Page 1

OLS20

Line guidance sensors

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

2006/42/EC

NO

SAFETY

OLS20

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Scope......................................................................................................... 5

1.3 Explanation of symbols............................................................................ 5

1.4 Further information................................................................................... 6

1.5 Customer service...................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Notes on UL approval............................................................................... 7

2.4 Limitation of liability................................................................................. 7

2.5 Requirements for skilled persons and operating personnel.................. 8

2.6 Hazard warnings and operational safety................................................. 8

2.7 Repairs...................................................................................................... 9

3 Product description........................................................................... 10

3.1 Product identification............................................................................... 10

3.2 Product features....................................................................................... 11

4 Transport and storage....................................................................... 12

4.1 Transport................................................................................................... 12

4.2 Transport inspection................................................................................. 12

4.3 Storage...................................................................................................... 12

5 Mounting............................................................................................. 13

5.1 Preparation for mounting......................................................................... 13

5.2 Mounting the sensor................................................................................ 13

6 Electrical installation........................................................................ 16

6.1 Safety......................................................................................................... 16

6.2 Pin assignment of the connections......................................................... 18

6.3 Connecting the supply voltage................................................................. 18

6.4 CAN connection........................................................................................ 19

7 Commissioning.................................................................................. 20

7.1 Overview of commissioning steps........................................................... 20

7.2 Commissioning the sensor for the first time.......................................... 20

7.3 First step to commissioning with CANopen............................................ 20

7.4 First step to commissioning with Modbus RTU....................................... 21

8 Operation............................................................................................ 22

8.1 Operation via CANopen............................................................................ 22

8.2 Operation via Modbus RTU...................................................................... 27

8.3 General notes on operation..................................................................... 28

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

3

Page 4

CONTENTS

9 Maintenance...................................................................................... 30

9.1 Cleaning..................................................................................................... 30

9.2 Maintenance............................................................................................. 30

9.3 Repairs...................................................................................................... 30

10 Decommissioning............................................................................. 31

10.1 Decommissioning..................................................................................... 31

11 Troubleshooting................................................................................. 32

11.1 Possible error indicators.......................................................................... 32

12 Technical data.................................................................................... 33

12.1 Optics / Features...................................................................................... 33

12.2 Supply........................................................................................................ 33

12.3 Interfaces.................................................................................................. 33

12.4 Output........................................................................................................ 33

12.5 Ambient conditions................................................................................... 34

12.6 Structural design...................................................................................... 34

13 Accessories........................................................................................ 35

14 Licenses.............................................................................................. 36

15 Annex.................................................................................................. 37

15.1 EU declaration of conformity.................................................................... 37

4

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use sensors from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied.

•

Compliance with local work safety regulations and general safety regulations for

•

sensor applications.

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully before starting any work on the sensor, in

order to familiarize yourself with the sensor and its functions.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the sensor so they remain accessible to staff at all times. If the

sensor is passed on to a third party, these operating instructions should be handed

over with it.

ABOUT THIS DOCUMENT 1

These operating instructions do not provide information on operating the machine in

which the sensor is integrated. For information about this, refer to the operating instruc‐

tions of the particular machine.

1.2 Scope

These operating instructions explain how to incorporate a sensor into a customer sys‐

tem. Step-by-step instructions are given for all required actions.

These instructions apply to all available device variants of the sensor.

Available device variants are listed on the online product page.

www.sick.com/ols20

b

Commissioning is described using one particular device variant as an example.

Simplified device designation in the document

In the following, the sensor is referred to in simplified form as “OLS20”.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.4 Further information

NOTE

All the documentation available for the sensor can be found on the online product page

at:

www.sick.com/ols20

b

The following information is available for download from this page:

Type-specific online data sheets for device variants, containing technical data and

•

dimensional drawings

EU declaration of conformity for the product family

•

Dimensional drawings and 3D CAD dimension models in various electronic for‐

•

mats

These operating instructions, available in English and German, and in other lan‐

•

guages if necessary

Other publications related to the sensors described here

•

Interface descriptions for IO-Link, CANopen and RS485 (Modbus)

•

Publications dealing with accessories

•

EDS device description file

•

IODD

•

SDD drivers for the SOPAS ET configuration software

•

1.5 Customer service

If you require any technical information, our customer service department will be happy

to help. To find your representative, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code etc. to ensure faster

processing.

6

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 Intended use

The OLS20 line guidance sensor is an opto-electronic sensor intended for detecting

luminescent guide tracks as well as reading out 1D codes when they are driven over by

automated guided vehicles.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

NOTICE

Radio interference may occur when the sensor is used in residential areas.

Only use the device in industrial environments (EN 61000-6-4).

b

2.2 Improper use

The sensor does not constitute a safety-relevant device according to the EC

•

Machinery Directive (2006/42/EC).

The sensor must not be used in explosion-hazardous areas.

•

Any other use that is not described as intended use is prohibited.

•

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

The sensor is not suitable for outdoor applications.

•

SAFETY INFORMATION 2

NOTICE

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, take note of the following information:

The sensor should be used only in line with intended use specifications.

b

All information in these operating instructions must be strictly complied with.

b

2.3 Notes on UL approval

The device must be supplied by a Class 2 source of supply.

UL Environmental Rating: Enclosure type 1

2.4 Limitation of liability

Applicable standards and regulations, the latest state of technological development,

and our many years of knowledge and experience have all been taken into account

when assembling the data and information contained in these operating instructions.

