Page 1

WI180C-PB

WI180C-PB PROFIBUS coupler

en

OPERATING INSTRUCTIONS

Page 2

Described product WI180C-PB

Manufacturer SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information This document is protected by copyright. The associated rights are reserved by

SICK AG. Reproduction of this document or parts of this document is only permissible

within the limits of the legal provisions of Copyright Law. Any modication, abridgment

or translation of this document is prohibited without the express written permission of

SICK AG.

The trademarks mentioned in this document are the property of their respective owners.

© SICK AG. All rights reserved.

Original document This document is an original document of SICK AG.

2

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 3

Contents

1 About this document .......................................................................................5

1.1 Purpose of this document ..........................................................................................5

1.2 Target group ................................................................................................................ 5

1.3 Information depth ....................................................................................................... 5

1.4 Symbols used .............................................................................................................5

1.5 Symbols and document conventions ........................................................................6

1.6 Product information ...................................................................................................7

1.7 Further information ....................................................................................................7

2 Safety information ...........................................................................................8

2.1 General safety notes ..................................................................................................8

2.2 Correct use .................................................................................................................. 8

2.3 Foreseeable misuse ................................................................................................... 8

3 Product description ..........................................................................................9

3.1 Product characteristics ..............................................................................................9

3.2 Setup and function ..................................................................................................... 9

3.3 Interfaces ..................................................................................................................10

3.3.1 PROFIBUS ..................................................................................................10

3.3.2 Power supply .............................................................................................10

3.3.3 Grounding..................................................................................................11

4 Transport and storage .................................................................................. 12

4.1 Transport ...................................................................................................................12

4.2 Storage ......................................................................................................................12

5 Mounting......................................................................................................... 13

5.1 Required materials ...................................................................................................13

5.2 Preparing mounting location ...................................................................................13

5.3 Scope of delivery ......................................................................................................13

5.4 Mounting procedure .................................................................................................13

5.5 Connecting the device ..............................................................................................14

6 Commissioning .............................................................................................. 15

6.1 Conguration ............................................................................................................15

6.2 Switching on .............................................................................................................15

7 Operation ........................................................................................................ 16

7.1 Safety ........................................................................................................................16

7.2 Daily thorough check ................................................................................................16

7.3 LED status indicators ...............................................................................................16

7.4 Addressing the devices ............................................................................................17

7.5 Communication via PROFIBUS ................................................................................18

7.5.1 Read access ..............................................................................................18

7.5.2 Write access ..............................................................................................19

7.6 WI180C-PB index map overview .............................................................................20

7.7 WLL180T index map overview (via WI180C-PB) ....................................................21

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

3

Page 4

8 Fault indicators .............................................................................................. 24

8.1 LED fault indicators ..................................................................................................24

8.2 Error codes ................................................................................................................24

8.2.1 Diagnostic faults for the WI180C-PB.......................................................24

8.2.2 Diagnostic faults for the WLL180T ..........................................................25

8.2.3 Communication error ...............................................................................25

9 Decommissioning ......................................................................................... 26

9.1 Dismantling ...............................................................................................................26

9.2 Disposal ....................................................................................................................26

10 Technical data ................................................................................................ 27

10.1 Dimensional drawings ..............................................................................................27

10.2 Technical data ..........................................................................................................28

10.3 Ordering information, accessories ..........................................................................29

4

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 5

1 About this document

Read these operating instructions carefully before you mount and commission the

WI180C-PB.

1.1 Purpose of this document

These operating instructions contain information required during the life cycle of the

WI180C-PB and its variants WI180C-PB(Sxx).

These operating instructions must be made available to all those who work with the

WI180C-PB(Sxx).

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the WI180C-PB(Sxx).

1.2 Target group

These operating instructions are intended for the following target groups: Project developers (planners, developers, designers), installers, electricians, programmers, operators and maintenance personnel.

The structure of these operating instructions is based on the life-cycle phases of the

WI180C-PB: Project planning, mounting, electrical installation, commissioning, operation, maintenance and disposal.

1ABOUT THIS DOCUMENT

1.3 Information depth

These operating instructions contain information about the following topics relating to

the WI180C-PB(Sxx):

− Product description

− Mounting

− Electrical installation

− Commissioning and conguration

Furthermore, when planning and using sensors such as the WI180C-PB(Sxx), technical

expertise is required, which is not covered in this document.

Ofcial and legal regulations for operating the WI180C-PB(Sxx) volume measurement

system must always be complied with.

You can nd further information on the Internet at www.sick.com.

1.4 Symbols used

Symbol Meaning

This symbol indicates a hazard where the product may be damaged by

improper handling.

This symbol refers to a hazard due to electrical charge which may

damage the product.

Subject to change without notice

This symbol precedes a note containing important additional information.

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

5

Page 6

1 ABOUT THIS DOCUMENT

1.5 Symbols and document conventions

WARNING!

