Page 1

UM18-2 Pro

Ultrasonic sensors

OPERATING INSTRUCTIONS

Page 2

Described product UM18-2 Pro

Manufacturer SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

Original document This document is an original document of SICK AG.

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is

only permissible within the limits of the legal determination of Copyright Law. Any

modication, abridgment or translation of this document is prohibited without the

express written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

2 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 3

Table of contents

Table of contents

1 General information ........................................................................... 7

1.1 Information regarding the operating instructions ....................7

1.2 Explanation of symbols .............................................................7

1.3 Limitation of liability ..................................................................8

1.4 Scope of delivery .......................................................................8

1.5 Customer service ....................................................................... 8

1.6 EU declaration of conformity .....................................................8

2 Safety .................................................................................................. 9

2.1 Correct use ................................................................................. 9

2.2 Improper use ..............................................................................9

2.3 Requirements for skilled persons and operating personnel 10

3 Identication .................................................................................... 11

3.1 Type label ................................................................................ 11

3.2 Type code ................................................................................ 12

4 Structure and function .................................................................... 13

4.1 Structure and status indicators ............................................. 13

4.2 Function ................................................................................... 14

5 Mounting .......................................................................................... 15

5.1 Mounting the ultrasonic sensor ............................................. 15

5.2 Smooth object surfaces ......................................................... 15

5.3 Mounting multiple ultrasonic sensors ................................... 16

5.3.1 Minimum mounting distances ............................... 16

5.3.2 Synchronization mode ............................................ 16

5.3.3 Multiplex mode ....................................................... 17

6 Electrical connection ..................................................................... 19

6.1 Safety ....................................................................................... 19

6.2 Wiring notes ............................................................................ 19

6.3 Connecting the ultrasonic sensor electrically ....................... 20

6.4 Connection diagrams ............................................................. 21

6.4.1 Ultrasonic sensors with switching outputs ............ 21

6.4.2 Ultrasonic sensors with analog outputs ................ 22

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 3

Page 4

Table of contents

7 Commissioning ................................................................................ 23

7.1 Ultrasonic sensors with switching outputs ............................ 23

7.1.1 Teach-in the switching point – method A .............. 23

7.1.2 Teach-in the switching point – method B .............. 23

7.1.3 Teach-in the window ............................................... 24

7.1.4 Teach-in the background ........................................ 24

7.1.5 Conguring as normally open or normally closed . 25

7.2 Ultrasonic sensors with an analog output ............................ 25

7.2.1 Conguring the scaling of the analog output ....... 25

7.2.2 Conguring the rising or falling output

characteristic curve ................................................ 26

7.3 Additional settings for all sensor models .............................. 26

7.3.1 Switching between teach-in and synchronization/

multiplex mode ....................................................... 26

7.3.2 Resetting the settings to the factory setting ......... 27

7.4 Temperature compensation ................................................... 28

7.5 Measured value lter .............................................................. 29

8 IO-Link interface .............................................................................. 32

8.1 Physical layer .......................................................................... 32

8.2 Process data ........................................................................... 33

8.3 Service data ............................................................................ 33

8.3.1 IO-Link-specic ........................................................ 33

8.3.2 SICK-specic UM18-21712A21_ .......................... 34

8.3.3 SICK-specic UM18-21712A21_ .......................... 35

8.3.4 SICK-specic UM18-21212A21_ .......................... 36

8.3.5 SICK-specic UM18-21812A21_ .......................... 37

8.4 Error Codes ............................................................................. 38

9 Cleaning and maintenance ............................................................. 39

9.1 Cleaning .................................................................................. 39

9.2 Maintenance ........................................................................... 39

10 Troubleshooting ............................................................................... 40

10.1 Possible fault indicators ......................................................... 40

10.2 Disposal ................................................................................... 40

4 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 5

Table of contents

11 Technical data .................................................................................. 41

11.1 Dimensions ............................................................................. 41

11.2 Optics/Performance ............................................................... 42

11.3 Power supply ........................................................................... 43

11.3.1 Sensors with switching outputs ............................. 43

11.3.2 Sensors with analog outputs ................................. 43

11.4 Inputs ....................................................................................... 43

11.5 Outputs .................................................................................... 43

11.5.1 Sensors with switching outputs ............................. 43

11.5.2 Sensors with analog outputs ................................. 44

11.6 Interfaces ................................................................................ 44

11.7 Ambient conditions ................................................................. 45

11.8 Structural design .................................................................... 45

11.9 "Detection zone" diagrams ..................................................... 46

12 Accessories ...................................................................................... 48

12.1 "Connect+ Adapter" (CPA) ...................................................... 48

13 CongurationOverview ................................................................... 49

13.1 Conguration overview for sensors with switching outputs . 49

13.2 Conguration overview for sensors with analog outputs ..... 49

13.3 Additional settings for all sensors ......................................... 50

Index .......................................................................................................... 51

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 5

Page 6

6 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 7

General information

1 General information

1.1 Information regarding the operating instructions

These operating instructions supplement the Quick start guide and contain

additional information and detailed descriptions for using SICK AG's

UM18-2 Pro ultrasonic sensors. These operating instructions are intended

for specialists and electricians.

1.2 Explanation of symbols

Warnings Warnings in these operating instructions are indicated by symbols.

The warnings are introduced by signal words that indicate the extent of

the danger.

These warnings must be observed at all times and care must be taken to

avoid accidents, personal injury, and material damage.

DANGER!

… indicates a situation of imminent danger, which will

lead to a fatality or serious injuries if not prevented.

WARNING!

… indicates a potentially dangerous situation, which may

lead to a fatality or serious injuries if not prevented.

CAUTION!

… indicates a potentially dangerous situation, which may

lead to minor/slight injuries if not prevented.

IMPORTANT!

… indicates a potentially harmful situation, which may

lead to material damage if not prevented.

Tips and recommendations

NOTE!

… highlights useful tips and recommendations as well as

information for ecient and trouble-free operation.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 7

Page 8

General information

1.3 Limitation of liability

Applicable standards and regulations, the latest state of technological

development and many years of knowledge and experience have all been

taken into account when assembling the data and information contained in

these operating instructions.

The manufacturer accepts no liability for damage caused by:

• Failing to observe the operating instructions

• Incorrect use

• Use by untrained personnel

• Unauthorized conversions

• Technical modications

• Use of unauthorized spare parts/wearing parts.

With special variants, where optional extras have been ordered, or owing to

the latest technical changes, the actual delivery may vary from the features

and illustrations shown here.

1.4 Scopeofdelivery

1.5 Customerservice

The scope of delivery includes the following:

• UM18-2 Pro ultrasonic sensor

• Optional: Accessories (→ Page 48, Chapter 12).

Supplied documentation:

• Quick start guide

Do not hesitate to contact our customer service should you require any

technical information.

Please refer to the back page of these operating instructions for your

agent's contact details.

NOTE!

Before calling, make a note of all type label data such as

type code, serial number etc. to ensure faster processing.

1.6 EU declaration of conformity

→ You can download the EU declaration of conformity online from

"www.sick.com/um18".

8 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 9

2 Safety

2.1 Correct use

2.2 Improper use

Safety

The UM18-2 Pro is an ultrasonic sensor for non-contact detection of

objects, animals, and persons.

SICK AG assumes no liability for losses or damage arising from the use of

the product, either directly or indirectly. This applies in particular to use of

the product that does not conform to its intended purpose and is neither

described nor mentioned in this documentation.

The UM18-2 Pro ultrasonic sensor does not constitute a safety component

according to the EC Machinery Directive (2006/42/EC).

The UM18-2 Pro ultrasonic sensor must not be used in areas having

a danger of explosions.

Any other use that is not described as correct use is prohibited.

Never install or connect accessories if their quantity and composition are

not clearly specied, or if they have not been approved by SICK AG.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 9

Page 10

Safety

2.3 Requirements for skilled persons and operating personnel

WARNING

Riskofinjuryduetoinsucienttraining!

Improper handling may result in considerable personal

injury and material damage.

For this reason:

• All activities should always be performed only by

designated persons.

These operating instructions list the training requirements for the various

elds of activity, as follows:

• Skilled personnel

Due to their specialist training, skills, and experience, as well as their

knowledge of the relevant regulations, such persons are able to perform

tasks delegated to them and detect any potential dangers on their own

initiative.

• Electricians

Due to their specialist training, skills, and experience, as well as their

knowledge of the relevant standards and provisions, such persons are

able to perform work on electrical systems and detect any potential

dangers on their own initiative.

In Germany, electricians must meet the specications of the BGV

A3 Work Safety Regulations (e.g. Master Electrician). Other relevant

regulations applicable in other countries must be observed.

