SICK TriSpector1000,TriSpector1008,TriSpector1030,TriSpector1060 Operating Instructions Manual

TriSpector1000

3D Vision

O P E R A T I N G I N S T R U C T I O N S

Described product

2011/65/EU

TriSpector1000

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Information on the operating instructions.............................................. 7

1.2 Explanation of symbols............................................................................ 7

1.3 Further information................................................................................... 8

2 Safety information............................................................................ 9

2.1 Intended use............................................................................................. 9

2.2 Improper use............................................................................................. 9

2.3 Laser safety............................................................................................... 9

3 Product description........................................................................... 10

3.1 System overview....................................................................................... 10

3.2 Scope of delivery....................................................................................... 10

3.3 System requirements............................................................................... 11

3.4 TriSpector1000 variants.......................................................................... 11

3.5 Dimensional drawings.............................................................................. 11

3.5.1 TriSpector1008........................................................................ 12

3.5.2 TriSpector1030........................................................................ 12

3.5.3 TriSpector1060........................................................................ 13

3.6 LED indicators........................................................................................... 13

4 Transport and storage....................................................................... 15

4.1 Transport................................................................................................... 15

4.2 Transport inspection................................................................................. 15

4.3 Storage...................................................................................................... 15

5 Mounting............................................................................................. 16

5.1 Mounting instructions............................................................................... 16

5.1.1 Mounting a microSD memory card......................................... 16

5.2 Field of view diagrams.............................................................................. 17

6 Electrical installation........................................................................ 18

6.1 Prerequisites for the safe operation of the device in a system............. 18

6.2 Connection diagram................................................................................. 19

6.3 Encoder..................................................................................................... 19

6.4 Pin assignment......................................................................................... 20

7 Operation............................................................................................ 22

7.1 Commissioning......................................................................................... 22

7.1.1 Installing SOPAS....................................................................... 22

7.1.2 Connecting the hardware........................................................ 22

7.1.3 Connecting the TriSpector1000 to SOPAS ET........................ 22

7.2 Description of the user interface............................................................. 23

7.2.1 Menus....................................................................................... 24

7.2.2 Image handling controls.......................................................... 24

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

3

CONTENTS

7.2.3 Image view modes................................................................... 25

7.2.4 Image view options.................................................................. 26

7.2.5 Image view controls................................................................. 27

7.3 Handling jobs and configurations............................................................ 27

7.4 Workflow steps.......................................................................................... 28

7.5 Image workflow step.................................................................................. 29

7.5.1 Scanning an object.................................................................. 29

7.5.2 Setting the field of view........................................................... 30

7.5.3 Adjusting the image settings................................................... 30

7.5.4 Configuring the trigger settings.............................................. 31

7.5.5 Recording images.................................................................... 32

7.6 Task workflow step..................................................................................... 32

7.6.1 Using the tools......................................................................... 32

7.6.2 Setting the region of interest.................................................. 33

7.6.3 Tool groups............................................................................... 34

7.6.4 Shape tool.................................................................................. 34

7.6.5 Blob tool.................................................................................... 35

7.6.6 Edge tool.................................................................................... 36

7.6.7 Plane tool................................................................................... 37

7.6.8 Fix Plane tool.............................................................................. 38

7.6.9 Peak tool.................................................................................... 38

7.6.10 Point tool................................................................................... 39

7.6.11 Area tool.................................................................................... 39

7.6.12 Distance tool.............................................................................. 40

7.6.13 Angle tool................................................................................... 40

7.6.14 Application example: Counting chocolates............................ 41

7.7 Results workflow step................................................................................ 43

7.7.1 Result handling........................................................................ 43

7.7.2 Tool result output..................................................................... 43

7.7.3 Decision model........................................................................ 44

7.7.4 Conditions................................................................................ 44

7.7.5 Digital outputs.......................................................................... 46

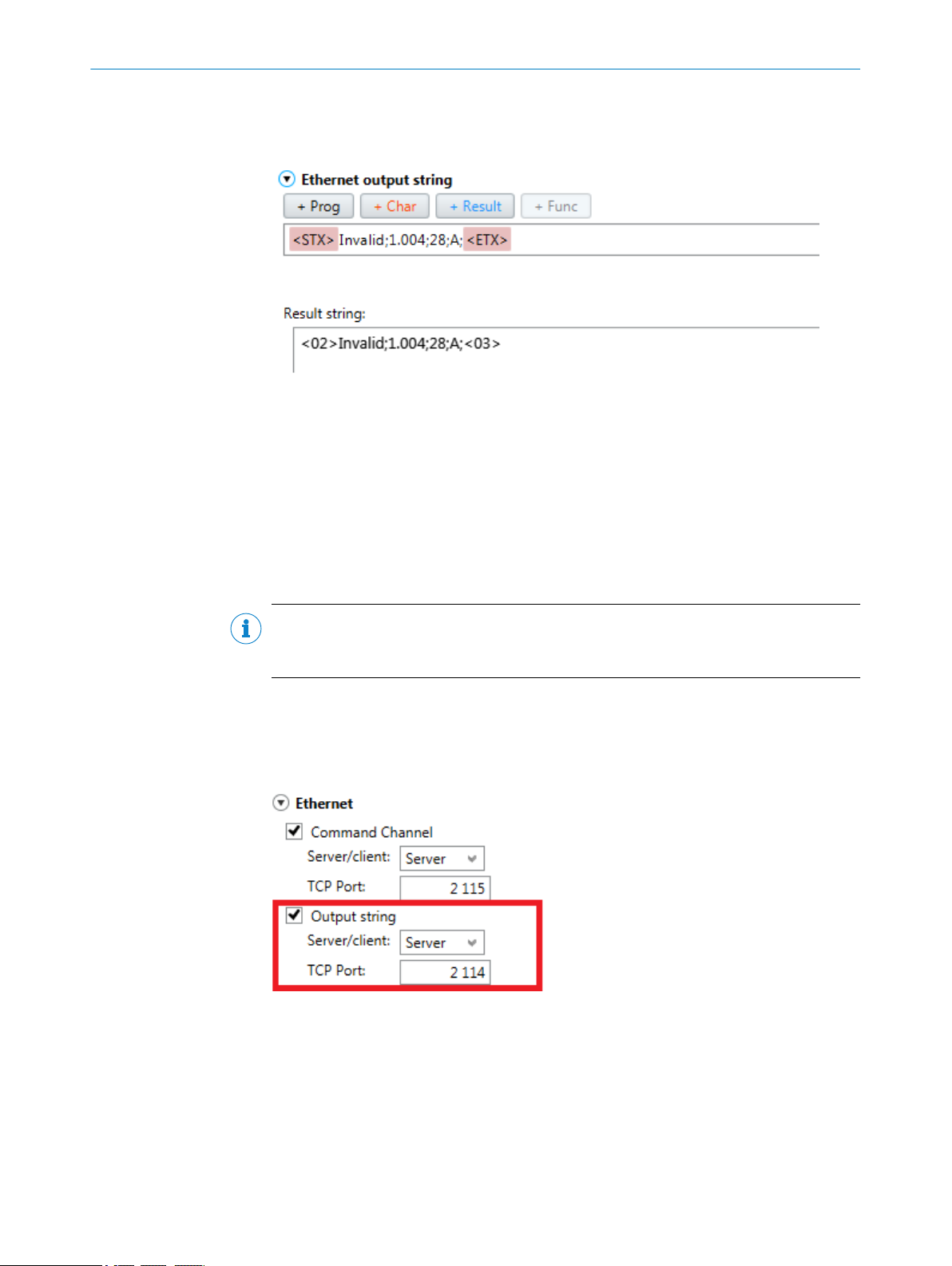

7.7.6 Ethernet output string............................................................. 46

7.7.7 Image logging........................................................................... 47

7.7.8 Functions and operators......................................................... 47

7.8 Interfaces workflow step............................................................................ 50

7.8.1 Configuring the digital in- and outputs................................... 50

7.8.2 Using the command channel.................................................. 50

7.8.3 Sending an output string......................................................... 50

7.8.4 Logging images to an FTP server............................................ 51

7.8.5 Enabling the web interface..................................................... 51

7.8.6 Setting parameters of the serial interface............................. 52

7.8.7 Logging images to a microSD memory card.......................... 52

7.8.8 Selecting jobs via digital inputs.............................................. 54

7.8.9 Fieldbuses................................................................................ 54

4

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

CONTENTS

7.9 Using the SOPAS ET emulator.................................................................. 54

7.9.1 Starting the emulator.............................................................. 54

7.9.2 Controlling the emulator.......................................................... 55

7.9.3 Selecting images to be used................................................... 56

7.9.4 Copying a configuration from the emulator........................... 56

7.10 Exporting and importing data.................................................................. 56

8 Maintenance...................................................................................... 58

8.1 Cleaning..................................................................................................... 58

8.2 Upgrading the firmware............................................................................ 58

8.3 Data backup and restoration................................................................... 58

9 Troubleshooting................................................................................. 59

9.1 General faults, warnings, and errors....................................................... 59

9.2 Repairs...................................................................................................... 60

9.3 Returns...................................................................................................... 60

9.4 Disposal..................................................................................................... 60

10 Technical data.................................................................................... 61

10.1 Features.................................................................................................... 61

10.2 Ambient data............................................................................................. 61

10.3 Interfaces.................................................................................................. 61

10.4 Mechanics and electronics...................................................................... 62

10.5 Input switching levels............................................................................... 62

10.6 Output switching levels............................................................................. 63

10.7 Performance............................................................................................. 63

11 Accessories........................................................................................ 64

12 Appendix............................................................................................. 65

12.1 Declarations of conformity....................................................................... 65

12.2 Licenses.................................................................................................... 66

12.3 Available commands for command channel........................................... 67

12.3.1 Sending a command............................................................... 67

12.3.2 Command examples................................................................ 67

12.3.3 General commands................................................................. 67

12.3.4 Tool commands........................................................................ 69

12.4 Connecting TriSpector1000 to CDF600-2200....................................... 72

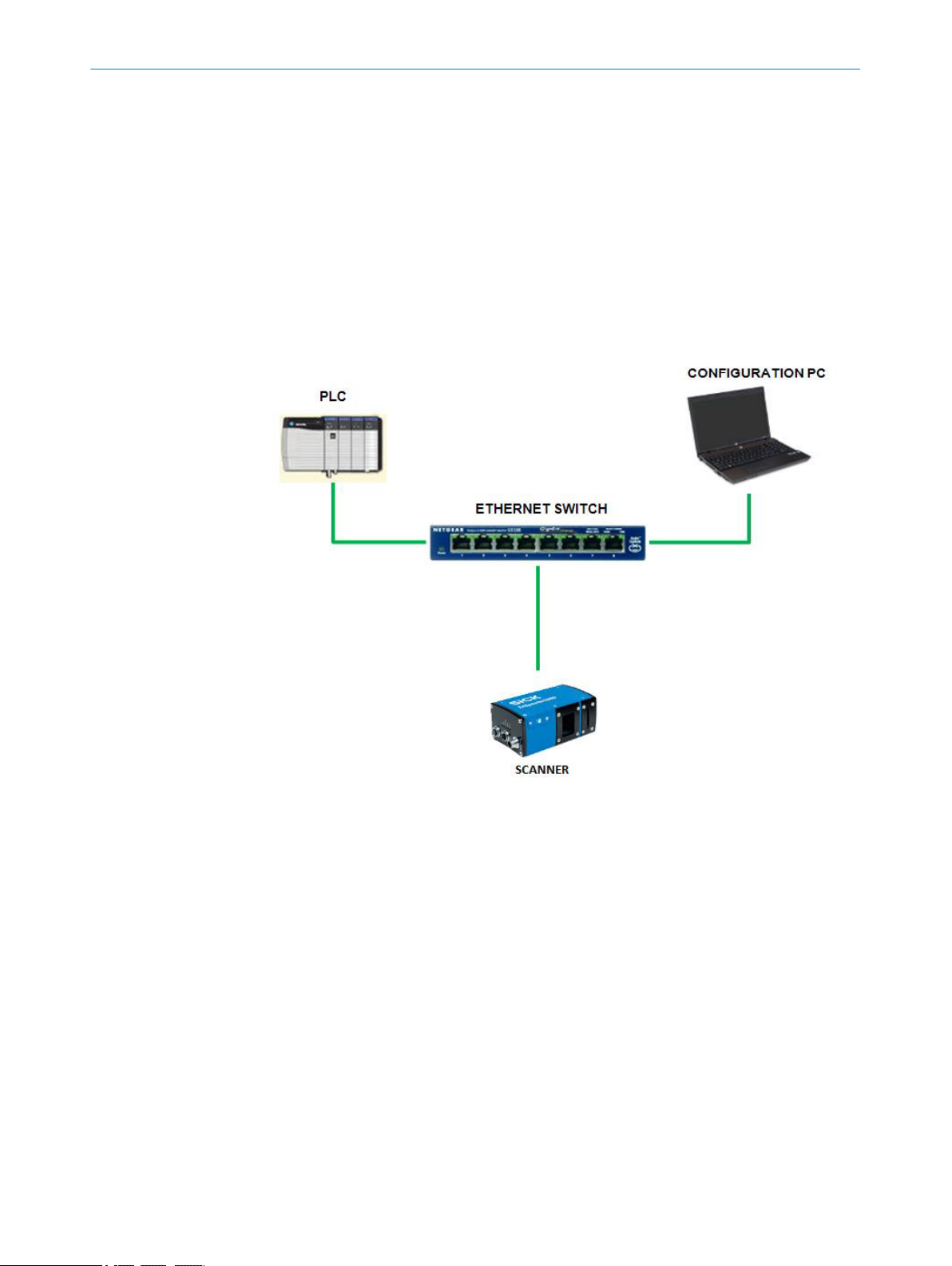

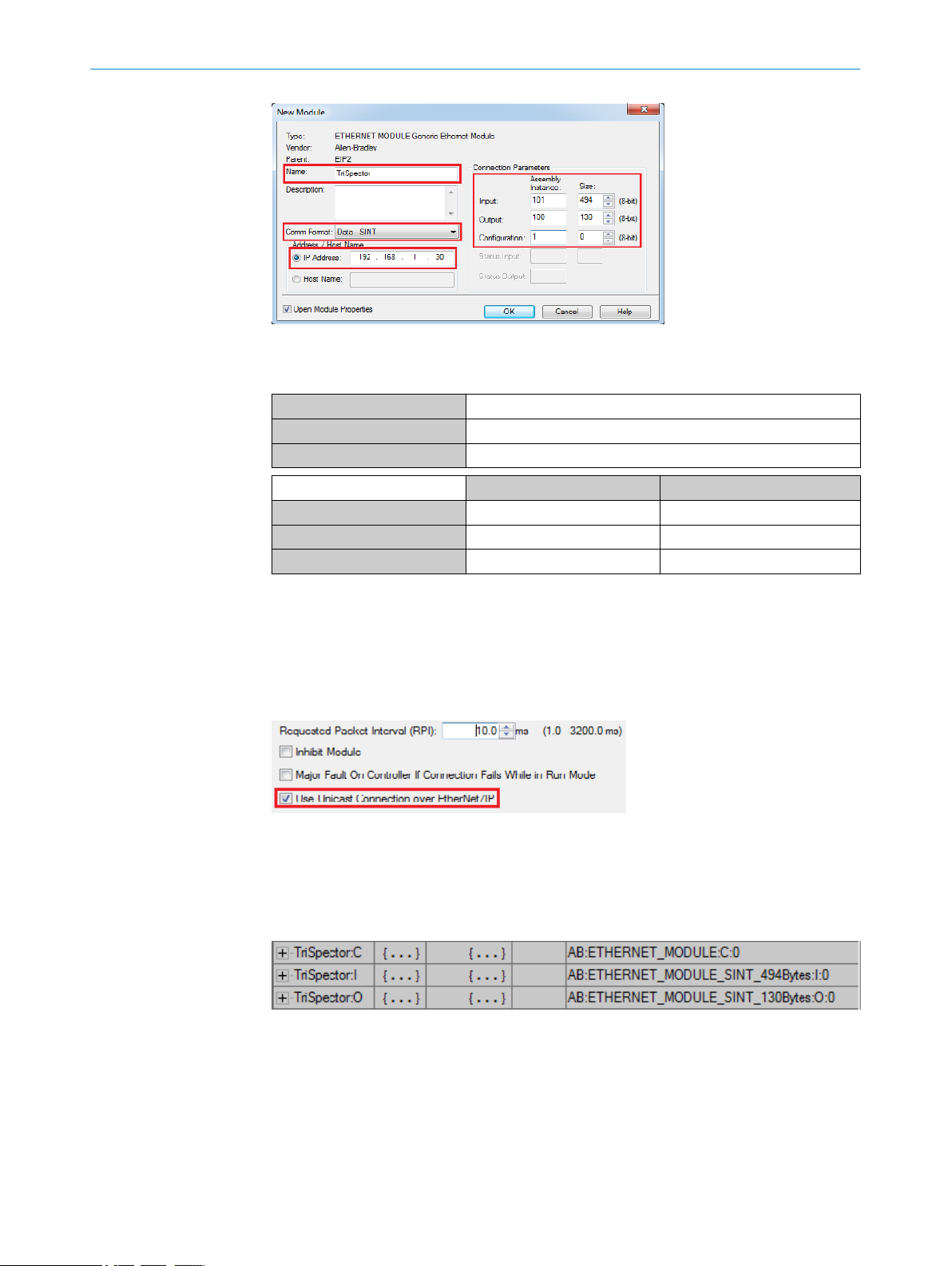

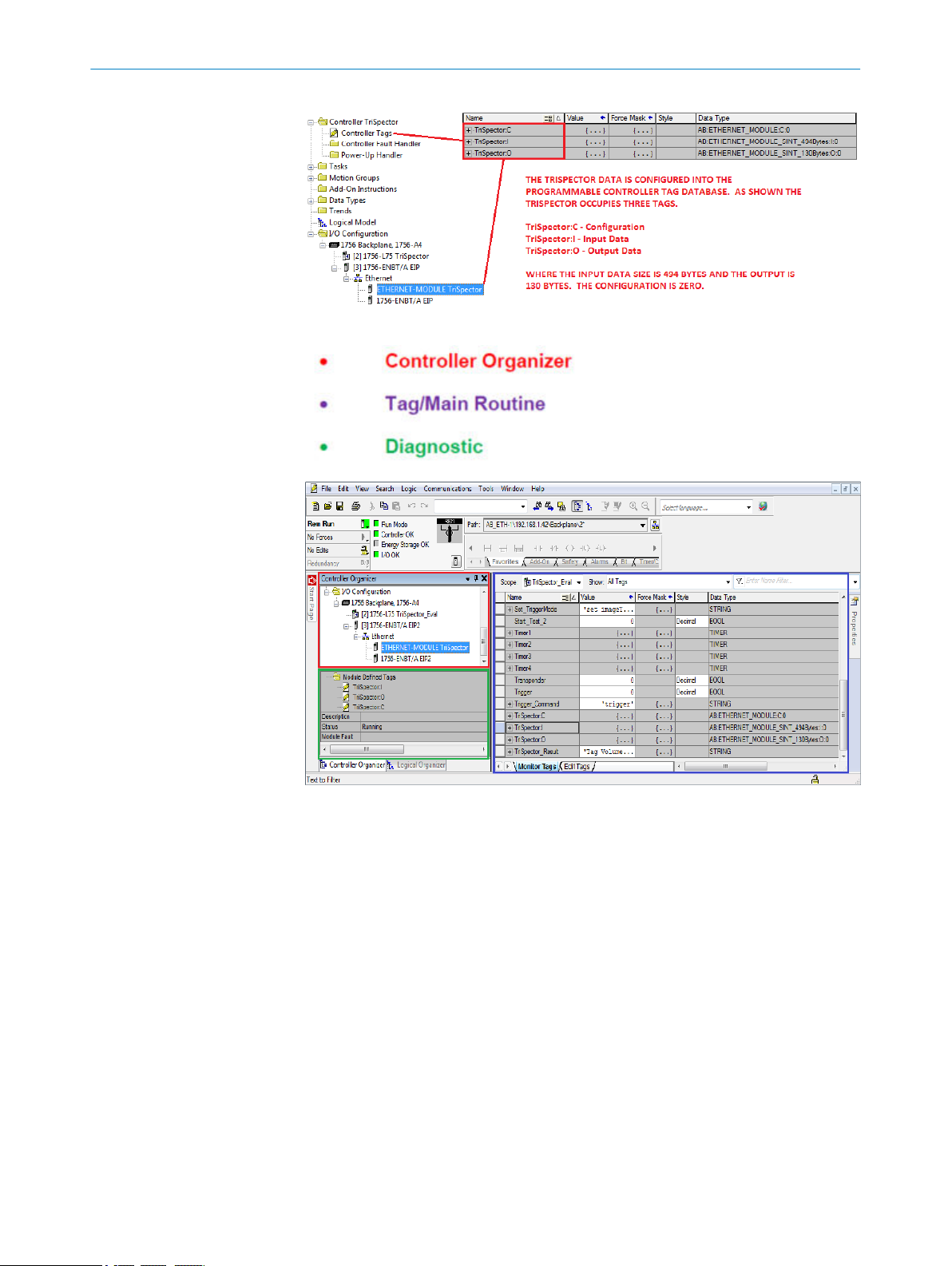

12.5 Setting up a TriSpector1000 to communicate via EtherNet/IP............. 73

12.5.1 Interfacing TriSpector1000 with an Allen Bradley/Rockwell

Programmable Controller........................................................ 73

