Page 1

en

QUICKSTART

RFH6xx

RFID read/write device (HF) with internal short

range antenna

RFH630-1102101S05

Intended use

The RFH630-1102101S05 read/write device is an intelligent SICK-4Dpro sensor from the RFH6xx product

family. The special device is used for the automatic,

stationary identication of transponders and their

management. The special device enables a process

reliable reading/writing of the die. The die acts as a

HF transponder (ISO15693) with an integrated coil

and IC (Integrated Circuit). The transponders are

located on moving or stationary objects.

As a compact device, the RFH630-1102101S05 has

an integrated antenna. It processes all standard ISO/

IEC-15693-compatible transponders on carrier frequency 13.56 MHz. Thanks to its intelligent process

logic, it can be used either as a stand-alone solution

or as part of a group in a network.

The RFH630-1102101S05 read/write device sends

the read results to a higher-level computer for further

processing via its host interface. Or it receives commands for transponder management (write, read, etc.)

via this interface.

Intended use also includes compliance with all information in this Quickstart.

For simplicity in this document, the

RFH630-1102101S05 read/write device is referred to

as the “device”.

About this document

The purpose of this Quickstart is to allow you to commission the device quickly and easily, and to achieve

initial read results with transponders.

The Quickstart describes the commissioning process

for an application with one device in ambient temperature range 0 °C to +50 °C, based on its default

setting. The optional CDB620-001 connection module

is used for the industrial-standard signal distribution

of the device.

Supplementary and other relevant documents

The RFH630 technical information contains more

detailed information pertaining to the mechanical

and electrical installation for the (part no. 8014957,

English version, PDF).

The technical information as well as additional information, such as application examples and downloads

of associated documents and associated software,

can be found on the SICK product page on the Internet at www.sick.com/RFH6xx.

- See also “Sources for additional information” on

page 5.

Information about conguration can be found in the

online help function of the SOPAS ET conguration

software.

Operating the device in a eldbus with line topology

The optional incorporation of the device in eldbuses

is described in the relevant Operating instructions

for the CDF600-2 PROFIBUS DP, CDF600-2 PROFINET, or CDF600 EtherCAT

“Sources for additional information” on page 5.

®

eldbus module. - See

Safety information

• This chapter concerns the safety of commissioning

personnel as well as operators of the system in

which the device is integrated.

• Read this Quickstart carefully before commissioning the device in order to familiarize yourself with

the device and its functions. The Quickstart is considered to be a part of the device and must be kept

in an accessible location in the immediate vicinity

of the device at all times!

• The following requirements must be met if the

IP 67 enclosure rating is to be maintained during

operation (otherwise, the device will no longer meet

the conditions for any specied enclosure rating):

• The side cover of the microSD card slot must

be screwed tight to the device.

• The SICK cables plugged into the M12 connections must be screwed tight.

• Any electrical connections that are not being

used must be tted with protective caps or

plugs that are screwed tight (as in the delivery

condition).

• Only operate the device without the cover for

a short period while inserting or removing the

memory card. During this time, protect the

device against moisture and dust.

• Opening the screws of the device housing will

invalidate any warranty claims against SICK AG. For

further warranty provisions, see the General Terms

and Conditions of SICK AG, e.g., on the delivery

note of the device

• Data integrity:

SICK AG uses standardized data interfaces, such

as standard IP technology, in its products. The

emphasis here is on the availability of products

and their features. SICK AG always assumes that

the integrity and condentiality of the data and

rights aected by the use of these products will be

ensured by the customer. In all cases, appropriate

security measures, such as network separation,

rewalls, virus protection, and patch management,

must be taken by the customer on the basis of the

situation in question.

Commissioning and conguration

Scope of delivery

• RFH630-1102101S05 special device. Electrical

connections tted with protective caps or plugs

if necessary. Without connecting cables and

brackets.

• Printed Quickstart: English (part no. 8023443),

German (part no. 8023442).

Step 1: Mounting and alignment

Equipment required

• At least 2 x M6 screws or 2 x M4 screws for mounting the device on a mounting device (bracket)

provided by the customer. Screw length is dependent on the mounting base (wall thickness of the

bracket). When using an optional SICK bracket, the

screws for mounting the device on the bracket are

included in the scope of delivery of the bracket.

Mounting requirements

• The permissible ambient conditions for operating

the device must be observed, e.g., ambient temperature, ground potential. - See “Technical data

(excerpt)” on page 4 and “Step 2: Electrical

installation” on page 2.

