Page 1

O P E R A T ING INS T R U CT I ONS

VMS4200 / VMS5200

Track and trace systems

Page 2

2

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Product described

Product name: VMS4200 / VMS5200

Document identification

Title: VMS4200 / VMS5200 operating instructions

Part number: 8022965

Status: 2018-08-16

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be trademarks and are only

used here for identification purposes.

Original documents

The German version 8022964 of this document is an original SICK AG

document.

SICK AG does not assume liability for the correctness of any unauthorized

translation.

In case of doubt, contact SICK AG or your local agency.

Legal notes

Subject to change without notice

© SICK AG. All rights reserved

Page 3

CONTENTS

3

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Content

1 About this document ............................................................................................ 6

1.1 Purpose of this document ........................................................................ 6

1.2 Abbreviations used................................................................................... 6

1.3 Symbols used ........................................................................................... 6

2 On safety ................................................................................................................ 7

2.1 Qualified safety personnel ....................................................................... 7

2.2 Intended use ............................................................................................. 7

2.3 General safety notes and protective measures ..................................... 8

2.3.1 Safety notes and symbols ........................................................ 8

2.3.2 General safety notes ................................................................. 9

2.3.3 Additional operating instructions ............................................. 9

2.3.4 Dangers connected with handling of the system .................. 10

2.4 RoHS Directive........................................................................................ 14

3 System description ............................................................................................. 15

3.1 Scope of delivery .................................................................................... 15

3.2 Structure of the volume measurement system .................................... 16

3.2.1 System components ............................................................... 16

3.2.2 Expanding the system with a reading station ........................ 19

3.3 Operating principle of the volume measurement system .................... 20

3.3.1 Operating modes ..................................................................... 20

3.3.2 Calculating the volume ........................................................... 22

3.3.3 Data processing and data output .......................................... 24

3.4 Nominal value conditions ...................................................................... 26

3.4.1 Fixed scale values ................................................................... 26

3.4.2 Dynamic scale value switchover ............................................ 29

3.5 System requirements ............................................................................. 30

3.5.1 Required interfaces ................................................................ 30

3.5.2 Requirements at the operation site ....................................... 30

3.5.3 Object requirements ............................................................... 30

3.5.4 Conveying equipment requirements ...................................... 30

3.5.5 Mounting requirements .......................................................... 31

3.6 Officially verifiable operation ................................................................. 34

3.6.1 Information labels ................................................................... 34

3.6.2 Security seal ............................................................................ 38

3.6.3 SD card with alibi memory ...................................................... 41

3.6.4 LFT display ............................................................................... 43

3.6.5 Test instructions for market surveillance .............................. 46

3.7 Status indicators .................................................................................... 50

3.7.1 LMS4xxx volume measurement devices ............................... 50

3.7.2 Status indicators on the SIM2000 controller ........................ 50

3.8 Interfaces ................................................................................................ 51

4 Mounting ............................................................................................................. 52

4.1 Mounting volume measurement devices ............................................. 52

4.1.1 Assembling the profiles of the telescopic tube ..................... 53

4.1.2 Mounting telescopic tube to the frame ................................. 53

4.1.3 Mounting the volume measurement devices to the retaining

plates ....................................................................................... 53

4.2 Mounting the measuring wheel encoder .............................................. 55

Page 4

CONTENTS

4

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

4.3 Mounting the photoelectric retro-reflective sensor and reflector

(optional) ................................................................................................ 56

4.4 Mounting the cabinet ............................................................................. 57

4.5 Dismantling the measurement system ................................................. 58

5 Electrical installation ......................................................................................... 59

5.1 Connection overview .............................................................................. 61

5.2 Connecting to the voltage supply .......................................................... 62

5.3 Connection for the Ethernet switch (set up at the factory) .................. 63

5.4 Connecting the volume measurement devices .................................... 64

5.5 Connecting the LFT display ................................................................... 65

5.6 Connection for the measuring wheel encoder ..................................... 66

5.7 Connection for the photoelectric retro-reflective sensor (optional) .... 67

5.8 Connecting to the customer interface .................................................. 68

6 Commissioning ................................................................................................... 69

6.1 Switching on the system ........................................................................ 69

6.2 Configuring the system with SOPAS ...................................................... 70

6.2.1 Installing SOPAS ET ................................................................ 70

6.2.2 Allocating IP addresses .......................................................... 72

6.2.3 Opening the configuration interface ...................................... 78

6.2.4 Logging into the device ........................................................... 80

6.2.5 Saving the parameters permanently ..................................... 80

7 Maintenance and repairs .................................................................................. 81

7.1 Monitoring and cleaning work ............................................................... 82

7.1.1 Control measurements ........................................................... 82

7.1.2 Visual inspection ..................................................................... 83

7.1.3 Cleaning the volume measurement devices ......................... 84

7.1.4 Checking the measuring wheel encoder components ......... 85

7.1.5 Cleaning the photoelectric retro-reflective sensor ................ 86

7.1.6 Keeping the cabinets cool ...................................................... 86

7.2 Replacing components .......................................................................... 88

7.2.1 Replacing the volume measuring device .............................. 88

7.2.2 Replacing the measuring wheel encoder .............................. 90

7.2.3 Replacing the photoelectric retro-reflective sensor .............. 91

8 Fault diagnosis ................................................................................................... 92

8.1 Response to errors................................................................................. 92

8.2 SICK Support .......................................................................................... 92

8.3 Fault indicators of the components ...................................................... 92

8.4 Troubleshooting for the SIC2000.......................................................... 93

8.4.1 Checking the trigger ................................................................ 93

8.4.2 Checking the incremental encoder ........................................ 94

8.4.3 Checking CAN cabling ............................................................. 95

8.5 Faults during operation ......................................................................... 96

8.6 Detailed fault analysis ........................................................................... 97

8.6.1 The status log .......................................................................... 97

8.6.2 Checking the status log with SOPAS ...................................... 97

9 Appendix .............................................................................................................. 98

9.1 Technical data ........................................................................................ 98

9.1.1 Data sheet ............................................................................... 98

Page 5

CONTENTS

5

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

9.1.2 Dimensional drawings of the volume measurement

devices ..................................................................................... 99

9.2 Compliance with EU directives ............................................................ 100

10 Disposal ............................................................................................................. 101

Page 6

1 ABOUT THIS DOCUMENT

6

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

1 About this document

Please read this chapter carefully before you begin working with this documentation and

the VMS4200 / VMS5200.

1.1 Purpose of this document

These operating instructions guide technical personnel in the safe mounting,

parameterization, electrical installation, commissioning, operation, and maintenance of

the VMS4200 / VMS5200 volume measurement system.

1.2 Abbreviations used

Controller Area Network = standardized fieldbus system that uses a message-based

data exchange protocol

Light emitting diode

Laser measurement scanner = 2D LiDAR sensor from SICK AG

Random Access Memory = direct-access volatile memory

SICK OPEN PORTAL for APPLICATION and SYSTEMS Engineering Tool = software for

configuring the VMS4200 / VMS5200

Volume Measurement System from SICK AG

1.3 Symbols used

Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or technical measure.

Notes provide information about the features of a device, application tips, or other useful

information.

Instructions requiring specific action are indicated by an arrow. Carefully read and follow

the instructions for action.

LED icons describe the status of a diagnostics LED. Examples:

The LED is illuminated continuously.

The LED is flashing.

The LED is off.

CAN

LED

LMS

RAM

SOPAS ET

VMS

Recommendation

Note

,

Page 7

ON SAFETY 2

7

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

2 On safety

This chapter concerns your own safety and the safety of the system operator.

▸

Please read this chapter carefully before you begin working with the volume

measurement system.

2.1 Qualified safety personnel

The volume measurement system must only be mounted, commissioned, and maintained

by properly qualified safety personnel.

The following qualifications are necessary for the various tasks:

Activities

Qualification

Mounting and

maintenance

Practical technical training

Knowledge of the current safety regulations in the workplace

Electrical installation

and device replacement

Practical electrical training

Knowledge of current electrical safety regulations

Knowledge of device control and operation in the particular

application concerned (e.g., conveying system, etc.)

Commissioning,

operation, and

configuration

Knowledge of the operation and control of the devices in their

particular application (e.g., conveying system)

Knowledge concerning the software and hardware environment of

the particular application concerned (e.g., conveying system)

Basic knowledge of the Windows operating system used

Basic knowledge of data transmission

Basic knowledge of the design and setup (addressing) of Ethernet

connections when connecting the system to the Ethernet

Table 1Qualified safety personnel

2.2 Intended use

The VMS4200 / VMS5200 volume measurement system is used to measure cubic and

non-cubic objects on flat conveying systems in industrial environments.

The objects must be dimensionally stable, opaque, and non-reflective.

The VMS4200 / VMS5200 determines length, width, and height, and can calculate the

volume of the smallest enveloping cuboid (box volume) using these values.

All measurement results are transferred to the customer network via the data interface of

the SIM2000 control unit.

The VMS5200 volume measurement system is verified as legal for trade and can be used

for billing purposes.

WARNING

Danger due to intended use

Intended use of the system can lead to danger to the life and limb of persons and damage

to the plant in which the system is integrated.

▸

The system should only be used in line with the intended use.

▸

The system should not be used outdoors or in an explosion-protected environment.

Page 8

2 ON SAFETY

8

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

2.3 General safety notes and protective measures

2.3.1 Safety notes and symbols

The following safety and hazard information is for your own safety, for the safety of third

parties, and for the protection of the volume measurement system. You should therefore

observe them at all times.

DANGER

Denotes an immediate hazard that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from electrical current).

WARNING

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from falling components).

CAUTION

Caution note

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of damage to the eye by laser beams).

NOTE

Denotes a potential risk of damage or functional impairment of the device or the devices

connected to it.

This symbol refers to supplementary technical documentation.

Page 9

ON SAFETY 2

9

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

2.3.2 General safety notes

General, recognized safety-related rules and regulations were taken into account in the

design and manufacture of the volume measurement system. However, risks for the user

resulting from the system cannot be completely ruled out. The safety notes below must

therefore be observed.

WARNING

Observe the following to ensure the safe use of the system as intended.

The notes in this documentation must be complied with.

All official and statutory regulations governing the operation of the system must be

complied with.

The national and international legal specifications apply to the installation and use of

the system, to its commissioning, and to recurring technical inspections, in particular:

– The accident prevention regulations and work safety regulations

– Any other relevant safety regulations

The manufacturer and user of the system are responsible for coordinating and

complying with all applicable safety specifications and regulations in cooperation with

the relevant authorities.

The checks must be carried out by qualified safety personnel or specially qualified and

authorized personnel, and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

These operating instructions must be made available to the operator of the system.

The system operator must be instructed by qualified safety personnel and must read

the operating instructions.

Maintenance and repair work may only be performed by trained and authorized SICK

AG service technicians or qualified safety personnel of the customer.

2.3.3 Additional operating instructions

Other operating instructions of the individual components are enclosed along with this

system description.

▸

When working on or with the system components, please observe the notes in the

relevant operating instructions.

Page 10

2 ON SAFETY

10

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

2.3.4 Dangers connected with handling of the system

Awareness of potential hazardous points in the system will help you to work in a safer

manner and thus prevent accidents.

Dangers due to electrical current

DANGER

Risk of injury due to electrical current

Electrical voltage can cause severe personal injury or death by electric shock.

▸

Electrical installation work may only be carried out by electrically qualified persons.

▸

Be sure to disconnect the voltage supply before attaching or detaching any electrical

connections.

▸

Only connect the system to a voltage source that meets the technical requirements.

▸

National and regional regulations must be complied with.

▸

Safety requirements relating to work on electrical systems must be complied with.

DANGER

Dangerous equipotential bonding currents

As a result of possible equipotential bonding currents between the device and other

earthing devices in the system, faulty earthing of the device can give rise to the following

dangers and faults:

Dangerous voltages on the metal housing, e.g., of the laser scanner.

