Page 1

O P E R A T I N G I N S T R U C T I O NS

EN

TPS

Driver assistance system

Page 2

Operating Instructions

TPS

This work is protected by copyright. Any rights derived from the copyright shall be reserved for SICK AG.

Reproduction of this document or parts of this document is only permissible within the limits of the legal

determination of Copyright Law. Alteration or abridgment of the document is not permitted without the explicit

written approval of SICK AG.

2 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 3

Operating Instructions

Contents

TPS

Contents

1 About these operating instructions ................................................................................. 6

1.1 Function of this document .................................................................................... 6

1.2 Target group .......................................................................................................... 6

1.3 Information depth ................................................................................................. 6

1.4 Abbreviations used ............................................................................................... 7

1.5 Symbols used ........................................................................................................ 7

2 Safety .................................................................................................................................. 8

2.1 Qualified safety personnel .................................................................................... 8

2.2 Applications of the system ................................................................................... 8

2.3 Intended use ......................................................................................................... 9

2.4 General safety notes and protective measures ...................................................... 9

2.4.1 Safety notes and symbols................................................................... 9

2.4.2 General safety notes .........................................................................10

2.4.3 Potential sources of danger .............................................................11

2.5 Protection of the environment............................................................................13

2.5.1 Power consumption ..........................................................................13

2.5.2 Disposal after final decommissioning ..............................................13

3 Product description .........................................................................................................14

3.1 Scope of delivery .................................................................................................14

3.2 System components ...........................................................................................14

3.3 System functionality ............................................................................................17

3.3.1 Front collision warning ......................................................................17

3.3.2 Rear End collision warning ...............................................................18

3.3.3 Road Departure Warning ..................................................................18

3.3.4 Black Spot Warning ...........................................................................19

3.4 Status indicators .................................................................................................20

4 Mounting ..........................................................................................................................22

4.1 Function test before mounting ...........................................................................22

4.2 Mounting the LiDAR sensor ................................................................................22

4.3 Mounting the bracket for the operator display ..................................................25

4.4 Mount the control cabinet ..................................................................................26

4.5 Mount the GPS receiver ......................................................................................27

4.6 Mounting the tone buzzer ...................................................................................27

5 Electrical installation ......................................................................................................28

5.1 Wiring plan ...........................................................................................................28

5.2 Connecting the LD-MRS front and rear LiDAR sensor ......................................30

5.3 Connecting the LMS151 RDW LiDAR sensor ....................................................31

5.4 Connecting the operator display ........................................................................33

5.5 Connecting the GPS receiver ..............................................................................36

5.6 Connecting the tone buzzer ................................................................................36

5.7 Connecting the control cabinet ..........................................................................37

5.8 Connecting the reverse signal (optional) ...........................................................38

5.9 Connecting the pause signal ..............................................................................38

5.10 Connecting the RDW lights (optional) ................................................................39

8021799/2017-09-26 Operating Instructions | SICK 3

Subject to change without notice

6 Commissioning ................................................................................................................40

6.1 Launching the system .........................................................................................40

6.2 The operator display in configuration mode ......................................................42

6.3 Making vehicle setup settings ............................................................................43

Page 4

Operating Instructions

Contents

TPS

6.4 Configuring the LiDAR sensors .......................................................................... 44

6.4.1 Starting sensor setup ....................................................................... 44

6.4.2 Front sensor set up........................................................................... 45

6.4.3 Rear sensor set up ........................................................................... 46

6.4.4 RDW sensor set up ........................................................................... 48

6.4.5 Saving sensor setup settings ........................................................... 50

6.5 Making Supervisor setup settings ..................................................................... 51

6.5.1 Front zones set up ............................................................................ 51

6.5.2 RDW setup ........................................................................................ 53

6.5.3 Saving sensor setup settings ........................................................... 54

6.6 Reverse Gear and components connection check ........................................... 54

6.7 Switch to the operating mode ............................................................................ 55

6.7.1 Quit configuration mode ................................................................... 55

6.7.2 Operating mode for person carrying out commissioning ............... 55

6.7.3 Enable operating mode for truck operators .................................... 57

7 Operation ......................................................................................................................... 58

7.1 Start the truck and system ................................................................................. 58

7.1.1 The operator display in the operating mode for truck drivers ........ 59

7.2 Forward Driving ................................................................................................... 59

7.2.1 Black spot warning ........................................................................... 60

7.3 Reverse Driving ................................................................................................... 60

7.4 Operate the system ............................................................................................ 61

7.4.1 Switching between day/night mode ................................................ 61

7.4.2 Collision warning in the event of obstacles in the warning

zone ................................................................................................... 62

7.4.3 Collision warning in the event of unintentional road

departure .......................................................................................... 63

7.4.4 React to collision awareness ........................................................... 63

8 Maintenance ................................................................................................................... 64

8.1 Overview of maintenance tasks ......................................................................... 64

8.2 Maintenance during operation .......................................................................... 64

8.2.1 Cleaning the LiDAR sensor ............................................................... 64

8.2.2 Visual inspection of the cables ........................................................ 65

8.3 Replacing components ....................................................................................... 65

8.3.1 Replacing a LiDAR sensor ................................................................ 66

8.3.2 Replacing the operator display ........................................................ 67

8.4 Activities on the web interface ........................................................................... 68

8.4.1 Calling up the web interface ............................................................ 68

8.4.2 Enable configuration mode on the display ...................................... 69

8.4.3 Activating operating mode for truck operators via the web

interface ............................................................................................ 70

8.4.4 Up- and downloading of GPS black spots ....................................... 70

8.4.5 Updating TPS software ..................................................................... 71

9 Fault diagnosis ................................................................................................................ 72

9.1 Response to faults .............................................................................................. 72

9.2 Fault indicators of the LMS151 ......................................................................... 72

9.3 Typical fault situations during commissioning .................................................. 73

9.3.1 Configuration incomplete or incorrect ............................................. 73

9.3.2 LiDAR sensor not available .............................................................. 73

9.4 Typical fault situations during operation ........................................................... 74

9.4.1 Viewing window of the LiDAR sensor contaminated ...................... 74

4 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 5

Operating Instructions

Contents

TPS

9.4.2 LiDAR sensor not available ...............................................................75

9.4.3 No image on display ..........................................................................76

9.5 SICK support........................................................................................................76

10 Annex ................................................................................................................................77

10.1 Technical data .....................................................................................................77

10.2 Dimensional drawings ........................................................................................78

10.2.1 Dimensional drawing of the 3D LiDAR sensor LD-MRS ..................78

10.2.2 Dimensional drawing of the 2D LiDAR sensor LMS151 .................78

10.2.3 Display dimensional drawing ............................................................79

10.2.4 Control cabinet dimensional drawing ..............................................80

10.2.5 Tone buzzer dimensional drawing....................................................80

10.3 Tone selection for tone buzzer ...........................................................................81

11 Figures and tables ...........................................................................................................82

11.1 List of tables ........................................................................................................82

11.2 List of figures .......................................................................................................83

11.3 Keywords index ...................................................................................................85

8021799/2017-09-26 Operating Instructions | SICK 5

Subject to change without notice

Page 6

Chapter 1 Operating Instructions

About these operating instructions

Activities

Target group

Mounting, electrical installation,

maintenance, and replacement

of system components

Qualified personnel, such as service technicians

or industrial electricians

Commissioning and

configuration

Qualified personnel, such as technicians or

engineers

Operating the system

Personnel qualified in running and operating the

system (truck operators)

Note

TPS

1 About these operating instructions

Please read through this chapter carefully before you use the documentation and work

with the TPS driver assistance system.

1.1 Function of this document

These operating instructions are designed to give technical personnel instructions on

the safe mounting, configuration, electrical installation, commissioning, operation and

maintenance of the Truck Protection System TPS.

These operating instructions do not provide information on operating the vehicle into

which the TPS is or will be integrated. For information about this instruction, refer to the

vehicle's operating instructions.

1.2 Target group

These operating instructions are intended for people who install, connect, commission,

operate, and maintain TPS.

Tab. 1 Target group

1.3 Information depth

These operating instructions contain information about the TPS driver assistance system

on the following topics:

Product description

Mounting

Electrical installation

Commissioning and configuration

Operation

Maintenance and repairs

Fault diagnosis and troubleshooting

Technical data and dimensioned drawings

When planning and using the TPS driver assistance system, technical skills are required

that are not covered by this document.

The official and legal regulations for operating the TPS must always be complied with.

Further information about the device components used in the TPS can be found in the

accompanying operating instructions.

6 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 7

Operating Instructions Chapter 1

About these operating instructions

TPS

LD-MRS

LMS

RDW

Recommendation

Note

1. / 2. ...

,

,

TPS

1.4 Abbreviations used

Truck Protection System = driver assistance system for haul trucks

Ladar Digital (Laser Radar) Multi-Layer Range Scanner = 3D LiDAR sensor from SICK AG

Laser measurement sensor = 2D LiDAR sensor from SICK AG

Road Departure Warning = functionality against unintended road departure

1.5 Symbols used

Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or technical measure.

Notes provide information about the features of a device, application tips, or other

information that may come in useful.

Instructions that must be carried out in the described order are referred to as step-by-step

instructions and are indicated by numbered lists. Carefully read and follow the instructions

for action.

Instructions for taking action are indicated by an arrow. Carefully read and follow the

instructions for action.

LED symbols describe the status of a diagnostics LED. Examples:

The LED is illuminated continuously.

The LED is flashing.

The LED is off.

Display symbols show the status of the 7-segment display:

Constant display of characters, e.g., U

Flashing display of characters, e.g., 8

Alternating display of characters, e.g., L and 2

8021799/2017-09-26 Operating Instructions | SICK 7

Subject to change without notice

Page 8

Chapter 2 Operating Instructions

Safety

NOTE

Note

TPS

2 Safety

This chapter concerns your own safety and the safety of the system operator.

Please read this chapter carefully before you begin working with TPS.

2.1 Qualified safety personnel

The TPS must only be mounted, commissioned, and maintained by adequately qualified

personnel.

A qualified person

has sufficient skills in the field of the respective equipment based on their technical

training and experience and

has been instructed by the manufacturer in system operation and all applicable safety

guidelines and

is familiar with all relevant country-specific occupational safety regulations, work safety

regulations, guidelines, and generally accepted technical rules and standards (e.g.,

DIN standards, VDE regulations, country-specific rules) to such an extent that he/she

is able to evaluate the safe condition of the power-operated equipment and if he/she

has access to and has read the operating instructions.

2.2 Applications of the system

TPS is a driver assistance system for haul trucks in surface mining. It consists of three

LiDAR sensors, a control cabinet, GPS and an interactive operator display.

The system warns the operator of possible collisions, entering hazardous areas (black

spots) and departure of the road (RDW).

