SICK VICOTEC320 Series, VICOTEC322, VICOTEC321, VICOTEC325, VICOTEC323 Operating Instructions Manual

Page 1

I

Title Page

VICOTEC320

Air Quality Tunnel Sensors

Measurement of NO, NO2, CO and visibility

MMMOPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MMM

Page 2

Described Product

Product name: VICOTEC320

Variants: VICOTEC321

VICOTEC322

VICOTEC323

VICOTEC325

Document ID

Title: Operating Instructions VICOTEC320

Part No.: 8011703/XF49

Version: V3-1

Release: 2019-09

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: info.pa@sick.de

Trademarks

IBM is a trademark of the International Business Machine Corporation.

MS-DOS is a Microsoft Corporation trademark.

Windows is a Microsoft Corporation trademark.

Other product names used in this document may also be trademarks and are only used

for identification purposes.

Original document

This document is an original document of SICK AG.

SICK AG assumes no liability for the correctness of an unauthorized translation.

If in doubt, contact SICK AG or your local representative.

Legal Information

Subject to change without notice.

© SICK AG. All rights reserved.

2

8011703/XF49/V3-1/2019-09 | SICKOPERATING INSTRUCTIONS | VICOTEC320

Subject to change without notice

Page 3

Contents

Contents

CONTENTS

1 About this document................................................................................. 7

1.1 Function of this document..............................................................................7

1.2 Scope of application ....................................................................................... 7

1.3 Target groups .................................................................................................. 7

1.4 Further information ......................................................................................... 7

1.5 Symbols and document conventions .............................................................7

1.5.1 Warning symbols ............................................................................ 7

1.5.2 Information symbols ....................................................................... 8

1.5.3 Warning levels and signal words....................................................8

1.6 Data integrity ................................................................................................... 8

2 For your safety............................................................................................ 9

2.1 Basic safety information ................................................................................. 9

2.2 Intended use .................................................................................................10

2.3 Responsibility of user....................................................................................10

3 Product description .................................................................................11

3.1 Product identification ...................................................................................11

3.1.1 Type plate......................................................................................11

3.2 Product features ...........................................................................................12

3.3 Device variants..............................................................................................12

3.4 Special features ............................................................................................12

3.5 Layout and function ......................................................................................13

3.5.1 Functional principle ......................................................................13

4 Project planning....................................................................................... 14

4.1 Assembly project planning............................................................................14

4.1.1 Arrangement along the tunnel section ........................................14

4.1.2 Arrangement in cross-section profile ...........................................14

4.1.3 Arrangement with special prerequisites ......................................16

4.2 Electrical installation project planning.........................................................17

5 Installation ................................................................................................ 19

5.1 Tools required ...............................................................................................19

5.2 Material required ..........................................................................................19

5.3 Preparing the installation location ...............................................................19

5.4 Transport .......................................................................................................19

5.5 Scope of delivery ...........................................................................................19

5.6 Assembly .......................................................................................................20

5.6.1 Fitting the assembly consoles ......................................................20

5.6.2 Fitting the VICOTEC320 sensors ..................................................21

5.6.3 Fitting the connection unit ...........................................................23

8011703/XF49/V3-1/2019-09 | SICK O P E R A T I N G I N S T R U C T I O N S | VICOTEC320

Subject to change without notice

3

Page 4

CONTENTS

5.7 Electrical installation .................................................................................... 24

5.7.1 Electrical protection ..................................................................... 24

5.7.2 Connecting the sensors to the connection unit .......................... 25

5.7.3 Connection unit cabling ............................................................... 26

6 Commissioning ........................................................................................ 32

6.1 Necessary technical knowledge for commissioning ................................... 32

6.2 Commissioning checklist.............................................................................. 32

6.2.1 Device data................................................................................... 32

6.2.2 Tunnel data................................................................................... 32

6.3 Alignment ...................................................................................................... 33

6.4 Spectral analysis........................................................................................... 35

6.5 Visibility and smoke detection ..................................................................... 35

6.6 Signal outputs............................................................................................... 36

6.7 Saving data ................................................................................................... 36

7 Operation .................................................................................................. 37

7.1 Operating the VICOTEC320 .......................................................................... 37

8 Using the VICOTEC320............................................................................ 38

8.1 Software SOPAS ET....................................................................................... 38

8.1.1 Functions (overview) .................................................................... 38

8.1.2 Installing the SOPAS ET software ................................................ 38

8.2 Using SOPAS ET ............................................................................................ 38

8.2.1 Creating a connection .................................................................. 38

8.2.2 Reading out the VICOTEC320 and operating manually .............. 44

8.2.2.1 Exporting messages ................................................. 47

8.2.3 Saving the current parameter set................................................ 48

9 Maintenance............................................................................................. 49

9.1 Cleaning ........................................................................................................ 49

9.1.1 Cleaning sensors .......................................................................... 49

9.1.2 Tunnel cleaning ............................................................................ 49

9.2 Maintenance work ........................................................................................ 50

9.2.1 Persons authorized to carry out maintenance............................ 50

9.2.2 Replacing the activated charcoal ................................................ 50

9.2.3 Replacing the drying agent cartridge .......................................... 51

9.2.4 Replacing the sender lamp and LED ........................................... 52

9.2.5 Replacing the CO sensor.............................................................. 56

9.2.6 Span Test...................................................................................... 57

9.2.6.1 Determination and setting of the span factors .......59

10 Troubleshooting .......................................................................................60

10.1 Error messages ............................................................................................. 60

4

8011703/XF49/V3-1/2019-09 | SICKO P E R A T I N G I N S T R U C T I O N S | VICOTEC320

Subject to change without notice

Page 5

CONTENTS

11 Technical data ..........................................................................................61

11.1 Dimension drawings......................................................................................61

11.1.1 Sender/receiver unit ....................................................................61

11.1.2 Reflector........................................................................................62

11.1.3 Connection unit.............................................................................63

11.2 Technical data ...............................................................................................64

11.3 Part Nos. ........................................................................................................66

11.3.1 Device components ......................................................................66

11.3.2 Type code ......................................................................................67

11.3.3 Accessories ...................................................................................68

11.3.4 Expendable and wearing parts.....................................................68

12 Annex .........................................................................................................69

12.1 Conformities and approvals..........................................................................69

12.2 Mapping table SCU .......................................................................................69

12.2.1 Measured values on SCU .............................................................69

12.2.2 Operating State Table...................................................................69

12.2.3 Status ............................................................................................70

12.2.4 Status of measured values ..........................................................70

12.3 Modbus Mapping Table ................................................................................71

12.3.1 Overview........................................................................................71

12.3.2 Status ............................................................................................73

12.3.3 Failure ...........................................................................................73

12.3.4 Maintenance request ...................................................................74

12.4 Password .......................................................................................................75

8011703/XF49/V3-1/2019-09 | SICK O P E R A T I N G I N S T R U C T I O N S | VICOTEC320

Subject to change without notice

5

Page 6

CONTENTS

6

8011703/XF49/V3-1/2019-09 | SICKO P E R A T I N G I N S T R U C T I O N S | VICOTEC320

Subject to change without notice

Page 7

1About this document

1.1 Function of this document

These Operating Instructions describe:

● Device components

● Installation

● Operation

● Maintenance work required for reliable operation

1.2 Scope of application

These Operating Instructions are only applicable for the measuring device described in the

product identification.

They are not applicable for other SICK measuring devices.

The standards referred to in these Operating Instructions are to be observed in the respective valid version.

1.3 Target groups

ABOUT THIS DOCUMENT 1

This Manual is intended for persons installing, operating and maintaining the device.

1.4 Further information

▸ Observe the supplied documents.

Additional instructions

The following documents are applicable in addition to these Operating Instructions:

● SOPAS ET Software Manual

1.5 Symbols and document conventions

1.5.1 Warning symbols

Symbol Significance

Hazard (general)

Hazard by voltage

Hazard in potentially explosive atmospheres

Hazard through explosive substances/substance mixtures

Hazard by ultraviolet radiation (UV light)

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

7

Page 8

1 ABOUT THIS DOCUMENT

1.5.2 Information symbols

Symbol Significance

Important technical information for this product

Important information on electric or electronic functions

1.5.3 Warning levels and signal words

DANGER:

Risk or hazardous situation which will result in severe personal injury or death.

WARNING :

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION:

Risk or hazardous situation which could result in less severe or minor injuries.

NOTICE:

Hazard which could result in property damage.

Note:

Hints

1.6 Data integrity

SICK AG uses standardized data interfaces such as standard IP technology, in its products.

The focus here is on the availability of the products and their properties.

SICK AG always assumes that the customer is responsible for the integrity and confidentiality of data and rights involved in connection with using the products.

In all cases, the customer is responsible for the implementation of safety measures suitable for the respective situation, e.g., network separation, firewalls, virus protection and

patch management.

8

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 9

2For your safety

2.1 Basic safety information

Read and always observe the safety and warning information in these Operating Instructions.

WARNING: Hazards thro ugh defe ctive devic e

The VICOTEC320 is likely to be unsafe when it:

● Shows visible damage on the outside.

● Has been penetrated by moisture.

● Has been stored or operated under irregular conditions.

When safe operation is no longer possible:

▸ Put the VICOTEC320 out of operation, separate all connectors from the

power supply and secure against unauthorized commissioning.

WARNING: Risk of explosions through explosive sample gas

▸ Do not use the VICOTEC320 to measure explosive, combustible or

flammable gases.

FOR YOUR SAFETY 2

WARNING: Explosion hazard in potentially explosive atmospheres

▸ Do not use the VICOTEC320 in potentially explosive atmospheres.

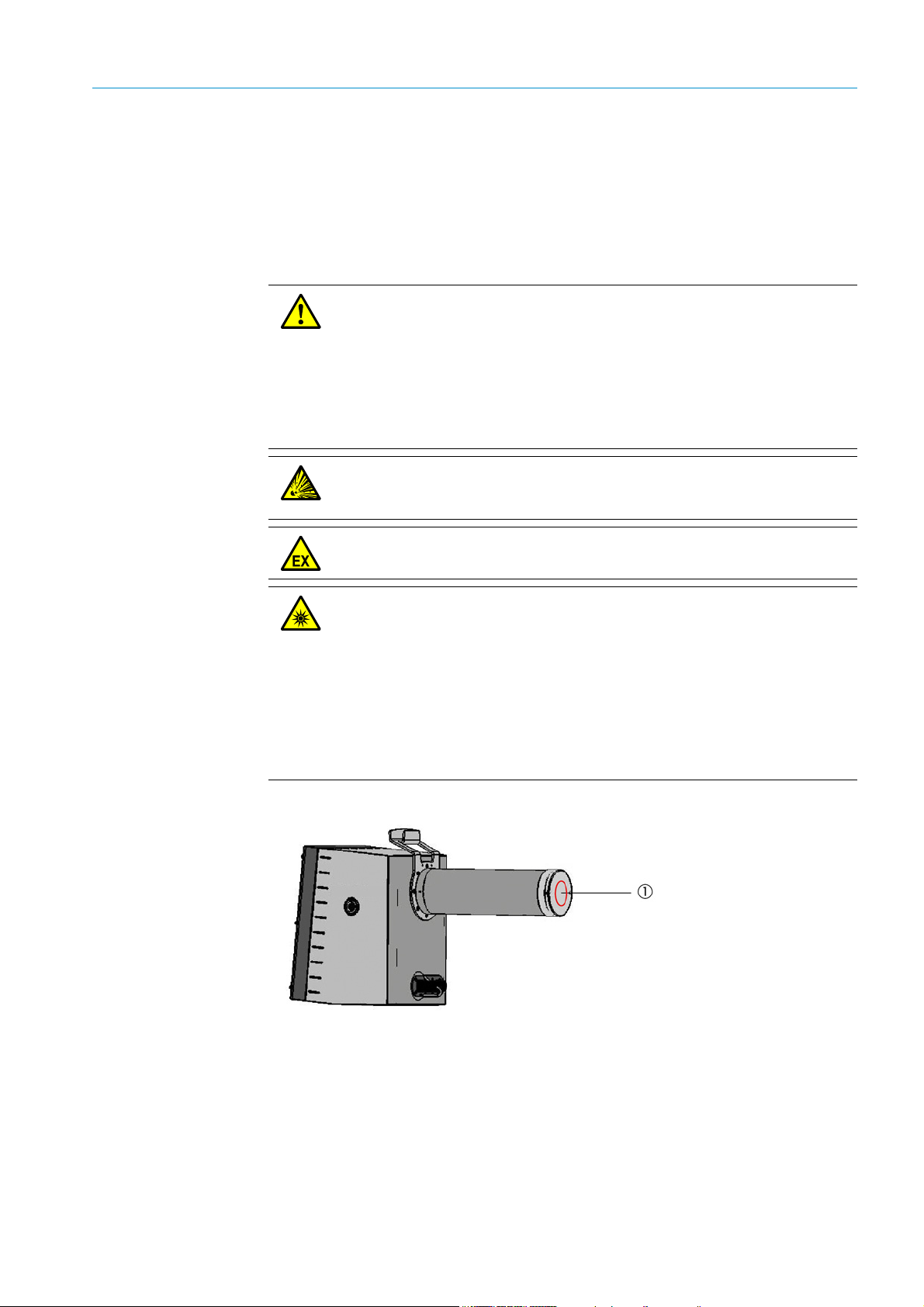

CAUTION: Eye injuries caused by improper handling of UV or blue light beams

The UV beam of the deuterium lamp or the blue light beam of the LED can

cause serious injuries through direct eye and skin contact. This results in the

following safety measures when working on the switched on device with access

to the light beam exit:

▸ Always wear UV protective goggles (in accordance with standard EN 170)

▸ The UV goggles do not provide protection against injuries caused by blue

light beams, therefore switch the LED off when working.