Incorrect functioning of or irreparable damage to the devices

Damage/irreparable damage to the cable shields due to heating and cable fires.

Measures

▸

Only skilled electricians should be permitted to carry out work on the electrical system.

▸

Ensure that the ground potential is the same at all grounding points.

▸

If the cable insulation is damaged, disconnect the voltage supply immediately and have

the damage repaired.

▸

Where local conditions are unfavorable and thus do not meet conditions for a safe

earthing method (same ground potential at all grounding points), take measures in

accordance with the following explanations.

Page 11

ON SAFETY 2

11

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

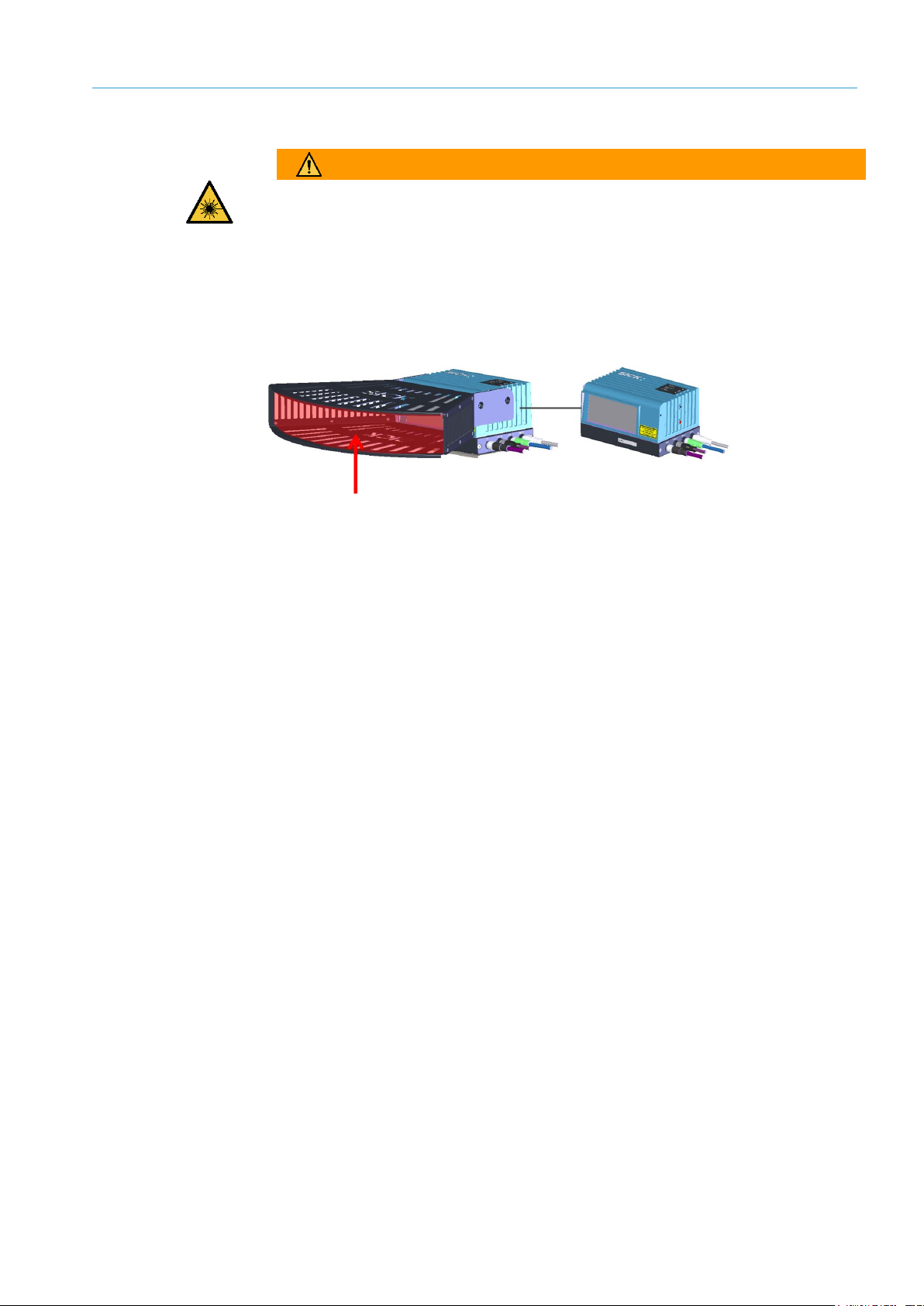

Danger due to laser light

WARNING

Damage to the eye by laser beams

The LMS4xxx volume measurement devices work with red, class-2 lasers.

The human eye is not at risk when briefly exposed to the radiation for up to 0.25 seconds.

Exposure to the laser beam for longer periods of time may cause damage to the retina.

The laser radiation is harmless to human skin.

The laser output aperture is the front screen of the devices.

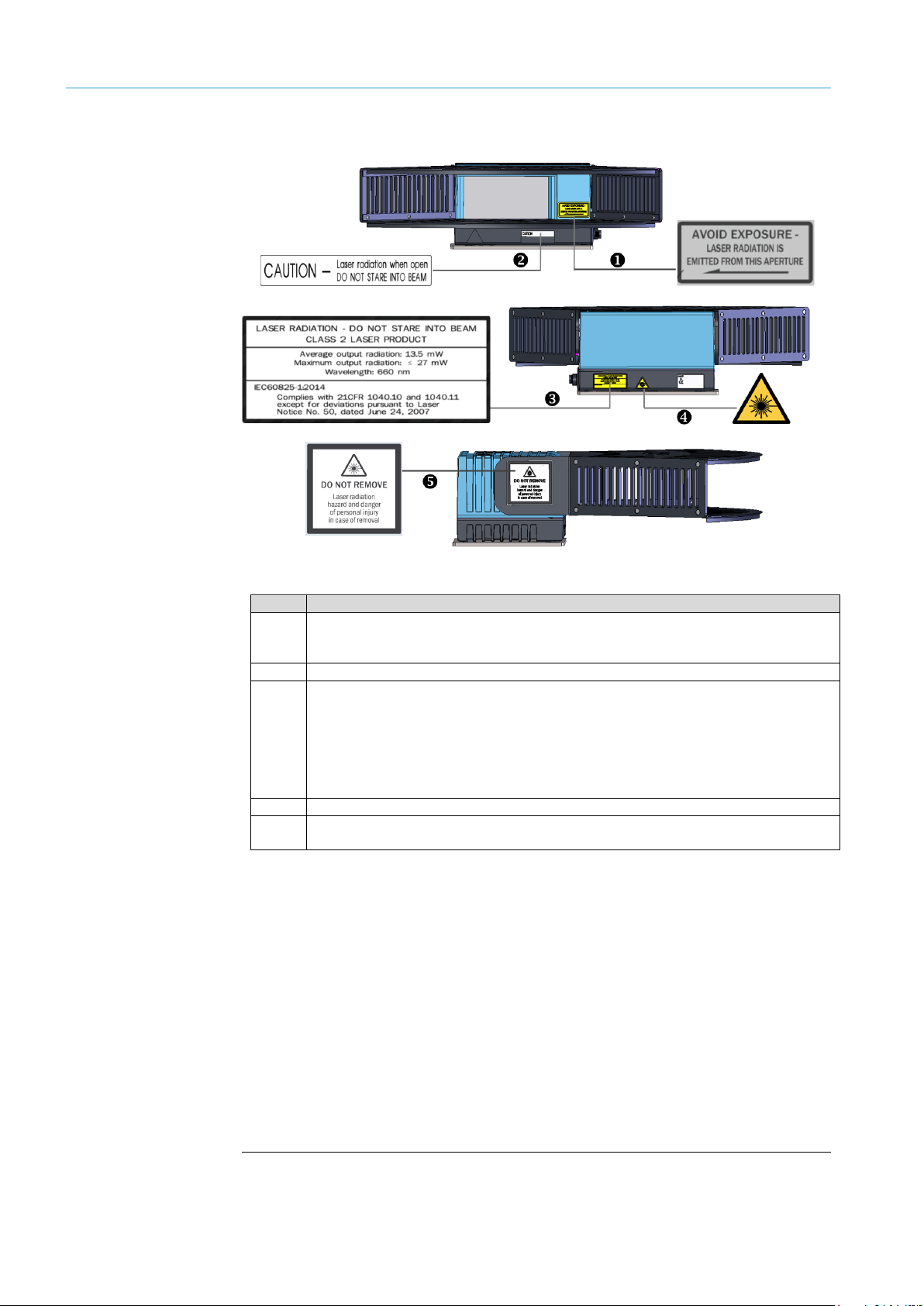

Fig.1: Laser output aperture of the laser scanner

▸

Do not look into the laser beam intentionally.

▸

Never point the laser beam at people’s eyes.

▸

If it is not possible to avoid looking directly into the laser beam, e.g., during

commissioning and maintenance work, suitable eye protection must be worn.

▸

Avoid laser beam reflections caused by reflective surfaces. Be particularly careful

during mounting and alignment work.

▸

Do not open the housing. Opening the housing will not switch off the laser. Opening the

housing may increase the level of risk.

▸

Applicable national regulations regarding laser protection must be observed.

Measures

Page 12

2 ON SAFETY

12

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

The laser warning labels are located on the respective devices.

Fig.2: Laser warning labels

No.

Meaning

1

Avoid exposure – Laser radiation is emitted from this aperture.

Laser output aperture corresponds to the front screen at the height of the position

shown.

2

Caution – Laser radiation when open. Do not stare into beam.

3

Laser radiation – Do not stare into beam. Class 2 laser product

Average output radiation: 13.5 mW

Maximum output radiation: 27 mW

Wavelength: 660 nm

IEC60825-1:2014

Complies with 21CFR 1040.10 and 1040.11 except for deviations pursuant to Laser

Notice No. 50, dated June 24, 2007.

4

Warning symbol: Laser radiation

5

Do not remove – Laser radiation hazard and danger of personal injury in case of

removal.

“RADIATION – DO NOT STARE INTO BEAM” is to be replaced with a warning label in a

language that the operators of the system understand. Laser warning labels in German

and French are included in the scope of delivery.

If the device is installed in a system/casing in way that means that the warning labels

are covered, other warning labels (not included with delivery) must be attached to the

system/casing next to the laser output aperture.

When operating with the trigger, the laser diode is switched on by the switch-on signal

and switched off again by the deactivation signal. When free output of measured

values is set, the laser diode is continuously on.

The device automatically monitors beam generation and automatically shuts down the

laser diode in the event of irregularities. If this happens, the red “Status” LED lights up.

The device stops sending measured values and an entry is added to the error memory.

Laser warning labels

Notes

Page 13

ON SAFETY 2

13

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Dangers when mounting

WARNING

Risk of injury due to components tipping over

If profiles of the mounting frame have been upended, they could possibly tip over during

disassembly.

▸

Do not do mounting work alone.

▸

Ask a second person to assist you. during mounting where necessary.

▸

Wear safety shoes.

Risks during operation

WARNING

Risk of injury and/or material damage caused by incorrect operation.

Risk of injury and/or material damage due to absence of qualification and/or incorrect

and non-intended use.

▸

Observe the notes on intended use.

▸

Only use the plant in perfect working order and for its intended purpose, keeping safety

and potential dangers in mind, and in compliance with the system documentation.

WARNING

Danger due to malfunction!

Cease operation if the cause of the malfunction has not been clearly identified.

▸

Take the system out of operation if an error cannot be clearly identified and safely

remedied.

Risks during maintenance

and repair work

NOTE

Repair work on the individual components may only be performed by qualified and

authorized service personnel.

NOTE

Claims under the warranty rendered void

If the device is opened, any warranty claims against SICK AG will be void.

▸

Do not open the device housing.

Page 14

2 ON SAFETY

14

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

2.4 RoHS Directive

This system has been designed for specific applications in industrial plants according to

article 2 (4) e, RoHS 2011/65 / EU, and must therefore only be used in such plants.