During the operation of the truck, the TPS will constantly monitor the surrounding of the

vehicle for obstacles. If an obstacle is detected in one or more of the configured warning

zones, the zone violation is reported to the operator visually and audibly.

When the truck enters a pre-defined black spot like a hazardous intersection, the crusher

or workshop area, the system indicates this by a visual and audible alarm as well.

In case the truck comes to close or too far away from the bund wall the road departure

warning function alerts the operator with an visually and acoustically alarm.

TPS only detects objects which are visible in the measurement plane for the LiDAR

sensor. Therefore, the LiDAR sensor must have a free view of the area to be monitored.

Using TPS means that hazardous situations, such as vehicles, equipment, infrastructure,

unintentional road departure, hazard areas or dangerous queuing up situations are

detected in good time and that accidents during operating are avoided.

8 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

TPS is a driver assistance system. This means that at all times the driver bears the full

responsibility for safe operation, in particular for people who are in the hazardous zones of

the vehicle.

Page 9

Operating Instructions Chapter 2

Safety

NOTE

HAZARD

WARNING

CAUTION

NOTE

TPS

2.3 Intended use

TPS may only be used as described in section 2.2 Applications of the system. It may only

be used by qualified personnel in the environment in which it was mounted and initially

commissioned by qualified safety personnel in accordance with these operating

instructions.

TPS is not a safety device for human protection and it therefore does not comply with

any safety standards. For safety applications, please contact SICK AG.

In the event of any other usage or of modification to the system – including in the context

of mounting and installation – any claims against SICK AG under the warranty will be

rendered void.

2.4 General safety notes and protective measures

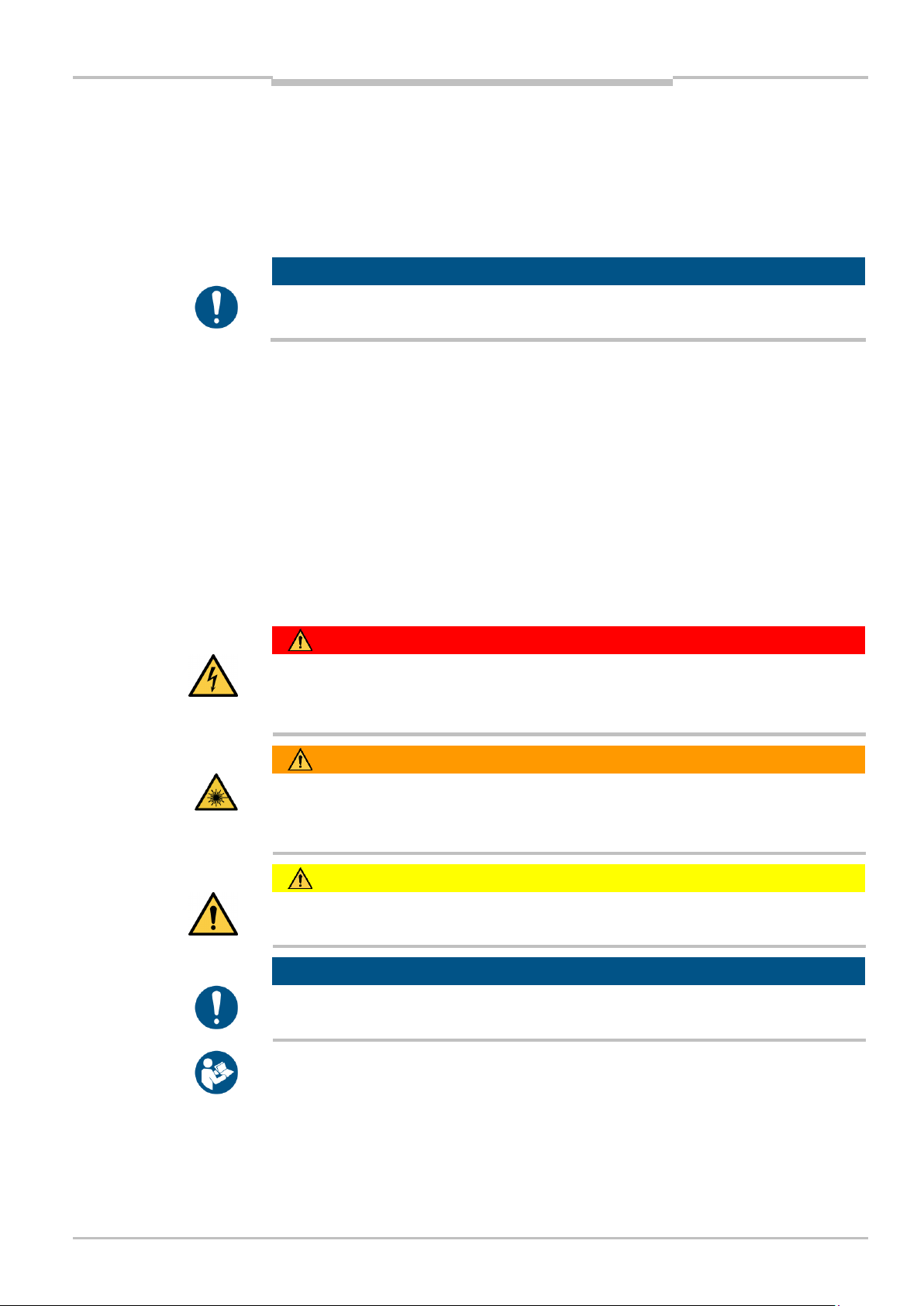

2.4.1 Safety notes and symbols

The following safety and hazard symbols are used for your own safety, for the safety of

third parties, and for the safety of the machine. You must therefore observe these symbols

at all times.

Denotes an immediate hazard that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in question

(the example here shows a risk of injury resulting from electrical current).

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in question

(the example here shows a risk of damage to the eye by laser beams).

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

Denotes a potential risk of damage or functional impairment to the device or the devices

connected to it.

This symbol includes a reference to supplementary technical documentation.

8021799/2017-09-26 Operating Instructions | SICK 9

Subject to change without notice

Page 10

Chapter 2 Operating Instructions

Safety

WARNING

WARNING

TPS

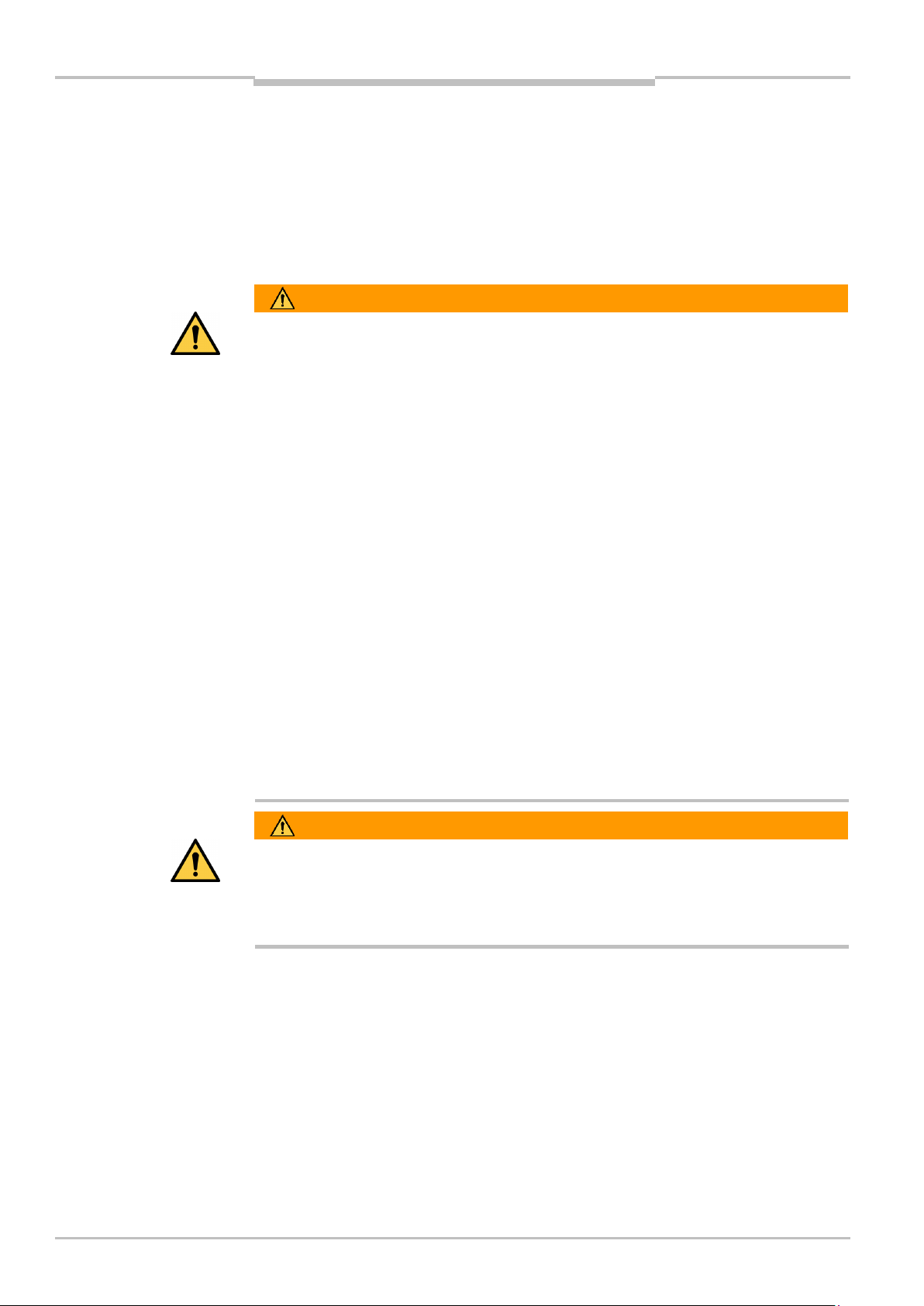

2.4.2 General safety notes

TPS has been designed in a way that allows for safe operation. However, a certain level of

risk will always remain.

Awareness of potential sources of danger in the system will help you to work in a safer

manner and thus prevent accidents.

To avoid risks, please also observe the special warnings in each of the individual chapters.

Safety notes

Observe the following to ensure the safe use of the system as intended.

The notes in these operating instructions must be complied with.

All official and statutory regulations governing the operation of the system must be

complied with.

The national and international legal specifications apply to the installation and use of

the system, to its commissioning, and to recurring technical inspections, in particular:

– The accident prevention regulations and work safety regulations

– Any other relevant safety regulations

The checks must be carried out by qualified safety personnel or specially qualified and

authorized personnel, and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

These operating instructions must be made available to the operator of the system.

The system operator must be instructed by qualified safety personnel and must read

the operating instructions.

