SICK Flexi Classic series, UE410-GU, UE410-MU, UE410-8DI, UE410-XU Operating Instructions Manual

...Page 1

Flexi Classic

Modular Safety Controller

OPERATING INSTRUCTIONS

en

Page 2

Operating instructions

Flexi Classic

This document is protected by the law of copyright, whereby all right s established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal det ermination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 3

Operating instructions

Flexi Classic

Contents

Contents

1 About this document.................................................................................................... 6

1.1 Function of this document................................................................................6

1.2 Target group .....................................................................................................6

1.3 Information depth.............................................................................................6

1.4 Scope................................................................................................................7

1.5 Abbreviations....................................................................................................7

1.6 Symbols used ................................................................................................... 7

2 On safety.....................................................................................................................11

2.1 Qualified safety personnel..............................................................................11

2.2 Applications of the device...............................................................................11

2.3 Correct use .....................................................................................................12

2.4 General safety notes and protective measures..............................................12

2.5 Environmental protection ...............................................................................14

2.5.1 Disposal.........................................................................................14

2.5.2 Separation of materials.................................................................14

3 Product description....................................................................................................15

3.1 Special features..............................................................................................15

3.2 Structure.........................................................................................................16

3.2.1 UE410-MU main module...............................................................16

3.2.2 UE410-GU main module................................................................17

3.2.3 UE410-8DI input extension module ..............................................18

3.2.4 UE410-XU input/output extension ................................................18

3.2.5 UE410-2RO/UE410-4RO output modules.....................................18

3.2.6 Gateways.......................................................................................18

3.2.7 Module overview, adjustments and facilities for connecting

sensors..........................................................................................19

3.3 UE410-MU main module ................................................................................22

3.3.1 Controls and status indicators ......................................................24

3.3.2 Terminal assignment.....................................................................25

3.3.3 Outputs..........................................................................................26

3.4 UE410-GU main module.................................................................................27

3.4.1 Controls and status indicators ......................................................28

3.4.2 Terminal assignment.....................................................................29

3.4.3 Global emergency stop with the UE410-GU ..................................29

3.4.4 Local emergency stop on the UE410-GU.......................................31

3.4.5 Inputs............................................................................................32

3.4.6 Outputs..........................................................................................32

3.4.7 Connection of a UE410-8DI...........................................................33

3.4.8 Power-up delay and response time of the UE410-GU ...................33

3.4.9 Diagnostics and troubleshooting for the UE410-GU......................33

3.5 UE410-XU module ..........................................................................................35

3.5.1 Controls and status indicators ......................................................35

3.6 UE410-MU/UE410-XU programs....................................................................36

3.6.1 Program 1......................................................................................37

3.6.2 Program 2......................................................................................38

3.6.3 Programs 3.1 and 3.2 ...................................................................39

3.6.4 Program 4......................................................................................40

3.6.5 Programs 5.1 and 5.2 ...................................................................41

3.6.6 Program 6......................................................................................42

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Page 4

Contents

3.6.7 Program 7..................................................................................... 43

3.6.8 Program 8..................................................................................... 44

3.6.9 Program 9..................................................................................... 45

3.6.10 Connection of sensors to the UE410-MU/UE410-XU.................... 46

3.7 UE410-GU programs...................................................................................... 49

3.8 UE410-8DI input extension module............................................................... 51

3.8.1 AND link........................................................................................ 52

3.8.2 OR link.......................................................................................... 53

3.8.3 Bypass .......................................................................................... 53

3.8.4 Reciprocal assignment — Mirror mode ......................................... 54

3.8.5 Connection of sensors to the UE410-8DI ..................................... 54

3.8.6 Controls and status indicators...................................................... 56

3.8.7 Inputs and outputs ....................................................................... 57

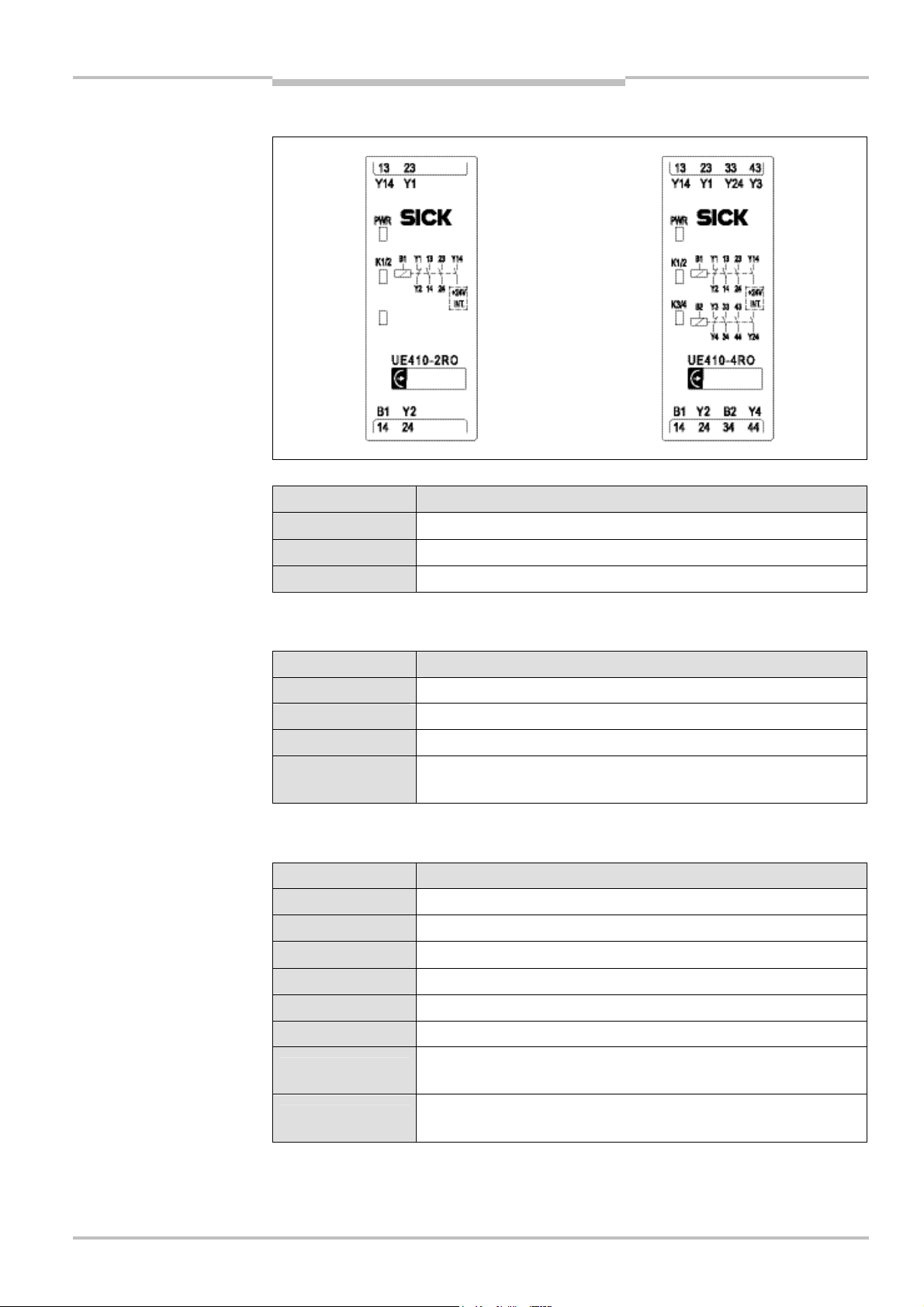

3.9 UE410-2RO/UE410-4RO output modules ..................................................... 57

3.9.1 Output module UE410-2RO.......................................................... 57

3.9.2 Output module UE410-4RO.......................................................... 58

3.9.3 Controls and status indicators...................................................... 59

3.9.4 UE410-2RO inputs and outputs.................................................... 59

3.9.5 UE410-4RO inputs and outputs.................................................... 59

Operating instructions

Flexi Classic

4 Special applications and functions........................................................................... 60

4.1 RE300 magnetic safety switch....................................................................... 61

4.2 IN4000 inductive safety switch...................................................................... 62

4.3 Testable single-beam photoelectric safety switches...................................... 63

4.4 Two-hand operation/jog mode....................................................................... 66

4.5 OR function.................................................................................................... 67

4.6 Muting function.............................................................................................. 68

4.6.1 Muting with two sensors............................................................... 69

4.6.2 Muting cycle..................................................................................69

4.6.3 Muting sensors............................................................................. 69

4.7 Placement of muting sensors ........................................................................ 70

4.7.1 Muting with two sensors (a sensor pair), crossed placement....... 71

4.7.2 4-sensor muting, sequential layout .............................................. 72

4.7.3 Muting with UE410-MU/UE410-XU............................................... 72

4.8 SICK muting sensors...................................................................................... 73

4.9 Bypass............................................................................................................ 74

4.10 Connecting S1, S2, S3................................................................................... 75

4.10.1 Operation with restart interlock.................................................... 75

4.10.2 Operation without restart interlock............................................... 75

4.10.3 Operation with external device monitoring (EDM) ........................ 75

4.11 Retriggering of the delayed OSSDs................................................................ 76

4.12 Grouping of subsystems ................................................................................ 78

4.13 ENABLE input................................................................................................. 79

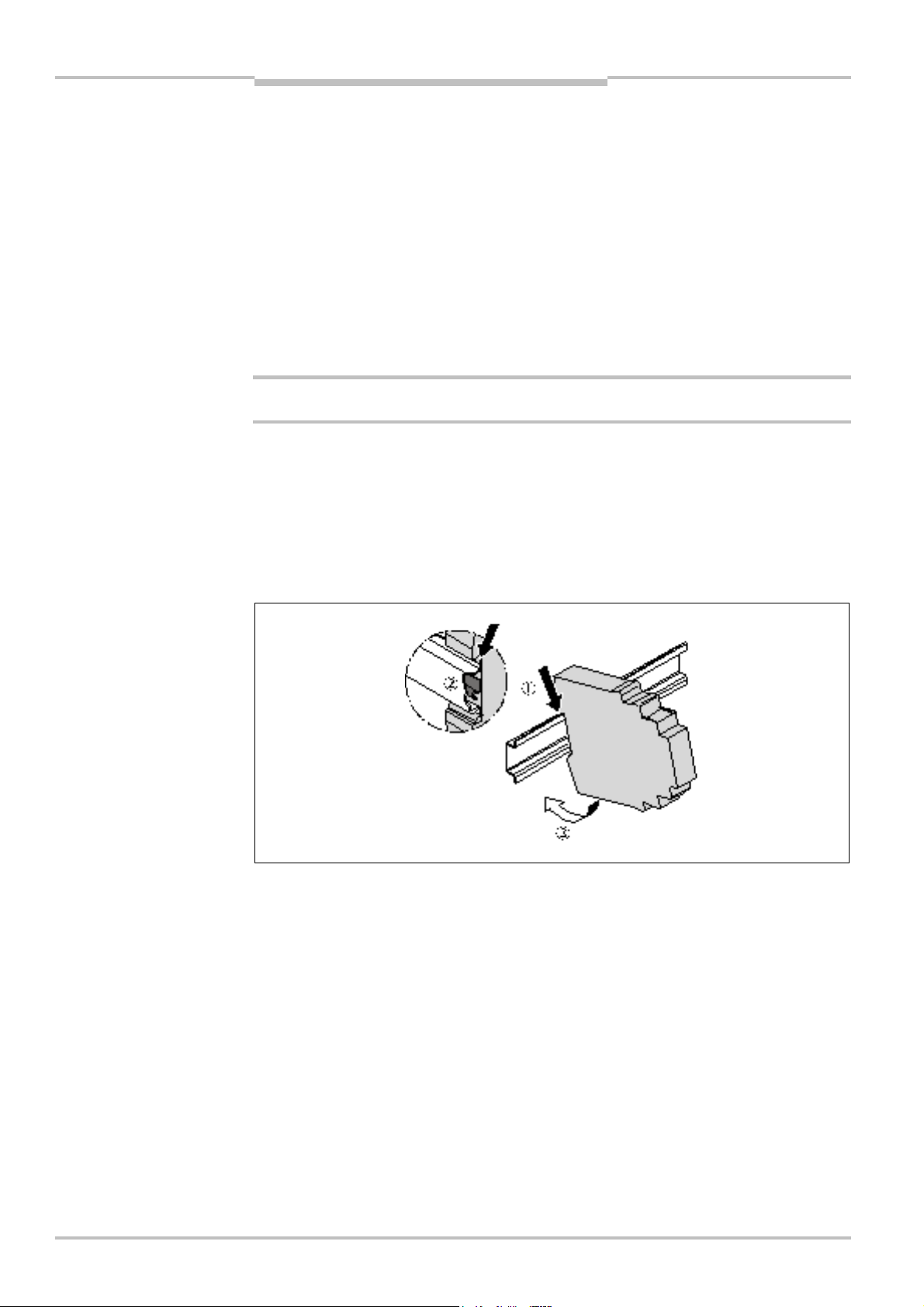

5 Mounting/dismantling .............................................................................................. 80

5.1 Steps for mounting the modules.................................................................... 80

5.2 Steps for dismantling the modules................................................................ 81

5.3 Removing the anti-manipulation cover .......................................................... 82

6 Electrical installation................................................................................................ 83

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 5

Operating instructions

Flexi Classic

Contents

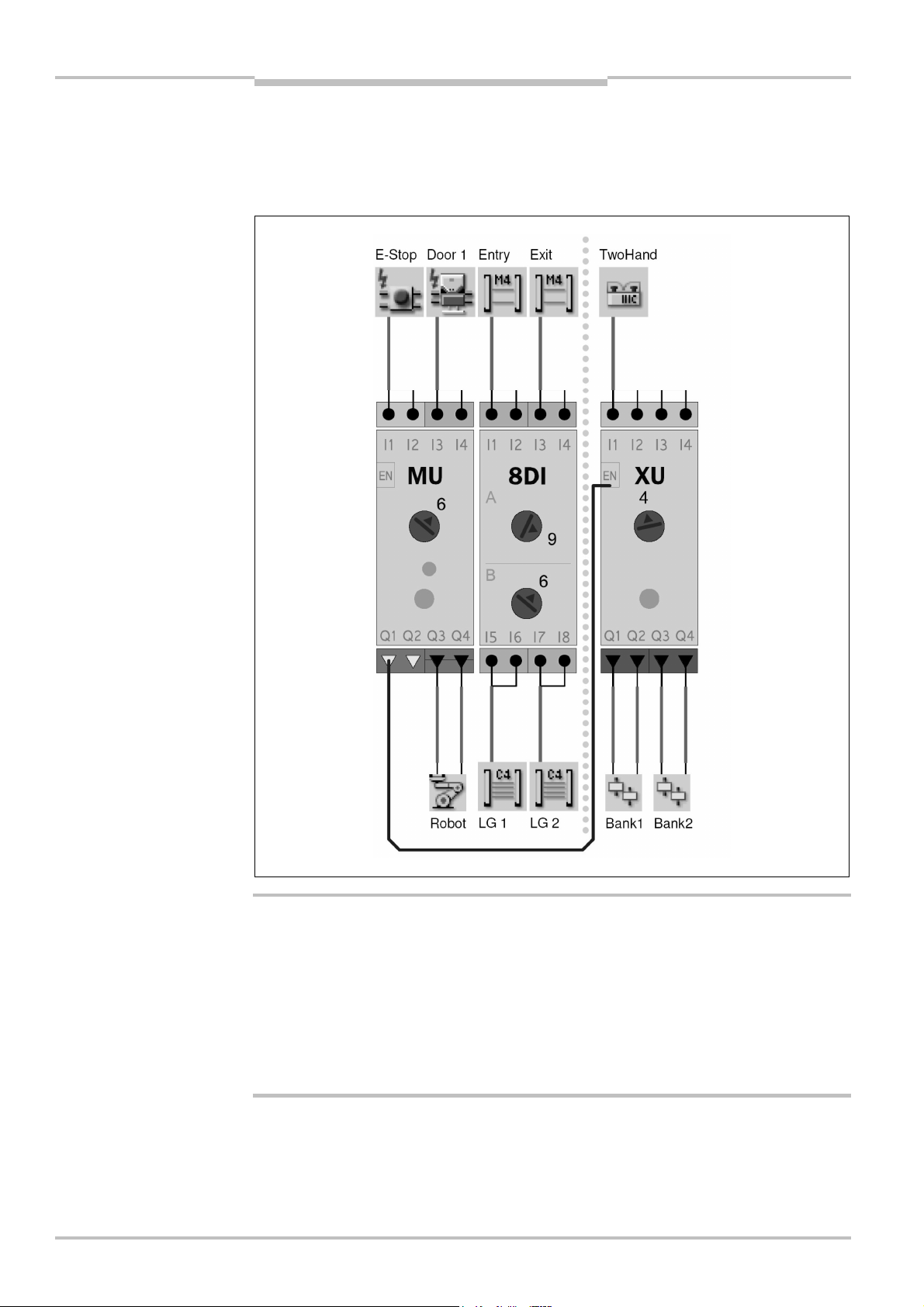

7 Application examples and connection diagrams......................................................85

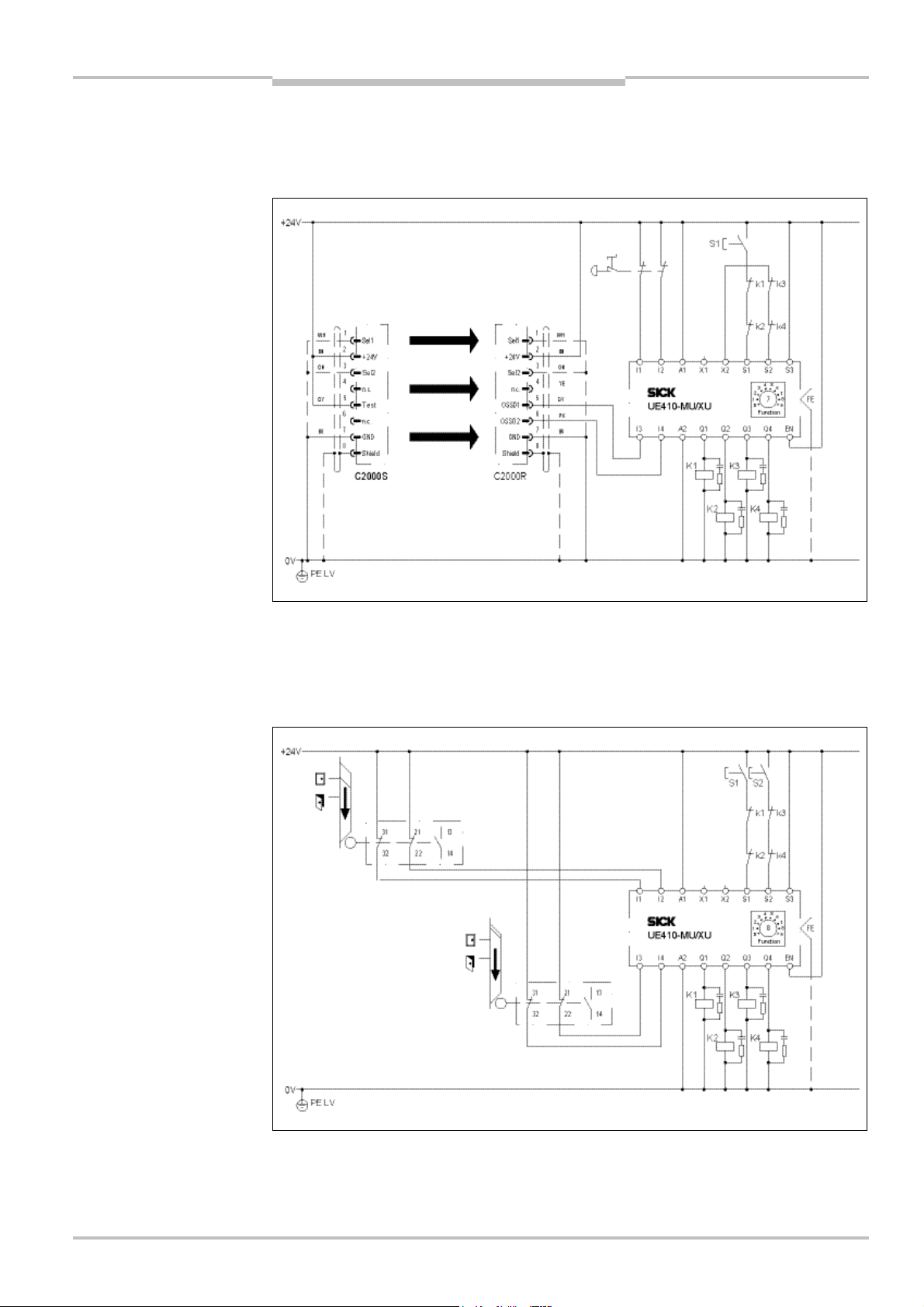

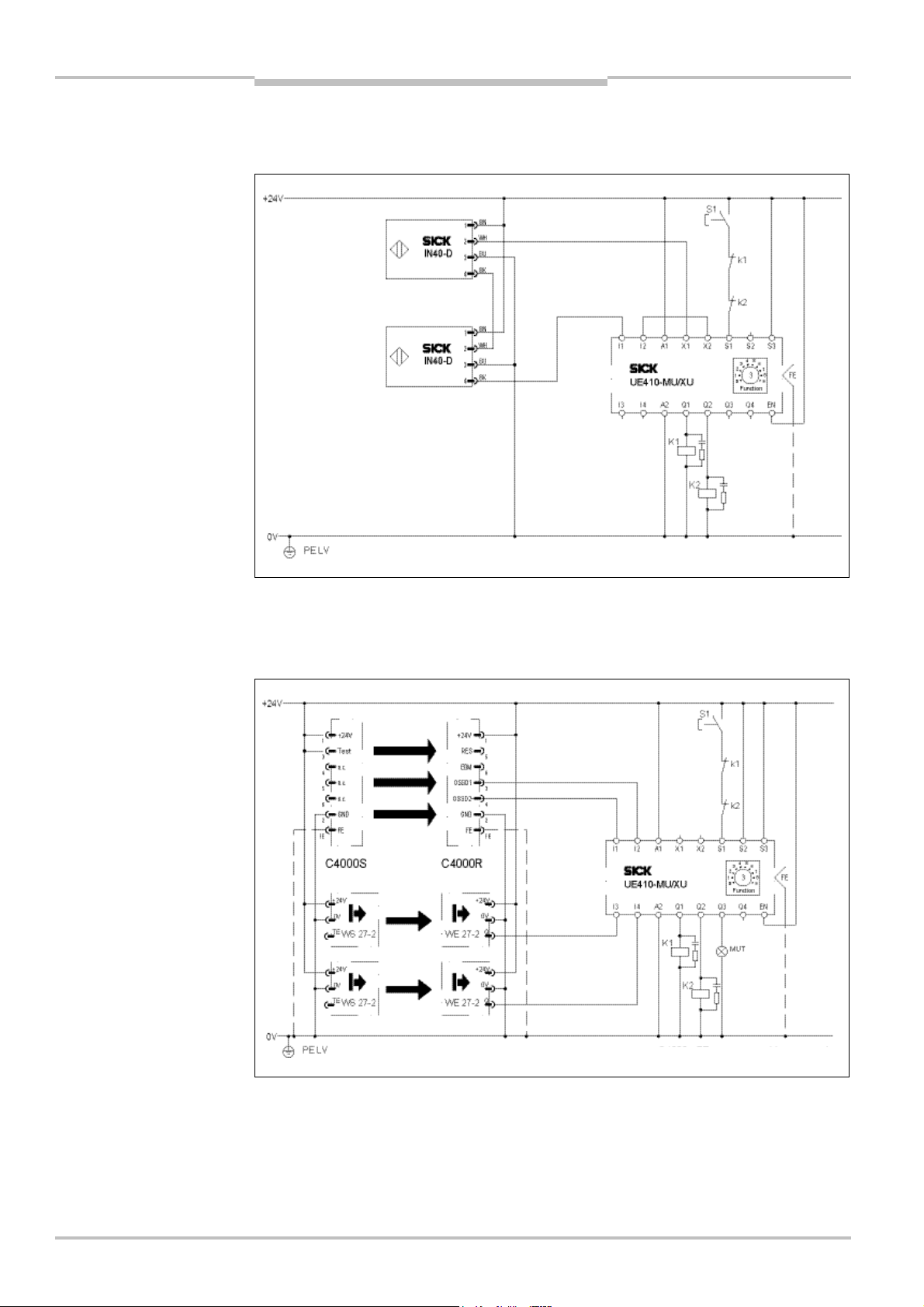

7.1 L21 on the UE410-MU/XU..............................................................................85

7.2 Emergency stop on the UE410-MU/XU...........................................................85

7.3 RE300 on the UE410-MU/XU.........................................................................86

7.4 Two-hand IIIC on the UE410-MU/XU...............................................................86

7.5 C2000 and emergency stop on the UE410-MU/XU, two hazardous

areas...............................................................................................................87