▸ Use the lamps only when they are perfectly safe. Operation is not allowed

when the lamp, supply lines or operating parts are visibly damaged.

Fig. 1: Sender/receiver unit

1 Light beam exit

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

9

Page 10

2 FOR YOUR SAFETY

2.2 Intended use

Devices of the VICOTEC320 series only serve continuous measurement of concentrations

of certain gases, visibility and the temperature in the atmosphere in road tunnels.

2.3 Responsibility of user

▸ Only put the VICOTEC320 into operation after reading the Operating Instructions.

▸ Observe all safety instructions.

▸ If there is something you do not understand: Contact SICK Customer Service.

Designated users

All operators of the VICOTEC320 should be specifically trained on this device, knowledgable

of relevant regulatio ns, and able to assess potential hazards related to its operation.

The VICOTEC320 may only be maintained by persons properly instructed on the tasks

assigned, possible risks and protective measures.

Operation

The device may only be operated by authorized persons who, based on their training on,

and knowledge of the specific device, as well as knowledge of the relevant regulations can

assess the tasks given and recognize the hazards involved.

Installing and maintaining

Skilled persons are required for installation and maintenance.

Please observe the information at the beginning of the respective Sections.

Correct use

▸ Only operate the VICOTEC320 according to the intended use (see “Intended use”,

page 10).

▸ Follow all specifications in these Operating Instructions and only operate the

VICOTEC320 as described in these Operating Instructions.

Contact your local SICK representative before performing any work described where the

information in these Operating Instructions is inadequate or capable of being misunderstood.

▸ Keep passwords in a separate, safe place and secure against unauthorized use.

▸ Pay attention to the prescribed maintenance work.

▸ Do not change any settings on or in the device and do not modify any components when

such changes are not described in these Operating Instructions or in documents referred

to in these Operating Instructions.

Special local requirements

▸ Observe the local laws, regulations and company internal operating instructions

applicable at the installation location.

Retention of documents

10

These Operating Instructions:

▸ Must be available for reference.

▸ Must be passed on to new owners.

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 11

3 Product description

3.1 Product identification

Product name: VICOTEC320

Manufacturer:

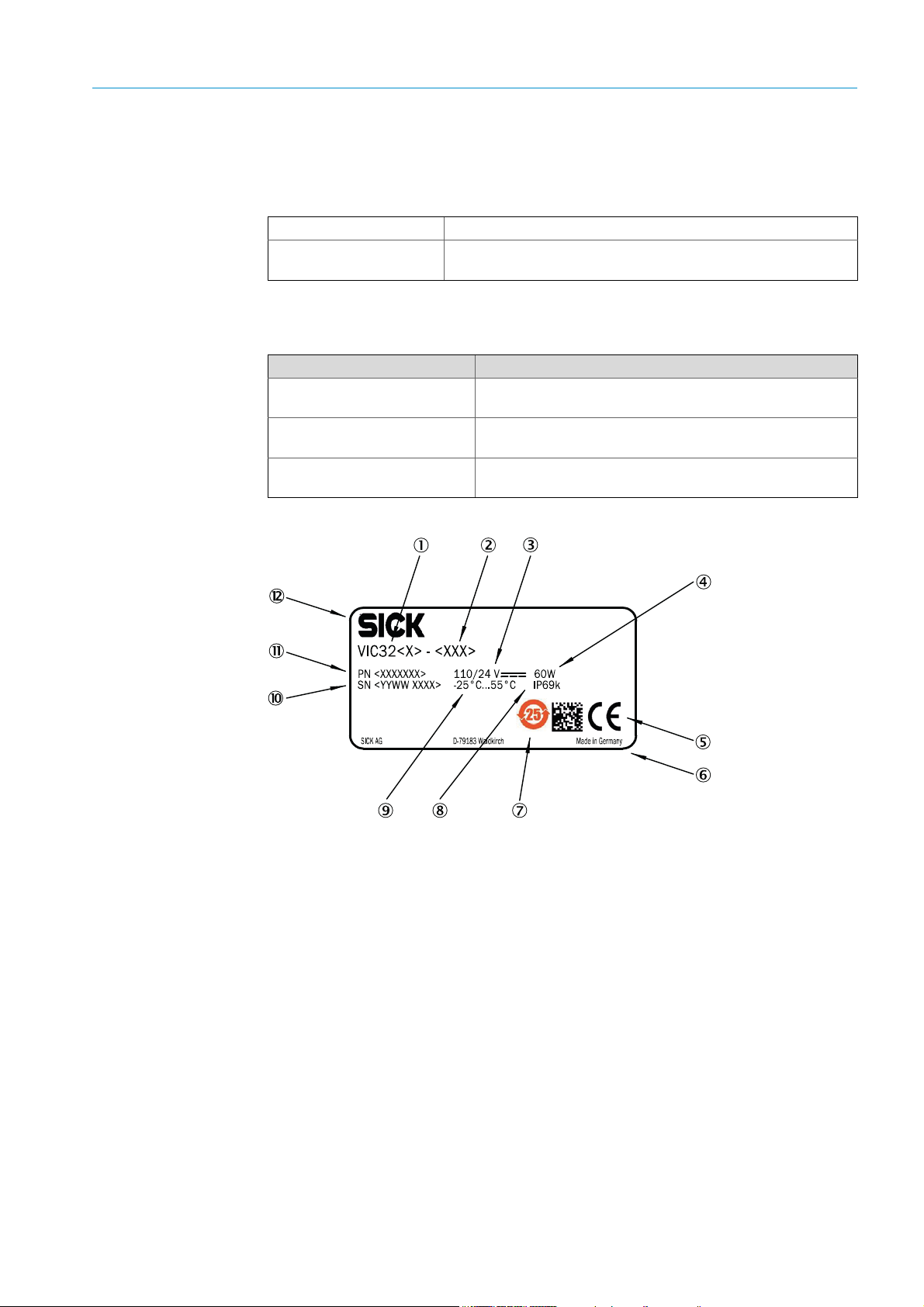

3.1.1 Type plate

The type plate is located at the following positions:

Device Type plate location

Sender/receiver unit

Reflector

Connection unit

PRODUCT DESCRIPTION 3

SICK AG

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Outside: Next to the connections

Inside: At the bottom of the left enclosure side

Outside: Next to the connections

Inside: At the middle of the right enclosure side

Outside: At the top of the right enclosure side

Inside: Next to the connections

Fig. 2: Type plate

1 Device name

2Type code

3Voltage supply

4 Max. power input according to IEC61010-1

5Bar code

6 CE label

7 China RoHS

8 Degree of protection (IP code)

9 Ambient temperature

10 Serial number

11 Material number

12 Company logo

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

11

Page 12

3 PRODUCT DESCRIPTION

3.2 Product features

● Fast, representative local measurement

● Very low detection limits for NO and NO

●

Automatic function monitoring and zero adjust

● Independent maintenance prompt when contaminated

● Very sturdy design: IP 69K, stainless steel 1.4571

● Compatible to assembly consoles and measuring path lengths of the VICOTEC 410 from

SICK

3.3 Device variants

The following device variants are available depending on the measuring task and the

application:

Variant Measured components

VICOTEC 321 Measurement of visibility and NO

VICOTEC 322 Measurement of visibility and NO

VICOTEC 323 Measurement of visibility, NO and NO

VICOTEC 325 Measurement of visibility, NO, NO2 and NOx (option: CO)

2

2

2

The device variants differ with respect to the following:

● Measurable components

● Connection unit interfaces

The sender/receiver unit and the reflector are available for the following measuring

distances:

● 10 m

The connection unit is available with the following interfaces:

● Analog/digital

● Ethernet

● The connection unit can contain an optional CO sensor (electrochemical cell)

3.4 Special features

● Operating hour meter for sender lamp and logbook function

● High-precision adjustment through automatic mirror tracking

● Integrated ambient temperature measurement

● Reflector, heated

● Communication via CAN System bus or Ethernet (optional)

12

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 13

3.5 Layout and function

PRODUCT DESCRIPTION 3

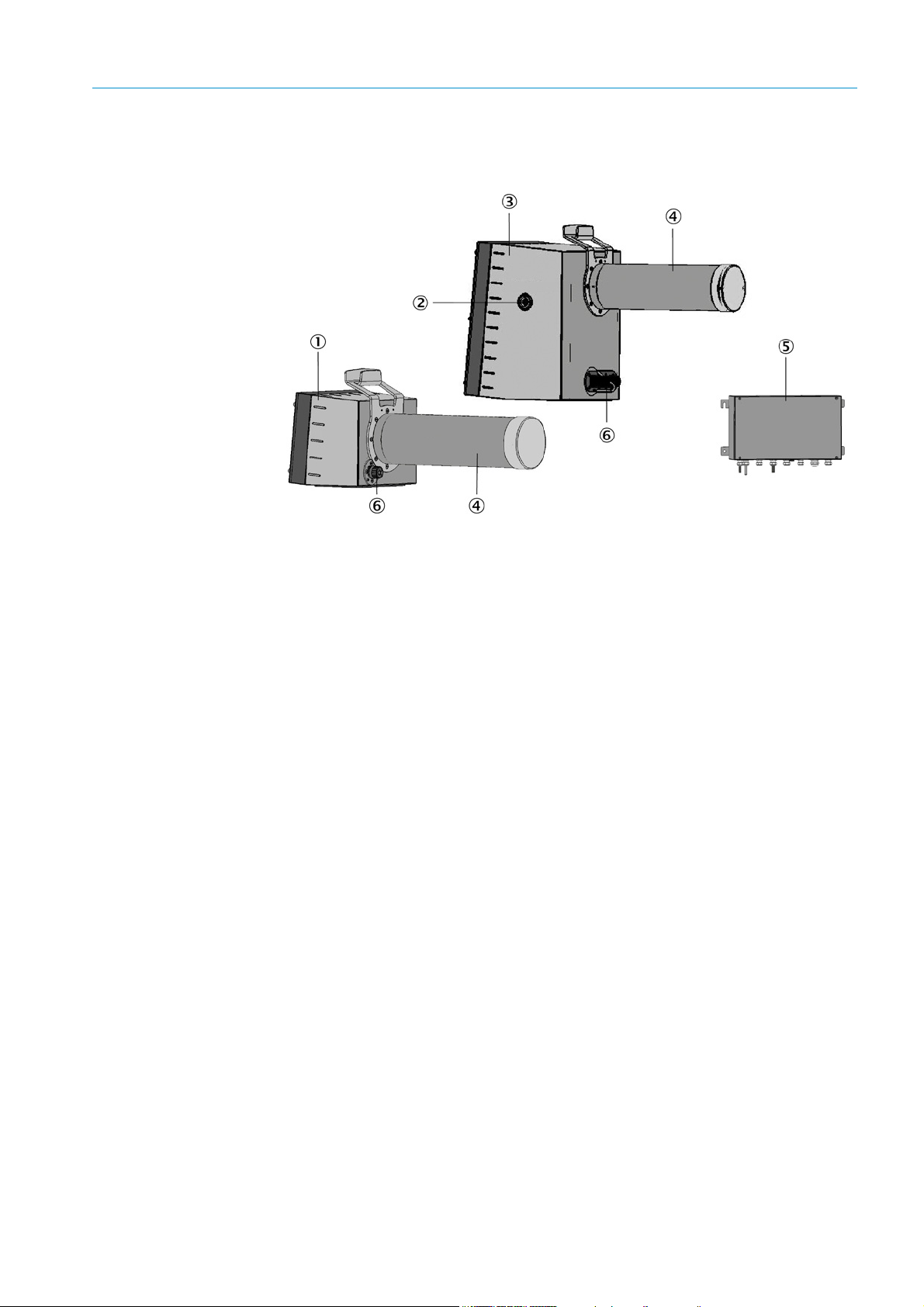

Fig. 3: Layout of measuring device components

1Reflector

2 LED matrix to signal automatic beam tracking

3 Sender/receiver unit

4 Dust protection tube

5 Connection unit

6 Plug connections

3.5.1 Functional principle

The VICOTEC320 is a sensor system for continuous measurement of NO, NO

(option) concentrations as well as visibility and temperature in road tunnels.