10 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 11

3 Identication

1

2354

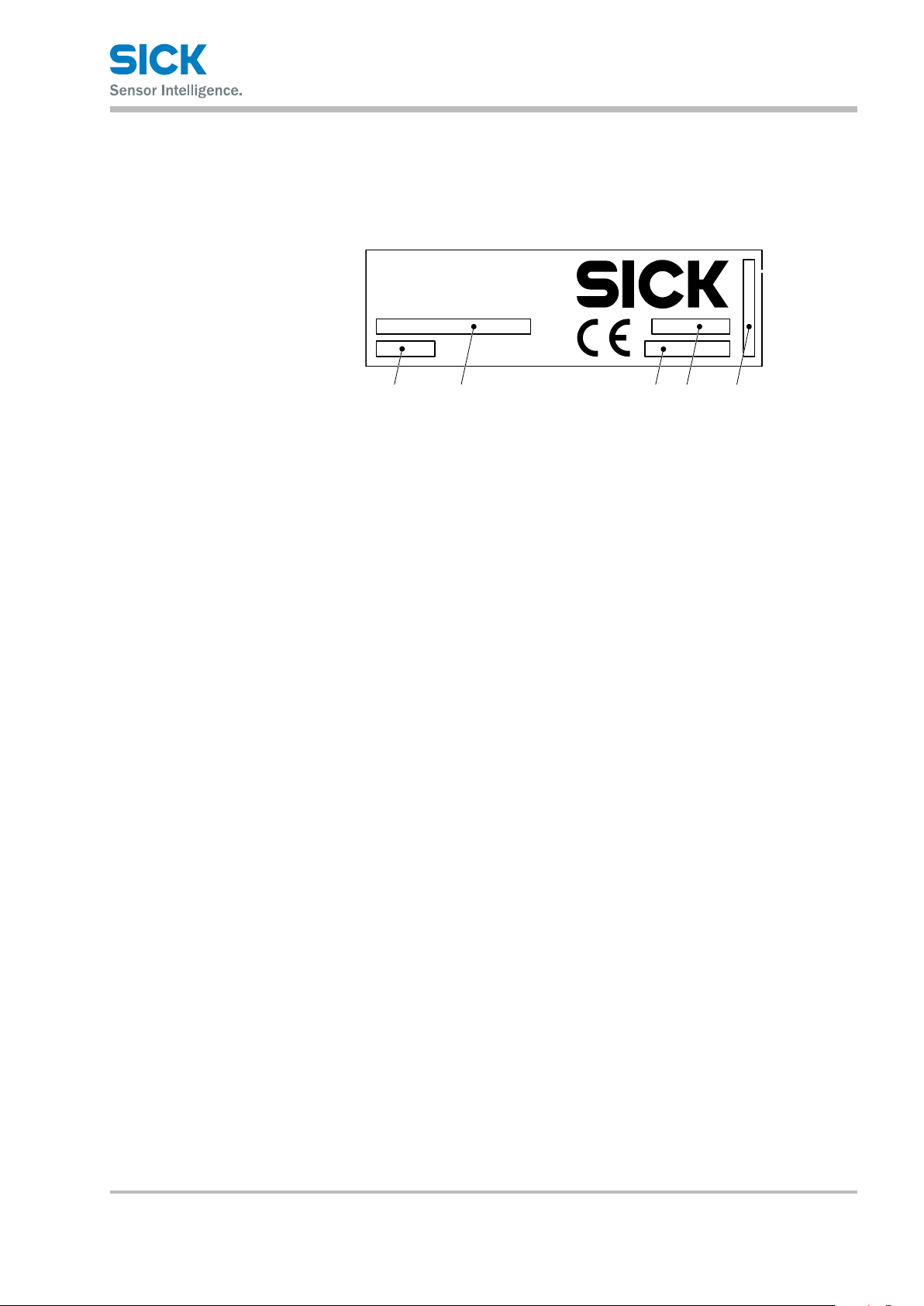

3.1 Type label

The ultrasonic sensor includes the following type label:

POWERQ

D-79183 Waldkirch

Made in Germany

Fig. 1: UM18-2 Pro type label

1 Order number

2 Type designation

3 Information about output

4 Supply voltage

5 Serial number

Identication

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 11

Page 12

Identication

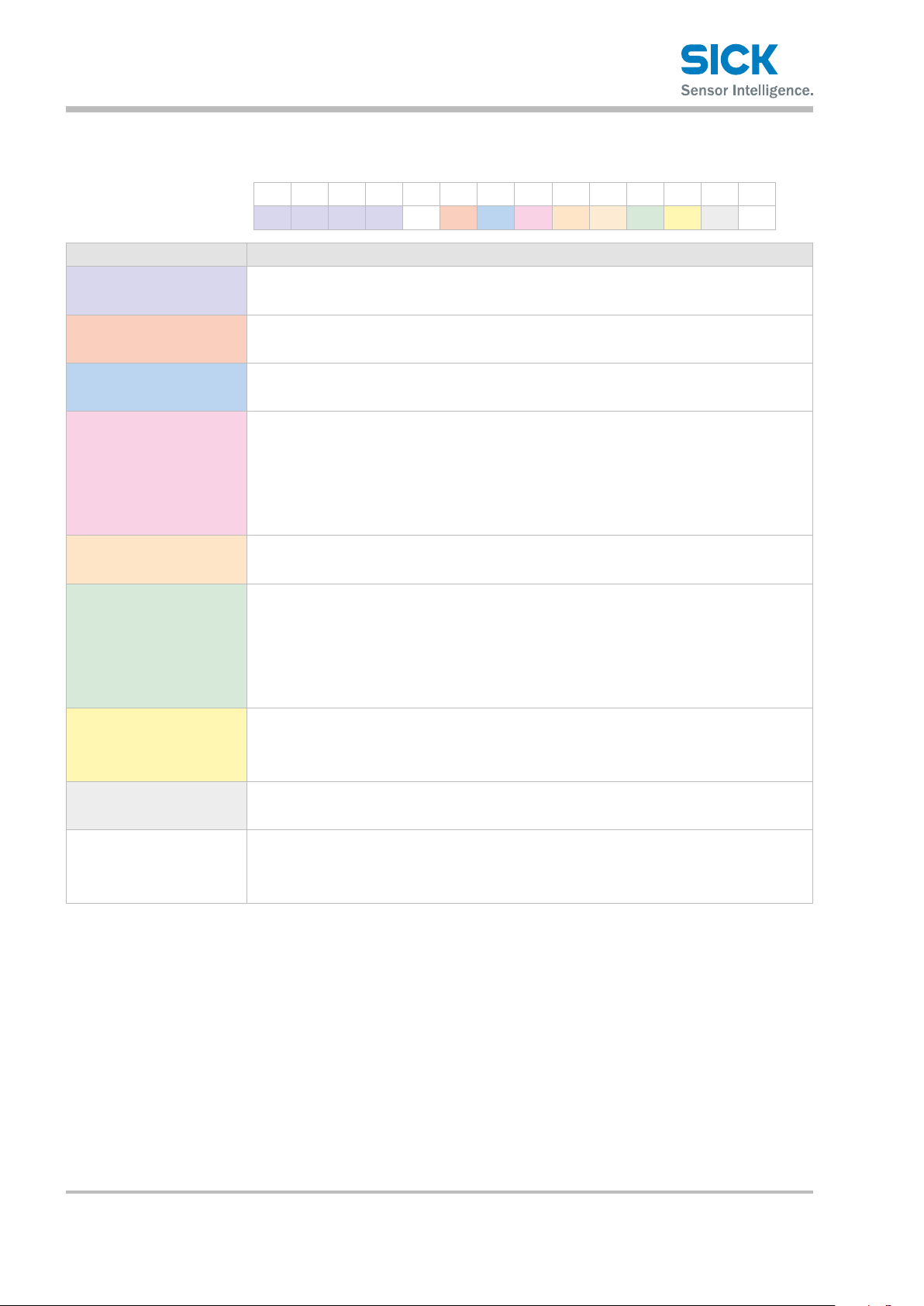

3.2 Type code

U M 1 8 – 2 1 7 1 2 A 2 1 1

1 2 3 4 5 6 7 8 9 10 11 12 13

Position Description

1 to 4

5

6

7

8 … 9

10

11

12

13

Table 1: Type code, UM18-2 Pro ultrasonic sensors

Product family

UM18

Generation

2 2. Generation

Principle of operation

1 Scanning principle

Detection range

7 20 mm … 150 mm, 250 mm

1 30 mm … 250 mm, 350 mm

2 65 mm … 350 mm, 600 mm

8 120 mm … 1000 mm, 1300 mm

Connectionandhousingversion

12 M12 plug, 5-pin, nickel-plated brass without display

Output function

A 1x Push-pull switching output

B 2x Push-pull switching output

6 1x Analog output 4 mA ... 20 mA

7 1x Analog output DC 0 V … 10 V

IO-Link

2 available

1 not available

Performance

1 Pro version

Alignment

1 Straight

2 Angled

12 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 13

4 Structure and function

4

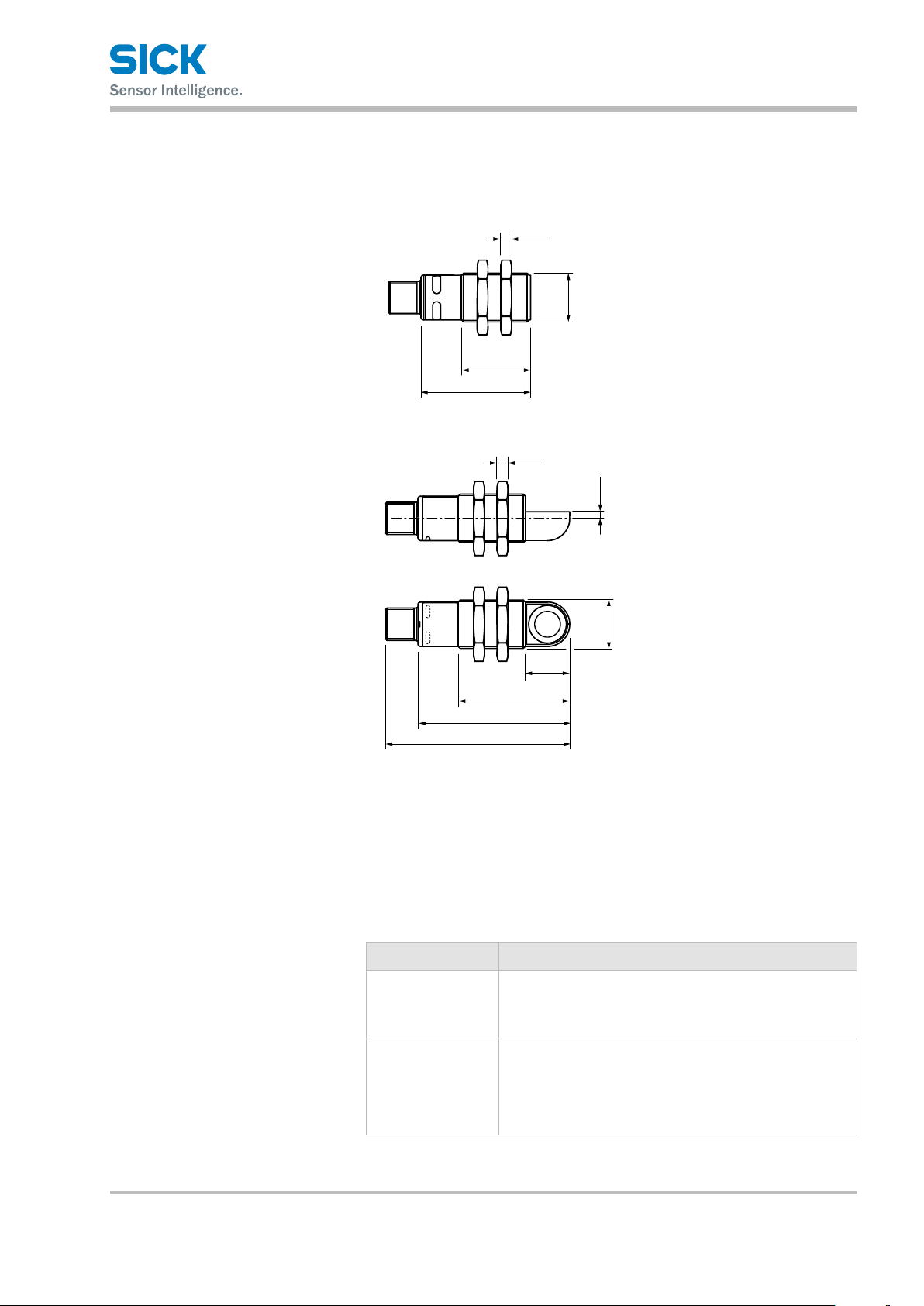

All dimensions in mm (inch)

1

4

(0.13)

1

4.1 Structure and status indicators

4

3

40.5 (1.59)

Structure and function

(0.16)

M18 x 1

2

25.5 (1.00)

2

(0.16)

3.4

3

4

16

41.5 (1.63)

56.5 (2.22)

68.5 (2.70)

Fig. 2: Structure: top "UM18-2xxxxxxx1 ultrasonic sensor"

bottom "UM18-2xxxxxxx2 ultrasonic sensor"

1 Connection

2 Mounting nuts, width across 24 mm

3 Supply voltage active LED status indicator (green)

4 Switching/analog output LED status indicator (orange)

(0.63)

M18 x 1

Status indicators (LEDs)

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 13

Status display Description

Green Supply voltage

• Green LED: Supply voltage on

• LED o: Supply voltage o

Orange

Table 2: Status indicators (LEDs)

Switching/analog output

• LED orange: Switching output active/measured value

within analog output scaling

• LED o: Switching output inactive/measured value

outside analog output scaling

Page 14

Structure and function

4.2 Function

The UM18-2 Pro is an ultrasonic sensor for performing non-contact

distance measurement or detection of objects, animals, and persons.

The circuit variations have the following operation modes: Distance to

Object (DtO), Window (Wnd), and Object between Sensor and Background

(ObSB). The measured distance value is transferred cyclically over an

IO-Link interface.

Depending on the model, the analog versions output a voltage or current

value corresponding to the measured distance value and the scaling on

the customer side.

14 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 15

5 Mounting

1

2

5.1 Mounting the ultrasonic sensor

Mounting

NOTE!

Distance measurement is not possible within the blind

zone of the ultrasonic sensor. → See Page 42,

Chapter 11.2.

NOTE!

→ For mounting accessories, see Internet

"www.sick.com/um18", Accessories.

1. Select the mounting location for the ultrasonic sensor according to

the requirement. Keep in mind the specications in the technical

data, such as the detection range. → For dimensions, see Page 41,

Chapter 11.1. → For detection range, see Page 46, Chapter 11.9.

2. Insert the ultrasonic sensor through the hole in the mounting bracket.

3. Tighten mounting nuts using a maximum torque of 15 Nm.

5.2 Smooth object surfaces

For smooth object surfaces, we recommend an angle of 90° ± 3° between

the sensor axis and the object surface. A larger angle is possible for rough

surfaces.

≤ ± 3° ≥ ± 3°

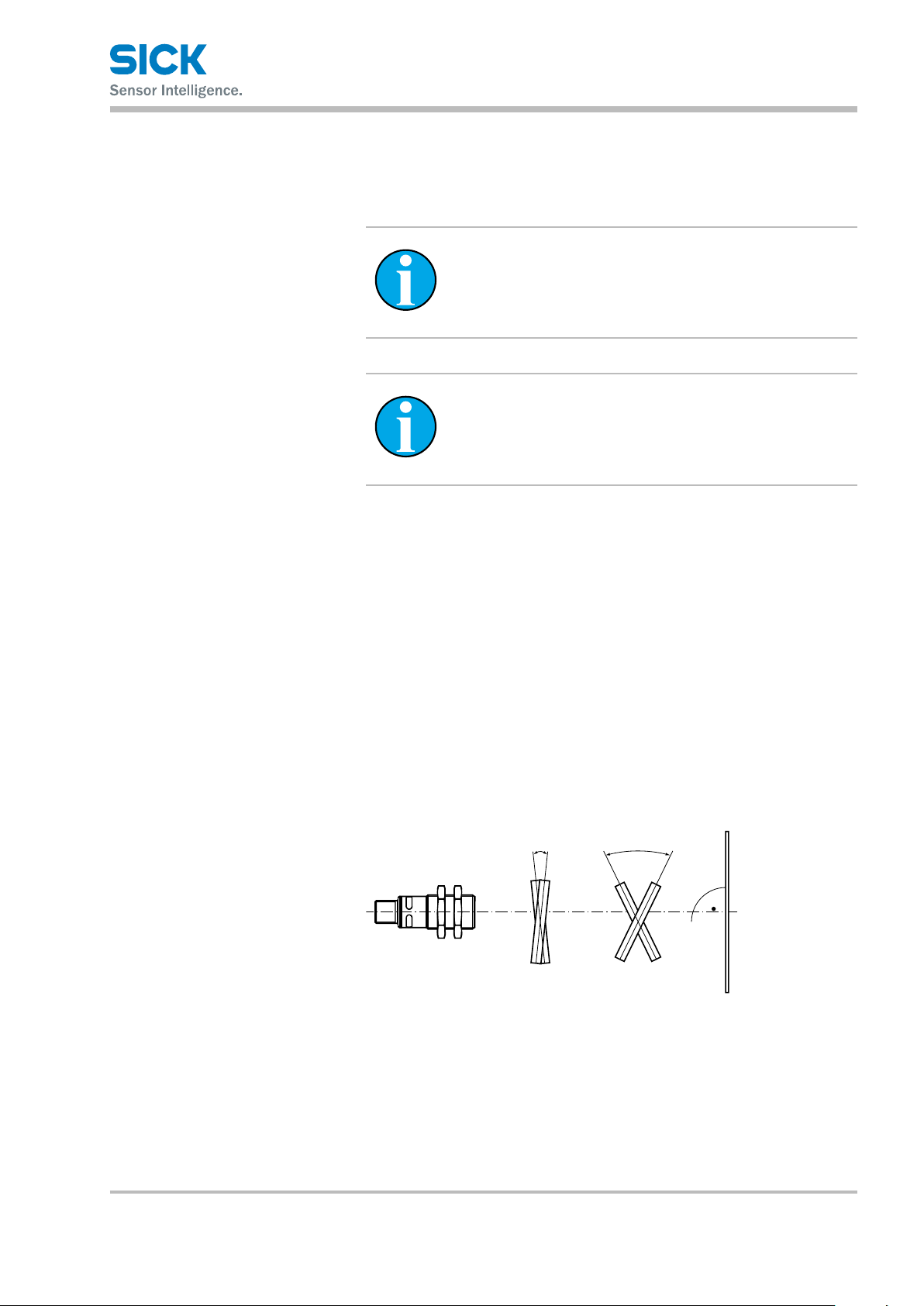

Fig. 3: Alignment of the sensor for smooth and rough object surfaces

1 Alignment for smooth object surfaces

2 Alignment for rough object surfaces

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 15

Page 16

Mounting

5.3 Mounting multiple ultrasonic sensors

5.3.1 Minimum mounting distances

If you would like to operate multiple ultrasonic sensors and the mount-

ing distance is lower than the value specied in Table 3 (page 16), we

recommend using synchronization or multiplex mode. Synchronization or

multiplex mode avoids mutual interference between the sensors.

→ For synchronization mode, see Page 16, Chapter 5.3.2.

→ For multiplex mode, see Page 17, Chapter 5.3.3.