The product is neither suited for nor certified for use outside of these plants. SICK

therefore cannot assume any type of warranty or liability for such use.

Page 15

SYSTEM DESCRIPTION 3

15

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

3 System description

This chapter describes the design and operating principle of the system.

3.1 Scope of delivery

NOTE

▸

It is recommended that you carefully check for and report transport damage of any kind

as soon as possible after receiving the system.

▸

Also verify that the delivery includes all components listed on the delivery note.

System components

2 LMS4421R-16000 volume measurement devices with laser protective cover

(VMS4200) or

2 LMS4521R-16000 volume measurement devices with laser protective cover

(VMS5200 MID)

1 LFT display (only VMS5200)

1 SIC2000 cabinet with SIM2000 controller, voltage supply module, and Ethernet

switch

1 measuring wheel encoder with mounting kit (e.g., DFV60, DBS36)

1 modular mounting set

2 beam blockers

Connecting cables

Optional

1 photoelectric retro-reflective sensor for triggered systems (e.g., WL18-3 or WL27-3)

Page 16

3 SYSTEM DESCRIPTION

16

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.2 Structure of the volume measurement system

3.2.1 System components

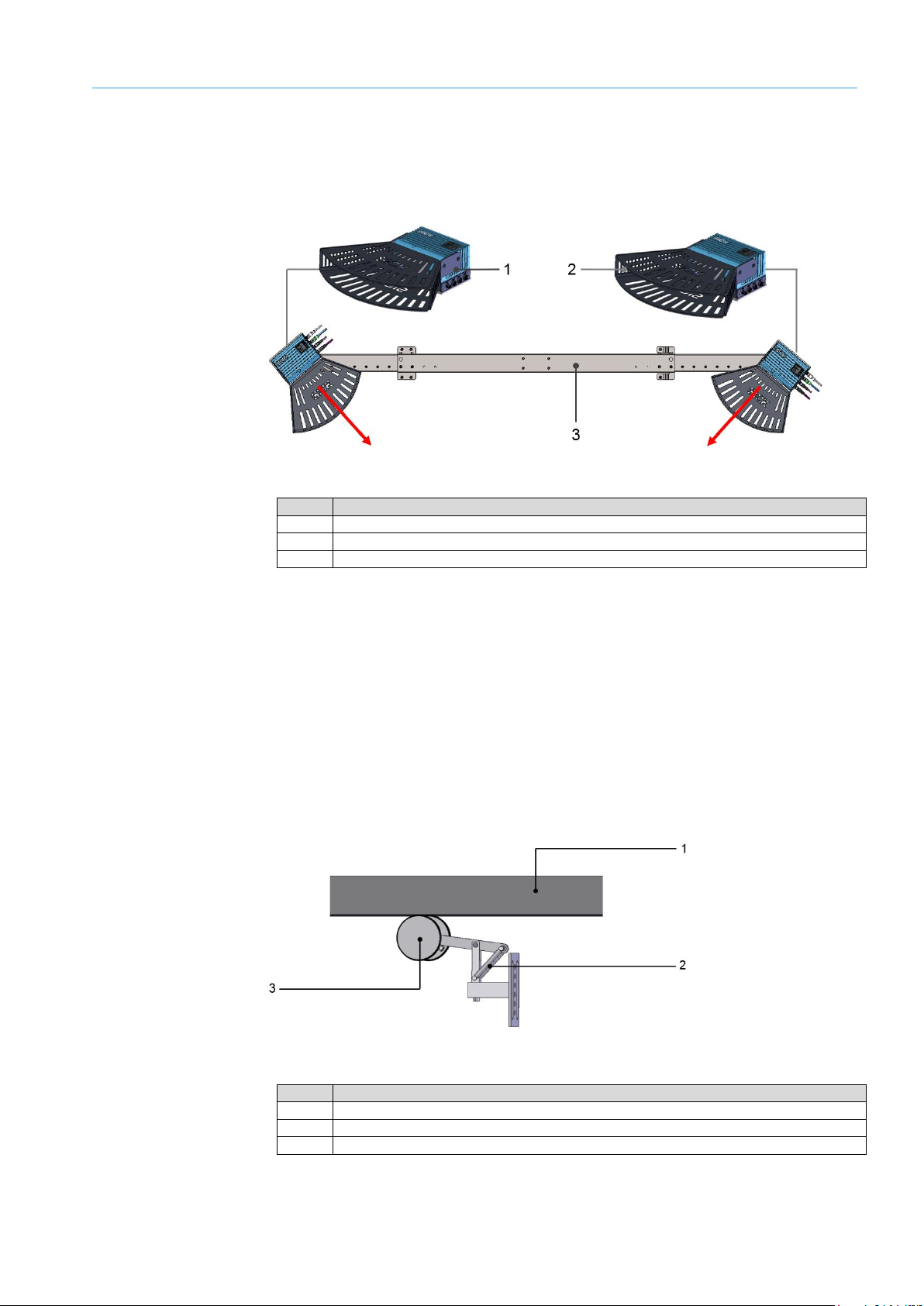

The VMS4200 / VMS5200 volume measurement system consists of two LMS4xxx volume

measurement devices, an LFT display, a measuring wheel encoder, and a cabinet

containing the SIM2000 control unit.

Systems for which measuring is triggered via a signal also have a photoelectric retro-

reflective sensor as an accessory.

Fig.3: System components

No.

Meaning

1

LMS4xxx volume measurement devices with laser protective cover

2

LFT display

3

Cabinet with SIM2000 control, voltage supply unit, and Ethernet switch

4

Measuring wheel encoder (e.g., DFV60)

5

Photoelectric retro-reflective sensor for triggered systems (e.g., WL-18-3)

All system components are mounted on a frame provided by the customer according to

the technical drawing. The volume measurement devices are mounted using a mounting

system included in the scope of delivery, which is attached to the frame.

Additional glare protection on the frame (beam blocker) prevents objects located outside

of the measuring range from being taken into account when calculating the measured

values.

The figures in these operating instructions show the mounting set consisting of a width-

adjustable telescopic tube with pre-mounted attachment mechanism for the volume

measurement devices and for mounting to a frame provided by the customer.

Note

Page 17

SYSTEM DESCRIPTION 3

17

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

The VMS4200 / VMS5200 volume measurement system consists of two LMS4xxx volume

measurement devices, which are mounted on the left and right above the conveying

equipment. The volume measurement devices configured as master and slave scan the

object and transmit the detected measuring points to the SIM2000 control unit.

Fig.4: Volume measurement devices

No.

Meaning

1

LMS4xxx master

2

LMS4xxx slave

3

Modular mounting set

The officially verifiable VMS5200 volume measurement system also has a separate LFT

display to show the measurement results, status information, the firmware version, and

the logbook (version history).

The measuring wheel encoder mounted below the conveyor belt is needed for position

determination of the object on the conveyor belt and for the calculation of the 3D model.

As part of this process, the encoder sends two incremental signals to the controller –

there is a 90-degree phase shift between the signals.

Measurement is performed directly on the running surface of the conveyor belt using a

precise measuring wheel, which is mounted on a spring-loaded arm.

Fig.5: Measuring wheel encoder (e.g., DFV60)

No.

Meaning

1

Running surface of the conveyor belt

2

Measuring wheel

3

Spring-loaded mounting arm

Volume measurement

devices

LFT display

Measuring wheel

encoder

Page 18

3 SYSTEM DESCRIPTION

18

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

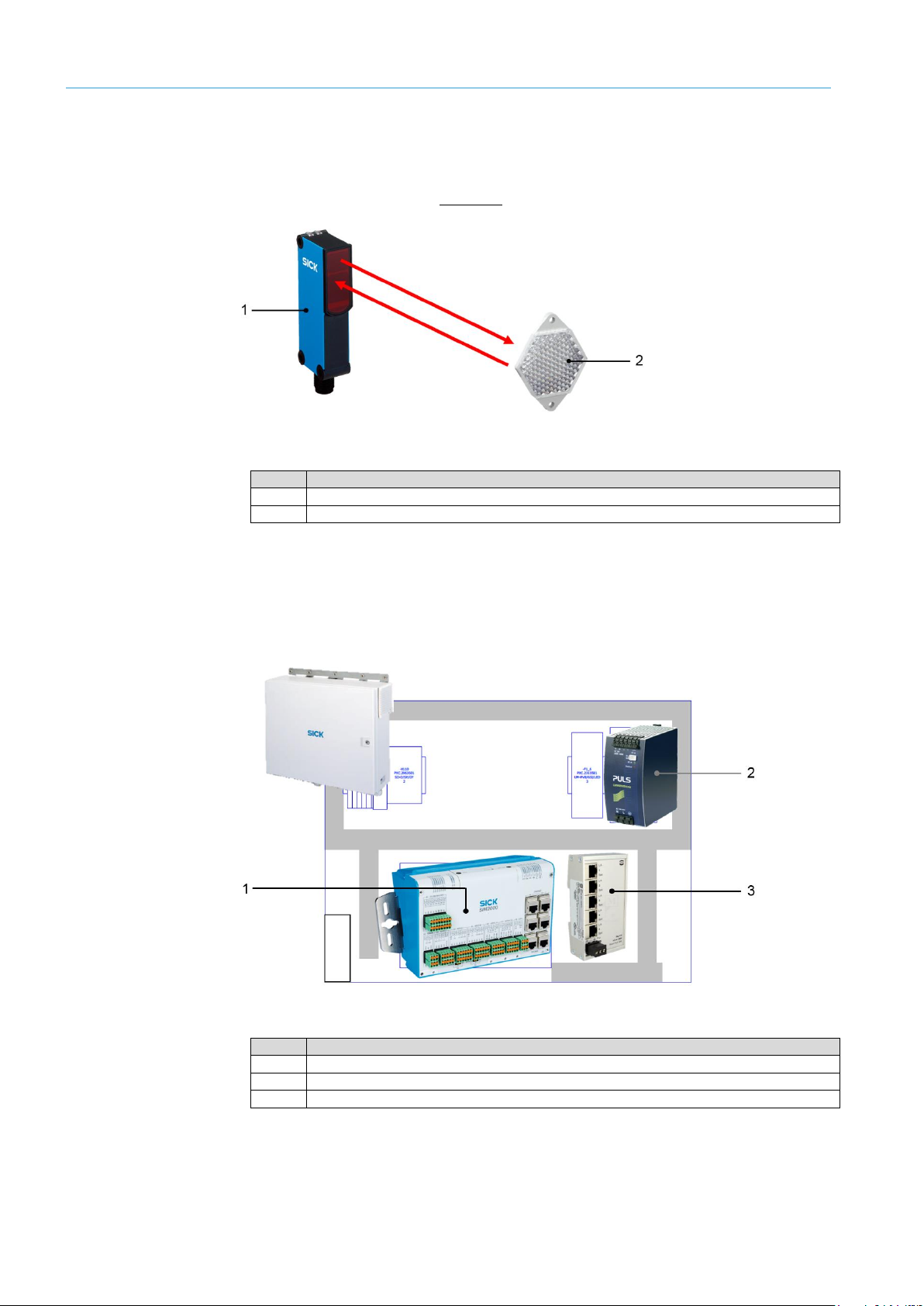

In the case of systems for which measuring is triggered, an additional photoelectric retro-

reflective sensor with reflector attached before the measuring field also provides a trigger

signal. The trigger signal activates the sensors and opens the internal reading gate. The

photoelectric sensor trigger is optionally available.

Fig.6: Photoelectric retro-reflective sensor with reflector (e.g., WL18-3)

No.

Meaning

1

Photoelectric retro-reflective sensor (e.g., WL18-3)

2

Reflector

The cabinet contains the SIM2000, which is the central control unit of the volume

measurement system, the voltage supply unit with fuse module for supplying voltage to

the components, and an Ethernet switch as the central interface for the sensor network.

In the case of the officially verifiable VMS5200, the SIM2000 also contains the legally

relevant memory (alibi memory) for the entire system.

