SICK RFU630-13102, RFU630-13100, RFU630-13103, RFU630-13104, RFU630-13105 Technical Information

...Page 1

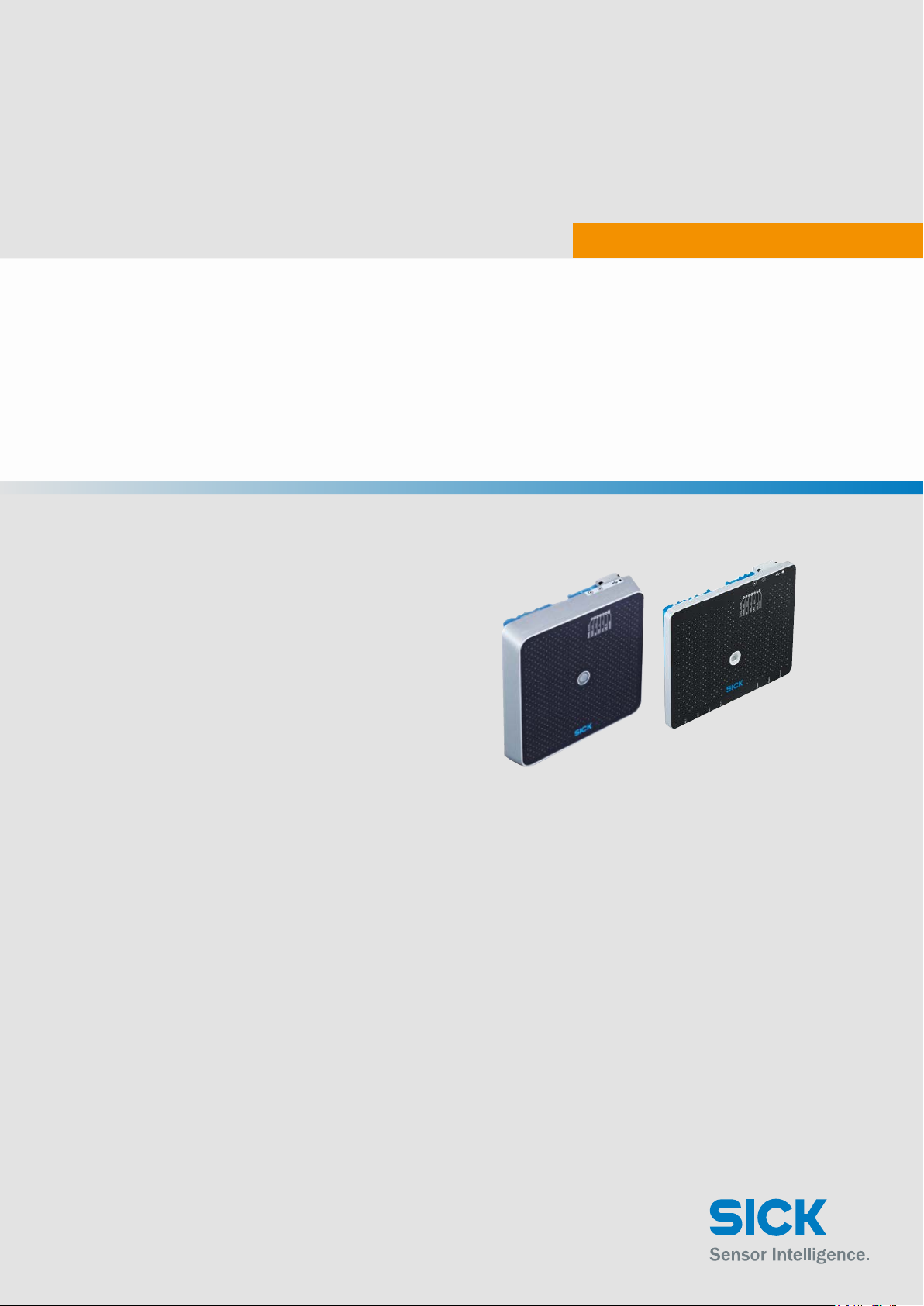

RFU63x

RFID WRITE/READ DEVICE (UHF)

TECHNICAL INFORMATION

Page 2

Technical Information

RFU63x RFID Write/Read Device (UHF)

Copyright

Copyright 2011 - 2016

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Trademark

Windows 2000, XP, Vista, Windows 7

are registered trademarks or trademarks of the Mi-

crosoft Corporation in the USA and other countries.

Adobe Reader is a registered trademark of Adobe Systems Incorporated.

2 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 3

Technical Information

RFU63x

Contents

Table of contents

1 About this document.........................................................................................................5

1.1 Purpose...........................................................................................................................5

1.2 Target group ...................................................................................................................5

1.3 Further sources for obtaining information ...................................................................6

1.4 Symbols used .................................................................................................................6

2 Safety information ............................................................................................................7

2.1 General notes .................................................................................................................7

2.2 Categories of safety notes.............................................................................................7

2.3 Warning note for electromagnetic radiation ................................................................8

3 Mounting.............................................................................................................................9

3.1 Notes on mounting.........................................................................................................9

3.2 Optional mounting accessories.................................................................................. 10

3.3 Mounting the CDB650-204 or CDM420-0006 connection module........................15

3.4 Mounting optionals UHF antennas ............................................................................ 16

4 Electrical installation ..................................................................................................... 27

4.1 Notes on the electrical installation ............................................................................ 27

4.2 Overview of all interfaces and connection options................................................... 28

4.3 M12 male and female connector pin assignments on the RFU630 ....................... 31

4.4 Pin assignments and lead color assignments of cables .......................................... 32

4.5 Notes on the electrical installation of the RFU630 at an ambient

temperature below 0 °C............................................................................................. 39

4.6 Prerequisites for the safe operation of the RFU630 in a system ............................ 41

4.7 Installation steps......................................................................................................... 44

4.8 Using the CDB650-204 connection module .............................................................50

4.9 Using the CDM420-0006 connection module .......................................................... 64

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 3

Page 4

Contents

Operating Instructions

RFU63x RFID Write/Read Device (UHF)

4 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 5

Technical Information Chapter 1

RFU63x

About this document

1 About this document

1.1 Purpose

Supplement to the

Operating Instructions

This document completes the following "RFU63x RFID write/read device (UHF)" quick starts

which are published in English:

– No. 8016526 for standard devices of the RFU630-131xx version serie, English edition

– No. 8015215 for standard devices of the RFU630-041xx version serie, English edition

The following information on the mounting and electrical installation of is summarized in

this document:

Optional mounting accessories (brackets)

Mounting of the optional antennas RFA630-x0x, RFA641-3340 and RFA651-5731

Pin and lead color assignments of cables

Measures for electrical installation of the RFU63x at an temperature below 0 °C

Prevention of ground potential equalization currents in applications with widely distrib-

uted systems

Electrical wiring diagrams for the CDB650-204 and CDM420-0006 connection mod-

ules relating to the RFU63x

The document applies for all standard variants of the RFU63x in the following two version

series (see also type plate):

Version serie Devcie type Region assignment

RFU630-131xx:

With integrated antenna

RFU630-041xx:

Without integrated

antenna

RFU630-13100

RFU630-13101

RFU630-13102

RFU630-13103

RFU630-13104

RFU630-13105

RFU630-13106/-13107

RFU630-13108

RFU630-13110

RFU630-13111

RFU630-13112

RFU630-13113

RFU630-04100

RFU630-04101

RFU630-04102

RFU630-04105

RFU630-04106

RFU630-04108

RFU630-04109

Europe/Saudi Arabia/South Africa

USA/Canada/Mexico

Australia

India

Brazil

China

Japan

Russia/Belarus

Korea

New Zealand Indonesia

Indonesia

Taiwan

Europa/South Africa

USA/Canada

Australia

China

Japan

Russia

Singapur

In the following the different standard variants of the RFU63x RFID write/read device (UHF)

in both version series are referred to i n simplified form as "RFU630", excep t where a distinc tion of the variants is necessary.

The specified material numbers (no.) for components are used as part numbers for the SICK

ordering system.

1.2 Target group

This document is intended for qualified and technical staff, authorized for mounting and

electrical installation.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 5

Page 6

Chapter 1 Technical Information

WARNING

About this document

RFU63x RFID Write/Read Device (UHF)

1.3 Further sources for obtaining information

"RFUI630-131xx RFID write/read device (UHF)“ Quickstart, no. 8016526

"RFUI630-041xx RFID write/read device (UHF)“ Quickstart, no. 8015215

Notes on intended use, scope of delivery, mounting and electrical installation in principle,

commissioning, configuration with SOPAS ET, maintenance, transport and storage as well

as on repair is included in the RFU63x quickstart.

Internet Product page of RFU630

www.sick.com/RFU63x

For type-depending, detailed technical data see online data sheets (PDF)

Dimensional drawings and 3D CAD dimension models in various electronic formats

Range diagram for the internal antenna (PDF) for RFU630-131xx

EC Declarations of Conformity (PDF)

Overview and description of the command strings (on demand)

SOPAS ET configuration software with online help function

RFID Product information with an overview of the accessories (PDF), no. 8016267 (Eng-

lish version) and no. 8016266 (German version)

RFU63x opera t ing i nst ructi ons of both ve rsion serie s (PDF ), i n Engl ish or Germa n , oth e r

languages if applicable

RFU63x technical information (PDF), no. 8014335 (English version), no. 8014334

(German version)

Support is also available from your sales partner in the web at www.sick.com/worldwide.

1.4 Symbols used

Some information in this document is highlighted as follows to facilitate quick access to this

information.

Risk of injury or risk of damage!

A warning refers to specific or potential dangers to the physical safety of the user. It is there

to protect the user against accidents.

The safety mark next to the warning, on the left, refers to the type of accident risk, e.g. electricity-related. The ascending warning levels (CAUTION, WARNING, DANGER) refer to the severity of the possible danger.

Always read the warnings carefully and make sure you comply with them.

1.4.1 Further markings

Important! This important note is there to advise you on special aspects.

DATA PROCESSING This type of script denotes a term in the user interface of the SOPAS ET configuration soft-

ware.

This symbol refers to supplementary technical documentation.

6 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 7

Technical Information Chapter 2

DANGER

WARNING

CAUTION

NOTICE

RFU63x

Safety information

2 Safety information

2.1 General notes

This chapter is about the safety of commissioning personnel, as well as operators of the

system in which the RFU630 is integrated.

Read the RFU63x quickstart carefully (printed version delivered with device) before

starting any work on the RFU630 in order to familiarize yourself with the device and its

functions. No. 8016526 is needed for RFU630-131xx version serie respectively no.

8015215 for the RFU630-041xx version serie.

The printed quickstart is considered a part of the device and must be kept in an accessible location in the immediate vicinity of the RFU630 at all times!

Read additionally the notes on mounting and the electrical installation in this technical

information as supplement to the quickstart.

Opening the housing of the RFU630 will invalidate any warranty claims against SICK

AG. For further warranty provisions, see the General Terms and Conditions of SICK AG,

e.g., on the delivery note of the RFU630.

Repair work on the RFU630 may only be performed by qualified and authorized service

personnel from SICK AG

2.2 Categories of safety notes

Risk of injury!

The combination of symbol and signal word indicates a situation of imminent danger, which

will lead to a fatality or serious injuries if not prevented.

Risk of injury!

T

he combination of symbol and signal word indicates a potentially dangerous situation,

which may lead to a fatality or serious injuries if not prevented.

Risk of injury!

The combination of symbol and signal word indicates a potentially dangerous situation,

which may lead to minor/slight injuries if not prevented.

Risk of damage!

A note indicates a potential risk of damage or impair on the functionality of the RFU63x RFID

write/read device or other connected devices.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 7

Page 8

Chapter 2 Technical Information

CAUTION

CAUTION

Safety information

RFU63x RFID Write/Read Device (UHF)

2.3 Warning note for electromagnetic radiation

RFU630-131xx

Health hazard due to high-frequency electromagnetic radiation!

The RFU630-13100 (region: Europe) is designed for operation in accordance with ETSI EN

302208. During operation with the integrated antenna and/or one or serverals externals

antenna(e), the human exposure regulations covered by EN 50364 must be observed.

In order to limit human exposure to electromagnetic fields, suitable safety distances

must be maintained during both short-term and long-term work in the radiation range

antenna(e).

Minimum distances to be maintained between the antenna and the human body during

long-term transmission:

30 cm with a max. radiation power of the antenna of 2 W ERP as per ETSI,

15 cm with a reduced radiation power of 1 W ERP,

10 cm with a radiation power of 0.5 W ERP.

The RFU630-13101 (region: USA/Canada/Mexico) satisfies the limit values of the FCC for

exposure to radiation in an uncontrolled environment.

During operation with the integrated antenna and/or one oder serverals externals an-

tenna(e), a safety distance of at least 20 cm must be maintained between the antenna

and the human body.

RFU630-041xx

Health hazard due to high-frequency electromagnetic radiation!

The RFU630-04100 (region: Europe) is designed for operation in accordance with ETSI EN

302208. During operation with the external RFA630-x00 antenna(e), the human exposure

regulations covered by EN 50364 must be observed.

In order to limit human exposure to electromagnetic fields, suitable safety distances

must be maintained during both short-term and long-term work in the radiation range

of the antenna(e).

Minimum distances to be maintained between the antenna and the human body:

30 cm with a max. radiation power of the antenna of 2 W ERP as per ETSI,

15 cm with a reduced radiation power of 1 W ERP,

10 cm with a radiation power of 0.5 W ERP.

The RFU630-04101 (region: USA/Canada/Mexico) satisfies the limit values of the FCC for

exposure to radiation in an uncontrolled environment.

During operation with the external RFA630-x01 antenna(e), a safety distance of at

least 20 cm must be maintained between the antenna and the human body.

8 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 9

Technical Information Chapter 3

RFU63x

Mounting

3 Mounting

3.1 Notes on mounting

RFU630-13101 UL-certified: Install the device only inside of buildings. The device is not

suitable for outdoor use.

The RFU630 should be attached as free from shock and vibration as possible.

If the external antenna or the RFU630 with an internal antenna is mounted in front of

the front metal surfaces, observe an angle of approx. 10°.

