SICK Profiler 2, PRO2-N100B25A1, 6052874, PRO2-P100B25A1, 6052873 Operating Instructions Manual

Page 1

Proler™ 2

SHORT RANGE DISTANCE SENSOR

OPERATING INSTRUCTIONS

Page 2

Copyright protection!

This work is copyright-protected. The rights founded by

this shall remain with company SICK AG. Reproduction

of the work or parts of this work shall only be permissible

within the limits of the legal provisions of copyright law.

Changes and abbreviations of this work are prohibited

without the express written agreement of SICK AG.

2 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 3

Table of contents

1 Introduction ........................................................................................ 8

1.1 Warranty .....................................................................................8

2 Safety Precautions............................................................................. 9

2.1 Safety Precaution Symbols ....................................................... 9

2.2 Mandatory Precautions .............................................................9

2.3 Precautions for Laser Use ...................................................... 10

2.3.1 Installation Precautions.......................................... 10

2.4 Warning Labels ....................................................................... 11

3 Information Before Use ................................................................... 12

3.1 General Description ................................................................ 12

3.2 Package Contents ................................................................... 13

3.2.1 Included Items ........................................................ 13

3.2.2 Options .................................................................... 13

3.3 Names and Functions of Parts .............................................. 14

3.3.1 Sensor ..................................................................... 14

3.3.2 Laser Emission and Measurement Ranges .......... 15

3.3.3 Cable Wire Colors and Roles .................................. 16

3.4 Installation .............................................................................. 17

3.4.1 Notes for installation .............................................. 17

3.4.2 Installing the Sensor ............................................... 17

4 Setup and Measurement Procedures ............................................. 18

4.1 Before Using the Proler 2 ..................................................... 18

4.1.1 Procedure for Using the Sensor ............................. 18

4.1.2 Setup and Measurement Process ......................... 19

4.2 Quick Setup ............................................................................. 20

4.2.1 Basic Measurement Settings ................................. 20

4.2.2 Return to Main Menu/Measurement Screen ........ 21

4.2.3 Initialize Settings ..................................................... 22

5 Operating the Sensor ....................................................................... 23

5.1 Sensor Screen ......................................................................... 23

5.1.1 Details of the Screen .............................................. 23

5.1.2 Screen Types and Switching Between Screens .... 24

5.1.3 Key Lock Function ................................................... 25

5.2 Main Screen ............................................................................ 25

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 3

Page 4

5.2.1 Main ......................................................................... 25

5.2.2 Input/Trigger ........................................................... 26

5.2.3 Storage .................................................................... 27

5.2.4 Other ........................................................................ 30

5.3 Setting ..................................................................................... 32

5.3.1 Camera .................................................................... 32

5.3.2 Prole ....................................................................... 35

5.3.3 Area .......................................................................... 38

5.4 Graph/Calc .............................................................................. 40

5.4.1 Graph Items (Area 1 to area 4) .............................. 41

5.4.2 Calc Items (Calculation 1 and calculation 2) ........ 42

5.5 Output ...................................................................................... 43

5.5.1 Output Items (OUT1 to OUT3) ................................ 44

5.5.2 Output Items (OUTA) ............................................... 45

6 PRO2-Navigator Setup Software ..................................................... 47

6.1 Setup Software Requirements ............................................... 47

6.1.1 Operating Environment ........................................... 47

6.2 Software Setup ....................................................................... 48

6.2.1 Installing the Driver ................................................. 48

6.2.2 Install the Software................................................. 49

6.2.3 Settings for High-speed Communication .............. 50

6.3 PRO2-Navigator Screen and Operating ................................. 51

6.3.1 Start PRO2-Navigator .............................................. 51

6.3.2 Main Screen (Measurement Screen) .................... 51

6.3.3 Common Setup ....................................................... 53

6.3.4 How to Change Settings ......................................... 54

6.4 Setup Procedure ..................................................................... 55

6.4.1 Connecting to the Sensor Head ............................. 55

6.4.2 Input/Trigger Settings ............................................. 56

6.4.3 Camera Settings ..................................................... 57

6.4.4 Prole Settings ........................................................ 59

6.4.5 Area Settings ........................................................... 61

6.4.6 Calculation Settings ................................................ 63

6.4.7 Output Settings ....................................................... 64

6.5 Storage Function ..................................................................... 65

4 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 5

6.5.1 Storage Settings ...................................................... 65

6.5.2 Data storage ............................................................ 66

6.5.3 Prole storage ......................................................... 67

7 Functions .......................................................................................... 69

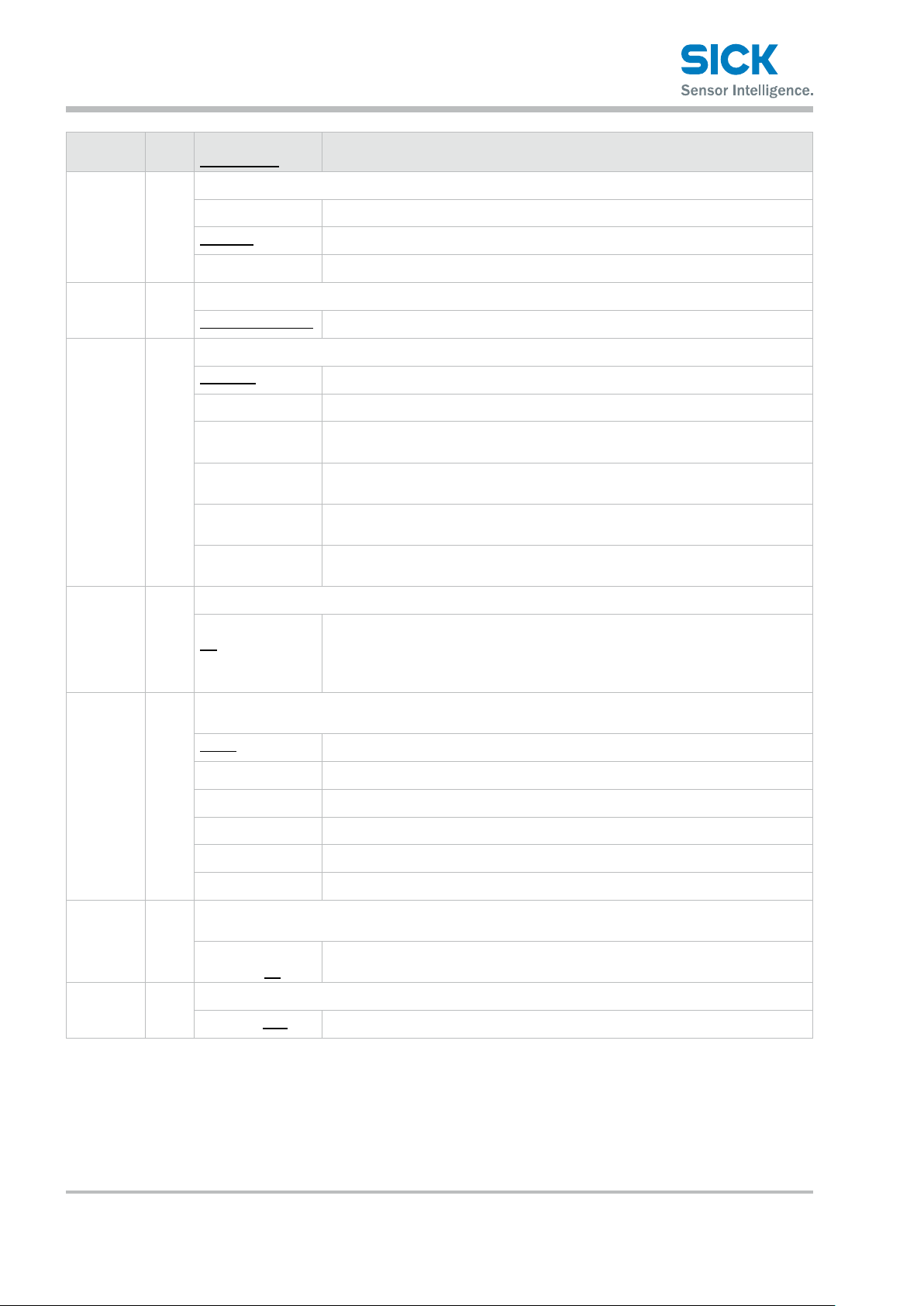

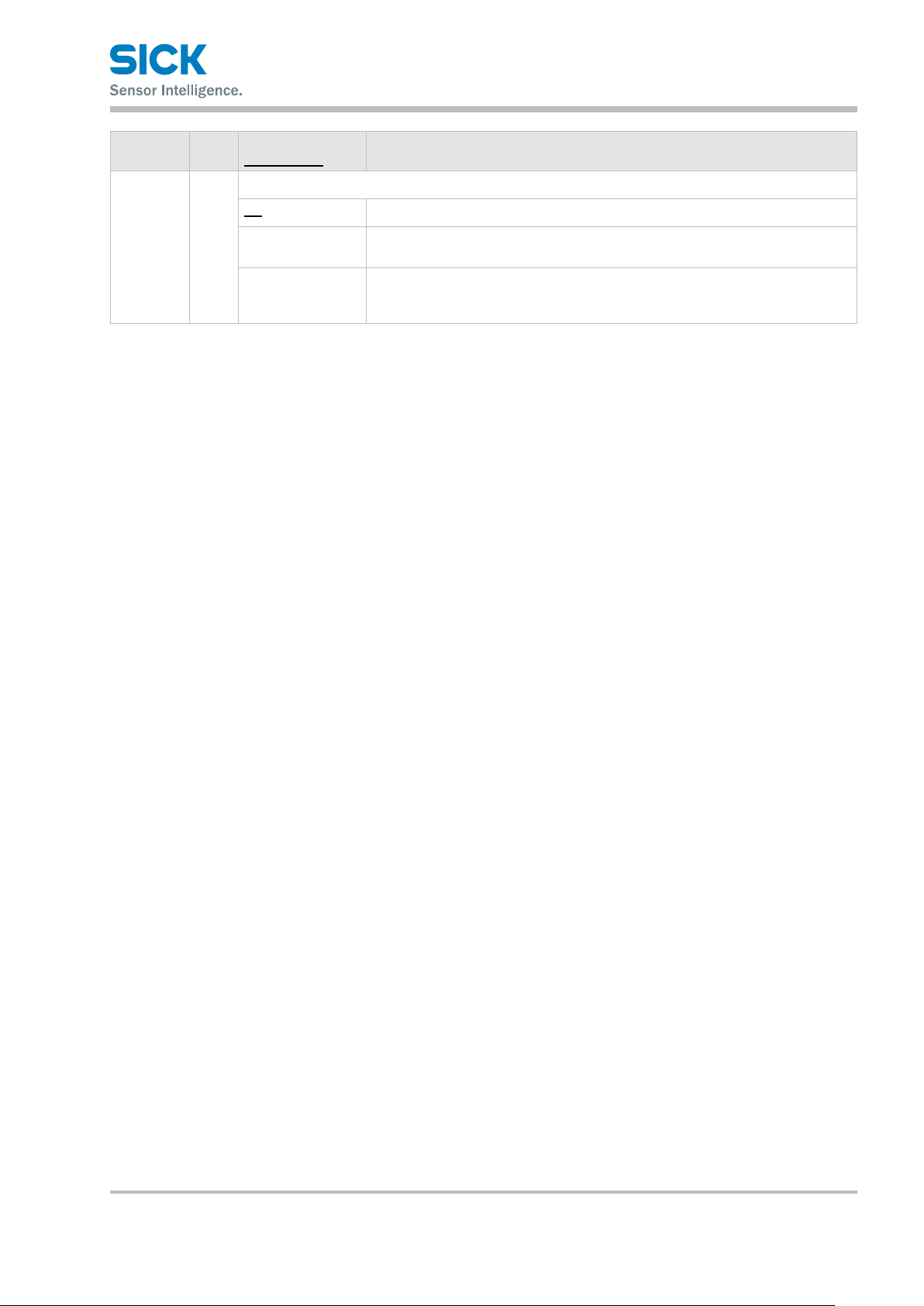

7.1 Settings Lists and Factory Settings ....................................... 69

7.2 Input/Trigger Settings ............................................................. 74

7.2.1 IN1/IN2/IN3/IN4 .................................................... 74

7.2.2 Reset/Inner hold/Inner trig .................................... 74

7.2.3 Input polar, Inp lter ................................................ 75

7.2.4 Trig action ................................................................ 75

7.2.5 Oset target ............................................................ 75

7.3 Storage Settings ..................................................................... 76

7.3.1 Storage .................................................................... 76

7.3.2 Start cond ................................................................ 76

7.3.3 Intermittent ............................................................. 77

7.3.4 Repeat ..................................................................... 77

7.4 Camera Settings ..................................................................... 78

7.4.1 Camera Mode ......................................................... 78

Operation of the camera mode ................................................................ 80

Mandatory settings when using HDR ..................................................... 82