• The device must be mounted using all 4 M6

threaded mounting holes (minimum 2) or 2 through

holes (both) provided. - See “Device layout” on

page 5.

• Stable mounting device with sucient load-bearing

capacity and suitable dimensions for the device.

Weight max. 760 g (not including cables). - See

“Device layout” on page 5.

• The device should be as free from shock and vibration as possible when mounted.

• To prevent mutual interference with a neighbor-

ing device, ensure that there is sucient distance

between the two devices which are being operated

simultaneously.

Mounting the device

1. Select a suitable mounting location for the device.

The mounting location and position depend on

the antenna elds of the device and the transponders used.

2. Optional: Attach mounting kit part no. 2048551

(optional accessory) to the device (see

RFH630 technical information, “Mounting”

chapter). Otherwise, mount the device on the

bracket provided by the customer using at least

2 M6 screws. Screw in the M6 screws to max.

6.5 mm into the threaded mounting holes ( see

“Device layout” on page 5).

3. Align the surface of the integrated antenna on

the device (front face) and where applicable the

external antenna of the transponder to the object.

Avoid any large metal surfaces positioned to the

front as far as possible.

4. Ensure that no electrically conductive objects,

such as metal objects, are positioned between

the device/external antenna and the transponder

during the read/write process. This would attenu-

ate the generated HF eld and thereby reduce the

scanning range of the device.

Scanning range of the read/write eld on the device

The maximum scanning range for communication

between the device and transponder depends on

various factors. Primarily, the dimensions of the

transponder's antenna positively aects the scanning

range. An additional factor for the scanning range

is the quality of the transponder, for example, the

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 1RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 1 23.11.2018 11:27:04

Page 2

antenna gain, the integrated transponder IC, and its

Connection Module

n

V

RFH630-1102101S05

Quickstart

Quickstart

Quickstart

Quickstart

associated sensitivity.

Important!

A successful reading/writing can only be guaranteed

if the transponder is orientated plan parallel the to the

antenna and in the middle of the read/write device.

Fig. 1: Optimal alignment of customer specic transponder

to the device

CDB620-001 connection module

Mount the CDB620-001 connection module in

the vicinity of the device. If you are using the

serial data interfaces (RS-232), we recommend

a max. distance of 3 m. Mount the CDB620-001

in such a way that the device remains accessible at all times. See also CDB620-001

connection module operating instructions (part

no. 8012119). - See “Sources for additional

information” on page 5

.

Step 2: Electrical installation

• The electrical installation must only be per-

formed by electrically qualied persons.

• Standard safety requirements must be met when

working in electrical systems.

• Electrical connections between the device and

other devices may only be created or disconnected

when there is no power to the system. Otherwise,

the devices may be damaged.

• When using connecting or extension cables with an

open end, make sure that bare wire ends are not

touching (risk of short-circuit when the supply voltage is switched on). Wires must be appropriately

insulated from each other.

• Wire cross-sections in the supply cable from the

customer's power system must be designed in

accordance with the applicable standards. 0.8 A

protection at the start of the feeding supply circuit

when the device is operated without a connection

module using a SICK cable.

• The power supply via a power supply unit must be

capable of buering a brief power failure of 20 ms.

• All circuits connected to the device must be designed as ES1 circuits. The power supply or power

supply unit must satisfy ES1 requirements in accordance with the currently applicable EN 62368-1.

(ES 1 = electrial source class 1).

NOTE

Risk of damage to the device due to possible short-

circuit!

The supply voltage input in the device is designed with

internal circuit protection to provide reverse polarity

protection. The internal functional earth, which also

corresponds to the negative pole of the device has a

direct connection to the metal housing of the device

due to reasons relating to high frequency.

If the supply voltage has the incorrect polarity, this will

not cause any damage provided that the device is not

connected (by

• either other cables or

• its housing)

to other peripheral devices that use the same grounding point.

WARNING

Risk of injury and damage caused by electrical

current!

The device is designed to be operated in a system

with professional grounding of all connected devices

and mounting surfaces to the same ground potential.

As a result of equipotential bonding currents between

the device and other grounded devices in the system,

faulty grounding of the device can have the following

consequences:

• Metal housings are vulnerable to dangerous currents

• Malfunction and destruction of devices

• Damage to the cable shields caused by heating,

resulting in cable res.

Ensure that the ground potential is the same at all

grounding points. See the “Electrical installation”

chapter in the RFH630 technical information for

measures to eliminate hazards.

If the cable insulation is damaged, disconnect the

power supply immediately and have the damage

repaired.

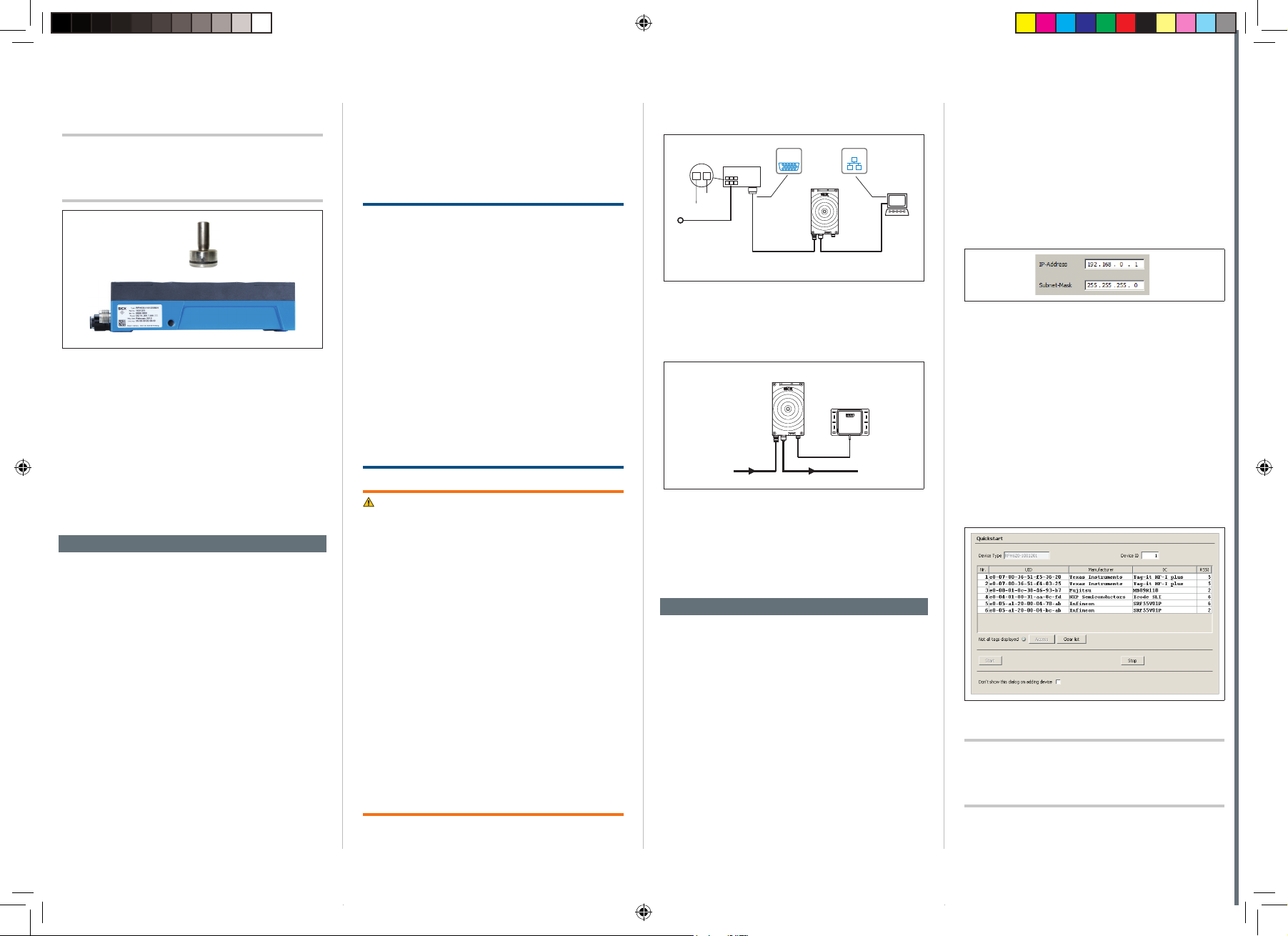

1. Connect the communication interface (e.g., Ethernet) of the device directly to the PC.

CDB620-001

(optional)

1

2

...

...

GND

V

S

S

Fig. 2: Electrical connection block diagram of the device for

commissioning in the default conguration

SerialSerial

RFH630-1102101S05

"Power/

Serial Data/

CAN/I/O"

e.g. cable

No. 2055419 (2 m)

EthernetEthernet

Configuratio

"Ethernet"

(Aux, Host)

e.g. cable

No. 6034414 (2 m)

Diagnostics

SOPASSOPAS

PC

2. If an external antenna is being used (e.g.,

RFA332-2032, part no. 1054399), connect it to

the antenna connection on the device.

External antenna

RFA332-2032

HOSTPower

Fig. 3: Device with RFA332-2032 external antenna

3. If necessary, connect a read pulse sensor, such

as a photoelectric sensor, to the “IN 1” switching

input of the CDB620-001.

4. Supply power to the device.

After successful initialization, the “Ready” LED

illuminates green.

Step 3: Conguration with PC

The SOPAS ET conguration software is used by

default to adjust the device parameters to the application and to the diagnostics in case of error.

a. Installing and starting the SOPAS ET

conguration software

1. Download and install the software from the relevant SICK product page on the Internet at

www.sick.com/SOPAS_ET:

• Latest version of the conguration software

• Current device description le (*sdd) for the

device.

2. For the conguration software, select the

“Complete” option as selected by the installation

wizard. Administrator rights may be required on

the PC to install the software.

3. Start the “SOPAS ET” program option after com-

pleting the installation. Path: Start > Programs >

SICK > SOPAS ET Engineering Tool > SOPAS.

4. Establish a connection between SOPAS ET and he

device via the automatically opened wizard. To do

so, select the device under the devices available

depending on the connected communication

interface, e.g., Ethernet.

5. The following IP address is congured by default

on the RFH630-1102101S05:

Fig. 4: Default IP address

6. SOPAS ET establishes communication with the

device and loads the associated device descrip-

tion le for the device. The

b. Identifying a transponder in Quickstart

mode

tab opens.

1. Bring one or more standards-compliant HF transponders into the working area of the internal antenna or, where applicable, the external antenna

of the device.

2. Click the “Start” button in the

tab in

SOPAS ET. SOPAS ET generates read pulses

continuously and lists the identied transponders

one after the other in the

window.

Fig. 5: SOPAS ET: Display of six identied transponders in the

Important!

window

The automatic triggering in Quickstart mode is intended for initial commissioning and not for permanent

use when operating the device under real conditions.

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 2RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 2 23.11.2018 11:27:10

Page 3

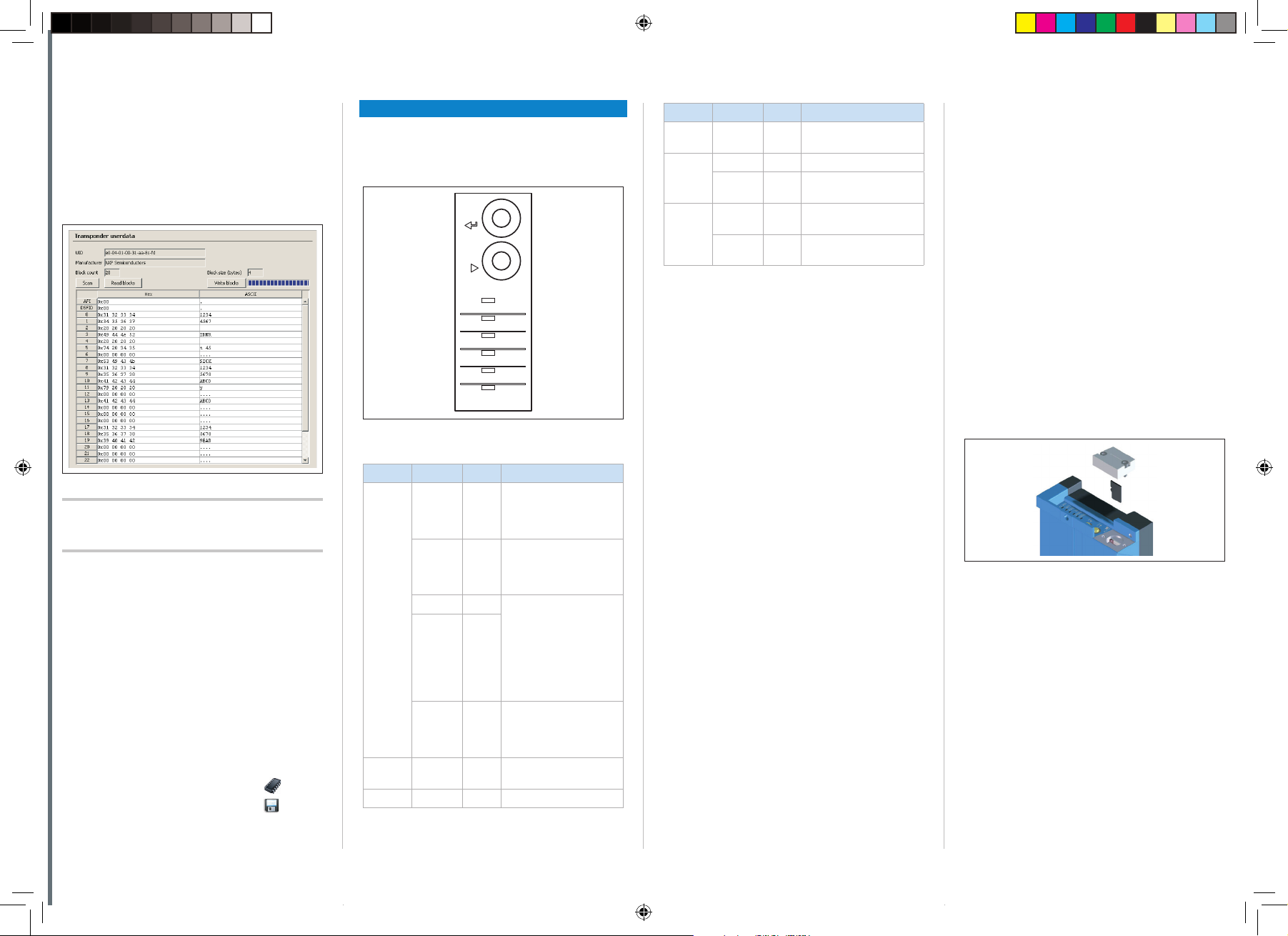

c. Accessing the data on a transponder

stop

Quickstart

transponder access

tran

sponder user data

transponder user data

parameters

1. In order to access the memory area of a transponder, click the

button in

.

2. Highlight the desired transponder (click it with the

mouse).

3. Click the

button. The

tab displays the content of the

selected transponder.

Fig. 6: SOPAS ET:

Important!

The UID (Unique Identier) of the transponder cannot

display window

be changed.

d. Continuing the conguration

1. Under SOPAS ET in the left-hand navigation tree,

edit the required tabs for the application using

the additional entries under

. These

include transponder processing, object trigger

control (e.g., via “Sensor 1” switching input), data

processing and output, data output interface(s),

and the function of the switching inputs and

outputs.

2. Test and, if necessary, modify the settings made

when operating the system under real conditions.

e. Completing the conguration

Permanently save the entire conguration once it

has been successfully tested:

Parameter set in the device: Click the

Conguration le on the PC: Click the

button.

button.

Device description

Device layout

- See “Device layout” on page 5.

Status indicators

-

Enter

Stop

Read Diagn

Ready

Result

RF

Data

CAN

LNK TX

TeachIn

Antenna

Sync

Userdef.

Display LED Color Status

Data Flashing Yellow Data transmission via

host interface

CAN Lights up Green CAN interface activated

Flashing Green Data trac via CAN

interface

LNK TX Flashing Green Data trac via Ethernet

interface

Lights up Yellow Physical Ethernet con-

nection

Tab. 1: Status indicators

Overview of interfaces and connection options

- See “Overview of interfaces and connection options” on page 3.

Overview of pin assignments

- See “Overview of pin assignments” on page 6.

MicroSD memory card (optional accessory)

Fig. 7: Optical status indicators

Status indicators on the rst display level

Display LED Color Status

Ready Lights up Green Lights up constantly after

O – Goes out when download-

Flashing Green PROFINET operation

Flashing Red

Flashing Red New rmware installation

Result Lights up Green Successful read process

RF Lights up Green HF eld is switched on

switching on and completion of successful self-test

(device ready)

ing or uploading conguration data from and to

the device

(single port): Flashes cyclically red (long) and green

(short) alternately.

Trying to establish a connection to a PLC (controller) or loss of connection

during operation

after download to device.

Do not turn o the supply

voltage!

(good read, 100 ms)

Function

The device saves its congured parameter values as

a parameter set in its internal permanent memory

on request. A optional plug-in memory card can be

used for additional parameter cloning on an external

device. If the card is available, the device also saves

the internal parameter set on this. To start cloning, save the parameter set in the device using the

SOPAS ET option “Save parameter permanently”. It is

used, among other things, to conveniently transfer the

parameter set to an exchange unit of the same type in

the event of an error.

As an alternative to the memory card, you can use the

optional CMC600 parameter storage module, which

can be used in the optional connection module, e.g,

CDB620-001 or CDM420-0001.

If both the memory card and the parameter storage

module are available, the device adopts the parameter set from the CMC600 parameter storage module

on restarting.

The rst time a parameter set is stored, we recommend that an empty memory card is used (if necessary, check and delete the contents of the card on the

PC using a card reader).

The memory card is not included with delivery.

on the Internet at www.sick.com/RFH6xx.

The memory card has no write protection that can be

activated.

Inserting the memory card

To avoid damaging the memory card, make sure

there is no power to the device when you insert or

remove it.

The card slot can be accessed on the device behind

the aluminum cover. - See ß, “Device layout” on

page 5.

Maintaining the IP 67 enclosure rating: - See “Safety

information” on page 1.

1. Turn o the supply voltage to the device.

2. To remove the cover, unscrew both Allen screws

(A/F 2).

3. Making sure it is in the correct position (with the

contacts pointing to the front and down – see the

symbol on the device), insert the memory card

into the card slot until it locks into place.

4. Screw the aluminum cover back on.

5. Turn on the supply voltage to the device.

Fig. 8: Inserting the memory card

6. Once it is switched on, the device automatically

detects the presence of a memory card and,

depending on the card's content, behaves as

follows:

• If the card is empty or if it contains a parame-

ter set that cannot be interpreted by the device,

the device saves its currently valid internal

parameter set to the card and starts with this

parameter set.

• If the card contains a parameter set that can

be interpreted by the device, the device permanently overwrites the currently valid internal

parameter set with this external parameter set.

The goal is for the internal parameter set and

the parameter set saved externally to always

be identical.

Only use types approved by SICK to ensure reliable

function of the memory card. See SICK product page

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 3RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 3 23.11.2018 11:27:13

Page 4

NOTE

Risk of data loss or irreparable damage to the

memory card!

The device does not signal the respective access to

the card used (read/write).

If the parameter set is saved with the option

“Save parameter permanently” in the device using

SOPAS ET, do not remove the memory card during

the process and do not switch o the supply voltage.

Technical data (excerpt)

Type RFH630-1102101S05

Product

category

Carrier frequency

Air interface

protocol

Transmitting

power

Scanning range

write/read

Transmission

rate air interface

Typical access

times

Host

interfaces

Host interfaces

(also over external modules)

Aux interfaces

(for conguration)

SICK CAN Sensor Network

Switching inputs

ISO/IEC-15693 compatible read/write

unit

HF (13.56 MHz)

ISO/IEC 15693, 18000-3 M1 (“mandatory” and “optional” command set)

1 W

Internal antenna: max. 10 mm

1)

26 kBit/s

UID read (64 bit/8 byte): 18 ms

1 block read (32 bit/4 byte): 13 ms

1 Block write (32 bit/4 byte): 16 ms

RS-232/422 (0.3 kBd … 115.2 kBd)

Ethernet TCP/IP (10/100 MBit/s)

EtherNet/IP™ (10/100 MBit/s)

PROFINET (single port, 10/100 MBit/s)

CANopen (20 ... 1,000 kBd)

PROFIBUS via CDF600-2 PROFIBUS

PROFINET via CDF600-2 PROFINET

Dual Port

®

EtherCAT

via CDF600 EtherCAT®

RS-232 (57.6 kBd)

Ethernet TCP/IP (10/100 MBit/s)

Via CAN interface

2 x IN (V

= max. 32 V, Iin = max. 5 mA),

in

opto-decoupled, adjustable debounce

time.

2 additional inputs via opitonal CMC600 module in optional

CDB620-001 module

Type RFH630-1102101S05

Switching

outputs

Optical indicators

Function key 2 x, Read Diagnosis, additional func-

Parametric data

backup

Supply voltage

V

S

Power consumption

Electrical connections

Housing Aluminum die cast, plastic (PPS)

Weight 712 g

Safety

Enclosure rating

Protection class

EMC

Shock

resistance

Shock resistance

Radio equipment approval

Ambient temperature

Relative humidity

1) With RFID transponder in plane parallel alignment to device antenna; depending on dimensions and quality of transponder.

Tab. 2: Technical specications

2 x OUT (each I

trically isolated from the supply voltage,

short-circuit protected, temperature

protected.

2 additional outputs via optional CMC600 module in optional

CDB620-001 module

6 x status indicators LEDs (Ready,

Result, RF, Data, CAN, LNK TX)

tions can be adjusted via SOPAS ET

MicroSD card (optional) or external via

optional CMC600 module in optional

CDB620-001 connection module

10V DC ... 30 V DC, ES1 in accordance

with currently applicable EN 62368-1

Max. < 6 W (with switching outputs

without load)

1 x male connector, M12, 17-pin,

A-coded

1 x female connector, M12, 4-pin,

D-coded

1 x female connector, TNC reverse

EN 62368-1

IP 67 (EN 60529:1991-10/

A2:2000-02)

III, (EN 61140:2011-01)

EN 301489-3 Receiver Class 2

EN 60068-2-6:2008-02

EN 60068-2-27:2009-05

Europe EN 300 330-2 /

FCC Part 15

Operation: –20 °C ... +50 °C

Storage: –25 °C ... +70 °C

0% ... 95%, non-condensing

≤ 100 mA), not elec-

out

For further technical specications, see the online

data sheet on the product page on the Internet at

www.sick.com/RFH6xx.

Regulatory notes

Europe: Simplied EU declaration of conformity

SICK AG hereby declares that the

RFH630-1102101S05 radio equipment complies

with the 2014/53/EU directive. The complete text of

the EU declaration of conformity is available at the

following web address: www.sick.com/RFH6xx.

FCC approval

The device fullls Part 15 of the FCC regulations:

The following prerequisites must be met:

• This device may not cause harmful interference,

and this device must accept any interference

received, including interference that may cause

undesired operation.

• Any changes or modications not expressly ap-

proved by the party responsible for compliance

could void the user's authority to operate this

device.

Operational restrictions

• USA: To comply with FCC part 15 rules in the United

States, the system must be professionally installed

to ensure compliance with the Part 15 certication.

It is the responsibility of the operator and profes-

sional installer to ensure that only certied systems

are deployed in the United States.

The use of the system in any other combination

(such as co-located antennas transmitting the

same information) is expressly forbidden.

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference in which case

the user will be required to correct the interference

at his own expense. Changes or modications not

expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

• USA/Canada: This device complies with part 15 of

the FCC Rules and Industry Canada licence-exempt

RSS standard(s) Operation is subject to the follow-

ing two conditions: (1) This device may not cause

harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

• Canada: This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed

and operated with minimum distance 20 cm between the radiator & your body. This Class A digital

apparatus complies with Canadian ICES-003.

This radio transmitter has been approved by

Industry Canada to operate with the antenna types

listed below with the maximum permissible gain

and required antenna impedance for each antenna

type indicated.

Antenna types not included in this list, having a

gain greater that the maximum gain indicated for

that type, are strictly prohibited for use with this

device.

• Internal antenna:

Maximum permissible antenna gain: 2 dBi

Required impedance: 50 Ohm

• External antenna RFA332:

Maximum permissible antenna gain: 2 dBi

Required impedance: 50 Ohm

• Under industry Canada regulations, this radio

transmitter may only operate using an antenna

of a type and maximum (or lesser) gain approved

for the transmitter by Industry Canada. To reduce

potential radio interference to other users, the

antenna type and its gain should be so chosen that

the equivalent isotropically radiated power (e.i.r.p.)

is not more than that necessary for successful

communication.

• Canada: This equipment complies with the Industry

Canada RSS standards for license-exempt radio

devices. Operation is subject to the following two

conditions: (1) The device may not cause harmful

interference, and (2) the device must accept any

interference received, including if this may cause

undesired operation. This equipment complies with

the IC radiation exposure limits for uncontrolled

environments. This equipment should be installed

and used with a minimum distance of 20 cm between the radiator and the human body.

• This Class A digital equipment complies with the

Canadian standard NMB-003..

Maintenance and care

The device does not contain any components that

require maintenance.

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 4RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 4 23.11.2018 11:27:13

Page 5

Transport and storage

Transport and store the device in the original packaging, with protective plugs and caps fully screwed on.

Do not store outdoors. To ensure that any residual

moisture present can escape, do not store the device

in airtight containers. Do not expose to any aggressive

substances. Storage conditions: Dry, dust-free, no

direct sunlight, as little vibration as possible, storage

temperature –25 °C to +70 °C, relative humidity

max. 95% (non-condensing).

Repairs

Repair work on the device may only be performed by

qualied and authorized service personnel from SICK

AG.

Disassembly and disposal

Any device which can no longer be used must be

disposed of in an environmentally friendly manner in

accordance with the respective applicable country-

specic waste disposal regulations. The device is

electronic waste and must under no circumstances

be disposed of with general waste!

Sources for additional information

You can obtain the Quickstart and further documentation online.

Select your country and language at

www.sick.com.

Enter the devices type designation or part num-

ber into the search eld.