Use one of the optional SICK mounting sets 1 to 4, also in combination if required

depending on the application. For mounting samples, regarding the RFU630-131xx version serie, see the following pages.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 9

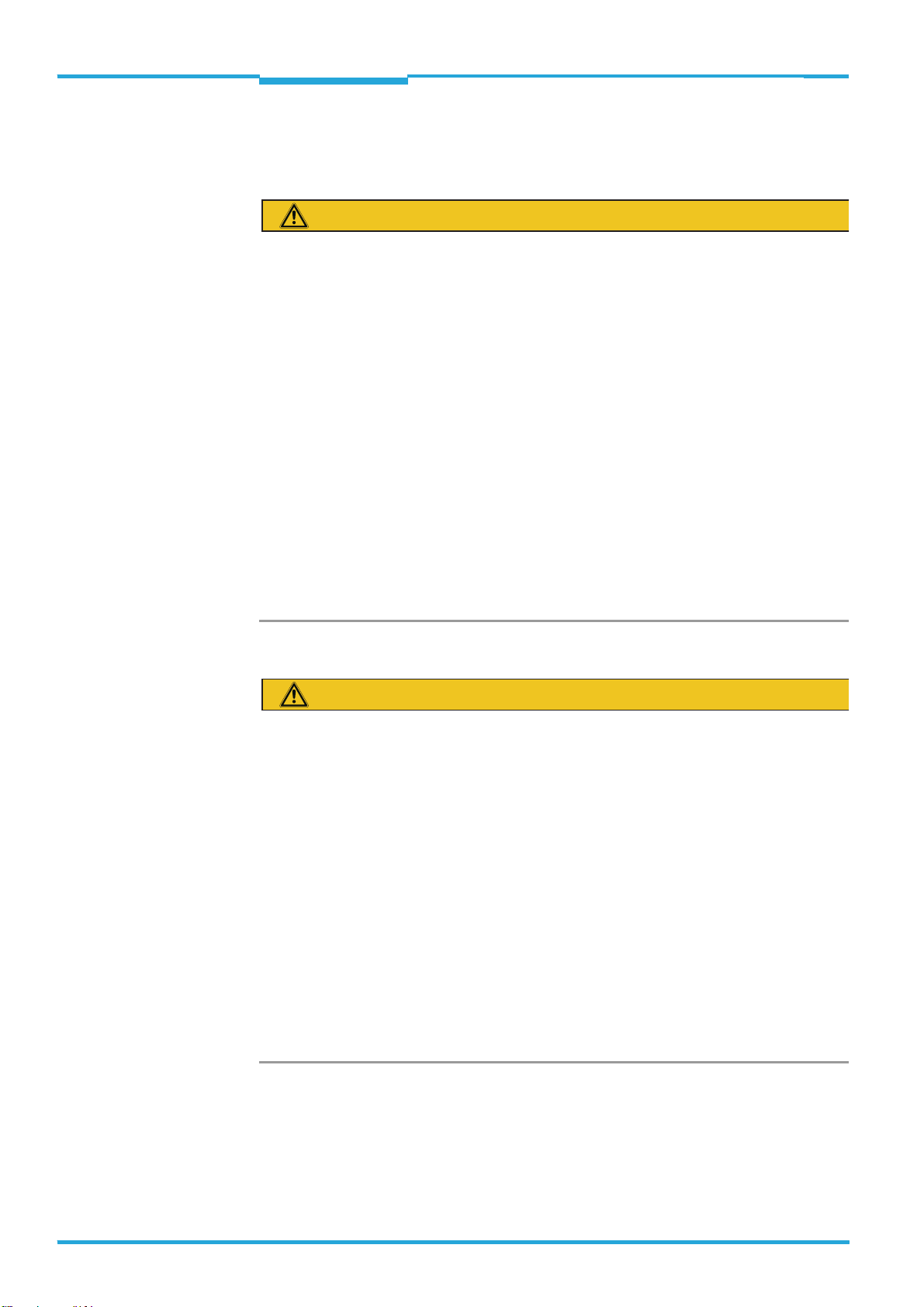

Page 10

Chapter 3 Technical Information

20

24

240

239

227

136.8

16

4

M6

Mounting plate 1 (for mounting to walls)

All dimensions in mm

30

227

198

61.2

0

7

218.6

32.5

53.5

240

136.8

16.4

5

7.5

M5

(12.5)

Ø

12

Ø

6.6

Ø 6

.6

Ø 5.5

M5

M6

RFU630-131xx

Hexagon screw

10 mm width

across flat

3 mm width

across flat

10 mm width across flat

Hexagon socket

3 mm width

across flat

Mounting

RFU63x RFID Write/Read Device (UHF)

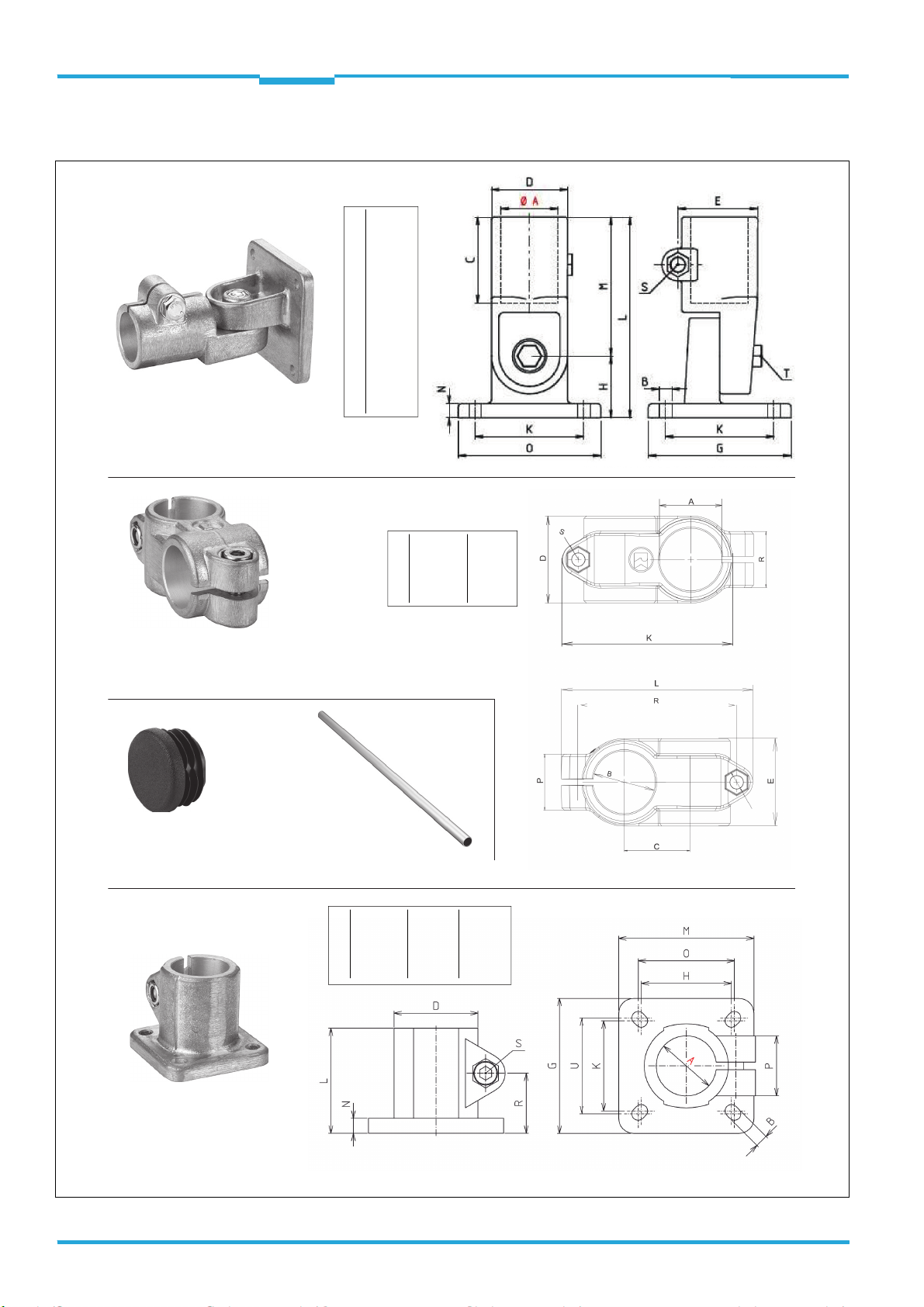

3.2 Optional mounting accessories

3.2.1 Installing wall mounting plate (no. 2060912) on the RFU630

10 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Procedure for attachment on the RFU630:

1. Either cut two M6 threads or install two bore holes with 6.5 mm through the assem-

bly base provided by the customer with a spacing of 227 mm.

2. For the time being,fasten two supplied M6 x 16 mm screws in the assembly base such

that the thread protrudes at least 8 mm up to the base of the screw head.

3. Install the mounting plate on the rear side of the RFU630 using the three supplied

M5 x 12 mm screws.

4. Attach the RFU630 together with the mounting plate onto the two protruding M6

screws and tighten them.

Page 11

Technical Information Chapter 3

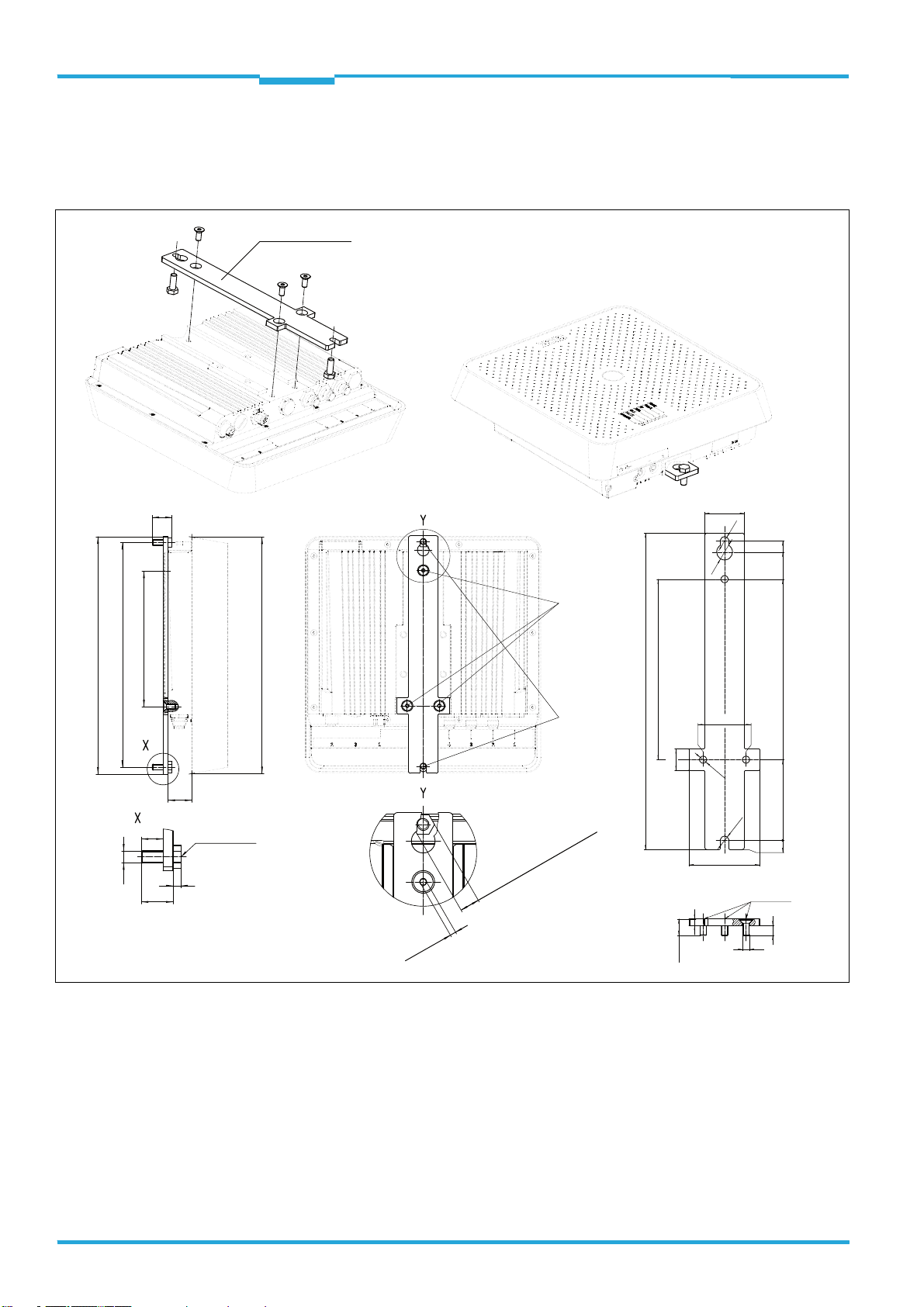

110

100

57

(40)

100

57

(40)

110

Presentation without screws

A - A

A

A

M6M4

6

M6

10.6

4 x Hexagon socket

kant 4 mm width across flat

Threaded mounting

hole M4 (4 x)

Threaded mounting

hole M6 (4 x)

All dimensions in mm

Threaded mounting hole

M6, 12 mm deep

Threaded mounting hole M6

for link clamp no. 2068919

(mounting grid 57 mm x 57 mm)

VESA adapter plate for Interrogators RFU63x

and RFU62x as well as for RFA630-x0x antenna

RFU630-131xx

M6 x 16, Hexagon socket

4 mm width across flat

Mounting

RFU63x

3.2.2 Installing VESA adapter plate (no. 2061688) on the RFU630

Procedure for attachment on the RFU630:

1. Install the adapter plate on the rear side of the RFU630 using the four supplied

M6 x 16 mm screws.

2. Affix the RFU630 and adapter plate to the VESA bracket using four M4 screws, or to a

standard industrial bracket with a 57 mm x 57 mm grid using four M6 screws.

The screw length depends on the wall thickness of the front end of the VESA bracket.

