trolle r, write-from

the contr o lle r, depending on the state of the write command.

During a write operation (disk not write-protected ), write data is input to the write

circuits. Fo r each write data pulse receiv ed , a flux reversal is recorded on the

disk by the read/write head.

During a read operation, each recorded flux rev e rsal is sensed by the read/write

head, converted to a raw data pulse and supplied to the controller.

Applications for the Floppy Disk D rive include:

• Key Entry System s

• Poin t-of-S ale Recording System s

• Word P ro cessin g System s

• Batch Termin al Data Storage

• Small Business Sy stem s Data Storage

• M icro p rogram Loading and E r ro r Logging

• Minicomputer Programs and Auxiliary Data Storage

1-2

Page 13

The drive provides random accessing of data with greater performance and

reliab ility and is an excellent alternate product to paper tape, reel-to - reel tapes,

card equipment, ca s settes, and cartridge drives.

DISK CARTRIDGE

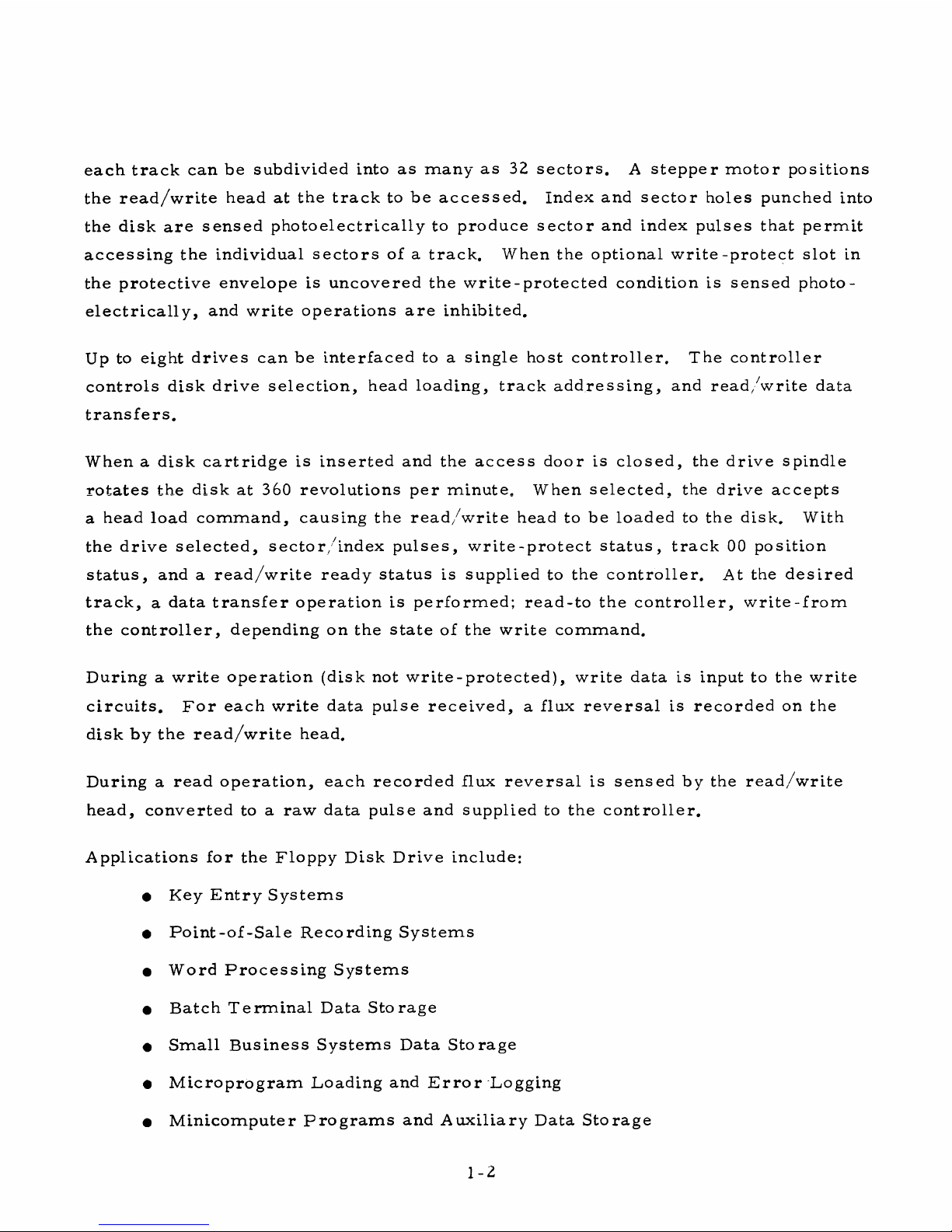

The disk cartridge is an 8 -inch -sq uare plastic protective envelope, in which the

floppy disk is sealed. The protective envelope contains apertures for spindle load

ing, head contact, secto r/index detection, and optional write-p rotect detection,

(see Figure 1 -2).

The recording m edia is a m agnetic-oxid e-coated floppy (flexible) m ylar disk sealed

within the plastic envelope for protection, self-cleaning, and ease of handling. The

disk should be handled and stored in clean environmen ts, free from magnetic

influences.

Figure 1-2. Floppy D isk and P rote ctive Envelope

1-3

Page 14

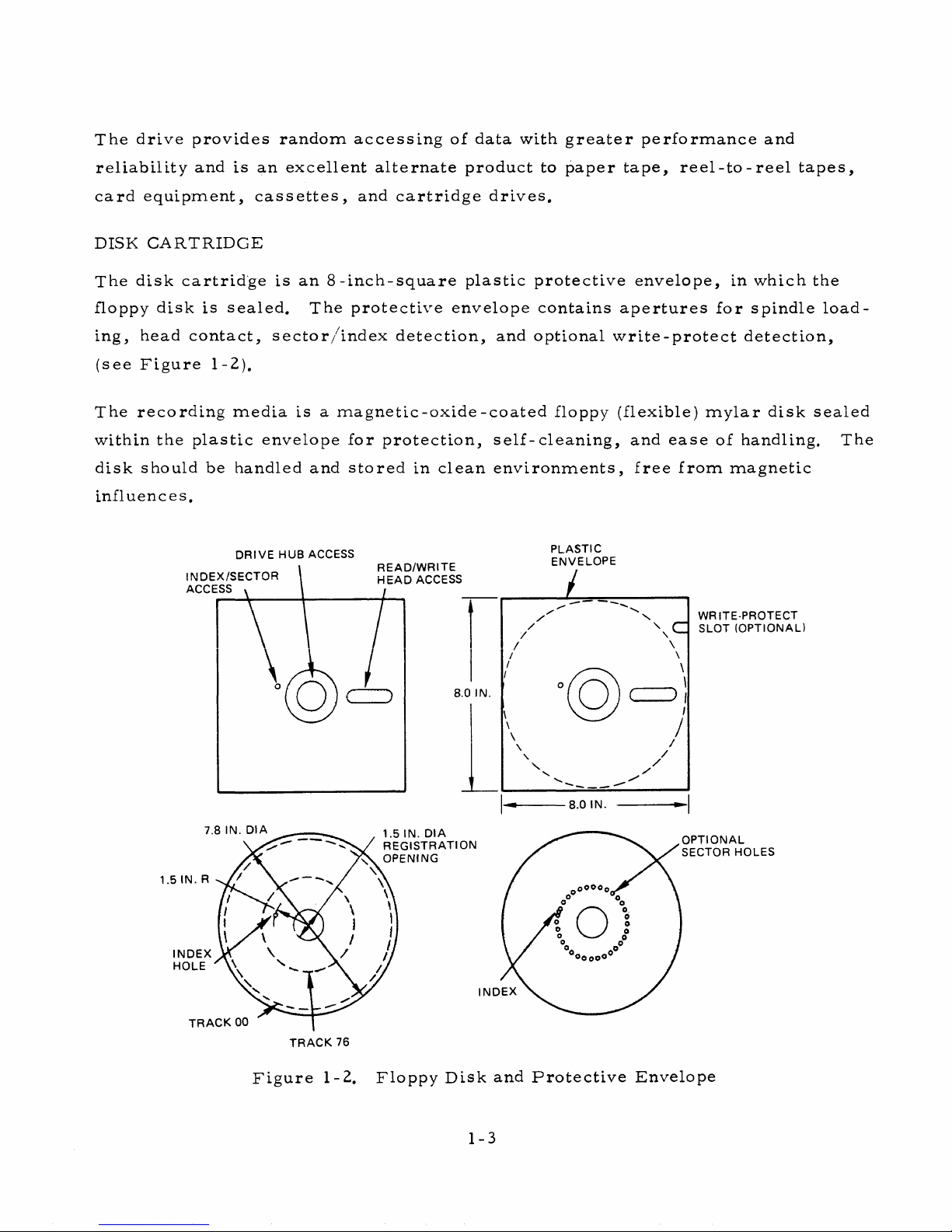

At no tim e should the surface of the med ia be touched, or the surface of the

envelope be written on. When not in use, the disk cartridge should be returned

to its protective storage envelope.

For reliable op eration, floppy disks should be stabilized in the same environment

as the using disk dr ives, for a period of at le a st five m in u tes, prior to installation.

The recommended floppy disk m eets the requirem ents of the following documents:

X3138/77-118 Am erican National Standard for Single Sided

Unformatted Flexible Disk Cartridge.

GA21-9190 IBM One-Sided, Original Equipment Manufacturing

Information.

EC M A/TC 1 9/? 7 / l6 Data Interchange on 200 m m Disk Cartridges using

double frequency recording at 13,262 ftprad on one

side.