A warning indicates a specic or potential danger.

This is intended to protect you against accidents.

Read and follow the warnings carefully!

Symbol Meaning

Danger (general)

Danger of electric shock

Danger in potentially explosive environments

Danger due to explosive substances

Danger due to inammable substances

Danger due to oxidizing agents

Danger due to toxic substances

Danger due to corrosive substances

Danger due to harmful substances

General note with important additional information

6

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 7

1.6 Product information

1ABOUT THIS DOCUMENT

Product name

Device version

Manufacturer

1.7 Further information

www.sick.com

The following information is available on the Internet:

− Other language versions

− Data sheets and application examples

− CAD data of drawings and dimensional drawings

− Certicates (e.g. EU declaration of conformity)

− Current device les

WI180C-PB, WI180C-PB(Sxx)

PROFIBUS

SICK AG

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 General safety notes

• The mounting, electrical installation and conguration of the device must be carried out by professionally qualied personnel only.

• Before mounting, it is imperative that you familiarize yourself with the operating

instructions for the connected devices.

• When mounting and electrical installation work is being carried out, always comply

with applicable health and safety and environmental regulations.

• The WI180C-PB must not be used outdoors or in areas with ammable/explosive

atmospheres!

• When installing the device, always consider the electrical connected loads.

• Replace faulty or damaged cables and male connectors immediately.

• Replace damaged or faulty couplers immediately.

• When mounting the device, it is imperative that you use suitable mounting equip-

ment and that you consider their specic requirements.

• Ensure a constant power supply to the device within the set parameters.

• Only operate the WI180C-PB within the set operating parameters.

• Regularly check that the WI180C-PB is functioning properly.

• Structural modications to the WI180C-PB are not permitted.

• The WI180C-PB is not designed as a safety product.

2.2 Correct use

Correct use requires that the WI180C-PB is used industrially indoors without any spe-

cic climatic and atmospheric requirements.

Any use outside of the areas mentioned in each case will be considered to be incorrect

use and void any warranty claims against SICK AG.

2.3 Foreseeable misuse

Not taking account of the pin assignment or using an incorrect adapter cable may

damage or destroy the connected PROFIBUS coupler.

Connecting the PROFIBUS coupler to signal or power cables that are too long may lead

to a loss of data and damage to the PROFIBUS coupler.

8

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 9

3 Product description

3.1 Product characteristics

The WI180C-PB is an interface coupler, which can be used to connect connected

devices (e.g. WLL180T) to the PROFIBUS DP. The relevant devices are connected via a

simple plug system on the side of the coupler.

Usually, the entire system is mounted on a mounting rail close to the application.

The coupler supports up to 16 connected devices, which are likewise connected to one

another via the plug system.

Further properties:

− Probus DP-V1 Slave

− Option to communicate via function block (e.g. Siemens SFB52 or SFB53).

Pre-congured SICK function blocks are available to download from www.sick.com.

− Transmission rates of 9.6 Kbits/s–12 Mbit/s

Further specications can be found in the technical data (see page 28).