The driver must follow relevant instructions and conduct inspections in order to ensure

that the screens of all LiDAR sensors are clean and undamaged

The LiDAR sensors must have a free field of vision. The sensor head must not be

covered by other objects, for example.

SICK AG recommends carrying out a system check before commissioning the system.

10 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Risk resulting from improper operation

Improper installation and commissioning, damaged components, and unsuitable ambient

conditions such as excessively cold or warm temperatures and high levels of dust, fog or

spray, may cause faults and faulty alarms and may result in a complete system crash.

Page 11

Operating Instructions Chapter 2

Safety

WARNING

WARNING

WARNING

CAUTION

Important

TPS

System does not comply with safety standards

TPS is not suitable for the protection of humans within the meaning of the applicable

safety standards for machines. The system therefore does not comply with safety

standards.

TPS is a driver assistance system. It provides the driver with visual and acoustic warnings

about objects outside of the truck, hazardous areas and departure of the road. At all times

the driver bears the full responsibility for safe operation, in particular for people who are in

the hazardous zones of the truck.

Location of use

The system is intended exclusively for use in industrial environments.

2.4.3 Potential sources of danger

Laser protection

Damage to the eye by laser beams

The LD-MRS 3D LiDAR senor used by TPS conform to laser class 1 (eye-safe) as per

EN/IEC 60825-1 (see laser warning label on the device for publication date), 21 CFR

1040.10 and 21 CFR 1040.11.

The LMS151 2D LiDAR sensor used by TPS corresponds to laser class 1 (eye safe) as per

EN/IEC 60825-1 (see laser warning label on the device for publication date).

This complies with 21 CFR 1040.10 with the exception of the deviations as per Laser

Notice No. 50, June, 2007.

The laser operates at a wavelength γ = approx. 905 nm (invisible infrared light). The laser

beam is not visible to the human eye.

The radiation emitted in normal operation is harmless to human skin and eyes.

Improper use (e.g., opening the housing and stopping the motor) can result in dangerous

exposure to radiation.

Never open the LiDAR sensor housing. Opening the housing does not interrupt the

operation of the laser beam.

Observe the laser safety regulations as per IEC 60 825-1 (latest version).

No maintenance is required to ensure compliance with laser class 1.

The laser output apertures are the optics cover on the LMS151 and LD-MRS LiDAR

sensors.

The laser warning is located on the right side of the LiDAR sensor.

8021799/2017-09-26 Operating Instructions | SICK 11

Subject to change without notice

Page 12

Chapter 2 Operating Instructions

Safety

HAZARD

WARNING

NOTE

WARNING

TPS

Electrical current

Risk of injury and damage caused by electrical current

Improper handling of live devices may lead to severe personal injury or death by electric

shock.

Electrical installation and maintenance work must always be carried out by personnel

authorized to do so.

The voltage supply must be disconnected when attaching and detaching electrical

connections.

Select and implement wire cross-sections and their correct fuse protection in

accordance with the applicable standards.

Do not touch any live components.

In the event of danger, immediately disconnect the system from the voltage supply.

Always use original fuses with the specified current rating.

Report any damaged cables to the maintenance team without delay.

Observe the current safety regulations when working on electrical systems.

Commissioning/Operation/Maintenance

Risk resulting from incorrect commissioning and configuration

Do not commission without testing by qualified safety personnel!

Before you operate the system or a device for the first time, you must have it checked and

approved by qualified safety personnel.

Claims under the warranty rendered void

Do not open the device housing. The devices are sealed.

If the device is opened, any warranty claims against SICK AG will be void.

Risk resulting from faults

Cease operation if the cause of the malfunction has not been clearly identified.

A defect in the system may result in fatal accidents or damage to the system.

Take the TPS out of operation if you cannot clearly identify the fault and if you cannot

safely remedy the problem.

12 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 13

Operating Instructions Chapter 2

Safety

Note

TPS

2.5 Protection of the environment

The system has been designed to minimize its impact on the environment. It consumes

very little power.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information regarding disposal.

2.5.1 Power consumption

Including its components, the system typically consumes 40 W.

The peak power consumption when starting up or in the event of integrated sensor heating

is 150 W.

2.5.2 Disposal after final decommissioning

Always dispose of unusable or irreparable devices in an environmentally safe manner in

accordance with the relevant national waste disposal regulations.

Dispose of all electronic assemblies as hazardous waste. The electronic assemblies are

easy to dismantle.

SICK AG does not take back devices that are unusable or irreparable.

8021799/2017-09-26 Operating Instructions | SICK 13

Subject to change without notice

Page 14

Chapter 3 Operating Instructions

Product description

Note

Important note

TPS

3 Product description

This chapter provides information on the special properties of the TPS driver assistance

system. It describes the design and operating principle of the system.

Always read this chapter before you mount, install and commission the system.

3.1 Scope of delivery

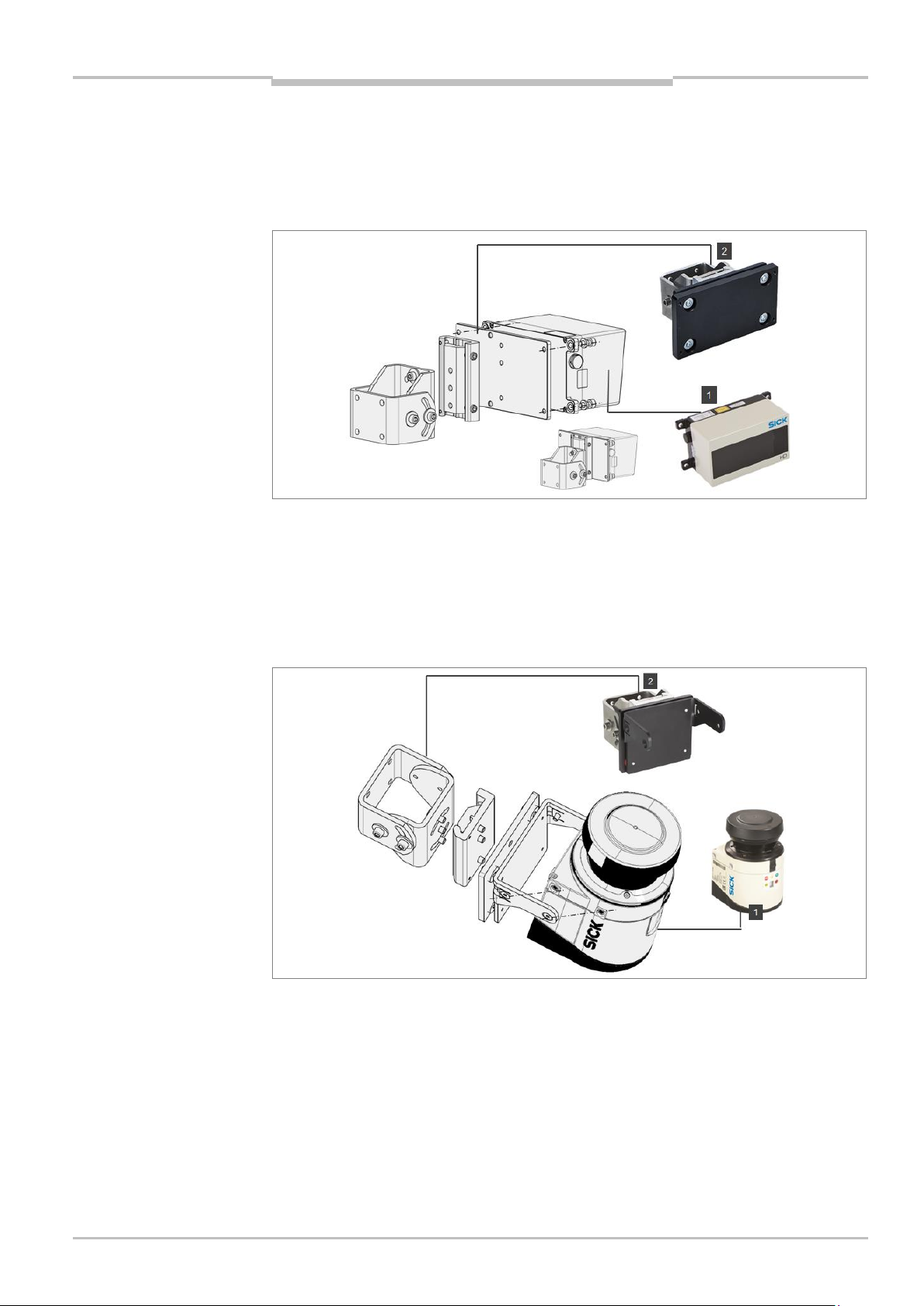

TPS consists of an LMS151 2D LiDAR sensor and two LD-MRS 3D LiDAR sensors, an

interactive operator display, a control cabinet, mounting kits with shock mounts and

connecting cables, GPS receiver, as well as a tone buzzer. Light signals can be optionally

used.

Fig. 1: Scope of delivery for TPS

Thorough check for completeness

It is recommended that you carefully check for and report transport damage of any kind

as soon as possible after receiving the system.

Also verify that the delivery includes all components listed on the delivery note.

3.2 System components

3D LiDAR sensor LD-MRS HD Front and Rear

The 3D LiDAR sensor LD-MRS HD mounted on the front and rear of the truck constantly

monitors the area in front resp. behind the truck, in a radius of up to 200 m (max. value of

warning zone of front LiDAR sensor).

The object detection is done with laser beams that the LD-MRS emits in four stacked

planes. The device measures the distance and the direction (the angle to the LD-MRS) of

the object.

14 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 15

Operating Instructions Chapter 3

Product description

TPS

The aperture angle is 100° for the front and back sensor.

Fig. 2: Laser output aperture of the LD-MRS Front and Rear

2D LiDAR sensor LMS151 RDW

The 2D LiDAR sensor LMS151 RDW mounted on the front of the truck constantly monitors

the area to the side of the truck.

The 2D LiDAR sensor scans its surroundings using a laser beam in a plane in the time-of-

flight process. The maximum aperture angle is 180°. If the emitted laser beam is reflected

by an object, the distance to the object is calculated.

Failure to install a suitable shock and vibration damper may result in a reduced system life

cycle.

Fig. 3: Laser output aperture of the LMS151 RDW

The operator display

The interactive operator display is the central component of the system. It visualizes the

outline of the truck and the warnings to the driver. Obstacles in the monitored area are

identified, and therefore can be quickly localized.

The display has a touch screen (1), which allows the operator to make entries during initial

commissioning and subsequent operation.

The operator display is attached to a mounting kit (2) with a swivel connector in the truck,

within the operators's field of view.