Minimum mounting distances

withoutsynchronizationmodeor

multiplex mode

Ultrasonic sensor Minimum distance for

parallel mounting

UM18-217x > 250 mm > 1300 mm

UM18-211x > 350 mm > 2500 mm

UM18-212x > 400 mm > 2500 mm

UM18-218x > 700 mm > 4000 mm

Table 3: Minimum mounting distances without synchronization mode or

multiplex mode

Minimumdistancewhen

devicesaremounted

opposite one another

5.3.2 Synchronizationmode

NOTE!!

The synchronization mode is not available in IO-Link

mode.

Descriptionofsynchronizationmode Synchronization mode begins automatically as soon as the sensors are

interconnected via PIN 5 (MF).

The sensors measure simultaneously in synchronization mode.

This operating mode prevents unwanted mutual interference since

measurements from dierent times are not incorrectly compared with one

another. The sensors can therefore be mounted without taking into account

mounting distances.

The acoustic pulses of a sensor deected by an object can still be analyzed

by neighboring sensors. This makes it possible to implement more reliable

and simultaneous monitoring of large areas with synchronization mode, but

without position detection of the recorded objects.

The detection zone is enlarged to a size which covers all synchronized

sensors. A maximum of 20 sensors of type UM18-2 Pro can be connected,

and they can also be combined with synchronizable SICK ultrasonic

sensors from other product families.

The response time of the overall system is determined by the sensor with

the highest response time.

16 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 17

Synchronizationmodestructureand

t

operating principle

5.3.3 Multiplex mode

Mounting

PIN 5

Fig. 4: Synchronization mode

NOTE!!

The multipex mode is not available in IO-Link mode.

Description of multiplex mode To change to multiplex mode, sensors must be interconnected via

PIN 5 (MF) and dierent addresses must be assigned to them using the

Connect+ software.

In multiplex mode, all sensors measure in alternation in a dened

sequence. This operating mode prevents unwanted mutual interference

since measurements from dierent times cannot be incorrectly compared

with one another. The sensors can therefore be mounted without taking

into account mounting distances.

Thanks to alternating measurement, the monitoring of large areas is

possible with additional position detection of recorded objects.

The detection zone is enlarged to a size which covers all connected

sensors. A maximum of 20 sensors of type UM18-2 Pro can be connected,

and they can also be combined with synchronizable SICK ultrasonic

sensors from other product families.

Since measurement by the sensors is done in alternation, the response

time of the total system is increased in accordance with the “overall

response time” formula.

NOTE!

For multiplex mode, you must assign a unique address to

the sensors. The "Connect + Adapter" and the associated

software is required for this (order no. 6037782)

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 17

Page 18

t

Mounting

Overallresponsetime Response time

n: Number of connected sensors

Multiplex mode structure and operating principle

PIN 5

Fig. 5: Multiplex mode

= 4 • [(1.1 ms • n) + 0.75 ms • (1 + 2 + … + n)] +

overall

sum of the response times of all connected sensors

18 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 19

6 Electrical connection

6.1 Safety

Incorrectsupplyvoltage

Workingwithliveparts

Electrical connection

IMPORTANT!

Equipmentdamageduetoincorrectsupplyvoltage!

An incorrect supply voltage may result in damage to

the equipment.

For this reason:

• Operate the ultrasonic sensor using only a protected

low voltage and safe electrical insulation as per

Protection Class III.

IMPORTANT!

6.2 Wiring notes

Equipment damage or unpredictable operation due to

workingwithliveparts!

Working with live parts may result in unpredictable

operation.

For this reason:

• Carry out wiring work only when the power is o.

• Connect and disconnect cable connections only when

the power is o.

IMPORTANT!

Faultsduetoincorrectwiring!

Incorrect wiring may result in operational faults.

For this reason:

• Follow the wiring notes precisely.

NOTE!

We recommend using preassembled cables for

the wiring. → For preassembled cables, see Internet

"www.sick.com/um18", Accessories.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 19

Page 20

Electrical connection

All electrical connections of the ultrasonic sensor are congured as M12

round connectors.

The IP 67 protection class is only achieved using screwed plug connectors

or cover caps.

By using suitable cable entries and wiring, you can avoid interference

from devices such as switching power supplies, motors, clocked drives,

and contactors.

• Lay cables as far away as possible from cables having a high level of

radiated emission. If needed, employ additional measures such as

shielding plates.

• Do not lay cables parallel to other cables, particularly devices with a high

level of radiated emission, such as frequency converters.

• Do not lay cables parallel to energy cables.

6.3 Connecting the ultrasonic sensor electrically

1. Ensure that there is no voltage.

2. Connect the ultrasonic sensor according to the connection diagram.

→ See Page 21, Chapter 6.4.

20 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 21

6.4 Connection diagrams

Q/C

1

2

3

5

Q/Q/C

NOTE!

The lead colors specied in Sections 6.4.1 and 6.4.2

apply to SICK AG's preassembled cables. The lead

colors may vary for preassembled cables from other

manufacturers.

→ For preassembled cables, see Internet

"www.sick.com/en/um18", Accessories.

6.4.1 Ultrasonicsensorswithswitchingoutputs

Electrical connection

UM18-21xxxAxxx

1

brn

L+

4

blk

blu

wht

gra

Q/¯

3

M

2

nc

5

MF

4

Fig. 6: UM18-21xxxAxxx connection diagram,

M12 plug, 5-pin, A-coded

Contact Marking Wire color Description

1 L+ Brown Supply voltage:

→ See Page 43, Chapter 11.3.

2 Nc White Not assigned

3 M Blue Supply voltage: 0 V

4

5 MF Gray Multifunction input/output for

Black Switching output /

IO-Link communication

• External teach-in

• Synchronization mode/multiplex

mode

• Connect+ communication

Table 4: Description of UM18-21xxxAxxx plug

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 21

Page 22

1

2

3

5

Electrical connection

6.4.2 Ultrasonicsensorswithanalogoutputs

UM18-21xxx6xxx,

UM18-21xxx7xxx

1

brn

L+

4

blk

blu

wht

gra

nc

3

M

2

Q

A

5

MF

4

Fig. 7: UM18-21xxx6xxx (4 … 20 mA) and UM18-21xxx7xxx (0 … 10 V)

connection diagram, M12 plug, 5-pin, A-coded

Contact Marking Wire color Description

1 L+ Brown Supply voltage:

→ See Page 43, Chapter 11.3.

2 Q

A

3 M Blue Supply voltage: 0 V

4 Nc Black Not assigned

5 MF Gray Multifunction input/output for

White Analog output

• External teach

• Synchronization mode/multiplex

mode

• Connect+ communication

Table 5: Description of UM18-21xxx6xxx and UM18-21xxx7xxx plugs

22 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 23

Commissioning

1

1

7 Commissioning

7.1 Ultrasonicsensorswithswitchingoutputs

→ For a graphical overview of the various setup options,

see Page 49, Chapter 13.1 and Page 50, Chapter 13.3.

7.1.1 Teach-intheswitchingpoint–methodA

Distance to object (DtO) In method A, the switching output is set when the object is located within

the taught-in switching range. The orange LED lights up when the switching

output is active.

Fig. 8: Teach-in the switching point – method A

1 Switching point

1. Position object at 1.

2. Apply "L+" to "MF" for approximately 3 seconds until both LEDs ash

simultaneously.

3. When both LEDs ash alternately, apply "L+" for approximately

1 second to "MF".

b The ultrasonic sensor's switching point has been taught-in.

The ultrasonic sensor is in normal operational mode.

Congure the switching output as normally closed or normally open.

→ See Page 25, Chapter 7.1.5.

7.1.2 Teach-intheswitchingpoint–methodB

Distance to object (DtO) In method B, the switching output is set when the object is located within

the taught-in switching range plus 8 %. The orange LED lights up when

the switching output is active.

+ 8 %

Fig. 9: Teach-in the switching point – Method B

1 Switching point

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 23

Page 24

21

1

Commissioning

1. Position object at 1.

2. Apply "L+" to "MF" for approximately 3 seconds until both LEDs ash

simultaneously.

3. When both LEDs ash alternately, apply "L+" to "MF" for approximately

3 seconds until both LEDs again ash alternately.

b The ultrasonic sensor's switching point has been taught-in.

The ultrasonic sensor is in normal operational mode.

Congure the switching output as normally closed or normally open.

→ See Page 25, Chapter 7.1.5.

7.1.3 Teach-inthewindow

Window The switching output is set when the object is located within the window.

The orange LED lights up when the switching output is active.

Fig. 10: Teach-in the window

1 Switching point 1

2 Switching point 2

1. Position object at 1.

2. Apply "L+" to "MF" for approximately 3 seconds until both LEDs ash

3. When both LEDs ash alternately, position object at 2.

4. Apply "L+" to "MF" for approximately 1 second.

b The ultrasonic sensor's switching point has been taught-in.

Congure the switching output as normally closed or normally open.

→ See Page 25, Chapter 7.1.5.

7.1.4 Teach-in the background

ObjectbetweenSensorand

Background(ObSB)

The output is set when the object is located between the sensor and a xed

background. The orange LED lights up when the switching output is active.

Even at changing ambient conditions the object is detected in the range of

0 % ... 85 % of the taught-in distance.

simultaneously.

The ultrasonic sensor is in normal operational mode.

85 %

Fig. 11: Teach-in the background

1 Background

24 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 25

1. Position object at 1.

12

2. Apply "L+" to "MF" for approximately 3 seconds until both LEDs ash

simultaneously.

