Page 1

V4000 Press Brake sensor system

for protecting the press brake

OPERATING INSTRUCTIONS

GB

Page 2

Operating instructions

V4000 PB

This document is protected by copyright. The SICK AG company retains this right. Reproducing this document in

whole or part is only permissible within the limits of the statutory regulations of copyright law. Modifying or

abridging the document is impermissible without the express written permission of from the SICK AG company.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 3

Insert

V4000 PB

Update

Update

Please take note of the following updates to this document!

a

WARNING

Based on Machinery Directive 2006/42/EC, we have added the following supplementary

data or change notices on our product to the following document.

Scope

This document is an original document.

Cited standards and directives

The standards and directives cited in these operating instructions might have changed.

The following list indicates the standards and directives that might have been cited and

their successive versions.

Kindly replace the standards and directives cited in these operating instructions with the

successive versions listed in the table.

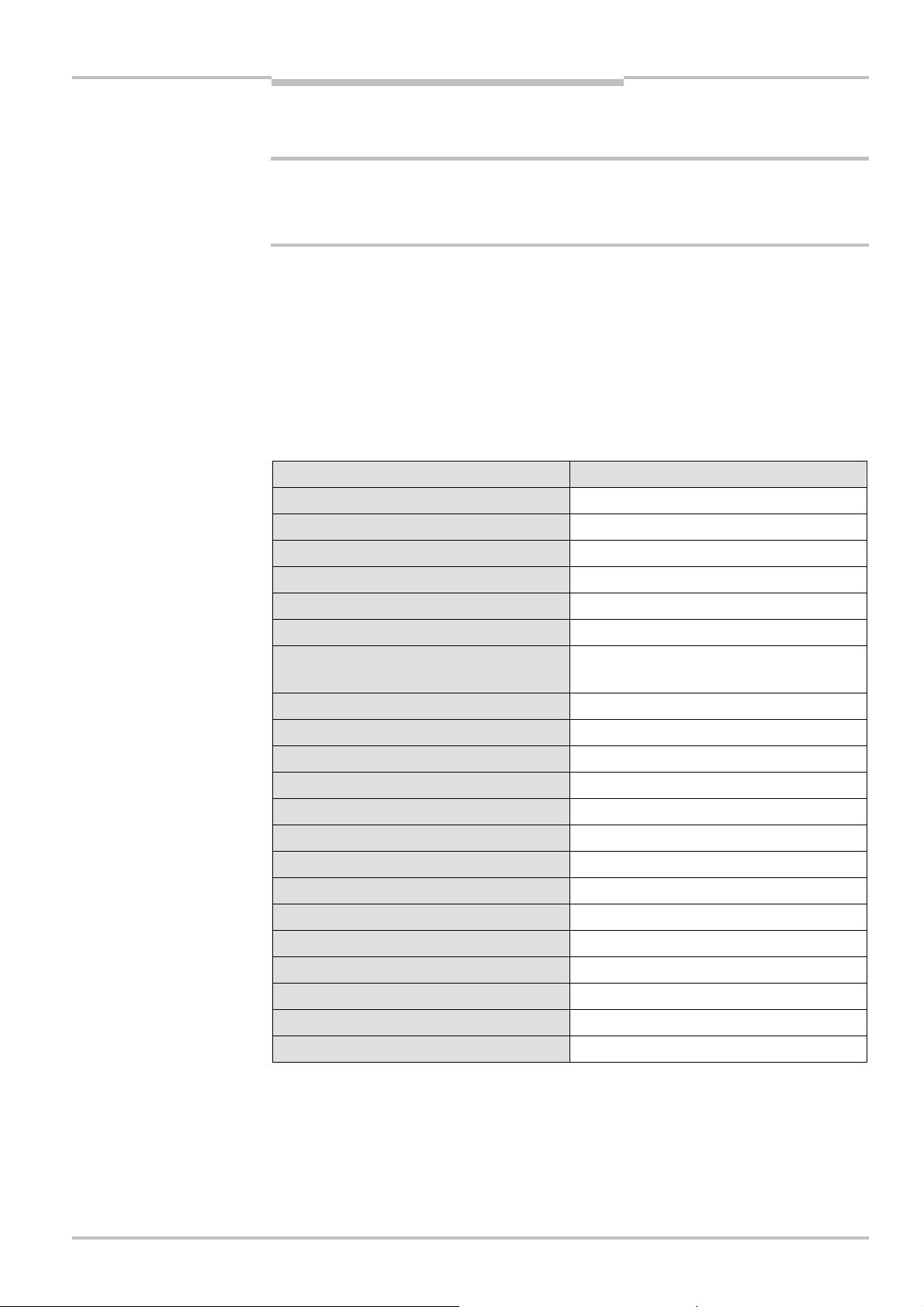

Previous standard or directive Successive standard and directive

Machinery Directive 98/37/EC Machinery Directive 2006/42/EC

Directive 93/68/EEC Directive 93/68/EC

EMC directive 89/336/EEC EMC directive 2004/108/EC

Low Voltage Directive 73/23/EC Low Voltage Directive 2006/95/EC

DIN 40050 EN 60529

IEC 536:1976 EN 61140

DIN EN 50178:1998-04/

VDE 0160:1998-04

EN 775 EN ISO 10218-1

EN 292-1 EN ISO 12100-1

EN 292-2 EN ISO 12100-2

EN 954-1 EN ISO 13849-1

EN 418 EN ISO 13850

EN 999 EN 999+A11)

EN 294 EN ISO 13857

EN 811 EN ISO 13857

EN 1050 EN ISO 14121-1

IEC 68, part 2-27 or IEC 68 EN 60068-2-27

IEC 68, part 2-29 EN 60068-2-27

IEC 68, part 2-6 EN 60068-2-6

EN 50178

prEN 501001 EN 61496-1

ANSI B11.19-1990 ANSI B11.19:200304, Annex D

1)

EN 999 will be replaced by EN ISO 13855.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 4

Insert

V4000 PB

Update

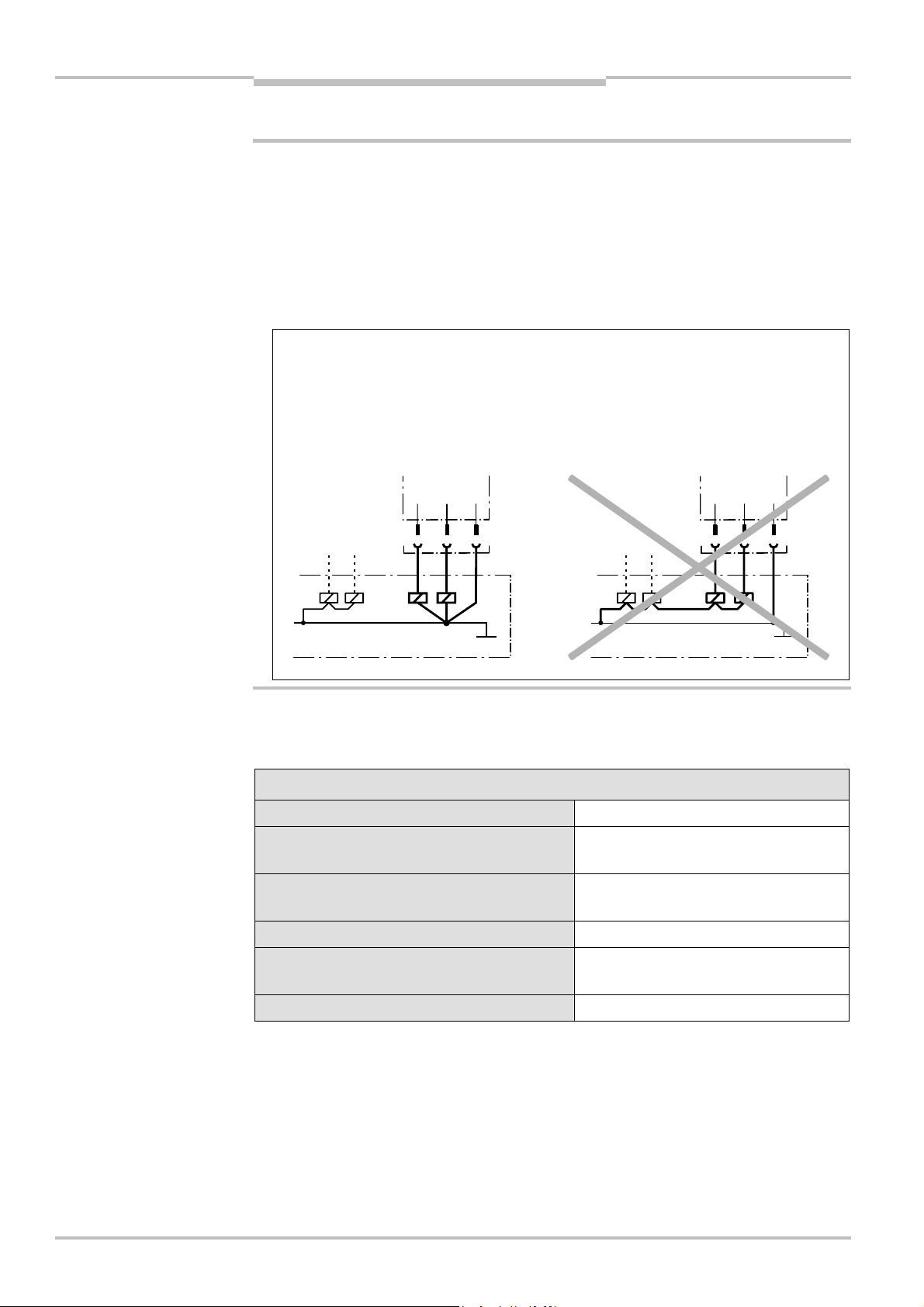

Electrical installation

Prevent the formation of a potential difference between the load and the protective

a

WARNING

device!

If you connect loads that are not reverse-polarity protected to the OSSDs or the safety

outputs, you must connect the 0 V connections of these loads and those of the

corresponding protective device individually and directly to the same 0 V terminal strip.

This is the only way to ensure that, in the event of a defect, there can be no potential

difference between the 0 V connections of the loads and those of the corresponding

protective device.

OSSD1

Safety output 1

OSSD2

Safety output 2

OSSD1

Safety output 1

OSSD2

Safety output 2

Note

Technical specifications

Safety-related parameters according to EN ISO 13849, EN 62061, IEC 61508:

V4000 PB: General system data

Type Type 4 (IEC 61496)

Safety Integrity Level2) SIL3 (IEC 61508),

SILCL3 (EN 62061)

Category Category 4 (EN ISO 13849)

Category 4 (EN 954

3)

)

Performance Level2) PL e (EN ISO 13849)

PFHd (mean probability of a dangerous failure

1.52×10–8

per hour)

TM (mission time) 16.6 years (EN ISO 13849)

EC declaration of conformity

You can obtain the EC declaration of conformity with the standards used at: www.sick.com

2) For detailed information on the exact design of your machine/system, please contact your local SICK

representative.

3) Only valid for the assumption of conformity until 28.12.2009. From then on it will only be permissible to use

the successor EN ISO 13849.

© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 5

Insert

V4000 PB

Update

Checklist for the manufacturer

L

Checklist for the manufacturer/installer for the installation of electro-

sensitive protective equipment (ESPE)

Details about the points listed below must be present at least during initial commissioning — they are, however,

dependent on the respective application, the specifications of which are to be controlled by the manufacturer/installer.

This checklist should be retained and kept with the machine documentation to serve as reference during recurring

tests.

1. Have the safety rules and regulations been observed in compliance with the directives/standards applicable to

the machine?

2. Are the applied directives and standards listed in the declaration of conformity? Yes

3. Does the protective device fulfil the required PL/SILCL and PFHd according to EN ISO 138491/EN 62061 and

the type according to EN 614961?

4. Is the access to the hazardous area/hazardous point only possible through the protective field of the ESPE? Yes

5. Have appropriate measures been taken to prevent (mechanical protection) or monitor unprotected presence in

the hazardous area when protecting a hazardous area/hazardous point and have these been secured against

removal?

6. Are additional mechanical protective measures fitted and secured against manipulation which prevent reaching

under, over or around the ESPE?

7. Has the maximum stopping and/or stopping/run-down time of the machine been measured, specified and

documented (at the machine and/or in the machine documentation)?

8. Has the ESPE been mounted such that the required safety distance from the nearest hazardous point has been

achieved?

9. Are the ESPE devices correctly mounted and secured against manipulation after adjustment? Yes

10. Are the required protective measures against electric shock in effect (protection class)? Yes

11. Is the control switch for resetting the protective device (ESPE) or restarting the machine present and correctly

installed?

12. Are the outputs of the ESPE (OSSDs, ASInterface Safety at Work) integrated in compliance with the required

PL/SILCL according to EN ISO 13849/EN 62061 and does the integration comply with the circuit diagrams?

