Page 1

WLG16 Bluetooth®

O P E R A T I N G I N S T R U C T I O N S

Page 2

WLG16 Bluetooth®

O P E R A T I N G I N S T R U C T I O N S

de

en

Page 3

Described product

WLG16 - Bluetooth®

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

Subject to change without notice

8022197 | SICK

Page 4

Contents

CONTENTS

1 Safety information............................................................................ 4

1.1 General safety notes................................................................................ 4

1.2 Notes on UL approval............................................................................... 4

2 Intended use...................................................................................... 4

3 Operating and status indicators...................................................... 4

4 Mounting............................................................................................. 5

5 Electrical installation........................................................................ 5

6 Commissioning.................................................................................. 8

7 Troubleshooting................................................................................. 12

8 Disassembly and disposal............................................................... 12

9 Maintenance...................................................................................... 12

10 Approvals............................................................................................ 13

10.1 Bluetooth® approvals............................................................................... 13

11 Technical data.................................................................................... 13

11.1 General technical data............................................................................. 13

11.2 Bluetooth technical data®....................................................................... 14

8022197 | SICK

Subject to change without notice

3

Page 5

1 SAFETY INFORMATION

1 Safety information

1.1 General safety notes

■

Read the operating instructions before commissioning.

■

cialists.

■

Not a safety component in accordance with the EU Machinery Directive.

■

When commissioning, protect the device from moisture and contamination.

■

These operating instructions contain information required during the life cycle of

the sensor.

1.2 Notes on UL approval

The device must be supplied by a limited voltage / limited current circuit or is intended

to be connected to a Class 2 source of supply. In case of a limited voltage / limited cur‐

rent circuit the device shall be supplied from an isolating transformer having a sec‐

ondary overcurrent protective device that complies with UL 248 to be installed in the

field rated either:

Connection, mounting, and setting may only be performed by trained spe‐

a) max 5 amps for voltages 0~20 V (0~28.3 V peak), or

b) 100/Vp for voltages of 20~30 V (28.3~42.4 V peak).

UL Environmental Rating: Enclosure type 1

2 Intended use

The WLG16 is an opto-electronic photoelectric retro-reflective sensor (referred to as

“sensor” in the following) for the optical, non-contact detection of objects, animals, and

persons. A reflector is required for this product to function. If the product is used for any

other purpose or modified in any way, any warranty claim against SICK AG shall become

void.

Photoelectric retro-reflective sensor with optional add-on for detecting transparent

objects (WLG-xx).

3 Operating and status indicators

4

Subject to change without notice

8022197 | SICK

Page 6

20

Ø 12,9

Ø 4,1

39,9

55,4

45,5

5

42

29,9

6

3

6,5

15

27,8

7,7

7,8

7,2

35,5

4,1

8,3

55,7

3

2

34,5

1

4

65

20

M12

18

Ø 4,1

39,9

55,4

55,7

45,5 5

7

42

29,9

52,9

6

17,5

3

6,5

15

28

7,5

35,5

4,1

3

2

34,5

1

4

65

OPERATING AND STATUS INDICATORS 3

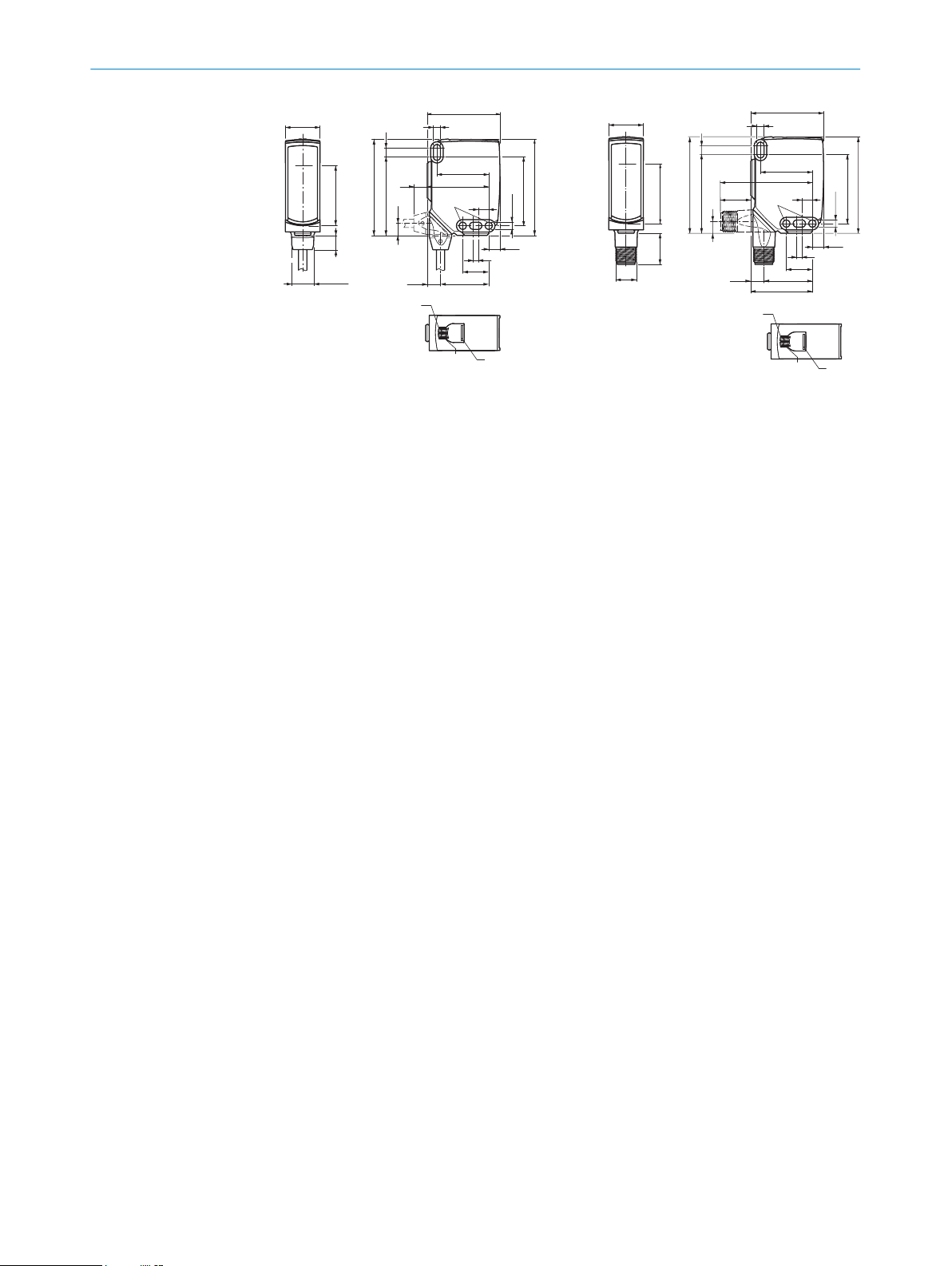

Figure 1: Dimensional drawing 1, cable

Center of optical axis

1

Fixing hole, Ø 4.1 mm

2

Connection

3

LED indicator green: Supply voltage

4

active

LED indicator yellow: Status of

5

received light beam

BluePilot blue: Alignment aid

6

4 Mounting

Mount the sensor and the reflector using suitable mounting brackets (see the SICK

range of accessories). Align the sensor and reflector with each other.

Note the sensor's maximum permissible tightening torque of < 1,3 Nm.

5 Electrical installation

The sensors must be connected in a voltage-free state (UV = 0 V). The following informa‐

tion must be observed, depending on the connection type:

– Male connector connection: Note pin assignment

– Cable: wire color

Figure 2: Dimensional drawing 2, male con‐

nector

Only apply voltage/switch on the voltage supply (UV > 0 V) once all electrical connec‐

tions have been established.