Fig.7: SIC2000 cabinet

No.

Meaning

1

SIM2000 controller (for the VMS5200 with alibi memory)

2

Voltage supply unit with fuse modules

3

Ethernet switch

Photoelectric sensor

trigger

Cabinet

Page 19

SYSTEM DESCRIPTION 3

19

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

3.2.2 Expanding the system with a reading station

The VMS4200 / VMS5200 volume measurement system can be expanded to include a

reading station. The reading station allows automated identification of objects by reading

their bar codes, which in turn enables faster process automation. Depending on the

application case, this station can consist of scanners, cameras and/or a combination of

both in any desired arrangement.

The devices are connected to the volume measurement system via the CAN bus of the

SIM2000 controller. The controller links the acquired identification data with the

dimensional values calculated by the VMS4200 / VMS5200 and outputs both data types

to the higher-level system.

Fig.8: Expanding the system with a reading station

The volume measurement system can also supply the focus information for the connected

camera systems.

Note

Page 20

3 SYSTEM DESCRIPTION

20

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.3 Operating principle of the volume measurement system

The VMS4200 / VMS5200 volume measurement system measures cubic and irregularly

shaped objects that are moved past the measuring station on flat conveying systems.

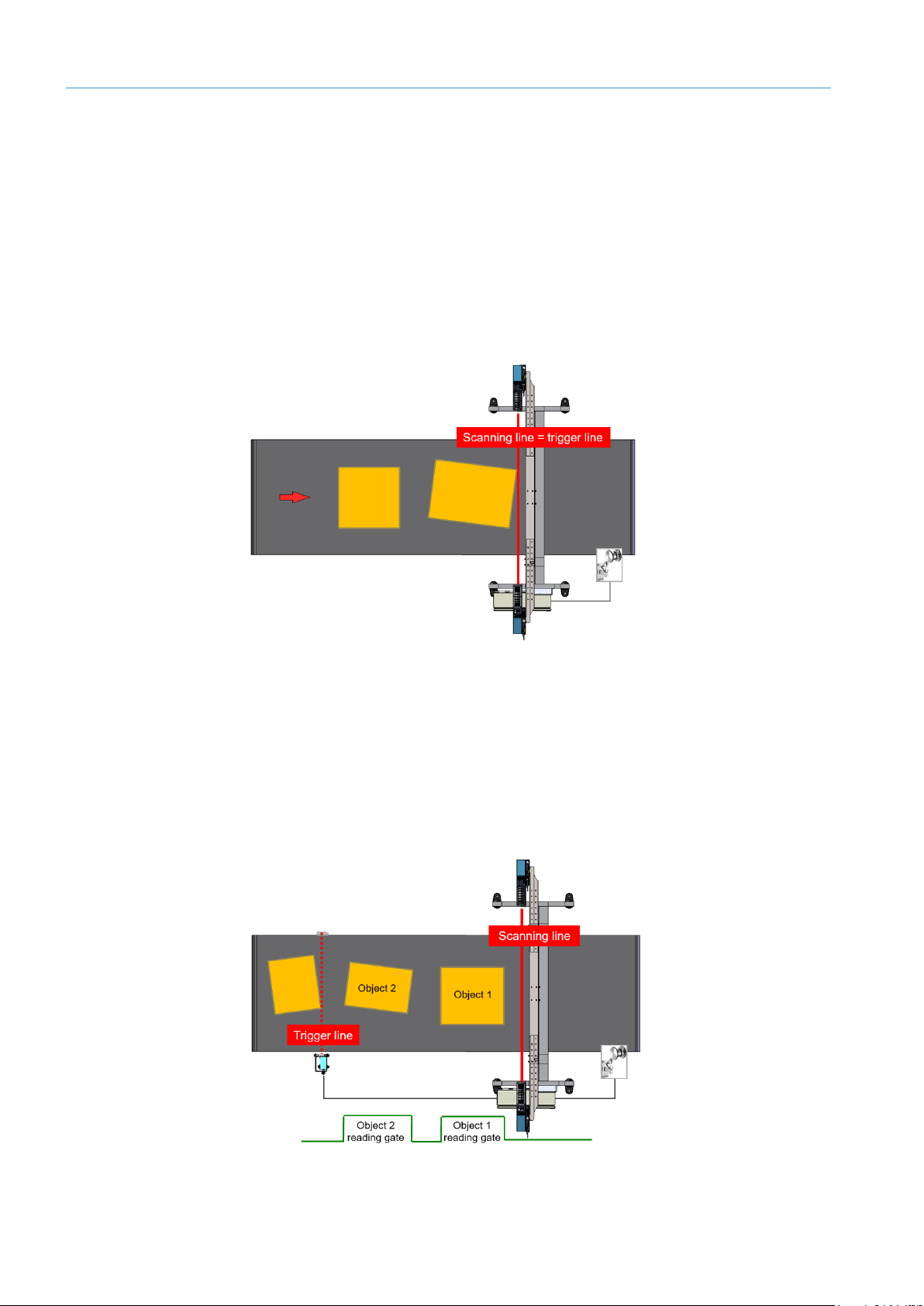

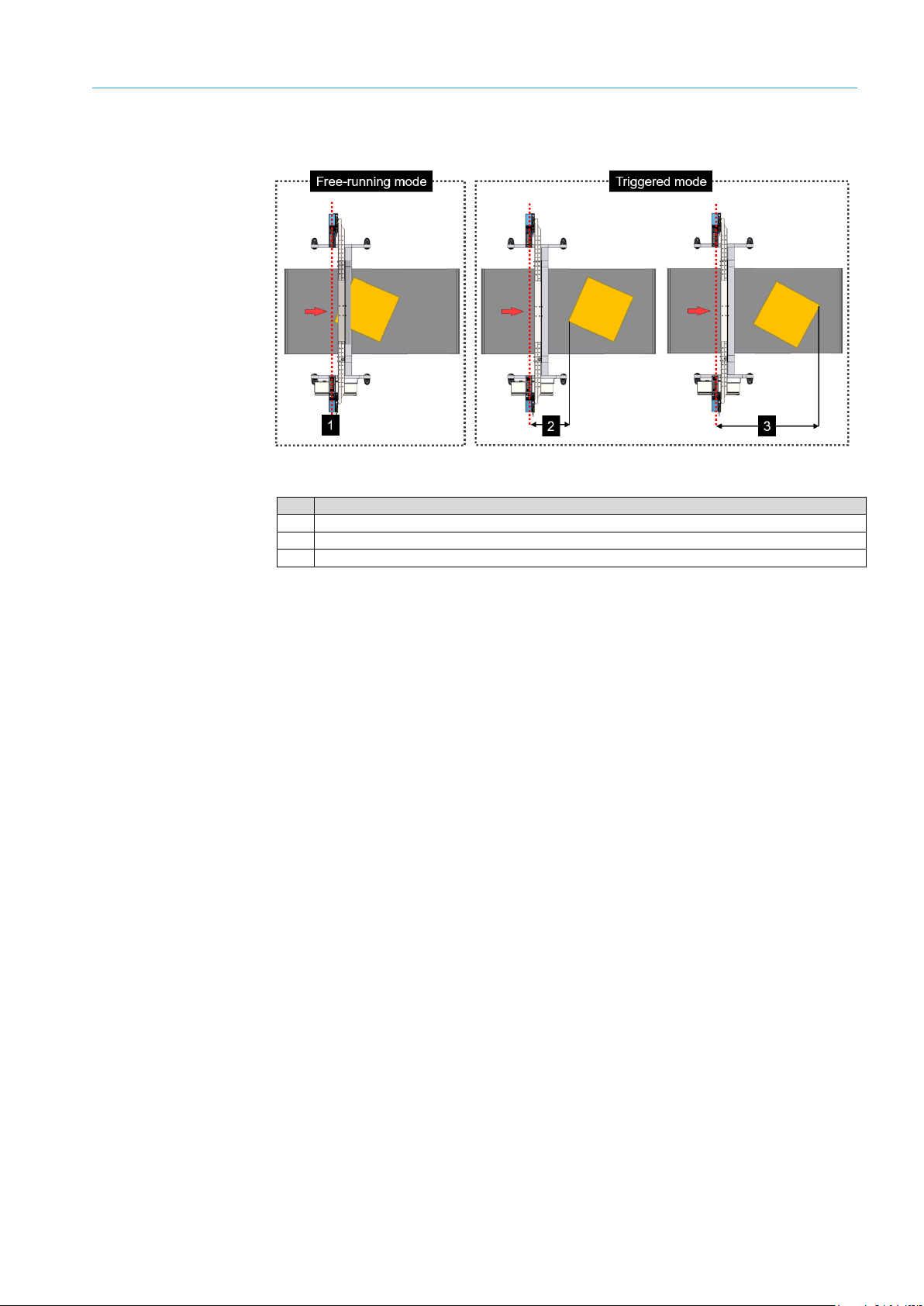

3.3.1 Operating modes

The volume measurement system can either be in free-running or triggered operating

mode.

In free-running mode, the volume measurement system detects the objects to be

measured itself. The measurement starts when an object enters the scanning line of the

volume measurement devices. It ends when the object leaves the scanning line.

Fig. 9: Free-running operating mode

In triggered mode, the object is detected via a trigger signal, not automatically. The trigger

signal can be triggered by the entry of the object into the path of a photoelectric retro-

reflective sensor or via a customer-controlled digital signal.

The trigger signal activates the volume measurement devices and opens the internal

reading gate. The reading gate determines the start and the end of the measuring

process. It corresponds to the trigger length in the conveying direction. The measuring

process lasts for as long as the reading gate is open, regardless of whether the object is

entering the scanning line or leaving it.

Fig. 10: Triggered operating mode

Object detection via a trigger signal also reliably detects very flat objects.

Free-running operating

mode

Triggered operating

mode

Note

Page 21

SYSTEM DESCRIPTION 3

21

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

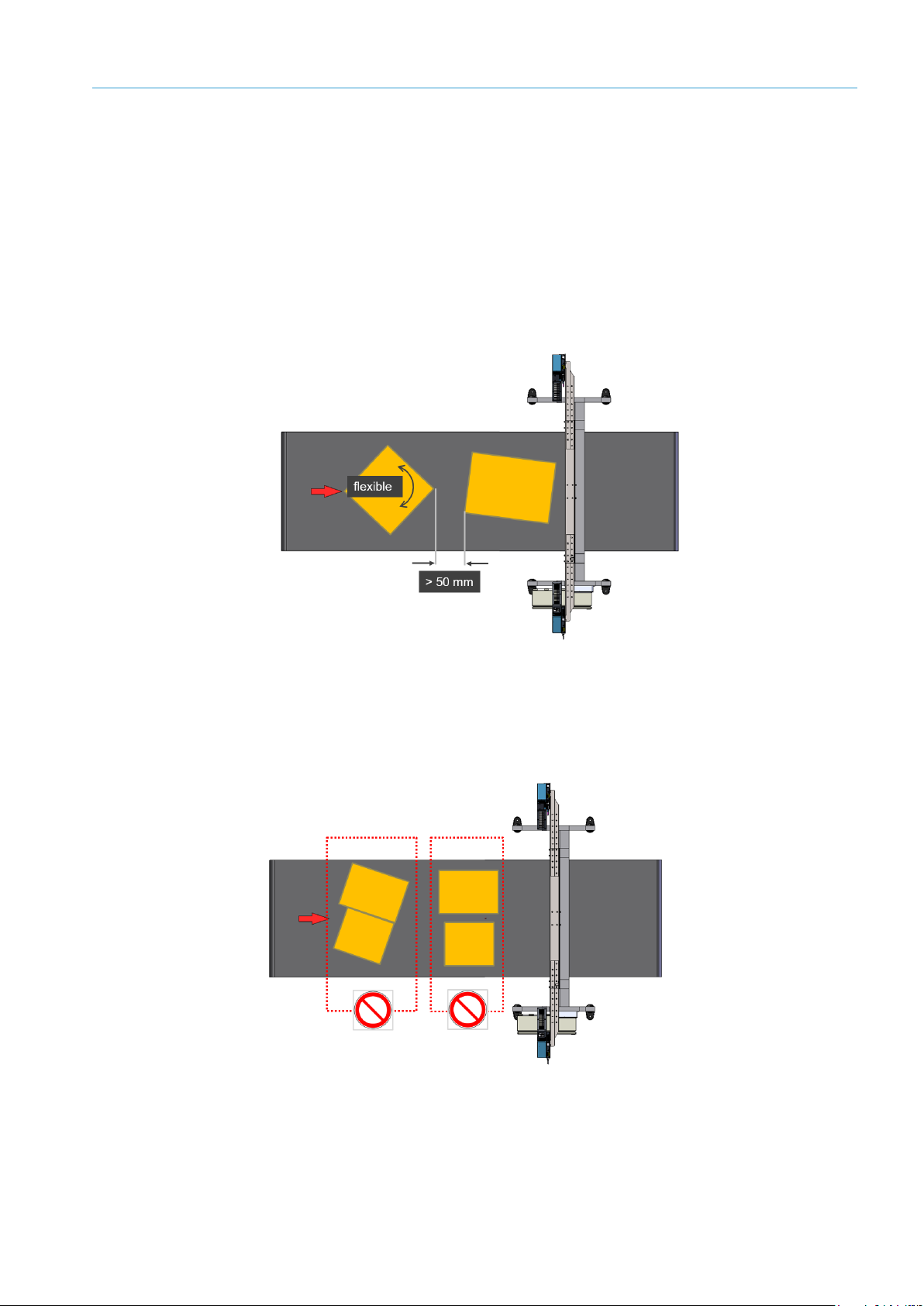

In both operating modes, the incremental encoder supplies information to the conveying