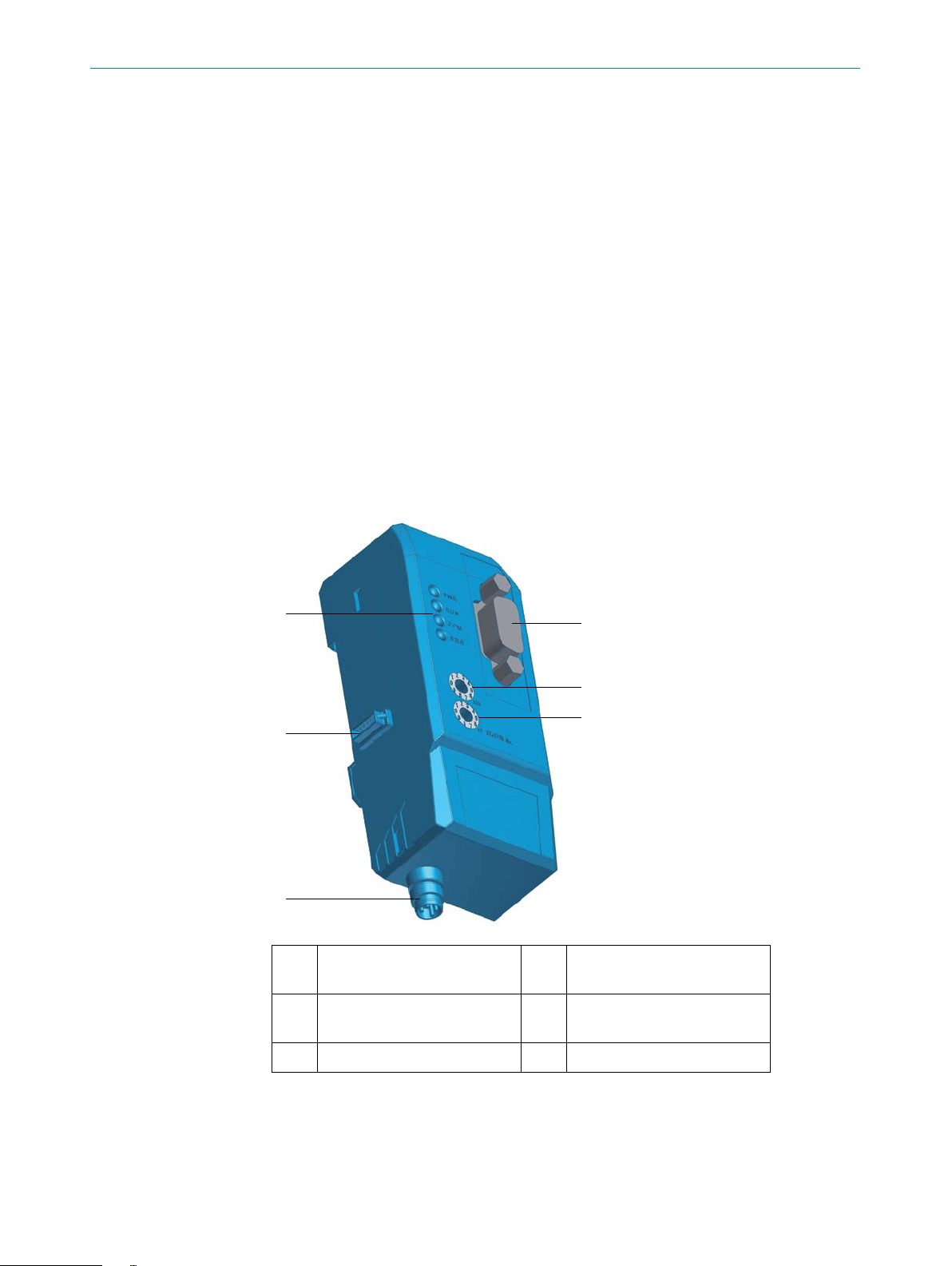

3.2 Setup and function

3PRODUCT DESCRIPTION

Subject to change without notice

1 D-sub connection (RS485),

9-pin, PROFIBUS

2 Switch station no. ×10 5 Bus male connector

3 Switch station no. ×1 6 Status LEDs

4 Power supply connection

(M8), 4-pin

(system bus)

