Page 1

RFU61x

RFID read/write device (UHF)

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

RFU610-106xx

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

Conformities

Due to the country-specific approvals for the device, the respective conformance infor‐

mation is type-dependent. For the specific device that you have, see the online typespecific data sheet at:

www.sick.com/RFU61x

•

The type designation of your device can be found on the type label.

The trademarks mentioned in this document are the property of the respective owners.

2

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Scope......................................................................................................... 5

1.3 Explanation of symbols............................................................................ 6

1.4 Further information................................................................................... 7

1.5 SICK service.............................................................................................. 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Improper use............................................................................................. 9

2.3 Internet protocol (IP) technology.............................................................. 9

2.4 Limitation of liability................................................................................. 9

2.5 Modifications and conversions................................................................ 10

2.6 Requirements for skilled persons and operating personnel.................. 11

2.7 Operational safety and particular hazards.............................................. 12

2.8 Repairs...................................................................................................... 12

3 Product description........................................................................... 13

3.1 Product ID.................................................................................................. 13

3.2 Product characteristics............................................................................ 15

4 Transport and storage....................................................................... 22

4.1 Transport................................................................................................... 22

4.2 Unpacking.................................................................................................. 22

4.3 Transport inspection................................................................................. 22

4.4 Storage...................................................................................................... 22

5 Mounting............................................................................................. 24

5.1 Overview of mounting procedure............................................................. 24

5.2 Preparation for mounting......................................................................... 24

5.3 Mounting location..................................................................................... 26

5.4 Mounting the device................................................................................. 27

5.5 Mounting external components............................................................... 28

6 Electrical installation........................................................................ 30

6.1 Safety......................................................................................................... 30

6.2 Wiring instructions.................................................................................... 34

6.3 Overview of all interfaces and connection options................................ 35

6.4 Pin assignments of electrical connections............................................. 39

6.5 Instructions for electrical installation when the ambient temperature

can fall below 0 °C................................................................................... 40

6.6 Installation steps...................................................................................... 41

6.7 Connecting the supply voltage................................................................. 43

6.8 Wiring the digital input............................................................................. 45

6.9 Wiring the data interface.......................................................................... 46

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

3

Page 4

CONTENTS

7 Commissioning.................................................................................. 47

7.1 Overview of the Commissioning Steps.................................................... 47

7.2 SOPAS ET configuration software............................................................ 47

7.3 Starting the SOPAS ET configuration software and connecting it to

the device.................................................................................................. 48

7.4 Initial commissioning................................................................................ 49

8 Operation............................................................................................ 51

8.1 Operating and status indicators.............................................................. 51

9 Maintenance...................................................................................... 55

9.1 Maintenance plan..................................................................................... 55

9.2 Cleaning..................................................................................................... 55

10 Troubleshooting................................................................................. 56

10.1 Overview of Potential Errors and Faults.................................................. 56

10.2 Detailed fault analysis.............................................................................. 56

10.3 Status log.................................................................................................. 57

10.4 SICK service.............................................................................................. 57

10.5 Repairs...................................................................................................... 57

10.6 Returns...................................................................................................... 57

10.7 Replacing the device................................................................................ 58

11 Decommissioning............................................................................. 60

11.1 Disposal..................................................................................................... 60

12 Technical data.................................................................................... 61

12.1 Features.................................................................................................... 61

12.2 Interfaces.................................................................................................. 62

12.3 Mechanics and electronics...................................................................... 62

12.4 Ambient data............................................................................................. 63

12.5 Working range diagram............................................................................ 63

12.6 Dimensional drawing................................................................................ 63

13 Accessories........................................................................................ 64

14 Annex.................................................................................................. 65

14.1 EU declaration of conformity / Certificates............................................. 65

14.2 Certification according to UL61010-1..................................................... 65

14.3 Signal assignment of cables with open cable end at one end.............. 65

14.4 Copyright notices...................................................................................... 66

14.5 Abbreviations used................................................................................... 66

4

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied.

•

Compliance with local work safety regulations and general safety regulations for

•

device applications

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully to familiarize yourself with the device and its

functions before commencing any work.

The operating instructions are an integral part of the product. Store the instructions in

the immediate vicinity of the device so they remain accessible to staff at all times.

Should the device be passed on to a third party, these operating instructions should be

handed over with it.

ABOUT THIS DOCUMENT

1

1.2 Scope

These operating instructions do not provide information on operating the machine or

system in which the device is integrated. For information about this, refer to the operat‐

ing instructions of the specific machine.

These operating instructions serve to incorporate the device into a customer system.

These operating instructions form part of the documentation provided to users. The

operating instructions supplement the Quick Start Guide with more detailed and addi‐

tional information. The Quick Start guide for initial commissioning is enclosed with the

devices in printed form. The Quick Start guide can also be downloaded from the follow‐

ing website:

www.sick.com/RFU61x

•

The operating instructions provide in-depth information on the following topics:

Interpreting the type code

•

Overview of product features and functions of the device

•

Scope of delivery of the device: enclosed components, required online access to

•

additional components

Operation of the device in an ambient temperature range below 0 °C: measures

•

and requirements for mounting and electrical installation

Applications with spatially distributed systems: measures to prevent possible

•

ground potential equalizing currents

Overview of all interfaces and connection options for the device

•

Wiring the individual interfaces of the device

•

Additional functions of the status indicators

•

Overview of operating options and available configuration tools for the device

•

Measures for eliminating interference

•

Step-by-step procedures are given for all required actions in the operating instructions.

These instructions apply to all available device variants of the product. Functions spe‐

cific to special devices are, where necessary, described in additional documents.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

More detailed information for identification of the available device type see "Type code",

page 13.

The available device variants, and information about the regionally related radio equip‐

ment approvals are listed on the online product page:

•

Commissioning is described in the operating instructions using one particular device

variant as an example. Commissioning is based on the basic parameter setting of the

device. Reading a transponder on an object serves as the basis for the simple applica‐

tion.

NOTE

The device approval was granted for a specific region. The region assignment cannot be

changed.

•

•

•

•

www.sick.com/RFU61x

Only use the device in the region for which it has been approved.

When reselling the device, inform the buyer of the fixed region assignment.

Should the device be passed on to a third party, these operating instructions and

the Quick Start Guide should be handed over with it.

For country-specific special features in the operation of the device, see “Operating

restrictions” in the Quick Start Guide. A printed copy of the Quick Start Guide is

supplied with the device. The Quick Start Guide can also be accessed in PDF for‐

mat on the device product page on the Internet at: www.sick.com/RFU61x.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. Signal

words introduce the instructions and indicate the extent of the hazard. To avoid acci‐

dents, damage, and personal injury, always comply with the instructions and act care‐

fully.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

6

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 7

1.4 Further information

NOTE

Further documentation for the device can be found on the online product page at:

www.sick.com/RFU61x

•

There, additional information has been provided depending on the product, such as:

Model-specific online data sheets for device variants, containing technical data,

•

dimensional drawing, and specification diagrams

EU declarations of conformity for the product family

•

Certificates of the product family

•

Dimensional drawings and 3D CAD dimension models of the device variants in var‐

•

ious electronic formats

Quick Start guides for initial commissioning of the device

•

This documentation, available in English and German, and in other languages if

•

necessary

Other publications related to the devices described here

•

Publications dealing with accessories

•

NOTE

In addition to the existing operating instructions, the use of the RFU parameter descrip‐

tion is recommended. This document explains the UHF-RFID-specific parameters of all

device variants of the RFU6xx product family at the "Service” user level.

The parameter description supports the user in configuring applications with the

SOPAS ET configuration software.

ABOUT THIS DOCUMENT 1

1.5 SICK service

If you require any technical information, our SICK Service will be happy to help. To find

your agency, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.,

to ensure faster processing.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The RFU61x RFID read/write device is an intelligent ID sensor from the SICK RFU6xx

(UHF) product family. Version (working range): Short Range.

The device is used for the automated, fixed identification of wireless-based data cards

(transponders) on moving or stationary objects, and for the management of these data

cards. The RFU610 base model processes all standard passive transponders in accor‐

dance with EPCglobal UHF C1G2 and ISO/IEC 18000-6C in the regional UHF carrier fre‐

quency range.

The device works in stand-alone operation. In read mode, the device transmits the

results via a host interface to a higher-level computer (e.g. PLC) for further centralized

processing. Network operation is possible for coordinating trouble-free readings of

devices at close proximity to one another, but without a coordinating summary of the

reading results by one of the devices involved.

The compact device contains an antenna integrated in the housing.

The device allows operation within a wide ambient temperature range. For details, see

"Technical data", page 61.

The device is primarily designed for use in industrial and logistics areas, and meets the

requirements for industrial ruggedness, interfaces and data processing. If necessary,

the device can be programmed to implement customer-specific modifications.

NOTE

The USB interface of the device is used in industrial environments only as a service

interface for temporary use (e.g. for configuration, troubleshooting). Permanent use in

operational use of the system as a host interface is not intended.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.1.1 Operational restrictions

NOTICE

Operational restrictions!

The frequency band of the device is configured for the specific type and region when

delivered. This enables the device to be operated in the respective approved region

without interfering with protected frequencies (such as mobile communications).

Operating the device in other regions, however, can interfere with protected frequen‐

cies.

■

Only use the device in the region for which it has been approved.

■

When reselling the device, inform the buyer of the fixed region assignment.

■

Should the device be passed on to a third party, these operating instructions and

the Quick Start Guide should be handed over with it.

■

For further country-specific operating requirements, see the Quick Start Guide, a

printed copy of which is enclosed with the device or can be downloaded online

(PDF) at:

°

www.sick.com/RFU61x

A region consists either of a group of countries or of only one country.

8

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 9

2.1.2 Regulatory notes

Europe: simplified EU declaration of conformity

SICK AG hereby declares that the RFU61x-106xx radio equipment complies with the

2014/53/EU directive. The complete text of the EU declaration of conformity is avail‐

able at the following web address:

•

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

•

•

•

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

■

SAFETY INFORMATION 2

www.sick.com/RFU61x

The device does not constitute a safety component in accordance with the respec‐

tive applicable safety standards for machines.

The device must not be used in explosion-hazardous areas, in corrosive environ‐

ments or under extreme environmental conditions.

Any use of accessories not specifically approved by SICK AG is at your own risk.

Device should be used only in accordance with its intended use.

All information in these operating instructions must be strictly observed.

2.3 Internet protocol (IP) technology

NOTE

SICK uses standard IP technology in its products. The emphasis is placed on availability

of products and services.

SICK always assumes the following prerequisites:

The customer ensures the integrity and confidentiality of the data and rights

•

affected by its own use of the aforementioned products.

In all cases, the customer implements the appropriate security measures, such as

•

network separation, firewalls, virus protection, and patch management.

2.4 Limitation of liability

Relevant standards and regulations, the latest technological developments, and our

many years of knowledge and experience have all been taken into account when com‐

piling the data and information contained in these operating instructions. The manufac‐

turer accepts no liability for damage caused by:

■

Failing to observe the operating instructions

■

Incorrect use

■

Use of untrained staff

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

NOTE

The product is a programmable device. The respective programmer is therefore respon‐

sible for his/her programming work and the resultant operation of the device. The liabil‐

ity and warranty of SICK AG is limited to the device specification (hardware functionality

and any programming interfaces) according to the agreed conditions. SICK AG will

therefore not be liable, among other things, for any damages resulting from the pro‐

gramming of the product by the customer or third parties.

2.5 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dangers.

Interrupting or modifying the device or SICK software will invalidate any warranty claims

against SICK AG. This applies in particular to opening the housing, even as part of

mounting and electrical installation.

2.5.1 Exception: temporarily opening the cover on the device

NOTICE

The user may open the housing only in order to obtain temporary access to the USB

interface or the slot for the optional memory card. For this purpose, the corresponding

side cover on the device can be opened temporarily.