Take care to ensure that the screwed in screws do not damage the housing of the

RFU630.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 11

Page 12

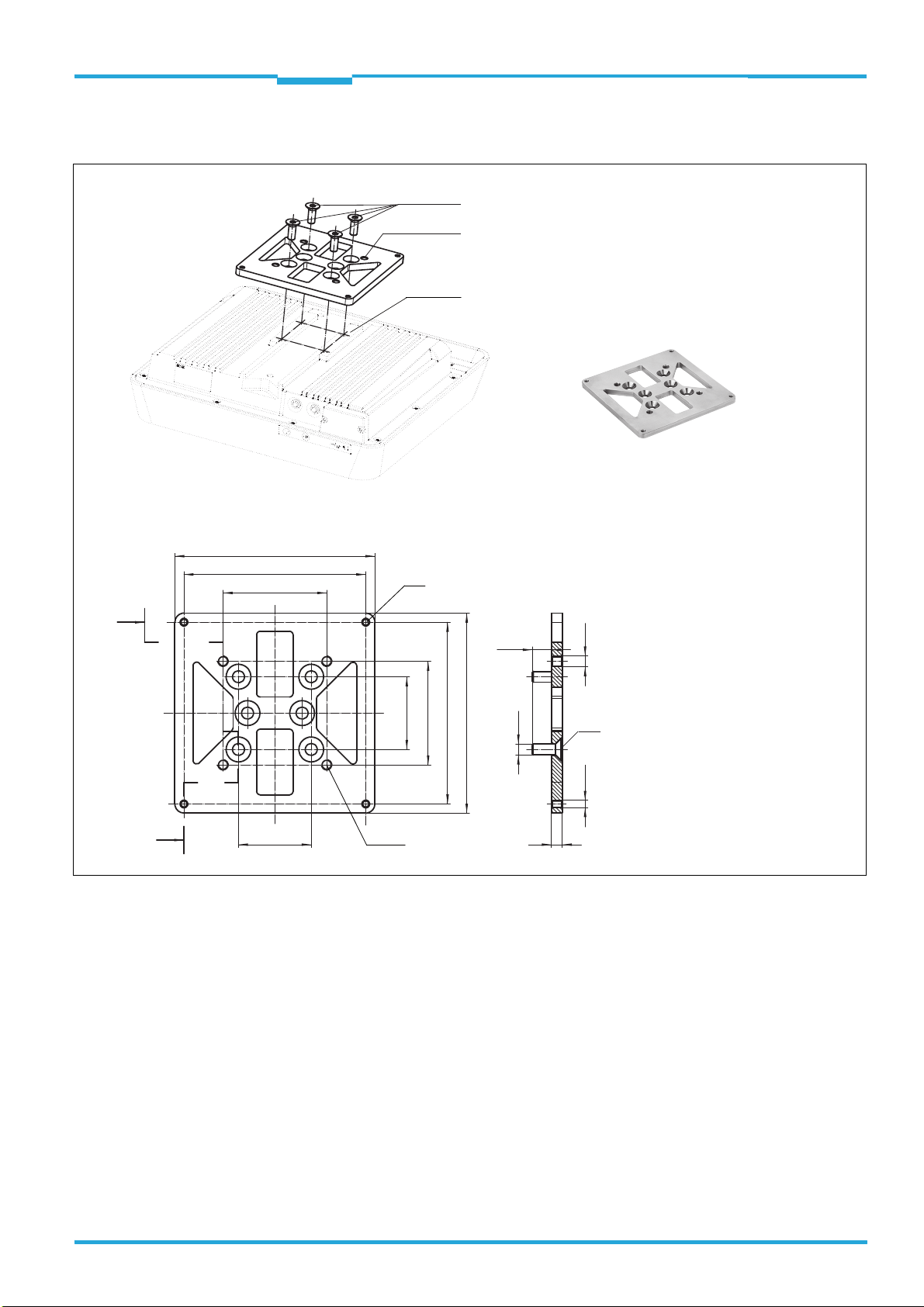

Chapter 3 Technical Information

All length measures in mm

Threaded mounting hole

M6, 11 mm deep

M6 x 12 mm,

self-locking

(4 x)

M6 x 16 mm

(6 x)

Mounting bracket

Angle

flange

Pivot mounting

bracket,

complete

95.2

M6

5

5

9.4

9.4

102.8

Ø 10Ø 18

80

90°

Ø 41.5

68

68

90°

60

84

30

RFU630-131xx

Mounting

RFU63x RFID Write/Read Device (UHF)

3.2.3 Installing pivot mounting bracket (no. 2061737) on the RFU630

Procedure for attachment on the RFU630:

1. Fasten the angle flange to the RFU630 (supplied are: 4x M6 x 16 mm screws with

A6 washer).

2. Fasten the mounting bracket to the assembly base provided by the customer (supplied

are: 2 x M6 x 16 mm screws with A6 washer). Do not tighten the screws just yet.

3. Fasten the RFU630 together with the mounting bracket to the angle flange (supplied

ar e: 4x self -lock ing M6 x 1 2 mm s crews and A6 washers). Do not tighten the screws just

yet.

4. Align RFU630 to the scanning point in two axes.

5. Tighten all screws.

12 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 13

Technical Information Chapter 3

Mounting sample

1 VESA adapter plate no. 2071862,

with 2 counter-sunk screws M6 x 12,

hexagon socket (AF4)

2 Link clamp with 4 cylinder head screws

M6 x 12, no. 2068919

3 Pipe, ∅ 30 mm, length 1 m, no. 532761

4 Sealing plug, ∅ 30 mm, no. 5327613

5 Cross clamp, no. 5327612

6 Base clamp, no. 5327611

1 2

3

6

3

5

4

4

Base (e.g. plate, provided by customer)

4 x cylinder head screw

M6 x 12, hexagon socket AF4,

self-locking

RFU63x

Mounting

3.2.4 Installing a customer-specific holder for the RFU630 by using pipe elements and clamp-connections, with VESA adapter plate no. 2071862 (sample)

Part 1: Total view

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 13

Page 14

Chapter 3 Technical Information

All dimensions in mm

Base clamp, no. 5327611

Sealing plug, ∅ 30 mm,

no. 5327613

Cross clamp, no. 5327612

Link clamp no. 2068919,

with 4 cylinder head screws M6 x 12

Pipe, ∅ 30 mm,

length 1 m,

no. 5327610

A

B

C

D

E

30.1

30.1

33

40

40

K

L

P

R

S

73

99

33

78

M8 x 25

A

B

D

G

H

30.1

6.5

40

60

40

K

L

M

N

O

42

50

60

8

42

P

R

S

U

33

29

M8 x 25

45

A

B

C

D

E

G

H

K

L

M

N

O

S

T

30.1

6.5

45

40

40

75

33

57

106

73

7

7 5

M8 x 35

M8 x 35

Mounting

Part 2: Dimensional drawings of components

RFU63x RFID Write/Read Device (UHF)

14 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 15

Technical Information Chapter 3

RFU63x

Mounting

3.3 Mounting the CDB650-204 or CDM420-0006 connection module

The mounting location for the connection module (distance to RFU630) depends on the

physical design (RS-232) and the transmission rate used of the serial data interface AUX 1.

Recommended cable length between RFU630 and connection module:

Max. 3 m with fixed data transmission 57.6 kBd.

For detailed information on mounting and the electrical installation, see:

"CDB650-204 connection module" operating instructions (no. 8016155, German +

English version) e.g. as PDF in the web via www.mysick.com/CDB

"CDM420-0006 connection module" operating instructions (no. 8014808, German +

English version) e.g. as PDF in the web via www.mysick.com/CDM

The documents are also supplied in printed form with the relating connection module.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 15

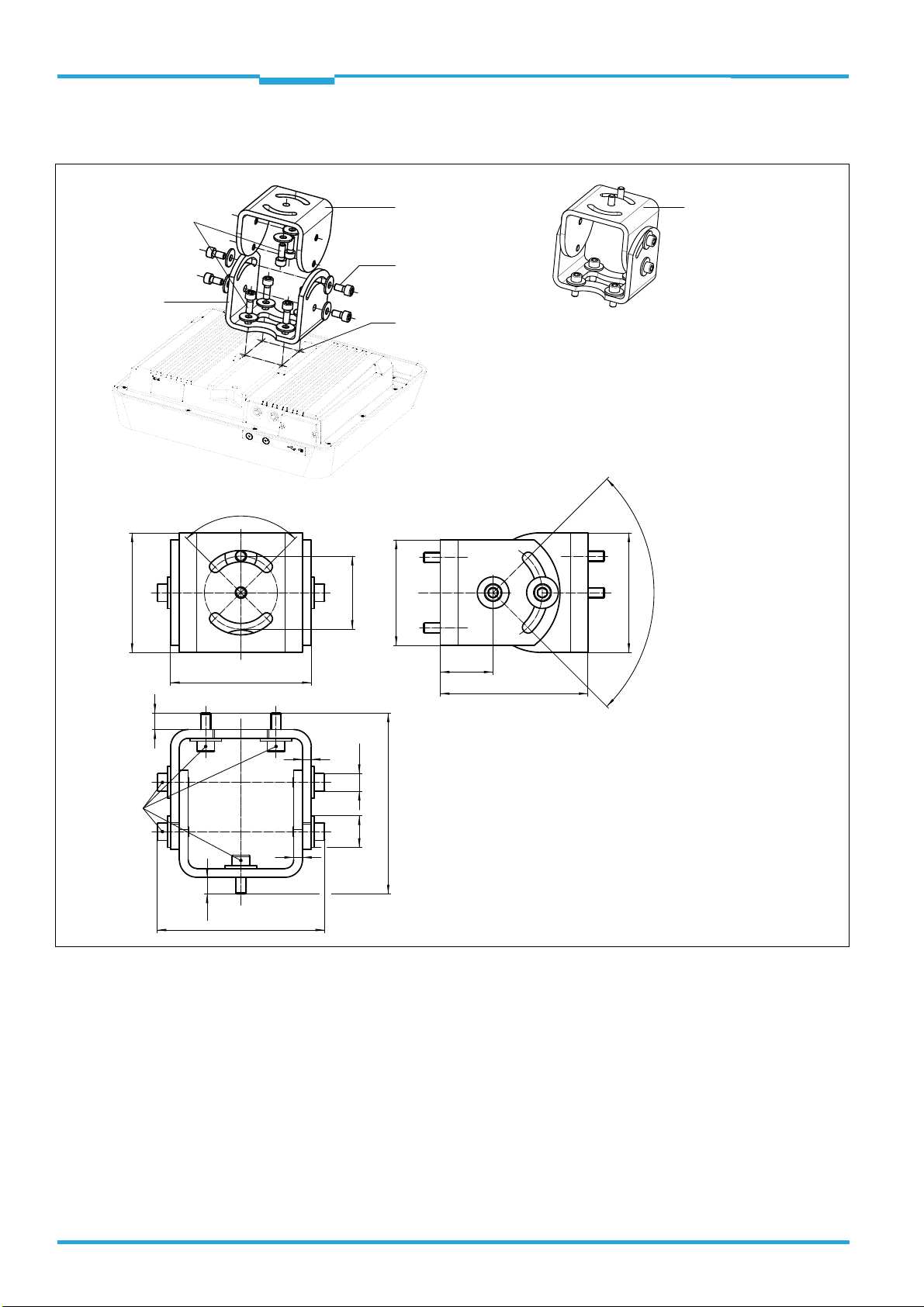

Page 16

Chapter 3 Technical Information

CAUTION

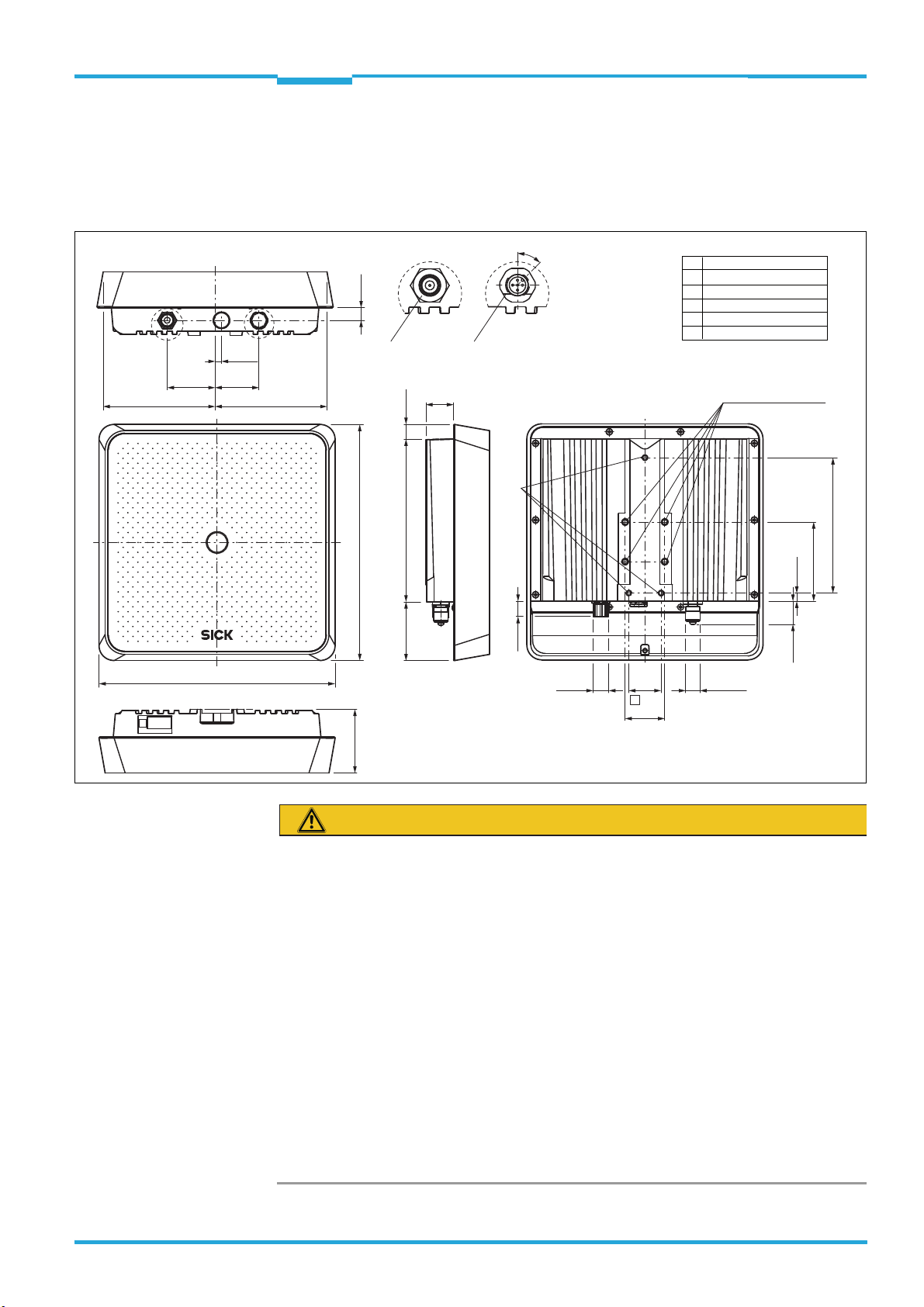

113.1 (4.45)

48.4

(1.91)

6.5

(0.26)

44.4

(1.75)

113.1 (4.45)

12.9

(0.51)

238.6 (9.39)

238.6 (9.39)

X

X

64.3

(2.53)

15.1

(0.59)

28

(1.10)

164.4 (6.47)

59.5

(2.34)

32.5

(1.28)

40

(1.57)

Ø 14.5

(0.57)

23.5

(0.93)

8.2

(0.32)

80 (3.15)

136.8 (5.39)

3

1

2

Alle Angaben in mm (inch)

All dimensions in mm (inch)

1

Sacklochgewinde M5, 8 tief

Tapped blind hole M5, 8 (0.31) deep

2

Sacklochgewinde M6, 11 tief

Tapped blind hole M6, 11 (0.43) deep

3

Elektrischer Anschluss (TNC, reverse)

Electrical connection (TNC, reverse)

Mounting

RFU63x RFID Write/Read Device (UHF)