13. Has the protective function been checked in compliance with the test notes of this documentation? Yes

14. Are the given protective functions effective at every setting of the operating mode selector switch? Yes

15. Are the switching elements activated by the ESPE, e.g. contactors, valves, monitored? Yes

16. Is the ESPE effective over the entire period of the dangerous state? Yes

17. Once initiated, will a dangerous state be stopped when switching the ESPE on or off and when changing the

operating mode, or when switching to another protective device?

18. Has an information label for the daily check been attached so that it is easily visible for the operator? Yes

19. Have you made sure that the protective device itself when mounted is not a source of danger during machine

operation (for example, catching between the device and parts of the machine)?

This checklist does not replace the initial commissioning, nor the regular inspection by qualified safety personnel.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 6

Insert

V4000 PB

Update

© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 7

Operating instructions

V4000 PB

Contents

Contents

1 About this document ......................................................................................................6

1.1 Function of this document....................................................................................

1.2 Target groups ........................................................................................................

1.3 Scope .....................................................................................................................

1.4 Depth of information.............................................................................................

1.5 Abbreviations.........................................................................................................

1.6 Symbols used ........................................................................................................

6

6

6

6

7

8

2 On safety..........................................................................................................................

2.1 Specialist personnel..............................................................................................

2.2 Applications of the system ...................................................................................

2.3 Correct use of the system..................................................................................

2.4 General protective notes and protective measures.........................................

2.5 Safety in operation.............................................................................................

2.6 Environmental protection ..................................................................................

2.6.1 Disposal ............................................................................................

3 Product description .....................................................................................................

3.1 Special features .................................................................................................

3.2 Safety concept....................................................................................................

3.2.1 Protection principle of the V4000 PB .............................................

3.2.2 Protective volume during the operating cycle ................................

3.2.3 Intrusion of the protective volume during the operating cycle......

3.3 Range of use ......................................................................................................

3.4 Structure of the device ......................................................................................

3.4.1 Sender and receiver.........................................................................

3.4.2 Displays at the sender and receiver ...............................................

3.4.3 Interfaces at the receiver.................................................................

3.4.4 PBI (press brake interface)..............................................................

3.4.5 CDS (Configuration & Diagnostics Software)..................................

3.4.6 External operating elements ...........................................................

3.5 Possible system configurations.........................................................................

3.5.1 Source of the operator signals ........................................................

3.5.2 Baud rate communication interface ...............................................

3.5.3 Application name .............................................................................

3.5.4 Repetition interval of power-up cycle..............................................

3.5.5 Mounting of receiver........................................................................

3.5.6 Speed-dependent muting................................................................

3.5.7 Position-sensing system ..................................................................

3.5.8 External device monitoring (EDM)...................................................

3.5.9 Default value for braking distance..................................................

3.5.10 Travel for determining the braking distance ..................................

3.5.11 Braking offset ...................................................................................

3.5.12 Target speed v

3.5.13 Monitoring of the slow closing speed v

point..................................................................................................

3.5.14 Maximum closing speed and maximum overall machine

overrun..............................................................................................

3.5.15 Travel for determining the overall machine overrun......................

3.5.16 Standstill time for determining the top dead centre......................

3.5.17 Start delay for closing movement ..................................................

for determining the braking distance ............... 36

slow

from the pinch

crawl

9

9

9

10

10

11

16

16

17

17

18

18

20

21

22

23

23

24

26

28

29

31

31

33

33

33

33

34

34

34

35

35

36

36

37

37

38

38

39

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Page 8

Operating instructions

V4000 PB

Contents

3.5.18 Time for standstill detection ............................................................ 39

3.5.19 Settling times for inputs ...................................................................

3.5.20 Discrepancy times for inputs ...........................................................

3.5.21 Start signal at reduced protective volume ......................................

3.5.22 Minimum state time for standard outputs......................................

3.5.23 Minimum switch-off time for safety-relevant outputs.....................

3.5.24 Bypass...............................................................................................

3.6 Protective operation ...........................................................................................

3.6.1 Power-up cycle ..................................................................................

3.6.2 Teach-in.............................................................................................

3.6.3 Protective volume modes in protective operation..........................

3.7 System sequences in protective operation.......................................................

3.7.1 Power-up cycle in standard mode....................................................

3.7.2 Teach-in.............................................................................................

3.7.3 Operating cycle in standard mode...................................................

3.7.4 Operating cycle in box mode............................................................

3.7.5 Operating cycle in back-stop mode .................................................

3.8 Alignment mode..................................................................................................

39

40

40

41

41

41

42

42

43

43

46

47

51

53

55

57

59

4 Mounting.......................................................................................................................

4.1 Steps for mounting .............................................................................................

4.1.1 Mounting the sender or receiver using SICK mounting kit 1.........

4.1.2 Mounting the sender or receiver using SICK mounting kit 2.........

4.1.3 Sticker: Information for daily inspection .........................................

5 Electrical installation...................................................................................................

5.1 Connecting the receiver ....................................................................................

5.2 Connecting the sender.......................................................................................

5.3 Making up the connections for receiver and sender.......................................

5.4 Connecting the PBI............................................................................................

5.5 External device monitoring (EDM) .....................................................................

5.6 Bypass.................................................................................................................

5.7 Configuration connection (serial interface).......................................................

6 Configuration................................................................................................................

6.1 Delivery state ......................................................................................................

6.2 Configuration preparations ................................................................................

7 Commissioning.............................................................................................................

7.1 Test notes ...........................................................................................................

7.2 Aligning sender and receiver .............................................................................

7.2.1 Initial alignment ................................................................................

7.2.2 Alignment following a tooling change..............................................

7.3 Function check ...................................................................................................

7.4 Regular checks of the protective device by specialist personnel...................

7.5 Daily checks of the protective device by authorised commissioned

persons ...............................................................................................................

60

60

60

61

62

63

63

66

67

67

69

70

71

72

72

73

74

74

74

74

81

83

86

86

8 Operation ......................................................................................................................

8.1 Switching the machine on..................................................................................

8.2 Selecting protective volume mode ....................................................................

8.3 Resetting .............................................................................................................

8.4 Carrying out a power-up cycle............................................................................

8.5 Carrying out teach-in ..........................................................................................

8.6 Bending in standard mode.................................................................................

88

88

89

89

89

91

92

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 9

Operating instructions

V4000 PB

Contents

8.7 Bending in box mode ........................................................................................ 92

8.8 Bending in back-stop mode..............................................................................

8.9 Changing the sheet thickness...........................................................................

8.10 Tool changing .....................................................................................................

8.11 Care and maintenance ......................................................................................

92

92

93

93

9 Diagnostics...................................................................................................................

9.1 Response to errors and malfunctions...............................................................

9.2 Error displays of the LEDs..................................................................................

9.3 Error displays of the 7-segment display............................................................

9.4 Extended diagnostics via CDS...........................................................................

9.5 SICK support.......................................................................................................

10 Technical data..............................................................................................................

10.1 Device data sheet ..............................................................................................

10.1.1 V4000 PB technical data.................................................................

10.1.2 Technical data for PBI (press brake interface).............................

10.1.3 Incremental encoder technical data.............................................

10.2 Dimensional drawings .....................................................................................

10.2.1 Sender and receiver.......................................................................

10.2.2 SICK mounting kit 1 .......................................................................

11 Ordering information .................................................................................................

11.1 Scope of delivery..............................................................................................

11.2 Available systems.............................................................................................

11.3 Accessories.......................................................................................................

12 Glossary ......................................................................................................................

13 Annex .......................................................................................................................

13.1 Detailed system sequences in protective operation......................................

13.1.1 Power-up cycle................................................................................

13.1.2 Teach-in ..........................................................................................

13.1.3 Standard mode ..............................................................................

13.1.4 Box or back-stop mode with interruption of the protective

volume ............................................................................................

13.2 Declaration of Conformity................................................................................

13.3 Manufacturer’s checklist.................................................................................

13.4 List of tables.....................................................................................................

13.5 List of illustrations............................................................................................

13.6 Index .................................................................................................................

94

94

94

95

97

98

99

99

99

105

106

107

107

108

109

109

109

109

111

114

114

114

116

118

120

122

124

125

126

128

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Page 10

Chapter 1 Operating instructions

V4000 PB

About this document

1 About this document

Read this chapter carefully before working with the operating instructions and the

V4000 Press Brake system.

For "V4000 Press Brake system" we shall use the abbreviation "V4000 PB" from now on.

1.1 Function of this document

These operating instructions are intended for the technical personnel of the machine

manufacturer or the machine operator in regards to safe mounting, electrical installation,

configuration, commissioning, operation and diagnostics of the V4000 PB sensor.

These operating instructions do not provide instructions for operating machines on which

the V4000 PB is, or will be, integrated. Information of this kind will be found in the

operating instructions for the machine.

1.2 Target groups

These operating instructions are intended for manufacturers, operators and the users of

press brakes which are to be protected by a V4000 PB. It also addresses people who

integrate the V4000 PB into a machine, initialise its use, or who check the unit.

Note

1.3 Scope

These operating instructions apply for the V4000 PB with the following type label entry in

the Operating Instructions field: 8 010 501. This document is part of SICK part number 8

010 501 (V4000 Press Brake sensor system in all available languages).

You will require a CDS (Configuration & Diagnostic Software) version 3.0 or greater for the

configuration and diagnostics of this system. To determine the software version, select the

Module info item from the ? menu in the menu bar.

1.4 Depth of information

These operating instructions contain information on the V4000 PB regarding the following

subjects:

Mounting

Electrical installation

Configuration and commissioning

Operation, care and maintenance

Planning and using protective devices such as the V4000 PB sensor also require specific

technical skills which are not detailed in these operating instructions.

When operating the V4000 PB sensor, the national, local and statutory rules and

regulations must be observed.

General information on health and safety using opto-electronic protective devices is

contained in the brochure "Safe Machines with Opto-Electronic Protective Devices".

Error diagnostics and remedying

Technical data and order numbers

Conformity and approval

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 11

Operating instructions Chapter 1

V4000 PB

About this document

Note

ANSI

BWS

CDS

EDM

ESPE

HMI

LD

LD LED

MP

NC

OMO

ORT

OSSD

PBDC

PBI

PTDC

PP

SP

SPLC

V4000 PB

We also refer you to the SICK homepage on the Internet at

http://www.sick.com

Here you will find:

These operating instructions in different languages for viewing and printing

The EC Declaration of Conformity

1.5 Abbreviations

American National Standards Institute

Electro-sensitive protective equipment (ESPE) (e. g. V4000 PB)

SICK Configuration & Diagnostic Software = software for configuring and diagnosing the

V4000 PB system

External device monitoring

Electro-sensitive protective equipment

Human machine interface

Laser diode

Light-emitting diode

Mute point

Numerical control

Overall machine overrun

Overall response time

Output signal switching device = signal output of the protective device to the controller

used for switching off the movement which is the source of danger

Programmed bottom dead centre

Press brake interface

Programmed top dead centre

Pinch point

to v

Switch-over point (from v

p

Safety programmable logic control

V4000 Press Brake (sensor system)

slow

)

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Page 12

Chapter 1 Operating instructions

V4000 PB

About this document

1.6 Symbols used

Recommendation

Note

;, , ;O(

O Yellow, Ö Yellow,

o Yellow

,

> Action …

a

WARNING

Recommendations are designed to provide some assistance for your decision-making

process regarding application of a certain function or technical measure.

Notes provide special information about the device.

Display indicators show the status of the 7-segment display of the receiver:

7 Constant display of the letter F

Flashing display of the letter F

7O) Alternating display of F and 2

LED symbols describe the state of an LED:

O The LED is illuminated constantly.

Ö The LED is flashing.

o The LED is off.

ON or OFF state:

ON

OFF

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

Warning!

A warning indicates concrete or potential dangers. They save you from harm.

Read warnings carefully and abide by them!

n

s r

Software notes show the location in the CDS (Configuration & Diagnostic Software) where

you can make the appropriate settings and adjustments. Go to the View menu, Dialogue

windows of the CDS and activate the item tabs to view the named dialogue boxes as

required. Otherwise use the software wizard to make the desired settings.

Sender and receiver

In drawings and diagrams, the s symbol denotes the sender and the symbol r the

receiver.

The term "dangerous state"

In the drawings in these operating instructions, the dangerous state (standard term) of the

machine is always represented as a movement of a machine part. In practical operation

there may be a number of different dangerous states:

Machine movements

Electrical conductors

Visible or invisible radiation

A combination of several risks and hazards

Representation of the signals for teach-in, alignment mode and selection of protective

volume mode

These operating instructions also describe the V4000 PB input and output signals. As a

way of uniquely representing the signals for teach-in, alignment mode and selection of

protective volume mode (input signals), tactile switching amplifiers (buttons, switches) are

used. The signals can be generated at the inputs of the V4000 PB by, for example, foot

switches, alignment buttons, teach-in buttons, selector switches and key-operated

switches or by the corresponding switching elements on the HMI of the press controller.

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 13

Operating instructions Chapter 2

V4000 PB

On safety

2 On safety

This chapter deals with your own safety and the safety of the operators.

> Read this chapter carefully before working with the V4000 PB or with the machine

protected by the V4000 PB.