Fig. 4: Operator display with mounting kit

8021799/2017-09-26 Operating Instructions | SICK 15

Subject to change without notice

Page 16

Chapter 3 Operating Instructions

Product description

TPS

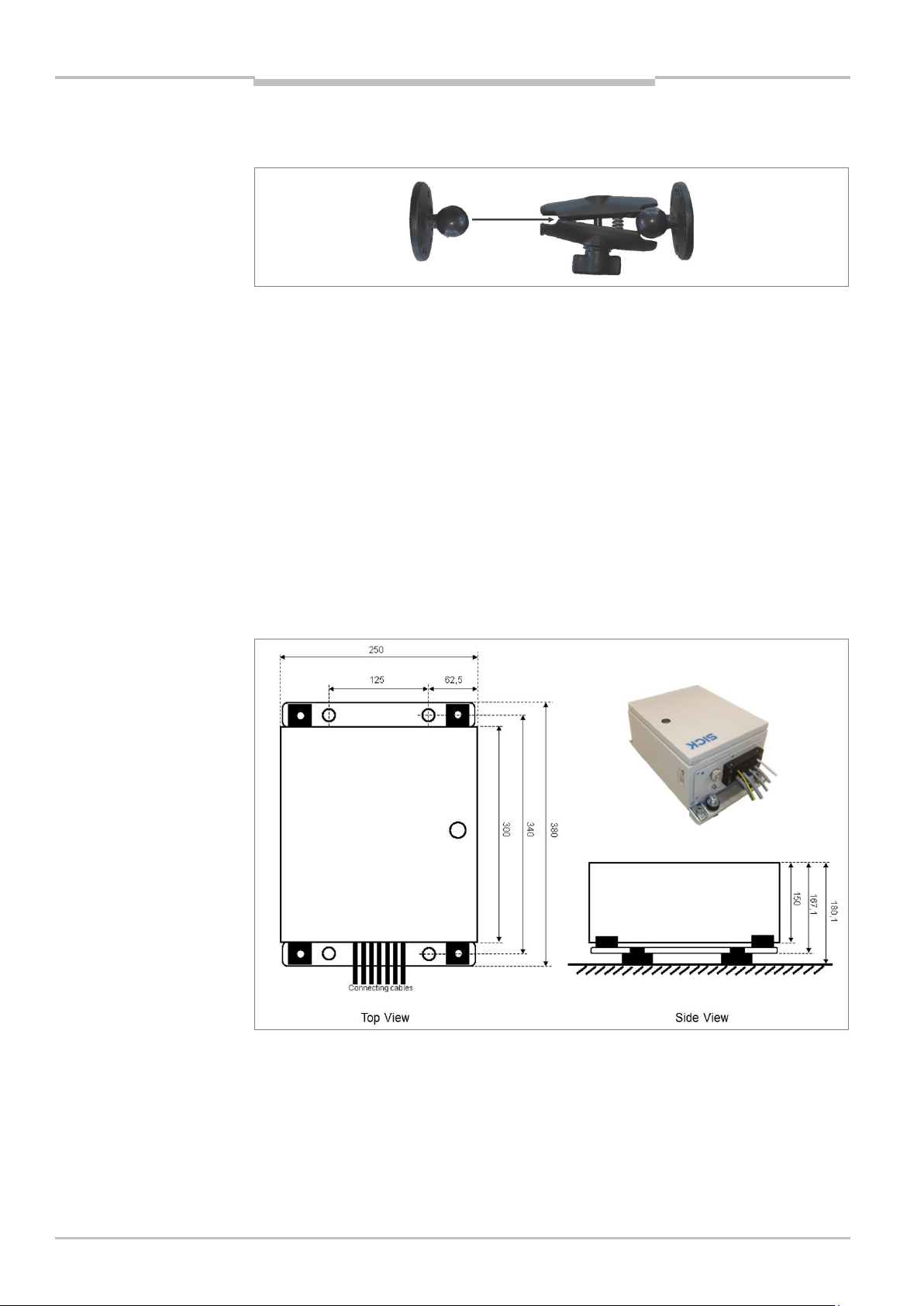

Control cabinet

The control cabinet connects the LiDAR sensors with the operator display. It also process

input signals and provides various output signals and power to the components.

Fig. 5: Control cabinet

To protect the control cabinet from shocks and vibration, damping measures must be

installed. The control cabinet comes with shock absorber mounting brackets.

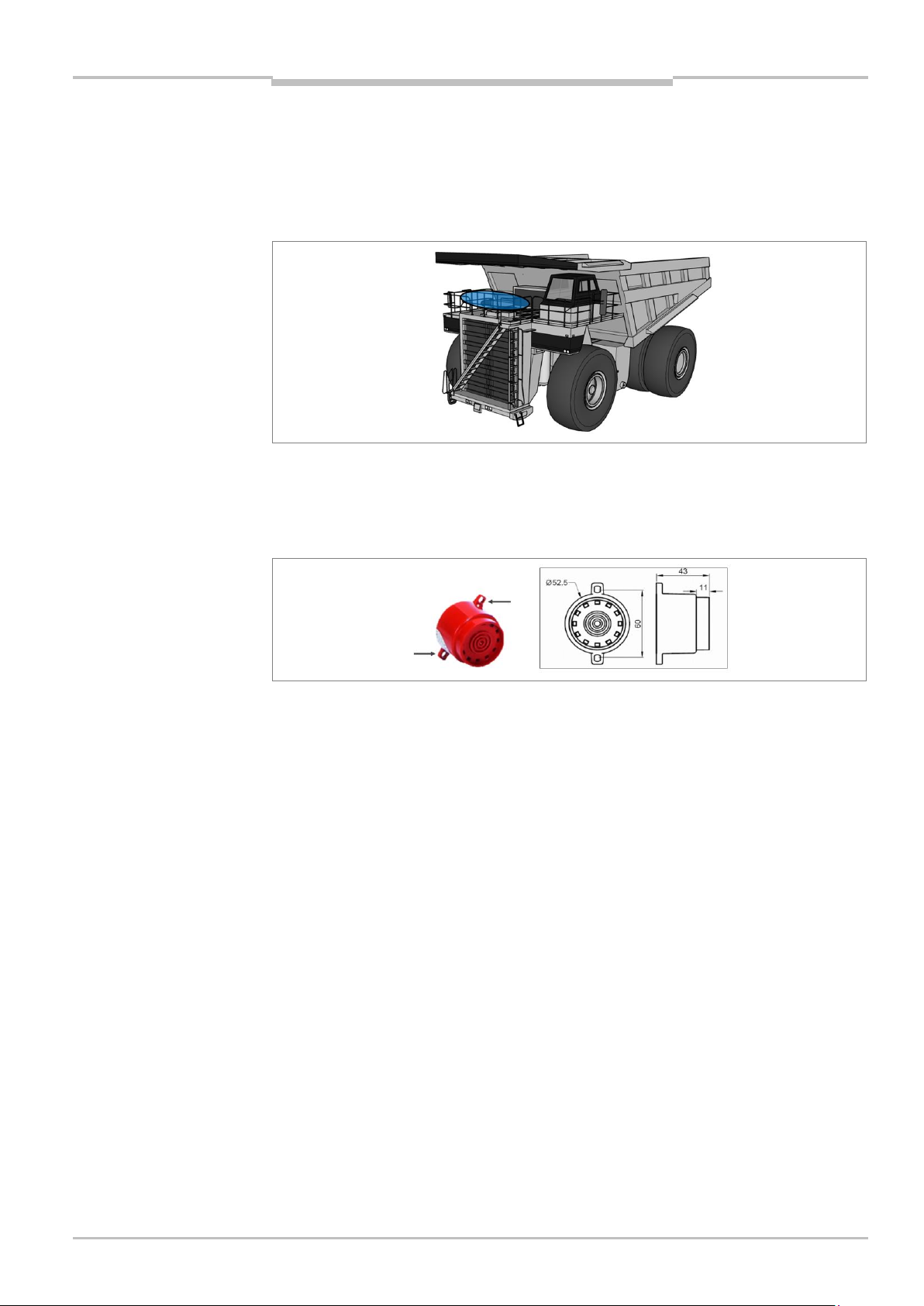

Tone buzzer

A tone buzzer supports the visual warning about an obstacle on the display with an

acoustic warning.

Fig. 6: Tone buzzer

GPS receiver

A GPS receiver is used for ego localization in world coordinates, speed, heading and more

information.

Fig. 7: GPS receiver

16 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 17

Operating Instructions Chapter 3

Product description

Note

TPS

Mounting kits with shock mounts

The TPS comes with mounting brackets with build-in shock absorber for the LMS151 RDW

and for both LD-MRS Rear and Front LiDAR sensors.

To protect the system components (sensors, control cabinet, operator display) from shocks

and vibration, damping measures must be installed. SICK AG recommends using the

included mounting kits with shock mounts that has built-in damper elements.

Failure to install a suitable shock and vibration damper may result in a reduced system life

cycle.

Fig. 8: Mounting kit for LMS151 RDW and LD-MRS Front and Rear

3.3 System functionality

The TPS is a driver assistance system for proximity detection and collision awareness for

heavy mining trucks. The system warns the operator of possible collisions, entering

hazardous areas (black spots) and departure of the road (RDW).

During the operation of the truck, the TPS will constantly monitor the surrounding of the

vehicle for obstacles. If such an obstacle is detected in one or more of the configured

warning zones, the zone violation is reported to the operator visually and audibly.

When the truck enters a predefined black spot like a hazardous intersection, the crusher

or workshop area, the system indicates this by a visual and audible alarm as well.

In case the truck comes to close or too far away from the left bund wall the road departure

warning function alerts the operator with an visually and acoustically alarm as well.