7.4.2 Image Brightness (Shutter Time and Gain) ........... 83

7.4.3 Camera Range ........................................................ 84

7.4.4 Received Light Waveform and Measurements ..... 85

7.5 Prole Settings ........................................................................ 86

7.5.1 Prole Extraction Settings ...................................... 86

7.5.2 Save Master ............................................................ 89

7.5.3 Prole Correction .................................................... 90

7.6 Area Settings ........................................................................... 95

7.6.1 Measurement Areas ............................................... 95

7.6.2 Measurement functions ......................................... 96

7.7 Calculation Settings .............................................................. 100

7.7.1 Average ..................................................................100

7.7.2 Hold........................................................................ 100

7.7.3 Span....................................................................... 101

7.7.4 Calculation Formulas ............................................101

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 5

Page 6

7.8 Output Settings ..................................................................... 102

7.8.1 Out target .............................................................. 102

7.8.2 Thresholds and Output ......................................... 102

7.8.3 Out action .............................................................. 104

7.8.4 Oset/Oset Value ............................................... 105

7.8.5 Analog Output Range ............................................ 107

7.9 Common Settings ................................................................. 108

7.9.1 Banks .....................................................................108

7.9.2 Baud rate ...............................................................108

7.9.3 Axis dir ................................................................... 109

7.9.4 On Timing .............................................................. 109

7.9.5 Lang/言語 .............................. 109

7.9.6 Screen Saver ......................................................... 110

7.9.7 Brightness .............................................................110

7.9.8 Initialize .................................................................110

7.9.9 Version ...................................................................110

8 Serial Communication ................................................................... 111

8.1 Communication Specications ............................................ 111

8.1.1 Communication Specications ............................111

8.1.2 Timing Chart During Communication ..................111

8.1.3 Command Format ................................................. 112

8.2 How to Acquire Measured Values ........................................ 113

8.2.1 Commands for Acquiring Measured Values ........ 113

8.2.2 Communication Command Examples ................. 113

8.3 How to Acquire Proles ......................................................... 114

8.3.1 Commands for Acquiring Prole Data ................. 114

8.3.2 How to Acquire Prole Data .................................. 114

8.4 Storage Data Acquisition Method ........................................ 116

8.4.1 Commands for Acquiring Storage Data ............... 116

8.4.2 How to Acquire Storage Data ............................... 117

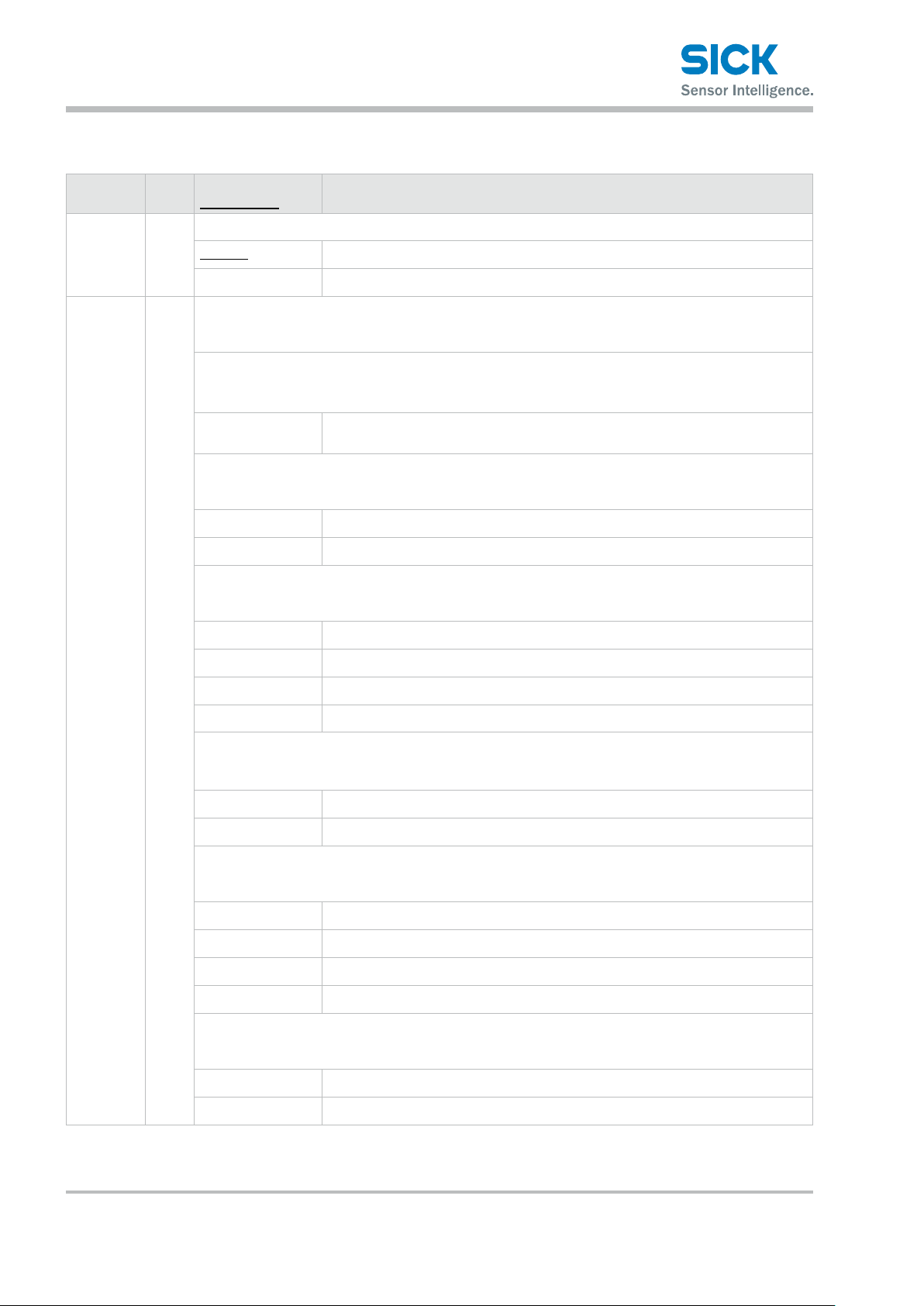

8.5 Setting Acquisition and Change Commands ......................119

8.5.1 Communication Command Examples ................. 119

8.5.2 Writing Settings to EEPROM ................................. 120

8.5.3 Camera Settings ...................................................120

8.5.4 Prole Settings ...................................................... 122

6 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 7

8.5.5 Area Settings ......................................................... 123

8.5.6 Calculation Settings ..............................................125

8.5.7 Output Settings ..................................................... 127

8.5.8 Input Settings ........................................................ 130

8.5.9 Storage Settings .................................................... 131

8.5.10 Other Settings ....................................................... 133

9 Specications.................................................................................134

9.1 Specications ........................................................................134

9.2 Connection diagram ............................................................. 135

9.2.1 Input Circuit Diagram ............................................ 135

9.3 Dimensions ........................................................................... 136

9.4 Timing Charts ........................................................................ 137

9.4.1 Measurement ........................................................137

9.4.2 I/O .......................................................................... 139

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 7

Page 8

Introduction

1 Introduction

1.1 Warranty

Before using this product, conrm that the product you have received is the

product that you requested.

• Read this manual thoroughly, and then keep this manual at hand so that

it can be used whenever necessary.

• If you lose this manual or if you have any questions regarding the

contents contained herein, contact our distributor from whom you purchased the product or download PDF from www.sick.com.

• Trademarks and registered trademarks appearing in this manual are the

property of their respective owners.

• The copyright of this manual is owned by SICK AG. All the contents

contained herein are protected by copyright law. Unauthorized copying of

this manual is strictly prohibited.

SICK AG products have undergone strict inspections. However, should your

product malfunction, conrm the symptoms of the malfunction, and then

contact our distributor from whom you purchased the product.

• The warranty period of this product is 1 year from the time of purchase.

• If a malfunction occurs attributable to the manufacturer, the product will

be replaced free of charge (a replacement will be sent).

However, the following cases are not covered by the warranty.

1. Malfunction caused by improper handling or usage.

2. Malfunction caused by something other than this product.

3. Malfunction caused by unapproved modications or repairs.

4. Malfunction caused by a natural disaster.

The warranty described here is limited to the delivered product.

SICK AG accepts no responsibility for any subsequent damages caused

by a product malfunction.

8 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 9

2 Safety Precautions

Read this manual carefully to ensure safe and correct use of this product.

This manual contains safety precautions that are designed to protect your

health and property as well as the health and property of any other users

of this product. Follow the installation and operating procedures described

in this manual, and do not use this product in any manner not described

herein.

2.1 Safety Precaution Symbols

Safety Precautions

WARNING

Indicates that incorrect use may lead to a hazardous

situation resulting in injury or death.

CAUTION

2.2 Mandatory Precautions

Indicates that incorrect use may lead to a hazardous

situation resulting in injury or property damage.

WARNING

• Do not look directly at the laser beam or intentionally

shine the laser beam in another person’s eyes. Doing

so may cause eye damage.

• This product cannot be used as protective equipment

for the purpose of protecting the human body.

• Disassembling or modifying this product may cause

injury, re, or electric shock.

• If you detect smoke or a strange odor during operation,

stop operating the product, and then stop the power

supply. If repairs are necessary, inform the distributor

that you purchased the product from.

• Use the product with the voltage indicated in the

specications.

• Do not touch the product or its cable with wet hands.

Doing so may lead to electric shock.

• Do not perform wiring while the power supply is on.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 9

Page 10

Safety Precautions

2.3 Precautions for Laser Use

WARNING!

• This product emits a Class 2 (II) visible laser beam that

is compliant with JIS/IEC/FDA laser safety standards.

• A Class 2 (II) warning and explanation label is axed

to the sides of this product.

• If you install this product in a piece of machinery that

will then be exported to the United States, you rst

need the approval of the American Food and Drug

Administration (FDA).

• If you install this product in your own equipment, clearly

indicate to the end user that this is a laser product and

provide explanations that ensure correct handling of

the product.

2.3.1 Installation Precautions

WARNING!

• Installing this product in a location with any of the

following conditions may lead to re, electric shock,

or malfunction:

• High humidity

• High temperatures caused by direct sunlight, etc.

• Very dusty

• Poor ventilation

• High static electricity

• Corrosive or ammable gas is present

• Product is exposed to liquids such as water, oil,

and chemicals

• Product is directly subjected to vibration or shock

• Leave the power supply o during wiring.

CAUTION

• Avoid wiring in parallel with or in the same piping

as high-voltage wires or power lines.

Doing so may lead to malfunctions caused by noise.

Also, shorten the power supply and signal wires as

much as possible.

• Be careful to avoid damaging the cables by pulling

on or applying unnecessary force on them.

10 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 11

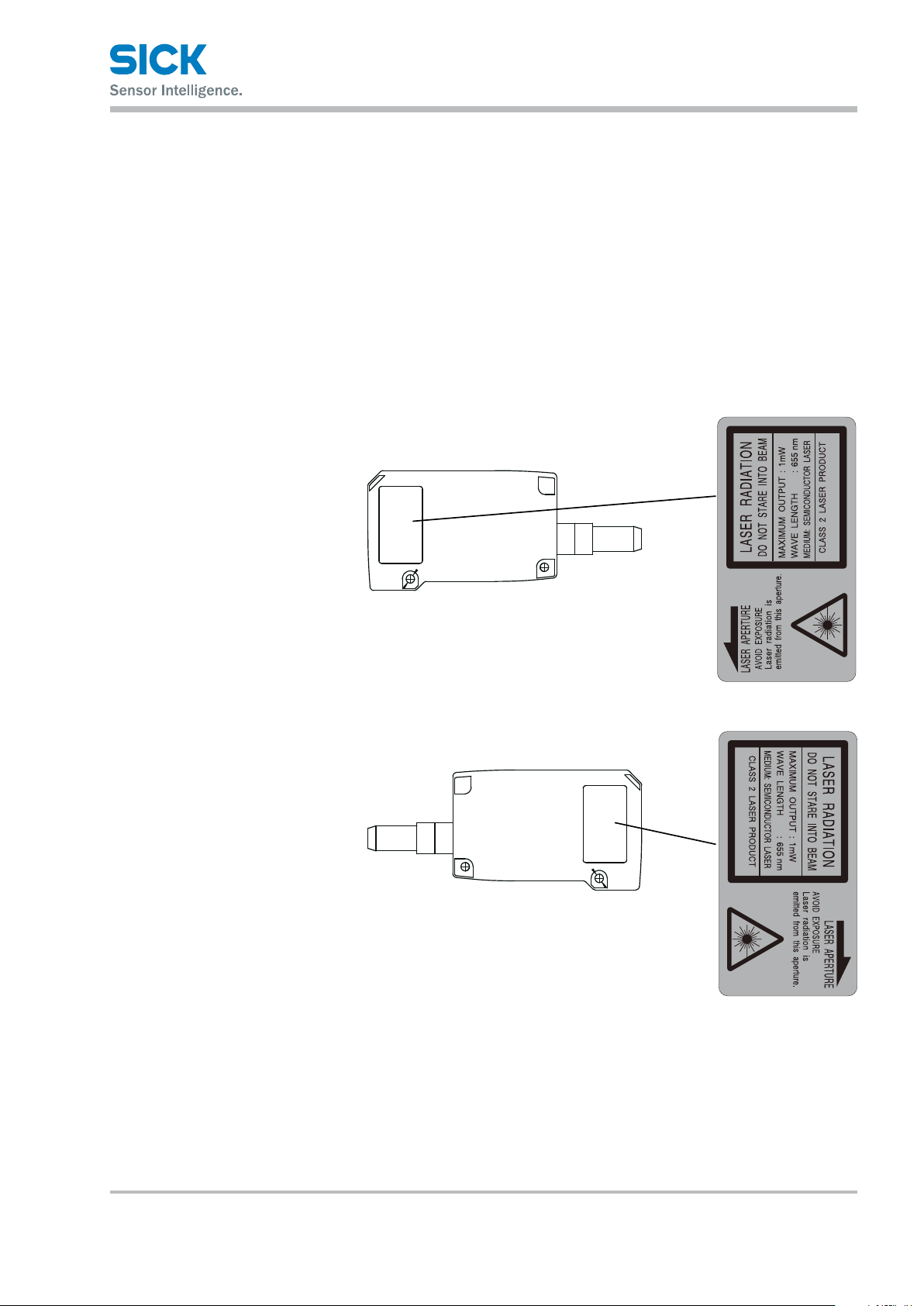

2.4 Warning Labels

Safety Precautions

This section explains the contents and axing position of the warning label

used on this product.

A laser beam is used in the location where this warning label is axed.

Looking directly at the laser beam may lead to loss of eyesight. Be sure

to follow the precautions shown below.

1. Do not look at the laser beam.

2. Do not remove the protective cover.

3. All individuals other than the proper operator must not

approach the product.

EN/IEC 60825-1:2014

Laser radiation – Do not look into the

laser beam – Laser class 2 (EN/IEC

60825-1:2014)

Complies with 21CFR1040.10 and

1040.11 except for deviations pursuant to laser notice No. 50, date June

24, 2007

Identical laser class for issue EN/IEC

60825-1:2007

(IEC 60825-1:2014)

(IEC 60825-1:2014)

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 11

Page 12

Information Before Use

3 Information Before Use

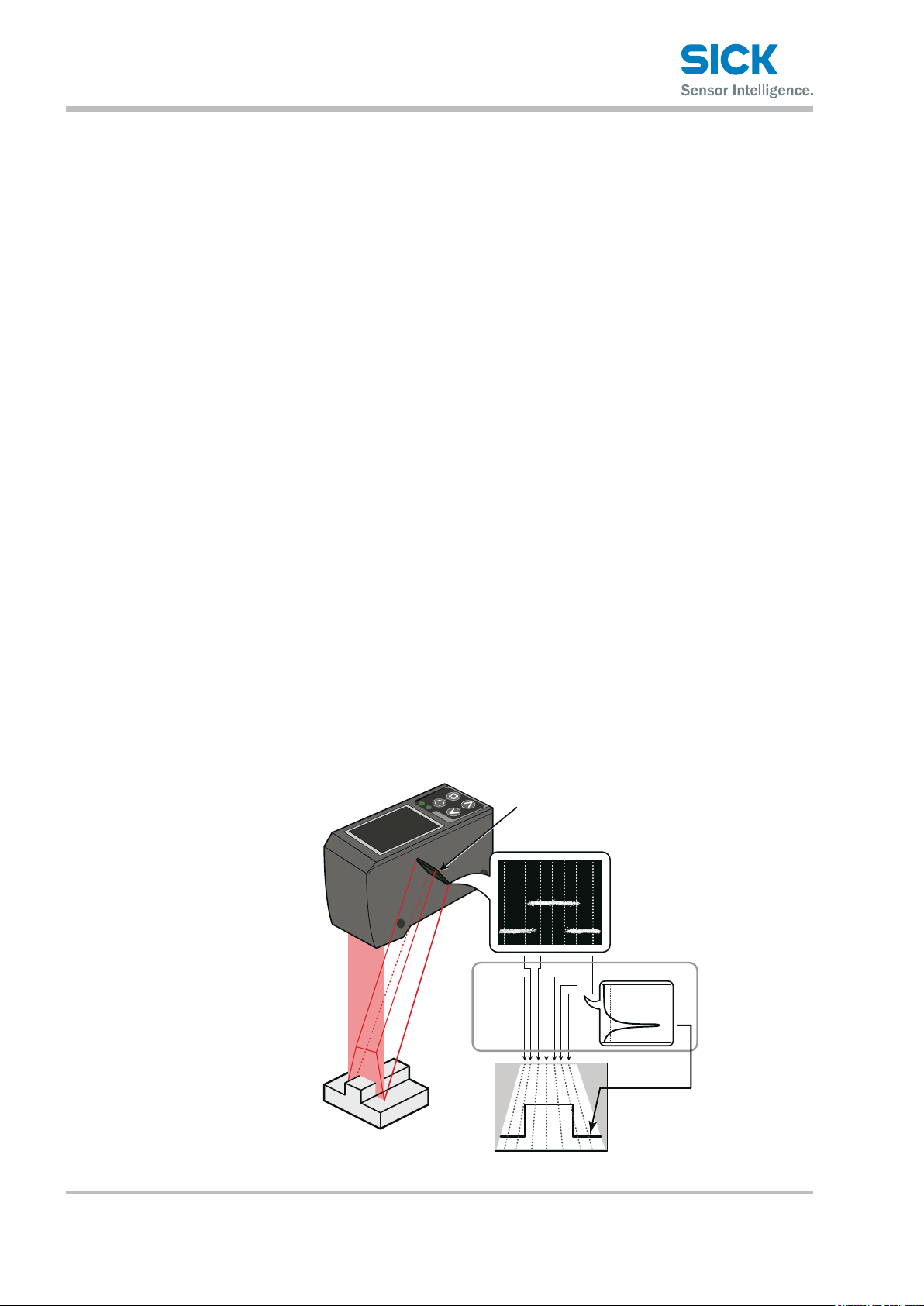

3.1 General Description

The Proler 2 is a high-precision prole measurement sensor.