7.6 i11 on the UE410-MU/XU, two independent hazardous areas.......................87

7.7 IN4000 on the UE410-MU/XU........................................................................88

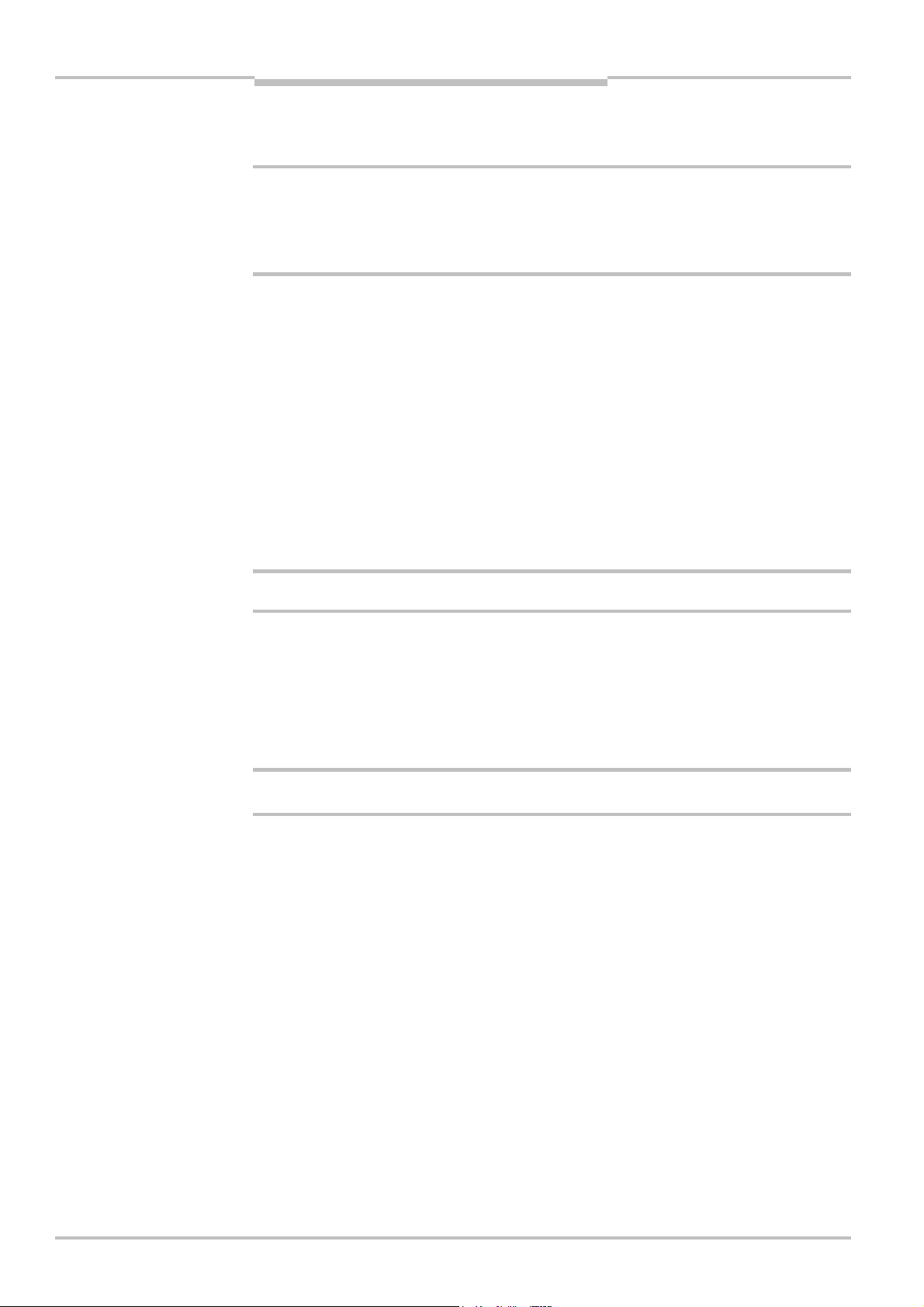

7.8 C4000 on the UE410-MU/XU, 2-sensor muting.............................................88

7.9 Global emergency stop with two UE410-GU...................................................89

8 Commissioning...........................................................................................................90

8.1 Validation of the application...........................................................................90

8.2 Test notes.......................................................................................................91

8.2.1 Tests before the first commissioning ............................................91

8.2.2 Regular testing..............................................................................91

8.2.3 Regular inspection of the protective device by qualified

safety personnel............................................................................91

9 Configuration..............................................................................................................92

9.1 Accepting the system configuration................................................................92

10 Diagnostics.................................................................................................................93

10.1 In the event of faults or errors........................................................................93

10.2 Replacement of a module ..............................................................................93

10.3 SICK support...................................................................................................94

10.4 Error indications of the ERR error LED............................................................94

10.5 Anti-manipulation measures...........................................................................95

11 Technical specifications ............................................................................................96

11.1 Data sheet......................................................................................................96

11.1.1 UE410-MU/UE410-XU modules ....................................................96

11.1.2 UE410-GU module...................................................................... 101

11.1.3 UE410-8DI input extension module ........................................... 105

11.1.4 UE410-2RO/UE410-4RO output modules.................................. 107

11.2 Dimensional drawings................................................................................. 111

11.2.1 UE410-MU and UE410-GU main modules.................................. 111

11.2.2 UE410-XU, UE410-8DI, UE410-2RO, UE410-4RO, UE410-

PRO, UE410-DEV, UE410-CAN modules..................................... 111

12 Ordering information............................................................................................... 112

12.1 Available modules ....................................................................................... 112

12.2 Accessories/spare parts.............................................................................. 115

12.2.1 Single-beam photoelectric safety switches ................................ 115

12.2.2 Non-contact safety switches....................................................... 116

12.2.3 Safety light curtains and multiple light beam safety devices ..... 117

12.2.4 Safety laser scanners and safety camera system...................... 117

12.2.5 Muting lamps and cables........................................................... 117

12.2.6 Anti-manipulation cover.............................................................. 117

13 Annex....................................................................................................................... 118

13.1 Compliance with EU directives..................................................................... 118

13.2 Manufacturer’s checklist............................................................................. 118

13.3 List of tables................................................................................................ 119

13.4 List of illustrations....................................................................................... 120

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

Page 6

Chapter 1 Operating instructions

About this document

Flexi Classic

1 About this document

Please read this chapter carefully before working with this documentation and the Flexi

Classic modular safety controller.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the machine manufacturer or the machine operator in regards to safe mounting, configuration,

electrical installation, commissioning, operation and maintenance of the Flexi Classic

modular safety controller.

These operating instructions do not provide instructions for operating machines on which

the safety controller is, or will be, integrated. Information on this is to be found in the appropriate operating instructions for the machine.

1.2 Target group

These operating instructions are addressed to planning engineers, machine designers and

operators of plants and systems which are to be protected by a Flexi Classic modular safe-

ty controller. They are also addressed to people who integrate the Flexi Classic modular

safety controller into a machine, initialise its use, or who are in charge of servicing and

maintaining the device.

Note

1.3 Information depth

These operating instructions contain the following information on the Flexi Classic modular

safety controller:

• mounting

• electrical installation

• commissioning and configuration

• care and maintenance

Planning and using SICK protective devices also require specific technical skills which are

not detailed in this documentation.

When operating the Flexi Classic modular safety controller, the national, local and statutory rules and regulations must be observed.

General information on accident prevention using opto-electronic protective devices can

be found in the competence brochure “Guidelines Safe Machinery”.

We also refer you to the homepage on the Internet at www.sens-control.com.

Here you will find information on:

• product and application animations

• configuration aid

• these operating instructions in different languages for viewing and printing

• fault, error diagnosis and

troubleshooting

• part numbers

• conformity and approval

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 7

Operating instructions Chapter 1

Flexi Classic

About this document

1.4 Scope

These operating instructions are original operating instructions.

These operating instructions apply to all Flexi Classic safety controller modules with the

following entry in the field Operating Instructions on the type label: “E-01” or higher. Take

into account the respectively applicable operating instructions (refer to the type label entry

on the modules).

1.5 Abbreviations

EDM

ESPE

OSSD

PLC

SIL

SILCL

Note

Ν, ∏, ν

= Take action …

WARNING

External device monitoring

Electro-sensitive protective equipment (e.g. C4000)

Output signal switching device

Programmable logic controller

Safety Integrity Level

SIL claim limit

1.6 Symbols used

Refer to notes for special features of the device.

LED symbols describe the state of a diagnostics LED. Examples:

Ν The LED is illuminated constantly.

∏ The LED is flashing.

ν The LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

Warning!

A warning notice indicates an actual or potential risk or health hazard. They are designed

to help you to prevent accidents.

Read carefully and follow the warning notices!

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

Page 8

Chapter 1 Operating instructions

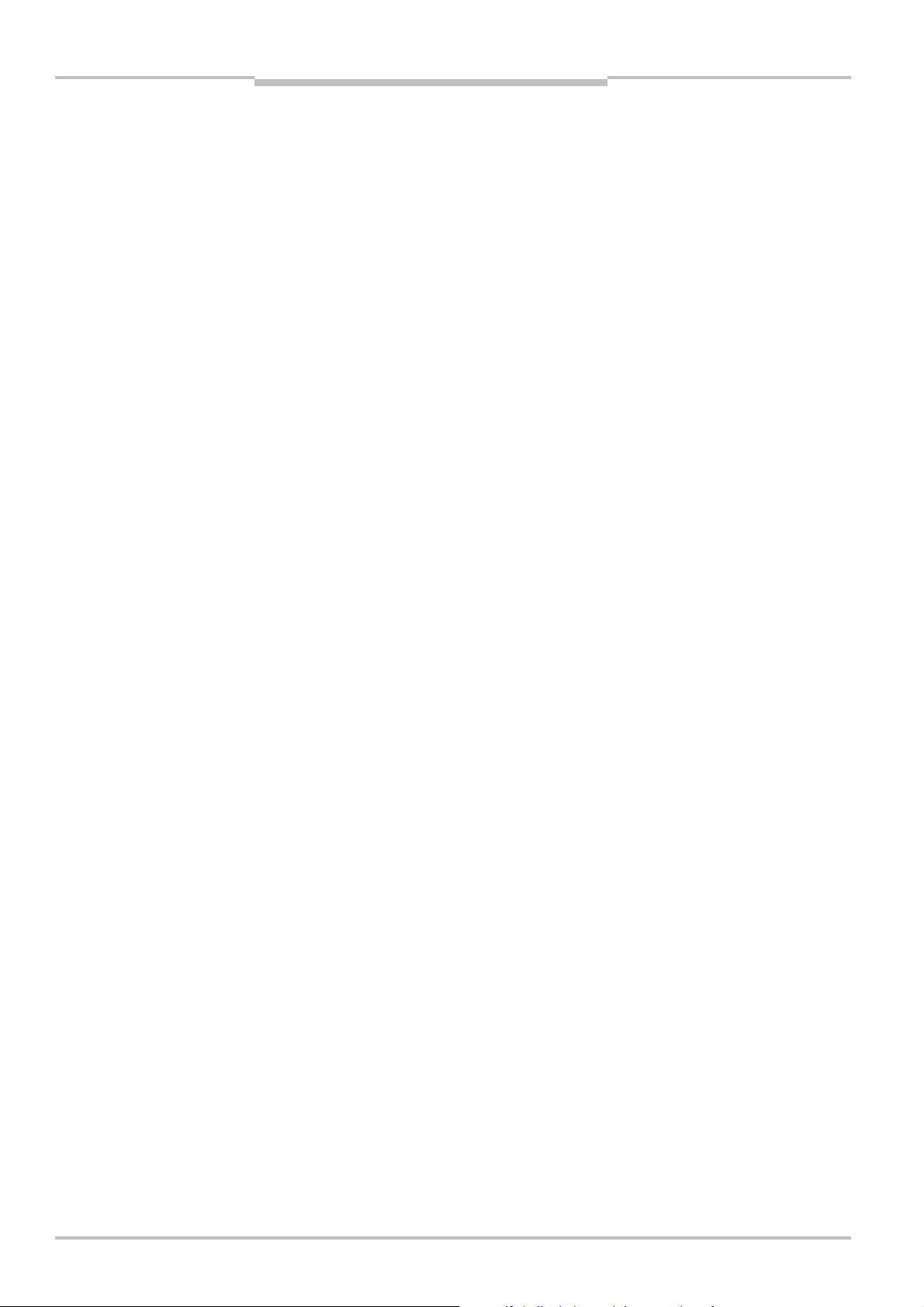

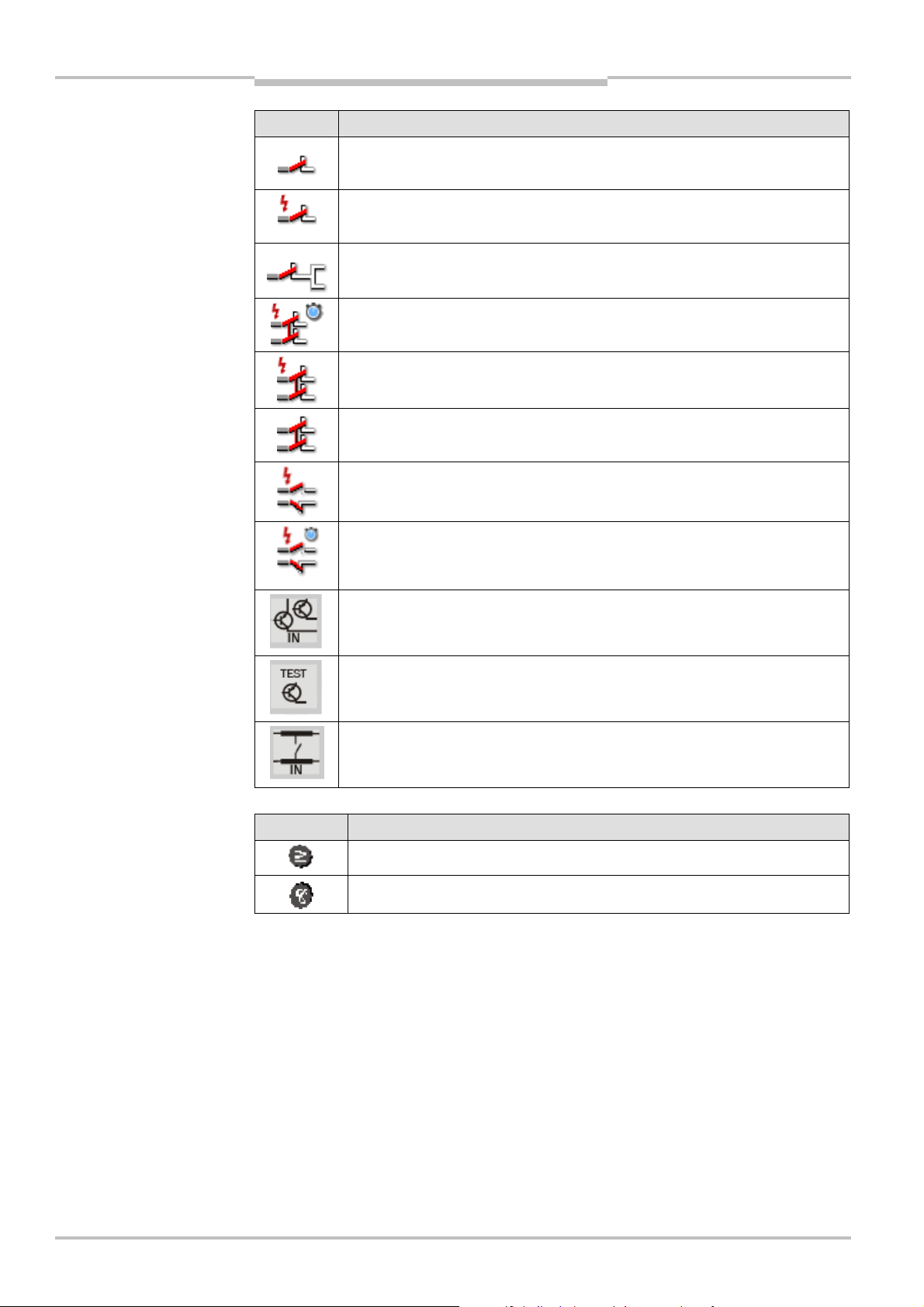

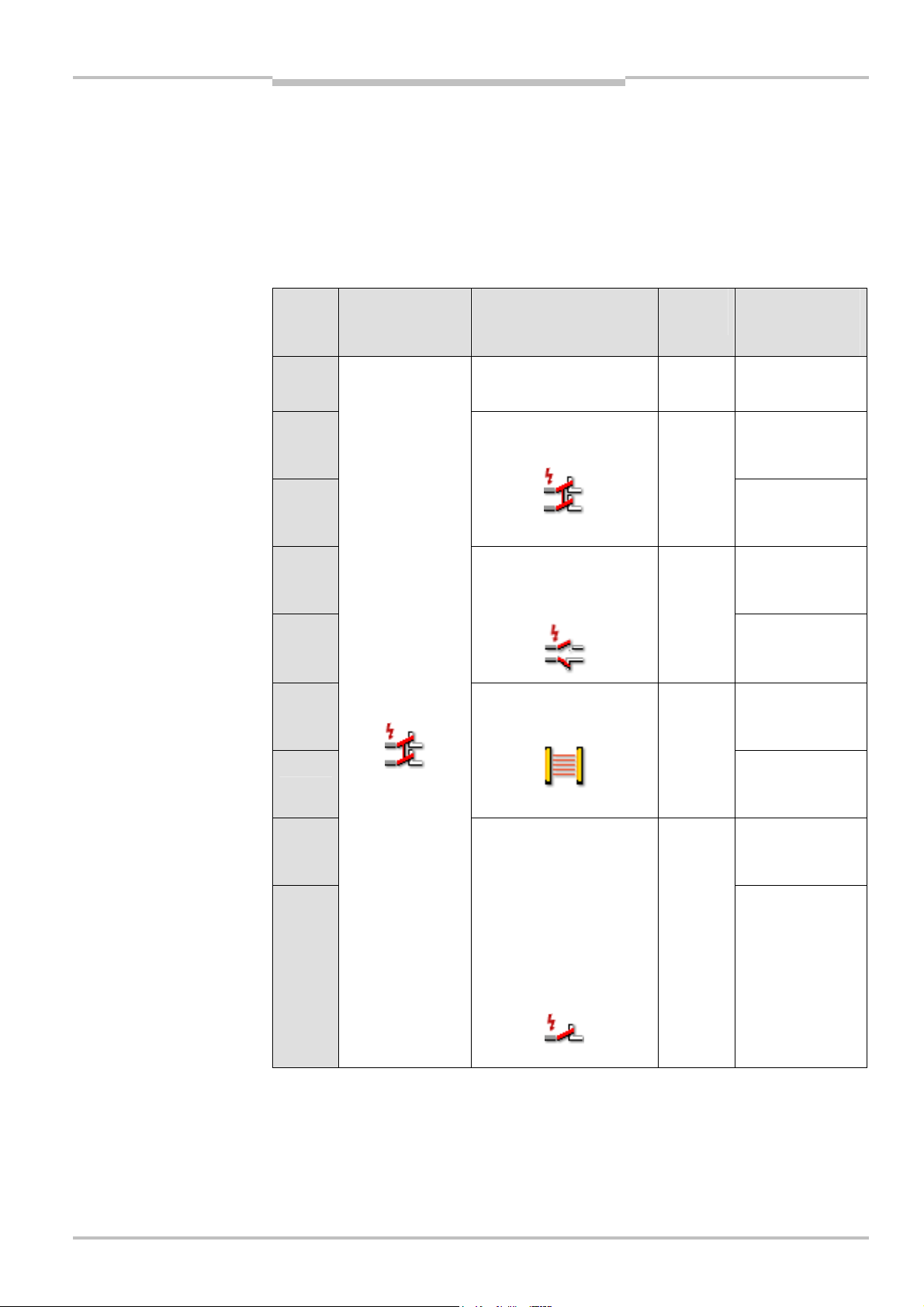

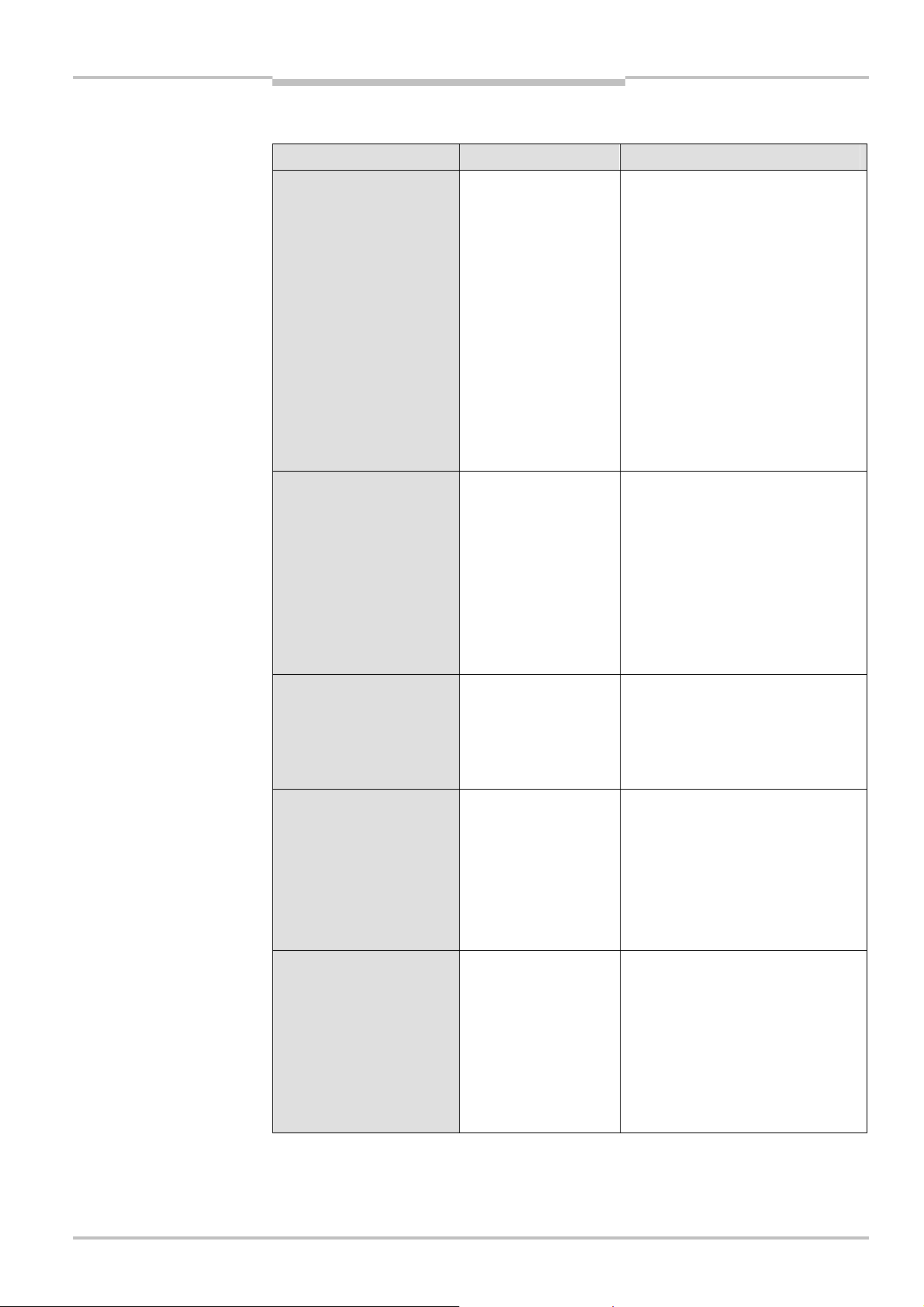

Tab.1:

Sensor symbols

About this document

Flexi Classic

Symbol Sensors

Electro-mechanical safety switches

Emergency stop button

Electro-sensitive protective equipment (ESPE)

Sensors that can be tested (e.g. photoelectric switches)

Inductive safety sensors (e.g. IN4000)

Two-hand operating panel (IIIA)

Two-hand operating panel (IIIC)

Jog mode via two-hand operating panel (IIIA) (time limit 5 s)

Muting lamp and Reset required lamp (not monitored)

Lamp permanently ON: Muting active

Lamp flashing 1 Hz: Reset required

Pressure sensitive mats (4-wire system)

Reset button

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Flexi Loop

Subject to change without notice

Page 9

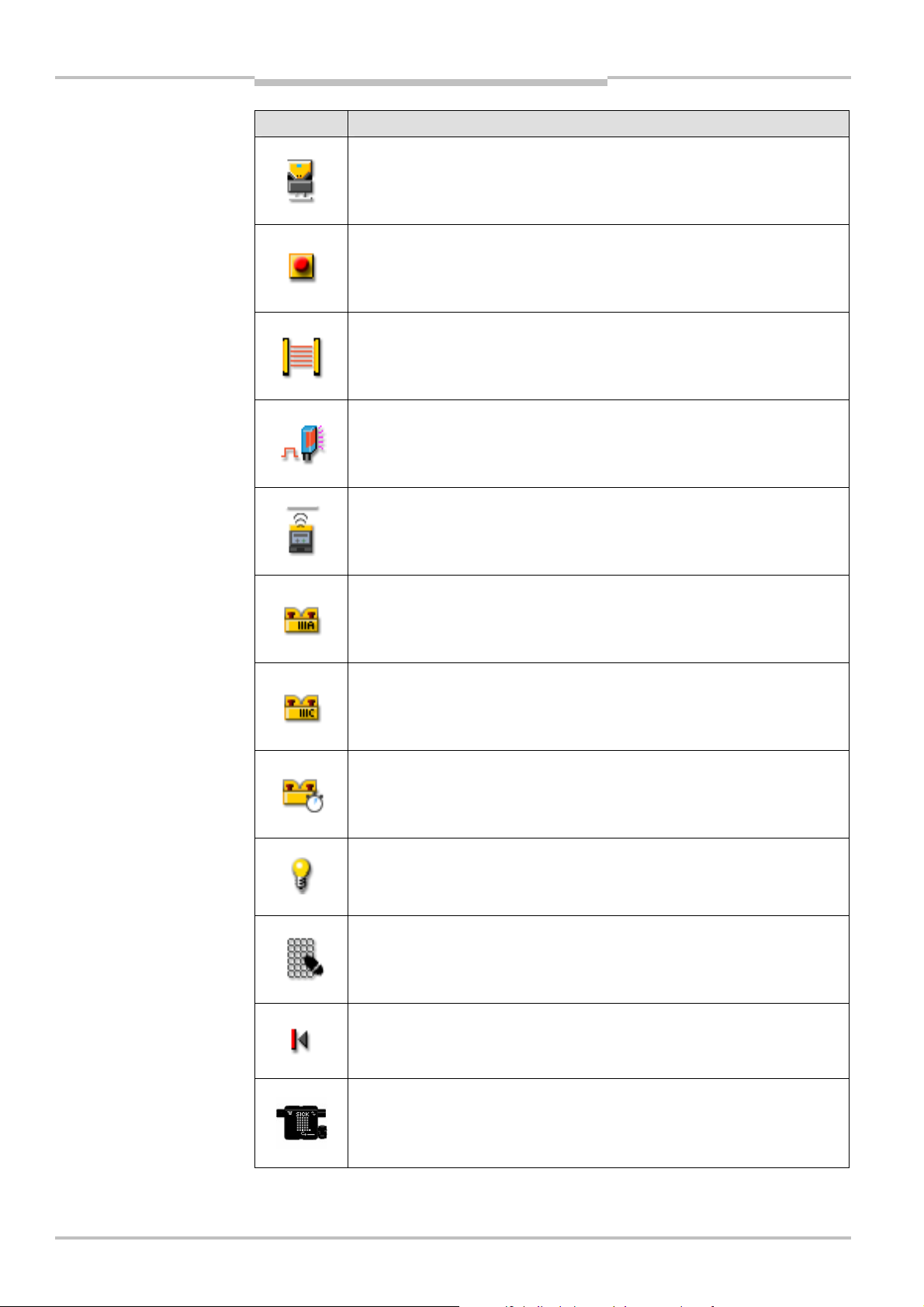

Operating instructions Chapter 1

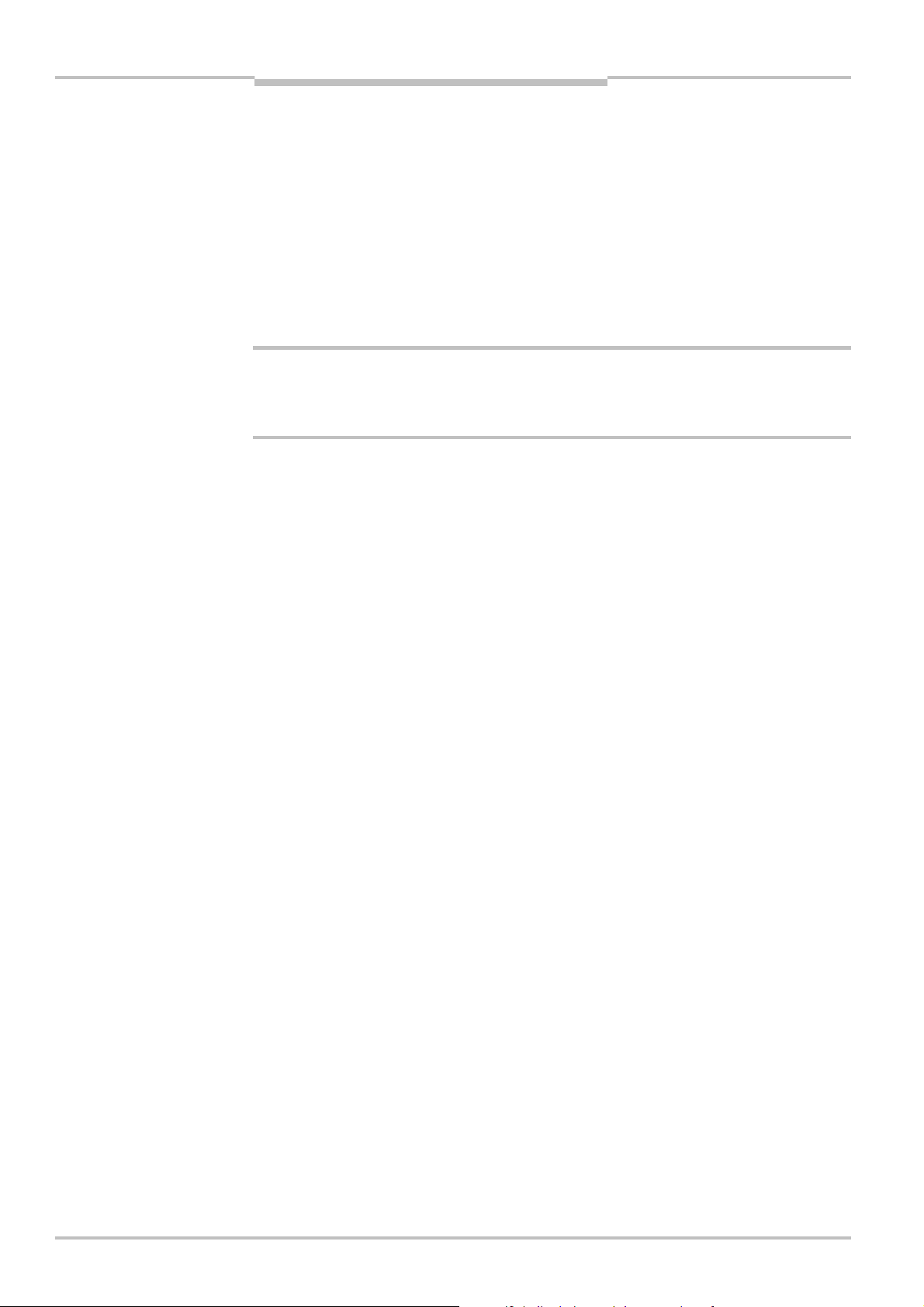

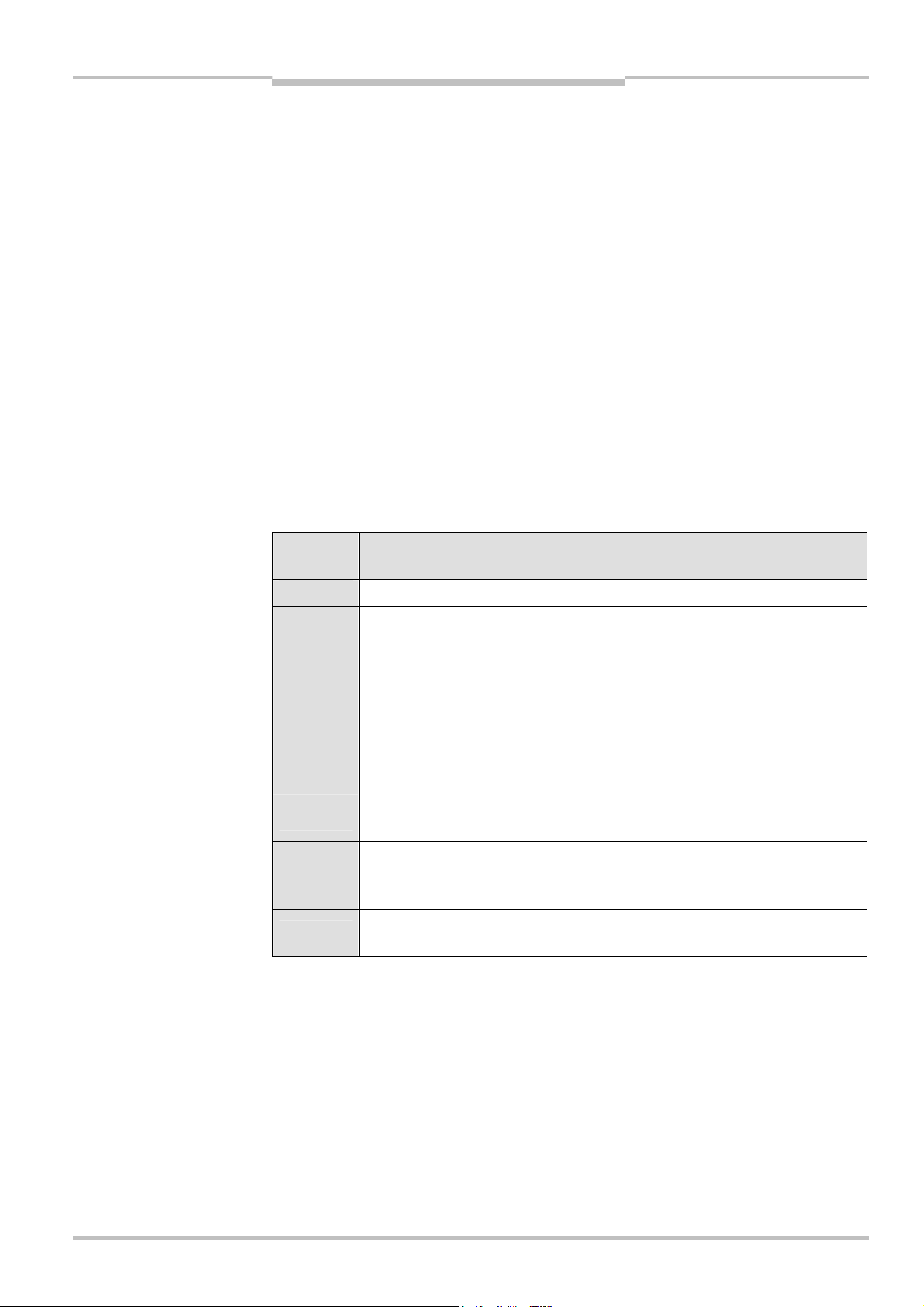

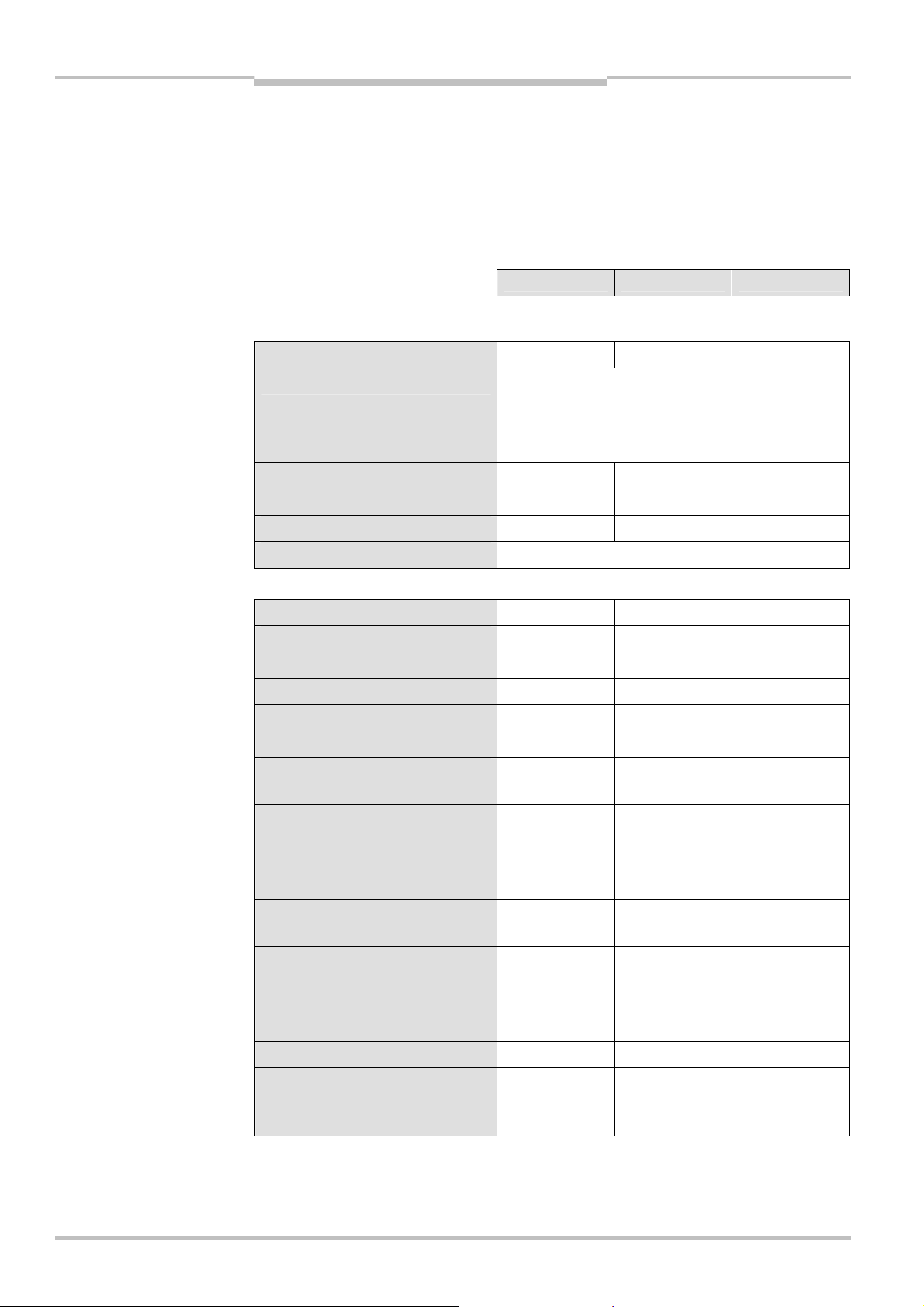

Tab.2:

Module function

Flexi Classic

About this document

symbols

Symbol Module functions

Bypass function with electro-mechanical dual-channel equivalent switch

(e.g. enabling switch),

Bypass function limited to 60 s

Muting station with two inputs for muting sensors

Retriggering

Monitored semiconductor output

Off delay

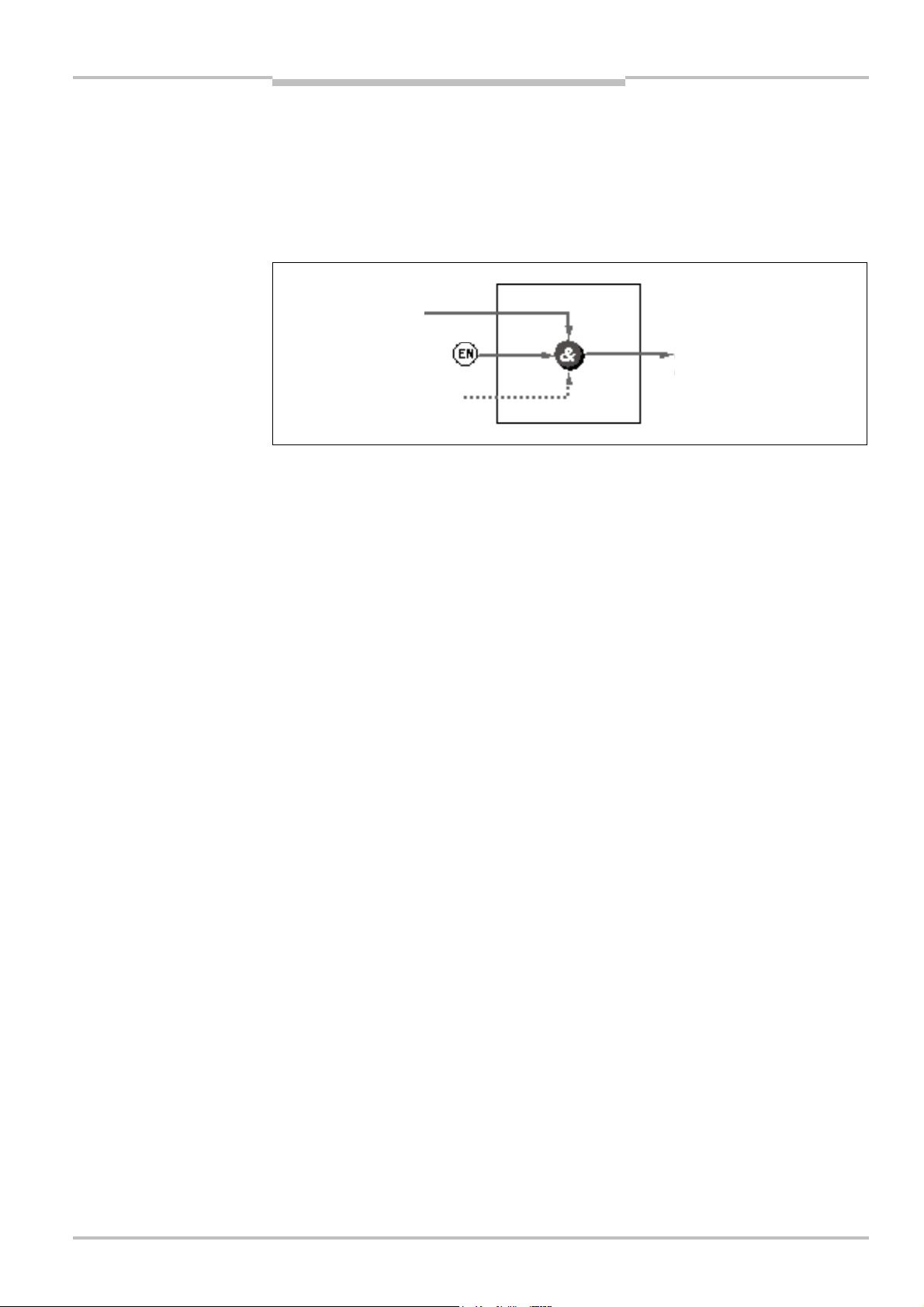

ENABLE (EN)