Explanations of the connection diagram (Tables 1 and 2):

Alarm = alarm output (see Table 4)

Health = alarm output (see Table 4)

8022197 | SICK

Subject to change without notice

MF (pin 2 configuration) = external input, teach-in, switching signal

QL1 / C = switching output, IO-Link communication

5

Page 7

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

5 ELECTRICAL INSTALLATION

DC: 10 ... 30 V DC

Table 1: DC

WLG16 -24162xxxA00

1 + (L+)

2 MF

3 - (M)

4 QL1/C

Default: MF

Default:

QL1/C

-34162xxxA00

Q Q

Q Q

-1x162xxxA00-24161xxxA0

0

-34161xxxA0

0

Q Q www.sick.com

Q Q

1 = brn

2 = wht

3 = blu

4 = blk

-1x161xxxA00-2416xxxxA01A99

-3416xxxxA01A99

8020349

www.sick.com

8020349

1 = brn

2 = wht

3 = blu

4 = blk

0.14 mm

AWG26

2

0.14 mm

2

AWG26

Table 2: DC

WLG16 -24165

xxxA00

-34165

xxxA00

-1x165

xxxA00

-24163

xxxA00

-34163

xxxA00

-1x163x

xxA00

-24166x

xxA00

-34166x

xxA00

-1x166x

xxA00

-24164x

xxA00

-34164x

xxA00

-1x164x

xxA00

1 + (L+)

2 MF

3 - (M)

4 QL1/C

Default: MF Alarm Alarm Alarm Alarm Health Health Health Health

Default:

Q Q

Q Q

Q Q

Q Q

QL1/C

1 = brn

2 = wht

3 = blu

4 = blk

0.14 m

2

m

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14 m

2

m

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14 m

2

m

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14 m

AWG26

2

m

6

Subject to change without notice

8022197 | SICK

Page 8

Table 3: Push / pull

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Alarm

‒ (M)

+ (L+)

Health

‒ (M)

+ (L+)

Alarm

‒ (M)

+ (L+)

Health

‒ (M)

Q

Push-pull

(≤ 100 mA)

Q

Push-pull

(≤ 100 mA)

ELECTRICAL INSTALLATION 5

Alarm

Alarm output: The sensor (WLG16) features a pre-failure notification output (“Alarm” in

connection diagram [Table 4]), which issues a notification if the sensor is only ready for

operation to a limited extent. The LED indicator flashes in this case. Possible causes:

Sensor or reflector is contaminated, sensor is out of alignment. In the good state: LOW

(0), if excessively contaminated HIGH (1).

Health

Health output: The sensor (WLG16) features a pre-failure notification output (“Health”

in connection diagram [Table 4]), which issues a notification if the sensor is only ready

for operation to a limited extent or the cable has been interrupted. Possible causes:

Sensor or reflector is contaminated, sensor is out of alignment, cable is damaged. In

the good state: HIGH (1), if excessively contaminated or in the event of cable interrup‐

tion LOW (0). The yellow LED indicator flashes in this case.

Table 4: Alarm / Health

Alarm (≤ 100 mA) Health (≤100 mA)

8022197 | SICK

Subject to change without notice

7

Page 9

Abstand in m

Schaltabstand

1

2

3

4

5

6

0 1 2 3 4 5 6

4

2,8

0

2,5

0

3,5

0

5

0

1,20

0

COMMISSIONING

6

6 Commissioning

Bluetooth® is switched on for initial commissioning. You can get SOPASair in the Google

PlayStore (Android) and in the App Store (iOS).

Operating system requirements: Android version 6.0, most current version of iOS.