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

9

Page 10

3 PRODUCT DESCRIPTION

4

2

1 3

3.3 Interfaces

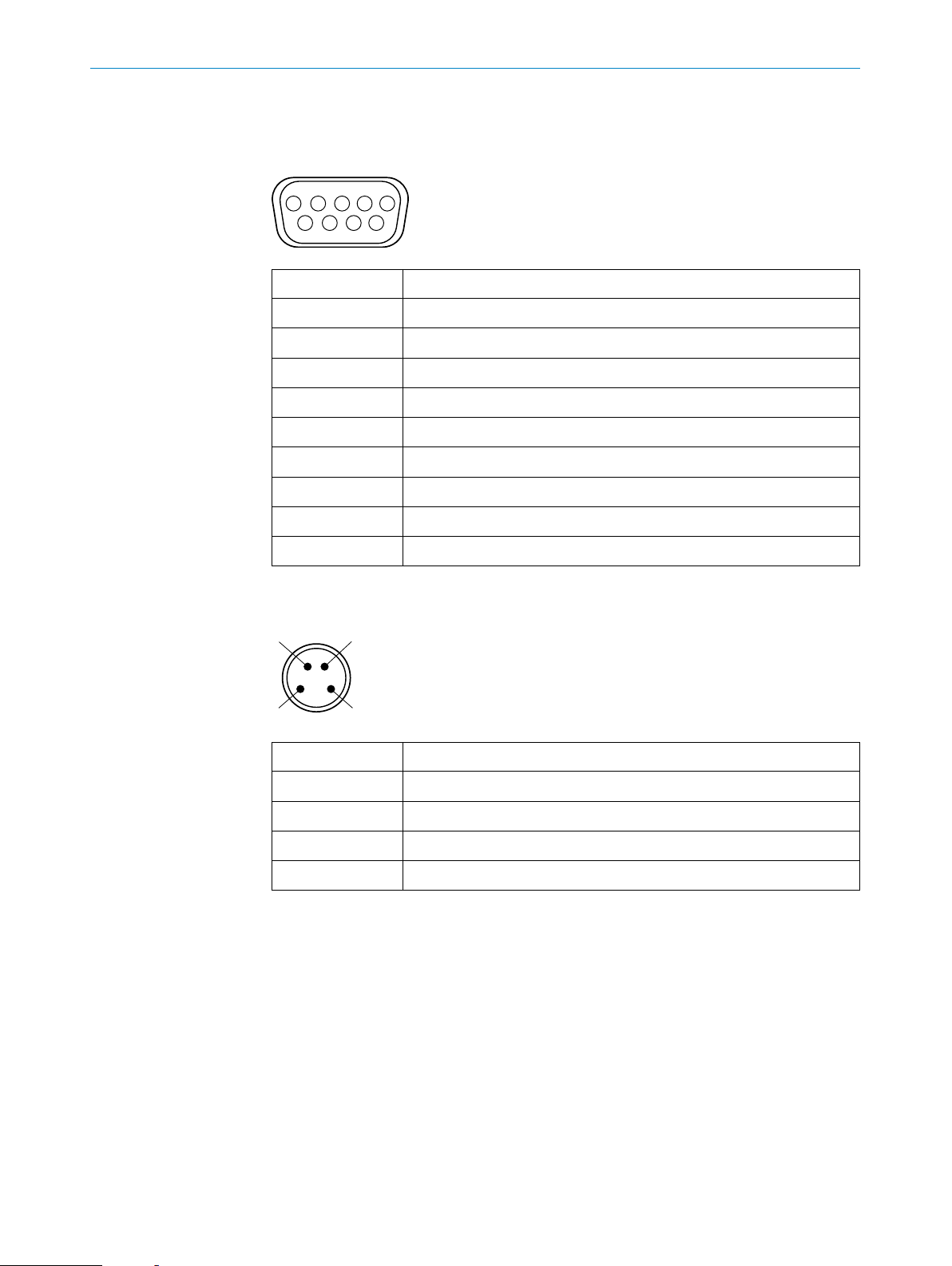

3.3.1 PROFIBUS

Pin Pin assignment

1 Not assigned

2 Not assigned

3 RxD+/TxD+

4 RTS

5 DGND

6 +5 VDC

7 Not assigned

12345

6789

3.3.2 Power supply

8 RxD-/TxD-

9 Not assigned

Pin Pin assignment

1 +12–24 VDC

2 Not assigned

3 GND

4 Not assigned

10

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 11

3.3.3 Grounding

3PRODUCT DESCRIPTION

The WI180C-PB is grounded via the mounting rail by means of a spring contact:

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

11

Page 12

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

Either transport the WI180C-PB in the original packaging or use a padded transport

container. Make sure that you comply with the maximum permitted environmental conditions (see page 28).

4.2 Storage

If you want to store the WI180C-PB for a relatively long time, pack it as you would for

transport. Make sure that the storage location complies with the permitted environmental conditions (see page 28).

12

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 13

5 Mounting

5.1 Required materials

You need the following additional materials to mount the WI180C-PB.

− grounded mounting rail (pre-mounted)

− pre-assembled cable (max. 30 m) with M8 female connector

(pin assignment see page 10)

− pre-assembled cable for PROFIBUS with D-sub male connector

(pin assignment see page 10)

− one or more signal sources (e.g. WLL180T)

− small slotted screwdriver

5.2 Preparing mounting location

1. Mount a grounded mounting rail in the same area as the application.

2. Lay the two pre-assembled cables so that they can easily be connected to the

connections of the WI180C-PB. If necessary, use cable channels, cable ties and

cable grips.

5MOUNTING

5.3 Scope of delivery

− WI180C-PB

− Quick start instructions

5.4 Mounting procedure

1. Carefully unpack the WI180C-PB.

2. Clamp the WI180C-PB onto the mounting rail, as shown in the image.

3. Clamp the series-connected devices onto the mounting rail as shown in their

mounting instructions.

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

13

Page 14

5 MOUNTING

4. Push the series-connected devices onto the 5-pin connection on the left side of the

WI180C-PB. Make sure that the sequence is correct (see the operating instructions

for the relevant device).

5. Fix the connected devices on the mounting rail without any spaces.

5.5 Connecting the device

Note:

Switch the power supply off before you connect or replace the devices.

1. Connect the male D-sub connector for the PROFIBUS connection to the PROFIBUS

connection on the WI180C-PB and secure it using the knurled screws.

2. Connect the female M8 connector on the power supply to the underside of the

WI180C-PB and screw the male connector tight.

14

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 15

6 Commissioning

6.1 Conguration

1. Adjust the PROFIBUS address provided on the two address switches on the front of

the WI180C-PB. Use a small screwdriver to do this.

Note:

The address can be in the range between 01 and 99.

The upper rotary switch "×10" represents a multiple of 10. The lower rotary switch "xy"

represents a value between 0 and 9.

The WI180C-PB must be restarted after every change of address by switching off and

on again, before the new address is transferred.

6COMMISSIONING

2. Call up your PLC/PROFIBUS development or conguration environment.

3. Download the current device le "Sick0E99.GSD" from www.sick.com.

4. Install the device le "Sick0E99.GSD" in your project planning software.

6.2 Switching on

1. Switch on the power supply for the WI180C-PB.

2. Wait approximately two seconds until the WI180C-PB indicates that it is ready

(see page 16).