The manufacturer accepts no liability for damage caused by:

■

Failing to observe the operating instructions

■

Improper use

■

Use by untrained personnel

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

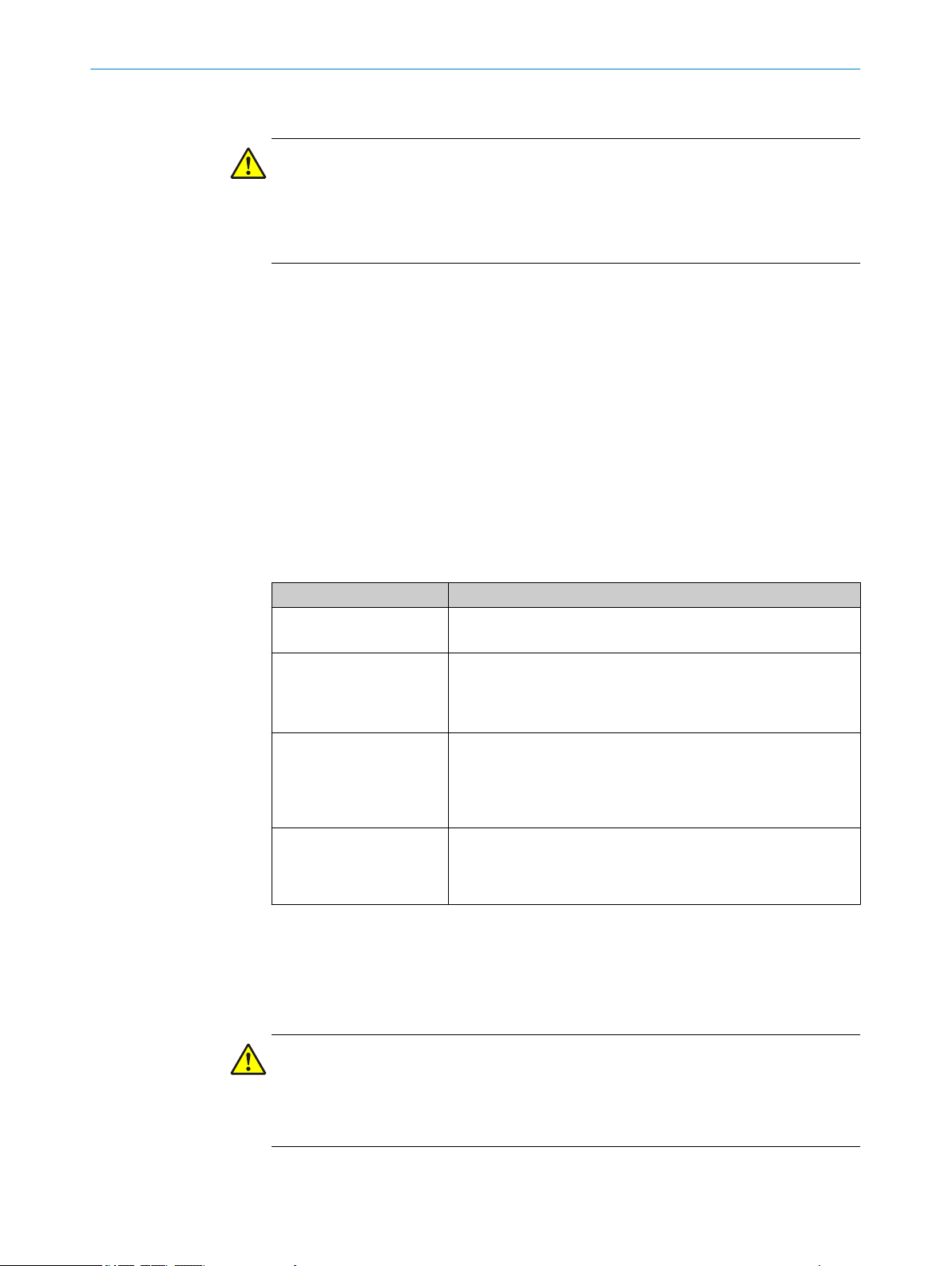

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the sensor may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualification requirements for the various

areas of work:

■

Instructed personnel have been briefed by the operating entity about the tasks

assigned to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks assigned to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g., Master Electrician). Other relevant regulations applicable in other

countries must be observed.

The following qualifications are required for various activities:

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Commissioning, configura‐

tion

Operation of the devices in

their particular application

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in their

■

particular application

Basic knowledge of the design and setup of the described con‐

■

nections and interfaces

Basic knowledge of data transmission

■

Knowledge of the operation and control of the devices in their

■

particular application

Knowledge of the operation and control of the devices in their

■

particular application

Knowledge of the software and hardware environment in the

■

application

2.6 Hazard warnings and operational safety

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan‐

gerous situations.

CAUTION EYE SAFETY

The OLS20 is equipped with LED illumination. The sensor meets the criteria of risk

group 2 according to IEC 62471:2006. The device emits potentially dangerous optical

radiation. Do not look into the lamp for extended periods of time during operation. This

could damage your eyes.

8

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 9

2.7 Repairs

SAFETY INFORMATION 2

Repair work on the sensor may only be performed by qualified and authorized person‐

nel from SICK AG. Interruptions or modifications to the sensor on the part of the cus‐

tomer will invalidate any warranty claims against SICK AG.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

9

Page 10

1

2

3

4

3 PRODUCT DESCRIPTION

3 Product description

3.1 Product identification

3.1.1 Type label

Figure 1: Type label

Type designation

1

ID no.