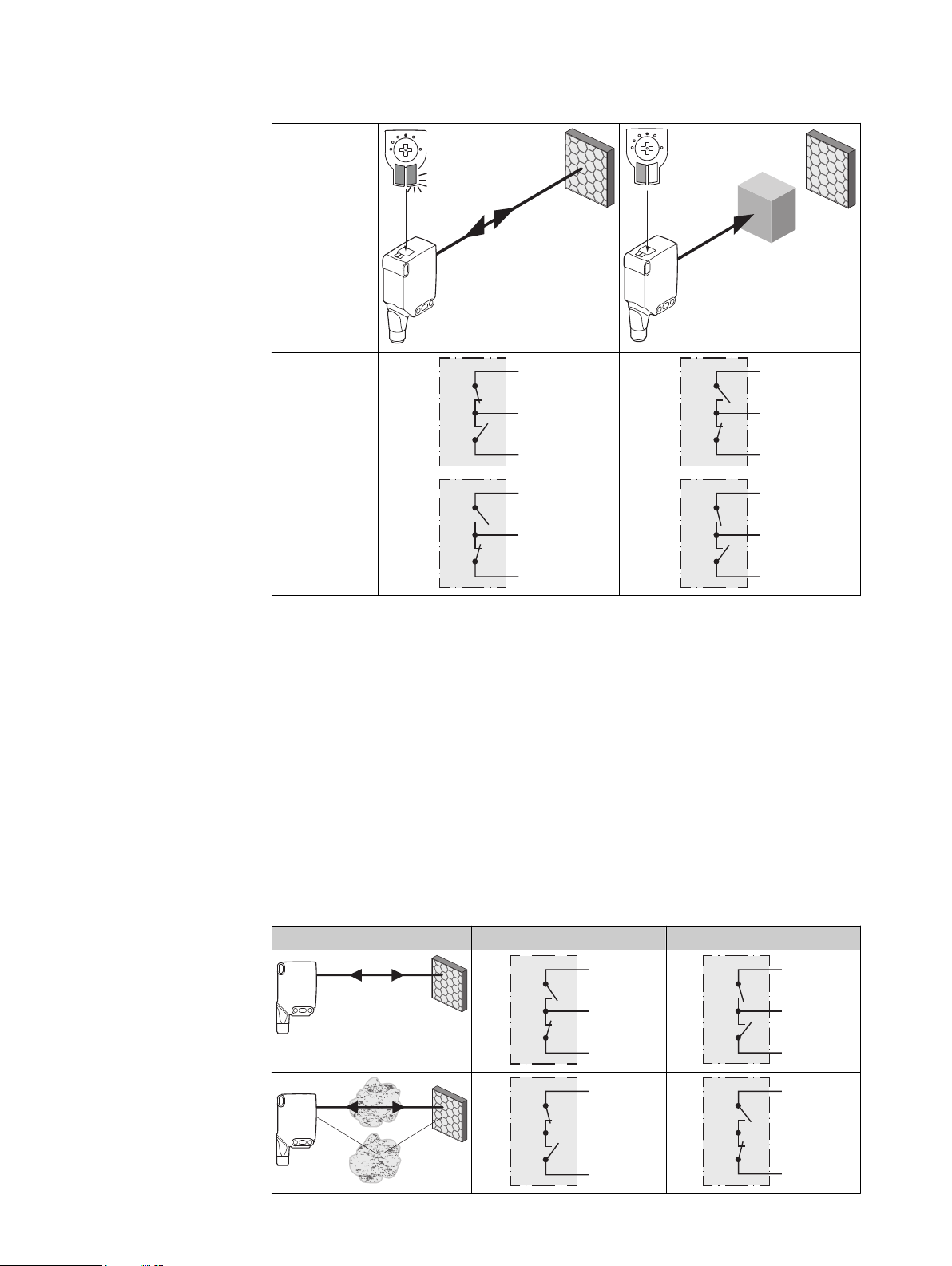

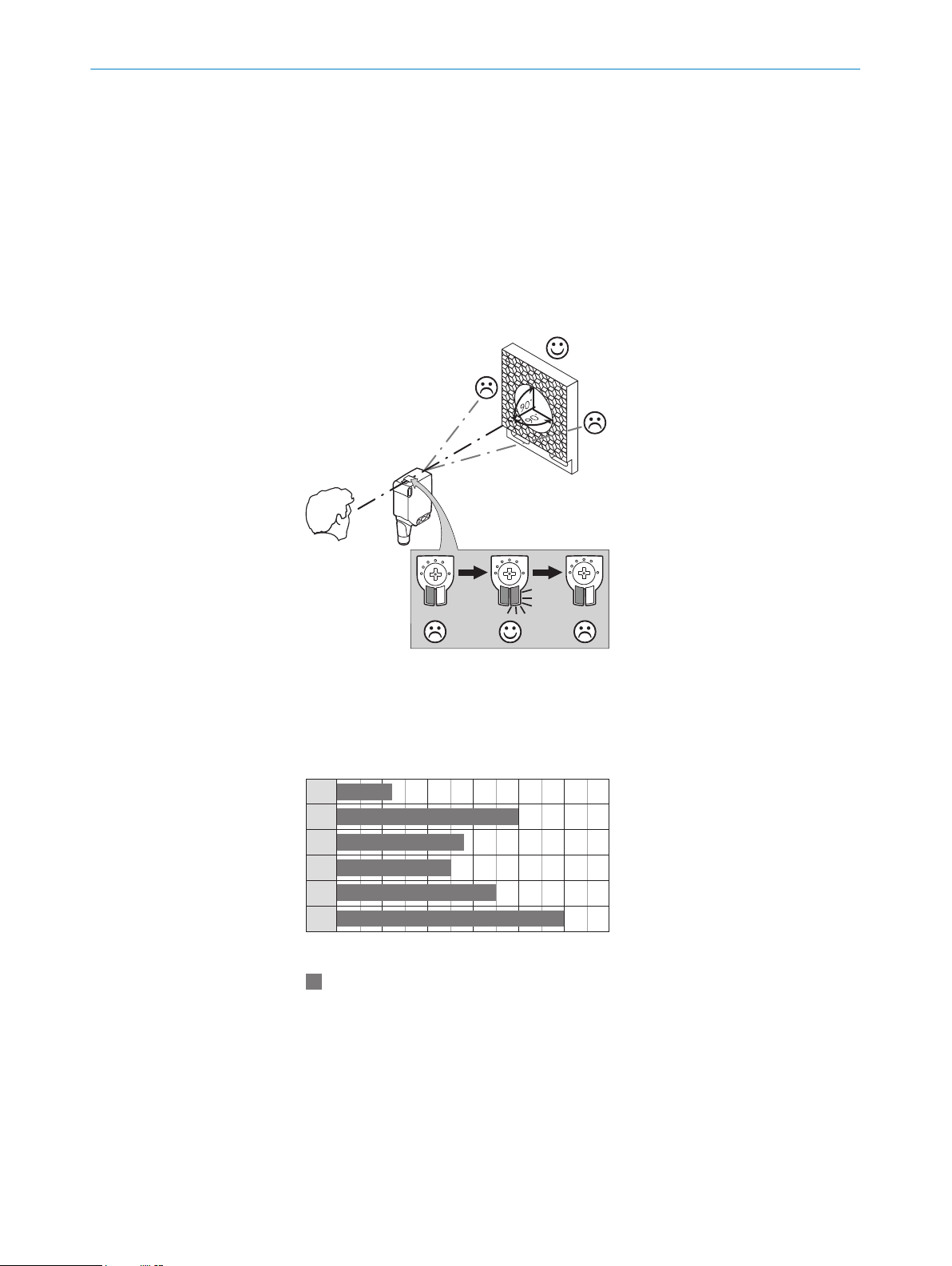

1 Alignment

Align the sensor with a suitable reflector. Select the position so that the red emitted light

beam hits the center of the reflector. The sensor must have a clear view of the reflector,

with no object in the path of the beam [see figure 3]. You must ensure that the optical

openings of the sensor and reflector are completely clear.

8

Figure 3: Alignment

2 Sensing range

Adjust the distance between the sensor and the reflector according to the corresponding

diagram [see figure 4].

Figure 4: Maximum distance between the sensor and the respective reflector type

Reflector PL10F CHEM

1

Reflective tape REF-AC1000 (50 x 50 mm)

2

Reflector PL10FH-1

3

Reflector PL10F

4

Reflector PL20F

5

Reflector P250F

6

Sensing range setting

Subject to change without notice

8022197 | SICK

Page 10

1 M

2

3 4 5

COMMISSIONING 6

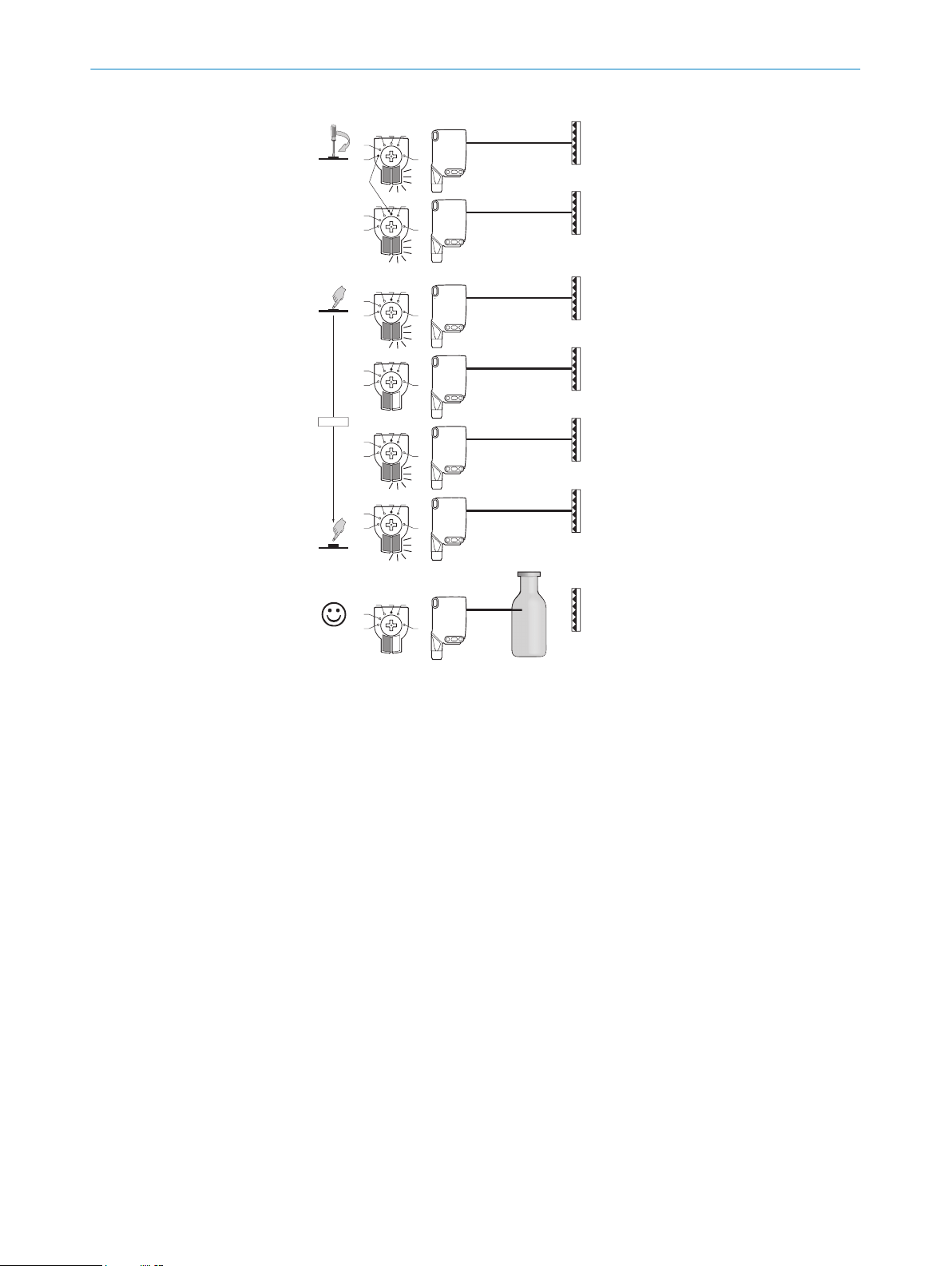

The push-turn element is used to set the object mode and switching threshold, see figures

5 and 6.

The WLG16 is equipped with AutoAdapt technology. The switching threshold is automati‐

cally adjusted in the event of contamination or after cleaning.

Turn the press-hold element (without pressing) to set the desired object mode. The

•

blue indication LED lights up according to the set object mode.

Press the press-turn element for about 1 to 3 seconds to set the switching threshold.

•

In the mode is changed between 1 and 4, the yellow indication LED lights up when

the reflector is in view of the sensor.

Lead the object into the path of the beam. The yellow indication LED goes out, mean‐

•

ing the object is detected and the setting is correct.

