Page 1

Series 1000 Room Temperature

Sensors, 1K Ω Platinum (375α) RTD

(MBC/RBC/MEC/UC)

Product Description

These sensors work with the Modular Building

Controller (MBC), Remote Building Controller (RBC),

Modular Equipment Controller (MEC) and Unitary

Controller (UC). The sensors detect room

temperature using a 1K Ω Platinum (375α)

Resistance Temperature Detector (RTD).

NOTE: These sensors can be mounted on electrical

boxes, stud-type mounting brackets, or

drywall. Obtain the necessary mounting

hardware and follow the appropriate

mounting procedures for the type of

installation required.

Product Numbers

Table1. Product Numbers and Descriptions.

Sensor

Product

Number*

544-760 Sensing only

544-770 Override and setpoint

544-780 Override, setpoint and temperature

display

* Product number suffixes indicate the display's

temperature scale (where applicable) and sensor

color: C = °C; F = °F, A = desert beige; B = white

(e.g., 544-770FA for °F, desert beige).

Warning/Caution Notations

WARNING

CAUTION

Item Number 540-743+2, Rev. DA

Description

Personal injury/loss of life may

occur if a procedure is not

performed as specified.

Equipment damage, or loss of

data may occur if you do not

follow procedure as specified.

Installation Instructions

Document No. 540-743

September 10, 2009

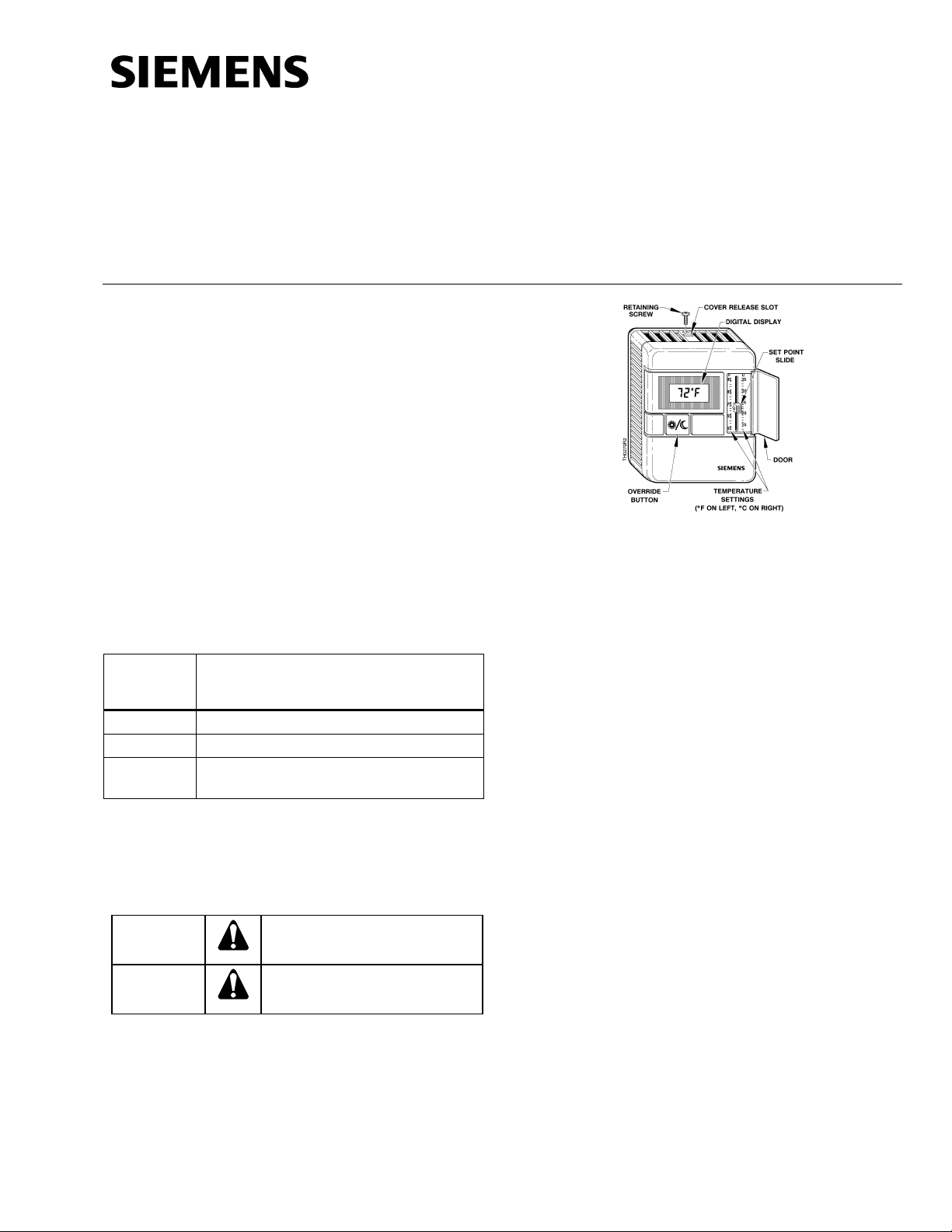

Figure 1. Room Temperature Sensor (Showing All

Optional Features).