3. When both LEDs ash alternately, apply "L+" to "MF" for approximately

10 seconds until both LEDs stop ashing.

b The ultrasonic sensor's switching point has been taught-in.

The ultrasonic sensor is in normal operational mode.

Congure the switching output as normally closed or normally open.

→ See Page 25, Chapter 7.1.5.

7.1.5 Conguringasnormallyopenornormallyclosed

Factory setting: normally open

1. Apply "L+" to "MF" for approximately 13 seconds until both LEDs ash

alternately.

2. The green LED ashes. The orange LED indicates the current setting:

Commissioning

• On: normally open

• O: normally closed

3. To change the setting, apply "L+" to "MF" for approximately 1 second.

The orange LED changes its status.

4. After conguring, wait approximately 10 seconds until the green LED

stops ashing.

b The setting has been applied. The ultrasonic sensor is in normal

operational mode.

7.2 Ultrasonicsensorswithananalogoutput

→ For a graphical overview of the various setup options,

see Page 49, Chapter 13.2 and Page 50, Chapter 13.3.

7.2.1 Conguringthescalingoftheanalogoutput

The orange LED lights up when the object is located within the congured

scaling.

The minimum distance between the two scaling limits is 1 mm. A failed

teach-in is indicated by the simultaneous rapid ashing of both LEDs.

The original settings are retained.

Fig. 12: Teach-in the analog output

1 Scaling limit near the sensor

2 Scaling limit away from the sensor

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 25

Page 26

Commissioning

1. Position object at 1.

2. Apply "L+" to "MF" for approximately 3 seconds until both LEDs ash

simultaneously.

3. When both LEDs ash alternately, position object at 2.

4. Apply "L+" to "MF" for approximately 1 second.

b The analog output has been taught-in. The ultrasonic sensor is in

normal operational mode.

NOTE!

You can teach-in the limit near the sensor or the limit

away from the sensor rst. You can teach-in the output

characteristics afterwards. → See the following section.

7.2.2 Conguringtherisingorfallingoutputcharacteristiccurve

Factory setting: "Rising output characteristic curve"

1. Apply "L+" to "MF" for approximately 13 seconds until both LEDs ash

alternately.

2. The green LED ashes. The orange LED indicates the current setting:

• On: Rising output characteristic curve

• O: Falling output characteristic curve

3. To change the setting, apply "L+" to "MF" for approximately 1 second.

The orange LED changes its status.

4. After conguring, wait approximately 10 seconds until the green LED

stops ashing.

b The setting has been applied. The ultrasonic sensor is in normal

operational mode.

7.3 Additional settings for all sensor models

7.3.1 Switchingbetweenteach-inandsynchronization/multiplexmode

NOTE!

The teach-in functionality is deactivated when

synchronization/multiplex mode is activated.

For synchronization/multiplex mode, the ultrasonic

sensors must be interconnected via the "MF" input (pin

5). You can operate a maximum of 20 UM18-2 Pro

sensors in synchronization/multiplex mode.

26 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 27

Commissioning

Factory setting: Teach-in

1. Switch o the supply voltage.

2. Apply "M" to "MF".

3. Switch on the supply voltage and wait approximately 3 seconds until

both LEDs ash simultaneously.

4. The green LED ashes. The orange LED indicates the current setting:

• On: Teach-in

• O: Synchronization/multiplex mode

5. To change the setting, apply "M" to "MF" for approximately 1 second.

The orange LED changes its status.

6. After conguring, wait approximately 10 seconds until the green LED

stops ashing.

b The setting has been applied. The ultrasonic sensor is in normal

operational mode.

→ For additional information about synchronization/multiplex mode and

the minimum mounting distances without synchronization/multiplex mode,

see Page 16, Chapter 5.3.

7.3.2 Resetting the settings to the factory setting

1. Switch o the supply voltage.

2. Apply "M" to "MF".

3. Switch on the supply voltage and wait approximately 13 seconds until

both LEDs stop ashing.

4. Before switching o the supply voltage, disconnect "M" from "MF" in

order to apply the factory setting.

b All settings have been reset to the factory setting. The ultrasonic

sensor is in normal operational mode.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 27

Page 28

Commissioning

7.4 Temperature compensation

The UM18-2 Pro sensors feature internal temperature compensation. Due

to the sensor heating up, the temperature compensation function will reach

its optimal working point after approximately one minute.

Temperature compensation is calibrated for standard mounting condi-

tions, using an aluminum mounting bracket and mounting screws, at the

factory. It is automatically and optimally calibrated to the individual installation situation when the sensor is cold and the switching output has been

deactivated for approx. 30 min., or the analog output has been outputting

a constant value of between 11 and 13 mA or 4.4. and 5.6 V for approx.

30 min. If the measured value changes over the course of these 30 min.,

the calibration process running in the background is aborted. The standard

parameters or the parameters last calibrated are retained. This function is

very helpful when the installation situation diers greatly from the standard

mounting conditions (e.g. in the case of thermally insulated mounting) and

a very high level of accuracy is required.

Temperature compensation can be switched o via

“Connect+ Adapter,” not temperature-compensated: 0.17 %/K

28 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 29

Commissioning

7.5 Measuredvaluelter

Filter settings The following lter settings can be selected for the UM18-2 Pro ultrasonic

sensors using "Connect+ Adapter":

Filter F00 provides an unltered output for the measured values.

This mode is not permitted, as undesired EMC faults could result.

Decreasing distance values are checked by lters F01 and F02 only for

plausibility and then output without any further conditions. After checking

for plausibility, increasing distance values are tracked only if they do not

exceed a specied tolerance range for the rate of increase. If the deviations

are too great, they are classied as interference variables by the software

and bridged for an adjustable holding time according to lter strength P.

Filter F01 provides interference protection against individual pulses such

as EMC spikes in connection with protection against measured value jumps

that are away from the sensor. The lter is suitable for bridging signal

jumps.

Filter F02 provides interference protection against individual pulses

such as EMC spikes in connection with protection against very brief

measured value jumps away from the sensor. The lter reacts very quickly

to measured values near the sensor and provides a smoothed output of

measured values based on approximately arithmetic averaging. This lter

is therefore especially suitable for smoothing uctuating measured values.

Smoothing according to the lter strength P.

Filter F03 and F04 do not include a plausibility check. Thereby they waive

an interference protection against single interfering impulses and thus

resulting measurement value jumps with direction to smaller (F03) or larger

(F04) distance values. In return they react very quickly to measurement

value changes in the preferred distance level (F03: near sensor; F04: away

from sensor) and provide a smoothed output of measurement values in

this distance level, according to lter strength P.

In the opposite direction an adjustable holding time as well as an averaging

take eect, both operating according to lter strength P.

With lter F03 background reections of unexpected objects are faded out.

With lter F04 foreground reections of unexpected objects (e.g. stirring

tools) are faded out.

Filteroverview

Filter feature Plausibility check Dwelltime Preferred distance

level

Functionality Interference

protection against

individual pulses

(EMC)

Filter F00 (No lter) No No No preference No

F01 (Approximation lter) Ye s Yes Near sensor No

F02 (Average value lter) Ye s Low Near sensor Yes

F03 (Foreground lter) No Yes Near sensor Yes

F04 (Background lter) No Yes Away from sensor Yes

Table 6: Filter overview

Bridging measured

value jumps

Near sensor/away

from sensor

Averaging

"Smoothing"

the output of

measured values

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 29

Page 30

Commissioning

Filter parameters

Filter type (F) Filter strength (P) Plausibility check Holding time

overxcycles

F00 – No No No No

F01 0 (factory setting) Ye s 4 Near sensor No

1 Yes 8 Near sensor No

2 Yes 12 Near sensor No

3 Yes 16 Near sensor No

4 Yes 20 Near sensor No

5 Yes 50 Near sensor No

6 Yes 100 Near sensor No

7 Yes 200 Near sensor No

8 Yes 500 Near sensor No

9 Yes 1000 Near sensor No

F02 0 Yes 4 Near sensor 2

1 (factory setting) Ye s 4 Near sensor 4

2 Yes 8 Near sensor 6

3 Yes 8 Near sensor 8

4 Yes 8 Near sensor 10

5 Yes 8 Near sensor 20

6 Yes 8 Near sensor 32

7 Yes 8 Near sensor 64

8 Yes 8 Near sensor 128

9 Yes 8 Near sensor 255

F03 0 Yes 4 Near sensor 1

1 Yes 8 Near sensor 2

2 Yes 12 Near sensor 3

3 Yes 16 Near sensor 4

4 Yes 20 Near sensor 8

5 Yes 50 Near sensor 16

6 Yes 100 Near sensor 32

7 Yes 200 Near sensor 64

8 Yes 500 Near sensor 128

9 Yes 1000 Near sensor 255

F04 0 Ja 4 Away from sensor 1

1 Ja 8 Away from sensor 2

2 Ja 12 Away from sensor 3

3 Ja 16 Away from sensor 4

4 Ja 20 Away from sensor 8

5 Ja 50 Away from sensor 16

6 Ja 100 Away from sensor 32

7 Ja 200 Away from sensor 64

8 Ja 500 Away from sensor 128

9 Ja 1000 Away from sensor 255

Table 7: Filter parameters

Preferred distance

level

Averaging

overxcycles

30 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 31

Commissioning

Cycle time The cycle time corresponds to the measuring interval of the respective

sensor type.

UM18-217xxxxxx: 8 ms

UM18-211xxxxxx: 8 ms

UM18-212xxxxxx: 16 ms

UM18-218xxxxxx: 20 ms

Factory setting • Sensors with switching output: lter type F01 and lter strength 0

• Sensors with analog output: lter type F02 and lter strength 1

Foreground suppression Use foreground suppression to suppress stray reections caused by

objects in the vicinity of the sensor.