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

15

Page 16

7 OPERATION

7 Operation

7.1 Safety

A few guidelines must be followed to ensure the operational safety of the WI180C-PB:

− Carry out a daily functional check (see page 16).

− If you want to connect devices to the WI180C-PB or remove devices, switch off the

power supply rst.

− Only operate the WI180C-PB under the specied operating conditions

(see page 28).

7.2 Daily thorough check

You should carry out the following functional checks once a day:

− Check the function of the LED indicators.

− Use appropriate status queries to check communication with each of the

connected devices.

7.3 LED status indicators

PWR RUN COM ERR Description

– – – – No power supply

X – – – Power supply established, device is

being initialized

X X – – Initialization completed

X X X – Communication with DP master

established, fault-free function

X ashes

acyclically

X –(100 ms) –/X X/ashes

–/X X/ashes

acyclically

No communication with bus

devices or serious fault

Fault has occurred

acyclically

X –/ashes

–/X X Incorrect conguration

acyclically

X –/ashes

cyclically

X –/X – ashes

–/X ashes

acyclically

Conguration not completed

No communication with DP master

cyclically

Table 1:X: on, –: off

16

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 17

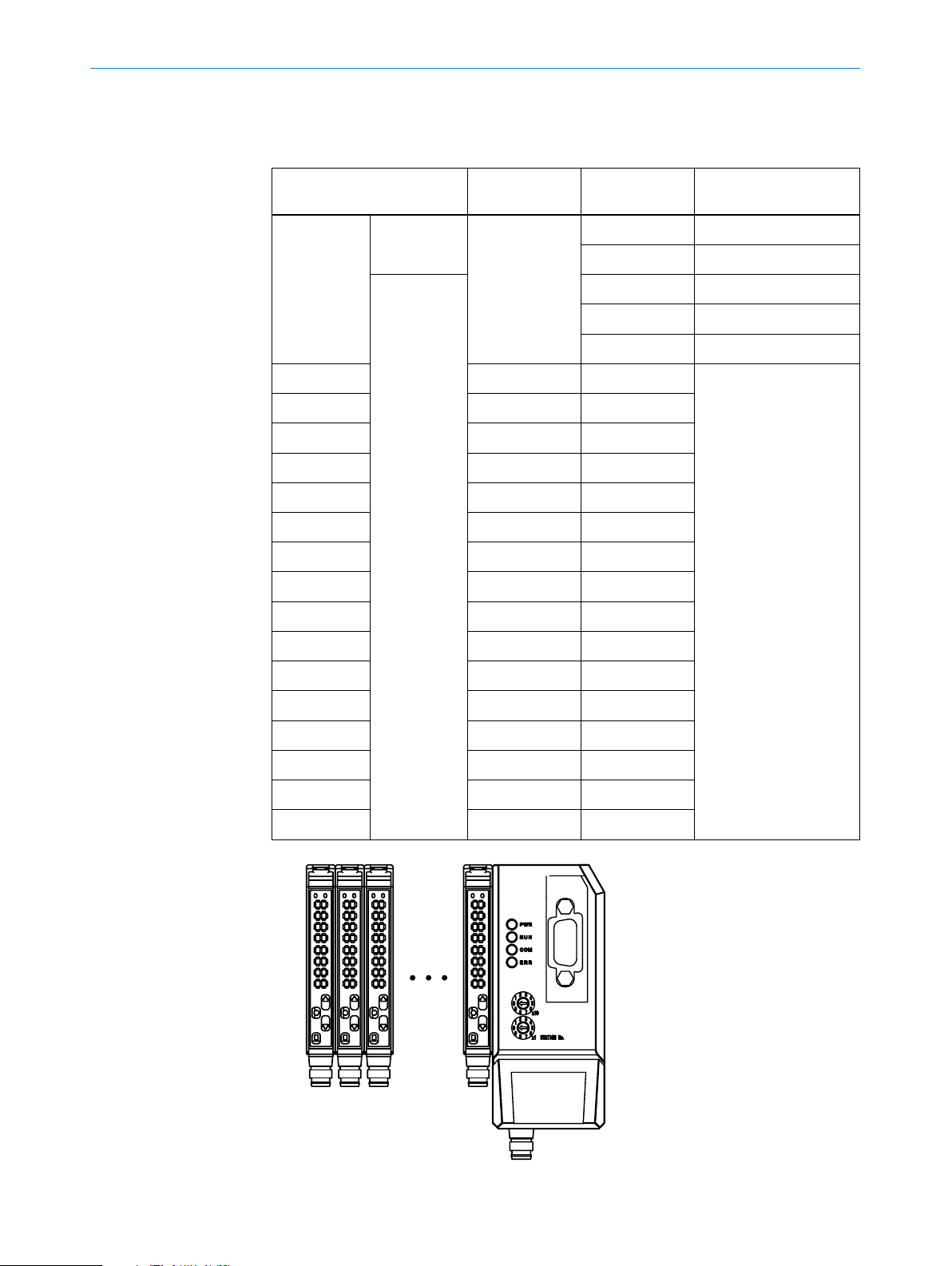

7.4 Addressing the devices

WI180C-PB

Slotnr. 234171

The individual devices are addressed in accordance with the following scheme:

7OPERATION

Slot number Device Example byte

address

Function

1 Output WI180C-PB 0 Teach-in version

2 b0: Reset fault

Input 0 Channel 1 status

2 Channel 2 status

4 External input status

2 Device #1 6 Light value received

3 Device #2 8

4 Device #3 10

5 Device #4 12

6 Device #5 14

7 Device #6 16

8 Device #7 18

9 Device #8 20

10 Device #9 22

11 Device #10 24

12 Device #11 26

13 Device #12 28

14 Device #13 30

15 Device #14 32

16 Device #15 34

17 Device #16 36

Subject to change without notice

Master

Slave 1

Slave 2

Slave 15

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

17

Page 18

7 OPERATION

7.5 Communication via PROFIBUS

Function blocks are used for communicating with the connected devices.

Examples:

Standard function blocks:

− Read SFB52 RDREC dataset

− Write SFB52 WRREC dataset

Device-specic SICK function blocks

− Function block for interpreting the acyclic service data

− Parser function for interpreting the cyclic process data

When read, the device's response returns a 4 byte header and the requested data.

A 3 byte header and a 1 byte value for the written data is returned when writing.

7.5.1 Read access

Command telegram

Access type Probus slot Index Dataset length

0x5E (read) 1 byte 1 byte 1 byte

Response telegram

Access type Probus slot Index Dataset length Data

0x5E (read) 1 byte 1 byte 1 byte max. 32 byte

Example

The dealer name of the rst connected device should be read out.

Access type Probus slot Index Dataset length

0x5E 0x06 (Slot 1) 0x05 (5) 0x10 (16)

The response data packet – consisting of 4+16 bytes – contains the requested values:

Byte address Value

18

0 0x53 ("S")

1 0x49 ("I")

2 0x43 ("C")

3 0x4B ("K")

4 0x20 (" ")

5 0x41 ("A")

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 19

7.5.2 Write access

Command telegram

Response telegram

7OPERATION

6 0x47 ("G")

7 0x00 (0)

Note:

The value "0x00" terminates the byte sequence.

Access type Probus slot Index Dataset length Data

0x5F (write) 1 byte 1 byte 1 byte max. 32 byte

Example

Access type Probus slot Index Dataset length

0x5F (write) 1 byte 1 byte 1 byte

An 8 byte tag name should be written to the WI180C-PB.

Value

Access type

Probus slot

Index

Dataset length

Byte address: 0

Byte address: 1

Byte address: 2

Byte address: 3

Byte address: 4

Byte address: 5

0x5F

0x00 (Slot 0)

0x08 (8)

0x08 (8)

0x54 ("T")

0x61 ("a")

0x67 ("g")

0x20 (" ")

0x6E ("n")

0x61 ("a")

Subject to change without notice

Byte address: 6

Byte address: 7

0x6D ("m")

0x65 ("e")

The response packet – consisting of 4 bytes – returns the number of bytes written

(0x08).

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

19

Page 20

7 OPERATION

7.6 WI180C-PB index map overview

Index no. Function Details Access Length

(Byte)

Description

0 Product/series b15–12 Manufacturer R 2 1: SICK AG

b11–8 Category 5: Communication unit

b7–0 Family 1: WI180C-PB

1 Product type R 2 1: WI180C-PB

2 Firmware version R 2

3 Protocol version R 2

4 Product revision R 2

5 Vendor name R 2–16 "SICK AG"

6 Product name R 2–32 "WI180C-PB"

7 Product ID R 2–16 "6052566"

8 User ID R/W 2–32 ASCII 32 characters max.

9 Operating status R 2 2: Run

10 Reserved

11 Network prole R 2–32 "Fieldbus PROFIBUS DP adapter

V1"

12...96 Reserved

97 Number of sensors R/W 2 0: no check

1–16: Check number of sensors

98 Error code R/W 2 Clear fault with desired value

99...209 Reserved

210 Warm start W 2 3: execute

211 Reserved

212 Return to factory

W 2 3: execute

settings

213...254 Reserved

255 System, reserved

20

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 21

7.7 WLL180T index map overview (via WI180C-PB)

7OPERATION

Index no. Function Details Access Length

(Byte)