2.1 Specialist personnel

The V4000 PB must be mounted, connected, commissioned and serviced only by

specialist personnel. Specialist personnel are defined as persons who

due to their technical training and experience possess sufficient knowledge in the field

of safety equipment for making press brakes safe

and

who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

have sufficient familiarity with the relevant national industrial safety regulations, work

safety regulations, directives and the generally recognised code of practice of the

industry (for example, DIN standards, VDE specifications, technical codes of other EC

member states) that they can judge whether the press brake is safe from the

occupational safety point of view

and

have access to and have read these operating instructions.

As a rule these will be specialist personnel, the manufacturer of the ESPE or even such

persons who have been given the corresponding training by the ESPE manufacturer, who

are mainly concerned with inspecting and testing ESPEs and have been commissioned by

the ESPE operator in this regard.

2.2 Applications of the system

The V4000 PB is an ESPE (electro-sensitive protective equipment) device designed to

protect the area beneath the die of press brakes at high closing speeds. As soon as an

object enters the protective volume beneath the die, the ESPE issues the signal to the

press controller to stop the fast closing movement and this system must then stop the

closing movement.

The V4000 PB system consists of a sender and a receiver which are mounted on the press

crosshead. The protective volume between the sender and the receiver moves with the

press crosshead and thus ensures that the safeguarded area stays beneath the die.

The system is a Type 4 ESPE as defined by to IEC 61 496-1 and 2 and is therefore allowed

for use with controls of safety category 4 in compliance with EN 954-1. It may be used in

safety applications up to SIL 3 in accordance with IEC 61 508.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Page 14

Chapter 2 Operating instructions

V4000 PB

On safety

Use of the V4000 PB in the open air or explosion hazard areas is not permitted. The

V4000 PB can only be used in normal industrial environments.

Do not use the V4000 PB as a separating protective measure!

a

WARNING

An opto-electronic protective device provides indirect protection, e.g., by switching off the

power at the source of the hazard. It cannot provide protection neither from parts thrown

out, nor from emitted radiation. Transparent objects are not detected.

Depending on its applications, mechanical protective devices may be needed in addition to

the V4000 PB.

2.3 Correct use of the system

The V4000 PB system is intended to be used solely at a fixed location on press brakes and

may only be used as defined by Section

only by specialist personnel and only on the machine where it has been mounted and

initially commissioned by specialist personnel in accordance with these operating

instructions.

SICK AG accepts no claims for liability if the equipment is used in any other way or if

modifications are made to the device, even in the context of mounting and installation.

2.2 "Applications of the system". It must be used

a

WARNING

Fig. 1: Warning regarding

laser class 1M

2.4 General protective notes and protective measures

Protective notes

Please observe the following protective notes in order to ensure the correct and safe use

of the V4000 PB.

Warnings on the V4000 PB must be observed without fail.

The V4000 PB meets the requirements of laser protection class 1 M. Do not look into

the laser beam neither with the naked eye nor using optical equipment (such as

binoculars).

LASER RADIATION

DO NOT STARE INTO THE BEAM OR VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

ACCORDING TO IEC 60825-1:2001

Max. output: < 5mW

Puls duration: < 2ms

Wavelength: 620 TO 650 nm

Complies with 21 CFR 1040.10 and 1040.11 except

for deviations pursuant to laser notice No. 50, July 2001

This device meets the norms: CDRH 21 CFR 1040.10, 1040.11 as well as DIN EN 60

825:2001. There the following note is required:”Caution – use of controls or

adjustments or performance of procedures other than those specified herein may result

in hazardous radiation exposure!”

The V4000 PB components must not be opened for maintenance work. Defective

devices have to be sent back to the manufactorer.

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 15

Operating instructions Chapter 2

V4000 PB

On safety

The national/international rules and regulations apply to the installation, commissioning

and periodic technical inspections of the V4000 PB, in particular:

– Machinery Directive 98/37/EC

– Provision and use of Work Equipment Directive 89/655/EEC

– The work safety regulations/safety rules

– Relevant national health and safety regulations

Manufacturers and operators of the machine on which the V4000 PB is used are

responsible for obtaining and observing all applicable safety regulations and rules.

The notices, in particular the test regulations (see Chapter

operating instructions (e.g. on use, mounting, installation or integration into the existing

machine controller) must be observed.

The tests must be carried out by specialist personnel or specially qualified and

authorised personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

The operating instructions must be made available to the operator of the machine where

the V4000 PB is fitted. The machine operator is to be instructed in the use of the device

by specialist personnel and must be instructed to read the operating instructions of the

V4000 PB and of the machine.

7 "Commissioning") of these

a

WARNING

2.5 Safety in operation

Dangers which the V4000 PB does not protect against!

The different ways in which the press brake can be used in manufacturing means that

indirect dangers may arise.

Please observe and comply with the following points in order to protect yourself against

dangers during machine operation.

The V4000 PB safeguards the hazardous point beneath the die at high closing speeds

(over 10 mm/s) or irrespective of the speed up to a gap of 6 mm. The maximum height of

the protective volume up to the lower edge of the die is 26 mm.

Maximum protection is provided in standard protective volume mode.

In the case of box-bending or back-stop operation, use of a restricted protective volume is

possible. With this kind of work, the reduced dimensions of the protective volume means

that only limited protection against getting caught or crushed is possible.

If parts of the body are brought into the hazardous point within a box, they will only be

detected behind the tolerance zone around the pressure axis. There is a danger of injury

by being caught or crushed.

For a time interval of 100–150 ms (just before the gap height of 6 mm is reached) there is

the possibility of an object which is moving into the space between the die and the

workpiece being crushed.

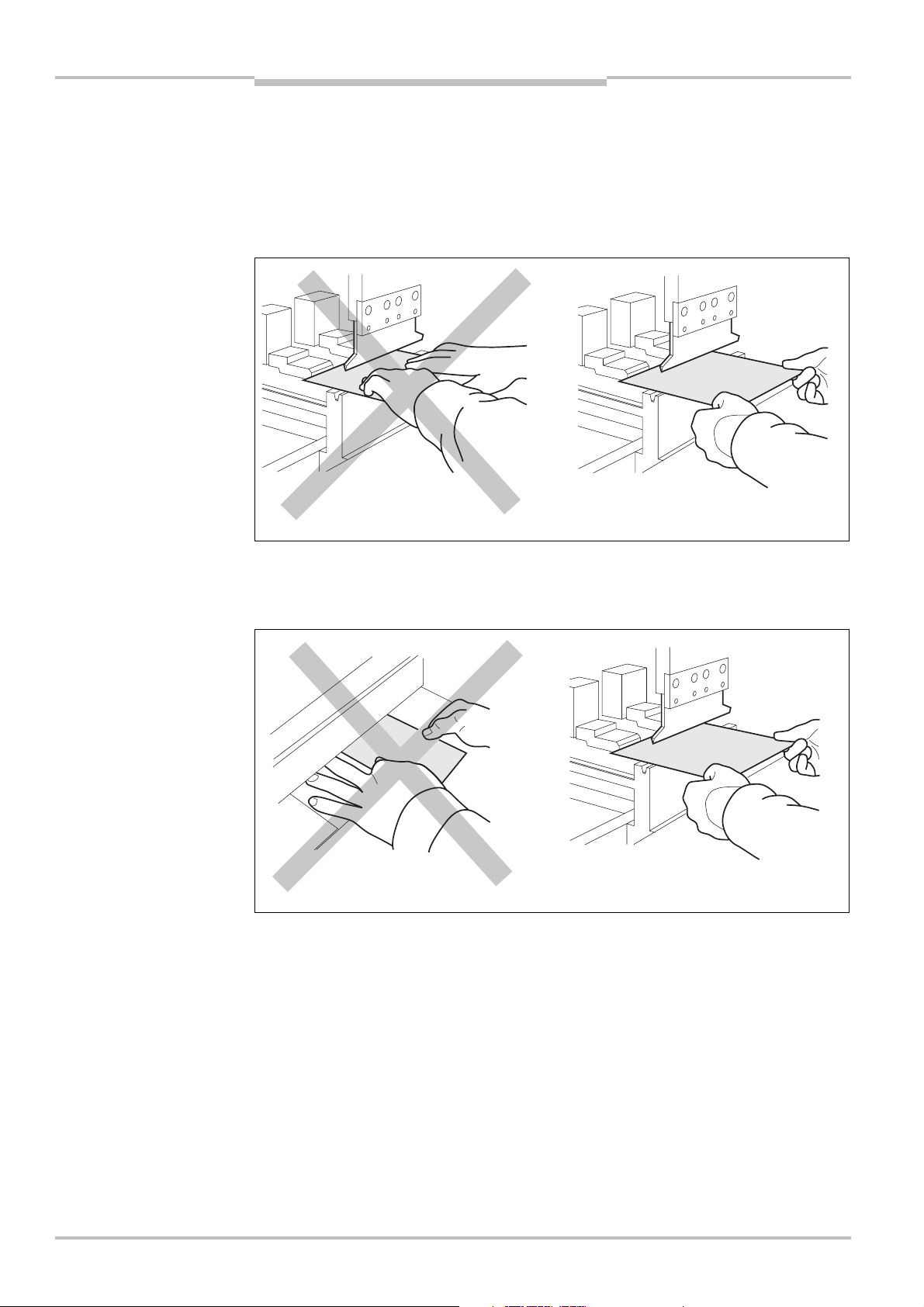

Correct handling of the workpiece

By handling the sheet properly you can avoid your hands or fingers being caught or

crushed.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Page 16

Chapter 2 Operating instructions

V4000 PB

On safety

> Use gloves to prevent:

– Injuries caused by edges, corners and burr

– Residues and rust caused by sweat from the hands getting on dies and workpieces

– Deposits on the hands

– Slipping of smooth workpieces

Fig. 2: Handling of the

workpiece 1

Fig.

3: Handling of the

workpiece 2

Note

> Hold the sheet by the left and right corners of the end facing you.

> Use both hands to hold the sheet firmly from below (thumb on top of the sheet, rest of

hand underneath)

> When holding the sheet, be sure not to spread your fingers.

Spread fingers will interrupt the protective volume of the V4000 PB. The protective

function of the V4000 PB will be triggered and the V4000 PB initiates a stop.

If the protective volume is limited (box-bending and back-stop operation) there will be an

additional risk of getting your hand caught.

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 17

Operating instructions Chapter 2

V4000 PB

Fig. 4: Handling of

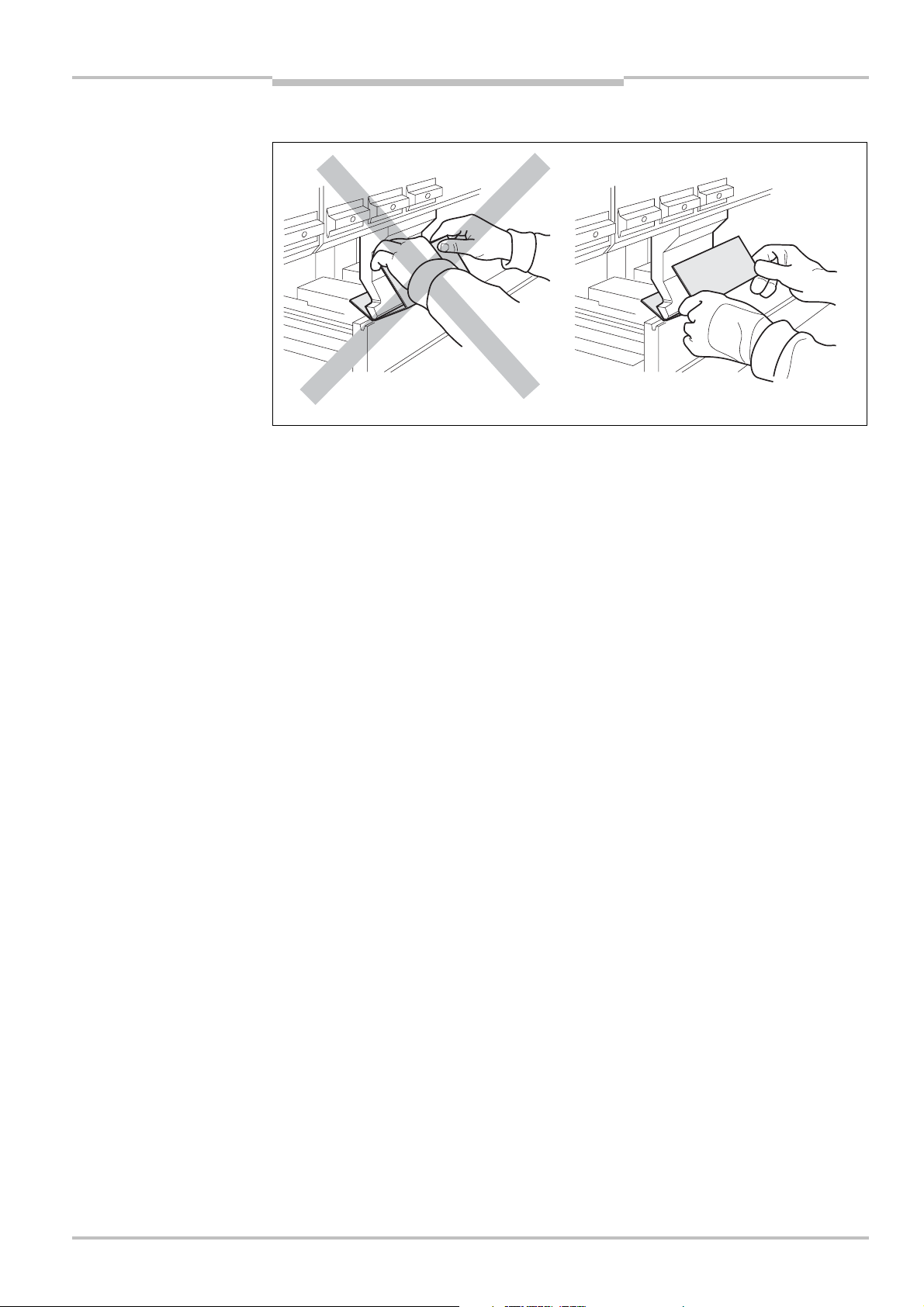

pre-flanged sheets

On safety

Correct handling of pre-flanged sheets

Note

If pre-flanged sheets are not handled correctly, your hands could get caught between the

sheet and the die or press crosshead.