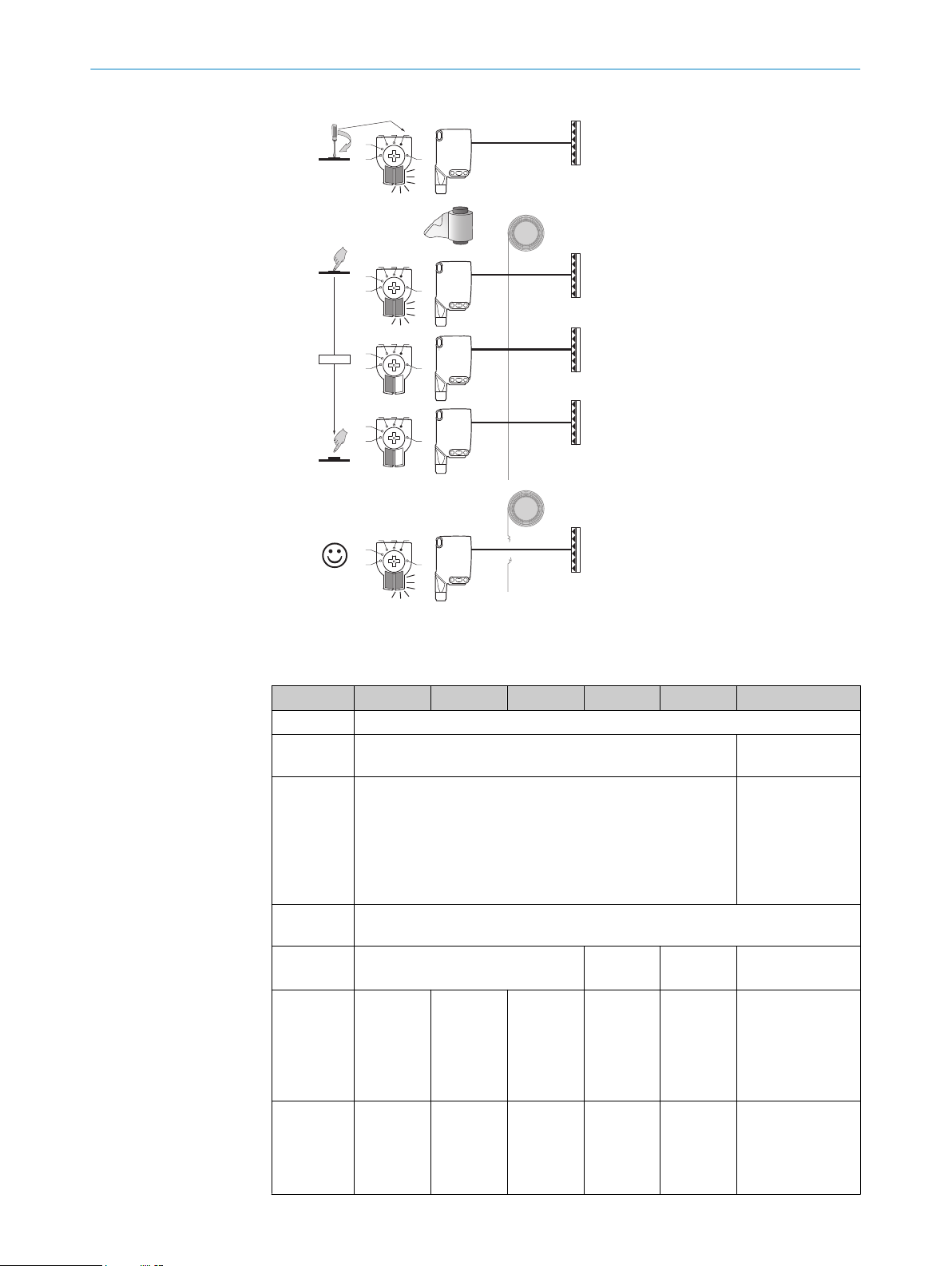

With object selection 5, the film must be in the path of the beam when the poten‐

•

tiometer is pressed. The yellow indication LED does not light up until the film is no

longer in the beam path. When this has been checked, the setting is correct.

The blue indication LED of mode M lights up when a setting has been selected via IO-

•

Link which deviates from the predefined parameter sets of modes 1-5. This mode

cannot be selected directly on the device.

Highly-transparent objects / Hoch-transparente Objekte / Oggetti trasparenti /

1

Objets ultra transparents / Objetos muy transparentes / 高透明物件

Semi-transparent objects / Semi-transparente Objekte / Oggetti semitrasparenti /

2

Objets semi-transparents / Objetos semitransparentes / Semi 透明物件

Opaque objects / Nicht-transparente Objekte / Oggetti non trasparenti / Objets

3

opaques / Objetos no transparentes / 不透明物件

Bottles/trays / Flaschen/Trays / Bottiglie/vassoi / Bouteilles/trays / Botellas/

4

bandejas / 瓶體/托盤

Check of foil tear / Folienriss-Kontrolle / Controllo rottura pellicola / Contrôle fis‐

5

sure du film / Control de rotura de lámina / 薄膜破裂檢查

M Manual (specific adjustment via IO-Link) / Manuell (spezifische Einstellung via IO-

Link) / Manuale (impostazione specifica tramite IO-Link) / Manuel (réglage

spécifique via IO-Link) / Manual (ajuste específico vía IO-Link) / 手動(藉由 IO-Link

的特別設置)

8022197 | SICK

Subject to change without notice

9

Page 11

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1...3 sec.

1

2

3

COMMISSIONING

6

1 2 3 4

Figure 5: Object mode 1 - 4

10

Subject to change without notice

8022197 | SICK

Page 12

5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1...3 sec.

1

2

3

COMMISSIONING 6

8022197 | SICK

Subject to change without notice

Figure 6: Object mode 5

Process data structure (Version 1.1)

A00 A70 A71 A72 A73 A75

IO-Link V1.1

Process

data

Bit 0 / Data

type

Bit 1 / Data

type

Bit... /

Descrip‐

tion / Data

type

Bit... /

Descrip‐

tion / Data

type

2 ...15 /

[empty]

QL2 / Boolean Qint.1 /

2 ...15 /

[time mea‐

surement

value] /

UInt 14

2 bytes 4 bytes

Byte 0: bits 15... 8

Byte 1: bits 7... 0

QL1 / Boolean

Boolean

2 … 15 /

[counter

2 … 15 /

[length /

value] /

UInt 14

measure‐

ment] /

speed

SInt14

QL2 /

Boolean

2 / Qint.

1 /

Boolean

3 … 15 /

[time mea‐

surement

value] /

UInt13

Byte 0: bits 31...

24

Byte 1: bits 13...

16

Byte 2: bits 15...

8

Byte 3: bits 7... 0

Qint.1 / Boolean

2 … 7 / [empty]