Required Tools

• Phillips size 1 or 2 screwdriver

• 1/16-inch (1.57 mm) Allen wrench, if needed

(192-632, package of 5)

• Small, flat-blade screwdriver

• Medium, flat-blade screwdriver

• Medium-duty electric drill

• 3/16-inch (4.8 mm) drill bit

• One-inch (25 mm) hole saw

• Small level

• Tape measure

• Marker or pencil

Expected Installation Time

30 minutes

Prerequisites

• Review these instructions before beginning.

• Installed: appropriate field wiring (standard

four-conductor or six-conductor room sensor

cables, plenum or non-plenum as required),

within the maximum wiring run length for the

individual field panel or equipment controller.

NOTE: All wiring must comply with National

Electric Code (NEC) and local

regulations.

Page 1 of 5

Page 2

Document No. 540-743

Installation Instructions

September 10, 2009

Accessories

Review Table 2 to verify that you have the appropriate mounting hardware.

For retrofit installations, normally follow the method used by the pre-existing device. You may need to replace

existing mounting hardware. Always mount the sensor vertically.

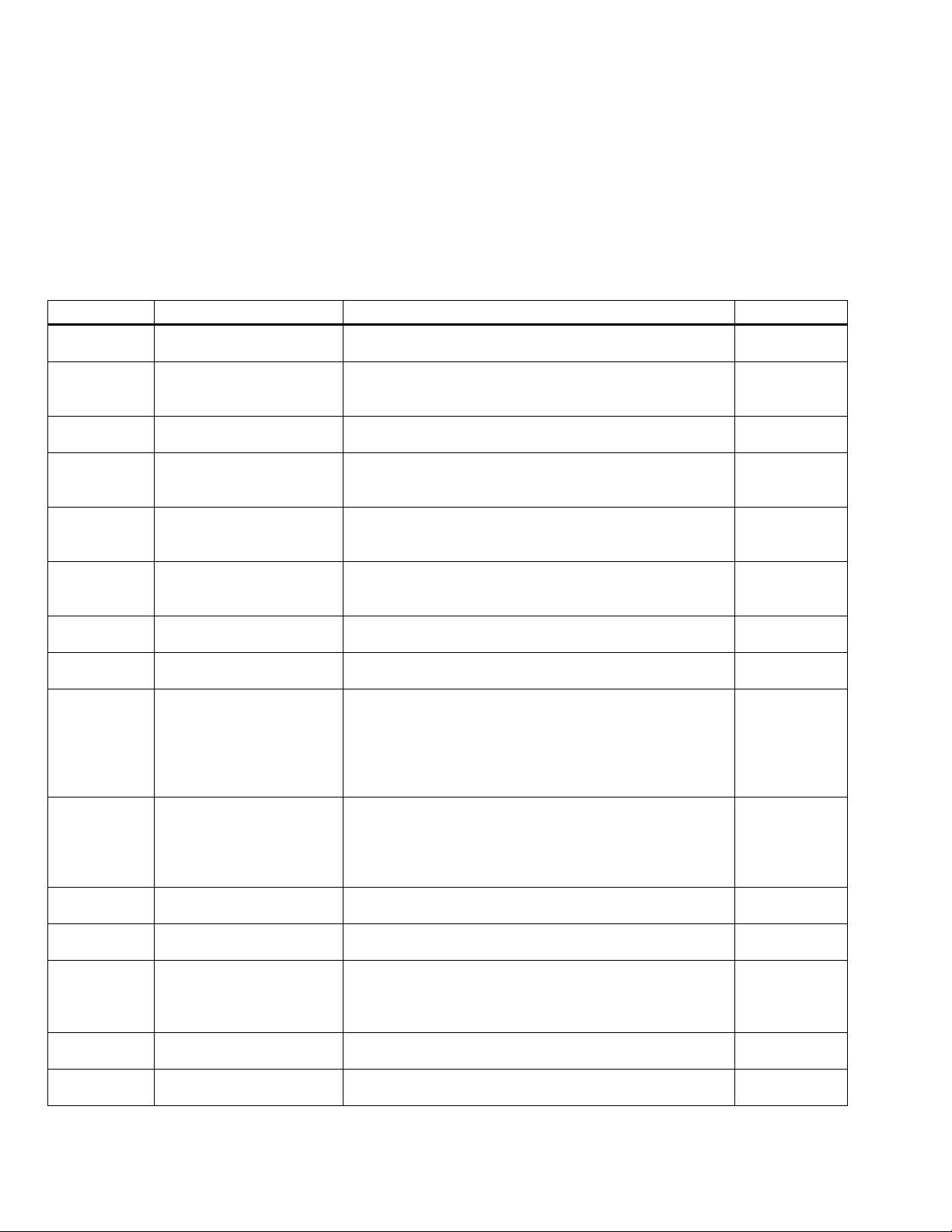

Table 2. Accessories.