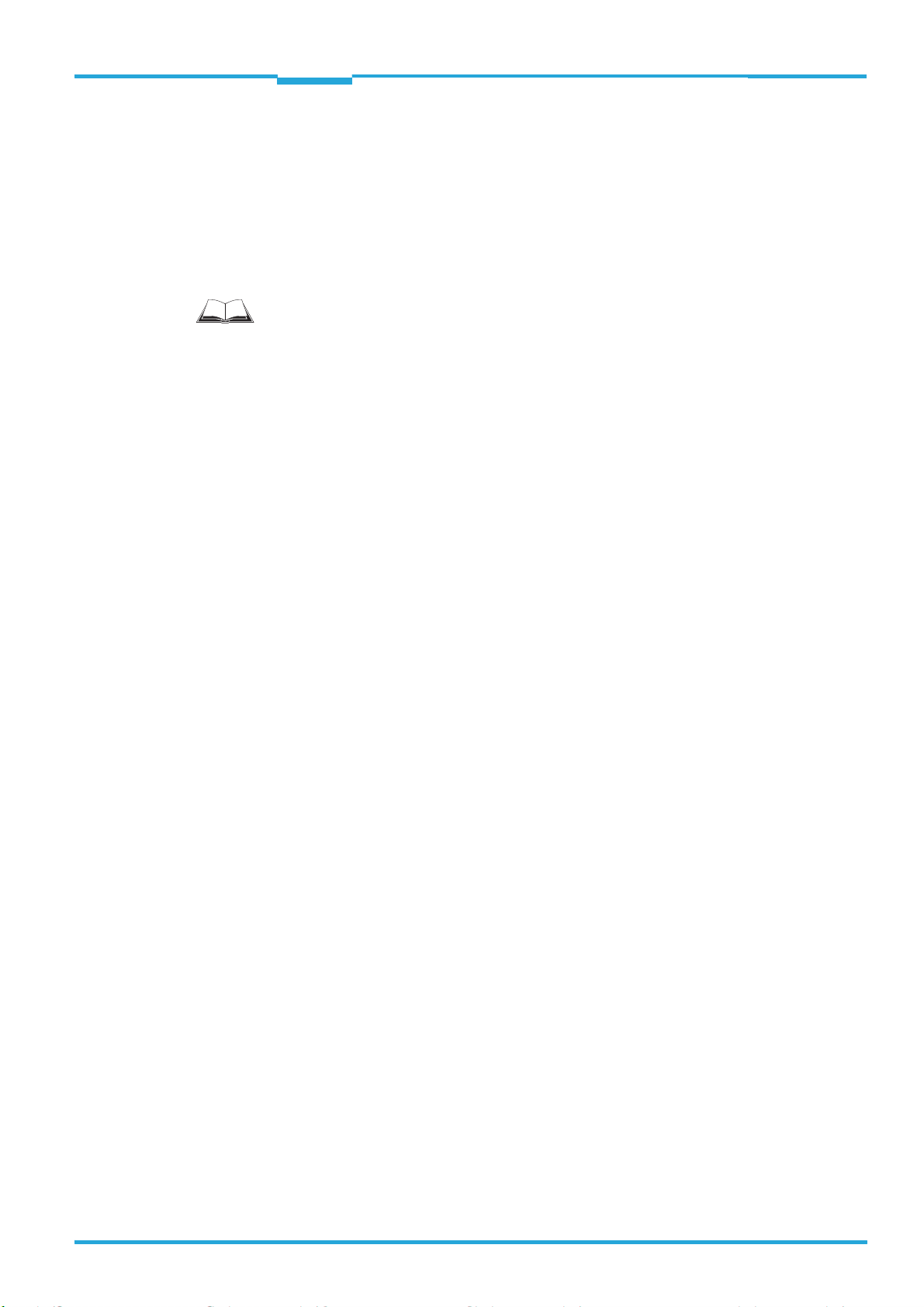

3.4 Mounting optionals UHF antennas

3.4.1 RFA630-000/-001 antenna

Health hazard due to high-frequency electromagnetic radiation!

The RFA630-000 antenna (region: Europe) is designed for operation in accordance with

ETSI EN 302208. During operation, the human exposure regulations covered by EN 50364

must be observed.

In order to limit human exposure to electromagnetic fields, suitable safety distances

must be maintained during both short-term and long-term work in the radiation range

antenna(e).

Minimum distances to be maintained between the antenna and the human body during

long-term transmission:

30 cm with a max. radiation power of the antenna of 2 W ERP as per ETSI,

15 cm with a reduced radiation power of 1 W ERP,

10 cm with a radiation power of 0.5 W ERP.

The RFA630-001 antenna (region: USA/Canada/Mexico) satisfies the limit values of the

FCC for exposure to radiation in an uncontrolled environment.

During operation, a safety distance of at least 20 cm must be maintained between the

antenna and the human body.

16 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 17

Technical Information Chapter 3

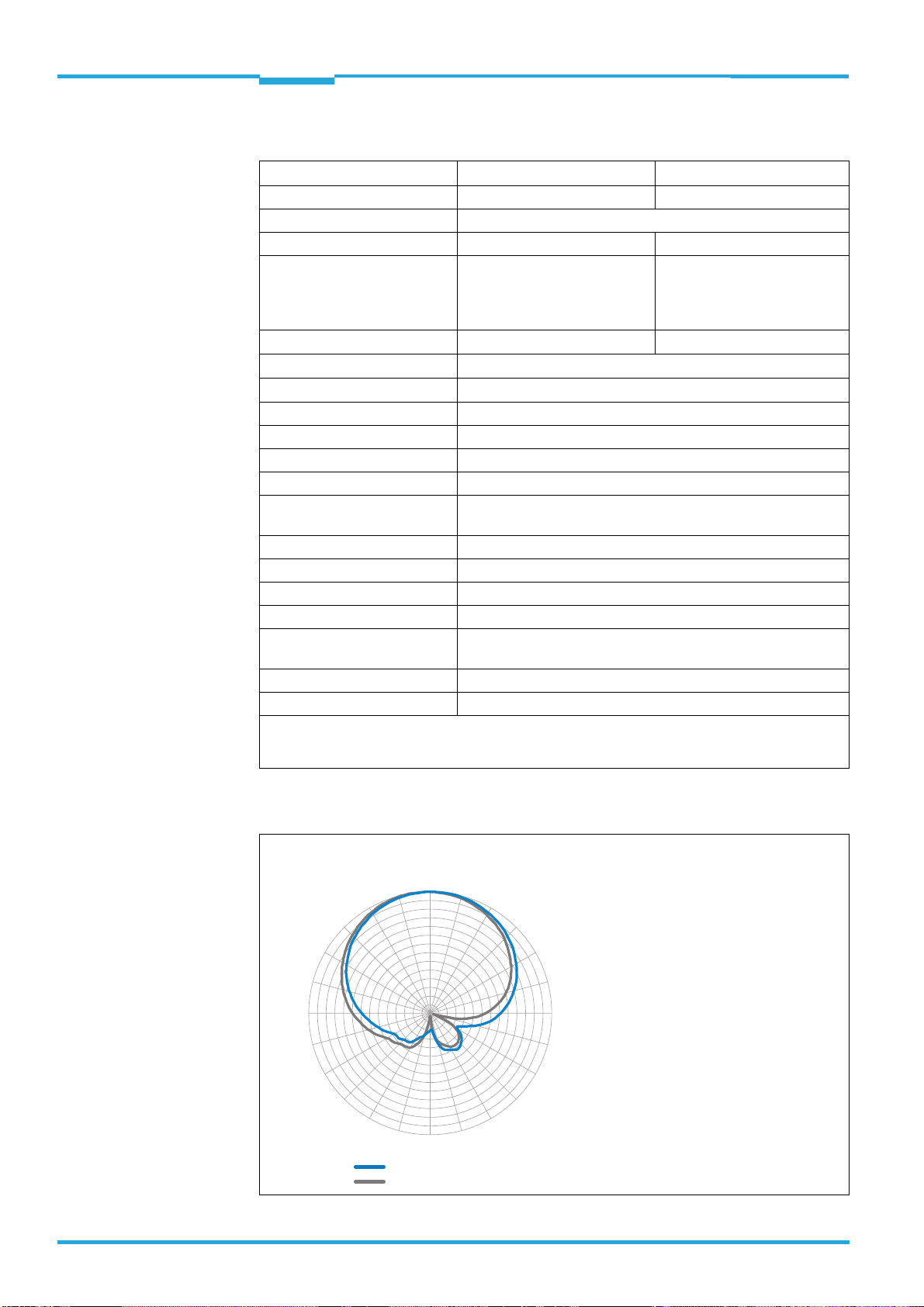

0°

15°

30°

45°

60°

75°

90°

105°

120°

135°

150°

165°

180°

–165°

–150°

–135°

–120°

–105°

–90°

–75°

–60°

–45°

–30°

–15°

–33

–30

–27

–24

–21

–18

–15

–12

–9

–6

–3

0

3

6

Elevation plane (vertical)

Azimuth plane (horizontal)

Measured gain in dBic at 866.5 MHz,

RHCP (Right-hand circular polarized)

9

Mounting

RFU63x

Technical Data

Type RFA630-000 RFA630-001

Part no. 1058383 1058384

Frequency band 860 MHz … 960 MHz

Carrier frequency 865 MHz … 868 MHz 902 MHz … 928 MHz

Permissible write/read device RFU630-13100 RFU630-13101

RFU630-13102

RFU630-13105

RFU630-13106/-13107

Maximum rated power

Polarization

4)

VSWR

Max. 2 W ERP

Circular /RHCP

Typical < 1,2

1)

3)

Max. 4 W EIRP

Gain Max. 9 dBic

Axial ratio Typical < 2 dB

3 dB aperature angle Typical 72 Grad

Front to back ratio Typical > 17 dB

Electrical connection TNC reverse, 50 Ohm

Housing (material) Aluminum, Front: polycarbonate

Enclosure rating IP 67

Weight 3 kg

Dimensions (L x W x H) 238.6 mm x 238.6 mm x 64.3 mm, see dimensional drawing

Mounting 4 x M6 threaded mounting holes (standard fixing grid

40 mm x 40 mm) or 3 M5 threaded mounting holes

Operation ambient temperature –25 °C … +50 °C

Stockage temperature –30 °C … +70 °C

Relative air humidity 5 % … 95 %, non-condensing

1) ERP = Equivalent Radiated Power. 2) EIRP = Equivalent Isotropic Radiated Power.

3) RHCP = Right-Hand Circular Polarisation.

4) VSWR = Voltage Standing Wave Ration.

2)

Radiation pattern diagram RFA630-000/-001

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 17

Page 18

Chapter 3 Technical Information

Internet Ordering information about the antennae and theirs accessories (mountings sets and con-

Mounting

RFU63x RFID Write/Read Device (UHF)

Accessories

nection cables of different lengths) is available on the following SICK product pages on the

web:

RFA630-000: www.sick.com/1058383

RFA630-001: www.sick.com/1058384

The corresponding power loss values of the cables in the frequency band of 860 MHz to 960

MHz are also listed there.

Mounting

The housing of the RFA630-00x antenna has the same dimensions and mounting thread

holes like the RFU630 write/read device. You can use the same optional mounting accessories (brackets, plates). To do so, see Chapter 3.2 Optional mounting accessories,

Page 10.

If several antennas are used in a reading station, e.g. two on each side of a conveyor system, make sure that the antennas are not directly facing each other, but are installed at

staggered parallel positions.

18 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 19

Technical Information Chapter 3

CAUTION

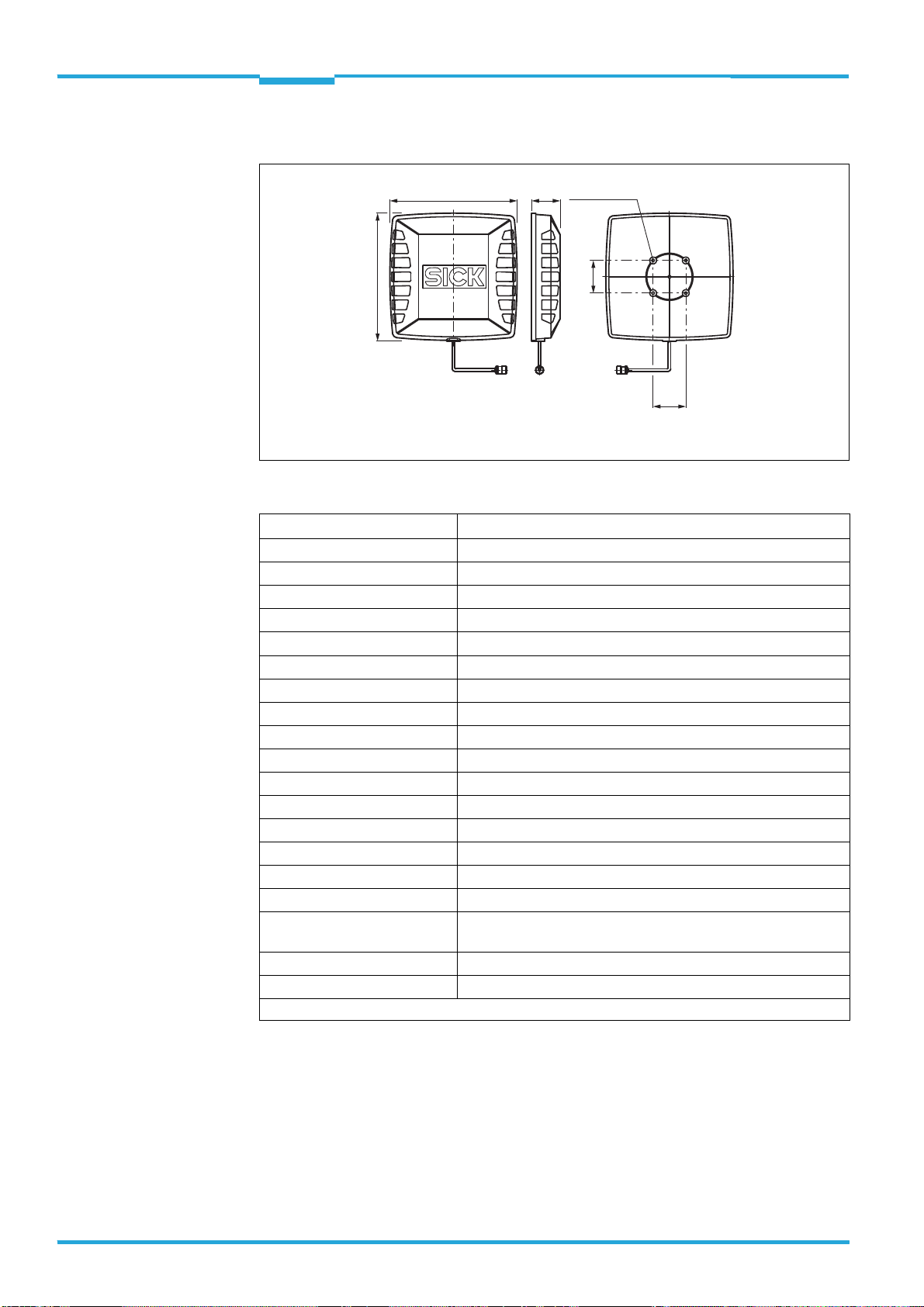

113.1 (4.45) 113.1 (4.45)