The characteristics of this product are shown below.

• This product achieves high-precision measurement by emitting a bandshaped laser beam and using a light-plane-intersecting method that

triangulates the reected light.

• Settings can be congured, measurements can be performed,

and output can be generated from the sensor. No amplier unit

or other auxiliary devices are necessary.

• Various settings can be set from the sensor or from the dedicated setup

software (PRO2-navigator).

• It is possible to measure 4 areas with a single measurement. For each

area, there are 13 types of measurement functions to select from.

• There are 4 camera modes available. This enables you to select

the optimum settings to match the environment of the production line

to be measured and the state of the target object.

With the light-plane-intersecting method, the reected light from the

emitted band-shaped laser beam is received by the light receiving element

(CMOS), and the prole is then measured from the resulting image data.

With the light-plane-intersecting method, two processes are used to

determine the height and position.

• Triangulation: To determine the height, this process obtains the received

light waveform (the waveform of the reected light) for each vertical line

of the image.

• Projection transformation: To determine the horizontal position,

this process mathematically calculates the actual position from

the image data.

Light recieving element (CMOS)

Image (image data)

Recieved light waveform

Projection

transformation

Prole (distance data)

Figure: Schematic diagram of Proler 2 series measurement

12 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 13

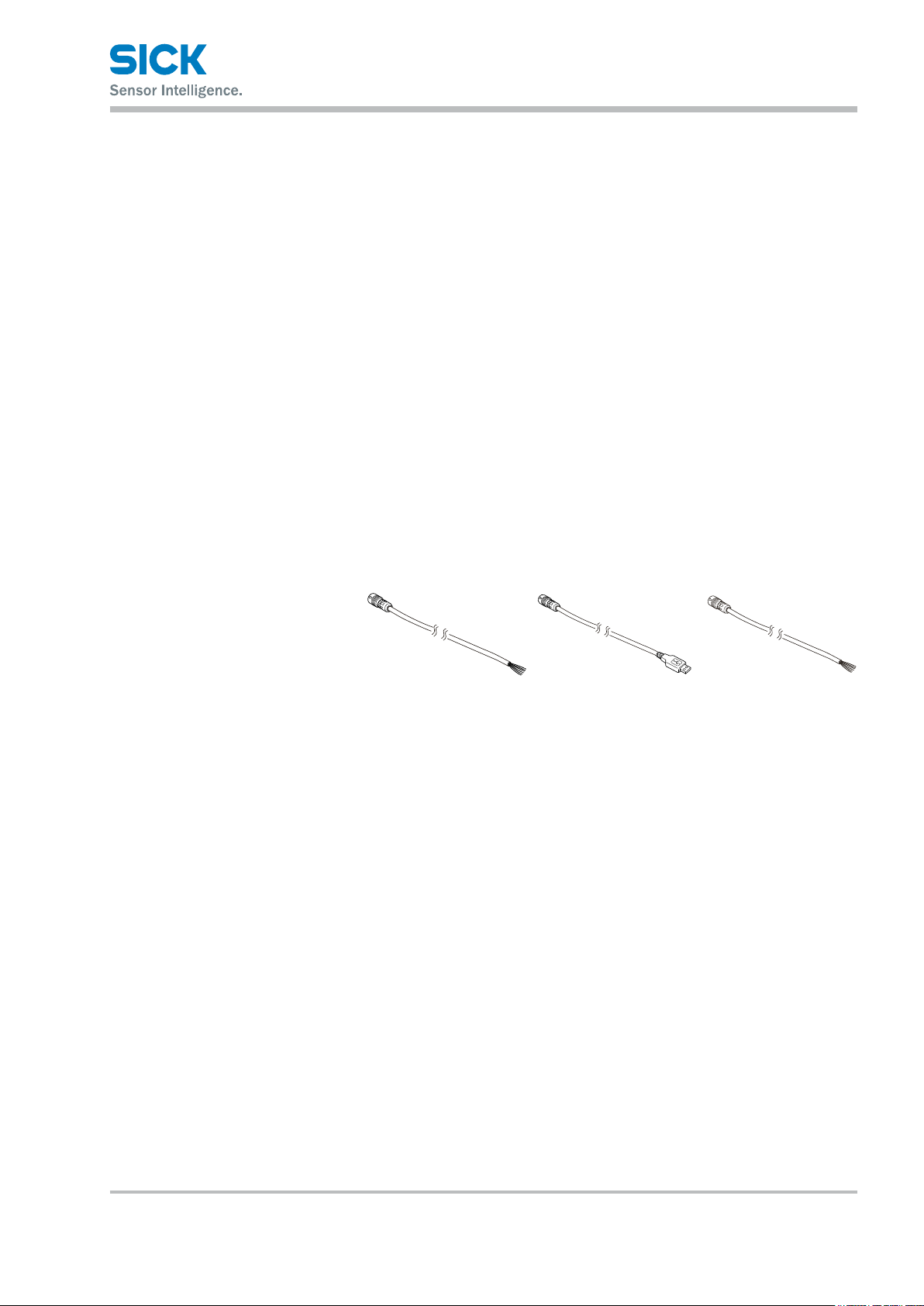

3.2 Package Contents

3.2.1 Included Items

3.2.2 Options

Information Before Use

Before using this product, conrm that the following items are contained

in the package:

• Sensor

• Mounting screws, M4 × 50 mm (2 pieces)

• Quickstart

• Setup software PRO2-navigator and User manual (USB ash drive)

• Laser warning labels (2 pieces)

Prepare the following options as necessary.

Main cable Communication cable

6053017,

STL-0H12-G02M (2 m)

6053018,

STL-0H12-G05M (5 m)

6053019,

STL-0H12-G10M (10 m)

6053020,

DSL-DH06-G1M8 (1.8 m)

(USB)

Communication cable

(discrete wire)

6053021,

DOL-SH06-G02M (2 m)

6053196,

DOL-SH06-G05M (5 m)

6053197,

DOL-SH06-G10M (10 m)

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 13

Page 14

Information Before Use

3.3 Names and Functions of Parts

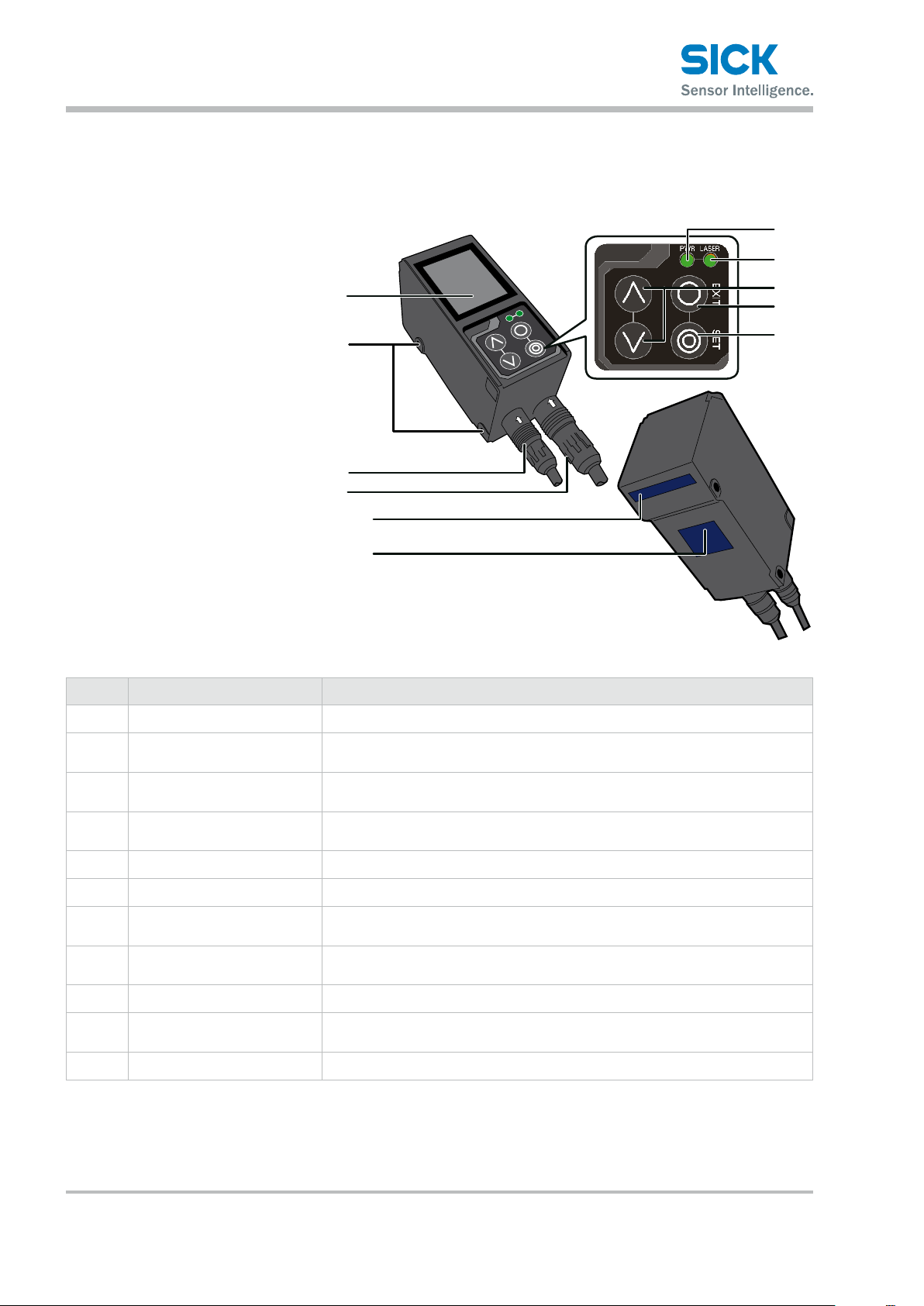

3.3.1 Sensor

7

8

1

2

3

4

5

6

Number Name Function

LCD display This part displays measured results and setting screens.

1

9

ß

à

Mounting holes Screws are inserted into these holes to x the sensor in place.

2

(Diameter: 4.2 mm)

Connector for

3

communi cation cable

Female connector, HRS, 12-

4

pin cable

Sender area, z-axis The laser beam is emitted from this window.

5

Field of view, x-axis The reected laser light is enters this window.

6

LED Indicator for power on

7

(green)

LED Indicator for Laser on

8

(green)

Cursor keys Use these keys to select setting items.

9

EXIT button Press this button to cancel setting details. Hold down this button (> 1 s) to switch

ß

SET button Press this button to conrm setting details.

à

Insert a communication cable into this connector to connect the PC and

the sensor.

Insert the main cable for power, I/O, and analog output into this connector.

This indicator lights when the power is on.

This indicator lights during laser emission.

to the main menu.

14 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 15

Information Before Use

(2.95)

(3.94)

(4.92)

Measuring distance

in mm (inch

(1.26)

h

in mm (inch)

in mm (inch)

(2.95)

(3.94)

(4.92)

Measuring distance

in mm (inch

WARNING

When using the sensor, never look into the laser

exposure window 5. Looking directly at the laser beam

may lead to loss of eyesight.

WARNING

Put the rubber cap on the connector which is not used to

protect from dust and water.

Note!

When using the sensor, do not cover the Sender area 5

or the Field of view 6.

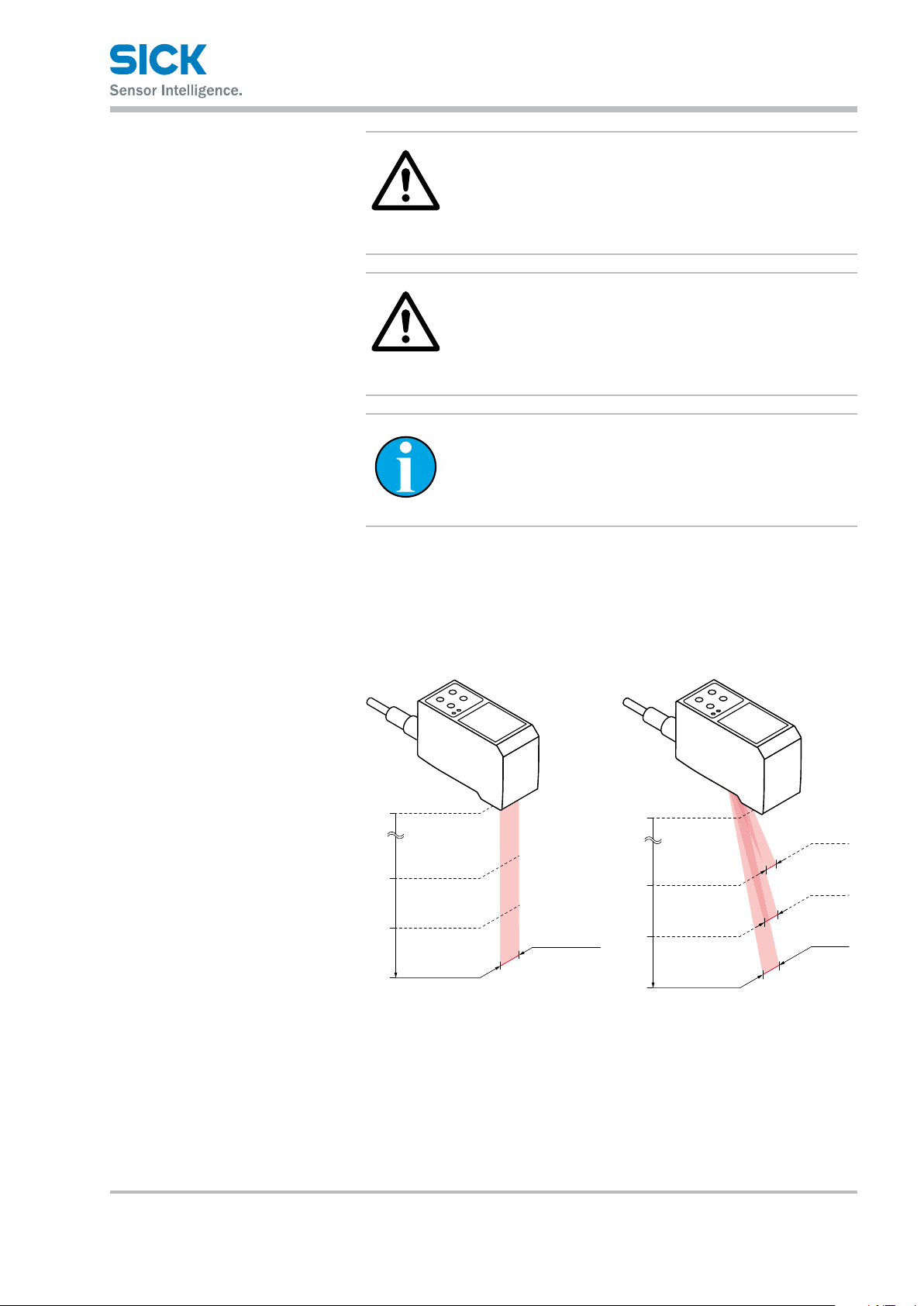

3.3.2 Laser Emission and Measurement Ranges

The sending and receiving area of this product are shown below.