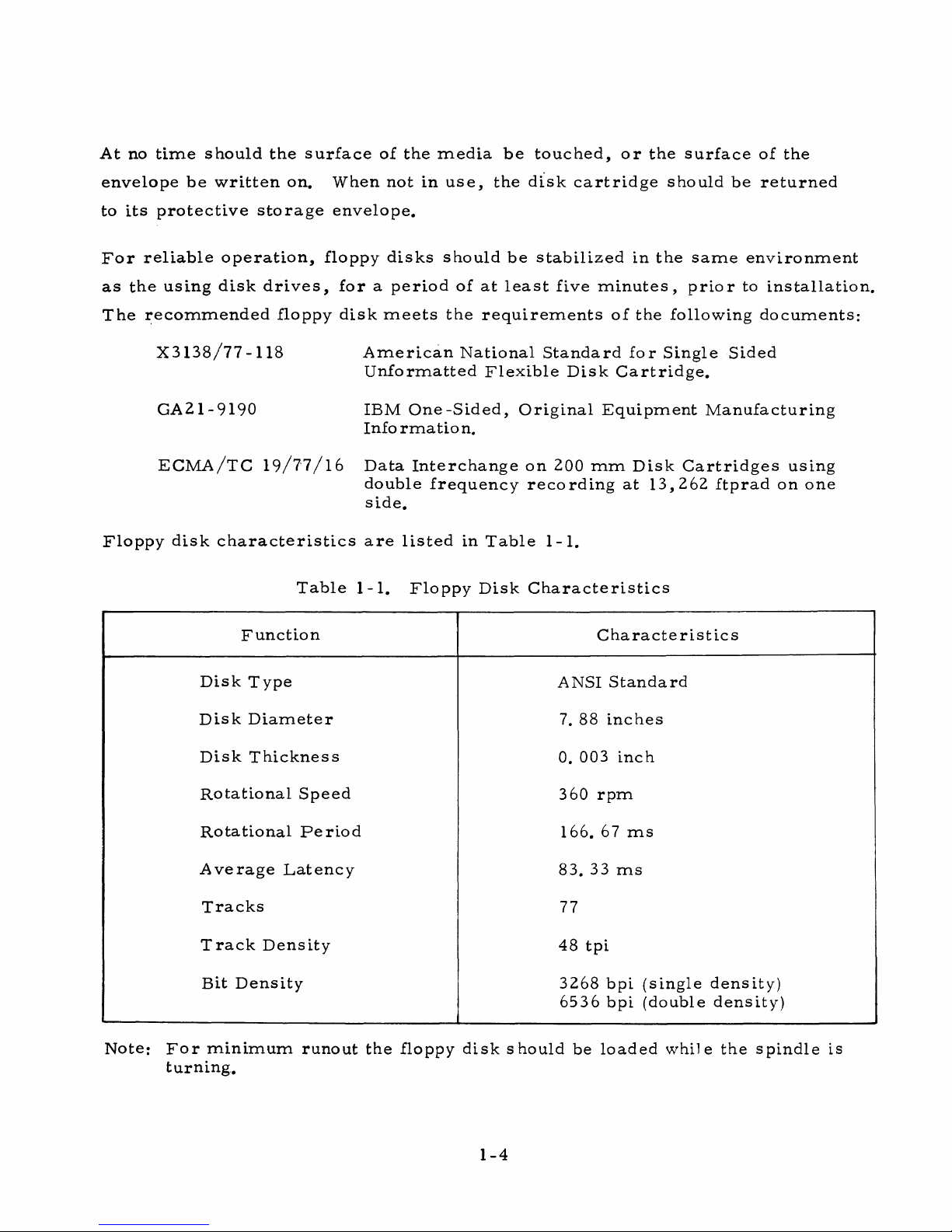

Floppy disk ch a racteristic s are listed in Table 1-1.

Table 1-1. Floppy Disk Cha racteristics

Function

Characteristics

Disk Type

ANSI Standard

Disk Diam eter

7. 88 inches

Disk Thickness

0. 003 inch

Rotational Speed

3 60 rpm

Rotational Period

166. 67 ms

Ave rage Latency

83. 33 ms

Tracks

77

Track Density

48 tpi

Bit Density

3268 bpi (single density)

6536 bpi (double density)

Note: For m inim um runout the floppy disk should be loaded while the spindle is

turning.

1-4

Page 15

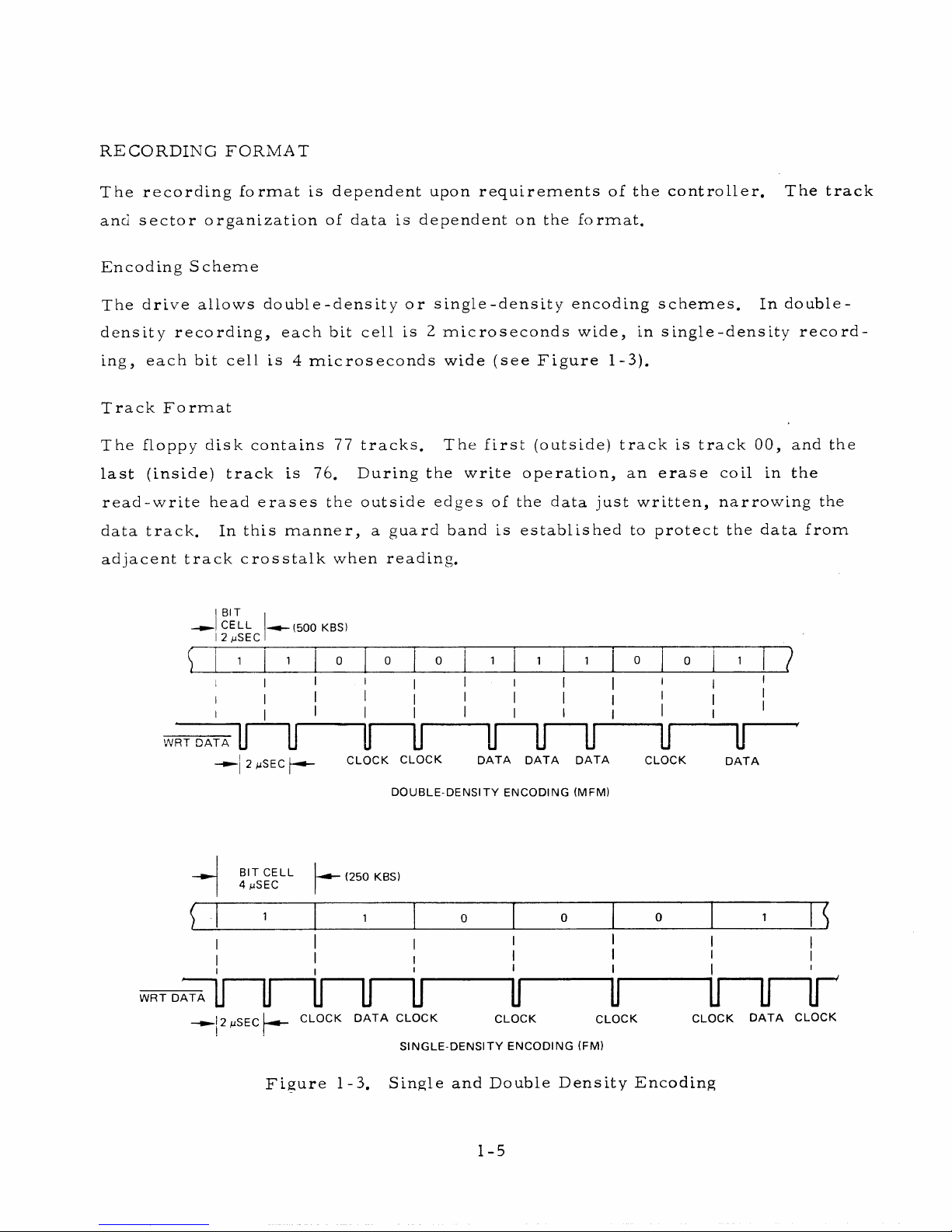

RECORDING FORMAT

The recording fo rmat l s dependent upon req u irem ents of the controller. The track

and s e ctor organization of data Is dependent on the format.

Encoding S chem e

The drive allows double-densIty or s Ingle-dens Ity encoding schemes. In double-

density reco rdin g, each bit cell Is 2 m icrosec o n d s wide, In s ingle-dens Ity rec ord

ing, each bit cell Is 4 mic roseconds wide (see Figure 1-3).

Track Fo r m a t

The floppy disk contains 77 tracks. The first (outside) tra c k is track 00, and the

last (Inside) track Ls 76. During the write operation, an era s e coll in the

re a d -w rlte head era se s the outside edges of the data just w ritten, narrowing the

data track. In this m anner, a guard band Is established to protect the data fro m

adjacent tra c k crosstalk when reading.

WRT DA TA

WRT DA TA

-► 1 CELL

12 mSEC

-* - (5 0 '0 KBS)

1

1

0

0 I 0

1

1 1

I I

I I

I I

FT

- ► ] 2 mSEC f— -

BIT C ELL

-

4 iuSEC

1

I

i n n n n r

j2 mSEC h - CLO CK D A TA C LO CK CLOCK CLO CK

j u i m j u if

CLOCK CLOCK DA TA D ATA DATA

DO U BLE -D E NSITY EN COD IN G (MF M)

(250 KBS)

1

0

i i ! i i

0

¥ u n n r

SING LE- DENS ITY E NCOD IN G (FM )

0

0

CLOCK DA TA

0 1

CLO CK D ATA CLOCK

1

Figure 1-3. Single and Double Density Encoding

1-5

Page 16

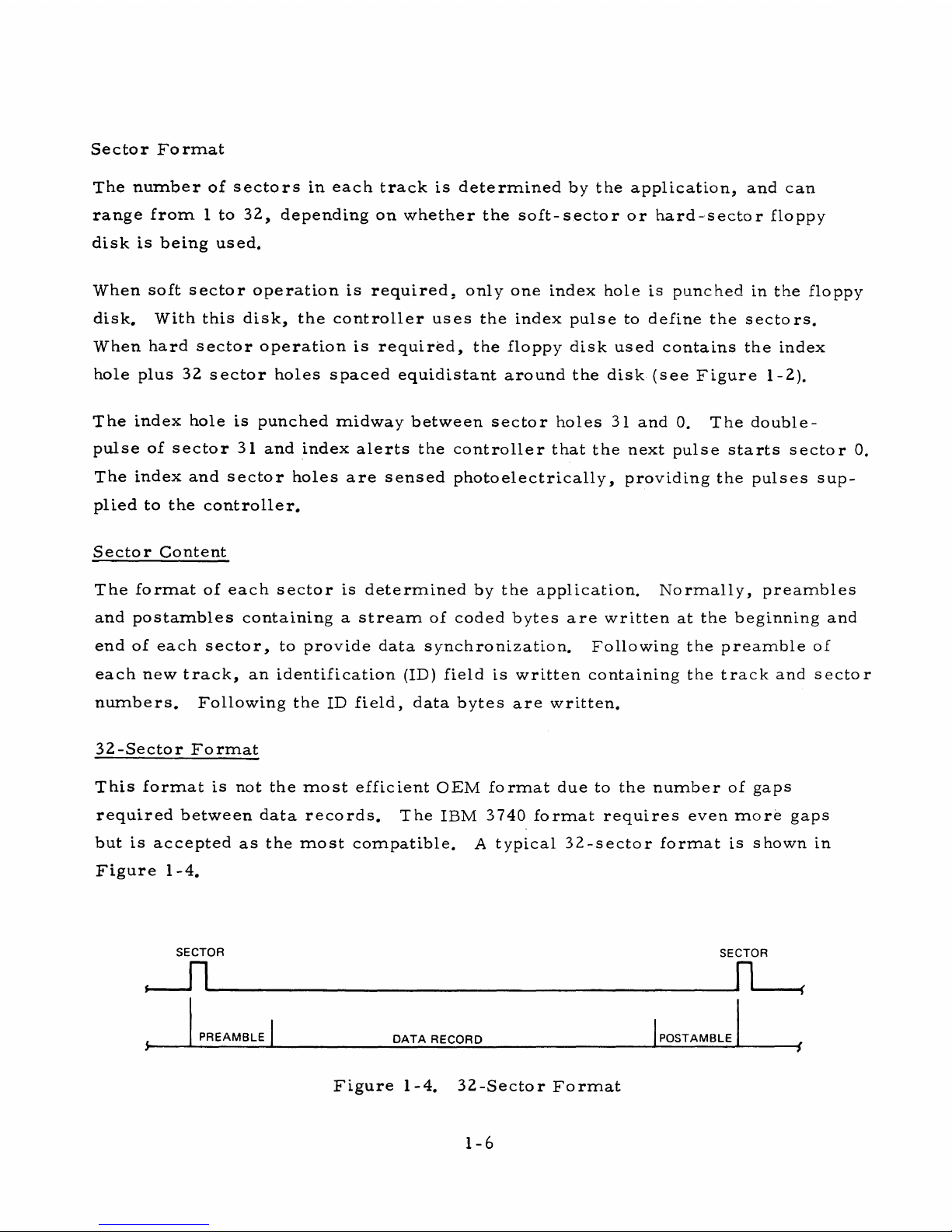

Sector Form at

The number of sectors In each track Is determined by the application, and can

range from 1 to 32, depending on whether the soft-se c to r or h a rd-se c tor floppy

disk is being used.