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

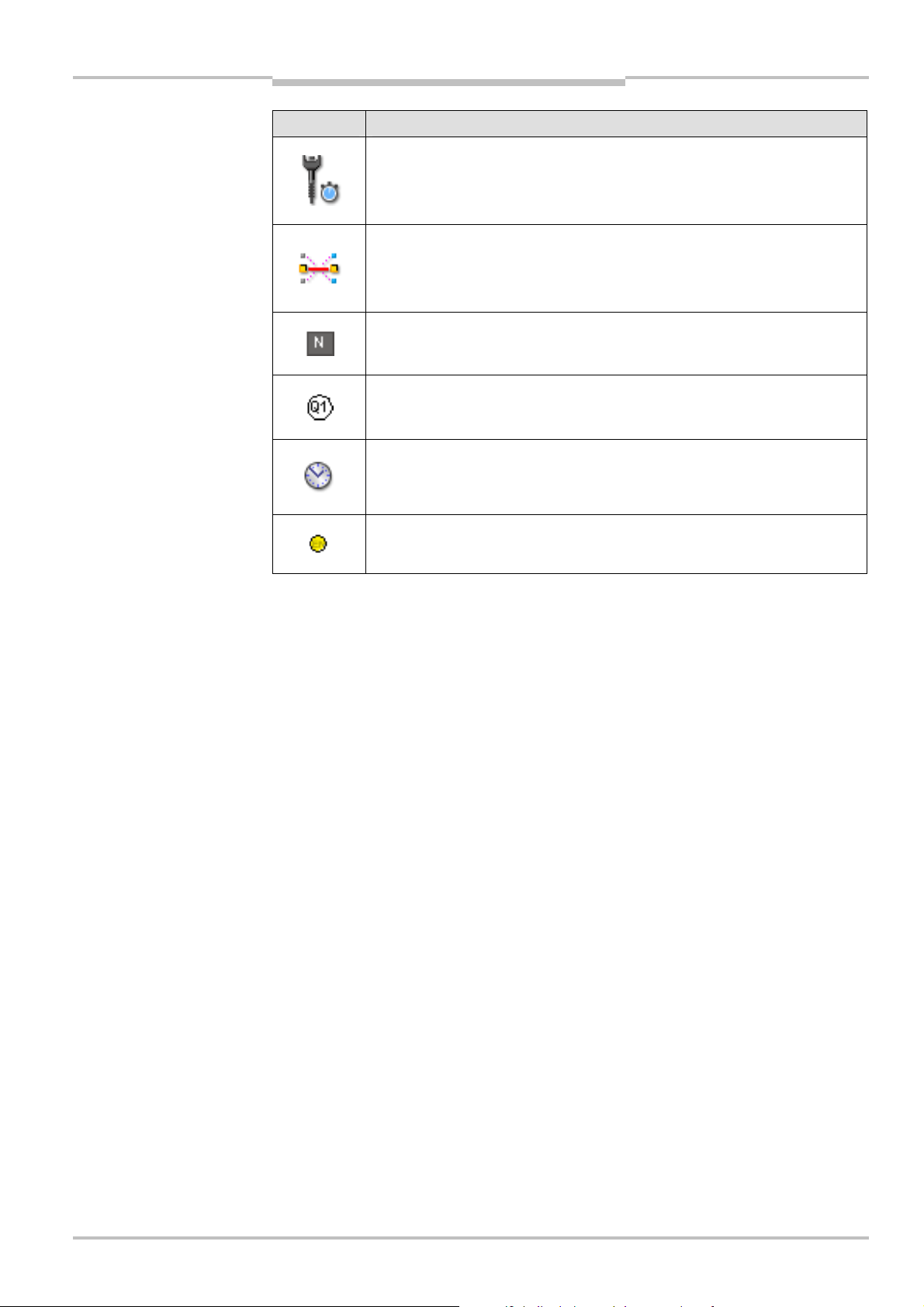

Page 10

Chapter 1 Operating instructions

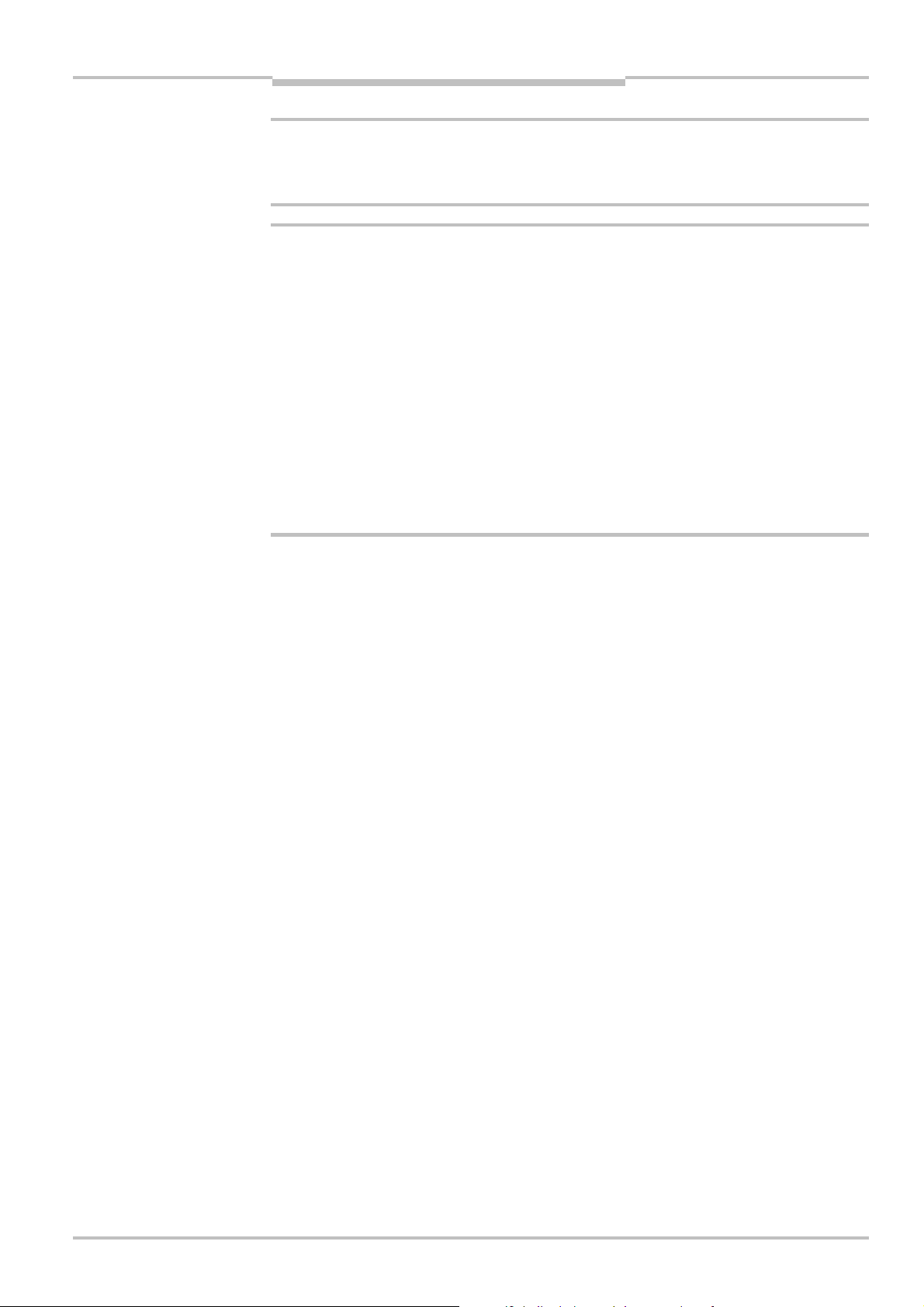

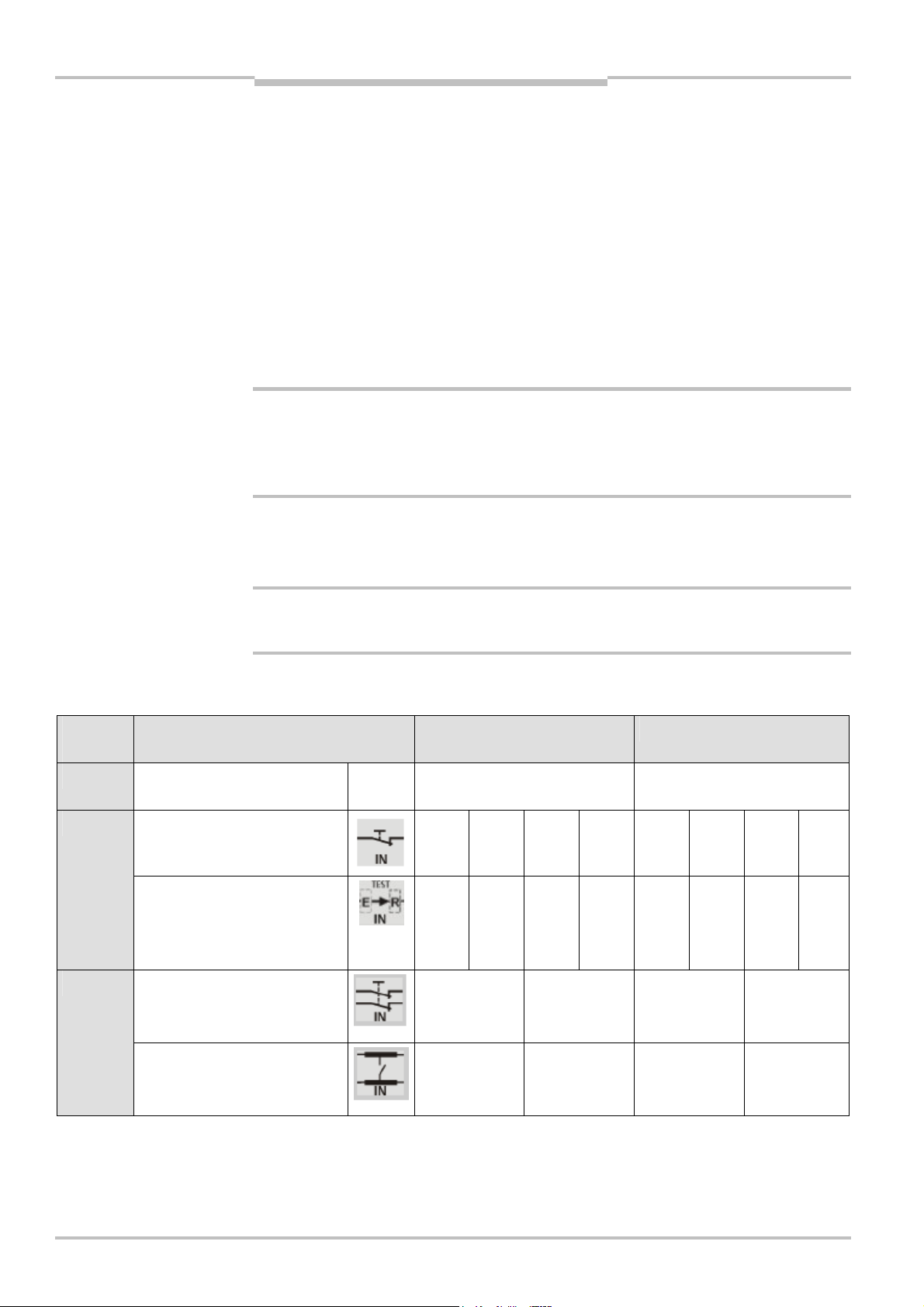

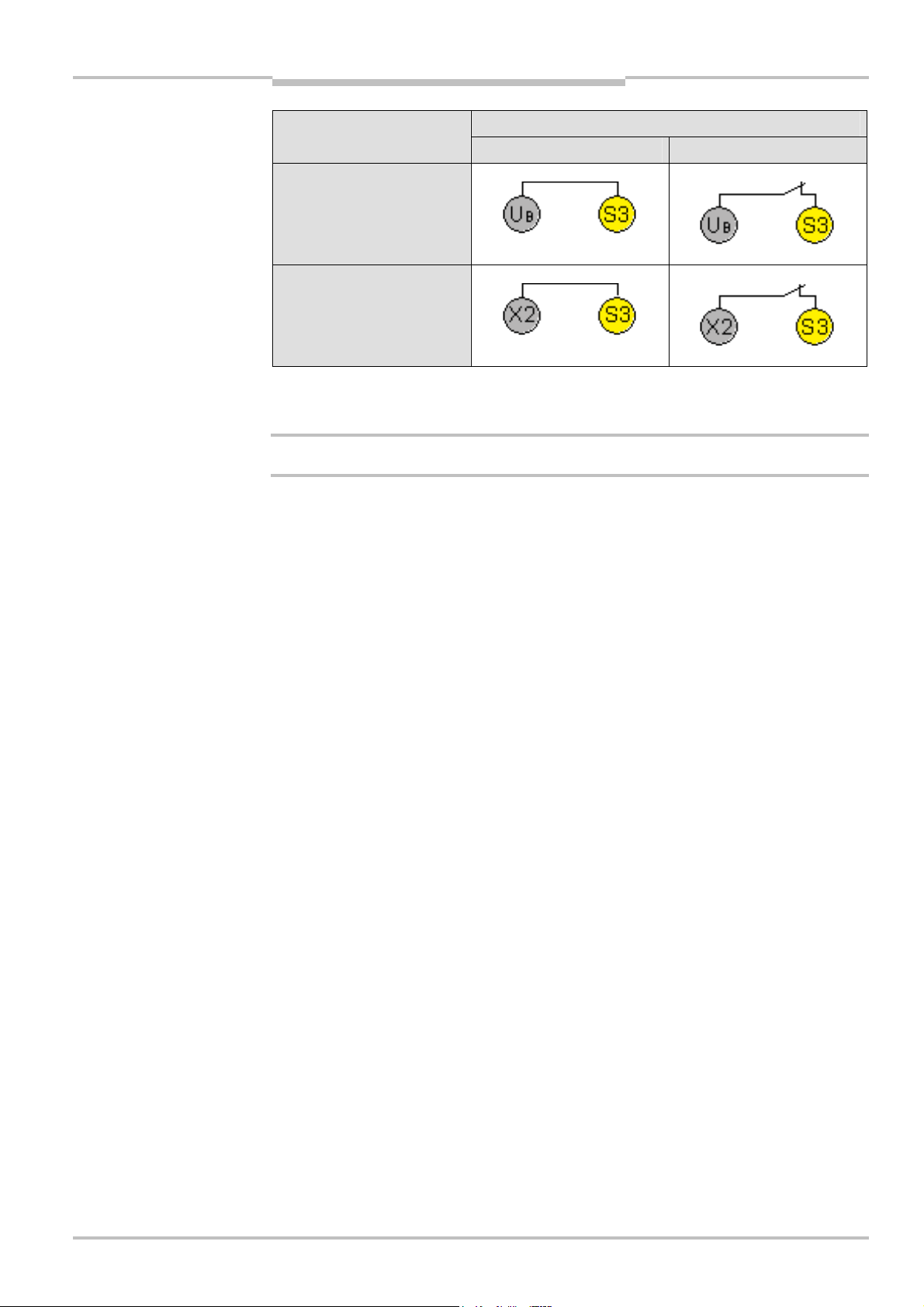

Tab.3:

Input assignment

Tab.4:

Logic symbols

About this document

Flexi Classic

symbols

Symbol Input assignment

Single-channel N/C contact

Single-channel N/C contact, cross-circuit detecting

Single-channel N/C contact at two inputs

Dual-channel N/C contact, equivalent, cross-circuit detecting, with

monitoring of synchronisation (1500 ms)

Dual-channel N/C contact, equivalent, cross-circuit detecting

Dual-channel N/C contact, equivalent

Dual-channel N/C / N/O contact, complementary, cross-circuit detecting

Dual-channel N/C / N/O contact, complementary, cross-circuit detecting,

with monitoring of synchronisation (1500 ms), (e.g. magnetically coded

switch RE300)

Dual-channel semiconductor input, monitored (ESPE)

Single-channel N/C contact/semiconductor input (e.g. sensors that can be

tested)

Switching mats, pressure-sensitive (4-wire system)

Symbol Logic

OR link

AND link

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 11

Operating instructions Chapter 2

Flexi Classic

On safety

2 On safety

This chapter deals with your own safety and the safety of the equipment operators.

= Please read this chapter carefully before working with the Flexi Classic modular safety

controller or with the machine protected by the Flexi Classic modular safety controller.

2.1 Qualified safety personnel

The Flexi Classic modular safety controller must be mounted, commissioned and serviced

only by qualified safety personnel.

Qualified safety personnel are defined as persons who …

• have undergone the appropriate technical training

and

• who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

• have access to the operating instructions of the Flexi Classic and those of the particular

modules and have read and familiarised themselves with them

and

• have access to the operating instructions for the protective devices (e.g. C4000)

connected to the safety controller and have read and familiarised themselves with

them.

2.2 Applications of the device

The Flexi Classic modular safety controller is a configurable control system for safety

applications.

The category in accordance with EN ISO 13 849-1 or the SIL in accordance with IEC 61 508

and the SILCL in accordance with EN 62 061 depend on the external circuit, the realisation

of the wiring, the choice of the sensors and their location at the machine.

The device corresponds to up to category 4 in accordance with EN ISO 13 849-1; applications can reach up to SIL3 in accordance with IEC 61 508, up to SILCL3 in accordance

with EN 62 061 or PL e in accordance with EN ISO 13 849-1. The emergency stop function

in the device corresponds to stop category 0 or 1 in accordance with EN 60 204-1.

In order to reach the SIL3 safety level (see chapter 11 “Technical specifications” on

page 96) in accordance with IEC 61 508, the following test must be made at least every

365 days:

• The Flexi Classic system must be powered down.

• The Flexi Classic system must be powered up.

• All safety functions of the connected safety sensors must be verified.

The type of safety sensors as well as the method of wiring must be chosen according to

the category which is to be achieved.

Opto-electronic and tactile safety sensors (e.g. light curtains, laser scanners, safety switches, sensors, emergency stop pushbuttons) are connected to the modular safety controller

and are linked logically. The corresponding actuators of the machines or systems can be

switched off safely via the switching outputs of the safety controller.

The Flexi Classic safety controller has been tested in accordance with UL 508.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Page 12

Chapter 2 Operating instructions

On safety

Flexi Classic

2.3 Correct use

The Flexi Classic modular safety controller may only be used as intended in section 2.2

“Applications of the device”. It may only be used by specialist personnel and only at the

machine at which it was mounted and initially commissioned by qualified safety personnel

in accordance with these operating instructions.

If the device is used for any other purposes or modified in any way — also during mounting

and installation — any warranty claim against SICK AG shall become void.

2.4 General safety notes and protective measures

Observe the safety notes and protective measures!

WARNING

Please observe the following items in order to ensure correct use of the Flexi Classic

modular safety controller.

• When mounting, installing and using the Flexi Classic, observe the standards and

directives applicable in your country.

• The national/international rules and regulations apply to the installation, use and

periodic technical inspection of the Flexi Classic modular safety controller, in particular:

– Machinery Directive 2006/42/EC

– EMC Directive 2004/108/EC (valid until 19.04.2016)

EMC Directive 2014/30/EU (valid from 20.04.2016)

– Provision and Use of Work Equipment Directive 2009/104/EC

– Low Voltage Directive 2006/95/EC (valid until 19.04.2016)

Low Voltage Directive 2014/35/EU (valid from 20.04.2016)

– The work safety regulations/safety rules

• Manufacturers and owners of the machine on which a Flexi Classic is used are

responsible for obtaining and observing all applicable safety regulations and rules.

• The notes, in particular the test notes (see chapter 8 “Commissioning” on page 90) of

these operating instructions (e.g. on use, mounting, installation or integration into the

existing machine controller) must be observed.

• The tests must be carried out by qualified safety personnel or specially qualified and

authorised personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time by third parties.

• These operating instructions must be made available to the operator of the machine

where the Flexi Classic is used. The machine operator is to be instructed in the use of

the device by qualified safety personnel and must be instructed to read the operating

instructions.

• To meet the requirements of the relevant product standards (e.g. EN 61 496-1), the

external voltage supply for the devices (SELV) must, among other aspects, be able to

bridge a power failure lasting 20 ms. Suitable power supplies are available as accessories from SICK.

• The modules of the Flexi Classic family conform to Class A, Group 1, in accordance with

EN 55 011. Group 1 encompasses all ISM devices in which intentionally generated

and/or used conductor-bound RF energy that is required for the inner function of the

device itself occurs.

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 13

Operating instructions Chapter 2

Flexi Classic

WARNING

WARNING

On safety

The Flexi Classic system complies, as per the “radiated emissions” generic standard,

with the requirements of class A (industrial applications).

The Flexi Classic system is therefore only suitable for use in an industrial environment.

Loss of the safety function through an incorrect configuration!

Plan and carry out configuration carefully!

The configuration of safety applications must be carried out with the greatest accuracy and

must match the status and the condition of the machine or system to be monitored.

= Check whether the configured safety application monitors the machine or system as

planned and whether the safety of a configured application is ensured at all times. This

must be ensured in each operating mode and partial application. Document the result

of this check!

= In each case, observe the instructions for commissioning and daily checking in the

operating instructions of the protective devices integrated into the safety application!

= Note the warnings and function descriptions of protective devices connected to the

safety controller! Contact the respective manufacturer of the protective device if in

doubt!

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Page 14

Chapter 2 Operating instructions

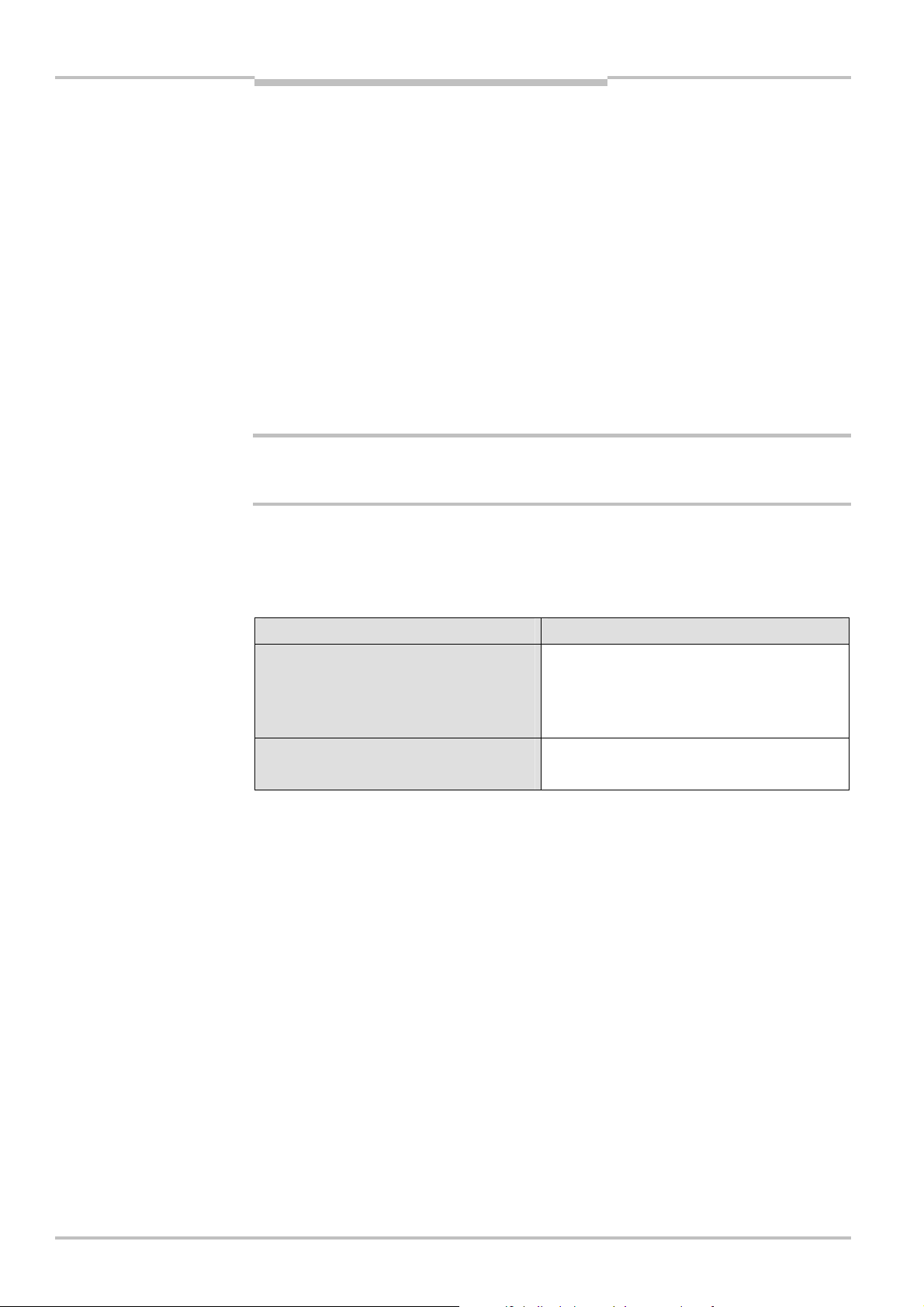

Tab.5:

Overview on

disposal

On safety

Flexi Classic

2.5 Environmental protection

The Flexi Classic modular safety controller has been designed to minimise environmental

impact. It uses only a minimum of power and natural resources.

= At work, always act in an environmentally responsible manner.

2.5.1 Disposal

Disposal of unusable or irreparable devices should always occur in accordance with the

applicable country-specific waste-disposal regulations (e.g. European Waste Code

16 02 14).

Note

WARNING

We would be pleased to be of assistance to you on the disposal of these devices.

Contact us.

2.5.2 Separation of materials

Material separation may only be performed by qualified safety personnel!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the

different materials in the Flexi Classic.

= Separate the housing from the rest of the parts (in particular the circuit board).

= Send the separated components for recycling as appropriate (see Tab. 5).

by components

Components Disposal

Product

Housing, circuit boards, cables,

connectors and electrical connecting

pieces

Packaging

Cardboard, paper

Electronic recycling

Paper/cardboard recycling

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 15

Operating instructions Chapter 3

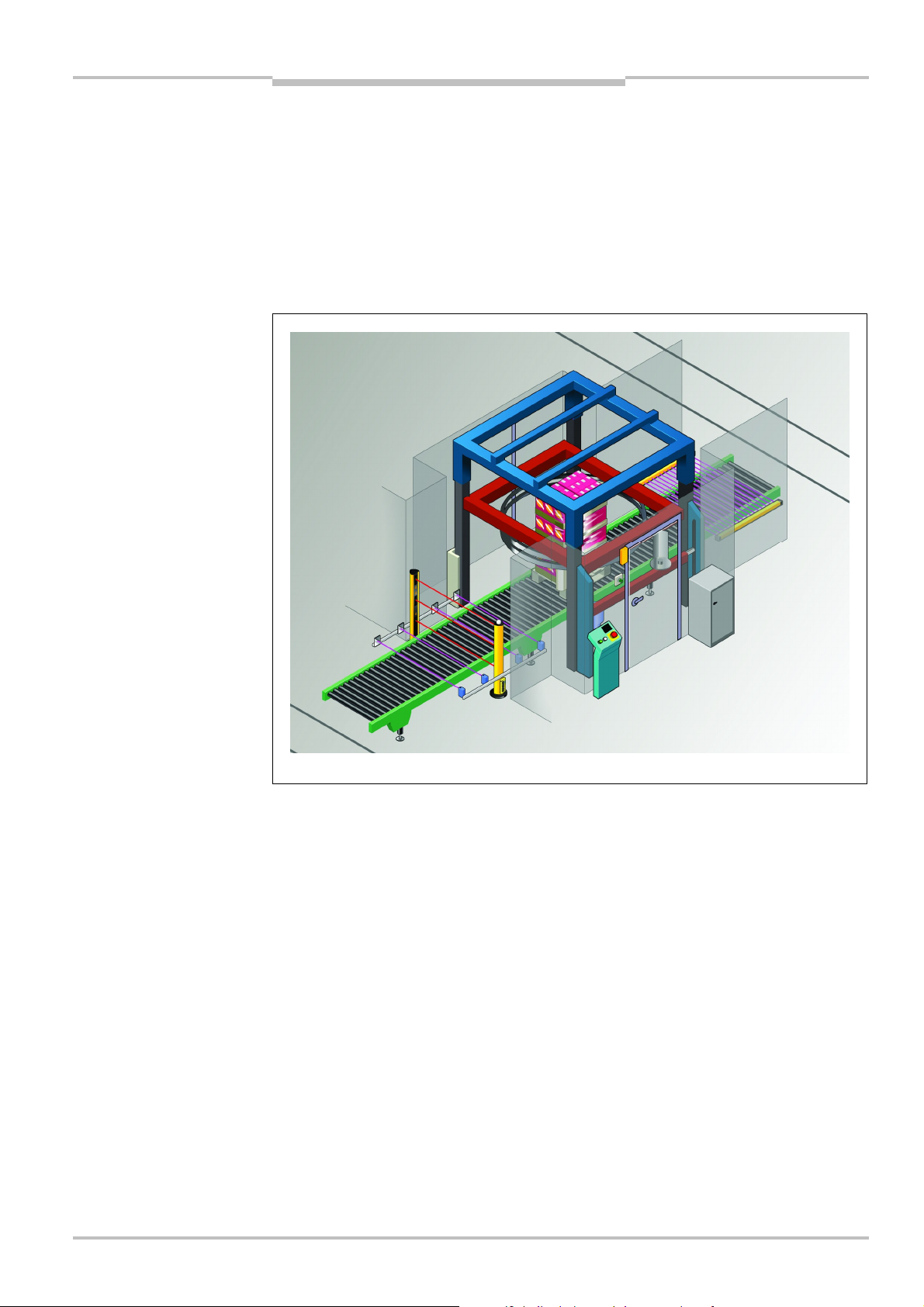

Fig.1:

Flexi Classic

modular

Flexi Classic

Product description

3 Product description

This chapter provides information on the special features and properties of the Flexi

Classic modular safety controller. It describes the construction and the operating principle

of the device.