2

Serial number

3

Maschine readable code

4

10

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 11

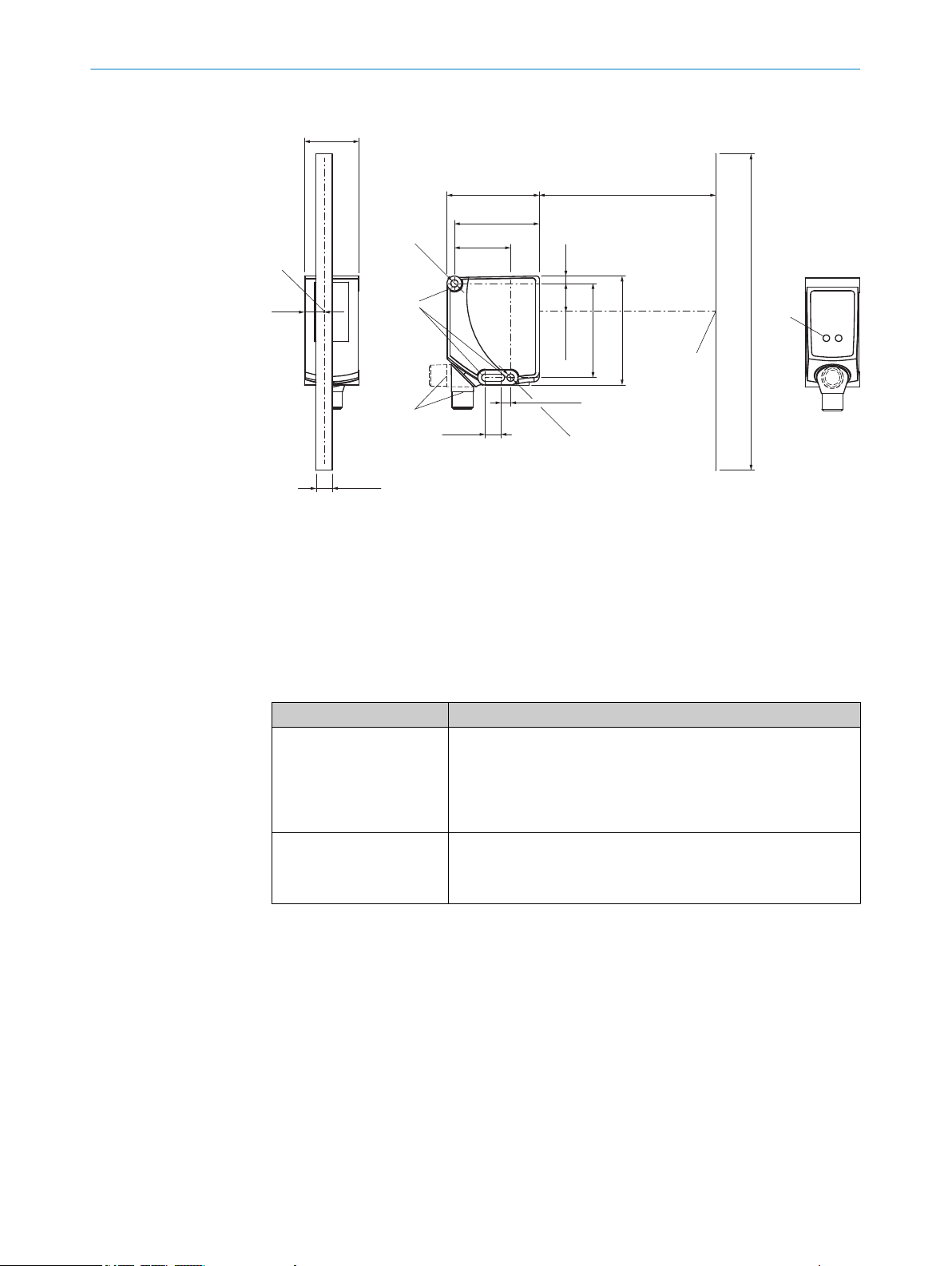

3.1.2 Structure and status indicators

11.3

(0.44)

9.3 (0.37)

5

2

4.2

(0.17)

180 (7.09)

100 (3.94)52.5 (2.07)

48.3 (1.9)

32 (1.26)

Ø

4.1

Ø

4.1

9 (0.35)

5.5 (0.22)

62 (2.44)

53.6 (2.11)

16.3 (0.64)

31 (1.22)

1

4

3

Figure 2: Device view

Optical axis

1

Field of view

2

Fixing hole

3

M12 device connection, can be rotated by 90°

4

Display unit

5

PRODUCT DESCRIPTION 3

Function indicators (LEDs)

Table 1: Function indicators (LEDs)

Function indicator Description

Q Switching output display

Yellow LED: Output active

•

LED off: Output inactive

•

LED flashing (10 Hz): Overcurrent/short-circuit protection has

•

triggered

PWR Operating status display

Green LED: Normal operation/Supply voltage on

•

LED off: No operation

•

3.2 Product features

The OLS20 line guidance sensor is an opto-electronic sensor which detects the line

center point of up to three luminescent tracks. To do so, the sensor stimulates the

guide track(s) with blue light and detects the remitted light using a receiver array.

This track is typically conventional adhesive tape or a colorful luminescence track. It is

not necessary to teach in the sensor.

For additional information on the adhesive tape and bar code labels recommended by

SICK, see the product accessories at www.sick.com/ols20.

In addition, the sensor reads 1D codes in “interleaved 2/5” format attached perpendic‐

ular to the track.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

11

Page 12

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

Improper transport

CAUTION DAMAGE TO THE PATTERN SENSOR DUE TO IMPROPER TRANSPORT!

Substantial material damage may result in the event of improper transport.

For this reason:

The device should be transported only by trained specialist staff.

•

The utmost care and attention is required at all times during unloading and trans‐

•

portation on company premises.

Note the symbols on the packaging.

•

Do not remove packaging until immediately before starting installation work.

•

4.2 Transport inspection

Immediately upon receipt at the receiving work station, check the delivery for complete‐

ness and for any damage that may have occurred in transit. In the case of transit dam‐

age that is visible externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany’s delivery note.

■

File a complaint.

4.3 Storage

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

To allow any residual dampness to evaporate, do not package in airtight contain‐

ers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Ambient conditions", page 34.

■

Relative humidity: see "Ambient conditions", page 34.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

12

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 13

5 Mounting

5.1 Preparation for mounting

1 Select the mounting site for the OLS20 in accordance with the following chapter

"Installation requirements", page 13.

2 Mount the OLS20 using the fixing holes.

"Structure and status indicators", page 11

"Accessories", page 35

5.1.1 Installation requirements

NOTICE

Radio interference may occur when the sensor is used in residential areas.

Only use the device in industrial environments (EN 61000-6-4).

■

Typical space requirements for sensor, see "Structural design", page 34.

■

Comply with technical parameters such as the permitted ambient conditions for

the operation of the sensor (e.g., temperature range, EM interference), see "Ambi‐

ent conditions", page 34.

■

Protect the sensor from direct sunlight.

■

Only affix the sensor using accessories supplied for this purpose -> there are no

screw connections on the sensor.

■

The light spot must cover the possible area of the three tracks.

■

Sensing distance: 100 mm

The sensing distance is the distance from the front sensor edge (housing edge) to

the track or the ground.

MOUNTING 5

5.1.2 Scope of delivery

The following are included with delivery:

OLS20 Optical Line Guidance Sensor

•

1 quick-start guide

•

Accessories:

Accessories (e.g., cables, fastening adapters) are only supplied if ordered separately.

5.2 Mounting the sensor

Arrangement over guide track

The OLS20 must be aligned orthogonally to the guide track with its light spot. The sens‐

ing range is 100 mm.