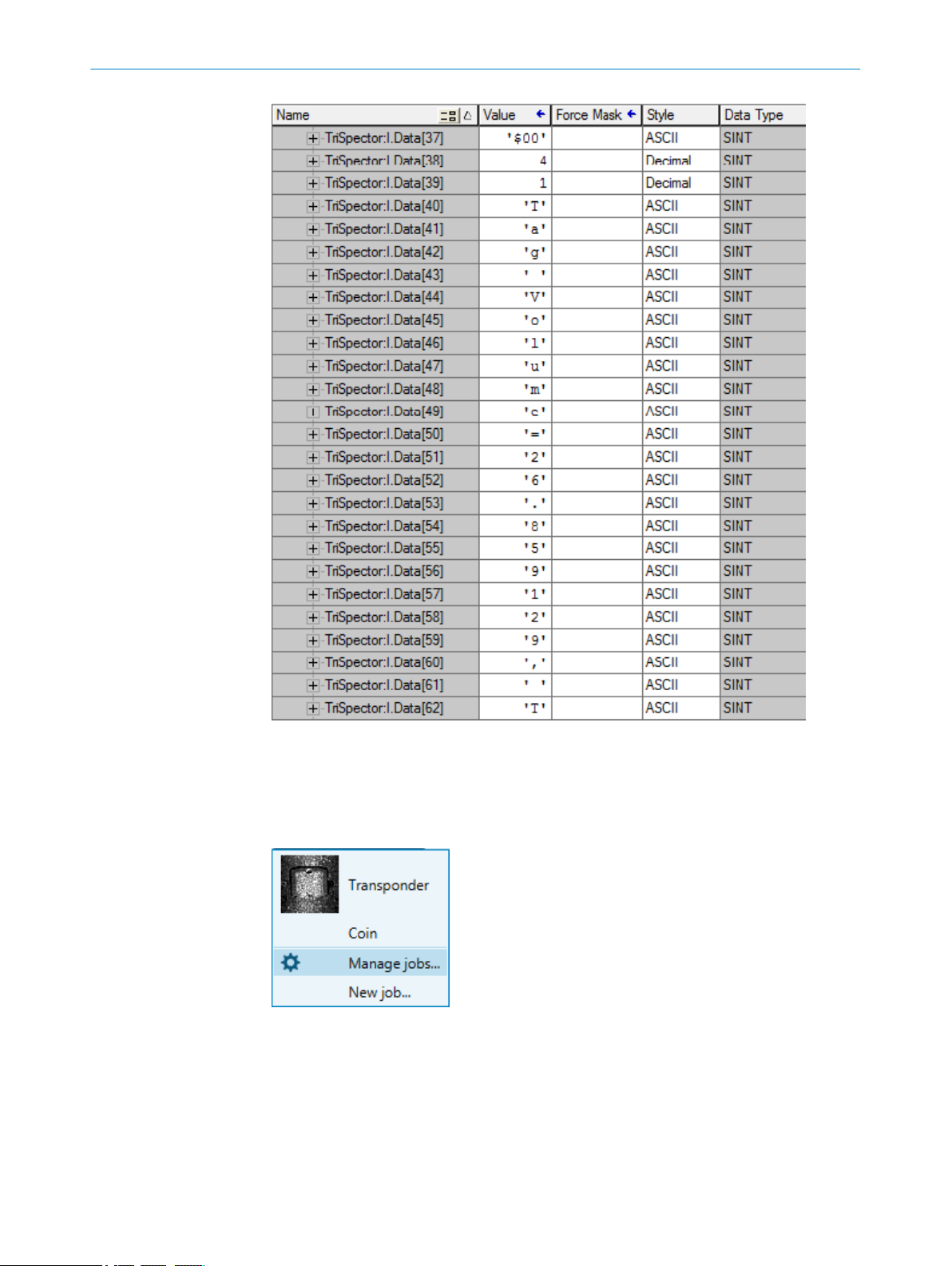

12.5.2 Input and Output Data Assemblies - TriSpector1000........... 74

12.5.3 Inside the Programmable Controller...................................... 77

12.5.4 Triggering a TriSpector1000.................................................... 80

12.5.5 Switching Jobs.......................................................................... 82

12.5.6 TriSpector1000 EtherNet/IP Compatibility............................ 84

12.6 TriSpector1000 Result Output Function Block....................................... 85

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

5

CONTENTS

12.6.1 About this document............................................................... 85

12.6.2 Overview................................................................................... 86

12.6.3 TriSpector1000 configuration................................................. 86

12.6.4 PLC Configuration.................................................................... 87

12.6.5 Modify the Function Block to fit your output.......................... 94

12.6.6 Troubleshooting....................................................................... 100

12.6.7 Function block differences...................................................... 102

6

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied.

•

Compliance with local work safety regulations and general safety regulations for

•

device applications

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully before starting any work on the device, in

order to familiarize yourself with the device and its functions.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

ABOUT THIS DOCUMENT 1

These operating instructions do not provide information on operating the machine or

system in which the device is integrated. For information about this, refer to the operat‐

ing instructions of the specific machine.

1.2 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

7

1 ABOUT THIS DOCUMENT

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.3 Further information

NOTE

Further documentation for the device can be found on the online product page at:

www.sick.com/TriSpector1000

The following information is available for download there:

■

Model-specific online data sheets for device variants, containing technical data,

dimensional drawings and diagrams.

■

EU declaration of conformity for the product family.

■

Dimensional drawings and 3D CAD dimension models in various electronic for‐

mats.

■

These operating instructions.

■

The device quickstart, in English and German.

■

Other publications related to the device described here.

■

Publications dealing with accessories.

8

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

2 Safety information

2.1 Intended use

The TriSpector1000 is an industrial 3D sensor that uses laser triangulation on objects

to produce 3D images. Embedded 3D image analysis tools are applied to the 3D

images. The results are sent to a control system via external interfaces.

The TriSpector1000 series is primarily designed for use in industrial and logistics areas,

and it meets the requirements for industrial ruggedness, interfaces and data process‐

ing.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

The device does not constitute a safety-relevant device according to the EC

•

Machinery Directive (2006/42/EC).

The device must not be used in explosion-hazardous areas, in corrosive environ‐

•

ments or under extreme ambient conditions.

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

SAFETY INFORMATION 2

2.3

Laser safety

The TriSpector1000 is equipped with a Class 2 laser according to EN/IEC

60825-1:2014 (Class 2M according to EN/IEC 60825-1:2007). It complies to 21 CFR

1040.10 except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.

The legal regulations on laser safety for the laser class of TriSpector1000 must be

adhered to.

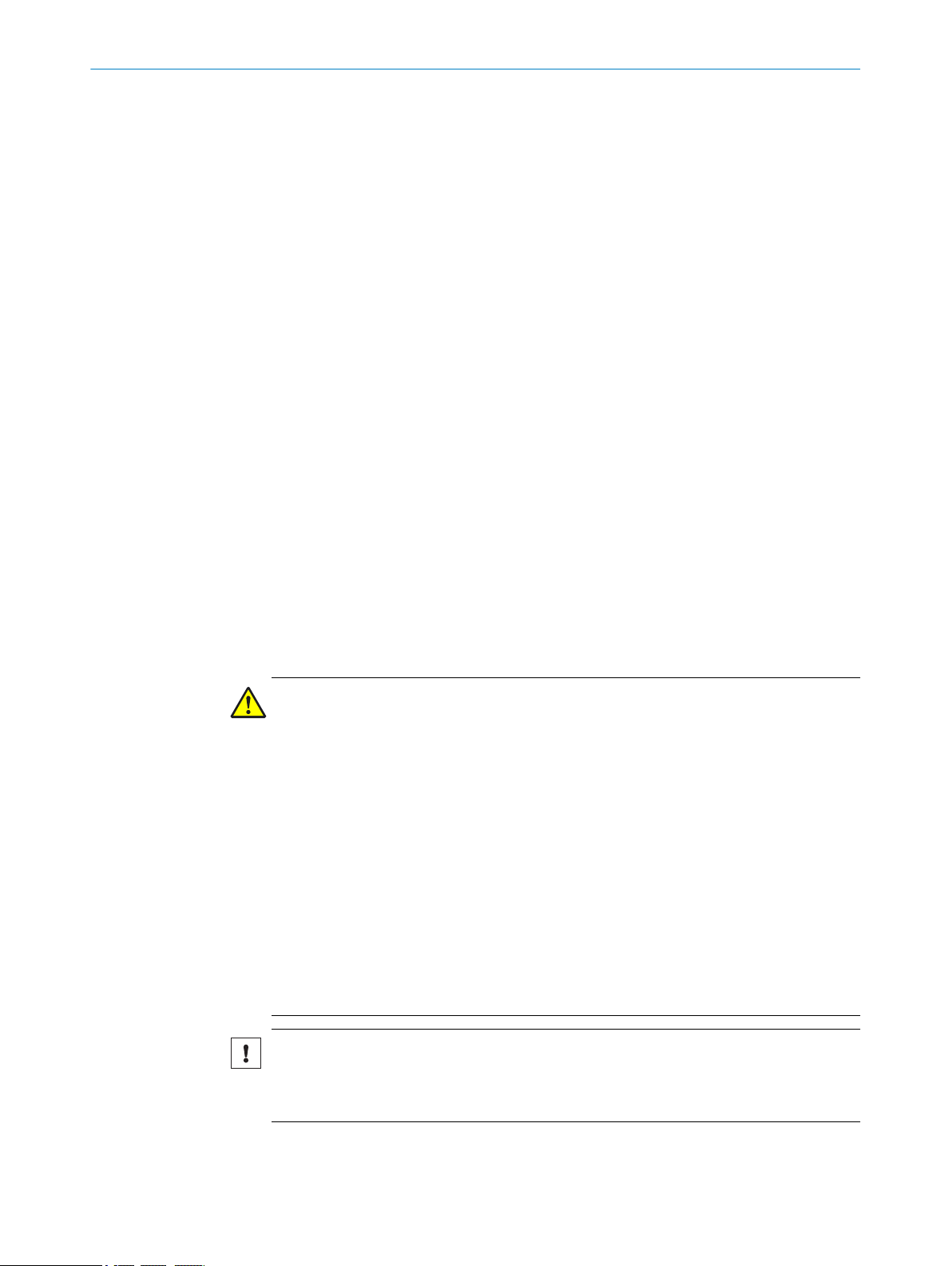

CAUTION

Optical radiation: Laser class 2

The human eye is not at risk when briefly exposed to the radiation for up to 0.25 sec‐

onds. Exposure to the laser beam for longer periods of time may cause damage to the

retina. The laser radiation is harmless to human skin.

■

Do not look into the laser beam intentionally.

■

Never point the laser beam at people's eyes.

■

If it is not possible to avoid looking directly into the laser beam, e.g., during com‐

missioning and maintenance work, suitable eye protection must be worn.

■

Avoid laser beam reflections caused by reflective surfaces. Be particularly careful

during mounting and alignment work.

■

Do not open the housing. Opening the housing will not switch off the laser. Open‐

ing the housing may increase the level of risk.

■

Current national regulations regarding laser protection must be observed.

NOTICE

If the TriSpector1000 is mounted in a system or a casing, so that the laser safety notice

signs are hidden, additional signs must be placed beside the exit aperture of the laser

beam on the system or casing. Additional signs are not included in the delivery.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

9

21

3 PRODUCT DESCRIPTION

3 Product description

3.1 System overview

The TriSpector1000 uses laser triangulation on objects to produce 3D images. Embed‐

ded 3D image analysis tools are applied to the 3D images. The results are sent to a

control system via external interfaces.

Laser triangulation means that the object is illuminated with a laser from one direction,

and the camera acquires an image of the laser line from another direction. Each

acquired image contains a height profile, which corresponds to a cross-section of the

object. By making a scan, which means collecting height profiles across the object

while it moves, a complete 3D image can be acquired.

3.2

Figure 1: Laser triangulation principle

1

2

Figure 2: Height profile Figure 3: 3D image

Scope of delivery

The delivery of the device includes the following components:

■

TriSpector1000 series sensor

■

Printed quickstart in English and German

■

Printed safety notes

Accessories

Accessories, such as brackets and connecting cables, are only supplied if ordered sep‐

arately.

Field of view

Laser

10

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

3.3 System requirements

For adequate SOPAS ET performance, use a PC with Intel Core I5 540M (2.53 GHz, 4

GB RAM) or better, and a screen resolution of at least 1024x768.

Graphics card: Intel® HD Graphics video card (or NVIDIA® NVS 3100M 512MB

GDDR3), or better. Make sure to use the latest graphic card drivers.

Ethernet connection is required, 100 Mbit/s or better. 1 Gbit/s or faster is recom‐

mended for best performance during configuration of the device via SOPAS ET.

Operating systems: Windows 7 or Windows 10 (64 bit is recommended).

SOPAS ET version: 2018.2 or higher

Hard drive: Minimum 550 MB.

Supported web browsers: Google Chrome (recommended due to advanced support of

WebGL and WebSockets) and Microsoft Edge.

SD memory card (optional): SICK microSD memory card (part no 4051366 or

4077575).

A mouse with at least three buttons (or a scroll wheel) is recommended.

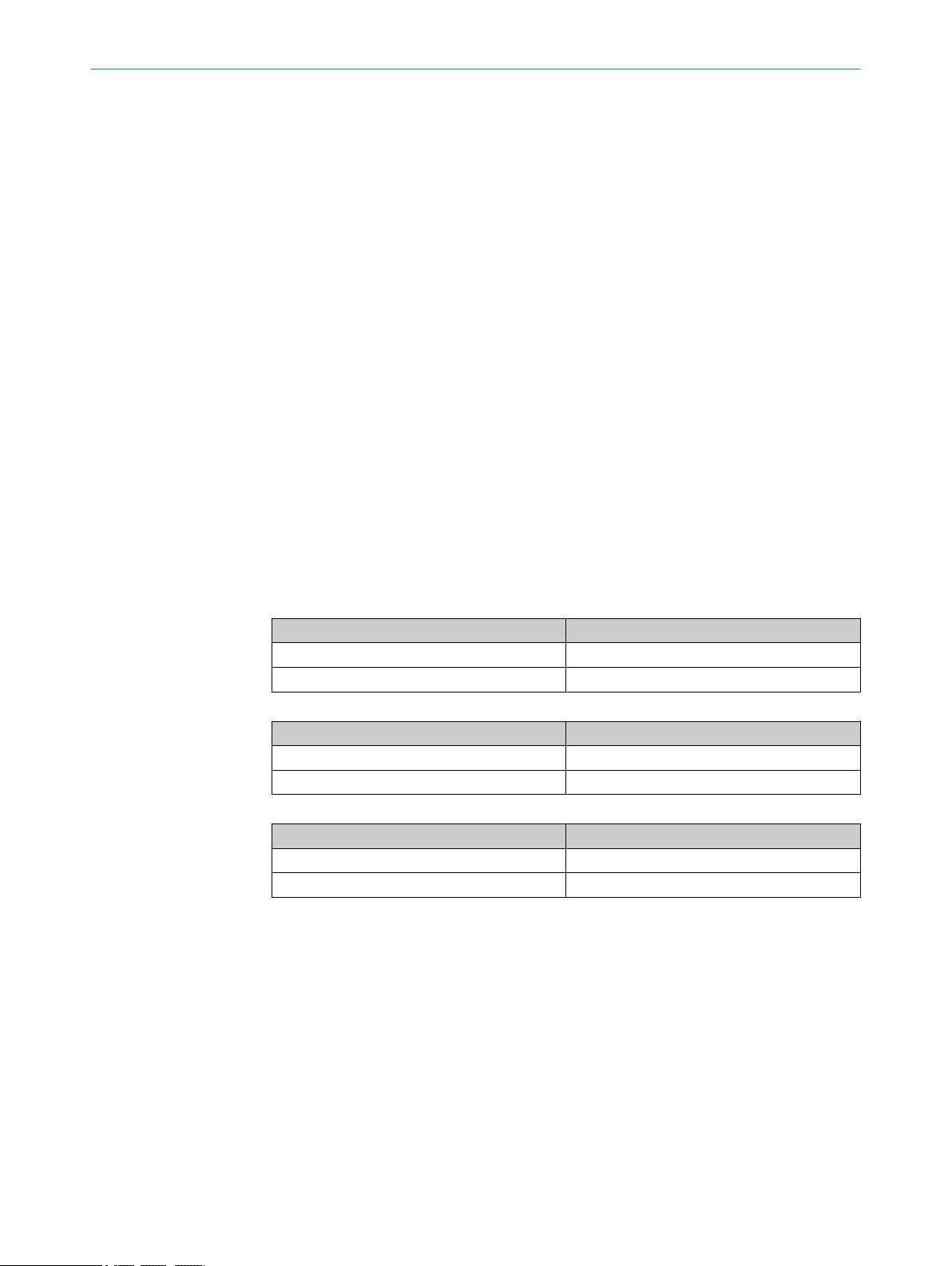

3.4 TriSpector1000 variants

PRODUCT DESCRIPTION 3

TriSpector1000 is available with three different field of view (FoV) sizes and two differ‐

ent window materials. PMMA is a plastic material used as an alternative material to

glass in food processing environments.

Table 1: TriSpector1008 (Small FoV)

Window material No.

Glass 1075604

PMMA 1060426

Table 2: TriSpector1030 (Medium FoV)

Window material No.

Glass 1072923

PMMA 1060427

Table 3: TriSpector1060 (Large FoV)

Window material No.