Sending area Receiving area

)

0

75

100

125

Approx. 32

Measuring widt

75

100

125

)

0

17 (0.67)

22 (0.87)

27 (1.06)

Measuring width

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 15

Page 16

Information Before Use

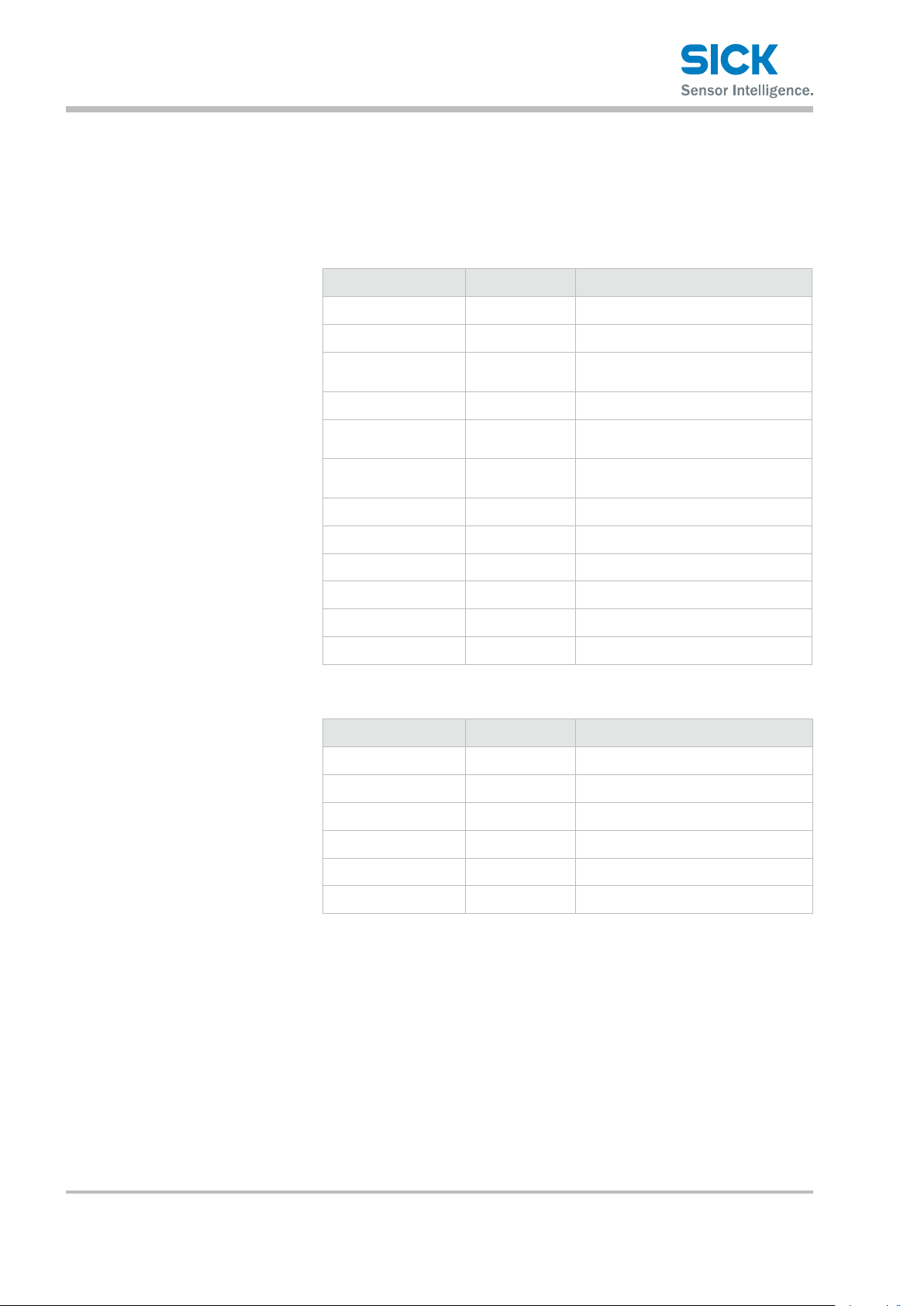

3.3.3 Cable Wire Colors and Roles

This section explains the colors of the wires and the roles of the Proler 2

cables.

Main cable This cable is used to supply power to the Proler 2 and for I/O connections.

Color Input or output Description

Purple Input Bank 1/reset

Orange Input Bank 2/hold

Gray

(narrow)

White Input Oset/stop laser emission

Gray

(coaxial core)

Gray

(coaxial shield)

Green — Ground GND

Yellow Output OUT1

Black Output OUT2

Red Output OUT3

Blue — Power supply GND

Brown — 12 to 24 V input

Input Bank 3/trigger

Output Analog output (4 to 20 mA)

— Analog GND

RS-485 cable This cable is used for RS-485 communication between the Proler 2

and a PLC or similar device.

Color Input or output Description

Orange — +A

Yellow — -A

Black — GND

Red — (N.C.)

Brown — (N.C.)

Green — (N.C.)

Reference: For the I/O circuit diagram, see “9.2 Connection diagram.”

16 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 17

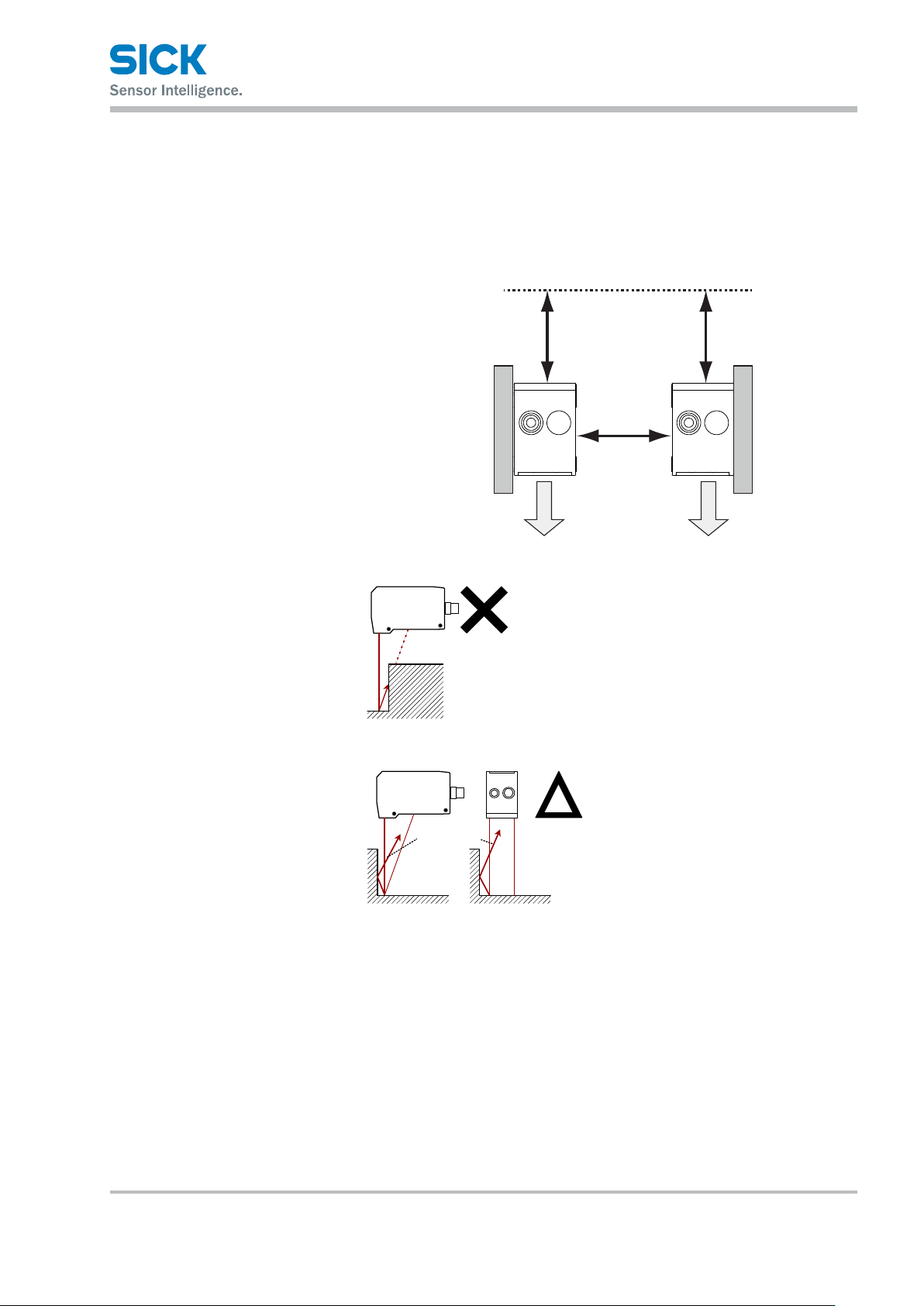

3.4 Installation

3.4.1 Notes for installation

Information Before Use

When you install this product, ensure that there is sucient space around

the product in order to prevent overheating.

Space required

above the sensor

40 mm or more

Space between sensors

40 mm or more

3.4.2 Installing the Sensor

Laser exposure

direction

迷光

Stray light

Laser exposure

direction

The Proler 2 performs measurements by emitting a parallel laser

beam and receiving the reected

light.

During measurement, ensure that

the laser beam and reected light

is not blocked by the target object.

Before using the product, check

that stray light, which is reected

by a wall or by highly reective

objects, does not have an eect

on the measurements.

1. Insert the included mounting screws (two M4 × 50 mm screws)

into the mounting holes to temporarily ax the sensor to a location

that is roughly in the desired location.

2. Measure the distance between the sensor and the detection

target object. Please make sure the measuring object is within the

measuring area.

3. Adjust the sensor position on the basis of the measurement result,

and then use the included nuts and washers to x the screws in place.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 17

Page 18

Setup and Measurement Procedures

4 Setup and Measurement Procedures

4.1 BeforeUsingtheProler2

4.1.1 Procedure for Using the Sensor

Before you use the Proler 2, install and setup the sensor according

to the procedure shown below.

1. Installation and light

axis adjustment

2. Wiring Connect the cables.

3. Settings Congure the settings related to measurement. You can use one of the

4. Measurement Perform measurements.

Install the sensor such that you can perform accurate measurements

of the measurement target.

Reference: For details on the installation of the sensor, see “3.4 Installation.”

following methods to congure the settings.

1. Sensor

• Congure all the settings from the Proler 2.

2. PRO2-Navigator

• Use the dedicated PRO2-Navigator setup software to intuitively

view and change all the settings.

3. Serial communication

• Use RS-485 communication to view and change all the settings

of the Proler 2.

With the Proler 2, measurement results can be output using one of the

following methods.

1. Judgment output (control output)

• The Proler 2 is equipped with three judgment outputs (control outputs).

2. Analog current output (4 to 20 mA)

3. Serial communication (RS-485 communication)

4. PRO2-Navigator (monitor display of measured values)

Tips: • Serial communication or PRO2-Navigator is required to output and check

stored data.

18 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 19

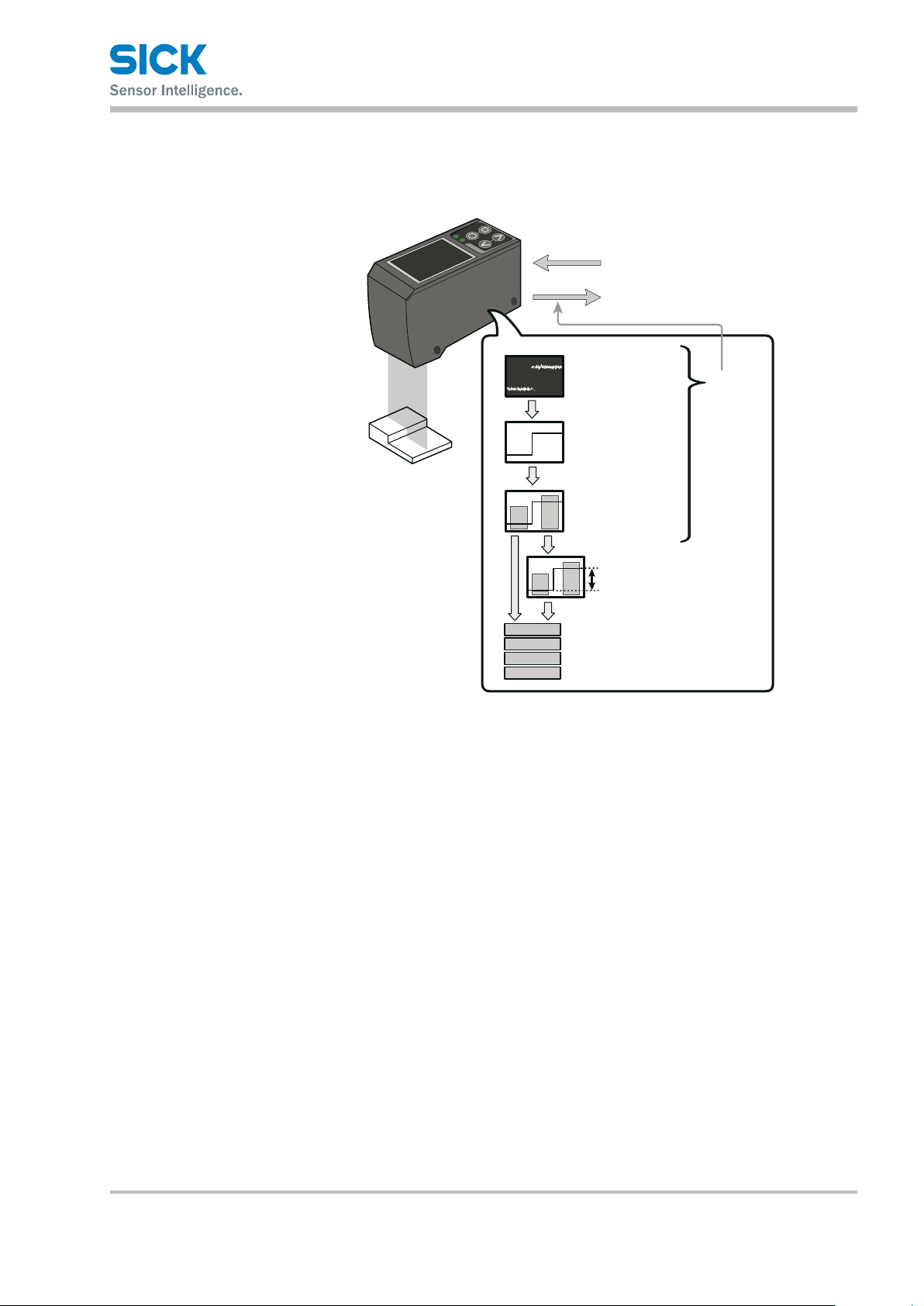

4.1.2 Setup and Measurement Process

The Proler 2 performs measurements according to the following ow.