When soft secto r operation is required, only one index hole is punched in the floppy

disk. With this disk, the controller uses the index pulse to define the sectors.

When hard secto r operation is required, the floppy disk used contains the index

hole plus 32 secto r holes spaced equidistant around the disk (se e Figur e 1-2).

The index hole is punched midway between sector holes 31 and 0. The double-

pulse of sector 31 and index ale rts the controller that the next pulse starts sector 0.

The index and sector holes are se nsed ph otoelectr ically, providing the pulses sup

plied to the controller.

Sector Content

The format of each secto r is determined by the application. Norm ally, preambles

and postam b les containing a stream of coded bytes are written at the beginning and

end of each se c tor, to provide data synchronization. Following the preamble of

each new track , an identification (ID) field is written containing the track and sector

numbers. Following the ID field, data bytes are written.

32-Sector F orm at

This format is not the m o s t efficient OEM format due to the number of gaps

required betw een data records. The IBM 3740 form at requires even m o re gaps

but is accepted as the m ost compatible. A typical 32-s e c to r format is shown in

Figure 1-4.

SECTOR

SECTOR

PREAM BLE

DA TA REC ORD

POSTAM BL E

Figure 1-4. 32-S ector Form at

1-6

Page 17

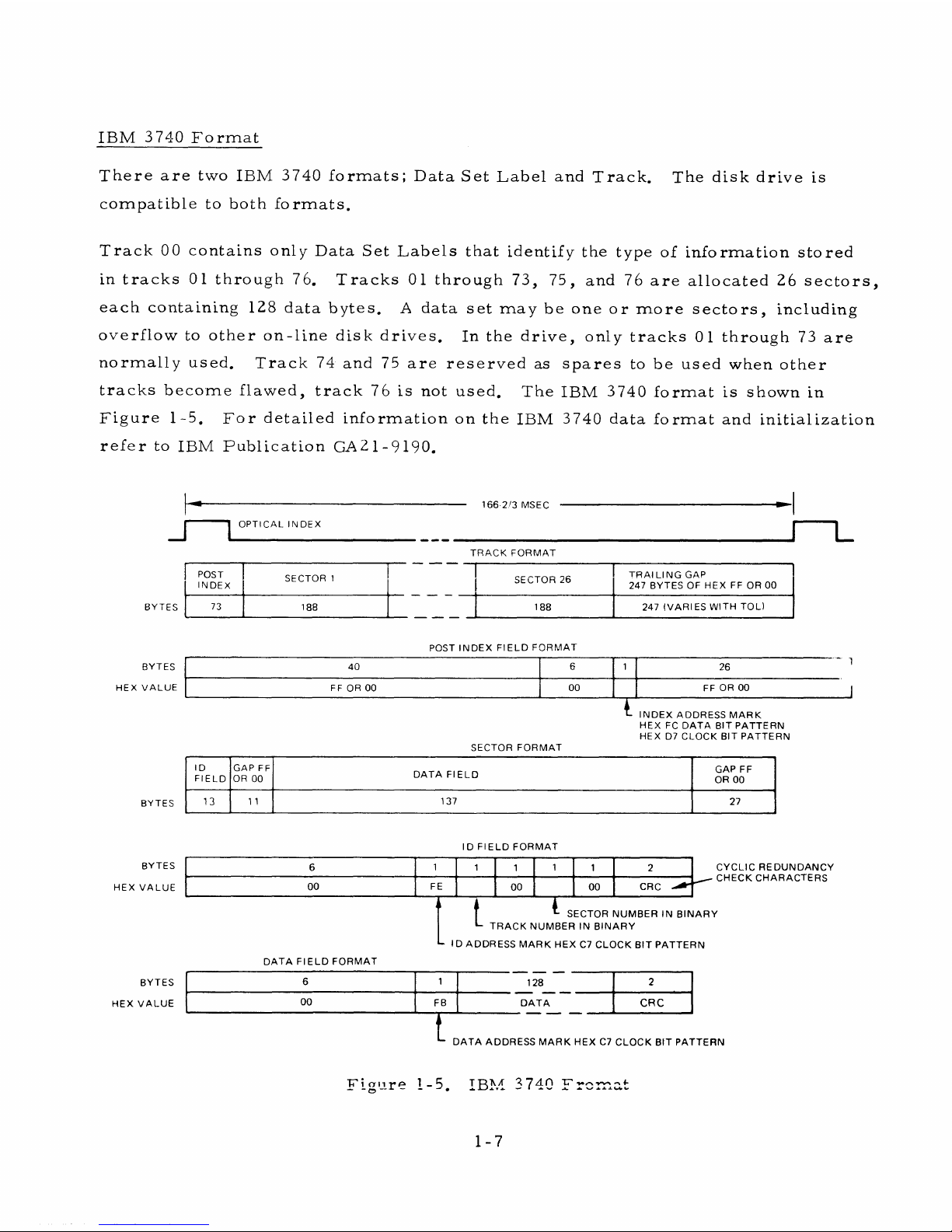

IBM 3 740 F o rm a t

There are two IBM 3740 form ats; Data Set Label and Track. The disk drive is

compatible to both form ats.

Track 00 contains only Data Set Labels that identify the type of information stored

in tracks 01 through 7 6. T r a cks 01 through 73, 75, and 76 are allocated 26 sectors ,

each containing 128 data bytes. A data set may be one or m o r e s e c tors, including

overflow to other on-line disk drives. In the drive, only tracks 01 through 73 are

no rm a lly used. T rack 74 and 75 are reserved as sp a res to be used when other

trac ks become flawed, track 76 is not used. The IBM 3740 form a t is shown in

Fig ure 1-5. For detailed information on the IBM 3740 data form at and initialization

re fe r to IBM Publication GA21-9190.

166-2/3 MSEC

J— L

OPTICAL INDEX

TRACK FORMAT

BYTES

J— L

POST

INDEX

SECTOR 1

SECTOR 26

TRA ILI NG GAP

247 BYTES OF HEX FF OR 00

73

188 188

247 (VARIES WITH TOL)

POST IND EX F IELD FO RMAT

BYTES

40 6

1

26

!

HEX VALUE

FF OR 00

00 FF OR 00 j

INDEX ADDRESS MARK

HEX FC DATA BIT PATTERN

HEX D7 CLOCK BIT PATTERN

BYTES

ID

FIELD

GAP FF

OR 00

DATA FIELD

GAP FF

OR 00

13

1 1

137

27

BYTES

HEX VALUE

BYTES

HEX VALUE

DATA FIELD FO RMAT

ID F IELD FO RMAT

6

1

1

1

1

1

2

00

FE

00 00 CRC

CYCLIC REDUNDANCY

CHECK CHARACTERS

t

L SECTOR NUMBER IN BINA RY

TRAC K NUMBER IN BIN ARY

L ID ADDRESS MAR K HEX C7 CLOCK BIT PATTERN

6

1

128

2

00

FB

DATA

CRC

I

DATA ADDRESS MA RK HEX C7 CLOCK BIT PATTERN

Figure 1-5. IBM 3 740 Frc

1-7

Page 18

DISK DRIVE ASSEMBLY

The disk drive ass e m bly can be installed in a standard 19-inch RETMA rack; two

horizontally, or four vertically. The drive can also be mounted in a table-top for

top loading applications.

The disk drive com p rises three m ajor assem blies-

• Printed Circuit Board (Electronics)

• Main Deck A ssem b ly

• Carrie r Assem b ly

Printed Circuit Board

All electronic circuitry required to convert the digital data input and output to

and from analog data for the rea d /w r ite head and head positioning information is

contained on one circuit board. Interface and DC connectors can be provided.

Logic is TTL with sele cted d iscrete and IC Components. The electron ics perform

the following functions:

• Read Chain

• Write Chain

• Ready Generation

• Index Detection

• Stepper M otor Control

• Interface D r ivers and Receiver s

• W rite-Protect (Option)

• Index/S ector Separator (Option)

• FM Data Separator (Option)

• Binary Select (Option)

1-8

Page 19

Main Deck Assem bly

The m ain deck a ssembly is the principal supporting asse m bly and contains the

following subassemblies;

Drive System

Positioning Svstem

Read Write S vs tern

Disk Cartridge Guide

and Ejector

Optical Sensing

- Spindle Drive m o tor, drive belt and pulley to

rotate spindle at 360 rpm.

- Stepping m o tor, lead s c rew and carriage, head

pressu re a rm and pressure pad to accurately

drive and position the read write head to the

desired track.

- Single-gap magnetic recording head with tunnel -

er a s e or s t raddl e - e rase feature. Read/w rite

head is contact type.

- Provides positive positioning and locking of disk

cartridge allowing prop er placement of the disk

cone. S pring-loaded ejection provides fast,

positive disk cartrid g e removal.

- Index and write - protect sensing by independent

LED and phototransistor sensing circuits. Also

track 00 sensing.

C a rrie r Assem bly

The c ar r i e r a s sem b ly is a secondary frame which pivots fro m the main deck

as sem bly and includes the following sub assem blies;

• Disk Centering Cone - P r e c isely cen ters and grips the floppy disk to the

s pindle.

• Head Load Mechanism - Solenoid, head p r e s s ure arm and pad. Ex erts

and sustains force, by the spring-loaded p r e ssu re

pad, to constrain the disk c artridge to the platten

and the read, write head.

Access Handle. Pushbutton latch release m echanism . Also

releases spring-loaded lock to discharge disk

cartridge.

OPTIONS-F E ATURES

The Floppy Disk Drive m ay be or d ered with basic configuration operating capa

bilities, or m ay be ord ered to include any or all available options. Each option

1-9

Page 20

offers unique operating features. Severa l options have connections designed into

the main printed circuit board, for low - c o s t custom er enhancement.

W r ite-P ro tect

The write-p rotect feature provides a write-inhibit function when a write -protect

floppy disk cartridge is used. The stored data is protected only if the cartridge

write-prote ct slot is present. With the slot cov ered, all write functions are

enabled.

Binary Select

The Binary Select option perm its any one of up to eight disk drives to be selected.

With the option installe d, SELECT lines are not dedicated but are used to contain a

binary select code. The SELECT 0 line is used to enab le/d isab le unit se lection,

while the SELECT 1, SELECT 2, and SELECT 3 lines contain a binary code between

0 and 7. When the SELECT 0 line is low (true), a decoder in the Binary Select

option log ic decodes the select code from the controller.

Radial Select

In the b a sic configuration, the disk drive does not accept com mands from the

contr oller, and does not supply status signals to the controller, until selected.