equipment for exact position definition of the object. This information is required to

calculate the length information and for correct assignment of the measurement results

to the object.

The supplying conveying equipment must pass on the objects to the volume

measurement system separately and at the minimum distance of 50 mm, which is

required for error-free processing. The objects may be placed on the conveyor belt in any

direction.

Fig. 11: Object conveyance with minimum distance and rotation angle

Objects that are touching or lying side-by-side cannot be measured using the volume

measurement system. The system does not give plausible measurement results in this

case.

Fig. 12: Unable to measure objects that are touching or lying side by side

Object tracking

Minimum distance

Page 22

3 SYSTEM DESCRIPTION

22

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.3.2 Calculating the volume

The calculation of measurement values begins as soon as an object is transported past

the volume measurement devices on the equipment below. The volume measurement

devices span a two-dimensional measuring range and scan the surfaces of the object

located within this range on the conveying equipment, without making contact. The

volume measurement device measures its surroundings in two-dimensional polar

coordinates, relative to its measurement origin. This is marked by a circular indentation

on the upper side of the housing.

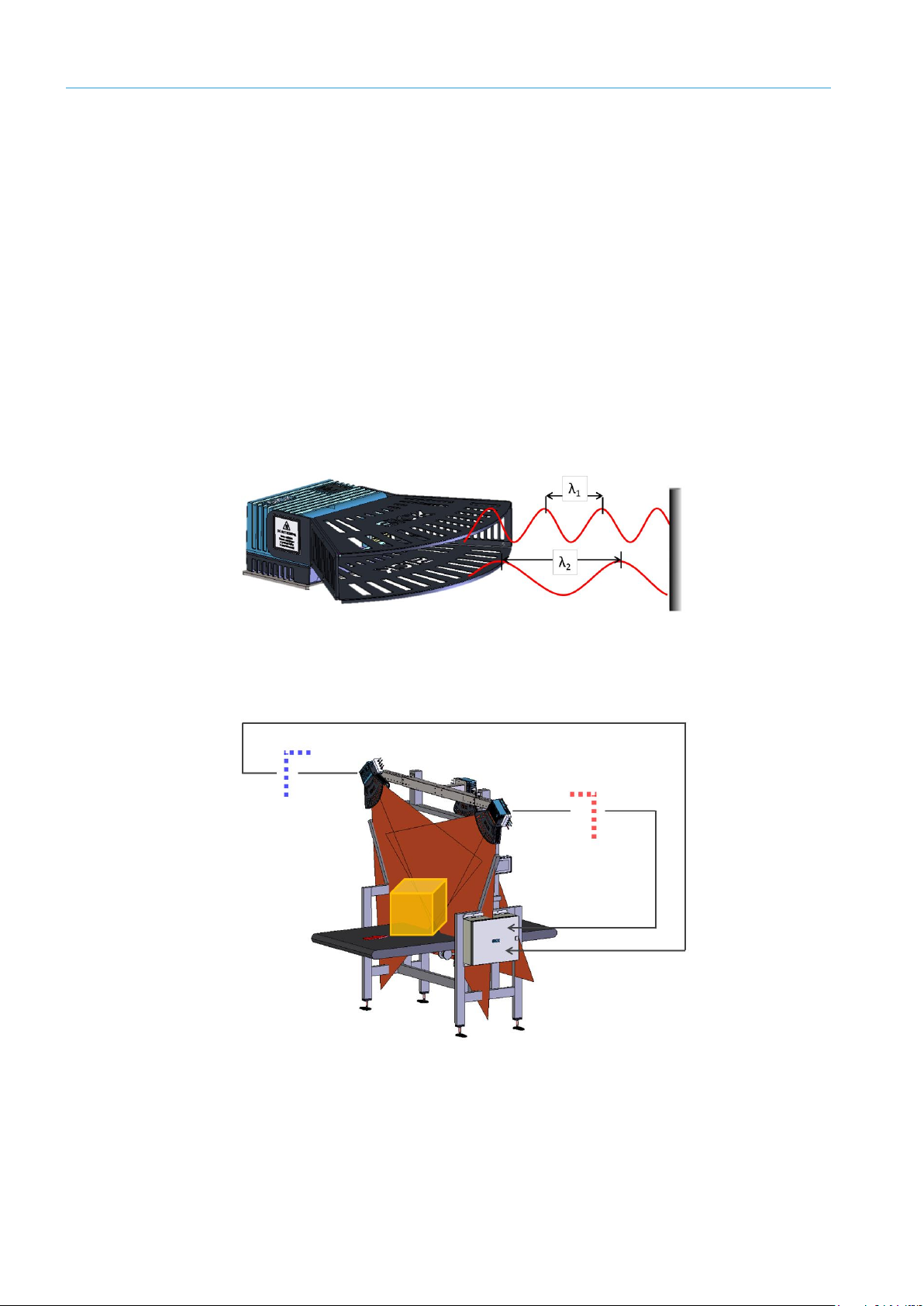

The VMS4200 / VMA5200 is an active system featuring a laser in the visible range (red).

It does not require position marks, reflectors, or object illumination.

If a laser beam strikes an object, the position of that object is determined in terms of

distance and angle. This functions according to the principle of phase shift (continuous

wave). There is a phase difference between the transmitter and receiver beams resulting

from the run time of the light and the wavelength used. This phase difference is used to

calculate the distance of the object from the zero point.

Fig. 13: Functioning of the volume measurement device

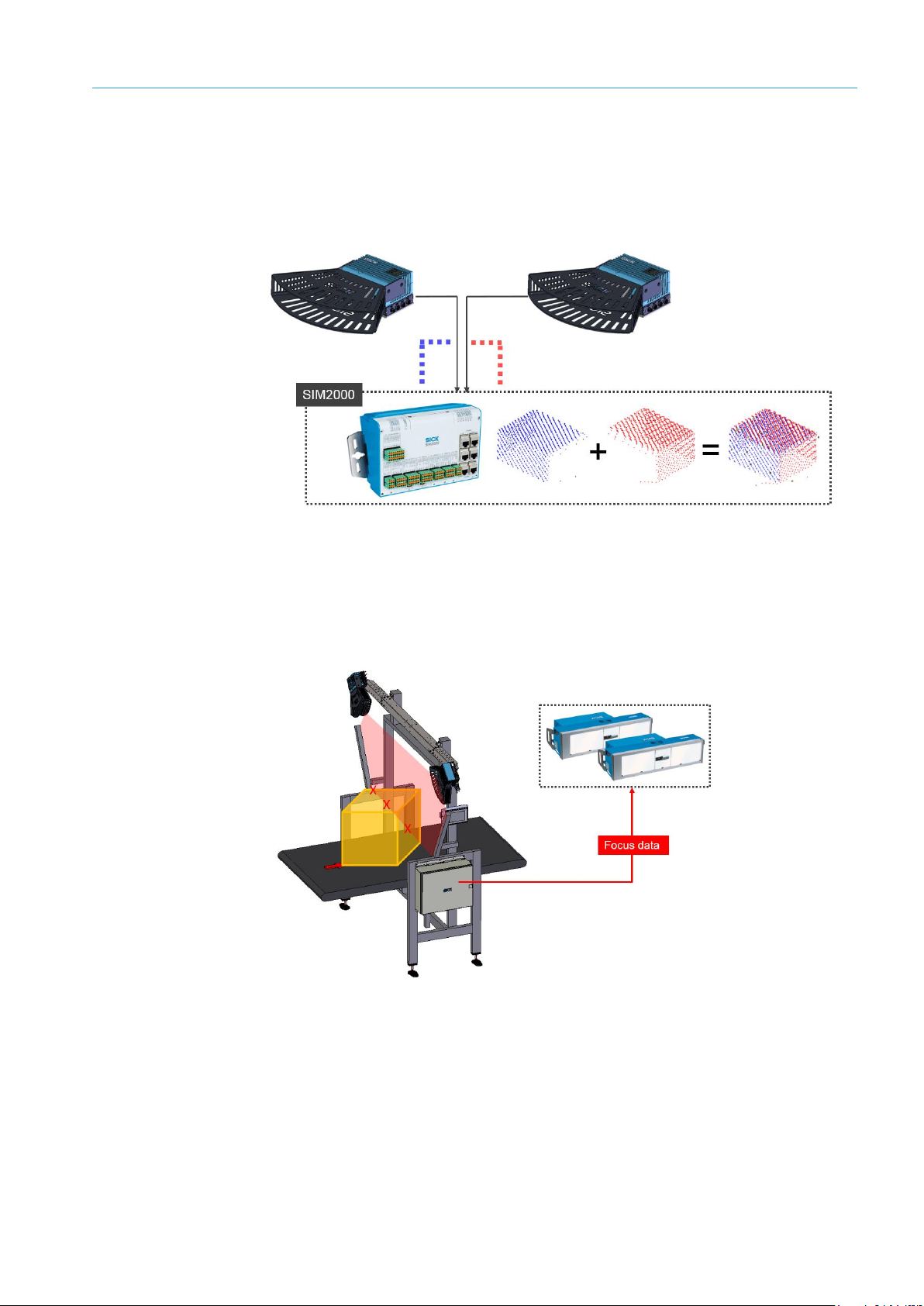

The measuring points determined by the two volume measurement devices are cyclically

transmitted to the SIM2000 controller.

Fig. 14: Measuring point determination by LMS4xxx

Page 23

SYSTEM DESCRIPTION 3

23

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Using the established speed of the conveyor element and the specific position of the

object on the belt, the controller creates a spatial model from which the smallest

rectangular box that fully encloses the object is determined and the values for volume,

length, width and height are calculated. The measurement results of the officially verified

volume measurement system are shown on a separate LFT display.

Fig. 15: Volume calculation in the SIM2000

If the VMS4200 / VMS5200 volume measurement system is working in a complete

system with a reading station, the contour data can be used as the basis for the dynamic

camera focusing. For this purpose, the controller supplies continuous information about

the distance of the measurement sensor to the object surface via the CAN bus.