> Hold the pre-flanged sheet by the left and right edges between the thumbs and index

fingers.

> Use both hands to hold the sheet firmly.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Page 18

Chapter 2 Operating instructions

V4000 PB

Fig. 5: Handling of

box-shaped workpieces

On safety

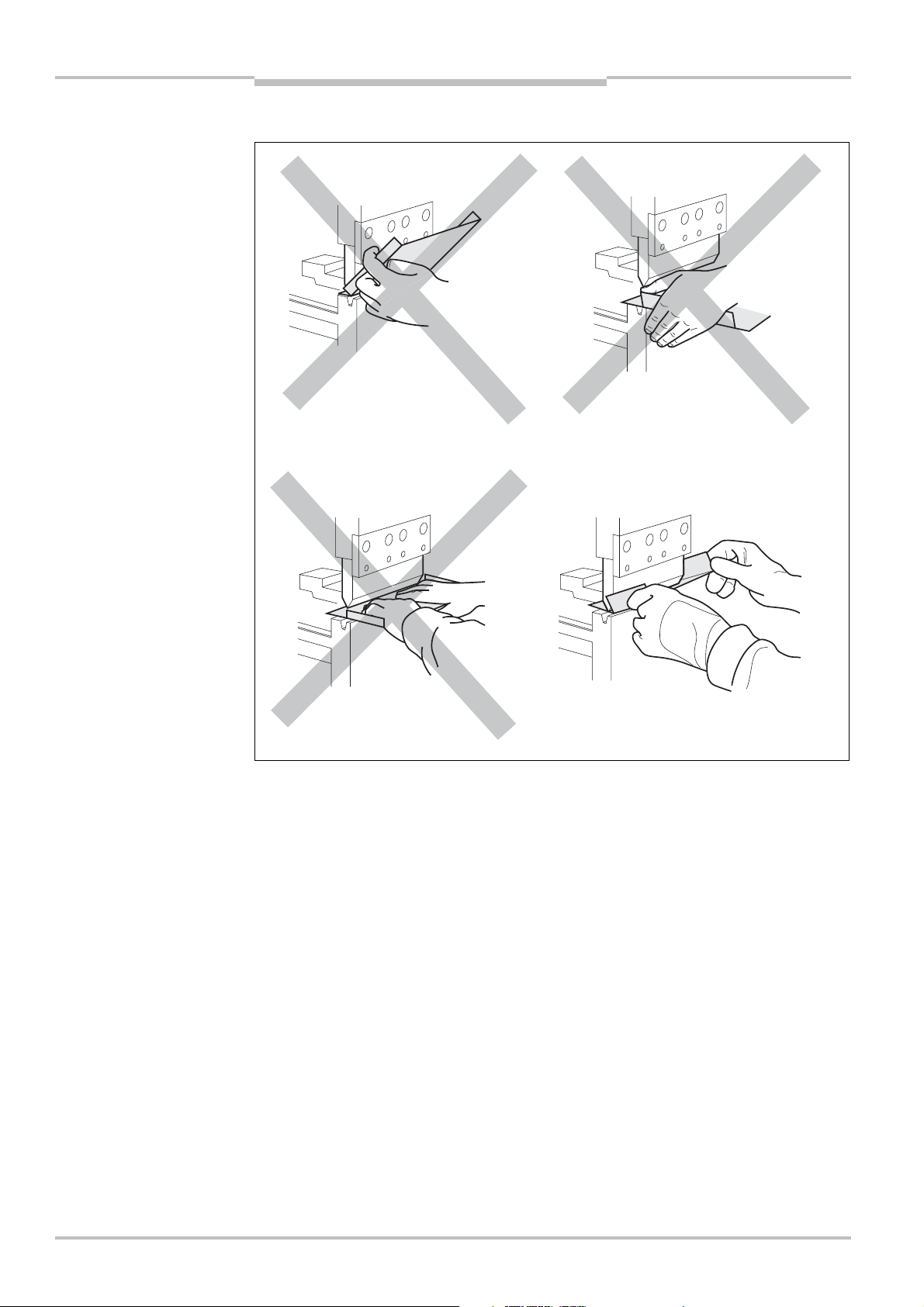

Correct handling with box-bending

Note

In box-bending and back-stop modes the protective volume is limited and a tolerance zone

around the pressure axis is hidden. If box-like workpieces are not handled correctly, your

hands could get caught between the workpiece and the die or press crosshead.

> Do not hold the upper box walls by the edges or corners on the pressure axis.

> Hold box-shaped workpieces by their back part (closest to you) outside the hazardous

point.

The V4000 PB cannot protect you against these dangers:

Crushing your hands or fingers between the workpiece and the press crosshead as a

result of handling the workpiece incorrectly during bending

Crushing your fingers between the die and the workpiece as a result of handling the

workpiece incorrectly

The risk of injury from workpieces falling when the press brake is opened

The risk of injury from large workpieces swinging upwards during bending

When bending aids are used:

Risk of injury due to the workpiece swinging up or down, or to the movement of the

bending aids

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 19

Operating instructions Chapter 2

V4000 PB

Note

On safety

When automatically traversing rear stops are used:

– Crushing your hands or fingers between the rear stops and the female die during

traversing movements towards the operator

– The operator being crushed by large workpieces being pushed at him by the rear stops

Risk of injury in the rear space arising from automatically traversing stops, moving tools,

workpieces or bending aids.

Access to the rear space or standing in the rear space must be prevented by means of the

appropriate safety devices, such as a light grid.

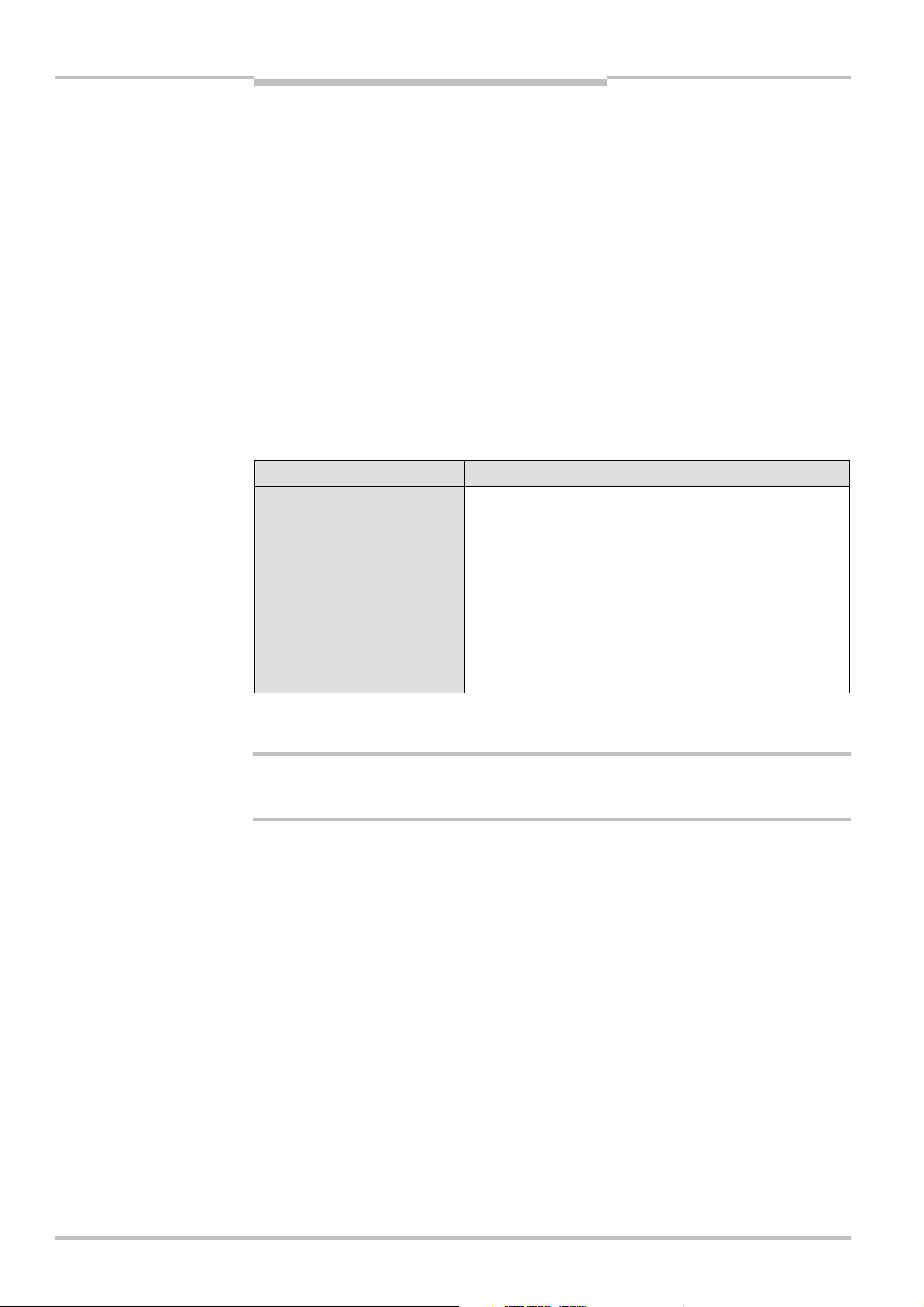

Dangers arising from mounting of the V4000 PB

> When mounting the V4000 PB make sure that there will be no crushing or shearing

points between the moving sender and receiver and other stationary machine parts or

devices in the vicinity of the machine.

> If hazardous points cannot be avoided, they must be made safe by other protective

measures or remedied by design changes.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Page 20

Chapter 2 Operating instructions

V4000 PB

On safety

2.6 Environmental protection

The V4000 PB has been designed to minimise environmental impact. It uses only a

minimum of power and natural resources.

> At work, always act in an environmentally responsible manner.

2.6.1 Disposal

Disposal of unusable or irreparable devices should always occur in accordance with the

applicable country-specific waste-disposal regulations

(e.g. European Waste Code 16 02 14).

Before you can turn over the devices for environmentally-friendly recycling, you must

separate the different materials of the V4000 PB from one another.

> Separate the housing from the remaining components (especially the PCB).

> Press the front lens out of the lens holder.

Tab. 1: Overview of disposal

by component

> Send the separated components to the corresponding recycling centres (see

Component Disposal

Product

Housing

Front lens

PCBs, cables, plugs and

electrical connection pieces

Metal recycling (aluminium)

Glass recycling (used glass)

Electronics recycling

Tab. 1).

Note

a

WARNING

Packaging

Cardboard, paper

Polyethylene packaging

We would be pleased to be of assistance on the disposal of the V4000 PB. Contact your

local SICK representative.

Material separation may only be performed by specialist personnel!

Exercise care when disassembling the devices. The danger of injury is present.

Paper/cardboard recycling

Plastic recycling

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 21

Operating instructions Chapter 3

V4000 PB

Product description

3 Product description

This chapter provides information on the special features and properties of the V4000 PB.

It describes the safety concept, the range of use, the structure and operating principle of

the device, configuration options and the various operating modes.

> Read this chapter before you mount, install and commission the V4000 PB.

3.1 Special features

Sender/receiver system

Response time 10 ms

Unambiguous status information via LED and 7-segment display shown directly on the

V4000 PB receiver

All inputs and outputs of the system integrated in the receiver

Simple combination of the V4000 PB system with alternative protective measures by

means of bypass inputs and outputs

No additional evaluation unit required in the control cabinet

V4000 PB system uses the existing measurement guides of the press brake for

determining speed, position and direction

Optional operation via hardware input devices or via the outputs of the press brake

controller (e.g. NC).