In open state, the device does not conform to a specified enclosure rating. The device

must be protected appropriately against moisture and dust.

Operate the device only for a short time without closed cover.

b

NOTE

The USB interface of the device is used in industrial environments only as a service

interface for temporary use (e.g. for configuration, troubleshooting). Permanent use in

operational use of the system as a host interface is not intended.

For further warranty provisions, see the General Terms and Conditions of SICK AG, e.g.

on the delivery note of the device.

2.5.2 Conditions for specified enclosure rating

To ensure compliance with the specified IP67 enclosure rating of the device, the follow‐

ing requirements must be met. If these requirements are not met, the device does not

fulfill any specified enclosure rating.

The joint side cover for the USB interface and the memory card slot is placed

•

against the device and screwed on tight.

The cables plugged into the electrical M12 and M8 connections must be screwed

•

tight.

Any M12 and M8 connections that are not being used must be sealed with protec‐

•

tive plugs or caps, depending on type. These plugs or caps must be screwed tight

(as in the delivery condition).

The same also applies to the EMC requirement (ESD) according to CE.

10

NOTICE

The type label on the lower side of the device contains a pressure equalizing membrane

attached in the middle. If the type label is damaged or removed, the leak tightness of

the device can no longer be guaranteed.

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 11

Positions of the individual elements see "Device view", page 15

NOTICE

The device can, if necessary, be operated for a short time without the side cover to per‐

form the following tasks:

Inserting or removing the optional memory card

•

Temporary use of the USB interface as a servicing interface

•

During this time, protect the device against moisture and dust.

2.6 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

This product documentation refers to the following qualification requirements for the

various activities associated with the device:

■

Instructed personnel have been briefed by the operator about the tasks assigned

to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g. Master Electrician). Other relevant regulations applicable in other

countries must be observed.

SAFETY INFORMATION 2

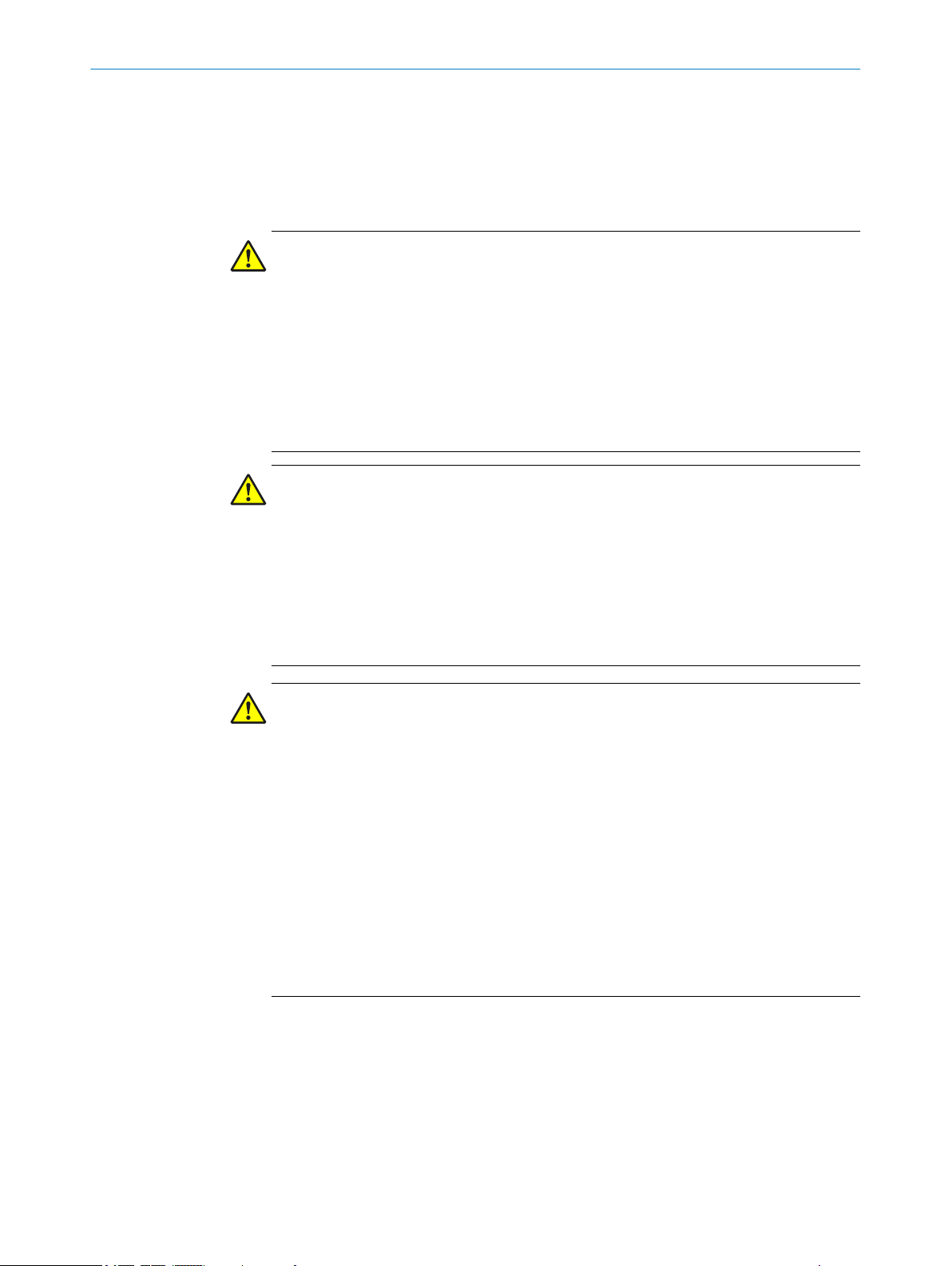

The following qualifications are required for various activities:

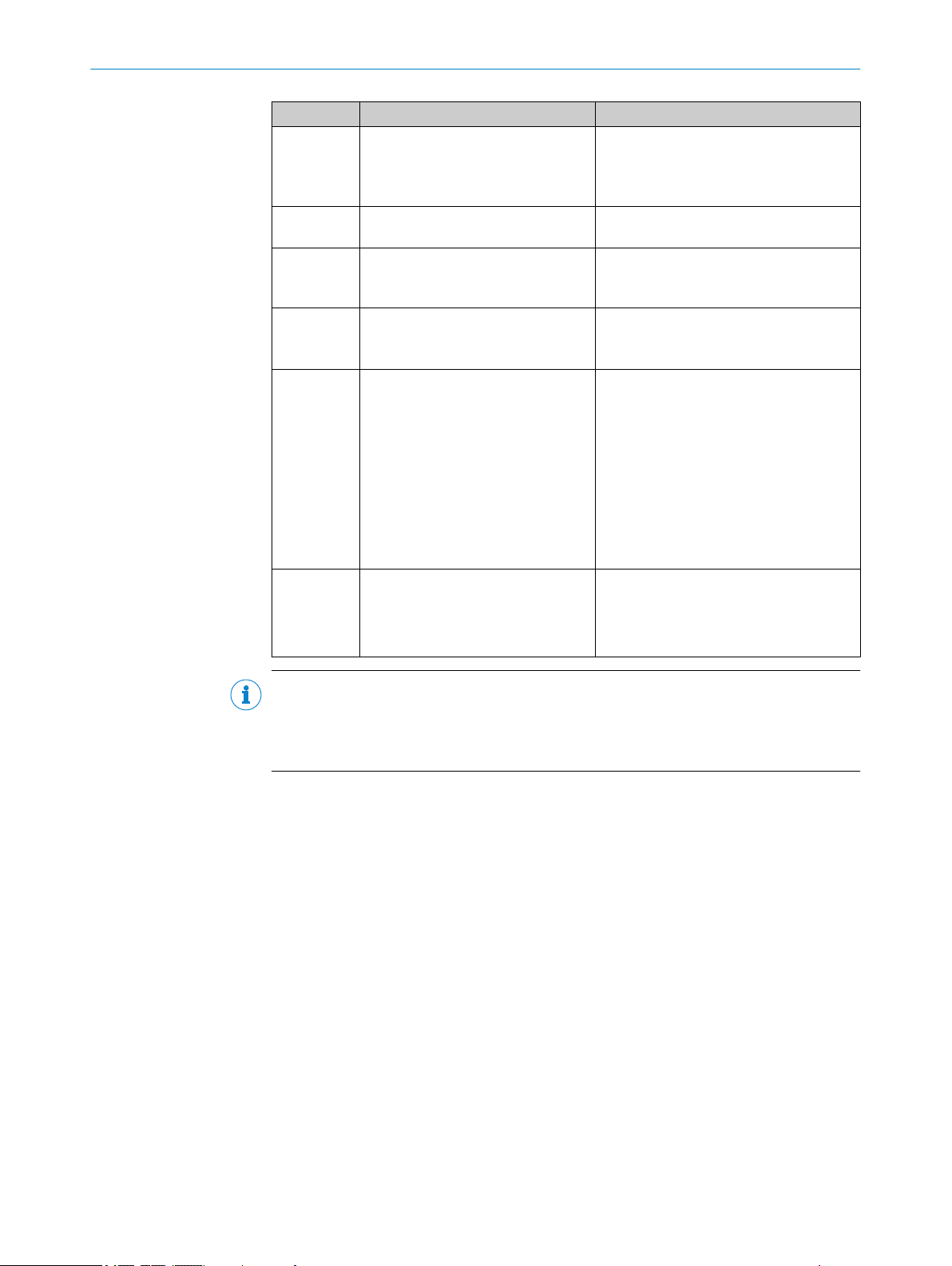

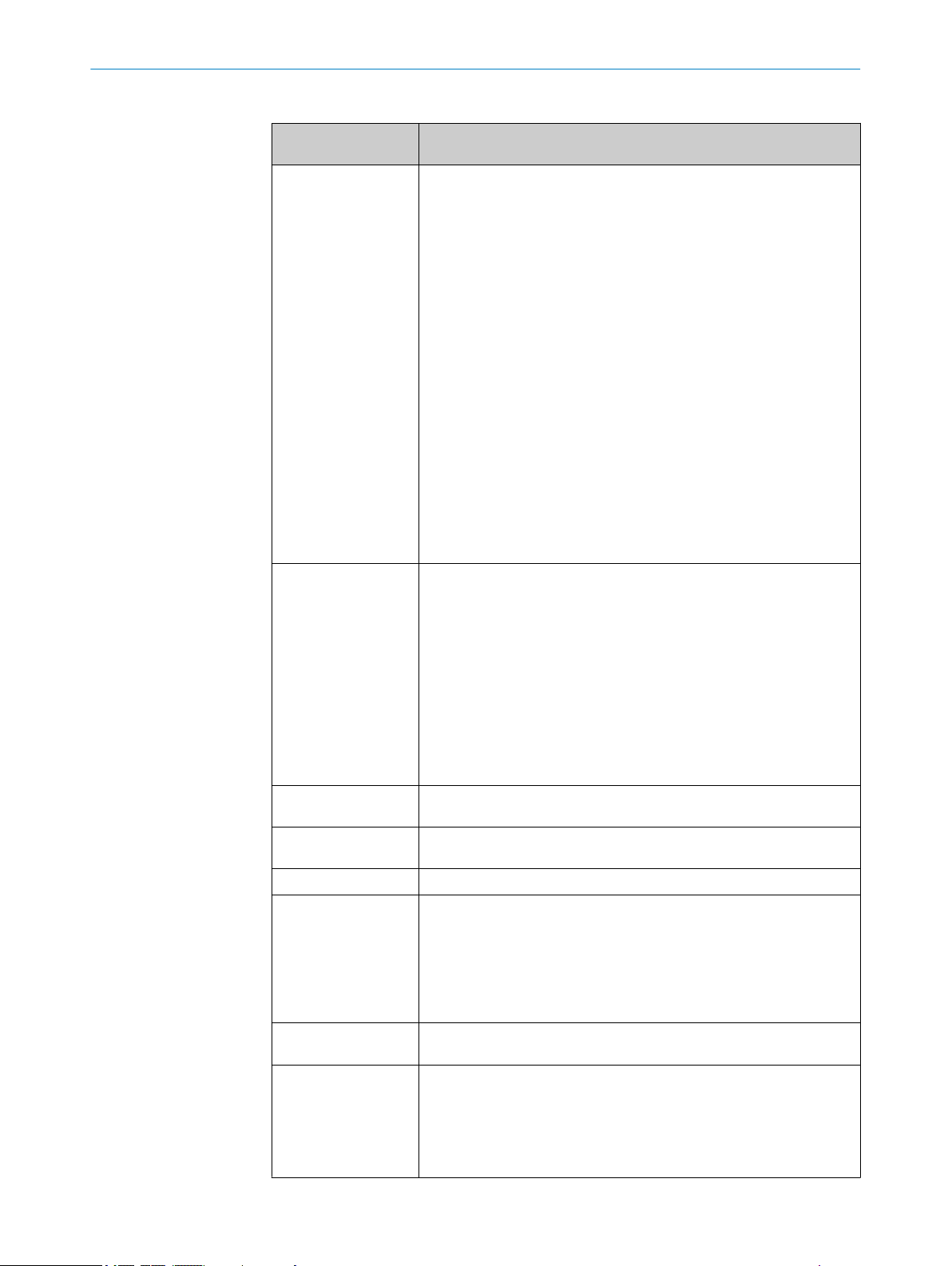

Table 1: Activities and technical requirements

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Commissioning, configura‐

tion

Operation of the device for

the particular application

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in their

■

particular application

Basic knowledge of the WindowsTM operating system in use

■

Basic knowledge of the design and setup of the described con‐

■

nections and interfaces

Basic knowledge of data transmission

■

Basic knowledge of RFID technology (identification with radio-

■

based data cards)

Knowledge of the programming of devices

■

Knowledge of the operation and control of the devices in their

■

particular application

Knowledge of the software and hardware environment for the

■

particular application

11

Page 12

2 SAFETY INFORMATION

2.7 Operational safety and particular hazards

Please observe the safety notes and the warnings listed here and in other chapters of

this product documentation to reduce the possibility of risks to health and avoid dan‐

gerous situations.

WARNING

Electrical voltage!

Electrical voltage can cause severe injury or death.

■

Work on electrical systems must only be performed by qualified electricians.

■

The power supply must be disconnected when attaching and detaching electrical

connections.

■

The product must only be connected to a voltage supply as set out in the require‐

ments in the operating instructions.

■

National and regional regulations must be complied with.

■

Safety requirements relating to work on electrical systems must be complied with.

WARNING

Risk of injury and damage caused by potential equalization currents!

Improper grounding can lead to dangerous equipotential bonding currents, which may

in turn lead to dangerous voltages on metallic surfaces, such as the housing. Electrical

voltage can cause severe injury or death.

■

Work on electrical systems must only be performed by qualified electricians.

■

Follow the notes in the operating instructions.

■

Install the grounding for the product and the system in accordance with national

and regional regulations.

2.8 Repairs

WARNING

Health hazard as a result of high-frequency electromagnetic radiation!

The RFU61x-10600 1) is designed for operation according to ETSI EN 302208. During

operation, the human exposure regulations covered by EN 50364 must be observed.

■

Limit human exposure to electromagnetic fields. Suitable safety distances must be

maintained during both short-term and long-term work in the radiation range of

the integrated antenna.

Minimum distances to be maintained between the antenna and the human body

during long-term transmission: 10 cm and maximum radiation power of the

antenna of 100 mW ERP (20 dBm) pursuant to ETSI.

The RFU61x-10601 2) satisfies the limit values of the FCC for exposure to radiation in

an uncontrolled environment.

■

During operation, a safety distance of at least 20 cm must be maintained between

the antenna and the human body.

Repair work on the device may only be performed by qualified and authorized person‐

nel from SICK AG. Interruptions or modifications to the device by the customer will inval‐

idate any warranty claims against SICK AG.

1)

For regional assignment, see type-specific online data sheet on the Internet at: www.sick.com/RFU61x

2)

For regional assignment, see type-specific online data sheet in the Internet at: www.sick.com/RFU61x

12

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 13

3 Product description

1

2

3

4

5

6

SICK AG, D-22143 Hamburg

Made in Germany

Manufactured: May 2016

0700

RFU6xx-xxxxx

DC 10...30V <26W

16410240

1062600

Type:

P/N:

MAC:

Power:

S/N:

00:00:00:00:00:00

6

1

2

3

4

5

RFU6xx-xxxx1

DC 12...30V <26W

1620 0001

1054397

Type:

P/N:

MAC:

Power:

S/N:

00:00:00:00:00:00

This device complies with Part 15 of

the FCC rules. Operation is subject to

the following two conditions:

(1) this device may not cause

harmful interference, and

(2) this device must accept any inter ference received, including interference

that may cause undesired operation.

SICK AG, D-22143 Hamburg

Made in Germany

Manufactured: May 2016

Proc. Cont. Eq.

E336916

3.1 Product ID

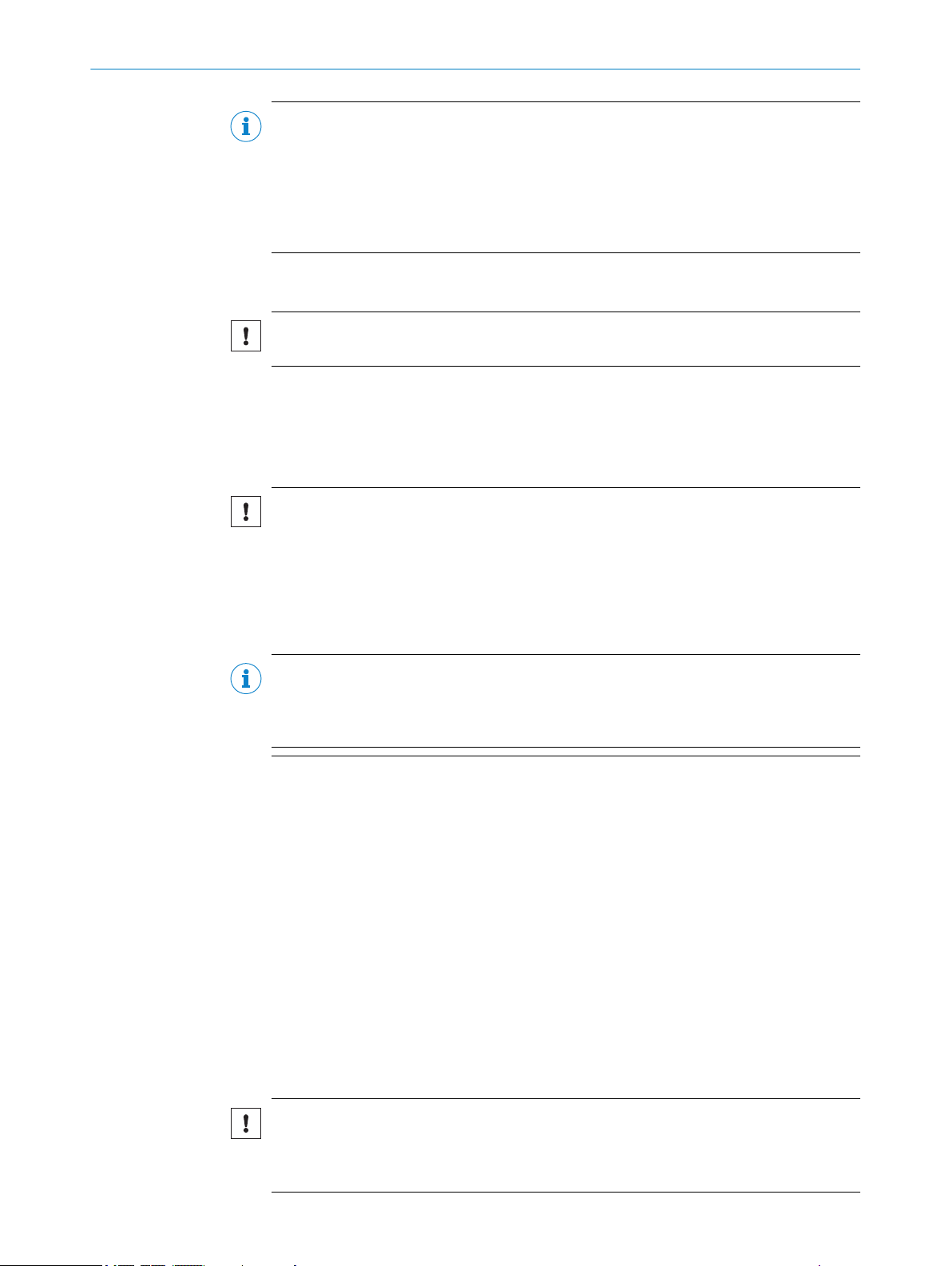

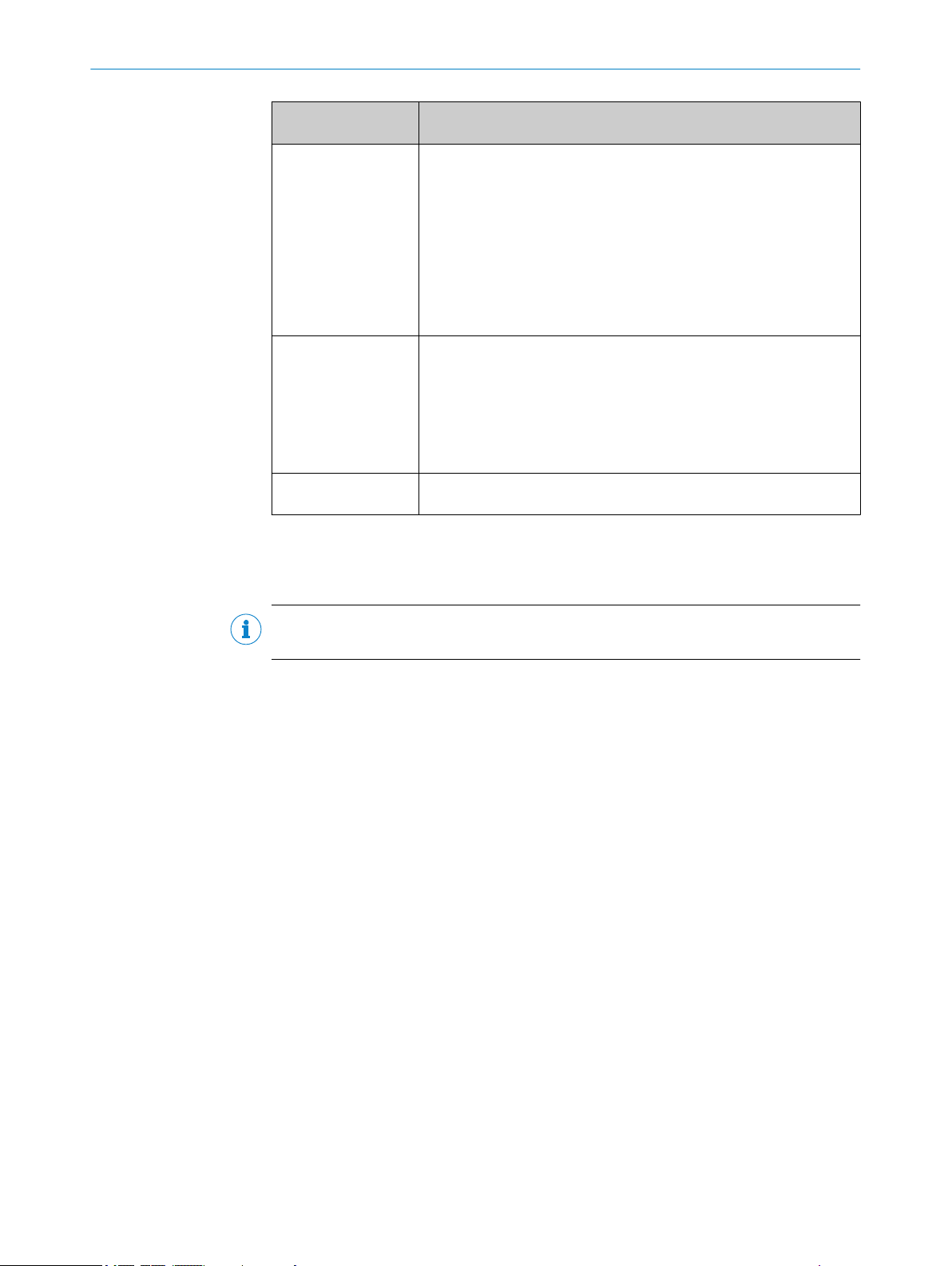

3.1.1 Type label

The type label gives information for identification of the device.