The sensor should be attached vertically over the guide track.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

13

Page 14

MOUNTING

5

Table 2: Mounting

Figure 3: Arrangement over guide track

The code can be arranged directly on the track or next to the track. If it is arranged next

to the track (field of view +/-50 mm), it is detected as an additional track.

14

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 15

+90 mm

-90 mm

0 mm

MOUNTING 5

Figure 4: Arrangement with branches and junctions

Arrangement with branches and junctions

If there are branches or junctions, we recommend arranging the tracks as illustrated.

The minimum distance between the tracks is 7 mm.

In addition, we recommend a minimum overlap length of the tracks of at least 10 cm.

At speeds greater than 2 m / s, this range should be increased.

Figure 4 also shows the sign convention of the LCP with the factory settings. (-90 mm ...

+90 mm on the cable side).

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

15

Page 16

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

6.1.1 Notes on electrical installation

CAUTION

Danger due to incorrect supply voltage!

An incorrect supply voltage may result in injuries from electric shocks and/or damage to

the device.

■

Only operate the sensor with safety/protective extra-low voltage (SELV/PELV).

NOTICE

Sensor damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

■

Only carry out wiring work when the power is off.

■

Only connect and disconnect electrical connections when the power is off.

■

The electrical installation must only be performed by electrically qualified person‐

nel.

■

Standard safety requirements must be observed when working on electrical sys‐

tems!

■

Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

■

When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

■

Wire cross-sections in the supply cable from the user’s power system must be

designed in accordance with the applicable standards. When this is being done in

Germany, observe the following standards: DIN VDE 0100 (Part 430) and DIN VDE

0298 (Part 4) and/or DIN VDE 0891 (Part 1).

■

Electrical circuits connected to the device must be configured as SELV circuits

(SELV = safety extra-low voltage/PELV = protective extra-low voltage).

■

Protect the device with a separate fuse at the start of the supply circuit.

6.1.2 Wiring notes

16

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

A shielded cable is not required in order to adhere to the electromagnetic compatibility

guidelines specified by DIN EN 60947-5-2. It is recommended, however, especially

when working with longer connecting cables.

The IP enclosure rating for the sensor is only achieved if the connected cable is com‐

pletely screwed in.

CAUTION

This is a class A product. In a household environment, this device can cause radio inter‐

ference. The user should take appropriate measures as required.

NOTE

Preassembled cables can be found online at:

www.sick.com/ols20

b

Subject to change without notice

Page 17

1

2

4

3

1

2

4

3

90

90

1

2

3

4

1

2

3

4

ELECTRICAL INSTALLATION

Please observe the following wiring notes:

■

During installation, pay attention to the different cable groups. The cables are

grouped into the following four groups according to their sensitivity to interference

or radiated emissions:

Group 1: Cables very sensitive to interference, such as analog measuring

°

cables

Group 2: Cables sensitive to interference, such as sensor cables, communi‐

°

cation signals, bus signals

Group 3: Cables which are a source of interference, such as control cables

°

for inductive loads, motor brakes

Group 4: Cables which are powerful sources of interference, such as output

°

cables from frequency inverters, welding system power supplies, power

cables

w

Cables in groups 1, 2 and 3, 4 must be crossed at right angles, see figure 5.

w

Cables in groups 1, 2 and 3, 4 must be routed in different cable channels or

metallic separators must be used, see figure 6 and see figure 7. This applies

particularly where cables of devices with a high level of radiated emission,

such as frequency converters, are laid parallel to sensor cables.

6

Figure 5: Cross cables at right angles

Figure 6: Ideal laying – Place cables in different cable channels

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

Figure 7: Alternative laying – Separate cables with metallic separators

17

Page 18

1

2

5

4 3

1

2

5

4 3

6 ELECTRICAL INSTALLATION

6.2 Pin assignment of the connections

M12 connection

Pin Pin assignment

1 - BN VIN

2 - WH CAN HIGH

3 - BU GND

4 - BK C / Q

5 - GY CAN LOW

M12 connection, RS485

Pin Pin assignment

1 - BN VIN

2 - WH RS485 A

3 - BU GND

4 - BK C / Q

5 - GY RS485 B

6.3 Connecting the supply voltage

The sensor must be connected to a voltage supply with the following properties:

Supply voltage DC 18 V ... 30 V (stabilized safety extra-low voltage (SELV/PELV) as

•

per current standard EN 60950-1)

Electricity source with at least 3 W power

•

Protecting the supply cables

To ensure protection against short-circuits/overload in the customer’s supply cables,

the wire cross-sections used must be appropriately selected and protected.

The following standards must be observed in Germany:

DIN VDE 0100 (part 430)

•

DIN VDE 0298 (part 4) and/or DIN VDE 0891 (part 1)

•

18

Electrical connection of OLS20

Ensure the voltage supply is not connected.

•

Turn the swivel connector into the desired position.

•

Connect the sensor according to the connection diagram.

•

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 19

6.4 CAN connection

We recommend connecting the ground cable to the CANopen communication interface

as a reference.

If there is no separate CAN GND in the system, this pin is to be connected to the FE.

ELECTRICAL INSTALLATION 6

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

19

Page 20

7 COMMISSIONING

7 Commissioning

7.1 Overview of commissioning steps

■

Connect the voltage supply.

■

Commission the sensor using the factory settings.

■

Configure the sensor.

7.2 Commissioning the sensor for the first time

NOTICE PUSHBUTTON DAMAGE DUE TO IMPROPER HANDLING!

Improper handling of the pushbuttons can damage them. This will make operation diffi‐

cult or impossible.

For this reason:

Only operate the pushbuttons with your fingers or a suitable pointing device.

•

Do not operate the pushbuttons using sharp or hard objects.

•

Establish voltage supply: When the sensor voltage supply is correct, the green “PWR”

LED lights up.

If at least one track is detected, switching output Q1 is “active” and the yellow “Q” LED

lights up.

7.3 First step to commissioning with CANopen

7.3.1 Setting the ID and baud rate

The following conditions must be met for communication with the CAN master:

A correct node ID must be set on the OLS20.

•

Correct is:

A node ID which is free in the CANopen network

°

A node ID which the master expects

°

The same baud rate must be set in the OLS20 as in the master.