Settings are also performed for each of these items.

Setup and Measurement Procedures

Laser control input

Trigger signal

Judgment output (control output)

Analog output

Camera imaging

Camera settings

Profile

Profile settings

Area measurement

Area settings

Output is

stopped

during

settings.

Area calculation

Calculation settings

Out 1

Out 2

Out 3

Analog

Result judgment and output

Output settings

1. Trigger

• Images are captured when the set conditions are met.

2. Camera

• An image is captured based to the settings.

3. Prole acquisition

• The prole (the sectional prole made by the reected laser light)

is acquired from the image.

4. Area measurement

• The specied position within the prole is measured.

5. Area calculation

• If necessary, the measured result of the area is calculated. e. g. Area

1 – Area 2 = Calc 1)

6. Result judgment and output

• The measured result is compared against the threshold, and then the

judgment result is output.

Tips: • With the Proler 2, you can save settings related to measurements

in “banks.” Up to eight banks can be saved.

Reference: For details on banks, see “7.9.1 Banks.”

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 19

Page 20

Setup and Measurement Procedures

4.2 Quick Setup

4.2.1 Basic Measurement Settings

You can take basic measurements simply by setting the following three

items. Congure the settings from the sensor or from the PRO2-Navigator

setup software.

• Shutter time

• Area

• Output conditions

Reference: For the actual screens and for information on the operations,

see the following pages.

Conguring settings from the sensor

Using PRO2-Navigator

1. Set the shutter time Position the measurement target, and then perform automatic adjustment.

The optimum shutter time will be set.

→ “6.3 PRO2-Navigator Screen and Operating.”

→ “5.3 Setting.”

2. Set the area Use the area setting to specify what part you will measure and how that

part will be measured.

1. Measurement area

• Set what part within the measurement range will be measured.

The set area must intersect the prole (the sectional waveform).

2. Measurement function

• Set the measurement function. You can select from functions

such as height and width.

Reference: For details on the area settings, see “7.6 Area Settings.”

3. Set the output conditions Congure the settings related to the output of the measured results.

First, specify the judgment and output target area.

• Output target

Select the target area (area 1 to area 4 and calculation 1 and

calculation 2).

1. Measurement output

The product judges whether the measurement is a pass or a fail,

and then outputs the result.

• Upper limit/lower limit

2. Analog current output (4 to 20 mA)

• 4 mA/20 mA

Set the lower and upper limits of the analog output range.

20 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 21

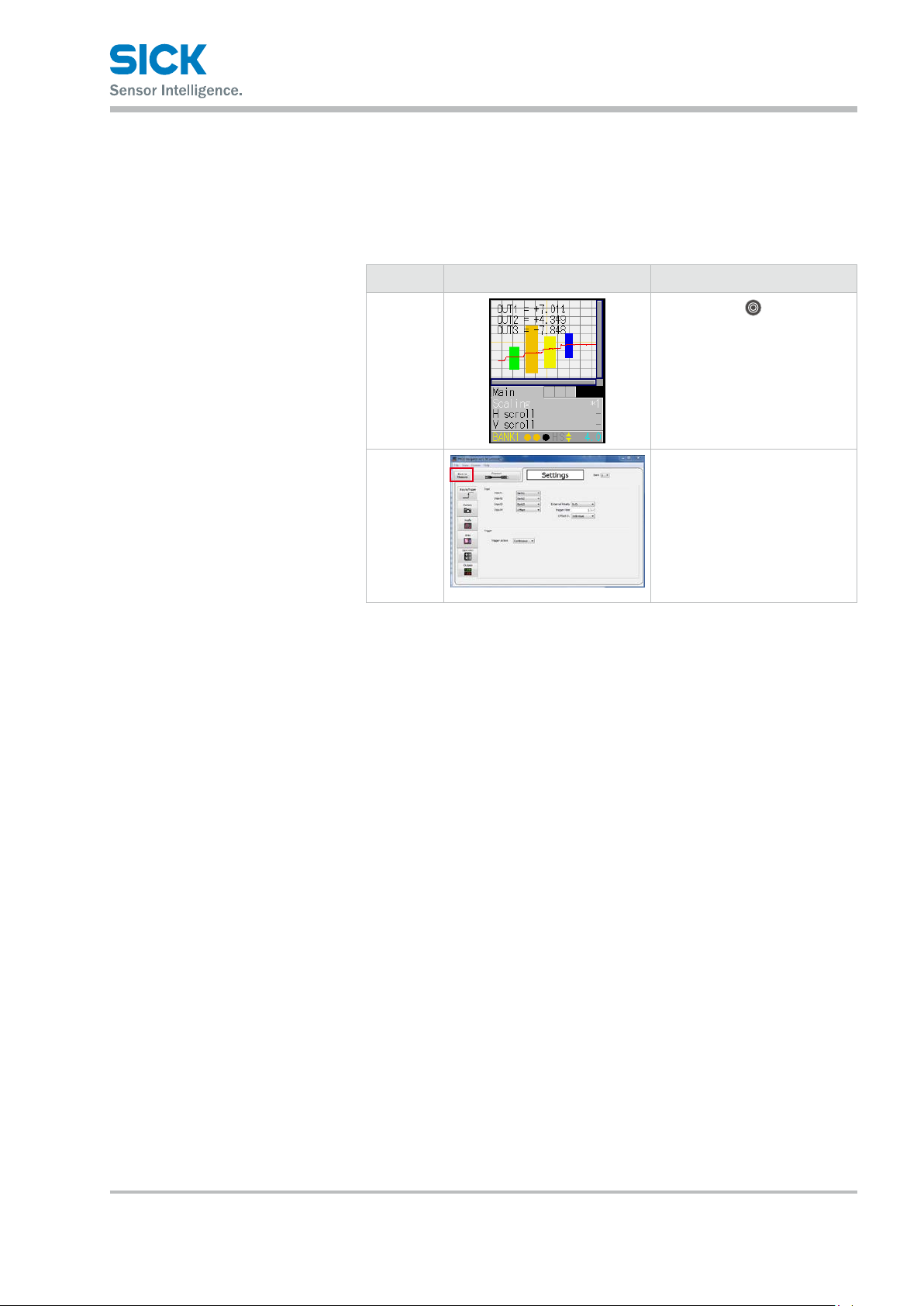

4.2.2 Return to Main Menu/Measurement Screen

When you have nished conguring settings or when you are not sure what

menu you are currently on, you can follow the procedures below to return

to the main menu (the measurement screen).

Related page

Screen image Operation

Setup and Measurement Procedures

Sensor

screen

Setup

software

Hold down the “EXIT” button.

* For the “In/Trig” and “Other”

tab, you need to select the tab,

and then hold down the “SET”

button to return to the main

menu.

Click “Back to Measure.”

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 21

Page 22

Setup and Measurement Procedures

4.2.3 Initialize Settings

This section describes how to initialize settings.

You can initialize one bank at a time or all banks at the same time.

Related page

Screen image Operation

Sensor

screen

Setup

software

Tips: • If you select “All” on the initialization menu, the Proler 2 will restart.

To initialize settings, on the

“Other” tab, display the “Initialize” menu, select “Bank” or

“All,” and then press the

“SET” button.

When the conrmation screen

displays the message “Reset to

factory initial value.,” press the

“SET” button again to execute

initialization.

On the measurement screen,

click “Common Setup.” The

Common Setup screen displays.

Click the target that you want to

initialize, and click “Bank Clear.”

A conrmation dialog displays.

Click “Yes” to execute initialization.

22 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 23

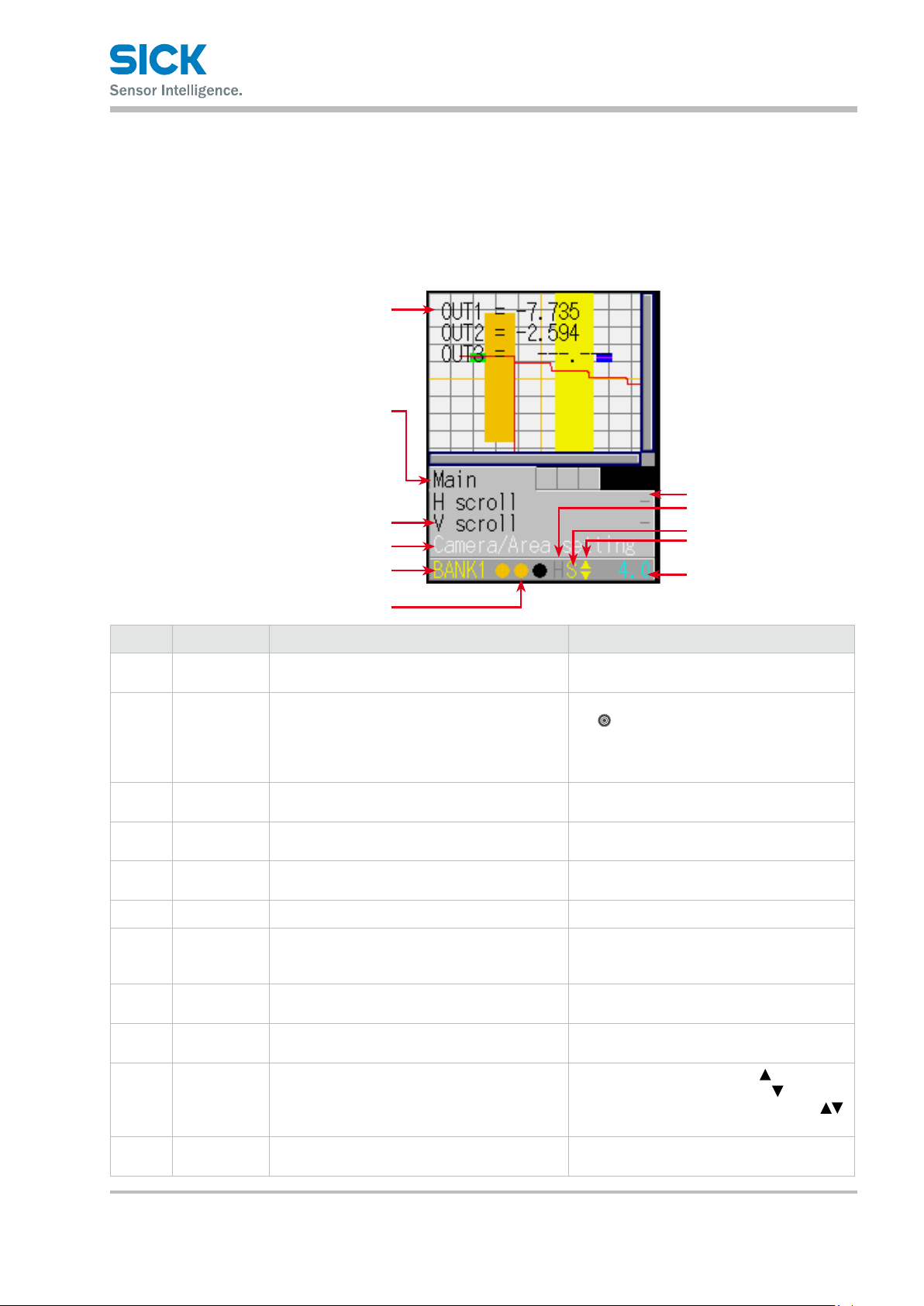

5 Operating the Sensor

5.1 Sensor Screen

5.1.1 Details of the Screen

This section explains the details of the screen display.

1

2

3

4

6

Operating the Sensor

5

8

9

ß

à

7

Number Display item Description Operation

Main screen The camera screen, prole waveform, and set

1

area are displayed here.

Tab The menu categories are displayed here.

2

You can also select this part.

Setting menu The setting menu is displayed here.

3

Three settings are displayed at one time.

Setting menu

4

(selected)

Parameter The parameters for the settings are displayed

5

Bank number The current bank number is displayed here. —

6

Output The control output statuses are displayed here

7

Hold input When the input is being held, an “H” is

8

Storage func-

9

tion

Cursor/Key

ß

Lock

Sampling

à

period

When a setting is selected, the color changes. When selected: White

here.

in the order – from the left – control output 1,

control output 2, control output 3.

displayed here.

The storage function operation status is displayed here.

A cursor that indicates the direction that

the screen can move in is displayed here or a "L"

that indicates the activated key lock.

The sampling period is displayed here.

The unit is “ms.”

—

Move the cursor to the tab, and then press

the

“SET” button to switch between the

tabs in order.

When not selected: Black

When selected: Blue

—

When setting the para meter: Yellow

When item selected: White

When setting the para meter: Yellow

When output is o: Black

When output is on: Orange

When input is being held:

“H” displayed in yellow

Trigger standby: Green

Storing: Yellow

When the screen can move up:

When the screen can move down:

When the screen can move up and down:

When the keys are locked: L

—

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 23

Page 24

Operating the Sensor

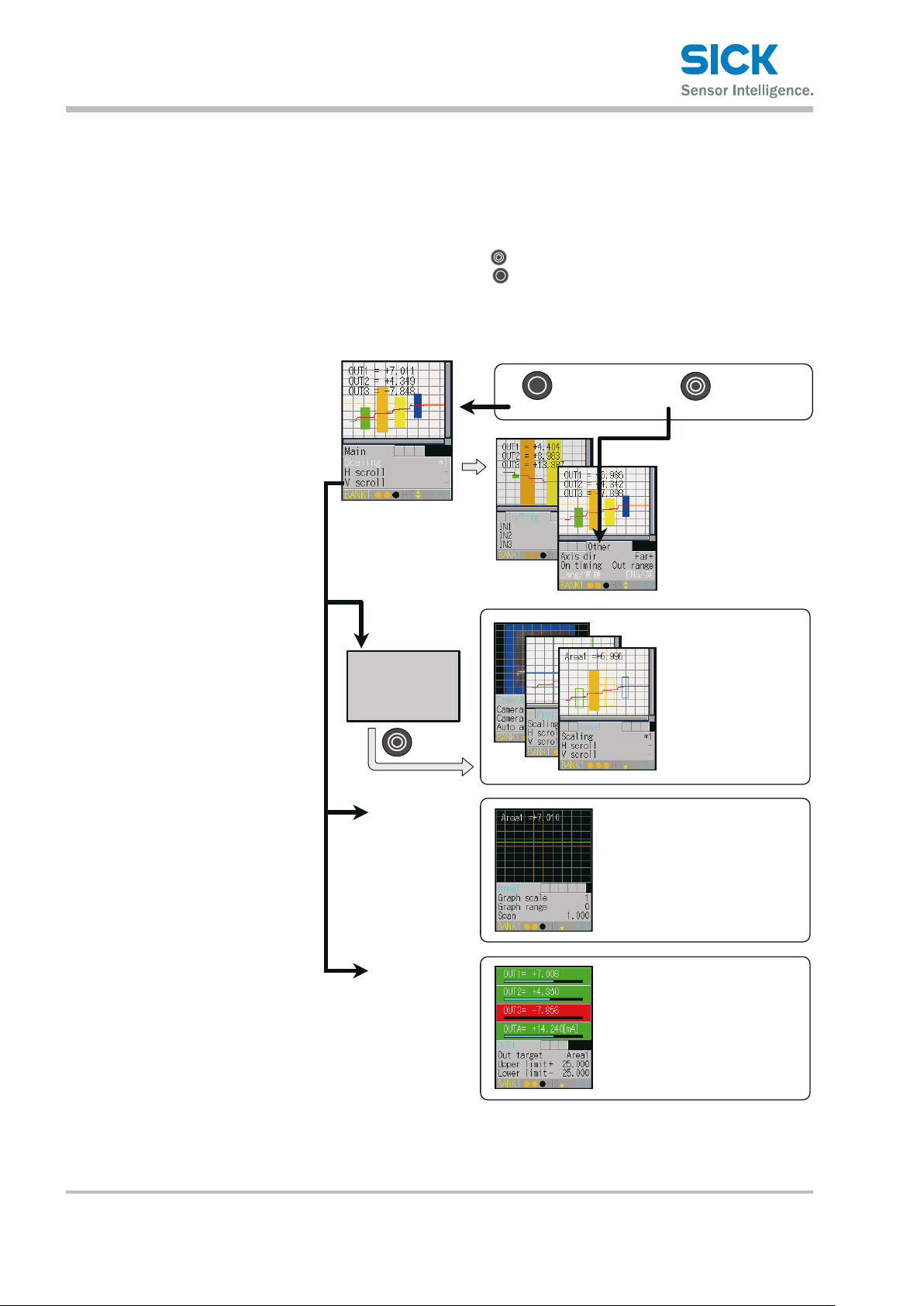

5.1.2 Screen Types and Switching Between Screens

This section explains the types of screens and how to switch between

the screens.