The type labels are located on the underside of the device.

Figure 1: Structure of the type label

The UL certification is dependent on the type. An existing UL certification can be found

on the type label.

PRODUCT DESCRIPTION 3

3.1.2 Type code

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

Figure 2: Structure of the type label with UL symbol

Type designation

1

Part number

2

Serial number

3

Supply voltage and power consumption

4

MAC address (placeholder)

5

Approval-related details (region-specific)

6

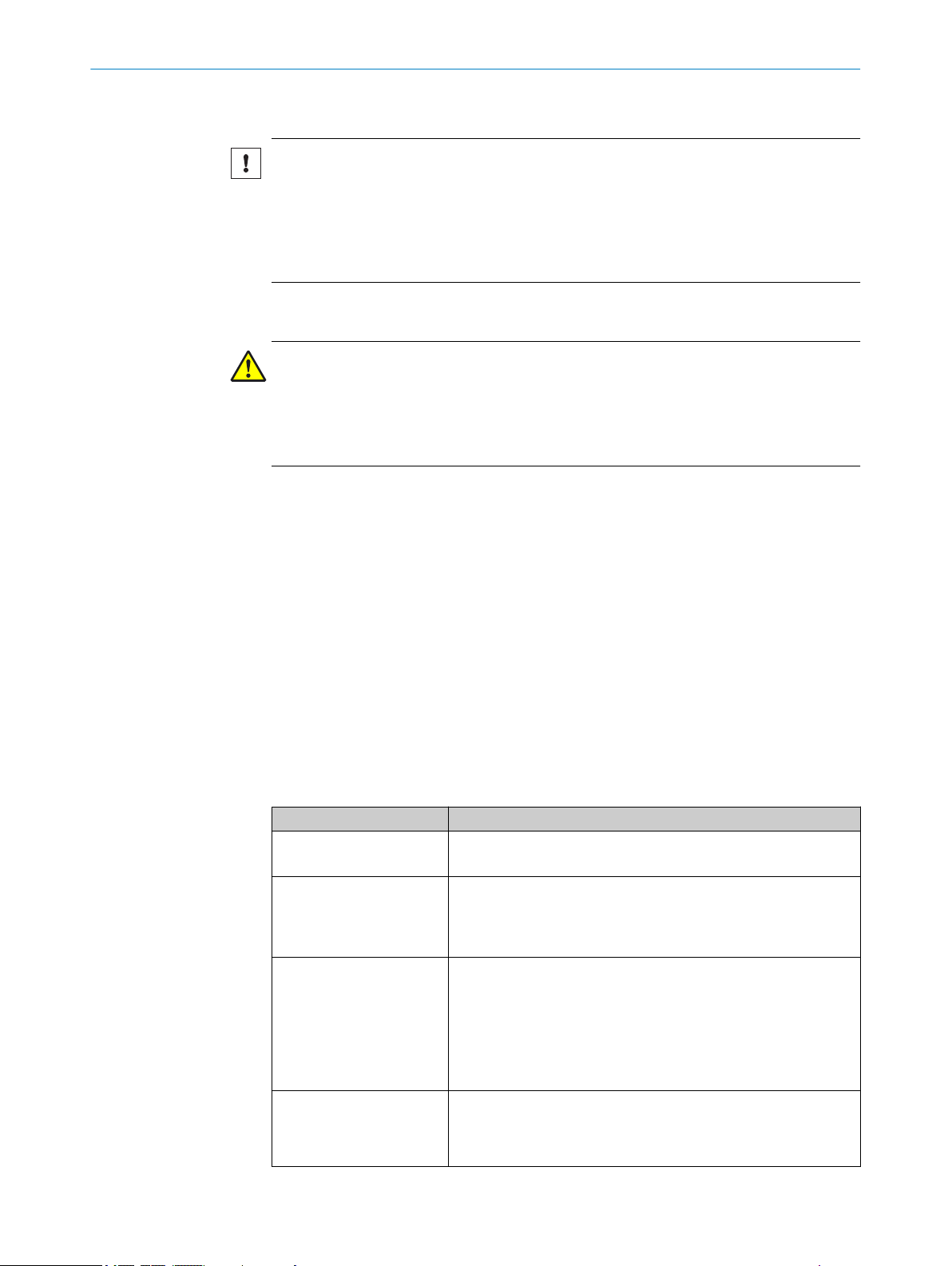

The devices of the RFU6xx product family are arranged according to the following type

code:

RFUxyz-abcde

R F U x y z - a b c d e

1 2 3 4 5 6 7 8 9 10 11

Position Description Characteristic

1 ... 2 RF (Radio Frequency Identification) –

3 Frequency band U: Ultra High Frequency

13

Page 14

3 PRODUCT DESCRIPTION

Position Description Characteristic

4 ... 5 Product family or version (working

6 Device type 0: Base type (EPCglobal UHF Class 1 Gen‐

7 Internal antenna 0: No integrated antenna

8 Connections for external antennas 0: No connection

9 Electrical connections 1: 1 x male connector, M12, 17-pin, A-

10 ... 11 Country-specific radio equipment

range)

approval

61: ≤0.5 m (Short Range)

62: ≤2 m (Mid Range)

63: ≤10 m (Long Range)

65: ≤10 m (Long Range)

eration 2, ISO/IEC 18000-6C)

1: With integrated antenna, circularly

polarized

3: 3 connections

4: 4 connections

coded; 1 x female connector, M12, 4-pin,

D-coded

4: Cable 0.9 m with male connector, DSub-HD, 15-pin

5: 1 x female connector, M12, 8-pin, Xcoded

6: 1 x male connector, M12, 4-pin, Acoded, 1 female connector, M8, 4-pin,

coded, 1 x female connector, M12, 8-pin,

X-coded

00: Europe ...

Type-dependent, see type-specific online

data sheet at:

www.sick.com/RFU61x

•

NOTE

Not all combinations are possible according to the type code. The available device vari‐

ants can be found online at:

www.sick.com/RFU61x

•

14

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 15

3.2 Product characteristics

92 (

3.62

)

1

9

8

94 (

3.70

)

106.4 (

4.19

)

ReadyRFLink/Act

microSD

40 (

1.57

)

16

(

0.63

)

36 (

1.42

)

â

80 (

3.15

) 38 (

1.50

)

12

(

0.47

)

71 (

2.80

)

40 (

1.57

)

5

(

0.20

)

6.4

(

0.25

)

17.5

(

0.69

)

78.8 (

3.10

)

1 3 2

91°

3 (

0.12

)

11.5 (

0.45

)

9.5 (

0.37

)

2

1

4

3

2 3

4 5

ß

á à

6

7

17.5

(

0.69

)

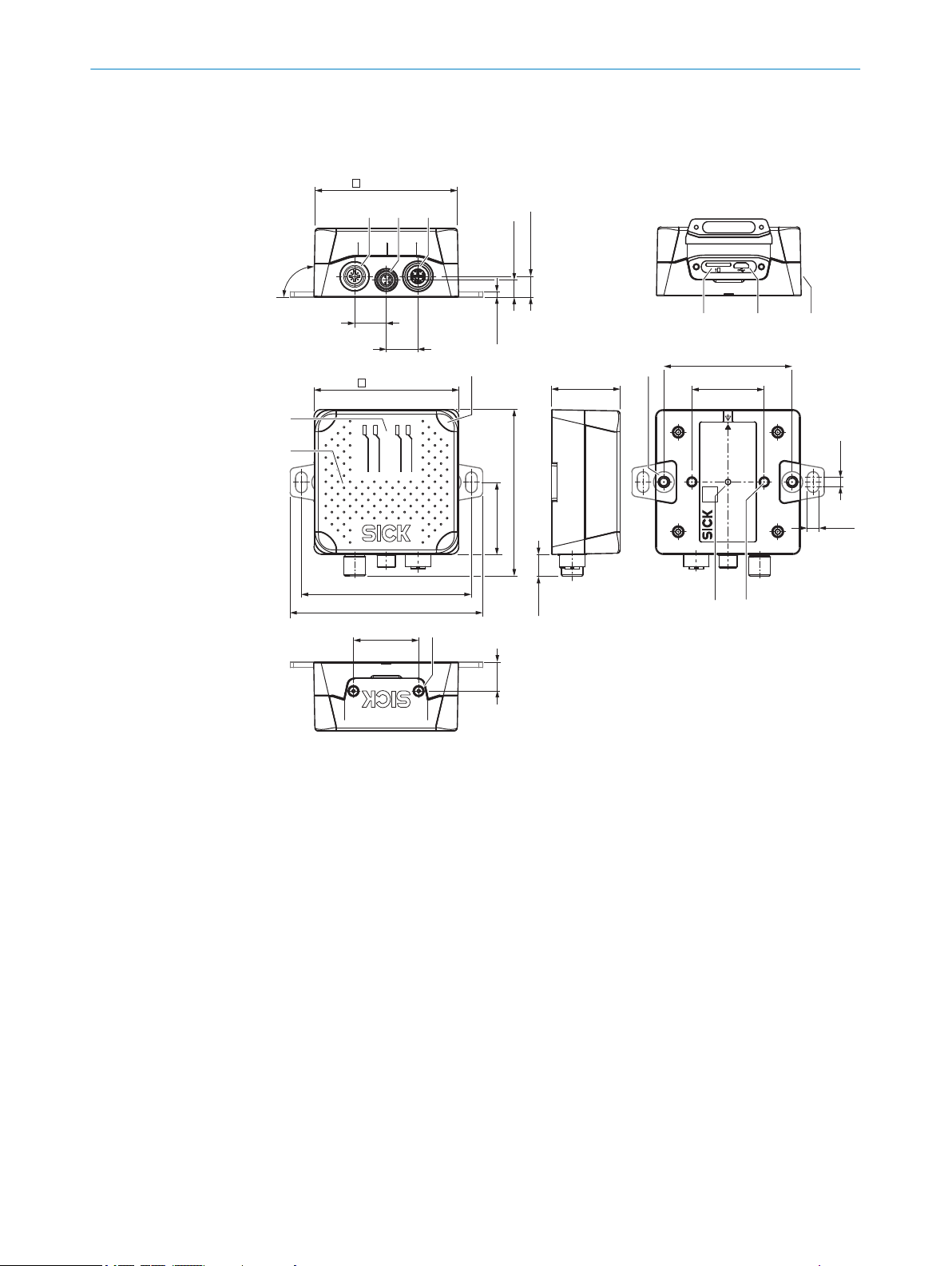

3.2.1 Device view

PRODUCT DESCRIPTION 3

Figure 3: RFU61x-106xx: Structure and dimensions, unit: mm (inch), decimal separator: period

Connection 1: Power (male connector, M12, 4-pin, A-coded)

1

Connection 3: Trigger (female connector, M8, 4-pin, coded)

2

Connection 2: PoE (female connector, M12, 8-pin, X-coded)

3

Slot for microSD memory card

4

“USB” connection (female connector, 5-pin, Micro B type). The USB interface must only be

5

used temporarily as a servicing interface!