The SICK CDS user interface provides ease of configuration and comprehensive

expanded diagnostics of the V4000 PB system

Reliable pinch-point monitoring even when workpiece surface has irregularities or

unevenness

Automatic functions

Determination and monitoring of the pinch point

Monitoring of the relevant overall machine overrun of the press brake as a function of

speed

Monitoring of the slow closing speed (≤ 10 mm/s) from pinch point V4000 PB (can be

configured)

Dynamic adaptation of the switch-over point

Position-dependent muting (6 mm above the pinch point)

Speed-dependent muting (configurable)

Checking of the die position to detect coarse maladjustment

Detection of box wall in front and rear spaces

Protective operation

3 protective volume modes with adapted protective volume shape corresponding to

bending task

Loading of press hydraulics minimised by box and back-stop modes without emergency

stop at box wall

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Page 22

Chapter 3 Operating instructions

6

r

/

r

V4000 PB

Product description

3.2 Safety concept

3.2.1 Protection principle of the V4000 PB

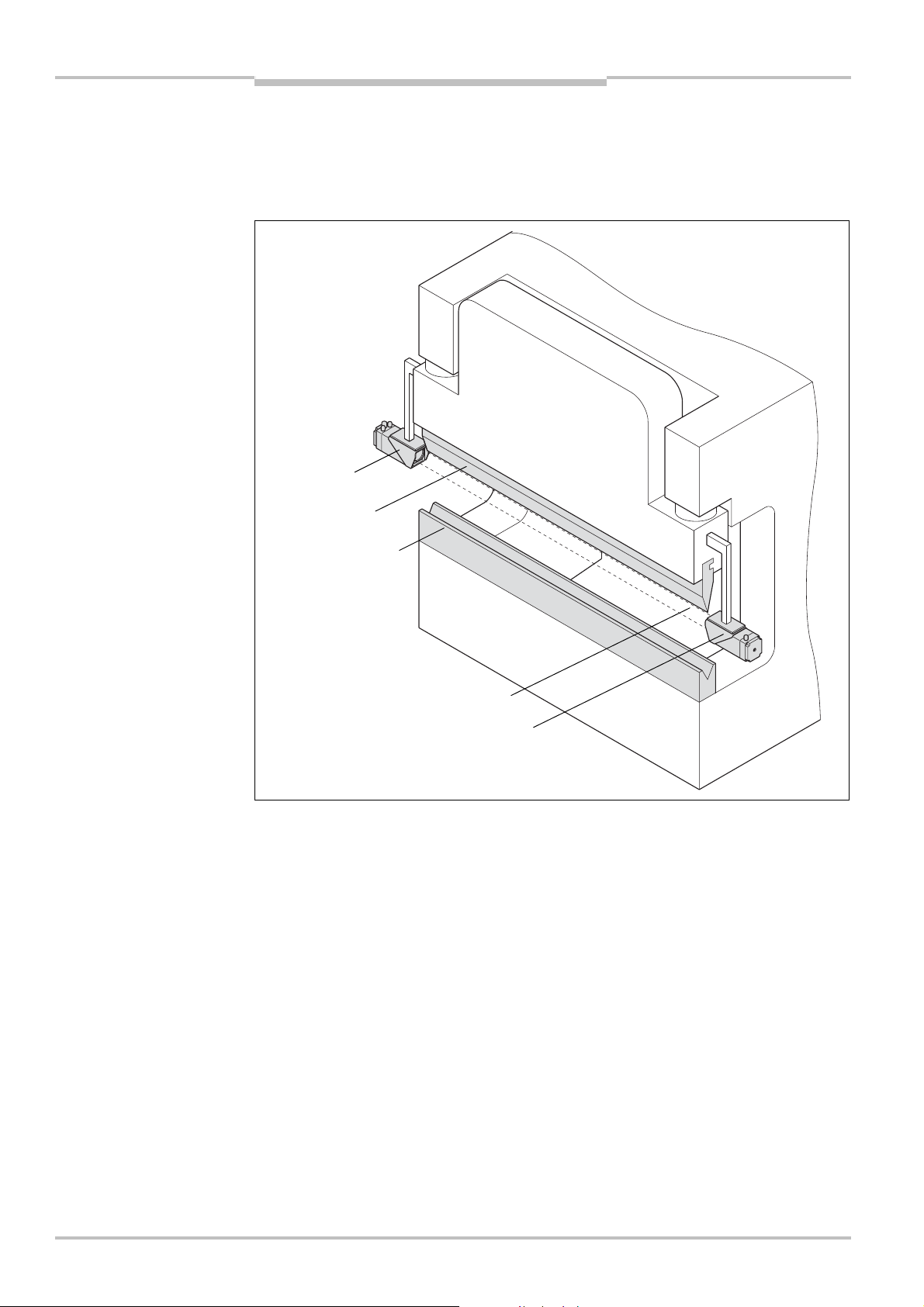

Fig.

: Press brake with

V4000 PB

Press crosshead

Receive

Die

Female die

Illumination field

protective volume

Sende

The V4000 PB consists of a sender and a receiver mounted on the press crosshead.

A light beam of light (illumination field) between sender and receiver forms a threedimensional protective field (protective volume) beneath the die tip measuring 40 mm

wide and 26 mm high. The protective volume follows the movement of the press

crosshead and in this way provides a travelling safety zone beneath the die tip.

The V4000 PB has three different kinds of protective volume (standard, box and backstop). These protective volumes differ in their dimensions and in their functions.

Should there be a partial or complete interruption of the protective volume by an object,

the output signal switching devices (OSSDs) of the ESPE which are integrated in the

receiver change over to the OFF state and generate a two-channel monitored switch-off

signal to the press controller which then must stop the closing movement of the press

crosshead with the die.

The evaluation and run concepts of the V4000 PB have been designed so that the ESPE

constantly checks its internal expected position (which depends on the operating mode,

the press crosshead position and the speed) against the actual external situation. Only

when the expected position is identical to the actual circumstances will the OSSDs remain

in the ON state. Any other result will put the OSSDs into the OFF state.

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 23

Operating instructions Chapter 3

7

d

V4000 PB

Product description

The V4000 PB safeguards the hazardous point beneath the die at high closing speeds

(> 10 mm/s) and a pass-through gap height of more than 6 mm. If the gap height between

the top of the workpiece and the die tip is 6 mm or less, the ESPE switches automatically

into muting mode.

If the muting option is activated at a low closing speed (≤ 10 mm/s), the system will

automatically go into muting mode even when the slow closing speed is reached. The

speed is monitored continuously.

In the muting state, the protective volume is inactive and the OSSDs stay in the ON state.

Note

Whether muting is permitted at the slow closing speed varies from country to country. This

option is by default disabled in the configuration.

In the event of system errors (such as an error being detected when the hardware is

tested) the V4000 PB switches into lock-out state.

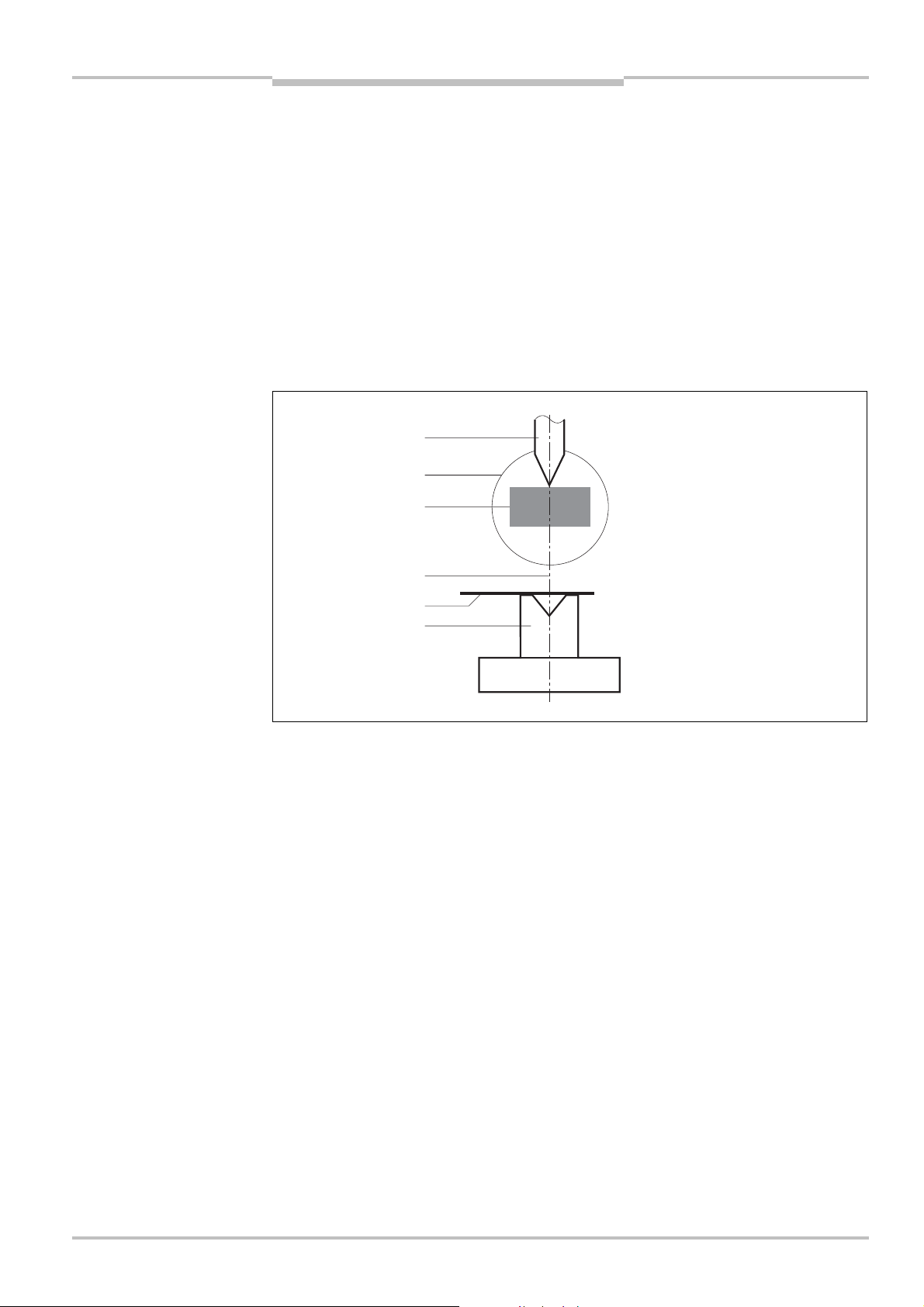

Fig.

: Definitions

Die

Illumination fiel

Protective volume

Pressure axis

Workpiece

Female die

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Page 24

Chapter 3 Operating instructions

V4000 PB

Product description

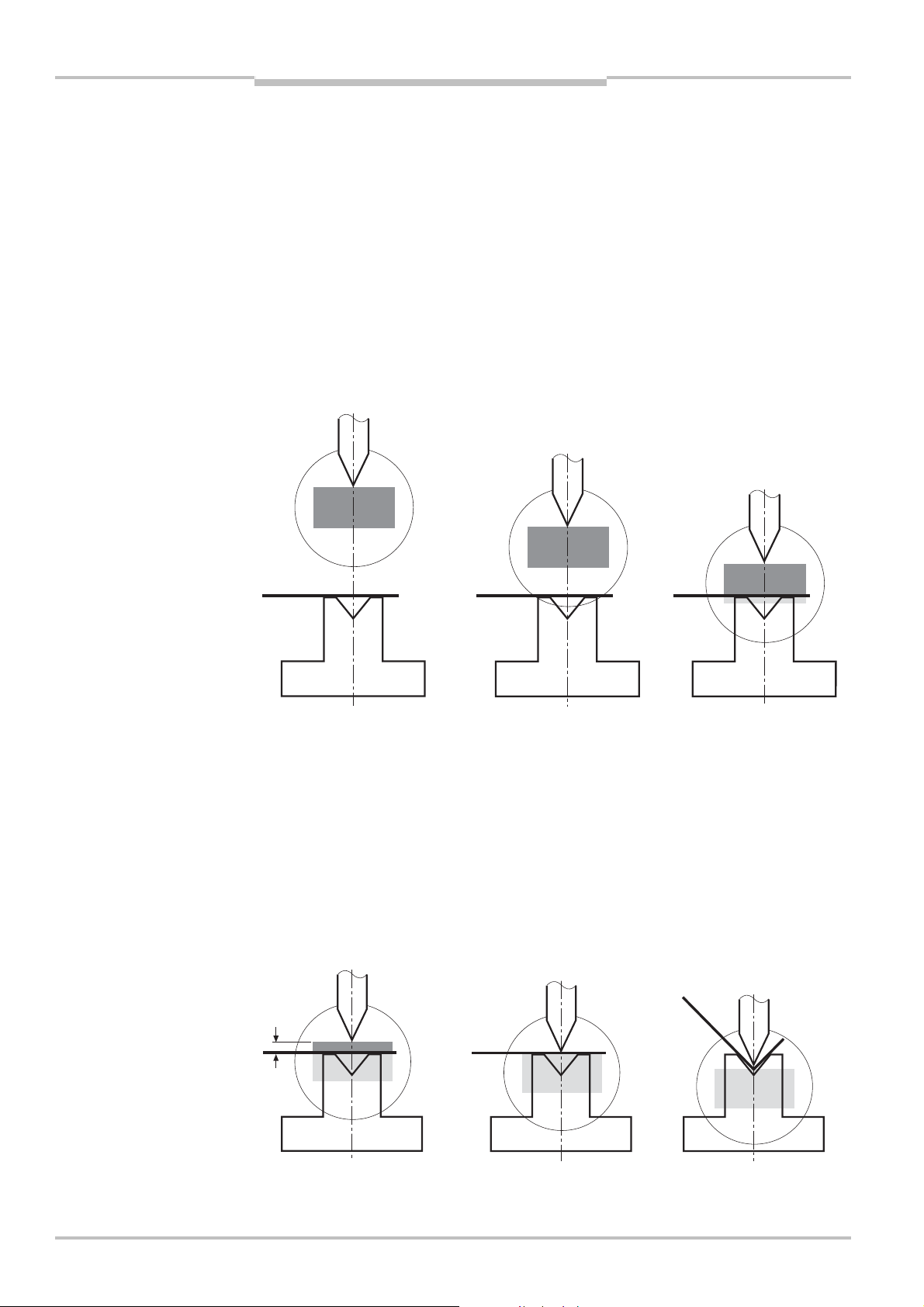

3.2.2 Protective volume during the operating cycle

This sequence shows the protective volume during one operating cycle.

Step

Protective volume

1 The die is at the

programmed top dead

centre.

The operator gives the

signal to start the

closing movement (foot

switch).

2 The die descends at

high speed

(> 10 mm/s).

The entire protective

volume is active.

3 At the switch-over point

the target speed is

requested by the

V4000 PB.

The press controller

initiates the braking

procedure.

The protective volume

stays active in the gap

opening.

Step

Protective volume

4 The calculation of the

switch-over point

includes an additional

6 mm safety gap

required to reach the

target speed (v

The protective volume

becomes inactive.

6 mm

slow

5 The die contacts the

workpiece (pinch point).

).

6 The die shapes the

workpiece. The

operating cycle ends at

the programmed bottom

dead centre. The die

goes back up.

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 25

Operating instructions Chapter 3

V4000 PB

Product description

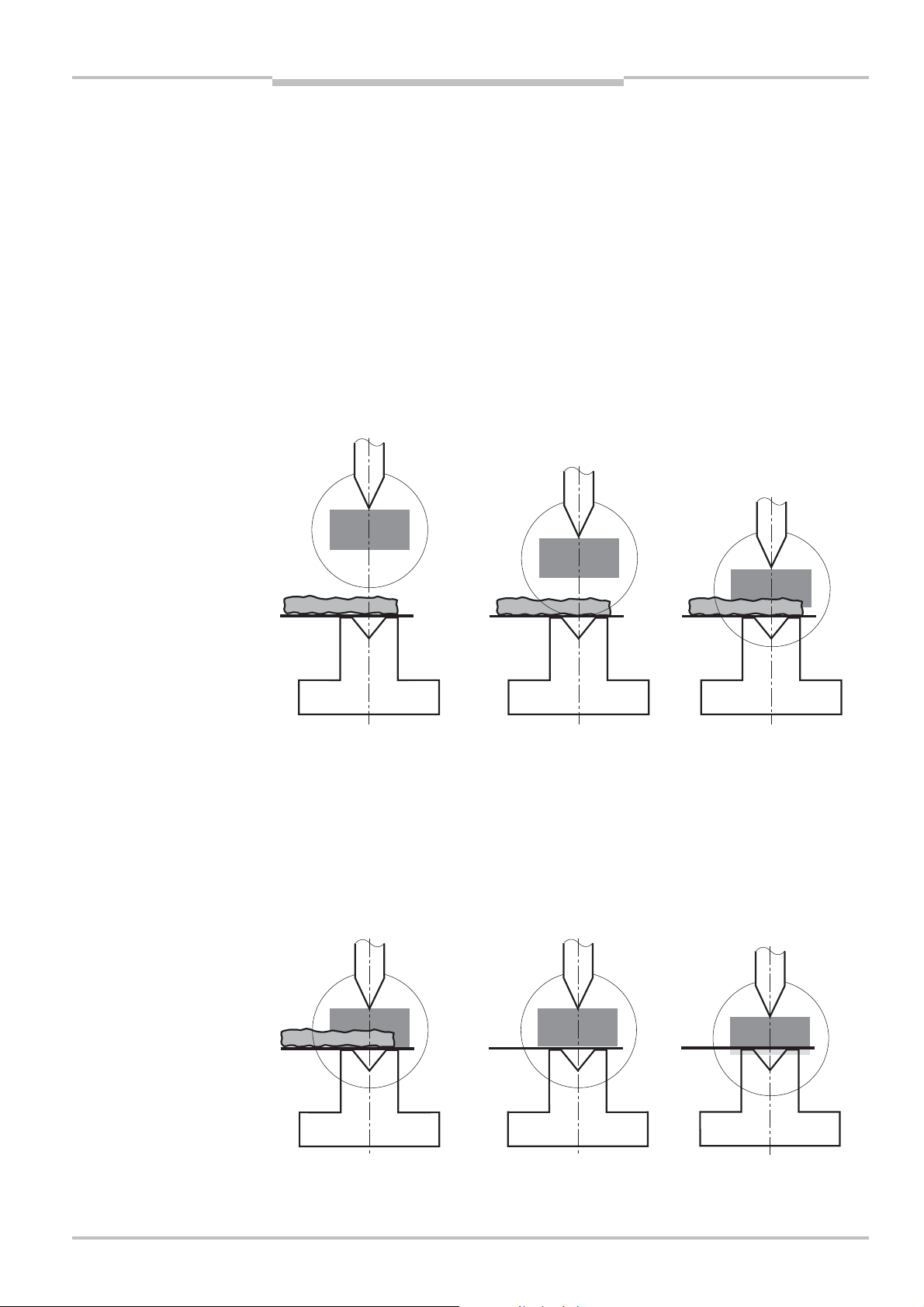

3.2.3 Intrusion of the protective volume during the operating cycle

This sequence shows how the V4000 PB responds when there is an interruption to the

protective volume.

Step

Protective volume

1 The die is at the

programmed top dead

centre.

There is a foreign object

on the workpiece or

female die.

The operator gives the

signal to start the

closing movement (foot

switch).

2 The die descends at

high speed

(> 10 mm/s).

The entire protective

volume is active.

3 Part of the protective

volume is interrupted by

the object.

The OSSDs go into the

OFF state and generate

a safe stop signal.

The press controller

must ensure the stop

procedure is

implemented.

Step

Protective volume

4 The die continues to

move in accordance

with the overall machine

overrun and stops at

least 5 mm above the

object.

5 The object is now

removed.

The protective volume is

clear again.

6 The operator gives the

signal once more to

start the closing

movement (foot switch).

The closing movement

starts and the operating

cycle resumes.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Page 26

Chapter 3 Operating instructions

V4000 PB

Product description

3.3 Range of use

The V4000 PB is an ESPE (electro-sensitive protective equipment) device designed to

protect the area beneath the die of press brakes at high closing speeds, it provides hand

and fingers protection.

The V4000 PB is suitable for stationary use in press brakes with a maximum distance of

7.5 m between the sender and the receiver.

The press brake must be designed to comply with the maximum stopping distance of

11 m.

This corresponds, for example, to a maximum overall machine overrun of 8.5 mm at a

maximum closing speed of 300 mm/s (see also Section

closing speed vcrawl from the pinch point").

Requirements for use of the V4000 PB

Before the V4000 PB can carry out its protective functions the following conditions must

be met:

It must be possible to influence the control of the press brake by electrical means.

The OSSDs of the V4000 PB must be incorporated into the press controller in such a way

that when the OSSDs give the switch-off signal:

– the dangerous state (high closing speed of > 10 mm/s) is stopped.

or

– the press, should the lock-out state occur, does not start up again.

The V4000 PB must be mounted and configured in such a way that it can detect objects

when they penetrate into the hazardous point.

3.5.13 "Monitoring of the slow

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 27

Operating instructions Chapter 3

r

7

y

r

t

C

V4000 PB

Product description

3.4 Structure of the device

The V4000 PB comprises the following components:

Sender

Receiver with interfaces

PBI with interfaces

CDS (software for configuration and diagnostics of the V4000 PB sensor)

In addition the V4000 PB needs control signals from external operating elements.

The sections which follow describe the individual components of the device.

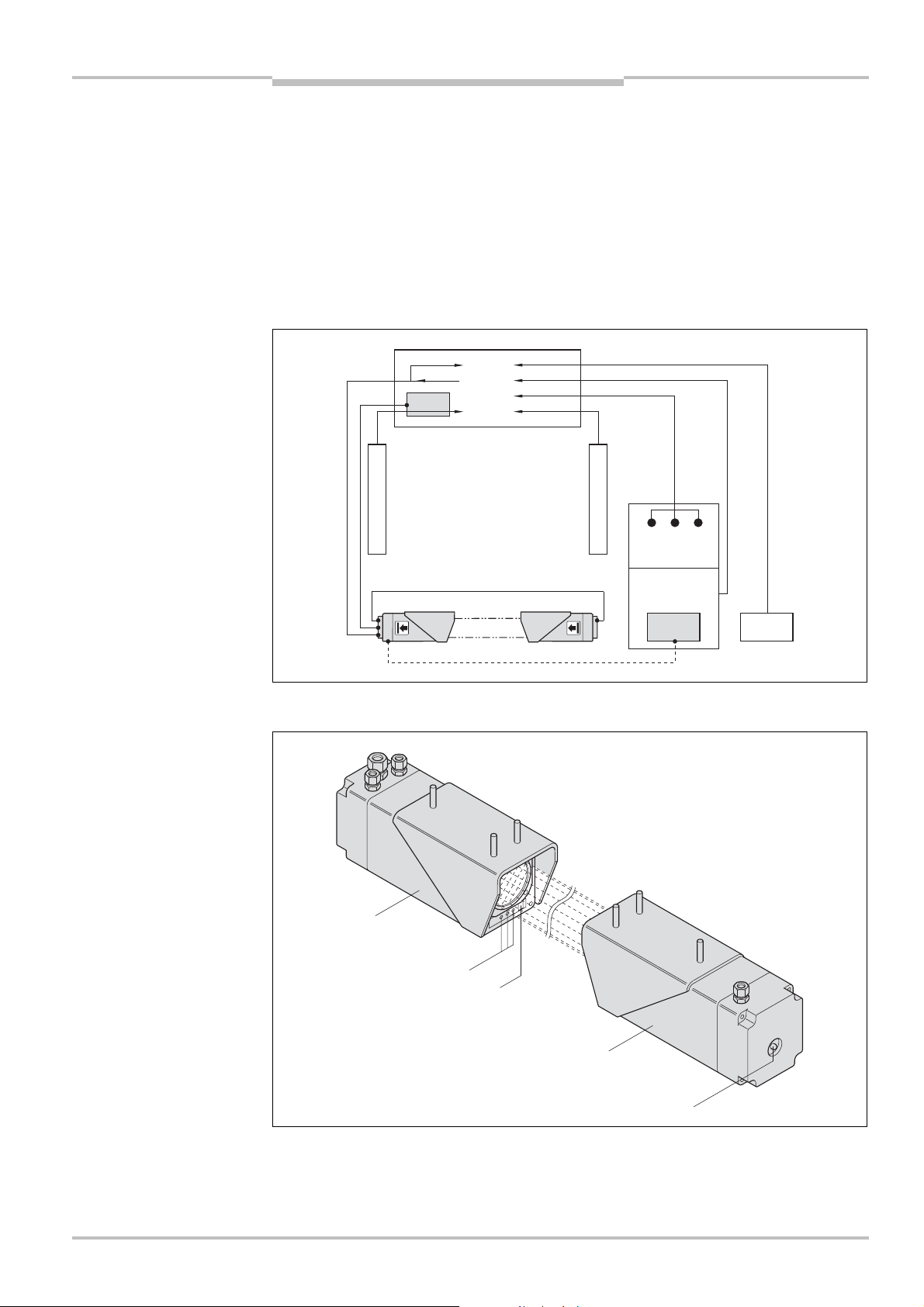

Fig. 8: Components

N

PBI

SPLC

Fig.

9: Sender and receiver

Incremental

encoders

3.4.1 Sender and receiver

Incremental

encoders

Operating

elements

HMI

CDS

Star

Receive

LEDs

-segment displa

Sende

LED

Sender and receiver are mounted on the press crosshead and follow the movements of

the crosshead. At start-up and every time there is a change of tooling, they need to be

precisely aligned to the length of the die used and to each other.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Page 28

Chapter 3 Operating instructions

w

V4000 PB

Product description

The laser diode in the sender emits light which is collected at the transmitting lens and

given parallel alignment. The beam of light, which has a constant diameter of 58 mm

(illumination field), travels along the lower side of the die to the receiver. In the receiver

the light beam is mapped at the image detector.

The evaluation electronics with all relevant inputs and outputs is built into the receiver.

Two output switching elements (OSSDs), which go into the OFF state when the sensor

function is triggered, pass on the signal for stopping the closing movement (high closing

speed > 10 mm/s).

3.4.2 Displays at the sender and receiver

Display at the sender

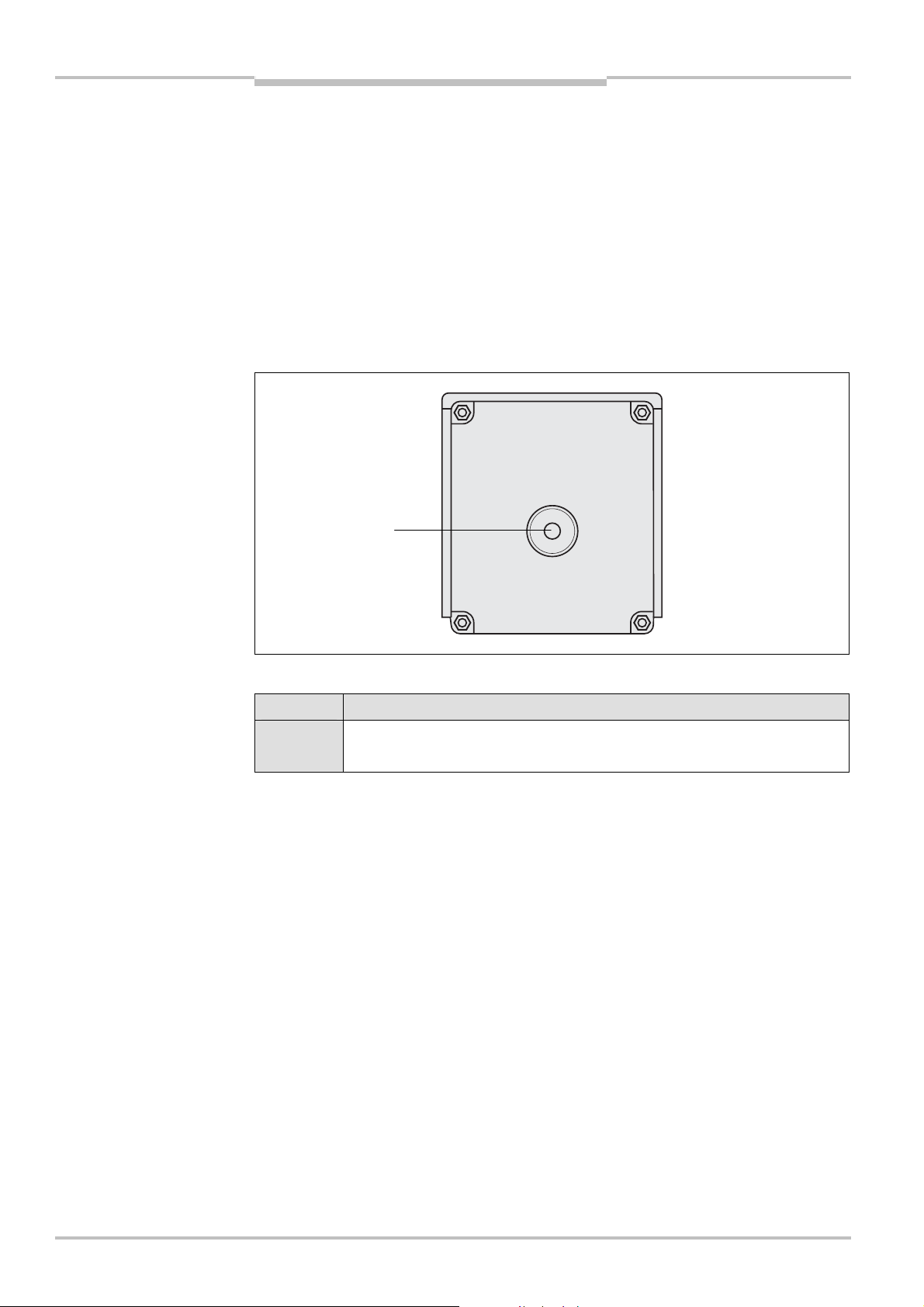

Fig. 10: Display at the sender

Tab.

2: Display at the sender

LED: Yello

An LED on the sender displays the status.

Display Meaning

O Yellow Power supply OK.

The sender of the V4000 PB is switched on.

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 29

Operating instructions Chapter 3

3:

w

7

y

V4000 PB

Product description

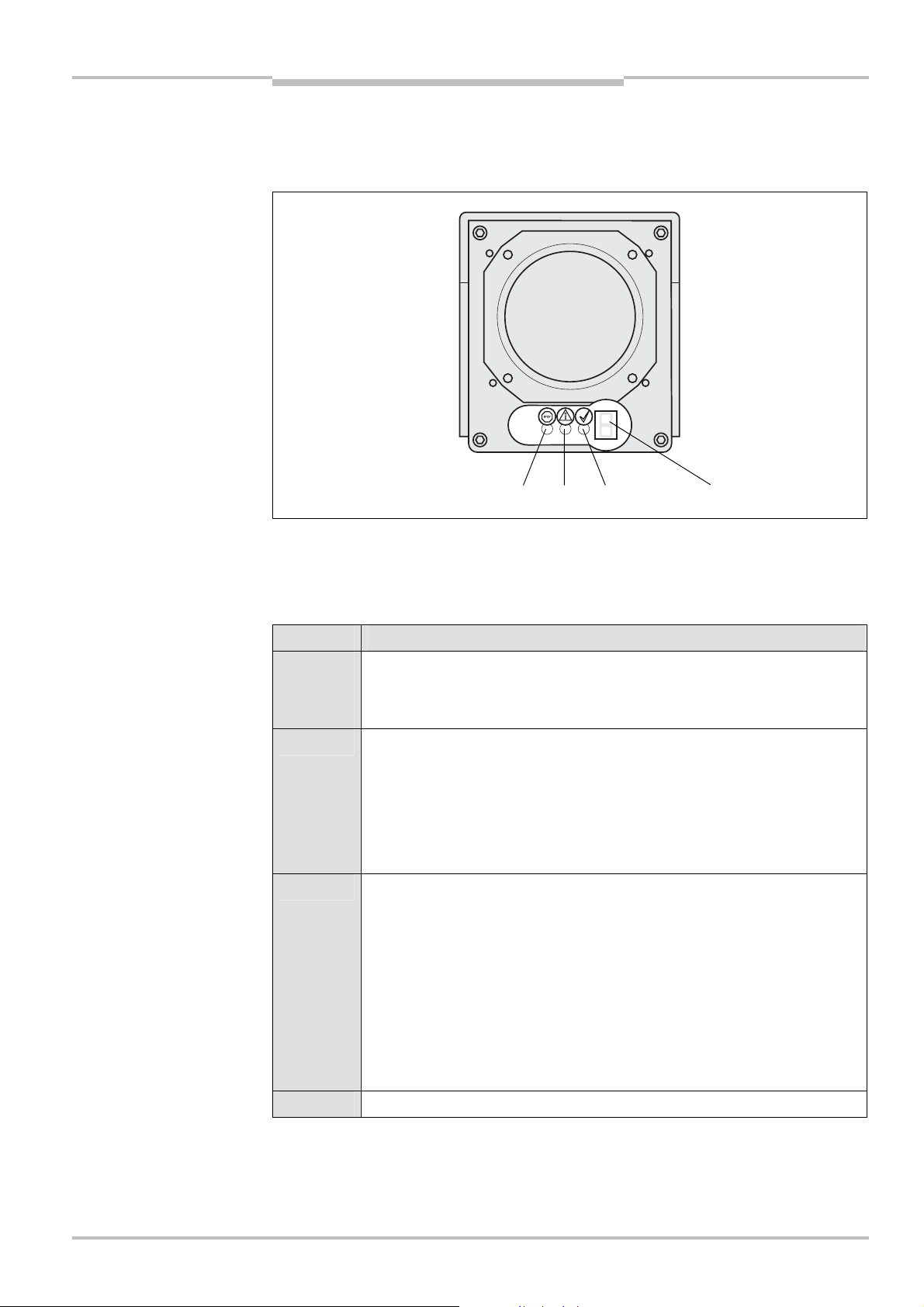

Displays at the receiver

The status of the system is displayed at the receiver by three LEDs and a

7-segment display.

Fig. 11: Displays at the

receiver

Yello

LEDs:

Red

Green

-segment displa

The LEDs tell the operator whether an input is expected and whether the OSSDs are in the

OFF or ON state.

The 7-segment display provides the operator with further information about the status of

the V4000 PB.

Tab.

the receiver display

Key to the LEDs on

Display Meaning

Ö Yellow

(10/90)

(90/10)

Operator action (input) is required (On % / Off % at 1 Hz)

– Alignment mode

– Teach-in request

O Yellow In production operation: Operator action (input) required

– In standard mode (release foot switch)

– In back-stop mode (first operation of the foot switch expected)

– In box mode (first operation of the foot switch expected)

During configuration: CDS connected and Configuration operating mode

selected

O Red System sending signals to switch off the machine

(OSSDs in the OFF state)

Additional states in which the red LED is illuminated:

– Self-test (system initialisation)

– Configuration

– Box mode

– Back-stop mode

– Lock-out state

– Alignment mode

O Green System free (OSSDs in the ON state)

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Page 30

Chapter 3 Operating instructions

V4000 PB

Tab. 4:

Key to the 7-segment

display on the receiver

Product description

Display Meaning

6 System error. The device is defective. Replace the receiver.

M Muting state

` Switch on. This is followed by self-testing of the V4000 PB

(system initialisation).

L Standard mode

= Box mode

} Back-stop mode

Note

Other

displays

Further explanations of the 7-segment display will be found in the following sections:

Displays during system initialisation when the machine is switched on (see Section

"

Switching the machine on")

Displays within alignment mode (see Section

Error displays within lock-out state (see Section

All of the other displays are error messages, displays within alignment

mode or displays during the self-test (system initialisation).

8.1

7.2 "Aligning sender and receiver")

9.2 "Error displays of the LEDs")

3.4.3 Interfaces at the receiver

The receiver of the V4000 PB has the following interfaces:

Digital interface

Serial interfaces for configuration and diagnostics

Interface for connecting the sender

Interface for connecting the PBI

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 31

Operating instructions Chapter 3

V4000 PB

Product description

Digital interface

The digital interface receives signals from the press controller or from external operating

elements and passes them on to the receiver; it also passes signals from the receiver on

to the press controller.

Tab. 5: Inputs and outputs at

the digital interface

Number

2 Actively tested semiconductor

Inputs and outputs

with safety relevance

switching outputs (OSSDs)

Function

For the switch-off signal to the press controller

which must stop the closing movement of the

press crosshead with the die

2 Inputs For the gated signal for starting the closing

movement

Number

Standard inputs and outputs Function

2 Pulsed outputs For the bypass signal

2 Inputs For the bypass signal

1 Input For external device monitoring (EDM)

1 Output For the target speed request to the press

controller

1 Input For activating alignment mode

1 Input For activating teach-in mode

3 Inputs For selecting the protective volume mode

(standard, box, back-stop) within protective

operation

1 Output For the signal to the press controller that

teach-in is being requested

Serial interface for configuration and diagnosis

The PC is connected to the receiver via the serial RS-232 interface for configuration of the

V4000 PB and for extended diagnostics with the SICK CDS Software in the event of

servicing. For a permanent connection of the PC (CDS) to the receiver an RS-422 interface

is available for extended diagnostics. A switch allows you to switch between the two

interfaces (see Section

6.1 "Delivery state").

Interface for connecting the sender

To allow control of the sender function by the receiver, the sender and the receiver are

electronically connected to the receiver via a signal line.

Interfaces for connecting the PBI

The receiver is provided with an interface for data transmission (incremental pulses of the

measurement guide) from the PBI.

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Page 32

Chapter 3 Operating instructions

V4000 PB

Product description

3.4.4 PBI (press brake interface)

Fig. 12: PBI (press brake

interface)

The incremental measurement guides of the press controller register the movement of the

press crosshead. The speed and direction of movement of the press crosshead and the

overall machine overrun are calculated by the V4000 PB from the signals of one

measurement guide and from other measured data (such as time).

The measurement guide is connected to the V4000 PB via the PBI in the control cabinet.

At the interface with the press controller the PBI taps onto the signals of the measurement

guide, decouples them and passes them on to the receiver.

Position detection must be checked to ensure it is working properly. The V4000 PB

monitors whether the signals (increments) from the measurement guide have a logical

order – in other words, whether they can be interpreted unambiguously as upward or

downward movement or standstill.

Example

If a start signal for the closing movement is detected by the safety-relevant inputs, it will be

assumed that the press brake is moving after a period of delay (start-up delay). If there is

no movement – in other words, the signals from the PBI cannot be unambiguously

interpreted as movement – the V4000 PB assumes that there is a fault in position

detection, switches the OSSDs into the OFF state, and goes into lock-out state.

The system will not change into the muting state unless the measurement system is

delivering correct information which agrees with the expected values.

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 33

Operating instructions Chapter 3

w

V4000 PB

Fig. 13: Display at the PBI

Product description

Display at the PBI

LED: Yello

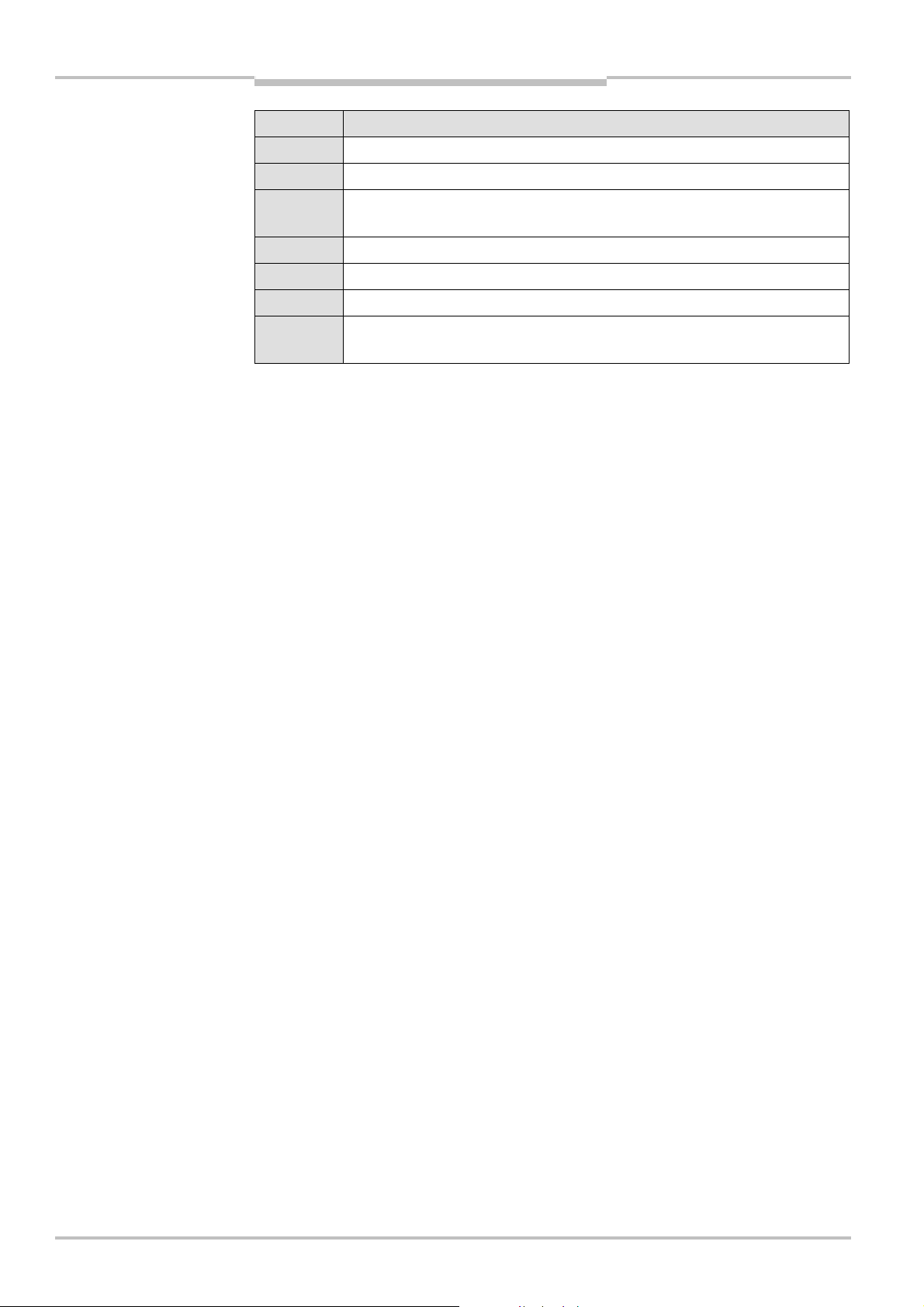

Tab.

6: Display at the PBI

Note

Display Meaning

O Yellow Power supply OK.

Interface at the PBI

The PBI of the V4000 PB has been designed for two-channel, incremental, linear

measurement guides with an RS- 422 interface. All signals of the measurement guide are

looped through.

3.4.5 CDS (Configuration & Diagnostics Software)

The V4000 PB is configured and diagnosed with the CDS software (Configuration &

Diagnostics Software) running on Windows 98 and later operating systems.

For more information see the Sections

3.5 "Possible device configurations" and 9.4

"Extended diagnostics via CDS".

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Page 34

Chapter 3 Operating instructions

t

C

t

C

V4000 PB

Product description

System configuration: version A

In the case of press brakes with PC control and a Windows user interface, the CDS for

configuration or diagnostics of the V4000 PB can be integrated into the control system.

Note

Fig. 14: System configuration

with PC control

Permanent – on-line - diagnostics and operation must be implemented solely via the

RS-422 interface.

N

PBI

SPLC

Fig.

15: System configuration

without PC control

Incremental

encoders

Incremental

encoders

Operating

elements

HMI

CDS

Star

System configuration: version B

In the case of press brakes without PC control or a Windows user interface, the CDS for

configuring the V4000 PB must be connected to the receiver. A permanent connection

with the CDS is not necessary.

N

PBI

SPLC

Incremental

encoders

CDS

Incremental

encoders

Operating

elements

HMI

Star

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 35

Operating instructions Chapter 3

V4000 PB

Note

Recommendation

Product description

3.4.6 External operating elements

For controlling the V4000 PB external signals are required. The V4000 PB has the

corresponding signal inputs for:

Starting the closing or opening movements of the press brake

Requesting alignment mode

Requesting or confirming teach-in

Selecting the protective volume mode (standard, box, back-stop)

Requesting bypass mode

The signals are generated either by operating elements such as buttons or selector

switches or by the outputs of the press controller (e.g. NC).

How these various possibilities are actually implemented (for example, foot switch,

alignment button, teach-in button, selector switch and key-operated switch, or

corresponding switching elements on the MMI of the press controller) falls within the area

of responsibility of the user.

All switching elements should be large and sturdy. It must be possible to operate them

reliably and simply while wearing gloves.

a

WARNING

n

3.5 Possible system configurations

This section describes the parameters and functions of the V4000 PB which can be

configured via CDS.

Check the V4000 PB after making changes!

After making any change to the configuration you must check the effectiveness of the

V4000 PB (function and configuration data).

When starting to configure the V4000 PB, you may save the configuration using an

application name with a maximum of 22 characters. You should use unique designations

with an evident relation to the concrete application name – such as "Machine name XYZ".

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Page 36

Chapter 3 Operating instructions

7

V4000 PB

Tab.

: Configurable

parameters and functions

Product description

Basic settings

Description in Section

Source of the operator signals 3.5.1

Baud rate of communication interface 3.5.2

Application name 3.5.3

Repetition interval of power-up cycle 3.5.4

Mounting of receiver 3.5.5

Position-sensing system 3.5.7

Increments per mm stroke

Measurement direction during closing movement

Speed-dependent muting 3.5.6

External device monitoring 3.5.8

Standstill time for determining the top dead centre 3.5.16

Start delay for closing movement 3.5.17

Time for standstill detection 3.5.18

Braking distance

Default value for braking distance 3.5.9

Travel for determining braking distance 3.5.10

Braking offset 3.5.11

Target speed v

Monitoring of the slow closing speed v

3.5.12

slow

from the pinch

crawl

3.5.13

point

Overall machine overrun

Max. overall machine overrun 3.5.14

Travel for determining overall machine overrun 3.5.15

Maximum closing speed 3.5.14

Inputs

Settling times for standard inputs

3.5.19

Settling times for safety-relevant inputs

Discrepancy time for safety-relevant inputs

3.5.20

Discrepancy time for protective volume selection

Maximum duration of 1st operation

3.5.21

(confirmation of reduced protective volume)

Start signal

Time for pause between 1st and 2nd operation

Outputs

Minimum state time for standard inputs 3.5.22

Minimum switch-off time of safety-relevant outputs 3.5.23

Bypass

Bypass 3.5.24

Discrepancy time for bypass inputs 3.5.20

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 37

Operating instructions Chapter 3

V4000 PB

Note

Product description

3.5.1 Source of the operator signals

With the CDS the V4000 PB can be configured to accept operator signals (alignment,

teach-in, reset, and selection of the protective mode) either from the CDS software or from

external touch elements such as buttons or selector switches. Use of CDS to provide these

operator signals requires a dedicated permanent (on-line) communication interface

between the V4000 PB and CDS via a RS-232 port.

Another method for providing operator signals to the V4000 PB is via the HMI of the

numerical control. These signals could be collected via touch buttons connected to the NC

interface or via software buttons on the HMI console.

Signals of the operating elements of the CDS overwrite signals of the external operating

elements. There could be inconsistencies between the system state and the state of the

V4000 PB.

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

n

3.5.2 Baud rate communication interface

By means of the CDS the baud rate (transmission rate) can be set at the serial interface

for configuration (between V4000 PB and connected PC). The setting will depend on how

powerful the PC is.

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

n

n

n

3.5.3 Application name

When starting to configure the V4000 PB, you may save an application name with a

maximum of 22 characters.

Here you should use unique designations with an evident relation to the concrete

application name – such as "Machine name XYZ".

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

3.5.4 Repetition interval of power-up cycle

The V4000 PB has an internal time monitor for certain functions. The time monitor should

ensure a regular check is made in the case of uninterrupted operation. The start times are

saved and compared with the current state. If the time for a particular function has

elapsed, a corresponding operator action will be requested.

Following an interruption to the supply voltage all times will be reset to zero.

The V4000 PB monitors the time since the last power-up cycle and requests a new powerup cycle if the configured value (≤ 24 h) is exceeded.

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

8010505/TL63/2009-11-27 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Page 38

Chapter 3 Operating instructions

V4000 PB

Product description

3.5.5 Mounting of receiver

In back-stop mode, the active protective volume segment as seen from the operator side is

behind the pressure axis.

In order to place the active protective volume correctly, it is necessary to specify during

configuration on which side of the press brake (as seen from the operator side) the

receiver is mounted.

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

n

3.5.6 Speed-dependent muting

Any one of the following conditions will result in automatic muting of the V4000 PB

(inactivation of the protective volume):

Gap size ≤ 6 mm above the taught-in pinch point

Upward movement

Note

In addition a closing movement at a low closing speed v

the system to go automatically into muting mode provided this option has been enabled

during configuration.

The closing speed is continually monitored. If the slow closing speed v

the muting state, muting will be deactivated and the protective volume activated.

With automatic muting at the slow closing speed v

close at slow closing speed despite an interruption of the protective volume.

If slow closing speed v

interrupted, the press will be stopped. After this the press brake can be closed at slow

closing speed via the press controller and a new start signal.

If slow closing speed has already been reached when the protective volume is interrupted,

a new start signal will not be needed.

If a slow closing speed (≤ 10 mm/s) is permitted by the applicable regulations as the sole

protective measure, the option may be activated by the machine setter. In ANSI standard

B11.3 "Safety Requirements for Power Press Brakes" the slow closing speed

(≤ 10 mm/s) is not specified as the sole protective measure!

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

has not yet been reached when the protective volume is

crawl

crawl

(≤ 10 mm/s) will also cause

crawl

is exceeded in

crawl

it is possible for the press brake to

n

3.5.7 Position-sensing system

The measurement guides (incremental encoders) of the press controller register the

position of the press crosshead.

Increments per mm stroke

The V4000 PB requires the resolution of the incremental encoder [INC/mm] in order to

calculate the speed and direction of movement of the press crosshead and the overall

machine overrun from the signals of one measurement guide and from other measured

data (such as time).

The incremental encoder must support two channels with at least 45 INC/mm and a

maximum of 300 INC/mm at a closing speed of 300 mm/s. The recommendation is

50 INC/mm.

The specifications of the encoder manufacturer can differ from those for the V4000 PB. If,

for example, pulses/mm or a resolution of 10 μm is specified, these have to be converted

into increments/mm.

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010505/TL63/2009-11-27

Page 39

Operating instructions Chapter 3

ON

F

OFF

V4000 PB

Product description

Measurement direction during closing movement

The 0° and the 90° signal of the incremental encoder are phase-shifted. During a closing

movement (positive sign) the V4000 PB expects the 0° signal to be leading.

Fig. 16: Incremental encoder

signals

0° signal

OF

Note

n

n

90° signal

ON

When connecting the incremental encoder channels, make sure that they do not swapped

or interchanged as this would lead to the direction of movement being misinterpreted. If a

measurement guide is replaced, you will need to check the configuration and input the

resolution of the new measurement guide into the configuration.

V4000 PB device symbol, context menu Configuration draft, Edit, Basic settings tab

3.5.8 External device monitoring (EDM)