The purpose of this option is to allow commands to be accepted and status signals

to be supplied, each over separate lin e s, without the drive selected. The following

signals can be optionally configured for radial operation:

• S T E P and STEP IN (Step Command)

HDLD (Head Load Command)

• READY (Ready Status)

• INDEX and SECTOR (Index and Sector Pulses)

When dedicated lines are provided for these sig n a ls, the disk drive need not be

selected by the controller. Each line m u st be assigned a separate pin number on

the interface connector. Spare pins are provided for this purpose.

1-10

Page 21

The unit is modified for Radial Select operation by changing jumpers between the

existing etch pads. The etch pads are located on the main printed circuit board.

Hard S ector

In the b a sic configuration, the use of a hard sector disk causes the INDEX line to

produce one index pulse and 32 sector pulses per each disk revolution.

With the Hard Sector option installed, the index and sector pulses are separated

and supplied to the controller on independent INDEX and SECTOR lines.

16/8 Sector

When the Hard Sector option is installed, the addition of the 16/8 Sector option

provides a 2-bit binary counter that counts down the 32 sector pulses from a hard-

sector disk. This countdown perm its each track to be divided into 16 or 8 sectors,

instead of 32 sec tors. The output of the first stage (16 se c to r s ), or the second

stage (8 sectors) is connected to the SECTOR output line to the controller.

Auto Erase

The era s e turn-on and turn-off delays are internally controlled by the Erase logic.

When the controller activates WRITE, the leading edge of WRITE initiates a

200 -m icrose cond era se turn-on delay; the trailing edge of WRITE initiates a

530-m ic rosecond erase turn-off delay. If the straddle-e ra se configuration is used,

a str a ddle-e r a s e head m ust be installed. This option re m ov es the time delays.

Pads are provided for installation of this option.

Data Separator (FM only)

In the basic configuration, the RAW DATA line to the controller produces a pulse

for each flux reversal read from the disk. Consequently, the RAW DATA input

contains both clock and data pulses. F or this reason, the con troller must have

circu its that separate the clock and data pulses.

The Data Separator option is installed for the disk drive to operate in the sin gle

density encoding mode (FM) only. When installed, this option separates the data

and clock pulses input o ver the RAW DATA line. Data pulses are supplied to the

1-11

Page 22

controller o ver an FM SEP DATA line, and synchronized clock pulses over an

FM SEP CLK line. Proper operation of the Data Separator option is based on a

format with no m issing clock pulses.

Auto Head Load

In the basic configuration, the re ad/write head Is automatically loaded when the

unit is sele c ted, and is automatically unloaded when the unit Is deselected. Alterna

tively, the unit m a y be configured to load the head in resp onse to a HDLD command

from the controller.

Activity Indicator

In the basic configuration, the activity Indicator is on when the drive Is selected.

The Activity Indicator option provides a m eans of substituting for the SELECT

status sig nal, one of the following status signals:

• HEAD LOAD

• RDY

Etch pads are provided on the m ain printed circuit board to optionally OR either

of the above signals with IN USE.

PCB A ss e m b ly Option Configurations

The m ain printed circuit board can be supplied in a b asic configuration or with the

optional configuration including Hard Sector and Data Separator.

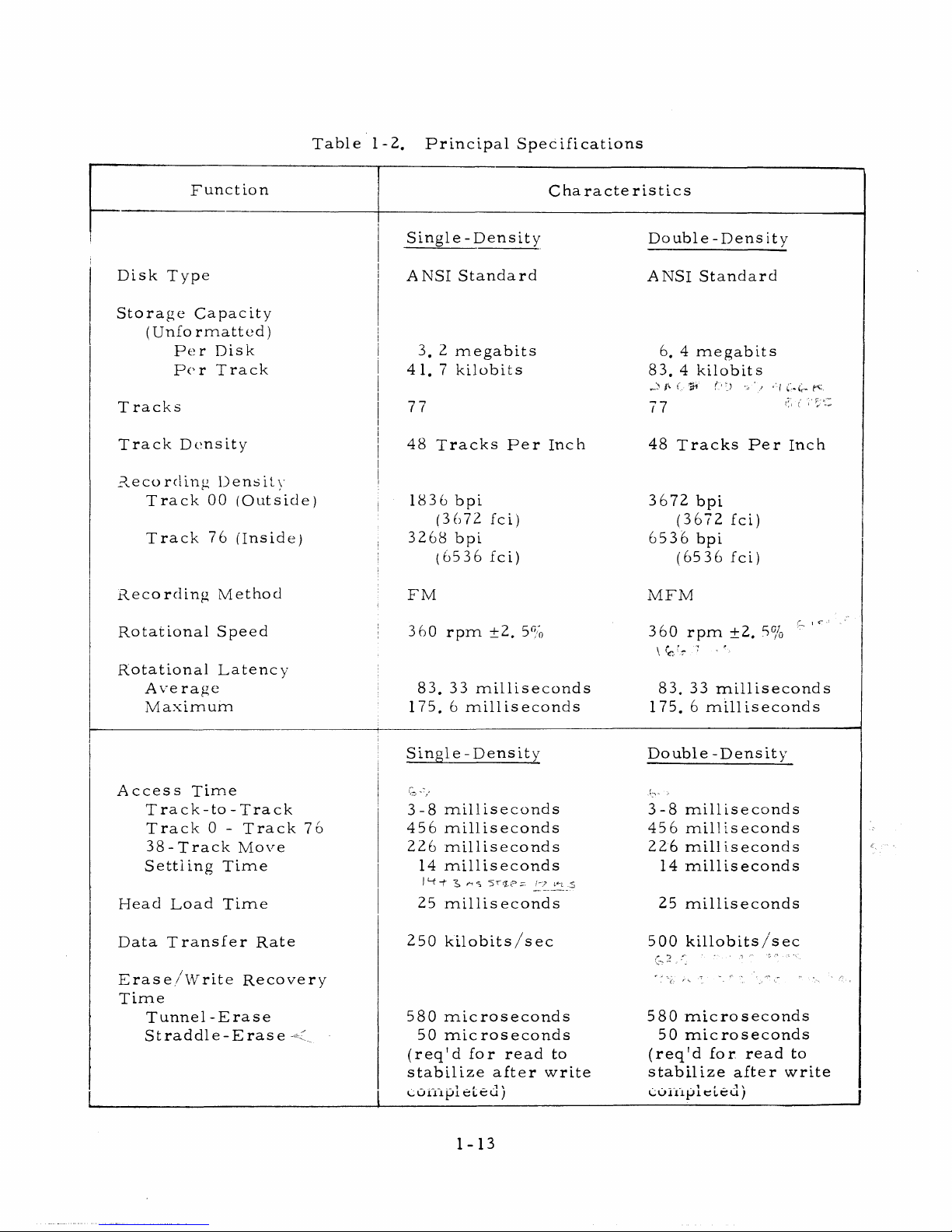

SPECIFICATIONS

A com prehensive list of principal specifications are provided in Table 1-2. The

list defines both sin gle-d en sity and d ouble-density c h ara cteristics, both disk drive

and interface logic le ve ls , and all physical and electrical par am eters.

1-12

Page 23

Table 1-2. Principal Specifications

Function

Characte ristics

Single -Density

Double - Dens ity

Disk Type

A NSI Standard

ANSI Standard

Storage Capacity

(Unfo rmatted)

Pe r Disk

Pe r Track

3. 2 megabits

41.7 kilobits

6. 4 megabits

83. 4 kilobits

T racks

77

77 <r.c

Tra ck Dens ity

48 Tracks P e r Inch

48 T rack s P e r Inch

Recording Density

Tra ck 00 (Outside)

Track 76 (Inside)

1836 bpi

(3672 fci)

3 2 68 bpi

(6536 fc i)

3672 bpi

(3672 fci)

6536 bpi

(6536 fci)

Recording Method

FM

MFM

Rotational Speed 3 60 rpm ±2.

5%

3 60 rpm ±2. 5%

\ y>r-r

:1 '

83. 33 milliseconds

175. 6 milliseconds

Rotational Latency

Average

Maximum

83. 33 milliseconds

175. 6 milliseconds

Single - Density

Double -Density

Acce ss Time

Track -to -Track

Tra ck 0 - Track 76

38 - Track Move

Settling Time

Head Load Time

3-8 milliseconds

456 milliseconds

226 m illiseconds

14 milliseconds

I'-f-f'

S ^ 5 r

,";.p m..s

25 milliseconds

3-8 m illiseconds

456 milliseconds

226 milliseconds

14 m illiseconds

25 milliseconds

Data Tran sfer Rate 250 kilobits/sec

500 killobits/sec

Era s e/W rite Recovery

Time

Tunnel -E ra s e

Straddle-E r a s e -<

.

580 m icrose conds

50 m icro s econds

(req'd for read to

stabilize after write

___

.

i

_ .1

\

Luiapi cicu

)

580 m icrosecond s

50 microseco nds

(req'd for read to

stabilize after write

COixiplelcu)

1-13

Page 24

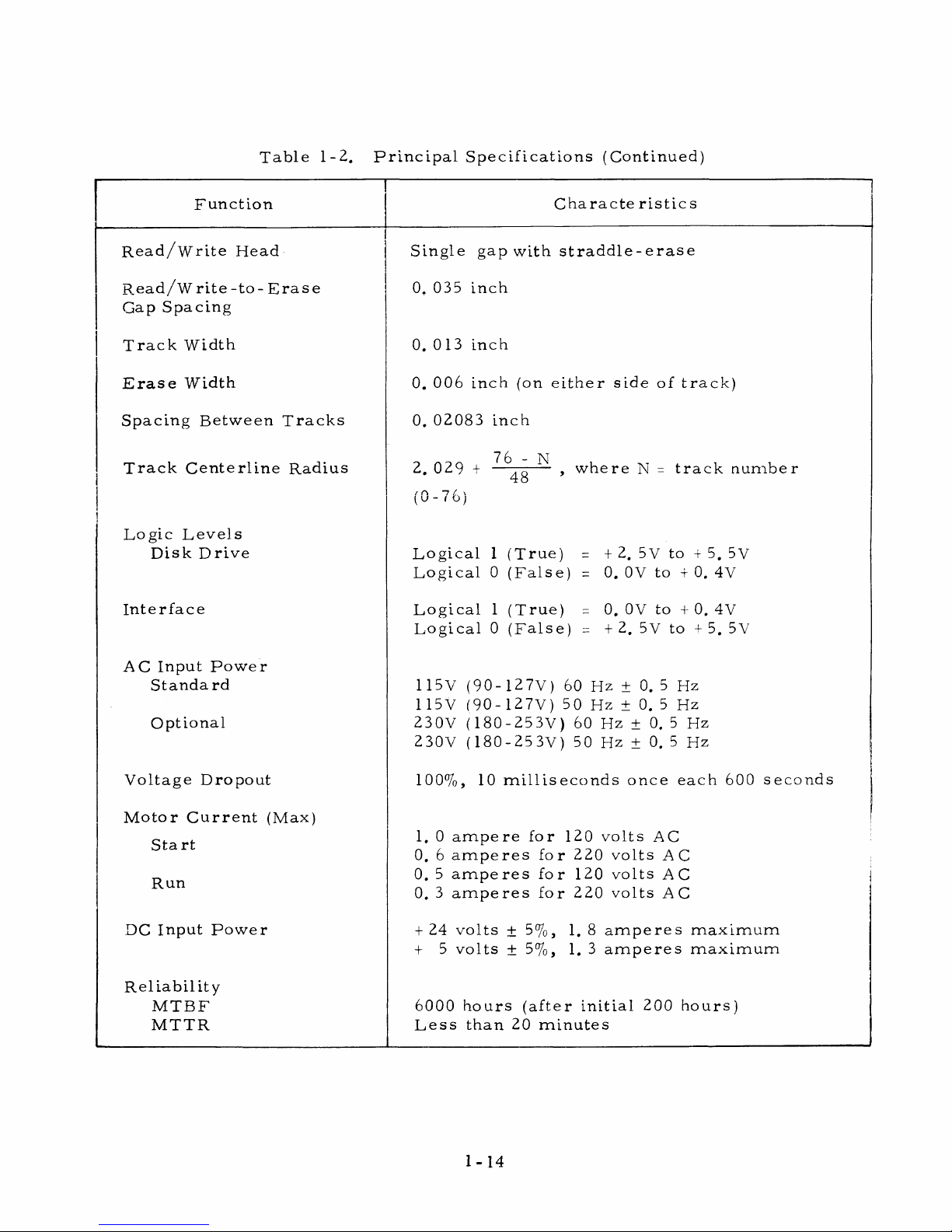

Table 1-2. Principal Specifications (Continued)