Glass 1075605

PMMA 1060428

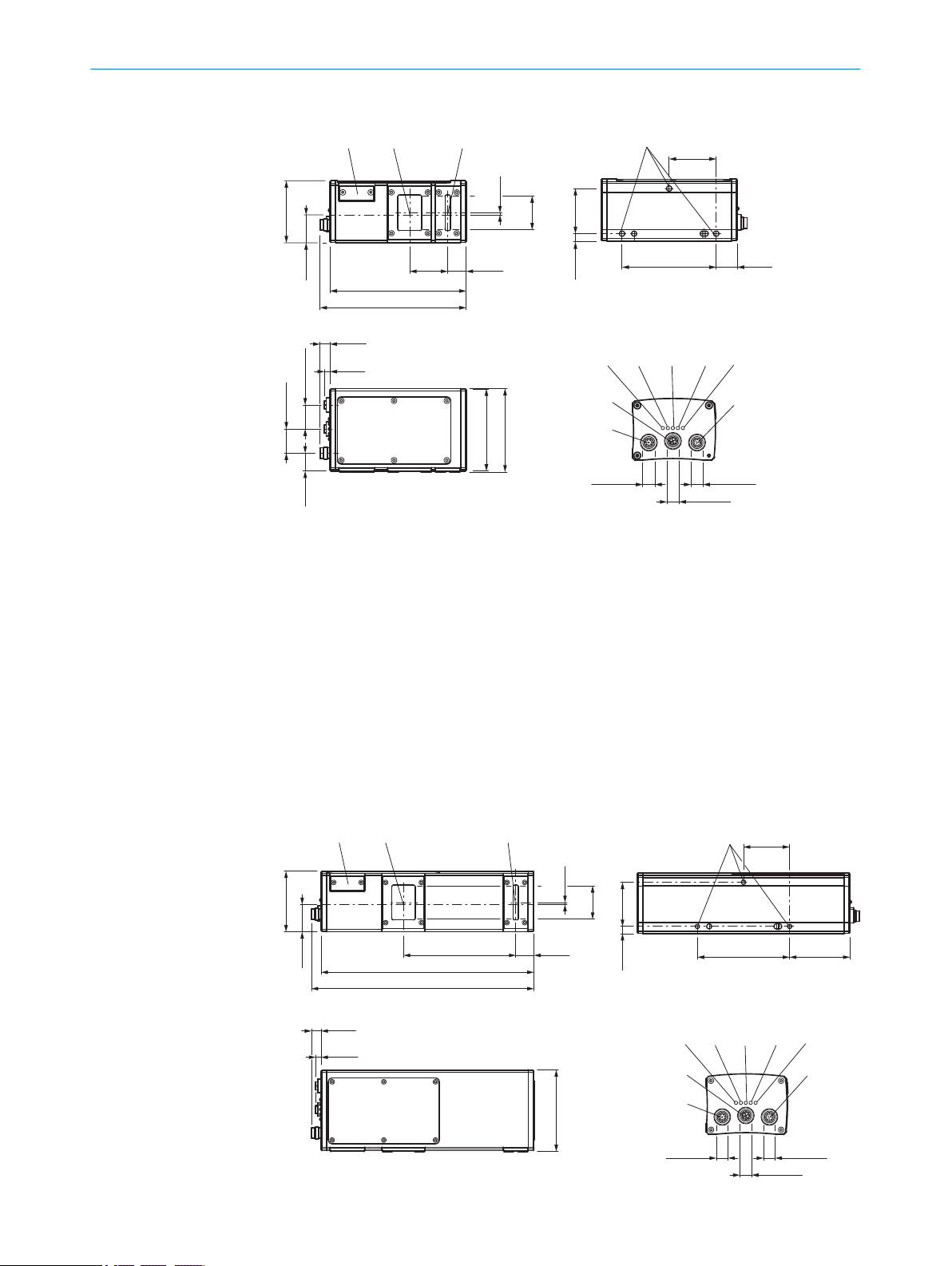

3.5 Dimensional drawings

See chapter 3.5.1, chapter 3.5.2 and chapter 3.5.3 for dimensional drawings for all

three TriSpector1000 variants. The dimensional drawings can also be downloaded as

CAD files from the TriSpector1000 device page at www.sick.com/TriSpector1000.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

11

61.9 (1.26)

27.9

(1.10)

2

(0.08)

34

(1.34)

38

(1.50)

18.5

(0.73)

136 (5.35)

145.9 (5.74)

9.9

(0.39)

5.6

(0.22)

24 (0.94)

24 (0.94)

18

82 (3.23)

83.3 (3.28)

45

(1.77)

7.4

(0.29)

47

(1.85)

94 (3.70)

21

(0.83)

á ß à

4 5 6 7 8

9

32

1

M12 x 1

M12 x 1

M12 x 1

1

2

4

á ß à

5 6 7 8

9

3

61.9 (2.44)

27.9

(1.10)

114.5 (4.51)

217 (8.54)

226.9 (8.93)

18.5

(0.72)

2

(0.08)

34

(1.34)

M12 x 1

M12 x 1

M12 x 1

45

(1.77)

7.4

(0.29)

61.5 (2.42)94 (3.70)

9.9

(0.39)

5.6

(0.22)

83.3 (3.28)

47 (1.85)

3 PRODUCT DESCRIPTION

3.5.1 TriSpector1008

3.5.2 TriSpector1030

12

Connector Encoder (thread inside)

1

Connector Gigabit Ethernet (Gig E)

2

Connector Power I/O (thread outside)

3

LED: On

4

LED: State

5

LED: Link/Data

6

LED: Result

7

LED: Laser

8

Fastening threads (M5x8.5 length)

9

Optical receiver (center)

ß

Optical sender (center)

à

SD-card

á

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

1

61.9 (1.26)

27.9

(1.10)

205.5 (8.09)

307 (12.09)

316.9 (12.48)

2

(0.08)

34

(1.34)

18.5

(0.73)

45

(1.77)

7.4

(0.29)

47

(1.85)

94 (3.70)

106.5

(4.19)

9.9

(0.39)

5.6

(0.22)

24 (0.94)

24 (0.94)

18

(0.71)

82 (3.23)

83.3 (3.28)

á ß à

1

2

4 5 6 7 8

3

9

M12 x 1

M12 x 1

M12 x 1

2

3

4

5

6

7

8

9

ß

à

á

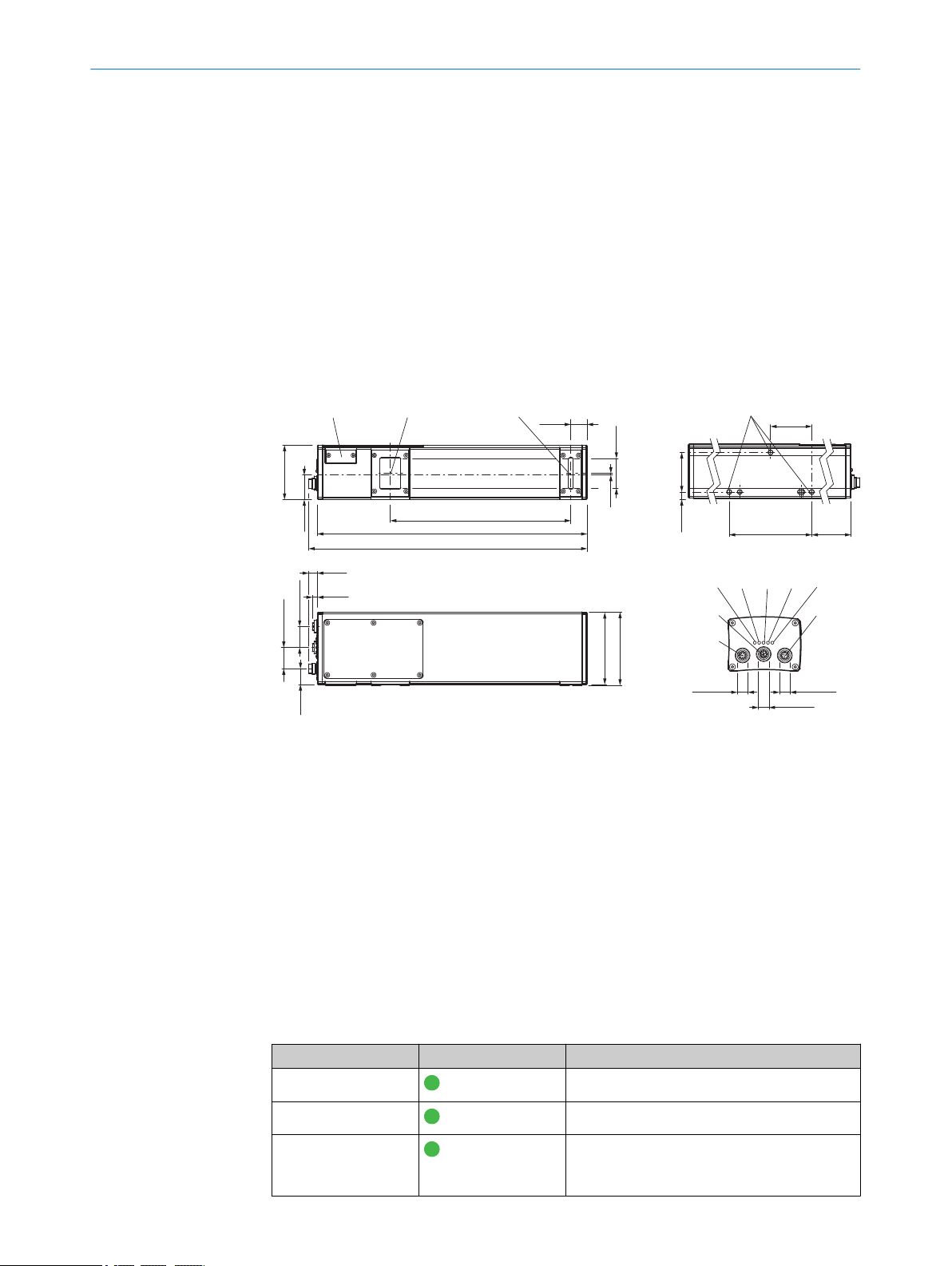

3.5.3 TriSpector1060

PRODUCT DESCRIPTION 3

Connector Encoder (thread inside)

Connector Gigabit Ethernet (Gig E)

Connector Power I/O (thread outside)

LED: On

LED: State

LED: Link/Data

LED: Result

LED: Laser

Fastening threads (M5x8.5 length)

Optical receiver (center)

Optical sender (center)

SD-card

3.6 LED indicators

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

Connector Encoder (thread inside)

1

Connector Gigabit Ethernet (Gig E)

2

Connector Power I/O (thread outside)

3

LED: On

4

LED: State

5

LED: Link/Data

6

LED: Result

7

LED: Laser

8

Fastening threads (M5x8.5 length)

9

Optical receiver (center)

ß

Optical sender (center)

à

SD-card

á

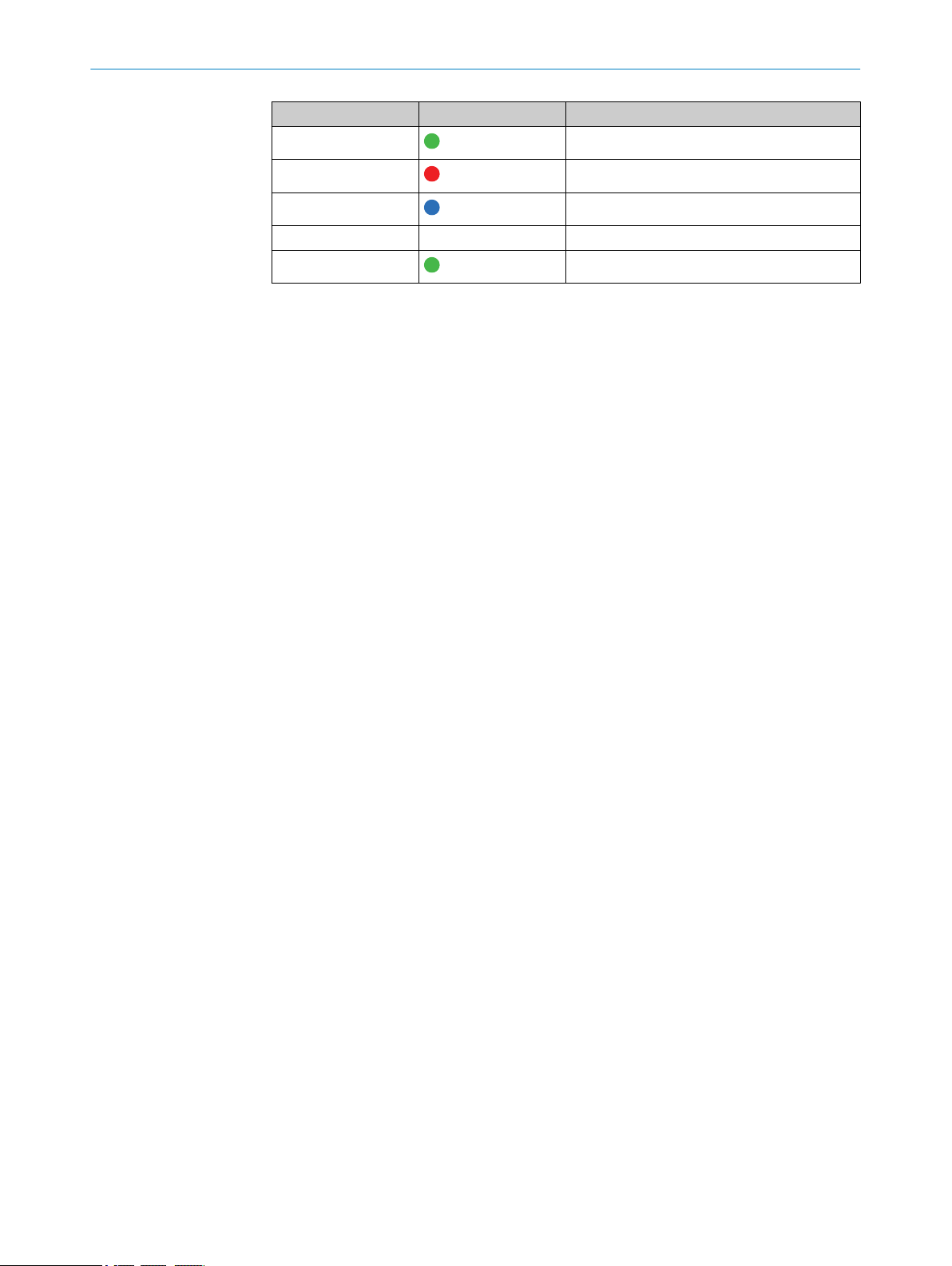

Name Color Function

On

State

Link/Data

Green Power on

Green Ready for trig input and image acquisition

Green Gigabit Ethernet (Gig E)

Link: LED on

Activity: LED blink

13

3 PRODUCT DESCRIPTION

Name Color Function

Result

Laser

Green Overall result: Pass

Red Overall result: Fail

Blue Result not found

No light Result invalid or neutral

Green Laser on

14

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

TRANSPORT AND STORAGE 4

4.2

Transport inspection

4.3 Storage

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Ambient data", page 61.

■

Relative humidity: see "Ambient data", page 61.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

15

5 MOUNTING

5 Mounting

5.1 Mounting instructions

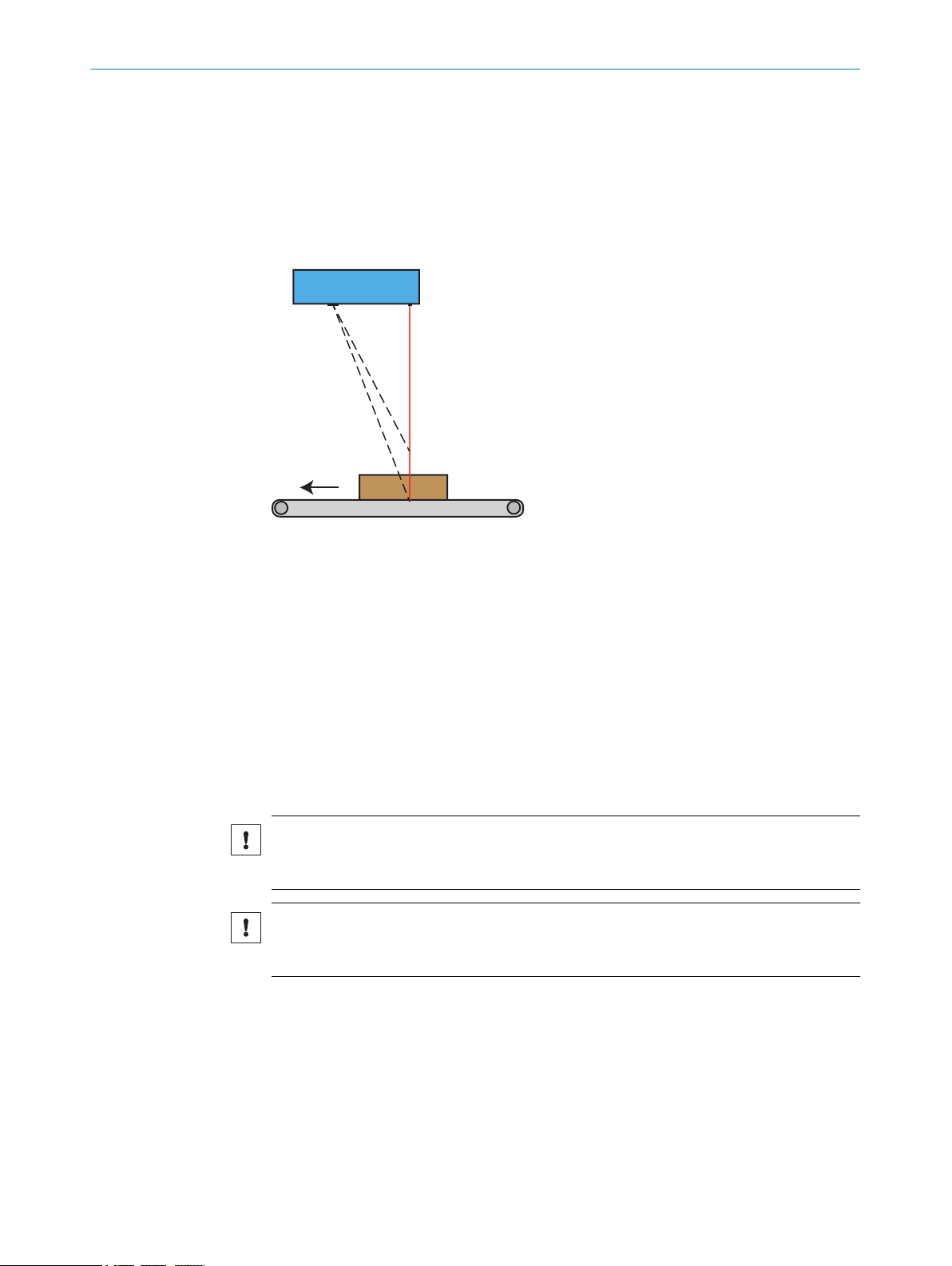

Mount the TriSpector1000 in a position above the surface to be scanned. See "Field of

view diagrams", page 17 for field of view diagrams and mounting distances. The

default scan direction is shown in figure 4. If a scan is performed in the opposite direc‐

tion, the acquired image will be mirrored.

Figure 4: Mounting position

For optimal performance:

■

Observe the ambient conditions for the operation of the TriSpector1000 (for exam‐

ple, ambient temperature and ground potential). See "Technical data", page 61

for specifications.

■

Ensure adequate heat transfer from the device, for example, via the mounting

bracket to the mounting base, or by means of convection.

■

Use a stable bracket with sufficient load bearing capacity and suitable dimensions

for the TriSpector1000.

■

Minimize shock and vibration.

■

Ensure a clear view of the objects to be detected.

5.1.1 Mounting a microSD memory card

NOTICE

If the TriSpector1000 is powered on, click the Eject button in the SD Card section under

the Interfaces workflow step before removing the microSD memory card.