48.4

(1.91)

6.5

(0.26)

44.4

(1.75)

12.9

(0.51)

XW

238.6 (9.39)

238.6 (9.39)

64.3 (2.53)

15.5

(0.61)

15.1

(0.59)

164.4 (6.47)

28

(1.10)

59.5

(2.34)

Ø 16

(0.63)

32.5

(1.28)

Ø 14.5

(0.57)

23.5

(0.93)

8.2

(0.32)

80 (3.15)

136.8 (5.39)

1

2

40

(1.57)

X

3

W

45°

4

Alle Angaben in mm (inch)

All dimensions in mm (inch)

1

Sacklochgewinde M5, 8 tief

Tapped blind hole M5, 8 (0.31) deep

2

Sacklochgewinde M6, 11 tief

Tapped blind hole M6, 11 (0.43) deep

Pin Leuchtfarbe / light color

1 LED: blau/blue

2 LED: grün/green

3 GND

4 LED: rot/red

5 N.C.

Ue / Vin = DC 10 V ... 30 V

I

e

/ Iin = max. 10 mA

3

TNC, reverse

4

5-pol. M12Stecker,

A-codiert

5-pin M12

male

connector,

A-coded

Mounting

RFU63x

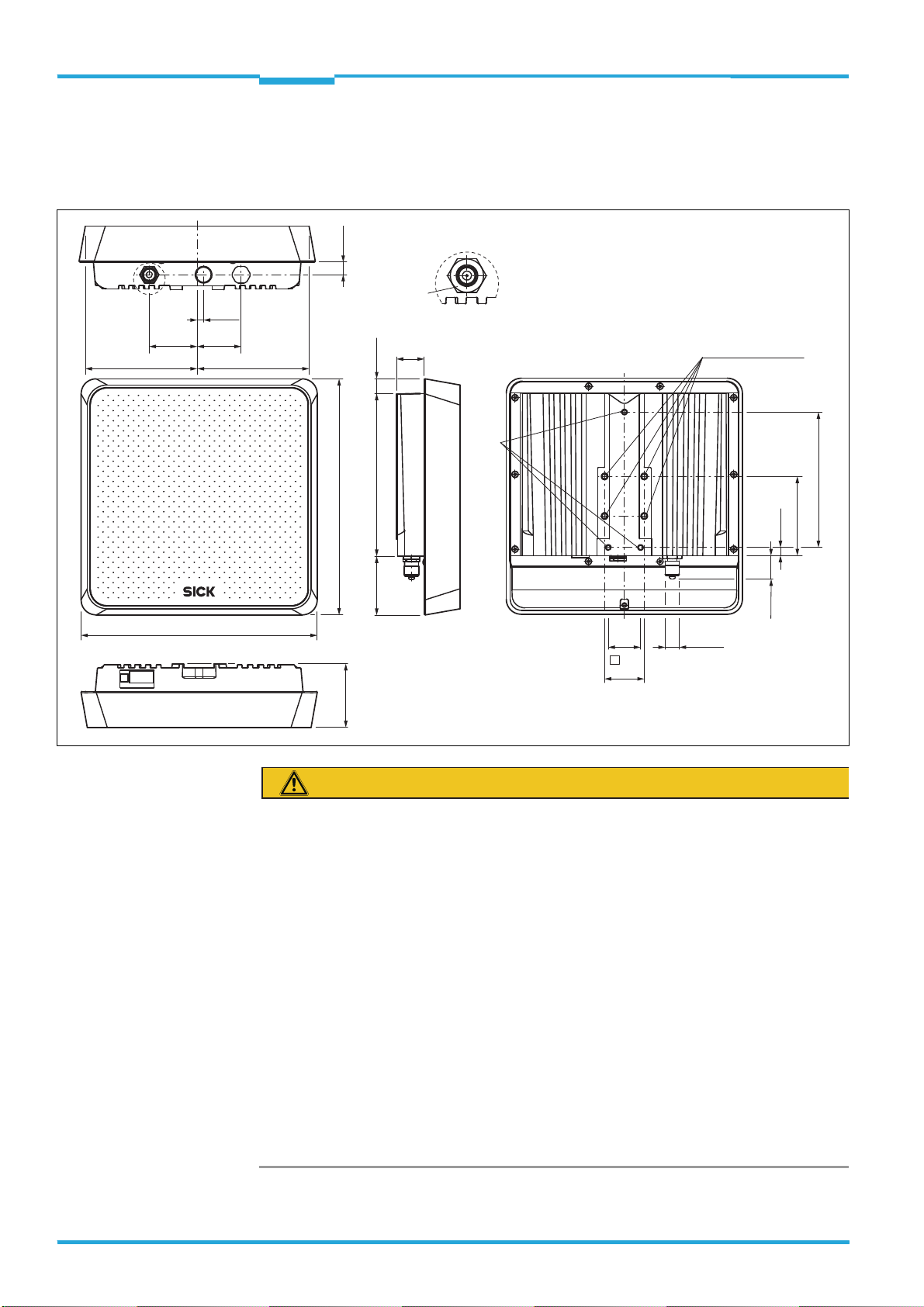

3.4.2 RFA630-100/-101 antenna

As special feature of this antenna a process feedback LED on the front plate center can be

powered externally for controlling the displayed RGB color to signalizise an event in the

reading process.

Health hazard due to high-frequency electromagnetic radiation!

The RFA630-100 antenna (region: Europe) is designed for operation in accordance with

ETSI EN 302208. During operation, the human exposure regulations covered by EN 50364

must be observed.

In order to limit human exposure to electromagnetic fields, suitable safety distances

must be maintained during both short-term and long-term work in the radiation range

antenna(e). Minimum distances to be maintained between the antenna and the human

body during long-term transmission:

30 cm with a max. radiation power of the antenna of 2 W ERP as per ETSI,

15 cm with a reduced radiation power of 1 W ERP,

10 cm with a radiation power of 0.5 W ERP.

The RFA630-101 antenna (region: USA/Canada/Mexico) satisfies the limit values of the

FCC for exposure to radiation in an uncontrolled environment.

During operation, a safety distance of at least 20 cm must be maintained between the

antenna and the human body.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 19

Page 20

Chapter 3 Technical Information

Mounting

RFU63x RFID Write/Read Device (UHF)

Technical Data

Type RFA630-100 RFA630-101

Part no. 1059946 1059947

Frequency band 860 MHz … 960 MHz

Carrier frequency 865 MHz … 868 MHz 902 MHz … 928 MHz

Permissible write/read device RFU630-13100 RFU630-13101

RFU630-13102

RFU630-13105

RFU630-13106/-13107

Maximum radiated power

Polarizsation

4)

VSWR

Max. 2 W ERP

Circular /RHCP

Typical < 1,2

1)

3)

Max. 4 W EIRP

Gain Max. 9 dBic

Axial ratio Typical < 2 dB

3 dB aperture angle Typical 72 Grad

Front to back ratio Typical > 17 dB

Electrical connection - TNC reverse, 50 Ohm

- 5-pin M12 male connector, A-coded for process feedback LED

Housing (material) Aluminum, front: polycarbonate

Enclosure rating IP 67

Weight 3 kg

Dimensions (L x W x H) 238.6 mm x 238.6 mm x 64.3 mm, see dimensional drawing

Mounting 4 x M6 threaded mounting holes (standard fixing grid

40 mm x 40 mm) or 3 M5 threaded mounting holes

Ambient temperature Operation: –25 °C … +50 °C, Stockage: –30 °C … +70 °C

Relative air humidity 5 % … 95 %, non-condensing

1) ERP = Equivalent Radiated Power. 2) EIRP = Equivalent Isotropic Radiated Power.

3) RHCP = Right-Hand Circular Polarisation.

4) VSWR = Voltage Standing Wave Ration

2)

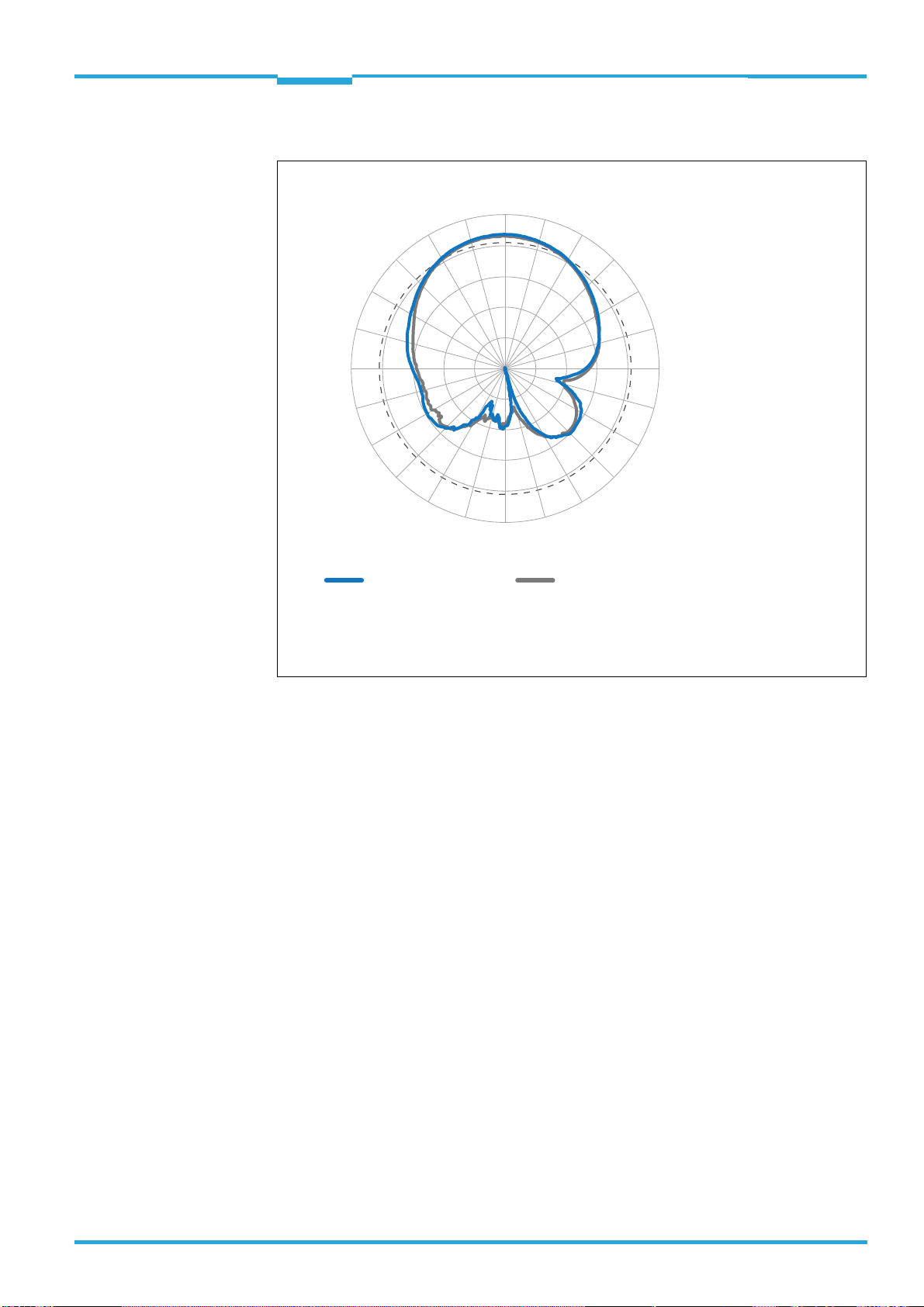

Radiation pattern diagram RFA630-100/-101

Measured gain in dBic at 866.5 MHz,

RHCP (Right-hand circular polarized)

0°

9

6

3

0

–3

–6

–9

180°

15°

30°

45°

60°

75°

90°

105°

120°

135°

150°

165°

–75°

–90°

–105°

–120°

–60°

–45°

–135°

–30°

–150°

–15°

–12

–15

–18

–21

–24

–27

–30

–33

–165°

Azimuth plane (horizontal)

Elevation plane (vertical)

20 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 21

Technical Information Chapter 3

RFU63x

Mounting

Accessories

Internet Ordering information about the antennae and theirs accessories (mountings sets and con-

nection cables of different lengths) is available on the following SICK product pages on the

web:

RFA630-100: www.sick.com/1059946

RFA630-101: www.sick.com/1059947

The corresponding power loss values of the cables in the frequency band of 860 MHz to 960

MHz are also listed there.

Mounting

The housing of the RFA630-10x antenna has the same dimensions and mounting thread

holes like the RFU630 write/read device. You can use the same optional mounting accessories (brackets, plates). To do so, see Chapter 3.2 Optional mounting accessories,

Page 10 .