Function

Characte r is tic s

Read /W rite Head

Single gap with s tra d d le - e r a se

Rea d /W rite -to- E ra se

0, 035 inch

Gap Spacing

Track Width

0. 0 13 inch

E r a se Width

0. 006 inch (on either side of track)

Spacing Between T racks

0. 02083 inch

Tra c k Centerline Radius

2. 029 + ,Q , where N - track num ber

4 o

/ n

n L \

yu-(V)

Logic Levels

Disk Drive

Logical 1 (True) = +2. 5V to + 5. 5V

Logical 0 (False) = 0. 0V to + 0. 4V

Interface

Logical 1 (True) = 0. 0V to + 0. 4V

Logical 0 (False) = +2. 5V to + 5. 5V

AC Input P ow e r

Standa rd

115V (90- 127V) 60 Hz ± 0. 5 Hz

115V (90- 127V) 50 Hz ± 0. 5 Hz

Optional

230V (180-253V) 60 Hz ± 0. 5 Hz

230V (180 - 25 3V) 50 Hz ± 0. 5 Hz

Voltage Dropout 100%, 10 milliseconds once each 600 seconds

Motor C u rrent (Max)

|

Start

1. 0 am p e re for 120 volts AC

0. 6 am peres for 220 volts AC

Run

0. 5 am peres for 120 volts AC j

0. 3 am peres for 220 volts AC

DC Input Power

+ 24 volts ± 5%, 1. 8 am peres maximu m

+ 5 volts ± 5%, 1. 3 am p e r e s m ax i m um

Reliability

M T B F

6000 hours (after initial 200 hours)

MT T R

Less than 20 minutes

1-14

Page 25

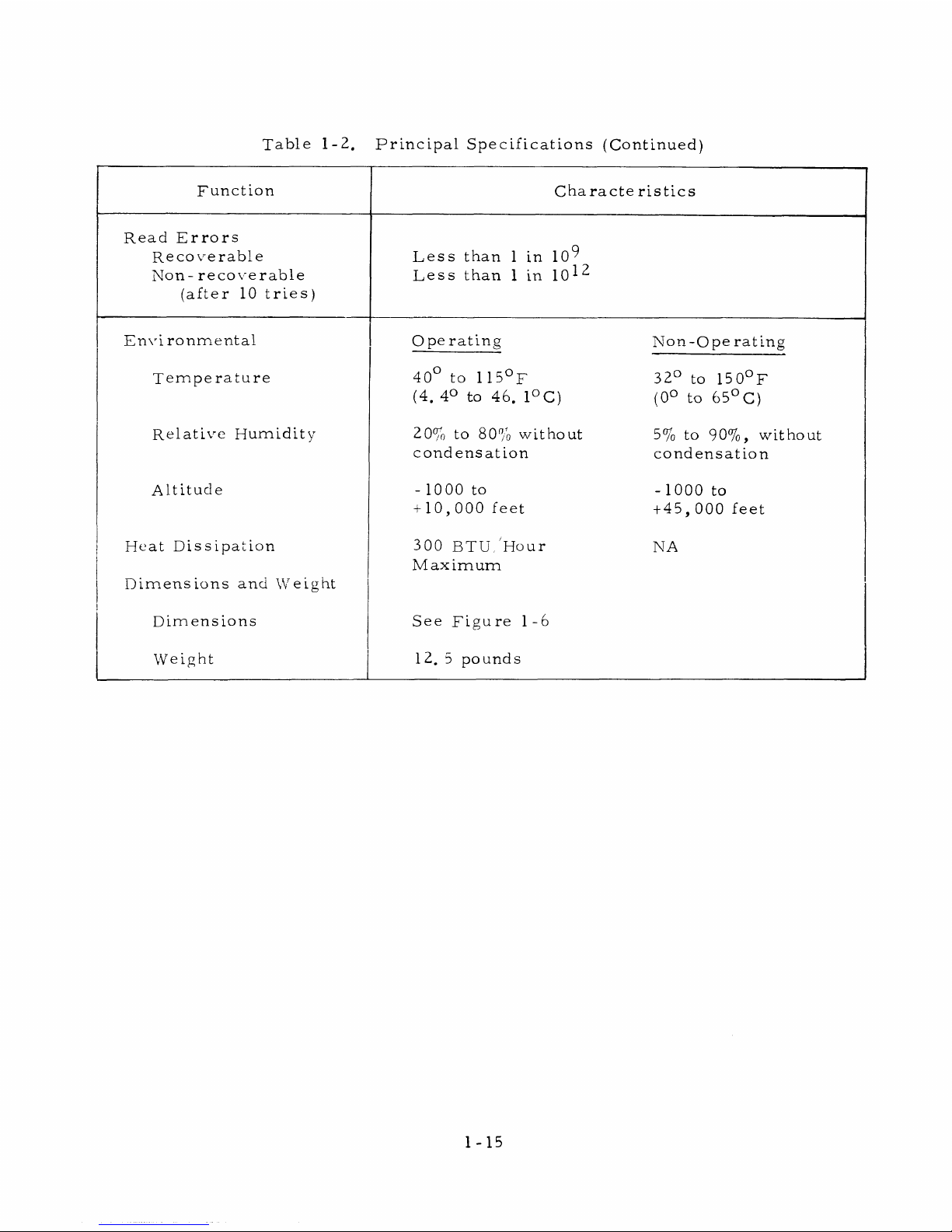

Table 1-2. Principal Specifications (Continued)

Function

Characte r is tics

Read E rro rs

Recoverable

Non-reco v e rable

(after 10 tri e s )

Less than 1 in 10^

Less than 1 in 1 0 ^

Envi ronmental O pe rating

Non-Ope rating

Tem p e rature

40° to 115°F

(4. 4° to 46. 1°C)

32° to 150°F

(0° to 65°C)

Relative Humidity

20% to 80% without

condensation

5% to 90%, without

condensation

Altitude - 10 00 to

+10,000 feet

- 1000 to

+4 5,000 feet

Heat Dissipation

Dimensions and Weight

300 BT U /Hour

Maxim um

NA

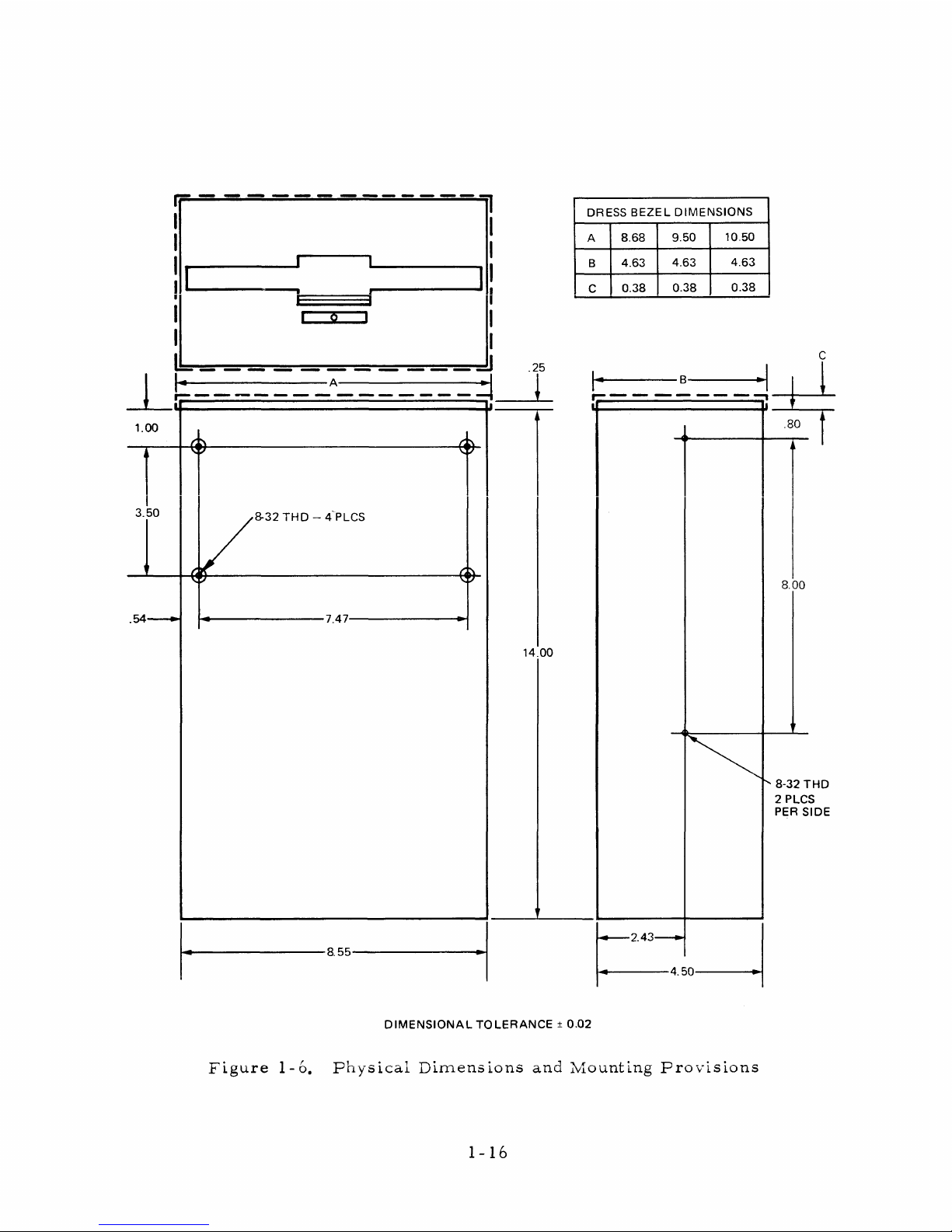

Dimensions See Figure 1-6

Weight

1 2. 5 pounds

1-15

Page 26

1.00

3.5 0

.54-

8-32 T H D — 4 PLCS

■7.47-

-8.5 5-

&

14.00

DRESS BEZEL DIM E N SIO N S

A

8.68

9.5 0

10.50

B

4.6 3

4.6 3

4.6 3

C

0.3 8

0.3 8

0.3 8

8-3 2 T H D

2 PLCS

PER SIDE

DIM ENSIO NAL T O L E R A N CE ± 0.02

Figure 1-6. Physical Dimensions and Mounting Provisions

1-16

Page 27

SECTION 2

OPERATION

GENERAL

The Floppy Disk Drive opera tes under complete control of the host controller,

after a floppy disk has been manually inserted. A front panel indicator is p ro

vided to indicate operating status.