The following screens are available on the Proler 2.

You can switch between screens by selecting the screen on the main

screen or by pressing the “SET” button with the tab selected.

Also, if you hold down the “EXIT” button on any screen, you will return

to the main screen. (Excluding the “Input/Trigger” and “Other” screens.)

Common operations

●

EXIT

Switch to the

Main screen

Hold down for 1 sec. or more

●When a tab is selected

SET

Select tab

In/Trig setting

Storage setting

Other setting

Switch from

the menu.

Setting

Output will be

stopped and go

to setup window.

Y:[SET] / N:[EXIT]

Graph/Calc

Setting

Output

Setting

Camera setting

Profile setting

Area setting (1 to 4)

SET

Area graph

Calc graph/setting

Output setting

24 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 25

5.1.3 Key Lock Function

Operating the Sensor

Key Lock is available to prevent miss-operation. It can be activated or

released by pressing buttons.

• Activate Key Lock

5.2 Main Screen

5.2.1 Main

Hold down the

for 3 seconds.

While keys are locked, the cursor shows as "L".

• Operation while Key Lock is activated

When any keys are pressed while Key Lock is activated, following message

will be shown.

"KEY LOCK You can not operate without unlock"

Setting through communication I/F is available while Key Lock is activated.

• Release Key Lock

Hold down the

for 3 seconds.

While keys are released, the cursor shows as " " or " "..

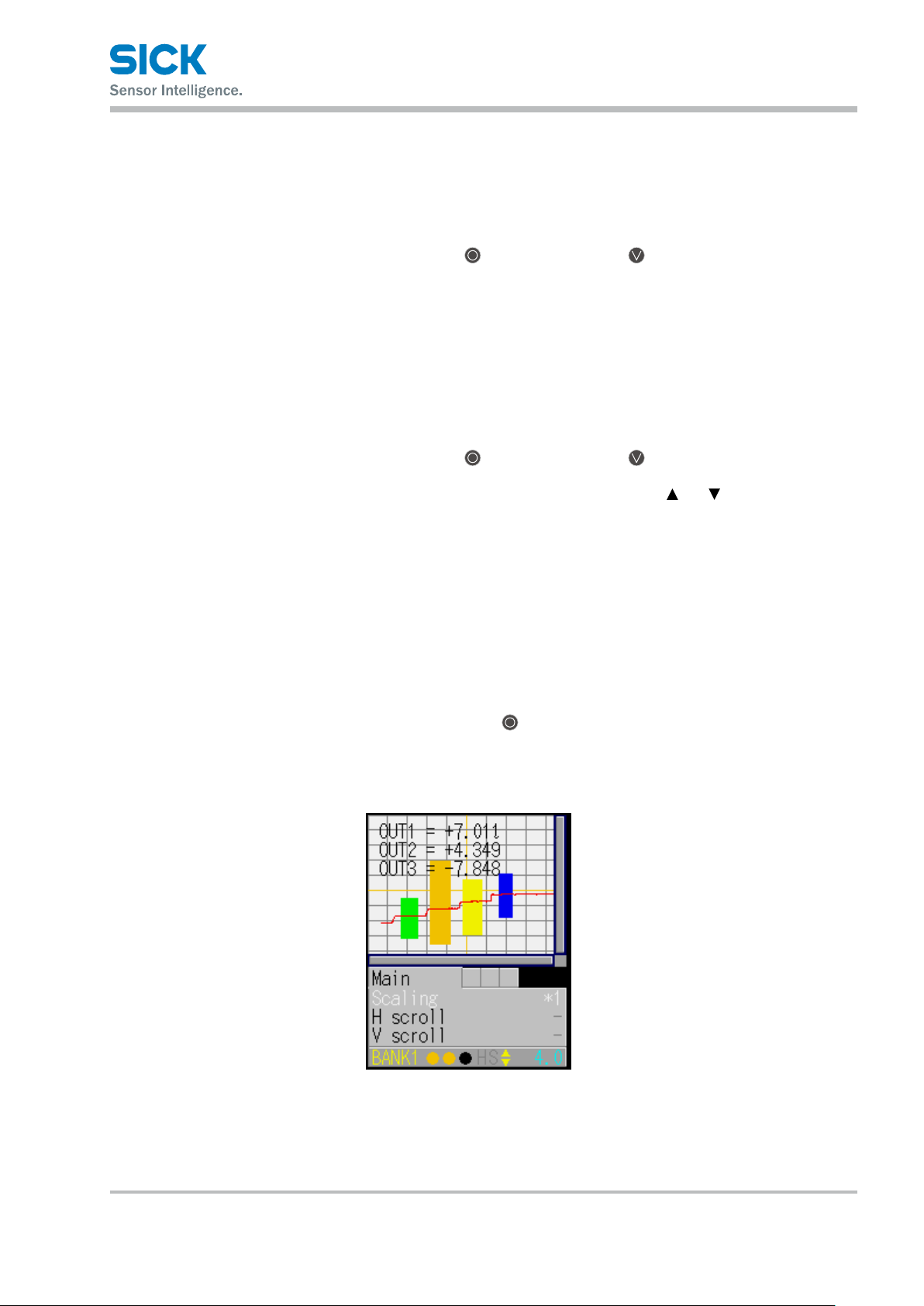

This section explains the items that can be selected on the main screen

and the operations of these items.

Table items marked in the following table with “Y”(= Yes) in the “Bank”

column can be set for each bank. In the same manner, items that have an

“N” (= No) for their bank are shared between all banks.

"EXIT" button and the "Down Cursor" button at a time

"EXIT" button and the "Down Cursor" button at a time

If you hold down the “EXIT” button on any screen, you will return

to this screen.

(Excluding the “Input/Trigger” and “Other” screens.)

You can switch to each other screen from this screen.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 25

Page 26

Operating the Sensor

5.2.2 Input/Trigger

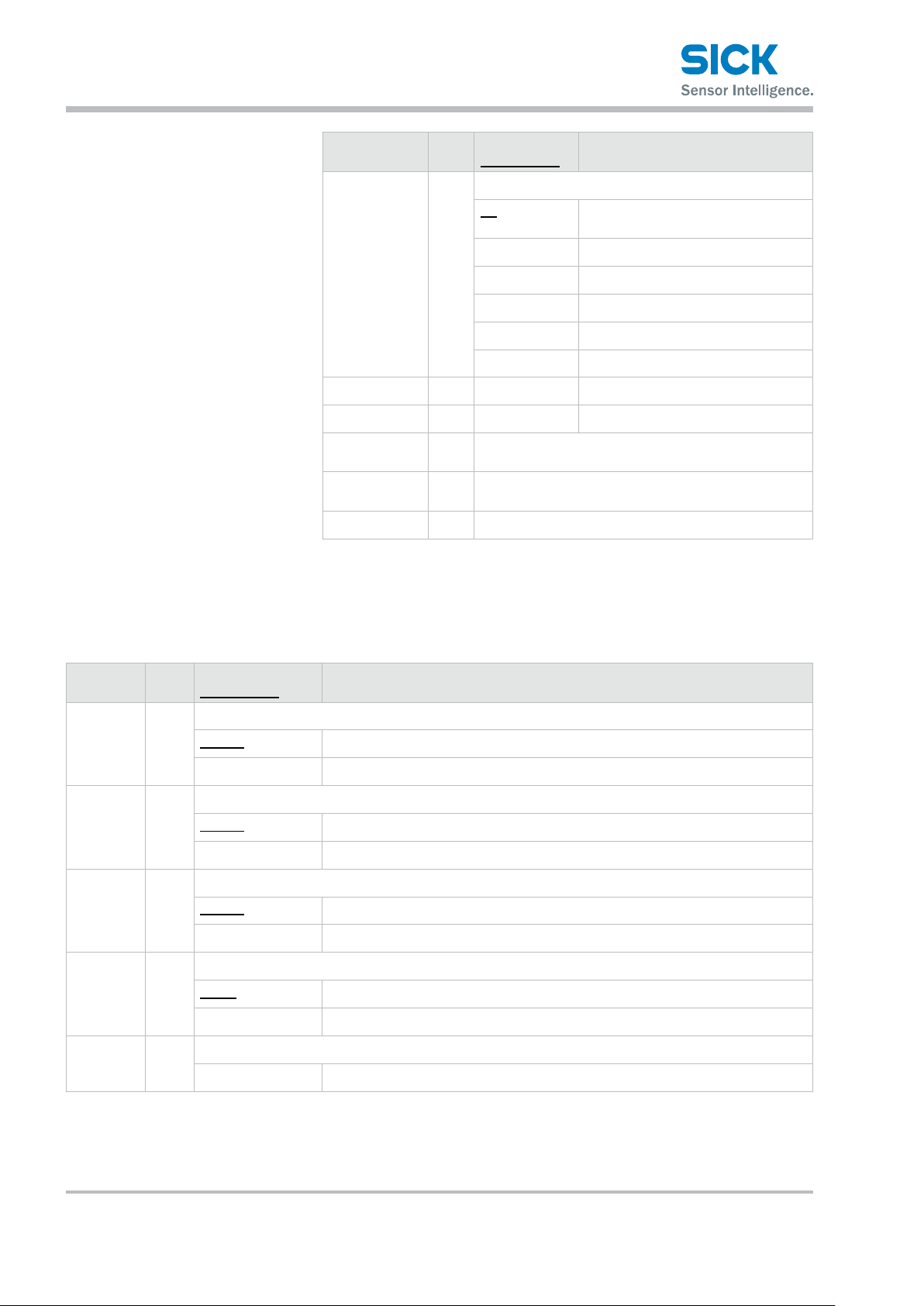

Setting item Bank Setting value/

default value

Scaling Y

H scroll Y — Move the display position horizontally.

V scroll Y — Move the display position vertically.

Camera/

Area setting

Graph/

Calc setting

Output — Switch to the output display/setting screen.

— Switch to the setting screen.

— Switch to the calculation setting screen. The measured

Expand or shrink the display range.

*1 Display at 100% size. The whole

*2 Display at 200% size.

*4 Display at 400% size.

*8 Display at 800% size.

*16 Display at 1600% size.

*32 Display at 3200% size.

result will be displayed as a graph.

General description

range will be displayed.

Set the operation of the input terminals and of the camera start trigger.

Setting

item

IN1 N

IN2 N Set the behavior of external input terminal IN2.

IN3 N Set the behavior of external input terminal IN3.

IN4 N Set the behavior of external input terminal IN4.

Reset — Execute the reset operation.

Bank Setting value/

default value

Set the behavior of external input terminal IN1.

BANK1 IN1 is used as the rst bit for switching banks.

Reset IN1 is used as the reset input terminal.

BANK2 IN2 is used as the second bit for switching banks.

Hold IN2 is used as the hold input terminal.

BANK3 IN3 is used as the third bit for switching banks.

Tri g ger IN3 is used as the trigger input terminal.

Oset IN4 is used as oset input.

LaserOFF IN4 is used as the laser emission stop input.

General description

Wait...

This is displayed when the reset operation is being executed.

26 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

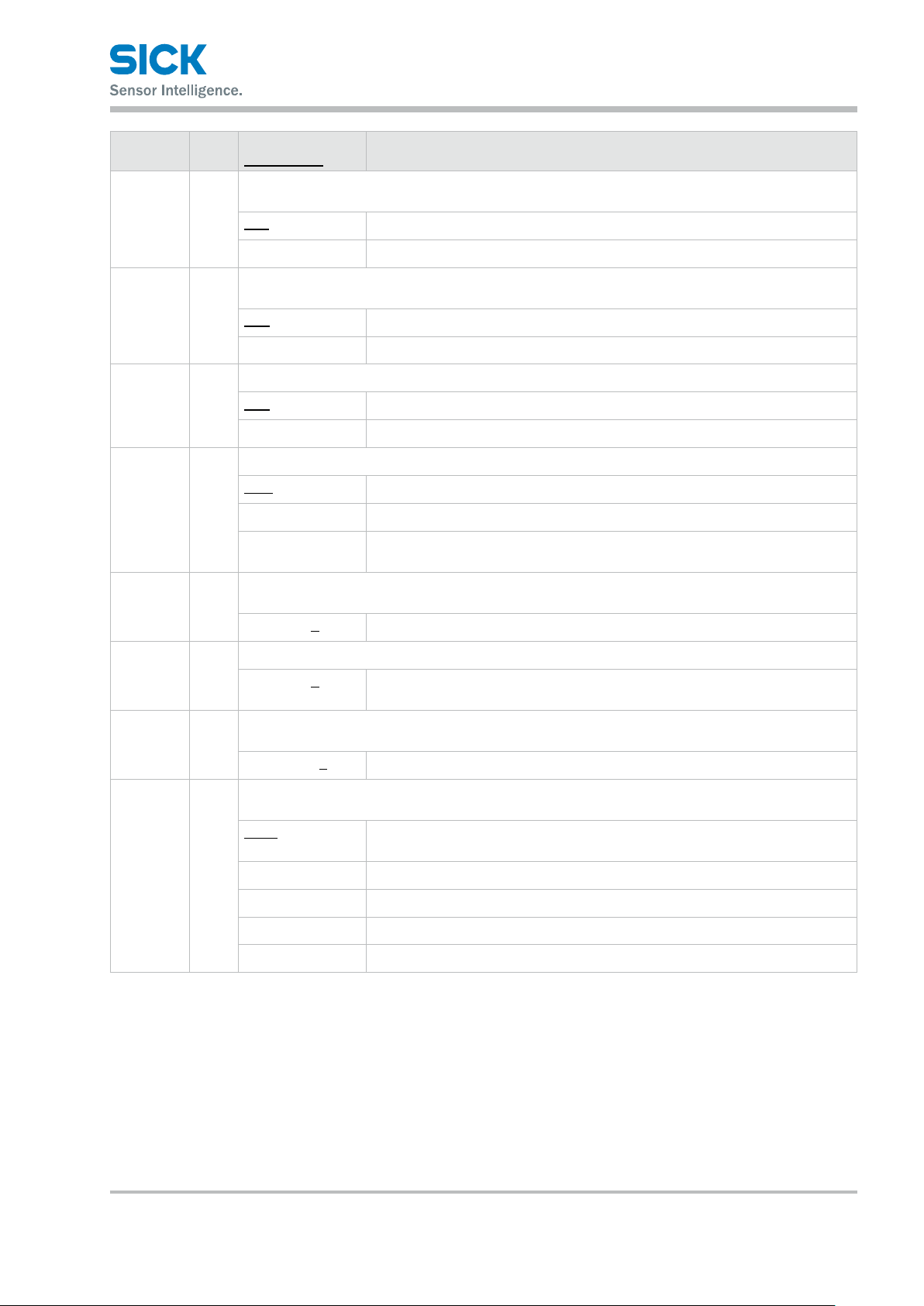

Page 27

Operating the Sensor

Setting

item

Inner hold — Each time that the SET button is pressed, the hold function will be turned on or o.