Fig. 16: Contour data as focus data for connected reading systems

Focus data

Page 24

3 SYSTEM DESCRIPTION

24

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.3.3 Data processing and data output

The SIM2000 is the volume measurement system’s central control unit. All the volume

measurement system information is processed here. It assumes the measuring points

from the volume measurement devices and uses this to generate a three-dimensional

model. It processes the signals from the measuring wheel encoder and (optionally from

the photoelectric retro-reflective sensor).

It calculates the volume and uses this to determine the length, width, and height. It

assigns the measurement results to the object and outputs them to the higher-level

system via a host telegram coordinated by the customer.

The calculated 3D point cloud of the calculated model can be optionally output here.

Fig. 17: Data output (host telegram)

In the case of an officially verifiable VMS5200, the measurement results are saved in the

SIM2000 alibi memory, which is required for verification, prior to output. The

measurement results are also displayed on the LFT display.

Fig. 18: Data processing (LFT mode)

VMS5200

Page 25

SYSTEM DESCRIPTION 3

25

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

You can define the output time via the SOPAS configuration software as follows.

Fig. 19: Configuring the time of the data output

No.

Meaning

1

Output as soon as possible after leaving the scanning line.

2

After a defined distance from X position in relation to the rear edge of an object.

3

After a defined distance from X position in relation to the leading edge of an object.

Configuring output

times

Page 26

3 SYSTEM DESCRIPTION

26

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.4 Nominal value conditions

The VMS4200 / VMS5200 volume measurement system can determine the length, width,

and height of the smallest rectangular box that fully encloses the object for cubic and

irregularly shaped measuring objects.

The different nominal operating conditions are described below depending on the object

size.

3.4.1 Fixed scale values

If the plant is operated without scale value switchover, the measuring range and scale

interval are fixed throughout the entire system depending on the application, and are

therefore the same for all measured objects.

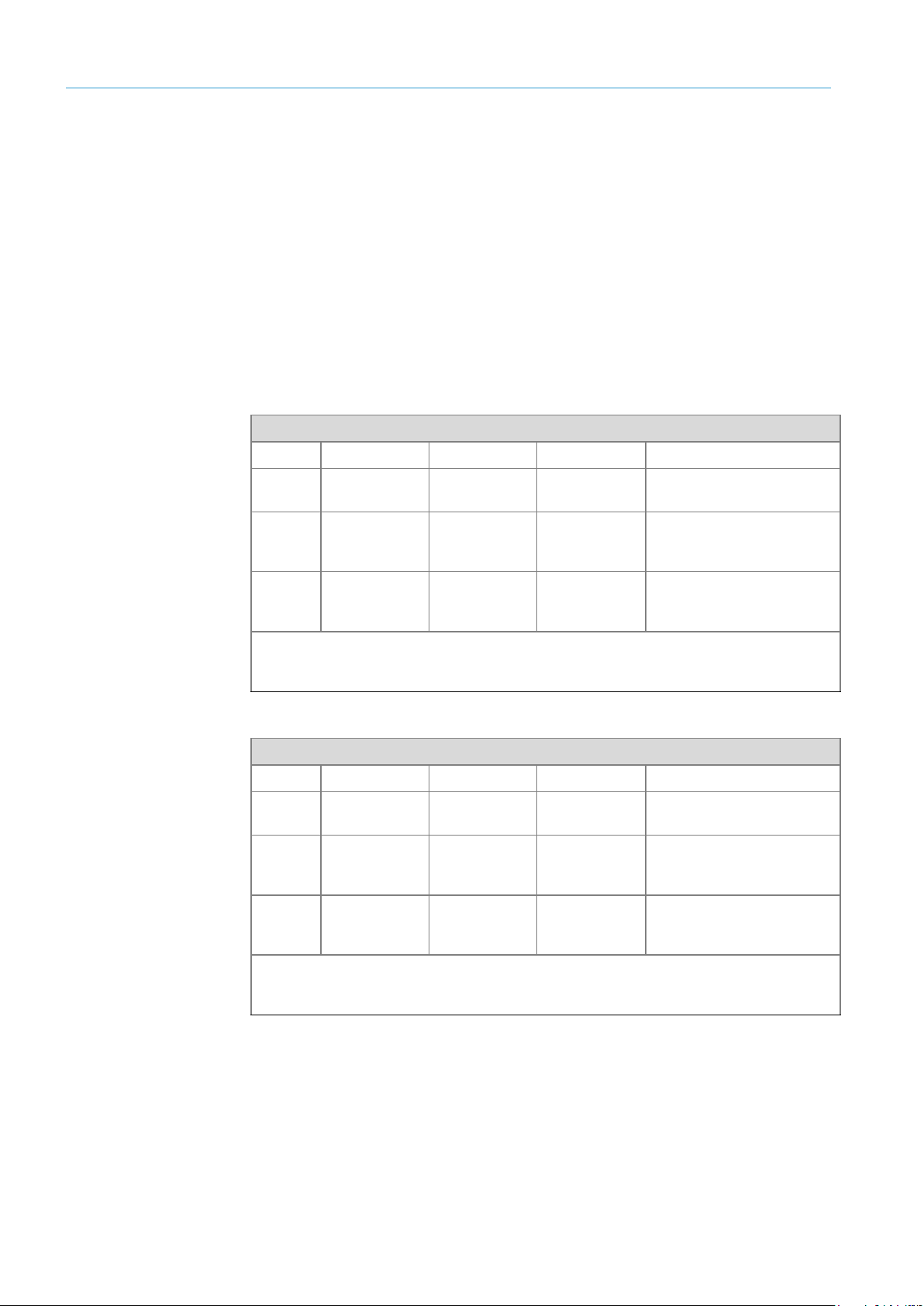

Measuring range and scale interval for VMS5200 (operating condition 1)

Min.

Max.

Scale value (d)

Comment

Length

≥ 50 mm

≥ 2.0"

5,500 mm

216.0"

5 mm

0.2"

Longest dimension of

measuring object

Width

≥ 50 mm

≥ 2.0"

1,600 mm

63.0"

5 mm

0.2"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 20 mm

≥ 1.0"

1,100 mm

< 43.0"

2 mm

0.1"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 2: Measuring range and scale interval for VMS5200 (operating condition 1)

Measuring range and scale interval for VMS5200 (operating condition 2)

Min.

Max.

Scale value (d)

Comment

Length

≥ 50 mm

≥ 2.0"

5,500 mm

216.0"

5 mm

0.2"

Longest dimension of

measuring object

Width

≥ 50 mm

≥ 2.0"

1,600 mm

63.0"

5 mm

0.2"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 50 mm

≥ 2.0"

1,100 mm

< 43.0"

5 mm

0.2"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 3: Measuring range and scale interval for VMS5200 (operating condition 2)

Page 27

SYSTEM DESCRIPTION 3

27

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

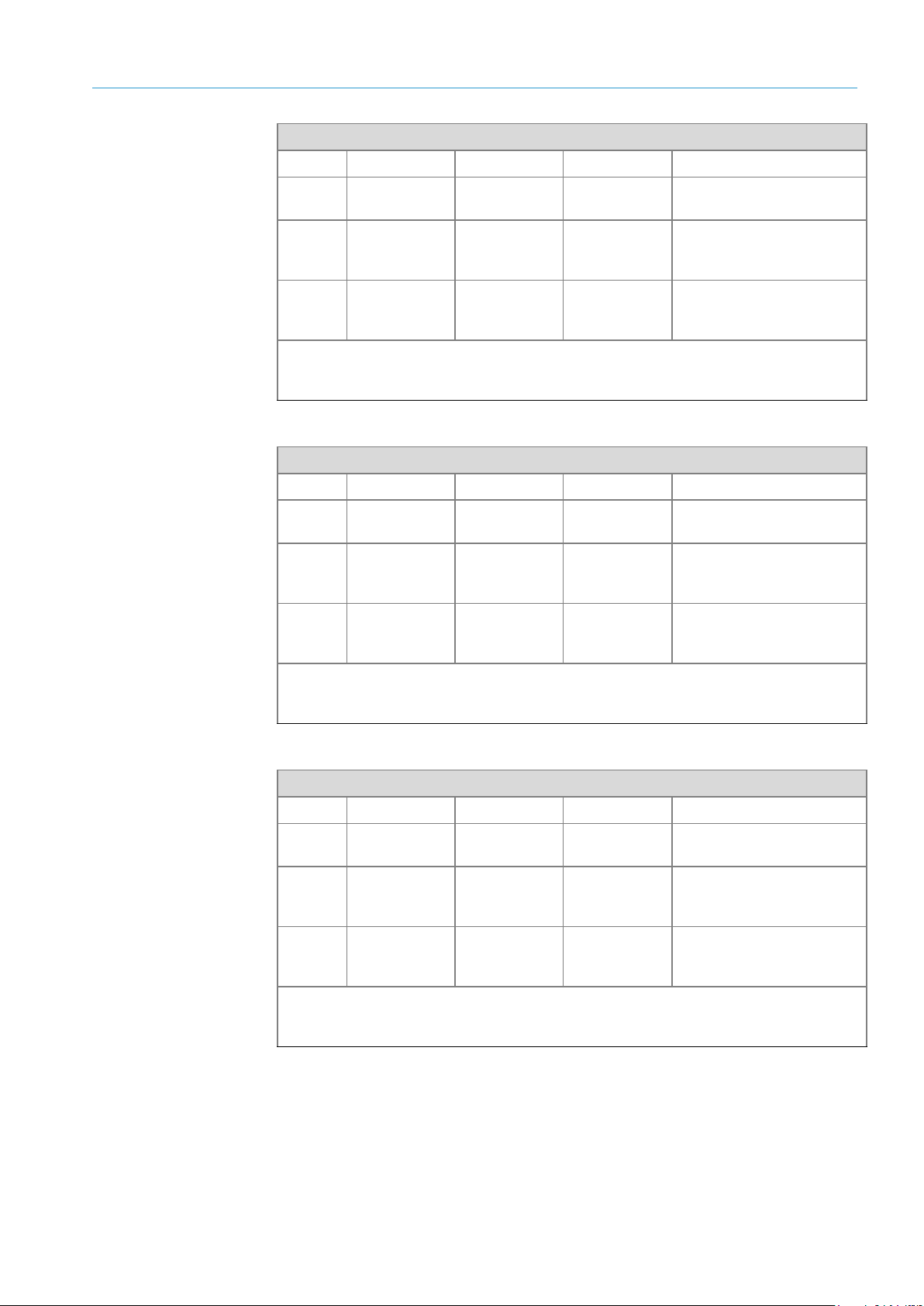

Measuring range and scale interval for VMS5200 (operating condition 3)

Min.

Max.

Scale value (d)

Comment

Length

≥ 100 mm

≥ 4.0"

5,500 mm

216.0"

10 mm

0.4"

Longest dimension of

measuring object

Width

≥ 50 mm

≥ 2.0"

1,600 mm

63.0"

5 mm

0.2"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 50 mm

≥ 2.0"

1,100 mm

< 43.0"

5 mm

0.2"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 4: Measuring range and scale interval for VMS5200 (operating condition 3)

Measuring range and scale interval for VMS5200 (operating condition 4)

Min.

Max.