•

The following parameters are factory set on the OLS20:

Node ID: 10

•

Baud rate: 125 kbit/s

•

The following communication parameters can be allocated to the OLS20:

Node ID: 1 to 127 (0 is generally assigned to the master)

•

Baud rate: 10 kbit/s, 20 kbit/s, 50 kbit/s, 125 kbit/s, 250 kbit/s, 500 kbit/s,

•

1,000 kbit/s

The sensor supports the configuration with LSS with a CANopen master.

The node ID and baud rate can also be set using the SOPAS ET configuration software,

which can be downloaded at: www.sick.com/SOPAS.

7.3.2 Process data objects (PDOs)

The OLS20 supports two transmit PDOs and no receive PDO.

Objects 0x1800 and 0x1801 contain the communication parameters.

20

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 21

7.3.3 PDO communication

The transmission type is factory-set to acyclic communication for TPDO1 and TPDO2. A

transmission period of 20 ms is factory-set for TPDO1 and TPDO2 so that TPDO1 and

TPDO2 are transmitted on a cyclical basis.

Changing the factory-set transmission type

The following options are available for the cyclical or acyclical output of transmit PDOs

by the OLS20:

Change the event timer in object 0x1800 or 0x1801 (see table 3)

•

Change the transmission type in object 0x1800 or 0x1801 (see table 3)

•

7.4 First step to commissioning with Modbus RTU

7.4.1 Setting the ID and baud rate

The following conditions must be met for communication with the Modbus master:

A correct slave address must be set on the OLS20.

•

Correct is:

A slave address that is free in the Modbus network

°

A slave address that the master expects

°

The same baud rate must be set in the OLS20 as in the master.

•

The following parameters are factory set on the OLS20:

COMMISSIONING

7

Slave address: 10 (valid settings 1 ... 247)

•

Baud rate: 9600 bps

•

The following communication parameters can be allocated to the OLS20:

Slave address: 1 to 247 (0 is generally assigned to the master)

•

Baud rate:

•

0: 1200 bps

1: 2400 bps

2: 4800 bps

3: 9600 bps

4: 19200 bps

5: 38400 bps

6: 57600 bps

7: 115200 bps

The slave address and baud rate can also be set using the SOPAS ET configuration soft‐

ware,

which can be downloaded at: www.sick.com/SOPAS.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

21

Page 22

8 OPERATION

8 Operation

8.1 Operation via CANopen

CANopen object directory

This chapter contains information on integration of the sensor using CANopen.

All sensor functions can be accessed via the CANopen interface. All settings can be

configured in this interface. The EDS file can also be found at www.sick.com/ols20.

8.1.1 OBD

This section only describes the objects that do not have a fixed definition in the

CANopen standard. Default values are listed only for parameters that can be modified

by the user.