NOTE!

Interfering objects must not create multiple reections.

The ultrasonic sensor must not be covered by interfering

objects that aect the detection range.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 31

Page 32

IO-Link interface

8 IO-Link interface

8.1 Physical layer

The ultrasonic sensors with switching outputs are IO-Link-capable in

accordance with the V1.1 specication.

You can download the specic sensor IO-Link device description online

from "www.sick.com/um18".

NOTE!

If an ultrasonic sensor in SIO mode has been taught-in

via teach-in or via a "Connect+ Adapter," we recommend

resetting the sensor to its factory setting before

conguration using IO-Link.

Description Value

SIO mode

(standard I/O mode)

Output rate • UM18-217xxxxxx: 8 ms

Speed COM2 (38.4 kBaud)

Process data width 16 bits (frame type 2.2)

Table 8: Physical layer

Yes

• UM18-211xxxxxx: 8 ms

• UM18-212xxxxxx: 16 ms

• UM18-218xxxxxx: 20 ms

32 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 33

IO-Link interface

8.2 Process data

The process data for the UM18-2 Pro ultrasonic sensors has a data width

of 16 bits.

Description Value

Access Read

Data 2 bytes

Data type UINT (unsigned integer)

Table 9: Process data

MSB LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Distance value (15-bit) with a resolution of 0.1 mm Q

Table 10: Data format – process data, distance value, and switching output Q

8.3 Servicedata

8.3.1 IO-Link-specic

Index

decimal

(hex)

16 (0x10) Manufacturer

17 (0x11) Manufacturer text R www.sick.com –

18 (0x12) Product name R UM18-2 –

19 (0x13) Product ID R UM18-21212A21 Sensor description

20 (0x14) Product text R Ultrasonic sensor –

22 (0x16) Hardware version R 5.0 –

23 (0x17) Firmware version R 1.0.42 –

Table 11: IO-Link-specic service data

Description Format Access Value range Example Remarks

R SICK AG

name

→ See IO-Link

specication.

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 33

Page 34

IO-Link interface

8.3.2 SICK-specicUM18-21712A21_

Index

Description Format Access Value range Example Remarks

decimal

(hex)

64 (0x40) Switching point 1 UINT16 R/W 306 ... 3609

(21 ... 248 mm)

65 (0x41) Switchback point 1 UINT16 R/W 320 ... 3624

(22 ... 249 mm)

71 (0x47) Switching point 2 UINT16 R/W 335 ... 65512

(23 ... 250 mm)

72 (0x48) Switchback point 2 UINT16 R/W 335 ... 65512

(23 ... 250 mm)

73 (0x49) Foreground

suppression

66 (0x42) Switching output

function

67 (0x43) Filter UINT8 R/W • 00: F00

UINT8 R/W 0 ... 1878

(0 ... 129 mm)

UINT8 R/W • 00: normally closed

• 02: normally open

2)

• 01: F01

• 02: F02

68 (0x44) Filter strength UINT8 R/W • 00: P00

• 01: P01

• 02: P02

• 03: P03

• 04: P04

• 05: P05

• 06: P06

• 07: P07

• 08: P08

• 09: P09

74 (0x4A) Teach via pin 5 in

SIO mode

UINT8 R/W • 00: deactivated

• 16: activated

320 corresponds

to

22 mm

Specify values

1)

as a multiple

of the internal

measurement value

1)

resolution (0.069 m).

–

→ See also

Page 29,

Chapter 7.5.

For the selected

measured value lter,

you can select a lter

strength between 0

(weak ltering eect)

and 9 (strong ltering

eect).

–

Teach

Index

decimal

(hex)

02 (0x02) TE ACH UINT W • 161: Method A

Description Format Access Value range Example Remarks

A teach overwrites

• 162: Method B

• 164: Two-way

reection barrier

• 168: Reset to

factory setting

a function that has

already been set with a

newly selected function.

If a teach is successful,

the old value is

retained.

→ See Page 23,

Chapter 7.1

and Page 49,

Chapter 13.1.

1) Window operation deactivated for values > 3638.

2) Operation with lter setting "F00" is not permitted, as EMC faults may occur in this case.

Table 12: SICK-specic service data UM18-21712A21_

34 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 35

8.3.3 SICK-specicUM18-21712A21_

IO-Link interface

Index

Description Format Access Value range Example Remarks

decimal

(hex)

64 (0x40) Switching point 1 UINT16 R/W 436 ... 5065

(30 ... 348 mm)

65 (0x41) Switchback point 1 UINT16 R/W 451 ... 5080

(31 ... 349 mm)

71 (0x47) Switching point 2 UINT16 R/W 466 ... 65512

(32 ... 350 mm)

72 (0x48) Switchback point 2 UINT16 R/W 451 ... 65512

(31 ... 349 mm)

73 (0x49) Foreground

suppression

66 (0x42) Switching output

function

67 (0x43) Filter UINT8 R/W • 00: F00

UINT8 R/W 0 ... 3246

(0 ... 223 mm)

UINT8 R/W • 00: normally closed

• 02: normally open

2)

• 01: F01

• 02: F02

68 (0x44) Filter strength UINT8 R/W • 00: P00

• 01: P01

• 02: P02

• 03: P03

• 04: P04

• 05: P05

• 06: P06

• 07: P07

• 08: P08

• 09: P09

74 (0x4A) Teach via pin 5 in

SIO mode

UINT8 R/W • 00: deactivated

• 16: activated

800 corresponds

to 55 mm

Specify values

1)

as a multiple

of the internal

1)

measurement value

resolution (0.069 mm).

–

→ See also Page 29,

Chapter 7.5.

For the selected

measured value lter,

you can select a lter

strength between 0

(weak ltering eect)

and 9 (strong ltering

eect).

–

Teach

Index

decimal

(hex)

02 (0x02) TE ACH UINT W • 161: Method A

Description Access Access Value range Example Remarks

A teach overwrites

• 162: Method B

• 164: Two-way

reection barrier

• 168: Reset to

factory setting

a function that has

already been set

with a newly selected

function.

If a teach is not

successful, the old

value is retained.

→ See Page 23,

Chapter 7.1

and Page 49,

Chapter 13.1.

1) Window operation deactivated for values > 5094.

2) Operation with lter setting "F00" is not permitted, as EMC faults may occur in this case.

Table 13: SICK-specic service data UM18-21112A21_

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 35

Page 36

IO-Link interface

8.3.4 SICK-specicUM18-21212A21_

Index

Description Format Access Value range Example Remarks

decimal

(hex)

64 (0x40) Switching point 1 UINT16 R/W 946 ... 8704

(65 ... 598 mm)

65 (0x41) Switchback point 1 UINT16 R/W 961 ... 8718

(66 ... 599 mm)

71 (0x47) Switching point 2 UINT16 R/W 975 ... 65512

(67 ... 600 mm)

72 (0x48) Switchback point 2 UINT16 R/W 961 ... 65512

(66 ... 599 mm)

73 (0x49) Foreground

suppression

66 (0x42) Switching output

function

67 (0x43) Filter UINT8 R/W • 00: F00

UINT8 R/W 0 ... 4236

(0 ... 291 mm)

UINT8 R/W • 00: normally closed

• 02: normally open

2)

• 01: F01

• 02: F02

68 (0x44) Filter strength UINT8 R/W • 00: P00

• 01: P01

• 02: P02

• 03: P03

• 04: P04

• 05: P05

• 06: P06

• 07: P07

• 08: P08

• 09: P09

74 (0x4A) Teach via pin 5 in

SIO mode

UINT8 R/W • 00: deactivated

• 16: activated

100 corresponds

to 69 mm

Specify values

1)

as a multiple

of the internal

1)

measurement value

resolution (0.069 mm).

–

→ See also Page 29,

Chapter 7.5.

For the selected

measured value lter,

you can select a lter

strength between 0

(weak ltering eect)

and 9 (strong ltering

eect).

–

Teach

Index

decimal

(hex)

02 (0x02) TE ACH UINT W • 161: Method A

Description Format Access Value range Example Remarks

A teach overwrites

• 162: Method B

• 164: Two-way

reection barrier

• 168: Reset to

factory setting

a function that has

already been set

with a newly selected

function.

If a teach is not

successful, the old

value is retained.

→ See Page 23,

Chapter 7.1

and Page 49,

Chapter 13.1.

1) Window operation deactivated for values > 8733.

2) Operation with lter setting "F00" is not permitted, as EMC faults may occur in this case.

Table 14: SICK-specic service data UM18-21212A21_

36 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 37

8.3.5 SICK-specicUM18-21812A21_

IO-Link interface

Index

Description Format Access Value range Example Remarks

decimal

(hex)

64 (0x40) Switching point 1 UINT16 R/W 1747 ... 18892

(120 ... 1298 mm)

65 (0x41) Switchback point 1 UINT16 R/W 1761 ... 18907

(121 ... 1299 mm)

71 (0x47) Switching point 2 UINT16 R/W 1776 ... 65512

(122 ... 1300 mm)

72 (0x48) Switchback point 2 UINT16 R/W 1761 ... 65512

(121 ... 1299 mm)

73 (0x49) Foreground

suppression

66 (0x42) Switching output

function

67 (0x43) Filter UINT8 R/W • 00: F00

UINT8 R/W 0 ... 12969

(0 ... 891 mm)

UINT8 R/W • 00: normally closed

• 02: normally open

2)

• 01: F01

• 02: F02

68 (0x44) Filter strength UINT8 R/W • 00: P00

• 01: P01

• 02: P02

• 03: P03

• 04: P04

• 05: P05

• 06: P06

• 07: P07

• 08: P08

• 09: P09

74 (0x4A) Teach via pin 5 in

SIO mode

UINT8 R/W • 00: deactivated

• 16: activated

2000 corresponds

to 138 mm

1)

1)

Specify values

as a multiple

of the internal

measurement value

resolution (0.069 mm).