P/N Description Used For Reference

PTX6.4SPS Sensor Power Supply

Module

182-621 Gym Guard Kit, desert

beige

182-621E Gym Guard Kit, satin

chrome

182-683 Metal (and Wood) Stud

Mounting Bracket

(pkg. 5)

182-685 Spring Clips: Finished

Drywall Mounting Kit

(10 pack)

192-506 Electrical Box Adapter

Plate Assembly Kit

(pkg. 5)

192-860 Finish Plate Kit 1 Gang 1

Sensor; stainless steel

536-666 Mounting Strap standard light switch plate (field-supplied) to mount

544-782* Single Adapter Base

Mounting Kit

544-783* Double Adapter Base

Mounting Kit

544-784 Non-conduit Rough-in

Kit, Double

544-785* Extender Ring Kit exterior brick or cement-type walls; fits to back of

544-800 Universal Adapter Kit retrofitting a previous horizontal installation to a

981-344 Electrical Box Cover

Plate Kit

— Various finish plates double-sensor, low-cost mounting for a variety of

* Product number suffixes indicate color: A = desert beige; B = white (e.g., 544-782B)

MBC/RBC applications with digital display 545-422

gyms and similar environments requiring a guard.

(Incompatible with adapter bases and the extender

155-222P25

(TB 193)

ring.)

See above. 155-222P25

(TB 193)

single-sensor rough-in installations. Kit includes

129-057

locator.

drywall mounting. 129-073

electrical boxes mounted flush with the wall and for

Figure 8

gyms and similar environments requiring a guard.

(Also see 544-782.)

single-sensor, low-cost mounting. Plate is 3.7 × 5.1

inches (9.5 × 12.9 cm)

155-252P25

(TB 238)

540-040

sensor on 2 × 4 electrical box

2 × 4 boxes, all single sensor installations on walls

540-237

Figure 8

with oversized holes, paint lines, etc., that need to be

covered, and on exterior brick/cement-type walls. Kit

includes Electrical Box Adapter Plate Assembly

(192-495. Adapter base is 3-1/2 × 5 inches

(8.8 × 12.7 cm).

4 × 6 boxes and all double sensor installations on

Figure 8

walls with oversized holes, paint lines, etc., that need

to be covered, and on exterior brick/cement-type

walls. Kit includes two mounting plates (192-720).

Adapter base is 5 × 7 inches (12.7 × 18 cm).

double-sensor non-conduit rough-in installations. Kit

540-784

includes locator.

—

sensor base plate

Figure 8

vertical one, or when the screw spacing does not fit

the electrical box adapter plate. Kit includes multislotted adapter plate.

2 × 4 box rough-ins. Kit includes locator and

—

connector.

155-252P25

applications.

(TB 238)

Page 2 of 5 Siemens Building Technologies, Inc.

Page 3

Mounting Information

Locate the sensor:

• according to design specifications and local

regulations.

• where the air circulates around it freely (not

in recessed areas or behind doors).

• allowing a minimum of 4 inches (100 mm)

free space above and below for proper

airflow, the front cover removal tool, and the

computer communication cable.

• away from drafts caused by doors, windows,

outside walls, air registers, pipes, return air

plenums, etc.

• away from heat sources such as strong

lights, fireplaces, direct sunlight, etc.

• on an inside wall (preferably), about 5 feet

(1.5 m) above the finished floor.

Document No. 540-743

Installation Instructions

September 10, 2009

NOTE: While not recommended, if you must mount

the sensor on exterior brick or cement-type

walls, see Accessories.

Drywall Mounting (No Rough-in),

Typical

1. Mark the center (cable) hole and the mounting

hole locations using the sensor base plate as a

template. See Figure 2.

CAUTION:

For drywall mounting, only use the top

and bottom holes.

2. Drill two 3/16-inch (4.8 mm) mounting holes.

3. Cut a 1-inch (25 mm) center hole with a hole

saw.

4. If using screws to attach the sensor, insert two

plastic wall anchors.

5. Pull about three inches (75 mm) of the cable

through the mounting hardware in the order

shown. See Figure 2.

Figure 2. Drywall Mounting (No Rough-in), Typical.