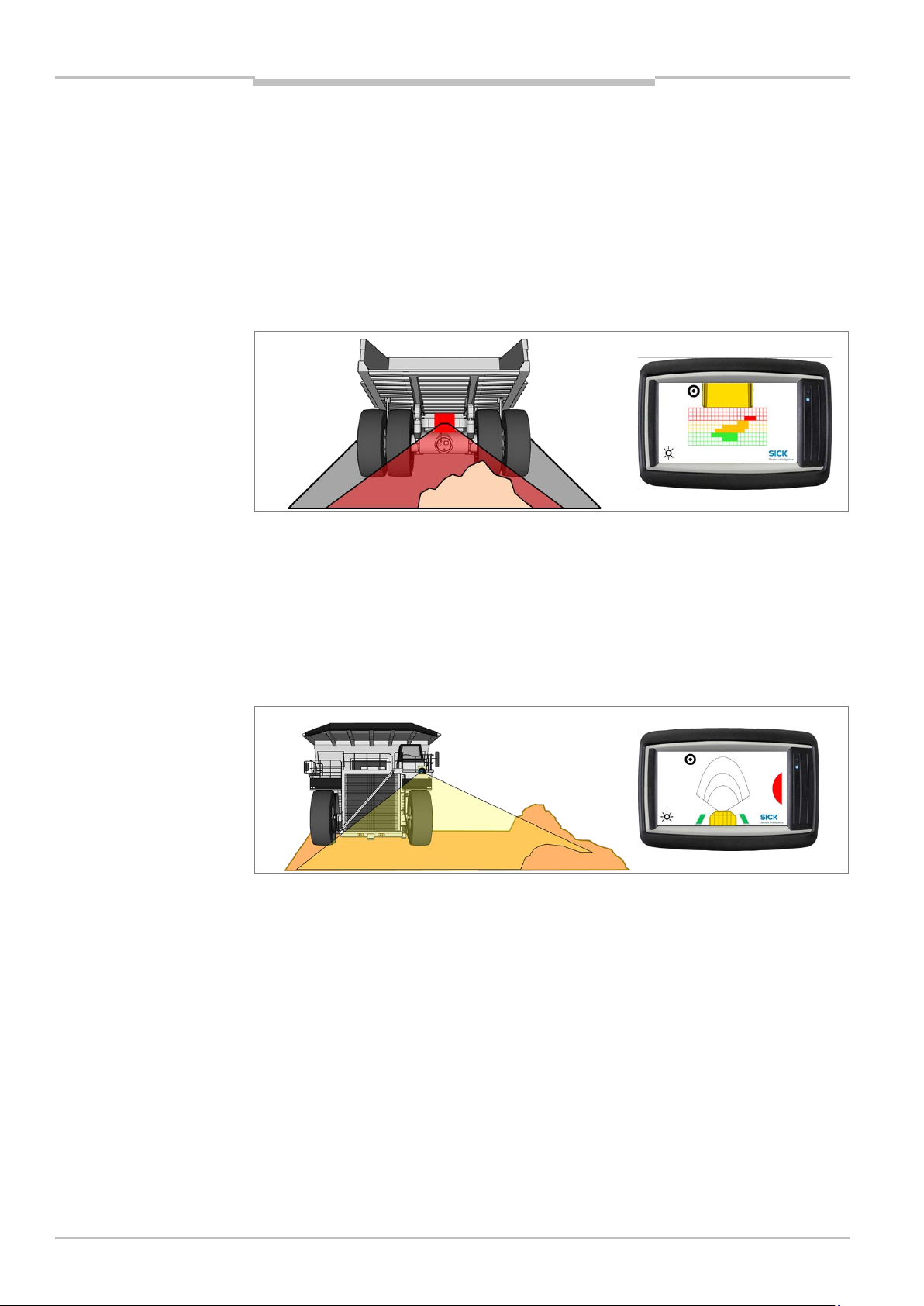

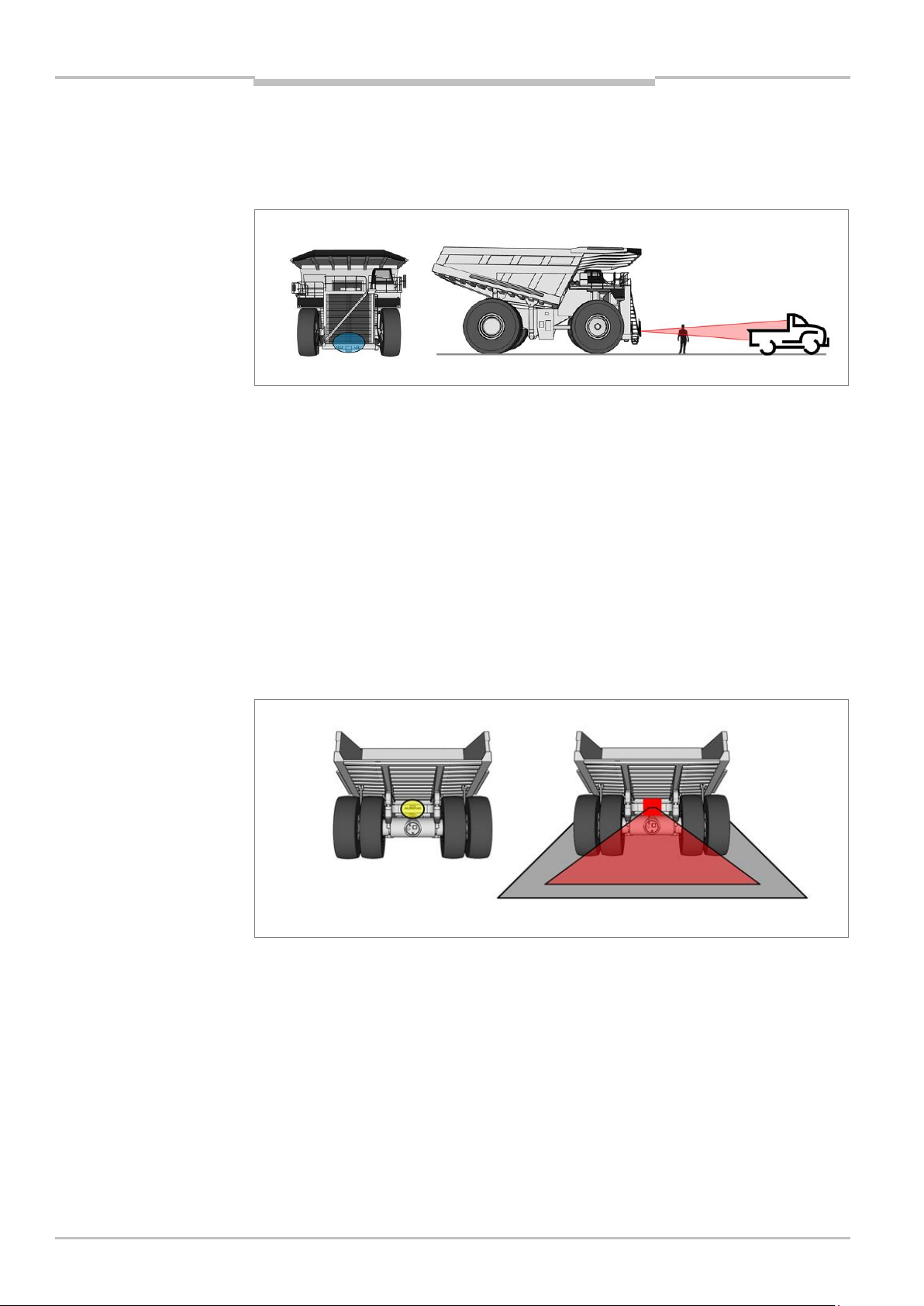

3.3.1 Front collision warning

The LD-MRS HD Front 3D LiDAR sensor monitors the area in front of the truck. It raises an

alarm when an obstacle is violating one of the 3 warning zones (green, yellow, red).

The range of the frontal warning zones is adapted automatically to the current driving

speed of the truck. Speed information is generated by the GPS receiver. In case GPS is

currently not available TPS uses as fall back the so called “low speed warning zones”.

8021799/2017-09-26 Operating Instructions | SICK 17

Subject to change without notice

Fig. 9: Front collision warning

Page 18

Chapter 3 Operating Instructions

Product description

Note

TPS

3.3.2 Rear End collision warning

The rear end collision warning supports the operator while he is driving in reverse gear

with low speed like when parking, unloading and reversing to a shovel.

The area directly behind the truck is monitored by the rear sensor. The LD-MRS HD Rear

3D LiDAR sensor scans the area behind the wheels and watches for obstacles like walls,

light or heavy vehicles or other mine site equipment that violate the light curtain by their

height.

The rear surveillance is activated only while the truck is in reverse gear. The wheels are

detected by the system and the measured points of the wheels are hidden.

Fig. 10: Rear End collision warning

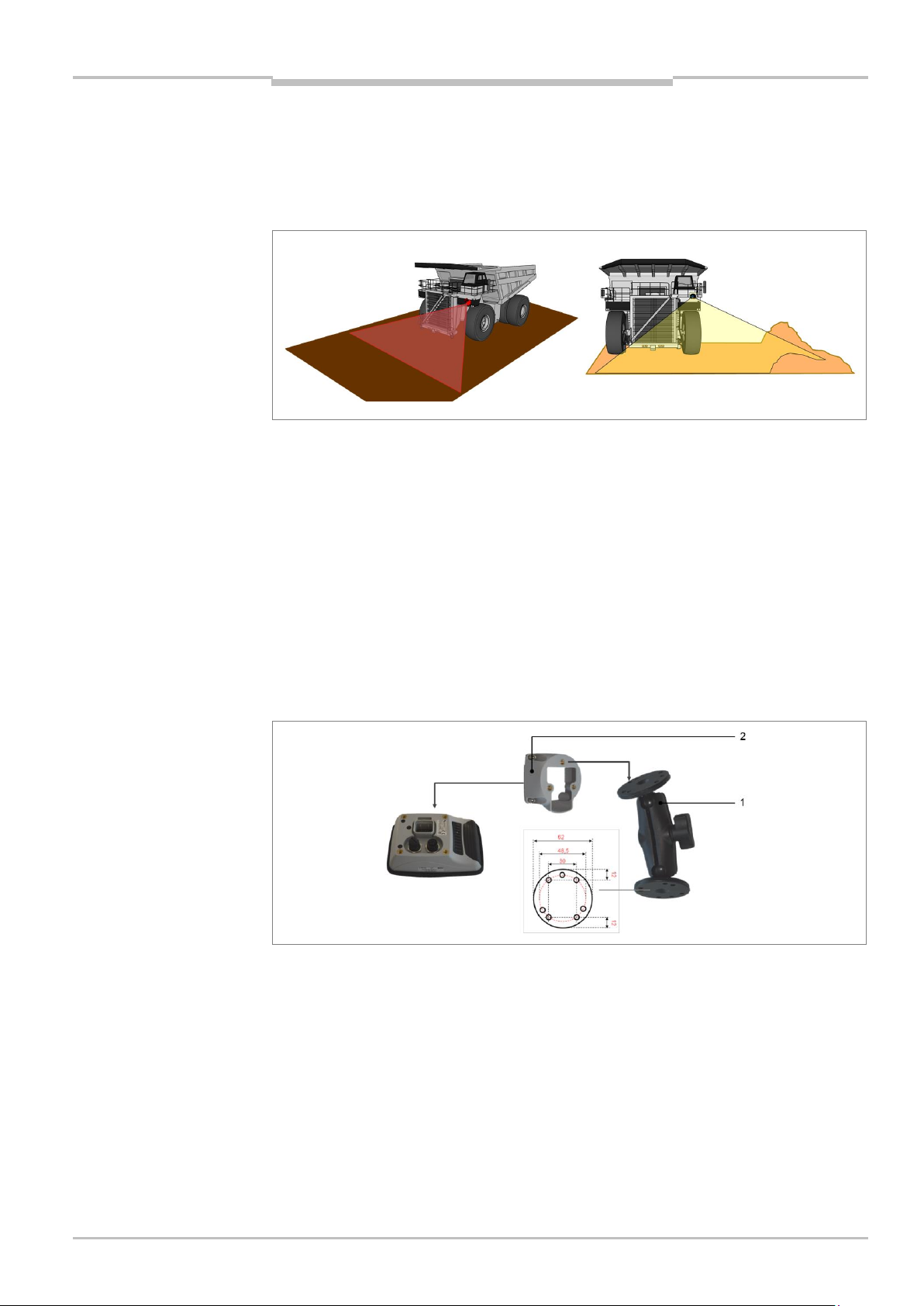

3.3.3 Road Departure Warning

The Road Departure Warning (RDW) function monitors the distance between the truck and

the left roadside barrier, i.e. bund walls. If the truck violates the set safety distances to

either side, a warning is issued to the driver. Broken bund wall or big rocks at the mine site

are be filtered automatically by the system for a smooth operation. The road boarder is

detected by the 2D LiDAR sensor LMS151 RDW.