The following functional principles are used:

● NO, NO

● CO: Electrochemical cell

● Visibility: Transmission measurement with blue LED

: DOAS (Differential Optical Absorption Spectroscopy)

2

and CO

2

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

13

Page 14

4 PROJECT PLANNING

4 Project planning

4.1 Assembly project planning

4.1.1 Arrangement along the tunnel section

The number and distribution of measuring points depends on the ventilation system used.

Single factors are:

● Type of tunnel profile

● Section route

● Ventilation system design

● Number and arrangement of fans

● Regional regulations

Measuring point selection depends primarily on the following criteria:

● A combination of VICOTEC320 with VICOTEC 410 or VISIC100SF is recommended for

optimum measuring results.

● The recommended distance between visibility measurements depends on whether

these are also to be used for smoke detection:

– Without smoke detection: ≤ 400 m

– With smoke detection: ≤ 150 m

● We recommend VISIC50SF for smoke detection.

● An even spread along the tunnel length is recommended for semi and transverse

ventilation, with at least 2 measuring points per ventilation section.

● NO/NO

preferably at the tunnel exit in tunnels with one-way traffic.

● Two-way traffic can still arise in tunnels with one-way traffic. It is therefore recommended

to install at least 3 measuring points for visibility in tunnels with lengthwise ventilation:

one each about 150 m from the entrance and at least one in the middle of the tunnel.

● It is recommended to install additional fog sensors (e.g. VISIC620) near the tunnel

portals when there is a risk that fog can be sucked into the tunnel. Dust particles acting

as additional condensation crystals can strengthen the fog effect in the tunnel sections.

Fog moisture overlays visibility due to dust particles. Fog sensors serve to prevent fog

drifts being sucked into the tunnel. Alternately, visibility can be measured at the tunnel

portals using measuring devices (e.g. VISIC100SF or VICOTEC450) that heat the air

sucked in and therefore evaporate fog moisture.

● When the tunnel roadway curves, ensure that the measuring beam between single

sensors is not interrupted by the tunnel wall, fixtures or vehicles passing each other (see

see “Arrangement with special prerequisites”, page 16).

can be measured every 400 – 1000 m. Position the measuring points

2

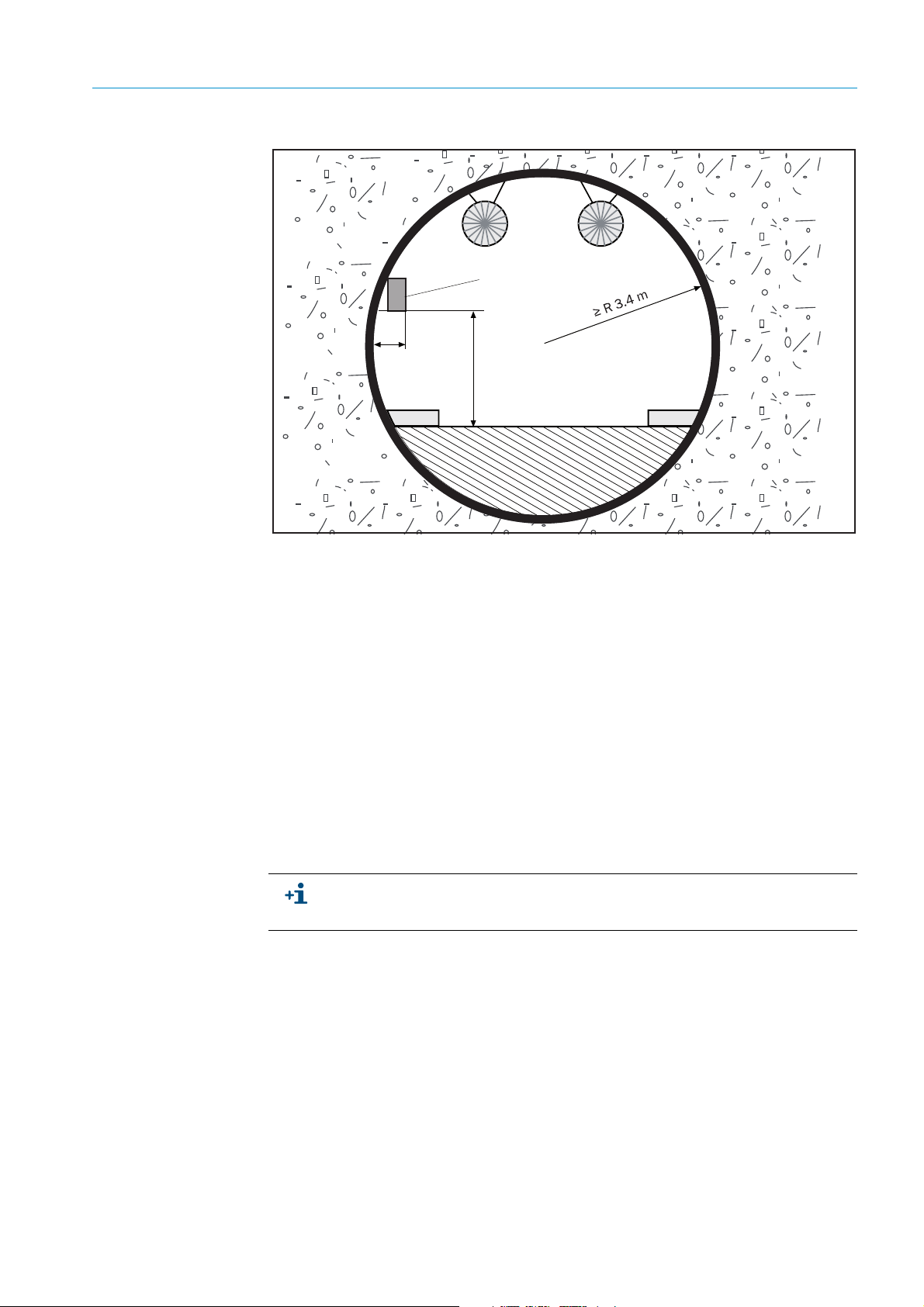

4.1.2 Arrangement in cross-section profile

Particle concentration distribution in a tunnel is generally very even across the profile

cross-section during traffic movement. Traffic flows and lengthwise flows through natural

ventilation and the piston effect of vehicle movement in separate tunnel sections for each

direction effect rapid swirling of the air in the tunnel. The turbulence behind vehicles

strengthens this effect.

The height is not critical due to excellent swirling. A fitting height between 2.8 and

4.5 meters is aimed at. The sensors contaminate faster when fitted lower and the

maintenance effort increases when the sensors are fitted higher.

14

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 15

PROJECT PLANNING 4

VICOTEC

320 sensor

2.8 … 4.5 m

400

Fig. 4: VICOTEC320 fitting height

Fitting location selection of the respective sensor pairs depends primarily on the following

criteria:

● Mount the sensors at a safe distance from traffic movement (see for example Section 2

of the German “Richtlinie für die Ausstattung und den Betrieb von Straßentunneln

RABT”, version 2006 (Regulations governing equipping and operating road tunnels)).

● Good access for maintenance and checking work must be ensured. Locate the sensors

in a protected recess when possible.

● Do not locate sensors in close vicinity to ventilators or in the fresh air flow from blowout

units so that the measured value records the effective concentration ratios.

● The measuring beam must run lengthwise between sensors and must not be hindered

by fixtures or vehicles passing each other. Fixtures that shine (e.g. emergency exit signs)

should be at least 1 m from the optical axis.

● No reflecting paint should be on the wall between sensors.

● Maintain a distance of 10

● Plan sufficient clearance to be able to flap or remove the enclosure cover.

Measured values of gases are kept constant at first when the light beams are

interrupted. A malfunction message is sent to the evaluation unit when interruptions

last lo nger than two minutes.

±

0.1

m between both sensors.

Fitting options:

● Both sensors on a wall in a recess (recommended).

● Both sensors on a wall above the side strip; requires safety measures for maintenance

work in cramped conditions.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

15

Page 16

4 PROJECT PLANNING

A

R

1

A

R

2

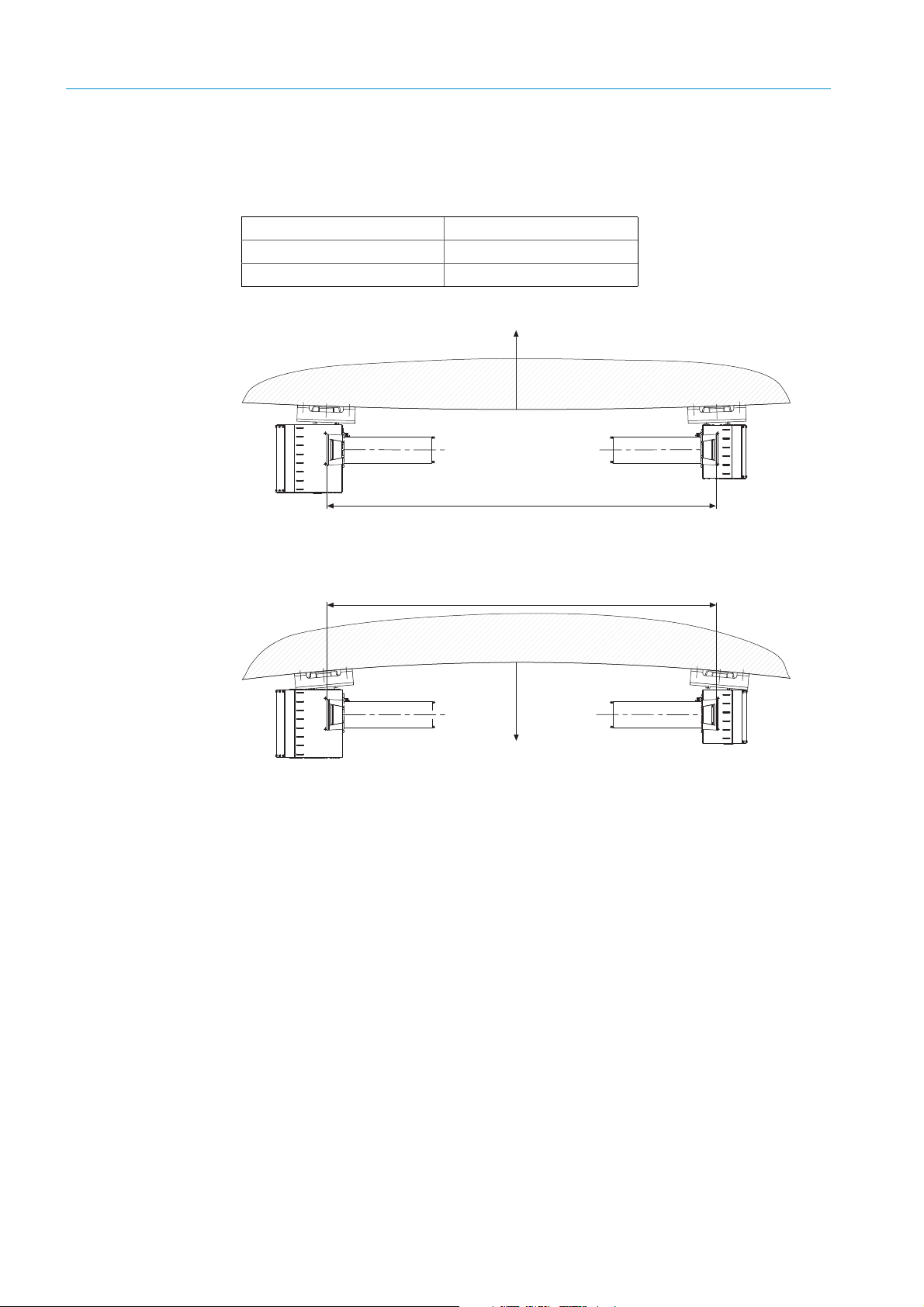

4.1.3 Arrangement with special prerequisites

Tunnel curvature

The sensors can be used with tunnel curvatures up to the following curve radiuses:

Measuring section (A) 10 m

Inner radius (R

Outer radius (R

) Min. 58 m

1

) Min. 147 m

2

Fig. 5: Fitting sensors on the inner curve wall

Fig. 6: Fitting sensors on the outer curve wall

Tunnel with sound insulation wall

Provide appropriate assembly bases onsite when fitting sensors on a tunnel wall with

sound insulation.