Scale value (d)

Comment

Length

≥ 100 mm

≥ 4.0"

5,500 mm

216.0"

10 mm

0.4"

Longest dimension of

measuring object

Width

≥ 100 mm

≥ 4.0"

1,600 mm

63.0"

10 mm

0.4"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 50 mm

≥ 2.0"

1,100 mm

< 43.0"

5 mm

0.2"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 5: Measuring range and scale interval for VMS5200 (operating condition 4)

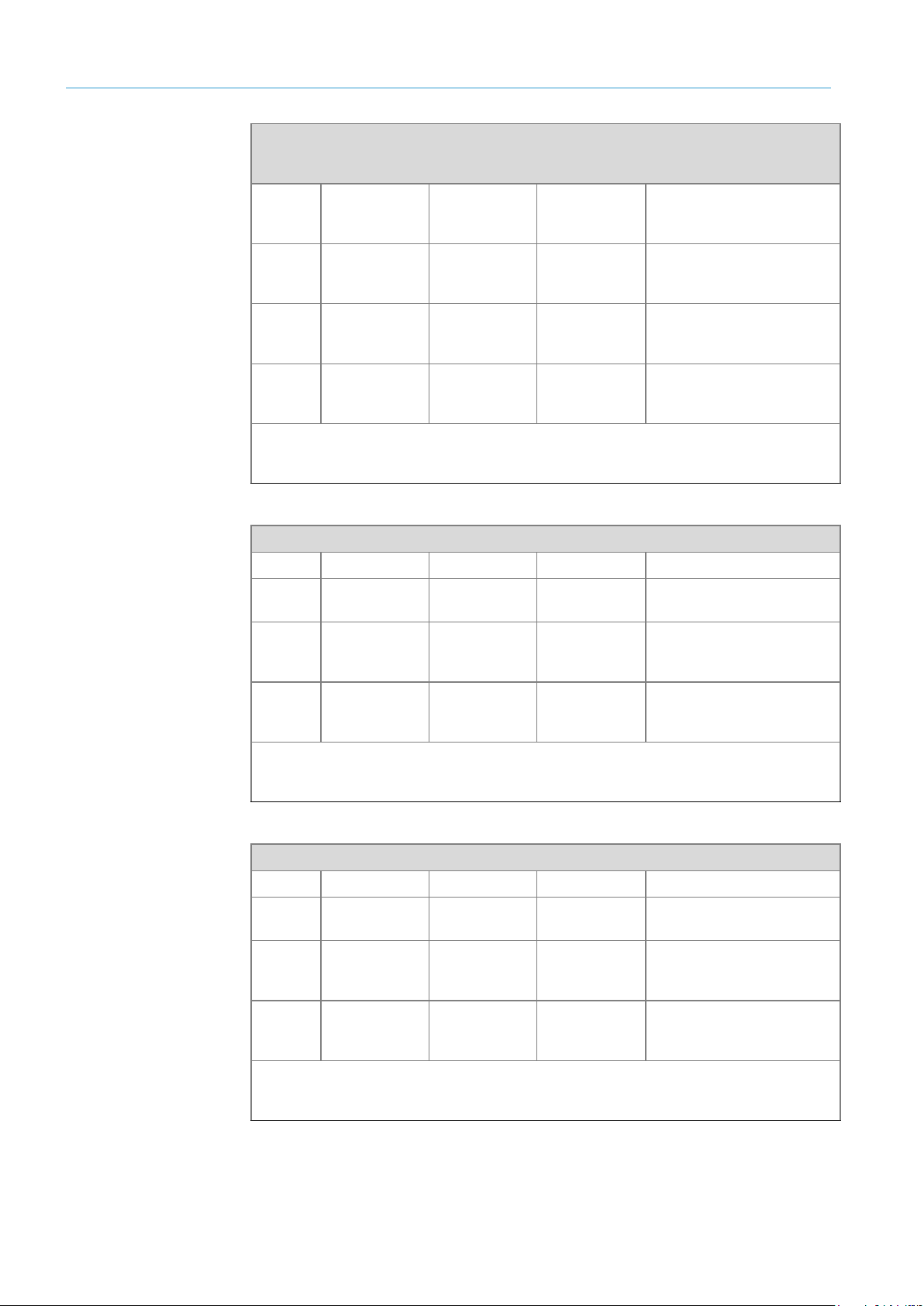

Measuring range and scale interval for VMS5200 (operating condition 5)

Min.

Max.

Scale value (d)

Comment

Length

≥ 100 mm

≥ 4.0"

5,500 mm

216.0"

10 mm

0.4"

Longest dimension of

measuring object

Width

≥ 100 mm

≥ 4.0"

1,600 mm

63.0"

10 mm

0.4"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 100 mm

≥ 4.0"

1,100 mm

43.0"

10 mm

0.4"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 6: Measuring range and scale interval for VMS5200 (operating condition 5)

Page 28

3 SYSTEM DESCRIPTION

28

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Measuring range and scale interval for VMS5200 (operating condition 6)

Min.

Max.

Scale value (d)

Comment

Length

≥ 100 mm

≥ 4.0"

5,500 mm

216.0"

10 mm

0.4"

Longest dimension of

measuring object

Width

≥ 50 mm

≥ 2.0"

1,600 mm

63.0"

5 mm

0.2"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 20 mm

≥ 1.0"

1,100 mm

43.0"

2 mm

0.1"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 7: Measuring range and scale interval for VMS5200 (operating condition 6)

Measuring range and scale interval for VMS5200 (operating condition 7)

Min.

Max.

Scale value (d)

Comment

Length

≥ 100 mm

≥ 4.0"

5,500 mm

216.0"

10 mm

0.4"

Longest dimension of

measuring object

Width

≥ 100 mm

≥ 4.0"

1,600 mm

63.0"

10 mm

0.4"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 20 mm

≥ 1.0"

1,100 mm

43.0"

2 mm

0.1"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 8: Measuring range and scale interval for VMS5200 (operating condition 7)

Measuring range and scale interval for VMS5200 (operating condition 8)

Min.

Max.

Scale value (d)

Comment

Length

≥ 200 mm

≥ 8.0"

5,500 mm

216.0"

20 mm

0.8"

Longest dimension of

measuring object

Width

≥ 50 mm

≥ 2.0"

1,600 mm

63.0"

5 mm

0.2"

Dimension of measuring

object orthogonal to longest

dimension

Height

≥ 20 mm

≥ 1.0"

1,100 mm

43.0"

2 mm

0.1"

Maximum height of

measuring object relative to

belt surface

v

min

: ≥ 0.1 m/s

v

max

: 4.0 m/s, start/stop operation permitted.

Minimum distance between objects: 50 mm / 2"

Table 9: Measuring range and scale interval for VMS5200 (operating condition 8)

Page 29

SYSTEM DESCRIPTION 3

29

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

3.4.2 Dynamic scale value switchover

In the case of dynamic scale value switchover, the scale interval can be changed depending

on the relevant measured object dimension, i.e., length, width, or height.

The defined scale intervals need to be documented on the information label. It is only

permitted to select scale intervals based on the scale values from section 3.4.1 Fixed scale

values.

The measurement accuracy switchover can take place from object to object. The switchover

point is set during commissioning and cannot be changed when the calibration switch is

activated and locked (for information on the calibration switch, see chapter 3.6.3 SD card

with alibi memory).

In the following example, the volume measurement system is working with the two scale

intervals 5 mm x 5 mm x 5 mm (scale values for operating condition 2) and 10 mm x

5 mm x 5 mm (scale values for operating condition 3). An object length of 2,000 mm has

been defined as the switchover point during commissioning.

Objects with a length less than or equal to 2,000 mm are measured under operating

condition 2 with the scale values 5 mm x 5 mm x 5 mm.

For objects with a length greater than 2,000 mm, the volume measurement system

automatically uses the scale values 10 mm x 5 mm x 5 mm due to the detected object

length.

Fig. 20: Dynamic scale value switchover

In the case of dynamic scale value switchover, the relevant scale values (see the tables

above) used by the VMS5200 are also displayed on the LFT display together with the

measurement result.

Example

Note

Page 30

3 SYSTEM DESCRIPTION

30

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.5 System requirements

3.5.1 Required interfaces

The following is required to operate the VMS5200 volume measurement system:

Supply voltage AC 100 ... 264 V / 50 ... 60 Hz for the VMS5200 components.

Host computer with RS-232, RS-422/485, Ethernet or PROFIBUS data interface for

further processing of the measurement results.

3.5.2 Requirements at the operation site

The operation site of the volume measurement system must have the following features:

Enclosed or covered spaces

Flat and firm surface

Low-vibration environment

Protected from wind and free of drafts

No direct sunlight

Well-lit

Clean and dry (air humidity 95%, non-condensing)

Room temperature from –10 °C to 50 °C

Regardless of the space requirements for the components, there must be enough space

at the operation site for the following activities:

Reading the measurement results off the LFT display

Opening the cabinet door completely

Cleaning, repair, and service

3.5.3 Object requirements

The transported objects must have the following properties:

Cubic and irregularly shaped objects can be measured.

All measuring objects must be dimensionally stable and have non-reflective and

opaque surfaces.

3.5.4 Conveying equipment requirements

The VMS4200 / VMS5200 volume measurement system is designed for flat conveying

systems.

The conveyor speed must not exceed 4 m/s.

Relative movements of the measuring objects are not permitted while measurements are

in progress. The measuring objects must not be exposed to any vibrations.

Page 31

SYSTEM DESCRIPTION 3

31

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

NOTE

Transport behavior of the packages

Any relative movement of the package to the conveyor belt will cause the measurement

results to be distorted.

Objects that rotate, vibrate, roll, or slip on the belt and uneven conveying surfaces may

reduce the accuracy.

General requirements

In an area before and after the measuring station, the conveying equipment must run

straight and evenly, and may not exhibit any deviation. Both the front and back area in

this case correspond to the maximum length of the measuring objects (see also

chapter 3.4 Nominal value conditions). If the specific installation position of the

measuring equipment does not meet this requirement, the maximum length of the

measuring objects must be restricted accordingly and is to be specified on the

information label (see chapter 3.6.1).

Positive or negative slopes of the conveying equipment must be kept flat enough to

prevent the measuring objects from sliding.

The conveying equipment must not have any shiny or reflective surfaces.

No guides for measuring objects may be installed in the vicinity of the measuring

station.

3.5.5 Mounting requirements

The measurement system requires both a stable, secure frame to prevent rotation and a

sufficient load bearing capacity to support the system components.

To achieve a high level of measurement accuracy, use the optional aluminum profiles

and the corresponding mounting kits for mounting.

The frame must be attached to the conveying system in such a way that it is free of

vibrations and oscillations.

The frame must be positioned at right angles to the conveying direction.

The maximum working range of the LMS4xxx is 3 m. The minimum distance between the

zero point of the LMS4xxx measurement and the measuring object is 700 mm. In the

delivery state, the zero point of the distance measurement is the origin of the laser

(marked with a point on the upper and lower side of the housing).

The working range of the LMS4xxx covers an angle of 70°.

Frame

Mounting the

LMX4xxx

Page 32

3 SYSTEM DESCRIPTION

32

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Fig. 21: Working range of the LMS4xxx

The volume measurement devices are mounted on the right and left of the conveying

equipment in such a way that it is free of vibrations and oscillations.

To achieve a high level of measurement accuracy, use the supplied mounting set with

telescopic tube and brackets when mounting the equipment. See also chapter 4.1

Mounting volume measurement devices.

The telescopic tube must be mounted precisely at right angles to the conveying

equipment.

To achieve an optimal read result, observe the following:

The smallest permissible distance of the measuring object from the zero point of the

LMS4xxx is 700 mm. The zero point is marked on both the upper and lower side of the

housing of the LMS4xxx.

Fig. 22: Requirements for mounting the LMS4xxx

The typical space requirement for the installation of the volume measurement system

is approximately 700 mm above the tallest object.

The volume measurement devices must have a clear view of the conveying system.

The laser beams of the LMS4xxx should not reach beyond the application space, so

that people or goods, which are being transported on an adjacent conveyor system, are

not detected. The boundary is set via beam separation (see below).

The maximum detection must be limited to the working range of three meters, as the

specified scale interval may otherwise not be achieved.

The LMS4xxx must be far enough away from bends, induction lines, start/stop areas,

areas with upward and downward slopes, and breaks in the conveying system.

Recommendation

Optimization

Page 33

SYSTEM DESCRIPTION 3

33

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

It is important to make sure that the volume measurement devices are aimed at the

beam blockers. The beam blockers attached to the mounting frame prevent objects

located outside of the measuring range from being taken into account when calculating

the measured values, therefore also preventing the falsification of the measurement

result.

The beam blockers of the lower volume measurement devices also enable detection of

objects with excessively low remission (black objects).