= Please read this chapter before mounting, installing and commissioning the device.

3.1 Special features

safety controller

The Flexi Classic series is a safety controller concept comprising different modules that

can be interconnected individually. This allows the system to be extended to up to 104

inputs or outputs.

Each of these modules has a compact width of 22.5 mm. The units are of plug-in style with

communication between the individual units over an internal bus.

The required logic and function is specified by means of rotary switches on the modules.

An exception thereof are the relay modules and the fieldbus modules that are used for

integration in a higher level controller without a safety function. These modules are output

units and have no effect on the logic set or the function of the upstream units.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Subject to change without notice

Page 16

Chapter 3 Operating instructions

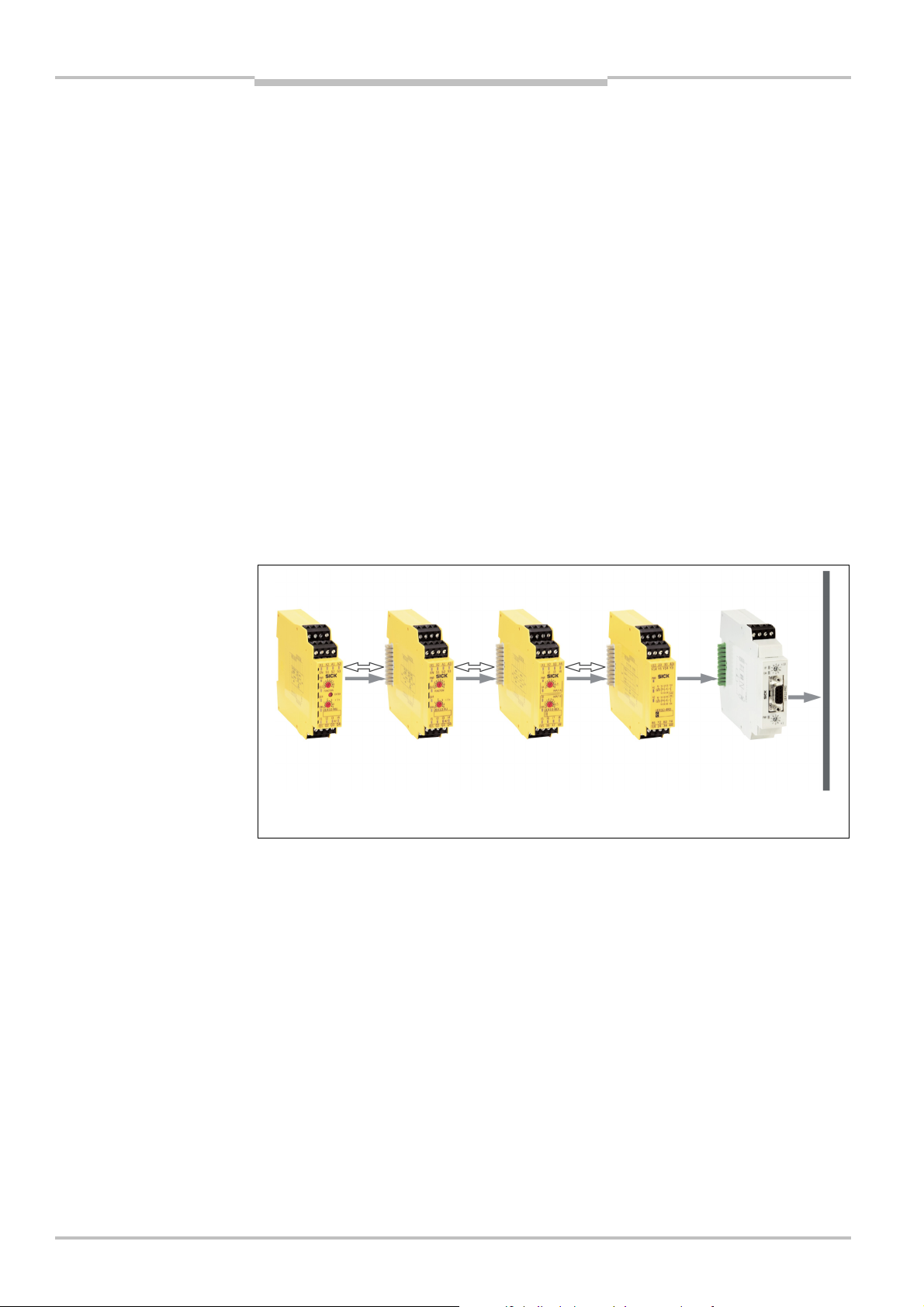

Fig.2:

Safety controller

Product description

Flexi Classic

The Flexi Classic series consists of the following modules:

• main module UE410-MU

• main module UE410-GU

• input/output extension module UE410-XU

• input extension module UE410-8DI

• output modules UE410-2RO and UE410-4RO

• gateways, e.g.

– UE410-PRO (PROFIBUS-DP)

– UE410-CAN (CANopen)

– UE410-DEV (DeviceNet)

– UE410-EN1 (EtherNet/IP)

– UE410-EN3 (Modbus TCP)

– UE410-EN4 (PROFINET IO)

3.2 Structure

A Flexi Classic system always consists of a single main module (UE410-MU or UE410-GU)

and, if necessary, additional input and output extensions as well as a corresponding bus

module.

structure Flexi Classic

(example with UE410-MU)

Main module

4 inputs /4 outputs

Input/output extension module

4 in puts/4 o utputs

Input extension module

8 in puts

UE410-8DIUE410-XUUE410-MU

Output module

2/4 outputs

UE410-2RO/

UE410-4RO

Gateway

E.g. UE410 -PRO, UE410-DEV,

UE410-CAN (see operating

instructions Flexi Classic

Gateways )

3.2.1 UE410-MU main module

The UE410-MU is the main module in which the system configuration of the entire Flexi

Classic system is stored.

The UE410-MU has 4 safety inputs, 4 semiconductor outputs and 2 test outputs. The

9 programs that are available can be set by means of rotary switches that ensure the

connection of a large number of safety components. Functions such as EDM, resetting,

etc. are selected by means of the wiring of S1, S2 and S3. The UE410-MU can control two

applications acting independently as well as two applications that are dependent on each

other.

Fieldbus

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 17

Operating instructions Chapter 3

Flexi Classic

Product description

The devices listed in the following can be connected to the UE410-MU and the modules

connected to it:

• emergency stop pushbuttons

• pressure sensitive mats

• two-hand controllers

• safety switches

• non-contact safety switches (e.g. RE300, T4000 Compact, IN4000)

• single-beam photoelectric safety switches (e.g. L21, L41)

• safety light curtains and multiple light beam safety devices (e.g. MSL, miniTwin,

C/M2000, C/M4000)

• safety laser scanners and safety camera systems (e.g. S300, V300, S3000)

Typical applications such as muting and OR links can be implemented simply, depending

on the setting of the program switch. If additional inputs or outputs are required, the

UE410-MU can be supplemented with a UE410-XU input/output extension module and/or

one or several UE410-8DI input extension modules.

If relay outputs are required, these can be implemented with the UE410-2RO/UE410-4RO

output modules.

Note

3.2.2 UE410-GU main module

The UE410-GU is a main module that can be used as an alternative to the UE410-MU. As

in the UE410-MU, the system configuration for the entire Flexi Classic system is saved in

the UE410-GU. The UE410-GU makes possible a global emergency stop function for several stations connected together that must each be equipped with a UE410-GU. A local

emergency stop is also possible on each UE410-GU.

The UE410-GU has 4 safety inputs (I1-I4), 1 semiconductor output (Q1), 1 output for a

lamp for “Global emergency stop status” and “Reset required” (Q2), 2 test outputs (X1, X2)

and 2 inputs and 2 outputs for the global emergency stop function (IP, IN, OP and ON). The

safe control inputs I5 and I6 are used to connect external device monitoring and a reset

button. The 9 available programs can be set using a rotary switch and make it possible to

connect a variety of safety components.

The following devices can be connected to the UE410-GU:

• emergency stop pushbutton

• safety switch

• non-contact safety switches (e.g. RE300, T4000 Compact)

• single-beam photoelectric safety switches (e.g. L21, L41)

• safety light curtains and multiple light beam safety devices (e.g. MSL, miniTwin,

C/M2000, C/M4000)

• safety laser scanners and safety camera systems (e.g. S300, V300, S3000)

If additional inputs are required, the UE410-GU can be expanded with one or more input

extension modules UE410-8DI.

The UE410-GU can also be expanded with a UE410-XU. This module does not act on the

global emergency stop.

If relay outputs are required, these can be implemented with the UE410-2RO/UE410-4RO

output modules.

The UE410-GU does not support all data sets from all gateways.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Subject to change without notice

Page 18

Chapter 3 Operating instructions

Notes

Product description

Flexi Classic

3.2.3 UE410-8DI input extension module

The UE410-8DI module is an input extension with 8 inputs that can be linked using the OR,

AND or Bypass logic function to the respectively upstream UE410-MU, UE410-GU or

UE410-XU module. The 9 switch positions of the UE410-8DI rotary switch determine which

safety components can be connected to the UE410-MU/GU/XU and which type of logic is

used. The input extension module UE410-8DI acts exclusively on the next UE410-MU,

UE410-GU or UE410-XU module positioned to the left in the module structure, thus forming a function group. It is allowed to connect a maximum of 8 UE410-8DI modules to a

UE410-MU, UE410-GU or UE410-XU.

For more informationen on this topic see section 4.12 “Grouping of subsystems” on

page 78.

3.2.4 UE410-XU input/output extension

The UE410-XU module is an input/output extension with 4 safety inputs, 4 semiconductor

outputs and 2 test outputs. It has the same switch positions, logic functions and facilities

for connecting sensors as the UE410-MU. In contrast to the UE410-MU and UE410-GU, the

UE410-XU cannot store the system configuration.

• A UE410-XU can only be operated in combination with a UE410-MU or UE410-GU main

module.

• A main module and a UE410-XU can be linked logically with each other, thus forming a

subsystem (for further information please refer to section 4.12 “Grouping of subsystems” on page 78).

Note

3.2.5 UE410-2RO/UE410-4RO output modules

The UE410-2RO/UE410-4RO output extensions make one or two dual-channel, contactbased outputs available. They do not have any influence on the specified logic instructions

of a system structure and are controlled by the UE410-MU, UE410-GU or UE410-XU outputs.

3.2.6 Gateways

Gateways (fieldbus modules) can be added to the Flexi Classic modular system for diagnostic purposes. They output the system configuration and the input/output states as well

as the error and status information of all the modules.

Several gateways are available, e.g.:

• UE410-PRO for PROFIBUS-DP

• UE410-DEV for DeviceNet

• UE410-EN1 for EtherNet/IP

The UE410-GU does not support all data sets from all gateways.

You will find a complete list of all gateways and the data sets supported in the operating

instructions “Flexi Classic Gateways” or in the Internet on our homepage www.senscontrol.com.

All gateways have 4 non-safe application diagnostic outputs. The outputs are short-circuit

protected (see also the Flexi Classic Gateways operating instructions).

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 19

Operating instructions Chapter 3

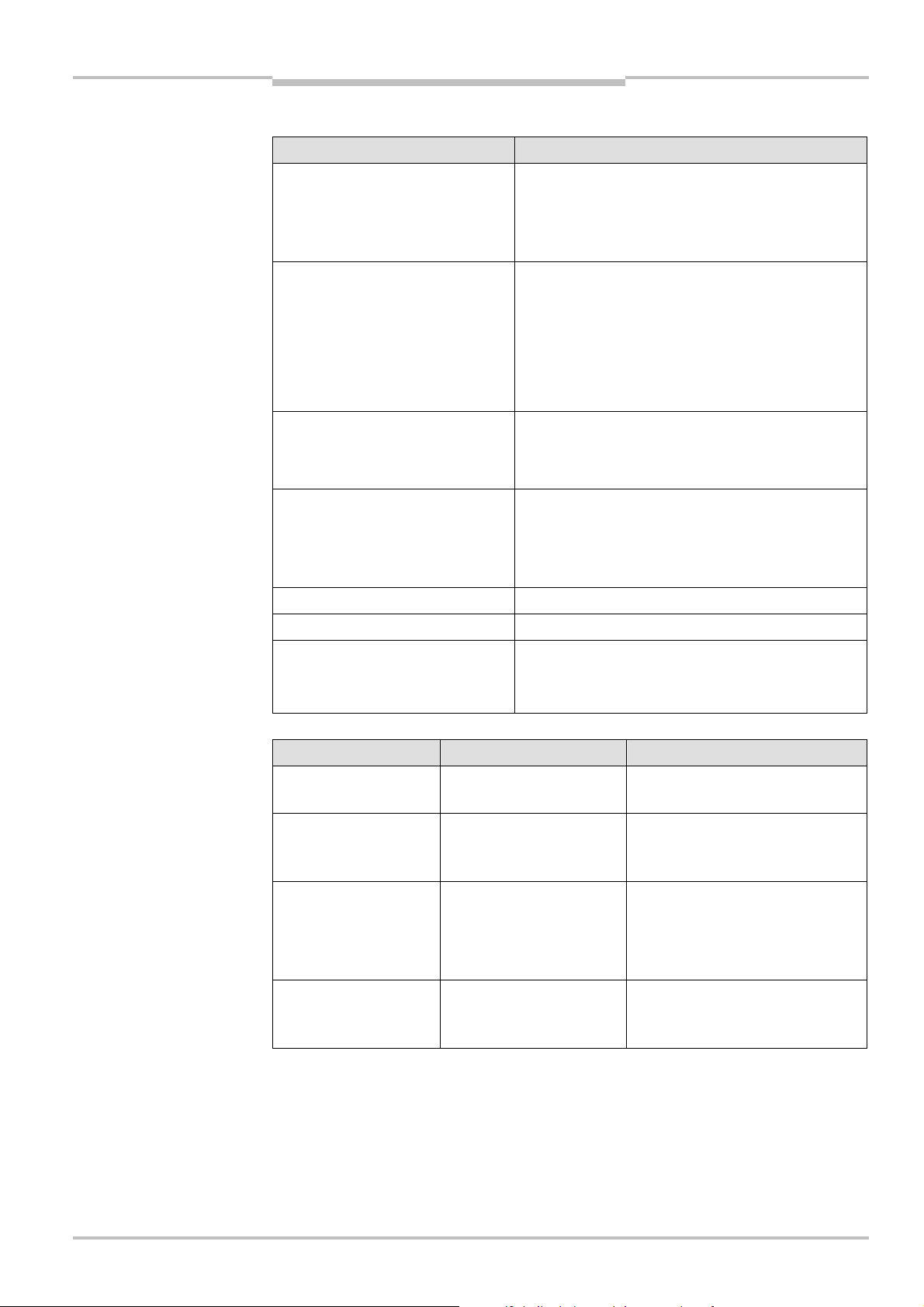

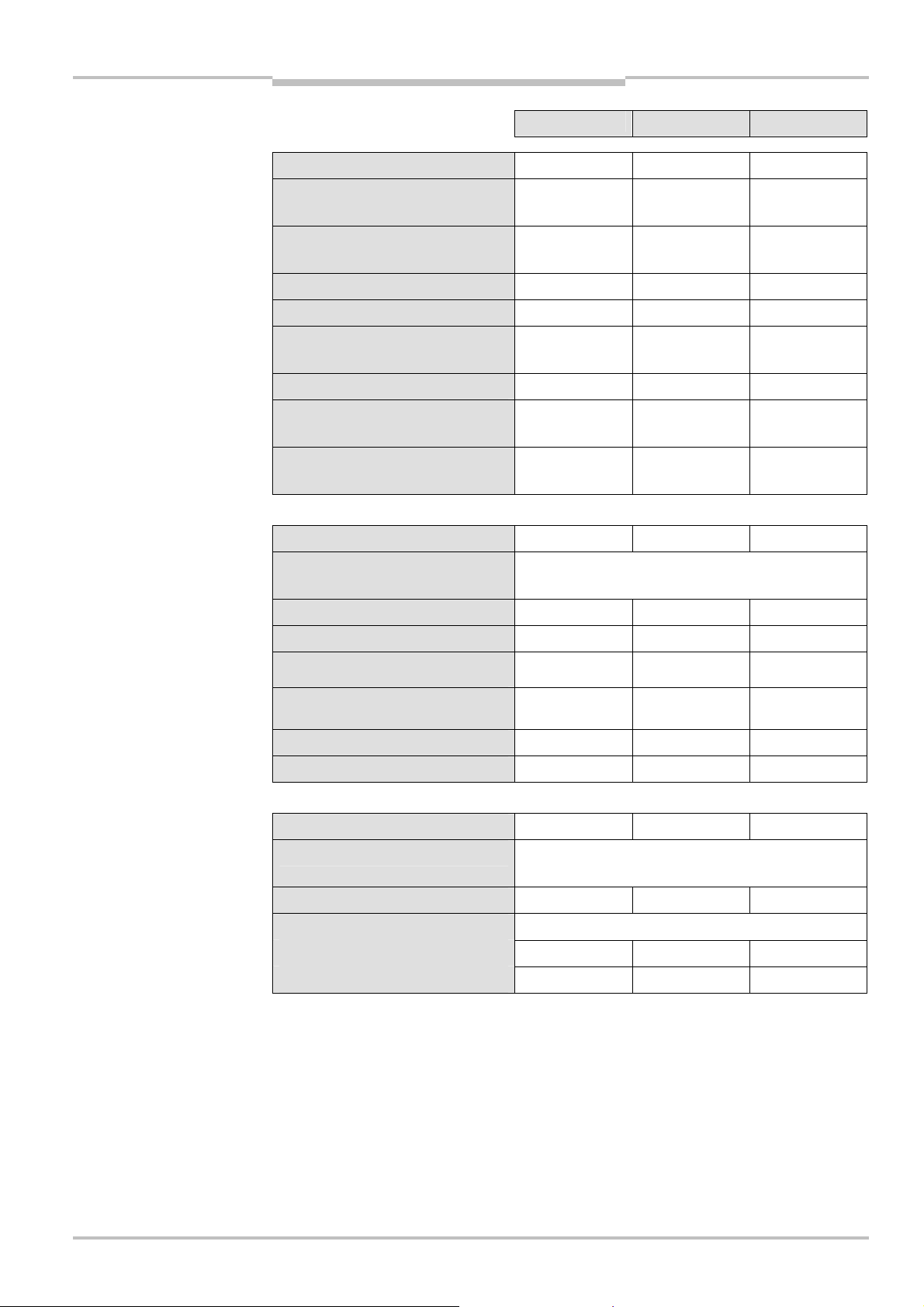

Tab.6:

Module overview

Tab.7:

Overview of setting

Flexi Classic

Product description

3.2.7 Module overview, adjustments and facilities for connecting sensors

Module Description

UE410-MU

• Main unit of the Flexi Classic modular safety

controller

• 4 safe inputs and 4 safe outputs

• Storage of the system configuration

UE410-GU

• Central function block of the Flexi Classic

modular safety controller

• Global emergency stop can be realized

• 4 safe inputs

• 1 safe output

• Storage of the system configuration

UE410-XU • Input/output extension/subsystem

• 4 safe inputs and 4 safe outputs

• Identical functionality as UE410-MU

UE410-8DI • Input extension

• 8 safe inputs

• Information coupling to the upstream UE410-

MU, UE410-GU or UE410-XU module

UE410-2RO 2 contacts (N/O), 1 signal contact (N/C)

possibilities

UE410-4RO 4 contacts (N/O), 2 signal contacts (N/C)

Flexi Classic gateways

e.g. UE410-PRO, UE410-DEV,

UE410-CAN

Setting possibility Can be set at the module Comment

ENTER button UE410-MU/UE410-GU

Status and diagnostics (information that is not

safety relevant) of a Flexi Classic on a fieldbus

(see Flexi Classic Gateways operating instructions)

Saving of all Flexi Classic system

programs, settings and wiring

Program 1-9

UE410-MU/UE410GU/UE410-XU

Selection of the safety sensors

and of the logic elements to be

connected

Off delay

0-5 s, 0-50 s or

0-300 s

UE410-MU/UE410-XU

Delays 1 or 2 outputs on the

module

3 different variants available

(Not on UE410-xxxT0)

Switch position 0-9 UE410-8DI

Selection of the logic elements

and of the safety sensors to be

connected

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Subject to change without notice