8 … 31 / [carrier

load] / UInt 24

11

Page 13

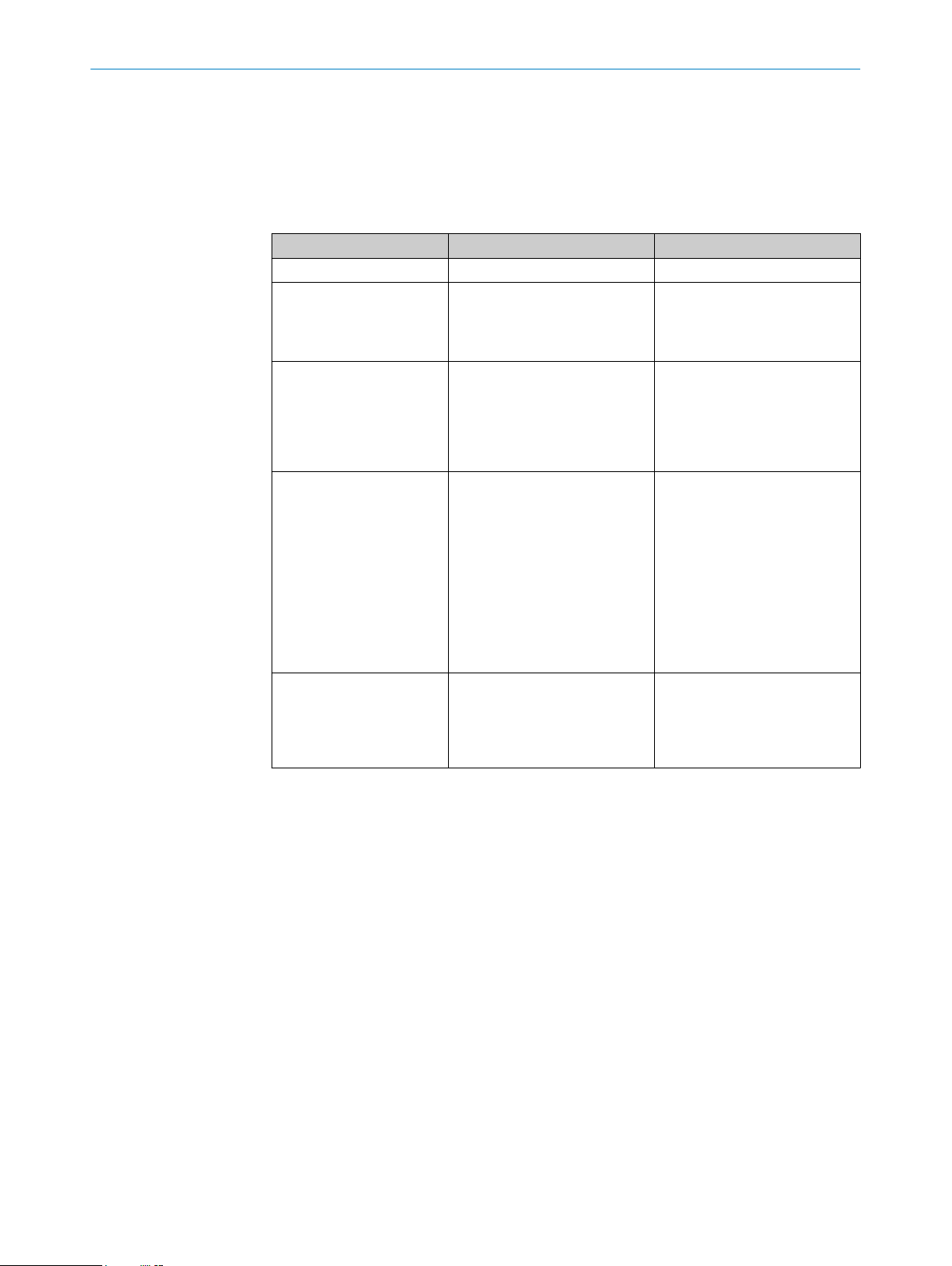

7 TROUBLESHOOTING

7 Troubleshooting

The Troubleshooting table indicates which measures are to be taken if the sensor stops

working.

LED indicator/fault pattern Cause Measures

Green LED flashes IO-Link communication None

Switching outputs do not

behave in accordance with

3

Yellow LED flashes Distance between sensor and

The sensor is not displayed

in SOPASair

No connection can be

made to the sensor

1. IO-Link communication

2. Change of the configuration

3. Short-circuit

reflector is too large / light

beam is not completely aligned

to the reflector / reflector is not

suitable / Front screen and/or

reflector is contaminated.

1. Connection to another handheld exists.

2.The hand-held is outside of

the transmission range of the

sensor.

3. Bluetooth LE in the sensor is

deactivated.

4. Bluetooth LE in the hand-held

is deactivated.

5. MAC address filter activated,

hand-held not authorized.

1. The Android or iOS version

does not comply with require‐

ments.

2. SOPASair version does not

contain the required driver.

1. None

2. Adjustment of the configura‐

tion

3. Check electrical connections

Check sensing range / check

alignment / SICK reflector is

recommended / Cleaning of the

optical surfaces (sensor and

reflector).

1. No connection or deactivation

of the existing connection.

2. Thorough check of installa‐

tion situation (e.g. shielding by

metal).

3. Activation of Bluetooth LE via

SiLink2 master or IO-Link

4. Activation of Bluetooth LE

5. No or change to MAC address

filter.

1. Check the operating system.

2. Uninstall SOPASair, install the

most current app version.

8 Disassembly and disposal

The sensor must be disposed of according to the applicable country-specific regula‐

tions. Efforts should be made during the disposal process to recycle the constituent

materials (particularly precious metals).

9 Maintenance

SICK sensors are maintenance-free.

We recommend doing the following regularly:

Clean the external lens surfaces

•

Check the screw connections and plug-in connections

•

No modifications may be made to devices.

Subject to change without notice. Specified product properties and technical data are

not written guarantees.

12

Subject to change without notice

8022197 | SICK

Page 14

10 Approvals

10.1 Bluetooth® approvals

Country Comments

Canada IC: 21147-W16

USA FCC ID: 2AHDR-W16

Europe + EFTA EU countries

This device complies with Part 15 of the FCC Rules and with Industry Canada licenceexempt RSS standard(s). Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any inter‐

ference received, including interference that may cause undesired operation.

APPROVALS 10

Belgium (BE), Bulgaria (BG), Denmark (DK), Germany (DE), Estonia

(EE), Finland (FI), France (FR), Greece (GR), Ireland (IE), Italy (IT),

Latvia (LV), Lithuania (LT), Luxembourg (LU), Malta (MT), Nether‐

lands (NL), Austria (AT), Poland (PL), Portugal (PT), Romania (RO),

Sweden (SE), Slovakia (SK), Slovenia (SI), Spain (ES), Czech

Republic (CZ), Hungary (HU), United Kingdom (GB), Republic of

Cyprus (CY).

EFTA countries

Iceland, Liechtenstein, Norway, Switzerland

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes: (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

11 Technical data

11.1 General technical data

WLG16P

Sensing range (with reflector P250F) 0 m ... 5 m

Light spot diameter/distance Ø 80 mm (5 m)

Supply voltage V

S

DC 10 ... 30 V

Current consumption ≤ 30 mA

< 50 mA

Output current I

max.

≤ 100 mA

Max. response time ≤ 500 μs

Switching frequency 1000 Hz

Enclosure rating IP 66, IP 67

Protection class III

Circuit protection A, B, C, D

1

2

3

4

5

6

8022197 | SICK

Subject to change without notice

13

Page 15

11 TECHNICAL DATA

WLG16P

Ambient operating temperature –40 °C ... +60 °C

1

We recommend using compound triangular reflectors or reflective tape to ensure reliable operation. Suitable reflectors and foils can be

found in the SICK accessories range. Use of reflectors with large-scale triple structures can negatively influence functionality.

2

16 VDC to 30 VDC, without load

3

10 VDC to 16 VDC, without load

4

Signal transit time with resistive load in switching mode. Deviating values possible in COM2 mode.

5

With a light/dark ratio of 1:1 in switching mode. Deviating values possible in IO-Link mode.