The assembly bases must provide a firm base suitable for reliable sensor fitting.

16

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 17

PROJECT PLANNING 4

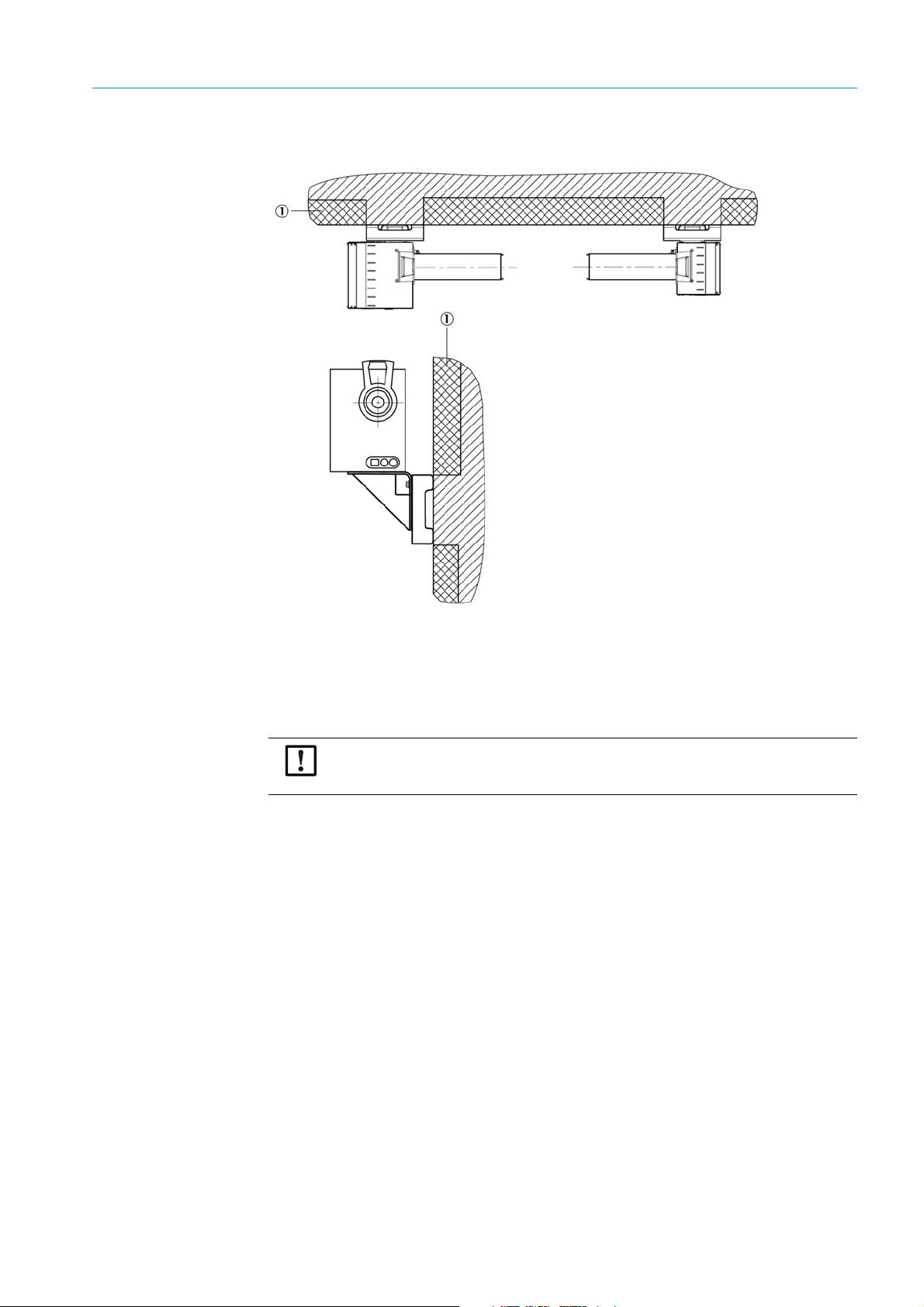

Fig. 7: Fitting sensors with sound insulation

1 Sound insulation

4.2 Electrical installation project planning

Observe the relevant safety regulations during all installation work. Take suitable

protective measures against all possible local risks or those arising in connection with

the system (see “For your safety”, page 9).

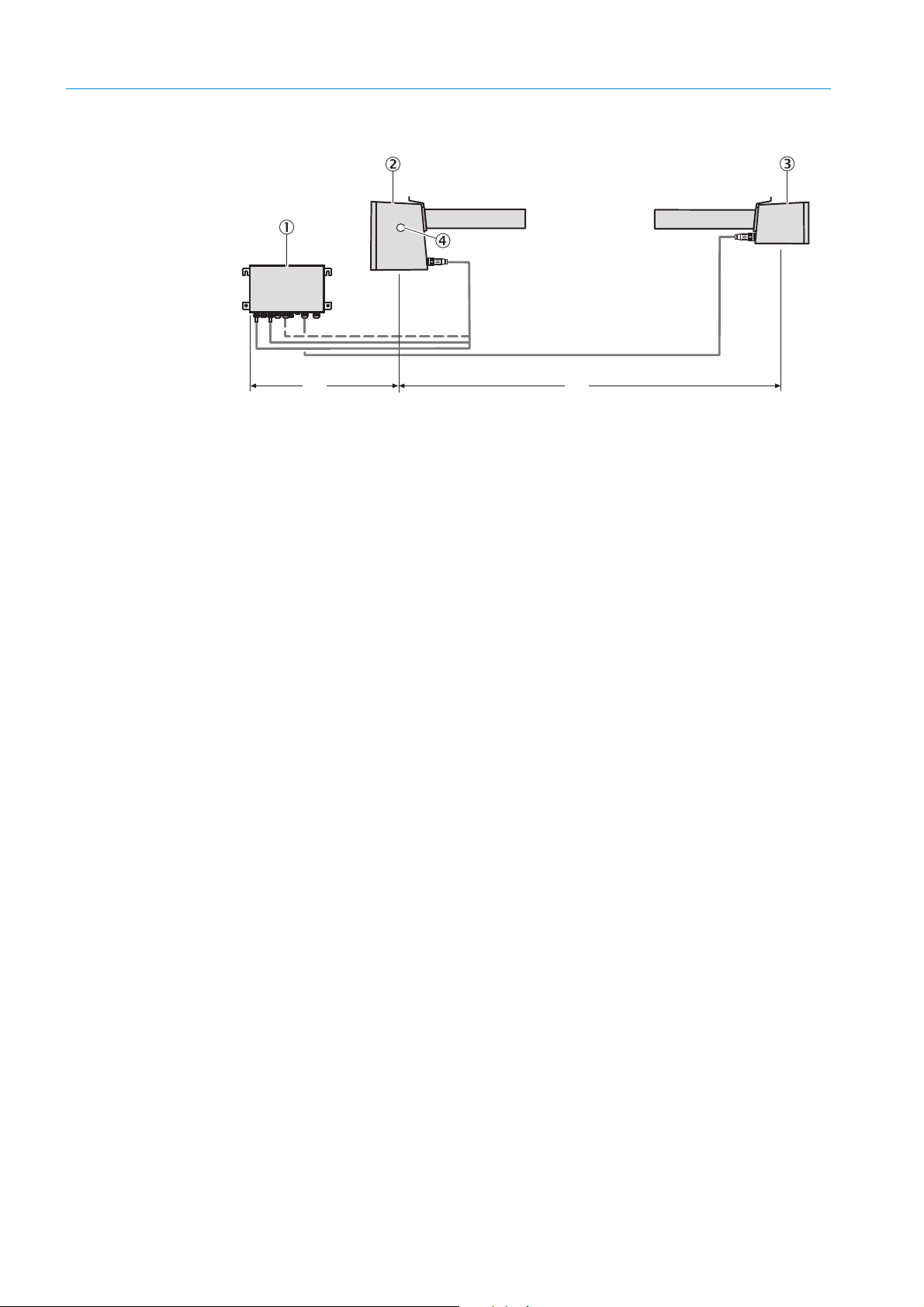

● Sender/receiver unit (2) must always be fitted on the left (see Fig. “Sensor arrange-

ment”, page 18), so that visor (4) is accessible.

● Position connection unit (1) so that it can be connected to the sender/receiver unit with

a 1 m long cable.

● It must be possible to separate every device singly from the power supply system, e.g.

using a switch or circuit breaker.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

17

Page 18

4 PROJECT PLANNING

Fig. 8: Sensor arrangement

1 Connection unit

2 Sender/receiver unit

3Reflector

4Visor

A Measuring path (10

B Max. 0.7 m (cable leng th max. 1 m)

B A

±0.1

m)

18

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 19

5 Installation

5.1 Tools required

Apart from standard tools (such as drill, water level, tape measure), you also need the

following tools for the installation:

–8 mm drill bit

–15 mm drill bit

–Blowout pump for dowel holes

–18 mm Allen key

–19 mm Allen key

–Jaw wrench, 22 mm

–Torque wrench

–Rubber or plastic hammer

– Two laser adjustment units (see “Accessories”, page 68)

5.2 Material required

– 2 stainless steel assembly consoles incl. fixing accessories

– Connection lines (see “Connection lines”, page 26)

INSTALLATION 5

5.3 Preparing the installation location

CAUTION: Accident risk through inadequate fastening of the device

▸ Consider the weight of the device when selecting fastenings.

▸ Check the load capability/state of the wall/rack on which the device is to be fitted.

Preparatory actions

▸ Secure the place of work

▸ Provide adequate lighting and power

▸ Provide a jack lift or stable ladder with clearance to wall

5.4 Transport

Only use the packing provided by SICK to transport sensors. Warranty claims are void

when this is not observed.

The packing can be obtained from SICK free of charge when required.

5.5 Scope of delivery

Included in scope of delivery:

● Sender/receiver unit (incl. screws for fastening on assembly console)

● Reflector (incl. screws for fastening on assembly console)

● Connection unit (incl. dowels and screws for wall fitting)

● Connection lines from the connection unit to the sender/receiver unit and to the

reflector

● Protective covers

Keep protective covers. Use protective covers when the equipment is put out of

operation for a short time (e.g. during tunnel cleaning).

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

19

Page 20

5 INSTALLATION

Not included in scope of delivery:

● Stainless steel assembly consoles for the sensors

5.6 Assembly

Assembly work must only be carried out by skilled persons familiar with the assembly work.