Inner trig — Each time that the SET button is pressed, the trigger will be turned on or o.

Input polar N Set the operation polarity of the external input terminals.

Trig action Y Set the measurement operation to perform when trigger input is received.

Trig count Y Set the count to use when “Trig action” is set to “Count.” The condition to enable this function is:

Bank Setting value/

default value

The condition to enable this function is: IN2: BANK2.

OFF

ON

The condition to enable this function is: IN3: BANK3.

N.O. The trigger turns on when input is applied.

N.C. The trigger turns o when input is applied.

N.O. The trigger turns on when input is applied.

N.C. The trigger turns o when input is applied.

Cont Measurements will be performed continuously.

1shot One measurement will be performed when trigger input is received.

Count When the predetermined number of trigger inputs are received,

Trig action: Count.

1 to 4095 [1] [Unit: Number of times]

General description

one measurement will be performed see Trig count.

Inp lter N Set the external input lter time to prevent chattering.

5 to 1275 [5] [Unit: μs] * You can set this value

in steps of 5 μs.

Trig delay Y Set the delay time between the trigger meeting the camera conditions and the camera actually taking

images.

5 to 20475 [5] [Unit: μs] * You can set this value in steps of 5 μs.

Oset

target

N Select the target on which to execute the oset.

The condition to enable this function is: IN4: Oset.

Indivi Depending on the input time, the oset will be executed on or cleared from

OUT1, OUT2, or OUT3 or on all of these.

All The oset will be executed on or cleared from all of OUT1, OUT2, and OUT3.

OUT1 The oset will be executed on or cleared from OUT1.

OUT2 The oset will be executed on or cleared from OUT2.

OUT3 The oset will be executed on or cleared from OUT3.

5.2.3 Storage

Congure the settings related to the storage function.

Serial communication or PRO2-navigator is required to check stored data.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 27

Page 28

Operating the Sensor

Setting

item

Storage N

No.of Data N Set the number of data saved starting from the start position.

Start cond N Used to select storage start conditions.

Start pos N Set the storage start position for the trigger.

Bank Setting value/

default value

Select data for storage.

OFF Storage not performed.

Measure Stores measurement values.

Prole Stores prole and measurement values.

1 to 65535 [1000] The upper limit is 8000 when storing a prole.

Continue Storage always executed.

Hold in Starts storage operation on a Hold start of the external input terminal.

Measure Storage starts from the point that the specied measurement target becomes

Alarm Storage starts from the instant that the specied measurement target becomes

UP limit Storage starts from the point that the specied measurement target exceeds the

LOW limit Storage starts from the point that the specied measurement target falls below

General description

measurable.

not measurable.

threshold.

the threshold.

-10000 to +10000

[0]

Start target N Used to select the target of the storage start condition.

The condition to enable this function is: Start cond: Measure, Alarm, UP limit, or LOW limit

Area1

Area2 Storage starts based on an area 2 value.

Area3 Storage starts based on an area 3 value.

Area4 Storage starts based on an area 4 value.

Calc1 Storage starts based on a calculation 1 value.

Calc2 Storage starts based on a calculation 2 value.

Threshold N Set the threshold when "UP limit" or "LOW limit" is selected for "Start cond".

The condition to enable this function is: Start cond: UP limit, LOW limit

-999.999 to

+999.999 [0]

Intermittent

N Data storage interval. All data is stored when the setting value is "0".

0 to 8191 [10]

[Unit: Number of samplings]

Using 0 as reference, a negative value indicates a previous position (pre-trigger)

while a positive value indicates a subsequent position (delay trigger). When the

storage target is prole, the value can be set in a range of -2000 to +2000.

Storage starts based on an area 1 value.

[Unit: Number of samplings]

28 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 29

Operating the Sensor

Setting

item

Repeat N Set the behavior when the number of storage data items reaches the upper limit.

Reference: For details on the camera settings, see “7.3 Storage Settings.”

Bank Setting value/

default value

ON Returns to the top and updates data, overwriting with the new data.

OFF Storage stops at the point that the upper limit value is reached.

Pause When the storage start condition is met, storage starts up to the limit and hold

General description

The storage target automatically changes to "OFF".

until the start condition is met and so on.

Once after storing up to the limit, it overwrite with new data.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 29

Page 30

Operating the Sensor

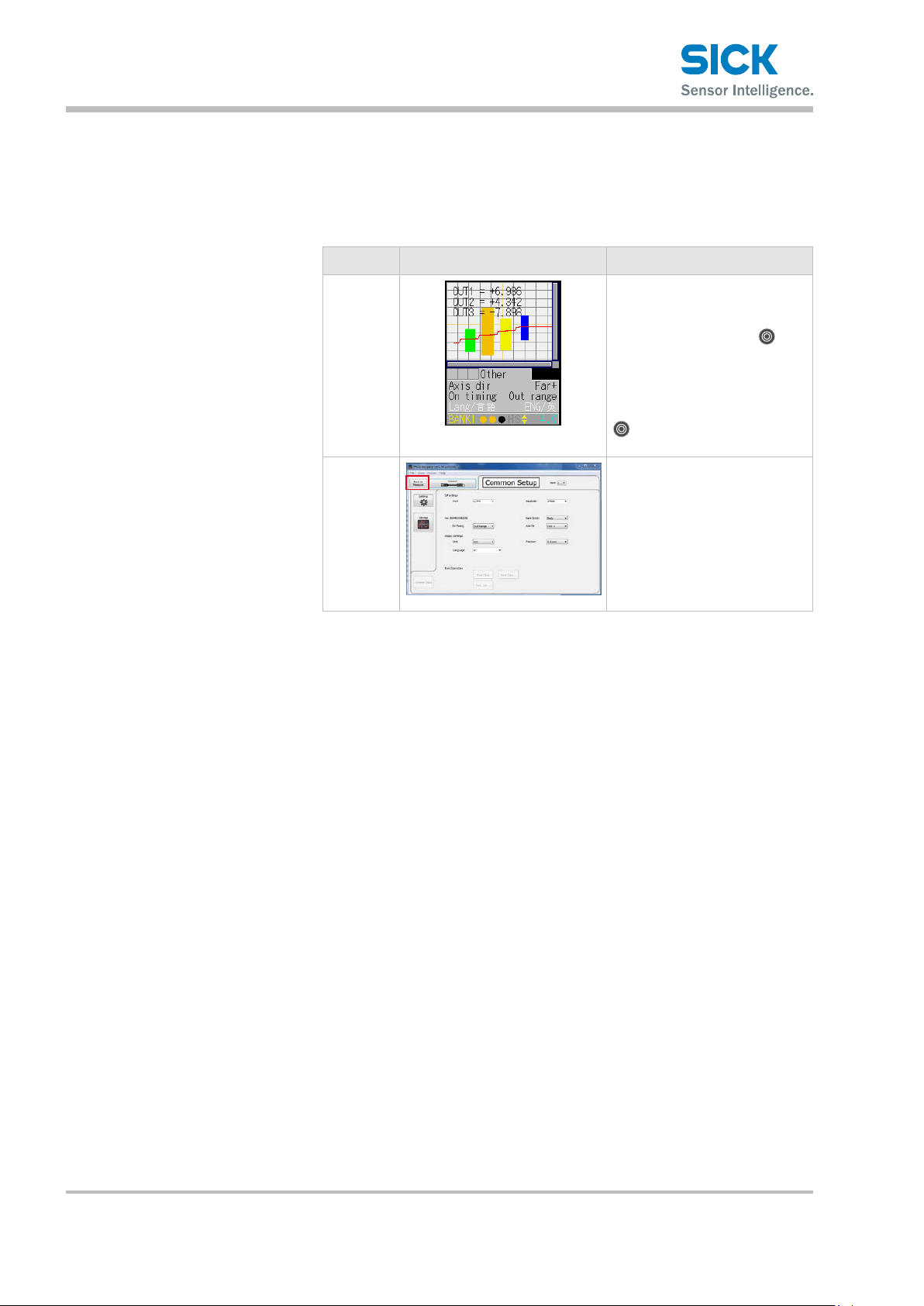

5.2.4 Other

Setting

item

Bank

switch

Bank N

Bank Setting value/

default value

N Select how to change between banks.

In/Para Sensor operations or the input terminals will be used to change between banks.

Comm Communication (including PRO2-Navigator) will be used to change between banks.

Change the bank. The display details vary depending on the settings of the input terminals.

The bank is determined by the details of this setting and the status of the input terminals.

The condition to enable this function is: Bank switch: In/Para.

Input terminal

settings

— You cannot switch the bank from

Input terminal

settings

1, 3, 5, 7 The bank is changed to number 1, 3, 5, or 7.

2, 4, 6, 8 The bank is changed to number 2, 4, 6, or 8.

Input terminal

settings

1, 5 The bank is changed to number 1 or 5.

General description

IN1: BANK1

IN2: BANK2

IN3: BANK3

the sensor.

Reset

IN2: BANK2

IN3: BANK3

IN1: Reset

IN2: Hold

IN3: BANK3

2, 6 The bank is changed to number 2 or 6.

3, 7 The bank is changed to number 3 or 7.

4, 8 The bank is changed to number 4 or 8.

Input terminal

settings

1, 2, 3, 4 The bank is changed to number 1, 2, 3, or 4.

5, 6, 7, 8 The bank is changed to number 5, 6, 7, or 8.

Input terminal

settings

1, 3 The bank is changed to number 1 or 3.

2, 4 The bank is changed to number 2 or 4.

5, 7 The bank is changed to number 5 or 7.

6, 8 The bank is changed to number 6 or 8.

Input terminal

settings

1, 2 The bank is changed to number 1 or 2.

3, 4 The bank is changed to number 3 or 4.

IN1: BANK1

IN2: BANK2

IN3: Trigger

IN1: Reset

IN2: BANK2

IN3: Trigger

IN1: BANK1

IN2: Hold

IN3: Trigger

30 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 31

Operating the Sensor

Setting

item

Baud rate N Select the communication baud rate.

Bank Setting value/

default value

5, 6 The bank is changed to number 5 or 6.

7, 8 The bank is changed to number 7 or 8.

Input terminal

settings

1 The bank is changed to number 1.

2 The bank is changed to number 2.

3 The bank is changed to number 3.

4 The bank is changed to number 4.

5 The bank is changed to number 5.

6 The bank is changed to number 6.

7 The bank is changed to number 7.

8 The bank is changed to number 8.

9.6K 9,600 bps

19.2K 19,200 bps

General description

IN1: Reset

IN2: Hold

IN3: Trigger

38.4K 38,400 bps

57.6K 57,600 bps

115K 115,000 bps

230K 230,000 bps

460K 460,000 bps

921K 921,000 bps

2.0M 2.0 Mbps

4.0M 4.0 Mbps

Axis dir N Set the increase/decrease direction of the measured value height with the measurement center

set as 0 mm.

Near+ Set the side close to the head as positive (+).

Far+ Set the side far from the head as positive (+).

On Timing N Set either within range or outside of range (as specied by the thresholds) as output judgment criteria.

Out range Output turns on when the value is outside the range specied by the threshold.

In range Output turns on when the value is within the range specied by the threshold.

Lang/言語 N Select the screen’s display language.

JPN/日 Information will be displayed in Japanese.

ENG/英 Information will be displayed in English.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 31

Page 32

Operating the Sensor

Setting

item

Screensaver

Brightness N

Initialize — Initialize the setting values to their factory default values.

Version — Display the version of the sensor. (This information is only displayed.)

Bank Setting value/

default value

N Select the behavior of the display after 30 seconds without any operation.

Dark Make the display backlight dark.

LCD O Turns OFF the display backlight. While the display backlight is OFF, the communi-

0 to 15 [15] Adjust the screen’s brightness.

All Initialize the setting values of all banks and the common settings.

Bank Initialize the setting values of the currently selected bank.

General description

cation speed will get faster.

When you execute this operation, the sensor will automatically restart.

5.3 Setting

This section explains the setting items on the setting screen.

The setting screen has three sets of settings:

“Camera,” “Prole,” and “Area.”

While the setting screen is displayed, judgment output (control output)

is stopped and out-of-range analog current output is generated

(approximately 24 mA).

Table items marked with “Y” in the “Bank” column can be set for each

bank. In the same manner, items that have an “N” for their bank are

shared between all banks.

5.3.1 Camera

Use the camera settings to congure camera (sampling) conditions such as

the camera mode, the camera area, and the exposure condition in order to

match the measurement target and environment.

Camera screen

Camera items You can use the camera settings to congure the following items.

32 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 33

Operating the Sensor

Setting

item

Camera

mode

Camera

range

Auto adjust — Performs an automatic adjustment to set the shutter time to the optimum value.

Gain Y Specify the light reception gain. The larger the number, the higher the gain.

Bank Setting value/

default value

Y

Select the camera mode.

Hi-res All of the pixels will be used by the camera.

Hi-spd Image capture time is reduced to 1/4 of the time in Hi-res mode.

HDR Screens captured by the camera at two dierent shutter speeds will be

NR This function eliminates noise by capturing an image with the laser on and

Y Sets the camera range.

The narrower the range, the shorter the imaging time and the sampling period become.

-— [Entire area]

Before you perform the automatic adjustment, set the actual measurement target in place,

and do not move the target during the adjustment.

When you execute automatic adjustment, “Camera mode” will automatically change to “Hi-res.”

Wait... Displays while automatic adjustment is being executed.

General description

Image acquisition time: 5 ms (with the maximum image area)

Resolution is reduced by half in both the horizontal and vertical directions.

Image capture time: 1.25 ms (maximum image area)

combined. This enables stable measurements of parts that are highly reective

or that are minimally reective.

another image with the laser o, and then determining the dierences between

the images.

1.00 Minimum gain

1.14

1.33

1.60

2.00

2.29

2.67

3.20

4.00

5.33

8.00 Maximum gain

Shutter Y Set the shutter time.

5 to 10235 [500] [Unit: μs] * You can set this value in steps of 5 μs.

HDR

shutter

Y The condition to enable this function is: Camera mode: HDR.

Sets the shutter speed to use when “Camera mode” is set to “HDR.”

This must be set to a value that is greater than the “Shutter” setting value (so that the shutter time

is longer).

When you set “Camera mode” to “HDR,” this is set to a value that is (shutter time × 4).

5 to 10235 [1000] [Unit: μs] * You can set this value in steps of 5 μs.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 33

Page 34

Operating the Sensor

Setting

item

Threshold Y Set the threshold (lower limit) of the light amount at which an alarm is triggered

Reject

level

Reference: For details on the camera settings, see “7.3 Storage Settings.”

Bank Setting value/

default value

* Normally you do not have to change this setting.

0 to 255 [32] [Unit: Received light amount]

Y Set the ratio to exclude when performing calculations from the received light waveform.

* Normally you do not have to change this setting.

0 to 127 [16] [No unit: (n + 1)/128]

General description

34 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 35

5.3.2 Prole

Operating the Sensor

Use the prole settings to congure the conditions for extracting proles

from the camera images.