DAILY OPERATION

The operating environment and the op e ra to r's careful handling of the disk drive

and the floppy disks enhance the appearance, and greatly extend the operating life

of the equipment.

Floppy Disk, Ilandl ing and Storage

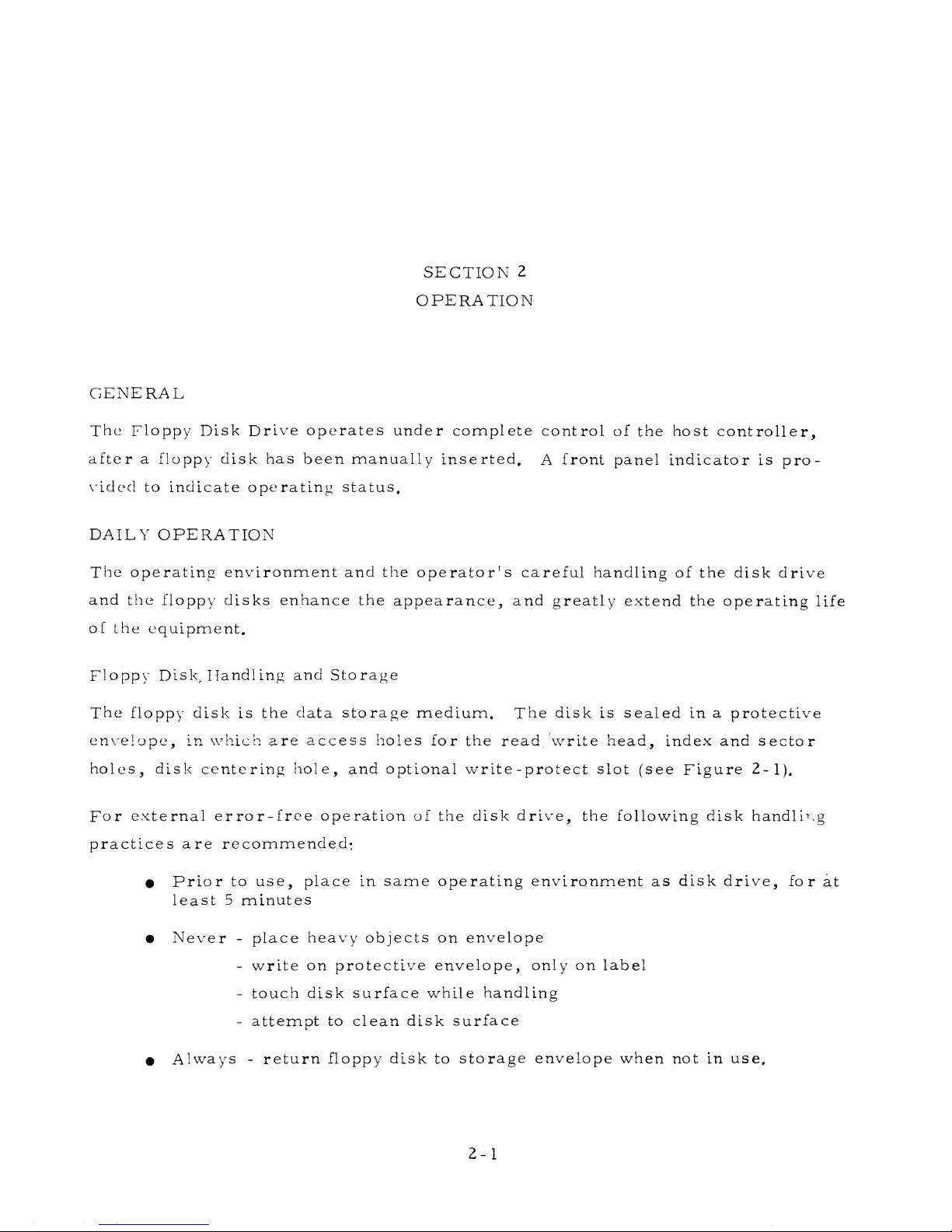

The floppy disk is the data storage medium. The disk is sealed in a protective

envelope, in which are access holes for the read/writ e head, index and s ecto r

holes, disk centering hole, and optional write-p rotect slot (see Figure 2-1).

For external e r r or - f re e operation of the disk drive, the following disk handling

practic es a re recom m ended:

• P rior to use, place in same operating environm ent as disk drive, for at

least 5 minutes

• Never - place heavy objects on envelope

- write on protective envelope, only on label

- touch disk surface while handling

- attempt to clean disk surface

• Always - return floppy disk to storage envelope when not in use.

2-1

Page 28

Figure 2-1. Floppy Disk and Storage Envelope

Floppy Disk Loading and Unloading

Correct loading of the floppy disk is essential for pro p er operation of the disk

drive.

The disk is sealed in the protective envelope with an adhesive label in the outside

left corner. Refer to Figure 2-1. The disk drive will not o perate if the floppy disk

is loaded upside-down. The c o rrect load conditions a re shown in F igure 2-2.

Loading and unloading procedur es for the disk drive are listed in Table 2-1.

2-2

Page 29

Figure 2-2. Floppy Disk Loading

Table 2-1. Floppy Disk Loading and Unloading

A ction

i

Reaction

P r e ss front panel

pus hbutton

Front panel unlatches and raises to open

position. Spindle cone removed fro m

drive cone. Disk cartridge released from

spring-loaded latched condition.

Insert floppy disk, label

up, into slot fully until

stopped

Disk cartridge co rrectly positioned over

drive spindle and firmly latched in spring-

loaded condition

Lower front panel until

latched

Spindle cone lowers and ce nters disk with

firm pre s s u r e. Disk rotates no rmally

with interlock closed.

W rite -P ro tect

W rite- p rotect guards against the destruction of stored data by circuit malfunctions

or during test and operations. A read and write disk cartridg e will have no open

slot punched in the c a rtridge, or the slot will be covered with an adhesive opaque

tab. A read-only disk c artrid g e will have an open punched slot ready for light

sensing by the write-p rotect circuit.

2-3

Page 30

SECTION 3

THEORY OF OPERATION

GENERAL

This section contains descriptive information on each function of the disk drive and

detailed theory of operation. The information is intended to serve as a training

guide for technical personnel requiring in-depth knowledge of the disk drive.

The disk drive contains three major s y s tem s, as shown in Figure 3-1:

• Control System

• Positioning System

• Read /W rite System

Figure 3-1. Floppy Disk D r ive, Simplified Block Diagram

3-1

Page 31

CONTROL SYSTEM

The control system provides the interface circuitry between the disk controller and

the disk drive. The operational status Is m onitored and reported to the disk con

troller. The disk controller add r e s ses a disk drive for on -line operation by ac t i

vating a unique s e lect line. Commands are then received and executed by the

selected disk drive. This technique allows m ultiple disk drive units to share co m

mon interface lines, while remaining individually selectable.

Command Execution

Commands are received by the disk drive in the form of a low -level interface

signal which designates one of the following operations:

•

SELECT

Place s disk drive on-line with controller

w

CTt?n

O X llj JT

Enables re a d /w rite head positioning

•

ST E P IN Determines read/w rite head direction

•

HEAD LOAD

Place s disk recording surface in contact with

(HDLD)

read/write head

•

WRITE

Enables write current to turn on and Inhibits

(WRT)

read output

•

WRITE DATA

Enables write data transfer from controller to

(WRT DATA) disk drive

SELECT and HDLD commands m ust precede a read or write operation. SELECT

enables all Input/output gates, while HDLD positions the read/write head for w r it

ing or reading on the floppy disk.

ST E P m oves the read/w r ite head to either a higher or lower track position depend

ing on the STEP IN line. Since relative track positioning is used, the disk con

troller m aintains current track position and generates the number of pulses ne ce s

sary to achieve a new track position. Once positioned, the disk controller initiates

a read or w rite operation

In a Write operation, the disk drive records the data in the sam e encoding method

presented by the disk controller.

3-2

Page 32

Status Sensing

Five disk drive status signals are gated to the i/O lines when the disk controller

selects a disk drive.

• WRITE PRO T E C T Hardw a re w rite -protect condition exists (if

(WRT PROTECT) write-protect disk used)

• TRACK 00

Read/write head positioned at track 00

• INDEX

Start of each tra ck

• SEC TOR

Start of new secto r (if sectored disk used)

• READY

Signifies disk drive is operational

• DISK CHANGE

Signals that the pack may have been changed

READY, WRT PR O TEC T , and DISK CHANGE a re static level status signals.

Ready status indicates a floppy disk is loaded and up to operating speed. Write-

protect status indicates write data cannot be recorded on the disk. Disk change

status indicates the door was opened during drive manual action. Index status

oc curs once per disk revolution. Track 00 status is available for initializing the

disk con troller trac k addres s register. This signal is developed from a photo

tr a n si s to r when the carria g e is m echanically aligned with track 00, and the stepper

motor is at phase A.

by moving the read/w rite head one track position per pulse. The following functions

accomplish this operation.

• Stepper Motor Control

• Stepper Motor

• Carria g e A ssembly

Stepper Motor Control

The step m otor control converts serial S T EP pulses to three sequential control

signals. Each signal energizes one of the stepper motor windings, causing a

15-degree rotation of the moto r shaft (one track position).

POSITIONING SYSTEM

The positioning system responds to STEP pulses received fro m the disk controller

3-3

Page 33

Stepper Motor

The v a riable-re lucta n c e stepping motor provides precision positioning of the rea d /

write head. The stepper m otor is energized by + 24 volts dc and operates in either

Detent or P ositioning mode.

In the Detent m ode, an internal generated m a gnetic field holds the rotor in a

fixed position. To m ove from detent, one of three control lines is grounded, d riv

ing the rotor to the next detent. Sequentially grounding control windings causes

the rotor shaft to rotate through detent positions at a maxim u m rate of 333 steps

per second. A lead screw on the exposed rotor shaft converts rotary movements

to linear movement to drive the carria ge assembly.

Carriage Assem bly

The carriage asse m bly rides on a lead screw while a fixed way prevents the

carriage from skewing. The way serve s as a guide while the lead screw drive

performs the in and out positioning.

The read/write head, attached to the carr iage asse m b ly , contacts the recording

surface when the drive is selected. This command re l e a ses a spring-loaded head

load arm that m ove s the floppy disk into contact with the read/w rite head.

READ/W RITE SYSTEM

The rea d /w r ite system records encoded data during a Write operation, and

retrieves data during a Read operation. The write (WRT) signal from the c o n

troller designates a Read when high or a Write when low.