5.6.1 Fitting the assembly consoles

The assembly consoles comprise 3 parts:

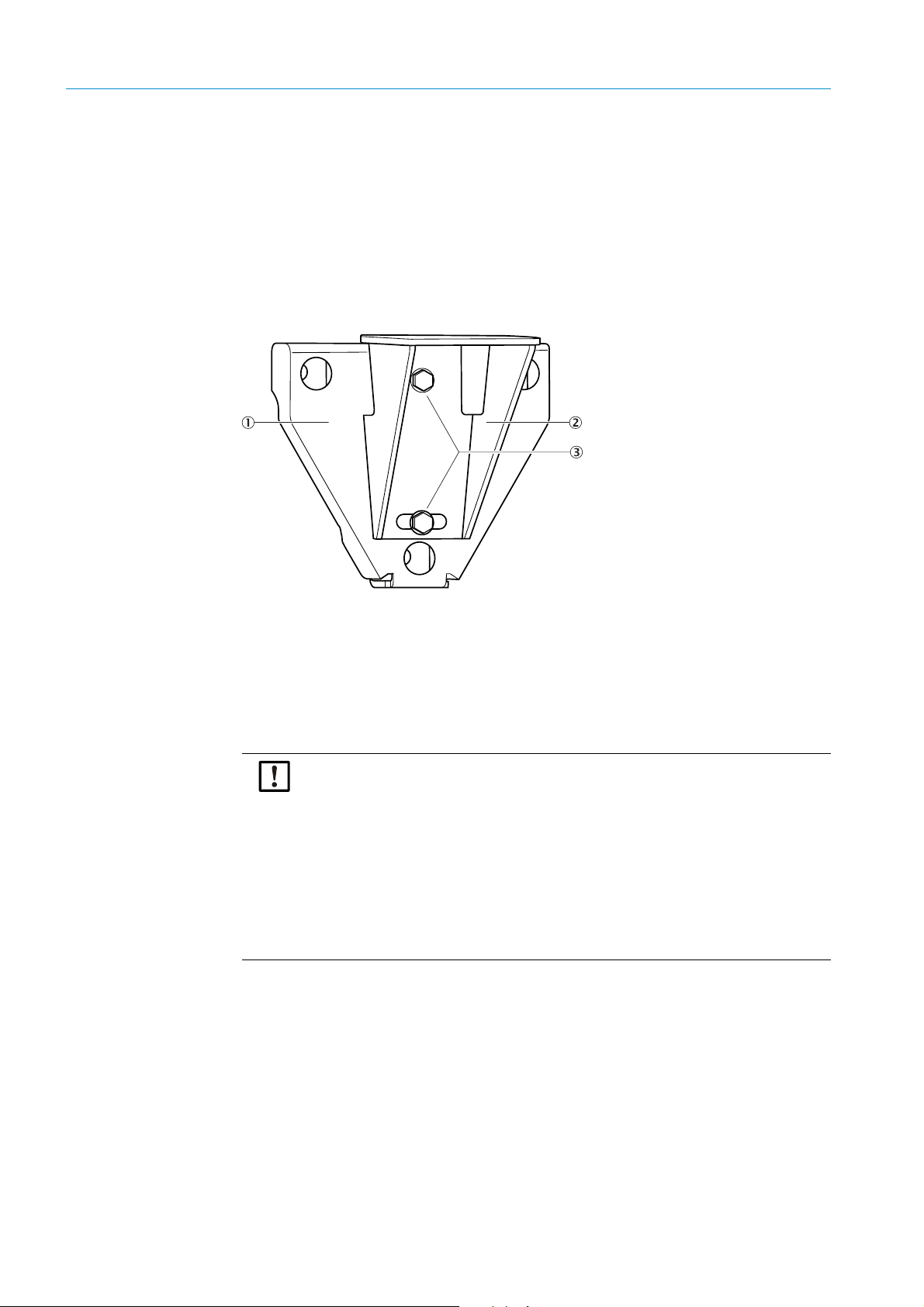

Fig. 9: Assembly console

1 Wall holder for wall fitting

2 Angle bracket to fasten the sensor

3Angle bracket screws

Two angle bracket screws fasten the wall holder and the assembly console together. The

angle bracket can be swiveled up to ±7.5° to compensate any assembly unevenness.

Observe the following points during assembly:

▸ Observe local valid safety measures.

▸ Only use high-strength and absolutely non-corrosive fastening material made of

stainless steel because the tunnel atmosphere is highly corrosive.

▸ Ensure there is enough space to remove the tube and device cover.

▸ Keep the length of the measuring section as exact as possible. Record small

deviations in the Assembly protocol.

▸ Mount both assembly consoles at the same height. Height differences in the optical

axis can be compensated later by swiveling the angle bracket.

▸ Align both assembly consoles at the same tilt angle to the tunnel wall. Different tilt

positions to the tunnel profile make the following sensor alignment difficult. Insert

washers under the wall holder when necessary.

Procedure

1 Determine the installation location for the assembly consoles according to the project

planning.

2 Drill the wall holder openings according to the Drilling plan, see see Fig. “Wall holder

assembly drilling plan”, page 21.

3 Insert dowels or wall ties according to the manufacturer's assembly specifications (walls

must be made of at least C20/25 to C25/30 concrete).

20

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 21

INSTALLATION 5

105105

210210

A

182

182

15

0

15

0

15

0

15

0

15

0

15 x 50

+2

0

15

0

4 Screw the wall holder on and tighten the screws with 70 Nm according to the

manufacturer's assembly specifications, use a torque wrench as necessary.

5 Screw the consoles on provisionally at first.

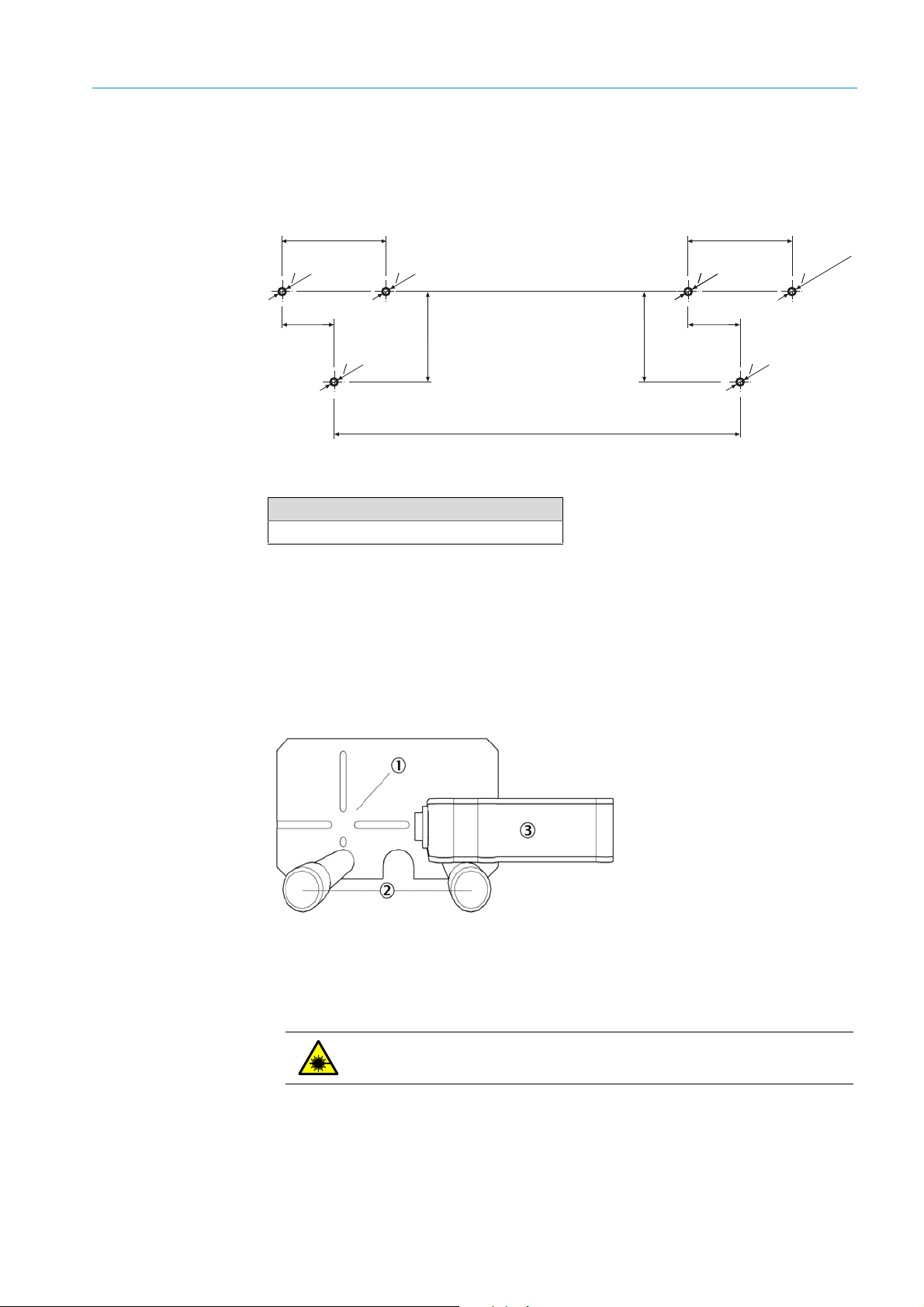

Fig. 10: Wall holder assembly drilling plan

Tolerances for measuring path A

±0.1

m

10

5.6.2 Fitting the VICOTEC320 sensors

1 Position the sender/receiver unit on the left assembly console and screw it on lightly

with both the retaining screws included in the delivery.

2 Position the reflector on the right assembly console and screw it on lightly with both the

retaining screws included in the delivery.

3 Screw a laser adjustment unit on each sensor above the tube using both knurled-head

screws.

Fig. 11: Laser adjustment unit

1 Crosshair

2Knurled-head screws

3 Adjustment laser

WARNING: Laser class 2

▸ Laser radiation – do not look in the beam.

4 Switch on the laser adjustment unit on the reflector.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

21

Page 22

5 INSTALLATION

5 Align the sensor horizontally so that the laser beam strikes the vertical line of the cross-

hair of the other laser adjustment unit see Fig. “Laser adjustment unit”, page 21). To do

this, tap very lightly against the front lower edge of the sensor enclosure with a rubber

hammer (see Fig. “Horizontal sensor alignment”, page 22).

Fig. 12: Horizontal sensor alignment

1 Retaining screws

2Angle bracket screws

6 Tighten both retaining screws of the sensor with 45 Nm, use a torque wrench as

necessary.

7 Slightly loosen the angle bracket screws.

8 Align the sensor vertically so that the laser beam strikes the horizontal line of the cross

hair of the other laser adjustment unit (see Fig. “Laser adjustment unit”, page 21). To do

this, tap very lightly against the front lower edge of the angle bracket with a rubber

hammer (see Fig. “Vertical sensor alignment”, page 22).

22

Fig. 13: Vertical sensor alignment

9 Tighten the angle bracket, use a torque wrench as necessary.

10 Check again whether the laser beam strikes the crosshair and correct as necessary.

11 Switch the laser adjustment unit off.

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 23

12 Repeat steps 5 to 11 on the opposite sensor and laser adjustment unit.

105105

210210

A

182

182

15

0

15

0

15

0

15

0

15

0

15 x 50

+2

0

15

0

13 Unscrew and remove the laser adjustment unit.

5.6.3 Fitting the connection unit

Position the connection unit so that it can be connected to the sender/receiver unit with

the 1 m long cables.

1 Determine the installation location for the connection unit according to the project

planning.

2 Drill the openings according to the Drilling plan, see Fig. “Connection unit assembly drill-

ing plan”, page 23.

3 Insert dowels or wall ties according to the manufacturer's assembly specifications (walls

must be made of at least C20/25 to C25/30 concrete).

4 Screw the connection unit on.

INSTALLATION 5

Fig. 14: Connection unit assembly drilling plan

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

23

Page 24

5 INSTALLATION

5.7 Electrical installation

WARNING : Hazard by voltage.

▸ Only allow an authorized electrician to work on the electric system.

▸ Observe the relevant safety regulations during all installation work.

▸ Take suitable protective measures against local risks and those arising from the

system.

WARNING: Endangerment of electrical safety during installation and

maintenance work when the power supply is not switched off

An electrical accident can occur during installation and maintenance work when the

power supply to the device or lines is not switched off using a power isolating switch/

circuit breaker.