6

A = UV-Anschlüsse verpolsicher

B = Ein- und Ausgänge verpolsicher

C = Störimpulsunterdrückung

D = Ausgänge überstrom- und kurzschlussfest

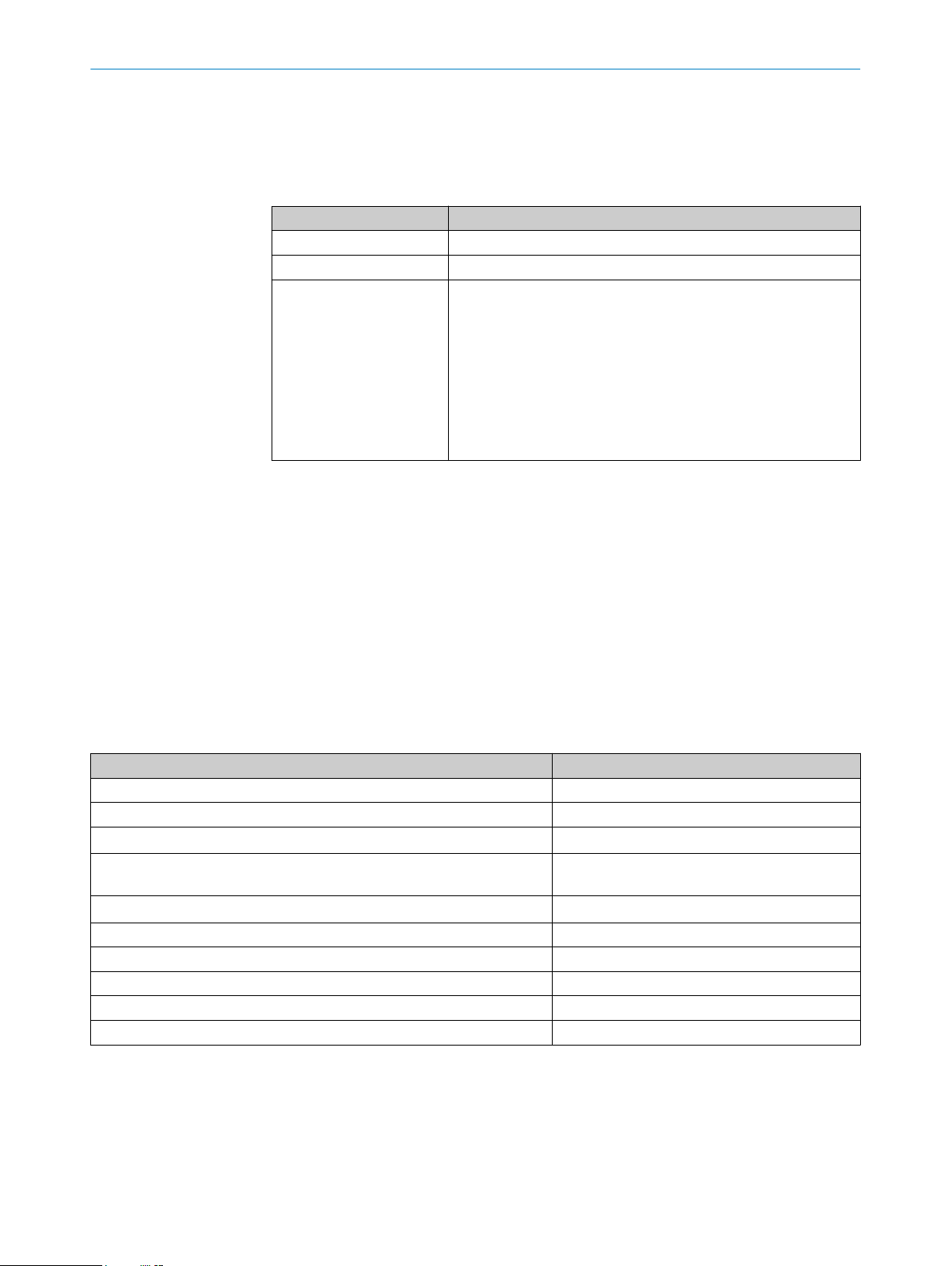

11.2 Bluetooth technical data®

Features Values

Bluetooth® sensing range 100 m on sight

Radio type BLE

Radio class 2

Bluetooth® module manufacturer BROADCOM

Cypress Semiconductor Corporation

198 Champion Court San Jose

CA 95134-1709

RF band 2402 - 2480 MHz

Output power 2 dBM

Declaration ID D033906

Qualified design ID 89630

Specification name 4.1

Member company SICK AG

14

Subject to change without notice

8022197 | SICK

Page 16

WLG16 Bluetooth®

B E T R I E B S A N L E I T U N G

de

en

Page 17

Beschriebenes Produkt

WLG16 - Bluetooth®

Hersteller

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Deutschland

Rechtliche Hinweise

Dieses Werk ist urheberrechtlich geschützt. Die dadurch begründeten Rechte bleiben

bei der Firma SICK AG. Die Vervielfältigung des Werks oder von Teilen dieses Werks ist

nur in den Grenzen der gesetzlichen Bestimmungen des Urheberrechtsgesetzes zuläs‐

sig. Jede Änderung, Kürzung oder Übersetzung des Werks ohne ausdrückliche schriftli‐

che Zustimmung der Firma SICK AG ist untersagt.

Die in diesem Dokument genannten Marken sind Eigentum ihrer jeweiligen Inhaber.

© SICK AG. Alle Rechte vorbehalten.

Originaldokument

Dieses Dokument ist ein Originaldokument der SICK AG.

16

Subject to change without notice

8022197 | SICK

Page 18

Inhalt

INHALT

12 Zu Ihrer Sicherheit............................................................................. 18

12.1 Allgemeine Sicherheitshinweise.............................................................. 18

12.2 Hinweise zur UL Zulassung...................................................................... 18

13 Bestimmungsgemäße Verwendung............................................... 18

14 Bedien- und Anzeigeelemente........................................................ 18

15 Montage.............................................................................................. 19

16 Elektrische Installation..................................................................... 19

17 Inbetriebnahme................................................................................. 22

18 Störungsbehebung............................................................................ 26

19 Demontage und Entsorgung............................................................ 26

20 Wartung.............................................................................................. 26

21 Zulassungen....................................................................................... 27

21.1 Bluetooth® Zulassungen......................................................................... 27

22 Technische Daten.............................................................................. 27

22.1 Allgemeine Technische Daten.................................................................. 27

22.2 Technische Daten Bluetooth®................................................................. 28

8022197 | SICK

Subject to change without notice

17

Page 19

12 ZU IHRER SICHERHEIT

12 Zu Ihrer Sicherheit

12.1 Allgemeine Sicherheitshinweise

■

Vor der Inbetriebnahme die Betriebsanleitung lesen.

■

Anschluss, Montage und Einstellung nur durch Fachpersonal.

■

Kein Sicherheitsbauteil gemäß EU-Maschinenrichtlinie.

■

Gerät bei Inbetriebnahme vor Feuchte und Verunreinigung schützen.

■

Diese Betriebsanleitung enthält Informationen, die während des Lebenszyklus des

Sensors notwendig sind.

12.2 Hinweise zur UL Zulassung

The device must be supplied by a limited voltage / limited current circuit or is intended

to be connected to a Class 2 source of supply. In case of a limited voltage / limited cur‐

rent circuit the device shall be supplied from an isolating transformer having a secon‐

dary overcurrent protective device that complies with UL 248 to be installed in the field

rated either:

a) max 5 amps for voltages 0~20 V (0~28.3 V peak), or

b) 100/Vp for voltages of 20~30 V (28.3~42.4 V peak).

UL Environmental Rating: Enclosure type 1

13 Bestimmungsgemäße Verwendung

Die WLG16 ist eine optoelektronische Reflexions-Lichtschranke (im Folgenden Sensor

genannt) und wird zum optischen, berührungslosen Erfassen von Sachen, Tieren und

Personen eingesetzt. Zur Funktion wird ein Reflektor benötigt. Bei jeder anderen Ver‐

wendung und bei Veränderungen am Produkt verfällt jeglicher Gewährleistungsan‐

spruch gegenüber der SICK AG.

Reflexions-Lichtschranke mit Zusatzoption zur Erkennung transparenter Objekte (WLGxx).

14 Bedien- und Anzeigeelemente

18

Subject to change without notice

8022197 | SICK

Page 20

20

Ø 12,9

Ø 4,1

39,9

55,4

45,5

5

42

29,9

6

3

6,5

15

27,8

7,7

7,8

7,2

35,5

4,1

8,3

55,7

3

2

34,5

1

4

65

20

M12

18

Ø 4,1

39,9

55,4

55,7

45,5 5

7

42

29,9

52,9

6

17,5

3

6,5

15

28

7,5

35,5

4,1

3

2

34,5

1

4

65

BEDIEN- UND ANZEIGEELEMENTE 14

Abbildung 7: Maßzeichnung 1, Leitung

Mitte Optikachse

1

Befestigungsbohrung, Ø 4,1 mm

2

Anschluss

3

Anzeige-LED grün: Betriebsspan‐

4

nung aktiv

Anzeige-LED gelb: Status Lichtemp‐

5

fang

BluePilot blau: Ausrichthilfe

6

15 Montage

Sensor und Reflektor an geeignete Befestigungswinkel montieren (siehe SICK-ZubehörProgramm). Sensor und Reflektor zueinander ausrichten.

Maximal zulässiges Anzugsdrehmoment des Sensors von < 1,3 Nm beachten.

16 Elektrische Installation

Anschluss der Sensoren muss spannungsfrei (UV = 0 V) erfolgen. Je nach Anschlussart

sind die folgenden Informationen zu beachten:

– Steckeranschluss: Pinbelegung beachten

– Leitung: Adernfarbe

Abbildung 8: Maßzeichnung 2, Stecker

Erst nach Anschluss aller elektrischen Verbindungen die Spannungsversorgung (UV > 0

V) anlegen bzw. einschalten.

Erläuterungen zum Anschlussschema (Tabellen 1 und 2).