If several antennas are used in a reading station, e.g. two on each side of a conveyor system, make sure that the antennas are not directly facing each other, but are installed at

staggered parallel positions.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 21

Page 22

Chapter 3 Technical Information

253

254.5

56.5

65

65

4 x M6 x 10

2

1

All dimensions in mm

1 N female connector

2 Threaded mounting holes (4 x)

Mounting

RFU63x RFID Write/Read Device (UHF)

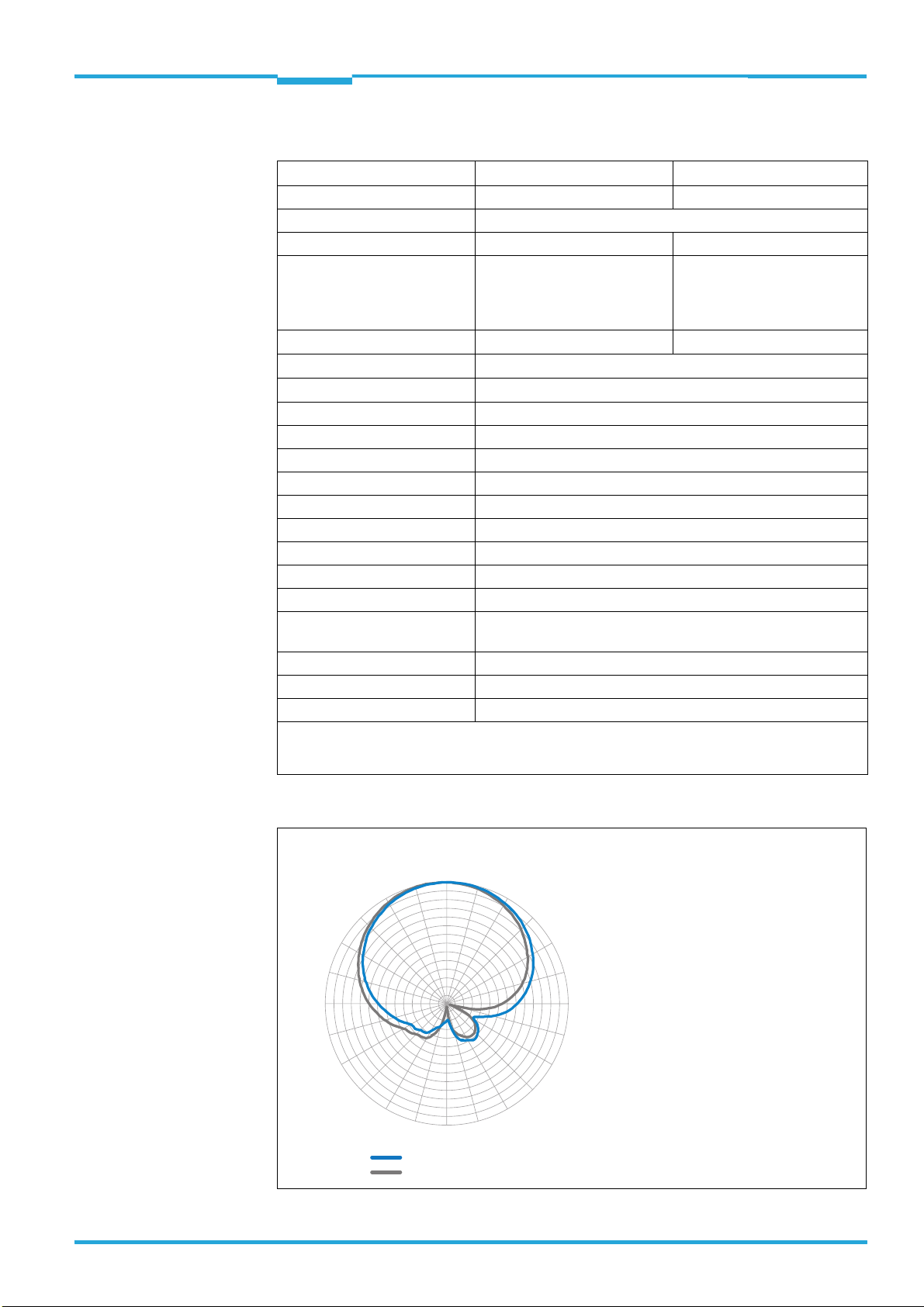

3.4.3 RFA641-3440 antenna

Technical Data

Type RFA641-3440

Part no. 6034316

Frequency range 860 MHz … 960 MHz (for Europe and USA)

Maximum radiated power 10 W

Polarization Circular

*)

VSWR

Gain 7 dBi ± 1 dBi

Axial ratio < 1dB

3 dB aperture angle

Front to back ratio

Electrical connection Cable 0.3 m with N female connector

Impedance 50 Ohm

Housing (material) ABS

Enclosure rating IP 54 accord. to EN 60529/A1

Weight Approx. 470 g

Dimension (L x B x H) 254.5 mm x 253 mm x 56.5 mm, see dimensional drawing

Mounting 4 x M6 threaded mounting holes, 10 mm deep

Operation ambient

temperature

Stockage temperature –20 °C ... +70 °C

Relative air humidity 5 % … 95 %, non-condensing

*) VSWR = Voltage Standing Wave Ration.

< 1.3 : 1

–20 °C ... +70 °C

22 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 23

Technical Information Chapter 3

–30

–20

–10

0

10

Measured gain in dBi at 900 MHz

0°

15°

30°

45°

60°

75°

90°

105°

120°

135°

150°

165°

180°

–165°

–150°

–135°

–120°

–105°

–90°

–75°

–60°

–45°

–30°

–15°

horizontal – vertical vertical – vertical

–3 dB at +33°

–3 dB at –34°

Aperature angle 67°

(main radiation

direction)

–3 dB at +34°

–3 dB at –35°

Aperature angle 69°

(main radiation

direction)

3 dB

Mounting

RFU63x

Radiation pattern diagram RFA641-3440

Internet Ordering information about the antenna and its accessories (mounting bracket and adapter

Accessories

cables [N male connector / TNC reverse] of different lengths) is available on the following

SICK product pages on the web:

www.sick.com/6034316

The corresponding power loss values of the cables in the frequency band of 860 MHz to 960

MHz are also listed there.

Mounting

If several antennas are used in a reading station, e.g. two on each side of a conveyor system, make sure that the antennas are not directly facing each other, but are installed at

staggered parallel positions.

Fixed wall-mounting (alignment not adjustable):

1. Mark and drill four fixing holes in the installation surface in accordance with the dimensional drawing.

2. When installing on a plate or frame, insert the supplied bolts from the rear through the

installation surface and tighten the antenna.

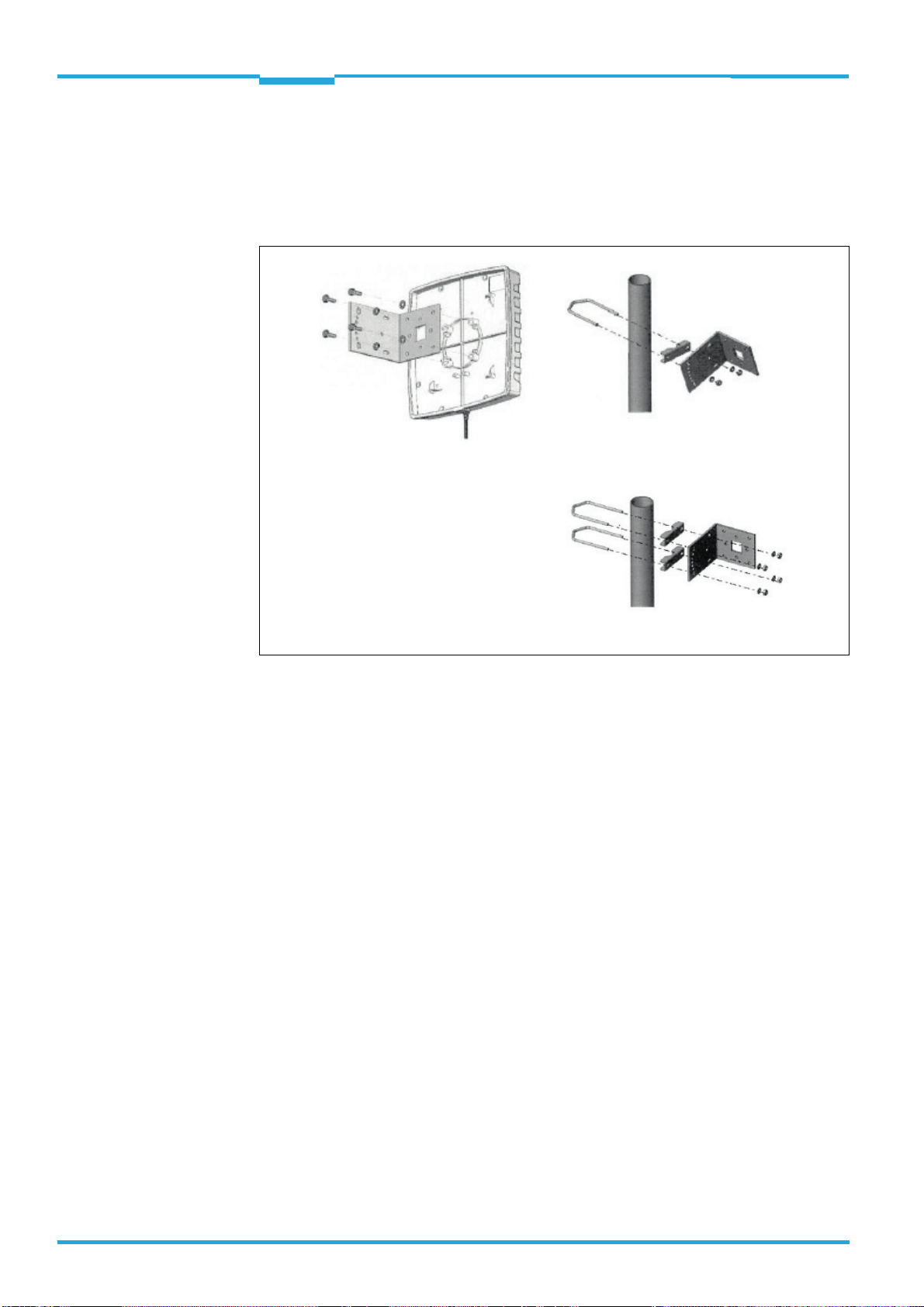

Installation to a tube (alignment adjustable in two axis):

Use the mounting bracket no. 5321692.

1. Tight the bracket to the antenna (step 1).

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 23

Page 24

Chapter 3 Technical Information

Step 1

Step 2a

Step 2b

Mounting

RFU63x RFID Write/Read Device (UHF)

2. Use a retainer and a bushing to install the bracket to the tube (step 2a).

Due to the combination of the retainer on the tube and the curved arranged drill holes

at the der leading edge of the bracket, the antenna can adjust in two axis to the objects.

If mounting across to the axis of the tube is sufficient, both retainers can also be used

for stable installation (step 2b).

24 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 25

Technical Information Chapter 3

RFU63x

Mounting

3.4.4 RFA651-5731 antenna

66

66

190

14

30

17.7

M5

1

14

1 Threaded pins (4 x)

2 N female connector

Technical Data

Type

Part no. 6036102

Frequency band 865 MHz ... 870 MHz (Europe)

Permissible write/read device RFU630-13100

Maximum radiated power

Polarization Linear

*)

VSWR

Gain Max. 8 dBic

Axial ratio

3 dB aperture angle

Front to back ratio

Electrical connection N female connector, 50 Ohm

Housing (material) Plastic (PP)

Enclosure rating IP 67 accord. to EN 60529: 1991-10; A1: 2002-02

Weight Approx. 0.8 kg

Dimensions (L x W x H) 190 mm x 190 mm x 30 mm, see dimensional drawing

Mounting 4 x Befestigungsgewindestange M5 x 17.7 mm

Ambient temperature

(operation/stockage)

Relative air humidity 5 % ... 95 %, non-condensing

*) VSWR = Voltage Standing Wave Ration

RFA651-5731

Typical < 1.3

–45°C ... +70 °C

190

38

20.2

All dimensions in mm

2

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 25

Page 26

Chapter 3 Technical Information

a

Internet Ordering information about the antenna and its accessories (mounting bracket and adapter

Mounting

RFU63x RFID Write/Read Device (UHF)

Accessories

cables [N male connector / TNC reverse] of different lengths) is available on the following

SICK product pages on the web:

www.sick.com/6036102

The corresponding power loss values of the cables in the frequency band of 865 MHz to 870

MHz are also listed there.

Mounting

If several antennas are used in a reading station, e.g. two on each side of a conveyor system, make sure that the antennas are not directly facing each other, but are installed at

staggered parallel positions.

Wall-mounting (alignment adjustable in two axis):

Use the mounting bracket no. 5322196.

1. For the foot of the bracket, mark and drill four fixing holes on the wall in accordance

with the dimensional drawing in the enclosed mounting instructions.

2. Install the cruciformed mounting plate of the adjusting arm to the antenna

3. Connect the cable to the antenna.

4. Fix the foot of the bracket on the wall using the enclosed bolts.

5. Align the antenna with the help of both hinges to the objects.

26 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 27

Technical Information Chapter 4

RFU63x

Electrical installation

4 Electrical installation

4.1 Notes on the electrical installation

The electrical installation must only be performed by electrically qualified persons.

Standard safety requirements must be met when working in electrical systems.

Electrical connections between the RFU630 and other devices may only be connected

or disconnected when the system is not live, otherwise the devices may be damaged.

The permissible ambient temperature range for this work is 0 °C to +50 °C.

RFU630-13101 (UL-certified):

– UL certified only if UL logo is printed on type plate.

– Install the device only inside of buildings. The device is not suitable for outdoor use.

– Lead the connection cables to the external device interfaces only inside of buildings.

– Use a supply voltage according to SELV (EN 60950-1:2006-04) and LPS (EN 60950-

1:2006-04) or Class 2 (UL 1310).

Operation of the RFU630 below 0 °C:

For information on configuring the electrical installation when using the RFU630-101xx

at temperatures down to –25 °C, see Chapter 4.5, Page 39.

When using connecting or extension cables with an open e nd, ma ke sur e that bare w ire

ends are not touching (risk of short-circuit when the supply voltage is switched on).

Take appropriate measures to isolate the wires.

Customer-specific provided cables:

Wire cross sections of the supply cable from the customer's power system as well of

data and switching signal cables should be designed in accordance with the applicable

standards.

All circuits connected to the RFU630 must be designed as SELV circuits. The power sup-

ply or power supply unit must satisfy the requirements of SELV in accordance with the

currently applicable EN 60950-1. (SELV = Safety Extra Low Voltage.)

Do not switch on the supply voltage for the RFU630 respectively the CDB650-204 or

CDM420-0006 connection module until the connection work has been completed and

the wiring work has been tested thoroughly.

Prerequisites for enclosure rating IP 65

The cover for the USB female connector and Micro SD card slot has to be screwed onto

the housing during normal operation.

Protect the RFU63x from moisture and dust when the cover is open.

The electrical connections not used have to be fitted with protective caps or plugs.

The same also applies for the EMC requirements (ESD) according to CE.

Cable lengths

The possible length of cable between RFU630 and the host computer depends on the

selected physical design of the host interface and the set data transmission rate. For the

serial interfaces, see Chapter 4.7.3 Wiring the data interface, Page 47.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 27

Page 28

Chapter 4 Technical Information

e.g. cable no. 2055419 (2 m)

e.g. cable no. 6049780 (2 m)

CDB650-204

SerialSerial

SerialSerial

e.g. cable

no. 6034414 (2 m)

e.g. cable

no. 6036106 (2 m)

Configuration

Diagnostics

SOPASSOPAS

“Power/Serial Data/CAN/I/O”

(AUX 1, HOST 1)

No. 1064114

...

...

1

2

DC 18 V ... 30 V

GND

PC

e.g. cable no. 2014054 (2 m)

“Serial RS-232” (AUX 1), alternatively to Ethernet AUX port

“Ethernet” (AUX 2)

DC 18 V ... 30 V

1)

“USB” (AUX 3),

alternatively to Ethernet AUX port

External antennae (optional)

2)

...