▸ Before starting the work on the device, ensure the power supply can be switched off

using a power isolating switch/circuit breaker in accordance with DIN EN 61010.

▸ Make sure the power isolating switch is easily accessible.

▸ An additional disconnecting device is mandatory when the power disconnector

switch cannot be accessed or only with difficulty after installation of the device

connection.

▸ After completion of the work or for test purposes, the power supply may only be

activated again by authorized personnel complying with the safety regulations.

WARNING: Endangerment of electrical safety through power cable with

incorrect rating

Electrical accidents can occur when the specifications for replacement of a removable

power cable have not been adequately observed.

▸ Always observe the exact specifications in the Operating Instructions (Technical data

Section) when replacing a removable power cable.

5.7.1 Electrical protection

– Insulation: Class of protection 1 in accordance with EN 61140

– Insulation coordination: Overvoltage category II in accordance with EN61010-1

– Contamination: Degree of contamination II in accordance with DIN EN 61010-1

CAUTION: Device damage through incorrect or non-existing grounding

During installation and maintenance work, it must be ensured that the protective

grounding to the devices and/or lines involved is effective in accordance with

EN 61010-1.

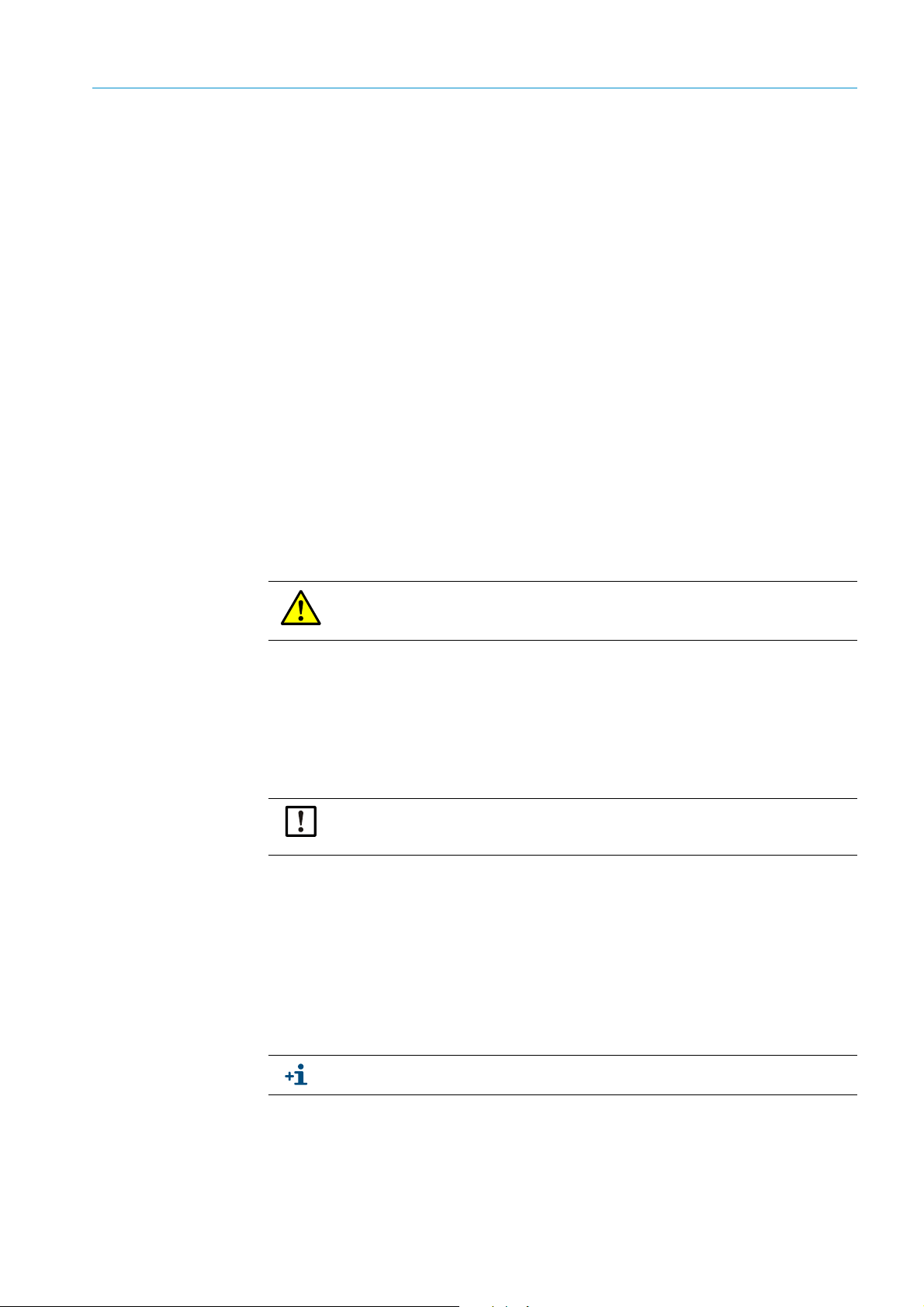

Note: Responsibility for system safety

The person setting the system up is responsible for the safety of the system in which the

device is integrated.

24

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 25

5.7.2 Connecting the sensors to the connection unit

1 Plug the connection lines that are mounted firmly on the connection unit in the

corresponding sockets of the sender/receiver unit.

2 Connect the connection line to the reflector with the connection unit:

Observe the wiring diagram on the rear of the cover.

a) Open the connection unit.

b) Unscrew M screw fitting for W3 (1).

INSTALLATION 5

c) Pull the connection line through the M screw fitting and connect to the W3

connection (2).

d) 35

e) Tighten the M screw fitting tight with a jaw wrench.

3 Plug the connection line into the reflector.

4 Fasten the connection lines to the tunnel wall.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

25

Page 26

5 INSTALLATION

5.7.3 Connection unit cabling

Connection lines

The following connection lines can be used:

For Line/type Max. length Cross-section

Energy supply:

115/230 V AC; 50/60 Hz

Digital input A2Y(L)2Y

Relay outputs A2Y(L)2Y

Etherne t

Analog outputs:

0…20 mA

–Category5 copper

line according to

ANSI/TIA -568

–Fiber optic cable

Screened and twisted

in pairs

Dependent on cable

resistance

Dependent on cable

resistance

Dependent on cable

resistance

– 100 m

– Up to about 5 km

according to type

Dependent on cable

resistance

3 x 1.5 mm

2 x 2 x 0.75 mm

4 x 2 x 0.75 mm

4 x 2 x 0.75 mm

2

2

2

2

Warranty claims are void when you use cables not released by SICK for use with the

VICOTEC320 (see “Connection lines”, page 26).

Cabling of voltage supply

Set the power voltage for the connection unit to 115 V or 230 V before connecting the unit

to the power supply system.

Use slide switch (1) in the connection unit to the correct voltage.

26

Fig. 15: Slide switch and voltage supply

1 Slide switch for voltage selection

2 Terminals for power supply

▸ Connect voltage supply according to terminal designation (L1/N/PE).

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 27

Fig. 16: Connection options for peripherals

1 Sender/receiver unit connection (2x)

2 Reflector connection

3 Ethernet (when used)

4 Input and/or output signals (when used)

5Voltage supply

INSTALLATION 5

Input/output cabling for analog/digital variants

The CAN bus terminator must be set to “ON” (LED must be on: see Fig. “Location of

LEDs in the connection unit for the analog/digital variant”, page 30)

The inputs and outputs of the connection unit are assigned as follows:

Input or output Assignment

Analog

Output 1 Visibility

Output 2 Temperature

Output 3 NO

Output 4 NO

Output 5 CO

Output 6 NO

Digital

Relay 1

Relay 2

Relay 3

2

x

Operation/fault for NO, NO

● Operation: Relay is closed

● Fault: Relay is open

, visibility

2

Maintenance request signal

● No maintenance request: Relay is open

● Maintenance request (e.g.: contamination): Relay is closed

Measuring operation signal

● Measuring operation: Relay is open

● Not in measuring operation (e.g. during maintenance, adjust-

ment etc.): Relay is closed

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

27

Page 28

5 INSTALLATION

Input or output Assignment

Operation/fault for CO (option)

Relay 4

● Operation: Relay is open

● Fault: Relay is closed

Input 1 Maintenance mode (measured values frozen)

I Analog Out

State

Analog

Output

0...20mA

Load

500Ω

12

Shield

AO1 AO2

- -

11 21

12 22

13 23

14 24

11 21

12 22

13 23

14 24

State

Analog

Output

0...20mA

Load

500Ω

12

12

34

Shield

AO1 AO2

- -

DO1 DO2

DO3 DO4

11 21

12 22

13 23

14 24

State

Digital

Output

Signal

Relais

State

Digital

Input

1

3

DI1 DI2

DI3 DI4

11 21

12 22

13 23

14 24

II Analog Out

2

4

III Digital Out

Operation/Fault

Maintenance call

Not in measuring

mode

IV Digital In

Maintenance

Visibility +

Visibility -

Temperature +

Temperature -

Not assigned

Not used

Not used

Not used

NO +

NO -

NO2 +

NO2 -

I - 11

I - 12

I - 21

I - 23

II - 11

II - 12

II - 21

II - 23

III - 11

III - 12

III - 22

III - 21

III - 14

III - 13

III - 23

III - 24

IV - 11

IV - 12

IV - 21

IV - 22

IV - 13

IV - 14

IV - 21

IV - 22

28

internal

I II III IV

external

Fig. 17: I/O modules and circuit diagram of analog modules without CO and NOx-inlets/outlets

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 29

INSTALLATION 5

Fig. 18: I/O modules and circuit diagram of analog modules with CO and NOx inlets/outlets

Module LED Significance

Digital out Green Active

Digital in Green Contact closed

Analog out Green Actual current value = rated current value

≤

Analog in

Green

Off

0mA

I

≥ 22 mA

on

Ion < 22 mA

▸ Connect the power supply.

Checking cabling

Correct cabling can be checked as follows (see Fig. “Location of LEDs in the connection

unit for the analog/digital variant”, page 30):

● The gateway LEDs are green (State, CAN, I/O).

● The error LED on the gateway is off.

● The 120 V LED and the 24 V LED are green.

● The status LEDs of the I/O module blink green.

● The reflector heating LED is green.

● The alignment LEDs on the sender/receiver unit flash sequentially.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

29

Page 30

5 INSTALLATION

Fig. 19: Location of LEDs in the connection unit for the analog/digital variant

1 Gateway state Green LED blinks in operation

Red LED on: CAN bus is connected but not initialized

2 I/O module state LED1 blinks in I²C bus cycle pulse

LED2 blinks in data transfer cycle pulse

3 Gateway CAN LEDs blink: Data transfer via CAN bus

LEDs on: No CAN bus connected

4 Gateway I/O LED1 blinks in I²C bus cycle pulse

LED2 blinks in data transfer cycle pulse

5 Gateway error LED on: No I/O module found on gateway

or one or more modules failed during operation

6120 V

724 V

8 Reflector heating 24 V

9 CAN bus connection LED is green: CAN bus terminator is activated.

30

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 31

Connecting the Ethernet cable for Ethernet variant

INSTALLATION 5

Fig. 20: Ethernet connection

▸ Lead the Ethernet cable through the nearest cable gland (see Fig. “Connection options

for peripherals”, page 27) and plug into switch (1).

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

31

Page 32

6 COMMISSIONING

6 Commissioning

6.1 Necessary technical knowledge for commissioning

The commissioning must only be performed by authorized technicians and is described in

the Service Manual.

Wait two hours after commissioning until the system has heated up. It has then reached

a thermal balance and delivers measured values within the tolerance band.

6.2 Commissioning checklist

The up-to-date Operating Instructions must be available.

Please request the up-to-date commissioning checklist from SICK Service.

First enter the customer data.

6.2.1 Device data

Ente r the devic e data here.

6.2.2 Tunnel data

– Serial number: See type plate or SOPAS.

– Specify kind and type of process optics.

Enter location and measuring point here.

SOPAS supports the value of the active measuring path.

32

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 33

6.3 Alignment

COMMISSIONING 6

The mechanical alignment of the measuring device and the reflector must have already

been performed by using the laser adjustment units.

Fig. 21: Menu Adjustment / Alignment.