Read/W rite Operation

The read/write head is esse n tia lly an electromagn et that can concentrate a high

magnetizing force over a very sm all area of the adjacent recording surface. When

recording, the flux field is alternated to magnetize the disk with the desired bit

pattern. The read/w rite head also contains a tunnel-erase or stradd le-erase

electromagnet, the function of which is to e ra se the edges of the recorded track as

data is being written. The width of the track is narrowed to approximately

0. 013-inch by this technique, to m inimize the effect of data previously written on

the track and possible crosstalk between tracks.

3-4

Page 34

When reading, the read/w rite electromagn et o perates as a sensor. A flux r eversal

on the recorded track induces a voltage a c ro s s the electromagnet coils. This vo lt

age is amplified and conditioned to recover the recorded information.

FUNCTIONAL DESCRIPTION

The disk drive is a m as s m em or y device featuring a removable floppy disk and

contact recording. The 250 khz/bit t ran s fer rate provides a high speed transfer

of data between the disk drive and a host disk controller. Multiple disk drives may

be connected in a radial or daisy-chained configuration with individual selection

and status monitoring.

The disk drive requires o p erato r intervention only for loading and unloading the

floppy disk; after which the disk controller rem otely operates the unit. Input ac

and dc power, control signals and write data a re supplied by the controller; the

disk drive responds with operating status and read data. A detailed functional

block d iagra m is shown in Figure 3-2.

WHITE PROTECT LED

Figure 3-2. Detailed Functional Rlnrk Diaa ram

O

...........

3-5

Page 35

The disk drive c o m pris e s the following functional systems;

• Spindle Drive System

• Spindle System

• Read Write Head Positioning System

• Head Load System

Spindle Drive System

The spindle drive sy stem provides rotational mo vemen t of the spindle using a

single-pha se moto r selected to m atch p rim ar y power of the host system. Various

drive m o tors are available that a ccomm o d ate prim ary power require m ents of 115

and 230 volts ac at 50 or 60 Hertz.

Rotation of the spindle is provided by a belt and pulley connected to the drive m otor

roto r shaft (see F ig u re 3-3). The d rive pulley is selectable for either 50 or 60 Hz

input power for rotational speed of 360 revolutions per minute. A floppy disk is

engaged with the spindle drive hub by the spindle syste m centering cone.

MO

PUI

SPINDLE AN D

PU LL E Y

Figure 3-3. Spindle Drive Sy stem

3-6

Page 36

Spindle System

The spindle sy stem consists of a spindle and a centering cone mounted on the deck

and c a r rie r, respectively. In the unload position, the centering cone ca rrie r is

pivoted open creating an aperture through which the floppy disk is inserted. In this

position, the centering cone is lifted, disengaging the disk from the spindle hub.

To load a disk, the o p e rato r in serts the

floppy disk then closes the handle, which

latches the c ar r ie r in the operating mode.

The centering cone (see Fig u re 3-4) is

attached to the c arrie r and is an open-

splined n on-m etallic device that p erfor m s

two functions:

• Aligns the disk media to the

spindle hub

• Engages the disk med ia to the

spindle drive system

As the ca r r ier is pivoted to the load po si

tion, the centering cone enters the floppy

disk center. Just pr ior to the fully closed

position of the handle, the centering cone

expander is automatically activated to

expand the centering cone, which grips and

aligns the floppy disk to the spindle, thus

centering the disk on the spindle.

Figure 3-4. Spindle System

Read/W rite Head Positioning System

The positioning sy stem co m pr ises a car riage asse m bly , a re a d /w r ite head and a

bidirectional stepper m o tor and lead screw (see Figur e 3-5). The stepper motor

rotational m ovements are converted to linear motion by driving the lead screw and

ca rriage assem bly .

3-7

Page 37

The re a d /w r ite head carriage rides on the

lead screw shaft and is held in horizontal

alignment. When the stepp er m oto r is

pulsed, the lead screw rotates clockwise

or counterclockwise, moving the carr ia g e

in or out, respectively.

The stepper m o tor has three pairs of

windings. In Detent, current flows in one

winding and maintain s the rotor in e l e ctro

magnetic detent. F o r positioning, the

windings are driven sequentially, causing

the rotor to rotate through detent positions

until the STE P c omm ands are halted. The

rotor then locks in that position, with the

last winding being driven. The sequence

in which the ste pper m o tor windings are

pulsed dictates rotational direction and,

subsequently, higher or low er track

ad dressing from the relative position.

Head Load S ystem

The head load syste m is, basically, a solenoid driver and a solenoid. When a c ti

vated by the HDLD com m a nd, the spring-loaded head load pad is released and

brings the recording su rface of the floppy disk into conform ance with the head.

To m inim ize disk surface and re a d /w rite head w ear, the HDLD com m and is

gated with SELECT . In the deselect or Idle m ode, head loading is automatically

disabled. The Head Load c om m and re quire s a 25-millisecond execution time.

Control and Data Timing

Figure 3-6 shows the sequence of control and data timing requirements.

Figure 3-5. Re ad/W rite Head

Positioning System

3-8

Page 38

AC POWER

_ J

-------

T

2 SEC MIN

DC POWER

90 ms MIN

V A LI D OUTPUT

CONTROL SIGNALS

SELECT

500 ns MAX

READY

"► HDLD

STEP IN

1 ms MIN

STEP

10 MS MIN

RAW DATA

WRITE

WRT

DATA

■25 ms MIN

■h }

I li

FORWARD

*

REVERSE |

t n T Hin j

jr*— 1 MS MIN

il

_L*J | , 3 ms MIN U

I | | 8 ms MAX I

1 I I

30 ms MIN

"tZZT

READ DATA I

200 ms ( TUNNEL ERASE)

0 ms (S TRADDLE ERASE).

ERASE h

1 BIT TIME M AX *

READ DATA

I I

50 ms MIN

V — !T

►J ■■■ »i U

530 ms (TU NN E L ER ASE)

0 ms (S T R ADD L E ERASE)

II

* 4 MICROSECONDS FM

2 MICROSECONDS MFM

8 MICROSECONDS FM

4 MICROSECONDS MFM

WRITE DATA

2 BIT **

TIMES MIN

Figure 3-6. Control and Data Timing

3-9

Page 39

LOGIC CONVENTIONS

The disk drive uses standard 5-volt TTL log ic, where a voltage m o r e positive than

+2. 4 volts (turn-on threshold) is considered a logica l one (high), and a voltage more

negative than +0. 4 volts (turn-off threshold) is con sidered a logical zero (low).

Interface signal logic le v e ls are inverted by line rece iver s and line dr ivers for use

by the disk drive and the contro ller, respectively. F o r all interface sign a ls, a

voltage m ore positive than +2. 4 volts (turn-off threshold) is considered a logical

zero, and a voltage m ore negative than +0. 4 volts (turn-on threshold) is considered

a logical one (see Figure 3-7).

The logic symbology used in the disk drive is shown in Figure 3-8. Each element

is describ ed and all conditions are defined.

DETAILED LOGIC DESCRIPTION

The detailed logic description is divided into three major functions:

• Control Logic

• Read/W rite Head Positioning Logic

• Read/W rite Logic

CONTROL LOGIC

The control logic contained in the disk drive perform s three prim e functions:

• Accepts controller SELECT command and enables all interface logic

• Detects and provides index and optional sector pulses

Figure 3-7. Interface Logic L evels

3-10

Page 40

GATES

HIGH IN, HIGH OUT

SCHM ITT A MP LIFI ERS

r > -

- D - J

HIGH IN, LOW OUT.

LOW IN, HIGH OUT

LINE D RI VER

HIGH IN, HIGH OUT.

OP ER AT ION AL

R = REFER ENCE VOLTAGE

OUTPU T VO LTAG E RANGE

DEPENDS ON REFERENCE

VOLTA GES A ND RAN GE OF

A A ND B INPUTS. A IS SEEN

AM PL IFI ED AT THE OUTPUT

B IS SEEN AM PL IFI ED AND

INV ER TE D A T THE OU TPUT

IF BOTH A AN D B AR E

ACT IVE, OUTPU T IS AN

ALG EB RA IC AD D ITIO N OF

INPUTS

AL L HIGHS IN, LOW OUT.

ANY LOW IN, HI GH O UT

EXCLU SIVE OR GATE

INPUTS NOT ID EN TI CA L,

HIGH O UTPUT INPUTS

IDE NT ICA L. LOW OUTPU T

1C ONE-SHOTS

OUTPUT PULSE DURAT ION

DET ER MIN ED BY E XT E R

NAL R C VA RIAB LE

RESISTOR IN DICATES

TIME A DJ UST ABL E OVER

A RA NGE

I F A GOES LOW. B GOES

HIGH FOR X TIME AND C

GOES LOW FOR X TIME.

CROSS-COUPLED LATCH

BO T H SET AN D R ESE T

HI G H, NO CHA N G E . SET

IN PU T LO W, Q IS HIG H

A N D Q IS L OW. RE SET

LOW , Q IS L OW AN D Q

IS HIG H . B OTH SET A N D

RES ET LOW, Q A N D Q

BO TH H IG H .

LIGH T E MIT TIN G DIODE

IF A IS MOR E POSITIVE

THA N B, L IGH T IS EM ITTED .

IF B IS MORE POSITIVE

THA N A, NO LIG HT IS

EMIT TED

D FLIP-FLOP

D HIGH AND C POSITIVE

TRA NS ITI ON = Q H IGH; D

LOW AN D C POSITIVE

TRA NS ITI ON = Q LOW.

EXCEPT: PR LOW HOLDS_Q

HIGH; CLR LOW HOLDS Q

HIGH. Q IS ALW A YS THE

INVERSE OF Q, EXCEPT

WHEN PR AN D CLR ARE

BOTH AT THE_SAME

TIME (Q A ND Q W ILL BOTH

BE HIGH)

JUMPERS

DAR K PADS

INDIC ATE JUMPERS

NO RM A LL Y FACT ORY

INS TA LL ED

LIGHT PADS

INDIC AT E OPTION AL

JUMPER IN ST A LL AT IO N

PHOTO TR ANS ISTO R

LIG HT ACTIVA TES

PHOTO TR ANS ISTO R

Figure 3-8. Logic Symbology (Sheet 1 of 2’

3- ii

Page 41

LOGIC LSI C HIP

THIS LOGIC CHIP IS A SEMI-CUSTOM LSI 22-PIN INTEGRATED CIRCUIT. THE CHIP USES C-MOS FET PAIRS AS

BUILDING BLOCKS FOR GENERA TING THE REQUIRED LOGIC FUNCTIONS. THE C-MOS REQUIRES LITTLE

CURRENT AND IS INSENSITIVE TO NOISE. A L L OUTPUTS WILL SINK 2.0 MILL1AMPERES. ALL INPUTS

REQUIRE 0.2 MILLIAMPER ES TO BE D RIVEN AN D THE INPUT AND OUTPUT SIGNALS AND PINS ARE

IDENTIFIED AS SHOWN AND AS LISTED BELOW.