Fig. 11: Road Departure Warning Function with In-Lane Symbol

The 2D LiDAR sensor must identify the bund wall to activate this function. Two green

blocks to the left and right of the truck on the display are indicating that the truck is in

lane.

RDW Pause Signal

The system provides a pause signal input. The signal is muting the alarm unit for the

following 30 seconds.

18 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 19

Operating Instructions Chapter 3

Product description

Note

TPS

RDW Flash Lights (Optional)

Two relay outputs are provided on two 2-wire cables for connection to external RDW signal

lights on the left and right front of the truck.

If the truck is in lane, both RDW lights are illuminated continuously

If the truck is moving unintentionally too close to the left bund wall, only the right light is

illuminated. The left RDW light will not be illuminated anymore.

In case of unintentional read departure to the right (center of the lane), only the left

RDW light is illuminated. The right RDW light is not illuminated anymore. This informs

truck drivers in the opposite direction that the truck is leaving the lane.

3.3.4 Black Spot Warning

TPS provides a function to mark mine site areas with GPS positions. Each GPS position

defines a position in world coordinates with a circular area around it. This area is called

“black spot” (1). This function can be used for two purposes:

On mine site may be locations where the road departure warning system has no usable

roadside barrier as a side reference. These locations may be crossroads,

loading/unloading or construction areas. These areas may be marked by their positions,

disabling the RDW function in their vicinity and thus suppressing false warnings.

Also the position is used for “black spot” marking and identification. Black spots are

hazardous areas like intersections, construction areas, crushers and workshops. TPS

warns the operator when the truck is entering a black spot to raise operator’s attention.

If the black spot is activated for the area the truck is currently placed or driving, the GPS

position is stored and a black spot with the radius of 80m (by default) is created and

stored.

Inside black spot areas, the driver may also disable all acoustic warnings (2). Therefore,

the speaker-icon is shown while the truck is inside the black spot area. Pressing this icon

disables all sound output.

The sound output is automatically turned on again when leaving the black spot area. This

function may be used to mute TPS while the truck is in maintenance in a workshop.

Note that for the correct function of black spots, GPS must be available.

8021799/2017-09-26 Operating Instructions | SICK 19

Subject to change without notice

Fig. 12: Black Spot Warning

Page 20

Chapter 3 Operating Instructions

Product description

Display

Meaning

LMS151 measuring and no error reported

LMS151 is either not in measuring mode (stopped by the user) or it is

running in measuring mode, but errors have occurred

OFF: no contamination (optics cover)

ON: contamination warning

Blinking: contamination error

Not used

Not used

TPS

3.4 Status indicators

2D LiDAR sensor

The 2D LiDAR sensor is fully automated in normal operation — no operator intervention is

required. The LEDs (1) signal the operational status of the 2D LiDAR sensor. In addition,

the 7-segment display (2) is also available for diagnostics when errors or faults occur

(see chapter 9.2 Fault indicators of the LMS151).

Fig. 13: Status indicators for the LMS511

Tab. 2: Status indicators of the LMS151

20 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 21

Operating Instructions Chapter 3

Product description

TPS

Operator display

The operator display distinguishes between two operating modes. The system enters

configuration mode when it is first started or following unlocking via the web interface.

It contains assistants for the configuration of the LiDAR sensor, the vehicle dimensions

and the supervisor setup.

In the operating mode, the display assists the operator with collision awareness, driver

assistance and for setting black spot warnings.

Fig. 14: The operator display in configuration and operating mode

Tone buzzer

The tone buzzer does not have any status indicators.

The DIP switch on the underneath of the housing can be used to set the tone selection (1)

and the volume (2).

Recommended settings: OFF, ON, ON, OFF, ON (01101)

Fig. 15: DIP switch on the tone buzzer

Additional information on this can be found in the appendix in chapter 10.3 Tone

selection for tone buzzer.

8021799/2017-09-26 Operating Instructions | SICK 21

Subject to change without notice

Page 22

Chapter 4 Operating Instructions

Mounting

NOTE

WARNING

Important note

Note

TPS

4 Mounting

4.1 Function test before mounting

Before mounting the TPS components on the truck, it is recommended that the functional

readiness of the devices should be checked.

1. Place the components on a table.

2. Connect the components according to the wiring diagram (see chapter 5.1 Wiring plan).

3. Establish the supply voltage and check the general operational readiness of the

components (see chapter 6.1 Launching the system).

It is recommended that the length of the cable should be checked in advance.

The control cabinet is equipped with fuses both in the 24 V and ground voltage supply

lines. If any of these fuses blow, disconnect from power immediately and check for the

cause.

4.2 Mounting the LiDAR sensor

The reliable and problem-free operation of the system depends primarily on the proper

mounting and alignment of the LiDAR sensor.

Be sure to closely observe the following notes during mounting:

Mount the LiDAR sensor so that it is protected from dirt and damage.

Ensure that the field of vision of the entire optics cover is not restricted.

Always mount the LiDAR sensors such that you are able to insert and remove the

connectors.

Avoid excessive shock and vibration loading on the LiDAR sensor.

In the event of heavy vibration, prevent the fixing screws from accidentally coming loose

using screw-locking devices.

The fine alignment is carried out later during the commissioning with the support of a

setup assistant (see chapter 6.4 Configuring the LiDAR sensors).

Make sure that the screws are easily accessible for fine alignment.

22 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 23

Operating Instructions Chapter 4

Mounting

TPS

Mounting LD-MRS HD Front and Rear

Mounting is carried out using the supplied mounting kit with shock absorber (2) for the LDMRS. For mounting the LD-MRS (1) safely at the mounting location, 4 M6 screws with

washers and lock washers are required. The supply voltage of the LD-MRS must be

switched off.

Fig. 16: Mounting the LD-MRS using mounting kit with shock absorber

Mounting LMS151 RDW

Mounting is carried out using the supplied mounting kit with shock absorber (2) for the

LMS151 RDW. For mounting the LMS151 RDW (1) safely at the mounting location, 4 M5

screws with washers and lock washers are required. The supply voltage of the LMS151

RDW must be switched off.

8021799/2017-09-26 Operating Instructions | SICK 23

Subject to change without notice

Fig. 17: Mounting the LMS151 RDW using mounting kit with shock absorber

Page 24

Chapter 4 Operating Instructions

Mounting

Note

Note

TPS

Mounting LD-MRS HD Front to the vehicle

The frontal sensor must be mounted at the very front of the truck, with its area of view

unobstructed in driving direction. The mounting height must be chosen so that relevant

objects, such as pick-up trucks, are within the area of view.

Fig. 18: Mounting position of the LD-MRS HD Front

For the best 3D LiDAR sensor coverage also of the very near proximity in front, the

mounting position marked in blue should be considered.

Please avoid obstructions due to the ladder etc. Recommended mounting height is approx.

1.7 m. Additional protective measures for the scanner would be required for this mounting

height (e.g. mud coverage etc.)

Mounting LD-MRS HD Rear to the vehicle

The rear collision protection system monitors the area directly behind the truck for

obstacles. The 3D LiDAR sensor is typically mounted above the rear axle of the truck

pointing downwards at an angle of about 45 degrees.

The scanner should be mounted close to the rear center of the truck.

24 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Fig. 19: Mounting position of the LD-MRS HD Rear

The exact angle is defined by its mounting height and will be adjusted during system

setup. Please avoid unnecessary obstructions.

Page 25

Operating Instructions Chapter 4

Mounting

Note

TPS

Mounting LMS151 RDW to the vehicle

The Road Departure Warning (RDW) LiDAR sensor must be mounted at the front of the

truck, towards the left side. The sensor is mounted with a tilt angle of approximately 35

degrees downwards as its field of view must include the road surface in front of the truck

as well as the left-side road barrier/ wall.

Fig. 20: Mounting position of the LMS151 RDW

The exact angle is defined by its mounting height and will be adjusted during system

setup. Please avoid unnecessary obstructions.

4.3 Mounting the bracket for the operator display

The operator display is mounted in the truck cab. It must be clearly visible for the truck

driver without them having to turn their head.

The operator display is mounted using the mounting kit included with delivery. This means

that the display is additionally protected against mechanical shocks.

The mounting kit is made up of the bracket (1) and an adapter (2) to hold the operator

display.

Fig. 21: Mounting the operator display

8021799/2017-09-26 Operating Instructions | SICK 25

Subject to change without notice

Page 26

Chapter 4 Operating Instructions

Mounting

Note

Note

TPS

Assemble the bracket and mount in the driver's cab

1. Assemble the individual components of the bracket as shown in the figure.

2. Mount the bracket in the vehicle. In order to do this, screw the foot of the bracket tight

in a suitable location in the truck cab.

The adapter and operator display are mounted during the electrical installation.

The connecting cables have to be inserted into the operator display in a later step. (see

chapter 5.4 Connecting the operator display).

4.4 Mount the control cabinet

The control cabinet must be mounted in a dry and cool position in the inside of the truck

e.g. inside the cabin behind the operator or passenger seat. It is not intended for outside

mounting.

Before mounting the control cabinet, check that all components can be reached by the

supplied cables.

26 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Fig. 22: Mounting the control cabinet

Page 27

Operating Instructions Chapter 4

Mounting

TPS

4.5 Mount the GPS receiver

The GPS receiver - with integrated antenna - must be mounted on the outside of the truck.

It must be in possible best clear view of the sky, but protected from mechanical

destruction like falling rocks. The recommended place is along the front railing of the

truck.

Fig. 23: Mounting the GPS receiver

4.6 Mounting the tone buzzer

Mount the tone buzzer in the operator cab behind the driver.

Fig. 24: Mounting the tone buzzer

8021799/2017-09-26 Operating Instructions | SICK 27

Subject to change without notice

Page 28

Chapter 5 Operating Instructions

Electrical installation

HAZARD

HAZARD

TPS

5 Electrical installation

Disconnect the power to the system

Make sure that all TPS components are disconnected from the voltage supply

during electrical installation.

Risk of injury due to electrical current

Standard safety requirements must be met when working on electrical systems.

The voltage supply must be disconnected when attaching and detaching electrical

connections.

5.1 Wiring plan

Establish the connections in accordance with the following wiring plan. Connect the

components according the wiring connection overview inside the control cabinet.

28 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Fig. 25: TPS wiring plan

Page 29

Operating Instructions Chapter 5

Electrical installation

TPS

8021799/2017-09-26 Operating Instructions | SICK 29

Subject to change without notice

Fig. 26: TPS wiring connection overview (inside control cabinet)

Page 30

Chapter 5 Operating Instructions

Electrical installation

No.

Connection

Description

1

Ethernet

Ethernet connection to a control cabinet

2

Data interfaces/synchronization

Not assigned

3

Power

Connection to the control cabinet

TPS

5.2 Connecting the LD-MRS front and rear LiDAR sensor

The 3D LiDAR sensor LD-MRS Front and LD-MRS Rear mounted on the front resp. on the

rear are connected to the control cabinet for power and the Ethernet connection.

The LD-MRS Front and Rear have the following connections:

Fig. 27: LD-MRS connections

Tab. 3: LD-MRS connections

Connection to voltage supply

The cable to connect the LD-MRS Front and Rear to the voltage supply has a round plug-in

connector on one side. The other side has an open end.

30 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Fig. 28: Connecting the LD-MRS to the control cabinet

1. Connect the round plug-in connector the connecting cable on the LD-MRS to the Power

female connector.

2. Run the connecting cable from the 3D LiDAR sensor to the control cabinet.

3. Connect the LD-MRS to the terminal block inside the control cabinet.

Page 31

Operating Instructions Chapter 5

Electrical installation

Wire color

Connection Terminal Block

Voltage supply

LD-MRS Front

LD-MRS Rear

Yellow

13

14

+24 V (Voltage)

Gray

13

14

+24 V (Voltage)

White

3 4 0 V (Ground)

Blue

3 4 0 V (Ground)

No.

Connection

Description

1

Power

Connection to the voltage supply

2

Data

Not assigned

3

I/O

Not assigned

4

Ethernet

Connection to the network

TPS

Place the wires in the control cabinet as follows.

Tab. 4: Connecting the LD-MRS Front and Rear to the voltage supply

Connection to Ethernet switch

Connect the 3D LiDAR sensor Front and Rear with the Ethernet switch inside the control

cabinet. Use the connecting cable with the round plug-in and the RJ45 connector.

Fig. 29: Connecting the LMS511 to the Ethernet switch

1. Connect the round plug-in connector into the female Ethernet connector of the 3D

LiDAR sensor.

2. Run the Ethernet cable from the 3D LiDAR sensor to the control cabinet.

3. Connect the RJ45 connector into a free port on the Ethernet switch.

5.3 Connecting the LMS151 RDW LiDAR sensor

The 2D LiDAR sensor LMS151 RDW mounted on the front for road departure warning is

connected to the control cabinet for power and the Ethernet connection.

The LMS151 RDW has the following connections:

Fig. 30: LMS151 connections

Tab. 5: LMS151 connections

8021799/2017-09-26 Operating Instructions | SICK 31

Subject to change without notice

Page 32

Chapter 5 Operating Instructions

Electrical installation

Wire color

Connection Terminal Block

Voltage supply

Brown

15

+24 V (Voltage)

White

15

+24 V (Voltage)

Blue

5

0 V (Ground)

Black

5

0 V (Ground)

Note

TPS

Connection to voltage supply

The cable to connect the LMS151 RDW to the voltage supply has an M12 plug connector

on one side. The other side has an open end with a shield.

Fig. 31: Connecting the LD-MRS to the control cabinet

1. Screw the M12 round connector of the connecting cable on the LMS151 to the Power

female connector.

2. Run the connecting cable from the 2D LiDAR sensor to the control cabinet.

It is recommended that cable shielding should be used for bundled and safe installation

of the cables.

3. Connect the LD-MRS to the terminal block inside the control cabinet.

Place the wires in the control cabinet as follows.

Tab. 6: Connecting the LMS151 RDW to the voltage supply

Connection to Ethernet switch

Connect the 2D LiDAR sensor RDW with the Ethernet switch inside the control cabinet. Use

the connecting cable with the M12 plug connector and the RJ45 connector.

Fig. 32: Connecting the LMS511 to the Ethernet switch

1. Screw the M12 round connector into the female Ethernet connector of the 2D LiDAR

sensor.

2. Run the Ethernet cable from the 2D LiDAR sensor to the control cabinet.

3. Connect the RJ45 connector into a free port on the Ethernet switch.

32 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 33

Operating Instructions Chapter 5

Electrical installation

Pin

Wire no.

Description

POWER

1 1 24 V

2 2 24 V

3 3 GND

4 4 GND

Pin assignment

TPS

5.4 Connecting the operator display

The operator display mounted in the operator's cab is connected to the voltage supply and

the Ethernet switch inside the control cabinet.

Fig. 33: Connecting the operator display

Tab. 7: Operator display – pin allocation of the connecting cable

Ethernet connecting cable

The Ethernet cable for connecting the display and control cabinet has an angled M12 male

connector (for connection on the display side) and a RJ45 connector (for connection on the

control cabinet).

8021799/2017-09-26 Operating Instructions | SICK 33

Subject to change without notice

Fig. 34: Connecting the operator display to the control cabinet

Page 34

Chapter 5 Operating Instructions

Electrical installation

TPS

Inserting cables on the operator display

Fig. 35: Inserting connecting cables on the operator display

1. Run the two connectors through the opening of the adapter.

2. Connect the female connector of the connecting cable into the male connector of the

operator display. Check that the plug connector is securely attached.

3. Insert the angled male connector of the connecting cable into the female connector of

the operator display and screw together the plug connector.

Mounting the adapter

After the cabling, mount the adapter on the operator display.

Fig. 36: Mounting the adapter on the operator display

1. Place the adapter on the reverse of the operator display.

2. Secure the adapter to the operator display using the four supplied screws.

34 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 35

Operating Instructions Chapter 5

Electrical installation

Wire no.

Connection Terminal Block

Voltage supply

1

16

+24 V (Voltage)

2

16

+24 V (Voltage)

3 6 0 V (Ground)

4 6 0 V (Ground)

Note

Note

TPS

Mounting the operator display on the bracket

Now mount the adapter with the operator display on the bracket.

Fig. 37: Mounting the adapter with the operator display on the bracket

1. Turn the bracket for mounting the operator display into a suitable position.

2. Place the adapter on the support plate of the bracket

3. Secure the adapter using the three supplied screws.

Connection to voltage supply

1. Run the power cable from the display to the control cabinet.

It is recommended that cable shielding should be used for bundled and safe installation

of the cables.

2. Connect the power cable to the voltage supply. Place the wires in the control cabinet as

follows.

Tab. 8: Connecting the operator display to the voltage supply

Connecting the Ethernet cable to the Ethernet switch

1. Run the Ethernet cable from the operator display to the Ethernet switch inside the

control cabinet.

It is recommended that cable shielding should be used for bundled and safe installation

of the cables.

2. Connect the RJ45 connector into a free port on the Ethernet switch.

8021799/2017-09-26 Operating Instructions | SICK 35

Subject to change without notice

Page 36

Chapter 5 Operating Instructions

Electrical installation

TPS

5.5 Connecting the GPS receiver

The GPS receiver mounted on the outside of the truck is connected to the GPS M8

connector inside the control cabinet.

Fig. 38: Connecting the operator display

1. Run the GPS receiver cable from the GPS receiver to the control cabinet.

2. Screw the M8 round connector into the female M8 connector in the control cabinet.

5.6 Connecting the tone buzzer

The tone buzzer is connected to the output siren cable from the control cabinet.

Fig. 39: Connecting the tone buzzer

For the connection, the tone buzzer is produced in the factory with three wires coming out

of it:

The connection to the 24 V supply voltage is carried out via the red wire. The wire is

extended using a conductor and run to the brown cable wire from the control cabinet.

The GND connection is carried out via the blue wire. This is connected to the blue cable

wire from the control cabinet.

The black wire is not connected.

36 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 37

Operating Instructions Chapter 5

Electrical installation

Wire color

Connection

Voltage supply

Brown

Voltage

+24 V

Blue

Ground

0 V

TPS

Accessories

The following accessories are required for connecting the tone buzzer:

Cable stripping knife

Wire stripper

2 connectors

Flat-head screwdriver

5.7 Connecting the control cabinet

Connect the control cabinet to the truck voltage supply. The connecting cable (Power IN,

Control cabinet) is connected to the control cabinet on one side. The other side has an

open end.

Fig. 40: Connecting the control cabinet to the voltage supply of the truck

1. Run the connecting cable from the control cabinet to the voltage supply of the truck.

2. Connect the control cabinet to the voltage supply.

Place the wires to the voltage supply as follows.

Tab. 9: Connecting the control cabinet to the voltage supply

8021799/2017-09-26 Operating Instructions | SICK 37

Subject to change without notice

Page 38

Chapter 5 Operating Instructions

Electrical installation

Wire color

Connection

Voltage supply

Brown

Voltage

+24 V

Blue

Ground

0 V

Wire color

Connection

Voltage supply

Brown

Voltage

+24 V

Blue

Ground

0 V

TPS

5.8 Connecting the reverse signal (optional)

Connect the control cabinet to the truck reverse gear signal. The connecting cable (Input,

Reverse signal) is connected to the control cabinet on one side. The other side has an

open end.

To activate the input signal, apply 24 V to this signal, ground reference is the GND of the

control cabinet voltage supply. Leave the signal input open to deactivate the signal.

Fig. 41: Connecting the control cabinet to the voltage supply of the truck

1. Run the connecting cable from the control cabinet to the reverse light cable of the truck.

2. Connect the control cabinet to the reverse light or reverse gear of the truck in parallel.

Place the wires to the voltage supply as follows.

Tab. 10: Connecting the control cabinet to the truck reverse light

5.9 Connecting the pause signal

Connect the control cabinet to any switch for the pause signal. The connecting cable

(Input, Pause) is connected to the control cabinet on one side. The other side has an open

end.

To activate the input signal close the wire with a key button or any switch. Leave the signal

input open to deactivate the signal.

1. Run the connecting cable from the control cabinet to a switch or key button.

2. Connect the wire to the switch or key button.

3. Close the brown and blue wire to active the pause signal.

Place the wires to the voltage supply as follows.

