Page 1

I

TRANSIC Extractive

MMMOPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MMM

Page 2

Beschriebenes Produkt

Produktname: TRANSIC Extractive

Dokument ID.: 8021262

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Telefon: +49 7641 469-0

Fax: +49 7641 469-1149

E-Mail: info.pa@sick.de

Production location

SICK AG

Nimburger Str. 11 · 79276 Reute · Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modification, expurgation or translation of this document is prohibited without the express written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved

Original document

This document is an original document of SICK AG.

2

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 3

Content

CONTENT

1 About this Document ................................................................................ 5

1.1 Limitation of Liability....................................................................................... 5

1.2 Purpose of this Document .............................................................................. 5

1.3 Target Group.................................................................................................... 5

1.4 Further Information ......................................................................................... 5

1.5 Additional Technical Documentation ............................................................. 6

1.6 Document Conventions................................................................................... 6

2 Important Safety Instructions .................................................................. 7

2.1 Supplemental Directives................................................................................. 7

2.2 Safety Conventions ......................................................................................... 7

2.3 Warning Signs ................................................................................................. 8

2.4 Mandatory symbols conventions.................................................................... 8

2.5 Safety Messages .............................................................................................8

2.6 Notices............................................................................................................. 9

2.7 Intended Use .................................................................................................10

2.7.1 RoHS Directive ..............................................................................10

2.7.2 Measured components.................................................................10

2.7.3 Measuring range...........................................................................10

2.8 Requirements for the Qualification of Personnel ........................................10

3 System Description .................................................................................11

3.1 Characteristics ..............................................................................................11

3.2 Gas Flow Diagram .........................................................................................12

3.3 Method of Operation .....................................................................................13

3.3.1 Settings .........................................................................................13

4 Installation ................................................................................................15

4.1 Mounting Plate ..............................................................................................15

5 Operation ..................................................................................................17

5.1 Interfaces ......................................................................................................17

5.1.1 Keypad ..........................................................................................17

5.2 Maintenance Interface..................................................................................18

6 Maintenance............................................................................................. 19

7 Technical Data .........................................................................................21

8 Disposal..................................................................................................... 23

8021262/V1-0/2017-04| SICK OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

3

Page 4

CONTENT

4

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 5

1About this Document

Note

This document regarding the TRANSIC Extractive:

● Contains information required during the life cycle of the System.

● Is available to all those people who work with the System.

Please read this document carefully and make sure that you understand the

content fully before working with the System.

1.1 Limitation of Liability

Note

Applicable standards and regulations, the latest state of technological development and many years of knowledge and experience have all been taken into

account, when assembling the data and information contained in this document.

The manufacturer accepts no liability for damage caused by:

● Failing to observe this document.

● Non-compliance of notices and regulations.

● Unauthorized installation and mounting of the TRANSIC Extractive.

● Arbitrary modifications.

● Use of unauthorized spare parts, consumables and accessories.

With special variants, where optional extras have been ordered, or owing to the

latest technical changes, the actual scope of delivery may vary from the features and illustrations shown here.

ABOUT THIS DOCUMENT 1

1.2 Purpose of this Document

This document describes the TRANSIC Extractive.

1.3 Target Group

This document is intended for qualified personnel which are authorized to perform installation, operation, and maintenance on the TRANSIC Extractive.

1.4 Further Information

Special local conditions

Follow all local laws, technical rules, and company-internal operating directives applicable

at the respective installation site of the TRANSIC Extractive.

Preserving the documents

This document and the additional technical documentation and information must be:

● Available for reference

● Passed on to new owners

8021262/V1-0/2015-09| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1.5 Additional Technical Documentation

● Operating instructions of the following system components:

Component Manufacturer

OI_TRANSIC151LP

● Technical System-Documentation (EPLAN) contains:

–Technical Data

–Wiring diagram

–Gas flow diagram

1.6 Document Conventions

▸ Instruction

Refer to another document.

All units of measurement in this document are originally metric units.

Subject to change without notice. Images might differ from actual design.

SICK

6

8021262/V1-0/2015-09| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 7

2Important Safety Instructions

Note

Read and follow all safety instructions in this document.

2.1 Supplemental Directives

WARNING

▸ Read and understand this document carefully prior to working on the

system or any other of its components.

▸ Only fully trained professionals from the respective field are permit-

ted to work on the system.

▸ Follow all operational procedures.

▸ Follow all local regulations.

▸ Follow all local regulations regarding working with gas and electrical

components.

▸ Entry to system area is only permitted to authorized personnel.

▸ Wear personal protective equipment (PPE) while on the system area.