PIN INPUTS

PIN OUTPUTS

+5V

1 LTRK 00

2 PHASE C

4

+5V 3

RDY

5

SELECT

6

STEP

7 LSTEP

9

DISK CHG

8

STEP INHIBIT

11

HDLD

10

STEP OPT

16

TRK 00

12 SEL OPT

20 PHASE A

13

LHDLD

22 PHASE B

14

DOOR CLOSED

15

POR

17 INDEX

18 GND

19

STEP IN

21 PHASE OPT

5

SELECT

1 7

INDEX RDY

3

STEP

DISK CHG

10

INHIBIT

20

STEP OPT

PHASE A

19

15

STEP IN

PHASE B

22

2

POR

PHASE C

12

SEL OPT

7

--------

IMI 4060 2

LSTEP

13

14

16

LHDLD

TRK 00

DOOR CLOSED

-

LTRK 00

STtP

------

21

PHASE OPT HDLD

11

18

INPUTS - THE DERIV ATION OF THE INPUTS IS EXPLAINED IN OTHER SECTIONS OF THIS MANUAL.

OUTPUTS - A BRIEF DESCRIPTION OF ALL OUTPUTS AND THEIR EQUATION IS LISTED BELOW.

HDLD = (LHD LD) (SEL OPT) (DOOR CLOSED)

READ/WRITE HEAD LOADED IF DRIVE IS SELECTED, IF A HEAD LOAD COMMAND IS

RECEIVED, AND PROVIDED THAT THE ACCESS DOOR IS CLOSED

TR K00 = (LTR K 00) (PHASE A)

TRACK 00 SIGNAL SENT TO CONTR OLLER IF OPTICAL SWITCH INDICATES TH AT CARRIAGE

BETWEEN TRACK 00 AND TRACK 1-1/2, AN D TH AT PHASE A OUTPUT IS PRESENT

STEP = (STEP OPT! (LSTEP! (STEP INHIBIT)

STEP OUTPUT ACTIVE IF STEP OPT AND LSTEP BOTH ACTIVE AND NOT DISABLED BY STEP

INHIBIT

RDY = (PORI (DOOR CLOSED) (TWO INDEX PULSES)

READY IS INACTIVE, HIGH, DURING POWER-ON AND IF DOOR IS OPEN

READY IS ACTIVE, LOW, IF POWER IS APPLIED WITH DOOR CLOSED, FOLLOWING TWO

INDEX PULSES AT INPUT

PHASE A = ACTIVE AT TRACK 00 WITH PHASE OPT HIGH. PHASE A AC TIVE EVERY THIRD TRACK

(0, 3, 6, ETC)

PHASE B = ACTIVE AT TRACKS 1, 4, 7, ETC

PHASE C = ACTIVE AT TRACKS 2, 5, 8, ETC

Figure 3-8. Logic Symbology (Sheet 2 of

Z\

3-12

Page 42

• M onitors flexible disk rotation to develop a ready status for the

Controller.

Select

When SELECT is inactive (high), the select logic inhibits all interface input

re c e ivers and output driv e r s to and from the disk drive. The select logic is

prim arily c om p rised of OR gate 4A, NOR gate 5A , and inverter 6B (see F ig

ure 3-9).

SE LE CT 0

SE LE CT 1

SELE CT 2

SELE CT 3

J3

26

28

30

32

r R A D I A L SEL I

I OPT IO N I ________

0 I SELE CT

1

0^ - 4

r s

BIN A R Y SELEC T O PTIO N

4-TO -IO

LINE

DECO DER

7C

0 -0 0

o-a

4

D-D 2

0 - D 6

0 -D 1

CHD 5

0 -D 3

0 - D 7

D - "

CH*

CH-

[ fn i

CH

4A

5A ^

-------

" 3 |6 B ^O

-----

f

n ~ - s n

i p HD I

SELECT

SELECT

-c>

4k >

( T O SEL O P TOF

LSI C IRC UIT 6D

/ TO LH D L D OF

LSI C IR C U IT 6D

Figure 3-9. Select Logic

When SELECT is inactive, gate 4A outputs a high through OPT D and is inverted

by 5A causing a low S ELECT signal to inhibit all disk change, ready, index, sector,

write - p r o tect, and track 00 logic. Inverter 6b outputs a high SELECT to inhibit

all head load, step, door interlock, and activity LED logic.

As shipped from the factory, a ju m p er plug is installed between the "0" Radial

Select pads, causing SELECT 0 to drive 4A. This assigns physical address 0 to

the disk drive. One of three other a d dre ss e s can be assigned, SELECT 1,

SELECT 2, o r SELECT 3, by rem oving the jum p er between the "0" pads and

installing it between the d esired Radial Select pads. Only one jum per can be con

nected to the disk drive. With the Radial Select feature, up to four disk drives

can be connected in daisv-chain fashion

3-13

Page 43

Binary Select (Option)

The Binary Select option allows up to eight disk drives to be da isy-ch ained to the

contro ller, with a d dresses 0 through 7. The option is comprised of 4 -to-10 line

decoder 7C, and eight sets of jumper pads (see Figure 3-9).

When SELECT 0 is inactive, the decoder is inhibited and all outputs are high.

When SELECT 0 is active , the decoder is enabled and only one low output is pro

duced. The decoder accepts a binary coded address on three selec t lin e s,

SELECT 1 through SELECT 3, and decodes them to produce a low output decimal

equivalent corresponding to the desired address.

The jumper plug is rem oved from the radial se lect option and installed between

the pads desired to assign the independent physical address of the disk drive.

Table 3-1 indicates the logic state of the SELECT lines for selecting each drive.

Table 3-1. Disk Drive Selection

Drive

SELECT 1

SELECT 2 SELECT 3

Selected

1

1 1

0

0

1 1

1

1

0

1

2

0 0

1

3

1

1

0

4

0

1

0

5

1

0

0

6

0

0

0

7

0 = Inactive state of interface signal (high)

1 = A ctive state of interface signal (low)

3-14

Page 44

Index/S ector Detection

A light-emitting diode (LED) and p hototra nsistor are physically positioned in the

disk drive to sense the index and secto r (optional) holes in the floppy disk. If the

Hard Sector option is installed, a 32 -sector disk should be used. Index pulse

detection logic is shown in Figure 3-10.

+5V

TO HAR D

SEC TOR

OP TION

FROM HA RD

SECTOR

OP TION

J l N D E X

□ HS

SELECT

ENAB LE

L

7B

J3

20

IN D E X

LT

TO R E A DY

LOGIC

Figure 3-10. Index Detection Logic

The index detection logic is com p rised of an LED and phototransis tor, a com pa r a

tor and an output line driver. The negative input to c o m para tor 3A is driven by the

output of the activated phototrans isto r. R e s isto r R32 supplies bias current to the

LED.

When the media blocks the LED output from the phototransistor, the input to the

co mparator is high. When the index hole is sensed , the input to the co m para tor is

low. Resi stors RIO, R9 and R l l provide a positive referen ce threshold voltage of

+ 2. 5 volts. F o r each index hole sensed, the com p arator output is a positive INDEX

pulse, nom inally 1. 7 millisecond in duration, and occ urring once per disk revolu

tion. The INDEX pulse is input to inte rfac e line d river 7B and inverted to provide

a low INDEX signal to the controller. F igure 3-11 shows index pulse timing.

Norm ally , OPT 0 is installed for soft se ctor operation.

Page 45

Hard Sector (Option)

With the Hard Sector option installed, and by

using a 3 2 -secto r floppy disk, the com para t o r

provides 32 SECTOR pu lse s, equally spaced

5. 2 m illiseco nds apart, during e ach disk

revolution, plus an INDEX pulse that oc curs

halfway between sector pulses 31 and 0.

Re fer to Fig u re 3-12.

The positive-going leading edge of the SEC TOR pulses from the c o m parator (F ig

ure 3-12) triggers one-shot 1C to produce a 0. 4 millisecond pulse, and complement.

The positive-going trailing edge of the complement (Q), trig g e rs one-shot 1C which

times for 3. 6 m illiseconds. After being triggere d by SECTOR pulse 31, the one-

shot is timing out* During this period, the INDEX pulse occ u r s , and one-shot 1C

can not be triggered.

The output of INDEX gate 2C drives INDEX gate 2C and resets flip-flop 3C of the

16 o r 8 Sector divider logic. The output of INDEX gate 2C is input to interface

166 .67 ± 3.3 3 MS ■

? 3-

■t

er

LJ

1.7 i 0.5 MS

Fig ure 3-11. Index Tlmins

INDEX line driv er 7B and the Ready logic. S ECTO R gate 2C provides the SECTOR

pulse inputs to interface SECTOR line driv e r 7B if the 32 - sector ju m pe r is installed.

The output of SECTOR gate 2C also drives the clock input to the 16 or 8 Sector

option, if it is Installed. Divlde-by-2 flip-flop 3C produces 8 and 16 SECTOR

pulses per disk revolution. If the 16-sector jum p er is installed, 16 pulses per

revolution are sent to the controller by interface SEC TOR driver 7B. If the 8 -sec

tor jum p e r is installed, 8 pulses per revolution will be provided to the controller.

Fig u re 3-13 shows INDEX and SEC TOR timing.

Ready

The Ready logic is used to m onitor the INDEX pulse for the rotational speed of the

floppy disk. When the required disk speed is reac h ed, the READY status is sent

to the controller. Once per revolution, the INDEX pulse is input to LSI chip 6D

(see Figure 3-14).

3-16

Page 46

F i g u re 3-12. H ard Se c to r and 16 o r 8 Sec to r Option L ogic

2.6 i 0.065 MS

F i g u re 3-13 . IN D E X /SE CT O R Tim in g

3-17

Page 47

+5V

F i g u r e 3-14. R ea d y Logic

When P OR is input and the a cc es s do or is clo sed , the LSI circ u it will p r o d u ce a

RDY signal af t e r re c e iv i n g two INDEX pulses.

If the R adial In d ex / S e c to r o p tio n (ju m p e r RI), is re m ov e d, the S E L E C T signal ls

not re qu i r e d to enable the INDEX and S E CT O R interfa c e dr iv e r s. If the Radial

Read y option (ju m pe r RR) is r e m o v e d , th e S E L E C T signal is not re q uire d to ena ble

the READ Y in te r f a ce dr i v e r . In both cond itio ns, the disk d riv e need not be

selected by the c on tr olle r until the disk is u p -to -sp e ed and re a d y . Optionally ,

jum p e r C can be in stalled to disable INDEX and SE C TO R until RDY is activ e . The

Activity LED option can be co n n e c ted to use the RDY signal to al e rt the o p e ra t or

when the unit is up - to -s p ee d and rea d y. E nabled at the sam e t im e , is the head

load solenoid logic and the d o o r lo ck option (see F i g u re 3-15),

Activity In dic ato r

The activ ity indica to r is an L E D , m ounted in the door push open b u tton on the

driv e s . It c an be op tionally connected to indicate one of fo u r disk driv e sig n als:

HDLD , R D Y, S E L E C T or IN USE. R e f er to F ig u re 3-1 5.

3-18

Page 48

J5

Fig ur e 3-15. H ead Loa d L ogic

As su p p lied f ro m the fac t o ry , the S E L E CT and IN USE co m m a nd s enab le the LED.

When S EL EC T and IN USE are inactiv e, A C T LE D d ri v e r 5D outputs a high and

the LE D re m a i n s off. W hen S EL EC T and IN USE a re ac tiv e, this dr iv e r o u tputs

a low, the re s is to r sup p lies bias cu rr e n t, and the LE D is turn e d on,

In lie u of S E L E C T , the activ ity L E D can be turn e d on by any one of two diff e re n t