13

2) e.g. RFA630-000 for region Europe1) Required minimum input voltage depends on the cable

length between CDB650-204 and RFU630-131xx,

see RFU63x-131xx operating instructions (no. 8016526)

EthernetEthernet

USBUSB

RFU630-

131xx

“Ethernet” (HOST 2)

Input 2

(e.g. encoder)

Input 1

(e.g. external reading trigger)

Output 1

(e.g. indicator lamp)

Output 2

RFU630-

131xx

e.g. cable no. 2055419 (2 m)

e.g. cable no. 6049780 (2 m)

“Serial RS-232/RS-422/485” (HOST 1), alternatively to Ethernet HOST port

CDB650-204

SerialSerial

e.g. cable

no. 6034414 (2 m)

“Power/Serial Data/CAN/I/O”

(AUX 1, HOST 1)

No. 1064114

...

...

1

2

DC 18 V ... 30 V

GND

HOST

Furt her d ata

processing

DC 18 V ... 30 V

1)

Inputs/Outputs = digital

Additional external inputs/outputs via

parameter cloning module CMC600

External antennae (optional)

2)

...

13

Reading result

2) e.g. RFA630-000 for region Europe1) Required minimum input voltage depends on the cable

length between CDB650-204 and RFU630-131xx,

see RFU63x-131xx operating instructions (no. 8016526)

EthernetEthernet

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.2 Overview of all interfaces and connection options

4.2.1 RFU630-131xx with integrated antenna

Configuration and diagnostics

28 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Reading mode

Page 29

Technical Information Chapter 4

CDB650-204

SerialSerial

e.g. cable

no. 6034414 (2 m)

Configuration

Diagnostics

SOPASSOPAS

No. 1064114

...

...

1

2

DC 18 V ... 30 V

GND

PC

e.g. cable no. 2014054 (2 m)

“Serial RS-232” (AUX 1), alternatively to Ethernet AUX port

“Ethernet” (AUX 2)

DC 18 V ... 30 V

1)

“USB” (AUX 3),

alternatively to Ethernet AUX port

...

14

RFU630041xx

SerialSerial

EthernetEthernet

USBUSB

1) Required minimum input voltage depends on the cable

length between CDB650-204 and RFU630-041xx,

see RFU630-041xx operating instructions (no. 8015215)

e.g. cable no. 2055419 (2 m)

e.g. cable no. 6049780 (2 m)

“Power/Serial Data/CAN/I/O”

(AUX 1, HOST 1)

External antennae (optional)

2)

2) e.g. RFA630-000 for region Europe

e.g. cable

no. 6036106 (2 m)

Electrical installation

RFU63x

4.2.2 RFU630-041xx without integrated antenna

Configuration and diagnostics

Reading mode

1

2

GND

DC 18 V ... 30 V

DC 18 V ... 30 V

Input 1

(e.g. external reading trigger)

Input 2

(e.g. encoder)

Output 1

(e.g. indicator lamp)

Output 2

Additional external inputs/outputs via

parameter cloning module CMC600

Inputs/Outputs = digital

1)

CDB650-204

No. 1064114

...

...

“Serial RS-232/RS-422/485” (HOST 1), alternatively to Ethernet HOST port

SerialSerial

External antennae (optional)

...

14

e.g. cable no. 6049780 (2 m)

“Power/Serial Data/CAN/I/O”

(AUX 1, HOST 1)

e.g. cable no. 2055419 (2 m)

length between CDB650-204 and RFU630-041xx,

see RFU63x-041xx operating instructions (no. 8015215)

2)

no. 6034414 (2 m)

e.g. cable

RFU630041xx

“Ethernet” (HOST 2)

Reading result

2) e.g. RFA630-000 for region Europe1) Required minimum input voltage depends on the cable

EthernetEthernet

HOST

Furt her d ata

processing

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 29

Page 30

Chapter 4 Technical Information

RFU630

Aux 1

RS-232

CAN

SOPAS ET

Configuration

Software

HOST

Further data

processing

Host 1

PC/HOST

RS-232

1)

RS-422

1)

RS-485

1)

1) Select one of the three options

2) Recommended on high data volume

◂ Configuration/Data output ▸

Aux 3

USB

◂ Configuration

◂ Configuration/Data output ▸

Ethernet

Aux 2 ◂ Configuration/Data output ▸

Host 2 ◂ Configuration/Data output

2)

▸

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.2.3 Using the data interfaces

Possible interface HOST 1 AUX 1 HOST 2 AUX 2 AUX 3

Assignable function

Read result output (format 1)

Read result output (format 2)

Read diagnosis output (fixed format)

Observation of HOST interface traffic

Configuration (SOPAS ET, commands)

= Output of the same function simultaneously possible via the interfaces

= Access only makes practical sense via one of the interfaces (risk of collision)

RS-232/-

RS-232 Ethernet Ethernet USB

422/485

Important! Only one of several selectable functions can be allocated to each interface.

The logical AUX interface of the RFU630 can operate the serial data interface, USB interface

and Aux port of the Ethernet interface in parallel.

In a similar manner, the logical HOST interface of the RFU630 can operate the serial data

interface and the Host port of the Ethernet interface in parallel. The physical RS-232 and

RS-422/485 Host interfaces cannot be used simultaneously.

However, the data released by means of a command string is only output on the interface

on which the request was received.

For output in real time, one of the two ports of the Ethernet interface must be selected.

30 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 31

Technical Information Chapter 4

“Power/Serial Data/CAN/I/0” connection Adapter cable M12 to D-Sub,

e.g. no. 2055419 (2 m)

CAN L

CAN H

TD+ (RS-422/485), HOST

TD– (RS-422/485),

TxD (RS-232), HOST

DC 18 V ... 30 V

TxD (RS-232), AUX

RxD (RS-232), AUX

RD+ (RS-422/485), HOST

GND

RD– (RS-422/485),

RxD (RS-232), HOST

Result 1 (switching output 1)

N.c.

N.c.

Result 2 (switching output 2)

7

6

Sensor 2 (switching input 2)

Sensor 1 (switching input 1)

SensGND

4

3

2

1

5

8

9

10

11

12

13

14

15

16

17

RFU630-131xx

Male connector, M12,

17-pin, A-coded

CAN L

CAN H

TD+ (RS-422/485), HOST

TD– (RS-422/485),

TxD (RS-232), HOST

DC 18 V ... 30 V

TxD (RS-232), AUX

RxD (RS-232), AUX

RD+ (RS-422/485), HOST

GND

RD– (RS-422/485),

RxD (RS-232), HOST

Result 1 (switching output 1)

Result 2 (switching output 2)

7

6

Sensor 2 (switching input 2)

Sensor 1 (switching input 1)

SensGND

4

3

2

1

5

8

9

10

11

12

13

14

15

Male connector,

D-Sub HD, 15-pin

4

3

2

1

TD+

TD–

RD+

RD–

“Ethernet” connection

RFU630-131xx

Female

connector,

M12, 4-pin,

D-coded

6

1

10

5

11

15

3

1

7

2

6

5

4

8

13

14

17

15

9

10

12

16

11

1

43

2

Electrical installation

RFU63x

4.3 M12 male and female connector pin assignments on the RFU630

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 31

Page 32

Chapter 4 Technical Information

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.4 Pin assignments and lead color assignments of cables

4.4.1 RFU63x ("Power/SerialData/CAN/I/0" connection) to CDB650-204

Connection cable 1:1: no. 6052286 (2 m), no. 6051194 (3 m), no. 6051195 (5 m)

Ambient temperature range:

Stationary installation: –40 °C to +80°C, mobile installation: –25 °C to +80°C

Supply voltage: DC 18 V ... 30 V

4.4.2 RFU630 ("Power/SerialData/CAN/I/0" connection) to CDM420-0006

a) Adapter cable no. 2056184 (0.35 m), no. 2049764 (0.9 m), no. 2055419 (2 m),

no. 2055420 (3 m), no. 2055859 (5 m)

b) Adapter cable, suitable for drag chain use, no. 2061480 (2 m), no. 2061605 (3 m),

no. 2061481 (5 m)

Ambient temperature range:

Stationary installation: –40 °C to +80°C, mobile installation: –25 °C to +80°C

Supply voltage: DC 18 V ... 30 V

12

3

2

13

1

11

10

16

9

4

5

14

6

17

7

8

15

Female connector,

M12, 17-pin, A-coded

(front view)

Illustration may differ

6

11

Male connector,

D-Sub HD, 15-pin

(front view)

10

5

1

15

Pin Signal Function Pin

2 DC 18 V ... 30 V Supply voltage 1

8 RxD (RS-232), AUX Aux interface (receiver) 2

7 TxD (RS-232), Aux Aux interface (sender) 3

15 Sensor 2 Switching input 2 4

1GND Ground 5

11 RD+ (RS-422/485), Host Host interface (receiver+) 6

12 RD– (RS-422/485)/

Host interface (receiver–) 7

RxD (RS-232), Host

5 TD+ (RS-422/485), Host Host interface (sender+) 8

6 TD– (RS-422/485)/

Host interface (sender–) 9

TxD (RS-232), Host

4 CAN H CAN bus (IN/OUT) 10

3 CAN L CAN bus (IN/OUT) 11

13 Result 1 Switching output 1 12

14 Result 2 Switching output 2 13

10 Sensor 1 Switching input 1 14

9 SensGND Common ground for all inputs 15

16 N.c. – –

17 N.c. – –

32 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 33

Technical Information Chapter 4

Female connector,

M12, 17-pin, A-coded

(front view)

...

Illustration may differ

3

1

7

2

6

5

4

8

13

14

17

15

9

10

12

16

11

Electrical installation

RFU63x

4.4.3 RFU630 ("Power/AUX/CAN/I/0" connection) to customer-specific connection unit (power supply unit or switching cabinet)

a) Adapter cable no. 6042772 (3 m), no. 6042773 (5 m), no. 6048817 (10 m)

Ambient temperature range:

Stationary installation: –40 °C to +80°C, mobile installation: –5 °C to +80°C

Supply voltage: DC 18 V ... 30 V, has to be protected by fuse 2 A

Pin Signal Function Color of lead

1 GND Ground Brown

2

DC 18 V ... 30 V

3 CAN L CAN-Bus (IN/OUT) White

4 CAN H CAN-Bus (IN/OUT) Green

5 TD+ (RS-422/485), Host Host interface (sender+) Pink

6 TD– (RS-422/485)/

TxD (RS-232), Host

7 TxD (RS-232), Aux Aux interface (sender) Black

8 RxD (RS-232), Aux Aux interface (receiver) Gray

9 SensGND Common ground for all inputs Red

10 Sensor 1 Switching input 1 Purple

11 RD+ (RS-422/485), Host Host interface (receiver+) Gray-pink

12 RD– (RS-422/485)/

RxD (RS-232), Host

13 Result 1 Switching output 1 White-green

14 Result 2 Switching output 2 Brown-green

15 Sensor 2 Switching input 2 White-yellow

16 N.c. – Yellow-brown

17 N.c. – White-gray

Supply voltage Blue

Host interface (sender–) Yellow

Host interface (receiver–) Red-blue

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 33

Page 34

Chapter 4 Technical Information

Electrical installation

RFU63x RFID Write/Read Device (UHF)

b) Adapter cable, suitable for drag chain use, ECOLAB, no. 2070425 (3 m), no. 2070426

(5 m), no. 2070427 (10 m)

Ambient temperature range:

Stationary installation: –40 °C to +80°C, mobile installation: –25 °C to +80°C

Supply voltage: DC 18 V ... 30 V, has to be protected by fuse 2 A

12

3

2

13

1

11

10

16

9

Female connector,

M12, 17-pin, A-coded

(front view)

Pin Signal Function Color of lead

1GND Ground Blue

2

3 CAN L CAN-Bus (IN/OUT) Green

4 CAN H CAN-Bus (IN/OUT) White

5 TD+ (RS-422/485), Host Host interface (sender+) Pink

6 TD– (RS-422/485)/

7 TxD (RS-232), Aux Aux interface (sender) Black

8 RxD (RS-232), Aux Aux interface (receiver) Gray

9 SensGND Common ground for all inputs White-black

10 Sensor 1 Switching input 1 Purple

11 RD+ (RS-422/485), Host Host interface (receiver+) Gray-pink

12 RD– (RS-422/485)/

13 Result 1 Switching output 1 White-green

14 Result 2 Switching output 2 Brown-green

15 Sensor 2 Switching input 2 White-yellow

16 N.c. – Yellow-brown

17 N.c. – White-gray

4

5

14

6

17

7

8

15

DC 18 V ... 30 V

TxD (RS-232), Host

RxD (RS-232), Host

...

Illustration may differ

Supply voltage Brown

Host interface (sender–) Yellow

Host interface (receiver–) Red-blue

34 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 35

Technical Information Chapter 4

Electrical installation

RFU63x

c) Adapter cable, suitable for drag chain use, no. 6045141 (5 m)

Ambient temperature range:

Stationary installation: –40 °C to +85°C, mobile installation: –25 °C to +80°C

Supply voltage: DC 18 V ... 30 V, has to be protected by fuse 2 A

12

3

2

13

1

11

10

16

9

Female connector,

M12, 17-pin, A-coded

(front view)

Pin Signal Function Color of lead

1GND Ground Gray

2

3 CAN L CAN-Bus (IN/OUT) Gray-pink

4 CAN H CAN-Bus (IN/OUT) Purple

5 TD+ (RS-422/485), Host Host interface (sender+) Red

6 TD– (RS-422/485)/

7 TxD (RS-232), Aux Aux interface (sender) Green

8 RxD (RS-232), Aux Aux interface (receiver) Brown

9 SensGND Common ground for all inputs White-yellow

10 Sensor 1 Switching input 1 Brown-green

11 RD+ (RS-422/485), Host Host interface (receiver+) Pink

12 RD– (RS-422/485)/

13 Result 1 Switching output 1 Red-blue

14 Result 2 Switching output 2 White-green

15 Sensor 2 Switching input 2 Yellow

16 N.c. – Yellow-brown

17 N.c. – White-gray

4

5

14

6

17

7

8

15

DC 18 V ... 30 V

TxD (RS-232), Host

RxD (RS-232), Host

...