IMPORTANT SAFETY INSTRUCTIONS 2

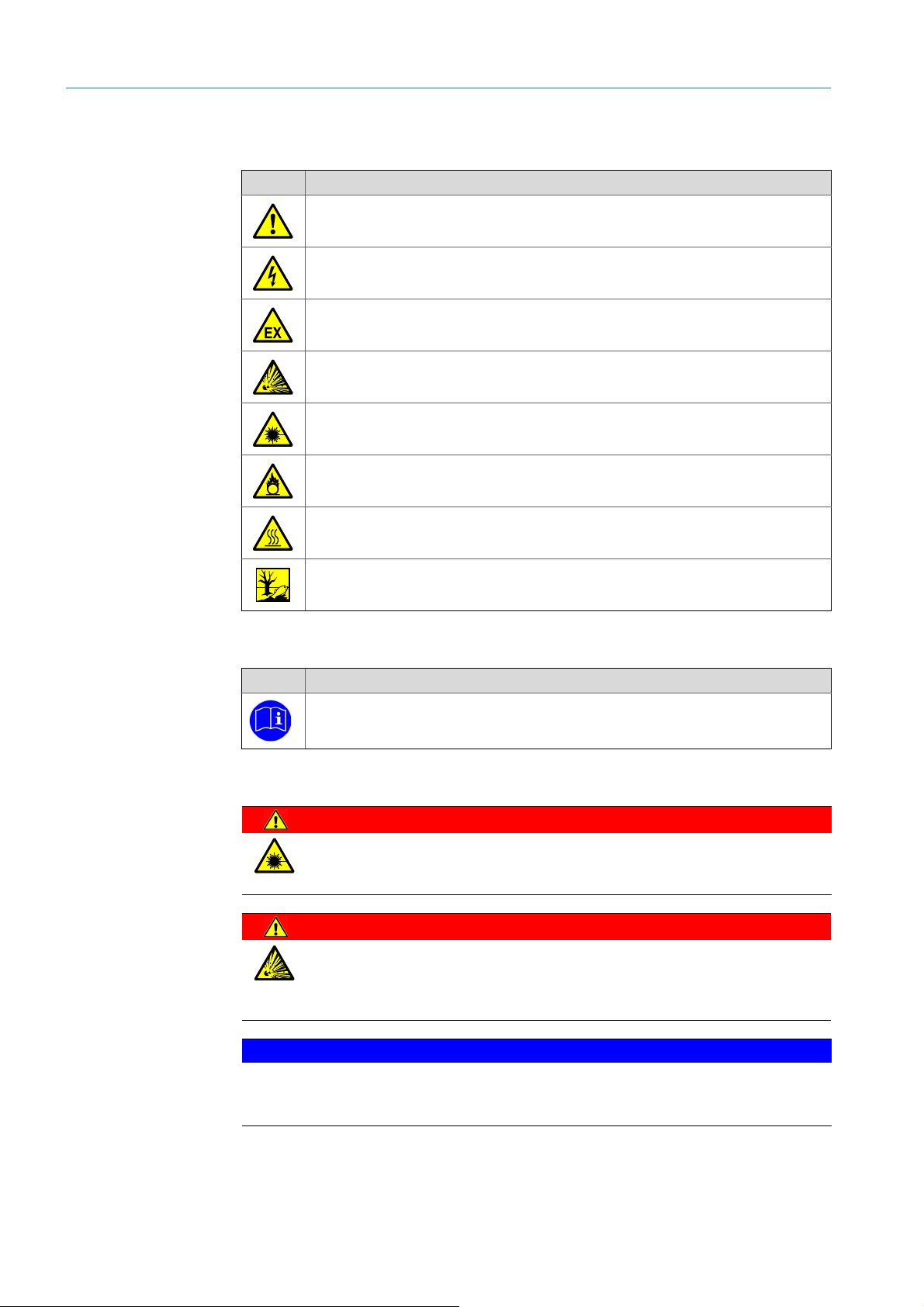

2.2 Safety Conventions

Symbols on system and system components labels, safety labels and in safety messages

inside this document are according to the current standards.

The following conventions for signal words are used in this document, complying with

ANSI Z535.6:

NOTICE

NOTICE is used to address practices not related to personal injury but to property dam-

ages.

DANGER

DANGER indicates a hazardous situation with a high risk level, which if

not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation with a middle risk level,

which if not avoide d, could result in death or serious inju r y.

CAUTION

CAUTION indicates a potentially dangerous situation with a low risk

level, which if not avoided may lead to minor or moderates injuries.

Note

Indicates important information and useful hints.

8021262/V1-0/2017-04| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

7

Page 8

2 IMPORTANT SAFETY INSTRUCTIONS

2.3 Warning Signs

Sign Significance

Hazard (general)

Hazard by voltage

Hazard in potentially explosive areas

Risk of explosion

Hazard by laser

Hazard by oxidizing substances

Hazard by hot surfaces

Hazard for the environment, nature and organic life

2.4 Mandatory symbols conventions

Symbol Significance

Refer to another document

2.5 Safety Messages

DANGER

LASER Protection Class 1

Hazard by laser. Serious injuries.

▸ Do not place reflective objects directly into the probe.

DANGER

RISK BY OXIDATION PROCESS

Death or serious injury will occur.

▸ Check ambient conditions before start installation and/or commis-

sioning.

NOTICE

ELECTROSTATIC CHARGE

Note the ESD regulations. Do not touch components inside the enclosure, these can be

damaged.

8

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 9

IMPORTANT SAFETY INSTRUCTIONS 2

DANGER

HAZARDOUS VOLTAGE

The system is supplied with mains voltage from the grid. Danger of

electrocution - contact will cause electric shock, burn or death.

▸ Only qualified personnel can perform electrical works on the system.

▸ Always exercise caution when handling cables and connectors.

▸ Before working on the system:

▸ Follow operational procedures such as Lockout-Tagout.

▸ Check that there is no residual voltage by measuring AC voltages.

WARNING

FLAMMABLE OR EXPLOSIVE GAS MIXTURE

Serious injuries.

▸ To avoid inflammable or explosive gas mixtures we recommend to

use only Nitrogen (N

) as propellant gas.

2

▸ If an inflammable or explosive gas mixtures can not be avoided

ensure proper treatment or disposal (exhaust) after sample gas outlet.

▸ If calibrating the TRANSIC151LP with ambient air, ensure proper

treatment or disposal (exhaust) after sample gas outlet.

2.6 Notices

NOTICE

SYSTEM WARRANTY

If you disregard the safety and hazard precautions, no warranty claim for damages will be

honored. If you alter parts of the System by your own initiative, all warranty claims will be

forfeited.

▸ Regard all safety and hazard precautions.

▸ Use only material supplied or approved by SICK for the system maintenance.

▸ Do not alter the system.

NOTICE

SYSTEM DAMAGE

Damage to any system components or parts can lead to malfunction of the entire System. Do not ignore damaged or broken parts, refer to this manual and contact SICK support immediately.

▸ Do not install damaged parts.

8021262/V1-0/2017-04| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

9

Page 10

2 IMPORTANT SAFETY INSTRUCTIONS

2.7 Intended Use

The TRANSIC Extractive is a stationary system and serves continuous measurement of oxygen in the industrial sector.

The sample gas is taken from a sampling point and feed through the gas analyzer

(extractive measurement).

Operation in explosion-hazard areas

Suitable for areas according to ATEX and IECEx (IEC 60079-10).

For further and detailed information about intended use of the TRNSIC151LP,

refer to the respective Operating Instructions.

2.7.1 RoHS Directive

This product is designed for applications in large industrial plants according to

Article 2 (4) e, RoHS 2011/65/EU and can therefore only be used in such systems.

The product is neither suitable nor approved for use outside of theses systems.

SICK cannot assume any kind of warranty or liability for use outside of these systems.

2.7.2 Measured components

Gases O2 (Oxygen)

2.7.3 Measuring range

Component Range Unit

O

2

0 ... 21 %

0 ... 100 %

ambient measurement 2 ... 21 %

2.8 Requirements for the Qualification of Personnel

Note

Qualified personnel

● Qualified personnel have the specialist training, skills, and experience, as

well as knowledge of the relevant regulations and standards, to be able to

perform tasks delegated to them and to detect and to avoid any potential

dangers independently.

● Electricians have the specialist training, skills, and experience, as well as

knowledge of the relevant standards and provisions to be able to carry out

work on electrical systems and to detect and avoid any potential dangers

independently.

10

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 11

3 System Description

3.1 Characteristics

The TRANSIC Extractive is an analysis system to measure and monitor oxygen.

The TRANSIC Extractive works extractive, i.e. the gas to be measured is taken from the gas

duct using a gas extraction probe or probes and fed to the analysis system via sample gas

line(s).

SYSTEM DESCRIPTION 3

Fig. 1: TRANSIC Extractive system components

Legend

TRANSIC151LP

1

2

Needle valve

3

Flow meter

4

Manual valve sample gas/reference gas

5

Sample and propellant gas outlet

6

Voltage supply unit

7

Injector pump

8

Propellant gas inlet

9

Pressure reducer

10

Grounding point

8021262/V1-0/2017-04| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

11

Page 12

3 SYSTEM DESCRIPTION

3.2 Gas Flow Diagram

12

Fig. 2: TRANSIC Extractive gas flow diagram

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 13

3.3 Method of Operation

The sample gas is fed through gas analyzer and flow meter via injector pump. The sample

gas and the propellant gas are mixed in the injector pump. This gas mixture is fed to the

sample gas outlet.

3.3.1 Settings

The sample flow rate can be adjusted via needle valve and/or propellant gas pressure

reducer:

▸ Needle valve open - higher sample gas flow.

▸ Needle valve close - lower sample gas flow.

▸ Higher propellant gas pressure - higher sample gas flow.

▸ Lower propellant gas pressure - lower sample gas flow.

▸ For calibration with ambient air or reference gases sample gas inlet can be switched via

manual valve.

SYSTEM DESCRIPTION 3

WARNING

FLAMMABLE OR EXPLOSIVE GAS MIXTURE

Serious injuries.

▸ To avoid inflammable or explosive gas mixtures we recommend to

use only Nitrogen (N

) as propellant gas.

2

▸ If an inflammable or explosive gas mixtures can not be avoided

ensure proper treatment or disposal (exhaust) after sample gas outlet.

▸ If calibrating the TRANSIC151LP with ambient air, ensure proper

treatment or disposal (exhaust) after sample gas outlet.

For further and detailed information about calibration of the TRANSIC151LP,

refer to the respective Operating Instructions.

8021262/V1-0/2017-04| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

13

Page 14

3 SYSTEM DESCRIPTION

14

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 15

4 Installation

4.1 Mounting Plate

INSTALLATION 4

Fig. 3: Mounting plate dimensions/connections

▸ Appropriate installation site:

–Wall

–Frame

–Rack

▸ Appropriate fixing material

–Bolts

–Nuts

– Dowels

–Anchoring

▸ (A) Grounding point

▸ Line connectors

– (B) Sample and reference gas connectors: Swagelok 6 mm (2x)

– (C) Sample gas exhaust: Swagelok 10 mm

– (D) Propel lant gas inle t : Swagelo k 6 m m

8021262/V1-0/2017-04| SICK OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

15

Page 16

4 INSTALLATION

16

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 17

5Operation

5.1 Interfaces

● Keypad

● Maintenance interface

5.1.1 Keypad

A display and four pushbuttons are located on the front enclosure panel.

The measured oxygen is shown on the display. LEDs signal the operating mode.

Characteristics Calibration of:

● Process pressure

● Humidity

● Carbon dioxide content

OPERATION 5

Note

Changes to parameters are password protected. The password allows access

for 30 minutes after entry.

Fig. 4: Keypad (source: TRANSIC151LP operating instructions)

Display modes

Display mode Display/LED Process

Start

(duration: 2,5 minutes)

Software Version

Self test

Pass

Normal operation Green LED remains on

Measured oxygen value

Self-test starts

Information: Self-test running

Warming up phase starts

Measured oxygen value is

shown continuously

Error state Red LED remains on

Error state number

Warning Yellow LED flashes

Measured oxygen value is dis-

Select function “Err“ in the

menu

played

8021262/V1-0/2017-04| SICK OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

17

Page 18

5 OPERATION

5.2 Maintenance Interface

The maintenance interface is located on the connector block above the display.

Functions

● Maintenance

● Calibration

● Changing parameters

● Configuration of alarm thresholds

For further and detailed information about operation, maintenance, and calibration of the TRANSIC151LP, refer to the respective Operating Instructions.

18

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 19

6 Maintenance

MAINTENANCE 6

For further and detailed information about maintenance of the TRANSIC151LP,

refer to the respective the Operating Instructions.

8021262/V1-0/2017-04| SICK OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

19

Page 20

6 MAINTENANCE

20

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 21

7Technical Data

The exact device specifications and performance data of the product may deviate from the

information provided here, and depends on the respective application and customer specifications.

TECHNICAL DATA 7

Measured value O

2

Max. number of measured values 1

Measuring principle Diode laser spectroscopy (TDLS)

Measuring ranges O2: 0 ... 5 Vol.-% / 0 ... 100 Vol.-%

Response time (t 90)< 10 s

Accuracy < 0,2 Vol.-%

Zero point drift ± 0,1 Vol.-% per year

Process temperature -20 °C ... 200 °C

(other temperature ranges on request)

Process pressure 800 hPa ... 15.000 hPa

(further pressure ranges on request)

Ambient temperature -20 °C ... +60 °C

Storage temperature -20 °C ... +80 °C

Ex-approvals - IECEx Sender/receiver unit:

II 1/2G Ex ib IIB T4 Gb; II 2D Ex ib tb IIIC T85°C Db

Measuring probe:

II 1/2G Ex op is IIB T4 Ga; II 2D Ex ib tb IIIC T85°C Db

Power supply:

II 2G Ex e mb [ib] IIB T4 Gb; II 2D Ex tb [ib] IIIC T85°C Db

Ex-approvals - ATEX Sender/receiver unit:

II 1/2G Ex ib IIB T4 Gb; II 2D Ex ib tb IIIC T85°C Db

Measuring probe:

II 1/2G Ex op is IIB T4 Ga; II 2D Ex ib tb IIIC T85°C Db

Power supply:

II 2G Ex e mb [ib] IIB T4 Gb; II 2D Ex tb [ib] IIIC T85°C Db

Ex-approvals - NEC/CEC (US/CA) Sender/receiver unit: Class I, Division 2, Group A, B, C, D T4

Measuring probe: Class I, Division 1 + 2, Group A, B, C, D T4

Electrical safety CE

Protection class IP66

Analog outputs 1 output:

0/4 ... 20 mA, 500

1 output:

0/4 ... 20 mA, 200

Only for ATEX/IECEx version TRANSIC151LP.

Digital outputs 1 relay contact:

30 V AC, 1 A/60 V DC, 0,5 A

1 NAMUR output:

Only for ATEX/IECEx version TRANSIC151LP.

Interfaces RS-485 (not for ATEX/IECEx version)

RS-232c (Service interface; not in ATEX/IECEx design)

USB (not approved for Ex-applications)

Dimensions (W x H x D)

500 x 500 x 400 mm / 19.68 x 19.68 x 15.74 in

(depending on version)

Weight (depending on configuration) 15 ... 30 kg / 33.06 ... 66.13 lbs

8021262/V1-0/2017-04| SICK OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

21

Page 22

7 TECHNICAL DATA

Power supply - Voltage 24 V DC

Power supply - Current consumption < 500 mA

Power consumption < 6 W

Corrective functions Adjustment with ambient air or test gases

Test functions Contamination check

TRANSIC151LP: 21,6...26,4 V

For ATEX/IECEx version via TSA151, a PELV power supply is

mandatory

TRANSIC151LP: <

240 mA

(depending on version)

TRANSIC151LP: <

5,2 W

(depending on version)

22

8021262/V1-0/2017-04| SICKOPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

Page 23

8 Disposal

DISPOSAL 8

Note

Note the relevant currently valid local and legal environment regulations and

directives for the disposal of industrial and electronic waste.

NOTICE

DISPOSAL OF BATTERIES, ELECTRIC- AND ELECTRONIC DEVICES

▸ According to the European Directives, batteries, accumulators and electrical or elec-

tronic devices must not be disposed of in general waste.

▸ The owner is obliged by law to return this devices at the end of their life to the respec-

tive public collection points.

▸ This symbol on the product, its package or in this document, indicates that a product is

subject to these regulations.

The following assemblies may contain substances which must be disposed of separately:

● Electronic:

Capacitors, accumulators, batteries.

● Displays:

Liquid in the LC-Displays.

● Sample gas lines:

Toxic substances of the sample gas could be penetrated or adhered into soft materials

of the gas path (e. g. hoses, seal rings). Please check if such effects must be taken into

account during disposal.

● Analyzer modules:

For detailed information to the disposal of analyzer modules, refer to the respective Operating Instructions.

8021262/V1-0/2017-04| SICK AG OPERATING INSTRUCTIONS | TRANSIC Extractive

Subject to change without notice

23

Page 24

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 211 5301-301

E-Mail info@sick.de

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail office@sick.hu

India

Phone +91 22 4033 8333

E-Mail info@sick-india.com

Israel

Phone +972 4 6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 274341

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +6 03 8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 472 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 30 2044 000

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7 495 775 05 30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 788 49

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2645 0009

E-Mail Ronnie.Lim@sick.com

Turkey

Phone +90 216 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 4 88 65 878

E-Mail info@sick.ae

United Kingdom

Phone +44 1727 831121

E-Mail info@sick.co.uk

USA

Phone +1 800 325 7425

E-Mail info@sick.com

Vietnam

Phone +84 945452999

E-Mail Ngo.Duy.Linh@sick.com

Further locations at www.sick.com

Operating Instructions/TRANSIC Extractive/8021262/V1-0/2017-04

SICK AG|Waldkirch |Germany|www.sick.com

Loading...

Loading...