–

→ See also Page 29,

Chapter 7.5.

For the selected

measured value lter,

you can select a lter

strength between 0

(weak ltering eect)

and 9 (strong ltering

eect).

–

Teach

Index

decimal

(hex)

02 (0x02) TE ACH UINT W • 161: Method A

Description Format Access Value range Example Remarks

A teach overwrites

• 162: Method B

• 164: Two-way reec-

tion barrier

• 168: Reset to factory setting

a function that has

already been set

with a newly selected

function.

If a teach is successful,

the old value is

retained.

→ See Page 23,

Chapter 7.1

and Page 49,

Chapter 13.1.

1) Window operation at value.

2) Operation with lter setting "F00" is not permitted, as EMC faults may occur in this case.

Table 15: SICK-specic service data UM18-21812A21_

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 37

Page 38

IO-Link interface

8.4 Error Codes

→ For error codes, see IO-Link specication V1.1.

38 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 39

9 Cleaning and maintenance

9.1 Cleaning

Cleaning and maintenance

IMPORTANT!

Equipment damage due to improper cleaning!

Improper cleaning may result in equipment damage.

For this reason:

• Never use cleaning agents containing aggressive

substances.

• Never use pointed objects for cleaning.

9.2 Maintenance

The ultrasonic sensor requires the following maintenance work at regular

intervals:

Interval Maintenancework To be performed by

Cleaning interval depends

on ambient conditions and

climate

Every 6 months Check the screw connections and plug connections. Specialist

Table 16: Maintenance schedule

Clean housing. Specialist

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 39

Page 40

Troubleshooting

10 Troubleshooting

10.1 Possible fault indicators

LEDs on the ultrasonic sensor Possible causes Troubleshooting

Green and orange LEDs

ash at the same rate for

3 seconds.

Table 17: Possible fault indicators

10.2 Disposal

Teach point is outside the permitted range. Check teach distance and perform teach

again.

Teach failed, for example, due to interfering

reections or mounting distances that are

too small when using multiple sensors.

Analog output only: Taught-in distance

between the scaling limits is below 1 mm.

• Check the sensor detection zone and keep

free. If necessary, shield existing sources

of interference.

• When using multiple sensors, observe

minimum mounting distances without

synchronization mode and operate

sensors in synchronization mode if

necessary.

→ See Page 16, Chapter 5.3.2.

Repeat teach for window limits.

Please observe the following when disposing of the removal sensor:

• Do not dispose of the device along with household waste.

• Dispose of the device according to the applicable regulations in your

country.

40 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 41

11 Technical data

4

All dimensions in mm (inch)

1

4

(0.13)

1

11.1 Dimensions

Technical data

NOTE!

You can download, save, and print the relevant online

data sheet for your ultrasonic sensor, including technical

data, dimensions, and connection diagrams,

from "www.sick.com/UM18".

(0.16)

4

M18 x 1

3

2

25.5 (1.00)

40.5 (1.59)

2

(0.16)

3.4

3

4

16

41.5 (1.63)

56.5 (2.22)

68.5 (2.70)

Fig. 13: Structure: top "UM18-2xxxxxxx1 ultrasonic sensor"

1 Connection

2 Mounting nuts, width across 24 mm

3 Supply voltage active LED status indicator (green)

4 Switching/analog output LED status indicator (orange)

bottom "UM18-2xxxxxxx2 ultrasonic sensor"

(0.63)

M18 x 1

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 41

Page 42

Technical data

11.2 Optics/Performance

Detection areas (typical) → See Page 46, Chapter 11.9, "”Detection zone” diagrams".

Operating range • UM18-217xxxxxx: 20 mm ... 150 mm

• UM18-211xxxxxx: 30 mm ... 250 mm

• UM18-212xxxxxx: 65 mm ... 350 mm

• UM18-218xxxxxx: 120 mm ... 1000 mm

Limiting range • UM18-217xxxxxx: 250 mm

• UM18-211xxxxxx: 350 mm

• UM18-212xxxxxx: 600 mm

• UM18-218xxxxxx: 1300 mm

Accuracy ± 1 % in relation to the current measured value

Repeatability ± 0.15 % in relation to the current measured value

Temperature compensation • Temperature drift compensated internally

→ See Page 28, Chapter 7.4.

• Temperature compensation can be switched o via

"Connect+ Adapter," not temperature-compensated: 0.17 %/K

Resolution ≥ 0.069 mm

Ultrasonic frequency • UM18-217xxxxxx: 380 kHz

• UM18-211xxxxxx: 320 kHz

• UM18-212xxxxxx: 400 kHz

• UM18-218xxxxxx: 200 kHz

Output time • UM18-217xxxxxx: 8 ms

• UM18-211xxxxxx: 8 ms

• UM18-212xxxxxx: 16 ms

• UM18-218xxxxxx: 20 ms

Initialization time < 300 ms

Switching frequency • UM18-217xxxxxx: 25 Hz

• UM18-211xxxxxx: 25 Hz

• UM18-212xxxxxx: 12 Hz

• UM18-218xxxxxx: 10 Hz

Response time

1)

• UM18-217xxxxxx: 32 ms

• UM18-211xxxxxx: 32 ms

• UM18-212xxxxxx: 64 ms

• UM18-218xxxxxx: 80 ms

1) For sensors with analog output: depending on the application, subsequent smoothing of the analog signal may increase the response time

by up to 200 %.

Table 18: Performance data

42 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 43

11.3 Powersupply

11.3.1 Sensorswithswitchingoutputs

Technical data

Supply voltage V

1)

,

s

• DC 15 … 30 V

sensors with switching output

UM18-2xxxxxAxxx

Power consumption (without load) < 1.2 W

Residual ripple ± 10 % within the acceptable supply voltage V

1) Limit values: Max. 8 A for operation in a short-circuit protected network.

Table 19: Supply – sensors with switching outputs

11.3.2 Sensorswithanalogoutputs

Supply voltage V

sensors with switching output

UM18-2xxxxx7xx

Supply voltage V

sensors with switching output

UM18-2xxxxx6xx

Circuit protection V

Power consumption (without load) < 1.2 W

Residual ripple ± 10 % within the acceptable supply voltage V

1) Limit values: Max. 8 A for operation in a short-circuit protected network.

Table 20: Supply – sensors with analog outputs

1)

,

s

1)

,

s

DC 15 ... 30 V DC

• DC 10 … 30 V DC at RL ≤ 100 Ω

• DC 20 … 30 V DC at RL ≥ 100 Ω

connections, reverse polarity protected

s

s

s

11.4 Inputs

Multifunction input MF • Teach-in

• Connect+ communication

• Synchronization/multiplex mode

Table 21: Inputs

11.5 Outputs

11.5.1 Sensorswithswitchingoutputs

Sensors with switching outputs UM18-2xxxxAxxx

Switching output • Push-pull: PNP/NPN

• HIGH: V

• IO-Link

– (< 3 V), LOW: < 3 V

s

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 43

Page 44

Technical data

Hysteresis • UM18-217xxxxxx: 2 mm

• UM18-211xxxxxx: 3 mm

• UM18-212xxxxxx: 5 mm

• UM18-218xxxxxx: 20 mm

Congurable via "Connect+ Adapter"

Circuit protection Short-circuit protected

Maximum output current < 100 mA

Table 22: Outputs – sensors with switching outputs

11.5.2 Sensorswithanalogoutputs

Sensors with analog outputs • UM18-2xxxx6xxx: 4 mA … 20 mA

• UM18-2xxxx7xxx: DC 0 … 10 V DC

Analog output

UM18-2xxxx6xxx

Analog output

UM18-2xxxx7xxx

• 4 mA … 20 mA

• RL ≤ 500 Ω, at V

• Rising, falling characteristic curve, congurable

• DC 0 … 10 V DC

• RL ≥ 100 Ω

≤ 20 V: max. load ≤ 100 Ω

s

• Rising, falling characteristic curve, congurable

Resolution 12 Bit

Circuit protection UM18-2xxxxx6xx: Voltage output is short-circuit protected

Table 23: Outputs – sensors with analog outputs

11.6 Interfaces

IO-Link For sensors with switching outputs

Connect+ Conguration interface for communication via "Connect+ Adapter"

accessories

Table 24: Interfaces

44 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 45

11.7 Ambient conditions

Protection class III

Electromagnetic compatibility

Ambient temperature range –25 °C … +70 °C

Storage temperature range –40 °C … +85 °C

Enclosure rating IP 67 according to EN 60529

1) Operation with lter setting "F00" is not permitted, as EMC faults may occur in this case.

Table 25: Ambient conditions

1)

EN 61000-6-2, EN 55011, Class A

EN 60947-5-2/-3

11.8 Structural design

Dimensions → See Page 41, Chapter 11.1.