Also, when using the prole position, height, and tilt correction,

set correction conditions.

Prolescreen

Height correction

reference position

(purple line)

Position correction

reference height

(blue line)

Tilt correction

reference position

(green line)

Proleitems You can use the prole settings to congure the following items.

Setting

item

Scaling Y

Bank Setting value/

default value

Expand or shrink the display range.

*1 Display at 100% size. The whole range will be displayed.

General description

*2 Display at 200% size.

*4 Display at 400% size.

*8 Display at 800% size.

*16 Display at 1600% size.

*32 Display at 3200% size.

H scroll Y -— Move the display position horizontally. When the display range is at 100% size,

you cannot move the display position.

V scroll Y Wait... Move the display position vertically. When the display range is at 100% size,

you cannot move the display position.

Tar get Y Select the measurement target.

Normal The standard setting to perform measurements.

Gap Select this setting when the target has large level dierences.

The level dierence edge precision will be improved.

Semi-trans Use this setting when you are measuring resin or other semi-transparent objects.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 35

Page 36

Operating the Sensor

Setting

item

Alarm limit Y Set the number of values (measured values to the right) to maintain when an alarm occurs.

Smoothing Y This function averages the prole in the horizontal (X-axis) direction to make the waveform smoother.

Correct

method

Bank Setting value/

default value

When you specify this setting, the specied number of values immediately before the alarm (to the

right) will be maintained.

If alarms occur repeatedly such that the set number of values is exceeded, an alarm (measured value

7FFF) is triggered.

0 to 14/HOLD [6] [Unit: Number of values] * HOLD: Alarm state is not entered.

[Unit: Number of measurements]

1 Averaging will not be performed.

2

4

8

16

32

64

128

Y Select the correction method.

To use this function, you have to perform master image registration. Also, when you change this setting,

you have to update the master image.

- Correction will not be performed.

General description

→

←

→

↑

←

↑

↑

H correct Y The position of the area at the specied height will be corrected by the dierence between the master

image and the measured prole.

To use this function, you have to perform master image registration. Also, when you change this setting,

you have to update the master image.

-28000 to +28000

[0]

V correct Y The height of the area at the specied position will be corrected by the dierence between the master

image and the measured prole.

To use this function, you have to perform master image registration. Also, when you change this setting,

you have to update the master image.

The condition to enable this function is: Correct method: ↑→, ↑←, or ↑.

-15000 to +14998

[-6500]

Tilt correct Y The prole tilt will be corrected so that the two specied points become level with each other.

ON/OFF —

Position correction will be performed on the basis of the left side.

Position correction will be performed on the basis of the right side.

Height correction will be performed, and then position correction (left side)

will be performed.

Height correction will be performed, and then position correction (right side)

will be performed.

Height correction will be performed.

[Unit: X coordinate] * You can set this value in steps of 2.

[Unit: Y coordinate] * You can set this value in steps of 2.

36 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 37

Operating the Sensor

Setting

item

Tilt cor pos Y Set the reference position of the second point to use in tilt correction.

Save

master

Reference: For details on the prole settings, see “7.5 Prole Settings.”

Bank Setting value/

default value

The reference position of the rst point is the “H correct” reference position.

To use this function, you have to perform master image registration. Also, when you change this setting,

you have to update the master image.

The condition to enable this function is: Tilt correct: ON.

-14998 to +15000

[0]

— Register the current prole as the master image.

Wait... This is displayed when the prole is being registered as the master image.

General description

[Unit: X coordinate] * You can set this value in steps of 2.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 37

Page 38

Operating the Sensor

5.3.3 Area

Area screen

To switch to the Area screen, select the tab in measurement mode,

and then press the “SET” button.

Area items You can use the area settings to congure the following items.

Setting

item

Scaling Y

H scroll Y -— Move the display position horizontally. When the display range is at 100% size,

V scroll Y -— Move the display position vertically. When the display range is at 100% size,

Coverage Y -— Set the range of the area.

Meas func Y Select the measurement function of the area. The unit is [mm] unless stated otherwise.

Bank Setting value/

default value

Expand or shrink the display range.

*1 Display at 100% size. The whole range will be displayed.

*2 Display at 200% size.

*4 Display at 400% size.

*8 Display at 800% size.

*16 Display at 1600% size.

*32 Display at 3200% size.

Average The average of the measured values within the area will be output.

General description

you cannot move the display position.

you cannot move the display position.

P height The largest measured value within the area will be output.

B height The smallest measured value within the area will be output.

Width The width of the prole that crosses the center of the area will be output.

P pos The position of the largest measured value within the area will be output.

B pos The position of the smallest measured value within the area will be output.

38 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 39

Operating the Sensor

Setting

item

Edge dir H Y Set the direction in which edges will be detected during the “Edge pos” measurement.

Direction Y Set the direction in which to perform measurements during the “Size” and “Diameter” measurements.

Inect

threshold

Correction Y Select whether to use the set position and height correction with this area.

Bank Setting value/

default value

Edge pos The position at which the prole crosses the center of the area will be output.

EdgeCount The number of times that the prole crosses the center of the area will be output.

Tilt A straight line approximating the prole will be determined, and then the tilt

Size The mathematical area of the section bounded by the prole and the area will be

Length The line length of the prole will be determined.

Diameter A circle approximating the prole will be determined, and then the diameter

Inect The position of the point which is inecting most will be output.

The condition to enable this function is: Meas func: Edge pos.

←

→

The condition to enable this function is: Meas func: Size or Diameter.

↑

↓

Y Set the threshold value. When detecting inecting point, it outputs when the inection reaches to this

value. The condition to enable this function is: Meas func: Inect

↓-255 ~ +255

[+3]

General description

[Unit: Number of times]

of this line will be measured.

[Unit: Degrees (°)] * Slope rising to the right will be treated as positive.

determined.

[Unit: mm2]

of this circle will be output.

Positions will be detected from the right side.

Positions will be detected from the left side.

The mathematical area will be measured from the lower side of the area up.

Diameter measurements will be made with the top part of the circle as convex.

The mathematical area will be measured from the top side of the area down.

Diameter measurements will be made with the lower part of the circle as convex.

The polarity means direction of the inection.

OFF The position and height correction will not be used.

ON The position and height correction will be used.

Reference: For details on the area settings, see “7.6 Area Settings.”

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 39

Page 40

Operating the Sensor

5.4 Graph/Calc

Graph/Calc screen

The measured results of each area are displayed as a graph.

You can also set calculation functions for adding or subtracting area

measured results.

You can set up to two calculation formulas in the format (calculation

target 1) (operator) (calculation target 2).

Example: If calculation target 1 is “area 1,” calculation target 2 is “area 2,”

and the operator is “+,” the calculation formula will be:

(area 1) + (area 2).

Table items marked with “Y” in the “Bank” column can be set for each

bank. In the same manner, items that have an “N” for their bank are

shared between all banks.

Reference: See “7.7 Calculation Settings.”

40 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 41

5.4.1 Graph Items (Area 1 to area 4)

You can use the graph display settings to congure the following items.

Operating the Sensor

Setting

item

Graph

scale

Graph

range

Span Y Set a span (multiplier) on the measured values.

Average Y Set the number of times over which to perform the moving average of the measured values.

Hold Y Select the measured result hold operation.

Reference: For details on the graph display settings, see “7.7 Calculation Settings.”

Bank Setting value/

default value

Y

Expand or shrink the display time axis (the horizontal axis).

1 to 6 [1]

Y Expand or shrink the measured value display range (the vertical axis).

0 to 6 [0]

0.001 to 1.999

[1.000]

1 to 1023 [32] [Unit: Number of times]

None The measured result will be output as-is. (Hold input will be ignored.)

Sample The measured value during hold input will be output.

Peak The maximum value during the hold input period will be output.

Bottom The minimum value during the hold input period will be output.

General description

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 41

Page 42

Operating the Sensor

5.4.2 Calc Items (Calculation 1 and calculation 2)

You can use the area calculation settings to congure the following items.

Setting

item

Graph

scale

Graph

range

Span Y Set a span (multiplier) on the measured values.

Hold Y Select the measured result hold operation.

Calc

target1

Bank Setting value/

default value

Y

Expand or shrink the display time axis (the horizontal axis).

1 to 6 [1]

Y Expand or shrink the measured value display range (the vertical axis).

0 to 6 [0]

0.001 to 1.999

[1.000]

None The measured result will be output as-is. (Hold input will be ignored.)

Sample The measured value during hold input will be output.

Peak The maximum value during the hold input period will be output.

Bottom The minimum value during the hold input period will be output.

Y Select the area for calculation target 1.

Area1

Area2

Area3

General description

Area4

Operator Y Select the operator of the calculation formula.

+ Calculation target 1 + calculation target 2

- Calculation target 1 - calculation target 2

Calc

target2

Reference: For details on the graph display settings, see “7.7 Calculation Settings.”

Y Select the area for calculation target 2.

Area1

Area2

Area3

Area4

42 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 43

5.5 Output

Operating the Sensor

Use the output display to view the current output status and to set

the judgment and analog outputs.

Table items marked with “Y” in the “Bank” column can be set for each

bank. In the same manner, items that have an “N” for their bank are

shared between all banks.

Output screen

When within the range specied by the thresholds: Green

When outside the range specied by the thresholds: Red

When the measured value is within the range specied

by the thresholds, the bar graph indicates the position of

the measured value in relation to the thresholds.

Tips: • The background colors of the output screen indicate the judgment

results corresponding to the current measured results.

• The output display in the lower part of the screen indicates the current

output status, so the background color and the output color may not

match.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 43

Page 44

Operating the Sensor

5.5.1 Output Items (OUT1 to OUT3)

When the OUT1, OUT2, or OUT3 tab is selected, you can use the output

display settings to congure the following items.

Setting

item

Out target Y

Upper limit Y Set the upper limit of control output.

Lower limit Y Set the lower limit of control output.

Out action Y Select the operation to perform during output.

Bank Setting value/

default value

Select the area or calculation to set as the output target.

Area1 The measured result of area 1 will be output.

Area2 The measured result of area 2 will be output.

Area3 The measured result of area 3 will be output.

Area4 The measured result of area 4 will be output.

Calc1 The result of calculation 1 will be output.

Calc2 The result of calculation 2 will be output.

-32.766 to +32.767

[+25.000]

-32.767 to +32.766

[-25.000]

Normal The normal on/o output will be performed.

1shot Each time that output is turned on, one-shot output will be performed.

General description

* The unit varies depending on the measurement function.

* The displayed value includes the “Oset value” setting.

* The unit varies depending on the measurement function.

* The displayed value includes the “Oset value” setting.

OnDelay When the output is turned on, output will be performed after a delay elapses.

Ready When trigger input is possible, output will be performed.

Strobe When the measured value is updated, one-shot output will be performed.

1shot2 When the measurement result exceeds the upper limit or lower limit, the output

will be turned on.

Output turns o (open state) in the trigger standby state.

Out polar Y Select the polarity to use for output.

N.O. When the measurement result exceeds the upper limit or lower limit, the output

will be turned on.

Output turns o (open state) in the trigger standby state.

N.C. When the measurement result is within the range dened by the upper limit and

lower limit, the output will be turned on. Output turns on (closed state) in the

trigger standby state.

Output

time

Y Set the output time.

The condition to enable this function is: Out action: 1shot, OnDelay, or Strobe.

0.1 to 204.7 [0.1] [Unit: ms] * You can set this value in steps of 0.1 ms.

44 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 45

Operating the Sensor

Setting

item

Oset

value

Hysteresis Y To prevent chattering, set the amount that the value can fall below (or exceed) the threshold before the

Oset Y A value will be added to or subtracted from the measured value so that the display value equals the

Bank Setting value/

default value

Y Set an oset value (value to be added) to the output result display.

When the external input “Oset” setting is set to “ON,” this oset value will be displayed.

-32.767 to +32.767

[0.00]

output state changes from the state outside the range specied by the thresholds.

0 / 4 / 8 / 16 /

32 / 50 / 75 /

100 / 150 / 200 /

300 / 500 /

750 / 1000 /

1500 /2000 [0]

“Oset value” setting.

For example, if the oset value is “0,” the display will be “0” when the oset operation is performed.

When measurement is not possible, oset input will be ignored.

OFF The oset will be cleared.

ON The oset operation will be performed.

General description

* The unit varies depending on the measurement function.

* You can set this value in steps that are 10 times the value of the minimum

display digit.

* The unit varies depending on the measurement function.

Reference: For details on the output display settings, see “7.8 Output Settings.”

5.5.2 Output Items (OUTA)

When the OUTA tab is selected, you can use the output display settings

to congure the following items.

Setting

item

Out target Y

20mA Y Set the upper limit of analog output.

4mA Y Set the lower limit of analog output.

Bank Setting value/

default value

Select the area or calculation to set as the output target.

Area1 The measured result of area 1 will be output.

Area2 The measured result of area 2 will be output.

Area3 The measured result of area 3 will be output.

Area4 The measured result of area 4 will be output.

Calc1 The result of calculation 1 will be output.

Calc2 The result of calculation 2 will be output.

-31.767 to +32.767

[+25.000]

-32.767 to +31.767

[-25.000]

General description

* The unit varies depending on the measurement function.

* The unit varies depending on the measurement function.

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 45

Page 46

Operating the Sensor

Tips:• Set the “20mA” and “4mA” input values so that they meet the following

conditions.

• If the following conditions are not met, analog output will not be

performed correctly.

• The “20mA” input value must be greater than the “4mA” input value.

• The dierence between the “20mA” and “4mA” input values must be

1.000 or more.

Reference: For details on the output display settings, see “7.8 Output Settings.”

46 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 47

6 PRO2-Navigator Setup Software

6.1 Setup Software Requirements

6.1.1 Operating Environment

The operating environment for this software is shown below.

Item Details

Computer A computer running Windows

Base OS Microsoft® Windows XP

Microsoft® Windows 7

Memory 512 MB or more

Hard disk 100 MB or more

®

®

PRO2-Navigator Setup Software

®

8017035/ZMO9/2017-06-08 • © SICK AG • Subject to change without notice. 47

Page 48

PRO2-Navigator Setup Software

6.2 Software Setup

6.2.1 Installing the Driver

This section explains the device driver installation procedure.

Tips: • Before performing the installation, exit all other applications that

are running on Windows

• Log in as a user with Administrator rights before installation.

1. Insert the setup software user’s manual USB ash drive.

2. Double-click the USB ash drive icon to open it.

3. Start the driver installation. Double-click “CDM v2.xx.xx WHQL Certied.

exe.” The “FTDIChip CDM Drivers” screen displays.

4. Open the “Device Driver Installation Wizard.”

Click [Extract].

®

5. Proceed with the driver installation.

Click [Next].

6. Complete the driver installation.

Click [Finish].

This completes the driver installation.

48 © SICK AG • Subject to change without notice. • 8017035/ZMO9/2017-06-08

Page 49

6.2.2 Install the Software

This section explains the setup software installation procedure.

1. Insert the setup software user’s manual USB ash drive.

2. Double-click the USB ash drive icon to open it.

3. Create a folder on your computer to save the PRO2-Navigator

setup software.

4. Copy the “PRO2_navigator.exe” le to the folder you created.

PRO2-Navigator Setup Software

5. Start the setup software.

Double-click the copied “PRO2_navigator.exe” le.

Setup software PRO2-Navigator starts.

6. Exit the setup software.

After setup software PRO2-Navigator has started normally,

on the “File” menu, click “eXit” or click the close button in the