NOTICE

The screws for the microSD memory card lid must be tightened with a torque of 0.3 Nm

to keep the IP65 classification.

16

Follow the steps below to insert or remove a microSD memory card to or from the

TriSpector1000. The microSD memory card slot is located next to the inspection win‐

dow.

1. Release the two screws to remove the lid.

2. Insert or remove the microSD memory card.

3. Re-mount the lid and tighten the screws with a torque of 0.3 Nm.

For a specification of supported microSD memory cards, see "System requirements",

page 11.

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

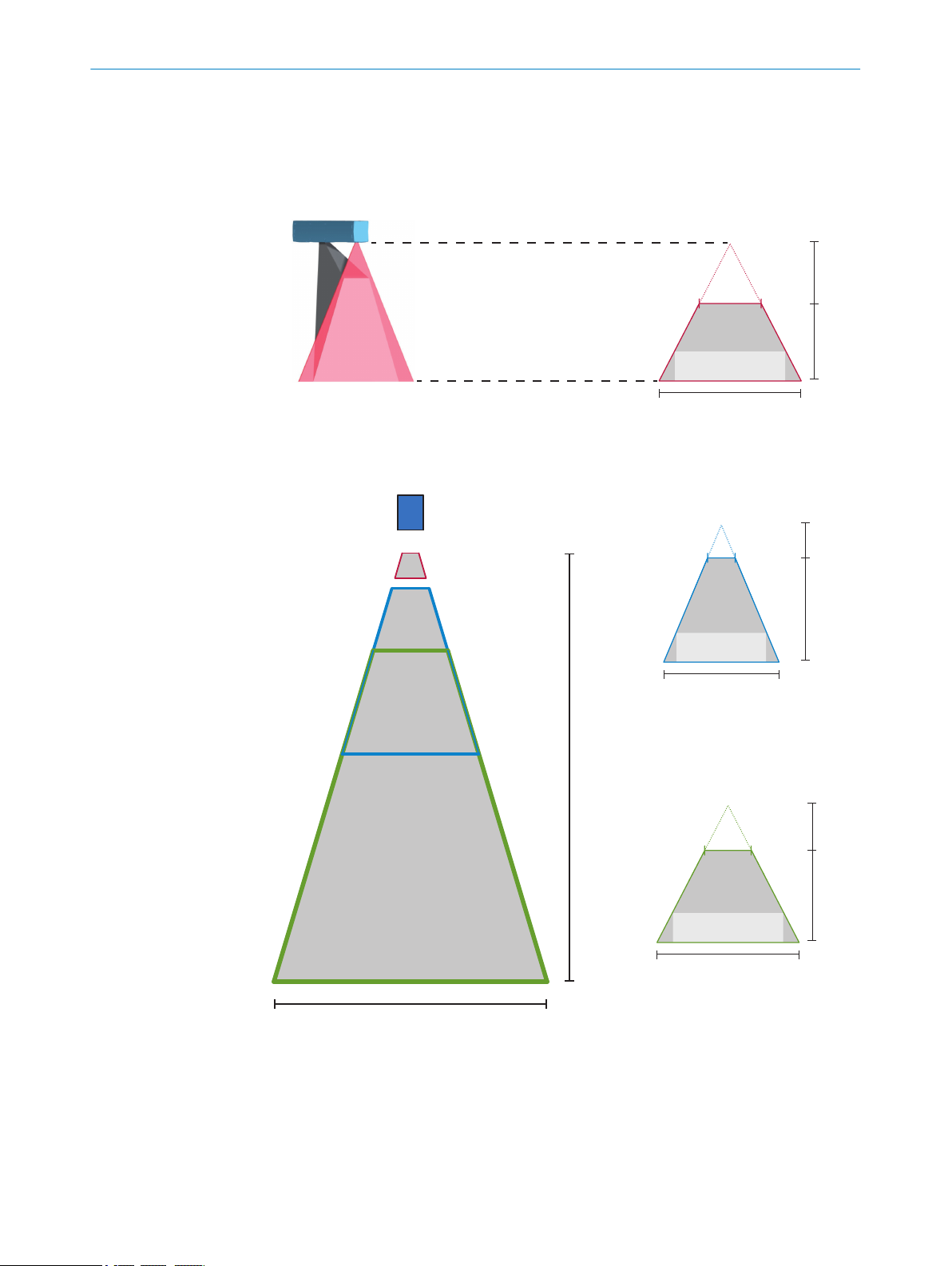

5.2 Field of view diagrams

56

(2.20)

60

(2.36)

75

(2.95)

H

W

65 x 15

(2.56 x 0.59)

40

(1.57)

TriSpector1008

291

(11.46)

800

(31.50)

660

(25.98)

H

W

540 x 200

(21.26 x 7.87)

180

(7.09)

TriSpector1060

141

(5.55)

400

(15.75)

330

(12.99)

H

W

270 x 100

(10.63 x 3.94)

90

(3.54)

TriSpector1030

Y

X

TriSpector1000

Y = Max. height range

X = Width at max.

working distance

Typical field of view

TriSpector1008

TriSpector1030

TriSpector1060

The maximum guaranteed image acquisition area in mm (inch) for each TriSpector1000

variant is shown in figure 5. The brighter areas represent typical image acquisition

areas.

MOUNTING

5

Figure 5: Field of view diagrams

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

17

ELECTRICAL INSTALLATION

6

6 Electrical installation

6.1 Prerequisites for the safe operation of the device in a system

WARNING

Risk of injury and damage due to electrical current!

Incorrect grounding of the device can result in equipotential bonding currents between

the device and other grounded devices in the system. This can lead to the following

dangers and faults:

Hazardous voltages are applied to the metal housings.

•

Devices will malfunction or sustain irrepairable damage.

•

Cable shieldings are damaged by overheating and cause cable fires.

•

Remedial measures:

Only qualified electricians should be permitted to carry out work on the electrical

•

system.

Install the grounding for the sensor and the system in accordance with national

•

and regional regulations.

Ensure that the ground potential is the same at all grounding points.

•

If the cable insulation is damaged, disconnect the voltage supply immediately and

•

have the damage repaired.

Observe the following safety measures:

■

Only skilled electricians with appropriate training and qualifications are permitted

to perform electrical installation.

■

Standard safety requirements must be met when working in electrical systems.

■

Electrical connections between the TriSpector1000 and other devices may only be

made or disconnected when there is no power to the system. Otherwise, the

devices may be damaged.

■

Where connecting cables with one end open are concerned, make sure that bare

wire ends do not touch each other (risk of short circuit when the supply voltage is

switched on). Wires must be appropriately insulated from each other.

■

Wire cross sections of the supply cable from the customer's power system should

be designed and protected in accordance with the applicable standards.

■

If the supply voltage for the TriSpector1000 is not supplied via the CDB650-204

connection module, the TriSpector1000 must be protected by a separate slowblow fuse with a max. rating of 2.0 A. This fuse must be located at the start of the

supply circuit.

■

All circuits connected to the TriSpector1000 must be designed as SELV circuits

(SELV = Safety Extra Low Voltage).

18

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

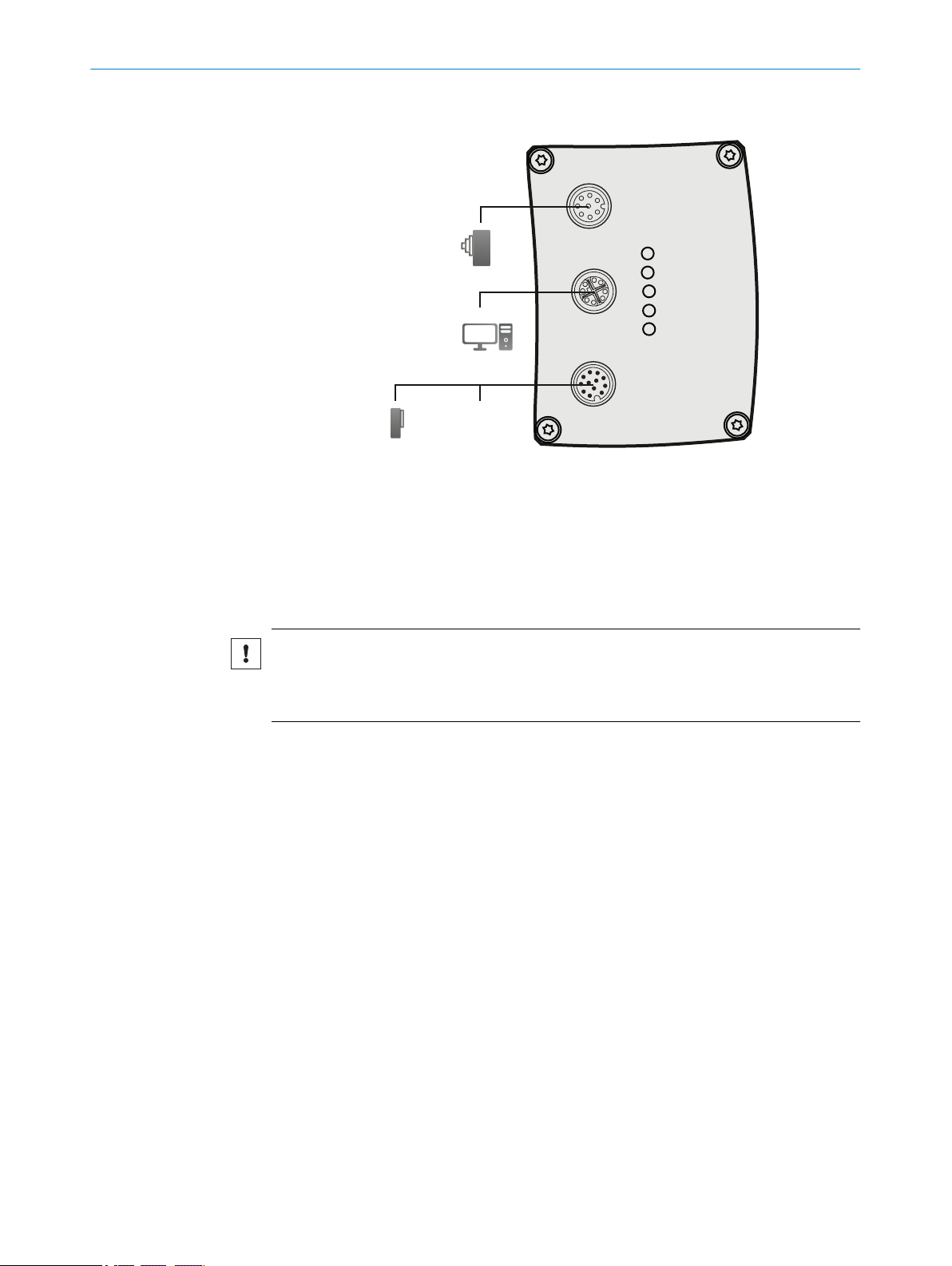

6.2 Connection diagram

Power

I/O

Gig

E

Encoder

On

State

Link/Data

Result

Laser

PC

24 V DC

Encoder

Photoelectric

switch

1

2

3

4

Figure 6: Connection diagram

Encoder

1

PC/Network

2

Photoelectric switch

3

24 V DC, voltage supply

4

ELECTRICAL INSTALLATION 6

6.3 Encoder

NOTICE

It is strongly recommended to use an encoder for measuring applications, such as

shape measuring and volume measuring. If no encoder is used, analysis results may be

inaccurate due to object traversing speed variations.

The encoder must fulfill the following requirements:

■

The encoder must be an incremental encoder.

■

The encoder must have a RS-422/TTL interface. In the case of strong magnetic

fields in proximity to the TriSpector1000 a recommended encoder (no. 1068997)

must be used to ensure optimal performance.

■

The connection requires two encoder channels (A/A¯ and B/B¯) to keep track of

movement and direction.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

19

4

3

6

5

7

8

1

2

4

3

6

5

7

8

1

2

6 ELECTRICAL INSTALLATION

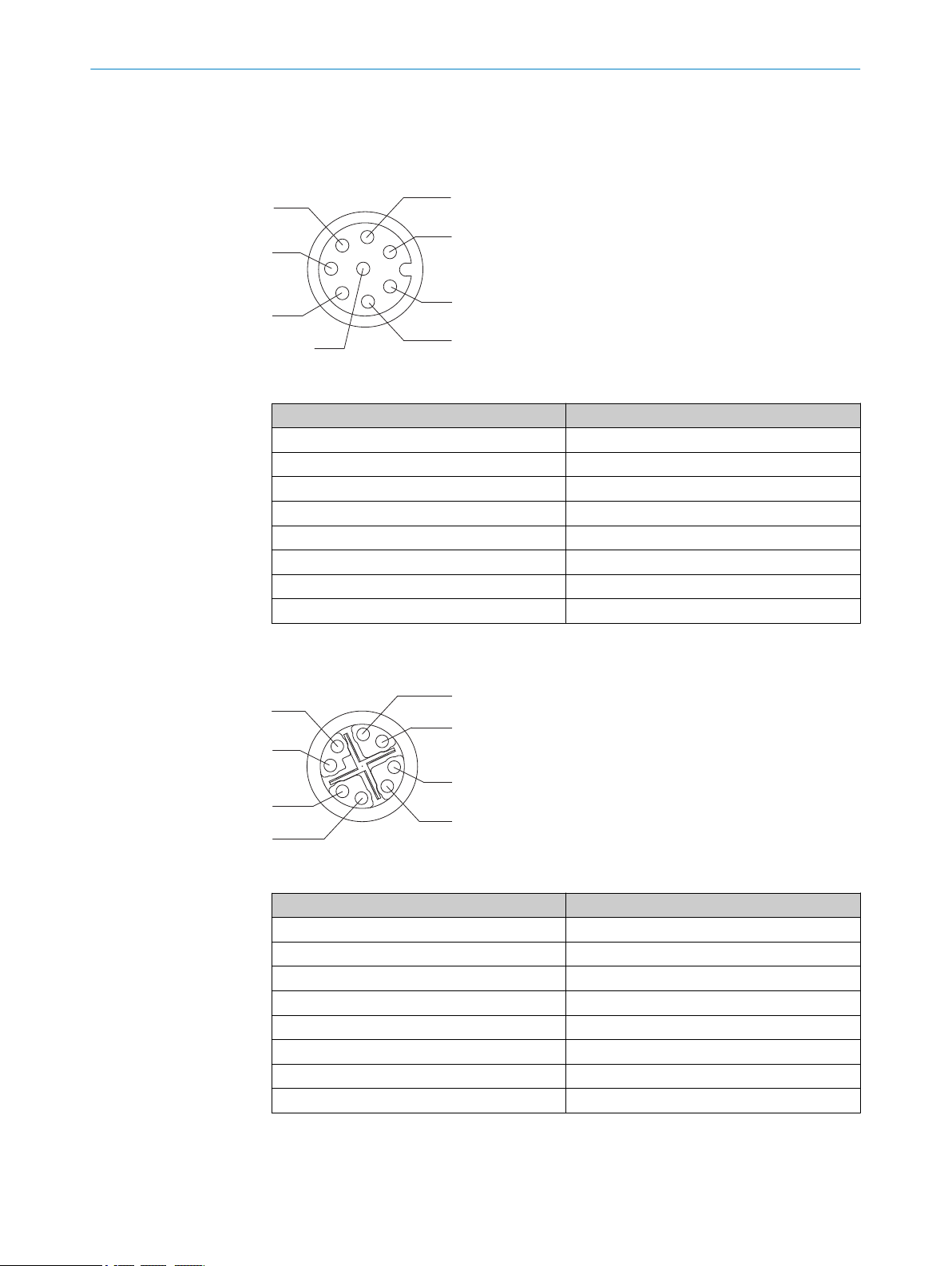

6.4 Pin assignment

Encoder I/O

Figure 7: M12 female connector, 8-pin A-coded

Pin Signal

1 A/ - RS-422 inverted input

2 A - RS-422 non-inverted input

3 B/ - RS-422 inverted input

4 B - RS-422 non-inverted input

5 (Not connected)

6 (Not connected)

7 GND (Power / Signal)

8 24 V Voltage supply output

Gigabit Ethernet

Figure 8: M12 female connector, 8-pin X-coded

Pin Signal

1 GETH_L1+

2 GETH_L1-

3 GETH_L2+

4 GETH_L3+

5 GETH_L3-

6 GETH_L2-

7 GETH_L4+

8 GETH_L4-

20

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

11

5

7

2

1

10

12

3

4

6

8

9

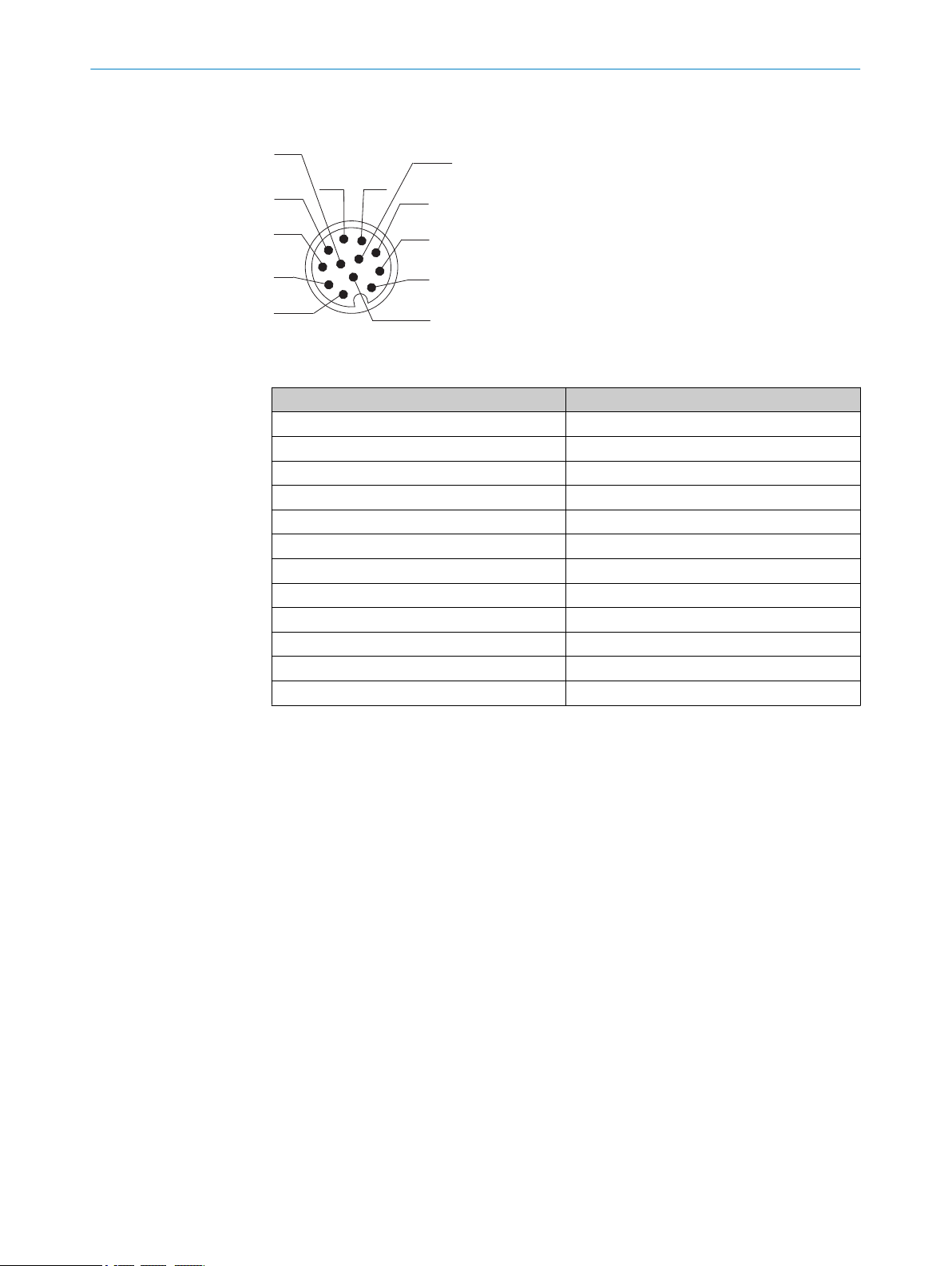

ELECTRICAL INSTALLATION 6

Power I/O

Figure 9: M12 male connector, 12-pin A-coded

Pin Signal

1 24 V Voltage supply input

2 Ground (Power / Signal)

3 24 V - I/O 3, Trigger in

4 24 V - I/O 4, Configurable

5 24 V - I/O 2, Input

6 24 V - I/O 5, Configurable

7 24 V - I/O 6, Configurable

8 24 V - I/O 1, Input

9 24 V - I/O 7, Configurable

10 Reserved

11 RS-232 Rx

12 RS-232 Tx

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

21

7 OPERATION

7 Operation

7.1 Commissioning

7.1.1 Installing SOPAS

The SOPAS Engineering Tool (ET) software for PC is used to connect and configure SICK

devices.

To install SOPAS ET:

1. Download the latest version of SOPAS ET from www.sick.com. Version 2018.2 or

higher is required.

2. Run the downloaded installation file.

3. Follow the instructions on the screen.

7.1.2 Connecting the hardware

1. Connect the Ethernet cable between the TriSpector1000 and the PC.

2. Connect the TriSpector1000 Power I/O cable to a 24 V DC power supply:

Brown: +24 V DC, Pin 1

Blue: Ground, Pin 2

3. Connect the encoder cable between the TriSpector1000 and the encoder (if

applicable).

7.1.3 Connecting the TriSpector1000 to SOPAS ET

1. Start SOPAS ET.

✓

The SOPAS ET main window opens. The main window is split into two panes, the

project pane to the left and the device pane to the right.

NOTICE

At the first use, the TriSpector1000 requires a SICK Device Driver (SDD). When

adding the device to a project, a prompt will appear with instructions on how to

install the driver. When prompted for SDD installation source, select Device upload.

NOTE

In the device list, the TriSpector1000 device is available on port 2111 and 2112.

Do not use port 2111. This port is used for debugging and may decrease the oper‐

ation speed.

2. To add the TriSpector1000 to the SOPAS project, select the device on port 2112 in

the device pane and click Add.

✓

A product icon appears in the project pane.

22

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

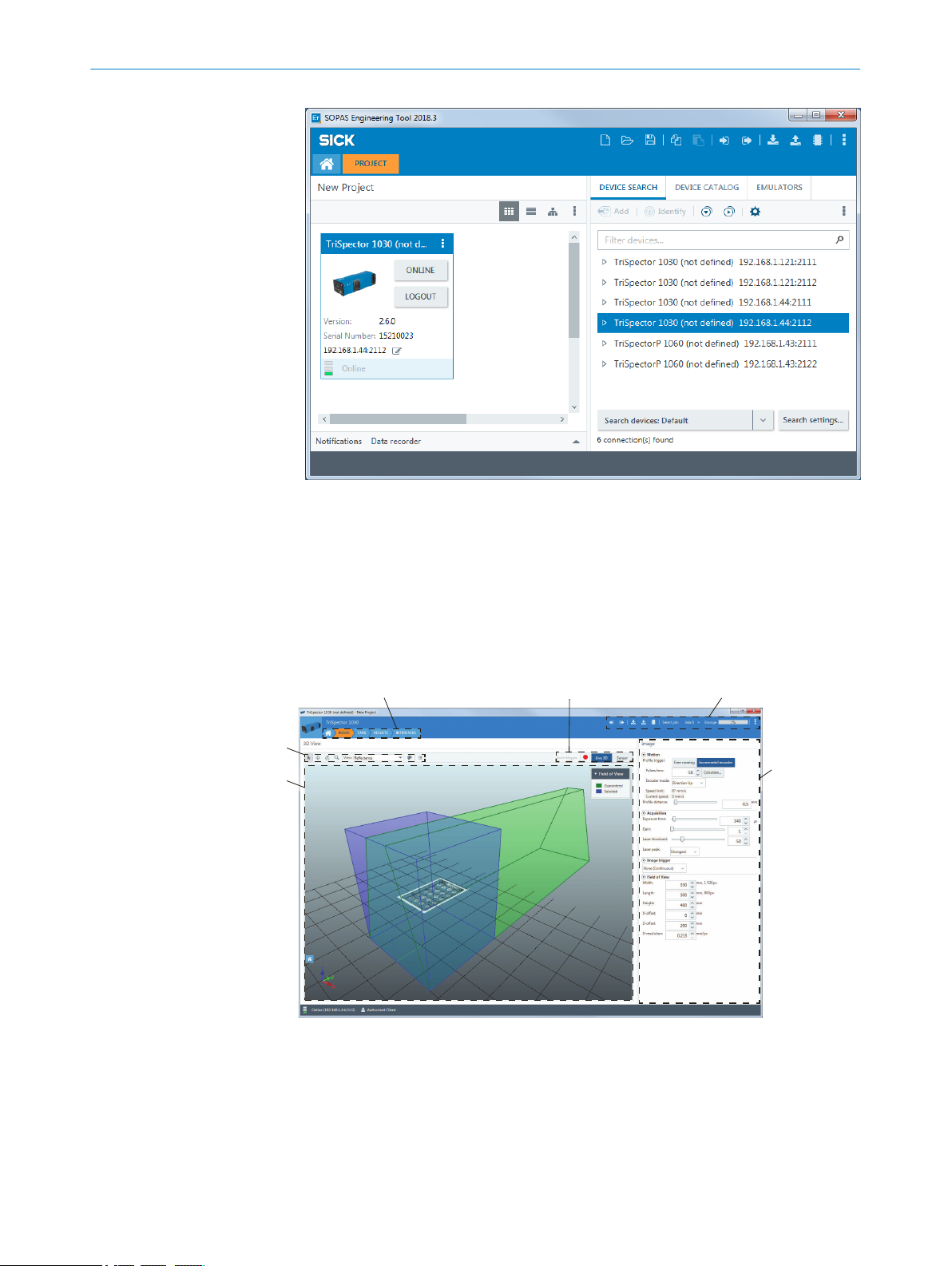

Figure 10: SOPAS ET main window

2

4 5

1

3

6

OPERATION 7

3. Double-click the product icon to open the SOPAS ET device window and start the

4. If there are IP address connection issues, click the Edit icon in the device tile to

7.2

Description of the user interface

The TriSpector1000 is configured through the SOPAS ET device window.

configuration.

make adjustments. The default IP address is 192.168.0.30.

Figure 11: SOPAS ET device window

Image area

1

Image handling controls and view options

2

Parameter pane

3

Workflow steps

4

Controls for image view, image recording (red), and Force trigger

5

SOPAS ET functions panel

6

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

23

7 OPERATION

7.2.1 Menus

Three menus are available in the SOPAS ET functions panel: the Device menu, the Para‐

meter menu and the Functions menu.

Device menu

Go online Establish a connection between SOPAS ET and the TriSpec‐

tor1000.

Go offline Switch the connection mode to offline. In this mode, parameter

values cannot be written to the device and measurements cannot

be monitored. The connection information in SOPAS ET remains

intact.

Switch to physical device Switch from the emulator to the TriSpector1000 and import the

configuration. This option is only enabled when running the emula‐

tor. For details, see "Copying a configuration from the emulator",

page 56.

Switch to simulated device Switch from the TriSpector1000 to the emulator. For details, see

"Starting the emulator", page 54.

Login... Log in to the device at a certain user level. When a device is added

to a SOPAS project, the user level is automatically set to Authorized

Client, which is the required level for saving parameter values to

the device. The current user level is shown below the image area.

Logout Cancel the login. Once the user has logged out, parameters

secured by the user level can no longer be changed.

Import... Import a saved device configuration from a PC. For details,

see "Exporting and importing data", page 56.

Export... Export the current device configuration to a PC. For details,

see "Exporting and importing data", page 56.

Create PDF Create a PDF which includes device parameters and their values.

Properties Open the Device Settings window.

Close Close the SOPAS ET device window.

Parameter menu

Write to device Write the configuration saved in the SOPAS project to the device.

Read from device Read the configuration from the device and saves it in the SOPAS

Save permanent Save the configuration in the device flash memory and to the

Functions menu

Load factory defaults Reset all SOPAS ET parameters including IP address.

Load application defaults Reset all SOPAS ET parameters except IP address.

Save image to file Save the current image to disk.

Image recording Save multiple images to disk. For details, see "Recording images",

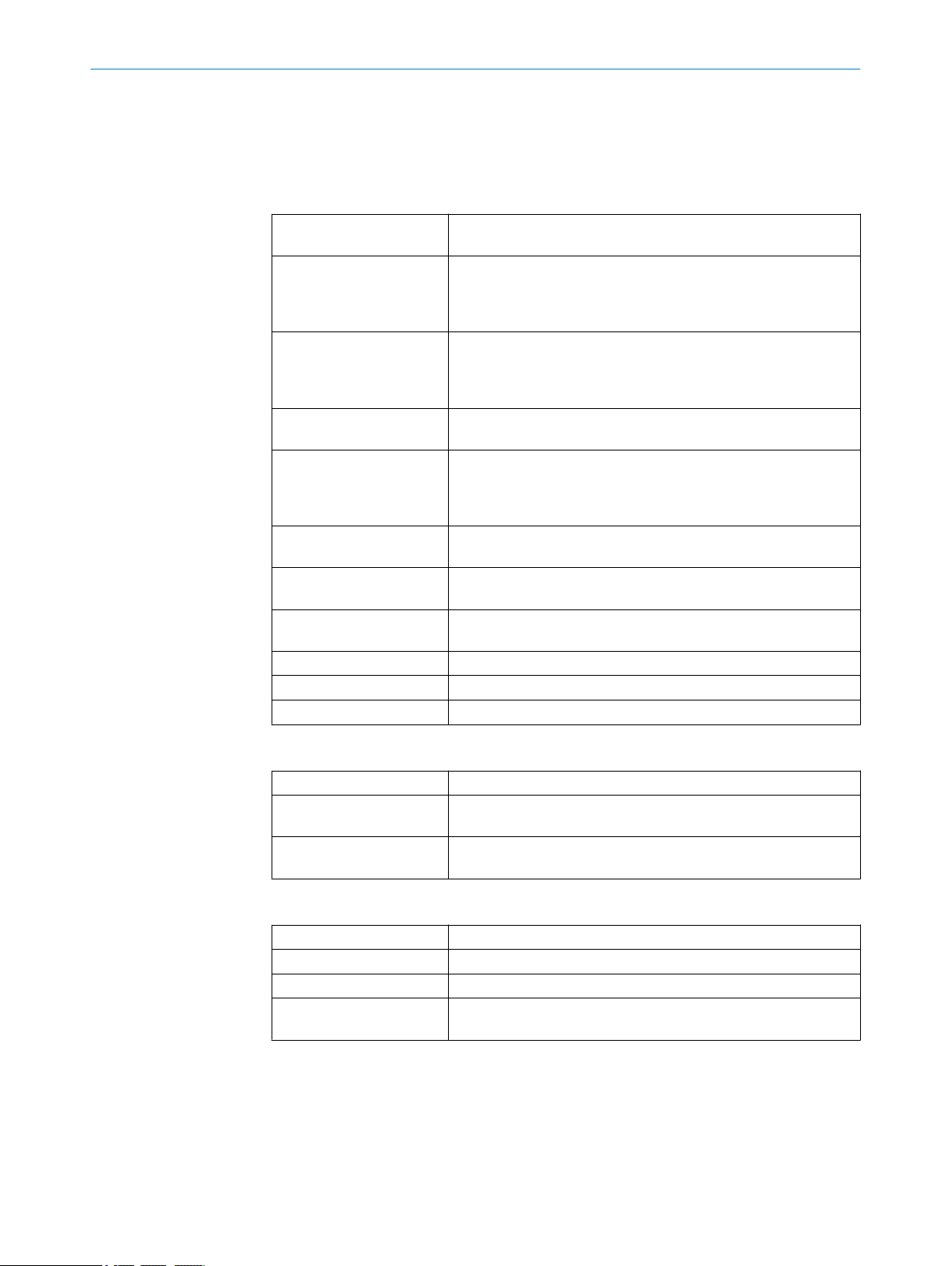

7.2.2 Image handling controls

Use the image handling controls to manipulate regions and perspective when viewing

images. As an alternative to the buttons, you can use a mouse with a scroll wheel, as

described below.

project.

microSD memory card (when applicable).

page 32.

24

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

Z

XY

OPERATION 7

Button Name Description

Select Click and drag to change the size and position of the image.

Shortcut command: Ctrl+Q.

Move Click and drag to move the image.

Shortcut command: Ctrl+W.

Shift+ press and hold the mouse scroll wheel.

Rotate Click and drag to rotate the image.

Shortcut command: Ctrl+E.

Press and hold the mouse scroll wheel.

Zoom Click and drag upwards to zoom in and downwards to zoom out.

Shortcut command: Ctrl+R.

Rotate the mouse scroll wheel.

3D navigation control

Use the 3D navigation control in the lower left corner of the image viewer to switch

between different viewing angles:

•

•

•

Figure 12: 3D navigation control

7.2.3 Image view modes

The following view modes are available:

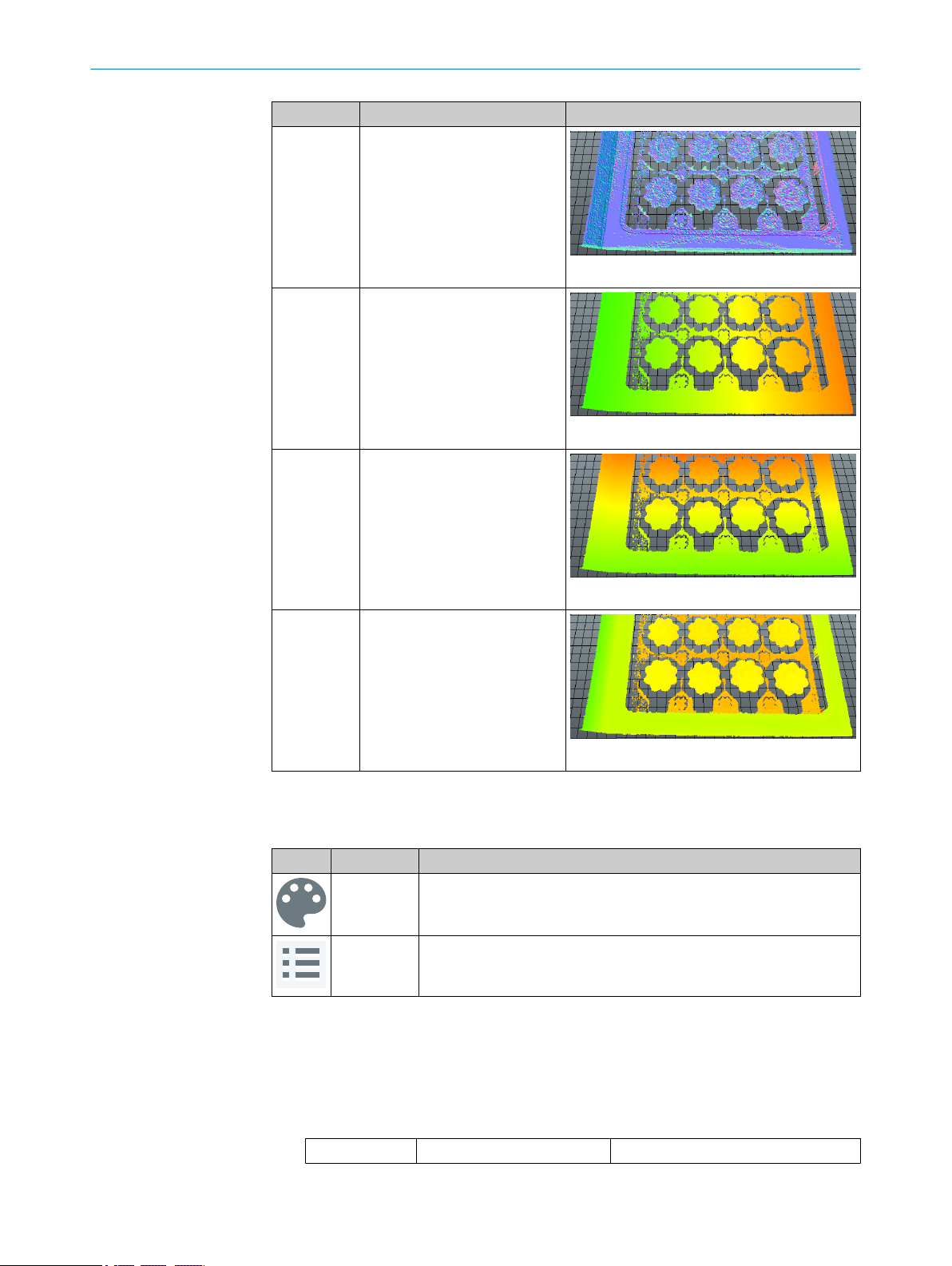

View mode Description Example

Reflectance Color is proportional to the

Reflectance

(Hybrid)

Click an arrowhead (X, Y or Z) to view a 2D projection of the object.

Click the same arrowhead twice to flip the 2D projection (for example, to switch

between the top and bottom view for the Z-axis).

Press Home to restore the original viewing position.

reflectance values along the

laser line.

Suitable to show the surface

details of an object, such as a

print.

Figure 13: Reflectance view mode

Color is proportional to depth (zcoordinate), color brightness is

proportional to the laser

reflectance.

Suitable to show large variations

in depth together with surface

details.

Figure 14: Reflectance (Hybrid) view mode

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

25

7 OPERATION

View mode Description Example

Normals Color is proportional to the ori‐

entation of the surface normal

vector.

Suitable to show small varia‐

tions in depth, such as surface

structures.

Figure 15: Normals view mode

X Color is proportional to x-coordi‐

nate.

Figure 16: X view mode

Y Color is proportional to y-coordi‐

nate.