Technical data

Weight • Straight: 25 g

• Angled: 30 g

Materials • Housing: Nickel-plated brass

• Ultrasonic transducer: polyurethane foam, glass epoxy resin

Connections Plug M12, 5-pin

Display • Green LED: operation

• Orange LED: on when switching/analog output is active

Table 26: Structural design

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 45

Page 46

(1.97)

(9.84)

(5.91)

(7.87)

(3.94)

Detection area in mm (inch)

Detection area in mm (inch)

100

(3.94)

150

(5.91)

150

(5.91)

Detection area in mm (inch)

100

(3.94)

50

(1.97)

50

(1.97)

0

Detection area in mm (inch)

0

50

(1.97)

150

(5.91)

100

(3.94)

200

(7.87)

250

(9.84)

300

(11.81)

350

(13.78)

3

4

5

2

1

Technical data

11.9 "Detectionzone"diagrams

UM18-217 UM18-211

250

2

200

150

3

1

100

4

5

50

0

100

(3.94)50(1.97)

Fig. 14: "UM18-217" detection zone

1 Detection zone depends on reection characteristics,

size, and alignment of the object

2 Limiting range

3 Operating range

4 Example object: aligned plate 500 mm x 500 mm

5 Example object: round bar with diameter 10 mm

0

50

(1.97)

100

(3.94)

Fig. 15: "UM18-211" detection zone

1 Detection zone depends on reection characteristics,

size, and alignment of the object

2 Limiting range

3 Operating range

4 Example object: aligned plate 500 mm x 500 mm

5 Example object: round bar with diameter 10 mm

46 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 47

UM18-212 UM18-218

200

(7.87)

300

(11.81)

300

(11.81)

200

(7.87)

100

(3.94)

100

(3.94)

0

Detection area in mm (inch)

3

4

5

2

1

0

100

(3.94)

300

(11.81)

200

(7.87)

400

(15.75)

500

(19.69)

600

(23.62)

Detection area in mm (inch)

500

(19.69)

500

(19.69)

250

(9.84)

250

(9.84)

0

Detection area in mm (inch)

3

4

5

2

1

0

500

(19.69)

250

(9.84)

750

(29.53)

1,000

(39.37)

1,250

(49.21)

1,500

(59.06)

Detection area in mm (inch)

Technical data

Fig. 16: "UM18-212" detection zone

1 Detection zone depends on reection characteristics,

2 Limiting range

3 Operating range

4 Example object: aligned plate 500 mm x 500 mm

5 Example object: round bar with diameter 10 mm

size, and alignment of the object

Fig. 17: "UM18-218" detection zone

1 Detection zone depends on reection characteristics,

size, and alignment of the object

2 Limiting range

3 Operating range

4 Example object: aligned plate 500 mm x 500 mm

5 Example object: round bar with diameter 10 mm

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 47

Page 48

Accessories

12 Accessories

NOTE!

For accessories, go to "www.sick.com/UM18", "Accessories".

12.1 "Connect+ Adapter" (CPA)

Description "Connect+ Adapter" with associated software

Programming tool including adapter, cable, and T-piece for USB (A/B)

Order No. 6037782

48 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 49

CongurationOverview

13 CongurationOverview

13.1 Congurationoverviewforsensorswithswitchingoutputs

Teach-in switching output

Default setting: Normally open contact, switching point (DtO) at maximum operating range

1 211 1

85 %

Teach-in switching point

(DtO= Distance to Object) –

method A

Position object at

Apply L+ at MF for approx.

3 s until both LEDs flash

simultaneously

Both LEDs: flash

Apply L+ at MF for approx. 1 s

1

alternately

Teach-in switching point

(DtO= Distance to Object + 8%) –

method B

Position object at 1 Position object at 1

Apply L+ at MF for approx.

3 s until both LEDs flash

simultaneously

Both LEDs:

Apply L+ at MF for approx.

3 s until both LEDs flash

again alternately

flash

alternately

Teach-in switching window

Apply L+ at MF for approx.

3 s until both LEDs flash

Both LEDs:

Position object at 2

Both LEDs:

Apply L+ at MF for approx. 1 s

Normal operation mode

simultaneously

flash

alternately

flash

alternately

Teach-in background (ObSB

mode = Object between Sensor

and Background)

Position background at 1

Apply L+ at MF for approx.

3 s until both LEDs flash

simultaneously

Both LEDs:

Apply L+ at MF for approx. 10 s

until both LEDs stop flashing

flash

alternately

13.2 Congurationoverviewforsensorswithanalogoutputs

Teach-in analog output

Default setting: Rising output

characteristics from min. to max.

operating range

Set normally closed/

normally open contact

Apply L+ at MF for approx.

13 s until both LEDs flash

Green LED: flashes

Orange LED:

To change the setting, apply

L+ at MF for approx. 1 s

Orange LED: switches status

Wait approx. 10 s

Green LED: stops flashing

alternately

on: normally open

off: normally closed

Teach-in analog output scaling

Position object at

Apply L+ at MF for approx. 3 s until

both LEDs flash simultaneously

Both LEDs:

Both LEDs:

Apply L+ at MF for approx. 1 s

flash

alternately

Position object at

flash

alternately

Normal operation mode

Set rising/falling

output characteristics

Apply L+ at MF for approx. 13 s

until both LEDs flash alternately

Green LED:

Orange LED:

To change the setting, apply

L+ at MF for approx. 1 s

Orange LED: switches status

Green LED: stops flashing

flashes

on: rising,

off: falling output

characteristics

Wait approx. 10 s

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 49

Page 50

CongurationOverview

13.3 Additional settings for all sensors

Further settings

Switching between teach-in and

synchronization/multiplex mode

Switch off the supply voltage

Apply M at MF

Switch on the supply voltage

Wait approx. 3 s until both LEDs

flash simultaneously

Green LED:

Orange LED: on: teach-in

To change the setting,

apply M at MF for approx. 1 s

Orange LED: changes status

Green LED: stops flashing

flashes

off: synchronization/

multiplex mode

Wait approx. 10 s

Normal operation mode

Reset to the factory setting

Switch off the supply voltage

Apply M at MF

Switch on the supply voltage

Wait approx. 13 s until both

LEDs stop flashing

Before switching off the supply

voltage, disconnect M from MF to

apply the factory setting

50 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 51

Index

Index

A

Accessories.................................................................... 48

Ambient conditions ....................................................... 45

Analog output

Output characteristics ................................................ 26

Scaling......................................................................... 25

C

Cleaning ......................................................................... 39

Commissioning

Sensors with switching outputs ................................. 23

Conguration Overview ................................................. 49

Connection diagram

Sensors with analog outputs ..................................... 22

Sensors with switching outputs ................................. 21

Correct use .......................................................................9

Customer service .............................................................8

D

Detection range ............................................................. 46

Dimensions .................................................................... 41

Disposal ......................................................................... 40

DtO (Distance to Object) ............................................... 23

E

EC declaration of conformity ...........................................8

Electrical connection..................................................... 19

Electricians .................................................................... 10

Error codes (IO-Link) ..................................................... 38

F

Factory setting

Reset to the factory setting ....................................... 27

Filter settings ................................................................. 29

Foreground suppression ............................................... 31

Function ......................................................................... 14

G

General information .........................................................7

I

Identication .................................................................. 11

Incorrect use .....................................................................9

Inputs ............................................................................. 43

IO-Link

Error Codes ................................................................. 38

Process data ............................................................... 33

Service data ................................................................ 33

IO-Link interface ............................................................ 32

L

LEDs ............................................................................... 13

Limitation of liability .........................................................8

M

Maintenance ................................................................. 39

Measured value lter .................................................... 29

Filter settings .............................................................. 29

Minimal mounting distances ........................................ 16

Mounting

For smooth object surfaces ....................................... 15

General information ................................................... 15

Minimum mounting distances ................................... 16

Multiple sensors ......................................................... 16

Multiplex mode .............................................................. 17

O

ObSB (Object between Sensor and Background) ....... 24

Operating instructions .....................................................7

Operating personnel

Requirements ............................................................. 10

Output characteristics .................................................. 26

Outputs

Sensors with analog outputs ..................................... 44

Sensors with switching outputs ................................. 43

Overview of settings ...................................................... 49

P

Performance data ......................................................... 42

Power supply ................................................................. 43

Process data (IO-Link) ................................................... 33

R

Reset .............................................................................. 27

S

Safety ................................................................................9

Electrical connection .................................................. 19

Scope of delivery ..............................................................8

Skilled personnel .......................................................... 10

Requirements ............................................................. 10

Smooth object surfaces ................................................ 15

Status displays .............................................................. 13

Status indicators ........................................................... 13

Structural design ........................................................... 45

Structure ........................................................................ 13

Synchronization mode .................................................. 16

Switching on ................................................................ 26

T

Teach-in

Distance to object (DtO) ............................................. 23

Method A ..................................................................... 23

Method B .................................................................... 23

Sensors with analog outputs ..................................... 25

Sensors with switching outputs ................................. 23

Two-way reection barrier .......................................... 24

8014865/ZUJ3/2018-11-29 • © SICK AG • Subject to change without notice 51

Page 52

Index

Window operation mode ............................................ 24

Window (Wnd) ............................................................. 24

Teaching in the analog output ...................................... 25

Technical data ............................................................... 41

Troubleshooting ............................................................. 40

Type code ....................................................................... 12

Type label ....................................................................... 11

W

Window .......................................................................... 24

Wiring notes ................................................................... 19

52 © SICK AG • Subject to change without notice • 8014865/ZUJ3/2018-11-29

Page 53

Page 54

8014865/ZUJ3/2018-11-29 ∙ 8M_DR ∙ (2018-11) ∙ A4 4c int47

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg