Page 1

TR110 Lock

Safety locking device

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

TR110 Lock

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Scope......................................................................................................... 5

1.2 Target groups of these operating instructions........................................ 5

1.3 Additional information.............................................................................. 5

1.4 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Requirements for the qualification of personnel.................................... 7

3 Product description........................................................................... 8

3.1 Structure and function............................................................................. 8

3.2 Product characteristics............................................................................ 9

3.3 Manual unlocking..................................................................................... 12

4 Project planning................................................................................ 15

4.1 Manufacturer of the machine.................................................................. 15

4.2 Operator of the machine.......................................................................... 15

4.3 Design........................................................................................................ 15

4.4 Integration in the electrical control system............................................. 17

4.5 Testing plan............................................................................................... 23

5 Mounting............................................................................................. 24

5.1 Safety......................................................................................................... 24

5.2 Changing the actuation direction............................................................. 24

5.3 Mounting the safety switch...................................................................... 25

5.4 Mounting straight and angled actuators................................................. 25

5.5 Mounting the radius actuator.................................................................. 26

5.6 Mounting the escape release.................................................................. 26

5.7 Mounting the emergency unlocking........................................................ 27

5.8 Mounting the cover caps.......................................................................... 27

5.9 Removing the cover caps......................................................................... 28

6 Electrical installation........................................................................ 29

6.1 Safety......................................................................................................... 29

6.2 Notes on cULus......................................................................................... 29

6.3 Device connection.................................................................................... 29

6.4 Connection of a safe series connection.................................................. 32

7 Commissioning.................................................................................. 35

7.1 Switching on.............................................................................................. 35

7.2 Teach-in..................................................................................................... 35

7.3 Testing....................................................................................................... 37

7.4 Regular thorough check........................................................................... 38

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

3

Page 4

CONTENTS

8 Operation............................................................................................ 39

8.1 Actuating the mechanical unlocking mechanism................................... 39

8.2 Actuating the emergency release............................................................ 39

8.3 Actuating the escape release.................................................................. 40

9 Troubleshooting................................................................................. 42

9.1 Safety......................................................................................................... 42

9.2 System status........................................................................................... 42

10 Decommissioning............................................................................. 44

10.1 Disposal..................................................................................................... 44

11 Technical data.................................................................................... 45

11.1 Data sheet................................................................................................. 45

11.2 Connecting cables.................................................................................... 48

11.3 Safety switch dimensional drawings....................................................... 49

11.4 Actuator dimensional drawings................................................................ 55

11.5 Dimensional drawings of the mounting bracket..................................... 60

12 Ordering information........................................................................ 62

12.1 Scope of delivery....................................................................................... 62

12.2 Ordering information................................................................................. 62

13 Accessories........................................................................................ 63

13.1 Actuator..................................................................................................... 63

13.2 Connectivity............................................................................................... 63

13.3 Additional accessories............................................................................. 65

14 Annex.................................................................................................. 66

14.1 Compliance with EU directives................................................................. 66

4

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Scope

These operating instructions are valid for the TR110 Lock safety locking device.

This document is included with the following SICK part numbers (this document in all

available language versions):

8023116

1.2 Target groups of these operating instructions

Some chapters of these operating instructions are intended for certain target groups.

However, the entire operating instructions are relevant for intended use of the product.

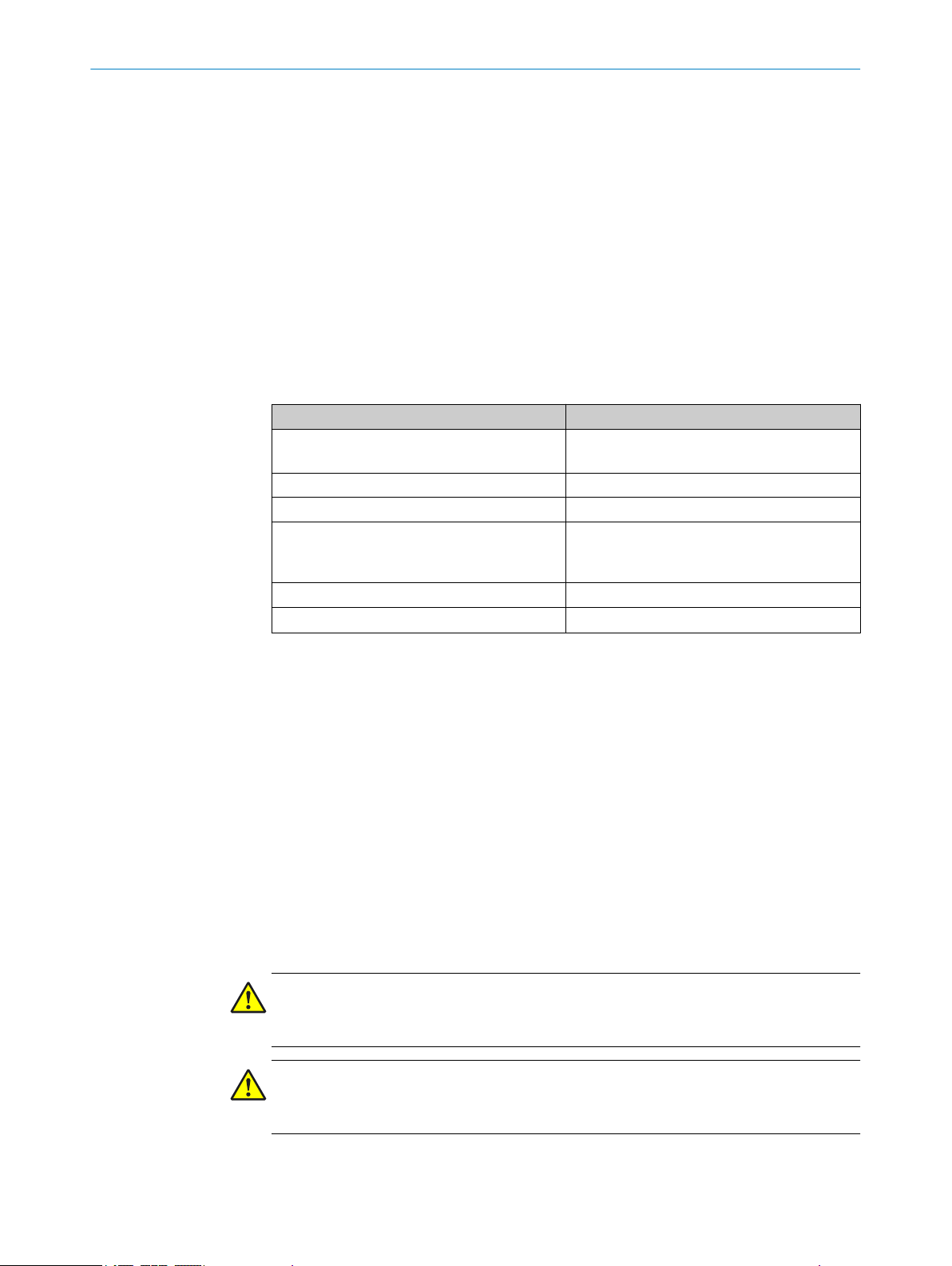

Table 1: Target groups and selected chapters of these operating instructions

Target group Chapter of these operating instructions

Project developers (planners, developers,

designers)

Installers "Mounting", page 24

Electricians "Electrical installation", page 29

Safety experts (such as CE authorized repre‐

sentatives, compliance officers, people who

test and approve the application)

Operators "Troubleshooting", page 42

Maintenance personnel "Troubleshooting", page 42

ABOUT THIS DOCUMENT 1

"Project planning", page 15

"Technical data", page 45

"Project planning", page 15

"Commissioning", page 35

"Technical data", page 45

1.3 Additional information

www.sick.com

The following information is available on the Internet:

This document in other languages

•

Data sheets and application examples

•

CAD data and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery Six steps to a safe machine

•

1.4

Symbols and document conventions

The following symbols and conventions are used in this document:

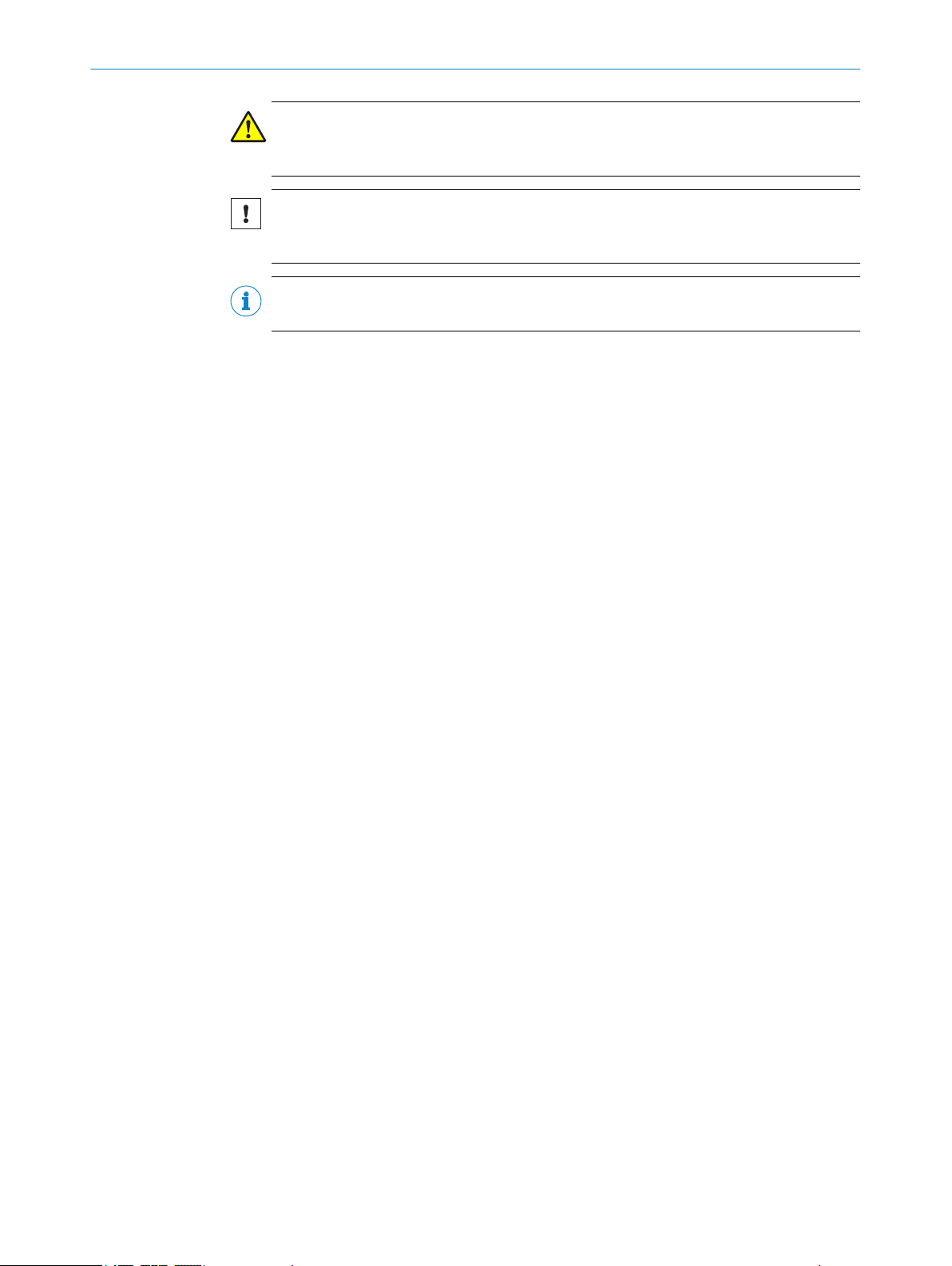

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

LED symbols

The arrow denotes instructions to action.

The check mark denotes the result of an instruction.

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

6

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 General safety notes

The safety locking device must be configured and operated correctly by qualified safety

personnel according to the machine requirements.

2.2 Intended use

When used in conjunction with a movable physical guard and the machine controller,

the safety locking device prevents the protective device from being opened while a dan‐

gerous machine function is being executed.

The safety locking device may only be used on the machine on which it was configured,

mounted, installed, and commissioned by qualified safety personnel in accordance with

these operating instructions.

Incorrect use, improper modification of or tampering with the safety locking device will

invalidate any warranty from SICK AG; in addition, any responsibility and liability of SICK

AG for damage and secondary damage caused by this is excluded.

NOTE

The safety locking device is also suitable for process protection.

SAFETY INFORMATION 2

2.3 Requirements for the qualification of personnel

The safety locking device must be configured, installed, connected, commissioned, and

serviced only by qualified safety personnel.

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting, electrical installation, and commissioning

For the task, a person is considered qualified when he/she has the expertise and expe‐

rience in the relevant field and is sufficiently familiar with the application of the protec‐

tive device on the machine to be able to assess whether it is in an operationally safe

state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

7

Page 8

3 PRODUCT DESCRIPTION

3 Product description

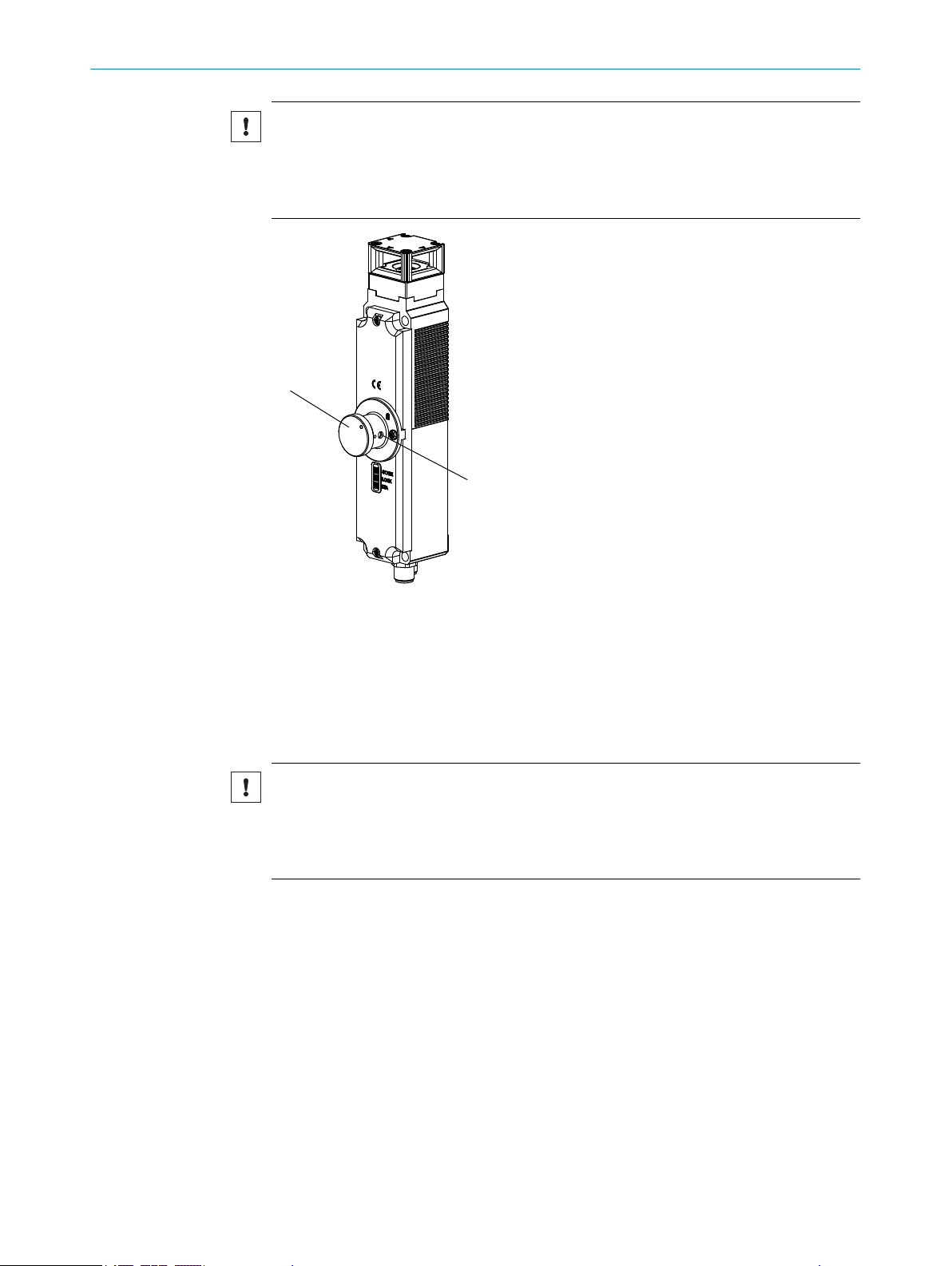

3.1 Structure and function

Structure

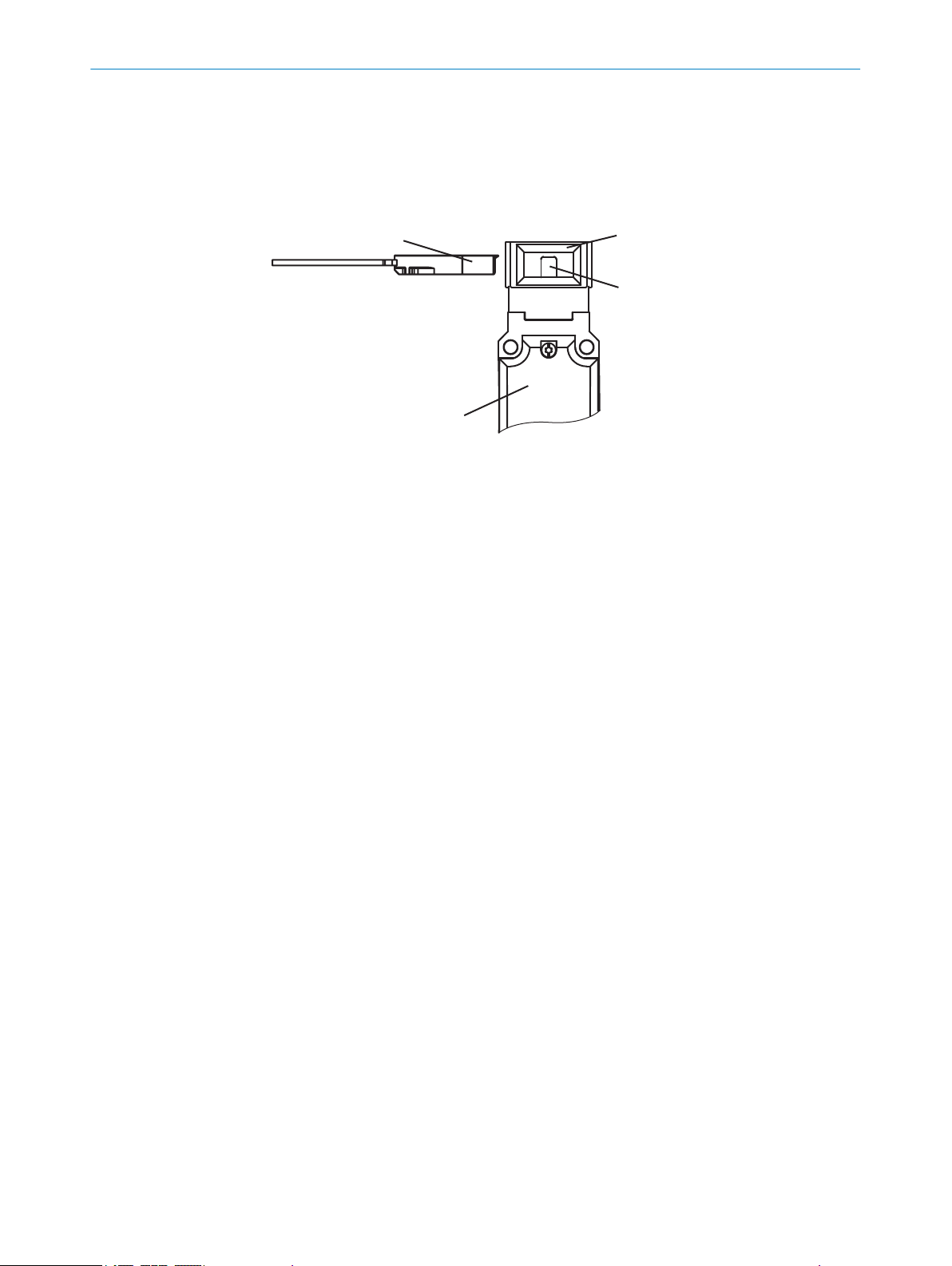

Figure 1: Structure of the TR110 Lock safety locking device

Safety switches

1

Coded actuator

2

Actuating head

3

Locking pin

4

The safety locking device is an interlocking device with a locking function. The safety

locking device consists of a safety switch and a coded actuator. The actuator has a high

coding level (uniquely coded).

Function

When the protective device is closed, the actuator is inserted into the actuating head of

the safety switch. In doing so, the locking pin is pressed downward by the actuator. If

the actuator reaches the end position, the locking pin moves into the provided hole of

the actuator.

Further functioning depends on whether the safety locking device is based on the

power to release or the power to lock principle.

In the power to release principle, the inserted actuator is immediately blocked and

•

the locking device is locked (to unlock the locking device, the locking solenoid

must be energized).

In the power to lock principle, the locking solenoid must be energized in order to

•

lock the locking device. If the locking solenoid is not energized, the actuator is only

held in position by retaining force (spring force). The actuator can be pulled out

again by overpowering the retaining force.

Complementary information

The code of the actuator is read out and evaluated using transponder technology.

•

•

If the code is valid, the door application diagnostic output (Out AUX DOOR)

switches to the ON state.

If the locking device is locked, the safe output signal switching devices (OSSD) are

switched to the ON state. In addition, the locking function application diagnostic

output (Out AUX LOCK) switches to the ON state.

8

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 9

If the locking device is locked, the actuator cannot be removed from the actuating

•

head.

The locking device can only be locked when the protective device is closed (pre‐

•

vention of incorrect closing).

3.2 Product characteristics

3.2.1 Product variants

Overview

The safety locking device is delivered with or without pushbuttons. You will find an

overview of important distinguishing features of the variants in the following.

PRODUCT DESCRIPTION 3

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

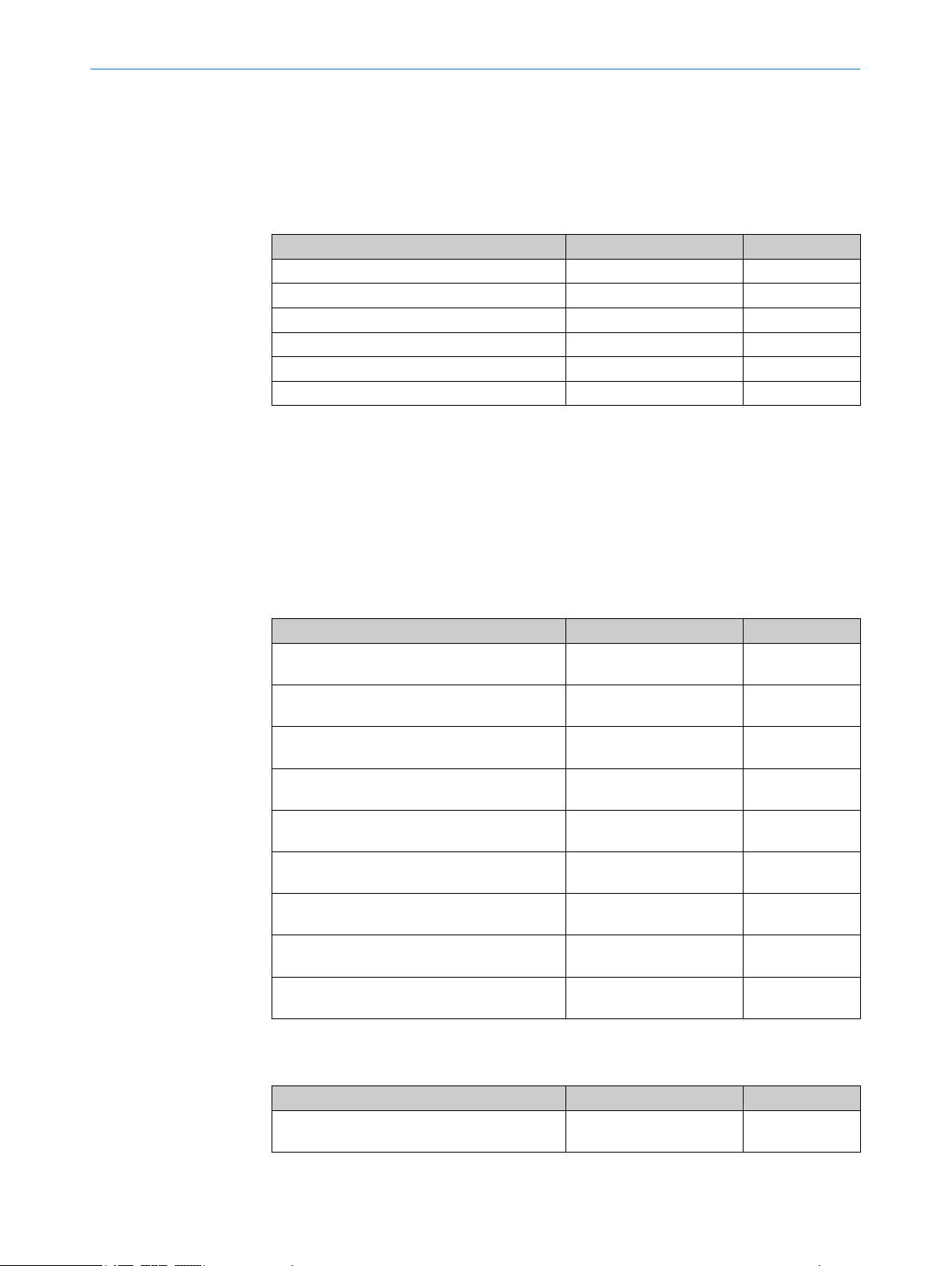

Figure 2: Device variants

TR110 Lock

1

TR110 Lock with pushbuttons

2

TR110 Lock

The TR110 Lock safety locking device differs between the following variants:

Power to lock principle

•

Power to release principle

•

Power to release principle with escape release

•

The variants also each have the following connection types:

For stand-alone connection, e.g. to a safety controller or a safety relay.

•

For connection to Flexi Loop

•

For OSSD cascading with T-connectors or in the control cabinet

•

TR110 Lock with pushbuttons

The TR110 Lock safety locking device with pushbuttons features two pushbuttons:

9

Page 10

3 PRODUCT DESCRIPTION

•

•

•

The TR110 Lock safety locking device with pushbuttons differs between the following

variants:

•

•

•

Further topics

•

3.2.2 OSSD

Output signal switching device: signal output for the protective device, which is used for

stopping the dangerous movement.

An OSSD is a safety switching output. The functionality of each OSSD is tested periodi‐

cally. OSSDs are always connected in pairs and must undergo dual-channel analysis for

safety reasons. An OSSD pair is formed from 2 OSSDs that are connected and analyzed

together.

The pushbuttons contain single-channel normally open contacts which can be

used to trigger control signals.

LEDs are located in the pushbuttons which can be controlled, e.g. to signal opera‐

tional statuses.

The pushbuttons can be assigned colors using cover caps.

Power to lock principle

Power to release principle

Power to release principle with escape release

"Ordering information", page 62

3.2.3 Application diagnostic outputs

Important information

NOTE

In the case of safety locking devices cascaded with T-connectors, the locking function

application diagnostic output (Out AUX LOCK) cannot be evaluated.

Different application diagnostic outputs

Depending on the device connection, the variants feature various application diagnostic

outputs.

Door application diagnostic output (Out AUX DOOR)

•

Locking device application diagnostic output (Out AUX LOCK)

•

Diagnostic application diagnostic output (Out AUX DIA)

•

3.2.4 Status indicators

The safety locking device indicates status information using multiple LEDs.

10

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 11

PRODUCT DESCRIPTION 3

Figure 3: Status LEDs

STATE

1

LOCK

2

DIA

3

Figure 4: Status LEDs

STATE

1

LOCK

2

DIAG

3

LEDs in the pushbuttons

4

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

11

Page 12

3 PRODUCT DESCRIPTION

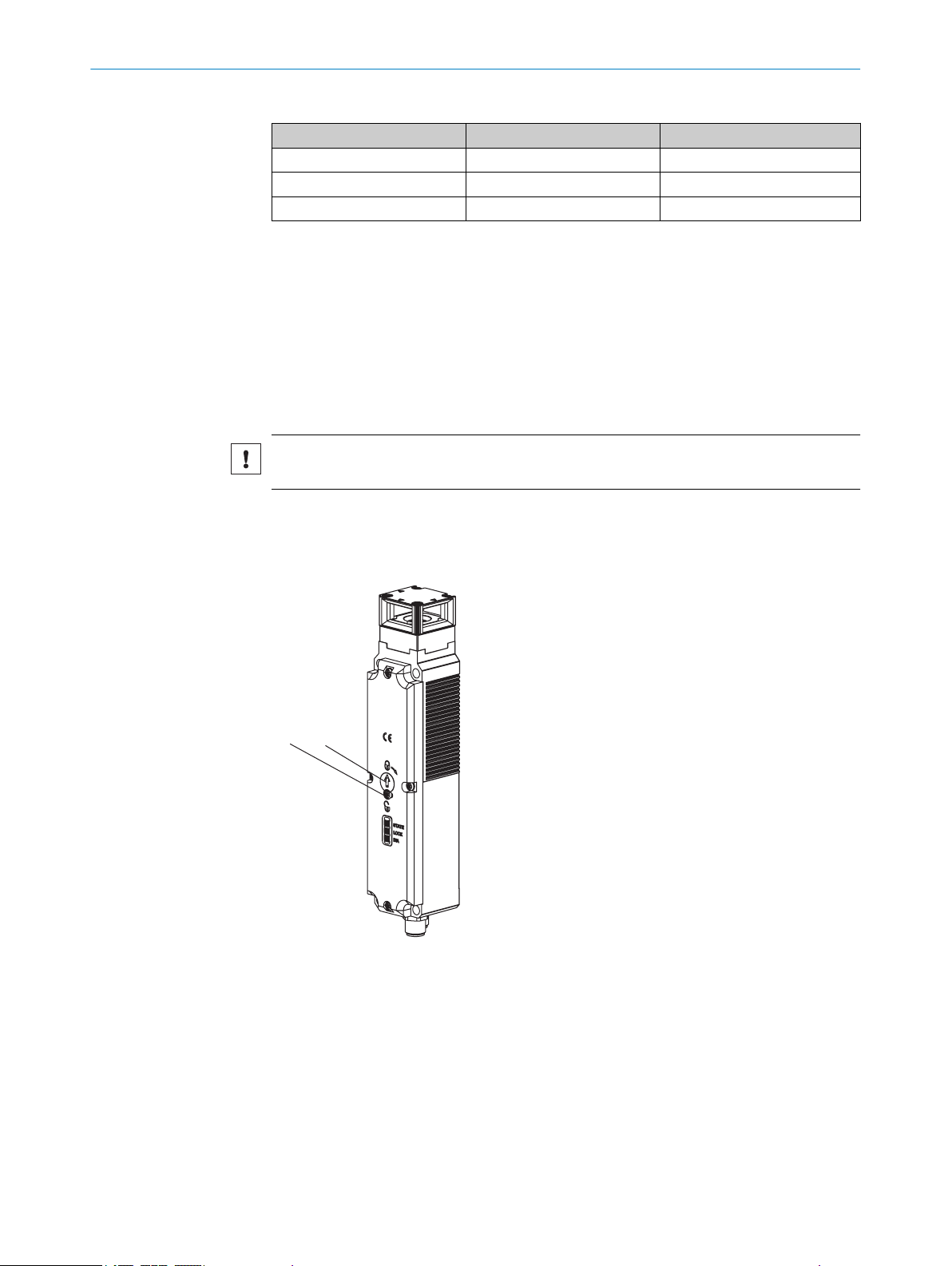

Table 2: Status LEDs

Item Name Color

1

2

3

The variants with 2 pushbuttons feature two LEDs in the pushbuttons. The LEDs of the

pushbuttons are controlled using two inputs.

STATE Green

LOCK Yellow

DIA Red

3.3

Manual unlocking

In some situations, it necessary to unlock the locking device manually (e.g. if faults are

present). When unlocking, the safe output signal switching devices (OSSD) switch to the

OFF status. A stop command must be generated as a result.

Important information

NOTICE

After manual unlocking, a function test must be performed (see "Testing", page 37).

3.3.1 Mechanical unlocking mechanism

Using the mechanical unlocking mechanism, the safety locking device can be unlocked

regardless of the status.

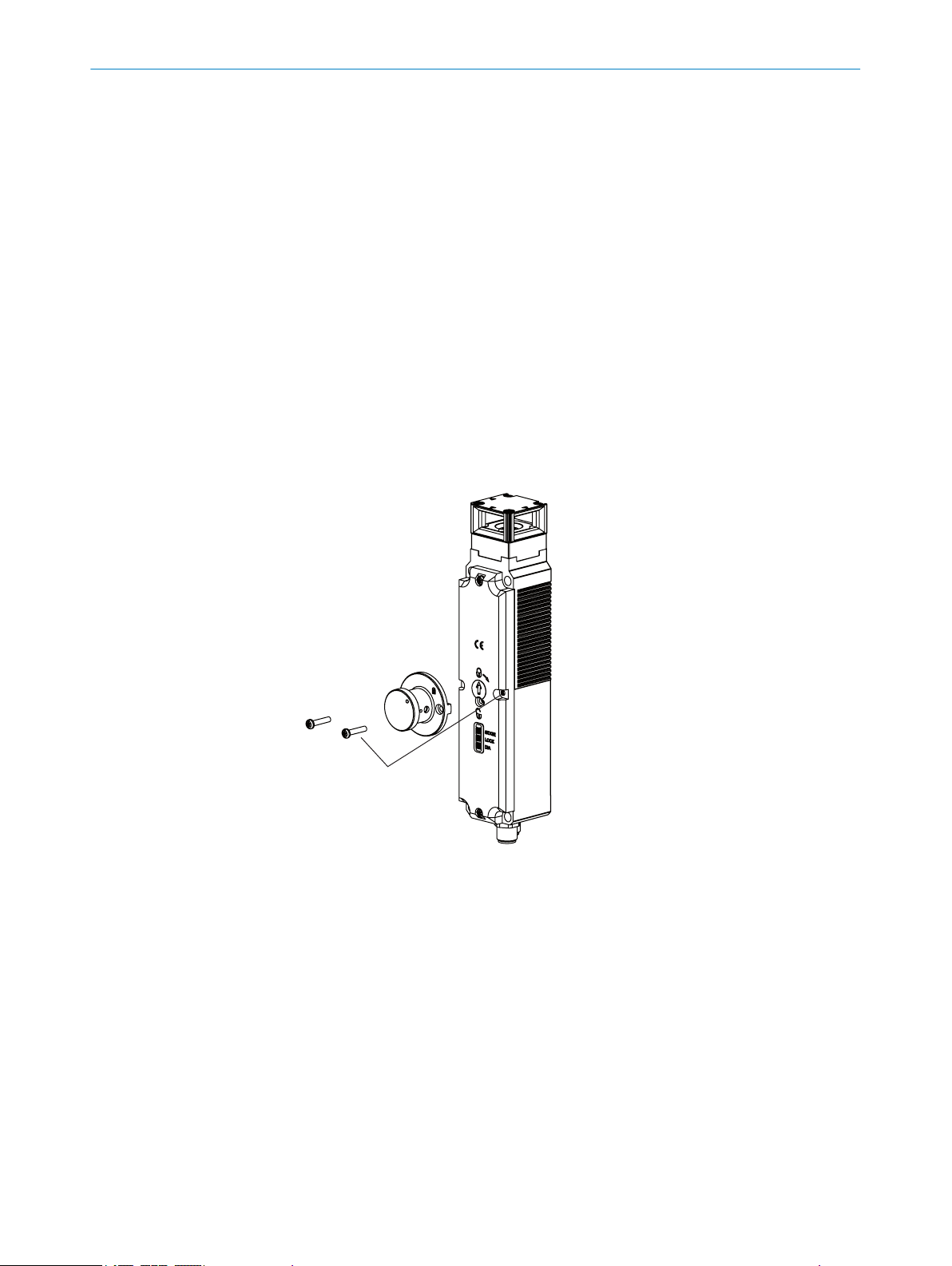

Figure 5: Mechanical unlocking mechanism

1

2

3.3.2 Emergency release

The emergency release can be retrofitted as an accessory. The emergency release can

be used to actuate the mechanical unlocking mechanism without tools.

12

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Retaining screw

Mechanical unlocking mechanism

Subject to change without notice

Page 13

PRODUCT DESCRIPTION 3

NOTICE

The emergency release must be able to be actuated manually outside of the pro‐

•

tected area without tools.

The emergency release must have a label stating that it may only be actuated in

•

an emergency.

3.3.3 Escape release

Figure 6: Emergency release

Emergency release

1

Stop bolt

2

The escape release makes it possible to open a closed protective device without tools

from within the hazardous area.

NOTICE

The escape release must be able to be actuated manually from inside the pro‐

•

tected area without tools.

Mount the escape release so that actuation can only take place from inside of pro‐

•

tected area (hazardous area).

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

13

Page 14

3 PRODUCT DESCRIPTION

Figure 7: Escape release

1

Red button of the escape release

14

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 15

4 Project planning

4.1 Manufacturer of the machine

DANGER

Failure to comply with manufacturer’s obligations

Hazard due to lack of effectiveness of the protective device

Carry out a risk assessment before using the safety locking device.

b

Do not tamper with or modify the components of the safety locking device.

b

Make sure that the safety locking device is only repaired by the manufacturer or by

b

someone authorized by the manufacturer. Improper repair can lead to a loss of the

protective function.

Make sure that switch-on commands which bring about a dangerous state of the

b

machine are not enabled until the protective device is closed and the lock is acti‐

vated.

Make sure that the lock is not deactivated until the dangerous state of the

b

machine has stopped.

Make sure that closing a protective device and activating the lock does not cause

b

a dangerous machine function to start by itself. This must be controlled by a sepa‐

rate start command.

The safety locking device must not be bypassed (contacts jumpered), turned away,

b

removed, or rendered ineffective in any other way. Take measures to reduce

bypassing options as necessary.

PROJECT PLANNING 4

Observe EN ISO 14119 for using interlocking devices associated with physical guards.

4.2 Operator of the machine

DANGER

Failure to observe operator obligations

Hazard due to lack of effectiveness of the protective device

Changes to the machine and changes to the mechanical mounting of the safety

b

locking device necessitate a new risk assessment. The results of this risk assess‐

ment may require the operator of the machine to meet a manufacturer’s obliga‐

tions.

Apart from the procedures described in this document, the components of the

b

safety locking device must not be opened or modified.

Do not carry out any repair work on components. Improper repair of the safety

b

locking device can lead to a loss of the protective function.

Make sure that replacement actuators are not used for bypassing. Restrict access

b

to actuators.

4.3 Design

4.3.1 Selection of the actuator

NOTICE

Selecting unsuitable actuators or improper mounting can damage the device.

Select the right actuator (see table 26).

b

Pay attention to the door radius and mounting options (see "Actuator dimensional

b

drawings", page 55).

Pay attention to the door hinge.

b

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

15

Page 16

4 PROJECT PLANNING

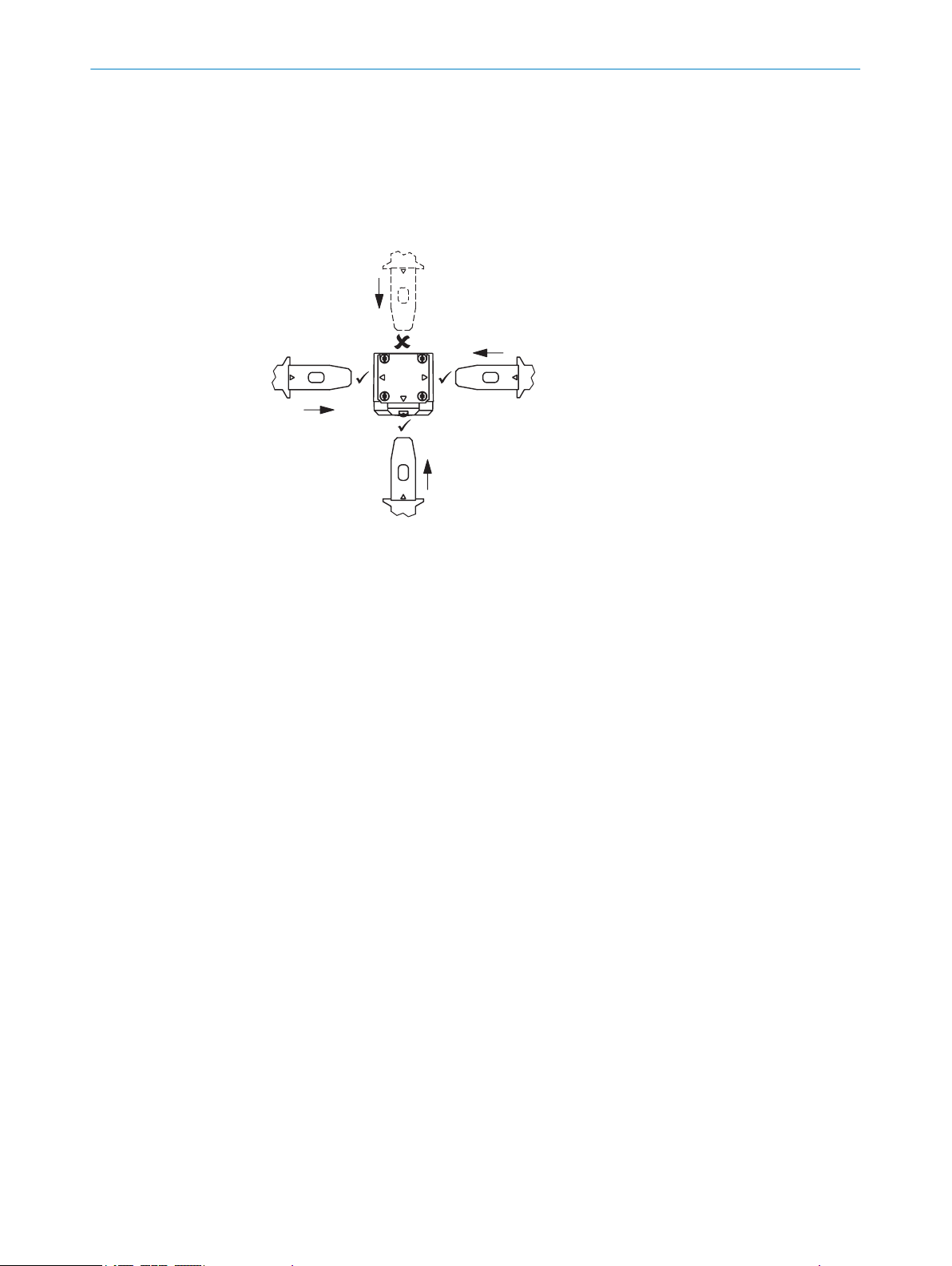

4.3.2 Actuating direction

Actuating direction

The safety locking device can be actuated from three horizontal directions (from the

left, from the front and from the right). If the safety locking device is to be actuated from

behind, an actuating head has to be used.

The safety locking device is not suited for an approach from a vertical angle.

4.3.3 Escape release

Figure 8: Directions of approach

Left

1

Front

2

Right

3

Rear (only possible with switched actuating head)

4

Further topics

"Changing the actuation direction", page 24

•

In order to mount the variant with the escape release, corresponding holes must be

made in the mounting surface.

The shaft of the escape release can be extended by 30 mm or 50 mm using with spac‐

ers

16

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 17

44/74/94

35

14

Figure 9: Escape release shaft

Escape release flange

1

Escape release shaft

2

Extension spacer

3

PROJECT PLANNING 4

4.4 Integration in the electrical control system

Switch-on commands that put the machine in a dangerous state may only be activated

when the protective device is closed and the locking device is locked. The locking

device may only be unlocked when the dangerous state has ended. Depending on the

safety concept, the signal is analyzed by safety relays or a safety controller, for example.

The connected controller and all devices responsible for safety must comply with the

required performance level and the required category (for example according to

ISO 13849-1).

The overall concept of the control system in which the safety locking device is inte‐

grated must be validated in accordance with ISO 13849-2.

4.4.1 Locking function

Prerequisites

A shared power supply is used for the control system and for the locking solenoids

•

of the safety locking device.

A clocked power supply is not used.

•

When connecting the locking solenoids to the output of a controller, this output

•

must supply sufficient current.

The activation of the locking solenoids of the safety locking device changes depending

on the locking principle.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

Power to release principle

Locking the locking device: Close the protective device, no voltage on the magnet

•

Unlocking the locking device: Apply voltage to magnet

•

If voltage is interrupted at the magnet, the locking device remains locked and the pro‐

tective device cannot be opened immediately.

17

Page 18

4 PROJECT PLANNING

WARNING

The locking device locks even when voltage is not present

People could get trapped!

If people are in the hazardous area, do not close the protective device even if volt‐

b

age is not present.

Or:

Use the variant with an escape release.

b

Power to lock principle

Locking the locking device: Apply voltage to magnet

•

Unlocking the locking device: Disconnect voltage from magnet

•

If voltage is disconnected at the magnet, the locking device is unlocked and the protec‐

tive device can be opened immediately.

DANGER

Hazard due to lack of effectiveness of the protective device

In the event of a voltage drop, the safety locking device unlocks regardless of whether

the dangerous state of the machine has ended.

Assess the risk of accident. Use for protecting people requires correct project plan‐

b

ning.

Activating the locking function

For single-channel activation of the locking function, the controller and the safety lock‐

ing device must have the same ground.

For dual-channel activation of the locking function, clock pulses are tolerated up to a

max. length of 5 ms. If possible, switch off the clocking of outputs in the control system.

NOTICE

The locking solenoid of the TR110 Lock safety locking device is controlled exter‐

•

nally (no control function within the device). Therefore, the TR110 Lock safety lock‐

ing device does not have any characteristic safety values for controlling the locking

function.

The safety level for controlling the locking function is determined exclusively by

•

external control (e.g. by the PFHd of an external standstill monitor).

Types for series connection of OSSDs have a separate pin MAG 0 V DC in order to apply

0 V to the locking solenoids (see "Device connection", page 29). In the other types,

the 0 V connection of the locking solenoid is connected using the 0 V connection of the

safety locking device.

18

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 19

MAG +24 V DC

MAG 0 V DC

MAG +24 V DC

0 V

4.4.2 OSSDs

PROJECT PLANNING

Figure 10: Connection of the locking solenoid

In types for series connection of OSSDs

1

In all other types

2

Safety locking devices with local inputs and outputs can be directly integrated into the

machine controller.

4

DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so the

b

protective function can be fulfilled.

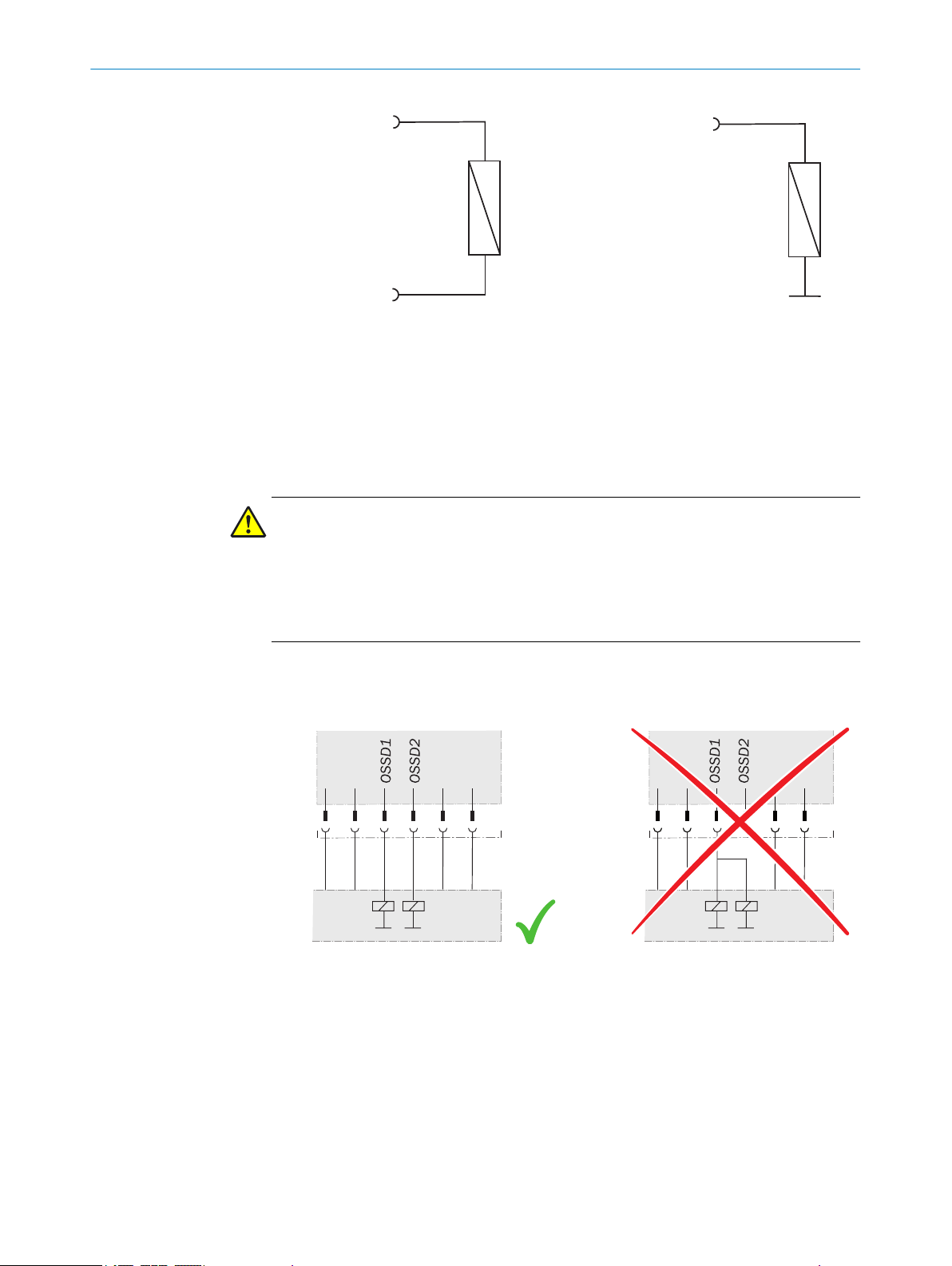

The output signals from an OSSD pair must not be connected to each other.

•

In the machine controller, both signals from an OSSD pair must be processed sep‐

•

arately.

Figure 11: Dual-channel and isolated connection of OSSD 1 and OSSD 2

The machine must switch to the safe state at any time if at least one OSSD in an

•

OSSD pair switches to the OFF state.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

19

Page 20

4 PROJECT PLANNING

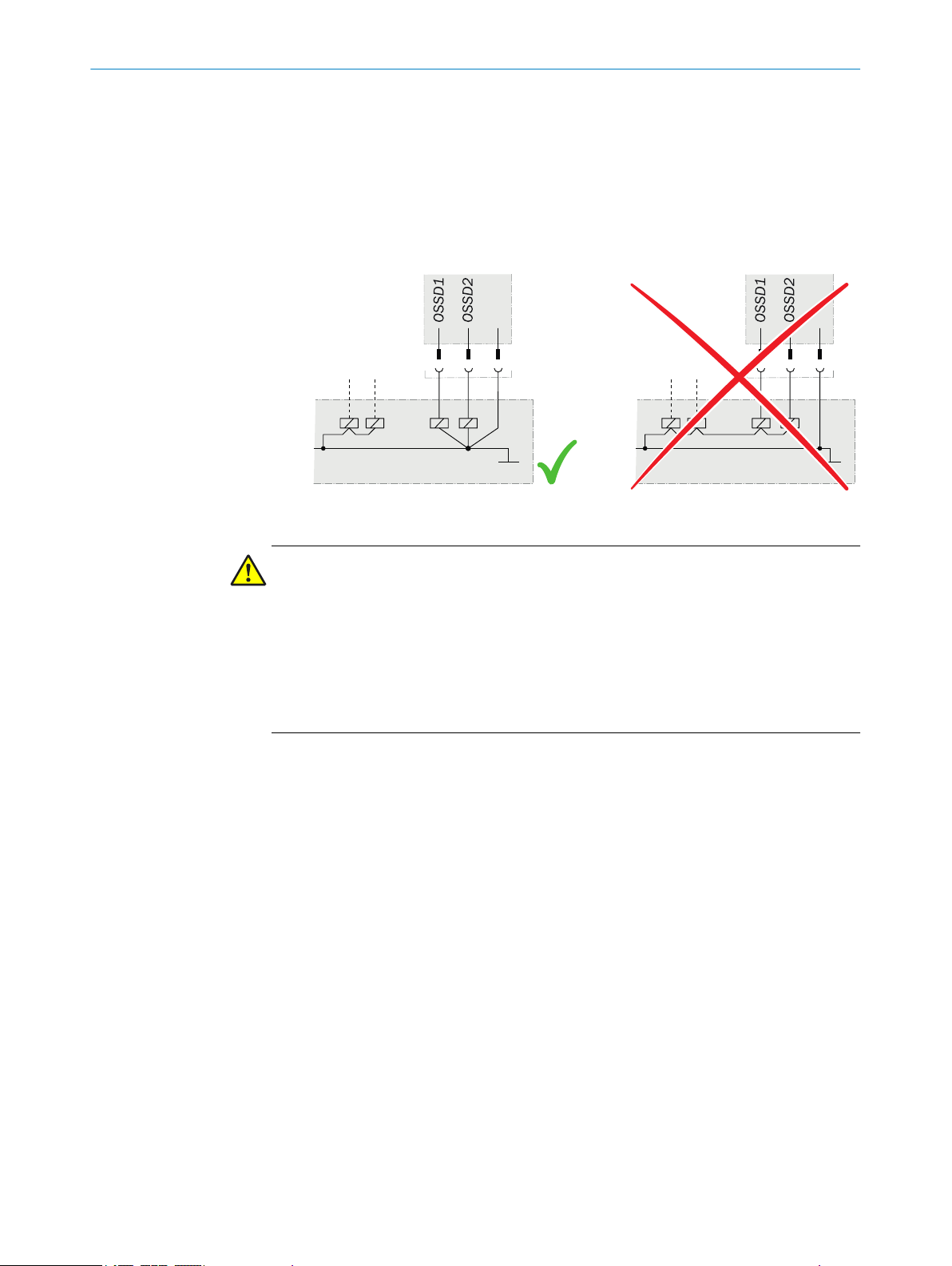

Prevent the formation of a potential difference between the load and the protec‐

•

tive device. If you connect loads to the OSSDs (safety outputs) that then also

switch if controlled with negative voltage (e.g. electro-mechanical contactor with‐

out reverse polarity protection diode), you must connect the 0 V connections of

these loads and those of the corresponding protective device individually and

directly to the same 0 V terminal strip. In the event of a fault, this is the only way to

ensure that there can be no potential difference between the 0 V connections of

the loads and those of the corresponding protective device.

Figure 12: No potential difference between load and protective device

DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Downstream contactors must be positively guided and monitored depending on applic‐

able national regulations or required reliability of the safety function.

Make sure that downstream contactors are monitored (external device monitoring,

b

EDM).

The OSSDs are short-circuit protected to 24 V DC and 0 V. If the safety locking device is

locked, the OSSDs signal the ON state with the HIGH signal level (non-isolated). If the

safety locking device is unlocked or there is a device fault, the OSSDs signal the OFF

state with the LOW signal level.

Do not use a control system with clocking or switch off the clocking function of the con‐

trol system. The device generates its own test pulses at the OSSDs. A downstream con‐

troller must tolerate these test pulses, which can have a length of up to 1 ms. The test

pulses are also output when the OSSDs are switched off. Depending on the sluggish‐

ness of the downstream device (controller, relay, etc.), this can lead to short switching

processes.

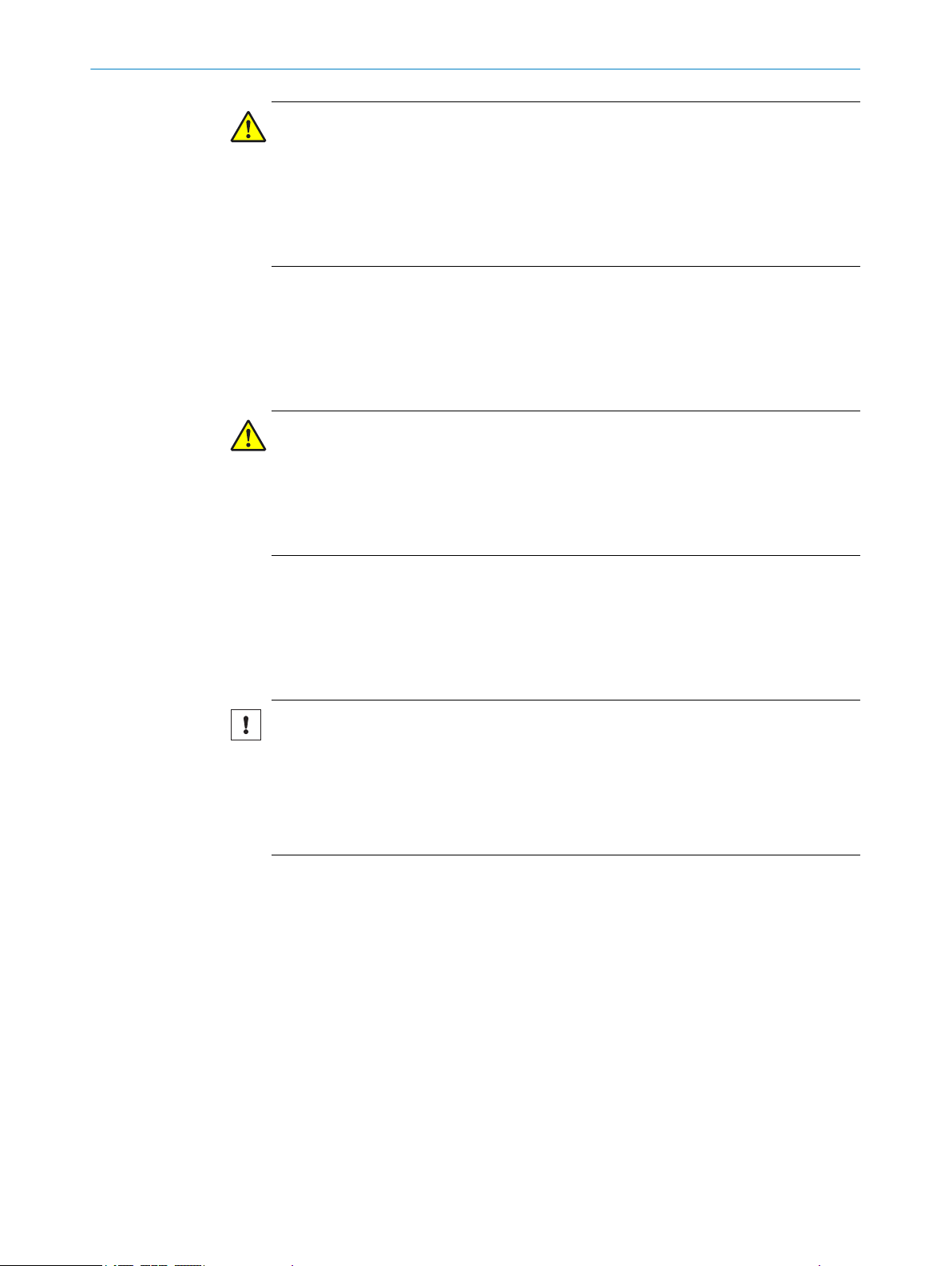

For inductive loads, the OSSDs must be protected with a freewheeling diode. RC sup‐

pressors must not be used:

4.4.3 Application diagnostic outputs

Door application diagnostic output (Out AUX DOOR)

The signal of the door application diagnostic output changes as soon as the actuator is

moved into or leaves the response range of the safety switch. In other words, the output

signal changes when the protective device is opened and closed. This is not a safety

output.

20

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 21

PROJECT PLANNING 4

Table 3: Switching behavior of the door application diagnostic output

Actuator Door application diagnostic output

Actuator not in response range OFF

Actuator in response range ON

Locking function application diagnostic output (Out AUX LOCK)

The signal of the locking function application diagnostic output changes as soon as the

locking function has been activated. This is not a safety output.

Table 4: Switching behavior of the locking function application diagnostic output

Locking function Locking function application diagnostic output

Locking function active ON

Locking function not active OFF

Fault application diagnostic output (Out AUX DIA)

The signal of the fault application diagnostic output changes as soon as a fault occurs.

This is not a safety output.

Table 5: Switching behavior of the fault application diagnostic output

Fault Fault application diagnostic output

Fault has occurred ON

No fault OFF

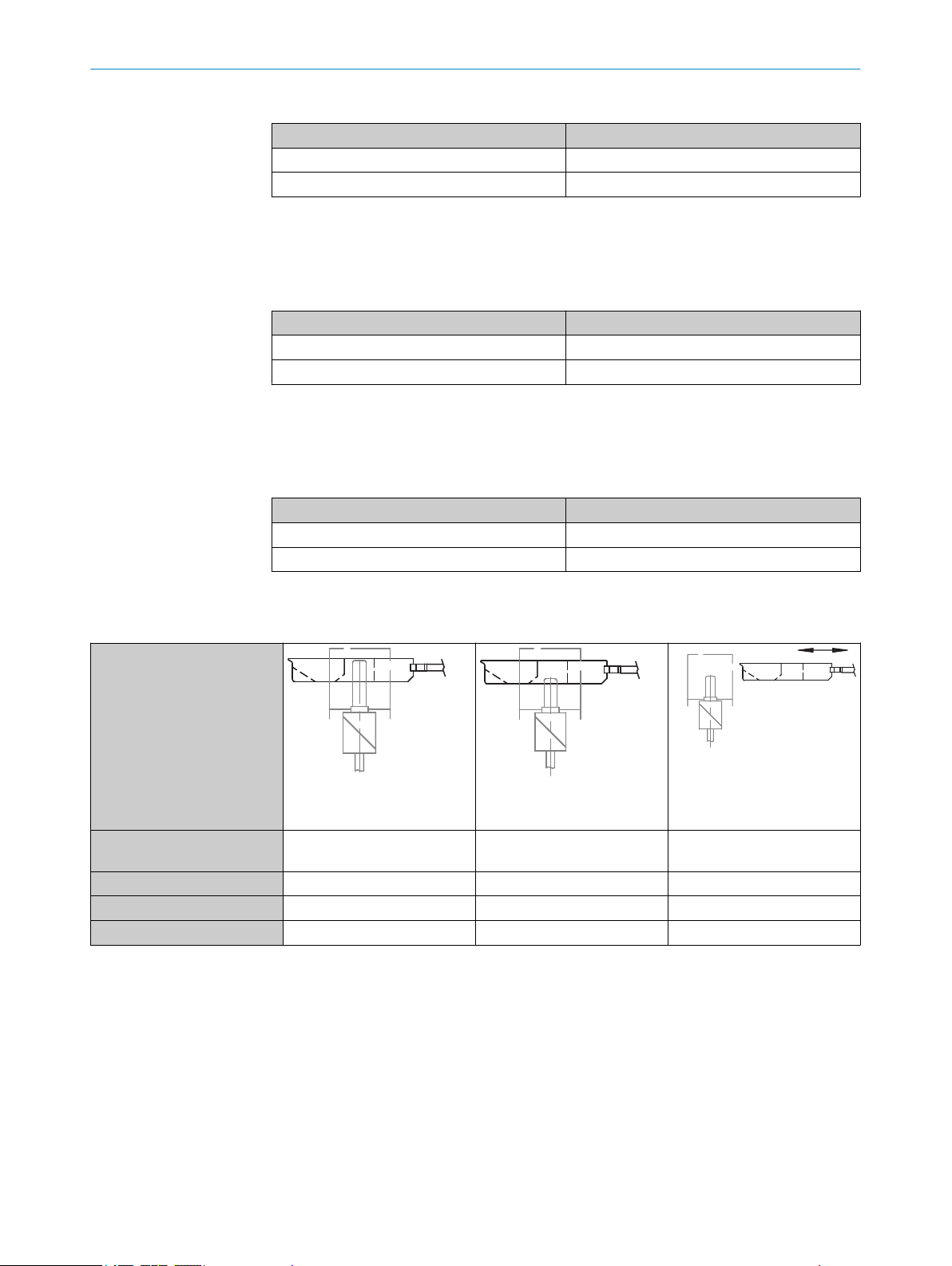

4.4.4 Switching behavior

Table 6: Switching behavior

Figure 15: Protective device

Figure 13: Protective device

closed and locked

Activating the locking func‐

tion

OSSDs ON OFF OFF

Out AUX LOCK ON OFF OFF

Out AUX DOOR ON ON OFF

ON OFF Not relevant

Figure 14: Protective device

closed but not locked

open

4.4.5 Safe series connection

OSSDs of several safety locking devices can be connected by safe series connection.

The connected OSSDs act like the OSSDs of a single device.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

21

Page 22

2

8

4

7

3

5

6

1

OSSD1

OSSD2

24 V DC

0 V DC

/

4

1

2

3

5

2

8

4

7

3

5

6

1

OSSD1

OSSD2

/

4

1

2

3

5

2

8

4

7

3

5

6

1

OSSD1

OSSD2

/

4

1

2

3

5

4 PROJECT PLANNING

Figure 16: Safe series connection

TR110 Lock

1

Safe evaluation unit

2

Male connector, M12, 8-pin

3

Male connector, M12, 5-pin

4

NOTICE

Connect the enable inputs of the OSSDs In 1 and In 2 directly to a power supply

•

unit (+24 VDC) or to the outputs OSSD 1 and OSSD 2 of another TR110 Lock

safety locking device.

There must not be any clocked controller signals at inputs In 1 and In 2.

•

The maximum number of safety locking devices depends on the following factors:

Applied supply voltage

•

Length of cables used

•

Cable cross-section of cables used

•

Load current

•

The voltage drop in the safe series connection has to be checked so that the defined

minimum voltage is still applied to the last safety locking device.

The number of safety locking devices in a safe series connection influences the

response time of the system (see table 17, page 45).

The safe series connection can be implemented using special T-connectors and an end

connector (see "Connection of a safe series connection", page 32).

4.4.6 Protection of the voltage supply

The voltage supply must be provided with fuse protection depending on the number of

safety locking devices and the required current for the outputs.

22

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Max. current consumption of a single safety locking device I

I

= I

max

I

TR110

I

OSSD1

I

OSSD2

I

OAUXL

+ I

TR110

= Operating current of the TR110 Lock safety locking device

= Load current of OSSD 1 (max. 150 mA)

= Load current of OSSD 2 (max. 150 mA)

= Load current of locking function application diagnostic output (max. 50 mA)

OSSD1+IOSSD2

+ I

OAUXL

+ I

OAUXD

max

:

Subject to change without notice

Page 23

PROJECT PLANNING 4

I

= Load current of door application diagnostic output (max. 50 mA)

OAUXD

Max. current consumption of a safe series connection of safety locking devices I

:

cade

I

= I

Cascade

n = Number of connected safety locking devices

OSSD1

+ I

OSSD2

+ n × (I

TR110

+ I

OAUXL

+ I

OAUXD

)

Cas‐

4.5

Testing plan

The safety locking device must be tested by appropriately qualified safety personnel

when commissioning, after modifications, and at regular intervals.

The regular thorough checks serve to investigate the effectiveness of the safety locking

device and discover defects because of modifications or external influences (such as

damage or tampering).

The manufacturer and user must define the type and frequency of the thorough checks

on the machine on the basis of the application conditions and the risk assessment.

Determination of the thorough checks must be documented in a traceable manner.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

23

Page 24

C

B

D

A

5 MOUNTING

5 Mounting

5.1 Safety

DANGER

Hazard due to unexpected starting of the machine

Death or severe injury

Make sure that the dangerous state of the machine is and remains switched off.

b

NOTICE

If incorrectly installed or if the ambient conditions are not suitable, the safety locking

device can be damaged.

Arrange the safety switch and actuator so that damage due to unintentional out‐

b

side influences is prevented.

Do not use a safety switch and actuator as a stop.

b

The set-up and mounting of the safety switch and actuator must be stable enough

b

to maintain proper operation.

Use only reliable mounting elements that can only be removed with tools.

b

If an opening is created in the physical guard due to alignment errors, it must not

b

impair the protective function.

5.2 Changing the actuation direction

Overview

The safety locking device can be actuated from three directions (A, B and C). The actua‐

tion direction only needs to be changed if the safety locking device is to be actuated

from behind (D).

Figure 17: Changing the direction of approach

Approach

24

1. Loosen the screws on the actuating head.

2. Turn the actuating head in the desired direction.

3. Tighten the screws to 1.2 Nm.

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 25

5.3 Mounting the safety switch

Important information

NOTICE

The actuator must not be used for guiding or used as a stop.

Prerequisites

To mount on the machine, the safety switch and actuator must be put together.

•

A clearance of 12 mm must be maintained around the actuating head.

•

Approach

The safety locking device may be in any installation position.

Mount the safety switch using 4 × M5 screws.

b

Observe the maximum tightening torque of 1.4 Nm.

b

MOUNTING 5

Figure 18: Mounting the safety switch

Mounting holes

1

12 mm clearance for actuator

2

Complementary information

Mounting brackets are available for the actuator and safety locking device as acces‐

sories (see "Dimensional drawings of the mounting bracket", page 60).

5.4 Mounting straight and angled actuators

Important information

NOTICE

The actuator must not be used for guiding or used as a stop.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

25

Page 26

5 MOUNTING

Prerequisites

To mount on the machine, the safety switch and actuator must be put together.

Approach

Mount the actuator using 2 × M4 screws.

b

Complementary information

Mounting brackets are available for the actuator and safety locking device as acces‐

sories (see "Dimensional drawings of the mounting bracket", page 60).

5.5 Mounting the radius actuator

Important information

NOTICE

The actuator must not be used for guiding or used as a stop.

Prerequisites

To mount on the machine, the safety switch and actuator must be put together.

•

The actuator must be positioned perpendicularly to the guide slot before insertion.

•

Approach

1. Mount the actuator using 2 × M5 screws.

2. For larger radii, the actuator can be aligned using the adjustment screw.

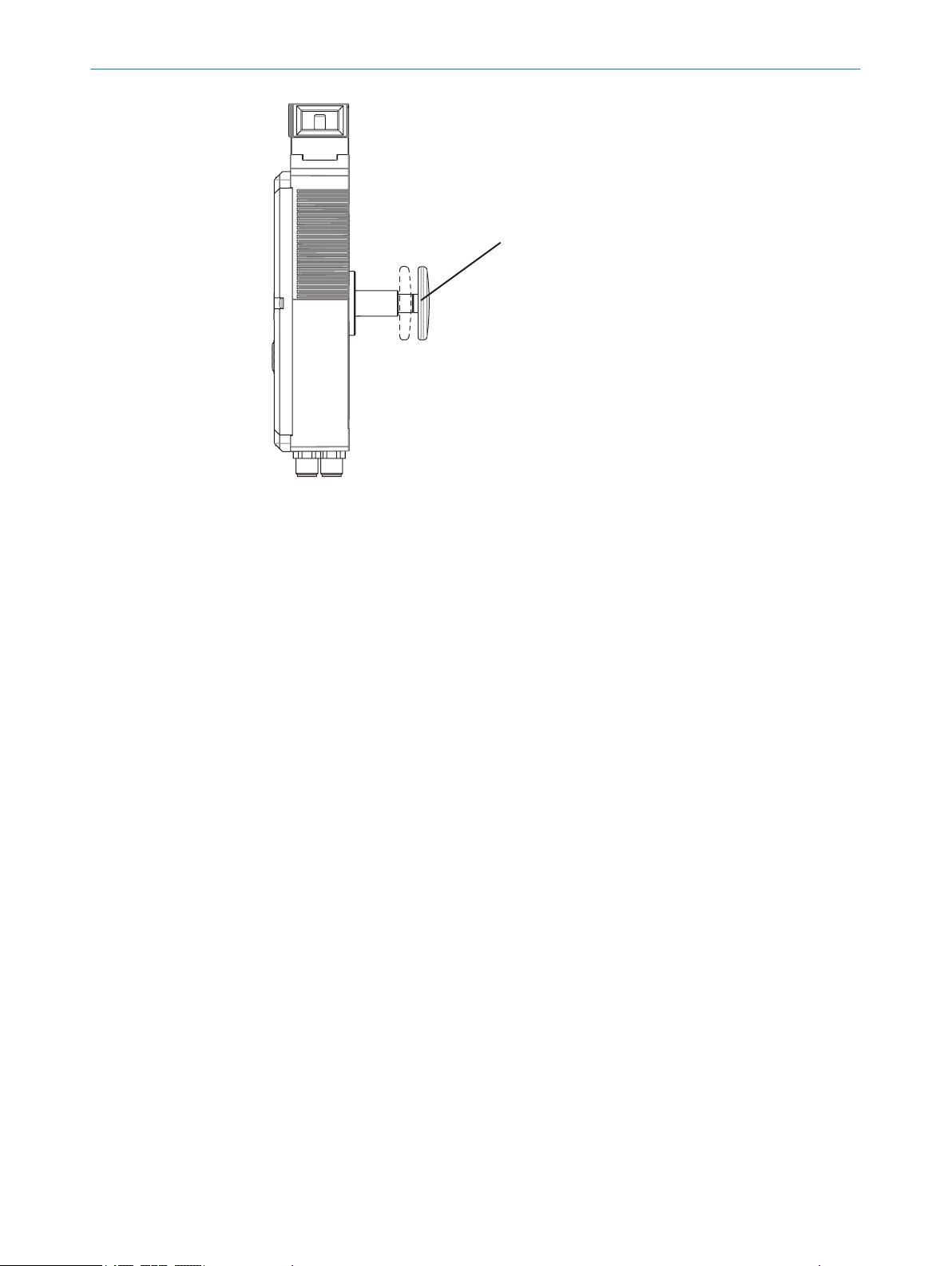

Figure 19: Adjustment screw for alignment

Adjustment screw

1

Complementary information

Mounting brackets are available for the actuator and safety locking device as acces‐

sories (see "Dimensional drawings of the mounting bracket", page 60).

5.6 Mounting the escape release

26

Prerequisites

Hole in the mounting surface for the escape release (see "Escape release",

•

page 16).

Spacers with lengths of 30 mm or 50 mm for the escape release shaft (optional).

•

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 27

Approach

1

1. Unscrew the red button of the escape release.

2. Extend the escape release shaft if necessary.

3. Insert the escape release shaft through the hole.

4. Mount the safety switch using 4 × M5 screws.

5. Screw on the red button of the escape release.

5.7 Mounting the emergency unlocking

Approach

1. Remove the center screws on the cover of the safety switch.

2. Remove the retaining screw of the mechanical unlocking mechanism.

3. Position the emergency release so that the blade of the emergency release can

reach into the slot of the mechanical unlocking mechanism.

4. Ensure that the emergency release is blocked by the ball catch, not by the stop

bolt.

5. Fasten the emergency release using the included screws M3 × 17. Tighten the

screws to 0.5 Nm.

6. Seal the emergency release.

MOUNTING 5

Figure 20: Mounting the emergency release

Screws of the safety switch

1

5.8 Mounting the cover caps

Approach

1. Turn the cover cap so that the point is pointing upward.

2. Insert the cover caps onto the pushbuttons.

3. Press on the cover caps until they audibly snap in.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

27

Page 28

Click!

5 MOUNTING

Figure 21: Cover cap mount‐

ing, step 1

5.9 Removing the cover caps

Approach

1. Carefully guide a small slot screwdriver between the bracket and cover cap.

2. Carefully lift out the cover cap.

Figure 24: Cover cap removal, step 1 Figure 25: Cover cap removal, step 2

Figure 22: Cover cap mount‐

ing, step 2

Figure 23: Cover cap mount‐

ing, step 3

28

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 29

6 Electrical installation

6.1 Safety

DANGER

Hazard due to electrical voltage

Hazard due to unexpected starting of the machine

Make sure that the machine is and remains disconnected from the power supply

b

during electrical installation.

Make sure that the dangerous state of the machine is and remains switched off

b

during electrical installation.

Make sure that the outputs of the safety locking device have no effect on the

b

machine during electrical installation.

DANGER

Incorrect connection of the safety locking device

Loss of safety function

In the case of insulating material/connection strands, observe the necessary tem‐

b

perature resistance and mechanical load capability.

Only use safe contacts for safety functions.

b

ELECTRICAL INSTALLATION 6

6.2

6.3

Notes on cULus

For use according to the requirements of UL 508, the following conditions must also be

met:

A power supply marked as “for use in class 2 circuits” must be used.

•

Alternative solutions must correspond to the following requirements: Electrically

•

isolated power supply unit with fuse protection in accordance with UL248. This

fuse should be rated for max. 3.3 A and be integrated in the 30 V DC voltage sec‐

tion.

A connecting cable must be used that is listed under UL Category Code CYJV / 7,

•

min. 24 AWG, min. 80 °C.

Device connection

Prerequisites

All electrical connections must be isolated from the supply network either through

•

safety transformers in accordance with IEC 61558‑2‑6 with output voltage limita‐

tion or through equivalent isolation measures (PELV).

Power devices that represent a strong source of interference must be locally iso‐

•

lated from the input and output circuits for signal processing. The cable routing of

the safety circuits should be separated from the cables of the power circuits by the

greatest possible distance.

In order to avoid EMC disturbances, the physical ambient and operating conditions

•

at the installation location of the device must comply with the requirements of

IEC 60204-1.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

29

Page 30

8

2

3

4

5 7

1

6

8

2

3

4

5 7

1

6

6 ELECTRICAL INSTALLATION

Stand-alone connection

Figure 26: Device connection (male connector, M12, 8-pin, A-coded)

Table 7: Device connection pin assignment (male connector, M12, 8-pin, A-coded)

Pin Wire color

1 White Out AUX DOOR Door application diagnostic out‐

2 Brown 24 V DC Voltage supply 24 V DC

3 Green MAG +24 V DC Magnet activation 24 V DC

4 Yellow Out AUX DIA Fault application diagnostic out‐

5 Gray OSSD 1 Output OSSD 1

6 Pink OSSD 2 Output OSSD 2

7 Blue 0 V Voltage supply 0 V DC

8 Red Out AUX LOCK Locking device application diag‐

1)

Applies to the extension cables recommended as accessories.

1)

Designation Description

put (not safe)

put (not safe)

nostic output (not safe)

For connection to Flexi Loop

Figure 27: Device connection (male connector, M12, 8-pin, A-coded)

Table 8: Device connection pin assignment for Flexi Loop variant (M12, 8-pin)

Pin Wire color

1 White Out AUX DOOR Door application diagnostic out‐

2 Brown 24 V DC Voltage supply 24 V DC

3 Green MAG +24 V DC Magnet activation 24 V DC

4 Yellow N.C. Not assigned

5 Gray OSSD 1 Output OSSD 1

6 Pink OSSD 2 Output OSSD 2

7 Blue 0 V Voltage supply 0 V DC

8 Red N.C. Not assigned

1)

Applies to the extension cables recommended as accessories.

1)

Designation Description

put (not safe)

30

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 31

8

2

3

4

5 7

1

6

12

3 4

5

8

2

3

4

5 7

1

6

ELECTRICAL INSTALLATION 6

For safe series connection

Figure 28: Device connection (male connector, M12, 8-pin, A-coded)

Table 9: Device connection pin assignment (male connector, M12, 8-pin, A-coded)

Pin Wire color

1 White Out AUX LOCK Locking device application diag‐

2 Brown 24 V DC Voltage supply 24 V DC

3 Green RST Hardware reset connection

4 Yellow In 2 Enable input for OSSD 2

5 Gray OSSD 1 Output OSSD 1

6 Pink OSSD 2 Output OSSD 2

7 Blue 0 V Voltage supply 0 V DC

8 Red In 1 Enable input for OSSD 1

1)

Applies to the extension cables recommended as accessories.

2)

When used as an individual safety locking device or as the first safety locking device in a safe series con‐

nection, apply 24 V DC.

1)

Designation Description

nostic output (not safe)

2)

2)

Figure 29: Device connection (male connector, M12, 5-pin, A-coded)

Table 10: Device connection pin assignment (male connector, M12, 5-pin, A-coded)

Pin Wire color

1)

Designation Description

1 Brown MAG 0 V DC Input for locking device 0 V DC

2 White Out AUX DOOR Door application diagnostic out‐

put (not safe)

3 Blue Out AUX DIA Fault application diagnostic out‐

put (not safe)

4 Black MAG +24 V DC Input for locking device 24 V DC

5 Gray N.C. Not assigned

1)

Applies to the extension cables recommended as accessories.

Variant with two pushbuttons

Figure 30: Device connection (male connector, M12, 8-pin, A-coded)

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

31

Page 32

12

3 4

5

6 ELECTRICAL INSTALLATION

Table 11: Device connection pin assignment (male connector, M12, 8-pin, A-coded)

Pin Wire color

1 White Out AUX DOOR Door application diagnostic out‐

2 Brown 24 V DC Voltage supply 24 V DC

3 Green MAG +24 V DC Magnet activation 24 V DC

4 Yellow Out AUX DIA Fault application diagnostic out‐

5 Gray OSSD 1 Output OSSD 1

6 Pink OSSD 2 Output OSSD 2

7 Blue 0 V Voltage supply 0 V DC

8 Red Out AUX LOCK Locking device application diag‐

1)

Applies to the extension cables recommended as accessories.

1)

Designation Description

put (not safe)

put (not safe)

nostic output (not safe)

Figure 31: Device connection (male connector, M12, 5-pin, A-coded)

Table 12: Device connection pin assignment (male connector, M12, 5-pin, A-coded)

Pin Wire color

1 White NO 1 Pushbutton 1 output (normally

2 Brown LED 1 LED 1 input

3 Green NO 2 Pushbutton 2 output (normally

4 Black LED 2 LED 2 input

5 Gray RST Hardware reset connection

1)

Applies to the extension cables recommended as accessories.

1)

Designation Description

6.4 Connection of a safe series connection

Overview

A maximum of 20 devices can be activated in series. The safe series connection can be

implemented using special T-connectors and an end connector. The safe evaluation

unit switches off the machine if a protective device is opened or a fault occurs at a

safety locking device.

Important information

open)

open)

32

NOTE

The locking device control (MAG 0 V DC), the application diagnostic outputs door

•

(Out AUX DOOR) and error application diagnostic outputs have to be wired sepa‐

rately.

In the case of safety locking devices cascaded with T-connectors, the locking

•

device application diagnostic output (Out AUX LOCK) cannot be evaluated.

Mount the connecting cable so that individual T-connectors (and thus a safety

•

locking device) cannot be easily jumpered.

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 33

55

44

33

2

2

1

1

5

6 7

8

4

321

ELECTRICAL INSTALLATION

Connection of the safe series connection (M12, 5-pin)

6

Figure 32: Safe series connection of several safety locking devices

TR110 Lock safety locking device

1

Connection cable, M12, 8-pin

2

T-connector

3

Connection cable (M12, 5-pin)

4

Connecting cable, M12, 5-pin, for connecting the safe series connection

5

Connecting cable, M12, 5-pin, for connecting the locking device controller

6

Safe evaluation unit

7

End connector

8

Figure 33: Internal circuitry: T-connector for safe series connection

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

33

Page 34

5

4

3

2

1

12

3 4

5

6 ELECTRICAL INSTALLATION

Figure 34: Internal circuitry: end connector for safe series connection

The 5-pin male connector of the last T-connector upstream of the safe evaluation unit is

the interface between the safe series connection and the safe evaluation unit.

Figure 35: Connection of the safe series connection (M12, 5-pin, A-coded, male connector)

Table 13: Pin assignment connection of the safe series connector (male connector, M12, 5-pin,

A-coded)

Pin Wire color

1 Brown +24 V DC Voltage supply 24 V DC

2 White OSSD 1 OSSD 1 output

3 Blue 0 V Voltage supply 0 V DC

4 Black OSSD 2 OSSD 2 output

5 Gray RST Hardware reset connection

1)

Applies to the extension cables recommended as accessories.

2)

All switches of a chain can be reset simultaneously with the RST input (reset input). For this, a voltage of

24 V must applied to the RST input for at least 3 s.

If the RST input is not used, it must be connected to 0 V.

1)

Designation Description

34

Further topics

"Accessories", page 63

•

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 35

7 Commissioning

7.1 Switching on

The device initializes after it is switched on. The OSSDs are in the OFF state during this

and the STATE LED flashes green at 5 Hz.

7.2 Teach-in

7.2.1 Safety

DANGER

Bypassing the protective device

The dangerous state may not be stopped in the event of non-compliance.

Document teaching-in of an actuator.

b

During regular thorough checks, make sure that the taught-in actuator is still being

b

used.

An actuator must be taught-in during commissioning. Only the most recently taught-in

actuator is valid.

COMMISSIONING 7

During a teach-in operation, the OSSDs are in the OFF state, i.e. the system is in a safe

state.

7.2.2 Teaching-in the first actuator in delivery condition

Important information

NOTE

Safety locking devices switched on in delivery condition have a teach-in readiness with

no time limitation.

NOTE

The teach-in process is invalid if canceled, e.g. by interruption of the voltage supply or

removal of the actuator.

Then the TR110 Lock safety locking device enters the safe error state, the DIA LED

lights up red, the STATE LED flashes (see "System status", page 42).

Approach

1. Apply the supply voltage to the safety switch.

✓

The STATE LED flashes 3 times repeatedly.

2. Insert the actuator into the actuating head (close the protective device).

✓

The teach-in process starts, the STATE LED flashes at approx. 1 Hz.

The teach-in process is completed after about 30 seconds. The STATE and DIA

LEDs flash in alternation.

3. Switch off the supply voltage at the safety switch for at least 3 seconds and then

switch it back on.

✓

The code for the actuator that was just taught-in is enabled in the safety switch.

4. Check the effectiveness of the protective device.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

35

Page 36

7 COMMISSIONING

7.2.3 Teaching-in the new actuator

Overview

The TR110 Lock safety locking device can be operated only with the actuator that was

last taught-in.

Important information

NOTE

Safety locking devices with an actuator that has already been taught-in have a teach-in

readiness of approx. 3 minutes after being switched on.

NOTE

If the safety switch detects an actuator that has already been taught-in, then the

•

teach-in process is canceled and the safety switch returns to normal mode.

If the safety switch detects a blocked code of a direct predecessor actuator, then

•

the teach-in process is canceled and the code of the previous actuator remains

active. The safety switch goes into an error state (see "System status", page 42).

Approach

1. Apply the supply voltage to the safety switch.

✓

The STATE LED flashes 3 times repeatedly.

2. Insert the actuator into the actuating head within 3 minutes.

3. The teach-in process starts, the STATE LED flashes at approx. 1 Hz.

✓

The teach-in process is completed after about 30 seconds. The STATE and DIA

LEDs flash in alternation.

4. Switch off the supply voltage at the safety switch for at least 3 seconds and then

switch it back on.

✓

This activates the new code and deactivates the old code.

5. Check the effectiveness of the protective device.

Complementary information

When a new actuator is taught-in, the safety switch blocks the code of the last actuator.

The latter cannot be taught-in again immediately when a new teach-in operation is per‐

formed. The blocked code is released again in the safety switch only after a third code

has been taught-in.

7.2.4 Teaching-in the actuator in safe series connection

Important information

NOTE

It is recommended to teach in the actuators not in the safe series connection, but indi‐

vidually.

36

Prerequisites

If the actuators need to be taught-in in a safe series connection, then it has to be possi‐

ble to switch from 0 V DC to 24 V DC at the RST inputs of the safety switches.

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 37

2

8

4

7

3

5

6

1

4

1

2

3

5

2

8

4

7

3

5

6

1

4

1

2

3

5

2

8

4

7

3

5

6

1

4

1

2

3

5

Figure 36: Connection to RST input

TR110 Lock

1

Male connector, M12, 8-pin

2

Signal for changing from 0 V DC to 24 V DC at RST

3

COMMISSIONING 7

Approach

Apply supply voltage to the safety switches.

b

✓

The STATE LEDs flash 3 times repeatedly.

Insert the actuators into the actuating heads.

b

Connect the RST to +24 V DC for at least 3 s.

b

The teach-in process on the safety switches of the safe series connection begins;

b

the STATE LEDs flash at approx. 1 Hz.

✓

The teach-in process is completed after about 30 seconds. The STATE and DIA

LEDs flash in alternation.

Reconnect the RST to +24 V DC for at least 3 s.

b

✓

The code for the actuators that were just taught-in is enabled in the safety

switches.

Check the effectiveness of all protective devices in the safe series connection.

b

7.3 Testing

DANGER

Hazard due to unexpected starting of the machine

Death or severe injury

Before carrying out the functional test, make sure that there are no people in the

b

hazardous area.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

Approach

Check that the device is functioning properly after installation and after every fault. To

do this, proceed as follows:

Mechanical functional test

Open the protective device and close it again. The components of the safety lock‐

b

ing device must not collide with other parts. When the protective device is closed,

the actuator must be in a position which enables the lock to be actuated.

37

Page 38

7 COMMISSIONING

Electrical functional test

1. Switch on the supply voltage.

2. Close all protective devices and activate the locks. The machine must not start up

on its own.

3. Check the lock. It must not be possible to open the protective device.

4. Start the machine function.

5. Make sure that the lock cannot be deactivated as long as the dangerous machine

function is active.

6. Stop the machine function and deactivate the lock.

7. Check whether the protective device is kept locked until there is no more risk of

injury (e.g., due to run-on movements).

8. Check the restart interlock. The machine function must not start while the lock is

deactivated.

9. Repeat steps 3 to 8 individually for each protective device.

Complementary information

NOTE

With the version in accordance with the power to lock principle, an active lock com‐

mand can be simulated by applying 24 V DC voltage to the “Lock input” contact.

7.4 Regular thorough check

Important information

DANGER

Insufficient checks or incorrect repair

Hazard due to lack of effectiveness of the protective device

In the event of wear or damage, replace the entire safety locking device with actu‐

b

ator. Never replace individual parts or assemblies.

Check the safety locking device following the inspection intervals specified in the

b

national rules and regulations.

Monitoring

The following checks must be done to ensure permanent and proper function:

Proper switching function

•

Safe mounting of all components

•

No damage, contamination, deposits or wear

•

No loose plug connectors

•

No manipulation by employees

•

38

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 39

8 Operation

8.1 Actuating the mechanical unlocking mechanism

Approach

1. Ensure that actuators are not under tensile stress.

2. Loosen the retaining screw with the screwdriver.

3. Use the screwdriver to rotate the mechanical unlocking mechanism in the direc‐

tion of the arrow to the following symbol:

✓

The locking device is unlocked.

OPERATION 8

Figure 37: Actuating the mechanical unlocking mechanism

Retaining screw

1

Mechanical unlocking mechanism

2

8.1.1 Moving the mechanical unlocking mechanism back after use

Approach

Use the screwdriver to move the mechanical unlocking mechanism back to the fol‐

b

lowing symbol:

Screw in the retaining screw and seal it (e.g. with locking varnish)

b

Open the protective device and close it again.

b

✓

The safety locking device operates in normal mode again.

Carry out a functional test.

b

8.2 Actuating the emergency release

Approach

1. Ensure that actuators are not under tensile stress.

2. Turn the emergency release clockwise until it latches at the following symbol:

✓

The locking device is unlocked.

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

39

Page 40

8 OPERATION

Figure 38: Actuating the emergency release

Emergency release

1

Stop bolt

2

8.2.1 Moving the emergency release back after use

Approach

Push the stop bolt inward, e.g. with a small screwdriver.

b

Move the emergency release back to the following symbol:

b

Seal the emergency release.

b

Open the protective device and close it again.

b

✓

The safety locking device operates in normal mode again.

Carry out a functional test.

b

8.3 Actuating the escape release

Approach

1. Press the red button of the escape release as far as it goes.

✓

The locking device is unlocked.

40

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 41

Figure 39: Fluchtentriegelung betätigen

Red button of the escape release

1

OPERATION 8

8.3.1 Moving the escape release back after use

Approach

Pull the red button of the escape release back out.

b

Open the protective device and close it again.

b

✓

The safety locking device operates in normal mode again.

Carry out a functional test.

b

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

41

Page 42

9 TROUBLESHOOTING

9 Troubleshooting

9.1 Safety

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Immediately shut the machine down if the behavior of the machine cannot be

b

clearly identified.

Immediately put the machine out of operation if you cannot clearly identify or allo‐

b

cate the fault and if you cannot safely remedy the fault.

Secure the machine so that it cannot switch on unintentionally.

b

DANGER

Hazard due to unexpected starting of the machine

When any work is taking place, use the protective device to secure the machine or

b

to ensure that the machine is not switched on unintentionally.

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Do not do repair work on device components.

b

Do not make changes to or manipulate device components.

b

Apart from the procedures described in this document, the device components

b

must not be opened.

NOTE

Additional information on troubleshooting can be found at the responsible SICK sub‐

sidiary.

9.2 System status

Important information

NOTE

Displays other than those described here indicate an internal device fault. In this case, please contact your respon‐

sible SICK subsidiary.

Status indicators

Table 14: Status indicators

Outputs LED indicators Status

Door OSSDs AUX

LOCK

Self-test X OFF OFF OFF OFF

42

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

AUX

DOOR

AUX

DIA

STATE DIA LOCK

Ö5 Hz

10 s

o o

Self-test after switch-on

Subject to change without notice

Page 43

Outputs LED indicators Status

Door OSSDs AUX

LOCK

AUX

DOOR

AUX

DIA

Normal operation Closed ON ON ON OFF

Closed OFF OFF ON OFF

Open OFF OFF OFF OFF

Teach-in Open OFF OFF OFF OFF

Closed OFF X ON OFF

X OFF X X OFF

Error display X OFF X X ON

X OFF OFF OFF ON

X OFF OFF OFF ON

X OFF OFF OFF ON

X OFF X X ON

X OFF OFF OFF ON

STATE DIA LOCK

O o O

Ö 1 x

o o

inverse

Ö 1 × o o

Ö 3 × o o

Ö1 Hz o o

Ö Ö o

Ö 1 × O o

Ö 2 × O o

Ö 3 × O o

Ö 4 × O o

Ö 5 × O o

o O

X Internal error

TROUBLESHOOTING 9

Door closed and locked

Door closed and not

locked

Door open

Teach-in readiness

Teach-in process

Teach-in process suc‐

cessful

Error during teachin (actuator removed

from the response

range before the teach‐

ing operation ended or

defective actuator

detected)

Input error (e.g. missing

test pulses, non-logical

switching state of the

predecessor in the

switch chain)

Read error (e.g. actua‐

tor defective)

Error at output (e.g.

cross-circuit, loss of

switching capability)

Locked actuator

detected

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

43

Page 44

10 DECOMMISSIONING

10 Decommissioning

10.1 Disposal

Approach

Always dispose of unusable devices in accordance with national waste disposal

b

regulations.

Complementary information

SICK will be glad to help you dispose of these devices on request.

44

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 45

11 Technical data

11.1 Data sheet

Table 15: Features

Features

Sensor principle Transponder

Coding Uniquely coded

Locking force F

With straight TR110-XAS actuator 3,900 N (EN ISO 14119)

With angled TR110-XABT actuator 1,500 N (EN ISO 14119)

With TR110-XAFx hinged actuator 2,600 N (EN ISO 14119)

Retaining force FZh (FZh = F

With straight TR110-XAS actuator 300 N (EN ISO 14119)

With angled TR110-XABT actuator 1,100 N (EN ISO 14119)

With TR110-XAFx hinged actuator 2,000 N (EN ISO 14119)

Actuating force 10 N

Retaining force 20 N

Force against which unlocking is possible ≤ 20 N

Actuating frequency ≤ 0.5 Hz

Starting speed ≤ 20 m/min

Overrun 5 mm

max

max

TECHNICAL DATA 11

/1.3)

Table 16: Safety-related parameters

Safety-related parameters

Performance level

Category

1)

PFHd 2) (mean probability of a dangerous fail‐

1)

PL e (EN ISO 13849-1)

4 (EN ISO 13849-1)

4.1 × 10

–9

ure per hour)

TM (mission time) 20 years (EN ISO 13849–1)

Type Type 4 (EN ISO 14119)

Coding level High coding level (EN ISO 14119)

Safe status when a fault occurs At least one safety-related semiconductor out‐

put (OSSD) is in the OFF state.

1)

Applies to monitoring the door position (interlocking monitoring) and locking monitoring.

2)

The locking solenoid is externally controlled and so does not contribute to the probability of failure. The

safety level of the locking device controller is determined exclusively by the external controller.

Table 17: Electrical data

Electrical data

Classification based on cULus Class 2

Protection class III (IEC 61140)

Utilization category DC-13: 24 V, 150 mA (IEC 60947-5-2)

Supply voltage U

Safety switches

Locking solenoid

V

20.4 V DC … 27.6 V DC

1)

20.4 V DC … 26.4 V DC

Current consumption

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

45

Page 46

11 TECHNICAL DATA

Electrical data

Safety switches

Locking solenoid

Pushbutton (LED)

40 mA

400 mA

10 mA

Power consumption of locking solenoid 6 W

External device protection

Safety switches

Locking solenoid

2)

0.25 A … 2 A

0.5 A … 8 A

Switch-on time of locking solenoid 100%

Contamination rating 3 (EN 60947-1)

Power-up delay

All except for TR110-SRUCAxx

TR110-SRUCAxx

1 s

< 8 s

Response time ≤ 260 ms (+5 ms for each additional safety

locking device in a safe series connection)

Release time 400 ms

Discrepancy time ≤ 10 ms (EN IEC 60947-5-3)

Risk time

Dwell time between successive locking/unlock‐

3)

260 ms

2.5 s

ing procedures

Rated insulation voltage Ui 50 V DC (IEC 60947-1)

Rated impulse withstand voltage U

imp

500 V (IEC 60947-5-1)

Rated short-circuit current 100 A

Locking principle

TR110-SRxxxx

TR110-SLxxxx

1)

The locking solenoid of the TR110 Lock safety locking device is externally controlled and supplied with

power.

2)

Medium time-lag triggering characteristics.

3)

The risk time is the time needed to detect internal and external faults. External errors affect the OSSDs

(short-circuit to an OSSD and cross-circuit between the two OSSDs). At least one of the two OSSDs is

safely switched off during the risk time.

Closed-circuit current principle

Open-circuit current principle

Table 18: Interfaces

Interfaces

System connection

TR110-SxxSAxx

Male connector, M12, 8-pin, A-coded

TR110-SxxFLxx

TR110-SxxCAxx

TR110-Sxx2Bxx

Male connector, M12, 8-pin, A coded, and

male connector, M12, 5-pin, A coded

46

O PE R AT I NG IN S TR U CT I ON S | TR110 Lock 8023119/15LY/2019-10-28 | SICK

Subject to change without notice

Page 47

TECHNICAL DATA 11

Table 19: Outputs

Output data

Type of output

Safety outputs 2 semiconductor outputs (OSSDs), p-switching,

short-circuit protected

Application diagnostic outputs p-switching, short-circuit protected

Output current (OSSDs)

ON state

OFF state

Output voltage (OSSDs)

ON state

OFF state

Test pulse duration (OSSDs)

All except for TR110-SRUCAxx

TR110-SRUCAxx

Test pulse interval (OSSDs)

All except for TR110-SRUCAxx

TR110-SRUCAxx

Application diagnostic outputs

Output current

Output voltage

N/O contacts of the pushbuttons (only TR110-SXXXBXX)

Output current

Output voltage

1 mA … 150 mA

≤ 250 µA

Uv -1.5 V DC … U

0 V DC … 1 V DC

300 µs

1 ms

≤ 100 ms

≤ 140 ms

1 mA … 50 mA

0.8 × Uv … U

v

1 … 50 mA

U

v

v

Table 20: Mechanical data

Mechanical data

Dimensions (W x H x D) See "Safety switch dimensional drawings",

page 49

Material

Safety switch housing

Actuating head

Plug connector

Fiberglass-reinforced thermoplastic

Zinc die cast

Nickel-plated brass

Weight 0.42 kg

Mechanical service life 1 × 106 switching operations

Table 21: Ambient data

Ambient data

Enclosure rating IP 67 (IEC 60529)

IP 69 (IEC 60529)

IP 69K (IEC 20653)

Enclosure rating of the variants with operating

IP 65 (IEC 60529)

buttons

Ambient operating temperature –20 °C … +55 °C

Vibration resistance EN IEC 60947-5-3

EMC EN IEC 60947-5-3

8023119/15LY/2019-10-28 | SICK O PE R AT I NG IN S TR U CT I ON S | TR110 Lock

Subject to change without notice

47

Page 48

11 TECHNICAL DATA

11.2 Connecting cables

Requirements for the connecting cables

Table 22: Requirements for the connecting cables

Parameter Value

Min. wire cross-section 0.25 mm²

R max. 60 Ohm/km

C max. 120 nF/km

L max. 0.65 mH/km

Recommended cable type = LIYY 8 x 0.25 mm² or 5 x 0.34 mm²

Maximum cable lengths

Table 23: Maximum cable lengths

Max. number of safety lock‐