Description

0 Product/series b15–12 Manufacturer R 2 1: SICK AG

b11–8 Category 1: Fiber photoelectric sensor

b7–0 Family 1: WLL180T, 1 output

2: WLL180T, 2 outputs

1 Product type R 2 17: WLL180T

2 Firmware version R 2 0x0200

3 Protocol version R 2 0x0001

4 Product revision R 2 0x0001

5 Vendor name R 2–16 "SICK AG"

6 Product name R 2–32 ASCII 32 characters max.

7 Product ID R 2–16 ASCII 16 characters max.

8 User ID R/W 2–32 Space

9 Operating status R 2 0: Init

1: Idle

2: Run

3: In use by user

10...12 Reserved

13 Parameter bytes R 2 Amount of parameter data to be

saved

14...97 Reserved

98 Error code R/W 2 Clear fault with desired value

99 Reserved

100 Display R/W 2 0: numerical display

1: bar graph

2: percentage display

101 Detection mode R/W 2 0: normal

1: rising signal edge of detected

light

2: falling signal edge of detected

light

3: differential value to the next

(left) unit

102 Teach-in mode CH1 R/W 2 0: 2-point

103 CH2 R/W 2

1: 1-point

2: Transparent

3: Zone

4: Auto

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

21

Page 22

7 OPERATION

Index no. Function Details Access Length

(Byte)

Description

104 Response time R/W 2 0: 16 µs

1: 70 µs

2: 250 µs

3: 3 ms

4: 8 ms

105 Transmitting power R/W 2 0: low

1: medium

2: normal

106 Input R/W 2 0: External teach-in

1: Test input

2: Synchronization

3: Reset the counter

4: Master teach-in

5: No function

107 Pushbutton lock R/W 2 0: cancel

1: complete block

2: blocked, external teach-in

108 Operating Mode CH1 R/W 2 0: light

109 CH2 R/W 2

1: dark

110 threshold level CH1 lower limit R/W 2 0...9999

111 CH1 upper limit R/W 2

112 CH2 lower limit R/W 2

113 CH2 upper limit R/W 2

114 Timer setting CH1 R/W 2 0: switch-off delay

115 CH2 R/W 2

1: pulse (one shot)

116 Switch-off delay CH1 R/W 2 0...9999: 0...9999 ms

117 Switch-on delay CH1 R/W 2

-1...-9: 0.1....0.9 ms

118 Switch-off delay CH2 R/W 2

119 Switch-on delay CH2 R/W 2

120...122 Reserved

123 hysteresis R/W 2 1...40%

124...125 Reserved

126 Energy saving mode R/W 2 0: Off

1: energy saving display

127 Display reversal R/W 2 0: normal

1: reversed display

128...199 Reserved

200 Save zero reset W 2 desired value

22

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 23

7OPERATION

Index no. Function Details Access Length

(Byte)

Description

201 Cancel zero reset W 2 desired value

202 1-point teach-in W 2 1: CH1

203 2-point teach-in W 2

2: CH2

204...209 Reserved

210 Warm start W 2 3: execute

211 Return to main menu W 2

212 Return to factory

W 2 3: execute

settings

213...254 Reserved

255 System, reserved

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

23

Page 24

8 FAULT INDICATORS

8 Fault indicators

8.1 LED fault indicators

PWR RUN COM ERR Description

X ashes

acyclically

X –(100 ms) –/X X/ashes

X –/ashes

acyclically

X –/X – ashes

Table 2:X: on, –: off

8.2 Error codes

8.2.1 Diagnostic faults for the WI180C-PB

Error code Description

0x06 Number of connected bus devices was reduced

0x09 Different number of registered and actually connected bus devices

0x0A Timeout during communication with bus device

0x0B Internal communication fault

–/X X/ashes

acyclically

No communication with bus

devices or serious fault

Fault has occurred

acyclically

–/X X Incorrect conguration

No communication with DP master

cyclically

0x0C Unexpected response from internal bus

24

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 25

8.2.2 Diagnostic faults for the WLL180T

Error code Description

0x12 End of the data

0x13 Attempt to write blocked parameters

0x14 Teach different output channel

0x15 Attempt to apply 2-point teach to a mode that does not support it

0x16 Forbidden parameter value for warm start or initialization

0x17 Parameter value outside of permitted limits

0x18 Index value outside of permitted limits

0x19 Attempt to teach counter mode

0x1B Received light value too weak during teach-in

0x1C Received light value too high during teach-in

0x1D Difference in received light values between rst and second point too

small during 2-point teaching

8FAULT INDICATORS

8.2.3 Communication error

Error code Description

0xB0 Forbidden index value

0xB1 Forbidden data length

0xB2 Forbidden slot number

0xB6 Access denied

0xB8 Defective parameters

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

25

Page 26

9 DECOMMISSIONING

9 Decommissioning

9.1 Dismantling

1. Switch off the power supply for the WI180C-PB.

2. Disconnect the male connector of the power supply and the PROFIBUS male

connector.

3. Detach the mountings for the connected devices.

4. Disconnect the connected devices from the bus male connector of the WI180C-PB.

5. Carefully push up the WI180C-PB until you can tip it forwards.

9.2 Disposal

6. Remove the WI180C-PB from the mounting rail.

At the end of its service life, the WI180C-PB must be disposed of correctly as waste

electronics. Take the regulations in your country into account also.