6. Mount the sensor base plate on the wall, noting

the UP arrow on the stabilizer plate:

a. Install either the two mounting screws

provided, the drive rivets provided, or

spring clips, but do not tighten.

CAUTION:

Pounding too hard or over-tightening may

cause the sensor base plate to crack or

bend.

b. Level the sensor base plate for

appearance.

c. Tighten the two mounting screws to the

sensor base plate.

7. Cut the cable, leaving about 3 inches (75 mm)

on the sensor side of the drywall.

CAUTION:

For retrofits: Before cutting the cable,

make sure it is disconnected from the

UC/MBC/RBC.

8. Unplug the terminal block from the back of the

printed circuit board (PCB) and terminate the

cable wires at the sensor terminal block. For sixposition terminal blocks, see Figure 3. For fourposition terminal blocks, see Figure 4. Also see

Figure 5 (MBC/RBC) or Figure 6 (UC). Reinstall

the terminal block.

Siemens Building Technologies, Inc. Page 3 of 5

Page 4

Document No. 540-743

Installation Instructions

September 10, 2009

Figure 3. Terminating to Six-position Terminal Block

(with Setpoint Switch).

Terminating the Cable Wires

NOTE: 1. All connections for one sensor must be

terminated in the same cabinet, whether

MBC, RBC, MEC or UC.

2. Unitary Controller installations: On the

UC Input/Output Card, place the

universal inputs jumper in the RTD

position.

Figure 4. Terminating to Four-position Terminal Block

(No Setpoint Switch).

9. Feed the extra cable back through the hole in

the rubber insulator.

10. Snap the sensor front to the sensor base plate

by first hooking the sensor front to the bottom

latches, and then pushing the top of the sensor

front into place until it latches.

11. Tighten the sensor front retaining screw. See

Figure 2.

12. Terminate the other end of the wires either (a) at

the MBC/RBC module terminal block(s)

(Figure 5) or (b) at the appropriate UC terminal

blocks (Figure 6.)

The installation is now complete.

Figure 5. MBC/RBC Wiring Example. (Wiring to

Full-featured Sensor 544-780).

Figure 6. UC Wiring. (Wiring to Full-featured

Sensor 544-780).

Page 4 of 5 Siemens Building Technologies, Inc.

Page 5

Document No. 540-743

Installation Instructions

September 10, 2009

TERMINAL BLOCK

6 SETPT*

5 COM2*

4 RTD

3 COM 1

2 LCDPR*

1 OVRRD*

MEC0045R1

SENSOR

SIG 2

COM 2

SIG 1

COM 1

24 VDC+

DI

DI1

DI2

DI3

DI4

49

50

51

52

SHIELD

AI17

AI18

AI19

AI20

9

53

54

55

56

+

+

+

+

-

DI5

10

11

DI6

12

13

DI7

14

15

DI8

16

+

24 VDC

SENSOR

SUPPLY

41

AI21

42

43

AI22

44

45

AI23

46

47

AI24

48

+

+

+

+

-

1

2

3

4

5

6

7

8

33

34

35

36

37

38

39

40

4. Pull the cable through the required mounting

hardware in the order shown.

* Optional feature

NOTE: 1. Some terminal blocks have only four terminal points.

2. Not all wires are used with all sensor models.

3. COM2 is the return signal path for the setpoint option.

4. Wiring configuration is only an example and can differ

depending on application.

Figure 7. MEC Wiring. (Wiring to Full-featured

Sensor 544-780).

Figure 8. Electrical Box and Rough-in Mounting,

Typical.

5. Install the two sensor mounting screws provided

but do not tighten.

Electrical Box and Rough-in

Mounting, Typical

1. If a locator is attached to the rough-in device,

remove the locator by removing the two screws

and lightly rocking the locator to pull it free.

2. Untie the twist tie and pull about three inches

(75 mm) of the sensor cable into the space.

3. If you have a single-sensor electrical box, install

the electrical box adapter plate. See Figure 8.

If you have a double-sensor electrical box,

install the required mounting plate(s).

If you use a universal adapter kit for a retrofit

6. Mount the sensor base plate on the wall, noting

the "UP" arrow on the stabilizer plate:

a. Level the sensor base plate for appearance

only.

b. Tighten the two mounting screws to the

sensor base plate.

CAUTION:

Over-tightening may cause the sensor

base plate to crack or bend.

7. Continue with Drywall Mounting (No Rough-in,

Typical), Steps 7 through 13.

The installation is now complete.

job, install the multi-slotted plate in place of the

electrical box adapter plate. See Figure 8.

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and

models as design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective

owners.

© 2009 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

Industry Sector

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

Your feedback is important to us. If you have

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com

Document No. 540-743

Printed in the U.S.A.

Page 5 of 5

U.S.A.

Loading...

Loading...