Z Color is proportional to depth (z-

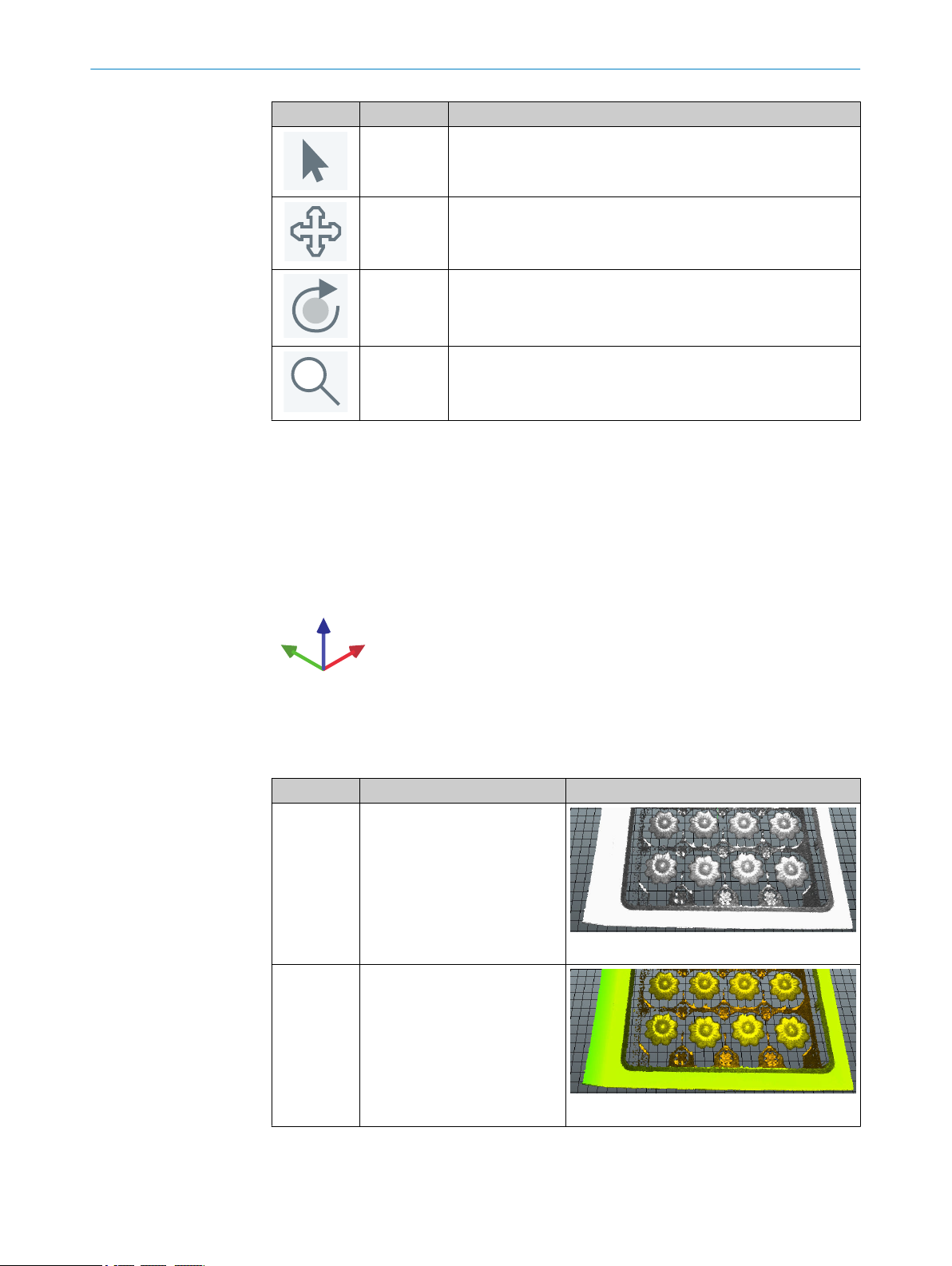

7.2.4 Image view options

The Color and Options buttons contain image view options.

Button Name Description

b

Figure 17: Y view mode

coordinate).

Suitable to show large variations

in depth.

Figure 18: Z view mode

Color View image in color or grayscale

Options Contains options for Color Range, Grid, Surface and Points, as described

below.

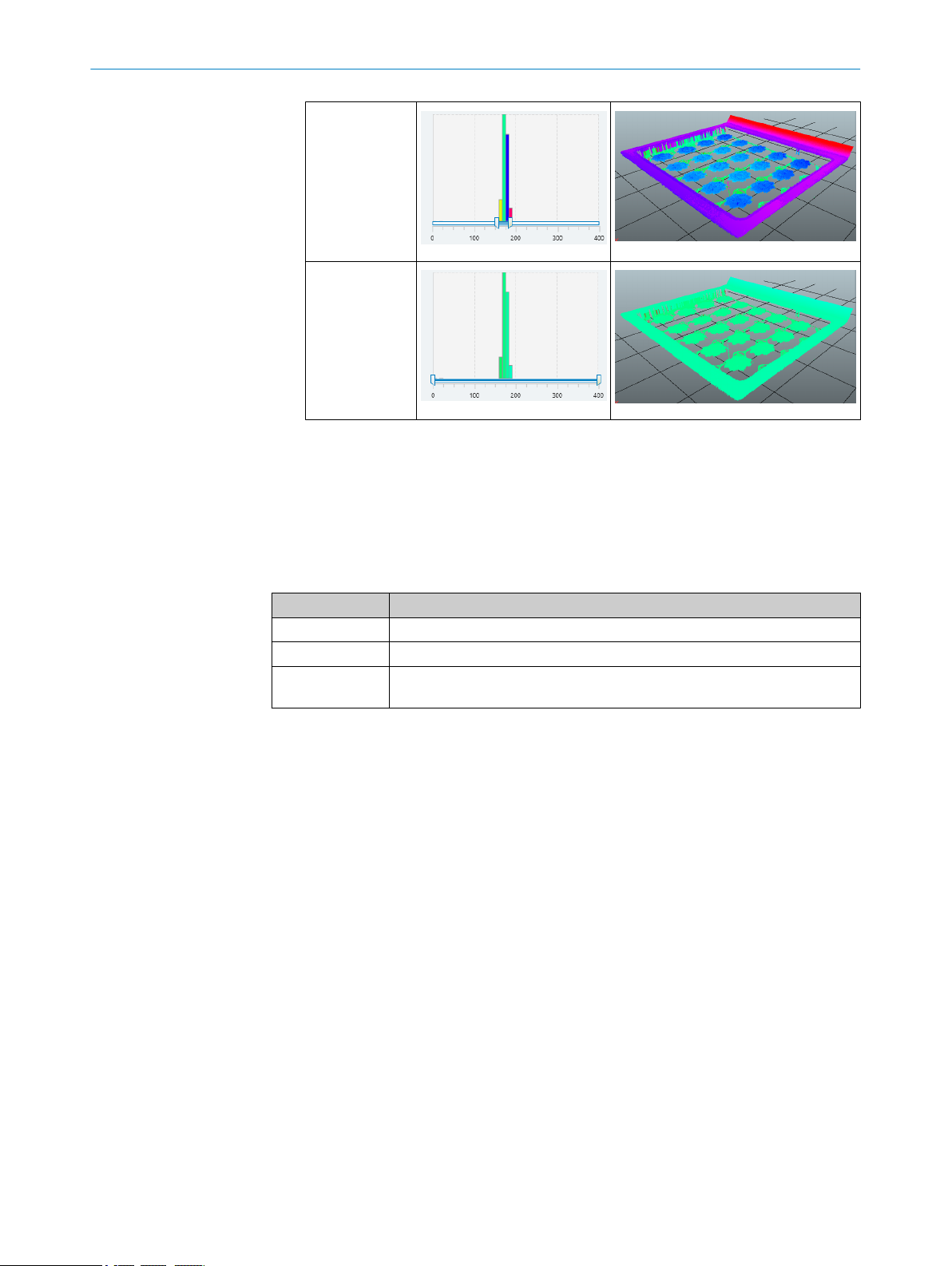

Click Color Range to adjust the color interval of the displayed image. This option is

only applicable for the X, Y, Z and Reflectance view modes.

The available color spectrum covers the whole range between the minimum and

the maximum value. Make the interval smaller if the scanned object is small, or to

view a part of the object in detail. This means that the whole color spectrum is

spread over a smaller interval, and it will be easier to see small variations in

depth.

Applied color range Resulting image

26

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

b

b

7.2.5 Image view controls

OPERATION 7

Narrow color

range

Broad color

range

Click Grid to show or hide the grid at the bottom of the field of view.

Click Surface to view the image as a continuous surface, or Points to view the image

as a point cloud. The point size can be adjusted by the user.

The image view controls are used to switch between the Live 3D image, the Job image,

and the Sensor view. Different image view controls are available in different workflow

steps.

Image view Description

Job Show the job image stored with the Save job image button.

Live 3D Display the latest scanned image.

Sensor Display the object as perceived by the image sensor. Use this view to adjust

image acquisition settings.

7.3 Handling jobs and configurations

A set of image, task and result settings is referred to as a job in SOPAS ET, while a set

of jobs and interface settings is referred to as a configuration.

Use SOPAS ET to manage jobs and to save the resulting configuration. A maximum of

32 jobs can be included in a configuration. Up to 32 tools can be applied to each job,

but only one Shape tool.

Loading a configuration

When powering on the TriSpector1000, the configuration stored on the microSD mem‐

ory card is automatically loaded into the device's working memory. If no microSD mem‐

ory card is inserted, or if there is no configuration stored on the microSD memory card,

the configuration is loaded from the device's flash memory to the working memory.

Managing jobs

Click the Select job menu in the SOPAS ET functions panel to manage and select jobs.

At the first use of the TriSpector1000, a new job ('Job 0') is created in the device's work‐

ing memory. When an existing configuration is loaded into the device's working memory,

the job that was active when the configuration was saved is automatically activated.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

27

7 OPERATION

Saving a configuration

NOTICE

If a configuration is not saved before disconnecting the power to the device, all settings

will be lost.

Select Save permanent from the Parameter menu in the SOPAS ET functions panel to save

a configuration from the device's working memory to the flash memory. If the device

has a microSD memory card inserted, the configuration is saved to both the flash mem‐

ory and the microSD memory card.

Cloning a device using a microSD memory card

Follow the steps below to clone a device, which means copying the configuration and IP

address from one device to another. The instruction requires that the first device has a

microSD card inserted and is connected to SOPAS ET.

1. In SOPAS ET, select Save permanent from the Parameter menu to save the current

configuration to the microSD memory card.

2. Move the microSD memory card from the first to the second device.

3. Power on the second device.

✓

The configuration on the microSD memory card is loaded into the working memory

of the second device.

4. Select Save permanent from the Parameter menu in the SOPAS ET functions panel to

save the configuration to the device's flash memory.

7.4 Workflow steps

To configure the TriSpector1000, click the workflow steps in the user interface (see

figure 19). It is possible to change workflow step at any time during the configuration.

Figure 19: Workflow steps

Image

The Image workflow step is used to set up image acquisition for good image quality. Two

different views are available: Live 3D and Sensor. See "Image workflow step", page 29

for more information.

Task

The Task workflow step contains tools for image analysis. Two different views are avail‐

able: Live 3D and Job. The Job image is the reference image where the tools are applied

and the tool configuration is done. See "Task workflow step", page 32 for more infor‐

mation.

Results

The Results workflow step contains settings for result processing and output handling.

Note that a bold red underscore in the input fields indicates syntax error. See "Results

workflow step", page 43 for more information.

28

Interfaces

The Interfaces workflow step contains settings for connections to external interfaces.

See"Interfaces workflow step", page 50 for more information.

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

7.5 Image workflow step

Scan

No scan

Forward scanning direction

Motion

Position Up

Direction Up

Scan

No scan

Scan

7.5.1 Scanning an object

The TriSpector1000 builds the image by acquiring a number of laser line profiles of a

moving object. Use an encoder if motion is not constant.

1. In the Motion section, select Profile trigger:Free running or Incremental encoder and

specify the parameters accordingly. If applicable, click Calculate for assistance with

encoder calculation. See "Encoder modes", page 29 for descriptions of the

encoder modes.

2. Move the object under the TriSpector1000 laser line to make a scan.

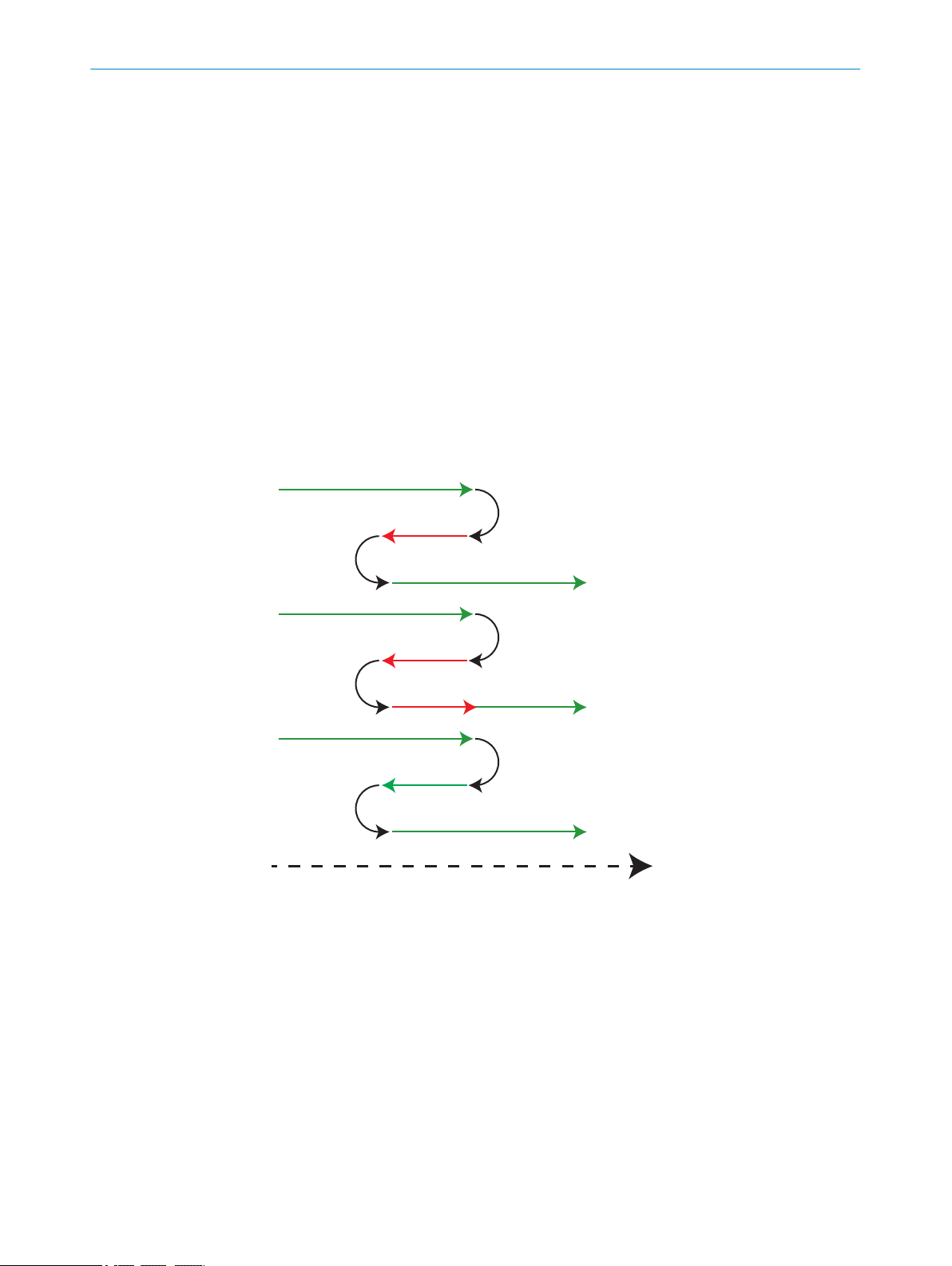

7.5.1.1 Encoder modes

The TriSpector1000 has a two directional (up/down) encoder pulse counter. The for‐

ward (up) scanning direction is defined as clockwise encoder shaft movement, as seen

from the tip of the shaft. See the Current speed parameter in the Image workflow step for

traversing speed. There are five encoder pulse counter-modes: direction up/down, posi‐

tion up/down and motion.

OPERATION

7

Figure 20: Encoder pulse counter-modes

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

29

7 OPERATION

7.5.2 Setting the field of view

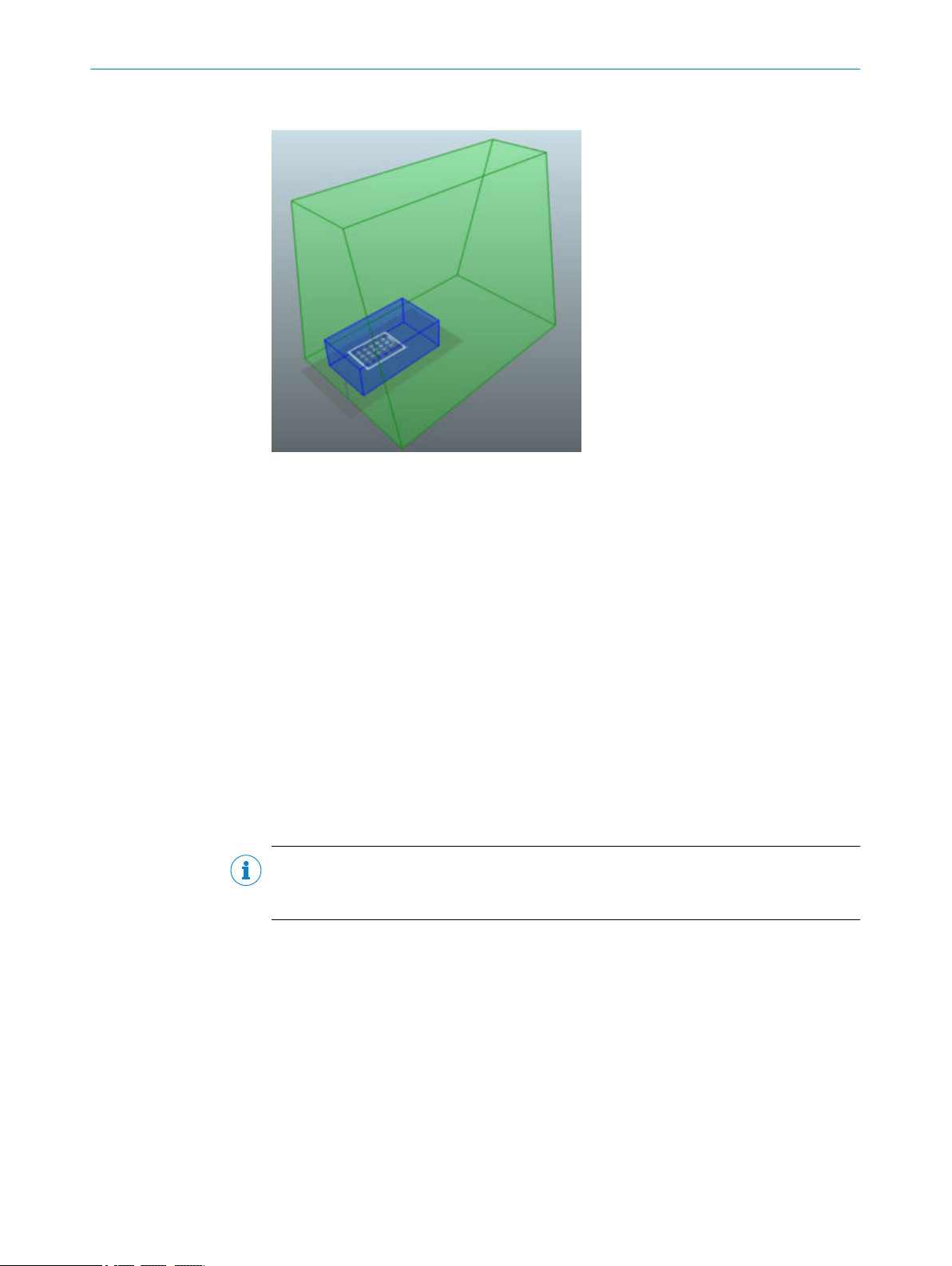

Figure 21: Field of view

The field of view consists of two regions displayed in the image area:

■

Guaranteed field of view (green region): The field of view where image acquisition

is possible. The guaranteed field of view for the TriSpector1000 consists of 2500

profiles, and the region length is determined by the Profile distance parameter.

■

Selected field of view (blue region): The region in which the camera acquires range

data for image analysis. The Width and Height of this region are set to maximum by

default. The default Length depends on the device model (120-480 mm).

Adjust the field of view to optimize performance:

■

Edit the Profile distance parameter in the Motion section in the parameter pane to

change the length of the guaranteed field of view. A smaller profile distance allows

a higher scan density but reduces the region length.

■

Use the value boxes in the Field of view section in the parameter pane to resize the

selected field of view. A smaller region allows faster processing and higher profile

frequency rate.