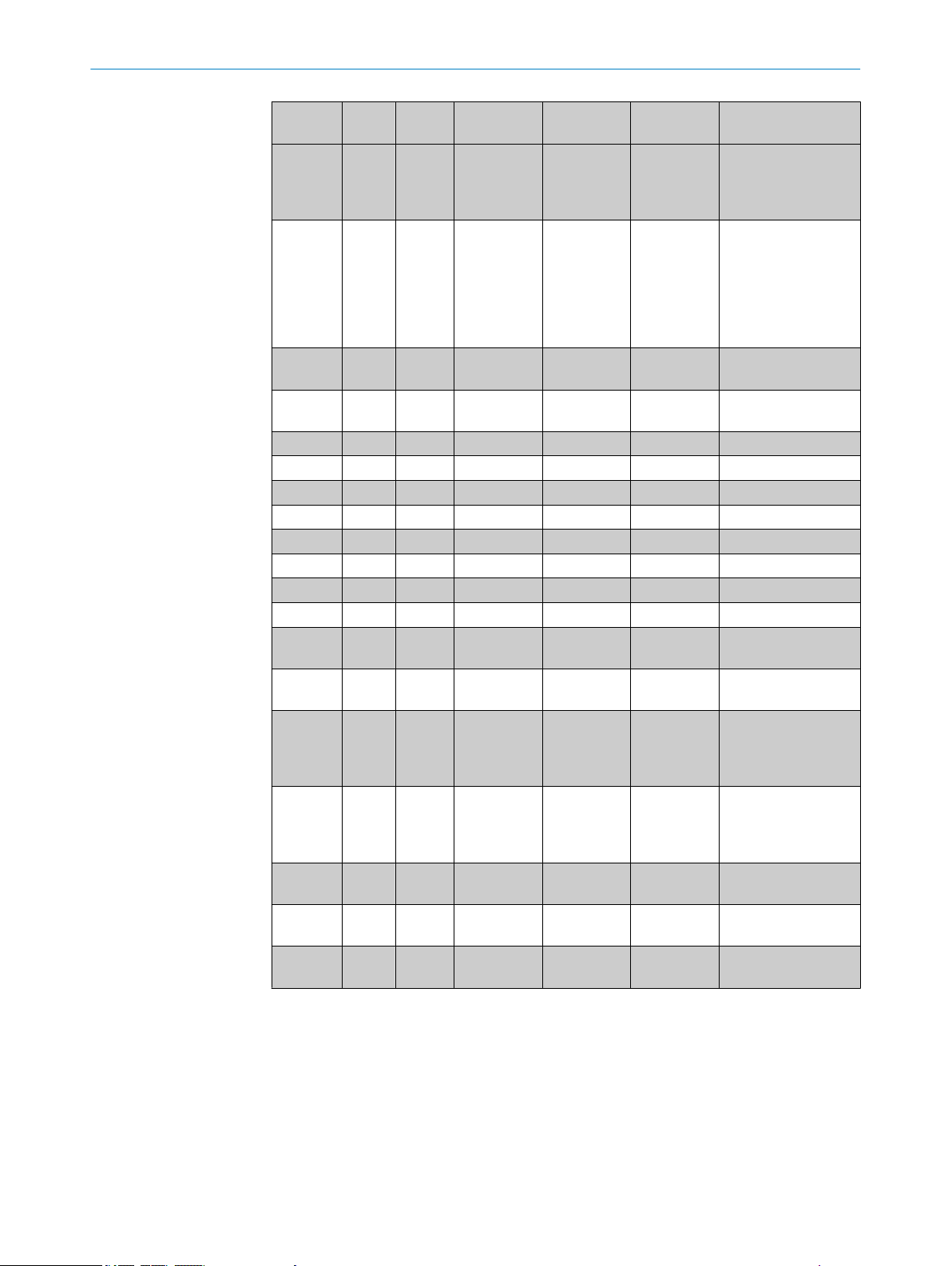

Table 3: OBD

Index Sub-

idx

0x1000 - RO Device type UINT32 No device profile sup‐

0x1001 - RO Error register UINT8

0x1005 - RW COB ID

0x1008 - RO Manufac‐

0x1009 - RO Manufac‐

0x100A - RO Manufac‐

0x100C - R/W Guard time UINT16

0x100D - R/W Life time UINT8

0x1014 - RW COB-ID

0x1015 - RW Inhibit Time

0x1016 RO Heartbeat

1 RW Consumer

2 RW Consumer

0x1017 - R/W Heart beat

0x1018 RO Identity

1 RO Vendor Id UINT32 0x01000056 (SICK

R/W Object name Default

value

0x00000080UINT32

SYNC

turer device

name

turer hard‐

ware rev

turer soft‐

ware rev

0x00000080UINT32

EMCY

0x0000 UINT16

Emergency

0x02 UINT32

Consumer

Entries

0x0 UINT32

Heartbeat

Time 1

0x0 UINT32

Heartbeat

Time 2

time

object

Type Description

ported

STRING Optical Line Guid‐

ance Sensor

STRING Hardware version,

sensor

STRING Firmware version,

sensor

UINT16

UINT8

AG)

22

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 23

OPERATION 8

Index Sub-

R/W Object name Default

idx

2 RO Product

code

3 RO Revision

number

4 RO Serial num‐

ber

0x1800 Transmit

PDO commu‐

nication

parameter 0

1 R/W COB ID 0x0000018AUINT32 see chapter 8.1.2

2 R/W Transmis‐

sion type

3 RW Inhibit Time 0x0 UINT16

5 R/W Event timer 0x014 UINT16

0x1801 Transmit

PDO Com‐

munication

Parameter 2

1 R/W COB ID 0x0000018AUINT32 see chapter 8.1.2

Type Description

value

UINT32

UINT32

UINT32

0xFF UINT8 see chapter 8.1.2

2 R/W Transmis‐

sion type

3 RW Inhibit Time 0x0 UINT16

5 R/W Event timer 0x014 UINT16 see chapter 8.1.2

0x1A00 RO Transmit

PDO Map‐

ping Para‐

meter 2

1 RW Mapping

Entry 1

2 RW Mapping

Entry 2

3 RW Mapping

Entry 3

4 RW Mapping

Entry 4

5 RW Mapping

Entry 5

6 RW Mapping

Entry 6

7 RW Mapping

Entry 7

0x1A01 RO Transmit

PDO Map‐

ping Para‐

meter 2

1 RW Mapping

Entry 1

0xFF UINT8 see chapter 8.1.2

0x00 UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00 UINT32

0x00000000UINT32

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

23

Page 24

8 OPERATION

Index Sub-

R/W Object name Default

idx

2 RW Mapping

Entry 2

3 RW Mapping

Entry 3

4 RW Mapping

Entry 4

5 RW Mapping

Entry 5

6 RW Mapping

Entry 6

7 RW Mapping

Entry 7

0x2001 Mounting

parameters

5 R/W Flipped

upside down

0x2002 Tape para‐

meters

1 R/W Typ. width

[m]

2 R/W Min. width

[m]

3 R/W Max. width

[m]

0x2003 Advanced

settings

1 R/W Off delay

track detec‐

tion

2 RW Off Delay

Code Detec‐

tion

Type Description

value

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

0x00000000UINT32

BOOL 0 => Positive posi‐

tions on cable outlet

side

1 => Negative posi‐

tions on cable outlet

side

FLOAT Typical track width.

The specification of

the typical track

width makes it possi‐

ble to output the cor‐

rect line center point

even at the edge of

the reading window.

5 mm FLOAT Minimum track width.

Smaller tracks are

ignored.

75 mm FLOAT Maximum track

width. Wider tracks

are ignored.

100 ms UINT16 If the track is not

detected (contamina‐

tion), the last

detected line center

point is output for a

defined number of

milliseconds.

100 ms UINT16 If the code is not

detected (contamina‐

tion), the last

detected code value

is output for a

defined number of

milliseconds.

24

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 25

OPERATION 8

Index Sub-

idx

3 RW Position

0x2018 RO Device sta‐

R/W Object name Default

value

0.0 ms The position values

smoothing

filter coeffi‐

cient

tus

Type Description

are smoothed over a

defined number of

milliseconds.

UINT16 0 = Device is OK

1= Maintenance

required

2 = Out of Specifica‐

tion

3 = Functional Check

4 = Failure

0x2019 RO Order num‐

UINT32 3 = Functional Check

ber

0x2021 Result data

1 RO LCP1

2 RO LCP2

3 RO LCP3

(LCPs)

1

1

1

1

INT16 see chapter 8.1.2

INT16 see chapter 8.1.2

INT16 see chapter 8.1.2

4 RO Status UINT8 see chapter 8.1.2

5 RO Width LCP1

6 RO Width LCP2

7 RO Width LCP3

1

1

1

INT16 see chapter 8.1.2

INT16 see chapter 8.1.2

INT16 see chapter 8.1.2

8 RO Code UINT8 see chapter 8.1.2

9 RO Extended

UINT32 see chapter 8.1.2

code

10 RO BarCode

Centerpoint

11 RO Quality of

Line

INT16 Centerpoint of the

detected bar code

UINT8 Line quality in % Ref‐

erence is a standard‐

ized minimum optical

contrast.

0x2023 Line level Line intensity value.

Reference is a stan‐

dardized line inten‐

sity.

1 RO Intensity line

UINT8

1

2 RO Intensity line

UINT8

2

3 RO Intensity line

UINT8

3

1

LCP = line center point

8.1.2 PDOs

The OLS20 has two TPDOs (TPDO01 and TPDO02) with fixed mapping and no RPDO.

TPDO1 can be accessed under the index 0x0180 + node ID, TPDO02 under 0x280 +

node ID. In its default state (node ID 0x0A), the index for TPDO1 is 0x018A.