Alarm = Alarmausgang (siehe Tabelle 4)

Health = Alarmausgang (siehe Tabelle 4)

8022197 | SICK

Subject to change without notice

MF (Pin-2-Konfiguration) = externer Eingang, Teach-in, Schaltsignal

QL1 / C = Schaltausgang, IO-Link Kommunikation

19

Page 21

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

1

2

4 3

16 ELEKTRISCHE INSTALLATION

DC: 10 ... 30 V DC

Tabelle 5: DC

WLG16 -24162xxxA00

1 + (L+)

2 MF

3 - (M)

4 QL1/C

Default: MF

Default:

QL1/C

-34162xxxA00

Q Q

Q Q

-1x162xxxA00-24161xxxA0

0

-34161xxxA0

0

Q Q www.sick.com

Q Q

1 = brn

2 = wht

3 = blu

4 = blk

-1x161xxxA00-2416xxxxA01A99

-3416xxxxA01A99

8020349

www.sick.com

8020349

1 = brn

2 = wht

3 = blu

4 = blk

0.14 mm

AWG26

2

0.14 mm

2

AWG26

Tabelle 6: DC

WLG16 -24165

xxxA00

-34165

xxxA00

-1x165

xxxA00

-24163

xxxA00

-34163

xxxA00

-1x163x

xxA00

-24166x

xxA00

-34166x

xxA00

-1x166x

xxA00

-24164x

xxA00

-34164x

xxA00

-1x164x

xxA00

1 + (L+)

2 MF

3 - (M)

4 QL1/C

Default: MF Alarm Alarm Alarm Alarm Health Health Health Health

Default:

Q Q

Q Q

Q Q

Q Q

QL1/C

1 = brn

2 = wht

3 = blu

4 = blk

0.14

2

mm

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14

2

mm

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14

2

mm

AWG26

1 = brn

2 = wht

3 = blu

4 = blk

0.14

mm

AWG26

2

20

Subject to change without notice

8022197 | SICK

Page 22

Tabelle 7: Push / Pull

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Q

‒ (M)

+ (L+)

Alarm

‒ (M)

+ (L+)

Health

‒ (M)

+ (L+)

Alarm

‒ (M)

+ (L+)

Health

‒ (M)

Q

push-pull

(≤ 100 mA)

Q

push-pull

(≤ 100 mA)

ELEKTRISCHE INSTALLATION 16

Alarm

Alarmausgang: Der Sensor (WLG16) verfügt über einen Vorausfallmeldeausgang

("Alarm" im Anschlussschema [Tabelle 4]), der meldet, wenn der Sensor nur noch ein‐

geschränkt betriebsbereit ist. Dabei blinkt die Anzeige-LED. Mögliche Ursachen: Ver‐

schmutzung von Sensor oder Reflektor, Sensor ist dejustiert. Im Gutzustand: LOW (0),

bei zu starker Verschmutzung HIGH (1).

Health

Health-Ausgang: Der Sensor (WLG16) verfügt über einen Vorausfallmeldeausgang

("Health" im Anschlussschema [Tabelle 4]), der meldet, wenn der Sensor nur noch ein‐

geschränkt betriebsbereit ist oder die Leitung unterbrochen ist. Mögliche Ursachen:

Verschmutzung von Sensor oder Reflektor, Sensor ist dejustiert, Leitung ist beschädigt.

Im Gutzustand: HIGH (1), bei zu starker Verschmutzung oder Leitungsunterbrechung

LOW (0). Dabei blinkt die gelbe Anzeige-LED.

Tabelle 8: Alarm / Health

Alarm (≤ 100 mA) Health (≤100 mA)

8022197 | SICK

Subject to change without notice

21

Page 23

Abstand in m

Schaltabstand

1

2

3

4

5

6

0 1 2 3 4 5 6

4

2,8

0

2,5

0

3,5

0

5

0

1,20

0

17 INBETRIEBNAHME

17 Inbetriebnahme

Bluetooth® ist bei der Ersteinbetriebnahme eingeschaltet. SOPASair erhalten Sie im

Google PlayStore (Android) und im App Store (iOS).

Anforderungen an das Betriebssystem: Android-Version 6.0, iOS aktuellste Version.

1 Ausrichtung

Sensor auf geeigneten Reflektor ausrichten. Positionierung so wählen, dass der rote Sen‐

delichtstrahl in der Mitte des Reflektors auftrifft. Der Sensor muss freie Sicht auf den

Reflektor haben, es darf sich kein Objekt im Strahlengang befinden [siehe Abbildung 9]. Es

ist darauf zu achten, dass die optischen Öffnungen von Sensor und Reflektor vollständig

frei sind.

22

Abbildung 9: Ausrichtung

2 Schaltabstand

Distanz zwischen Sensor und Reflektor mit dem zugehörigen Diagramm [siehe Abbildung

4] abgleichen.

Abbildung 10: maximaler Abstand zwischen Sensor und dem jeweiligen Reflektortyp

Reflektor PL10F CHEM

1

Reflexionsfolie REF-AC1000 (50 x 50 mm)

2

Reflektor PL10FH-1

3

Reflektor PL10F

4

Reflektor PL20F

5

Reflektor P250F

6

Subject to change without notice

8022197 | SICK

Page 24

1 M

2

3 4 5

INBETRIEBNAHME 17

Einstellung Schaltabstand

Mit dem Drück-Dreh-Element werden Objektmodus und Schaltschwelle eingestellt, siehe

Abbildungen 5 und 6.

Die WLG16 ist mit der AutoAdapt-Technologie ausgestattet. Im Falle einer Verschmutzung

oder nach einer Reinigung wird die Schaltschwelle automatisch angepasst.

Drehen Sie das Drück-Dreh-Element (ohne zu drücken), um den gewünschten Objekt‐

•

modus einstellen. Eine blaue Anzeige-LED leuchtet entsprechend dem eingestellten

Objektmodus .

Drücken Sie das Drück-Dreh-Element für ca. 1…3 sec., um die Schaltschwelle einzu‐

•

stellen.

Im Falle der Moduswahl 1 bis 4 leuchtet die gelbe Anzeige-LED bei Sicht des Sensors

auf den Reflektor.

Führen Sie das Objekt in den Strahlengang, die gelbe Anzeige-LED erlischt, d.h. das

•

Objekt wird erkannt und die Einstellung ist korrekt.

Bei der Objektauswahl 5 muss sich die Folie im Strahlengang befinden, während

•

dem Drücken des Potentiometers. Die gelbe Anzeige-LED leuchtet erst, wenn sich die

Folie nicht mehr im Strahlengang befindet. Wenn dies überprüft wurde, dann ist die

Einstellung korrekt.

Die blaue Anzeige-LED des Modus M leuchtet, wenn via IO-Link eine Einstellung

•

gewählt wurde, welche von den vordefinierten Parameter-Sets der Modi 1-5 abweicht.

Dieser Modus kann nicht direkt am Gerät angewählt werden.

Highly-transparent objects / Hoch-transparente Objekte / Oggetti trasparenti /

1

Objets ultra transparents / Objetos muy transparentes / 高透明物件

Semi-transparent objects / Semi-transparente Objekte / Oggetti semitrasparenti /

2

Objets semi-transparents / Objetos semitransparentes / Semi 透明物件

Opaque objects / Nicht-transparente Objekte / Oggetti non trasparenti / Objets

3

opaques / Objetos no transparentes / 不透明物件

Bottles/trays / Flaschen/Trays / Bottiglie/vassoi / Bouteilles/trays / Botellas/

4

bandejas / 瓶體/托盤

Check of foil tear / Folienriss-Kontrolle / Controllo rottura pellicola / Contrôle fis‐

5

sure du film / Control de rotura de lámina / 薄膜破裂檢查

M Manual (specific adjustment via IO-Link) / Manuell (spezifische Einstellung via IO-

Link) / Manuale (impostazione specifica tramite IO-Link) / Manuel (réglage spécifi‐

que via IO-Link) / Manual (ajuste específico vía IO-Link) / 手動(藉由 IO-Link 的特

別設置)

8022197 | SICK

Subject to change without notice

23

Page 25

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1...3 sec.

1

2

3

INBETRIEBNAHME

17

1 2 3 4

Abbildung 11: Objektmodus 1 - 4

24

Subject to change without notice

8022197 | SICK

Page 26

5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1 M

2

3 4 5

1...3 sec.