■

Make the pixels in the selected field of view more square by setting the X-resolution

parameter to a value similar to the Profile distance parameter.

NOTE

If the X-resolution and the profile distance differ more than a factor 3, some tools may

not work properly.

7.5.3 Adjusting the image settings

To adjust the image settings to get a good 3D image:

1. Click the Sensor button located above the image area to see the laser profile which

can be used as reference when adjusting the exposure time and gain. See "Laser

line exposure time", page 31 for examples.

2. Click the Live 3D button and perform a scan.

3. In the Acquisition section, adjust the Exposure time and Gain until the 3D live view

looks good.

Try to keep the gain low, and instead increase the exposure time. This will reduce

noise in the image.

4. Adjust the Laser threshold parameter to determine which image sensor intensity val‐

ues to include when locating laser peaks. A high threshold value results in less

30

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

OPERATION 7

noise in the range image, while a low threshold value makes it possible to detect

weak laser peaks.

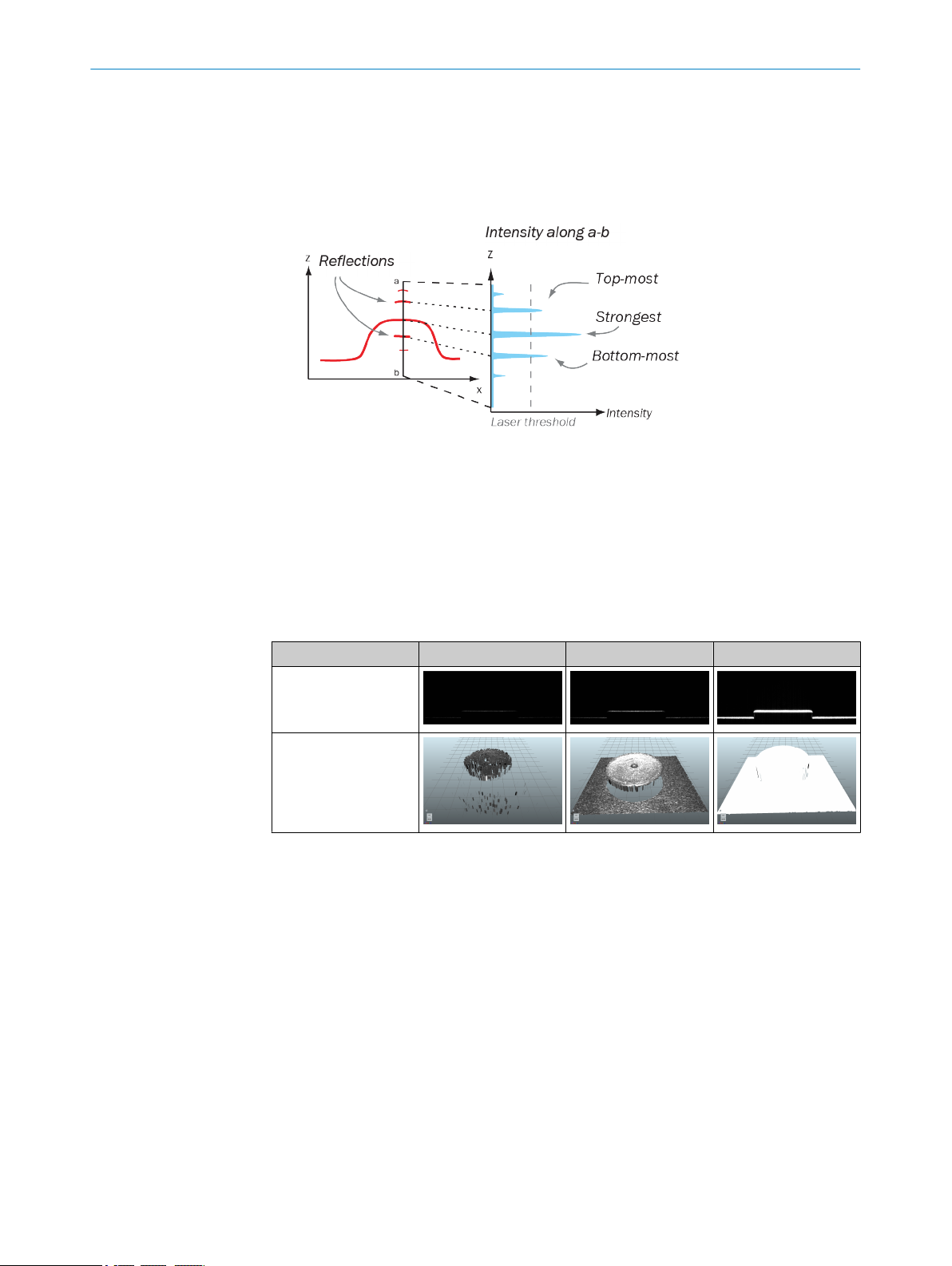

5. Select laser line acquisition criteria in the Laser peak list:

Strongest locates the point with the highest intensity.

°

Top Most and Bottom Most locate the highest or lowest point with an intensity

°

higher than the value set by the Laser threshold parameter. See figure 22.

Figure 22: Laser line acquisition criteria.

6. Repeat the procedure if necessary.

7.5.3.1 Laser line exposure time

The optimal exposure time yields a gray line in the 2D sensor image representation. A

slightly brighter line is preferable to a slightly darker line. A solid white laser line indi‐

cates a too long exposure time and will result in an overexposed image. See the images

below for examples of 2D sensor images and Live 3D images depicting short exposure

time, normal exposure time, and long exposure time (from left to right).

View Short exposure time Normal exposure time Long exposure time

Sensor view

Live 3D view

7.5.4 Configuring the trigger settings

The Image Trigger section is used to determine when image acquisition starts.

Set the Image trigger parameter to None (Continuous) to acquire images continuously.

b

Select Object trigger to define a plane on a certain height. The image acquisition

b

starts when an object is above the specified plane.

Select Command Channel to trigger the image acquisition from the command chan‐

b

nel.

Set the parameter to Trigger on I/O 3 to trigger the TriSpector1000 by digital I/O via

b

a photoelectric switch or a PLC. The image acquisition can be delayed by time (ms)

or distance (mm) from the signal input.

The TriSpector1000 triggers on a rising edge. The trigger pulse must be at least 50

μs. The TriSpector1000 ignores succeeding pulses during image acquisition.

Click the Force trigger button above the image area to start an image acquisition. If

b

an acquisition is already ongoing, it will be interrupted and re-started.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

31

7 OPERATION

7.5.5 Recording images

Use the Image recording button ( ) to save 3D images to disk. The saved images can be

used in the emulator to configure tools offline. See "Using the SOPAS ET emulator",

page 54 for information on how to use the emulator.

The saved images are Portable Network Graphics (.png) files which contain both range

data and reflectance data. Each file name includes the name of the active job, the

image number and the overall image decision.

To save images to disk:

1. Click the Image recording button.

✓

2. Select a destination folder.

3. Select the Max number of images checkbox to specify the maximum number of

4. Select the Reset image numbering checkbox to overwrite existing files in the destina‐

5. Click the Start button.

✓

6. Click the Image recording button stop the image recording. If the Max number of images

The Image recording settings window opens, and the Image recording button turns

black.

images to save.

tion folder.

The image recording starts. An image is saved each time a scan is made.

checkbox was selected, the recording will stop automatically when the specified

number of images have been saved.

7.6 Task workflow step

7.6.1 Using the tools

1. After the image configuration has been done in the Image workflow step, select

the Task workflow step.

✓

The image is shown in the Live 3D view.

2. Click the Save Job Image button.

✓

The Tools buttons appear and the image view changes to Job.

3. Click on a tool button to apply the tool to the image. You can apply multiple tools to

the image, but only one Shape tool.

4. Click the eye symbol ( ) in the parameter pane to toggle the visual representa‐

tion on or off. If applicable, click one more time to also show the tool's region of

interest.

Selecting a tool in the parameter pane will always show the visual representation

for the tool.

The Job image view shows the saved job image. Tools can only be applied in this view.

The Live 3D view shows the latest scanned image.

For an example of how to use tools for image analysis, see "Application example: Count‐

ing chocolates", page 41.

32

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

7.6.2 Setting the region of interest

Figure 23: The region of interest (yellow)

The region of interest is the region that a tool is applied to. The region of interest is set

for each tool and is displayed as a yellow box in the image area.

OPERATION 7

To set the region of interest for a tool:

1. Select a tool in the parameter pane.

2. Click the Select button in the image handling controls panel.

3. In the 3D navigation control in the lower left corner of the image area, click the

green arrowhead for a FRONT view.

4. Use the Height range slider in the Settings section in the parameter pane to adjust

the height of the 3D region, so that it covers only the region of interest. This is

important to only include relevant data, and to reduce the processing time.

5. In the 3D navigation control, click the blue arrowhead for a TOP view.

6. Select the most applicable Region shape in the parameter pane.

7. Use the region of interest handles (figure 24) or the region of interest manipulator

(figure 25) in the image area to adjust the sides and position of the 3D region, so

that it covers only the region of interest.

8. If needed, select Masks in the parameter pane to apply a mask that excludes nonrelevant parts from the region.

Region of interest handles

Figure 24: Region of interest handles.

Hover over the region of interest to highlight its handles. Click and hold a handle to

move or scale the region of interest, according to figure 24.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

33

y

x

y

x

7 OPERATION

7.6.3 Tool groups

Region of interest manipulator

Figure 25: Region of interest manipulator.

Click on the arrows in the image area to move, scale or rotate the region of interest,

according to figure 25.

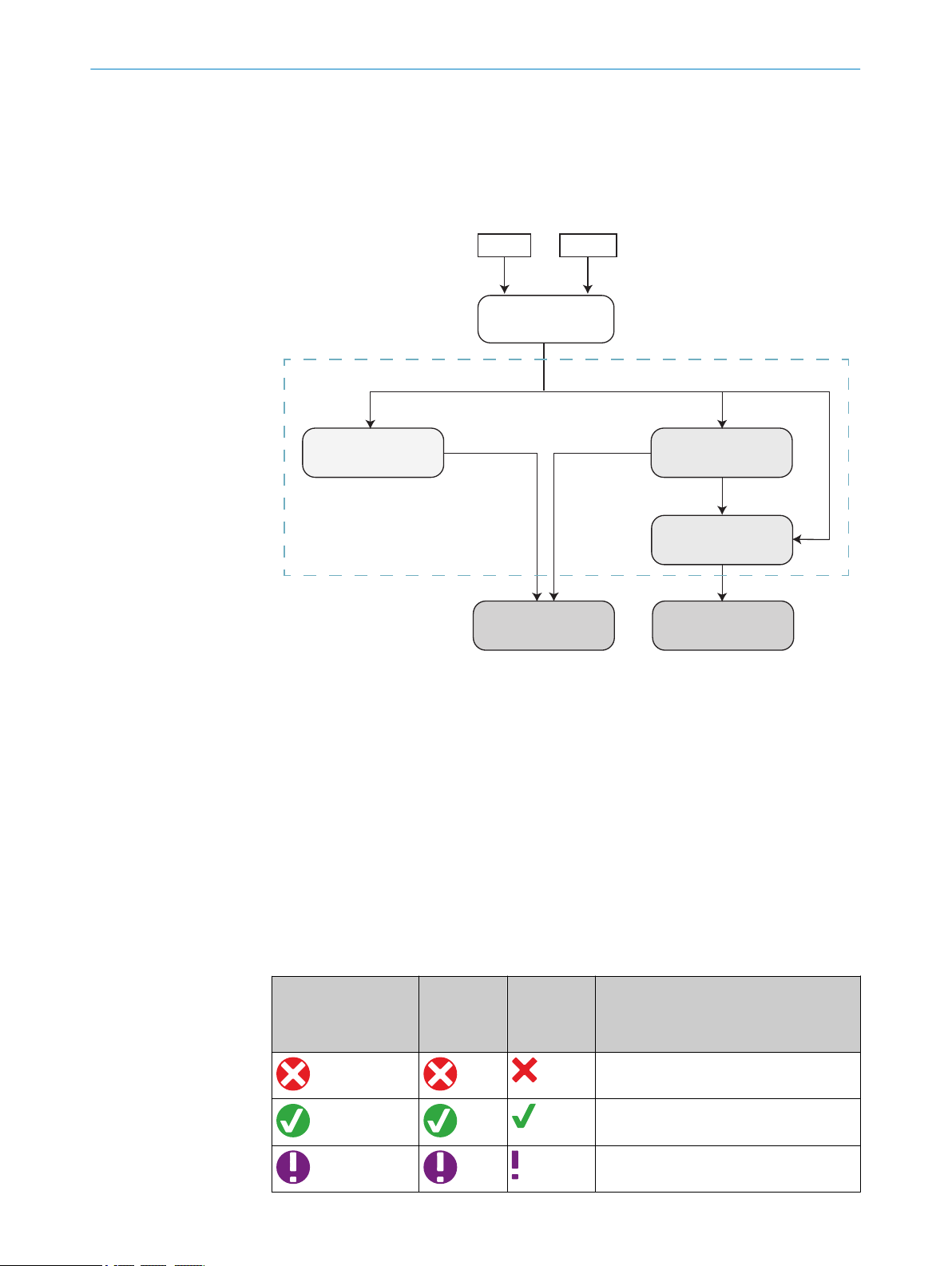

The tools are divided into three groups:

Find tools Locate objects of different shapes, or features such as

edges and planes.

7.6.4 Shape tool

Inspect tools Inspect properties on located objects or fixed regions in

the image.

Measure tools Measure distance and angle between located objects or

features.

Each tool group includes the following tools:

Find tools Shape tool, Blob tool, Edge tool, Plane tool, Fix Plane tool,

Point tool, Peak tool

Inspect tools Area tool

Measure tools Angle tool, Distance tool

Shape The Shape tool locates a 3D shape in the image and reposi‐

tions other tools accordingly. Use the Shape tool when the

position or rotation of the object varies.

NOTE

If the X-resolution and the profile distance of the image differ more than a factor 3, the

Shape tool will not work properly. To adjust the values, see "Setting the field of view",

page 30.

Shape tool settings

Setting Description

Region shape Set the shape of the region of interest to rectangular or elliptical.

Height range Set upper and lower bounds of the region of interest on the Z-axis.

34

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

y

x

OPERATION 7

Setting Description

Min. search score Minimum search score for Pass/Fail criteria. Lower search scores

than set value returns in a 'Not Found' result.

Min. edge threshold Only include shapes of greater height than the minimum thresh‐

old.

Robustness Set trade-off between speed and robustness. Low robustness will

result in fewer data points considered to find shape.

Rotation Maximum allowed shape rotation to search for. The greatest possi‐

ble value is ±180 degrees.

Masks Mask a part of the image to exclude it from the search.

Shape tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

Rotation Rotation in degrees.

Score Score value (0-100).

Tx, Ty, T

z

Translation (x, y, z) in mm.

7.6.5 Blob tool

Linking other tools to the Shape tool

If other tools are added after the Shape tool, they will be linked to the Shape tool and

their regions will be repositioned according to the found shape. Drag and drop tools

onto the Shape tool in the parameter pane to link them. Drag and drop tools outside the

Shape tool to unlink them.

Figure 26: Tools linked to Shape tool

Blob The Blob tool locates clusters of points within a defined

height interval and cluster size. This makes it possible to

measure volume, area, angle, and bounding box.

Blob tool settings

Setting Description

Region shape Set the shape of the region of interest to rectangular or elliptical.

Height range Set upper and lower bounds of the region of interest on the X-axis.

Blob area Only include blobs that have an area within a specified range.

Ignore data Exclude all data above or below an assigned plane (defined by a

Plane or Fix Plane tool) from the analysis.

Blob volume Enable blob volume measurement, either from the bottom of

the region of interest or from an assigned plane.

Sort by Sort the list of found blobs by X-position, Y-position or area.

Invert blobs Invert blobs to locate holes and gaps instead.

Exclude border blobs Remove all blobs that touch the region of interest or image border.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

35

7 OPERATION

Setting Description

Fill holes Remove single pixel holes in blob.

Calculate angles Calculate angles of blobs. The blob angle is the angle between the

x-axis and an axis around which it would be easiest to rotate the

blob.

Calculate bounds Calculate bounding box position, width, and length.

Show blob markers View a marker for each found blob in the image area.

Erode Trim outer edge of blobs to separate discrete blobs when height

map data overlaps.

Accuracy Set trade-off between speed and accuracy, setting a high speed

will downscale the image used for processing.

Masks Mask a part of the image to exclude it from the search.

Blob tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

NumBlobs Number of blobs detected.

Select the Blobs checkbox to use the number of

blobs as a Pass/Fail-condition.

OverallVolumeDecision OK/Not OK.

Select the Volume checkbox to use the blob vol‐

ume as a Pass/Fail-condition. The checkbox is

only visible if blob volume measurements have

been enabled in the Settings section.

First blob/blobs[]:

index

■

cogX

■

cogY

■

cogZ

■

■

■

■

■

■

■

■

■

■

*

*

width

*

length

*

cx

*

cy

boundsAngle

area

blobAngle

volume

*

*

volumeDecision

If activated in the tool

*

-

Index of blob in list.

■

X-center of blob.

■

Y-center of blob.

■

Z-height of X/Y-center.

■

Width of bounding box.

■

Length of bounding box.

■

X-center of bounding box.

■

Y-center of bounding box.

■

Bounding box angle (±90° from x-axis).

■

Blob area in mm2.

■

Blob angle in degrees (±90° from x-axis).

■

Volume in cm3.

■

OK/Not OK. Blob volume threshold per

■

blob.

7.6.6 Edge tool

36

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Edge The Edge tool finds edges in the range data.

Edge tool settings

Setting Description

Height range Set upper and lower bounds of the region of interest on the X-axis.

Min. edge threshold Only include edges of greater height than the minimum threshold.

Raise the value to remove noise.

Edge side Position line approximation on top or below of edge.

Subject to change without notice

OPERATION 7

Setting Description

Polarity Find rising edges, falling edges, or both.

Selection Select which edge the Edge tool chooses: first edge, last edge or

strongest edge found.

Edge sharpness Adjust to find sharper or softer edges.

Probe spacing Set the distance (in pixels) between edge locator probes, orthogo‐

nal to the search direction.

Outlier mode Manually or automatically trim data points for line approximation.

Manual mode enables the outlier distance setting.

Outlier distance Only include data points within this distance (mm) for line approxi‐

mation.

Masks Mask a part of the image to exclude it from the search.

Edge tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found.

MidPointX, MidPointY, MidPointZ Edge center point (x, y, z).

DirectionX, DirectionY, DirectionZ Edge direction (x, y, z).

Score Score value (0-100).

Select the Score checkbox to use the score

value as a Pass/Fail-condition.

Mean deviation Mean deviation from line approximation (mm).

Select the Mean deviation checkbox to use

the mean deviation as a Pass/Fail-condition.

7.6.7 Plane tool

Plane The Plane tool uses pixels inside its region of interest to find

a flat surface. Use the Plane tool to define plane features for

use with other tools, or to use the tool output independently.

Plane tool settings

Setting Description

Region shape Set the shape of the region of interest to rectangular or elliptical.

Height range Set upper and lower bounds of the region of interest on the Z-axis.

Robustness Set trade-off between speed and robustness. Low robustness will

result in fewer data points considered to find a plane.

Percentile Set the span of height data points to include when calculating

plane.

Show used points Indicates the data points used to calculate plane.

Masks Mask a part of the image to exclude it from the search.

Plane tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

Score Score value (0-100).

Select the Score checkbox to use the score

value as a Pass/Fail-condition.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

37

7 OPERATION

7.6.8 Fix Plane tool

Result Output

Tilt Angle between the normal vector to the

plane and the z-axis (in degrees).

