SICK TMS88 Series, TMS61 Series, TMM88 Series, TMS88A, TMM88A Operating Instructions Manual

...Page 1

TMS/TMM88, TMS/TMM61

Inclination sensors with CANopen interface

OPERATING INSTRUCTIONS

Page 2

Described product

1- and 2-dimensional inclina

tion sensors:

TMS88A

TMM88A

TMS88B

TMM88B

TMS88D

TMM88D

TMS61B

TMM61B

Manufacturer

SIC

G

K A

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

ork is protected by copyright. Any rights derived from the copyright shall be

This w

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

ument is an original document of SICK AG.

his doc

2

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 4

1.1 Function of this document....................................................................... 4

1.2 Explanation of symbols............................................................................ 4

2 Safety information............................................................................ 5

2.1 Intended use............................................................................................. 5

2.2 Incorrect use............................................................................................. 5

2.3 Requirements for the qualification of personnel.................................... 5

3 Overview............................................................................................. 6

4 Technical data.................................................................................... 7

4.1 Technical data for TMS88A/TMM88A..................................................... 7

4.2 Technical data for TMS88B/TMM88B.................................................... 8

4.3 Technical data for TMS88D/TMM88D.................................................... 10

4.4 Technical data for TMS61B/TMM61B.................................................... 11

5 Transport and storage....................................................................... 14

5.1 Transport................................................................................................... 14

5.2 Transport inspection................................................................................. 14

5.3 Storage...................................................................................................... 14

6 Mounting............................................................................................. 15

7 Connection......................................................................................... 16

8 Description of operation................................................................... 17

8.1 Function overview..................................................................................... 17

9 CANopen interface............................................................................ 18

9.1 Communication profile............................................................................. 18

9.2 Node IDs and COB IDs.............................................................................. 20

9.3 Layer setting services (LSS)..................................................................... 21

9.4 Network management: NMT.................................................................... 24

9.5 Service data objects (SDO)...................................................................... 28

9.6 Process data objects (PDO)..................................................................... 29

9.7 Object directory......................................................................................... 32

9.8 Error messages: Emergency.................................................................... 41

9.9 Automatic baud rate detection (to CiA AN-801)..................................... 42

9.10 Status LED (to CiA DR-303-3).................................................................. 43

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

3

Page 4

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Function of this document

These operating instructions are intended to give technical personnel working for the

machine manuf

installation, commissioning, and operation of the TMS/TMM61 and TMS/TMM88 incli‐

nation sensors.

These operating instructions do not provide information on operating the machine in

which an inclination sensor is integrated. For information about this, refer to the operat‐

ing instructions of the particular machine.

1.2 Explanation of symbols

Warnings in these operating instructions are labeled with symbols. The warnings are

int

oduced by signal words that indicate the extent of the danger. These warnings must

r

be observed at all times and care must be taken to avoid accidents, personal injury,

and material damage.

DANGER

… indica

injuries if not prevented.

tes a situation of imminent danger, which will lead to a fatality or serious

acturer or machine operator instructions on the mounting, electrical

WARNING

… indica

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indica

prevented.

NOTE

… hig

trouble-free operation.

tes a potentially dangerous situation, which may lead to a fatality or serious

tes a potentially harmful situation, which may lead to material damage if not

hlights useful tips and recommendations as well as information for efficient and

4

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 5

2 Safety information

2.1 Intended use

The TMS/TMM88 and TMS/TMM61 inclination sensors are measuring devices consist‐

ing of an e

the measuring devices are designed include recording inclinations in solar thermal

energy, photovoltaics or heavy-duty vehicle applications.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.2 Incorrect use

TMS/TMM88 and TMS/TMM61 inclination sensors do not constitute safety compo‐

nent

sensors must not be used in explosion-hazardous areas. Any other use that is not

described as intended use is prohibited. Any use of accessories not specifically

approved by SICK AG is at your own risk.

WARNING

Dan

Any incorrect use can result in dangerous situations.

Therefore, take note of the following information:

■

■

lectronic sensor and integrated evaluation electronics. The tasks for which

s in ac

ger due to improper use!

Inclination sensors should be used only according to intended use specifications.

All information in these operating instructions must be strictly complied with.

SAFETY INFORMATION 2

cordance with the EC Machinery Directive (2006/42/EC). The inclination

2.3 Requirements for the qualification of personnel

The personnel who work on and with the device must be suitably authorized, trained,

and suff

•

•

•

Table 1: Skilled personnel qualifications

Task Qualification

Mounting

Electrical installation

Commissioning, configura‐

t

iciently qualified. Skilled personnel refers to the following:

A member of staff who has received specialist training, which is backed up by

additional knowledge and experience.

A member of staff who knows the relevant technical terms and regulations.

A member of staff who can appraise the work assigned to them, recognize poten‐

tial hazards, and take suitable safety precautions.

hnical training

Tec

•

Knowledge of current workplace safety regulations

•

trotechnical training

Elec

•

Knowledge of the current electrotechnical workplace safety

•

regulations

Knowledge of the operation and control of the sensor in the

•

particular application

ec

hnical training

T

ion, and oper

ation

•

Knowledge of the operation and control of the sensor in the

•

particular application

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

5

Page 6

3 OVERVIEW

3 Overview

Properties

■

1-dimensional inclina

■

2-dimensional inclination sensor with measuring range: 90° (X/Y)

■

High sampling rate and bandwidth

■

High resolution (0.01°)

■

High accuracy (up to 0.02°)

■

Compensated cross sensitivity

■

Configurable vibration suppression

■

Intelligent and flexibly adaptable sensor fusion algorithm for dynamic applications

tion sensor with measuring range: 360° (±180°)

(TMS/TMM88D)

■

Convenient CANopen interface

Meets the requirements of CiA DS-301, device profile CiA DSP-410

°

Baud rates from 10 kbit/s up to 1 Mbit/s

°

Automatic baud rate detection

°

Setting of node ID and baud rate via LSS service

°

■

Functions:

One or two (TMS/TMM88D) Transmit PDOs: Can be mapped dynamically

°

(RTR, cyclic, event-driven, synchronized)

SYNC consumer (sync. sending of the Transmit PDOs following receipt of a

°

SYNC message)

EMCY producer fault monitoring using heartbeat or node guarding/lifeguard‐

°

ing

■

UV-resistant, impact-resistant plastic housing or compact and rugged aluminum

housing

■

Suitable for industrial use:

Temperature range: -40 °C to +80 °C

°

Enclosure rating: IP65/67 (TMS/TMM88D: IP67/69)

°

TMS 1-dimensional inclination sensors are used to measure inclinations in the 360°

range. TMM 2-dimensional inclination sensors are used to measure inclinations in 2

±90° ranges (X/Y). To ensure high levels of accuracy, the sensors are calibrated at the

factory.

A compact and rugged design makes the sensors an ideal solution for measuring

angles in harsh environments. They are compatible for use in all manner of applications

in industry and automotive engineering. All parameter settings can be made easily via

the CANopen interface or with the PGT-12-Pro hand-held programing tool.

Areas of application

■

A

ricultural and forestry machinery

g

■

Construction machinery and special-purpose vehicles

■

Solar thermal energy and photovoltaics

■

Automated guided systems

■

Crane and lifting technology

6

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 7

4 Technical data

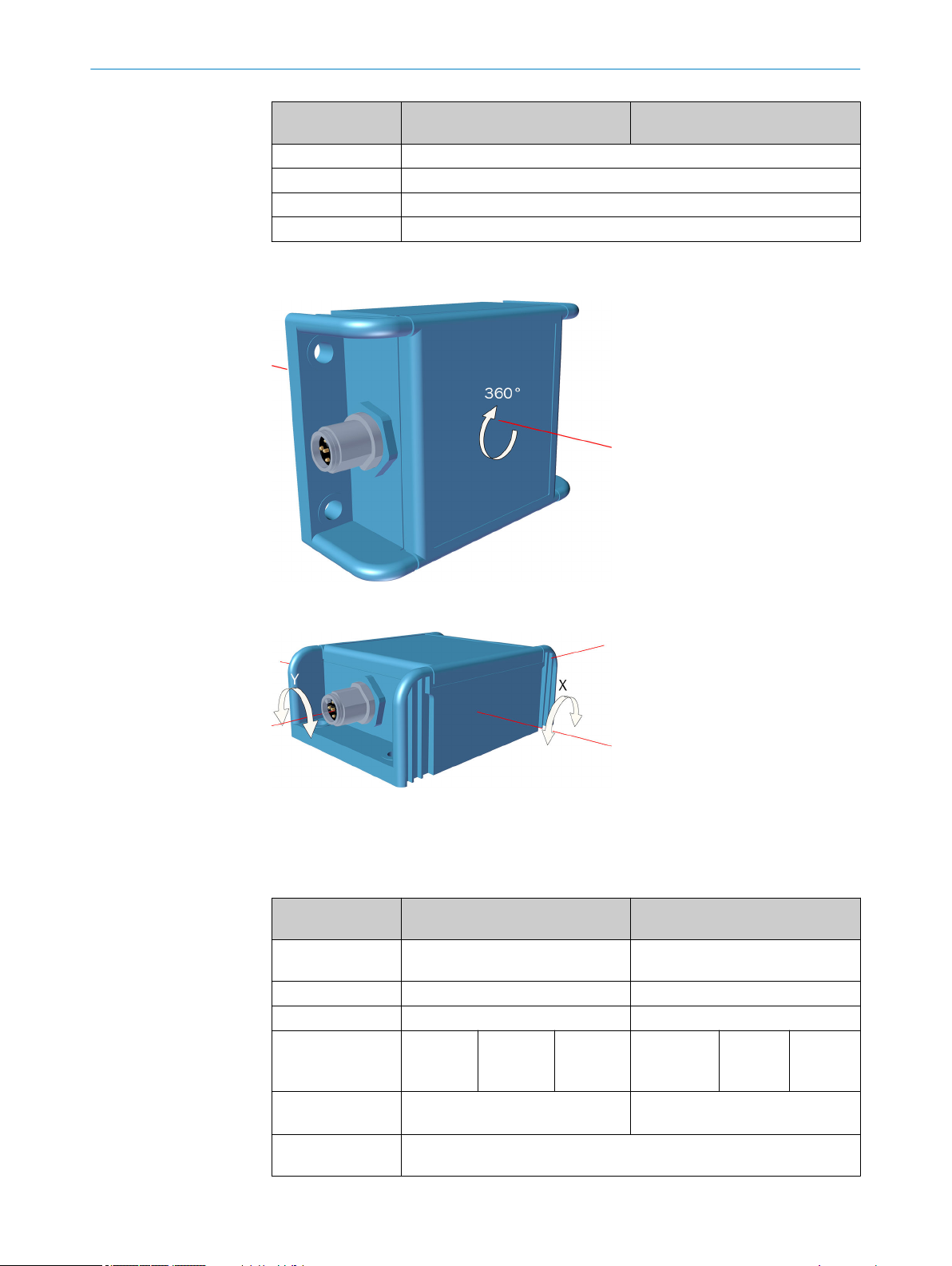

Notice

NOTE

This c

hapter contains an extract of the technical data. For full details, see the TMS/

TMM88 (8019180), TMS/TMM88 Dynamic (8023359), TMS/TMM61 and TMM55

product information.

4.1 Technical data for TMS88A/TMM88A

Table 2: Technical data for TMS88A/TMM88A

General parame‐

1)

s

ter

Number of measur‐

ing axes

Measuring ranges 360° ±90°

Resolution 0.01° 0.01°

Accuracy Range

Cross sensitivity

ated)

pens

(com

Temperature coeffi‐

cient (zer

Sampling rate 80 Hz

Limit frequency Typ. 20 Hz, 2nd order (no digital filter) / 0.1 ... 25 Hz, 8th order (with digi‐

Operating tempera‐

ture

Properties

Data rates 10 k, 20 k, 50 k, 62.5 k, 100 k, 125 k, 250 k, 500 k , 800 kbit/s,

Functions Polling of angle, cyclic and synchronized transmission,

Electrical parameters

Supply voltage 8 to 36 V DC

Current consump‐

tion

Mec

CAN connection 2 x 5-pin M12 plug connectors (male connector - female connector,

Enclosure rating IP65/67

Dimensions /

Weight

CANopen conformity

CiA DS-301, v4.2.0 Application layer and communication profile

o point)

hanical parameters

1 2

0...360°

- Typ. ±0.09° (±0.10%FS)

Typ. ±0.008°/K

ilter)

tal f

-40 °C to +80 °C

1 Mbit/s

omatic detection

Aut

al filter (critically damped (default) or Butterworth low pass, 8th

digit

order), configuration via object directory

<33 mA @ 24 V

looped thr

Large plastic housing: 66 mm x 90 mm x 36 mm / approx. 215 g

ough) to CiA 303-1

TECHNICAL DATA 4

TMS88A TMM88A

Typical

±0.04°

Maximum

±0.10°

Range

up to ±60°

o ±70°

up t

up to ±80°

up to ±85°

Max. ±0.45° (±0.50%FS)

Typical

±0.02°

±0.04°

±0.08°

±0.16°

Maximum

±0.05°

±0.10°

±0.20°

±0.40°

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

7

Page 8

4 TECHNICAL DATA

General parame‐

1)

ter

s

TMS88A TMM88A

CiA DS-410 Device profile for inclinometer

CiA DSP-305 Layer setting service (LSS) and protocols

CiA DR-303-3 Indicator specification (status LED)

CiA AN-801 Automatic bit-rate detection

1)

All specified angular accuracies apply after a run-in time of 10 min at 25 °C, limit frequency 0.3 Hz,

absolut

e calibration accuracy (at 25 °C): ±0.05°

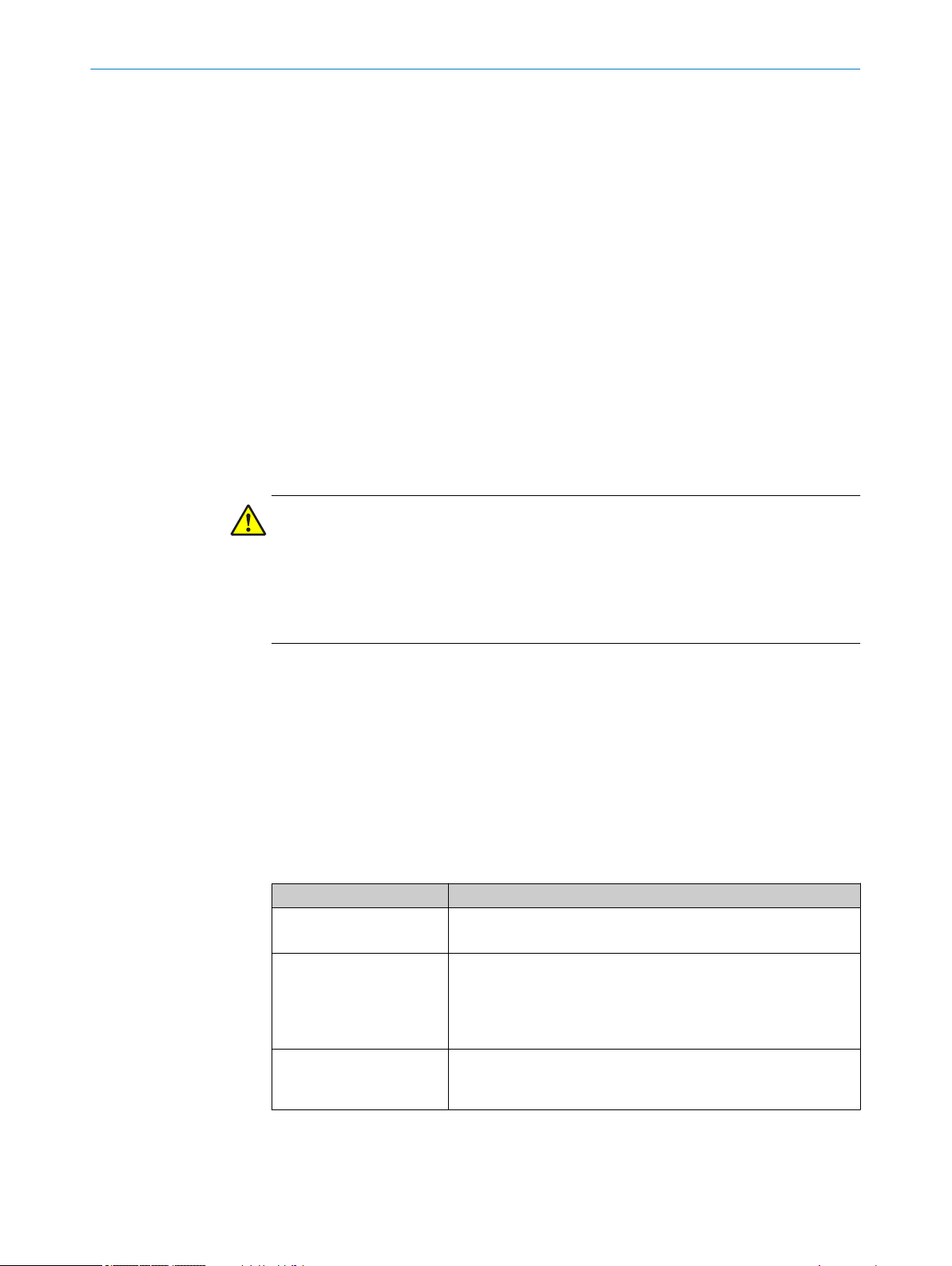

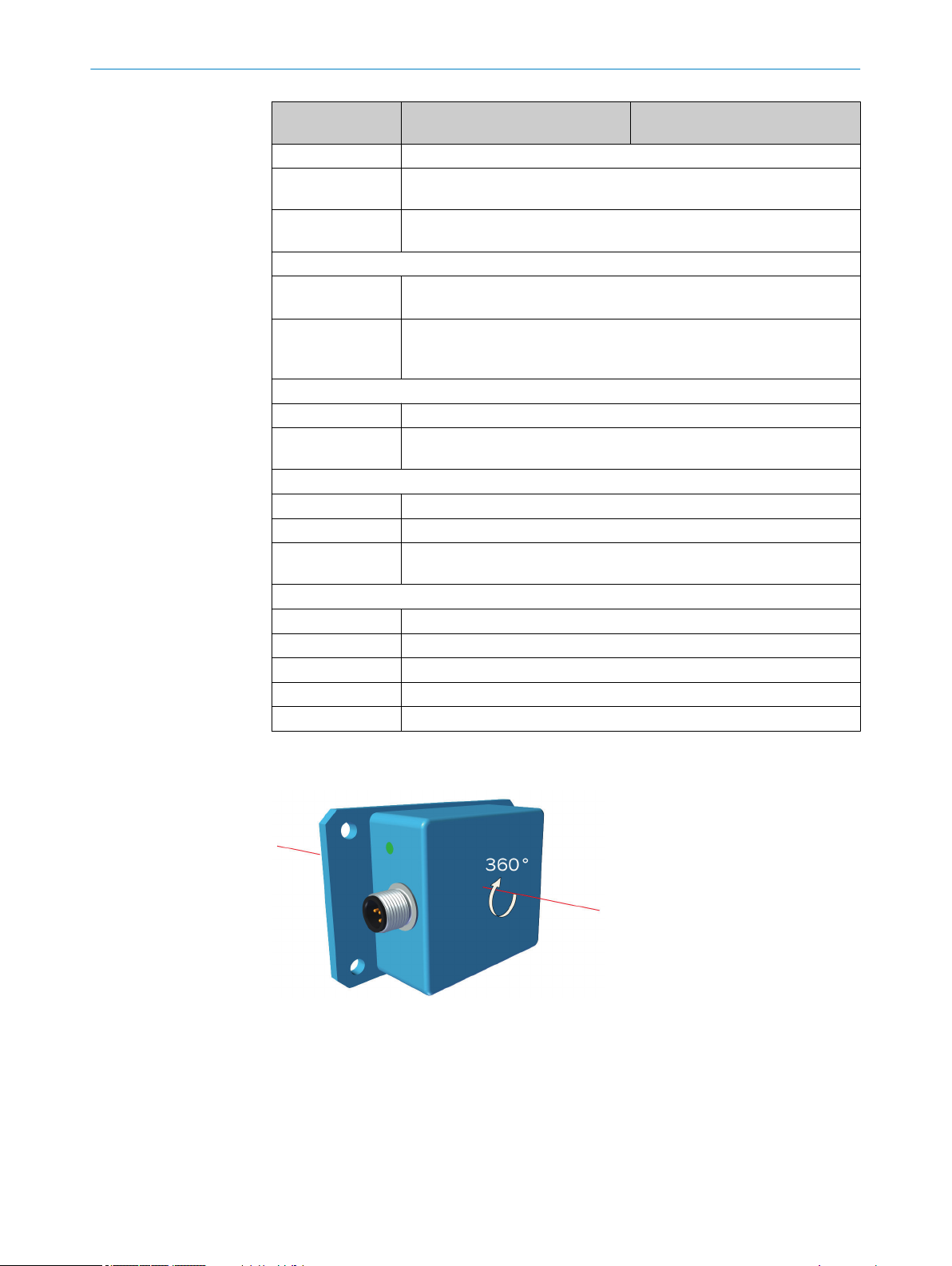

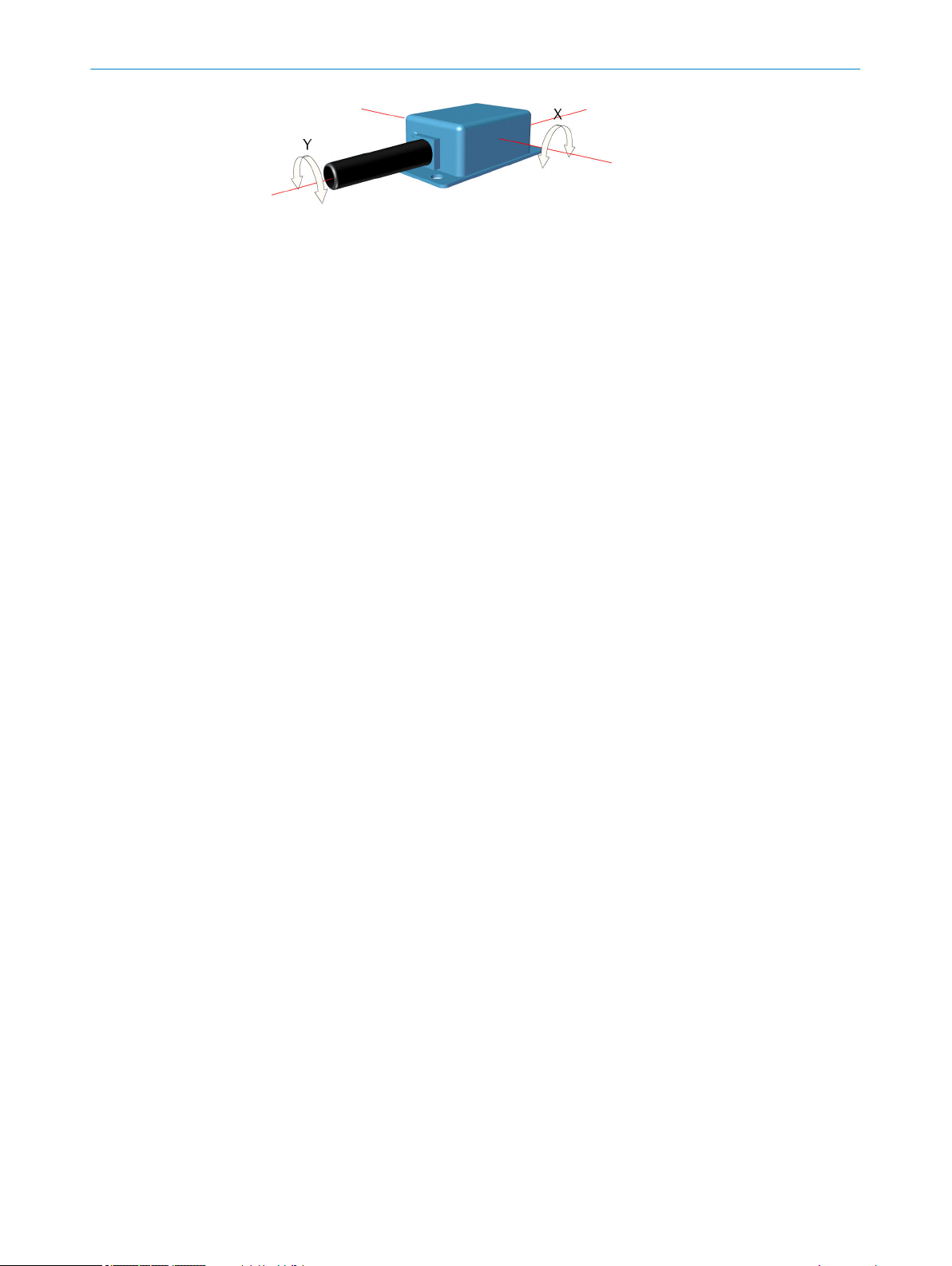

Figure 1: TMS88A measuring axis (large plastic housing)

Figure 2: TMS88A measuring axes (large plastic housing)

4.2 Technical data for TMS88B/TMM88B

Table 3: Technical data for TMS88B/TMM88B

General parame‐

1)

ters

Number of measur‐

ing axes

Measuring ranges 360° ±90°

Resolution 0.01° 0.01°

Accuracy Range

Cross sensitivity

pens

(com

ated)

Temperature coeffi‐

cient (zer

o point)

1 2

0...360°

- Typ. ±0.10° (±0.11%FS)

Typ. ±0.008°/K

TMS88B TMM88B

Typical

±0.15°

Maximum

±0.25°

Range

up to ±60°

o ±80°

up t

Typical

±0.10°

±0.20°

Max. ±0.20° (±0.22%FS)

Maximum

±0.20°

±0.30°

8

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 9

TECHNICAL DATA 4

General parame‐

1)

ter

s

TMS88B TMM88B

Sampling rate 80 Hz

Limit frequency Typ. 20 Hz, 2nd order (no digital filter) / 0.1 to 25 Hz, 8th order (with digi‐

ilter)

tal f

Operating tempera‐

-40 °C to +80 °C

ture

Properties

Data rates 10 k, 20 k, 50 k, 62.5 k, 100 k, 125 k, 250 k, 500 k, 800 kbit/s, 1 Mbit/s

omatic detection

Aut

Functions Polling of angle, cyclic and synchronized transmission,

al filter (critically damped (default) or Butterworth low pass, 8th

digit

order), configuration via object directory

Electrical parameters

Supply voltage 8 to 36 V DC

Current consump‐

<16 mA @ 24 V

tion

hanical parameters

Mec

CAN connection 1 x 5-pin M12 sensor plug connector (male connector)

Enclosure rating IP65/67

Dimensions /

ght

Wei

Aluminum housing: 58 mm x 90 mm x 31 mm / approx. 200 g

CANopen conformity

CiA DS-301, v4.2.0 Application layer and communication profile

CiA DS-410 Device profile for inclinometer

CiA DSP-305 Layer setting service (LSS) and protocols

CiA DR-303-3 Indicator specification (status LED)

CiA AN-801 Automatic bit-rate detection

1)

All specified angular accuracies apply after a run-in time of 10 min at 25 °C, limit frequency 0.3 Hz,

e calibration accuracy (at 25 °C): ±0.05°

absolut

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

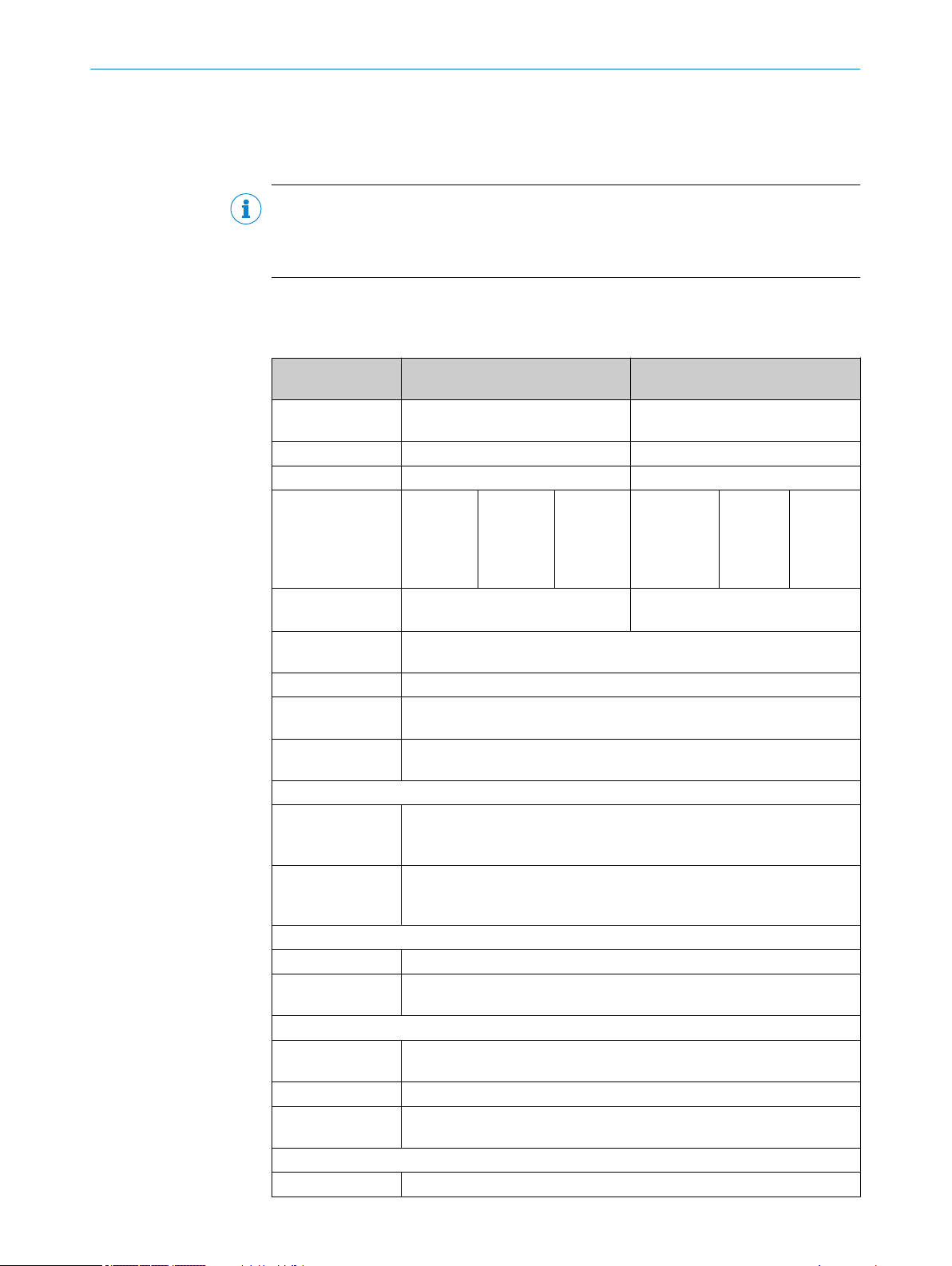

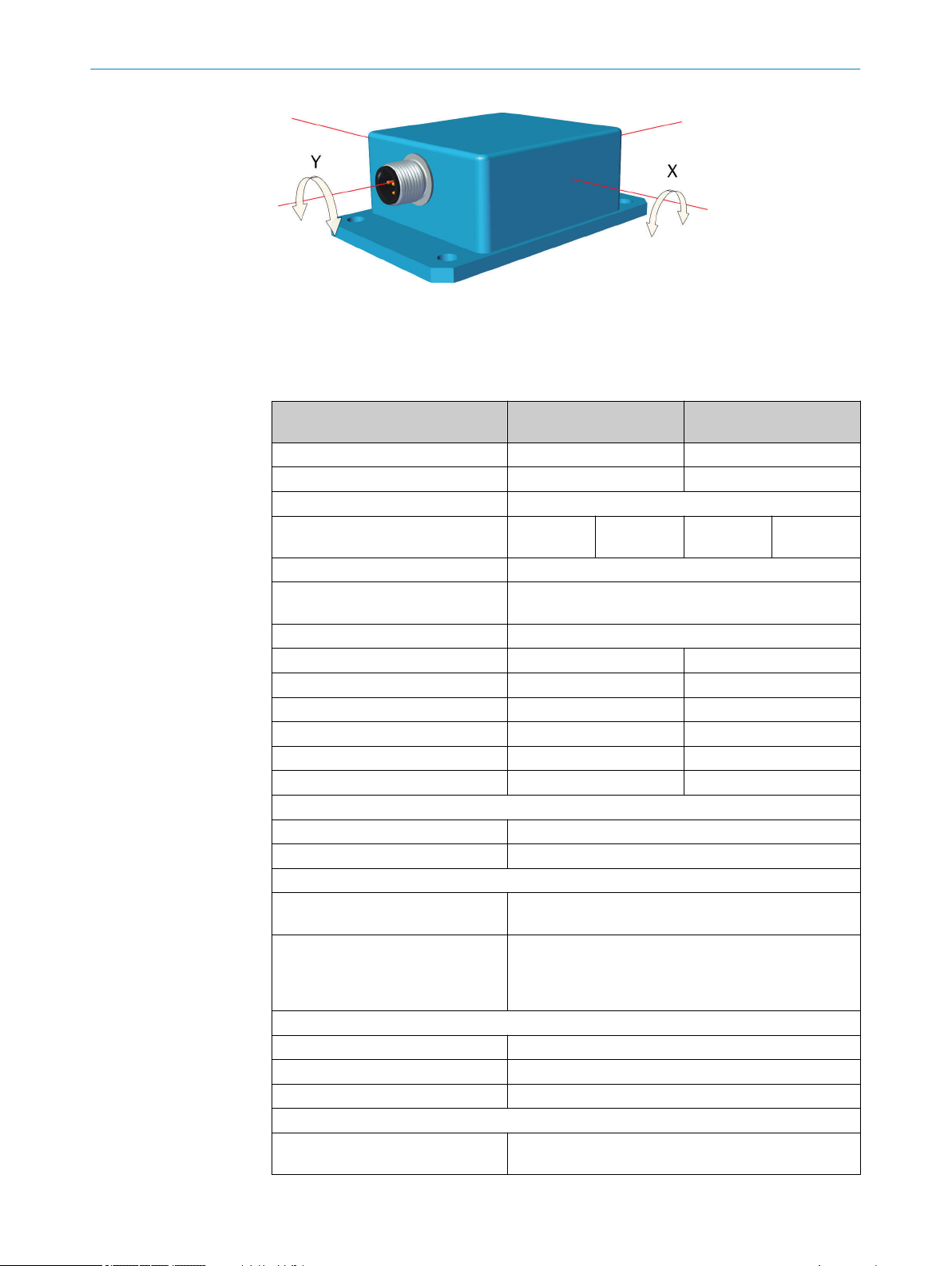

Figure 3: TMS88B measuring axis (aluminum housing)

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

9

Page 10

4 TECHNICAL DATA

Figure 4: TMM88B measuring axis (aluminum housing)

4.3 Technical data for TMS88D/TMM88D

Table 4: General parameters for the dynamic inclination sensor

General parameters for the dynamic

inclina

tion sensor

Number of measuring axes 1 2

Measuring ranges 360° ±90°

Resolution 0.01°

Static accuracy

Dynamic accuracy ±0.5° (typical)

Duration of spurious acceleration

ssion (configurable)

suppre

Temperature coefficient (zero point) ±0.01°/K (typical)

General parameters for the IMU

Measuring ranges ±8 g ±250 °/s

Resolution 0.244 mg 0.00875 °/s

In run bias stability – 6 °/h (typical)

Angular random walk (ARW) – 0.2 °⁄√h

Temperature coefficient (zero point) 0.2 mg/K (typical) 0.005 °/s/K (typical)

General parameters

Sampling rate 200 Hz

Operating temperature -40 °C to +80 °C

Properties

Data transmission rates

Functions

Electrical parameters

Supply voltage 8 to 36 V DC

Current consumption 15 mA @ 24 V

Maximum output current 350 mA

Mechanical parameters

Electrical connection

1

2

TMS88D TM88D

±0.3° (typi‐

cal)

±0.5° (ma

mum)

±0.3° (typi‐

cal)

±0.5° (maxi‐

mum)

xi‐

100 to 10000 ms

Acceleration sensor Gyro sensor

10k, 20k, 50k, 100k, 125k, 250k, 500k, 800k bit/s,

1 Mbit/s; A

utomatic detection

Polling of angle, cyclic and synchronized transmission,

terization, sensor fusion filter, digital low pass fil‐

parame

ter (critically damped or Butterworth, 8th order), configu‐

ration via a digital interface

2 x sensor plug connectors, 5-pin M12 (male connector female c

onnector, looped through)

10

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 11

TECHNICAL DATA 4

General parameters for the dynamic

inclina

tion sensor

1

TMS88D TM88D

Enclosure rating IP67/69

Dimensions of large plastic housing 66 mm x 90 mm x 36 mm

Weight approx. 200 g

CANopen conformity

CiA DS-301, v4.2.0 Application level and communications profile

CiA DS-410 Device profile for inclinometer

CiA DSP-305 Layer setting service (LSS) and protocols

CiA DR-303-3 Indicator specification (status LED)

CiA AN-801 Automatic bit rate detection

1

All specified angular accuracies apply after a run-in time of 10 min. at 25 °C, absolute calibration accu‐

y (at 25 °C): ±0.05°

rac

2

All specified accuracies apply after a run-in time of 10 min. at 25 °C

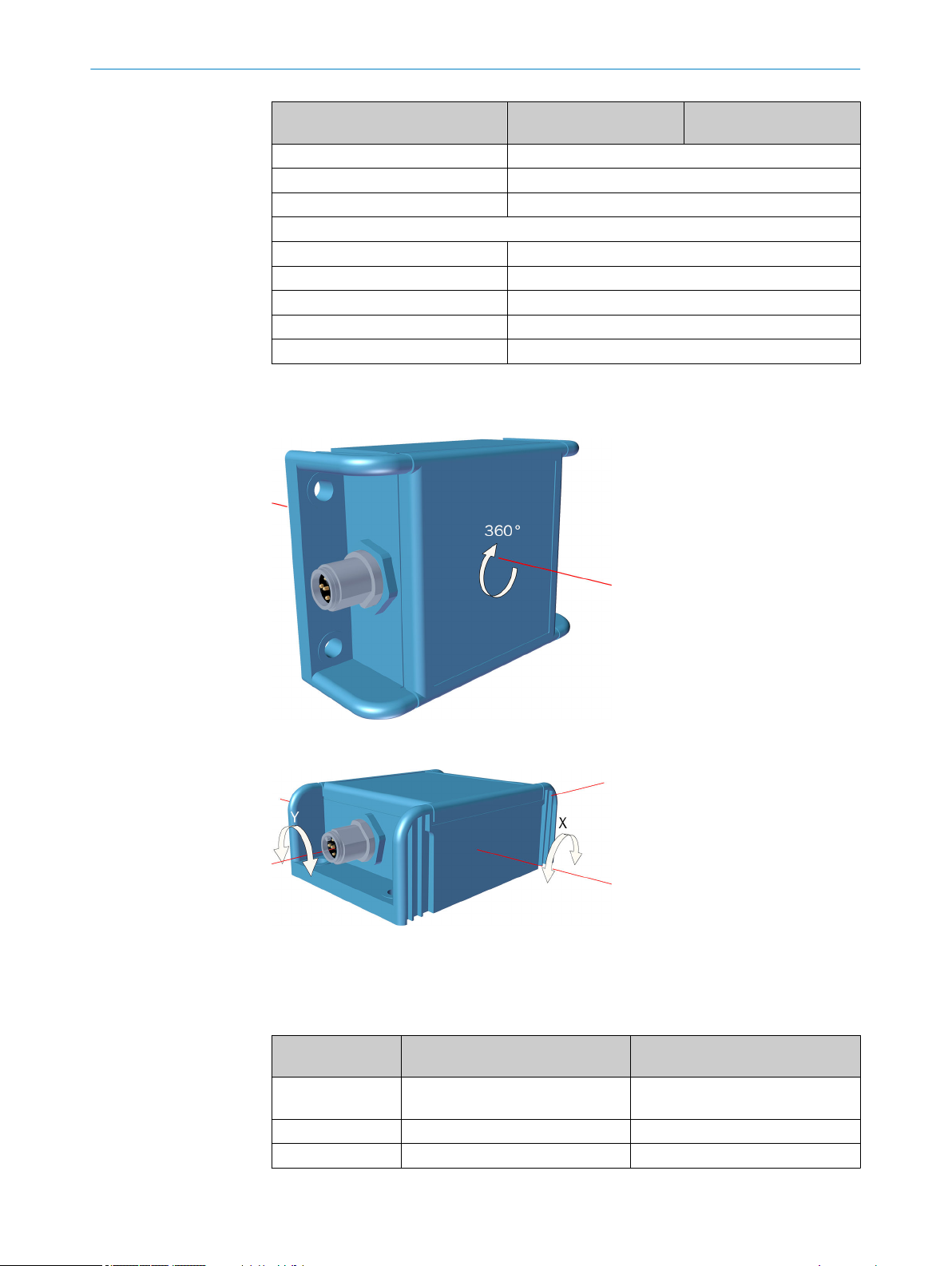

Figure 5: TMS88D measuring axis (large plastic housing)

Figure 6: TMM88D measuring axes (large plastic housing)

4.4 Technical data for TMS61B/TMM61B

Table 5: Technical data for TMS61B/TMM61B

General parame‐

1)

s

ter

Number of measur‐

ing axes

Measuring ranges 360° ±90°

Resolution 0.01° 0.01°

1 2

TMS61B TMM61B

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

11

Page 12

4 TECHNICAL DATA

General parame‐

1)

ter

s

Accuracy Range

0...360°

Cross sensitivity

pens

(com

ated)

Temperature coeffi‐

cient (zer

o point)

- Typ. ±0.09° (±0.10%FS)

Typ. ±0.01°/K

TMS61B TMM61B

Typical

±0.15°

Maximum

±0.25°

Range

up to ±60°

up to ±80°

Typical

±0.10°

±0.20°

Max. ±0.45° (±0.50%FS)

Maximum

±0.20°

±0.30°

Sampling rate 80 Hz

Limit frequency Typ. 20 Hz, 2nd order (no digital filter) / 0.1 to 25 Hz, 8th order (with digi‐

ilter)

tal f

Operating tempera‐

-40 °C to +80 °C

ture

Properties

Data rates 10 k, 20 k, 50 k, 62.5 k, 100 k, 125 k, 250 k, 500 k, 800 kbit/s, 1 Mbit/s

omatic detection

Aut

Functions Polling of angle, cyclic and synchronized transmission,

al filter (critically damped (default) or Butterworth low pass, 8th

Digit

order), configuration via object directory

Electrical parameters

Supply voltage 8 to 36 V DC

Current consump‐

<16 mA @ 24 V

tion

hanical parameters

Mec

CAN connection Cable, 5-wire, 0.2 m, with 5-pin M12 male connector

Enclosure rating IP65/67

Dimensions /

ght

Wei

Small plastic housing: 68 mm x 36.3 mm x 20.7 mm / approx. 80 g (with

cable)

CANopen conformity

CiA DS-301, v4.2.0 Application layer and communication profile

CiA DS-410 Device profile for inclinometer

CiA DSP-305 Layer setting service (LSS) and protocols

CiA DR-303-3 Indicator specification (status LED)

CiA AN-801 Automatic bit-rate detection

1)

All specified angular accuracies apply after a run-in time of 10 min at 25 °C, limit frequency 0.3 Hz,

e calibration accuracy (at 25 °C): ±0.05°

absolut

12

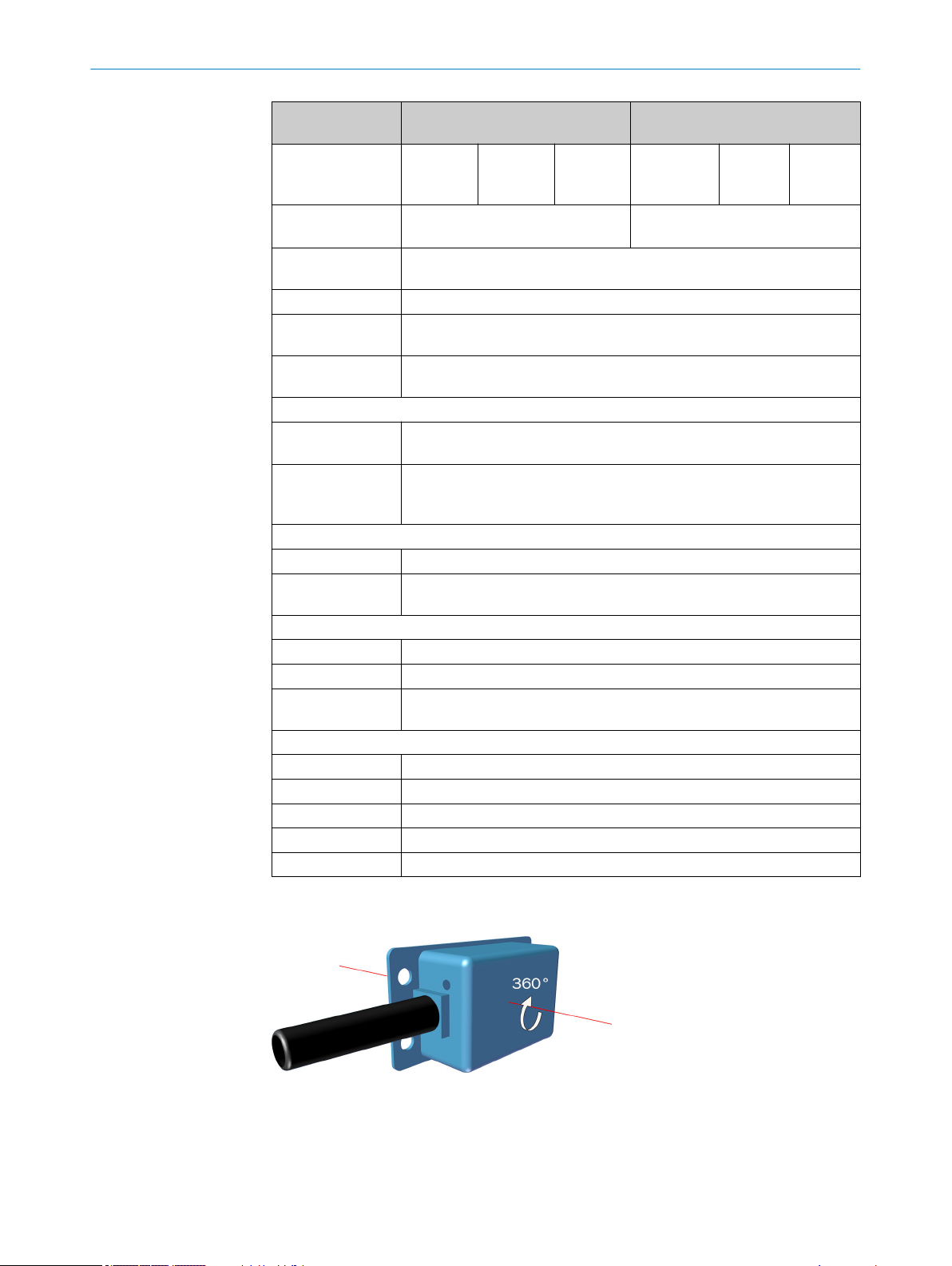

Figure 7: TMS61B measuring axis (small plastic housing)

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 13

Figure 8: TMS61B measuring axis (small plastic housing)

TECHNICAL DATA 4

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

13

Page 14

5 T

RANSPORT AND STORAGE

5 Transport and storage

5.1 Transport

For your own safety, please read and observe the following notes:

NOTE

Dama

ge to the device due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

5.2 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

dama

ge that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany's delivery note.

■

File a complaint.

5.3 Storage

NOTE

plaints regarding defects should be filed as soon as these are detected. Damage

Com

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

ecommend

R

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

For storage periods of longer than 3 months, check the general condition of all

ation: Use the original packaging.

components and packaging on a regular basis.

14

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 15

6 Mounting

4 x 45°

58 (2.28)

45 (1.77)

10

(0.39)

75 (2.95)

90 (3.54)

4 x Ø 5.4

(0.21)

90 (

3.54)

75 (2.95)

45 (1.77)

R 2,9

66 (2.60)

68 (2.68)

47.7 (1.88)

57.7 (2.27)

Ø 5 (0.20)

19.7 (0.78)

33.9 (1.33)

36.3 (1.43)

MOUNTING 6

Layout of the fixing holes

The hole

s for screw-mounting the sensor are located in the baseplate of the inclination

sensor (dimensions in mm).

Figure 9: Fixing holes, aluminum housing

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Figure 10: Fixing holes, large plastic housing

Figure 11: Fixing holes, small plastic housing

NOTICE

e is a risk of damage to the housing if inadequate lifting accessories are used!

Ther

Use suitable washers for plastic housings.

•

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

15

Page 16

1

2

3

4

5

2

1

4

5

3

7 CONNECTION

7 Connection

Plug connector pin assignment

TMS/

with a standard 5-pin M12 round male connector (A-coded). TMS/TMM61 inclination

sensors are supplied with a 20 cm long cable at the end of which there is a 5-pin M12

round male connector (A-coded). TMS/TMM88A and TMS/TMM88D inclination sensors

also have a 5-pin M12 female connector (A-coded). The pin assignment corresponds to

CiA DR-303-1.

Table 6: CANopen M12 male connector pin assignment

TMM88A, TMS/TMM88B and TMS/TMM88D inclination sensors are equipped

Pin Signal Pin assignment

1 CAN_SHLD Screen

2 CAN_V+ Supply voltage (+24 V)

3 CAN_GND GND / 0 V / V-

4 CAN_H CAN_H bus cable

5 CAN_L CAN_L bus cable

Table 7: CANopen M12 female connector pin assignment

Pin Signal Pin assignment

1 CAN_SHLD Screen

2 CAN_V+ Supply voltage (+24 V)

3 CAN_GND GND / 0 V / V-

4 CAN_H CAN_H bus cable

5 CAN_L CAN_L bus cable

Bus terminator

NOTE

The inc

16

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

lination sensors do not have an internal terminator.

Subject to change without notice

Page 17

8 Description of operation

8.1 Function overview

The inclination sensors have a standardized CANopen interface according to CiA

DS-301 and a de

meters can be accessed via the object directory (OD). The individual configuration can

be saved in the internal permanent memory (EEPROM). The following CANopen func‐

tions are available:

■

One or two (TMS/TMM88D) sending data objects (Transmit PDOs), dynamically

mappable to four possible operating modes:

■

■

■

■

■

One service data object (standard SDO)

■

Error messages based on emergency object (EMCY) with support:

■

■

■

■

Monitoring mechanisms: heartbeat as well as node guarding / lifeguarding

■

Save and restore functions for all parameters (store and load parameter field)

■

Status and error display via bi-color LED (according to CiA DR-303-3)

vice profile according to CiA DS-410. All measured values and para‐

Specific request via remote transmit request (RTR) message

Cyclic transmission based on interval time

Event-controlled transmission on inclination change

Synchronous transmission following receipt of a SYNC message

Of the general error register

Of the manufacturer specific status register

Of the pre-defined error field

DESCRIPTION OF OPERATION 8

There are more manufacturer-specific / profile-specific properties in addition to the CiA

DS-301 functionality:

■

Limit frequency (digital filter), freely configurable

■

Sensor fusion filter, freely configurable (TMS/TMM88D only)

■

Configuration of the minimum change in angle for Transmit PDO transmission

event

■

Change in direction of the inclination angle

■

Zero-point setting of the inclination angle

■

Setting of node ID and baud rate via LSS service according to CiA DSP-305

■

Automatic baud rate detection according to CiA AN-801

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

17

Page 18

Physical layer

Dat

a link layer

e.g., DS401

DSP 410

Device profile for inclinometer

e.g., DS 402

CAN Application Layer (CAL) defined by DS 301

9 CANOPEN INTERFACE

9 CANopen interface

9.1 Communication profile

The CANopen communication profile (documented in CiA DS-301) regulates how the

ices in a CANopen network exchange data.

dev

9.1.1 CANopen in the OSI model

The CANopen protocol is a standardized Layer 7 protocol for the CAN bus. This layer is

ba

sed on t

he CAN Application Layer (CAL).

Figure 12: CANopen in the OSI layers model

NOTE

yers 3 to 6 are not used in the CANopen definition.

La

9.1.2 Communication channels

CANopen features various communication channels (SDO, PDO, Emergency Messages).

T

se channels are formed with the help of the communication object identifier (COB

he

ID). The COB IDs are based on the node IDs of the individual devices on the CANopen

bus (see "Node IDs and COB IDs", page 20).

18

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 19

LSS, NMT

SDO, PDO, EMGY

Master

Node-ID = 0

Slave

Node-ID = 1 ... 127

Stub cables

P

LC

Trunk cable

End

CANOPEN INTERFACE 9

Figure 13: Master/slave model

a

yer setting services (LSS) are used to set the node ID of the inclination sensor

L

•

(see "Layer setting services (LSS)", page 21).

After this, the inclination sensor can be addressed via the network management

•

services (NMT) (see "Network management: NMT", page 24) and its CANopen

state machine can be switched to the necessary status (Pre-Operational, Opera‐

tional, or Stopped) by the master.

In Pre-Operational status, communication and configuration can be carried out via

•

service data objects (SDO) (see "Service data objects (SDO)", page 28). In Oper‐

ational status, communication is also possible via process data objects (PDO) and

emergency messages (EMGY).

9.1.3 Topology

T-connectors or Y-cables are used to integrate the inclination sensors into the CANopen

t

unk cable (the T-connectors are available as accessories). The trunk cable must be

r

terminated at the end. This is not necessary for the stub cables that are connected to

the sensors.

NOTE

Sinc

e TMS/TMM88A and TMS/TMM88D inclination sensors have a female connector

with looped-through CAN bus, they can also be integrated into the trunk cable without

the need for T-connectors or Y-cables.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Figure 14: Example: Network topology

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

19

Page 20

9 CANOPEN INTERFACE

9.1.4 Integrating an inclination sensor into a CANopen network

An ESD file makes it easy to link the inclination sensors to a CANopen master.

T

ile contains information on the following features of the inclination sensors:

his f

Information about the device manufacturer

•

Name, type and version number of the device

•

Type and version number of the protocol to be used for this device

•

Inclination sensor default parameters

•

Process data default configuration

•

Figure 15: ESD file integration

9.2 Node IDs and COB IDs

There can be a maximum of 128 devices on a CANopen network: one master and up to

127 slav

The COB IDs (communication object identifiers) of the communication channels are

derived from this ID.

Table 8: Overview of node IDs and COB IDs

Calculation of COB ID

[dec]

hex]

[

0 0 Network management Receive

128

0080h

128 + node ID

0080h + node ID

384 + node ID

0180h + node ID

640 + node ID

0280 + node ID

1408 + node ID

0580h + node ID

1536 + node ID

0600h + node ID

es. Every device has a unique node ID (node address).

ID ranges

[dec]

hex]

[

128

0080h

129 … 255

0081h … 00FFh

385 … 511

0181h … 01FFh

641 to 767

0280h to 02FF

1409 … 1535

0581h … 05FFh

1537 … 1663

0601h … 067Fh

Function Direction from the

point of view of the

sensor

SYNC Receive

gency message Transmit

Emer

ransmit PDO 1 Transmit

T

Transmit PDO 2 (TMS/

h

TMM88D only)

ransmit SDO Transmit

T

eceive SDO Receive

R

Send

20

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 21

CANOPEN INTERFACE 9

Calculation of COB ID

[dec]

he

x]

[

1792 + node ID

0700h + node ID

2020

07E4h

2021

07E5h

Example

The sensor r

eceives node ID = 5, then sends emergency messages via ID 133, Trans‐

mit PDO 1 via ID 389, and SDOs via ID 1413.

The layer setting services can be used to configure the node ID of the sensor (see

"Layer setting services (LSS)", page 21).

9.3 Layer setting services (LSS)

Layer setting services are supported to set the node ID and the baud rate of the inclina‐

t

ion sensor

The LSS slave is accessed via its LSS address (identity object), which is stored in object

1018h.

.

ID ranges

[dec]

hex]

[

1793 … 1919

0701h … 077Fh

2020

07E4h

2021

07E5h

Function Direction from the

point of view of the

sensor

N

ode guarding, heart‐

beat, boot up

Transmit LSS Transmit

Receive LSS Receive

Transmit

The LSS address comprises:

Manufacturer ID

•

Product code

•

Revision number

•

Serial number

•

The master uses the LSS services to request the individual services that are then exe‐

cuted by the inclination sensor. The LSS telegrams facilitate communication between

LSS master and LSS slave.

The following COB IDs are used:

07E4h = LSS slave to LSS master

07E5h = LSS master to LSS slave

Format of an LSS telegram

NOTE

An LSS t

elegram is always 8 bytes long. Byte 0 contains the command specifier (CS),

followed by 7 bytes for the data. All bytes that are not in use must be set to zero.

Table 9: Format of an LSS telegram

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

CS Data

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Switch Mode Global

The S

witch Mode Global command switches the configuration mode on or off. The com‐

mand remains unconfirmed and the inclination sensor does not respond.

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

21

Page 22

9 CANOPEN INTERFACE

Table 10: Format of the Switch Mode Global command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h 04h Mode 00h 00h 00h 00h 00h 00h

Byte 1 mode:

00h = Sw

itches LSS configuration mode off

01h = Switches to LSS configuration mode

Configure Node ID

T

his command is used t

Table 11: Format of the Configure Node ID command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h 11h Node ID 00h 00h 00h 00h 00h 00h

o set the node address.

Byte 1 node ID:

01h = node addre

ss 1

…

7Fh = node address 127

Response:

Table 12: Response to the Configure Node ID command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E4h 11h Error

code

Error

ext

00h 00h 00h 00h 00h

end

Byte 1 error code:

00h = Conf

iguration successful

01h = Parameter invalid

FFh = Contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific; it is always 00h in the case of the inclina‐

tion sensor.

Configure Bit Timing Parameters

T

his command is used t

Table 13: Format of the Configure Bit Timing Parameters command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h 13h 00h Table

o set the baud rate based on a baud rate table.

00h

index

00h 00h 00h 00h

Byte 1 table index from the baud rate table:

Table 14: Baud r

Table index Baud rate Supported

0 1,000 kbit/s Yes

1 800 kbit/s Yes

2 500 kbit/s Yes

3 250 kbit/s Yes

4 125 kbit/s Yes

ate table

22

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 23

CANOPEN INTERFACE 9

Table index Baud rate Supported

5 100 kbit/s Yes (TMS/TMM88D only)

6 50 kbit/s Yes

7 20 kbit/s Yes

8 10 kbit/s Yes

9 Automatic detection Yes

Response:

Table 15: R

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E4h 13h Error

Byte 1 error code:

esponse to the Configure Bit Timing Parameters command

code

Error

extend

00h 00h 00h 00h 00h

00h = Conf

iguration successful

01h = Parameter invalid

FFh = Contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific; it is always 00h in the case of the inclina‐

tion sensor.

Store Configuration

T

he command s

aves the configuration.

NOTE

The conf

iguration is not saved in the non-volatile memory (EEPROM). Object 1010h –

Save Parameters must be used in order to do this.

Table 16: Format of the Store Configuration command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h 17h 00h 00h 00h 00h 00h 00h 00h

Response:

Table 17: R

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E4h 17h Error

esponse to the Store Configuration command

00h 00h 00h 00h 00h

end

code

Error

ext

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Byte 1 error code:

00h = Stor

e successful

01h = Store Configuration command is not supported

02h = Error occurred during store operation

FFh = Contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific; it is always 00h in the case of the inclina‐

tion sensor.

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

23

Page 24

9 CANOPEN INTERFACE

Inquire LSS Address Service

This command c

an be used to read out the node ID of the inclination sensor and, from

object 1018h, the manufacturer ID, the product code, the revision number, and the ser‐

ial number.

Table 18: Format of the Inquire LSS Address Service command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h CMD 00h 00h 00h 00h 00h 00h 00h

Byte 0 CMD from the command table:

Table 19: C

CMD Parameter Subindex of object 1018h

5Eh Node ID

5Dh Serial number .4

5Ch Revision number .3

5Bh Product code .2

5Ah Vendor ID .1

ommand table

Response:

Table 20: R

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E4h CMD Data-X

esponse to the Inquire LSS Address Service command

Data-X Data-X Data-X

(LSB)

(MSB)

00h 00h 00h

NOTE

ata is 4 bytes long in little-endian byte sequence. If fewer than 4 bytes of data are

The d

read out, the remaining bytes are set to 0.

Identify Non-Configured Slave Device

The command is used t

Table 21: Format of the Identify Non-Configured Slave Device command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E5h 4Ch 00h 00h 00h 00h 00h 00h 00h

Response:

Table 22: Response to the Identify Non-Configured Slave Device command

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

07E4h 50h 00h 00h 00h 00h 00h 00h 00h

9.4 Network management: NMT

Network management (NMT) initializes the nodes in a CANopen network. It also adds

the node

There is only one NMT master (network management master) in a CANopen network. All

other devices, including the inclination sensor, are NMT slaves. The NMT master moni‐

tors all devices and can change their status.

s to the network, as well as stopping and monitoring them.

o identify non-configured devices.

24

A PLC or a PC usually serves as the NMT master.

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 25

9.4.1 CANopen state machine

Like every CANopen slave, the inclination sensor features what is known as a CANopen

s

ate machine. The following statuses can be identified:

t

Table 23: Status of the CANopen state machine

Status Description

Initializing Initialization commences. Both the device application and device

Pre-Operational The inclination sensor is ready for configuration; acyclic communi‐

Operational In this status, the inclination sensor is fully ready for operation and

Stopped In this status, the inclination sensor is not actively communicating

9.4.2 Network management services

CANOPEN INTERFACE 9

communica

switches to Pre-Operational status.

cation can take place via SDO. However, the inclination sensor is

not yet able to commence PDO communication and is not sending

out any emergency messages.

can transmit messages autonomously (PDOs, emergency mes‐

sages).

(althou

guarding).

tion are initialized. After this, the node automatically

gh communication is still being actively monitored via node

NMT services are used to switch between the individual statuses of the CANopen state

mac

. The NMT telegrams for device monitoring use the COB ID 0 and thus have the

hine

highest priority.

Table 24: Format of the NMT telegram

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

00h CCD Node ID 00h 00h 00h 00h 00h 00h

Table 25: Meaning of byte 0

Byte 0, CCD Parameter

01h Start Remote Node

s the inclination sensor to Operational status.

Set

02h Stop Remote Node

s the inclination sensor to Stopped status and stops it communicating

Set

(although communication is still being actively monitored via node guard‐

ing).

80h Enter Pre-Operational

s the inclination sensor to Pre-Operational status. All communication

Set

channels except the PDOs can be used.

81h Reset Node

sets the values of the profile parameters to the default values. After this,

Re

the inclination sensor switches to Reset Communication status.

82h Reset Communication

s the inclination sensor to Reset Communication status. After this, the

Set

inclination sensor switches to Initialization status.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

25

Page 26

Switch on or reset

Initialization

Pre-Operational

Operational

Stopped

9 CANOPEN INTERFACE

Transitions between the individual operating statuses

Figure 16: Process diagram of status changes

Table 26: T

Transition Description

1 After switching on, the inclination sensor switches to Initialization status.

2 After Initialization, the inclination sensor automatically switches to Pre-Oper‐

3 and 8 The Start Remote Node command switches the inclination sensor to Opera‐

4 and 7 The Enter Pre-Operational State command resets the inclination sensor to

5 and 6 The Stop Remote Node command switches the inclination sensor to

9, 10, and 11 The Reset Node command switches the inclination sensor to Initialization

12, 13, and 14 The Reset Communication command switches the inclination sensor to Ini‐

9.4.3 Boot-up message

To signal that the device is ready for operation following switching on, a “boot-up mes‐

s

a

permanently linked to the set device address (700h + node ID).

ransitions between operating statuses

at

ional status.

tional status.

-Operational status.

Pre

Stopped status.

status.

zation status.

tiali

ge” is sent out. This message uses the ID of the NMT error control protocol and is

9.4.4 Node guarding and heartbeat

26

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

The inclination sensor can be monitored permanently with the node guarding protocol

or t

artbeat protocol.

he he

Subject to change without notice

Page 27

CANOPEN INTERFACE 9

NOTE

It is not pos

lel with a single node. If the heartbeat time parameter of object 1017h is not equal to

0, the heartbeat protocol is used.

Node guarding

sible to use the node guarding protocol and the heartbeat protocol in paral‐

The node guar

ding telegram is sent to poll the status of the inclination sensor at regular

intervals. The sensor responds within the response time configured in objects 100Ch

(guard time) and 100Dh (life-time factor).

This time is referred to as the node life time. It is calculated as follows:

“Node life time” = “guard time” x “life-time factor”

If the inclination sensor does not send a response within this time, the connection is

considered to have been lost.

Table 27: Format of the node guarding telegram

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

700h +

node ID

Table 28: Meaning of byte 0

Byte 0, status Parameter

Bit 7 Toggle bit

Bits 6 ... 0 Operating status of the inclination sensor:

Status 00h 00h 00h 00h 00h 00h 00h

The bit c

127 = Pre

5 = Operational

4 = Stopped

0 = Boot Up

hanges its value every time it is polled.

-Operational

Example for an inclination sensor in Operational operating status:

85h, 05h, 85h = no err

or

85h, 05h, 05h = error

NOTE

If node guardin

g is active, the inclination sensor expects to receive a corresponding sta‐

tus query from an NMT master within a certain time frame. If it does not, the slave

switches to Pre-Operational status.

Heartbeat

If the he

artbeat telegram is used, the inclination sensor sends its status autonomously

at cyclic intervals. This can be monitored by every other node in the network.

The heartbeat time is configured with object 1017h.

Table 29: Format of the heartbeat telegram

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

700h +

node ID

Table 30: Meaning of byte 0

Byte 0, status Parameter

Bit 7 Toggle bit

Status 00h 00h 00h 00h 00h 00h 00h

T

hanges its value every time it is polled.

he bit c

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

27

Page 28

9 CANOPEN INTERFACE

Byte 0, status Parameter

Bits 6 ... 0 Operating status of the inclination sensor:

NOTE

Hear

tbeat has a significant influence on the bus load of the CANopen network but only

generates half the bus load of node guarding.

9.5 Service data objects (SDO)

Service data objects (SDO) form the communication channel through which device

parame

SDOs can be used to transmit data of any length. The data might have to be split into

several CAN messages. An SDO is always transmitted with confirmation, i.e. the receipt

of every message is acknowledged by the receiver.

Transmit SDO and Receive SDO

ters are transmitted. They are used for status queries.

127 = Pre

5 = Operational

4 = Stopped

0 = Boot Up

-Operational

The inc

lination sensor has a Transmit SDO channel and a Receive SDO channel, to

which two CAN identifiers are assigned.

SDO communication corresponds to the client-server model. The inclination sensor

functions as an SDO server.

In its request, the SDO client (e.g., the PLC) specifies the parameter, the access method

(read/write), and the value, if applicable. The inclination sensor executes read or write

access and responds to the request.

The maximum data length of a CAN telegram of 8 bytes is assigned by an SDO as fol‐

lows:

Table 31: Format of the SDO telegram

COB-ID CCD Index Subinde

x

600h +

node ID

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Data

The command code (CCD) identifies whether read or write access is required. In the

ev

ent of an error, the data range will contain a 4-byte error code which provides infor‐

mation about the cause of the error.

28

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 29

Request

R

esponse

CANOPEN INTERFACE 9

Figure 17: Example request/response telegram

In the e

xample, the inclination sensor (ID = 5) receives the read request (CCD = 40h)

for object 1000h from the PLC via ID 0605h (Receive SDO 0600h + inclination sensor

ID).

The inclination sensor responds by sending ID 0585h (Transmit SDO 0580h + inclina‐

tion sensor ID) with feedback (CCD = 43h).

9.6 Process data objects (PDO)

Process data objects (PDO) are used for rapid and efficient data exchange of real-time

d

ta (e.g., I/O data, setpoint values or actual values).

a

PDOs are transmitted without confirmation.

The inclination sensor supports one or two (TMS/TMM88D) transmit PDOs.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

29

Page 30

Transmit-PDO

9 CANOPEN INTERFACE

Figure 18: Structure of the Transmit PDO

Table 32: Format of the PDO telegram

COB-ID Data

0180h +

node ID

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

9.6.1 PDO mapping

The format of the PDO telegram between master and inclination sensor must be agreed

t

ough what is known as PDO mapping. The process data can be arranged at will in

hr

the PDO message. The address (i.e. index and subindex) and the size (number of bits)

from the entry in the object directory are entered in the mapping object for this pur‐

pose.

Example:

Object 1A00h is factory-set to contain the following objects, depending on sensor type:

6010.00h - inclination value, axial (TMS) or longitudinal (TMM)

6020.00h - inclination value, lateral (TMM only)

The content of the objects is transmitted in the Transmit PDO telegram.

Table 33: Example Transmit PDO telegram (TMS)

COB-ID Data

0180h +

node ID

Table 34: Example Transmit PDO telegram (TMM)

COB-ID Data

0180h +

node ID

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Inclination value,

axial

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Inclination value

udinal

longit

Inclination value

lateral

N

ot used

Not used

30

The following objects can be mapped in the TPDOs:

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 31

CANOPEN INTERFACE 9

Table 35: Mappable objects

Index Subindex Size Description Format

0x3100 1 16 Euler angle: pitch signed, 0.01°/bit

0x3100 2 16 Euler angle: roll signed, 0.01°/bit

0x3101 1 16 Quaternion: w signed, 1/30000 / bit

0x3101 2 16 Quaternion: x signed, 1/30000 / bit

0x3101 3 16 Quaternion: y signed, 1/30000 / bit

0x3101 4 16 Quaternion: z signed, 1/30000 / bit

0x3102 1 16 Acceleration, x-axis signed, 1/4096g / bit

0x3102 2 16 Acceleration, y-axis signed, 1/4096g / bit

0x3102 3 16 Acceleration, z-axis signed, 1/4096g / bit

0x3103 1 16 Yaw rate, x-axis signed, 7/800°/s /

bit

0x3103 2 16 Yaw rate, y-axis signed, 7/800°/s /

bit

0x3103 3 16 Yaw rate, z-axis signed, 7/800°/s /

bit

0x6010 0 16 Slope long16 signed, 0.01°/bit

0x6020 0 16 Slope lateral16 signed, 0.01°/bit

0x6511 0 8 Temperature signed, 1K/bit

9.6.2 PDO data transmission

The PDOs can be transmitted cyclically or acyclically. This is determined by the Transmit

P

DO and t

Synchronized data transmission

In synchronized data transmission, the process data is transmitted with the SYNC mes‐

sages. The cycle is formed from a multiple of the SYNC messages. The factor can be

between 1 and 240.

Cyclic data transmission

In cyclic data transmission, the inclination sensor sends the PDO at defined intervals.

The associated period duration is configured in object 1800.05h.

Acyclic data transmission

For acyclic data transmission, the inclination sensor is triggered by one of the following

criteria:

Application-specific / device-specific triggering

•

The sending of the PDO is triggered by an event. This event is defined in object

3001h (TPDO 1 only).

On request (RTR telegram)

•

In this case, another bus node (usually the master) requests the process data.

NOTE

For t

he inclination sensor to output the PDO cyclically or acyclically, the transmission

type must be changed in the Transmit PDO in object 1800.02h (see "Transmit PDO –

Transmission type (1800h/1801h)", page 35).

he transmission type defined in its subindex 02.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

31

Page 32

9 CANOPEN INTERFACE

9.7 Object directory

The object directory contains all data objects which can be accessed from outside and

h ha

whic

into three parts:

■

■

■

The parameters it contains can be read and written with the standard SDO based on

index and subindex.

The following sections describe all parameters in the object directory of an inclination

sensor including index, subindex, data type, access right and default value (factory set‐

ting). The Storage column indicates whether a parameter can be saved in the internal

permanent memory (write save signature to OD index 1010h/01h).

9.7.1 Communication parameters (to CiA DS-301)

Table 36: Communication parameters in the object directory

Index Subindex Parameter Data type Access Default value Storage

1000h 0 Device type (device profile 410) UNS32 ro 1019Ah/

1001h 0 Error register UNS8 ro 0

1002h 0 Manufacturer status register UNS32 ro 0

1003h Predefined error field

0 Number of error entries UNS32 rw 0

1..5 Error code (oldest error assigned to highest

index)

1005h 0 COB ID sync message UNS32 rw 80h

1008h 0 Device name VSTR const dep. on type

100Ah 0 Software version (“Vxx.yy”) VSTR const dep. on type

100Ch 0 Guard time (multiple of 1 ms) UNS16 rw 0 x

100Dh 0 Life-time factor UNS8 rw 0 x

1010h Save parameters (signature: 's','a','v','e' - 65766173h in subindex 1...4)

0 Highest subindex supported UNS32 ro 4

1 Save all parameters (OD: 0x1000-0x9FFF) UNS32 rw 1

2 Save communication parameters

(OD: 0x1000-0x1FFF)

3 Save application parameters

(OD: 0x6000-0x9FFF)

4 Save manufacturer parameters

(OD: 0x2000-0x5FFF)

1011h Restore default parameters (signature: 'l','o','a','d' - 64616F6Ch in subindex 1...4)

0 Highest subindex supported UNS32 ro 4

1 Restore all parameters (OD: 0x1000-0x9FFF) UNS32 rw 1

2 Restore communication parameters

(OD: 0x1000-0x1FFF)

3 Restore application parameters

(OD: 0x6000-0x9FFF)

4 Restore manufacturer parameters

(OD: 0x2000-0x5FFF)

ve an impact on communication, application and state machines. It is divided

Communication-specific part (index: 0x1000 – 0x1FFF)

Manufacturer-specific part (index: 0x2000 – 0x5FFF)

Profile-specific part (index: 0x6000 – 0x9FFF)

2019Ah

UNS32

UNS32 rw 1

UNS32 rw 1

UNS32 rw 1

UNS32 rw 1

UNS32 rw 1

UNS32 rw 1

ro 0

32

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 33

CANOPEN INTERFACE 9

Index Subindex Parameter Data type Access Default value Storage

1014h 0 COB ID emergency message UNS32 ro 80h + node

ID

1015h 0 Inhibit time between two EMCY messages (multi‐

ple of 100 µs)

1017h 0 Heartbeat rate time (multiple of 1 ms, 0 deacti‐

va

ted)

1018h Identity object

0 Highest subindex supported UNS8 ro 4

1 Vendor ID (SICK AG ident number) UNS32 ro 01000056h

2 Product code UNS32 ro {dep. on

3

4

Revision number UNS32 ro {dep. on

Serial number UNS32 ro {dep. on

1200h Server SDO1 parameters

0 Highest subindex supported UNS8 ro 2

1 COB ID client > server UNS32 ro 600h + node

2 COB ID server > client UNS32 ro 580h + node

1800h Transmit PDO 1 communication parameters

0 Highest subindex supported UNS8 ro 5

1 COB-ID UNS32 ro 180h + node

2 Transmission type (synchronous / asynchronous

manufac

turer-specific)

3 Inhibit time between two Transmit PDO mes‐

sages (multiple of 100 µs)

4 Compatibility entry UNS8 rw 0 x

5 Event Timer (multiple of 1 ms, 0 deactivated) UNS16 rw 0 x

1801h Transmit PDO2 communication parameters (TMS/TMM88D only)

0 Highest subindex supported UNS8 ro 5

1 COB-ID UNS32 ro 280h + node

2 Transmission type (synchronous / asynchronous

manufac

turer-specific)

3 Inhibit time between two TPDO messages (multi‐

ple of 100 µs)

4 Compatibility entry UNS8 rw 0 x

5 Event timer (multiple of 1 ms, 0 deactivated) UNS16 rw 0 x

1A00h Transmit PDO 1 mapping parameters

0 Highest subindex supported UNS8 ro dep. on type

1 Mapping entry 1, both types: TMS / TMM UNS32 rw 0x60100010 x

2 Mapping entry 2, type: TMS / TMM UNS32 rw 0 /

3 Mapping entry 3 UNS32 rw 0 x

4 Mapping entry 4 UNS32 rw 0 x

UNS16 rw 0 x

UNS16 rw 0 x

type}

type}

type}

ID

ID

ID

UNS8 rw 1 x

UNS16 rw 0 x

x

ID

UNS8 rw 1 x

UNS16 rw 0 x

x

0x60200010

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

33

Page 34

9 CANOPEN INTERFACE

Index Subindex Parameter Data type Access Default value Storage

5 Mapping entry 5 UNS32 rw 0 x

6 Mapping entry 6 UNS32 rw 0 x

7 Mapping entry 7 UNS32 rw 0 x

8 Mapping entry 8 UNS32 rw 0 x

1A01h Transmit PDO2 mapping parameters (TMS/TMM88D only)

0 Highest subindex supported UNS8 ro 2

1 Mapping entry 1 UNS32 rw 0x31000110 x

2 Mapping entry 2 UNS32 rw 0x31000210 x

3 Mapping entry 3 UNS32 rw 0 x

4 Mapping entry 4 UNS32 rw 0 x

5 Mapping entry 5 UNS32 rw 0 x

6 Mapping entry 6 UNS32 rw 0 x

7 Mapping entry 7 UNS32 rw 0 x

8 Mapping entry 8 UNS32 rw 0 x

1F51h Program download - control

0 Highest subindex supported UNS8 ro 3

1 Firmware range UNS8 rw 1

2 Range for configuration 1

ss for manufacturer only)

(acce

3 Range for configuration 2

ss for manufacturer only)

(acce

UNS8 rw 1

UNS8 rw 1

9.7.1.1 Error register (1001h)

The error register indicates the general error status of the device. Each bit stands for an

er

or group. If a bit is set (= 1), at least one error in this group is currently active. The

r

content of this register is transmitted in every EMCY message. The following error

groups may be encountered:

Table 37: Error register (1001h)

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Manufac‐

turer-spe‐

cific error

Accuracy

Warning

If the device is in error status (at least one error active), this is indicated by bit 0 being

t

. In the event of a communication error (overrun of send/receive buffer, guarding

se

error or CAN controller in passive/busoff mode), bit 4 is set. A profile-specific error (sen‐

sor error) is indicated by bit 5. Bit 7 signals a manufacturer-specific error (EEPROM

error).

9.7.1.2 Manufacturer status register (1002h)

This register indicates the current status of all detectable errors. Each bit represents a

s

ic error. If a bit is set (= 1), this error is currently active. The lower-value 16 bits of

pecif

this register (bits 15 to 0) are transmitted in the first two bits of the manufacturer-spe‐

cific part of each EMCY message as well as in the additional information field (bits 31

to 16) of the predefined error field 1003h.

Profile-spe‐

cific error

Error register (1001h)

Communi‐

cation

error

Not used

At least

one error

active

34

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 35

Table 38: Manufacturer status register (1002h)

9.7.1.3 Predefined error field (1003h)

Each inclination sensor keeps a list of the five most recent errors that have occurred.

Ent

y 1003.00h contains the number of error entries in the error field. All other

r

subindices contain all of the error states that have occurred in chronological order. The

most recent error is always listed under subindex 01h. The oldest error is located in the

highest available subindex (value of 1003.00h). It is removed from the list first when

more than five errors occur. When an error occurs, a new error entry is added to 1003h

and an EMCY message is also sent by way of notification. An error entry is structured as

follows:

Table 39: Error entry in predefined error field (1003h)

Additional information field (bits 31 to 16) Error code (bits 15 to 0)

Bits 15 to 0 of the manufacturer-specific regis‐

t the time the error occurred)

(a

Bit field

ommunic

C

ation error

CANOPEN INTERFACE 9

Manufacturer status register (1002h)

Bit31...Bit16 Bit15...Bit8 Bit7...Bit0

Not used

Error entry in predefined error field (1003h)

ter 1002h

Bit field

Device error

Communic

0x0000 Error reset or no more errors pending

0x5010 Sensor er

0x5020 Sensor error Y

0x8110 Receive / send buffer overflow

0x8120 CAN warning limit exceeded

0x8130 Node guard event

0x8140 Exit busoff status

Bit field

ation error

r

or / sensor error X

Bit field

Device error

To delete the entire content of the error list, write a value of 0 to entry 1003.00h.

9.7.1.4 Saving (1010h) and restoring (1011h) parameters

Changes that are made to parameters in the object directory are applied immediately.

So t

hat the modified parameters remain active even after a reset, they must be saved

in the internal permanent memory. Writing the Save signature (65766173h) to entry

1010.01h transmits all current parameters from the object directory to the permanent

memory.

To reset the object directory to the factory settings, write the Load signature

(64616F6Ch) to entry 1011.01h. This writes the factory parameters to the permanent

memory. The changes are applied after a Reset Application (NMT command) or a Hard‐

ware Reset (if only a Reset Communication (NMT command) is sent, only the factory

settings of the communication parameters are effective initially).

It is possible to save or load only parts of the object directory by writing the signature to

subindex: 02h, 03h, or 04h.

9.7.1.5 Transmit PDO – Transmission type (1800h/1801h)

The entries 1800.02h/1801.02h are used to define how the sending of the PDO is trig‐

g

er

ed.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

35

Page 36

9 CANOPEN INTERFACE

Table 40: Transmit PDO - Transmission type (1800.02h/1801.02h)

Transmis‐

sion type

1...240 Synchronous (cyclic)

253 Transmission exclusively with RTR

254 Asynchronous, manufacturer-specific

9.7.2 Manufacturer-specific part

Table 41: Manufacturer-specific part of the object directory

Index SubindexP

2002h 0 Automatic busoff recovery BOOL rw 0 x

3000h Digital filter settings

3001h Transmit PDO 1, send when angle changes, types TMS88/TMS61

3001h Transmit PDO 1, send when angle changes, types TMM88/TMM61

3002h Sensor fusion configuration (TMS/TMM88D only)

Transmit PDO - Transmission type (1800.02h/1801.02h)

D

escription

Transmission after every 1...240th receipt of the SYNC object

Only synchronized transmission with SYNC possible

y

clic sending and/or sending when angle changes can be activated by means of

C

corresponding configuration.

arameter Data

type

Access Default

value

0 Highest subindex supported UNS16 ro 2

1 Filter type (0=off, 1=Butterworth,

ically damped)

2=crit

2 Digital filter limit frequency

UNS16 rw 2 x

UNS16 rw 2000 x

(100...25000/8000, in mHz)

0 Highest subindex supported UNS16 ro 2

1 Activate/deactivate send when angle

ges (1/0)

chan

2 Minimum change in angle for axial

UNS16 rw 0 x

UNS16 rw 100 x

axis (in °/100)

0 Highest subindex supported UNS16 ro 3

1 Activate/deactivate send when angle

ges (1/0)

chan

2 Minimum change in angle for longitu‐

) axis (in °/100)

dinal (X

3 Minimum change in angle for lateral

UNS16 rw 0 x

UNS16 rw 100 x

UNS16 rw 100 x

(Y) axis (in °/100)

0 Highest subindex supported UNS8 ro 2

1 Activate/deactivate sensor fusion

UNS8 rw 1 x

(1/0)

2 Maximum interference suppression

in ms)

time (

3 Activate/deactivate dynamic gyro off‐

orrection (1/0)

set c

4 Perform gyro offset correction.

UNS16 rw 5000 x

UNS8 rw 1 x

UNS8 wo Writing 1 performs the offset correc‐

tion and permanently saves the cal‐

culated values. The process takes

approx. 2 s.

Storage

36

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 37

CANOPEN INTERFACE 9

Index SubindexP

3100h Output Euler angles (TMS/TMM88D only)

3101h Output quaternion (TMS/TMM88D only)

3102h Output acceleration sensor raw data (TMS/TMM88D only)

3103h Output yaw rate sensor raw data (TMS/TMM88D only)

5555h Reserved index (for manufacturer access only)

arameter Data

type

5 Level of dynamic offset correction,

value range from 1 (slightly dynamic)

to 10 (very highly dynamic)

0 Highest subindex supported UNS8 ro 2

1 Pitch Euler angle (in °/100) INT16 ro -

2 Roll Euler angle (in °/100) INT16 ro -

0 Highest subindex supported UNS8 ro 4

1 Quaternion scalar part w (in

1/30000)

2 Quaternion vector part x (in

1/30000)

3 Quaternion vector part y (in

1/30000)

4 Quaternion vector part z (in

1/30000)

0 Highest subindex supported UNS8 ro 3

1 Acceleration, x-axis (in 1/4096 g) INT16 ro -

2 Acceleration, y-axis (in 1/4096 g) INT16 ro -

3 Acceleration, z-axis (in 1/4096 g) INT16 ro -

0 Highest subindex supported UNS8 ro 3

1 Yaw rate, x-axis (in 7/800 °/s) INT16 ro -

2 Yaw rate, y-axis (in 7/800 °/s) INT16 ro -

3 Yaw rate, z-axis (in 7/800 °/s) INT16 ro -

UNS8 rw 3 x

INT16 ro -

INT16 ro -

INT16 ro -

INT16 ro -

Access Default

value

Storage

9.7.2.1 Automatic busoff recovery (2002h)

This feature regulates the behavior of the inclination sensor whenever it is in busoff sta‐

tus

. When activated, the inclination sensor can switch out of this status back to the

error-active status with reset error counters. To do this, it must detected 11 consecutive

recessive bits on the bus 128 times.

When deactivated, the inclination sensor remains in busoff status.

9.7.2.2 Digital filter settings (3000h/3002h)

The inclination sensor supports an option to make the continuously generated angle

v

alue mor

e insensitive to external vibration interference. Oscillation/vibration interfer‐

ence up to 0.1 Hz can be suppressed with the configurable 8th order low-pass filter.

The sensor has two digital filters which can be selected according to the area of appli‐

cation in which the sensor is being used.

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

37

Page 38

0 1 2 3 4 5 6 7 8 9 10

0

5

10

15

Step response 8th order filter

Time [s]

Step

Butterworth, fc = 2 Hz

Butterworth, fc = 0.5 Hz

critically damped, fc = 2 Hz

critically damped, fc = 0.5 Hz

Tilt [°]

9 CANOPEN INTERFACE

Table 42: Filter selection

Filters Configurable

Butterworth 0.1 Hz to 25 Hz Static inclination measurement with high damping against

Critically

damped

The digital filter is selected via entry 3000.01h. The limit frequency is set via object

3000.02h. V

Areas of application

F

equency range

r

ations

vibr

0.1 Hz to 8 Hz Inclination measurement for applications subject to specific

dynamics / without overshoot in the event of changes in

angle combined with good damping

s from 100 (= 0.1 Hz) to 25,000/8,000 (= 25 Hz/8 Hz) are permitted.

alue

Figure 19: Pulse response of both filters

38

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61 8019054/14IT/2019-06-27 | SICK

Subject to change without notice

Page 39

0.01 0.1 1 10 100

-80

-70

-60

-50

-40

-30

-20

-10

0

10

Frequency [Hz]

Gain [dB]

Gain response 8th order filter

Butterworth, fc = 2 Hz

Butterworth, fc = 0.5 Hz

critically damped, fc = 2 Hz

critically damped, fc = 0.5 Hz

CANOPEN INTERFACE 9

Figure 20: Amplitude characteristic of both filters

The sensor fusion filter uses as a measurand not only the Earth's gravitational field but

also the y

aw rate information from a gyroscope. This enables external accelerations and

vibrations to be suppressed without causing a noticeable delay in the calculation of the

angle information.

Filters Configurable range Areas of application

Sensor fusion 100 ms to 10.000 ms Dynamic applications, measurements while

9.7.2.3 Transmit PDO 1, send when angle changes (3001h)

The event-driven sending of Transmit PDO 1 when the angle changes can be activated

(= 1) and deac

tivated (= 0) via entry 3001.01h.

For activation, the transmission type for Transmit PDO 1 must be set to asynchronous,

manufacturer-specific (1800.02h = 254). Subindices 02h and 03h can be used to set

the minimum necessary change in angle separately for the longitudinal (X) and the lat‐

eral (Y) axis. These two angle values are specified in °/100 (100x angle value) and can

be set to user-defined values starting from 1 (= 0.01°).

If sending when the angle changes is activated, in Operational status, the inclination

sensor will always send Transmit PDO 1 again whenever the inclination value of the lon‐

gitudinal and/or the lateral axis has changed by the angle value set under 3001.02h

and 03h. The difference in angle between the current inclination value and the last

angle value sent with Transmit PDO 1 is constantly calculated and checked.

Every time the status switches to Operational, the inclination sensor signals the current

8019054/14IT/2019-06-27 | SICK

Subject to change without notice

position by sending Transmit PDO 1 once (only if 3001.01h = 1).

acce

lerating, braking, or driving through

curves, measurement with no signal delay time

OPERATING INSTRUCTIONS | TMS/TMM88, TMS/TMM61

39

Page 40

9 C

ANOPEN INTERFACE

NOTE

If minor diff

erences in angle are entered under 3001.02h and 03h, we recommend

activating the digital filter (index 3000h) in order to minimize the effect of vibrations

and thus the frequent sending of Transmit PDO 1.

9.7.3 Profile-specific part (to CiA DS-410)

Table 43: Profile-specific part of the object directory

Index SubindexP

6000h 0 Resolution (multiple of 0.001°) UNS16 ro 10

6010h 0 Inclination value, longitudinal (X axis,

6011h 0 Operating parameter, longitudinal

6012h 0 Default value for longitudinal (X) axis INT16 rw 0 x

6013h 0 Offset value for longitudinal (X) axis INT16 rw 0 x

6014h 0 Difference offset value for longitudi‐

6020h 0 Inclination value, lateral (Y axis, 100x

6021h 0 Operating parameter, lateral (inver‐

6022h 0 Default value for lateral (Y) axis INT16 rw 0 x

6023h 0 Offset value for lateral (Y) axis INT16 rw 0 x

6024h 0 Difference offset value for lateral (Y)

arameter Data

100x angle v

(inversion, zero-point setting)

nal (X

angle value in °)

sion, zero-point setting)

axis

) axis

alue in °)

Access Default

type

INT16 ro -

UNS8 rw 0 x

INT16 rw 0 x

INT16 ro -

UNS8 rw 0 x

T16 rw 0 x

IN

value

Storage

9.7.3.1 Resolution (6000h)

The resolution of all inclination sensors is set to a fixed value of 0.01° (default: 10 *

0.001°). All angle v

alues in the object directory (6010h, 6012h, 6013h, 6014h plus

6020h, 6022h, 6023h, 6024h) must be interpreted as a multiple of 0.01°.

Example:

Angle value = -2370 x 0.01° → -23.70°

9.7.3.2 Longitudinal and lateral angle values (6010h and 6020h)

Up-to-date angle values for the inclination axes can be accessed both via SDO access

t

he object directory (in any device status) and with a Transmit PDO. When zero-point

o t

setting is activated (operating parameters: 6011h and 6021h), the inclination angle is

calculated as follows:

Inclination value = inclination value physically measured + difference offset value +

offset value