Page 20

Chapter 3 Operating instructions

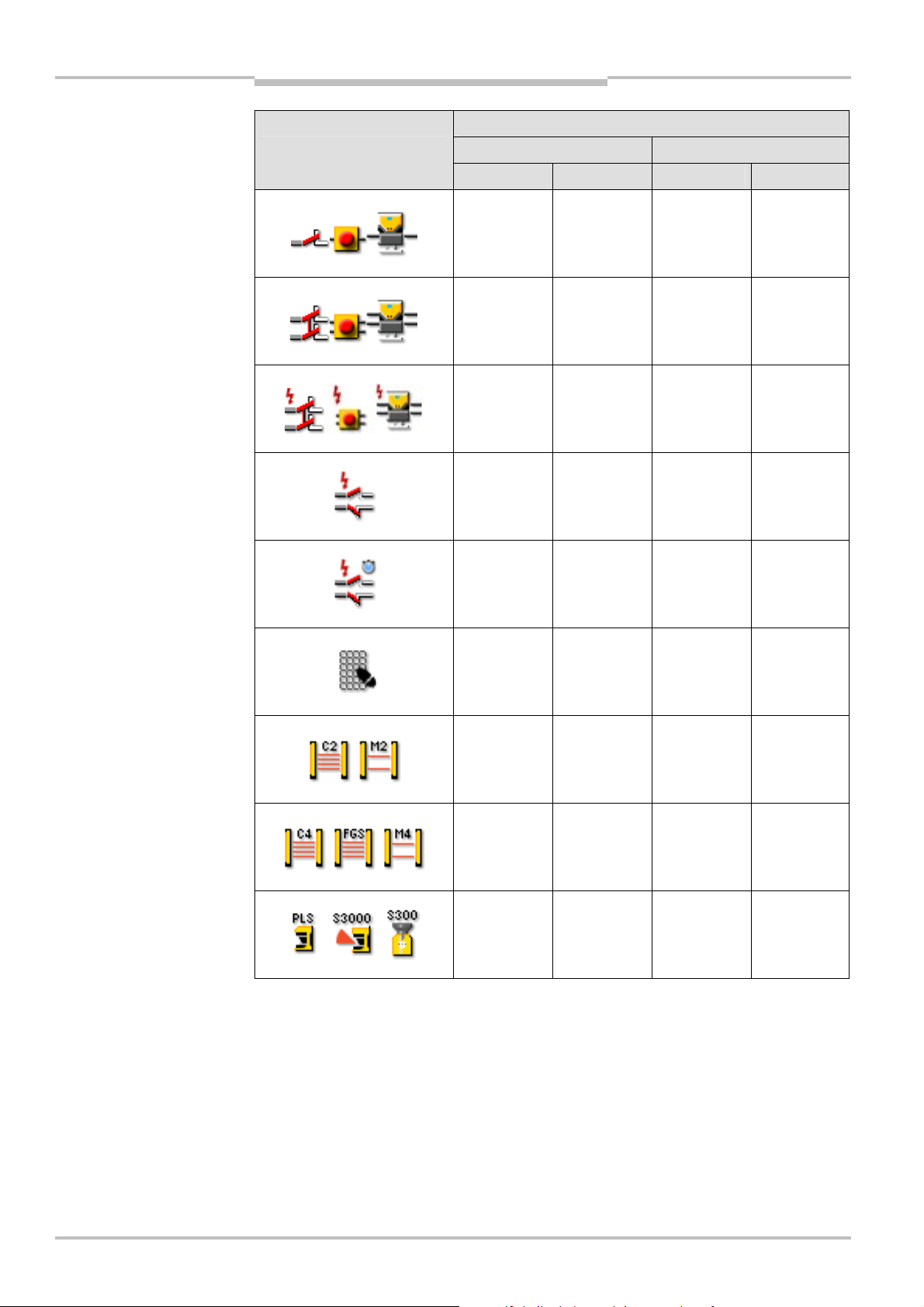

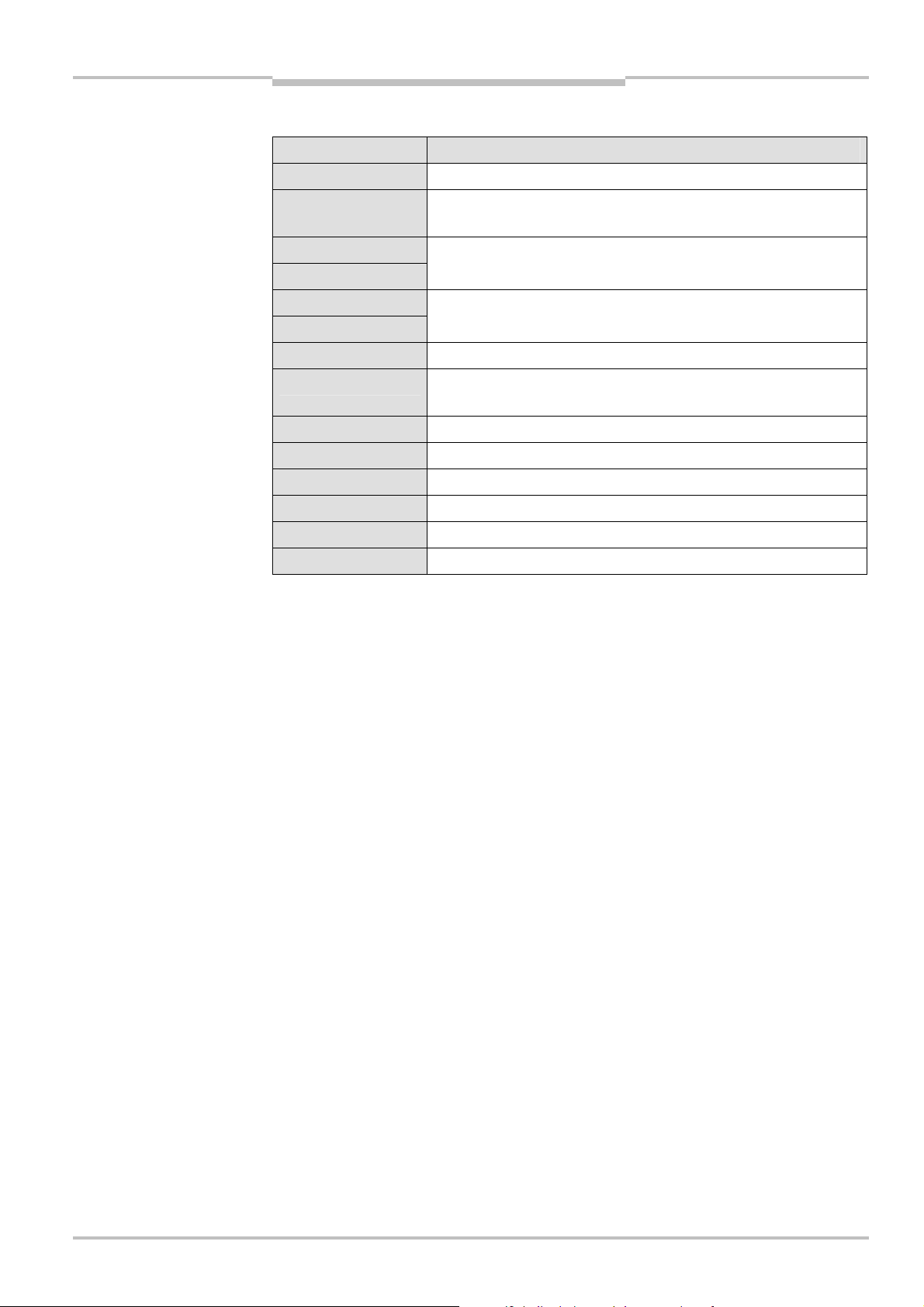

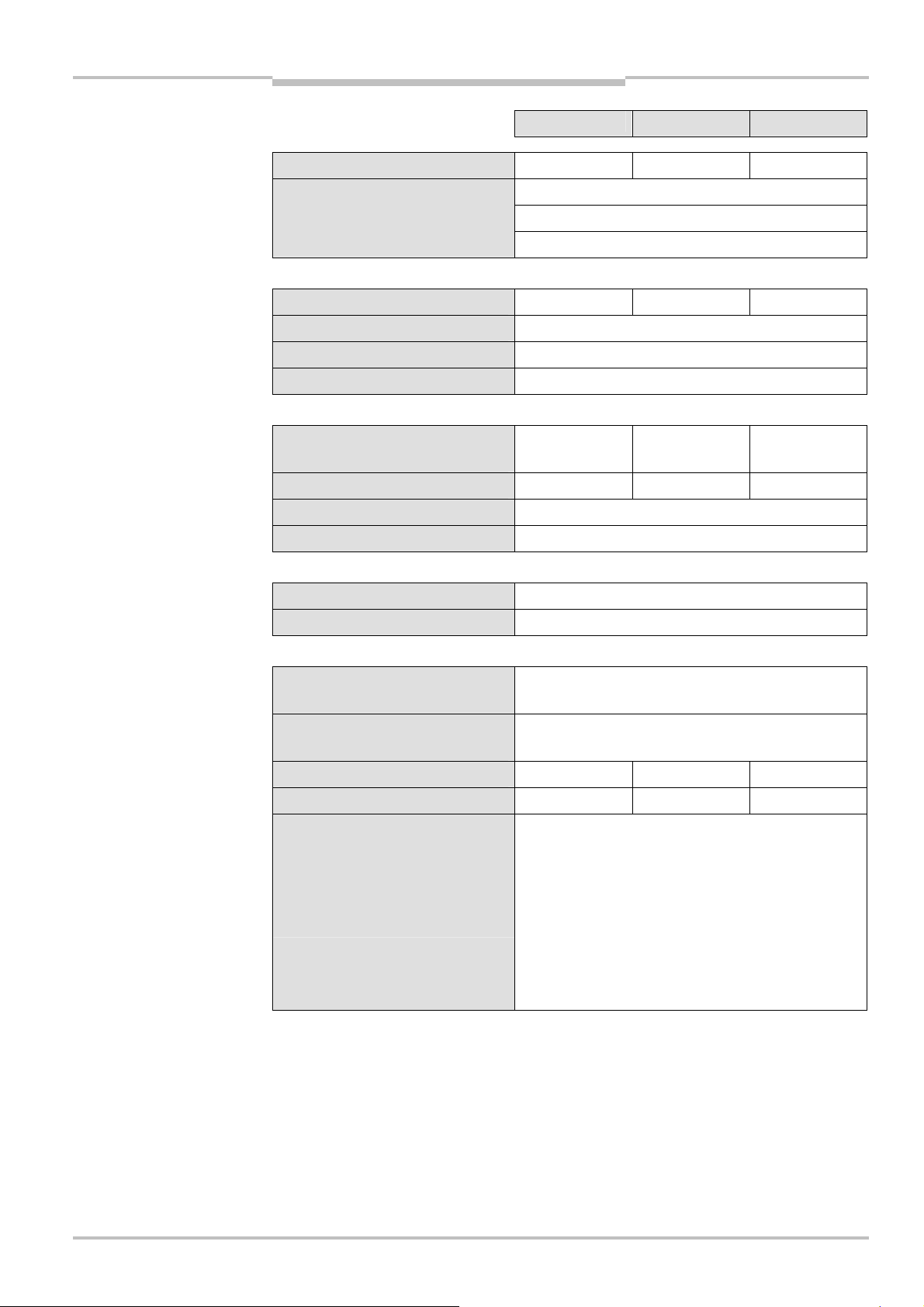

Tab.8:

Connection of sen

-

Product description

Flexi Classic

sors to the UE410-MU,

UE410-XU and UE410-8DI

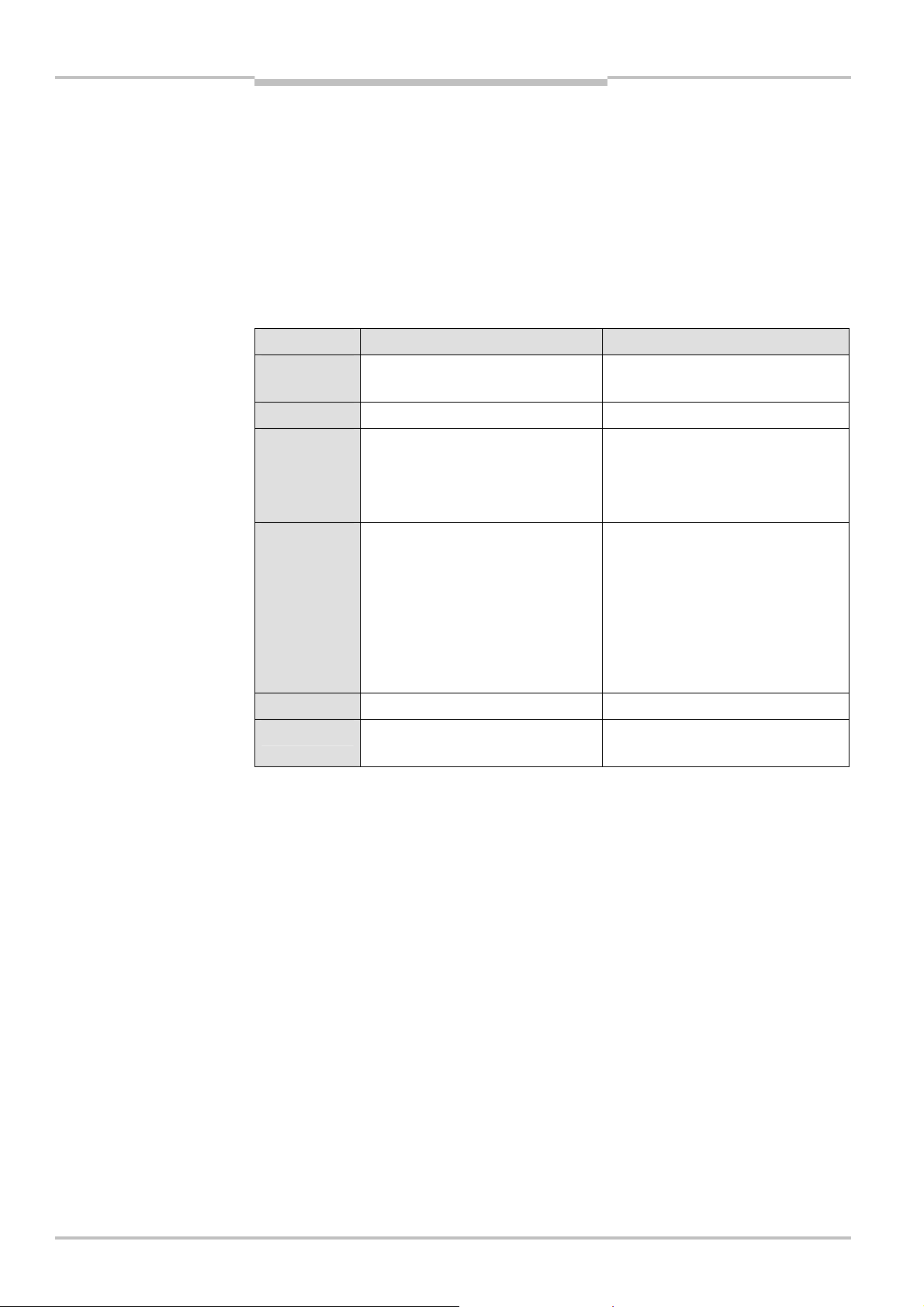

Sensor

Program

UE410-MU/UE410-XU UE410-8DI

A (I1/I2) B (I3/I4) A (I1-I4) B (I5-I8)

7, 8 1, 2, 7, 8, 9 1, 6, 7 1, 6, 7

7, 8 1, 2, 7, 8, 9 6, 7 6, 7

1, 5, 6, 9 5, 6 2, 3, 8 2, 3, 8

– – 4 4

2 – 5 5

1 – 2 2

3, 7, 8 1, 2, 7, 8, 9 6, 7 6, 7

3, 7, 8 1, 2, 7, 8, 9 6, 7 6, 7

3, 7, 8 1, 2, 7, 8, 9 6, 7 6, 7

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 21

Operating instructions Chapter 3

Flexi Classic

Product description

Sensor

Program

UE410-MU/UE410-XU UE410-8DI

A (I1/I2) B (I3/I4) A (I1-I4) B (I5-I8)

4 4 – –

– 5.2 – –

– 5.1 – –

2 – 5 5

3 – – –

1, 5, 6, 7, 8

1, 2, 6, 7, 8,

2, 3, 6, 7, 8 2, 3, 6, 7, 8

9

3 – 1 1

3 3 – –

1, 5, 6, 9 5, 6 2, 3, 8 2, 3, 8

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Subject to change without notice

Page 22

Chapter 3 Operating instructions

Fig.3:

Scheme programs 1

-3Fig.4:

Scheme program 4

Product description

Flexi Classic

3.3 UE410-MU main module

The UE410-MU main module is the main module of the Flexi Classic modular safety controller. Only one UE410-MU can be integrated for each Flexi Classic system. A UE410-MU

can control up to two applications acting independently or two applications that are dependent on each other.

In order to increase the number of inputs, one or more UE410-8DI extension modules can

be used additionally.

An additional UE410-XU module can be used in order to increase the number of outputs

(for further information refer to section 4.12 “Grouping of subsystems” on page 78).

The system configuration is stored in the UE410-MU main module (ENTER button to accept

the program settings and system configuration) (for further information refer to section 9.1

“Accepting the system configuration” on page 92).

9 programs that can be set with a screwdriver at the program switch are available.

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 23

Operating instructions Chapter 3

Fig.5:

Scheme

Fig.6:

Scheme program 8

Flexi Classic

programs 5-7, 9

Product description

Note

WARNING

The following functions can be set by selecting the program and connecting the terminals

S1, S2, and S3 at the module:

• type of the logic and of the safety sensors to be connected

• restart interlock

• external device monitoring (EDM)

Q1 and Q2 always switch off within the response time.

Q31) and Q4 can be deactivated with off delay by using the lower rotary switch (depending

on the device variant 0-5 s/0-50 s/0-300 s/not on UE410-xxxT0).

The outputs are tested periodically in order to detect errors in the safety outputs Q1-Q4.

When using XU modules see section 4.12 “Grouping of subsystems” on page 78.

For further information see section 3.6 “UE410-MU/UE410-XU programs” on page 36.

Subsequent changes to the program or to the wiring (S1-S3) without saving will result in a

safety-related shutdown.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Subject to change without notice

1)

Q3 has various functions; see section 3.6 “UE410-MU/U E410-XU programs” on page 36.

Page 24

Chapter 3 Operating instructions

Fig.7:

UE410

-

MU controls

Tab.9:

UE410

-

MU

Button for accepting the

Program switch

Switch for off delay

Product description

Flexi Classic

3.3.1 Controls and status indicators

and status indicators

system configuration

(not on UE410-xxxT0),

see Tab. 10

indications

LED indicators Meaning

PWR (green) Supply voltage present

Q1/Q2, Q3/Q4 (green) Switching state of the safety outputs (high level)

Q3/Q4 (green flashing) Q3/Q4 to high level during the course of the delay time

ERR (red flashing)

Indication for erroneous operational status on this

module, see chapter 10 “Diagnostics” on page 93

ERR (red)

Indication for erroneous operational status on the whole

system (the error is on another module), see chapter 10

“Diagnostics” on page 93

EN, S1-S3 (green) Voltage is present.

I1-I4 (green) Signal is present.

I1/I2 flash in phase Cross-circuit between I1/I2

I3/I4 flash in phase Cross-circuit between I3/I4

I1/I2 flash out of phase Process error at I1/I2

I3/I4 flash out of phase Process error at I3/I4

I1 to I4 flashes

Synchronization time/concurrence error, expected signal

is not present at the respective input.

S1-S3 flashes Expected signal is not present (e.g. EDM or Reset).

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Other indicators Device error, see chapter 10 “Diagnostics” on page 93

Subject to change without notice

Page 25

Operating instructions Chapter 3

Tab.10:

UE410

-MU

Tab.11:

UE410

-

MU terminal

Flexi Classic

Product description

operating elements

assignment

Switch/button Function

FUNCTION

10-step rotary switch (position 0 forbidden) for setting an input

circuit function (see section 3.6 “UE410-MU/UE410-XU programs”

on page 36)

X1s, X10s,

2)

X1min

10-step rotary switch for setting the off delay time (see section 3.6

“UE410-MU/UE410-XU programs” on page 36)

ENTER Button for accepting the system configuration (Teach-in).

See section 9.1 “Accepting the system configuration” on page 92.

3.3.2 Terminal assignment

Assignment Description

I1/I2 Input for logic path A

I3/I4 Input for logic path B

EN ENABLE input, activates the logic path(s)

S1

S2

Input for reset buttons (RESET), restart interlock (EDM), retriggering,

etc.

S3

A1 (+UB)

Voltage supply

A2 (GND)

X1

X2

Test outputs: cross-circuit detecting and short-circuit detecting control

signals for controlling safety sensors

3)

Q1-Q4 Monitored semiconductor outputs (OSSD)

Q3

Is used in Program 3 as the output for the muting lamp and Reset

required.

3)

2)

The maximum adjustable duration of the switch off delay is 5, 50 or 300 s depending on the device variant,

see section 12.1 “Available modules” on page 112.

3)

When using multiple modules see section 4.12 “Grouping of subsystems” on page 78.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Subject to change without notice

Page 26

Chapter 3 Operating instructions

WARNING

Product description

Flexi Classic

3.3.3 Outputs

You have two possibilities to reach SIL3 or Category 4 for your application:

• dual-channel wiring of the outputs, e.g. Q1/Q2 to K1/K2

or

• single-channel wiring only with routing within protected areas such as in a control

cabinet, e.g. Q1 to K1/K2.

Safety-oriented devices must be suitable for safety related signals!

A function interruption of safety outputs results in a loss of the safety functions so that the

risk of serious injury exists.

• Do not connect any loads that exceed the rated values of the safety outputs.

• Wire the Flexi Classic system so that 24 V DC signals cannot contact the safety outputs.

• Connect the GND wires of the power supply to earth so that the devices do not switch

on when the safety output line is applied to frame potential.

• Use suitable components or devices that fulfil all the applicable regulations and

standards.

Actuators at the outputs can be wired single-channeled. In order to maintain the respective

Safety Integrity Level the lines have to be routed in such a manner that cross circuits to

other live signals can be excluded, for example by routing them within protected areas

such as in a control cabinet or in separate plastic-sheathed cables.

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 27

Operating instructions Chapter 3

Flexi Classic

Product description

3.4 UE410-GU main module

The UE410-GU is a main module that can be used as an alternative to the UE410-MU. The

system configuration is stored in the main module (for further information please refer to

section 9.1 “Accepting the system configuration” on page 92).

Only one UE410-GU can be used per Flexi Classic system.

In order to increase the number of inputs, one or more UE410-8DI extension modules can

be used additionally.

To increase the number of outputs, an additional UE410-XU can be used (see section 4.12

“Grouping of subsystems” on page 78). A total of up to 12 Flexi Classic modules and one

gateway can be connected to the UE410-GU.

The UE410-GU makes possible a global emergency stop function for several stations connected together that must each be equipped with a UE410-GU. If the global emergency

stop on a module is operated, the safety outputs on all modules switch off. To reset a global emergency stop, the reset button must be operated on the same module on which the

global emergency stop was triggered.

Note

A global emergency stop must always be reset manually.

Along with the global emergency stop function, on each module it is also possible to select

a local emergency stop function with or without restart interlock. The local emergency stop

only acts on the safety output on the related module. A local emergency stop can be reset

either automatically or manually.

The safety output Q1 always switches within the response time. A switch off delay as on

the UE410-MU is not possible with the UE410-GU.

Different programs for the local inputs can be selected with the aid of a rotary switch.

9 programs are available using which the following functions can be set:

• type of the safety sensors to be connected

• global emergency stop or global and local emergency stop

• automatic or manual reset of a local emergency stop

For further information see section 3.7 “UE410-GU programs” on page 49.