1

2

3

INBETRIEBNAHME 17

Abbildung 12: Objektmodus 5

Process data structure (Version 1.1)

A00 A70 A71 A72 A73 A75

IO-Link V1.1

Process

data

Bit 0/ Data

type

Bit 1/ Data

type

Bit... /

Descrip‐

tion / Data

type

Bit... /

Descrip‐

tion / Data

type

2...15 /

[empty]

QL2 / Boolean Qint.1 /

2...15 /

[Time

measure‐

ment

value] /

UInt 14

2 Byte 4 Byte

Byte 0 : Bit 15... 8

Byte 1: Bit 7... 0

QL1 / Boolean

Boolean

2 … 15 /

[Counter

2 … 15 /

[Length /

value] /

UInt 14

measure‐

ment] /

speed

SInt14

QL2 / Boo‐

lean

2 / Qint.

1 / Boo‐

lean

3 … 15 /

[Time

measure‐

ment

value] /

UInt13

Byte 0 : Bit 31...

24

Byte 1: Bit 13... 16

Byte 2: Bit 15... 8

Byte 3: Bit 7... 0

Qint.1 / Boolean

2…7 / [empty]

8 … 31 / [Carrier

load] / UInt 24

8022197 | SICK

Subject to change without notice

25

Page 27

18 STÖRUNGSBEHEBUNG

18 Störungsbehebung

Tabelle Störungsbehebung zeigt, welche Maßnahmen durchzuführen sind, wenn die

Funktion des Sensors nicht mehr gegeben ist.

Anzeige-LED / Fehlerbild Ursache Maßnahme

grüne LED blinkt IO-Link Kommunikation keine

Schaltausgänge verhalten

sich nicht gemäß 3

gelbe LED blinkt Abstand zwischen Sensor und

In SOPASair wird der Sen‐

sor nicht angezeigt

Es kann keine Verbindung

zum Sensor aufgebaut wer‐

den

1. IO-Link Kommunikation

2. Änderung der Konfiguration

3. Kurzschluss

Reflektor ist zu groß / Licht‐

strahl ist nicht vollständig auf

Reflektor ausgerichtet / Reflek‐

tor ist nicht geeignet / Fronst‐

scheibe und/oder Reflektor ist

verschmutzt.

1. Verbindung zu einem ande‐

ren Handheld besteht.

2.Das Handheld befindet sich

außerhalb des Sendebereichs

des Sensors.

3. Bluetooth LE im Sensor ist

deaktiviert.

4. Bluetooth LE im Handheld ist

deaktiviert.

5. MAC-Adressfilter aktiviert,

Handheld nicht autorisiert.

1. Die Android bzw. iOS-Version

entspricht nicht den Anforderun‐

gen.

2. SOPASair Version enthält

nicht den erforderlichen Treiber.

1. keine

2. Anpassung der Konfiguration

3. Elektrische Anschlüsse prü‐

fen

Schaltabstand prüfen / Ausrich‐

tung prüfen / Reflektor von SICK

wird empfohlen. / Reinigung der

optischen Flächen (Sensor und

Reflektor).

1. keine bzw. Deaktivierung der

bestehenden Verbindung.

2. Prüfung der Einbausituation

(z.B. Abschirmung durch Metall).

3. Aktivierung von Bluetooth LE

per SiLink2 Master oder IO-Link

4. Aktivierung von Bluetooth LE

5. keine bzw. Änderung des

MAC-Adress-Filters.

1. Prüfen Sie das Betriebssys‐

tem.

2. Deinstallieren Sie SOPASair,

Installieren Sie die aktuellste

App-Version.

19 Demontage und Entsorgung

Die Entsorgung des Sensors hat gemäß den länderspezifisch anwendbaren Vorschrif‐

ten zu erfolgen. Für die enthaltenen Wertstoffe (insbesondere Edelmetalle) ist im Rah‐

men der Entsorgung eine Verwertung anzustreben.

20 Wartung

SICK-Sensoren sind wartungsfrei.

Wir empfehlen, in regelmäßigen Abständen

die optischen Grenzflächen zu reinigen

•

Verschraubungen und Steckverbindungen zu überprüfen

•

Veränderungen an Geräten dürfen nicht vorgenommen werden.

Irrtümer und Änderungen vorbehalten. Angegebene Produkteigenschaften und techni‐

sche Daten stellen keine Garantieerklärung dar.

26

Subject to change without notice

8022197 | SICK

Page 28

21 Zulassungen

21.1 Bluetooth® Zulassungen

Land Kommentare

Canada IC: 21147-W16

USA FCC ID: 2AHDR-W16

Europa + EFTA EU Länder

This device complies with Part 15 of the FCC Rules and with Industry Canada licenceexempt RSS standard(s). Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interfe‐

rence received, including interference that may cause undesired operation.

ZULASSUNGEN 21

Belgium (BE), Bulgaria (BG), Denm ark (DK), Germany (DE), Esto‐

nia (EE), Finland (FI), France (FR), Greece (GR), Ireland (IE), Italy

(IT), Latvia (LV), Lithuania (LT), Luxembourg (LU), Malta (MT),

Netherlands (NL), Austria (AT), Poland (PL), Portugal (PT), Romania

(RO), Sweden (SE), Slovakia (SK), Slovenia (SI), Spain (ES), Czech

Republic (CZ), Hungary (HU), Unit ed Kingdom (GB), Republic of

Cyprus (CY).

EFTA Länder

Iceland, Liechtenstein, Norway, Switzerland

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appa‐

reils radio exempts de licence. L'exploitation est autorisée aux deux conditions suivan‐

tes: (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

22 Technische Daten

22.1 Allgemeine Technische Daten

WLG16P

Schaltabstand (mit Reflektor P250F) 0 m ... 5 m

Lichtfleckdurchmesser/Entfernung Ø 80 mm (5 m)

Versorgungsspannung U

V

DC 10 ... 30 V

Stromaufnahme ≤ 30 mA

< 50 mA

Ausgangsstrom I

max.

≤ 100 mA

Ansprechzeit max. ≤ 500 μs

Schaltfrequenz 1000Hz

Schutzart IP 66, IP 67

Schutzklasse III

Schutzschaltungen A, B, C, D

1

2

3

4

5

6

8022197 | SICK

Subject to change without notice

27

Page 29

22 TECHNISCHE DATEN

WLG16P

Betriebsumgebungstemperatur –40 °C ... +60 °C

1

Für einen zuverlässigen Betrieb empfehlen wir die Verwendung von Feintripel-Reflektoren oder Reflexionsfolie. Geeignete Reflektoren und

Folien finden Sie im Zubehör-Programm von Sick. Die Verwendung von Reflektoren mit großer Tripelstruktur kann die Funktionsfähigkeit

beeinträchtigen.

2

16VDC...30VDC, ohne Last

3

10VDC...16VDC, ohne Last

4

Signallaufzeit bei ohmscher Last im Schaltmodus. Abweichende Werte im COM2-Modus möglich.

5

Bei Hell-Dunkel-Verhältnis 1:1 im Schaltmodus. Abweichende Werte im IO-Link-Modus möglich.

6

A = UV-Anschlüsse verpolsicher

B = Ein- und Ausgänge verpolsicher

C = Störimpulsunterdrückung

D = Ausgänge überstrom- und kurzschlussfest

22.2 Technische Daten Bluetooth®

Merkmale Werte

Bluetooth® Reichweite 100 m auf Sicht

Funkart BLE

Funkklasse 2

Hersteller Bluetooth® Modul BROADCOM

Cypress Semiconductor Corporation

198 Champion Court San Jose

CA 95134-1709

RF Band 2402 - 2480 MHz

Ausgangs-Leistung 2 dBM

Declaration ID D033906

Qualified Design ID 89630

Specification Name 4.1

Mitglieds Unternehmen SICK AG

28

Subject to change without notice

8022197 | SICK

Page 30

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 211 5301-301

E-Mail info@sick.de

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail office@sick.hu

India

Phone +91 22 4033 8333

E-Mail info@sick-india.com

Israel

Phone +972 4 6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 274341

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +6 03 8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 472 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 30 2044 000

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7 495 775 05 30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 788 49

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2645 0009

E-Mail Ronnie.Lim@sick.com

Turkey

Phone +90 216 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 4 88 65 878

E-Mail info@sick.ae

United Kingdom

Phone +44 1727 831121

E-Mail info@sick.co.uk

USA

Phone +1 800 325 7425

E-Mail info@sick.com

Vietnam

Phone +84 945452999

E-Mail Ngo.Duy.Linh@sick.com

Further locations at www.sick.com

SICK

8022197 | SICK

Subject to change without notice

29

Loading...

Loading...