1 Open “Adjustment/Alignment” in the SOPAS menu tree.

Fine adjustment of horizontal alignment

1 Slightly loosen the retaining screws of the measuring device on the assembly console so

that the device can be moved.

2 Using a small plastic or rubber hammer, very carefully tap the position shown below (see

Fig. “Vertical sensor alignment”, page 34).

3 Tap until the VIS X value on the display reaches <0.15.

4 Tighten the retaining screws again.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

33

Page 34

6 COMMISSIONING

Fig. 22: Horizontal sensor alignment

1 Retaining screws

2Angle bracket screws

Fine adjustment of vertical alignment

1 Slightly loosen the angle bracket screws.

2 Using a small plastic or rubber hammer, very carefully tap the position shown below (see

Fig. “Vertical sensor alignment”, page 34).

3 Tap until the VIS Y value on the display reaches <0.15.

4 Tighten the angle bracket screws again.

Fig. 23: Vertical sensor alignment

34

The LED grid in the visor of the sender/receiver unit shows the position of the light

beam in relation to the reflector center. After fine adjustment, one of the 3 x 3 LEDs in

the center of the grid should light.

If a LED outside the 3 x 3 LEDs in the center lights, fine adjustment must be performed

again.

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 35

6.4 Spectral analysis

Fig. 24: Menu Parameter/Spectral analysis

COMMISSIONING 6

1 Open “Parameter/Spectral analysis” in the SOPAS menu tree.

2 Enter the installation altitude (above sea level).

6.5 Visibility and smoke detection

Fig. 25: Menu Parameter/Visibility

1 Open “Parameter/Visibility” in the SOPAS menu tree.

>>>

Default setting: Smoke detection not activated.

Measured values of gases are kept constant at first when the light beams are

interrupted. A malfunction message is sent to the evaluation unit when interruptions

last lo nger than two minutes.

2 To activate smoke detection: Set checkmark.

A value above 22 mA is transmitted at the analog output when the light beams are

interrupted (quick drop of visibility). No malfunction message is output.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

35

Page 36

6 COMMISSIONING

6.6 Signal outputs

Fig. 26: Menu Parameter\Signal output

1 Open “Parameter/Signal output” in the SOPAS menu tree.

2 Change the predefined setting when required.

6.7 Saving data

Fig. 27: SOPAS main window

1 Open “Project/Save as” in the SOPAS main window.

2 Specify project name and storage location.

36

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 37

7Operation

7.1 Operating the VICOTEC320

The VICOTEC320 runs automatically after commissioning and does not require further

operator intervention. You can however use the SOPAS ET software to change the

configuration or display measured values.

OPERATION 7

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

37

Page 38

8 USING THE VICOTEC320

8Using the VICOTEC320

8.1 Software SOPAS ET

The SOPAS ET software serves to set the VICOTEC320 parameters. The parameter records

can be stored as a Project file as well as archived on the PC. Measured values can also be

read out.

8.1.1 Functions (overview)

The Online Help of the SOPAS ET software (Help menu) describes the general function of

the software and how to use it.

● Menu language selection

● Setting up communication with the VICOTEC320

● Password protected configuration for different operator levels

● Output current measured values

● System diagnostics

The password can be found in the Annex, see “Password”, page 75.

8.1.2 Installing the SOPAS ET software

1 Start the PC and insert the Installation CD.

2 Call setup.exe directly from the CD when installation does not start automatically.

3 Follow the operating instructions to complete installation.

8.2 Using SOPAS ET

The SOPAS ET interface is described in the SOPAS ET Manual.

See menu: Help/SOPAS ET Manual.

8.2.1 Creating a connection

Connect data interfaces

1 Ensure the supply voltage of the VICOTEC320 is switched on.

2 Switch the PC on.

3 Make sure the WLAN is switched off.

4 Connect PC (Ethernet interface) and VICOTEC320 via Ethernet line.

5 Insert the network cable.

6 Wait until the laptop has initialized the Ethernet interface (approx. 1 min.)

Start the SOPAS ET software

1 Start the software.

>>>

The device should be found automatically and added to the project.

38

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 39

2 The IP address of the device must be adapted.

a) Click “Edit IP address”.

>>>

The TCP/IP settings window opens.

USING THE VICOTEC320 8

b) Record the current IP settings (if the device was logged off the customer network and

then has to be logged in again).

c) Select the [Automatic] button.

>>>

A corresponding IP address is displayed.

d) Confirm with [OK].

>>>

The IP address is sent to the device.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

39

Page 40

8 USING THE VICOTEC320

3 Install device driver.

a) Click “Install device driver”.

b) Select the device driver source. Recommended: Select “Device upload”.

c) Confirm with [OK].

>>>

Driver is loaded from the device.

Setting device parameters

1 Double-click “Offline”.

>>>

The Go online window opens.

2 Select the “Read parameters” function.

3 Double-click the header

>>>

The device window opens.

40

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 41

Login to the device

1 Click “Login” at the top of the menu bar.

>>>

The login window opens.

2 Enter the desired user level “Authorized operator”.

3 Enter password (see “Password”, page 75).

4 Click [Login].

Integration in customer network

The sensor IP address of the device must be adapted to the customer network when

the VICOTEC320 is integrated in a network or connected to a customer WLAN

module.

1 Close the device window.

In the SOPAS main window

USING THE VICOTEC320 8

2 Click the button next to the IP address [pen].

>>>

The TCP/IP settings window opens.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

41

Page 42

8 USING THE VICOTEC320

3 Enter the network information (to be provided by the customer) for the device in section

“Use the following IP settings”.

4 Confirm with [OK].

>>>

The Change TCP/IP settings window opens.

5 Confirm with [Yes].

>>>

The Change the TCP/IP settings of the device ... window opens.

6 Confirm with [Yes].

>>>

The settings are transferred to the device.

>>>

The Device not found window opens.

7 Confirm with [OK].

8 Connect the device with the customer network.

42

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 43

USING THE VICOTEC320 8

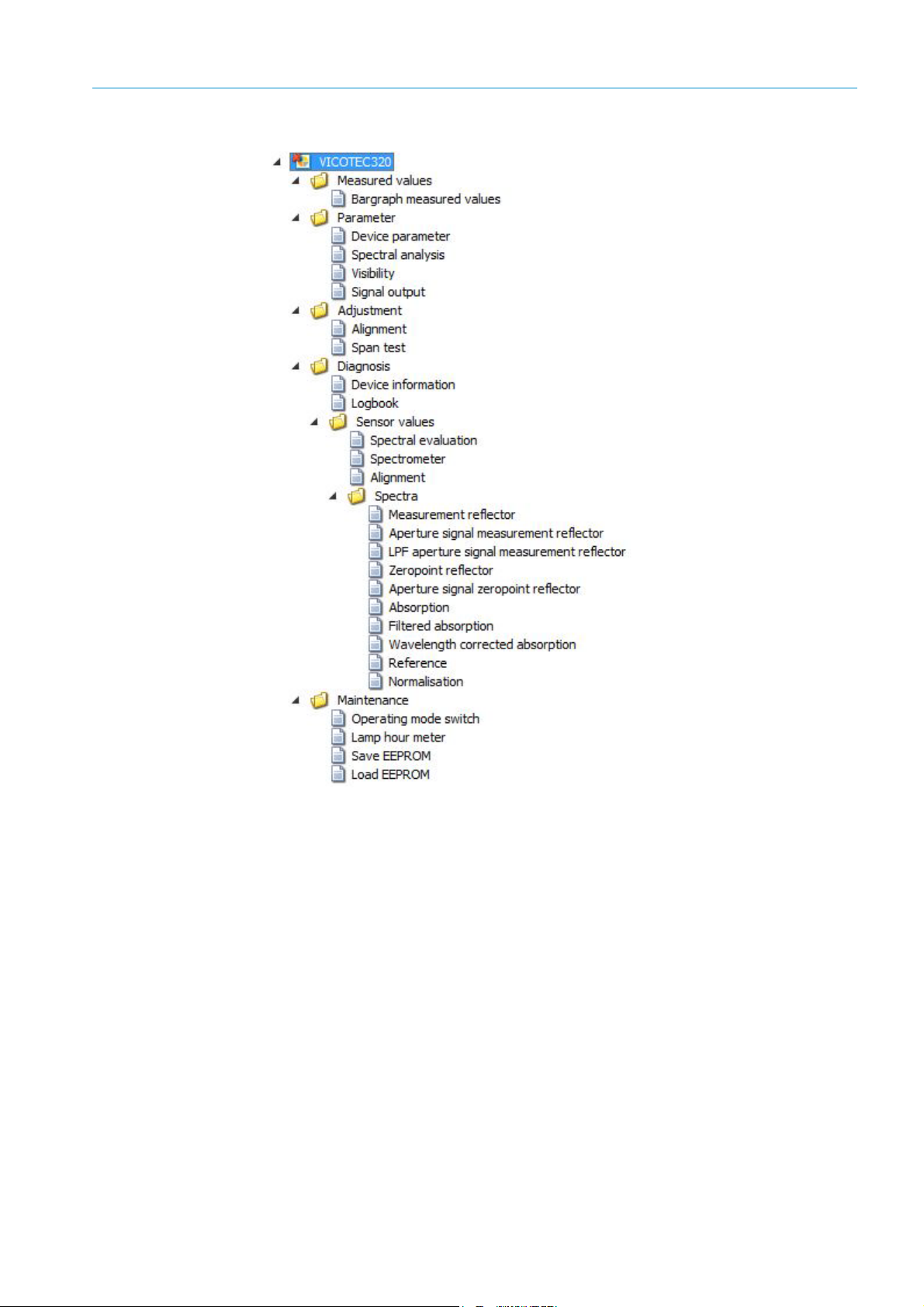

Fig. 28: Menu tree VICOTEC320

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

43

Page 44

8 USING THE VICOTEC320

8.2.2 Reading out the VICOTEC320 and operating manually

The corresponding operator level must first be selected to configure a device with the

SOPAS ET software. The SOPAS ET software runs in the operator level “Operator” after commissioning and parameters can only be read.

– To change the operating level to “Authorized operator”: Login via the [Login] button >

enter password (see “Password”, page 75).

– Double-click one of the functions in the project tree to start this function.

– To save all the data, select the “Export SDV file” command in the Device menu .

The following tabs are important for you; the other tabs are shown colored gray and are only

relevant for Service technicians.

Bargraph measured values

44

Fig. 29: Bargraph measured values

This screen shows whether the sensors are in measuring operation or whether a fault or

maintenance requirement exist.

Apart from that, the current measured values for visibility, temperature, NO, NO

and NOx

2

are displayed (depending on the device variant).

When fault or maintenance request is shown, the measurement triggering the fault or

maintenance request is shown next to the measured values.

The “Uncertain” LED next to the measured values signals that the measured value is

“uncertain” (e.g.: Calibration range exceeded. → Logbook).

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 45

Alignment

USING THE VICOTEC320 8

Fig. 30: Alignment

Nominal values

1 Offset <100

2 A,B,C,D: 250-500

The light beam is tracked automatically to the center of the reflector.

Manual alignment is only possible for authorized operators:

Device information

Menu: Diagnosis/Device information:

This screen shows the serial number, device process and operating hours of the sender

lamp.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

45

Page 46

8 USING THE VICOTEC320

Logbook

All sensor messages are stored in the Logbook. Messages marked with a red dot are still

active, messages with a green dot are already completed.

Messages can be filtered according to type:

▸ Click on the dropdown box and select the type of message required.

Fig. 31: Logbook

Symbol Remark

Logbook fill level in %.

When the characters are

Warning mode: Further entries are not accepted.

Circular buffer mode: Oldest entries are overwritten.

Data storage:

Symbol

not crossed out

Symbol

crossed out

Circular buffer mode

Warning mode

Entries Number of entries of selected filter.

Filter for messages Only filtered messages are shown.

Reset Clear all entries.

- Show active failures

- Show all failures

- Show active maintenance request

- Show all maintenance requests

- Show active uncertain

- Show all uncertain

- Show active extended messages

- Show all extended messages

- Show active messages

- Show all messages

Classification

→

red

: The logbook is full.

: Compressed.

: Uncompressed.

Further on in this Table.