Side type label

6

Optics cover with integrated antenna

7

4 x multi-colored LED (status)

8

4 x multi-color LED (process feedback)

9

2 x M5 threaded mounting holes, 6 mm deep, for attaching the mounting straps

ß

2 x M5 blind tapped holes, 7 mm deep, for alternative mounting of the device

à

type label with integrated pressure compensation membrane

á

2 x screw (M2,5 socket screw), captive, for side cover

â

3.2.2 Working range of the antenna

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

Sensing range of the reading and writing field

The environment influences the UHF field of the integrated antenna, making it impossi‐

ble to provide a “clear” demarcation of the sensing range.

15

Page 16

–33

–30

–27

–24

–21

–18

–15

–12

–9

–6

–3

0°

15°

30°

45°

60°

75°

90°

105°

120°

135°

150°

165°

180°

–165°

–150°

–135°

–120°

–105°

–90°

–75°

–60°

–45°

–30°

–15°

2

1

0

3 PRODUCT DESCRIPTION

•

•

In addition to the read results, the RFU device can also output diagnostic data that pro‐

vide an indication of the write and read quality. This data can be used to achieve opti‐

mum read results when setting up the system.

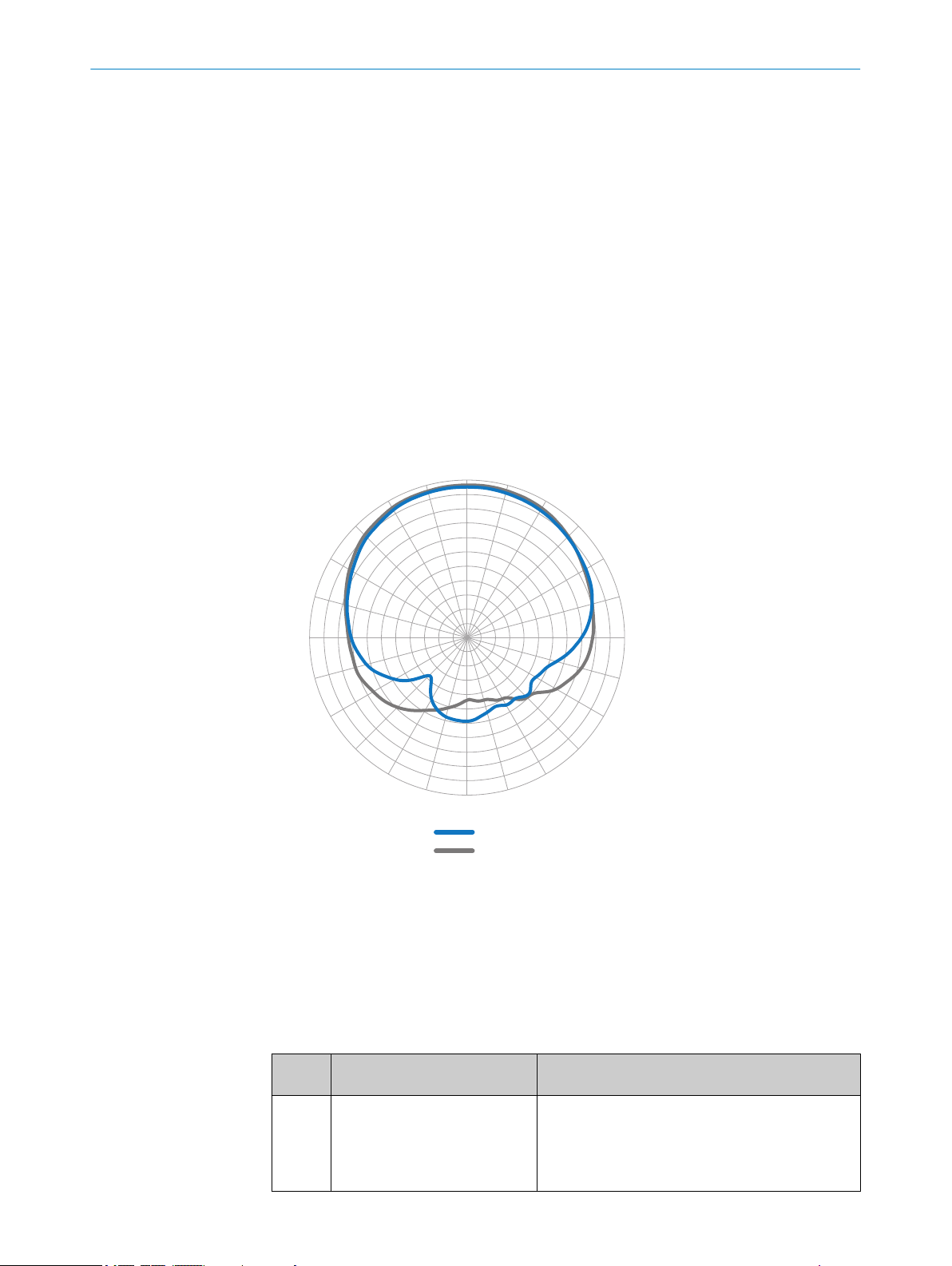

The radiation pattern shown here for the device’s antenna was obtained in a repro‐

ducible environment (absorber chamber as a reflection-free space) for illustrative pur‐

poses. The diagram may therefore only have limited applicability to your specific appli‐

cation. The diagram shows how the UHF field propagates in a reflection-free space, but

cannot be used on-site to draw any conclusions on the likely sensing range in a real

application.

Application-specific reflections can result in both overreaches and “holes”

(destructive interferences).

Other factors that can significantly impact the sensing range include:

Quality of the transponder. The quality depends on the antenna gain, the inte‐

°

grated transponder IC and its sensitivity, the reflected energy.

Material of the carrier object (plastic, wood, metal)

°

Objects between the device and transponder that can affect the UHF field

°

(items, liquids, people)

3.2.3 Scope of delivery

16

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Figure 4: Radiation pattern of the integrated antenna of the RFU61x (typical): Measured antenna

gain in dBic at 866.5 MHz, LHCP (left-hand circularly polarized)

Horizontal plane (azimuth)

1

Vertical plane (elevation)

2

The delivery of the device includes the following components:

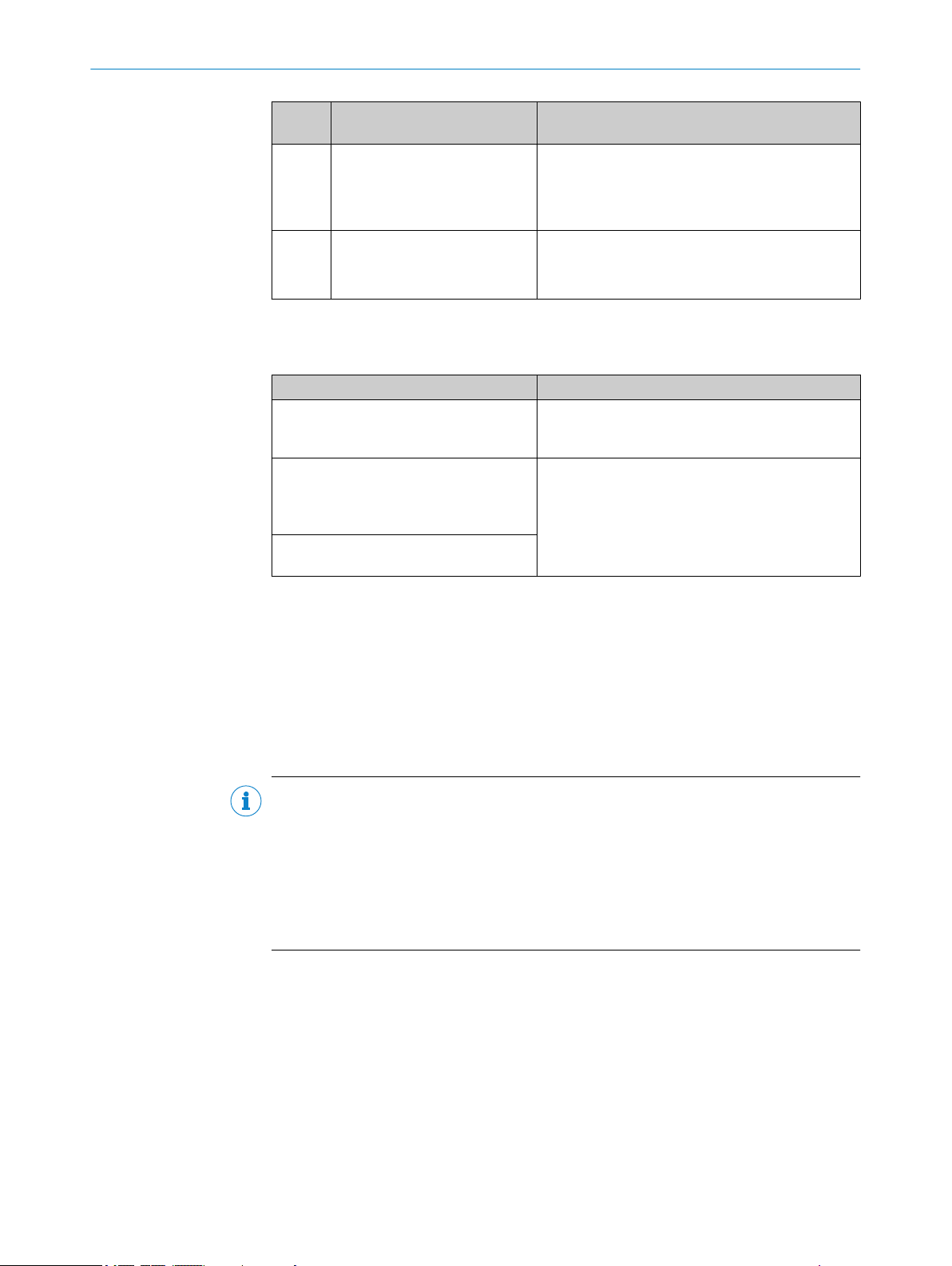

Table 2: RFU61x: scope of delivery

No. of

units

1 Device in the version ordered

Component Notes

RFU61x-106xx

(region assignment)

The M12 and M8 electrical connections sealed with

tightly-fastened protective plugs or caps.

The joint side cover for the USB interface and the

memory card slot is closed and screwed tight.

Subject to change without notice

Page 17

PRODUCT DESCRIPTION 3

No. of

units

1 Mounting kit, consisting of

Component Notes

Fastening clamps, protruding after mounting for fas‐

2 x mounting strap

•

2 x countersunk head screw

•

with hexagon socket, M5 x 8

Printed Quick Start Guide, num‐

ber of language versions depen‐

dent on region.

tening the device from the front at both sides. Alter‐

natively for mounting from the rear: 2 M5 threaded

mounting holes on the rear of the device.

All available language versions of the Quick Start

Guide can also be found online as PDFs at:

www.sick.com/RFU61x

•

The following associated components are not included in the delivery. The components

are available on the Internet.

Table 3: RFU61x: Other components

Component Notes

SOPAS ET configuration software and

device description file (*.sdd-file) for the

RFU61x

RFU61x operating instructions as PDF in

English, French and German. Other lan‐

guages are available online where applic‐

able.

RFU parameter description as PDF in Eng‐

lish and German.

Available online at:

www.sick.com/SOPAS_ET

•

Available online at:

www.sick.com/RFU61x

•

Accessories

The following accessories for constructing a complete RFID read/write station are not

included in the scope of delivery of the device. If required, order accessories separately.