WARNING

Subsequent changes to the program will result in a safety-related shutdown without

saving.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

Page 28

Chapter 3 Operating instructions

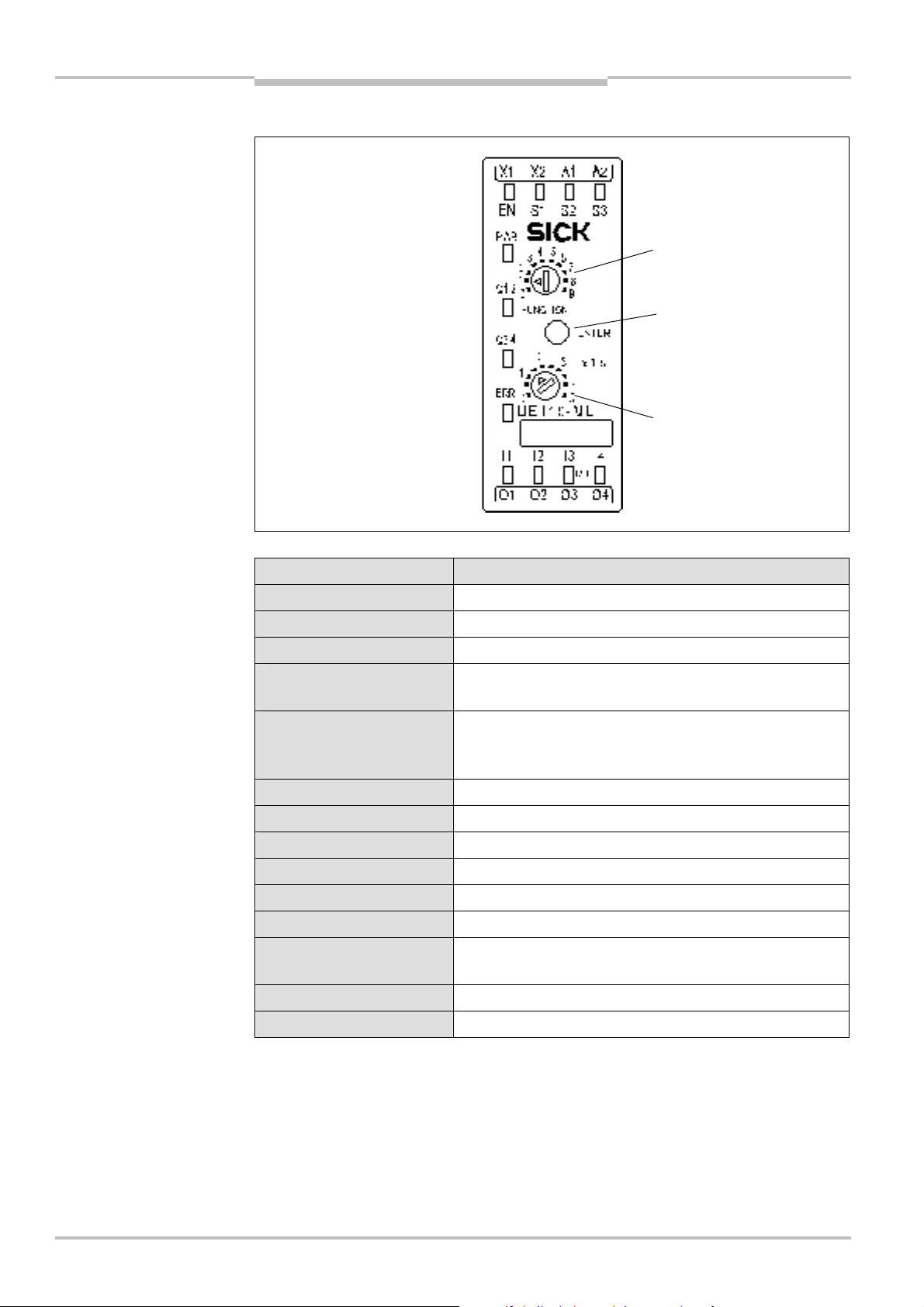

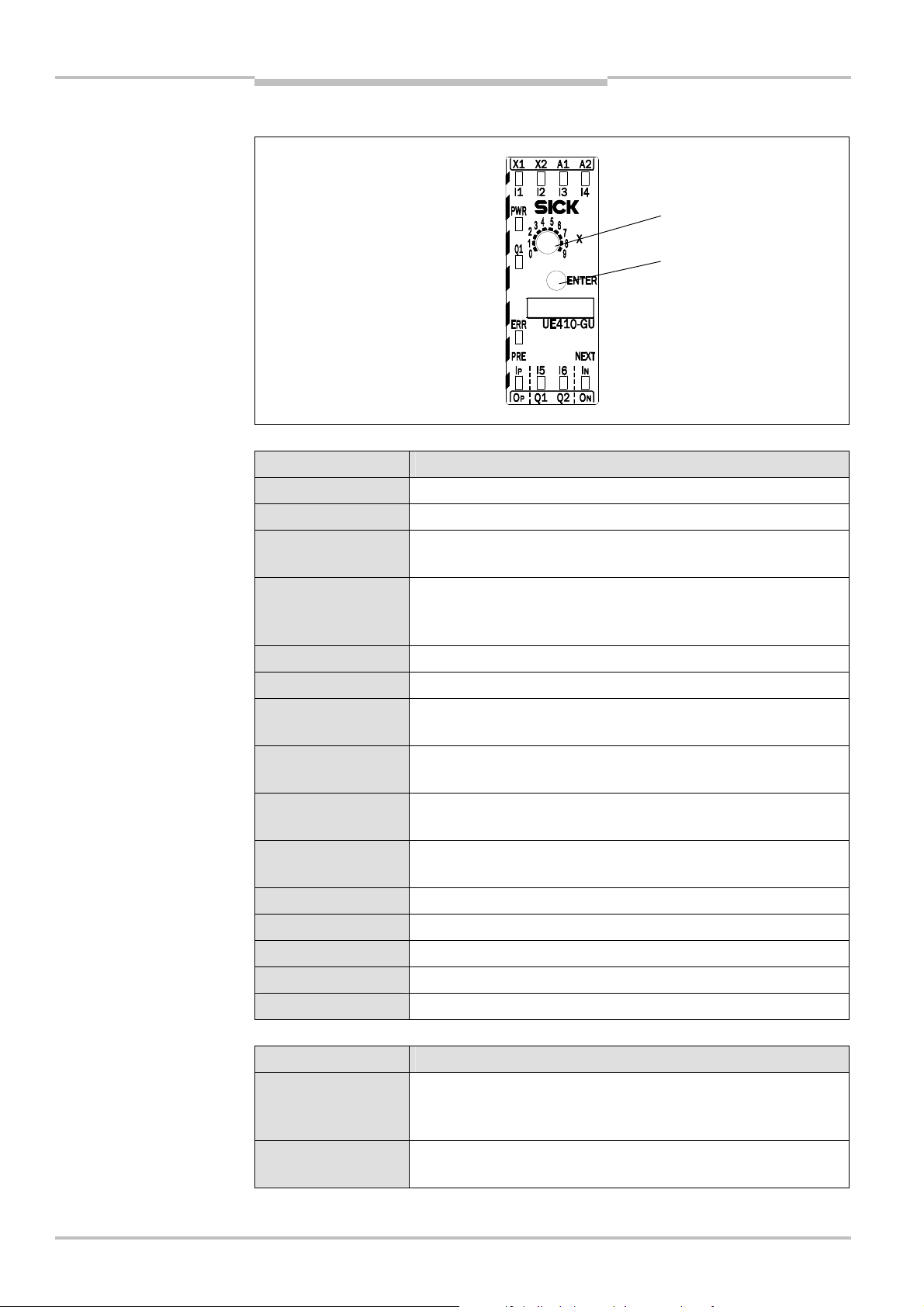

Fig.8:

UE410

-

GU controls

Tab.12:

UE410

-

GU

Tab.13:

UE410

-

GU

Program switch

Button for accepting the

Product description

Flexi Classic

3.4.1 Controls and status indicators

and status indicators

system configuration

indications

LED indicators Meaning

PWR (green) Supply voltage is present.

Q1 (green) Safety output Q1 is high.

ERR (red flashing)

Indication for erroneous operational status on this module, see

chapter 10 “Diagnostics” on page 93

ERR (red)

Indication for erroneous operational status on the whole system

(the error is on another module), see chapter 10 “Diagnostics”

on page 93

I1/I2 (green) Global cut-off path closed

I3/I4 (green) Cut-off path closed

I1/I2 (green flashing

Cross-circuit between I1/I2

in phase)

I3/I4 (green flashing

Cross-circuit between I3/I4

in phase)

I1/I2 (green flashing

Process error at I1/I2

out of phase)

I3/I4 (green flashing

Process error at I3/I4

out of phase)

I5 (green) External device monitoring contact is closed.

operating elements

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

I6 (green) Reset button is closed.

IP (green) Input IP is high.

IN (green) Input IN is high.

Other indicators Device error, see chapter 10 “Diagnostics” on page 93

Switch/button Function

X

10-step rotary switch (position 0 forbidden) for setting an input

circuit function, see section 3.7 “UE410-GU programs” on

page 49

ENTER

Button for accepting the system configuration (Teach-in), see

section 9.1 “Accepting the system configuration” on page 92

Subject to change without notice

Page 29

Operating instructions Chapter 3

Tab.14:

UE410

-

GU terminal

Flexi Classic

Product description

3.4.2 Terminal assignment

assignment

Assignment Description

I1/I2 Global emergency stop (equivalent switch with test pulses)

I3/I4

Local emergency stop (local input, depending on the program

set)

A1 (+UB)

Voltage supply

A2 (GND)

X1

X2

Q1 Single-channel safety output (OSSD)

Q2

Test outputs: cross-circuit detecting and short-circuit detecting

control signals for controlling safety sensors

4)

4)

Connection for the lamp for “Global emergency stop status” and

“Reset required”

I5 Connection for the external device monitoring (EDM)

I6 Connection for the reset button

I

P

I

N

O

P

O

N

Input signal from the previous module (PRE_IN)

Input signal from the next module (NEXT_IN)

Output signal to the previous module (PRE_OUT)

Output signal to the next module (NEXT_OUT)

Notes

3.4.3 Global emergency stop with the UE410-GU

The global emergency stop makes possible the simultaneous shut down of the safety outputs on several Flexi Classic stations connected together that are each equipped with a

UE410-GU as the main module.

• In theory as many UE410-GU modules as required can be connected together to form a

global emergency stop system. However, it is recommended not to exceed 32 modules,

because each module increases the response time of the overall system (see the information on the global response time in section 11.1.2 “UE410-GU module” of the technical data on page 101).

• The different UE410-GU modules that together form a global emergency stop circuit do

not need to be in the same protected area. Faults in the area OX and IX, e.g. a shortcircuit or cross circuit, are detected and will result in shutdown.

• All UE410-GU modules that are on a common global emergency stop cut-off path must

be connected to the same GND connection.

Principle of operation

As long as the system is enabled, each UE410-GU sends a signal to the previous UE410GU (PRE) and to the next UE410-GU (NEXT). If the global emergency stop is activated on a

module (falling edge on I1/I2), then this module sets its safety output Q1 as well as the

signals to its neighboring modules (outputs OP and ON) to low. The neighboring modules

now also set their safety output Q1 as well as their outputs OP and ON to low.

The status of the global emergency stop is also output via the output Q2. If the global

emergency stop is activated on this UE410-GU, this status is indicated with a signal

flashing at 2 Hz on output Q2. If the global emergency stop has been activated on another

UE410-GU, then this status is indicated with a continuous high on output Q2.

4)

When using multiple modules see section 4.12 “Grouping of subsystems” on page 78.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Subject to change without notice

Page 30

Chapter 3 Operating instructions

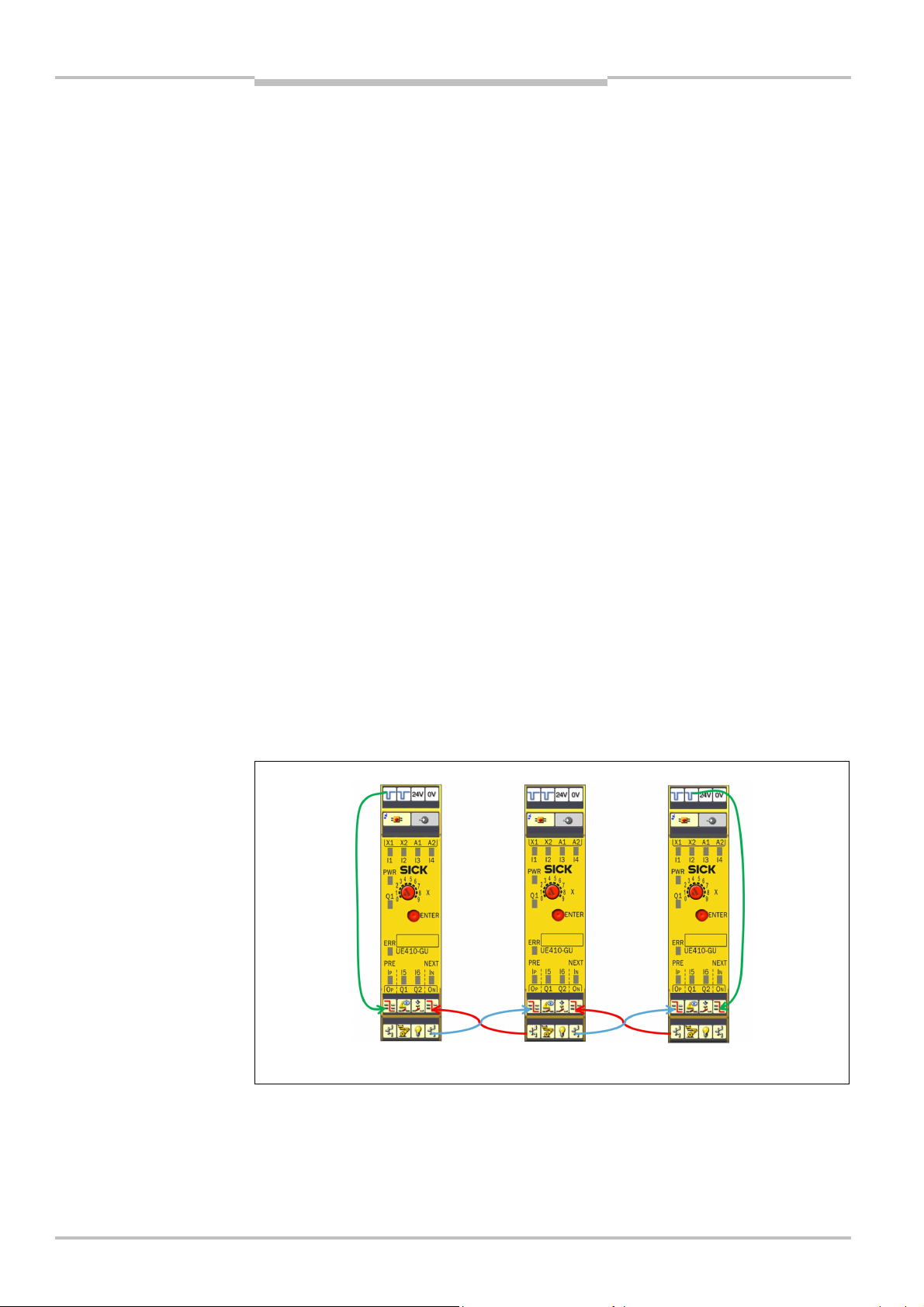

Fig.9:

Connecting several

First module

Last module

Module(s) in the middle

Product description

Flexi Classic

Once the cause of the global emergency stop has been rectified (inputs I1 and I2 are high

again, e.g. protective field clear), then the UE410-GU on which the global emergency stop

was originally triggered signals on output Q2 the status Reset required with a signal

flashing at 1 Hz.

Reset

A global emergency stop can only be reset manually. The reset must be undertaken on the

same module on which the global emergency stop was triggered.

Once the global cut-off path for this module is closed again (inputs I1 and I2 are high

again, e.g. protective field clear) and the reset button on this module is then operated, the

safety output Q1 on this module as well as the outputs OP and ON switch to high again.

The following conditions are to be noted for the reset:

• Only the falling edge is evaluated.

• The minimum actuation time for the reset button is ≥ 50 ms.

• The maximum actuation time for the reset button is ≤ 5 s.

If one of these criteria is not met, the emergency stop is not reset.

Wiring of the modules

To connect several UE410-GU modules together, the input IN on the previous UE410-GU

must be connected to the output OP on the next UE410-GU and the output ON on the previous UE410-GU must be connected to the input IP on the next UE410-GU.

For the specification of the connection cable please refer to the data sheet in section 11.1.2 “UE410-GU module” on page 101.

The first and last UE410-GU in an emergency stop system act as end modules. An end

module is a UE410-GU that has only one neighboring station. These modules are defined

by the wiring of the outputs X1 and X2.

• The end module without PRE is defined by wiring X1 to IP.

• The end module without NEXT is defined by wiring X2 to IN.

This wiring is saved with the configuration and checked each time on switching on.

UE410-GU modules

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 31

Operating instructions Chapter 3

Flexi Classic

WARNING

Product description

Test the entire emergency stop function after any change to the wiring!

If a UE410-GU is subsequently removed from an emergency stop system and the system is

then correctly wired, this change will not be detected. For this reason the entire emergency

stop function must always be tested after any change to the wiring.

Stand-alone mode of a UE410-GU

It is also possible to operate a UE410-GU as a standalone device. For this purpose X1

must be wired to IP and X2 must be wired to IN on this device.

3.4.4 Local emergency stop on the UE410-GU

A local emergency stop can be configured on each UE410-GU depending on the program

set (see section 3.7 “UE410-GU programs” on page 49).

Principle of operation

If the local emergency stop is activated on a UE410-GU (falling edge on I3 and/or I4, depending on the program set), this module sets its safety output Q1 to low. The signals O

and ON remain high, i.e. the local emergency stop only acts on the safety output on the

UE410-GU on which the local emergency stop was triggered.

Once the cause of the local emergency stop has been rectified (inputs I3 and I4 are high

again, e.g. protective field clear), the safety output Q1 on the module switches to high

again after a successful reset.

P

Reset

A local emergency stop can be reset either manually or automatically depending on the

program set:

• Automatic reset: Once the local cut-off path is closed again (e.g. protective field clear),

then the safety output Q1 on the module also switches to high again.

• Manual reset: Once the local cut-off path is closed again (e.g. protective field clear),

output Q2 starts to flash at 1 Hz. If the reset button is then operated, the safety output

Q1 on the module switches to high again.

The following conditions are to be noted for the manual reset:

• Only the falling edge is evaluated.

• The minimum actuation time for the reset button is ≥ 50 ms.

• The maximum actuation time for the reset button is ≤ 5 s.

If one of these criteria is not met, the emergency stop is not reset.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Subject to change without notice

Page 32

Chapter 3 Operating instructions

Notes

Product description

Flexi Classic

3.4.5 Inputs

Connection of the emergency stop pushbutton for the global emergency stop

(I1 and I2)

A two-pole equivalent safety switch must be connected to the inputs I1 and I2 as the

emergency stop pushbutton for the global emergency stop. The emergency stop pushbutton is tested via the connection of X1–I1 and X2–I2.

Connection of the sensors for the local emergency stop (I3 and I4)

The sensors for the local emergency stop are connected to the inputs I3 and I4 (see section 3.7 “UE410-GU programs” on page 49). The sensors are tested via the connection of

X1–I3 and X2–I4.

Connection of the external device monitoring (EDM) (I5)

The external device monitoring (EDM) is connected to I5.

Before each enable it is checked whether I5 is high. If this condition is not met, the safety

output Q1 is not set to high.

Connection of the reset button (I6)

The reset button must be connected to input I6.

• The reset button acts both as a reset button for the global emergency stop and for the

local emergency stop, if a program with manual reset is set for the local emergency stop

(program 2, 4, 6 or 8) (see section 3.7 “UE410-GU programs” on page 49).

• If a program with automatic reset is set for the local emergency stop, then the reset

button only acts on a global emergency stop, i.e. if a global emergency stop has been

triggered on the module and the module has the status Reset required.

WARNING

WARNING

3.4.6 Outputs

Lay the single-channel connection in a protected area!

To achieve SIL3 or category 4, you must lay the single-channel connection Q1 to K1/K2

such that cross-circuits to other electrical signals can be excluded, e.g. by laying in pro-

tected areas such as in a control cabinet or in separate plastic-sheathed cables.

Safety-relevant devices must be suitable for safety-relevant signal requirements!

Serious injury may occur due to breakdown of safety outputs or loss of required safety

functions.

• Do not connect loads that exceed the rated value of the safety outputs.

• Wire the Flexi Classic system so that 24 V DC signals cannot contact the safety outputs.

• Connect the GND wires of the power supply to earth so that the devices do not switch

on when the safety output line is applied to frame potential.

• All UE410-GU modules that are on a common global emergency stop cut-off path must

be connected to the same GND connection.

• Use appropriate components or devices in accordance with regulations and standards.

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 33

Operating instructions Chapter 3

Flexi Classic

Note

Product description

3.4.7 Connection of a UE410-8DI

A UE410-8DI acts on the cut-off path A/B on a UE410-GU as follows:

• Input A (I1-I4) , QA acts on the global cut-off path.

• Input B (I5-I8) , QB acts on the local cut-off path.

An OR function or a bypass function that acts on the global cut-off path of the UE410-GU

(switch position 7 or 8, input A on the UE410-8DI) is not permitted and will result in a

configuration error (ERROR).

3.4.8 Power-up delay and response time of the UE410-GU

Power-up delay

The power-up delay of the UE410-GU is calculated as follows:

Power-up delay = local power-up delay + (N–1) × global power-up delay

Where:

Local power-up delay = power-up delay for the module on which the emergency stop was

triggered and reset

Global power-up delay = power-up delay of the other modules in the system

N = number of the UE410-GU modules in the system

You will find the values for the power-up delay on the data sheet in section 11.1.2 “UE410GU module” on page 101.

WARNING

Response times

Extended response time of the overall system on the usage of several UE410-GU

modules!

In a system consisting of several UE410-GU modules connected together, the power-up

delay and the response time are increased depending on the number of UE410-GU modules connected together. Take this aspect into account on planning your system. Otherwise the operator of the system will be in danger.

The response time of the UE410-GU is calculated as follows:

Response time = local response time + (N–1) × global response time

Where:

Local response time = response time of the module on which the emergency stop was

triggered

Global response time = response time of the other modules in the system

N = number of the UE410-GU modules in the system

You will find the values for the response times on the data sheet in section 11.1.2

“UE410-GU module” on page 101.

3.4.9 Diagnostics and troubleshooting for the UE410-GU

If a system with a global emergency stop function comprising several UE410-GU modules

is either entirely or partially at the standstill, then you can determine which module has

triggered the emergency stop as follows:

= Based on the LED indicators on any UE410-GU module in the system check whether the

emergency stop has been triggered by this module or the direction of the module that

has triggered the global or local emergency stop, see Tab. 15.

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Subject to change without notice

Page 34

Chapter 3 Operating instructions

Fig.10:

Diagnostic displays

Tab.15:

Diagnostics on the

Tab.16:

Significance of the

LED I3/I4: sensor with local

LED Q1: safety

output Q1

LED I1/I2: emergency stop

LED I

: status of all previous

LED I

: status of all next

on the UE410-GU

Product description

Flexi Classic

UE410-GU

Ν The LED or lamp is

illuminated constantly.

∏ The LED or lamp is

flashing (1 Hz).

⌠∏ The LED or lamp is

flashing (2 Hz).

ν The LED or lamp is off.

X Any

pushbutton with global action

P

modules

action

N

modules

= Also pay attention to the lamp on output Q2 (“Global emergency stop status”, “Reset

required”) on the related UE410-GU.

Q1 I1/I2 I3/I4 I

ν Ν ν Ν Ν ν

I

P

Lamp Q2 Cause

N

A local emergency stop has been

triggered on this station.

ν Ν X ν X Ν

A previous station has triggered a

global emergency stop.

ν Ν X X ν Ν

A next station has triggered a global

emergency stop.

Note

diagnostics LEDs I5 and I6 on

the UE410-GU

ν ν X X X ⌠∏

A global emergency stop has been

triggered on this station.

ν Ν Ν Ν Ν ∏ Reset is required on this station.

Ν Ν Ν Ν Ν ν

The safety output on the module is

active and the system enabled.

A combination of several causes may occur, e.g. if a local emergency stop and a global

emergency stop have been triggered.

LED I5 and I6 indications

In normal operation with safety output Q1 active the LEDs I5 and I6 are ν Off.

LED Meaning

I5 illuminates Ν Green

The safety output Q1 is shut down, the external actuators

have dropped out. Otherwise check the wiring.

I5 flashes ∏ Green

EDM error. Check the wiring. If necessary, replace the

actuator.

I6 illuminates Ν Green The reset button is pressed. Otherwise check the wiring.

I6 flashes ∏ Green

The reset button has been operated for too long. Check the

wiring if necessary.

Also note the description of the LED indicators on the UE410-GU in section 3.4.1 “Controls

and status indicators” on page 28 as well as chapter 10 “Diagnostics” on page 93.

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 35

Operating instructions Chapter 3

Fig.11:

UE410

-

XU controls

Program switch

Switch for off delay

Flexi Classic

Product description

3.5 UE410-XU module

The UE410-XU module is an input/output extension or a subsystem with 4 safe inputs and

outputs. It has the identical functionality to the UE410-MU main module, however without

the system save using the ENTER button.

The UE410-XU cannot be used as a stand-alone device and always requires a UE410-MU

main module.

3.5.1 Controls and status indicators

and status indicators

(not on UE410-xxxT0)

Indicators, controls and terminal assignments are the same as on the UE410-MU main

module (see Tab. 9-Tab. 11).

