Page 1

PS30

Pattern sensor

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

PS30

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Information on the operating instructions.............................................. 6

1.2 Scope......................................................................................................... 6

1.3 Explanation of symbols............................................................................ 6

1.4 Further information................................................................................... 7

1.5 Customer service...................................................................................... 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Improper use............................................................................................. 8

2.3 Modifications and conversions................................................................ 8

2.4 Limitation of liability................................................................................. 8

2.5 Requirements for skilled persons and operating personnel.................. 9

2.6 Hazard warnings and operational safety................................................. 9

2.7 Repair........................................................................................................ 10

3 Product description........................................................................... 11

3.1 Product ID.................................................................................................. 11

3.2 Product features and functions............................................................... 11

3.3 Operating modes...................................................................................... 12

3.4 Display and operating elements.............................................................. 13

3.5 Display....................................................................................................... 15

3.6 Bar graph................................................................................................... 15

4 Transport and storage....................................................................... 16

4.1 Transport................................................................................................... 16

4.2 Transport inspection................................................................................. 16

4.3 Storage...................................................................................................... 16

5 Mounting............................................................................................. 17

5.1 Scope of delivery....................................................................................... 17

5.2 Mounting requirements............................................................................ 17

5.3 Mounting the device................................................................................. 19

6 Electrical installation........................................................................ 20

6.1 Notes on the electrical installation.......................................................... 20

6.2 Wiring notes.............................................................................................. 21

6.3 Note on the swivel connector................................................................... 23

6.4 System configuration................................................................................ 24

6.5 Connecting the device electrically........................................................... 24

6.6 Pin assignment of the connections......................................................... 25

7 Commissioning.................................................................................. 27

7.1 Pushbutton damage................................................................................. 27

7.2 Steps to take............................................................................................. 27

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

3

Page 4

CONTENTS

7.3 Setting up the encoder............................................................................. 27

7.4 Operation without encoder or machine cycle......................................... 30

8 Operation............................................................................................ 32

8.1 Pushbutton damage................................................................................. 32

8.2 Navigation................................................................................................. 32

8.3 Selecting an option................................................................................... 32

8.4 Changing the value................................................................................... 32

8.5 Settings menu........................................................................................... 33

8.6 Teach menu............................................................................................... 37

8.7 Monitoring menu....................................................................................... 42

8.8 Info menu.................................................................................................. 43

9 Operation via Ethernet TCP/IP........................................................ 44

10 Operation via SOPASair.................................................................... 45

10.1 Integrating the PS30 pattern sensor in the network.............................. 45

10.2 Monitoring menu....................................................................................... 46

10.3 Teach-in menu........................................................................................... 46

10.4 Settings menu........................................................................................... 49

10.5 Device info menu...................................................................................... 50

10.6 Settings menu (of the SOPASair WebUI)................................................. 51

10.7 Analysis menu........................................................................................... 51

11 Troubleshooting................................................................................. 53

11.1 Notes on troubleshooting......................................................................... 53

11.2 Possible error indicators.......................................................................... 53

11.3 Troubleshooting guide.............................................................................. 54

12 Maintenance...................................................................................... 60

12.1 Maintenance............................................................................................. 60

12.2 Cleaning the device.................................................................................. 60

13 Decommissioning............................................................................. 62

13.1 Disassembly and disposal....................................................................... 62

13.2 Returning devices..................................................................................... 62

14 Technical data.................................................................................... 63

14.1 Dimensional drawings.............................................................................. 63

14.2 Optics/features......................................................................................... 63

14.3 Supply........................................................................................................ 64

14.4 Inputs......................................................................................................... 64

14.5 Outputs...................................................................................................... 64

14.6 Interfaces.................................................................................................. 64

14.7 Encoder..................................................................................................... 65

14.8 Ambient conditions................................................................................... 65

14.9 Structural design...................................................................................... 65

4

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 5

CONTENTS

15 Accessories........................................................................................ 66

15.1 Connectivity............................................................................................... 66

15.2 Mounting systems..................................................................................... 67

16 Menu structure................................................................................... 69

16.1 Setup menu............................................................................................... 69

16.2 Monitr menu.............................................................................................. 69

16.3 Teach menu............................................................................................... 69

16.4 Settng menu.............................................................................................. 70

16.5 Info menu.................................................................................................. 70

17 Annex.................................................................................................. 71

17.1 EU declaration of conformity and certificates........................................ 71

17.2 Certification according to UL60947-5-2................................................. 71

17.3 Licenses.................................................................................................... 71

18 Index.................................................................................................... 72

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied

•

Compliance with local work safety regulations and general safety regulations for

•

device applications

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully before starting any work on the device, in

order to familiarize yourself with the device and its functions.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

These operating instructions do not provide information on operating the machine in

which the device is integrated. For information about this, refer to the operating instruc‐

tions of the specific machine.

1.2 Scope

These operating instructions serve to incorporate the device into a customer system.

Instructions are given in stages for all actions required.

These instructions apply to all listed device variants of the product.

Available device variants are listed on the online product page.

www.sick.com/PS30

b

Commissioning is described using one particular device variant as an example.

Simplified device designation in the document

In the following, the sensor is referred to in simplified form as “PS30” or “device”.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

6

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 7

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.4 Further information

ABOUT THIS DOCUMENT 1

NOTE

All the documentation available for the device can be found on the online product page

at:

www.sick.com/PS30

b

The following information is available for download from this page:

Type-specific online data sheets for device variants, containing technical data and

•

dimensional drawings

EU declaration of conformity for the product family

•

Dimensional drawings and 3D CAD dimension models in various electronic for‐

•

mats

These operating instructions, available in English and German, and in other lan‐

•

guages if necessary

Other publications related to the devices described here

•

Publications dealing with accessories

•

IO-Link driver files and IO-Link Technical Information v1.1

•

1.5 Customer service

If you require any technical information, our customer service department will be happy

to help. To find your agency, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.,

to ensure faster processing.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The PS30 pattern sensor is an opto-electronic sensor intended for non-contact recogni‐

tion of recurring patterns. A machine cycle as the input signal, e.g., via an encoder or a

motor feedback system, is required to operate the pattern sensor.

Alternatively, the speed of the material can be stored as a constant. This alternative is

intended for applications with a constant or only slowly changing material speed.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.2 Improper use

The device does not constitute a safety-relevant device according to the EC

•

Machinery Directive (2006/42/EC).

The device must not be used in explosion-hazardous areas.

•

Any other use that is not described as intended use is prohibited.

•

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

The device is not suitable for the following applications (this list is not exhaustive):

As a safety device to protect persons, their hands, or other body parts

•

Underwater

•

In explosion-hazardous areas

•

Outdoors, without additional protection

•

NOTICE

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

The device should be used only in line with intended use specifications.

b

All information in these operating instructions must be strictly complied with.

b

2.3 Modifications and conversions

Modifications and conversions to the pattern sensor and/or the installation may result

in unforeseeable dangers.

Before any technical modifications to and expansions of the pattern sensor, the prior

written approval of the manufacturer must be obtained.

2.4 Limitation of liability

Applicable standards and regulations, the latest state of technological development,

and our many years of knowledge and experience have all been taken into account

when assembling the data and information contained in these operating instructions.

The manufacturer accepts no liability for damage caused by:

■

Failure to observe the operating instructions

■

Improper use

■

Use by untrained personnel

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, wear and tear parts, and accessories

8

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 9

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training!

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualification requirements for the various

areas of work:

■

Instructed personnel have been briefed by the operating entity about the tasks

assigned to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks assigned to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g., Master Electrician). Other relevant regulations applicable in other

countries must be observed.

SAFETY INFORMATION 2

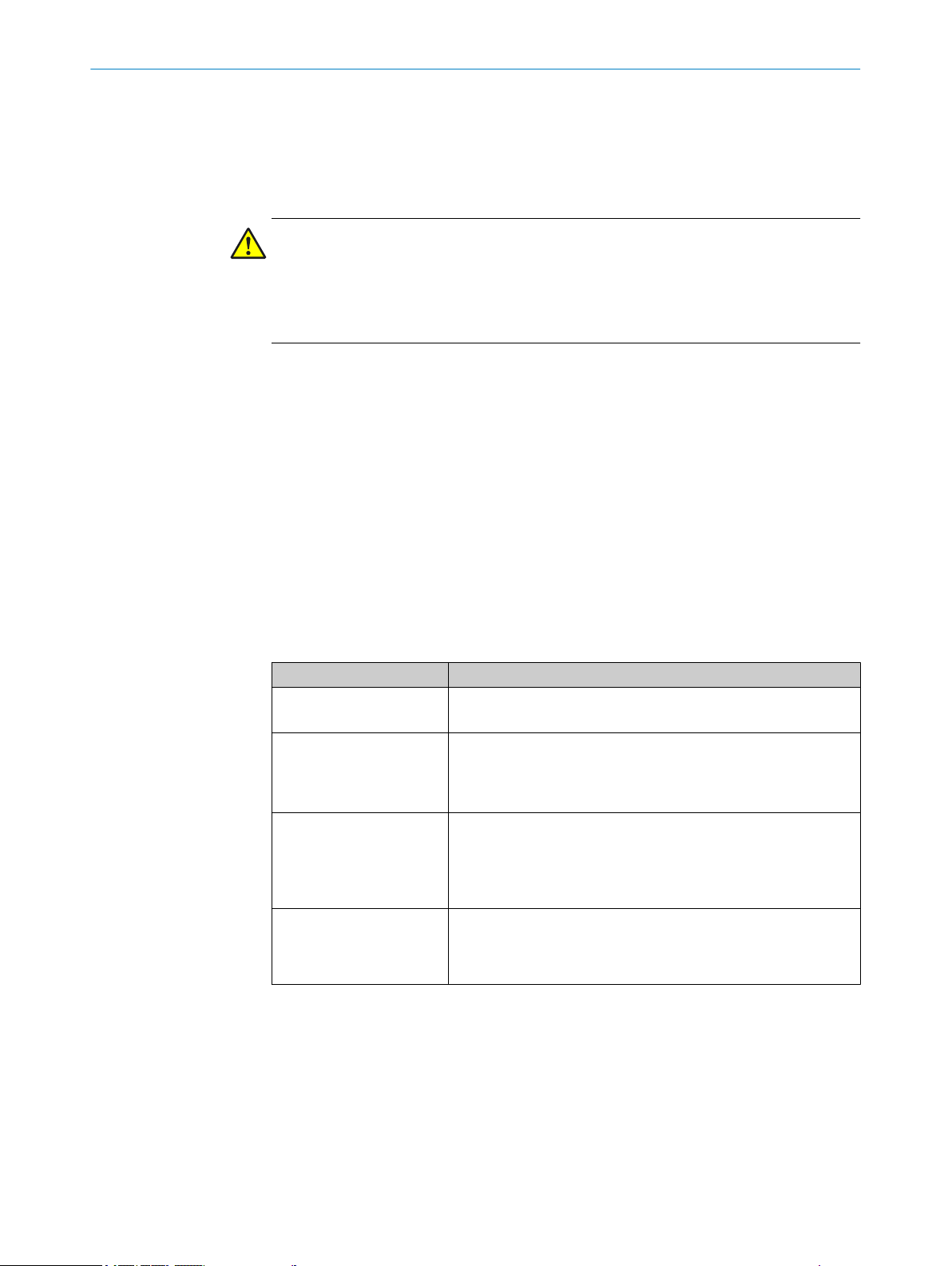

The following qualifications are required for various activities:

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in

■

their particular application

Commissioning,

configuration

Basic knowledge of the design and setup of the described

■

connections and interfaces

Basic knowledge of data transmission

■

Knowledge of the operation and control of the devices in

■

their particular application

Operation of the devices in

their particular application

Knowledge of the operation and control of the devices in

■

their particular application

Knowledge of the software and hardware environment in the

■

application

2.6 Hazard warnings and operational safety

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan‐

gerous situations.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

2.6.1 Eye safety

CAUTION

The device is equipped with LEDs. The device meets the criteria of risk group 1 accord‐

ing to IEC 62471:2006. No special measures are required (e.g., eye protection).

2.7 Repair

The product is a replacement device. The device is not intended to be repaired. Interfer‐

ence with or modifications to the device on the part of the customer will invalidate any

warranty claims against SICK AG.

10

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 11

3 Product description

1

2

3 5

4

1

2

2

5

3

4

3.1 Product ID

3.1.1 Type label

The type label is located on the back of the pattern sensor.

Figure 1: Type label

Type designation

1

Material number

2

MAC address

3

Serial number

4

Machine-readable code

5

PRODUCT DESCRIPTION 3

3.2 Product features and functions

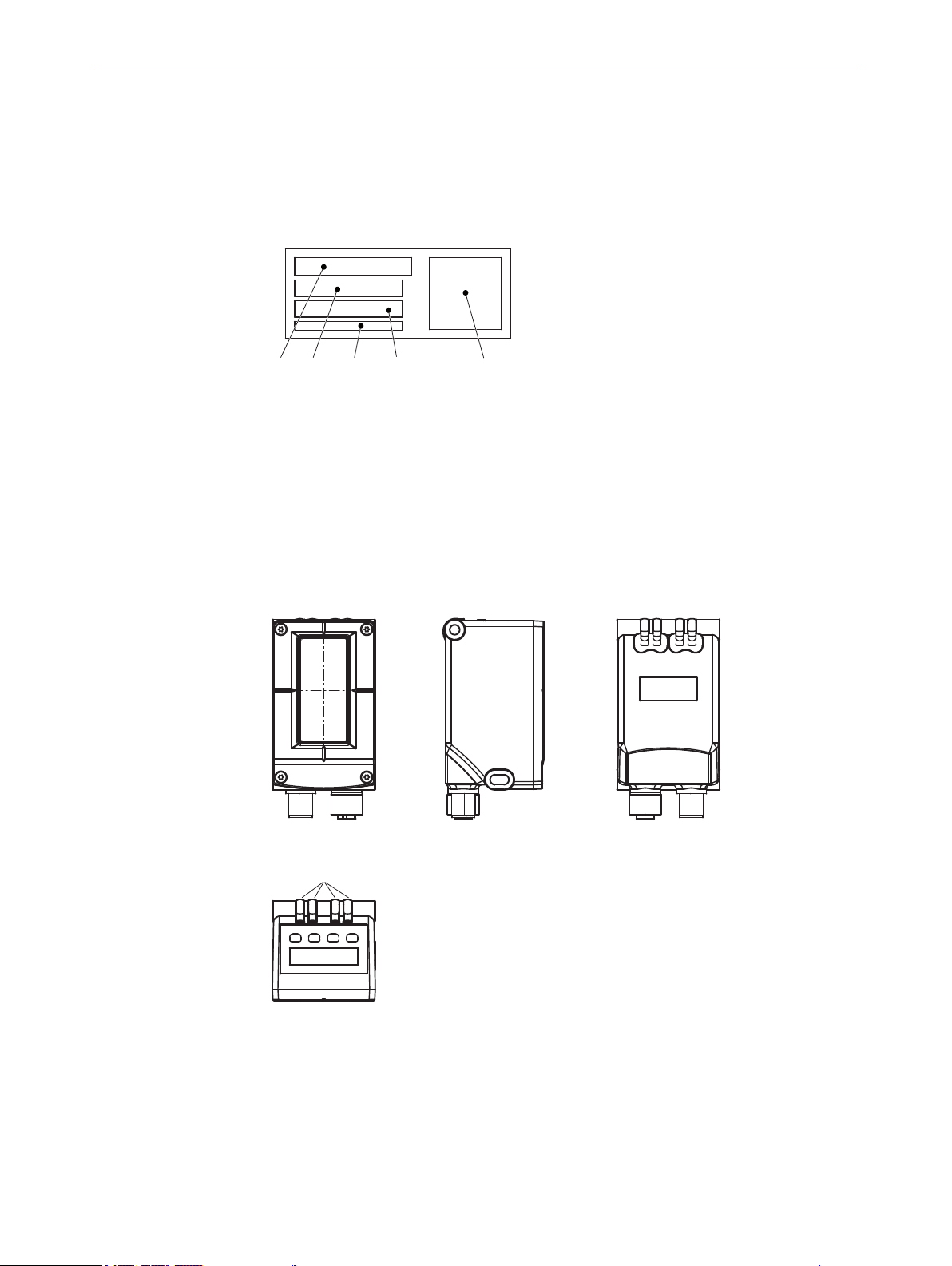

3.2.1 Device view

Figure 2: PSS Prime light emission long housing side

Center of the optical axis

1

Fixing hole

2

M12 male connector, 12-pin/M12 female connector, 4-pin, rotatable

3

Function indicators

4

Display and control unit

5

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

11

Page 12

1

2

3 PRODUCT DESCRIPTION

3.2.2 Product characteristics

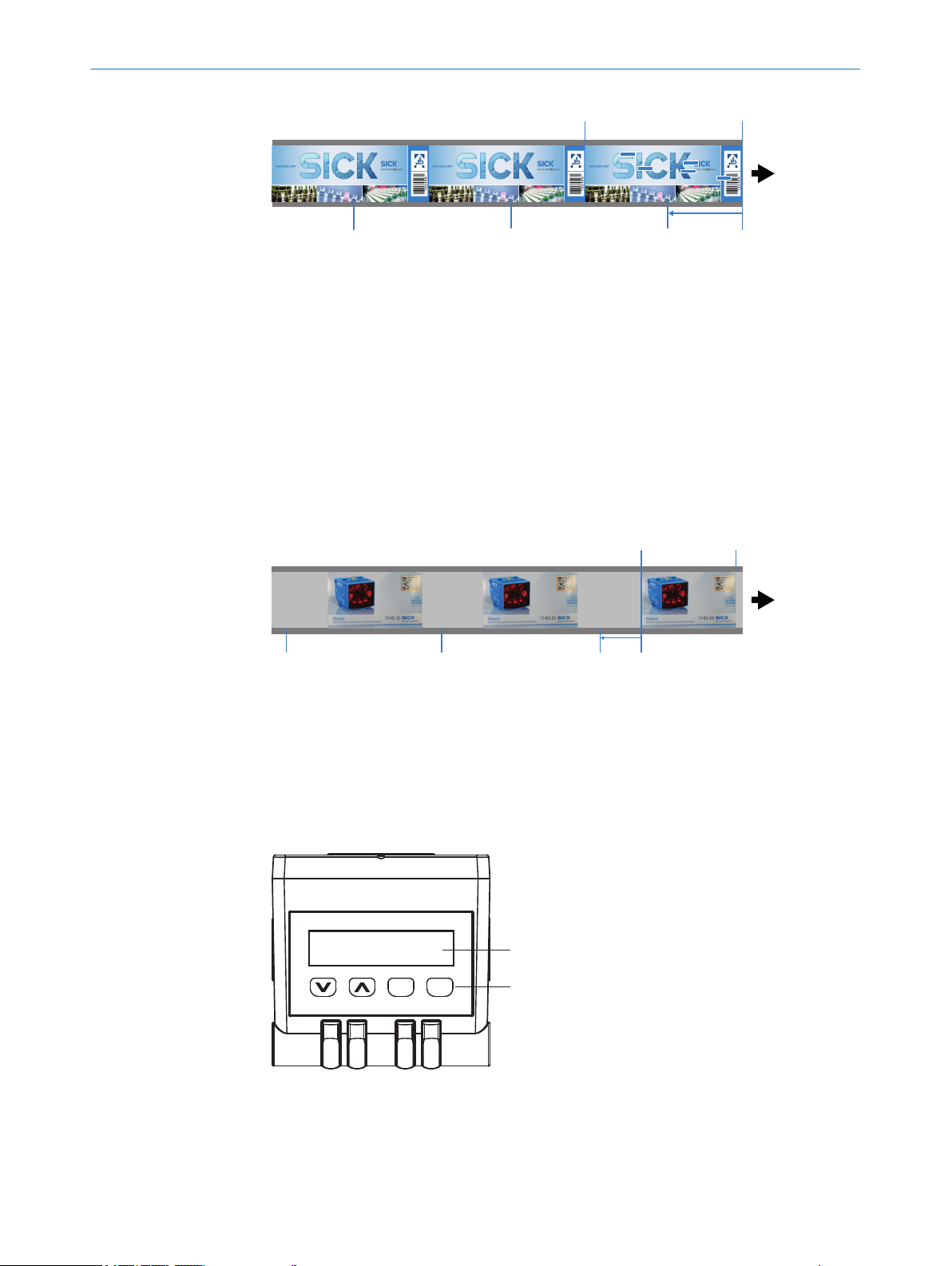

Figure 3: Recorded image from the perspective of the “PS30 pattern sensor”

Field of view

1

Light spot

2

Vertical bars: Cuts of the individual lines, corresponds to the encoder resolution.

Blue square marks: Clear and contrast-rich pattern areas automatically selected by the

sensor. Five areas have been selected in this example.

Function

The PS30 pattern sensor is an opto-electronic sensor that detects recurring patterns in

a contactless manner.

The principle of operation is based on a line camera which constantly searches for con‐

trast differences and sharp edges in the print image (see figure). These distinct and

unique areas in the pattern are automatically selected by the sensor during the teach-in

process. If the image and contrast pattern stay the same, these points will be in exactly

the same locations. The sensor evaluates grayscale information.

A taught-in image is used as a reference for the subsequent detection of a recurring

contrast pattern. The print marks usually used for determining position are no longer

necessary. When a pattern matching the reference pattern is identified, a switching out‐

put is initiated.

The PS30 pattern sensor requires for its operation information about the speed of the

material, e.g., from encoder pulses, from a motor feedback system, or as a defined vari‐

able with a fixed value or a value updated via TCP/IP.

3.3 Operating modes

The PS30 pattern sensor can be operated in one of two modes:

1 Endless material

2 Single object

3.3.1 Endless material operating mode

When further processing endless materials such as film and paper webs to produce, for

example, labels and packaging with a constant repeat length, exact determination of

position is essential, e.g., to determine the cut position.

12

Typically, the target cut position is selected as the start point of the reference image,

and the reference image is terminated before the end of the repeat length. The start

point of the teach-in area is the position of the switching signal. A switching point offset

can also be configured.

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 13

1 2

3

444

Figure 4: Recorded image from the perspective of the “PS30 pattern sensor”

1 2

3

444

1

356 4

EscSet

2

Teach Stop

1

Teach Start

2

Offset

3

Signal

4

3.3.2 Single object operating mode

In this case the position is to be determined for repeating, separate objects with identi‐

cal patterns but not separated by a fixed distance. An object, or a section of the object

is taught in as a reference.

The end of the teach-in area is used as the position for outputting the switching signal.

A switching point offset can be defined.

PRODUCT DESCRIPTION 3

Figure 5: Endless material operating mode

Teach Stop

1

Teach Start

2

Offset

3

Signal

4

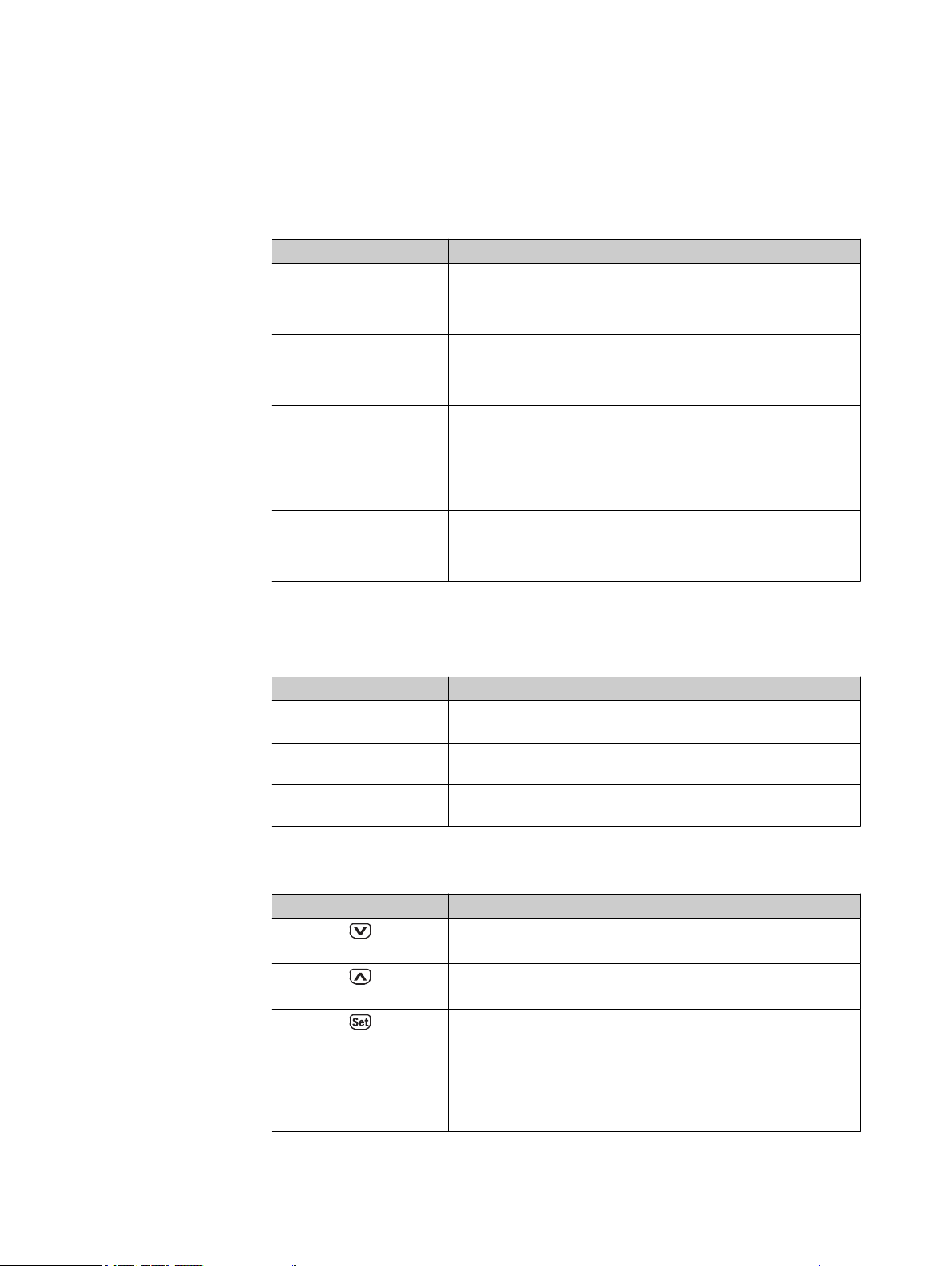

3.4 Display and operating elements

Figure 6: Display and operating elements

1

2

3

Display

Pushbuttons

Function indicator (yellow) “Act”

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

13

Page 14

3 PRODUCT DESCRIPTION

4

5

6

Function indicators (LEDs)

Table 1: Function indicators (LEDs)

Function indicator Description

Act Data transfer display

Link Ethernet connection display

Q Switching output display

ON Operating status display

Function indicator (green) “Link”

Function indicator (yellow) “Q”

Function indicator (green) “ON”

Yellow LED: Data transfer

•

LED off: No data transfer

•

Green LED: Ethernet connection available

•

LED off: No Ethernet connection available

•

Yellow LED: Output high

•

LED off: Output low

•

LED flashing (10 Hz): Overcurrent/short-circuit protection

•

has triggered

Green LED: Normal operation/Supply voltage on

•

LED off: No operation

•

Symbols on the display

The following symbols may appear on the display: “RUN”, “MEN” and “SET”.

Table 2: Symbols on the display

Icon Description

RUN RUN symbol is lit up: The display shows the current operating data

of the sensor.

MEN MEN symbol is lit up: You are in the menu structure and have not

yet reached the last selection level.

SET SET symbol is lit up: Sensor settings can be changed and,

for example, values set.

Pushbuttons

Table 3: Pushbuttons

Pushbutton Description

Select operating menu, parameter, or option

•

Reduce value

•

Select operating menu, parameter, or option

•

Increase value

•

Short press:

•

•

Switch to the next-lowest menu level

°

Save parameter change

°

Confirm selection

°

Long press (> 2 sec.):

Start the operating menu

°

14

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 15

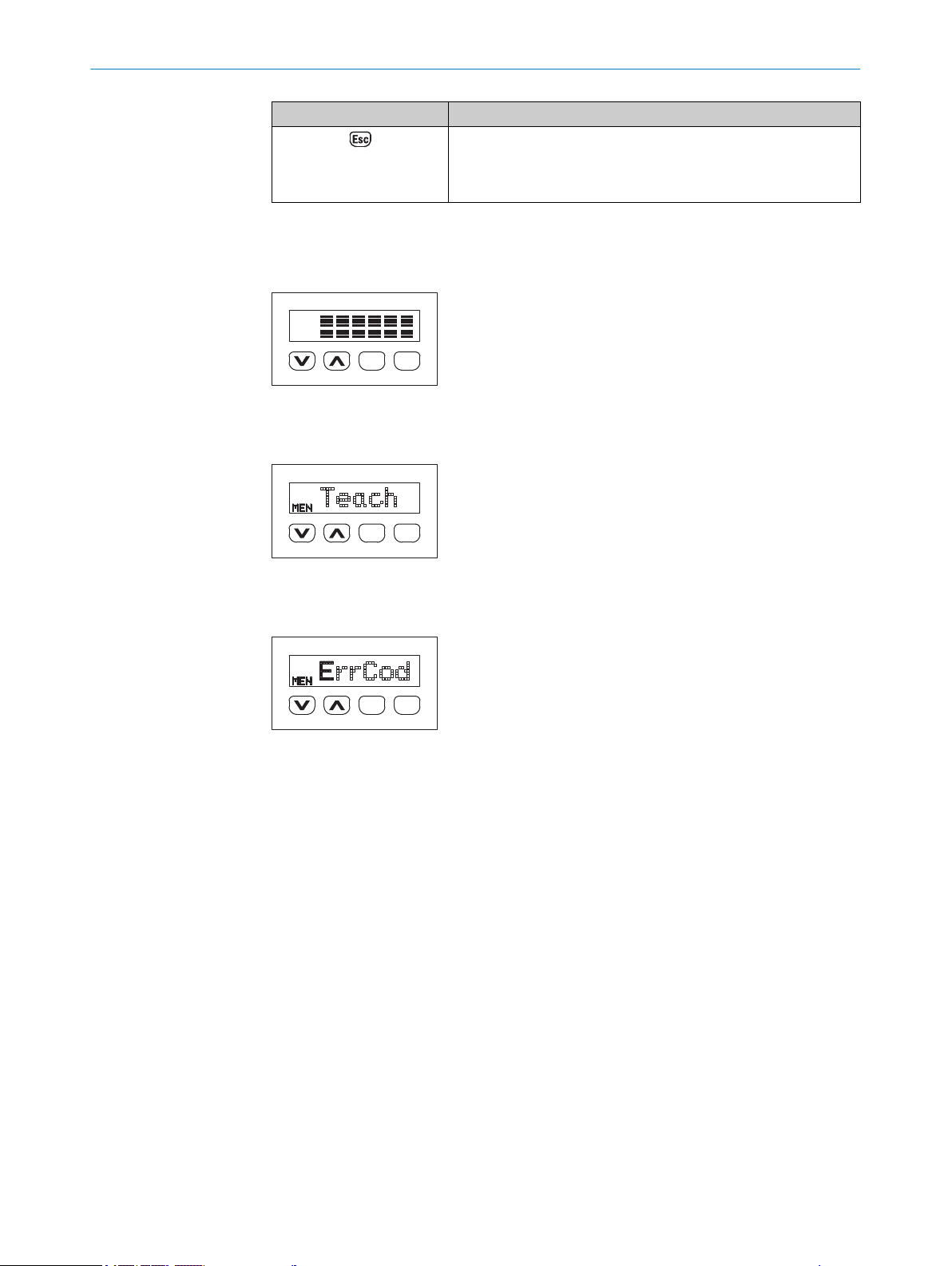

3.5 Display

EscSet

RUN

EscSet

Teach

MEN

EscSet

ErrCod

MEN

Pushbutton Description

Short press: Exit parameters without saving. Switch to the

•

next-highest menu level.

Long press: Exit parameters without saving. Change to the

•

default display - Quality of Run.

Default display

Figure 7: Default display

Operating menus - Monitoring/Setting/Teach-in/Info

PRODUCT DESCRIPTION 3

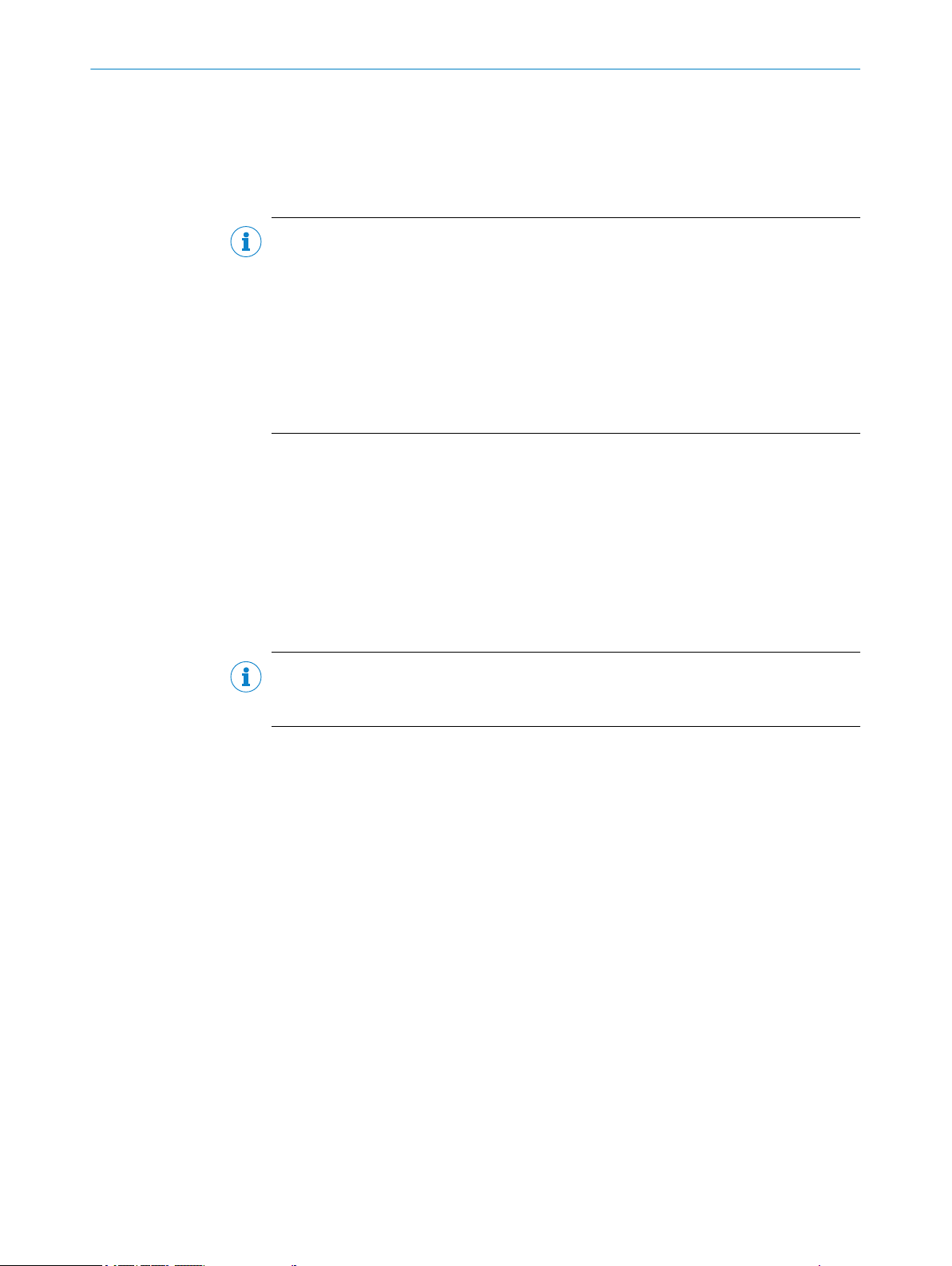

3.6 Bar graph

Figure 8: Operating menu

Parameters using example of monitoring

Figure 9: Parameter display

Teach-in quality

After teach-in has been run, the number of flashing bars indicates the quality of the

teach-in process:

If 3 or more bars are flashing: the teach-in process was successful.

•

If fewer than 3 bars are flashing: check whether the signal is switching correctly. If

•

the signal is not switching correctly, repeat the teach-in process.

Process quality

When the RUN symbol is lit up, the number of bars indicates the process quality.

If 2 or fewer bars are flashing: check whether the signal is switching correctly.

•

If the signal is not switching correctly, verify that the sensor is installed correctly,

•

and check the quality of the print image and the mechanical guiding of the object.

If necessary, repeat the teach-in process.

•

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

15

Page 16

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTE

Damage to the sensor due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

4.2

Transport inspection

4.3 Storage

Immediately upon receipt at the receiving work station, check the delivery for complete‐

ness and for any damage that may have occurred in transit. In the case of transit dam‐

age that is visible externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany’s delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 63.

■

Relative humidity: see "Technical data", page 63.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

16

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 17

5 Mounting

5.1 Scope of delivery

Included with delivery:

PS30 pattern sensor

•

Blind plug for M12 Ethernet connection

•

Adjustment tool

•

Optional: accessories, see "Accessories", page 66

•

Quickstart

•

5.2 Mounting requirements

Typical space requirement for the device, see type-specific dimensional drawing,

•

see "Technical data", page 63.

Comply with technical data, such as the permitted ambient conditions for opera‐

•

tion of the device (e.g., temperature range, EMC interference emissions, ground

potential),

To prevent condensation, avoid exposing the device to rapid changes in tempera‐

•

ture.

Protect the device from direct sunlight.

•

The device must only be mounted using the pairs of mounting threads/fixing holes

•

provided for this purpose.

Shock and vibration-free mounting.

•

The light spot must cover a significant area on the print image. Select an area with

•

high contrast differences and unique pattern elements as the significant area. The

center of the light spot is marked with a notch on the upper side of the housing.

Sensing distance: 20 mm

•

The sensing distance is the distance from the front edge of the sensor (housing

edge) to the sensing target (e.g., an object).

MOUNTING 5

NOTE

We recommend using the supplied adjustment tool to align the pattern sensor.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

17

Page 18

☺

1 2

1 2

3

α

1

5 MOUNTING

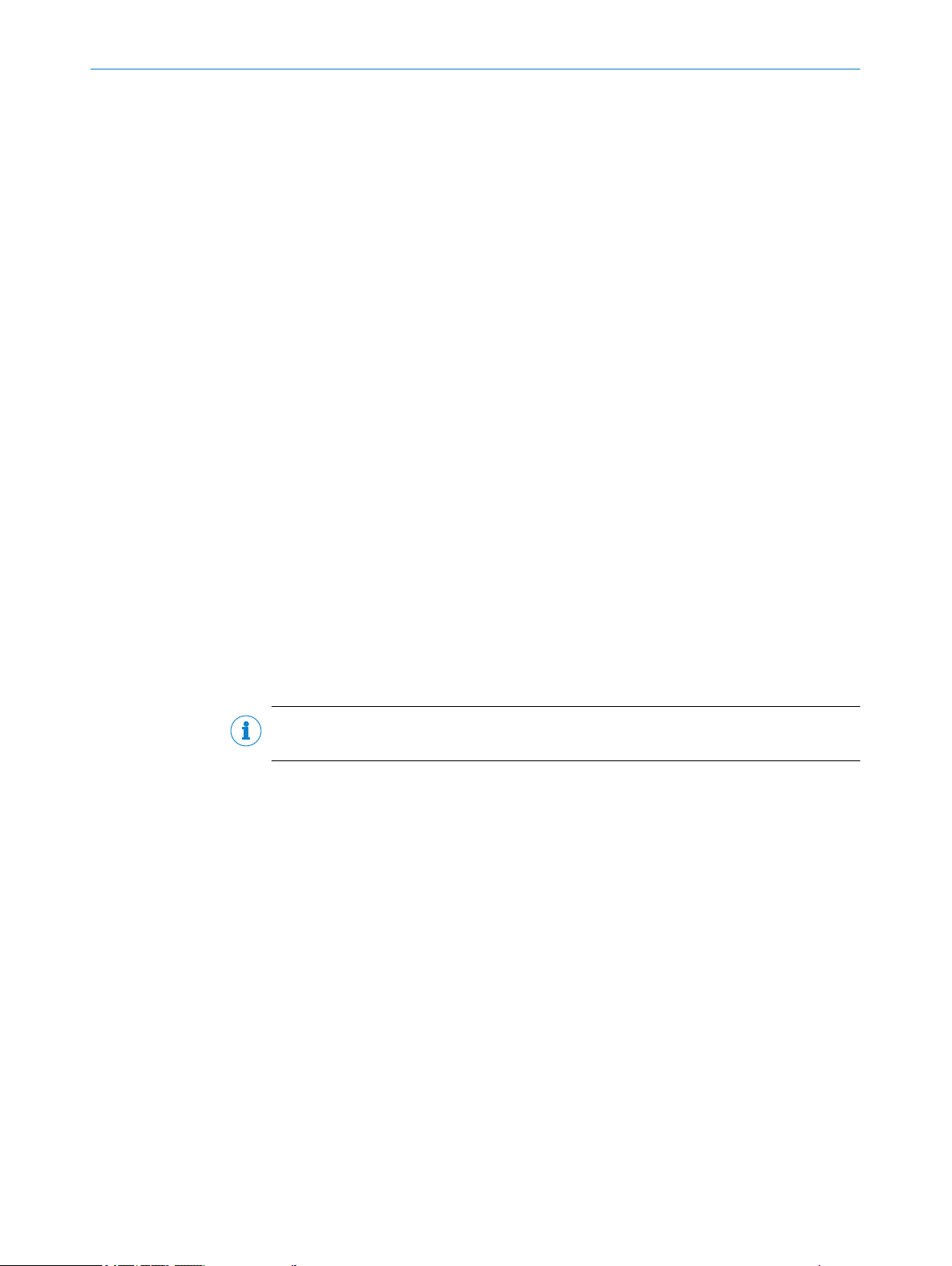

Significant areas

Figure 10: Align the light spot on the print image

Start (SET/ET)

1

Stop (SET/ET)

2

Q

3

The gray squares correspond to the print areas with unique features.

Arrangement when scanning on a flat surface or flat material

Figure 11: Arrangement of the pattern sensor when scanning on a flat surface or flat material

SD

1

α: 15° angle

SD: 20 mm sensing distance

18

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 19

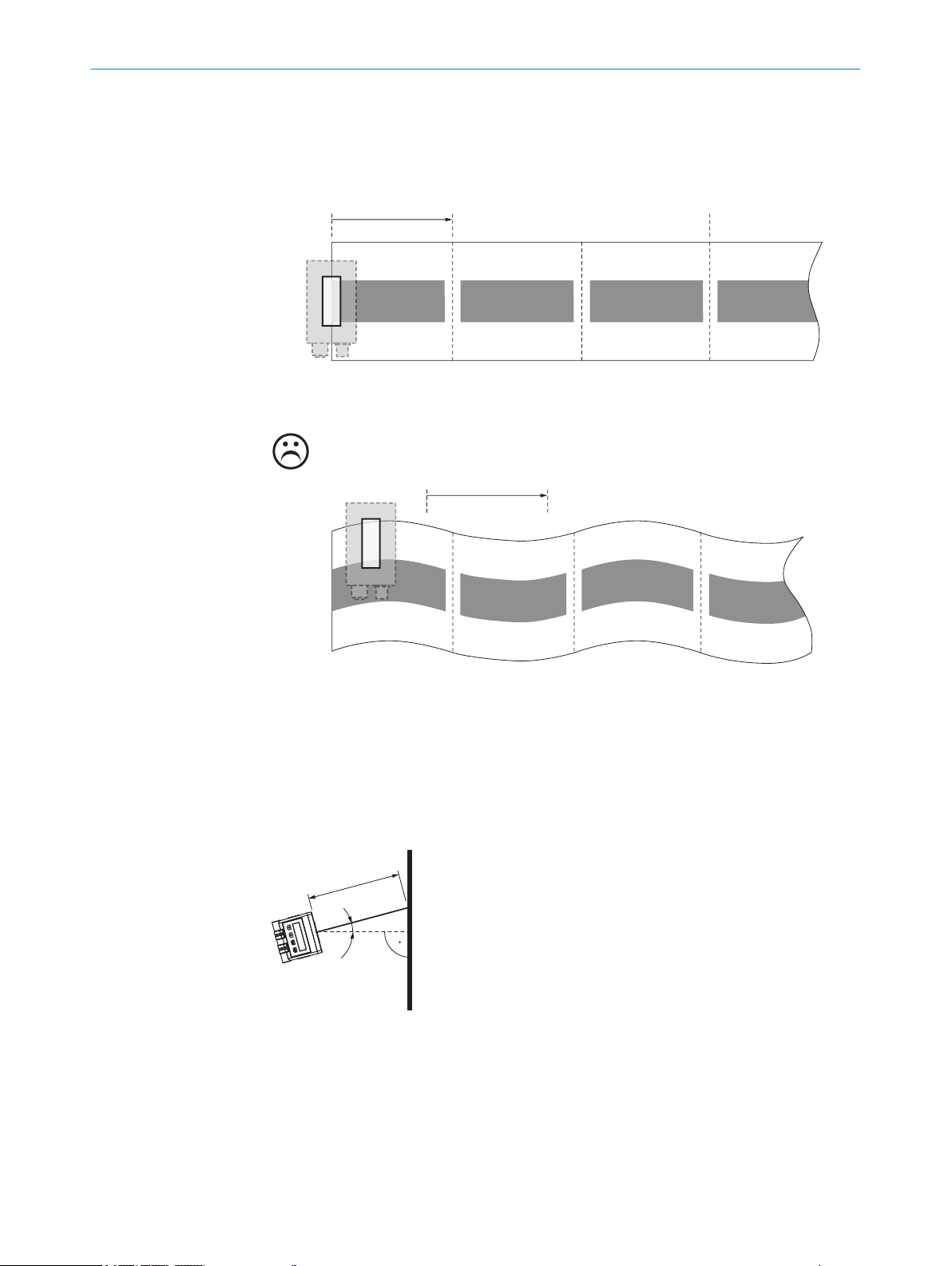

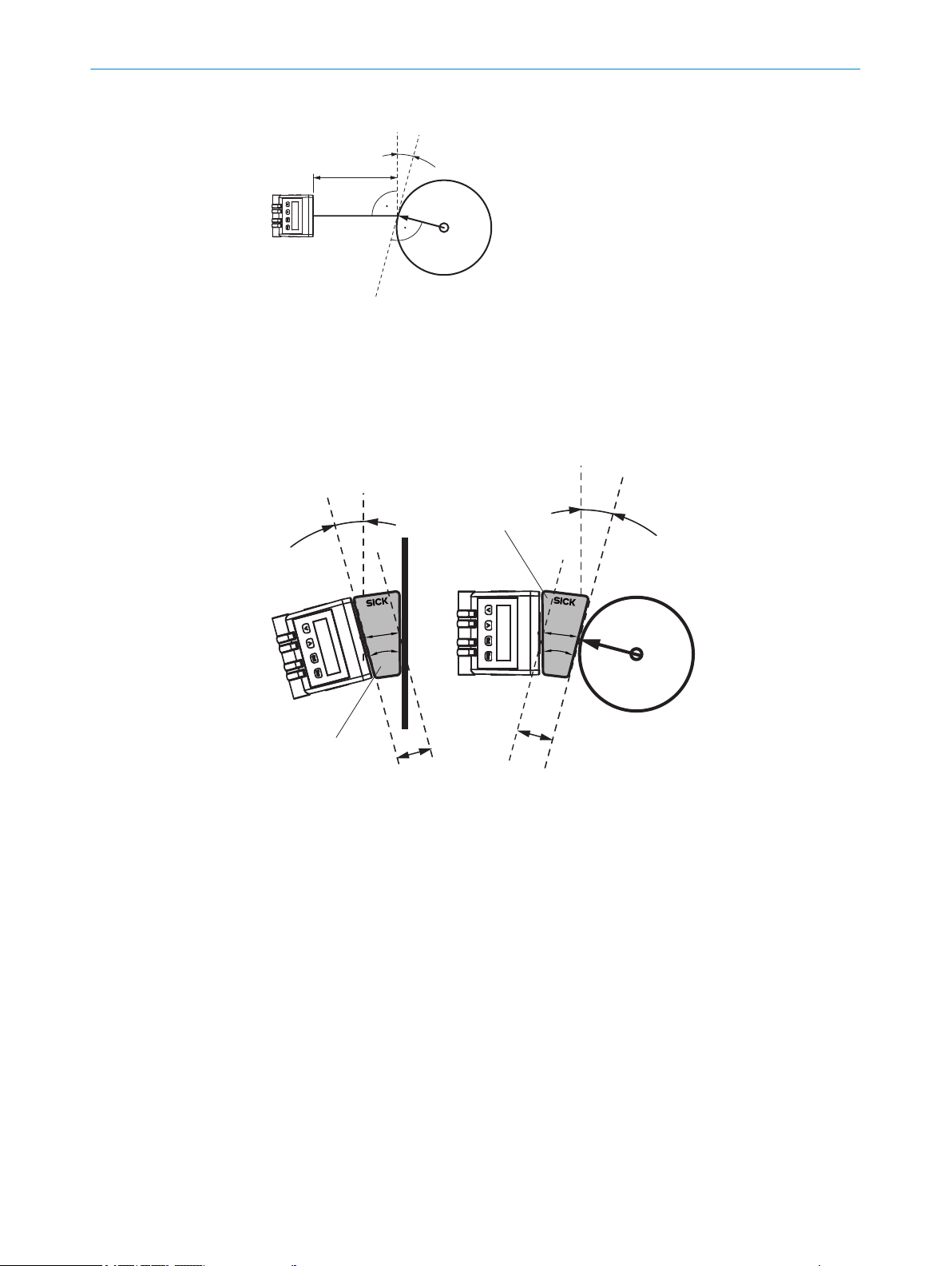

Arrangement when scanning rotary systems

α

1

α

α

1

1

2

3

2

3

4

4

Figure 12: Arrangement of the pattern sensor when scanning rotary systems

SD

1

α: 15° angle

SD: 20 mm sensing distance

Using the adjustment tool

MOUNTING 5

Figure 13: Using the adjustment tool

Adjustment tool

1

20 mm

2

15°

3

SD

4

5.3 Mounting the device

1. Select a mounting location for the pattern sensor (see "Mounting requirements",

page 17).

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

2. Mount the pattern sensor using the fixing holes (see "Technical data", page 63).

19

Page 20

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Notes on the electrical installation

NOTICE

Device damage due to incorrect supply voltage!

An incorrect supply voltage may result in damage to the device.

■

Only operate the device with safety/protective extra-low voltage (SELV/PELV).

■

The sensor is a device of protection class III.

NOTICE

Device damage due to incorrect supply voltage!

An incorrect supply voltage may result in damage to the device.

Only operate the device with an LPS (limited power source) in accordance with IEC

•

60950-1 or an NEC Class 2 power supply unit.

NOTICE

Device damage or unpredictable operation due to working with live parts!

Working with live parts may result in unpredictable operation.

■

Only carry out wiring work when the power is off.

■

Only connect and disconnect electrical connections when the power is off.

■

The electrical installation must only be performed by electrically qualified person‐

nel.

■

Standard safety requirements must be met when working on electrical systems!

■

Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

■

When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

■

Wire cross-sections in the supply cable from the user’s power system must be

selected in accordance with the applicable standards.

■

Only operate the device with an LPS (limited power source) in accordance with IEC

60950-1 or an NEC Class 2 power supply unit.

■

All circuits connected to the device must be designed as SELV/PELV circuits.

■

Operation in short-circuit protected network at max. 8 A.

NOTE

Layout of data cables

■

Use screened data cables with twisted-pair wires.

■

Implement the screening design correctly and completely.

■

To avoid interference, e.g., from switching power supplies, motors, clocked drives,

and contactors, always use cables and layouts that are suitable for EMC.

■

Do not lay cables over long distances in parallel with voltage supply cables and

motor cables in cable channels.

20

The IP enclosure rating for the device is only achieved under the following conditions:

■

The cables plugged into the connections are screwed tight.

■

Any other covers present must be closed and lie flush on the device.

If these instructions are not complied with, the IP enclosure rating for the device is not

guaranteed!

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 21

6.2 Wiring notes

ELECTRICAL INSTALLATION

NOTICE

Faults due to incorrect wiring!

Incorrect wiring may result in operational faults.

■

For data transmission, use only shielded cables with twisted-pair wires.

■

Follow the wiring notes precisely.

NOTE

Preassembled cables can be found online at:

www.sick.com/PS30

b

All electrical connections of the device are configured as M12 round connectors. The

enclosure rating is only achieved with screwed plug connectors or cover caps.

Please observe the following wiring notes:

■

A correct and complete cable shielding design is required for trouble-free data

transmission.

■

The cable shield must be connected at both ends in the control cabinet and at the

device. The cable shield of the pre-assembled cables is connected to the knurled

nut of the male/female connector and thus also to a large area of the device hous‐

ing.

■

The cable shield in the control cabinet must be connected to a large area of the

signal ground, see figure 17.

■

Appropriate measures must be taken to prevent equipotential bonding currents

flowing through the cable shield.

■

During installation, pay attention to the different cable groups. The cables are

grouped into the following four groups according to their sensitivity to interference

or radiated emissions:

6

Group 1: Cables very sensitive to interference, such as analog measuring

°

cables

Group 2: Cables sensitive to interference, such as sensor cables, communi‐

°

cation signals, bus signals

Group 3: Cables which are a source of interference, such as control cables

°

for inductive loads, motor brakes

Group 4: Cables which are powerful sources of interference, such as output

°

cables from frequency inverters, welding system power supplies, power

cables

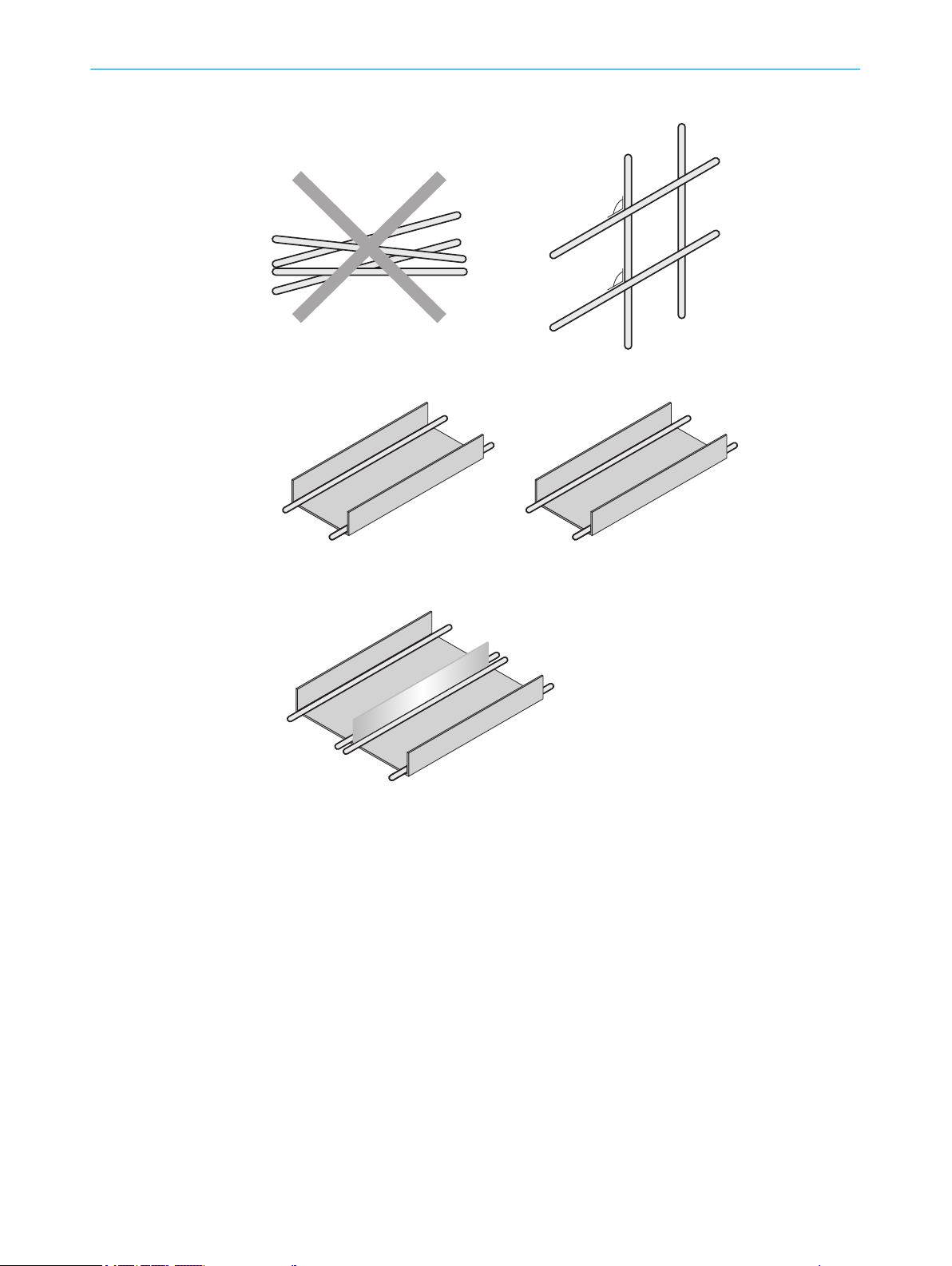

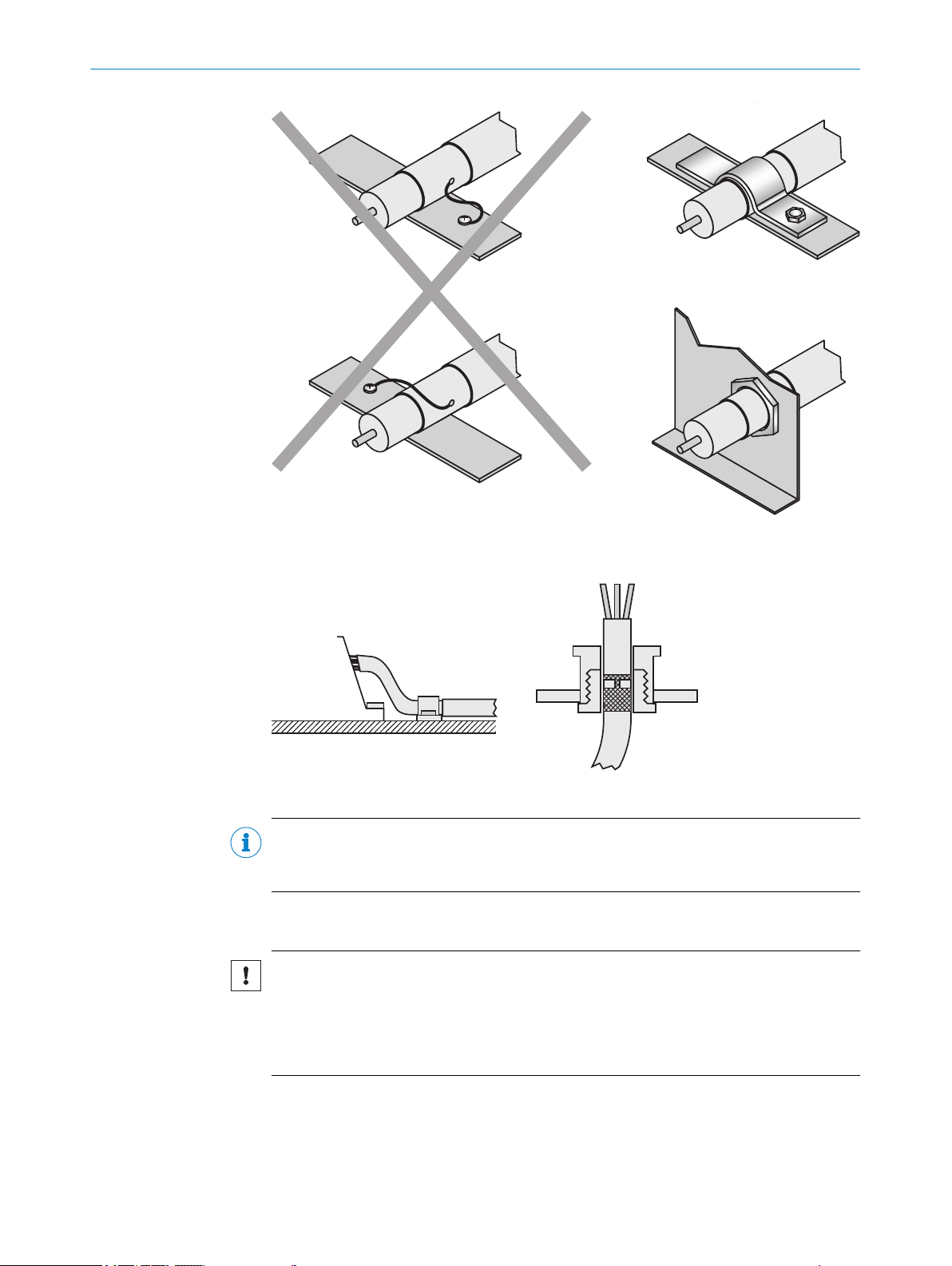

w

Cables in groups 1, 2 and 3, 4 must be crossed at right angles, see figure 14.

w

Cables in groups 1, 2 and 3, 4 must be routed in different cable channels or

metallic separators must be used, see figure 15 and see figure 16. This

applies particularly where cables of devices with a high level of radiated emis‐

sion, such as frequency converters, are laid parallel to sensor cables.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

21

Page 22

1

2

4

3

1

2

4

3

90

90

1

2

3

4

1

2

3

4

ELECTRICAL INSTALLATION

6

Figure 14: Cross cables at right angles

Figure 15: Ideal laying – Place cables in different cable channels

Figure 16: Alternative laying – Separate cables with metallic separators

22

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 23

ELECTRICAL INSTALLATION 6

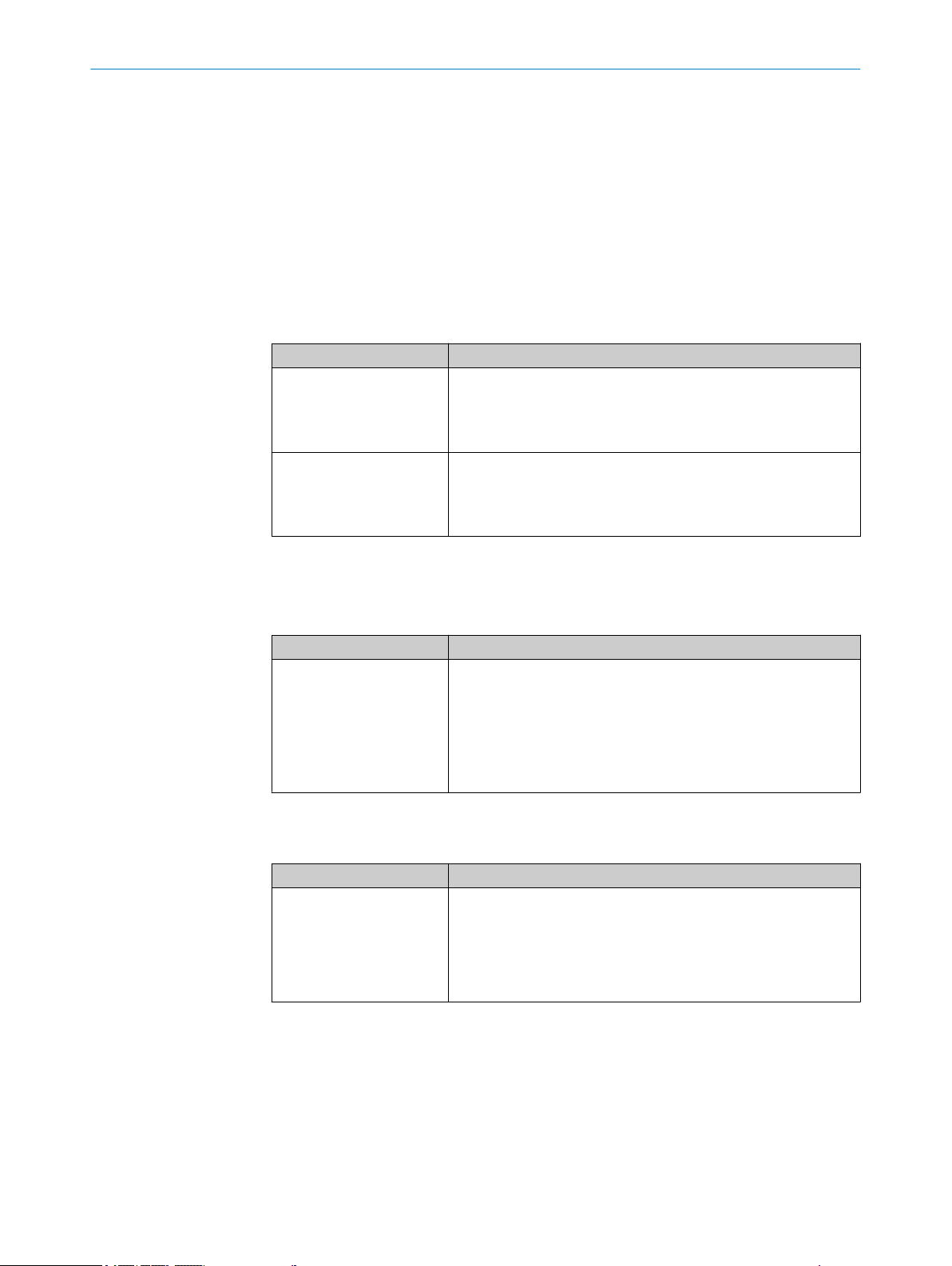

Figure 17: Make an extensive and low-impedance ground connection of the cable shield in the

control cabinet

Figure 18: Shield connection in plastic housings

NOTE

Prevent equipotential bonding currents via the cable shield with a suitable grounding

concept.

6.3 Note on the swivel connector

NOTICE

Damage to the connector unit from over-tightening!

The connector unit on the device has two opposite end positions.

■

Do not rotate the connector unit from either of the two end positions by more than

180°.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

23

Page 24

1

2

3

4 5

6

7

8

9

6 ELECTRICAL INSTALLATION

6.4 System configuration

The integration of the PS30 pattern sensor into the machine controller is shown in the

following figure. The information on the movement of the material does not necessarily

need to be provided by an encoder, the signal can of course also be created by a motor

feedback system or the controller.

Alternatively, the speed of the material can be stored as a constant. This alternative is

intended for applications with a constant or only slowly changing material speed.

The connection to an operating terminal is not essential, but is recommended to allow

the visually-supported operation and diagnostic features to be used. If no connection to

the HMI is provided, e.g., the device is operated via the display and operating elements

on the pattern sensor itself, a PC can, where necessary, be connected via Ethernet for

commissioning and/or service work, and to utilize the SOPASair configuration tool pro‐

vided on the web server.

Figure 19: Example system configuration

PC

1

SOPASair

2

Ethernet TCP/IP

3

OPC DA, JSON API

4

HMI

5

PLC

6

Function blocks

7

TTL/HTL

8

A machine cycle as the input signal, e.g., via an encoder or a motor feedback system

9

6.5 Connecting the device electrically

DANGER

Pre-assembled cables see "Technical data", page 63.

1. Ensure the voltage supply is not connected.

2. If necessary, turn the swivel connector into the desired position as shown in the

figure.

24

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 25

1

2

Figure 20: Rotate the swivel connector, establish the electrical connection

M12 (A-coded)

FE (shield)

L+

M

AT

1

2

brn

blu

3

wht

5

pnk

Enc B

4

grn

Enc ¯B

6

yel

Q

OUT

7

blk

nc

9

red

Status

OUT

10

vio

Enc A

11

gra/pnk

Enc ¯A

12

red/blu

ET

8

gra

1

nc

1

2

3

11

4

5

6

7

8

9

1

10

12

Supply voltage, external teach-in signal and, if applicable, encoder signal and switch‐

1

ing output

Ethernet

2

3. Connect the device according to the connection diagram.

6.6 Pin assignment of the connections

6.6.1 Pin assignment for supply voltage and encoder signals

ELECTRICAL INSTALLATION 6

Figure 22: Male connector, M12, 12-pin, Acoded

Figure 21: Connection diagram for supply volt‐

age, external teach-in signal, encoder signal and

switching output

nc: not connected

1

Table 4: Description of supply voltage male connector, external teach-in signal, encoder signal

and switching output

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

Pin Marking Wire color Description

1 L+ Brown Supply voltage: +12 … +30 V DC

2 M Blue Supply voltage: 0 V

3 nc White Not assigned (spare)

4 Enc B Green Encoder signal B

5 AT Pink Blanking input

6 Enc B(overline) Yellow Encoder signal B’

7 Q

OUT

Black Switching output (see "Technical

data", page 63)

8 ET Gray External teach-in signal

25

Page 26

Tx+

Rx+

Tx–

Rx–

1

2

4

wht/grn

ora

wht/ora

grn

3

M12 (D-coded)

3

2

4

1

6 ELECTRICAL INSTALLATION

Pin Marking Wire color Description

9 nc Red Not assigned (spare)

10 Status

11 Enc A Gray/pink Encoder signal A

12 Enc Ā Red/blue Encoder signal A’

6.6.2 Pin assignment for Ethernet

The pattern sensor is equipped with a 100Base-T Ethernet connection.

Figure 23: Ethernet connection diagram

Table 5: Ethernet female connector description

Pin Marking Wire color Description

1 Tx+ White/orange Send data signal, not inverted

2 Rx+ White/green Receive data signal, not

3 Tx- Orange Send data signal, inverted

4 Rx- Green Receive data signal, inverted

OUT

Violet Sensor status (see "Technical

data", page 63)

Figure 24: Female connector, M12, 4-pin, Dcoded

inverted

26

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 27

7 Commissioning

7.1 Pushbutton damage

NOTICE

Pushbutton damage due to improper handling

Improper handling of the pushbuttons can damage them. This will make operation diffi‐

cult or impossible.

For this reason:

Only operate the pushbuttons with your fingers or a suitable pointing device.

•

Do not operate the pushbuttons using sharp or hard objects.

•

7.2 Steps to take

1. Switch on the supply voltage. “RUN” appears on the display during initial commis‐

sioning. In this case, press the SET pushbutton for at least 2 seconds. “Setup”

appears on the display.

2. Set the parameters for the encoder (see "Setting up the encoder", page 27).

3. Select “Endless material” or “Single object” operating mode (see "Operating

modes", page 12).

4. If necessary, change the resolution (see "Settings menu", page 33).

5. Run the teach-in process and, if necessary, set identical areas for blanking.

You can choose between the following options for the teach-in process:

°

°

°

°

You can choose between the following options for blanking:

°

°

°

6. If necessary, set an offset for adjustment of the switching point:

°

°

COMMISSIONING 7

Manual start-length teach-in via the “Teach” menu, see "Teach menu",

page 37

Start-stop teach-in via an external teach-in signal, see "Executing start-stop

teach-in via an external teach-in signal", page 34

Start-length teach-in via an external teach-in signal, see "Executing start-

length teach-in via an external teach-in signal", page 35

Start-length teach-in via SOPASair or Ethernet , see "Integrating the PS30 pat‐

tern sensor in the network", page 45

Blanking via the “Blank” parameter in the Teach menu of the control panel

see "Blanking areas (Blank) parameter", page 40

Blanking via the AT input, see "Specifying image areas via an “AT” external

signal", page 42

Blanking via SOPASair or Ethernet, see "Teach-in menu", page 46

via the “Offset” menu item in the Teach menu of the control panel see

"Switching point offset (OffSet) parameter", page 39

via SOPASair or Ethernet, see "Teach-in menu", page 46

NOTE

Teach-in via an external signal always has priority over the other teach-in methods.

7.3 Setting up the encoder

NOTE

The encoder resolution (EncRes) must be between 100 μm ... 600 μm. If necessary,

use a configurable encoder. Provided the above encoder resolution range is adhered to,

you can also use an existing motor feedback system.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

27

Page 28

1

2

3

4

COMMISSIONING

7

Menu structure

For details of the menu structure, see "Menu structure", page 69.

Encoder settings

“Setup” is shown on the display during initial commissioning. During this setup, the

device will prompt for the settings of the encoder used. The following parameters must

be entered for the encoder:

“EncTyp” (encoder type)

•

“EncRes” (encoder resolution) → See the following section on calculating the

•

encoder resolution

“EncDir” (encoder direction)

•

If you are not using an encoder, accept the factory settings for these parameters. Fur‐

ther settings can be configured in SOPASair (see "Operation via SOPASair", page 45).

NOTE

To ensure a correct signal, the rotational direction during the teach-in process must

match the configured encoder direction.

Calculating the encoder resolution

Figure 25: Calculating the encoder resolution

U

1

S

2

n

3

Encoder

4

The graphic is provided as an example for the purposes of illustrating the encoder reso‐

lution. The roller geometry is not essential. The encoder resolution is the path covered

by the material from encoder bar to encoder bar.

The encoder resolution (EncRes) can be calculated using the following formula:

S = U/n

S: Encoder resolution

U = External circumference of the roller

n: Number of encoder bars in 360°

28

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 29

Setup menu encoder settings

Table 6: Setup menu encoder settings

Display Description

EncTyp Select the encoder type.

Options

TTL: 4.5 V ... 5.5 V, TTL / RS-422 (differential)

•

HTL: 12 V ... 30 V, HTL / push-pull

•

Factory setting

TTL

•

EncRes Set the encoder resolution.

Adjustment range

100 μm ... 600 μm (in 1 μm increments)

•

Factory setting

100 μm

•

EncDir Select the encoder direction.

Options

Auto: the direction is determined automatically at the beginning

•

of the teach-in process

CW: clockwise

•

CCW: counter-clockwise

•

Factory setting

Auto

•

COMMISSIONING 7

Figure 26: Clockwise direction of rotation Figure 27: Counter-clockwise direction of rota‐

tion

Running the Setup menu

“Setup” appears on the display.

1. Press the SET pushbutton. The “EncTyp” (encoder type) parameter is displayed.

2. Press the SET pushbutton. The current value is displayed.

3. Select the encode type using the arrow pushbuttons.

4. Press the SET pushbutton; the “EncRes” (encoder resolution) parameter is dis‐

played. The first digit on the left flashes.

5. Press the up arrow pushbutton to increase the digit. Press the down arrow push‐

button to decrease the digit.

6. Press the SET pushbutton. The next digit flashes.

7. Repeat steps 5 and 6 until the last digit has been set. The “EncDir” (encoder direc‐

tion) parameter is displayed.

8. Select the encoder direction using the arrow pushbuttons.

9. Press the SET pushbutton. The prompt “Store?” is displayed.

10. Perform one of the following steps:

Press the SET pushbutton to save all inputs for the encoder. The Monitor

°

menu is displayed.

Press the ESC pushbutton to cancel the process.

°

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

29

Page 30

Setup

EncTyp

EncRes

…

…

EncDir …

Store? Settng

1

2

3

1

2

COMMISSIONING

7

Figure 28: Setup during initial commissioning

Default setting: TTL

1

Range: TTL/ HTL

Description: The encoder type must be specified.

Default setting: 100 µm

2

Range: 100 μm ... 600 μm in 1 μm increments

Description: The encoder resolution must be specified.

Default setting: Auto

3

Range: Auto/ CW/ CCW

Description: The direction of rotation of the encoder must be specified.

NOTE

The encoder settings are retained even after a reset. You can change the encoder set‐

tings later in the “Setting” menu.

7.4 Operation without encoder or machine cycle

If no external encoder will be used, the speed can be stored as a constant via

SOPASair. For general information on using SOPASair, see "Operation via SOPASair",

page 45.

To store the speed of the material as a constant, open the following page in your web

browser: 192.168.100.100/velocity.

If the IP address of the sensor was changed, insert that value (in place of

192.168.100.100).

30

Figure 29: Appearance of the display when not using an encoder

Using an external encoder

1

Speed in mm/s

2

Proceed as follows:

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 31

COMMISSIONING 7

1. Deselect the checkbox.

2. Enter the material speed in mm/s.

Save the settings using “save changes”.

The PS30 will now use the stored speed.

The specified speed is stored in the udiEncEmulationVelocity variable. This can be

changed dynamically via TCP/IP. Any changes in speed can therefore be taken into con‐

sideration. For real-time conditions, we recommend using an encoder signal or machine

cycle.

For a detailed description of the Ethernet interface and information about

udiEncEmulationVelocity, see www.sick.com/PS30.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

31

Page 32

8 OPERATION

8 Operation

8.1 Pushbutton damage

NOTICE

Pushbutton damage due to improper handling

Improper handling of the pushbuttons can damage them. This will make operation diffi‐

cult or impossible.

For this reason:

Only operate the pushbuttons with your fingers or a suitable pointing device.

•

Do not operate the pushbuttons using sharp or hard objects.

•

8.2 Navigation

You can select a menu, parameter, option or value using the SET pushbutton and the

arrow pushbuttons. The menu path is specified in the relevant chapters of these

instructions.

For the overall menu structure and navigation (see "Menu structure", page 69).

8.3 Selecting an option

1. Select the desired parameter using the SET pushbutton and the arrow pushbut‐

tons.

2. Select the desired option using the arrow pushbuttons.

3. Perform one of the following steps:

°

°

4. Perform one of the following steps to return to the default display: Quality of Run:

°

°

8.4 Changing the value

1. Select the desired parameter using the SET pushbutton and the arrow pushbut‐

tons.

2. Press the SET pushbutton. The current value of the parameter is displayed. The

first digit on the left flashes.

3. Press the up arrow pushbutton to increase the digit. Press the down arrow push‐

button to decrease the digit.

4. Press the SET pushbutton to save the digit entered. The next digit flashes.

Press the ESC pushbutton to cancel the process.

5. Repeat steps 3 and 4 until the last digit is saved. The parameter name is dis‐

played.

6. Press the SET pushbutton repeatedly until the Quality of Run default display is

shown again. Alternatively, you can wait for approx. one minute. The display will

automatically switch back to the default display if no pushbuttons are pressed.

Press the SET pushbutton to save the change.

Press the ESC pushbutton to cancel the process. The parameter name is dis‐

played again.

Press the SET pushbutton repeatedly until the status display is displayed

again.

Wait for approx. one minute. The display will automatically switch back to the

status display if no buttons are pressed. Any settings you have made will also

be saved.

32

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 33

8.5 Settings menu

OPERATION 8

The Settings menu – displayed as

ration parameters listed below.

To access the parameters in the Settings menu, press SET then select the parameter

using the arrow pushbuttons.

The available options are selected by pressing SET followed by the arrow pushbuttons,

and confirmed by pressing SET.

8.5.1 Operating mode (Mode) parameter

Table 7: Operating mode (Mode) parameter

Parameter Description

Endl Endless material operating mode

Single Single object operating mode

Factory setting: Endl – Endless material

8.5.2 Encode type (EncTyp) parameter

Table 8: Encode type (EncTyp) parameter

Parameter Description

EncTyp Select the encoder type.

Settng – is used to configure the sensor configu‐

MEN

A web with recurring, connected patterns is moved past the pat‐

tern sensor. The switching point corresponds to the start of the

teach-in area. An offset can be used to shift the switching point.

Single, non-connected objects are moved past the pattern sensor.

The switching point corresponds to the end of the taught-in object

area. An offset can be used to shift the switching point.

Options

TTL: 4.5 V ... 5.5 V, TTL / RS-422 (differential)

•

HTL: 12 V ... 30 V, HTL / push-pull

•

Factory setting

TTL

•

8.5.3 Encode resolution (EncRes) parameter

Table 9: Encode resolution (EncRes) parameter

Parameter Description

EncRes Set the encoder resolution

Adjustment range

100 ... 600 μm (in 1 μm increments)

•

Factory setting

100 μm

•

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

33

Page 34

OPERATION

8

8.5.4 Encoder direction (EncDir) parameter

Table 10: Encoder direction (EncDir) parameter

Parameter Description

EncDir Select the encoder direction

8.5.5 External teach-in (ETeach) parameter

Table 11: External teach-in (ETeach) parameter

Option Description

Start-stop teach-in (StaSto) The rising signal edge at the input starts the teach-in process, the

Start-length teach-in

(StaLen)

Options

Auto:

•

CW: clockwise

•

CCW: counter-clockwise

•

Factory setting

Auto

•

falling signal edge ends the teach-in process. About teach-in: see

"Executing start-stop teach-in via an external teach-in signal",

page 34

The rising signal edge at the input starts the teach-in process. The

teach-in process is automatically ended by the sensor after the

teach-in length entered as a parameter is reached. About teach-in:

see "Executing start-length teach-in via an external teach-in sig‐

nal", page 35

Factory setting: StaSto – Start-stop teach-in

8.5.5.1 Executing start-stop teach-in via an external teach-in signal

Prerequisite: The encoder settings, the operating mode, and the resolution have been

configured.

1. Press and hold the SET pushbutton for at least 2 seconds to access the “Monitr”

menu.

2. Select the “StaSto” option.

Menu path: Status display → SET→ Monitr → Arrow pushbuttons → Setting → SET →

Mode → Arrow pushbuttons → ETeach → SET → StaSto

3. Position the light spot at a significant point on the print image. This point later

becomes the start point. When using the Endless material operating mode, the

start point corresponds to the switching point.

4. Apply an external voltage signal to the “ET” input. The teach-in process starts. The

current point is saved as the start point.

5. Pass a maximum of one object length/format length through the light spot in the

rotational direction of the encoder with positional accuracy. Note that to ensure a

correct signal, the rotational direction during the teach-in process must match the

configured encoder direction (EncDir).

6. Remove the external voltage signal from the “ET” input. The current point is saved

as the end point. The stop point is the switching point when in Single object oper‐

ating mode. The teach-in process ends. The display shows the message “Busy”.

7. When using the Endless material operating mode, continue moving formats

through the light spot until the message “Busy” disappears. When using the Single

object operating mode, no further objects are required. The calculation of the

teach-in image and the reference areas is performed while the message “Busy” is

displayed. Once the teach-in process is complete, the quality of the teach-in

process is displayed as a bar graph:

34

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 35

If 3 or more bars are flashing: the teach-in process was successful.

°

If fewer than 3 bars are flashing: check whether the signal is switching cor‐

°

rectly. If the signal is not switching correctly, the teach-in process must be

repeated.

8. The bar graph flashes for another 10 format lengths, then the display automati‐

cally changes to the “Quality of Run” status display. The bar graph indicating the

process quality no longer flashes. The RUN symbol is displayed.

Requirements

Note the “Minimum format length”, “Maximum format length” and “Minimum for‐

•

mat height” technical data, see "Technical data", page 63.

The light spot must cover a significant area on the print image. Select an area with

•

high contrast differences and unique features as the significant area, see "Mount‐

ing requirements", page 17.

The sensing distance (distance from the front edge of the sensor to the object)

•

and the angle of the pattern sensor to the image must be adhered to, see "Mount‐

ing requirements", page 17.

Avoid fluctuations in distance and height.

•

Teach in a maximum of a complete format length/object length.

•

8.5.5.2 Executing start-length teach-in via an external teach-in signal

OPERATION

8

Prerequisite: The encoder settings, the operating mode, and the resolution have been

configured.

1. Press and hold the SET pushbutton for at least 2 seconds to access the “Monitr”

menu.

2. Select the “StaLen” option.

Menu path: Status display → SET→ Monitr → Arrow pushbuttons → Setting → SET →

Mode → Arrow pushbuttons → ETeach → SET → StaSto →Arrow pushbuttons →

StaLen

3. Press the SET pushbutton. The currently entered object length/format length is

displayed.

4. Press the SET pushbutton. The first digit on the left flashes.

5. If necessary, change the value, see "Changing the value", page 32.

6. Position the light spot at a significant point on the print image. This point later

becomes the start point. When using the Endless material operating mode, the

start point corresponds to the switching point.

7. Apply an external voltage pulse to the “ET” input. The teach-in process starts at

the rising signal edge. The current point is saved as the start point.

8. Pass the format or object through the light spot in the rotational direction of the

encoder with positional accuracy. Note that to ensure a correct signal, the rota‐

tional direction during the teach-in process must match the configured encoder

direction (EncDir).

9. After the entered teach-in length has run through, the teach-in process stops auto‐

matically. When using the Single object operating mode, the end point of the

teach-in process corresponds to the switching point.

10. When using the Endless material operating mode, continue moving formats

through the light spot until the message “Busy” disappears. When using the Single

object operating mode, no further objects are required. The calculation of the

teach-in image and the reference areas is performed while the message “Busy” is

displayed. The quality of the teach-in process is shown as a bar graph on the dis‐

play:

If 3 or more bars are flashing: the teach-in process was successful.

°

If fewer than 3 bars are flashing: check whether the signal is switching cor‐

°

rectly. If the signal is not switching correctly, the teach-in process must be

repeated.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

35

Page 36

8 OPERATION

11. The bar graph flashes for another 10 format lengths, then the display automati‐

cally changes to the “Quality of Run” status display. The bar graph indicating the

process quality no longer flashes. The RUN mode is displayed.

Requirements

Note the “Minimum format length”, “Maximum format length” and “Minimum for‐

•

mat height” technical data, see "Technical data", page 63.

The light spot must cover a significant area on the print image. Select an area with

•

high contrast differences and unique features as the significant area, see "Mount‐

ing requirements", page 17.

The sensing distance (distance from the front edge of the sensor to the object)

•

and the angle of the pattern sensor to the image must be adhered to, see "Mount‐

ing requirements", page 17.

Avoid fluctuations in distance and height.

•

Teach in a maximum of one format length/object length.

•

8.5.6 Ethernet configuration (Ethern) parameter

NOTE

Changes to the “Ethern” parameter are not adopted until the device is restarted.

Set the Ethernet configuration using the “Ethern” parameter.

For more information about the Ethernet interface, see "Operation via SOPASair",

page 45.

For the menu structure and navigation, see see "Menu structure", page 69.

Table 12: Ethern parameter

Parameter Description

IPAdr Enter an IP address.

Factory setting

MSB: 192

•

Byte 2: 168

•

Byte 1: 100

•

LSB: 100

•

SubMas Enter IP network mask.

Factory setting

MSB: 255

•

Byte 2: 255

•

Byte 1: 255

•

LSB: 0

•

D gate Enter default gateway.

Factory setting

MSB: 0

•

Byte 2: 0

•

Byte 1: 0

•

LSB: 0

•

Table 13: “Ethern” parameter - default values

Parameter Description

DHCP Factory setting: Deactivated.

MAC ID Individual address

36

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 37

Entering IPAdr, SubMas, DHCP, MAC ID and D gate

The “IPAdr”, “SubMas” and “D gate” parameters are entered in an identical manner.

Entry for the IP address is described here.

1. Select the “IPAdr” parameter under “Ethern”.

2. Press the SET pushbutton. The current value for the “Most significant byte” is dis‐

played. The first digit on the left flashes.

3. Press the up arrow pushbutton to increase the digit. Press the down arrow push‐

button to decrease the digit.

4. Press the SET pushbutton to save the digit entered. The next digit flashes.

5. Repeat steps 3 and 4 until the last digit is saved. The value of the next byte is dis‐

played.

6. Repeat steps 3 to 5 for the second, third and fourth byte (least significant byte).

7. After you have set the value of the fourth byte by pressing the SET pushbutton, the

“IPAdr” parameter is displayed.

8.5.7 Device reset (Reset) parameter

Performing a reset

Table 14: Device reset (Reset) parameter

Parameter Description

Reset Perform a reset.

Options

Yes: Perform a reset.

•

No

•

Factory setting

No

•

OPERATION 8

1. Select the “Reset” parameter in the “Settng” menu (see "Settings menu",

page 33).

2. Press the SET pushbutton.

3. Select the “yes” option.

4. Press the SET pushbutton to reset the device to its initial state. Press the ESC

pushbutton to cancel the process.

8.6 Teach menu

The Teach menu – displayed as

teach-in via the control panel. It can also be used to configure a switching point offset

and blanking areas for manual and external teach-in.

To access the parameters in the Teach menu, press SET then select the parameter

using the arrow pushbuttons.

The available options are selected by pressing SET followed by the arrow pushbuttons,

and confirmed by pressing SET.

8.6.1 Manual start-length teach-in via the control panel (StaLen) parameter

Requirements

Note the “Minimum format length”, “Maximum format length” and “Minimum for‐

•

mat height” technical data (see "Technical data", page 63).

The light spot must cover a significant area on the print image. Select an area with

•

high contrast differences and unique features as the significant area (see "Mount‐

ing requirements", page 17).

Teach – is used to execute the manual start-length

MEN

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

37

Page 38

OPERATION

8

The sensing distance (distance from the front edge of the sensor to the object)

•

and the angle of the pattern sensor to the image must be adhered to (see "Mount‐

ing requirements", page 17).

Avoid fluctuations in distance and height.

•

Teach in a maximum of one format length or object length.

•

StaLen parameter

Table 15: StaLen parameter

Value / option Description

Length Enter the length of the teach-in area in mm. Use a maximum of

the format length or object length as the teach-in length.

Currently entered format

length

START? Set the start point for the teach-in process.

Busy When using the Single object operating mode, move one object

Displays the currently entered length of the teach-in area. Confirm

or change the current length of the teach-in area.

Input range

15 mm ... 1,000 mm

•

Factory setting

240 mm

•

past the sensor; no further objects are required for the teach-in.

When using the Endless material operating mode, continue mov‐

ing patterns through the light spot until the message “Busy” disap‐

pears.

Performing start-length teach-in

Prerequisite: The encoder settings, the operating mode, and the resolution have been

configured.

1. Press and hold the SET pushbutton for at least 2 seconds to access the “Monitr”

menu.

2. Select the “StaLen” parameter.

Menu path: Status display→ SET→ Monitr → Arrow pushbuttons → Teach → SET →

StaLen

3. Press the SET pushbutton. The currently entered format length is displayed.

4. Press the SET pushbutton. The first digit on the left flashes.

5. If necessary, change the value, see "Changing the value", page 32.

6. Repeat step 5 until the last digit is saved. The “Start?” parameter is displayed.

7. Position the light spot at a significant point on the print image. This point later

becomes the start point. When using the Endless material operating mode, the

start point corresponds to the switching point.

8. Press the SET pushbutton. The point is saved as the start point. The display shows

the message “Busy”.

9. When using the Single object operating mode, move the object past the sensor.

The stop point of the teach-in process corresponds to the switching point in Single

object operating mode.

When using the Endless material operating mode, continue moving formats

through the light spot until the message “Busy” disappears. The quality of the

teach-in process is shown as a bar graph on the display:

If 3 or more bars are flashing: the teach-in process was successful.

°

If fewer than 3 bars are flashing: check whether the signal is switching cor‐

°

rectly. If the signal is not switching correctly, the teach-in process must be

repeated, see "Manual start-length teach-in via the control panel (StaLen)

parameter", page 37.

38

O PE R AT I NG IN S TR U CT I ON S | PS30 8018916.ZYN1/2018-05-17 | SICK

Subject to change without notice

Page 39

10. The bar graph flashes for another 10 format lengths, then the display automati‐

1 2

3

1 2

3

cally changes to the “Quality of Run” status display. The bar graph indicating the

process quality no longer flashes. The RUN symbol is displayed.

8.6.2 Switching point offset (OffSet) parameter

NOTE

If an offset is required, it must be entered after the areas to be blanked are set.

The offset is reset to 0 mm after every new teach-in.

OPERATION 8

Figure 30: Setting the offset (switching point shift) for Endless material operating mode

Teach Stop

1

Teach Start

2

Offset

3

Figure 31: Setting the offset (switching point shift) for Single object operating mode

Teach Stop

1

Teach Start

2

Offset

3

Offset parameter

You can shift the switching point for the “Q” switching output using the Offset parame‐

ter.

For the menu structure and navigation, see "Menu structure", page 69.

8018916.ZYN1/2018-05-17 | SICK O P ER A TI N G I NS T RU C TI O NS | PS30

Subject to change without notice

39

Page 40

www.sick.com

1 32

8 OPERATION

Table 16: Offset parameter

Parameter Description

Offset Shifts the switching point for the “Q” switching output to the

desired position. In Endless material operating mode, the start

point of the teach-in process is used as the switching point; in Sin‐

gle object operating mode, the stop point of the teach-in process

is used as the switching point.

Adjustment range

0 mm … taught-in format length in mm

•

Factory setting

0 mm

•

Setting the offset

Prerequisite: The encoder settings, the operating mode, and the resolution have been

configured.

1. Press and hold the SET pushbutton for at least 2 seconds to access the “Monitr”

menu.

2. Select the “Offset” parameter.

Menu path: Status display → SET→ Monitr → Arrow pushbuttons → Teach → SET →

StaLen→ Arrow pushbuttons → Offset

3. Press the SET pushbutton. The currently entered offset is displayed.