Read cycle trigger sensor, e.g. photoelectric retro-reflective sensor for object-spe‐

•

cific triggering

Suitable number of transponders depending on the application

•

3.2.4 Product features and functions (overview)

NOTE

In addition to the existing operating instructions, the use of the RFU parameter descrip‐

tion is recommended:

This parameter description explains the UHF-RFID-specific parameters of all

•

device variants of the RFU6xx product family up to and including the “Service”

user level.

The parameter description supports the user in configuring applications with the

•

SOPAS ET configuration software.

The parameter description is available in English (part no. 8023085) and German (part

no. 8023084) as well as other languages if required.

The RFU parameter description can be found on the online product page at:

www.sick.com/RFU61x

•

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

17

Page 18

3 PRODUCT DESCRIPTION

Table 4: Overview of product features and functions of the device

Product feature/func‐

tion

Security and ease of

use

Convenient operation/

configuration

Reading Operation

Mode

Read cycle

Radio interface(s)

Transponder Process‐

ing

Transponder Manage‐

ment

Data processing

Characteristic

Rugged, compact metal housing, CE marking (Europe)

•

Automatic self-test at system start

•

Diagnostic tools for device setup and (remote) device monitoring

•

Configurable output of the read results including read diagnostics

•

data in two output formats

Operating data request. In the event of an error: output of codified

•

error messages on request

Test string function (heartbeat) can be activated to signal that the

•

device is ready for operation

Future-proof due to firmware update via data interface

•

Future-proof SOPAS ET configuration software with password-pro‐

•

tected configuration mode

SICK AppSpace ready: The device already includes SensorApp for

•

integrating it into existing communication networks

Low power consumption

•

Wide supply voltage range. Supply via separate power source or

•

PoE.

Large ambient temperature range. For details, see "Technical data",

•

page 61

Parameter cloning (to back up the configuration data in the internal

•

device memory):

By pluggable microSD memory card 1) externally in the device

°

Configuration (online or offline) using SOPAS ET configuration soft‐

•

ware

Single Tag ID Wizard (assistant) to help with initial configuration

•

Configuration and starting of device functions via a web server

•

(SOPASair) or command strings

Optional function blocks for easier integration into PLC programs

•

PROFINET single port : Configuration via GSD parameterization

•

Application-specific programming is possible using the SICK AppStu‐

•

dio development environment.

You can find further information on the Internet at: www.sick.com/

SICK_AppStudio

Status and process feedback indicators via LEDs

•

Start/stop operation: For reading one or more transponders during

•

a read cycle.

Start and stop conditions of the read cycle can be configured in the

•

object trigger control: digital input

Integrated antenna

•

Base model RFU610 supports all standard passive transponders

•

that are compatible with EPCglobal UHF Class 1 Generation 2 or

ISO/IEC-18000-6C

Reading, writing, and multiple overwriting of the data on the

•

transponders, depending on the application

Within a process chain, the device supplying the data is a partial

•

component for the complete visualization of data

Decoding of the UII in HEX, BIN and ASCII. Supports GS1 TDS and

•

other industry-specific standards such as VDA55xx.

Variable read data output based on event-dependent evaluation

•

conditions

Influencing the output string by filtering and output sorting

•

Implementation of application-specific data output protocols using

•

the SICK AppStudio development environment (flexible back-end

integration)

18

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 19

PRODUCT DESCRIPTION 3

Product feature/func‐

tion

Data communication Host interface

Electrical Interfaces

Connectivity (Design)

1)

Optional accessories.

2)

USB interface must only be used temporarily as a servicing interface!

Characteristic

Two data output formats configurable.

•

The output is switchable to different physical or logical interfaces.

•

Parallel operation is possible. For outputting the data to a furtherprocessing computer.

Aux interface

Fixed data output format.

•

The output is switchable to different physical or logical interfaces.

•

For the device configuration and diagnostics as well as the

transponder access.

Host interface

•

Ethernet (supported protocols include, amongst others,

°

PROFINET single port).

Aux interface

•

Ethernet, USB

°

1 digital input for external trigger sensor

•

Voltage supply (power or PoE)

•

RFU61x-106xx: 2 x M12 male circular connector, 1 x M8 male circu‐

•

lar connector, 1 x USB (Micro B type)

2)

3.2.5 Memory card

NOTE

The memory card is an optional accessory and is not included in the scope of delivery.

Functions

The device can execute the following functions on the plug-in microSD memory card:

Saving the parameter set (cloning function)

•

Semi-automatic, additional storage of the internal parameter set (device configura‐

tion data) on an external memory medium. This takes place in the framework of

the recommended backup concept for the 4Dpro device parameter sets.

This function is initiated by using the “permanent” option to save the internal

°

parameter set, e.g. via the SOPAS ET configuration software.

The function is used, among other things, to conveniently transfer the para‐

°

meter set to an replacement device of the same type in the event of an fault.

A MicroSD memory card that can be plugged into the device serves as an

°

optional, external medium

Recording of diagnostic read data

•

Continuous recording of diagnostic read data after the first manual start, e.g., via

SOPAS ET. Recording is resumed after a device restart if the function has been

permanently set.

Other functions on request.

•

We recommend using an empty memory card when storing a parameter set for the first

time (if necessary, use a PC and card reader to check and delete the contents of the

card).

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

19

Page 20

1

2 3

PRODUCT DESCRIPTION

3

NOTE

Only use types approved by SICK to ensure reliable function of the memory card. You

can find these as accessories online at:

www.sick.com/RFU61x

•

The memory card has no write protection that can be activated.

Indication of operational readiness

The “microSD” optical indicator shows the status of the memory card after installation

in the device. It lights up in different colors according to the status, see "Optical status

indicators on the display panel", page 51.

NOTICE

Possible data loss!

When the indicator is green (operational), this does not mean that the device is actually

accessing the memory card for reading or writing.

Do not remove the memory card or switch off the supply voltage while the follow‐

b

ing functions are taking place in the device via the SOPAS ET configuration soft‐

ware:

■

Saving the parameter values using the “permanent” option

■

Starting functions that access the memory card (e.g. concurrent logging of

data)

Inserting the memory card in the device:

NOTICE

Risk of damage to the memory card!

To safely install the memory card, make sure there is no power to the device

b

before you insert it.

Ensure the IP67 enclosure rating of the device is maintained see "Conditions for speci‐

fied enclosure rating", page 10.

The card slot on the device is located under the cover foil on the side opposite the elec‐

trical connections.

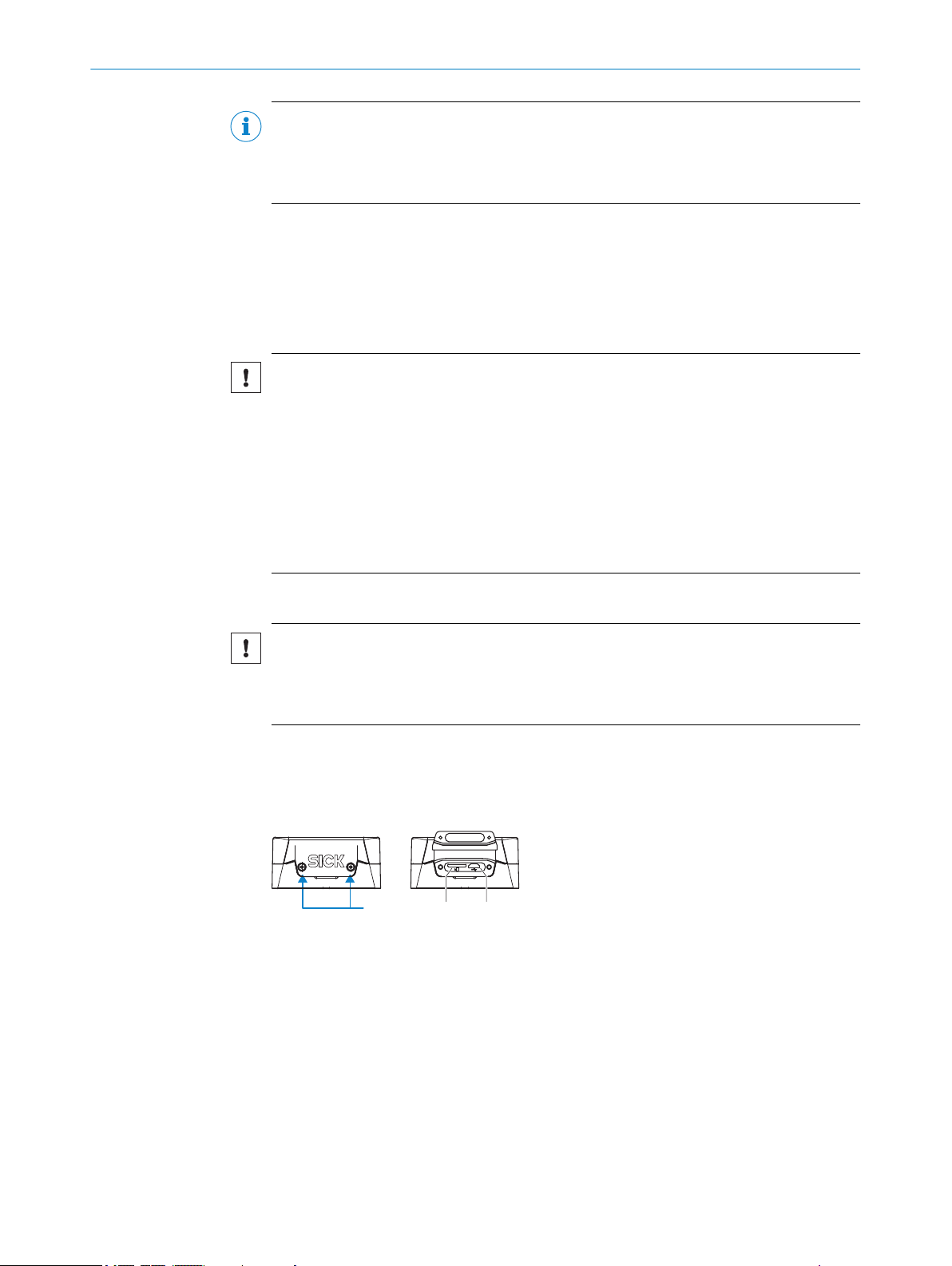

Figure 5: Slot for MicroSD memory card and “USB” connection

2 x screw, M2.5 hexagon socket

1

Slot for microSD memory card

2

“USB” connection (female connector, 5-pin, Micro B type)

3

1. Switch off the supply voltage to the device.

2. Loosen both screws on the cover.

3. Carefully fold up the cover.

4. Making sure it is in the correct position, insert the memory card into the slot until

it locks into place. When doing so, orient the contacts so that they are facing

towards the device and downwards as per the symbol on the device.

20

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 21

PRODUCT DESCRIPTION 3

5. Screw the cover back on. Recommended tightening torque for the cover screws:

30 Ncm ± 5 Ncm.

6. Switch on the supply voltage for the device.

Interpretation of the stored parameter set

Once it is switched on, the device automatically detects the presence of a memory card

and, depending on the card’s content, behaves as follows:

■

If the memory card is empty or if does not contain a parameter set that can be

interpreted by the device: the device saves its currently valid internal parameter

set to the card (provided there is sufficient storage space) and starts with the

internal parameter set.

■

If the card contains a parameter set that can be interpreted by the device: the

device overwrites the currently valid internal parameter set with this external para‐

meter set.

The goal is for the internal parameter set and the parameter set saved externally to

always be identical.

Removing the memory card from the device:

NOTICE

Risk of damage to the memory card!

To safely remove the memory card while the device is in operation:

b

In SOPAS ET, execute the Remove SD card command under Analysis/SD card and

°

wait for SOPAS ET to provide confirmation.

If this command is not accessible, the memory card can also be removed

°

when there is no power to the device.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

21

Page 22

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

4.2

Unpacking

■

Before unpacking, it may be necessary to equalize the temperature to protect the

device from condensation.

■

Handle the device with care and protect it from mechanical damage.

■

Remove the protective caps or protective plugs on the electrical connections

immediately before connecting the connecting cable to prevent dirt and moisture

from entering.

4.3 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

4.4 Storage

22

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Electrical connections are provided with protective caps and plugs (as they are on

delivery).

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 61.

Subject to change without notice

Page 23

TRANSPORT AND STORAGE 4

■

Relative humidity: see "Technical data", page 61.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

23

Page 24

MOUNTING

5

5 Mounting

5.1 Overview of mounting procedure

The procedure for mounting the device is divided into the following steps:

1. Select a suitable mounting location for the device.

The mounting location and position depend on the following factors:

Identification task

°

Working range of the device (see "Working range of the antenna", page 15)

°

Transponder used

°

Environmental influences

°

2. Mount the device at the intended reading point and temporarily align the device to

the object with transponder. Make sure that there is a suitable distance to the

object.

3. If required, mount the read-cycle sensor for object-specific triggering.

After the electrical installation is complete and while adjusting the device parameters to

suit the application:

4. Finely align the device to the object and adjust it.

5. Test for successful reading and writing of the device in operational use of the

application.

5.2 Preparation for mounting

5.2.1 Installation requirements

Space requirements

■

For the typical space requirements, see the:

Dimensional drawing of the device see "Device view", page 15 and propaga‐

°

tion of the UHF field, see "Working range of the antenna", page 15.

The device does not require any physical or visual contact with the transponders. The

device does, however, need to be aligned with the reading space.

Environmental influences

■

Comply with technical data, such as the permitted ambient conditions for opera‐

tion (e.g. approved region, ambient temperature range, ground potential), see

"Technical data", page 61.

■

To prevent condensation, avoid exposing the device to rapid changes in tempera‐

ture.

■

To prevent additional external heating of the device, protect the device against

sunlight.

■

In order to avoid reflections of the UHF waves and any associated physical phe‐

nomena, make sure if possible that there are no metal surfaces on the side of the

device in the direction of the transponder.

Possible disturbances of the UHF field caused by reflections of the UHF waves are:

Overreaches

°

“Holes” (destructive interferences)

°

■

To avoid attenuation of the UHF field by absorption, exclude the following between

device and transponder:

Electrically conductive material, e.g. liquids (water)

°

Persons or animals

°

Mounting

24

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 25

MOUNTING

■

Fasten the device using the 2 fastening clamps supplied or the 2 M5 threaded

mounting holes.

■

Mount the device where they will not be exposed to shocks or vibration.

5.2.2 Instructions for mounting the device when the ambient temperature can fall below 0 °C

The device can also be operated at low ambient temperatures. For details, see "Techni‐

cal data", page 61.

NOTE

For the electrical installation procedure, see "Instructions for electrical installation when

the ambient temperature can fall below 0 °C", page 40

NOTICE

Operating the device at the lower limit of the permissible ambient temperature range

The ensure the device can produce the required heating power, do not expose the

device to strong air flows (e.g. from a ventilation system).

If necessary, take appropriate measures to shield the device from air flows.

b

NOTICE

If the ambient temperature is below 0 °C, please note:

5

Do not move the connecting cables to the device

•

5.2.3 Auxiliary equipment required

■

If the two fastening clamps of the enclosed mounting kit do not cover the mount‐

ing situation of the application, the customer must provide a suitable mounting

device (bracket). The bracket requires sufficient load-bearing capacity, see "Tech‐

nical data", page 61 and dimensions adapted to the device, see "Device view",

page 15.

■

2 M5 screws to attach the device to a bracket if the supplied mounting straps are

not used.

NOTE

The screws are for mounting the device on mounting equipment (bracket) supplied

by the user. The screw length required depends on the mounting base (wall thick‐

ness of the bracket).

When using an optional SICK bracket, the screws for mounting the device on the

bracket are included in the scope of delivery.

NOTICE

Risk of damage to the device!

Screws that are not suitable for the length of the threaded mounting holes can

damage the device.

M5 threaded mounting hole for mounting from the rear: screw in screws to a

•

maximum depth of 7 mm!

M5 threaded mounting holes for mounting strap: Do not exceed the maxi‐

•

mum screw-in depth of 6 mm!

■

Tool and tape measure

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

25

Page 26

5 MOUNTING

5.2.4 Mounting device

The device can be mounted using the 2 mounting straps (supplied mounting kit part no.

2105772) after attachment on the device from the front or rear. The associated 2 M5

threaded mounting holes for the fastening clamps are each located on the outside of

the rear of the device, in the recess, see "Device view", page 15.

Figure 6: Back view RFU61x: device with mounted mounting straps

Alternatively, the device is fastened using the 2 M5 internal threaded mounting holes.

The threaded mounting holes are also located on the rear of the device.

Further, optional SICK brackets

The device can be mounted using additional optional SICK brackets, a combination of

SICK brackets and elements, or a customer-specific bracket.

SICK offers prefabricated brackets which are optimally suited for mounting the device

in a wide range of applications.

Also see on Internet at:

www.sick.com/RFU61x

•

NOTE

Dimensional drawings for SICK brackets and, if applicable, mounting instructions can

be found online at: www.sick.com

To do so, enter the 7-digit part number of the bracket in the search field.

b

User-supplied brackets

A user-supplied bracket should meet the following requirements:

■

Stable mounting device

– Allow the device to be aligned in the x and y axes.

– The mounting device must be able to bear the weight of the device, including

connecting cables, in a shock-proof manner, see "Technical data", page 61.

– In mounting situations with strong vibrations, it may be necessary to provide

shock mounts.

■

For mounting the device according to the dimensional drawing: 2 suitable holes for

M5 screws.

5.3

26

Mounting location

When selecting the mounting location, the following factors are significant:

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 27

Spatial working range of the antenna

•

Distance to objects with a transponder

•

Influence of the environment on the UHF field produced, for example:

•

°

°

°

5.4 Mounting the device

WARNING

Risk of injury due to damage to the device

For reasons of safety, if a device shows visible signs of damage do not put it into opera‐

tion, or take it out of operation immediately.

Damage includes, for example, depending on type:

Housing: cracking, splitting or fracture

•

Electrical connections: cracks or detachment from the housing

•

Device with cable connection: damage to the cable outlet or cable itself

•

NOTICE

Risk of damaging the device!

Observe the maximum screw-in depth of the blind tapped holes on the device. Longer

screws than the specified screw-in depth damage the device.

MOUNTING

Metal surfaces located to the side of and in the vicinity of the device

Electrically conductive liquids between the antenna and transponder

Persons between the antenna and transponder

5

Use screws of suitable length.

b

Basic arrangement of the device to the transponders

UHF transponders have dipole antennas and therefore preferential directions within the

radiation field of the antenna. The transmitting and receiving performance will be

higher or lower depending on the orientation of the dipole antenna of the transponder

to the axis perpendicular to the antenna surface. The reading and writing rate and sens‐

ing range can therefore be subject to fluctuations.

NOTE

If the dipole antenna of the transponder is oriented lengthwise along the axis perpen‐

dicular to the antenna surface, no reading or writing of the transponder will be possible.

Figure 7: The optimal orientation of the transponder for good writing and reading results is

demonstrated here for an external UHF antenna

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

27

Page 28

10°

1

5 MOUNTING

Mounting and aligning the device

NOTICE

Avoid mutual interference when operating several devices

When the reading/writing ranges of several independently operated devices overlap,

this can lead to mutual impairment of the system performance of the devices.

In order to avoid such constellations, the devices each offer Sync mode.

With the Sync Mode, several devices can be synchronized in read/write behavior. For

this purpose, the devices must be connected to one another via an Ethernet network.

Sync mode then ensures that only one device at a time is performing a read/write oper‐

ation and therefore communicating over the air interface. One master controls up to

three slaves.

1. Prepare the base for mounting the bracket of the device, see "Preparation for

mounting", page 24.

Recommendation: Depending on the application it may be possible to use one of

the optional SICK brackets. If necessary, perhaps also in combination with other

SICK brackets.

2. At the intended reading location, place an object with transponder within the work‐

ing range of the device (static object only).

3. Mount the device bracket onto the base.

4. Tighten screws through the bracket into the blind tapped holes of the device and

slightly tighten.

5. Orient the front side of the device towards the object.

Ensure, where possible, that there are no large metal surfaces located in

°

front of the device.

If this is unavoidable, do not mount the device in the same plane as the sur‐

°

face but rather at an angle of inclination of approx. 10°.

Figure 8: Selected angle of inclination of the device or external antennas when there

is a large metal surface in front, e. g. 10°

Metal surface

1

6. Tighten the screws.

✓

The device is approximately aligned with the object to be detected.

7. Check the general suitability of the alignment for objects of different sizes and

varying positions of the transponder in operational use of the application.

5.5

Mounting external components

5.5.1 Mounting the external read cycle trigger sensor

Conveying line

To detect objects with transponders, mount the trigger sensor in suitable proximity to

the device in front of the device in the opposite direction to the direction of movement.

28

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 29

MOUNTING 5

NOTE

A large selection of photoelectric sensors and accessories (brackets, connecting

cables) can be found online at: www.sick.com

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

29

Page 30

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

6.1.1 Notes on electrical installation

Connection work

Electrical installation must only be performed by electrically qualified personnel.

•

Standard safety requirements must be observed when working on electrical sys‐

•

tems!

All connection work must be performed at ambient temperatures above 0 °C, see

•

"Ambient data", page 63

Electrical connections between the device and other devices may only be made or

•

separated in a voltage-free state. Otherwise, there is a risk of damaging the

devices.

Where connecting cables with one end open are concerned, make sure that bare

•

wire ends are not touching (risk of short circuit when the supply voltage is switched

on). Wires must be appropriately insulated from each other. This also applies to

unused wires.

The wire cross-sections of the data and, if applicable, switching signal cables must

•

be selected in accordance with the applicable national standards.

NOTE

For additional instructions on operating the device at ambient temperatures below

0 °C, see "Prerequisites", page 40

Supply voltage

Connect the device only to the permissible supply voltage, see "Connecting the

•

supply voltage", page 43

The wire cross-sections in the supply cable from the user’s power system must be

•

selected in accordance with the applicable national standards. When this is being

done in Germany, observe the following standards: DIN VDE 0100 (Part 430) and

DIN VDE 0298 (Part 4) and/or DIN VDE 0891 (Part 1).

All circuits connected to the device must be designed as ES1 circuits. The voltage

•

supply or power supply unit must satisfy ES1 requirements in accordance with the

currently applicable EN 62368-1, see "Mechanics and electronics", page 62.

Only switch on the supply voltage to the device , after first:

•

Completing the connection work

°

Carefully checking the wiring work

°

30

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

Subject to change without notice

Page 31

ELECTRICAL INSTALLATION 6

Data cables

NOTE

Layout of data cables

Use shielded data cables with twisted-pair wires.

•

The possible cable length between the device and host computer depends on:

•

The chosen physical version of the host interface

°

The data transmission rate set in the device

°

For further information, see "Wiring the data interface", page 46.

Implement the shielding design correctly and completely.

•

To avoid interference, always use EMC-compliant cables and layouts. This applies,

•

for example, to cables for switched-mode power supplies, motors, clocked drives,

and contactors.

Do not lay cables in parallel with voltage supply cables or motor cables in cable

•

channels over longer distances.

Conditions for specified enclosure rating

To ensure compliance with the specified IP67 enclosure rating of the device, the follow‐

ing requirements must be met. If these requirements are not met, the device does not

fulfill any specified enclosure rating.