Fig. 23: Beam blockers for restricting the laser beams to the measuring range

Beam separation

Page 34

3 SYSTEM DESCRIPTION

34

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.6 Officially verifiable operation

The MID-compliant, and therefore officially verifiable, VMS5200 system has been typetested by the Physikalisch-Technische Bundesanstalt (PTB). It can therefore be used for

billing purposes.

When operating the VMS5200 in a situation requiring official legal-for-trade verification,

be sure to comply with applicable national law. SICK can assist you with this in an

advisory capacity on request. However, this assistance is not a substitute for legal advice.

3.6.1 Information labels

There are two types of information labels:

To ensure that the VMS5200 volume measurement system is operated in such a way

that it can be verified as legal for trade, one or two system information labels –

depending on whether fixed scale values or dynamic scale value switchover is in

operation – containing information about the maximum and minimum dimensions for

the length (L), width (W), and height (H), as well as the relevant scale value (d) must be

attached to the volume measurement system in a highly visible location.

The missing values are to be entered by hand on site, using waterproof permanent ink.

Each system information label must be attached to the system in such a manner that it

can be seen by the operator and assigned to the volume measurement system.

The type labels of the LMS4xxx volume measurement devices contain additional

information and are to be affixed to the information label in the LMS 1 and LMS 2

fields. The SW field contains the version number of the device software.

The label with the metrology information label must also be attached.

The SIM2000 system controller type label is affixed to the metrology information label.

Page 35

SYSTEM DESCRIPTION 3

35

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

System information label with fixed scale values

If fixed scale values are defined for the VSM5200, the relevant operating condition is

specified on the information label in indelible ink.

The fix scale value and the measuring unit (mm or inch) must be specified on the

namepalte in indelible ink.

The LMS4xxx type labels must be affixed in the appropriate fields.

Fig. 24: Nameplate for the VMS5200 for fixed scale values with affixed type labels for the

LMS4xxx

Page 36

3 SYSTEM DESCRIPTION

36

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

System information labels with dynamic scale value switchover

In the case of dynamic scale value switchover, the scale values of the two scale intervals

used must be described in two separate information labels and attached to the system

indelibly.

The dynamic scale value and the measuring unit (mm or inch) must be specified on the

information label for scale interval 1 in indelible ink. The type labels for the LMS4xxx are

also affixed to this nameplates.

The dynamic scale value with the associated dimension values must be specified on the

nameplates for scale interval 2.

Fig. 25: MID Nameplates for the VMS5200 (dynamic scale value switchover) with affixed type

labels for the LMS4xxx

Page 37

SYSTEM DESCRIPTION 3

37

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Metrology information label

The metrology marking – M18 for the year 2018 in the figure below – must be indicated

in accordance with Article 21 of the MID. Additionally, the CE marking and the number of

the notified body – 0102 for PTB in the figure below – must be indicated.

The SIM2000 system controller type label is affixed to the metrology information label.

Fig. 26: Sample label for the metrology marking, CE marking, and number of the notified body

with SIM2000 type label

The nature of the metrology information label must be such that its removal will result in

the destruction of the label itself or of a security seal.

Note

Page 38

3 SYSTEM DESCRIPTION

38

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.6.2 Security seal

In order to protect measurement systems that have been verified as legal for trade

against manipulation, all legally relevant components that influence the measurement

result must be provided with seals in accordance with the seal diagram depicted in the

figure below.

The security seals are attached to the VMS5200 components after mounting and the

conformity check.

NOTE

Never tamper with the seal

The seals must not be broken.

If a seal is broken, the verification validity period will end prematurely, and the VMS5200

must no longer be used for billing purposes. This must be reported to the manufacturer

and the office of weights and measures.

Security seals prevent the attachment mechanism of the volume measurement devices

and the plug connectors of the connections from misaligning.

Fig. 27: Security seals for the VMS5200 volume measurement devices

No.

Meaning

1

Security seal on the mounting plate of the modular bracket on the frame.

2

Security seal on the two adjusters of the telescopic tube.

3

Security seal on the retaining plates of the volume measurement devices.

4

Security seal on all plug connectors for the electrical connections.

Seal on the

VMS5200

Page 39

SYSTEM DESCRIPTION 3

39

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

A manipulation protective plate protects the SIM2000 controller installed in the cabinet

against disassembly and removal of the connections. The protective plate also prevents

the DIP switch from shifting.

The service flap on the upper side of the controller is also sealed to prevent the microSD

memory card containing the alibi memory from being removed.

Fig. 28: SIM2000 security seals

No.

Meaning

1

Manipulation protective plate.

2

Security seal on the manipulation plate.

3

Security seal on the service flap.

4

Data lines protected against removal.

5

Cable entries protected against removal.

A manipulation protective plate protects the Ethernet switch installed in the cabinet

against disassembly and removal of the connecting cables.

Fig. 29: Ethernet switch security seals

No.

Meaning

1

Manipulation protective plate.

2

Security seal on the manipulation plate.

Security seal

on the SIM2000

Security seal on the

Ethernet switch

Page 40

3 SYSTEM DESCRIPTION

40

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

The measuring wheel encoder is protected against disassembly and disconnection of the

connecting cable.

Fig. 30: Security seals on the measuring wheel encoder (DFV60 in the image)

No.

Meaning

1

Security seal on the bracket.

2

Security seal on the male connector.

The LFT display is protected against disassembly and disconnection of the connecting

cable.

Fig. 31: Security seals on the LFT display

No.

Meaning

1

Security seal on the LFT display housing.

2

Security seal on the male connectors.

Security seal on the

Ethernet switch

Security seal on the LFT

display

Page 41

SYSTEM DESCRIPTION 3

41

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

3.6.3 SD card with alibi memory

The slot for the microSD card containing the alibi memory is located beneath the sealed

service flap on the upper side of the device. A second SD card containing the firmware is

included with delivery.

Fig. 32: MicroSD card with alibi memory and firmware

Alibi memory

Measurement and calibration legislation stipulates that a measured value which is

detected on a measurement device that has been verified as legal for trade in an

application requiring official verification, and is transmitted to an electronic data

processing system must be available to read from the alibi memory for at least three

months before it can be overwritten with new data sets.

Documentation takes place in what is referred to as an alibi memory, which is a fixed

component of the officially verifiable system. This memory must be approved by the

Physikalisch-Technische Bundesanstalt (PTB) or another notified body.

The VMS5200 volume measurement system uses the alibi memory to ensure compliance

with official verification regulations for measurement data, and to provide traceability for

all measurement processes within the measurement system. For this purpose, the alibi

memory stores all measured values recorded along with their date, time, and a unique

consecutive alibi ID.

NOTE

The operating entity of the VMS5200 system variant is responsible for complying with

the relevant regulations and guidelines at all times in connection with operating the

system in a way that is verified as legal for trade.

Page 42

3 SYSTEM DESCRIPTION

42

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Separation of application software and metrological software

The firmware of the volume measurement system is separated into an application part

and a metrologically relevant part.

This separation allows customer-specific parameters to be changed via the SOPAS

configuration software without violating the LFT conformity of the volume measurement

system.

The software relevant to the LFT conformity with the associated LFT parameters is

protected by a calibration switch. This calibration switch is also located beneath the

sealed service flap.

It is interlocked by turning the calibration switch to the zero position.

Fig. 33: Calibration switch for interlocking the metrological software parameters

Page 43

SYSTEM DESCRIPTION 3

43

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

3.6.4 LFT display

When operating the VMS5200 volume measurement system in a way that is verified as

legal for trade, the measurement results are displayed one after another on an LFT

display connected to the controller.

The LFT display also allows users to display system information, the current firmware

version, and a version history.

Fig. 34: User interface of the LFT display

The screen is controlled by gently touching the respective touch pads. The touch pads on

the LFT display vary according to the operational context.

NOTE

Notes on the correct use of the LFT display

You are only permitted to touch the LFT display with your fingers. Gently press the touch

pads to operate them. Do not apply force.

Do not operate the LFT display with pointed or sharp objects; otherwise, the surface of the

LFT display will become damaged.

NOTE

The operation of the LFT display only permits the display of measurement data and

system information.

No measurement and system data can be changed.

Page 44

3 SYSTEM DESCRIPTION

44

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Displaying the measurement results

The MEASUREMENT tab displays the results of the last measurement. The length, width,

and height are output with scale values in mm.

The status line provides additional information about the measurement result and

indicates, for example, whether the measurement was completed successfully (display

reads 0 0 0 0). Other numerical sequences indicate the reason why a measurement was

invalid.

Fig. 35: LFT display – display of the measurement results

Displaying the firmware version

The VERSION tab displays the current firmware statuses of the system components with

the firmware checksums saved in the SIM2000. The checksum of the metrologically

relevant LFT test parameters saved in the SIM2000 is also listed.

Fig. 36: LFT display – display of the firmware versions

Page 45

SYSTEM DESCRIPTION 3

45

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

The HISTORY buttons can be used to call up current and any older version statuses of a

component.

Fig. 37: LFT display – display of the firmware versions (history)

Displaying the data sets saved in the alibi memory

The ALIBI BROWSER tab displays the data sets saved in the alibi memory. Enter a date to

specify the date from which the data sets should be displayed.

The display is automatically updated.

Fig. 38: LFT display – display of the data sets saved in the alibi memory

Page 46

3 SYSTEM DESCRIPTION

46

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

3.6.5 Test instructions for market surveillance

This chapter describes the procedure for inspecting the certified VMS5200 measurement

system with regard to:

The performance of metrological measurements with defined test objects and the

display of the measurement results on the LFT display.

The display of data sets stored in the alibi memory on the LFT display.

The display of system component firmware versions via the LFT display.

Starting the system

▸

Establish the voltage supply of the devices via the voltage supply unit in the SIC2000.

All system components start up automatically and are then ready for use.

The LFT display shows the MEASUREMENT tab. No measured values are available yet.

Measuring test objects

▸

Measure test objects made from a dimensionally stable material of various shapes and

surface qualities.

▸

The measurements can be performed in both free-running and triggered mode (for

more information on this, see also chapter 3.3.1 Operating modes).

The nominal dimensions (length, width, height) must cover approximately 90%, 50%,

and 10% of the total measuring range for each dimension.

The actual dimensions must not be less than the minimum dimensions or exceed

the maximum dimensions specified for the VMS4200 / VMS5200.

▸

Ensure that the required minimum distance of 50 mm is maintained between the test

objects.

▸

Compare the dimension values displayed on the LFT display with the actual values of

the respective measured test object.

Valid measurement results have the status 0 0 0 0. They are LFT-verified and can be used

for billing.

Note

Note

Page 47

SYSTEM DESCRIPTION 3

47

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Displaying values saved in the alibi memory

The measured values saved in the alibi memory of the VMS5200 can be displayed on the

display.

▸

Switch to the ALIBI BROWSER tab in the LFT display. The data sets saved in the alibi

memory are listed line by line. A maximum of 20 data sets can be displayed on one

page.

Valid measurement results have the status 0 0 0 0. They are LFT-verified and can be

used for billing.

▸

Use the arrow buttons to change between the individual pages. The numbers between

the arrow keys indicate which page you are on and how many pages there are in total.

Symbol

Meaning

Opens the first page.

Changes from the current page to the previous page.

Changes from the current page to the next page.

Opens the last page.

▸

Enter a date to set the period for which you want to display the alibi memory values.

This list is updated automatically.

Page 48

3 SYSTEM DESCRIPTION

48

8022965/2018-08-16|SICK

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Subject to change without notice

Displaying firmware versions

▸

Switch to the VERSION tab in the LFT display.

The current firmware statuses of the system components are displayed together with

the checksum saved in the SIM2000.

▸

Press the HISTORY button to call up current and any older version statuses of a

component.

Page 49

SYSTEM DESCRIPTION 3

49

8022965/2018-08-16|SICK

Subject to change without notice

O RI G IN A L O P ER A TI N G I NS T RU C TI O NS | VMS4200 / VMS5200 volume measurement system

Displaying the history of the checksum for LFT parameters

▸