Illustration may differ

Supply voltage White

Host interface (sender–) Black

Host interface (receiver–) Blue

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 35

Page 36

Chapter 4 Technical Information

Female connector,

M12, 17-pin, A-coded

(front view)

Illustration may differ

3

1

7

2

6

5

4

8

13

14

17

15

9

10

12

16

11

Male connector, M12,

4-pin, D-coded

(front view)

Male connector,

RJ-45, 8-pin

(front view)

Illustration may differ

1

43

2

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.4.4 RFU630 ("Power/AUX/CAN/I/0" connection) to customer-specific power supply unit

Adapter cable no. 6048319 (10 m)

Ambient temperature range:

Stationary installation: –40 °C to +85°C, mobile installation: –25 °C to +80°C

Supply voltage: DC 18 V ... 30 V, has to be protected by fuse 2 A or

Supply voltage: DC 12 V ... 30 V, has to be protected by fuse 2.5 A

Pin Signal Function Color of lead

1 GND Ground Brown

2

DC 18 V (12 V) ... 30 V

Supply voltage Blue

4.4.5 RFU630 ("Ethernet" connection) to Ethernet (RJ-45) or PROFINET (RJ-45)

Ethernet cables:

a) Adapter cable no. 6034414 (2 m), no. 6044400 (3 m), no. 6034415 (5 m),

no. 6030928 (10 m), no. 6036158 (20 m)

Ambient temperature range:

Stationary installation: –20 °C to +60°C, mobile installation: –0 °C to +50°C

b) Adapter cable, suitable for drag chain use, ECOLAB no. 6050198 (2 m), no. 6050199

(3 m), no. 6050200 (5 m), no. 6050201 (10 m), no. 6050596 (20 m)

Ambient temperature range: mobile installation: –25 °C to +60°C

Pin Signal Function Pin

1 TD+ (Ethernet) Sender+ 1

3 TD– (Ethernet) Sender– 2

2 RD+ (Ethernet) Receiver+ 3

4 RD– (Ethernet) Receiver– 6

36 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

PROFINET cables:

a) Adapter cable no. 6048244 (2 m), no. 6048245, (5 m), no. 6048246 (10 m)

b) Adapter cable with M12 male connector, angled (here not shown): no. 6048253 (2 m),

no. 6048254 (5 m), no. 6048255 (10 m)

Page 37

Technical Information Chapter 4

Male connector, M12,

4-pin, D-coded

(front view)

Male connector,

RJ-45, 8-pin

(front view)

Illustration may differ

1

43

2

Electrical installation

RFU63x

Ambient temperature range:

Stationary installation: –40 °C to +70°C, mobile installation: –20 °C to +60°C

Pin Signal Function Pin

1 TD+ (Ethernet) Sender+ 1

3 TD– (Ethernet) Sender– 2

2 RD+ (Ethernet) Receiver+ 3

4 RD– (Ethernet) Receiver– 6

4.4.6 RFU630 ("Ethernet“ connection) to PROFINET (open end)

Ethernet cables:

a) Adapter cable no. 6048247 (2 m), no. 6048248 (5 m), no. 6048249 (10 m)

Ambient temperature range:

Stationary installation: –40 °C to +70°C, mobile installation: –20 °C to +60°C

PROFINET cables:

b) Adapter cable with M12 male connector, angled (here not shown): no. 6048256 (2 m),

no. 6048257 (5 m), no. 6048258 (10 m), no. 6048259 (25 m)

Ambient temperature range:

Stationary installation: –40 °C to +70°C, mobile installation: –20 °C to +60°C

43

1

Male connector, M12,

4-pin, D-coded

(front view)

Pin Signal Function Color of lead

1 TD+ (Ethernet) Sender+ Yellow

2

3 RD+ (Ethernet) Receiver+ Orange

4RD– (Ethernet) Receiver– Blue

2

TD– (Ethernet)

Illustration may differ

Sender– White

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 37

Page 38

Chapter 4 Technical Information

Female connector,

M12, A-coded

(front view)

Illustration may differ

1

43

5

2

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.4.7 CDB650-204 or CDM420-0006 connection module to CAN network

CAN data cable no. 6021166 (5 m)

Ambient temperature range:

Stationary installation: –40 °C to +70°C, mobile installation: –20 °C to +70°C

Pin Signal Funktion Color of lead

1– Shield –

2 DC +24 V Supply voltage Red

3GND Ground Black

4 CAN H CAN-Bus (IN/OUT) White

5 CAN L CAN-Bus (IN/OUT) Blue

4.4.8 CDB650-204 or CDM420-0006 connection module (Host interface RS-232 of RFU630) to PC

RS-232 data cable no. 2020319 (3 m)

Ambient temperature range:

Stationary installation: –30 °C to +90°C, mobile installation: –5 °C to +90°C

5

1

6

9

Female connector,

D-Sub, 9-pin

(front view)

Pin Signal Function Color of

lead

1– – – –

2 RxD (RS-232) Host interface (receiver) Brown 43 / 34 (TxD Host)

3 TxD (RS-232) Host interface (sender) Blue 44 / 35 (RxD Host)

4– – – –

5 GND Ground Black 42 / 36 (GND)

6 ... 9 – – – –

Terminal CDB650-204/

Terminal CDM420-0006

38 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 39

Technical Information Chapter 4

RFU63x

Electrical installation

4.5 Notes on the electrical installation of the RFU630 at an ambient temperature below 0 °C

The RFU630 can be operated at ambient temperatures between +50 °C and –25 °C.

4.5.1 Prerequisites

RFU630-13101 UL-certified: Install the device only inside of buildings. The device is not

suitable for outdoor use.

All other variants: For use outdoors, use suitable weather protection, which prevents

the device from heating up due to direct sunlight during the summer and protects the

device from being cooled by the wind during the winter.

Use supply voltage DC 18 V ... 30 V if:

– RFU630 is connected to the optional CDB650-204 or CDM420-0006 connection

module by a specified SICK cold-resistant cable.

– RFU630 is operated without a SICK connection module and connected with a spe-

cified SICK cold-resistant cable.

Protect the cable by a separate fuse 2 A at the start of the incoming supply circuit.

Use supply voltage DC 12 V ... 30 V if:

– RFU630 is optionally operated without a SICK connection module and connected

with the specified SICK cold-resistant cable no. 6048319 (2 x 2.5 mm

Protect the cable by a separate fuse 2.5 A at the start of the incoming supply circuit.

Use SICK standard cables for the ambient temperature range specified, also see

Chapter 4.4 Pin assignments and lead color assignments of cables, Page 32.

Only carry out connection work in ambient temperatures ranging from 0 °C to +50 °C.

The connecting cables must be fixed in place.

All cables connected to the device are locked. Yellow protective caps or plugs are

screwed onto any electrical connections that are not in use.

The RFU630 may only be operated in ambient temperatures below 0 °C when no

mounting or connection work is being carried out.

When the device is operated on the lowest limit value of the ambient temperature of

–25 °C, it must not exposed to strong air movement (e.g. inhouse due to ventilation).

2

, 10 m).

4.5.2 Behavior of the device after switch-on

Following application of the supply voltage and initialization, the RFU630 can immediately

be accessed by the SOPAS ET configuration software.

Internal temperature of housing

Below –25 °C "Ready" LED continuously flashes yellow.

–20 °C ... –25 °C "Ready" LED continuously flashes green (warm-up phase).

From –20 °C "Ready" LED permanently lights up green.

Behavior after switch-on

Device is not operational as –25 °C is below the specified minimum limit

value.

Device is not operational (communication channel still disabled) until the

internal temperature has increased to –20 °C as a result of the heat generated by the electronics.

Duration approx. 2 min.

The device has started regular operation.

Once the supply voltage has been applied, the device uses integrated temperature sensors

to measure its internal temperature. This is handled during booting.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 39

Page 40

Chapter 4 Technical Information

Electrical installation

RFU63x RFID Write/Read Device (UHF)

Supplement to the RFU630 operating instructions:

Status indicators on the first display level

Display LED Farbe Status

Ready

= LED flashes

Yellow Flashing, frequency 1 Hz.

Internal temperature of RFU63x below –25°C.

The device is not ready for operation

Green Flashing, frequency 1 Hz.

Internal temperature of RFU63x between –25°C and –20°C.

The device is not ready for operation.

After a warm-up phase of approx. 2 min, the RFU63x starts regular operation.RFU630.

40 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 41

Technical Information Chapter 4

DANGER

RFU630

closed current loop

with equalizing currents

via cable shield

grounding point 2

grounding point 1

grounding potential difference

PLC

Reading clock

sensor

I

U

CDB650-

204

= metal housing = plastic housing

= shielded electrical cable

RFU63x

Electrical installation

4.6 Prerequisites for the safe operation of the RFU630 in asystem

The RFU630 is designed and tested for electrical safety according to EN 60950-1: 200604/A1: 2010-03/A11: 2009-03/A12: 2011-02. It is connected to the peripheral devices

(power supply, clock reading pulse sensor(s), PLC, Host etc.) via shielded cables. The cable

shield, for example, for the data cable rests against the metal housing of the RFU630. The

device can either be grounded through the cable shield or through one of the blind hole

threads on the rear side.

If the peripheral devices have metal housings and if the cable shields also lie on their housings, it is assumed that all devices involved in the installation have the same ground poten-

tial.

This is achieved for instance by complying with the following conditions:

Mounting the devices on conductive metal surfaces

Correctly grounding the devices/metal surfaces in the system

If necessary, low-impedance and current carrying equipotential bonding between areas

with different ground potentials.

If these conditions are not met, e.g. on devices in a widely distributed system over several

buildings, potential equalization currents may, due to different ground potentials, flow along

the cable shields between the devices, which can lead to hazards.

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 41

Risk of injury/risk of damage via electrical current!

Potential equalization currents between the RFU630 and other grounded devices in the

system can have the following effects:

Dangerous voltages on the metal housing of the RFU630, for instance

Incorrect function or irreparable damage to the devices

Damage/irreparable damage of the cable shield due to heating and cable fires

Where local conditions are unfavorable and thus do not meet conditions for a safe

earthing method (same ground potential at all grounding points), take measures in

accordance with the following explanations.

Page 42

Chapter 4 Technical Information

grounding point 1

Electro-

optical

signal

isolator

Electro-

optical

signal

isolator

PLC

Reading

clock sensor

grounding point 2

RFU630

shielded electrial cablemetal housing fiber optic cable

Electrical installation

RFU63x RFID Write/Read Device (UHF)

Remedial measures

The most common solution to prevent potential equalization currents on cable shields is to

ensure low-impedance and current carrying equipotential bonding. If this is not possible, the

following solution approaches serve as a suggestion.

Important! We expressly advise against opening up the cable shields. Doing this means that the EMC

limit values can no longer be complied with and that the safe operation of the device data

interfaces can no longer be guaranteed.

a) Measures for widely distributed system installations

On widely distributed system installations with correspondingly large potential differences,

we recommend setting up local islands and connecting them using commercially available

electro-optical signal isolators. This measure achieves a high degree of resistance to electromagnetic interference while at the same time complying with all the requirements of

EN 60950-1.

The ground loop is isolated by using the electro-optical signal isolator between the islands.

Within the islands, a stable equipotential bonding prevents equalizing currents at the cable

shields.

b) Measures for small system installations

For smaller installations with only slight potential differences, insulated installation of the

RFU630 and of peripheral devices may be a sufficient solution.

42 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 43

Technical Information Chapter 4

electrically

insulatetd

grounding point 2 grounding point 3grounding point 1

grounding potential difference

U

shielded electrial cable

PLC

Reading clock

sensor

RFU630

RFU63x

Electrical installation

Even in the event of large differences in the ground potential, ground loops are effectively

prevented, meaning that equalizing currents can no longer flow via the cable shields and

metal housing.

Important! The power supply for the RFU630 and the connected peripheral devices must also guaran-

tee the required level of insulation.

Under certain circumstances, a tangible potential can develop between the insulated metal

housings and the local ground potential.

Special national regulations for Sweden and Norway

Varning och atjarder

Utrustning som ar kopplad till skyddsjord via jordat vagguttag och/eller via annan utrustning

och samtidigt ar kopplad till kabel-TV nat kan i vissa fall medfora risk for brand.

For att undvika detta skall vid anslutning av utrustningen till kabel-TV nat galvanisk iso-

lator finnas mellan utrustningen och kabel-TV natet.

Advarsel og tiltaker

Utstyr som er koplet til beskyttelsesjord via nettplugg og/eller via annet jordtilkoplet utstyr

- og er tilkoplet et kabel - TV nett, kan forarsake brannfare.

For a unnga dette skal det ved tilkopling av utstyret til kabel-TV nettet installeres en gal-

vanisk isolator mellom utstyret og kabel-TV nettet.

Corresponding English translation

Devices which are connected to the electrical system PE of the building via a mains connection or other devices with a connection to the PE, and which are connected to a cable distribution system with coaxial cables, can under certain circumstances cause a risk of fire.

Connections to a cable distribution system must therefore be made such that electrical

insulation is offered below a certain frequency range (galvanic separating link).

8014335/YUO7/2016-04-04 © SICK AG · Germany · All rights reserved · Subject to change without notice 43

Page 44

Chapter 4 Technical Information

“DC 18 V ... 30 V”

“Sensor 2”

“Host 1” (serial)

“Aux 1” (serial)

“Result 2”

“Result 1”

“CAN”

“Sensor 2”

“Sensor 1”

“External input 2“

2)

“External input 1“

2)

“Sensor 1”

DC 18 V ... 30 V

1)

“AUX”

PLC

CAN bus

1)

PLC

“Result 1”

“Result 2”

PLC

PLC

“External output 1“

2)

“External output 2“

2)

CDB650-204/CDM420-0006

Connection module

Photo-electric

switch

Reading clock

Futher

functions

“HOST 1” (serial)

“AUX 1” (serial)

RS-232

CMC600

1) Required minimum input voltage depends on the cable length between CDB650-204 and RFU630, see RFU63x-131xx (no. 8016526) respectively

RFU63x-041xx (no. 8015215) operating instructions

2) An optional CMC600 paramenter cloning module is required to provide the additional switching inputs and outputs.

HOST/PLC

Further data

processing

PC

Configuration

Diagnosistics

2)

Write/read device

Interface

RFU630

Tra nsp onde r

Internal/external

antenna(s)

“Ethernet” (Host 2/Aux 2)

“USB” (Aux 3)

RS-232/422/485

Ethernet

USB

“Host 2”

Ethernet

“Aux 2”

“Aux 3”

Photo-electric

switch

End of

reading pulse

(alternatively)

Incremental encoder

Path increment

Electrical installation

RFU63x RFID Write/Read Device (UHF)

4.7 Installation steps

4.7.1 Block diagram: wiring the optional the CDB650-204 or CDM420-0006 connection module (overview)

The commissioning and configuration of the connection module as well as the technical

data are described in the:

"CDB650-204 connection module" operating instructions (no. 8016155, German +

English version) e.g. as PDF in the web via www.sick.com/CDB

"CDM420-0006 connection module" operating instructions (no. 8014808 German +

English version) e.g. as PDF in the web via www.sick.com/CDM

The documents are also supplied in printed form with the relating connection module.

Important! Wiring the signals without SICK Connection Module

If a customer-specific connection unit is used, the wiring in principle of the data interfaces

(serial and CAN) and switching interfaces signals can be designed according to the following

wiring diagrams for the CDM420-0006 connection module.

44 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014335/YUO7/2016-04-04

Page 45

Technical Information Chapter 4

Electrical installation

RFU63x