The joint side cover for the USB interface and the memory card slot is placed

•

against the device and screwed on tight.

The cables plugged into the electrical M12 and M8 connections must be screwed

•

tight.

Any M12 and M8 connections that are not being used must be sealed with protec‐

•

tive plugs or caps, depending on type. These plugs or caps must be screwed tight

(as in the delivery condition).

The same also applies to the EMC requirement (ESD) according to CE.

NOTICE

The type label on the lower side of the device contains a pressure equalizing mem‐

brane. If damaged, water and dust leaks could occur.

Positions of the individual elements see "Device view", page 15

NOTICE

The device can, if necessary, be operated for a short time without the side cover to per‐

form the following tasks:

Inserting or removing the optional memory card

•

Temporary use of the USB interface as a servicing interface

•

During this time, protect the device against moisture and dust.

8024536//2019-08-30 | SICK O PE R AT I NG IN S TR U CT I ON S | RFU61x

Subject to change without notice

31

Page 32

SICK

Device

7 46

Power Supply

U

= 8

= 9

1 2 3

I

5

System

Controller

6 ELECTRICAL INSTALLATION

6.1.2 Prerequisites for safe operation of the device

WARNING

Risk of injury and damage caused by electrical current!

As a result of equipotential bonding currents between the device and other grounded

devices in the system, faulty grounding of the device can give rise to the following dan‐

gers and faults:

■

Dangerous voltages are applied to the metal housings.

■

Devices will behave incorrectly or be destroyed.

■

Cable shielding will be damaged by overheating and cause cable fires.

Remedial measures

■

Only skilled electricians should be permitted to carry out work on the electrical sys‐

tem.

■

If the cable insulation is damaged, disconnect the voltage supply immediately and

have the damage repaired.

■

Ensure that the ground potential is the same at all grounding points.

■

Where local conditions do not meet the requirements for a safe earthing method,

take appropriate measures (e.g., ensuring low-impedance and current-carrying

equipotential bonding).

The device is connected to the peripheral devices (voltage supply, any local trigger sen‐

sor(s), system controller) via shielded cables. The cable shield – for the data cable,

for example – rests against the metal housing of the device. The device can be

grounded through the cable shield or through a blind tapped hole in the housing,

for example.

If the peripheral devices have metal housings and the cable shields are also in contact

with their housings, it is assumed that all devices involved in the installation have the

same ground potential.

This is achieved by complying with the following conditions:

■

Mounting the devices on conductive metal surfaces

■

Correctly grounding the devices and metal surfaces in the system

■

If necessary: low-impedance and current-carrying equipotential bonding between

areas with different ground potentials

32

O PE R AT I NG IN S TR U CT I ON S | RFU61x 8024536//2019-08-30 | SICK

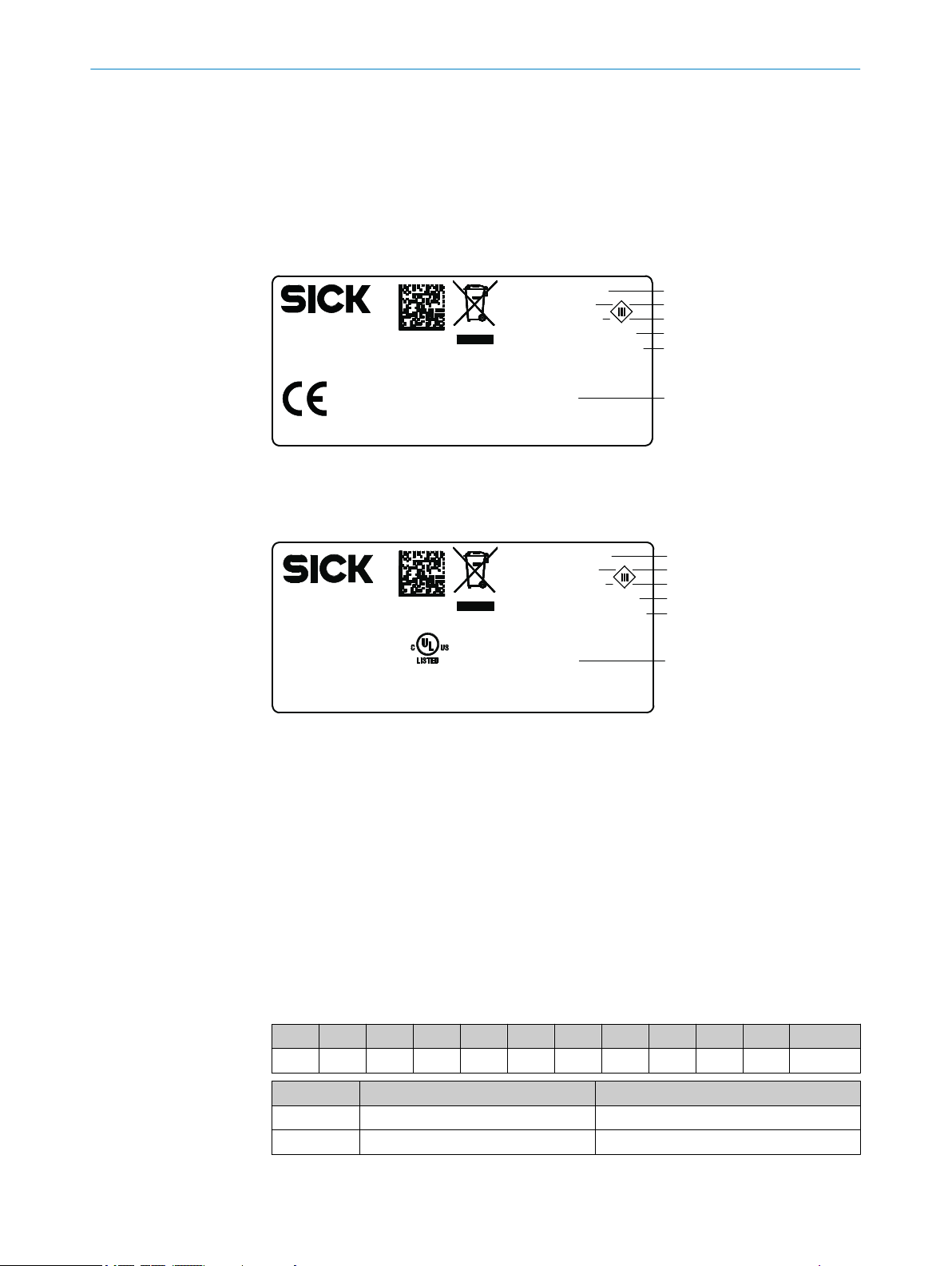

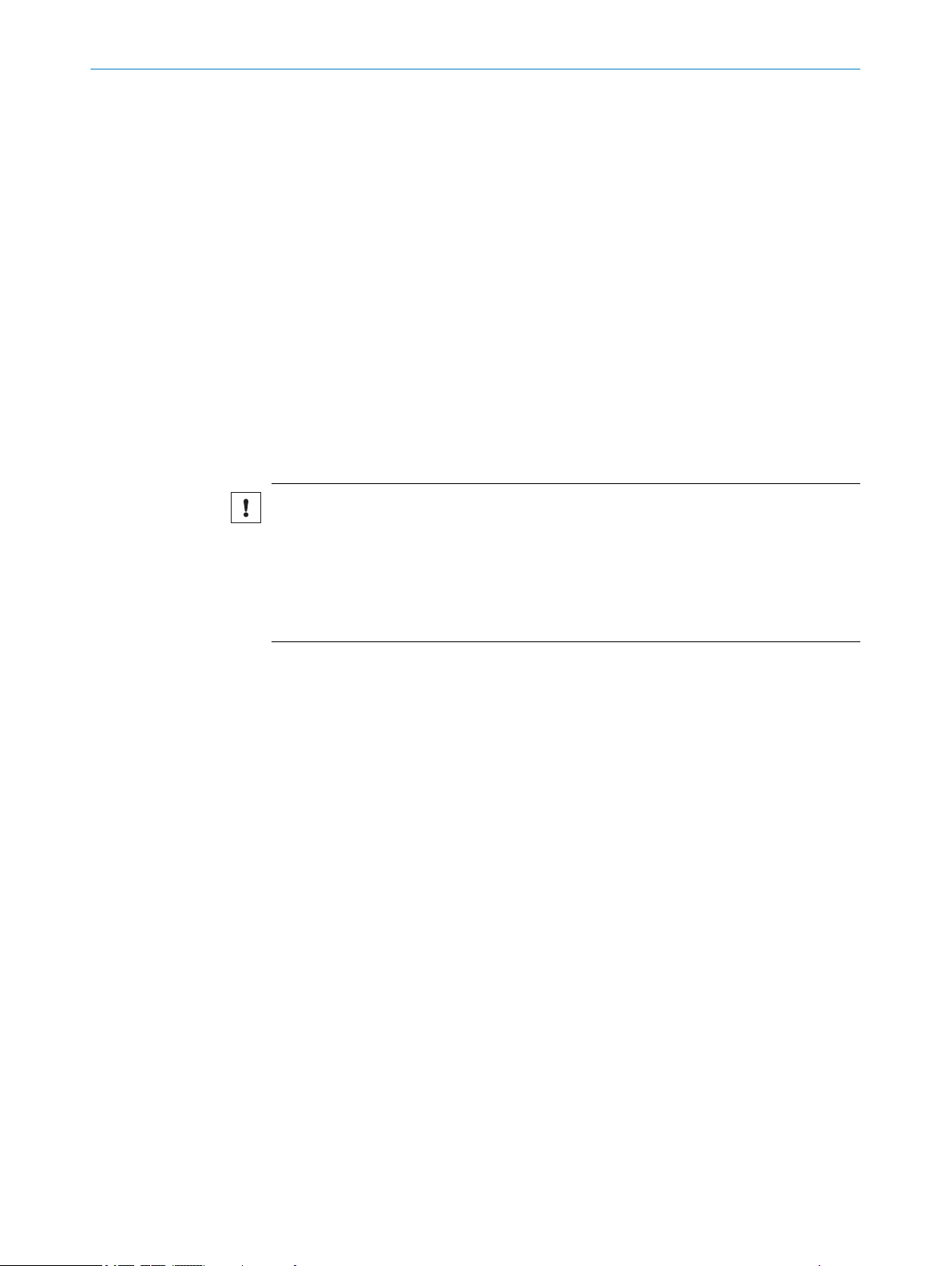

Figure 9: Example: Occurrence of equipotential bonding currents in the system configuration

System controller

1

Device

2

Voltage supply

3

Grounding point 2

4

Closed current loop with equalizing currents via cable shield

5

Ground potential difference

6

Subject to change without notice

Page 33

Electro-

optical

signal

isolator

Electro-

optical

signal

isolator

Power

Supply

SICK

Device

1 2 2 43

6 5

System

Controller

= 7

= 8

= 9

6

Grounding point 1

7

Metal housing

8

Shielded electrical cable

9

ELECTRICAL INSTALLATION

If these conditions are not fulfilled, equipotential bonding currents can flow along the

cable shielding between the devices due to differing ground potentials and cause the

hazards specified. This is, for example, possible in cases where there are devices within

a widely distributed system covering several buildings.

Remedial measures

The most common solution to prevent equipotential bonding currents on cable shields

is to ensure low-impedance and current-carrying equipotential bonding. If this equipo‐

tential bonding is not possible, the following solution approaches serve as a suggestion.

NOTICE

We expressly advise against opening up the cable shields. This would mean that the

EMC limit values can no longer be complied with and that the safe operation of the

device data interfaces can no longer be guaranteed.

Measures for widely distributed system installations

On widely distributed system installations with correspondingly large potential differ‐

ences, the setting up of local islands and connecting them using commercially available

electro-optical signal isolators is recommended. This measure achieves a high degree