Select the required device.

All documentation and other downloadable

content relating to the device can be found under

Downloads.

The SOPAS ET conguration software can be

downloaded under Software.

Documentation for the accessories that can be

used can be downloaded under Accessories.

Function blocks for the device

www.sick.com/software

Documents on request

• Overview of the device command language

Support is also available from your sales partner:

www.sick.com/worldwide.

Device layout

1

100 (3.94)

147 (5.79)

17.4

(0.69)

10.4 (0.44)

20.6

(0.81)

54.5 (2.15)

39.3

12.3

(0.48)

(1.55)

6.5

(0.26)

16.1

(0.63)

9

8

Fig. 9: Dimensions (in mm) and device structure

1. 4 x M6 threaded mounting holes, 6.5 mm depth

2. 2 x M5 through holes, 4.5 mm, as an alternative for

mounting the device

3. Connection for external antenna (female connector, TNC

reverse)

4. “Ethernet” connection (female connector, M12, 4-pin,

D-coded)

5. Swivel connector

6. Function keys ▾ (Step) and p (Enter)

7. 6 x RGB LEDs, multi-colored (status indicators)

8. Slot for microSD memory card, behind screw-mounted

cover

9. “Power/Serial Data/CAN/I/O” connection (male connec-

tor, M12, 17-pin, A-coded)

71.9 (2.83)

87.5 (3.44)

Enter

mircoSD

2

7.8

100 (3.94)

30 (1.18)

(0.31)

12.5

(0.49)

6.4 (0.25)

9.1 (0.36)

1

(5.5)

139.6

3

2

4

5

6

7

Sync

TeachIn

Userdef.

Antenna

Read Diagn

Stop

Ready

Result

LNK TX

CAN

Data

RF

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 5RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 5 23.11.2018 11:27:15

Page 6

Overview of all interfaces and connection options

CDB620-001 (optional)

1

2

GND

V

S

V

S

Switching input 1

(e. g. external reading clock)

Switching input 2

(e. g. incremental encoder)

Switching output 1

(e. g. LED)

Switching output 2

Additional external inputs / outputs via

optional parameter storage module CMC600

in connection module CDB620

Switching input / output = digital

CMC600

...

...

"Power/Serial Data/CAN/I/O"

Adapter cable (female connector, M12,

17-pin, A-coded / male connector,

"Serial RS-232/422" (Host 1), read result alternative to Ethernet

SerialSerial

"Serial RS-232" (Aux 1), alternative to Ethernet Aux port

Null modem cable (female connector, D-Sub, 9-pin /

female connector, D-Sub, 9-pin), TxD and RxD crossed

RFH630-1102101S05

External antenna (optional),

e.g. RFA332)

(Aux 1, Host 1)

D-Sub-HD, 15-pin)

"Ethernet" (Aux 2)

"Ethernet" (Host 2)

read result

Adapter cable (male connector,

M12, 4-pin, D-coded /

male connector, RJ-45, 8-pin)

EthernetEthernet

SOPASSOPAS

Configuration

Diagnostics

HOST

Further data

processing

PC

Overview of pin assignments

Connection "Ethernet"

43

female connector,

M12, 4-pin, D-coded

2

1

1

TD+

2

RD+

3

TD–

4

RD–

Connection "Power/Serial Data/CAN/I/0"

12

3

2

13

4

5

14

6

17

7

1

male connector, M12,

11

10

17-pin, A-coded

16

9

8

15

1

GND

2

V

S

3

CAN L

4

CAN H

5

TD+ (RS-422), Host

6

TD– (RS-422),

TxD (RS-232), Host

7

TxD (RS-232), Aux

8

RxD (RS-232), Aux

9

SensGND

10

Sensor 1 (switching input 1)

11

RD+ (RS-422), Host

12

RD– (RS-422),

RxD (RS-232), Host

13

Result 1 (switching output 1)

14

Result 2 (switching output 2)

15

Sensor 2 (switching input 2)

16

n.c.

17

n.c.

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 6RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 6 23.11.2018 11:27:16

Page 7

(Blank page)

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 7RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 7 23.11.2018 11:27:16

Page 8

(Blank page)

8023443/11W0/2018-11-20 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 8RFH6XX | SICK

8023443-11W0_QS_RFH630-1102101S05_EN_201801120_final.indd 8 23.11.2018 11:27:16

8023443/11W0/2018-11-20 • 8M_TM • Printed in Germany • All rights reserved • Subject to change without notice

Loading...

Loading...