26

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 27

10 Technical data

10

10.1 Dimensional drawings

10TECHNICAL DATA

25.3

39

38.2

33.2

18.835

27.1

92

102.55

37.9

Subject to change without notice

10.4

No. Description No. Description

1 PWR-LED 5 Switch station no. (x1 and x10)

2 RUN-LED 6 Power supply connection (M8),

4-pin

3 COM-LED 7 Bus male connector (system bus)

4 ERR-LED 8 D-sub connection (RS-485), 9-pin,

PROFIBUS

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

27

Page 28

10 TECHNICAL DATA

10.2 Technical data

Description Value

Electrical

Supply voltage 12 – 24 VDC ± 10%

Power consumption 2 W

Switch-on delay (WI180C-PB) 500 ms

Switch-on delay (overall system) 2000 ms

Prole PROFIBUS DP-V1

Maximum number of modules to be con-

16

nected

Transmission rates in kbit/s 9.6/19.2/45.45/93.75/187.5/500/

1.500/3.000/6.000/12.000

Maximum distance between nodes 1.200 m @ 9.6 – 93.75 kbit/s

1.000 m @ 187.5 kbit/s

400 m @ 500 kbit/s

200 m @ 1.500 kbit/s

100 m @ 3.000 – 12.000 kbit/s

Process data 2x output, 1x input, 14 bit received light

Asynchronous data Fieldbus index map, see page 20 ff.

Transmission interface RS-485

LEDs PWR, RUN, COM, ERR (3x green, 1x red)

EMC

Product safety

Mechanical

Power supply Male M8 plug connector, 4-pin

Other interfaces Male bus connector, 5-pin, internal

system bus

D-sub, 9-pin, PROFIBUS

Noise immunity (Length of cable ≤30 m) in accordance with EN 61000-6-2/

EN 61131-2

Emission in accordance with EN 55011, class A

Protection class 3

Short-circuit protection in accordance with VDE 0160

Protection category IP50

Sensitivity to vibrations IEC 68, 10 – 55 Hz

Shock resistance IEC 68, 500 m/s² (~50 G)

Housing material Polycarbonate

Dimensions (HxWxD) in mm 39.2 x 102.55 x 39

Connections M8, 4-pin, power supply

D-sub, 9-pin, PROFIBUS

Male bus connector, 5-pin, bus con-

nector

Environmental

parameters

28

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Air humidity (operation/storage) 35 – 85% relative humidity

Subject to change without notice

Page 29

Temperature range (storage) -40 – +70 °C

10TECHNICAL DATA

Temperature range (Operation, ≤3 connected

devices)

Temperature range (Operation, ≤8 connected

devices)

Temperature range (Operation, ≤16 connected

devices)

10.3 Ordering information, accessories

Part number Type Description

6009870 D0L-0804-G02M Female connector, M8, 4-pin, straight, 2 m cable

6009872 D0L-0804-G05M Female connector, M8, 4-pin, straight, 5 m cable

6009871 D0L-0804-W02M Female connector, M8, 4-pin, angled, 2 m cable

6009873 D0L-0804-W05M Female connector, M8, 4-pin, angled, 5 m cable

5313011 BF-EB01-W190 End piece for mounting rails

-25 – +55 °C

-25 – +50 °C

-25 – +45 °C

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

29

Page 30

30

WI180C-PB | PROFIBUS COUPLER 8018416.YM10/COMAT/ 2015-03-13 | SICK AG

Subject to change without notice

Page 31

Subject to change without notice

WI180C-PB | PROFIBUS COUPLER8018416.YM10/COMAT/ 2015-03-13 | SICK AG

31

Page 32

8018416.YM10 /2015-03-13 ∙ COMAT/ITL (2015-03) ∙ USmod 4c int44

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0)22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0)2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 4000 121 000

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Gemany

Phone +49 211 5301-301

E-Mail info@sick.de

Great Britain

Phone +44 (0)1727 831121

E-Mail info@sick.co.uk

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail office@sick.hu

India

Phone +91–22–4033 8333

E-Mail info@sick-india.com

Israel

Phone +972-4-6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 (0)3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603 808070425

E-Mail enquiry.my@sick.com

Netherlands

Phone +31 (0)30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 837 40 50

E-Mail info@sick.pl

Romania

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7-495-775-05-30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 (0)1-47 69 990

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2645 0009

E-Mail tawiwat@sicksgp.com.sg

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail info@sick.ae

USA/Mexico

Phone +1(952) 941-6780

1 (800) 325-7425 – tollfree

E-Mail info@sick.com

Vietnam

Phone +84 8 62920204

E-Mail Ngo.Duy.Linh@sicksgp.com.sg

More representatives and agencies

at www.sick.com

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...