The TPDO1 is structured as follows:

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

25

Page 26

8 OPERATION

Table 4: CANopen PDO01

Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

TPDO1 LSB

LCP1

Table 5: Byte 7 status

Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7

Status #LCP bit0#LCP Bit1#LCP Bit2x Device

Table 6: TPDO2

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

TPDO2 LSB

Width

line 1

#LCP UINT3 The numbers are assigned the following meanings:

Device status Bool 0 => Sensor ok

Code flipped Bool 0 => Code was read from the minus to the plus side

Code valid Bool 0 => No code read

MSB

LCP1

MSP

Width

line 1

LSB

LCP2

LSB

Width

line 2

MSB

LCP2

MSP

Width

line 2

0 => No track found

2 => One track found

3 => Two tracks found: Diverter on minus side (fac‐

tory setting)

6 => Two tracks found: Diverter on plus side (fac‐

tory setting)

7 => Three tracks found

1 => Sensor not OK, see 0x2018

of the sensor

1 => Code was read from the plus to the minus side

of the sensor

1 => Valid code has been read

LSB

LCP3

status

LSB

Width

line 3

MSB

LCP3

x Code

MSP

Width

line 3

Status Bar code

flipped

x x

Code

valid

Table 7: Byte 8 bar code

Bar code Code 0 ... 255

8.1.3 Transmission types

The transmission type of the respective TPDO can be set in index 0x1800 or 0x1801.

This index comprises the following subindexes:

Table 8: Subindexes

SubindexName Permissible

1 COB-ID - The COB ID is automatically adjusted to the

2 Transmission type 0xFE, 0xFF The transmission type is set here.

3 not used - Not used

4 Compatibility entry - Not used

5 Event timer 0 ... 65535 The event timer sets the time between two

Bit 0-7

Description

values

note ID and should not be amended by the

user.

transmissions from the TPDO in [ms]. A value

of 0 deactivates the transmission of the

process data. The smallest logical value rec‐

ommended here is 10 ms.

26

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 27

8.2 Operation via Modbus RTU

“Input registers” register group (read-only)

The “input registers” can be read using function code 0x04.

Device identification section

The device identification details (all of data type ASCII string) can be found from 0x00

onwards in the address range of the input register.

Table 9: Device Identification

Address Name #Registers Description

0 Vendor name 4 SICK AG

4 Product code 4

8 Firmware version 6

14 Vendor URL 6 www.sick.com

20 Product name 16 Optical Line Guidance Sensor

36 Model name 9 OLS20XXXX

45 Serial number 4

49 Application name 16

65 SickModbusProfileVersion 6

OPERATION 8

Index section

The registers of the index section contain the addresses (data type UINT16) of the sub‐

sequent sections. The registers are therefore all 2 bytes in size and hold the same con‐

tent. The values are stored in the following table:

Table 10: Index

Address Name Value

128 Number of sections within table 0x4

129 Length of section 1 - Status 0x1

130 Start address of section 1 0x00F0

131 Register type of section 1 0x0

132 Length of section 2 - Results 0x0B

133 Start address of section 2 0x00C0

134 Register type of section 2 0x0

135 Length of section 3 - Commands 0x10

136 Start address of section 3 0x0060

137 Register type of section 3 0x1

138 Length of section 4 - Configuration 0x9

139 Start address of section 4 0x0090

140 Register type of section 4 0x1

Result section

The result data start at address 0xC0:

Table 11: Results

Address Contents #Registers

192 Status 1

193 BCP 1

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

27

Page 28

8 OPERATION

Address Contents #Registers

194 Bar code 2

196 LCP1 1

197 LCP2 1

198 LCP3 1

199 Width1 1

200 Width2 1

201 Width3 1

202 Quality of Line 1

Status section

Table 12: Status

Address Contents #Registers

240 Device status 1

“Holding registers” register group (read-write)

The following registers are used to configure the sensor via Modbus and can be read

using function code 0x03, written to individually using function code 0x06, or written to

continuously using function code 0x10.

Commands section

Table 13: Commands

Address Contents #Registers

96 Set Application name 16

Configuration section

Table 14: Configuration

Address Contents #Registers Description

144 Reading direction 1 0: Head to connector

1: Connector to head

145 Typical tape width 1 Unit [mm]

146 Minimum tape width 1 Unit [mm]

147 Maximum tape width 1 Unit [mm]

148 Q off delay 1 Unit [ms]

149 Barcode off delay 1 Unit [ms]

150 Q inverter 1 0: not inverted

1: inverted

151 Position smoothing filter coeffi‐

cient

2 FLOAT (≥ 0.0)

Default 2.0

8.3 General notes on operation

8.3.1 Output of line center points

The OLS20 is capable of detecting up to three line center points (LCPs). The position of

each line center point is output to a resolution of 1 mm. The geometric center of the

sensor’s longitudinal axis is the zero point, see "optical center", page 11.

28

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 29

x m m m

OPERATION 8

By default, the positive measuring range is towards the cable outlet, and the negative

measuring range is on the opposite side.

If only one line center point is found, this is output as LCP2. If a further line center point

is found, it is output as LCP1 or LCP3, depending on its direction. If three LCPs are

found, then each LCP is output.

If there are multiple tracks in the field of view, the track closest to zero is the main track

(LCP2).

To make it easier for the control system to evaluate this data, the combination of tracks

detected is output in an additional data item #LCP. The LCPs are binary-weighted:

Table 15: Line center points

LCP1 detected LCP2 detected LCP3 detected #LCP Note

no no no 0 Special case: No track

detected

no Yes no 2 Only one track detected

Yes Yes no 3 Single diverter on the minus

side detected (factory set‐

ting)

no Yes Yes 6 Single diverter on the plus

side detected (factory set‐

ting)

Yes Yes Yes 7 Double diverter detected

The principle of LCP1 < LCP2 < LCP3 always applies to the LCPs.

8.3.2 Inversion of the relative position

This function enables the user to invert the convention that the positive range is at the

cable outlet. This makes it easier to install the sensor when rotated by 180°.

The position can be inverted via CANopen, or via Modbus or IO-Link.

The inversion of the position signal (sensor flipped) does not affect the LED behavior.

8.3.3 Bar code detection

The OLS20 has the option of detecting 1D bar codes in the interleaved 2/5 format. Up

to 4-digit bar codes are detected and read out in this case.