Select the Tilt checkbox to use the tilt value as

a Pass/Fail-condition.

Cx, Cy, Cz, Nx, Ny, N

z

Equation of the plane through center point +

normal.

Px, Py, Pz, P

d

Equation of the plane through Px*x + Py*y +

Pz*z + Pd = 0.

Fix Plane The Fix Plane tool is used to manually set a reference plane

in the field of view. The reference plane can be used as fea‐

ture for other tools.

Fix Plane tool settings

Setting Description

Position X Center point of plane on X axis.

Position Y Center point of plane on Y axis.

Position Z Center point of plane on Z axis.

XZ angle Angle around the X axis.

YZ angle Angle around the Y axis.

7.6.9 Peak tool

Fix Plane tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

Cx, Cy, Cz, Nx, Ny, N

z

Equation of the plane through center point +

normal.

Px, Py, Pz, P

d

Equation of the plane through Px*x + Py*y +

Pz*z + Pd = 0.

Peak The Peak tool finds the point with the minimum or maximum

height value in its region of interest.

Peak tool settings

Setting Description

Region shape Set the shape of the region of interest to rectangular or elliptical.

Height range Set upper and lower bounds of the region of interest on the X-axis.

Type Find point with the minimum or maximum height value.

Use Median filter Use a filter to remove noise spikes in the heightmap.

Kernel size Radius of the median filter.

Masks Mask a part of the image to exclude it from the search.

38

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

7.6.10 Point tool

Σ

OPERATION 7

Peak tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

x, y, z Peak position (x, y, z).

Select the Height checkbox to use the height (zposition) as a Pass/Fail-condition.

Point The Point tool is used to manually set a reference point in

the field of view. The tool can be used to define point fea‐

tures for use with other tools, or to use the tool output inde‐

pendently.

Point tool settings

Setting Description

Position X Point position on the X axis.

Position Y Point position on the Y axis.

Position Z Point position on the Z axis.

Snap to data Place the point on the data height in the XY plane for the saved

Job image (disables the Z-slider). This only applies when training

the Point tool in Job view.

7.6.11 Area tool

Point tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

x, y, z User-defined position (x, y, z).

Area The Area tool calculates surface coverage by counting points

within a defined 3D region, or within a specified intensity

interval inside the region.

Area tool settings

Setting Description

Region shape Set the shape of the region of interest to rectangular or elliptical.

Height range Set upper and lower bounds of the region of interest on the X-axis.

Use intensity Use grayscale intensity data in addition to height.

Intensity range Limit the area tool to a specific range of image intensities.

Masks Mask a part of the image to exclude it from the search.

Area tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

Coverage Percentage of region coverage within the

region of interest.

Select the Coverage checkbox to use the cover‐

age percentage as a Pass/Fail-condition.

8021808/12ID/2019-01 | SICK O PE R AT I NG IN S TR U CT I ON S | TriSpector1000

Subject to change without notice

39

7 OPERATION

7.6.12 Distance tool

Result Output

Area Area in mm2.

Distance The Distance tool measures the distance between two tool

key points.

Distance tool settings

Setting Description

Feature A First referenced feature for measuring dis‐

tance.

Feature B Second referenced feature for measuring dis‐

tance.

Measure type Use right angle or point-to-point measuring.

Right Angle projects a point feature onto a

■

line feature, and measures the distance

between the projected point and the line

feature.

Point To Point measures the distance

■

between point features.

Measure distance in Select dimensions to measure distance in.

7.6.13 Angle tool

Distance tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found

Distance Distance in mm.

Select the Distance checkbox to use the dis‐

tance as a Pass/Fail condition.

GUI operations

Use the Switch features button ( ) to switch Feature A and Feature B.

Use the Select features button ( ) to enable or disable selection of features in the

image area.

Angle The Angle tool measures the angle between two planes.

Angle tool settings

40

Setting Description

Feature A First referenced plane tool for measuring

angle.

Feature B Second referenced plane tool for measuring

angle

O PE R AT I NG IN S TR U CT I ON S | TriSpector1000 8021808/12ID/2019-01 | SICK

Subject to change without notice

Angle tool result output

Result Output

Decision OK/Not OK/Invalid/Neutral/Not found.

Angle Angle in degrees.

GUI operations

Use the Switch features button ( ) to switch Feature A and Feature B.

Use the Select features button ( ) to enable or disable selection of features in the

image area.

7.6.14 Application example: Counting chocolates

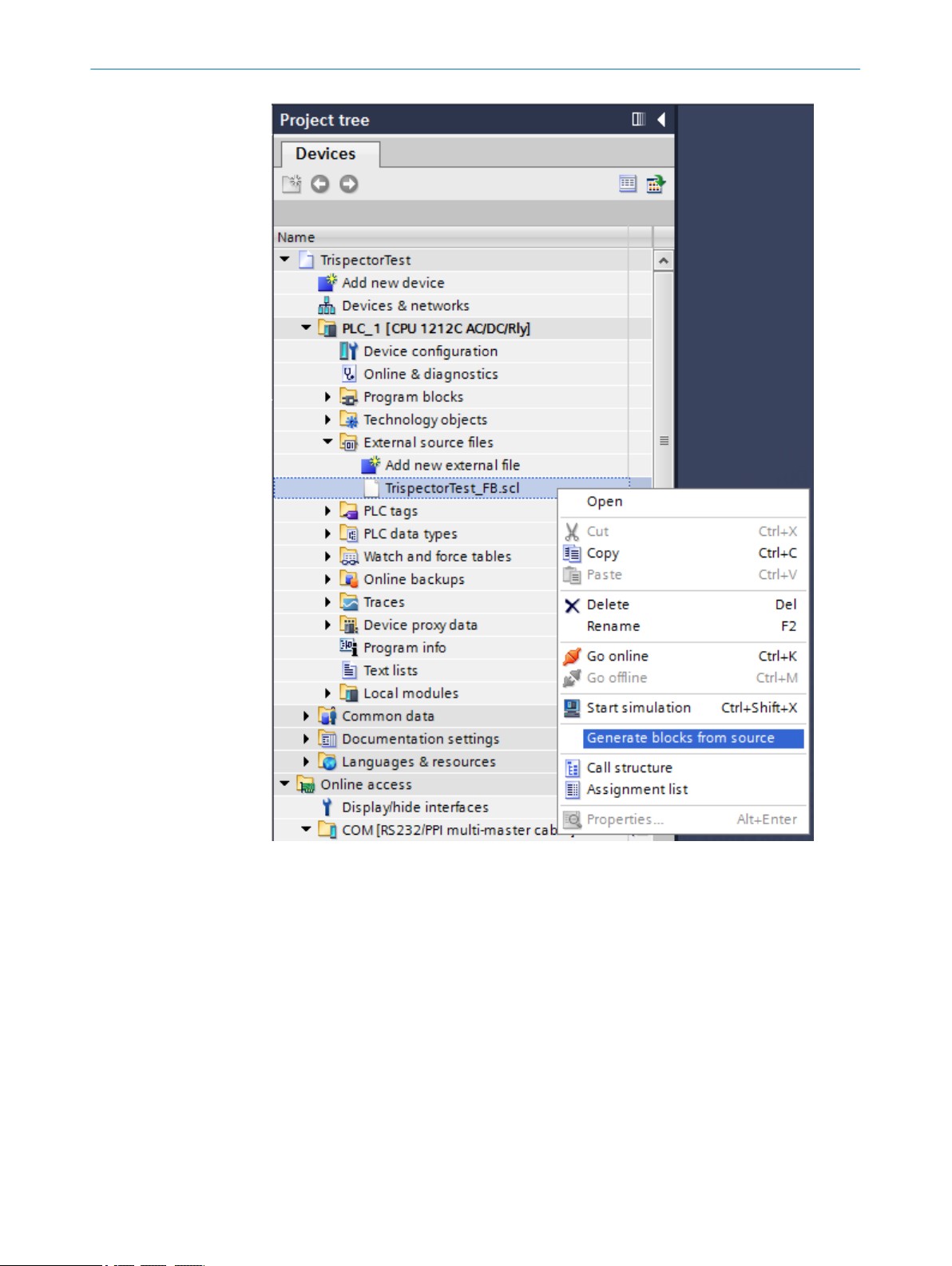

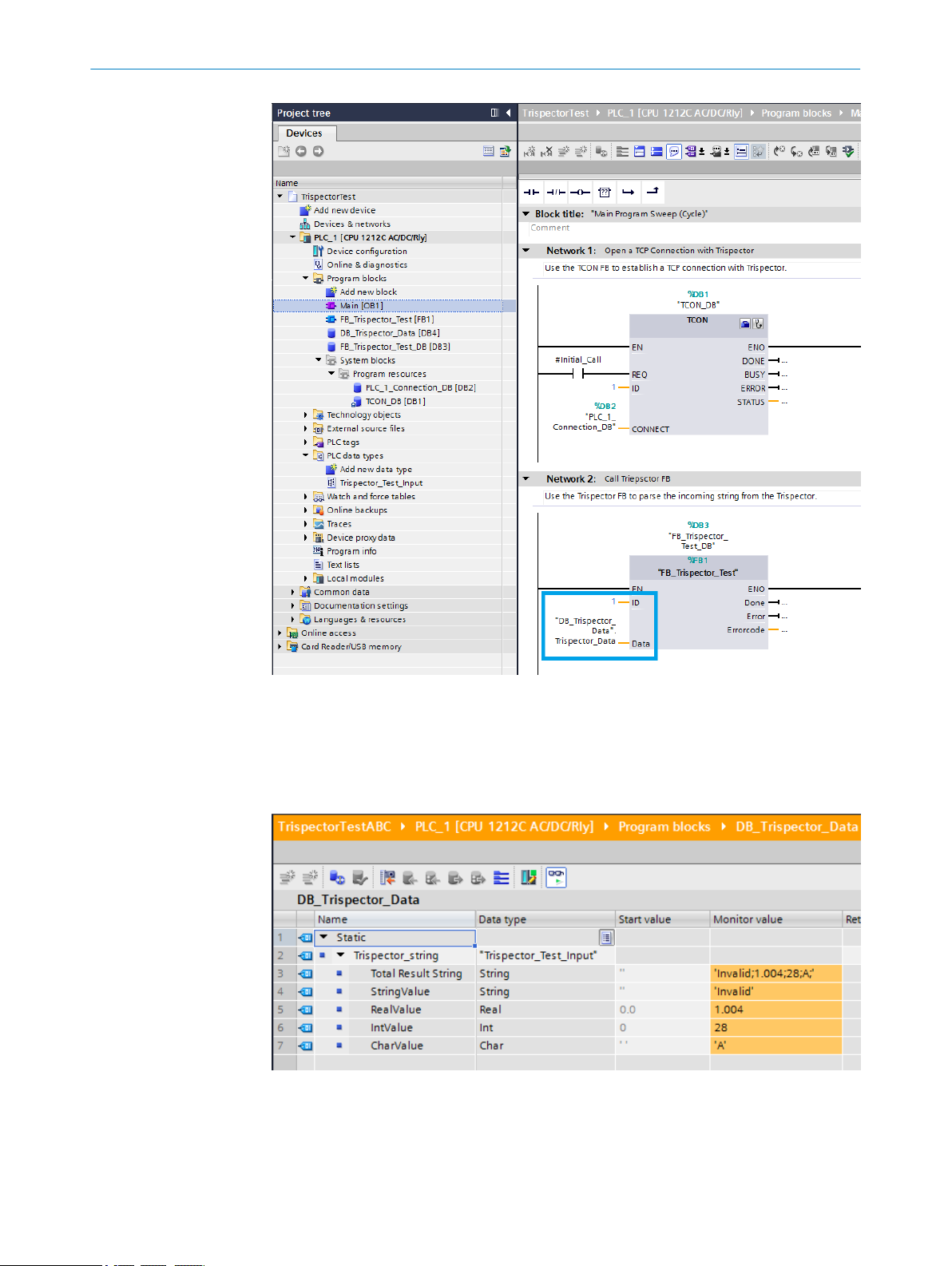

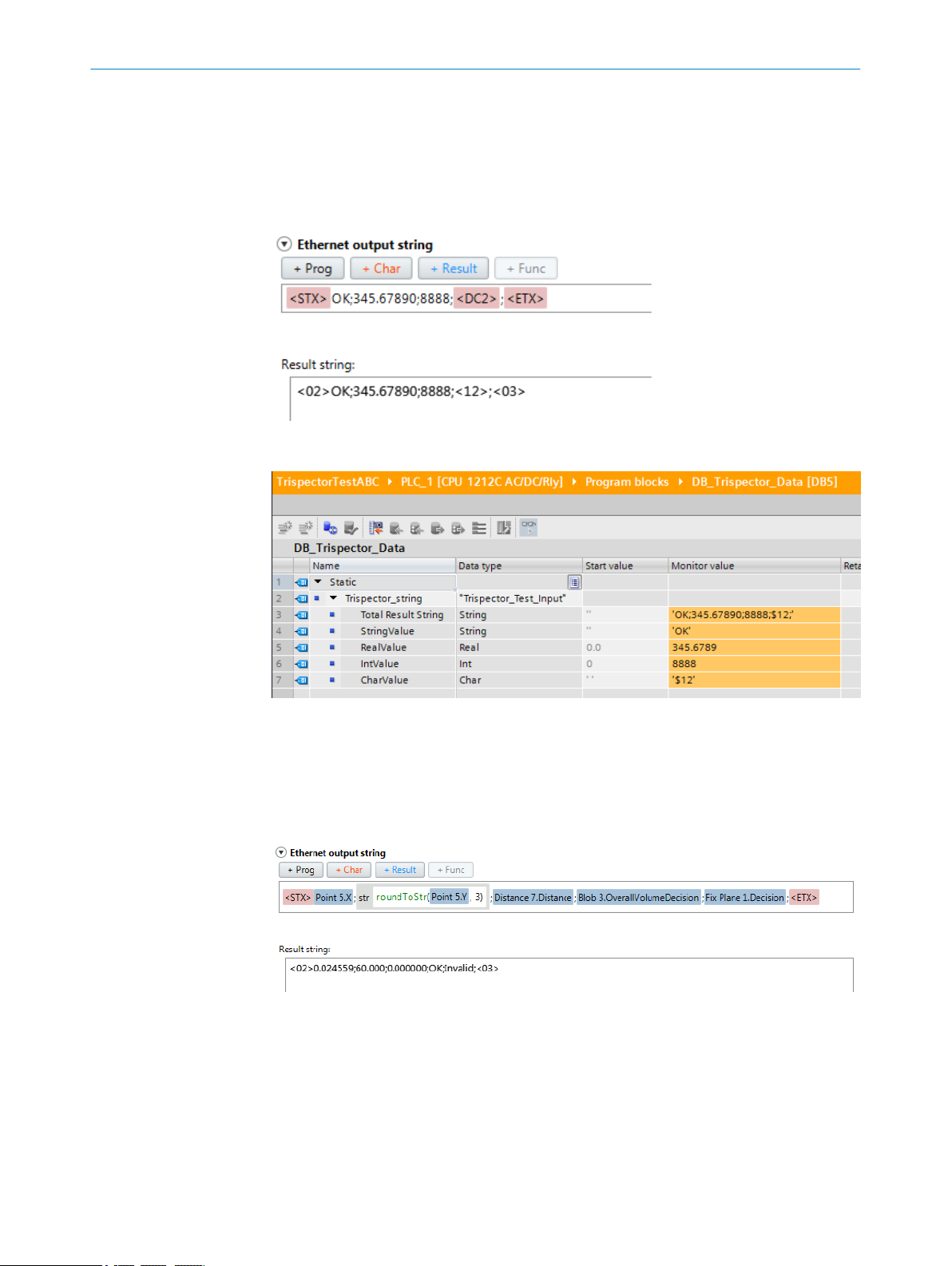

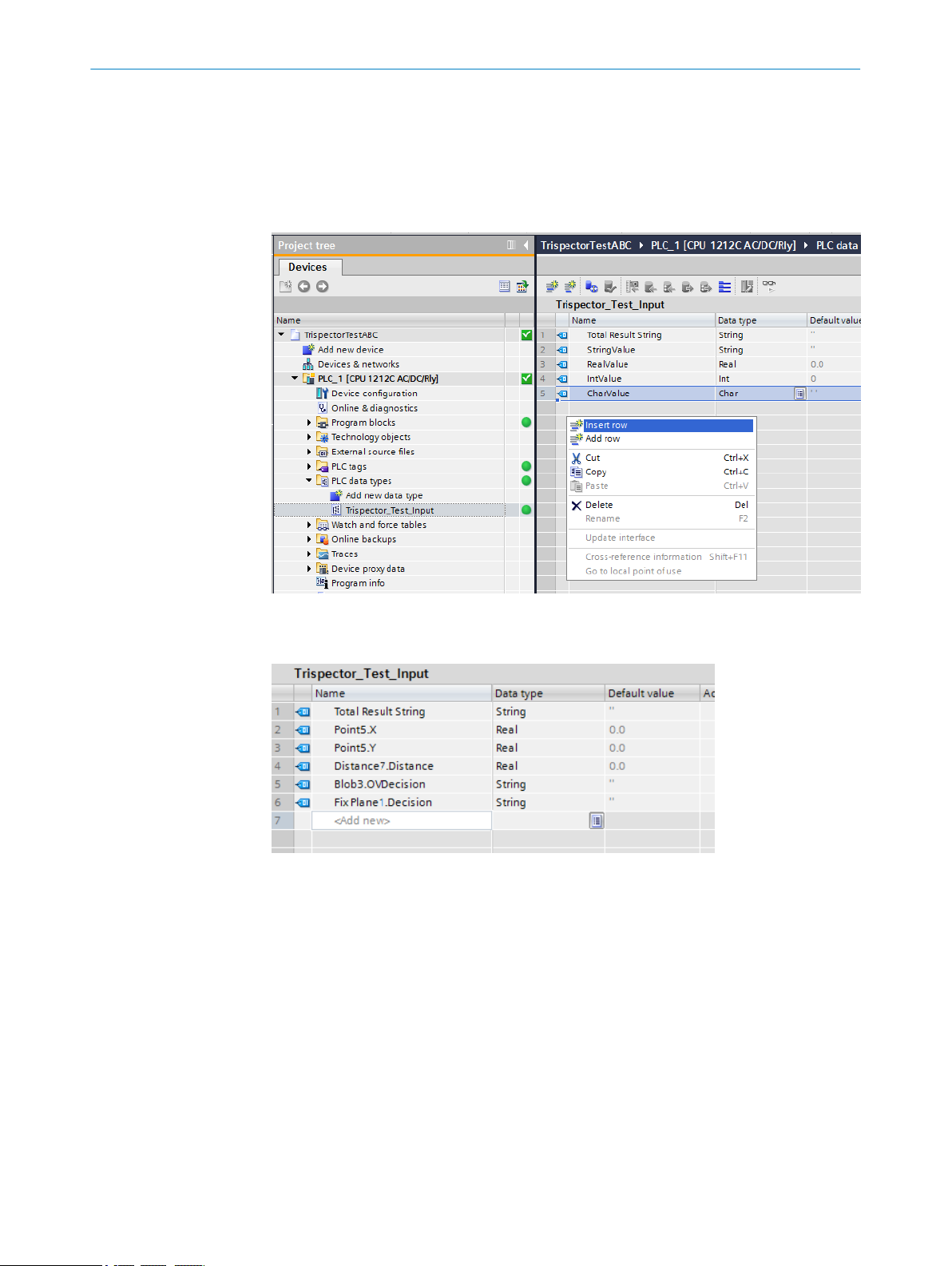

The following steps describe how to use tools to count the number of chocolates in a