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 35

Subject to change without notice

Page 36

Chapter 3 Operating instructions

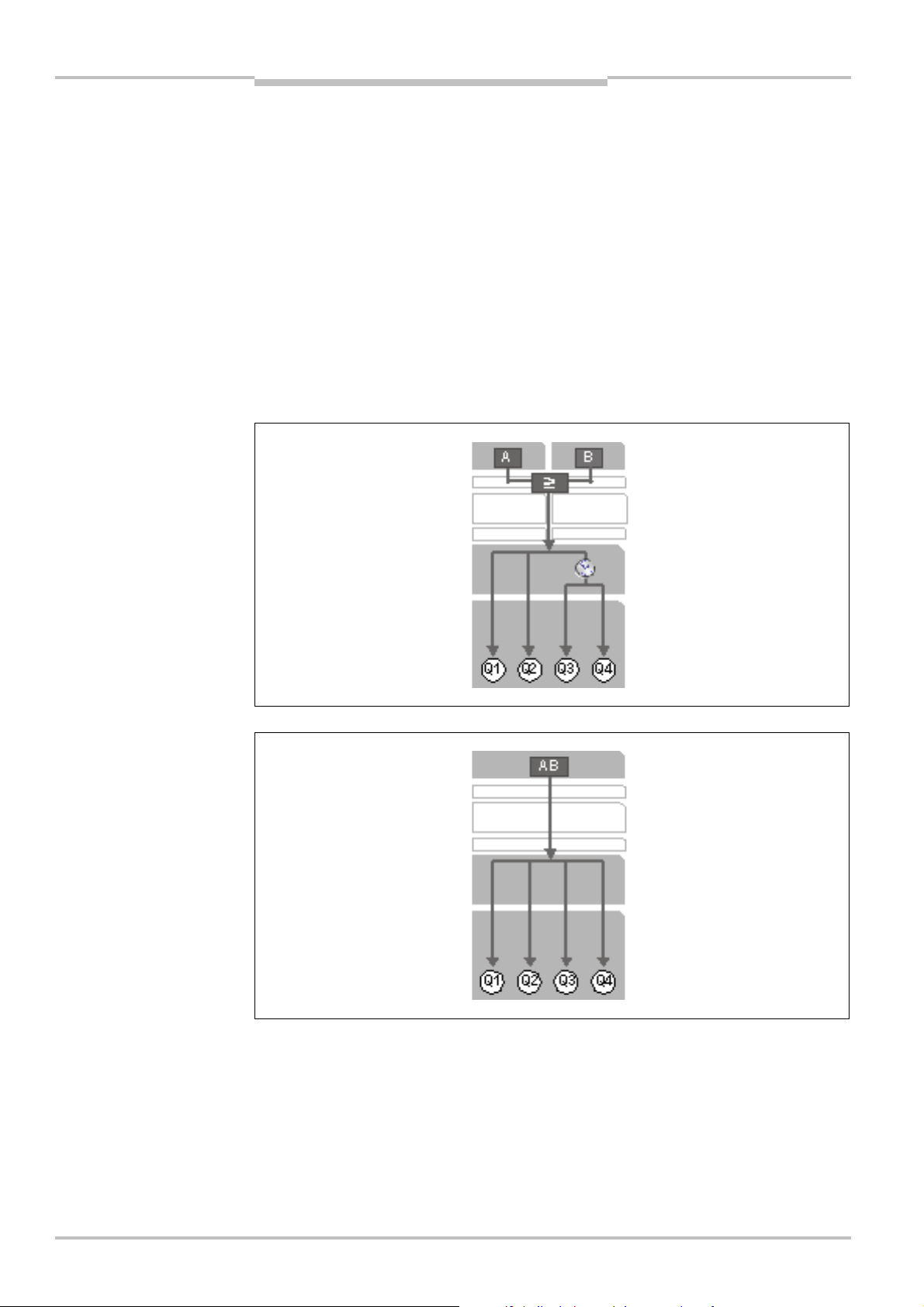

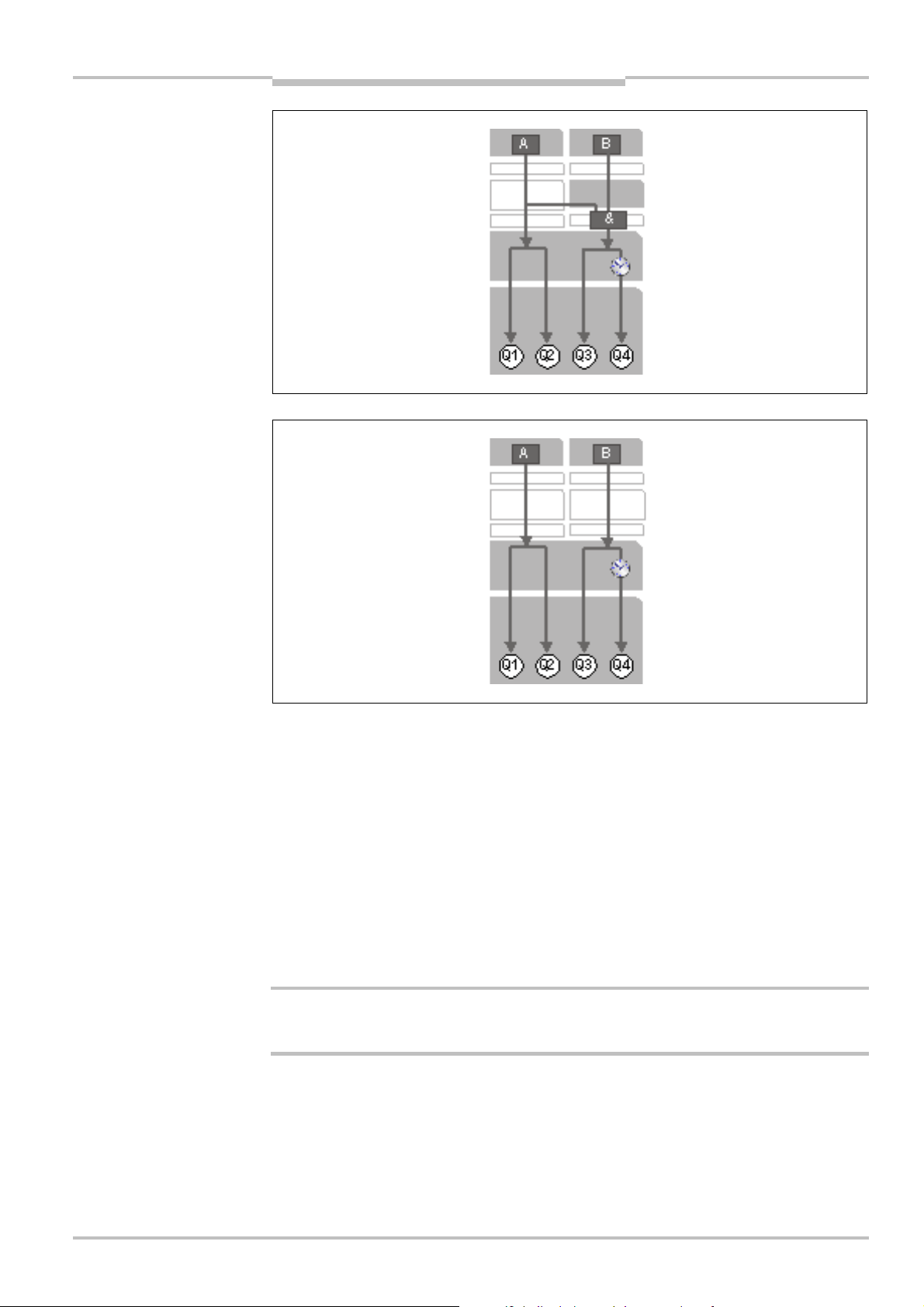

Tab.17:

UE410-MU/UE410

-

Product description

Flexi Classic

3.6 UE410-MU/UE410-XU programs

The modules have 9 settable programs each that can be set via a rotary switch.

Up to two applications acting independently or two applications that are dependent on

each other (A and B) can be controlled. These can act independently or dependent on

each other, depending on the program (see Fig. 3-Fig. 6).

The program selection determines the type of safety sensor equipment to be connected

and the logic instructions.

XU programs

Program Description

0 Module inactive

1-2

Input control circuit A is linked by means of OR logic to input control

circuit B and acts on all the safety outputs Q1-Q4.

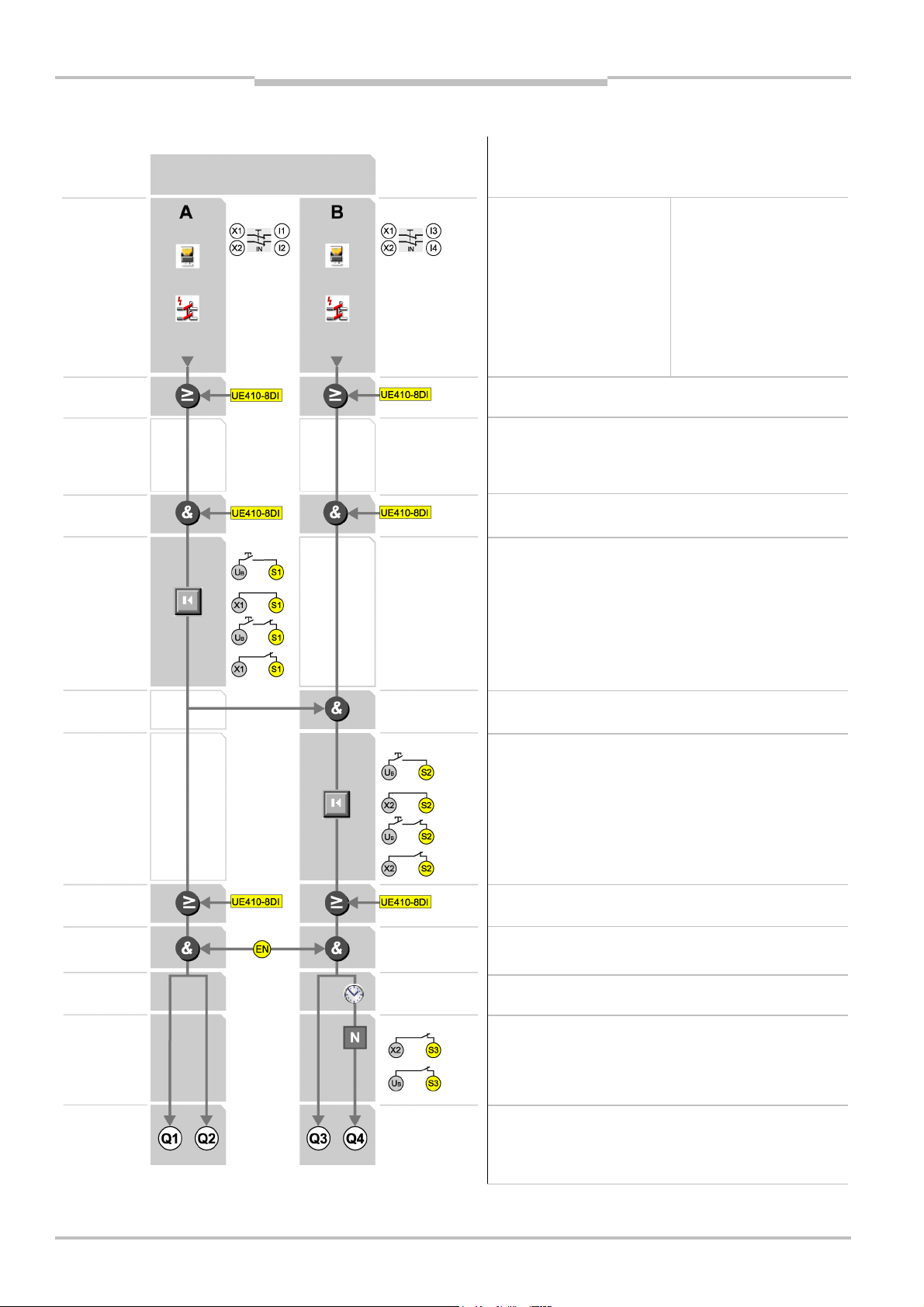

3.1-3.2 • Input control circuit A acts on the safety outputs Q1, Q2, Q4.

• Input control circuit B is muting input and controls the muting lamp

via Q3.

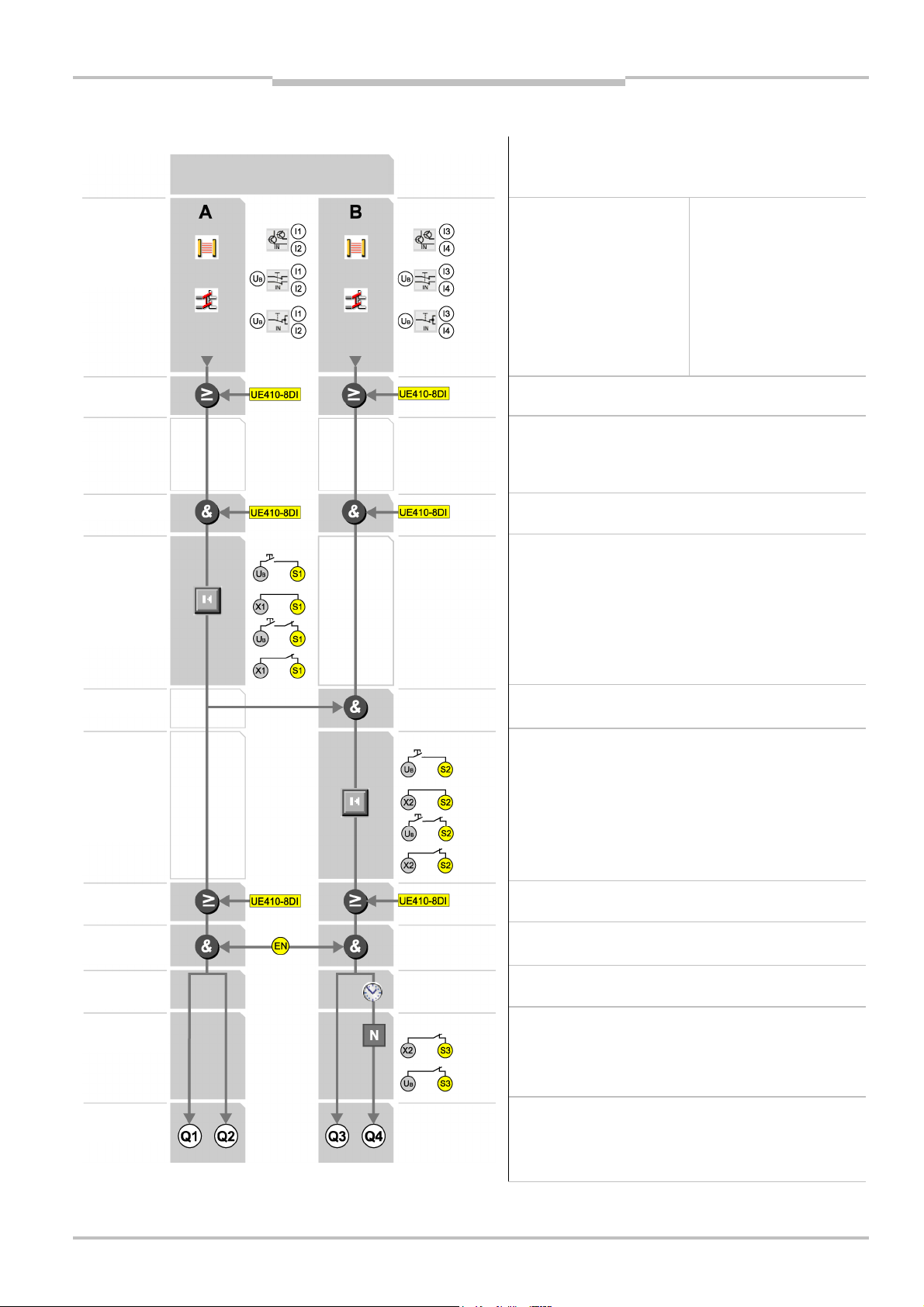

4 Input control circuit AB acts on all the safety outputs AB (two-hand IIIC).

5-7 • Input control circuit A acts on both safety outputs Q1/Q2 and Q3/Q4.

• Input control circuit B acts only on the safety output Q3/Q4.

8 • Input control circuit A acts only on the safety output Q1/Q2.

• Input control circuit B acts only on the safety output Q3/Q4.

9 • Input control circuit A acts on both safety outputs Q1/Q2 and Q3/Q4.

• Input control circuit B acts only on the safety output Q3/Q4.

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011509/YPP0/2015-10-26

Subject to change without notice

Page 37

Operating instructions Chapter 3

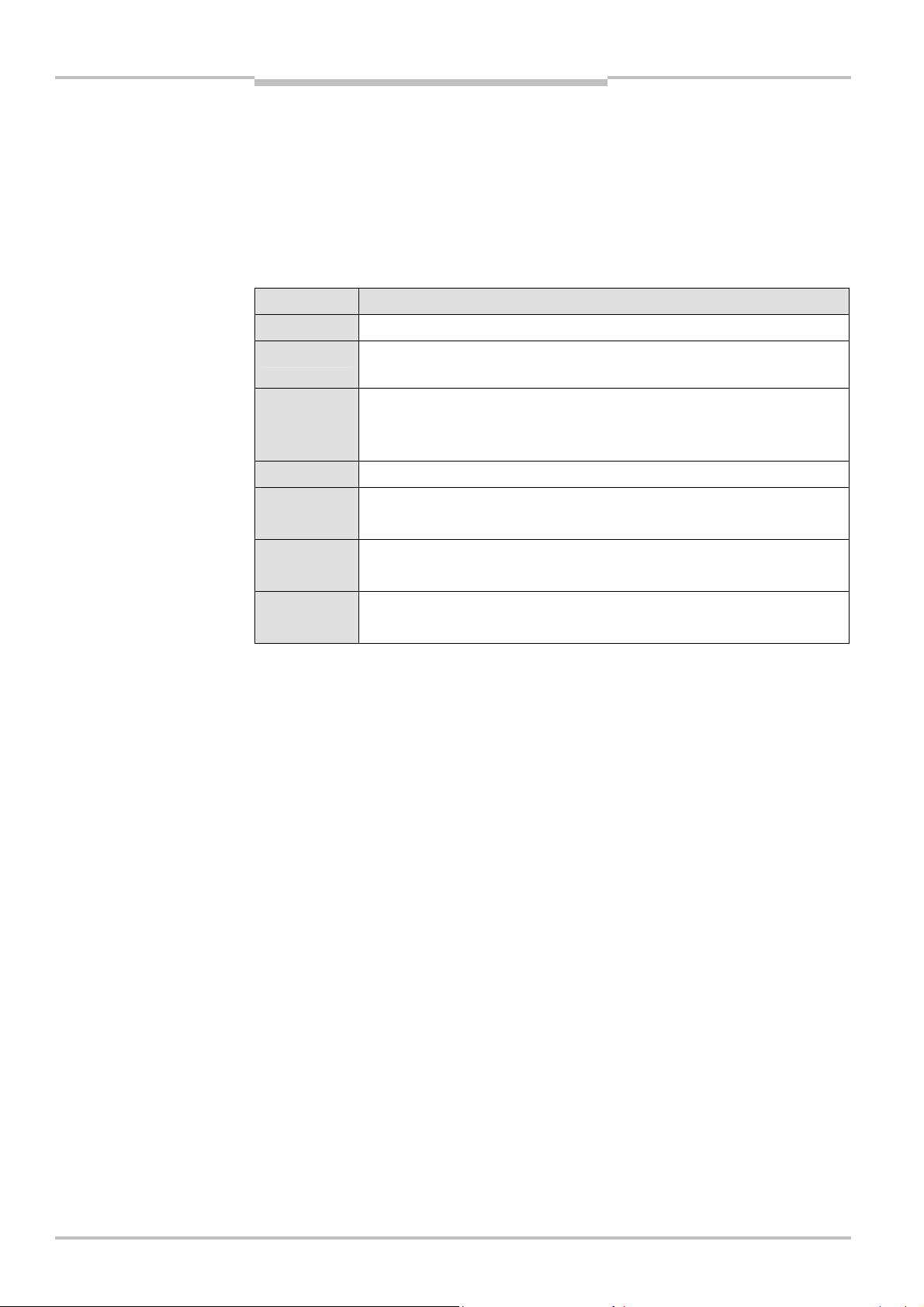

Inputs/

OR

AND

Restart

Bypass

ENABLE

Retriggering

Product description

Flexi Classic

3.6.1 Program 1

1 logic path

sensors

interlock

A

Dual-channel equivalent N/C

contact

Cross-circuit detecting control

signals

Synchronous time monitoring

(1500 ms)

Pressure-sensitive switching

mats (four-wire)

Flexi Loop

OR with UE410-8DI — switch position 7

AND with UE410-8DI — switch position 1-6

Connecting of S1:

∂ with restart interlock Q1/Q2, without EDM

∂ without restart interlock Q1/Q2, without EDM

∂ with restart interlock Q1/ Q2, with EDM

∂ without re start interlock Q 1/Q2, with EDM

B

Single-channel N/C contact

Dual-channel equivalent N/C

contact ( not cross-circuit

detecting)

ESPE (sensors with

semiconductor output)

Off delay

Outputs

Connecting of S2:

S2 may not be connected.

OR limited 60 s with UE410-8DI — switch position 8

Always wire ENABLE (expected 24 V DC)!

At ENABLE low Q1-Q4 are always low.

Off delay acts on Q3/Q4

(not on UE410-xxxT0).

Connecting of S3:

with/without EDM Q3/Q4

∂ retriggering ON

Undelayed OSSDs Q1/Q2

Delayable OSSDs Q3/Q4

with/without EDM Q3/Q4

∂ retriggering OFF

8011509/YPP0/2015-10-26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 37

Subject to change without notice

Page 38

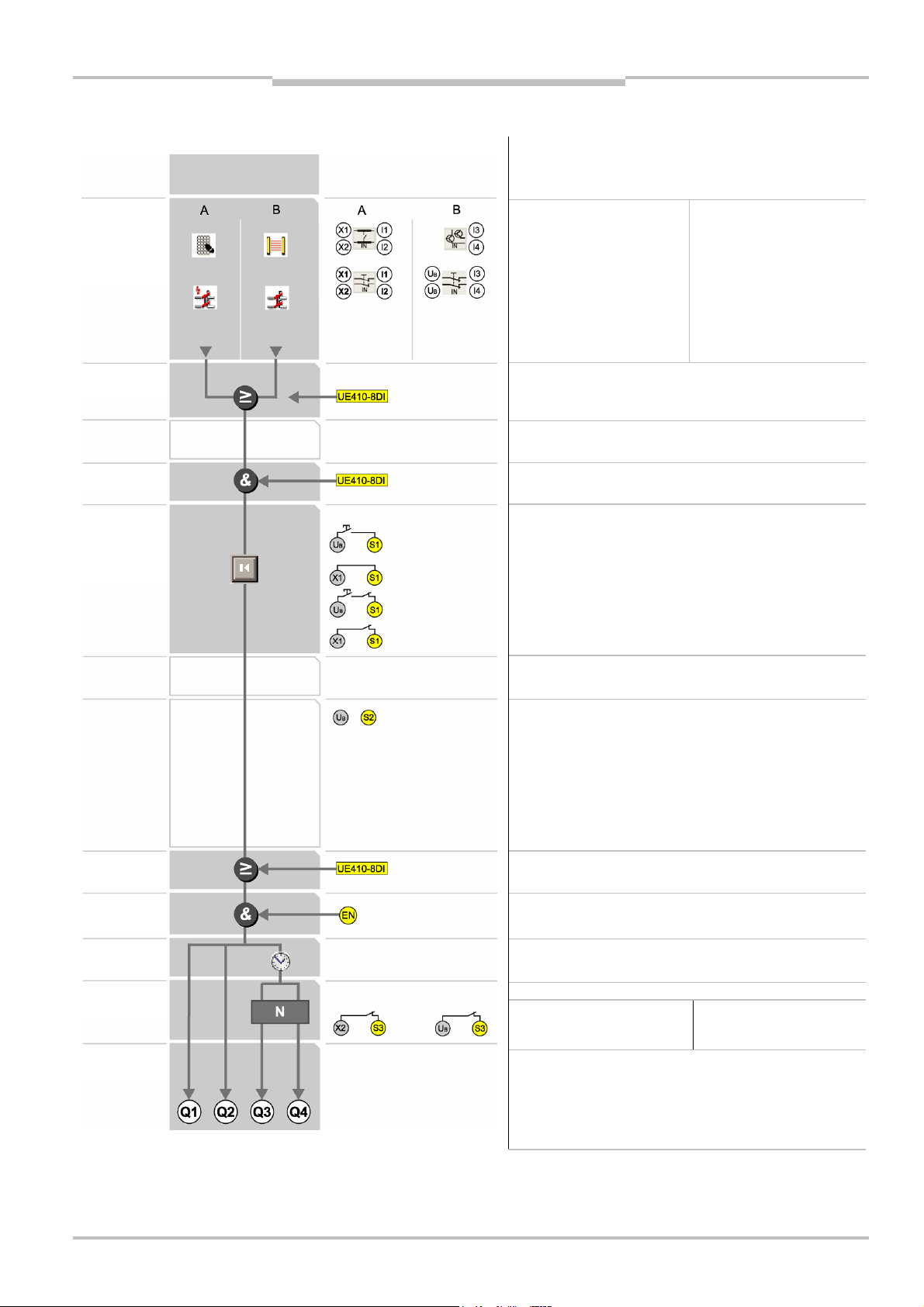

Chapter 3 Operating instructions

Inputs/

OR

AND

Restart

Bypass

Retriggering

Product description

Flexi Classic

3.6.2 Program 2

1 logic path

sensors

interlock

A

Dual-channel complementary

N/C / N/O contact

ESPE (e.g. RE300)