Tab. 11: Connecting the control cabinet to the voltage supply

38 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 39

Operating Instructions Chapter 5

Electrical installation

Wire color

Connection

Voltage supply

Brown

Voltage

+24 V

Blue

Ground

0 V

TPS

5.10 Connecting the RDW lights (optional)

Connect control cabinet to the RDW lights (optional) at the front of the truck. The

connecting cable for the left RDW signal lights (Flash Light Left, Sensor RDW) and the right

RDW signal lights (Flash Light Right, Sensor RDW) are connected to the control cabinet on

one side. The other sides have open ends.

1. Run the connecting cable from the control cabinet to the RDW lights.

2. Connect the wire to flash lights.

Place the wires to the voltage supply as follows.

Tab. 12: Connecting the control cabinet to the RDW lights

Fig. 42: Connecting the control cabinet to the RDW lights (optional)

8021799/2017-09-26 Operating Instructions | SICK 39

Subject to change without notice

Page 40

Chapter 6 Operating Instructions

Commissioning

WARNING

Note

TPS

6 Commissioning

No PC is required for initial commissioning.

Do not commission without testing by qualified safety personnel

Before you commission the system for the first time, you must have it checked and

approved by qualified safety personnel. Observe the notes provided in Chapter 2 Safety.

6.1 Launching the system

All system components are automatically launched when starting the truck and checked in

a self-test.

Fig. 43: Self-test of the system on the operator display

The system is ready for operation after approx. 60 seconds. A notification appears

informing you that the system has not yet been (completely) configured.

Fig. 44: Information about incomplete configuration

Warnings (optical and acoustical) may occur as the system setup is yet to be done. This is

no malfunction and can be ignored.

40 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 41

Operating Instructions Chapter 6

Commissioning

TPS

Start configuration

Press OK to confirm you have seen the notification.

TPS is started in the configuration mode. An overview page with the individual setup steps

is automatically displayed on the operator display.

Fig. 45: Configuration mode after launching for the first time

Display of the operational readiness of the devices

The LMS151 2D LiDAR sensor visualizes operational readiness via the green OK LED (1).

The 7-segment display is blank.

The operation LED (3) must illuminate on the operator display.

The LD-MRS 3D LiDAR sensor has no readiness visualization.

Fig. 46: Testing operational readiness of the devices

8021799/2017-09-26 Operating Instructions | SICK 41

Subject to change without notice

Page 42

Chapter 6 Operating Instructions

Commissioning

Function/symbol

Meaning

Vehicle setup

Opens the assistant for the configuration of the vehicle

size.

In addition, it is possible to set a vehicle ID.

Sensor setup

Opens the assistant for the configuration of the LD-MRS

Front, Rear and LMS151 RDW LiDAR sensors.

Zone setup

Opens the assistant for the configuration of the warning

zones.

Not OK

Indicates that the relevant setup step has not yet been

completed or has not been completed successfully.

OK

Indicates that the relevant setup step has been completed

successfully.

The parameters are permanently saved.

Reset

Resets all parameters to their factory settings.

Info

Shows, among other things, the version of the software and

the current system status.

In addition, it is possible to test the output and input

signals.

Quits the configuration mode and switches into the

operating mode for the person carrying out commissioning.

It is only possible for the person carrying out

commissioning to switch to the operating mode if all setup

steps have been successfully completed and marked with a

green check mark.

TPS

6.2 The operator display in configuration mode

The following functions are available in configuration mode:

Tab. 13: Functions in the configuration mode

42 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 43

Operating Instructions Chapter 6

Commissioning

Important Note

TPS

6.3 Making vehicle setup settings

Make the vehicle setup settings in the first step.

Click on the Vehicle setup icon. The Entering truck size setup page is opened.

Navigation

As soon as the entries have been completed on one assistant page, use the next icon to

navigate to the following page.

When changing the assistant page, the settings and information that have been provided

are temporarily saved.

Changing the truck size parameter on the following page will affect sensor mounting

positions. Truck size must be configured before sensor setup.

If truck size setup must be changed when sensors where already configured, all sensor

parameters must be checked afterwards.

Input the vehicle ID

The vehicle ID is usually a unique number for each vehicle within the mine site. This

number is displayed in the operator screen and written in the event log for identification.

The number is limited to 4 digits (0..9999).

Click on the plus or minus icon to set the desired number. The value displayed

increases or decreases by 1 with each click.

If you click and hold on the icon, the value automatically goes up or down in increments

of 1 (auto repeat).

Input truck size

Enter the truck dimensions in the appropriate places. Please use image shown on the

screen for reference.

The TPS is scalable and adjustable to different truck sizes and types. Therefore the

individual measures of the vehicle have to be configured.

8021799/2017-09-26 Operating Instructions | SICK 43

Subject to change without notice

Page 44

Chapter 6 Operating Instructions

Commissioning

Note

TPS

Saving settings

Click on the done icon. The settings are permanently saved in the system.

You will then be taken back to the overview page with the individual setup steps.

The setup step Vehicle setup now has a green check mark.

6.4 Configuring the LiDAR sensors

6.4.1 Starting sensor setup

When setting up the parameters for the LiDAR sensors, an assistant provides support for

all LiDAR sensors.

Click on the Sensor setup icon.

Sensor setup is done in a separate screen, showing all available sensors, a green check

mark or red not ok mark indicator is shown at each of them.

After the successful completion of any sensor setup, the indicator that was initially a red

not ok mark will turn to a green check mark.

44 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

The result of the sensor setup, displayed in the main setup page, will not turn to a green

check mark until all of the individual sensors have been successfully configured.

Navigation

As soon as the entries have been completed on one assistant page, use the next icon to

navigate to the following page.

When changing the assistant page, the settings and information that have been provided

are temporarily saved.

Page 45

Operating Instructions Chapter 6

Commissioning

Note

TPS

6.4.2 Front sensor set up

In order to detect different vehicle sizes from haul truck up to small service and utility

vehicles, the front 3D LiDAR sensor has to be adjusted to cover a large observation zone

dependent on the individual mounting position. The setup procedure assists the installing

personal accordingly.

Click on the Front icon.

In the front sensor setup, only position measurements of the sensor position are required.

Enter the appropriate values and complete setup.

Sensor Front: Mounting position

The system setup firstly requires the designation of the front scanner mounting position.

Click on the plus or minus icon to set the distances. The value displayed increases or

decreases by 5 cm with each click.

If you click and hold on the icon, the value automatically goes up or down in increments

of 5 (auto repeat).

Sensor Front: Adjustment

The system setup requires the adjustment of the front sensor.

Although it is not verified here, angular adjustment of the frontal sensor is critical to

achieve the desired range and accuracy of the warning zones. Please use care to manually

verify the mounting of the sensor.

8021799/2017-09-26 Operating Instructions | SICK 45

Subject to change without notice

Page 46

Chapter 6 Operating Instructions

Commissioning

TPS

Front Sensor: Pitch angle adjustment

For a high mounting position (e.g. above the air intake) apply a pitch angle (parallel to the

ground) up to 1 degree. The tilt angle should be about 1 degree.

Saving settings

Click on the done icon. The settings are permanently saved in the system.

You will then be taken back to the sensor setup page with the individual setup steps for

the LiDAR sensors.

The setup step Front now has a green check mark.

6.4.3 Rear sensor set up

In order to assist the operator in reversing e.g. against walls and crushers and to be able

to deliver an effective aid to the driver, the rear 3D LiDAR sensor has to be adjusted to

cover the area behind the tires according to the mounting position.

Click on the Rear icon.

The setup procedure therefore assists the installer. The rear sensor setup comprises 3

steps:

Position setup: In this step, the mounting position of the sensor is defined.

Pitch angle setup: In this step, the pitch angle (downward tilt) of the scanner is verified

and must be tuned to match the required setting. This includes the mechanical

adjustment of the sensor pitch angle. Adjust the sensor as indicated until the green

signal is reached.

Aperture angle setup: The aperture angle of the rear sensor may be limited by the rear

wheels of the truck. During this setup step, the wheels are automatically detected and

removed from the sensors detection area. To begin the processing, press Start on the

setup page.

Rear Sensor Setup:

The system setup requires the designation of the rear scanner mounting position.

46 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Page 47

Operating Instructions Chapter 6

Commissioning

Note

TPS

Click on the plus or minus icon to set the distances. The value displayed increases or

decreases by 5 cm with each click.

If you click and hold on the icon, the value automatically goes up or down in increments

of 5 (auto repeat).

Rear sensor: Adjustment preparation

Place the vehicle on flat ground. Make sure no person or object is standing behind the

vehicle.

Rear sensor: Pitch angle

The system further assists the installer in guiding through the pitch angle calibration

procedure.

Indicates that the pitch angle is too small. Increase the pitch angle of the rear 3D LiDAR

sensor downwards until the level indicator is green.

Indicates that the pitch angle is too large. Decrease the pitch angle of the rear 3D LiDAR

sensor upwards until the level indicator is green.

Failure to reach a green indicator will result in the overall setup to fail.

8021799/2017-09-26 Operating Instructions | SICK 47

Subject to change without notice

Page 48

Chapter 6 Operating Instructions

Commissioning

TPS

Rear sensor: View area adjustment

Press start to detect the limits (wheels) and to set the sensor angles. Make sure no person

or object is located behind the vehicle. The final result (status) needs to be Success in

order for the overall setup to be successful.

Saving settings

Click on the done icon. The settings are permanently saved in the system.

You will then be taken back to the sensor setup page with the individual setup steps for

the LiDAR sensors.

The setup step Rear now has a green check mark.

6.4.4 RDW sensor set up

Click on the RDW icon.

The 2D LiDAR sensor setup for the RDW comprises 2 steps:

Position setup: This step requires the designation of the RDW scanner mounting

position.

Pitch angle setup: This step assists the installing personal in offering an adjustment

check as an assistance function.

RDW Sensor Mounting position

The system setup requires the designation of the LMS151 RDW 2D LiDAR sensor

mounting position.

48 Operating Instructions | SICK 8021799/2017-09-26

Subject to change without notice

Click on the plus or minus icon to set the distances. The value displayed increases or

decreases by 5 cm with each click.

If you click and hold on the icon, the value automatically goes up or down in increments

of 5 (auto repeat).

Page 49

Operating Instructions Chapter 6

Commissioning

Note

TPS

Sensor RDW: Adjustment preparation

Place the vehicle on flat ground. Make sure no person or object is standing behind the

vehicle.

Sensor RDW: Pitch angle adjustment

The system further assists the installer in guiding through the pitch angle calibration

procedure.

1. Pitch angle (downward tilt) of the scanner is verified and must be tuned to match the

required setting. This includes the mechanical adjustment of the sensor pitch angle.

Adjust the sensor as indicated until the green signal is reached.

Failure to reach a green indicator will result in the overall setup to fail.