46

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 47

Symbol Remark

Export

(Only in SOPAS ET)

Update Update display of logbook entries.

Last Data Scroll back.

Next Data Scroll forward.

All entries selected via the filter (→ Further back in this Table) are saved on the PC as .log file.

Format: CSV (comma-separated list). Viewable in, e.g., EXCEL.

Sort in ascending/descending order.

To switch sorting on or change sequence: Touch column header.

Consecutive message number.

Red

LED: Message still pending.

Green

LED: Message no longer pending.

USING THE VICOTEC320 8

Device Activating element: System, measured value identifier (sample gas component), subassembly,

Entries

Text Logbook message.

Classification F = Failure

Date start Format: yy-mm-dd

Time start Format: hh:mm:ss

Date stop Format: yy-mm-dd

Time end Format: hh:mm:ss

[1] Only for compressed data storage

8.2.2.1 Exporting messages

1 Click [Export].

2 Select the storage location and file names.

3 Click [Save].

>>>

The Logbook is saved as a Log file.

Evalu ation mo dule

[1]

Number of times the error has occurred.

M = Maintenance request

C = Check

U = Uncertain

X = Extended message

For “

Uncompressed

For “

Compressed

For “

Uncompressed

For “

Compressed

Uncompressed

For “

For “

Compressed

For “

Uncompressed

For “

Compressed

”: Occurrence of message.

”: Last occurrence of message.

”: Occurrence of message.

”: Last occurrence of message.

”: Clearing of message.

”: Last clearing of message.

”: Clearing of message.

”: Last clearing of message.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

47

Page 48

8 USING THE VICOTEC320

Operating mode switch

Fig. 32: Menu Maintenance/Operating mode switch

This screen serves to switch between Measuring mode and Maintenance mode. Apart from

that, a reference cycle and a system restart can also be initiated. The parameters are not

deleted. The connection between SOPAS and VICOTEC320 must be established again after

a system restart (see “Creating a connection”, page 38).

8.2.3 Saving the current parameter set

1 Save the parameter set. The saved file can then be restored, for example on new hard-

ware.

Select: Device/Export SDV file

2 Storing the project (a “project” can be several devices). This file can then, for example,

be printed but can however not be restored in the device.

a) To store the current parameter set, select the Save as command in the Project menu.

b) Enter a file name in the dialog window and confirm with [Save].

48

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 49

9 Maintenance

9.1 Cleaning

Set device to Maintenance mode

9.1.1 Cleaning sensors

The tube can be removed in order to clean the protective screen of the sender/receiver unit

or reflector.

1 Loosen both nuts at the end of the tube and pull the tube off.

2 Clean the protective screens with clean optical tissues.

3 Check the tube and the optical beam path for soiling though deposits or animals and

clean when necessary.

4 Position the tube and tighten both nuts.

MAINTENANCE 9

CAUTION: Eye injuries caused by improper handling of UV or blue light beams

The UV beam of the deuterium lamp or the blue light beam of the LED can cause serious

injuries through direct eye and skin contact. This results in the following safety measures when working on the switched on device with access to the light beam exit:

▸ Always wear UV protective goggles (in accordance with standard EN 170)

▸ The UV goggles do not provide protection against injuries caused by blue light beams,

therefore switch the LED off when working.

▸ Use the lamps only when they are perfectly safe. Operation is not allowed when the

lamp, supply lines or operating parts are visibly damaged.

9.1.2 Tunnel cleaning

▸ Set device to Maintenance mode

Fig. 33: Menu Maintenance/Operating mode switch

1 Open “Maintenance/Operating mode switch” in the SOPAS menu.

2 Click [Maintenance] below Operation.

Cover every sensor tube with a protective cap during tunnel cleaning.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

49

Page 50

9 MAINTENANCE

9.2 Maintenance work

9.2.1 Persons authorized to carry out maintenance

Maintenance going beyond the tasks described here must be performed by authorized

technicians only and is described in the Service Manual.

WARNING : Hazard by voltage.

Live parts are accessible when the device is open!

▸ Switch the supply voltage off before opening the device.

▸ Only use suitable, insulated tools.

9.2.2 Replacing the activated charcoal

The activated charcoal sachet is located in the sender/receiver unit.

▸ Replace the used activated charcoal bag with a new one.

50

Fig. 34: Replacing the activated charcoal bag

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 51

9.2.3 Replacing the drying agent cartridge

The drying agent cartridge is located in the reflector.

▸ Unscrew the lid with pin key and replace the drying agent cartridge.

MAINTENANCE 9

Fig. 35: Replacing the drying agent cartridge

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

51

Page 52

9 MAINTENANCE

9.2.4 Replacing the sender lamp and LED

Exchange the sender lamp at regular intervals. These intervals are approx. 1 to 4 years. The

intervals can also be longer or shorter depending on the configuration of the devices and

the ambient conditions in the tunnel.

52

Fig. 36: Position of sender lamp

1Sender lamp

WARNING: The sender lamp is hot

Risk of skin burns

▸ Let the sender lamp cool down before exchanging it.

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 53

Fig. 37: Sender lamp with LED unit

1Sender lamp

2 LED unit

3 Connection of LED unit power supply

4 Connection of sender lamp power supply

Exchanging the sender lamp with LED unit

MAINTENANCE 9

WARNING : Hazard by voltage.

Live parts are accessible when the device is open!

▸ Switch the supply voltage off before opening the device.

▸ Only use suitable, insulated tools.

1 Loosen 6 screws on the rear side of the SR-unit and swivel the rear side out.

2 Pull off the voltage supply line of the LED.

3 Loosen screw (crosshead) of the plug of the sender lamp voltage supply and disconnect

the plug.

Fig. 38: Sender lamp

1 Connection of voltage supply line

2 Screws of sender lamp

3 Connection of LED unit power supply

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

53

Page 54

9 MAINTENANCE

4 Loosen the plug of the LED unit's (3) power supply connection.

Note:

Risk of contamination of the optical mirrors after removing the sender lamp.

▸ Cover the opening to the optical mirrors after removing the sender lamp.

5 Loosen the two screws (5 mm Allen screw) on the sender lamp and take the sender lamp

off

.

6 Remove the cap from the new sender lamp.

7 Plug in new sender lamp and screw tight.

8 Connect the plug (1) and screw tight.

9 Insert plug (3).

10 Screw the rear cover tight.

Adjustment is not required.

Note:

Reset the lamp hour meter (Maintenance > Lamp hour meter) after exchanging the light

source.

54

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 55

Replacing the LED unit

Fig. 39: Remove the LED unit from the sender lamp

1 Screws for fastening the LED unit

2Sender lamp

3 Connection of LED unit power supply

MAINTENANCE 9

Note:

The fastening screws of the LED unit are not self-locking.

Note:

The optical surfaces can be contaminated when touched with your fingers.

▸ Avoid touching the optical surfaces with your fingers.

1 Loosen 6 screws on the rear side of the SR-unit and swivel the rear side out.

2 Loosen the two fastening screws of the LED unit.

3 Loosen the plug of the LED unit's power supply connection (3).

4 Pull the LED unit off.

5 Plug in new LED unit and screw tight.

6 Insert plug (3).

7 Screw the rear cover tight.

Adjustment is not required.

Note:

Reset the lamp hour meter (Maintenance > Lamp hour meter) after exchanging the light

source.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

55

Page 56

9 MAINTENANCE

9.2.5 Replacing the CO sensor

▸ Replace the CO sensor once a year (recommendation).

Procedure

1 Disconnect both connection lines from the terminals of the small electronic board of the

CO sensor.

2 Loosen 2 screws (see Fig. “Position of the CO sensor in the connection unit”, page 56).

3 Pull off the upper part of the CO sensor.

4 Insert the new CO sensor.

5 Screw the new CO sensor tight.

6 Reconnect both connection lines as previously.

7 Switch the voltage supply of the connection unit on again.

WARNING : Hazard by voltage.

Live parts are accessible when the device is open!

▸ Switch the supply voltage off before opening the device.

▸ Only use suitable, insulated tools.

Fig. 40: Position of the CO sensor in the connection unit

1Screws

56

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 57

9.2.6 Span Test

MAINTENANCE 9

Note:

Perform the span test every 5 years.

Tools required

Part No. Designation

2046658 Test tool

Fig. 41: Menu Adjustment/Span test

Designation/function Description

Span test LED shows the status.

Start Span test Activates the span test.

Maintenance Activates the Maintenance mode.

Malfunction LED shows whether the system has a malfunction.

Maintenance

LED shows whether the system is in Maintenance

mode.

1 Login as “Authorized operator”.

2 Select Adjustment/Span test in the menu.

3 Click [Maintenance].

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

57

Page 58

9 MAINTENANCE

4 Attach the test tool on the front of the sender/receiver unit.

Fig. 42: Attach the test tool on the front of the sender/receiver unit.

5 Click the [Start Span test] button.

>>>

The system performs a zero adjust with the test reflector, followed by a reference

cycle. The current status is shown in the Operating state text field.

>>>

The process takes approx. 10 minutes and is terminated when “Spantest (insert

cuvette)” is displayed.

6 Check the signal strength

▸ Menu: Diagnosis/Sensor values/Spectra/Measurement reflector.

>>>

The maximum intensity for NO should be in the range from 23000 to 28000 and for

NO

in the range from 42000 to 48000.

7 Observe the measured values for the zero point for approx. 5 minutes and determine the

2

average zero point. Use this value as zero point offset for the next steps.

Example: The default values of the test cuvettes must be added to the zero point offset.

The zero point offset can also be negative.

8 Insert cuvette or filter and wait for at least 5 minutes until the measurement has

stabilized.

9 Observe the displayed measured value for approx. 5 minutes and use the average value.

Compare the measured value with the default value of the test cuvette + zero point

offset (= actual default value). If required, calculate the correction factor (span

coefficient) (see “Determination and setting of the span factors”, page 59).

10 Repeat steps 7 to 9 for every test point.

11 Click [Maintenance] and wait until operating state shows “Maintenance remove

cuvette”.

Do not remove test tool beforehand.

12 Remove the test tool.

13 Restart the system:

▸ Menu: Maintenance/Operating mode switch/System reset

▸ Click [Start system reset].

14 Wait for one minute. Reconnect SOPAS ET (switch “Online”).

15 Wait until the reference cycle has completed.

>>>

The operating state is now “Measuring”.

58

8011703/XF49/2019-09| SICKO PE RA T IN G I NS TR U CT IO N S | VICOTEC320

Subject to change without notice

Page 59

9.2.6.1 Determination and setting of the span factors

Nominal value of neutral density filter

Measured value of neutral density filter VIS measurement offset–

---------------------------------------------------------------------------------------------------------------------------------------------------------------

span

NO/NO2

Nominal value of cuvette

Measured value of cuvette

---------------------------------------------------------------

=

MAINTENANCE 9

The span factors for the VIS, NO and NO

neutral density filters (VIS) or gas cuvettes (NO, NO

VIS NO NO

2 x filter 2039966 NO Mid 2043200 NO2 High 2043204

cuvette must be determined using calibrated

2

).

2

2

VIS measurement

Calculate the span factor according to the following equation:

NO/NO

measurement:

2

Calculate the span factor according to the following equation:

The determined span factors must fulfil the following criteria.

Span factor SOPAS variable

Nominal/

typical

Lower

tolerance

Upper

tolerance

VIS VIS_coeff 1 0.85 1.15

NO NO_coeff 1 0.7 1.3

NO

2

NO2_coeff 1 0.7 1.3

Enter span factors

Fig. 43: Menu Parameter/Spectral analysis

1 Open “Parameter/Spectral analysis” in the SOPAS menu tree.

2 Enter span coefficient NO/NO2.

8011703/XF49/V3-1/2019-09| SICK O PE RA T IN G I NS TR U C TI ON S | VICOTEC320

Subject to change without notice

59

Page 60

10 TROUBLESHOOTING

10 Troubleshooting

10.1 Error messages

Error messages are shown in the SOPAS ET configuration software Logbook.

Source Error message Significance Clearance

System Lamp fault Sender lamp does not go on.

System Mirror adj. End

Visibility No signal

System Lamp spectro

System Lamp 4Q

System Temp. Extern

Tem per ature

System CO failure

System System start

System Zero adjust

System Span test