The OLS20 outputs the number value of the bar code via CANopen, or via Modbus or

IO-Link.

In addition to track tape, SICK also offers a set of numbered bar codes as accessories

see "Accessories", page 35. The assignment of the bar code value to a certain drive

command or piece of position information must be done on the control side.

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

29

Page 30

9 MAINTENANCE

9 Maintenance

9.1 Cleaning

CAUTION DEVICE DAMAGE DUE TO IMPROPER CLEANING!

Improper cleaning may result in device damage.

For this reason:

•

•

Clean the front screen at regular intervals with a lint-free cloth and plastic cleaning

agent. Cleaning agents containing solvents are not allowed.

The cleaning interval essentially depends on the ambient conditions.

9.2 Maintenance

The sensor requires the following maintenance work at regular intervals:

Table 16: Maintenance schedule

Interval Maintenance work To be performed by

Cleaning interval depends on

ambient conditions and climate

Every 6 months Check the screw connections

Never use cleaning agents containing aggressive substances.

Never use sharp objects for cleaning.

Clean housing, particularly the

front screen.

and plug connectors.

Specialist

Specialist

9.3 Repairs

Repairs on the sensor may only be carried out by the manufacturer. Any interruption or

modification of the sensor will invalidate the manufacturer warranty.

30

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 31

10 Decommissioning

10.1 Decommissioning

Removing the sensor

1. Switch off the supply voltage to the sensor.

2. Detach all connecting cables from the sensor.

3. If the sensor is being replaced, mark its position and alignment on the bracket or

surroundings.

4. Remove the sensor from the slot.

Disposing of the sensor

Any sensor which can no longer be used must be disposed of in an environmentally

friendly manner in accordance with the applicable country-specific waste disposal regu‐

lations. The sensor is electronic waste and must under no circumstances be disposed

of with general waste.

DECOMMISSIONING 10

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

31

Page 32

11 TROUBLESHOOTING

11 Troubleshooting

Potential faults and rectification measures are described in the table below and in the

next chapter.

In the case of faults that cannot be rectified using the information below, please con‐

tact the manufacturer. See the back page for your agency.

11.1 Possible error indicators

Table: Possible error indicators

Error pattern Possible causes Troubleshooting

Q-LED flashes yellow Short-circuit / Overcurrent /

Sensor is not connected prop‐

erly

Disconnect sensor from the

power network / Check pin

assignment / Reconnect sen‐

sor / Check the current at the

switching output

32

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 33

12 Technical data

NOTE

The relevant online data sheet for the OLS20, including technical data, dimensions, and

connection diagrams, can be downloaded, saved, and printed at www.sick.com/ols20.

12.1 Optics / Features

Table 17: Optics / Features

Light sender

Wavelength 450 nm

Light spot size 180 mm x 11 mm

Sensing distance 100 mm

Sensing distance tolerance ± 10 mm

Sensing rate 5 ms

Bar code types 2/5 interleaved

Module width (min.) ≥ 1.5 mm

Track radius (min.) ≥ 0.5 m

Initialization time < 10 s

1

Average service life 100,000 h at TU = +25 °C.

TECHNICAL DATA 12

1

Blue LED

Track field of view +/-90 mm

Code field of view +/-50 mm

12.2 Supply

12.3 Interfaces

12.4 Output

Table 18: Supply

Supply voltage V

Power consumption (with‐

1

S

18 V DC … 30 V DC

< 3 W

out load)

Residual ripple < 5 Vss within permitted supply voltage UV (must not exceed or be

less than the UV tolerances.)

1

Limit values

Table 19: Interfaces

CANopen

1

Configuration and process interfaces

IO-Link (V1.1, COM3)

Modbus (RS485)

1

Configuration and process interfaces

IO-Link (V1.1 COM3)

1

depending on type

Table 20: Output

Switching output Q PUSH/PULL

Active ≥ UV – 2 V

•

Inactive ≤ 2 V

•

Circuit protection Output Q1 overcurrent and short-circuit protection (see Table 1)

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

33

Page 34

12 TECHNICAL DATA

Maximum output current < 100 mA (total I

12.5 Ambient conditions

Table 21: Ambient conditions

Protection class III, for operation with safety/protective extra-low voltage (SELV/

Electromagnetic compati‐

bility

Ambient temperature range –10 °C … +55 °C

Storage temperature range –20 °C … +75 °C

Ambient light immunity 60,000 lx

Enclosure rating IP64

Noise EN60068-2-64

Shock resistance/Impact

load

12.6 Structural design

Table 22: Structural design

Dimensions (W x H x D) 31 mm x 62 mm x 52.5 mm

Weight 250 g

Materials Housing: metal, discharge plate: glass

Connections

1

Male connector IN = 2 A

2

Use of a shielded cable is recommended for longer cables.

= Q1)

OUT

PELV)

EN 61000-6-2, EN 55011, Class A

EN 60086-2-27

Male connector, M121, 5-pin

•

2

34

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 35

13 Accessories

NOTE

Accessories can be found on the online product page at:

www.sick.com/ols20

ACCESSORIES 13

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

35

Page 36

14 LICENSES

14 Licenses

SICK uses open-source software. This software is licensed by the rights holders using

the following licenses among others: the free licenses GNU General Public License (GPL

Version2, GPL Version3) and GNU Lesser General Public License (LGPL), the MIT

license, zLib license, and the licenses derived from the BSD license.

This program is provided for general use, but WITHOUT ANY WARRANTY OF ANY KIND.

This warranty disclaimer also extends to the implicit assurance of marketability or suit‐

ability of the program for a particular purpose.

More details can be found in the GNU General Public License. For complete license

texts, see www.sick.com/licensetexts. Printed copies of the license texts are also avail‐

able on request.

36

O PE R AT I NG IN S TR U CT I ON S | OLS20 8023752/2019-04-01 | SICK

Subject to change without notice

Page 37

15 Annex

15.1 EU declaration of conformity

The EU declaration of conformity can be downloaded from the Internet at:

www.sick.com/ols20

ANNEX 15

8023752/2019-04-01 | SICK OP E RA T IN G I N ST R UC T IO N S | OLS20

Subject to change without notice

37

Page 38

Further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 01

E-Mail info@sick.de

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972-4-6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 (0)11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail info@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

8023752/2019-04-01/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...